Patents

Literature

86 results about "Oil analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil analysis (OA) is the laboratory analysis of a lubricant's properties, suspended contaminants, and wear debris. OA is performed during routine predictive maintenance to provide meaningful and accurate information on lubricant and machine condition. By tracking oil analysis sample results over the life of a particular machine, trends can be established which can help eliminate costly repairs. The study of wear in machinery is called tribology. Tribologists often perform or interpret oil analysis data.

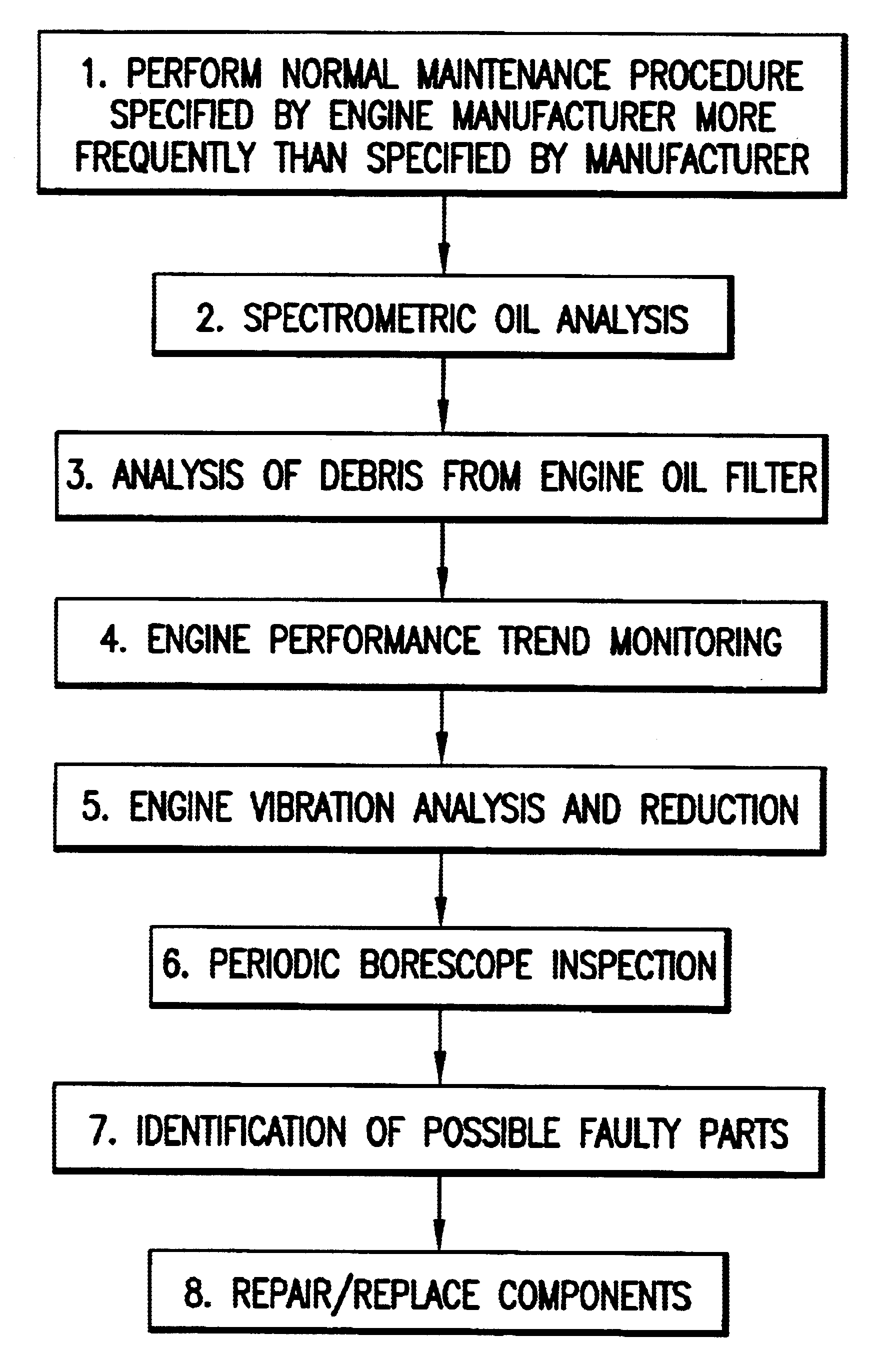

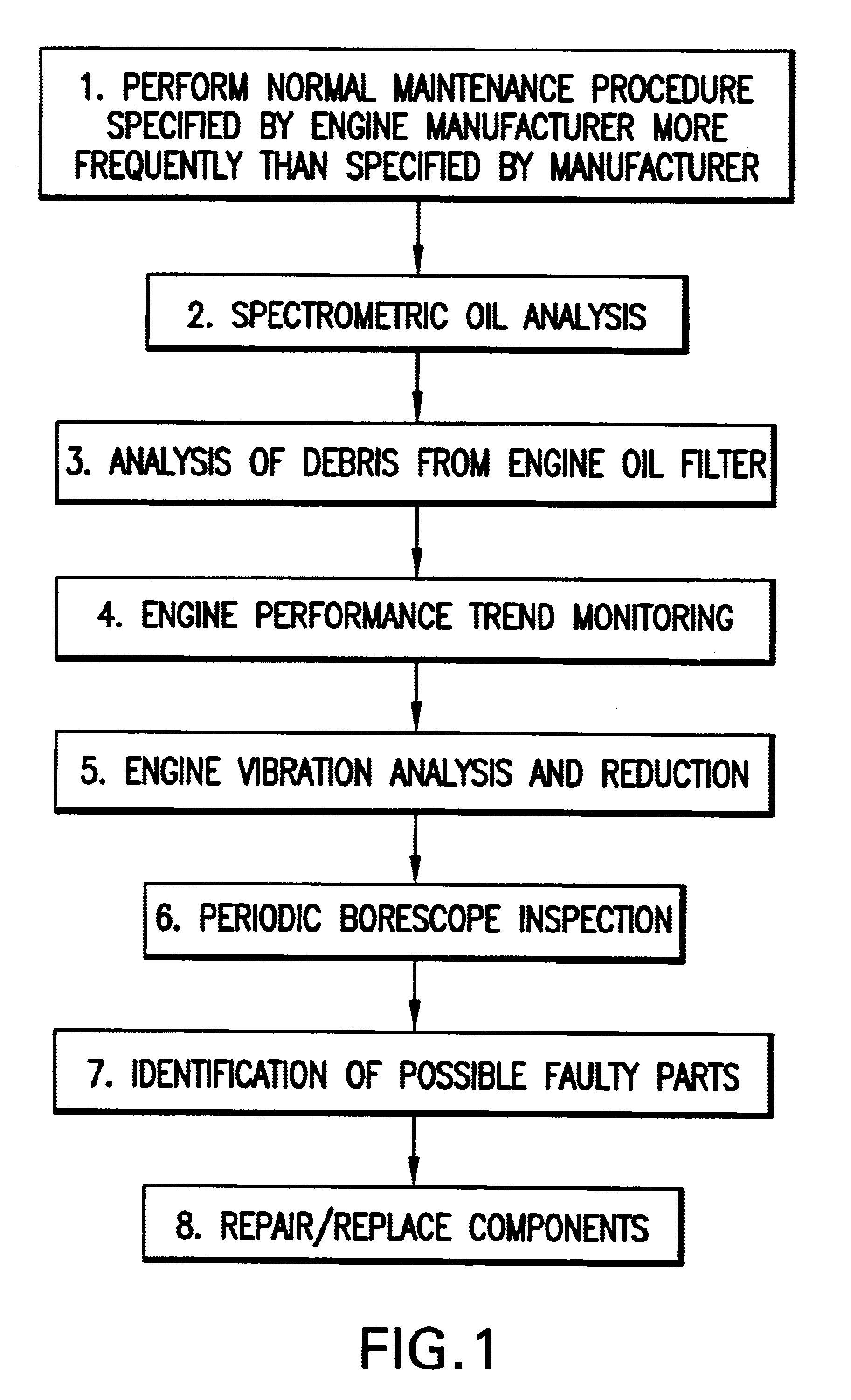

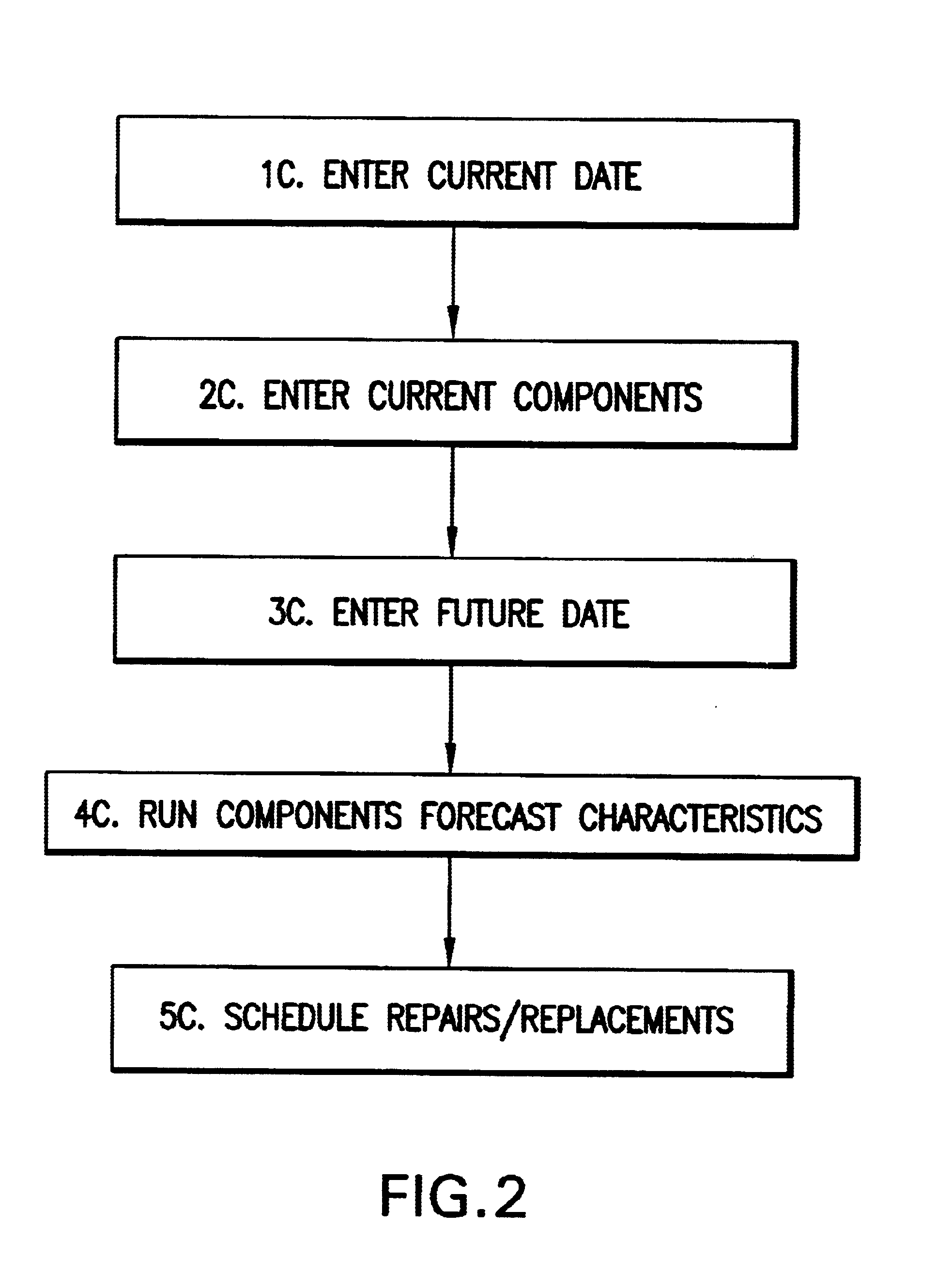

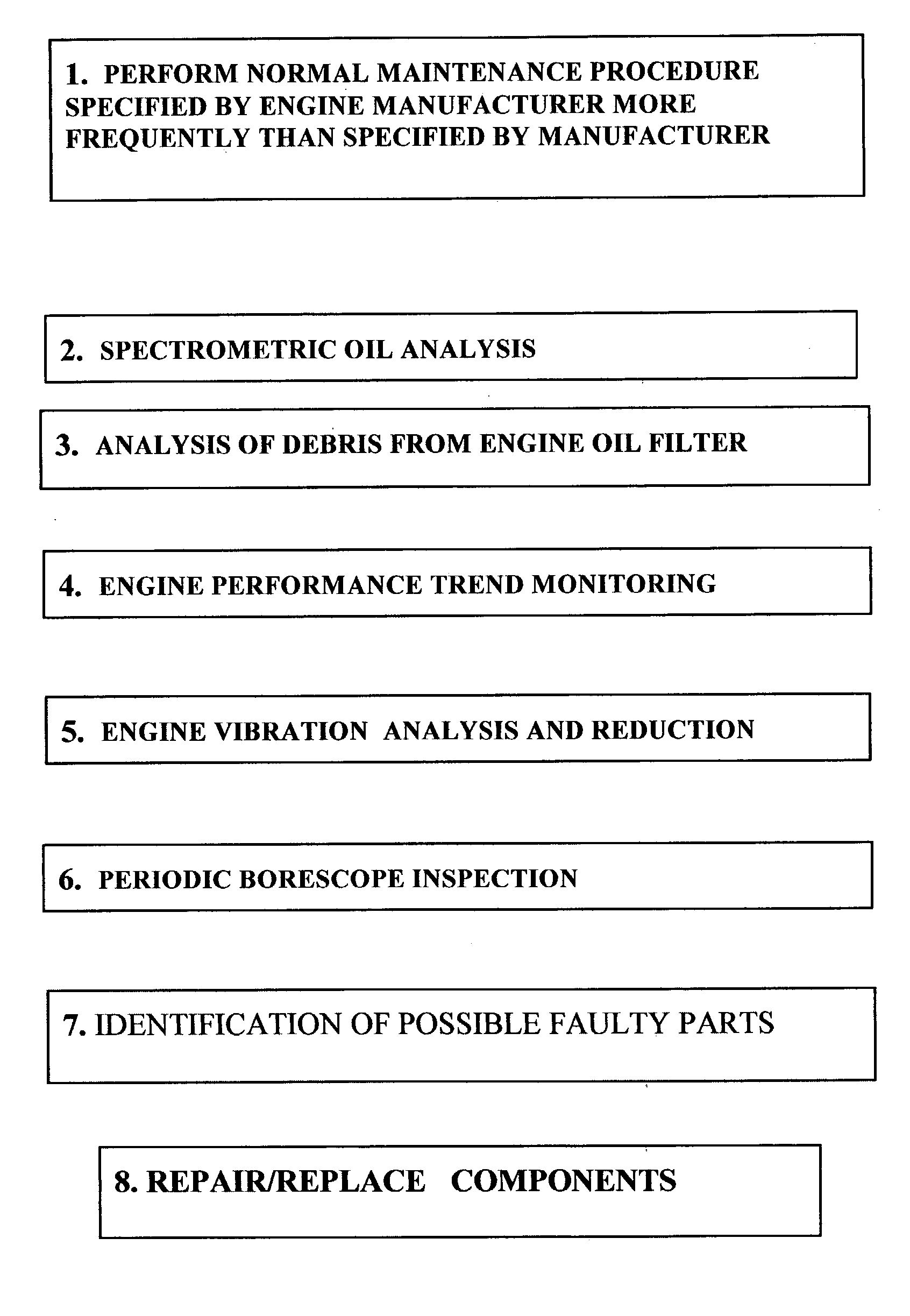

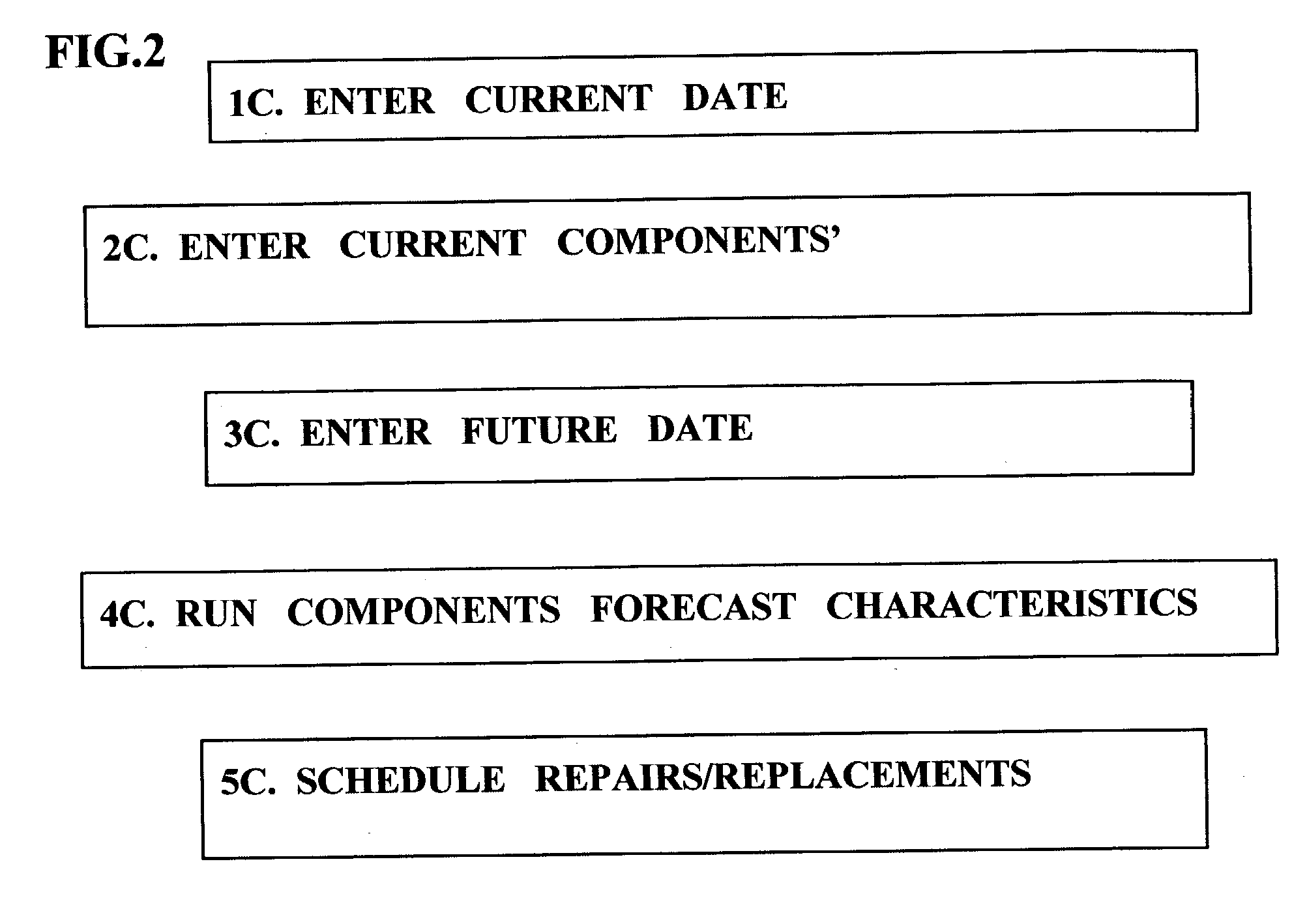

Aircraft engine reliability business model

A business model algorithm for maintaining aircraft engines in reliable and safe operating condition without the necessity of performing major engine overhaul in which engine manufacturers' maintenance procedures are enhanced and performed more frequently and supplemented by engine trend analysis, engine oil analysis, engine vibration analysis, borescope inspection and computer algorithm forecasting to identify, repair, and / or replace engine components without necessity of major engine overhaul.

Owner:BANGERT BARRY +1

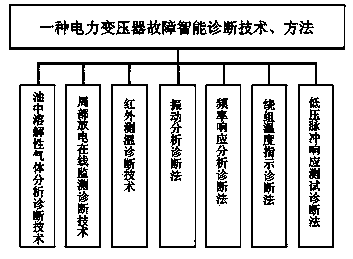

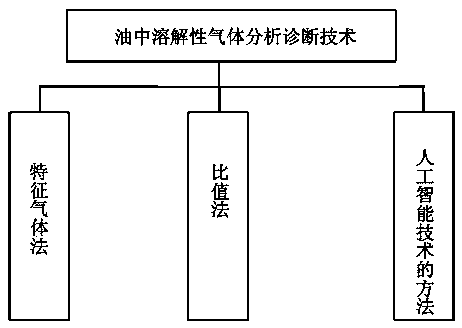

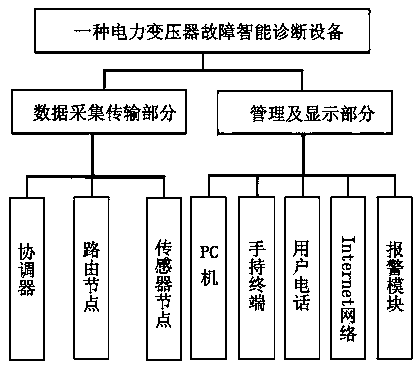

Power transformer fault intelligent diagnosis technology, method and device

InactiveCN103513139AOptimize parameter valuesGood conditionTesting dielectric strengthLow voltageData acquisition

The invention discloses power transformer fault intelligent diagnosis technology, method and device, and relates to power transformer fault intelligent diagnosis technology and method and the intelligent diagnosis device based on the technology and the method. The intelligent diagnosis device comprises a data acquisition and transmission part and a management and display part. The intelligent diagnosis device is characterized in that power transformer fault intelligent diagnosis technology and method comprise a dissolved gas in oil analysis and diagnosis technology, a partial discharge online monitoring and diagnosis technology, an infrared temperature measurement diagnosis technology, a vibration analysis and diagnosis method, a frequency response analysis and diagnosis method, a winding temperature indication diagnosis method and a low voltage impulse response test diagnosis method, and fault intelligent diagnosis is carried out. According to the invention, a multi-parameter state monitoring method is used, and multiple fault intelligent diagnosis technologies and methods are integrated; valuable data which can be used to diagnose a fault and find out the position are given; the cause of the defect is eliminated; the shutdown time and the cost are reduced; and the purposes of power transformer intelligent monitoring and intelligent diagnosis are realized.

