Patents

Literature

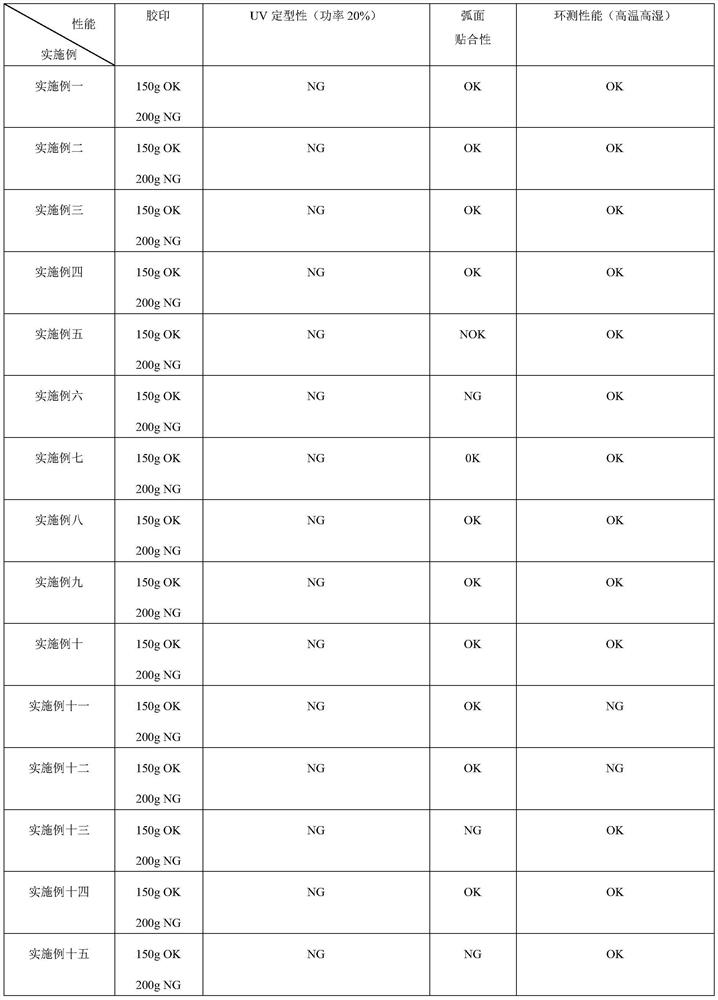

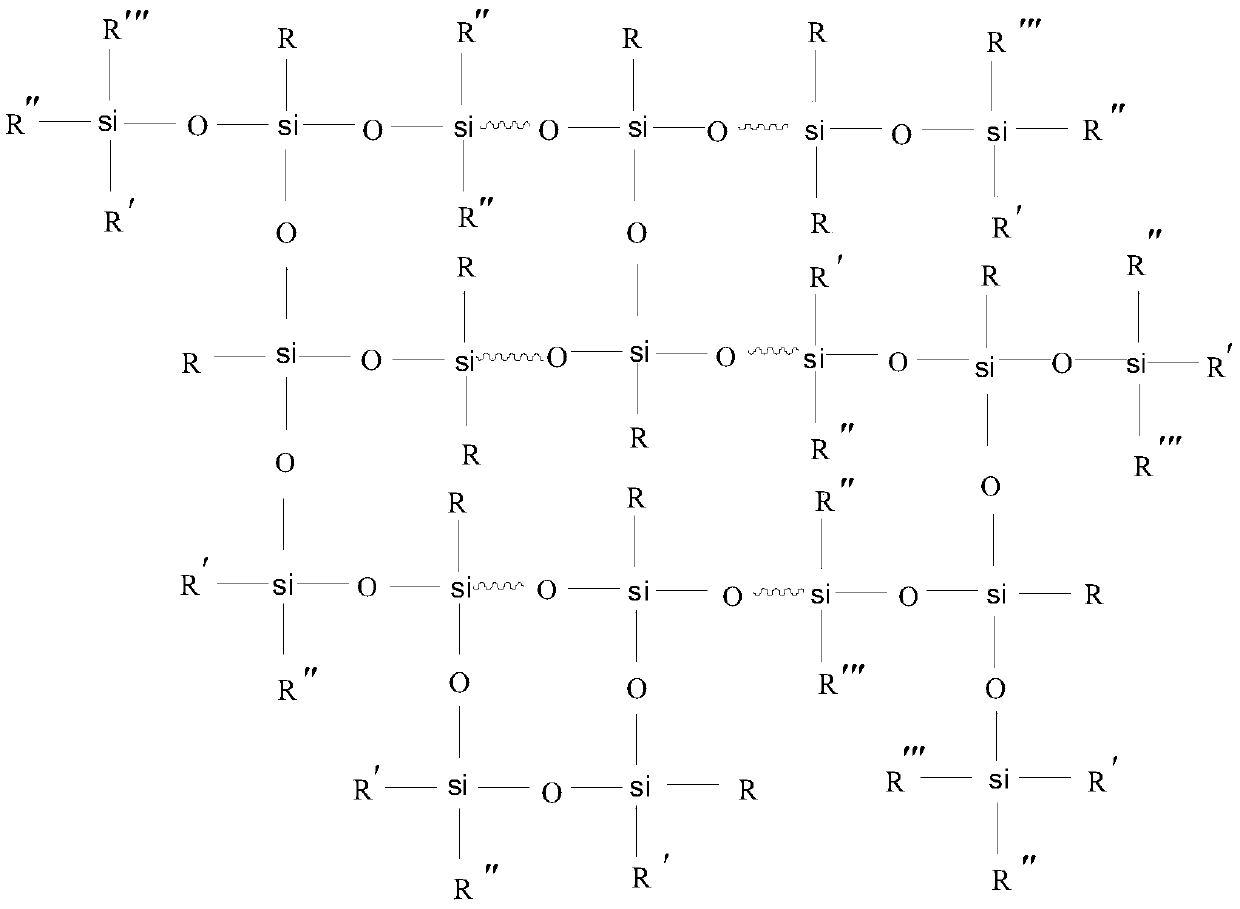

58results about How to "Stable peel force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making fog face release paper

ActiveCN102330381AReduce reflective effectGood haze effectPaper coatingCoatingsPlatinumPolyurethane adhesive

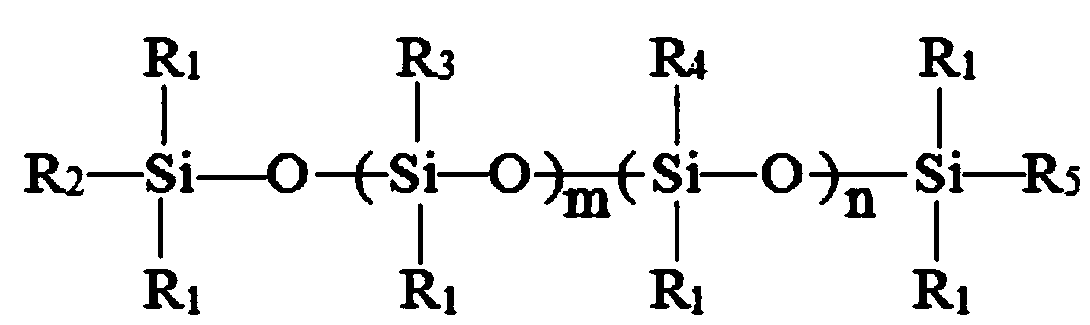

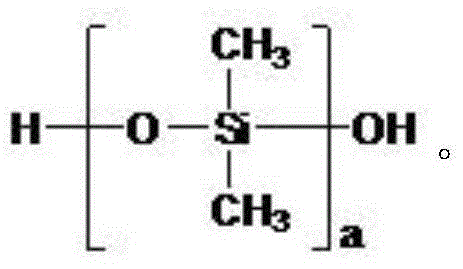

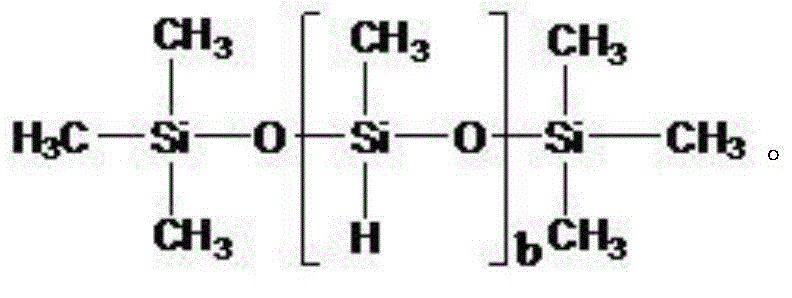

The invention relates to a method for making fog face release paper, which mainly comprises the following steps of: a first step of laminating a laminated layer on one lateral surface of body paper of the release paper by a laminating machine and cooling; a second step of coating a layer of fog face release agent on the laminated layer; and a third step of drying the fog face release agent. A rawmaterial formula of the fog face release agent comprises 25 to 35 percent of hydroxyl silicone oil, 0.5 to 4 percent of curing agent, 2 to 8 percent of catalyst, 15 to 55 percent of polyurethane adhesive, 0.3 to 5 percent of fumed silica and 10 to 50 percent of filler, wherein the curing agent is methyl hydrogen silicone fluid; the catalyst is platinum; and the filler is talcum powder of which the practical diameter is less than or equal to 15 microns. The method disclosed by the invention has simple production process and is convenient to operate. The cost is reduced. The concave-convex surface of laminated paper is filled and leveled up by the release agent mixed with a fog agent. The fog face release paper which has stable stripping strength and ensures the adhesive surface of a pressure sensing adhesive to have a good haze effect can be produced, so that the adhesive surface has a low-reflection effect.

Owner:太仓斯迪克新材料科技有限公司

Electrostatic resistant film and product including the same

InactiveCN101321426AImprove performanceStable peel forceFilm/foil adhesivesElectrostatic chargesProtection layerMembrane configuration

The invention relates to an antistatic membrane and articles containing the membrane. The membrane comprises: a basilar membrane; a conducting layer located on one surface of the basilar membrane; a protecting layer located on the surface of the conducting layer opposite to the basilar membrane to protect the conducting layer. The protecting layer contains particles restricting reduction of conductivity of the membrane surface and macromolecular film forming polymer. The grain diameter of at least part of particles is larger than the thickness of the protecting layer.

