Patents

Literature

38results about How to "Improve good rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

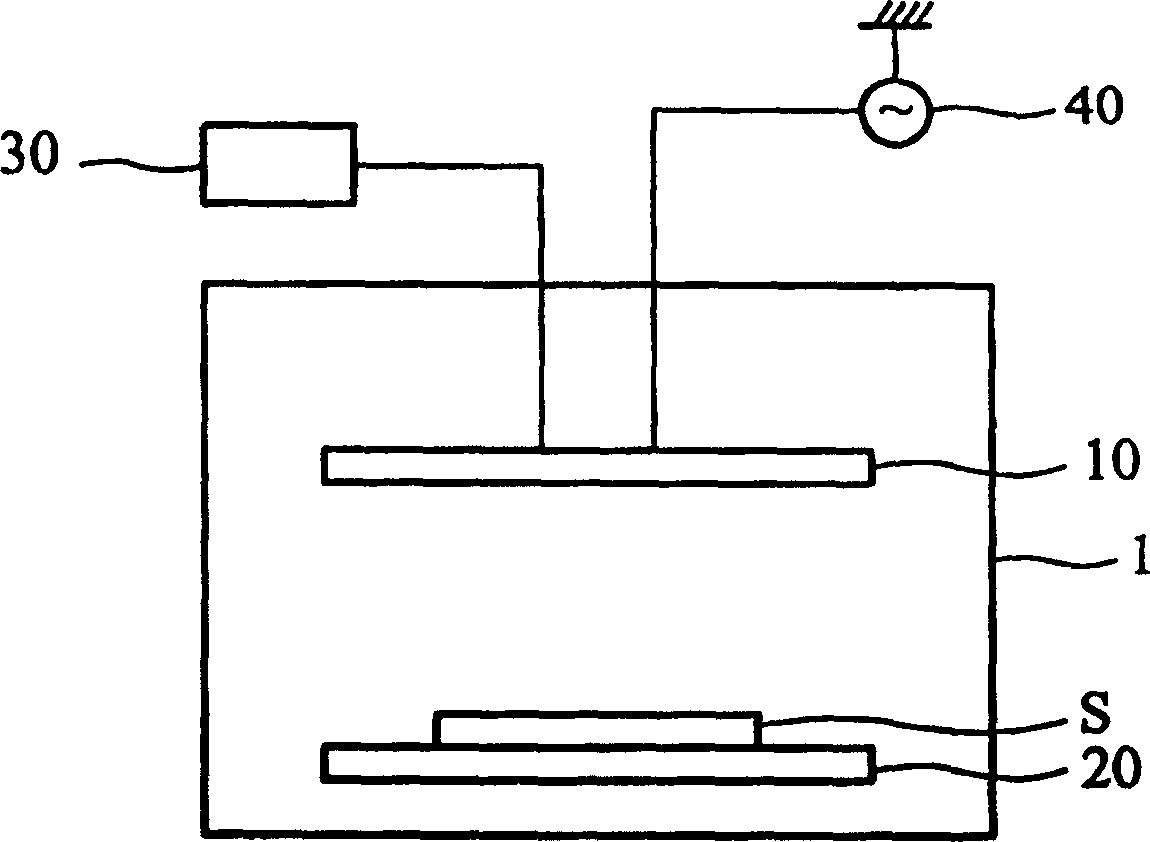

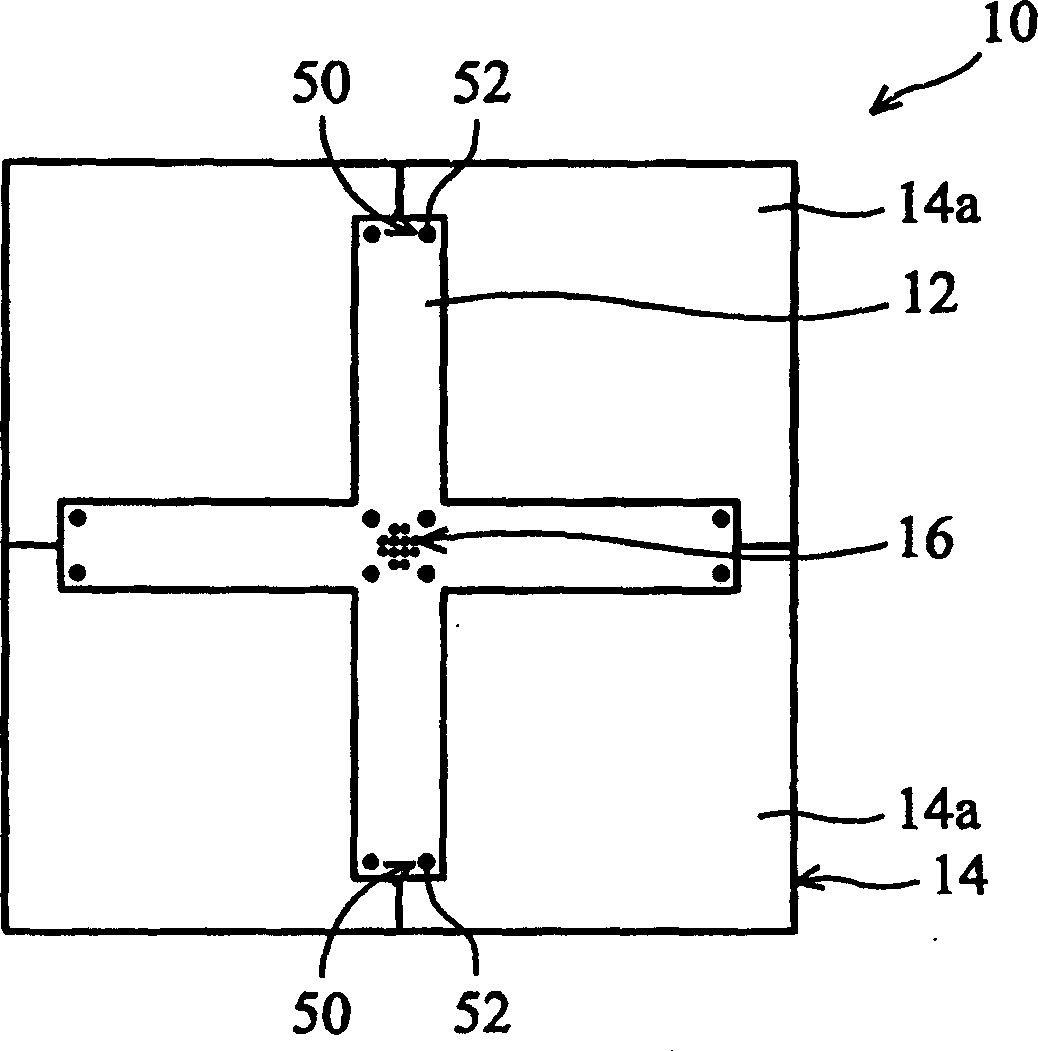

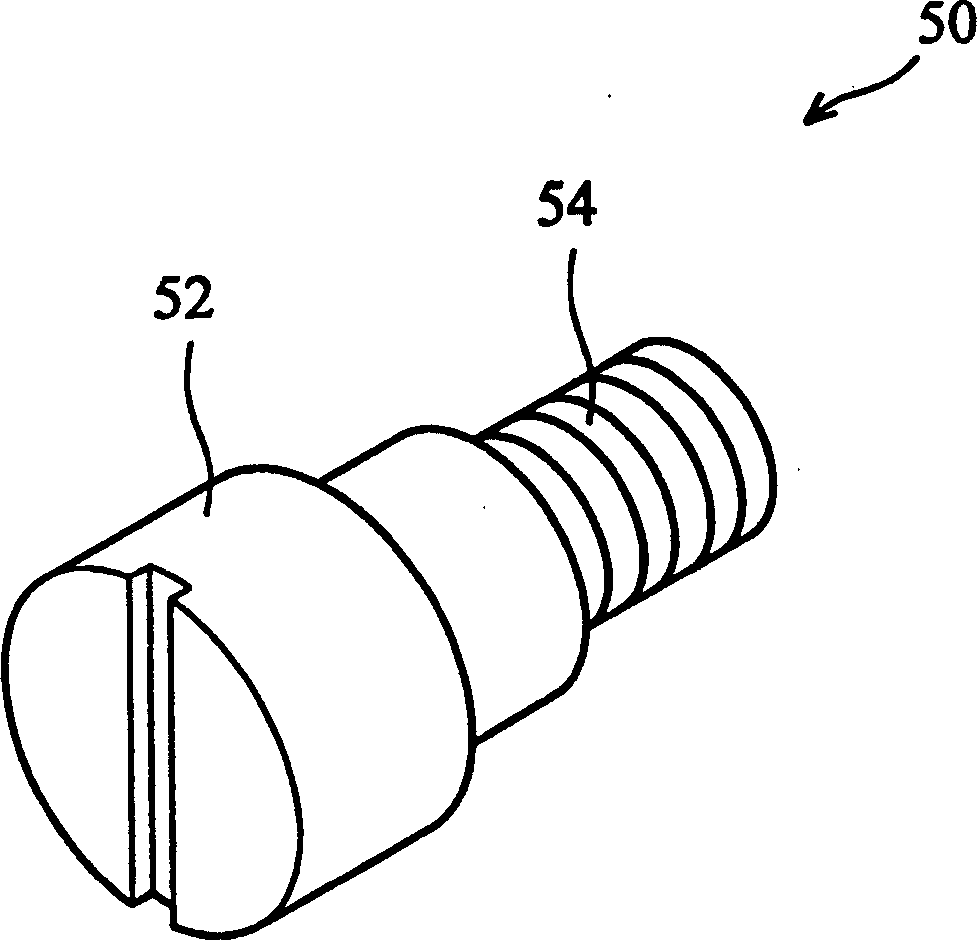

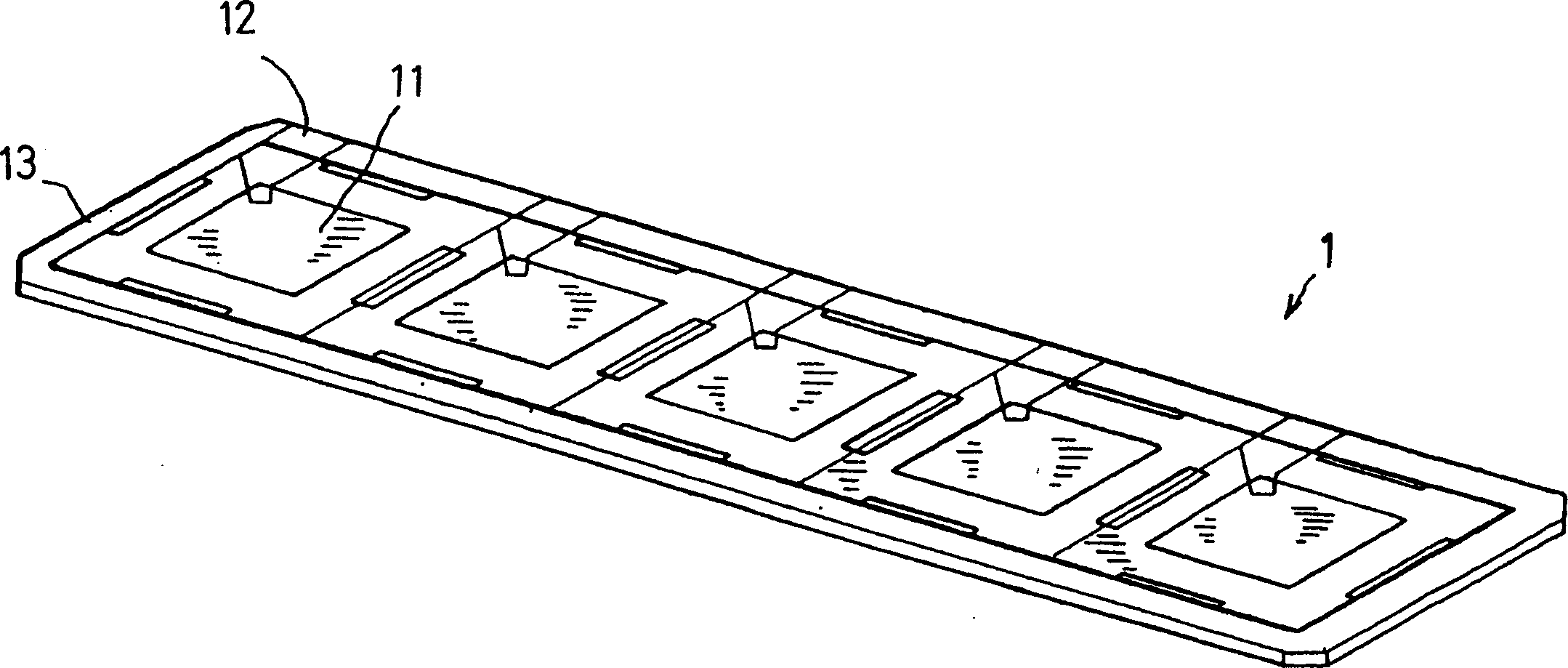

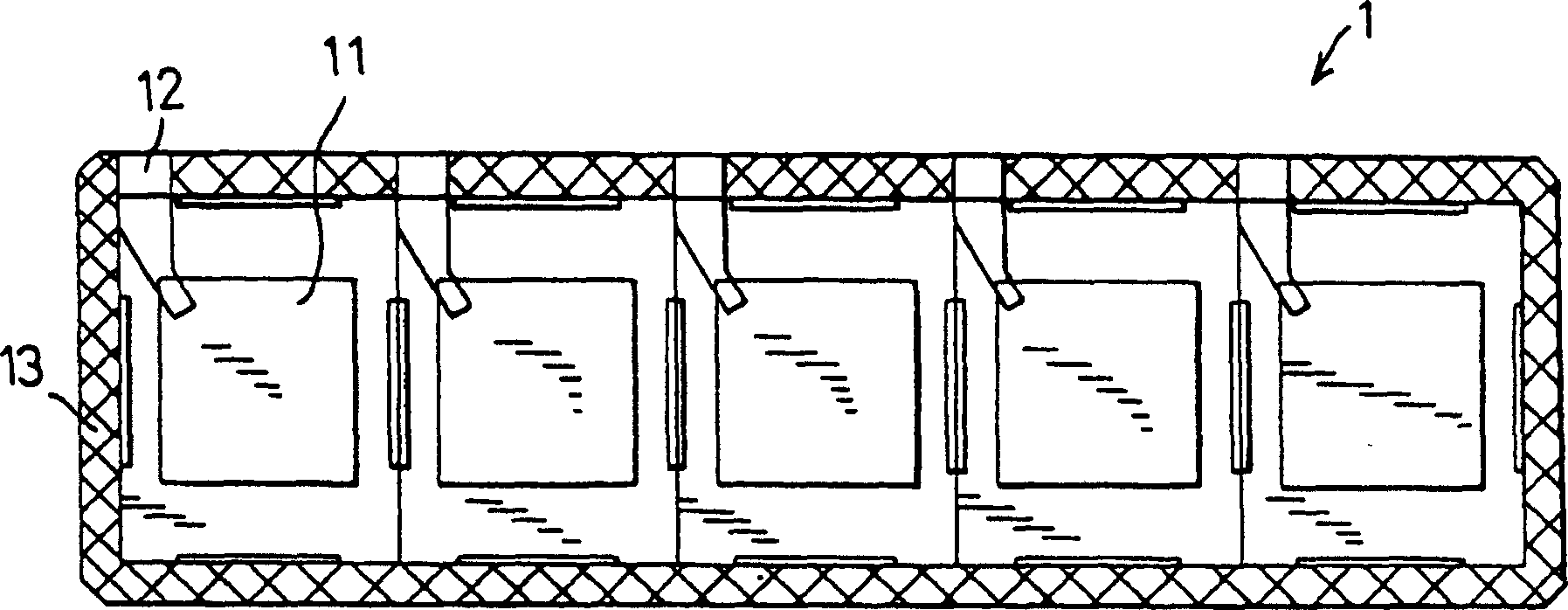

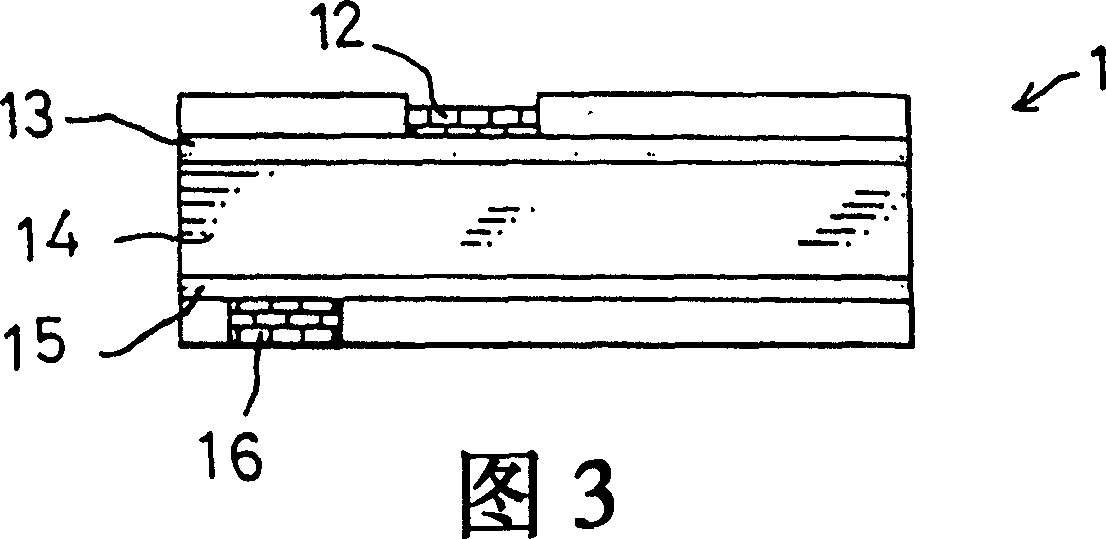

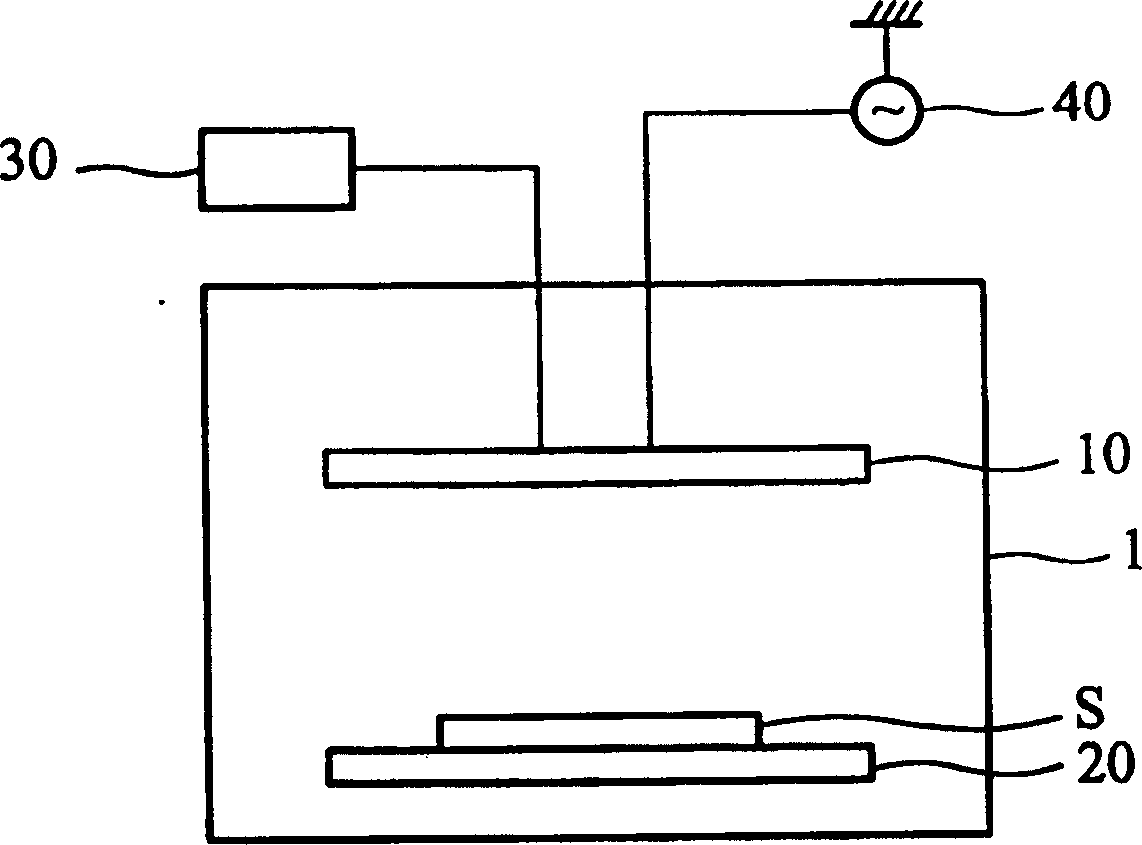

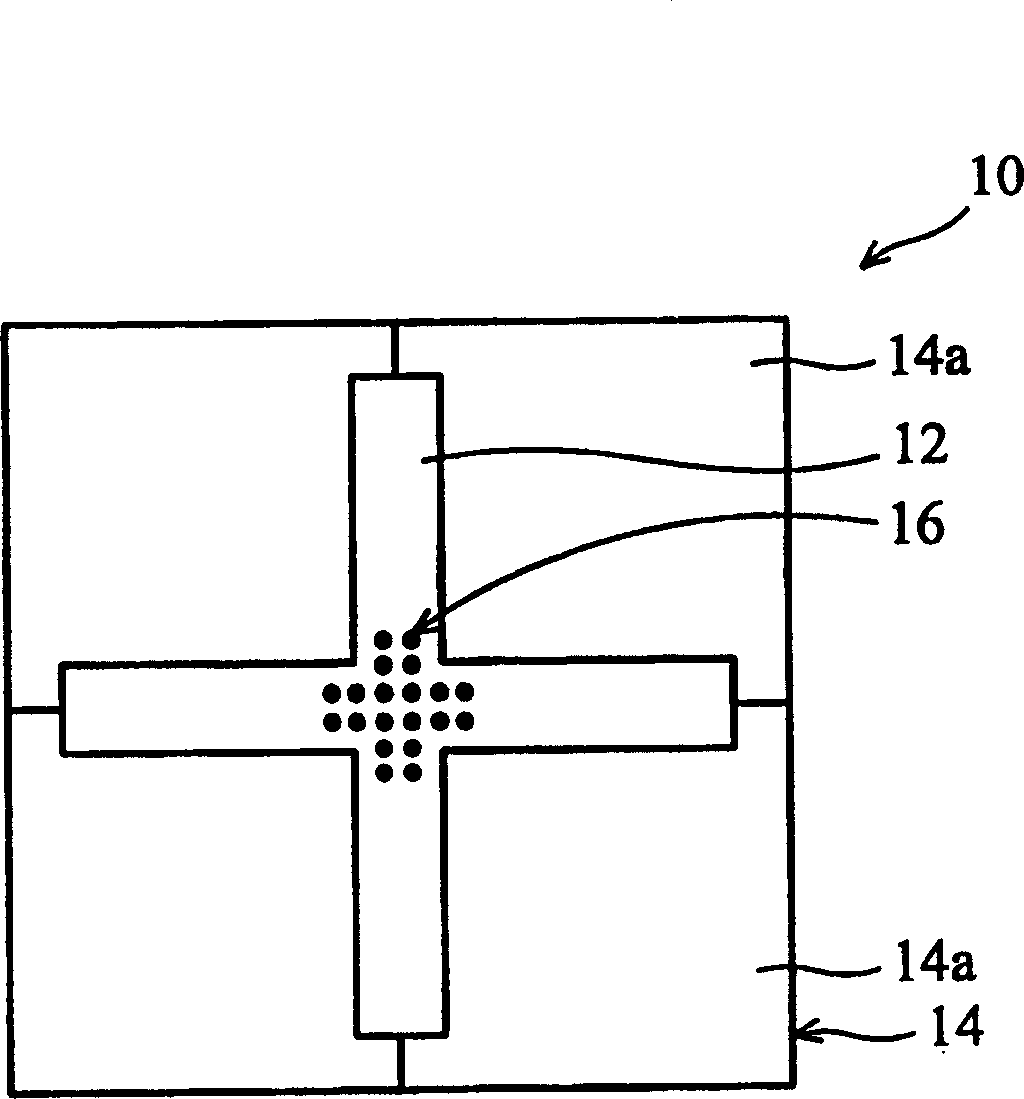

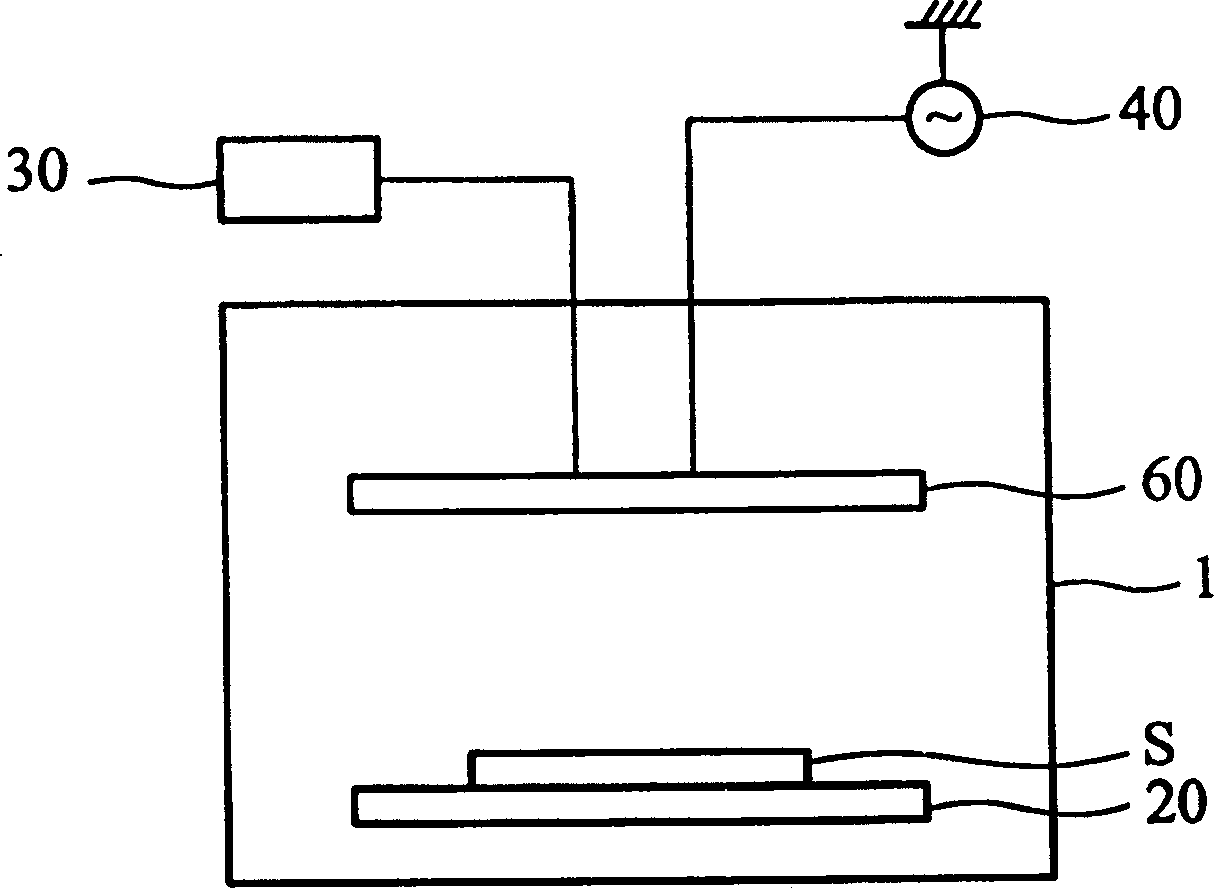

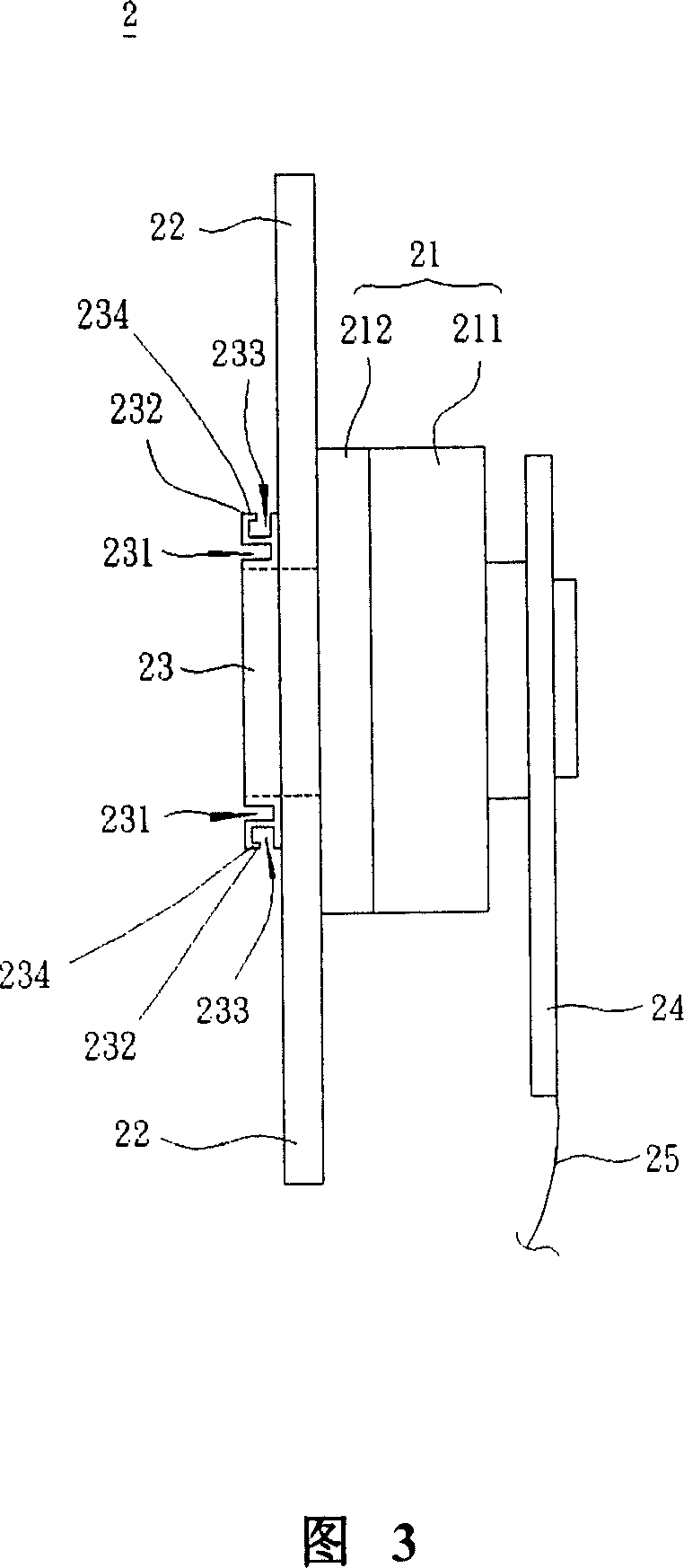

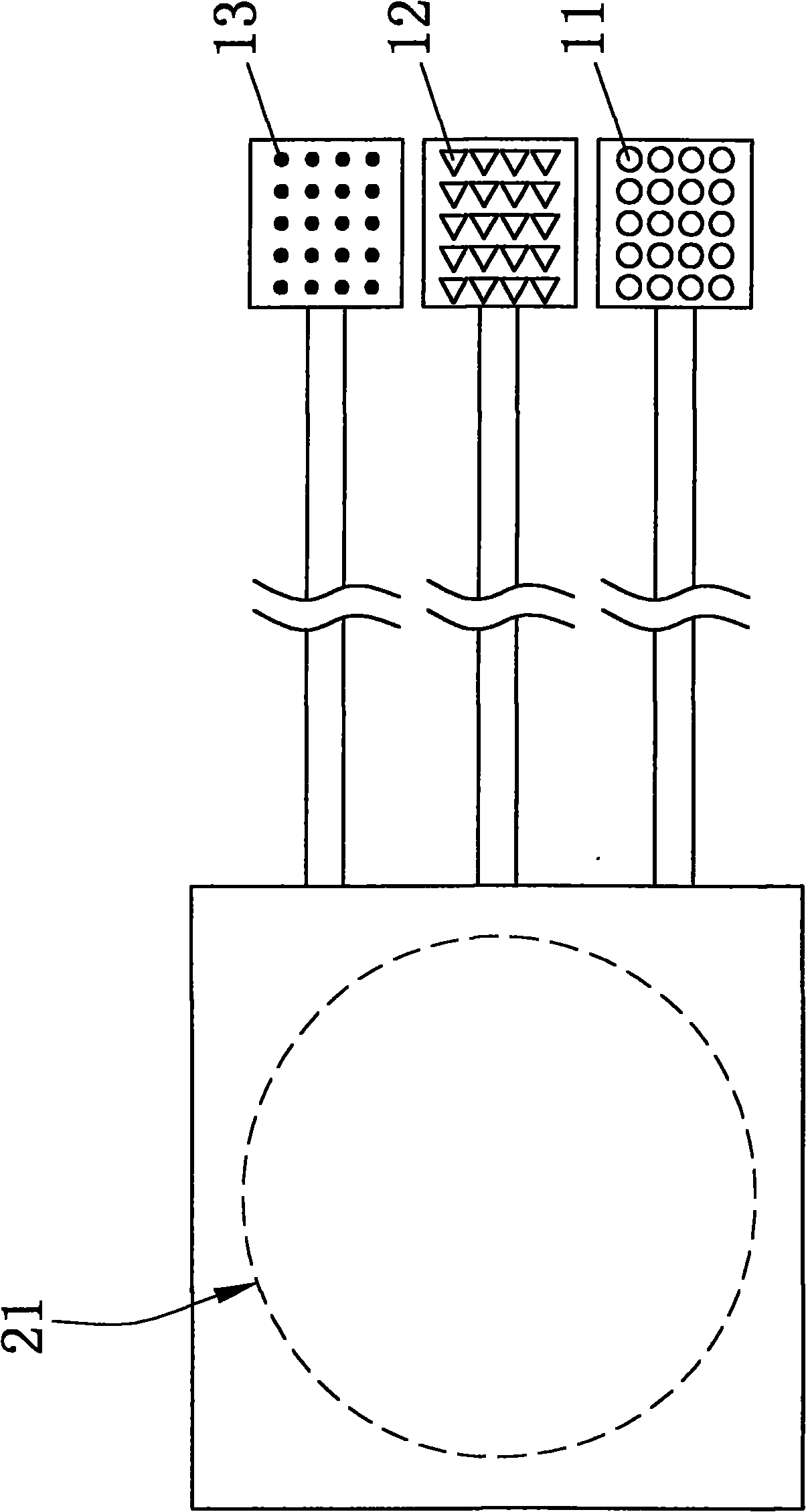

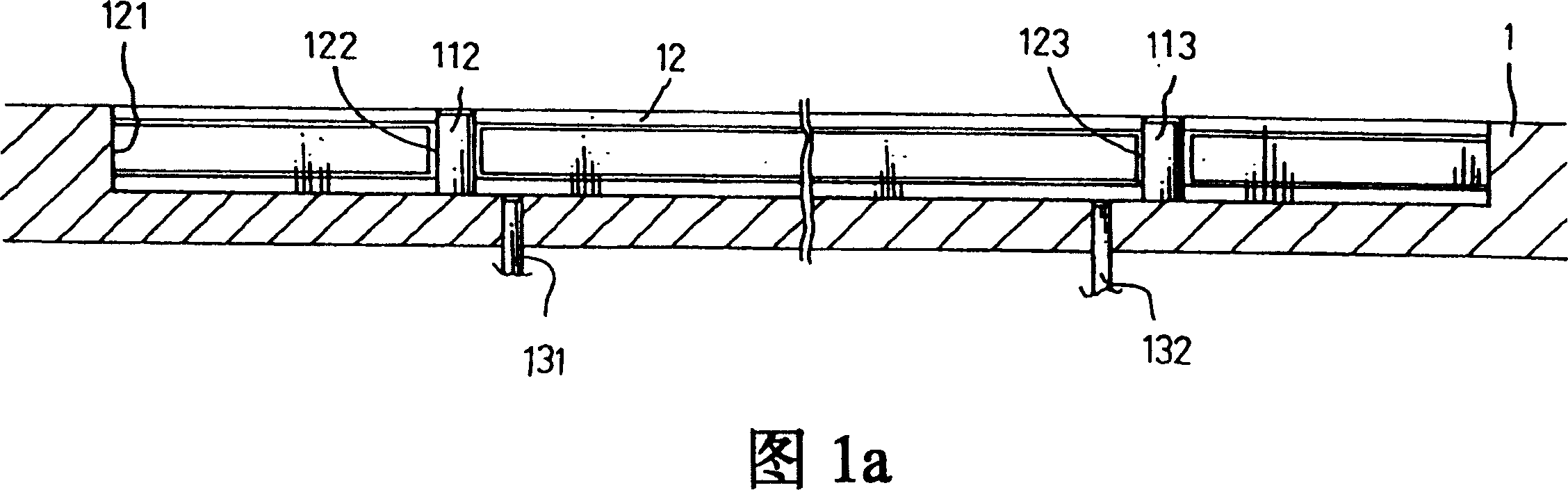

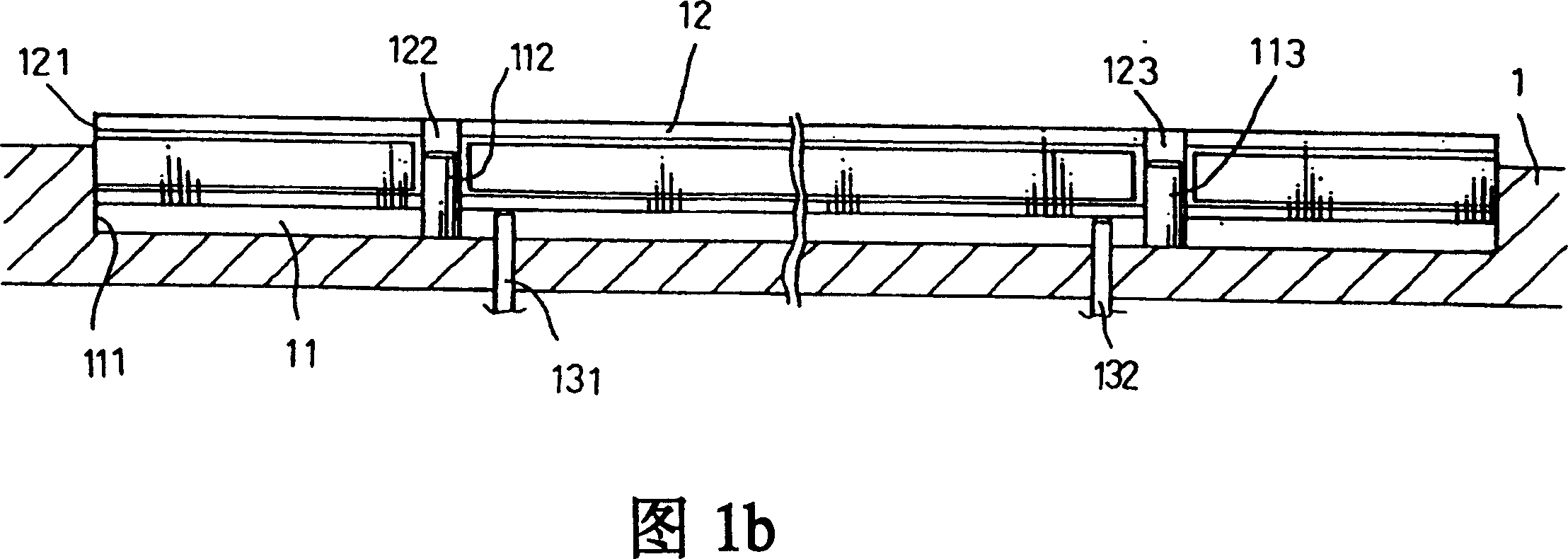

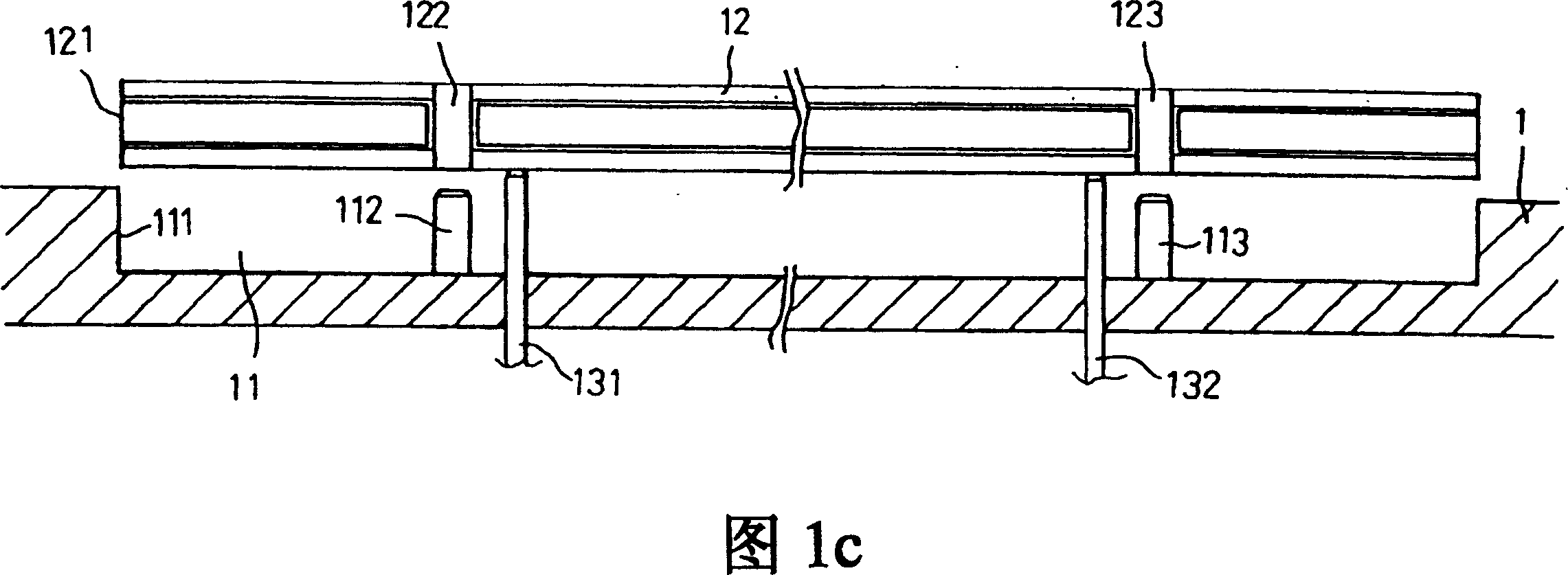

