Patents

Literature

34results about How to "Prevent hanging on the wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

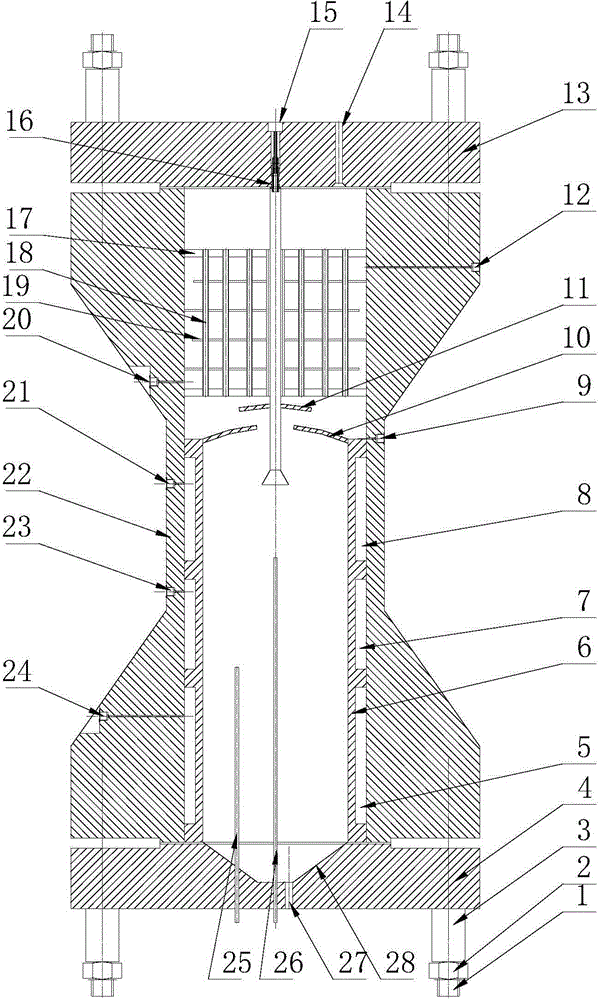

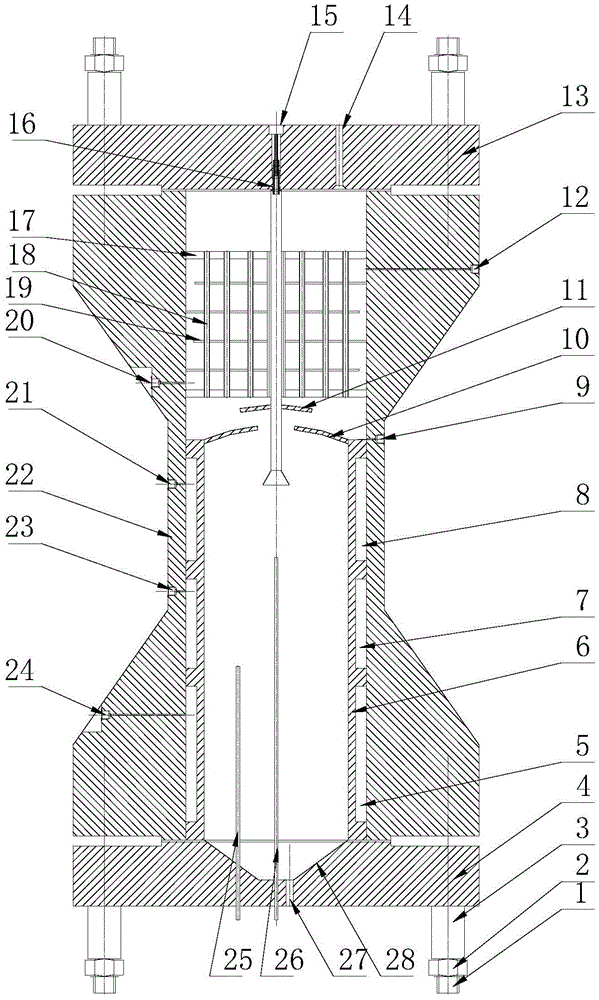

Evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water

ActiveCN104478064AReduce material selectionAchieve separationWater/sewage treatment by oxidationWater useSaline water

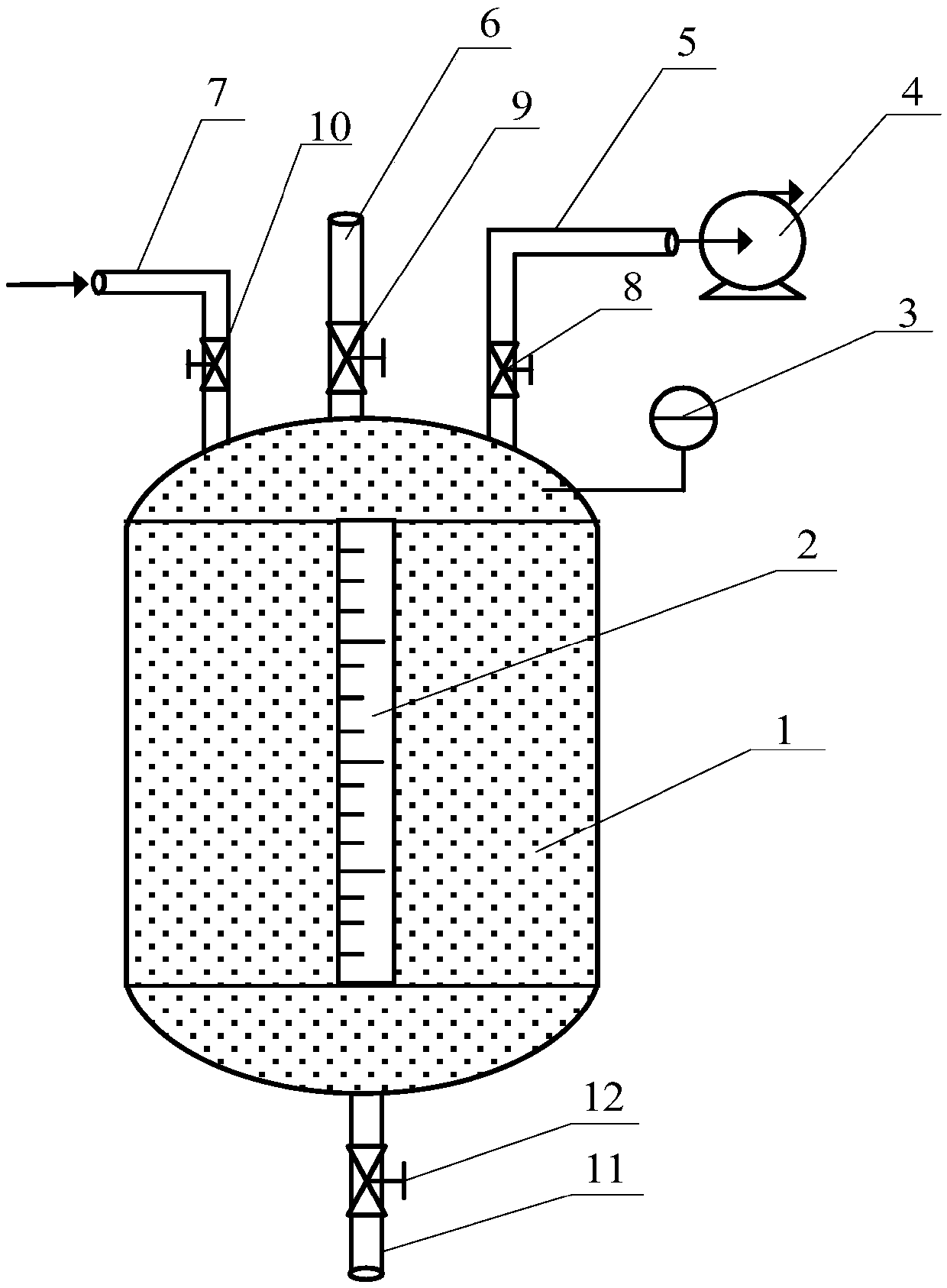

The invention relates to an evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water. The cylinder is fixed with an upper end cover and a lower end cover; the middle part of the upper end cover is provided with a burner component which extends to the inside of the cylinder; the upper end cover is provided with a gas-phase outlet and a sewage secondary inlet; the upper part in the cylinder is fixedly provided with a shell-and-tube heat exchanger; the upper part of the cylinder is provided with a sewage primary inlet and a normal temperature sewage outlet; the cylinder is provided with a subcritical water outlet; the lower part in the cylinder is fixedly provided with a multilayer evaporation wall; a plurality of annular spaces are formed between the multilayer evaporation wall and the cylinder from top to bottom; the cylinder is sequentially provided with a plurality of evaporation wall water inlets; the upper edge of the multilayer evaporation wall is provided with an evaporation wall spherical baffle; the lower end of the burner component is fixedly provided with a burner spherical baffle; and the bottom of the lower end cover is provided with a brine outlet. The oxidation reactor effectively prevents the preheater, reactor and pipelines from blockage and corrosion, reduces the quantity of pure water used by the evaporation wall, and can reduce the reactor volume and lower the noble alloy consumption.