Owner:3M INNOVATIVE PROPERTIES CO

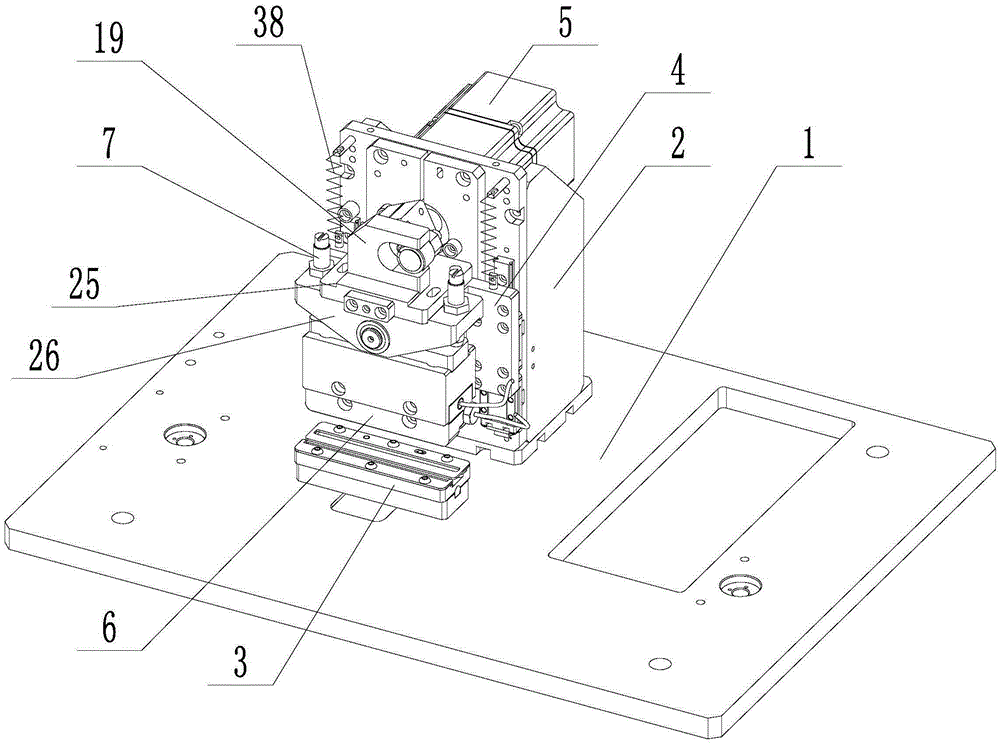

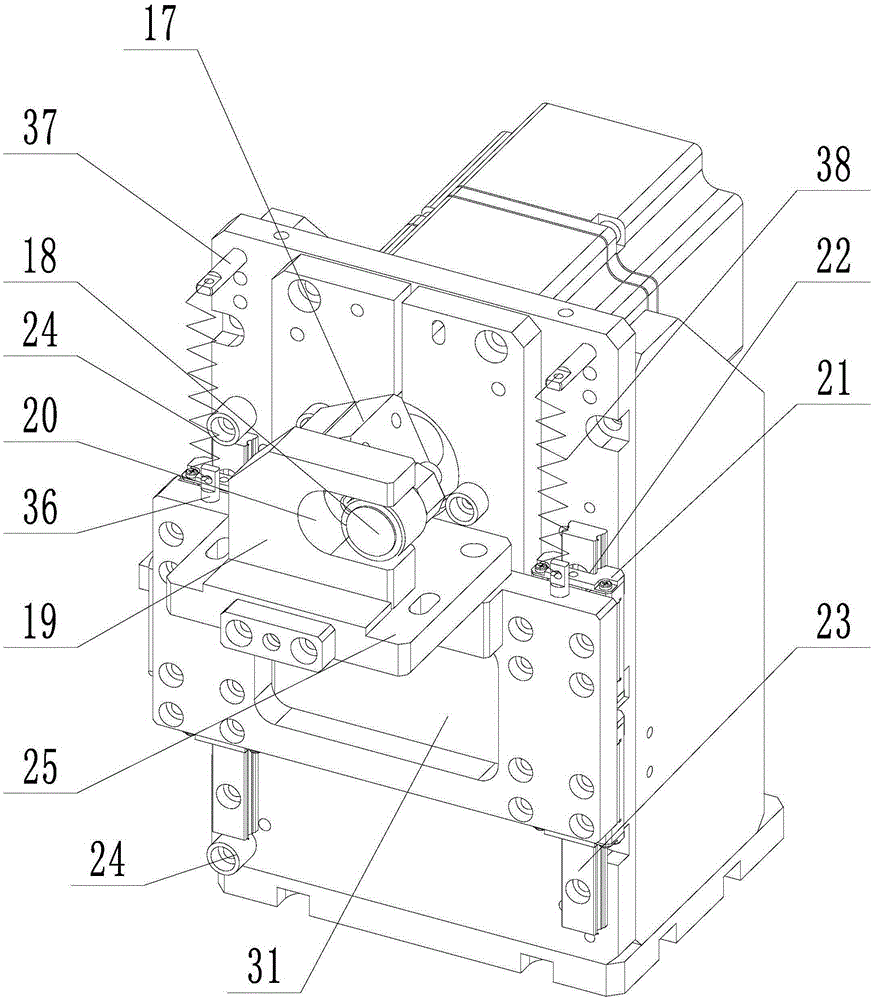

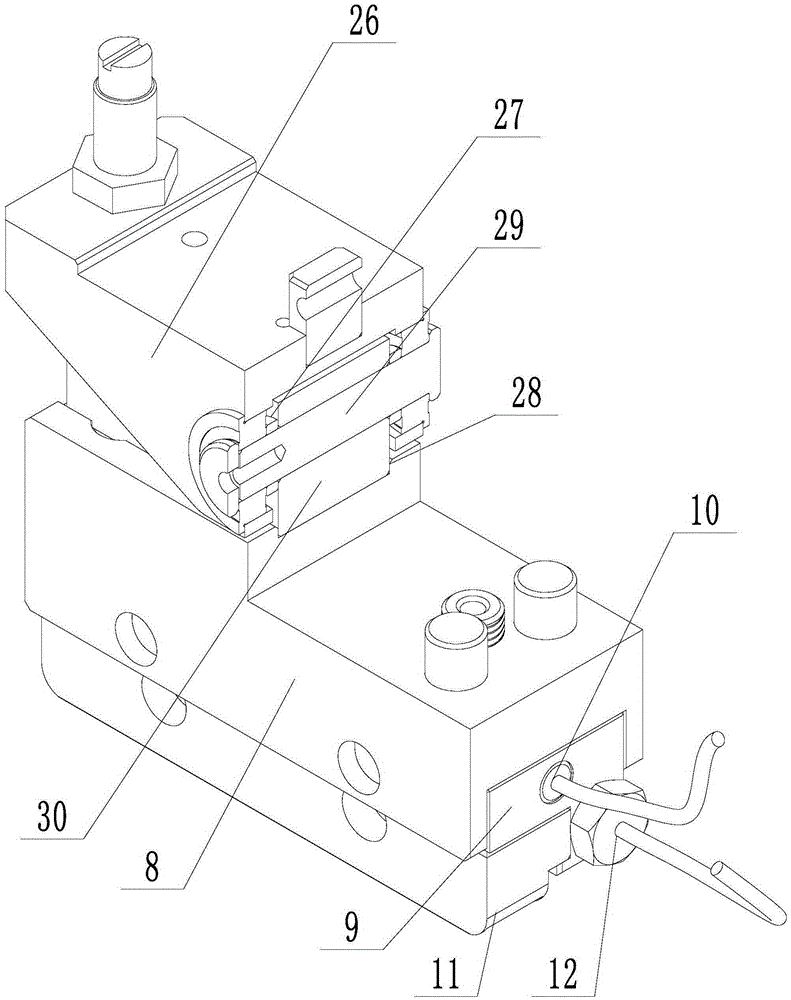

Hot-pressing carrier tape sealing mechanism

ActiveCN105523236AStable peel forceSmall temperature fluctuationsWrapper twisting/gatheringIsolation effectLoop control

The invention discloses a hot-pressing carrier tape sealing mechanism, and aims at solving the shortages that noise and vibration are high, a phenomenon of deviation of a carrier tape from a guide rail is liable to cause, a heat isolation effect between a sealing cutter and other components is poor, a temperature fluctuation on the sealing cutter is high, and accurate control cannot be realized, in the existing carrier tape hot-sealing mechanism. The hot-pressing carrier tape sealing mechanism disclosed by the invention comprises a hot-sealing base, wherein a drive component installation seat and a floating guide rail component are connected to the hot-sealing base; a vertically-lifting moving component is connected to the drive component installation seat in a sliding way, and a servo motor for driving the moving component to carry out lifting motion is fixedly connected to the drive component installation seat; a cutter bit component is rotationally connected to the lower end of the moving component; a buffer is connected between each of the two sides of the upper end of the cutter bit component and the moving component; the cutter bit component comprises a heat isolation block and a heating block; a heating rod is arranged in the heating block; a sealing cutter is connected to the lower end surface of the heating block; a temperature detector is installed between the sealing cutter and the heating block; and the temperature detector, the heating rod and a temperature controller form a closed-loop control loop.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

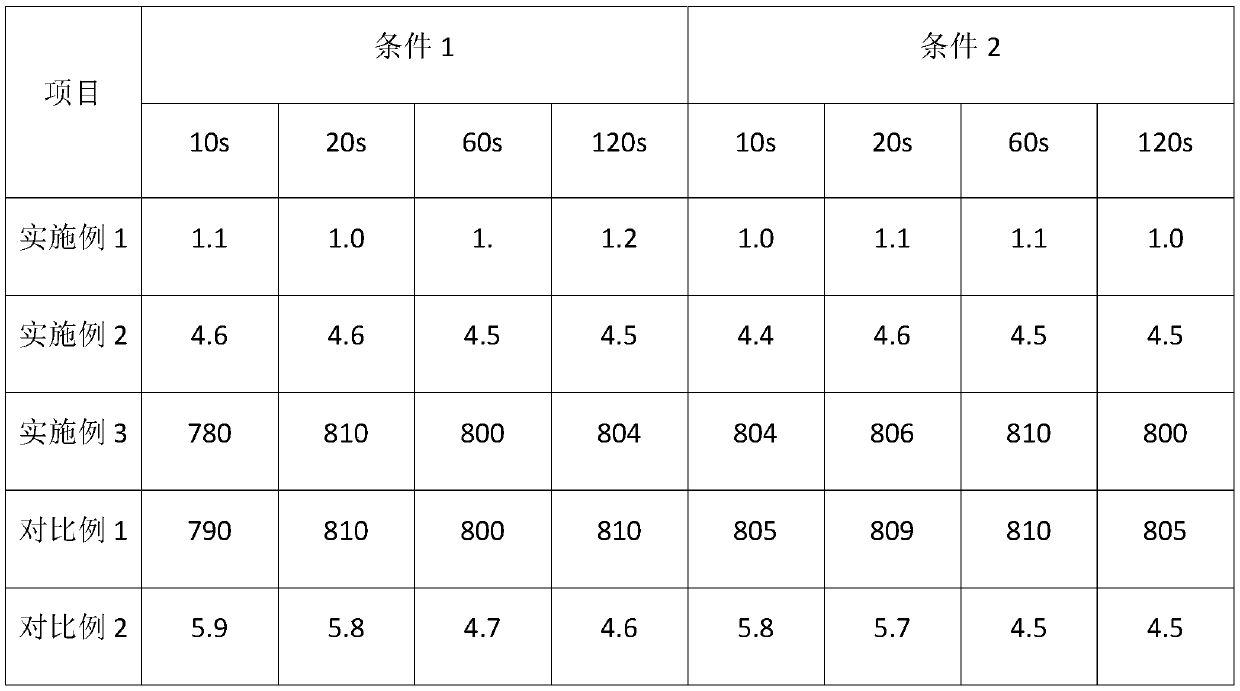

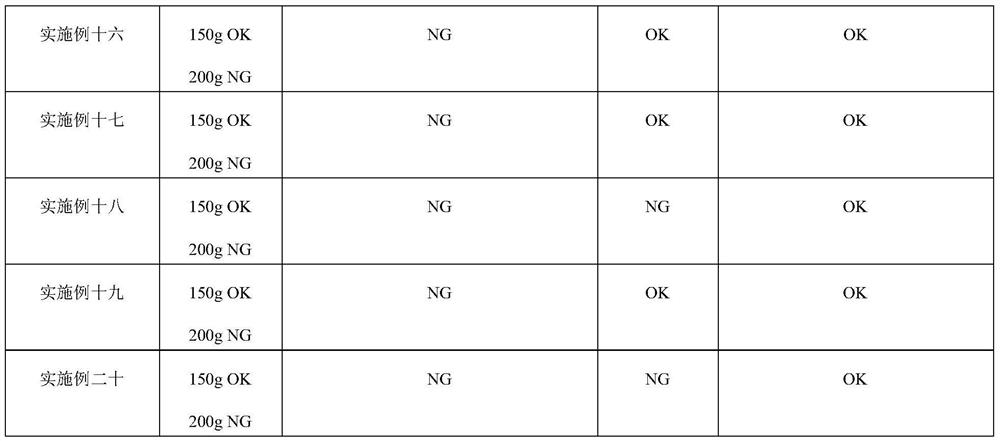

Quick-curing organosilicon pressure-sensitive adhesive and adhesive tape

InactiveCN110343483AFast cross-linking rateStable peel forceMacromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer scienceFunctional monomer

The invention discloses a quick-curing organosilicon pressure-sensitive adhesive, and belongs to the field of adhesives. The organosilicon pressure-sensitive adhesive is obtained by carrying out an addition reaction on a polysiloxane methyl vinyl MQ organosilicon tackifier containing vinyl under the action of a cross-linking agent, a reaction inhibitor and a platinum catalyst. According to the organosilicon pressure-sensitive adhesive provided by the invention, through selection of monomers, especially selection of functional groups and proportions of the functional monomers, optimization andimprovement of a process, and selection of a matching effect of the catalyst and the functional groups of the functional monomers, the adhesive can achieve the purpose of direct winding and quick curing after a base material is coated, and good viscous force and stripping force can be ensured.

