Patents

Literature

147results about "Press and blow machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

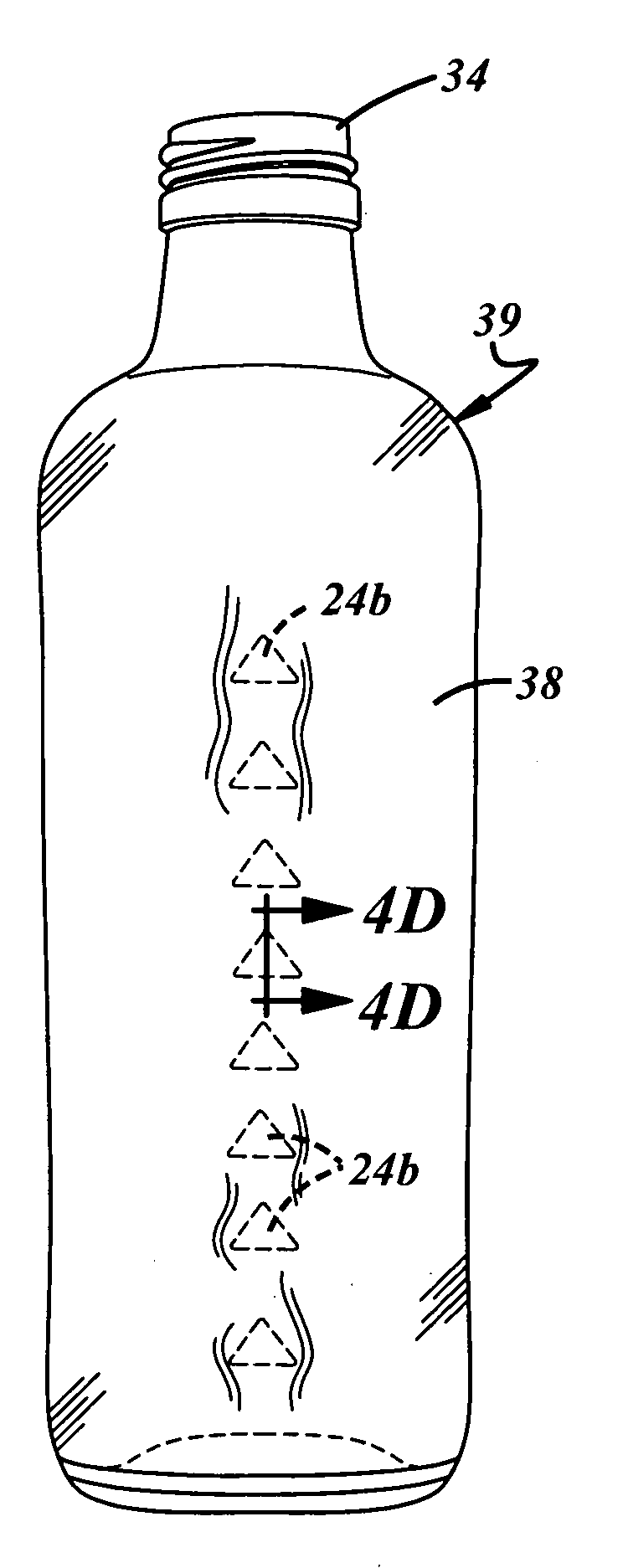

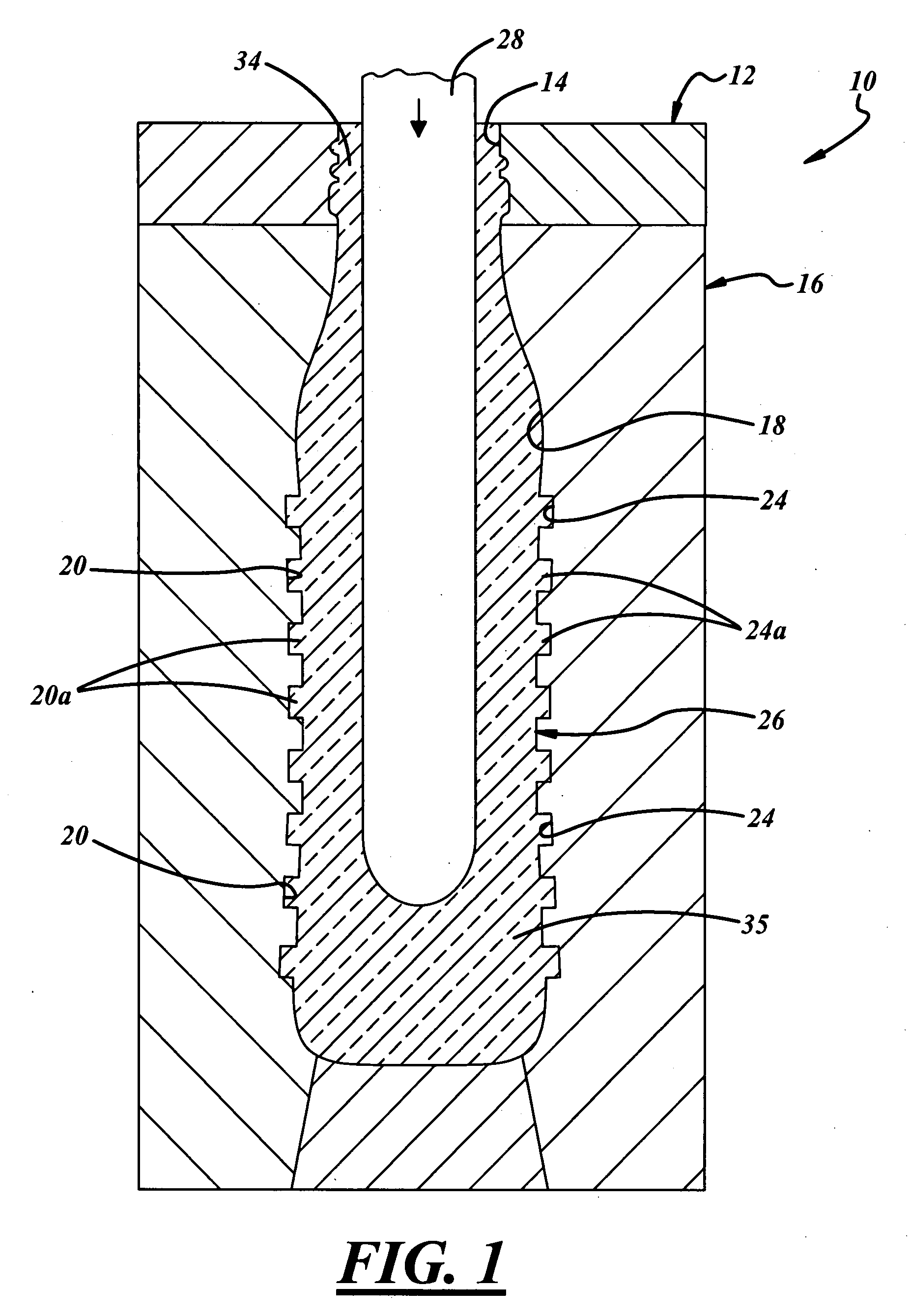

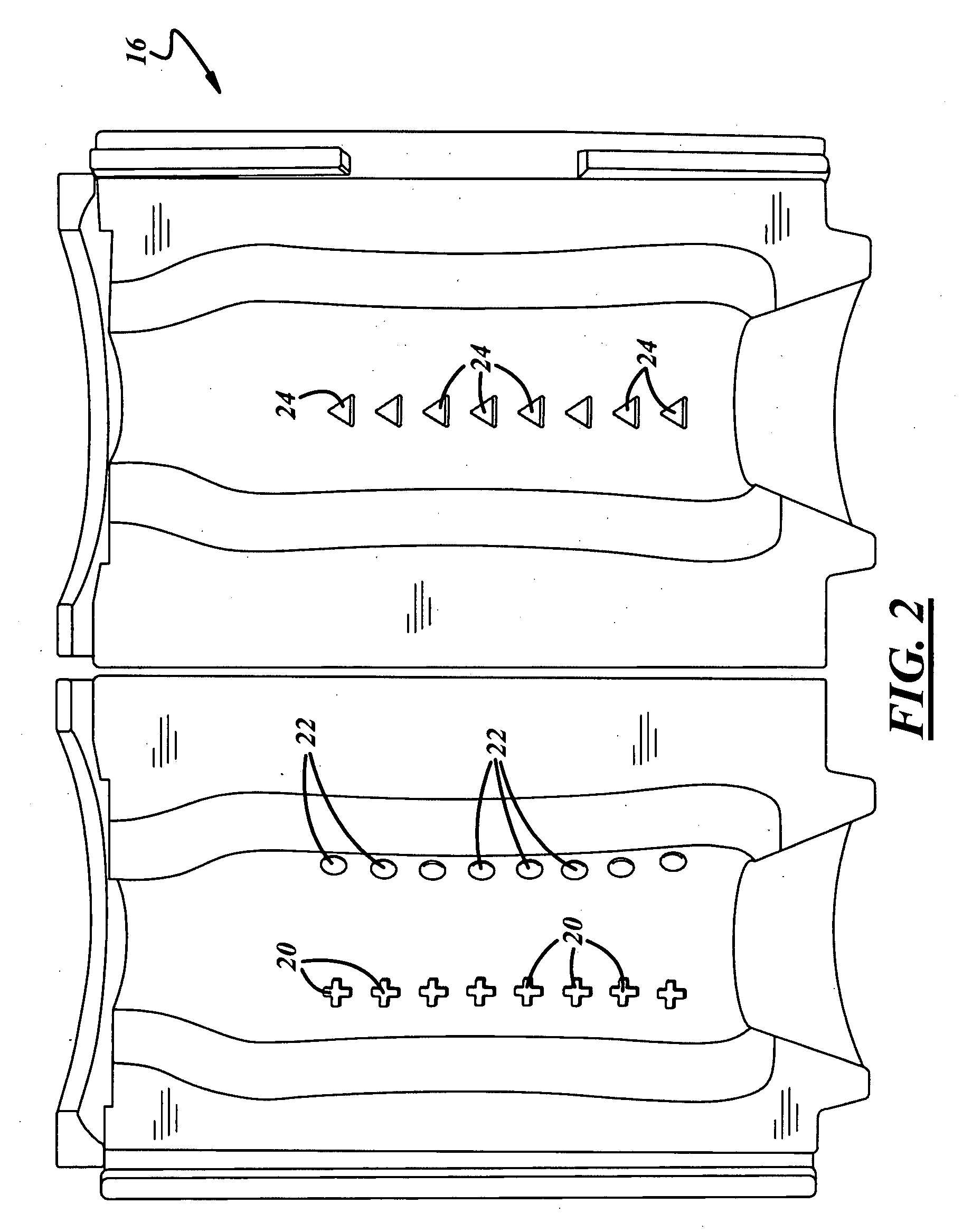

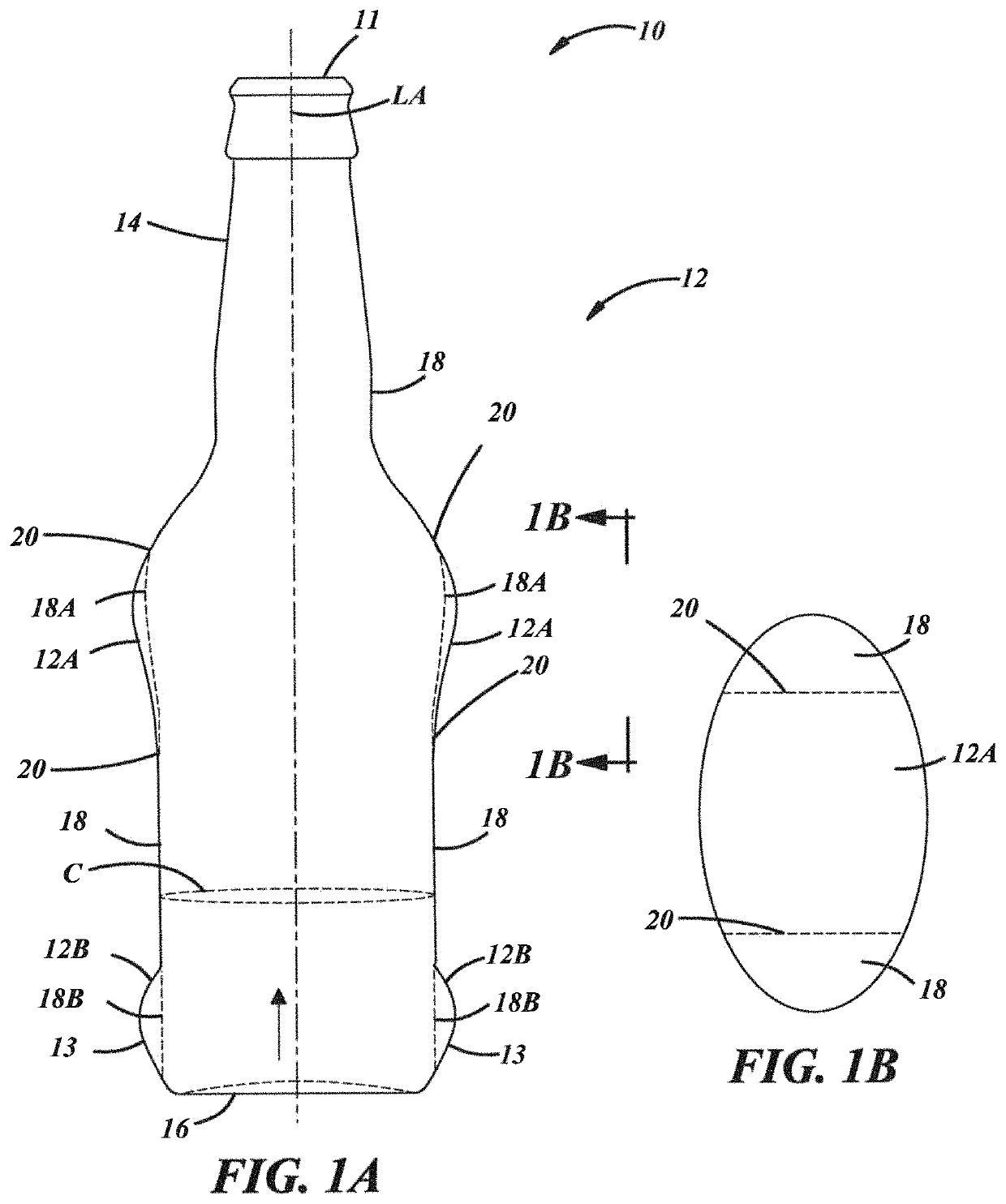

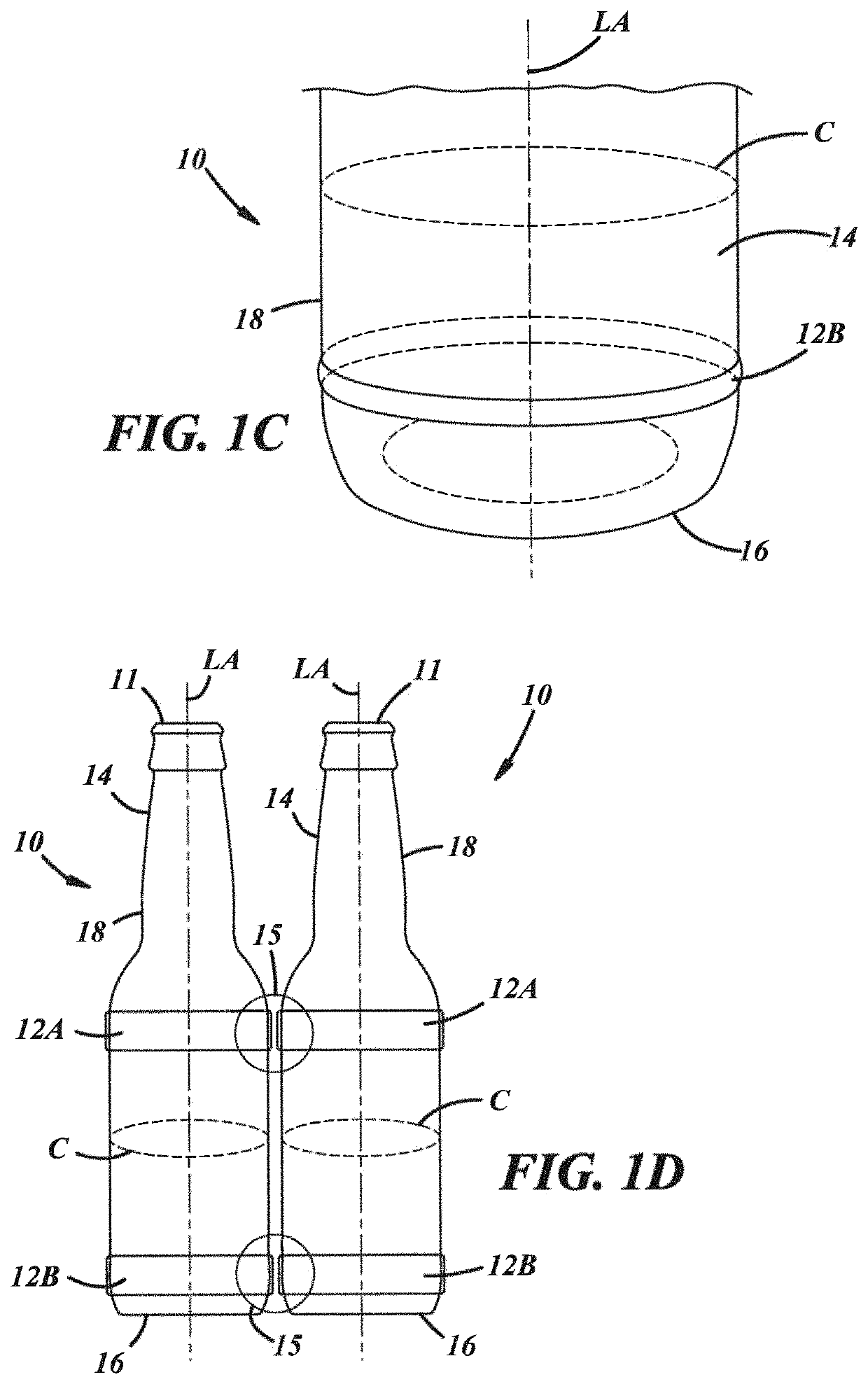

Narrow neck glass container with internal embossments and method of manufacture

InactiveUS20090084799A1Large containersPress and blow machinesMechanical engineeringGeometric pattern

A narrow neck glass container includes a container body and a container neck finish. The container neck finish has an external closure attachment diameter of not more than 36 mm, and the container body has at least one internal embossment of predetermined geometry. The at least one internal embossment preferably comprises a plurality of internal embossments in a geometric pattern.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Production of a pharmaceutical container from the melt

ActiveUS20100203270A1High dimensional accuracyConsiderable cost advantageLayered productsGlass pressing apparatusEngineeringMechanical engineering

The invention proposes a process for the production of a container for pharmaceutical and medical applications made from glass, preferably from a borosilicate glass, wherein the container is produced by a press-blow process where the container is initially preformed in a pressing step, by making a ram press a dispensed glass drop into a mold that is open at its bottom, and where the parison so produced is given its final form by a subsequent blowing step.

Owner:SCHOTT PHARMA AG & CO KGAA

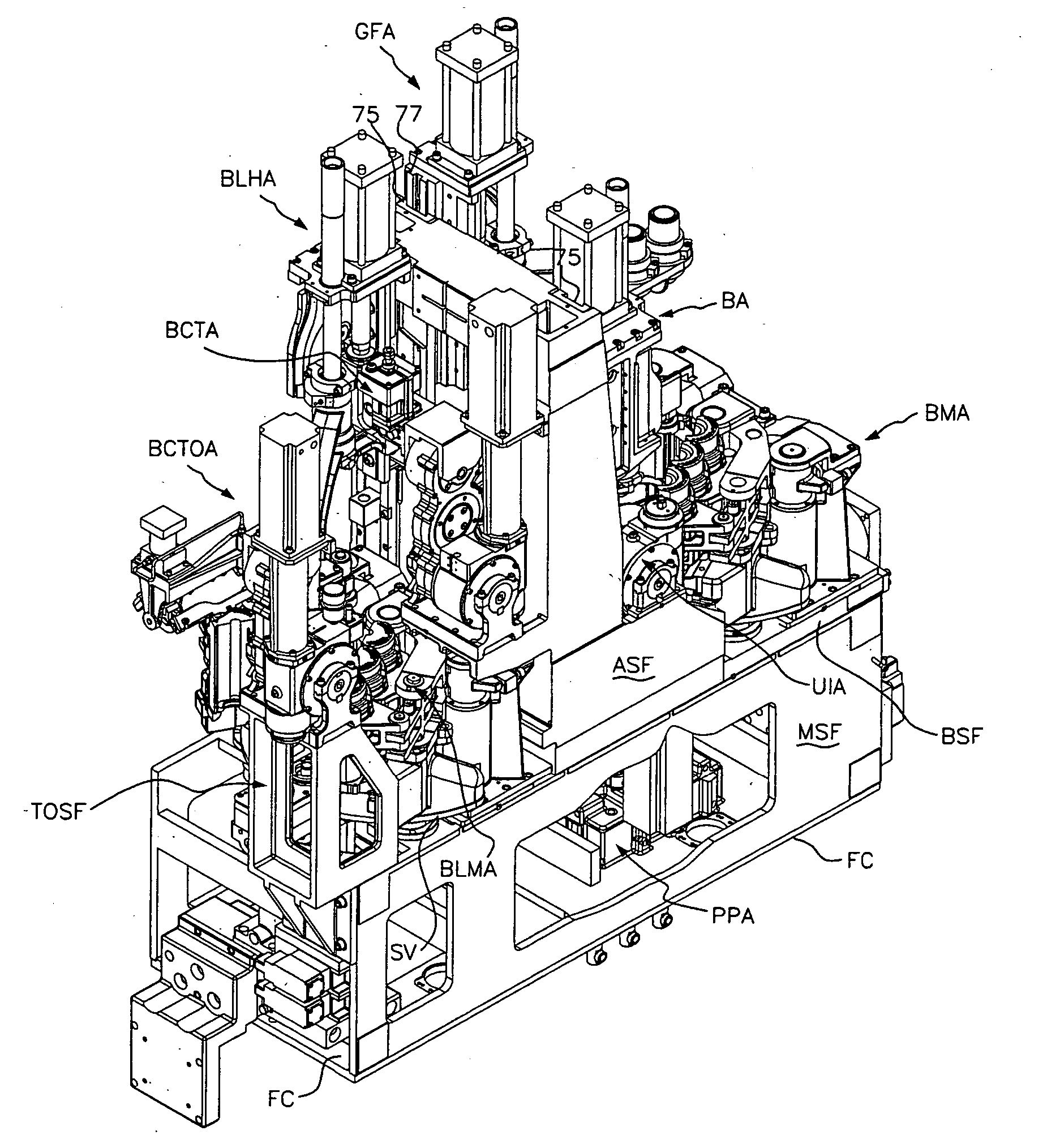

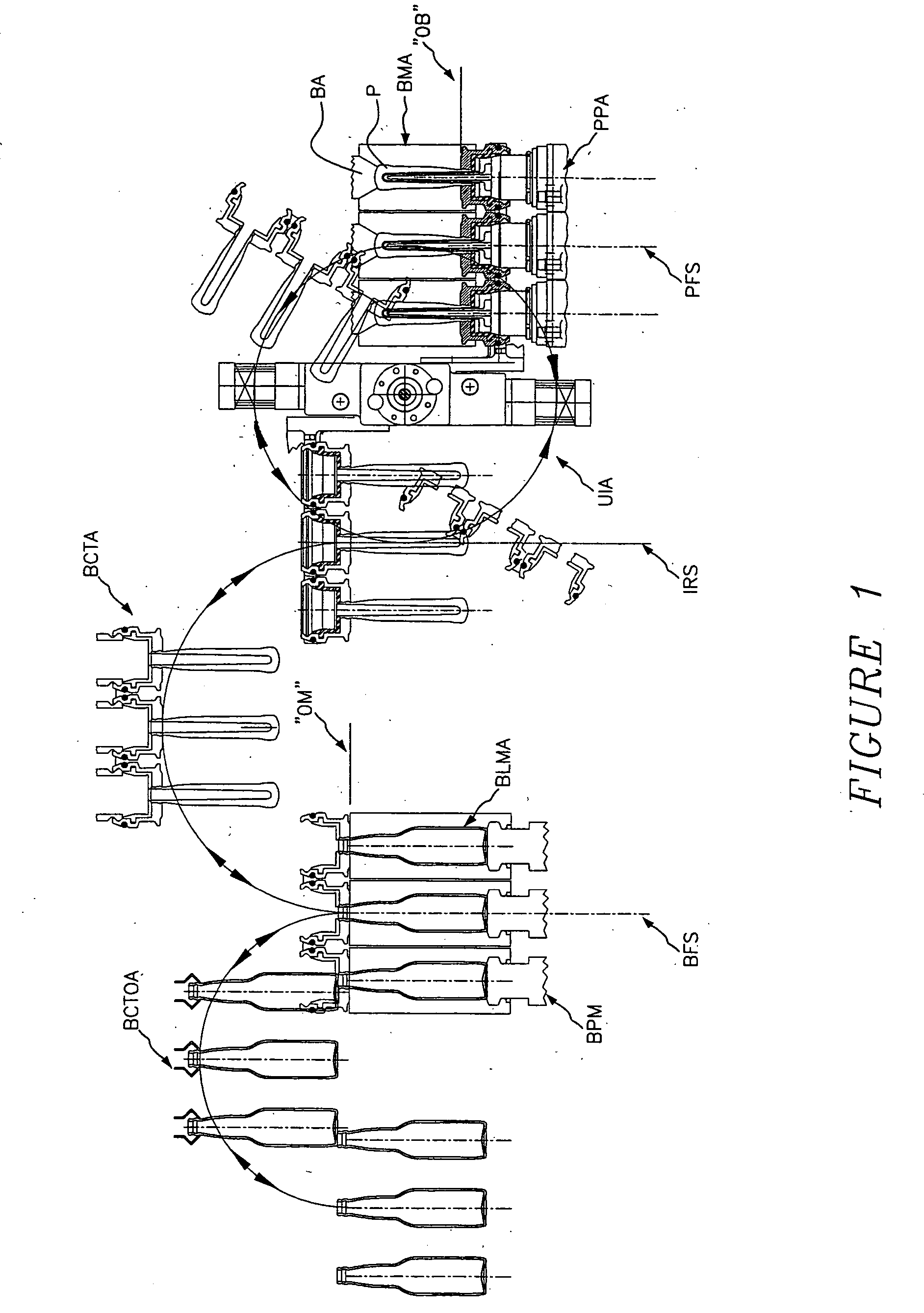

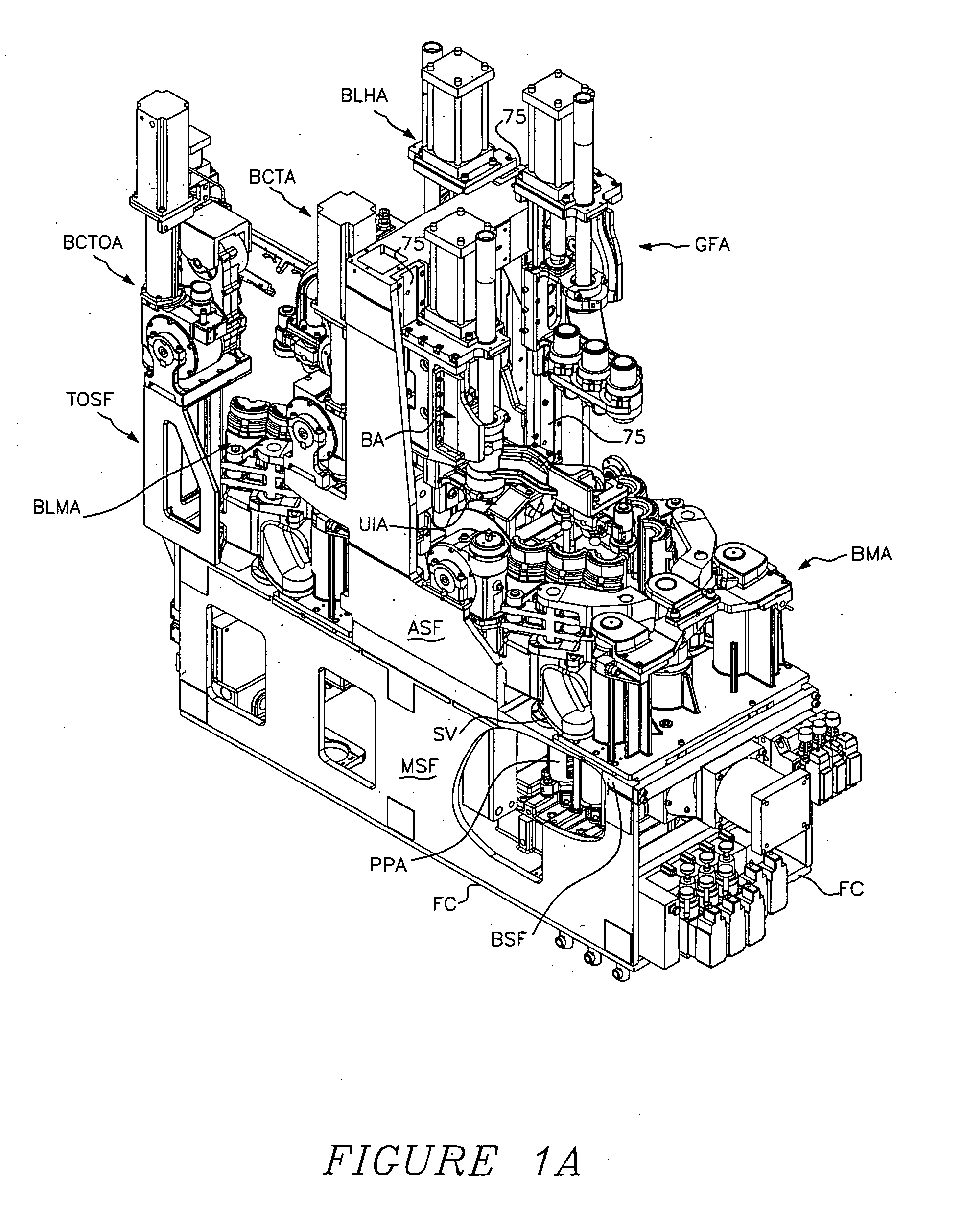

Method and a machine for the production of hollow glassware articles

InactiveUS20050235697A1Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusMolding machineGlass vessel

