Patents

Literature

167results about How to "Achieve positioning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

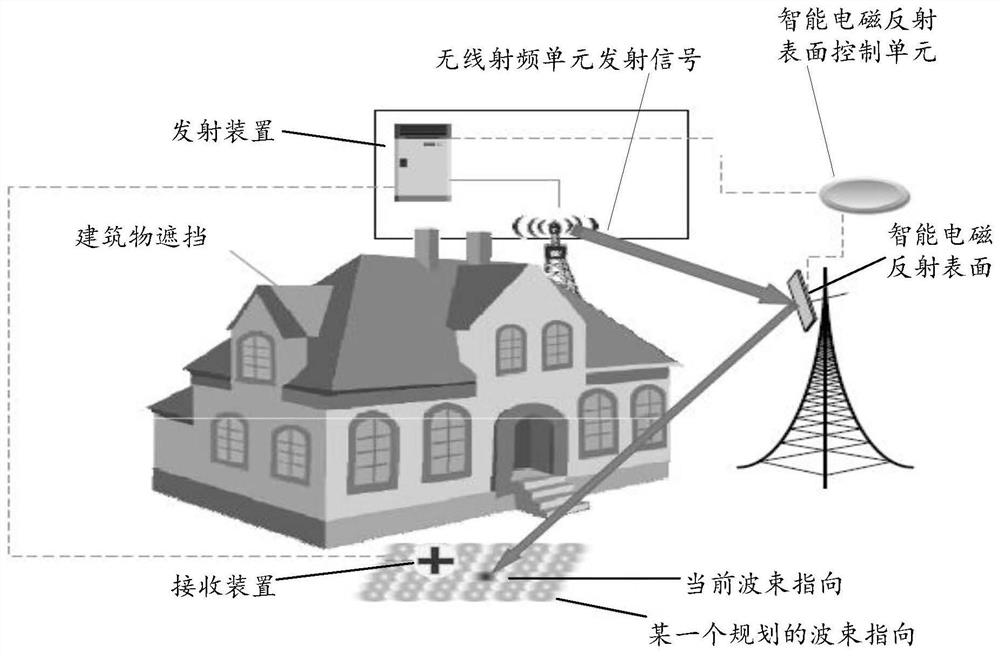

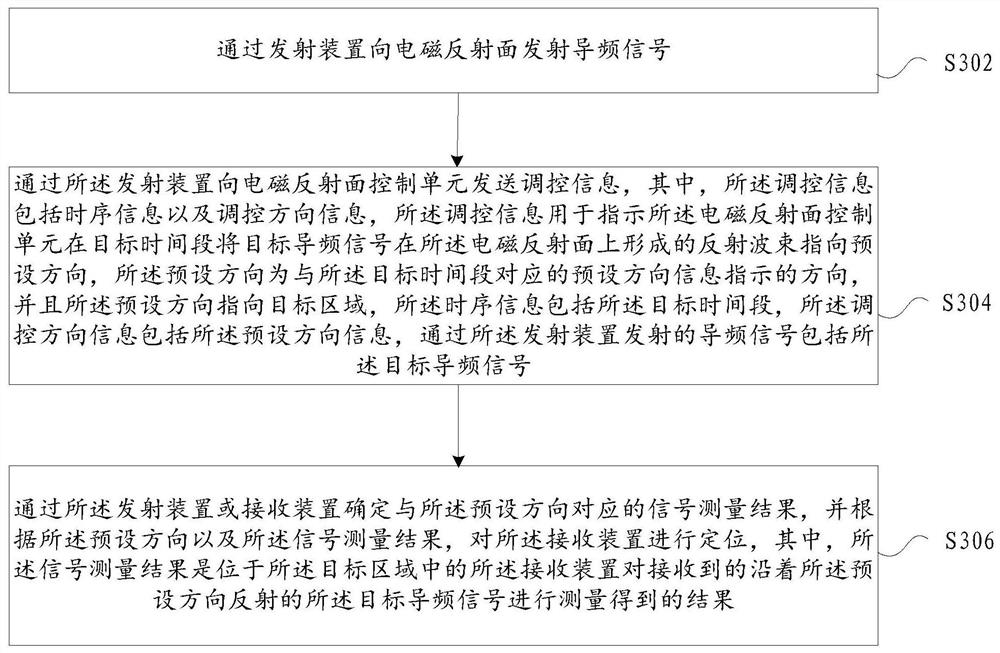

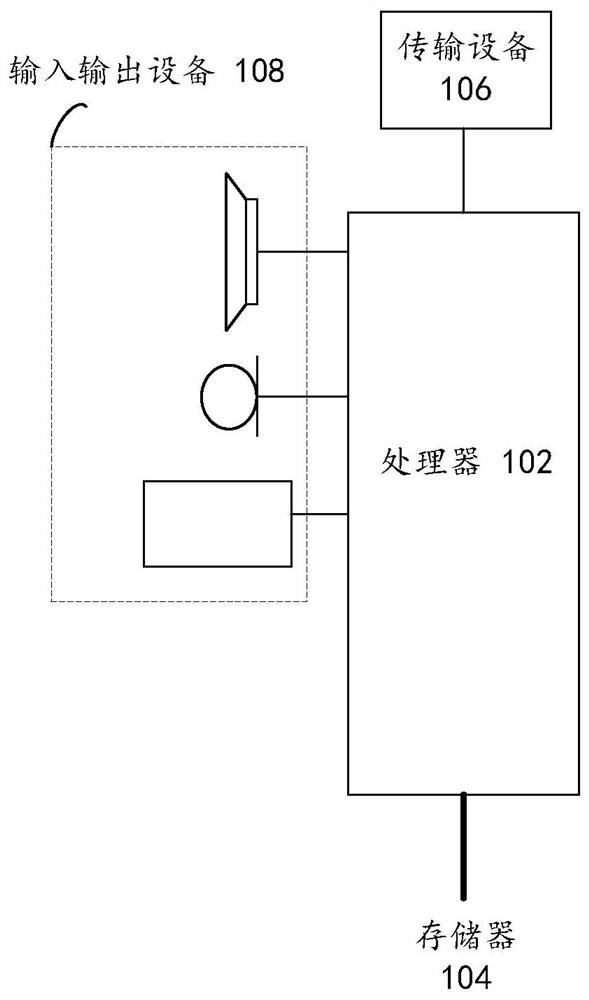

Receiving device positioning method, device and system, storage medium and electronic device

PendingCN111866726AAchieve positioning effectSignal allocationPilot signal allocationControl cellReflected waves

The embodiment of the invention provides a positioning method, device and system of a receiving device, a storage medium and an electronic device. The method comprises the following steps of transmitting a pilot signal to an electromagnetic reflecting surface through a transmitting device; regulation and control information being sent to the electromagnetic reflecting surface control unit throughthe transmitting device; wherein the regulation and control information comprises the time sequence information and regulation and the control direction information, the regulation and control information being used for indicating the electromagnetic reflection surface control unit to point a reflection wave beam formed by the target pilot signal on the electromagnetic reflection surface to a preset direction in a target time period, and the preset direction being a direction indicated by preset direction information corresponding to the target time period; and determining a signal measurementresult corresponding to the preset direction through the transmitting device or the receiving device, and positioning the receiving device according to the preset direction and the signal measurementresult. According to the method, a technical problem that the terminal cannot be positioned by utilizing the characteristics of the electromagnetic reflecting surface in the prior art is solved, andthe effect of positioning the terminal by utilizing the characteristics of the electromagnetic reflecting surface is achieved.

Owner:ZTE CORP

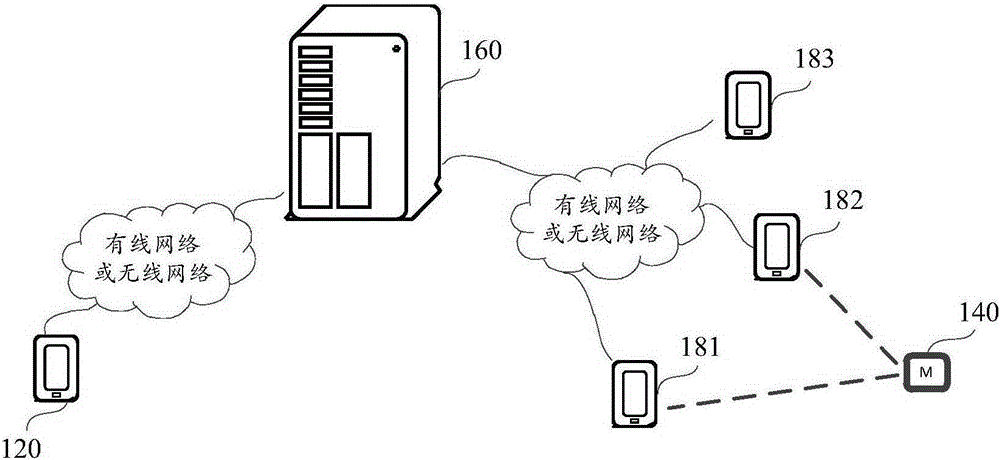

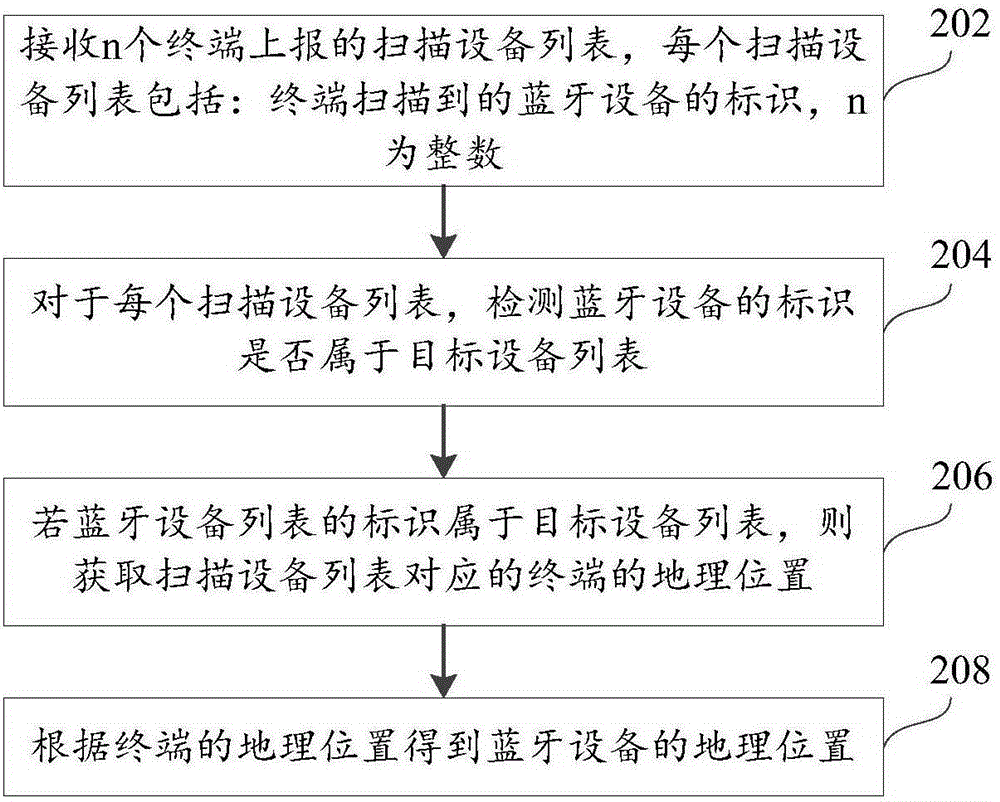

Method and apparatus for positioning equipment

ActiveCN105263104ASolve the positioning problemAchieve positioning effectWireless commuication servicesLocation information based serviceGeolocationBluetooth

The invention discloses a method for positioning equipment, and belongs to the field of Bluetooth positioning. The method comprises the steps of receiving scanned equipment lists reported by the number of n terminal, each scanned equipment list including a scanned identifier of Bluetooth equipment by a terminal; for each scanned equipment list, detecting whether the identifier of the Bluetooth equipment belongs to a target equipment list, if so, obtaining geographic location of the corresponding terminal to the scanned equipment list, and obtaining the geographic location of the Bluetooth equipment according to the geographic location of the terminal. The invention solves the problem that the positioning of the Bluetooth equipment requires the knowledge of the last occurring location of the Bluetooth equipment in the prior art; and achieves the effect that without knowing the last occurring location of the Bluetooth equipment, and when the lost Bluetooth equipment is still moving, and positioning the Bluetooth equipment through the geographic location of other terminals.

Owner:TENCENT TECH (SHENZHEN) CO LTD

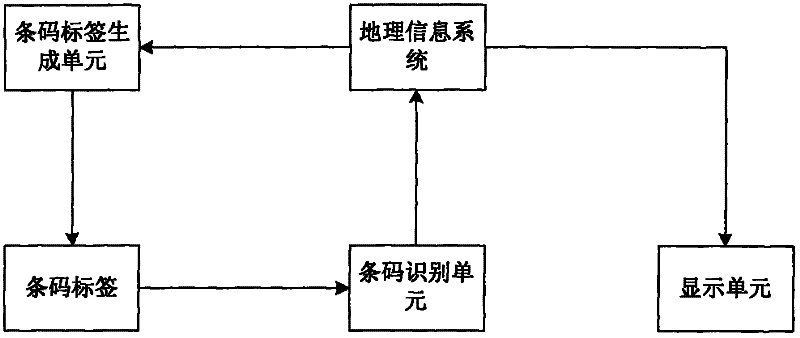

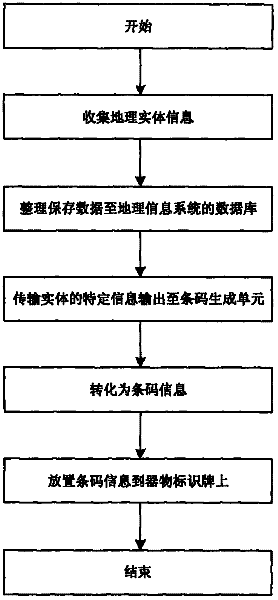

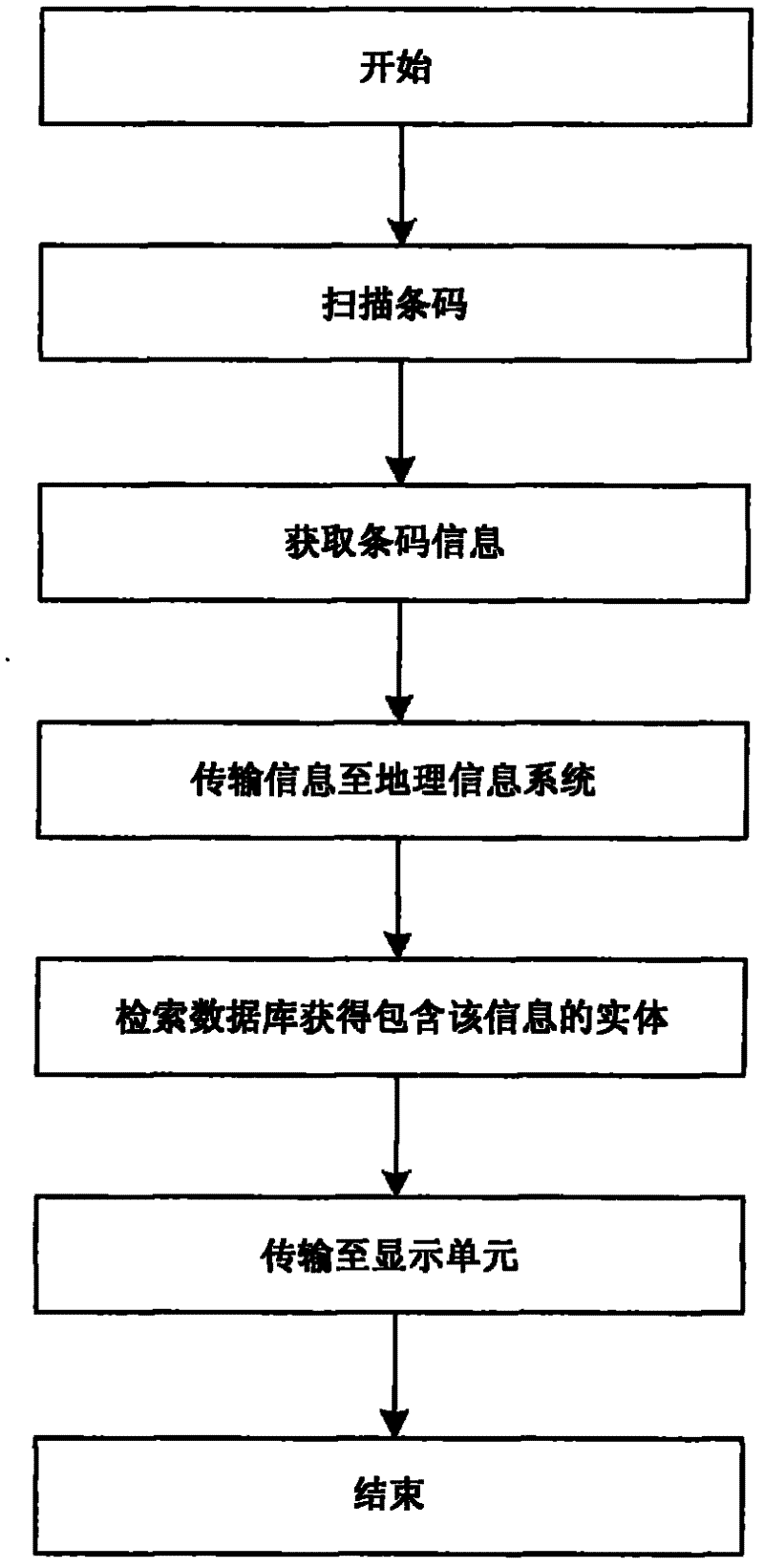

Positioning method and positioning system based on bar code identification technology and GIS (Geographic Information System) technology

InactiveCN102479214AAchieve positioningAchieve positioning effectSpecial data processing applicationsSensing by electromagnetic radiationMobile deviceComputer science

The invention relates to a positioning method and system based on a bar code identification technology and a GIS (Geographic Information System) technology. The positioning system comprises a GIS, a bar code tag generation unit, a bar code tag, a bar code identification unit and a display unit, wherein the GIS is connected with the bar code tag generation unit, the bar code identification unit and the display unit, the bar code tag generation unit is connected with the bar code tag, and the bar code tag is connected with the bar code identification unit. The method and system provided by the invention have the following beneficial effects that: a positioning effect based on an electronic map can be realized in badly shielded environment; the positioning precision is controllable, and the positioning effect can be realized in any space in which the bar code tag can be arranged; the method and the system have no special requirement on equipment and materials, and special instruments are not needed to be installed at the place to be positioned; and the method and the system are simple to operate and easy to popularize, and can realize the positioning effect in combination with common mobile devices such as a smart phone and the like.

