Patents

Literature

31results about How to "Structural changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dustproof cabinet, dustproof method and computer

InactiveCN101498959ASimple structureStructural changesDigital processing power distributionEngineeringUltimate tensile strength

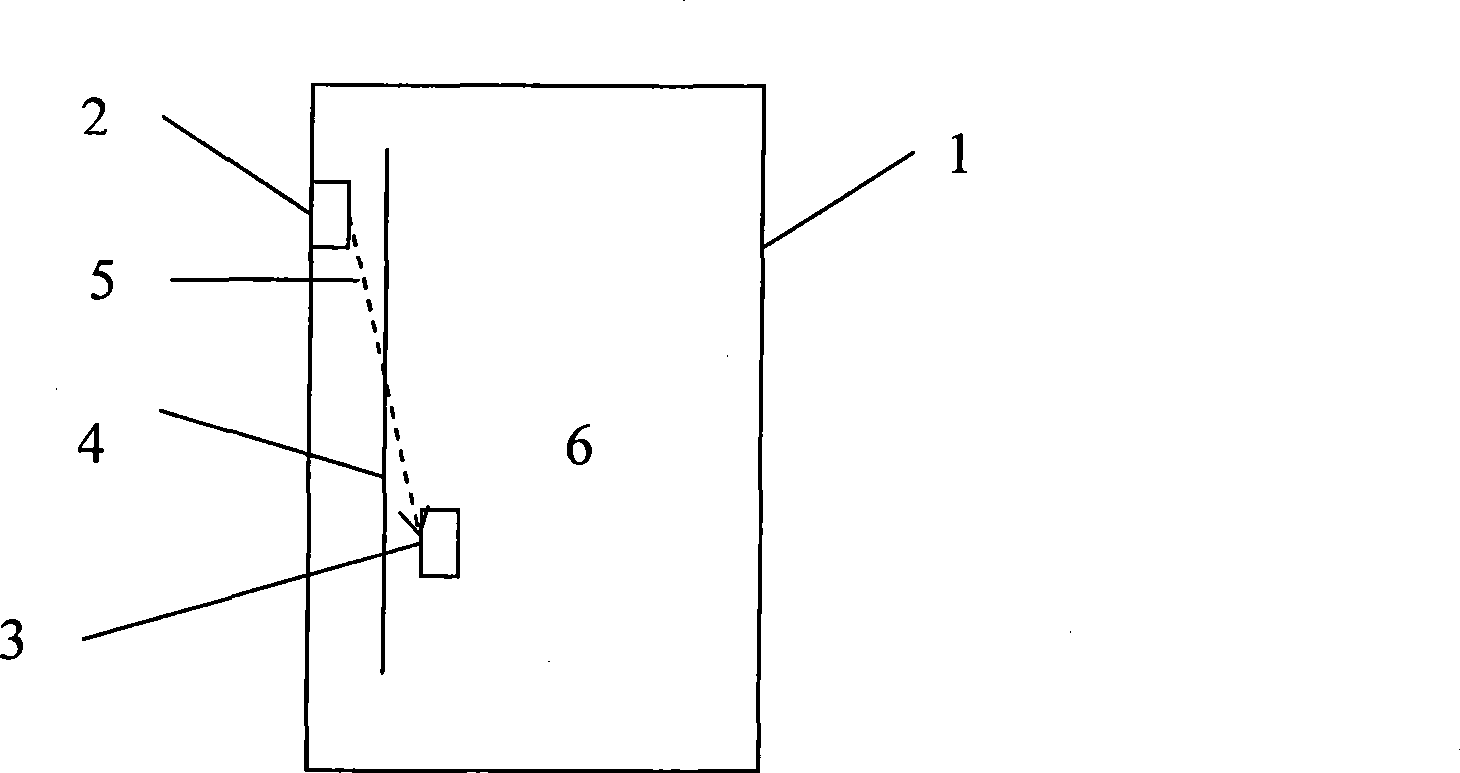

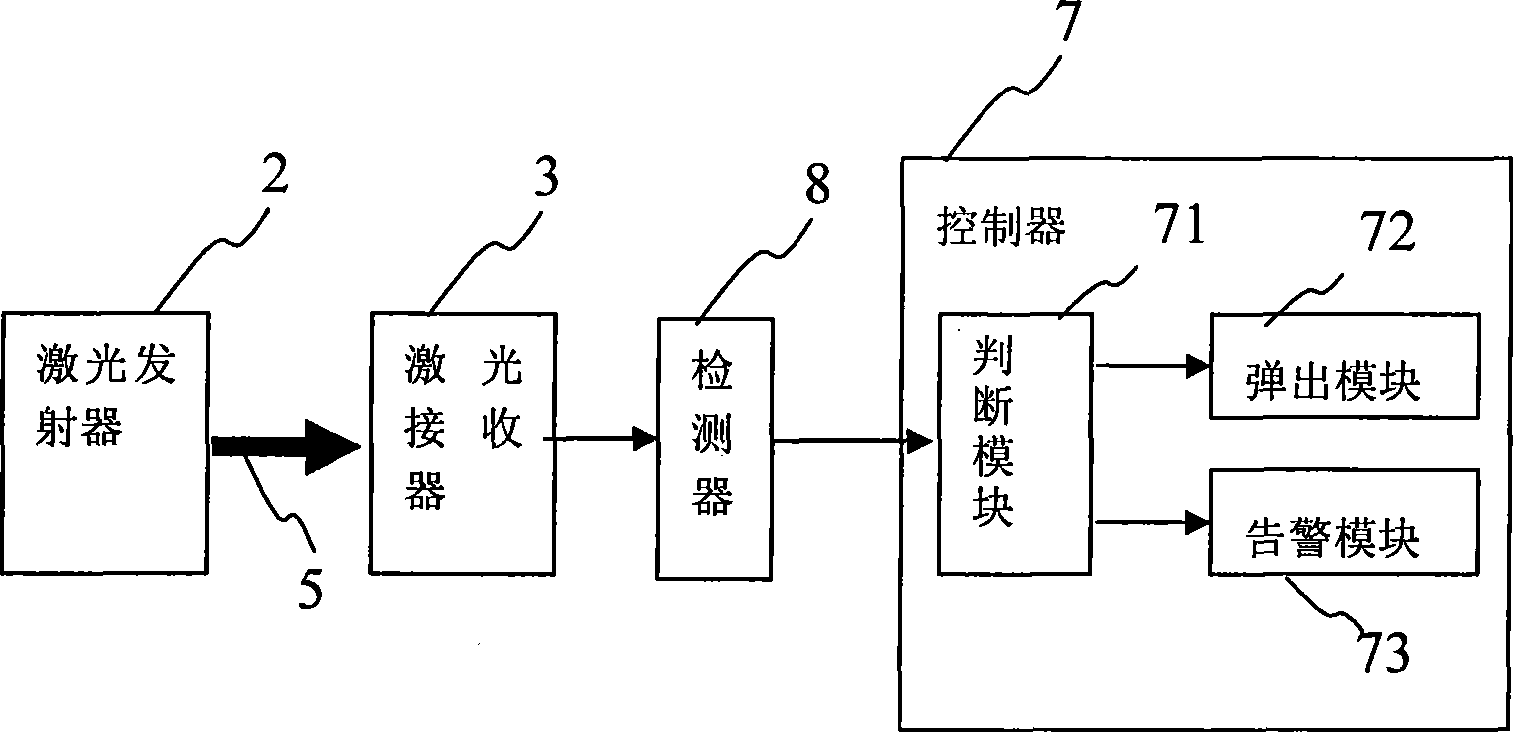

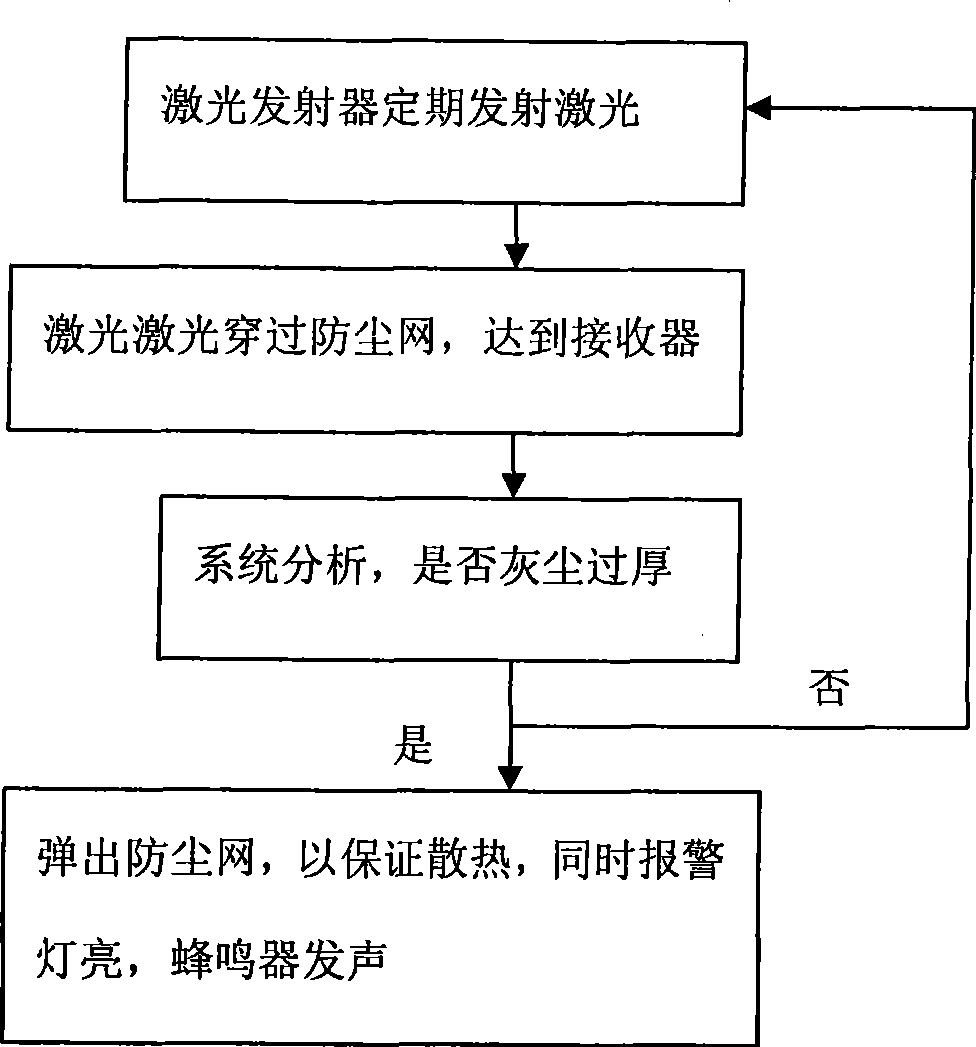

The invention provides a dustproof chassis, a dust removing method and a computer; the dustproof chassis comprises a dustproof net provided on the vent of the chassis; an emitter provided on one side of the dustproof net fro emitting the beam passing through the dustproof net; a receiver provided on the other side of the dustproof net for receiving the beam emitted by the emitter; a detector for detecting the strength of the beam receive by the receiver; a controller for ensuring the dust thickness of the dustproof net and adopting the dust suppression according to the strength of the beam receive by the receiver. The invention has function of dust prevention and dust measuring; when the system detects that there are too much dust on the dustproof net, it will pops the dustproof net and notifies the users to clear by alarm lamp, buzzer and other manners.