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO SAB DE CV

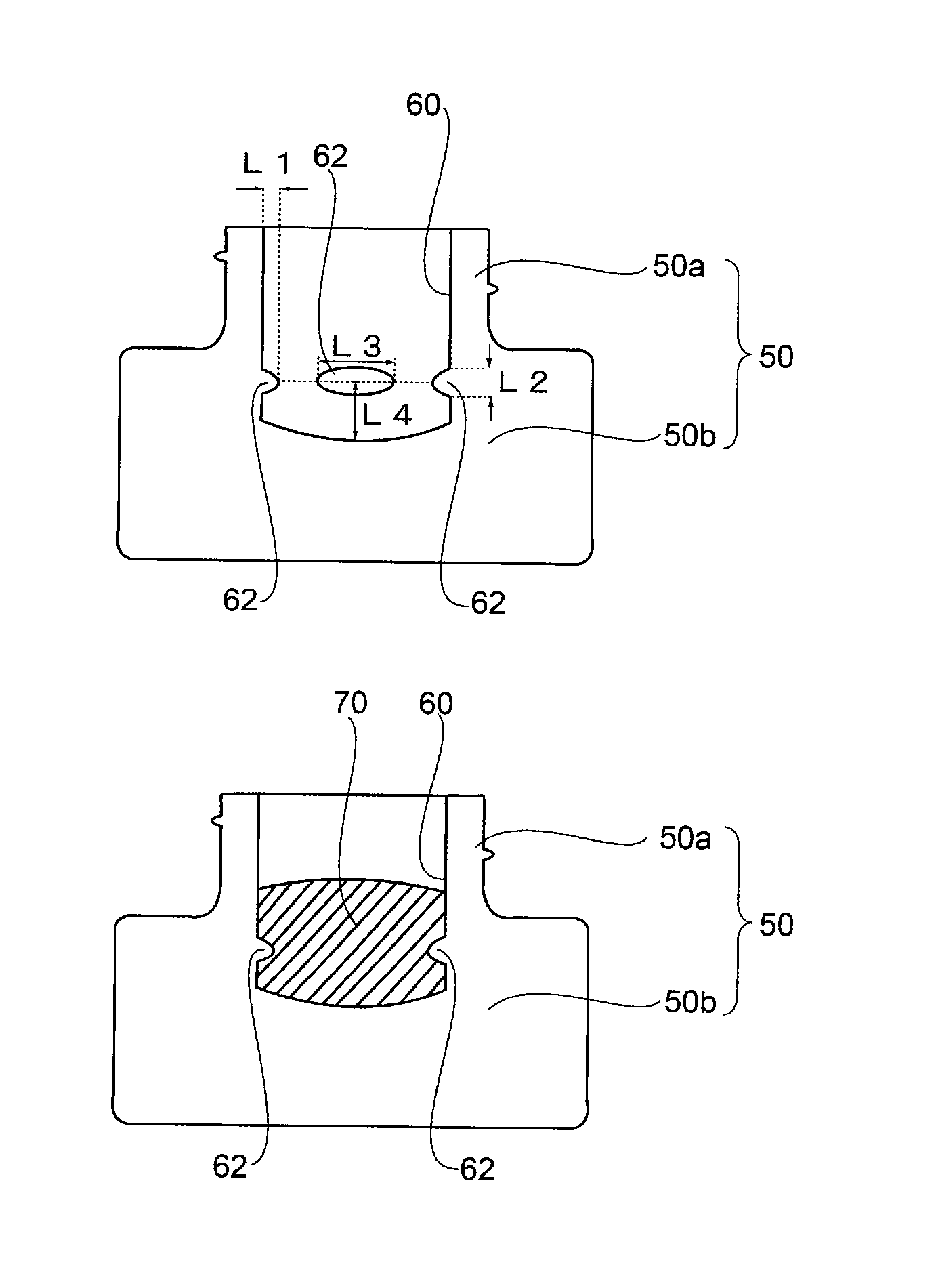

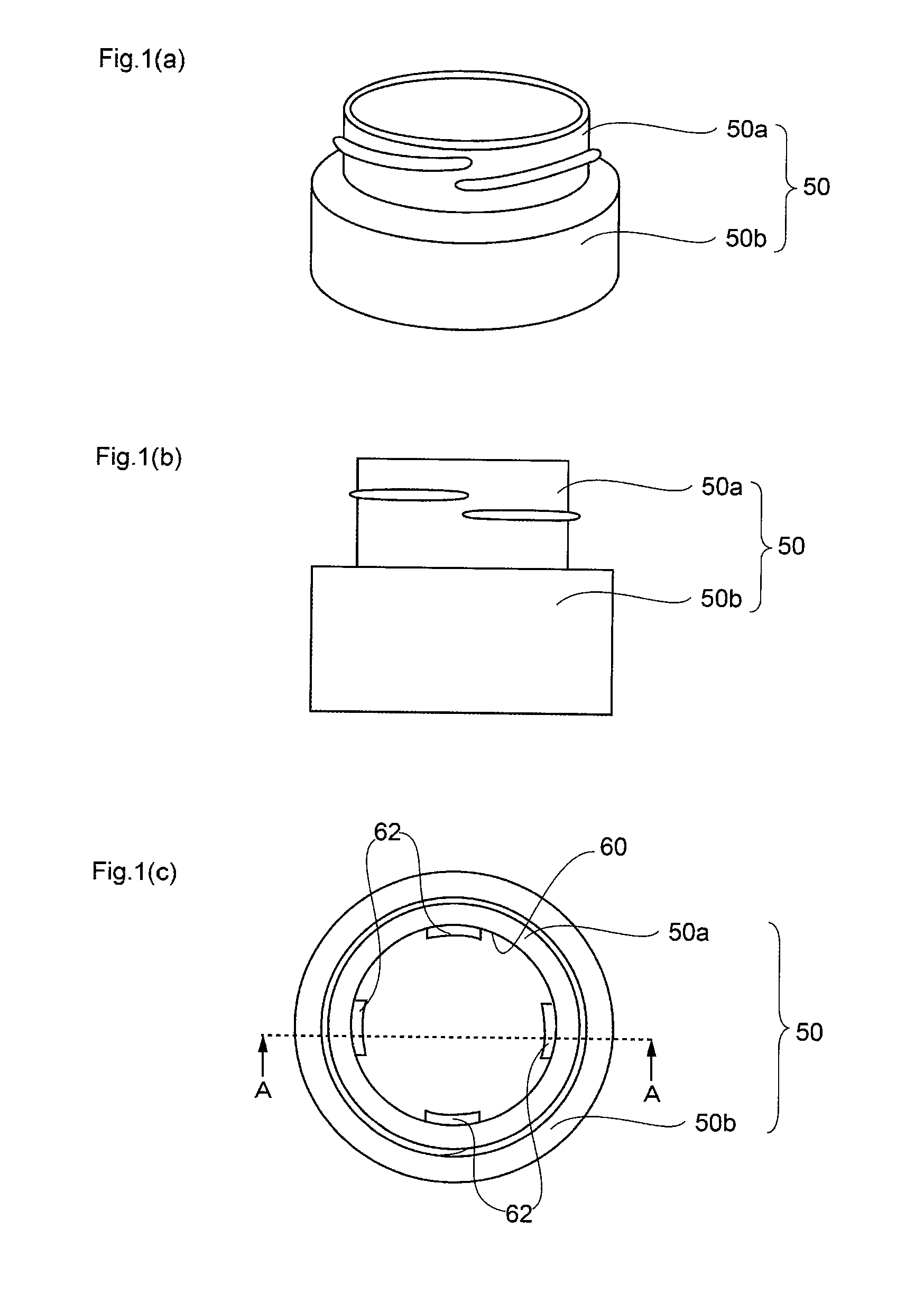

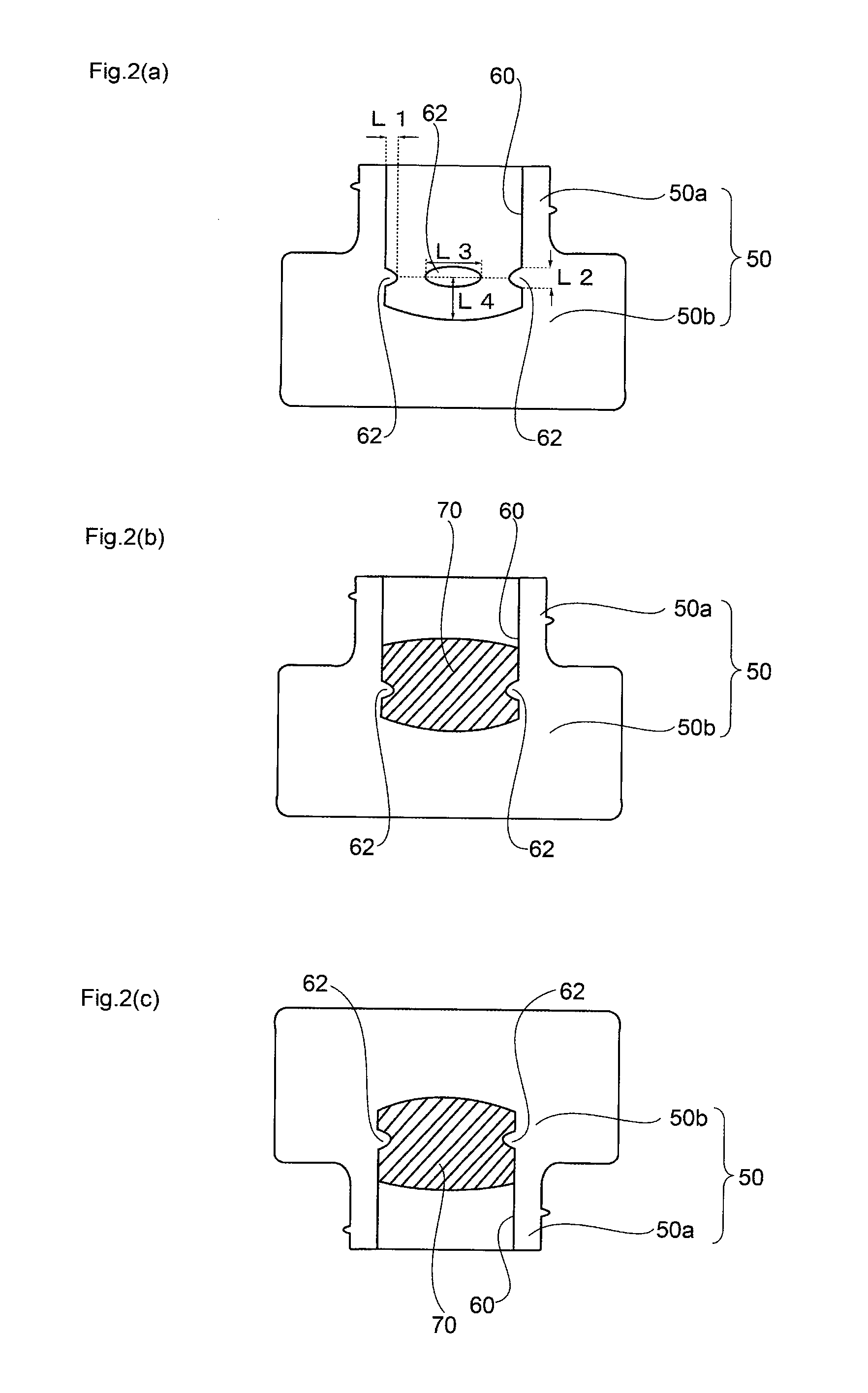

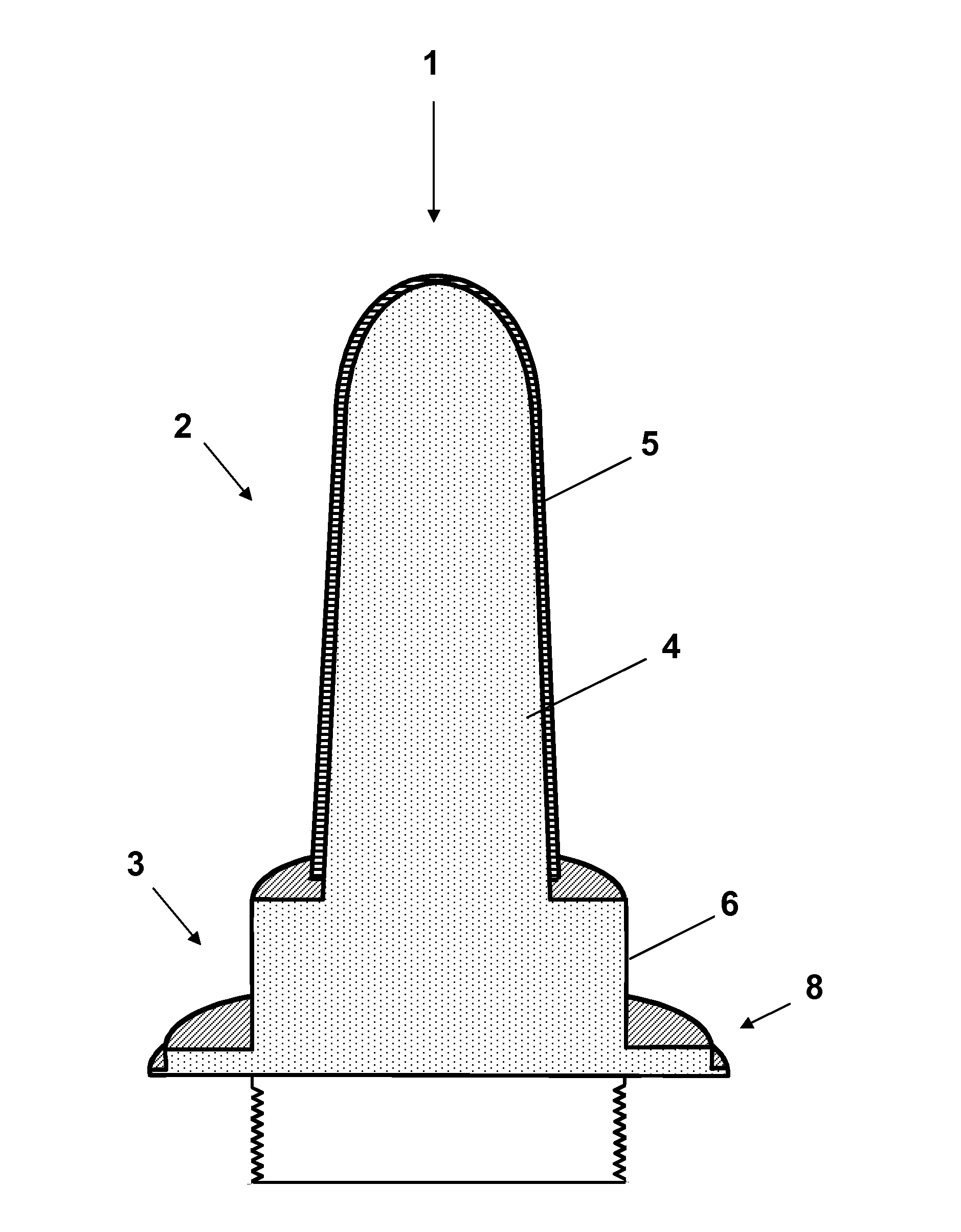

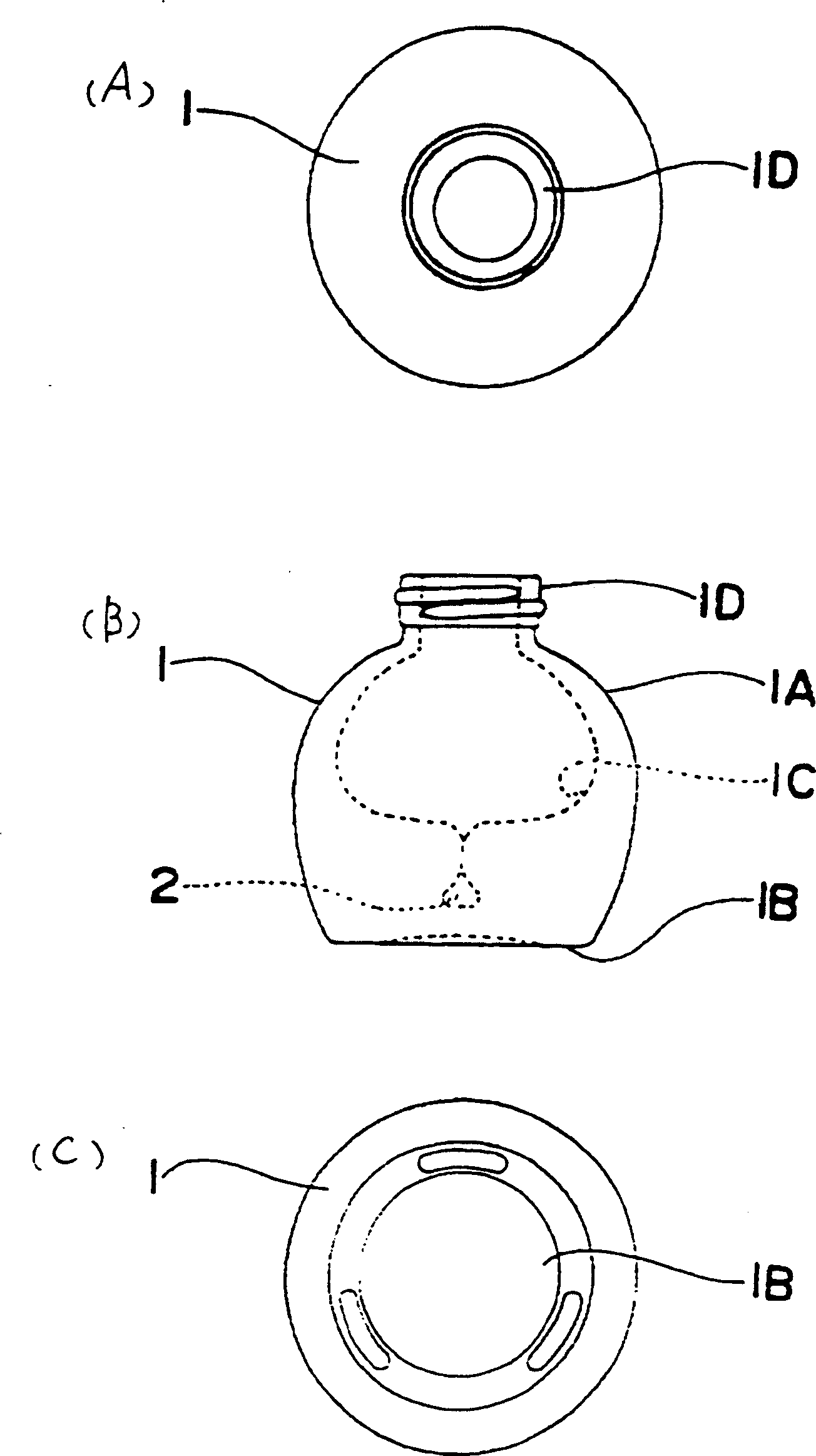

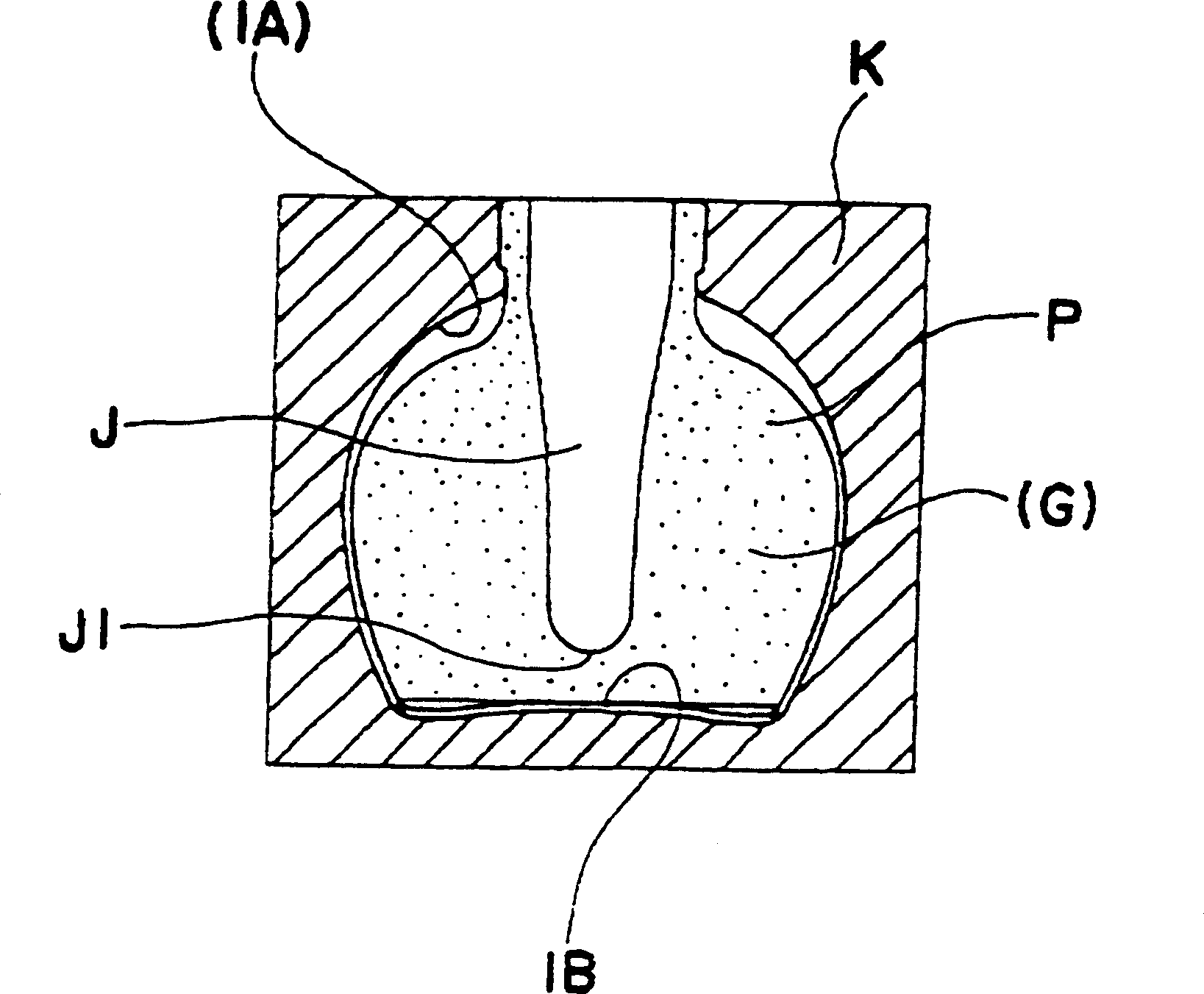

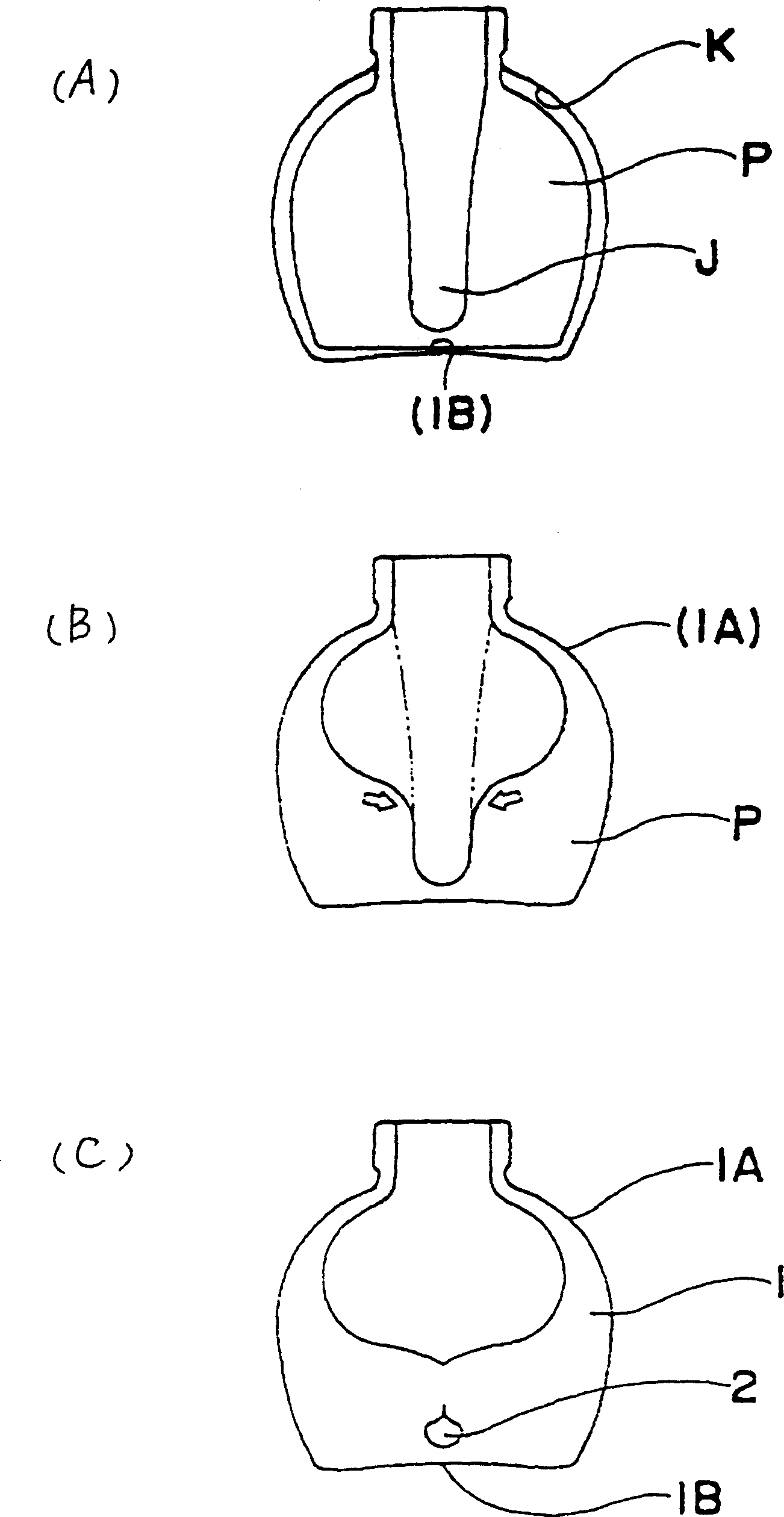

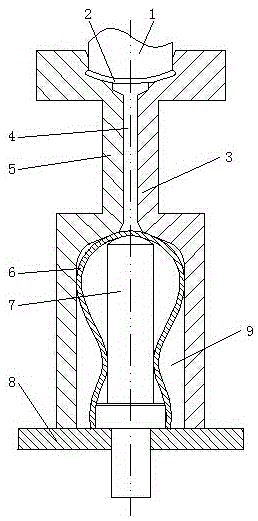

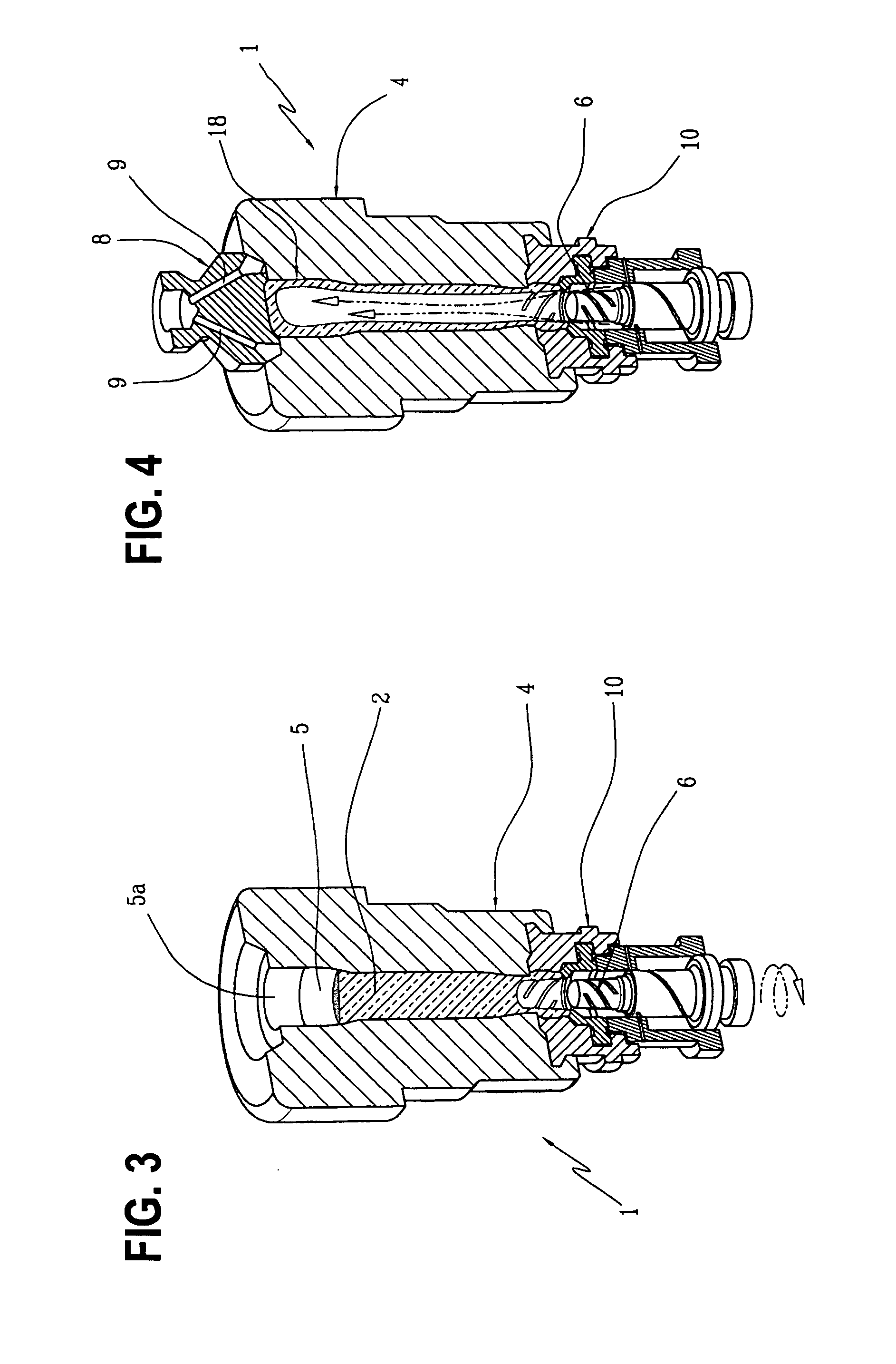

One-press manufacturing method for glass container and glass container

ActiveUS20160083280A1Simple designSuppresses fallingLayered productsBottlesEngineeringMechanical engineering

There are provided a one-press manufacturing method for a glass container that can form uneven shapes on an inner peripheral surface of a glass container and a glass container that is obtained by the one-press manufacturing method.The one-press manufacturing method for a glass container includes the following steps (A) to (E);(A) a step of putting a gob in a pressing mold and then inserting a plunger, which includes an unevenness forming member provided so as to be capable of being received in the plunger, into the gob while the unevenness forming member is received in the plunger,(B) a step of forming a glass container having a finished shape, which includes an uneven shape on an inner peripheral surface thereof, by pressing the unevenness forming member against the surface of the gob, which comes into contact with the unevenness forming member, to the outside from the inside of the plunger,(C) a step of receiving the unevenness forming member in the plunger,(D) a step of extracting the plunger, in which the unevenness forming member is received, from the glass container having a finished shape that includes the uneven shape on the inner peripheral surface thereof, and(E) a step of transporting the glass container having a finished shape, which includes the uneven shape on the inner peripheral surface thereof, to a cooling mold and cooling the glass container having a finished shape.

Owner:KOA GLASS CO LTD

Apparatus and method for heat treating glass sheets

InactiveUS20120324950A1Increase valueReduce of dimensional changeCharging furnacePress and blow machinesParticulatesEngineering

