Patents

Literature

59results about How to "Not easy to fly out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

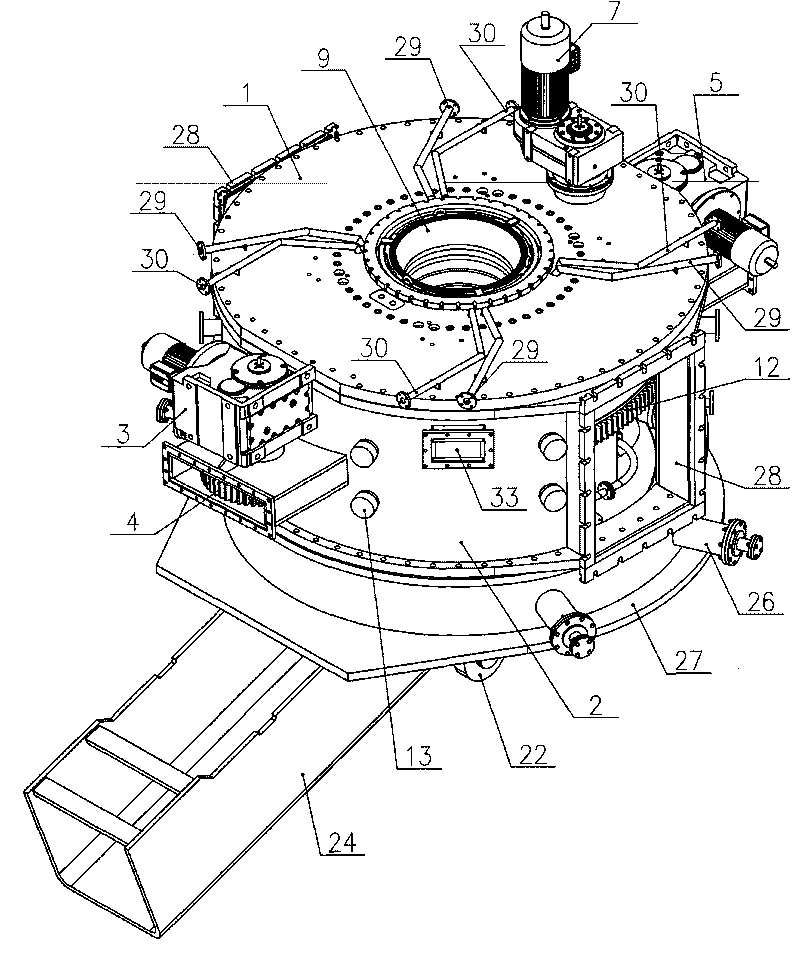

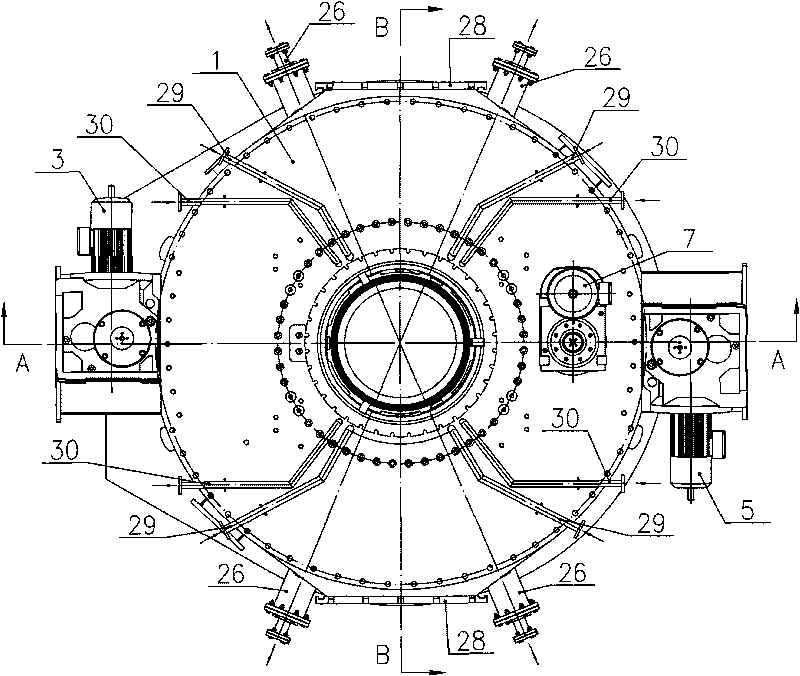

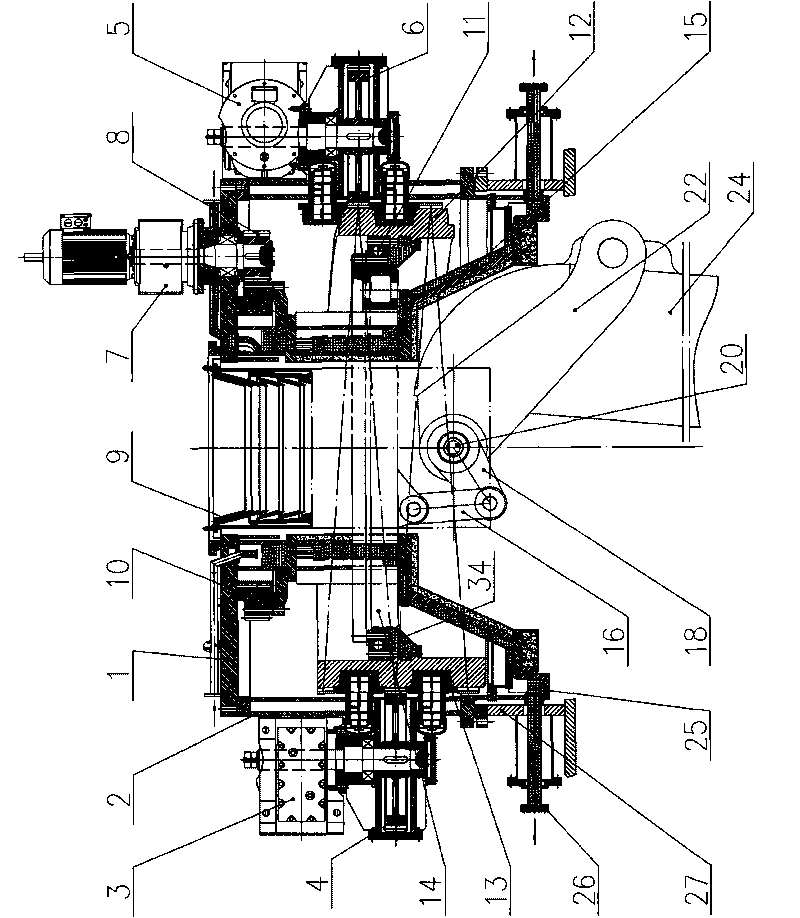

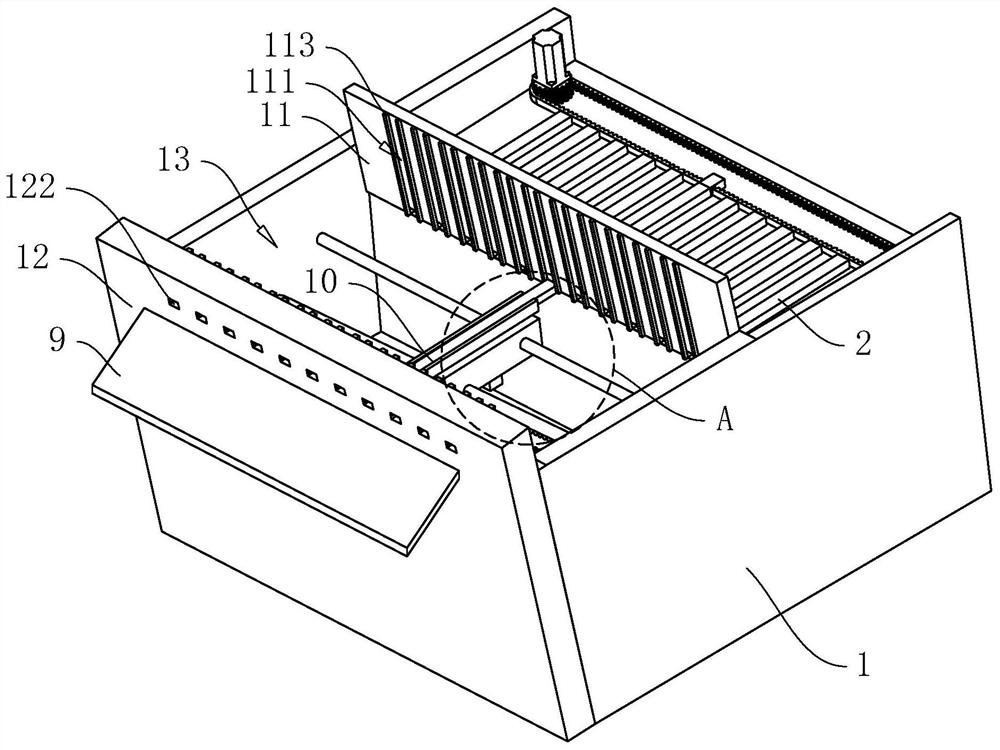

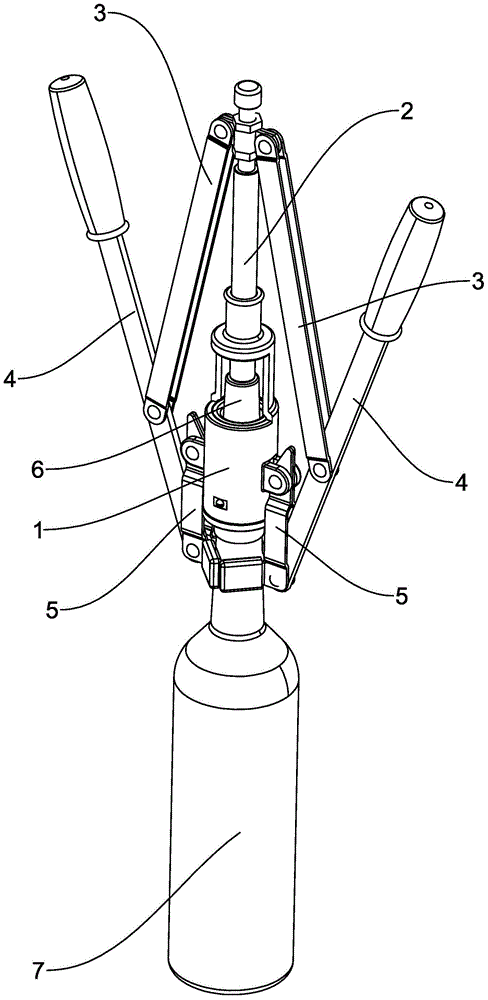

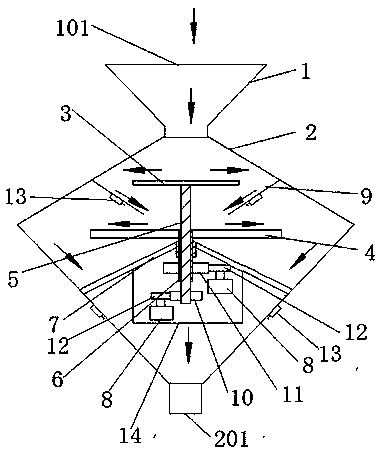

Blast furnace roof material distributing device

ActiveCN101701271AThe principle of mechanical transmission is simpleFabric flexibleBell-and-hopper arrangementEngineeringMechanical drive

The invention relates to a blast furnace roof material distributing device which is characterized by comprising a top cover, a shell, a center throat pipe, a left suspension shaft, a right suspension shaft, a left movable arm, a right movable arm, a chute, a rotating mechanism and a tilting mechanism, wherein the shell is fixedly connected with a steel ring of a furnace roof, and the top cover is fixedly connected with the shell; an output opening at the lower end of the center throat pipe is arranged above an input opening at the upper end part of the chute; the left end at the upper part of the chute is clamped on the left movable arm, and the right end at the upper part of the chute is clamped on the right movable arm; the left movable arm is fixedly connected with the left suspension shaft by a spline, and the right movable arm is fixedly connected with the right suspension shaft by a spline; the left suspension shaft and the right suspension shaft are respectively connected with a rotating cylinder of the rotating mechanism by bearings; the left suspension shaft is fixedly connected with a left crank of the tilting mechanism, and the right suspension shaft is fixedly connected with a right crank of the tilting mechanism. The invention has the characteristics of simple mechanical drive principle, flexible material distribution, high running precision, reliable operation, convenient use and maintenance and long service life.