Owner:NINGBO SHIYOU INFORMATION TECH

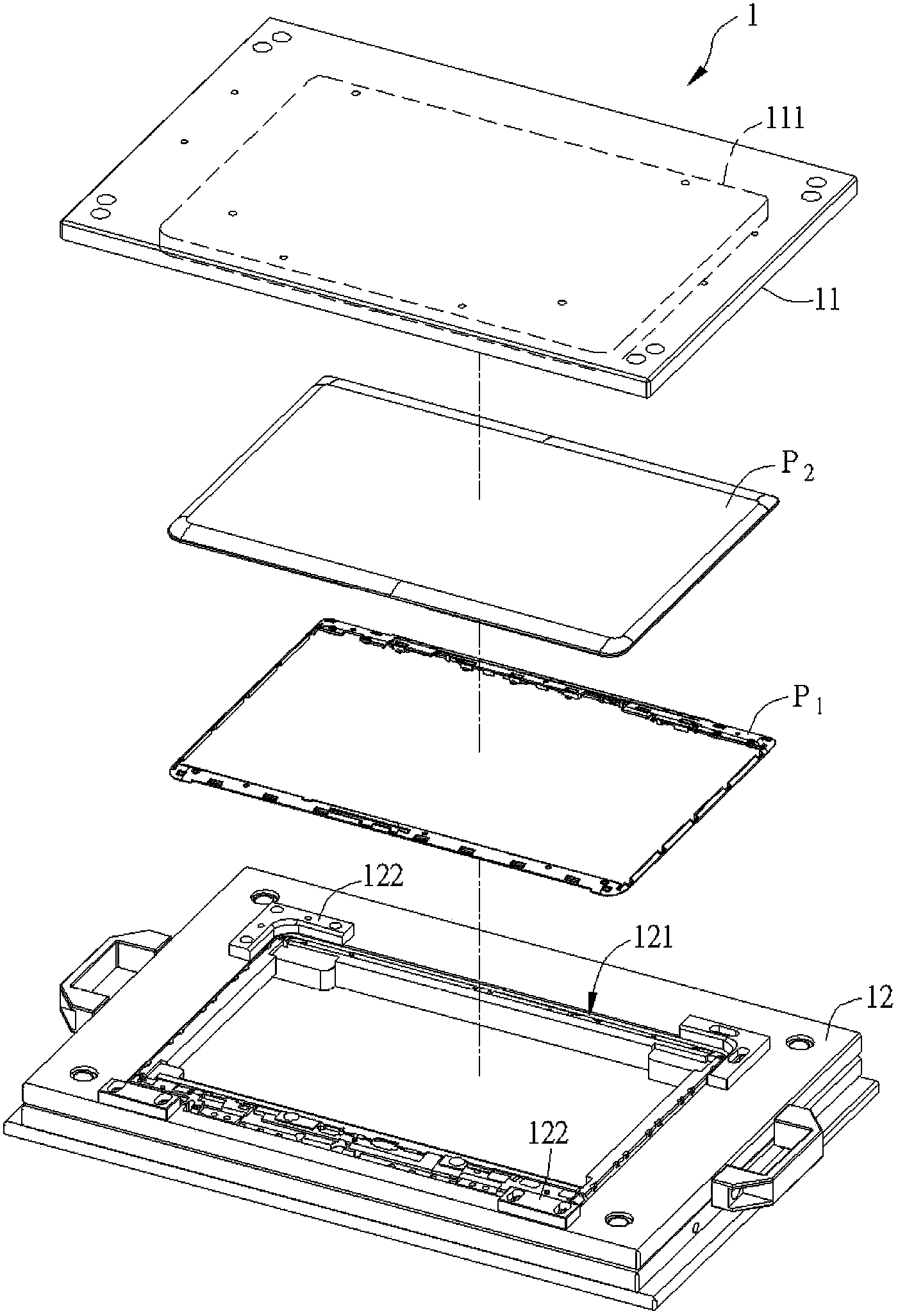

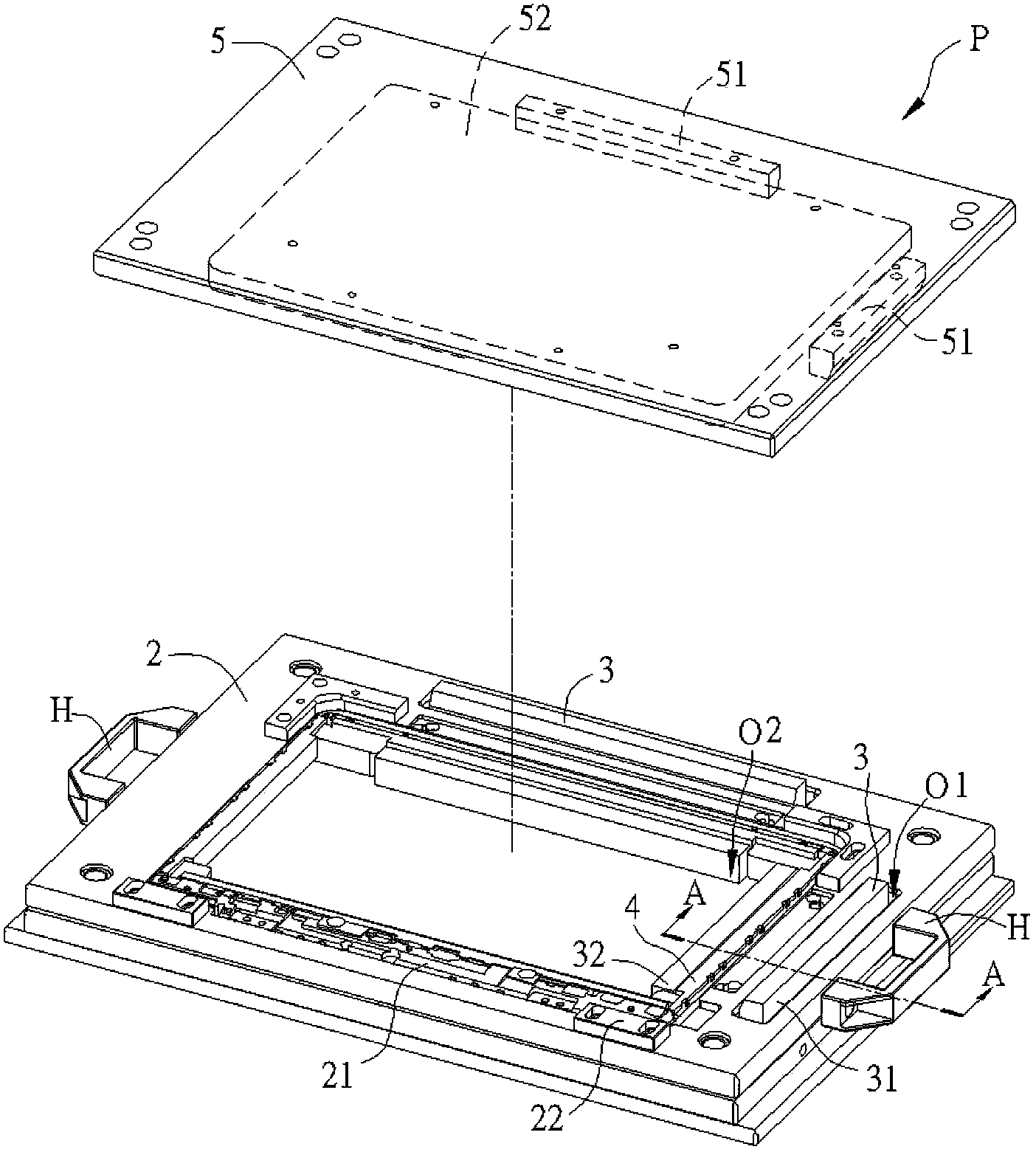

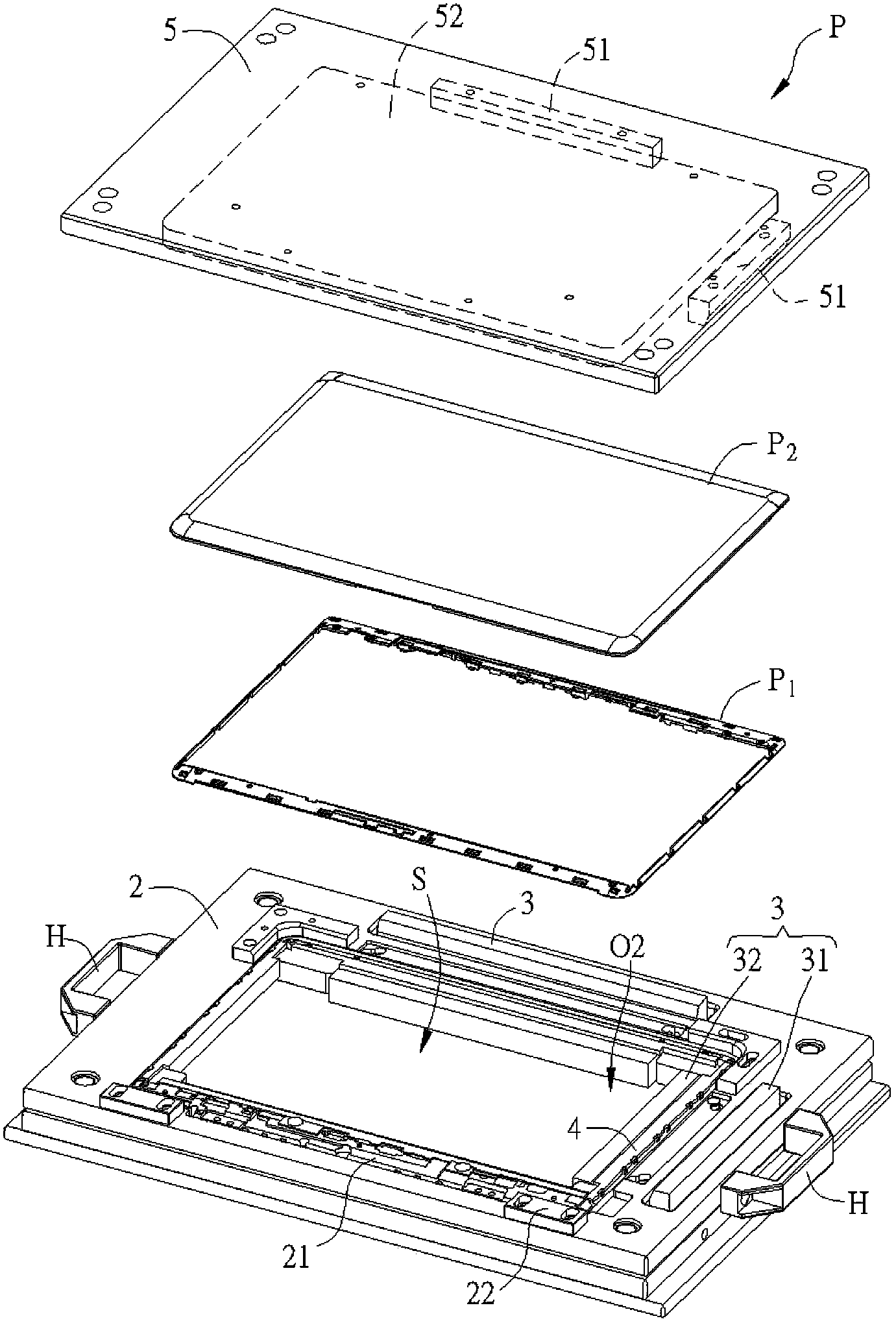

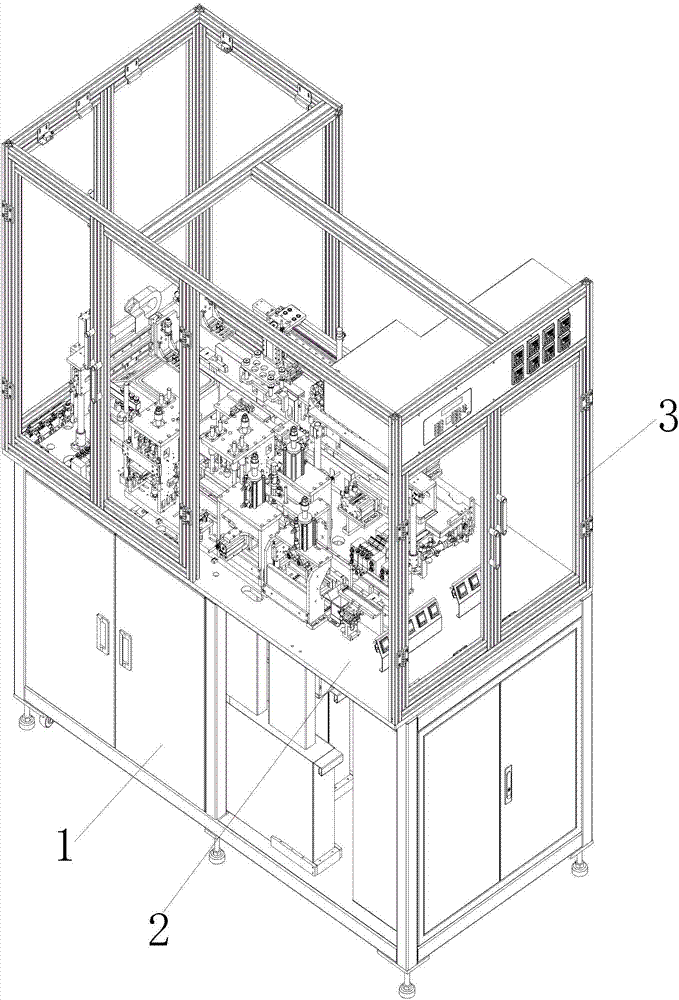

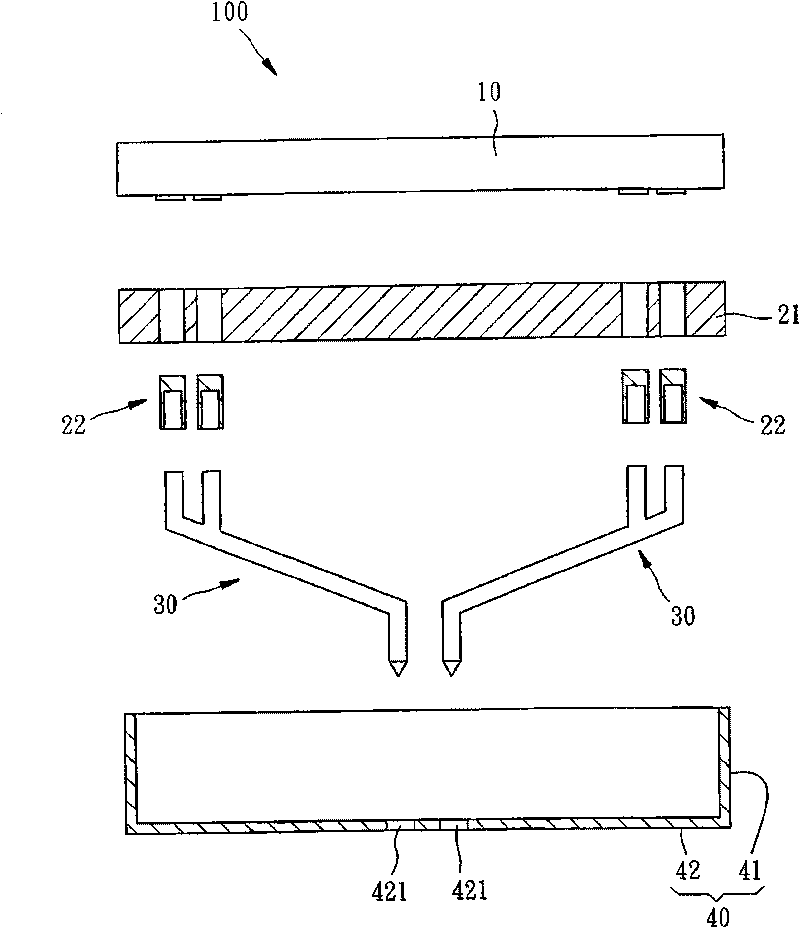

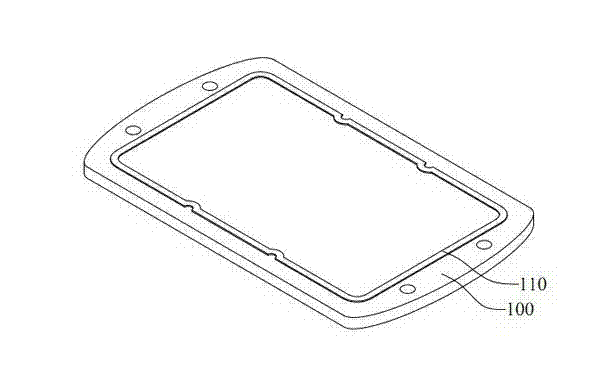

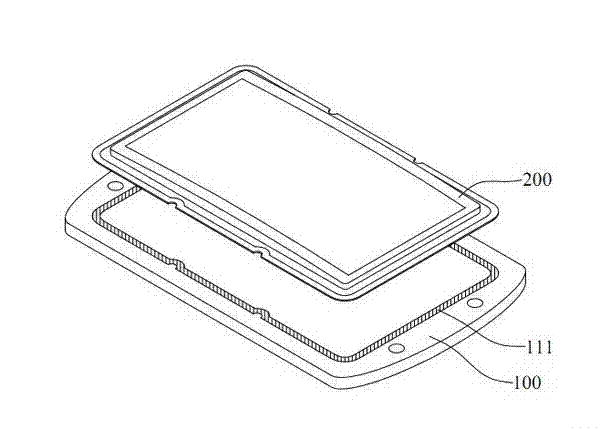

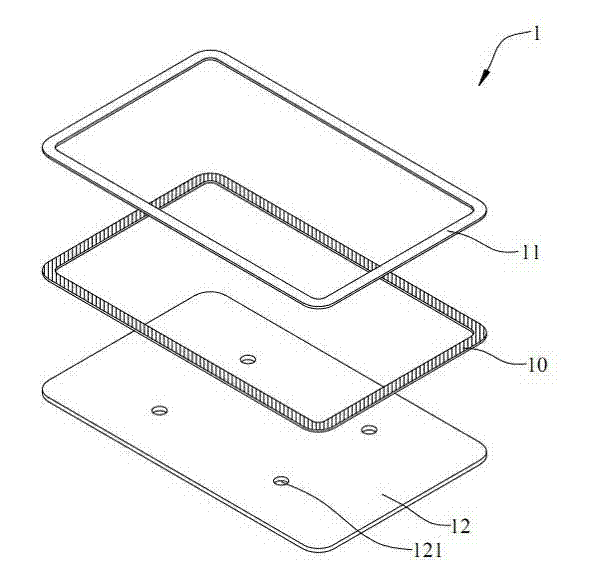

Lamination device

The invention relates to a lamination device, which comprises a base, at least two slide blocks, at least two movable positioning blocks and a laminating member. The base has an accommodation space for accommodating a first workpiece and a second workpiece. The two slide blocks are movably embedded in at least two adjacent sides of the base respectively, and each block exposes a first part and a second part. The two movable positioning blocks are arranged corresponding to the two slide blocks respectively and are movably located at the inner side of the accommodation space. The laminating member can cover the base to laminate the first workpiece and the second workpiece, and has at least two convex parts arranged corresponding to the first parts of the two slide blocks respectively. When the laminating member covers the base, the convex parts abut against the first parts of the slide blocks and drive the whole movement of the slide blocks. The second parts of the slide blocks drive the respectively corresponded movable positioning blocks to move toward the inner wall of the accommodation space so as to press the first workpiece and the second workpiece against the inner wall of the accommodation space. With the lamination device provided by the invention, the two workpieces can achieve more accurate mutual positioning, tolerance can be overcome so as to improve the accuracy of the lamination process.