Owner:王丽华

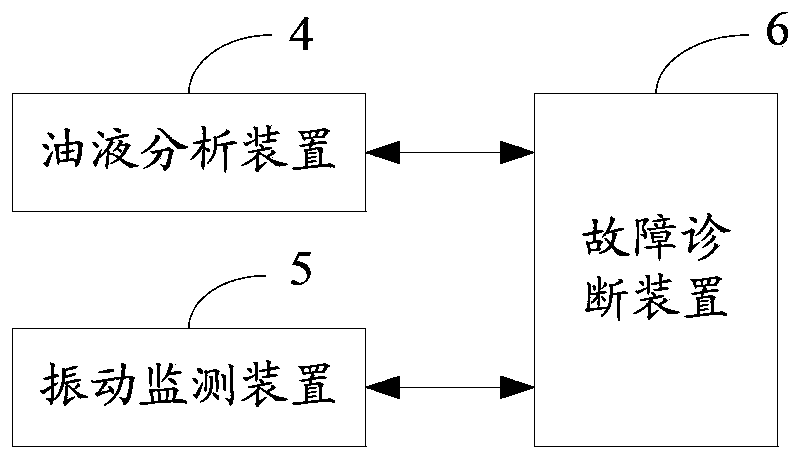

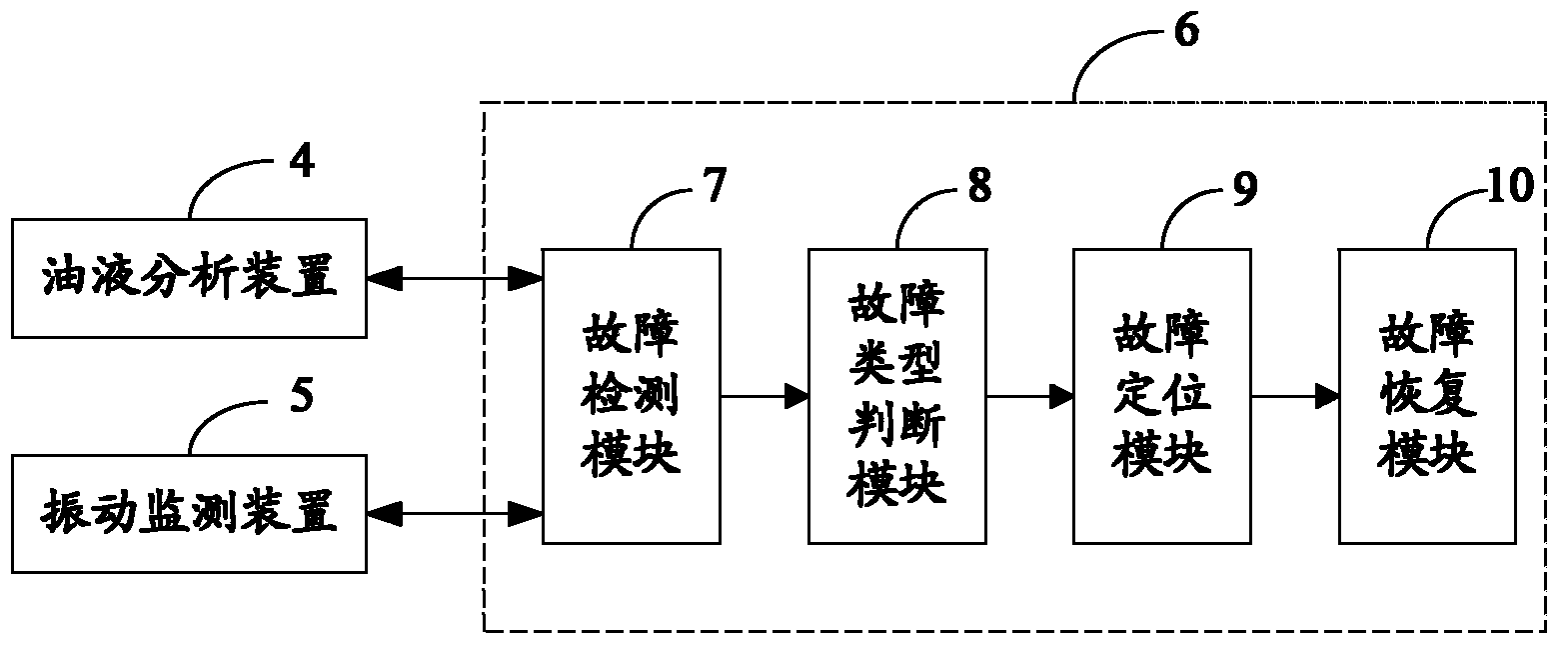

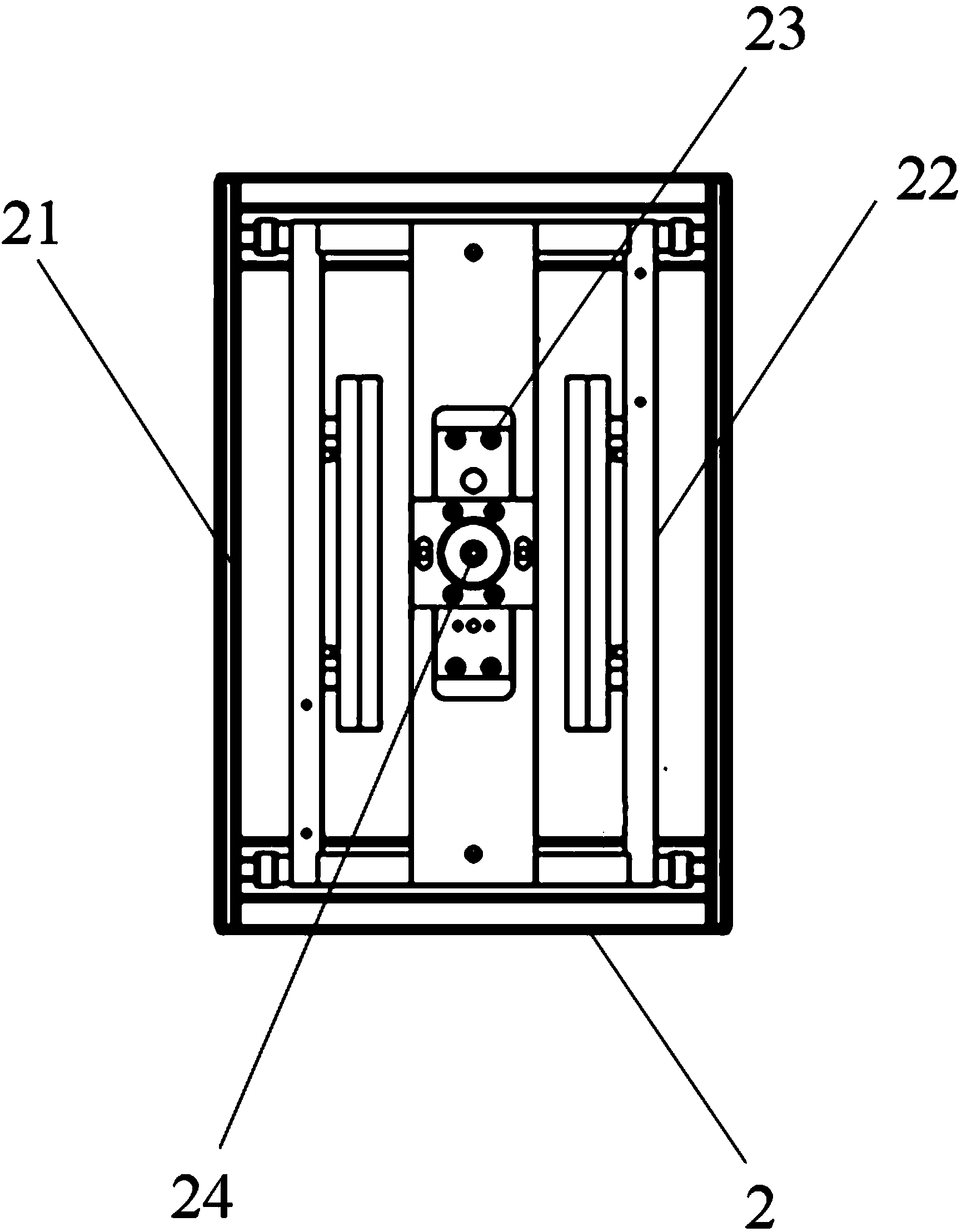

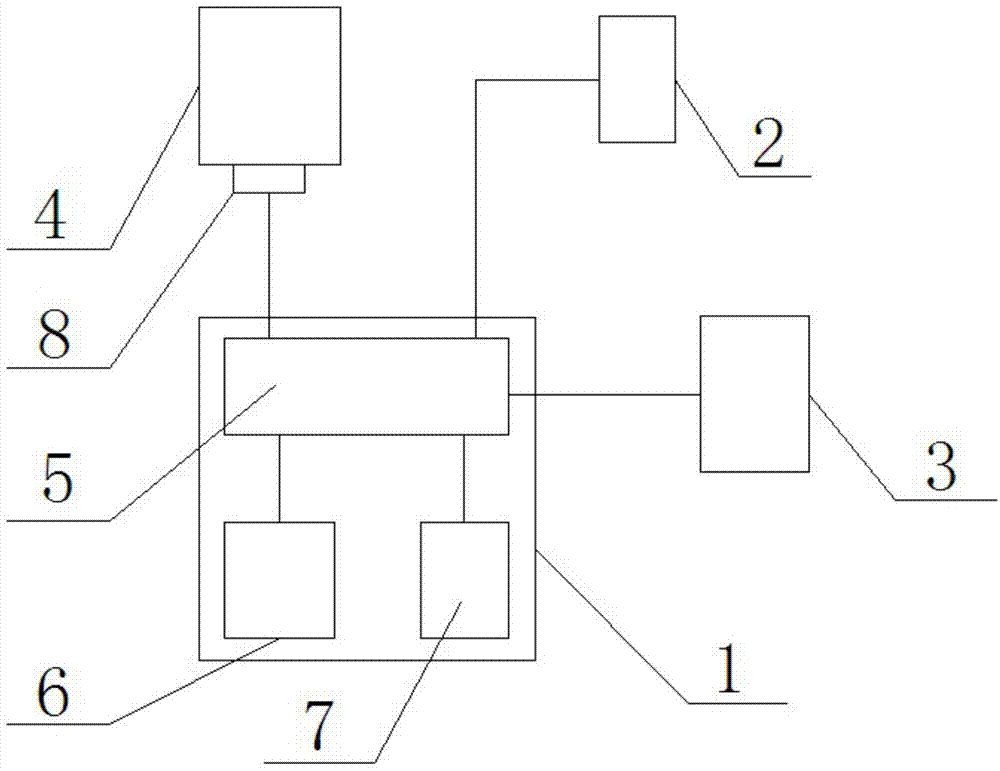

Online fault diagnosis system of wind turbine generator gear case

InactiveCN103364189AComprehensive monitoringImprove reliabilityMachine gearing/transmission testingParticle size analysisElectricityTurbine

The invention provides an online fault diagnosis system of a wind turbine generator gear case. The online fault diagnosis system of the wind turbine generator gear case comprises an oil analysis device, a vibration monitoring device and a fault diagnosis device. The oil analysis device is used for carrying out real-time online analysis on oil of the wind turbine generator gear case and sending oil analysis results to the fault diagnosis device according to detection signals sent by the fault diagnosis device. The vibration monitoring device is used for monitoring vibration conditions of the wind turbine generator gear case in real time and sending vibration data of the wind turbine generator gear case to the fault diagnosis device according to the detection signals. The fault diagnosis device is used for sending the detection signals to the oil analysis device and the vibration monitoring device periodically, carrying out contrastive analysis on the received oil analysis results and vibration data of the wind turbine generator gear case, and carrying out fault diagnosis on the wind turbine generator gear case according to contrastive analysis results. The online fault diagnosis system of the wind turbine generator gear case can carry out real-time online fault diagnosis on the inside and the outside of the gear case at the same time, has high fault diagnosis reliability, and improves possibility and feasibility of maintenance beforehand.

Owner:中国水利电力物资华南有限公司 +1

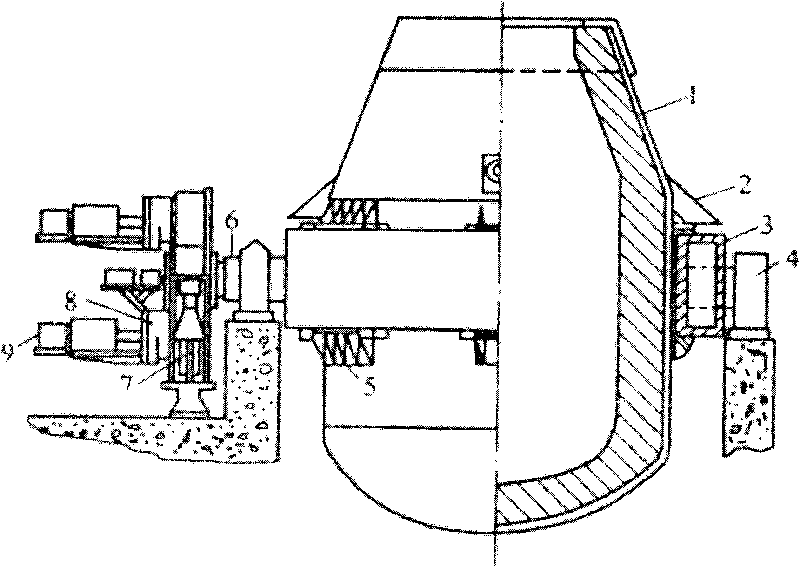

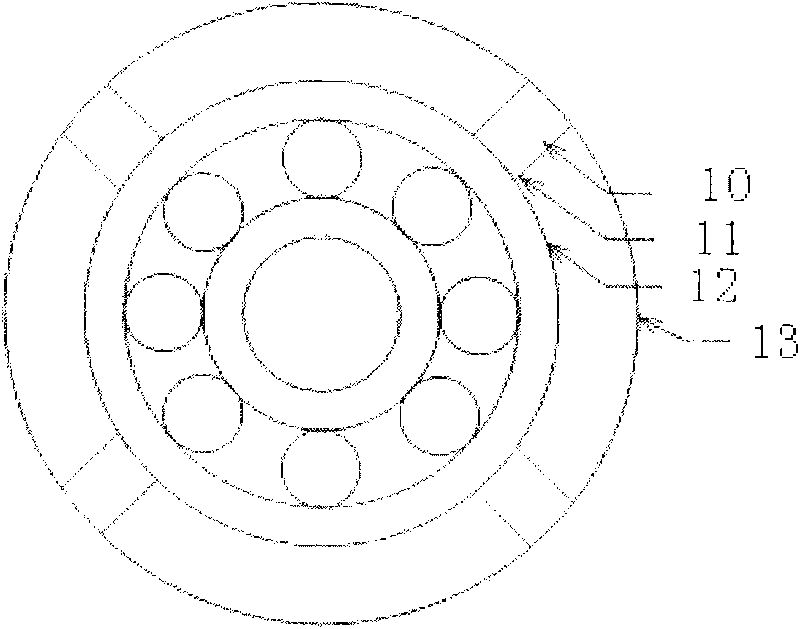

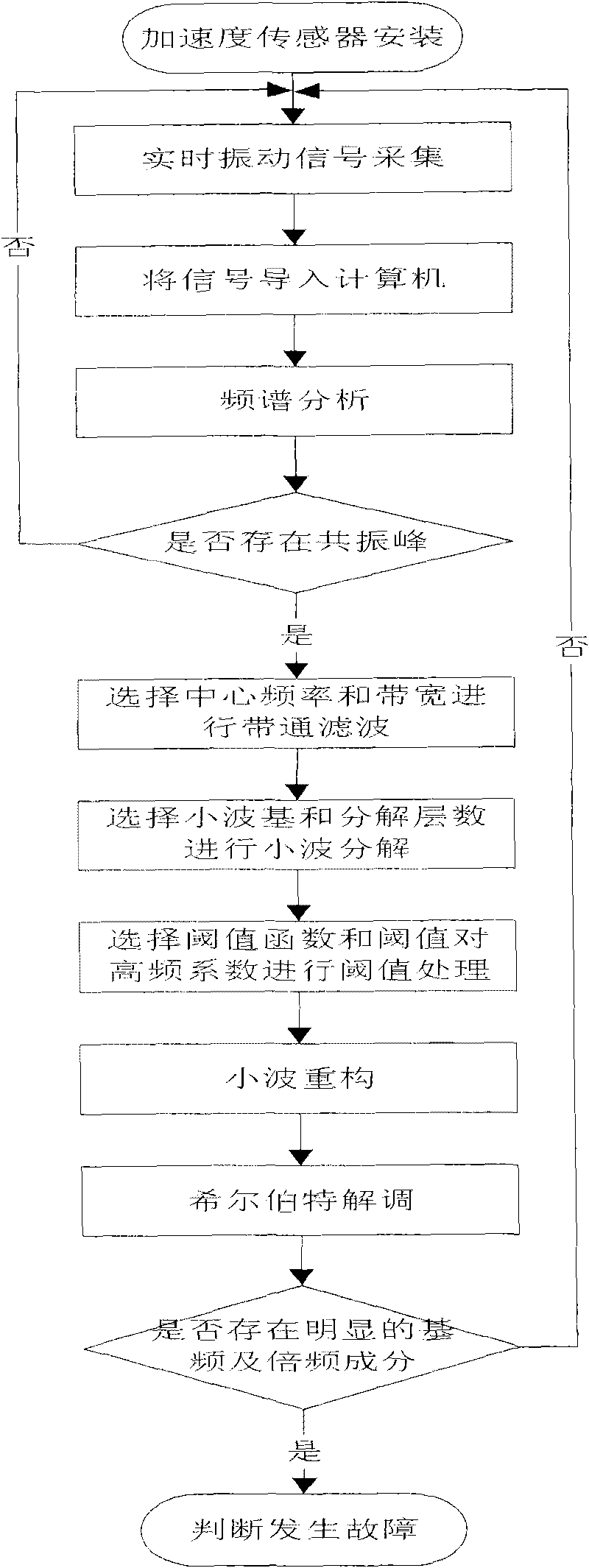

Method of fault diagnosis on ball socketed bearing of steel-making converter by comprehensive analysis

InactiveCN101726413ASmall attenuationEasy extractionVibration measurement in solidsMachine bearings testingBandpass filteringEngineering

The invention discloses a method of fault diagnosis on a ball socketed bearing of a steel-making converter by comprehensive analysis. The method carries out fault diagnosis on the ball socketed bearing of the steel-making converter by using vibration signal analysis and grease oil analysis. The method comprises the following steps of: firstly, selecting evenly distributed measuring points on the periphery of the outer ring of the bearing, and then punching bearing seats at the measuring points; carrying out resonance demodulation and wavelet noise reduction analysis on acquired bearing vibration signals; firstly, selecting centre frequency and bandwidth according to frequency bands generated in resonance peaks in a frequency spectrogram to carry out bandpass filtering, and then carrying out wavelet noise reduction and Hilbert demodulation treatment on the filtered signals; on the basis of detecting the conventional typical properties, carrying out qualitative and quantitative analysis on the components and the content of metal wearers in oil samples by using spectrum analysis and ferrographic analysis, and judging according to the detection result; and comparing and synthesizing two analysis results to make a fault diagnosis report. The invention can effectively increase the accuracy of fault diagnosis, thereby being beneficial to discovering fault hidden troubles as early as possible and avoiding major accidents happening.

Owner:BEIJING UNIV OF TECH

Failure diagnosis method of power equipment

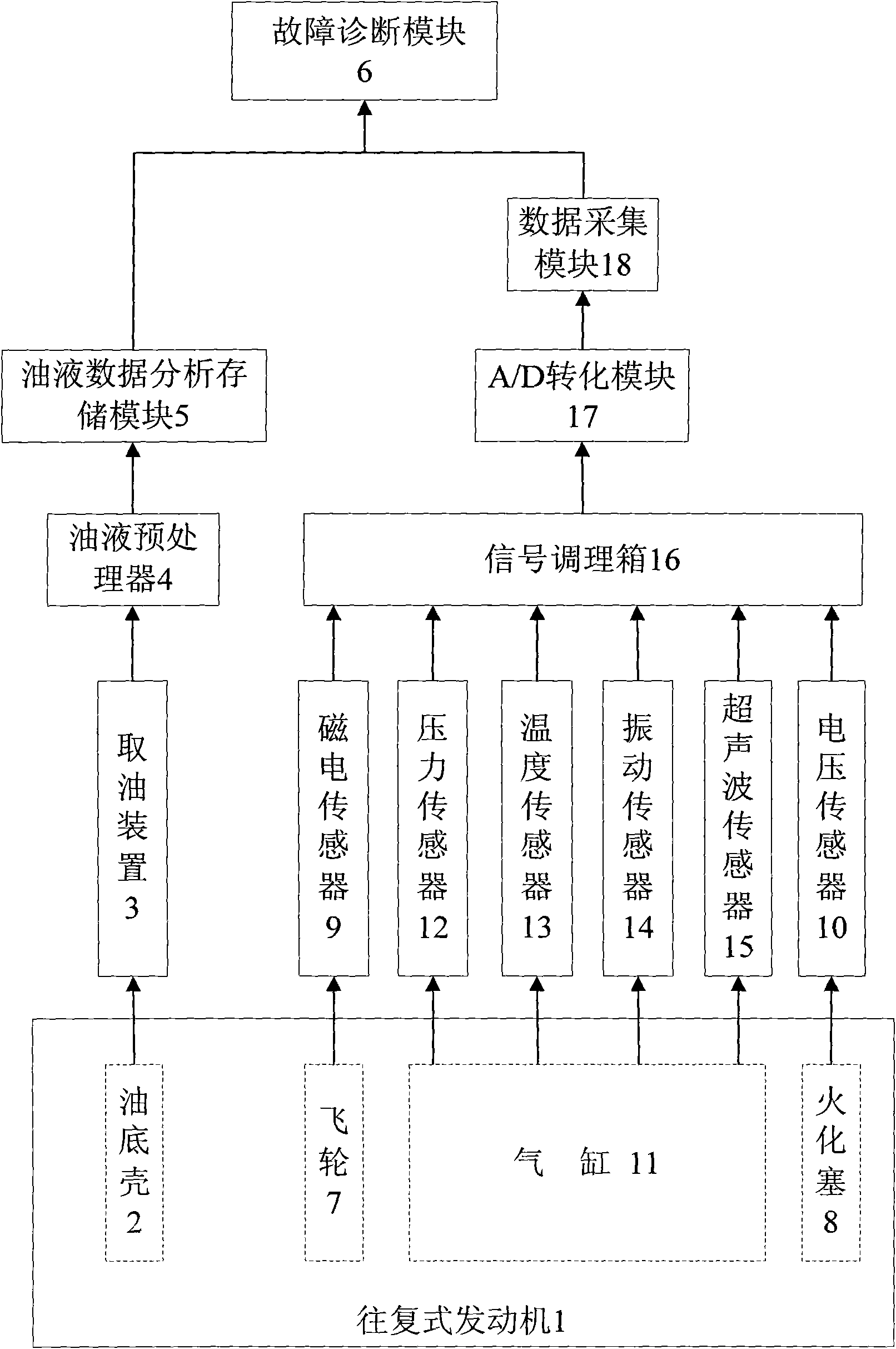

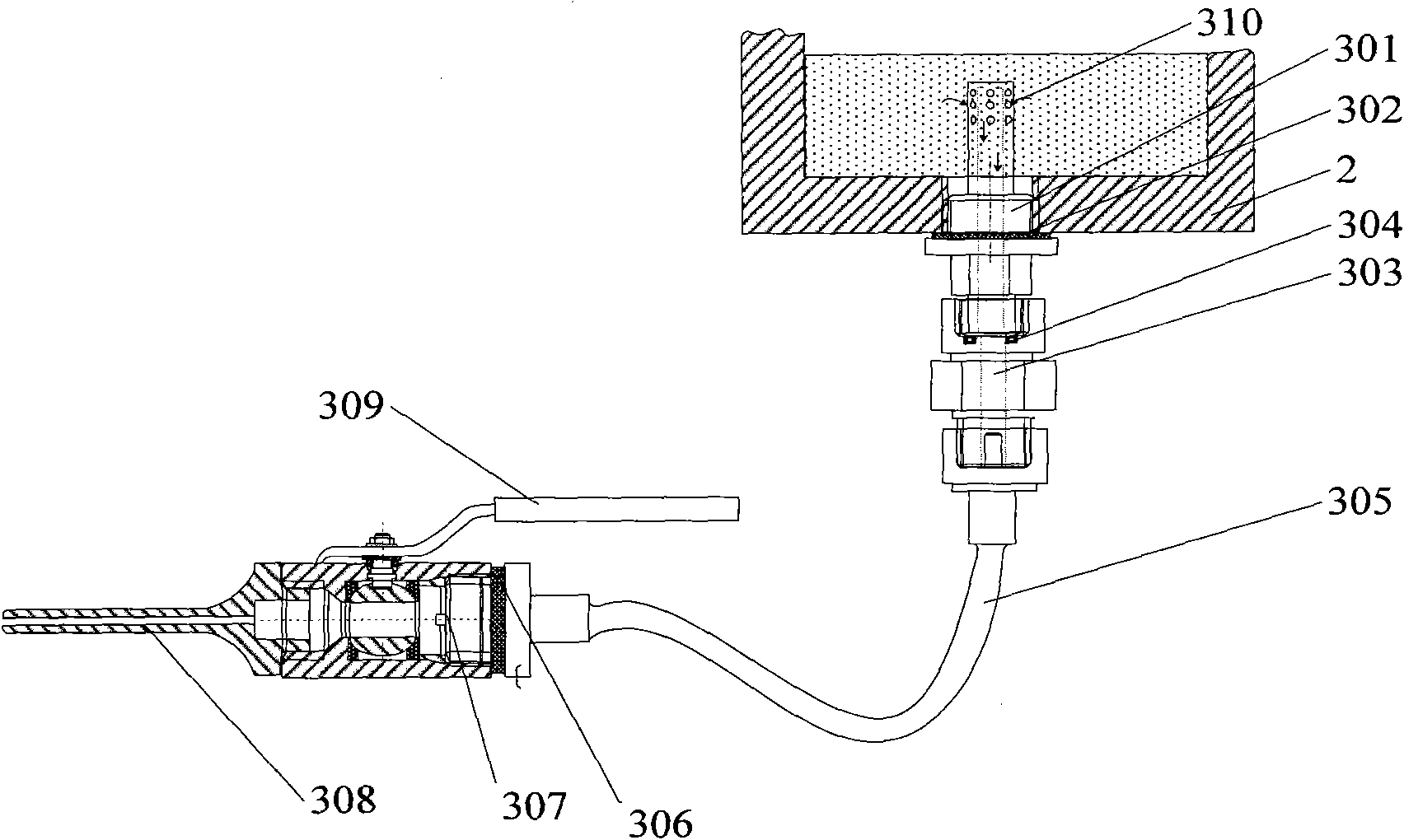

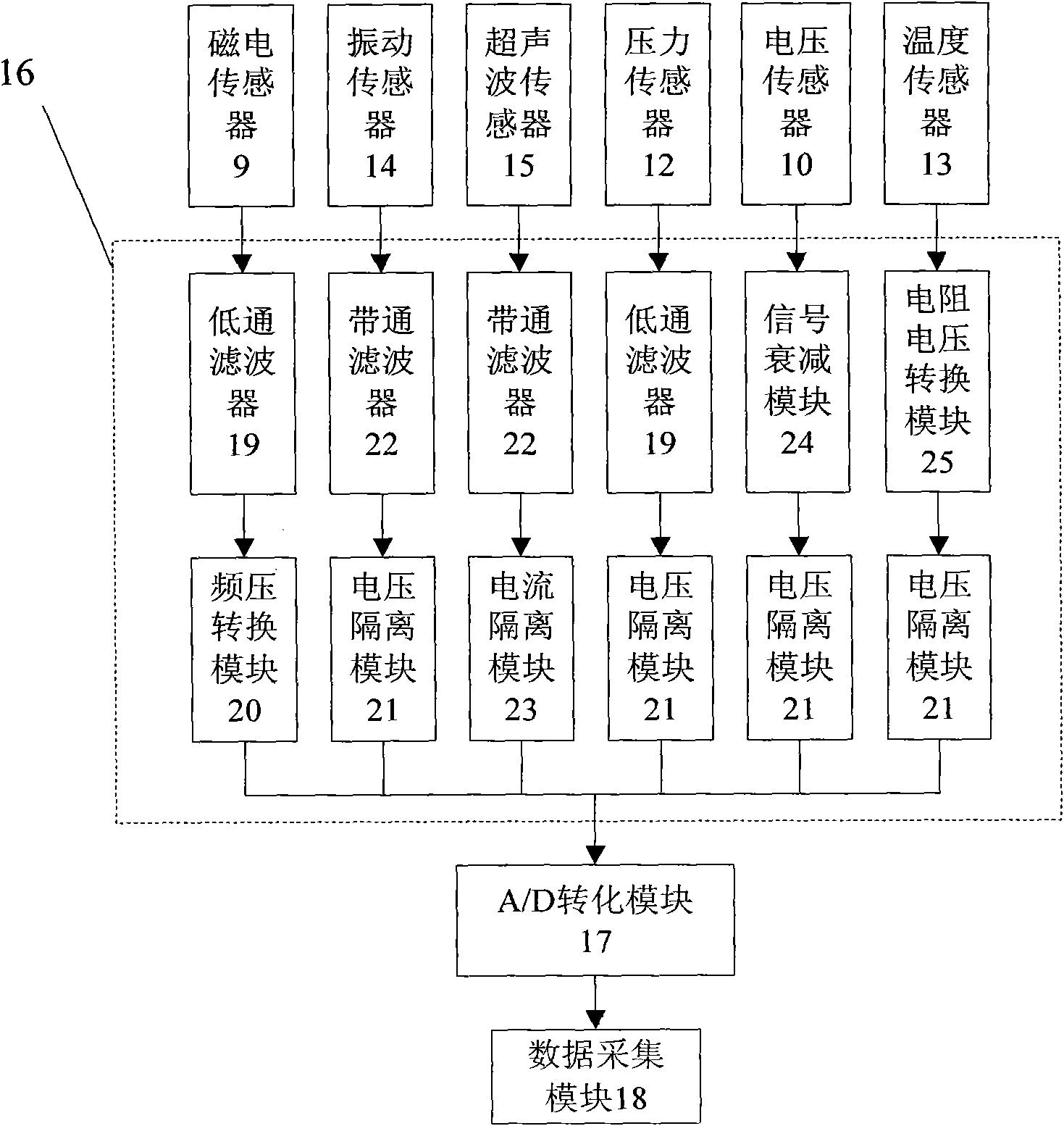

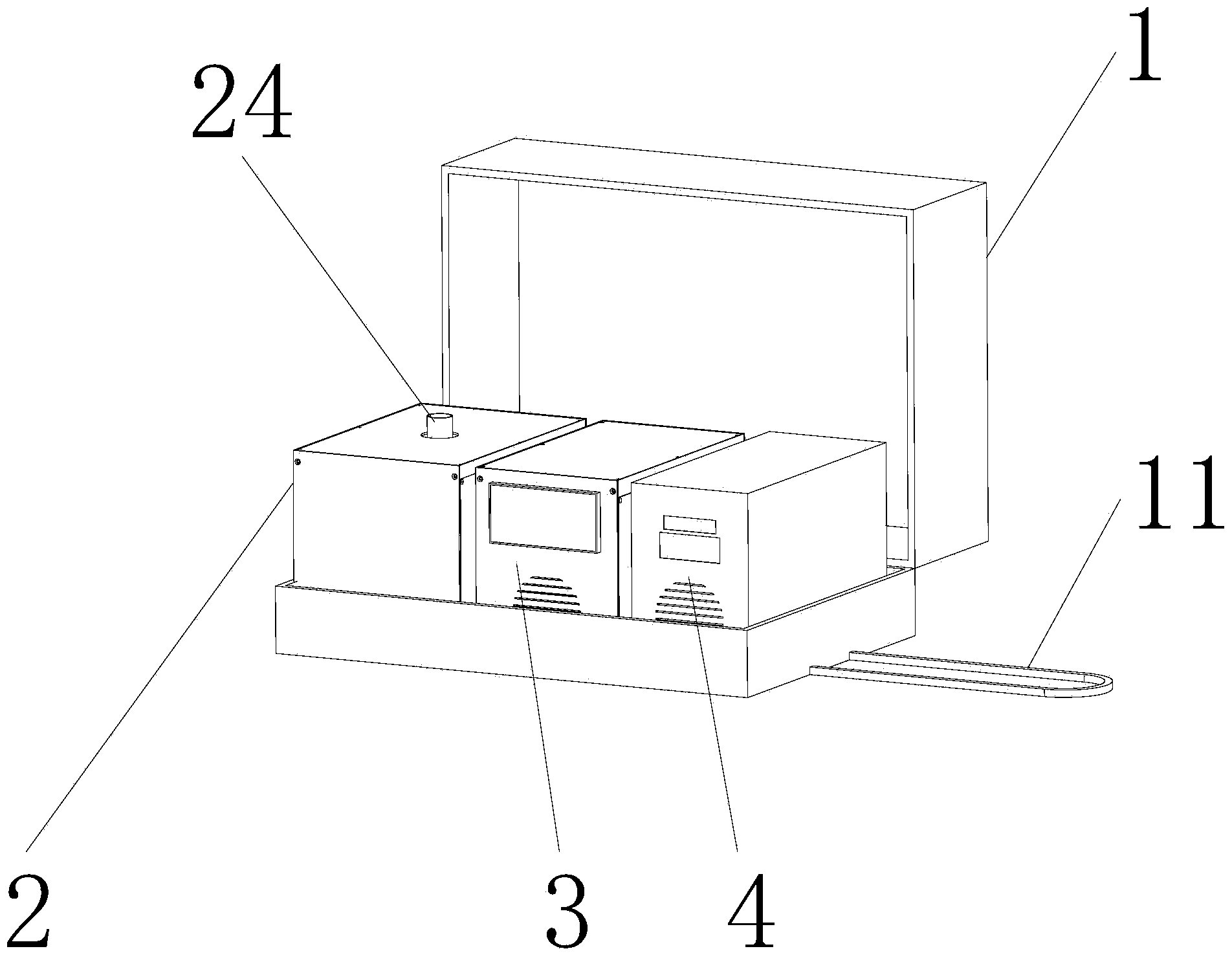

InactiveCN101798957AHigh degree of integrationSatisfy Failure PredictionMachines/enginesEngine componentsData acquisitionPower equipment

