Patents

Literature

171 results about "Narrow neck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Narrow Neck is a suburb of Auckland, New Zealand.. Until the mid-19th century, Devonport was connected with the rest of the North Shore by a causeway between Ngataringa Bay and the Hauraki Gulf.This causeway gave the appearance of a "narrow neck".

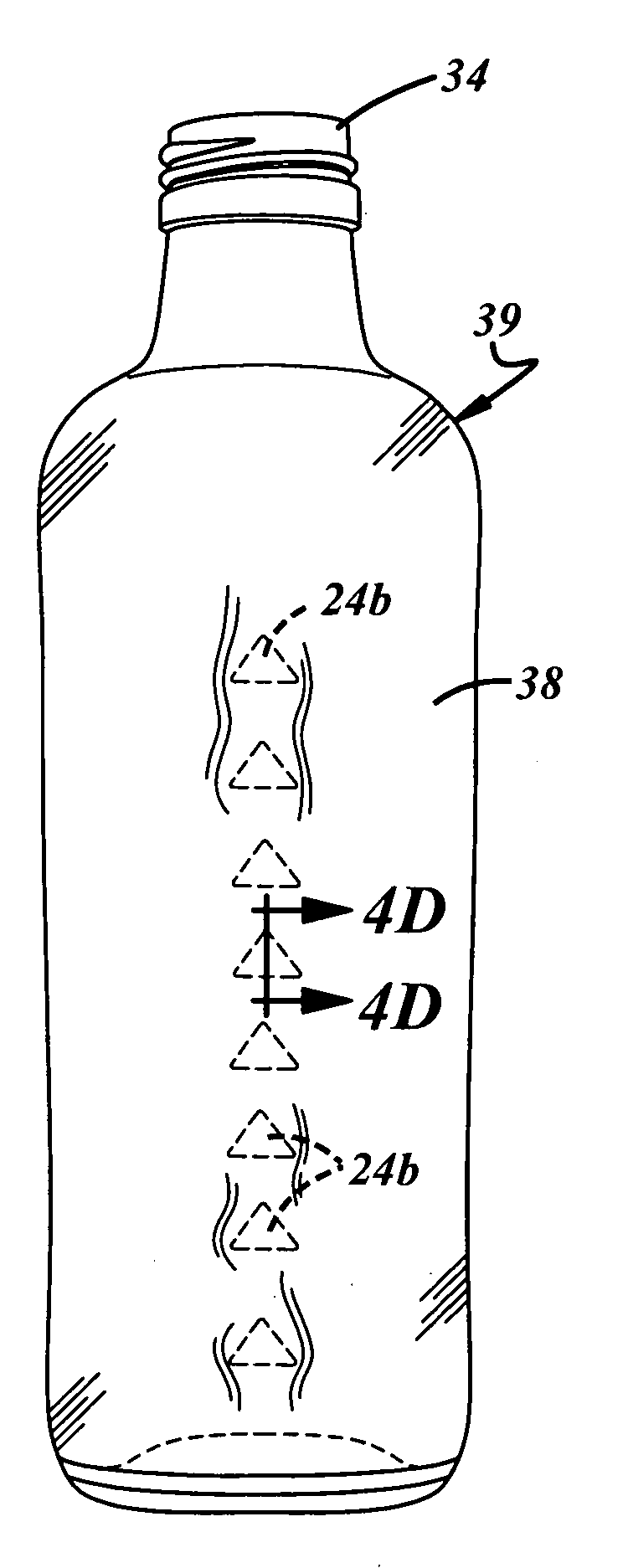

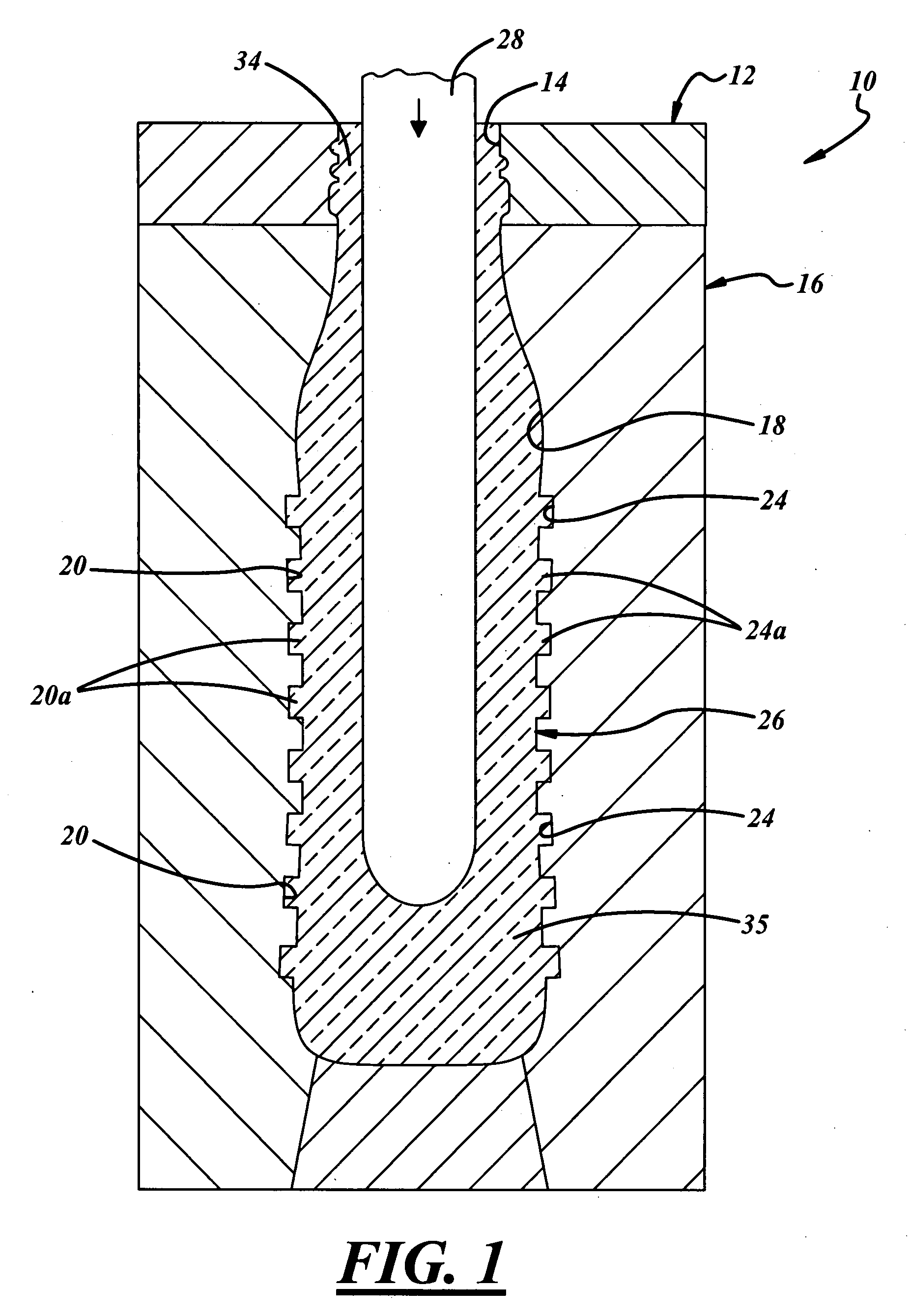

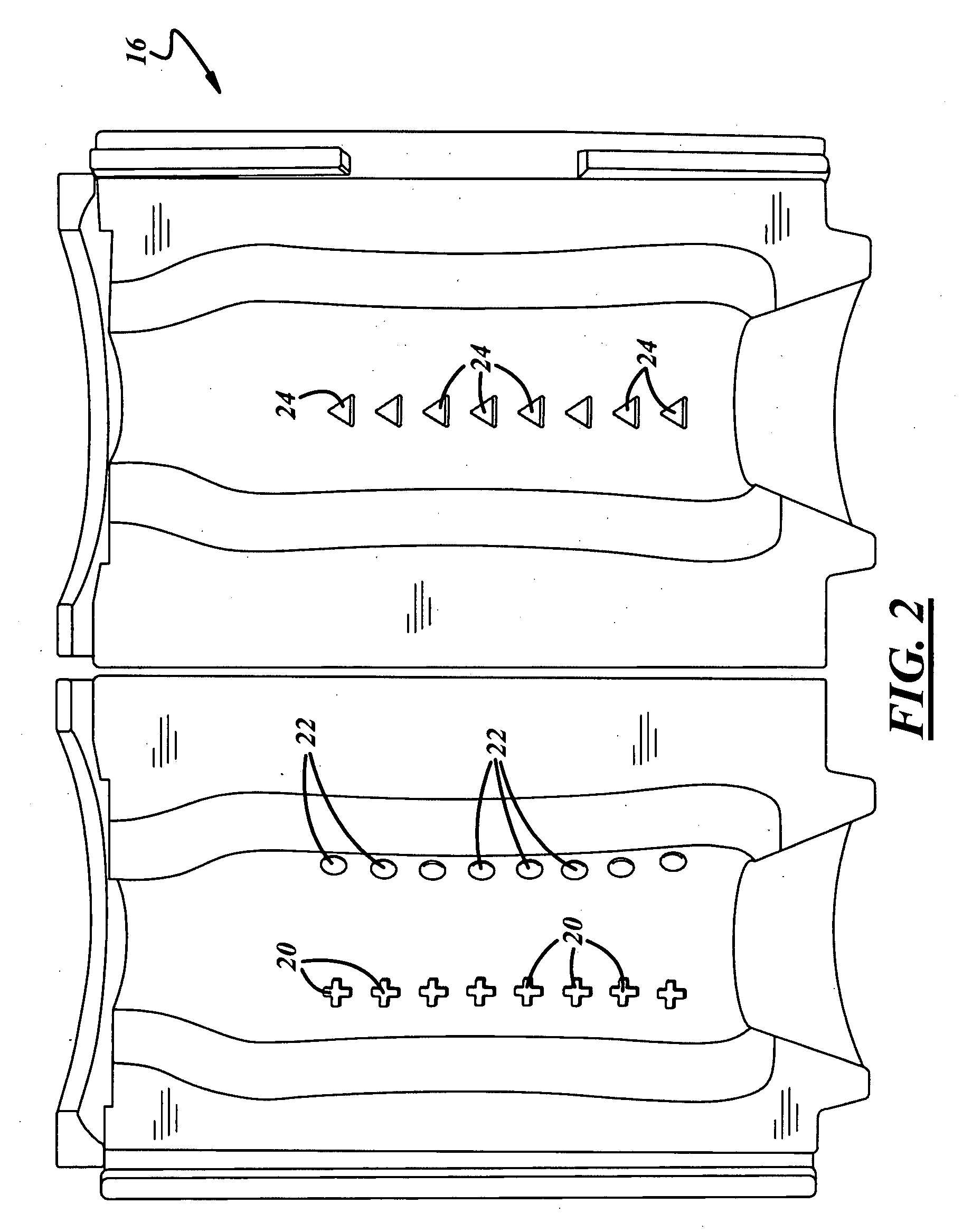

Narrow neck glass container with internal embossments and method of manufacture

InactiveUS20090084799A1Large containersPress and blow machinesMechanical engineeringGeometric pattern

A narrow neck glass container includes a container body and a container neck finish. The container neck finish has an external closure attachment diameter of not more than 36 mm, and the container body has at least one internal embossment of predetermined geometry. The at least one internal embossment preferably comprises a plurality of internal embossments in a geometric pattern.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

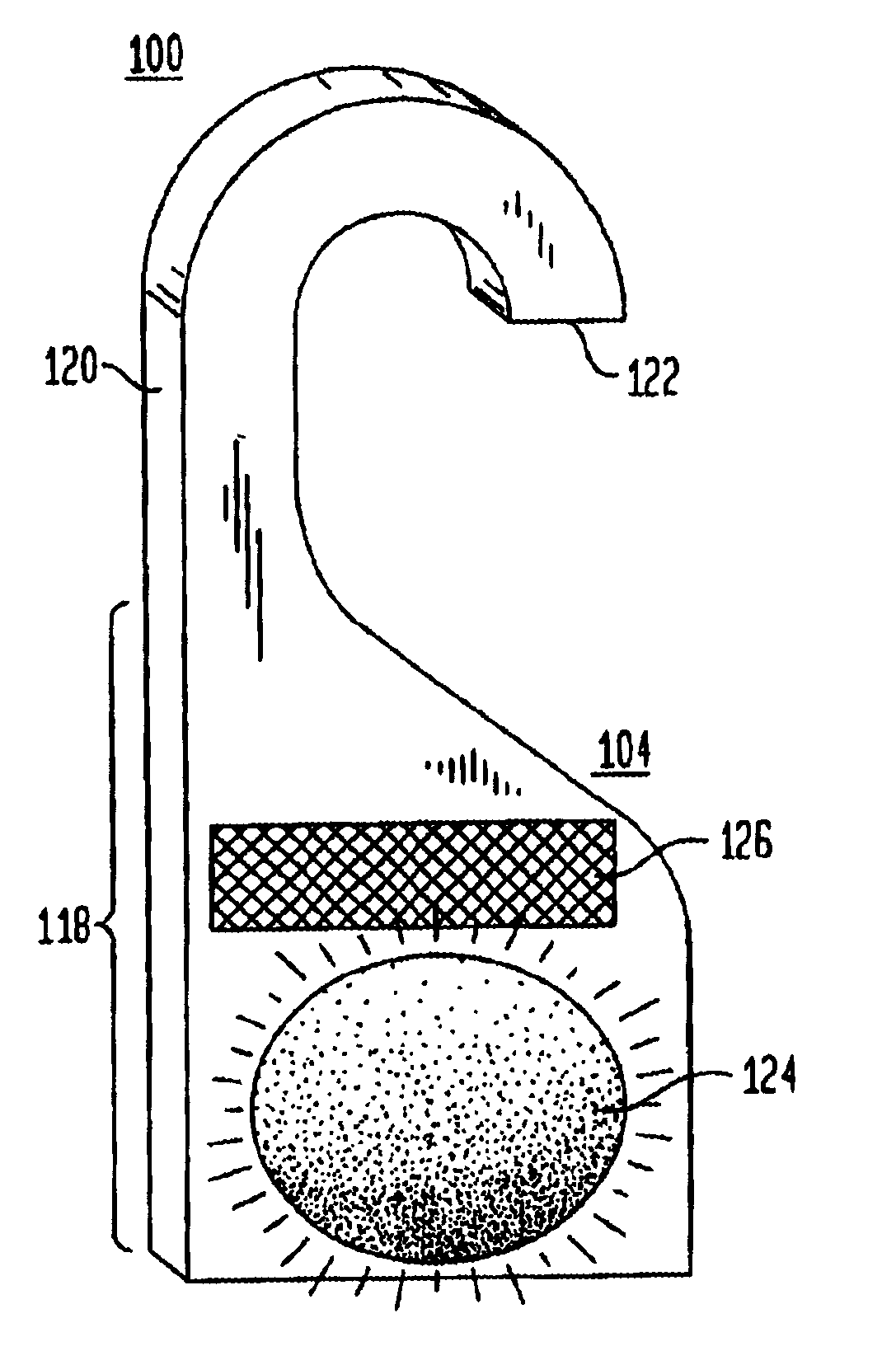

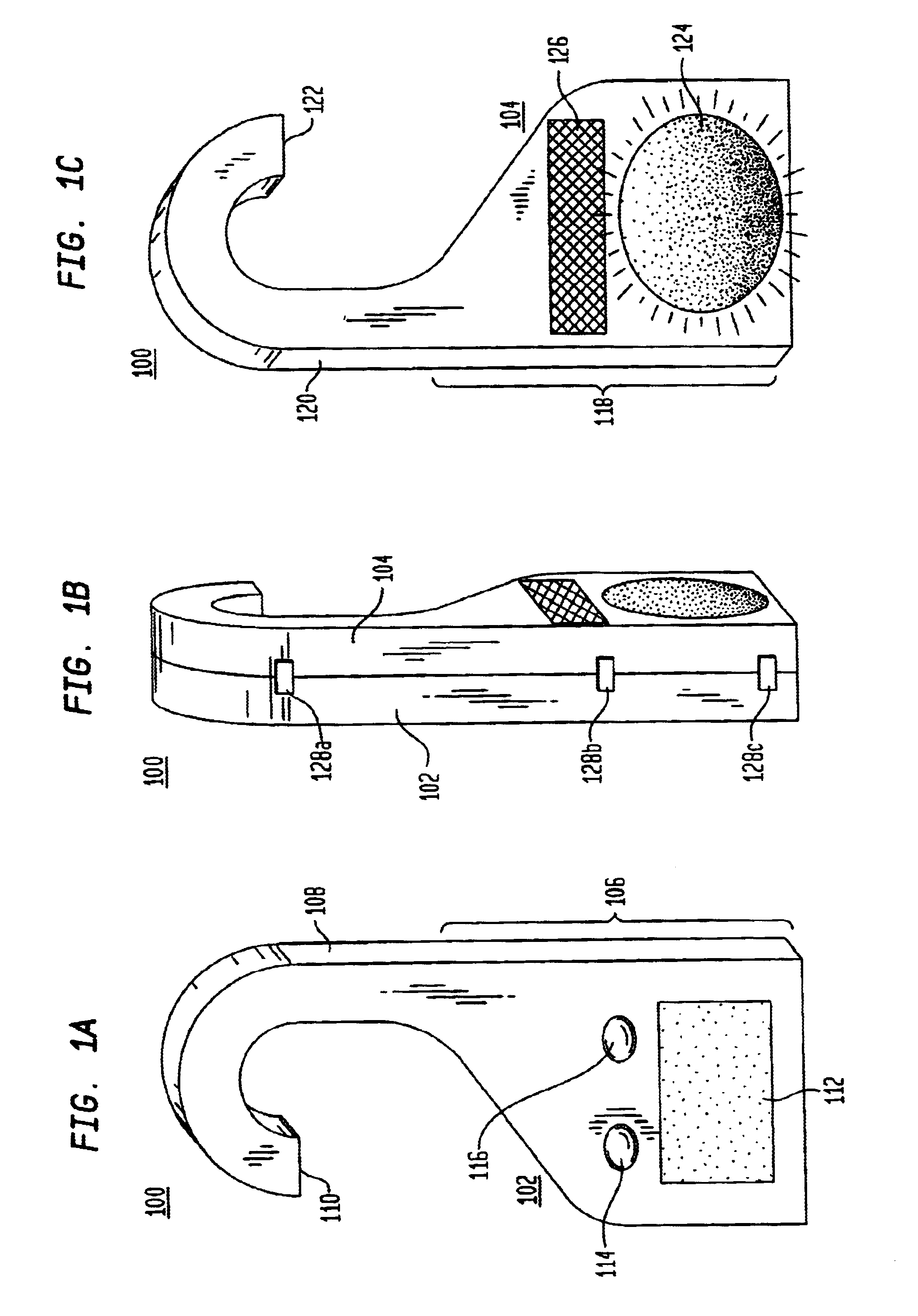

Portable emergency response system

InactiveUS6690288B1Easy to carryElectric/electromagnetic visible signallingElectric transmission signalling systemsRadio receiverRadio reception

An emergency response system including a smoke detector and an evacuation guide. The emergency response system and evacuation guide are separate components removably attached to each other, and each has a shape that includes a long, narrow neck and a curved handle, which permits both the smoke detector and evacuation guide to be installed by hanging each from a door knob. The smoke detector includes, in addition to means for sensing smoke and means for emitting an alarm, a radio transmitter that generates and transmits an activation signal in the form of radio waves. The radio waves are detected by a radio receiver in the evacuation guide. Upon receipt of the activation signal, a digital recording and playback device delivers a message to occupants of the home or building. A flashlight contained within the evacuation guide also is illuminated.