Owner:太仓斯迪克新材料科技有限公司

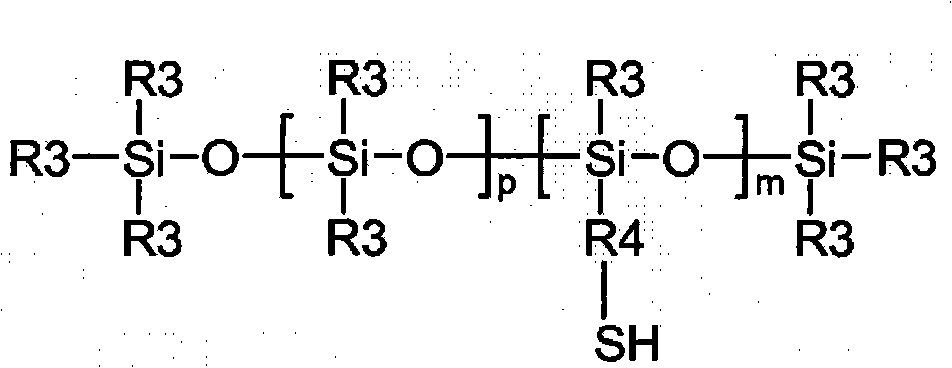

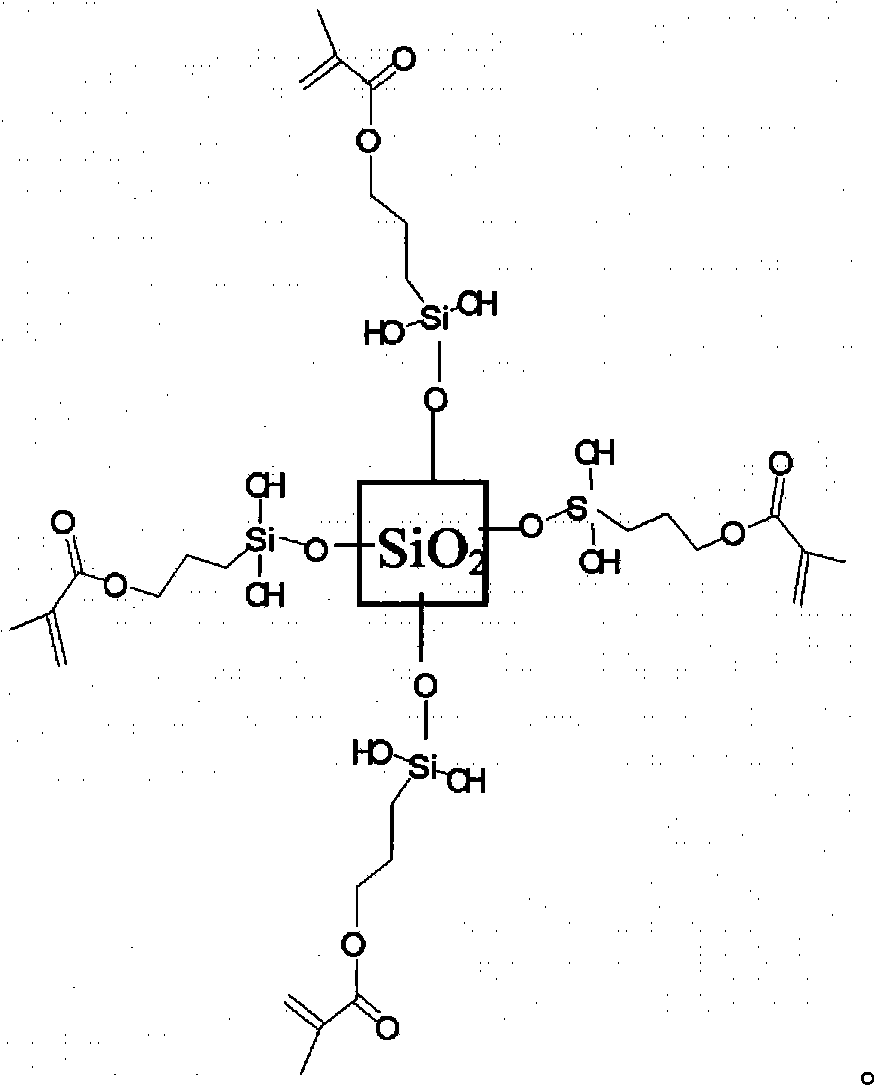

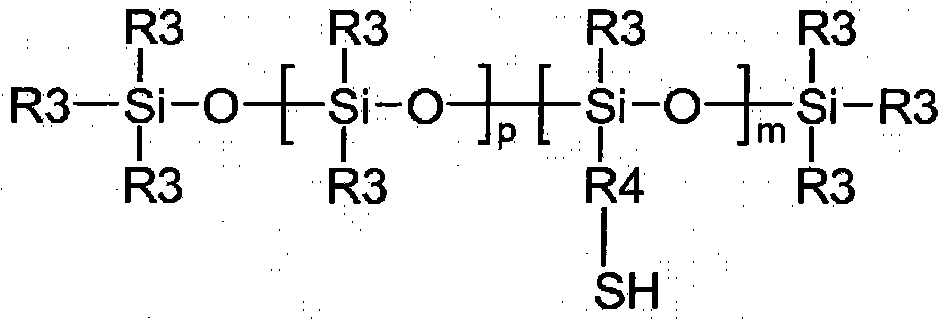

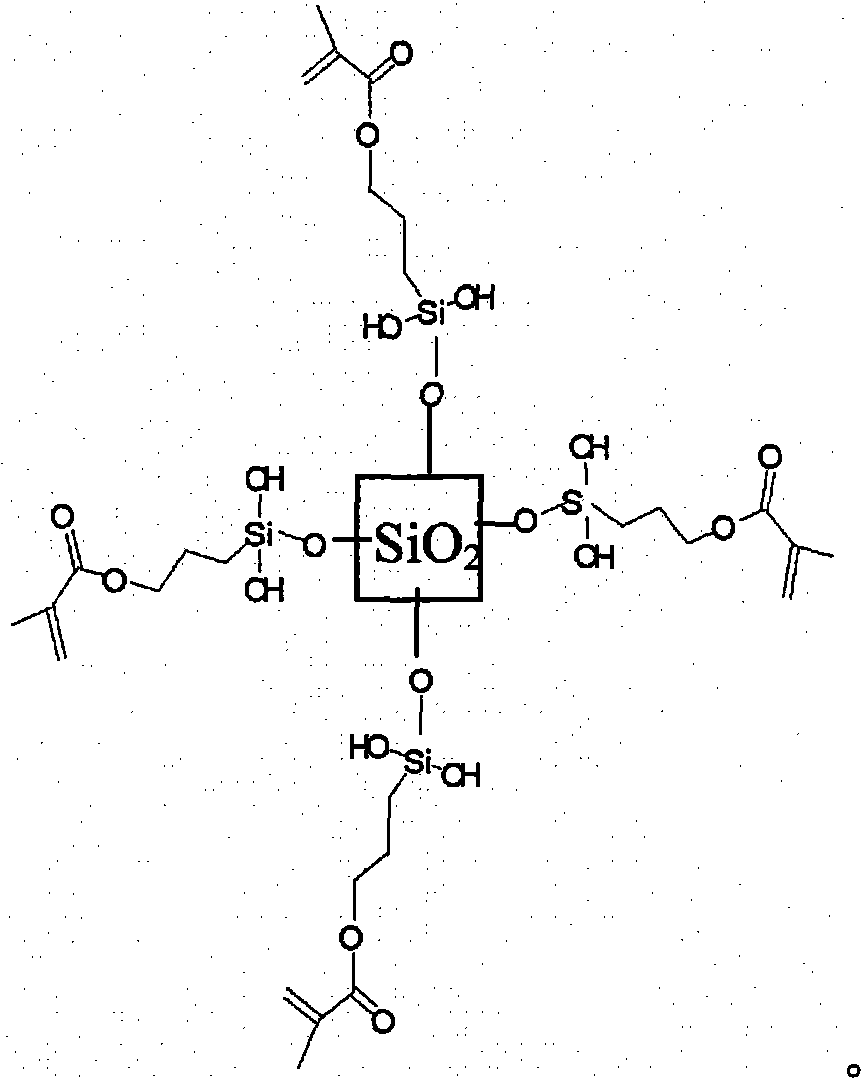

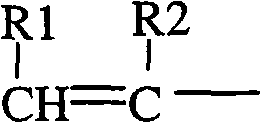

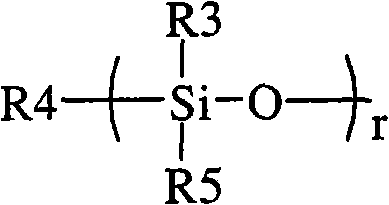

Copolymers of nanoparticles, vinyl monomers and silicone

InactiveCN101910228AStable peel forceMaterial nanotechnologyFilm/foil adhesivesSilica nanoparticlesMeth-

A copolymer comprises the reaction product of (a) (meth)acrylate functionalized nanoparticles, (b) vinyl monomer, and (c) mercapto-functional silicone. The (meth)acrylate functionalize nanoparticles are selected from the group consisting of silica nanoparticles, zirconia nanoparticles, titania nanoparticles, and combinations thereof.

Owner:3M INNOVATIVE PROPERTIES CO

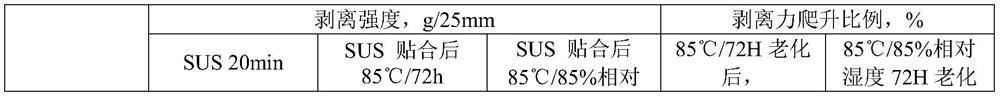

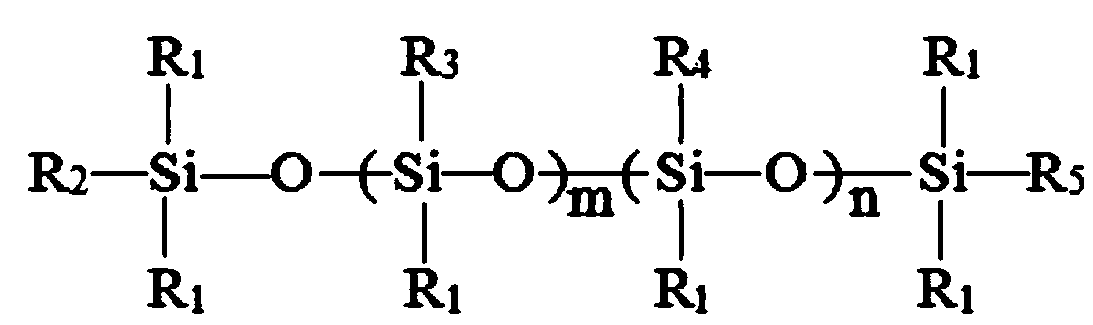

Low-climbing organic silicon pressure-sensitive adhesive and preparation method and application thereof

PendingCN113388362AStable peel forceThe synthesis operation process is simpleMacromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer scienceMeth-

The invention discloses a low-climbing organic silicon pressure-sensitive adhesive and a preparation method and application thereof, and belongs to the technical field of pressure-sensitive adhesive silica gel protective films. The organic silicon pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 100 parts of vinyl polysiloxane, 20 to 100 parts of methyl MQ silicon resin, 0.5 to 1.5 parts of a cross-linking agent, 0.5 to 1 part of a catalyst, 0.05 to 1 part of an inhibitor and 100 to 200 parts of a diluting solvent. Vinyl polysiloxane with a special structure and vinyl content and cross-linking agent silicon-hydrogen group-containing silicone oil with a special structure and hydrogen content are adopted, the prepared organic silicon pressure-sensitive adhesive is low in stripping force and obvious in climbing effect under high-temperature and high-humidity conditions; the adhesive is simple in synthesis operation process, low in cost and convenient to produce and use.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Copolymers of nanoparticles, vinyl monomers and silicone

InactiveCN101910224AStable peel forceMaterial nanotechnologyFilm/foil adhesivesSilica nanoparticlesFunctionalized nanoparticles

A copolymer comprises the reaction product of (a) (meth)acrylate functionalized nanoparticles, (b) vinyl monomer, and (c) silicone macromer. The (meth)acrylate functionalize nanoparticles are selected from the group consisting of silica nanoparticles, zirconia nanoparticles, titania nanoparticles, and combinations thereof.

Owner:3M INNOVATIVE PROPERTIES CO

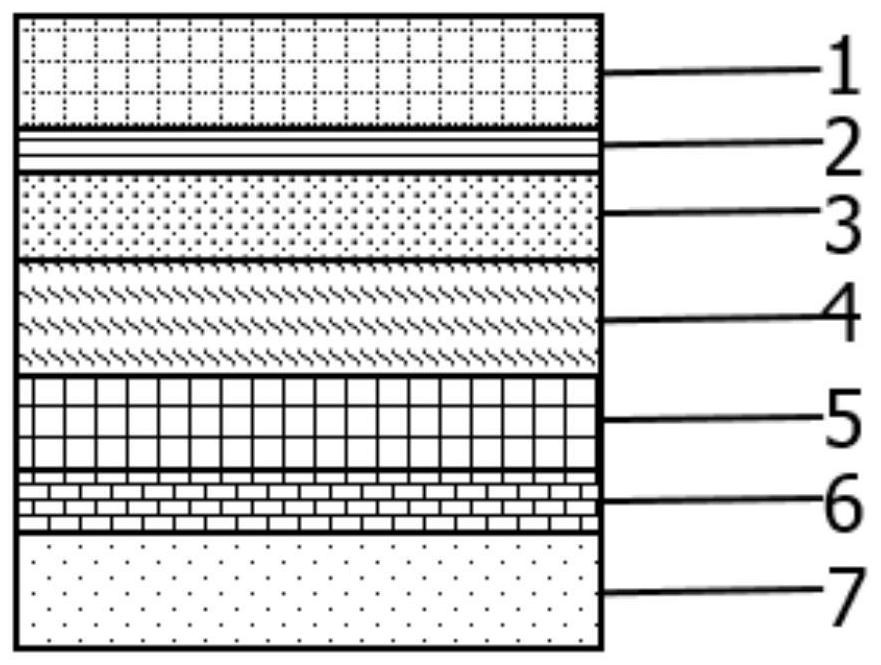

3D curved surface AF coated screen mobile phone protective film and preparation method thereof

ActiveCN113211911AHigh light transmittanceSame polarization directionSynthetic resin layered productsRubber layered productsAdhesiveUltraviolet