Owner:LENOVO (BEIJING) LTD

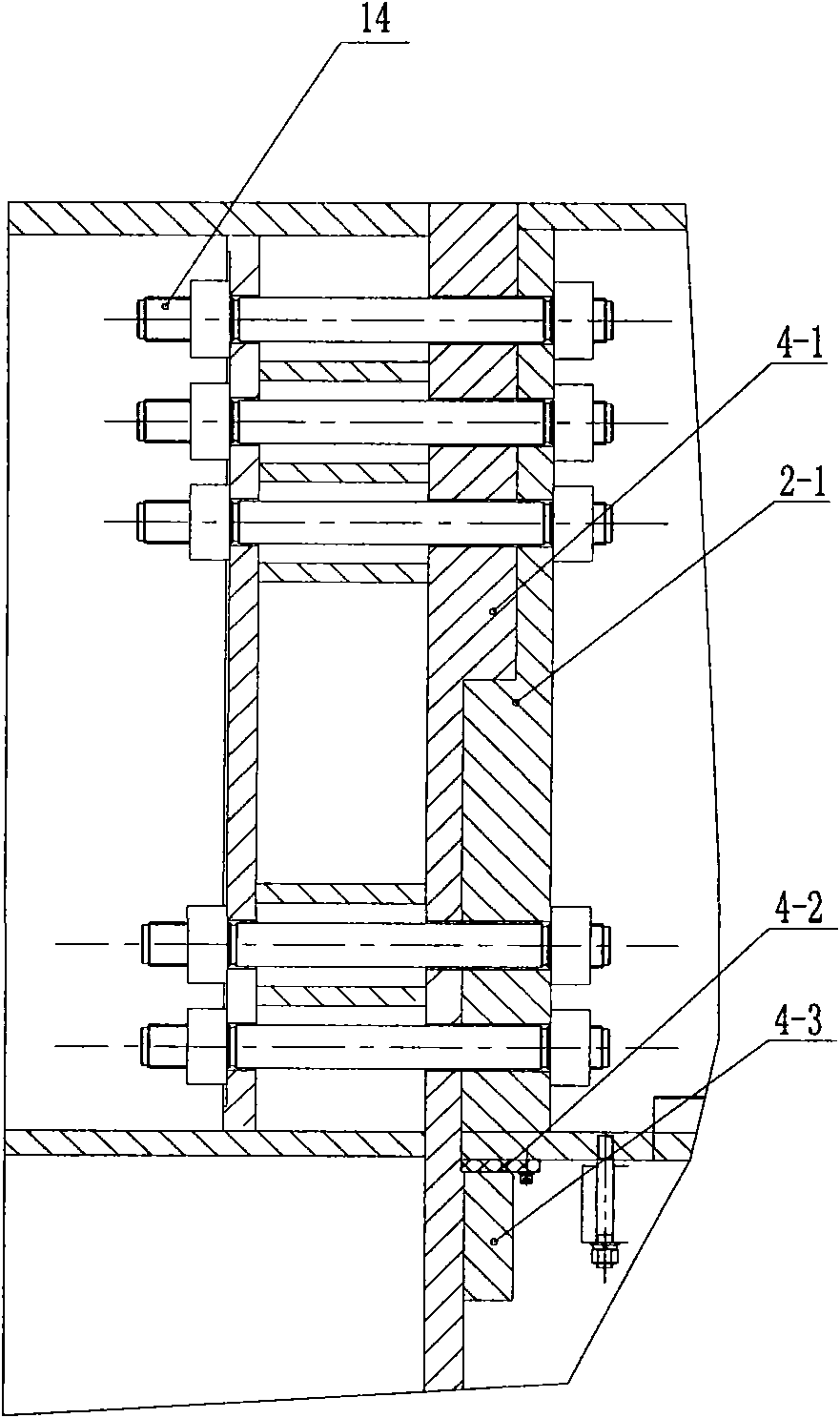

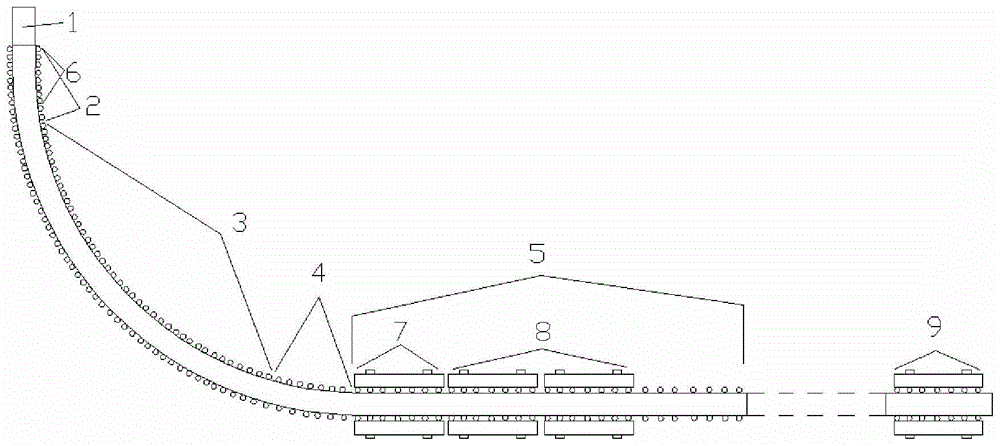

Method for producing ultra-thick plate continuous casting blank

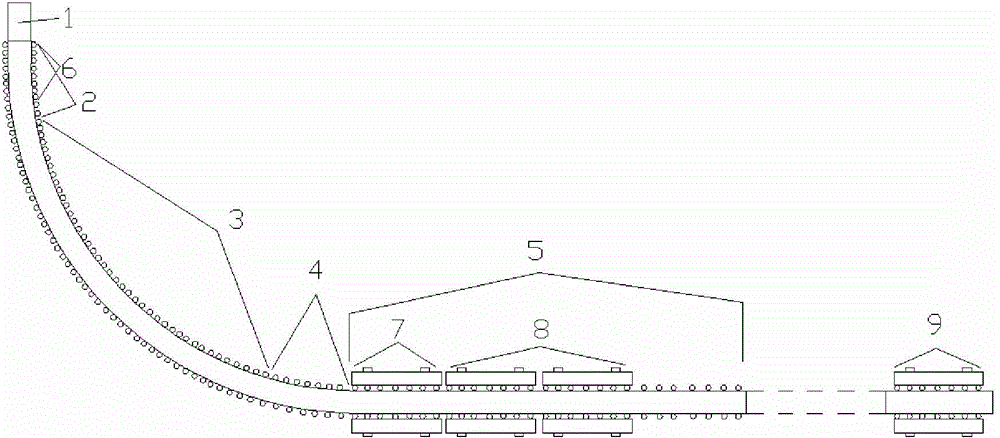

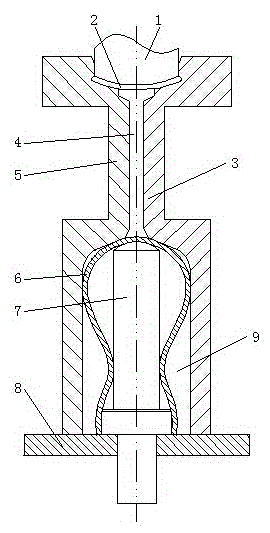

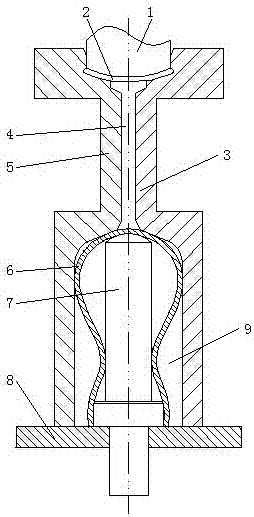

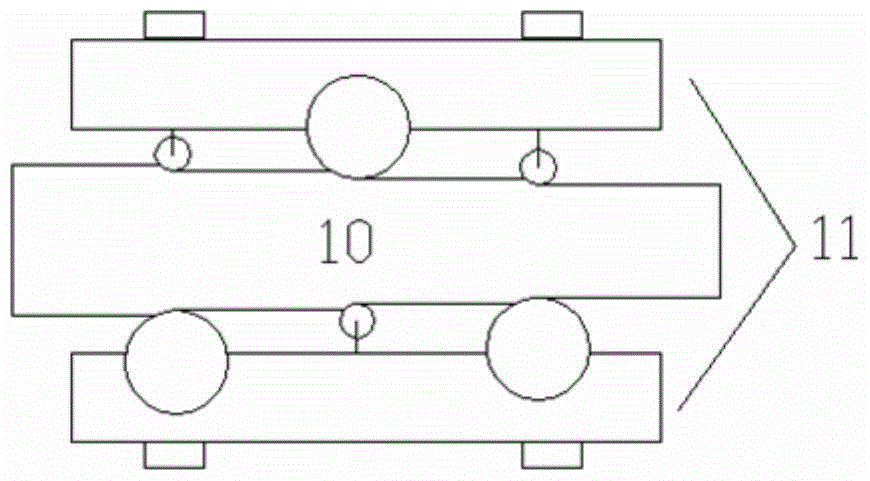

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

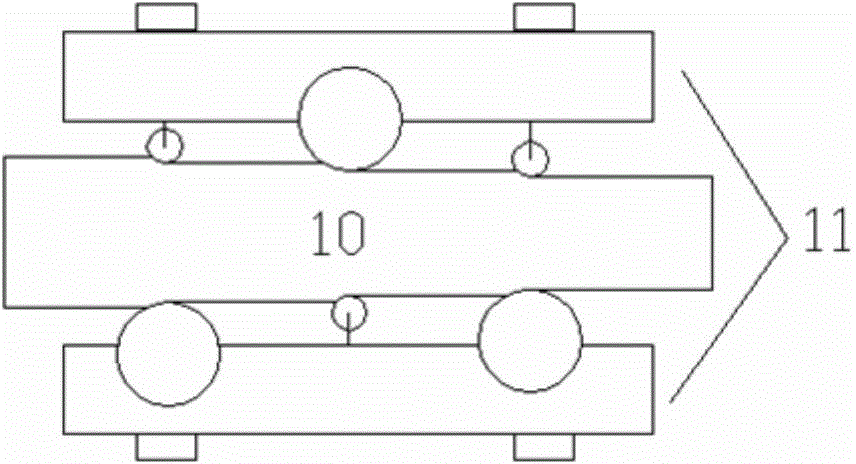

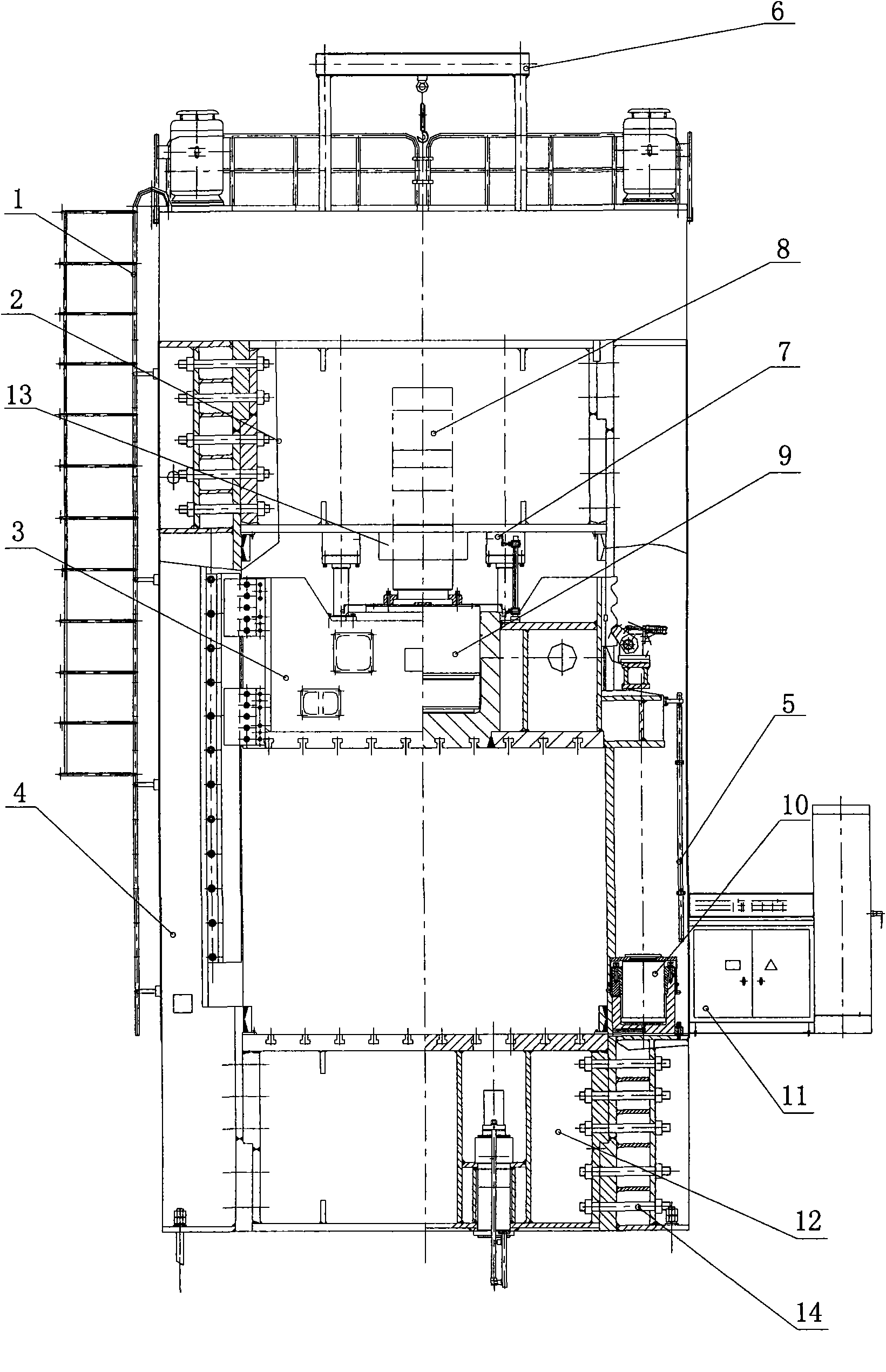

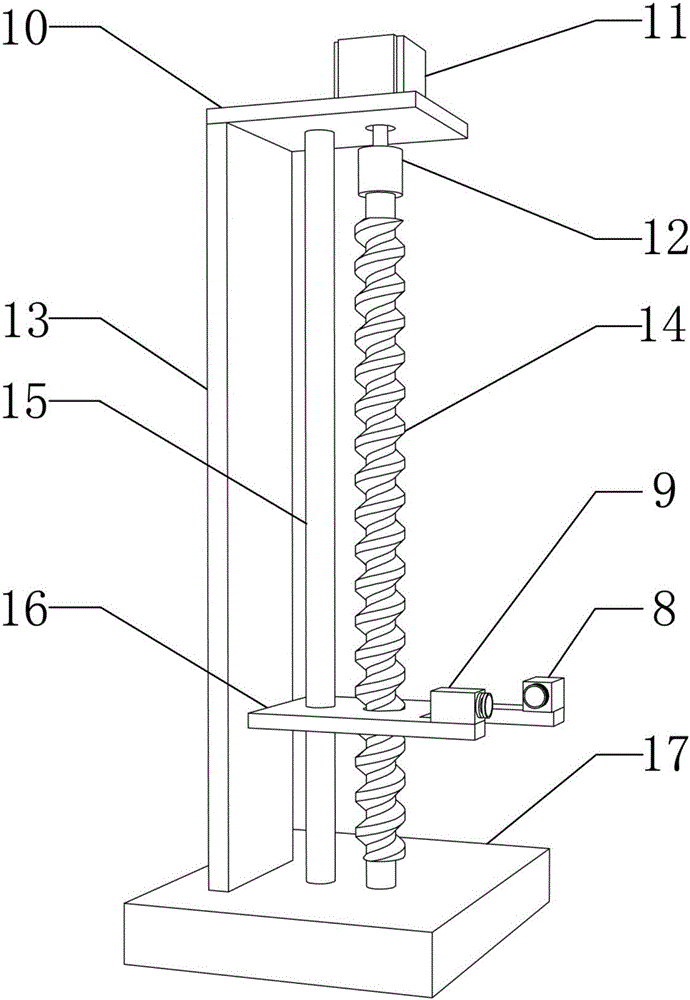

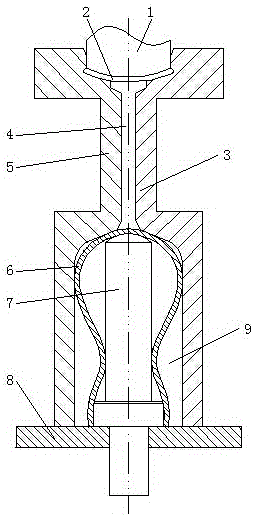

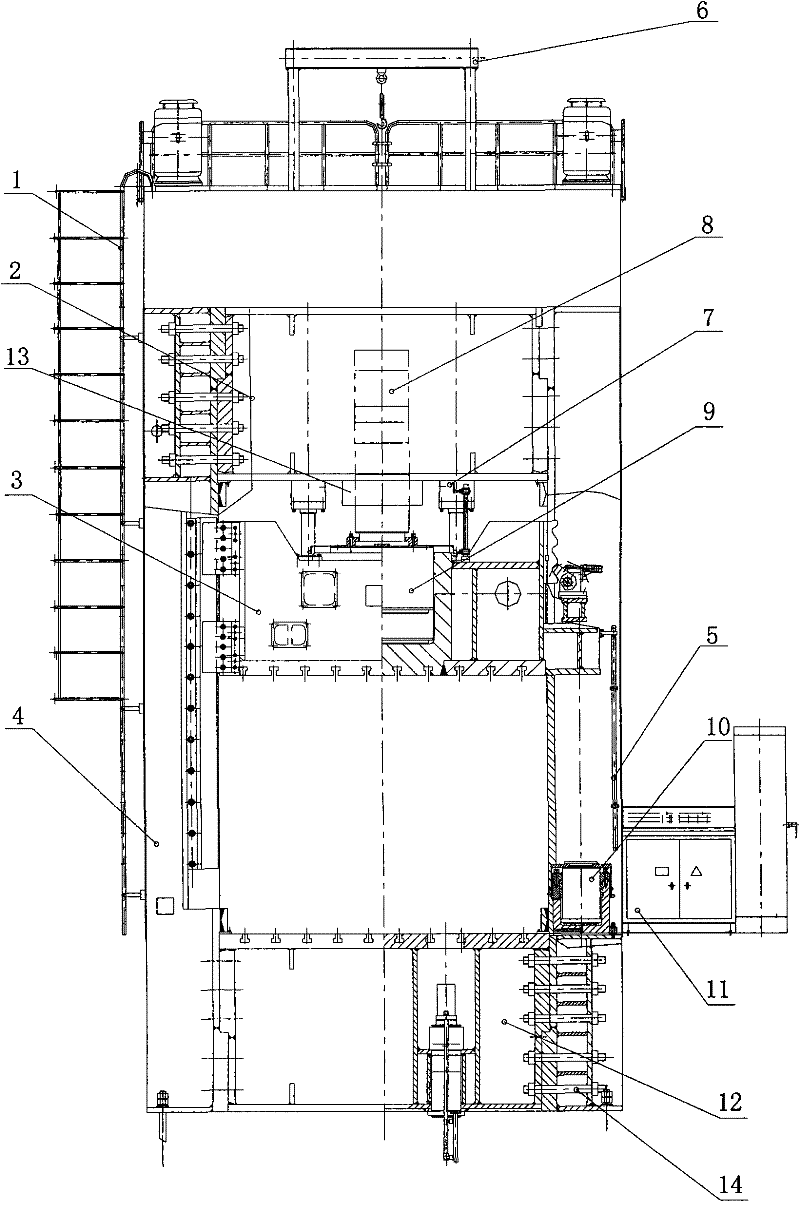

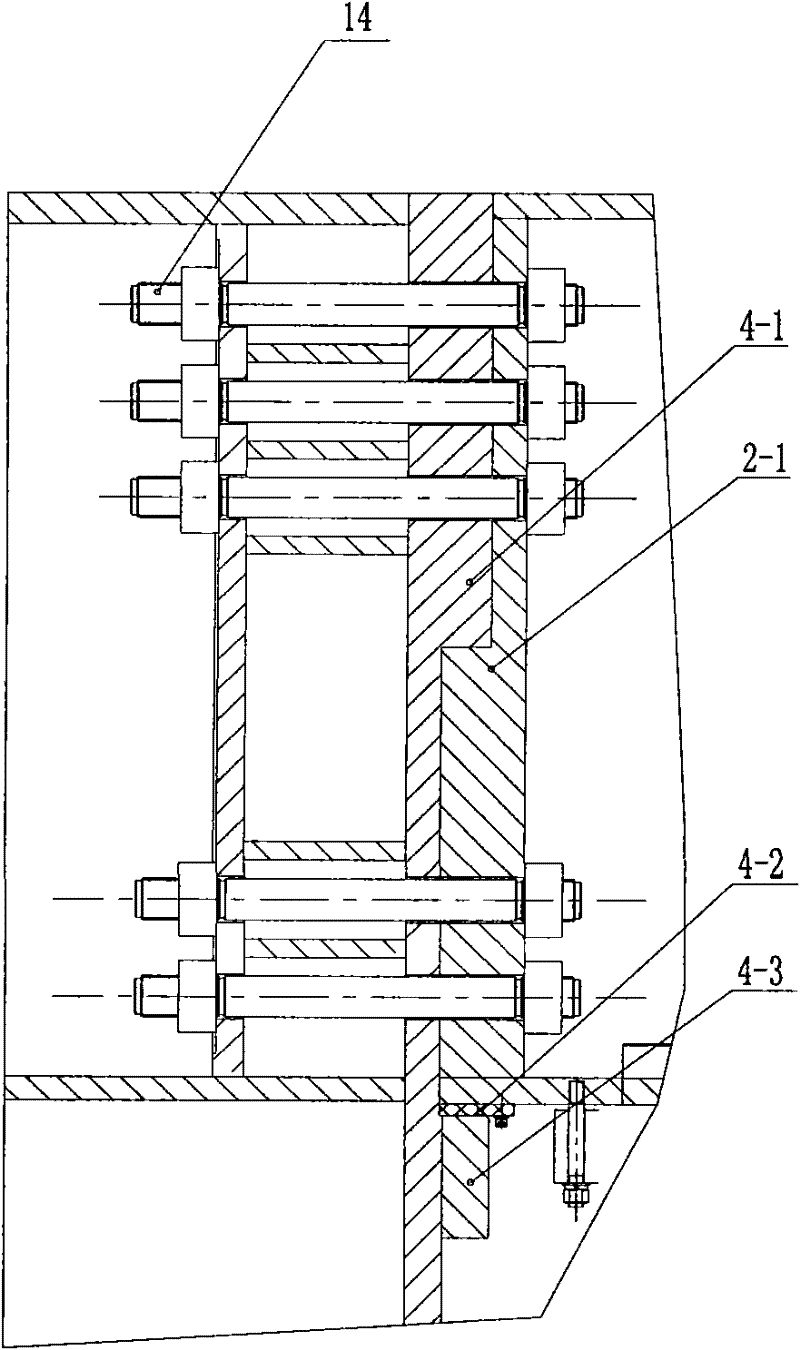

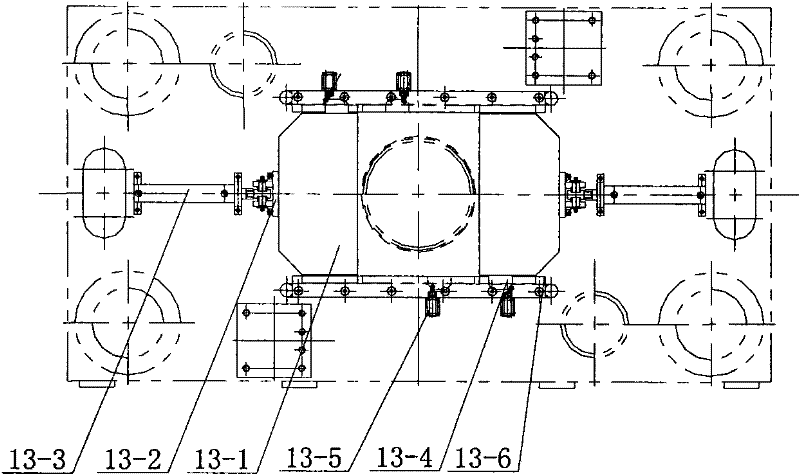

Combined framewrok non pull rod type glass product hydraulic press with adjustable stroke

The invention relates to a combined framework non pull rod type glass product hydraulic press with adjustable stroke, comprising a stand platform, a supporting post, an upper transverse beam, a main working oil cylinder, a slide block, a lower transverse beam and an electric control box which is mounted at the side of a machine body. The combined framework non pull rod type glass product hydraulicpress with adjustable stroke is characterized in that the internal side of the supporting post is provided with a shoulder; the upper transverse beam and the lower transverse beam are provided with shoulders, and the upper transverse beam and the lower transverse beam are fastened with the shoulder of the supporting post through the shoulders and bolt fastening components to form a gantry framework type machine body structure; and the lower plane of the upper transverse beam is provided with a gate device. The combined framework non pull rod type glass product hydraulic press with adjustablestroke has simple and reasonable structure as well as convenient installation and connection, lightens of the weight of a main machine, saves large amount of steel, greatly reduces the manufacture cost of the hydraulic press as the main working oil cylinder adopts a cylinder action type slide block structure inside which a plunger is totally mounted to result in the reduction of the length of an oil cylinder by approximate 4 / 5 and reduction of oil consumption of the hydraulic press by at least 4 / 5. The total power and the pump energy of the electric motor of the hydraulic press are below 50 percent of those of the traditional hydraulic press, the electric energy and industrial oil are obviously saved, and the production cost can be reduced for users.

