Device and method for separating abrasive particles in lubricating oil based on surface acoustic waves

A surface acoustic wave and separation device technology, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, measurement devices, and use sound waves/ultrasonic waves/infrasonic waves for material analysis. It can solve the problem of non-ferromagnetic abrasive particles that cannot be separated and are not widely used , different deflection, etc., to achieve the effect of easy integration, high energy density, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

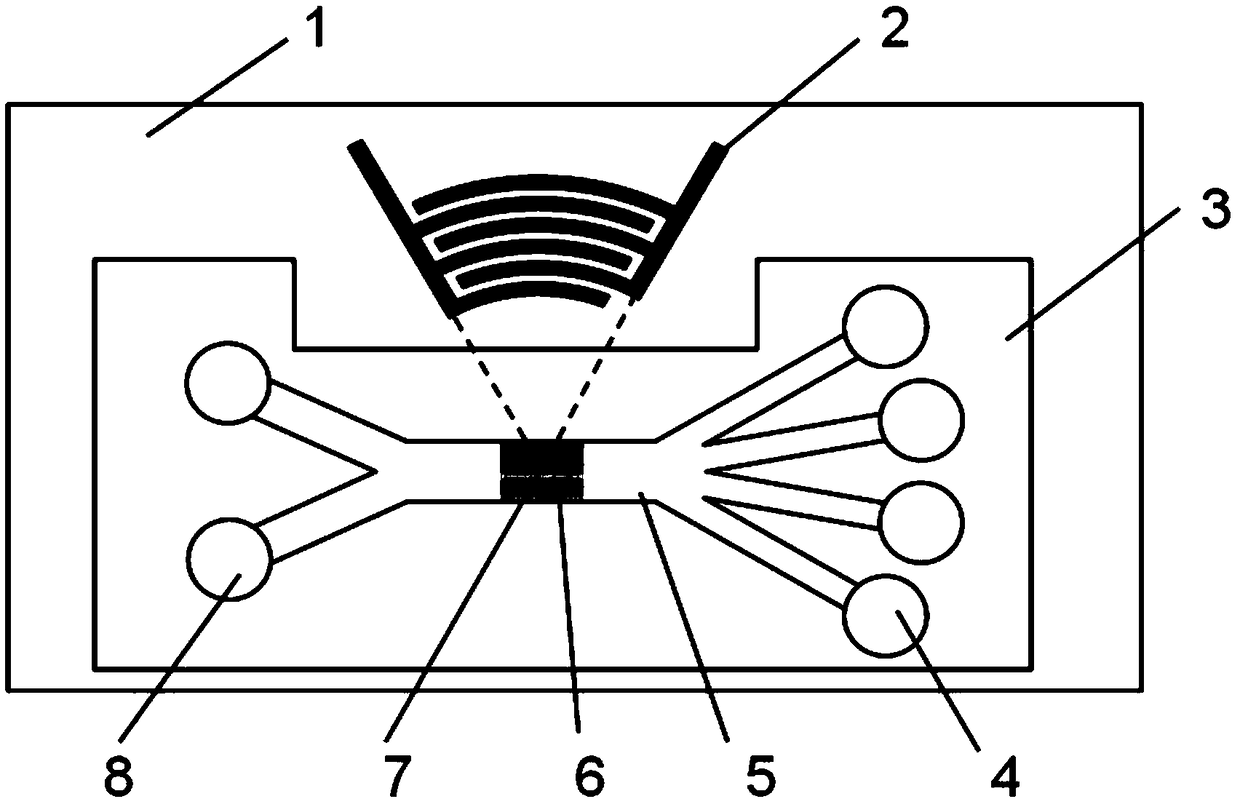

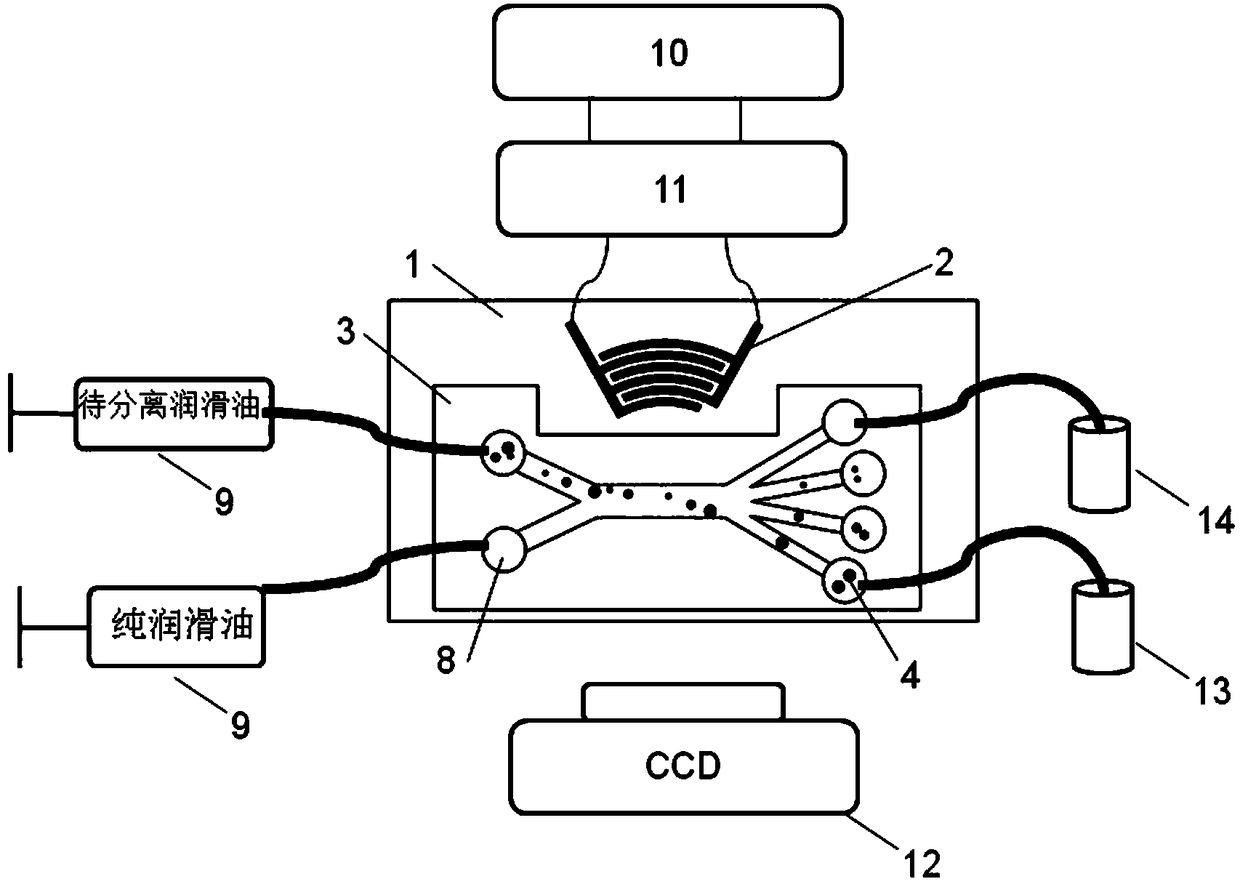

[0041] Such as figure 1 As shown, a lubricating oil abrasive separation device based on surface acoustic waves includes a piezoelectric substrate 1, and the material of the piezoelectric substrate 1 is lithium niobate (128°YX-LiNbO 3 ); processing the focusing type interdigital electrode 2 and the microfluidic channel on the piezoelectric substrate 1, the main channel 5 of the microfluidic channel is perpendicular to the central axis of the interdigital electrode 2, and the geometric center of the microfluidic channel is in line with the interdigital The focus of the electrodes 2 coincides to ensure that the abrasive particles in the lubricating oil flow through this area and are subjected to the strongest sound radiation force and are shifted to varying degrees;

[0042] The interdigitated electrode 2 is a sputtered double-layer structure, the bottom layer of chromium (5 nanometers) and the upper layer of platinum (80 nanometers), which not only reduces the impedance of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com