Packaging structure of LED and packaging method thereof

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as offset, packaging size and difficult control of spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

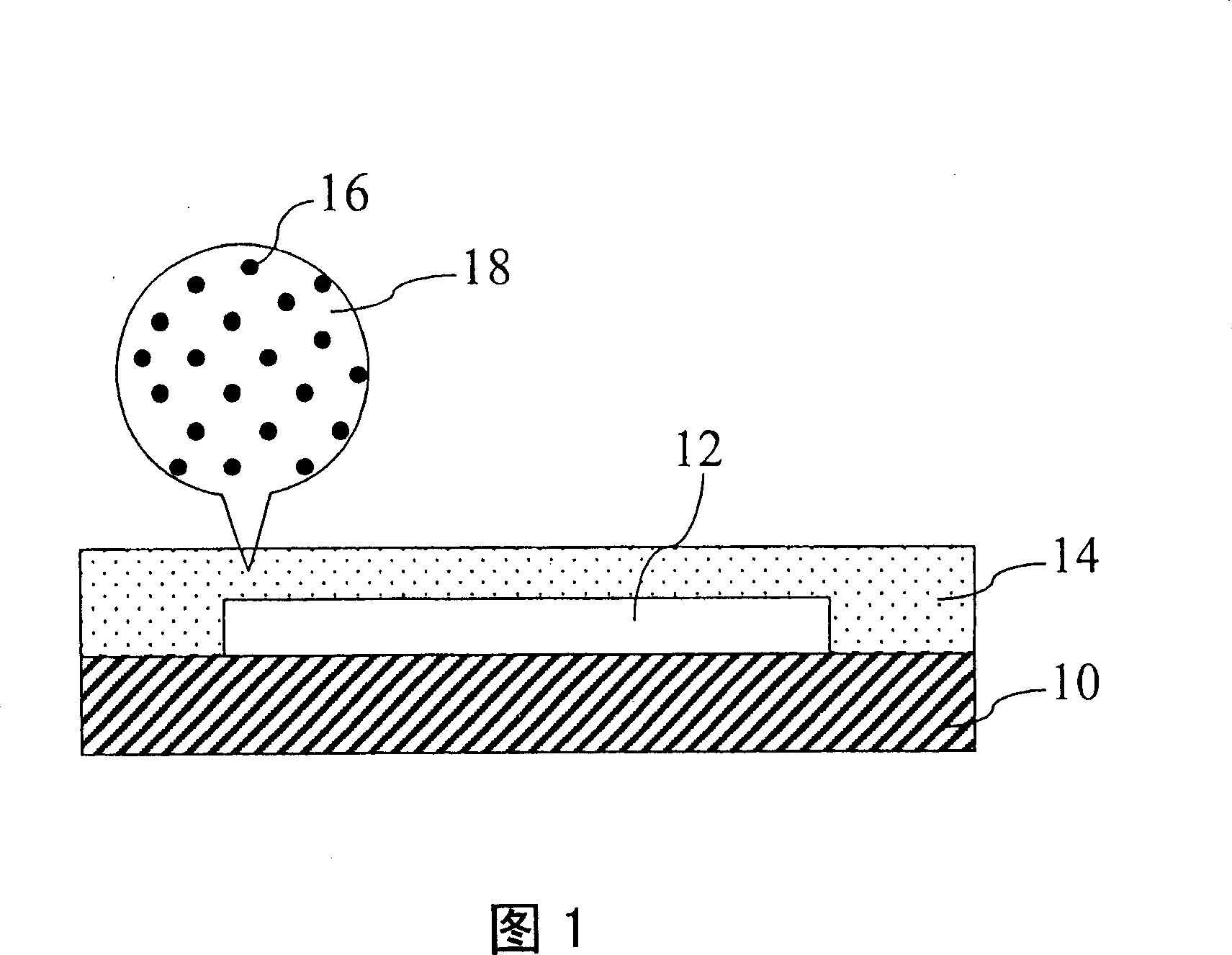

[0034] The light-emitting diode (LED) module packaging technology of the present invention uses liquid phosphor-containing gel as the module packaging material, and uses a mold method and is based on the principle of liquid-saturated solid precipitation and solidification to produce an LED packaging structure.