The invention relates to a failure diagnosis method of power equipment, comprising the following steps: (1) installing a failure monitoring and predicting system comprising a reciprocating engine, an oil extraction device, an oil preprocessor, an oil data analyzing and storing module, a failure diagnosis module, a magnetoelectric sensor, a voltage sensor, a pressure sensor, a temperature sensor, a vibration sensor, an ultrasonic wave sensor, a signal conditioning box, an analog-to-digital conversion module and a data acquisition module; (2) judging whether the acquired data exceed the upper limit of the threshold values of the normal phase and the amplitude according to the oil analysis data and the data acquired by each sensor, if not, continuing operating the equipment, if so, carrying out phase deviation and amplitude data quantifying; (3) establishing a fuzzy evaluation matrix of the amplitude and the phase signal according to a fuzzy evaluation method; and (4) carrying out failure diagnosis on various acquired data according to the fuzzy evaluation matrix. The invention has overall acquisition means, can satisfy the failure predicting and monitoring functions and has high diagnosis precision. The invention can be widely applied to various reciprocating machines.

Owner:BEIJING INFORMATION SCI & TECH UNIV

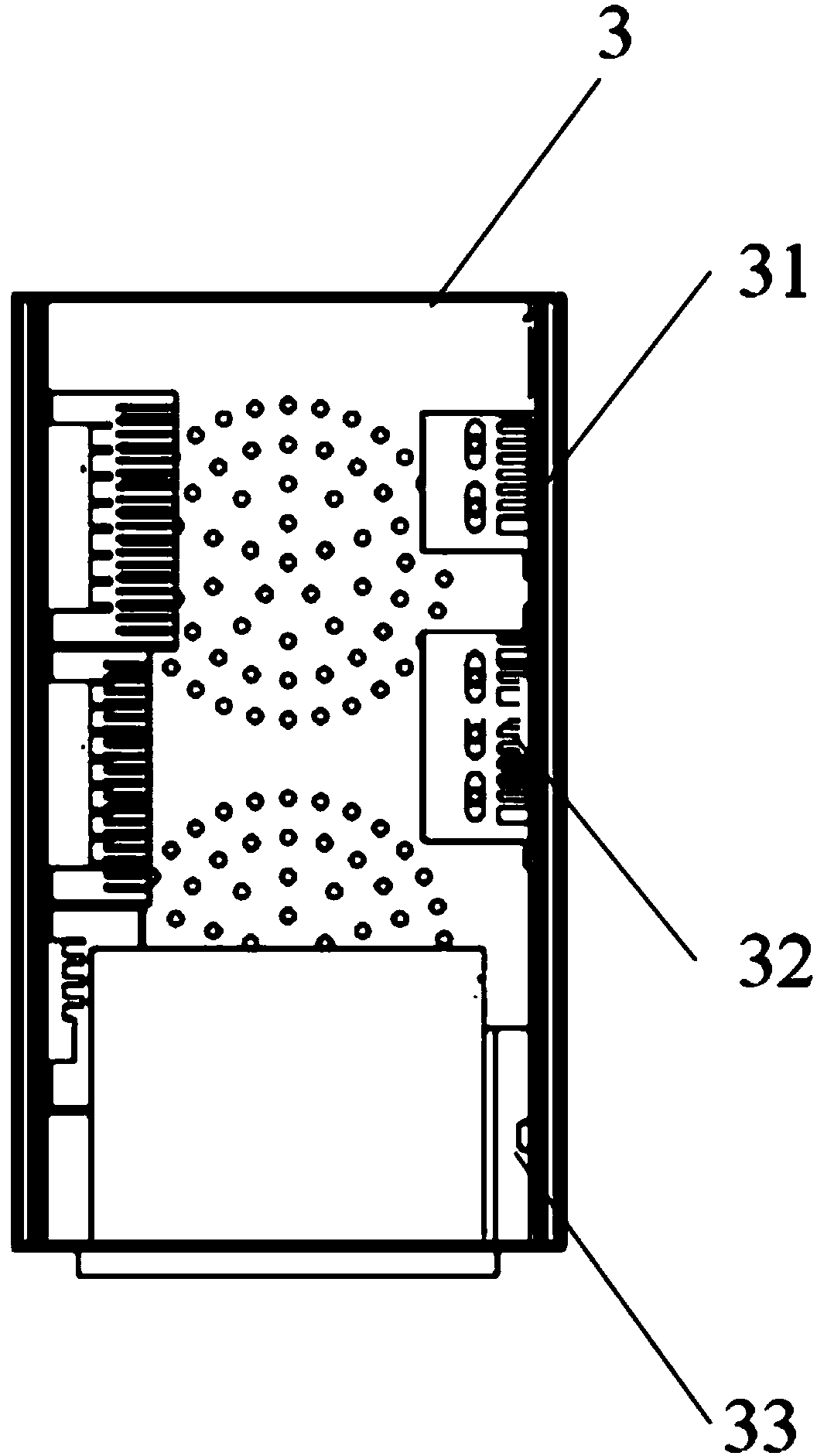

Portable low-field nuclear magnetic resonance old frying oil analysis meter

ActiveCN103411991AQuick checkEasy to carryAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceDisplay device

The invention discloses a portable low-field nuclear magnetic resonance old frying oil analysis meter. The analysis meter comprises a portable tank and a display, wherein the portable tank internally comprises a magnetic body cabinet, a radio-frequency cabinet and a spectrometer. According to the analysis meter, a sample is put into a sample feeding hole, the sample in a magnetic field is stimulated by a radio-frequency coil after a radio-frequency signal generated by the spectrometer is firstly subjected to power amplification by a radio-frequency power amplifier in the radio-frequency cabinet, a nuclear magnetic resonance signal of the sample is received by the radio-frequency coil after the stimulation is finished and then is received and processed by the spectrometer after being filtered and amplified by a pre-amplifier, software aiming at the quality analysis and application of edible oil is preinstalled in the spectrometer, and a result is obtained after analysis. The required time for detecting a sample does not exceed two minutes. The portable low-field nuclear magnetic resonance old frying oil analysis meter has the main characteristics of being convenient to carry, capable of quickly detecting and beneficial to field detection, and ensuring high correctness and stability of a detection result obtained by utilizing a low-field nuclear magnetic resonance technique.

Owner:SHANGHAI NIUMAI ELECTRONICS TECH

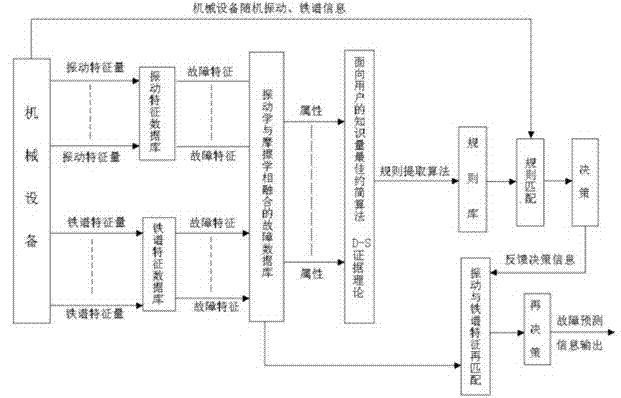

Method for diagnosing failure of rotary machine by fusing oil and vibration

ActiveCN103207070AImprove accuracyHigh precisionMachine gearing/transmission testingOil analysisRule matching

The invention discloses a method for diagnosing a failure of a rotary machine by fusing oil and vibration. The method comprises the following steps of: establishing a vibration characteristic database and a ferrographic characteristic database of the rotary machine respectively; fusing the vibration characteristic database and the ferrographic characteristic database to form a failure database; reducing and fusing the failure database to form a rule base consisting of a plurality of rules; performing rule matching to obtain a decision pre-making information; performing decision remaking for failure prediction by matching the failure database according to the decision pre-making information to obtain re-prediction information; and outputting the re-prediction information. The vibration characteristic database obtained by vibration analysis and the ferrographic characteristic database obtained by oil analysis are comprehensively used for failure diagnosis, so that failure diagnosis accuracy is improved; and in addition, a failure decision is pre-made by failure matching, and the decision pre-making information is matched with the failure database to obtain re-predicted failure diagnosis information, so that the failure diagnosis accuracy is further improved.

Owner:广研检测(广州)有限公司

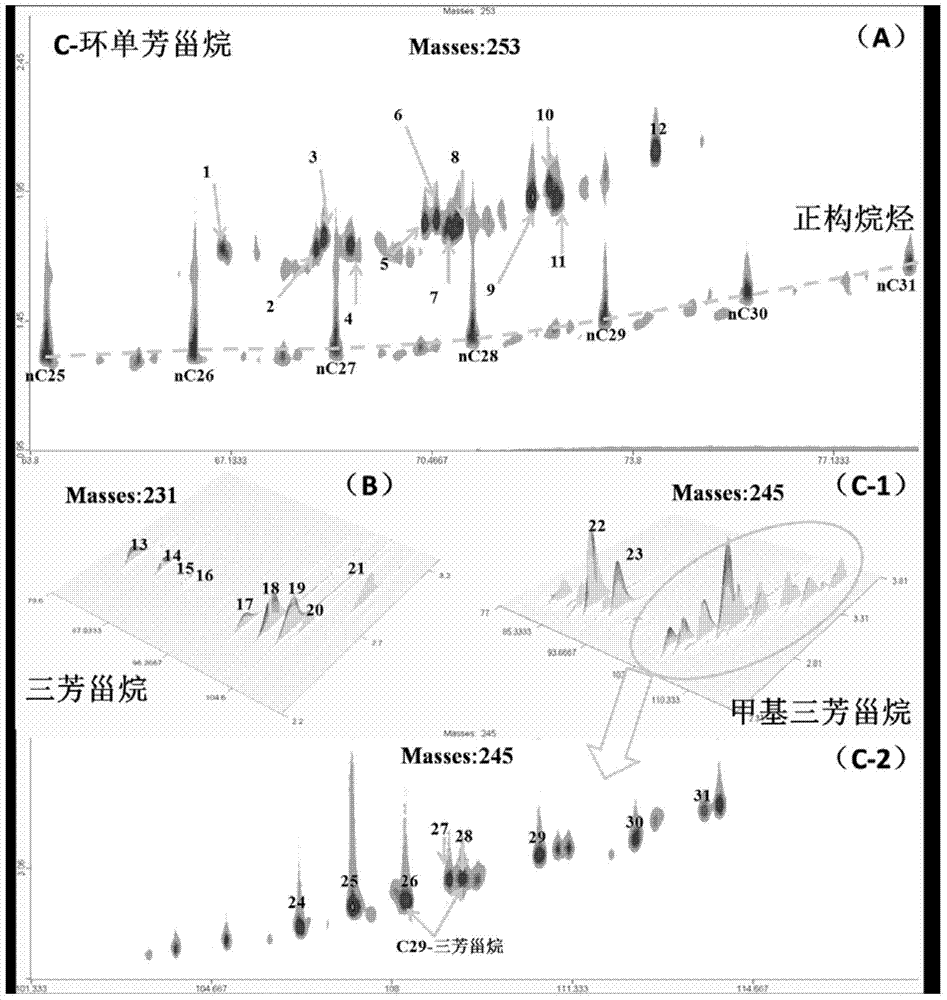

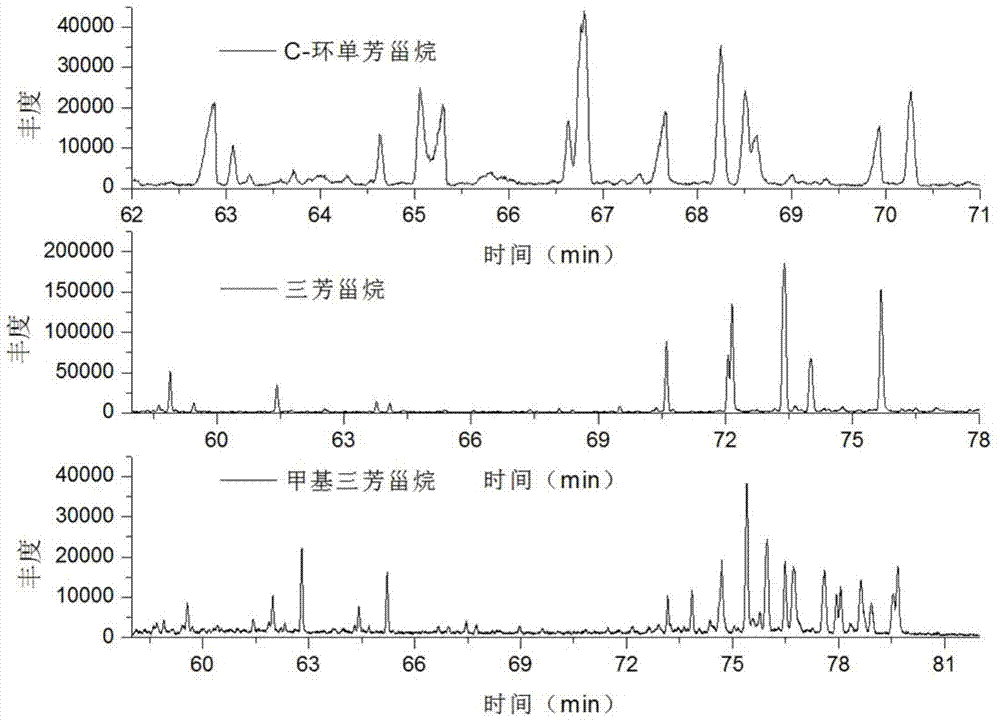

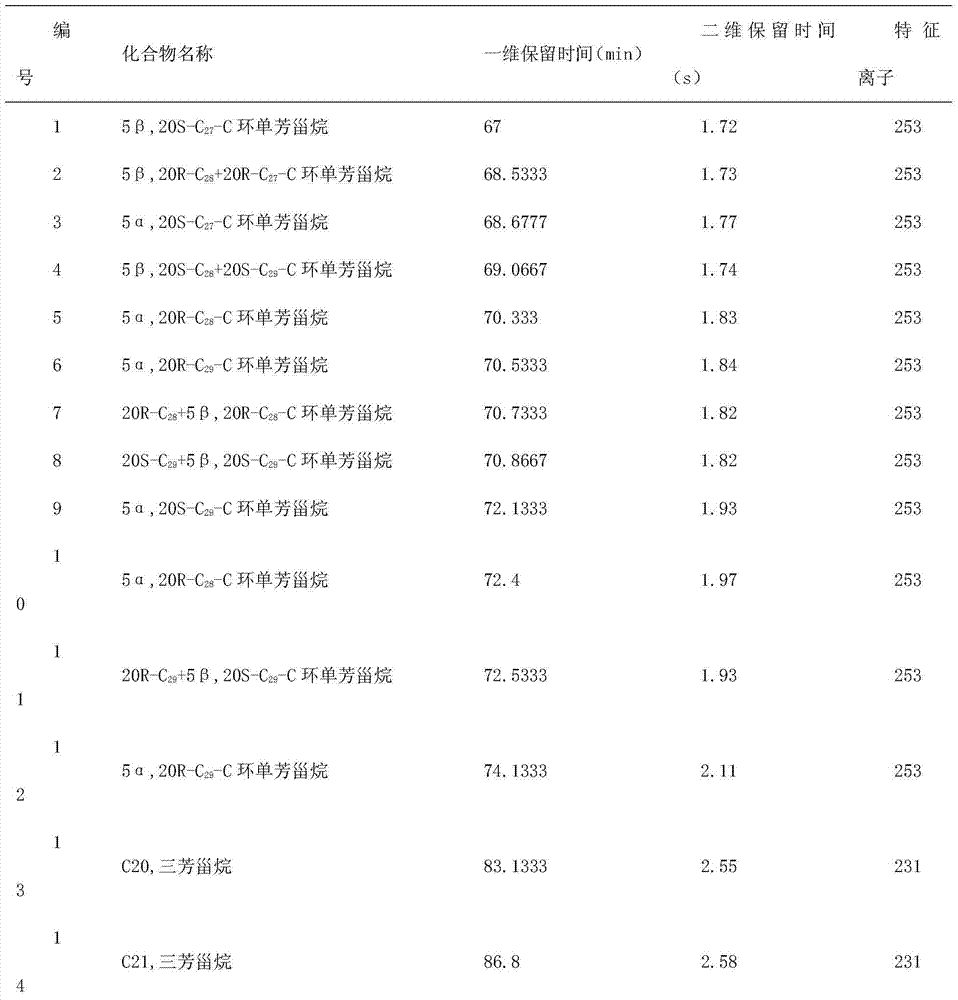

Comprehensive two-dimensional gas chromatography quantitative analysis method of aromatic sterane compound in petroleum

The invention provides a comprehensive two-dimensional gas chromatography quantitative analysis method of an aromatic sterane compound in petroleum. The method comprises the following steps: fully dissolving and soaking crude oil with a solvent and then filtering to obtain a filtrate; heating to evaporate and concentrate the filtrate to prepare filtrate concentrate; collecting a saturated hydrocarbon group component and an aromatic group component; preparing a saturated hydrocarbon group component sample and an aromatic group component sample and storing the samples at low temperature; analyzing the two samples by using a comprehensive two-dimensional gas chromatograph and a flight time mass detector; performing data processing on spectrograms obtained in the steps to obtain corresponding retention time and peak area integration result. The analysis method can be used for performing full oil analysis and group component analysis; an orthogonal separation system thereof can completely separate the aromatic steroid hydrocarbons from alkane, so that the problems such as common rolling peak, base line interference and insufficient peak capacity can be excellently solved, and the aromatic sterane compound can be accurately measured.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