Owner:CASETEK COMP (SUZHOU) CO LTD +1

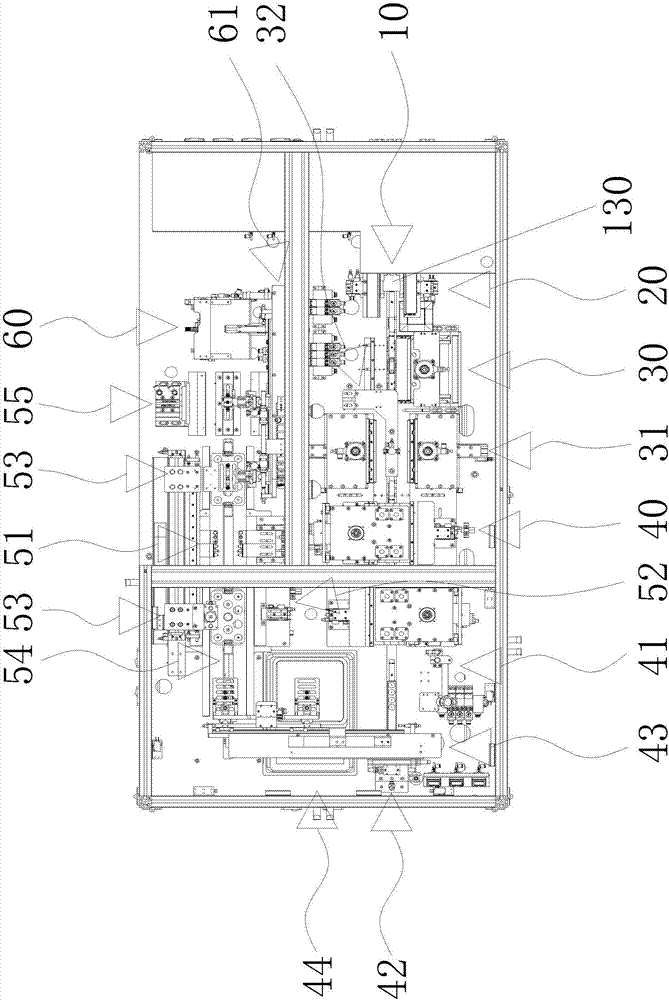

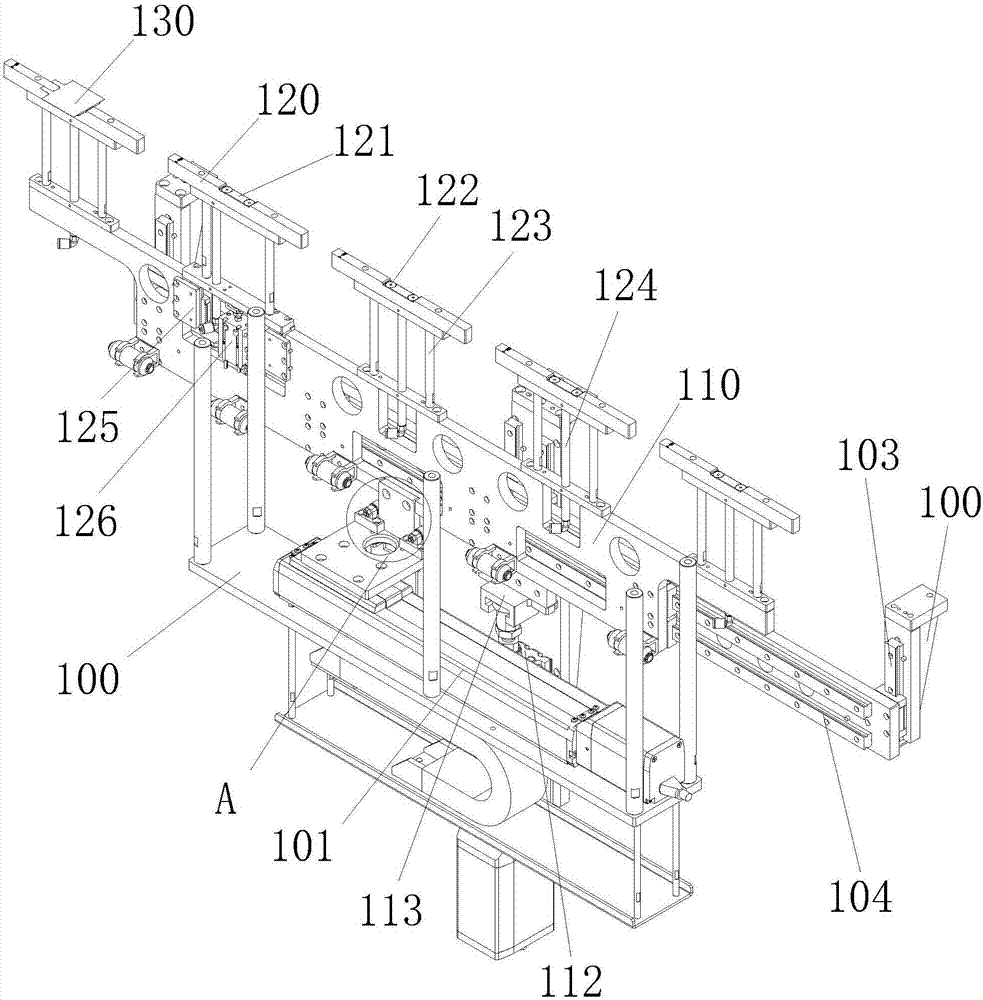

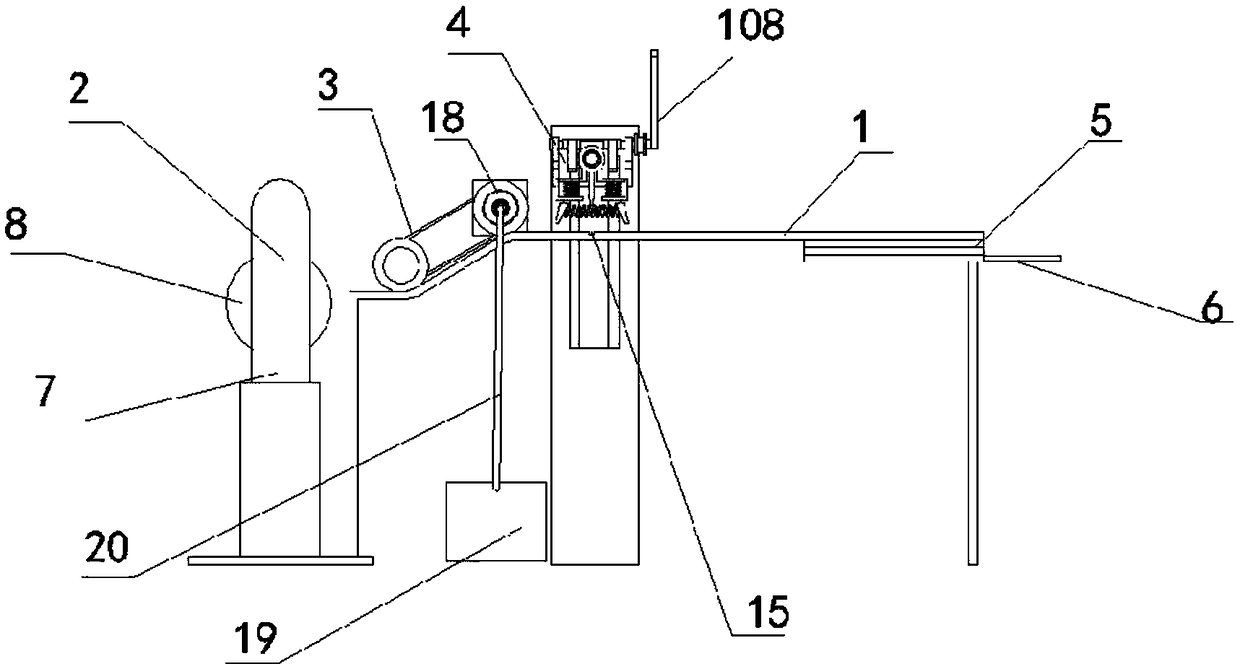

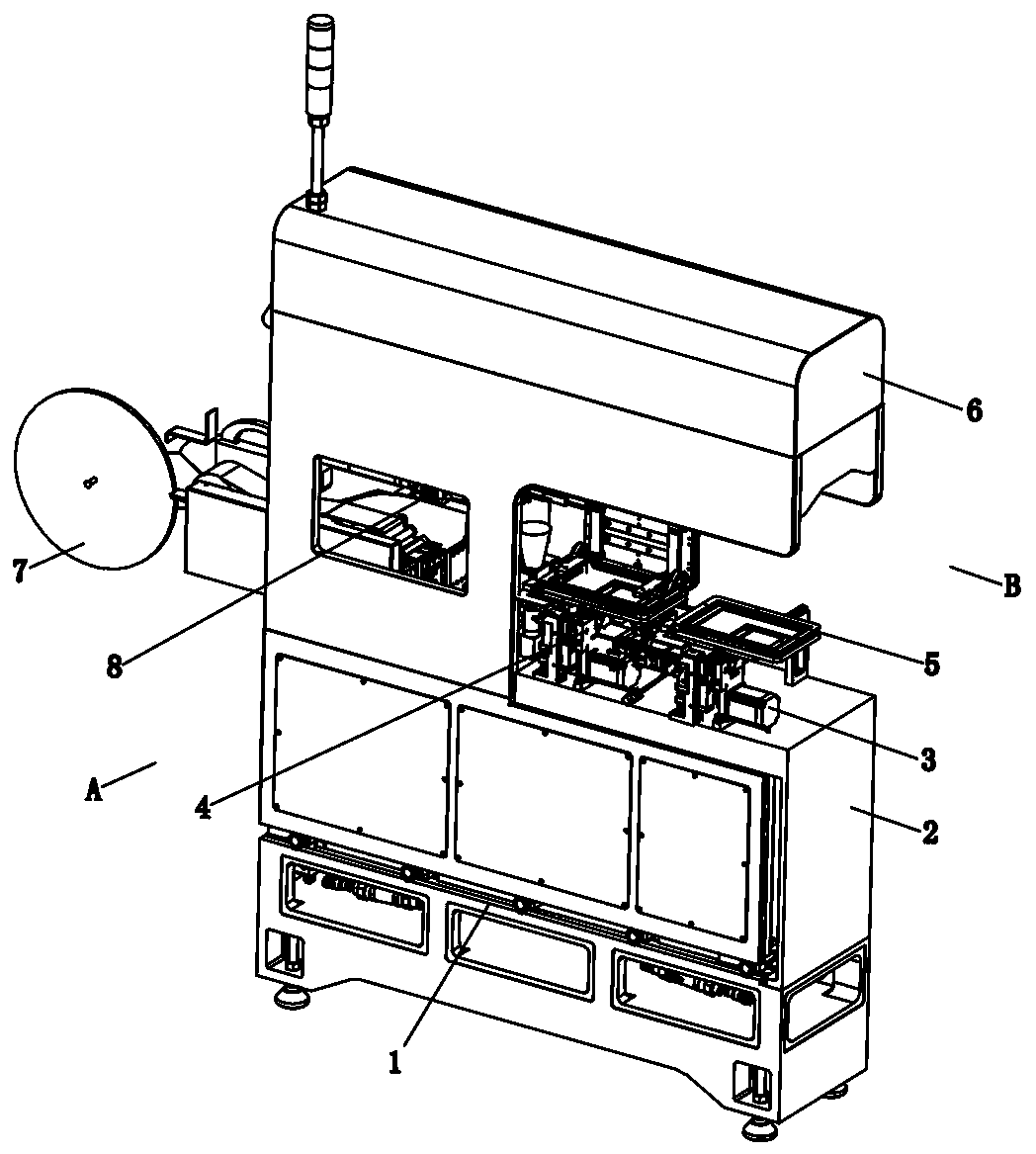

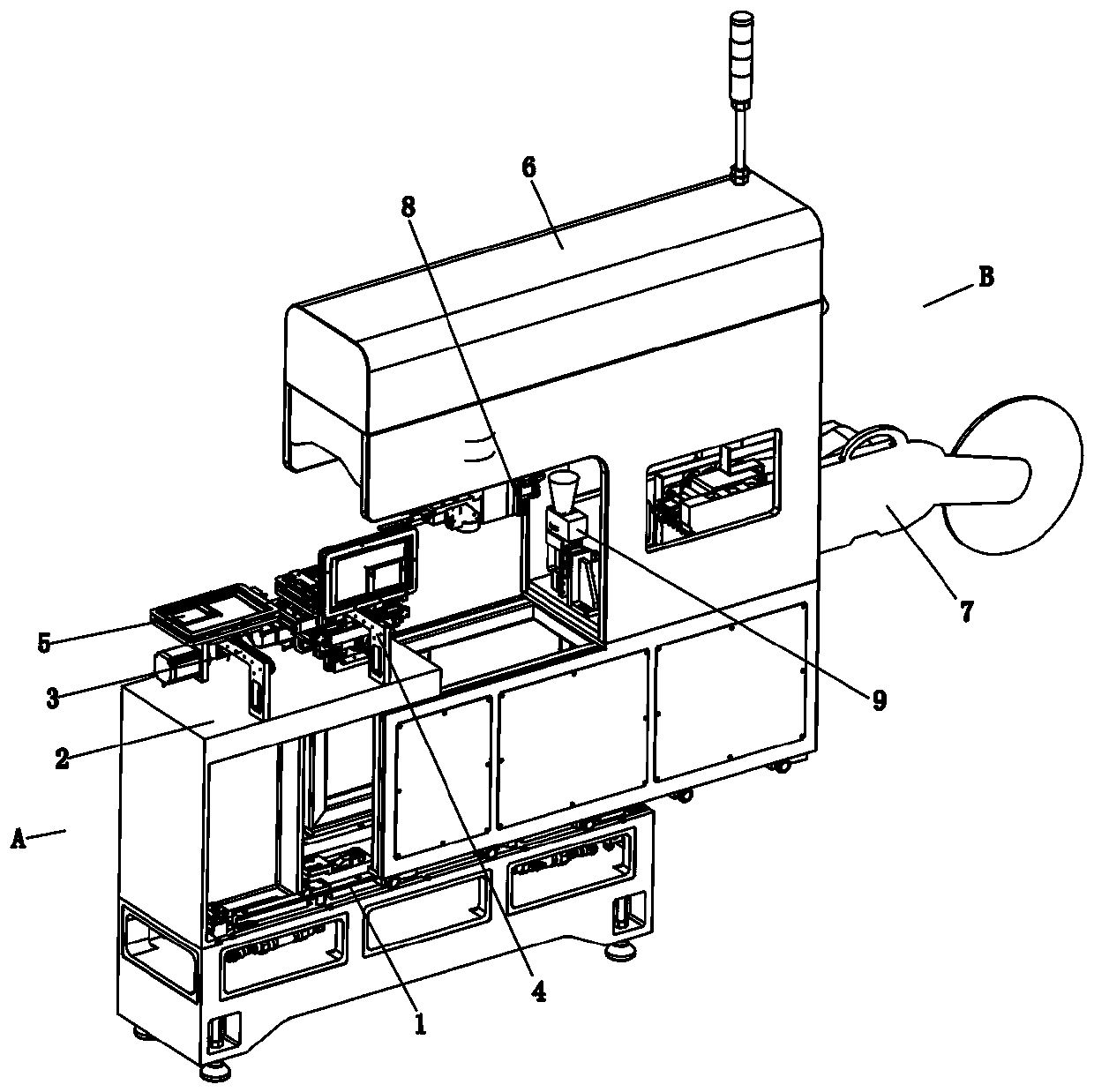

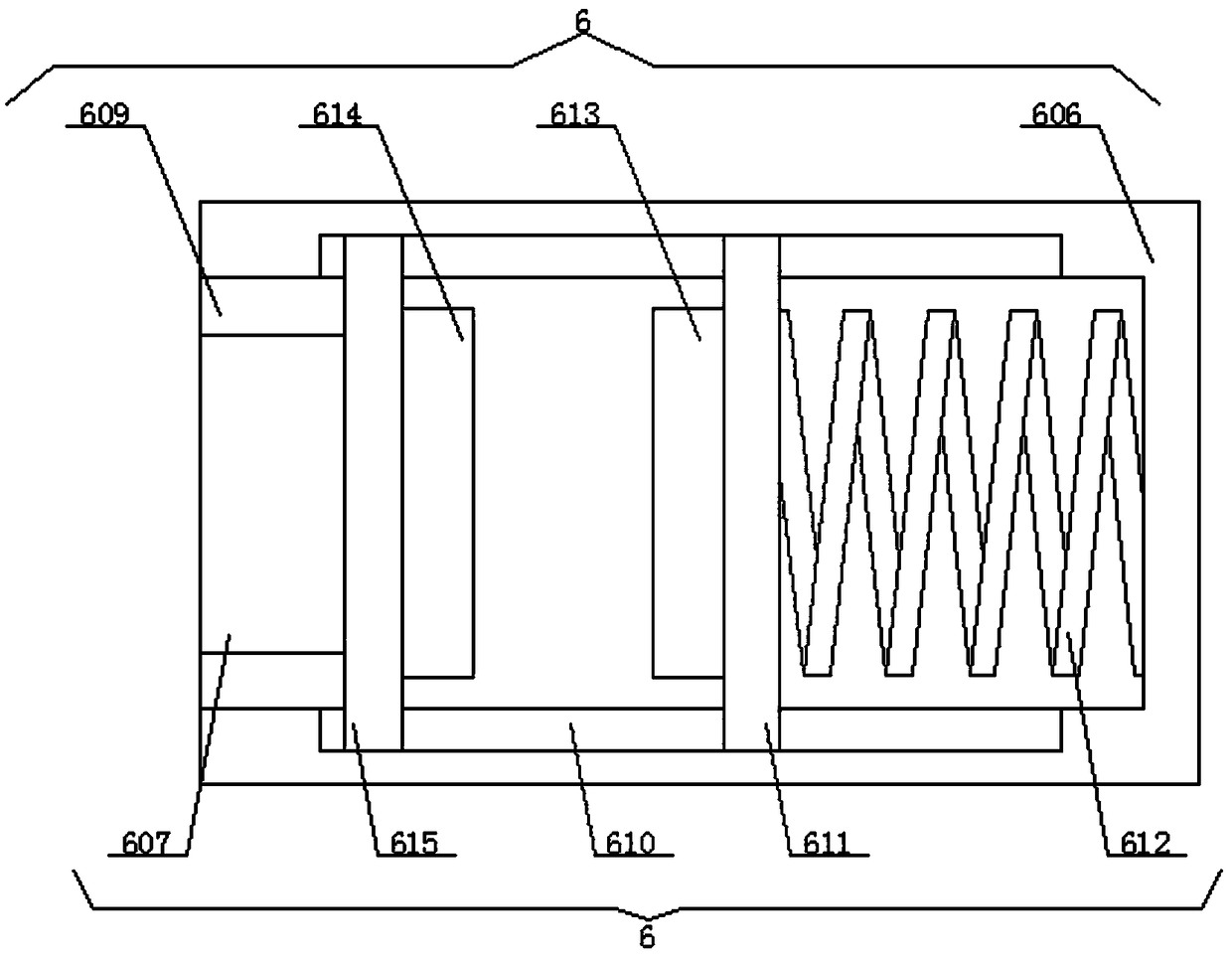

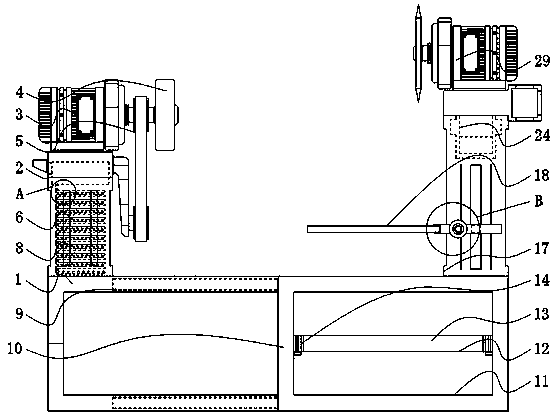

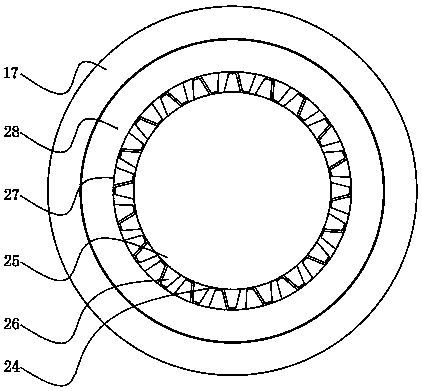

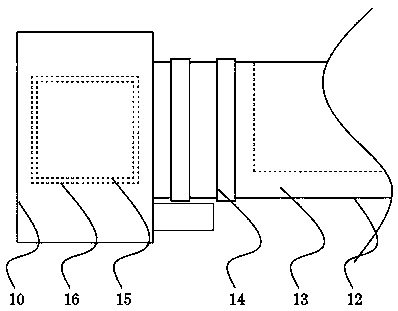

Flanging machine

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

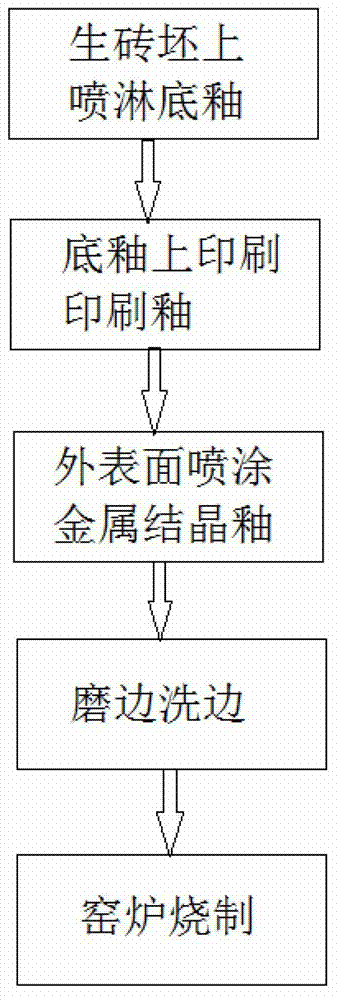

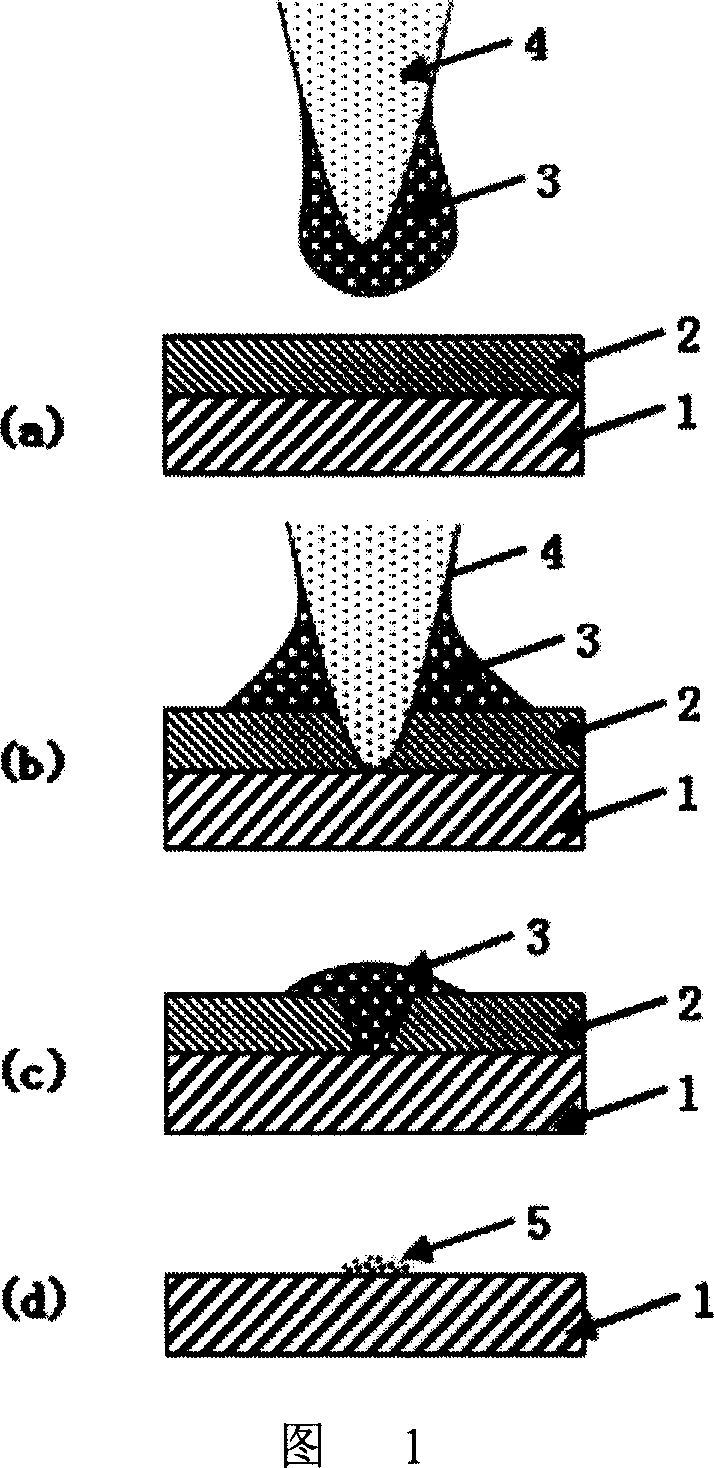

Method for manufacturing metallic-crystal enameled brick

InactiveCN102815972ACrystallization effect is naturalThe crystallization effect appears naturallyBrickGlaze

The invention discloses a method for manufacturing a metallic-crystal enameled brick, which comprises base enamel 1, printing enamel 2 and metallic-crystal enamel 3, wherein the method comprises the following technical procedures: spraying the base enamel on a crude brick billet so as to form the base enamel 1; printing the printing enamel 2 on the base enamel 1; coating the metallic-crystal enamel 3 on the outer surface which is printed by the printing enamel 2; polishing and washing edges; and processing one-time bake in a kiln so as to obtain a product. According to benefit effect of the method, the method is characterized by natural crystallization effect, positionable crystal body, controllable crystallization effect, one-time and quick bake and working time conservation and can be widely applied to methods for manufacturing each metallic-crystal glaze ceramic tile.

Owner:佛山瑭虹釉料科技有限公司

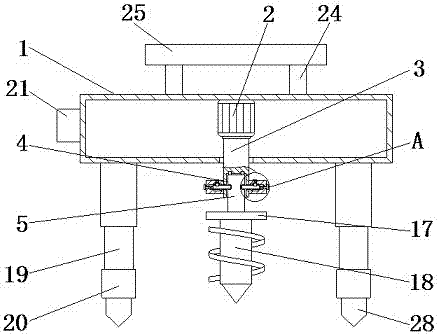

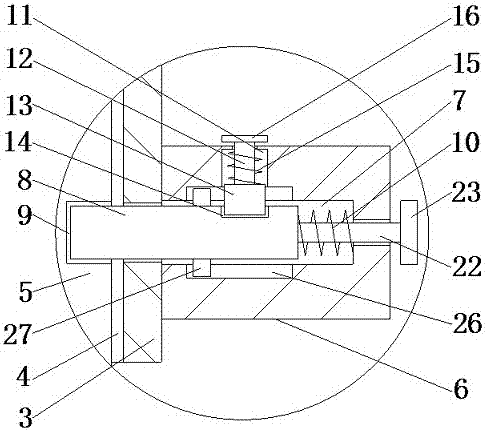

Agricultural hole digger

InactiveCN107241939AAchieve the effect of rotationAchieve a fixed effectPlantingFurrow making/coveringAgricultural engineeringDrill

The invention discloses an agricultural hole digger. The agricultural hole digger comprises a supporting plate; a motor is fixedly arranged at the axle center of the top of an internal cavity of the supporting plate; a rotating shaft of the motor is fixedly connected with a first connecting rod; the supporting plate is penetrated by the bottom of the first connecting rod, and the bottom of the first connecting rod is designed to extend to the outside of the supporting plate; the bottom of the first connecting rod is provided with a first groove. According to the agricultural hole digger, the motor is used for driving the first connecting rod to rotate; the first connecting rod is provided with the first groove for accommodating of a second connecting rod, and the second connecting rod and a drill rod are driven to rotate; an inserting rod and a first clamping groove are used for fixing the second connecting rod; a clamping block and a second clamping groove are used for fixing the inserting rod; the drill rod is used for digging holes; the drill rod can be replaced; different hole diggers are replaced to dig holes of different sizes; and convenience is provided.

Owner:王建芳

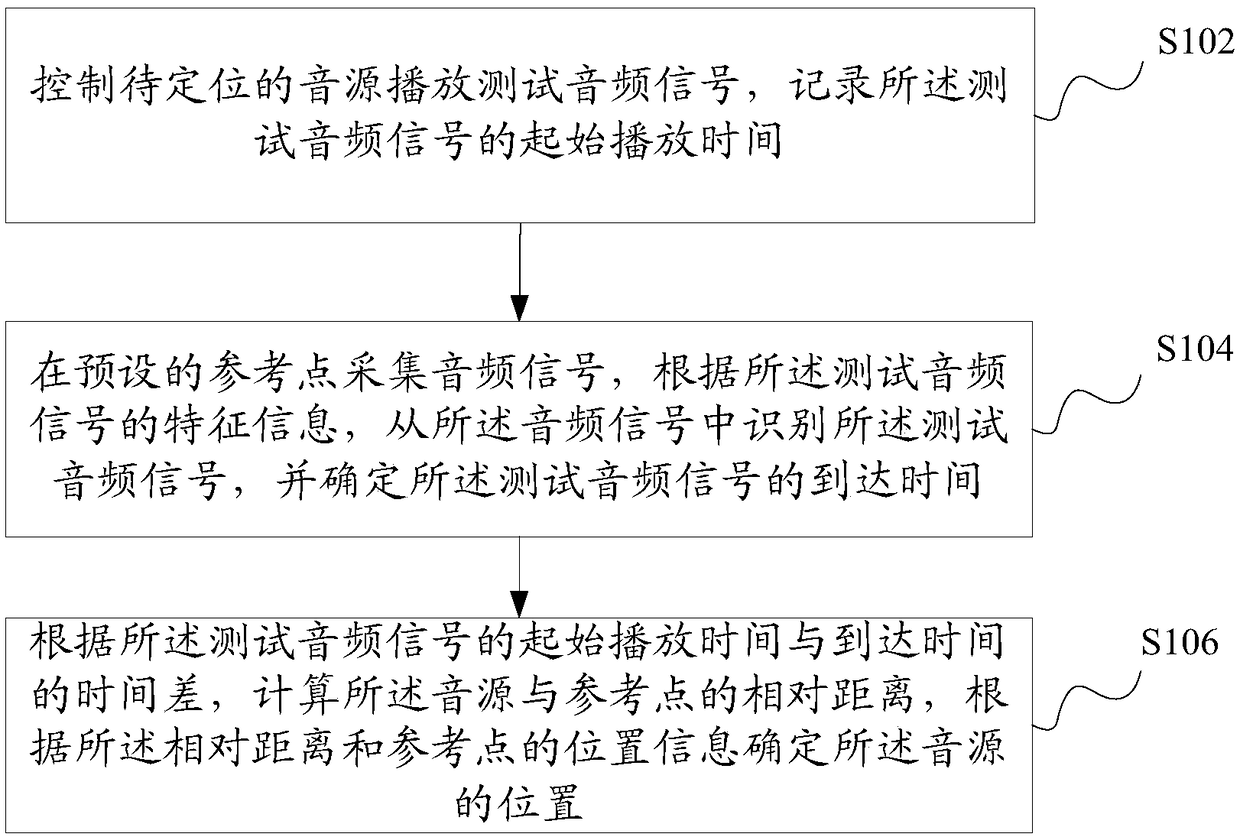

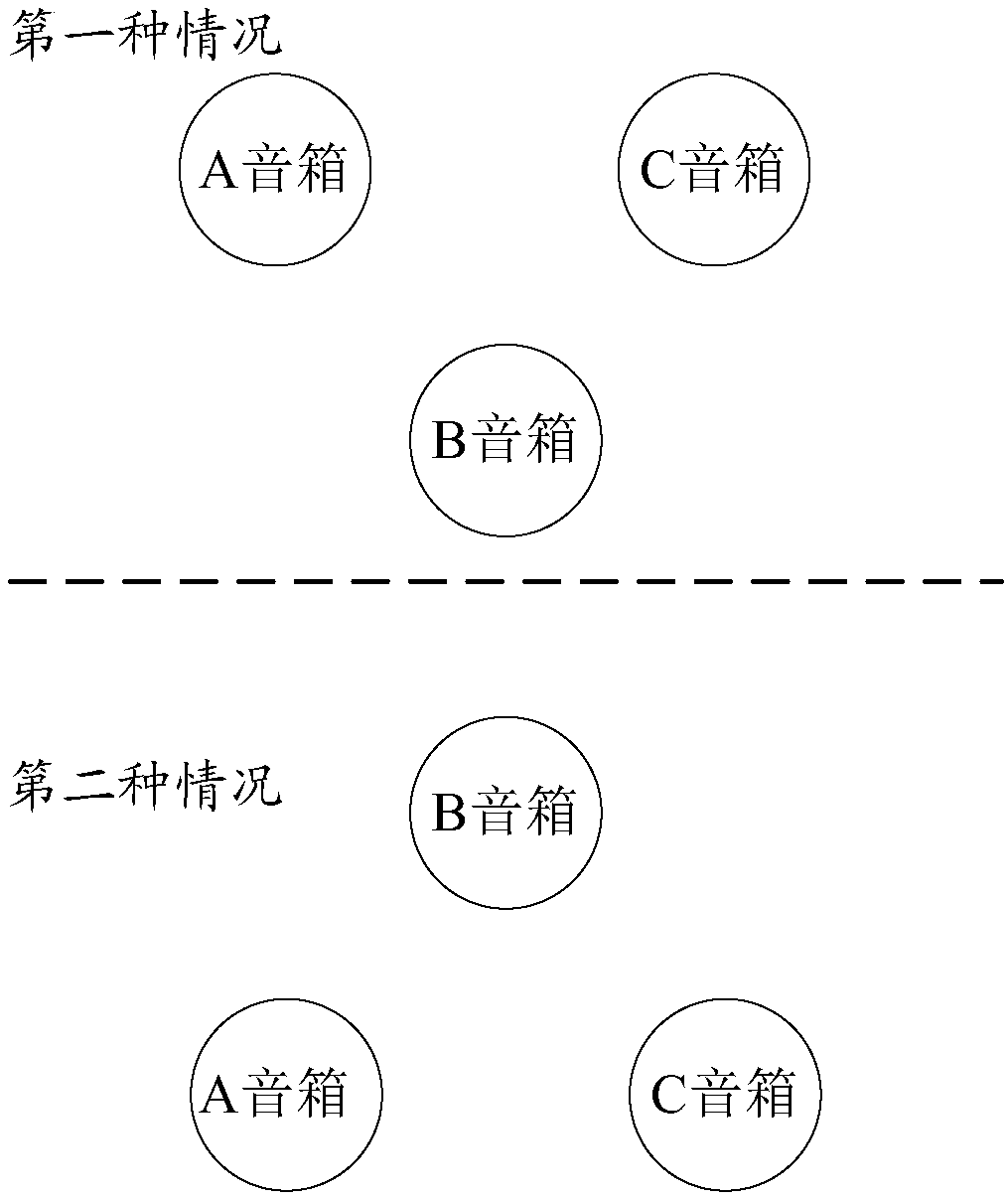

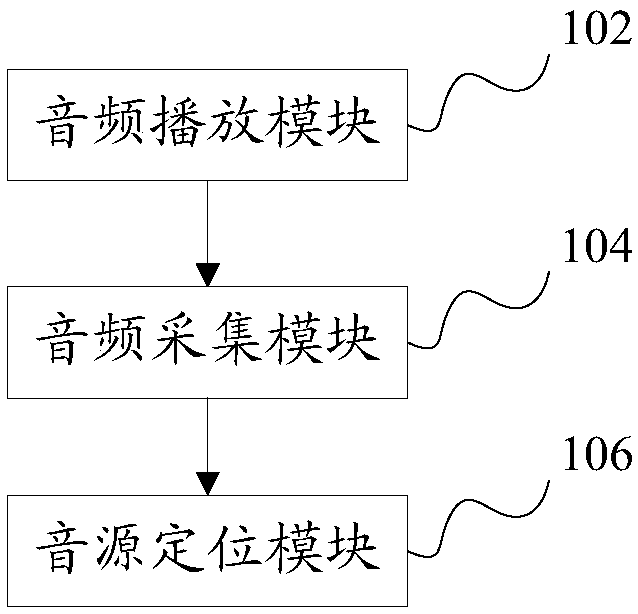

Sound source locating method, sound source locating system, sound box system locating method and sound box system

InactiveCN108429998AAchieve positioning effectOvercoming the problem of inaccurate positioningSignal processingTransducer circuitsAttenuation coefficientStart time

The invention provides a sound source locating method and a sound source locating system, and the method comprises the following steps: controlling a to-be-located sound source play test audio signal,and recording start play time of the test audio signal; acquiring an audio signal at a preset reference point, identifying the test audio signal from the audio signal according to feature informationof the test audio signal, and determining arrival time of the test audio signal; according to difference between start play time and arrival time of the test audio signal, calculating relative distance between the sound source and the reference point, and determining a position of the sound source according to the relative distance and the position information of the reference point. The method and the system provided by the invention overcome a problem of inaccuracy of sound source locating caused by judging the position of the sound source through a propagation attenuation coefficient in the conventional technologies, achieve the technical effect of accurately locating the sound source and provide quality guarantee for performing sound field restoration through the sound source.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Location method for nano materials synthesis used catalyst

InactiveCN1920665ARealize on-site positioningHigh selectivityPhotomechanical apparatusChemistryResist

The invention relates to a method for positioning the catalyst of carbon composition nanometer tube, wherein it comprises: (1), coating photo resist on the substrate to be dried; (2), preparing catalyst solution; (3), using the needle of atomic force microscope with catalyst solution to pass through the photo resist coat, to transfer the solution on the needle sharp to the substrate; (4), removing photo resist to obtain the substrate positioned with catalyst image. The invention can obtain the catalyst image whose line width is in 1 mum, point diameter is in 1micrometer, and position accuracy is in 5 mum, while it is at centimeter range; and it can accurately position at least two kinds of catalysts on one substrate. Compared with common nanometer dip pen print technique, the invention can deposit more material, and the deposited catalyst can composite carbon nanometer tube.