Owner:WADDELL DEBBIE

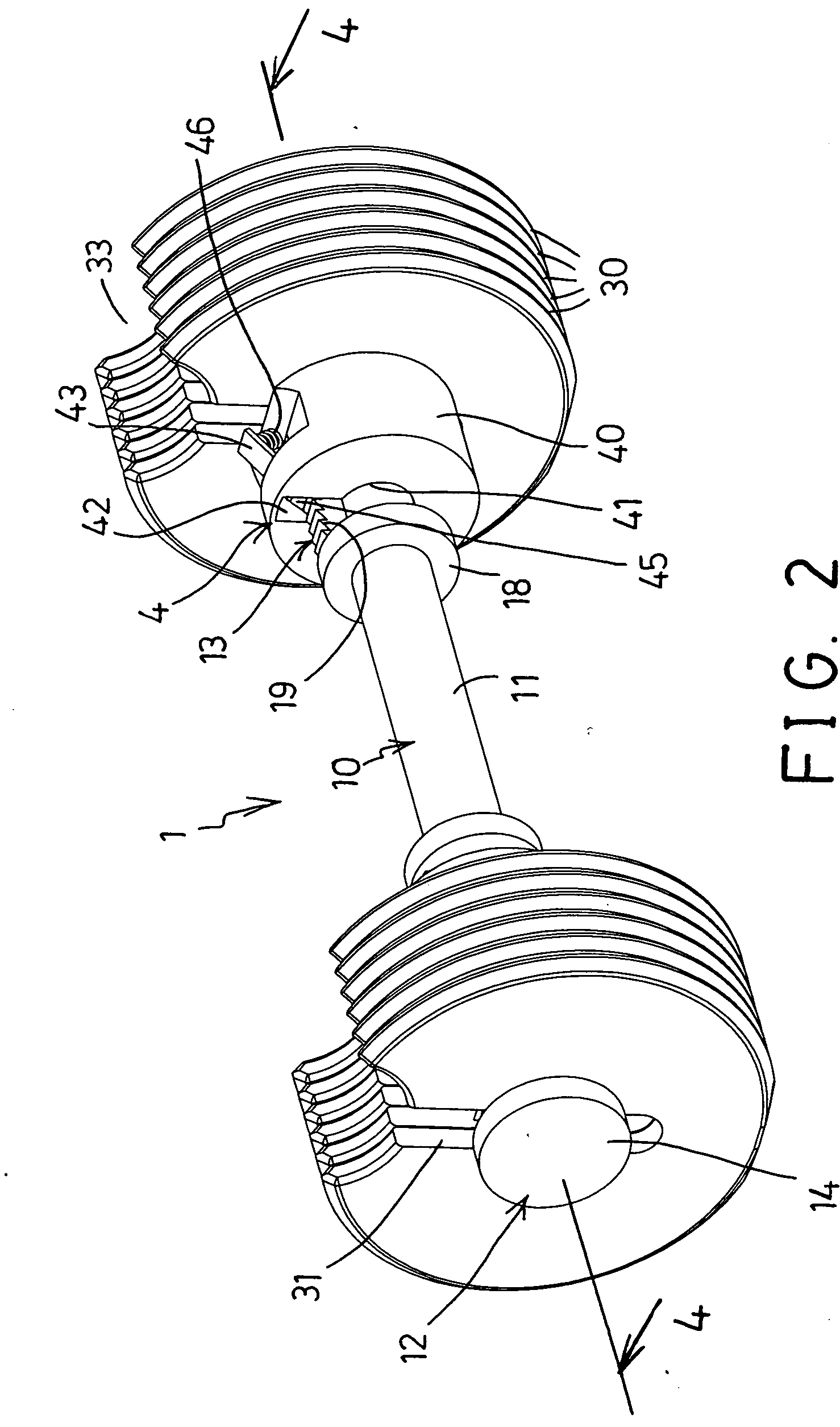

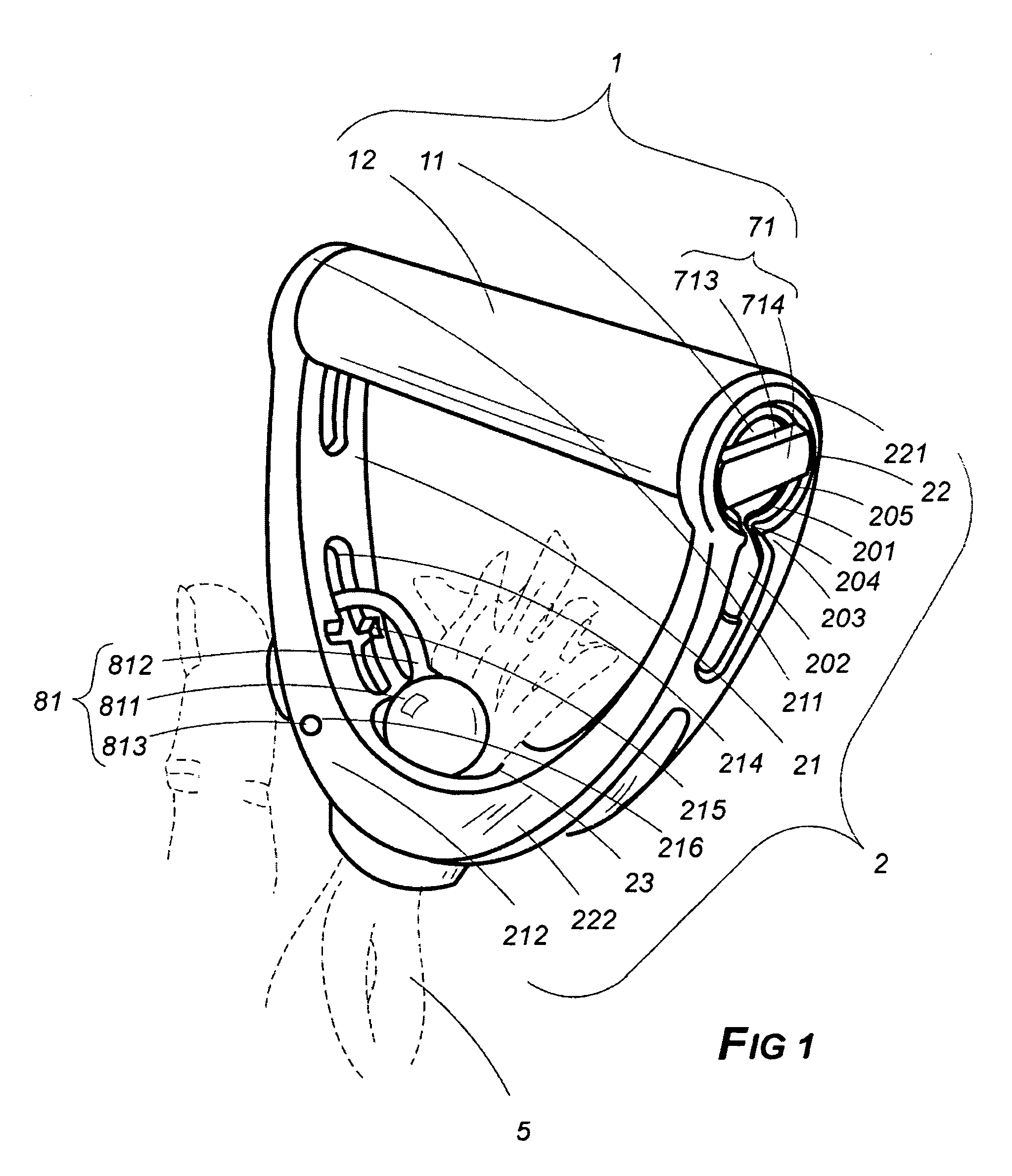

Inflatable cushion retention system

Owner:AUTOLIV ASP INC

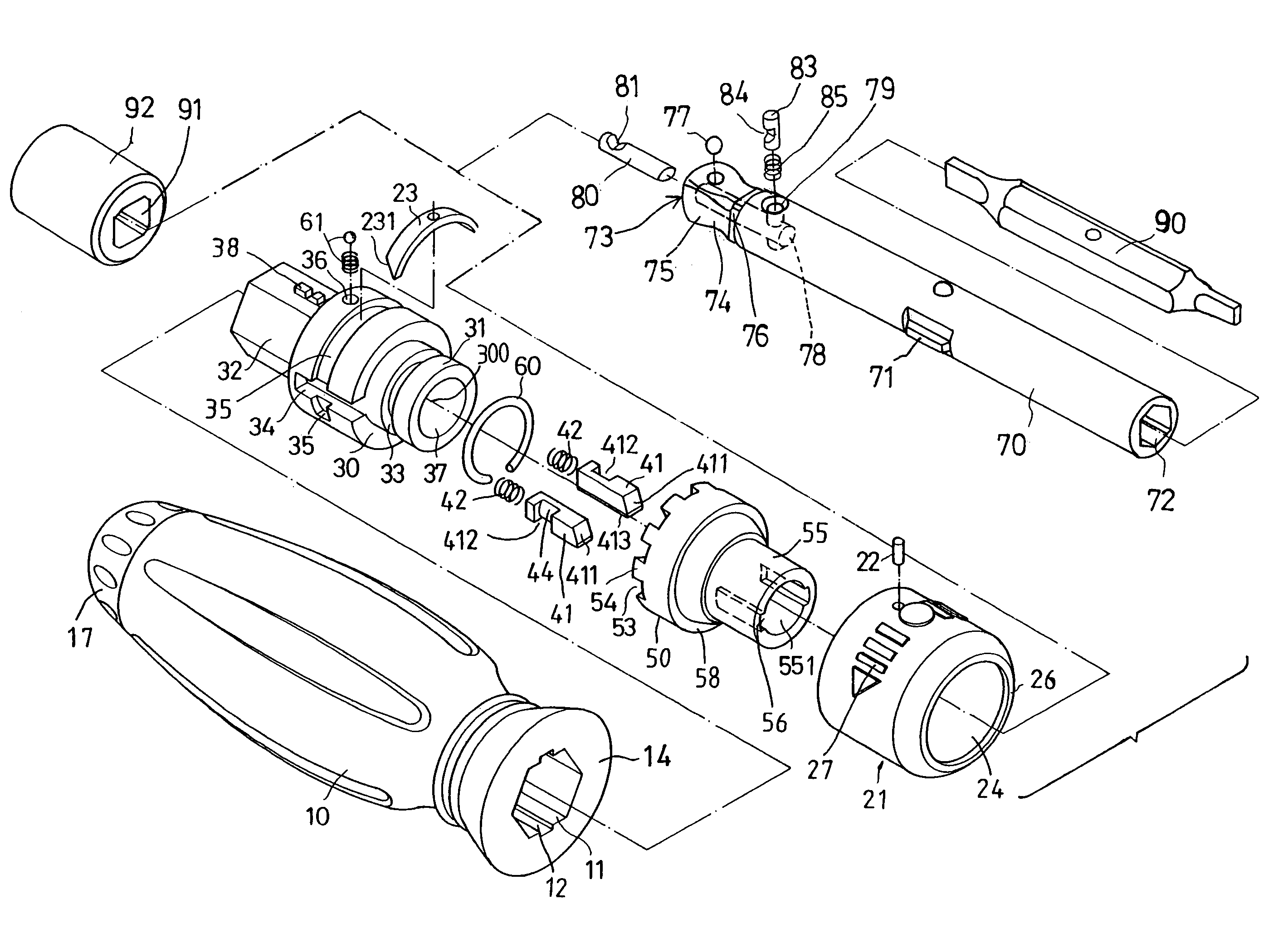

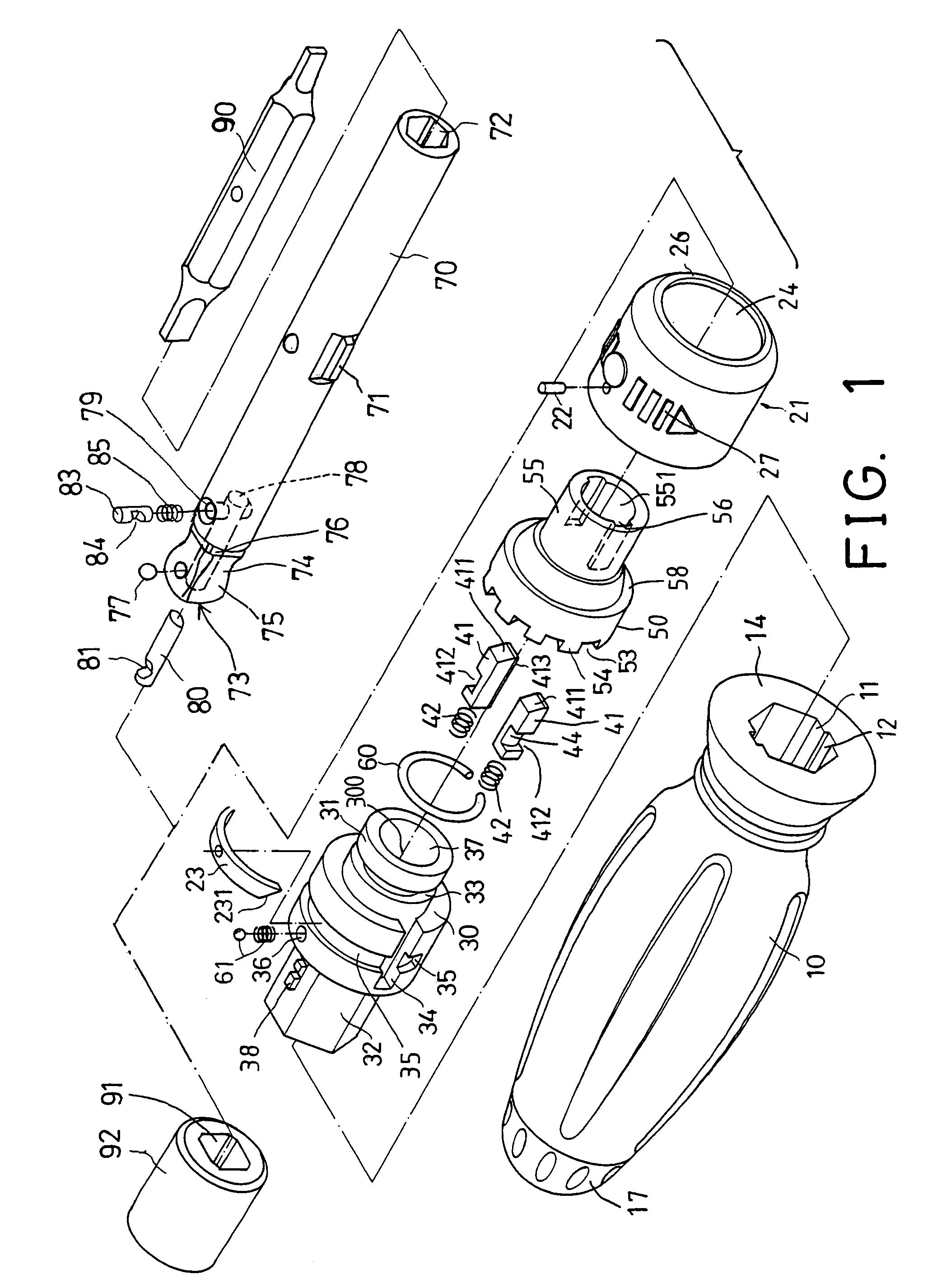

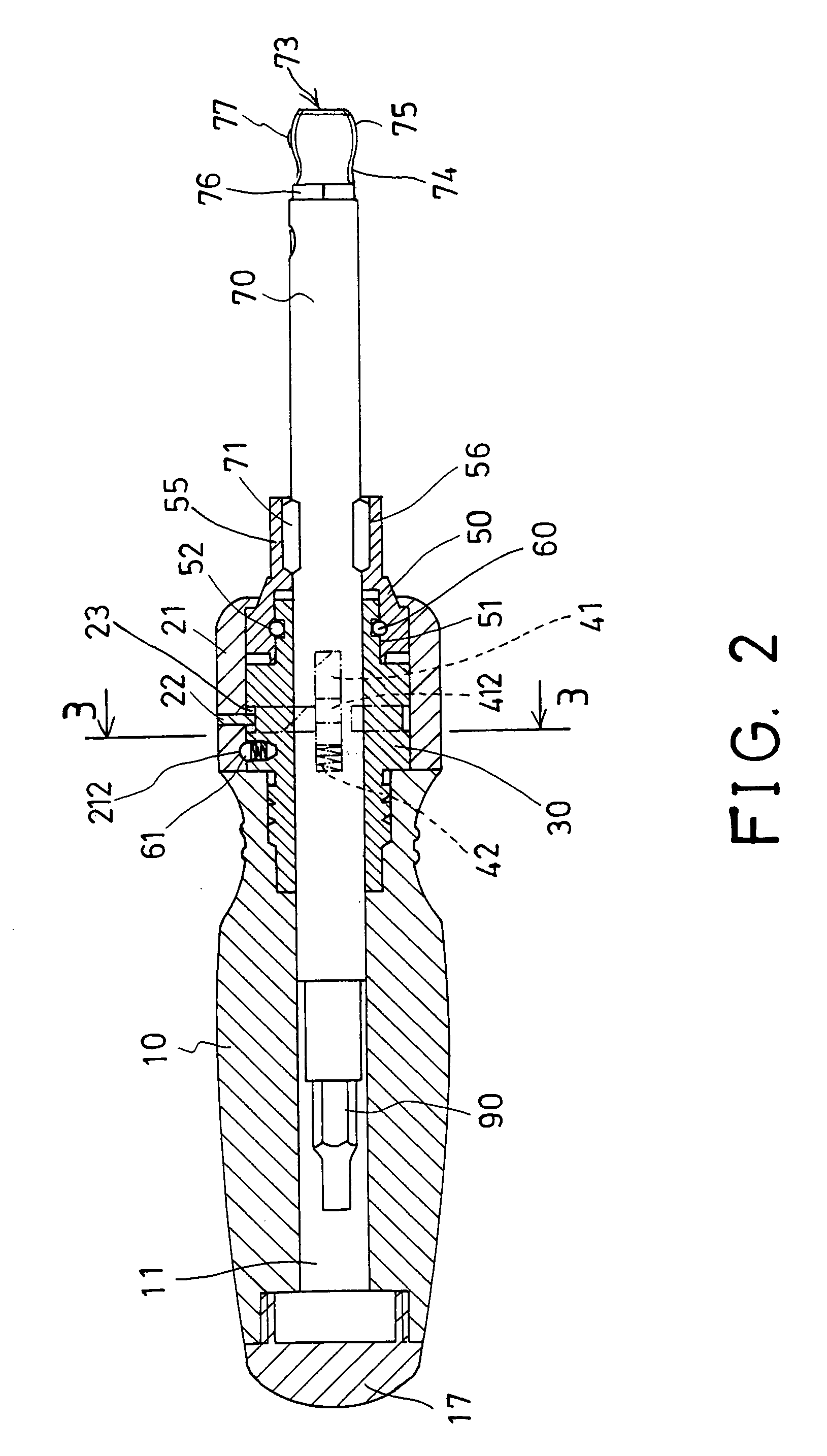

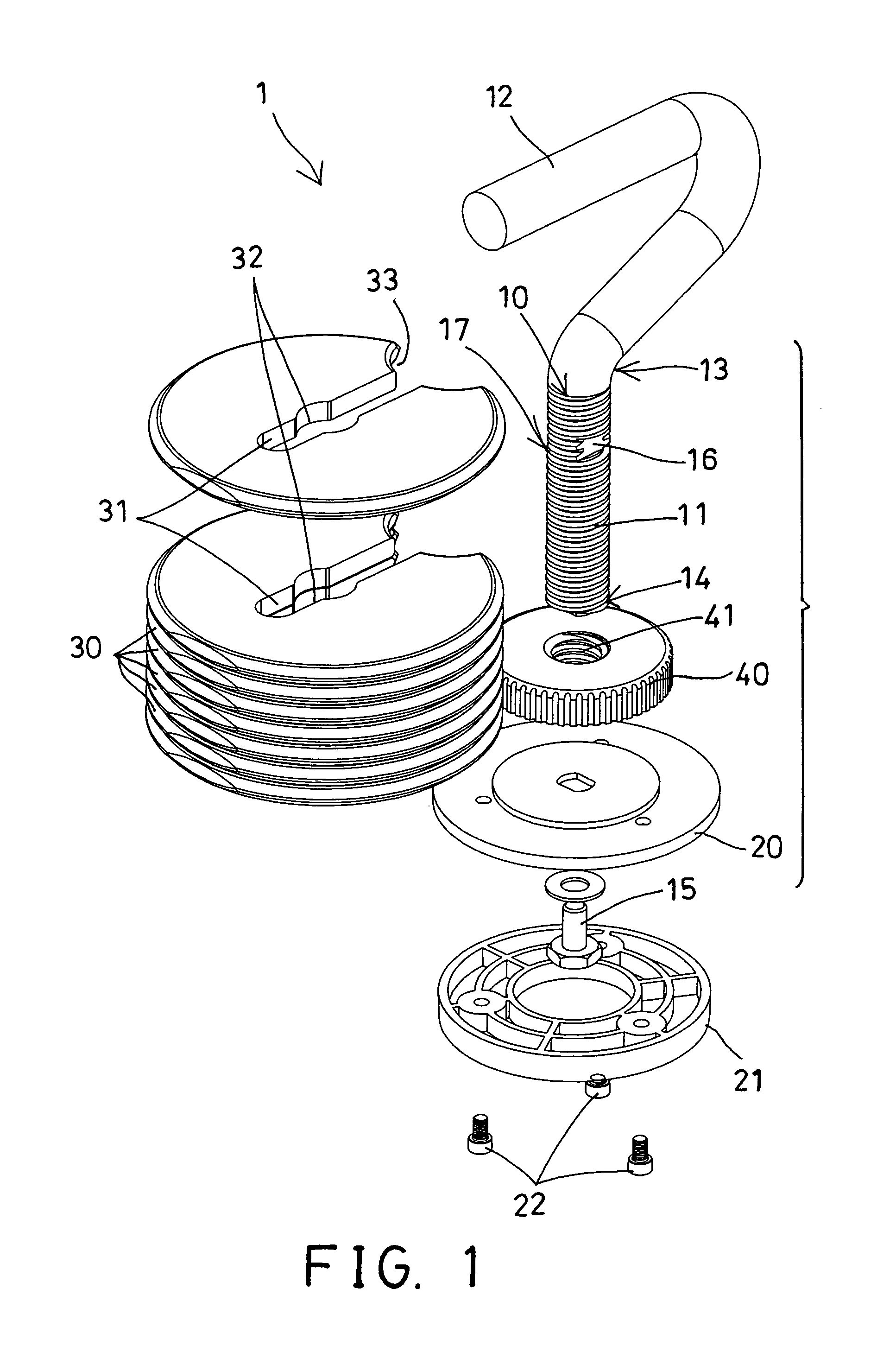

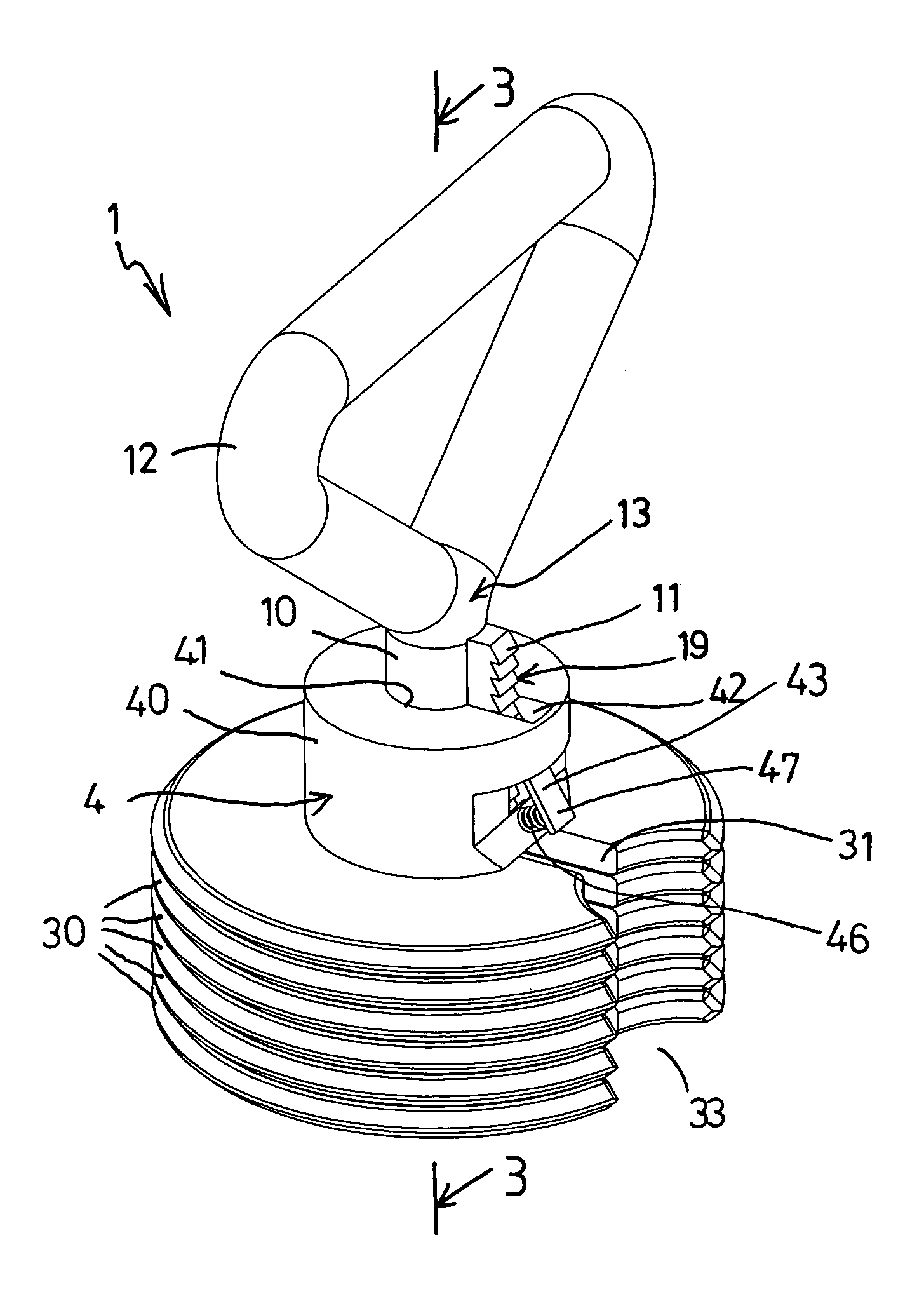

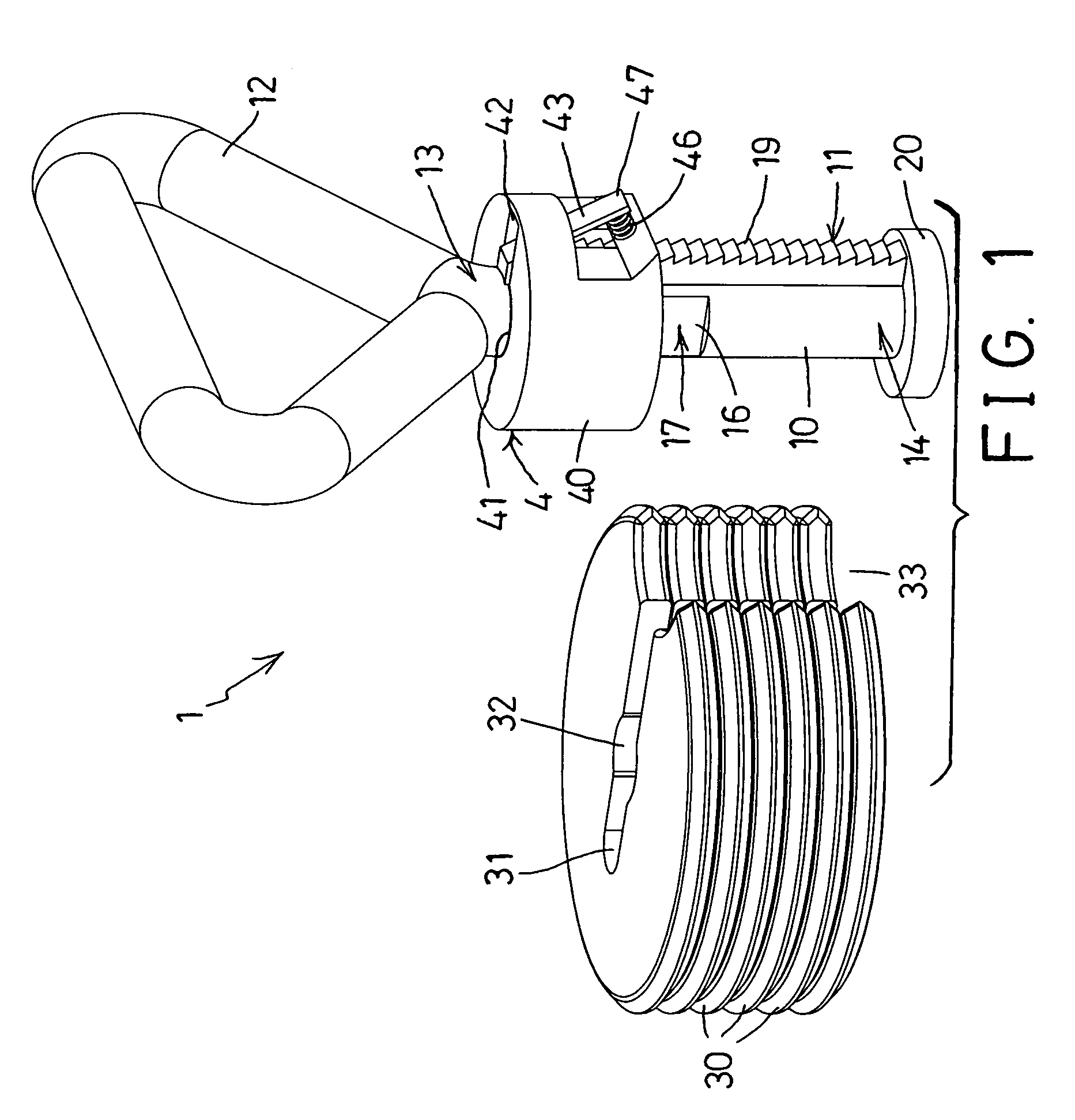

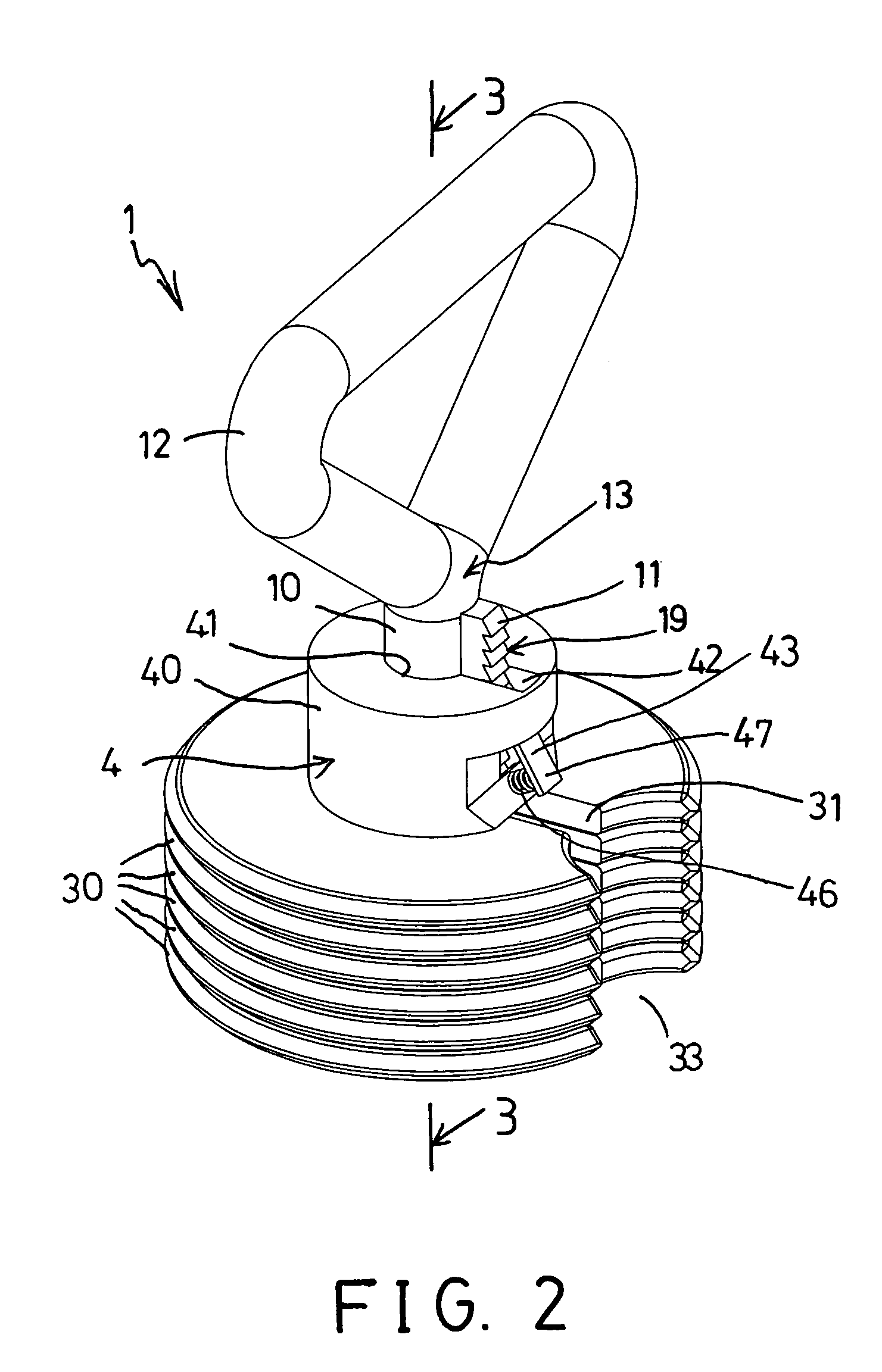

Ratchet tool having improved driving shank

Owner:CHEN SU SHIA

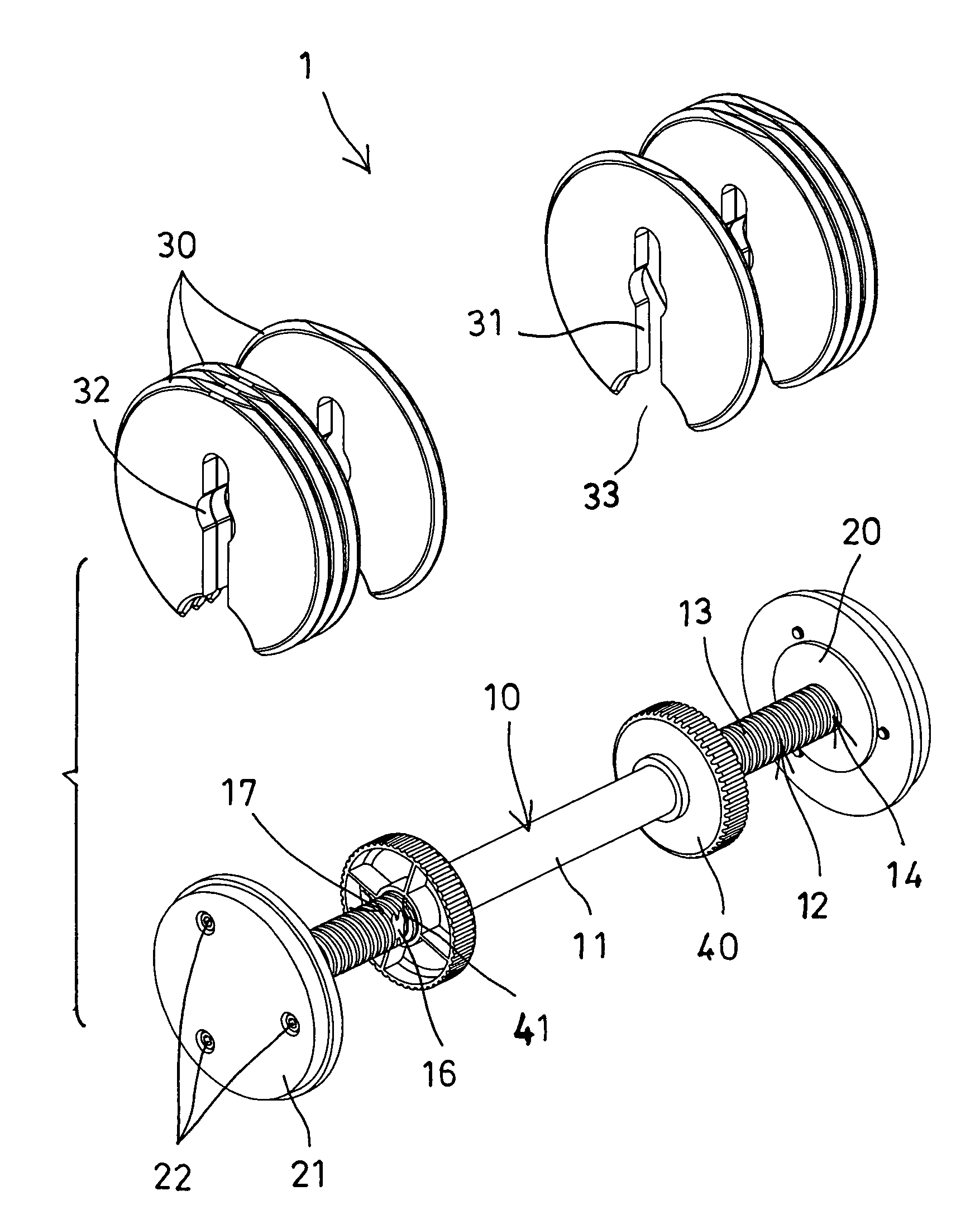

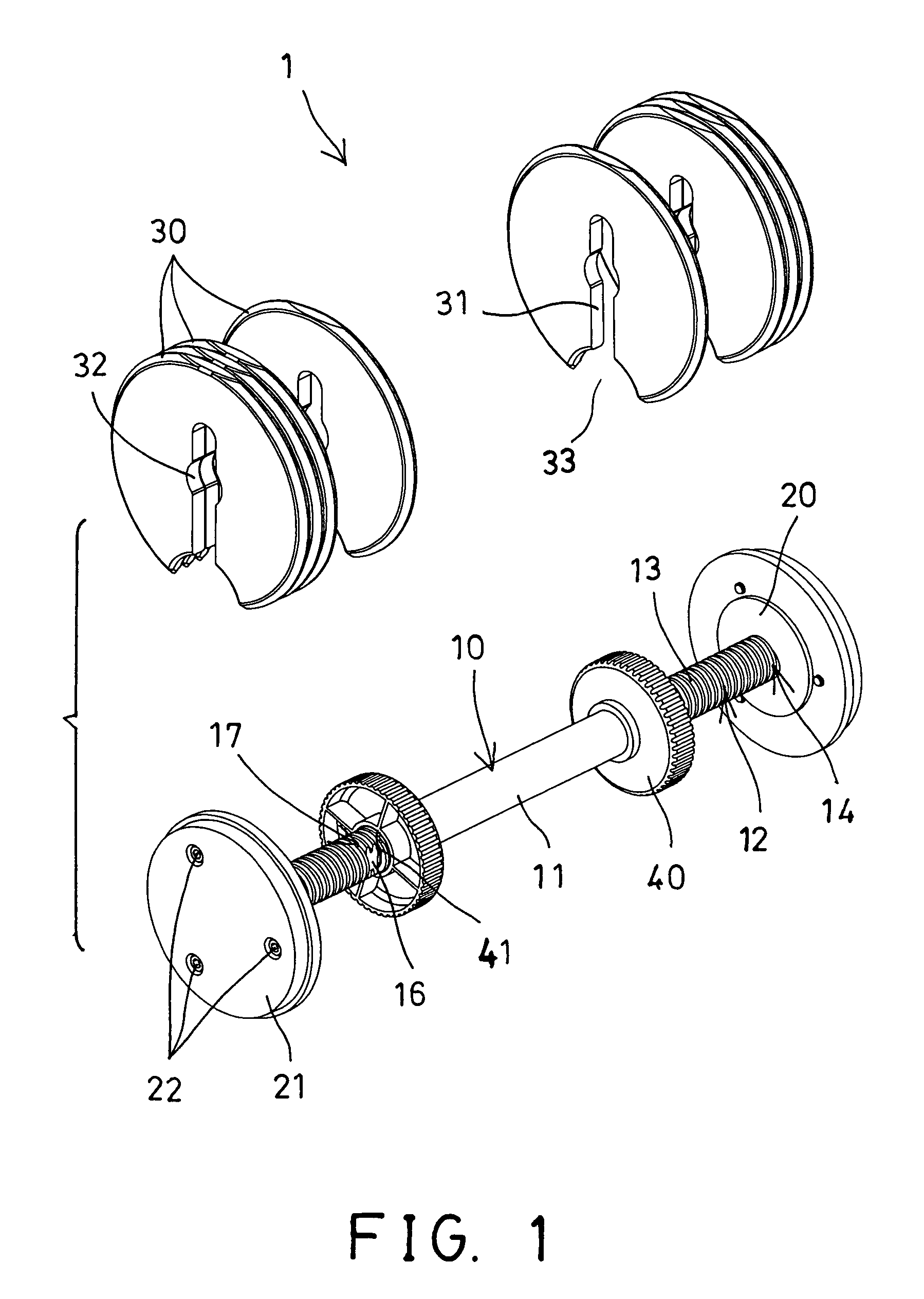

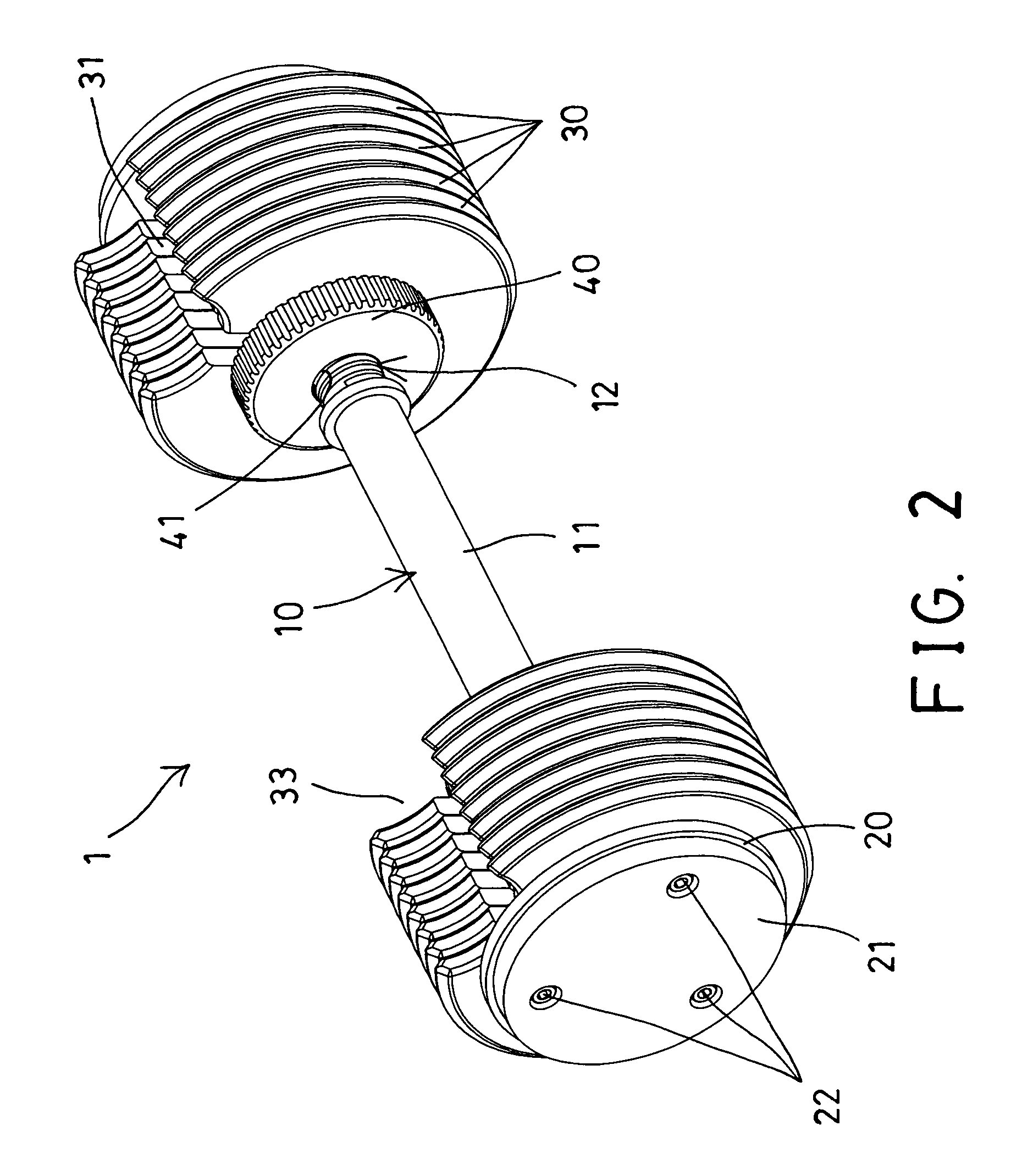

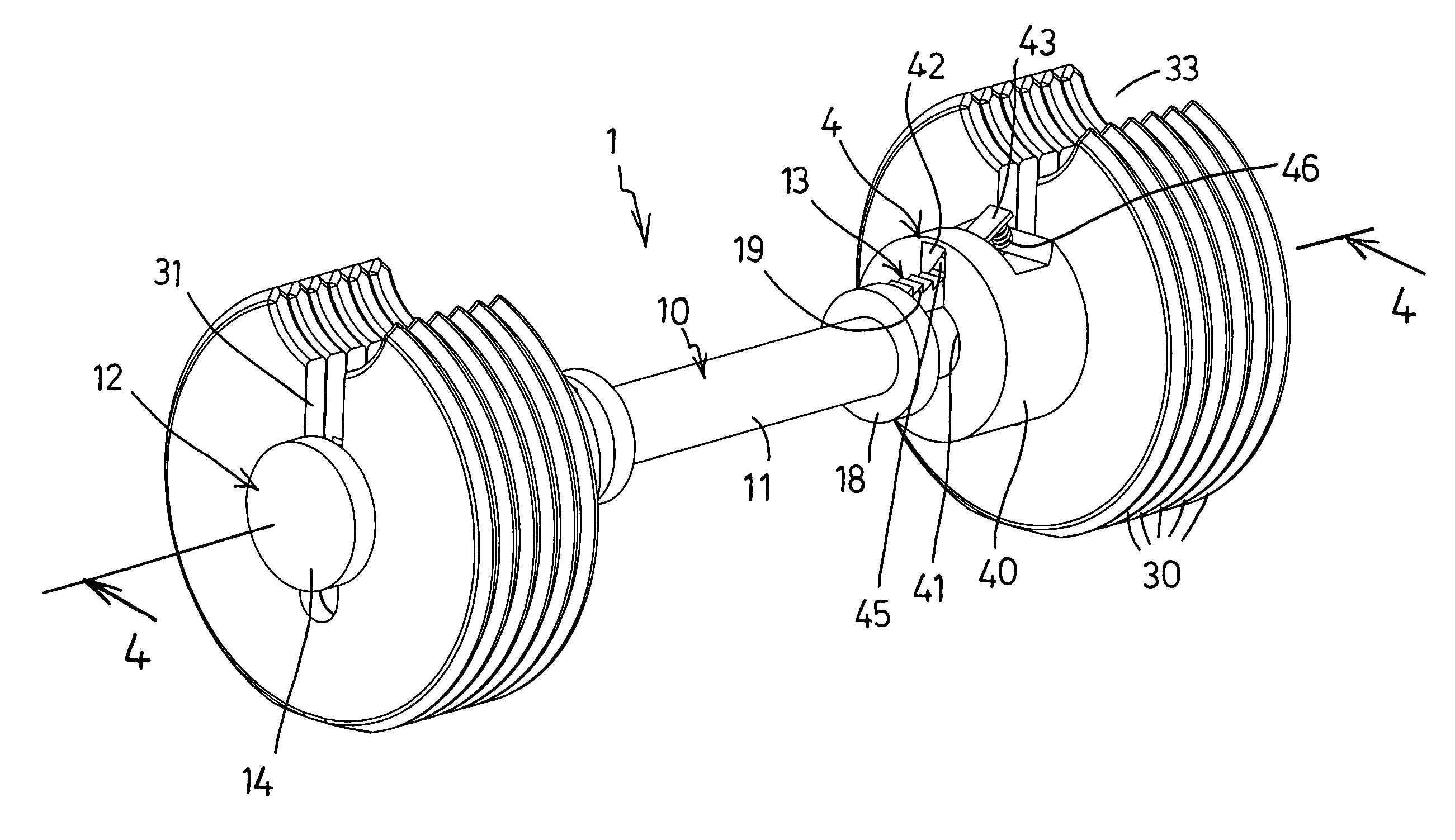

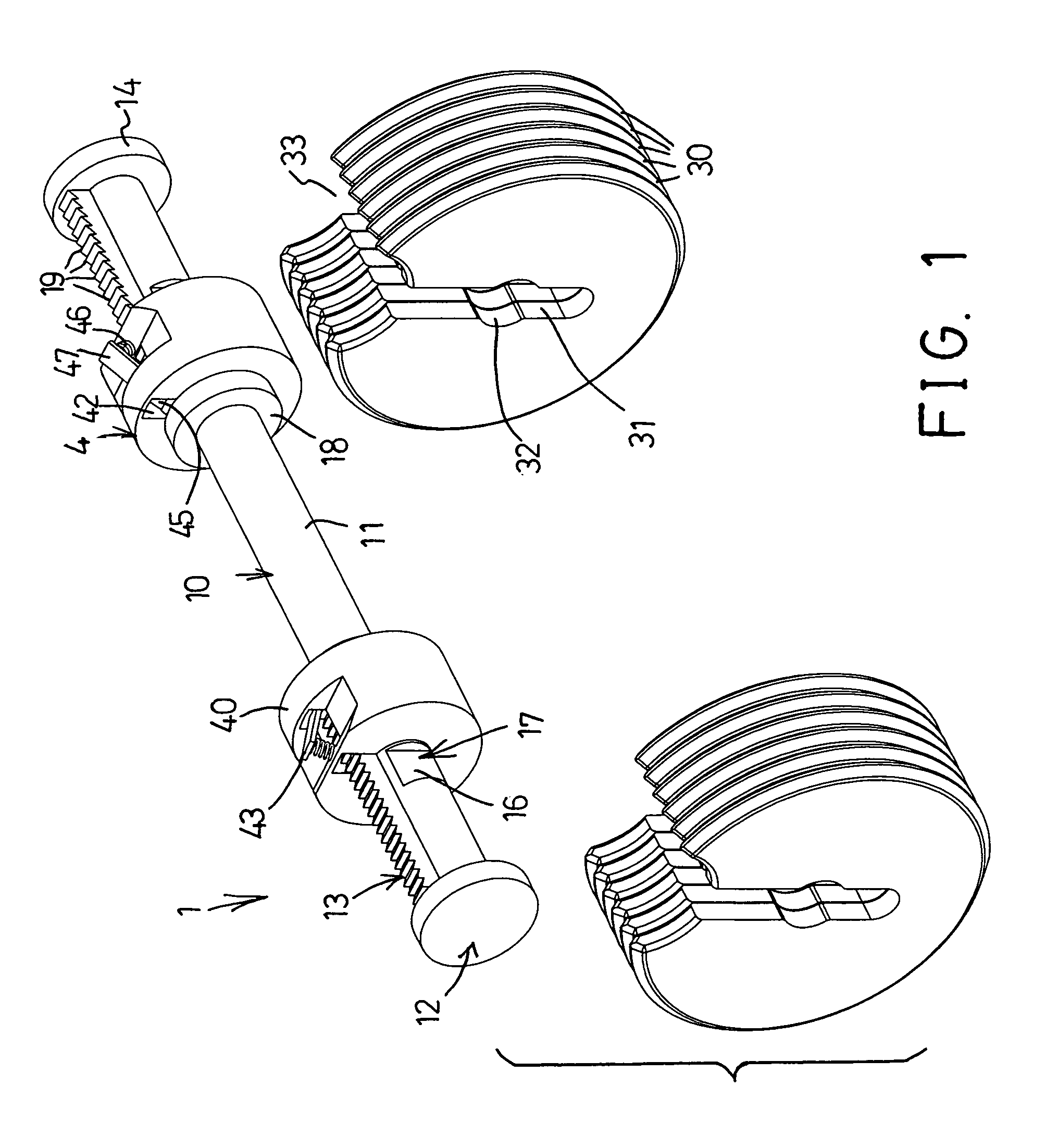

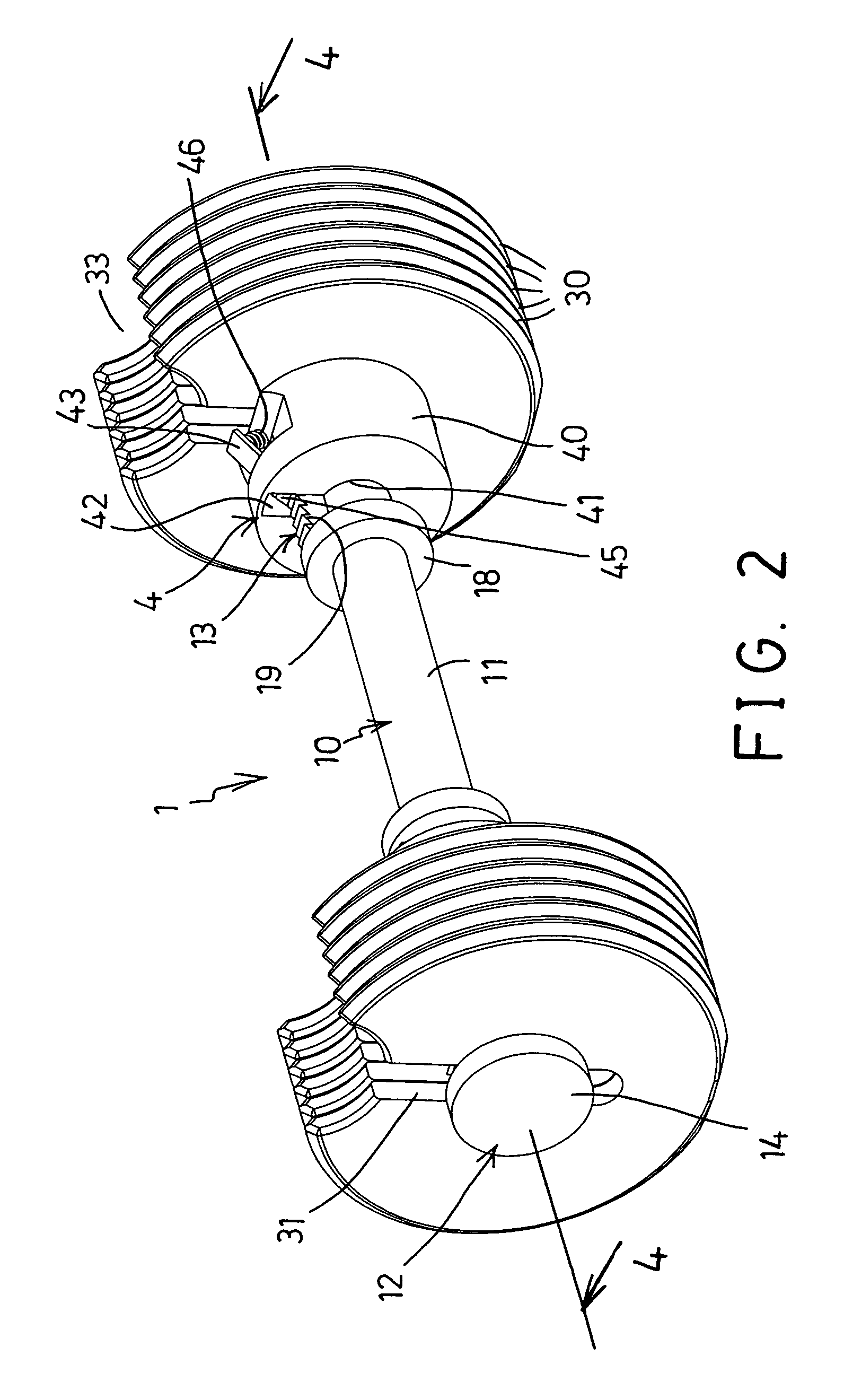

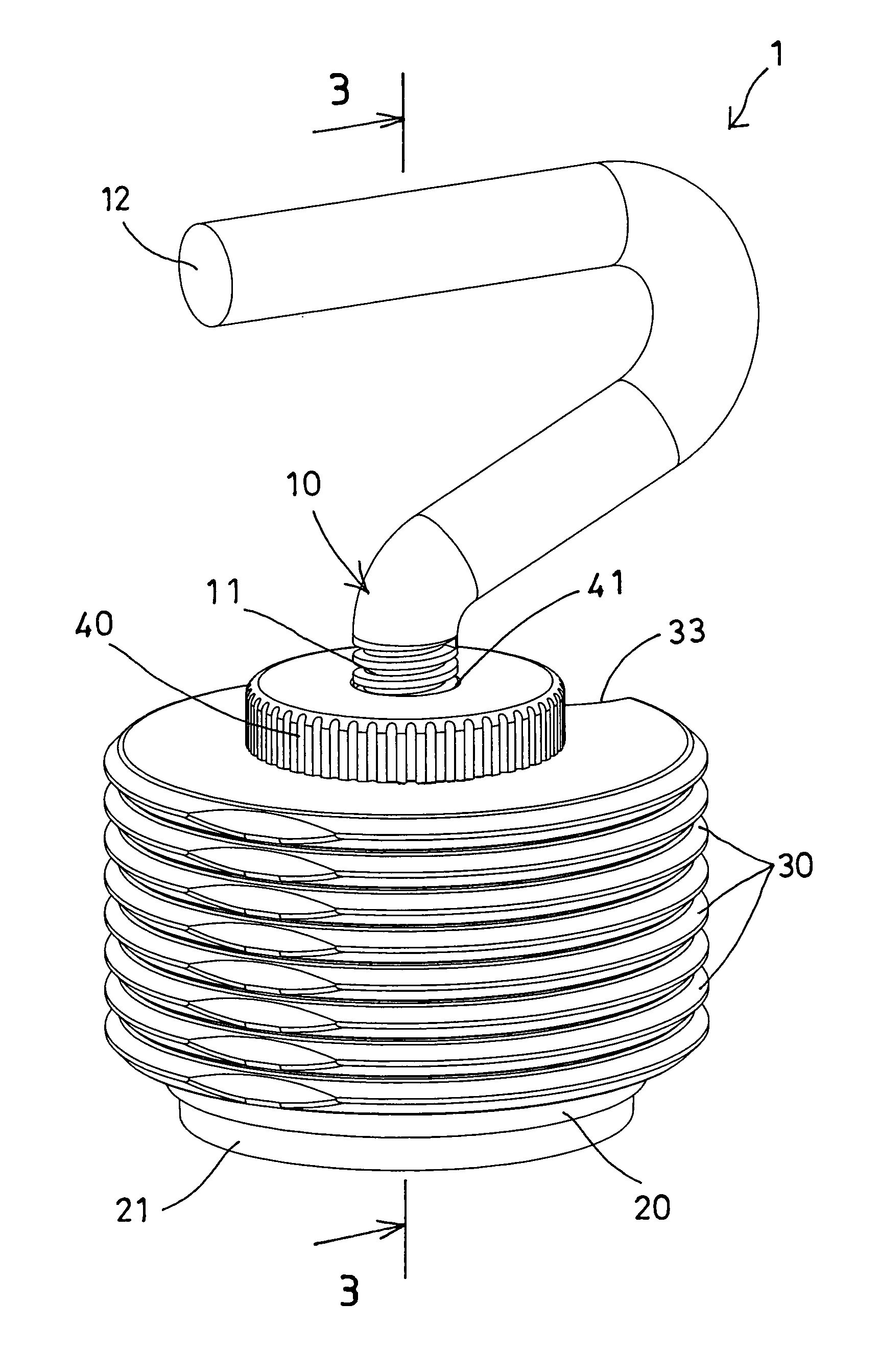

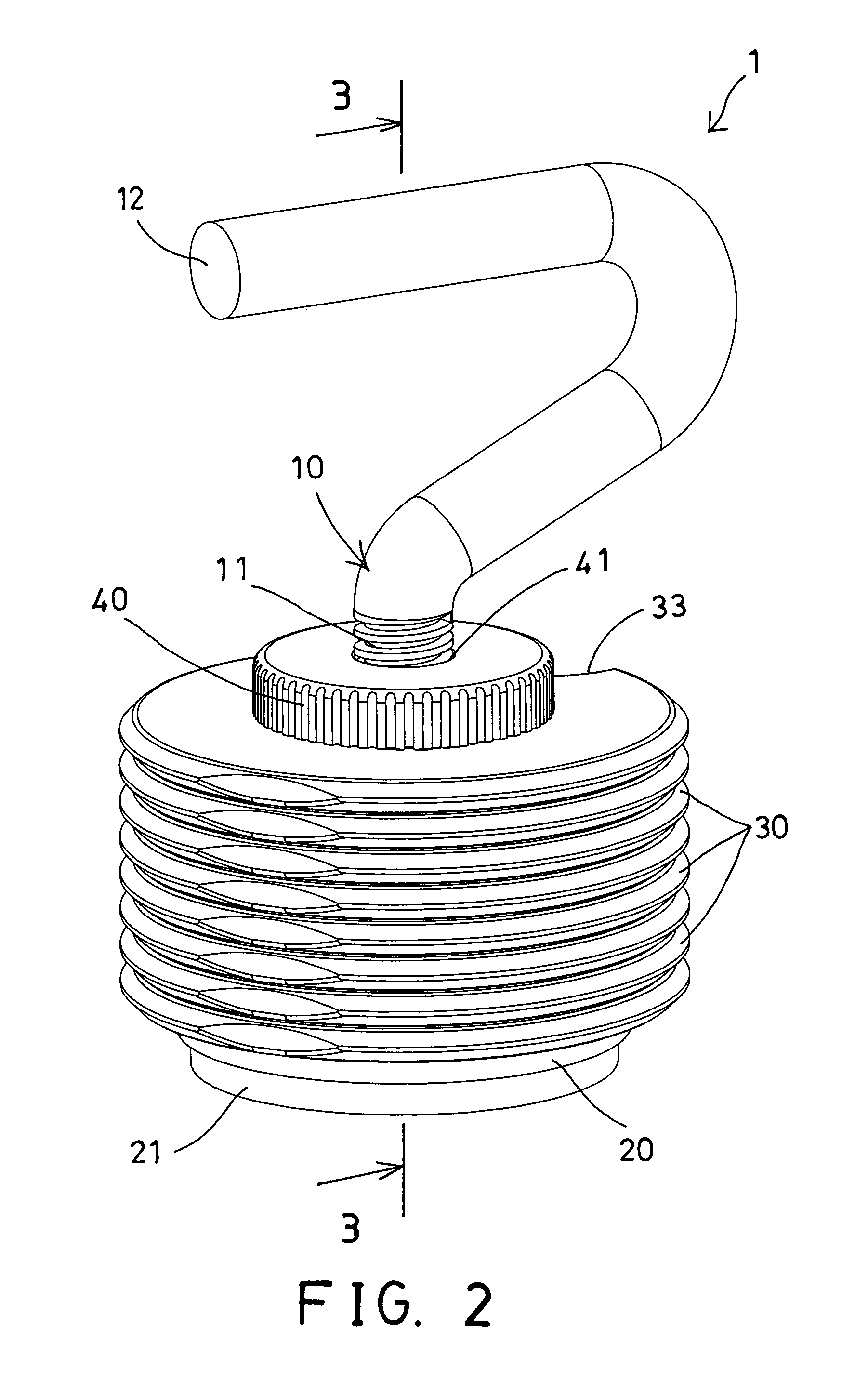

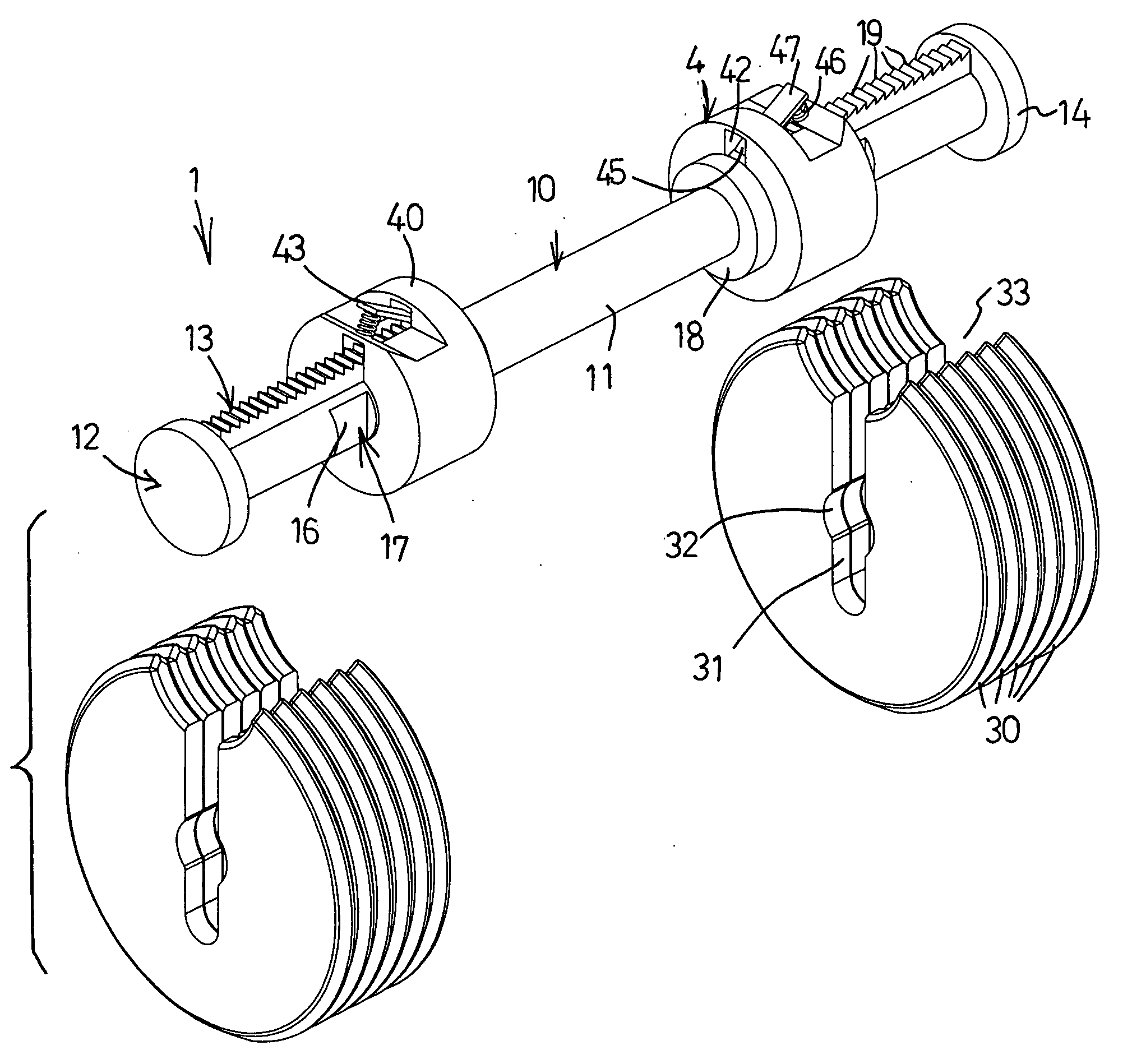

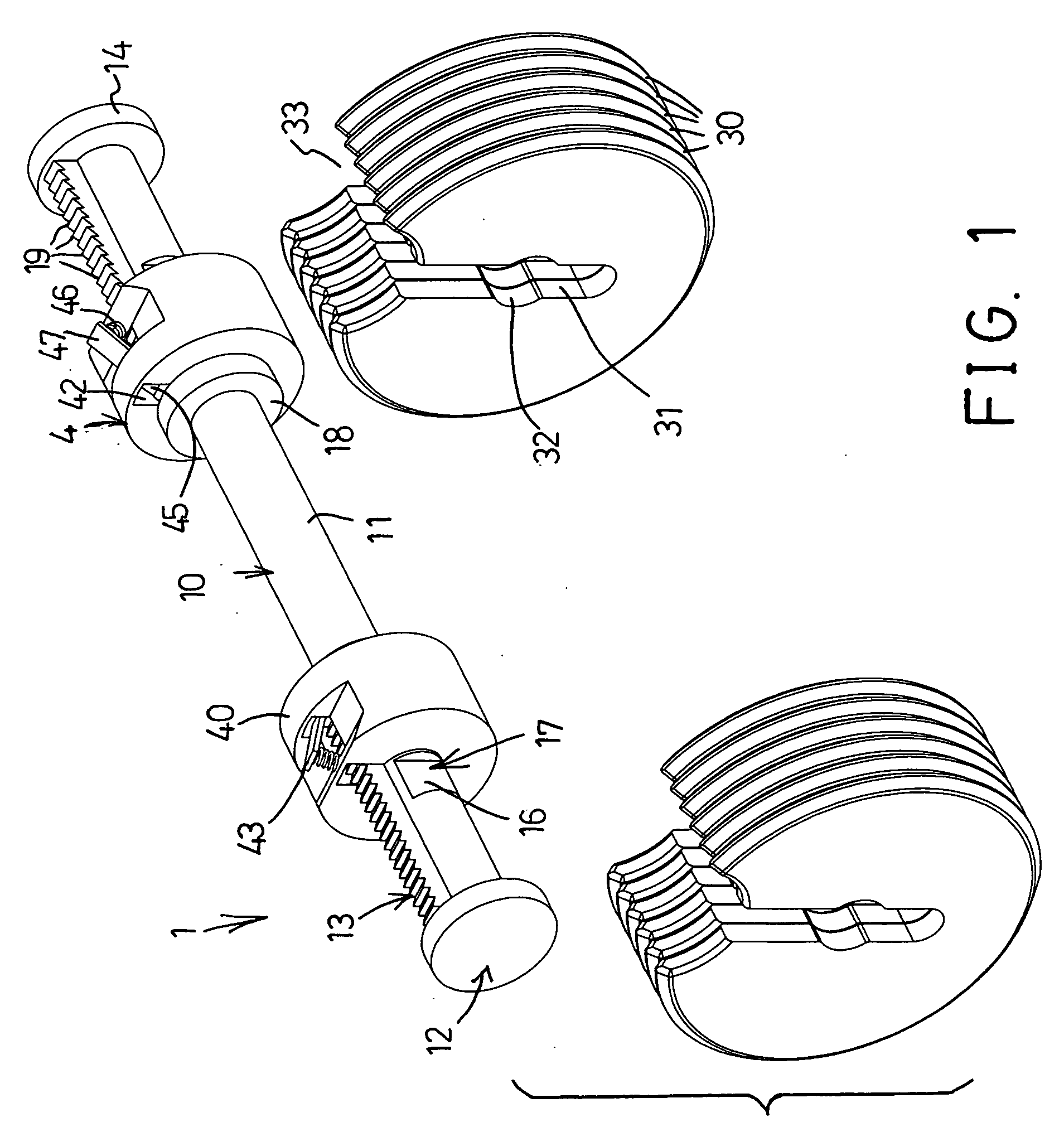

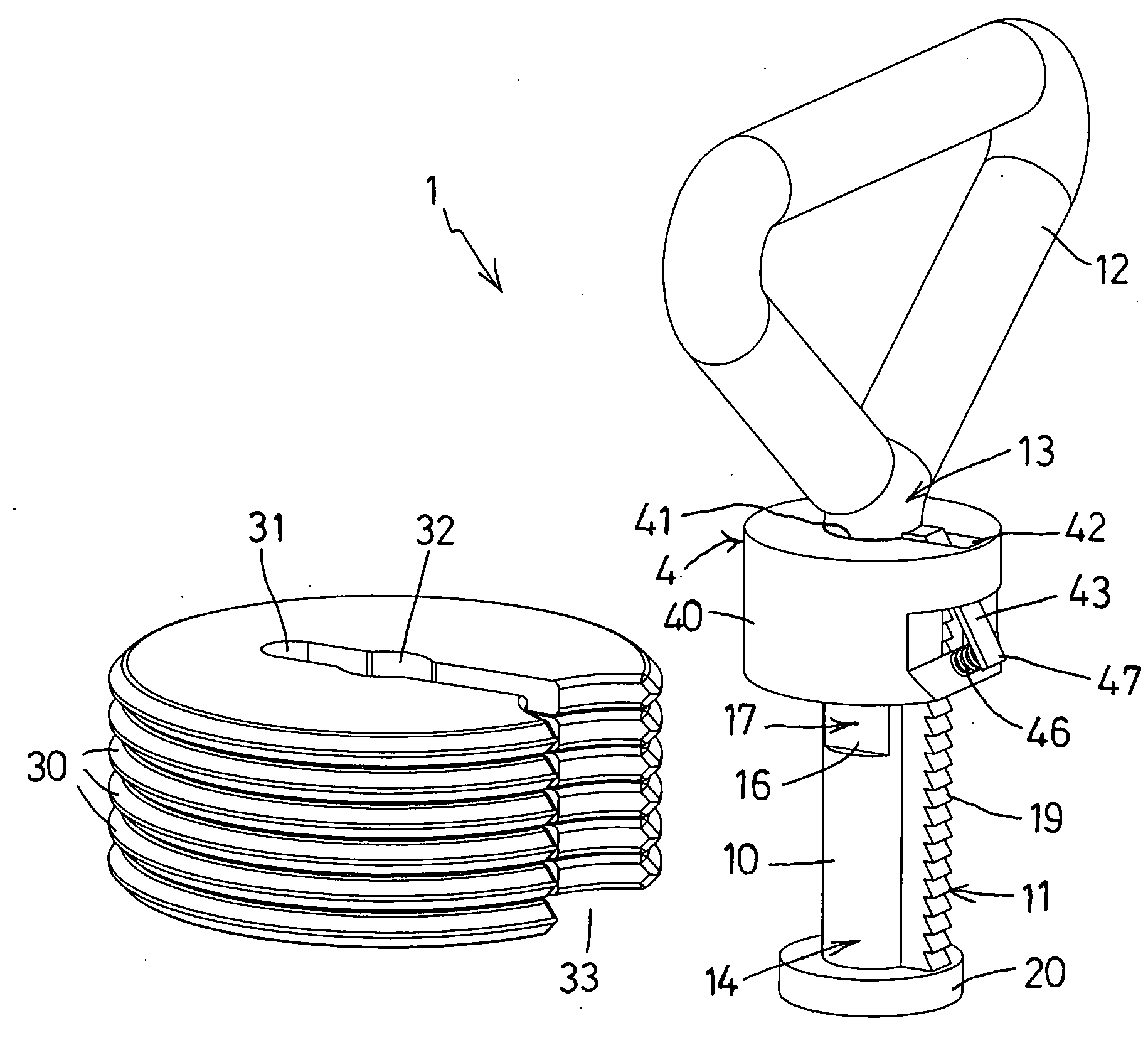

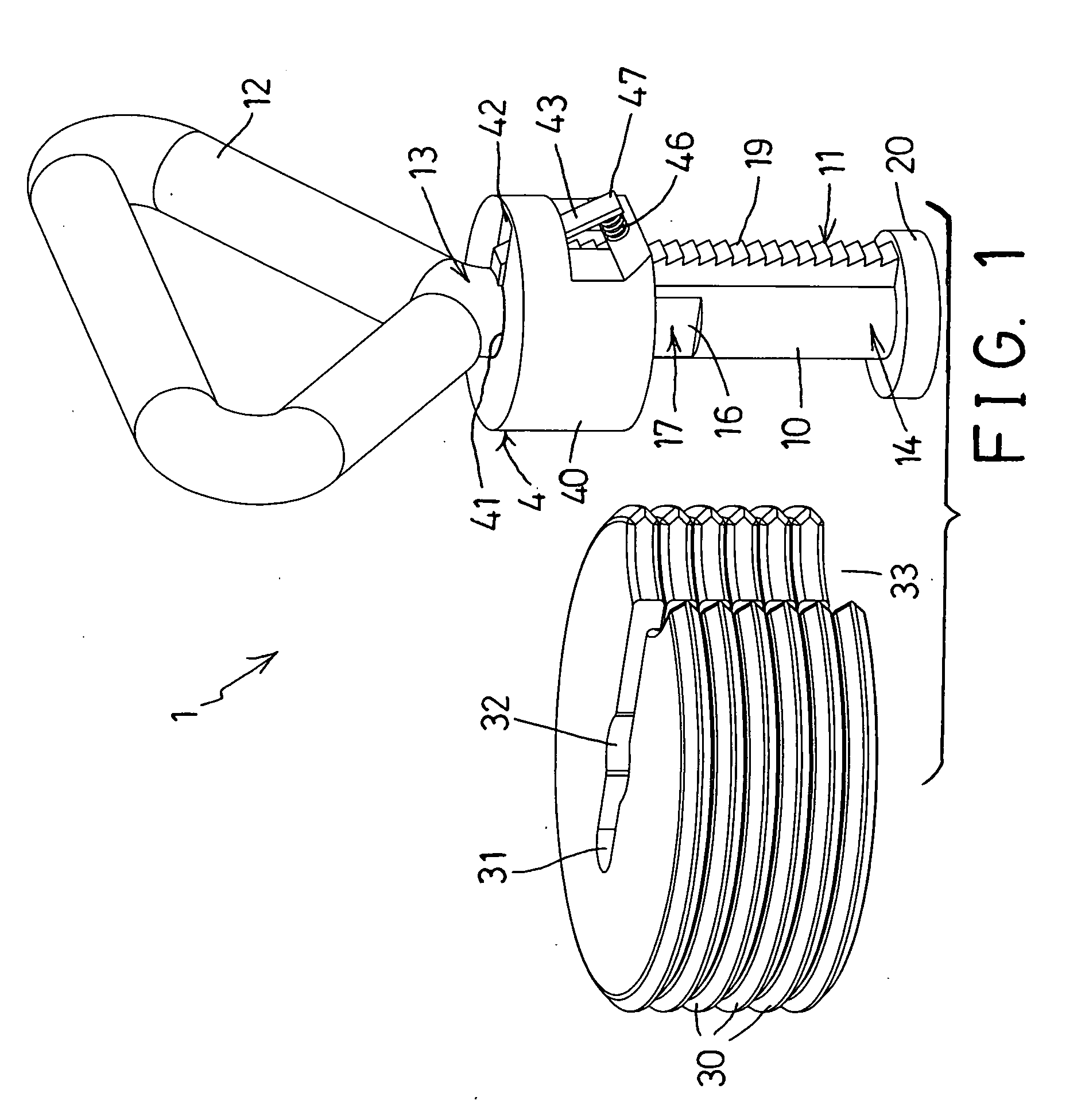