Owner:TIANJIN TIANDUAN PRESS CO LTD

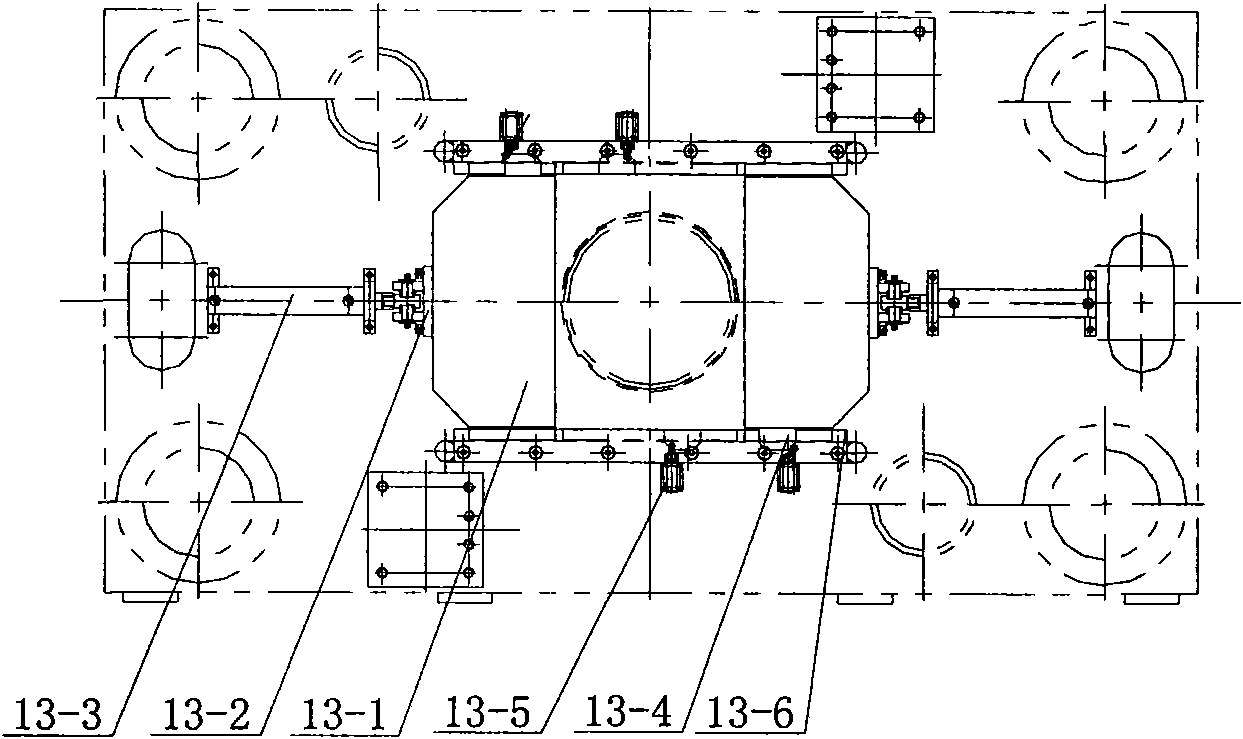

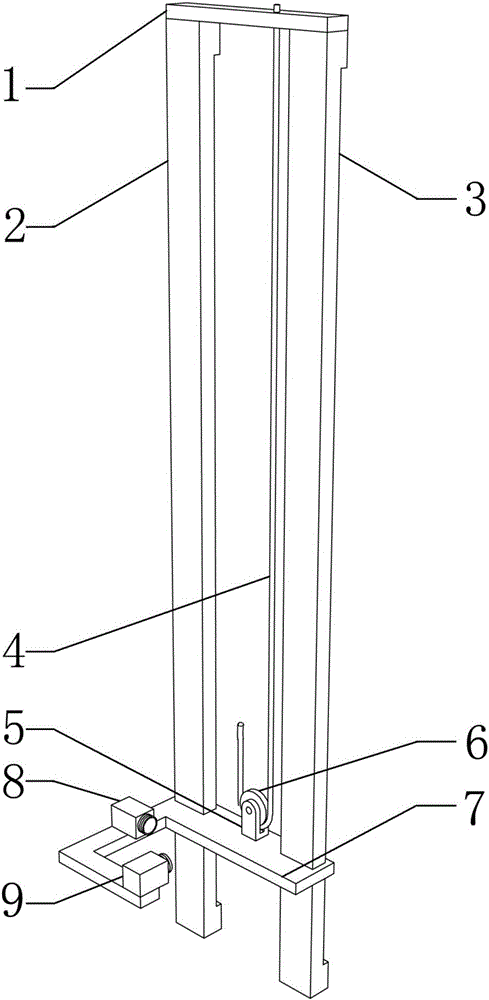

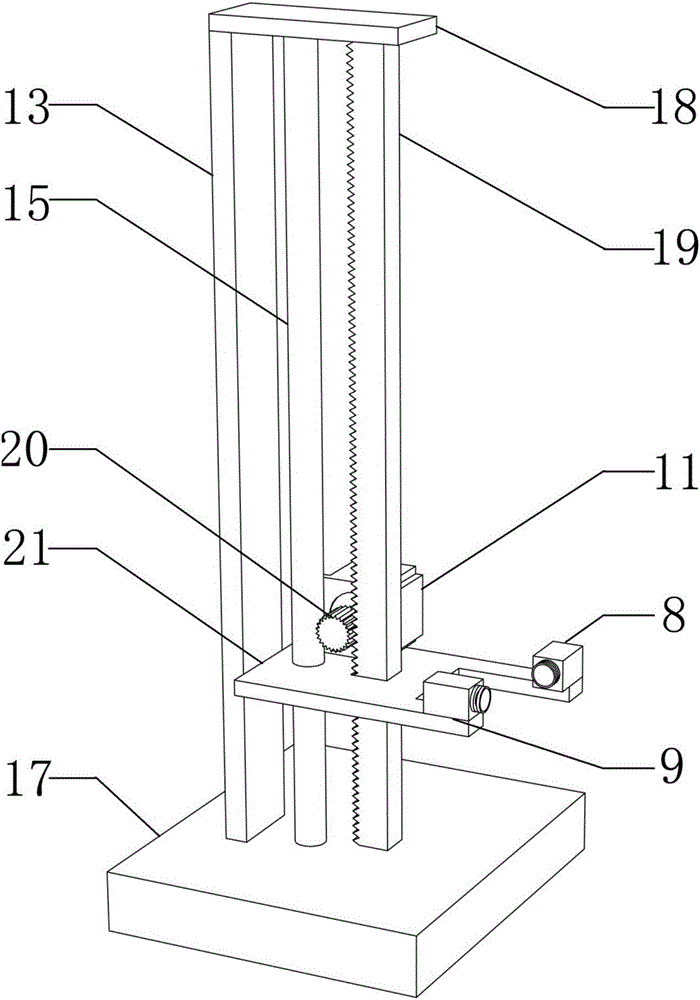

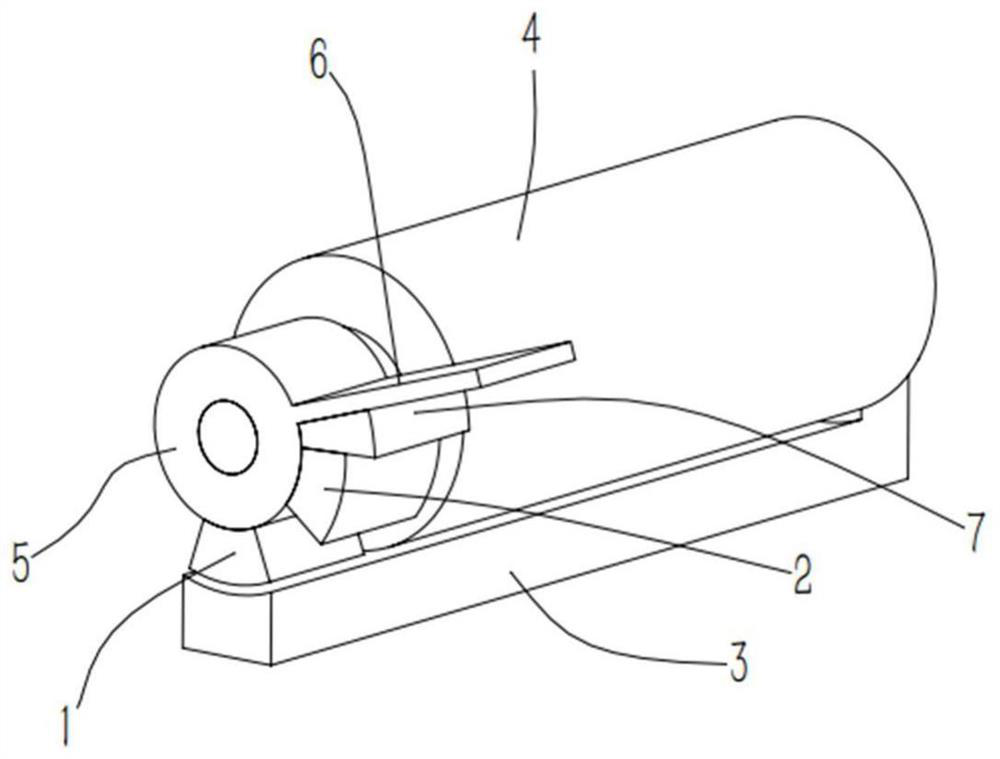

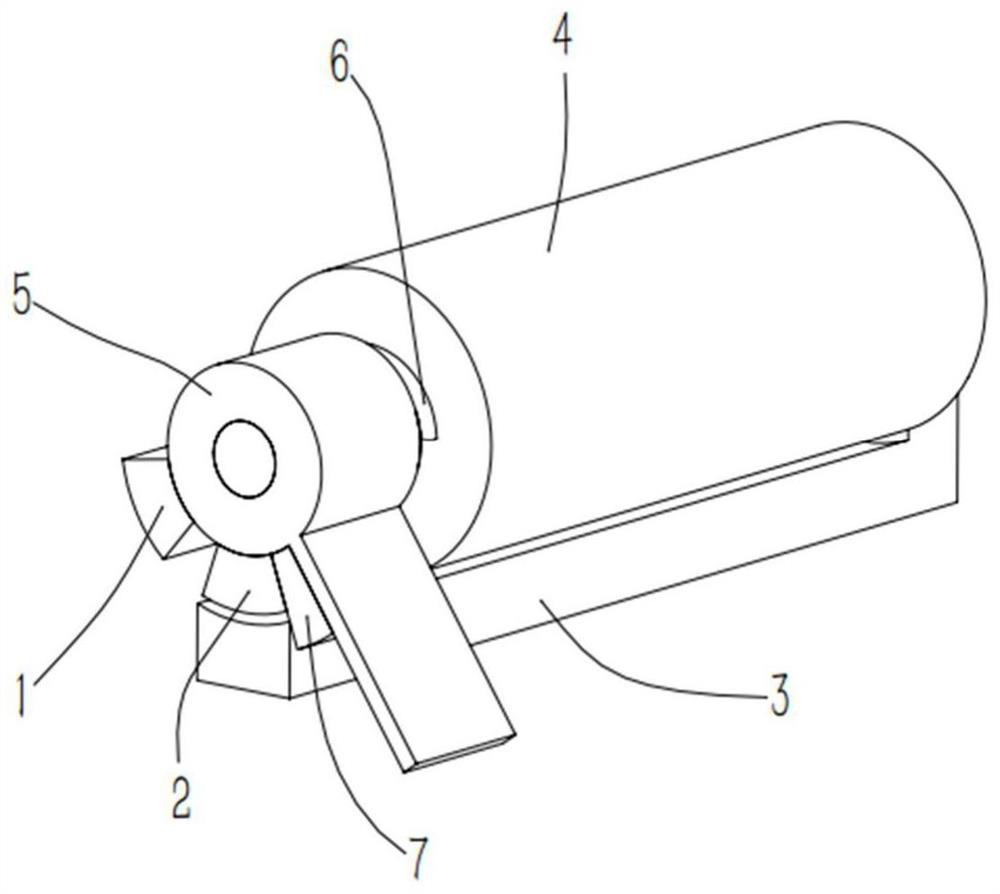

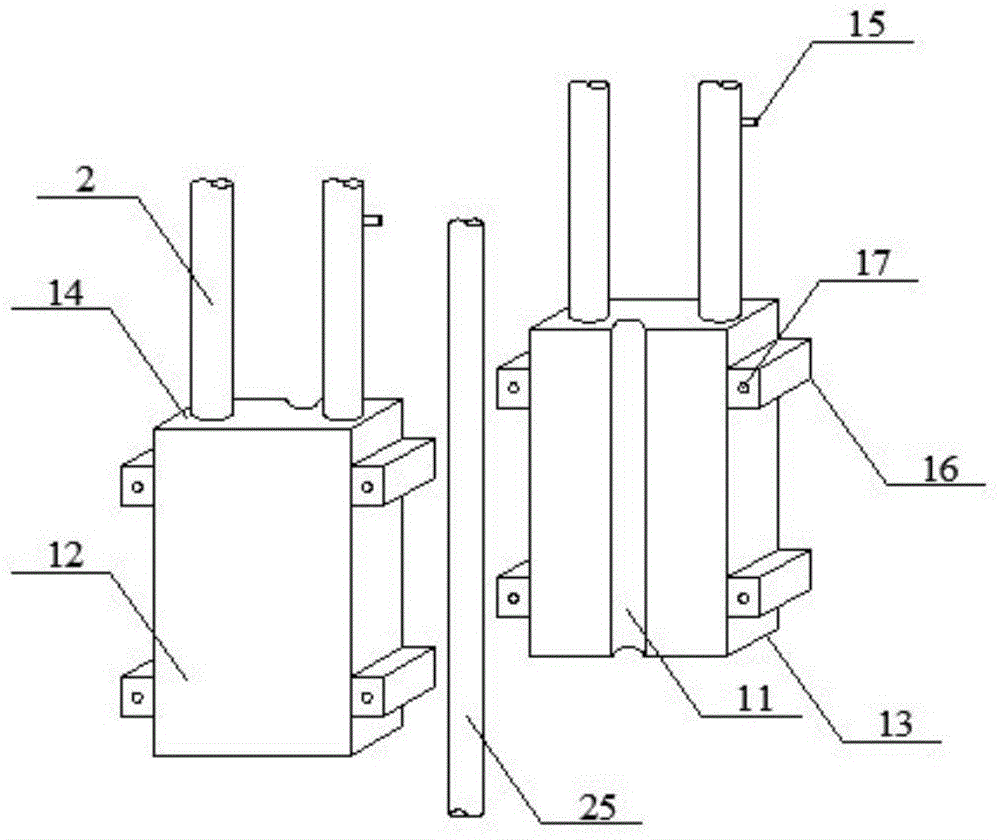

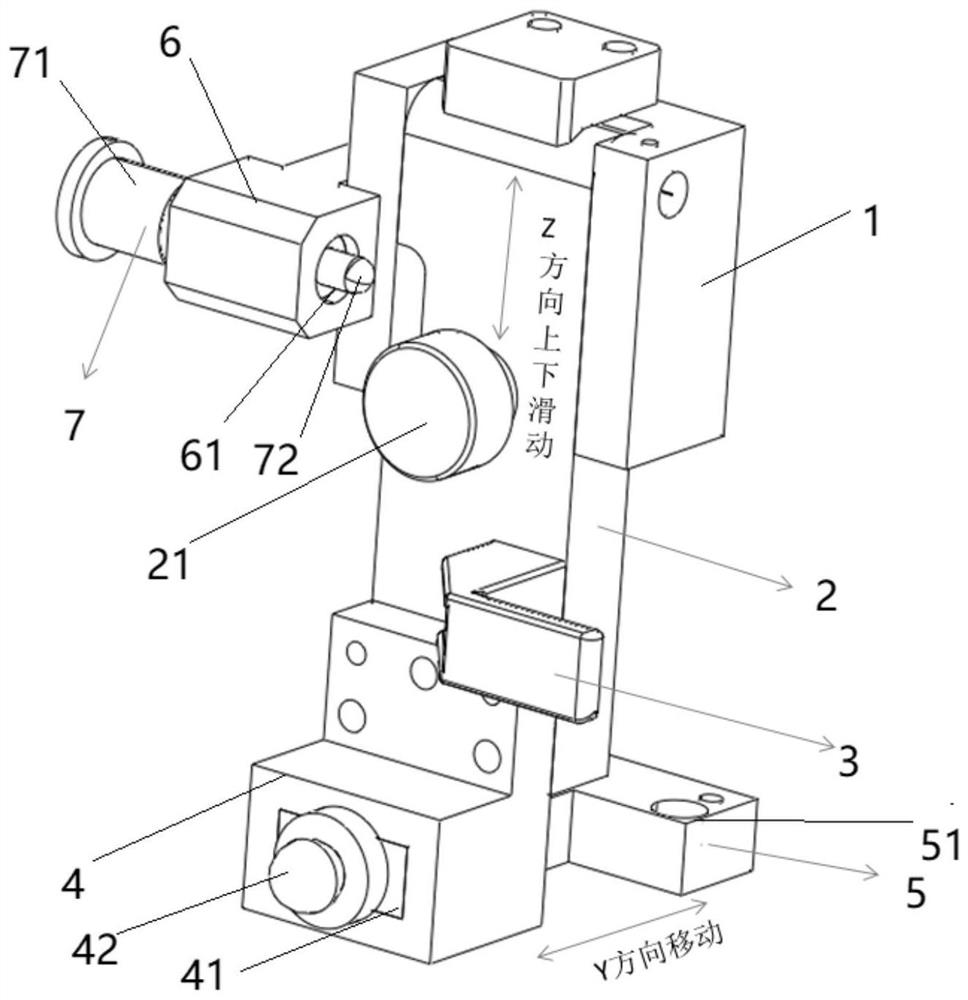

Measuring device capable of achieving real-time measuring of geometric dimensioning of cross section of sample and application thereof

ActiveCN105973699AStructural changesThe tensile test process has no effectStrength propertiesStress–strain curveTest material

The invention discloses a measuring device which can be used for a tensile test machine and can carry out real-time measuring on the geometric dimensioning of a cross section in the sample tensile testing process and application of the measuring device. A true stress-strain curve of a material to be tested is acquired, and the tensile mechanical behavior of the material is scientifically and effectively analyzed. The measuring device is composed of a movable platform, a camera I, a camera II, a support, a drive device and the like. The measuring device can be directly installed on an ordinary tensile test machine in a modularization mode and can measure the real-time geometric dimensioning of the cross section of a sample in the tensile process, and the measuring device is ingenious in structure, simple and practical.

Owner:DALIAN MARITIME UNIVERSITY

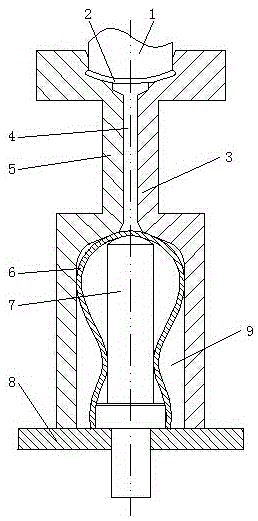

Process for manufacturing glass goblets by machine blowing and machine pressing in sequence

ActiveCN105084717AIncrease color varietiesStructural changesPress and blow machinesGlass productionSocial benefitsMolding machine

The invention relates to a process for manufacturing glass goblets by machine blowing and machine pressing in sequence, relating to a preparation method of glass goblets. The process comprises the steps: preparing a glass raw material, melting the material in a furnace, supplying a goblet body material by a supplying machine, blowing goblet bodies by a blowing machine, manually transferring the goblet bodies to a fire cutting machine for cutting, manually transferring the goblet bodies to a mold of a press molding machine, supplying a goblet handle and goblet support material by a supporting machine, carrying out press molding by a press molding machine to obtain goblet handles and goblet supports, connecting each goblet handle with the outer bottom of each goblet body, manually transferring the goblets to a fire polishing machine for polishing, manually transferring the polished goblets to an annealing furnace for annealing, discharging out of the annealing furnace, checking and packaging. By adopting the process, the glass goblets are successfully manufactured by machine blowing and machine pressing in a combined manner, the product quality is significantly improved, the production cost is greatly lowered, the amount of labour used is greatly reduced, the goblet bodies, the goblet handles and the goblet supports are various in structures, the colors and patterns of the glass goblets are significantly increased, and obvious economic benefits and significant social benefits are achieved; and the process also has a promotion value.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

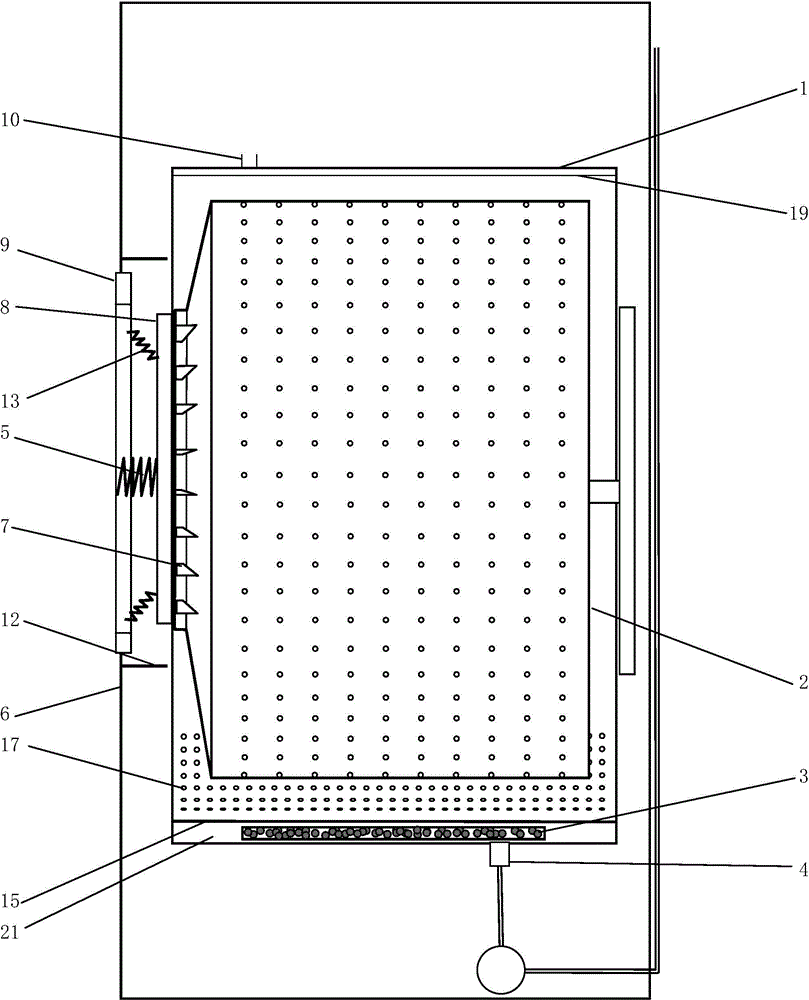

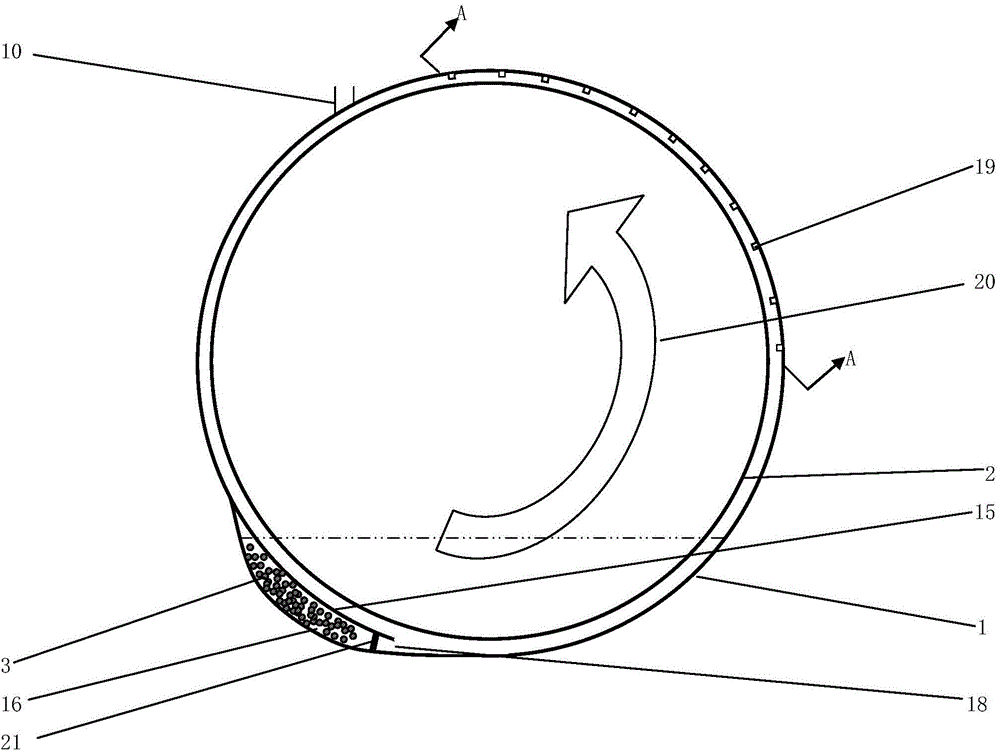

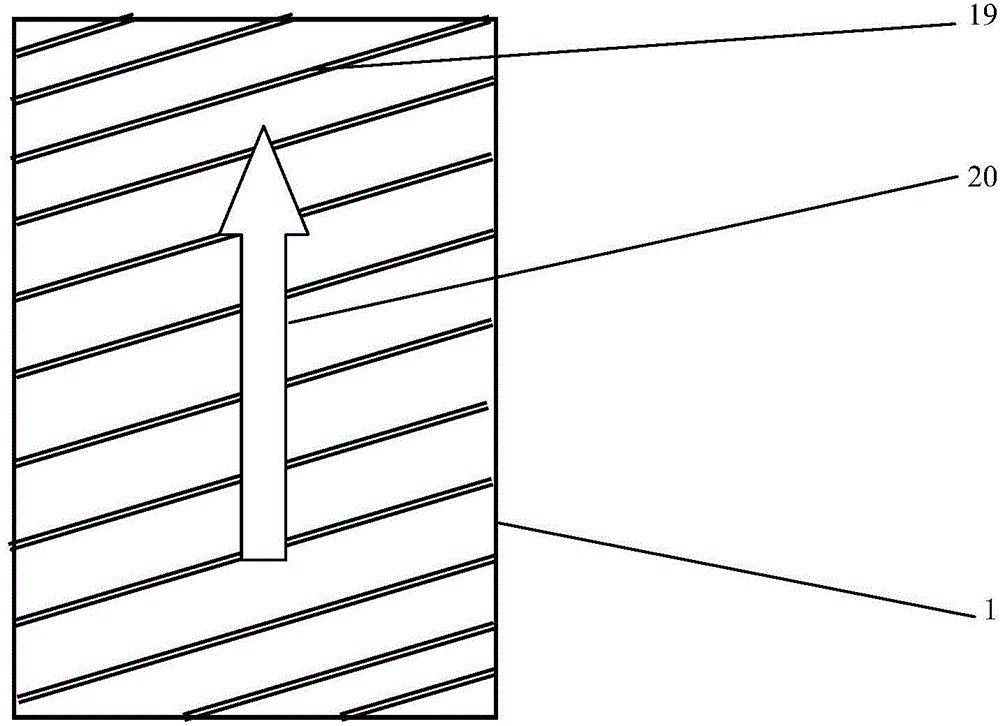

Washing machine and inter-tub cleaning method thereof

InactiveCN103820975AAvoid secondary pollutionStructural changesHollow article cleaningOther washing machinesFront loadingWater level

The invention relates to an inter-tub cleaning method of a washing machine. The two-tub washing machine comprises an inner tub 2 and an outer tub 1; after a long time of use, dirt accumulates in an interlayer between the inner and outer tubs and contaminates clothes. According to the prior art, cleaning particles 2 are placed between the inner and outer tubs of the washing machine; during washing, the inner tub 2 of the washing machine rotates to drive the cleaning particles 3 to collide and clean the walls of the inner and outer tubs of the washing machine; when the washing machine, especially a front-loading washing machine, operates, a washing water level is generally low, so that the inner wall of the upper half of the outer tub is never cleaned. During tub cleaning, the rotating speed of the inner tub is adjusted so that washing water carries the cleaning particles and scours to the top of the inner wall the outer tub, and the whole walls of the inner and outer tubs are cleaned. A storage chamber 16 is further arranged in the bottom of the outer tub and used for storing the cleaning particles during dewatering, so that noise from collision with the tub walls and wear and even jamming of the inner tub are avoided.

