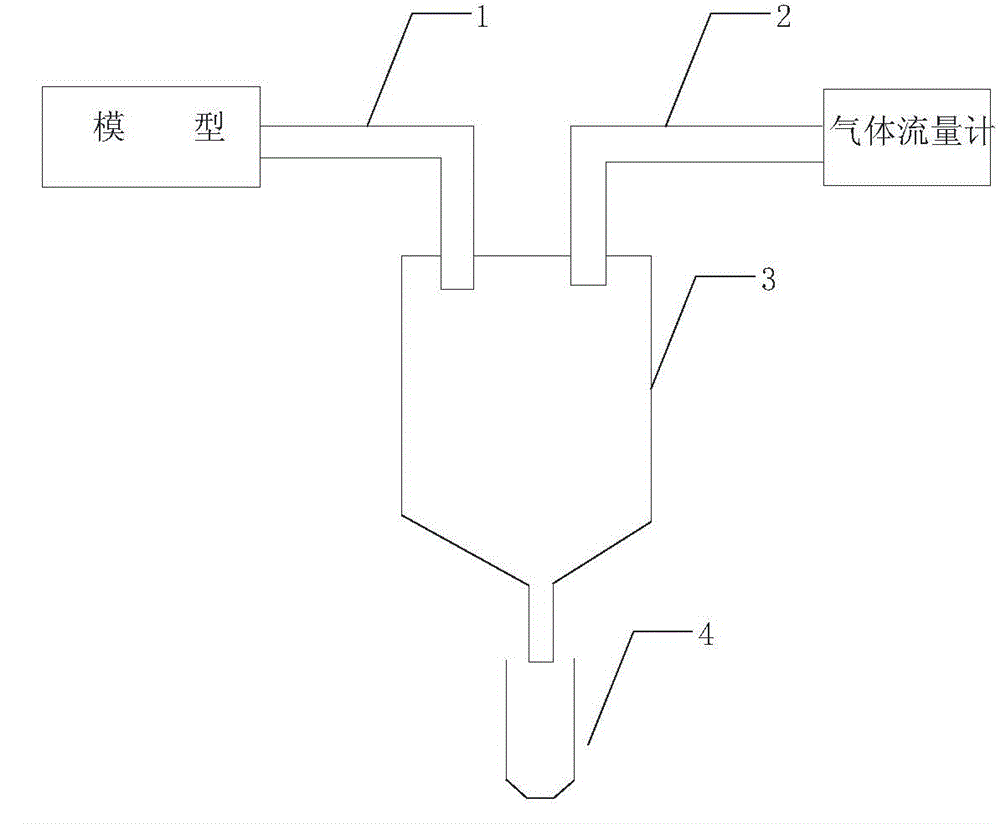

Multilevel gas-liquid two-phase separation device

A phase separation and secondary separation technology, applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve problems such as experimental result errors, insufficient gas-liquid separation, and inability to collect carbon dioxide gas completely, and ensure accurate degree, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