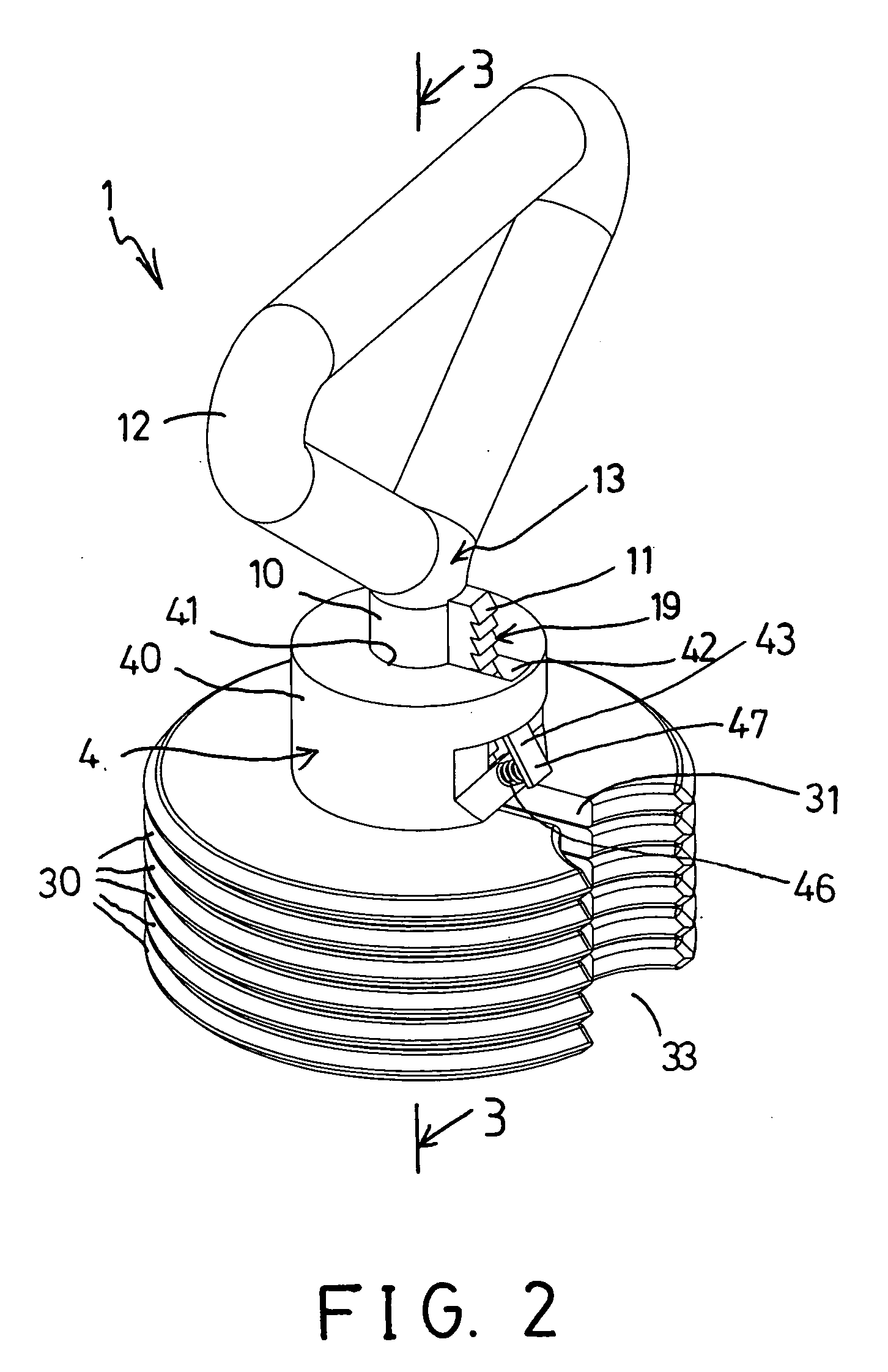

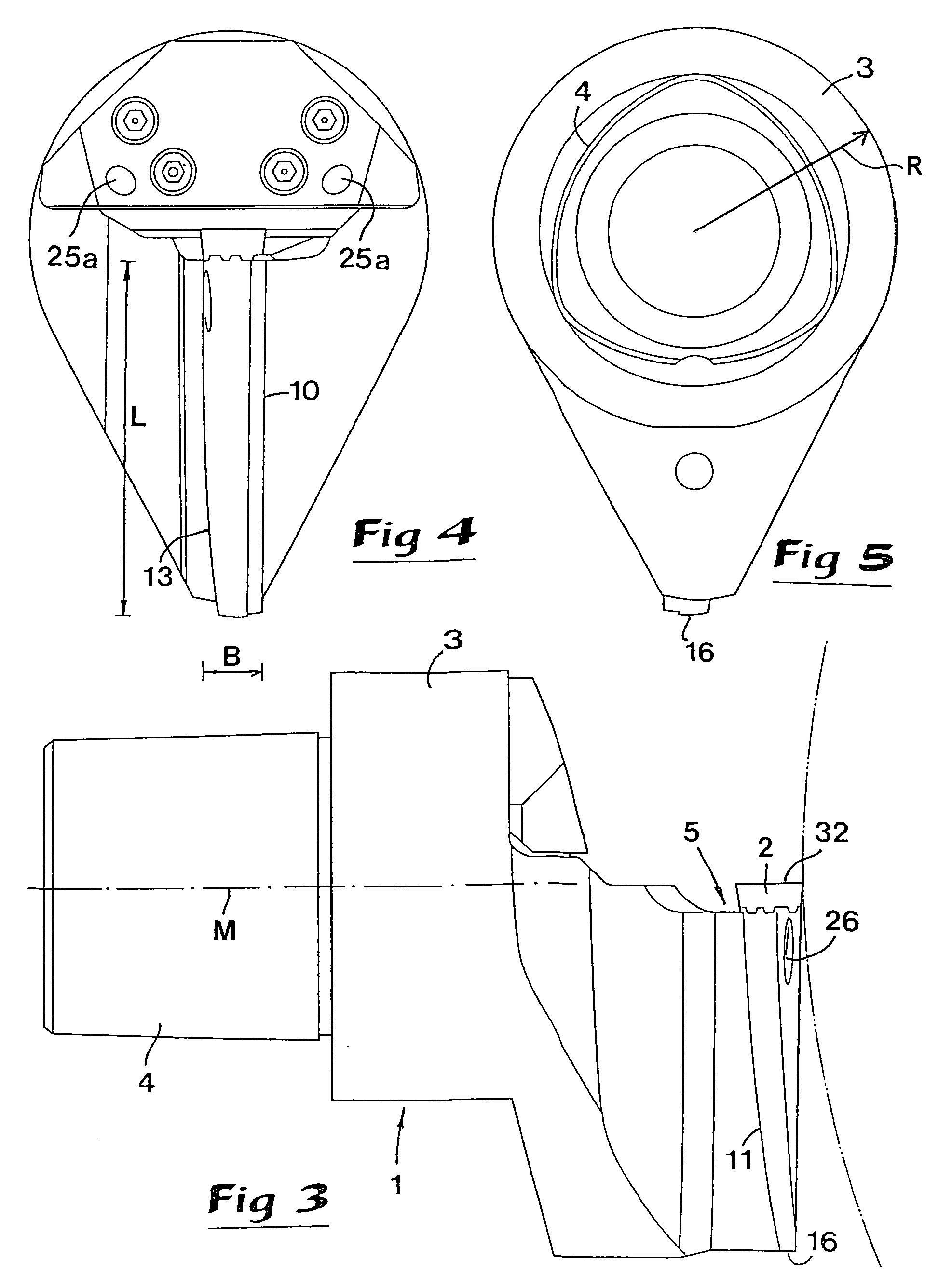

Adjustable dumbbell

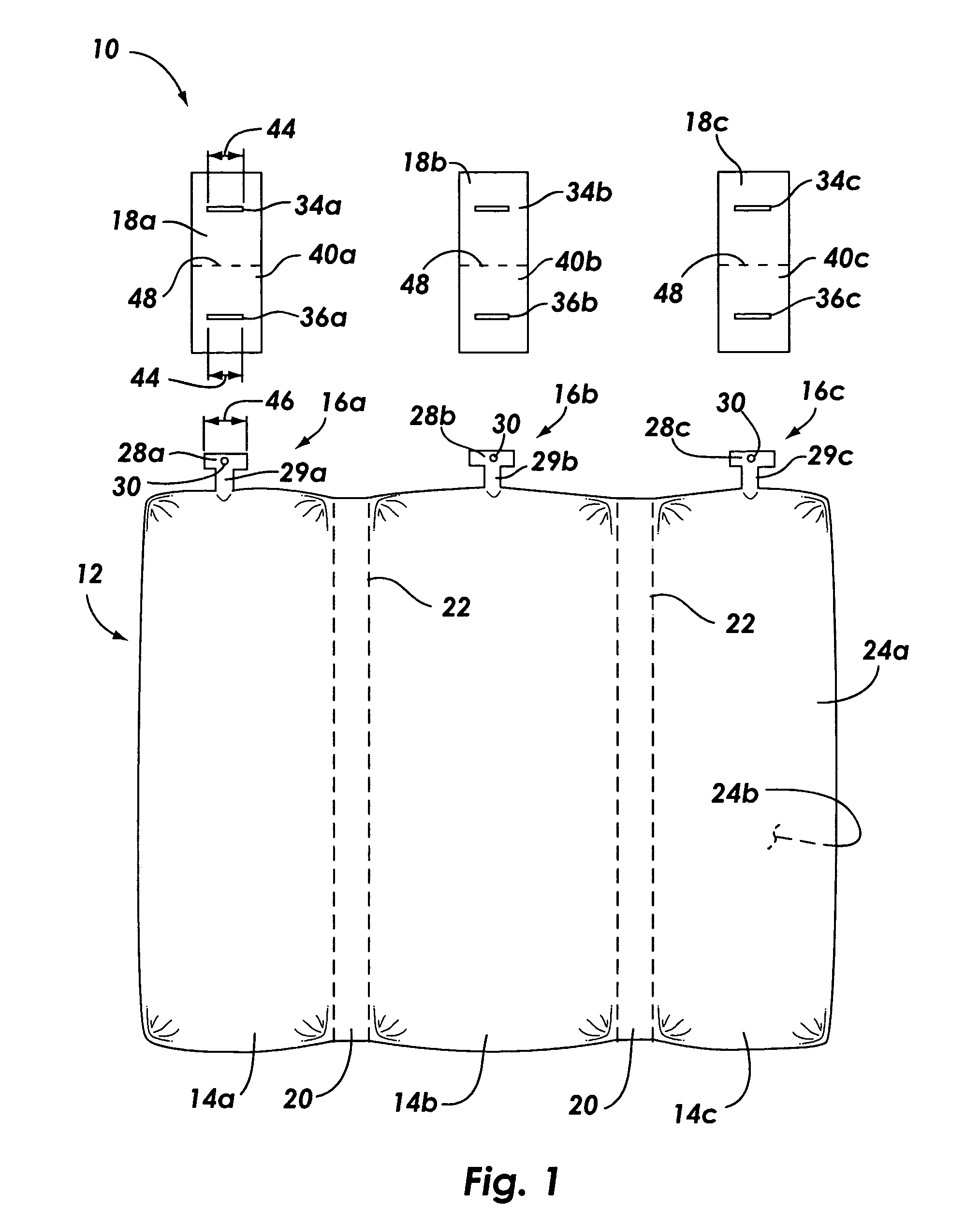

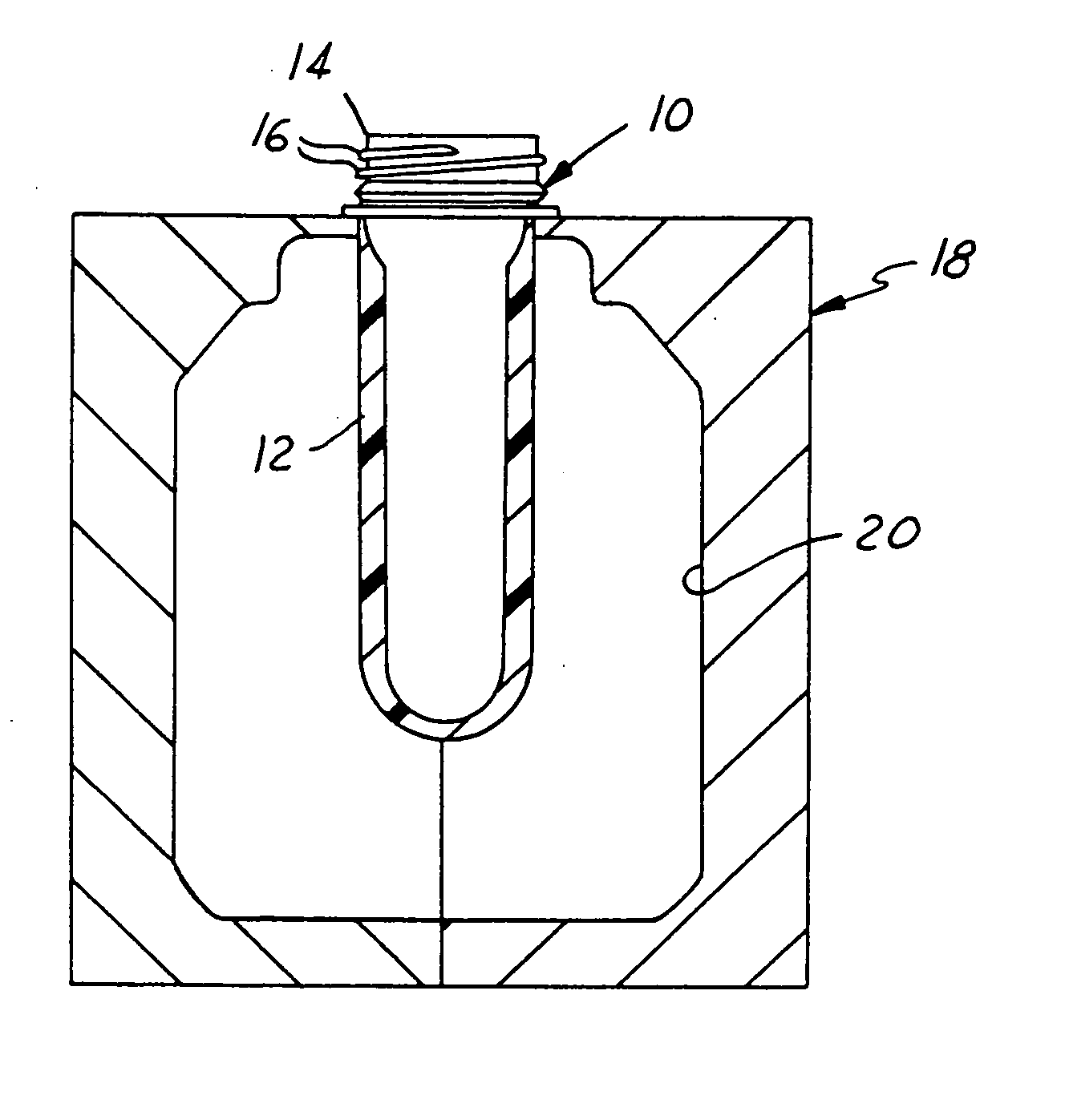

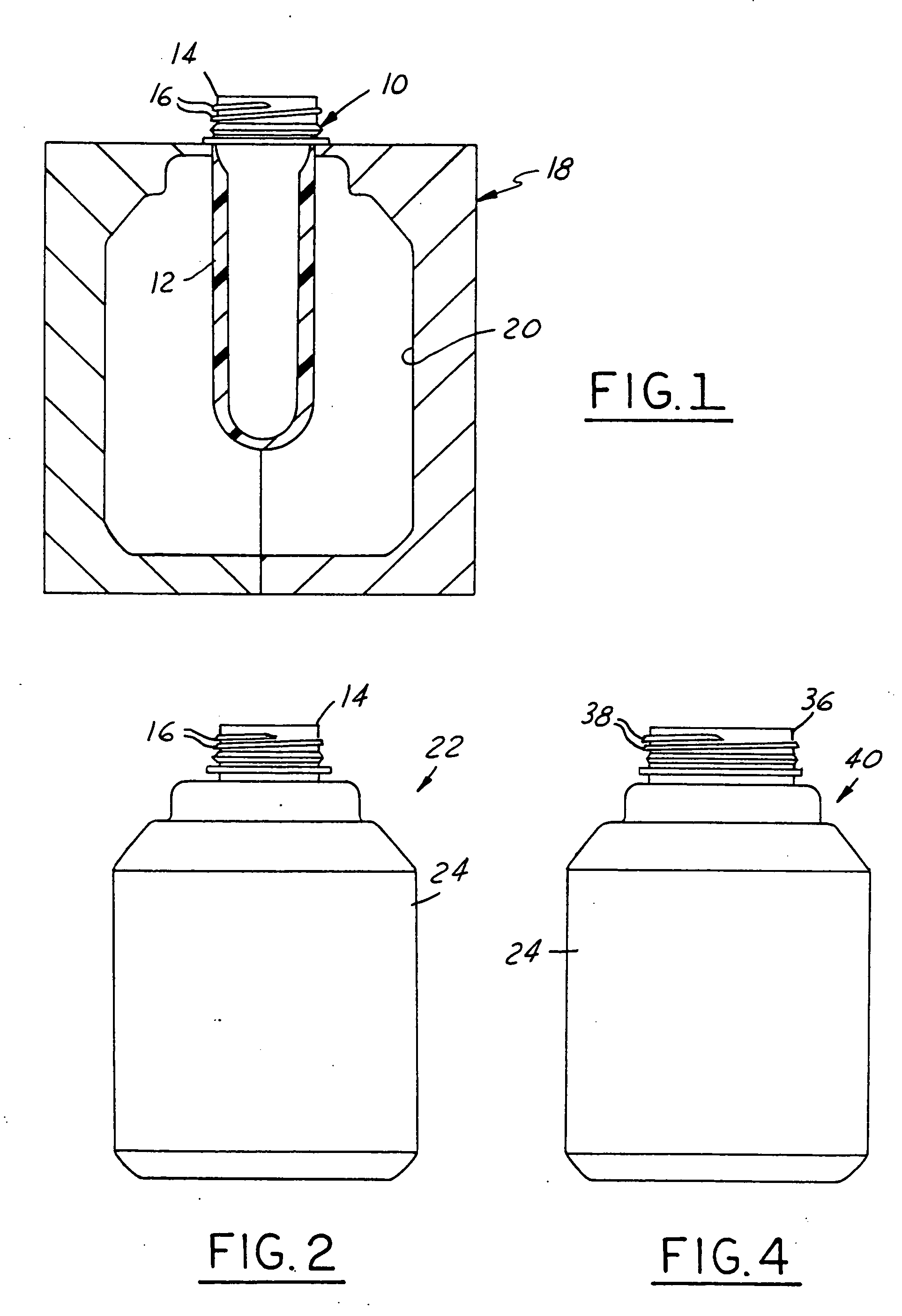

InactiveUS7731641B1Easily and adjustably attachedEasily and adjustably to and disengagedDumb-bellsDumbbellMechanical engineering

An adjustable dumbbell includes a handle having a narrowed neck segment formed on each end portion and having a base plate attached to each end portion, two or more weight members each having a slot for receiving the narrowed neck segment of the handle, and each having an enlarged opening communicating with the slot for receiving the handle and for retaining the weight members to the handle when the weight members are offset from the narrowed neck segment of the handle, and a lock nut is engaged with the handle for quickly retaining the weight members to the handle after the weight members have been disengaged from the narrowed neck segment of the handle.

