Sampling device for liquid sample

A technology for sampling devices and liquid samples, applied in sampling devices, analytical materials, instruments, etc., can solve problems such as time-consuming and labor-intensive, easy to cause failure, short service life, etc., to improve safety and data reliability, The effect of high accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

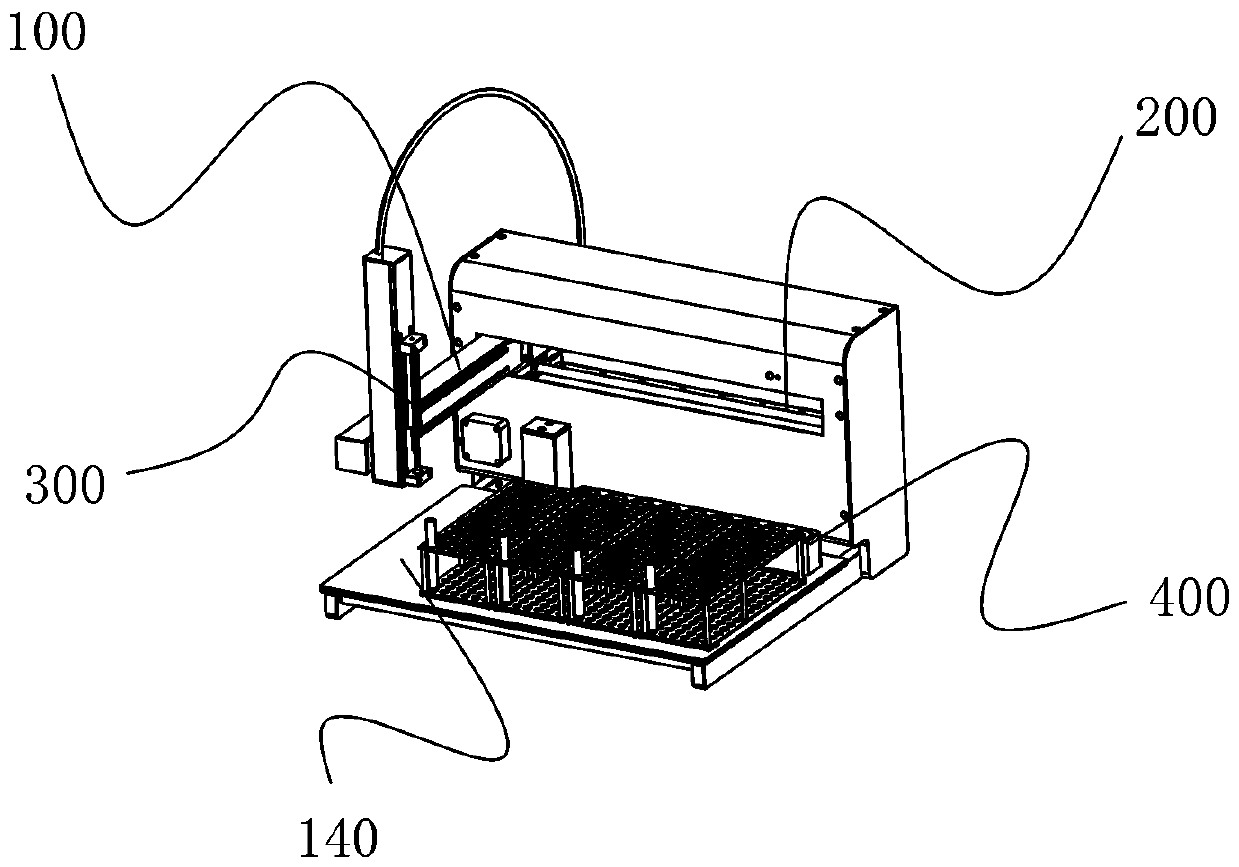

[0040] Such as Figure 1 to Figure 9 As shown, a liquid sample sampling device includes a frame 100 , a drive structure 200 , a pipetting head assembly 300 and a cleaning structure 400 disposed in the frame 100 .