Owner:碧流天能(北京)科技股份有限公司

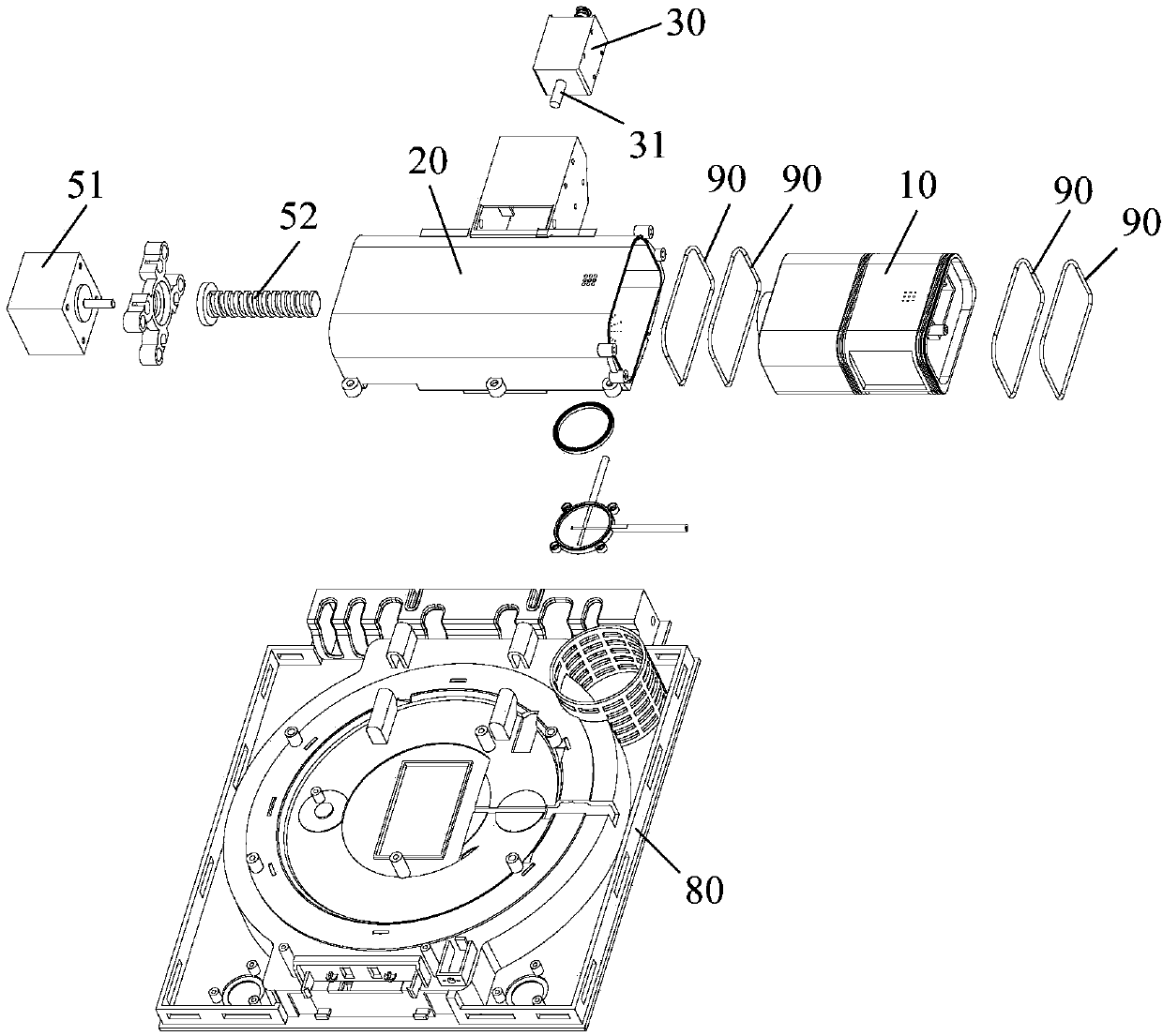

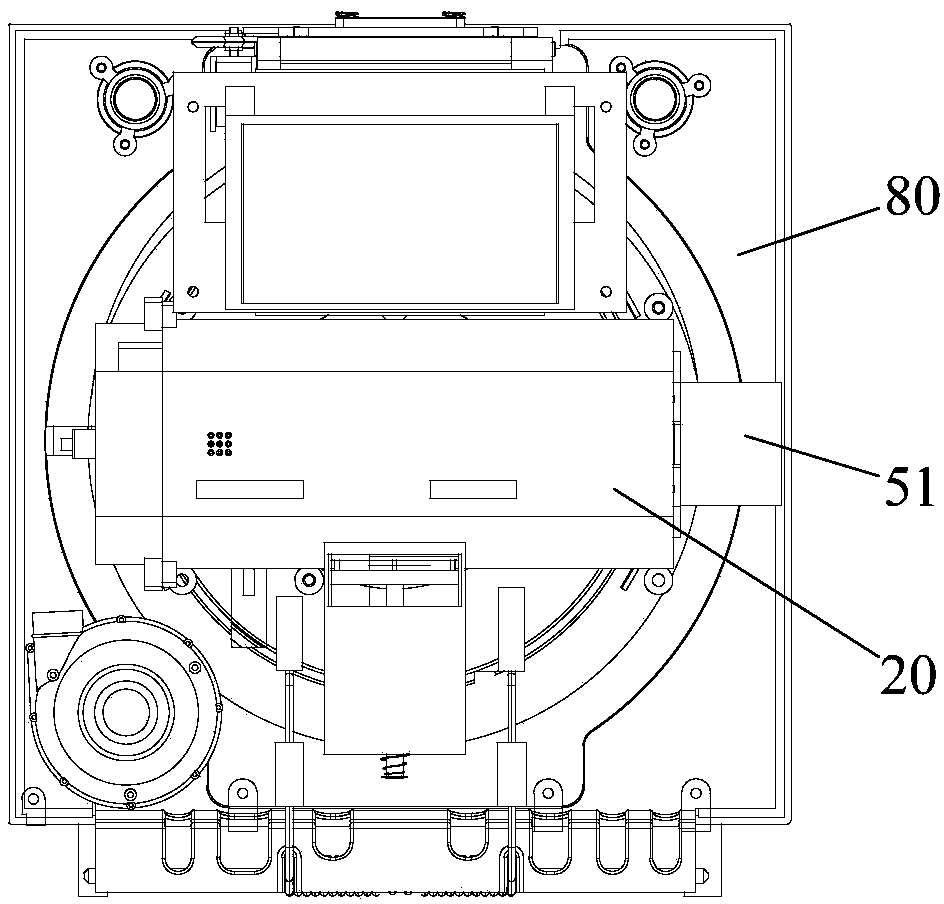

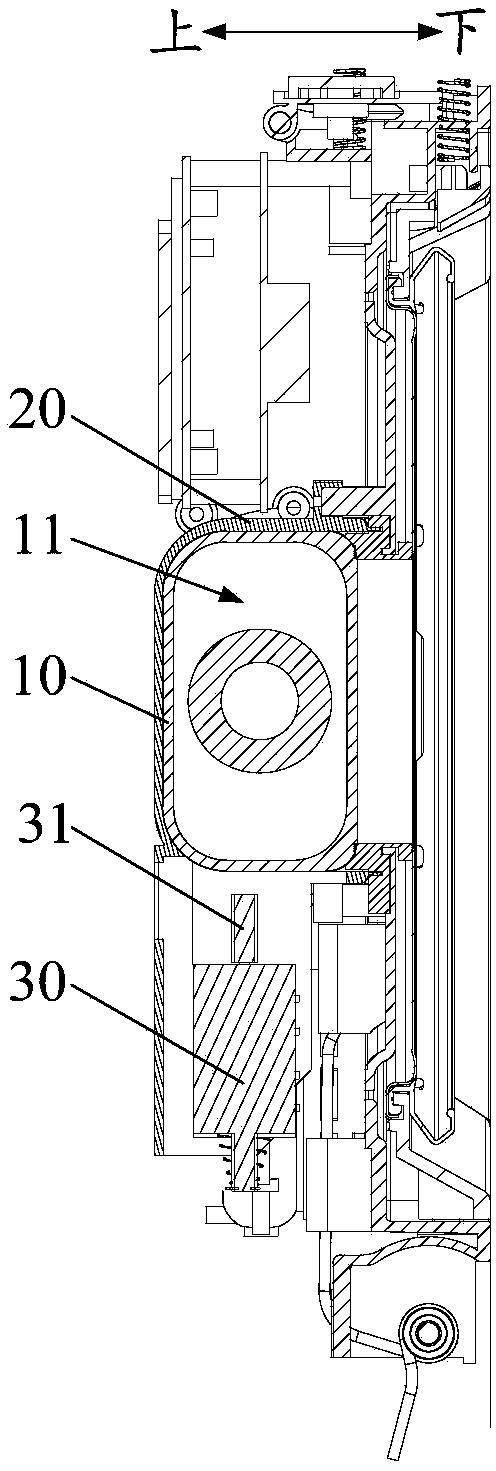

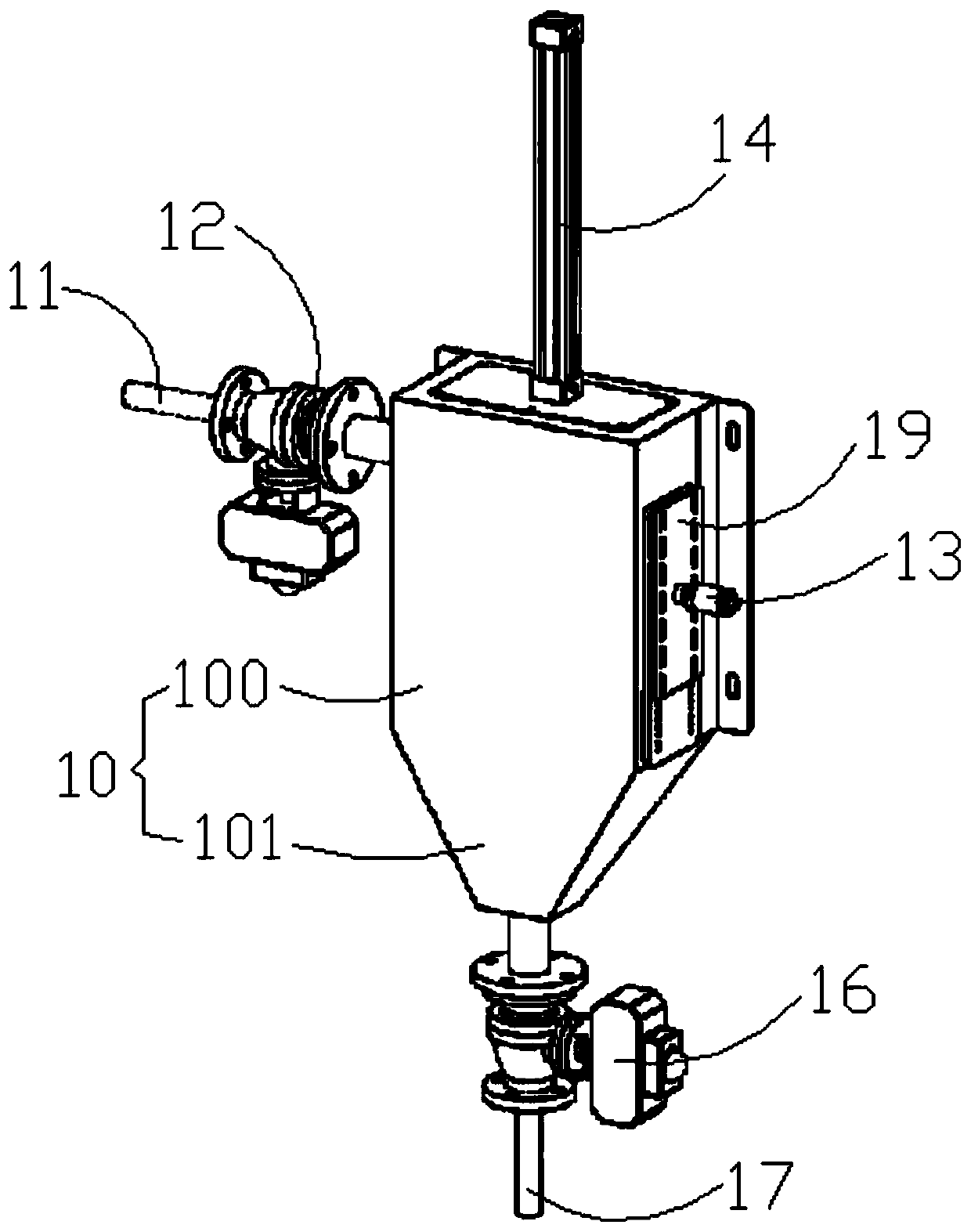

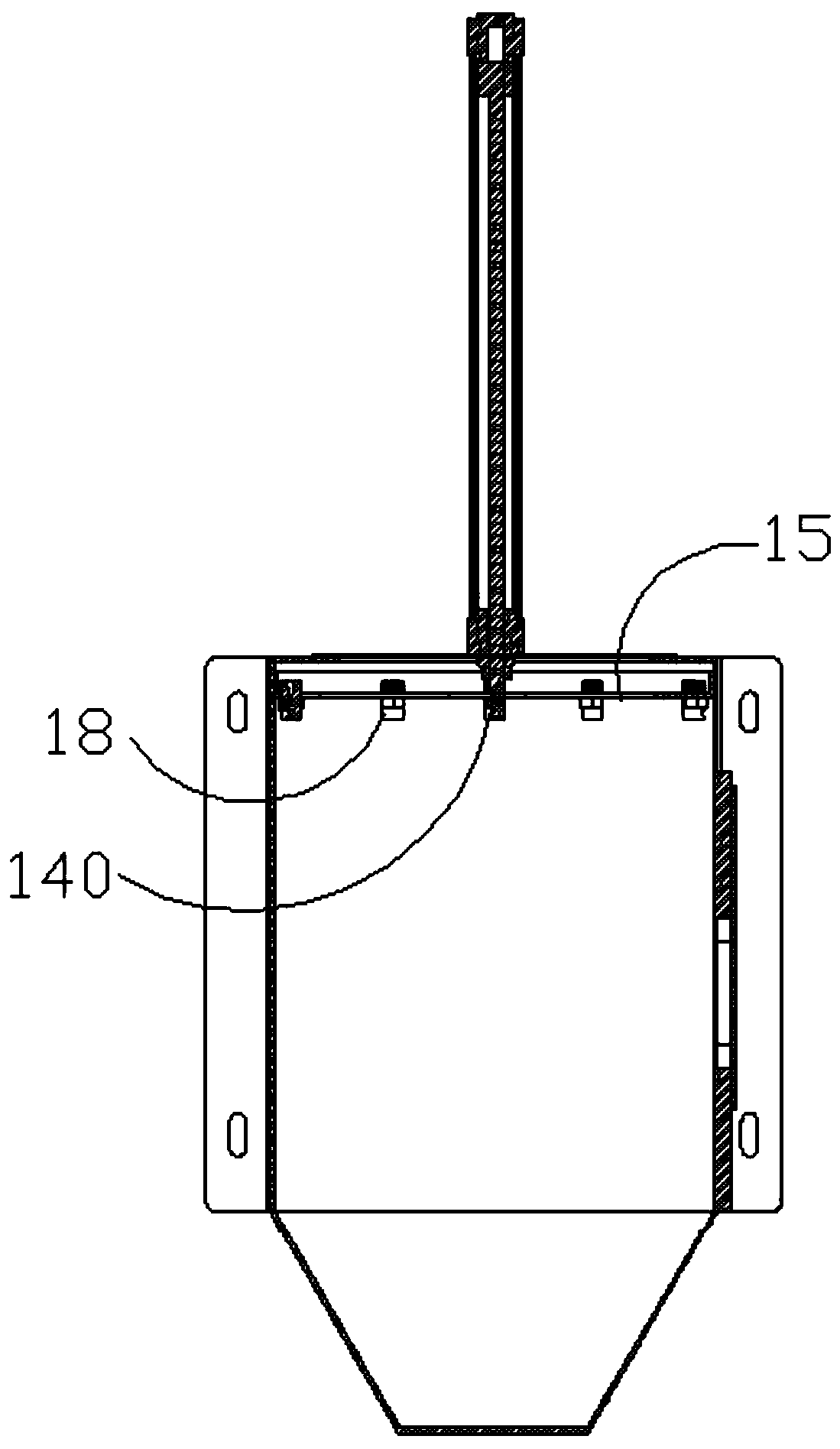

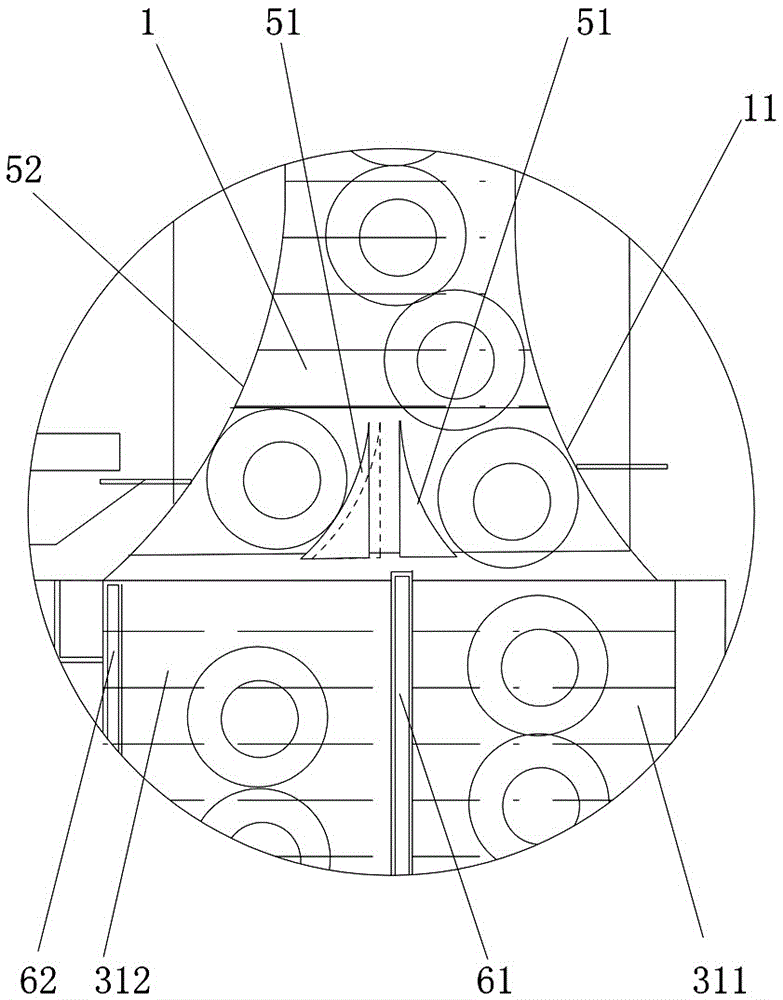

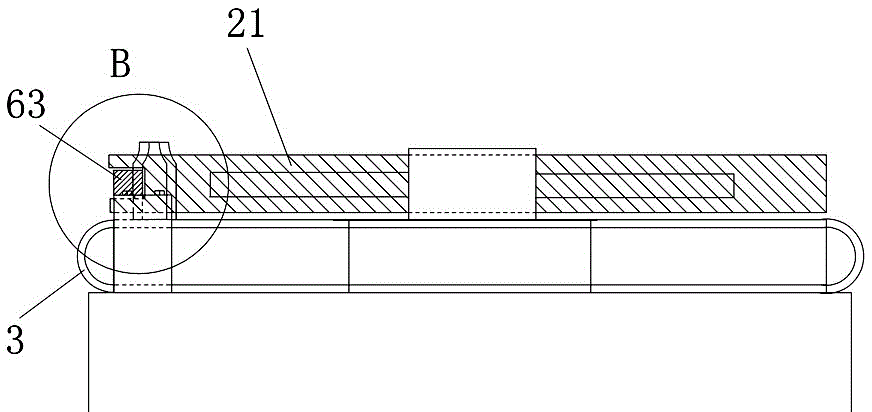

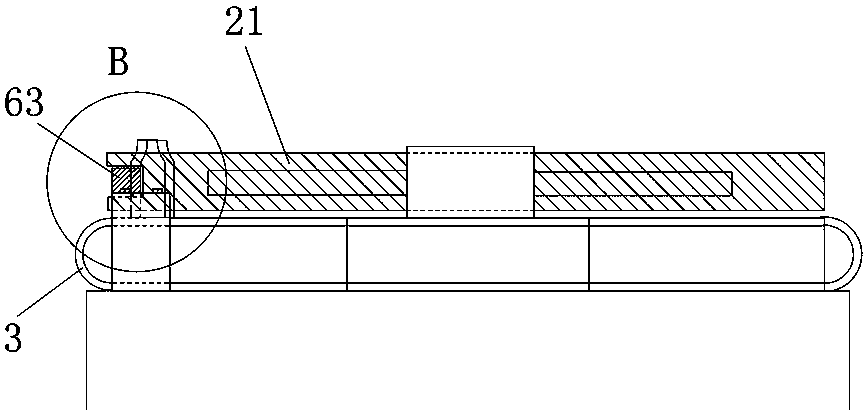

Material washing device and cooking utensil

PendingCN109965710AGuaranteed unloadingEasy to unloadPressure-cookersCooking vessel constructionsEngineeringMechanical engineering

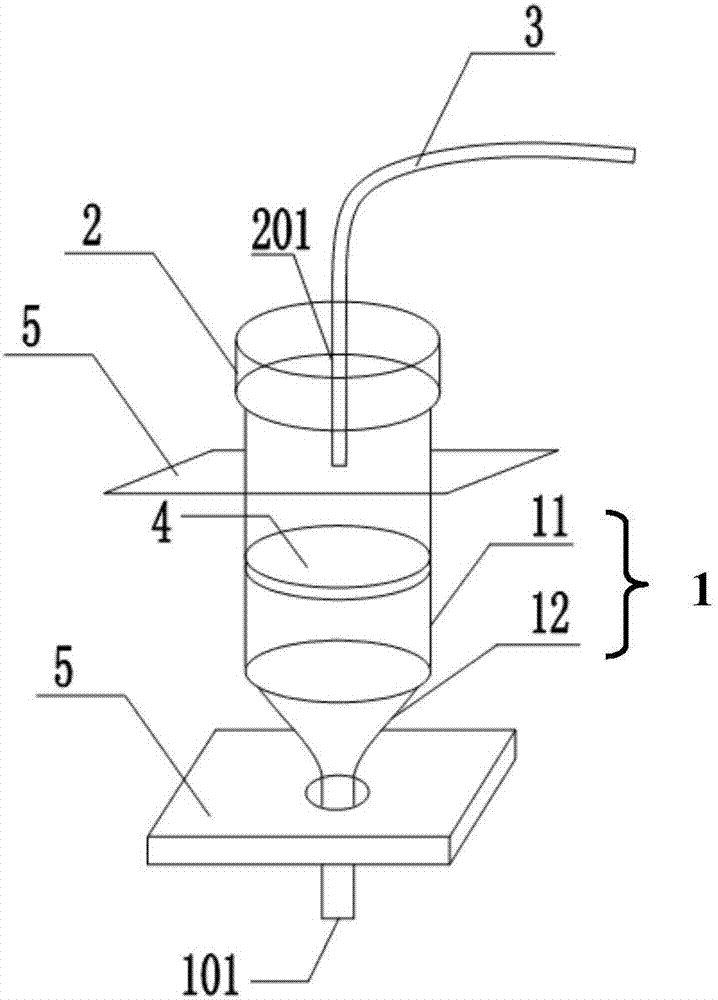

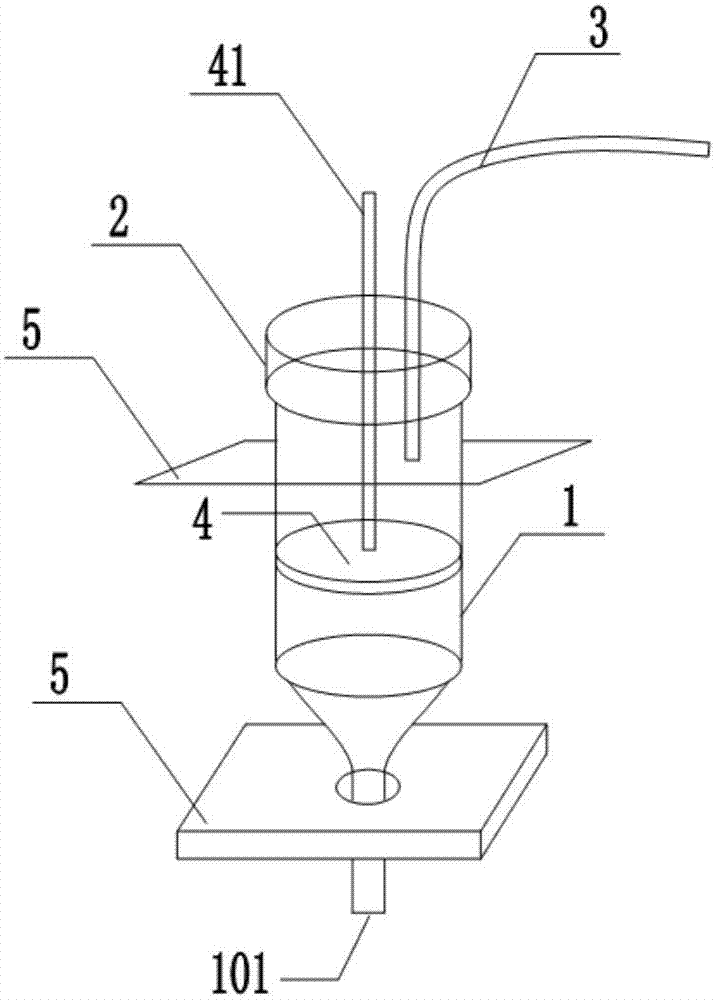

The invention provides a material washing device and a cooking utensil. The material washing device comprises a plunger, a plunger sleeve and a blanking structure, wherein the plunger is provided witha washing cavity, and an unloading hole is arranged in the bottom of the washing cavity; the plunger is sleeved by the plunger sleeve, the plunger sleeve is provided with a discharging hole adaptiveto the unloading hole, and the plunger sleeve can generate relative movement with the plunger, so that the discharging hole communicates with the unloading hole when the plunger is at a first preset position; and the blanking structure is matched with the washing cavity for discharging materials in the washing cavity. For the material washing device provided by the invention, when the plunger moves to the first preset position relative to the plunger sleeve, the unloading hole communicates with the discharging hole, so that most of the materials can be discharged under the effect of gravity; and meanwhile, the blanking structure matched with the washing cavity is additionally arranged, the blanking structure can promote the materials inside the washing cavity to be discharged, and thus thethoroughness of blanking is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