Owner:PEKING UNIV

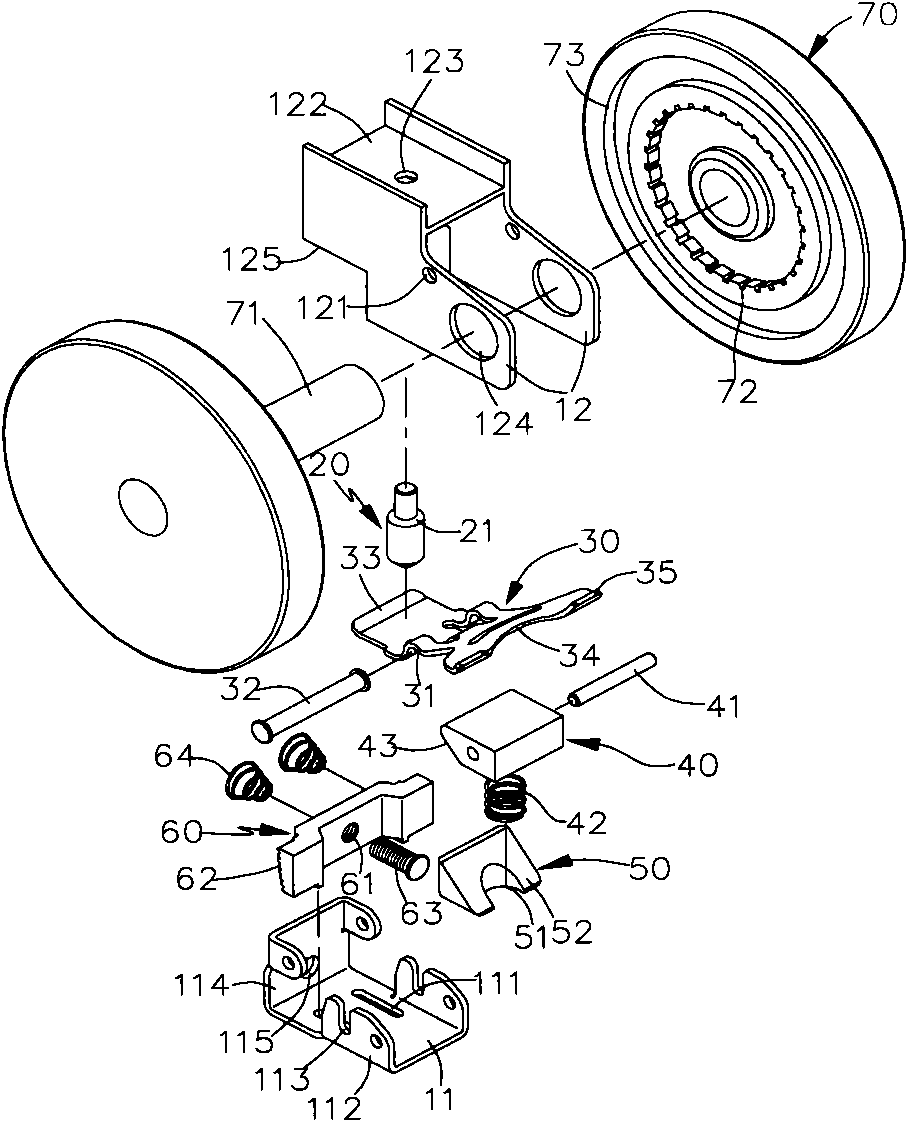

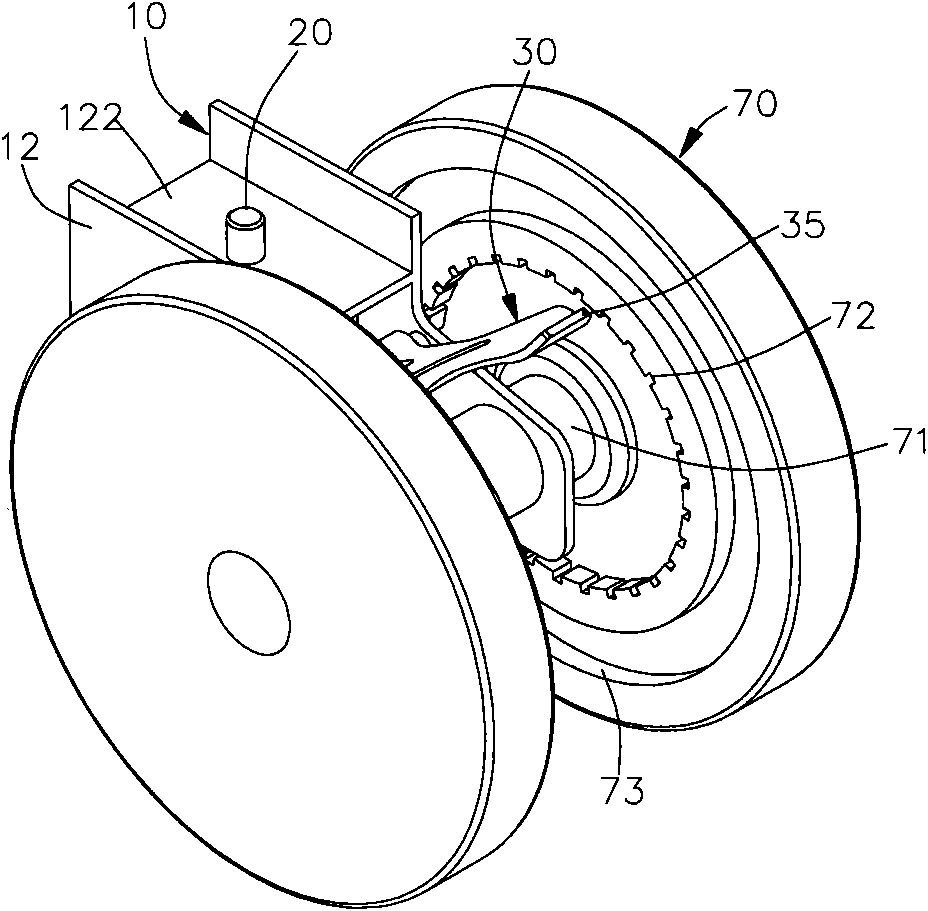

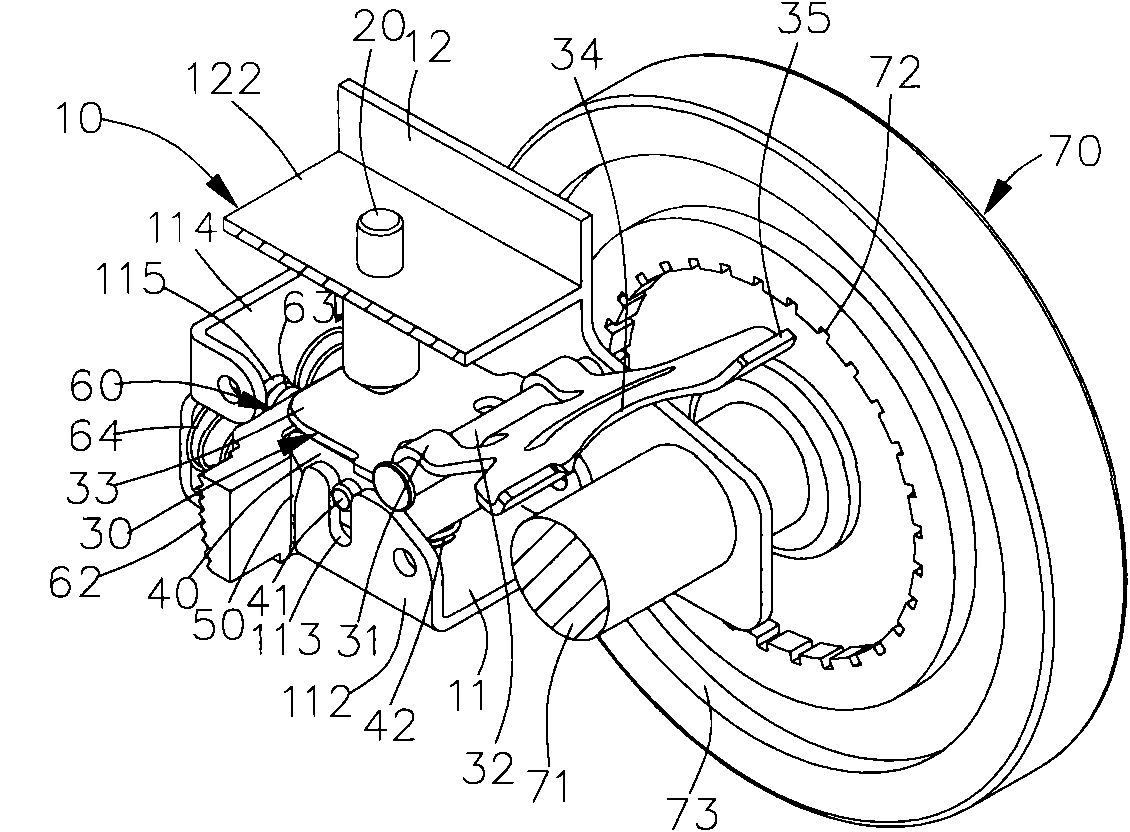

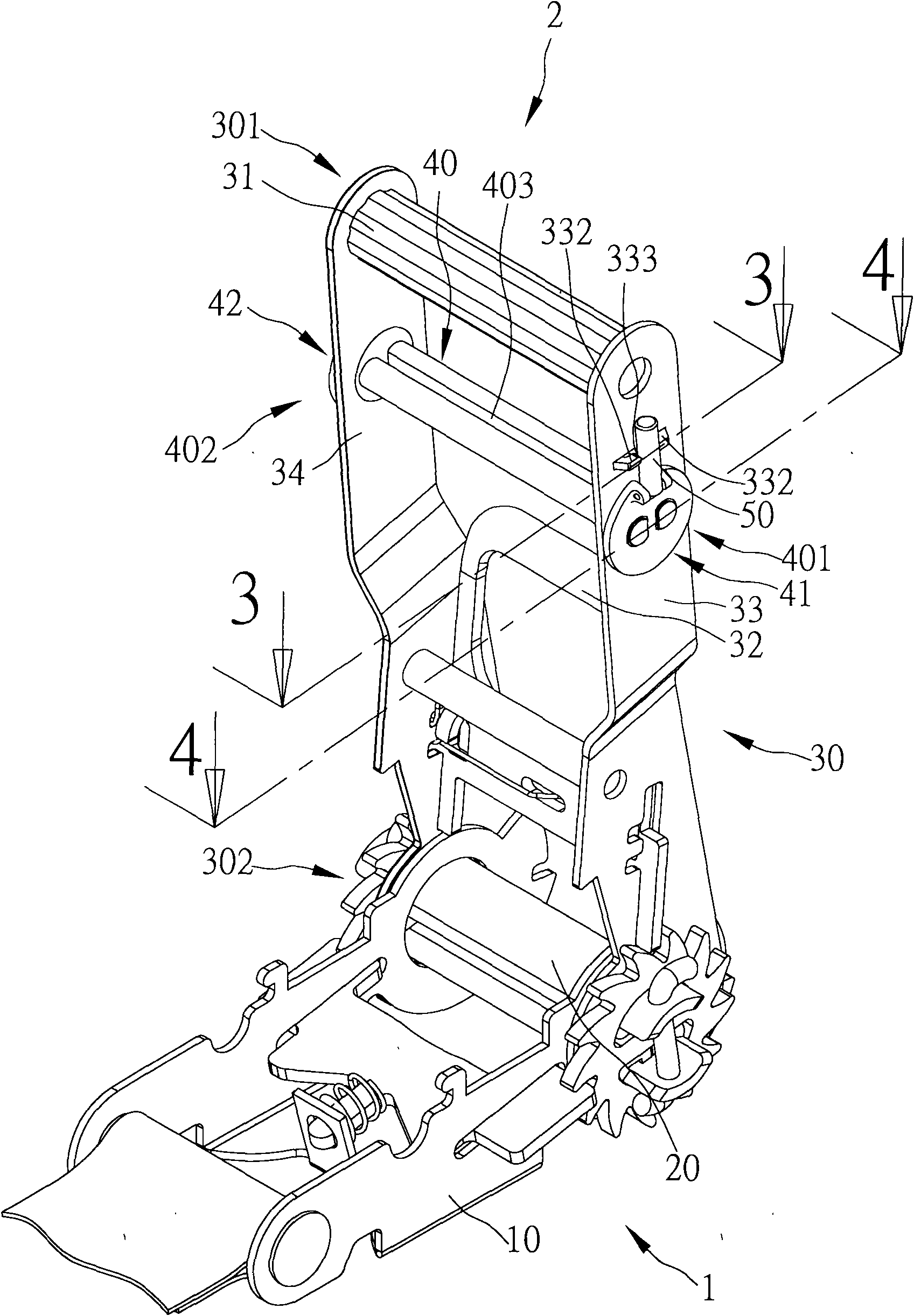

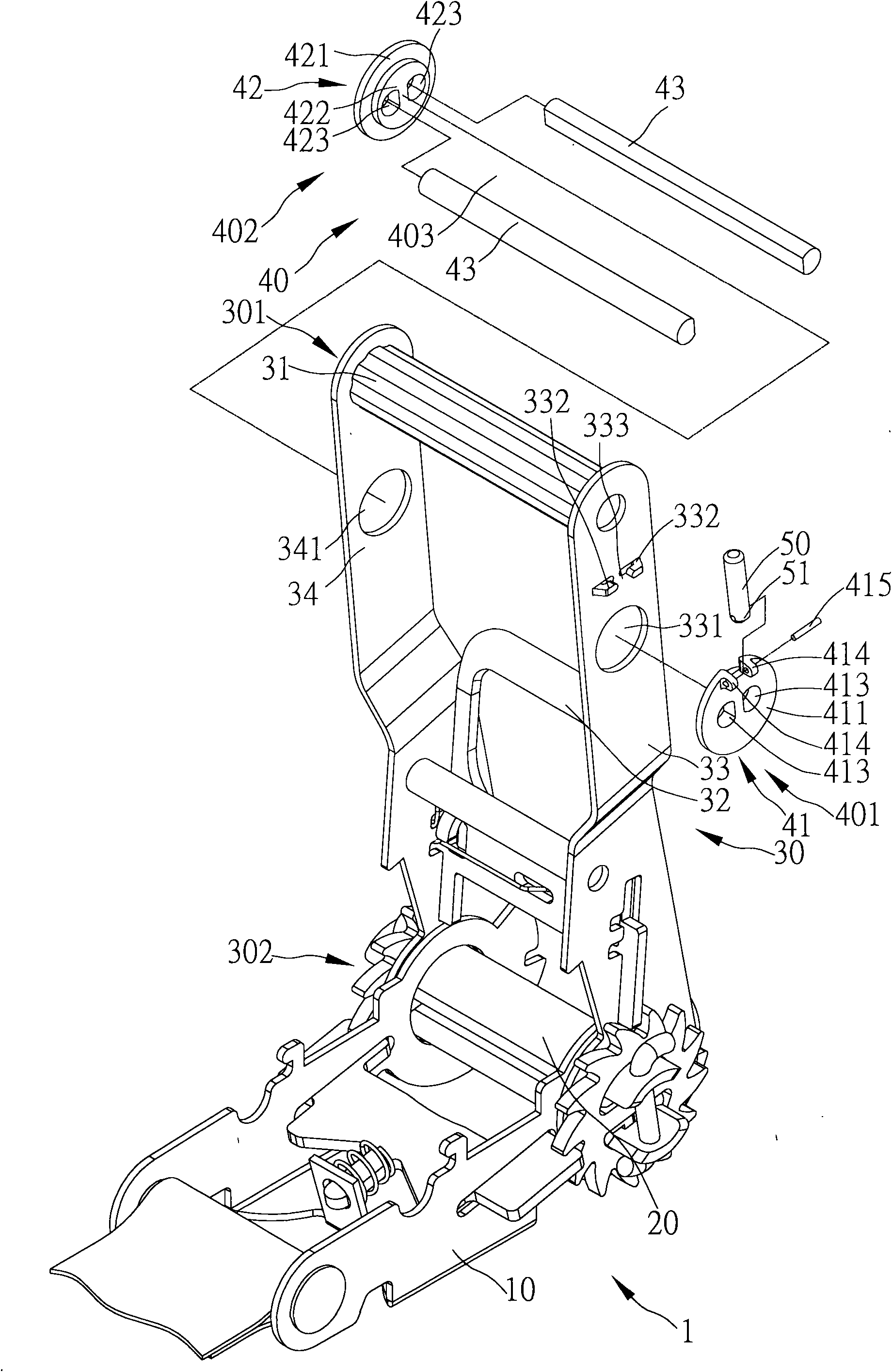

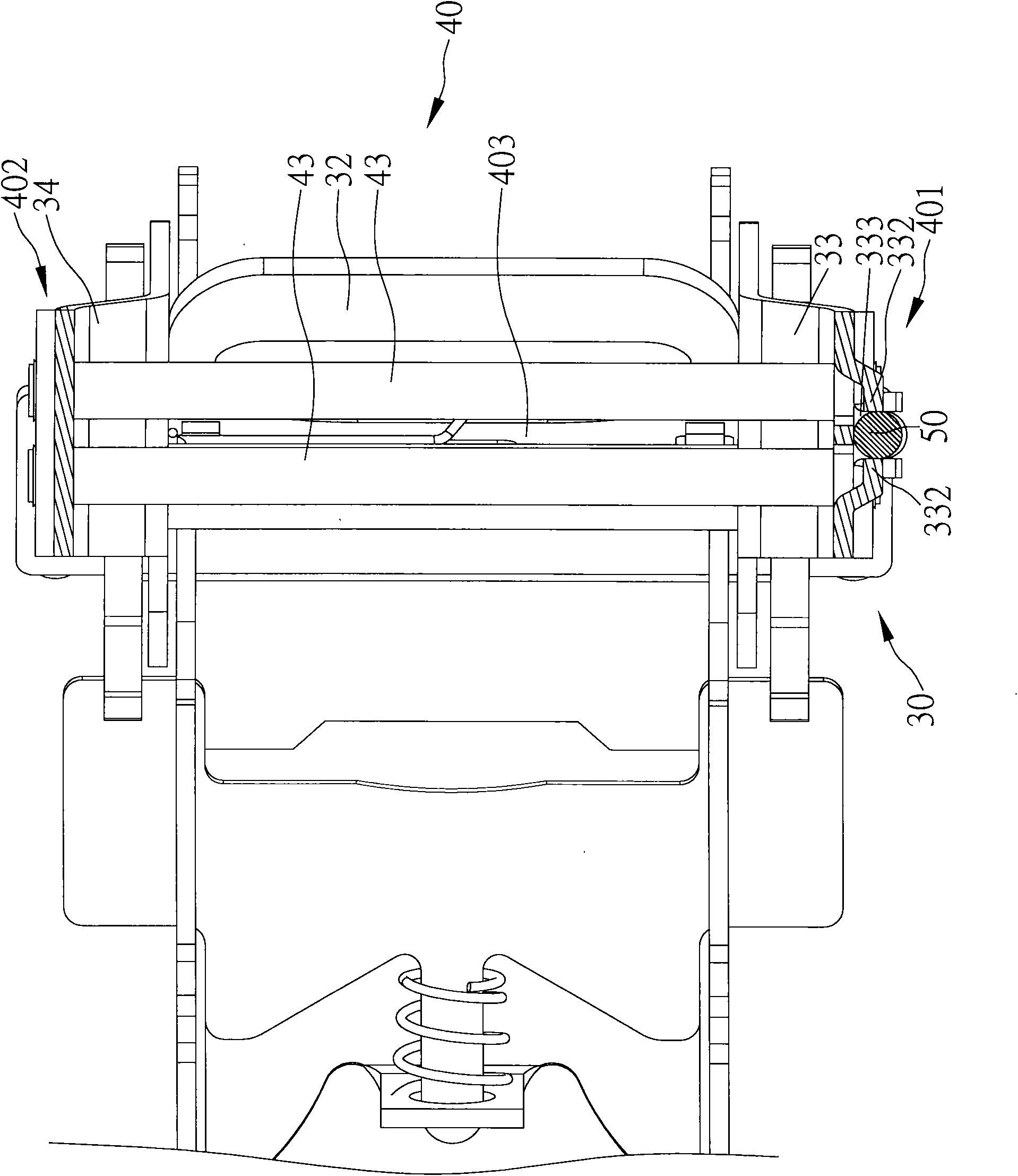

Caster with brake structure

The invention discloses a caster with a brake structure, comprising a frame body, an operation part which penetrates the frame body, a pivot piece which is rotatably pivoted on the frame body, a lifting block which is arranged on the frame body in an elastic reset lifting manner, an anti-skid block which is arranged on the frame body in an elastic reset displacement manner, and a rotating wheel which is rotatably arranged on the frame body. When the caster is positioned, the operation part is used for pushing the pivot piece to rotate, a clamping edge of the pivot piece is inserted in a positioning ditch of the rotating wheel for positioning the rotating wheel, the pivot piece simultaneously pushes the lifting block to descend, the lifting block can push and resist a sliding block to carry out horizontal displacement in the pushing and resisting means during the descending displacement, and the sliding block further pushes the anti-skid block to carry out the displacement and oppresses the oppression surface of the rotating wheel for positioning the rotating wheel, thereby simultaneously inserting the pivot piece in the positioning ditch on the inner side of the rotating wheel, using the anti-skid block to oppress the oppression surface of the rotating wheel, using the dual-positioning to achieve the effect of indeed positioning the rotating wheel, and solving the shortcoming that the positioning is not indeed caused by only using one positioning technology in the past.

Owner:CATIS PACIFIC MFG CORP

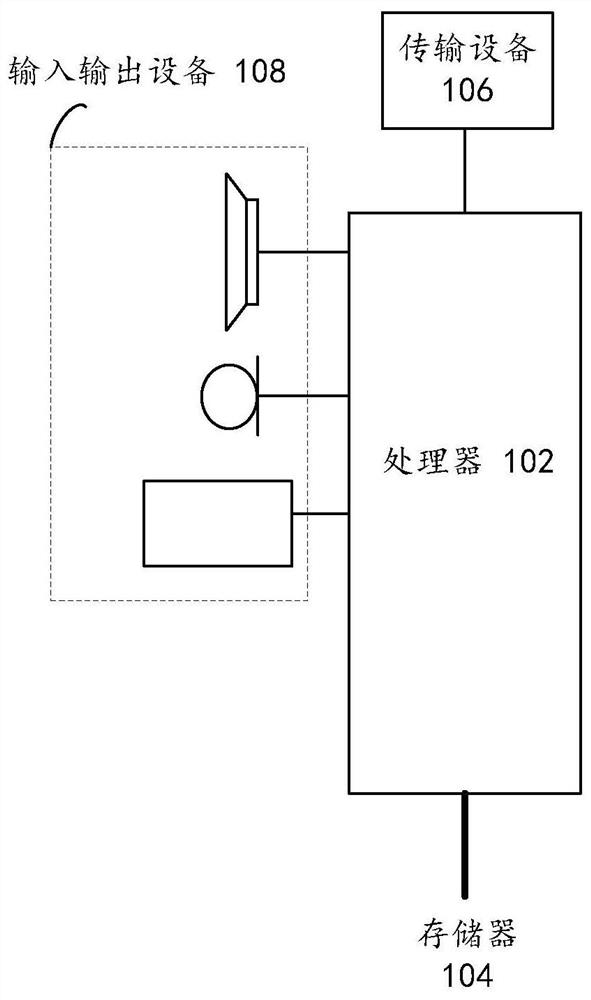

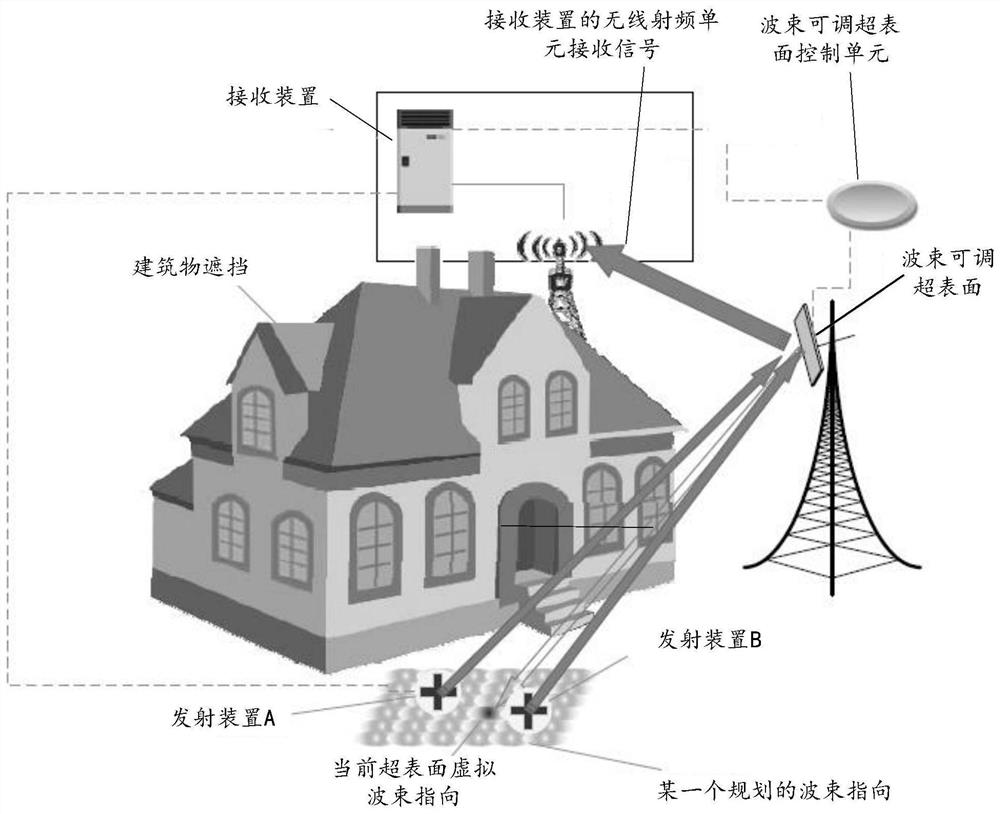

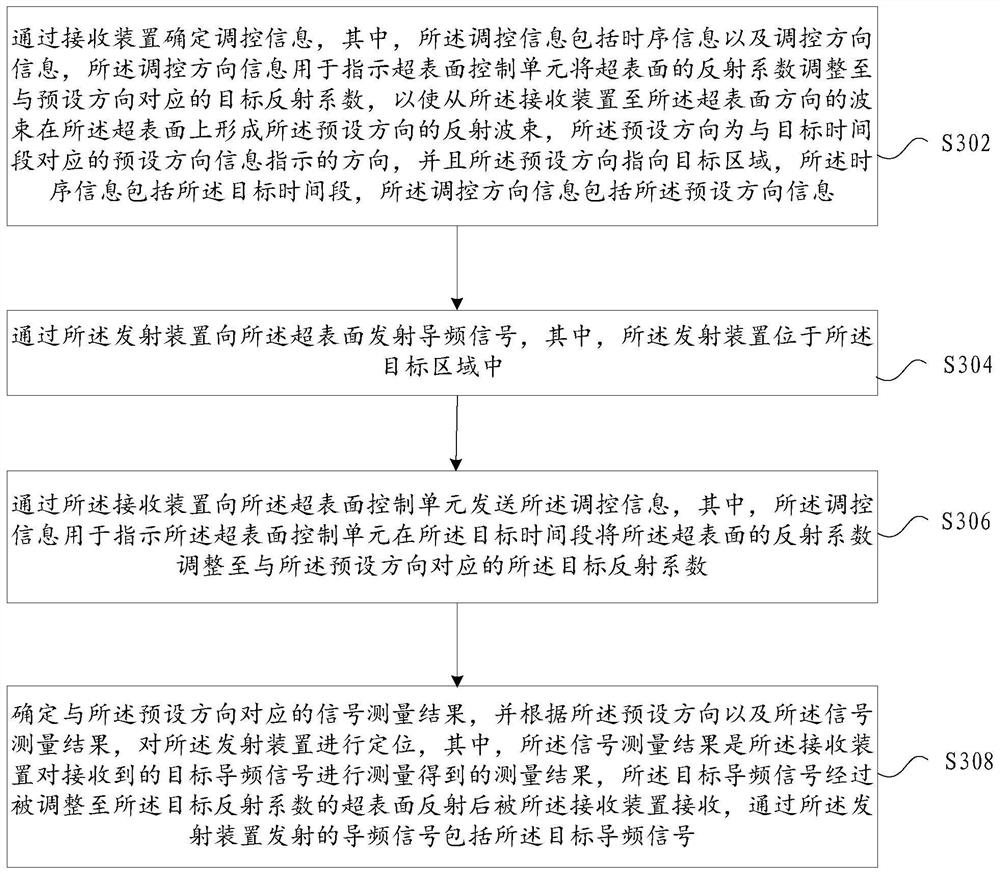

Positioning method, device and system of transmitting device, storage medium and electronic device

PendingCN111867054AAchieve positioning effectPassive radio relay systemsPosition fixationControl engineeringControl cell

The embodiment of the invention provides a positioning method, device and system for a transmitting device, a storage medium and an electronic device. The method comprises steps of determining the regulation and control information through a receiving device, the regulation and control direction information being used for indicating a metasurface control unit to adjust a reflection coefficient ofa metasurface to a target reflection coefficient corresponding to a preset direction; transmitting a pilot signal to the metasurface through a transmitting device; sending regulation and control information to the metasurface control unit through a receiving device, wherein the regulation and control information is used for indicating the metasurface control unit to adjust the reflection coefficient of the metasurface to the target reflection coefficient corresponding to the preset direction in the target time period; and determining a signal measurement result corresponding to the preset direction, and positioning the transmitting device according to the preset direction and the signal measurement result. Through application of the method, a technical problem that the terminal cannot be positioned by utilizing the characteristics of the metasurface in related technologies is solved, and the effect of positioning the terminal by utilizing the characteristics of the metasurface is achieved.

