Packaging mould with electrostatic discharge protection

A technology for electrostatic discharge protection and electrostatic charge, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., and can solve problems such as static electricity residue and chip damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

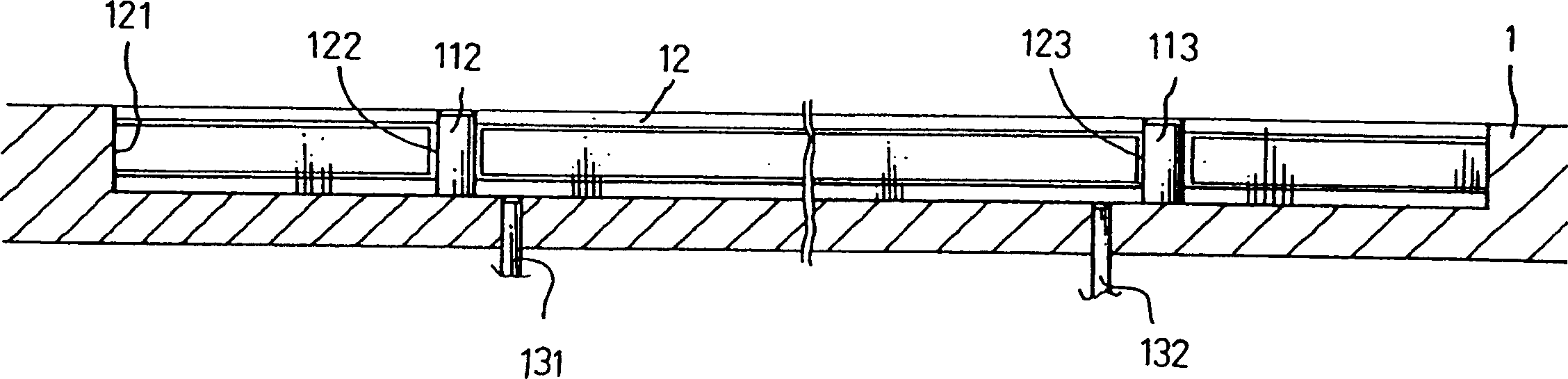

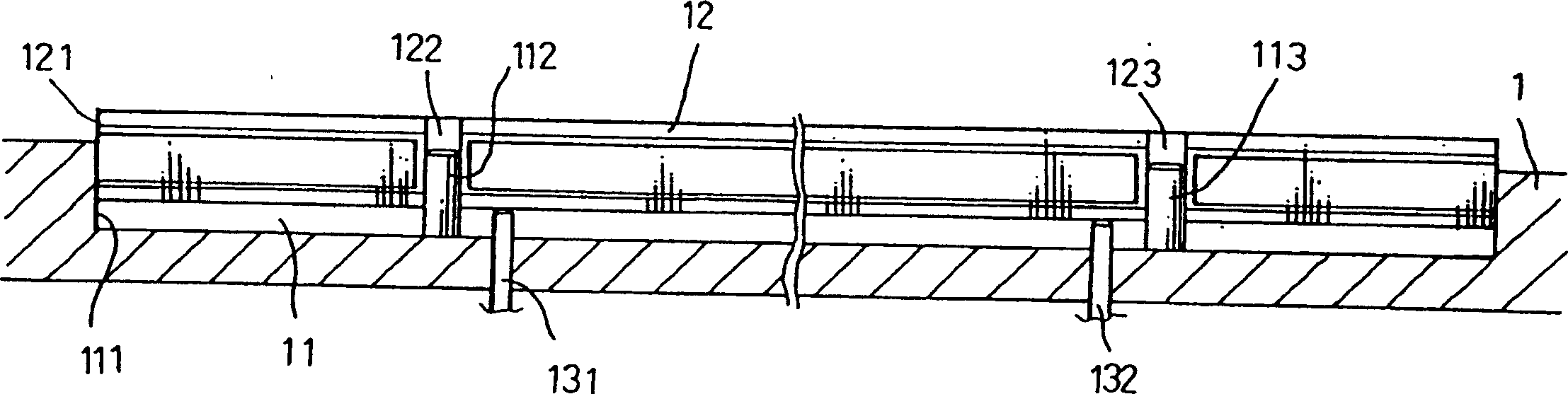

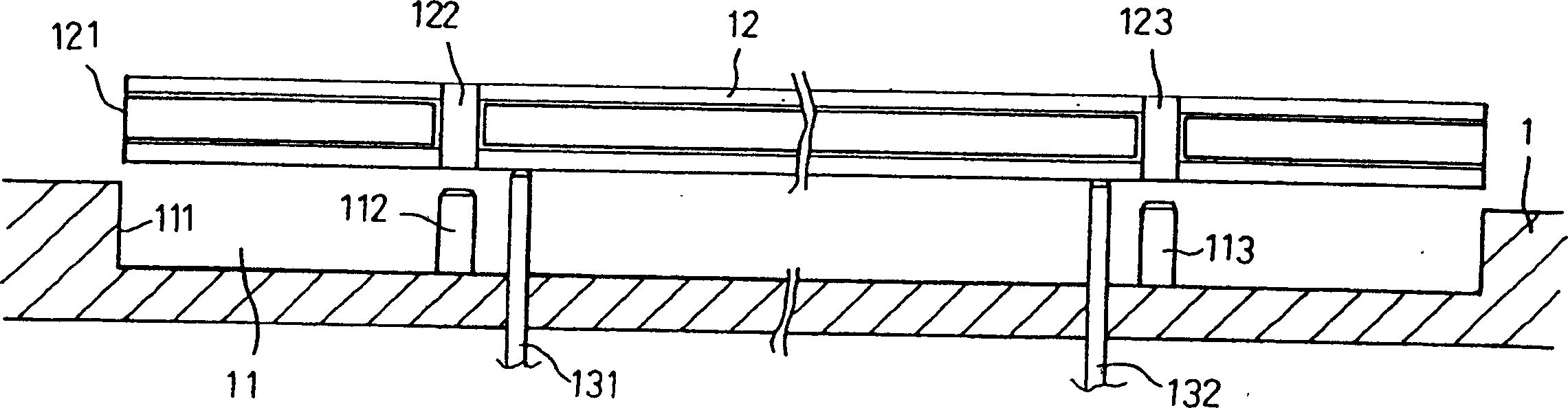

[0012] figure 2 Packaging mold 2 showing the ESD protection of the present invention. The packaging mold 2 includes at least one groove 21 , and each groove 21 is used for accommodating a packaging substrate 22 . The groove 21 has an inner wall 211 . The inner sidewall 211 of the groove 21 is in electrical contact with the outer sidewall 221 of the packaging substrate 22 . The height of the outer wall 221 of the package substrate 22 is a first height H1, and the height of the inner wall 211 of the groove 21 is a second height H2, and the second height H2 is greater than the first height H1.

[0013] The groove 21 also has a plurality of positioning columns 212 , 213 , etc., for passing through the positioning holes 222 , 223 of the packaging substrate 22 , so that the packaging substrate 22 is positioned in the groove 21 . The positioning holes 222 , 223 of the package substrate 22 are in electrical contact with the positioning posts 212 , 213 of the groove 21 . The depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com