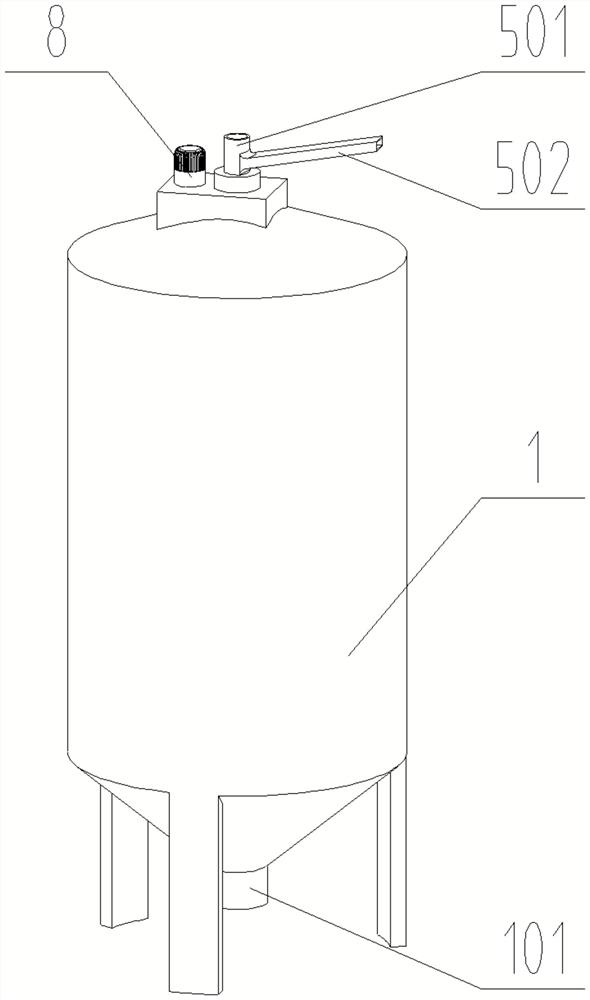

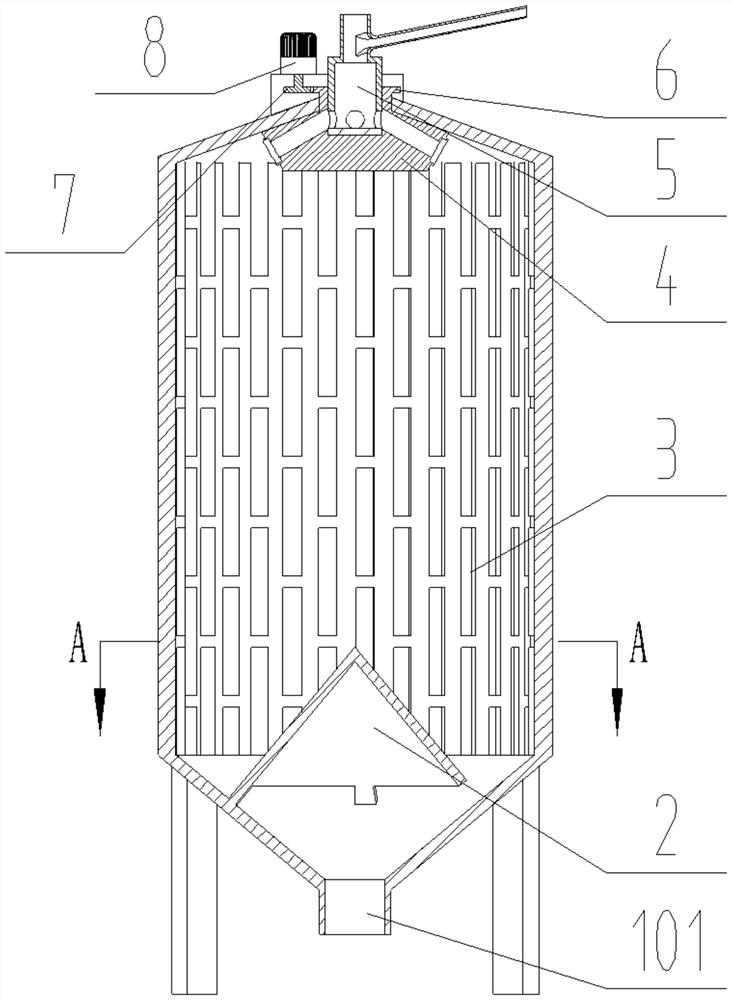

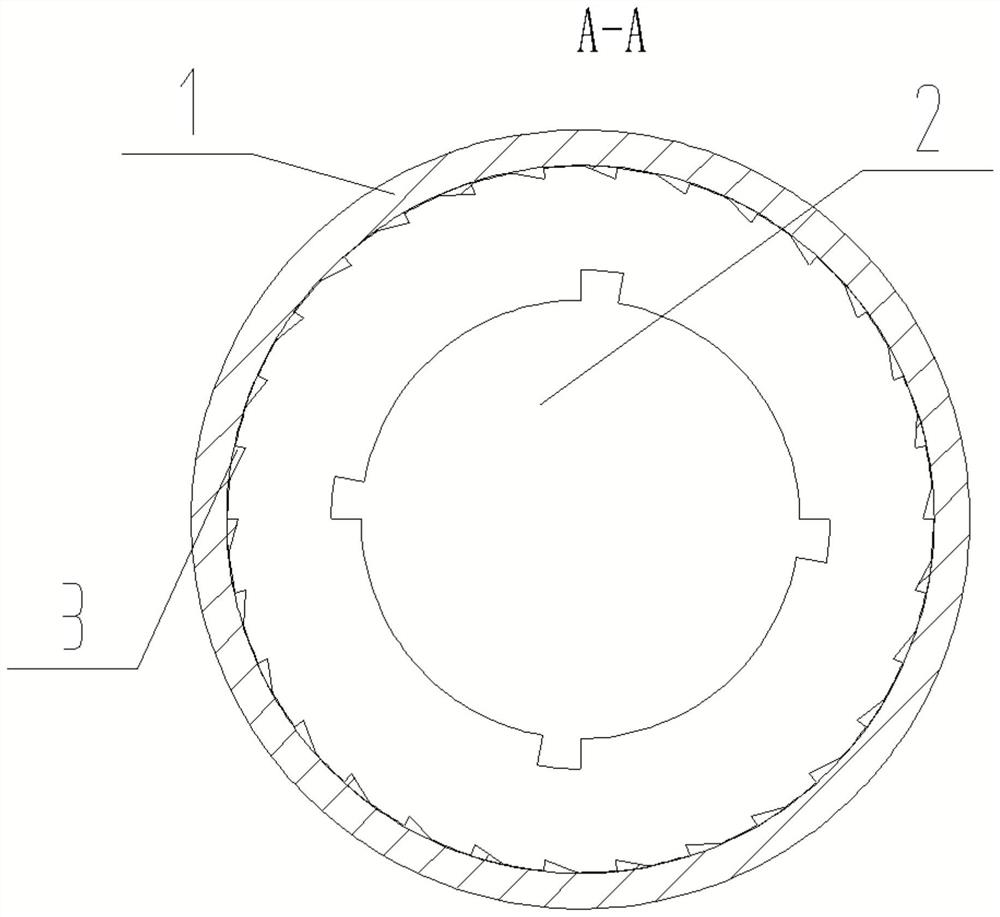

High-viscosity liquid sampling device

InactiveCN109540598ASpeed up the flowPrevent hanging on the wallWithdrawing sample devicesEngineeringGas-filled tube

The invention discloses a high-viscosity liquid sampling device. The high-viscosity liquid sampling device comprises a sample storage chamber. The sample storage chamber is provided with an air inflation pipe, an air suction pipe, a sample feeding pipe, a sample discharging pipe and a liquid level indicator. An air inflation valve is arranged on the air inflation pipe. The air inflation pipe is used for inflating the air into the sample storage chamber. An air suction valve is arranged on the air suction pipe. The air suction pipe is used for extracting air out of the sample storage chamber. The sample feeding pipe is provided with a sample feeding valve. The sample feeding pipe is used for introducing a liquid sample into the sample storage chamber. The sample discharging pipe is providedwith a sample discharging valve. The sample discharging pipe is used for discharging the liquid sample from the sample storage chamber. The liquid level indicator is used for displaying the liquid level in the sample storage chamber. The high-viscosity liquid sampling device promotes the smooth flow of the high-viscosity liquid on the inner wall of the sample storage chamber by utilizing the pressure generated by the air inflation pipe. The condition that, the liquid is adhered to the inner wall of the sample storage chamber to form a wall hanging phenomenon, cause the non-accurate result ofthe sampling amount, and finally cause the non-accurate result of the sampling analysis, can be avoided.

Owner:山西钢科碳材料有限公司

Adhesive pressing device

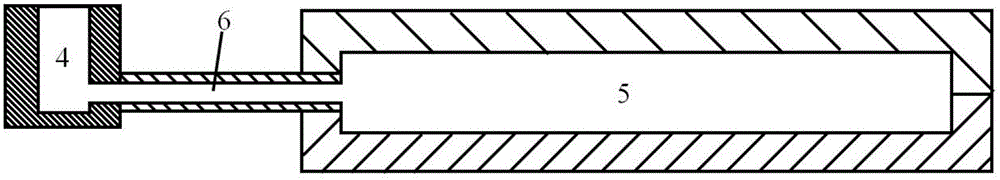

InactiveCN107290880APrevent hanging on the wallAvoid frequent refillsNon-linear opticsPistonAdhesive

The invention provides an adhesive pressing device which comprises a cylinder, a cylinder cover and an air inlet pipe communicated with a compressed air source. The cylinder and the cylinder cover form a space for storing a frame adhesive. An inlet is formed in the cylinder cover. The air inlet pipe stretches into the upper portion inside the cylinder from the inlet. An outlet is formed in the bottom of the cylinder. The adhesive pressing device further comprises a piston arranged inside the cylinder. The piston can be pushed by the compressed air source to move on the inner wall of the cylinder in an attached mode so as to press out the frame adhesive stored inside the adhesive pressing device. When the frame adhesive in the device needs to be pressed out, the phenomenon that the frame adhesive close to the inner wall of the device is hung to the wall can be avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Thickening agent for fracturing fluid, preparation method thereof and fracturing fluid

InactiveCN110028945APrevent hanging on the wallImprove liquidityDrilling compositionFracturing fluidAmmonium bromide

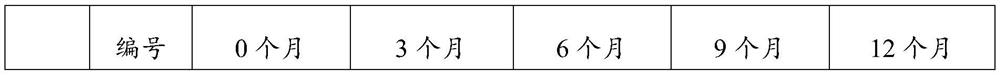

The invention provides a thickening agent for a fracturing fluid, a preparation method of the thickening agent and the fracturing fluid. The thickening agent comprises the following components in percentage by mass: 18.0%-22.0% of aviation kerosene, 32.0%-38.5% of polyacrylamide, 4.0%-6.0% of an emulsifier, 0.5%-1.0% of cetyl trimethyl ammonium bromide, 0.5%-1.0% of sodium dodecyl benzene sulfonate, 5.0%-8.0% of ethylene glycol, and the balance of water. After being stored and transported for a long time, the thickening agent is still uniform, does not have obvious oil-liquid separation, and still has good fluidity at-30 DEG C. After being used, the fracturing fluid prepared by the thickening agent has no obvious wall-hanging phenomenon.

Owner:DAQING AOPUQI CHEM ADDITIVES

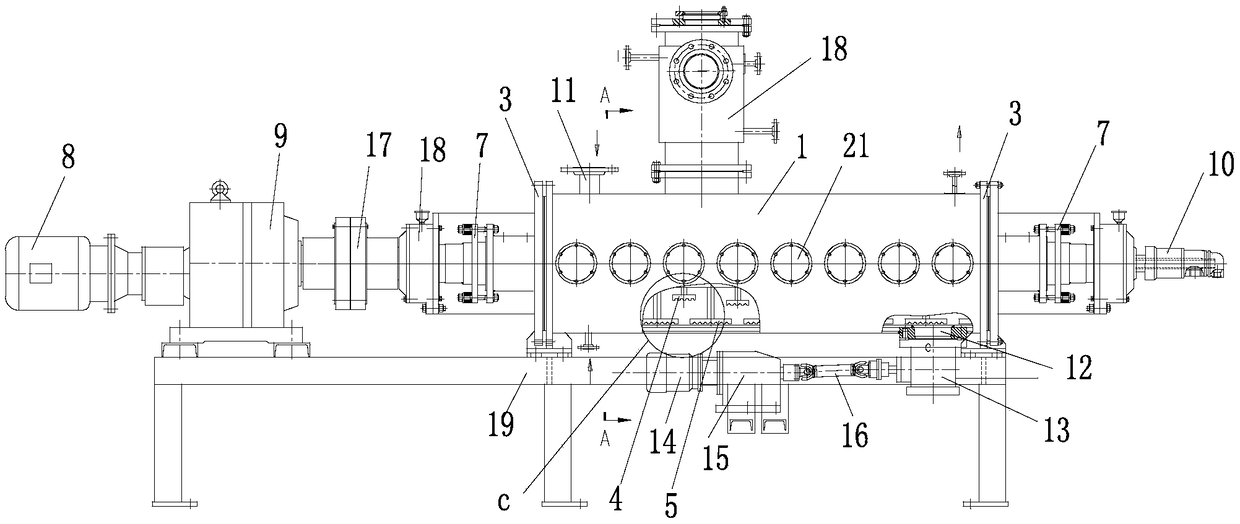

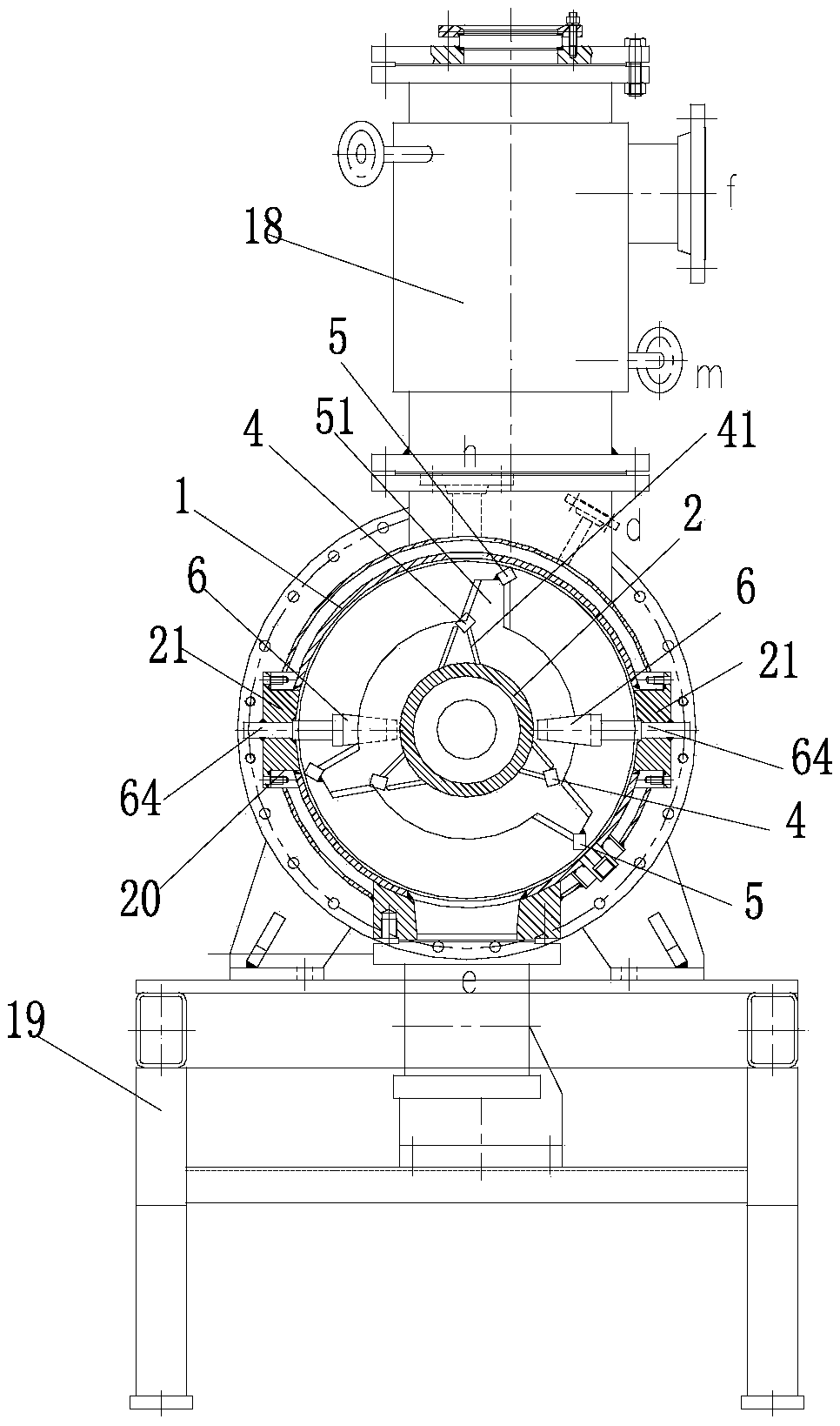

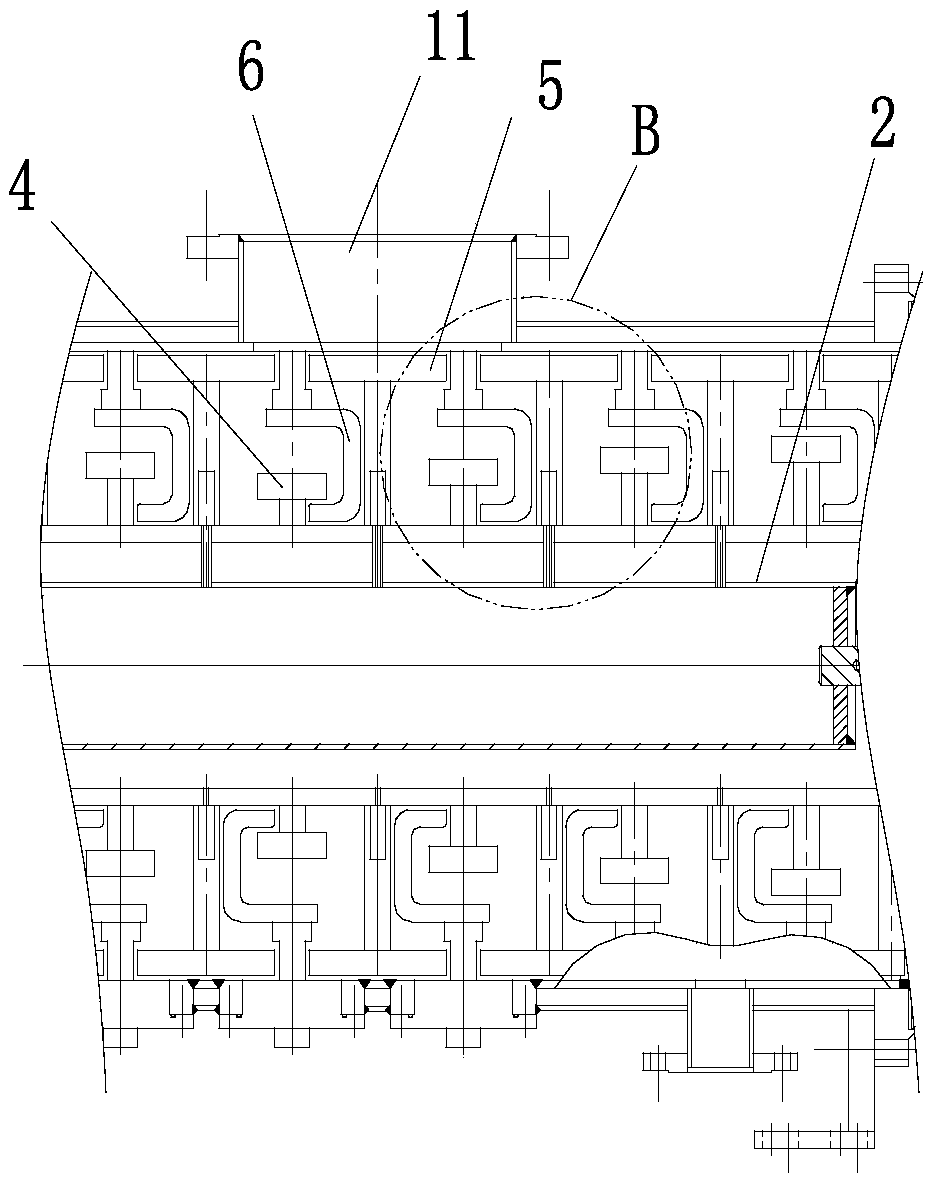

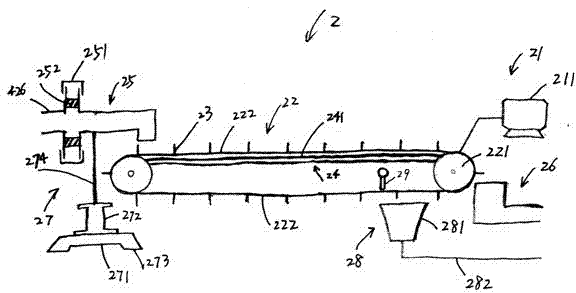

Horizontal homotaxial self-cleaning film evaporator

PendingCN109432810ANo anti-aliasingRealize continuous mass productionEvaporator accessoriesEngineeringEvaporator

The invention discloses a horizontal homotaxial self-cleaning film evaporator which comprises a barrel. A hollow principle axle is transversely arranged in the inner cavity of the barrel, a pluralityof inner scrapers which are arranged spirally and edge wall outer scrapers which are sequenced spirally are axially distributed on the hollow principle axle in the barrel, the inner scrapers and the edge wall outer scrapers are spaced separately, a plurality of axially and parallelly distributed fixed scrapers are arranged on one side, two sides or a plurality of sides of the inner wall of the barrel, one or more fixed scrapers in a same radial section in the barrel are located between the inner scraper and the edge wall outer scraper, the fixed scrapers are connected to the inner wall of thebarrel through handles, the inner scrapers are connected to the outer wall of the hollow principle axle through paddle plates, and the edge wall outer scrapers are connected to the outer wall of the hollow principle axle through hollow paddle plates. The horizontal homotaxial self-cleaning film evaporator solves the problem that the unit volume heat exchange area is small, and the heat exchange area is increased according to mutual connecting and position relationships of the inner scrapers, the edge wall outer scrapers, the fixed scrapers, the paddle plates and the paddle plates.