Owner:ZTE CORP

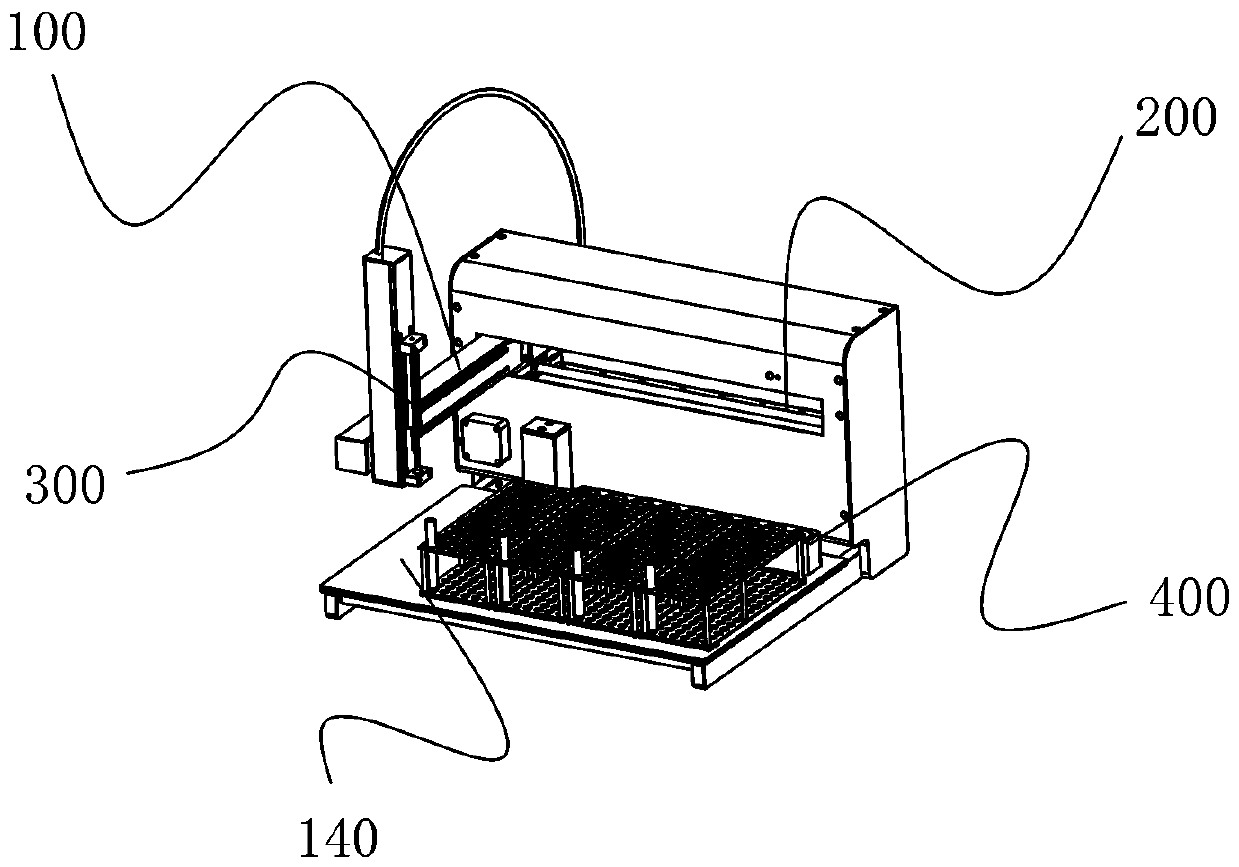

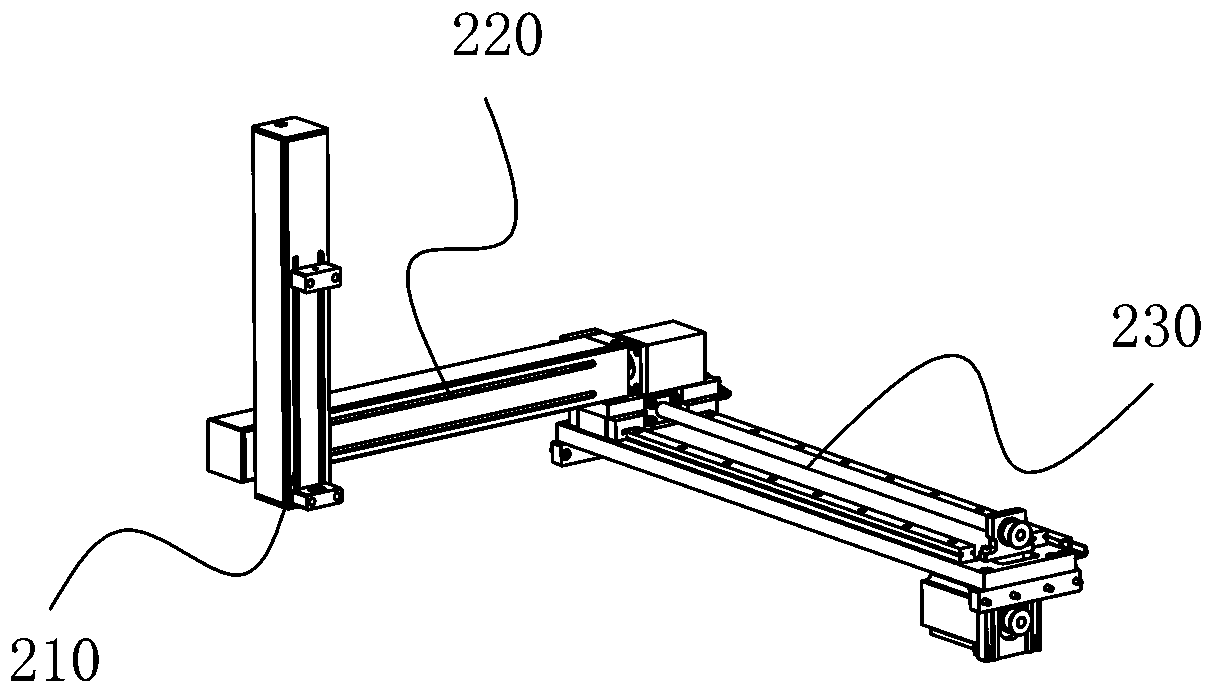

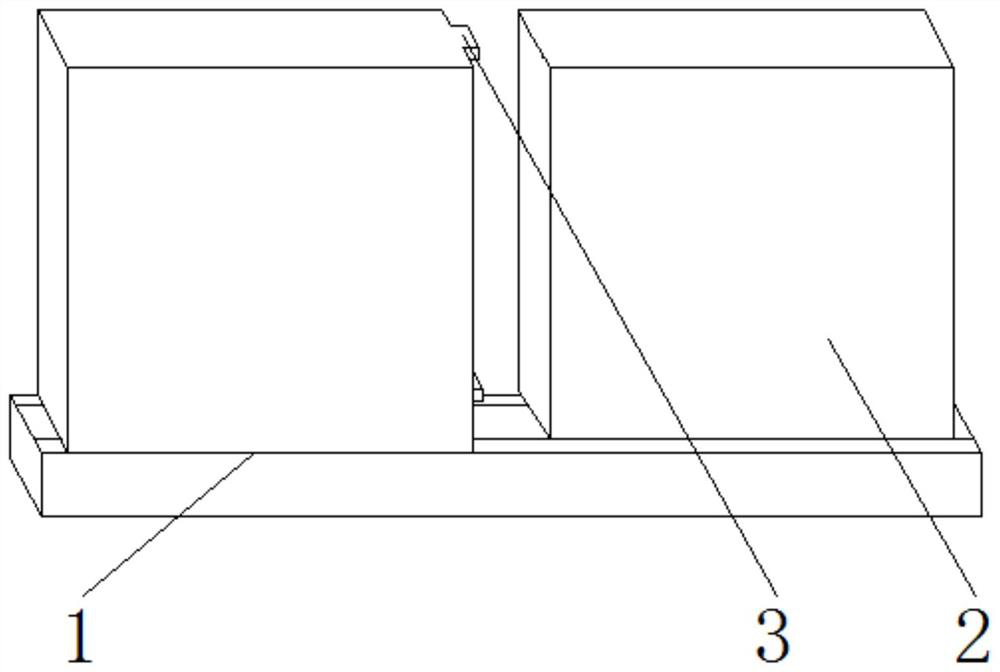

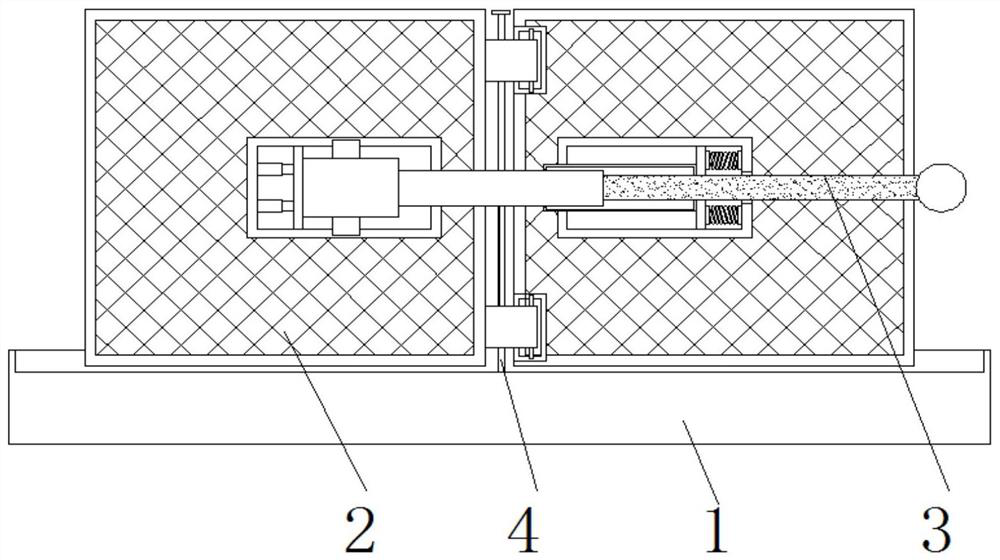

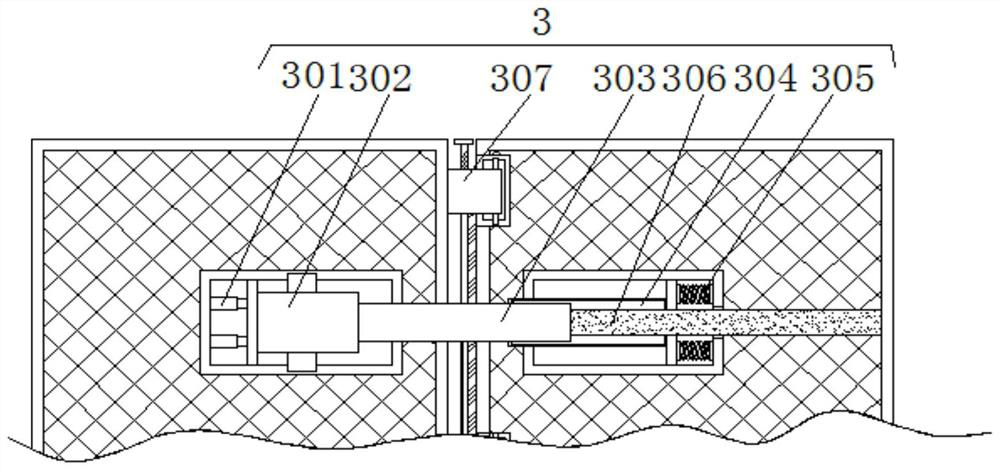

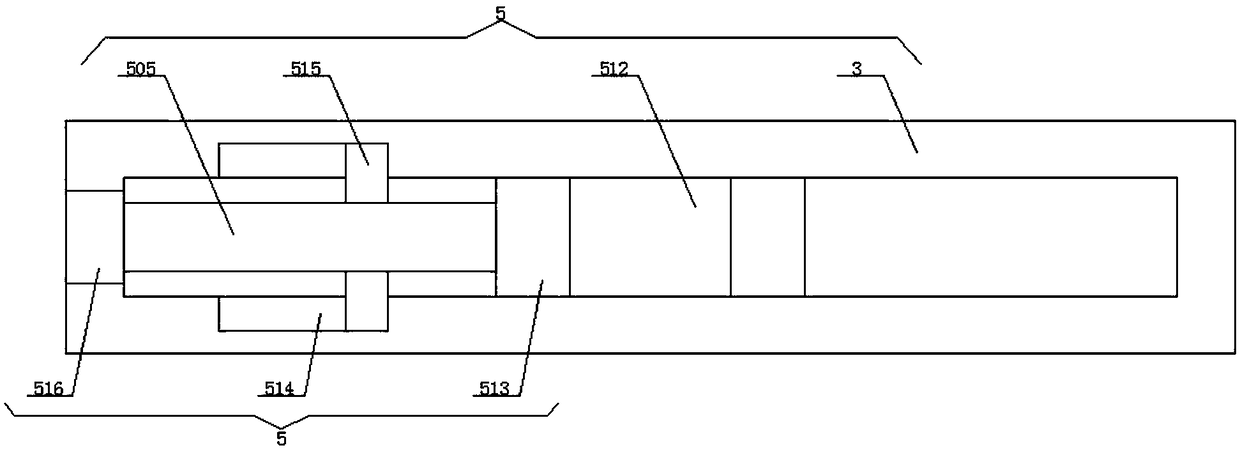

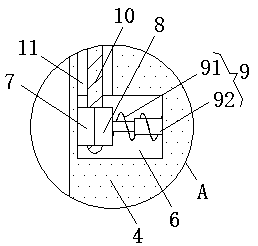

Sampling device for liquid sample

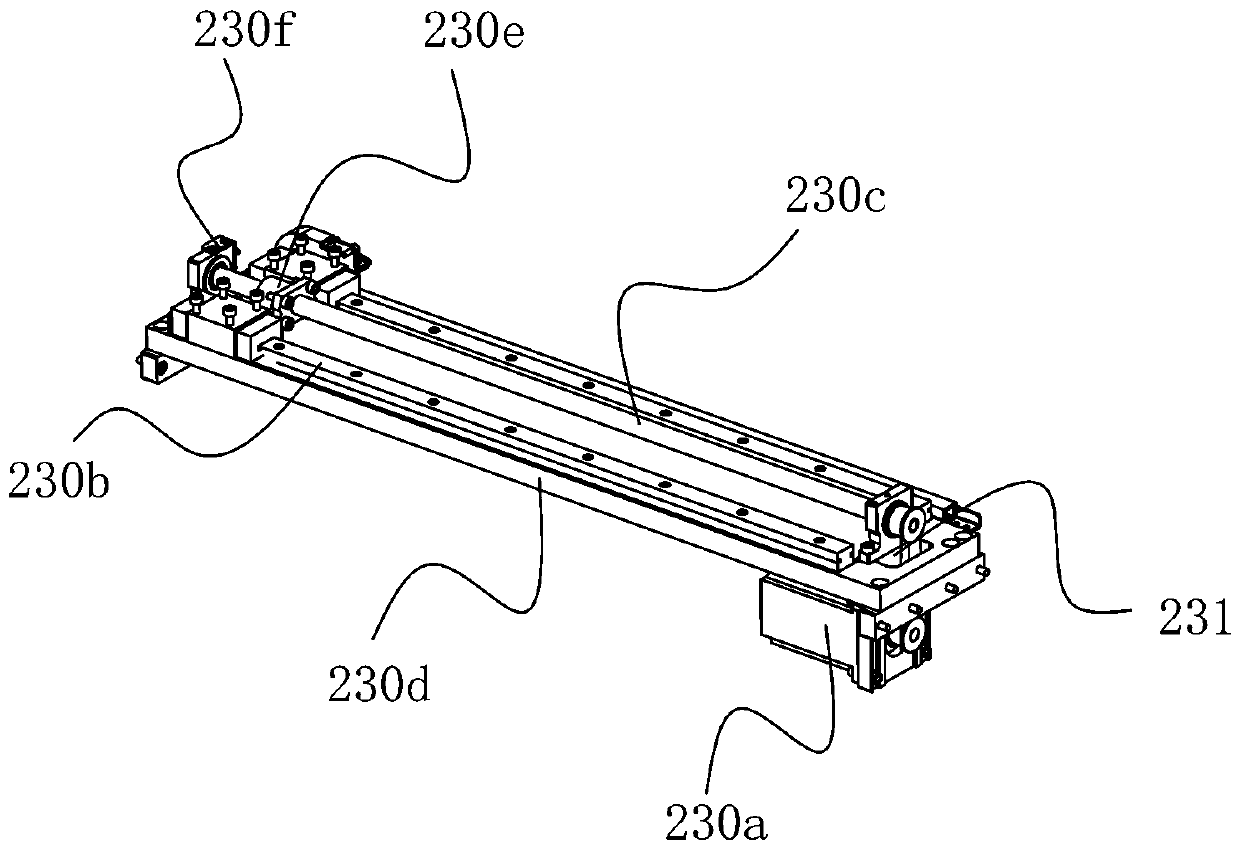

PendingCN107831040AAchieve positioning effectSave spaceWithdrawing sample devicesEngineeringMechanical engineering

The invention relates to the technical field of liquid collection, in particular to a sampling device for a liquid sample. The sampling device comprises a driving structure, a liquid suction head assembly and a cleaning structure, wherein the driving structure comprises an Z-axis driving mechanism, a Y-axis driving mechanism and an X-axis driving mechanism which are jointly matched; the sampling device is skillfully and accurately positioned by the driving mechanism, and can be cleaned and reutilized by the cleaning structure after the liquid suction head assembly completes primary sampling; when the liquid sample is collected for the second time, the influence by the previous collected liquid sample is avoided. The sampling device has the advantages that the structure arrangement is reasonable, and the operation is convenient.

Owner:宁波市锦祥电气科技有限公司

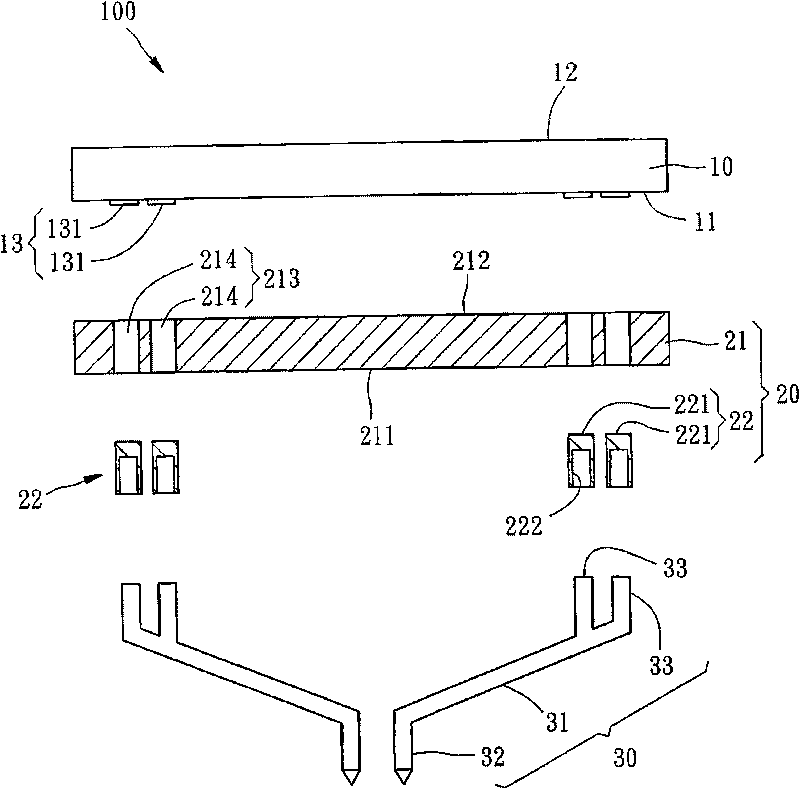

Probe card

InactiveCN101726635ASimplify the combined procedureAccuracy increaseElectrical measurement instrument detailsElectrical testingProbe cardBiomedical engineering

The invention relates to a probe card comprising a circuit board, a probe fixing seat and a plurality of probes, wherein the circuit board is provided with a plurality of welding pads; the probe fixing seat is provided with a positioning plate and a plurality of combining pieces; the positioning plate is provided with a plurality of positioning holes; the combining pieces are arranged in the positioning holes and electrically connected with the welding pads of the circuit board; each probe is provided with a body part, a tip part connected with one end of the body part, and at least two fixing parts connected with the other end of the body part; the two fixing parts have a preset distance and are respectively and electrically connected with the combining pieces; and the two fixing parts with the preset distance are connected with the combining pieces in the positioning holes of the positioning plate for realizing a positioning effect and simplifying an assembly procedure.

