Method for recovering solvent in non-condensable gas containing solvent vapor and device thereof

A recovery method and solvent-containing technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of increased solvent consumption, high solvent consumption, large solvent loss, etc., and achieve reduced solvent consumption and good absorption effect. , The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0018] Both the solvent-rich wash oil obtained in step A and the washed oil obtained in step B after desolvation are sent to a heat exchange device to realize heat exchange.

[0019] The solvent-rich washing oil obtained in the step A is heated to 120°C and then enters the washing oil analysis device, and the analysis is completed under the working condition of 140°C.

[0020] The precipitated wash oil obtained in step B is cooled to 25° C. and then enters the wash oil analysis device.

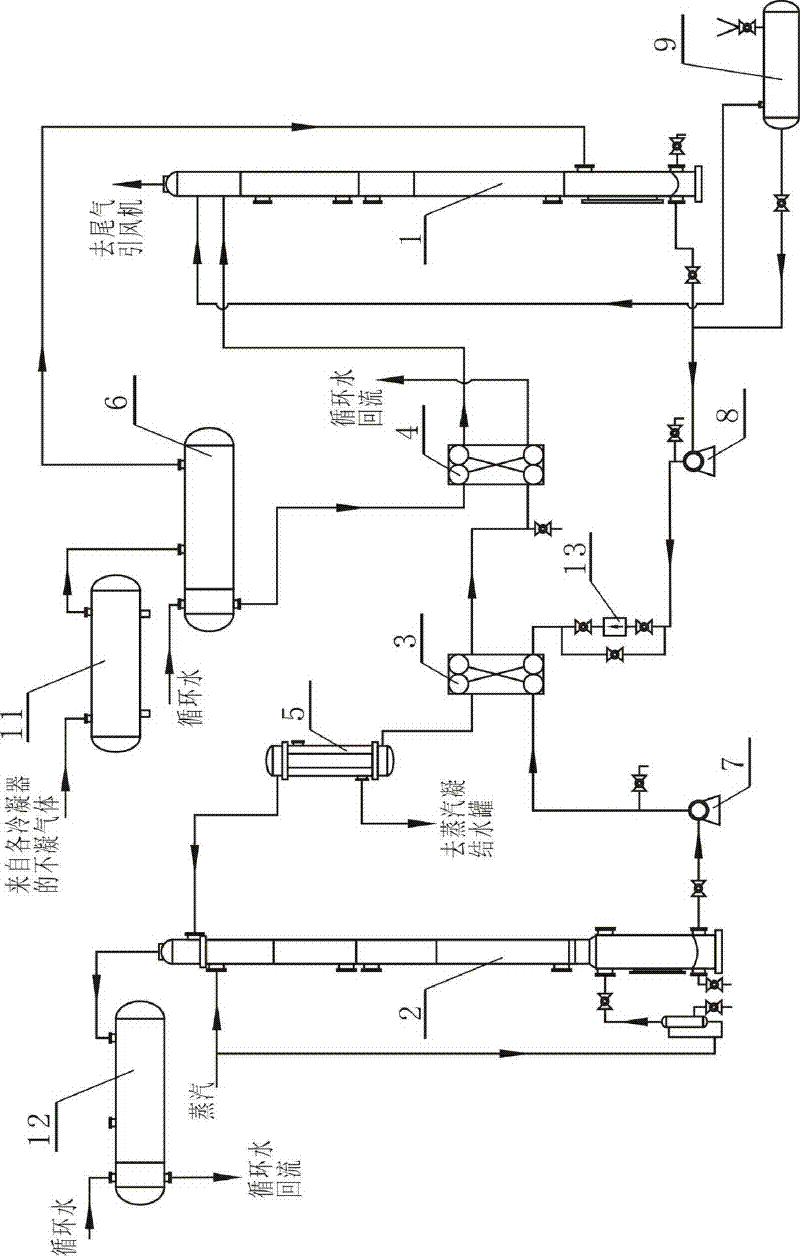

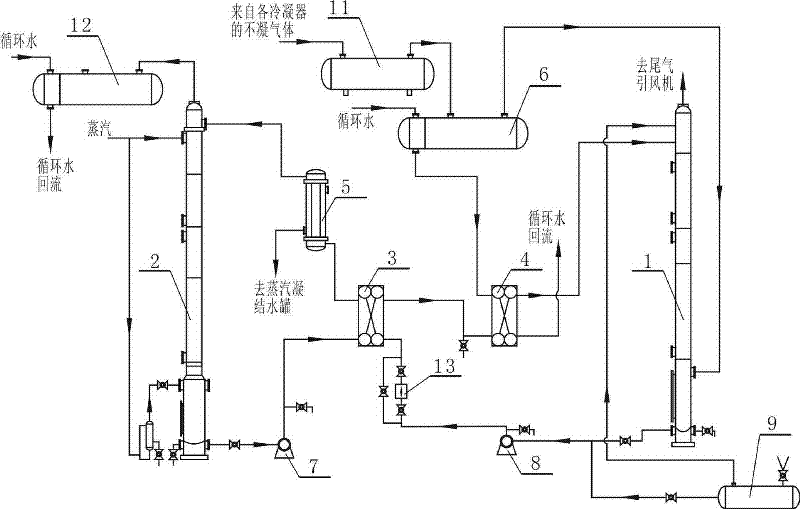

[0021] Such as figure 1 As shown, the device of the present invention comprises tail gas balance tank 11, oil washing absorption tower 1, oil washing analysis tower 2 and analysis tower condenser 12, and the top of described oil washing absorption tower 1 is connected with oil washing storage tank 9; The bottom of the oil washing absorption tower 1 is connected to the tail gas balance tank 11 through the tail gas condenser 6, and the bottom of the oil washing absorption tower 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com