Owner:WISDRI ENG & RES INC LTD

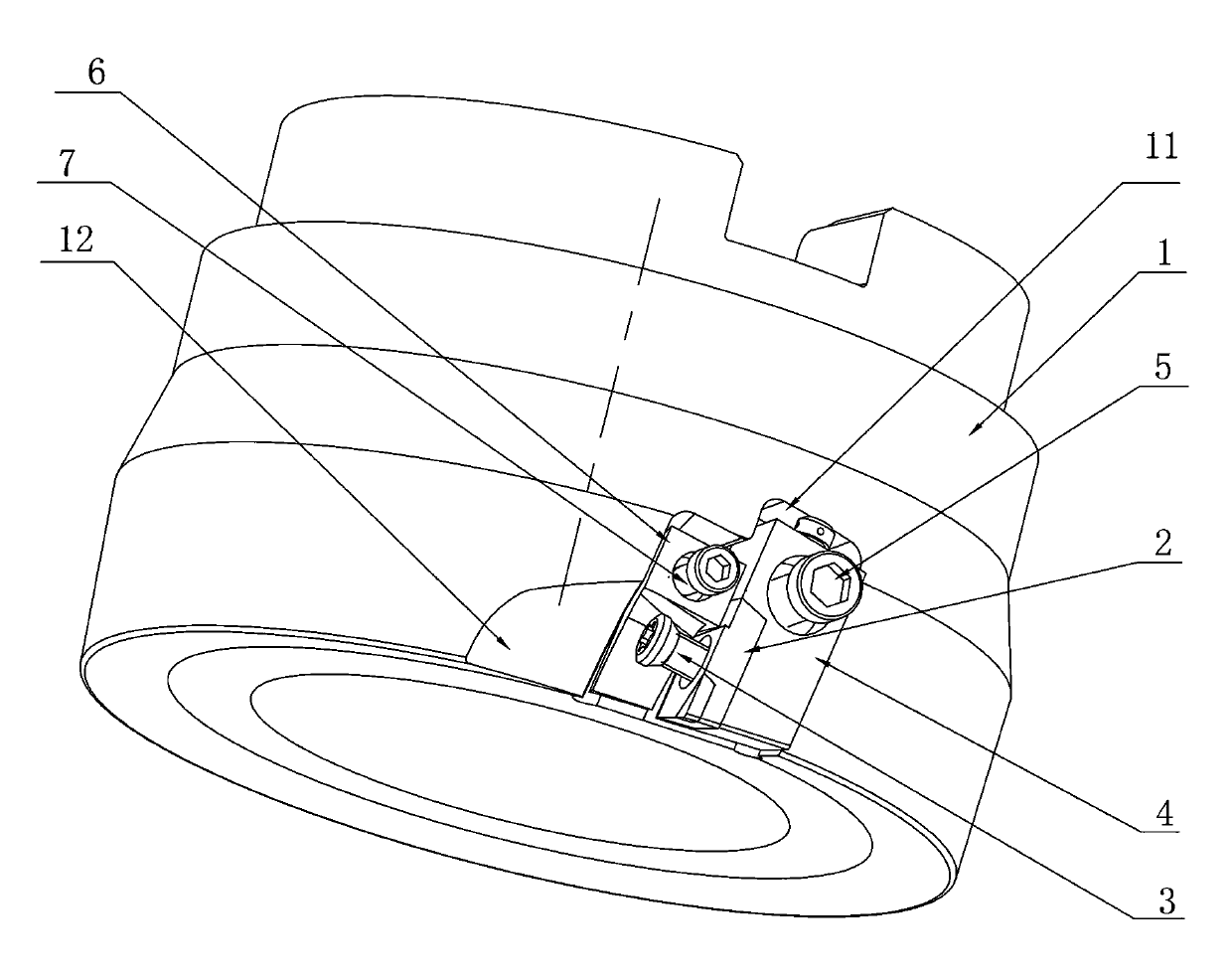

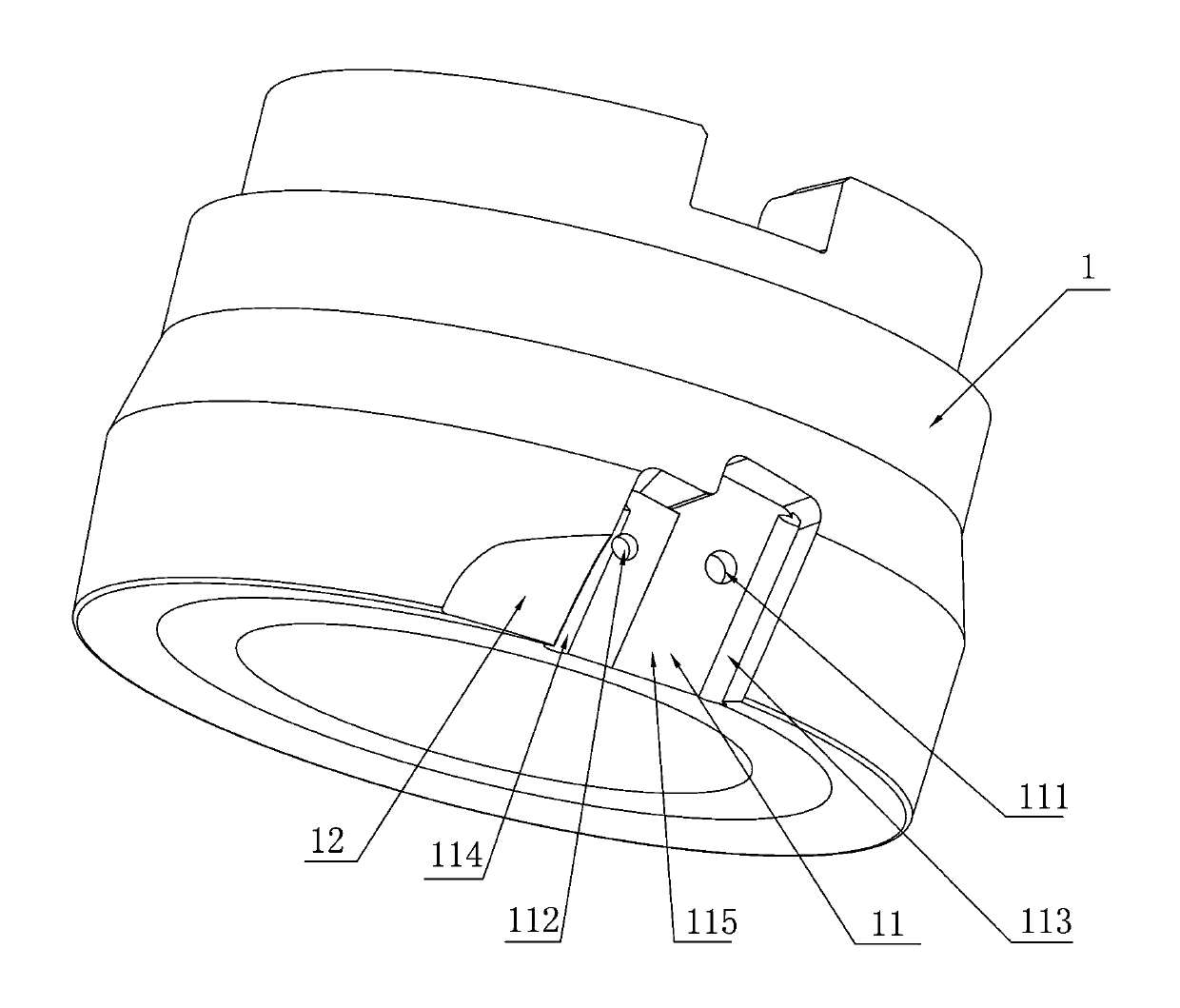

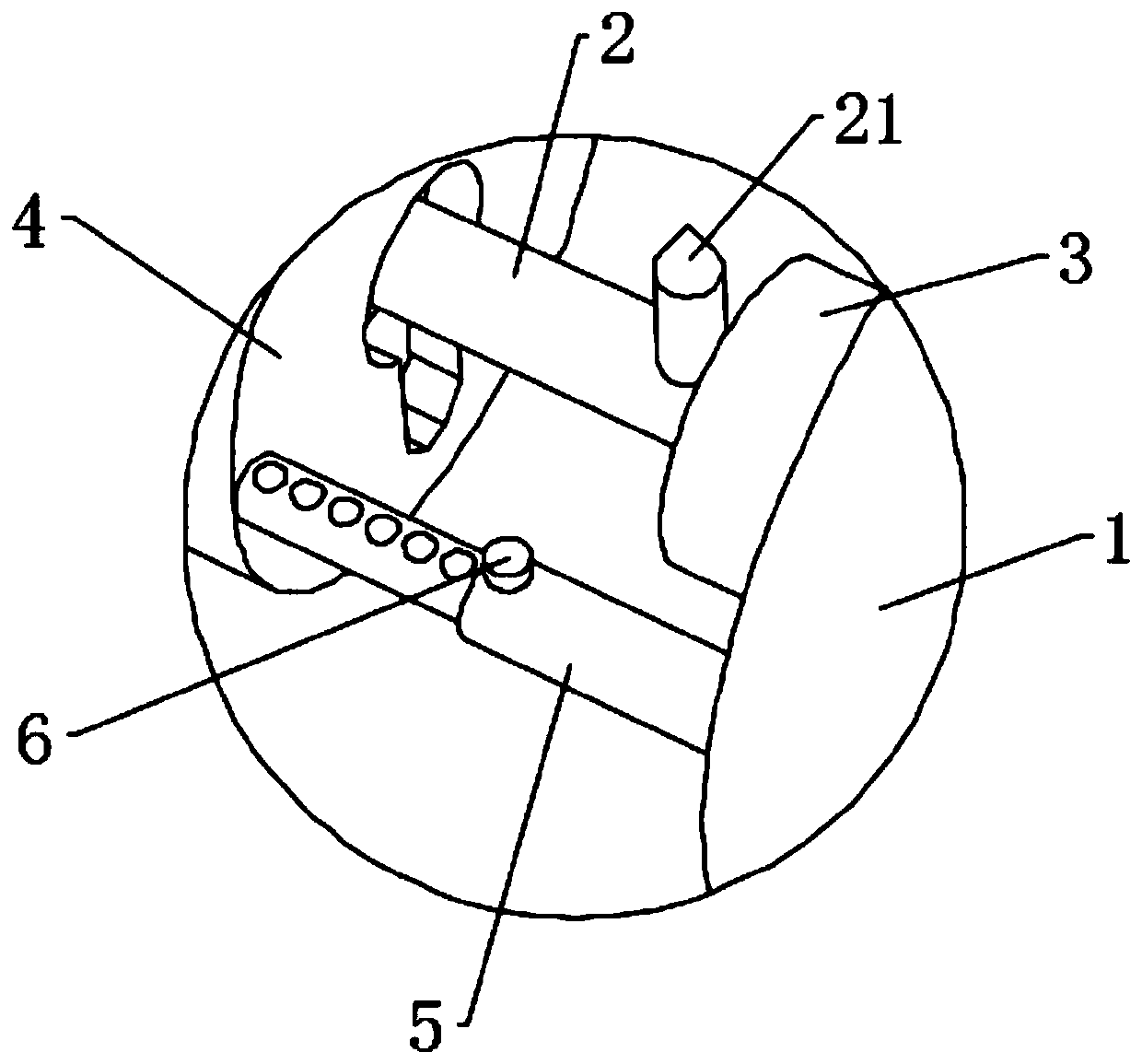

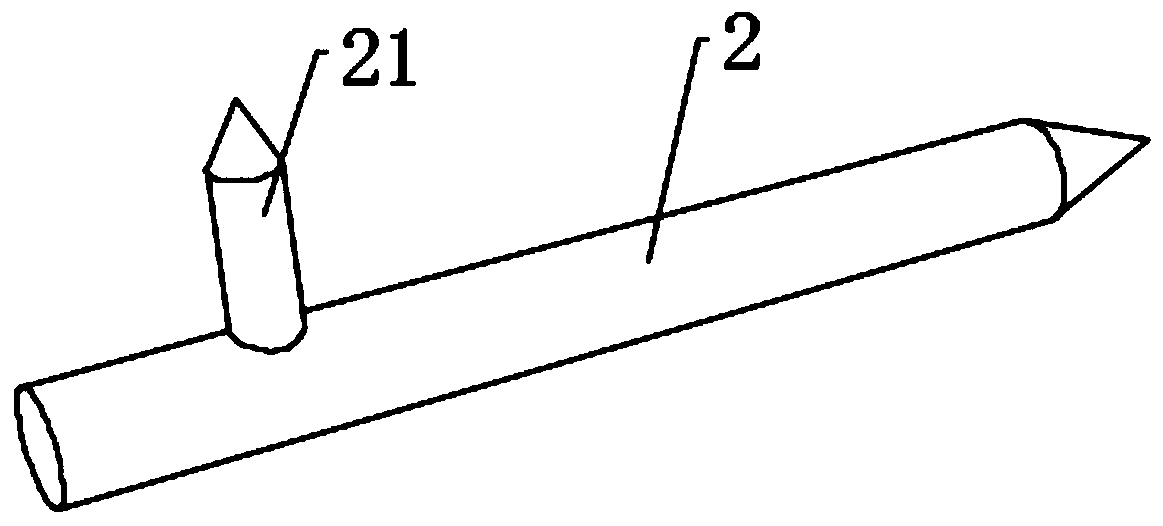

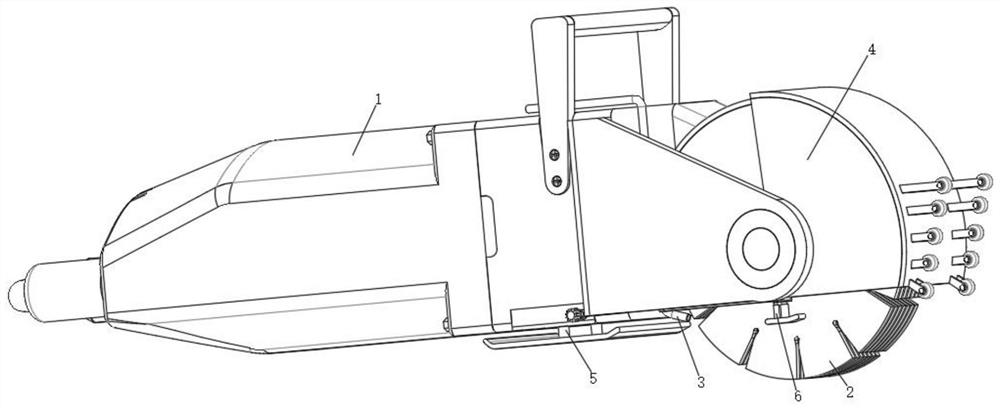

Cutting tool having fly-off prevention structure

The invention discloses a cutting tool having a fly-off prevention structure. The cutting tool having a tool body, a blade and a tool holder, the blade is installed on the tool holder, the tool body is provided with a tool slot, the tool holder is installed in the tool slot through a tool holder fastener, the front end of the tool slot is provided with a tool slot top surface along the cutting rotation direction of the cutting tool, one side of the blade facing the tool slot top surface is provided with a compaction inclined surface, a wedge is wedged between the tool slot top surface and the compaction inclined surface, and the wedge is connected with the tool slot through a wedge fastener. The cutting tool has the advantages of simple and compact structure, convenient processing and making, low production cost, convenient blade installing and dismounting, and good fly-off prevention effect.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