Owner:任文涛

Process for manufacturing glass goblet through mechanical blowing before mechanical pressing

InactiveCN106348573AIncrease color varietiesStructural changesGlass pressing apparatusGlass reforming apparatusSocial benefitsEconomic benefits

The invention provides a process for manufacturing glass goblet through mechanical blowing before mechanical pressing and relates to a preparation method of glass cups. The process comprises: preparing glass raw materials; melting materials in a furnace; supplying a cup body material through a feeding machine; blowing a cup body through a bubble blowing machine; manually transferring the cup body into a notch of a fire cutting machine; manually transferring the cup body into a die of a die pressing machine; supplying a cup rod material and a cup support material through the feeding machine; pressing the materials through the die pressing machine to form a cup rod and a cup support, and connecting the cup rod and outer bottom of the cup support; manually transferring the cup into a fire polishing machine and polishing; manually transferring the polished cup into an annealing furnace and annealing; discharging the cup out of the annealing furnace; checking; packaging. By adopting the process provided by the invention, the glass goblet can be manufactured through combining the mechanical blowing and the mechanical blowing; the quality of a product is remarkably improved, the production cost is greatly reduced and the labor amount is greatly reduced; structures of the cup body, the cup rod and the cup support are variable, so that varieties and design of the glass goblet are remarkably increased; the process has remarkable economic benefits and social benefits and has promoting value.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

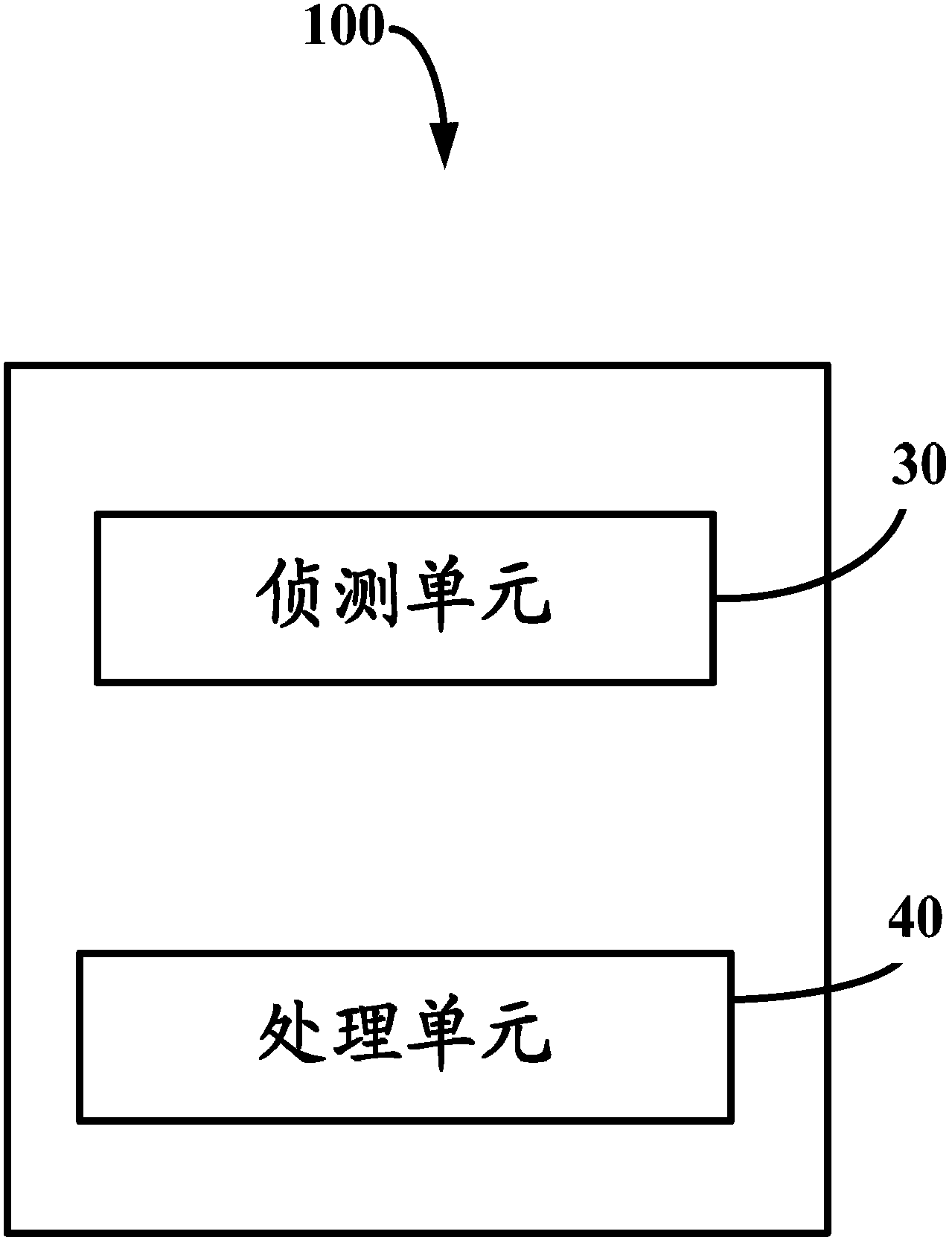

Electronic device with mirror function

InactiveCN103513707AImprove practicalityAdd funDigital data processing detailsCathode-ray tube indicatorsHuman–computer interactionBackground color

The invention relates to an electronic device with a mirror function. The electronic device comprises a display screen and a protection screen. The display screen is used for displaying visible content and the protection screen is made of transparent materials and arranged on the display screen in order to protect the display screen. The electronic device further comprises a detection unit and a processing unit. The detection unit is used for detecting operation of starting the mirror function by a user and generating a triggering signal. The processing unit is used for receiving the triggering signal generated by the detection unit and then controlling the display screen to display a background color with a reflecting effect in a whole screen mode for reflecting light. Thus, the display screen displaying the background color is matched with the protection screen to form a mirror. By means of the electronic device with the mirror function, practicability and entertainment of the electronic device are improved based on the function of an existing electronic device and the structure of the existing electronic device will not be altered greatly.

Owner:FU TAI HUA IND SHENZHEN +1

Mold for manufacturing goblet on presser

InactiveCN105084716AIncrease color varietiesStructural changesPress and blow machinesGlass productionMachine pressSocial benefits

The invention relates to a mold for manufacturing a goblet on a presser. The mold is characterized by being a two-open mold, wherein the interior of the mold forms a cup stand die cavity, a cup rod die cavity and a cup body die cavity from top to bottom when a left mold block and a right mold block are closed together, an ejector rod is arranged in the cup body die cavity and is connected to a base plate, and a punching head is positioned on the cup stand die cavity. The mold for manufacturing the goblet on the presser is capable of successfully realizing machine blowing and machine pressing combined manufacturing of a glass goblet, the product not only preserves the advantages of blow manufacturing but also is capable of significantly improving the production capacity, so that the product quality is significantly improved, the production cost is greatly reduced, the amount of labor used is greatly reduced, the structures of a cup body, a cup stem and a cup stand are most changeful to significantly increase the colors and patterns of glass goblets, and the mold has significant economical and social benefits and popularization value.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

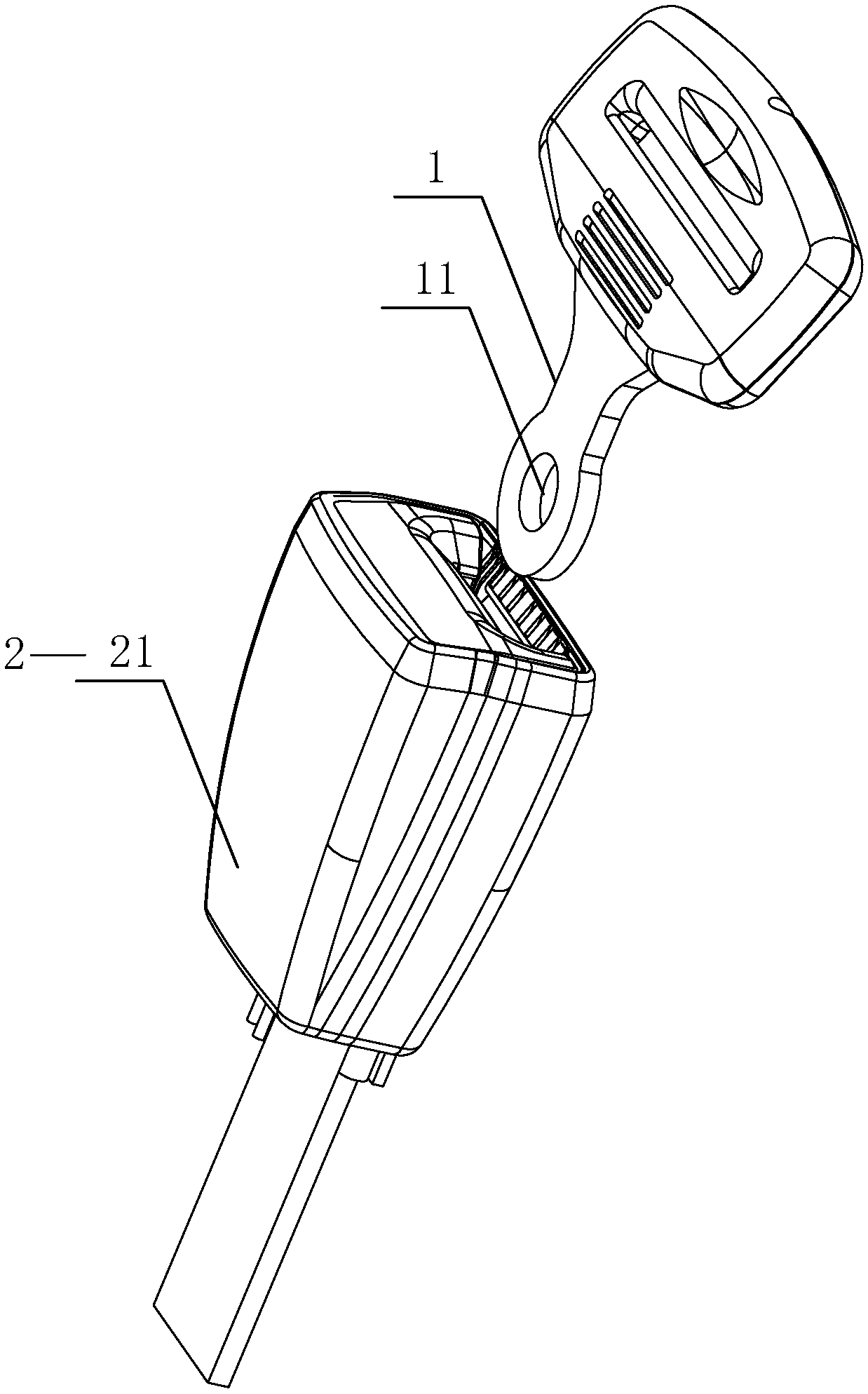

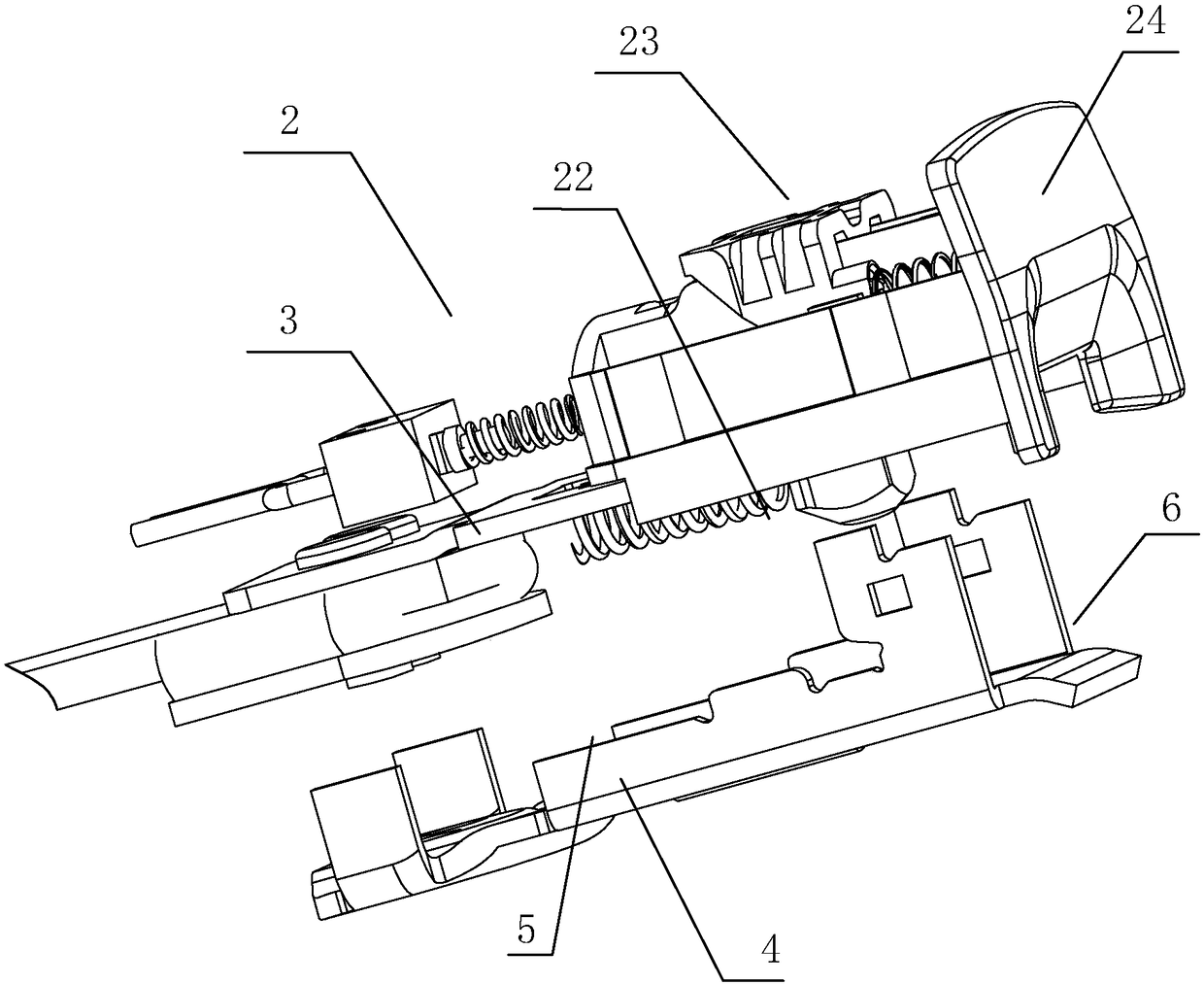

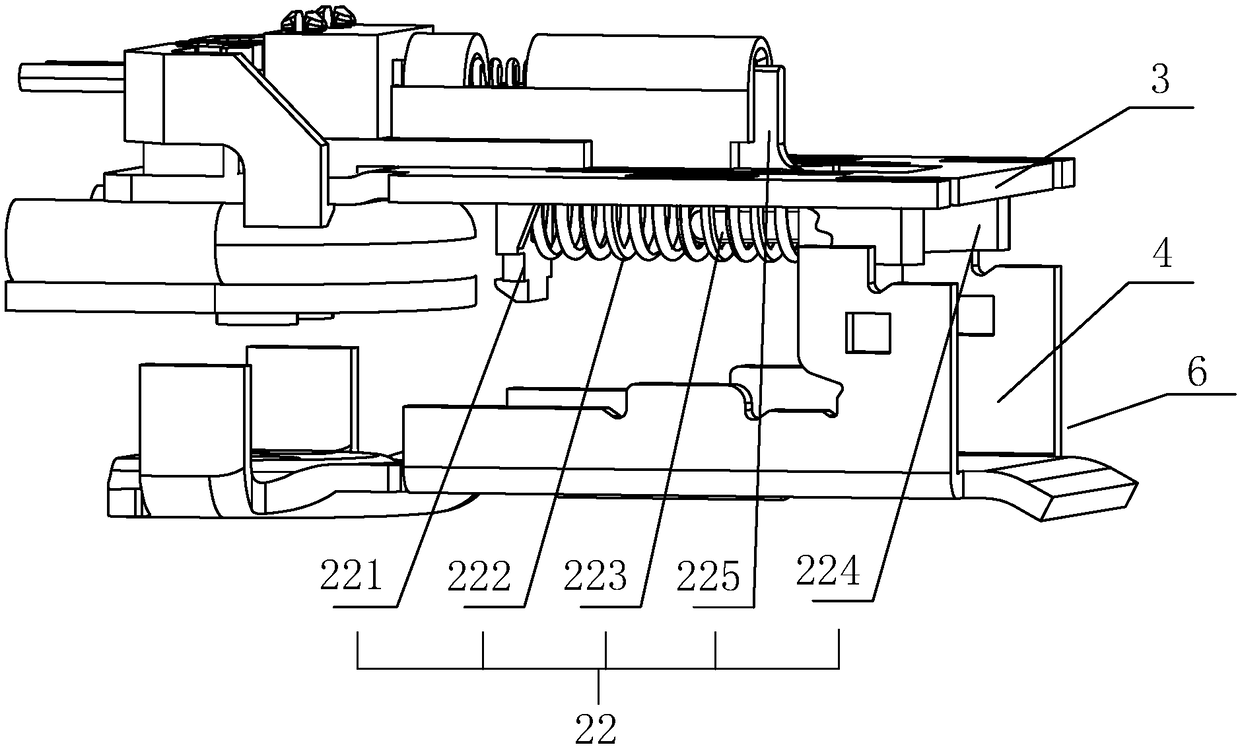

Seat belt latch device

The invention belongs to the field of car seat belt latches and aims to provide a seat belt latch device. The technical solution mainly comprises a tongue and a latch which is connected to the tonguein a matching and clamping manner. The seat belt latch device is characterized in that the latch comprises an outer case, a sliding mechanism, a clamping and fastening mechanism and an unlocking mechanism, that a connecting plate is inserted into the outer case, that a bottom plate is connected to the lower part of the connecting plate in a clamping manner, that a cavity and a groove opening are arranged between the connecting plate and the bottom plate, that a through hole is formed in the bottom plate, that the sliding mechanism comprises a blocking plate, a first spring, an inserting rod, asliding block, a clamping and connecting piece and protrusions, that the protrusions are all slidably connected in sliding grooves formed in a connecting piece, that the inserting rod is fixedly connected to the sliding block, that the clamping and fastening mechanism comprises a central component, a second spring and a clamping block, that the clamping block is slidably inserted and connected inthe central component, and that the unlocking mechanism comprises a sliding button, third springs, sliding plates and guide rails. The seat belt latch device has the advantages of small size and goodappearance.

Owner:盐城默成汽车内饰科技有限公司

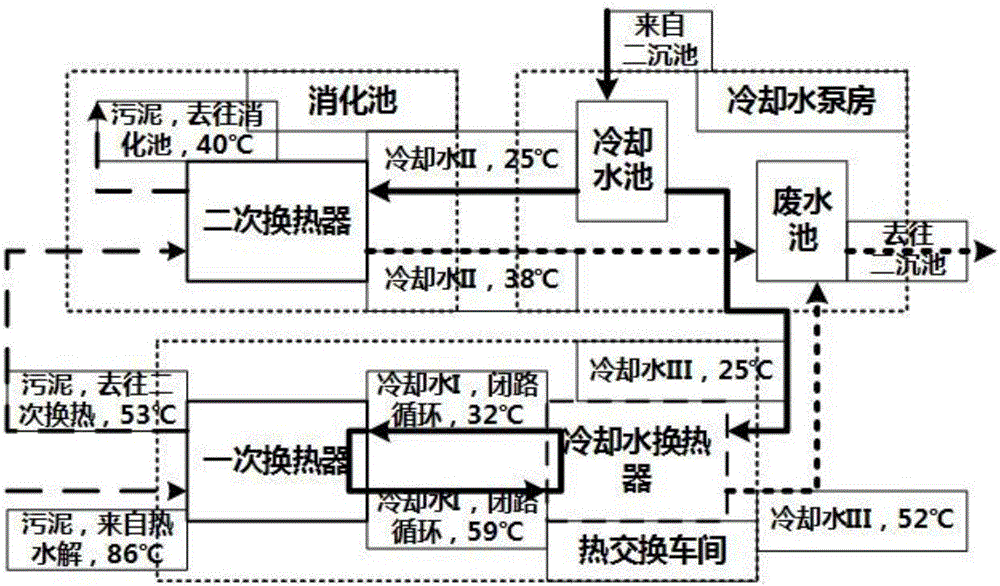

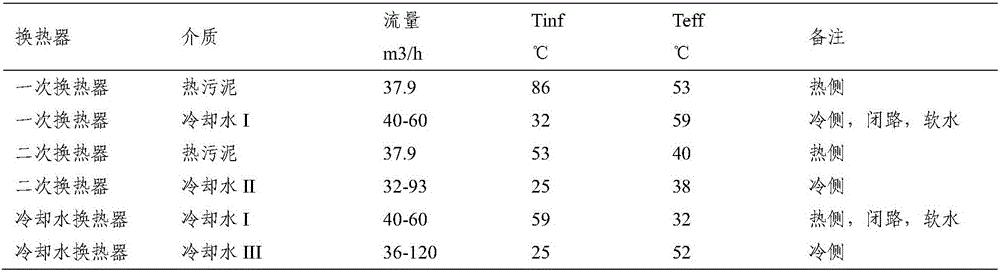

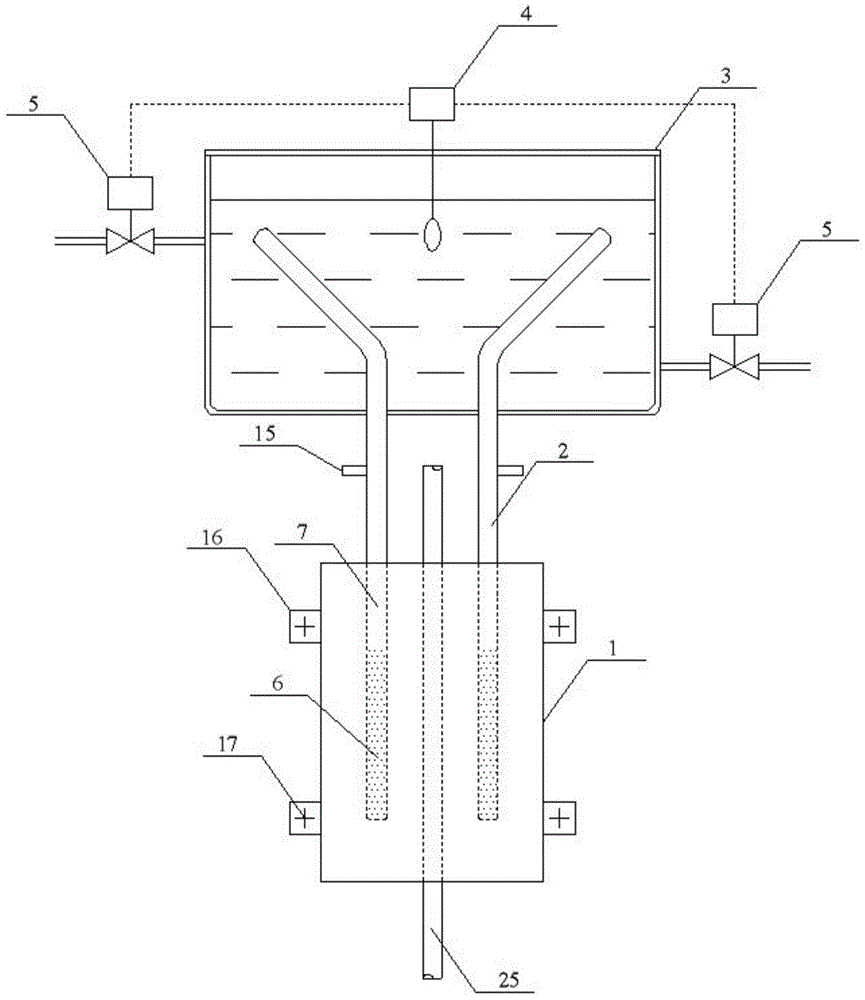

Sludge treatment heat exchange system

PendingCN106746438AReach the reaction temperatureGood anaerobic digestion effectSpecific water treatment objectivesBiological sludge treatmentSoft waterRecuperator