Owner:浙江索孚科技有限公司

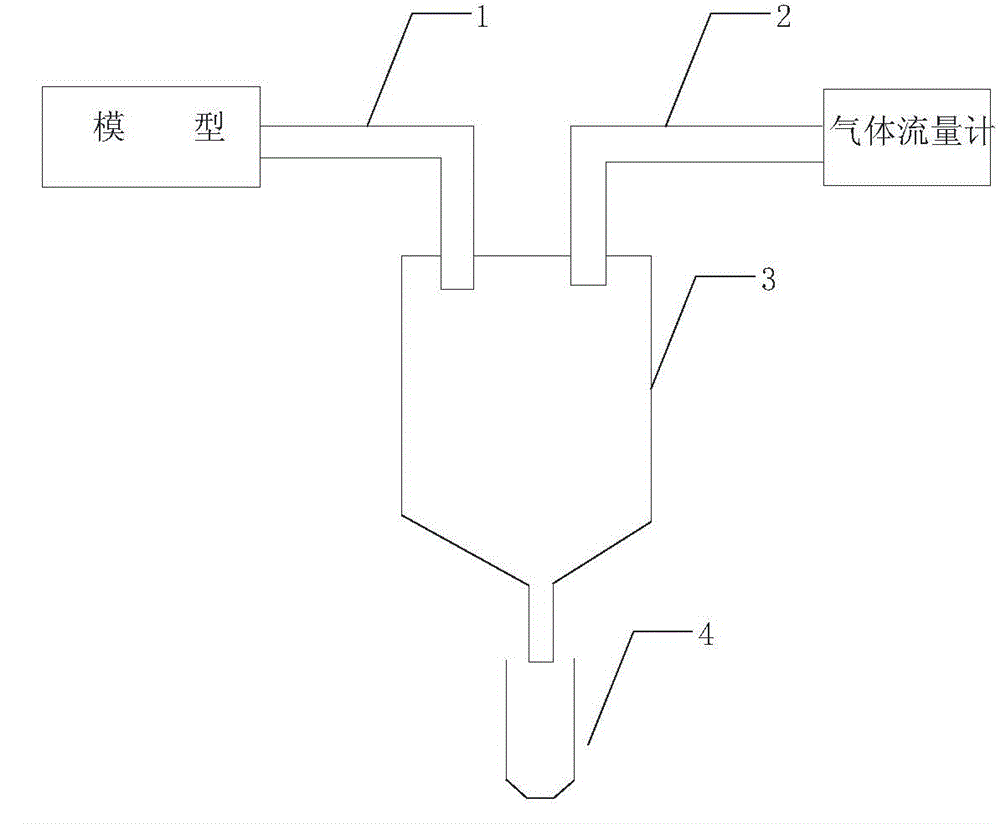

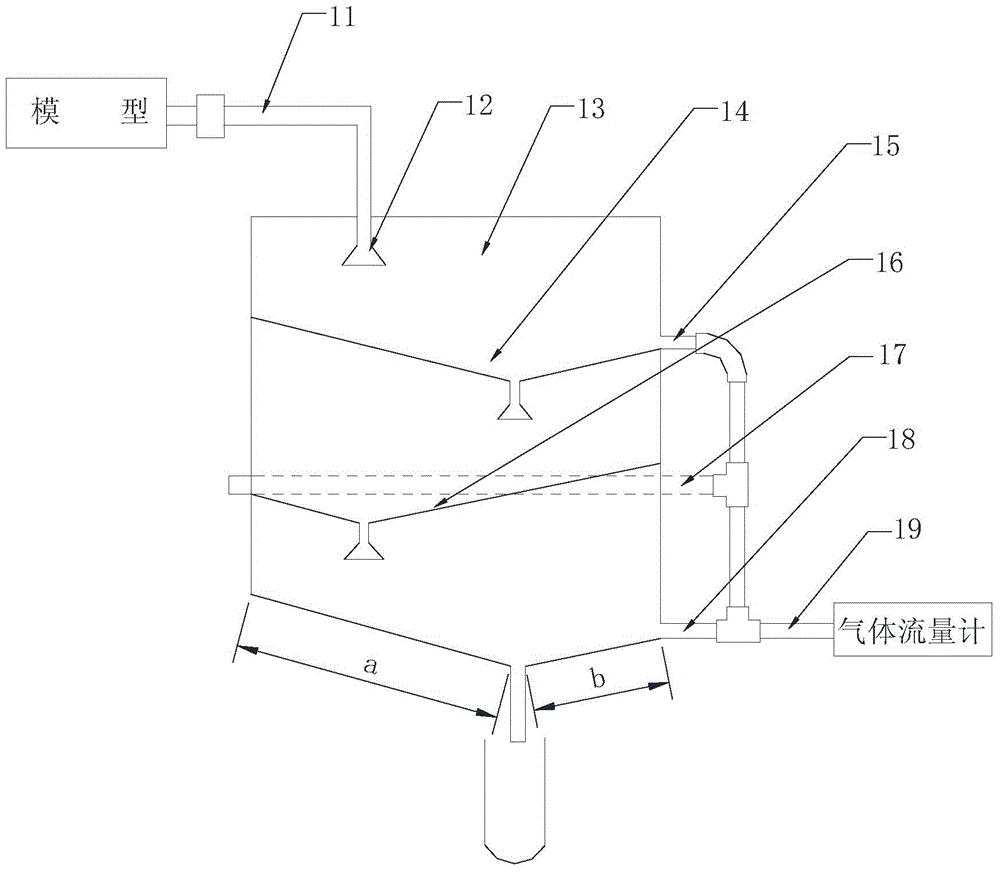

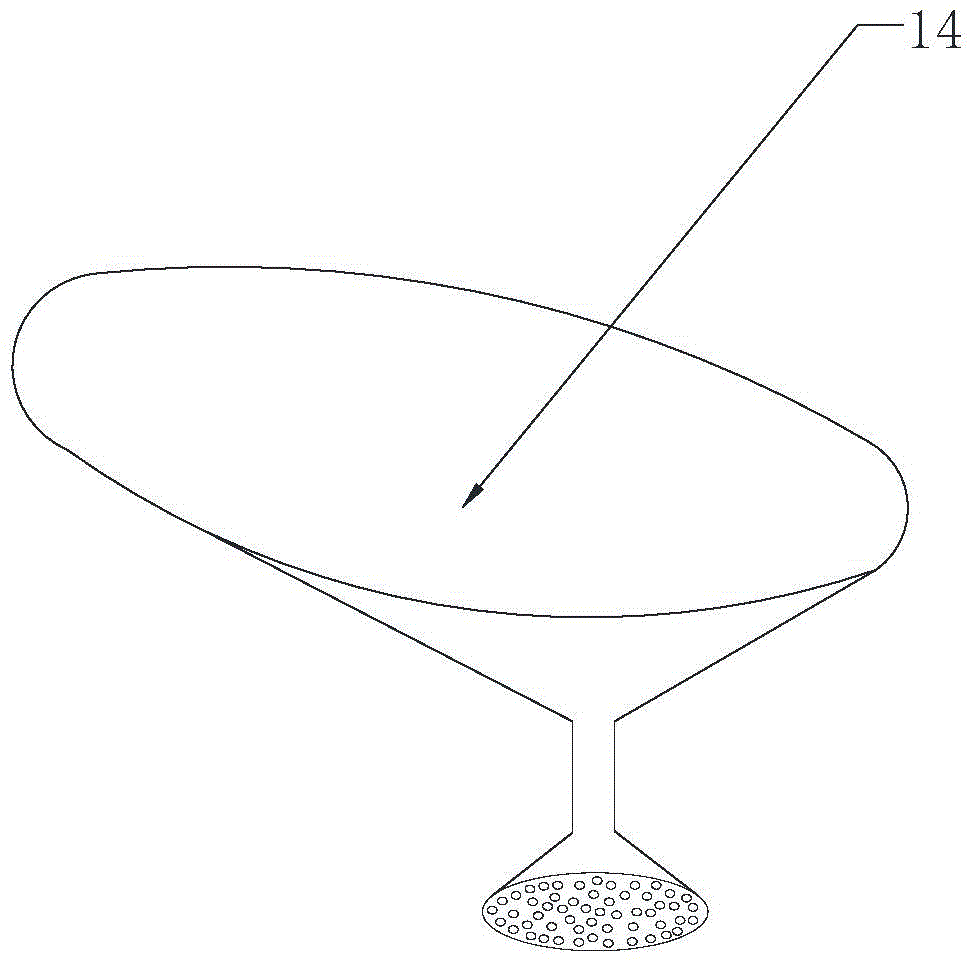

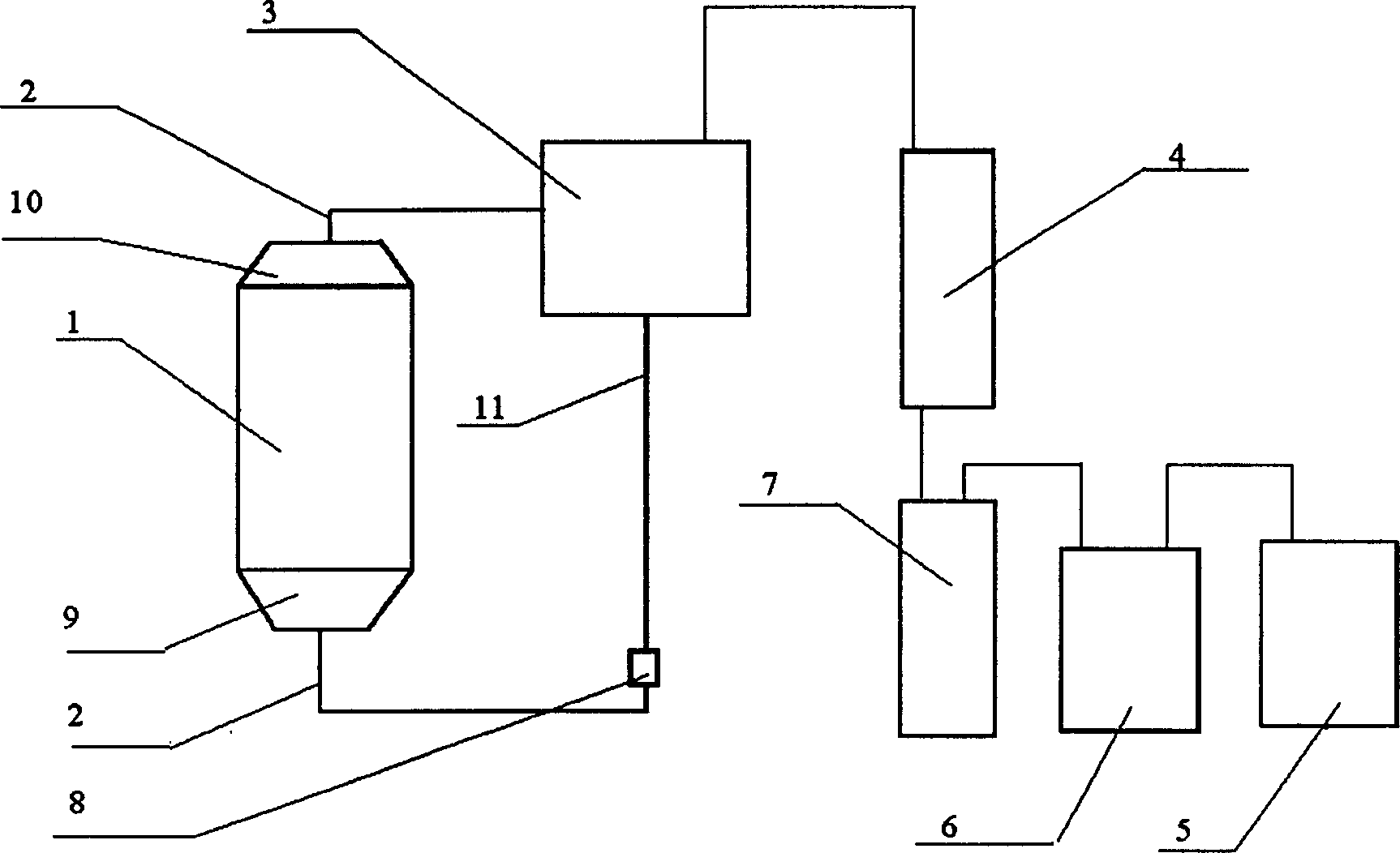

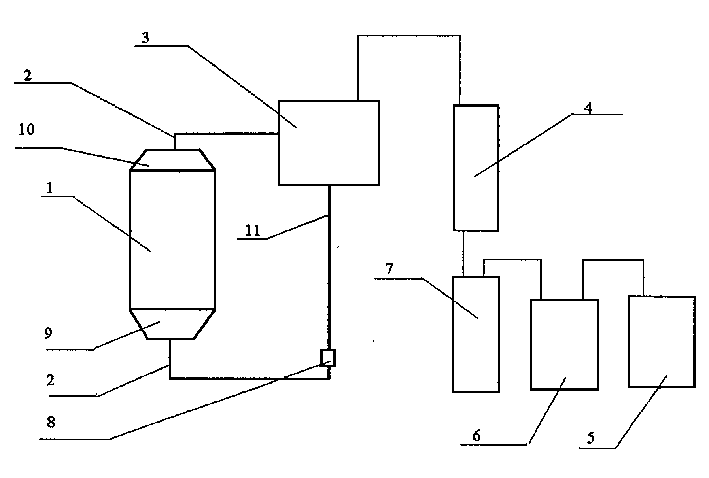

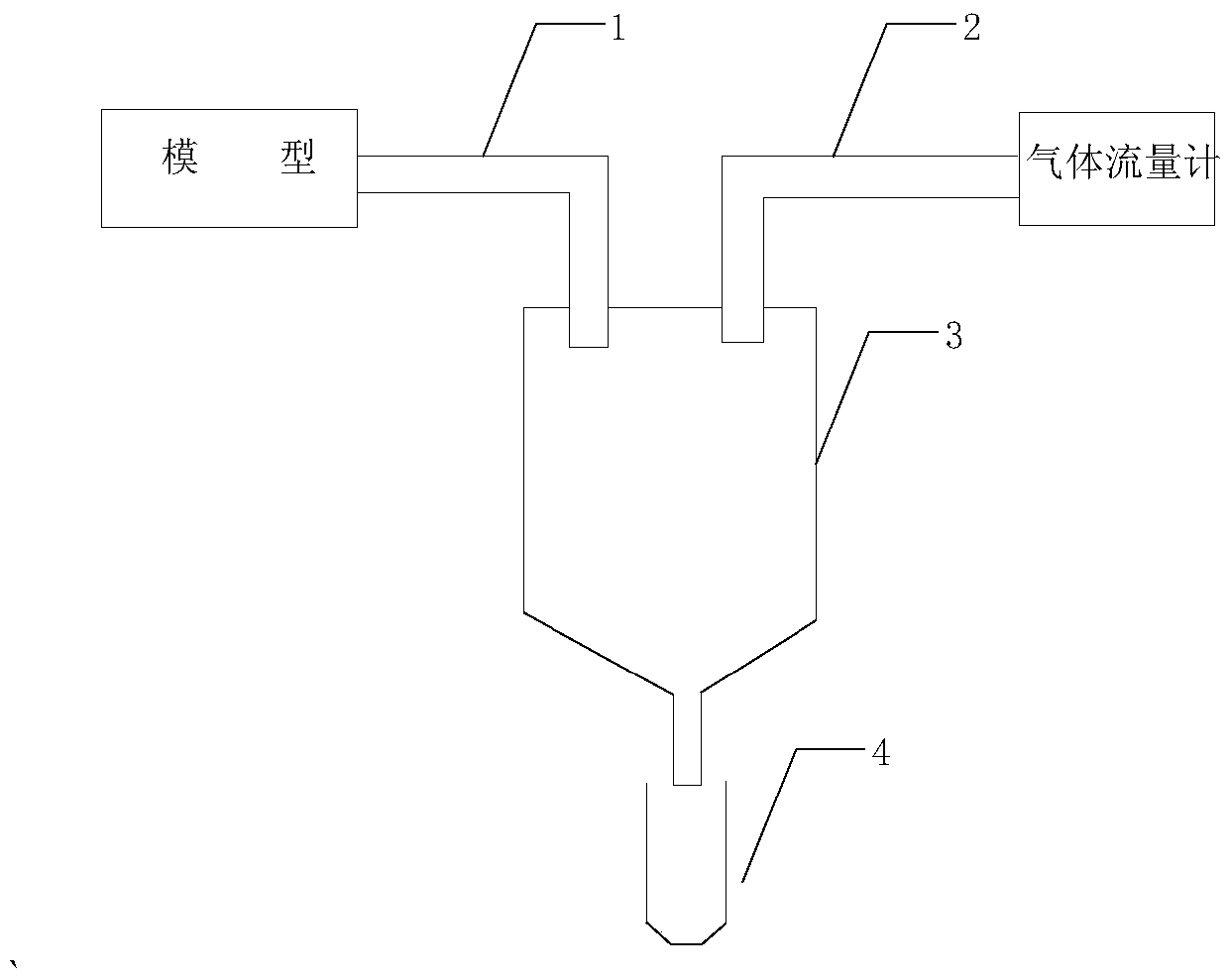

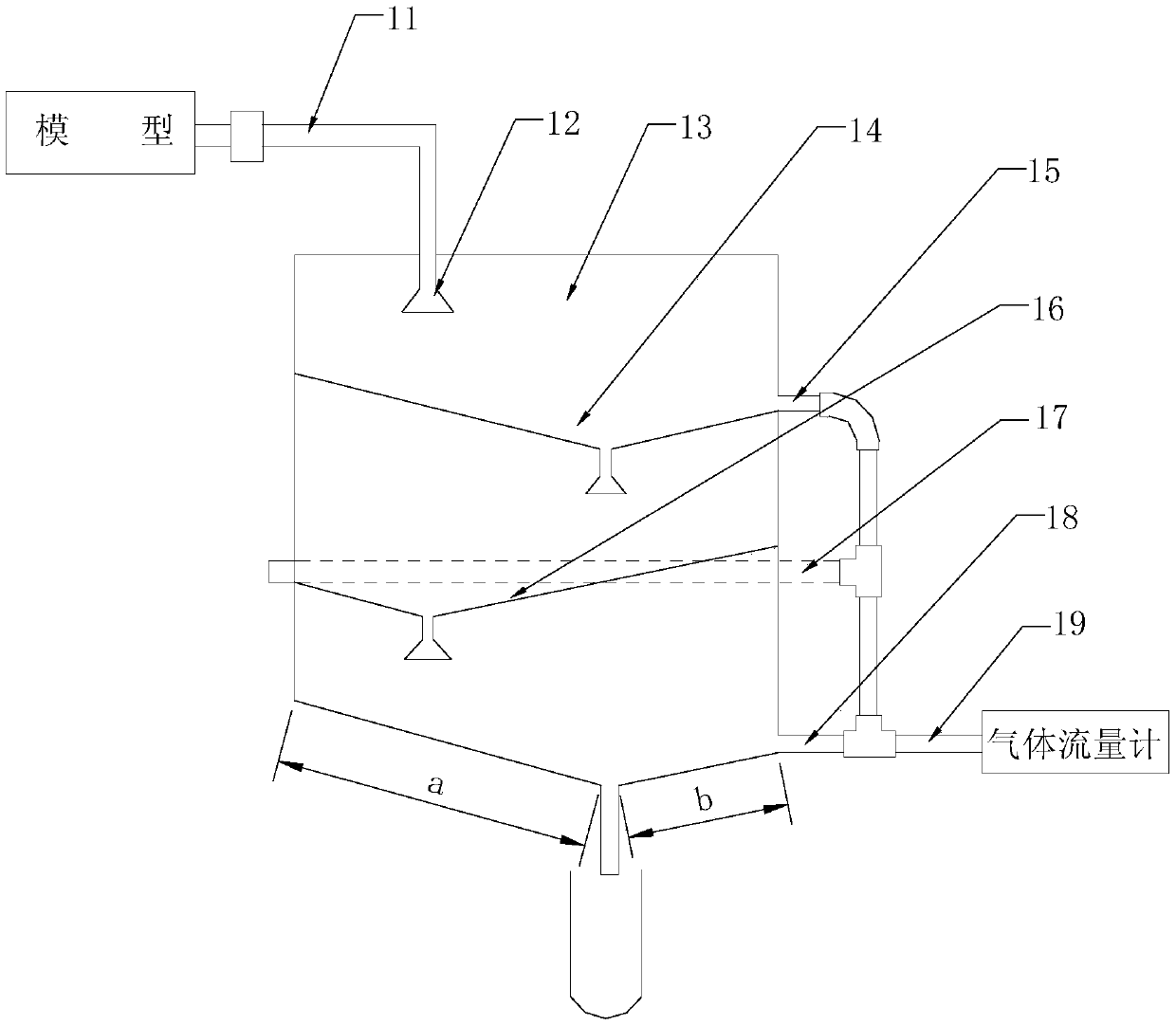

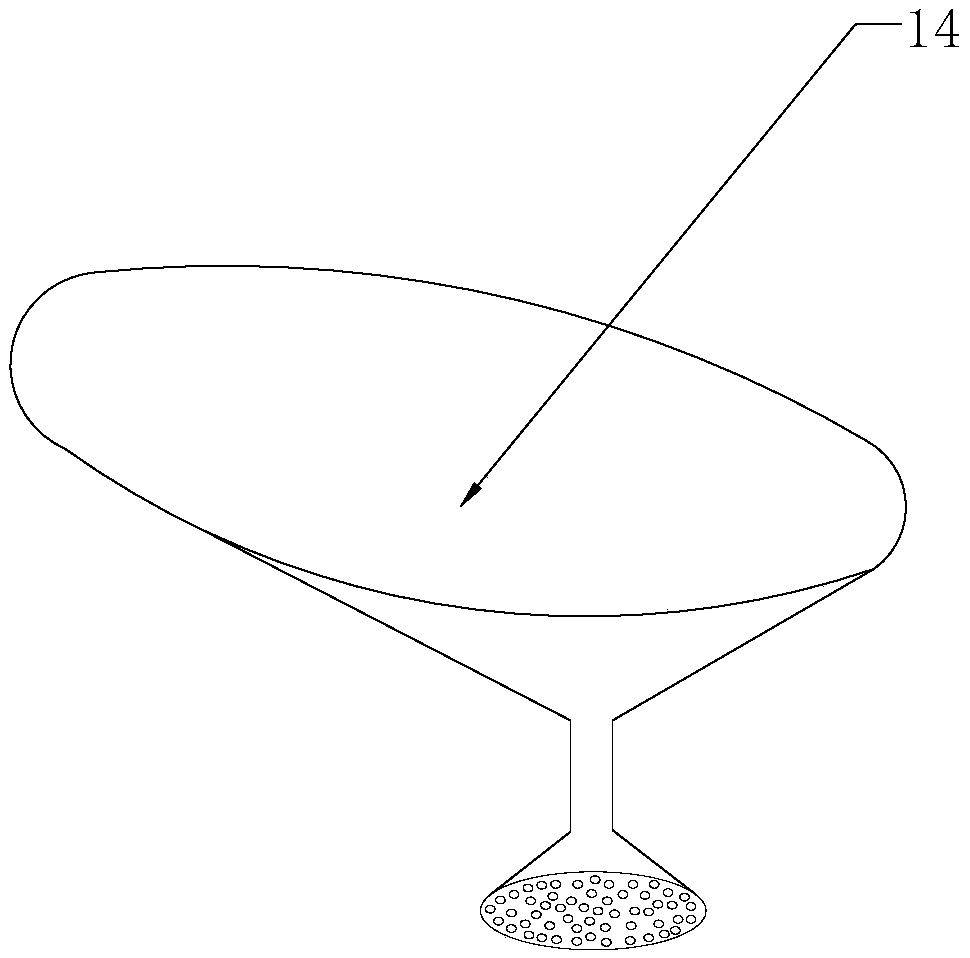

Multilevel gas-liquid two-phase separation device

InactiveCN104689604AEasy to separateGuaranteed accuracyLiquid degasificationThree levelSeparation technology

The invention discloses a multilevel gas-liquid two-phase separation device, which solves the problems in the existing separation device that gas-liquid separation is not thorough and carbon dioxide cannot be collected completely. Three-level separation technology is adopted by the separation device, wherein a first-level separation sieve adopts a nozzle-type structure for sieving, and a second-level separation sieve and a third-level separation sieve both adopt an eccentric funnel-type structure, so that a gas-liquid mixture can be separated as long as possible on an area as large as possible, the gas-liquid mixture is fully separated, a