Detachable balancing optical assembly

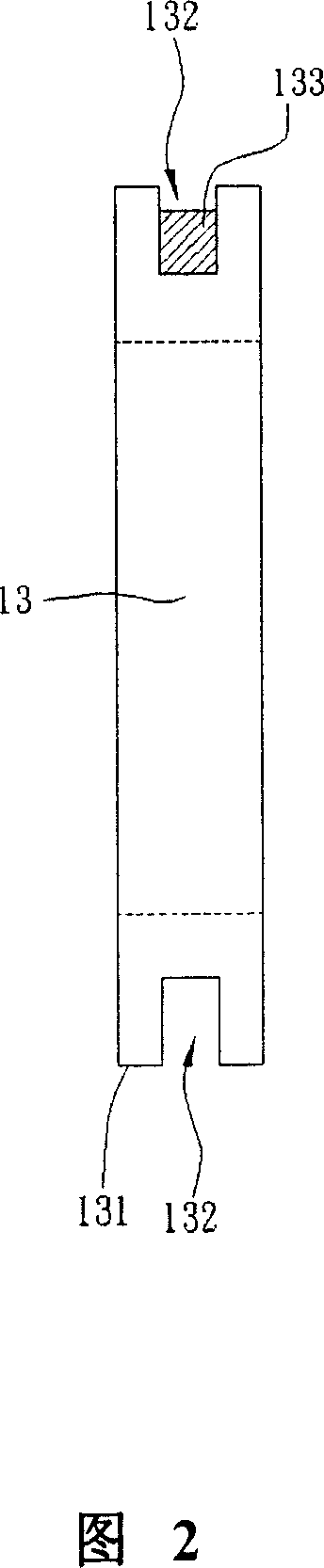

A detachable technology for optical components, which is applied in the field of detachable balanced optical components, can solve problems such as unbalance, easy loosening of weight 133, and overall rotation away from the optical component 1, so as to improve the good rate, save costs, increase The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