Owner:CORNING INC

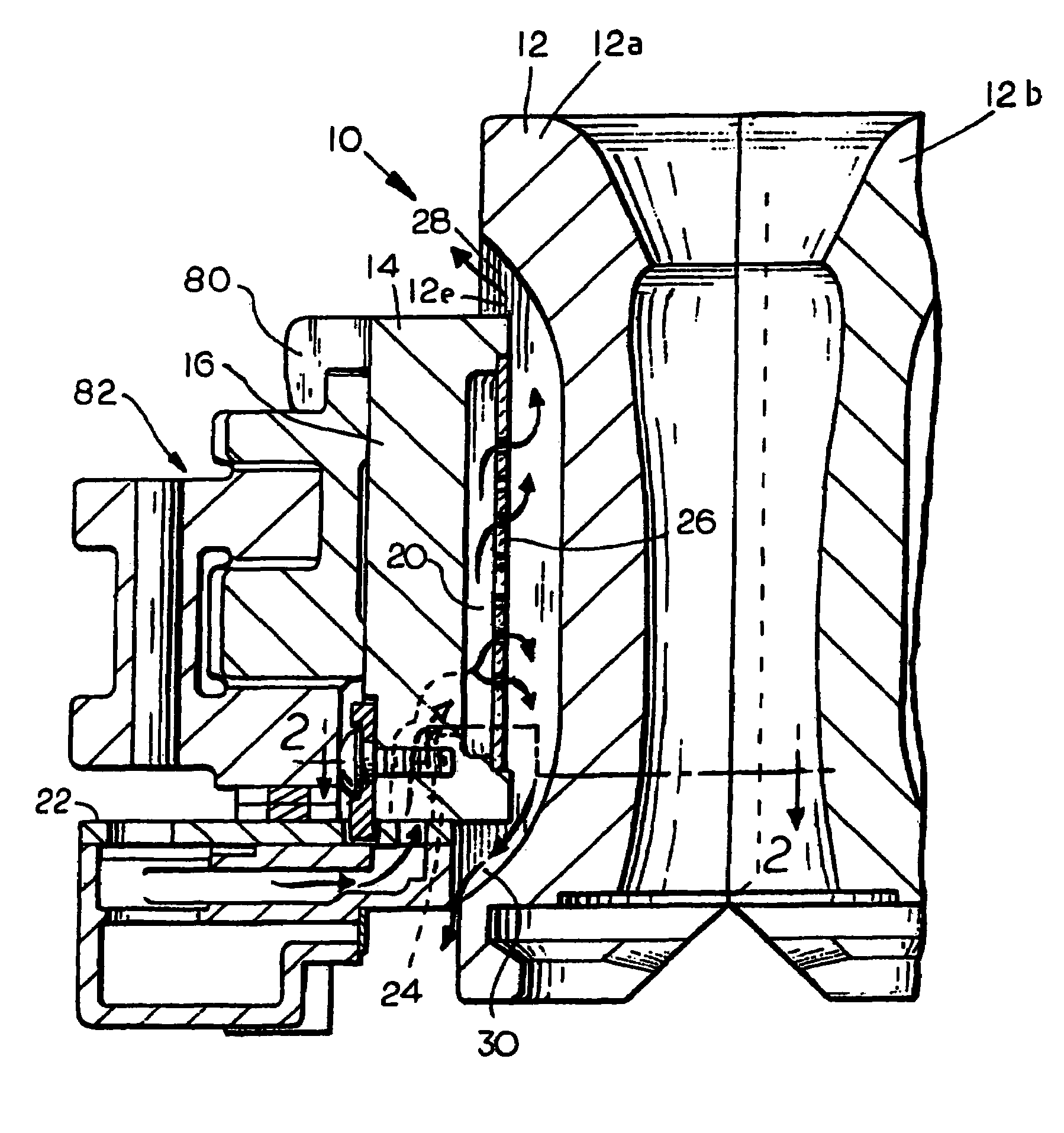

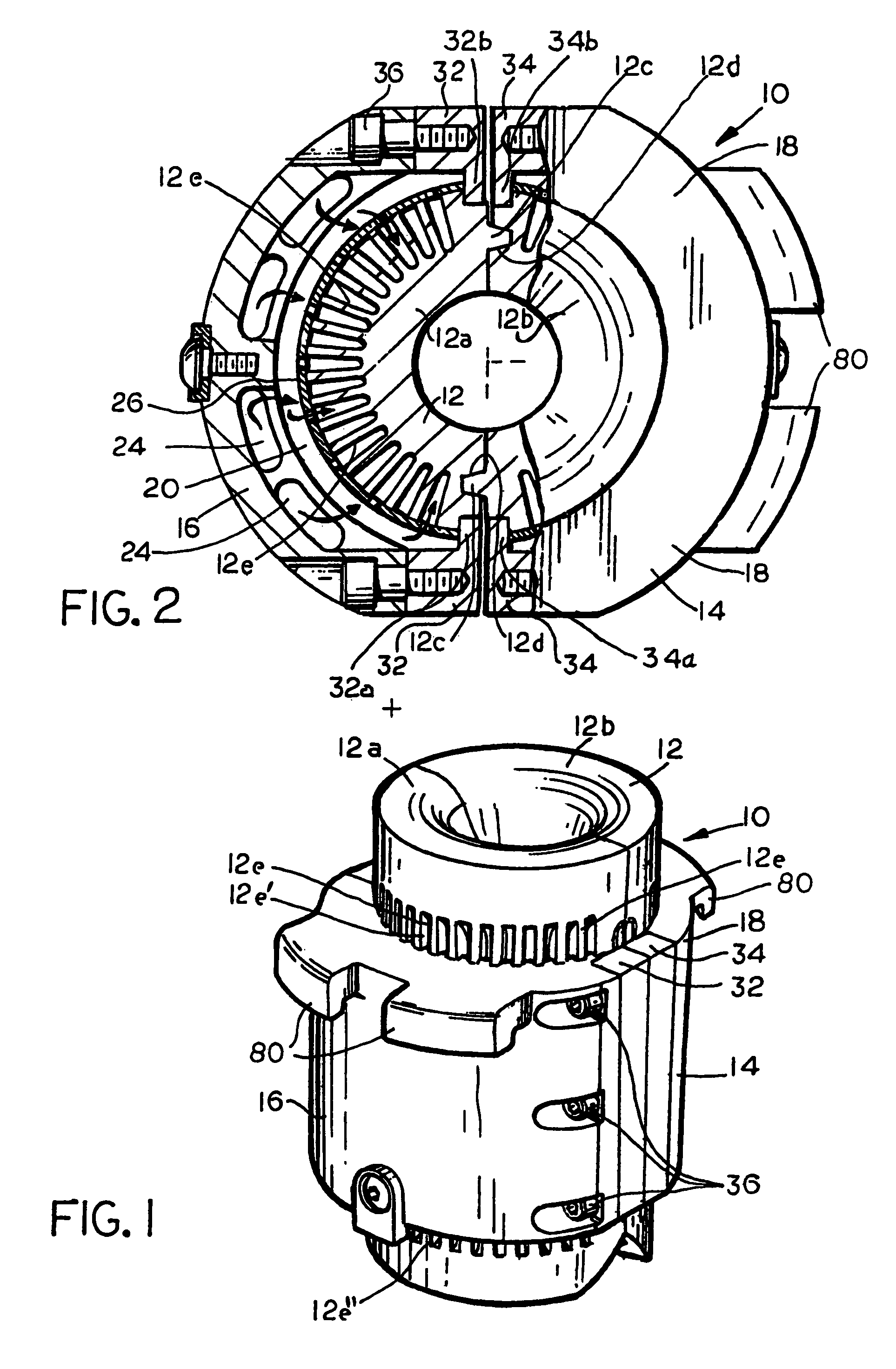

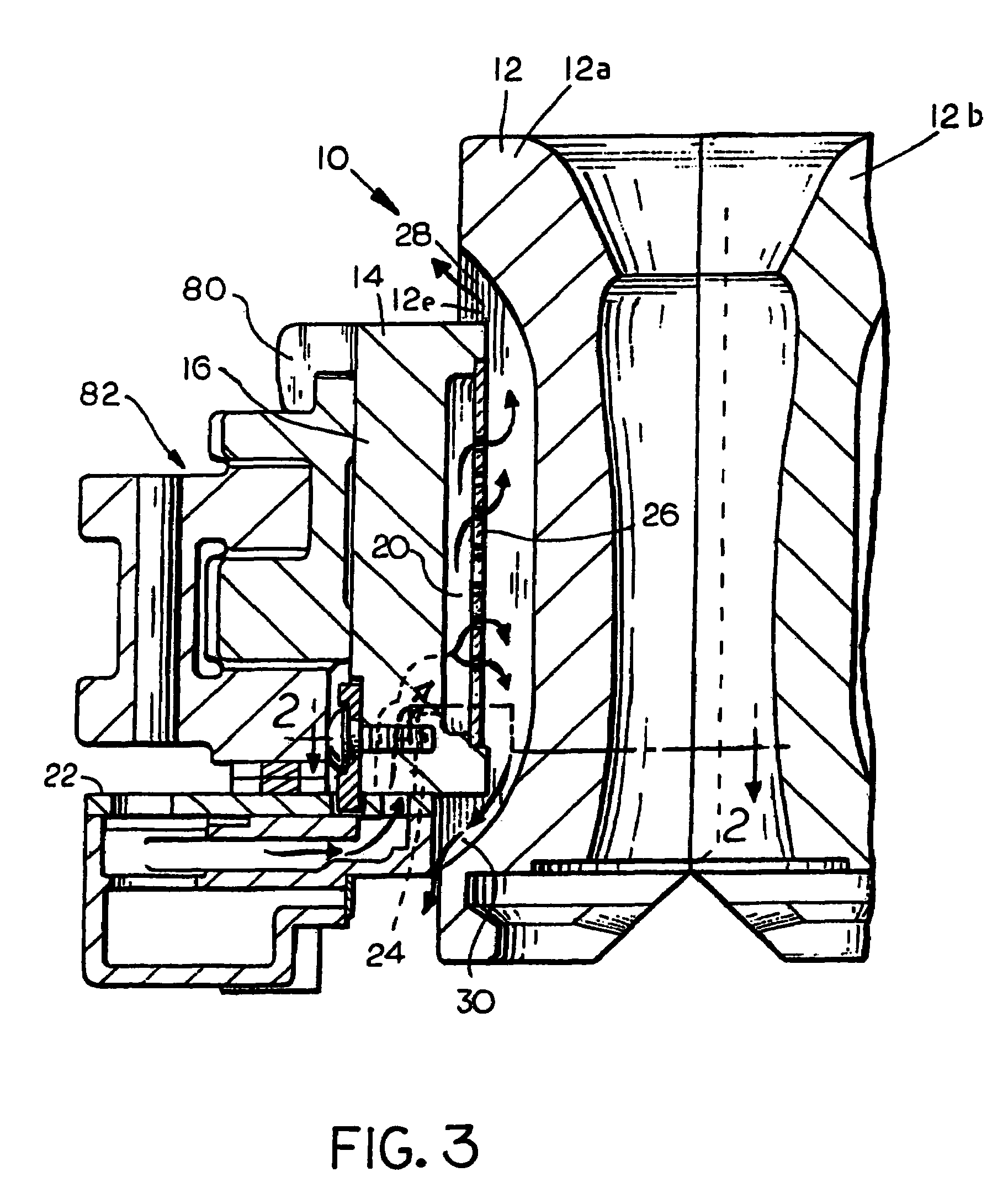

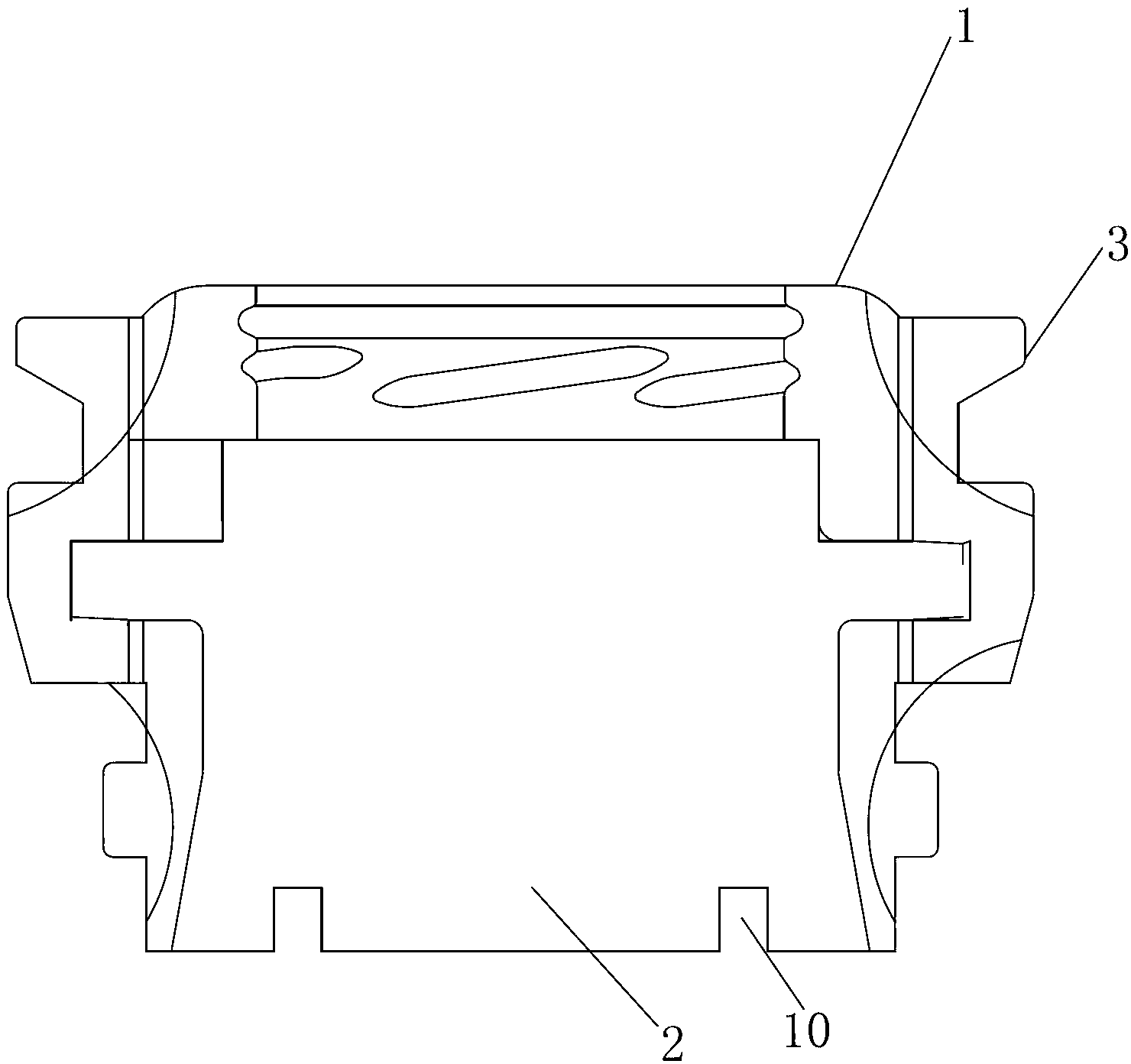

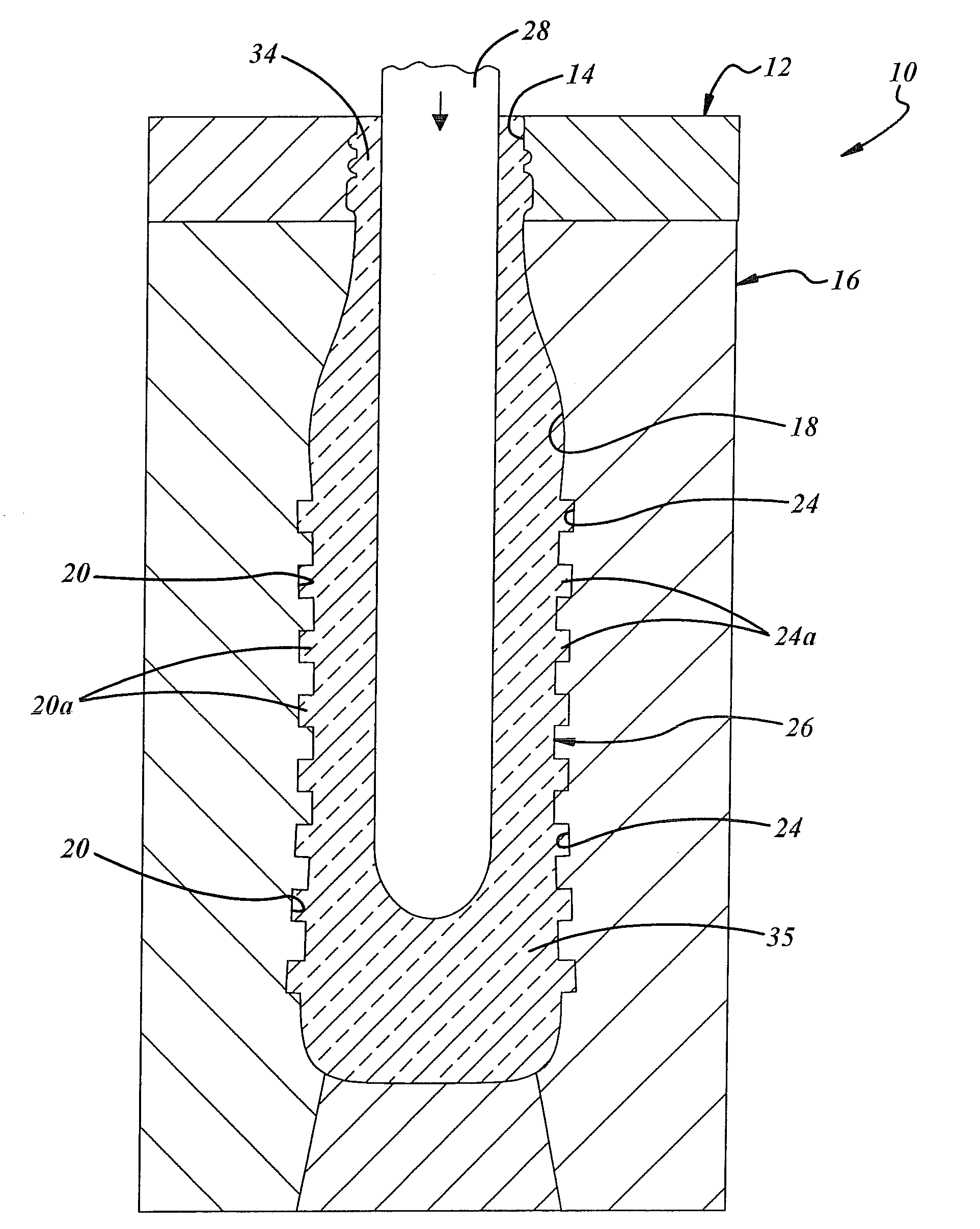

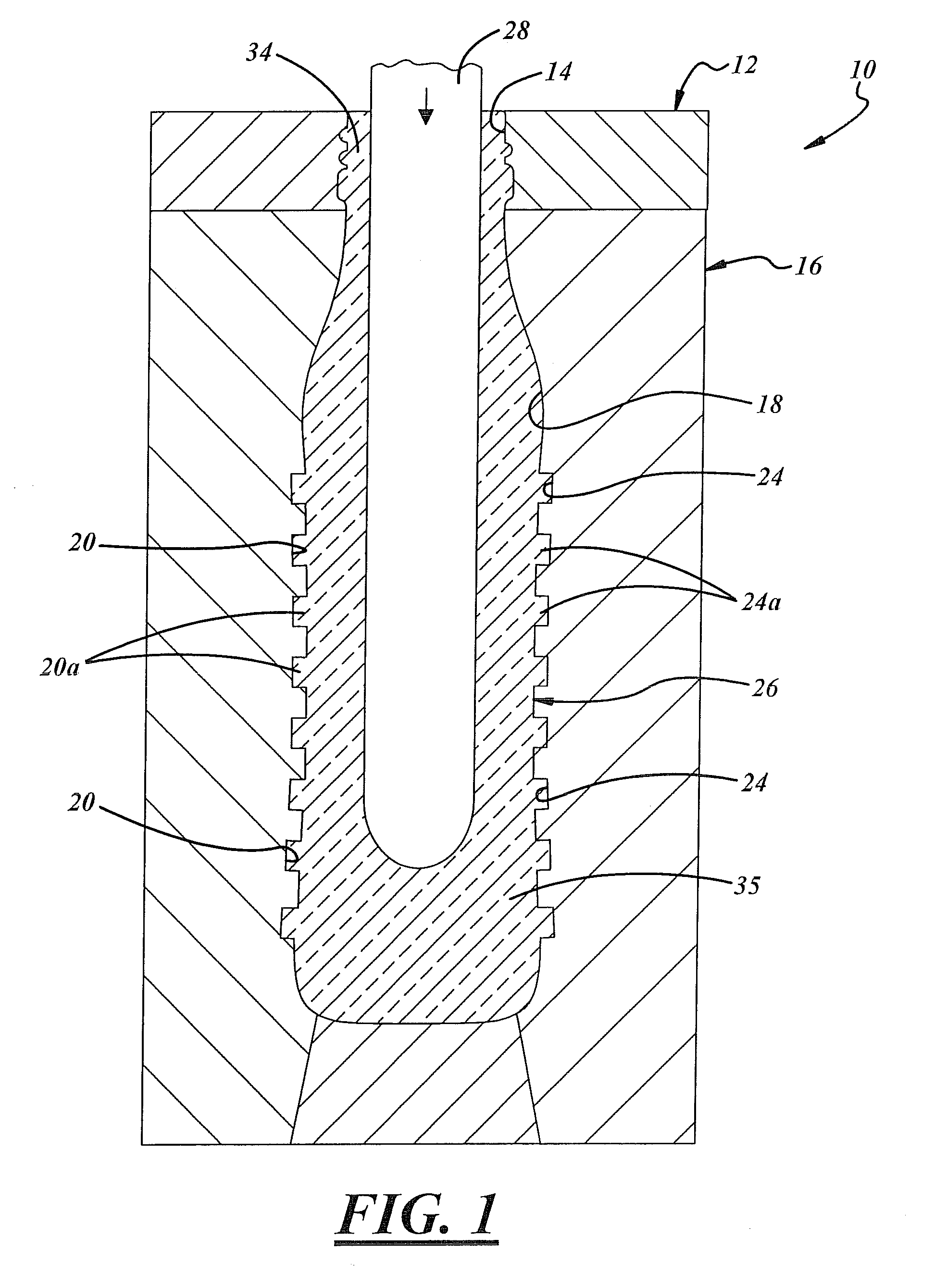

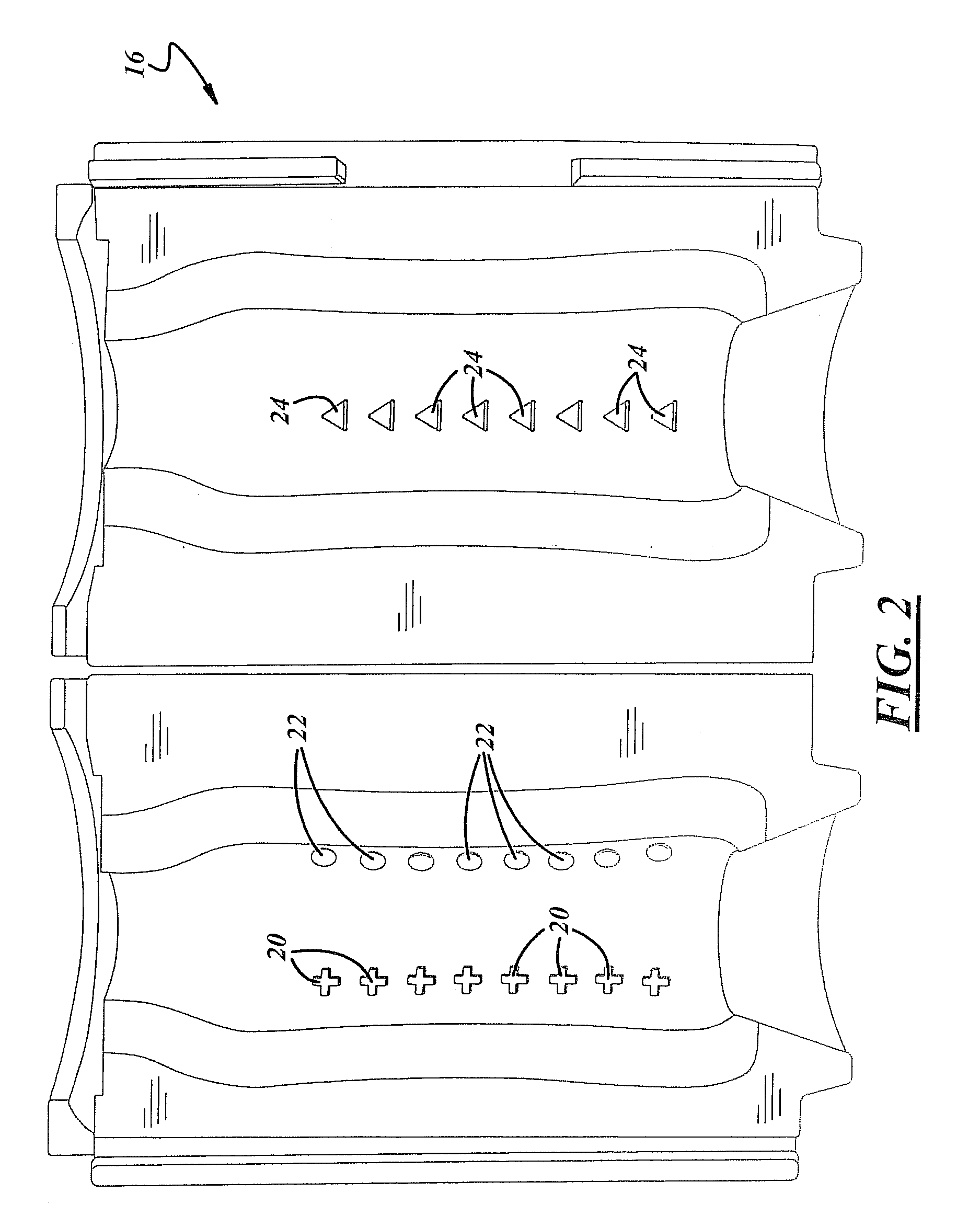

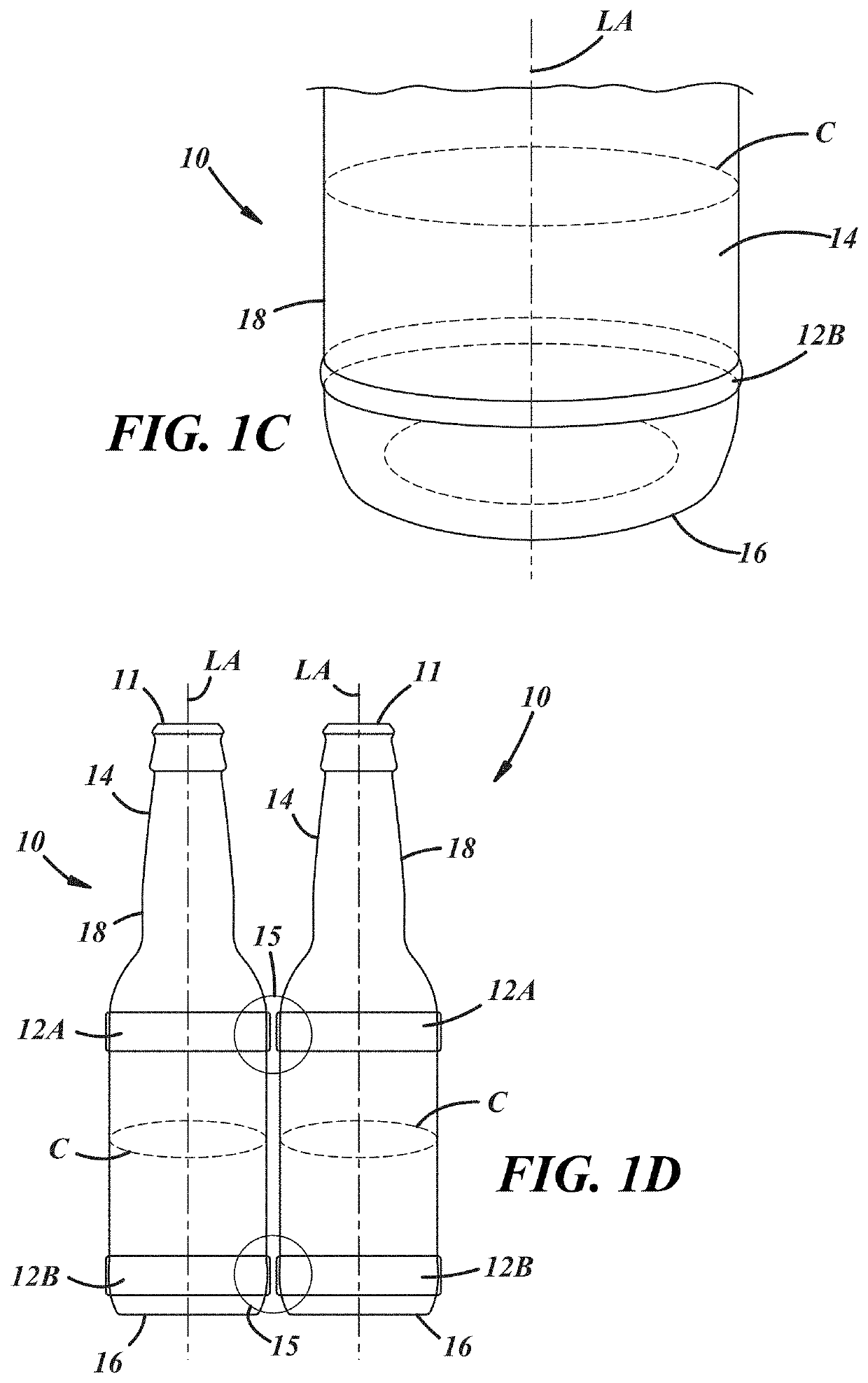

Mold assembly for glass articles

InactiveUS7698907B1Increase ratingsReduce manufacturing costGlass drawing apparatusGlass transportation apparatusMaterials scienceAxial length

A mold assembly (10; 40) for molding a hollow glass article comprising a mold (12) that is made up of a separable pair of mold elements (12a, 12b; 42) and a mold holder (14; 44) that surrounds a portion of the mold of substantial axial length. The mold is separable from the mold holder, and the exterior of each mold segment is provided with a plurality of cooling fins (12e; 42e). The mold holder is made up of a separable pair of mold holder sections (16, 18; 46), and each mold holder section has a fluid flow passage (20; 50) extending therethrough. The fluid flow passage is radially open to permit fluid flowing therethrough to flow inwardly against the fins of an adjacent mold element. Each mold holder section has a perforated screen (26; 56) affixed thereto to vary the distribution of the flow of fluid from the mold holder section against the fins of the adjacent mold element.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

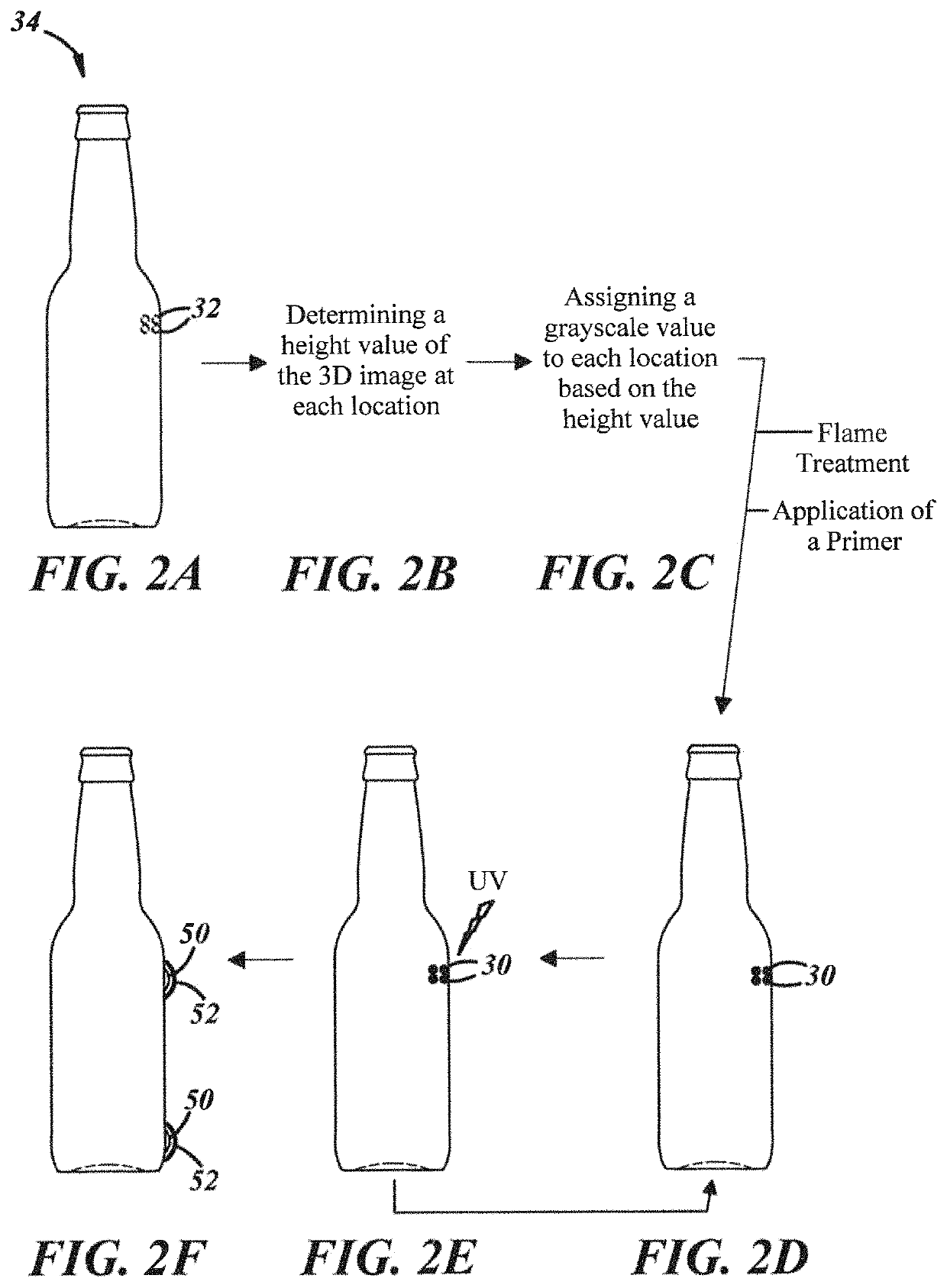

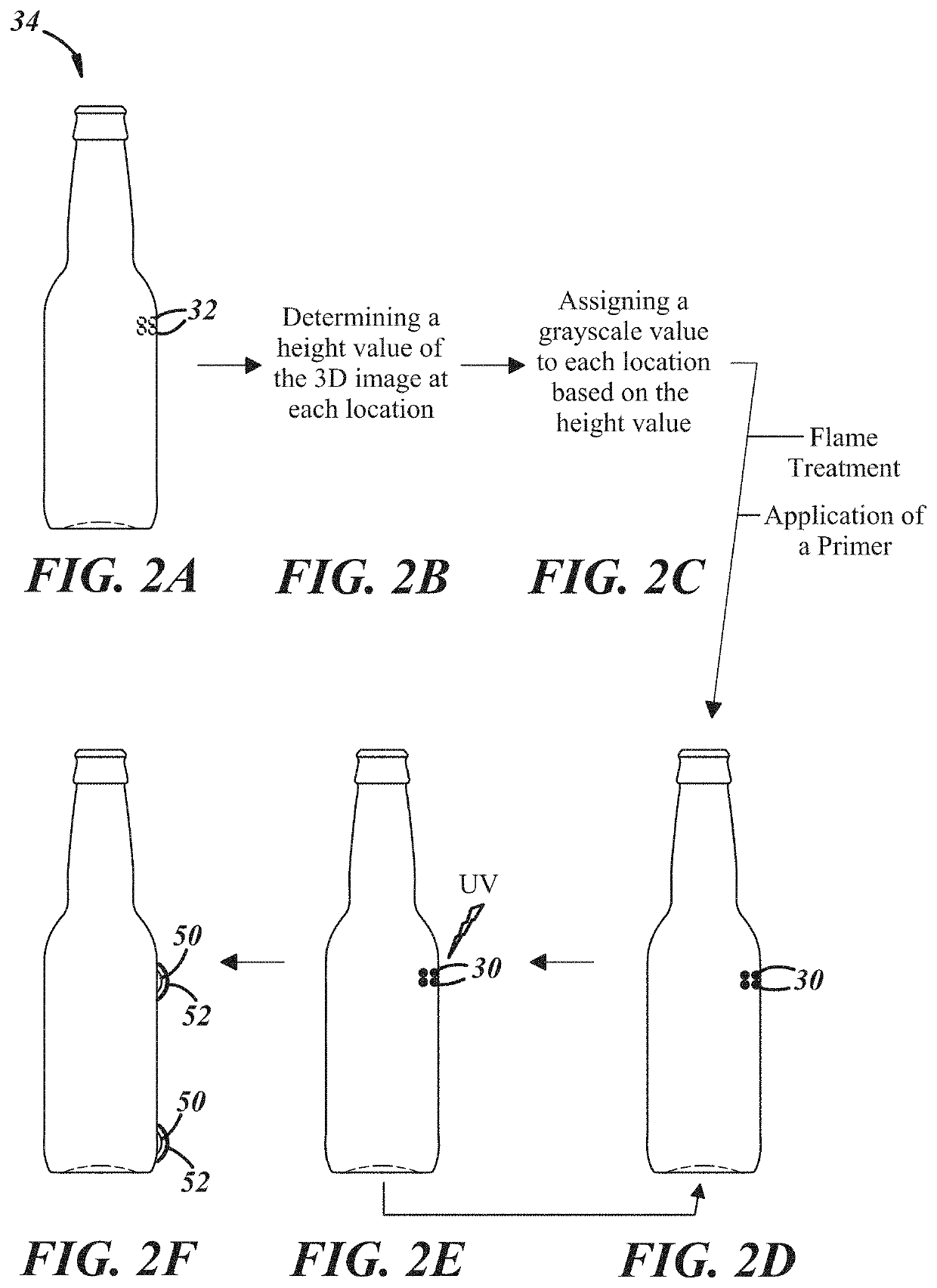

Three-dimensional printing on glass containers

This disclosure describes substrate(s) formed with a three-dimensional (3D) feature thereon, and method(s) of printing the same. One method includes identifying a plurality of locations on a substrate surface where the three-dimensional feature will be formed, determining a height value of the three-dimensional feature at each location, assigning a grayscale value to each location based on the height value, and applying ink to the substrate surface at each location according to the assigned grayscale value.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

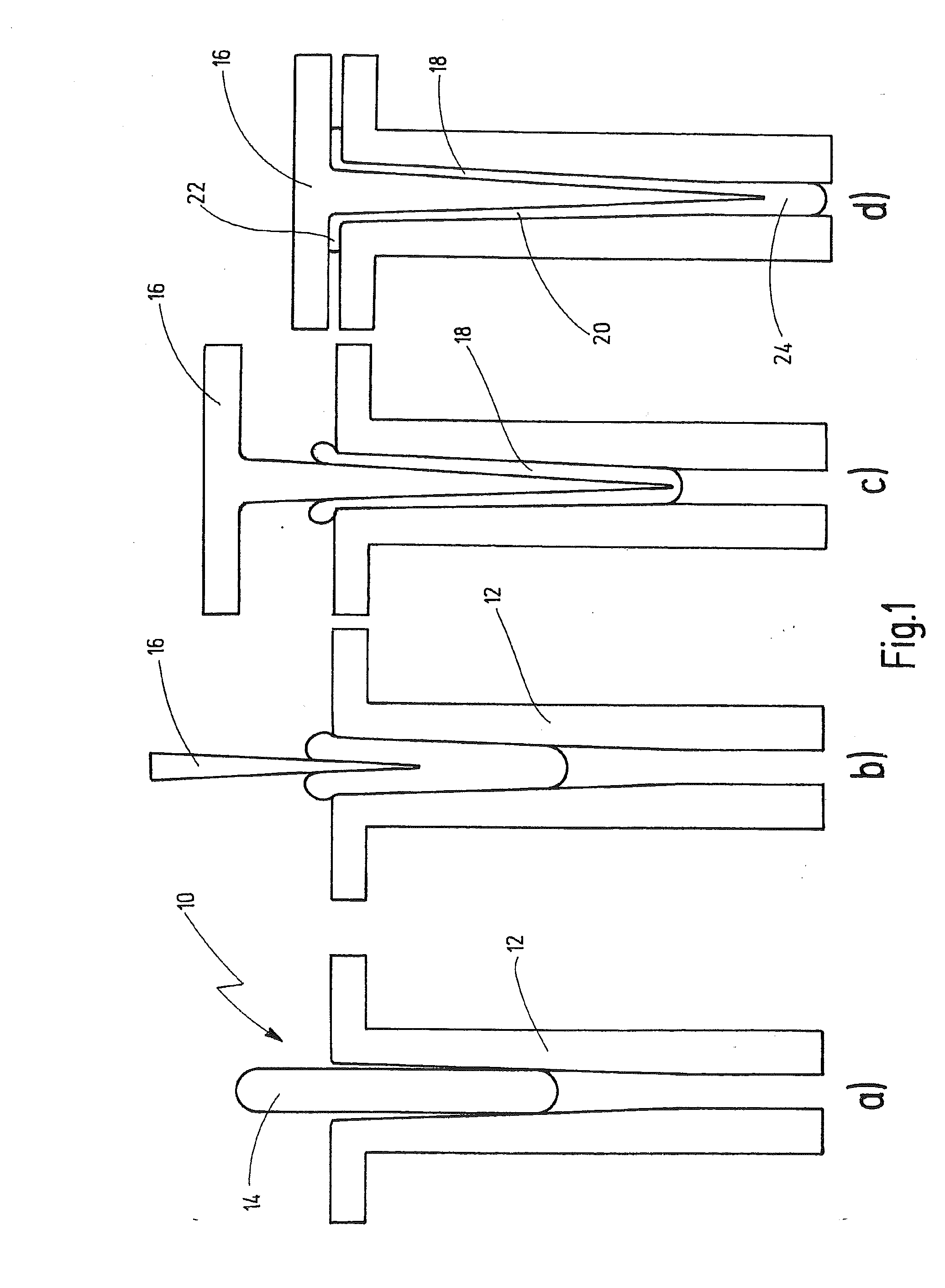

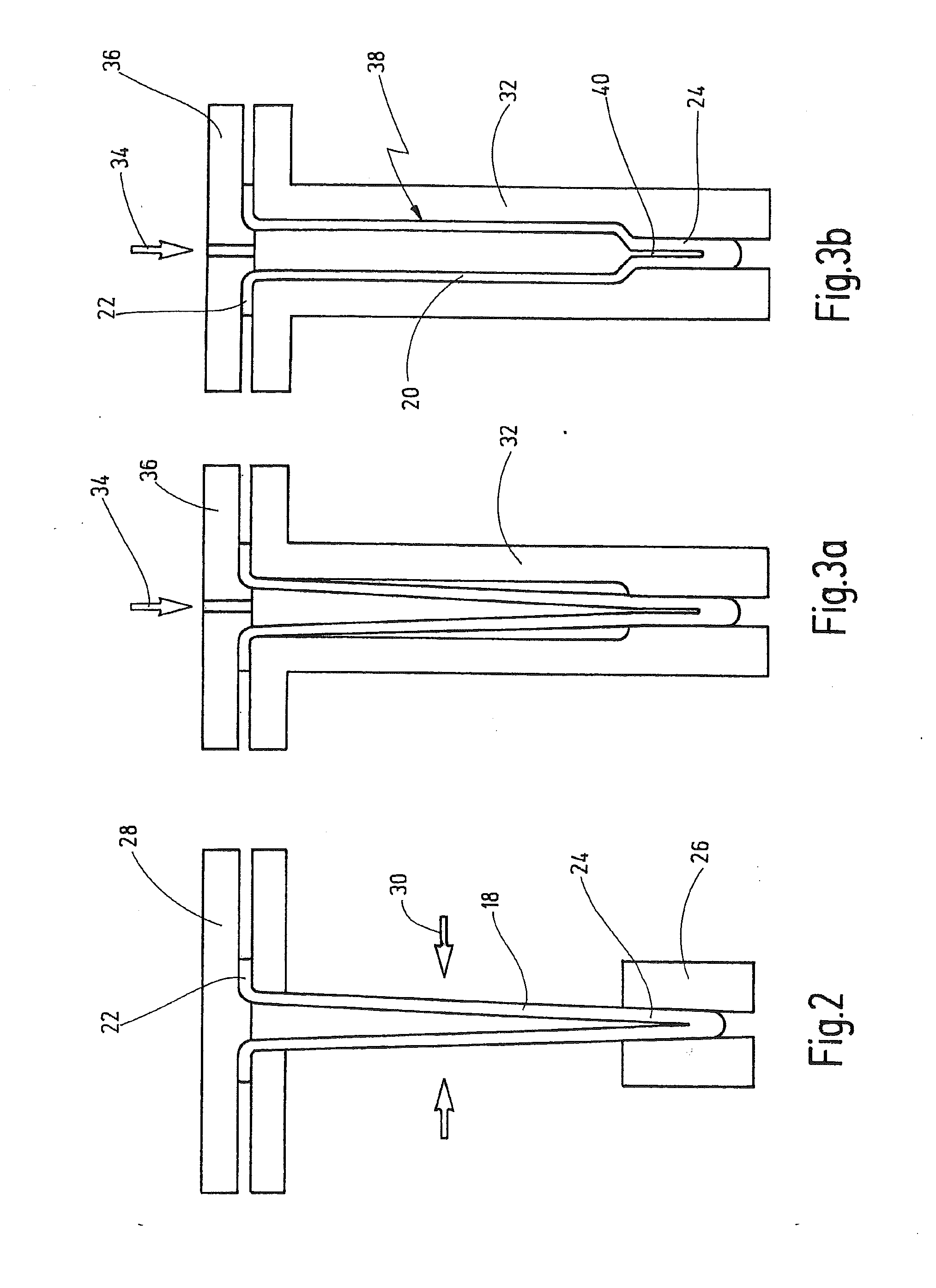

Process and device for manufacturing a hollow glass body

InactiveUS20150135773A1Not to damageBlowing machine gearingsGlass drawing apparatusGuide tubeHollow core

A process for manufacturing a hollow glass body by means of an individual section (IS) machine in a press and blow, narrow-neck press and blow, or blow and blow process, with a driving means that moves a plunger axially, to produce selected geometrical contours in a glass gob. The process steps include:aligning and attaching a positioning ring directly, or via intermediate elements, on the IS machine, on which positioning ring a positioning device is provided,aligning a guide tube, on an outer jacket surface on which a guide device is disposed and interacts with the positioning device of the positioning ring in the assembled condition,aligning a plunger with a non-rotationally symmetrical plunger head with a guide device disposed thereon , which interacts with a positioning device provided in the assembled condition on, or in, the inner jacket surface of the guide tube such that the non-rotationally symmetrical outer contour of the plunger head passes through an aperture tool allocated to the IS machine during the press or blow procedure, and the contours of the plunger head and of the aperture tool generate the profile of the inner, or outer, wall of the hollow glass body.