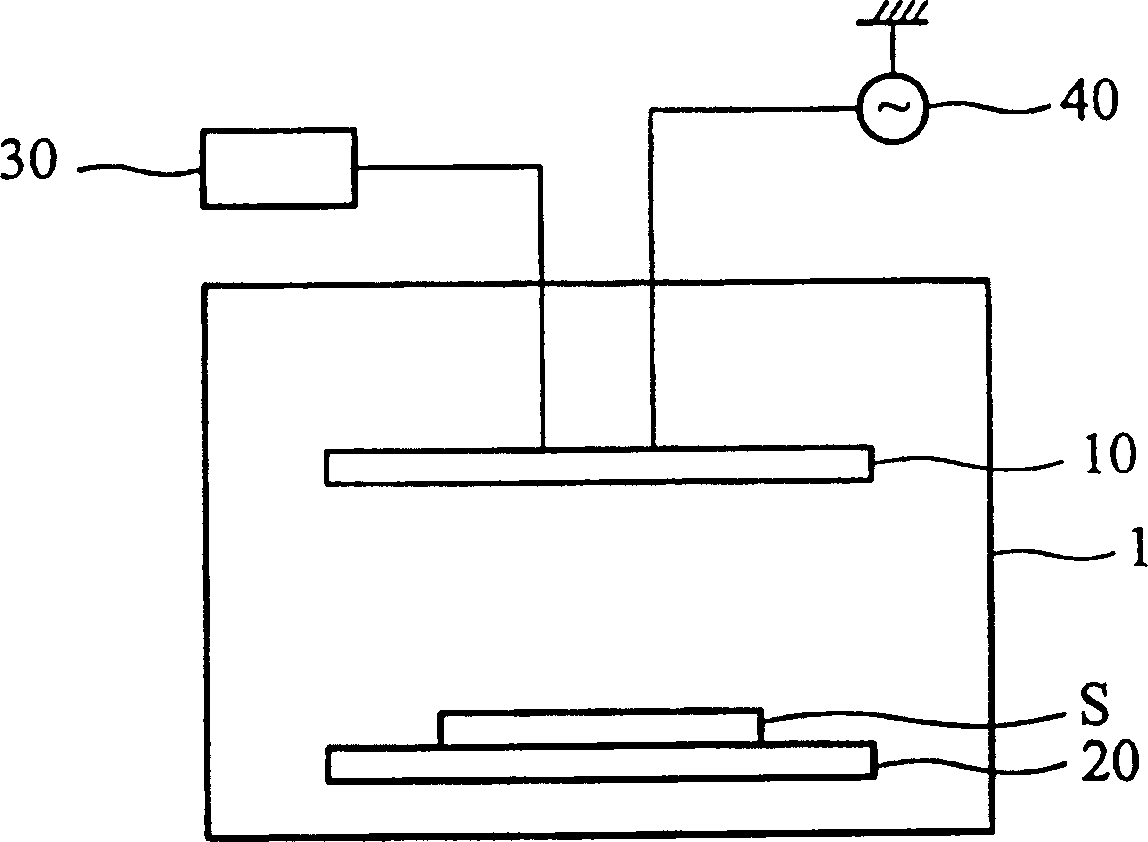

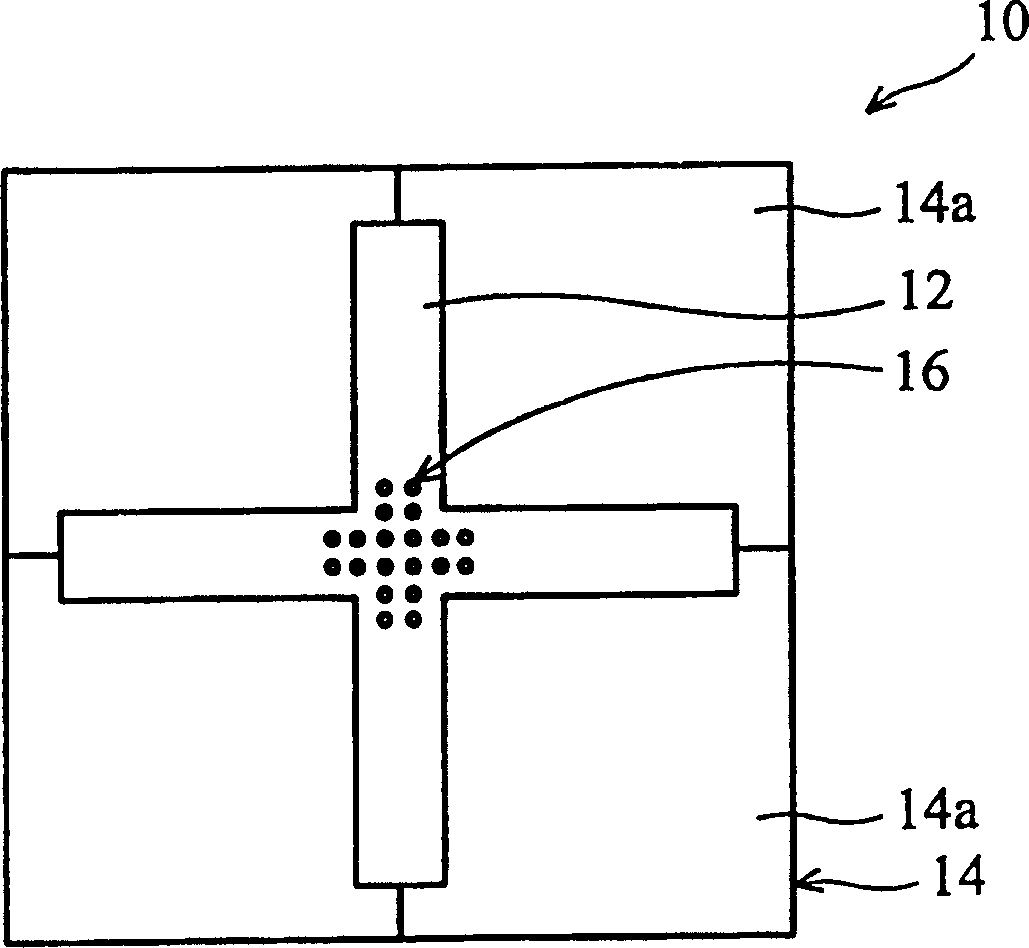

Plasma processing apparatus

InactiveCN1501762AAvoid arcing phenomenonAvoid bright spotsElectric discharge tubesSemiconductor/solid-state device manufacturingElectric arcPlasma processing

The invention provides a plasma processing unit, wherein the upper plate electrode comprises a gas demarcation strip and an insulating cover plate covered on the top of the gas demarcation strip, and plurality of mounting portions for mounting the gas demarcation strip and the insulating cover board, each mounting portion includes a screw and a nut. The invention can eliminate product defects and increase quality ratio.