The invention discloses a sludge treatment heat exchange system, which comprises a primary heat exchanger, a secondary heat exchanger, a cooling water heat exchanger, a cooling water pool and a waste water pool; an inlet of the primary heat exchanger is a pyrohydrolyzed sludge input end, and sludge flowing through the primary heat exchanger is delivered into an inlet of the secondary heat exchanger, connected with an outlet of the primary heat exchanger, through the outlet of the primary heat exchanger; through an outlet of the secondary heat exchanger, sludge, the temperature of which is cooled to the set temperature of the anaerobic digestion technology after flowing through the secondary heat exchanger, is delivered to a digestion pool connected with the outlet of the secondary heat exchanger; cooling water of the primary heat exchanger is soft water and can be recycled after flowing through the cooling water heat exchanger; a cooling water inlet end of the secondary heat exchanger is connected with the cooling water pool, a cooling water outlet is connected with the waste water pool; and the waste water pool is connected with a secondary settling pool. According to the sludge treatment heat exchange system, the technical problem that a mud-field heat system during transformation of a sludge treatment system of the existing sewage treatment plant is compatible after being upgraded is solved, so as to realize the maximum utilization of a low-cost transformation mode and stable running of the original equipment, and the like.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Process of making glass goblets by machine blowing first and then machine pressing

ActiveCN105084717BIncrease color varietiesStructural changesPress and blow machinesGlass productionBlow moldingSocial benefits

The process of making glass goblets by machine blowing and then machine pressing of the present invention relates to the preparation method of glass cups. Cup body→Manually turn the cup body into the fire-cut power cut→Manually turn the cup body into the mold of the compression molding machine→Feeder supplies the cup stem and cup holder→The compression molding machine presses the cup stem and cup holder and puts the cup The rod is connected with the outer bottom of the cup body→manually transfer the cup to the fire polishing machine for polishing→manually transfer the polished cup to the annealing furnace for annealing→out of the annealing furnace→inspection→package. The invention successfully realizes the combination of machine blowing and pressing to make glass goblets, which significantly improves product quality, greatly reduces production costs, and greatly reduces the amount of labor. variety, has significant economic and social benefits, and has promotional value.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

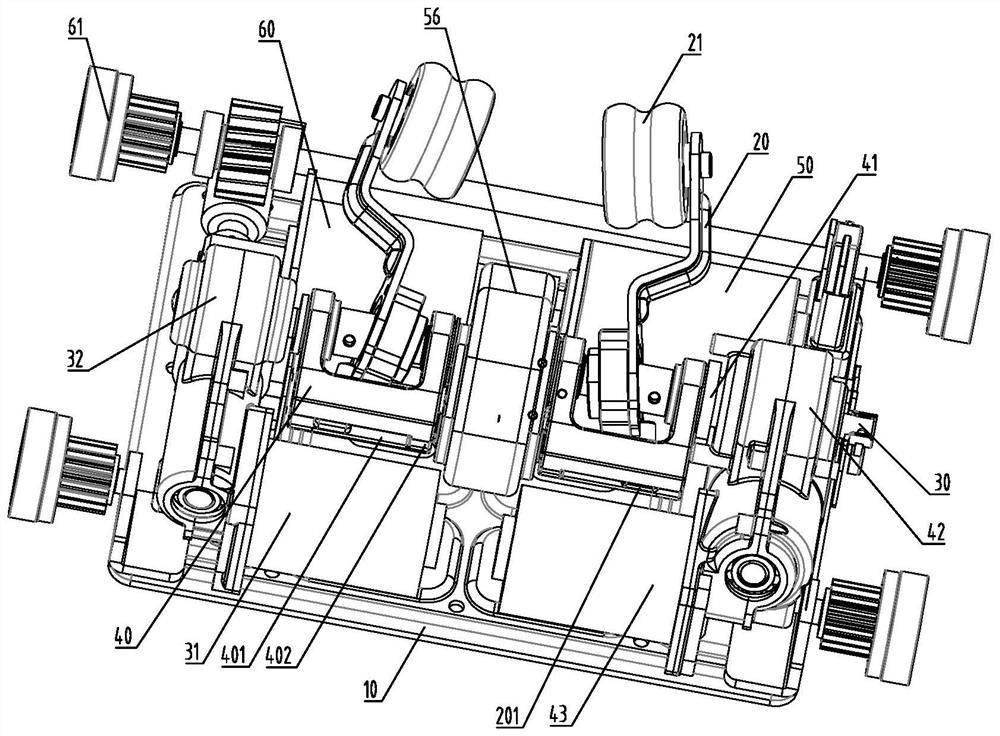

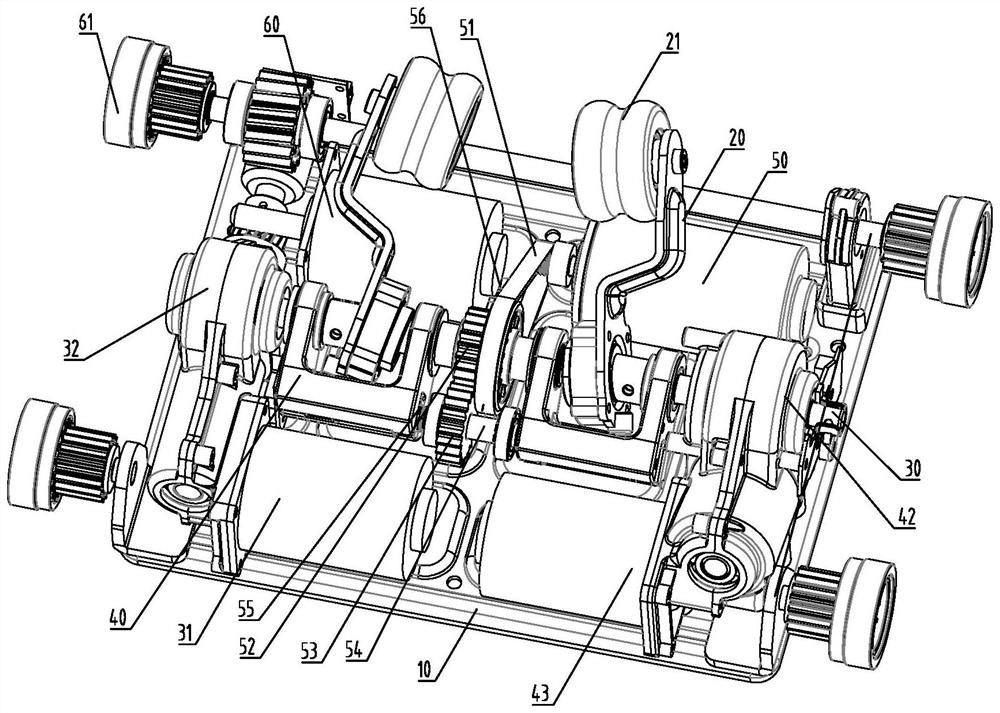

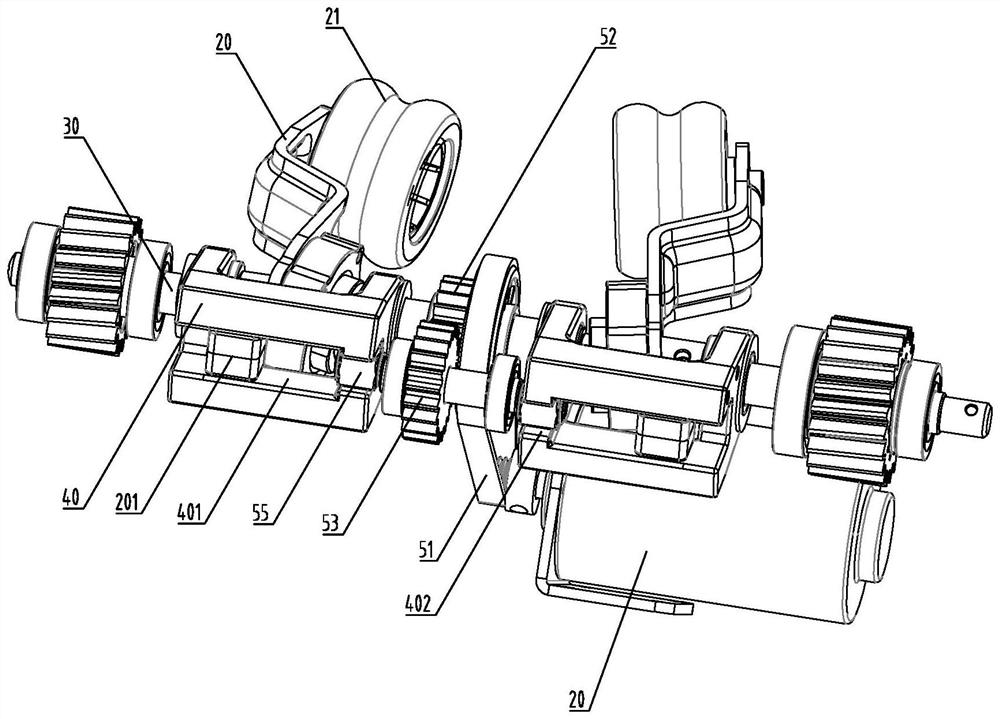

Massage chair and massage machine core thereof

PendingCN114587954ARealize tapping actionAvoid location differencesVibration massageRoller massageElectric machineryCrank

The massage chair comprises a machine core frame, a kneading assembly, an adjusting assembly, a left massage crank arm and a right massage crank arm, the kneading assembly comprises a kneading shaft, the adjusting assembly comprises a rotating seat, and the massage chair is further provided with a knocking frame, a knocking motor, a transmission component, a first gear, a second gear and a knocking shaft; the knocking frame sleeves the kneading shaft and is fixedly connected with the rotating seat, the first gear sleeves the kneading shaft, the knocking shaft and the second gear are mounted on the knocking frame, the knocking shaft is movably connected with the rotating seat, and the second gear sleeves the knocking shaft, is fixedly connected with the knocking shaft and is in meshing transmission with the first gear. The knocking motor is arranged on the machine core frame and drives the first gear to rotate through the transmission part, so that the massage crank arm is driven to swing back and forth through the rotating seat to realize the knocking action; therefore, the massage machine core has the functions of containing the massage crank arms, adjusting the massage force, kneading and knocking.

Owner:HENGLIN HOME FURNISHINGS CO LTD

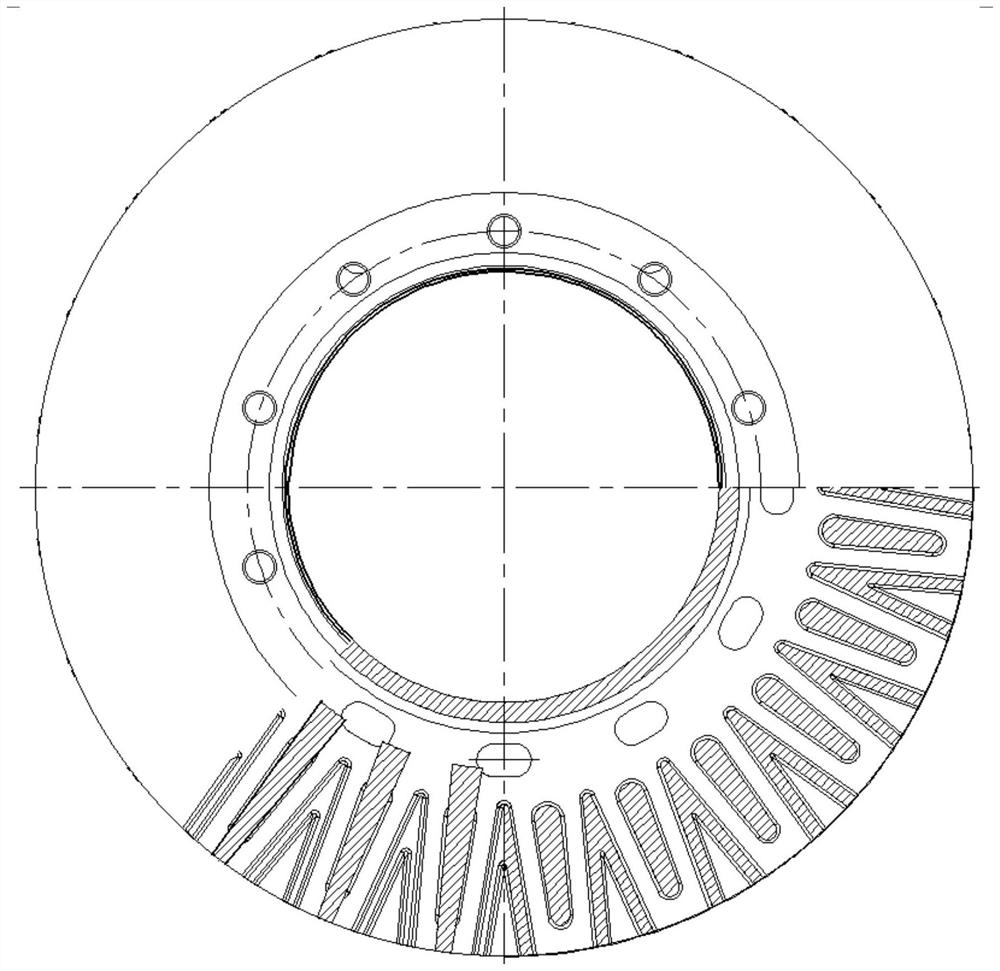

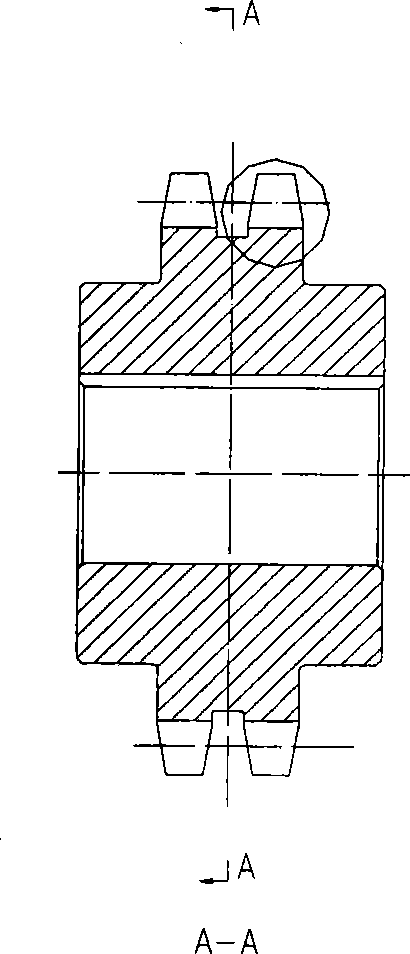

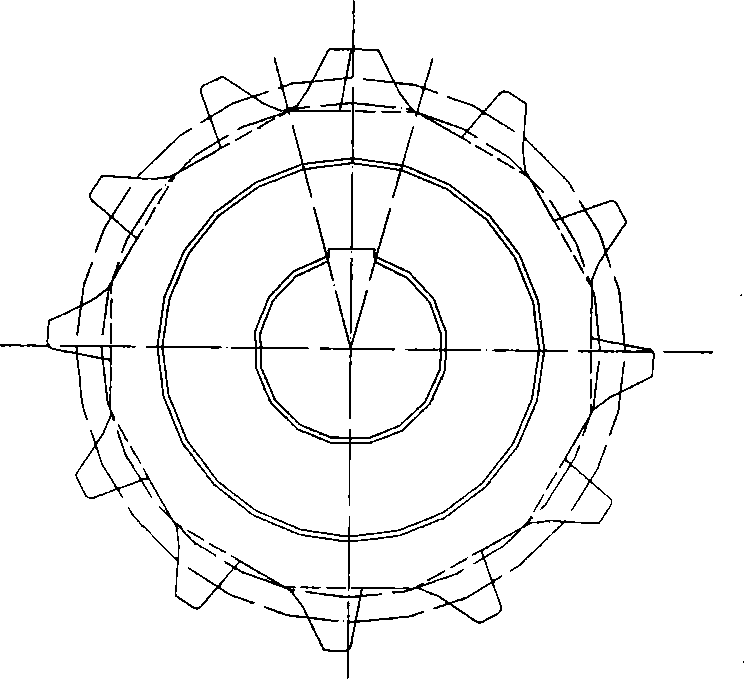

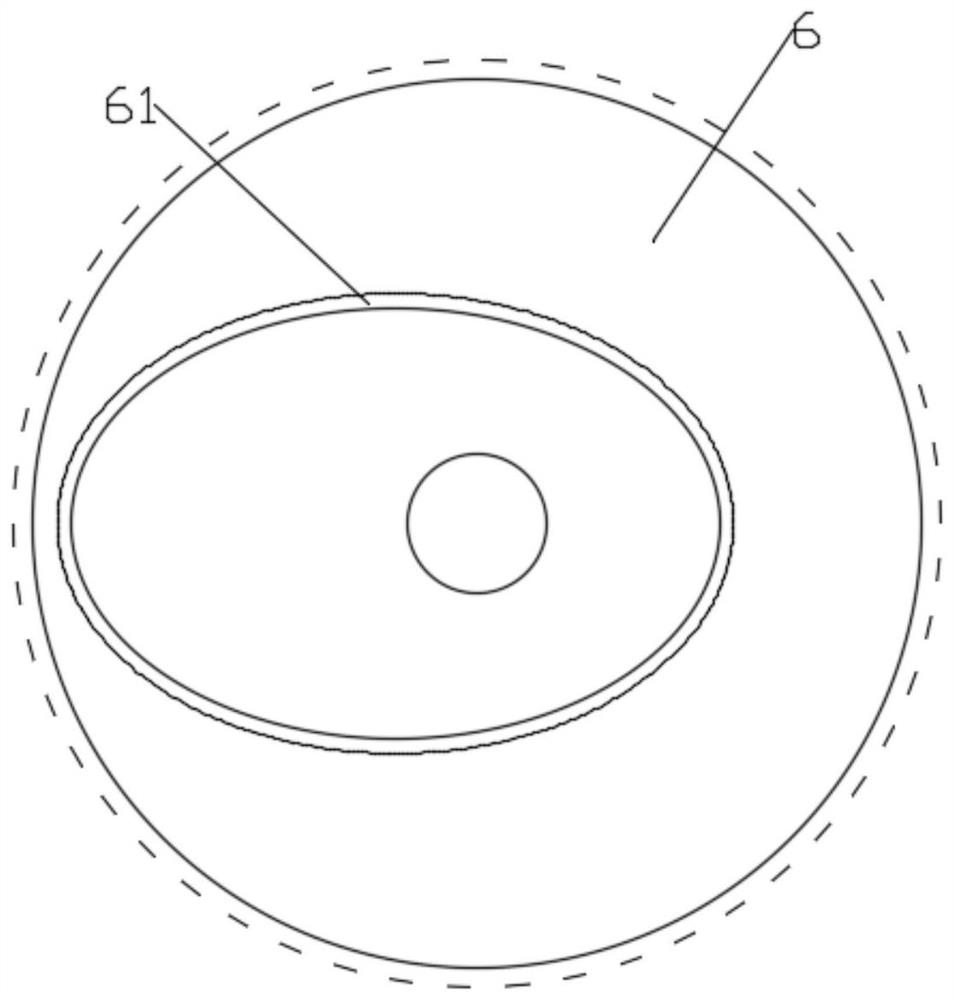

A press self-generating device

ActiveCN109818476BReduce environmental stressReduce occupancyDynamo-electric machinesEngineeringMaterials science

The invention discloses a pressing self-generating device which comprises a stator iron core, a rotor iron core, first magnetic steel, second magnetic steel and a coil, wherein the magnetism of the first magnetic steel is opposite to the magnetism of the second magnetic steel, the coil is wound on the stator iron core, the rotor iron core can rotate around the center of the coil, and the first magnetic steel and the second magnetic steel are attached to the outer circumferential surface of the stator iron core. As the air gap is very small, a closed magnetic circuit can be formed between a cantilever of the stator iron core and the magnetic steel. By pressing a pressing sheet on the rotor iron core, the rotor iron core rotates, and the magnetic steel opposite to a stator cantilever is changed from the first magnetic steel into the second magnetic steel. The magnetic flux in the coil sleeving the stator iron core is changed from positive to negative (or from negative to positive), and the changed magnetic field induces voltage in the coil. Mechanical energy can be converted into electric energy to replace dry batteries in a remote controller, environmental pressure caused by use ofthe dry batteries is avoided, and the pressing self-generating device is compact in structure and convenient to install in various remote controllers.