Owner:SAINT-GOBAIN OBERLAND

Preparation method of high-performance glass bottle

PendingCN110316964AGood chemical stabilityHigh strengthPress and blow machinesBlow machinesHeating timeDrying time

The invention relates to the technical field of glass bottles, in particular to a preparation method of a high-performance glass bottle. The method can effectively remove internal stress of the glassbottle, so that the glass bottle has good strength and impact resistance and is not easy to break. The method includes the steps of S1, raw material preparation; S2, raw material crushing; S3, drying,wherein crushed raw materials are dried, the moisture content is reduced, the drying temperature is 100-120 DEG C, the drying time is 2-3 hours, and the raw materials need to be continuously stirredin the drying process; S4, raw material mixing and stirring, wherein all the raw materials are added into a mixing device for stirring and mixing, so that the raw materials are uniformly mixed and stirred, the stirring rotation speed is 250-260 r / min; S5, melting, wherein the mixed raw materials are conveyed into a smelting furnace for heating, the heating temperature is 1550-1600 DEG C, and heating time is 9-11 hours; S6, molding of the glass bottle; S7, cooling; S8, annealing, wherein the annealing temperature is 380-600 DEG C, and the annealing time is 180-220 minutes; S9, cooling; S10, inspecting and packaging.

Owner:CANGZHOU XINGCHEN GLASS PROD

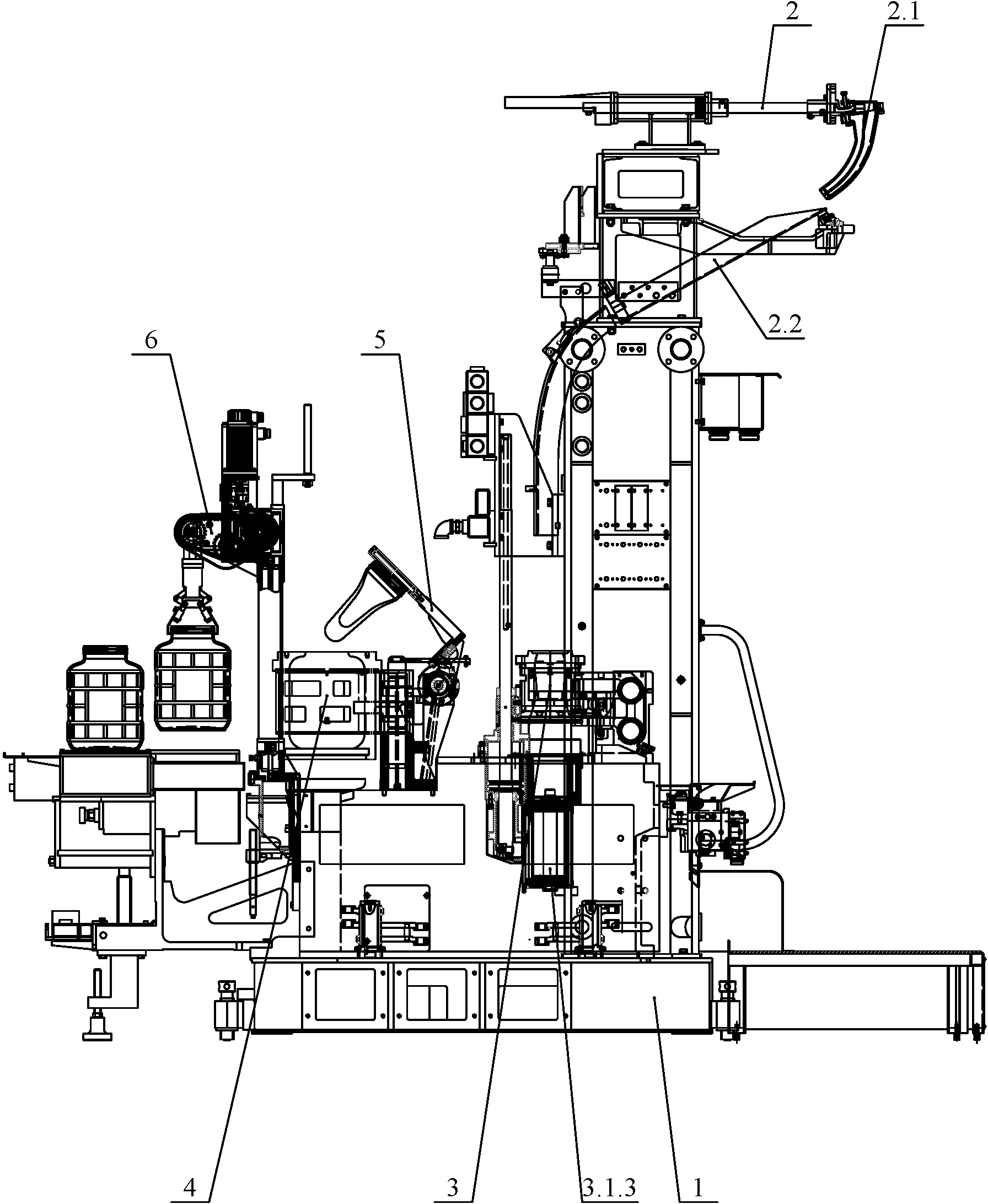

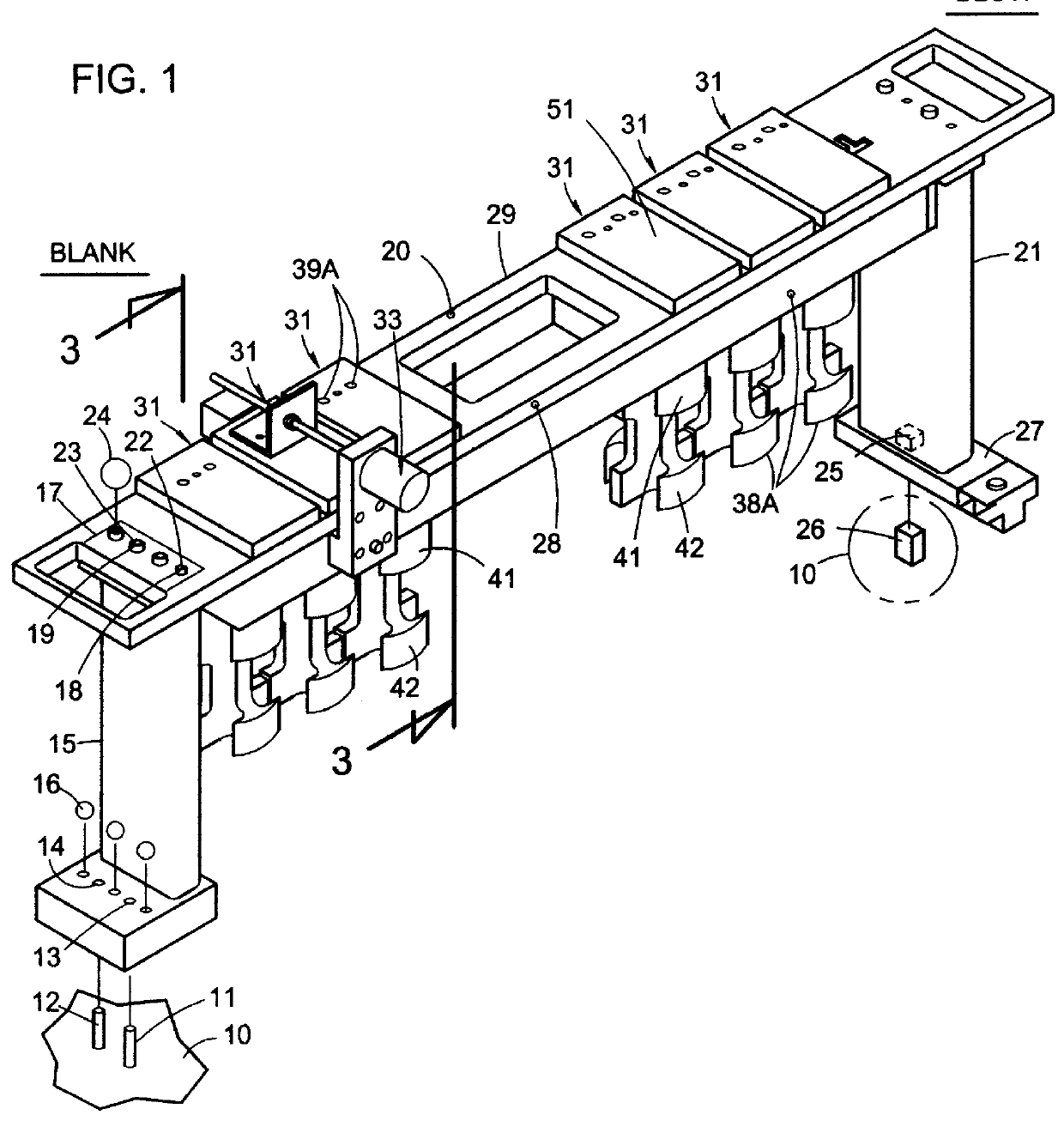

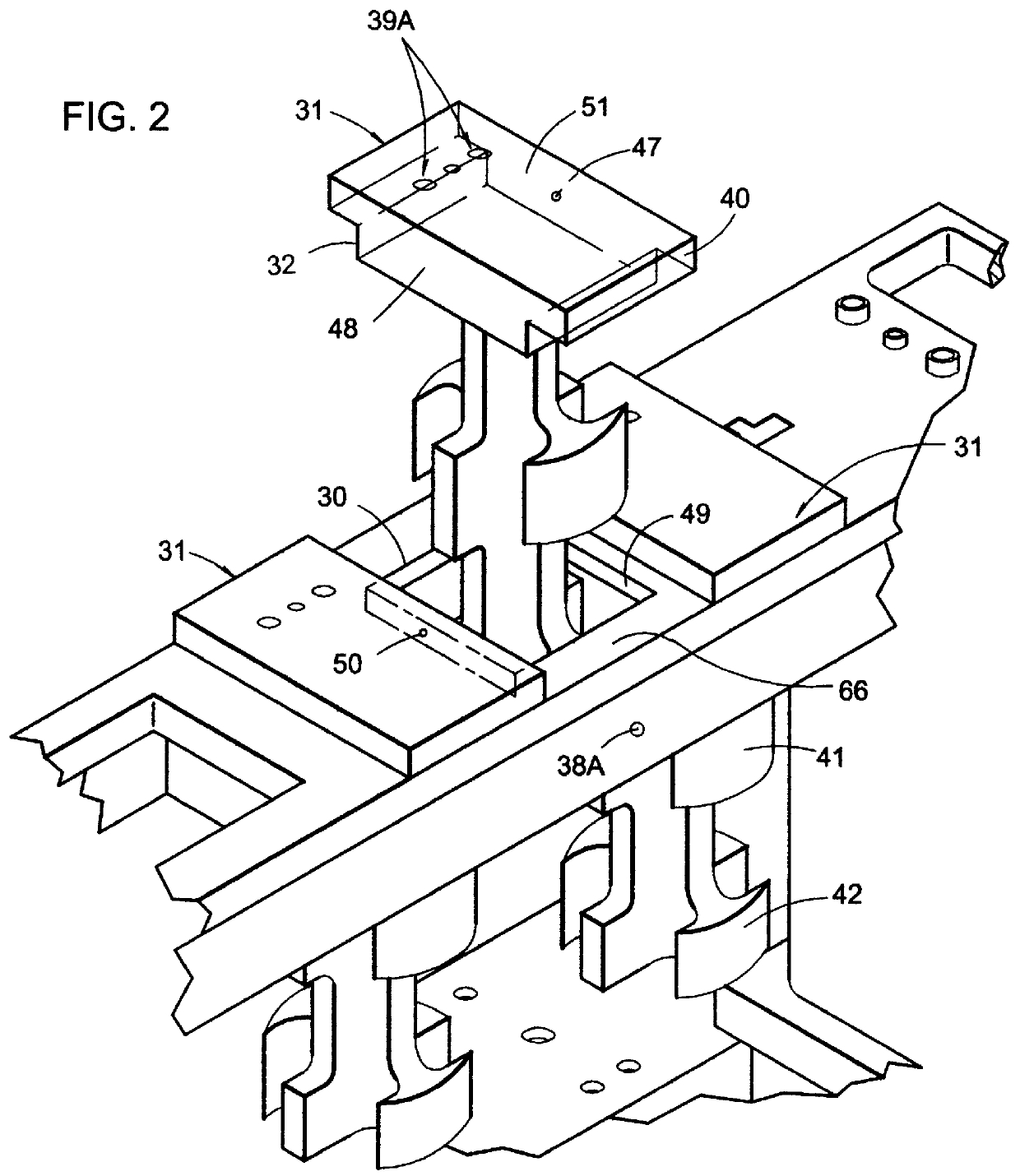

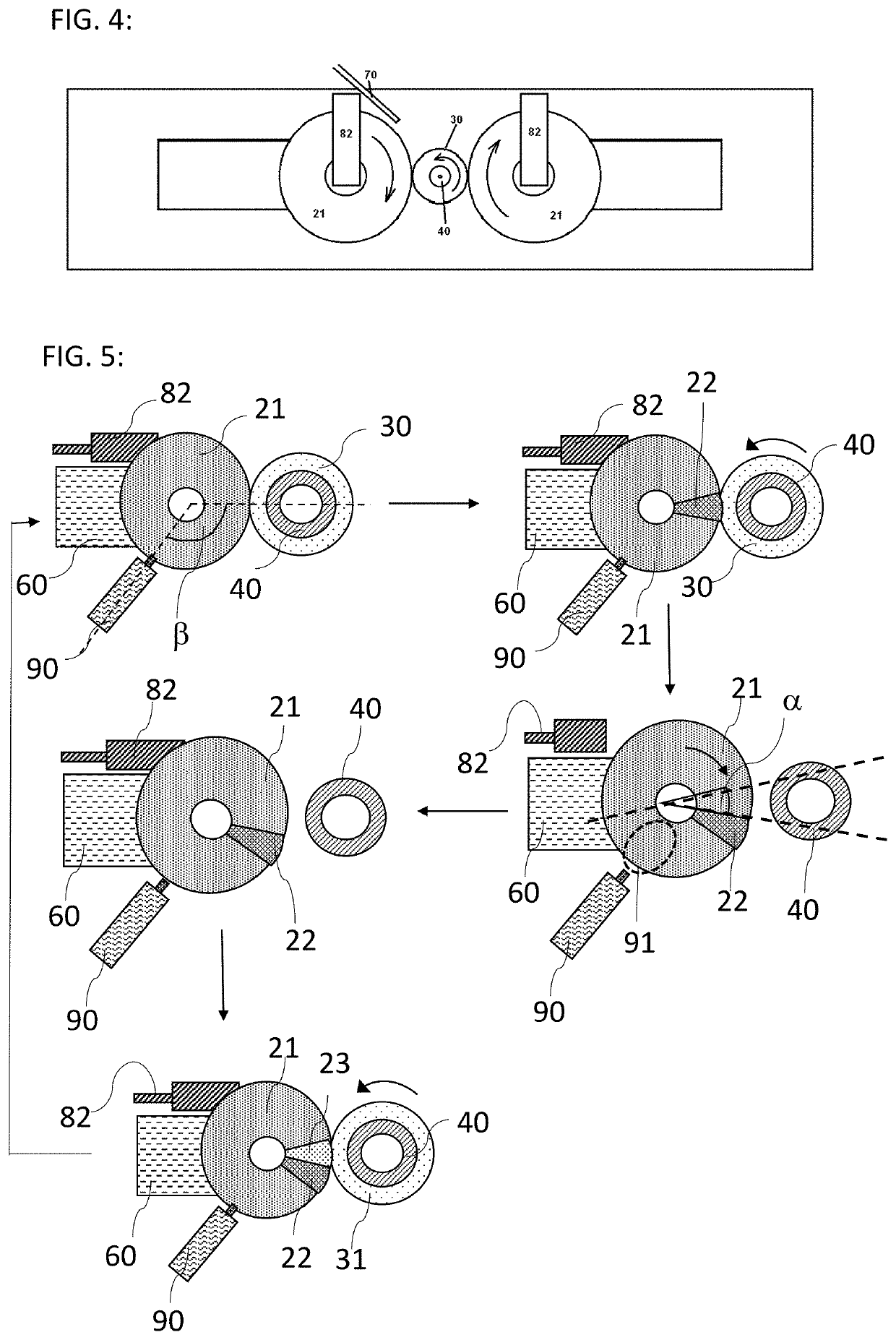

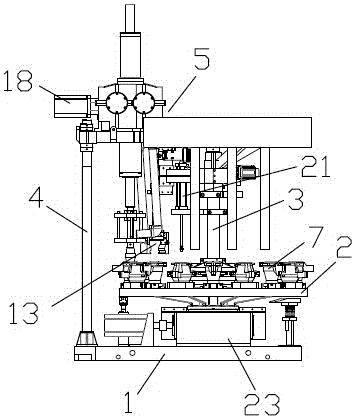

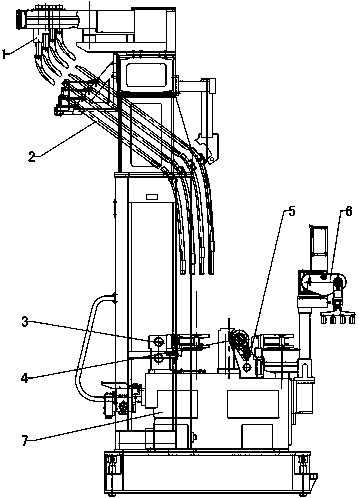

Bottle-making machine and production process for manufacturing extra-large glass bottles

ActiveCN104108856ARealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesEngineeringBottle

The invention relates to a bottle-making machine and a production process for manufacturing extra-large glass bottles, and belongs to the field of bottle-making machine equipment. The bottle-making machine comprises a rack, and a primary mold forming mechanism, a formed mold forming mechanism and a turnover mechanism which are arranged on the rack, wherein the primary mold forming mechanism comprises a stamping device, a primary mold and a parallel switching mechanism; the stamping device is mounted on the rack; the parallel switching mechanism comprises a horizontal guide shaft mounted on the rack, a clamp arm which sleeves on the horizontal guide shaft, and a first spline shaft, a first rocker arm, a first connecting rod and a first switching cylinder which vertically sleeve at two sides of the rack; one end of the first connecting rod is hinged with the clamp arm while the other end of the first connecting rod is hinged with the first rocker arm; the first rocker arm is connected with the first switching cylinder through the first spline shaft; the primary mold is mounted on the clamp arm. The bottle-making machine has the beneficial effects that the extra-large glass bottles are produced in a manner of automatic mechanized production for replacing manual production, so that the yield of the extra-large glass bottles is increased and the quality of the extra-large glass bottles is improved.

Owner:SHANDONG JIAFENG GLASS MACHINERY

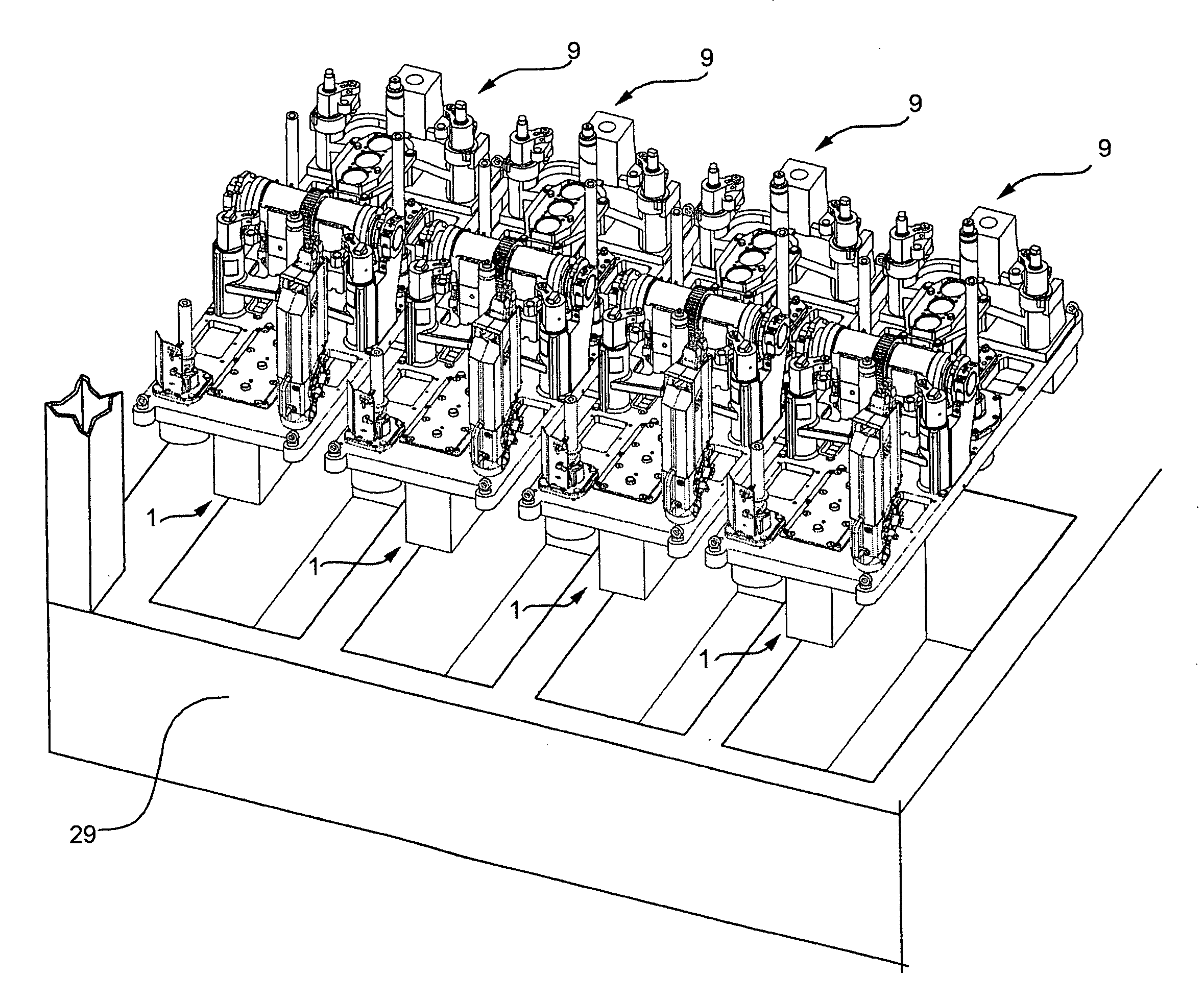

I.S. machine

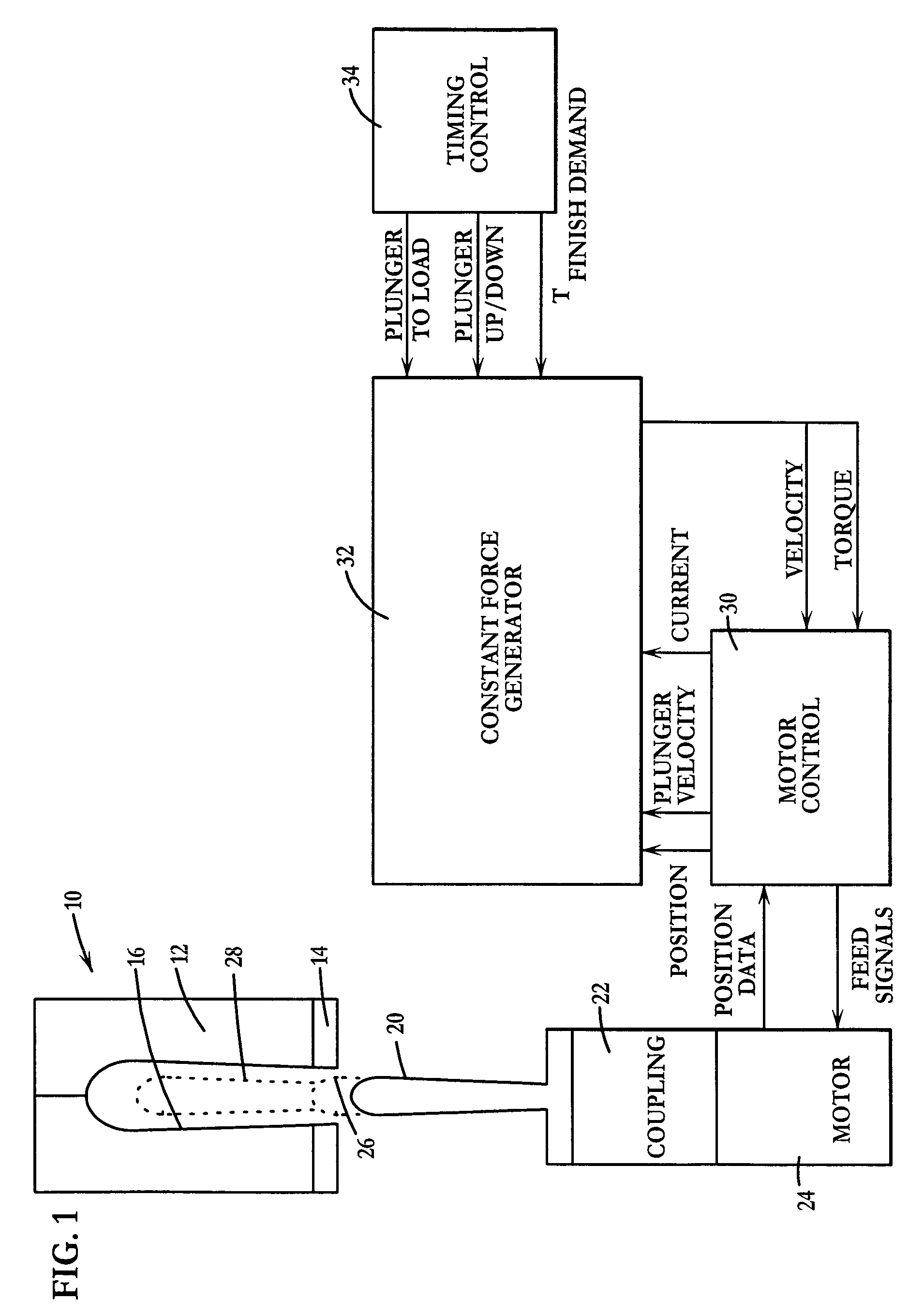

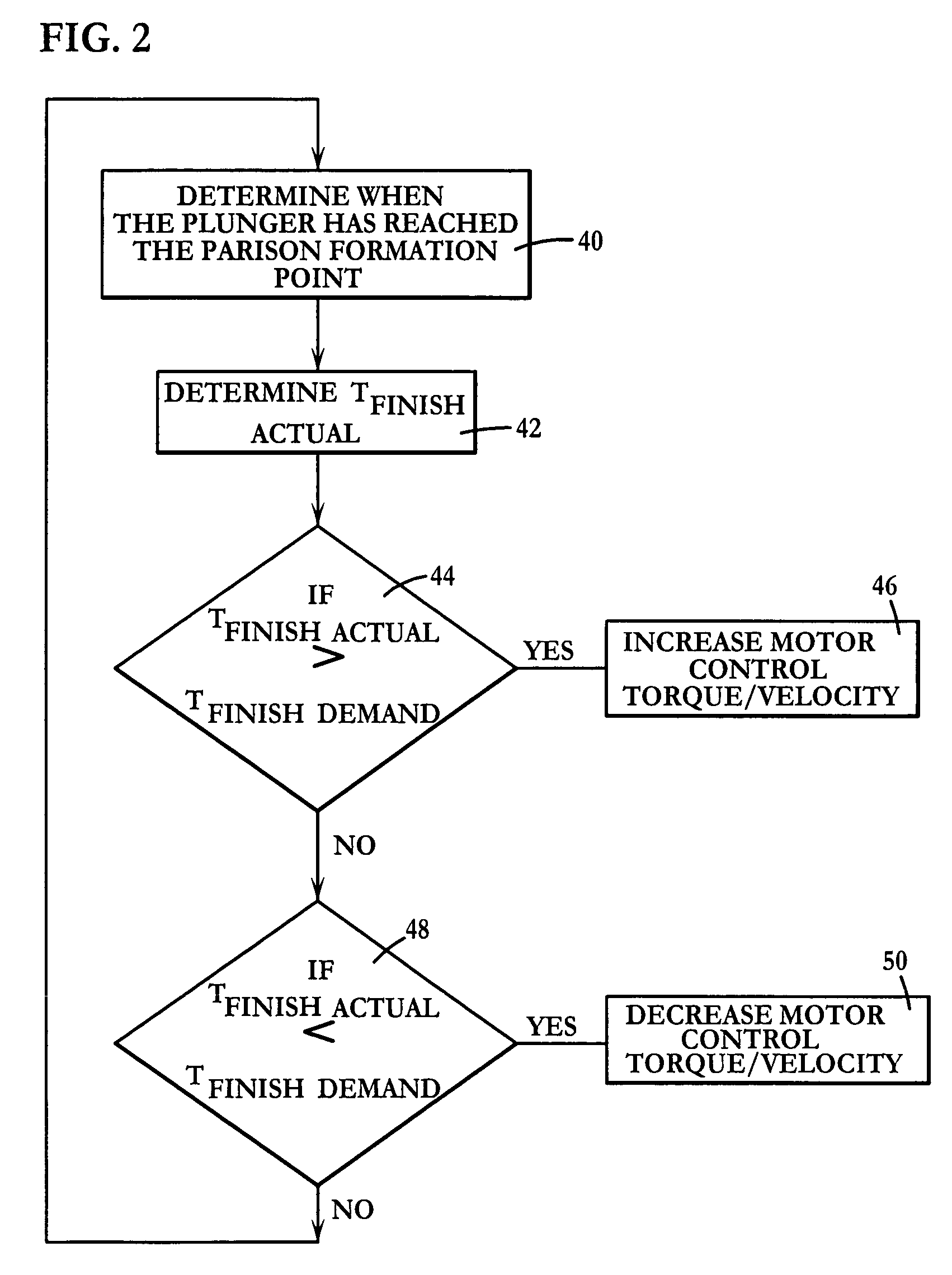

An I.S. Machine is disclosed which includes a structure displaceable from a start location to an end location and a motor for displacing that structure. A control controls the operation of the motor to displace the structure and the speed of displacement can be varied by changing inputs to the control. A fixed period of time from a datum to the ideal time when the structure will be displaced to its end location is set and compared with an actual period and a selected input to the control is provided for changing the speed of the structure to reduce the difference.

Owner:EMHART GLASS SA

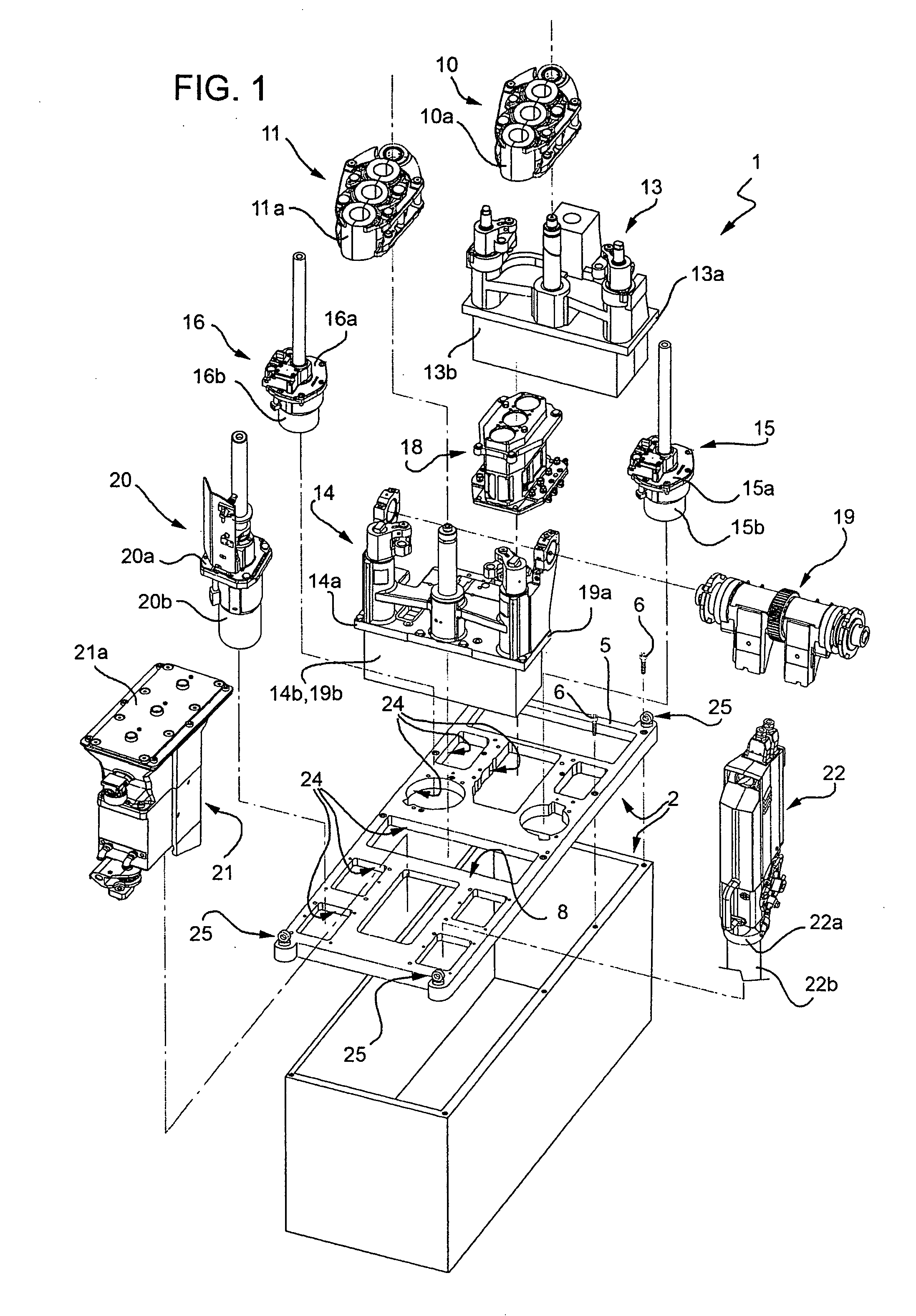

Forming section of a hollow glass items production machine and relevant support structure

InactiveUS20100018255A1Straightforward and low-costGlass pressing apparatusPress and blow machinesPunchingEngineering

In a machine for forming glass items, a forming section has a forming assembly, and a bottom support structure for supporting the forming assembly. The forming section has a rough mold; a finish mold; a transfer assembly for transferring at least one glass mass being formed from the rough mold to the finish mold; an extractor for extracting at least one glass item from the finish mold; a glass mass guide device, a mold closing device, and a punching device associated with the rough mold. The forming section also has and a pneumatic blower device and a cooling device associated with at least the finish mold The bottom support structure has a bottom hollow frame, and at least one top plate separate from the bottom frame and on which the whole forming assembly rests and is connected.