good separation effect is achieved, meanwhile, a three-level collection mode is adopted, gas after each level of separation is collected, and separated gas is completely collected, so that guarantee is provided for carbon dioxide drive physical simulation experiment.

Owner:大庆航天三沃新技术产业有限责任公司

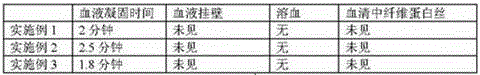

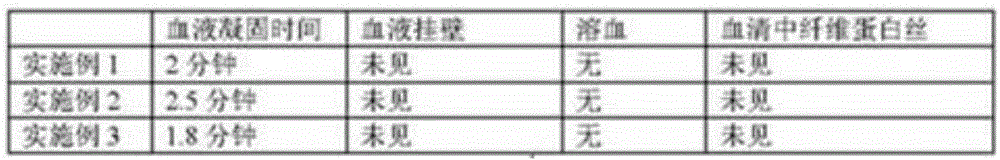

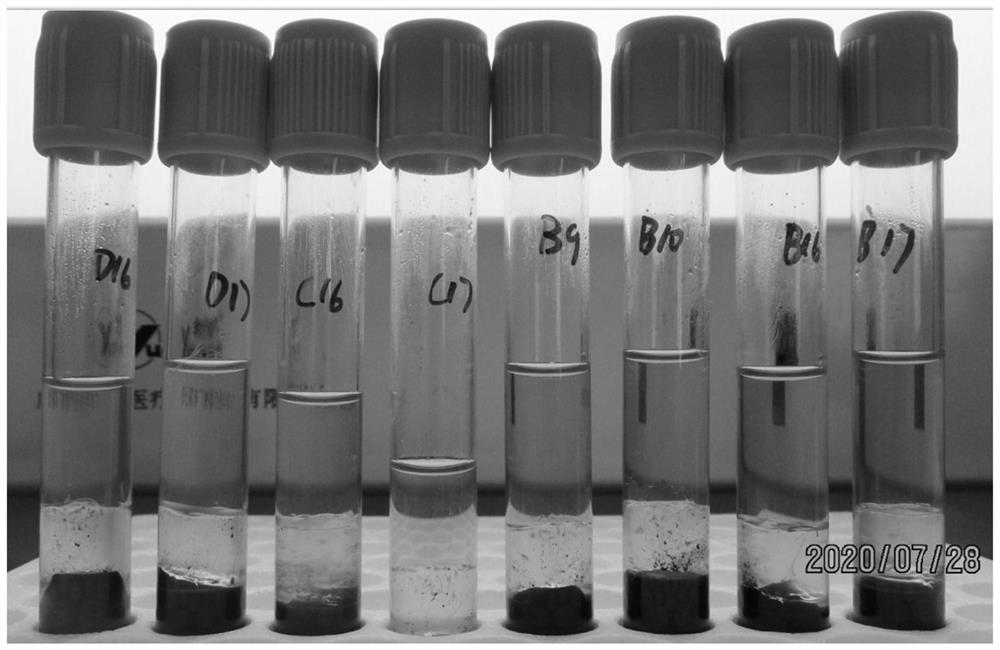

Blood coagulant and preparation method thereof

InactiveCN106124276APrevent hanging on the wallHanging phenomenon will not formPreparing sample for investigationExperiments in immunologySilicon dioxide

The invention relates to a blood coagulant and a preparation method thereof. The blood coagulant comprises polymer of alpha-hydro-omega-hydroxyl (oxy-1,2-ethanediyl), polyvinylpyrrolidone, polysorbate, polysorbate, silicon dioxide powder and isopropyl alcohol. The coagulant obtained can effectively shorten the time for blood coagulation, cannot enable blood to attach to the vascular wall, cannot interfere with results of biochemical test and immunological test, is long in period of validity and has excellent performance.