Owner:NANJING UNIV OF POSTS & TELECOMM

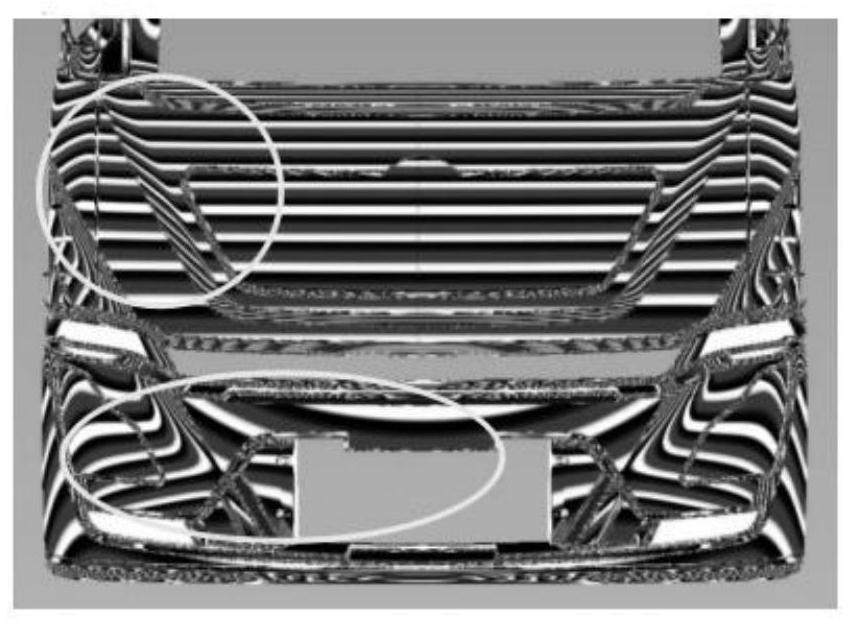

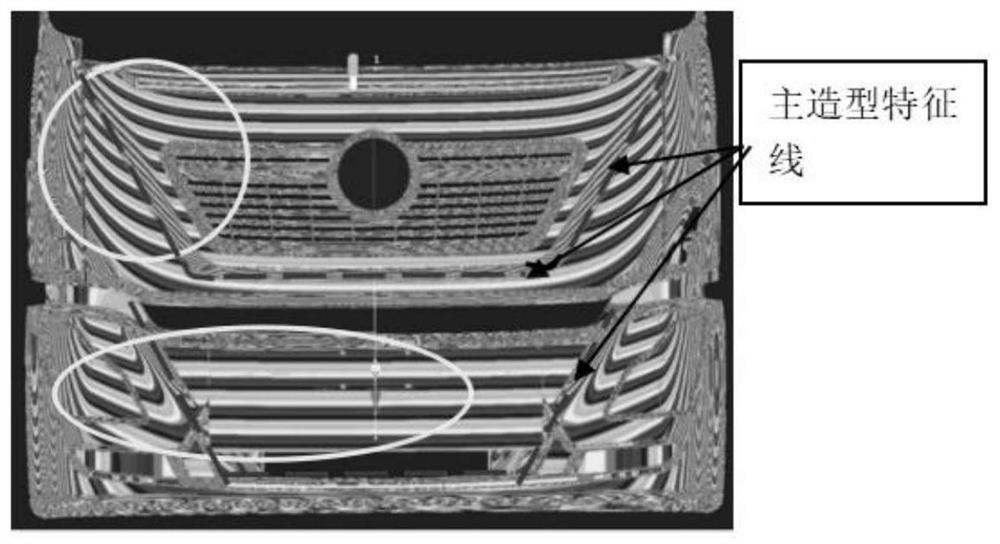

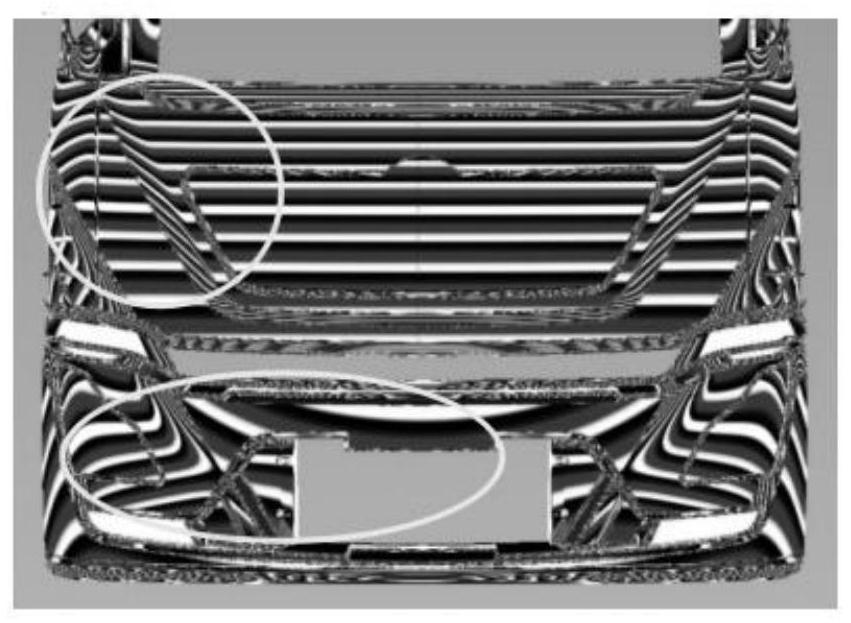

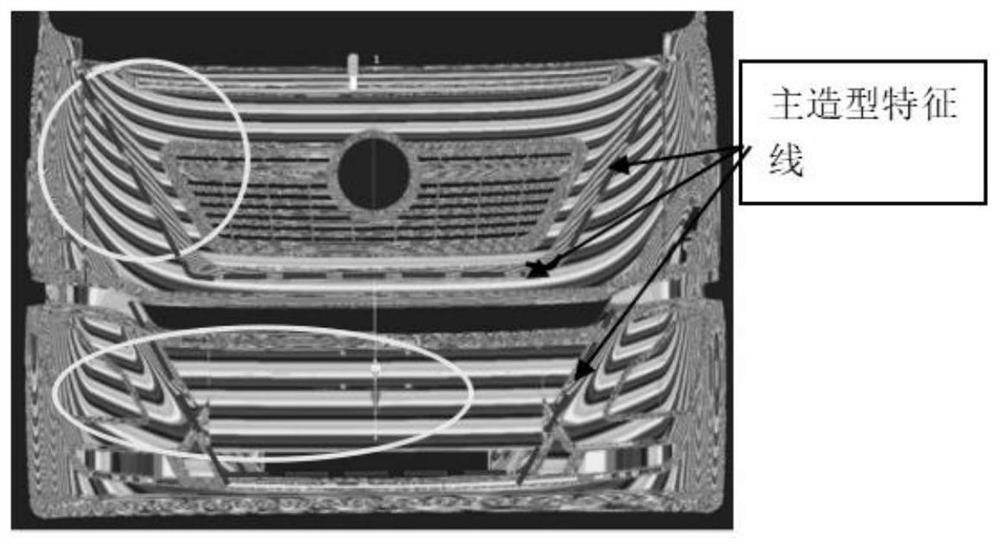

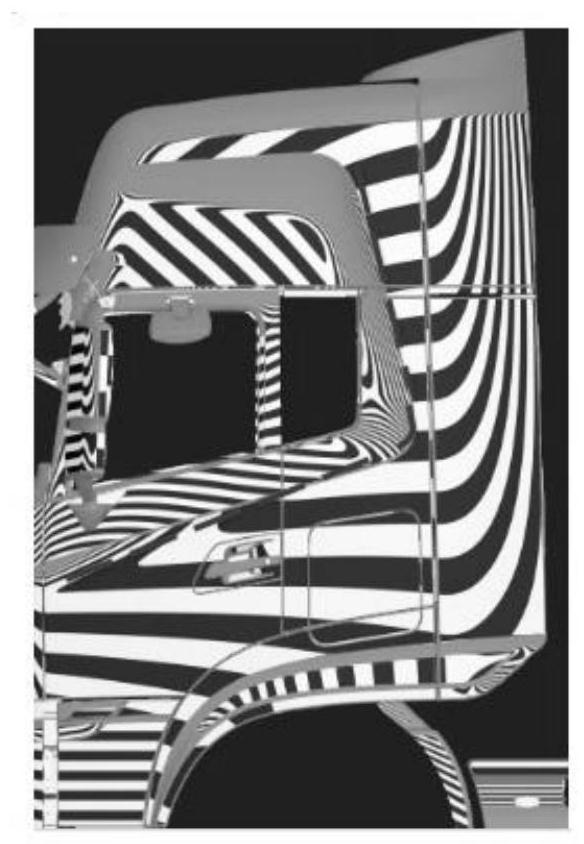

Design method for solving inconsistent highlight of vehicle body profile

ActiveCN112287458ASave human effortShort cycleGeometric CADSpecial data processing applicationsAlgorithmSimulation

The invention discloses a design method for solving the problem of inconsistent highlight of a vehicle body profile. The method comprises the following steps: finding out main modeling characteristicsof a front side view of a vehicle body; finding out main modeling characteristics of the front view of the vehicle body; finding out transition characteristics between two views of the vehicle body;analyzing the highlight trend of the main modeling features from a front side view; analyzing the highlight trend of the main modeling features from the front view; profile highlight conditions corresponding to a front view and a front side view of a light source are respectively checked from X, Y and Z directions of vehicle body coordinates, highlight is required to be consistent with a characteristic line trend, highlight radian is full, highlight convex and concave dimensions are taken as judgment standards, convex and concave fluctuation cannot occur, only single convex and single concavedistribution and uniform highlight density can occur. Highlight among components is smooth without sudden change. According to the invention, profile deviation caused by profile highlight adjustment is very small, and the change of the internal structure of a part and the change of engineering arrangement and structure cannot be caused.

Owner:DONGFENG COMML VEHICLE CO LTD

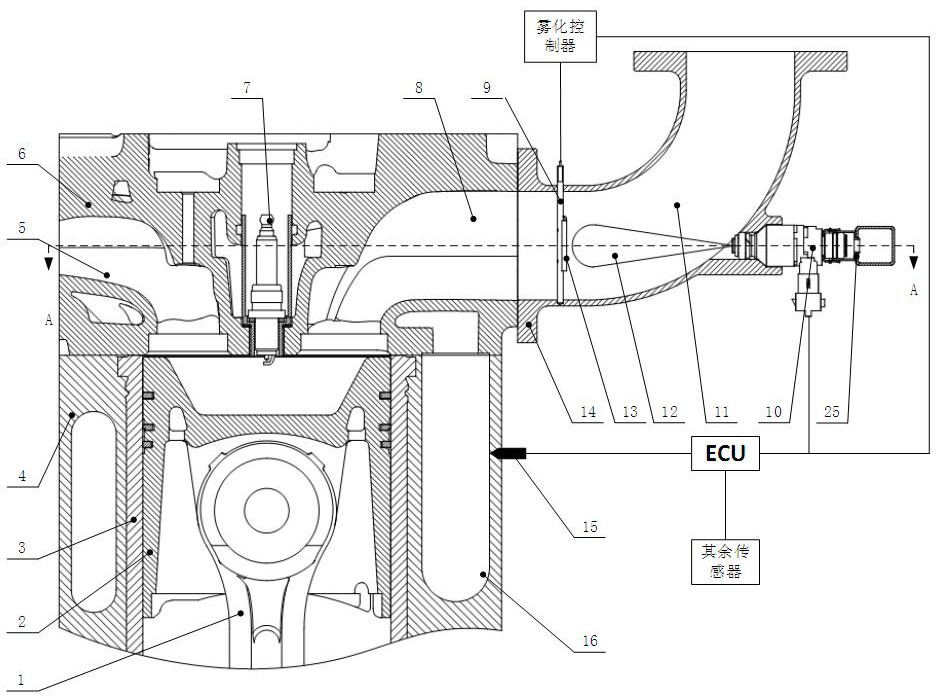

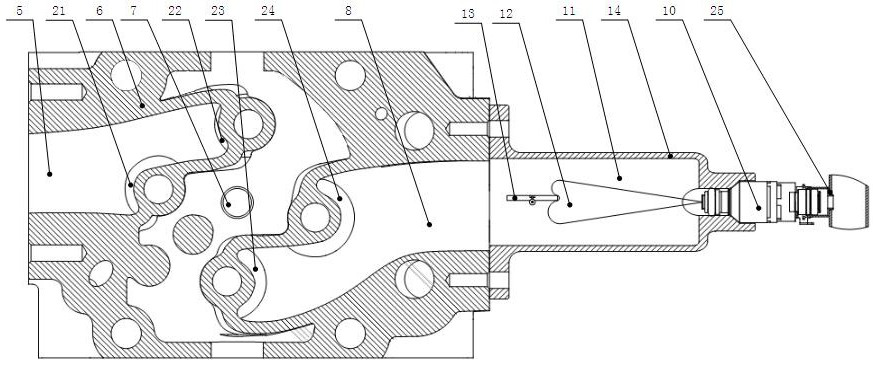

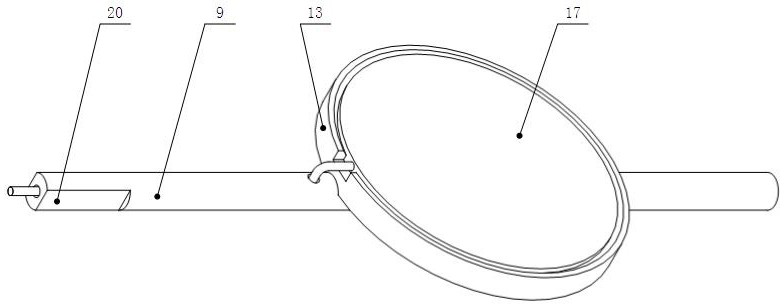

Methanol engine cold starting device and method

PendingCN114233494ASolve the cold start problemStructural changesElectrical controlCombustion-air/fuel-air treatmentInjectorElectronic control unit

The invention relates to the technical field of engine control, in particular to a methanol engine cold starting device and method. Comprising an air inlet manifold installed on the air inlet side of a cylinder cover, the cylinder cover is installed on a cylinder body, a cooling water temperature sensor for detecting the temperature of cooling water is installed in a water jacket of the cylinder body, the water jacket is communicated with a water jacket on the cylinder cover, an air inlet manifold cavity in the air inlet manifold is connected with an air inlet channel of the cylinder cover to form an air inlet flow channel, and a methanol oil sprayer is installed on the air inlet manifold. A rotatable ultrasonic atomization device is mounted on the intake manifold on one side of an oil beam opposite to the methanol oil injector, the ultrasonic atomization device is controlled by an atomization controller, and the atomization controller, the methanol oil injector and the cooling water temperature sensor are all connected with an electronic control unit (ECU) of the methanol engine. According to the invention, the normal starting of the methanol engine at a lower environment temperature and in a severe environment is realized.

Owner:TAIYUAN UNIV OF TECH

Combined framewrok non pull rod type glass product hydraulic press with adjustable stroke

The invention relates to a combined framework non pull rod type glass product hydraulic press with adjustable stroke, comprising a stand platform, a supporting post, an upper transverse beam, a main working oil cylinder, a slide block, a lower transverse beam and an electric control box which is mounted at the side of a machine body. The combined framework non pull rod type glass product hydraulic press with adjustable stroke is characterized in that the internal side of the supporting post is provided with a shoulder; the upper transverse beam and the lower transverse beam are provided with shoulders, and the upper transverse beam and the lower transverse beam are fastened with the shoulder of the supporting post through the shoulders and bolt fastening components to form a gantry framework type machine body structure; and the lower plane of the upper transverse beam is provided with a gate device. The combined framework non pull rod type glass product hydraulic press with adjustablestroke has simple and reasonable structure as well as convenient installation and connection, lightens of the weight of a main machine, saves large amount of steel, greatly reduces the manufacture cost of the hydraulic press as the main working oil cylinder adopts a cylinder action type slide block structure inside which a plunger is totally mounted to result in the reduction of the length of an oil cylinder by approximate 4 / 5 and reduction of oil consumption of the hydraulic press by at least 4 / 5. The total power and the pump energy of the electric motor of the hydraulic press are below 50 percent of those of the traditional hydraulic press, the electric energy and industrial oil are obviously saved, and the production cost can be reduced for users.

Owner:TIANJIN TIANDUAN PRESS CO LTD

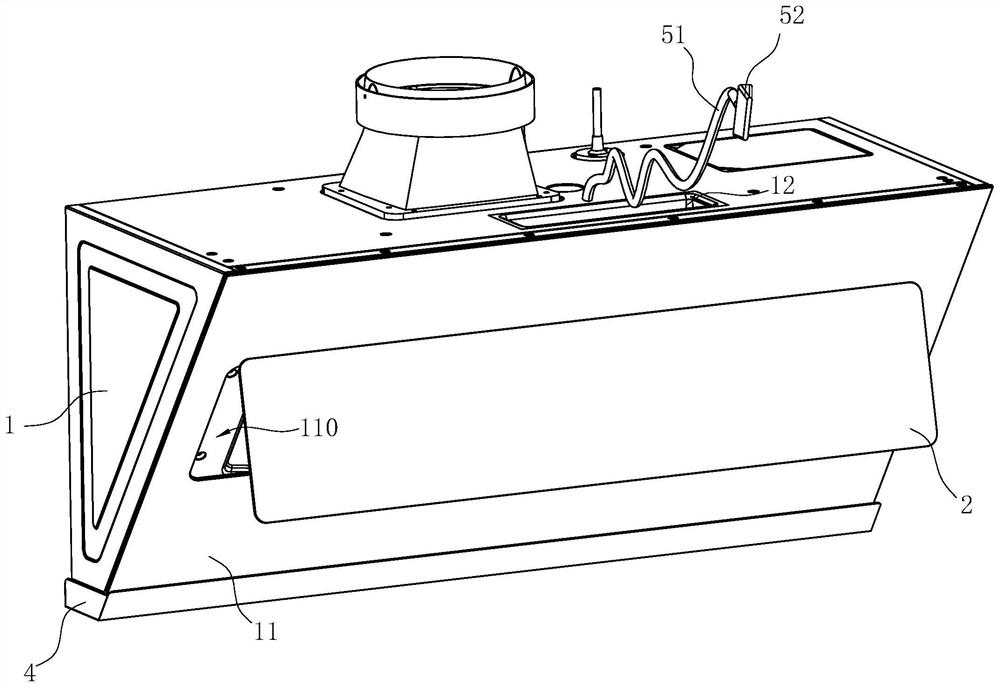

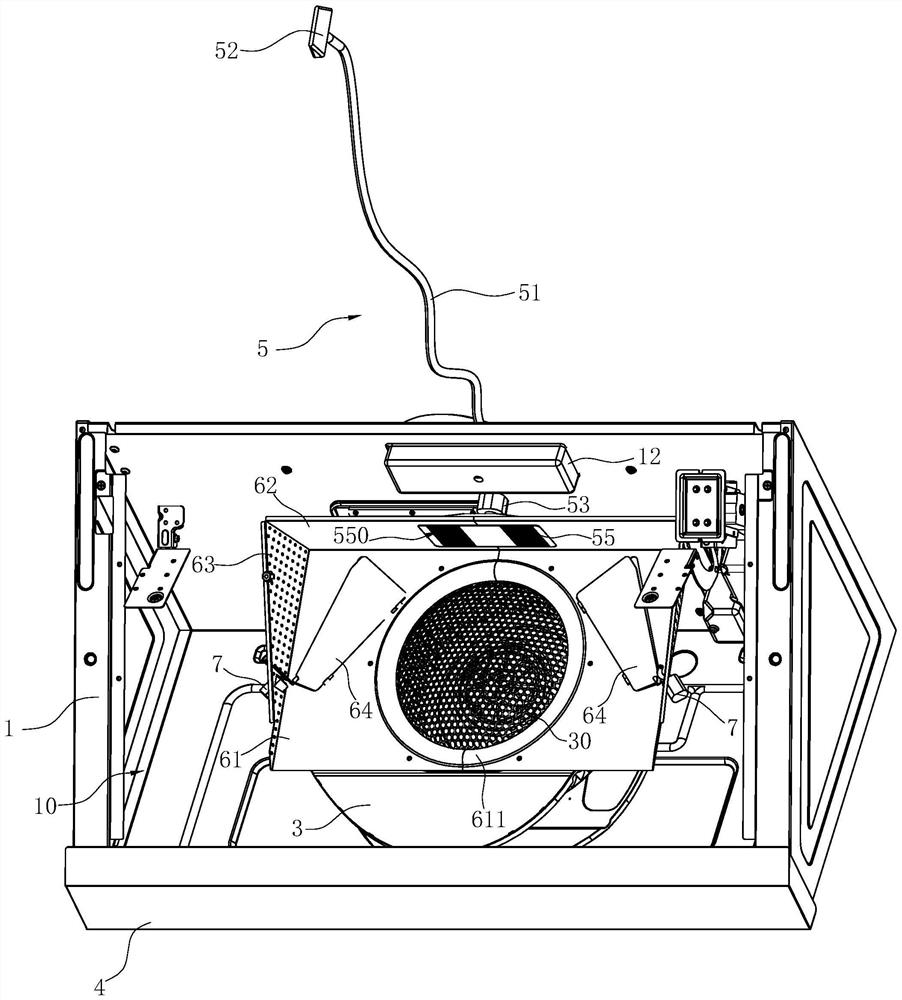

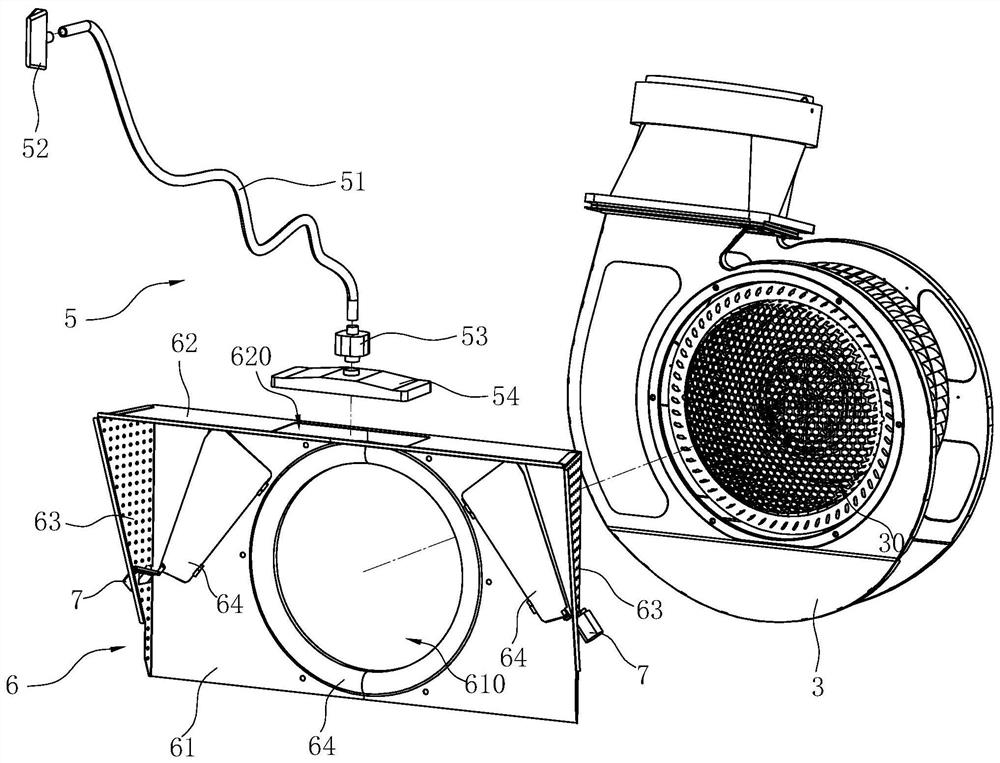

a range hood

ActiveCN112856507BAddressing the downsides of wipe cleaningStructural changesDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A Design Method to Solve the Inconsistency of the Highlights of the Body Shape