Owner:AU OPTRONICS CORP

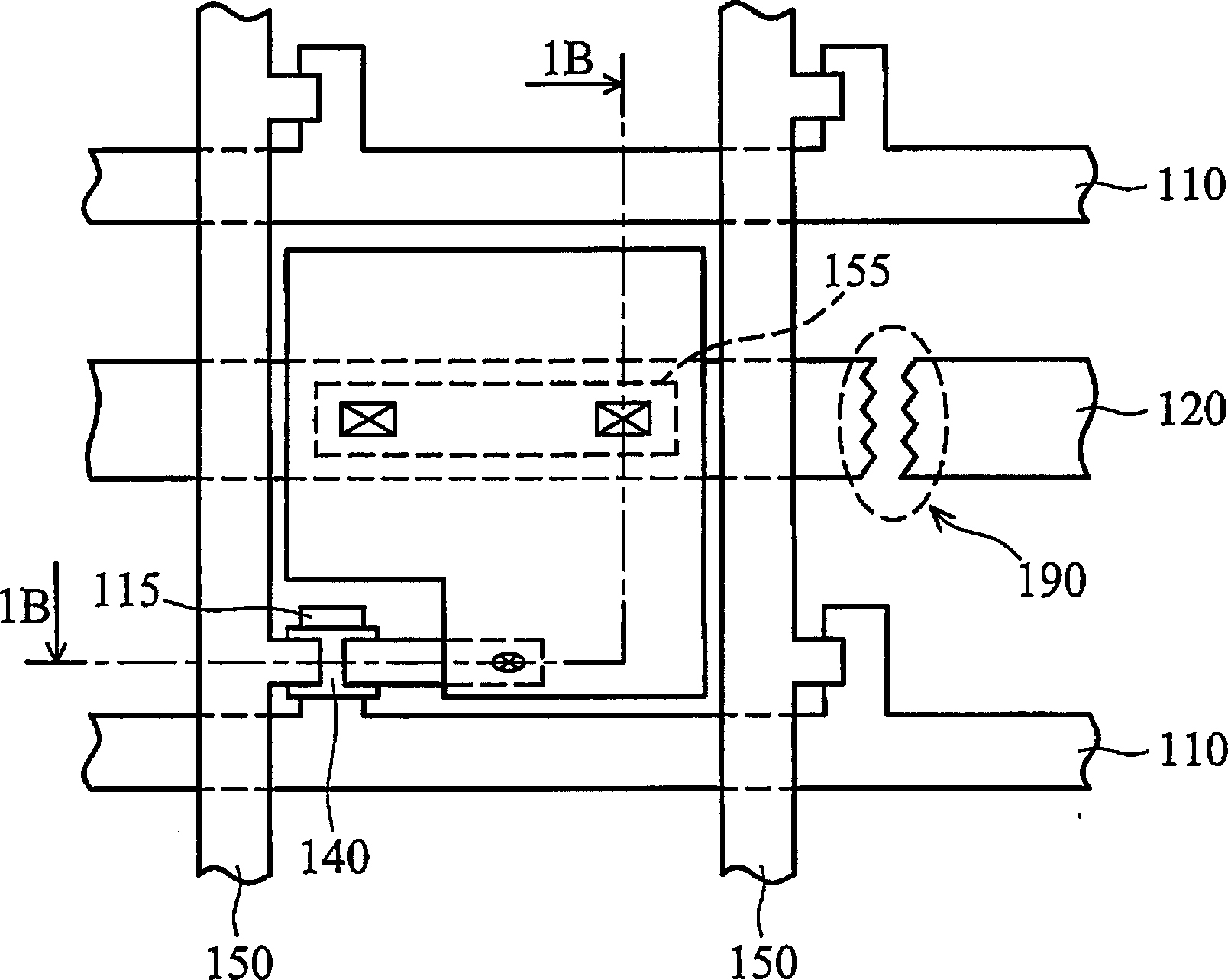

Packaging baseplate having electrostatic discharge protection

InactiveCN1479370AImprove good rateSemiconductor/solid-state device detailsSolid-state devicesElectrostatic discharge protectionCapacitance

Each die-casting orifice of package base plate is connected to first copper wire mesh layer electrical. The copper wire mesh is positioned at periphery of top surface of package base plate. Static charge generated in procedure of package chips is leaded to first copper wire mesh layer through die casting orifice. The static charge is gathered and confined at capacitance composed of first copper wire mesh layer, dielectric layer and second copper wire mesh layer. Or using a through hole connected to first and second copper wire mesh layers through metal pads and bearing object lead static charge out. Thus, by using capacity effect or conductive effect, the static charge is leaded out so as to raise qualified rate.

Owner:ASE SHANGHAI

Printed circuit board

InactiveCN101534600AImprove good rateAvoid short circuit conditionsPrinted circuit assemblingPrinted circuit detailsEngineeringPrinted circuit board

A printed circuit board comprises at least two adjacent through holes penetrating through the board and two bonding pads. Each bonding pad encloses the through hole and is arranged on the surface of the printed circuit board and used for welding a perforation type subassembly, wherein each bonding pad takes the shape with a tapered end so that soldering tin overflows along the direction of the tapered end in the welding process, thus further preventing the soldering tin from overflowing to an adjacent bonding pad and then causing short circuit.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

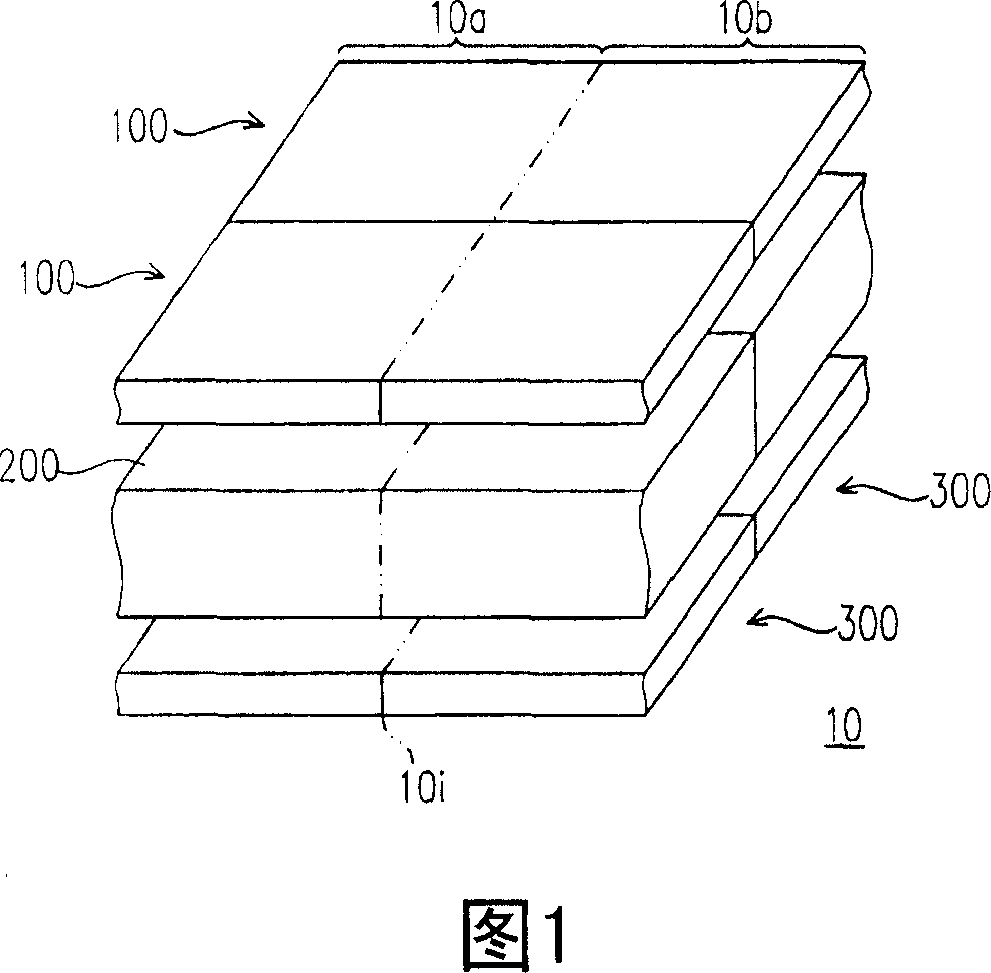

Liquid crystal display device and manufacturing method thereof

ActiveCN1632683AImprove product good rateIncrease the aperture ratioTransistorStatic indicating devicesCapacitanceLiquid-crystal display

It is a LCD device and its process method, which comprises the following steps: to form at least one storage capacitor structure composed of first metal layer, second metal layer and a dielectric layer in middle at the down base; then to form an isolation layer on the inner surface of the upper base and stretch it into the LCD layer to keep the thickness of the LCD layer; then to form a common electrode between the down base and the isolation layer, which are connected with the first metal layer though separately transparent conducting layer.