Owner:BOTTERO SPA

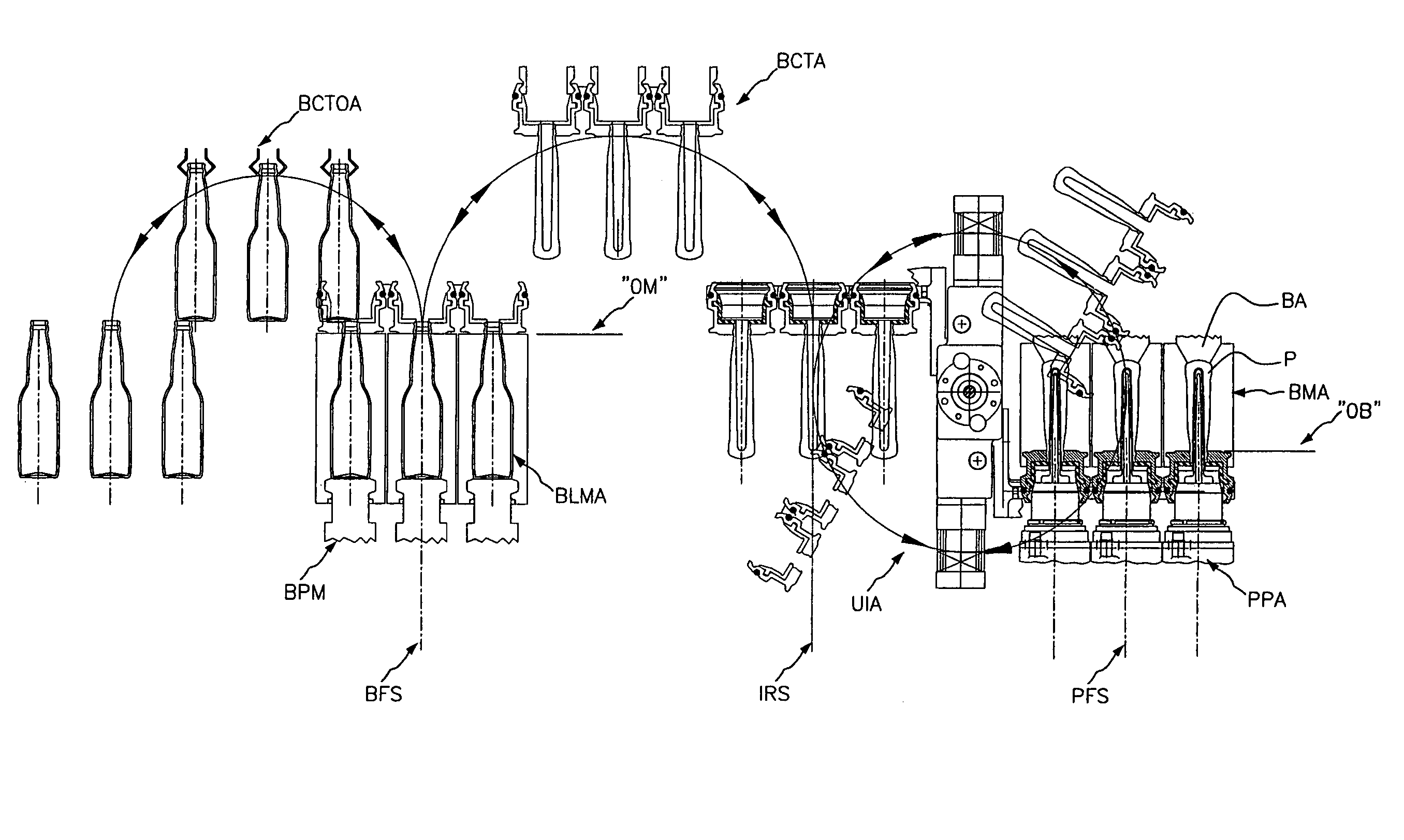

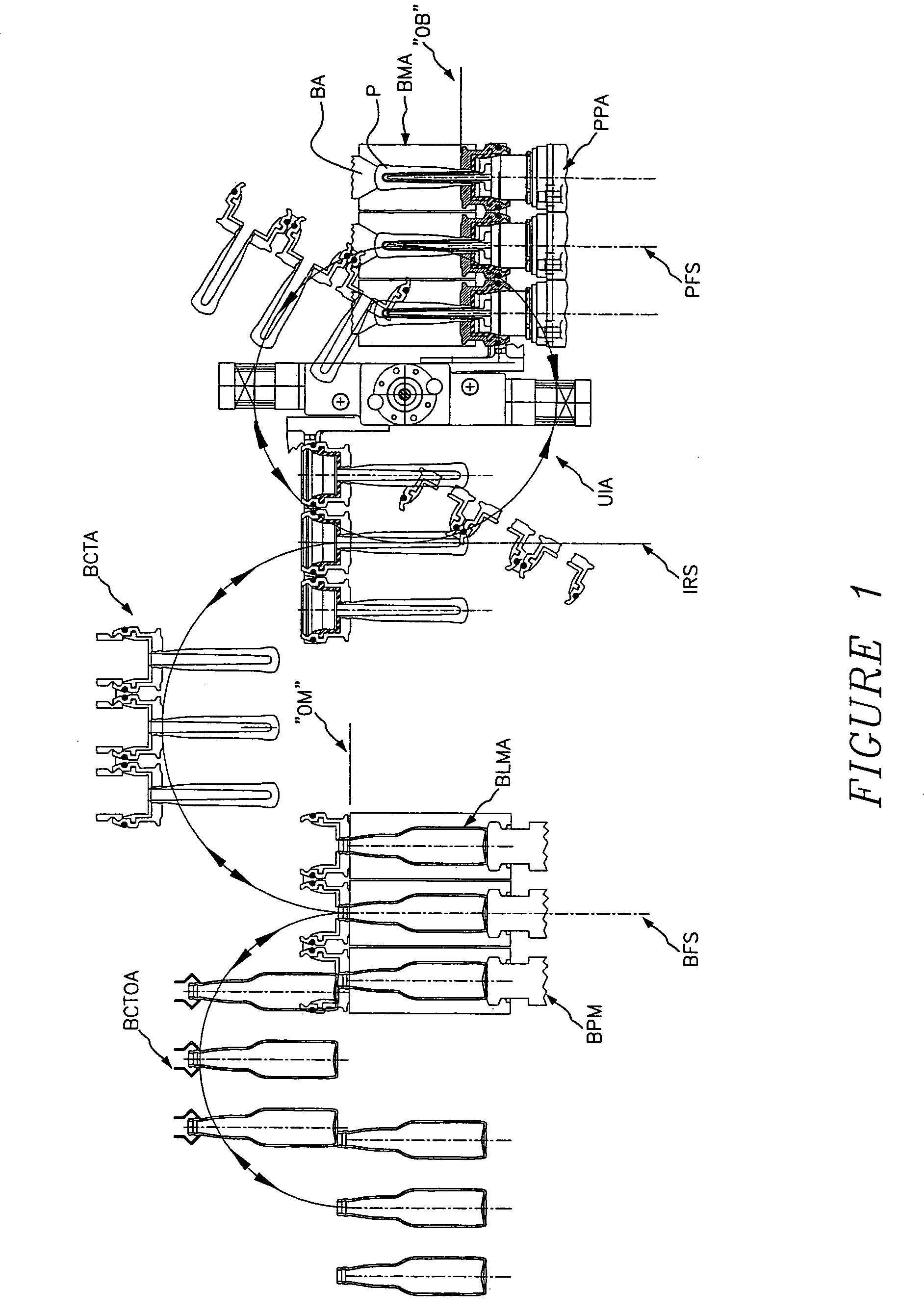

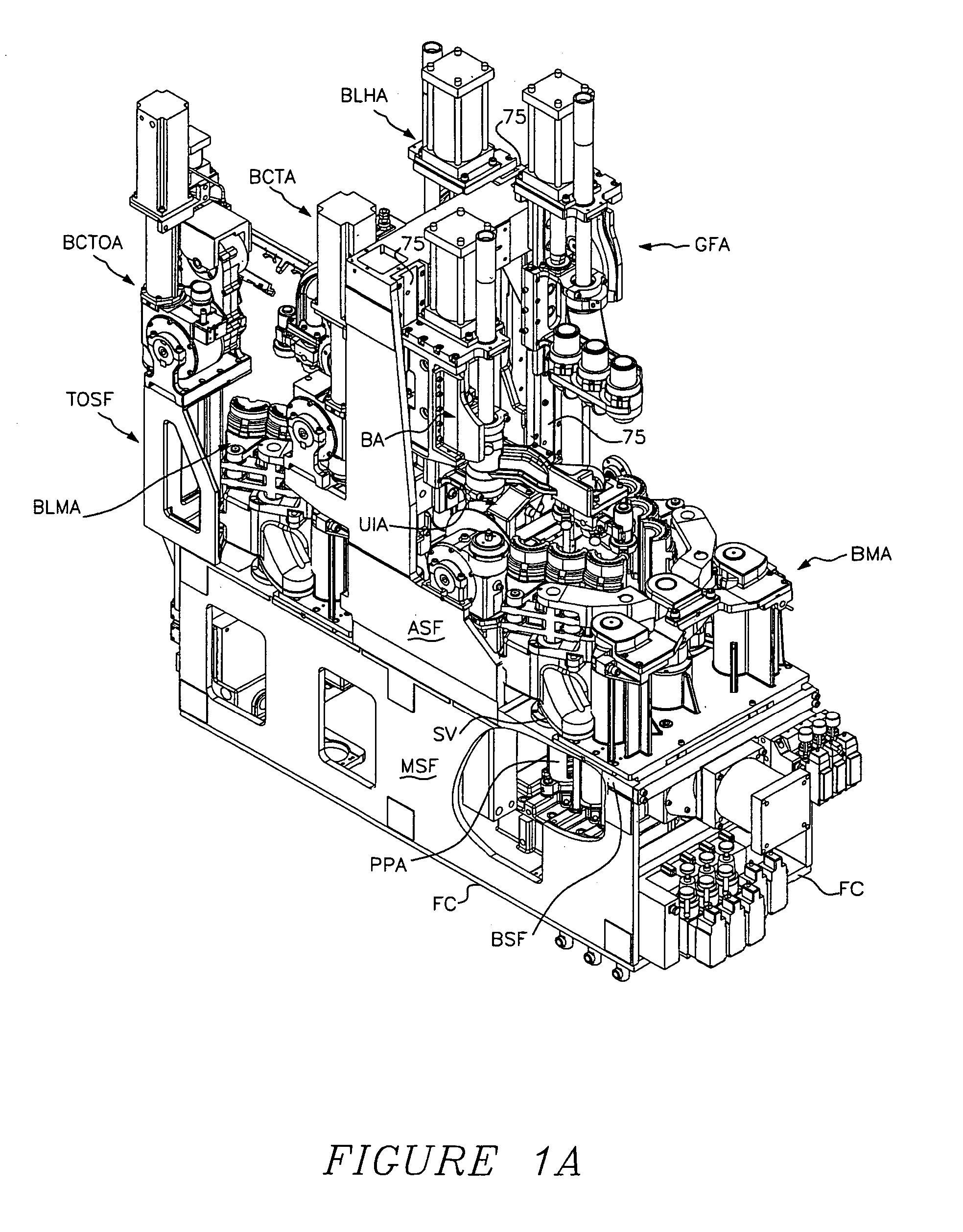

Method and a machine for the production of hollow glassware articles

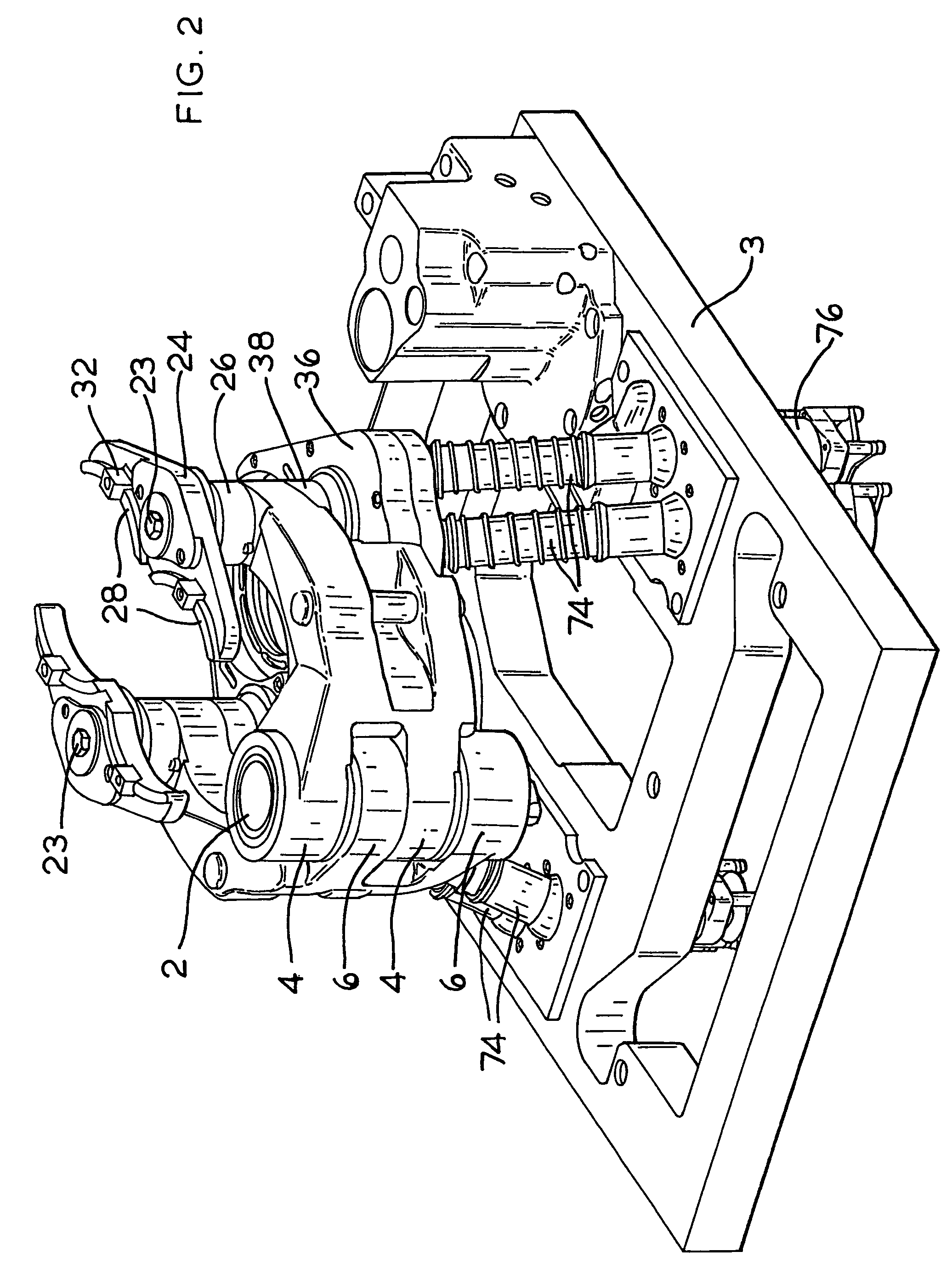

InactiveUS7024887B2Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusEngineeringNeck rings

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO

Aligning fixture for mold opening and closing mechanism

InactiveUS6085552AImproved mold openImproved close mechanismBlowing machine gearingsGlass pressing apparatusTransducerEngineering

A mold opening and closing mechanism includes an aligning mechanism which has a horizontal mounting plate including a number of vertical openings for the number of molds, that is supported by a pair of spaced vertical uprights secured to the section frame top surface. A plurality of aligning cylinders are located in the vertical openings in the horizontal mounting plate and move parallel with the mold holder motion. Each cylinder includes surfaces configured to mate with the clamping surfaces of the mold holders. The axis of one of the aligning cylinders is held but not clamped at the theoretical centerline so it can move to the actual centerline when the mold holders are located at the advanced clamped closed position. A position transducer is mounted parallel with the mold holder motion to sense movement of the axis of one of the aligning cylinders and a computer receiving positional data from the transducer compares the theoretical centerline with the actual centerline determined from the data and defines a displacement offset for the displacement program to align the mold holders to the theoretical centerline.

Owner:EMHART GLASS SA

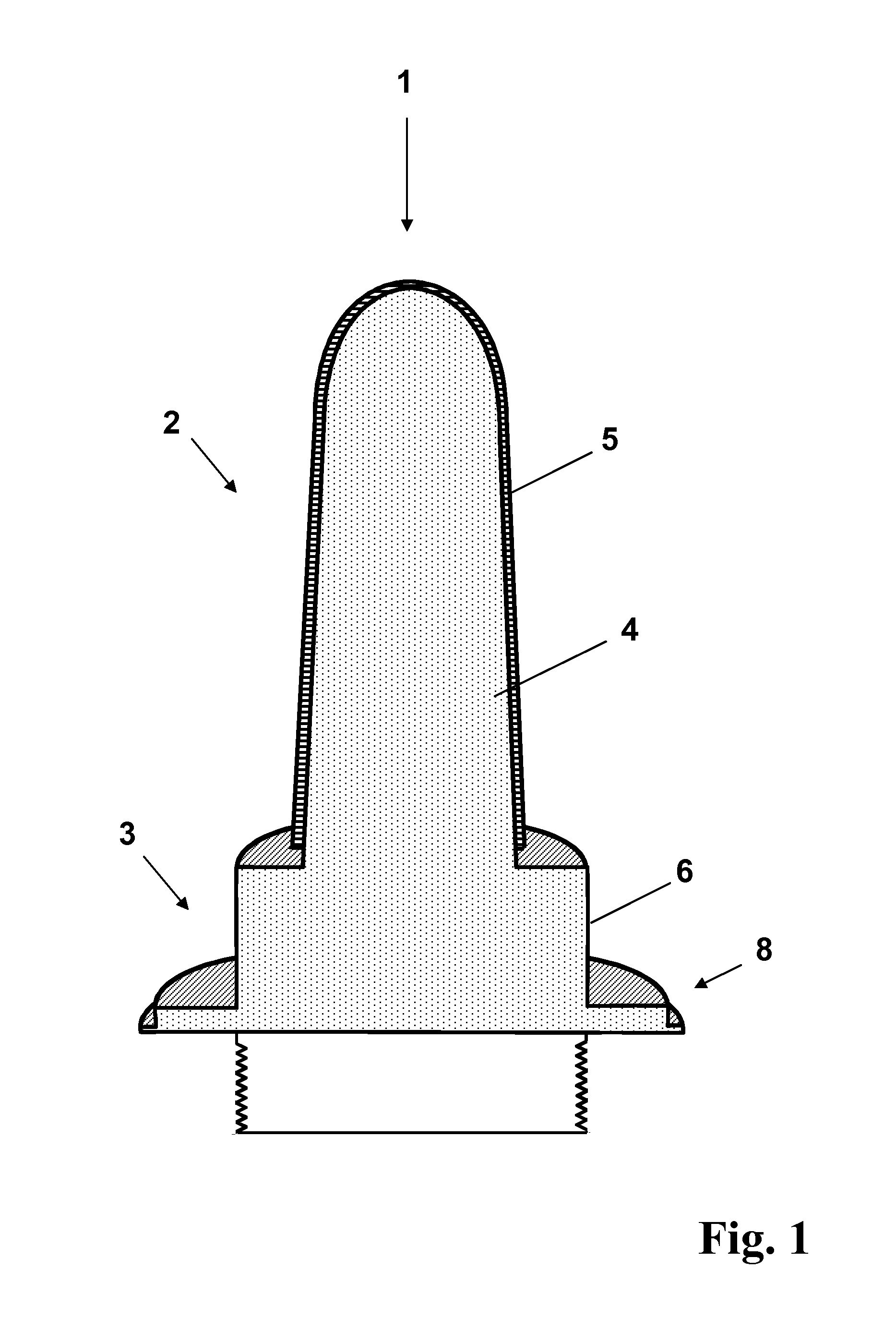

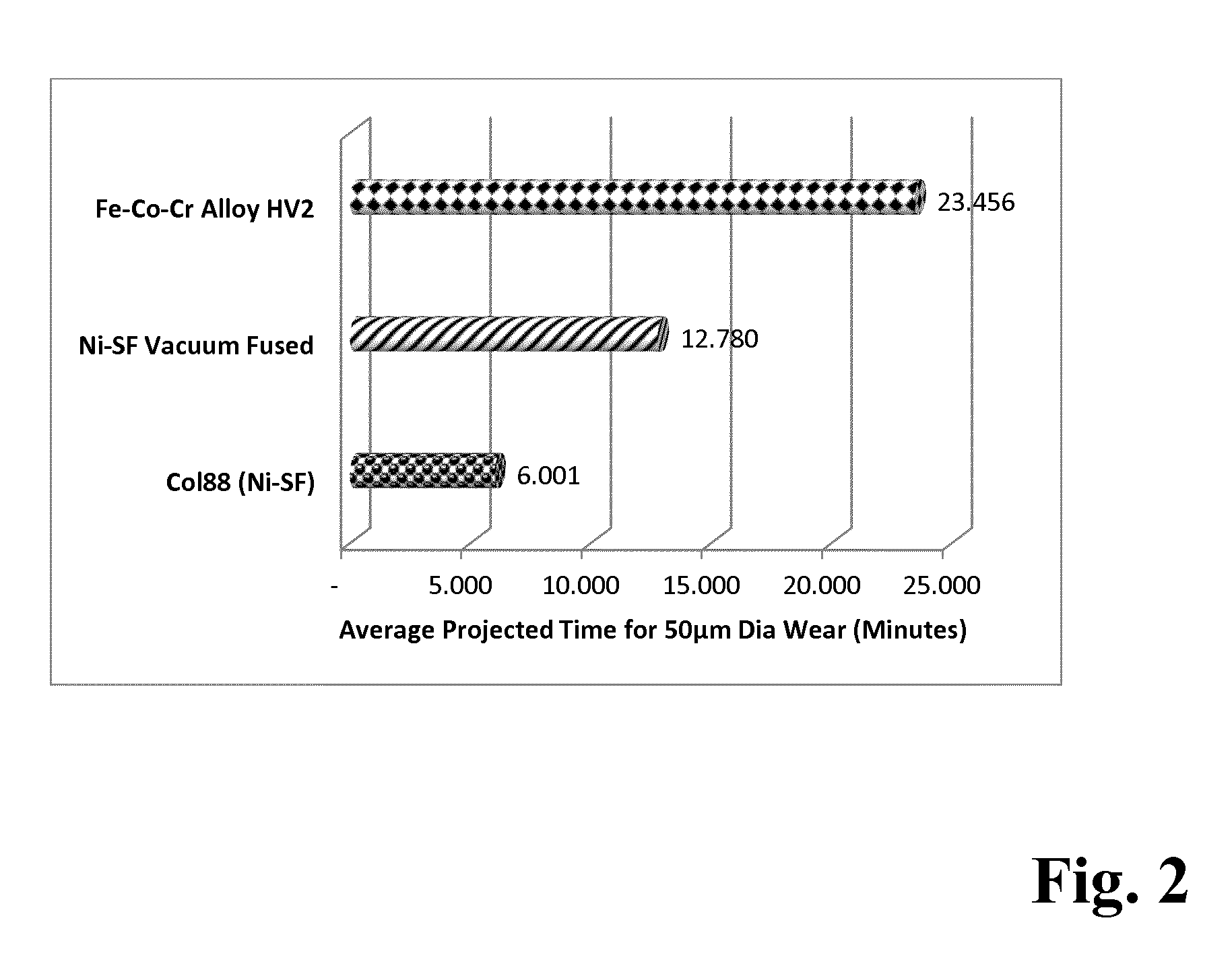

Plunger for use in manufacturing glass containers

InactiveUS20150000347A1Produced easily and cost-effectivelyIncrease resistanceHot-dipping/immersion processesMolten spray coatingMetal coatingAlloy

A plunger for use in manufacturing glass containers comprises a first portion configured for contact with a gob of molten glass, and a second portion. At least the first portion has a metal coating of a self-fluxing Fe-based alloy and with a microhardness between 300 HV0.3 and 900 HV0.3. The Fe-based alloy comprises in wt. %): C, 0.5-2.5; Si, 1.0-4.0; B, 1.5-6.0; Cr, 15.0-30.0; Ni, 0-5.0; Co, 15.0-40.0; W, 1.2-5.0; Mo, 0-5.0; Cu, 0-5.0; P, 0-3.0; and N, 0-1.0. The Fe-based alloy may further comprise metals selected from Al, Mn, Nb, S, Ti, V, Zn And Zr each in an individual amount that ranges from 0.01 wt. % to about 2 wt. %, with the overall content of the additional metals less than 10 wt. %.