ActiveCN112287458BSave human effortShort cycleGeometric CADSpecial data processing applicationsSimulationStructural engineering

The invention discloses a design method for solving the inconsistency of highlights on the profile of a vehicle body. It includes the following steps: find out the main shape features of the front view of the car body; find out the main shape features of the front view of the car body; find out the transition features between the two views of the car body; The front view analyzes the highlight trend of the main modeling features; the light source is viewed from the X, Y, and Z directions of the body coordinates to view the profile highlights corresponding to the front view and the front side view, and the highlight is required to be consistent with the trend of the feature line, and the highlight arc Full, with the two dimensions of highlight convex and concave as the judging standard, no convex and concave undulations, only single convex and single concave distribution, high light density and uniformity, smooth highlights between parts without sudden changes. According to the invention, the profile deviation caused by profile highlight adjustment is very small, which will not lead to changes in the internal structure of parts, and will not cause changes in engineering layout and structure.

Owner:DONGFENG COMML VEHICLE CO LTD

Novel brake disc for trailer axle

The invention provides a novel brake disc for a trailer axle, and relates to the technical field of brakes. The HT250 material of a traditional trailer brake disc is completely abandoned, a novel aluminum ceramic material is selected, the material performance is higher than that of a 6061 series material, the structure of the brake disc is changed, heat dissipation holes are added, the heat dissipation performance is more excellent, and the hidden danger that the brake performance is seriously affected due to continuous high temperature of the brake disc caused by continuous braking is avoided.

Owner:聊城市特力汽车零部件有限公司

A measuring device capable of realizing real-time measurement of sample cross-sectional geometric dimensions and its application

ActiveCN105973699BStructural changesThe tensile test process has no effectStrength propertiesMeasurement deviceStress–strain curve

The invention discloses a measuring device which can be used for a tensile test machine and can carry out real-time measuring on the geometric dimensioning of a cross section in the sample tensile testing process and application of the measuring device. A true stress-strain curve of a material to be tested is acquired, and the tensile mechanical behavior of the material is scientifically and effectively analyzed. The measuring device is composed of a movable platform, a camera I, a camera II, a support, a drive device and the like. The measuring device can be directly installed on an ordinary tensile test machine in a modularization mode and can measure the real-time geometric dimensioning of the cross section of a sample in the tensile process, and the measuring device is ingenious in structure, simple and practical.

Owner:DALIAN MARITIME UNIVERSITY

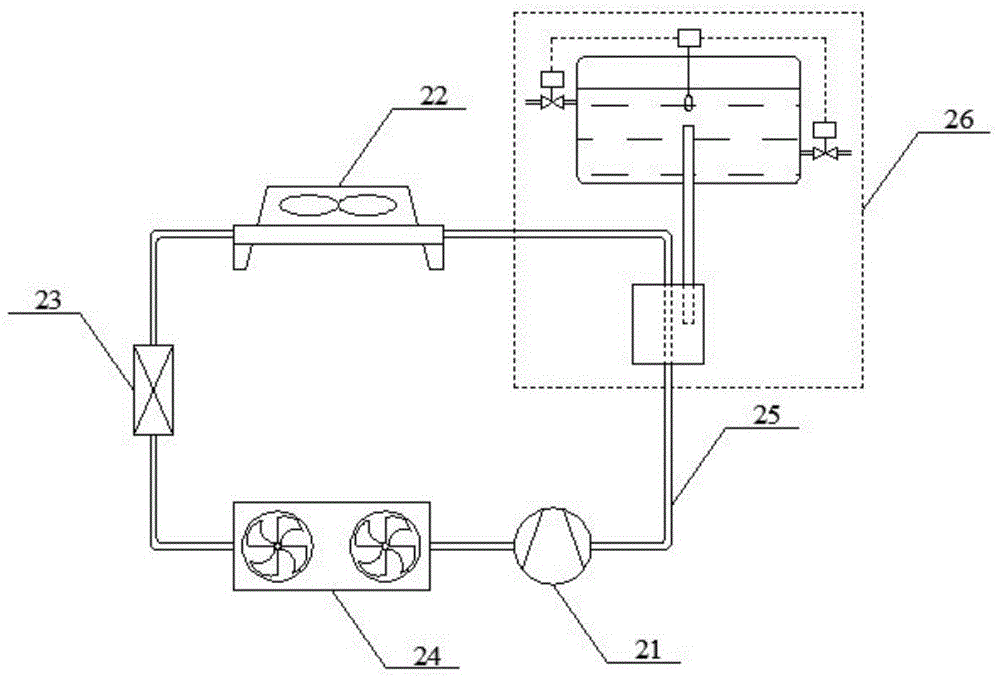

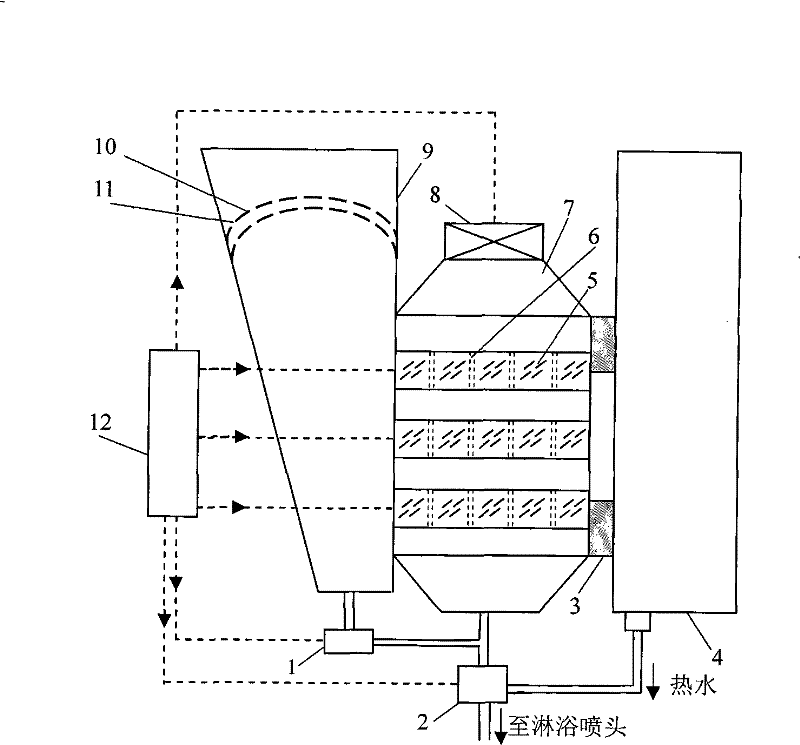

A thermosiphon hot water system for recovery of exhaust energy from household air conditioners

ActiveCN103925683BImprove heat transfer efficiencyGood recovery of waste heatEnergy recovery in ventilation and heatingHeat recovery systemsSiphonEnergy recovery

Owner:BEIJING UNIV OF TECH

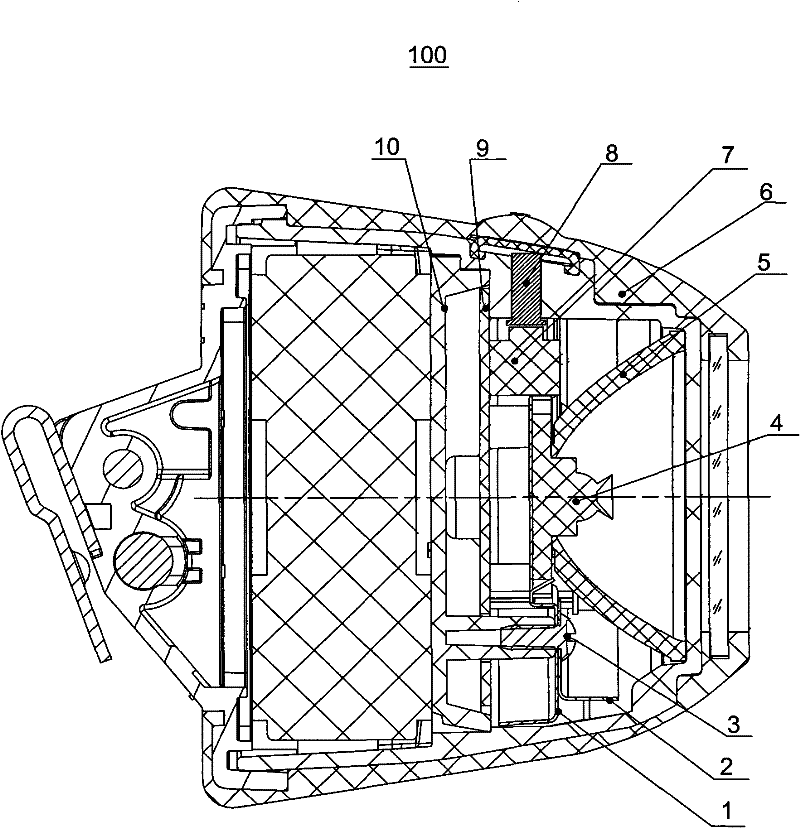

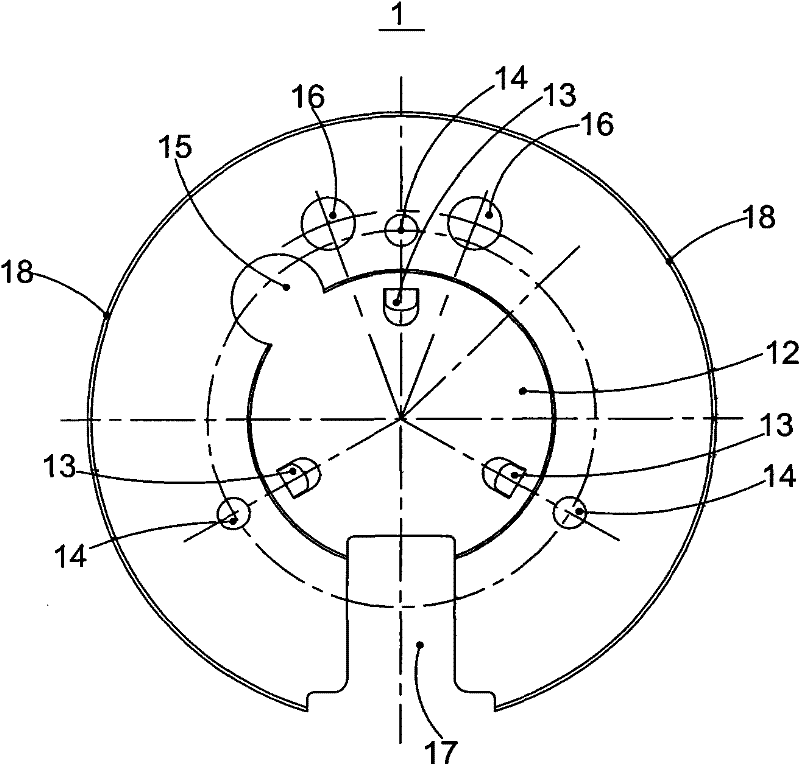

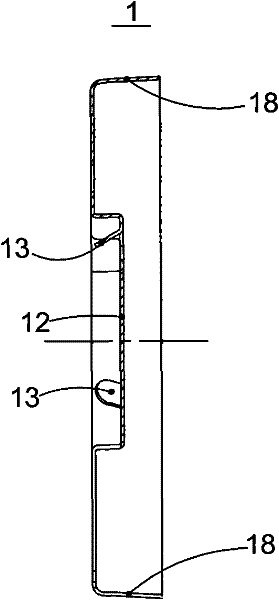

led lights

ActiveCN101737651BEffective coolingReliable coolingPoint-like light sourceElectric circuit arrangementsEngineeringElectromagnetic shielding

The invention provides an LED (Light Emitting Diode) lamp (100) which has both heat radiating function and electromagnetic shielding function. The LED lamp (100) comprises a shell (6) and an LED light source assembly which comprises an LED light source (4), a drive circuit board (9) and an LED light source switch control device. A heat radiating device which separates the LED light source (4) from the drive circuit board (9) is arranged in the LED lamp (1000) and comprises a main heat radiating board (1) and an auxiliary heat radiating board (2), and the auxiliary heat radiating board is attached to the main heat radiating board (1). Since the main heat radiating board (1) and the auxiliary heat radiating board (2) can effectively and reliably cool the drive circuit board (9) and the main heat radiating board (1) can cover the drive circuit board (9) effectively, therefore, the LED light source assembly achieves reliable electromagnetic shielding function and guarantees the stable working of the LED light source.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

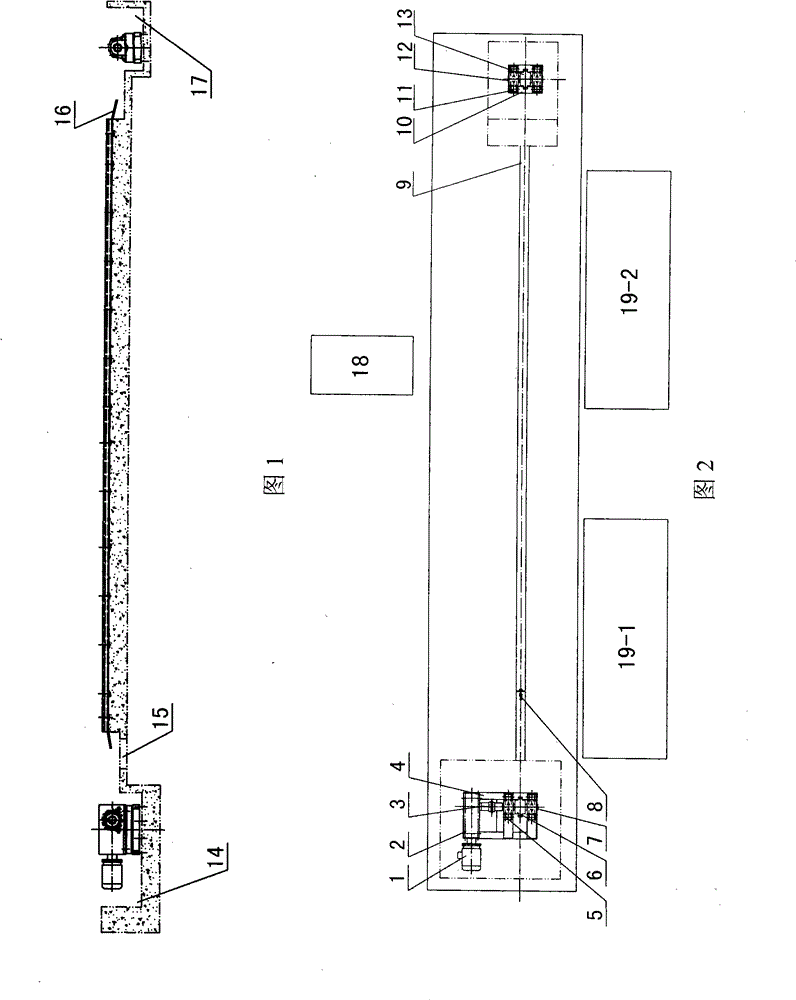

Method for cleaning falling coal on operating platform of stamp-charged coke oven

ActiveCN101550345BReduce labor intensityReduce the use effectOven incrustations prevention/removalCoke ovenMiddle line

The invention relates to a method for cleaning falling coal on an operating platform of a stamp-charged coke oven. The method is characterized in that a scraper conveyer is longitudinally arranged on an operating platform in the central line of a stamping vehicle and a coke oven, and a scraper is driven by the motion of the scraper conveyer to clean the falling coal and transport the falling coalto the end part to enter in a feeding chute to a collecting room. The method enables the coal falling on the operating platform to be conveniently and rapidly cleaned through the scraper and taken away through the scraper conveyer, therefore, the labor intensity of workers is greatly reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

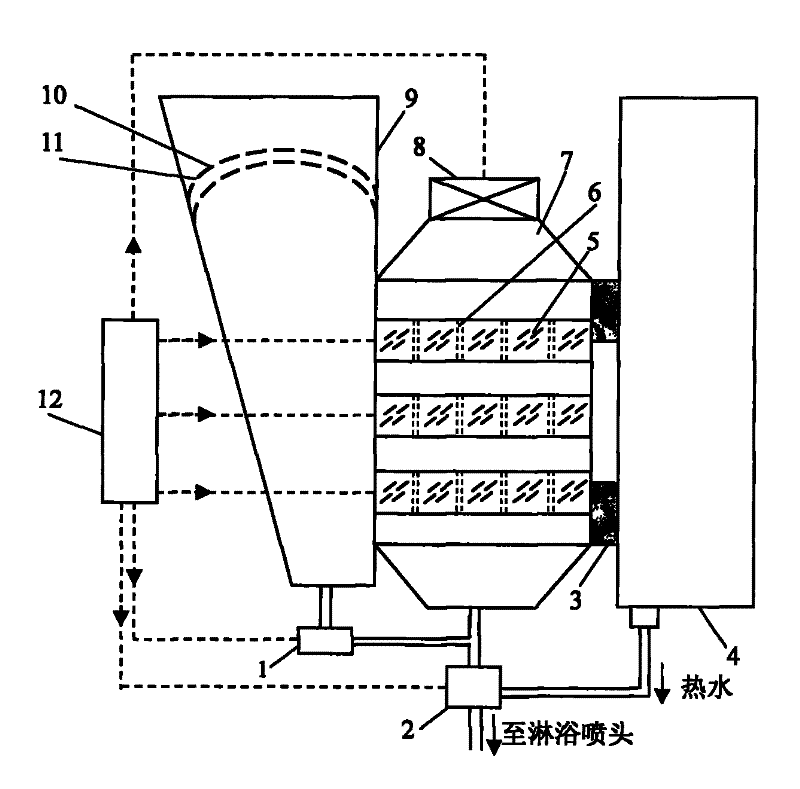

Water heater accessory system with functions of drying and blowing hot wind

InactiveCN101639289BStructural changesWith constant temperature heatingAir heatersHair dryingEngineeringElectric control

The invention relates to a water heater accessory system with the functions of drying and blowing hot wind, which mainly comprises an electronic control valve for drying, an electronic control valve for switching hot wind and hot water, a magnet for adsorption, positive temperature coefficient (PTC) ceramic heating elements, a thermostatic heater, a fan, a drier, a bracket, an electric control unit, and the like, wherein the fan, the PTC ceramic heating elements, and the like form the thermostatic heater; the PTC ceramic heating elements comprise a plurality of layers; the thermostatic heateris connected with the drier through the electronic control valve for drying; and the thermostatic heater and a water heater are connected with a shower nozzle through the electronic control valve forswitching hot wind and hot water. The invention has the functions of drying clothes and blowing the hot wind, is independent of the water heater and can be adsorbed on the water heater by the magnet.The heating elements are made of PTC ceramics which have the characteristic of thermostatic heating, and the shower nozzle of the water heater is used as a channel of hot wind during blowing the hot wind. The invention has convenience, fastness and low cost.

