Shelling resistant pre-coated sand and preparation method thereof

A technology of coated sand and quartz sand, which is applied in the field of coated sand, can solve problems such as shelling and easy core penetration, and achieve the effect of eliminating shelling, reducing the tendency of shelling, and improving the quality of inner and outer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

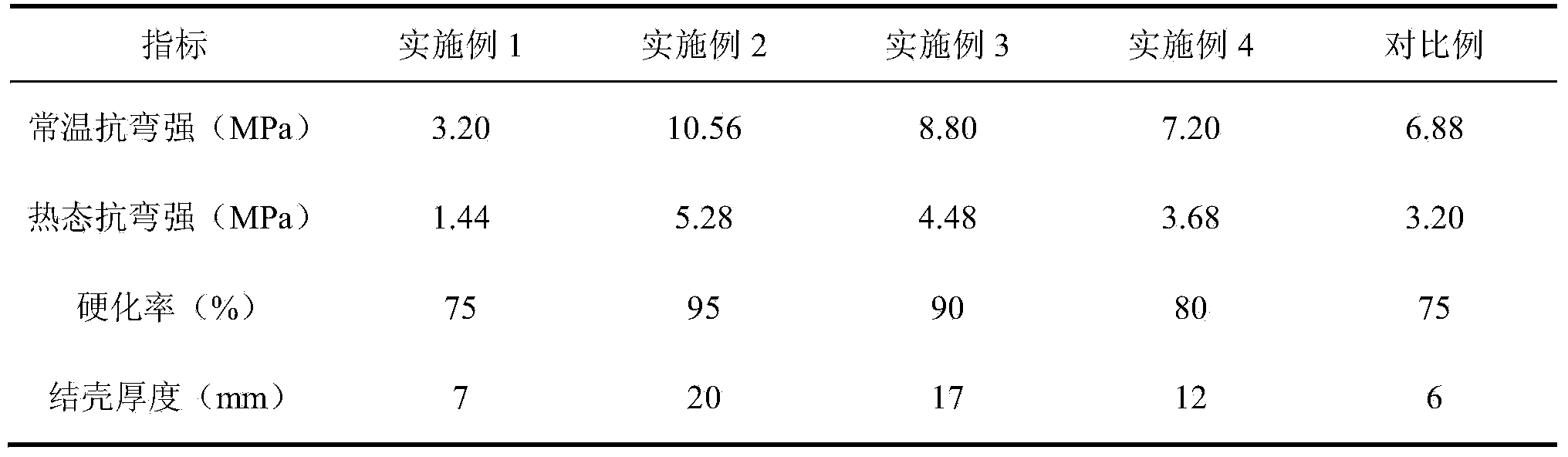

Examples

Embodiment 1

[0020] Put the raw sand composed of 70% quartz sand and 30% phase-change quartz sand according to the mass into the sand mixer, heat it to 120°C, add a coupling agent accounting for 0.1% of the binder mass, and carry out the first 5s Mix it once. Next, add a binder accounting for 1% of the mass of the original sand, and carry out the second mixing and grinding for 25 seconds. Then, add 0.1% additive and 3% curing agent accounting for the mass of the binder, and carry out the third mixing and grinding for 45s. Finally, after adding 1% lubricant to the mass of the binder and stirring evenly, the temperature was lowered to 60°C, crushed and sieved to obtain coated sand.

Embodiment 2

[0022] Put the raw sand composed of 90% quartz sand and 10% phase-change quartz sand according to the mass into the sand mixer, heat it to 130°C, add a coupling agent accounting for 0.5% of the binder mass, and carry out the first 10s Mix it once. Next, add a binder accounting for 4% of the mass of the original sand, and carry out the second mixing and grinding for 15 seconds. Then, add 1.0% additives and 15% curing agent accounting for the mass of the binder, and carry out the third mixing and grinding for 30 seconds. Finally, after adding 5% of the lubricant in the mass of the binder and stirring evenly, the temperature was lowered to 70°C, crushed and sieved to obtain coated sand.

Embodiment 3

[0024] Put the raw sand composed of 80% quartz sand and 20% phase-change quartz sand according to the mass into the sand mixer, heat it to 140°C, add a coupling agent accounting for 0.3% of the binder mass, and carry out the first 8s. Mix it once. Next, add a binder accounting for 2.5% of the mass of the original sand, and carry out the second mixing and grinding for 20 seconds. Then, add 0.6% additives and 10% curing agent accounting for the mass of the binder, and carry out the third mixing and milling for 60s. Finally, after adding 3% lubricant in the mass of the binder and stirring evenly, the temperature was lowered to 80°C, crushed and sieved to obtain coated sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com