Owner:PLEADER YAMAICHI

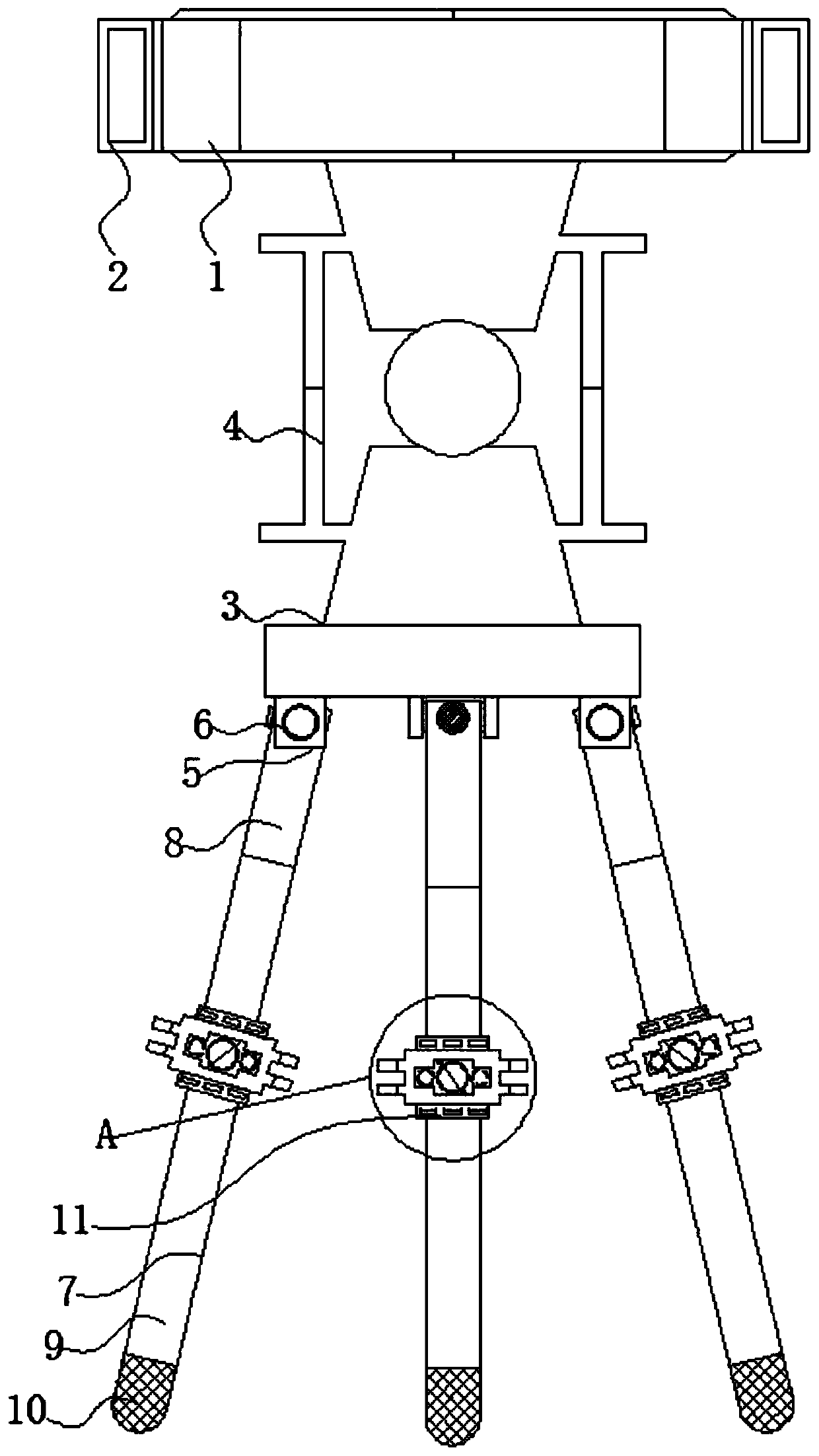

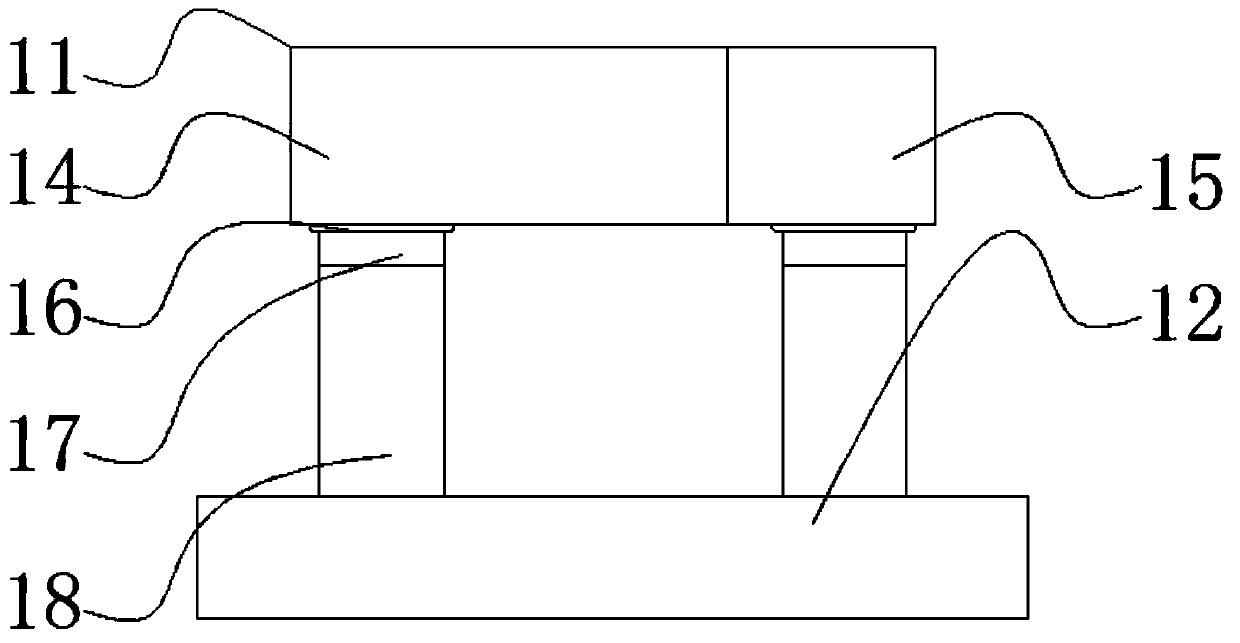

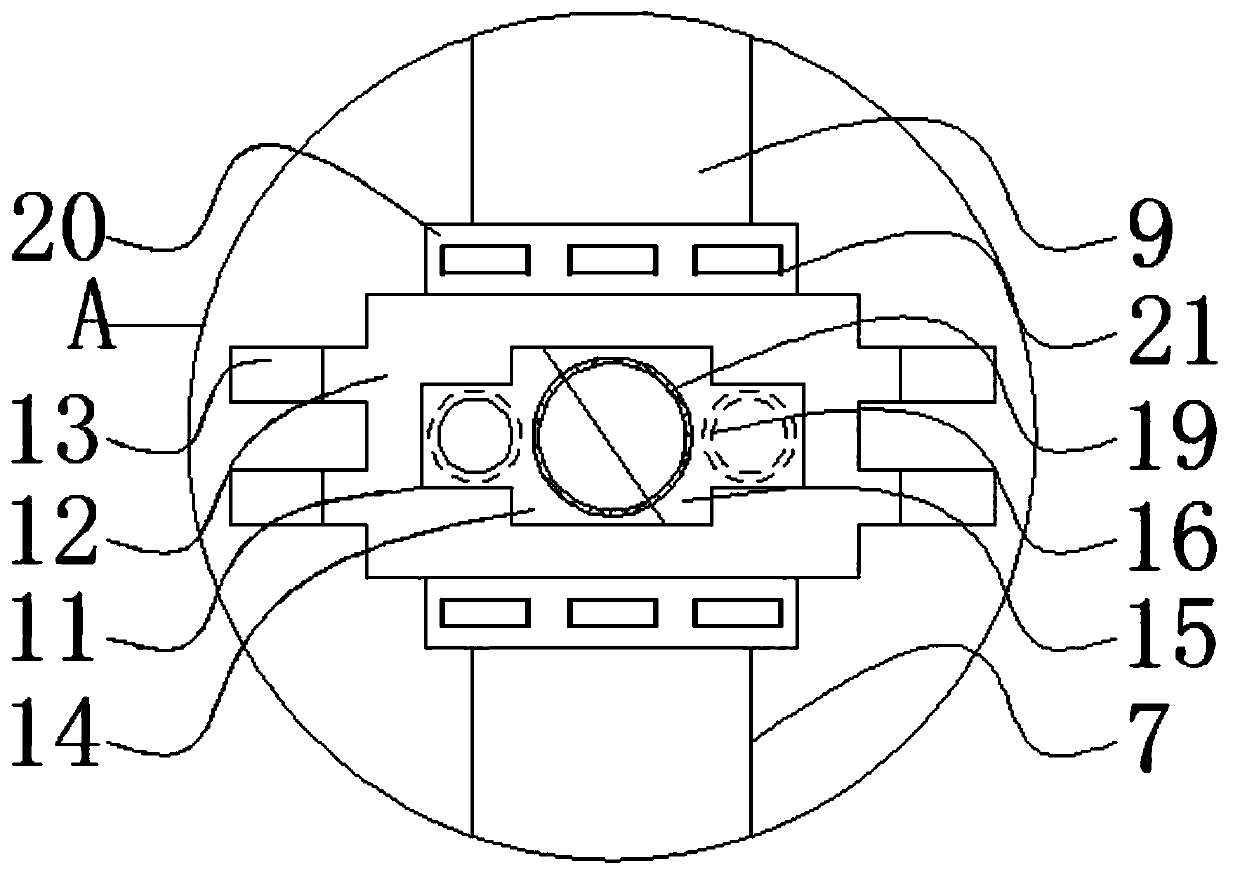

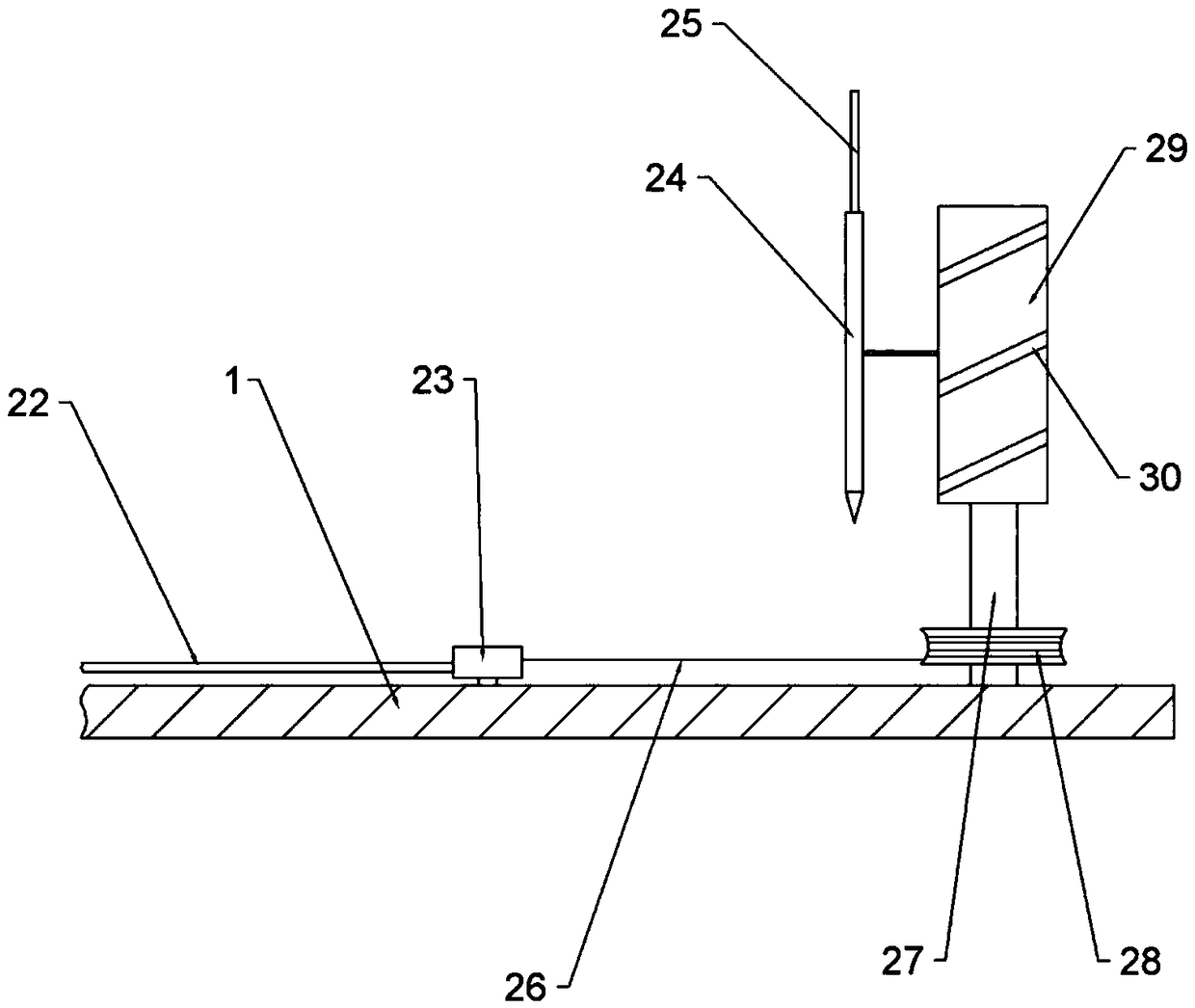

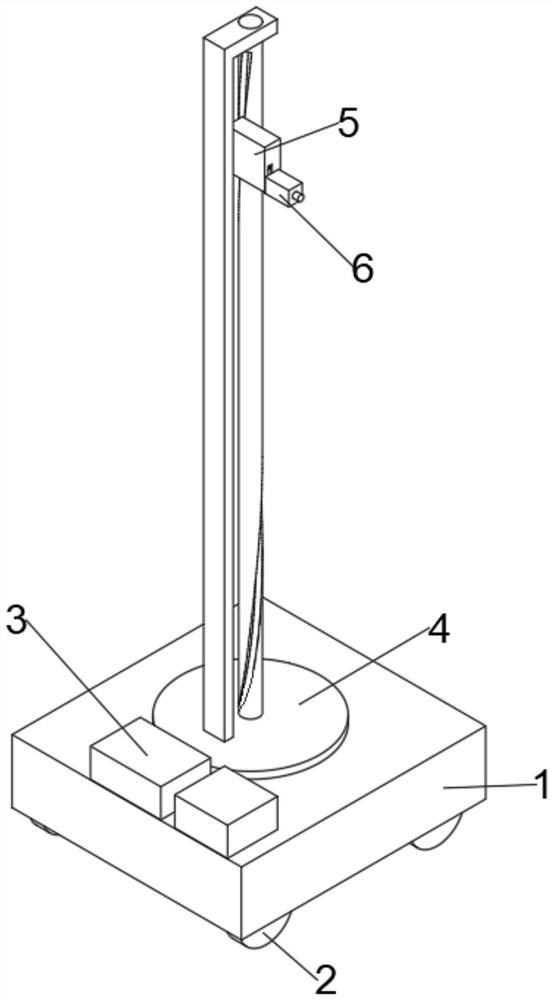

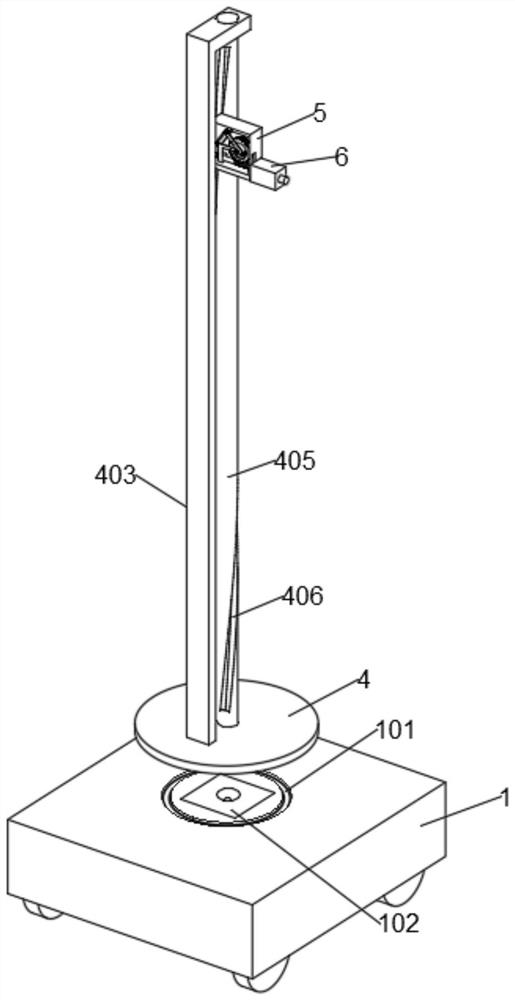

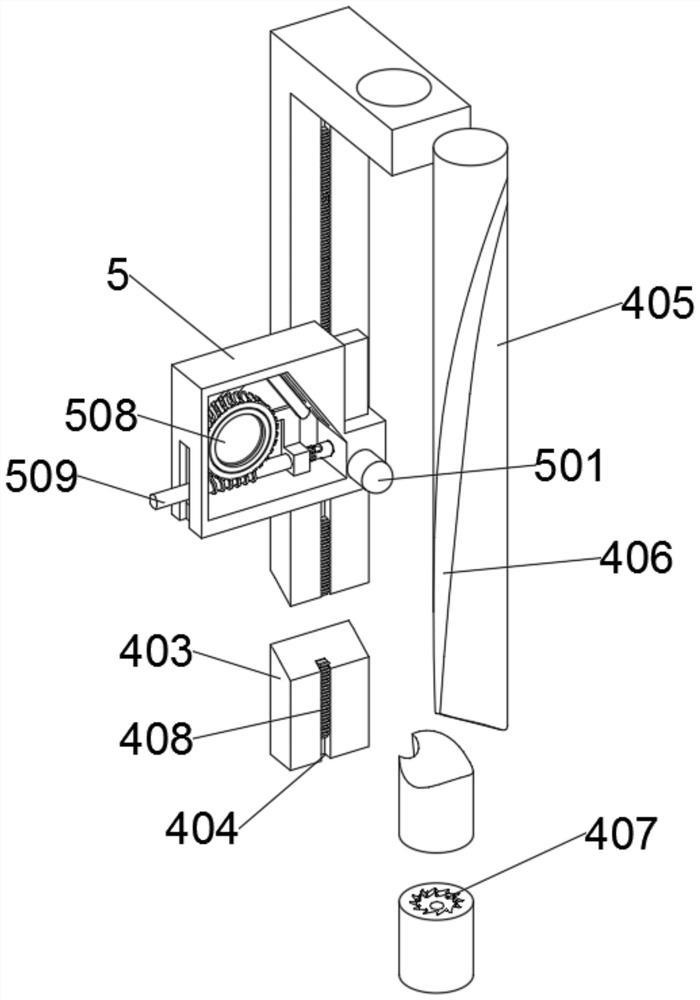

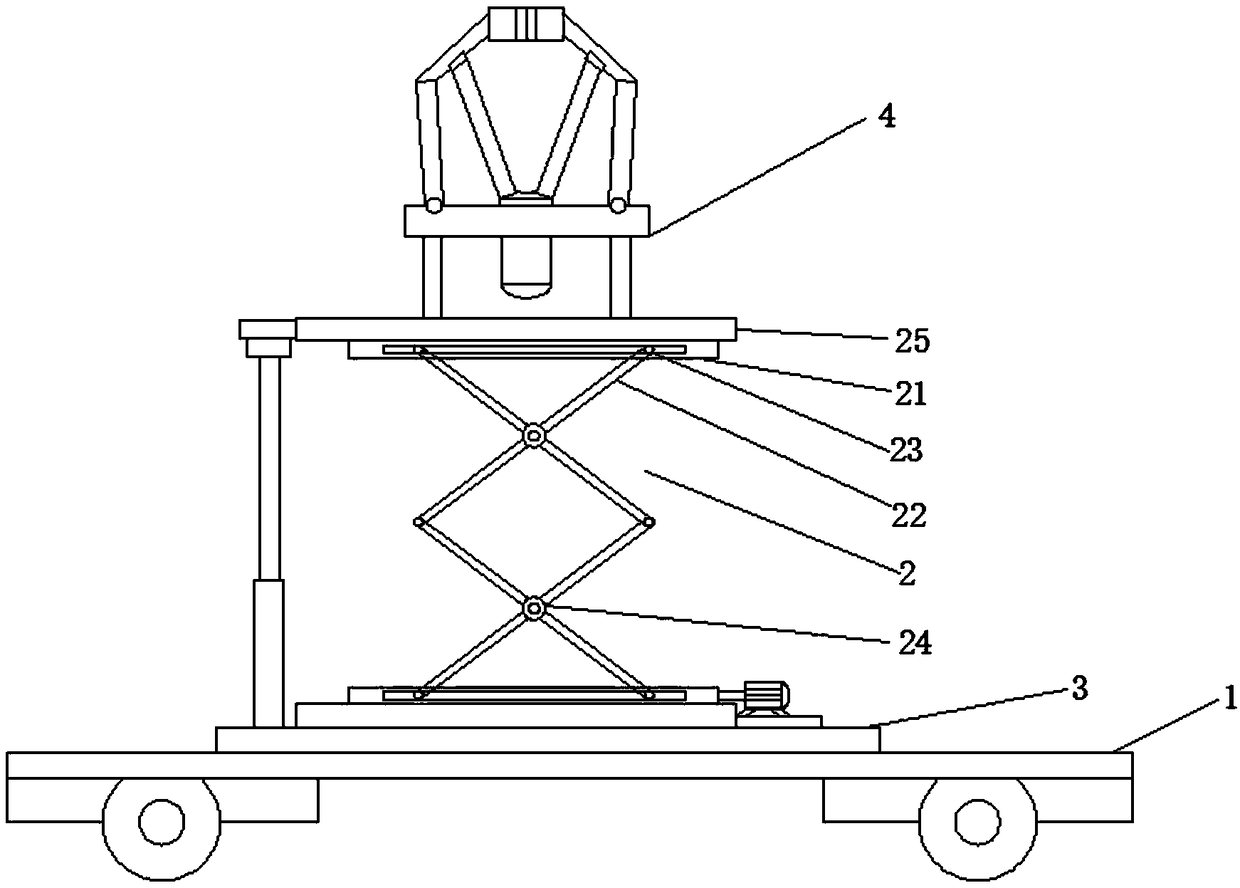

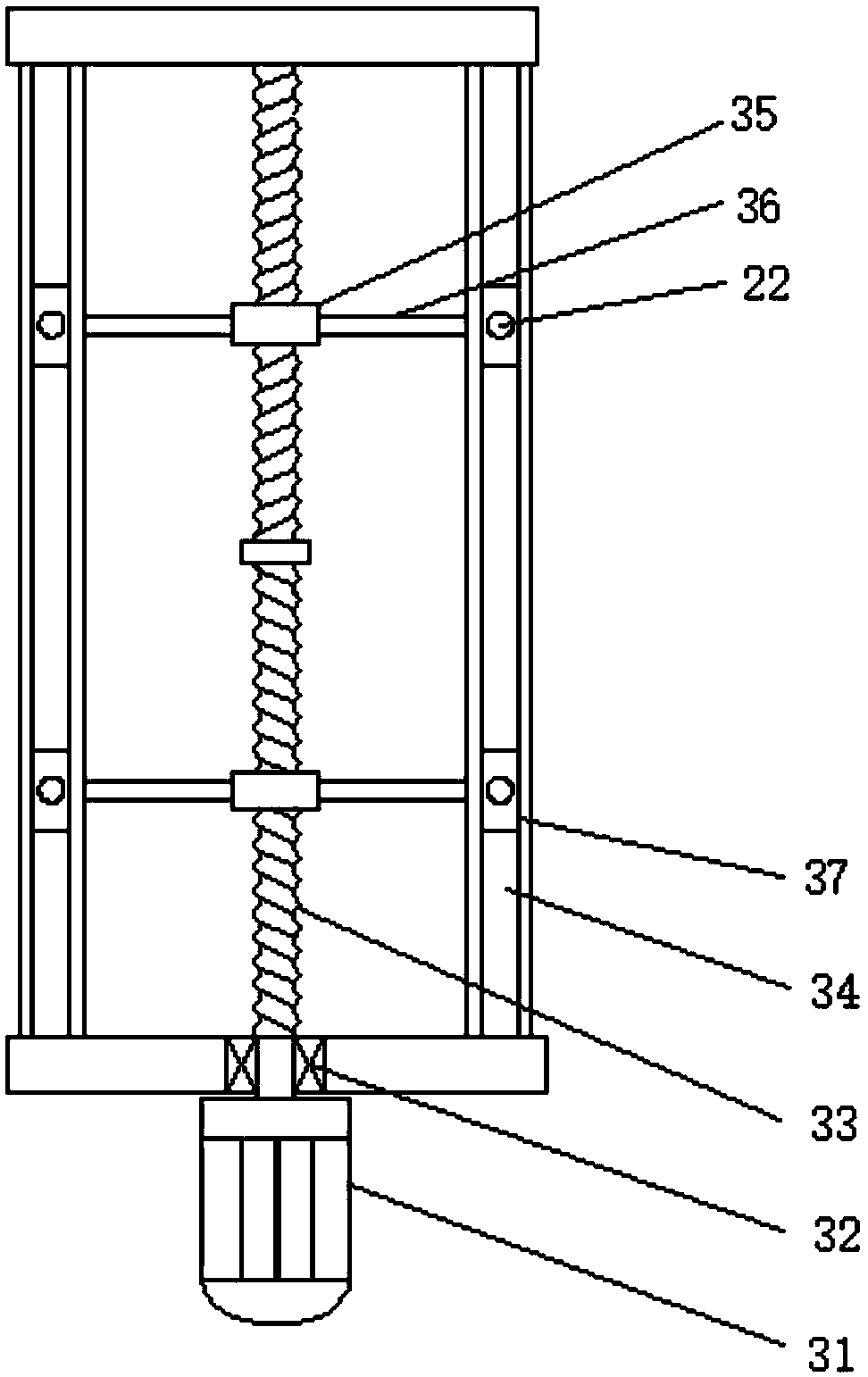

Equipment for measuring internal size of steel ladle by using laser range finder and operation method thereof

ActiveCN111238411AIncrease purchase costReduce cost of measurementUsing optical meansElectromagnetic wave reradiationLaser rangingMaterial consumption

The invention relates to equipment for measuring the internal size of a steel ladle by using a laser range finder and an operation method thereof. The equipment comprises a laser range finding mechanism and a bunching mechanism, and a side connection guardrail frame is arranged at the bottom end of the laser range finding mechanism. The beneficial effects of the equipment are that: According to the equipment for measuring the internal size of the steel ladle by using the laser range finder and the operation method thereof, the size condition of any area in the steel ladle can be measured, theinternal condition of the steel ladle can be simply simulated, the melting loss degree of the area is judged by comparing with relevant parameters when the steel ladle is on line, the internal condition of the steel ladle can be simply simulated through the method, the refractory material melting loss degree of the steel ladle and the steel weighing amount condition of the steel ladle can be calculated, and an original method for optimizing manual measurement by using the rod is adopted; finally, ladle service monitoring and ladle lining size control data and information can be provided for steel ladle service monitoring, a foundation is laid for saving refractory material consumption and prolonging the ladle life, major accidents of steel ladle furnace penetration are effectively prevented and safe operation and smooth production of steel ladle service are guaranteed.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

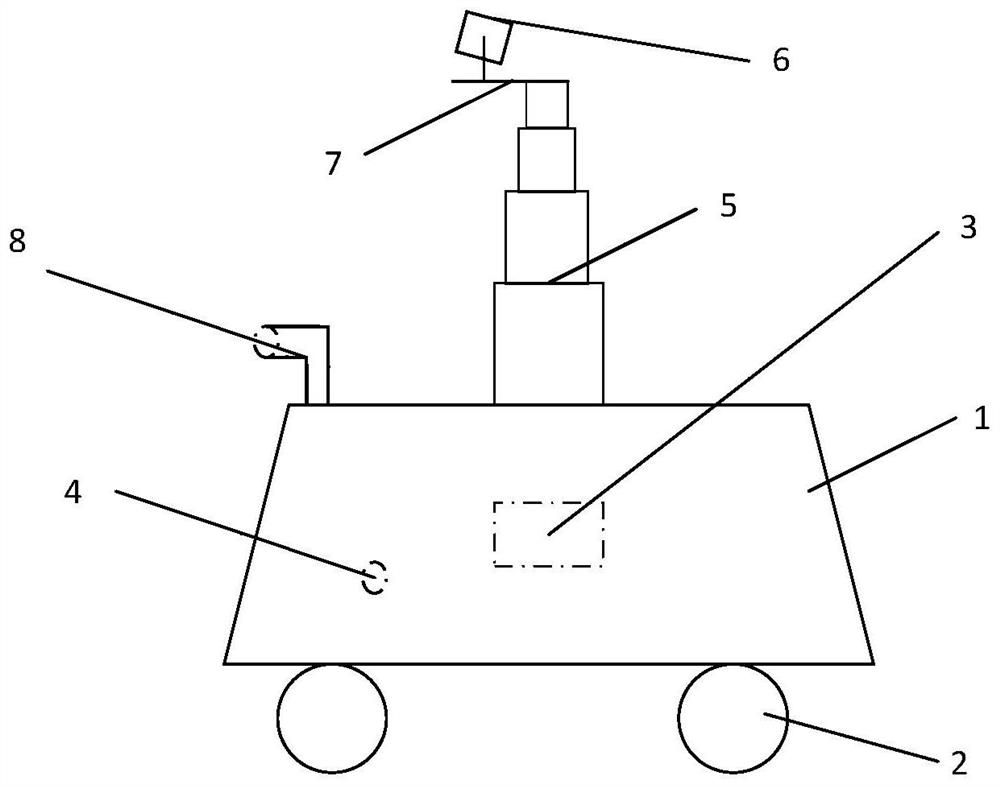

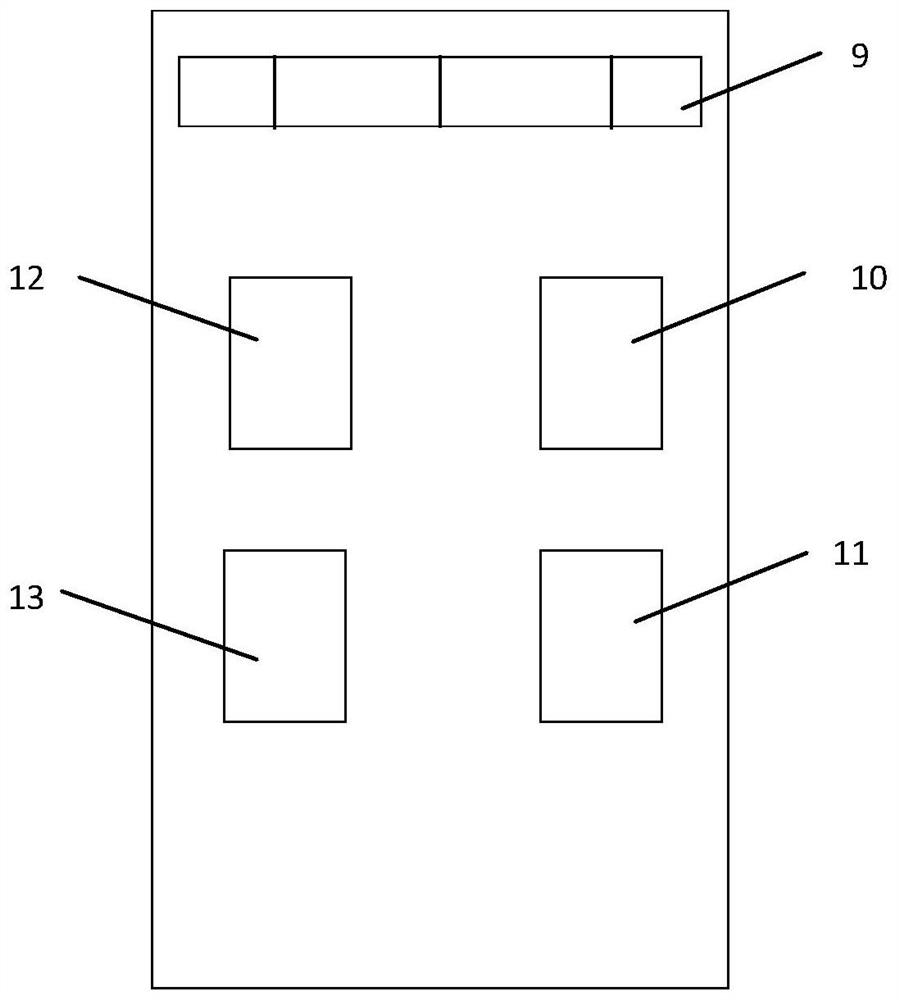

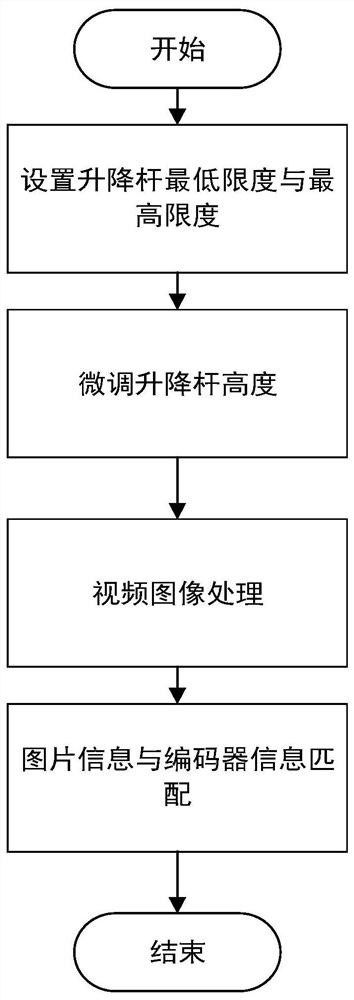

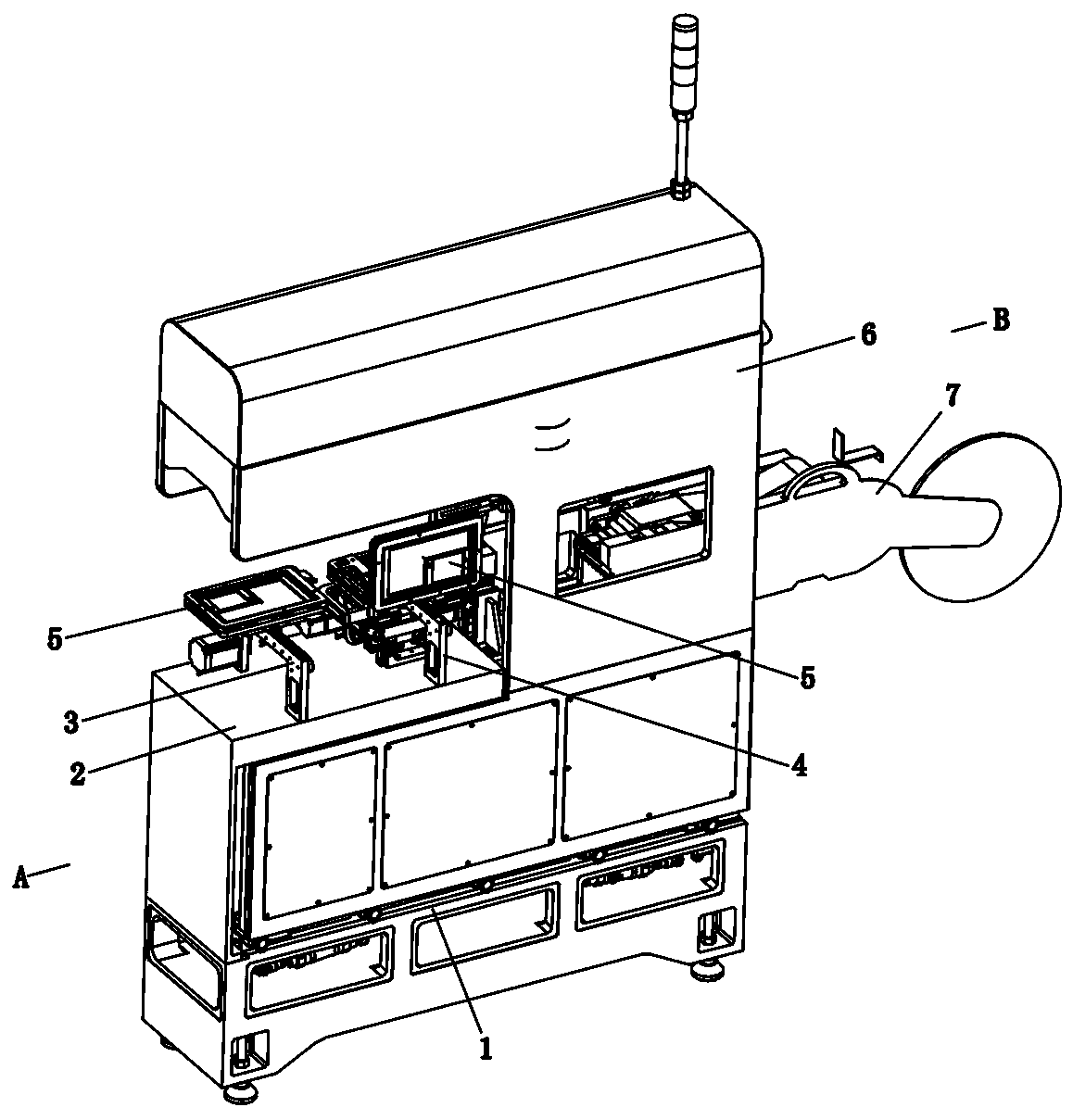

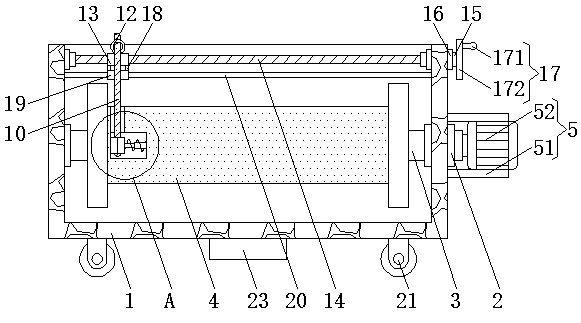

Unmanned inspection robot for power distribution room

ActiveCN112157642AImprove the level of intelligenceSave manpower and timeTelevision system detailsProgramme-controlled manipulatorControl engineeringCamera module

The invention relates to an unmanned inspection robot for a power distribution room. The unmanned inspection robot comprises a vehicle body, wheels, a vehicle body driving mechanism and a core controlboard, and further comprises a lifting holder, a camera holder, a camera module, a direct current motor with an encoder and a magnetic conduction sensor which are correspondingly connected with the core control board; and a magnetic circuit is laid in front of a power distribution cabinet in the power distribution room. The power distribution room inspection process comprises the steps of 1), controlling the lifting holder to be at the lowest height; 2), performing uniform inspection along the magnetic circuit according to the magnetic conduction sensor, and acquiring an inspection image in real time through the camera module until one round of inspection is completed; and 3), controlling the lifting holder to ascend, and repeatedly executing the steps 2) and 3). The core control board identifies an electric energy meter detecting device arranged on the power distribution cabinet from the inspection image so as to acquire the position of the power distribution cabinet and the height of the electric energy meter detecting device. According to the unmanned inspection robot for the power distribution room, compared with the prior art, manual time can be greatly saved, meanwhile, manual positioning is not needed, efficiency is greatly improved, and potential safety hazards can be reduced to the minimum.

Owner:SHANGHAI DIANJI UNIV

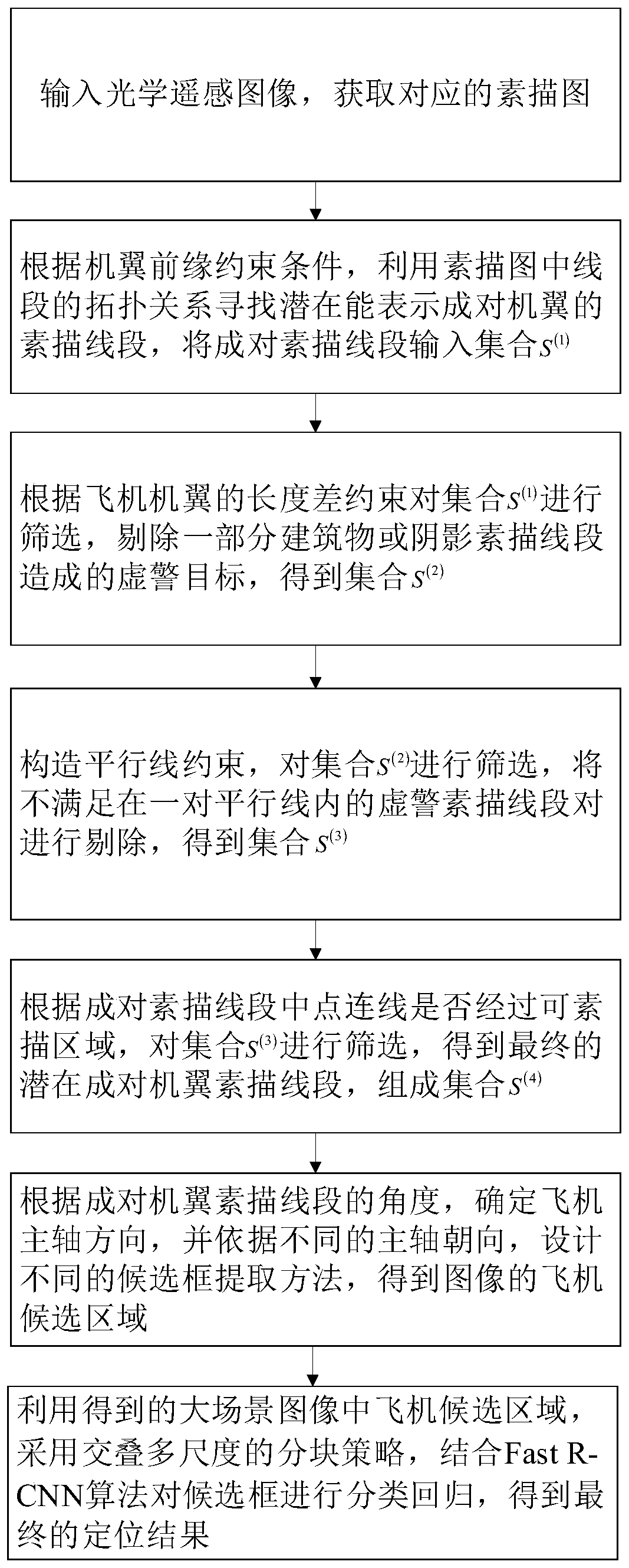

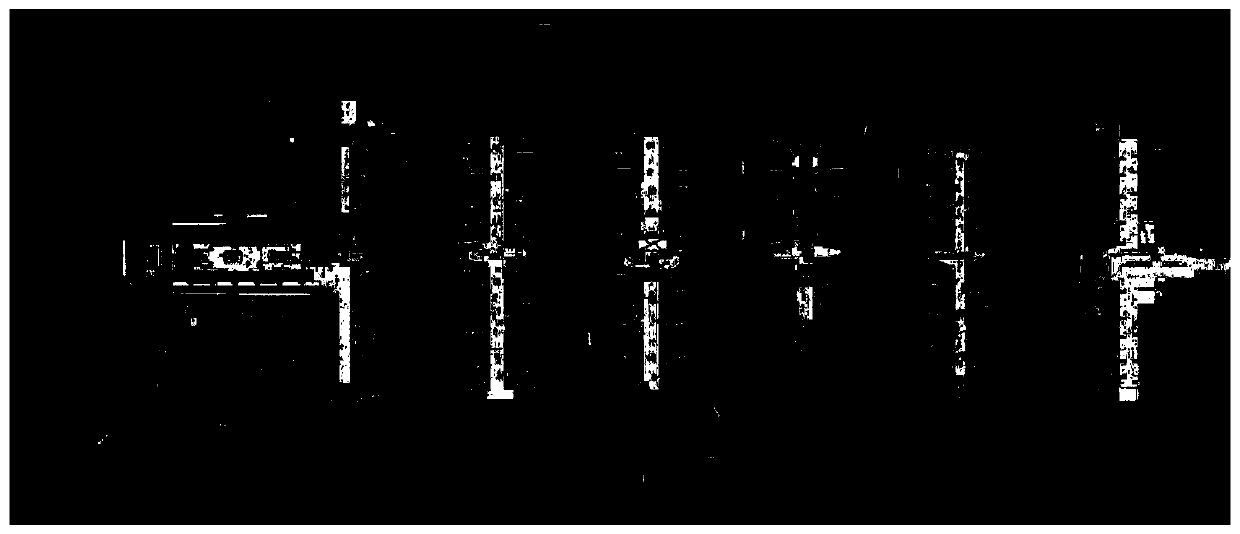

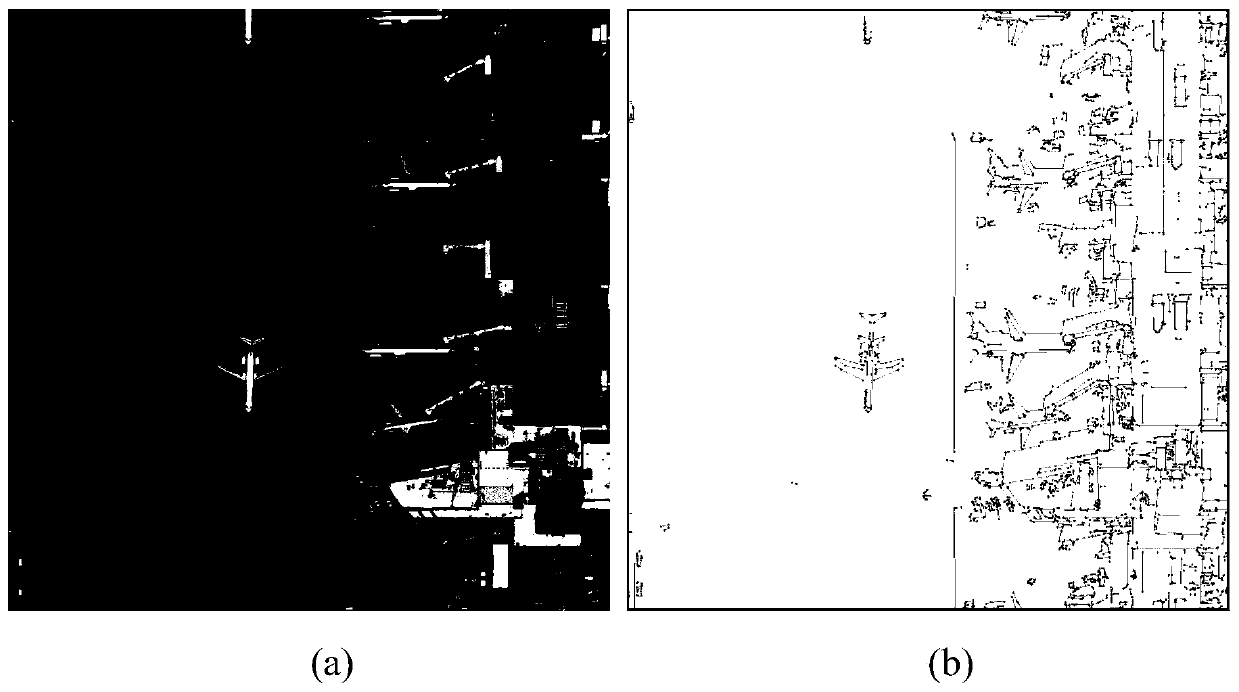

Airplane target detection method based on a sketch map candidate box strategy and Fast R-CNN

ActiveCN110222638AQuick extractionEfficient extractionScene recognitionJet aeroplaneRelationship extraction

The invention discloses an airplane target detection method based on a sketch map candidate box strategy and Fast R-CNN. The method includes extracting sketch line segments which possibly form an airplane wing by utilizing the geometric position relation of line segments in the sparse representation model of the sketch map, judging the orientation of an airplane main shaft according to the extracted paired sketch line segments, and designing different methods according to different main shaft directions to obtain candidate frames of the airplane; and performing classification regression on thecandidate frame by using the obtained candidate frame in combination with a Fast R-CNN network and by using an overlapping multi-scale partitioning strategy to obtain a final target detection result.The method for extracting the candidate frame of the airplane target in the image by adopting a weak supervision mode can also be used for carrying out classification identification through an SVM orinputting other classification regression networks for further identification to obtain the position of the airplane target in the image so as to achieve the purpose of airplane detection in the image.

