Full-automatic separation gel injection molding machine for vacuum blood collection tube

A vacuum blood collection tube and forming machine technology, applied in the field of medical equipment, can solve problems such as incoordination, low work efficiency, hanging on the wall, etc., and achieve the effect of ensuring the stop distance, ensuring stability, and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

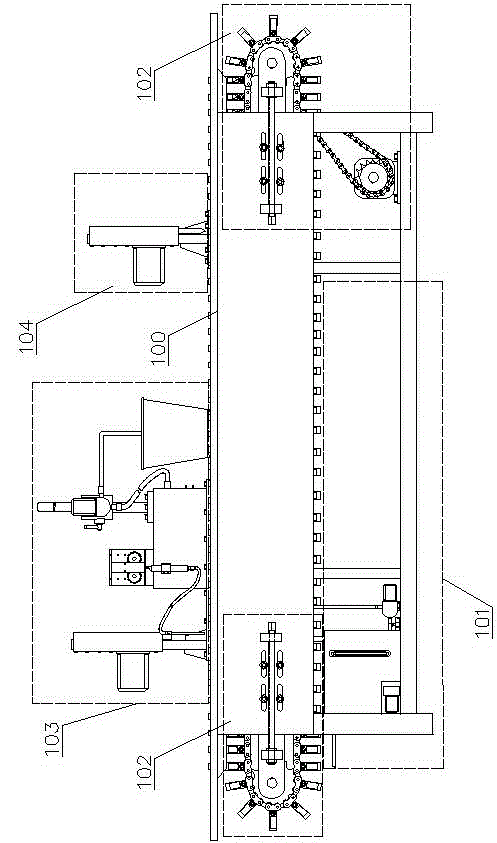

[0037] see Figure 1 ~ Figure 2 , this embodiment includes a machine 100 , a cooling spray device 101 , a transmission device 102 , a glue dispensing device 103 and a forming device 104 .

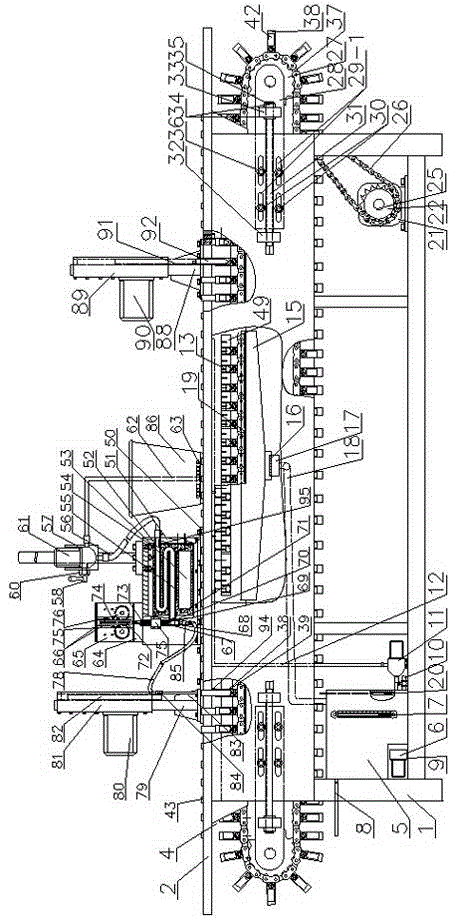

[0038] Described machine platform 100 comprises frame 1, panel 2, and panel 2 is fixed on the upper end of frame 1, and panel 2 is provided with a conveying trough 4, and the side wall of conveying trough 4 has spray port 19, and the conveying trough Bottom has overflow port 49.

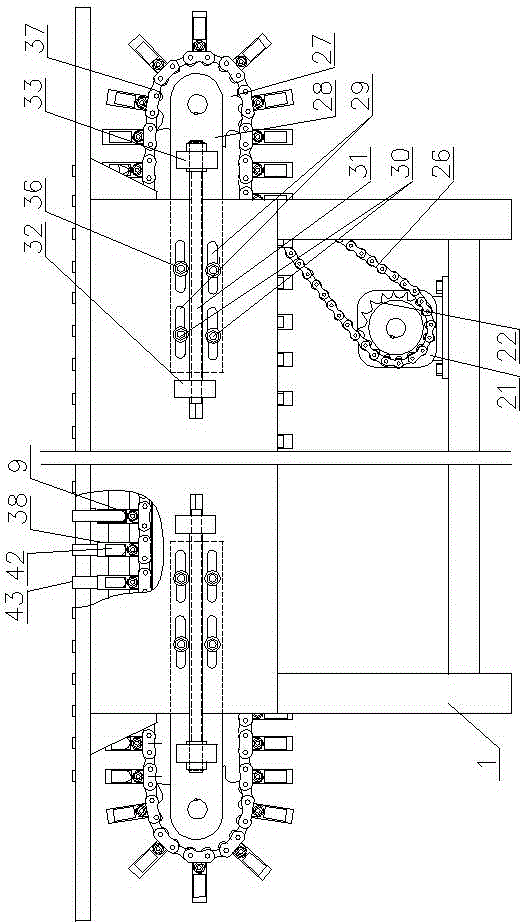

[0039] see Figure 3 ~ Figure 6 , in this embodiment, the transmission device 102 includes a servo motor 21, a No. 1 sprocket 22, a No. 2 sprocket 24, two transmission sprockets 27, two transmission shafts 23, and a blood collection tube sleeve 38. The described The servo motor 21 is fixed on the bottom of the frame 1, the No. 1 sprocket 22 is connected with the servo motor 21, the No. 2 sprocket 24 is inserted into a transmission shaft 23 and fixed, and the No. 1 sprocket 22 and the No. 2 sprocket 24 pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com