Owner:CHEN PAUL

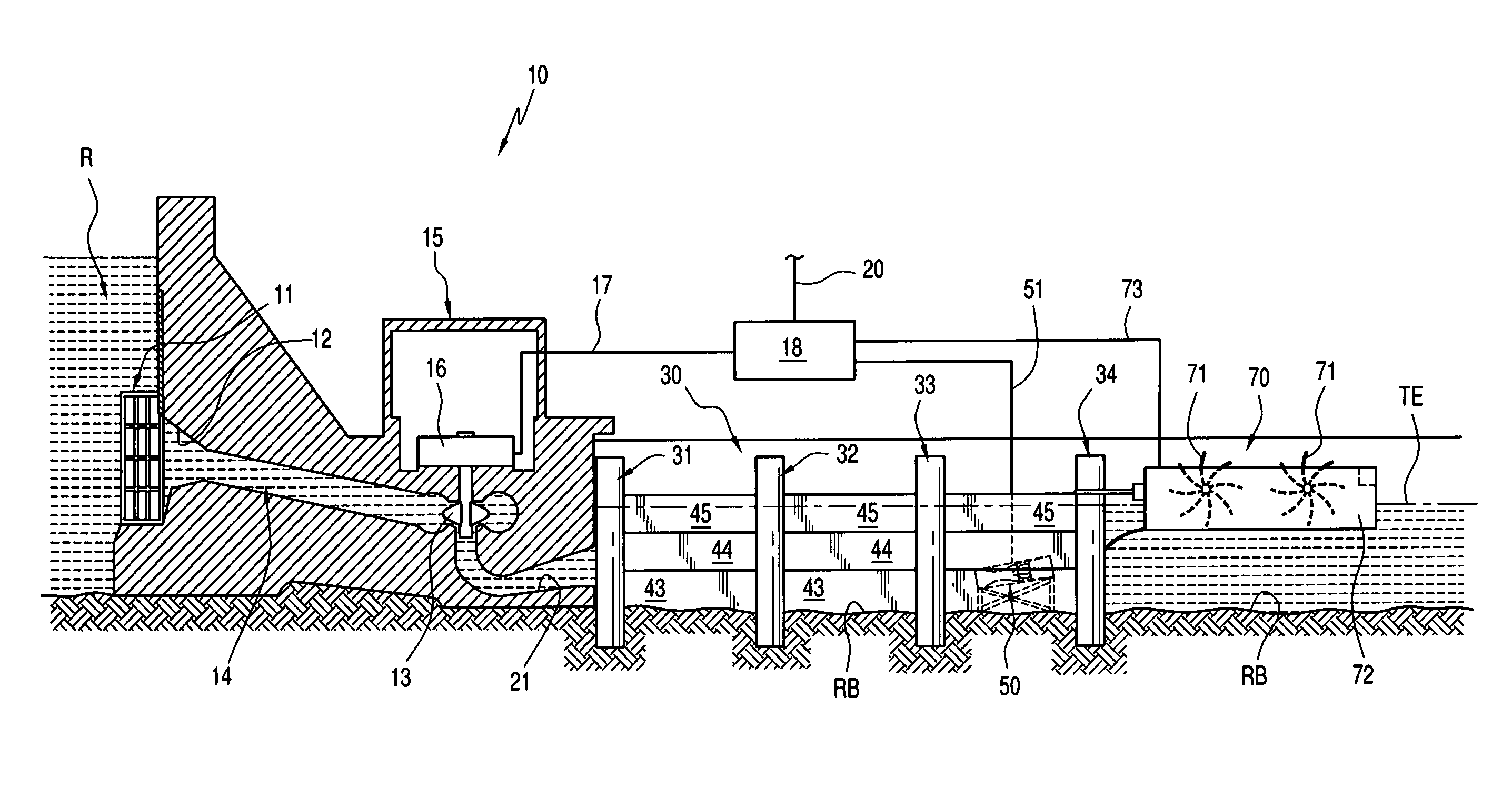

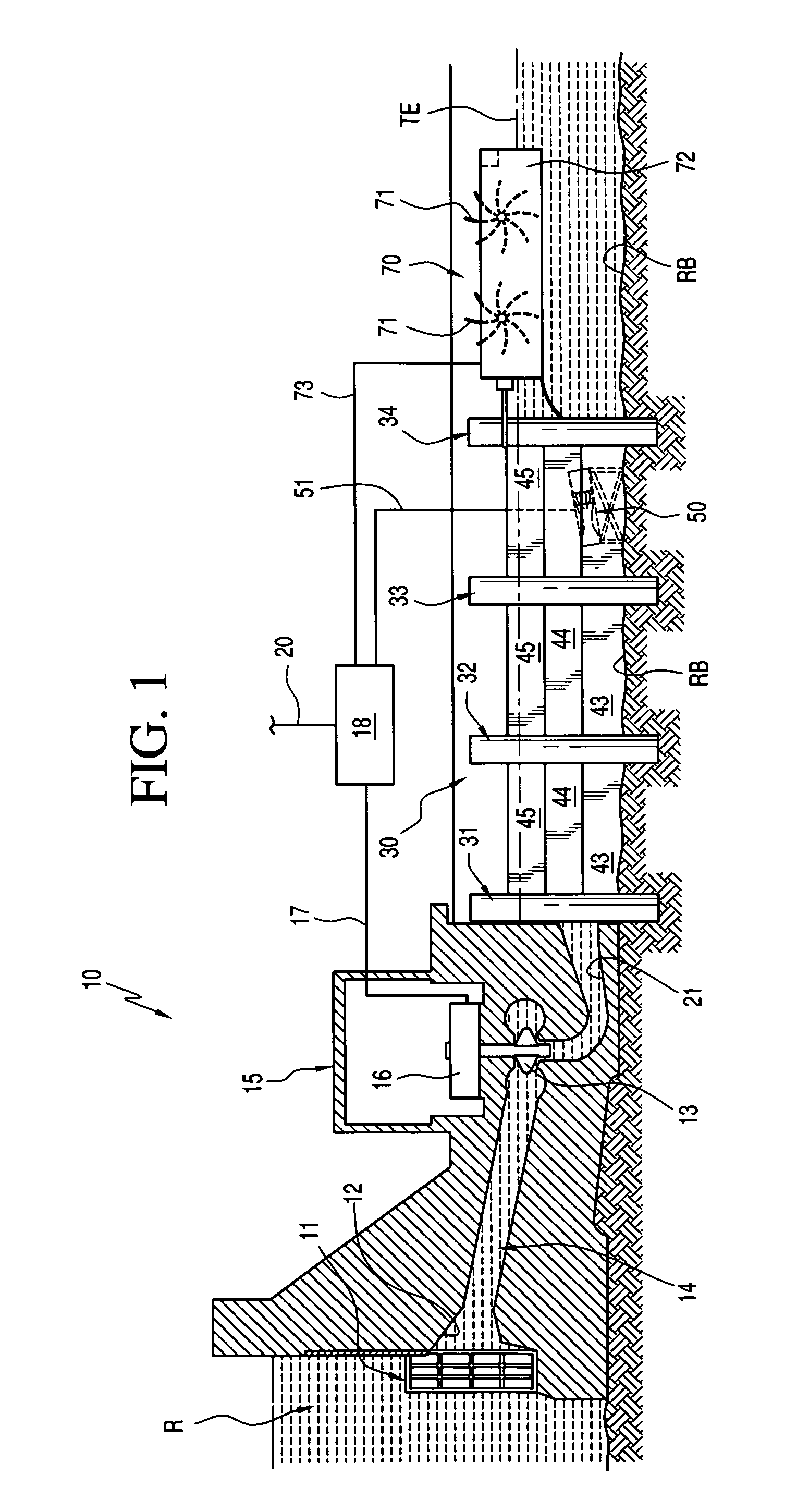

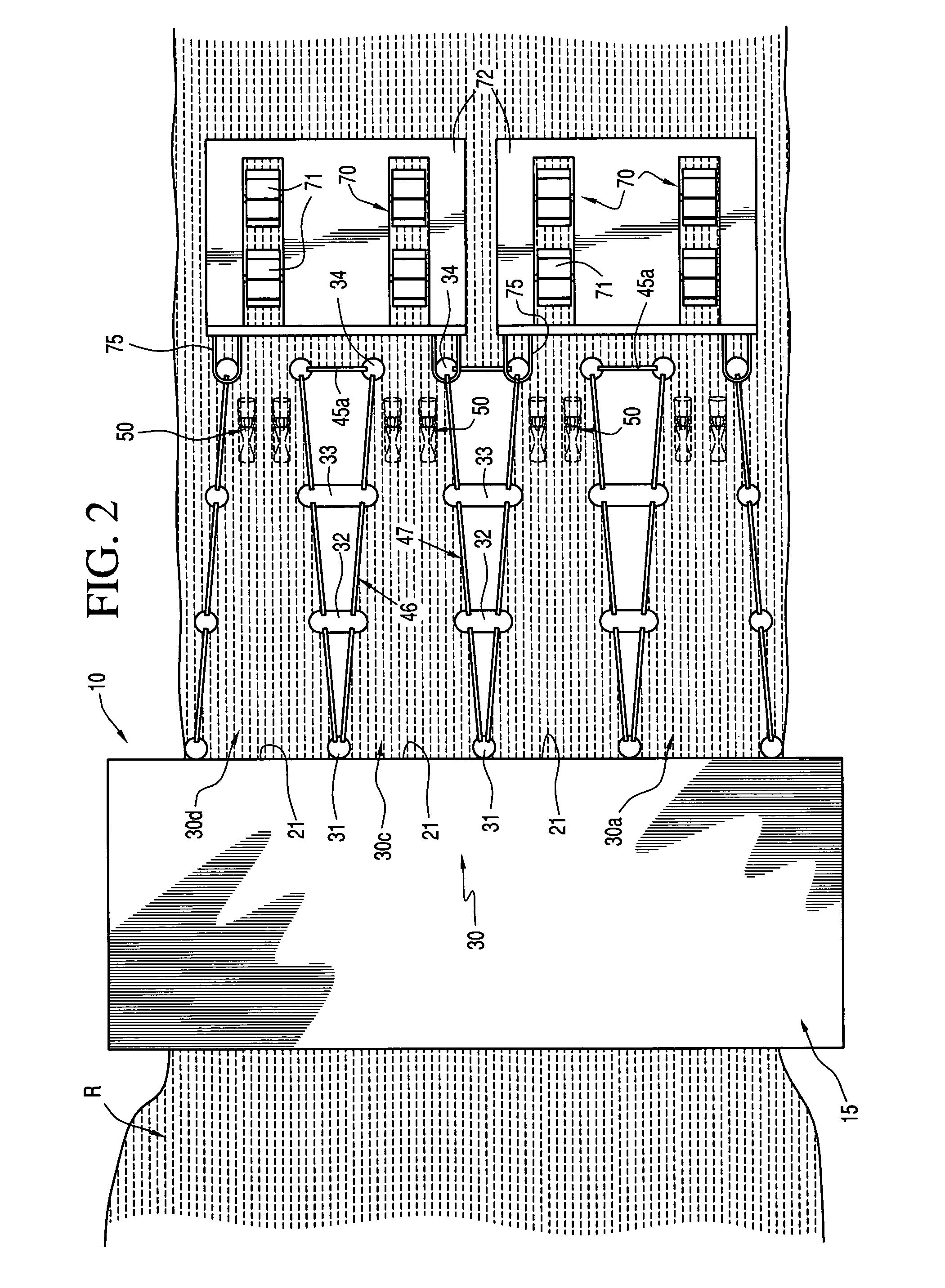

Apparatus for hydroelectric power production expansion

InactiveUS7478974B1Maximize productionLower life cycle costsWater-power plantsReaction enginesEngineeringElectric power

Normally hydroelectric dam powerhouses use river flow once before discharging it as turbulent tailwater, ineffective to spin turbines. The present invention uses tapered channels to confine and constrict turbulent tailwater into laminar flow that drives turbines both submersible and floatable utilizing the same water three times concurrently to generate new electricity. Channels originate adjacent to draft tube outlets, constrict in the downstream direction to create narrow necks where turbine / generators benefit from debris free, increased velocity and laminar flows to generate electricity. Hydroelectricity uses zero fuel, creates zero waste and has zero carbon dioxide emissions. Structures are uncomplicated, construction is within project boundaries minimizing environmental impacts and speeding projects coming online. New facilities are protected by existing dam security. Hydroelectricity replaces less dependable renewable energy systems.

Owner:KELLY WILLIAM LOWELL

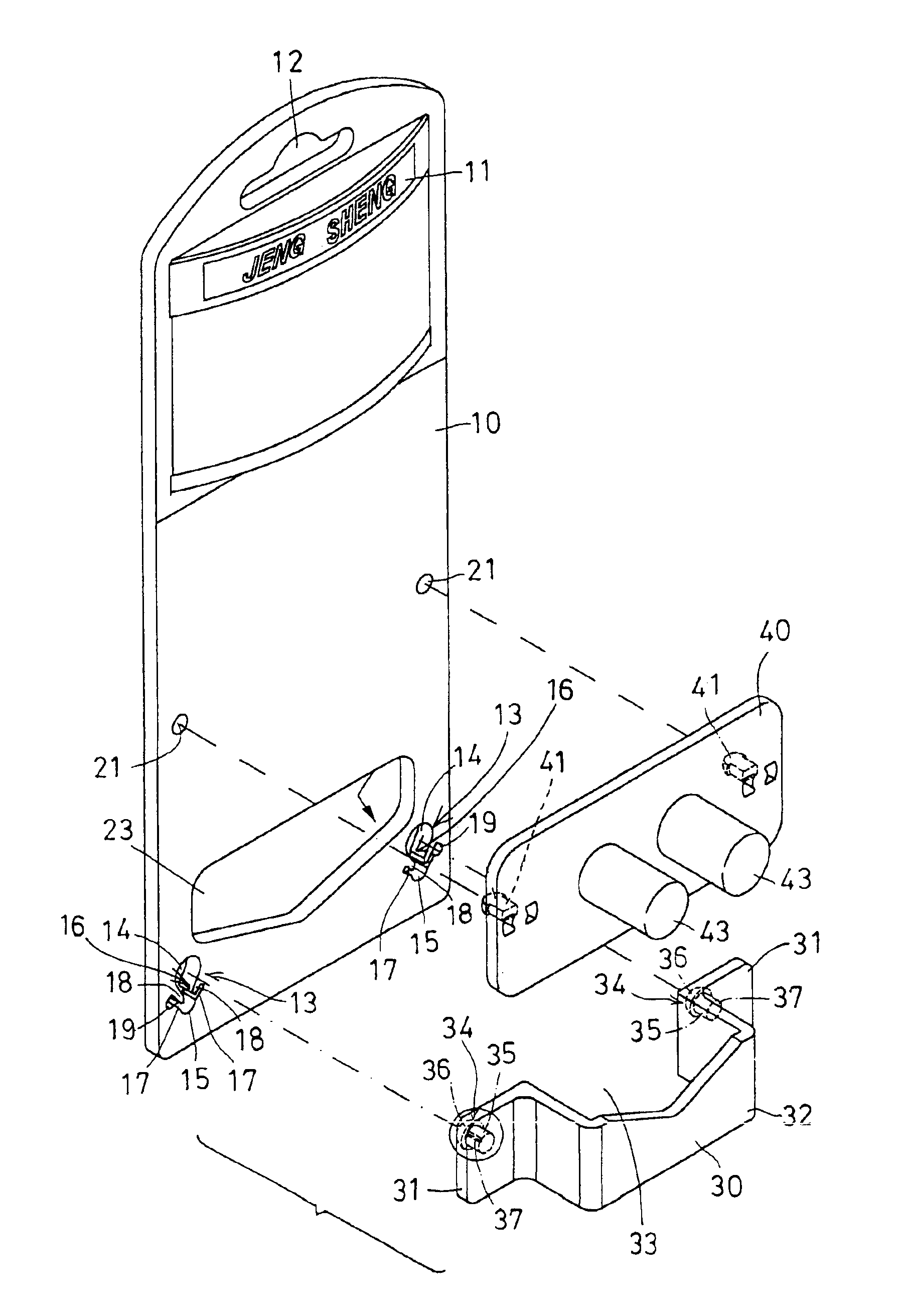

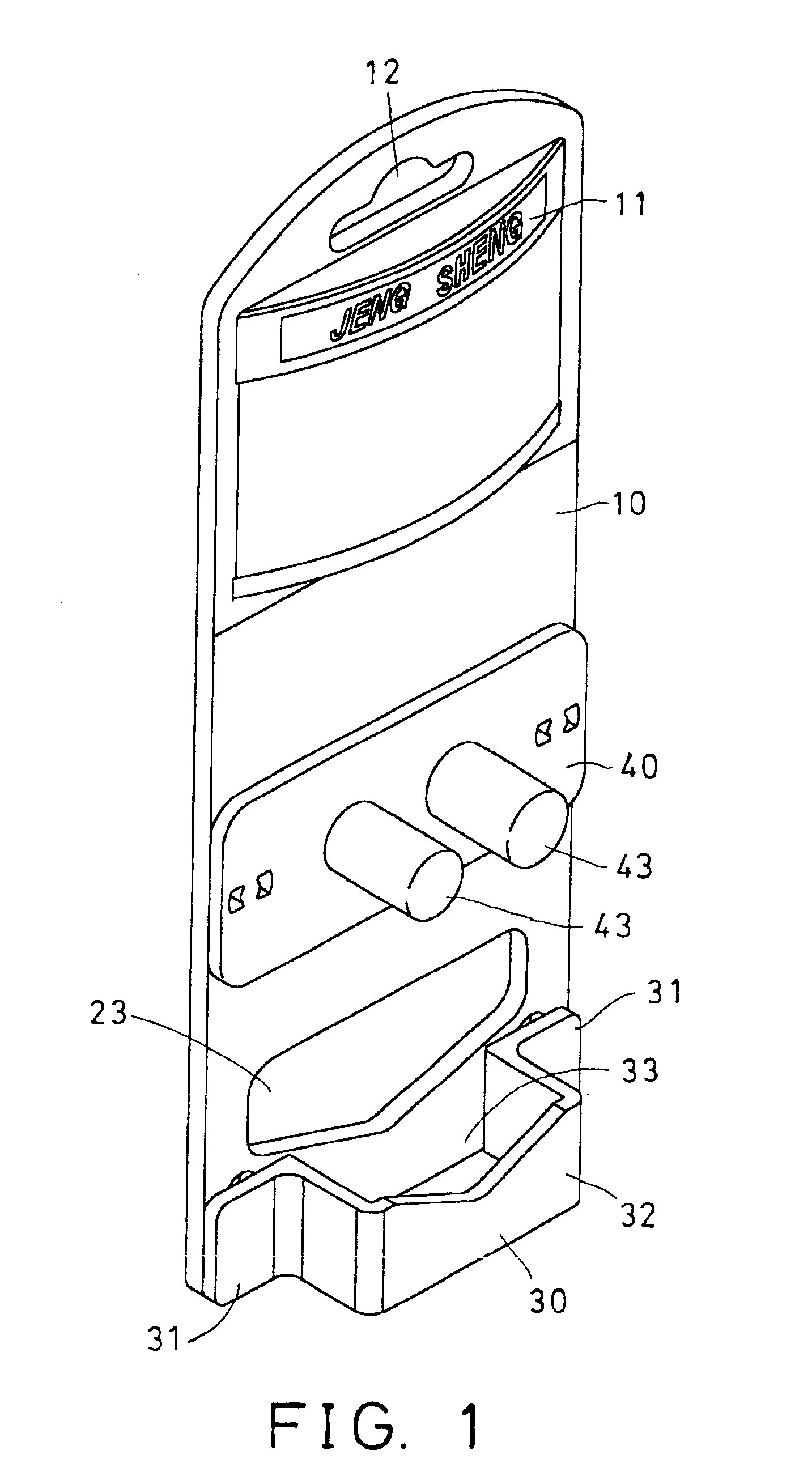

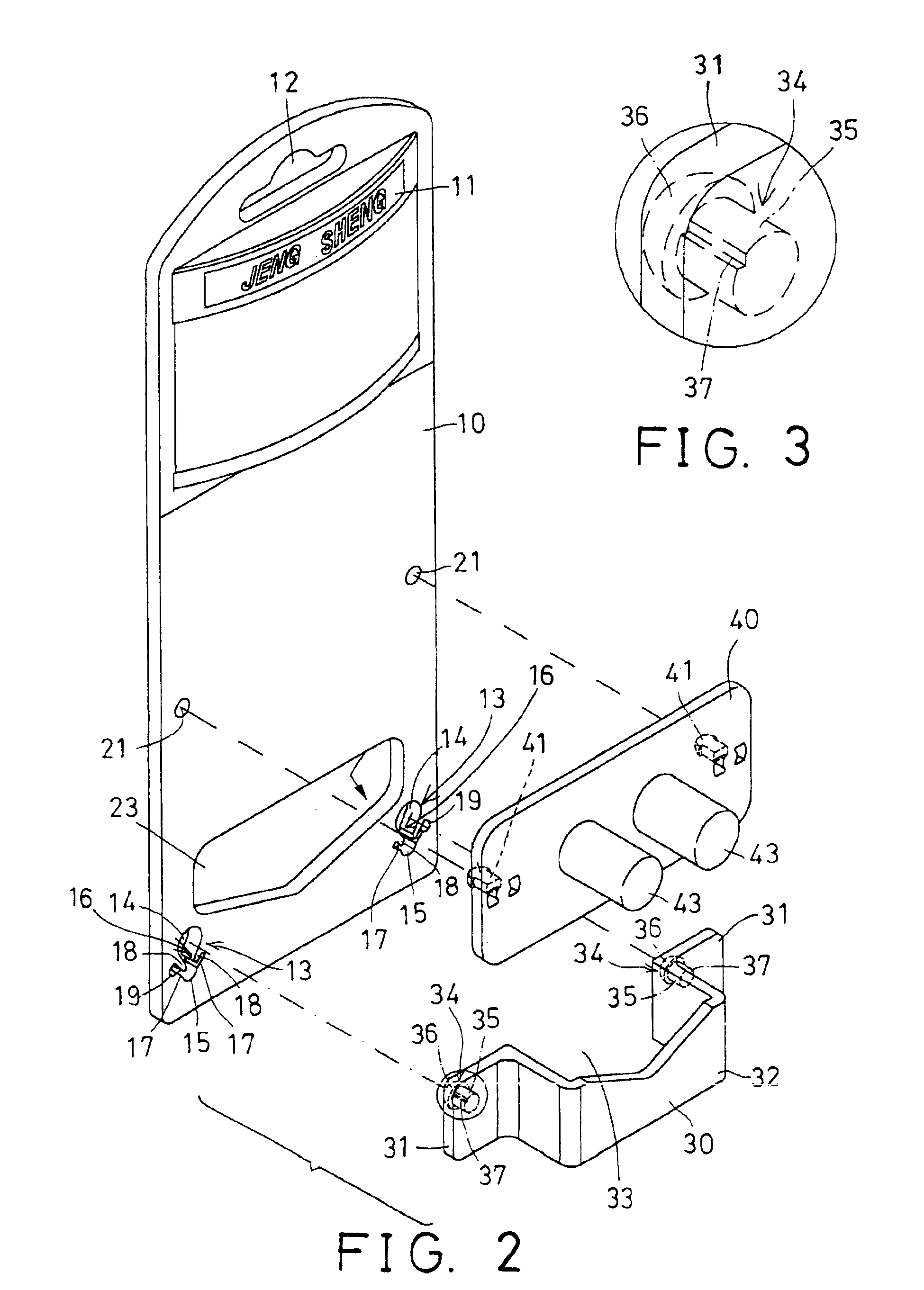

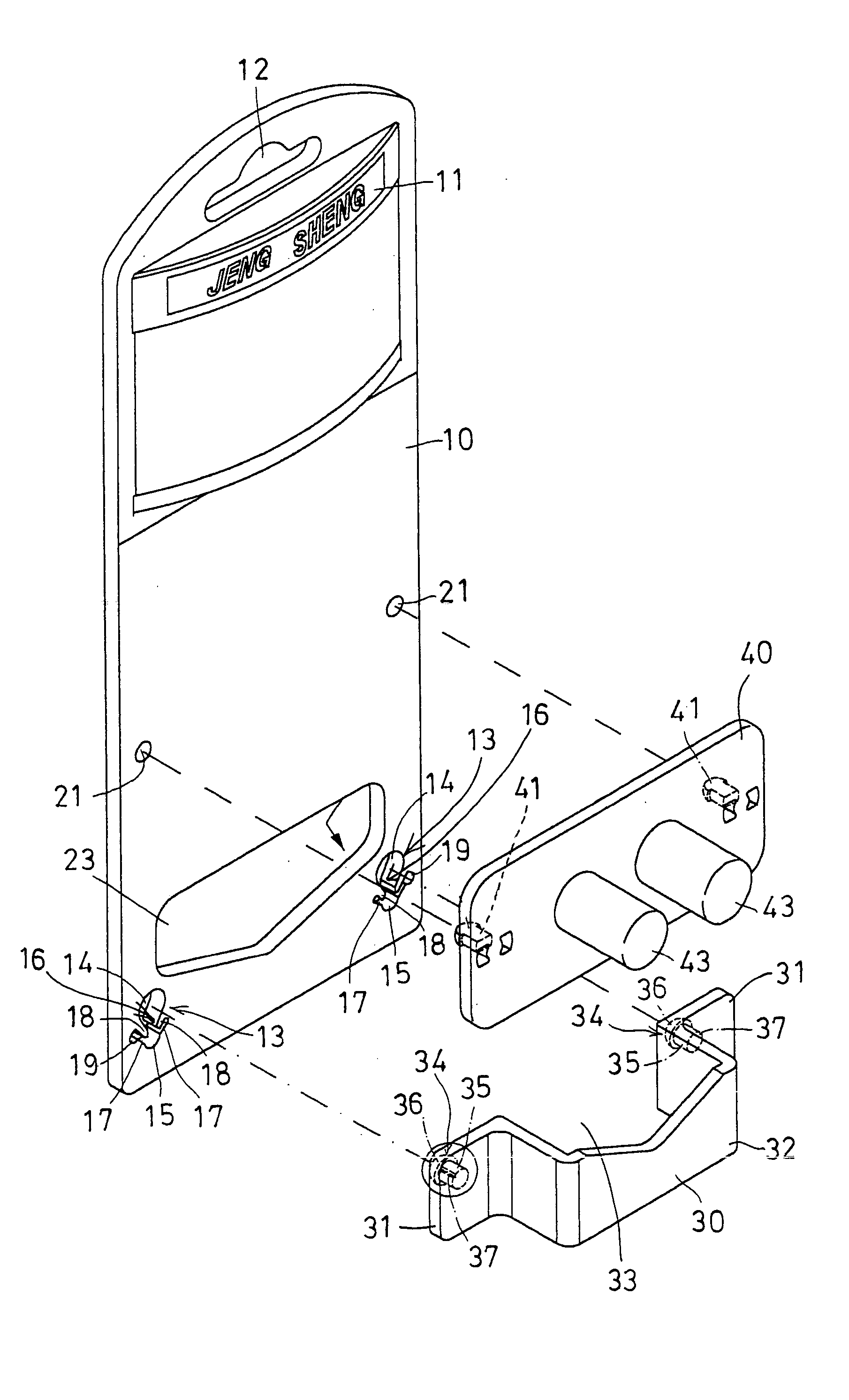

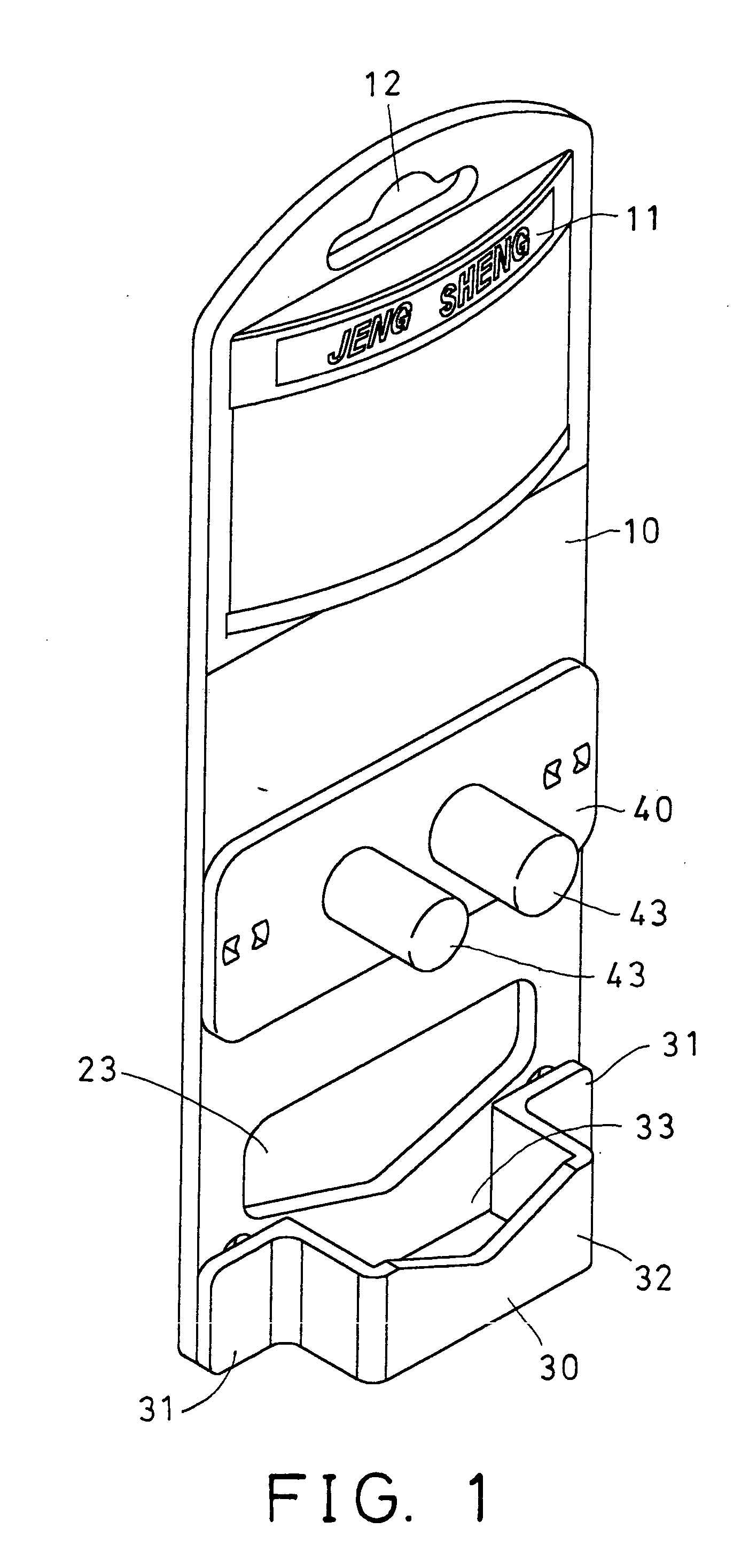

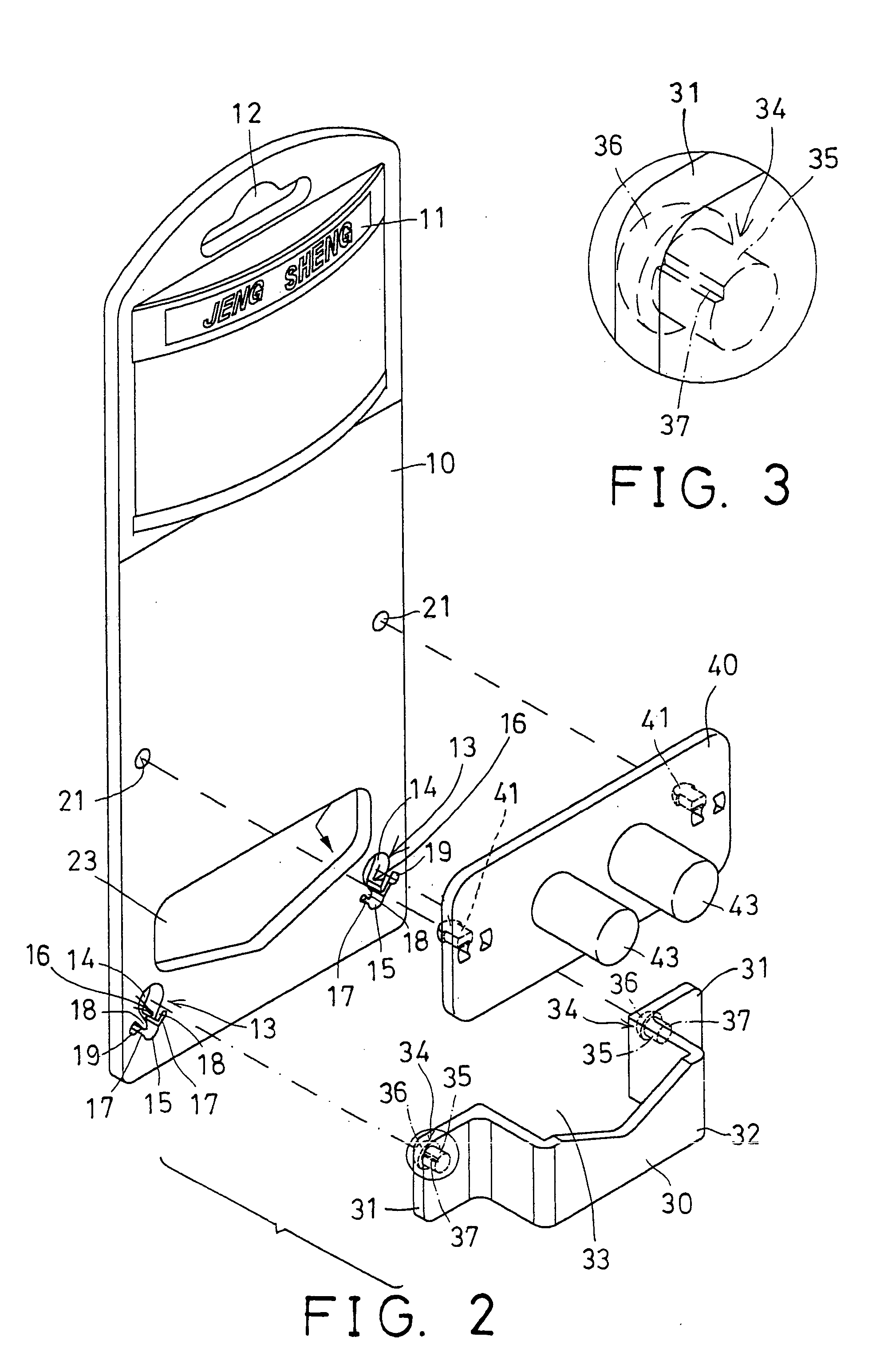

Tool holding and displaying device

A tool holding and displaying device includes a plate having a narrower neck portion formed between an upper orifice and a lower aperture. The upper orifice of the plate includes an inner diameter greater than that of the lower aperture of the plate, and a bracket includes a latch having an enlarged head formed on a pin for engaging into the upper orifice of the plate. The enlarged head of the latch is greater than the lower apertures of the plate, to engage with the plate, and to anchor the bracket to the plate. The plate includes one or more spring arms to engage with the pin of the latch of the bracket, to lock the latch of the bracket to the plate.