The invention discloses a 3D curved surface AF coated screen mobile phone protective film and a preparation method thereof. A hardened layer, a PET layer with the polarization angle of 70-100 degrees, a modified photo-thermal dual-curing acrylic polyurethane layer, a non-optical-axis optical elastic layer and a special silica gel pressure-sensitive adhesive layer for an AF screen are adopted as main structures; thenon-optical-axis optical elastic layer has no polarization angle; an upper protection layer can realize a self-separation function, and the modified photo-thermal dual-curing acrylic polyurethane layer adopts specific material components, so that both thermal curing and photo-curing can be carried out. The protective film and the preparation method thereof have the advantages that bending forming molds of different specifications do not need to be customized according to the sizes of different 3D curved surface AF coated screen mobile phones during production, forming can be completed only through cutting and flaking, film pasting can be achieved at a client side in the follow-up process only through positioning film covering and ultraviolet lamp UV curing and attaching, hot-pressing high-temperature operation and demolding are not needed in the whole process, the overall production efficiency is remarkably improved, and the production cost is greatly reduced.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

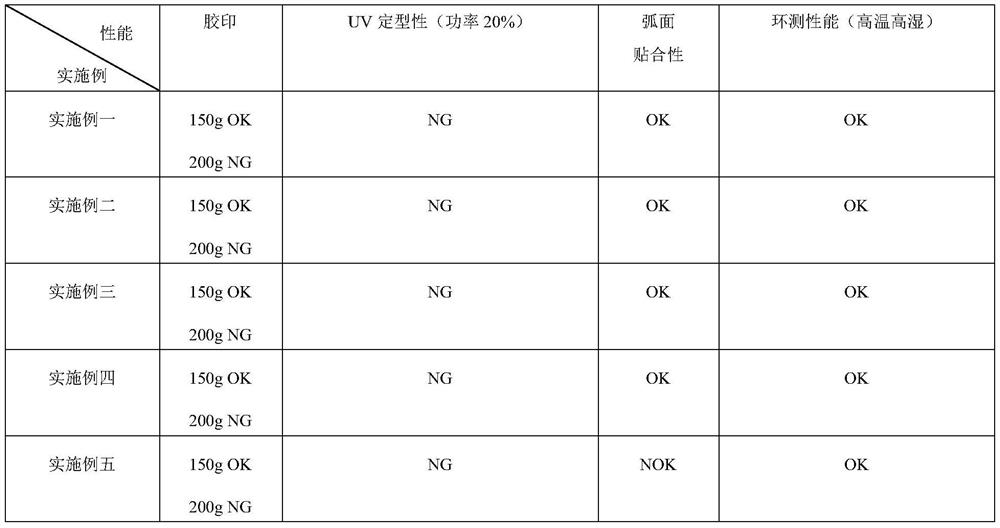

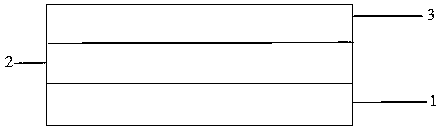

Process film production method for process of stable adhesion after high temperature, and product thereof

InactiveCN110437760ASolve the problem of sharp increase in peeling forceStable peel forceNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesLength wavePhotoinitiator

The invention discloses a process film production method for a for process of stable adhesion after a high temperature, and a product thereof. A substrate in the process film is a PET, PO, PVC or PP optical film with a thickness of 25-200 [mu]m, and one side of the optical film is subjected to corona treatment; and a pressure-sensitive adhesive layer is a UV viscosity reducing adhesive layer, andcomprises 0.1-5% of a photoinitiator having an absorption wavelength of 200-400 nm and 0.5-10% of nanocrystall beads, and the pressure-sensitive adhesive is applied to the corona surface of the substrate, and is covered with a release film, the peeling strength before UV is 500-5000 g / 25 mm, and the peeling strength after UV is 0-100 g / 25 mm. The peel strength is stable when the process film is used in a high temperature environment, so the problem that the peeling strength of the UV viscosity reducing adhesive film in the high temperature environment is greatly increased is solved, the residual glue phenomenon is avoided, the stability of the technology process is increased, and the yield and the efficiency are improved. The product is mainly applied to the processing process of a film group at present.

Owner:上海精珅新材料有限公司

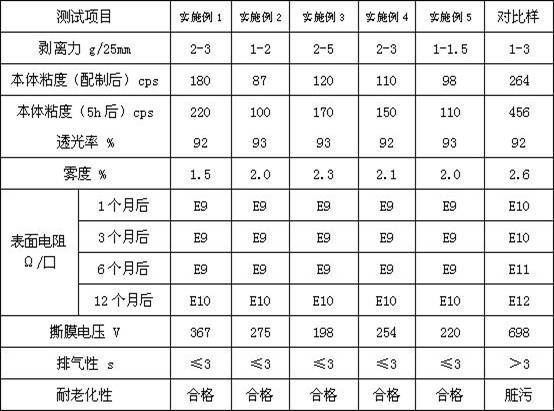

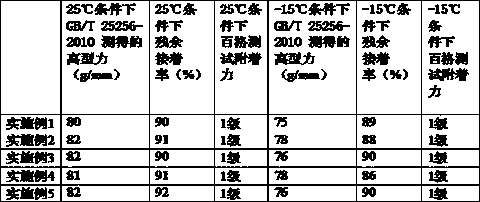

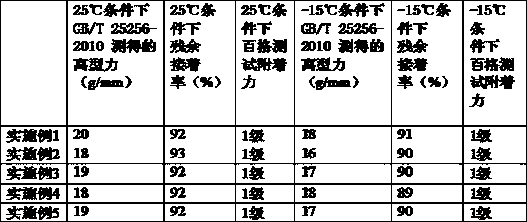

Antistatic polyurethane protective film and preparation method thereof

ActiveCN113372842AWith process stabilityPersistentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to an antistatic polyurethane pressure-sensitive adhesive protective film and a preparation method thereof. The antistatic polyurethane pressure-sensitive adhesive protective film is prepared by uniformly coating a polyurethane pressure-sensitive adhesive on a plastic film substrate and baking at high temperature, wherein the polyurethane pressure-sensitive adhesive is prepared from the following components in parts by mass: 100 parts of polyurethane resin slurry, 50-300 parts of a dissolving agent, 3-15 parts of a curing agent, 0.02-1.2 parts of a delay catalyst and 0.1-1.5 parts of an antistatic agent; the delay catalyst is a thermal activation type amine delay catalyst; and the antistatic agent is an ionic liquid antistatic agent. According to the antistatic protective film, the silicon transfer phenomenon of an organic silicon pressure-sensitive adhesive is avoided, the antistatic protective film also has stripping force stability and aging resistance superior to those of an acrylate pressure-sensitive adhesive, meanwhile, the antistatic protective film has a stable and excellent antistatic effect, and the protective film has good self-exhaust performance, good adhesion performance, soft and residue-free torn film, stable stripping force and excellent aging performance. The preparation method disclosed by the invention is simple in process and easy for industrial production and control.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

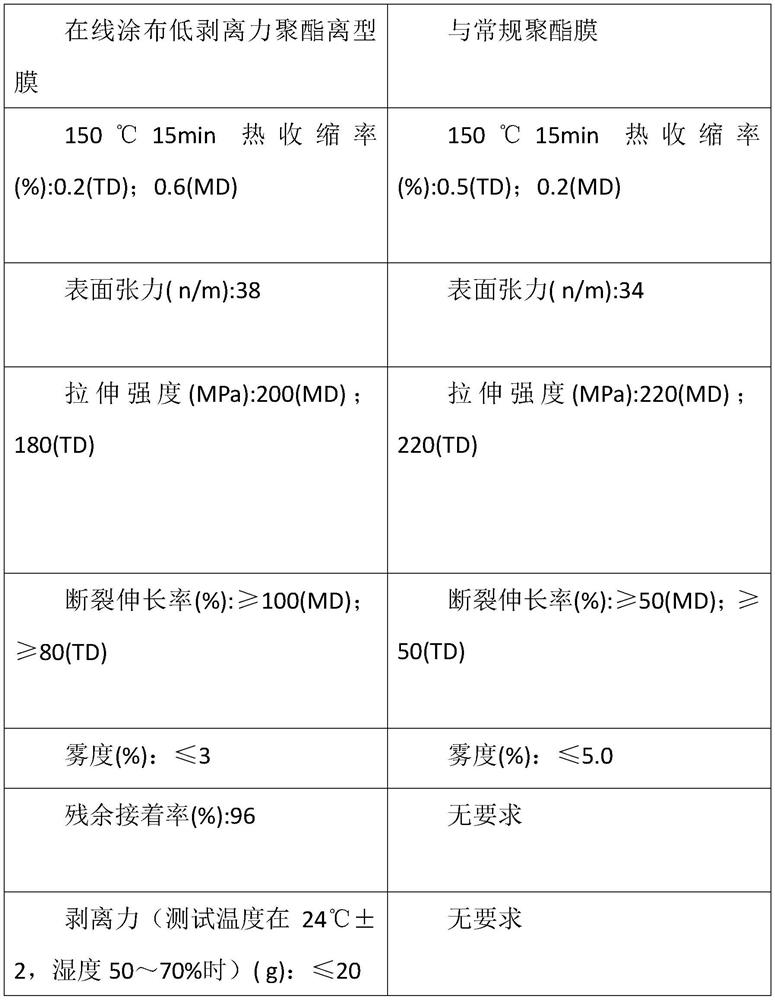

On-line coating low-stripping-force polyester release film and preparation method thereof

InactiveCN113416503ASolve the problem of high peel forceSmall peeling forceFilm/foil adhesive release linersPolyester coatingsPolymer sciencePolyester resin

The invention relates to an on-line coating low-stripping-force polyester release film which comprises a polyester base film and a release coating coating surface of one side of the polyester base film. The polyester base film is composed of film-grade polyester resin, fluorine-containing polyester resin and antistatic polyester resin, the weight percentage of each component is as follows: 80-90% of film-grade polyester resin, 5-10% of fluorine-containing polyester resin and 5-10% of antistatic polyester resin; the polyester base film is of a single-layer structure and is prepared through melt extrusion and two-way stretching, and the thickness of the polyester base film is 20-60 micrometers. The release coating is formed by coating release coating liquid and carrying out baking and curing treatment, and the thickness of the release coating is 1-5 microns. The on-line coating low-stripping-force polyester release film provided by the invention is prepared through the processes of release coating liquid and base film preparation, single-layer extrusion, coating curing and the like, has the characteristics of low stripping force, stable release force, heat resistance, antifouling property and the like, and can meet the use requirements of packaging labels such as adhesive labels, electronic labels, bar codes and the like in the industries of electronics, medicines, daily chemicals, foods and the like.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