Owner:MEC - HLDG

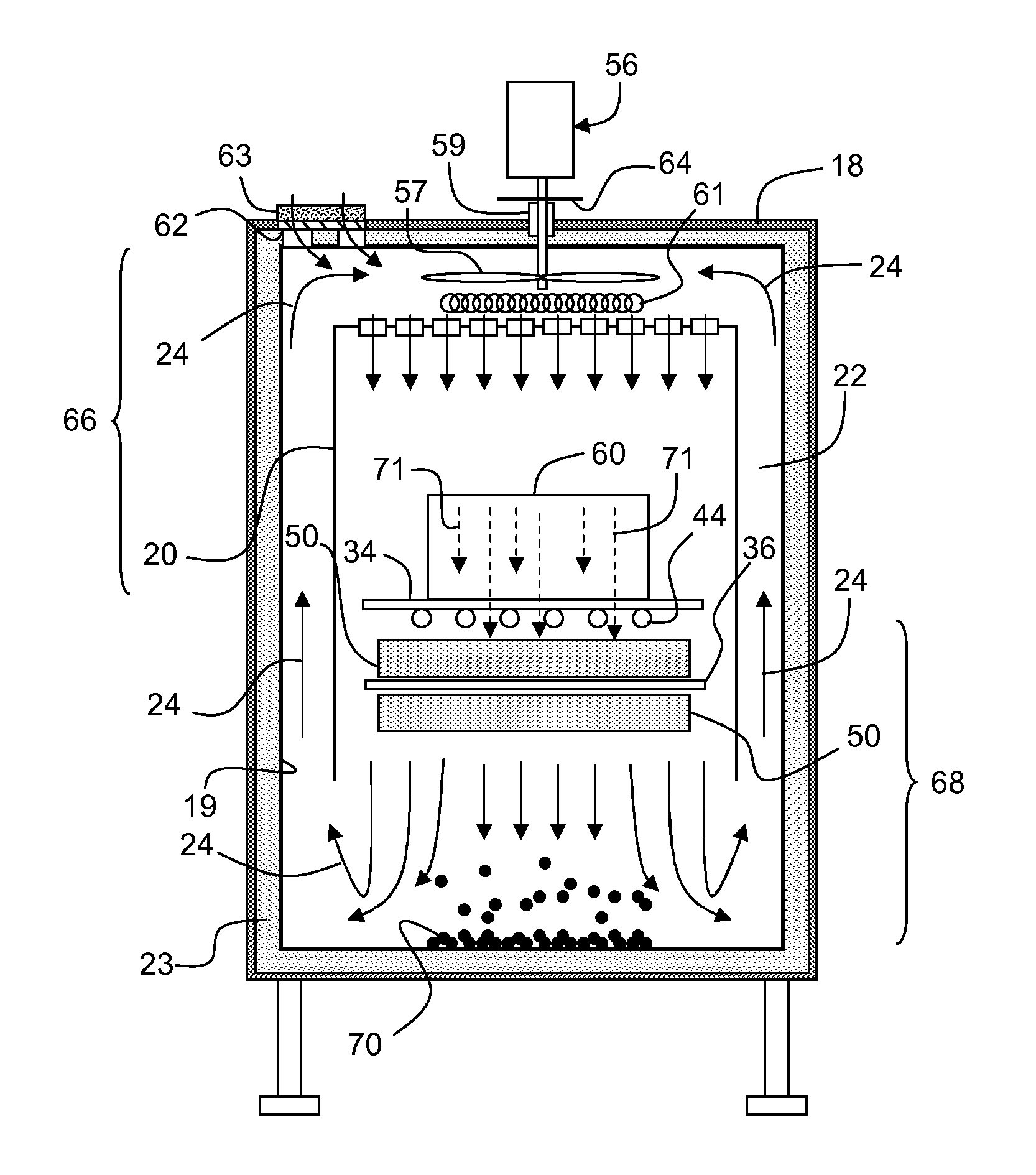

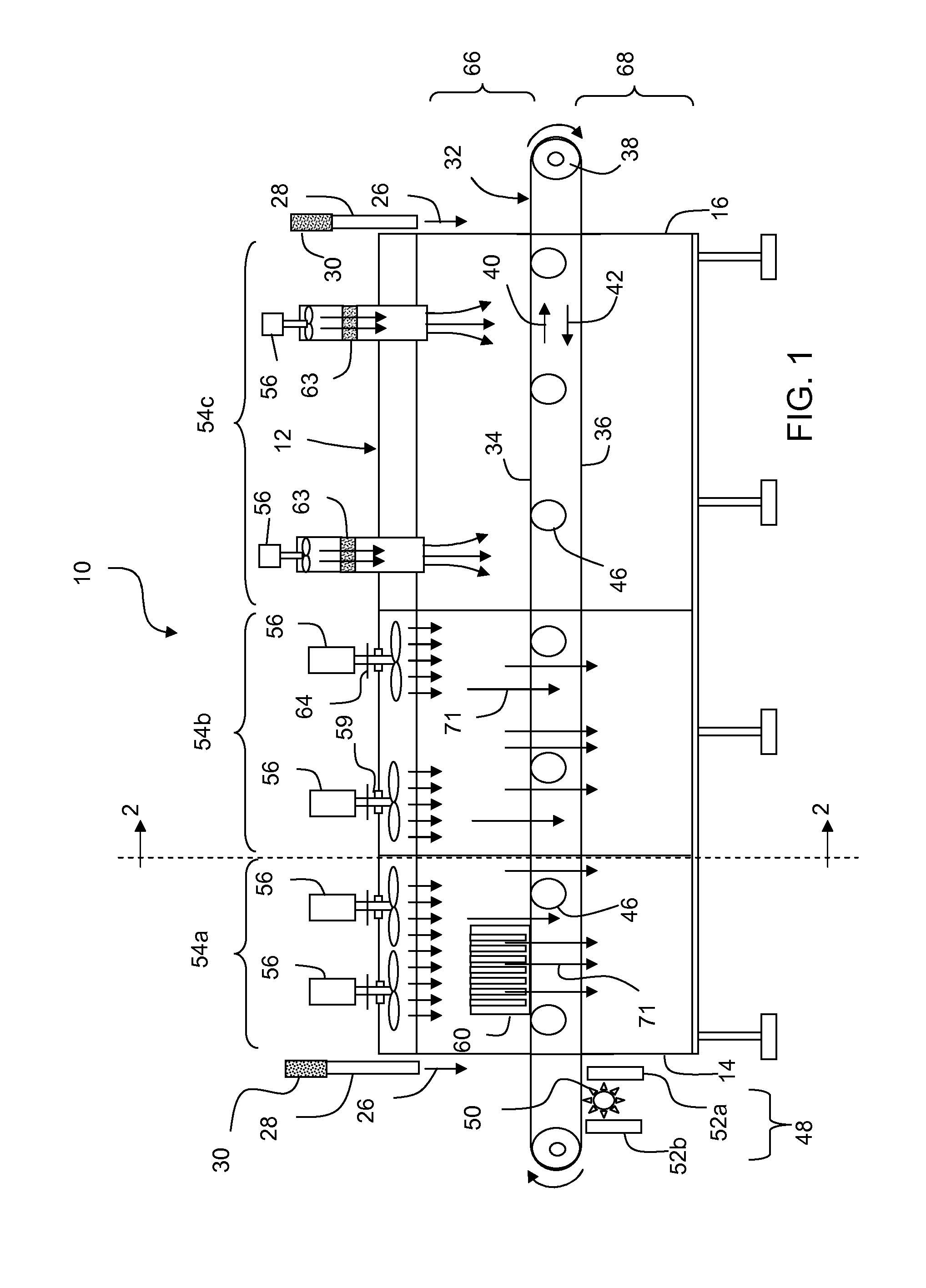

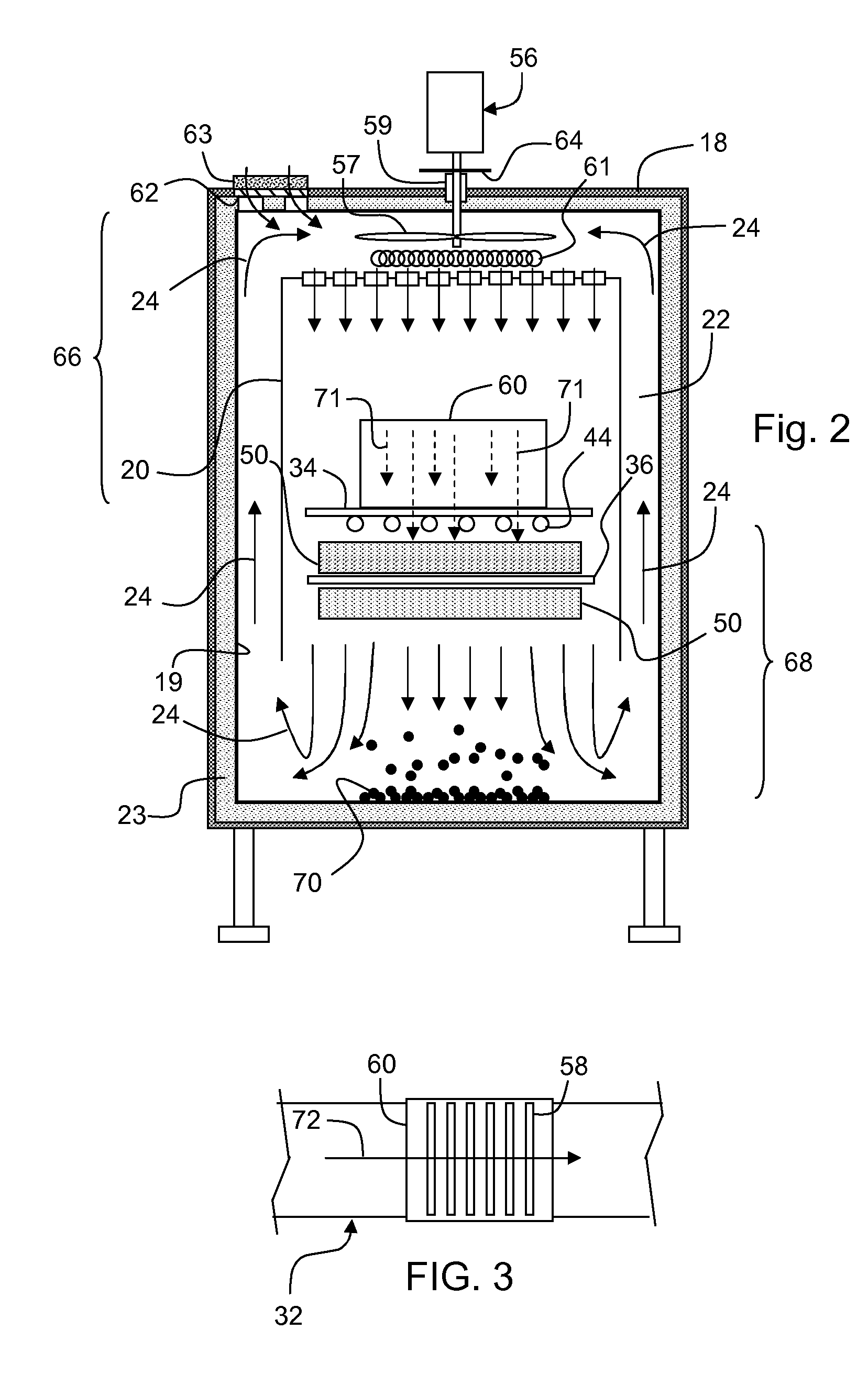

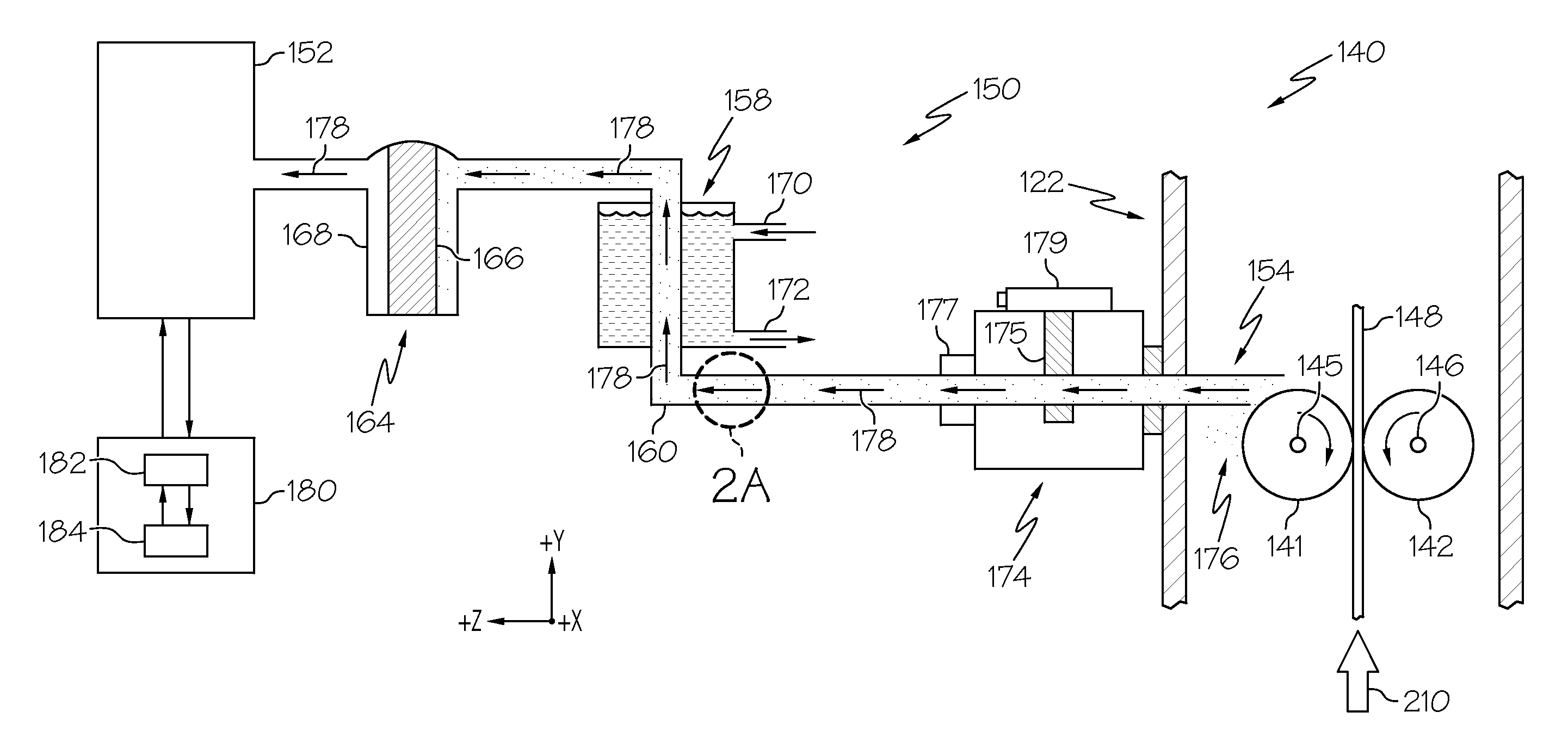

Glass manufacturing apparatuses with particulate removal devices and methods of using the same

InactiveUS8484995B2Reduce generationReduced onclusion defectsCharging furnaceGlass furnace apparatusFiberglass meshGlass fiber

Owner:CORNING INC

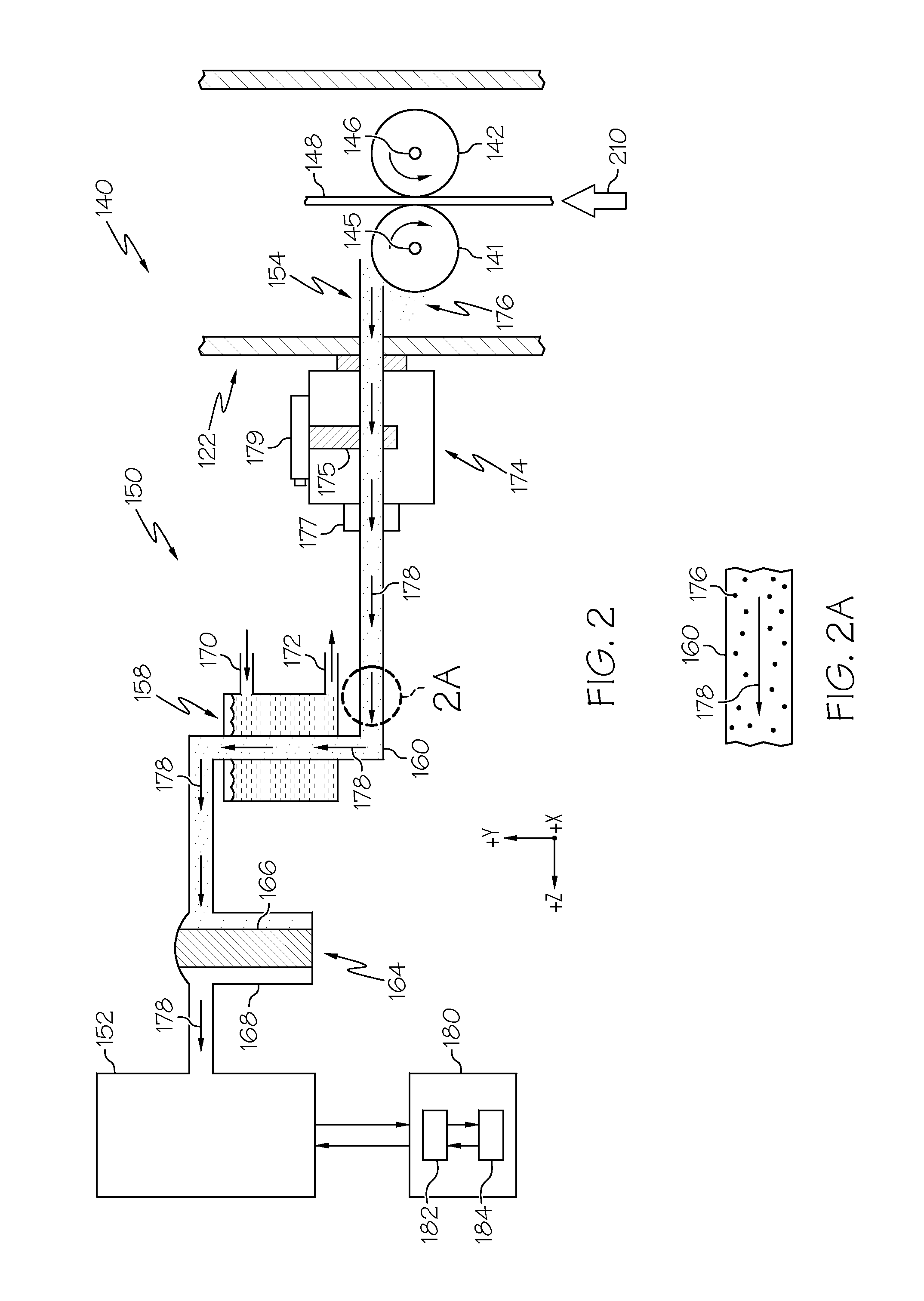

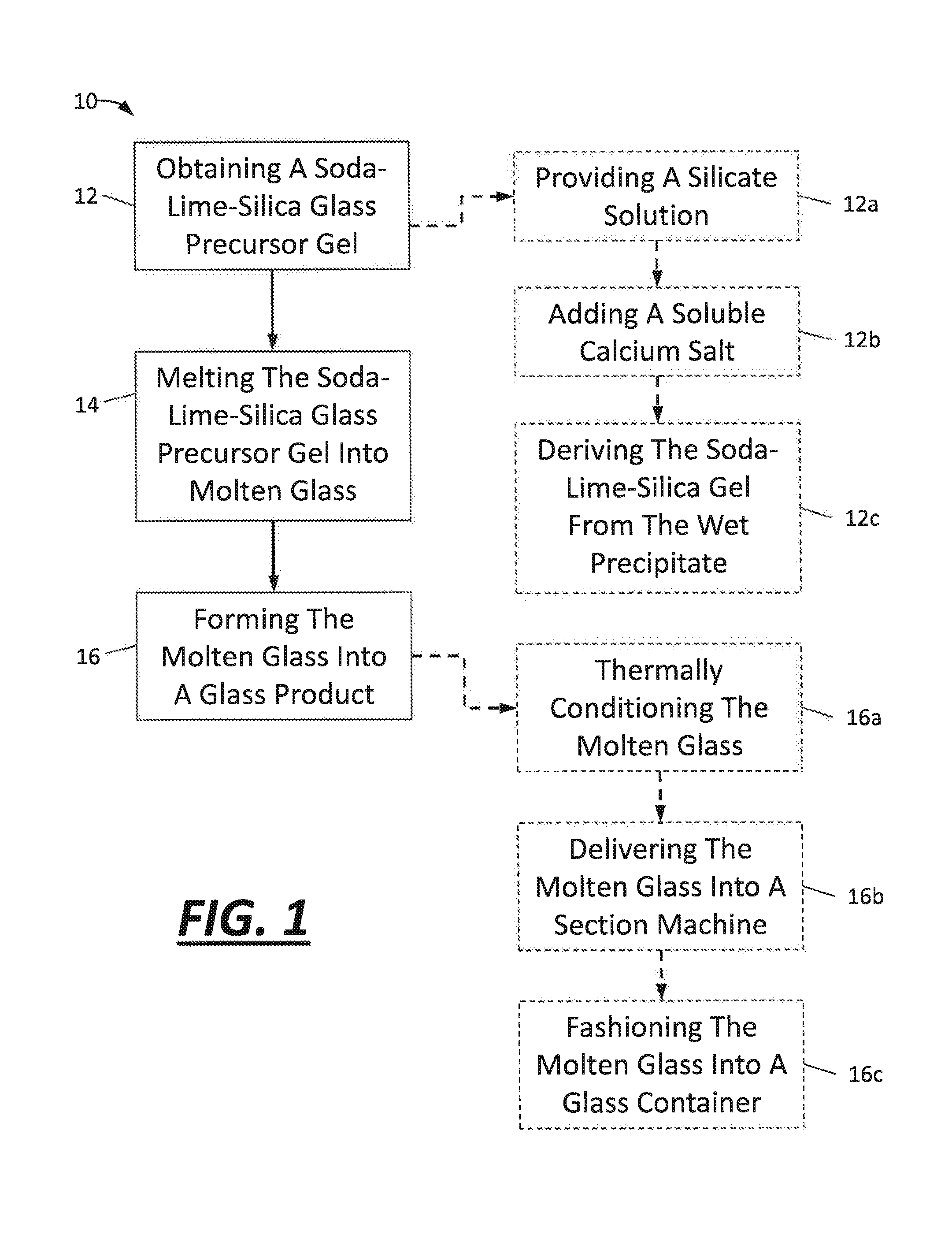

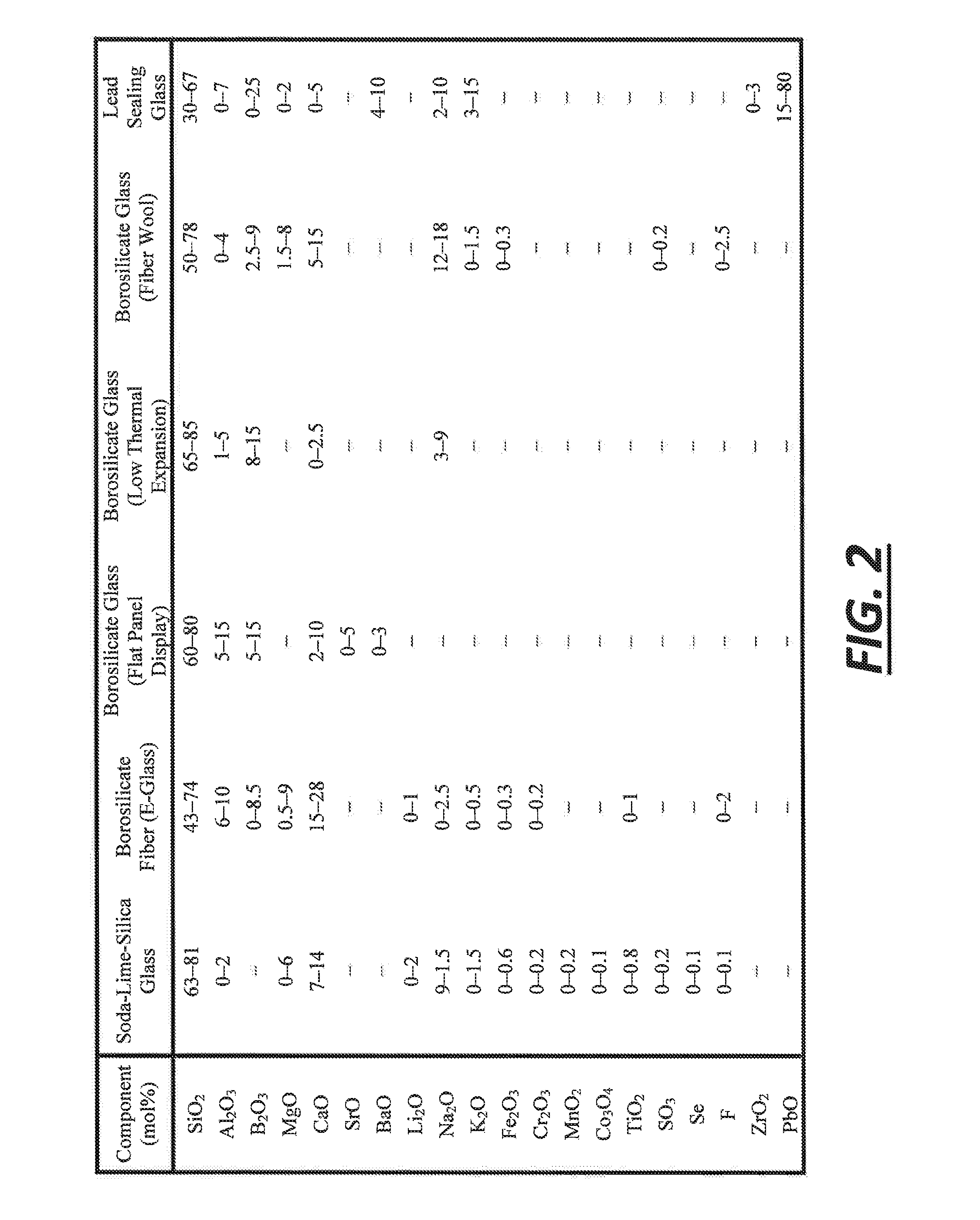

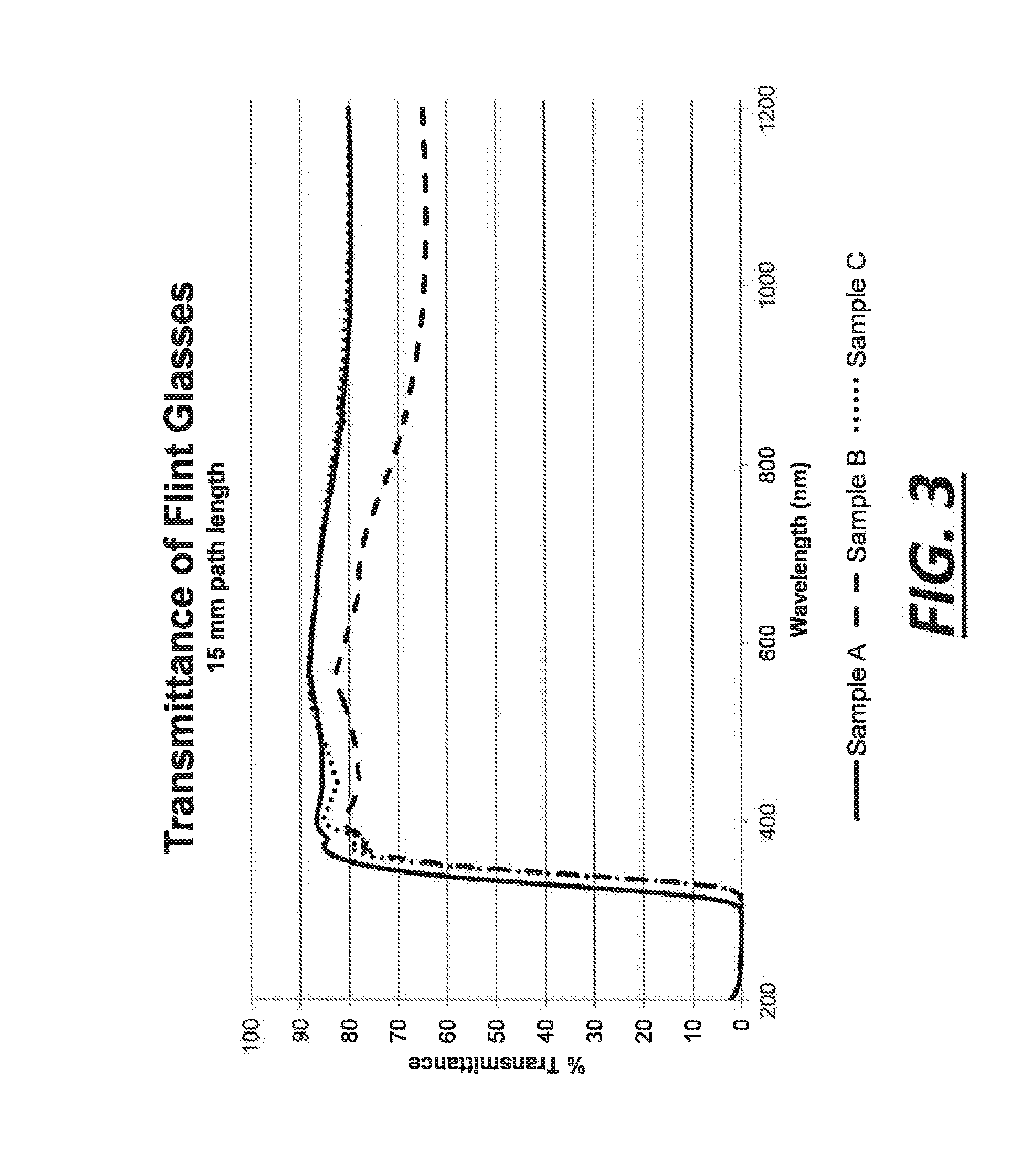

Glass Precursor Gel

A glass precursor gel and a method of making a glass product from the glass precursor gel are disclosed. The glass precursor gel includes a bulk amorphous oxide-based matrix that is homogeneously chemically mixed and includes 30 mol % to 90 wt. % silica and at least one of the following: (A) 0.1 mol % to 25 mol % of one or more alkali oxides in sum total, (B) 0.1 mol % to 25 mol % of one or more alkaline earth oxides in sum total, (C) 1 mol % to 20 mol % boric oxide, (D) 5 mol % to 80 mol % lead oxide, or (E) 0.1 mol % to 10 mol % aluminum oxide. A method of making a glass product from the glass precursor gel involves obtaining the glass precursor gel, melting the glass precursor gel into molten glass, and forming the molten glass into a glass product.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Die used for bottle molding and stamping assembly

InactiveCN103011558AEffective protectionReduce punch pressurePress and blow machinesEngineeringBottle

The invention discloses a die used for a bottle molding and stamping assembly. The die is composed of two semi-rings. A first through hole is arranged in the die to allow a punch to enter and exit; positioning loops used for connection with holding clamps are projected at the periphery of the die; and a plurality of air discharge ducts are arranged at the bottom of the die. According to the invention, since the plurality of air discharge ducts are arranged at the bottom of the die, air can be discharged when the punch rapidly travels, so the pressure of the punch is reduced, and the die is effectively protected.

Owner:DEQING CAIFU GLASS

Glass material with activated and antibacterial functions and method for preparing glassware

InactiveCN108751699APromote absorptionTo promote metabolismPress and blow machinesEscherichia coliStaphylococcus aureus

The invention relates to a glass material, in particular to a glass material with activated and antibacterial functions and provides a method for preparing glassware from the glass material. The glassmaterial is prepared from components in parts by weight as follows: 50-70 parts of quartz powder, 1-5 parts of shell powder, 10-15 parts of feldspar powder, 0-5 parts of boric acid, 10-15 parts of borax, 0-5 parts of aluminium oxide, 0-5 parts of sodium carbonate and 2-5 parts of an inorganic activated and antibacterial material. The prepared glassware with the activated and antibacterial functions is moistened and transparent, product qualification ratio can reach 95% or higher, antibacterial rate for Escherichia coli and staphylococcus aureus reaches 96% or higher, and when the glassware with the activated and antibacterial functions is used for accommodating baijiu, taste is improved obviously; by means of a far infrared function, macromolecular-cluster water can be activated into micromolecular-cluster water, dissolved gas is discharged rapidly, and absorption and metabolism of a body are facilitated.

Owner:济南生禾生物科技有限公司

Process for manufacturing glass goblets by machine blowing and machine pressing in sequence

ActiveCN105084717AIncrease color varietiesStructural changesPress and blow machinesGlass productionSocial benefitsMolding machine

The invention relates to a process for manufacturing glass goblets by machine blowing and machine pressing in sequence, relating to a preparation method of glass goblets. The process comprises the steps: preparing a glass raw material, melting the material in a furnace, supplying a goblet body material by a supplying machine, blowing goblet bodies by a blowing machine, manually transferring the goblet bodies to a fire cutting machine for cutting, manually transferring the goblet bodies to a mold of a press molding machine, supplying a goblet handle and goblet support material by a supporting machine, carrying out press molding by a press molding machine to obtain goblet handles and goblet supports, connecting each goblet handle with the outer bottom of each goblet body, manually transferring the goblets to a fire polishing machine for polishing, manually transferring the polished goblets to an annealing furnace for annealing, discharging out of the annealing furnace, checking and packaging. By adopting the process, the glass goblets are successfully manufactured by machine blowing and machine pressing in a combined manner, the product quality is significantly improved, the production cost is greatly lowered, the amount of labour used is greatly reduced, the goblet bodies, the goblet handles and the goblet supports are various in structures, the colors and patterns of the glass goblets are significantly increased, and obvious economic benefits and significant social benefits are achieved; and the process also has a promotion value.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

Machine for the production of hollow glass

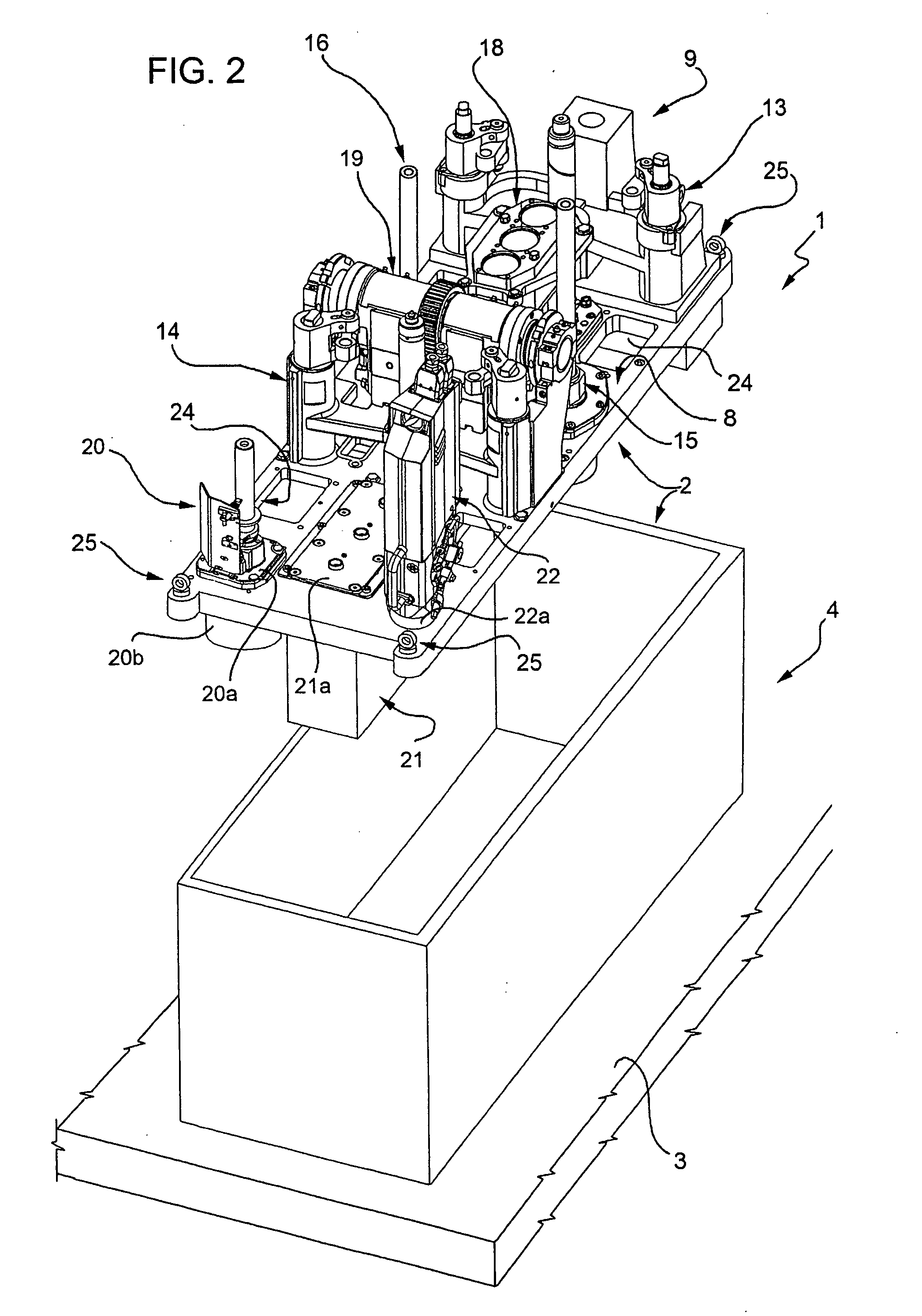

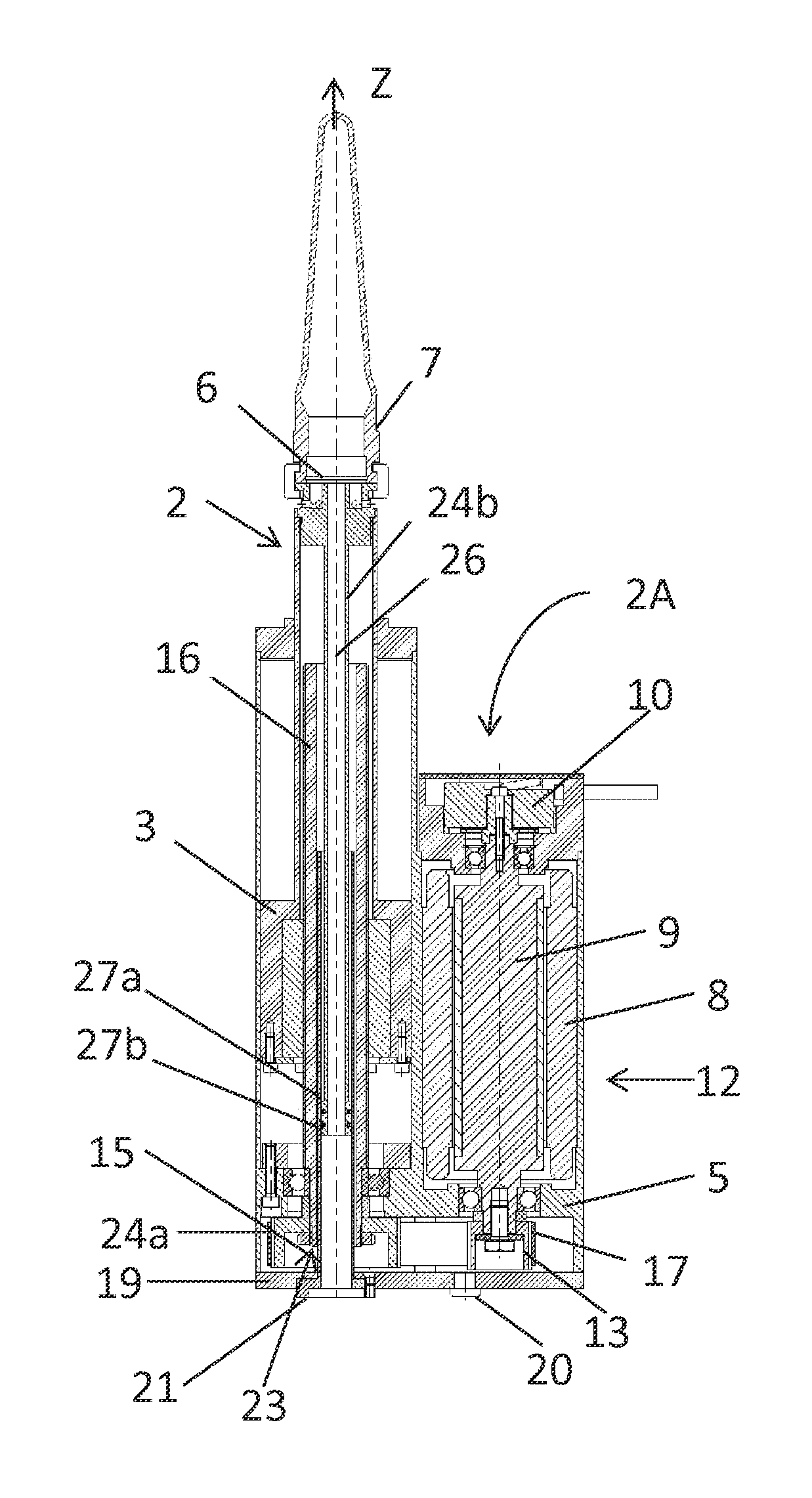

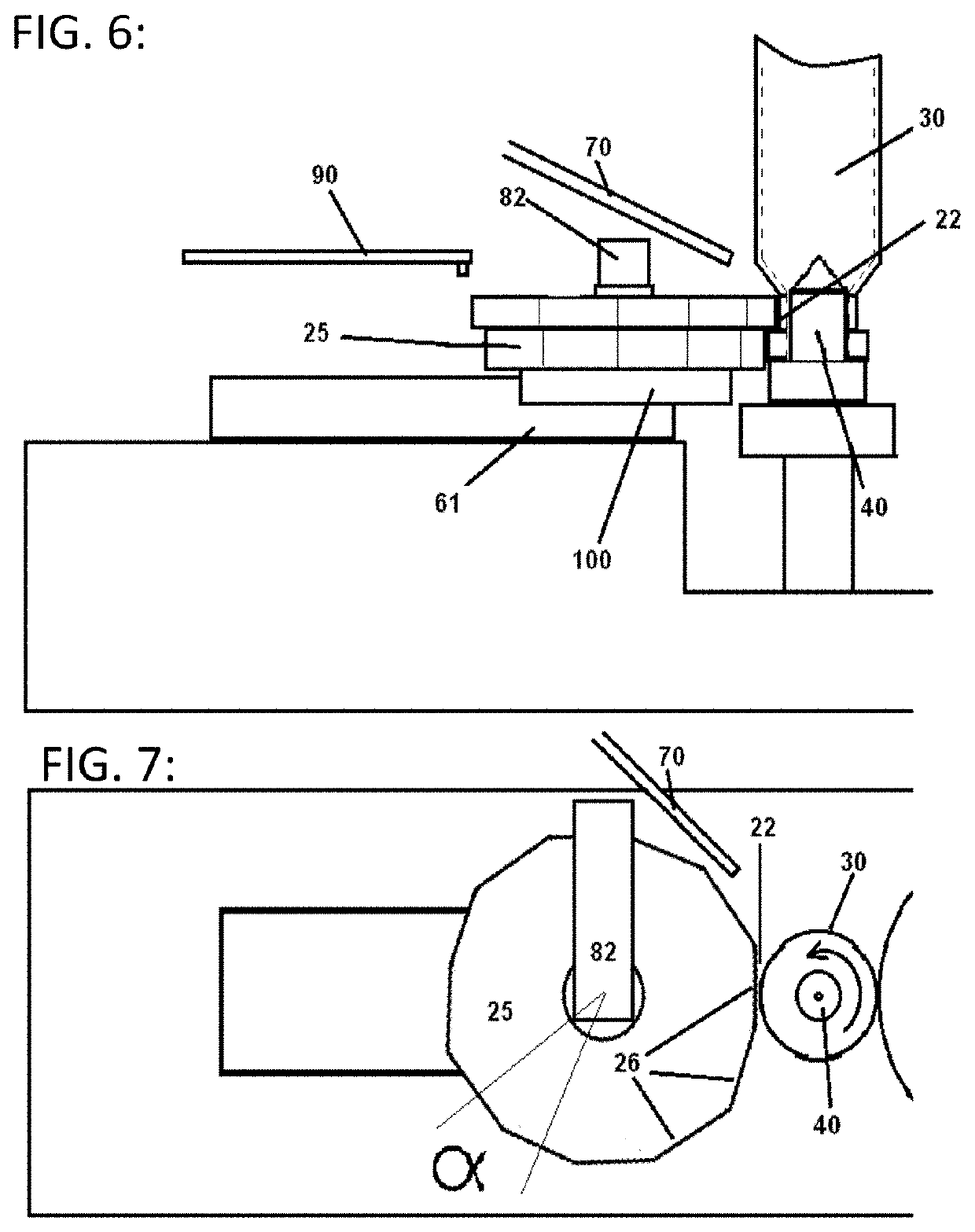

ActiveUS20140109618A1Easy to operateReduce spacingGlass pressing apparatusOther manufacturing equipments/toolsMechanical engineeringGlass forming

The present invention relates to a system for aligning and positioning a male mechanism—pneumatic or servo-electric—to be used at the blank station side of a section of a hollow glass forming machine. The system comprises a mechanism, comprising at least one plunger or a driving unit driven by a servomotor, a guide flange composed of an internal flange for retaining the mechanism in position, and an external flange.The system further comprises a base plate for supporting the mechanism. The plate is mounted on at least one guide bar, rigidly fixed to the resting face of the external flange and intended to allow the base plate to slide along a sliding direction substantially orthogonal to the plane wherein the external flange lies. The base plate rests on a height adjustment group, suspended to said upper plane and intended to move the plate along the guide.