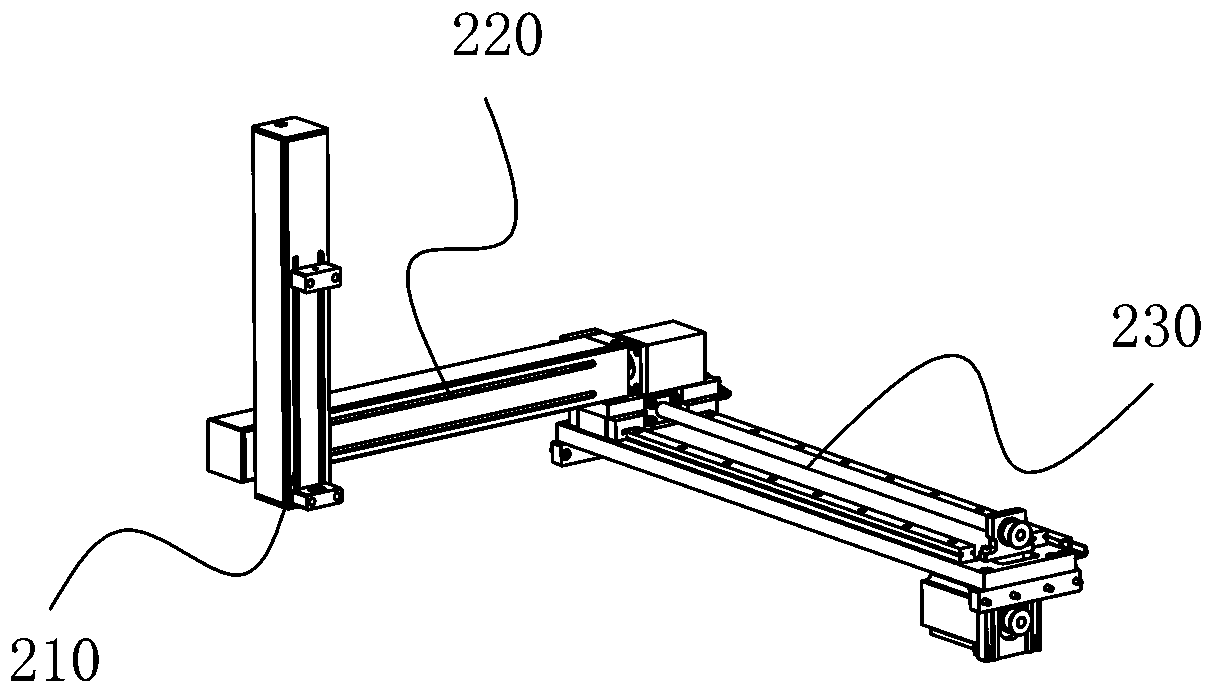

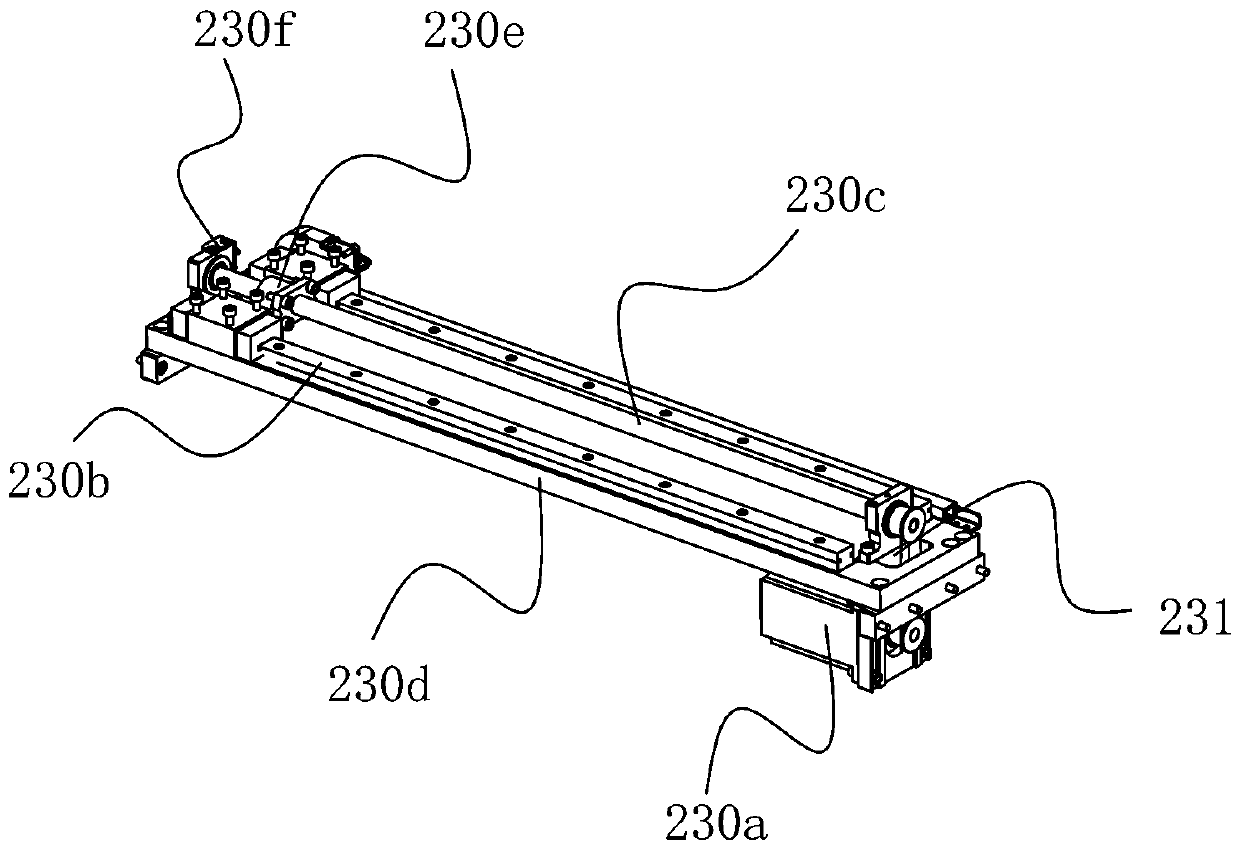

[0041] The driving structure 200 includes a Z-axis driving mechanism 210 , a Y-axis driving mechanism 220 and an X-axis driving mechanism 230 that can be linked and cooperated. The X-axis driving mechanism 230 is arranged in the frame 100, the X-axis slide table 230d, the X-axis slider 230e, the X-axis motor 230a and the X-axis screw rod 230c extending along the X-axis direction, the X-axis slide table 230d and The X-axis motors 230a are respectively arranged in the frame 100, the X-axis sliding table 230d is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com