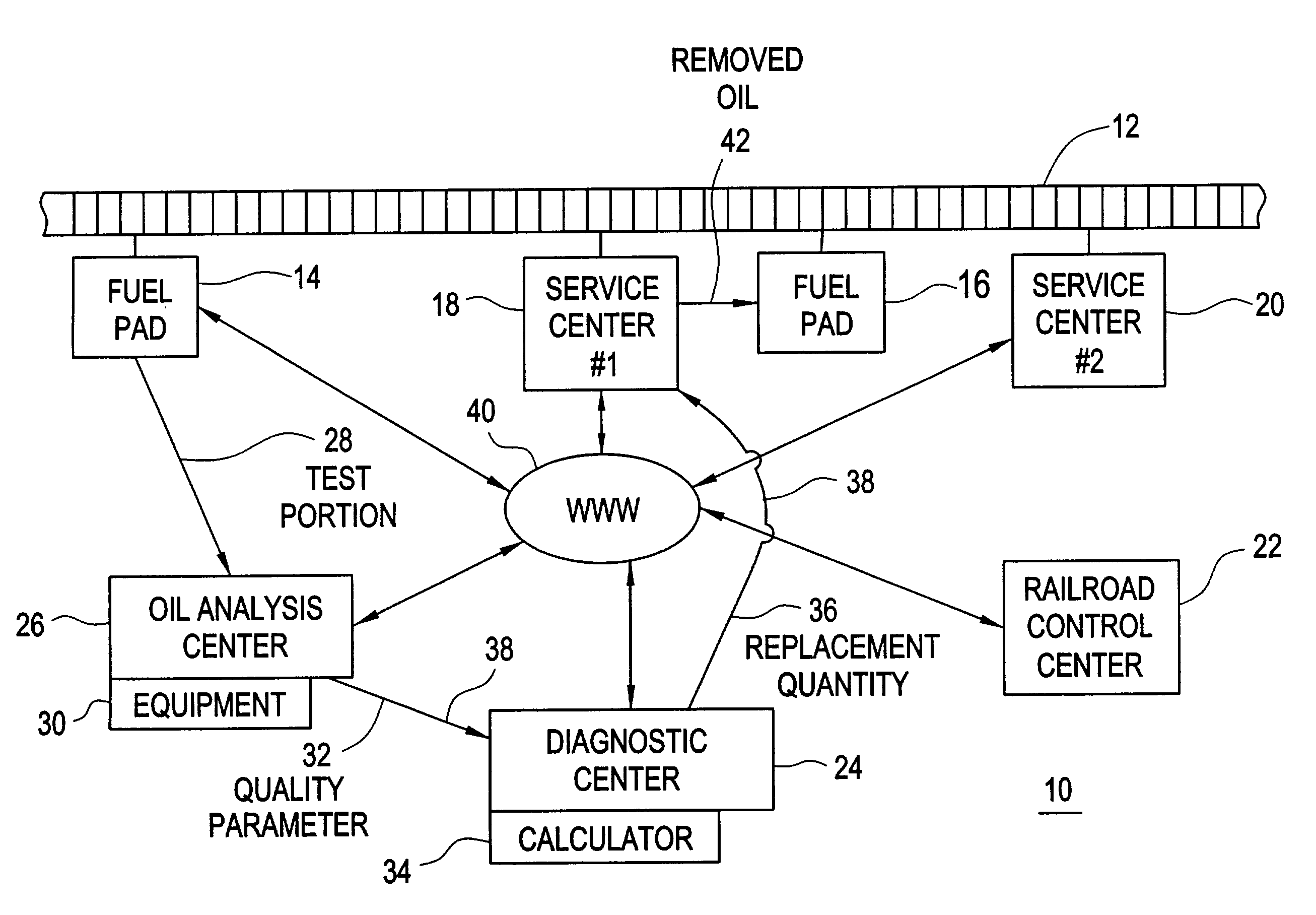

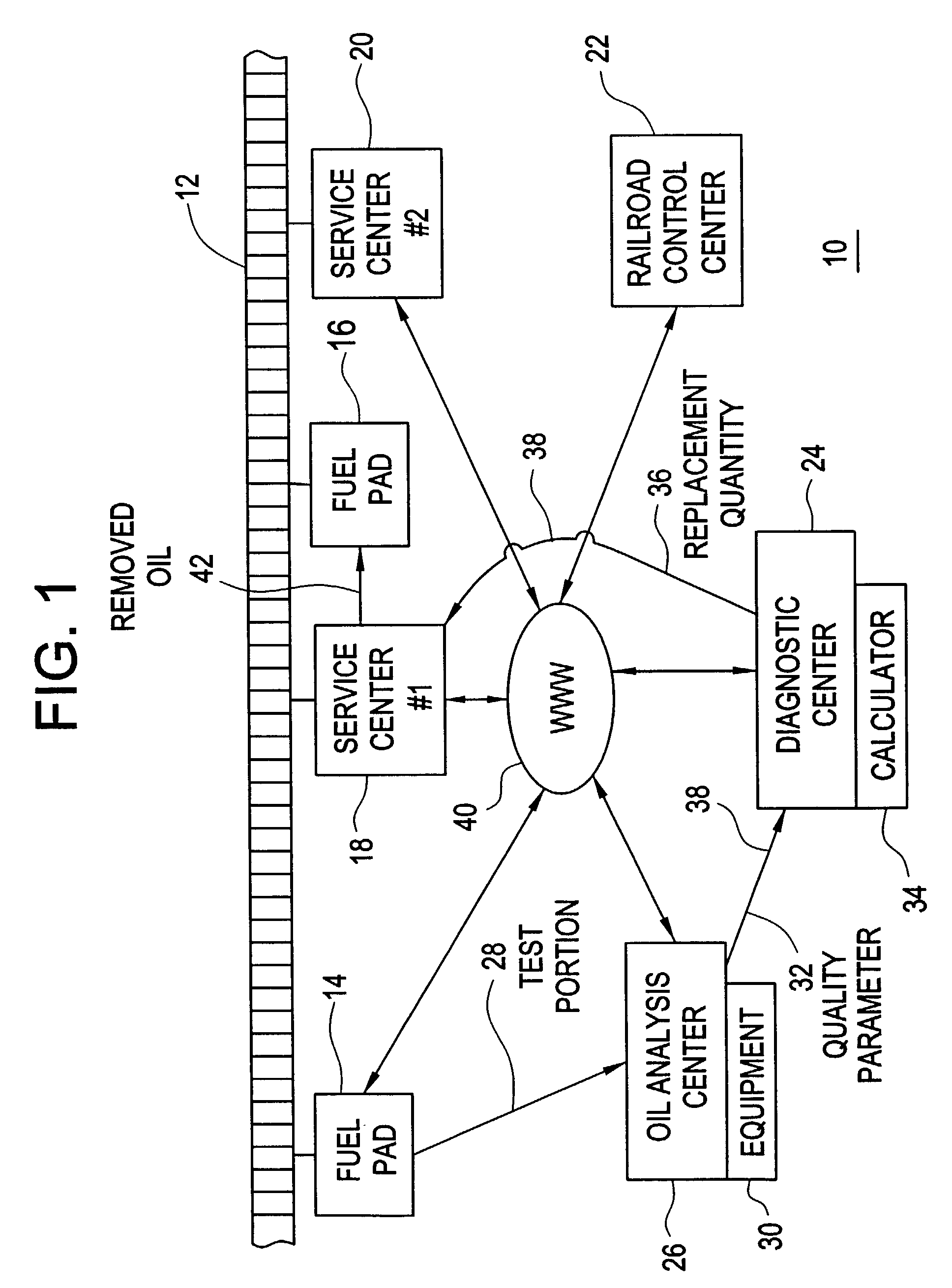

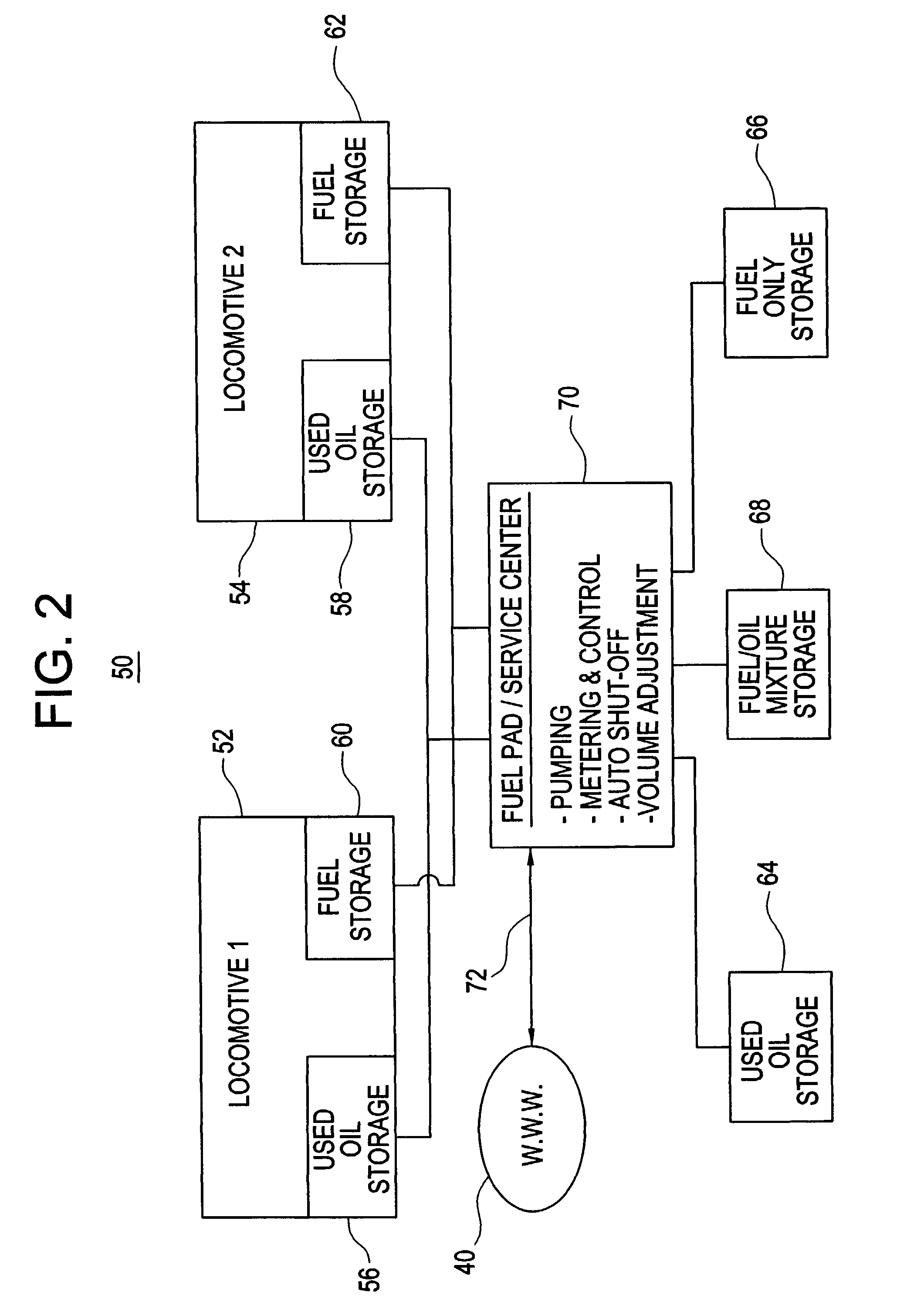

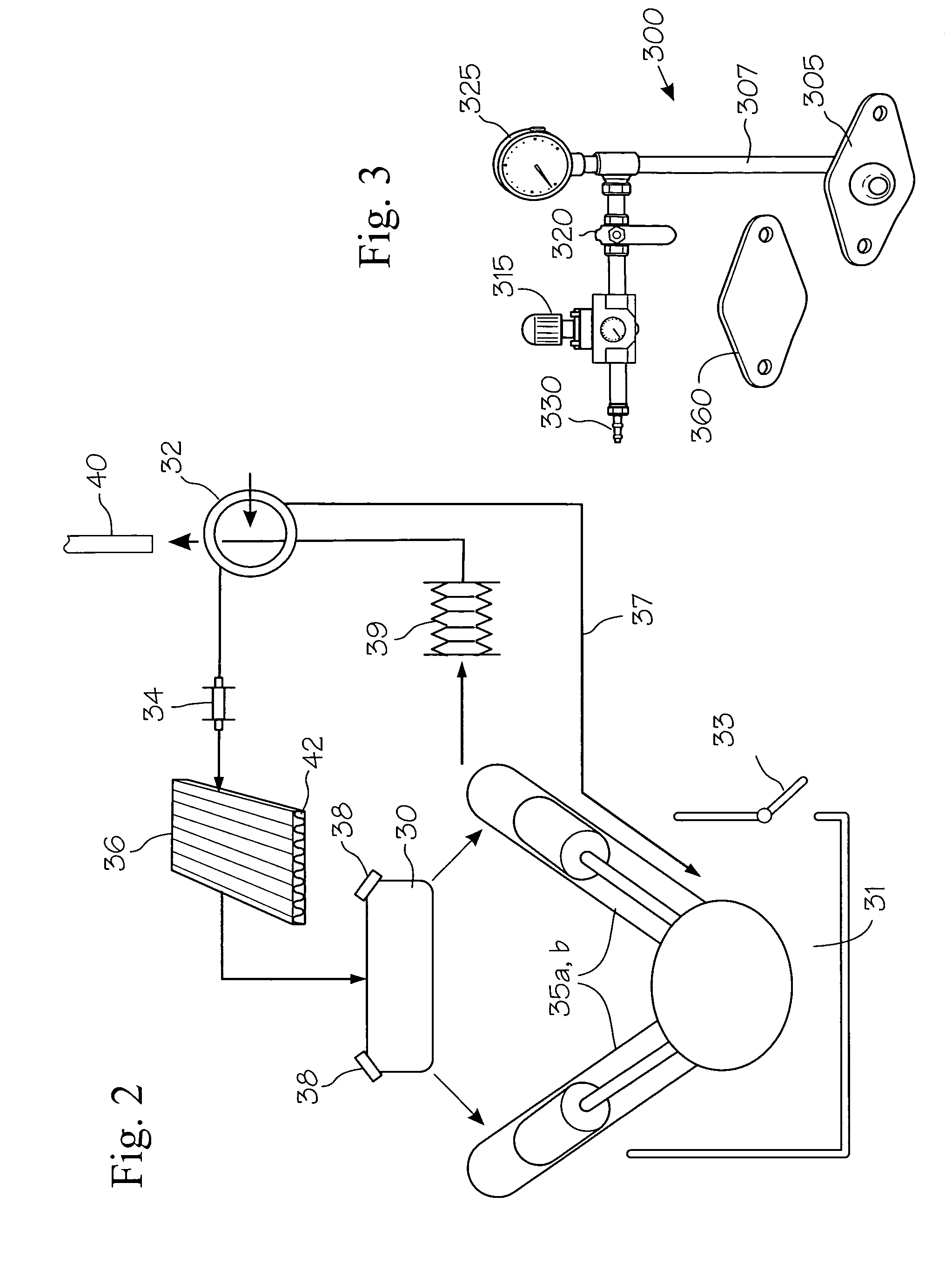

Lubricant management method for a vehicle

A system (10) for ensuring the quality of lubricating oil in an engine of a locomotive without the need for specialized diagnostic and fluid handling systems on the locomotive. A test portion (28) of lubricating oil is removed from the engine and is analyzed at an oil analysis center (26) to determine an oil quality parameter (32). The oil quality parameter is used as an input to a calculator (34) to determine a quantity of oil (36) that must be replaced by fresh oil during a current maintenance outage in order to ensure that the engine oil quality will remain acceptable throughout a forthcoming operating period. In this manner, a complete change-out of the lubricating oil may be delayed or avoided. The oil replacement decision and quantity is communicated to a service center (18) via a communications link such as the Internet (40) prior to the arrival of the locomotive at the service center. The used oil may be removed from the engine using a portable transfer device and mixed with fuel in a fuel storage tank for subsequent refueling of other locomotives.

Owner:GE GLOBAL SOURCING LLC

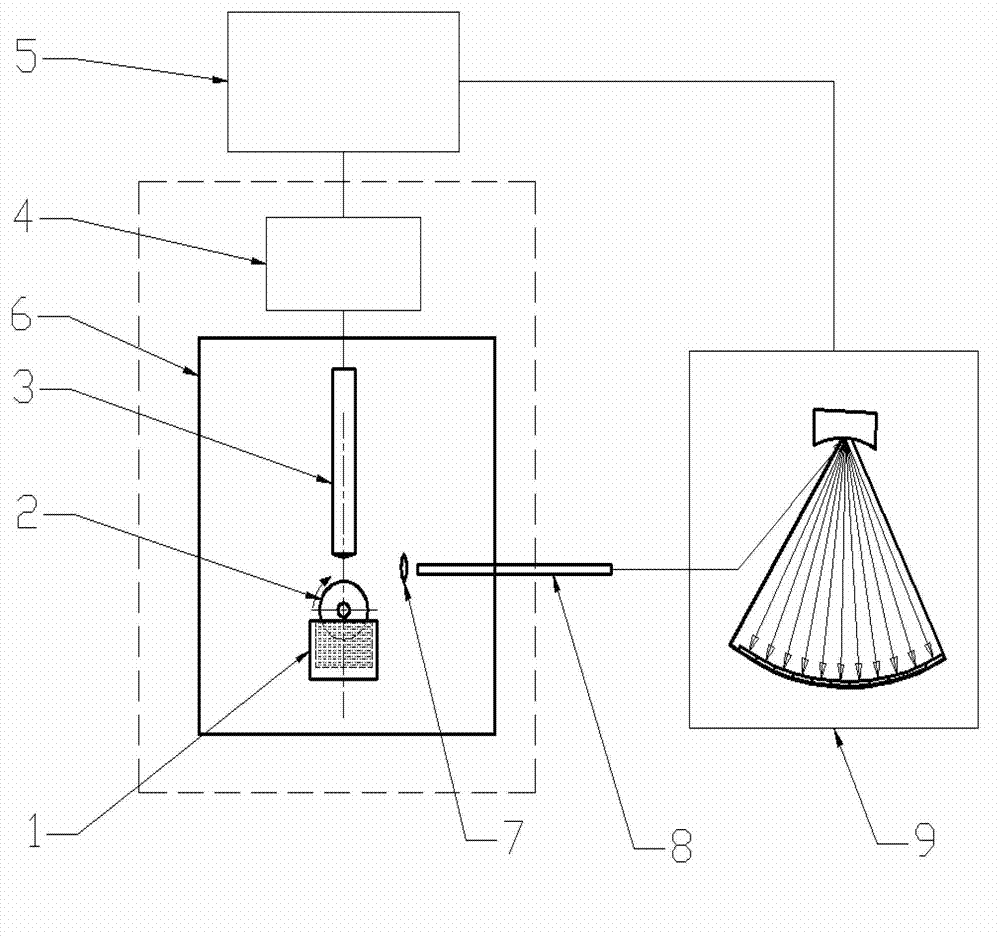

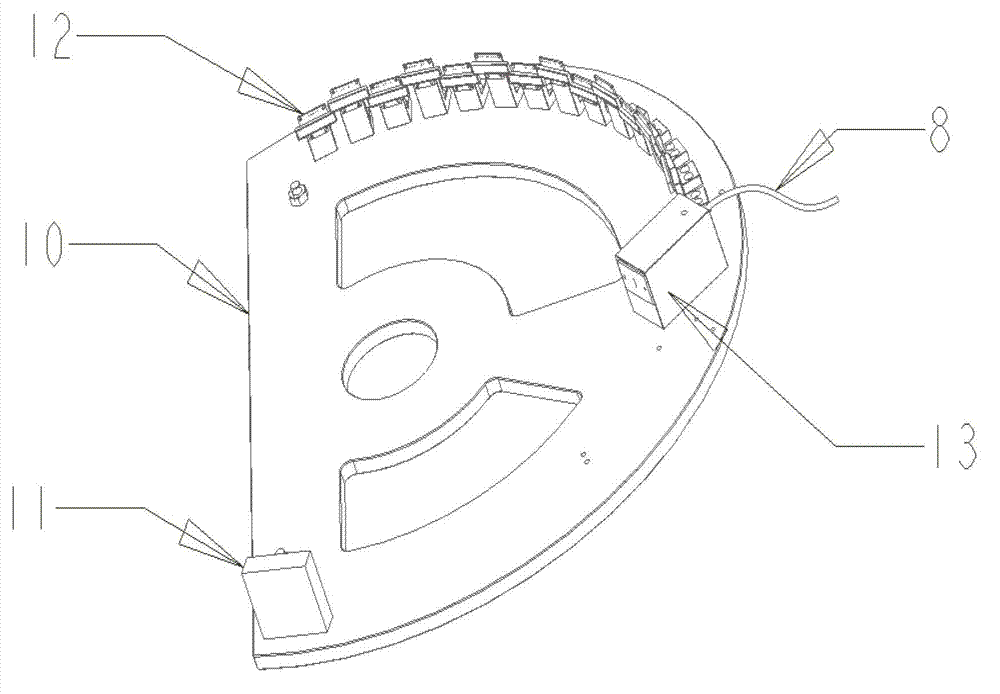

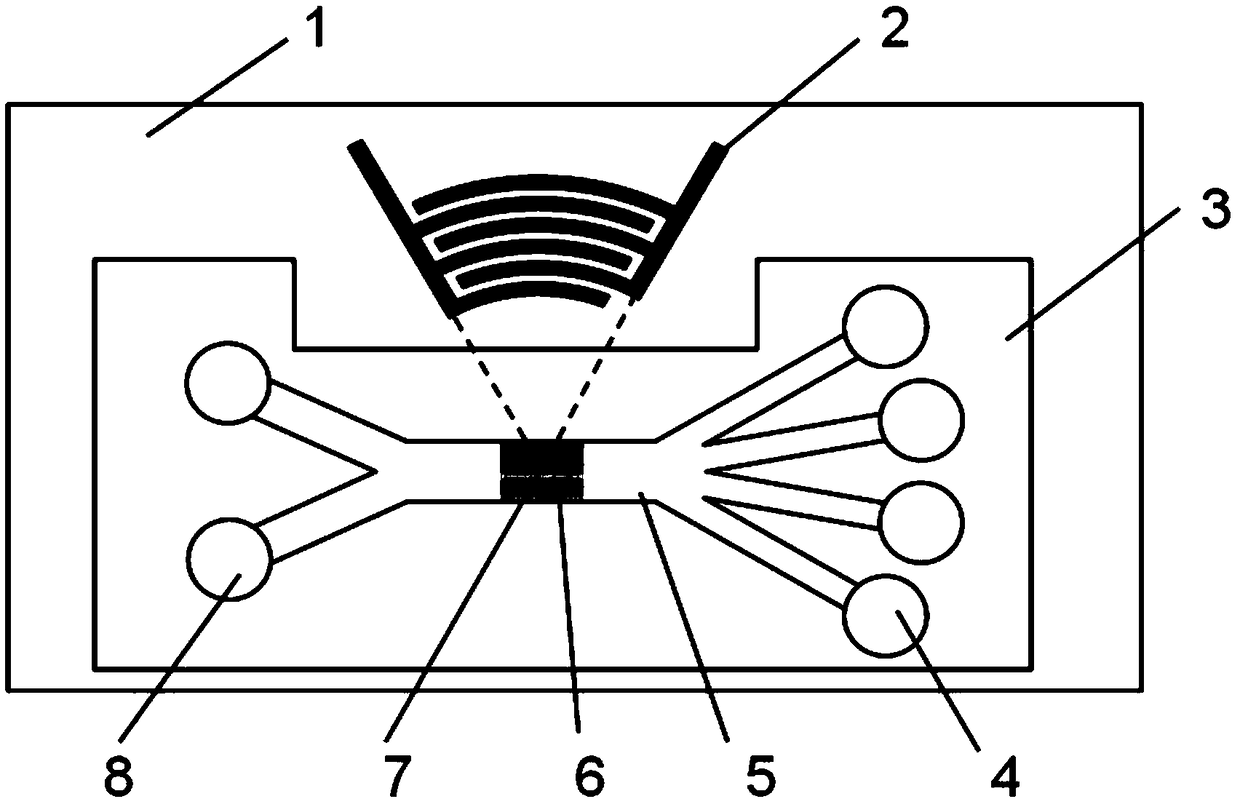

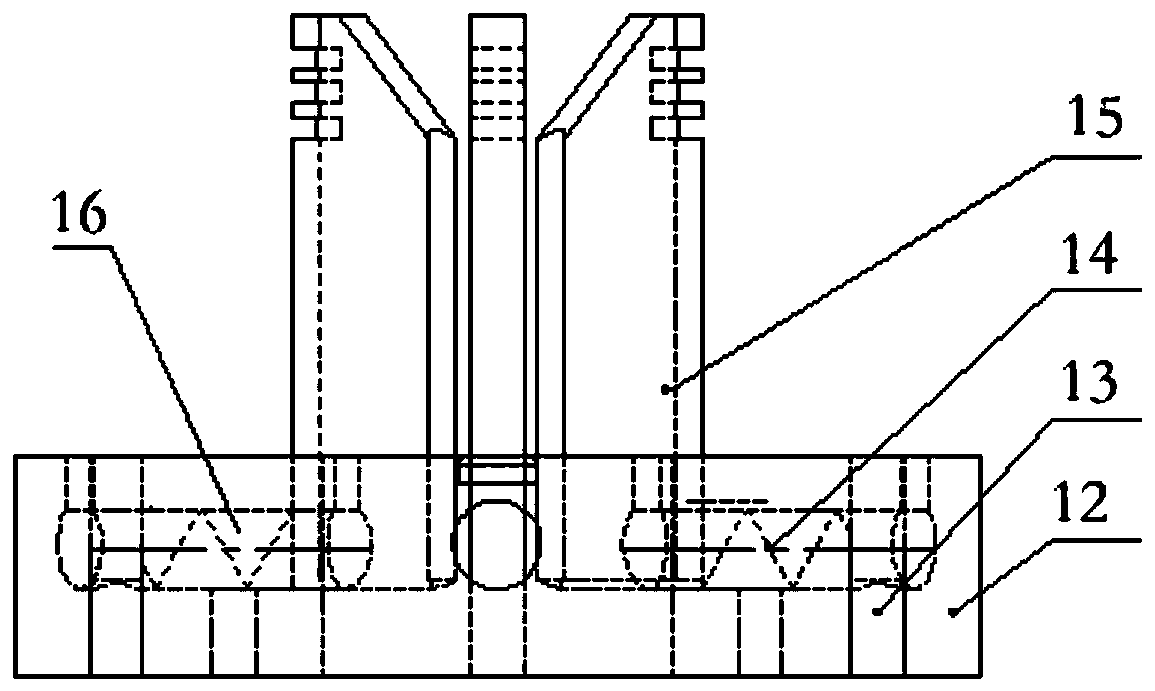

Special oil analysis device based on gathered optical fiber signal transmission and double-layer multi-CCD (Charge Coupled Device) detection

ActiveCN103115915AReduce volumeImprove mobile reliabilityAnalysis by electrical excitationGratingHigh pressure

The invention discloses a special oil analysis device based on gathered optical fiber signal transmission and double-layer multi-CCD (Charge Coupled Device) detection, and the special oil analysis device is used for detecting the content of various metal elements in an oil sample. A rotating disc electrode drives oil to an analytical gap, spark discharge is generated by high voltage between two electrodes, and the metal elements in the oil sample are excited to generate emission spectra; and light with different wavelengths is transmitted to a grating to be split through optical fibers and then irradiated to different CCDs, and the content of multiple elements is obtained through light intensity signal detection and digital operation of spectral lines. The special oil analysis device comprises a light source part, an optical fiber transmission system, a light splitting system, a photoelectric detection system and a control circuit, wherein the light source part comprises a high-voltage generator, a rod electrode and the rotating disc electrode; and the light splitting system fixedly arranges an incidence gap, a concave grating and the CCDs on a Rowland circle device by virtue of a Paschen-Runge device. Compared with an existing instrument, the special oil analysis device disclosed by the invention has the characteristics of fast analysis, simultaneous detection on more than ten elements, direct sampling, no sample pretreatment, easiness for operation and convenience for maintenance.

Owner:广东中科谛听科技有限公司

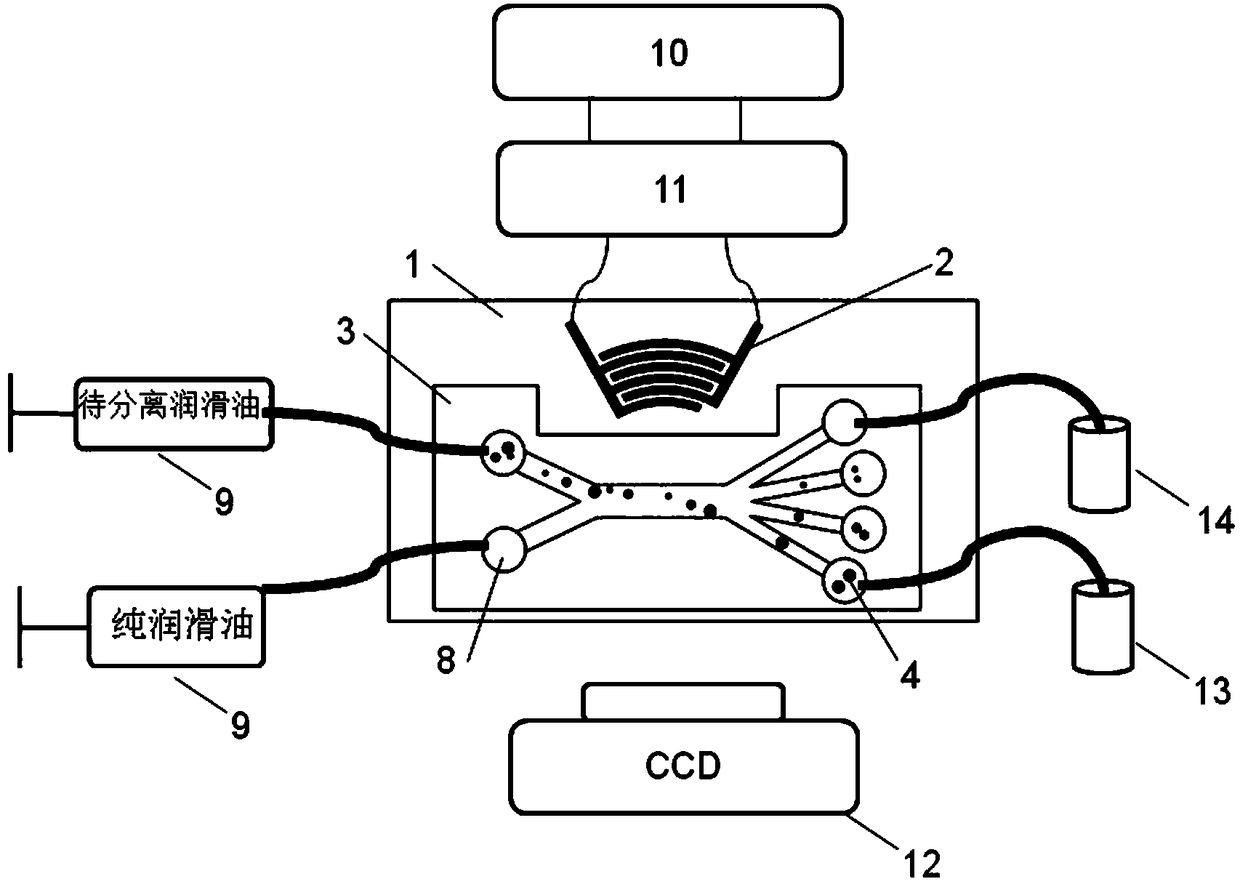

Device and method for separating abrasive particles in lubricating oil based on surface acoustic waves

PendingCN109212027AReal-time observation of the separation processHighly integratedAnalysing solids using sonic/ultrasonic/infrasonic wavesLaboratory glasswaresHigh energySurface acoustic wave

The invention relates to the technical field of lubricating oil analysis and detection, in particular to a device and a method for separating abrasive particles in lubricating oil based on surface acoustic waves. The advantages of high energy density and easiness in integration of surface acoustic waves are fully utilized in combination with a micro-flow channel of a special geometric shape processed by a soft lithography technology, thereby realizing on-line continuous separation of the abrasive particles in the lubricating oil, and laying a foundation for precise detection of the abrasive particles. The separation device and method omit the structures of a physical filter screen and the like, avoid dirty blockage, and have a high integration degree and a good on-line separation effect.

Owner:DALIAN MARITIME UNIVERSITY

Aircraft engine reliability business model

A business model algorithm for maintaining aircraft engines in reliable and safe operating condition without the necessity of performing major engine overhaul in which engine manufacturers' maintenance procedures are enhanced and performed more frequently and supplemented by engine trend analysis, engine oil analysis, engine vibration analysis, borescope inspection and computer algorithm forecasting to identify, repair, and / or replace engine components without necessity of major engine overhaul.