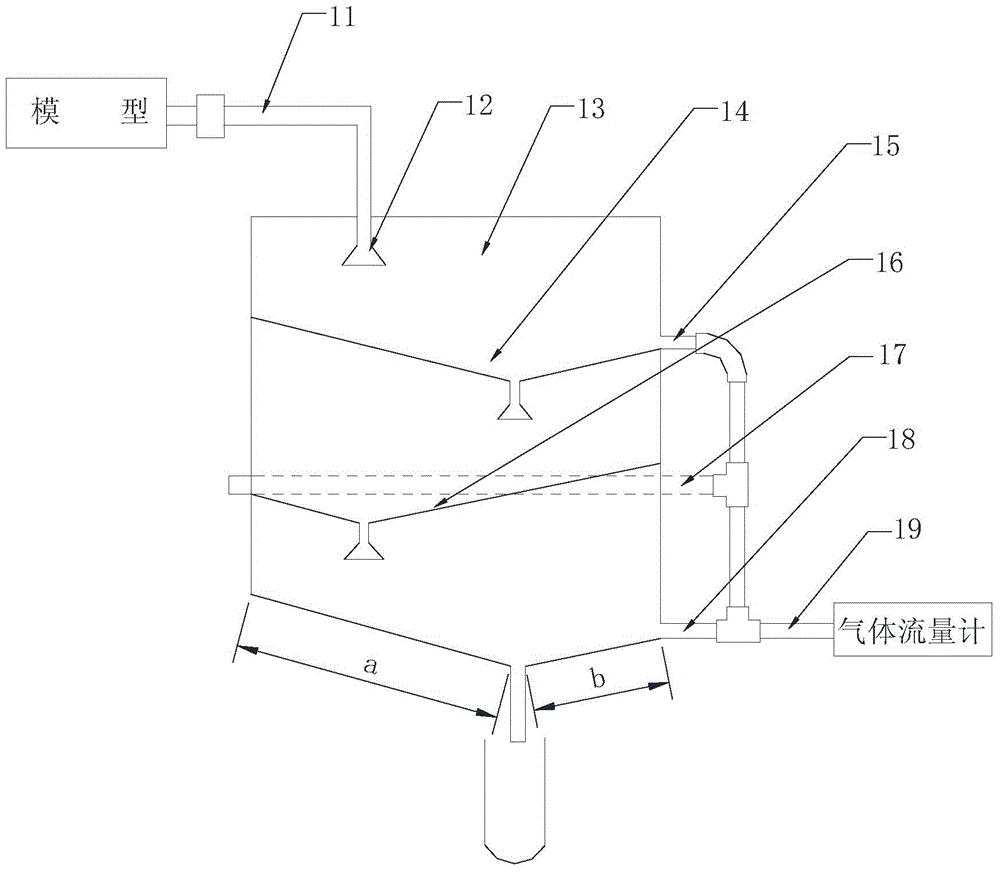

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

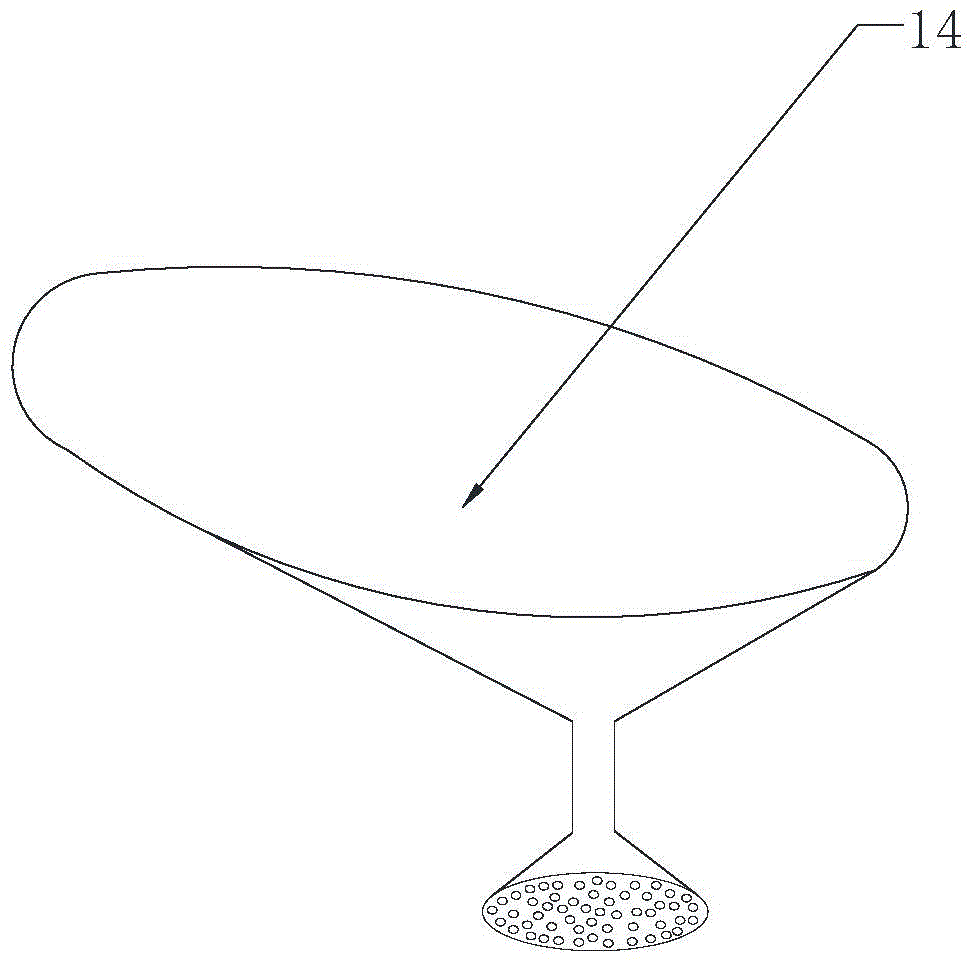

[0017] Depend on figure 2 combine image 3 Shown: a multi-stage gas-liquid two-phase separation device, including a cylinder 13, a mixed liquid inlet pipe 11 and a gas collecting pipe 19, the cylinder 13 is composed of a cylinder and a bottom, wherein the cylinder is cylindrical or elliptical Cylindrical, the bottom adopts an eccentric funnel structure, and the upper mouth of the funnel is a slanted mouth with a high left side and a low right side. The outlet of the cylinder is also located on the right side of the center line of the cylinder 13, so the left side of the bottom of the cylinder 13 The inclined wall a is longer than the right inclined wall b; the mixed liquid inlet pipe 11 extends into the cylinder from the top of the cylinder body 13, and the outlet of the mixed liquid inlet pipe 11 is provided with a primary separation screen 12, and the primary separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com