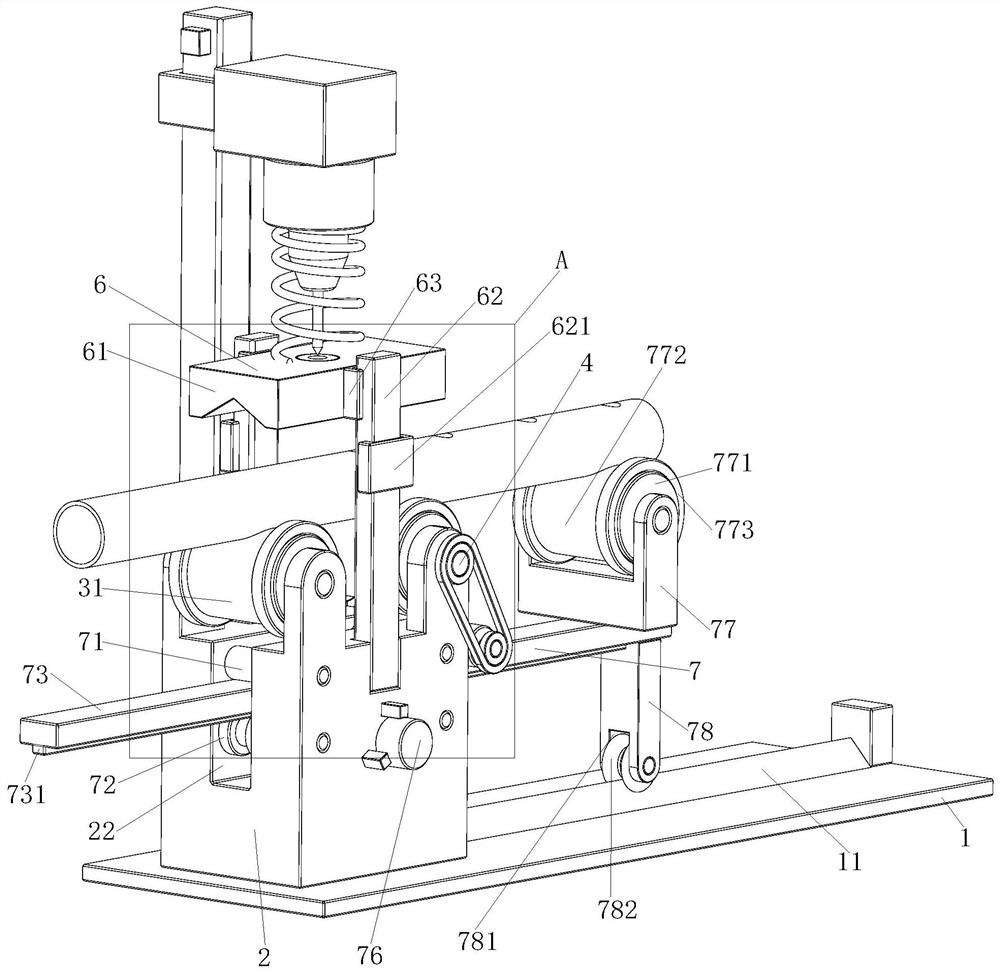

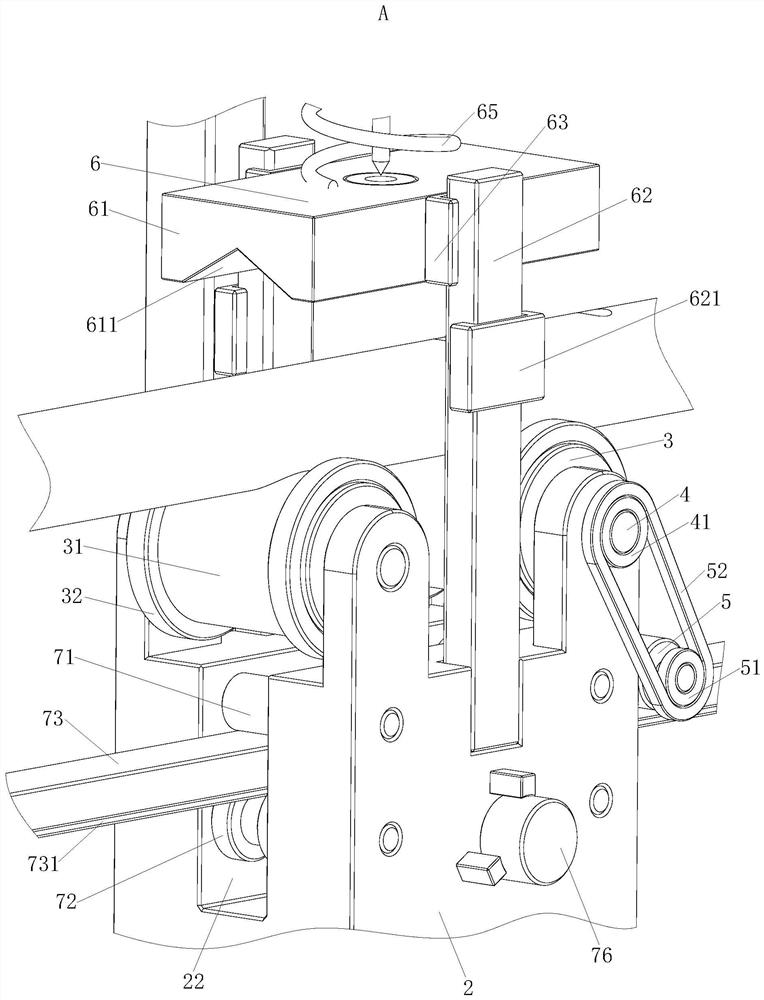

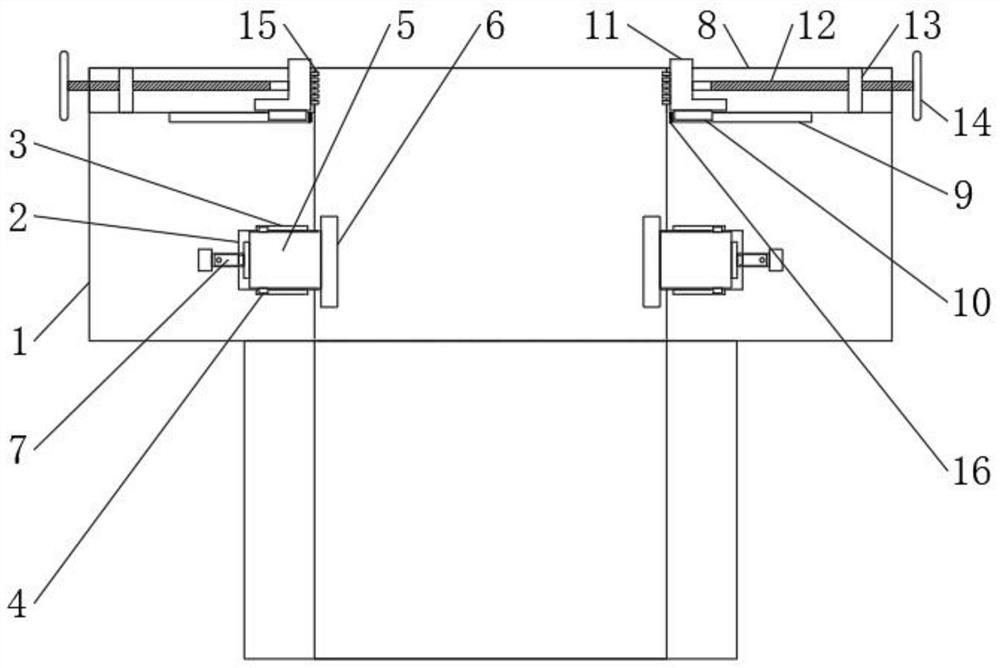

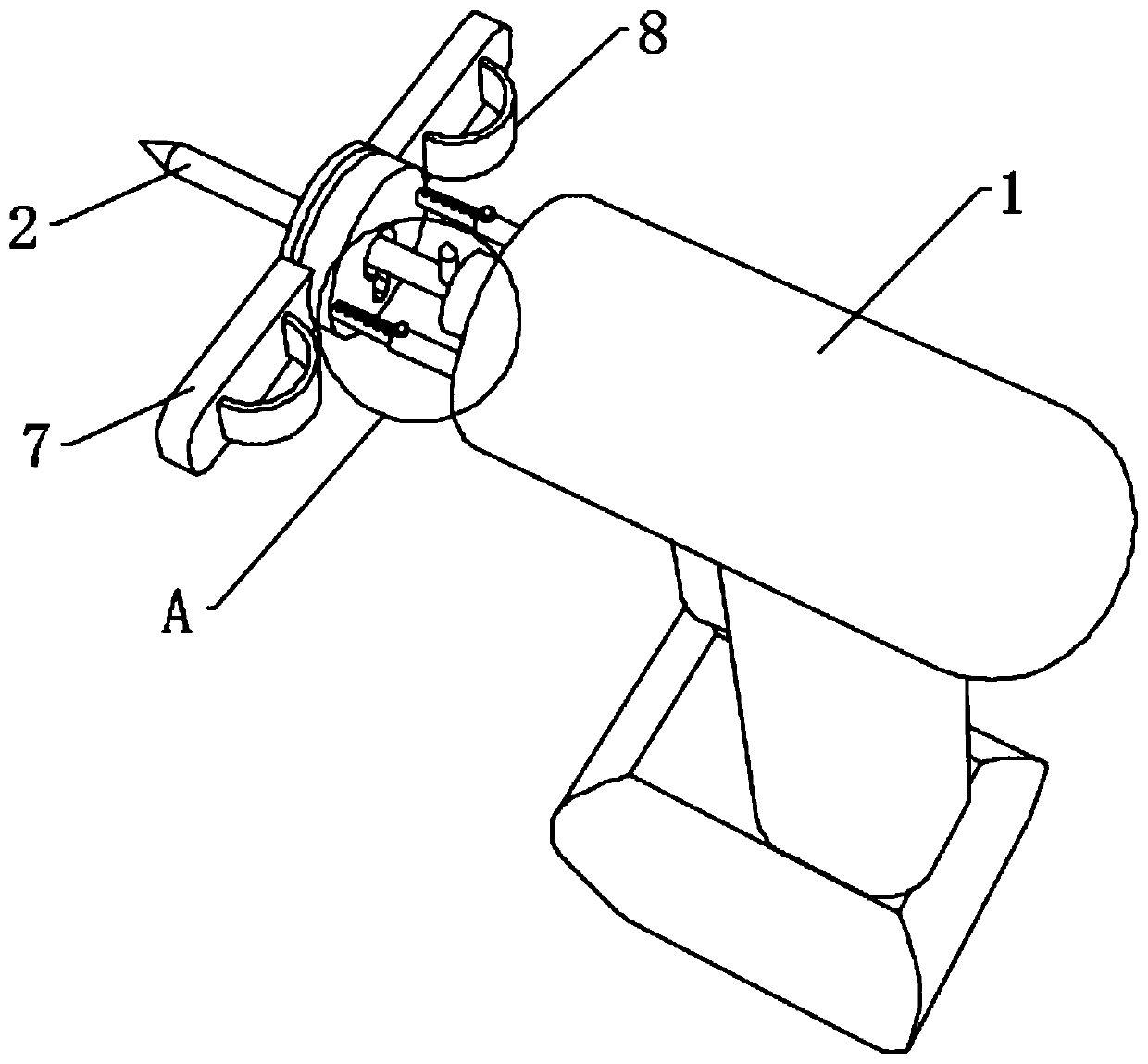

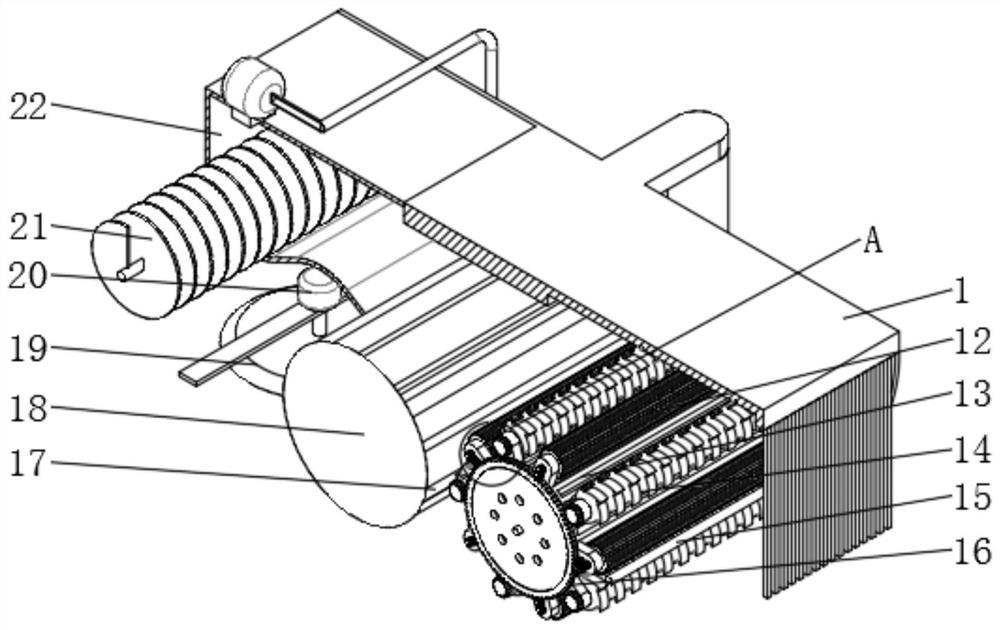

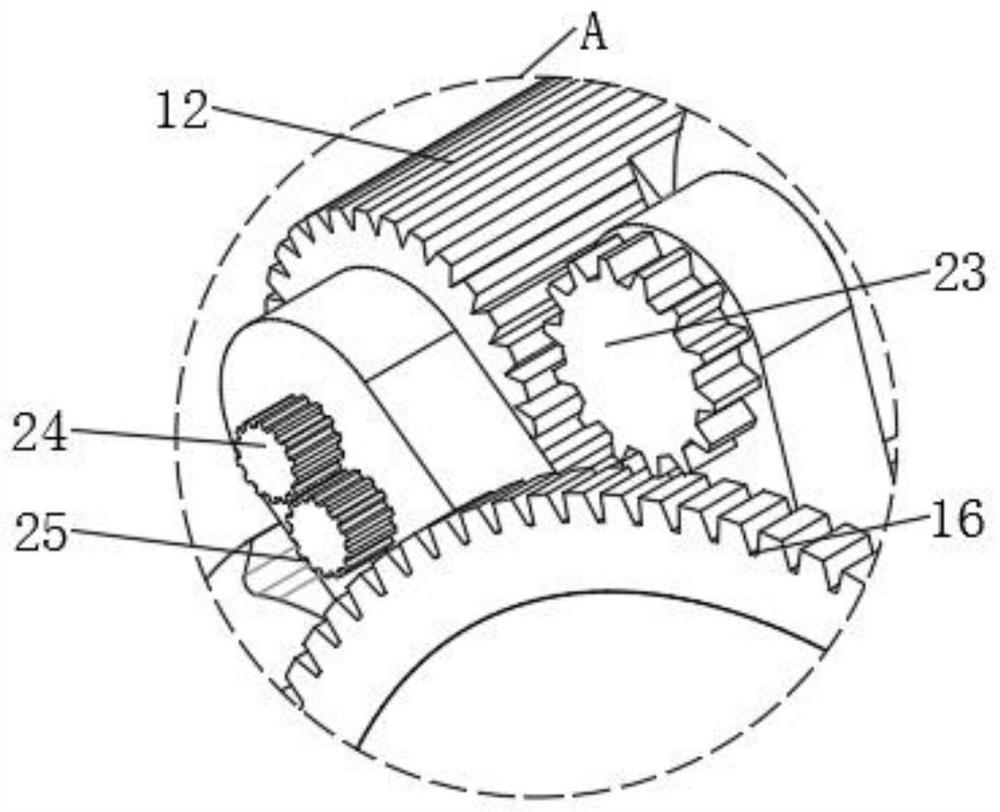

Circular pipe polishing device for heating and ventilation

InactiveCN108747789AImprove polishing efficiencyReduce workloadPolishing machinesGrinding drivesEngineering

The invention relates to a polishing device, in particular to a circular pipe polishing device for heating and ventilation. According to the technical scheme, the circular pipe polishing device for heating and ventilation can be used for polishing multiple circular pipes, lightens the working burden of workers, and improves the polishing efficiency. The circular pipe polishing device for heating and ventilation comprises a base plate, a driving mechanism, a supporting seat, a first mounting plate, rotating mechanisms, a sliding rail, a sliding block, a lifting plate, a transmission mechanism,a polishing mechanism, a lifting mechanism and a second mounting plate. The second mounting plate is fixedly connected to the top of the base plate through the supporting seat, and the driving mechanism is fixedly connected to one side of the base plate. The multiple rotating mechanisms are fixedly connected to the first mounting plate at equal intervals. The circular pipe polishing device for heating and ventilation has the beneficial effects of comprehensively and quickly polishing the multiple circular pipes, improving the polishing efficiency, and lightening the working burden of the workers.