Owner:BANGERT BARRY +1

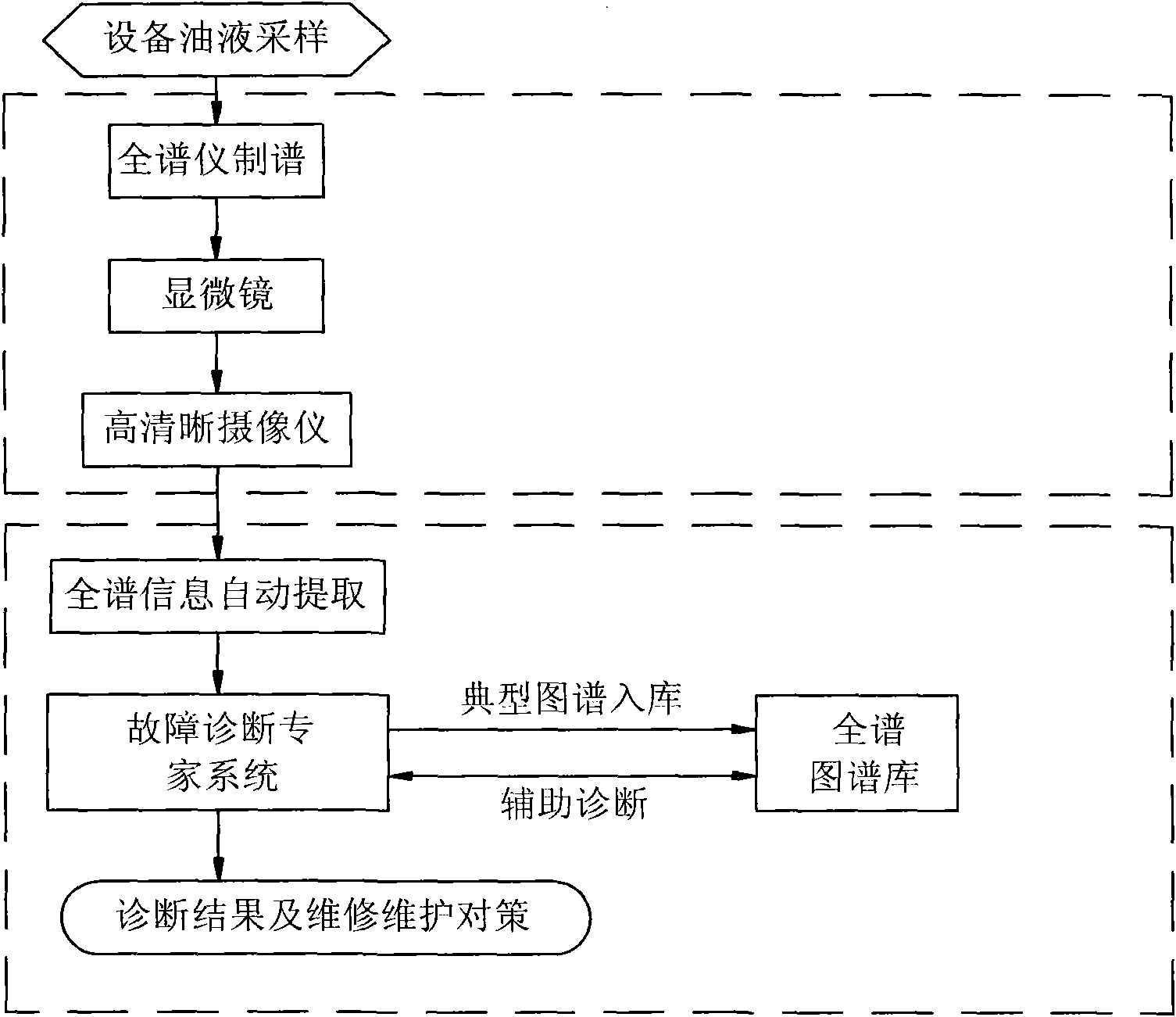

Oil analysis method for diagnosing equipment failure

InactiveCN101832902AInformativeImprove clarityStructural/machines measurementParticle size analysisCellulosePrill

The invention discloses an oil analysis method for diagnosing an equipment failure. The method comprises the following steps of: 1) arranging cellulose nitrate filter membranes with different filter pore sizes in turn from large pore size to small pore size and allowing oil to be tested to flow through the cellulose nitrate filter membranes in turn; 2) arranging the cellulose nitrate filter membranes on a glass slide in turn from large pore size to small pore size; 3) dissolving the cellulose nitrate filter membranes with dimethyl formamide aqueous solution to leave wear particles arranged according to a particle size gradient on the glass slide; and 4) shooting and analyzing the wear particles on the glass slide to diagnose the equipment failure. The oil is filtered by using the cellulose nitrate filter membranes with different filter pore sizes and the wear particles on the glass slide are arranged according to different sizes, so that the method contributes to microscope observation and video camera shooting, realizes richer information content, higher definition and higher wear particle dispersion degree on an acquired wear map and contributes to realizing automatic recognition of the wear map and improving the accuracy of failure diagnosis.

Owner:CHONGQING UNIV

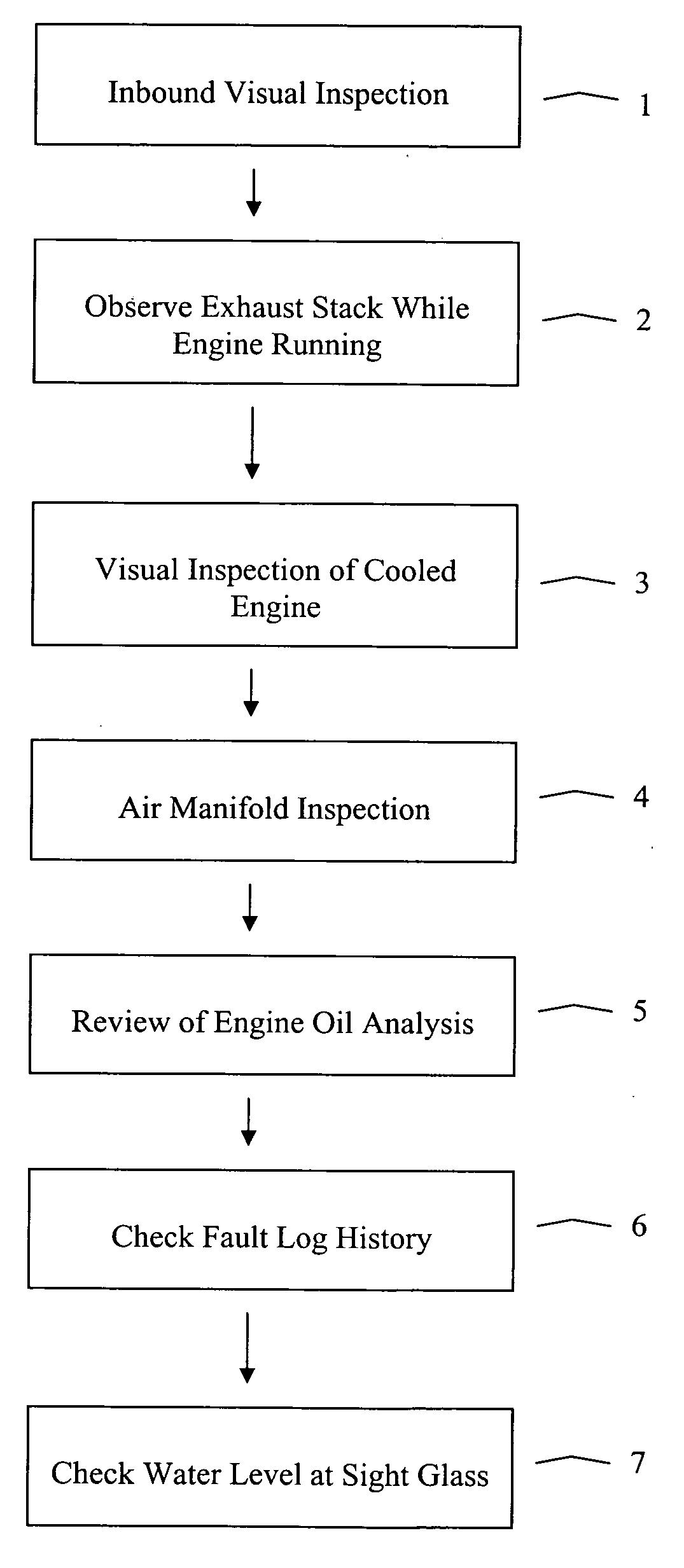

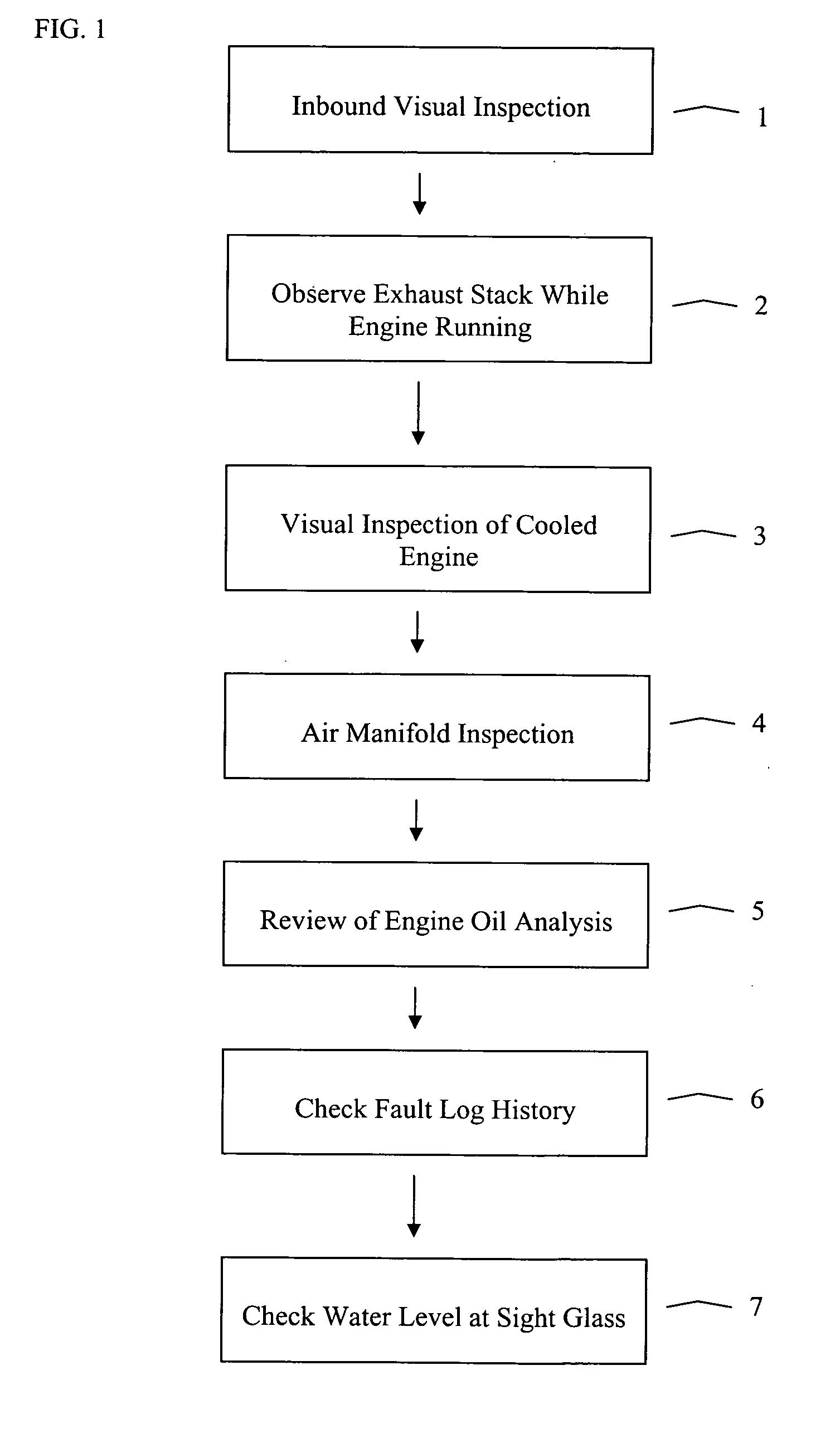

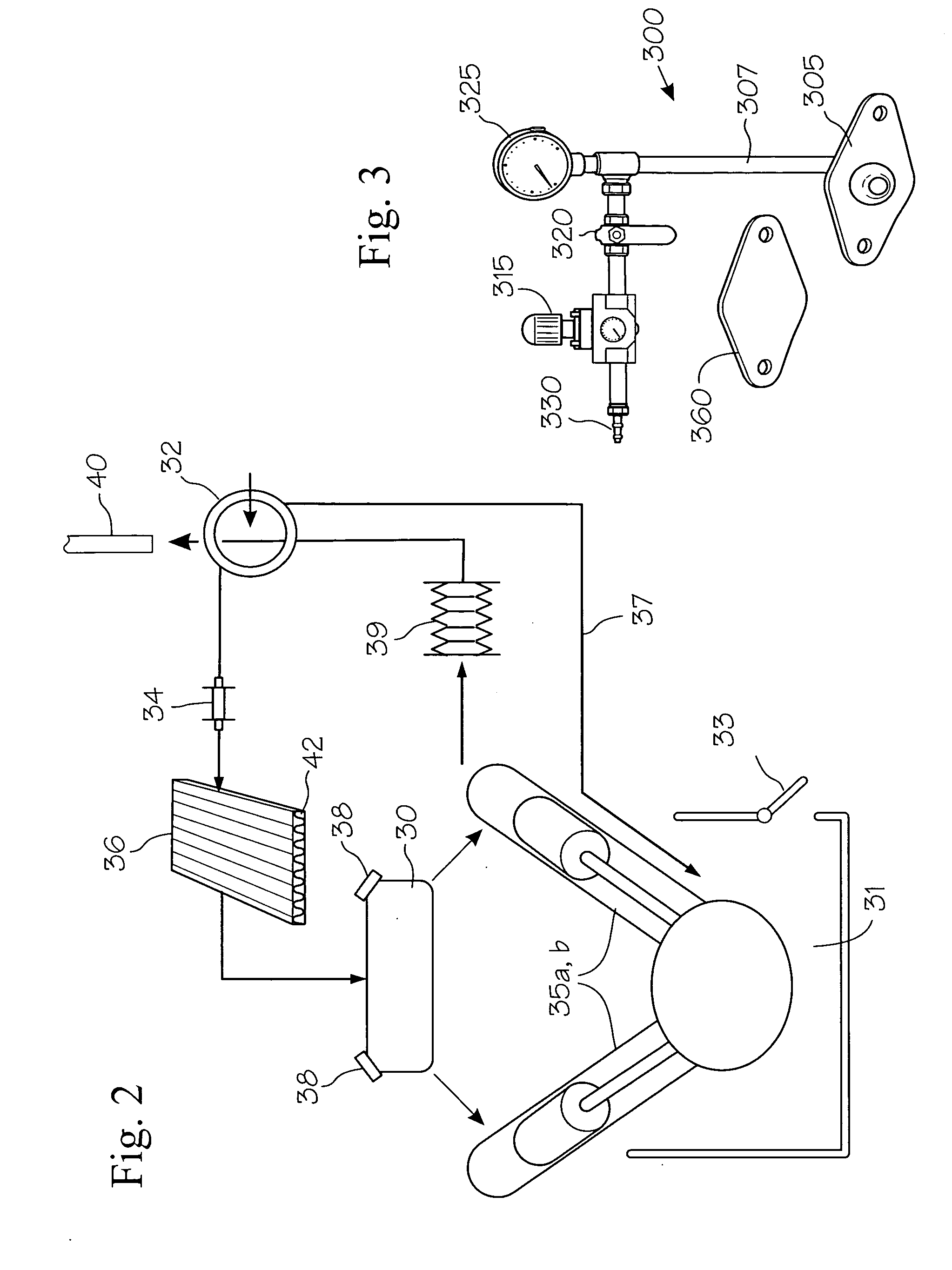

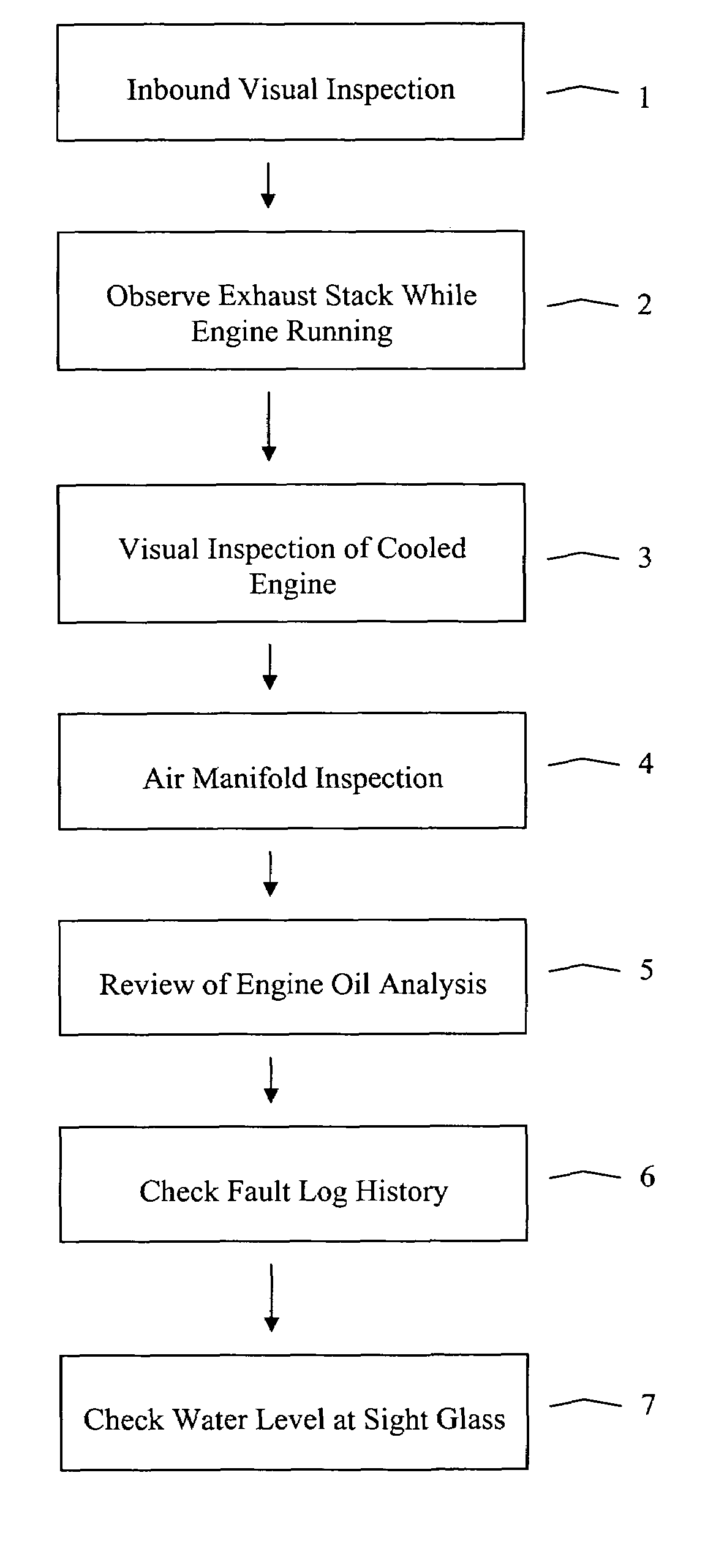

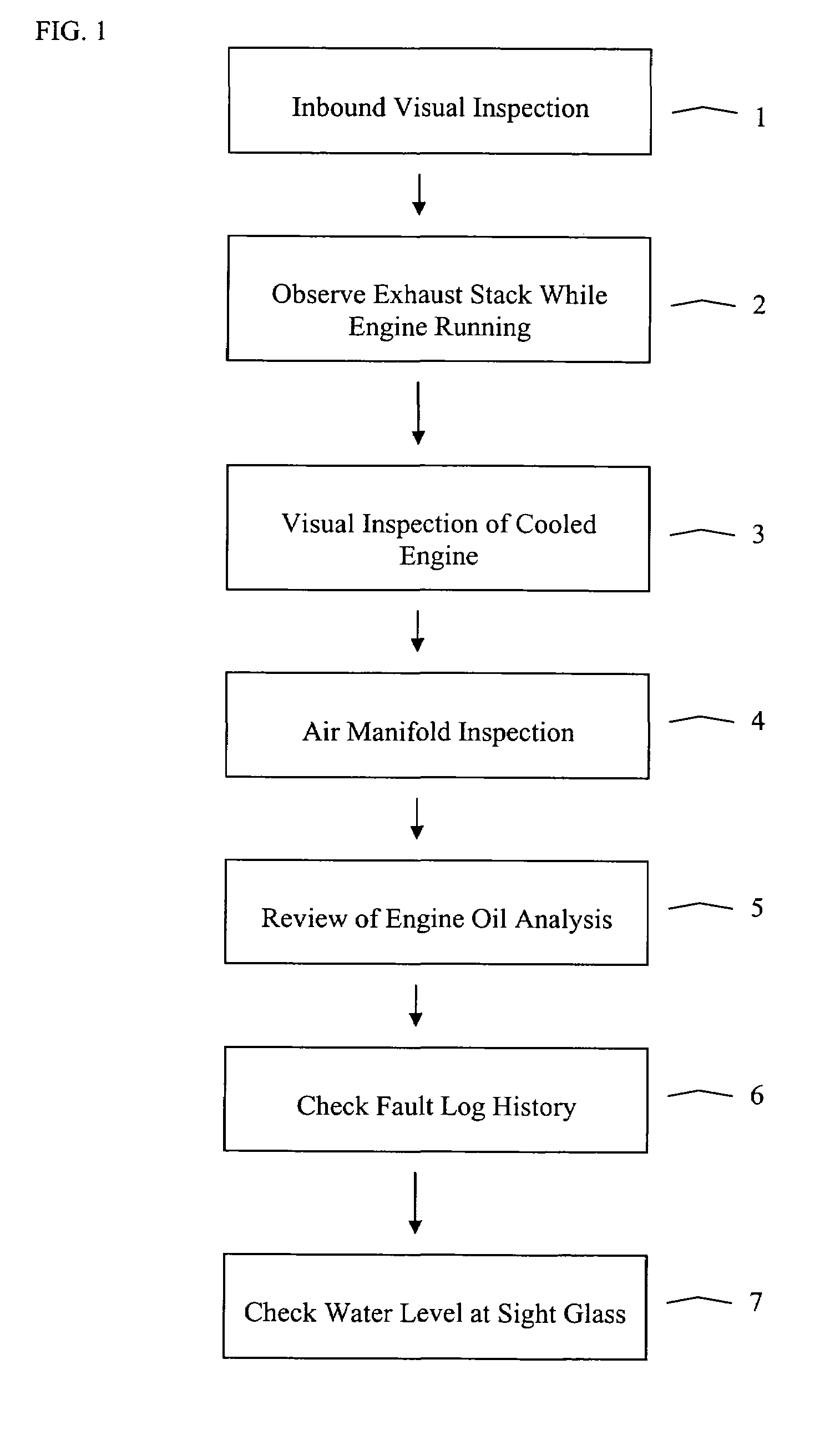

Method of detecting a water leak in a locomotive

Disclosed herein are methods for detecting a water leak in a locomotive engine cooling system comprising numerous components, each being a potential source of leakage of water. The method typically comprises performing at least one inspection providing an indication of a water leak from an engine cooling system of the locomotive. The step of performing at least one inspection may comprise at least one of several steps including performing a visual inspection to determine if water is leaking from a portion of the cooling system external to the engine; performing a visual inspection of exhaust of the engine to detect an indication of water vapor in the exhaust; performing a visual inspection to detect an indication of water leaking into an intake air manifold 30 of the engine; performing an engine oil analysis to detect water in the engine lubricant; reviewing a fault log history for the locomotive; and checking a level of a cooling system sight glass. The method allows for the isolation of potential sources of the water leak from one another so as to prevent false positive leak identification caused by transient water flow between the potential sources. If an engine cylinder assembly is a component identified as a potential source of the water leak during the water pressurization test, the method enables further testing to confirm leakage at such cylinder assembly, before undertaking the costly and time-consuming process of removing the cylinder assembly from the engine. Cylinder assemblies can be tested for leaks by performing an air leak test disclosed herein.

Owner:GE GLOBAL SOURCING LLC

A kind of cyhalofop-ethyl aqueous emulsion and preparation method thereof

The invention relates to a method for preparing pesticides, in particular to a cyhalofop-ethyl aqueous emulsion and a preparation method thereof, belonging to the technical field of pesticide processing. The emulsion in water includes cyhalofop-ethyl emulsifier, solvent, preservative, thickener, antifreeze and water, and the original medicine of cyhalofop-ethyl is mixed with emulsifier and solvent and stirred to form a uniform oil phase; , antifreeze, preservative, etc. are mixed together to form a uniform water phase; slowly pour the oil phase into the water phase, and under high-speed (5000-6000r / min.10min) shear emulsification, a well-dispersed milky white liquid is obtained. The cyhalofop-ester aqueous emulsion has good fluidity before and after storage, does not agglomerate, does not separate water, does not separate oil, has good stability, and its biological activity is equivalent to that of the same dose of emulsifiable concentrate. However, the cost is lower than that of emulsifiable concentrate, and the prospect of popularization and application is broad.