Owner:CHINA JILIANG UNIV

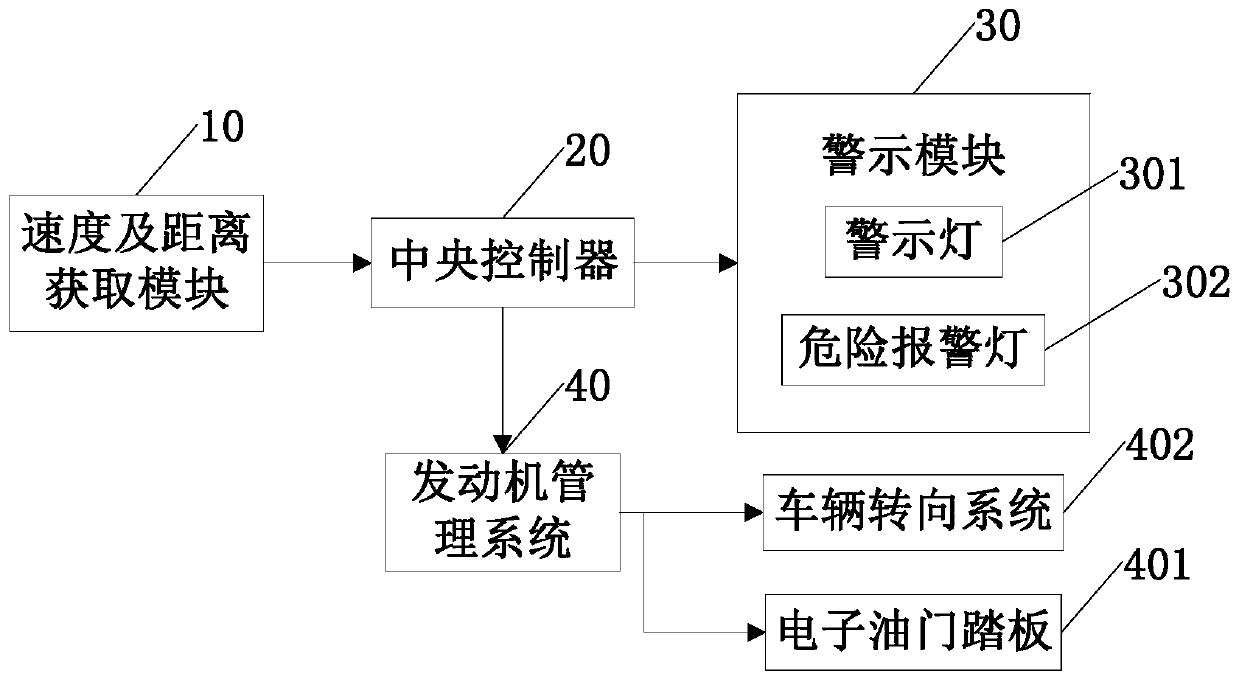

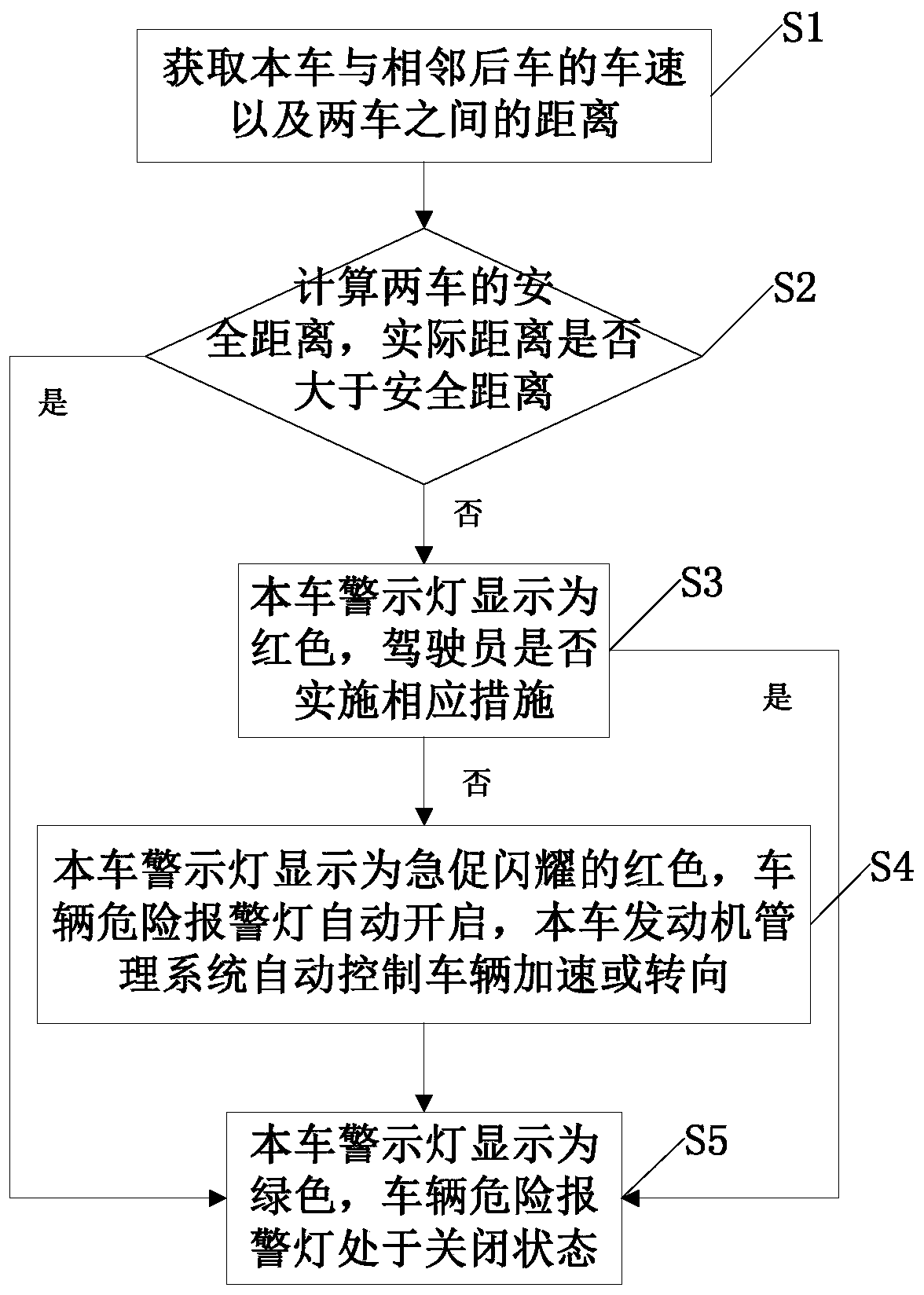

A warning system and warning method for preventing vehicle rear-end collision

ActiveCN106882183BStructural changesAvoid rear-end collision accidentsExternal condition input parametersSignalling/lighting devicesRear-end collisionTraffic accident

The invention discloses a warning system preventing vehicle tailgating and a warning method, and relates to the field of vehicle safety. The warning system preventing vehicle tailgating is arranged in a vehicle to be used for preventing vehicle tailgating and collision to trigger a traffic accident, comprises a speed and distance obtaining module, a central control unit and a warning module, wherein the speed and distance obtaining module is used for obtaining realistic vehicle speeds and a realistic vehicle distance of the vehicle and a rear vehicle; the central control unit is used for receiving vehicle speed and vehicle distance information of the vehicle and the rear vehicle, calculating a corresponding safe distance according to the information and simultaneously judging whether the realistic vehicle distance is bigger than the safe distance or not; the warning module is used for giving a warning instruction according to a judging result of the central control unit to warn drivers of the vehicle and the rear vehicle to notice to control the vehicle speeds and steering to prevent vehicle tailgating. The invention further discloses the corresponding warning method. According to the warning system preventing vehicle tailgating and the warning method, the drivers can be warned to corresponding measures in advance when the distance between the two front and rear adjacent vehicles is over short and a tailgating and collision risk exists, and thus occurrence of the tailgating and collision accident is avoided.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

A kind of method for producing extra-thick plate continuous casting billet

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

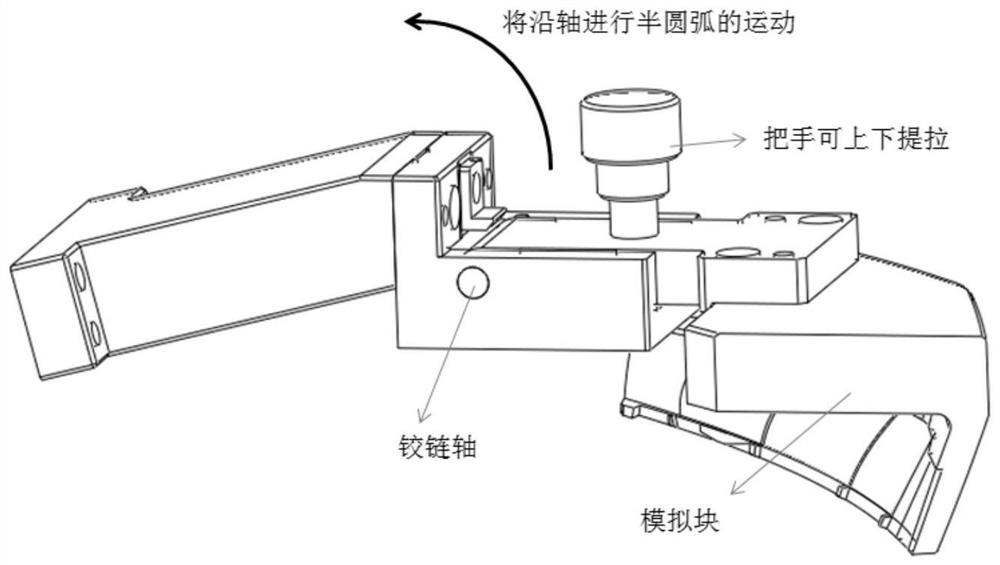

Connecting structure for profiling gauge

PendingCN112781464AResolve Motion InterferenceOptimize motion trajectoryMechanical counters/curvatures measurementsStructural engineeringControl theory

The invention relates to a connecting structure for a profiling gauge. The connecting structure comprises a U-shaped plate, a first sliding block, a handle, a connecting plate and a second sliding block, and the first sliding block is movably arranged in the U-shaped plate; the handle is arranged on the side wall of the first sliding block; the connecting plate is connected with one end of the first sliding block, and a sliding groove is formed in the connecting plate; and one end of the second sliding block is movably connected in the sliding groove and can relatively slide in the length direction of the sliding groove, and the other end of the second sliding block is fixedly connected with the profiling gauge. The connecting structure for the profiling gauge has the advantages that the structure of a simulation block fixing block is changed, original single hinge motion is decomposed into combined motion mechanisms in the up-down direction and the left-right direction, and the problem of motion interference caused by space limitation is solved; and the vertical movement in the Z direction and the left-right movement in the Y direction are added, and the two movement mechanisms are respectively provided with different guides, so that the movement track of the detection tool fixing block is optimized, and the detection failure is avoided.

Owner:SHANGHAI HUATE AUTOMOTIVE PARTS

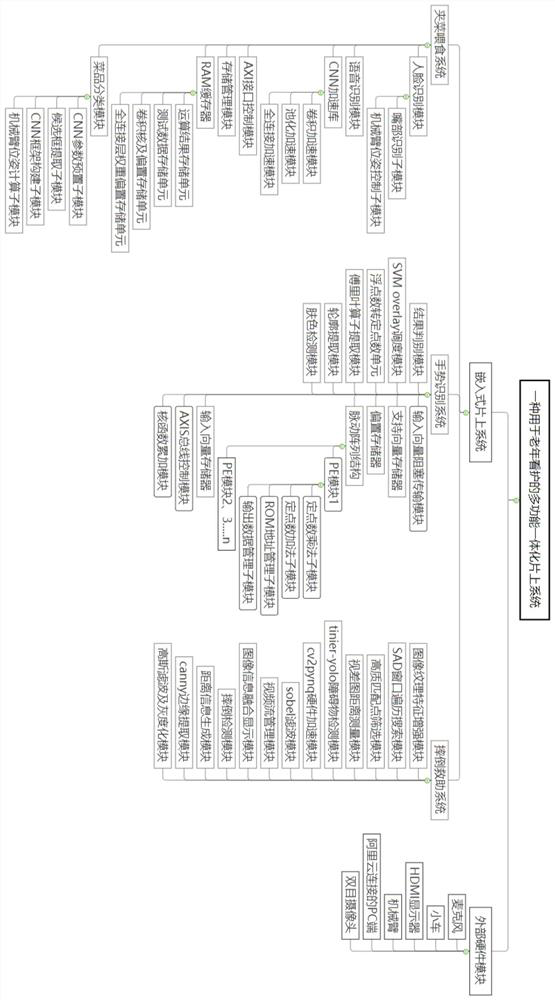

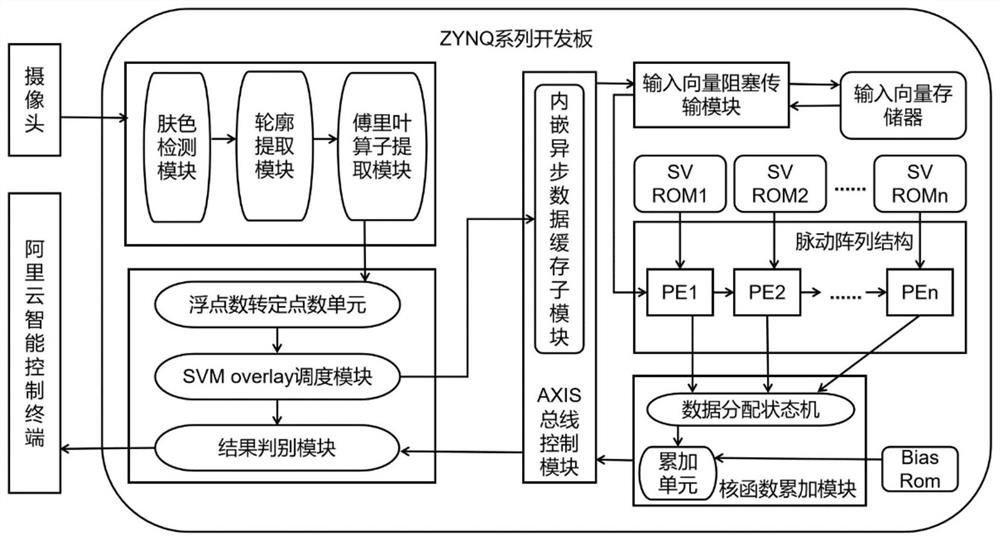

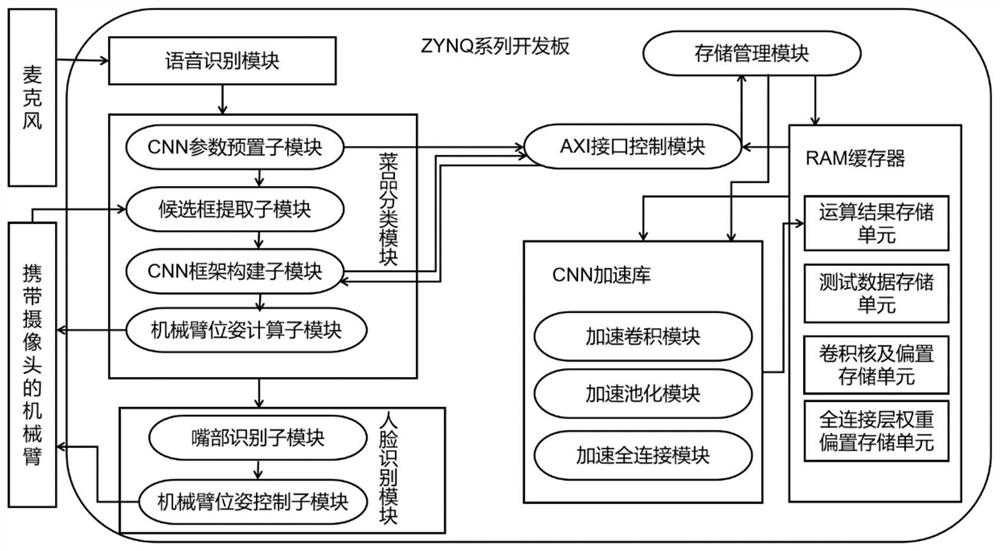

Multifunctional integrated system-on-chip for old people nursing

PendingCN112347034AStructural changesFast update speedInput/output for user-computer interactionImage enhancementOlder peopleCircuit design

The invention relates to a multifunctional integrated system-on-chip for old people nursing, which belongs to the technical field of SOC embedded development, deep learning and computer vision. According to the system, through circuit design and control of an AliCloud server in a block debug of vivado, gesture recognition, food clamping and feeding and tumble rescue are achieved in a ZYNQ series development board, and the system specifically comprises three parts: 1) through image preprocessing and SVM prediction, gesture recognition is achieved; 2) through voice recognition, dish target candidate box extraction and face recognition, dish CNN classification prediction is carried out, and then dish clamping and feeding are realized; through fall detection and trolley control, binocular vision distance measurement is completed, and fall rescue is achieved. According to the system, the circuit design flexibility is improved, the storage resources are reduced, the calculation resources arereduced, the correctness is ensured, the speed is increased, comprehensive road condition information is provided for a user, meanwhile, the real-time performance is good, the actual use requirementis met, the occupied volume of a product is reduced, and the cost is low.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

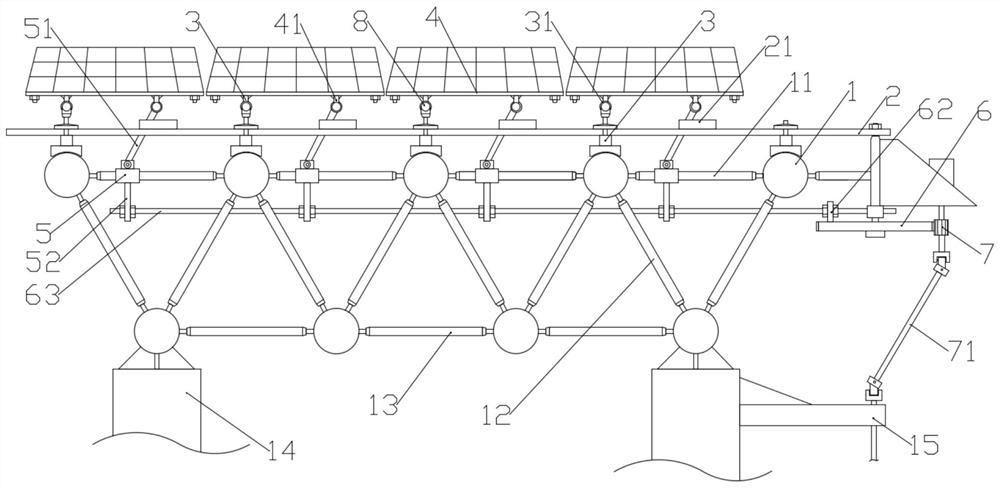

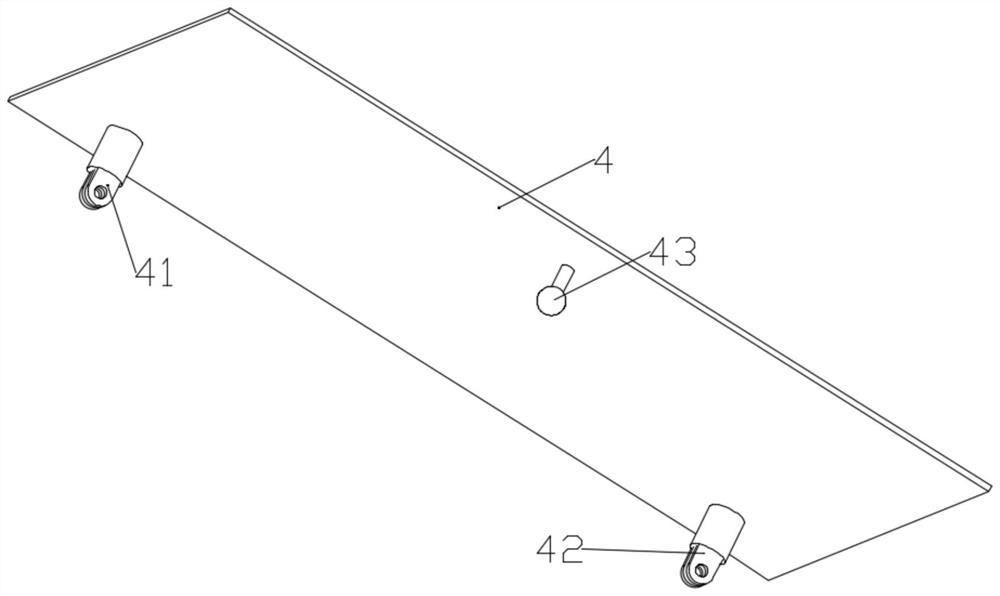

Net rack capable of being provided with double-shaft following photovoltaic support

InactiveCN112367025AStructural changesIncrease direct exposurePhotovoltaic supportsSolar heating energyStructural engineeringMechanical engineering

The invention discloses a net rack capable of installing a double-shaft following photovoltaic support, and the net rack comprises a net rack body which comprises a connecting ball, an upper cross rod, a lower cross rod and an inclined support rod, wherein the upper cross rod, the lower cross rod and the inclined support rod are connected to the connecting ball; and the net rack also comprises a support rod, a hinge seat, a canopy body and a photovoltaic panel bottom plate for installing a photovoltaic panel, wherein the hinge seat is vertically connected above the connecting ball; the hinge seat is connected to the canopy body, a hinge sleeve is arranged above the hinge seat, a hinge shaft and a ball head are arranged on the two sides of the photovoltaic panel bottom plate respectively, and the hinge shaft is obliquely arranged relative to the photovoltaic panel bottom plate and connected to the hinge sleeve; the ball head is connected to the upper end of the supporting rod through aspherical surface, the lower end of the supporting rod is connected to the upper cross rod through a sliding sleeve, and the upper cross rod is connected to the upper cross rod driving device. The characteristics of the structure of the net rack are ingeniously utilized, so that the photovoltaic panel installed on the upper portion can achieve double-shaft following, the direct irradiation degreeof the photovoltaic panel is improved to the maximum extent, and the power generation efficiency of the photovoltaic panel is improved.

Owner:江苏星宇钢结构工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com