Owner:CHIANG KUO CHUAN

Adjustable dumbbell

InactiveUS7811213B2Easily and adjustably attached to and disengagedWeight memberDumb-bellsDumbbellEngineering

Owner:CHEN PAUL

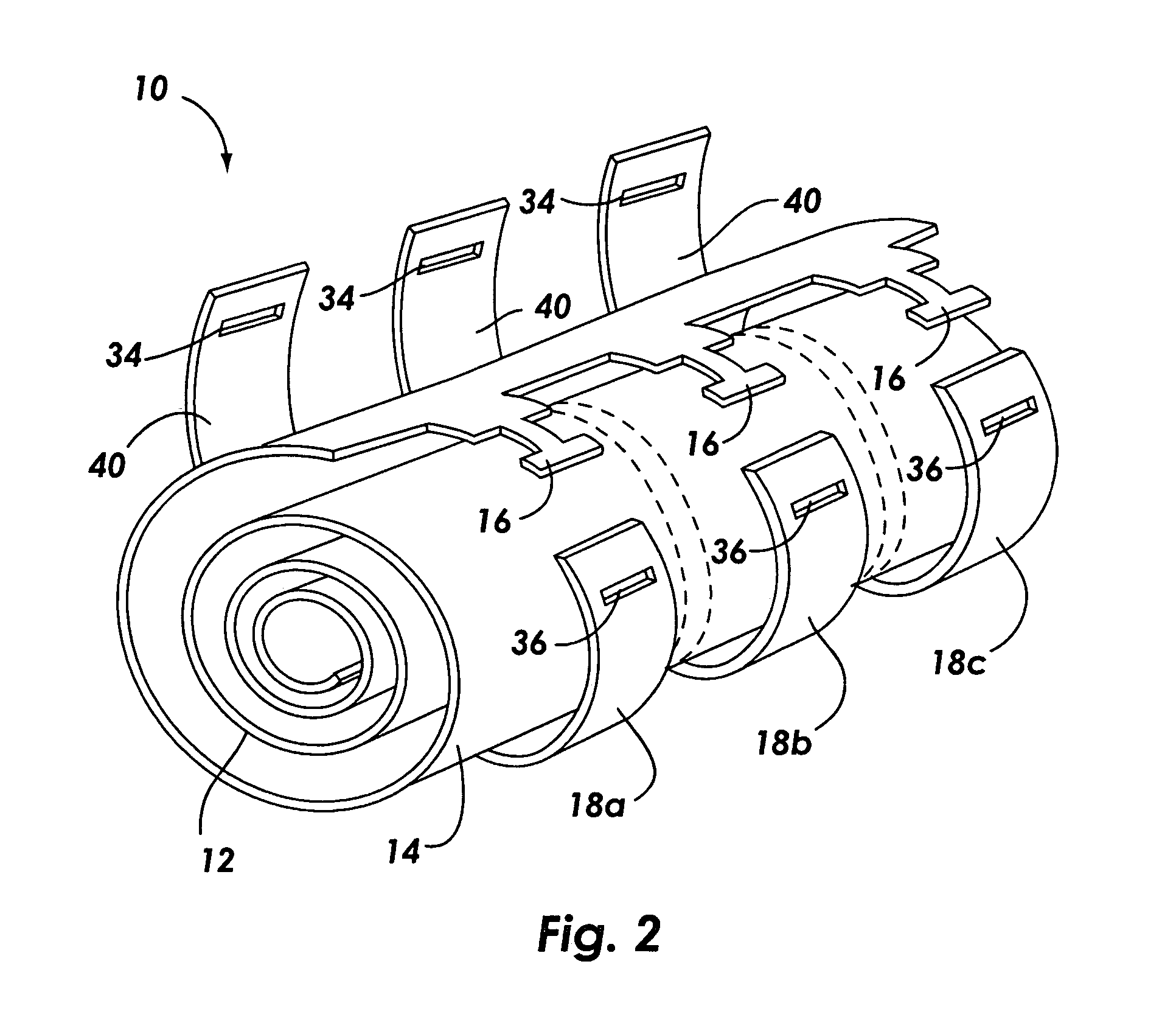

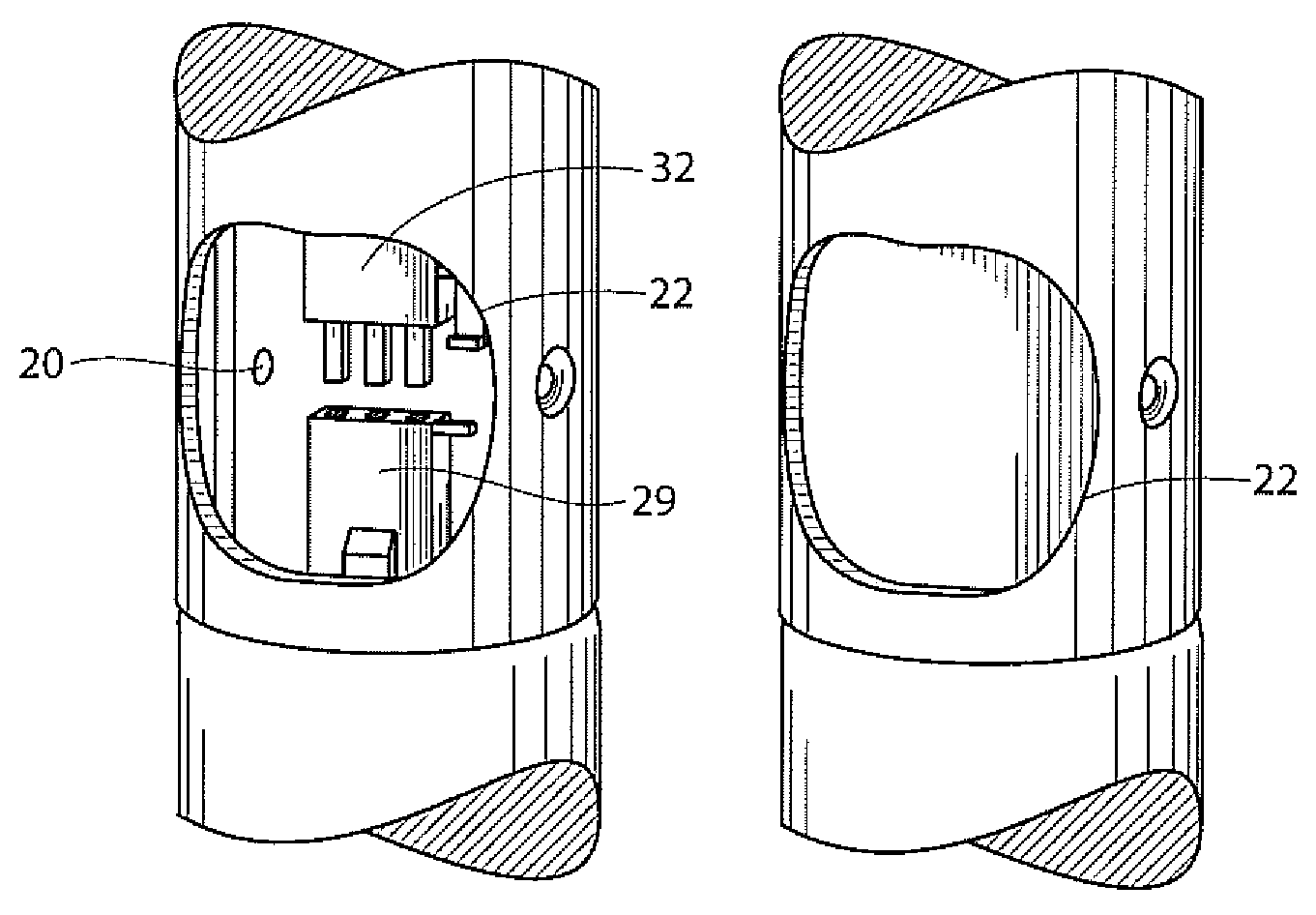

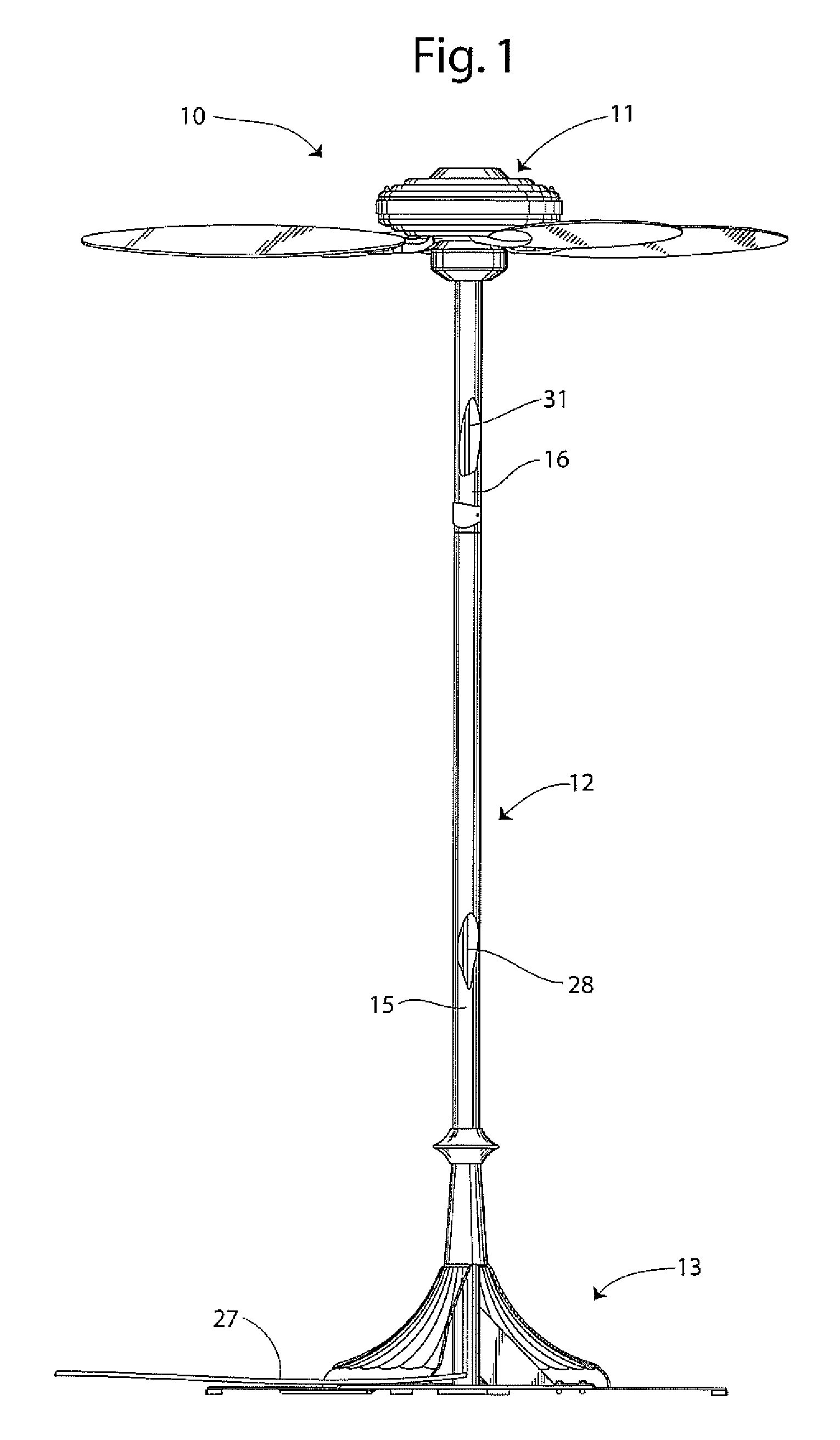

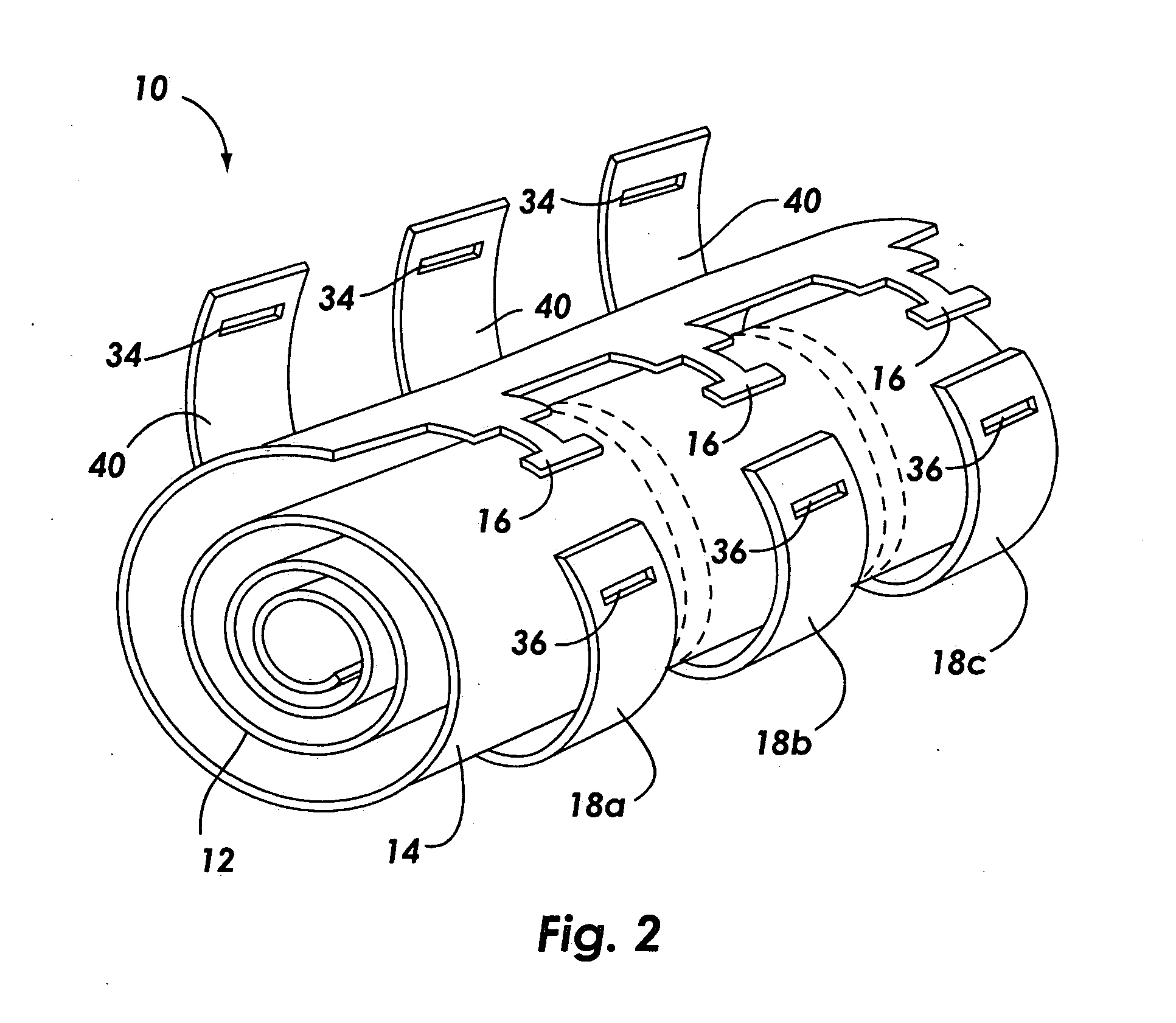

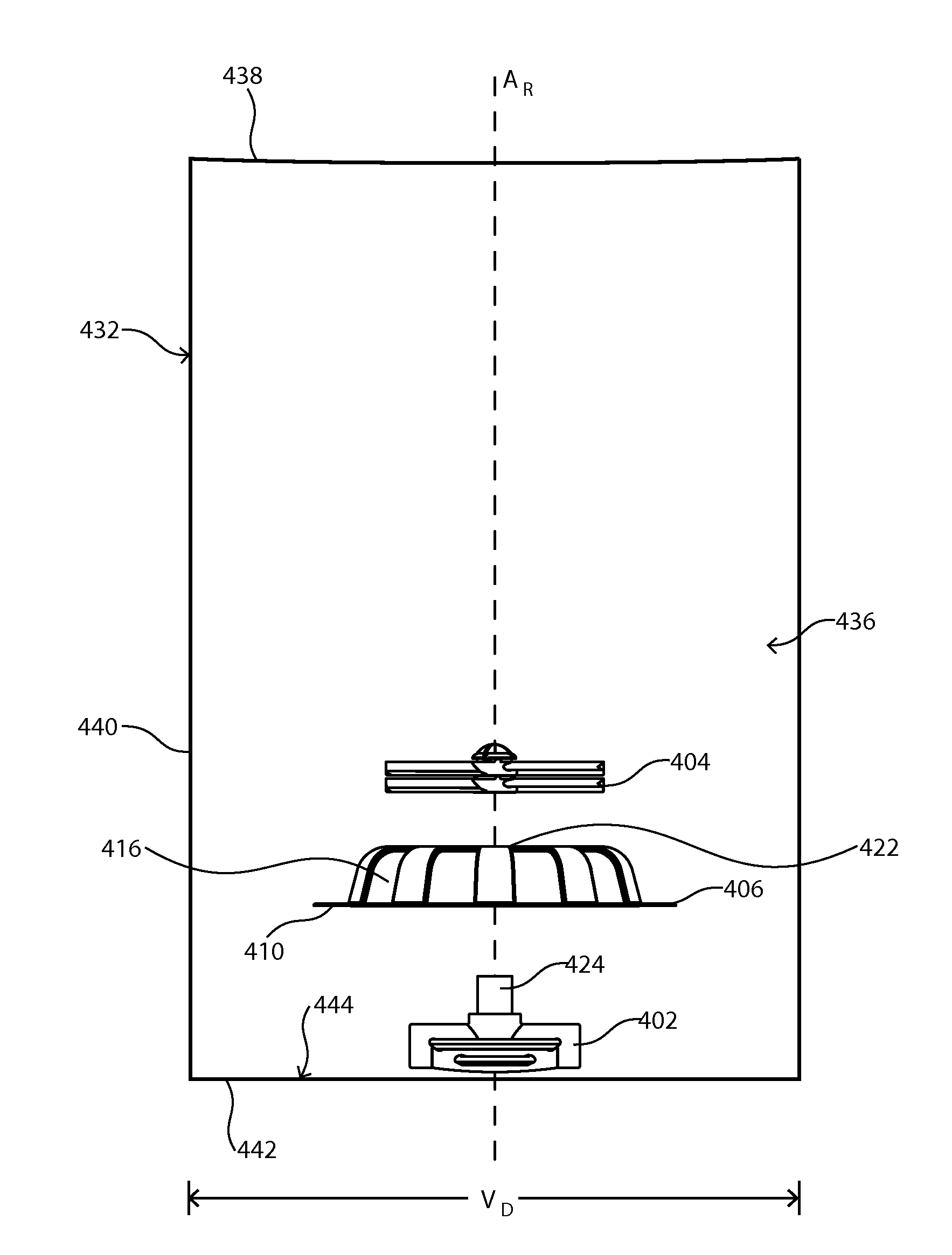

Electrical connector within tubular structure

InactiveUS7361039B2Engagement/disengagement of coupling partsNon-electric lightingEngineeringElectrical connector

An electrical connector within a tubular structure is disclosed which includes a pole (12) having a tubular bottom portion (15) and a tubular top portion (16). The bottom portion has a top connecting end (17) having a narrowed neck (18) with a large notch (19). The pole top portion has a bottom connecting end (21) having an internal diameter sized to receive the neck of the bottom portion. The pole top portion also has a window (22) therein. A cover plate (24) is configured to be mounted over the window. The structure also includes an electrical cord (27) which provides an electrical current to a device coupled to the pole. The electrical cord has a first portion (28) terminating with a female electrical coupler or connector (29) and a second portion terminating with a male electrical coupler (32). The male coupler or connector is configured to be received within the female coupler.

Owner:HUNTER FAN

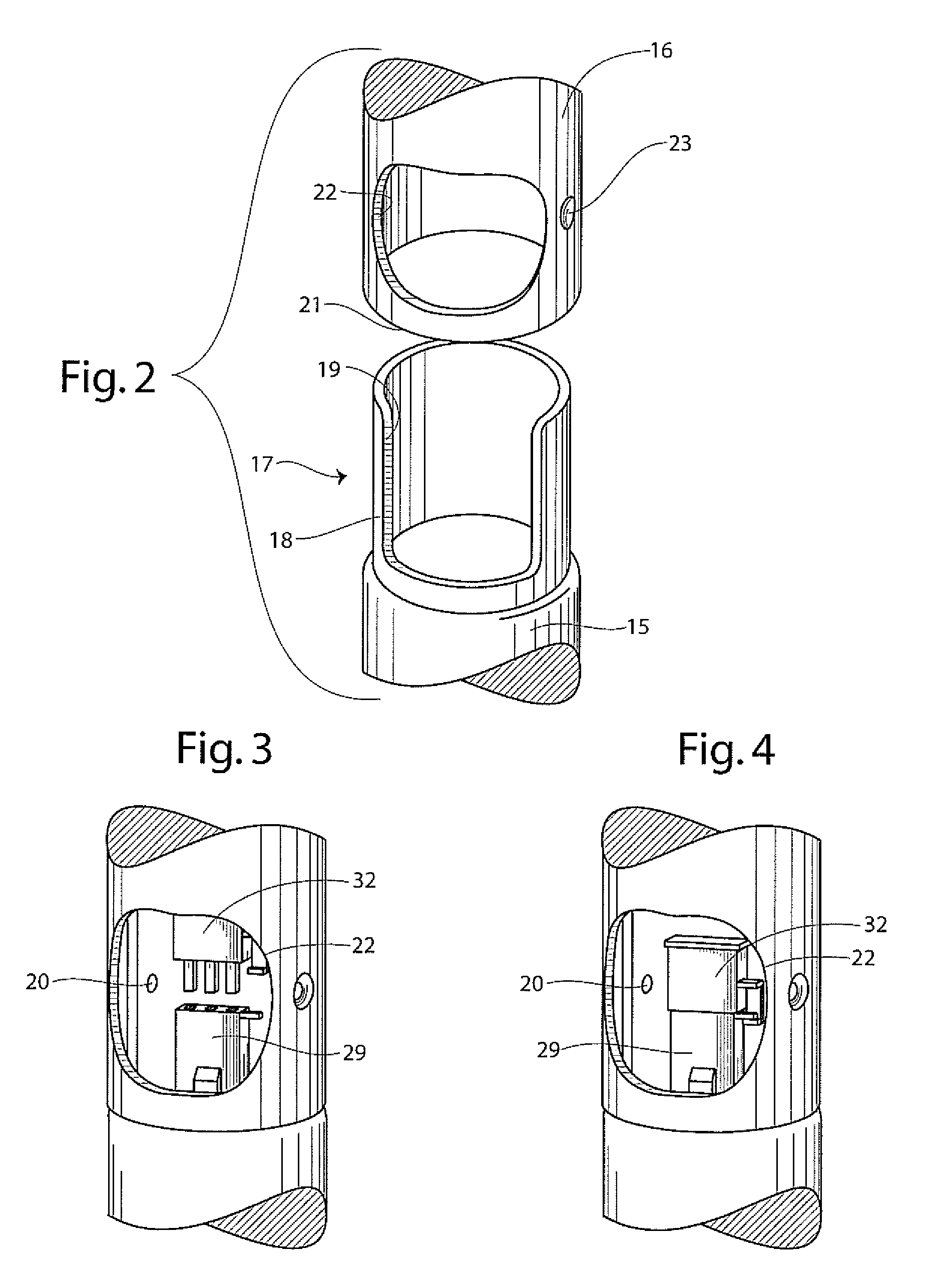

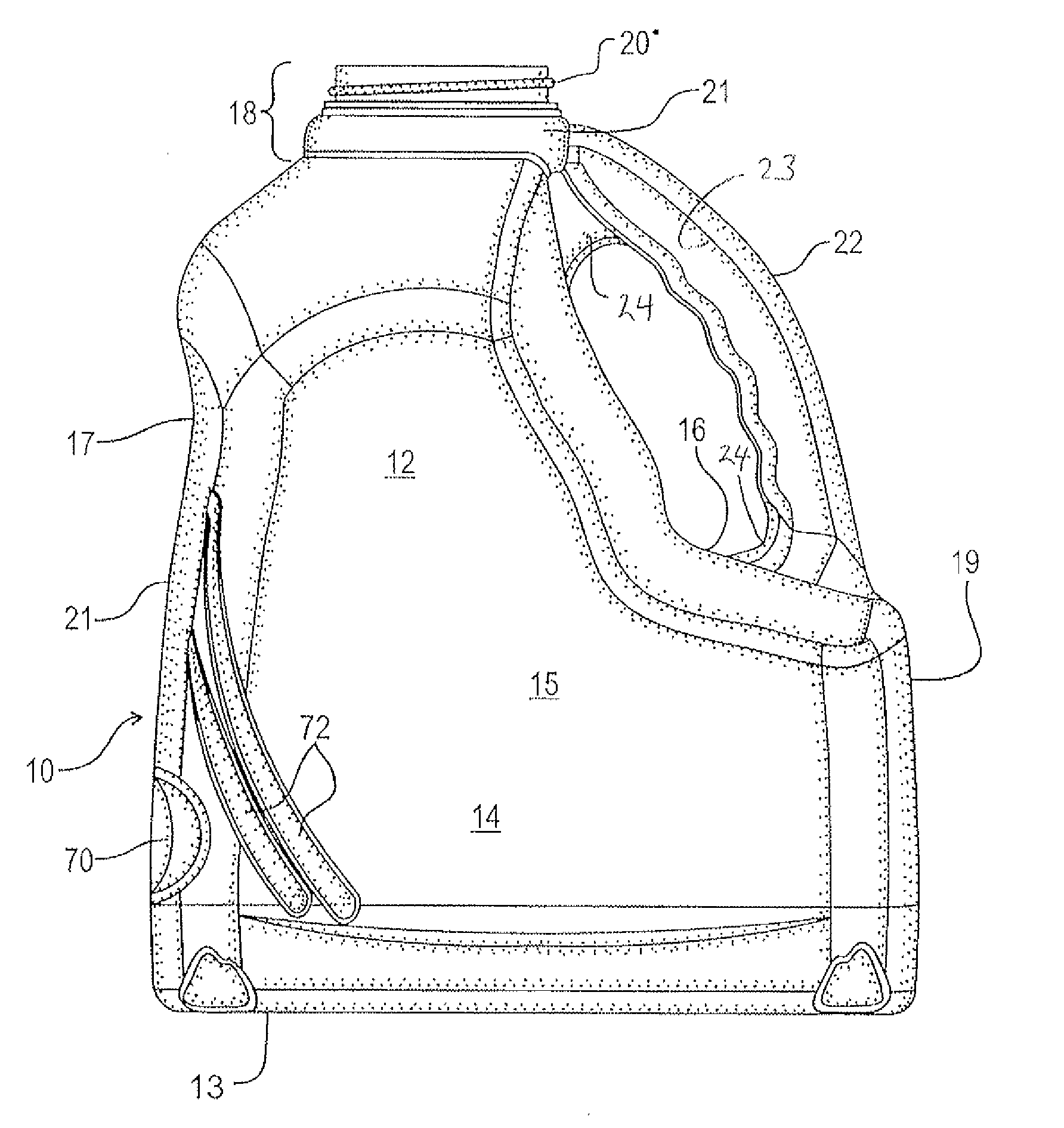

Adjustable kettlebell

InactiveUS7731640B1Easily and adjustably attachedEasily and adjustably to and disengagedDumb-bellsScrew threadMechanical engineering

Owner:CHEN PAUL

Adjustable dumbbell

InactiveUS20100190618A1Easily and adjustably attachedEasily and adjustably to and disengagedDumb-bellsDumbbellEngineering

An adjustable barbell or dumbbell or exercise device includes a handle having a narrowed neck segment formed on each end portion and having a base plate attached to each end portion, two or more weight members each having a slot for receiving the narrowed neck segment of the handle, and each having an enlarged opening communicating with the slot for receiving the handle and for retaining the weight members to the handle when the weight members are offset from the narrowed neck segment of the handle, and a sliding member slidably attached onto each end of the handle for engaging with the weight members after the weight members have been disengaged from the narrowed neck segment of the handle and for retaining the weight members to the handle.

Owner:CHEN PAUL

Adjustable kettlebell

InactiveUS20100190619A1Quickly and easily attachedSimple structureDumb-bellsEngineeringMechanical engineering

