A press self-generating device

A self-generating and limiting device technology, applied in electromechanical devices, electrical components, etc., can solve problems such as dirty households, equipment, economic burden on users, inconvenient remote control structure design, etc., to save space and avoid large overall structure. changes, the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

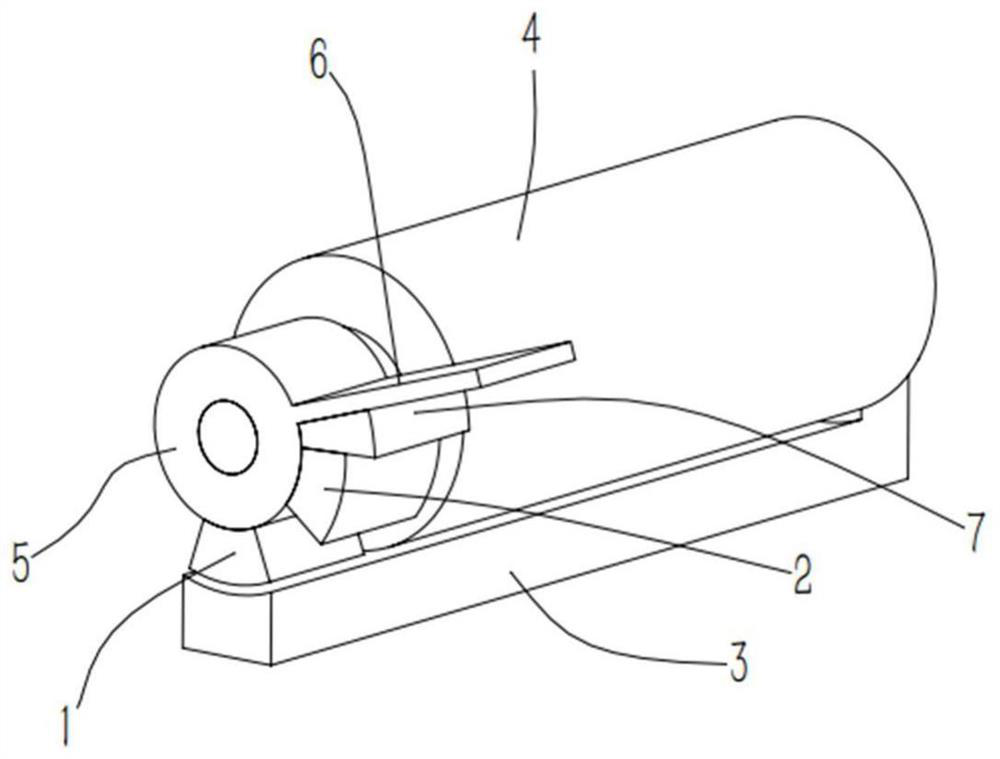

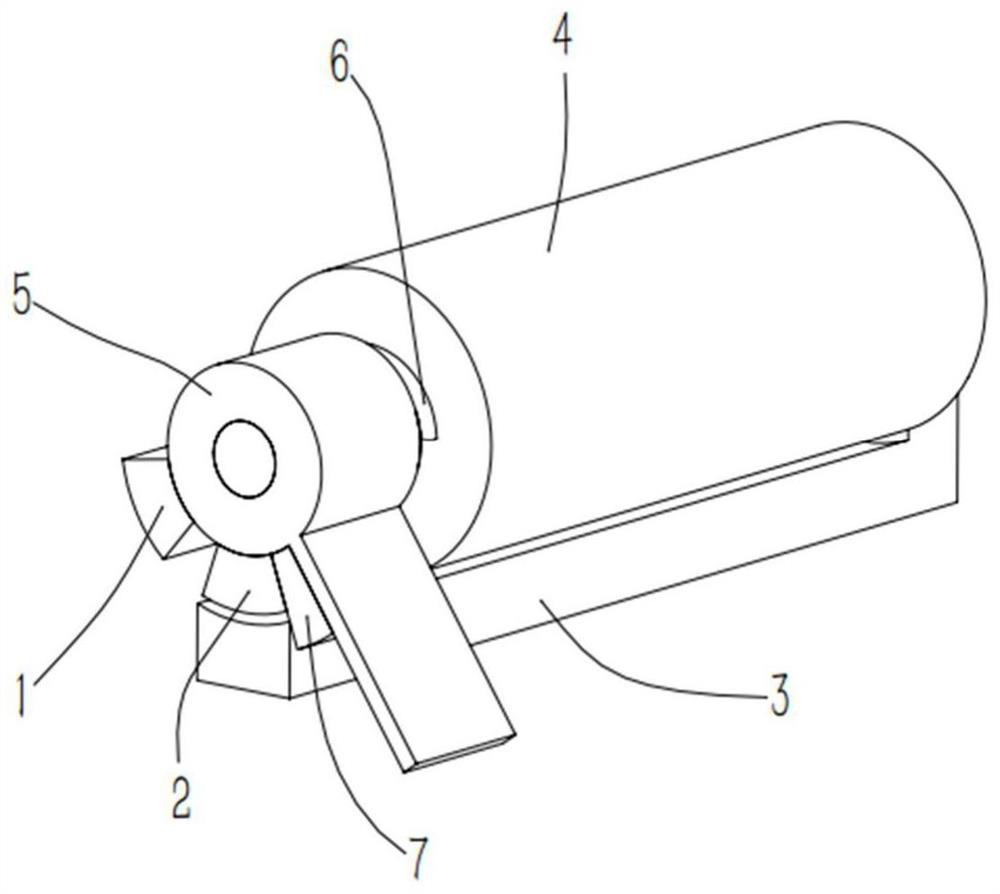

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 and figure 2 , The pressing self-generating device of the present invention includes a stator core 3, a rotor, a coil 4, a torsion spring 6, a first limiting device 7 and a second limiting device. The stator core 3 includes an upper cantilever and a lower cantilever arranged in parallel and an iron yoke between the upper and lower cantilever. The rotor includes an annular rotor core 5 and a first magnetic steel 1 and a second magnetic steel 2 fastened to the outer circumference of the rotor core 5 with opposite magnetic properties. The outer circumferential surface of the rotor core 5 has a protruding pressing piece. The pressing sheet can be produced integrally with the rotor core 5 . The coil 4 and the rotor core 5 are sequentially sleeved on the upper cantilever of the stator core 3 along a direction away from the iron yoke. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com