Owner:AU OPTRONICS CORP

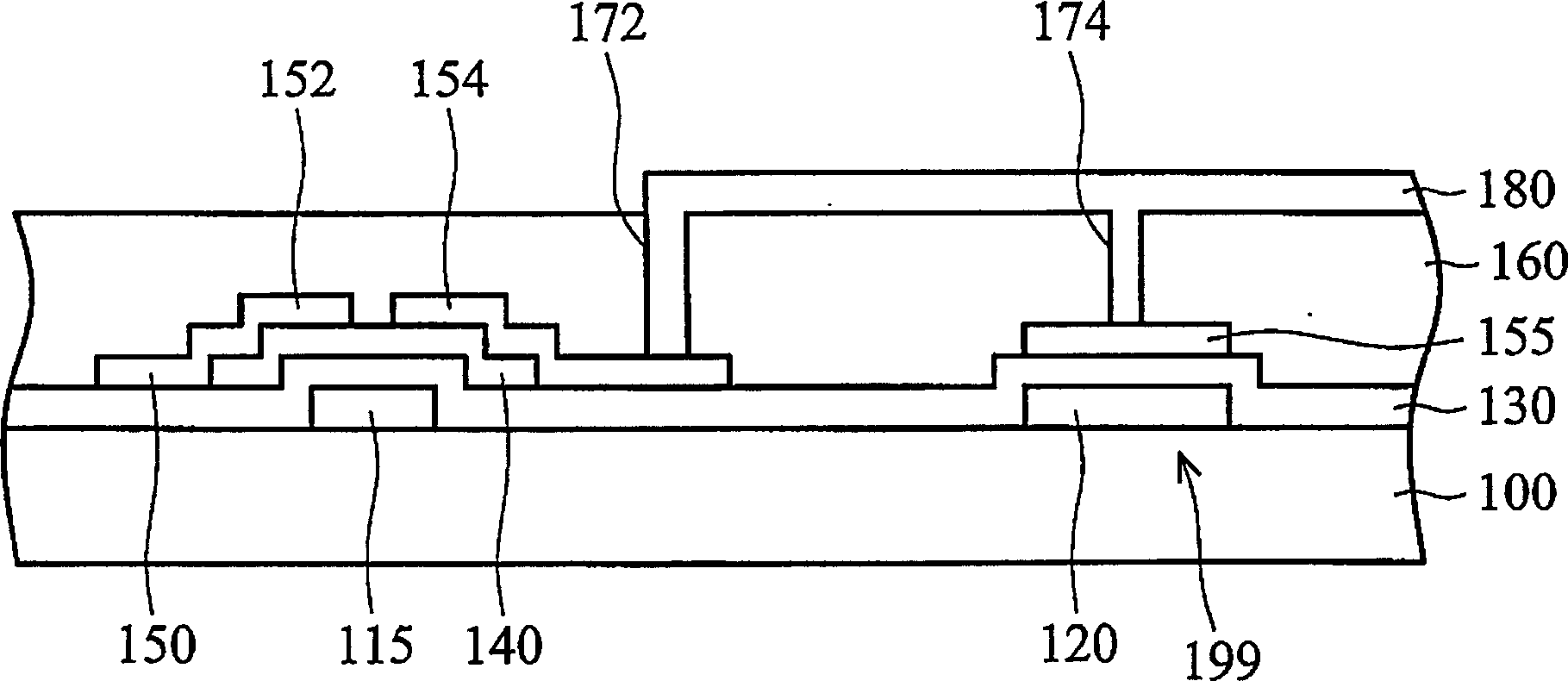

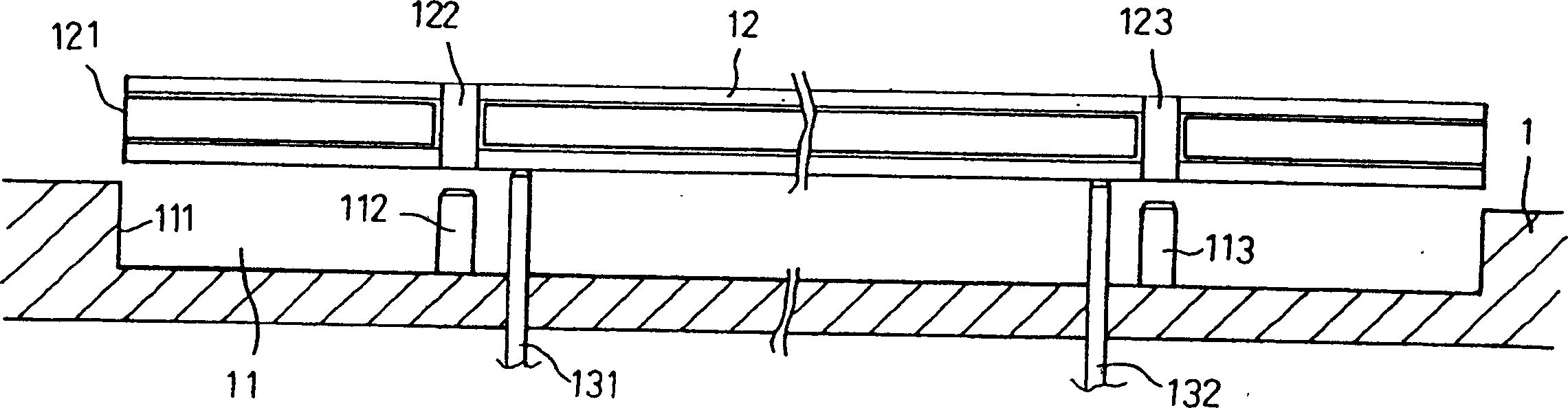

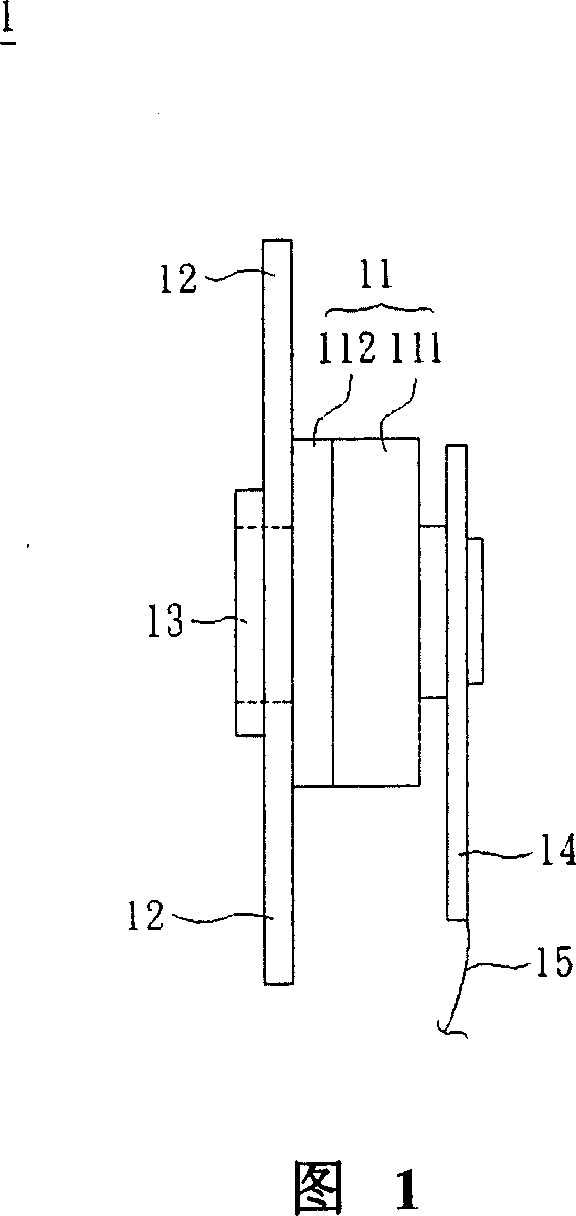

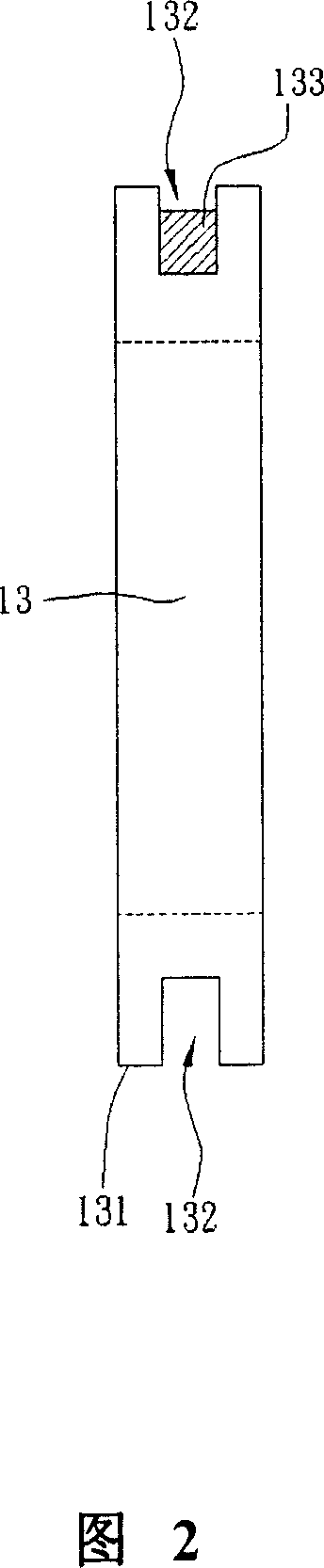

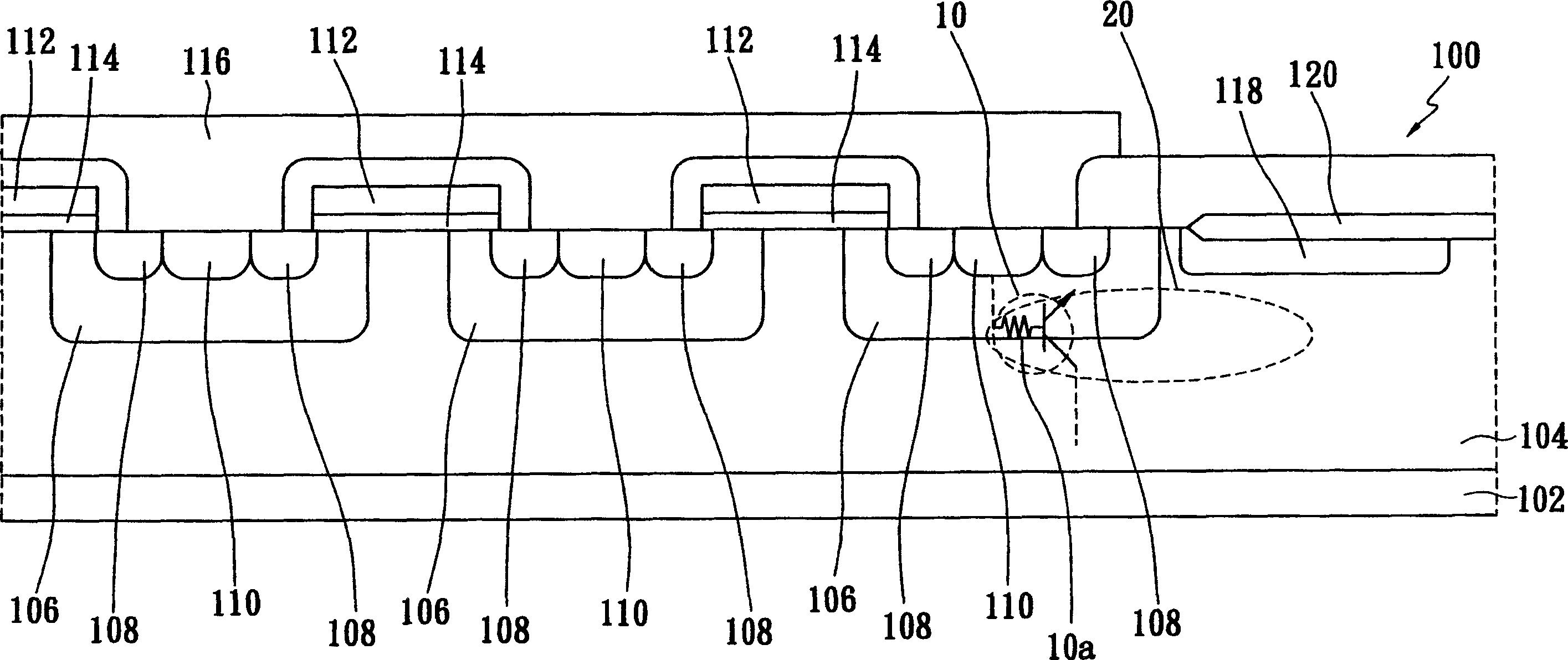

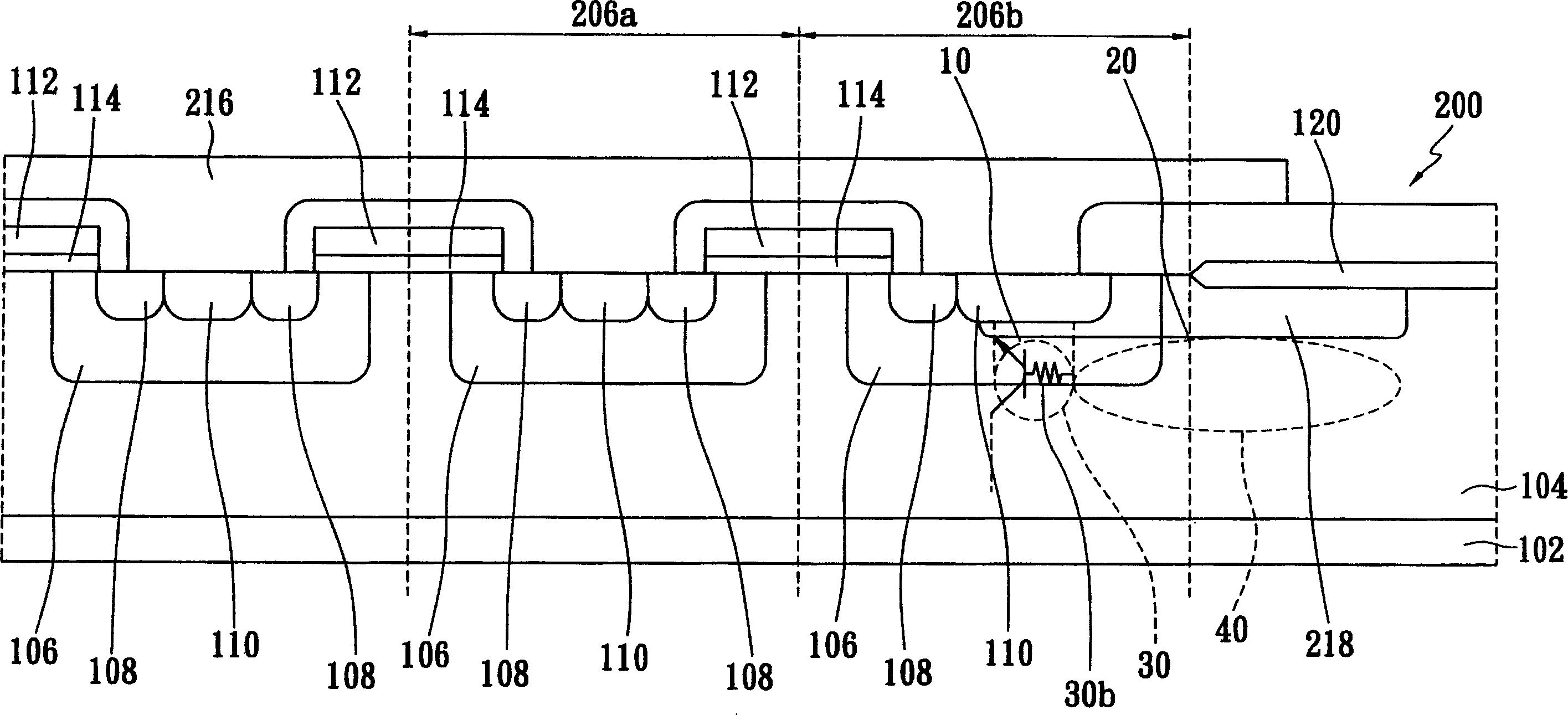

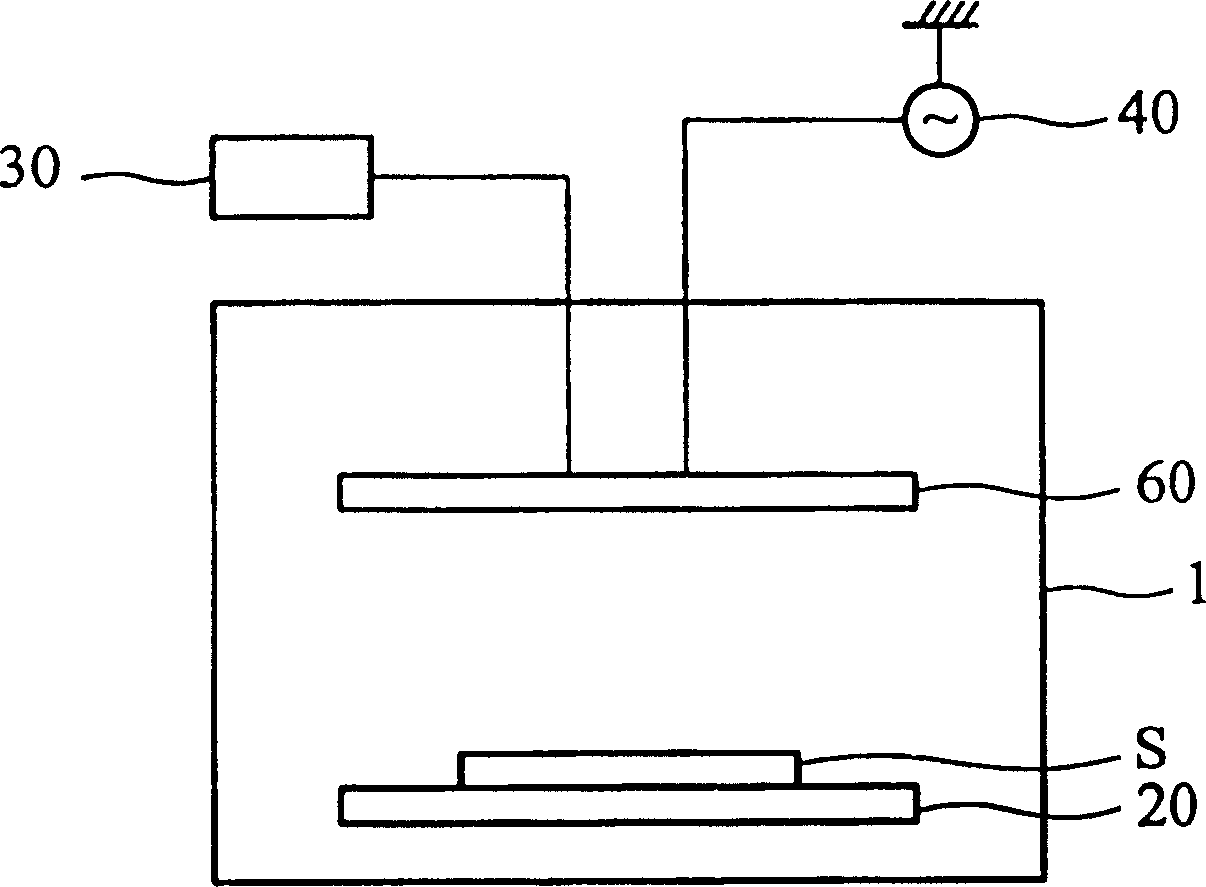

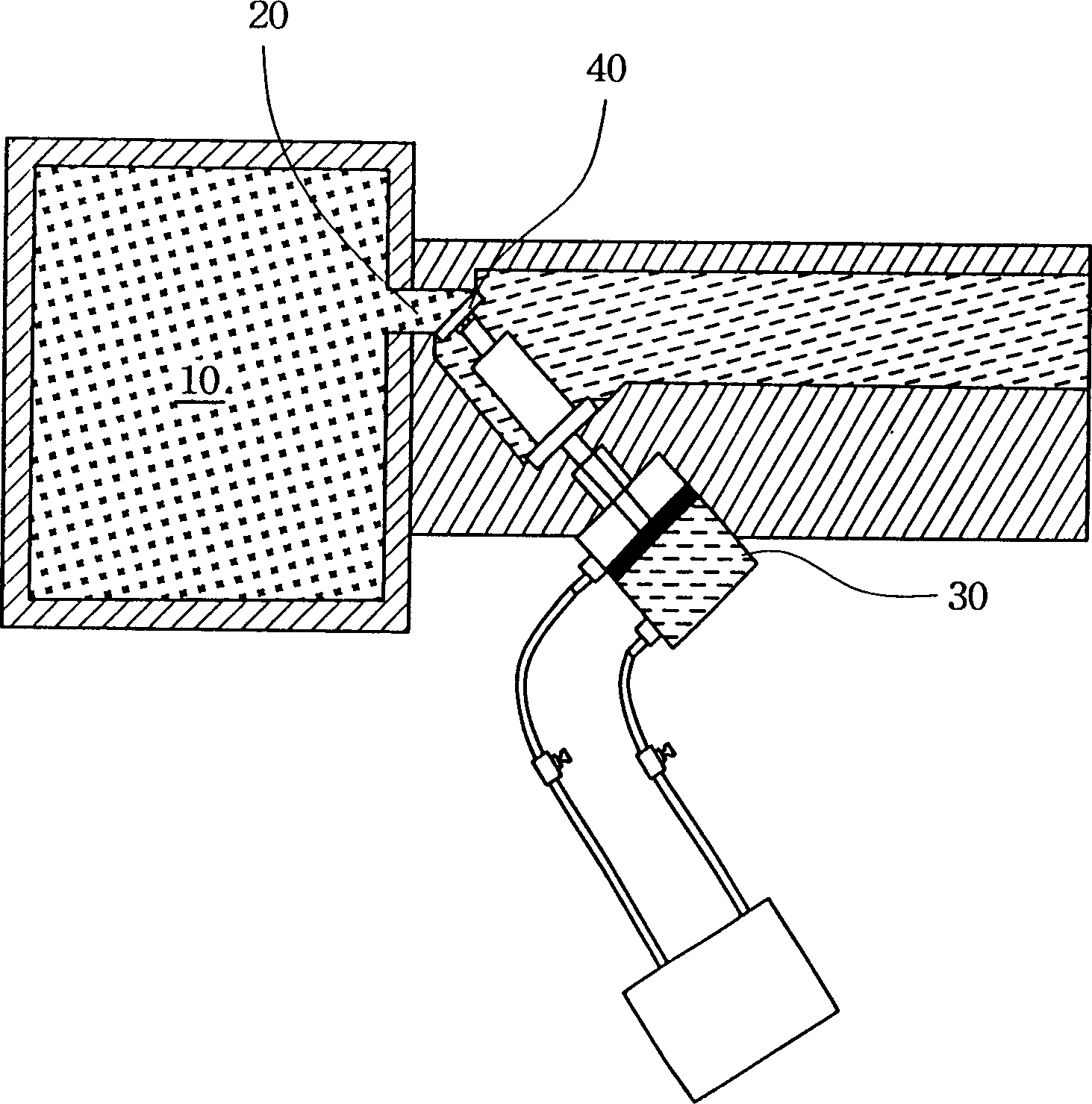

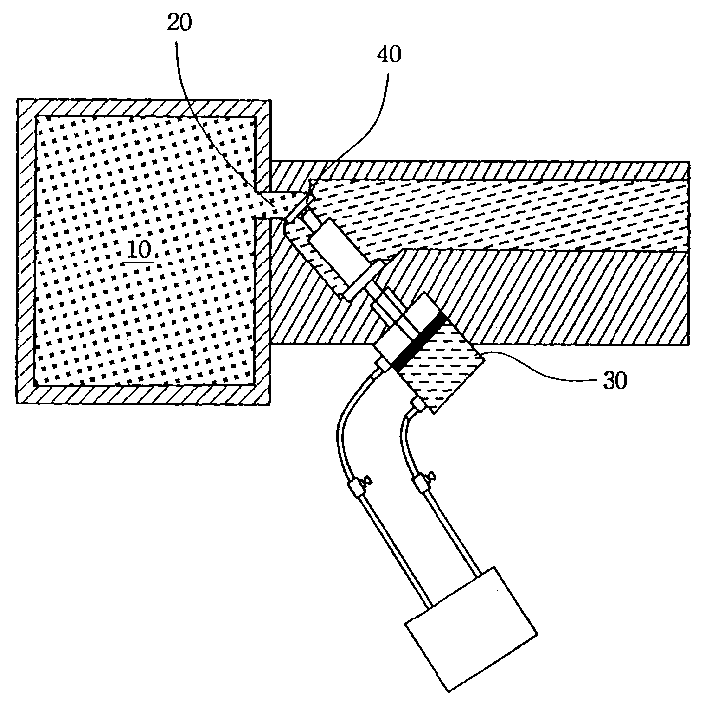

Plasma processing apparatus

InactiveCN1501763AAvoid breakingReduce short circuitElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProduct defect

The invention provides a plasma processing unit, wherein the upper plate electrode comprises an insulating cover plate and a supporting frame mounted on the bottom of the insulating cover plate to support the insulating cover plate, it also has a hole, and gas demarcation strip constructed through insulating material. The unit is mounted in the hole for supporting the frame. The invention can eliminate product defects and increase quality ratio.

Owner:AU OPTRONICS CORP

Method for processing special-shaped PTFE supporting piece for filter

A method for processing a special-shaped PTFE supporting piece for a filter comprises the following processing steps of 1) weighing, wherein powdery or granulous PTFE resin materials of piece weight of a product are weighed; 2) rough pressing, wherein the weighed PTFE resin materials are added to a rough pressing mould cavity for mould pressing, the pressure of the mould pressing is 2-5Kg, pressure is kept for 3-5 seconds, and the rough pressing is carried out at indoor temperature; 3) sintering, wherein a billet after rough pressing is placed in a sintering furnace to be sintered, sintering temperature is 360-375 DEG C, sintering time is 6 hours, and the billet is naturally cooled to the indoor temperature; 4) fine pressing, wherein the sintered billet is placed in a fine pressing mould cavity for fine pressing forming, the pressure of the fine pressing is 3-5Kg, dwell time is 2-3 seconds, and the fine pressing is carried out at the indoor temperature; 5) burr removing. Products processed through the method are high in precision, high in quality and high in qualification rate, processing is simple, and the products are suitable for batch production and processing.

Owner:陈广建

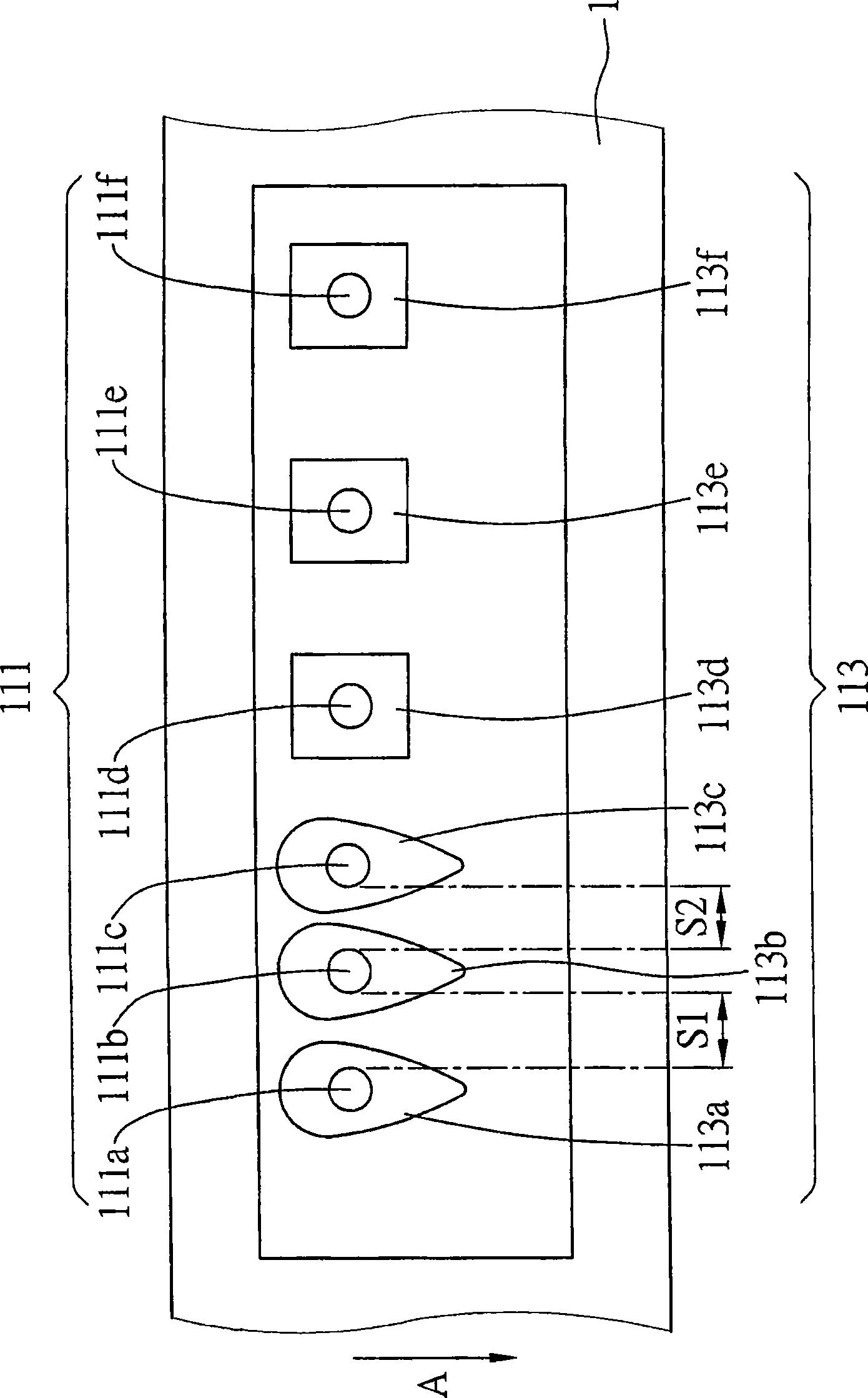

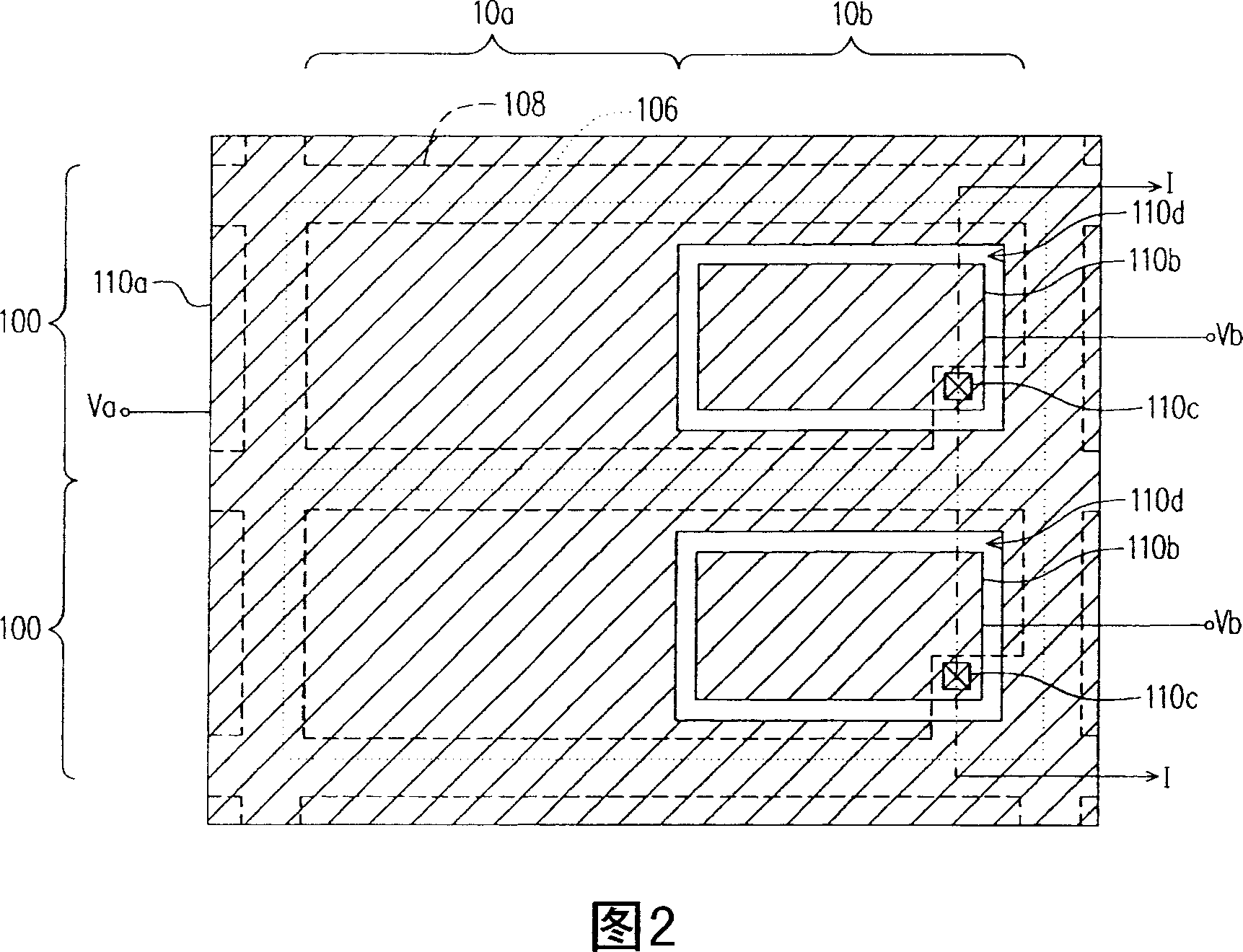

Baseplate of color filter and active element array, and pixel structure of liquid crystal display faceplate

ActiveCN1959502AWiden perspectiveImprove good rateStatic indicating devicesNon-linear opticsColor filter arrayLiquid-crystal display

A liquid crystal display consists of color filtering base plate pixel structure including the first and the second electrode patterns being separately connected to different voltage input end; active element array base plate pixel structure including the first and the second pixel electrodes, the first and the second grid drain electrode capacities and the first and the second storage capacities; liquid crystal face plate pixel structure including pixel structures of said color filtering base plate and active element array base plate.

Owner:AU OPTRONICS CORP

Processing method for quick-frozen peeled green soy beans

InactiveCN104542904AShort processing timeFreshness is not affectedFruits/vegetable preservation by freezing/coolingQuick FreezeSoy bean

The invention relates to a processing method for quick-frozen peeled green soy beans. The quick-frozen peeled green soy beans are produced through the steps of raw material inspecting, steam bubble cleaning, blanching, cooling with precooling water, peeling soy beans, steam bubble cleaning, blanching, cooling with precooling water, vibrating and draning, quick freezing, and selecting and packaging. The processing method is simple, high in product favorable rate, and short in processing time of the peeled soy beans; the freshness of the peeled soy beans is not influenced; the tincture is uniform; the taste is not changed; low-temperature long-term freezing is adopted; the freezing effect is good.

Owner:ANHUI DONGBAO FOOD

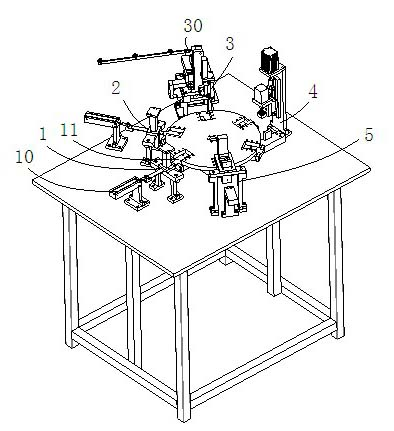

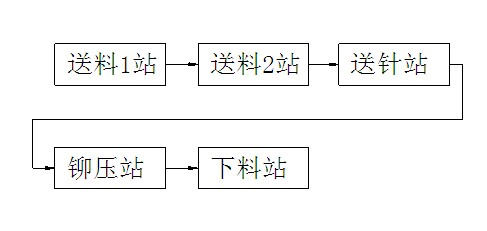

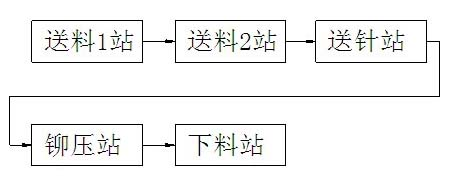

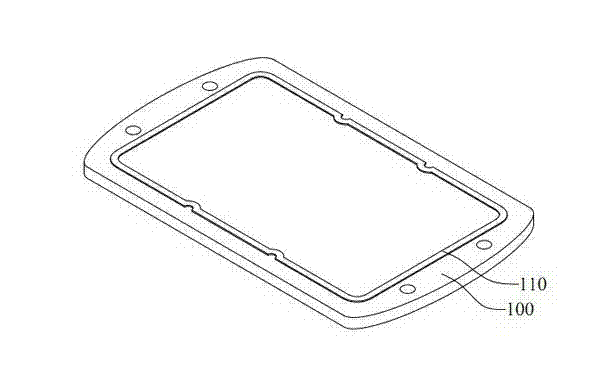

Production process for ear ring machine

The invention relates to a production process for an ear ring machine, which comprises the following steps: placing a fixed seat and a movable seat into a first vibration plate and a second vibration plate respectively to allow the fixed seat and the movable seat to enter a feeding tank under direct vibration, feeding into a fixture, passing a copper wire through a regulating wheel tensioning mechanism, passing the copper wire through a guide hole, cutting the copper wire off with a spring cutter, allowing the copper wire to enter a needle shift position under dead weight, delivering the copper wire to the position of a pressure needle, pressing the pressure needle into the joining hole of the fixed seat and the movable seat, rotating a rotating disc to a next procedure, tightly pressing the needle by upper and lower cylinders with the drive of the upper and lower cylinders, allowing the upper and lower cylinders to push a motor and a riveting and pressing head to rotate forward and backward to rivet and press the copper to prevent the fixed seat and the movable seat from separating, and thus, realizing a moving function; allowing a rotating disc to enter a feeding station, and ejecting a finished product by an ejecting head into the feeding tank to complete feeding. As mechanical operation is used in place of manual operation, the assembly speed is high, the production efficiency is high and the yield of finished products is improved relatively. The production process can realize industrial production and automatic production.

