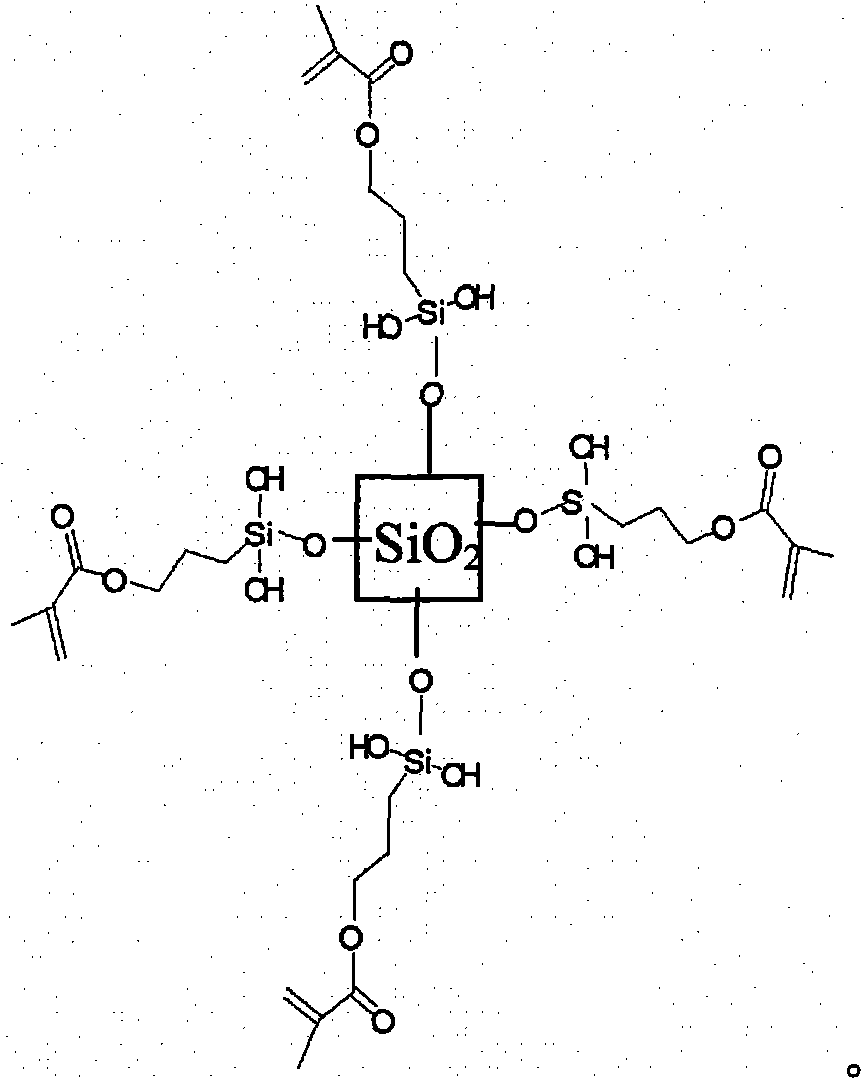

Copolymers of nanoparticles, vinyl monomers and silicone

A technology of vinyl monomers and nanoparticles, applied in nanotechnology, nanotechnology, grafted polymer adhesives, etc., can solve the problems of loss of adhesion, accumulation of peeling force and sheet removal force, and achieve stability The effect of peel force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

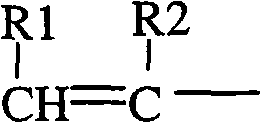

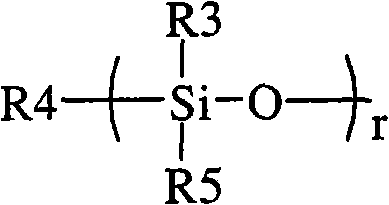

Method used

Image

Examples

example

[0103] Objects and advantages of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention.

[0104] Material

[0105] demonstrative

name, chemical formula and / or structure

availability

MEK

methyl ethyl ketone

Sigma-Aldrich

C2H5OH

Sigma-Aldrich

CH3OH

Sigma-Aldrich

SiMac

Methacryloxypropyl polydimethylsiloxane

Shin-Etsu

VAZO-64

DuPont

[0106] Isooctylsilane

Sigma-Aldrich

Prostab 5198

polymerization inhibitor

CIBA

MMA

Sigma-Aldrich

IBMA

Isobutyl methacrylate

Sigma-Aldrich

A-174

3-Methacryloxypropyltrimethoxysilane

Sigma-Aldrich

[0107] Synthesis of methacry...

example 1

[0113] Example 1: Synthesis of SiMac / IBMA / A-174 (60 / 35 / 5) modified 5nm silica:

[0114] 72g SiMac, 42g IBMA (isobutyl methacrylate), 17.14g A-174 modified silica (35% solids in MEK), 168.86g MEK, and 0.3602g VAZO64 were added to a narrow neck quart bottle . In the resulting homogeneous mixture, N 2 5 minutes. The vial was sealed and placed in a hot water bath at 55°C with shaking for 24 hours. The final solids content in MEK was 39.4%. No gel was observed.

example 2

[0117] Example 2: Synthesis of MA / NVP / SiMac / AA / A-1745nm Modified Silica

[0118] 23.1g MA (methyl acrylate), 17.9g NVP (N-vinylpyrrolidone), 2.6g AA (acrylic acid), 15.4g SiMac, 2.9g A-174 modified silica (containing 35% of solid), 158 g MEK, and 0.1809 g VAZO 64 were added to a narrow neck quart bottle. In the resulting homogeneous mixture, N 2 5 minutes. The vial was sealed and placed in a hot water bath at 55°C with shaking for 24 hours. The final solids content was 29.2%. The solution was diluted to 12.5% solids with a 50 / 50 blend of IPA / toluene prior to coating on PET.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com