Owner:郭方全

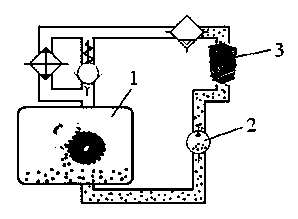

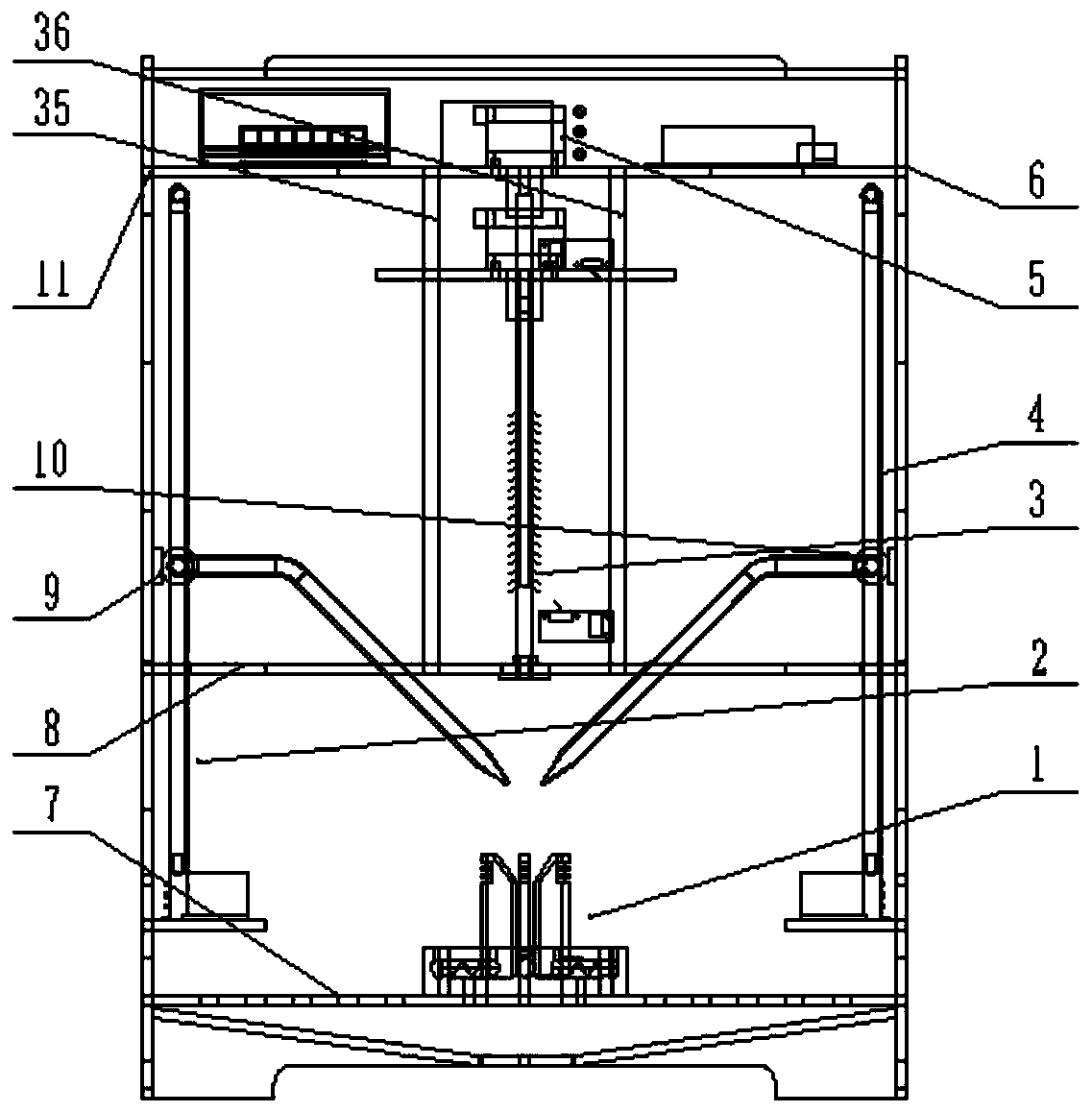

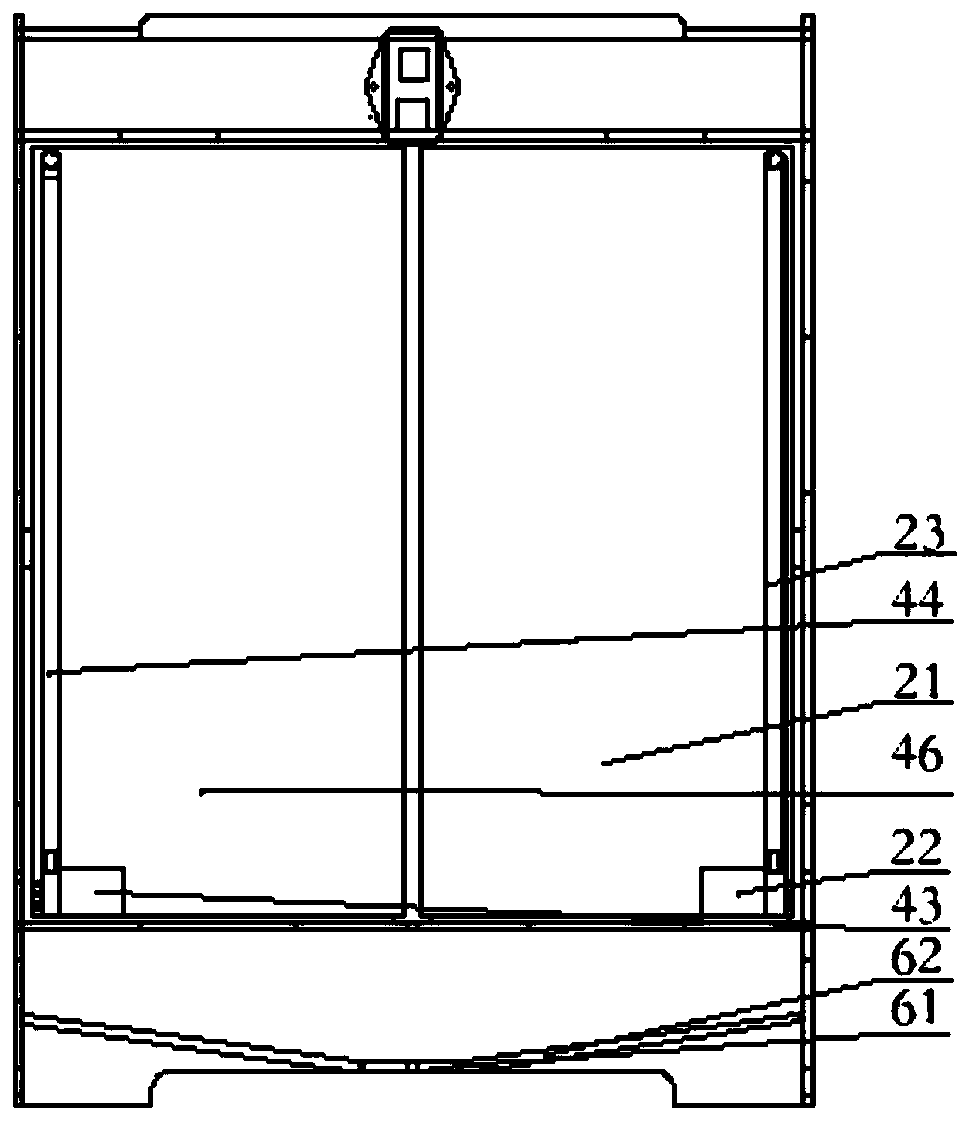

Transformer electrical fault gas simulation device

InactiveCN109254233AIncrease insulation distanceEasy to operateTesting dielectric strengthElectricityHigh pressure

The invention discloses a transformer electrical fault gas simulation device, and relates to the field of the transformer fault diagnosis. The device comprises a tank body, a pressure balance releasing device, a temporary storage tank and a tee valve arranged at the top of the tank body; the tee valve is located at the top of the tank body, the tee valve is used for connecting the tank body, the pressure balance releasing device and the temporary storage device or any two of them; an electrode system for applying the electric field is arranged in the tank body, and the electrode layer comprises a high-voltage electrode and a ground electrode. The device can be used for electric fault simulation of the transformer to guarantee that the test process is completely isolated from the atmosphereinterference and the simulation test of different insulation mediums and different electric fields can be performed under the same test environment. The device provides basic reference data for gas dissolved in oil analysis of the novel transformer oil, thereby prejudging whether fault potential is existent when the novel transformer oil transformer is in operation through the gas dissolved in oil analysis technology, and quickly diagnosing the fault reason after the fault occurs.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

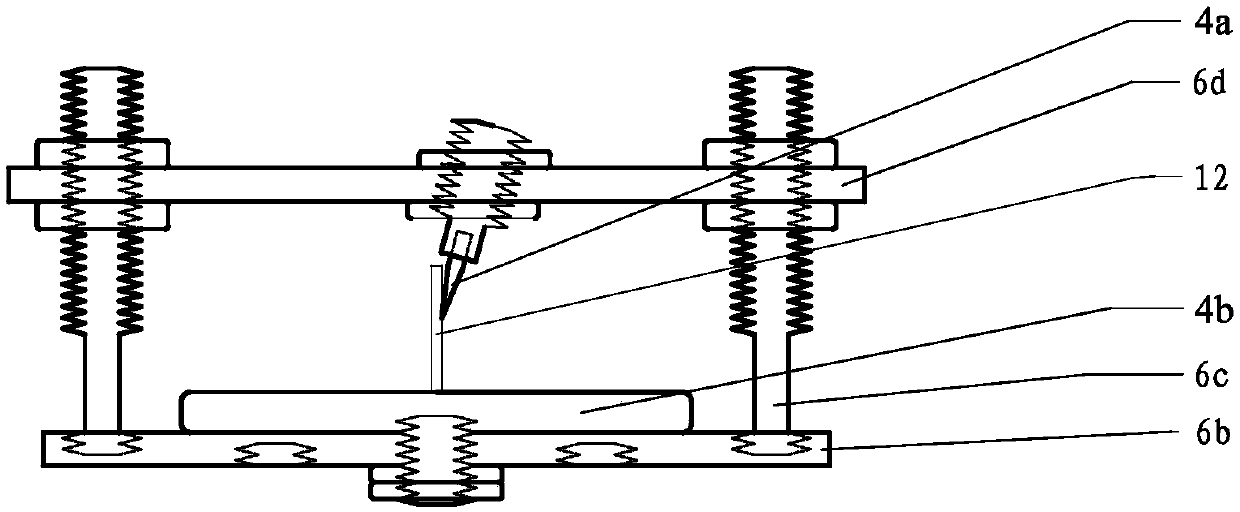

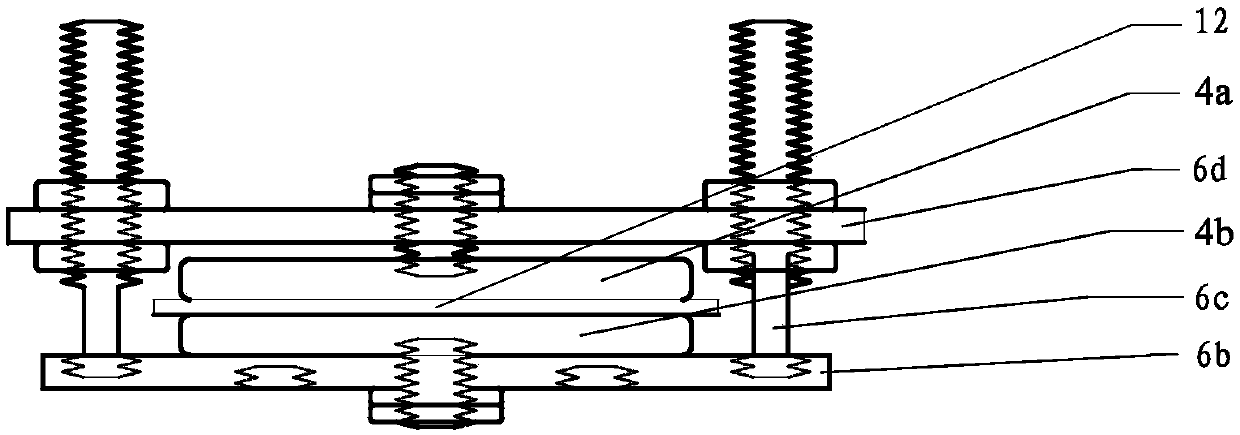

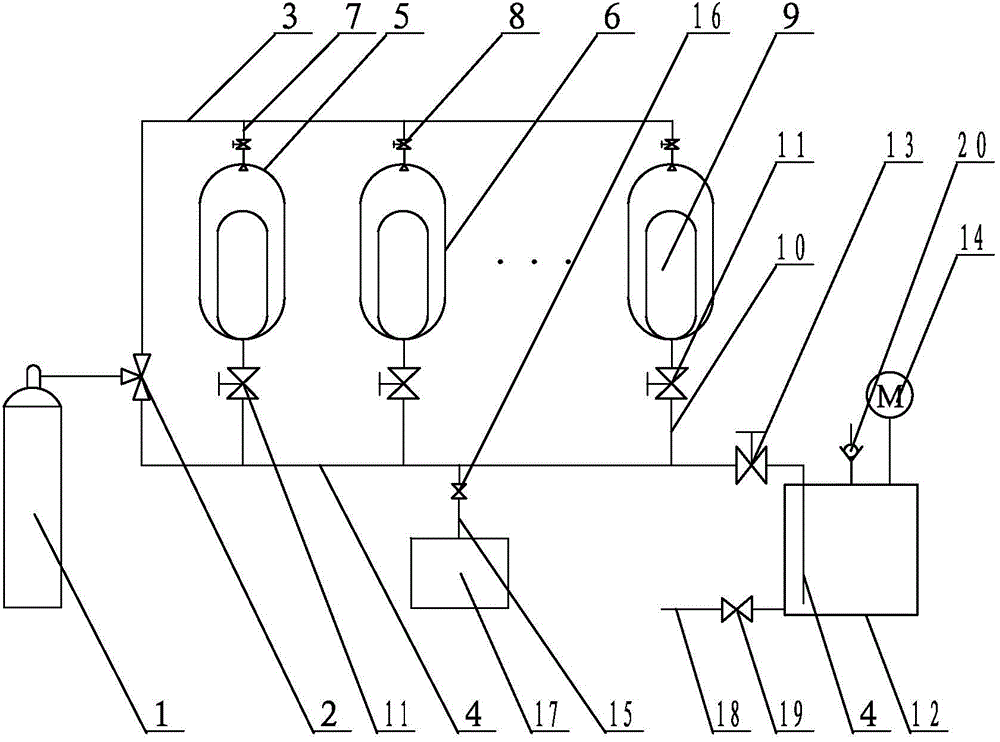

Device and method for on-site inspection of online monitor for dissolved gas in transformer oil

ActiveCN104880538APrevent impact detection structureSimple structure and portableMaterial analysisOil canGas cylinder

The invention relates to the technical field of transformer oil analysis and inspection, in particular to a device for on-site inspection of an online monitor for dissolved gas in transformer oil. The device comprises a gas bottle and oil sample tanks, the gas bottle is connected with a three-way valve through a pipeline, the three-way valve is connected to the oil sample tanks and an oil collection tank through a gas feeding pipe and an oil feeding pipe respectively, the oil sample tanks include multiple testing oil sample tanks and a new oil tank, an elastic oil-resistant airbag is arranged inside each oil sample tank, an oil sample is contained in each elastic oil-resistant airbag, a bottom outlet of each elastic oil-resistant airbag is communicated with the oil feeding pipe, a collection valve is arranged on the oil feeding pipe correspondingly to the oil collection tank which is connected with a vacuumizing device, and an inspection branched pipe is arranged on the oil feeding pipe and connected to a to-be-inspected device through an inspection valve. The device is simple and portable in structure, suitable for on-site inspection of the online monitor for the dissolved gas in the oil and high in inspection accuracy. The invention further provides a method using the device. The online monitor for the dissolved gas in the oil can be inspected quickly, and inspection accuracy is guaranteed.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

Oil Analysis

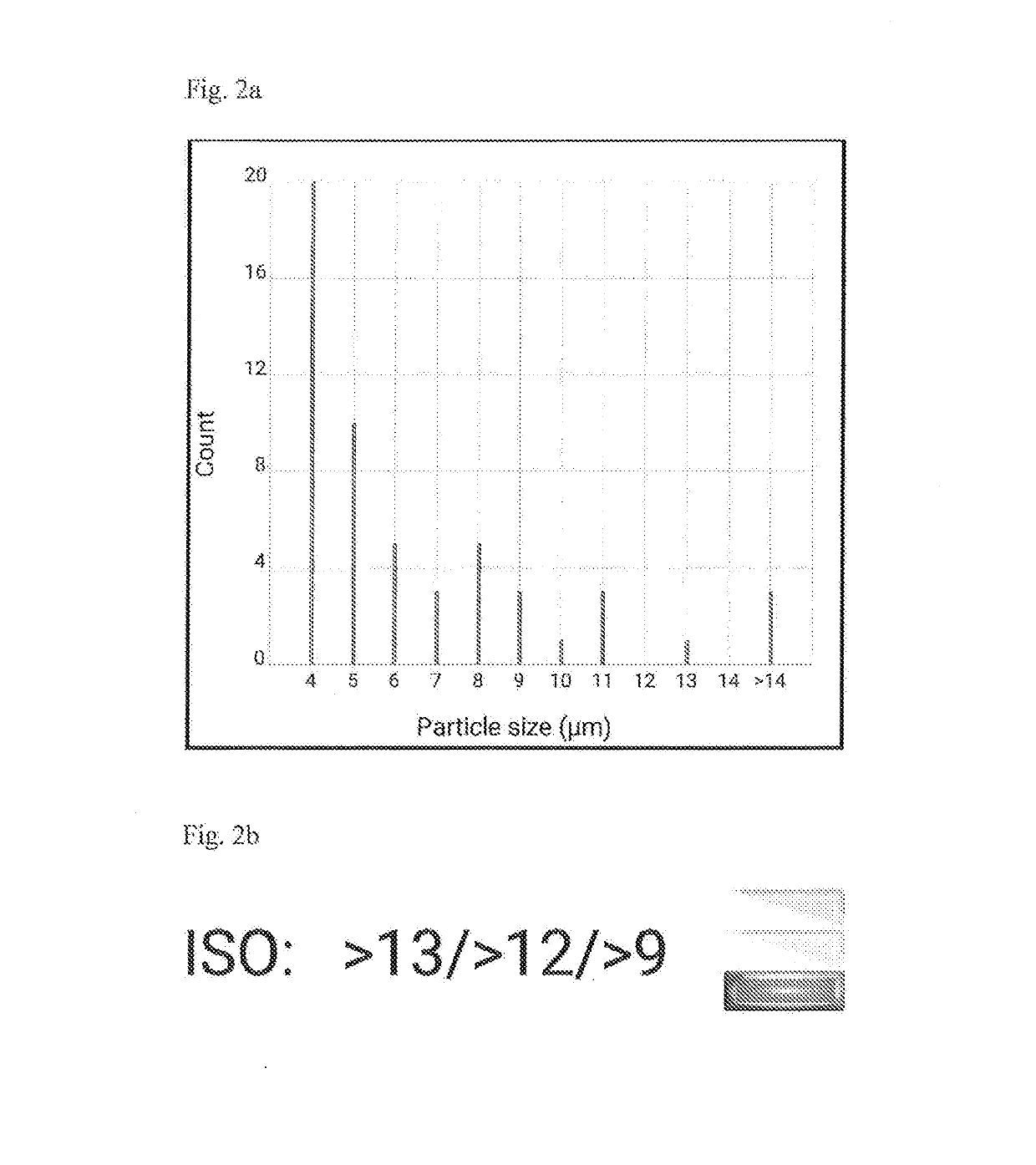

ActiveUS20190162711A1Cheap methodParticle size analysisMaterial testing goodsWear particleEngineering

A method for assessing the condition of an oil using a portable computer coupled to a camera comprises: separating wear particles from a sample of the oil; capturing an image of the separated wear particles using the camera; and analysing the image and generating information about the condition of the oil using the portable computer. The method may be used for tracking the condition of an oil in a machine over a period of time. The methods are particularly useful for assessing the condition of an industrial oil e.g. a lubricating oil that has been used to lubricate moving parts in a machine.

Owner:CASTROL LTD

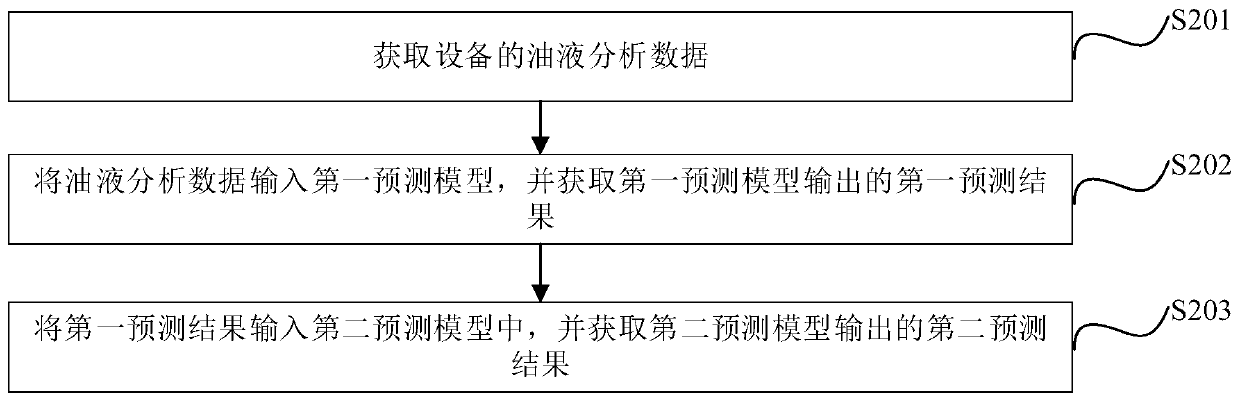

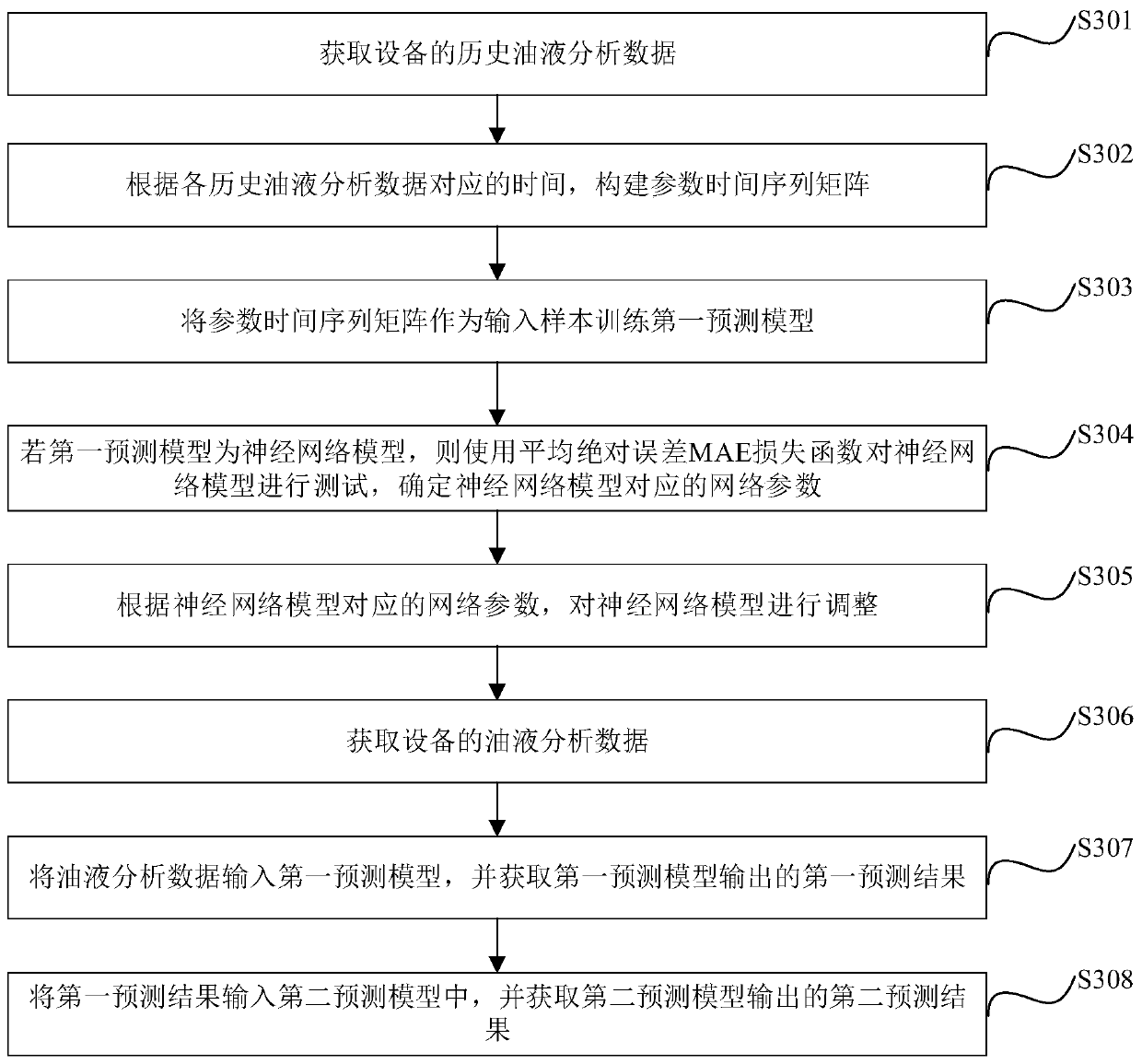

Equipment wear prediction method and device

InactiveCN110954314AImprove forecast accuracyMachine part testingColor/spectral properties measurementsAnalysis dataComputational physics

The invention provides an equipment wear prediction method and device. The method comprises the following steps: acquiring oil analysis data of equipment, wherein the oil analysis data comprises at least one oil parameter; the oil analysis data is input into a first prediction model, a first prediction result output by the first prediction model is obtained, the first prediction model is established through historical oil analysis data training of equipment, and the first prediction result comprises prediction data of at least one oil parameter at the current moment; and the first prediction result is input into a second prediction model, a second prediction result output by the second prediction model is acquired, the second prediction model is established through training of the historical first prediction result and the historical wear data of the equipment, and the second prediction result comprises wear condition prediction of the equipment and fault position prediction of the equipment. In this way, the prediction accuracy of equipment abrasion can be improved.