Owner:XIDIAN UNIV

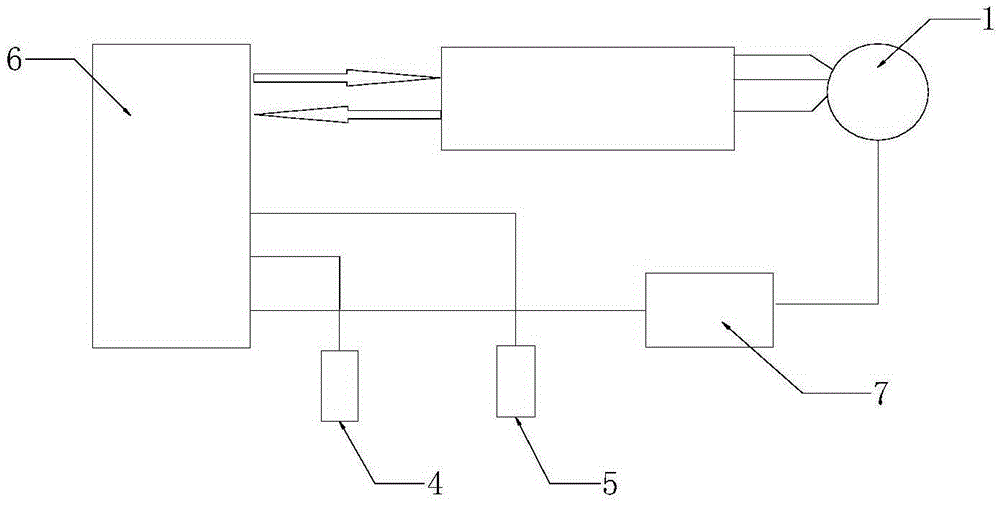

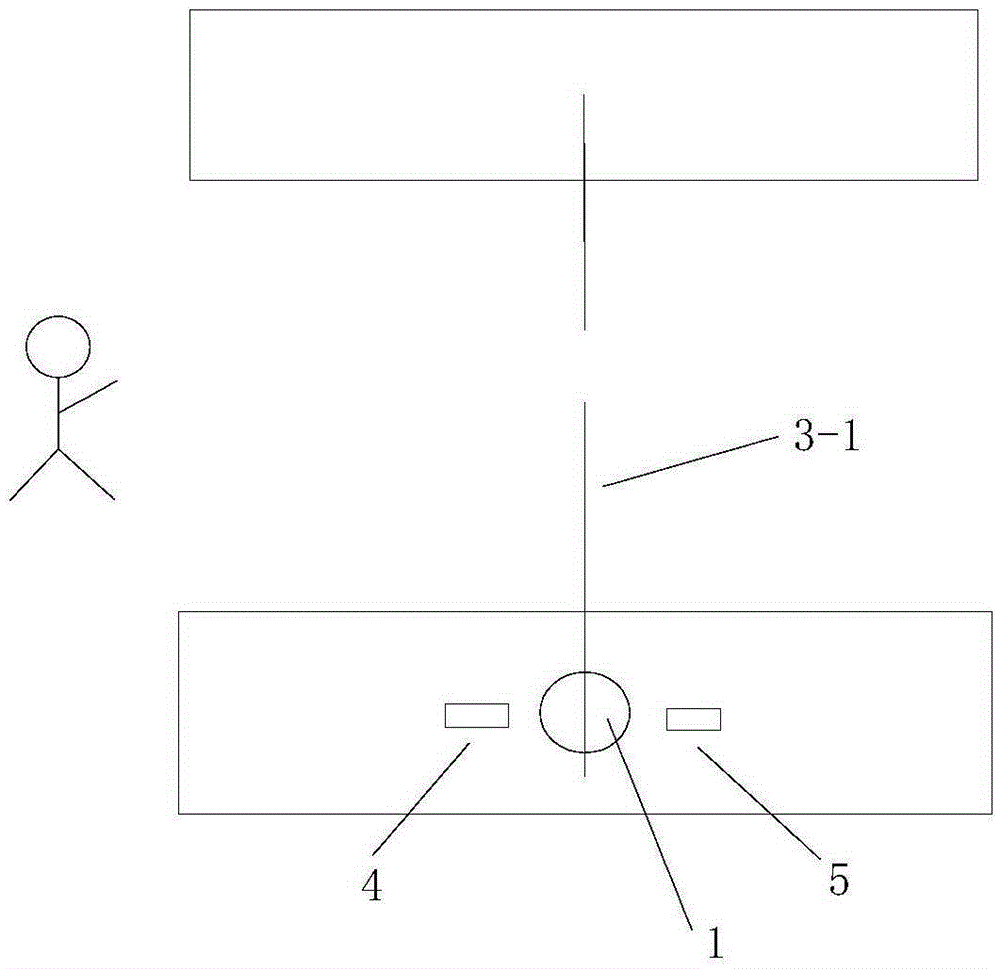

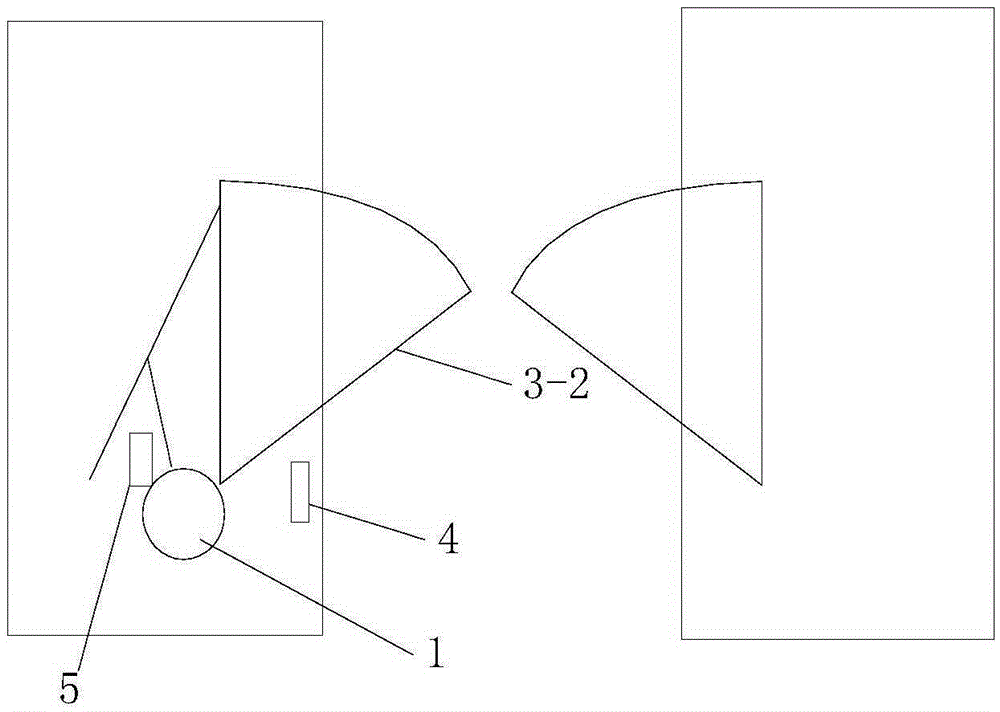

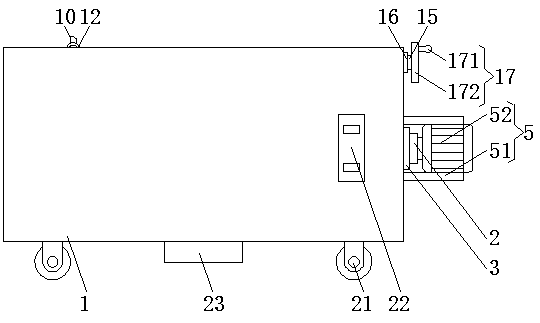

Automatic anti-collision passage gate machine and control method thereof

ActiveCN106609500AGuaranteed uptimeNo jitterTraffic restrictionsElectronic commutatorsBrushless motorsEngineering

The embodiment of the invention discloses an automatic anti-collision passage gate machine. The automatic anti-collision passage gate machine comprises a gate machine body and a brushless direct current motor provided with a hall sensor and arranged in the gate machine body. The gate machine body is internally provided with a CPU which is connected with the brushless direct current motor with the hall sensor and used for driving and controlling the brushless direct current motor with the hall sensor through currents, and a current detecting device is arranged between the CPU and the brushless direct current motor with the hall sensor. The gate machine body is further provided with a sensor A and a sensor B inside. The sensor A and the second B are connected with the CPU. The application of the brushless direct current motor with the hall sensor to the passage gate machine is provided, the characteristics of the brushless motor are utilized, the anti-collision problem is solved, the positioning overshooting problem is solved, and the shaking and noise problems in service are solved. The automatic anti-collision passage gate machine is simple in mechanical structure and convenient to install and debug.

Owner:李杰成

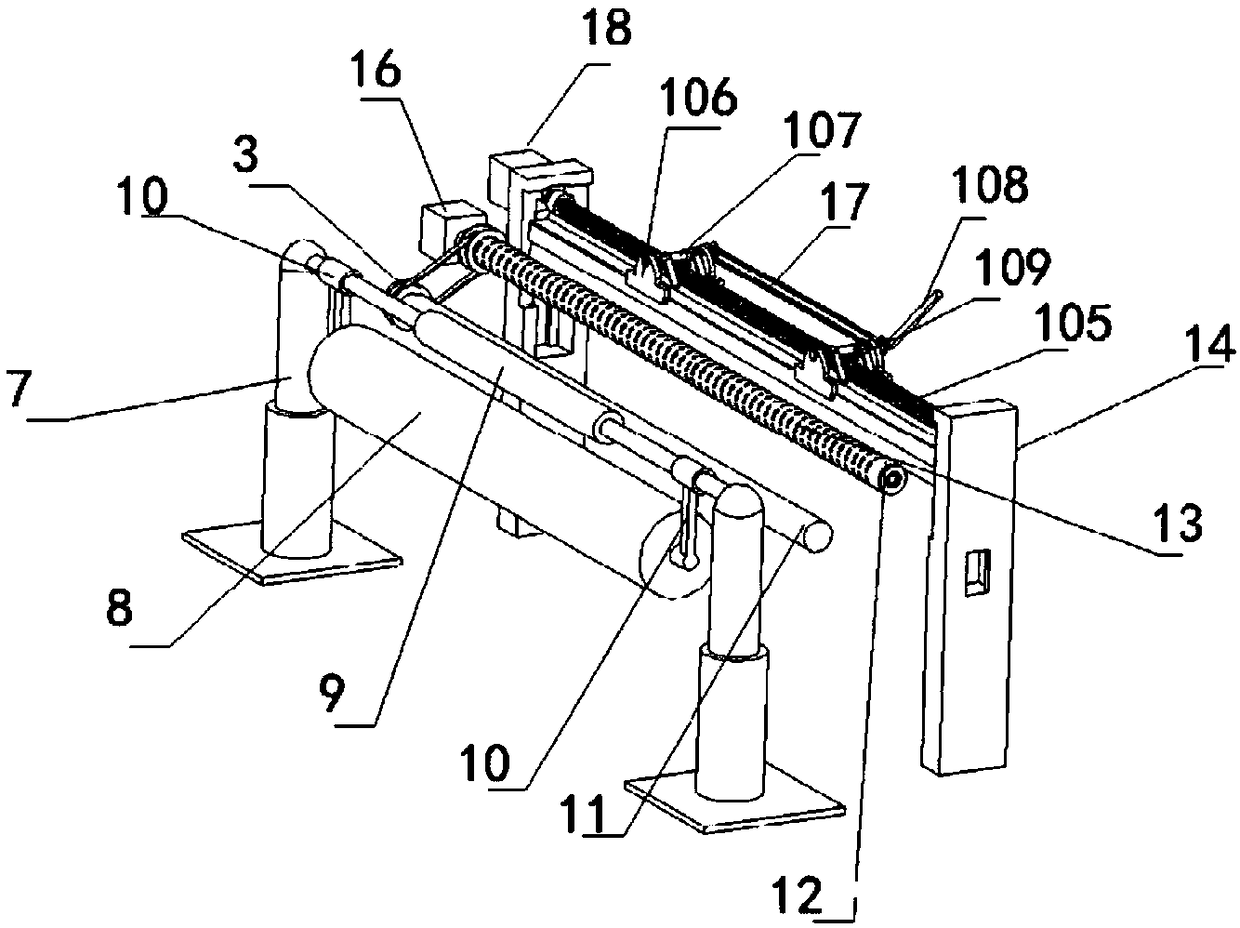

Positioning device for garment cutting

ActiveCN108716105AReduce labor intensityReduce the hassle of manual ironingSevering textilesHandrailEngineering

The invention relates to the cloth processing field and relates to a positioning device for garment cutting. The positioning device comprises a stander, a lifting machine, an ironing roll set and a cutting part, wherein the stander is provided with a folding plate, and the folding plate is provided with a handrail; the lifting machine comprises a hydraulic cylinder, the hydraulic cylinder is provided with a fixing frame, and the fixing frame is provided with a fixing rod; the ironing roll set comprises a first roll and a second roll, the first roll is provided with a cavity, an ironer is arranged in the cavity and is connected with a steam generator, through holes are densely formed in the wall surface of the first roll, and a first motor is arranged at one end of the first roll; and the cutting part comprise an electric lifting platform, a cutting machine and a pre-pressing mechanism, the cutting machine is provided with a leveling plate and a cutting late, a notch is formed in the cutting plate and is provided with a cutting knife, the cutting knife is connected with a screw rod, a second motor is arranged at one end of the screw rod, the pre-pressing mechanism comprises a fixingplate, the fixing plate is connected with a rotating shaft, and the rotating shaft is provided with a pre-pressing rod and an operation rod. According to the scheme, the problems of cutting size errors, high labor intensity and tedious operation steps on the manual processing process of garment cloth in the prior art are solved.

Owner:重庆博工商贸有限责任公司

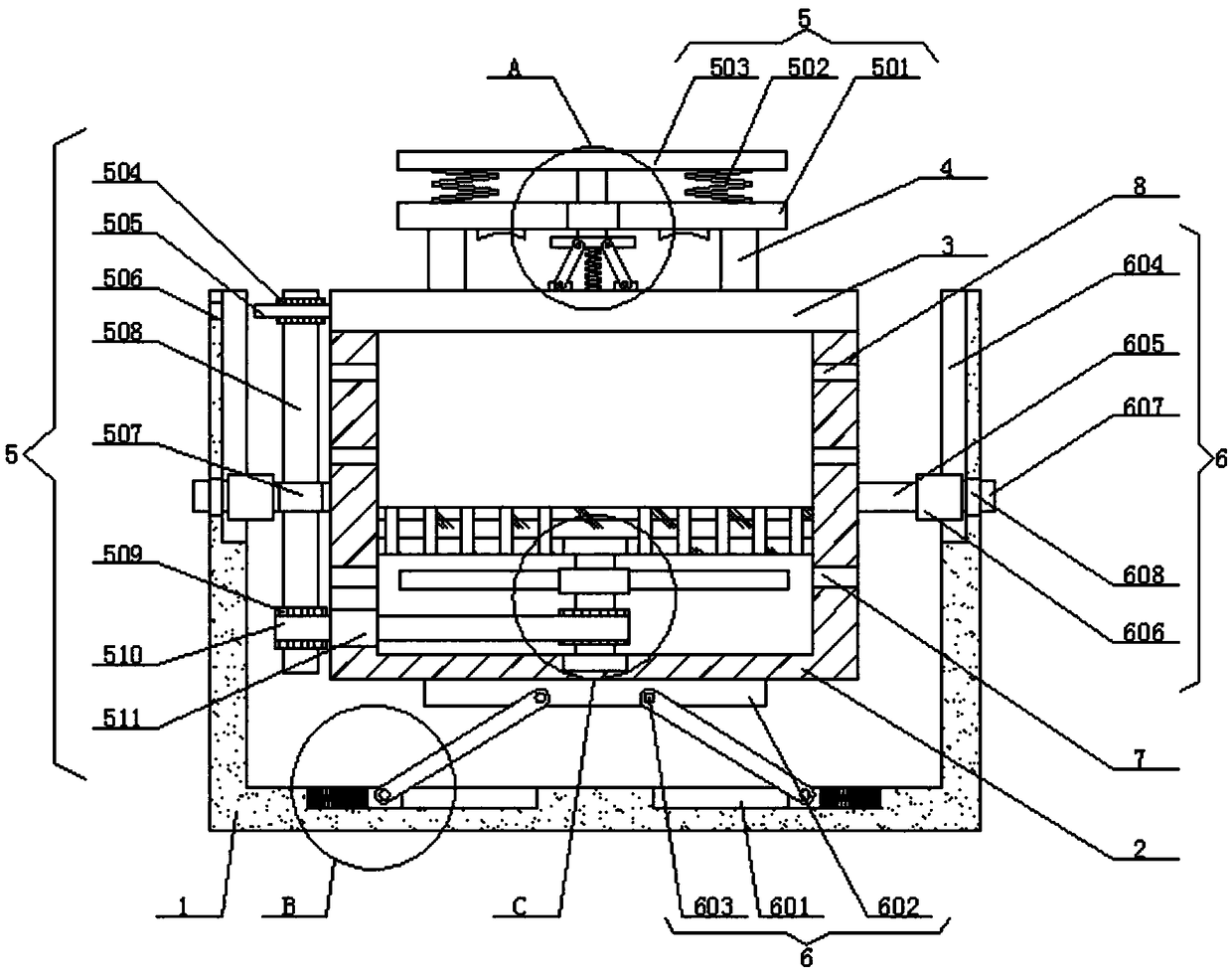

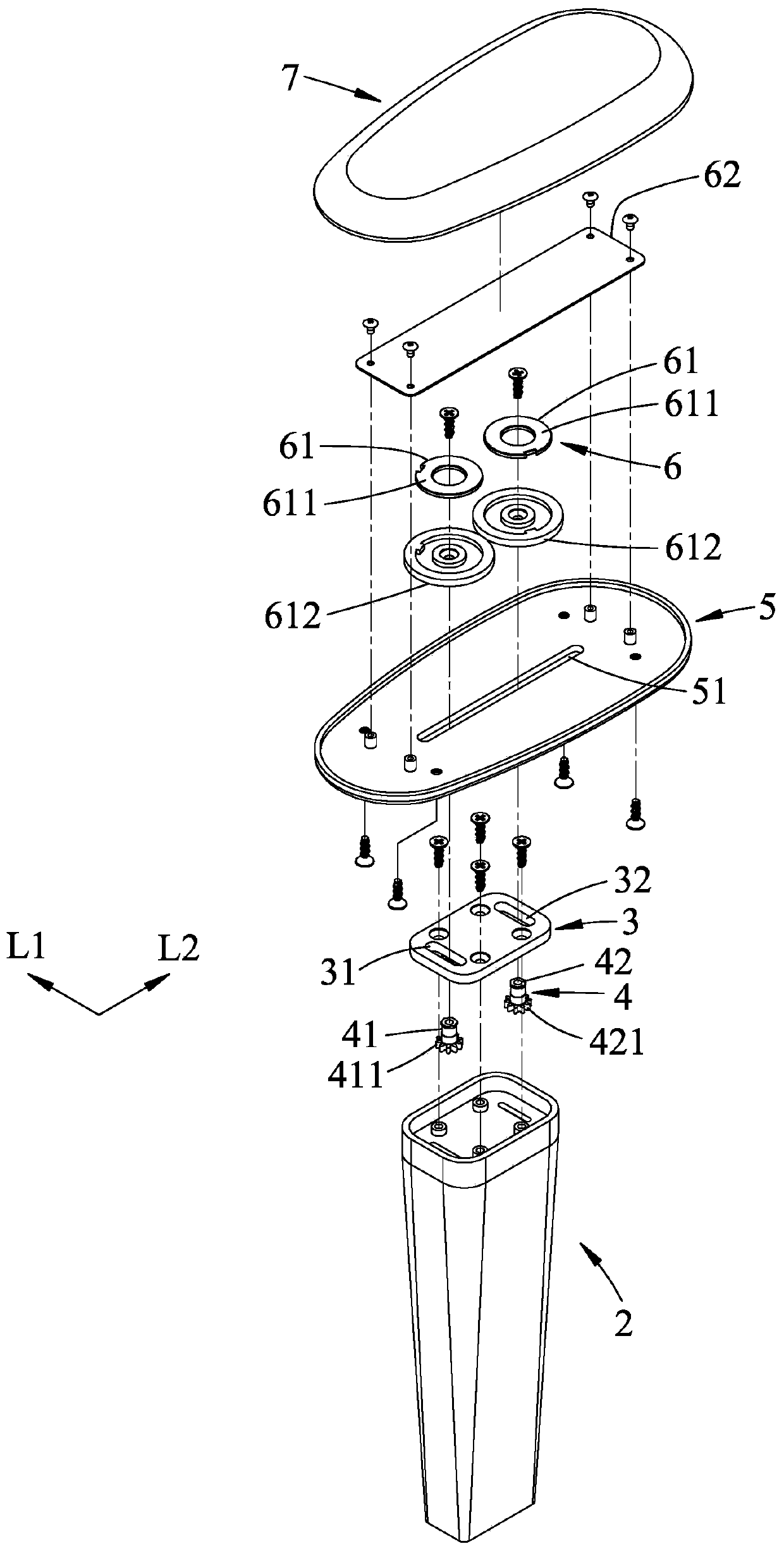

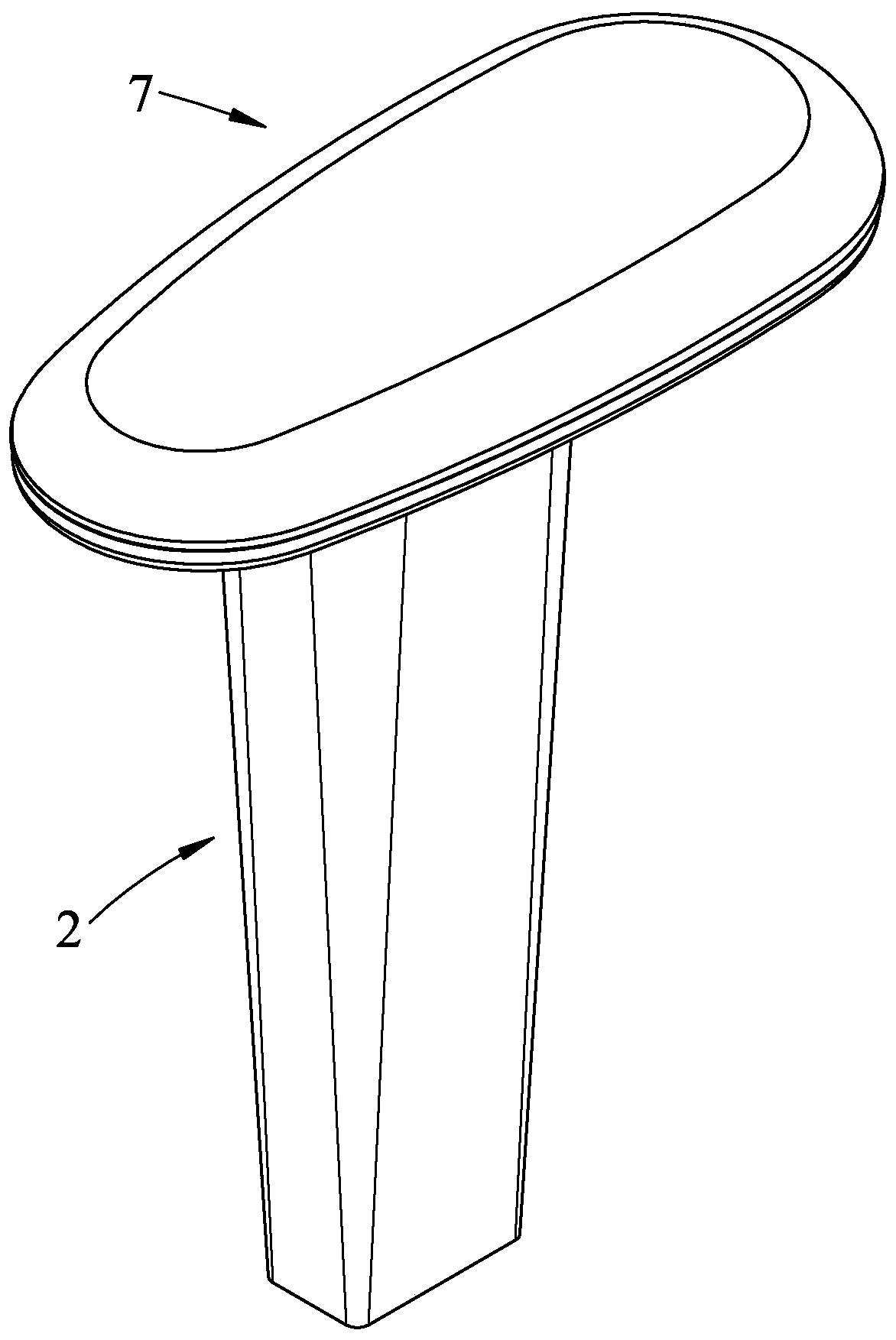

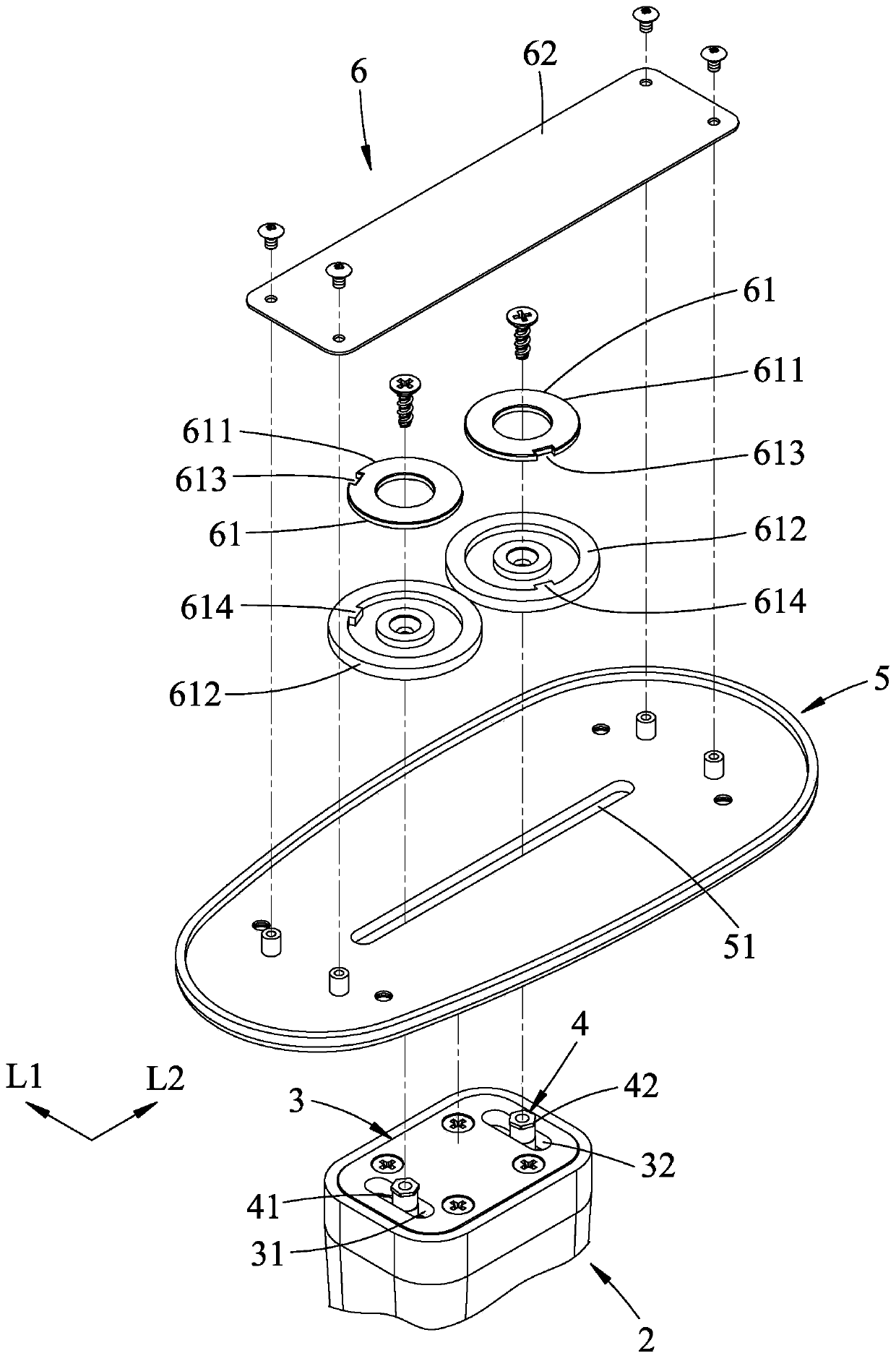

Universal electronic product assembling platform and assembling process thereof

ActiveCN110524901AGuaranteed installation stabilityImprove efficiencyMechanical engineeringEngineering