Owner:CHEN PAUL

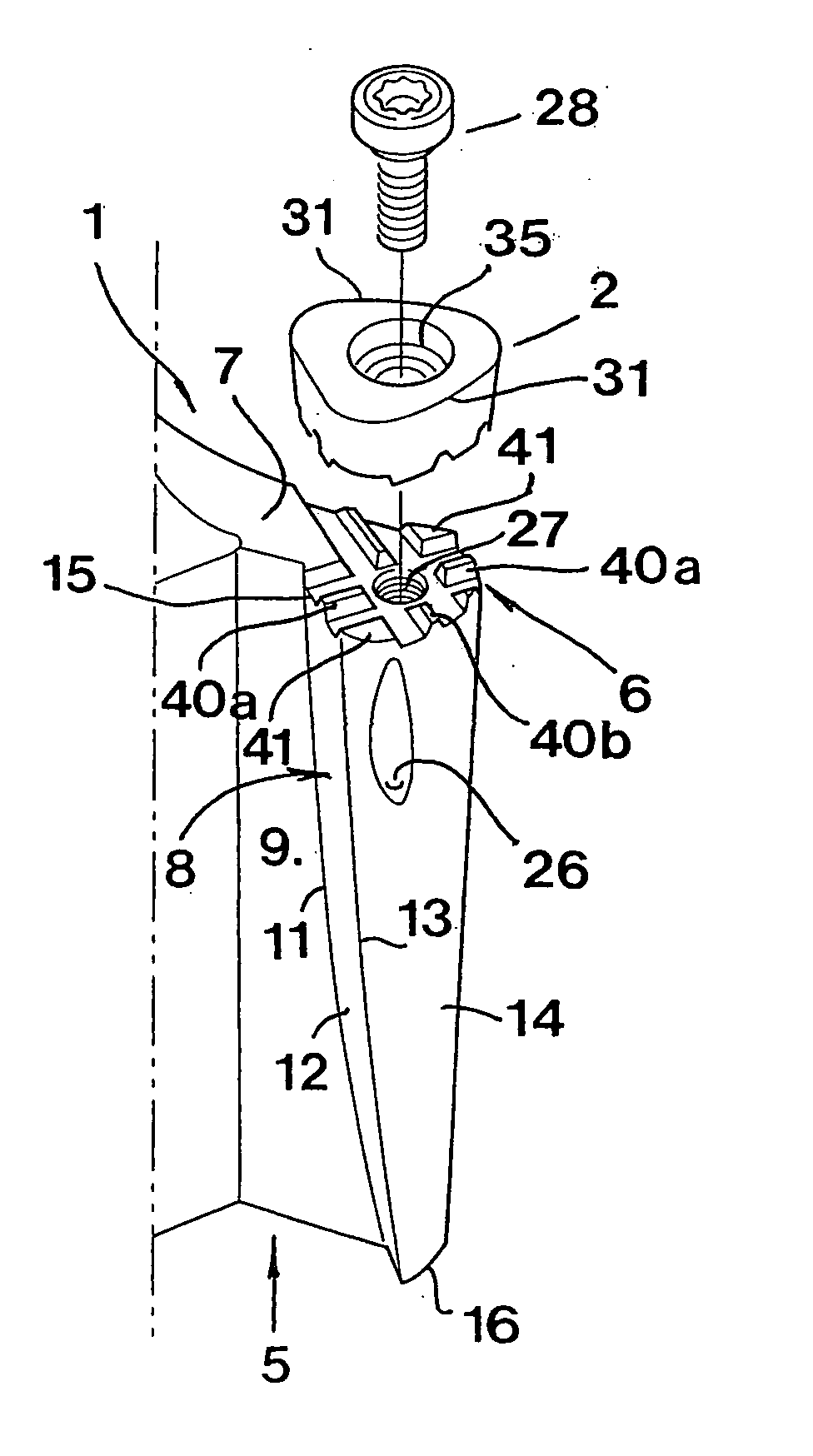

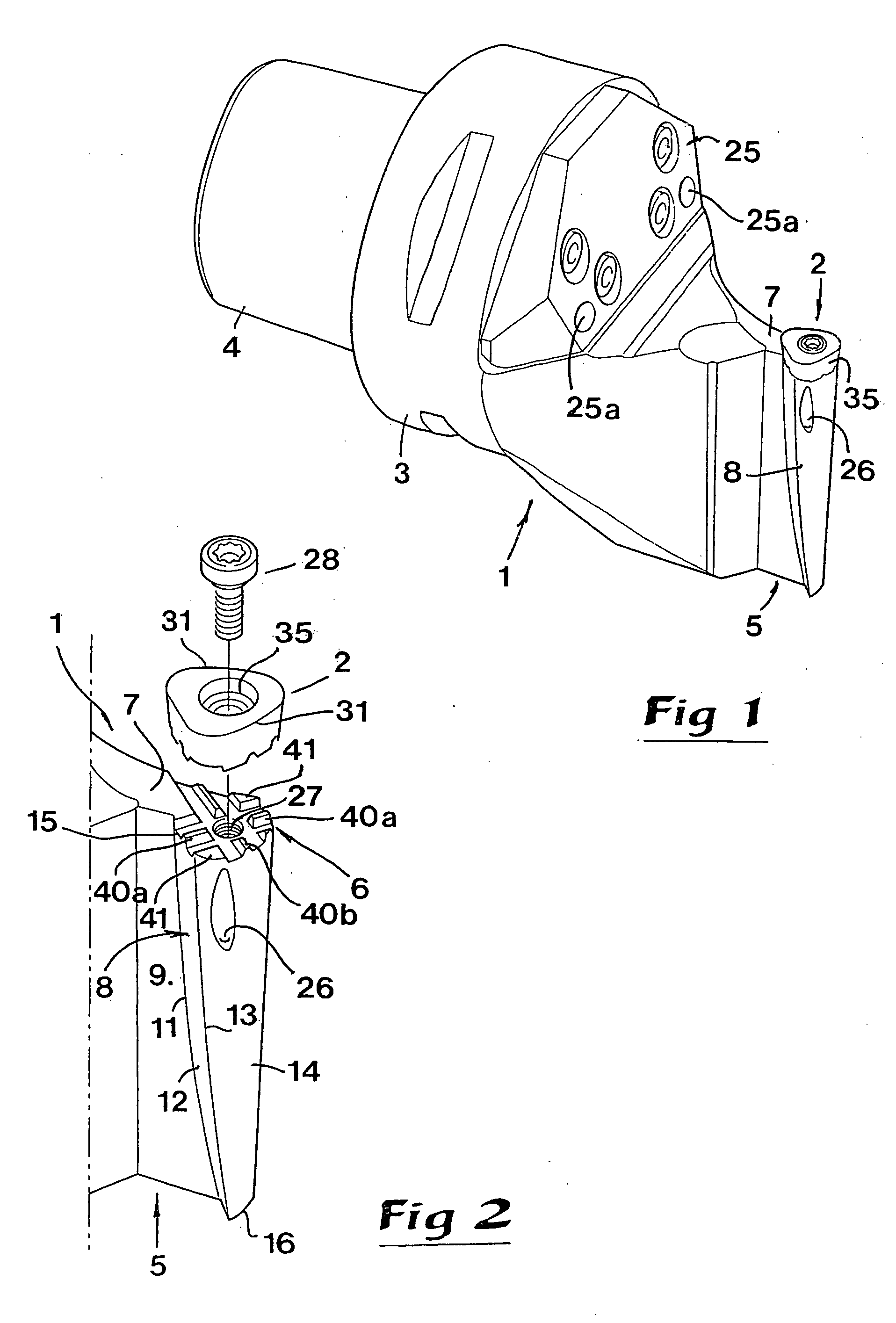

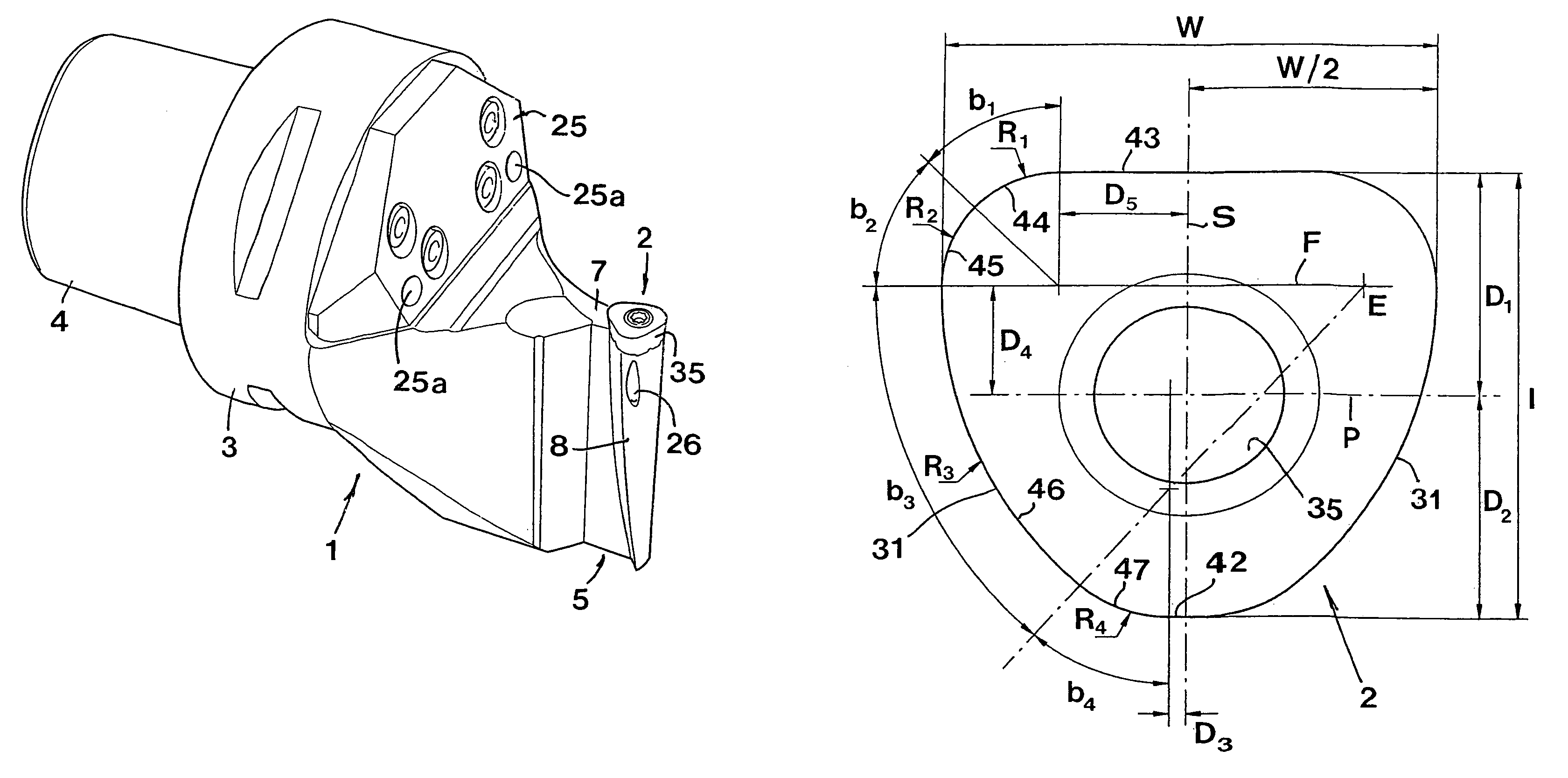

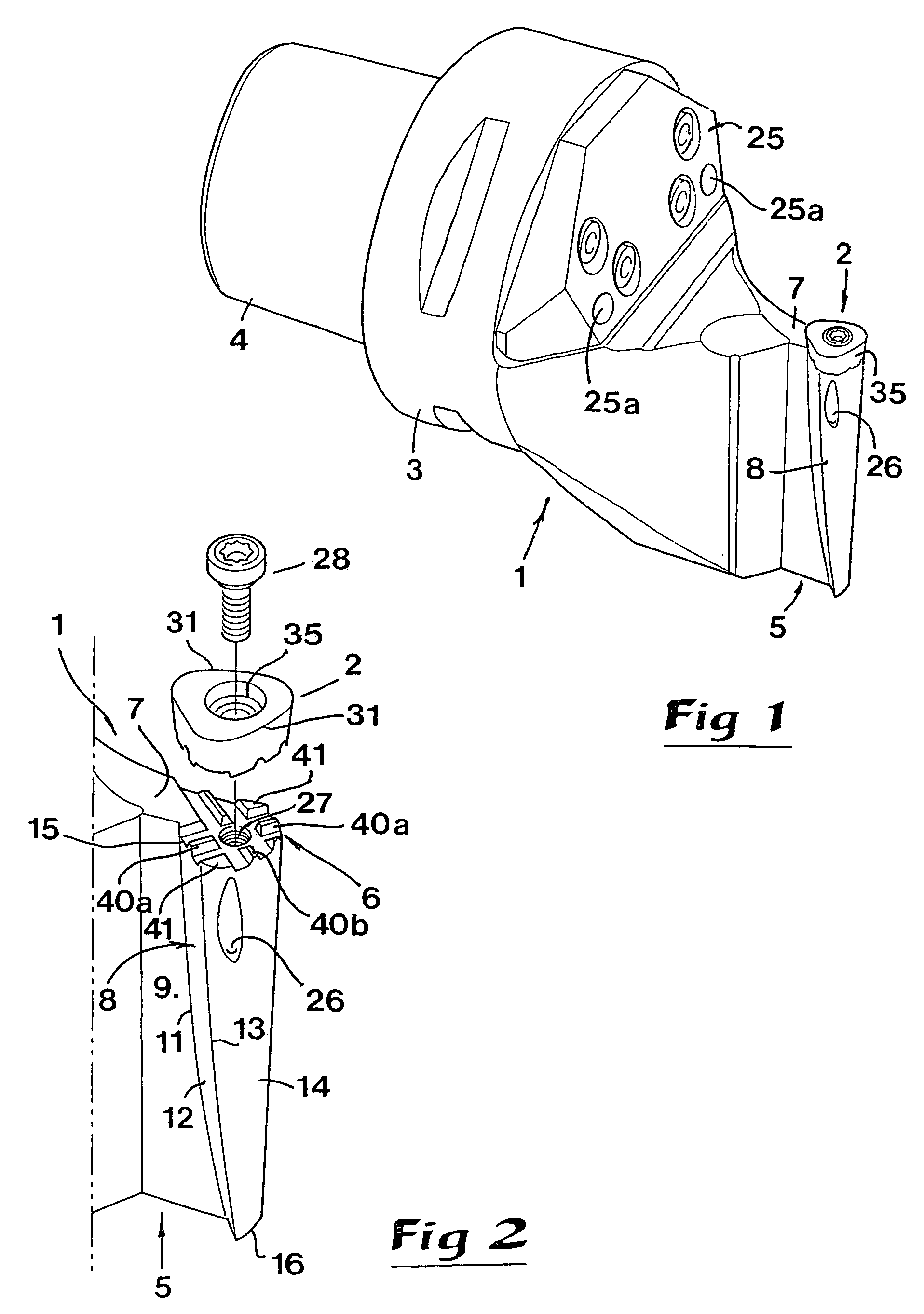

Tool and cutting insert for the fine turning of grooves in workpieces

A tool for the fine-turning of grooves in workpieces including a basic body having a rearwardly extending mounting part, and a forwardly projecting bracket. The bracket includes a narrow neck part and an enlarged support part disposed at an end of the neck part. The support part, which forms an insert seat, extends laterally from the neck part wherein the seat is arranged asymmetrically with respect to an imaginary center line of the basic body. A cutting insert includes a bottom side supported on the insert seat. The insert includes two spaced apart convexly arched side cutting edges arranged so that the imaginary center line passes therebetween. A hole is provided through the insert for receiving a fastening screw. The bottom side and the insert seat include mutually engaging stabilizing structures preventing angular displacement of the insert about an axis of the hole.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

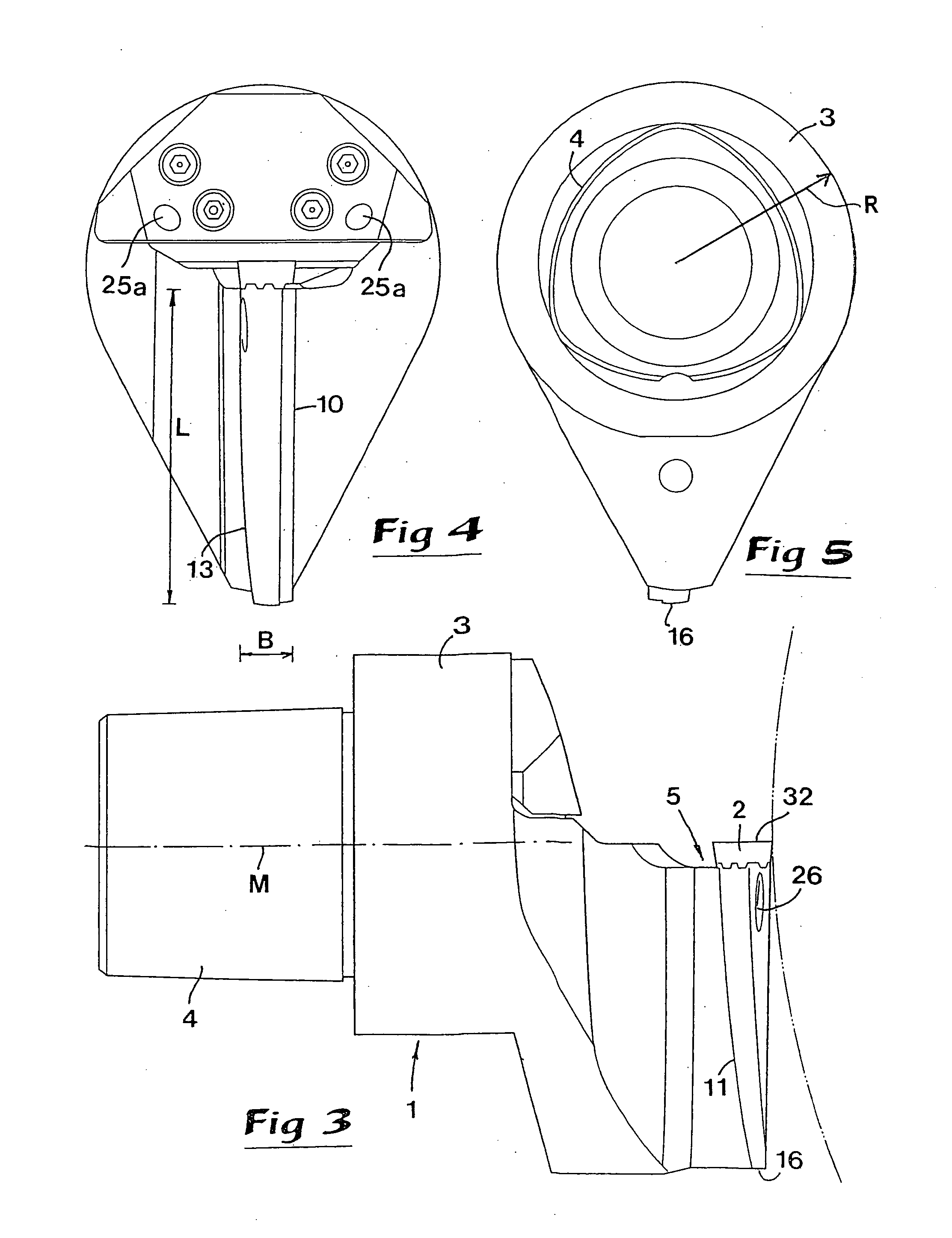

Resonance type micromechanical accelerometer

InactiveCN1844931AAvoid breakingRealize overload protectionAcceleration measurementTuning forkAccelerometer

The invention discloses a resonance micro chemical accelerometer, which comprises a basic plate, a weigh block, a suspend beam, a lever amplifying device, a sound fork, a driving electrode, a detecting electrode, a tooth axle and a backstop. Wherein, said structure is axial symmetry; the weight block is circle whose middle part is mounted with a suspend beam, a lever amplifying device, a sound fork, a driving electrode, a detecting electrode, a tooth axle and a backstop; the backstop is outside the weight block; the circle shape of weight block can make the element own larger weight block in limited volume; the resonance beam has two ends to be fixed with sound forks, while two ends are connected to the outer element with narrow necks, to effectively reduce the energy couple between the resonance beam and outer structure; two symmetry sound forks can realize differential output of resonance frequency. The invention can improve the sensitivity, resolution and detecting accuracy of accelerometer.

Owner:BEIHANG UNIV

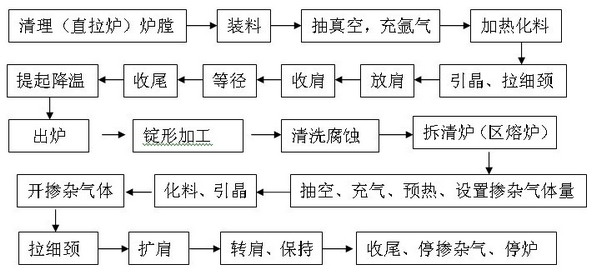

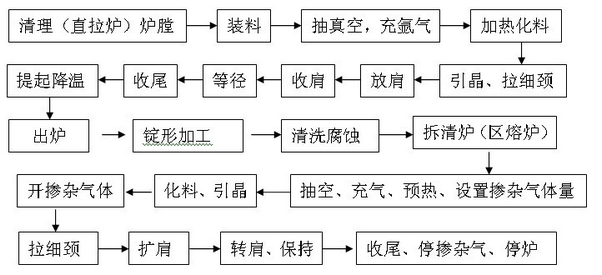

Method for preparing vacuum zone melting high resistant silicon single crystal

ActiveCN101525764AHigh resistivityEnhanced ultra-high purityPolycrystalline material growthBy zone-melting liquidsZone meltingSingle crystal

The invention discloses a method for preparing vacuum zone melting high resistant silicon single crystal, comprising the two sequential major processes: polysilicon purification and crystal forming of silicon single crystal, wherein, the process of polysilicon purification comprises the steps of cleaning fire, charging, evacuating, preheating, melting materials heat sealing, growing narrow necks, shouldering, shoulder circuiting, equating diameter, ending and repeating; the process of crystal forming of silicon single crystal comprises the steps of cleaning fire, charging, evacuating, preheating, processing of chemicals, crystal seeding, shouldering, shoulder circuiting, equating diameter, ending and blowing out. With the method of the invention adopted to prepare silicon single crystal, electric resistivity, ultra-high purity, resistivity profile, uniformity of cross-section electric resistivity and minority carrier lifetime are greatly improved; purity of the silicon single crystal is above 11N, electric resistivity reaches 8000 omega / cm-30000omega / cm, uniformity of cross-section electric resistivity is less than 15%, and minority carrier lifetime is more than 600-1000Mus, thus greatly improving performance, stability and safety of the devices while realizing mass production of vacuum zone melting high resistant silicon single crystal.

Owner:峨嵋半导体材料研究所

Adjustable kettlebell

InactiveUS7811212B2Quickly and easily attachedSimple structureDumb-bellsEngineeringMechanical engineering

Owner:CHEN PAUL

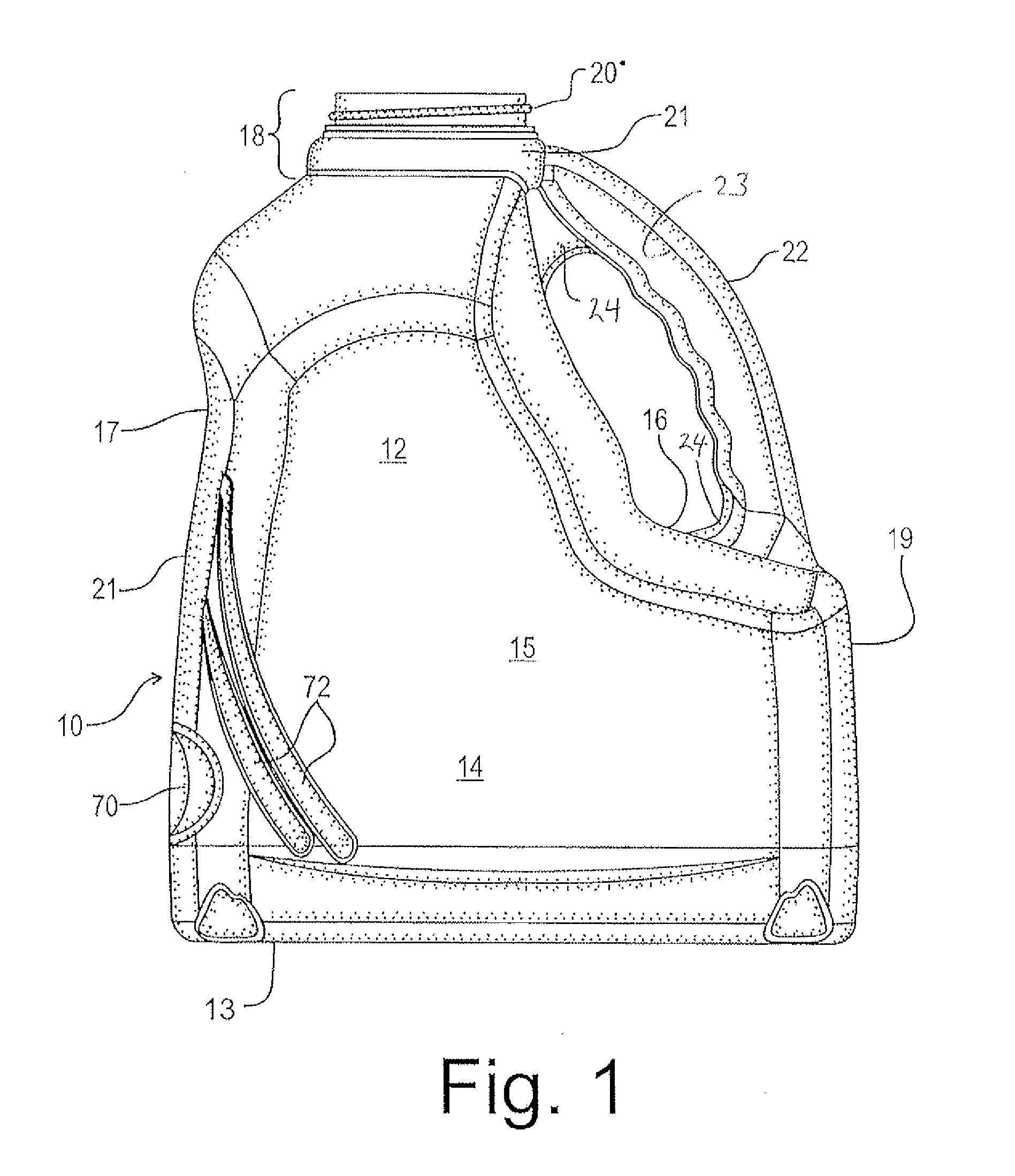

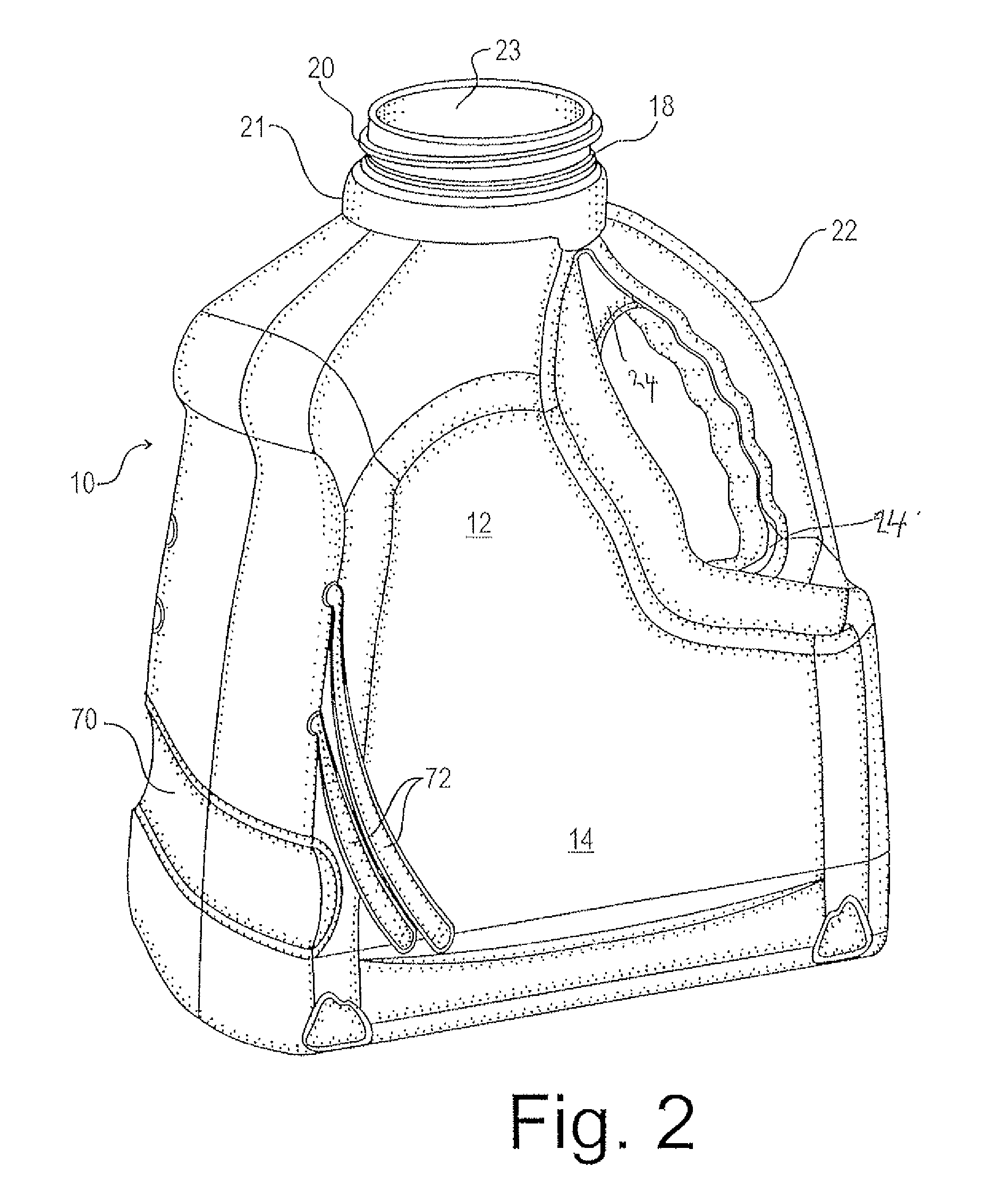

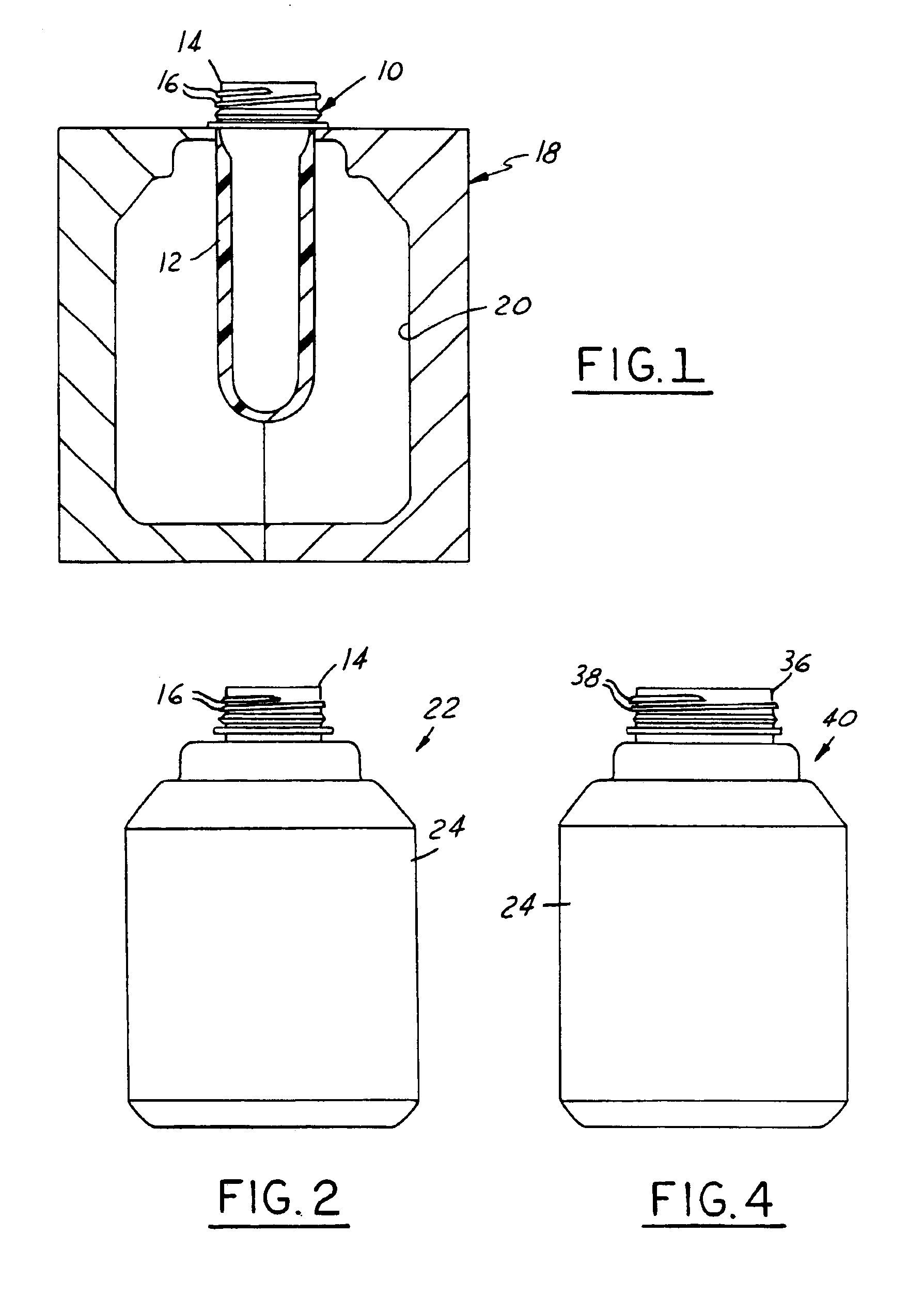

Bottle and cap with Anti-glug feature

The invention relates to a combination of bottle and cap for dispensing a liquid. The bottle includes a narrow neck and a hollow handle. The hollow interior of the handle communicates at its upper and lower end with the interior of the body, to permit a flow of air through the neck opening, via the interior of the handle, to a lower region within the interior of the container so as to minimize glugging during pouring. The cap comprises a cap body attachable to the neck of the bottle. The cap includes on its crown first and second openings, for dispensing liquid and intake of air, respectively. The cap is configured to attach to the container body so as to position the second opening generally facing the handle, while the first opening is opposed to the handle. During pouring, air flows into the second opening within the cap as liquid exits the first opening, with the inflowing air being channeled into the hollow handle interior with minimal interference with the outflowing liquid so as to introduce air into the interior of the body to displace the liquid being poured from the bottle.

Owner:RWACHSBERG HLDG

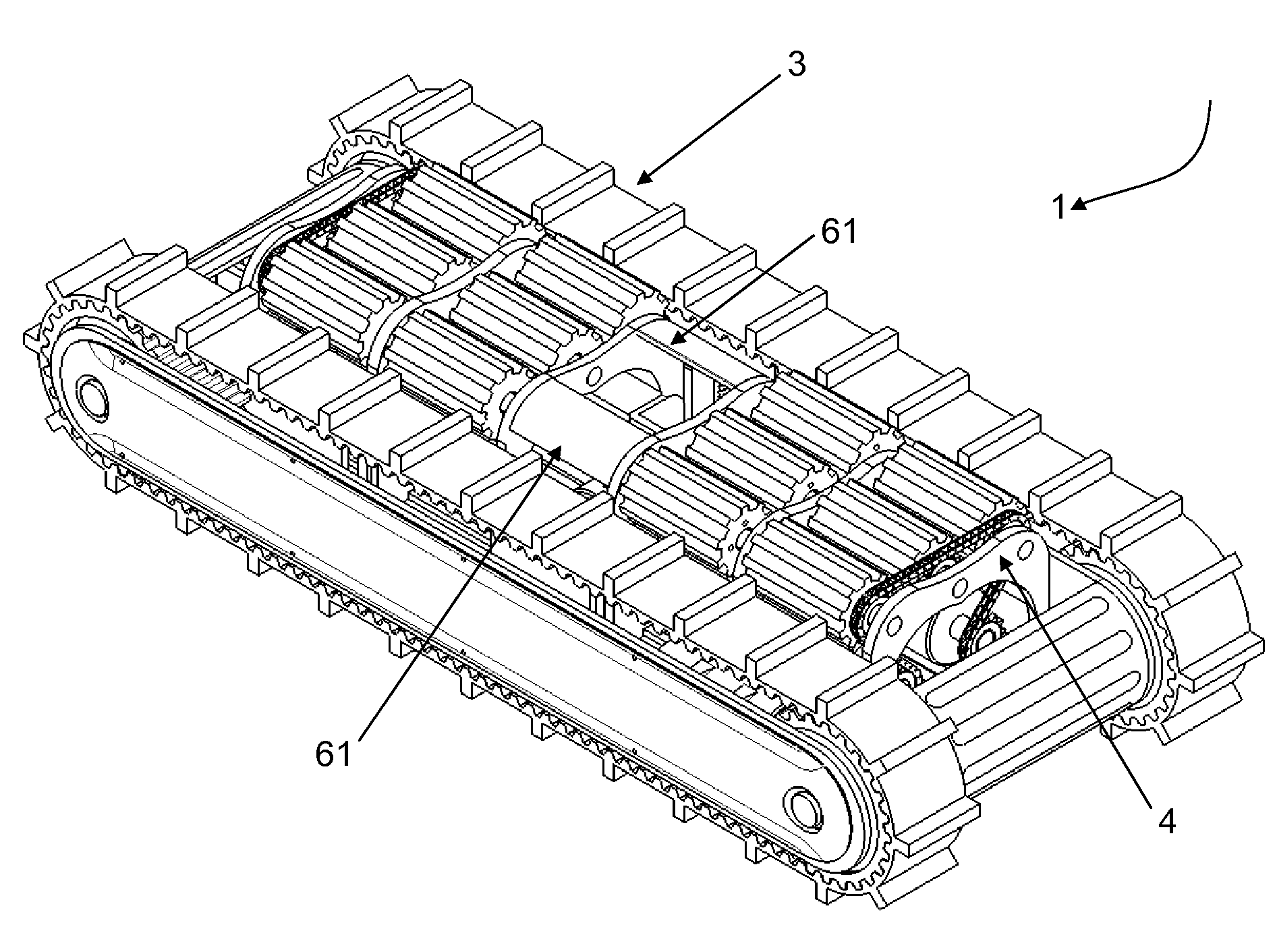

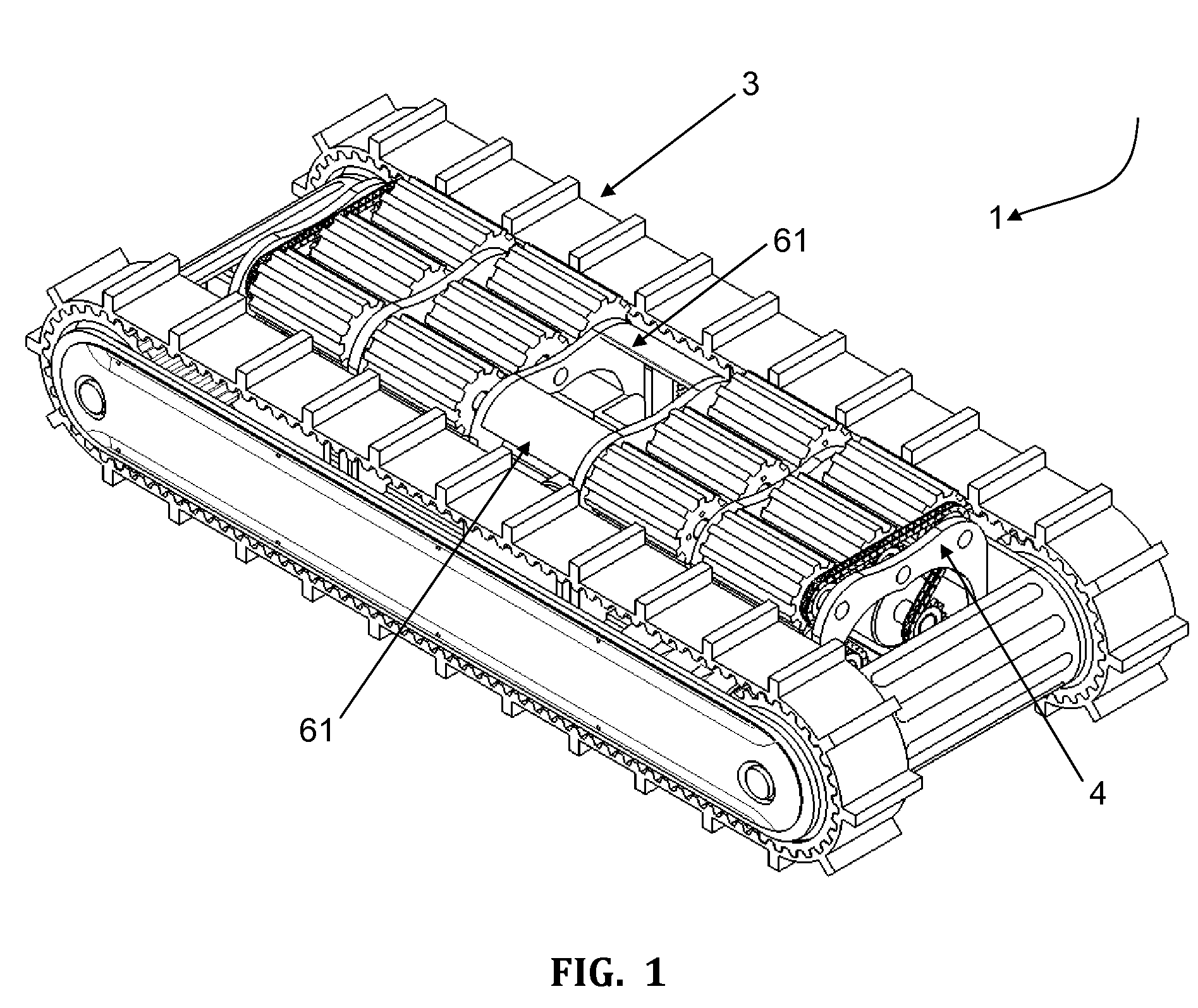

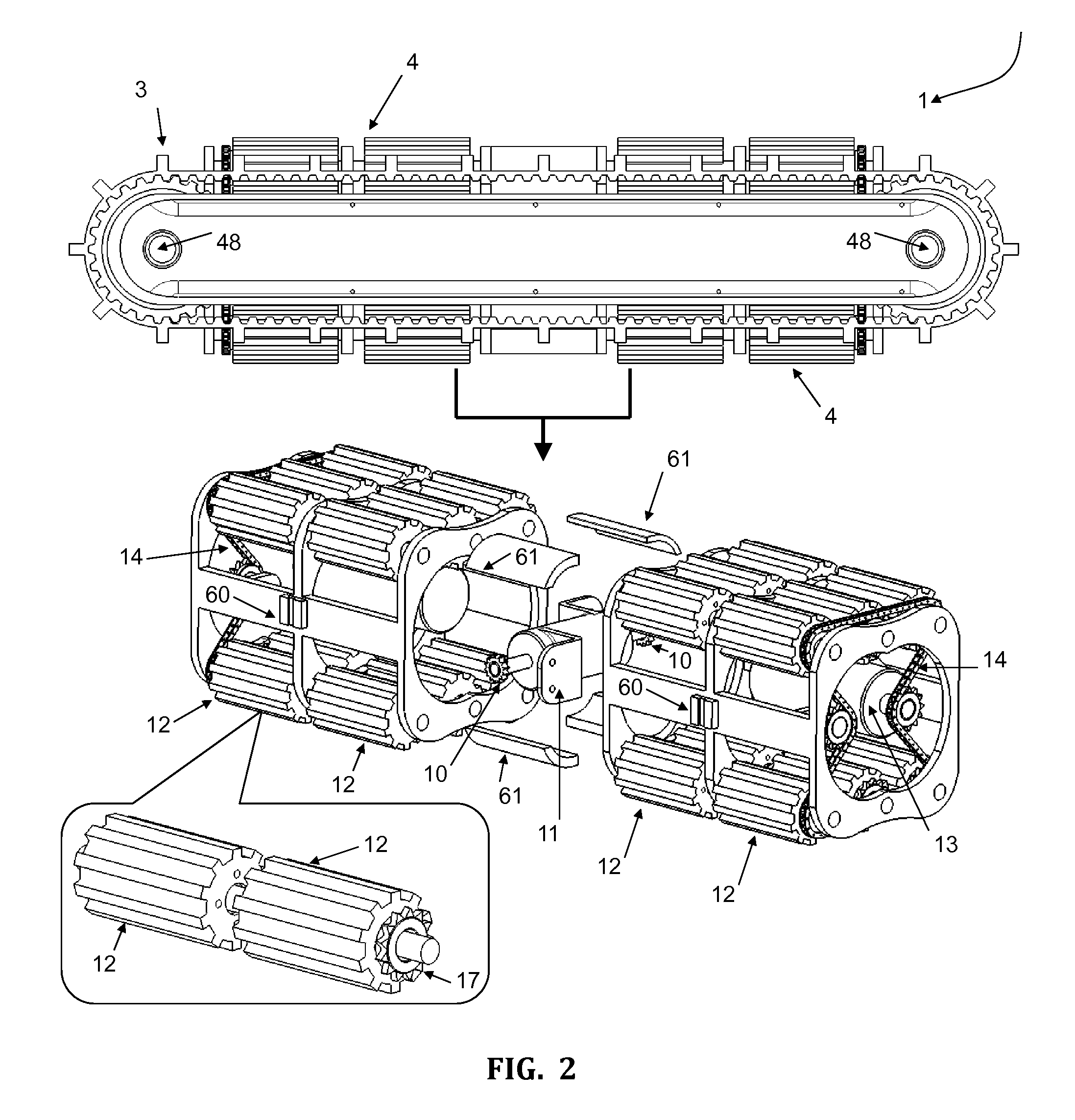

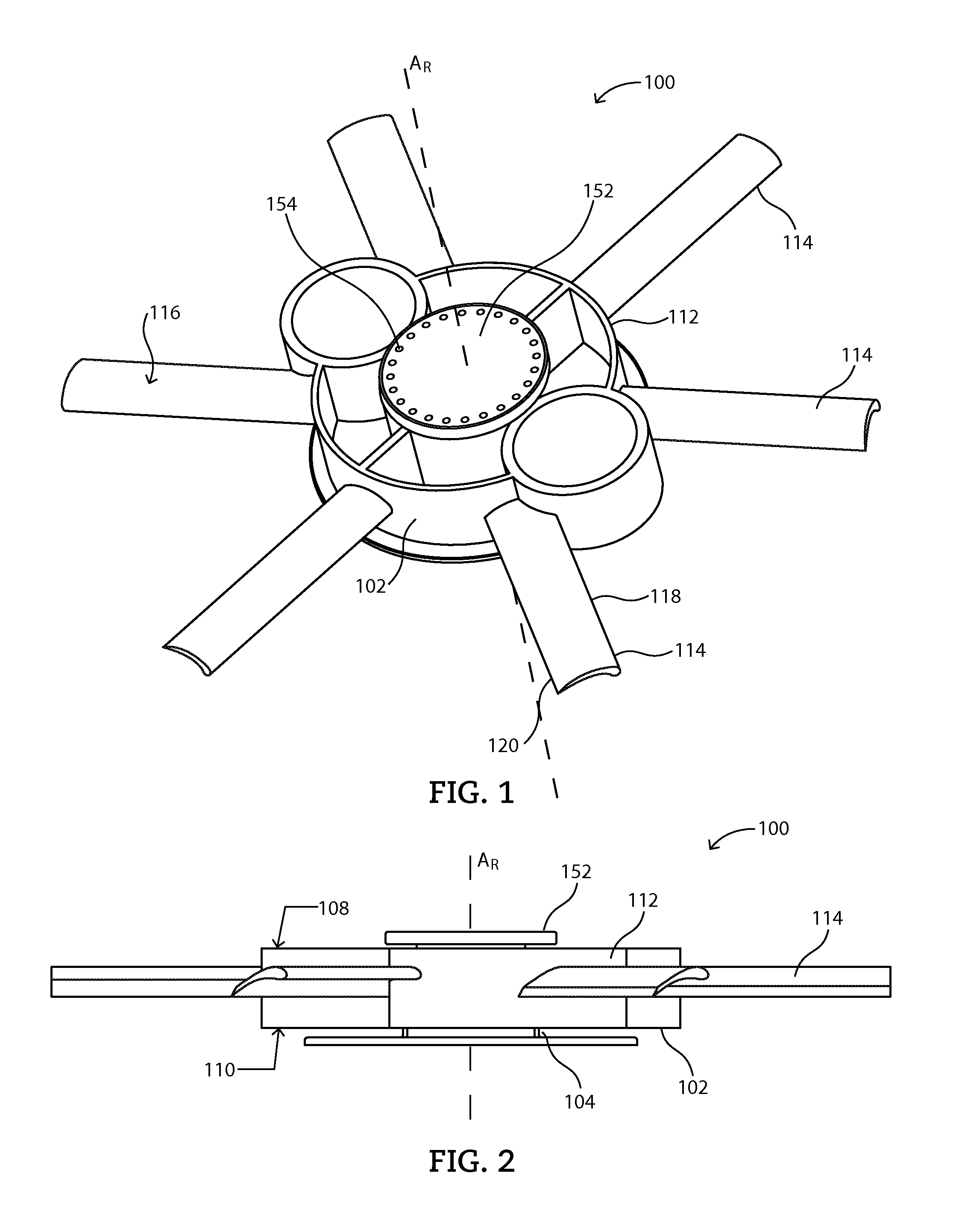

Mobile robot with hybrid traction and mobility mechanism

A robot has a track assembly having tracks configured to move the robot in a first direction and a wheel assembly having wheels configured to move the robot in a second direction orthogonal to the first direction. A toggling assembly switches between the track assembly and the wheel assembly. The robot modules can mate with each other. The robot module has an elongated shaft with a head and a narrow neck. The shaft extends outward from the side of the robot module. A mating robot module has a clamping mechanism with opposing clamps which in an opened position receive the shaft. In a closed position, the clamps define an opening which matches and engages the cross-section of the neck of the elongated shaft. The clamping mechanism has a drive mode to drive the module, a clamping mode for docking, and neutral mode for alignment prior to clamping.