Owner:北京昊鹏智能技术有限公司

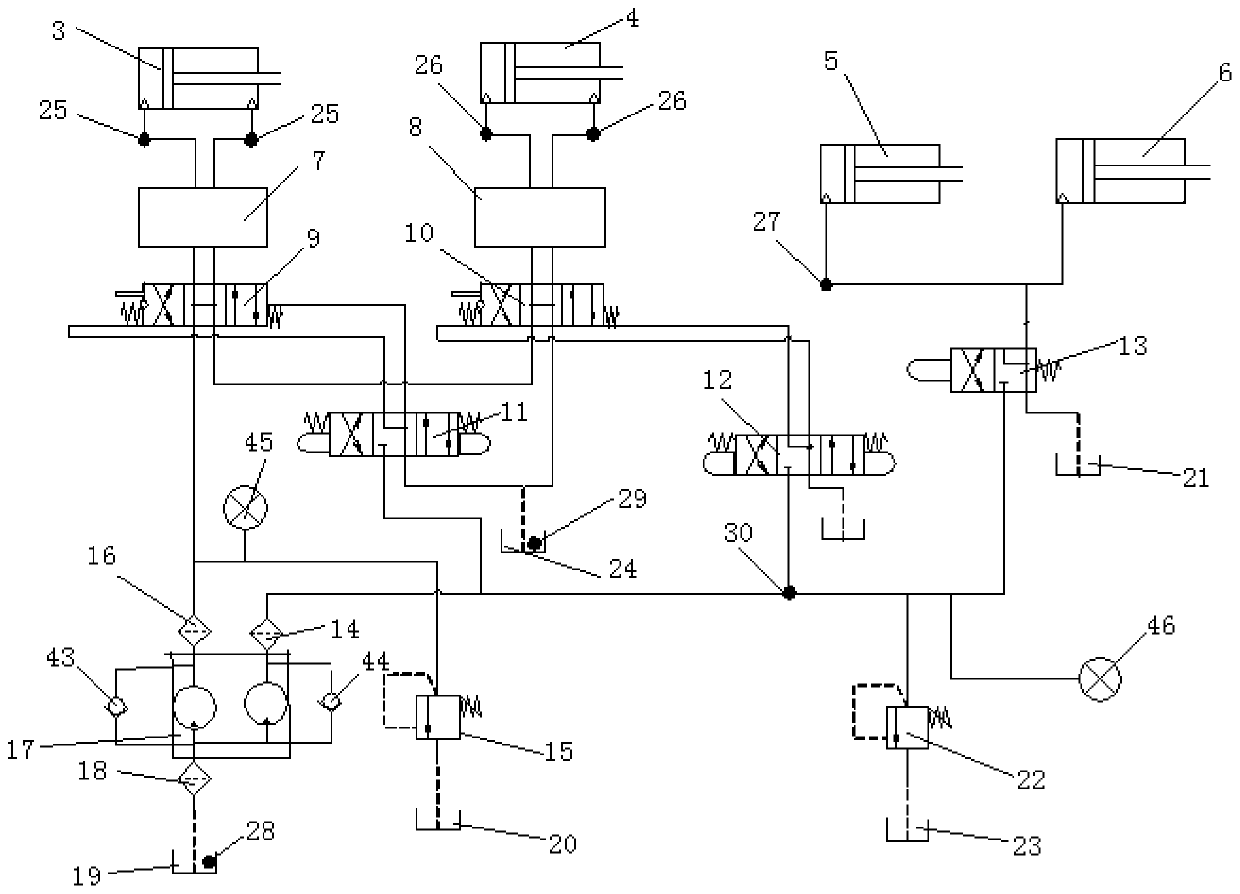

Device for detecting and treating mine machine hydraulic oil pollution

InactiveCN103541947AAvoid performance impactLess damageFluid-pressure actuator testingControl systemPollution

The invention relates to a detection device, in particular to a device for detecting and treating mine machine hydraulic oil pollution. The device comprises a control device, an embedded oil analysis sensor, an alarming device and an oil filter, wherein the embedded oil analysis sensor and the oil filter are installed in a loop of a hydraulic system, and the control device is connected with the embedded oil analysis sensor, the alarming device and the oil filter. The device for detecting and treating mine machine hydraulic oil pollution has the advantages that by detecting oil samples in the hydraulic system in real time through the sensor, the pollution status of hydraulic oil in an oil path of the hydraulic system can be detected in real time; when the pollution status reaches a certain degree, an alarm can be timely given, besides, the oil filter is controlled by the control system to purify the hydraulic oil, so that influence caused by severe hydraulic oil pollution on the performance of mine machines and on other aspects is avoided, damage conditions of the mine machines are reduced, and the service life of the mine machines is prolonged.

Owner:陈咸均

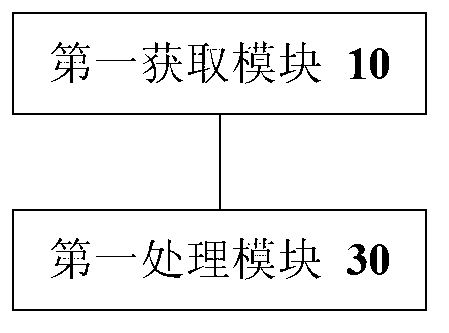

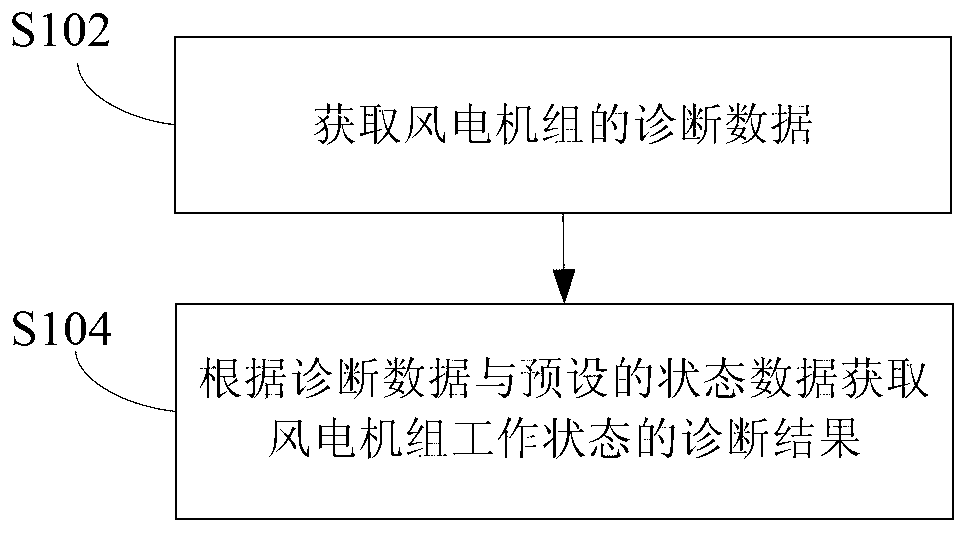

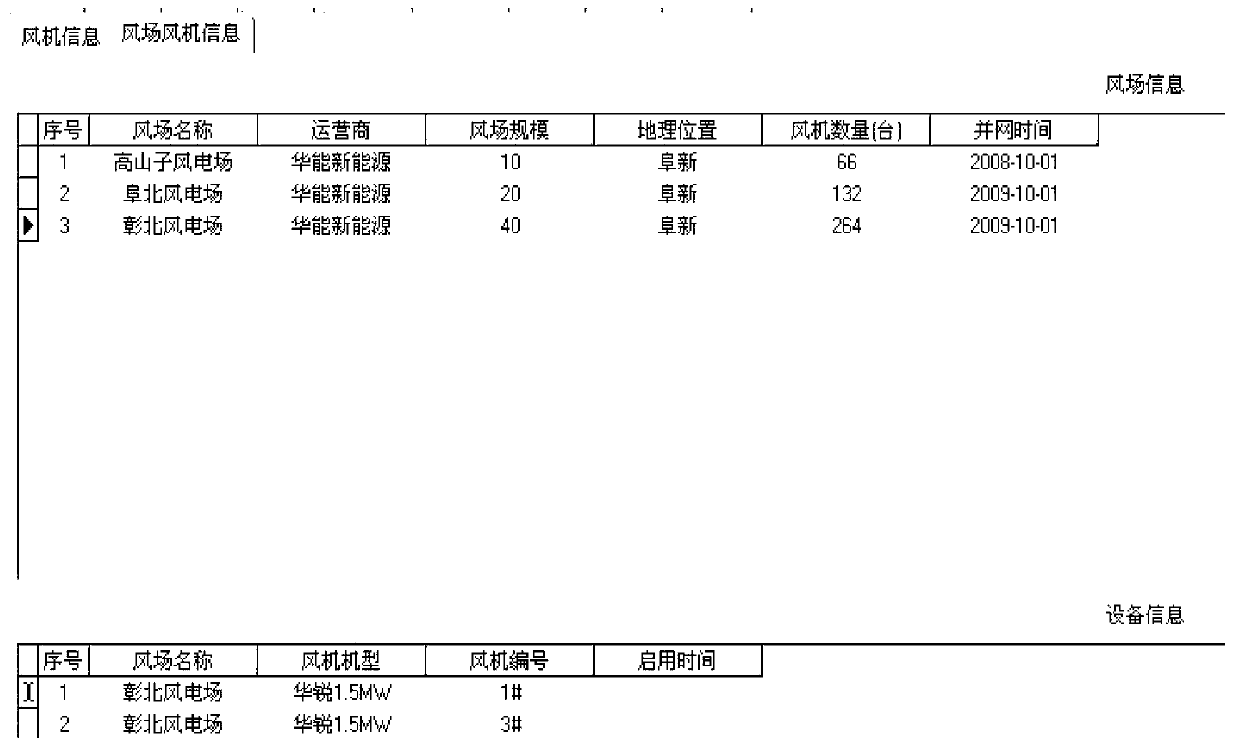

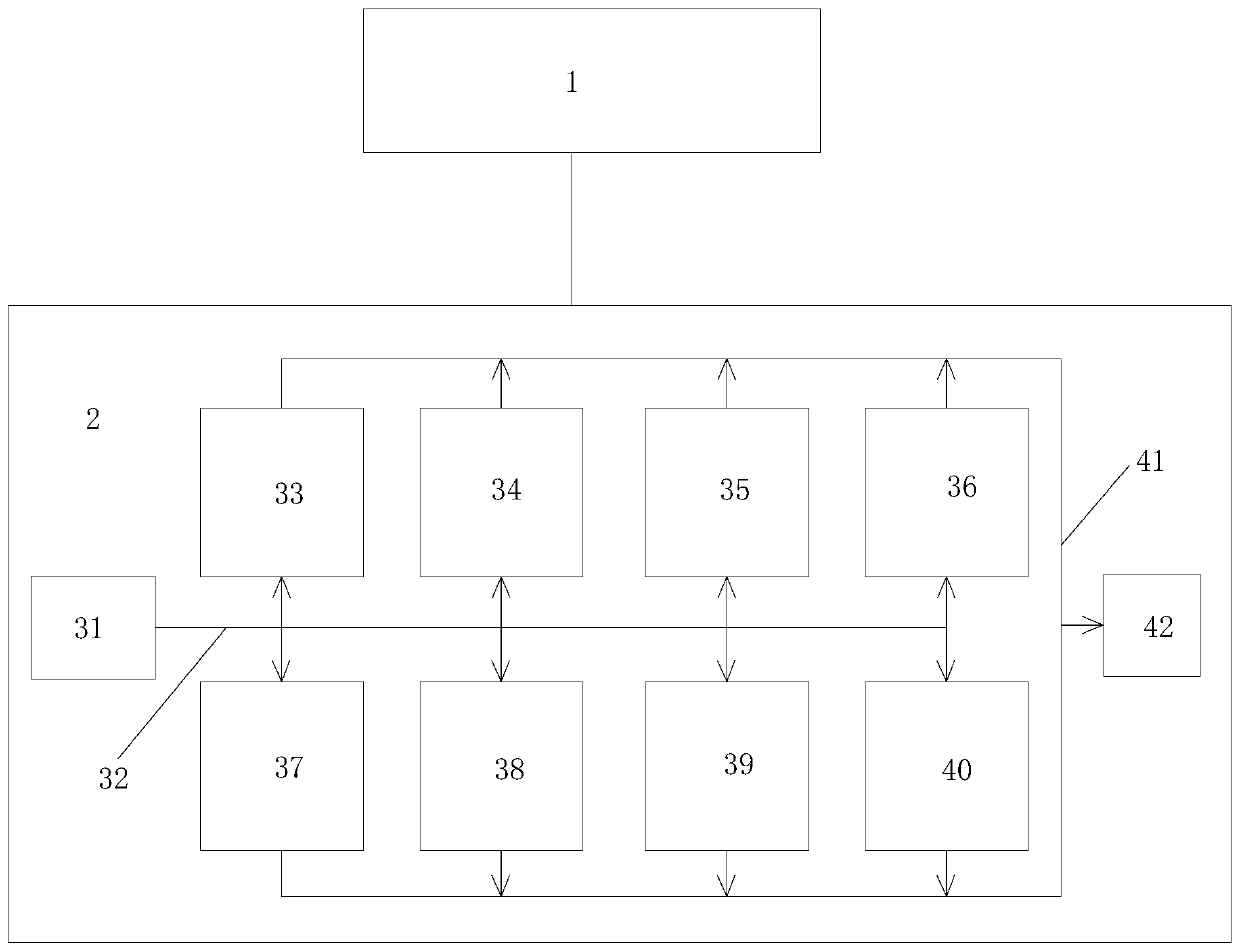

Diagnostic method, device and system of working states of wind generation set

ActiveCN103344435AImprove reliabilityGuaranteed safe operationEngine testingElectricityDiagnostic data

The invention discloses a diagnostic method, device and system of working states of a wind generation set. The method comprises the steps of acquiring the diagnostic data of the wind generation set, wherein the diagnostic data comprises oil analysis data and attribute data of the wind generation set, and acquiring a diagnostic result of the working states of the wind generation set according to the diagnostic data and preset state data. Through the diagnostic method, device and system of the working states of the wind generation set, the purpose of diagnosing and early warning of frictional wearing situations of all parts of the wind generation set accurately is achieved, the problem that only a lubricating oil state can be detected and the wearing state of the wind generation set cannot be acquired is solved, reliable bases are provided for maintenance before malfunction, the reliability of the wind generation set is improved, and the wind generation set is guaranteed to be operated safely.

Owner:SHENYANG ORIGINAL CHEM CO LTD

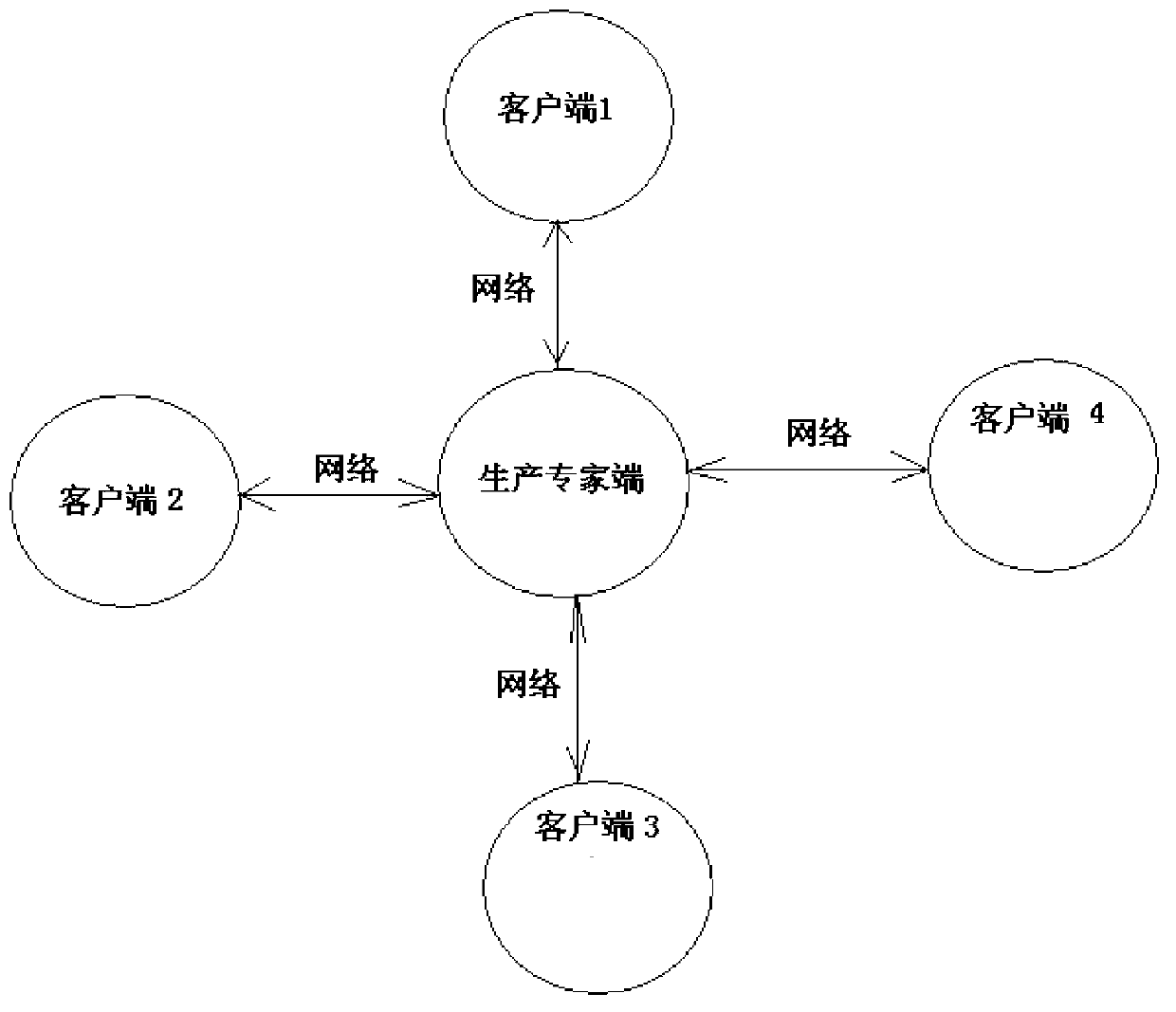

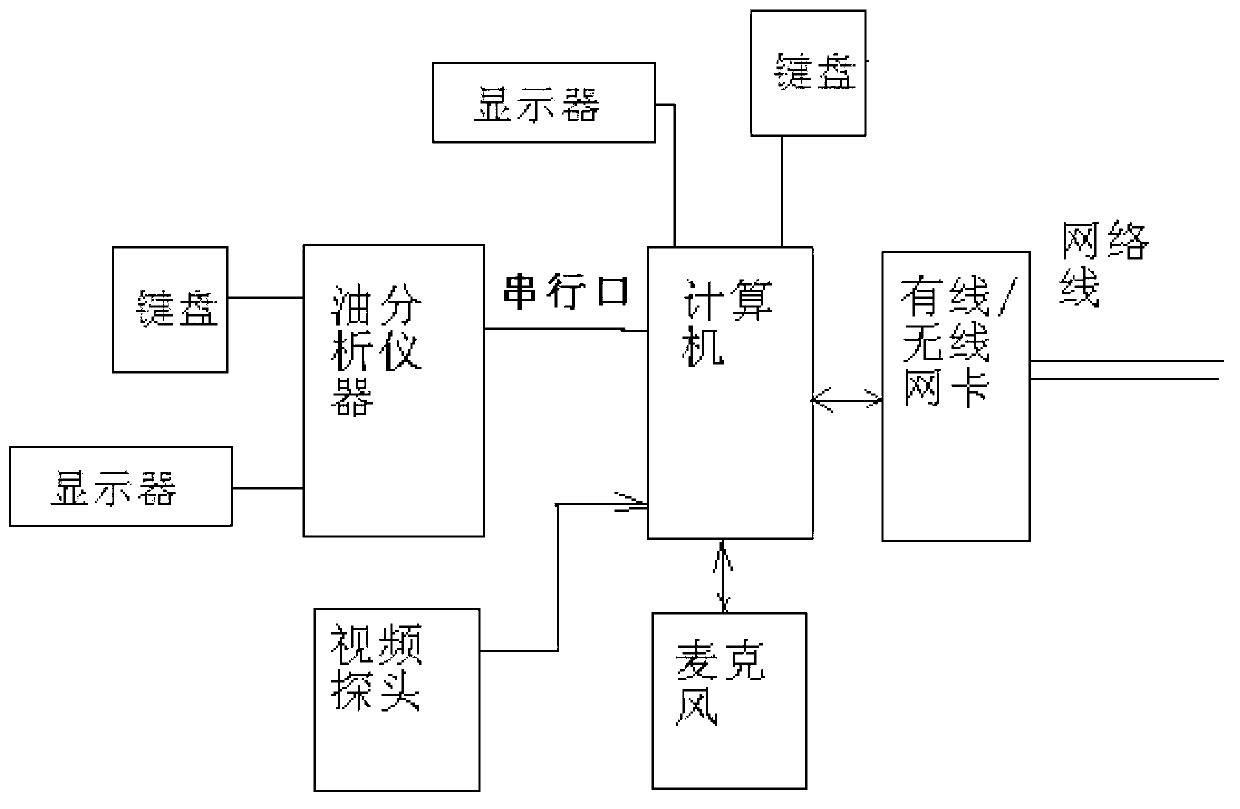

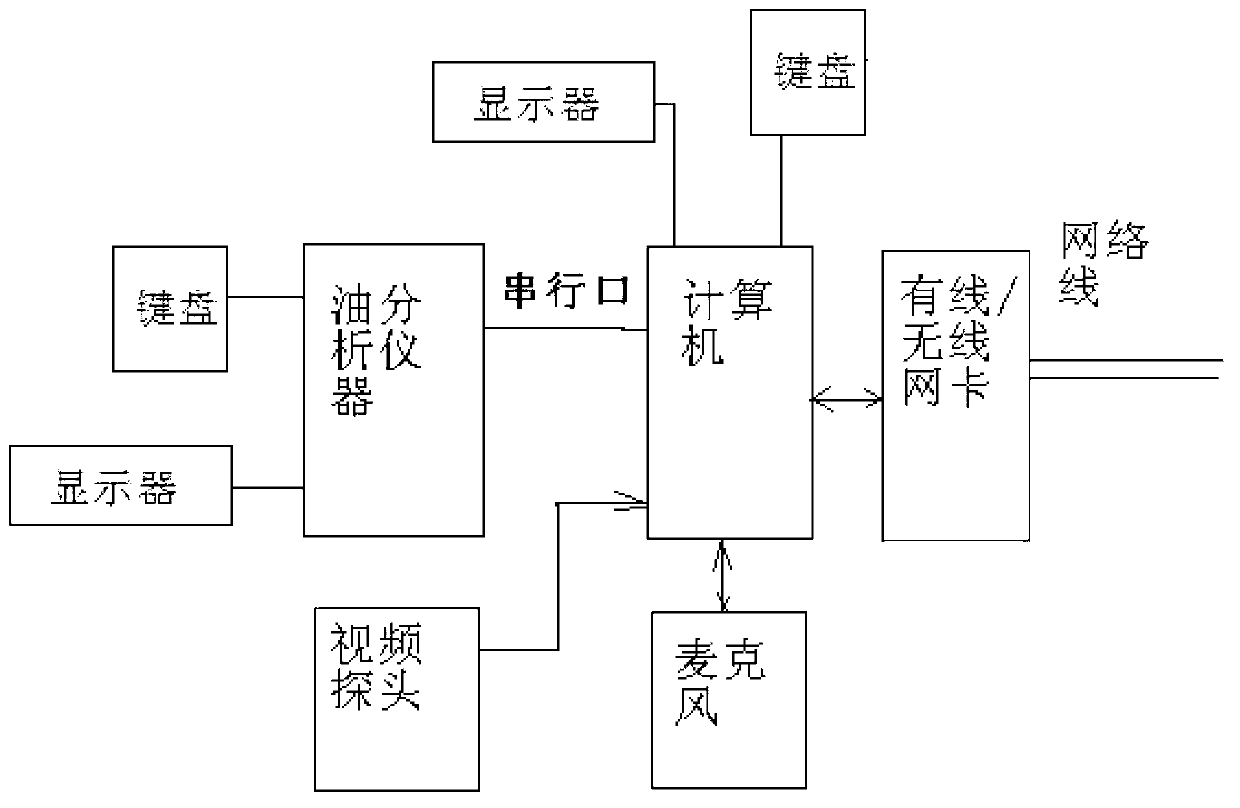

Oil analysis apparatus remote expert diagnosis system base on network

The invention belongs to the field of electric power safety operation detection apparatus, and more specifically relates to an oil analysis apparatus remote expert diagnosis system base on network, which is characterized in that the product comprises a production expert terminal and a client with remote expert diagnosis function; both of the production expert terminal and the client comprise an oil analysis apparatus, a computer, a video probe, a microphone and a network interface card; both of the network interface cards of the production expert terminal and the client are connected by Internet. The invention improves the level of the after-sale service, and satisfies the timeliness requirement of the client to the after-sale service of the product, and minimizes the unnecessary service frequency of the apparatus producer for the client, and reduces the cost.

Owner:昆山汇杰电气有限公司

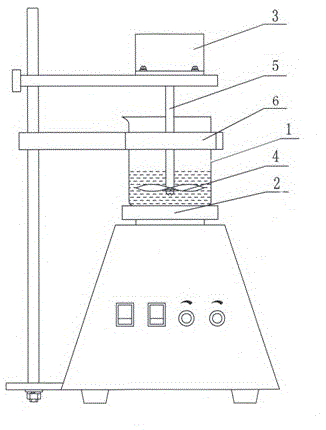

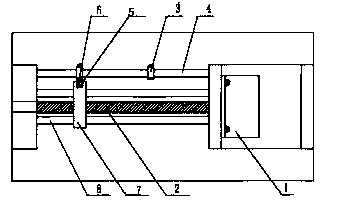

Uniform oil product mixing device for petroleum analyzing instrument

InactiveCN104677717AWell mixedImprove the mixing effectPreparing sample for investigationThermodynamicsEngineering

The invention discloses a uniform oil product mixing device for a petroleum analyzing instrument. The device comprises an oil product storing container, a heating block arranged below the oil product storing container, and an agitating driving device arranged at one side of the oil product storing container; an agitating shaft of the agitating driving device extends into the oil product storing container; a heating element is arranged in the heating block; agitating blades or agitating bars are fixedly connected to the agitating shaft; the heating block is connected with a temperature controller; the temperature controller is electrically connected with the agitating driving device; the agitating blades comprise a pair of transverse blades and a pair of longitudinal blades, wherein the transverse blades are fixedly connected with the agitating shaft through a transverse shaft, and the longitudinal blades are vertically fixed to the transverse blades through a longitudinal shaft. The device has the advantages that an oil sample can be synchronously heated and agitated, and moreover, the structure is simple, and the operation is convenient.