Owner:HEBEI XINLE MEDICAL EQUIP SCI & TECH

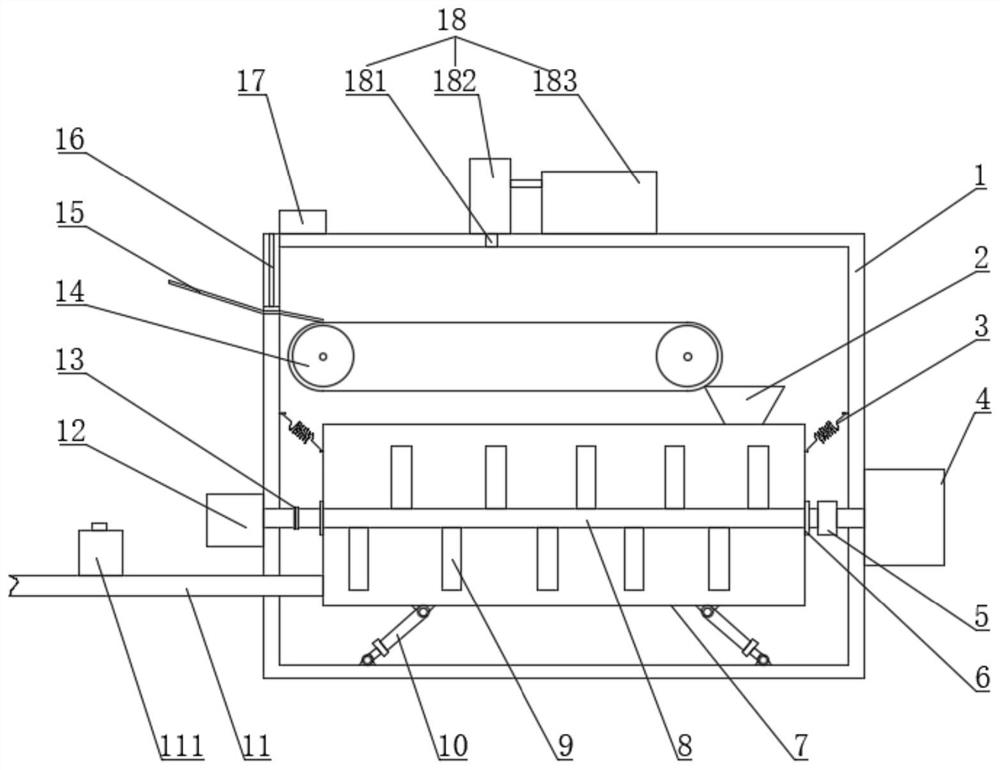

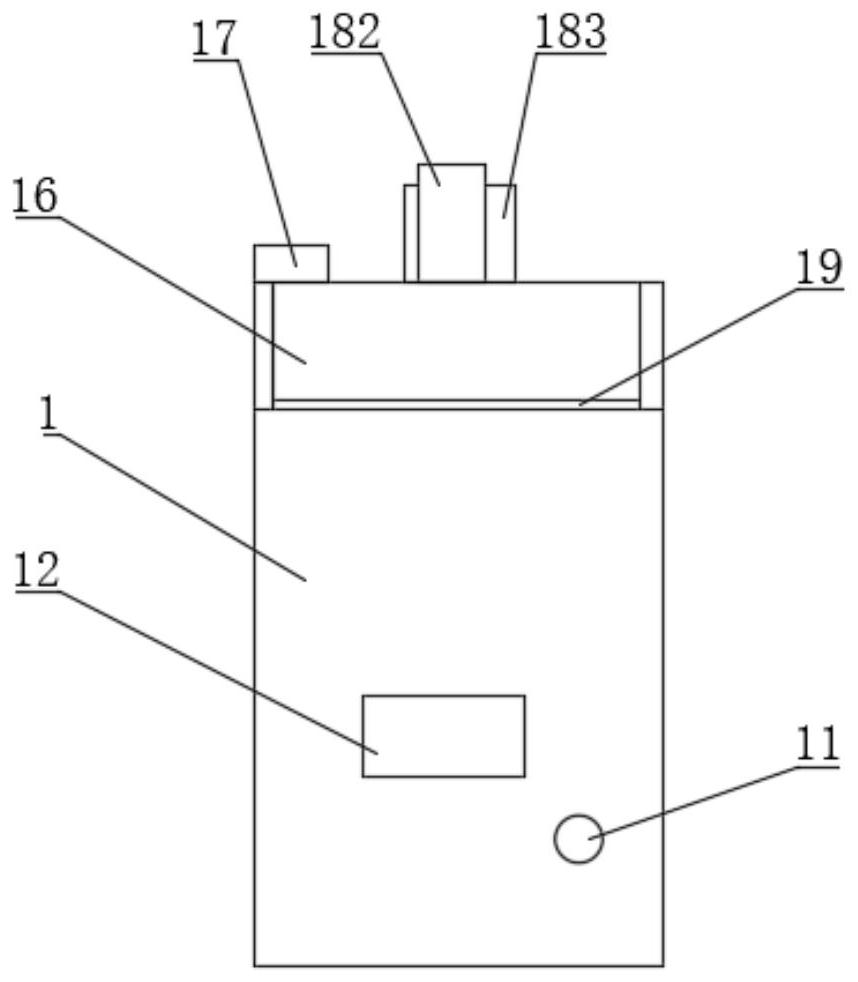

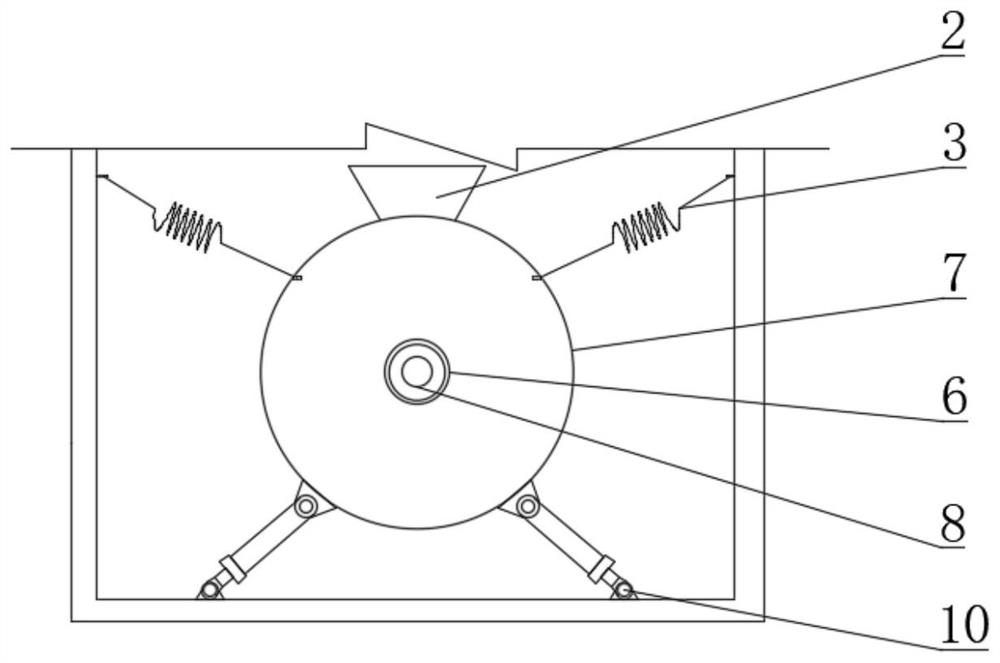

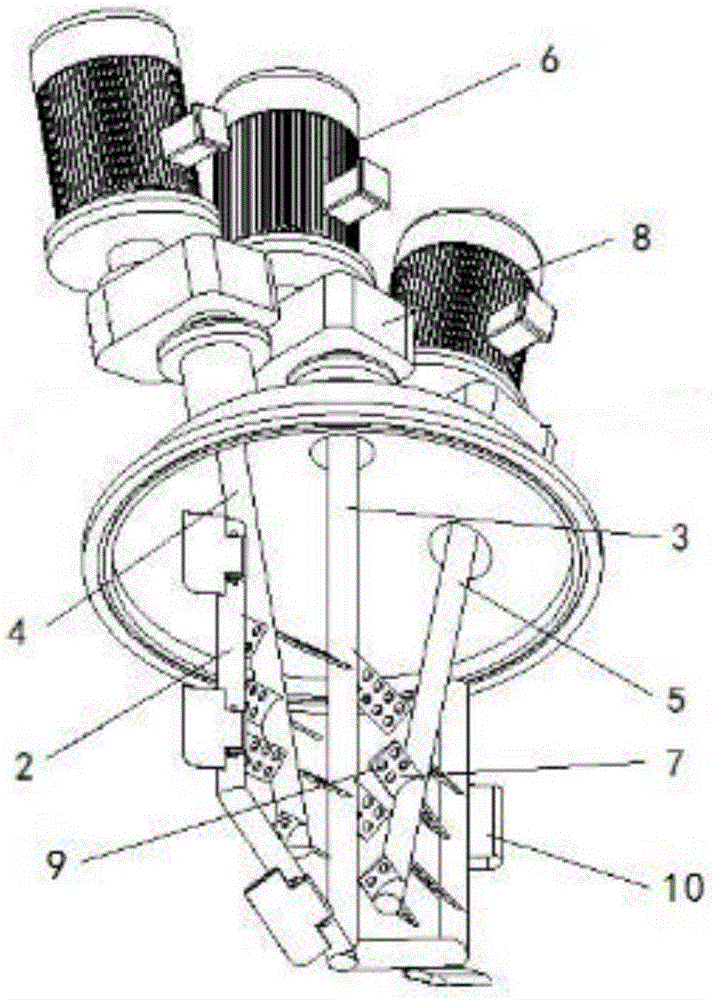

Engineering spoil in-situ stirring and solidifying device

PendingCN113634150ASame natureRealize automatic and precise controlRotary stirring mixersMixer accessoriesLiquid storage tankFirming agent

The invention discloses an engineering spoil on-site stirring and solidifying device which comprises a machine shell, a spraying device and a stirring device; an opening for feeding is formed in one side of the machine shell, and a conveying device is arranged at the position, close to the opening, in the machine shell; the spraying device is arranged above the machine shell, the spraying device comprises a liquid storage tank, a metering pump and a nozzle which are sequentially connected, and the nozzle extends into the machine shell and faces the position over the conveying device; the stirring device is arranged in the machine shell, the stirring device comprises a stirring bin and a stirring shaft, the upper portion of the stirring bin communicates with a feeding hopper, and the feeding hopper is connected with the tail end of a transmission device; and a discharging pipe is connected to the lower part of the stirring bin and extends to the outer part of the machine shell. The mixing proportion of waste slurry and a curing agent can be automatically and accurately controlled, and then the waste slurry and the curing agent enter the stirring bin to be stirred, so that the curing agent is further uniformly mixed with the waste slurry.

Owner:DA CHENG KE CHUANG INFRASTRUCTURE CO LTD

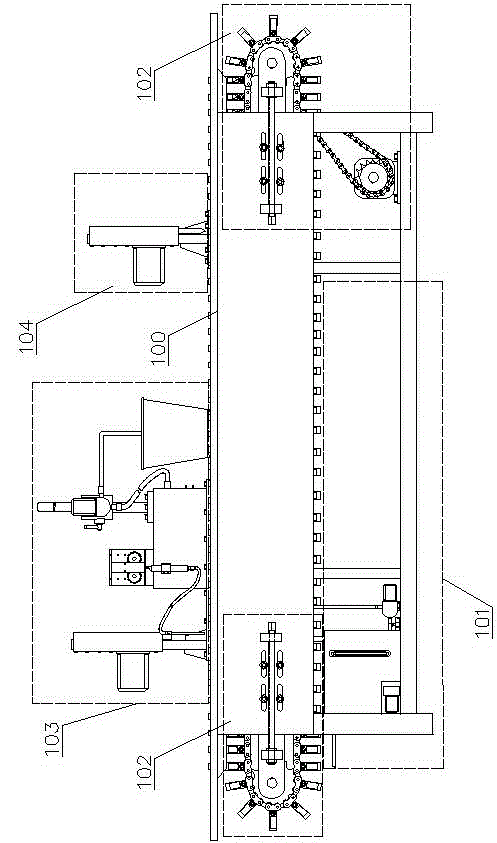

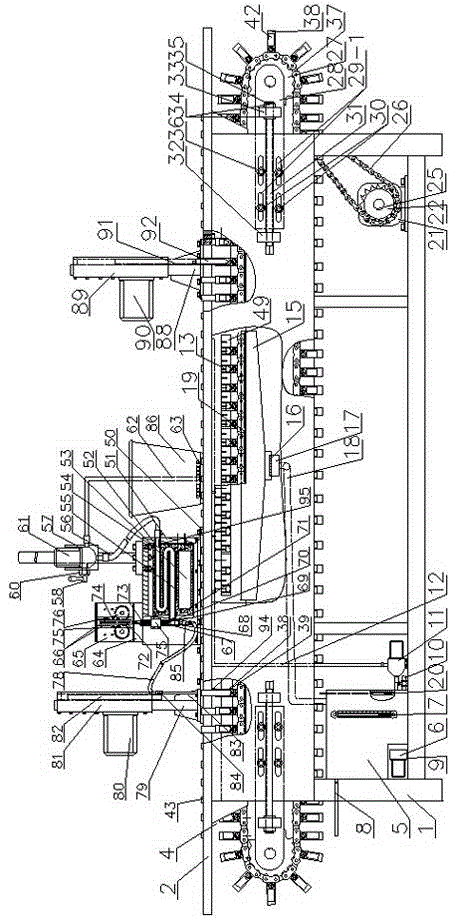

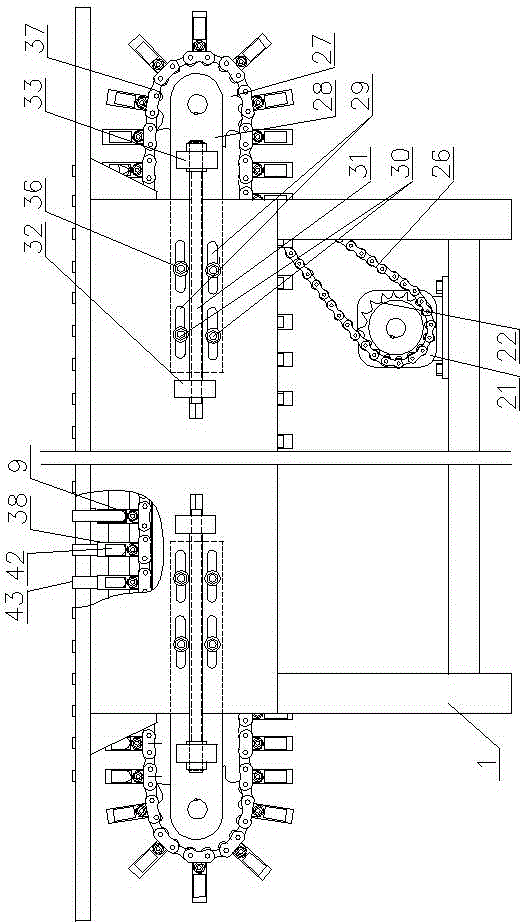

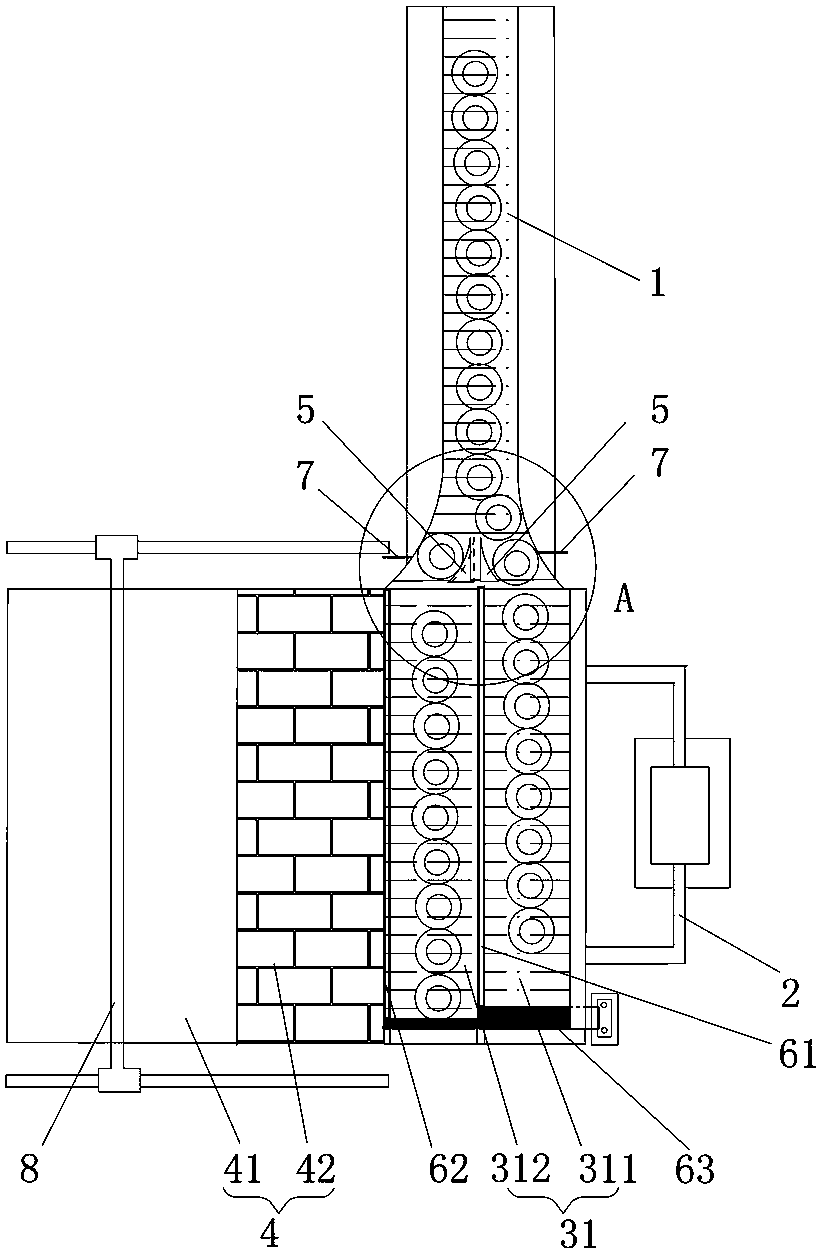

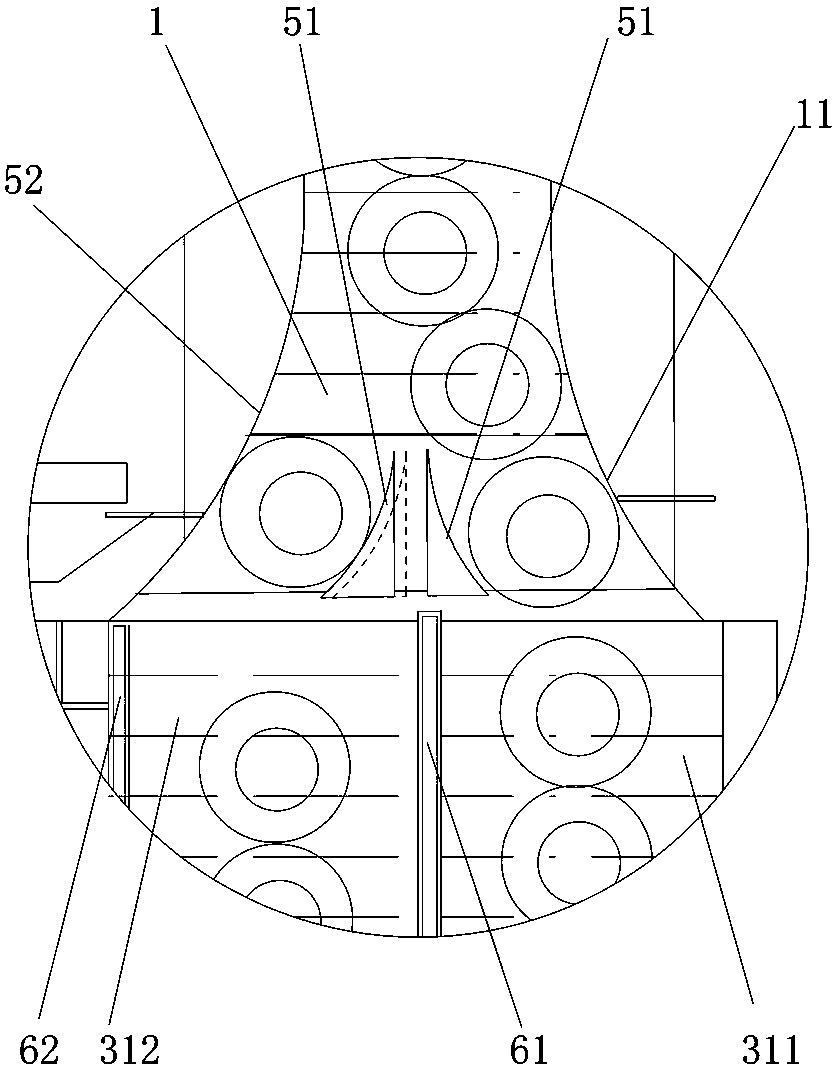

Full-automatic separation gel injection molding machine for vacuum blood collection tube

InactiveCN104526943APrevent hanging on the wallGuaranteed accuracyCoatingsBlood Collection TubeInjection molding machine

The invention relates to a full-automatic separation gel injection molding machine for a vacuum blood collection tube. The machine comprises a machine stand, a cooling spraying device, a transmission device, a glue dropping device and a molding device, wherein the machine stand comprises a rack and a panel; the panel is fixed at the upper end of the rack; a conveying groove is formed in the panel; the transmission device is mounted in the rack and comprises a servo motor, a transmission chain and the blood collecting tube; the transmission chain is positioned in the conveying groove; the glue dropping device comprises an attraction assembly, a heating assembly, a glue compaction assembly and a glue dropping assembly which are sequentially connected; a spraying head is arranged on the cooling spraying device and penetrates into the conveying groove; the blood collecting tube in the conveying groove is sprayed and cooled; a molding cone is arranged on the molding device and is used for performing pushing and sizing on the separation gel in the blood collection tube. The machine is reasonable in structural design; automatic integration of gel injection, gel dropping and molding is realized; the separation gel is not polluted, and good blood separation effect is achieved well.

Owner:杭州拱康医疗科技有限公司

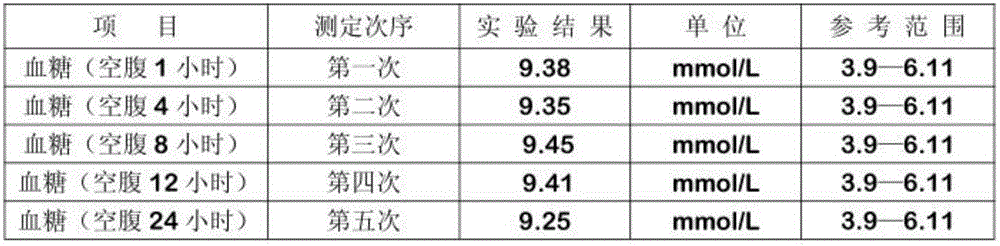

Nano-coagulant for blood

InactiveCN106769325APrevent hanging on the wallAccelerate solidificationPreparing sample for investigationOmegaOxygen

The invention belongs to the technical field of nano-coagulants for blood, and discloses a nano-coagulant for blood. The nano-coagulant for blood is characterized by being prepared from a polymer of alpha-hydrogen-omega-hydroxyl (oxygen-1,2-ethanediyl), polyvinylpyrrolidone, polysorbate, polysorbitol, silicon dioxide powder and isopropanol, wherein the volume ratio of the polymer of alpha-hydrogen-omega-hydroxyl (oxygen-1,2-ethanediyl) to the polysorbate to the polysorbitol to the isopropanol is equal to (1-5): (60-80): (25-45): 1000; the mass volume ratio of the polyvinylpyrrolidone to the isopropanol is equal to (3-6g): 1000ml; the mass volume ratio of the silicon dioxide powder to the isopropanol is equal to (8-16g): 1000ml. The nano-coagulant provided by the invention can effectively shorten blood coagulation time, avoids the phenomenon of wall hanging of the blood, is good in serum separation effect, does not interfere the detection results of biochemistry and immunology experiments, is long in shelf life and has excellent performance; the nano-coagulant is sterile water-based type, is safe in transportation and free from bacteria and heat source, and can stabilize the blood glucose result.