Owner:冯广吉

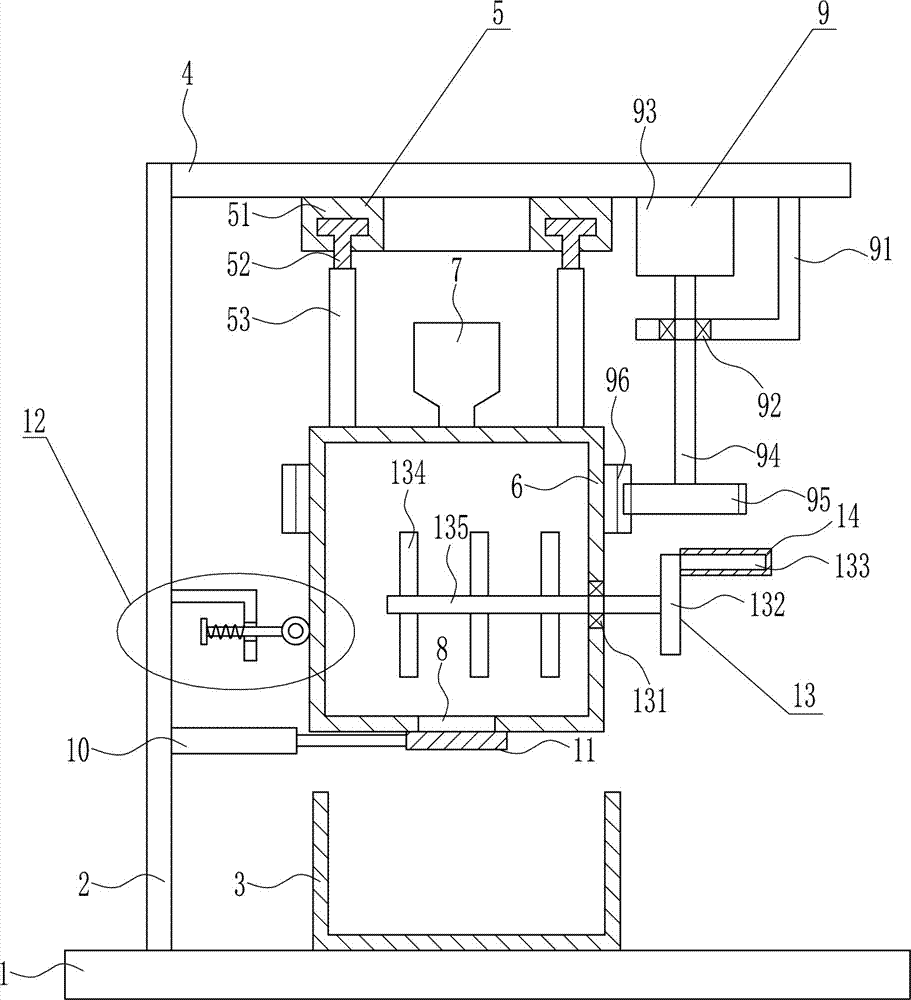

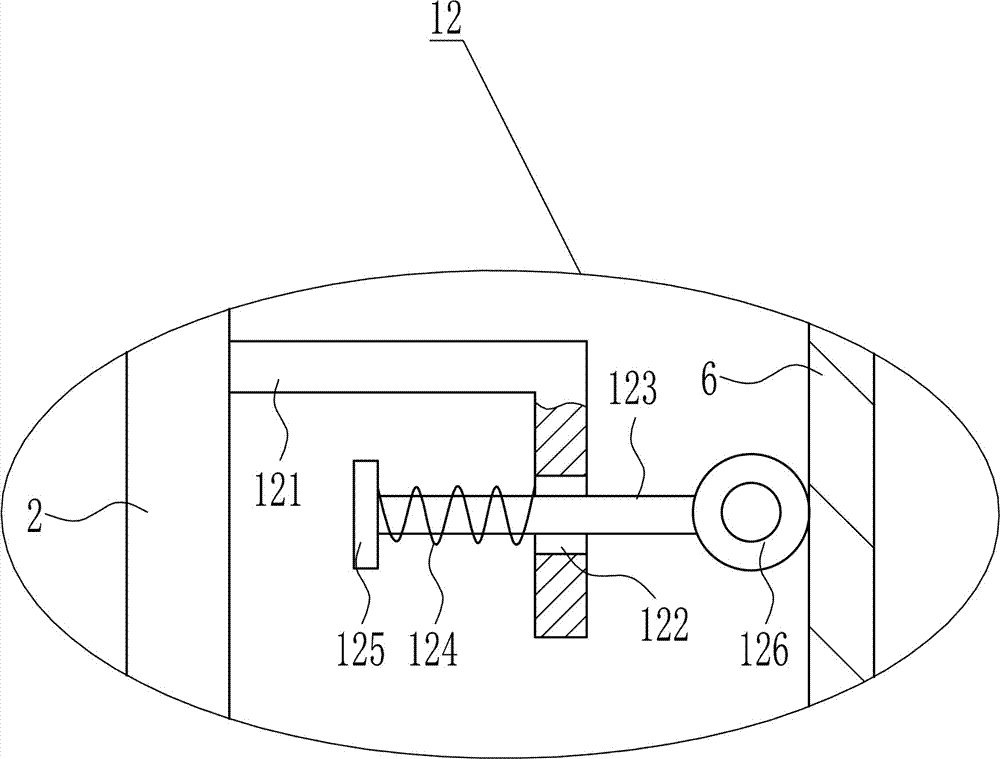

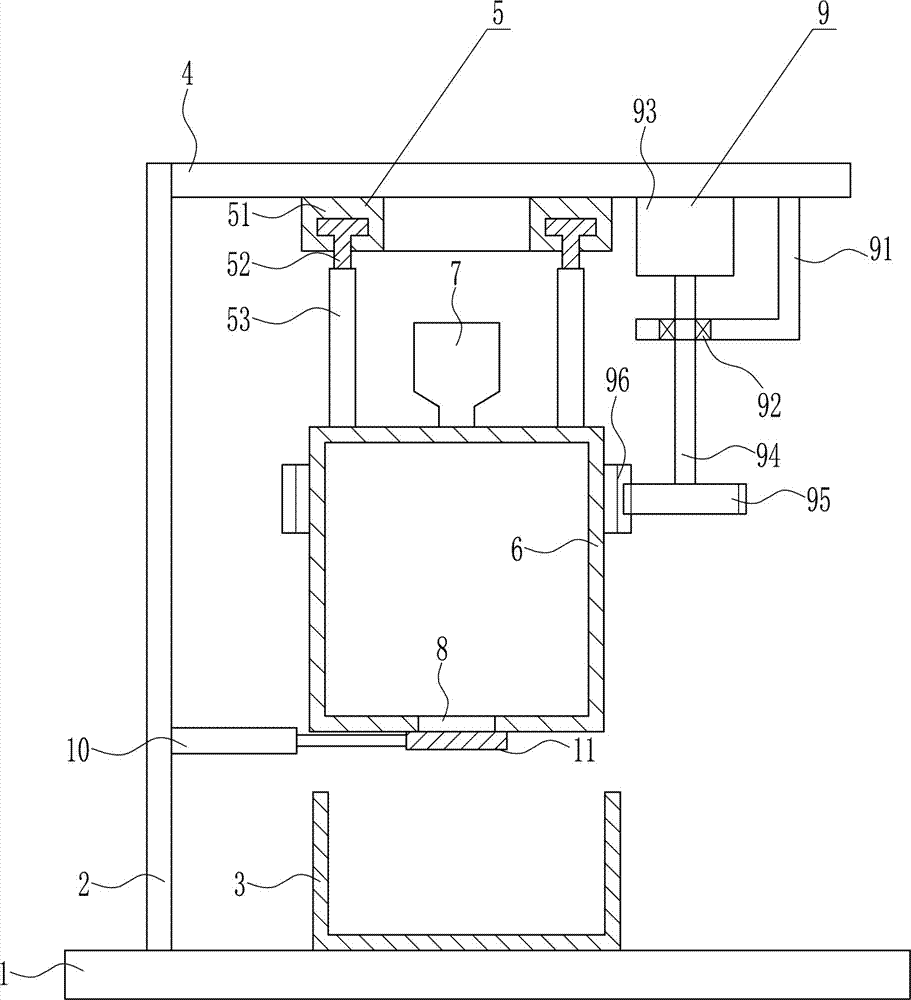

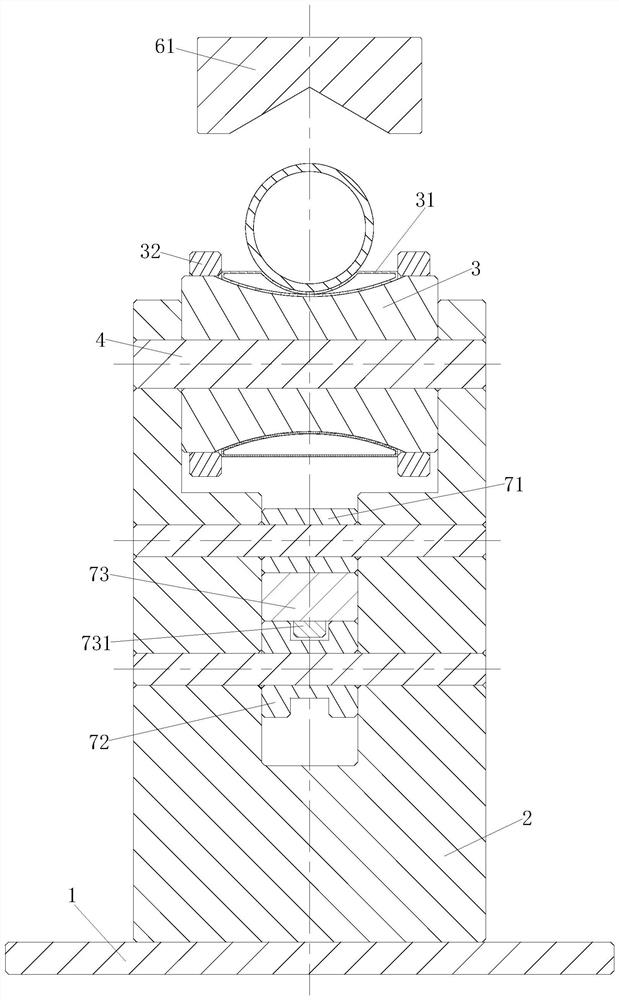

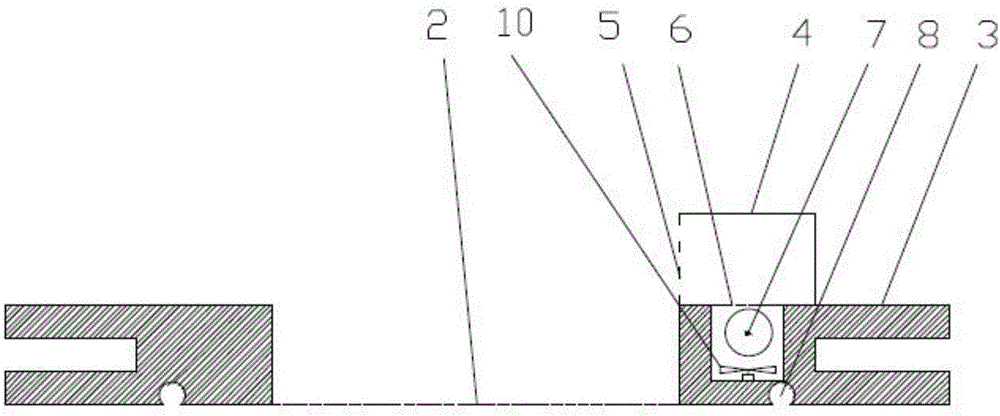