Owner:金湖县综合检验检测中心

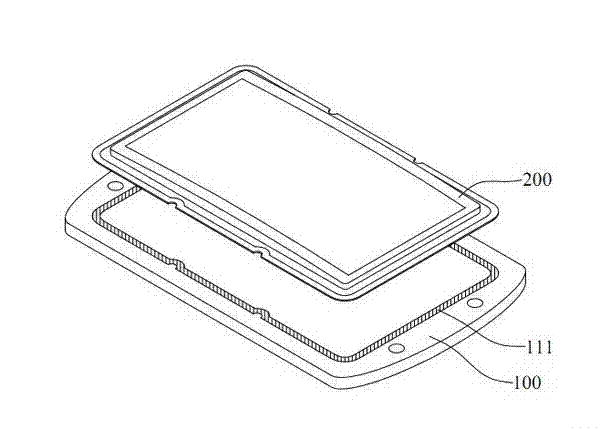

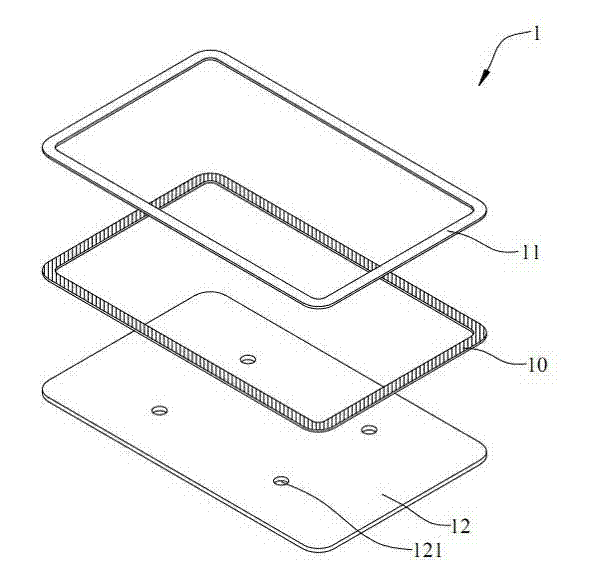

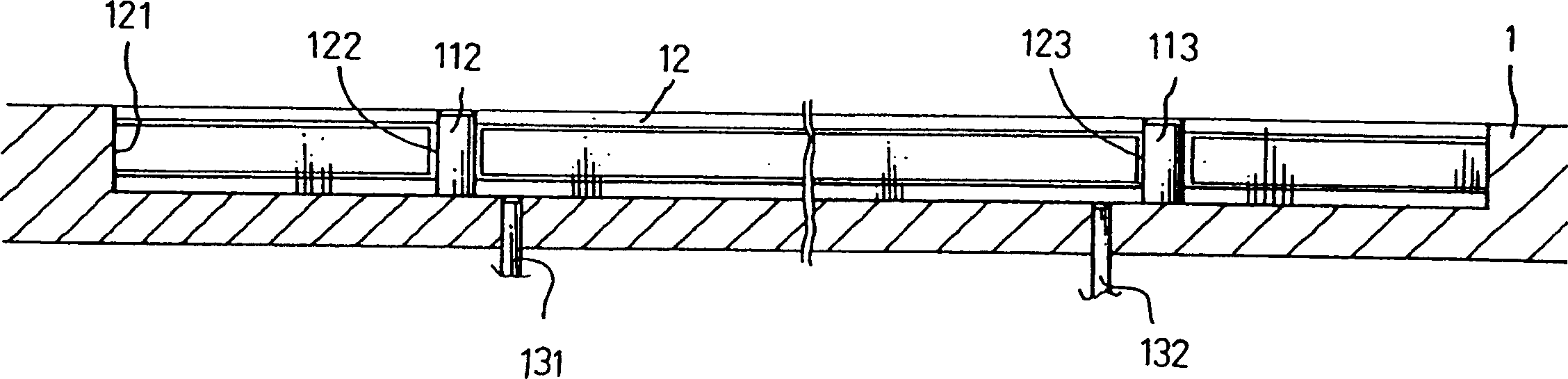

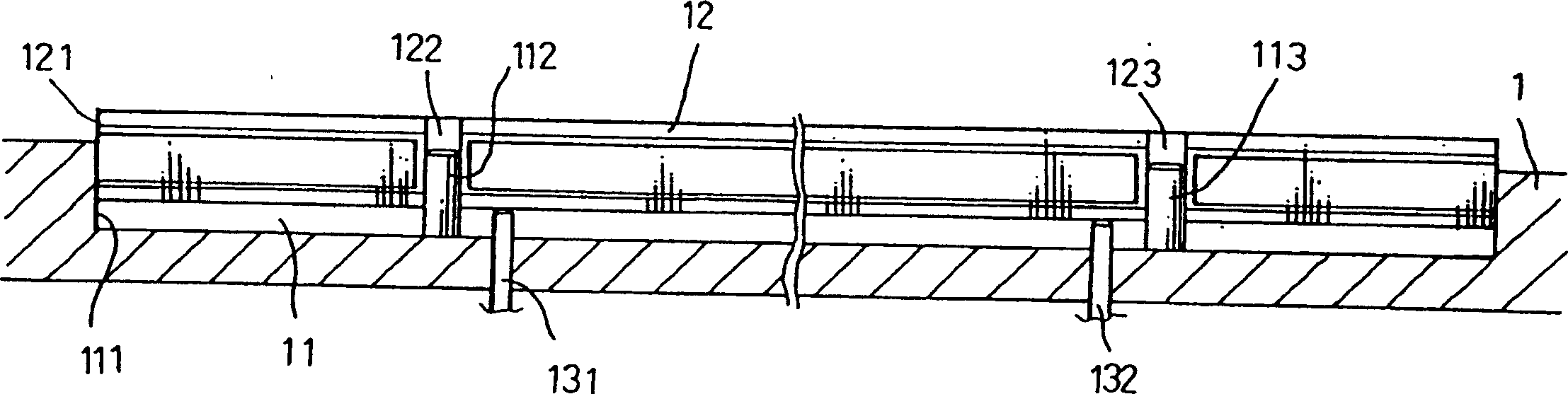

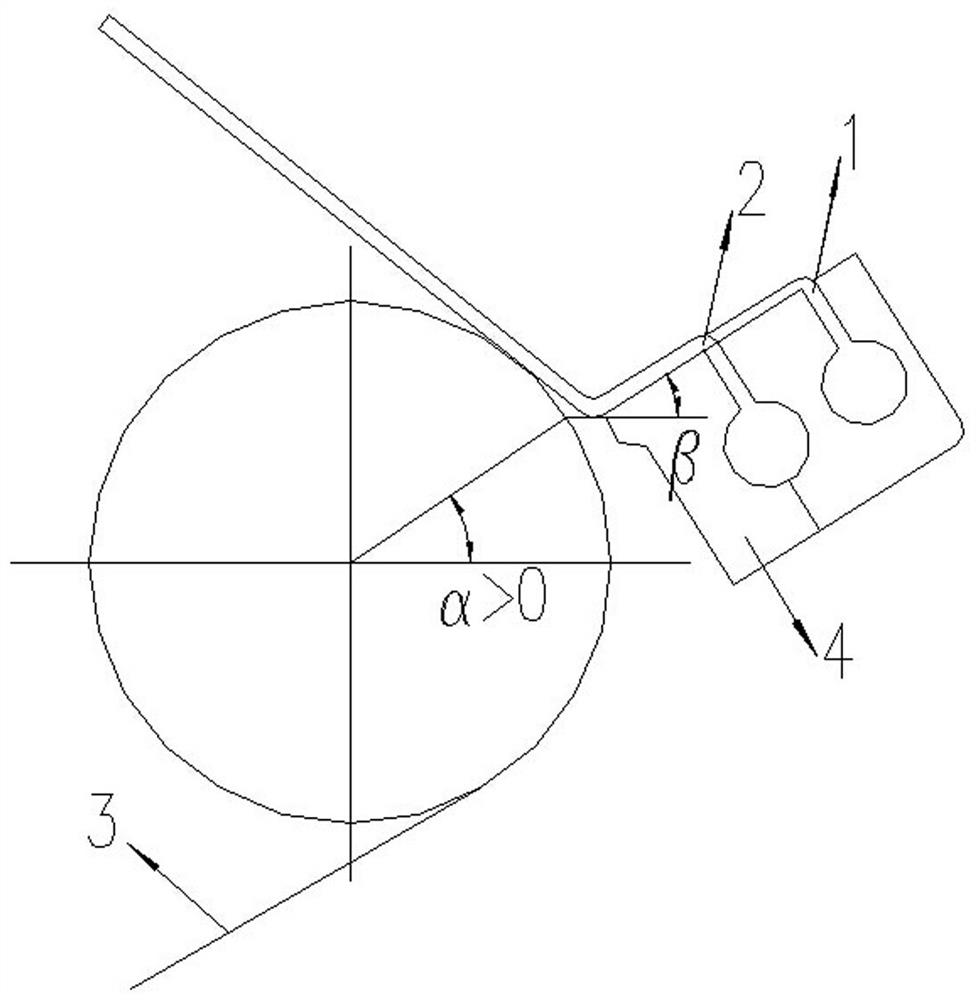

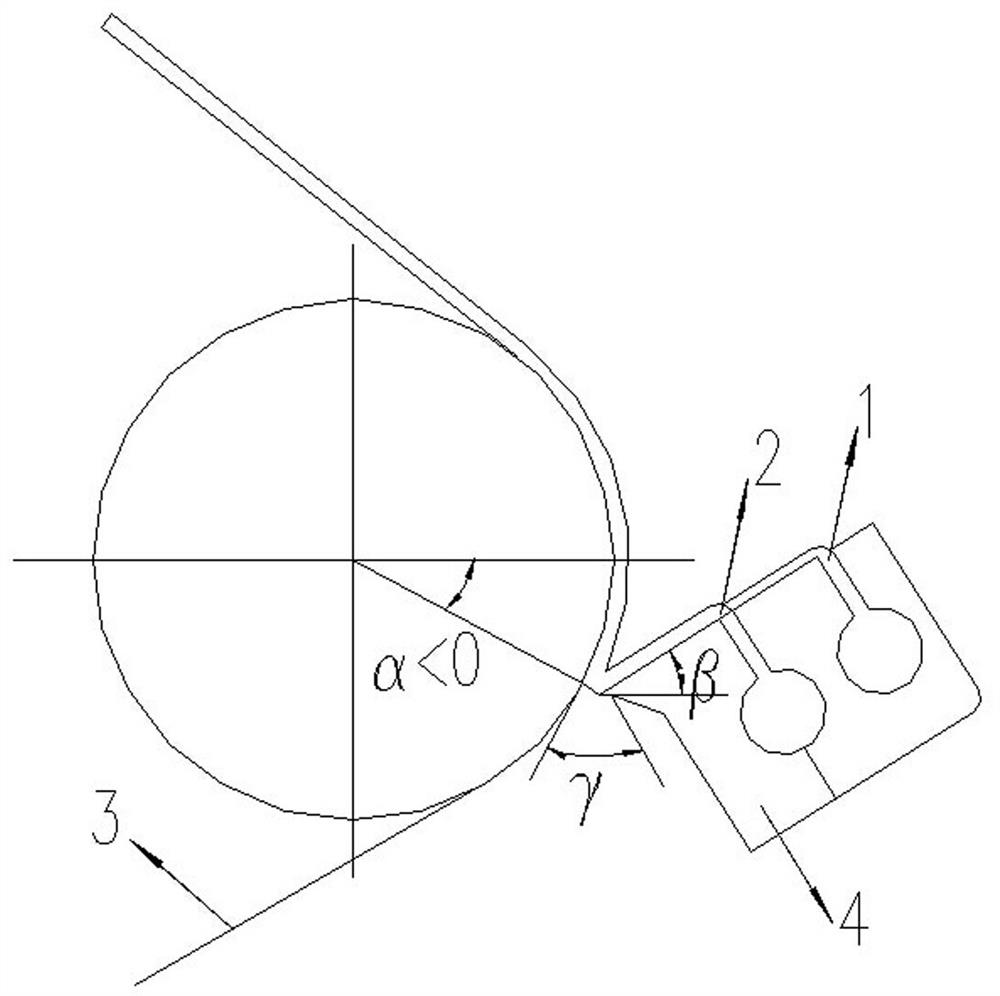

Adhesive tape, adhering device and adhering method thereof

InactiveCN103241447AImprove good rateAchieve positioning effectFlexible coversWrappersBiomedical engineeringDe bonding

The invention discloses an adhesive tape which is formed by stacking of a first de-bonding layer, an adhering layer and a second de-bonding layer. The second de-bonding layer is provided with a positioning portion, and the total area of the second de-bonding layer is larger than that of the first de-bonding layer. In addition, the invention further discloses an adhering device and an adhering method thereof. A base of the adhering device is provided with an accommodating groove and a positioning unit, and the adhesive tape is arranged in the accommodating groove of the base so as to enable the positioning portion of the adhesive tape and the positioning unit of the base to be positioned. A supporting member is provided, the first de-bonding layer is removed to expose the adhering layer, and the supporting member is adhered with the adhering layer mutually. By increasing the area of the second de-bonding layer, the problem that the shape of an existing adhesive tape is too narrow is solved, positioning fixation of the adhesive tape and the supporting member during adhering is achieved through the positioning portion, time and effort are saved, operation error rate is reduced simultaneously, and sticking quality is improved further.

Owner:ASKEY TECH JIANGSU +1

Packaging mould with electrostatic discharge protection

InactiveCN1479359AIncrease contact timeFree from damageSemiconductor/solid-state device manufacturingElectrostatic discharge protectionEngineering

The package mould possesses at least one flute to accommodate at least one package base plate. The package base plate possesses outer sidewall with first height, and the flute possesses inner sidewall with second height. The outer wall is connected to the inner wall electrically, and the second height is larger than the first height in order to prolong the contact period between the outer wall and the inner wall when the base plate leaves package mould. Thus, static electricity produced in process of leaving the package mould will be discharged through the assembly. The invention reduces damages caused by electrostatic so as to increase package proporty.

Owner:ADVANCED SEMICON ENG INC

Detachable balancing optical assembly

InactiveCN1940774AImprove good rateLow costElectrography/magnetographyMountingsEngineeringColor wheel

A balanced optical component of detachable type is prepared as setting motor at one side of color wheel and coverage plate at another side of color wheel, setting a force exerting region on one surface of coverage plate as said surface being set opposite to color wheel.

Owner:PRODISC TECH INC

Conductive pasty material, method for controlling its viscosity and electronic component using same

InactiveCN1372269AReduce thicknessImprove performanceFixed capacitor electrodesFixed capacitor dielectricConductive pasteSulfur

A conductive paste having a desired viscosity that does not change with time and having a stable viscosity characteristic, and an electronic component formed using the conductive paste. The conductive paste includes conductive powder, an organic vehicle, and at least one compound selected from the group consisting of a compound having a tertiary amine structure and being soluble in the organic vehicle, and a heterocyclic structure containing nitrogen but not containing sulfur and being soluble in the organic vehicle. Compounds dissolved in the organic vehicle.

Owner:MURATA MFG CO LTD

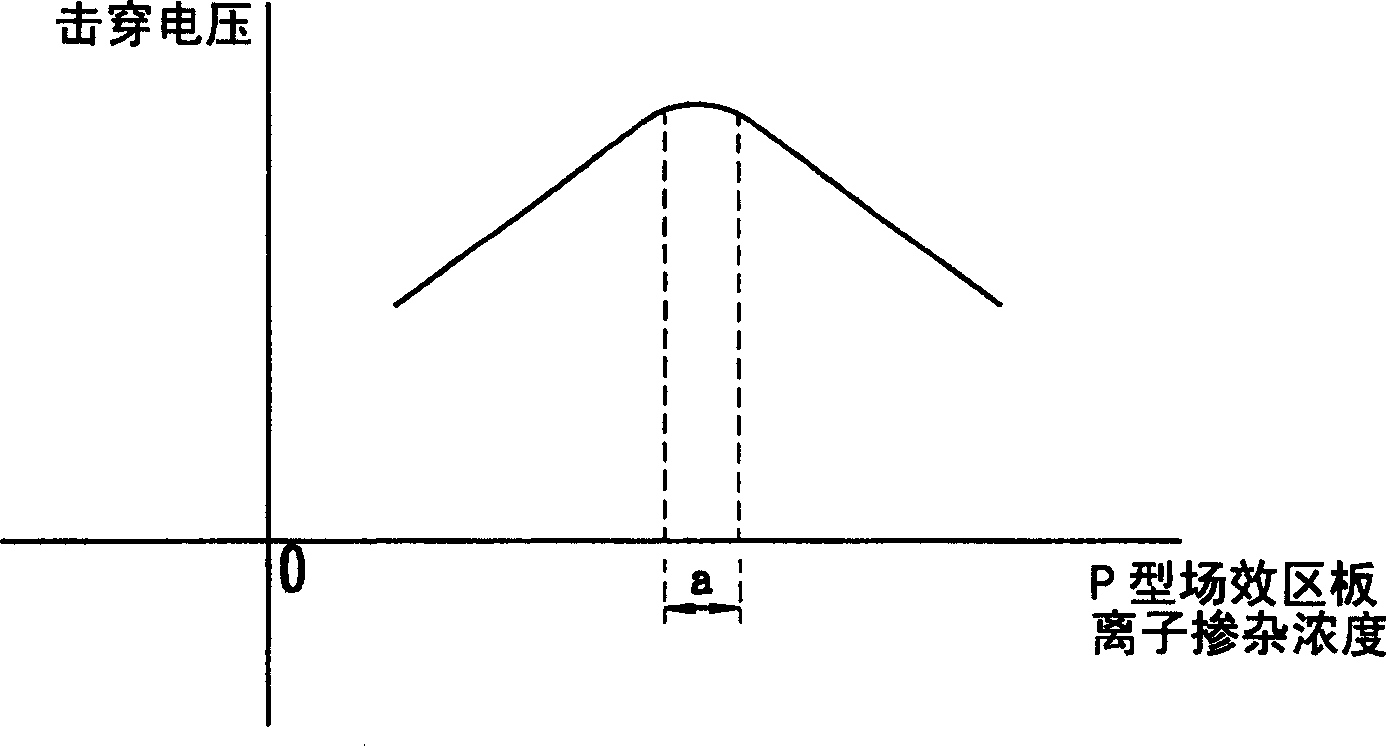

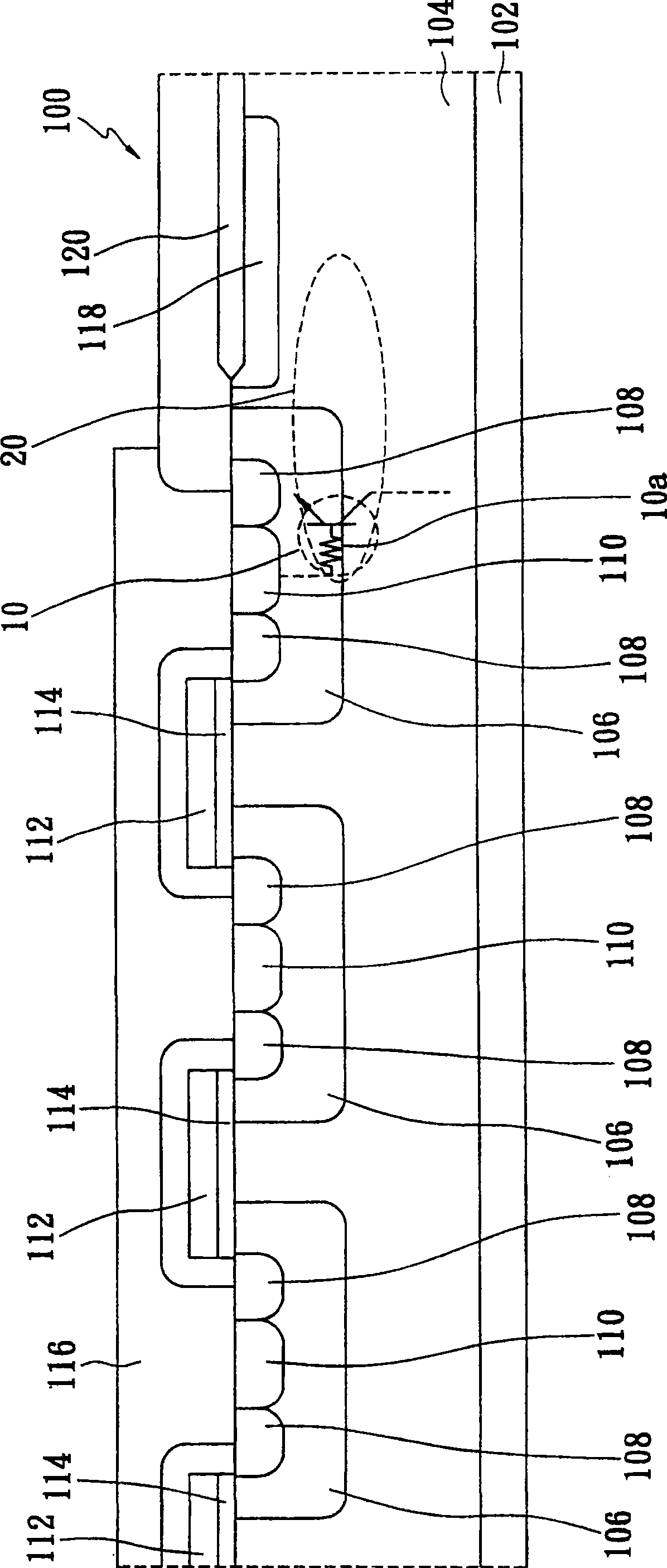

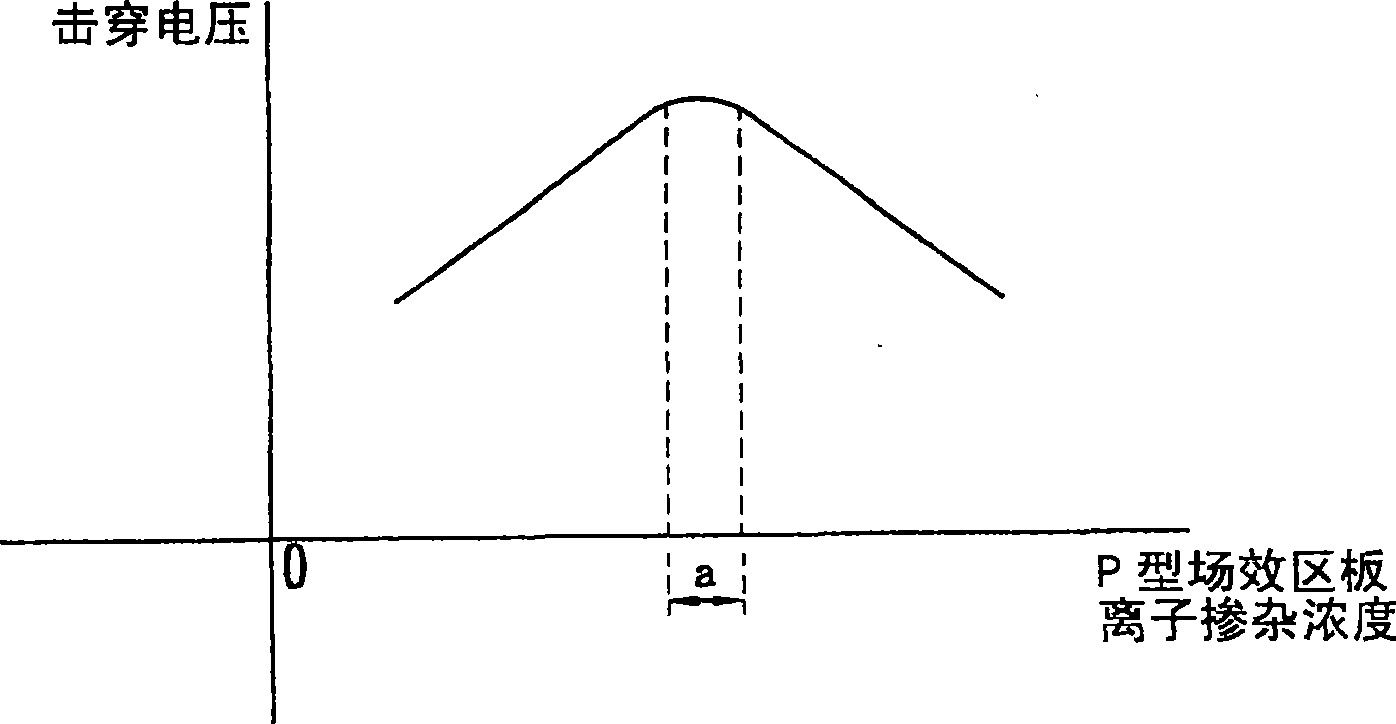

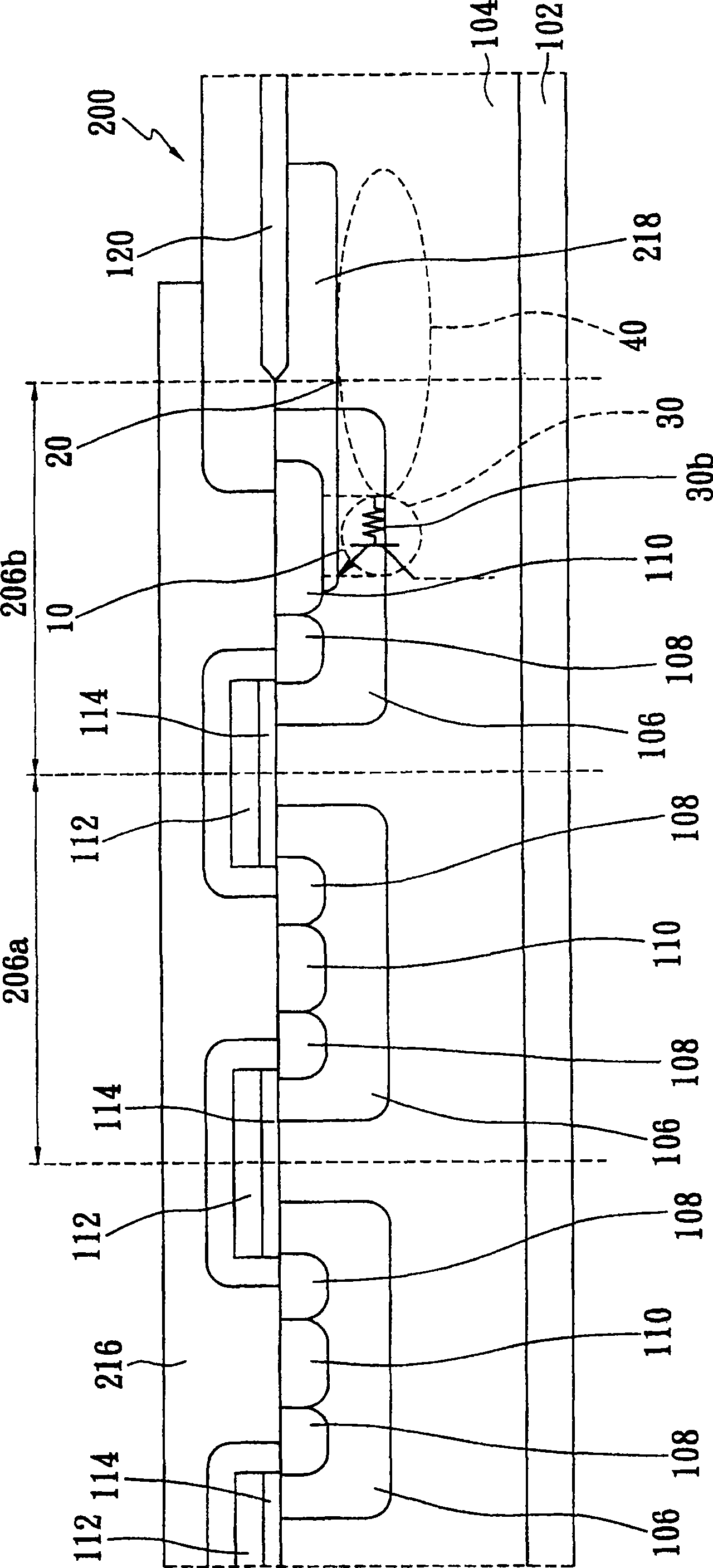

Transistor structure with breakdown protection

InactiveCN1862828AImprove breakdown energyReduced avalanche breakdown voltageTransistorIon dopingTransistor

This invention relates to transistor structure with breakdown protection. It can improve transistor anti breakdown energy, and it can enlarge the ion doping concentration redundancy degree of the prearranged avalanche breakdown voltage. The parasitic bipolar type transistor is avoided be ducting by this transistor structure, and the anti breakdown current can be improved. The structure has one metal field effect area block at the same time to enlarge the ion doping concentration redundancy degree needed of the prearranged avalanche breakdown voltage.