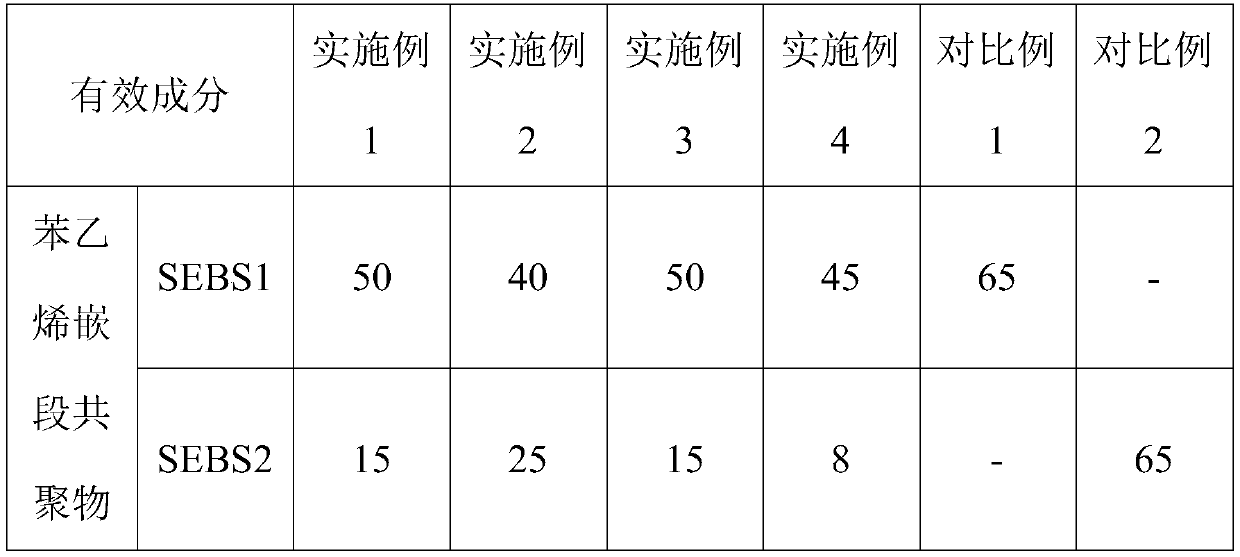

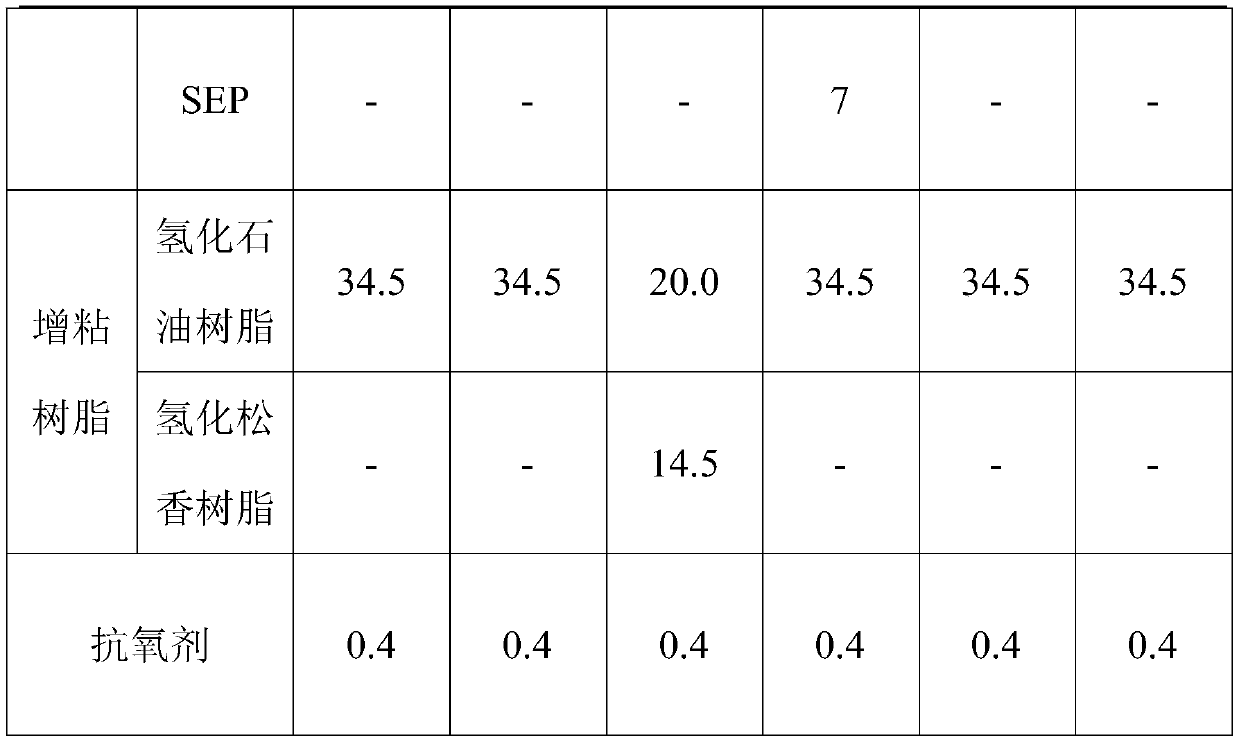

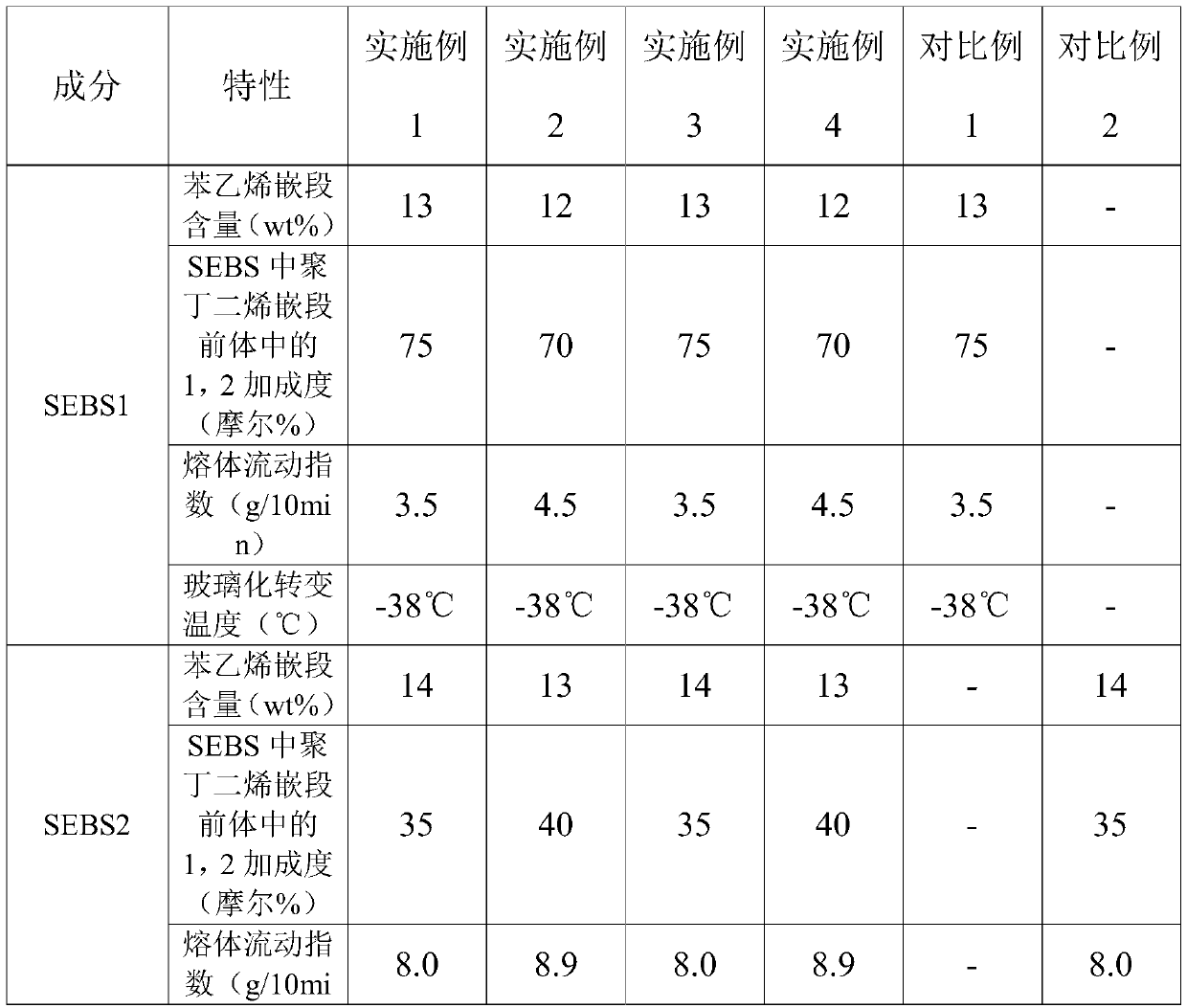

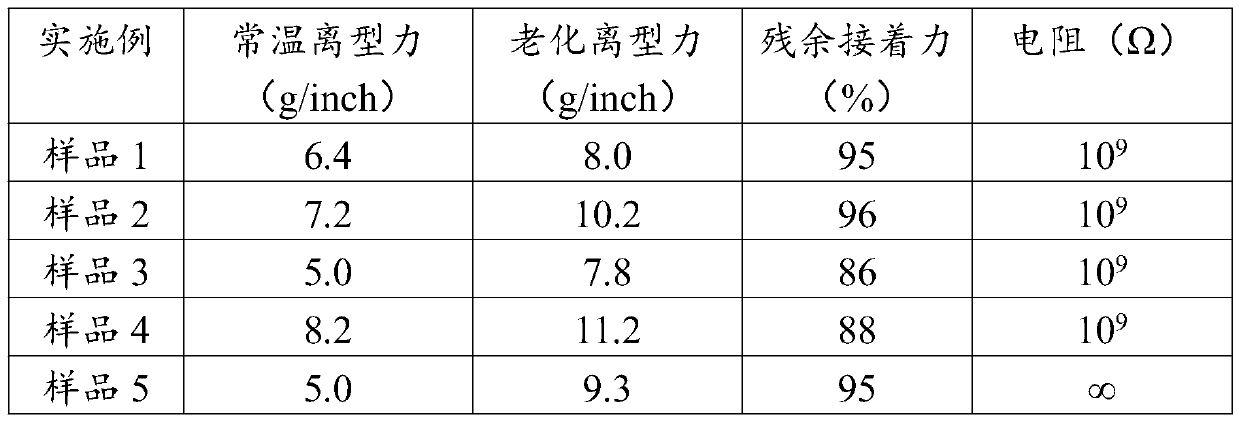

Hot melting pressure-sensitive glue as well as preparation method and application thereof

ActiveCN109777331ANo pollutionImprove stabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesTectorial membranePlasticizer

The invention discloses a hot melting pressure-sensitive glue as well as a preparation method and application thereof. The hot melting pressure-sensitive glue comprises the following effective components in parts by weight: 55-70 parts of styrene segmented copolymer, 30-45 parts of tackifying resin, and 0.1-0.5 part of an antioxidant. The preparation method comprises the following steps: mixing styrene segmented copolymer, tackifying resin and antioxidant to obtain a mixture; pelletizing the mixture in water; drying. The hot melting pressure-sensitive glue is used for preparing a protection film; the hot melting pressure-sensitive glue is free from plasticizer such as mineral oil and polybutene oil; the problems of oil separating out and smoking in processing are avoided; a die head is notinfluenced; the production can be continuously carried out; generation of three wastes in production is avoided; the environmental pollution is avoided.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Antistatic agent, antistatic release film and preparation method of antistatic release film

InactiveCN111518472AStable characteristicsStable chemical and physical propertiesElectrically-conductive paintsPolymer scienceFilm material

The invention relates to the technical field of film material preparation, in particular to an antistatic agent, an antistatic release film and a preparation method of the antistatic release film. Theantistatic release film comprises a base film layer and a functional layer, wherein the functional layer is prepared from the antistatic agent. The antistatic agent comprises the following componentsin parts by weight: 0.05-0.5 parts of a conductive monomer, 20-40 parts of light-cured organic siloxane resin, 60-80 parts of a light-cured organic silicon release agent and 0.05-0.5 parts of a photoinitiator. The antistatic release film disclosed by the invention is stable in characteristics, adopts a photocuring mode, is thorough in curing, forms a polymer film, and is stable in chemical and physical properties, stable in stripping force and antistatic capacity, good in adhesive force and less in silicon transfer. The process is simple and is completed at one time, the production efficiencyis high, the cost is low, and few waste materials are generated in production.