Owner:湖北金杏科技发展有限公司

Production and processing technology for titanium chloride with high stability

The invention provides a production and processing technology for titanium chloride with high stability. When titanium chloride is produced with a fused salt chlorination process, high-temperature titanium chloride gas produced in a fused salt chlorination furnace and containing chloride impurities is subjected to dust collection by a dust collector and then enters a leaching tower for leaching with a titanium chloride liquid, a water spray nozzle is arranged at the top of the leaching tower and sprays water by introduction of chlorine, water entering the leaching tower is subjected to a hydrolysis reaction with low-melting-point complexes such as NaAlC14 and NaFeC14 entrained in the titanium chloride gas as well as AlCl3, aluminum oxide and ferric oxide are produced, enters a leaching tank in the leaching tower with titanium chloride and are mixed into mud slurry, and the mud slurry in the leaching tank is returned to the dust collector for dust collection. The production and processing technology for titanium chloride has the advantages as follows: the low-melting-point complexes such as NaAlC14 and NaFeC14 in a side reaction can be removed, and long-term stable operation of a fused salt chlorination reactor system is guaranteed.

Owner:雷雨婷

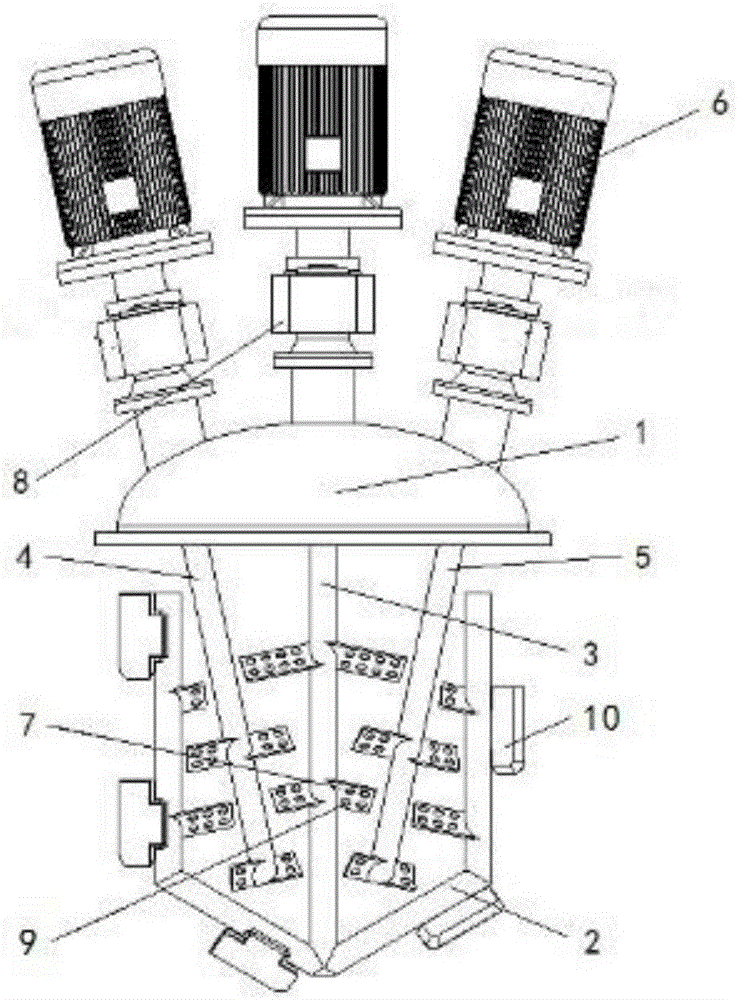

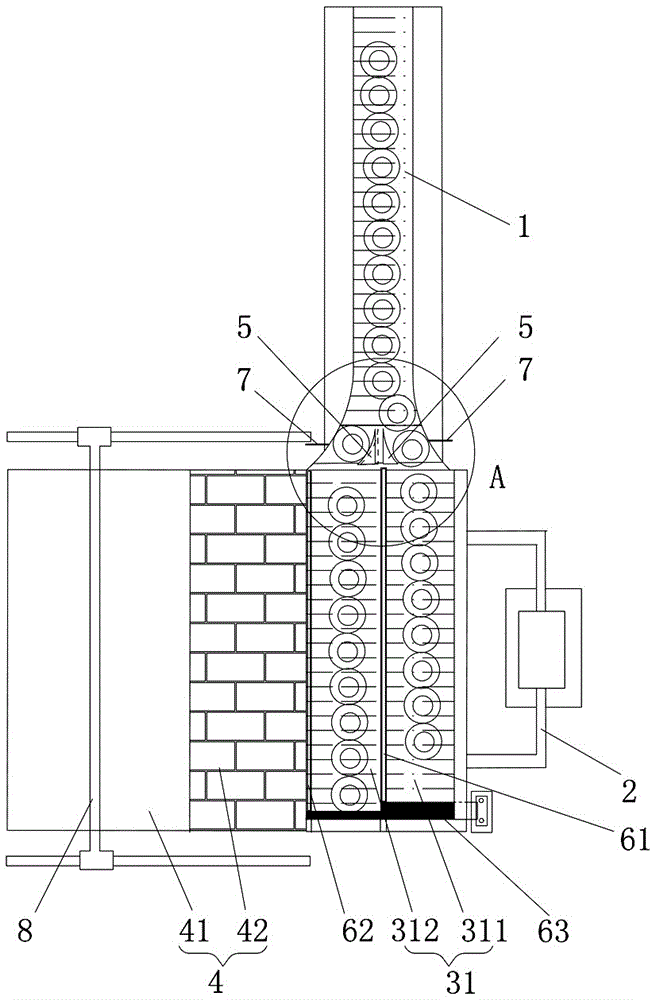

Raw meal homogenizer for cement production

ActiveCN108793788BEasy to collectRelieve pressureTransportation and packagingMixersPolyesterElectric machinery

Owner:东方希望重庆水泥有限公司

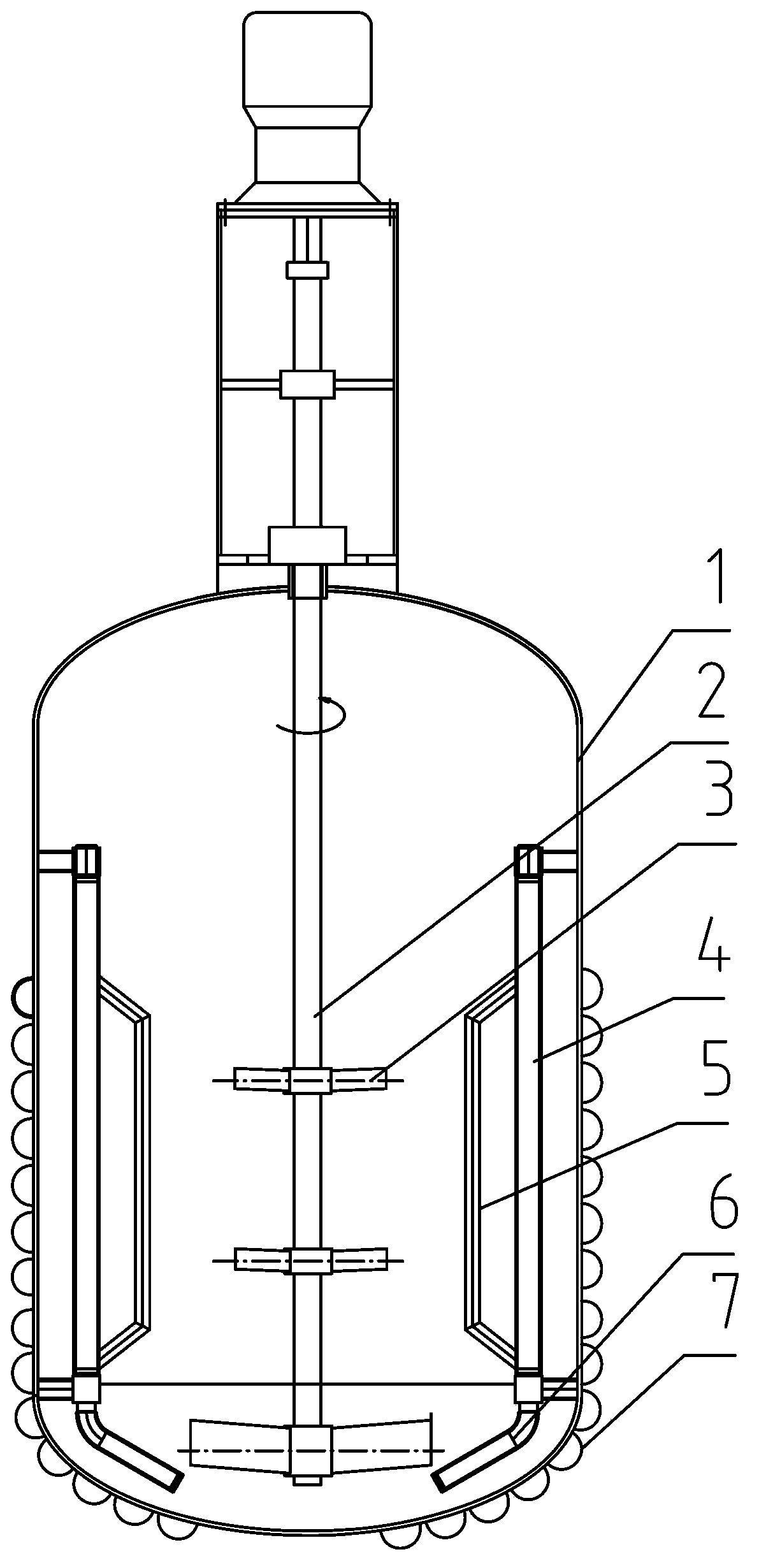

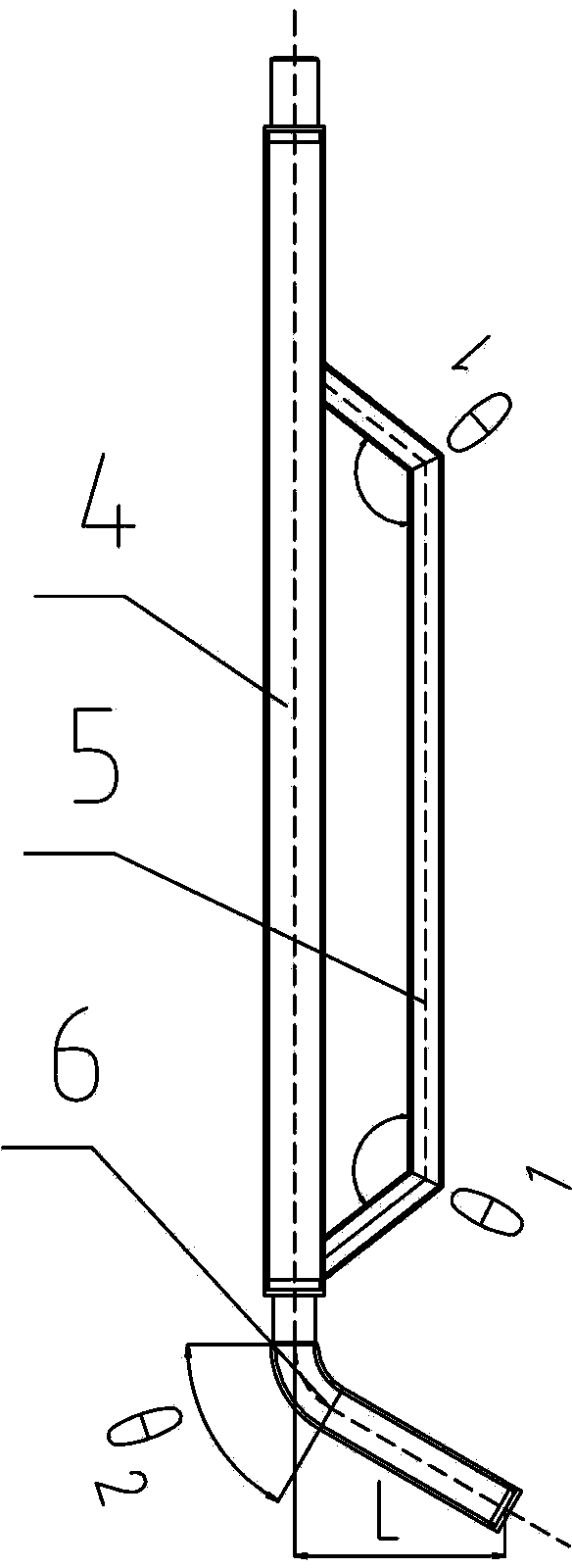

Multi-shaft mixer for materials of high viscosity or low viscosity

InactiveCN106040042APrevent hanging on the wallEnhance mechanical homogeneity strengthTransportation and packagingMixing methodsEngineeringEnergy consumption

The invention discloses a multi-shaft mixer for materials of high viscosity or low viscosity. The multi-shaft mixer comprises a cover, a U-shaped stirring paddle, a first straight stirring paddle, a second straight stirring paddle, a third straight stirring paddle, speed reducers and motors, wherein the driving ends of the first straight stirring paddle, the second straight stirring paddle and the third straight stirring paddle respectively penetrate through the cover; the opening in the U-shaped stirring paddle faces upward vertically, and is right under the cover; the center in the bottom of the U-shaped stirring paddle is fixedly connected with the bottom of the first straight stirring paddle; stirring blades of the U-shaped stirring paddle, the first straight stirring paddle, the second straight stirring paddle and the third straight stirring paddle are arranged in a staggered manner, while every two adjacent stirring blades are on different planes. Therefore, according to the multi-shaft mixer, the stirring direction of a material is changed constantly; the material is stirred and cut in layers; the mechanical homogeneous strength of the viscous material is enhanced; the stirring time is shortened; equipment energy consumption is reduced; the product quality is improved.

Owner:无锡意凯自动化技术有限公司

Discharging device

The invention belongs to the technical filed of casting, and provides a discharging device. The discharging device is mainly used for quantitatively subpackaging of casting coating so as to solve theproblem of a wall hanging phenomenon and the uncontrollable discharging quality in the prior art. The discharging device includes a hopper, a feeding pipe, a feeding valve, a material level sensor, anair cylinder, a material pushing plate, a discharging pipe, and a discharging valve; when the discharging device is used, through the material pushing plate and an air blowing nozzle arranged on thematerial pushing plate, the wall hanging phenomenon of the coating for casting in the discharging process is avoided effectively, the discharging quality is controlled, and waste of the coating is reduced while discharging is convenient; and the same weight of different materials are discharged, an installing position of the material level senor on a material level sensor installing plate is adjusted, quantitative subpackage can be realized, and a special hopper of the materials with certain property does not need to be used, so that the discharging device is high in universality and wide in using.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Processing method of ice-cream cone with yoghourt

InactiveCN107047760APrevent hanging on the wallPromote the development of market economyMilk preparationAdditive ingredientIce cream

The invention discloses a processing method of ice-cream cone with yoghourt, and belongs to the technical field of food processing. The method comprises the following steps: processing of beewax-chitosan-sodium alginate film liquid, processing of an ice-cream cone, processing of yoghourt, processing of the ice-cream cone with the yoghourt, standing, packing with paper and the like. The main materials are the yoghourt and the ice-cream cone, a film coats the ice-cream cone, beewax-chitosan-sodium alginate is used as a main ingredient of the coated film, hydrophobicity of the film is improved, and permeability of the yoghourt to the ice-cream cone is reduced. The coated film is a natural edible coated film, beewax has special honey fragrance, and therefore, consumers not only can eat the box-packed yoghourt, but also can eat the ice-cream cone with the yoghourt without wasting. Wasting of yoghourt due to the fact that the yoghourt hangs on the wall of a packing box is avoided, the cost for box packing for sale of yoghourt is saved, environmental pollution caused by yoghourt packing materials is reduced, development of the yoghourt market economy is prompted, and a new method is provided for creating a popular yoghourt eating mode.

Owner:GUIZHOU UNIV

High-speed feed and discharge system

ActiveCN106829417AImprove bottle unscrambling efficiencyOvercoming the wall hanging of liquid medicineConveyorsConveyor partsEngineeringButt joint

The invention discloses a high-speed feed and discharge system. The high-speed feed and discharge system comprises a feed mesh belt, a forward-pushing device and a collecting device, wherein a feed system body of the high-speed feed and discharge system further comprises a bottle arranging mesh belt; at least two bottle arranging channels arranged in parallel on the bottle arranging mesh belt; a bottle inlet of each bottle arranging channel is in butt joint with a bottle outlet of the feed mesh belt; bottle clamping devices which can guide bottles on the feed mesh belt to the corresponding bottle arranging channels and control the opening and closing of the bottle arranging channels are arranged at the butting joint part; the forward-pushing device is used for pushing bottles on each bottle arranging channel into the collecting device; and the speed of the bottle arranging mesh belt is lower than that of the feed mesh belt. The high-speed feed and discharge system disclosed by the invention has the advantages that the condition that the liquid is adhered to the walls of the bottles, caused by that the bottles collide with each other is avoided, the efficiency of feeding the bottles can also be guaranteed.

Owner:TRUKING TECH LTD

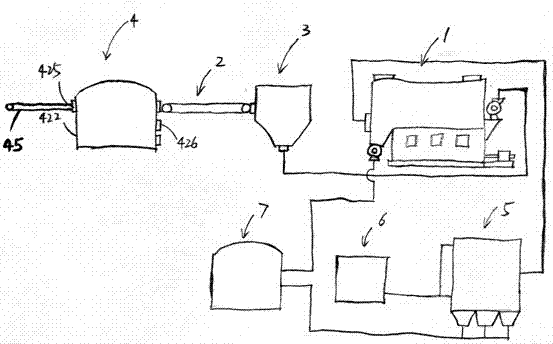

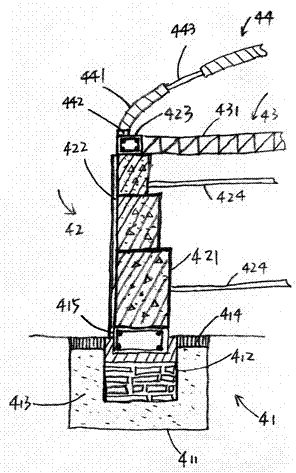

Drying treatment system of slurry

ActiveCN103134285BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingThermal insulationSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. The inner wall of an overhaul door of the slurry drying machine in the treatment system is made of materials which are not apt to deform under high temperature and smooth in surface, so that the phenomenon of wall sticking of sticky materials is avoided. The inner wall and the outer wall of the overhaul door are separated from each other through thermal insulation materials, so that deformation of the outer wall and the inner wall is reduced to the minimum degree, and tightness of the overhaul door can be guaranteed. A set of electric actuator is introduced, and automation in opening and closing of the overhaul door can be achieved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

On-line three-phase flow evaporation concentration device with solid particle for preventing liquid on wall

An in-line three-phase tream evaporation concentrator able to effectively prevent surface sticking features that a kind of physiological inertial solid particles are added to vapor-liquid stream evaporation concentrator to form a naturally circulating three-phase fluidized bed, where the said solid particles can prevent the surface sticking phenomenon. The said concentrator has heater, heating pipe, separation chamber, vapor and condenser, condensed liquid tank, vacuum buffer tank, vacuumizing pump, and discharger.