Owner:BOTTERO SPA

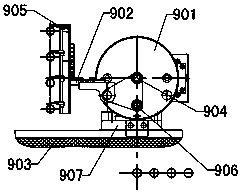

Narrow Neck Glass Container with Integral Embossments and Method of Manufacture

A narrow neck glass container includes a container body and a container neck finish. The container neck finish has an external closure attachment diameter of not more than 36 mm, and the container body has at least one internal embossment of predetermined geometry. The at least one internal embossment preferably comprises a plurality of internal embossments in a geometric pattern.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Method and apparatus for the hot forming of glass workpieces, and hot-formed glass container

ActiveUS20200123038A1Reduce formationReduce wearInfusion syringesPharmaceutical containersFree rotationThermoforming

Owner:SCHOTT PHARMA SCHWEIZ AG

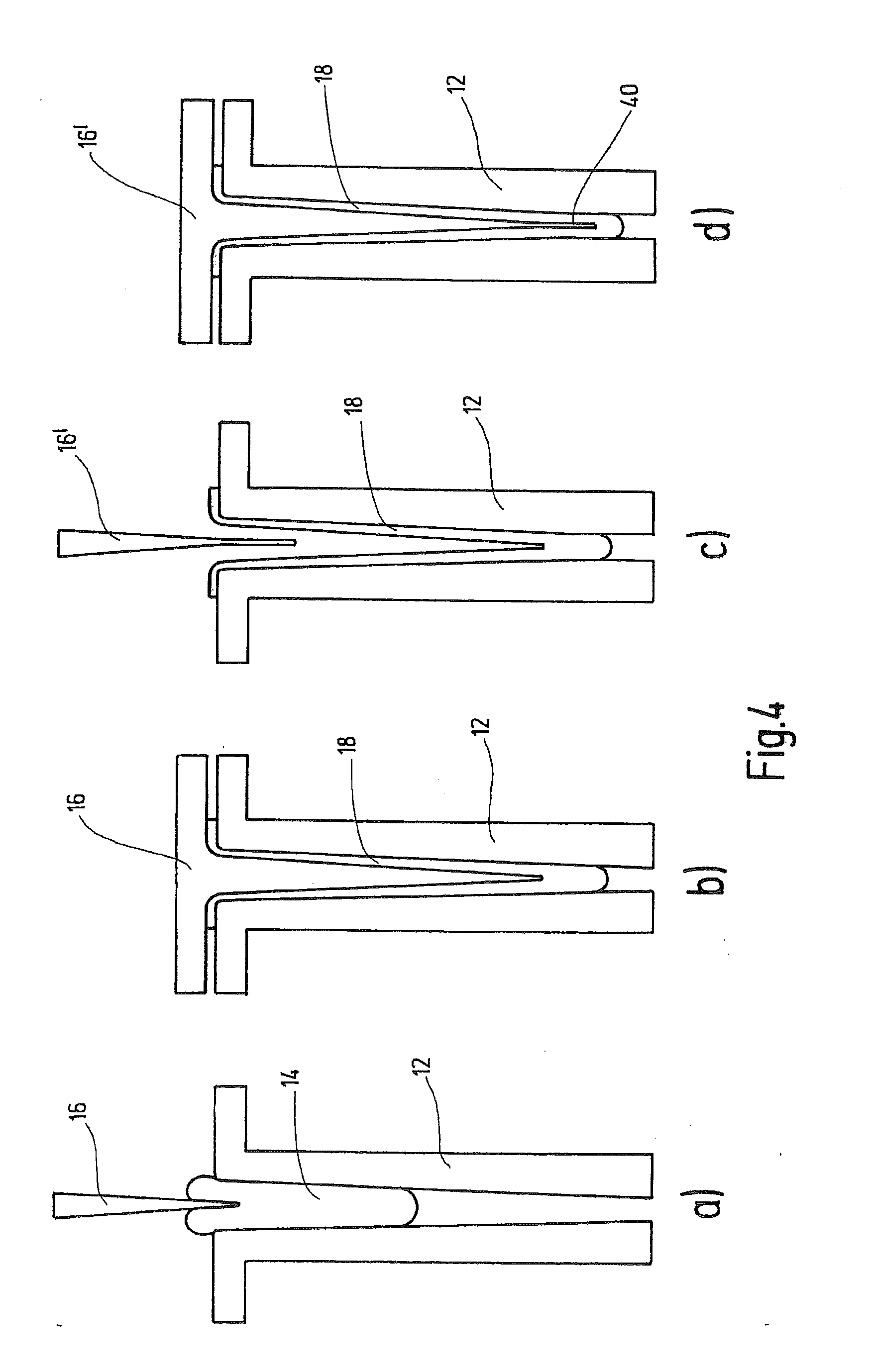

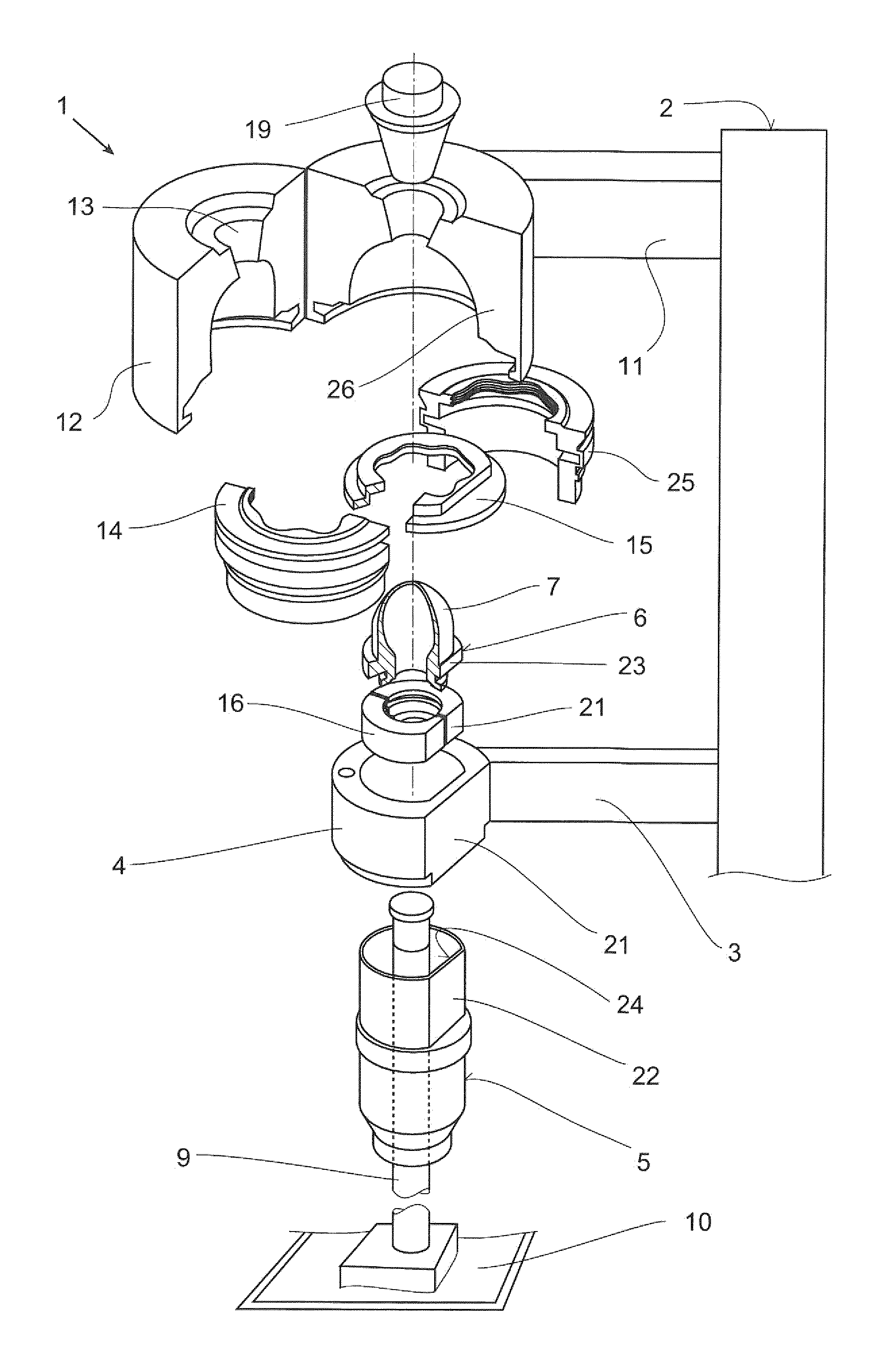

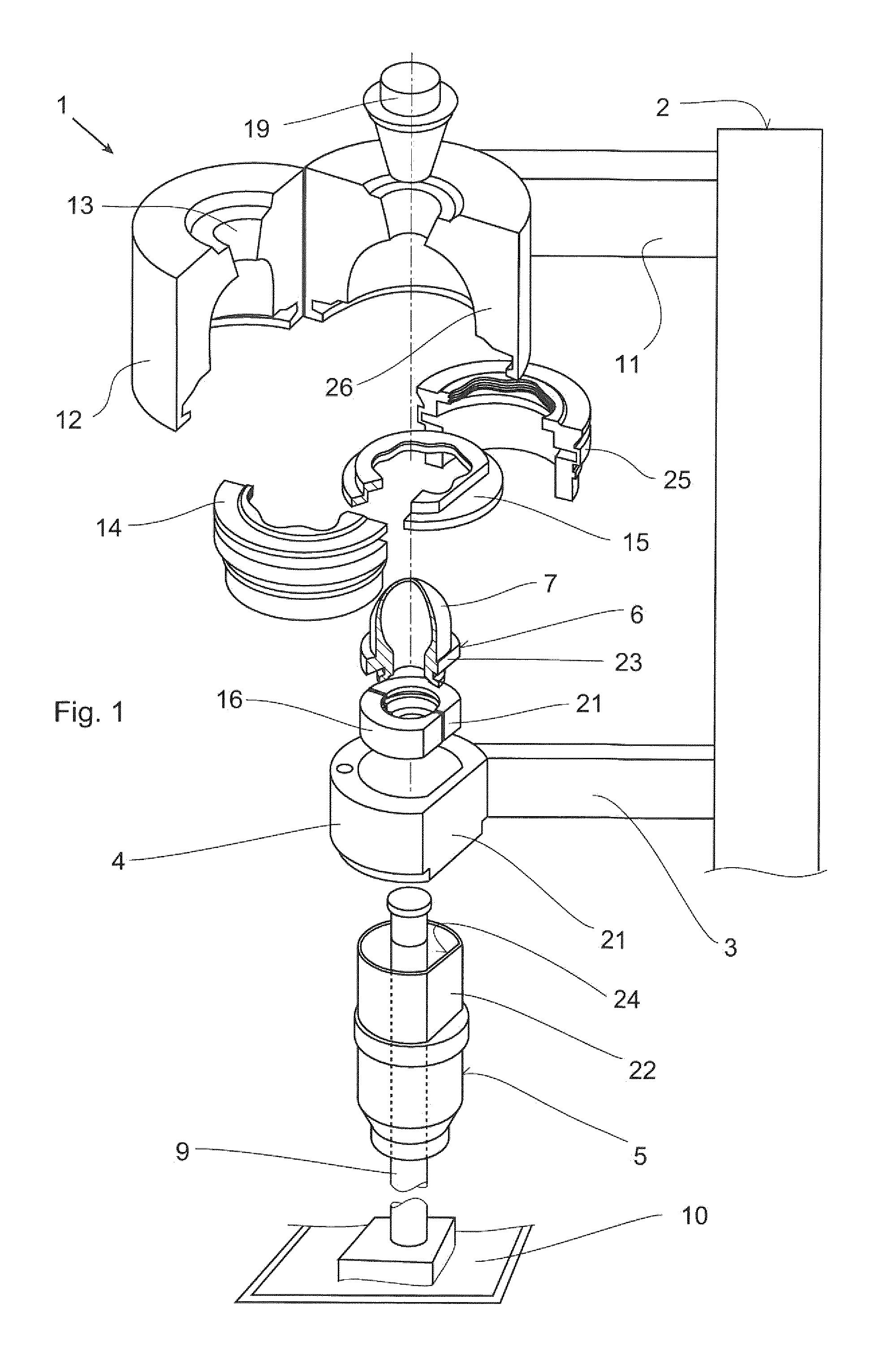

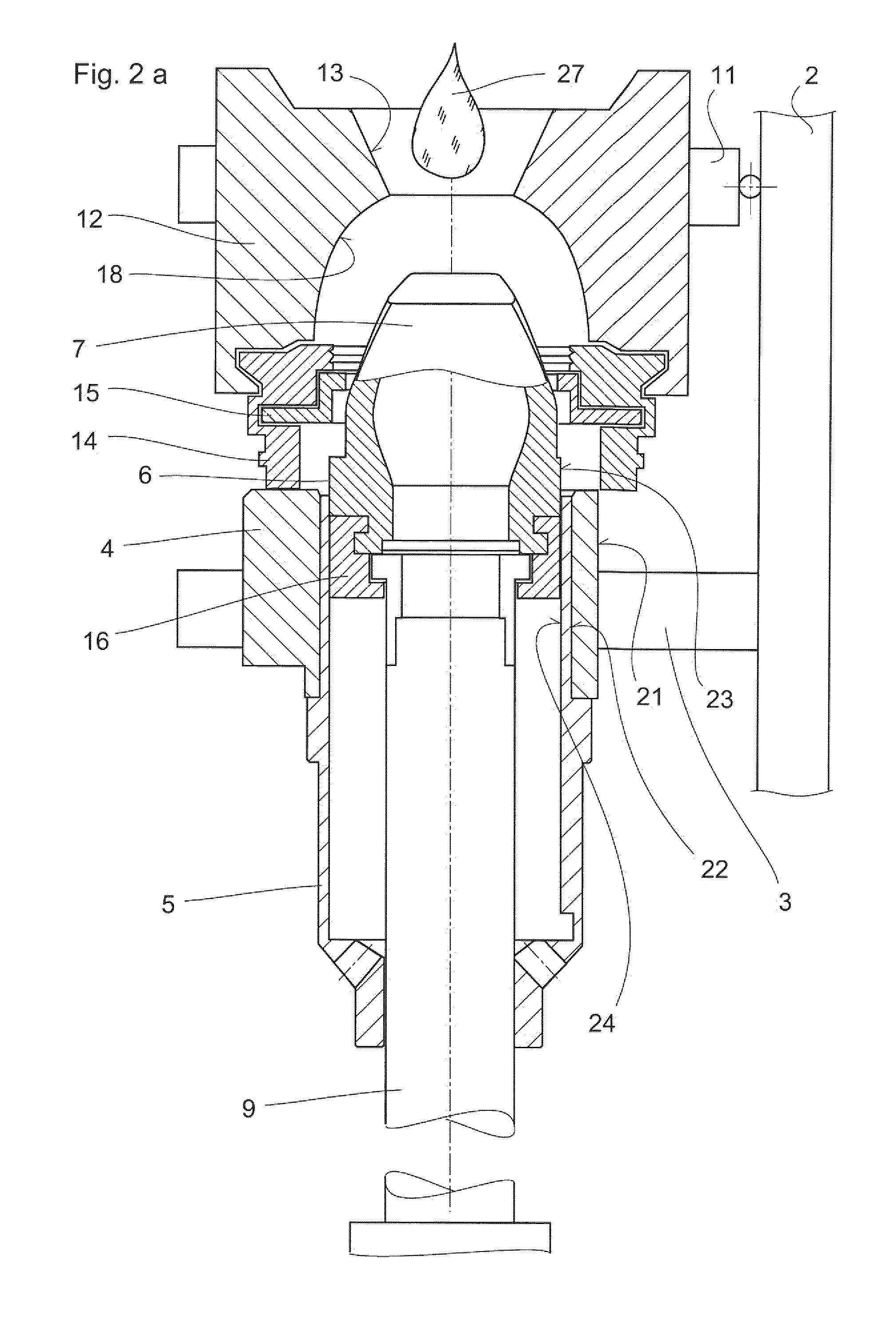

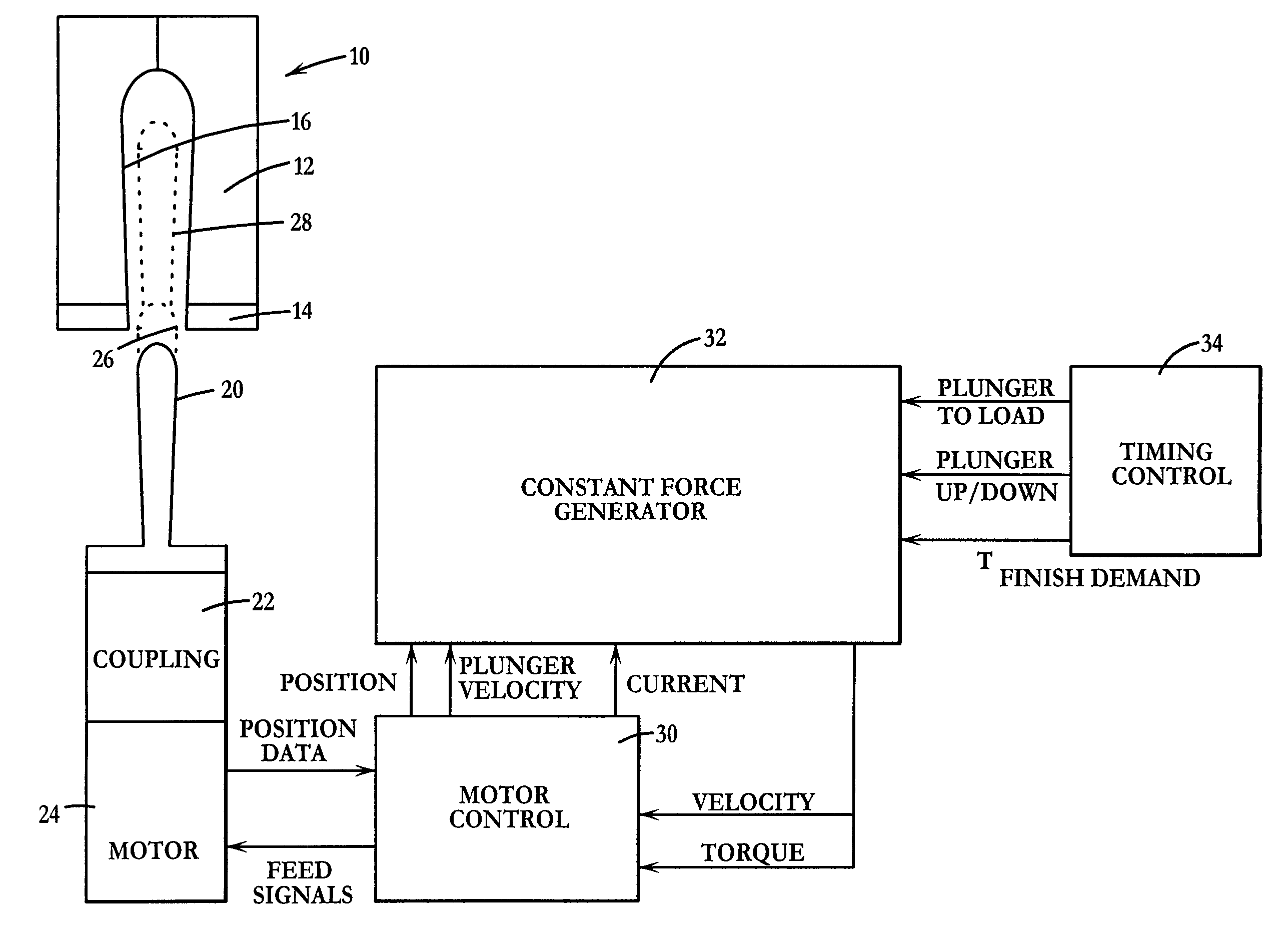

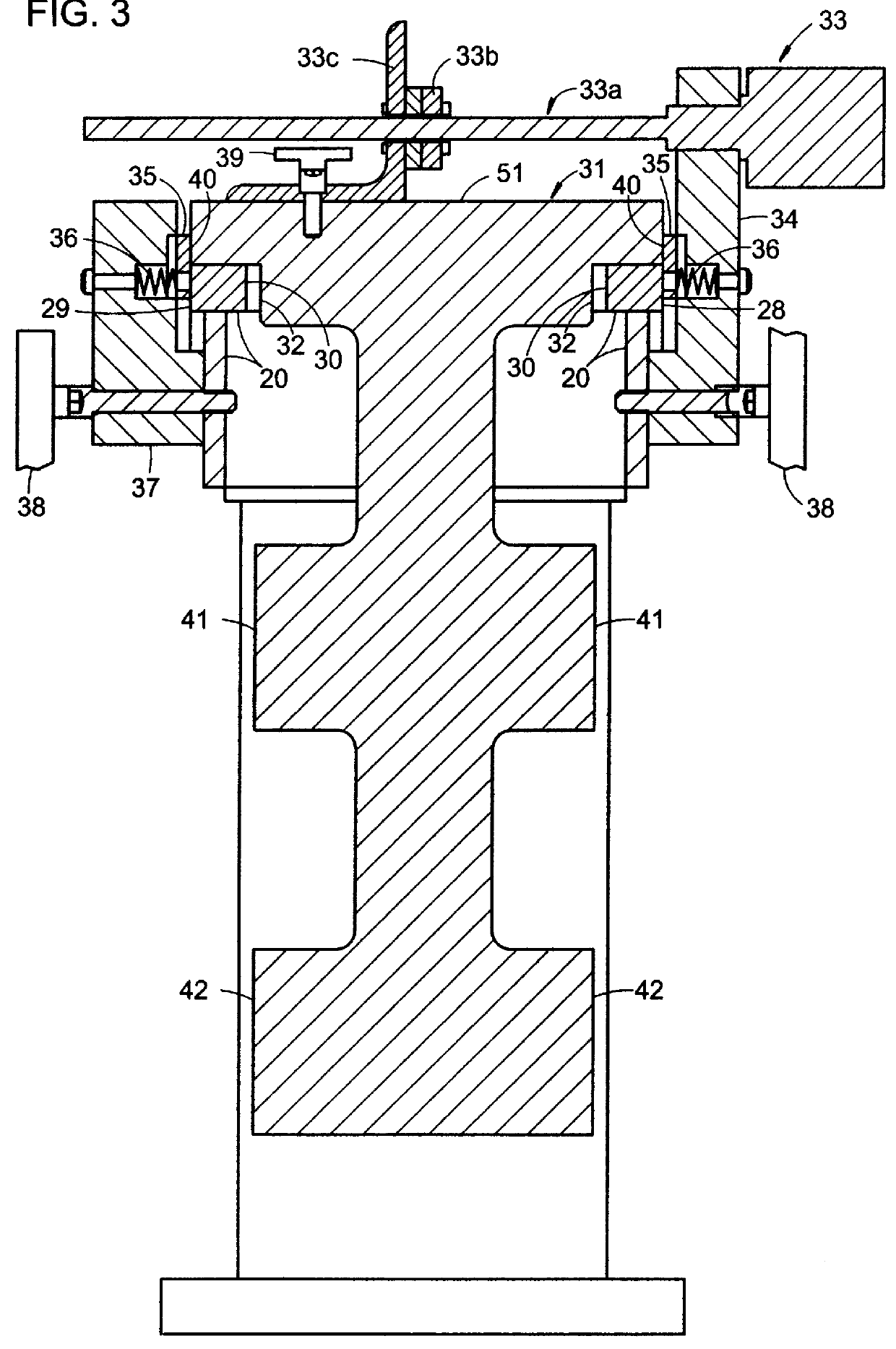

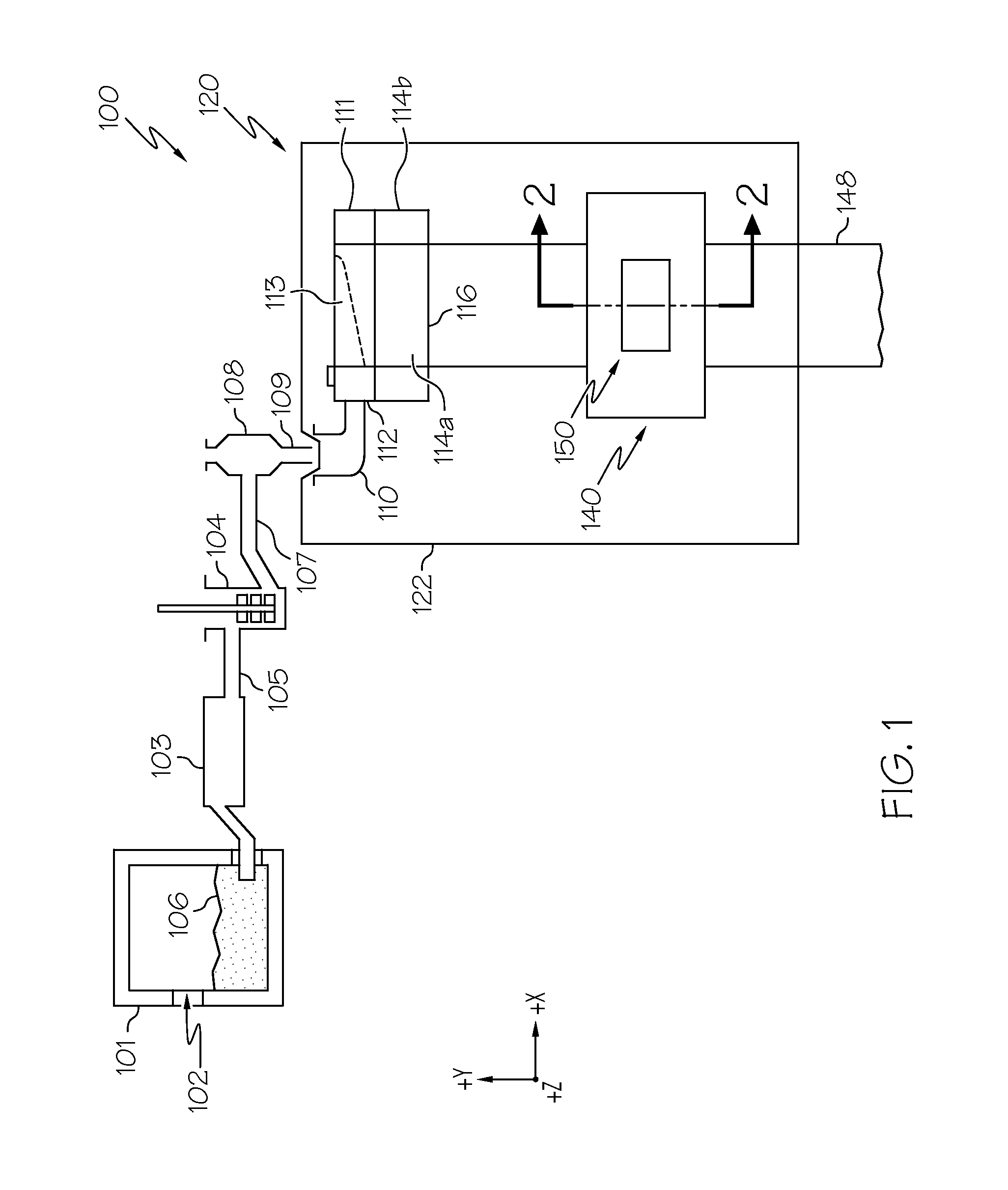

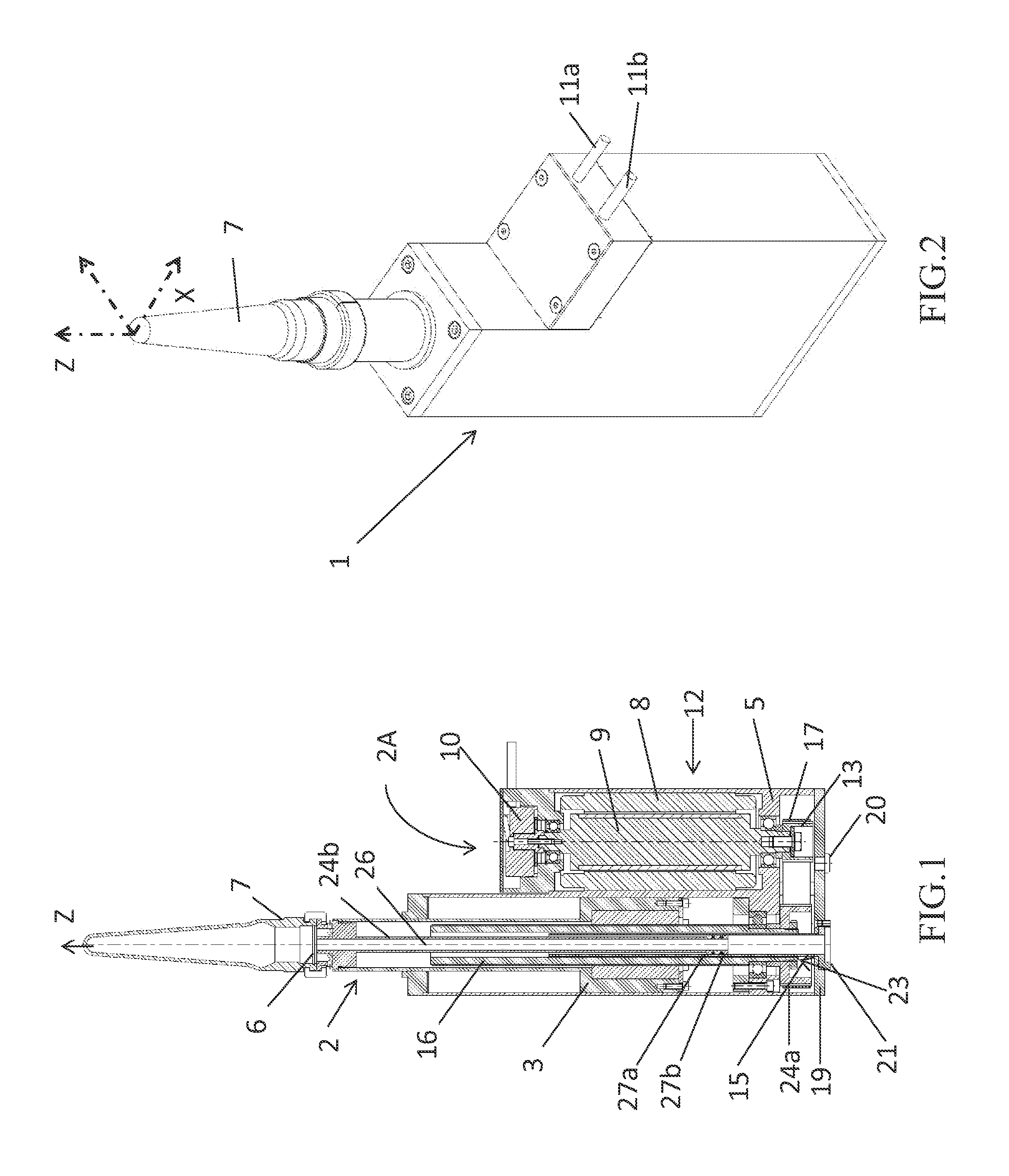

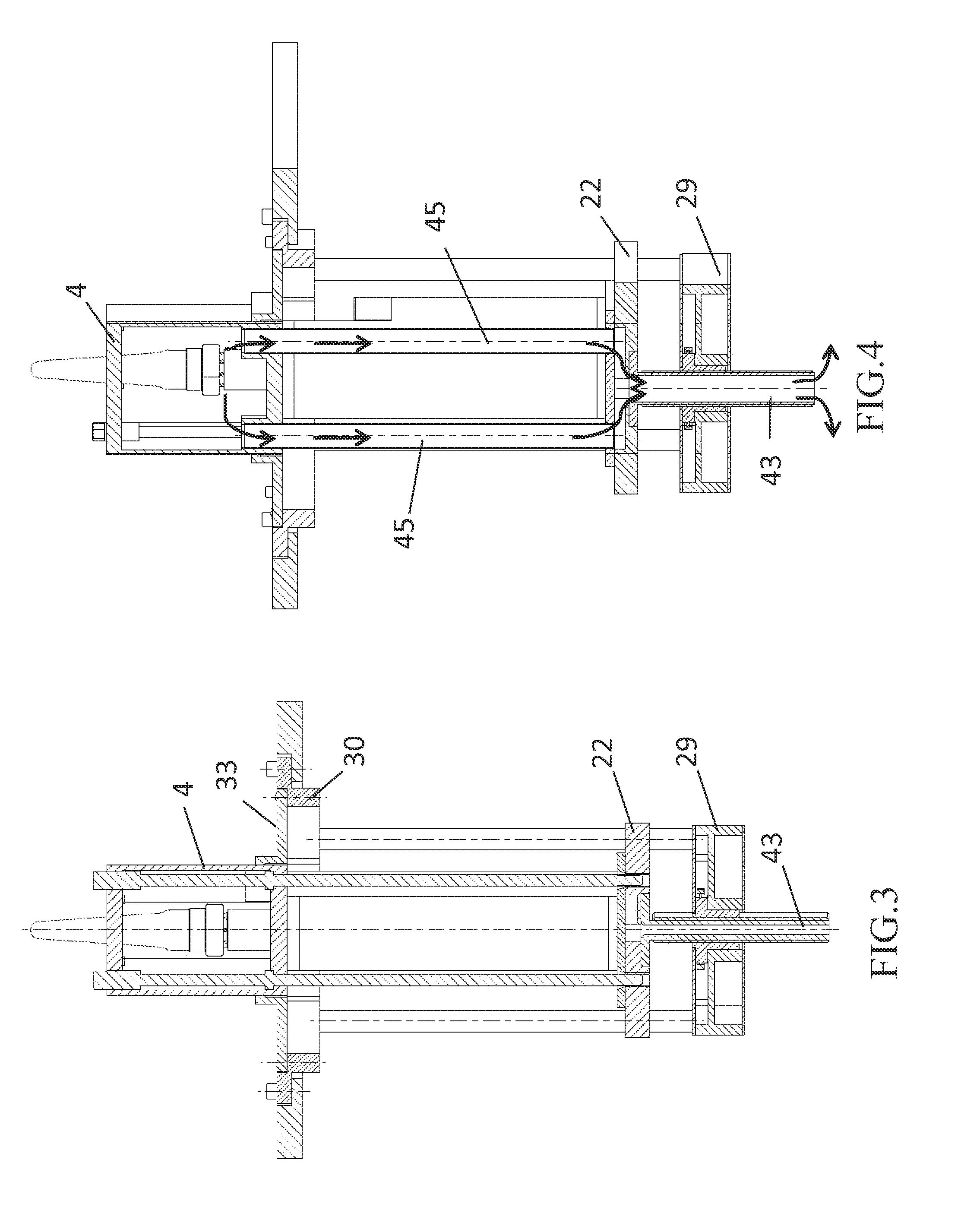

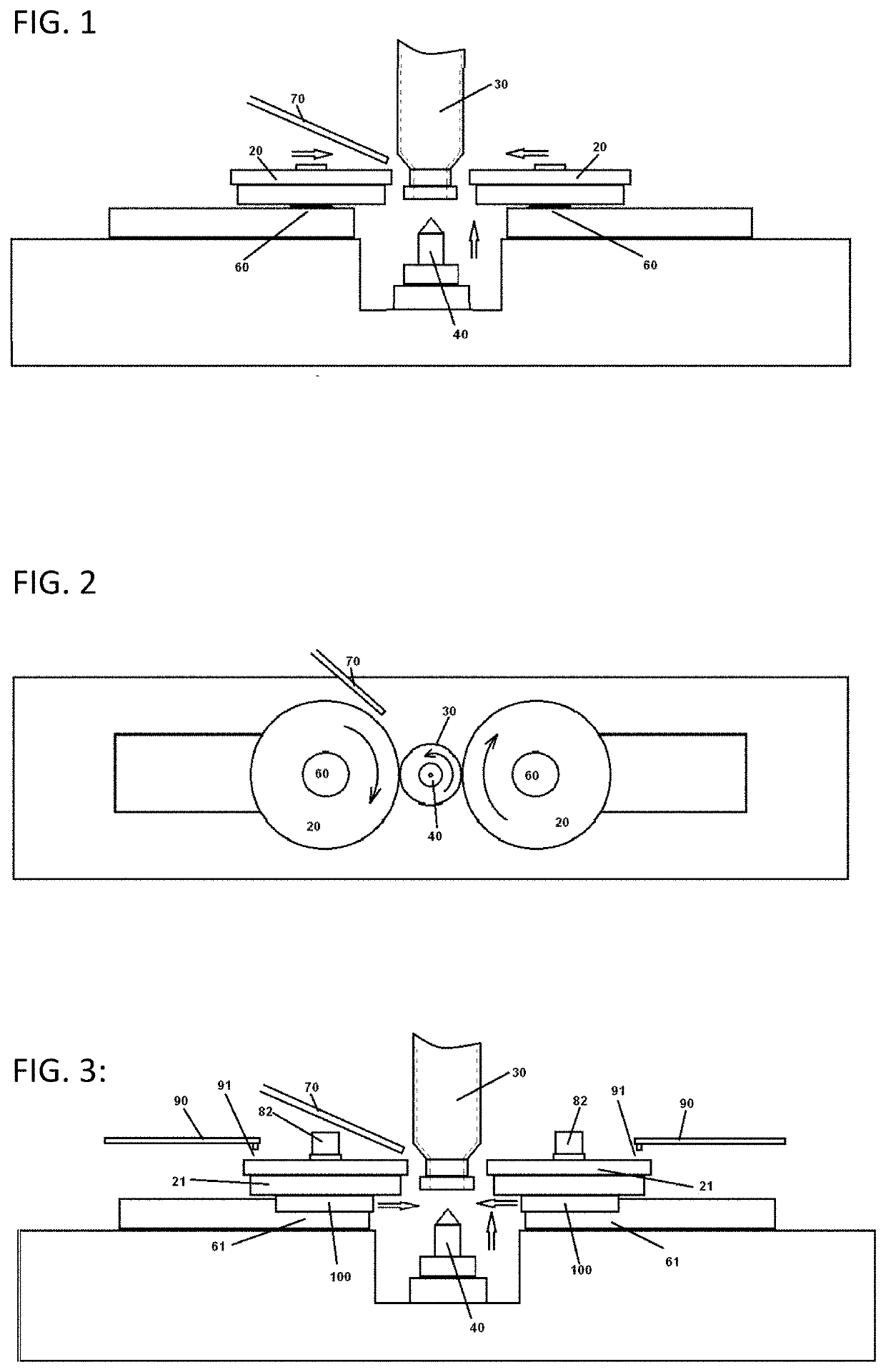

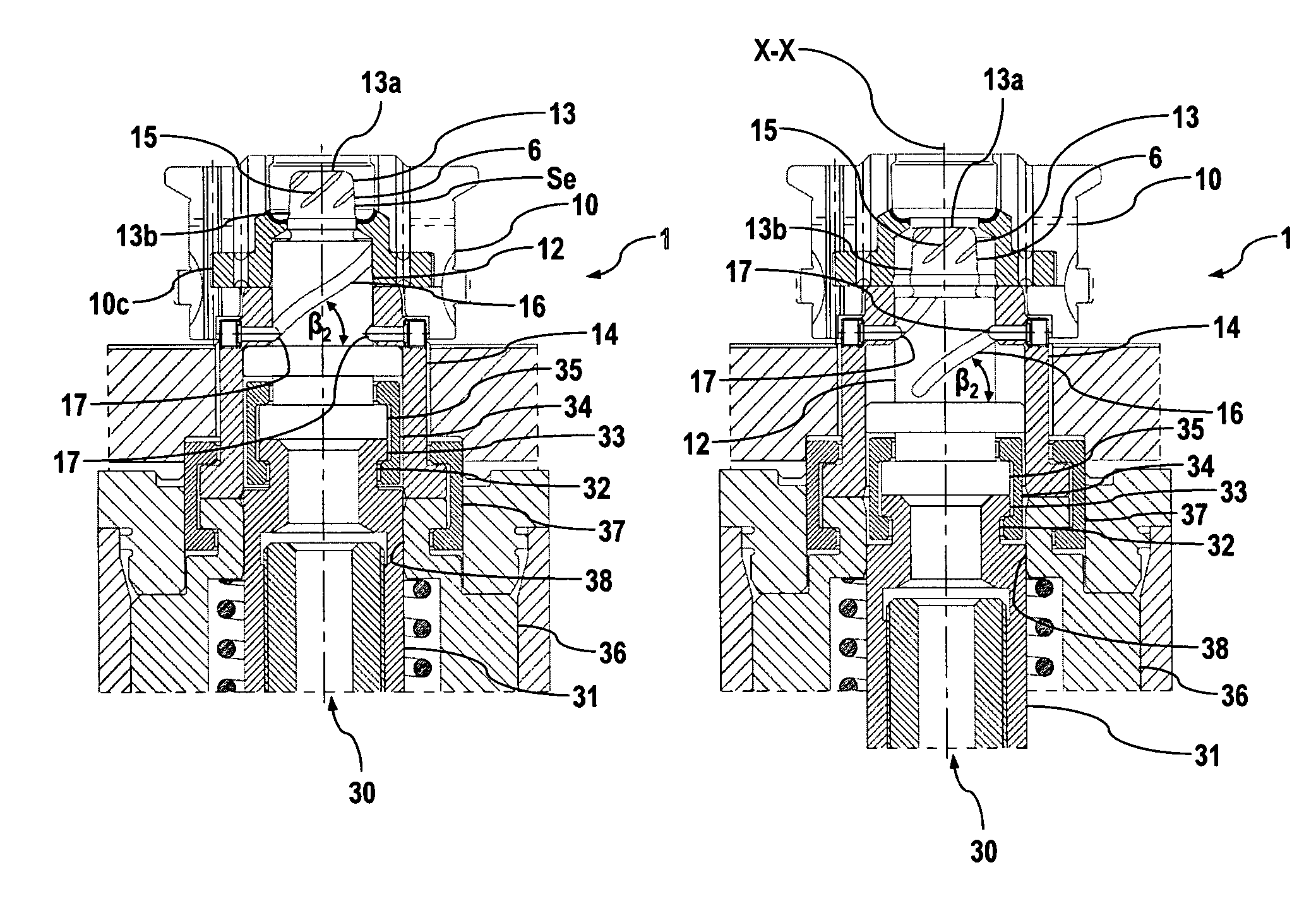

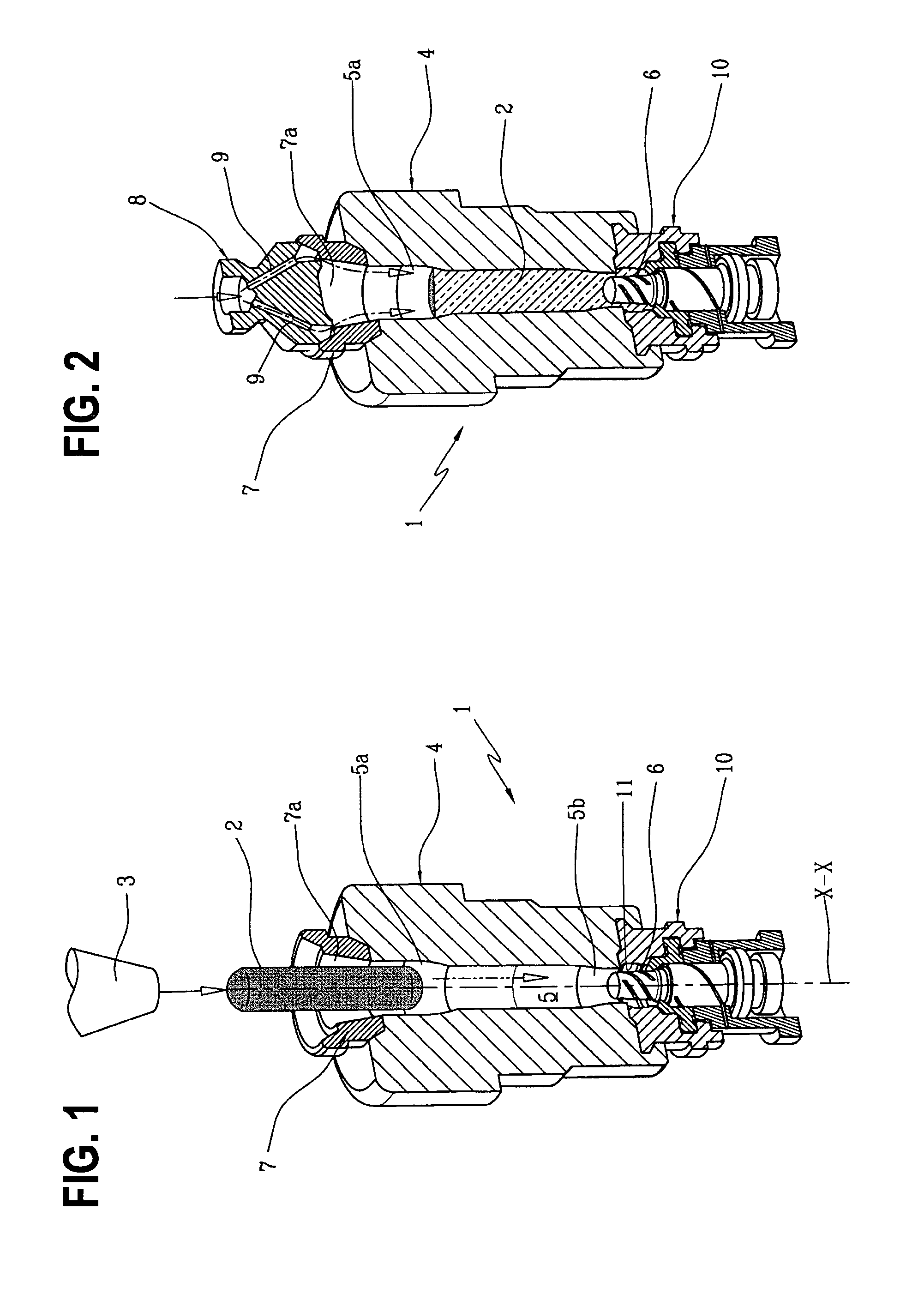

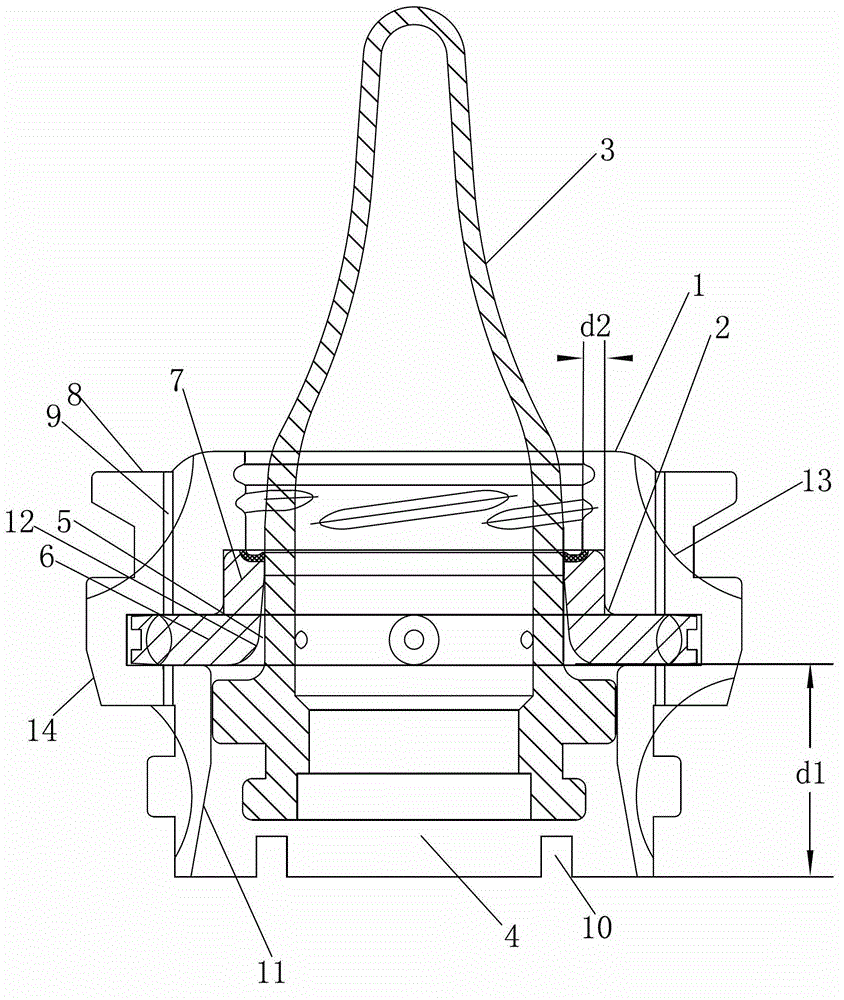

Process and equipment for the fabrication of glass containers with internally threaded neck

ActiveUS20130299444A1Easy to controlSimilar performanceBottlesGlass pressing apparatusEngineeringBottle

The present invention relates to a process and equipment for the fabrication of glass containers with internally threaded neck and such containers. The plunger (6) is from the glass leaving an imprint corresponding to the mouth (M) of a bottle, wherein the plunger has at least one helical groove (15) in its outside surface. During the extraction, the plunger is rotated around a longitudinal axis (X-X) performing a roto-translational motion to unscrew the plunger out of the partially solidified glass, leaving an internal thread in the mouth (M) of the bottle. The roto-translational motion for the extraction of the plunger is generated by: a linear actuator (30) acting on the plunger (6), thereby effecting a linear movement of the plunger (6) along said longitudinal axis (X-X), a guide body (14) wherein the plunger (6) is moved relative to the guide body (14) along said longitudinal axis (X-X), and a helical guide (16, 17) coaxial to the longitudinal axis (X-X) and being provided between said guide body (14) and said plunger (6) and transforming said linear movement effected by said linear actuator (30) on said plunger (6) into said roto-translational motion of said plunger (6).

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Stamping assembly of bottle moulding

The invention discloses a stamping assembly of bottle moulding. The stamping assembly comprises a die and a ring, wherein a first through-hole and a second through-hole used for moving in and out for a punch are respectively arranged in the die and the ring, the ring is arranged in the die and is integrally composed of a retainer ring and a supporting ring, a diameter of the supporting ring is less than that of the retainer ring, the retainer ring clamps the die, the punch is sleeved in the first through-hole and the second through-hole, and a head of the punch exposes out of the die. Periphery of the die is projected with a positioning ring for connecting a hold plier, the positioning ring is provided with a plurality of heat dissipating grooves along a circumferential direction, and the heat dissipating grooves are arranged along a moving direction of the punch. According to the invention, the positioning ring of the die is provided with the plurality of heat dissipating grooves along the circumferential direction, and the heat dissipating grooves are arranged along the moving direction of the punch, so that the stamping assembly can rapidly sending out the heat, and thus improve mouth moulding of the bottle and increase processing quality.

Owner:DEQING CAIFU GLASS

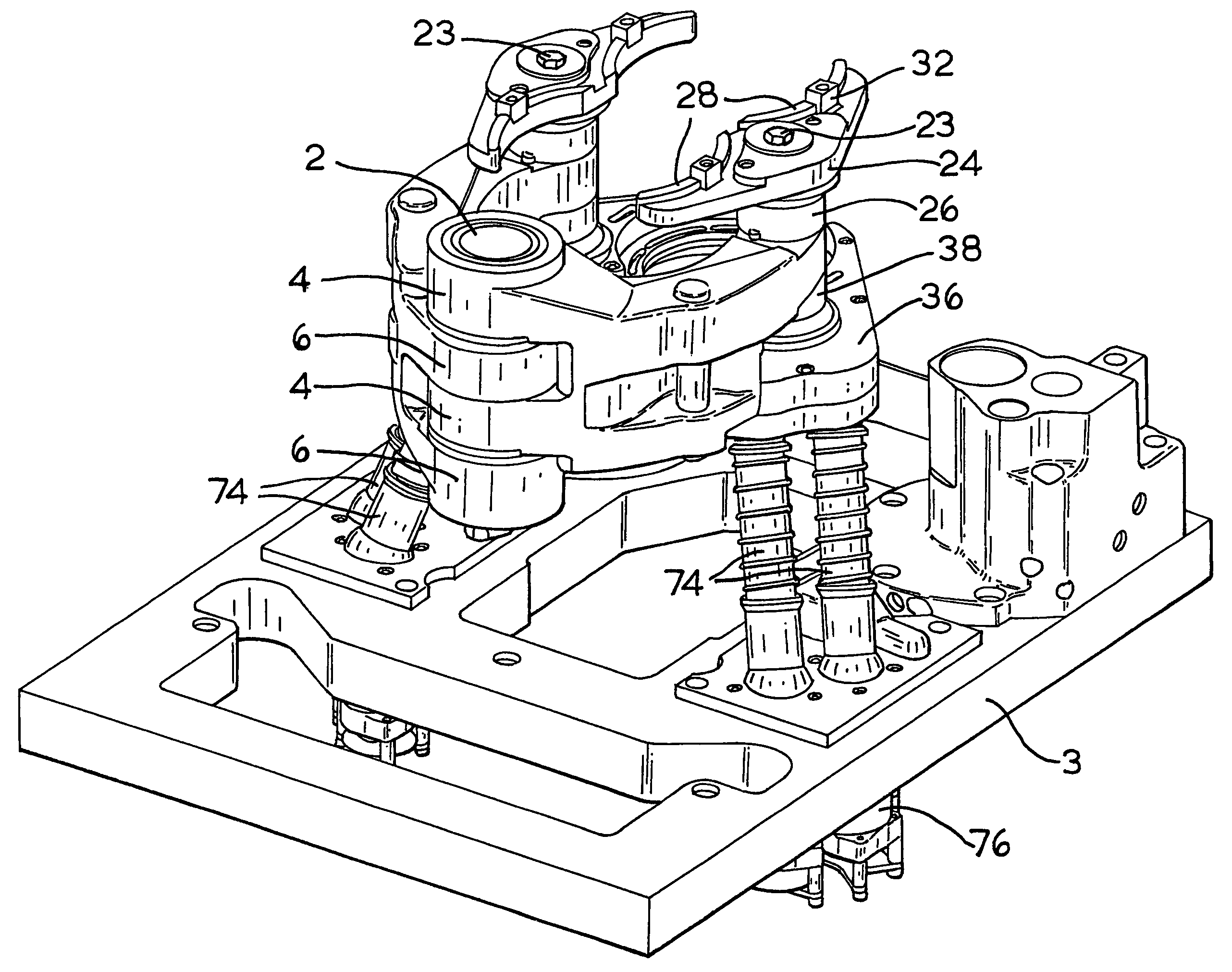

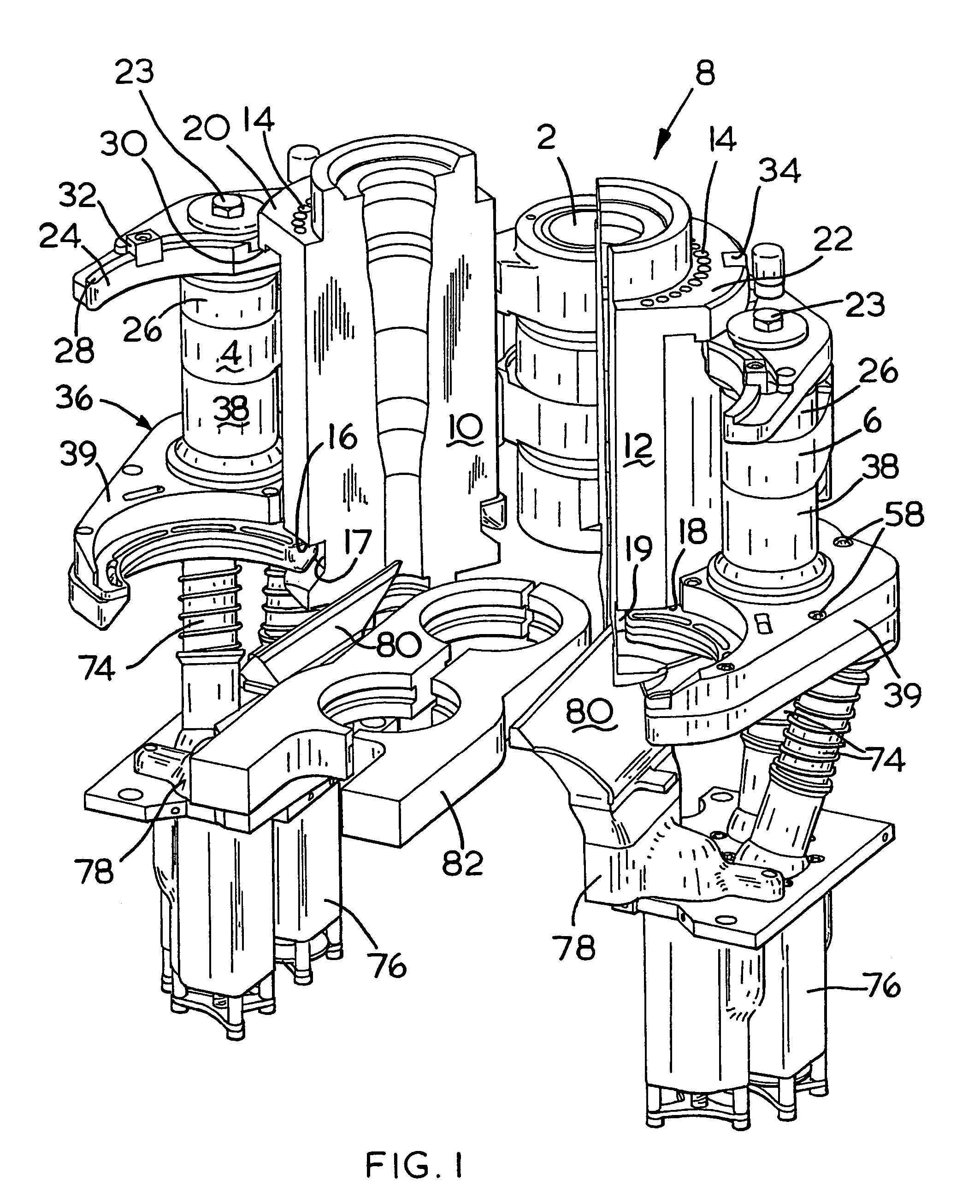

Mold support mechanism for an I.S. machine

ActiveUS7134301B2Glass drawing apparatusGlass transportation apparatusEngineeringMechanical engineering

A mold cooling system is disclosed for the blank mold halves of an I.S. machine. The mold halves are supported at their bottom by a lower hanger assembly which includes a discrete plenum for each of the mold halves. Each plenum is isolated and has its own air supply which includes an adjustable flow control. This provides complete control of the mold cooling process.