Owner:苏州鸿科新材料科技有限公司

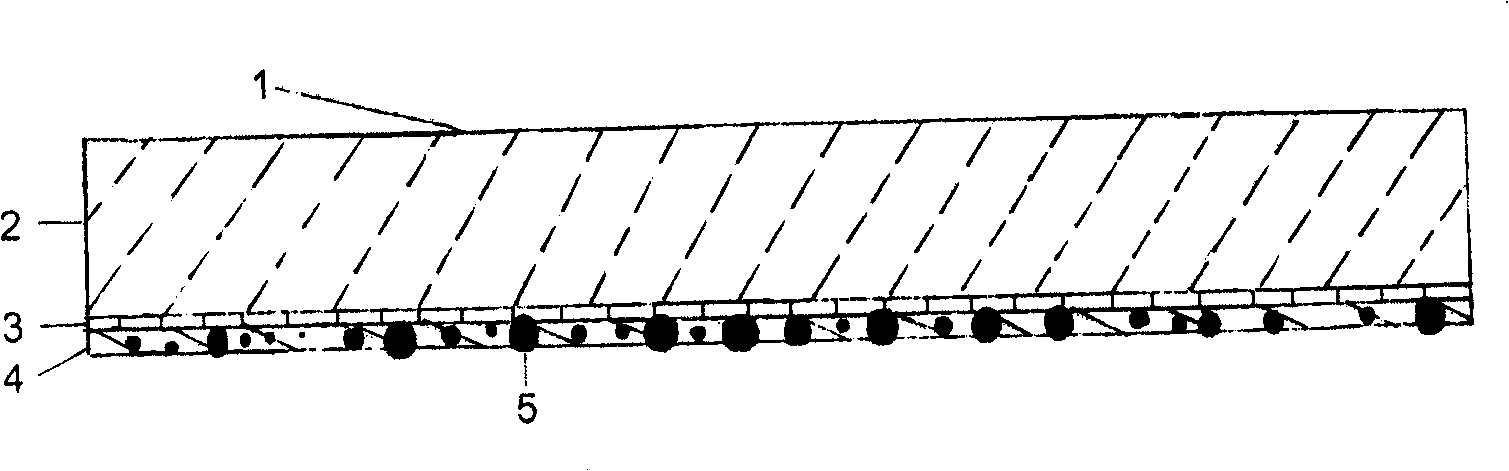

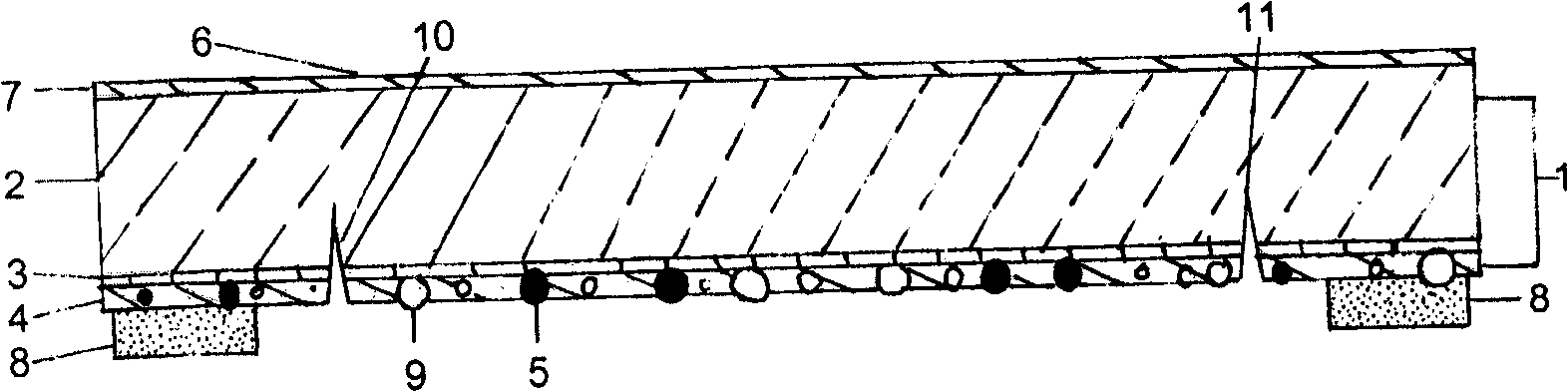

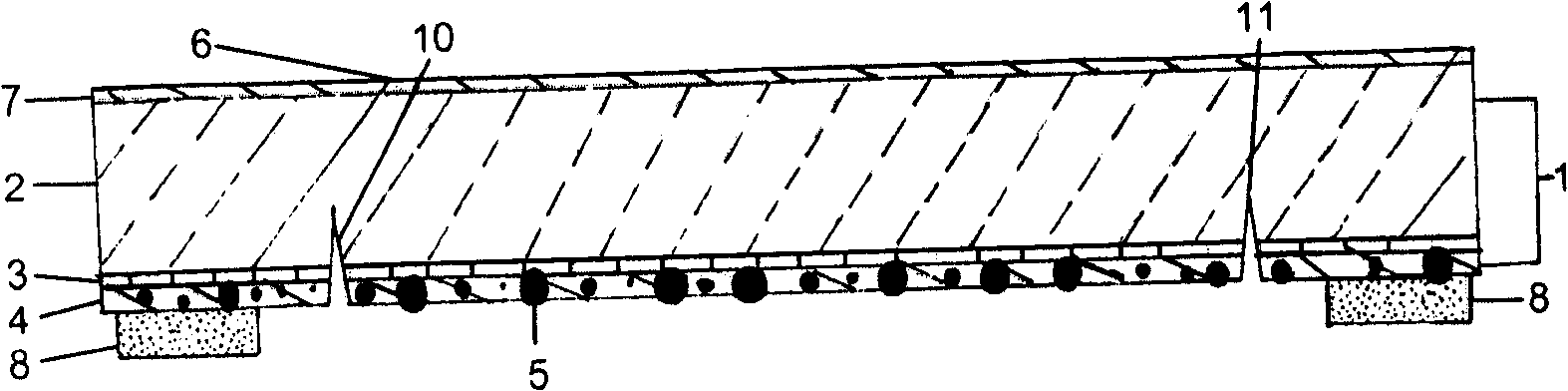

Surface mount component carrier tape upper cover tape and processing method thereof

InactiveCN101955015ADoes not cause problems with changes in peel strengthSave raw materialsFlexible coversWrappersSurface mountingHot melt

The invention discloses a surface mouth component carrier tape upper cover tape which comprises a PET thin film, wherein a hot melt adhesive layer formed by a hot melt adhesive is coated on the lower surface of the PET thin film, two parallel longitudinal die lines are formed on the hot melt adhesive layer, and die lines which are shaped like an inverted V are formed on the left side and the right side of the two longitudinal die lines. When the surface mouth component carrier tape upper cover tape is used, a client can obtain stable stripping force by only needing to tear apart in the direction of the inverted V along the positions of the die lines after joint, the strength of the stripping force can be determined by the size of a small-diameter cutting knife and different depths formed by cutting, and the upper cover tape of the left and the right die lines still leave on a lower tape, thereby avoiding the problem of leading the stripping strength of the cover tape to change; furthermore, the upper cover tape can save raw materials and save processing cost; and the processing method can be completed once and the processing method is simple.

Owner:WUJIANG YAOXIN PHOTOELECTRICITY

Optical transparent double-sided tape

InactiveCN108690521AImprove residual adhesionReduce transfer rateCoatingsFilm/foil adhesive release linersAdhesiveHigh heat

The invention discloses an optical transparent double-sided tape. The optical transparent double-sided tape comprises a light-peeling release film, a first optical adhesive layer, a transparent substrate layer, a second optical adhesive layer, and a heavy-peeling release film, the light-peeling release film comprises a first basic film layer and a light-peeling release agent layer used for coatingthe surface of the first basic film layer, the light-peeling release agent layer is obtained by solidifying with a light-peeling release agent, the heavy-peeling release film comprises a second basicfilm layer and a heavy-peeling release agent layer used for coating the surface of the second basic film layer, and the heavy-peeling release agent layer is obtained by solidifying with a heavy-peeling release agent. The optical transparent double-sided tape overcomes the defects that the current release agents can keep stable low peel strength under normal temperature and high temperature, realizes low peel strength under low temperature, and increases the product weatherability.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Single-resisting one-side release film

InactiveCN108690514AImprove weather resistanceImprove residual adhesionFilm/foil adhesivesCoatingsDistillationDibenzoyl Peroxide

The invention discloses a single-resisting one-side release film. A release agent layer is obtained by solidifying a release agent. The release agent comprises the following components: prepolymerizedresin, methylhydroquinone, 3-epoxypropane, dodecyl glycidyl ether, and 1-hydroxy cyclohexyl phenylketone. The prepolymerized resin is obtained by the following steps: mixing cyclohexyl methacrylate,beta-carboxyethyl acrylate, acrylic acid in a stirring barrel, and uniformly stirring the materials at a low speed to form a primary mixture; mixing primary mixture, xylene, and benzoyl peroxide, andadding a mixture in a reaction vessel to obtain a polymer solution; stirring the polymer solution and 2-hydroxyethyl vinyl ether at a high speed, and heating the materials and performing heating distillation to remove xylene to obtain the prepolymerized resin. The single-resisting one-side release film cannot generate unfavorable influence on electric property of a circuit board, increases the reliability of the circuit board, and realizes low-energy rapid light-curing under UV light irradiation.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Easy-to-peel MLCC release film and preparation method thereof

ActiveCN113978086AGood compatibilityGood dispersionSynthetic resin layered productsPolymer scienceGraphene flake

The invention belongs to the technical field of films, and particularly relates to an easy-to-peel MLCC release film and a preparation method thereof. An online PET release agent coating technology is adopted, and plasma is adopted to treat the surface of the film in the production process, so that the binding force between silicone oil and the film is better, and the peeling property to ceramic is better; and the release film comprises at least two layers: the surface layer comprises siloxane modified molybdenum disulfide, montmorillonite or graphene sheet inorganic material and PET, and the base layer is 100% PET. The invention also provides a production process of the release film, wherein the production process comprises the following steps: (1) preparing a base film with at least two layers of structures; (2) heating and longitudinally stretching the base film; (3) treating the surface of the base film by plasmas; (4) coating the treated surface of the base film with silicone oil emulsion; and (5) heating and transversely stretching the thick film of the uncured emulsion coating layer to complete coating layer curing, heat setting and cooling. The siloxane-modified two-dimensional nano material can improve the smoothness of the surface layer, so that the surface roughness of the film is reduced.

Owner:常州钟恒新材料股份有限公司

A kind of 3D curved surface AF coating screen mobile phone protective film and preparation method thereof

ActiveCN113211911BHigh light transmittanceSame polarization directionSynthetic resin layered productsRubber layered productsColloidal silicaUV curing

The invention discloses a 3D curved surface AF coating screen mobile phone protective film and a preparation method thereof, which adopts a hardened layer, a PET layer with a polarization angle of 70-100°, a modified photothermal double-cured acrylic polyurethane layer, and optical axis-free optical elasticity. Layer and special silicone pressure-sensitive adhesive layer for AF screen as the main structure, the optical elastic layer without optical axis has no polarization angle, the upper protection layer can realize self-separation function, and the modified photothermal dual-curing acrylic polyurethane layer adopts specific material components, both It can be heat-cured and light-cured; the advantage is that it is not necessary to customize bending molding molds of different specifications according to the size of different 3D curved AF coated screen mobile phones during production. It only needs to be cut and made to complete the molding. At the end, the film can be pasted only by positioning the film and UV curing and pasting with ultraviolet lamps. In the whole process, there is no need for hot pressing and high temperature operation and demoulding, the overall production efficiency is significantly improved, and the production cost is greatly reduced.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

Preparation method of double-sided antistatic protective film for graphite sheet calendering

InactiveCN107151342AStable peel forceHigh light transmittanceSilicaCoatingsPolyethylene terephthalate glycolAntistatic agent

The invention discloses a preparation method of double-sided antistatic protective film for graphite sheet calendering; the preparation method comprises the steps of 1) preparing nano white carbon black; 2) preparing an antistatic agent; 3) preparing a coating liquid; 4) applying the coating liquid to PET (polyethylene terephthalate) film, and drying; 5) coating one side of the PET film with the antistatic agent, and drying; 6) coating the other side of the PET film with the antistatic agent, and drying to obtain the double-sided antistatic protective film for graphite sheet calendering. The double-sided antistatic protective film for graphite sheet calendering, having more stable peeling force and higher transparency, is prepared herein; the double-sided antistatic protective film for graphite sheet calendering is low in cost and good in environmental friendliness. The double-sided antistatic protective film for graphite sheet calendering prepared herein has double-side antistatic property, with peeling force controlled to 4-9 g and transparency not less than 85%.

Owner:苏州美辰新材料有限公司

Silicon paintable antistatic emulsion with good stability and preparation method thereof

ActiveCN109852203AConductiveGood and stable conductivityElectrically-conductive paintsEmulsionCarbon nanotube

The invention relates to the technical field of antistatic emulsion, and discloses a silicon paintable antistatic emulsion with good stability and a preparation method thereof. The silicon paintable antistatic emulsion comprises following components in parts by weight: 5 to 20 parts of a linear silane coupling agent containing an epoxy group, 0.05 to 1 part of phenyl hydroxyl net like silicon resin, 5 to 50 parts of conductive polymer (polythiophene), 0.5 to 20 parts of a water solution of single-walled carbon nanotubes, 1 to 5 parts of a surfactant, and 30 to 55 parts of water. After the silicon paintable antistatic emulsion is painted on a film, the prepared antistatic film has a good and stable antistatic performance, and then silicon is painted on the antistatic film to prepare an antistatic release film, which has a good antistatic performance and also has a release function.

Owner:中山市聚力有机硅技术有限公司

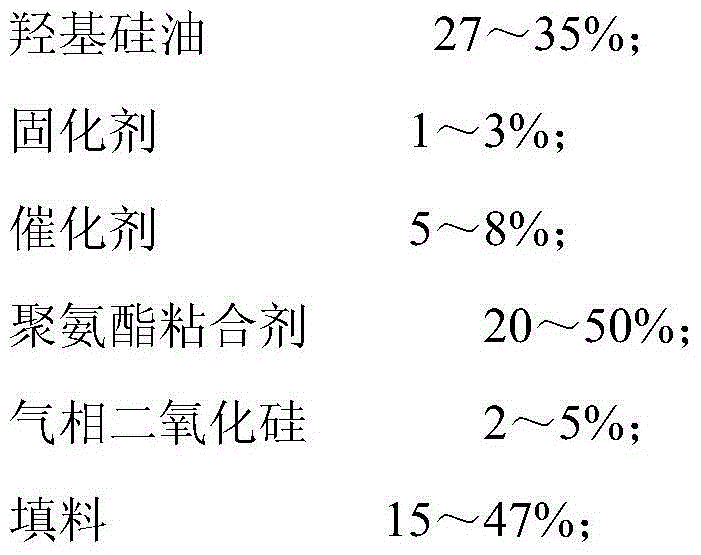

Method for making matte release paper for pressure sensitive tapes

The invention discloses a method for making matte release paper for pressure sensitive tapes, which mainly comprises the following steps: 1, laminating a laminating layer on the surface of one side of release base paper, and then cooling the laminating layer; 2, coating a matte release agent on the laminating layer; and 3, drying the matte release agent. The matte release agent is prepared from the following raw materials: 27-35% of hydroxy silicone oil, 1-3% of curing agent, 5-8% of catalyst, 20-50% of polyurethane adhesive, 2-5% of fumed silica, and 15-47% of packing, wherein the curing agent is methyl hydrogen silicone oil; the catalyst is platinum; and the packing is talcum powder with particle diameter of less than or equal to 15 microns. The method disclosed by the invention is simple in production process and convenient to operate; the cost is reduced; and the release agent mixed with a fogging agent fills and levels up concave and convex parts of the surface of laminating paper, and matte release paper which is stable in stripping force and enables the surface of a pressure sensitive tape to have a good matte effect can be produced, so that the tape surface achieves a low light reflection effect.