Owner:BEN TZVI PINHAS PHD DR

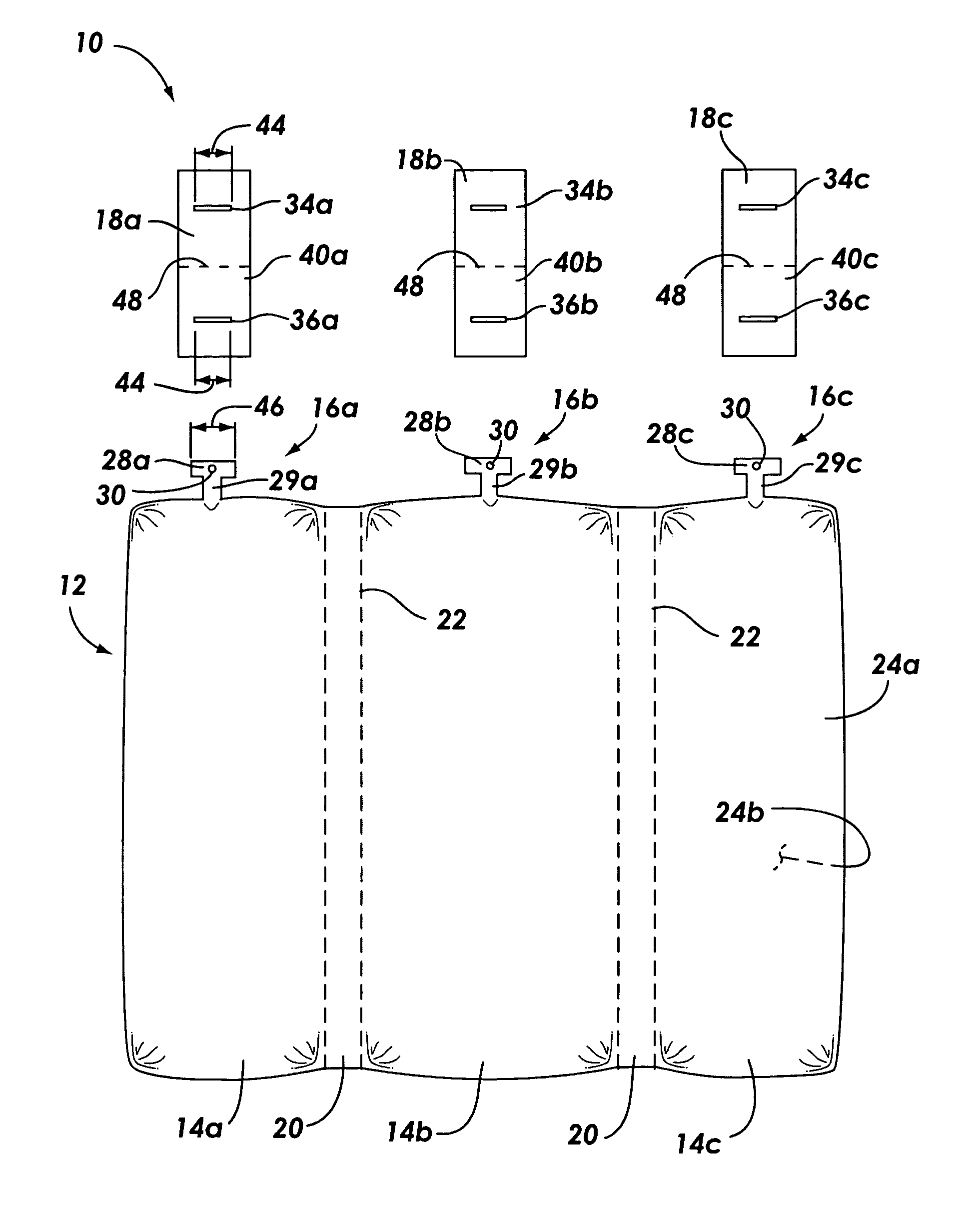

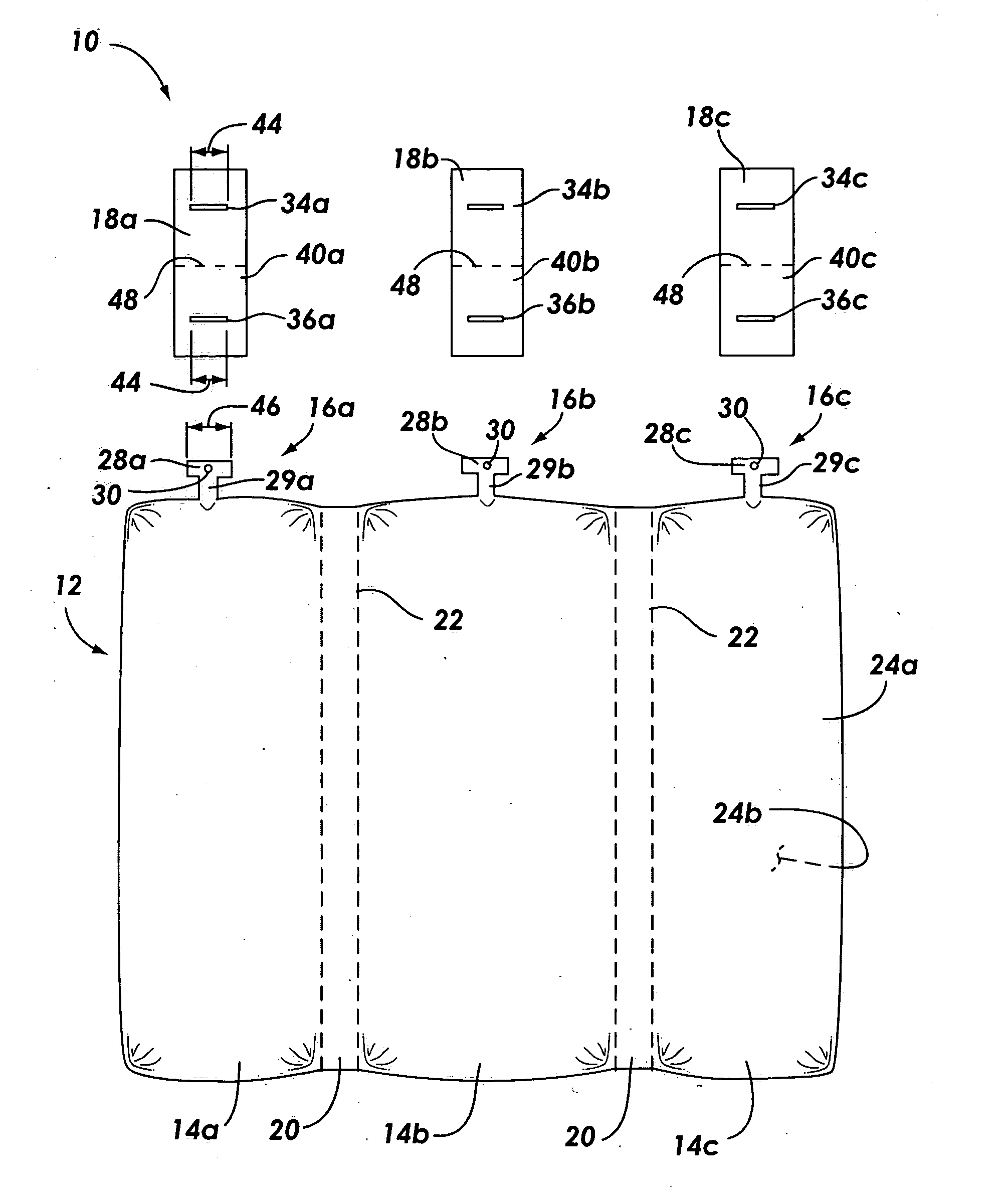

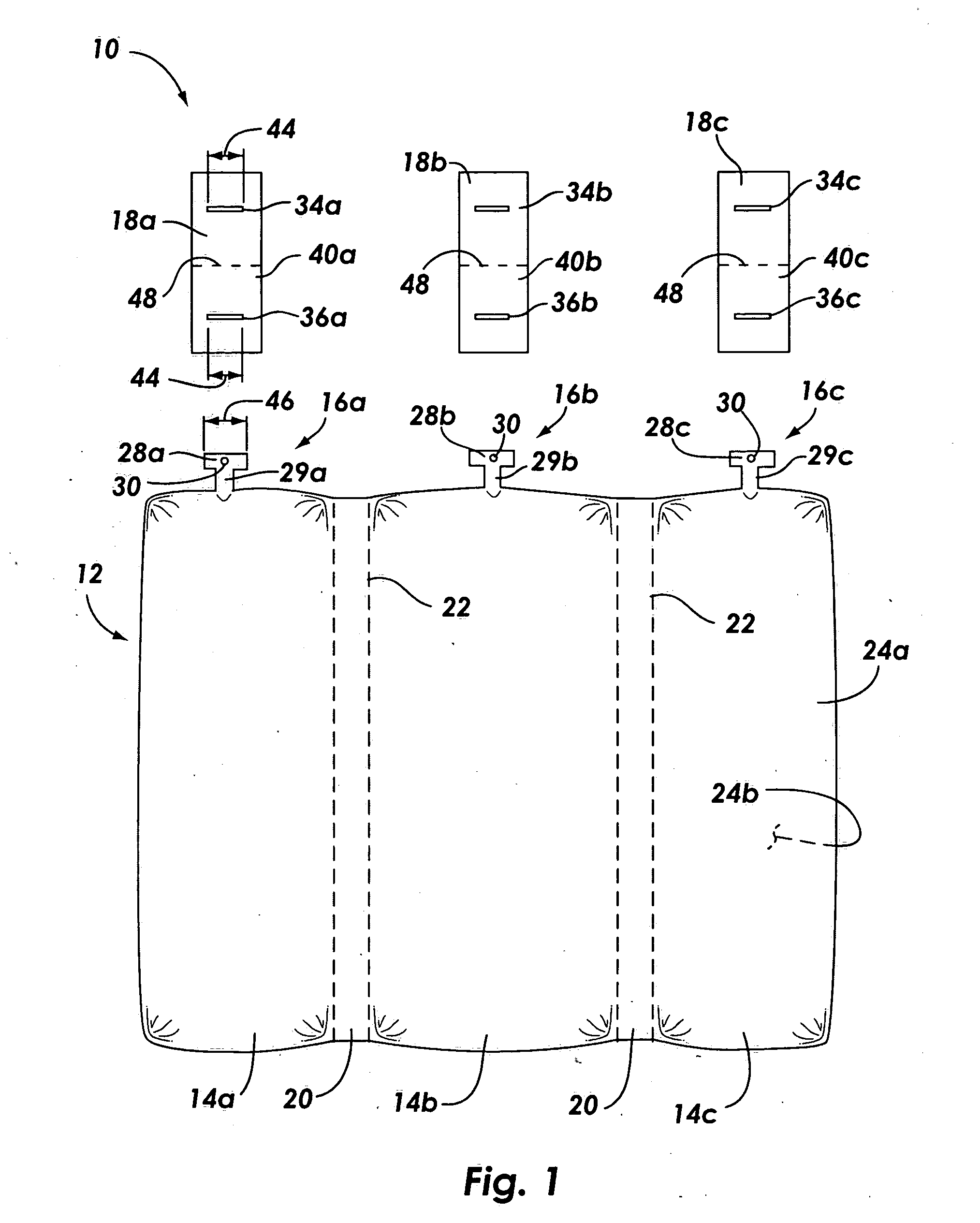

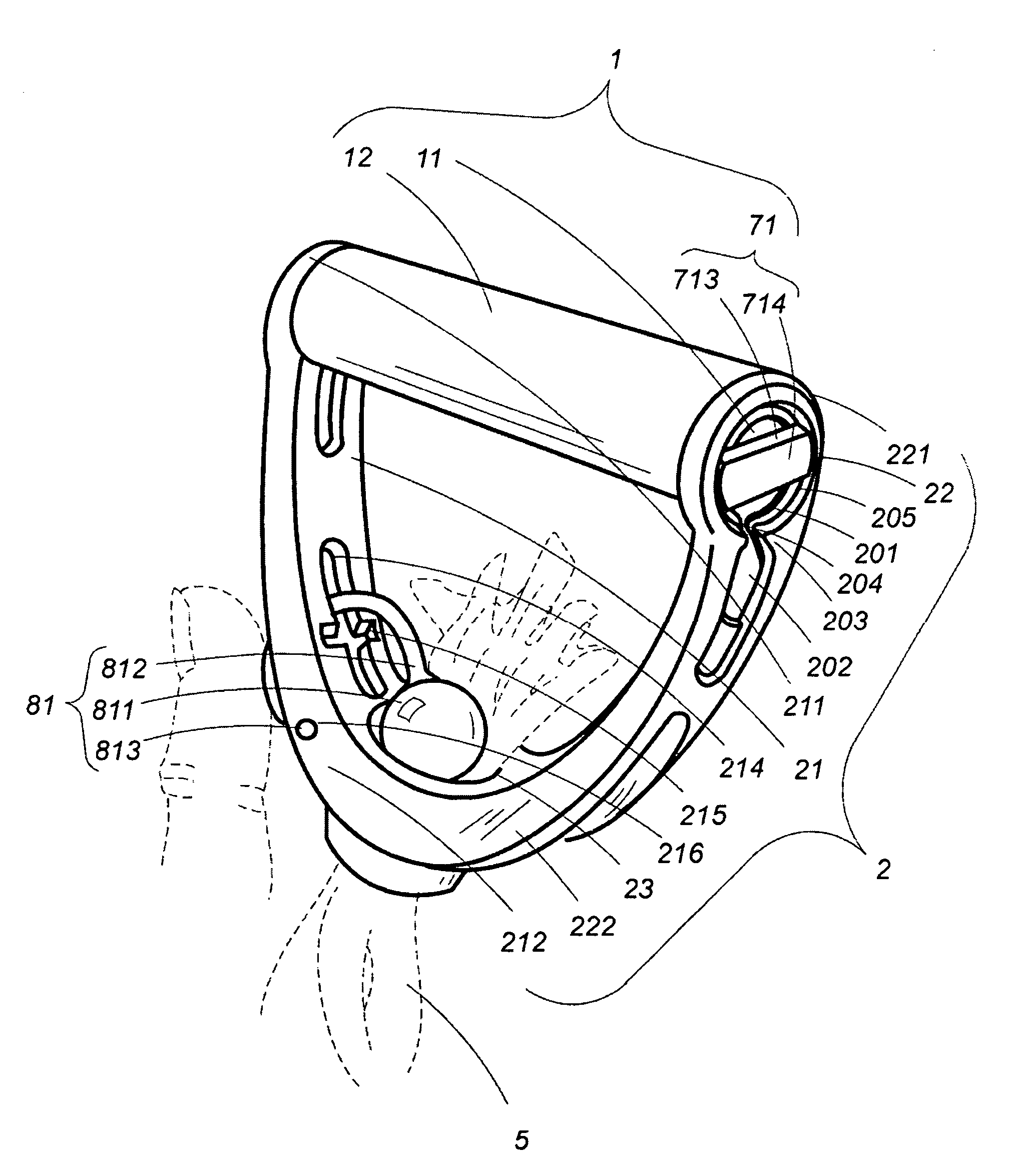

Inflatable cushion retention system

ActiveUS20050082798A1Simple designEasy to usePedestrian/occupant safety arrangementEngineeringCushion

The cushion retention system includes a cushion, at least one tab attached to the cushion, and a supporting member having an intermediary region and at least one aperture. The cushion is positioned in a folded condition. The supporting member is disposed along an outer periphery of the cushion. The tab, which includes a head and a narrow neck, interlocks with the aperture on the supporting member to retain the supporting member along an outer periphery of the folded cushion. In this interlocked condition, the supporting members apply an inward compressive force to retain the cushion in a folded condition.

Owner:AUTOLIV ASP INC

Stretched container threads and method of manufacture

InactiveUS20050153089A1Improve throughputOther chemical processesSynthetic resin layered productsCompression moldingBlow molding

Owner:GRAHAM PACKAGING PET TECH

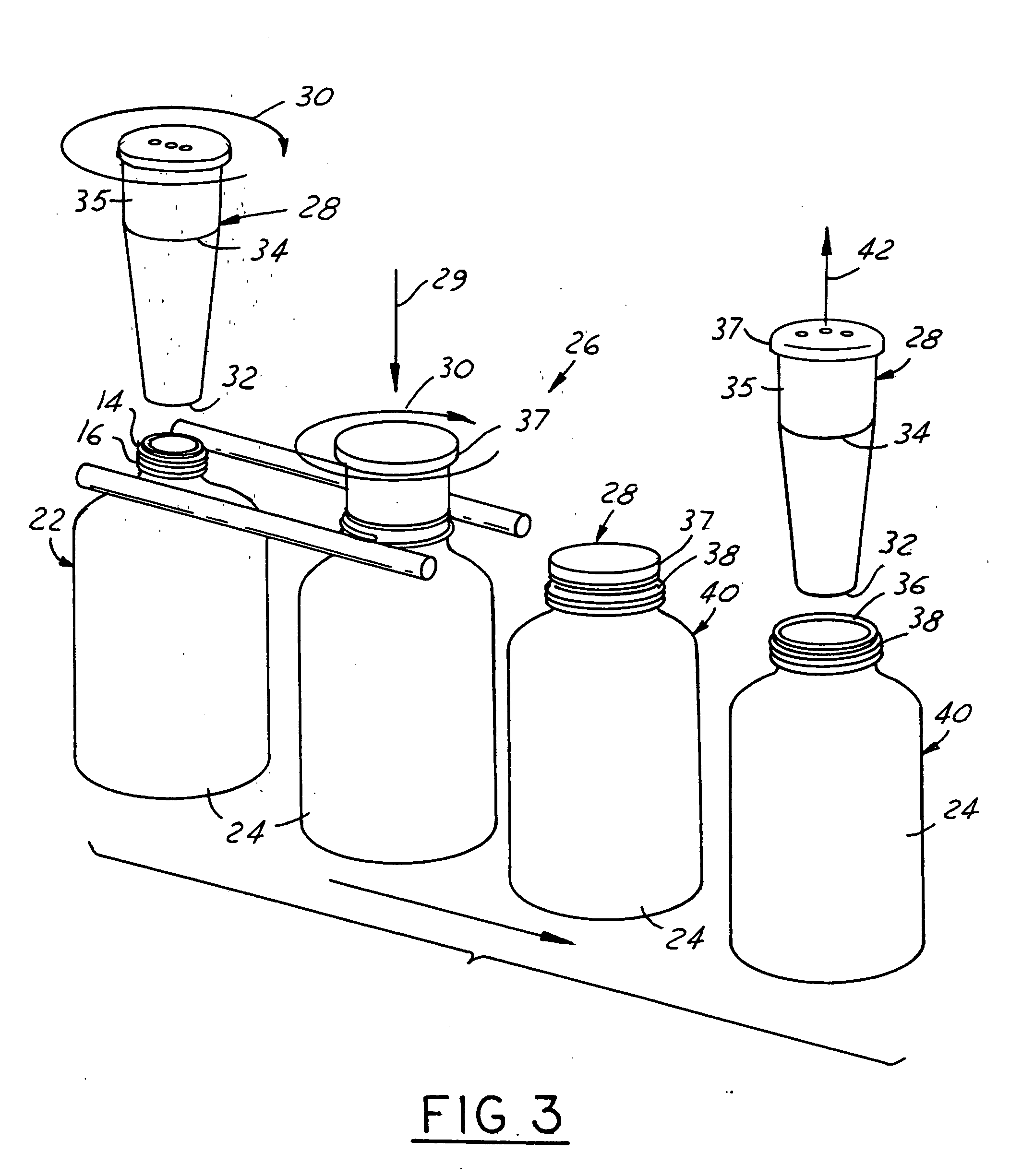

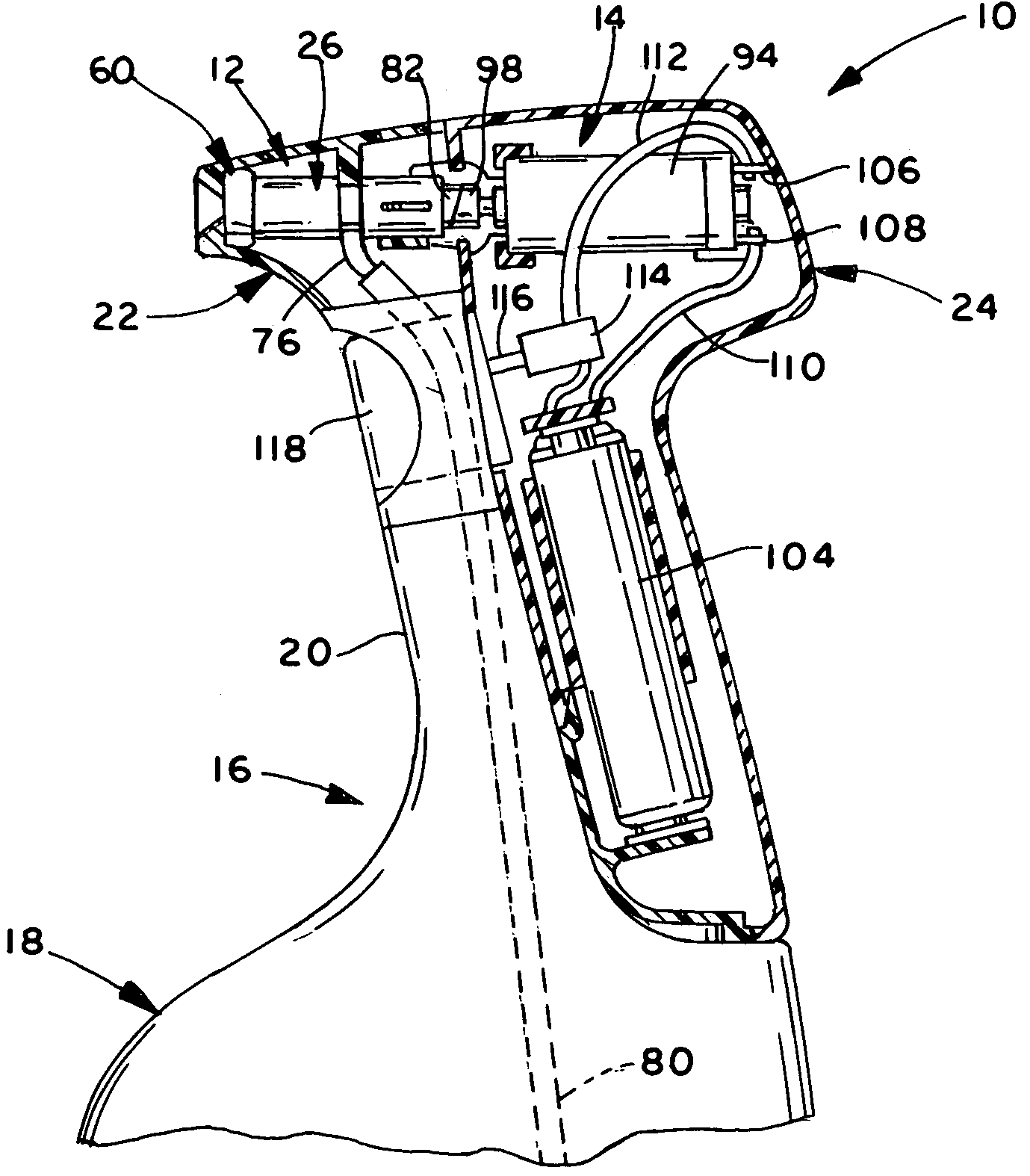

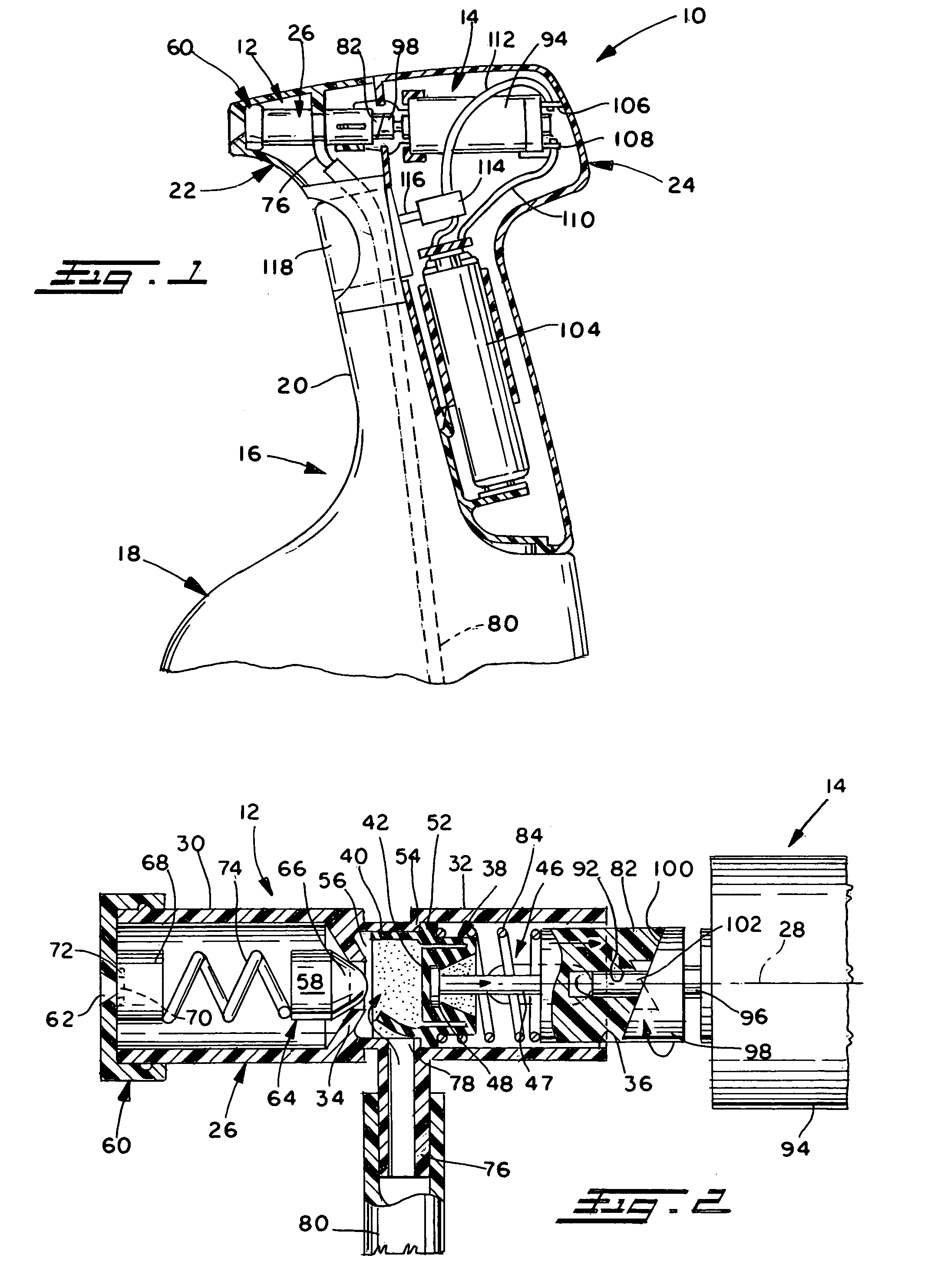

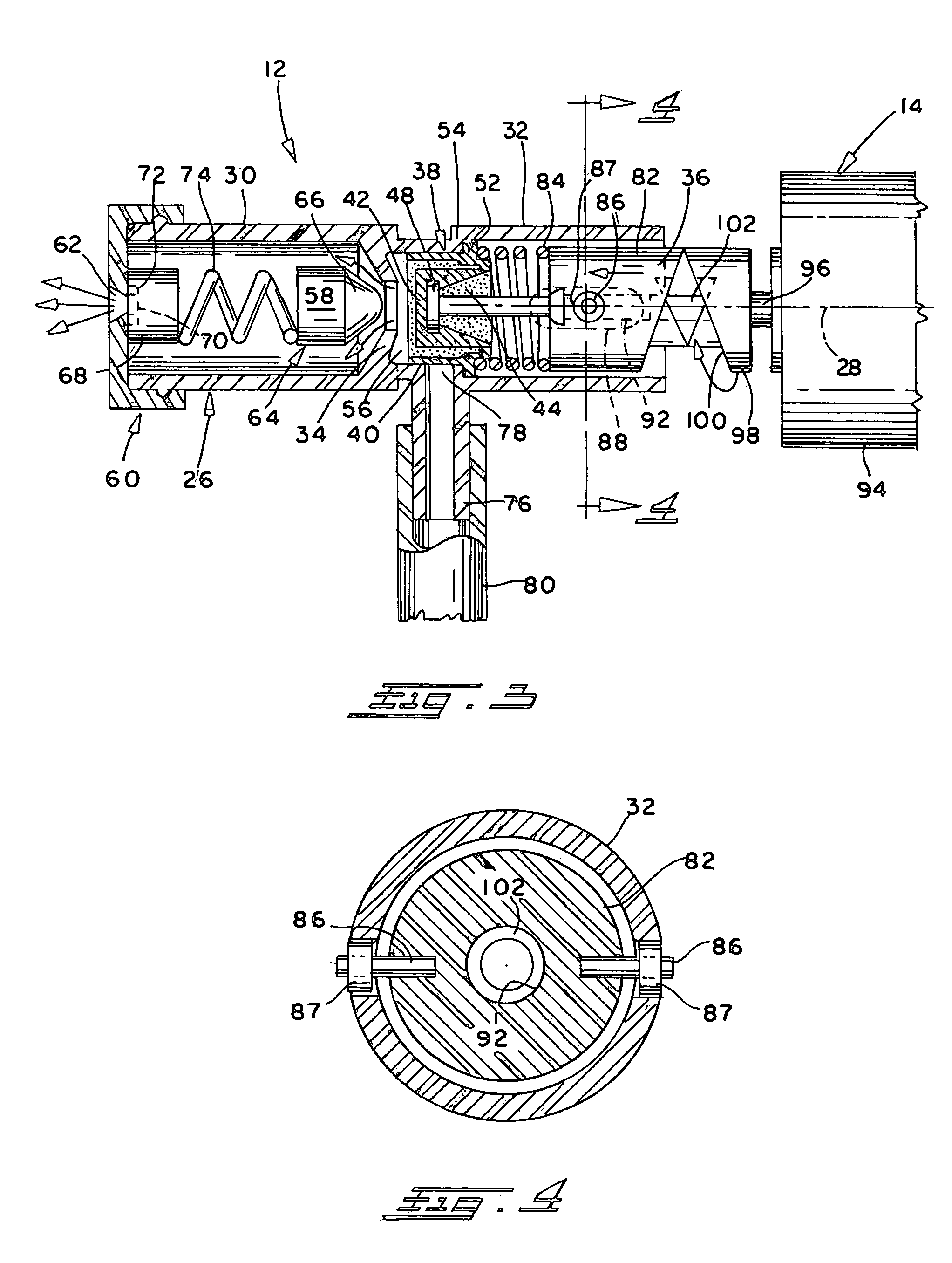

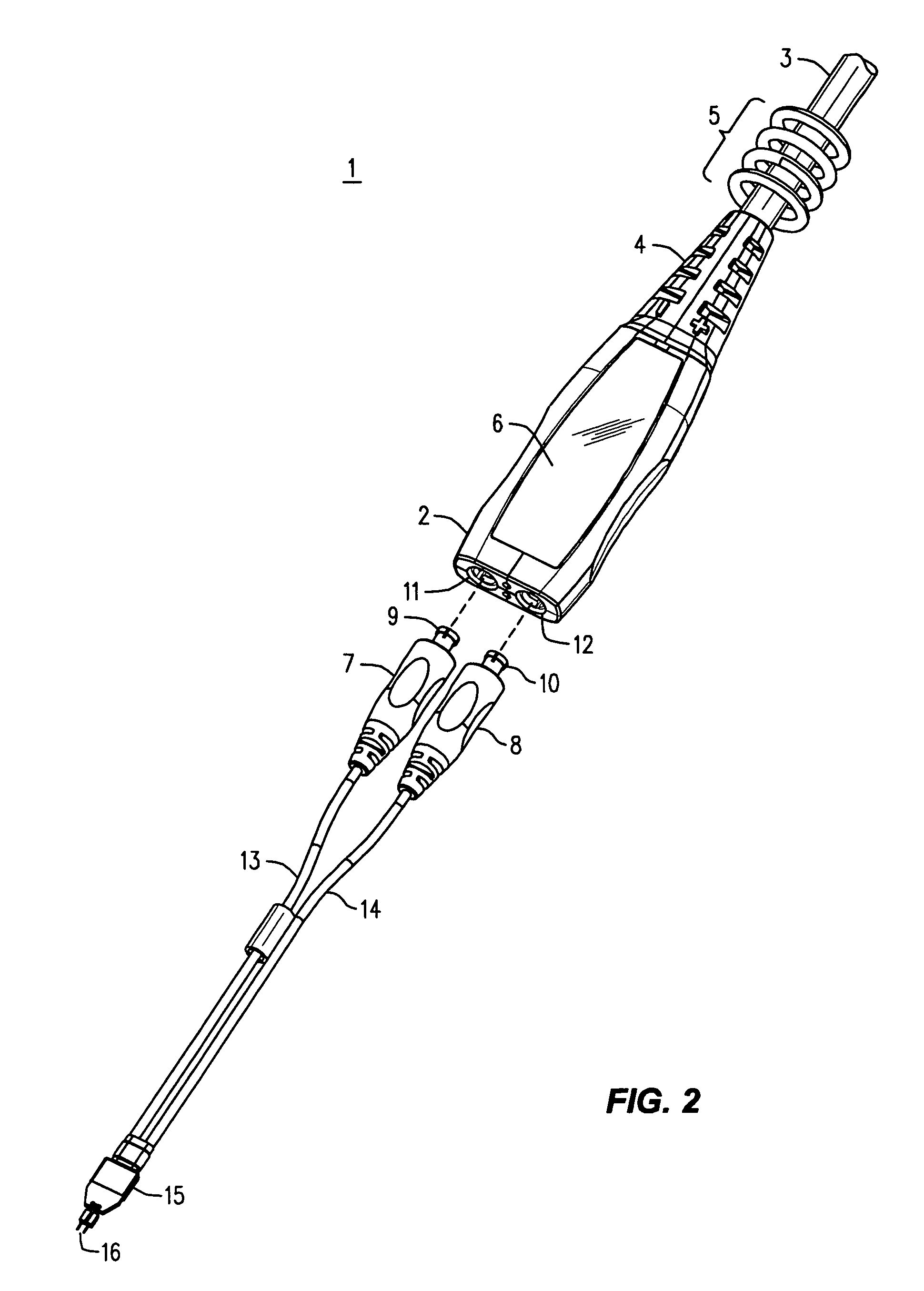

Pump drive unit for battery operated fluid dispensers

InactiveUS7318539B2Uniform wearImprove pumping capacityCam-followersLarge containersPump chamberHand held

A battery operated, handheld fluid dispenser comprises a supply container having a body portion and a narrow neck extending upwardly therefrom. A pump and discharge unit is mounted on the upper end of the neck and comprises a pump diaphragm and pump chamber for pumping liquid from the container to a discharge nozzle. A battery powered pump drive unit is mounted on the container and comprises an electric motor having an output shaft coupled with the pump diaphragm through a cam and cam follower arrangement to displace the diaphragm through a pump stroke when the motor is energized. The cam is rotatably driven by the motor, and the cam follower is attached to the diaphragm, whereby rotation of said cam axially displaces the diaphragm, and the cam and cam follower have interengaging dual cam faces for balancing lateral forces therebetween during rotation of said cam relative to said cam follower.