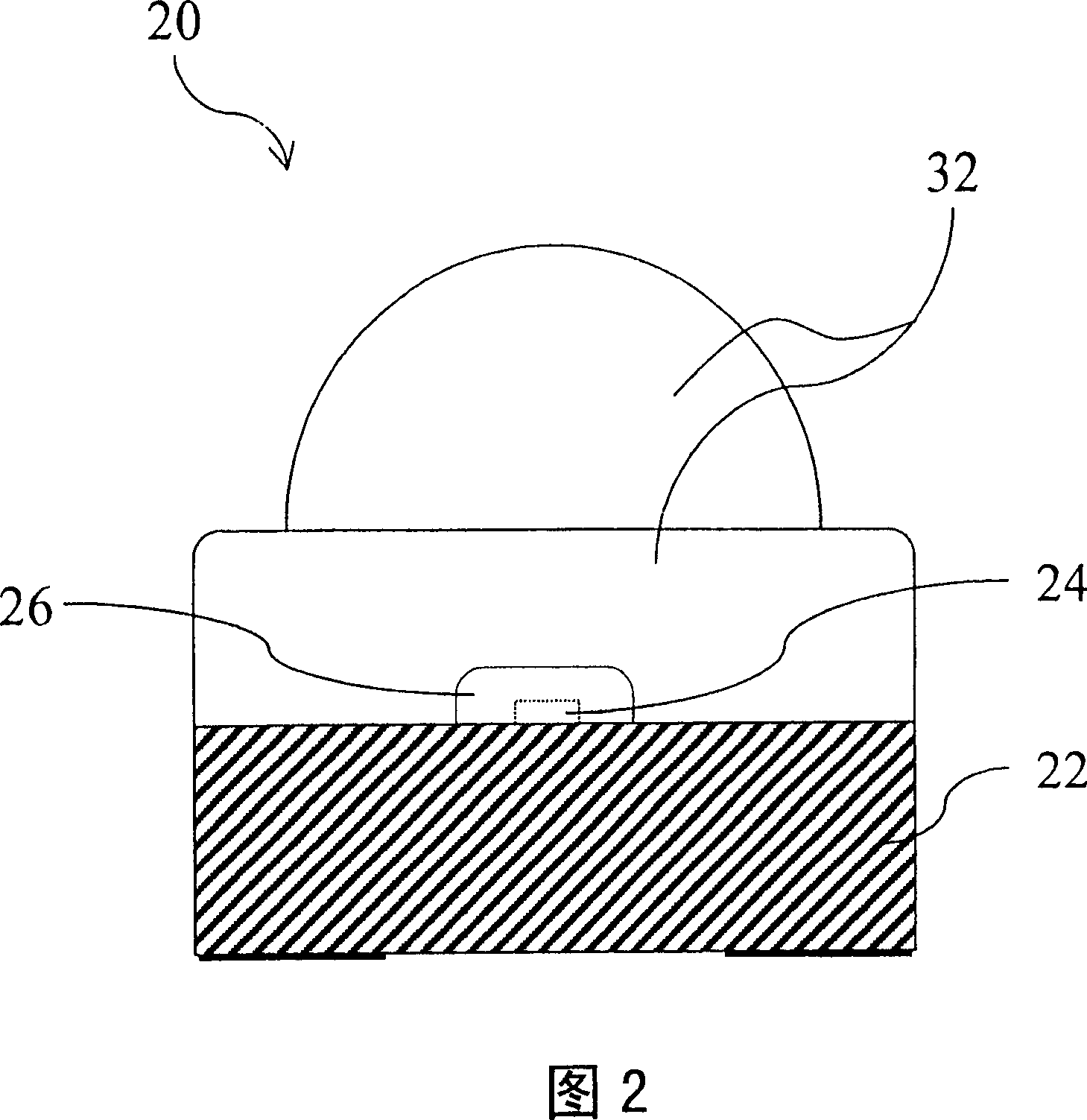

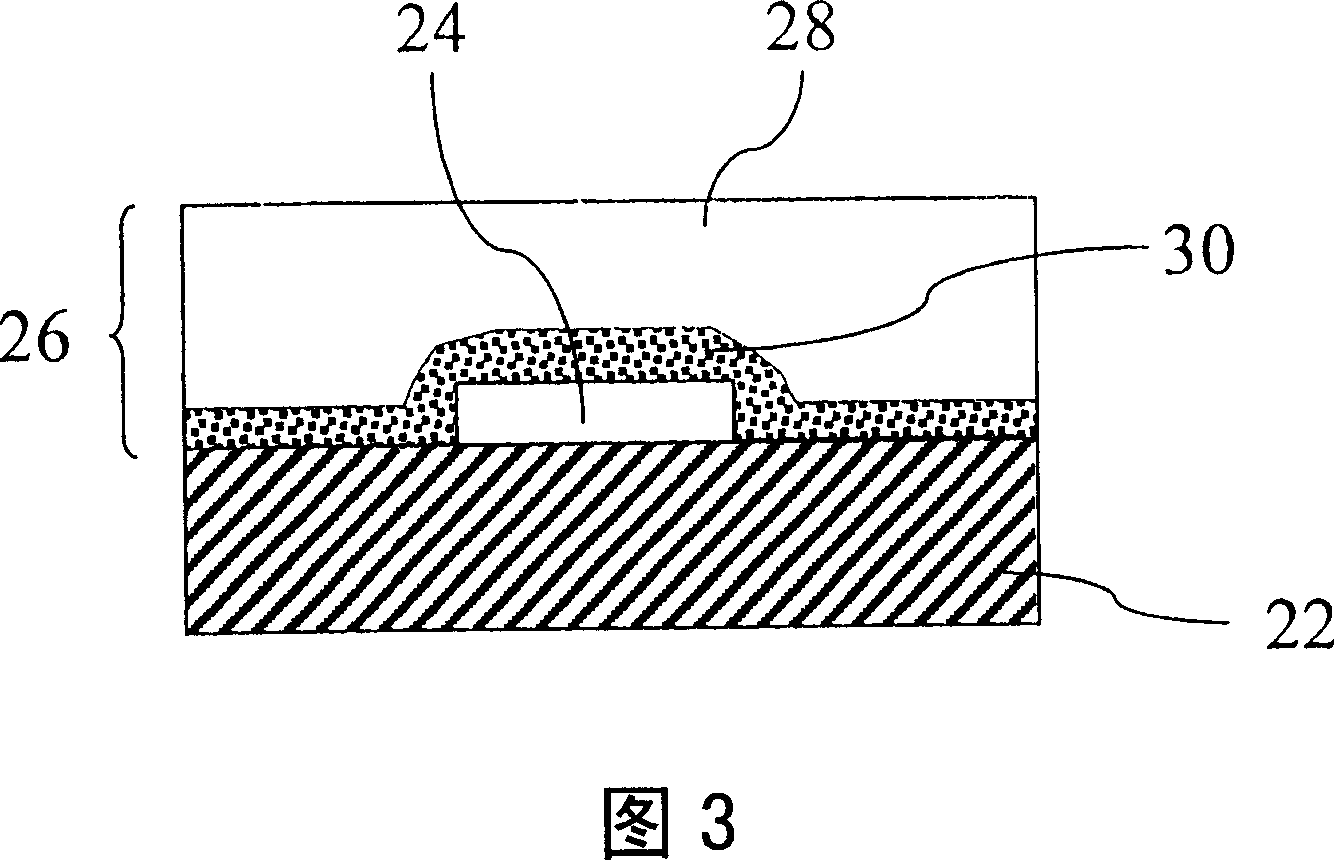

[0035] Please refer to FIG. 2, which is a cross-sectional view of the light-emitting diode packaging structure of the present invention. An LED packaging component 20 includes a substrate 22, which is usually a printed circuit board (PCB) or a metal frame. A light-emitting diode (LED) unit is mounted on the substrate 22, which is an LED die 24, and a phosphorescent medium layer 26 covers the substrate 22 to cover the LED die 24, and an external encapsulant 32 is coated Outside the phosphorescent medium layer 26; wherein the phosphorescent medium layer 26, as shown in FIG. 3, contains an encapsulation gel 28, and a phosphor precipitation layer 30 is deposited on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com