Owner:太仓斯迪克新材料科技有限公司

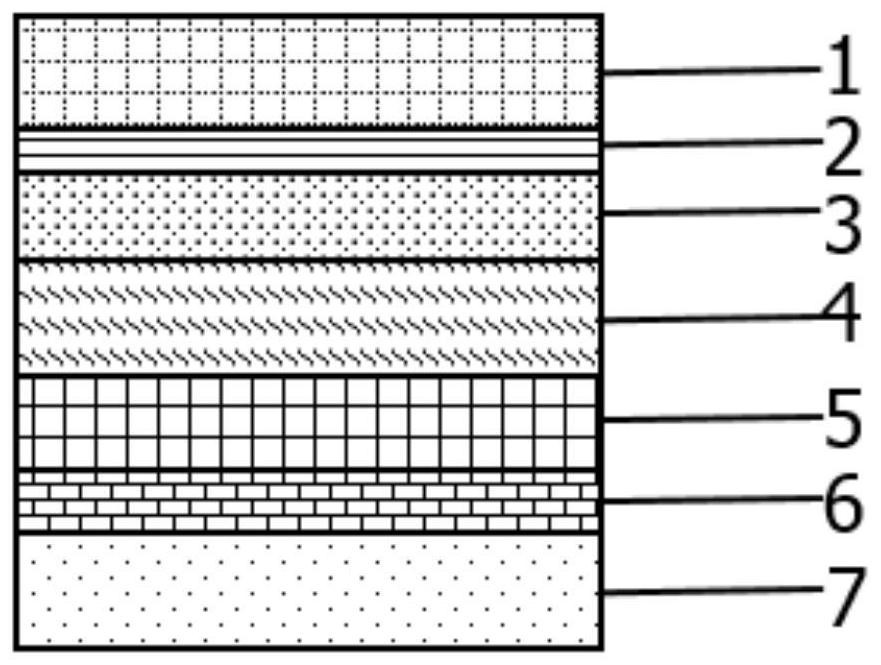

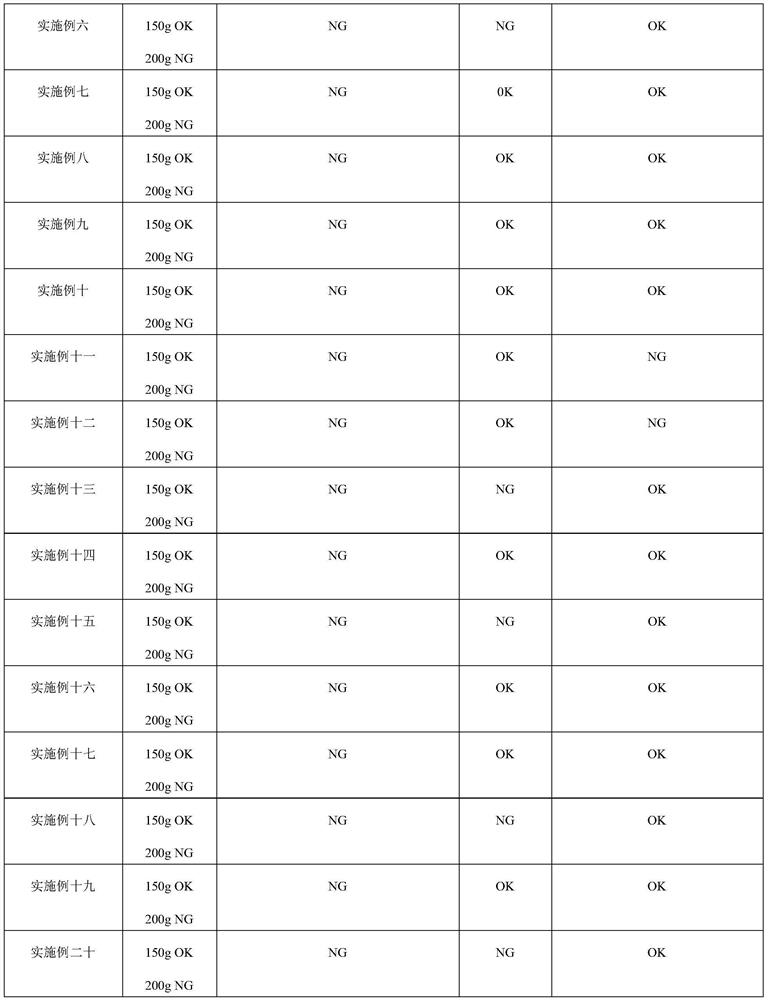

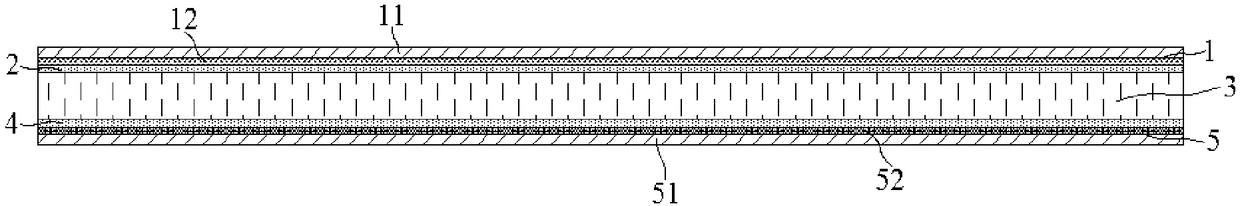

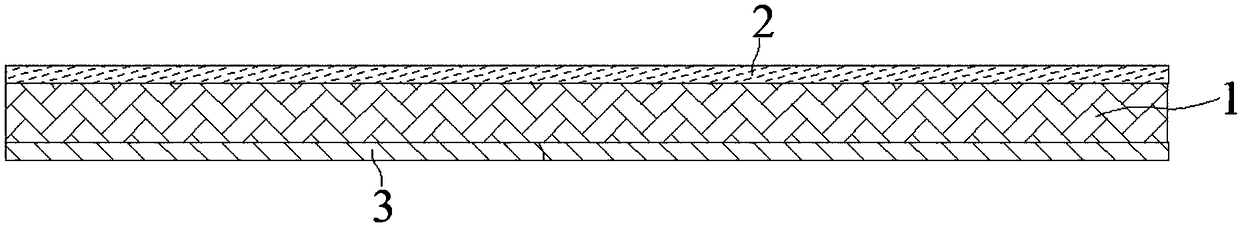

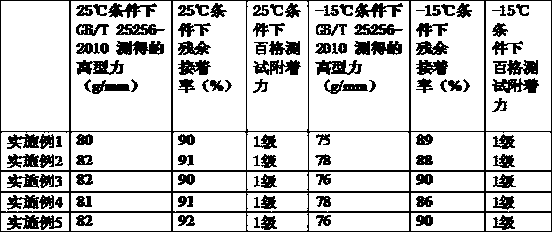

Preparation method of efficient antistatic process film for attachment of OLED module and product of preparation method

InactiveCN109679520AEliminate adsorptionPut an end to the situationFilm/foil adhesive primer layersFilm/foil adhesive release linersViscosityPressure sensitive

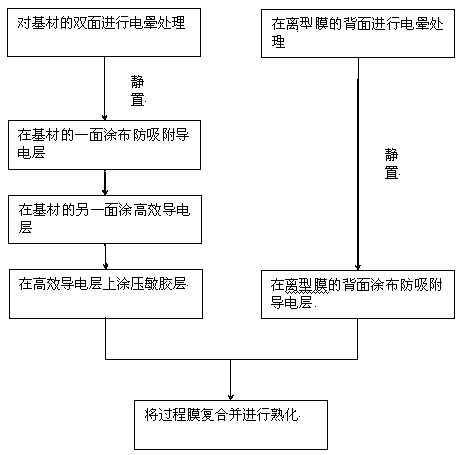

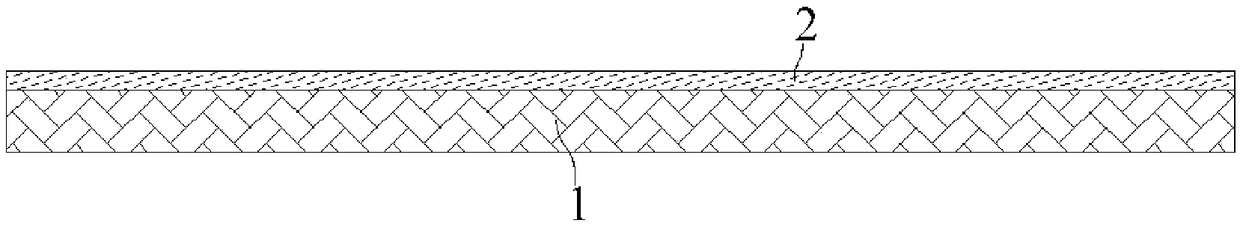

The invention discloses an efficient antistatic process film for attachment of an OLED module and a production method of the efficient antistatic process film. The process film consists of an anti-adsorption conductive layer, a base material, an efficient conductive layer, a pressure-sensitive adhesive layer and a release film, one side of the base material is coated with the anti-adsorption conductive layer, the other side, which is a corona surface, is coated with the efficient conductive layer, and then the base material is attached to the release film through the pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer is a UV light viscosity-reduction adhesive layer and has antistatic performance. The back surface of the release film is coated with the anti-adsorption conductive layer. According to the process film of the invention, the anti-static requirements of a film surface and the back surface of the release film are increased on the basis of the anti-static property of the adhesive surface of the process film, so that electrostatic adsorption cannot be generated in the picking and using processes of the film, and the stability of the process is increased; meanwhile, the resistance of the adhesive surface is greatly reduced, the possibility of dust adsorption and electrostatic breakdown is low, the yield and the efficiency are improved, and the method is mainly applied to the attachment process of an OLED screen module at present.

Owner:上海精珅新材料有限公司

Method for preparing optical release film for polarizer

InactiveCN107129590AStable peel forceHigh residual rateCoatingsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a method for preparing an optical release film for a polarizer. The method comprises the following steps: 1) preparing a coating solution; 2) coating the coating solution on a PET (Polyethylene Terephthalate) film; 3) drying the coated PET film at the temperature of 120-170 DEG C; 4) performing optical detection on the dried PET film; and 5) coiling and molding the PET film which is proved to be qualified through the optical detection, thereby obtaining the optical release film for the polarizer. According to the method disclosed by the invention, the optical release film for the polarizer with stable release force and high residual ratio is prepared. According to the optical release film for the polarizer prepared using the method disclosed by the invention, the release force is controlled to be 20-24g, and the residual ratio is not less than 85%.

Owner:苏州市星辰科技有限公司

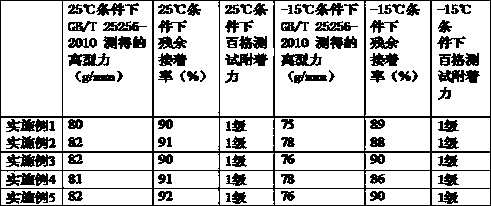

Polyurethane pressure-sensitive adhesive protective film and preparation method thereof

ActiveCN114133909AImprove heat resistanceStable peel forcePolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesPolymer scienceAdhesive

The invention relates to the technical field of pressure-sensitive adhesive protective films, in particular to a preparation method of a polyurethane pressure-sensitive adhesive protective film, which comprises the following steps: S1, preparing a dihydroxy silane coupling agent; s2, preparing a polyurethane pressure-sensitive adhesive subjected to chain extension by a dihydroxy silane coupling agent; and S3, preparing the polyurethane pressure-sensitive adhesive protective film subjected to chain extension by the dihydroxy silane coupling agent. The polyurethane pressure-sensitive adhesive protective film provided by the invention has the characteristics of stable stripping force at 180 DEG C, hydrolysis resistance and high temperature resistance.