Owner:EMHART GLASS SA

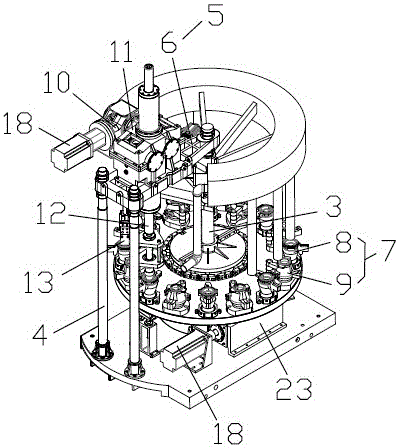

Dual-purpose blowing-pressing kettle machine

PendingCN106630555AReduce the number of peopleCompact structurePress and blow machinesGlass productionDual purposeEngineering

The invention relates to the field of novel glassware pressing machinery, and in particular discloses a dual-purpose blowing-pressing kettle machine. The kettle machine comprises a base, a rotating disc, a rotating shaft, an upright post and a support frame, wherein the rotating disc is arranged on the base; and the rotating shaft as well as the upright post and support frame for fixing and supporting the rotating disc are arranged in the rotating center of the rotating disc. The kettle machine is characterized in that a plurality of groups of glass machining molds are arranged on the rotating disc; the glass machining molds comprise pressing molds and blowing molds; stamping devices corresponding to positions of the glass machining molds are arranged on the support frame; and a kettle clamping manipulator capable of transversely traveling or longitudinally retracting and inflation devices corresponding to the positions of the glass machining molds are connected onto the rotating shaft. The dual-purpose blowing-pressing kettle machine is compact in structure and high in degree of automation, the production efficiency can be greatly improved, and the blowing and pressing processes of kettle processing can be completed by equipment, so that the equipment cost is greatly reduced, and the number of operators can be reduced by one half at least.

Owner:FOSHAN SENTAI MACHINERY MOLD CO LTD

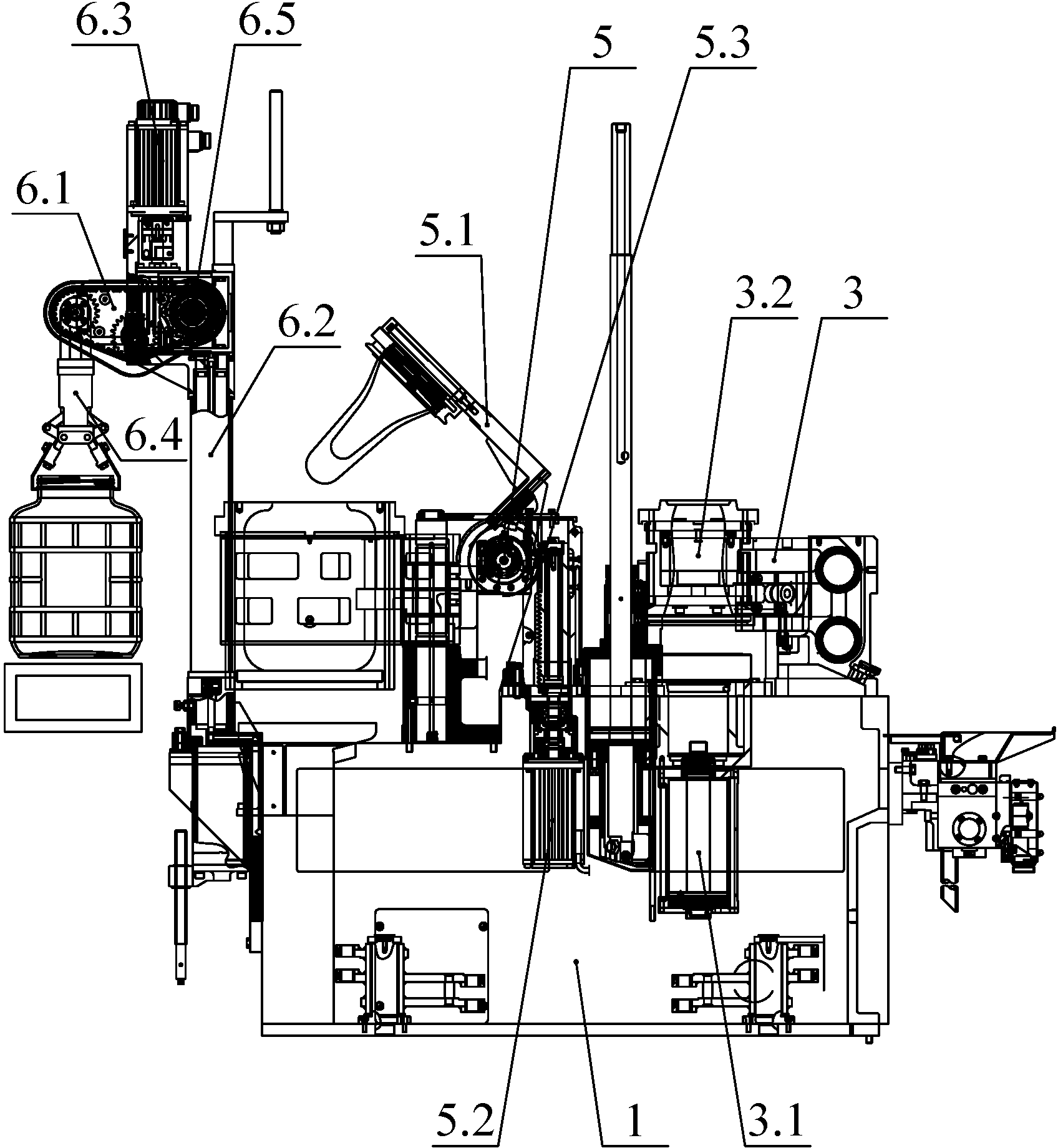

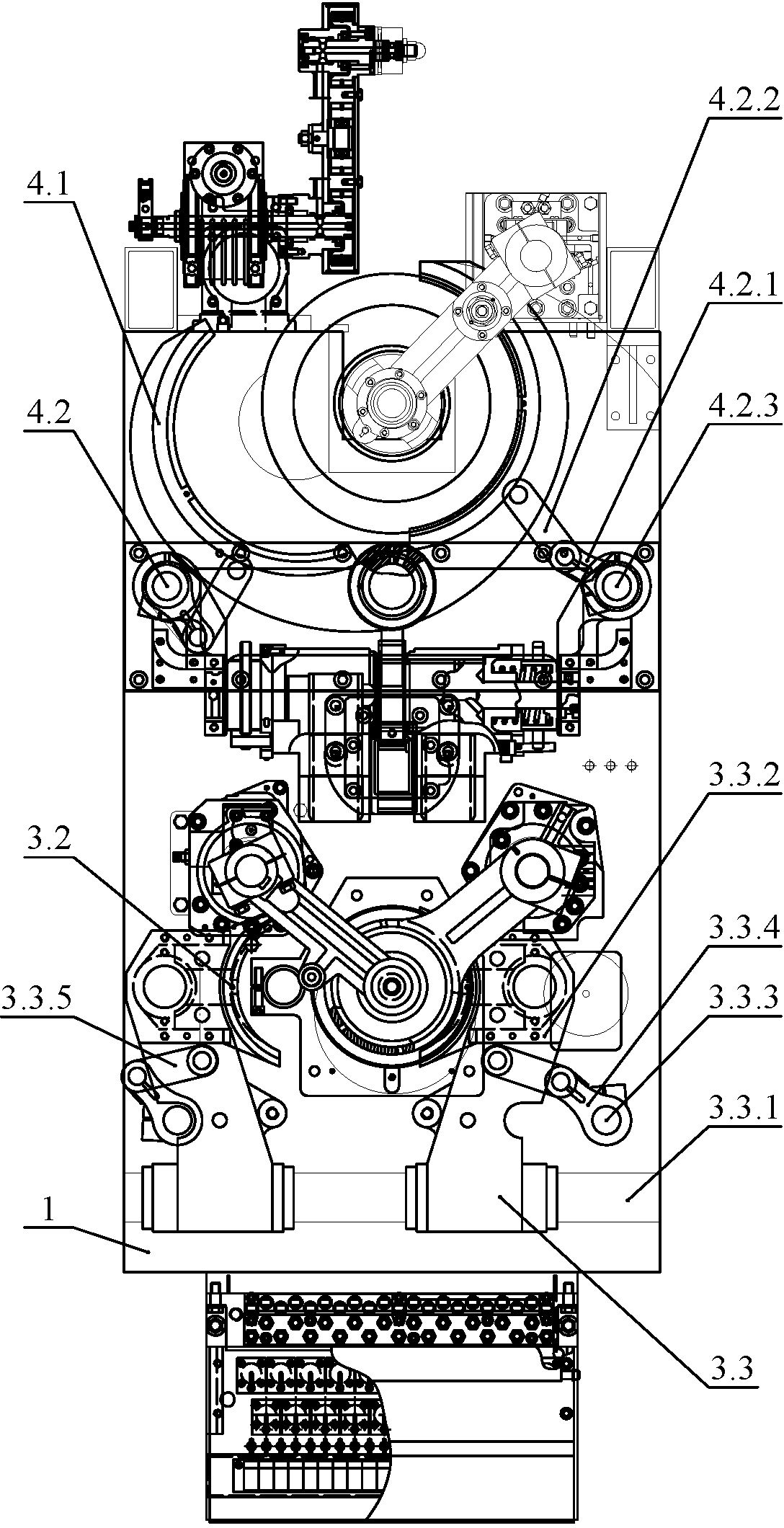

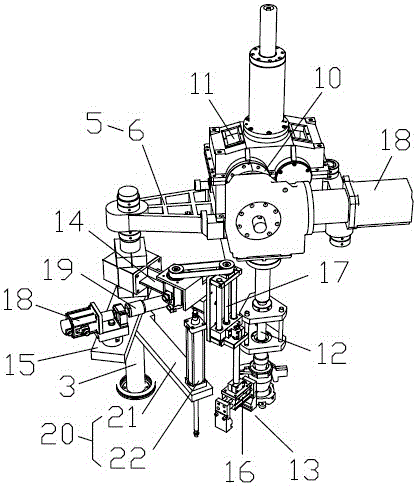

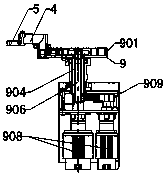

Four-drip multifunctional bottle making machine and small-opening press-and-blow production process implemented by same

The invention discloses a four-drip multifunctional bottle making machine and a small-opening press-and-blow production process implemented by the same, and belongs to the technical field of bottle making machines. The four-drip multifunctional bottle making machine is characterized in that an initial section mold forming mechanism (3) and a forming mold forming mechanism (5) are of parallel switch structures, and a servo turnover mechanism (4) is arranged between the initial section mold forming mechanism (3) and the forming mold forming mechanism (5); a material distributing integrated packaging module (105) is arranged on a servo material distributing mechanism (1), a detachable material distributor is arranged on the material distributing integrated packaging module (105), at least twogroups of discharge openings are formed in the material distributor, and small-opening quick-change press-and-blow mechanism (15) with four independent cavities are arranged below the initial sectionmold forming mechanism (3). The four-drip multifunctional bottle making machine and the small-opening press-and-blow production process have the advantages that four initial section preforms can be synchronously stamped by the aid of the four-drip multifunctional bottle making machine and the small-opening press-and-blow production process at one step, and conditions can be provided to speciallyproducing high-grade lightweight bottles; the material distributing integrated packaging module of the material distributing mechanism with group count further can be replaced, accordingly, differenttypes of drip can be distributed and supplied, and the four-drip multifunctional bottle making machine and the small-opening press-and-blow production process are convenient and speedy and are universally applicable to various bottle making models with different specifications.

Owner:SHANDONG JIAFENG GLASS MACHINERY

Three-Dimensional Printing on Glass Containers

ActiveUS20200346971A1Additive manufacturing apparatusDuplicating/marking methodsEngineeringMechanical engineering

This disclosure describes substrate(s) formed with a three-dimensional (3D) feature thereon, and method(s) of printing the same. One method includes identifying a plurality of locations on a substrate surface where the three-dimensional feature will be formed, determining a height value of the three-dimensional feature at each location, assigning a grayscale value to each location based on the height value, and applying ink to the substrate surface at each location according to the assigned grayscale value.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com