Owner:TIANJIN UNIV

Removal method of low melting point complexes in molten salt chlorination production titanium tetrachloride eluting tower

ActiveCN106629832BPrevent hanging on the wallGuaranteed uptimeTitanium tetrachlorideSlurryNitrogen gas

Provided is a method for removing a low-melting-point complex in an elution tower for producing titanium tetrachloride through fused salt chlorination. When titanium tetrachloride is produced by adopting a fused salt chlorination method, high-temperature titanium tetrachloride gas containing chloride impurities and produced by a fused salt chlorination furnace is subjected to dust removal of a dust collector and then enters the elution tower to perform elution by using titanium tetrachloride liquid, a water sprinkling spray head is arranged at the top of the elution tower, the water sprinkling spray head sprinkles water by leading nitrogen, the water entering the elution tower performs hydrolysis reaction with NaAlCl4 and NaFeCl4 low-melting-point complexes entrained in the titanium tetrachloride gas and AlCl3 to generate aluminum oxide and ferric oxide, the oxides enter an elution tank of the elution tower along with the titanium tetrachloride and are mixed in the slurry, and the slurry in the elution tank returns to the dust collector for dust collection. The method has the advantages that the NaAlCl4 and NaFeCl4 low-melting-point complexes in side reaction can be removed, and long-time and stable operation of a fused salt chlorination reactor system is ensured.

Owner:中信钛业股份有限公司

Fused salt chlorination production technology of low-impurity titanium tetrachloride

InactiveCN109809471APrevent hanging on the wallGuaranteed uptimeTitanium halidesTitanium chlorideSide reaction

The invention relates to a fused salt chlorination production technology of low-impurity titanium tetrachloride. The fused salt chlorination production technology comprises the following steps: when producing titanium chloride through a fused salt chlorination method, collecting dust from high-temperature titanium chloride gas which is generated in a fused salt chlorination furnace and contains chloride impurities through a dust collector; then enabling the gas to enter an eluting tower and eluting with titanium chloride liquid; arranging a water spraying nozzle at the tower top of the elutingtower; introducing chlorine gas and enabling the water spraying nozzle to spray water; carrying out a hydrolysis reaction on the water entering the eluting tower with NaAlCl4 and NaFeCl4 low-melting-point coordination compounds and AlCl3 entrained in the titanium chloride gas to generate aluminum oxide and iron oxide; enabling the aluminum oxide and the iron oxide to enter an eluting groove of the eluting tower along with the titanium chloride and mixing into mud; and then returning the mud in the eluting groove back to the dust collector and carrying out dust collection. The fused salt chlorination production technology of the low-impurity titanium tetrachloride has the advantages that the NaAlCl4 and NaFeCl4 low-melting-point coordination compounds in a side reaction can be removed, anda fused salt chlorination reactor system is enabled to stably operate for a long time.

Owner:王鹏

Method for removing low-melting-point complexes in side reaction in production of titanium chloride

InactiveCN109809469APrevent hanging on the wallGuaranteed uptimeTitanium halidesTitanium chlorideReactor system

The invention relates to a method for removing low-melting-point complexes in a side reaction in production of titanium chloride. The method comprises the following steps: when the titanium chloride is produced by a fused-salt chlorination method, enabling high-temperature titanium chloride gas containing chloride impurities and generated in a fused-salt chlorination furnace to enter a leaching tower to be leached by titanium chloride liquid after dust collection by a dust collector; arranging a water spraying nozzle at the top of the leaching tower, enabling the water spraying nozzle to carryout water spraying by introducing chlorine gas, and carrying out a hydrolysis reaction on water entering the leaching tower with NaAlCl4 and NaFeCl4 low-melting-point complexes and AlCl3 entrained inthe titanium chloride gas to generate aluminium oxide and iron oxide; and enabling the titanium chloride to enter a leaching groove of the leaching tower and mix into mud, and then returning the mudin the leaching groove to the dust collector for dust collection. The method involved in the invention has the advantages that the NaAlCl4 and NaFeCl4 low-melting-point complexes in the side reactioncan be removed, and long-time stable operation of a fused-salt chlorination reactor system can be ensured.

Owner:田长对

Evaporating wall supercritical water oxidation reactor capable of direct separation of salt and subcritical water

ActiveCN104478064BReduce material selectionAchieve separationWater/sewage treatment by oxidationWater useSaline water

Owner:碧流天能(北京)科技股份有限公司

Multistage gas-liquid two-phase separation device

InactiveCN104689604BEasy to separateGuaranteed accuracyLiquid degasificationLaboratory apparatusThree levelSeparation technology

Owner:大庆航天三沃新技术产业有限责任公司

Blood coagulant as well as preparation method and application thereof

PendingCN114813270AShort clotting timeImprove radiation resistancePreparing sample for investigationPolyethylene glycolPyrrolidinones

The invention relates to the technical field of biological materials, and particularly discloses a blood coagulant as well as a preparation method and application thereof. The blood coagulant is prepared from nano silicon dioxide, a vinyl pyrrolidone-vinyl acetate copolymer, polyethylene glycol stearate and a solvent, wherein the mass ratio of the nano silicon dioxide to the vinyl pyrrolidone-vinyl acetate copolymer to the polyethylene glycol stearate is (1-5): 1: (1-10). The blood coagulant prepared by the invention is short in coagulation time, and the obtained serum is high in quality; irradiation sterilization can be performed, and the performance of a product subjected to irradiation sterilization, aging and other treatments is equivalent to that of a product before treatment; the product performance is not influenced while the validity period is prolonged to 1 year, and the phenomena of sedimentation and caking are avoided in the storage process; the clinical detection requirements can be met.

Owner:南雄阳普医疗科技有限公司

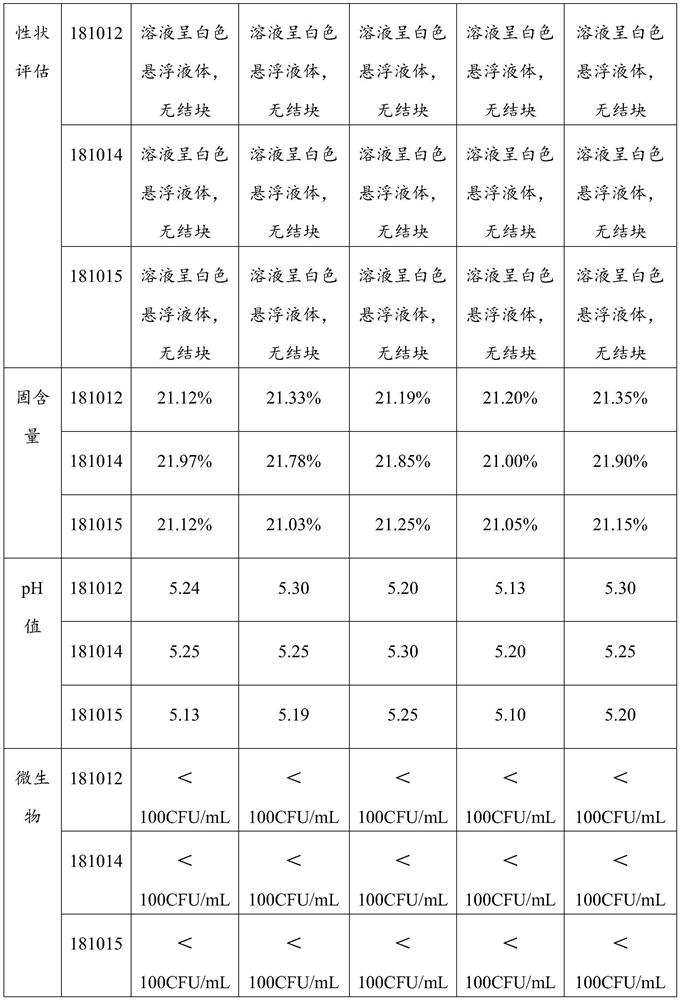

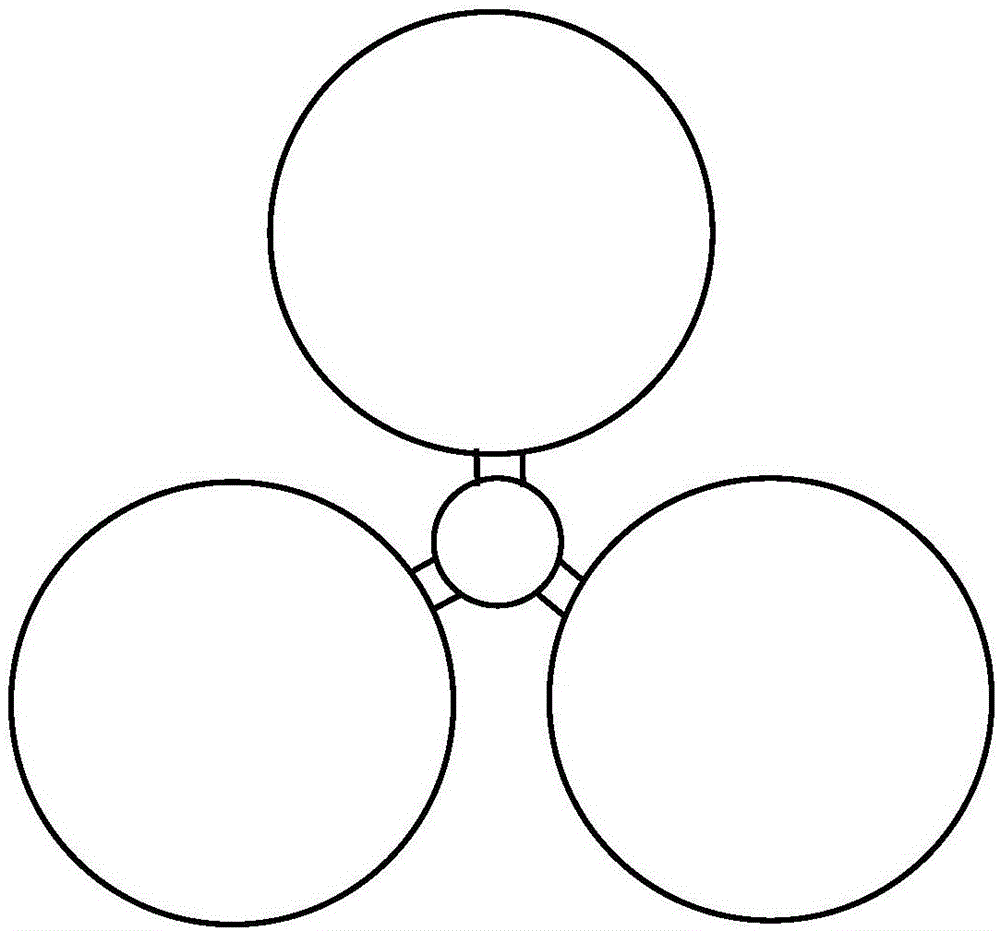

Real-time fluorescent PCR detection system based on rotary microfluidic chip

InactiveCN103820316BEasy to detectImprove experiment processing efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsCycle controlMicroform

The invention relates to a real-time fluorescence PCR (polymerase chain reaction) detection system based on a rotary type microfluidic chip. The system comprises an annealing low-temperature area, an extension appropriate temperature area, a thermal change high temperature area, a rotating module, a PCR reagent accommodating cavity, an injection micro-channel, an instrument fixing base and a fluorescence detection system, wherein a temperature cycle control module comprises the annealing low-temperature area, the extension appropriate temperature area and the thermal change high temperature area; a micro-channel cycle PCR amplification module comprises the rotating module, the PCR reagent accommodating cavity, the injection micro-channel and the instrument fixing base; and a fluorescence spectrum detection module comprises the fluorescence detection system. According to the system, three modules, namely, the micro-channel cycle PCR amplification module, the temperature cycle control module and the fluorescence spectrum detection module are integrated, so that the portable micro PCR fluorescence real-time detection system applicable to space operation requirements is realized, and purposes of function integration, structure microform, lightness, small size and full-automatic detection are achieved.

Owner:BEIJING UNIV OF TECH

A high-speed feeding and discharging system

The invention discloses a high-speed feed and discharge system. The high-speed feed and discharge system comprises a feed mesh belt, a forward-pushing device and a collecting device, wherein a feed system body of the high-speed feed and discharge system further comprises a bottle arranging mesh belt; at least two bottle arranging channels arranged in parallel on the bottle arranging mesh belt; a bottle inlet of each bottle arranging channel is in butt joint with a bottle outlet of the feed mesh belt; bottle clamping devices which can guide bottles on the feed mesh belt to the corresponding bottle arranging channels and control the opening and closing of the bottle arranging channels are arranged at the butting joint part; the forward-pushing device is used for pushing bottles on each bottle arranging channel into the collecting device; and the speed of the bottle arranging mesh belt is lower than that of the feed mesh belt. The high-speed feed and discharge system disclosed by the invention has the advantages that the condition that the liquid is adhered to the walls of the bottles, caused by that the bottles collide with each other is avoided, the efficiency of feeding the bottles can also be guaranteed.

Owner:TRUKING TECH LTD

A kind of preparation method based on catalytic oxidation-hydrolysis-segmental crystallization to prepare pyromellitic acid

ActiveCN111960939BUniform particle sizeImprove heat transfer efficiencyPreparation from carboxylic acid anhydridesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystDistillation

The invention discloses a preparation method for preparing pyromellitic acid based on catalytic oxidation-hydrolysis-segmented crystallization. The reaction is carried out in a microchannel reactor with a catalyst coating; the reacted gas is cooled and captured by a trap, cooled and crystallized, and then centrifuged. The centrifuged mother liquor is subjected to atmospheric distillation. The residual liquid is added into the hydrolysis kettle for hydrolysis treatment; finally, the hydrolysis liquid is filtered, and the filtrate is subjected to subsection cooling crystallization, centrifugation, and vacuum drying to obtain the target product, pyromellitic acid. The method is simple to operate, and the obtained target product has a high yield.

Owner:连云港鹏辰特种新材料有限公司

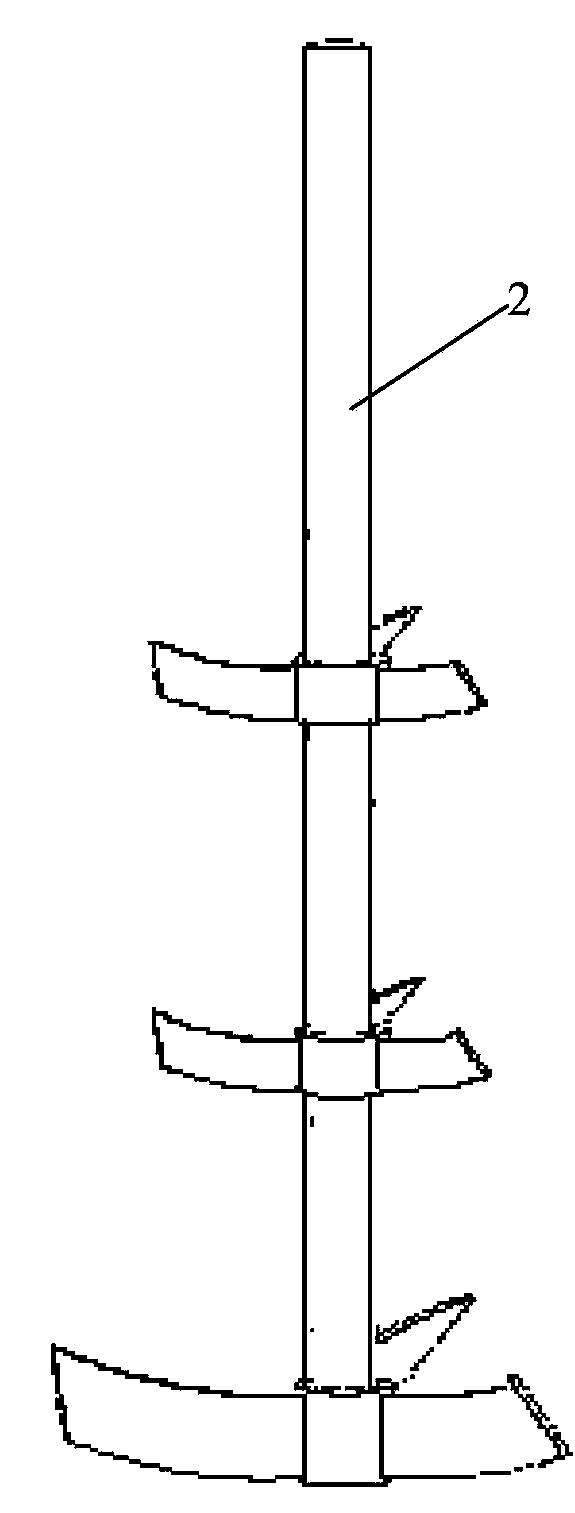

Stirring reaction device for synthesizing super absorbent resin

InactiveCN102784613BReduces paddle stickingPromote exchangeChemical/physical/physico-chemical stationary reactorsSuper absorbentMechanical engineering

The invention discloses a stirring reaction device for synthesizing a super absorbent resin. The device comprises a stirring kettle, wherein a stirrer is arranged in the stirring kettle; the stirrer comprises a rotary shaft and blades arranged on the rotary shaft; the each blade has three rotary bending angles, comprising a backward bending angle, an upper rake angle and a blade breaking angle; the backward bending angle means an angle formed by bending the blade around the rotary shaft as the centerof a circle in the horizontal peripheral direction; the upper rake angle means an angle formed by bending the blade in the vertical direction; and the blade breaking angle means a rotating angle formed by rotating the blade through taking a radius as a central shaft, wherein the radius is a radius in a horizontal periphery formed by taking the rotary shaft as the center of the circle.

Owner:NANJING TECH UNIV

Thickener for fracturing fluid, preparation method thereof, and fracturing fluid

InactiveCN110028945BPrevent hanging on the wallImprove liquidityDrilling compositionKeroseneFracturing fluid

The invention provides a thickening agent for a fracturing fluid, a preparation method of the thickening agent and the fracturing fluid. The thickening agent comprises the following components in percentage by mass: 18.0%-22.0% of aviation kerosene, 32.0%-38.5% of polyacrylamide, 4.0%-6.0% of an emulsifier, 0.5%-1.0% of cetyl trimethyl ammonium bromide, 0.5%-1.0% of sodium dodecyl benzene sulfonate, 5.0%-8.0% of ethylene glycol, and the balance of water. After being stored and transported for a long time, the thickening agent is still uniform, does not have obvious oil-liquid separation, and still has good fluidity at-30 DEG C. After being used, the fracturing fluid prepared by the thickening agent has no obvious wall-hanging phenomenon.

Owner:DAQING AOPUQI CHEM ADDITIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com