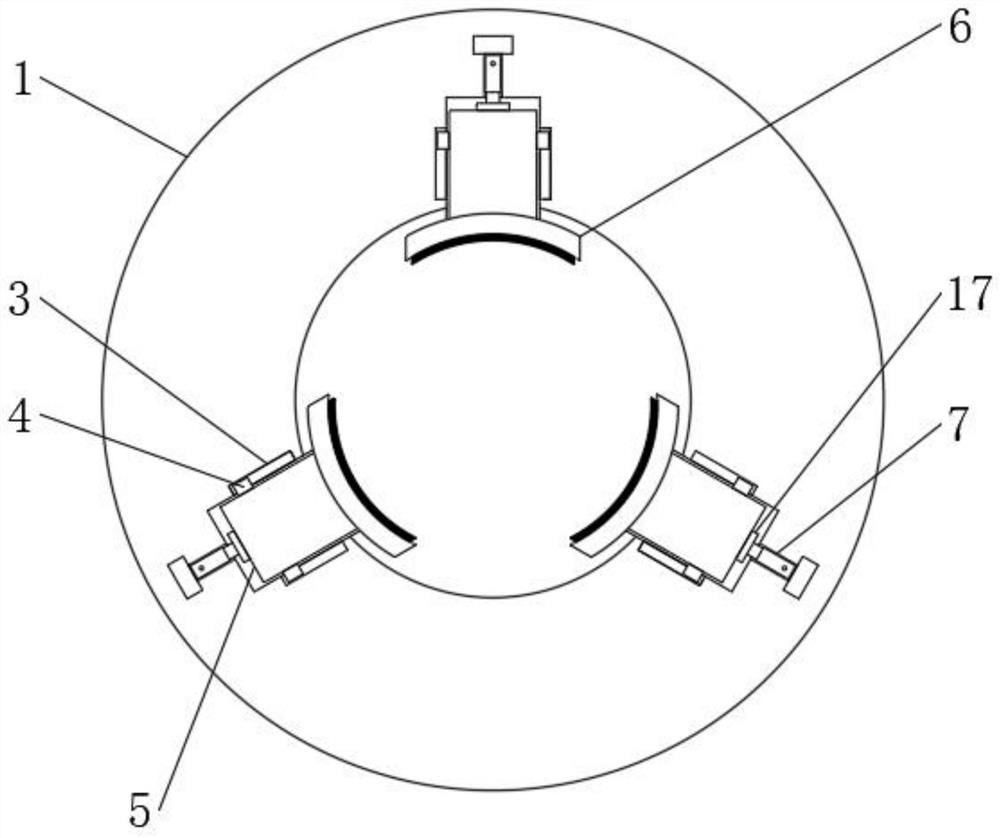

Rapid drilling clamp for round pipe

InactiveCN112548166AGuaranteed machining accuracyImprove machining accuracyDrill jigsBoring/drilling machinesPull forceElectric machinery