Owner:GUANGDONG HONGQING ELECTRONICS MATERIALS TECH CO LTD

Optical release film

InactiveCN108690525AImprove weather resistanceImprove residual adhesionCoatingsFilm/foil adhesive release linersDistillationDibenzoyl Peroxide

The invention discloses an optical release film. The optical release film comprises a base film layer, a release agent layer coated at the surface of the base film layer, and the release agent layer is obtained by solidifying a release agent. The release agent comprises the following components: prepolymerized resin, methylhydroquinone, 3-epoxypropane, dodecyl glycidyl ether, and 1-hydroxy cyclohexyl phenylketone. The prepolymerized resin is obtained by the following steps: mixing cyclohexyl methacrylate, beta-carboxyethyl acrylate, and acrylic acid in a stirring barrel, and uniformly stirringthe materials at a low speed to form a primary mixture; mixing primary mixture, xylene, and benzoyl peroxide and adding a mixture in a reaction vessel to obtain a polymer solution; stirring the polymer solution and 2-hydroxyethyl vinyl ether at a high speed, and heating the materials and performing heating distillation to remove xylene to obtain the prepolymerized resin. The release film increases the product weatherability, cannot generate unfavorable influence on electric property of a circuit board, and increases the reliability of the circuit board.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Light peeling-type release agent and preparation method thereof

InactiveCN108690387AImprove weather resistanceImprove residual adhesionNon-fibrous pulp additionPaper coatingDistillationDibenzoyl Peroxide

The invention discloses a light peeling-type release agent and a preparation method thereof. The release agent layer is obtained by prepolymerized resin, methylhydroquinone, 2-hydroxymethyloxetane, dodecyl glycidyl ether, and 1-hydroxy cyclohexyl phenylketone. The prepolymerized resin is obtained by the following steps: placing 40-50 parts of cyclohexyl methacrylate, 15-30 parts of beta-carboxyethyl acrylate, and carbamate (methyl)acrylic ester in a stirring barrel, and uniformly stirring the materials at a low speed to form a primary mixture; mixing the primary mixture obtained in the step 1), xylene, and 0.2-0.4 parts of benzoyl peroxide, and adding a mixture in a reaction vessel to obtain a polymer solution; stirring the polymer solution and 5-12 parts of 2-hydroxyethyl vinyl ether at ahigh speed, and heating the materials and performing heating distillation to remove xylene to obtain the prepolymerized resin. The light peeling-type release agent keeps stable low peel strength under low temperature, and increases the product weatherability.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Method for making fog face release paper

ActiveCN102330381BReduce reflective effectGood haze effectPaper coatingCoatingsPlatinumPolyurethane adhesive

The invention relates to a method for making fog face release paper, which mainly comprises the following steps of: a first step of laminating a laminated layer on one lateral surface of body paper of the release paper by a laminating machine and cooling; a second step of coating a layer of fog face release agent on the laminated layer; and a third step of drying the fog face release agent. A rawmaterial formula of the fog face release agent comprises 25 to 35 percent of hydroxyl silicone oil, 0.5 to 4 percent of curing agent, 2 to 8 percent of catalyst, 15 to 55 percent of polyurethane adhesive, 0.3 to 5 percent of fumed silica and 10 to 50 percent of filler, wherein the curing agent is methyl hydrogen silicone fluid; the catalyst is platinum; and the filler is talcum powder of which the practical diameter is less than or equal to 15 microns. The method disclosed by the invention has simple production process and is convenient to operate. The cost is reduced. The concave-convex surface of laminated paper is filled and leveled up by the release agent mixed with a fog agent. The fog face release paper which has stable stripping strength and ensures the adhesive surface of a pressure sensing adhesive to have a good haze effect can be produced, so that the adhesive surface has a low-reflection effect.

Owner:太仓斯迪克新材料科技有限公司

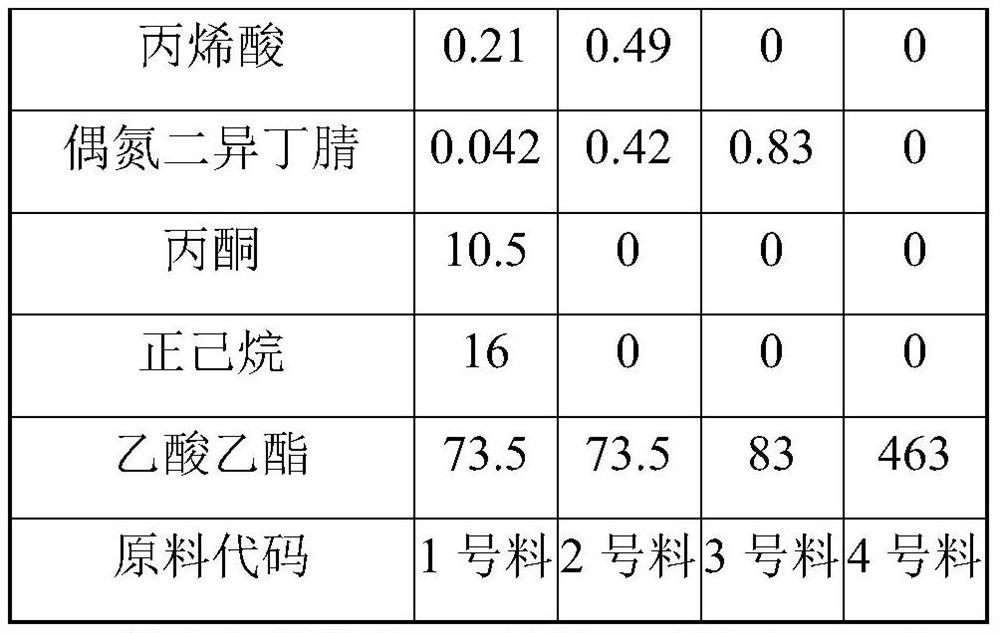

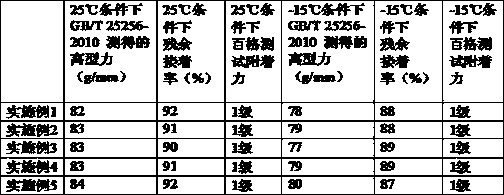

A kind of ultra-fine sticky-peeling force acrylic pressure-sensitive adhesive and preparation method thereof

ActiveCN109294492BSmall peeling forceStable peel forceEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylatePolymer science

The invention belongs to the technical field of pressure-sensitive polyacrylate adhesives, and provides an ultra-micro adhesion and peel strength pressure-sensitive acrylic adhesive and a preparationmethod thereof. The pressure-sensitive acrylic adhesive is prepared through a multistep reaction and grading dropwise addition process of a pressure-sensitive acrylate adhesive. The pressure-sensitiveacrylic adhesive comprises 15-25 wt% of 2-ethylhexyl acrylate, 2-5% of octadecyl acrylate, 0-0.5 wt% of acrylic acid, 1-3 wt% of hydroxyethyl acrylate, 0.8-2 wt% of an initiator and 70-80 wt% of a solvent. A long-chain alkyl ester having a longer side chain than the 2-ethylhexyl acrylate is introduced to enhance the flexibility of the chain, increase the use amount of a functional monomer and provide many cross-linking points, and a peel strength of below 1 g is obtained by combining multiple solvents and adjusting the synthesis process.

Owner:上海英诺威新材料科技有限公司

Double-resisting one-side release material

InactiveCN108690522AImprove residual adhesionReduce transfer rateCoatingsFilm/foil adhesive release linersVinyl etherBenzoyl peroxide

The invention discloses a double-resisting one-side release material. The release material comprises a base film layer, a release agent layer coated at the upper surface of the base film layer, an antistatic coating layer coated at the lower surface of the base film layer, and the release agent layer is obtained by solidifying a release agent. The release agent comprises the following components:prepolymerized resin, methylhydroquinone, 3-epoxypropane, dodecyl glycidyl ether, and 1-hydroxy cyclohexyl phenylketone. The prepolymerized resin is obtained by the following steps: mixing a primary mixture, xylene, and benzoyl peroxide, adding a mixture in a reaction vessel to obtain a polymer solution; stirring the polymer solution and 2-hydroxyethyl vinyl ether at a high speed, and heating thematerials and performing heating distillation to remove xylene to obtain the prepolymerized resin. The release material keeps stable low peel strength under low temperature, and realizes low-energy rapid light-curing under UV light irradiation.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

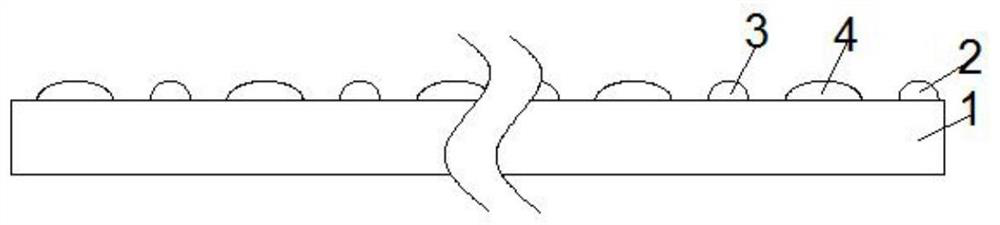

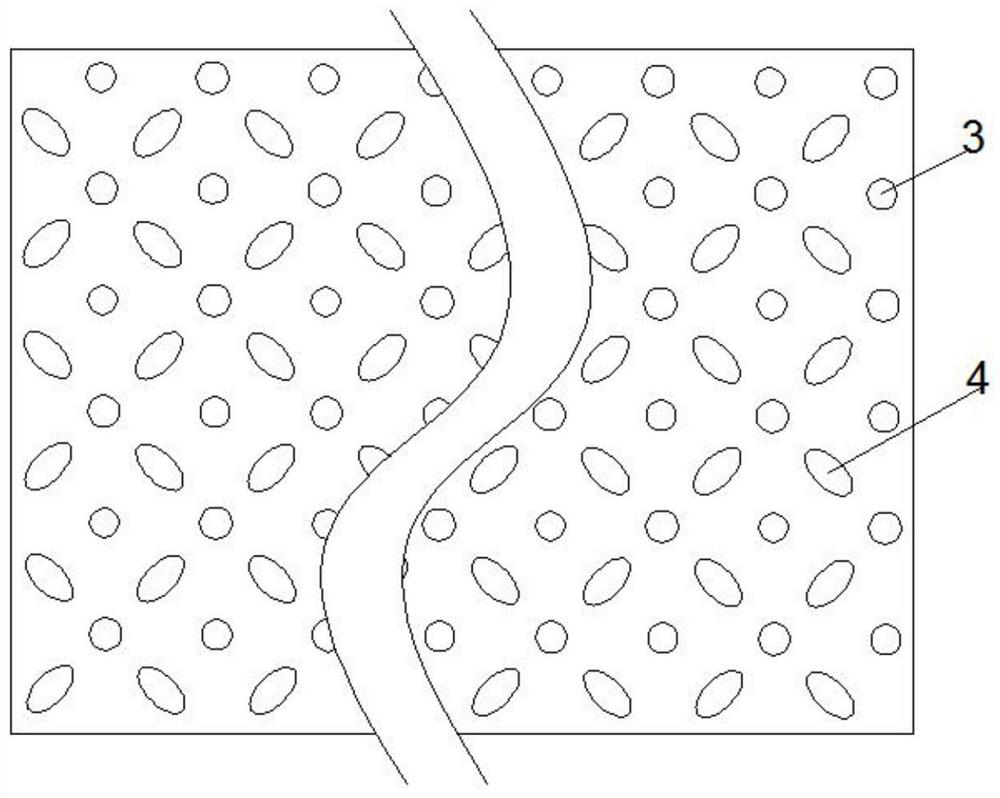

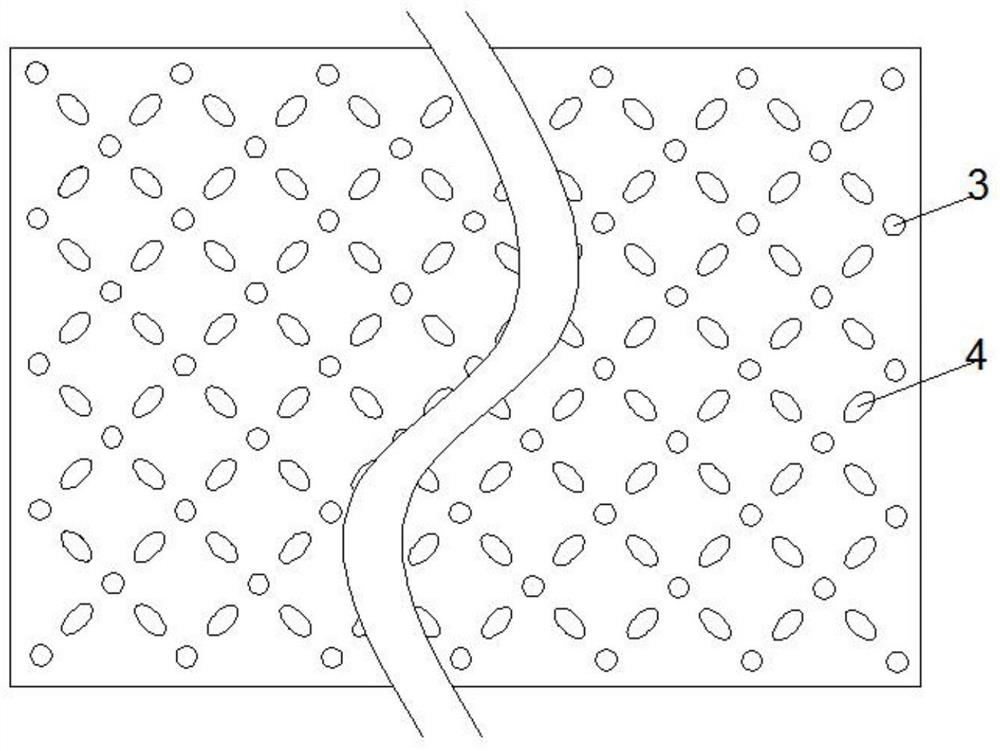

Dot-matrix PET protective film and mesh roller thereof

PendingCN113292937ACompatibleImprove the exhaust effectLiquid surface applicatorsFilm/foil adhesivesEngineeringMaterials science

The invention discloses a dot-matrix PET protective film which comprises a base material layer; a salient point layer is fixed on the base material layer, the salient point layer comprises a plurality of first salient points and second salient points, the first salient points and the second salient points are uniformly distributed, and the top points of the first salient points and the top points of the second salient points are on the same plane. The dot-matrix PET protective film has the advantages of high performance, high compatibility, ultrahigh exhaust property and reworkability.

Owner:苏州值羽光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com