Owner:SYST GEN

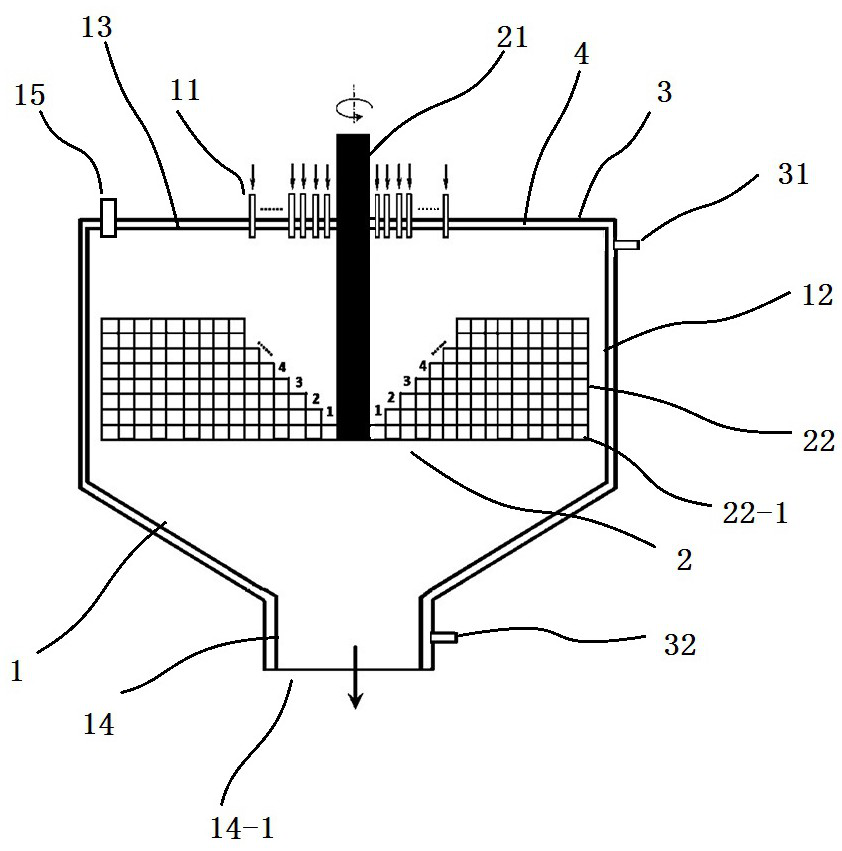

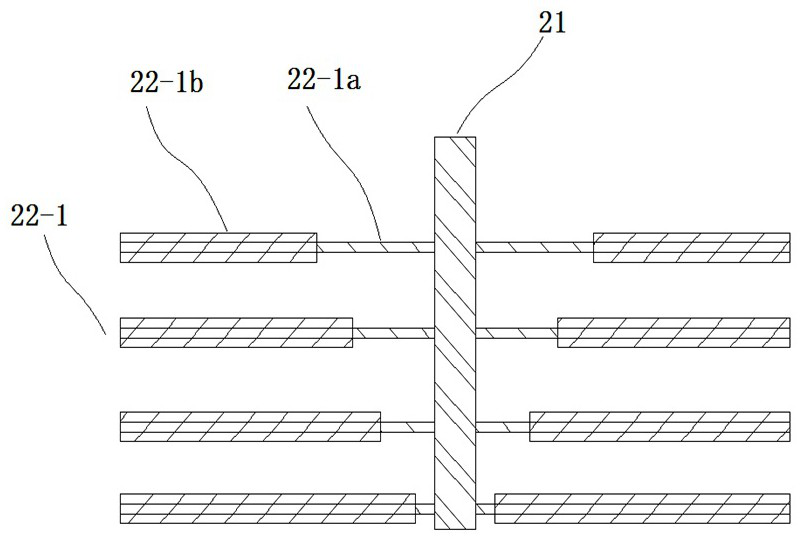

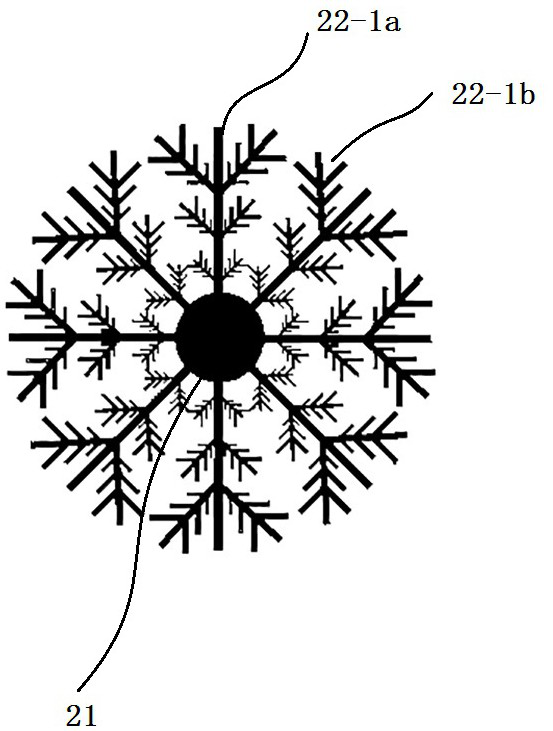

Rotating equipment and using method

PendingCN112830569AReduce the cost of qualityReduce manufacturing costRotary stirring mixersTransportation and packagingMicroorganismEngineering

The invention discloses rotating equipment and a using method, and belongs to the technical field of rotating equipment. The rotating equipment comprises a box shell and a rotating device arranged in the box shell; the rotating device comprises a vertically arranged rotating shaft and a dispersion assembly which is mounted on the rotating shaft and is of a fractal geometric structure; and the dispersion assembly comprises a plurality of dispersing layers, and each dispersing layer at least corresponds to one material inlet. Compared with the prior art, the weight and cost of the rotor can be greatly reduced, the rotor is not prone to damage when making contact with solid during high-speed rotation, and damage to microorganisms can be greatly reduced when the rotor is used in the biological reaction process; when multi-strand material feeding and high-viscosity fluid are involved, the distribution uniformity of the materials in the rotating device can be greatly improved, the distribution and mixing of each strand of feeding in the rotating bed are controlled, and the heat transfer, mass transfer and reaction efficiency of the materials in the rotating device is greatly improved.

Owner:FUZHOU UNIV

Plate shape control method for high-carbon steel in thin slab continuous casting and rolling production

ActiveCN113578961AReduce defective rateMeet the characteristicsRoll mill control devicesIncreasing energy efficiencySteelmakingThin slab

The invention discloses a plate shape control method for high-carbon steel in thin slab continuous casting and rolling production, and belongs to the field of steel production. The method comprises the following steps of a steelmaking process, a cast rolling process and a slow cooling process, the cast rolling process comprises continuous casting, rough rolling, induction heating, finish rolling, layer cooling and coiling; during continuous casting, the thickness of a casting blank is 90-110 mm, the pulling speed is controlled within the range of 4.0-4.8 m / min, and the temperature difference of the section of the casting blank is controlled within 70 DEG C; in the finish rolling procedure, an F3 working roller is a high-speed steel roller, and an F4 working roller and an F5 working roller are high-nickel-chromium rollers; the convexity of the F3 working roller is set to be 200 microns larger than that of other produced steel types, and the load distribution of each rack adopts the principle of sequentially decreasing. Compared with the prior art, the good rate of the straight hair curled plate shape is improved.

Owner:RIZHAO STEEL HLDG GROUP

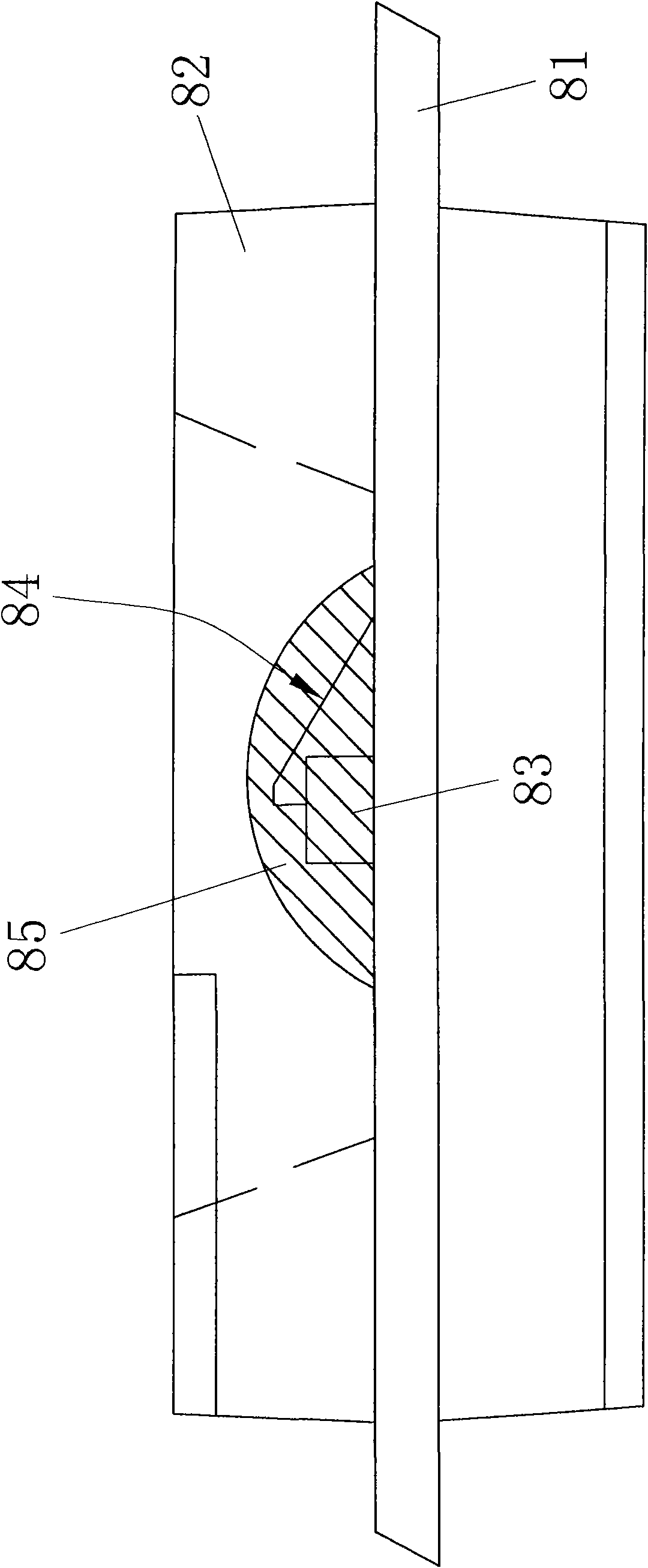

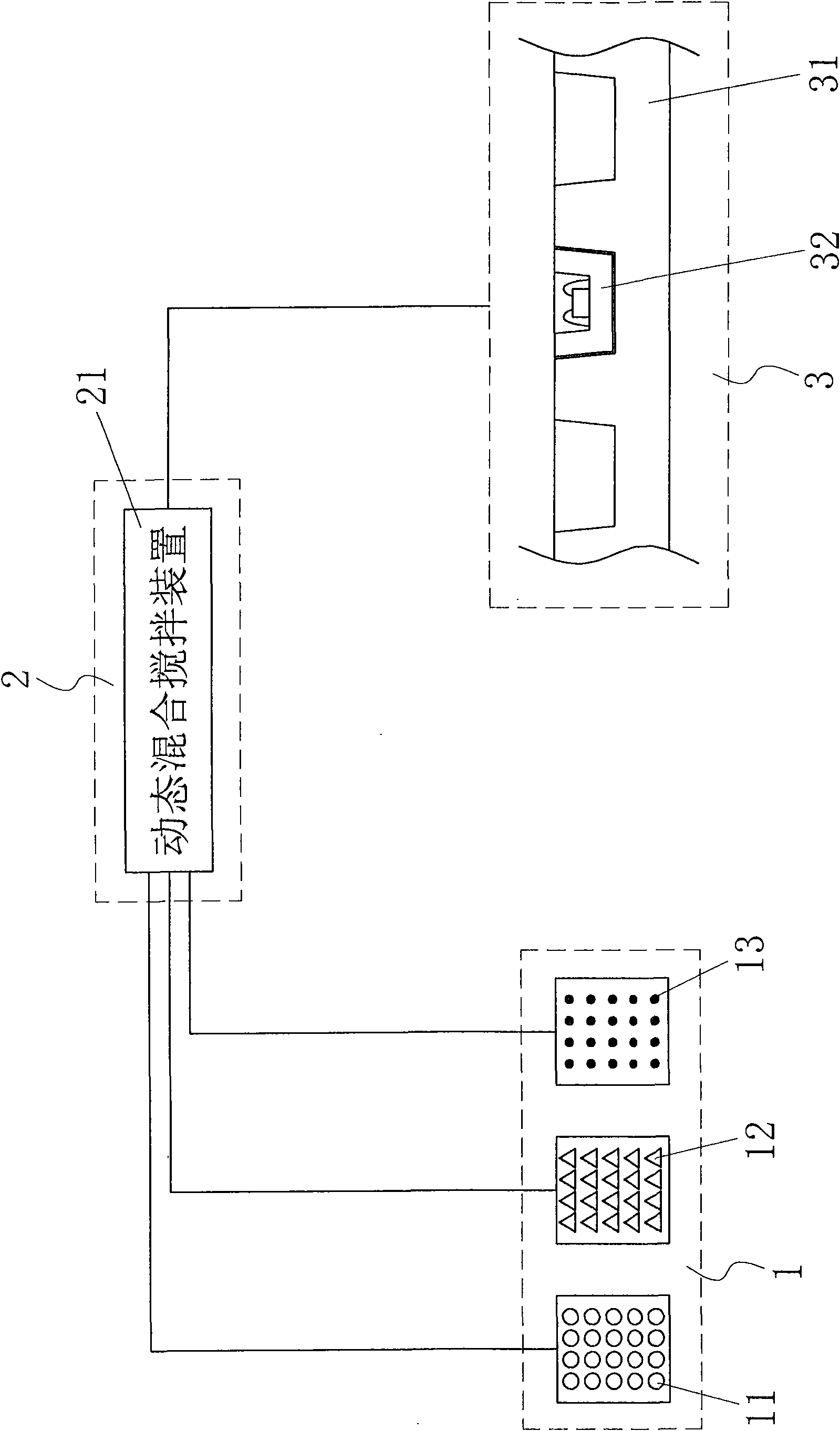

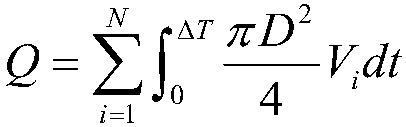

Forming method for uniformly distributing fluorescer on light-emitting diode

InactiveCN101882654AUniform brightness distributionGuaranteed qualitySemiconductor devicesLiquid stateEngineering

The invention provides a forming method for uniformly distributing a fluorescer on light-emitting diode (LED), comprising the following steps: a materials-preparing step, i.e. preparing a first liquid glue, a second liquid glue and a fluorescent material liquid glue; a dynamic stirring step, i.e. transmitting the first liquid glue, the second liquid glue and the fluorescent material liquid glue together prepared in the materials-preparing step to a dynamic mixing and stirring device for carrying out dynamic stirring so as to form a uniform liquid fluorescer; and an ejection forming step, i.e. ejecting the uniform liquid fluorescer obtained in the dynamic stirring step into the base of the LED of a mould and forming. By adopting the steps of the method in the invention, the fluorescer can be distributed uniformly in the base of the LED of the mould, brightness which is projected outwards by each batch of LED crystals is distributed uniformly, and the quality of each batch of finished products can be ensured, thereby further greatly improving the good rate of the products, saving human resource and greatly shortening manufacturing time.

Owner:川连机械股份有限公司

Packaging mould with electrostatic discharge protection

InactiveCN1315167CIncrease contact timeFree from damageSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The package mould possesses at least one flute to accommodate at least one package base plate. The package base plate possesses outer sidewall with first height, and the flute possesses inner sidewall with second height. The outer wall is connected to the inner wall electrically, and the second height is larger than the first height in order to prolong the contact period between the outer wall and the inner wall when the base plate leaves package mould. Thus, static electricity produced in process of leaving the package mould will be discharged through the assembly. The invention reduces damages caused by electrostatic so as to increase package proporty.

Owner:ADVANCED SEMICON ENG INC

Plasma processing apparatus

InactiveCN1230045CAvoid breakingReduce short circuitElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProduct defect

The invention provides a plasma processing unit, wherein the upper plate electrode comprises an insulating cover plate and a supporting frame mounted on the bottom of the insulating cover plate to support the insulating cover plate, it also has a hole, and gas demarcation strip constructed through insulating material. The unit is mounted in the hole for supporting the frame. The invention can eliminate product defects and increase quality ratio.

Owner:AU OPTRONICS CORP

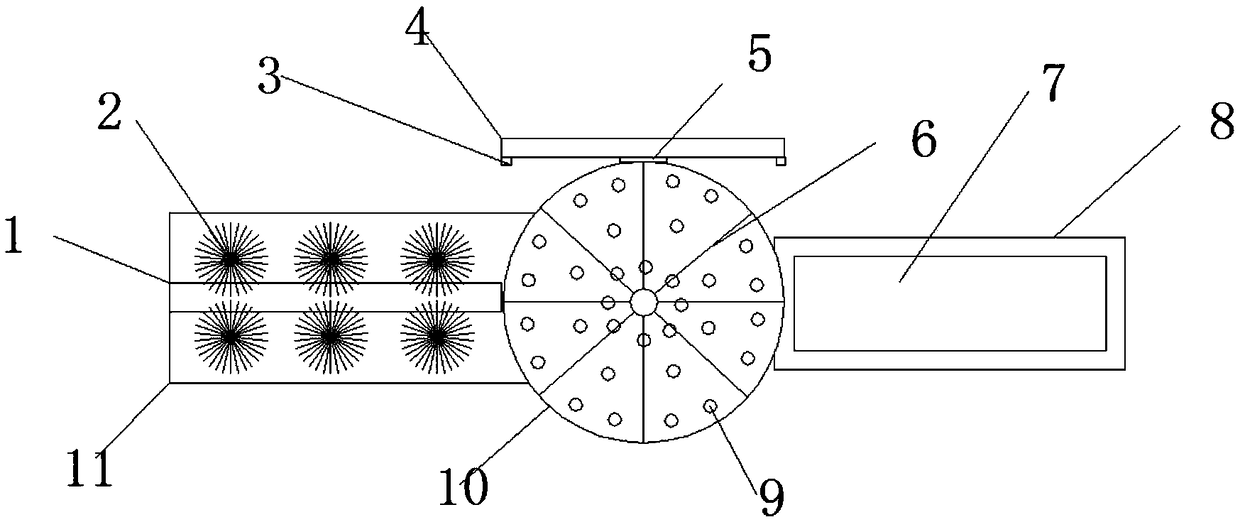

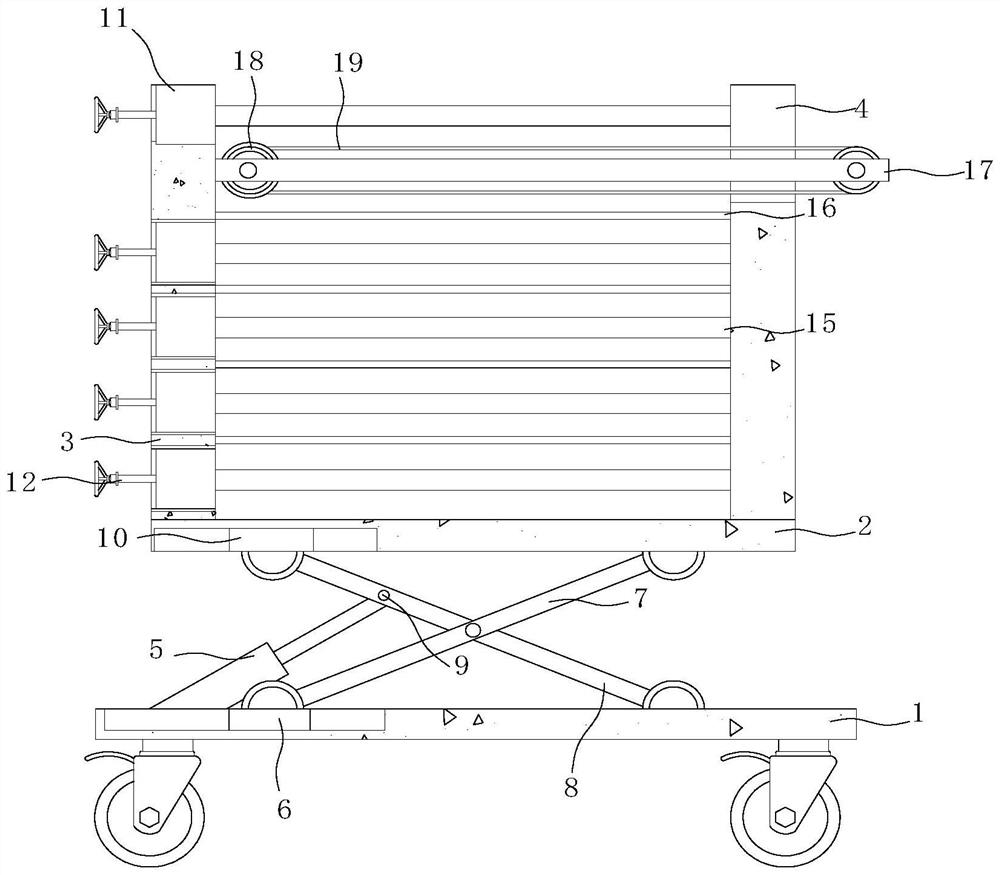

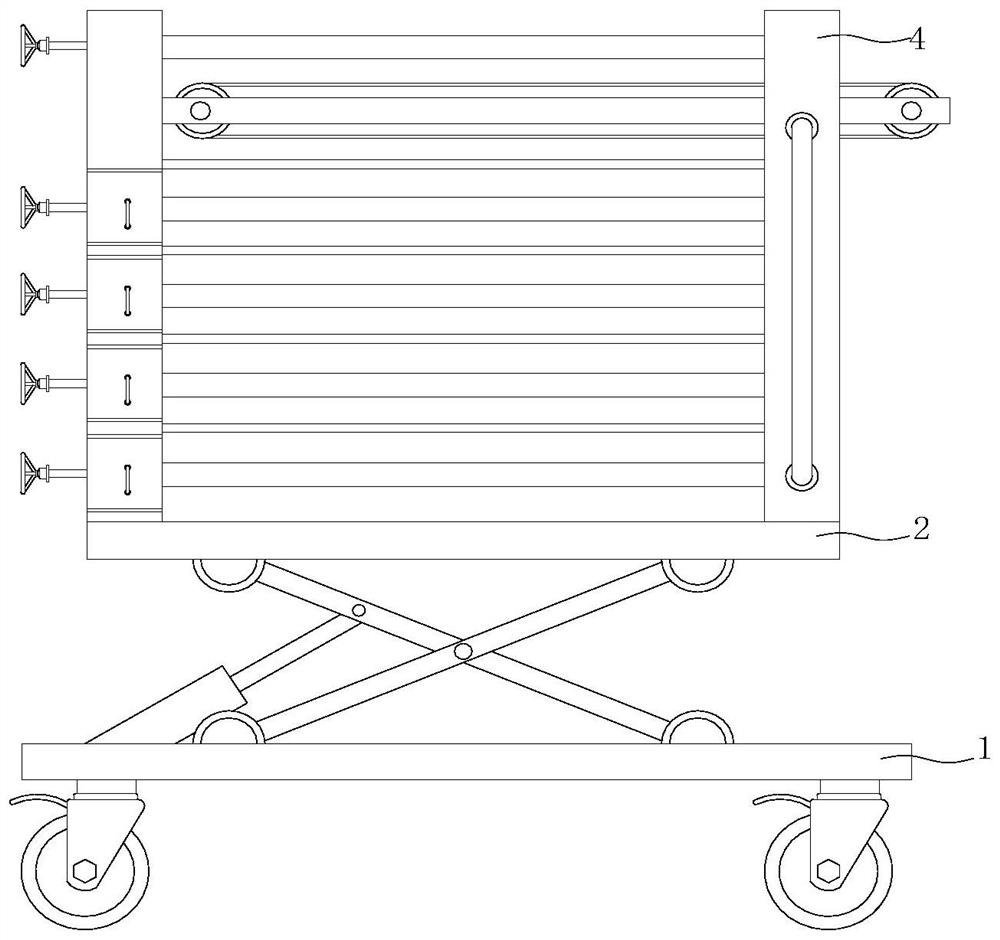

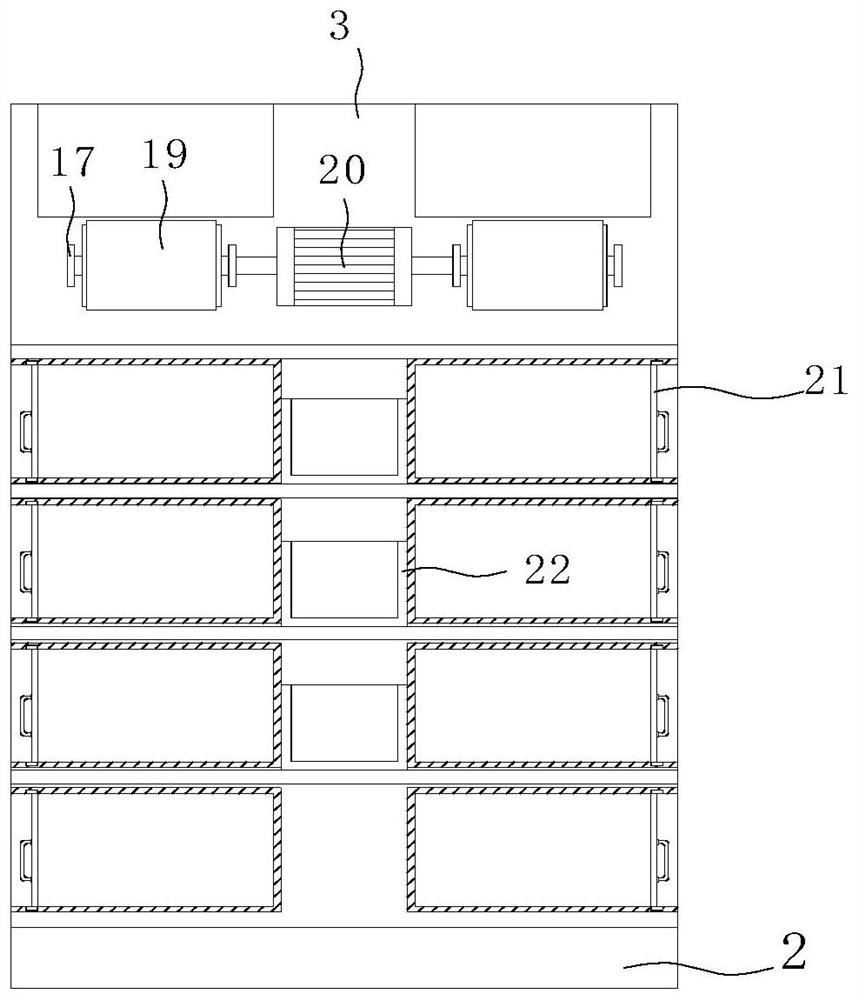

A kind of LED chip cleaning and drying device

ActiveCN106299043BReduce rotationImprove good rateSemiconductor/solid-state device manufacturingSemiconductor devicesSpray nozzleEngineering

The invention relates to an LED wafer cleaning and drying device. The LED wafer cleaning and drying device comprises an operating platform, a turnplate and a drying drum, wherein a conveyor belt A is arranged above the operating platform; a plurality of rotatable brushes for brushing particles on the surface of a wafer are arranged on the operating platform; one ends of the brushes are positioned on the operating platform; the other ends of the brushes are positioned above the conveyor belt A and are tightly adhered to the upper surface of the conveyor belt A; one side of the turnplate is connected with an upper cover through a hinge; a rotating shaft is arranged in the center of the inner part of the turnplate; the rotating shaft is connected with a plurality of rotating vanes; a plurality of liquid draining holes are formed in the bottom of the turnplate; the turnplate is connected with the drying drum through a transfer drum; a conveying plate B is arranged inside the drying drum; spray nozzles are formed above and below the turnplate. The LED wafer cleaning and drying device can solve the problem that in the LED wafer producing process, the surface of the wafer is contaminated.