The invention discloses a universal electronic product assembling platform and an assembling process thereof. The universal electronic product assembling platform comprises a platform part and an assembling part, wherein the platform part and the assembling part are mutually inserted and installed in the horizontal direction to form an integral structure, and the platform part comprises an assembling assembly, a supporting table, feeding pulling bodies, a platform assembly and a jig; the assembling assembly is horizontally arranged, and the supporting table is arranged on one side of the assembling assembly. The two feeding pull bodies are arranged on the horizontal supporting face in parallel in a spaced mode. The platform assembly is arranged on one side of the feeding pull body; the assembling part comprises a support assembly, a feeding assembly and an assembling component, wherein whole support assembly is of a laterally-placed U-shaped structure, and the assembling component is arranged on the upper side edge of the laterally-placed U-shaped structure in a suspended mode and arranged above the platform assembly; the feeding assembly is arranged on one side of the support assembly. The universal electronic product assembling platform can be suitable for bottom layer universal assembling platforms of various different products and assembling processes, the assembling process is effectively simplified, and the assembling efficiency is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Clamping assembly for fabricated building splicing

PendingCN113846758AStable splicingThe splicing is firmly secured by snap jointsBuilding constructionsClassical mechanicsScrew thread

The invention relates to a clamping assembly for fabricated building splicing. The clamping assembly comprises a transverse plate, two fixing plates are movably mounted at the top of the transverse plate, connecting mechanisms are movably mounted in the fixing plates, and the tops of the fixing plates are in threaded connection with fixing screws; and the connecting mechanisms comprise telescopic rods, limiting plates, clamping plates, clamping seats, springs, locking screw rods and inserting blocks, the telescopic rods are fixedly mounted in the fixing plates on the left side, the limiting plates are fixedly mounted on the right sides of the telescopic rods, and the clamping plates are fixedly connected to the right sides of the limiting plates. According to the clamping assembly for fabricated building splicing, firstly, the locking screw rods penetrate through right side fixing plate to be in threaded connection with the clamping plate in the left side fixing plate, a user rotates a handle to enable a clamping block to move rightwards till the clamping block completely enters the clamping seats, when no gap exists between the two fixing plates, the fixing screws are rotated to lock the two fixing plates, and finally, the locking screw rods are rotated in the opposite direction, so that the locking screw rods retreat from the right side fixing plate.

Owner:宋卓

Manual puller with residual band winder

InactiveCN101767662AAvoid exposureDoes not affect handlingBundling machine detailsEngineeringMechanical engineering

The invention relates to a manual puller with a residual band winder, which comprises a body, a base, a roller and a handle, the handle comprises a first end and a second end, the first end of the handle is provided with a held part, the roller is pivotally connected with the base and the second end of the handle, the handle is also provided with a pulling part, which can ratchet the roller, and when the held part is operated, the roller can wind a binding band; and the residual band winder is positioned between the held part and the pulling part, and comprises a band-winding assembly, which can wind the residual band. A rocking handle of the residual band winder can move between a winding position and a retaining position, the residual band can be wound on the band-winding assembly by rotating the rocking handle, or the rocking handle can be retained in the body, so that the band-winding assembly cannot rotate to prevent the residual band from getting loose.

Owner:黄汉卿

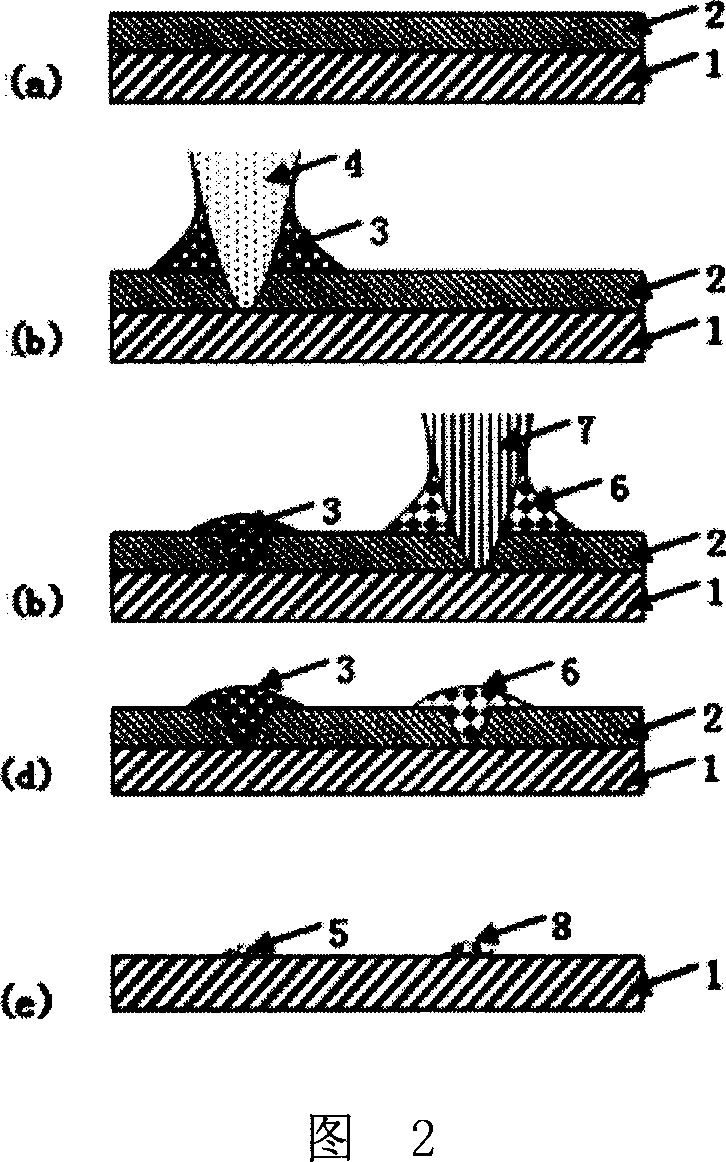

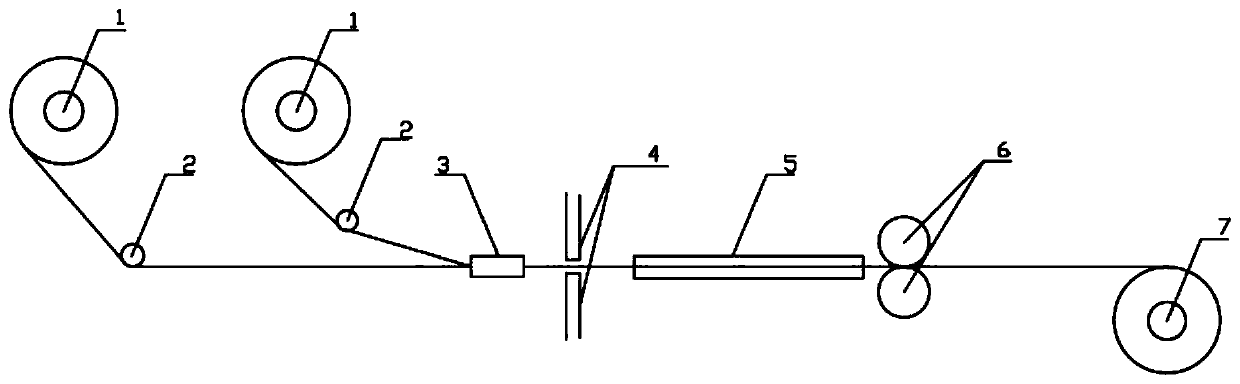

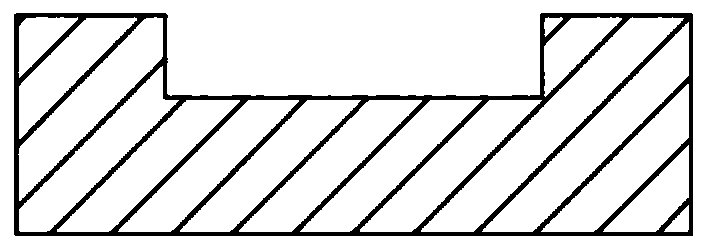

Manufacturing method of special-shaped composite interface

The invention discloses a manufacturing method of a special-shaped composite interface. The method comprises pay-off wheels, wire guiding wheels, a guide hole, spot welding electrodes, a hydrogen protection pipe, hot rollers and a take-up wheel. The method comprises the following steps of strip shaping, wherein a base material is subjected to precision grooving by using a cold-rolled concave-convex roller, a noble metal strip is shaped by using a mold to match the size of a base-material cold-rolled groove; strip cleaning and annealing, wherein the base material and the noble metal strip are cleaned by using ultrasonic waves, the surface oil stains are removed, and heat treatment is carried out to an annealed state in a reducing atmosphere; and strip spot welding positioning and compounding, wherein under the cooperation of a take-up and pay-off device, spot welding is carried out through a spot welding motor after limiting of the guide hole, and the positioning effect is achieved. According to the method, a mode of batch cold rolling finish machining of the single metal and accurate positioning of the composite strip is adopted, the material utilization rate is improved, the instability in the production process is reduced, the required special-shaped interface shape can be obtained with high efficiency and high quality, and uniformity and stability of the shapes of the head and tail interfaces of strip are guaranteed.

Owner:SHANGHAI TOUCH METALS TECH

Environment-friendly equipment for retaining freshness of citruses

ActiveCN109229967ARealize resetAchieve rotationShock-sensitive articlesPackaging fruits/vegetablesGear wheelEngineering

The invention discloses environment-friendly equipment for retaining the freshness of citruses, and relates to the technical field of citrus freshness retaining. The equipment includes a protection box, the protection box is internally provided with a placement box, the placement box is internally provided with a support plate, the two ends of the support plate are fixedly connected with the innerside wall of the placement box, the upper surface of the support plate is provided with air holes, the upper surface of the placement box is fixedly connected with a separation plate, the upper surface of the separation plate is fixedly connected with support columns which are symmetrical, the tops of the support columns are fixedly connected with air supply mechanisms, and the protection box isinternally provided with a positioning mechanism. According to the environment-friendly equipment for retaining the freshness of the citruses, movement of a toothed bar is used for driving rotation ofa first gear, rotation of a second gear is achieved, air flows into the placement box, the temperature in the placement box is reduced, the freshness of the citruses is thus retained, the storage life of the citruses is prolonged, the stability of the placement box is improved, the elasticity of a third strong spring and repulsive force between a first magnet and a second magnet are used, and theeffect of positioning the placement box is achieved.

Owner:湖北漳发农业科技股份有限公司

Electric power construction winding device

The invention discloses an electric power construction winding device. The electric power construction winding device comprises a shell, wherein first bearings are clamped on the left side surface andright side surface of the inner wall of the shell; the interiors of the two first bearings are in sleeve connection with a first rotating shaft; the outer surface of the first rotating shaft is fixedly connected to a take-up reel; the right end of the first rotating shaft is fixedly connected to an output shaft of a driving device; the left side surface of the driving device is fixedly connectedto the right side surface of the shell; and a groove is formed in the left side of the front of the take-up reel. According to the electric power construction winding device, a thread cap moves towardthe right on the surface of a threaded rod under the action of the threaded rod by arranging the driving device and can enable a cable to synchronously move through a positioning ring so as to achieve a positioning effect; after a layer of cables are wound on the surface of the take-up reel, the winding work of the second layer of cables can be performed by clockwise rotating a rocking bar; and the manual supporting is not needed in the whole winding work process, so that the working quality of people can be ensured by reducing the labor intensity of people.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Inspection security equipment for data center machine room

PendingCN114360092AAvoid squint blurAvoid the situationChecking time patrolsClosed circuit television systemsData centerElectric machinery

The invention discloses inspection security equipment for a data center machine room, and belongs to the technical field of inspection security equipment. An inspection security device for a data center machine room comprises an inspection security vehicle, an annular sliding groove is formed in the middle of the upper side of the inspection security vehicle, a mechanical box is embedded in the middle of the inspection security vehicle, a motor output shaft is provided with two limiting blocks in an up-down structure, empty grooves are formed in the limiting blocks, and limiting teeth are rotationally connected into the empty grooves through pin shafts; springs are fixedly arranged on the inner sides of the limiting teeth, a rotating disc is arranged in the middle of the upper portion of the inspection security vehicle, a circular block is arranged in the middle of the bottom face of the rotating disc, and the structures are in close fit, so that the camera of the device can move up and down, the camera can be flush with and located at the same height as equipment models needing to be collected, and the equipment models can be directly obtained; and the condition that the strabismus is blurred or cannot be acquired due to the change of the equipment model, the indicator light and the display data state only can be identified through the strabismus angle of a camera in the prior art is avoided.

Owner:吴国辉

Surface grinding device with cooling structure for machining manual wrench

InactiveCN110883644AIncrease contact areaImprove cooling effectBelt grinding machinesOther manufacturing equipments/toolsPhysicsSurface grinding

The invention relates to a surface grinding device with a cooling structure for machining a manual wrench. The surface grinding device comprises a device body and a cooling mechanism. A lateral side base is arranged on the top of the left end of the device body. A transmission mechanism is arranged at the top end of the lateral side base. A grinding belt is arranged on the right side of the top end of the transmission mechanism. A grinding wheel is placed at the right end of the grinding belt. The cooling mechanism is located in the middle of the lateral side base. A movable strip is arrangedin the right end of the device body. The surface grinding device with the cooling structure for machining the manual wrench has the advantages that by means of a cooling pipeline of an S-shaped structure, cooling liquid can be conveniently carried, the contact area of the cooling pipeline and the cooling liquid can be conveniently increased due to the S-shaped structure design, and the cooling effect is improved; and moreover, the cooling effect can be further improved through cooling of air holes, the device body can be cooled when the device body performs transmission, grinding and other machining operations through the transmission mechanism, and therefore the cooling and protecting effect of the surface grinding device is improved.

Owner:东莞市史雷帝三维数控科技有限公司

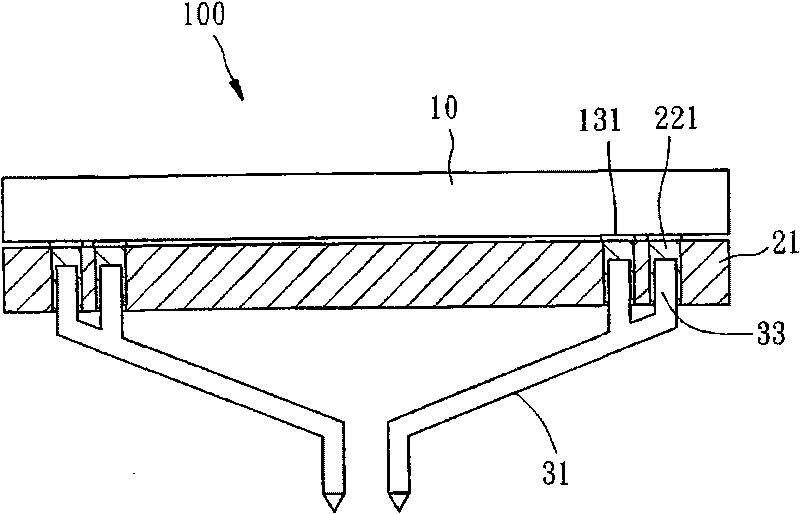

Adhesive tape, adhering device and adhering method thereof

InactiveCN103241447AImprove good rateAchieve positioning effectFlexible coversWrappersBiomedical engineeringDe bonding

The invention discloses an adhesive tape which is formed by stacking of a first de-bonding layer, an adhering layer and a second de-bonding layer. The second de-bonding layer is provided with a positioning portion, and the total area of the second de-bonding layer is larger than that of the first de-bonding layer. In addition, the invention further discloses an adhering device and an adhering method thereof. A base of the adhering device is provided with an accommodating groove and a positioning unit, and the adhesive tape is arranged in the accommodating groove of the base so as to enable the positioning portion of the adhesive tape and the positioning unit of the base to be positioned. A supporting member is provided, the first de-bonding layer is removed to expose the adhering layer, and the supporting member is adhered with the adhering layer mutually. By increasing the area of the second de-bonding layer, the problem that the shape of an existing adhesive tape is too narrow is solved, positioning fixation of the adhesive tape and the supporting member during adhering is achieved through the positioning portion, time and effort are saved, operation error rate is reduced simultaneously, and sticking quality is improved further.

Owner:ASKEY TECH JIANGSU +1

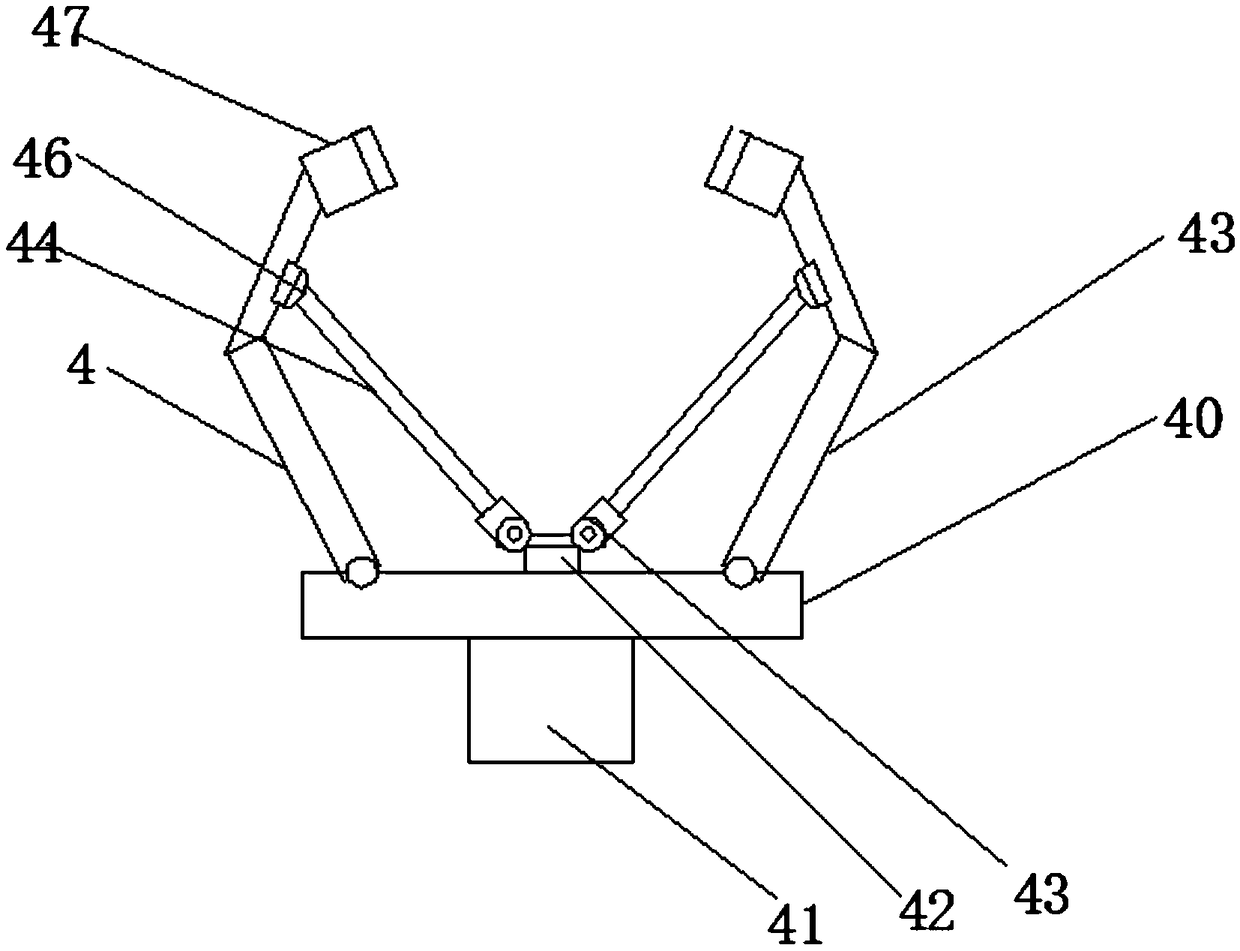

Device for picking thorny fruits

InactiveCN108617258AGuaranteed accuracyAchieve positioning effectPicking devicesEngineeringThreaded rod

The invention discloses a device for picking thorny fruits. The device for picking thorny fruits comprises a base, a machine frame, a transmission base, a clamping device and a supporting device, wherein the machine frame is installed on the base, the transmission base is located at the bottom end of the machine frame, a top plate is installed at the bottom end of the machine frame, a transmissionconnecting rod is arranged between the top plate and the transmission base for connection, a transmission threaded rod penetrates through the middle of the transmission base, and is a bidirectional threaded rod, a partition plate is arranged in the middle of the transmission threaded rod, the direction of a thread in the front side of the partition plate is opposite to the direction of a thread in the back side of the partition plate, and two transmission sleeves are arranged on the transmission threaded rod, and are located on the front side and the back side of the partition plate respectively. According to the device for picking thorny fruits, the transmission connecting rod is driven by a thread transmission mechanism to move, the operation height is adjusted accordingly, the positioning effect is achieved, and the accuracy when fruits are clamped is kept.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

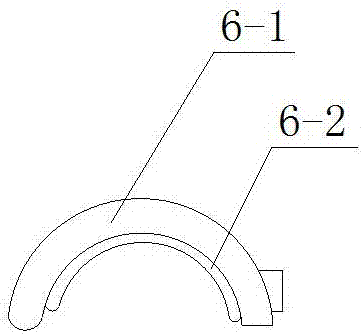

Armrest

The invention relates to a handrail device which comprises a base, a fixed plate, a first pivot, a second pivot, a handrail plate and a positioning unit. The fixed plate comprises a first moving groove extending along a first direction; the first pivot is arranged in the first moving groove in a penetrated manner; the second pivot is arranged on the fixed plate; the handrail plate comprises a sliding groove extending along a second direction and the first and second pivots are arranged in the sliding groove in a penetrated manner; the positioning unit comprises a positioning module and a positioning plate with a magnetic attraction force with the positioning module; the handrail plate moves relative to the fixed plate to drive one of the positioning module and the positioning plate to moverelative to the other one; the magnetic attraction force will generate resistance for the movement of the handrail plate relative to the fixed plate. Therefore, the moving position and the rotating angle of the handrail plate can be adjusted in a section-free manner, the using comfort level can be enhanced, and the handrail device has a more excellent market potential.

Owner:PAO SHEN ENTERPRISES

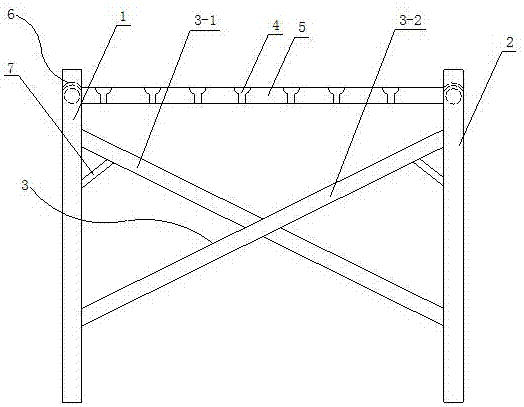

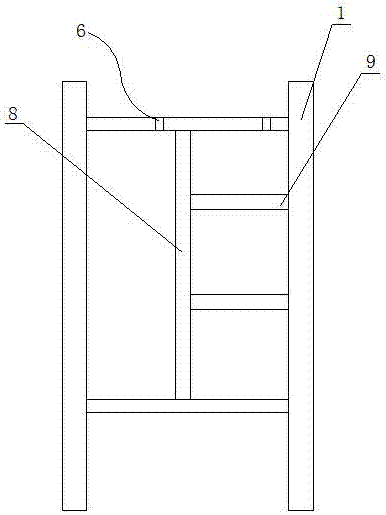

Scaffold structure

InactiveCN106906992ASimple structureEasy to climbScaffold accessoriesEngineeringBuilding construction

The invention discloses a scaffold structure which comprises a supporting assembly a and a supporting assembly b. The supporting assembly a and the supporting assembly b are fixedly connected through fixing rods; a transverse board is arranged at the top ends of the supporting assembly a and the supporting assembly b and moves between the supporting assembly a and the supporting assembly b through movable parts; a plurality of meshes are formed in the transverse board; reinforcing bars are arranged at the connection positions of the supporting assembly a and the fixing rods as well as the supporting assembly b and the fixing rods; a vertical rod is arranged in the middles of the supporting assembly a and the supporting assembly b; and a plurality of transverse rods are fixed between the vertical rod and the supporting assembly a as well as between the vertical rod and the supporting assembly b. The scaffold structure has the beneficial effects that the structure is simple, climbing is facilitated, stability and flexibility are enhanced, the transverse board can be adjusted according to the width of a construction site to achieve the positioning effect, the transverse board is convenient to dismount, sand on the feet of constructors can fall off through the meshes, the constructors can be effectively prevented from falling over by treading on pebbles in the construction process, and safety performance is higher.

Owner:JIANGSU YUEFA CONSTR ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com