Owner:JIANGSU XINGAOKE ANALYTICAL INSTR

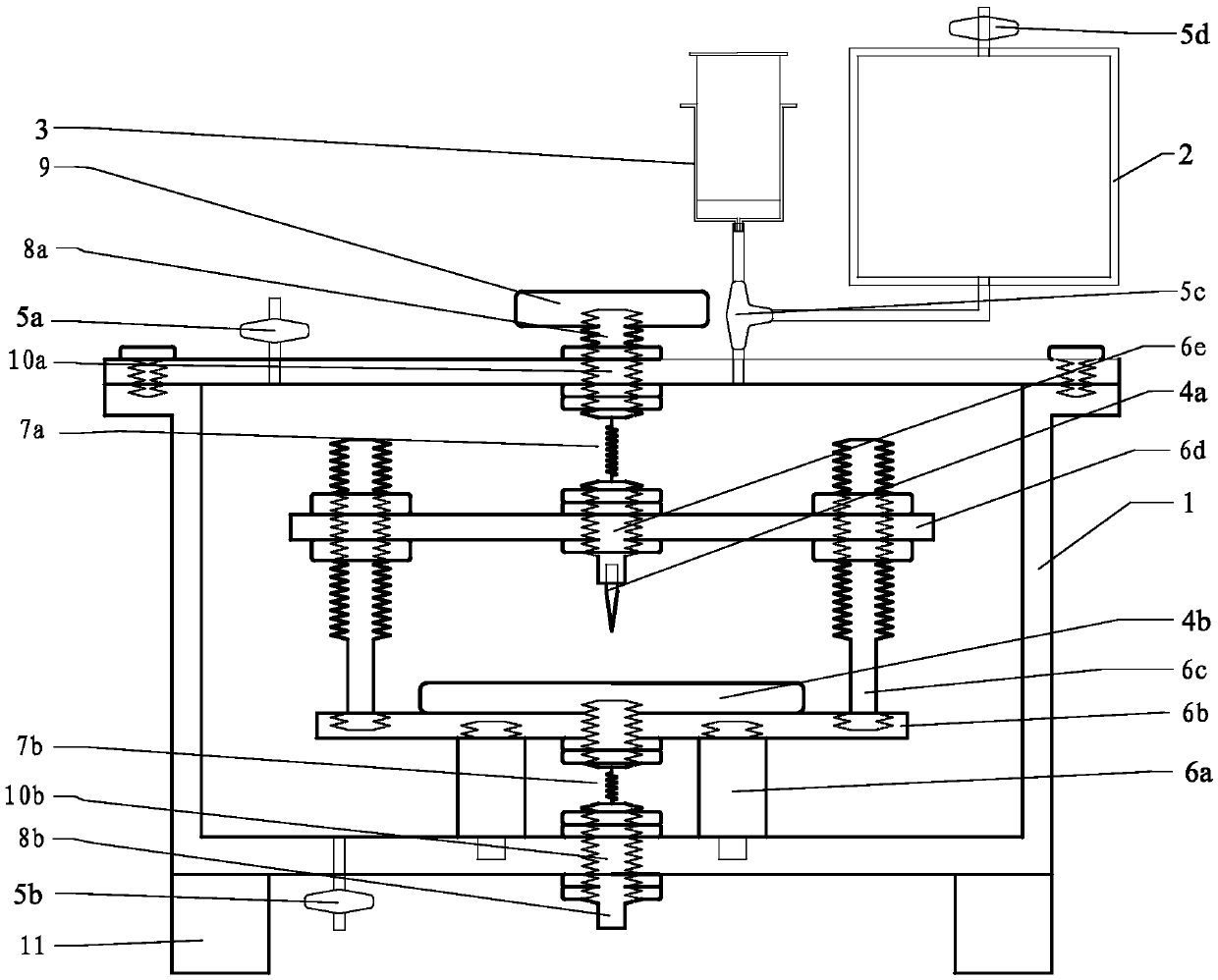

Automatic cleaning device for oil sample ferrography analysis glass test tube

The invention discloses an automatic cleaning device for an oil sample ferrography analysis glass test tube, and belongs to the field of oil analysis. The device comprises a test tube clamp unit, a cleaning agent adding unit, a brushing unit, a clear water washing unit, a control unit and a shell, wherein the test tube clamp unit is fixed on a clamp supporting plate, and the clamp supporting plateand the shell are fixed; the cleaning agent adding unit is fixed to a first conduit fixing frame, the first conduit fixing frame and the shell are fixed, a test tube brush is driven by a motor to rotate at a high speed, the inner wall of the test tube is washed by the generated washing force and a cleaning agent, and the test tube is washed by the washing unit, so that the purpose of thoroughly cleaning the test tube is achieved. The automatic cleaning device is simple and safe to operate, automatic cleaning can be realized by designing parameters, the cleaning efficiency is high, quantitative use of the cleaning agent is realized, waste is avoided, and workers are greatly liberated.

Owner:TAIYUAN UNIV OF TECH

Method of detecting a water leak in a locomotive

Disclosed herein are methods for detecting a water leak in a locomotive engine cooling system comprising numerous components, each being a potential source of leakage of water. The method typically comprises performing at least one inspection providing an indication of a water leak from an engine cooling system of the locomotive. The step of performing at least one inspection may comprise at least one of several steps including performing a visual inspection to determine if water is leaking from a portion of the cooling system external to the engine; performing a visual inspection of exhaust of the engine to detect an indication of water vapor in the exhaust; performing a visual inspection to detect an indication of water leaking into an intake air manifold 30 of the engine; performing an engine oil analysis to detect water in the engine lubricant; reviewing a fault log history for the locomotive; and checking a level of a cooling system sight glass. The method allows for the isolation of potential sources of the water leak from one another so as to prevent false positive leak identification caused by transient water flow between the potential sources. If an engine cylinder assembly is a component identified as a potential source of the water leak during the water pressurization test, the method enables further testing to confirm leakage at such cylinder assembly, before undertaking the costly and time-consuming process of removing the cylinder assembly from the engine. Cylinder assemblies can be tested for leaks by performing an air leak test disclosed herein.

Owner:GE GLOBAL SOURCING LLC

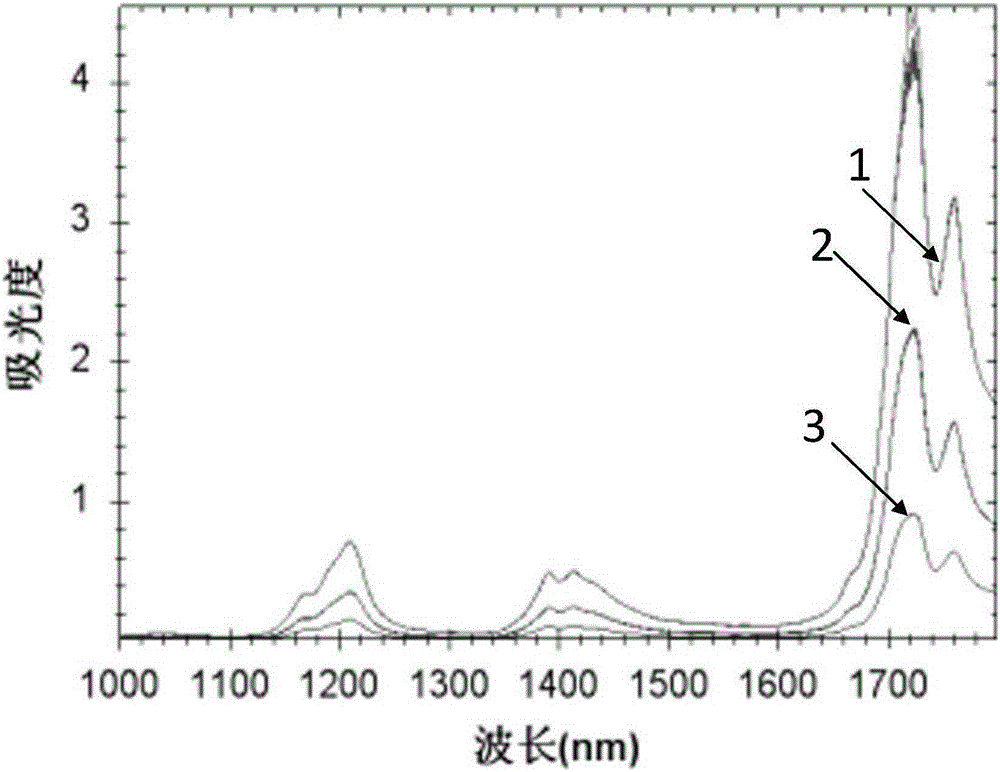

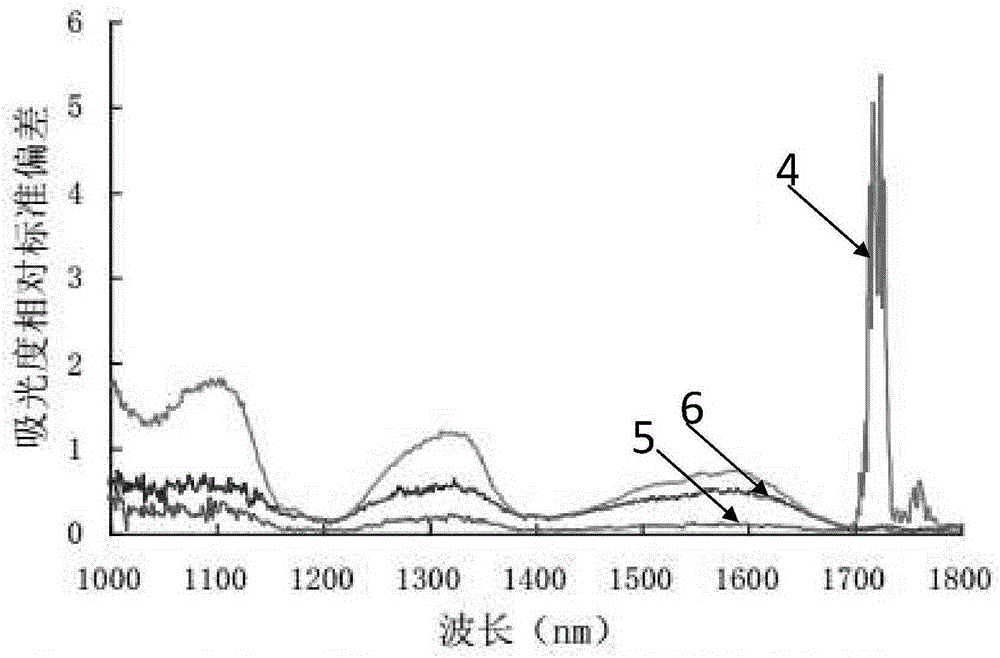

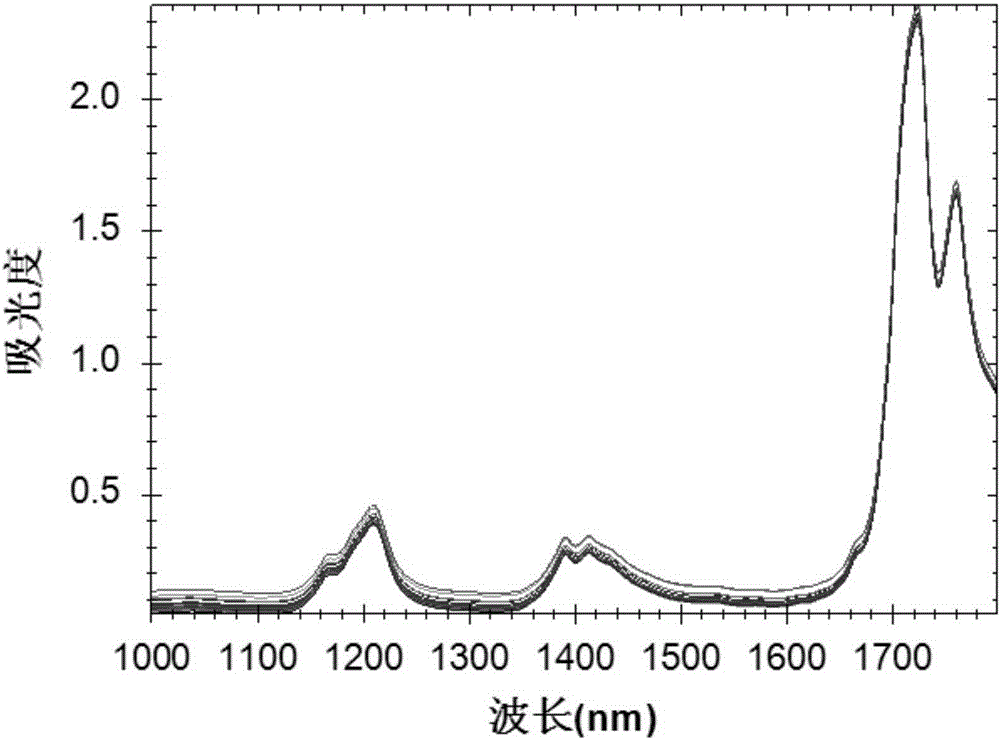

Infrared detection method for rapeseed oil quality and application

ActiveCN105181641AGuaranteed accuracyGuaranteed stabilityMaterial analysis by optical meansStepwise regressionRapeseed

The invention belongs to the technical field of grease analysis, and particularly relates to an infrared detection method for the rapeseed oil quality and application. The infrared detection method comprises the following steps that rapeseed oil samples are collected; physical-chemical testing is performed on the rapeseed oil samples; infrared scanning is performed on the rapeseed oil samples; abnormal sample removal and sample set partition are performed on obtained light absorption values; pretreating is performed; obtained pretreating light absorption values are analyzed and screened to obtain near infrared spectrum characteristic wavelengths; a prediction model of the rapeseed oil quality is established through a stepwise regression method. According to the infrared detection method, the obtained information is visualized and reliable, the characteristic wavelengths of the rapeseed oil quality are determined, the number of the characteristic wavelengths is few, and an analysis method of establishing the model through the characteristic wavelengths is applied to improve the precision of the model. On the condition of the same prediction precision, the prediction speed of the method is high; meanwhile, rapeseed oil analysis established through the method is more comprehensive, and use and popularization are easy.

Owner:HUAZHONG AGRI UNIV

Coal mining machine hydraulic oil quantitative analysis system

InactiveCN110173482AImprove evaluation efficiencyEffective evaluationFluid-pressure actuator testingElemental analysisEngineering

The invention discloses a coal mining machine hydraulic oil quantitative analysis system. The system comprises a hydraulic system, and an oil analysis system connected with the hydraulic system. Multiple oil extraction points are arranged in the coal mining machine hydraulic system, firstly, at the oil extraction points, oil is collected into a coal mining machine oil collection center, and classifying and pretreatment are carried out, and oil flows to detection devices in a quantitative manner in fixed batches, through detection of eight items of 40 DEG C kinematic viscosity, water, open flash points, the total acid number, the spectral elemental analysis, the pollution degree, the direct reading iron spectrum and the iron spectrum wear analysis, oil analysis data of the oil extraction points can be obtained, finally, the oil analysis data are transmitted to a coal mining machine oil evaluation center, and the coal mining machine hydraulic oil comprehensive report is obtained; and thehydraulic oil quality is detected, the failure of the hydraulic system is prevented, and the coal mining production efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Automatic liquid sample injector for petroleum analytical instrument

The invention discloses an automatic liquid sample injector for a petroleum analytical instrument. The automatic liquid sample injector comprises a stepper motor and a screw rod making linear motion along with the stepper motor. The screw rod is sheathed with a sliding block, the sliding block is sleeved on a guide rail, and the inner side of the sliding block is embedded with a magnet able to generate electromagnetic induction with a Hall element. The guide rail is equipped with a pair of Hall elements arbitrarily movable in position. The automatic liquid sample injector makes use of the Hall elements to control the position so as to make sample injection control more accurate and in-place, and is free of the problems of loss of synchronism and inaccurate positioning. Also adjustment of the Hall elements is convenient, so that positioning becomes very simple, and operation can be more convenient.

Owner:JIANGSU XINGAOKE ANALYTICAL INSTR

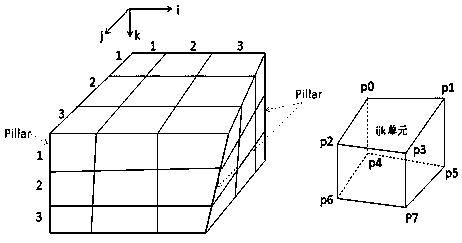

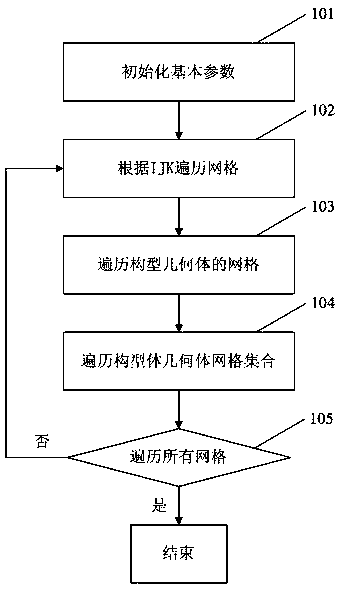

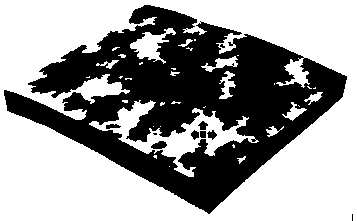

Automatic identification method for reservoir configuration interface in oil reservoir geologic model

ActiveCN111401451AEnhanced overall recoveryDetails involving 3D image dataClimate change adaptationPhysical propertyGeophysics

The invention provides an automatic identification method for a reservoir configuration interface in an oil reservoir geologic model. The automatic identification method for the reservoir configuration interface in the oil reservoir geologic model comprises the following steps: 1, initializing basic parameters; 2, traversing the grids according to the IJK; 3, traversing the grids of the configuration geometry formed in the step 2; 4, traversing the configuration geometry grid set generated in the step 3 to generate a configuration geometry boundary grid set; 5, adding the geomorphic geometry into the configuration set established in the step 1, returning to the step 2, and continuing to traverse the grids until all the grids are traversed and stored. The automatic identification method forthe reservoir configuration interface in the oil reservoir geologic model can describe the connectivity between different configuration units (interfaces), count geometric attributes and physical property parameters of the configuration units, and provide a basis for configuration unit-based remaining oil analysis and scheme optimization.

Owner:CHINA PETROLEUM & CHEM CORP +1

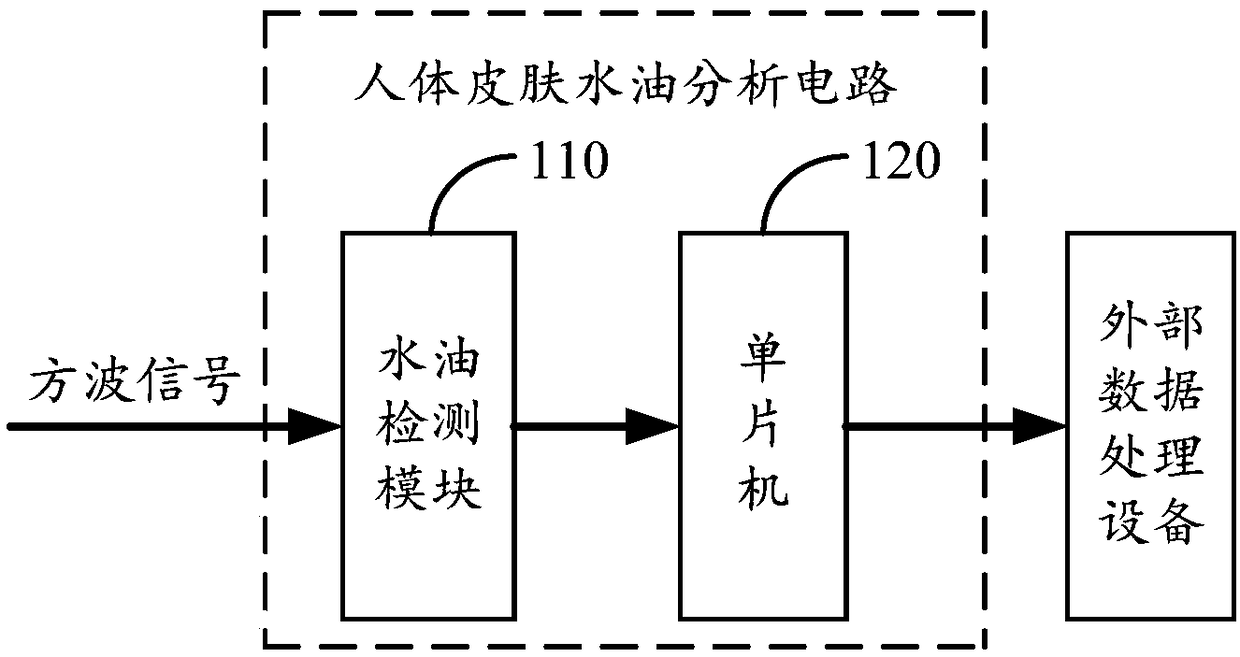

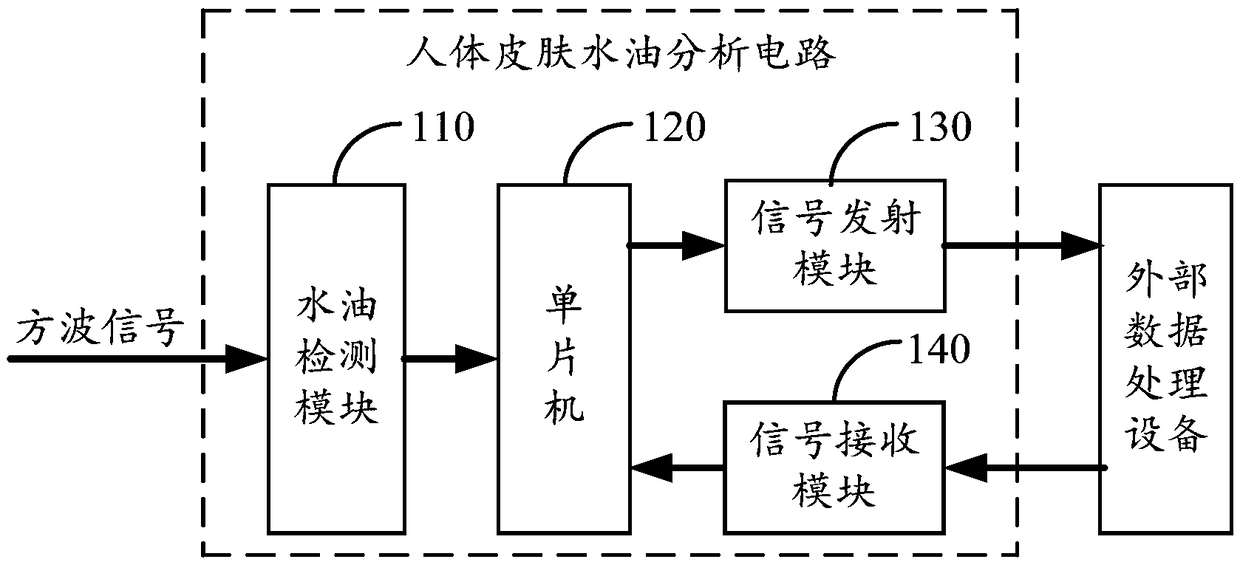

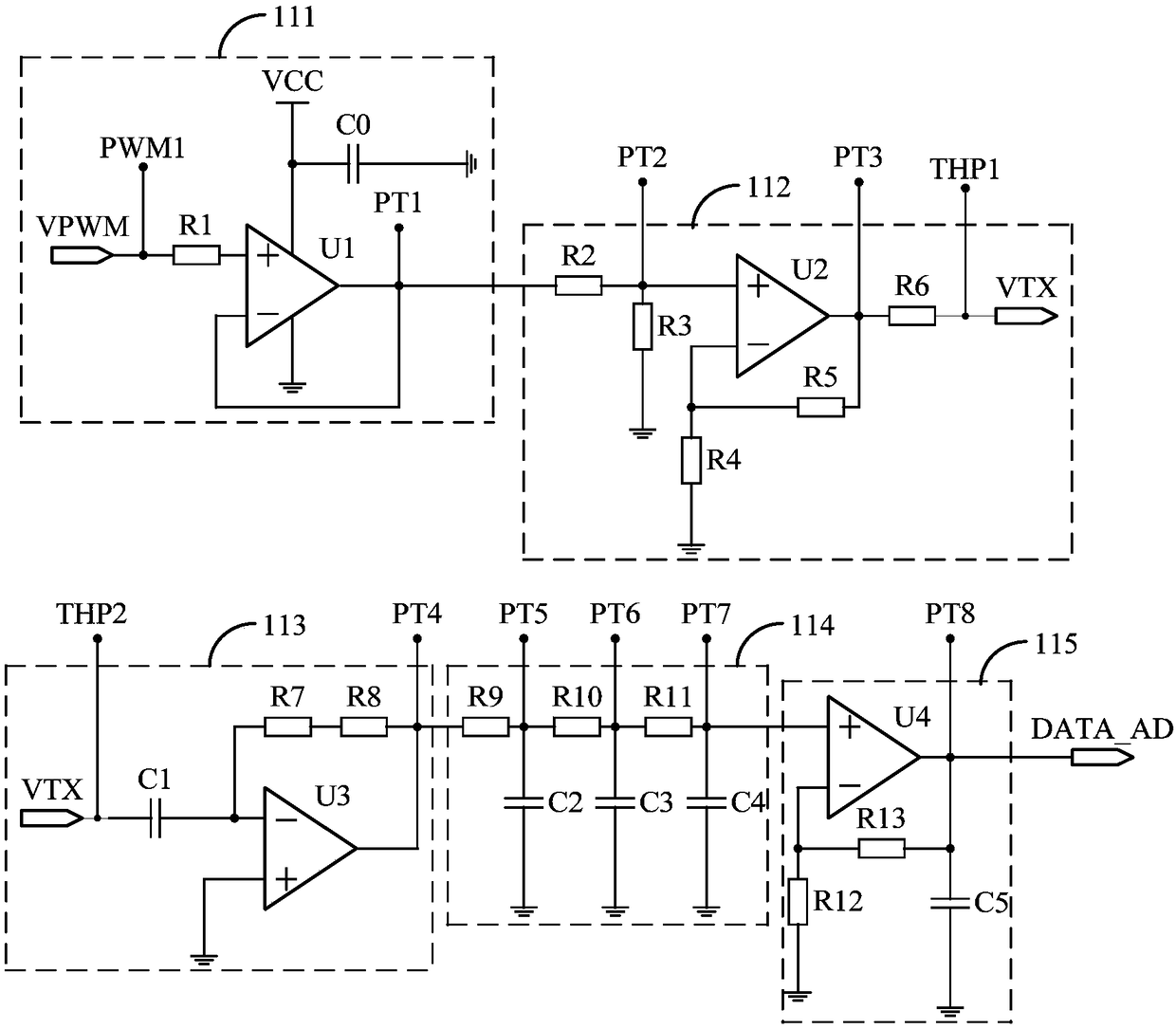

Human skin water and oil analysis circuit and skin tester

InactiveCN108700859AAvoid polarizationStable waveformProgramme controlComputer controlMicrocontrollerMicrocomputer

A human skin water and oil analysis circuit includes a water and oil detection module (110) and a single chip microcomputer (120). The water and oil detection module (110) is configured to receive a square wave signal, and use the square wave signal as an excitation signal to detect a percentage of human skin water and oil, and obtain a voltage signal capable of reflecting a percentage of human skin water and oil data; the single chip (120) is used for The voltage signal obtained by the water and oil detecting module (110) is subjected to analog-to-digital conversion, and the analog-digital converted voltage signal is sent to an external data processing device, so that the external data processing device performs data analysis on the voltage signal, and detects Percentage data of human skin water and oil. A skin tester includes the human skin water and oil analysis circuit. In the above manner, the accuracy of the human skin water and oil percentage test data can be improved.

Owner:SHENZHEN H&T INTELLIGENT CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com