Owner:六安联众工业自动化技术有限公司

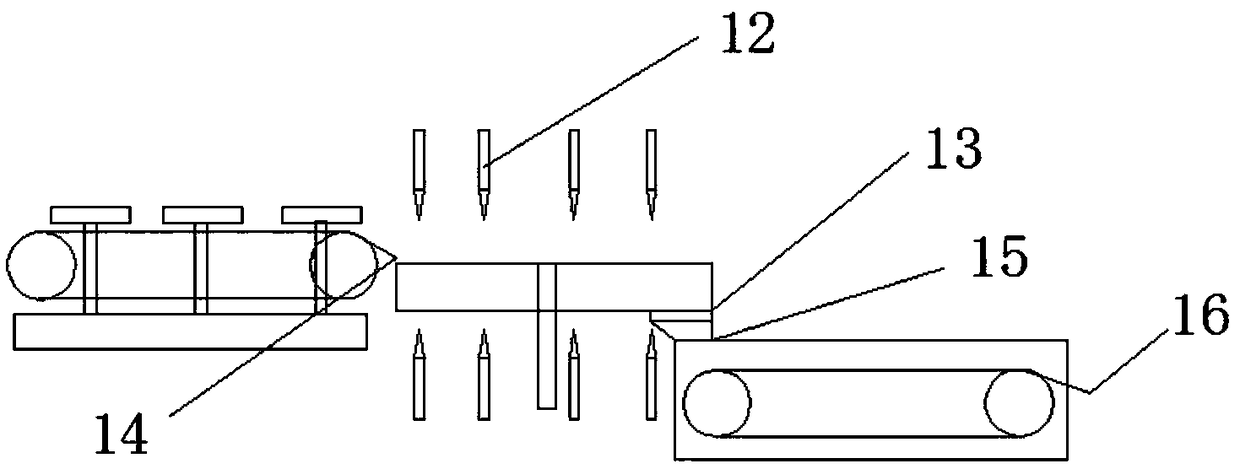

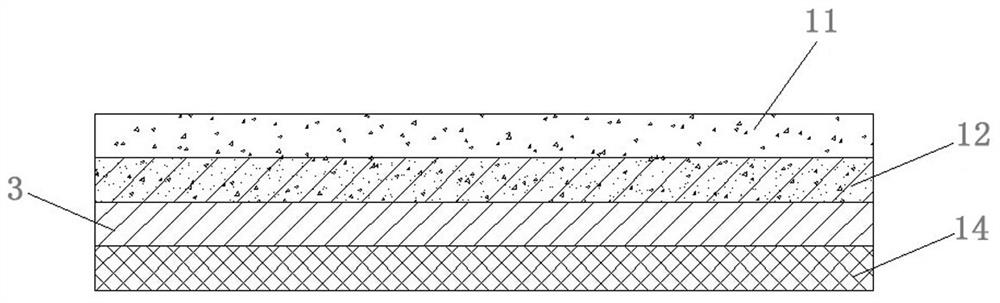

A kind of production technology of nano-silver wire transparent conductive film

ActiveCN108250469BHigh light transmittanceImprove good rateElectrically-conductive paintsFilm baseTransparent conducting film

The invention relates to a production process of nano-silver wire transparent conductive film, comprising the following steps: (1) base material preparation: the selected base material is a PET base, and the prepared PET base is hardened; (2) coating Cloth the configured coating nano-silver wire coating solution and protective glue coating solution: apply the configured nano-silver wire coating solution and protective glue coating solution to the PET film base through coating equipment respectively; (3 ) Drying: drying the coated film; (4) Winding: winding the finished product. The process of the invention can effectively improve the good rate of the nano-silver wire conductive film, and accelerate the substitution of the nano-silver wire conductive film for ITO.

Owner:LUCKY HUAGUANG GRAPHICS

Transistor structure with breakdown protection

InactiveCN100514671CImprove breakdown energyReduced avalanche breakdown voltageTransistorParasitic bipolar transistorIon doping

The invention relates to a transistor structure with breakdown protection, which can improve the withstand breakdown energy of the transistor and expand the redundancy of ion doping concentration required by the predetermined avalanche breakdown voltage. The transistor structure prevents the parasitic bipolar transistor from being turned on, and can improve the avalanche breakdown resistance current of the transistor. At the same time, the transistor structure has a metal field effect block, which is used to expand the redundancy of the ion doping concentration required for the predetermined avalanche breakdown voltage.

Owner:SYST GEN

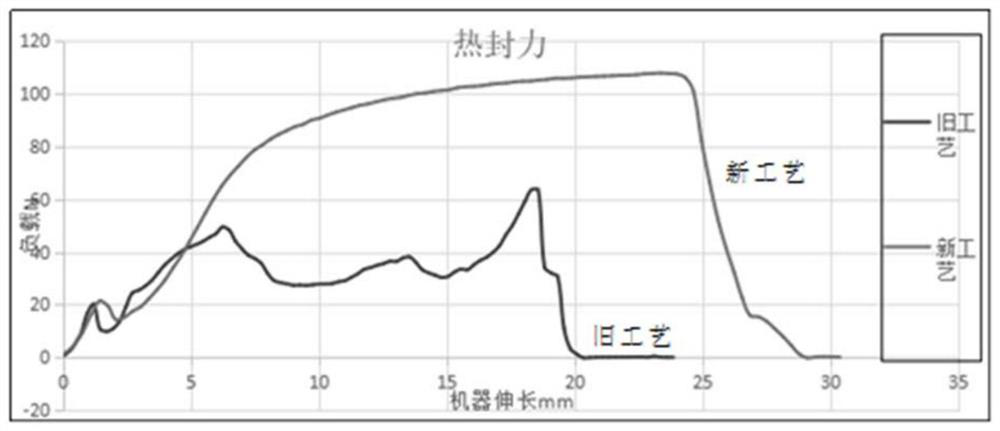

Flexible package battery packaging process

PendingCN112768780AAccelerated agingShorten the processing cycleFinal product manufactureElectrolyte accumulators manufactureMetal stripsProcess engineering

The invention provides a flexible package battery packaging process. The packaging process comprises the following steps: S1, cutting and laminating a coated pole piece, and cutting a reserved position of a pole lug into the same size as a metal strip; S2, fixedly connecting a metal belt with the pole piece to form a tab metal belt; S3, packaging the two sides of the tab metal belt with aluminum plastic films by using a high-frequency electromagnetic heating process; and S4, performing cold sealing after hot melting of the tab metal belt and the aluminum-plastic film is completed. According to the packaging process of the flexible package battery, the problems of pollution, damage or poor processing and the like of the tabs in the processing process of a manufacturer are effectively avoided; and the tab processing technology and the battery cell processing technology are combined, so that the processing period is shortened, the excellent rate is improved, and the problem of aging of the tab caused by secondary heating in the battery cell manufacturing process can be solved.

Owner:TIANJIN ENERGIES

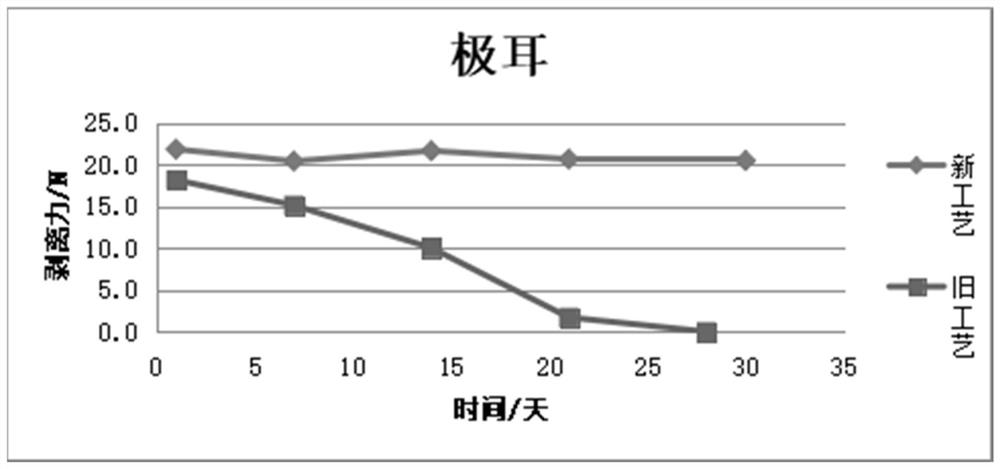

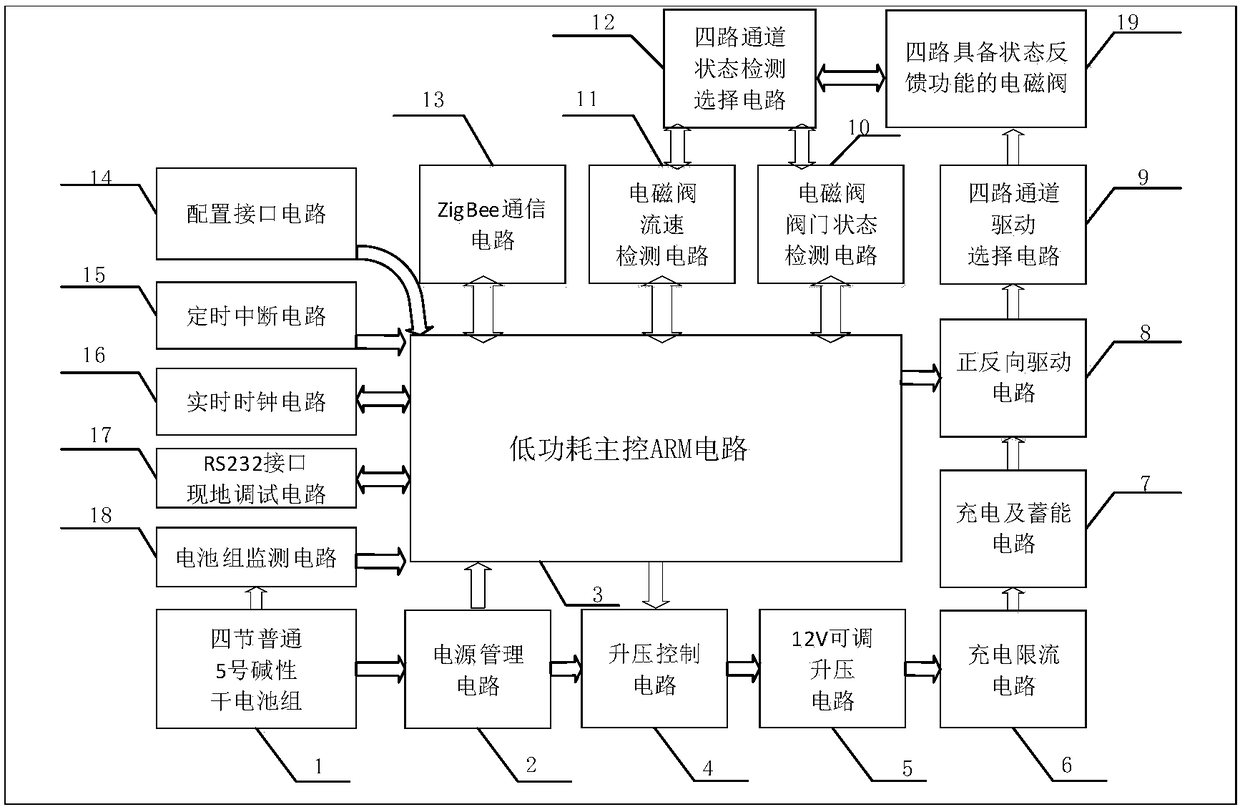

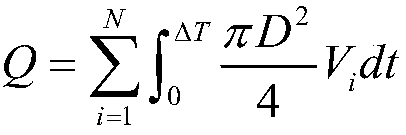

A field precision water-saving irrigation controller

ActiveCN105766568BEasy buy replacementEasy to buy and replaceClimate change adaptationWatering devicesVoltage pulseLow voltage

Owner:NANJING NARI GROUP CORP +1

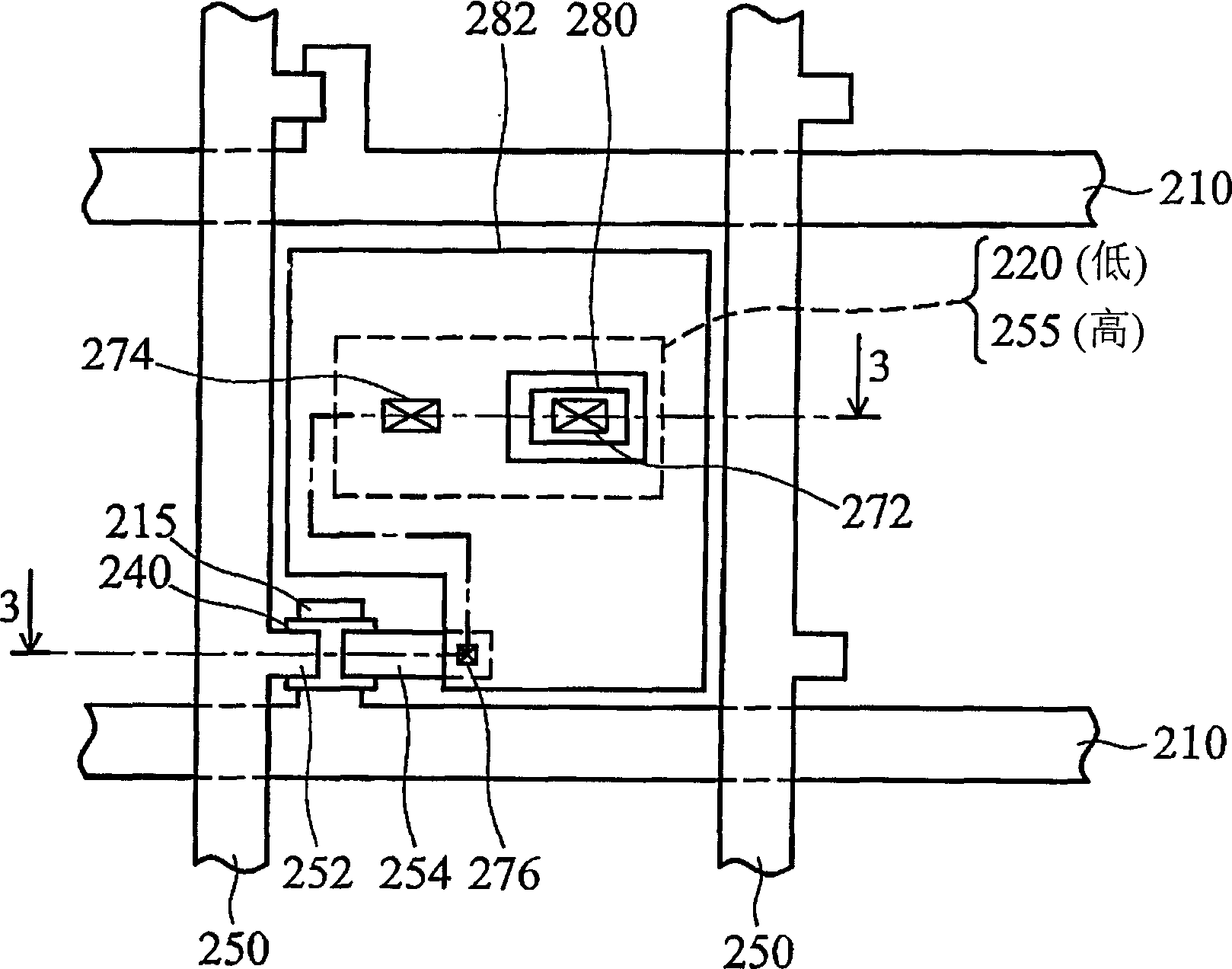

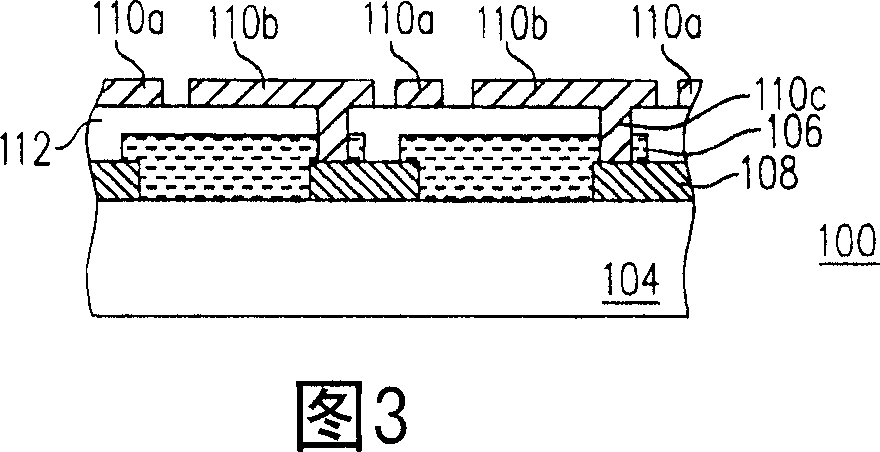

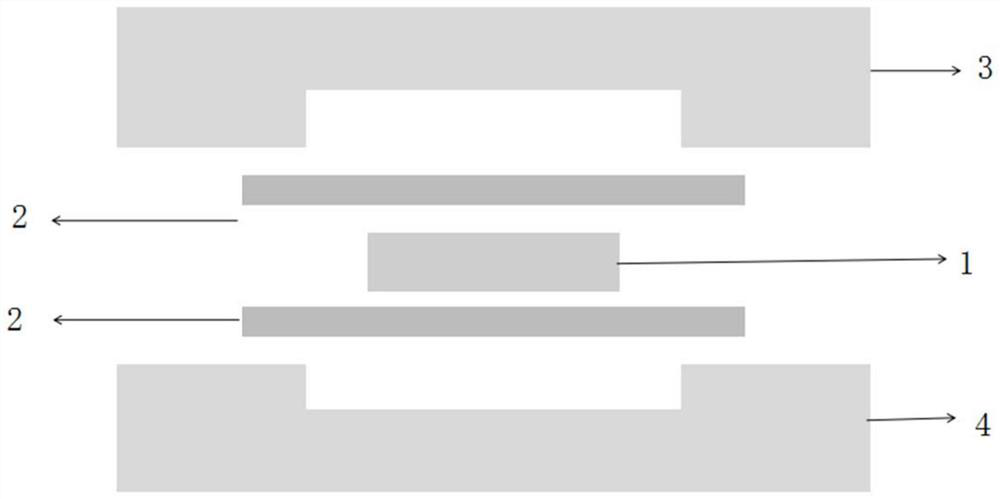

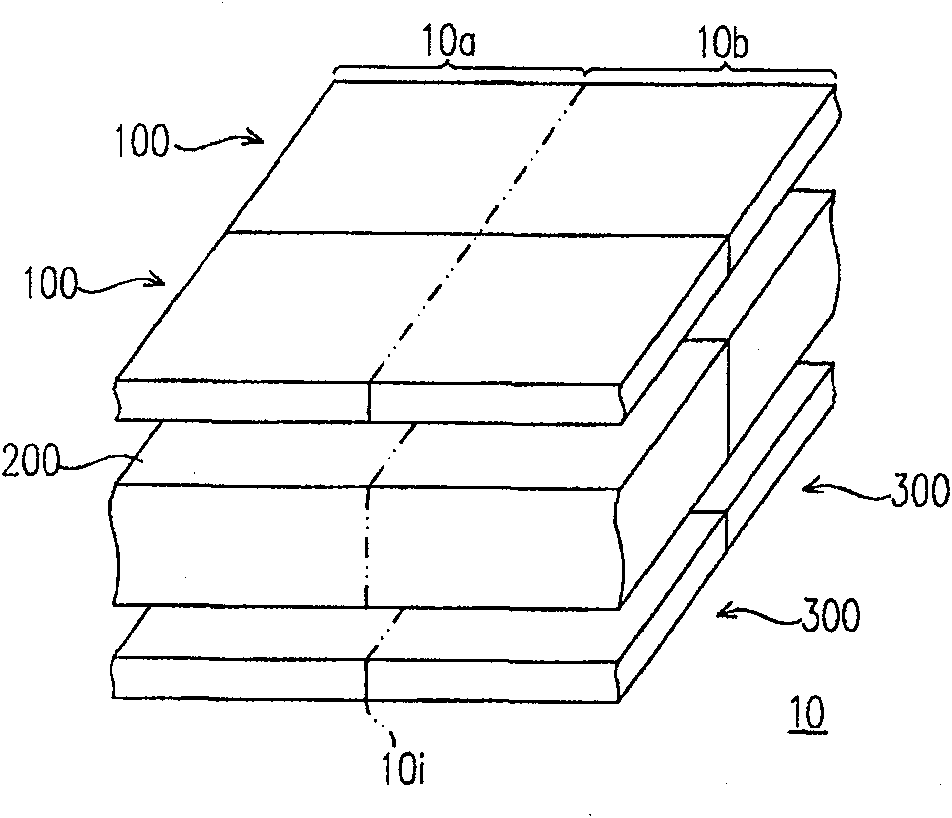

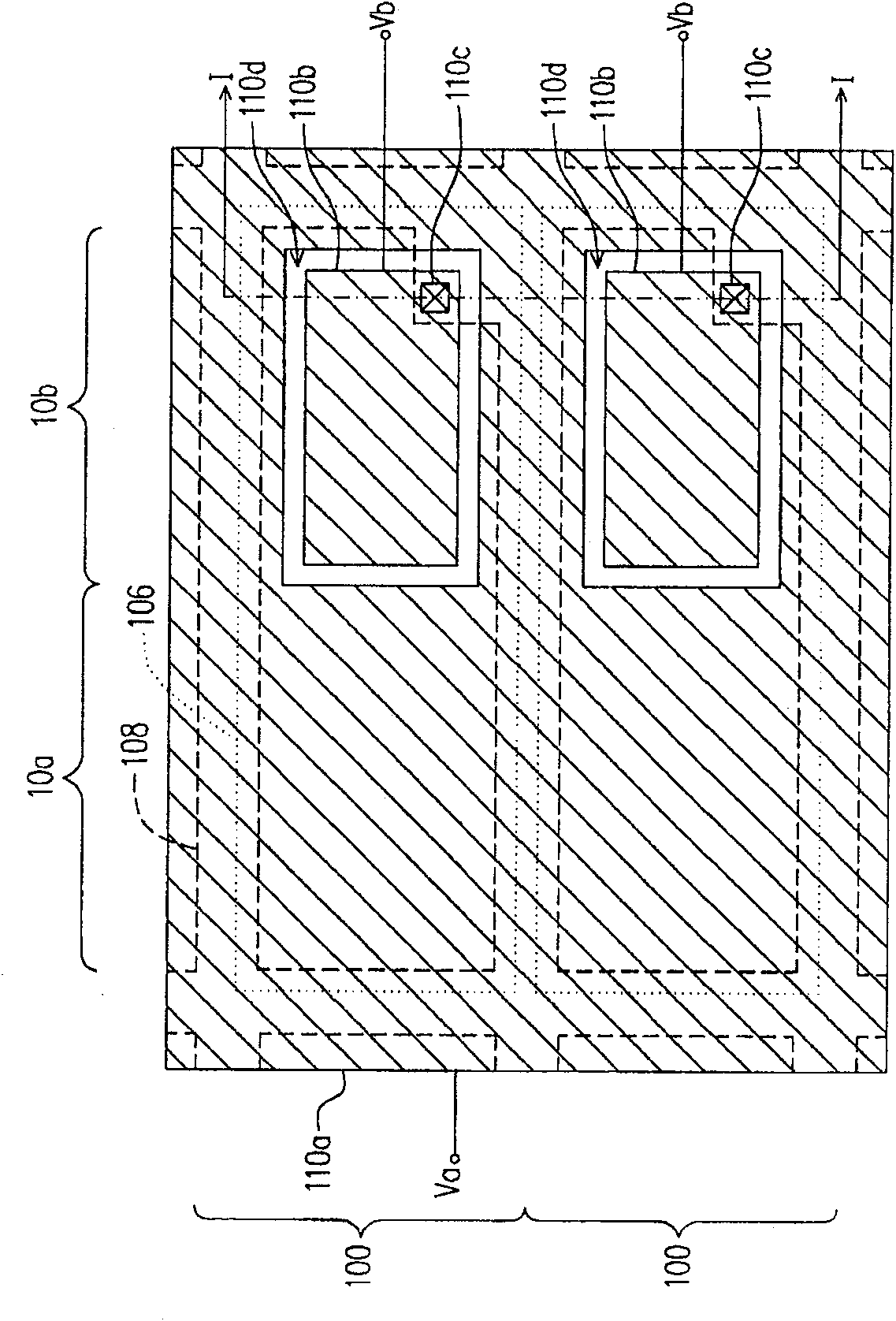

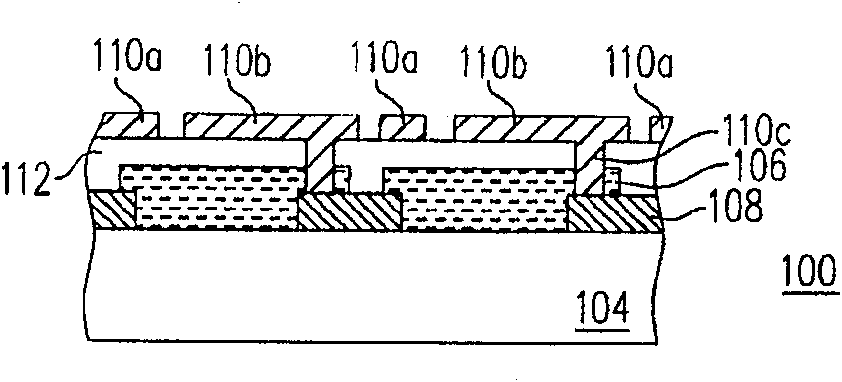

Pixel structure of active part array substrates

ActiveCN100573889CWiden perspectiveImprove good rateSemiconductor/solid-state device detailsSolid-state devicesCapacitanceLiquid-crystal display

The present invention proposes a pixel structure of an active element array substrate, including: a scanning line and a data line arranged on the substrate; a double-drain thin film transistor including a gate, a source, a first drain, and a second drain, The gate is electrically connected to the scanning line, the source is electrically connected to the data line, there is a first gate-drain capacitance between the gate and the first drain, and there is a second gate between the gate and the second drain Drain capacitance; the first pixel electrode and the second pixel electrode are electrically connected to the first drain and the second drain respectively; and the first common wiring and the second common wiring are respectively arranged on the first and second Below the pixel electrode, there is a first storage capacitor between the first common wiring and the first pixel electrode, a second storage capacitor between the second common wiring and the second pixel electrode, and the first and second gate drains The capacitors are different, and the first and second storage capacitors are different. The liquid crystal display of the invention can have better yield and lower manufacturing cost.