Owner:POWER SPRAYER +1

Keyed handgrip assembly

The handhold of an exercise handgrip turns freely while seated between the open ends of the upwardly extending prongs. It can be easily removed by moving the specially formed end part of the handhold into an access opening wide enough to slip the end part through. In positioning the handhold's end part for this removal, it must be forcibly snapped through a narrow opening. By reversing the procedure, the handhold can easily be returned to its place of rotation. The specially formed end part of the handhold must, therefore, have a narrow neck-like portion to fit through the narrow opening but the end part must also be enlarged to keep it in place for rotation. Preferably, there is also a stem and ball unit in one of the prongs which swings into place to trap exercise sheeting, cord or other media within an opening at the handgrip's bottom portion.

Owner:LIFELINE INT +2

Simple method for culturing haematococcus pluvialis to produce astaxanthin

ActiveCN101586140AReduce purchasesPromote vegetative growthMicroorganism based processesFermentationBetaxanthinsBiology

The invention discloses a simple method for culturing haematococcus pluvialis to produce astaxanthin; the method comprises three culturing processes of narrow neck flask, plastic cask or Nylon bag, cement pit; each step passes through various physical and chemical environmental parameters, such as nitrogen and phosphorus contents, pH value, incubation temperature, illumination intensity, illumination time, exact adjusting and controlling measure of adding with halite or halogeno salt, H2O2 and FeCl2 and cell state, etc; each step has definite object, and reasonable control such that the haematococcus pluvialis has excellent vegetative growth, fast conversion of vegetative growth to non-vegetative growth, and accumulates much astaxanthin, thereby improving the efficiency and stability of culturing, converting and accumulating, and effectively preventing the pollution of mixed algae; because the invention is an open culturing and does not need closed photobioreactor, thereby greatly reducing the production cost and obviously improving the productivity, and open culturing haematococcus pluvialis to produce astaxanthin in large scale.

Owner:LIJIANG CHENGHAI BAOER BIOLOGICAL DEV +1

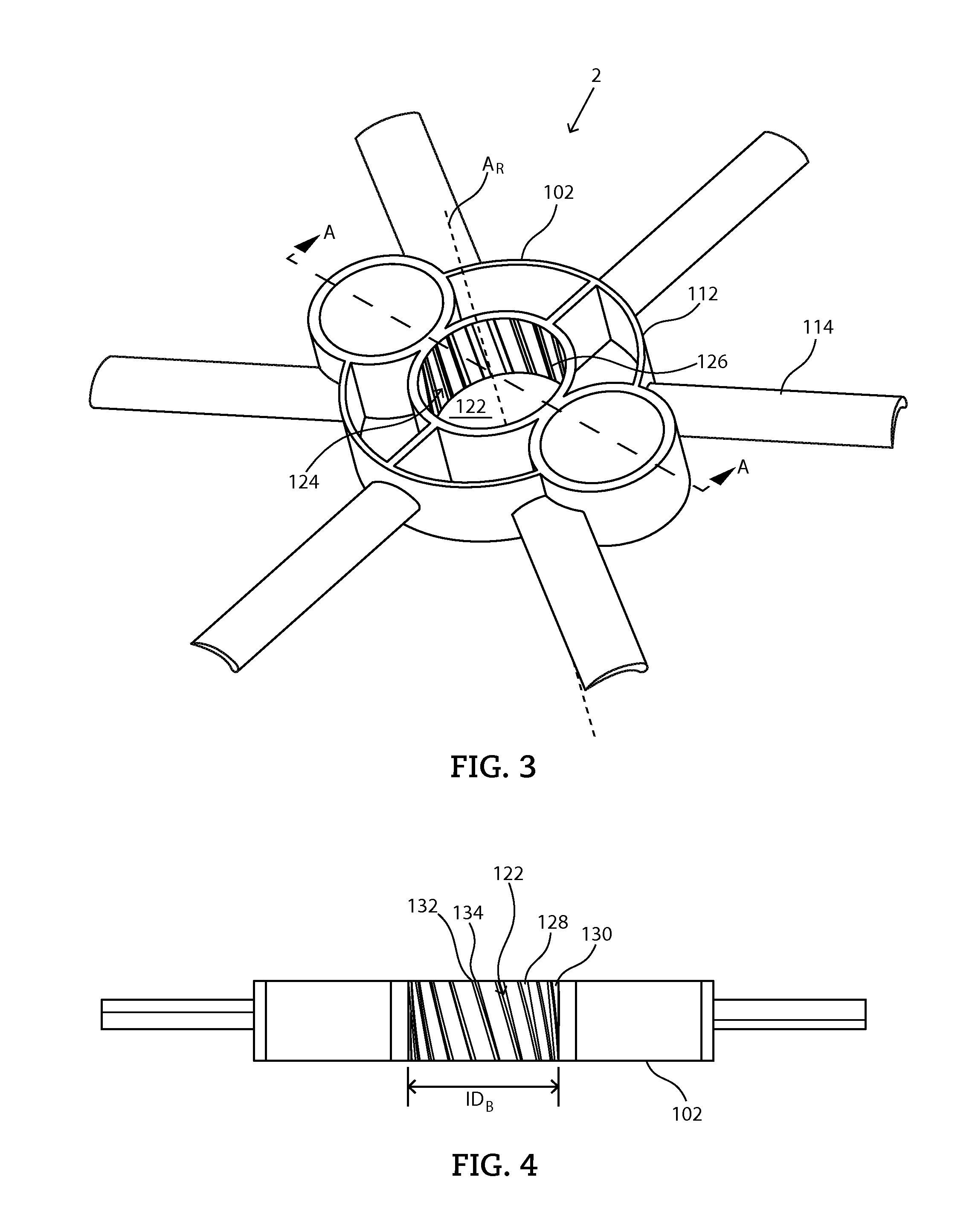

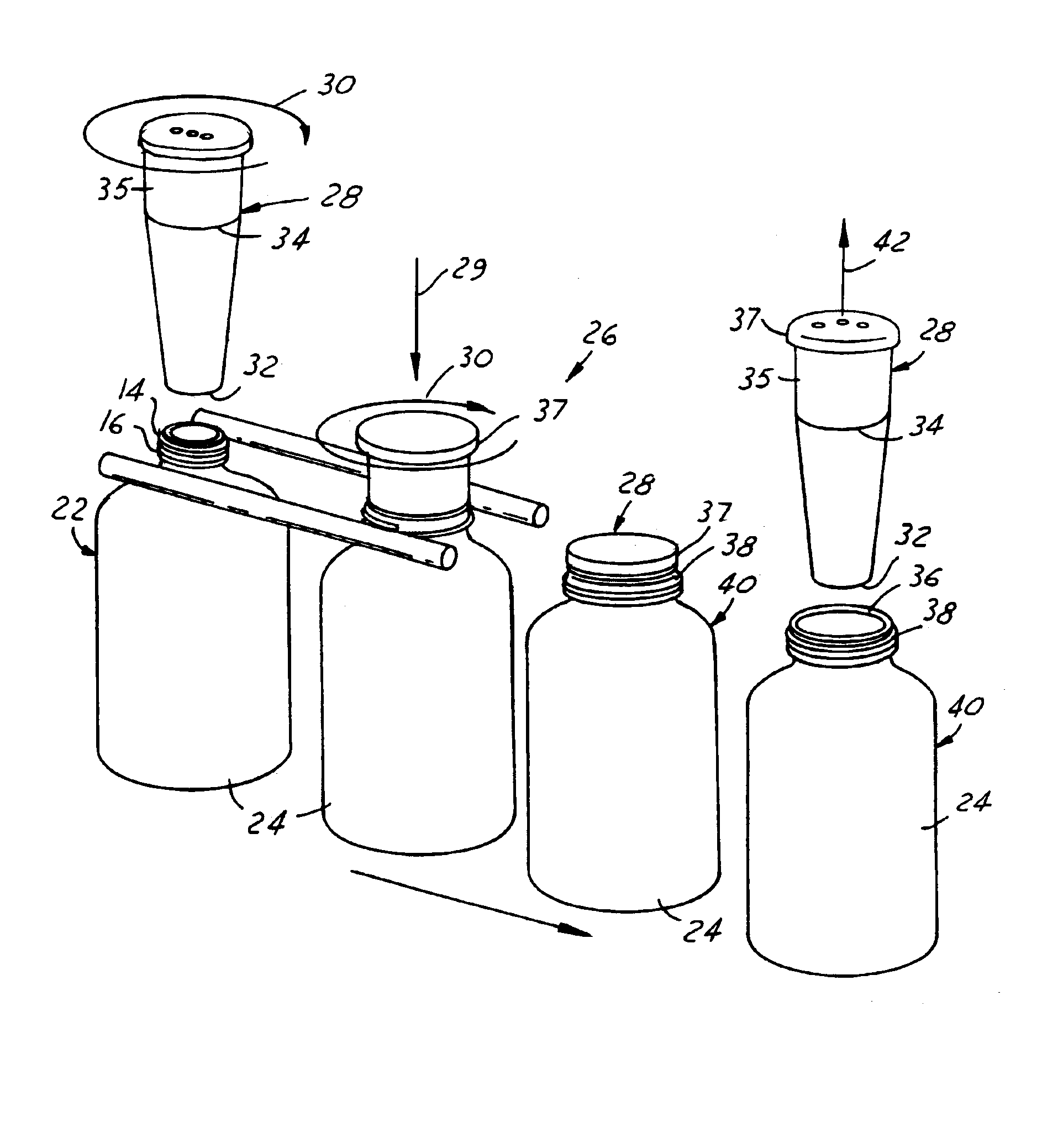

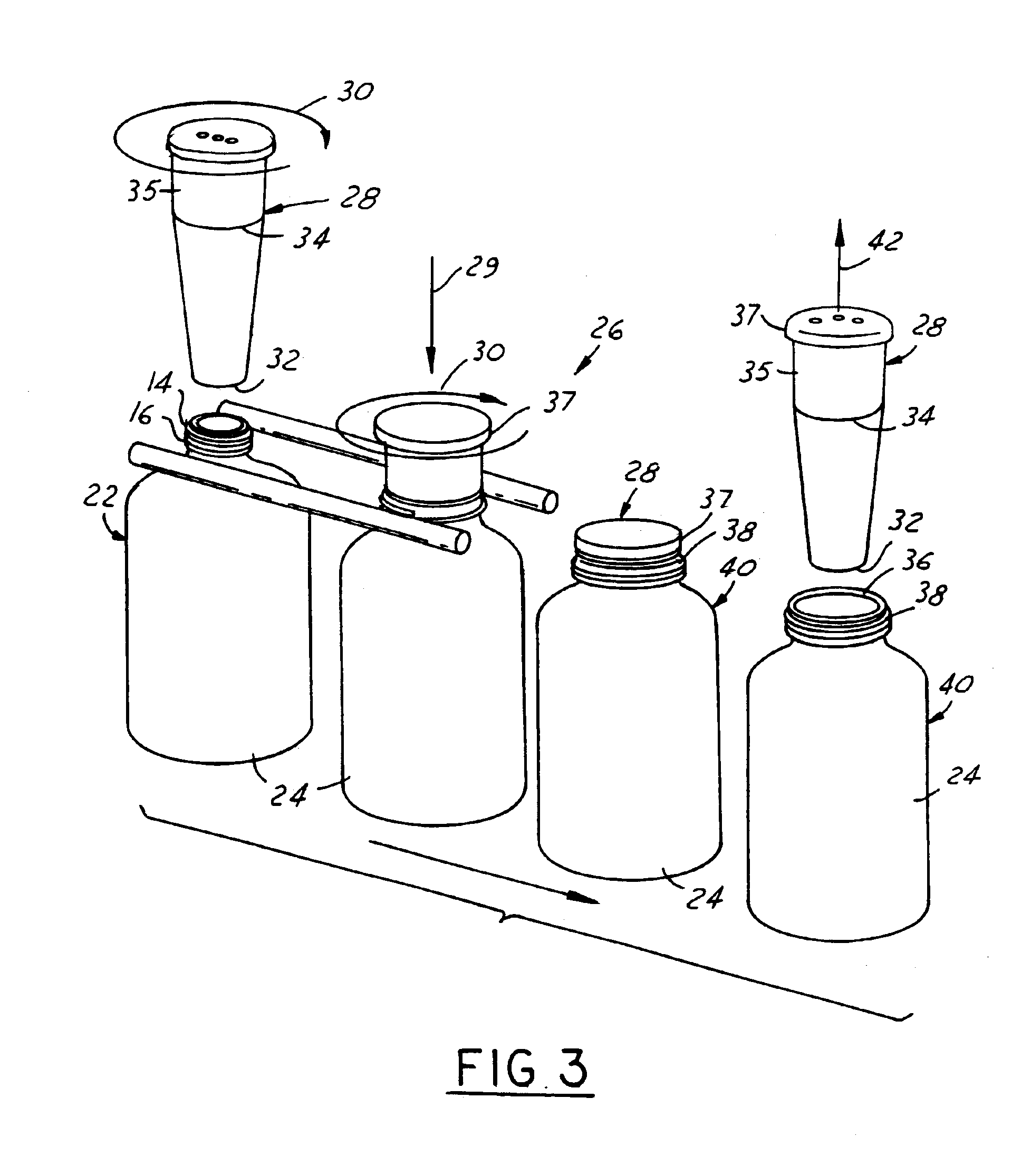

Mixing assemblies including magnetic impellers

The present disclosure relates to improved magnetic mixing assemblies and mixing system. The magnetic mixing assemblies can provide improved mixing action, ease of use, and low friction. The mixing assemblies can be adapted for use with a wide variety of containers including narrower neck containers and flexible containers.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Method for preparing 6-inch P-type solar silicon single crystals through Czochralski method and zone melting method

InactiveCN102304757AMeet the requirements for the production of 6-inch P-type solar silicon single crystalBy zone-melting liquidsBy pulling from meltCzochralski methodZone melting

The invention relates to a method for preparing 6-inch P-type solar silicon single crystals through a Czochralski method and a zone melting method. The method comprises the following steps: adopting the Czochralski method to clean a Czochralski hearth, charge, vacuumize, inject argon, heat and melt materials, perform seeding, pull narrow necks, grow shoulders, obtain the shoulders, obtain crystals with equal diameter, end, lift and cool and discharge; and then processing the ingot shape, cleaning and corroding to meet the standard of the zone melting material, and then adopting the zone melting method to continue to pull gas-doped single crystals. The gas-doped single crystal zone melting method is combined with the single crystal Czochralski production method; and by controlling vacuumizing and aerating, the concentration of the doping gas and the Czochralski method technological parameter range, the process method can meet the requirement for producing the 6-inch P-type solar silicon single crystals.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

Tool and cutting insert for the fine turning of grooves in workpieces

ActiveUS7063487B2Reduce and eliminate needReduce in quantityCutting insertsTurning toolsNeck partsEngineering

A tool for the fine-turning of grooves in workpieces including a basic body having a rearwardly extending mounting part, and a forwardly projecting bracket. The bracket includes a narrow neck part and an enlarged support part disposed at an end of the neck part. The support part, which forms an insert seat, extends laterally from the neck part wherein the seat is arranged asymmetrically with respect to an imaginary center line of the basic body. A cutting insert includes a bottom side supported on the insert seat. The insert includes two spaced apart convexly arched side cutting edges arranged so that the imaginary center line passes therebetween. A hole is provided through the insert for receiving a fastening screw. The bottom side and the insert seat include mutually engaging stabilizing structures preventing angular displacement of the insert about an axis of the hole.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

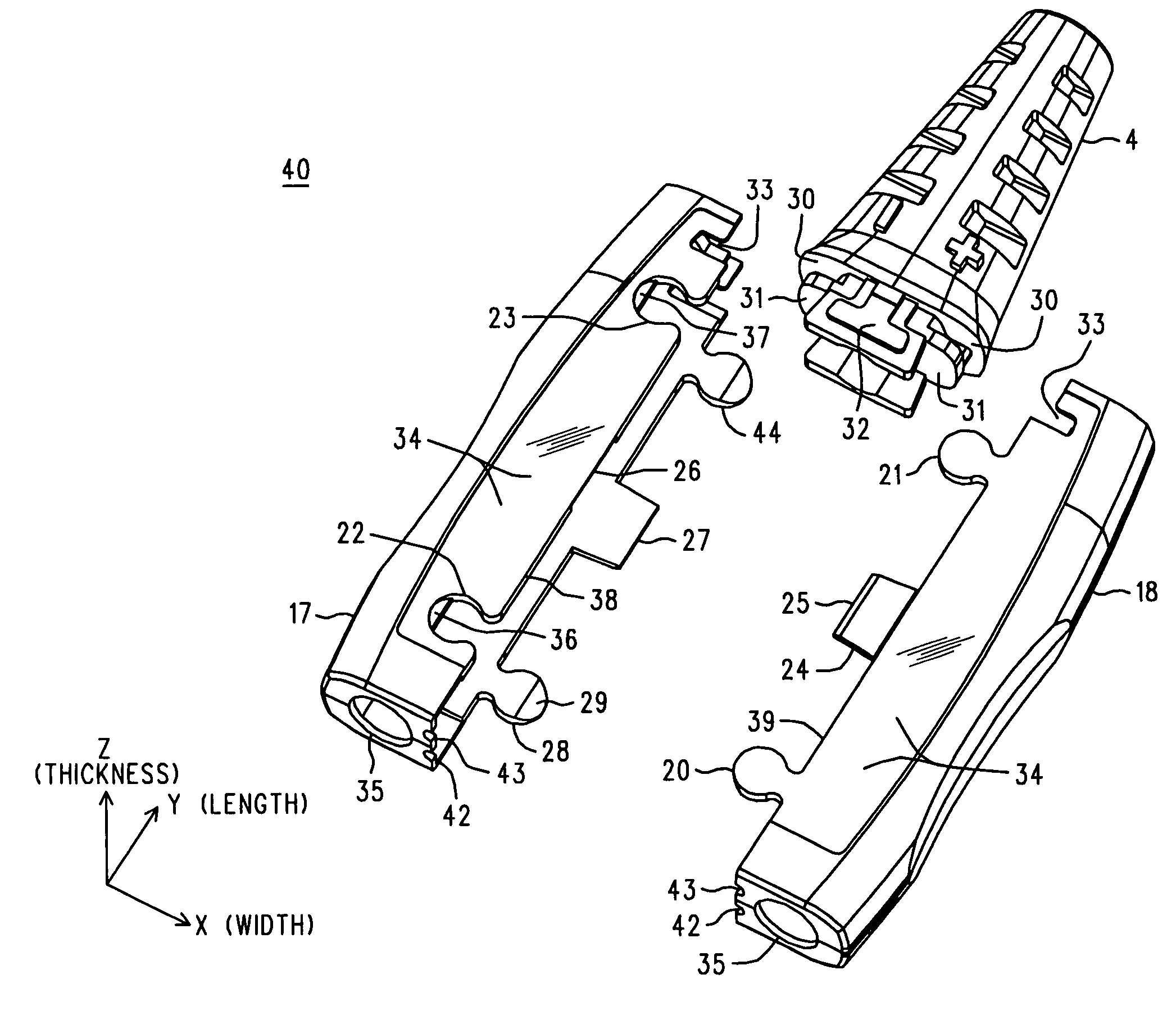

Housing for a thin active probe

InactiveUS7163424B2High aspect ratioUseful apertureElectrical measurement instrument detailsCoupling device detailsEngineeringNatural position

A housing for a thin active probe has two identical molded housing-halves that when assembled form a cavity that encloses the chassis upon which is carried the active circuitry of the probe. The parts exhibit complementary self-symmetry about a longitudinal axis, such that when one is rotated about that axis it performs the mating functions needed to interlock with another part representing its un-rotated self. Interlocking is accomplished by circular tabs and sockets that interfere and prevent the parts from separating once the tabs are in the sockets. The circular tabs are joined to the balance of the housing-half that carries them by a narrow neck and can be sprung over the other housing-half to return to their natural position and fit into a circular socket in that other housing-half. A tapered edge or ramp portion on the underside of each circular tab allows it to automatically spring out of the way as the two parts are moved toward each other in a direction generally perpendicular to the longitudinal axis of the parts. Each circular socket contains a stop that prevent its tab from completely passing through the socket. Each housing-half has a straight tab between its circular tabs that enter an interior recess on the other housing-half to support its circular sockets as they receive their tabs. Each housing-half contains in a front surface an entire aperture for a detachable probe lead, and each contains in a rear surface at least one half-aperture that, when the two housing-halves are joined, forms a larger aperture whose perimeter engages a corresponding groove in a strain relief for a cable. The exterior surface of the mated housing-halves has, on each side through which runs the line of the mating edges, a flat shallow recess. The interlocking circular tabs and sockets are located within the extent of this shallow recess, which can receive an adhesive label that may conceal and stiffen the interlocking circular tabs and sockets.

Owner:AGILENT TECH INC

Tool holding and displaying device

A tool holding and displaying device includes a plate having a narrower neck portion formed between an upper orifice and a lower aperture. The upper orifice of the plate includes an inner diameter greater than that of the lower aperture of the plate, and a bracket includes a latch having an enlarged head formed on a pin for engaging into the upper orifice of the plate. The enlarged head of the latch is greater than the lower apertures of the plate, to engage with the plate, and to anchor the bracket to the plate. The plate includes one or more spring arms to engage with the pin of the latch of the bracket, to lock the latch of the bracket to the plate.

Owner:CHIANG KUO CHUAN

Stretched container threads and method of manufacture

InactiveUS6884382B2Improve throughputOther chemical processesDomestic articlesBlow moldingCompression molding

A method of making a plastic container having a body and a finish with at least one external thread includes injection or compression molding a plastic preform having a body and a finish with at least one external thread, blow molding the body of the preform to form the body of the container, and either prior to, subsequent to or both prior and subsequent to blow molding the container body, expanding the injection or compression molded preform finish to form a container finish having at least one injection or compression molded external thread. In the preferred embodiments of the invention, the finish is expanded after the container body is blow-molded. The invention can be implemented to expand a narrow-neck preform or container finish to a wide-mouth preform or container finish.

Owner:GRAHAM PACKAGING PET TECH

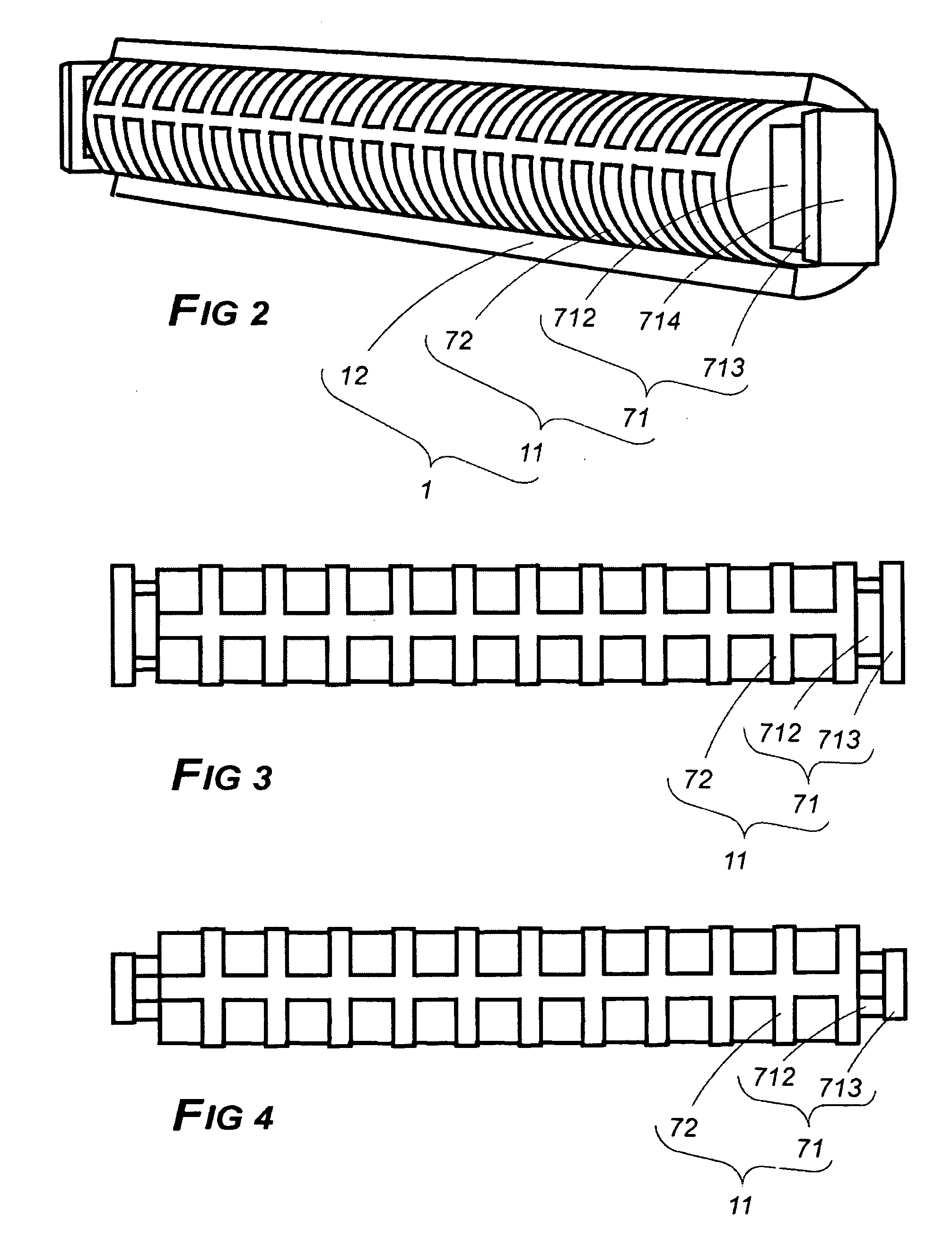

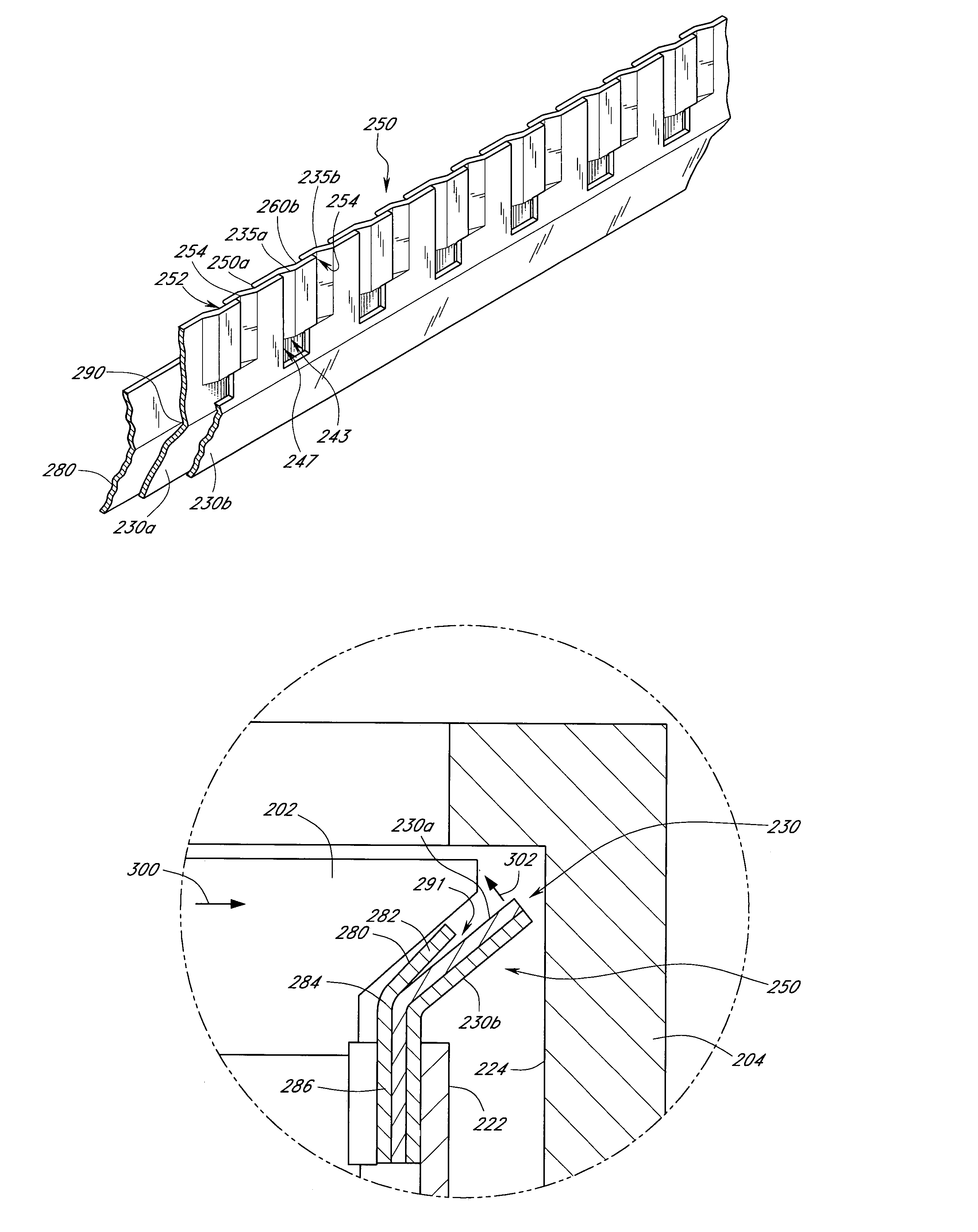

Reinforced sealing element

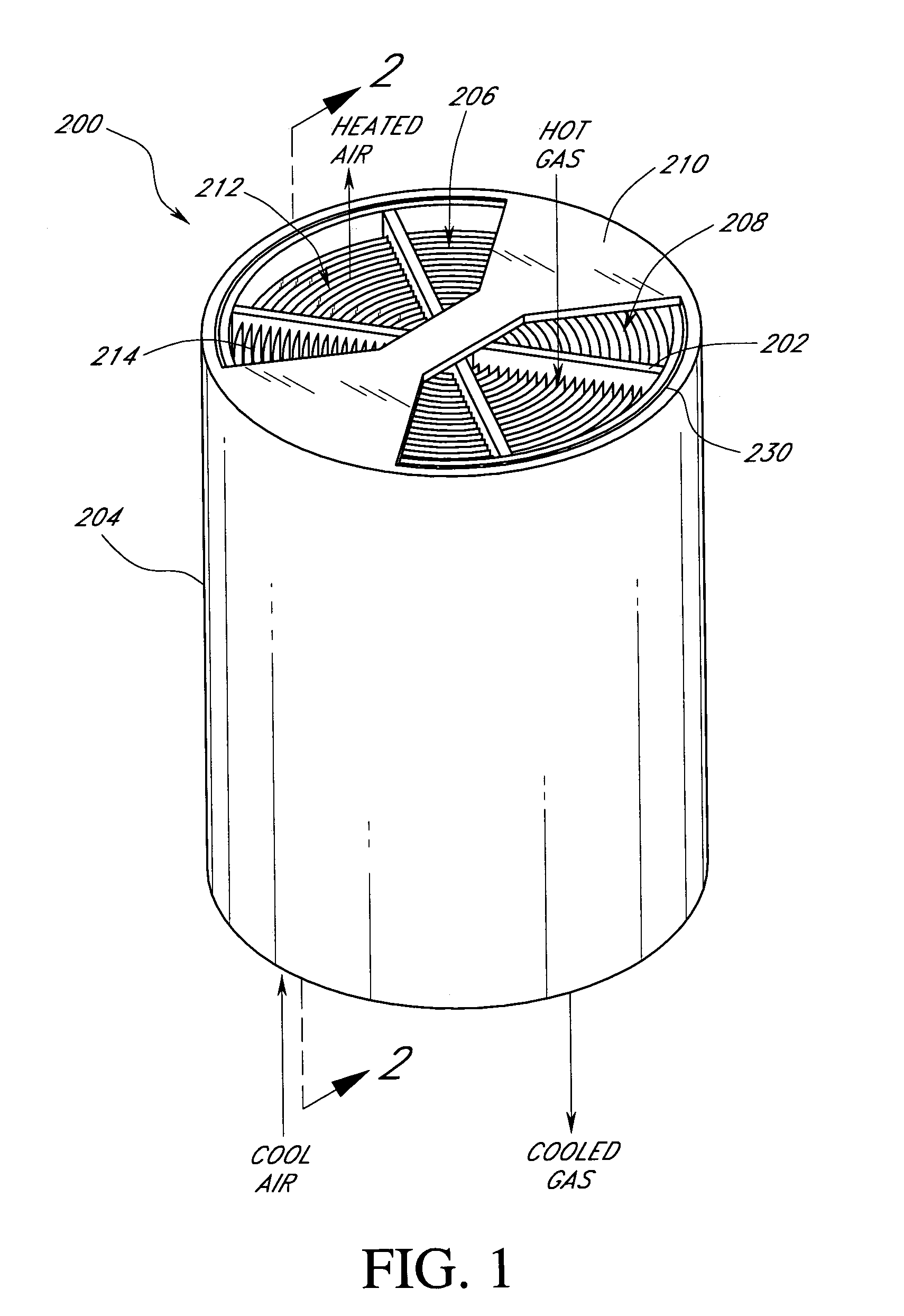

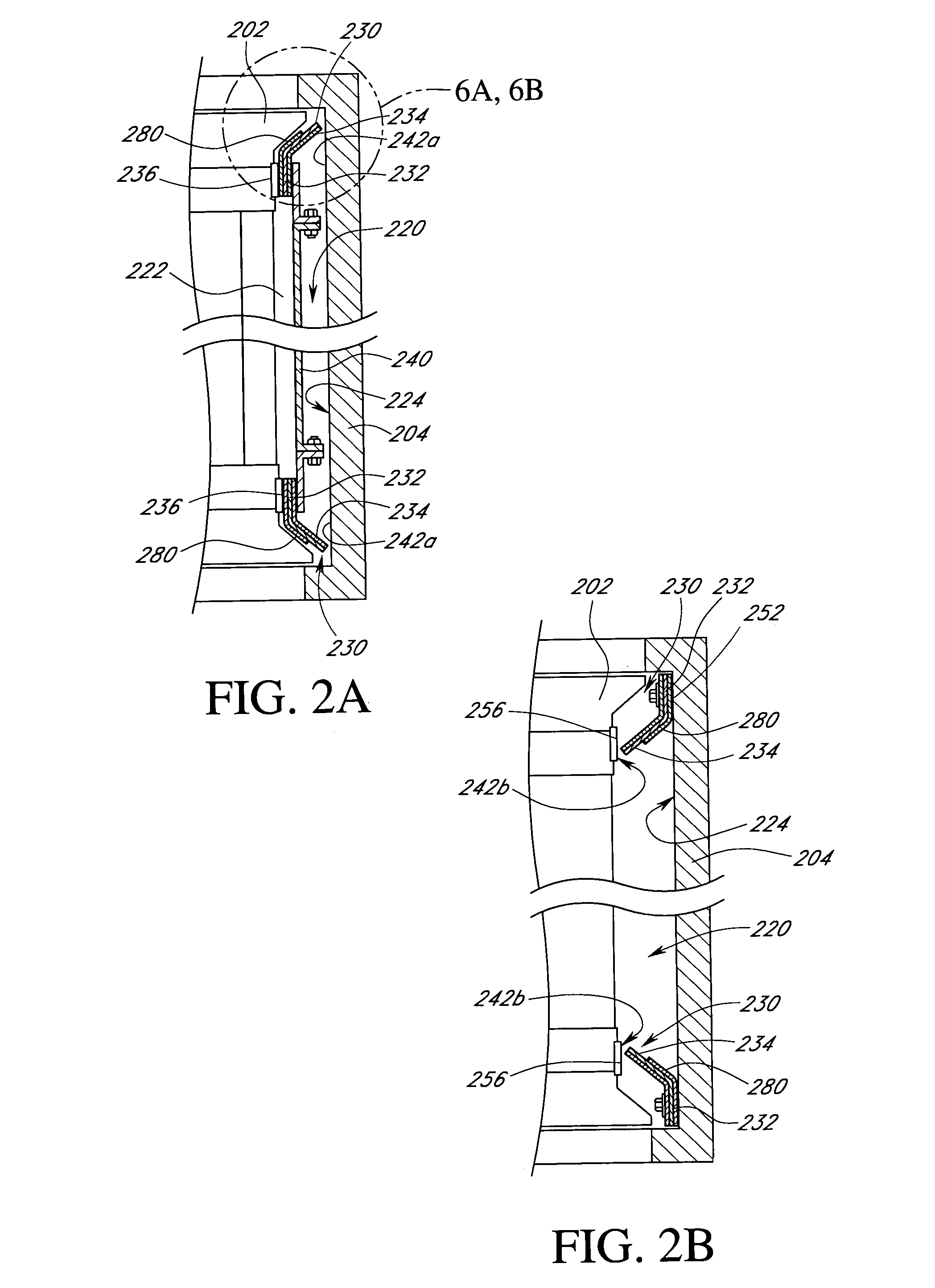

ActiveUS7231958B1Damage suppressionAvoid damageEngine sealsCombustion processAir preheaterEngineering

A seal for a regenerative air preheater. The seal is comprised of two members that each have a plurality of tabs and slots. The tabs and slots interlock so that the tabs on one member are positioned adjacent the slots on the other member. The tabs have a narrow neck section and a wider sealing section. The wider sealing sections overlay and the narrow neck sections are positioned within a recessed region of the notch on the opposite member so as to interlock the two members. The seal is mounted either to the rotor or to the inner wall of the housing so as to extend through the bypass gap between the rotor and the inner wall of the housing. As the tabs are flexible, the tabs may resiliently deform as a result of the tabs making contact with the sealing surface of the heat exchanger. The air preheater further comprises a reinforcing section that stabilizes the tabs when the tabs resiliently deform.

Owner:PARAGON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com