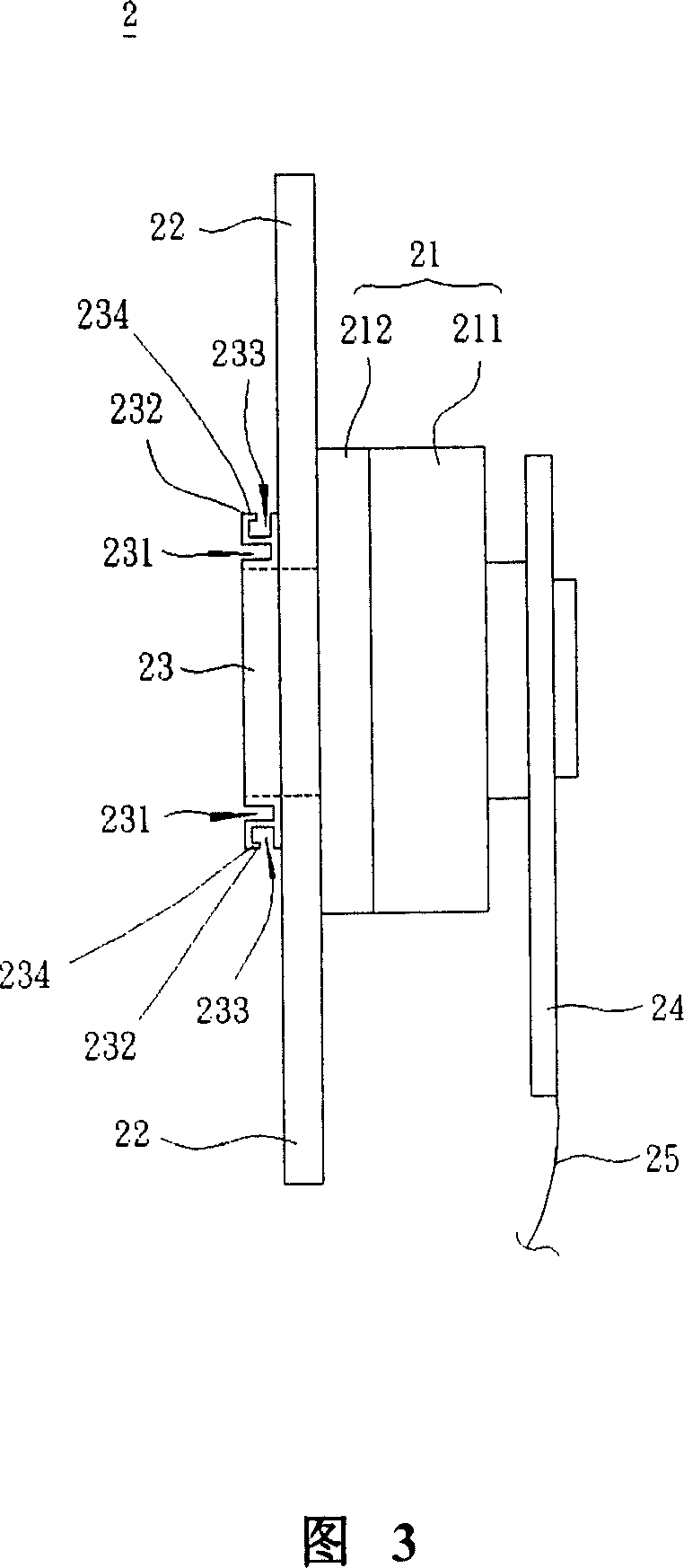

[0038] A detachable balanced optical assembly according to a preferred embodiment of the present invention will be described below with reference to related drawings.

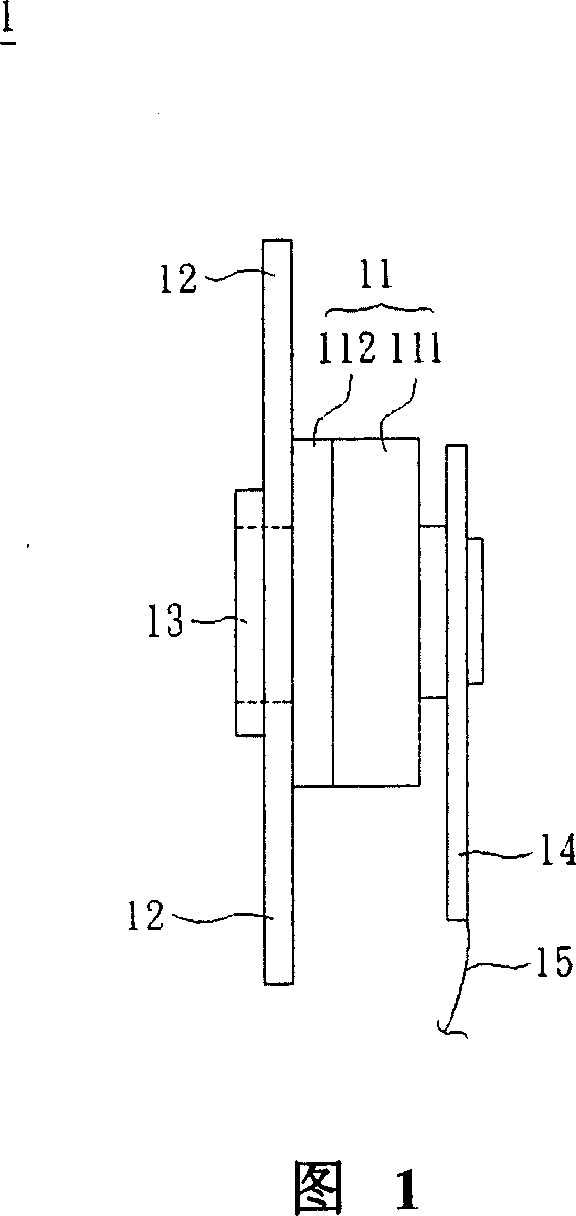

[0039] As shown in FIG. 3 , the detachable balanced optical assembly 2 according to a preferred embodiment of the present invention includes a motor 21 , a color wheel 22 and a cover 23 .

[0040] The motor 21 is arranged on one side of the color wheel 22. In this embodiment, the motor 21 is composed of a motor body 211 and an axis cover 212, and the axis cover 212 is a hole fitted in the center of the color wheel 22. And it is connected with the motor body 211 . Here, the motor body 211 is mainly composed of a magnet coil (not shown in the figure), a silicon steel sheet (not shown in the figure) and a coil (not shown in the figure). When the coil is energized, the steel sheet generates a magnetic force and a magnetic field, and the magnetic field changes in an orderly manner through the positive and negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com