Owner:AU OPTRONICS CORP

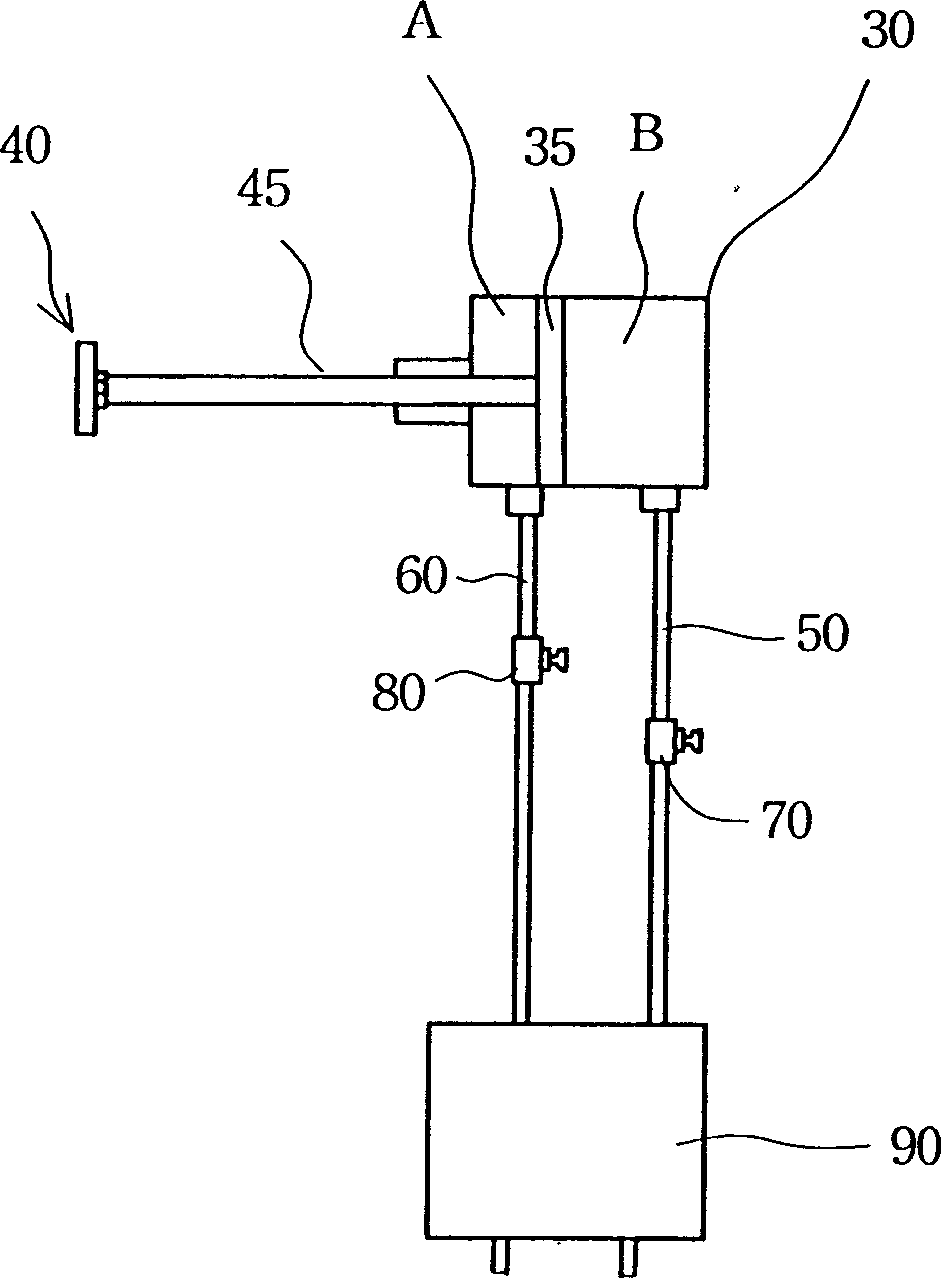

Pneumatic driver with valve kinematic speed adjustment

InactiveCN1472463AReduce in quantityImprove good rateOperating means/releasing devices for valvesInterior spaceEngineering

A pneumatic driver for regulating the moving speed of valve has a main container body whose internal space is divided by a piston into two spaces with respective opening for installing tube, a pressure regulating valve installed to said tube for regulating the pressure of gas coming in said main container body, and a valve with a long axle connected to said piston via said opening. The pressure of gas in the container is regulated by said pressure regulating valve to control the speed of piston and in turn the moving speed of valve.

Owner:SILICON INTEGRATED SYSTEMS

Modular shared bicycle service device

PendingCN111967841AAvoid disputesAvoid economic lossApparatus for meter-controlled dispensingOffice automationService provisionModular design

The invention relates to a modular shared bicycle service device. The modular shared bicycle service device is characterized in that the whole process from lending to returning of shared bicycles is completed through modular design, social resources are saved through an innovative service providing mode, problems that the loss rate and the damage rate are high and the like during operation and maintenance of the shared bicycles are solved, and various social contradictions caused by disordered parking of the shared bicycles are solved.

Owner:吴多海

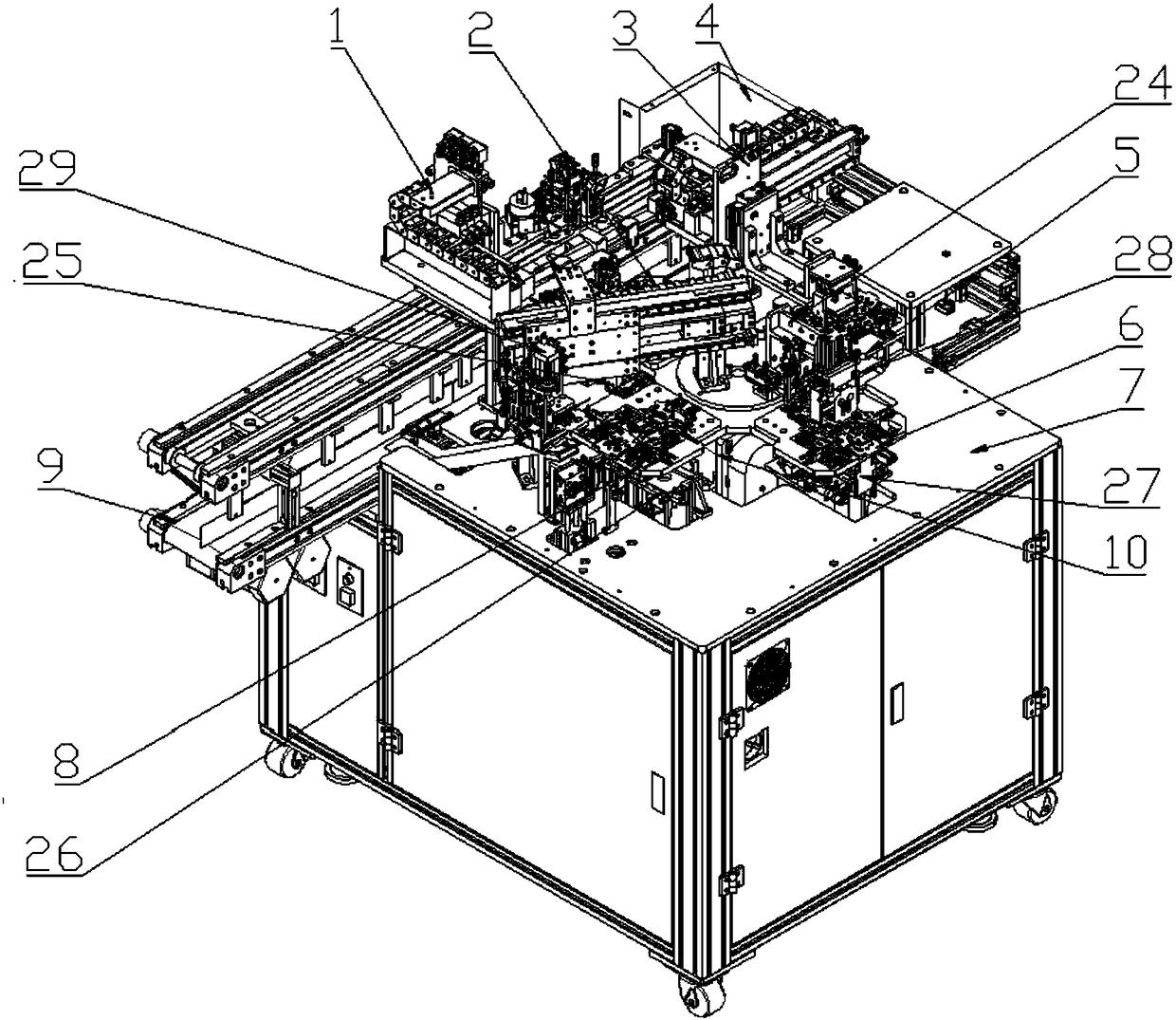

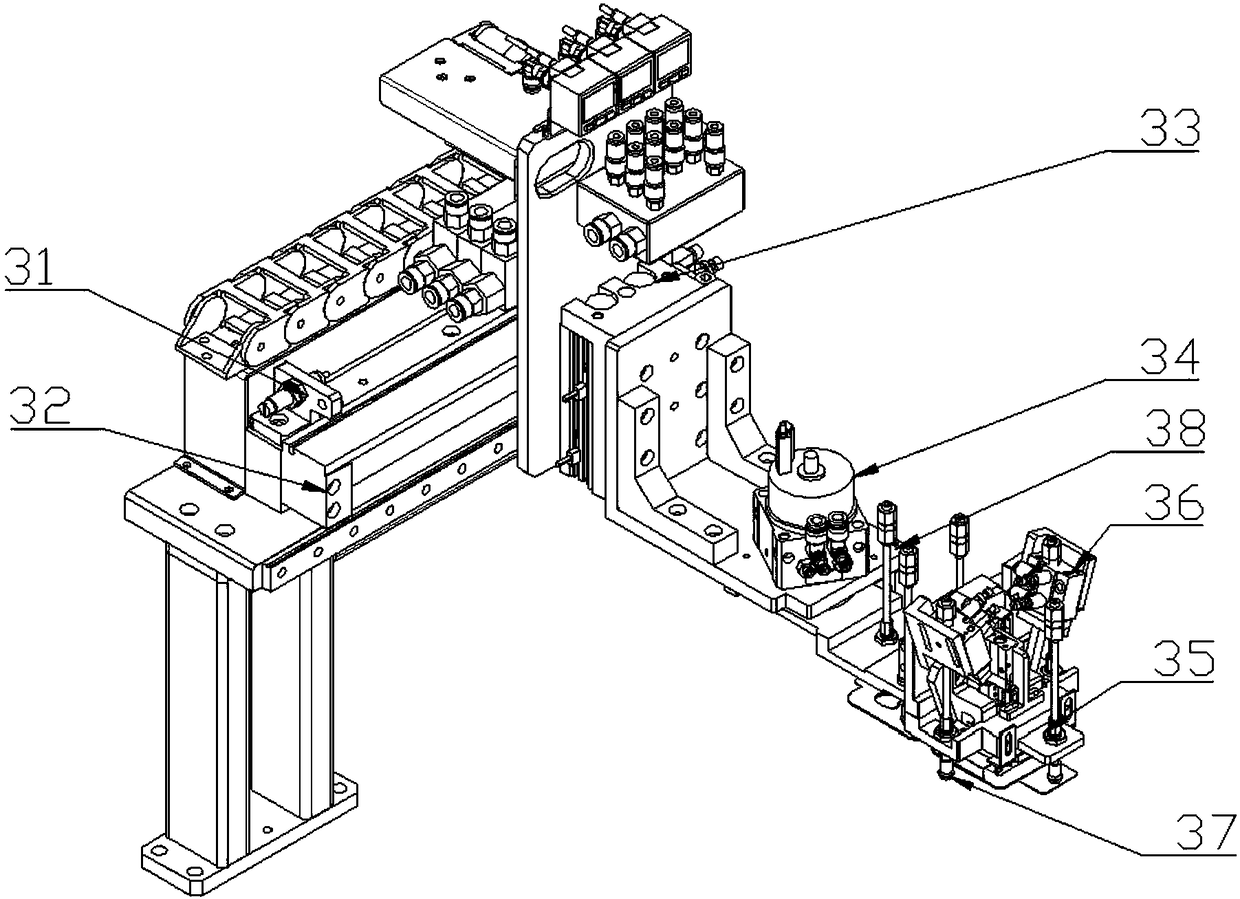

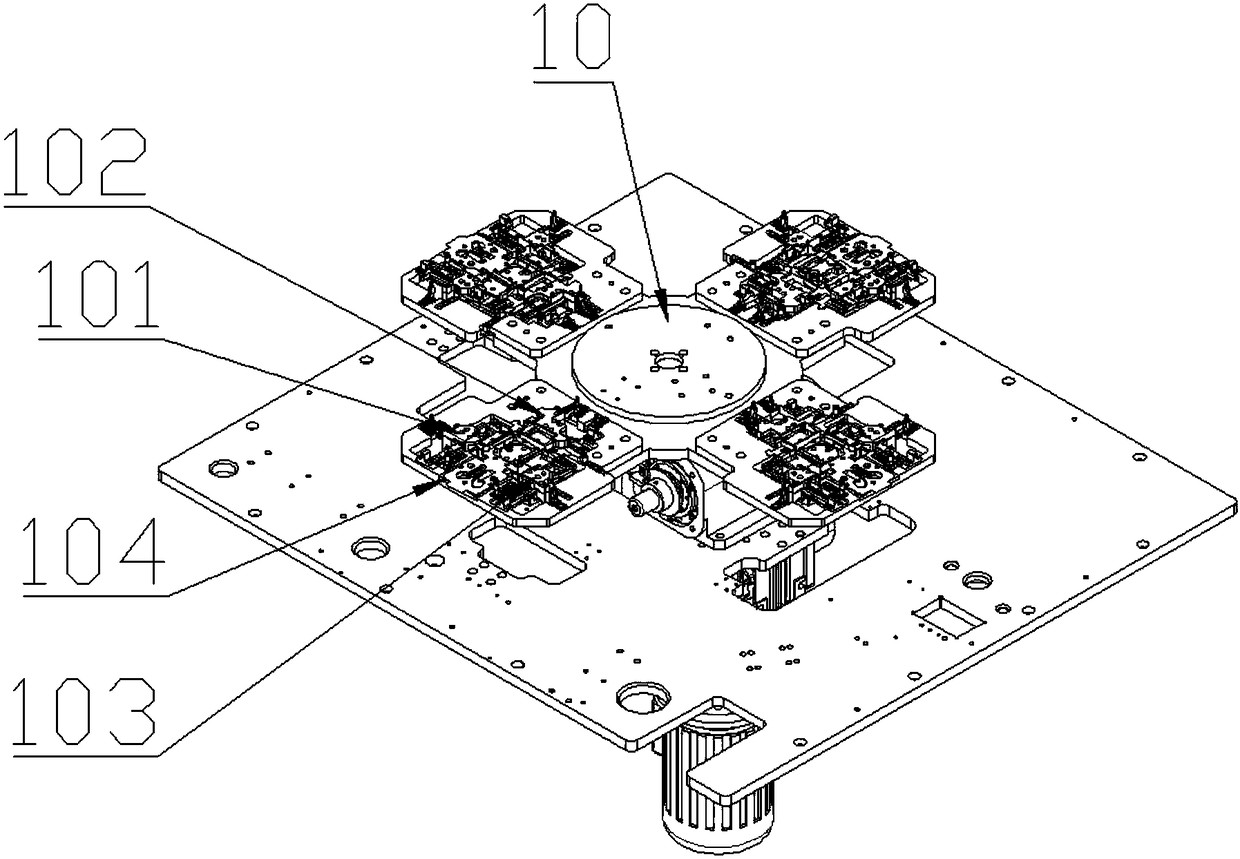

A headphone cable packaging molding machine

Owner:东莞道元自动化技术有限公司

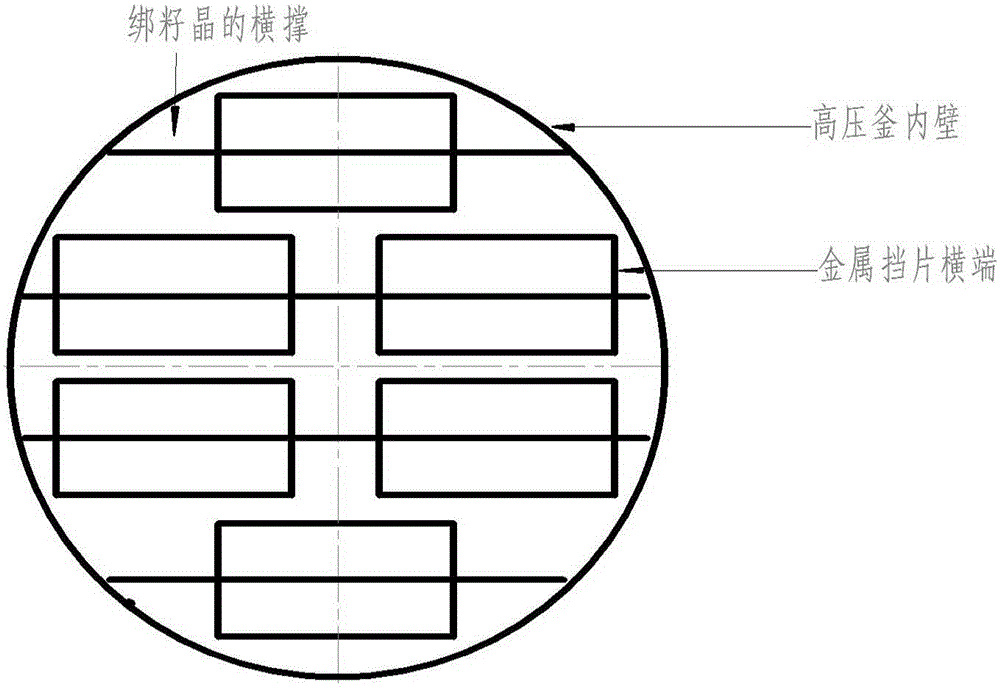

A method for controlling inclusions in artificial lenses

ActiveCN103540997BPromote growthImprove yieldPolycrystalline material growthFrom normal temperature solutionsIntraocular lensMedicine

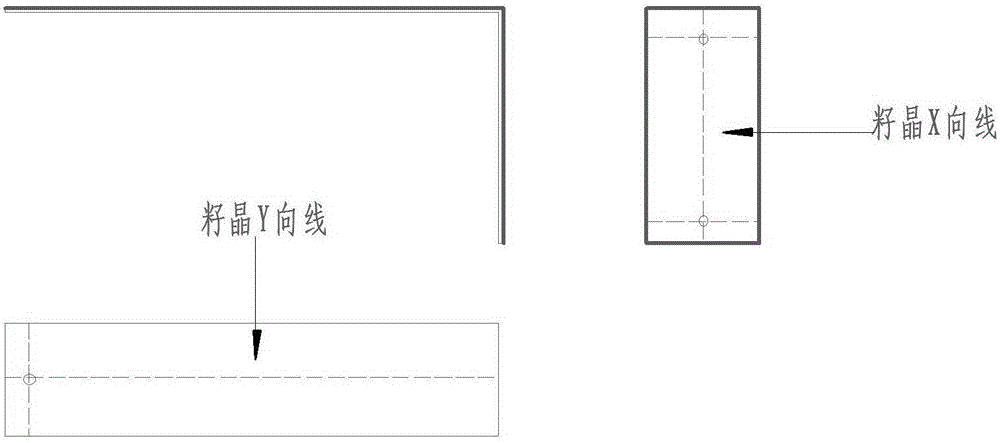

The invention relates to a method for controlling intraocular lens inclusions, which specifically includes the following steps: (1) designing an L-shaped baffle, the L-shaped baffle is designed for three directions of X, Y, and Z of the IOL: Y direction The length is the same as the length of the seed crystal; the Z direction is subject to the requirements of the artificial crystal; the X direction needs to be determined according to the growth amount in the X direction plus the width of the seed crystal in the X direction under different process conditions; (2) Surface treatment and cleaning of the L-shaped block , Cleaning; (3) Install an L-shaped block on the seed crystal and fix it on the seed crystal frame; (4) Put the seed crystal frame in an autoclave to grow artificial crystals. The invention has the advantages of reducing the growth of inclusions, improving the level and good rate of inclusions of artificial crystals, and improving the utilization rate of raw materials at the same time.

Owner:北京石晶光电科技股份有限公司

Intelligent logistics device for perfume

InactiveCN114655549AAvoid harmAvoid shaking situationsConveyorsExternal fittingsMechanical engineeringThreaded rod

The invention discloses an intelligent logistics device for perfume, and relates to the technical field of intelligent logistics. The intelligent logistics device for perfume comprises a base, a clamping assembly and a lifting assembly, a supporting table is arranged at the top of the base, a first supporting square column and a second supporting square column are fixedly installed at the top of the supporting table, and walking wheels are fixedly installed at the bottom of the base. The adjusting box, the rotating handle, the two-way threaded rod, the umbrella-shaped gear and the clamping plates are used in cooperation, the distance between the two sets of clamping plates can be adjusted according to the sizes of different perfume bottles, in the transportation process, the deviation situation is reduced, the situation that the perfume bottles fall off is avoided, and due to the arrangement of anti-abrasion pads on the clamping plates, the service life of the perfume bottles is prolonged. According to the perfume bottle clamping device, damage to the surfaces of perfume bottles can be avoided while the perfume bottles are clamped, the good rate of the perfume bottles is indirectly improved, multiple sets of perfume bottles can be clamped, and the storage space of the device is increased.

Owner:湖州御梵化妆品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com