The invention belongs to the technical field of drilling equipment, and particularly relates to a rapid drilling clamp for a round pipe, which comprises a bottom plate, a support block, a first roller, a first rotating shaft, a first motor, a positioning mechanism and a length fixing mechanism; a drilling mechanism moves downwards, a first spring is compressed, elastic force generated by the firstspring enables a positioning block to press the round pipe, a V-shaped groove automatically guides the round pipe, automatic positioning and clamping of the round pipe are achieved, and the positioning and clamping time is shortened; the drilling mechanism continues to move downwards for drilling; the drilling mechanism moves upwards to drive the upper end of the first spring to move upwards, when the tension of the first spring is larger than the gravity of the positioning block and a sliding block, the positioning block moves upwards, automatic loosening of the round pipe is achieved, and the loosening time is shortened; and after the round pipe is loosened, the first motor drives a second chain wheel to rotate, drives a first chain wheel to rotate and drives the first roller to rotate,so that the round pipe moves to the position determined by the length fixing mechanism, the drilling mechanism conducts drilling again, circulating drilling is achieved, and time is saved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Polishing device for processing electrically operated tricycle

ActiveCN110091227ANot easy to fly outAvoid the danger of flying out with the schoolEdge grinding machinesGrinding carriagesEngineering

The invention relates to the technical field of mechanical processing, and discloses a polishing device for processing an electrically operated tricycle. The polishing device comprises a sleeve pipe,a rectangular opening is formed in the right side of the sleeve pipe, a storing plate is transversely arranged in the rectangular opening, the two opposite sides of the storing plate are respectivelyand rotataly connected with the two opposite sides of the rectangular opening through a shaft pin, a T-shaped sliding groove is formed in the lower side of the storing plate, an adjusting mechanism isarranged in the T-shaped sliding groove, a strip-shaped groove is formed in the right side of the sleeve pipe, a protecting mechanism is arranged in the strip-shaped groove, a motor is fixedly connected with the left side of the sleeve pipe, a worm rod is fixedly connected with the output end of the motor, one end of the worm rod penetrates through the side wall of the sleeve pipe and is fixedlyconnected with a sand wheel sheet, an annular block is fixedly connected within the sleeve pipe transversely, and a filtering mechanism is connected with the upper side of the annular block. The polishing device for processing the electrically operated tricycle has the advantages that the polishing safety can be improved, the health of the workers is not prone to being damaged, the dust is not prone to producing, and the debris after polishing can be further recovered.

Owner:徐州玉伟机械设备有限公司

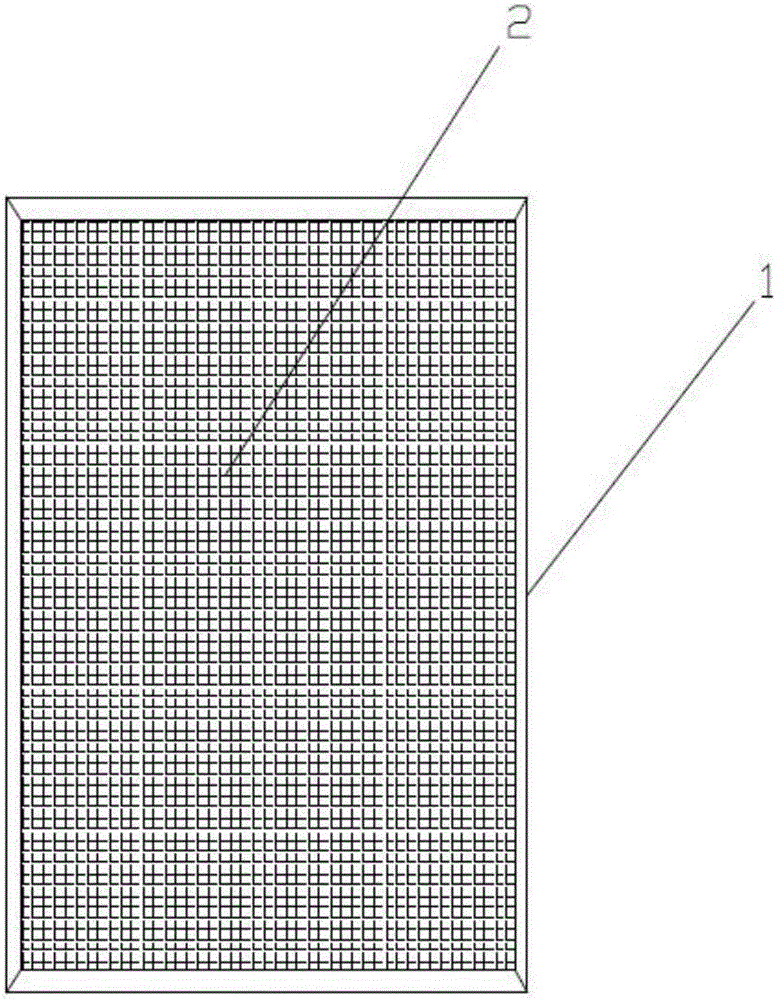

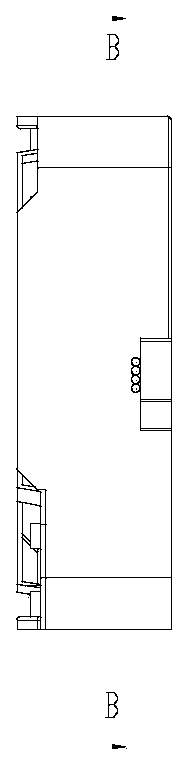

Mosquito-killing screen window with cleaning function

ActiveCN106368593AEfficient killingIt is not easy to fly intoInsect protectionInsect catchers and killersEngineeringWindow screen

The invention discloses a mosquito-skilling screen window with a cleaning function. A buckling groove which is matched with a buckling rubber strip is formed in one side of a frame body in the circumferential direction of the frame body. A window screen is clamped in the buckling groove of the frame body through the buckling rubber strip. The frame body comprises two symmetrical horizontal frames and two symmetrical vertical frames. A lamp groove is formed in the side, opposite to the buckling groove, of one vertical frame, an opening of the lamp groove is covered with a vibrating screen which is used for electrically shocking mosquitoes and electrically connected with the lamp groove, and a mosquito-lured lamp is mounted in the lamp groove. A plurality of electric fans are mounted in the lamp groove in the length direction of the lamp groove, and the electric fans blow air towards the opening of the lamp groove. One side of a mosquito-skilling box is fixedly connected to the outer side, close to the lamp groove, of the corresponding vertical frame, and the mosquito-skilling box communicates with the lamp groove. A net allowing mosquitoes to fly therein is arranged on the side, facing the window screen, of the mosquito-skilling box. The mosquito-skilling screen window with the cleaning function can effectively kill mosquitoes and completely removing mosquito corpses.

Owner:ANHUI KATA DOOR & WINDOW

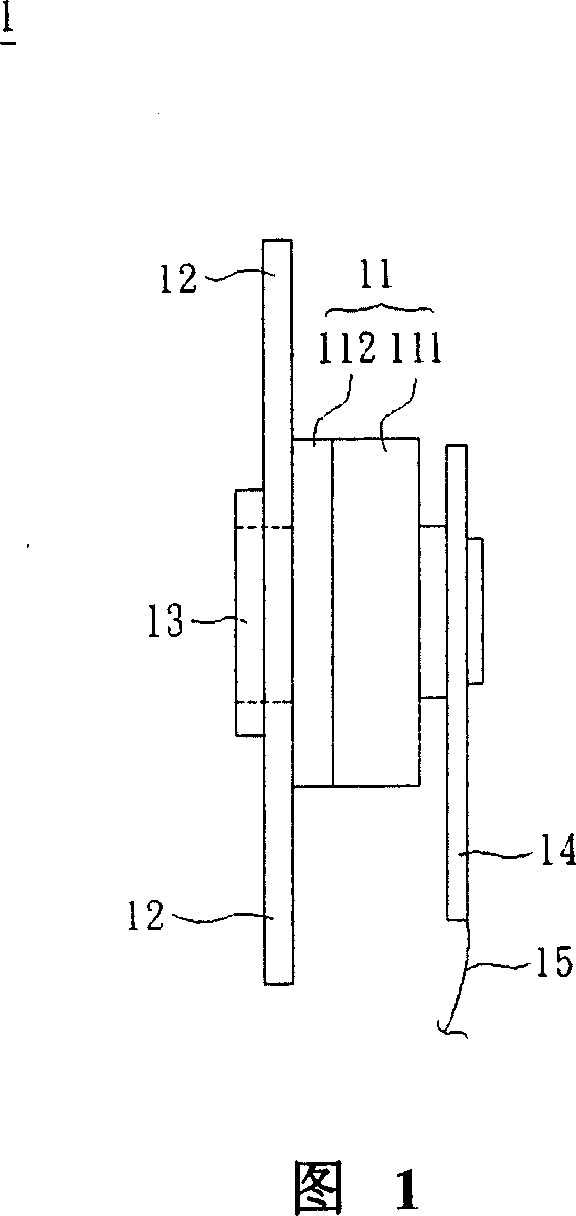

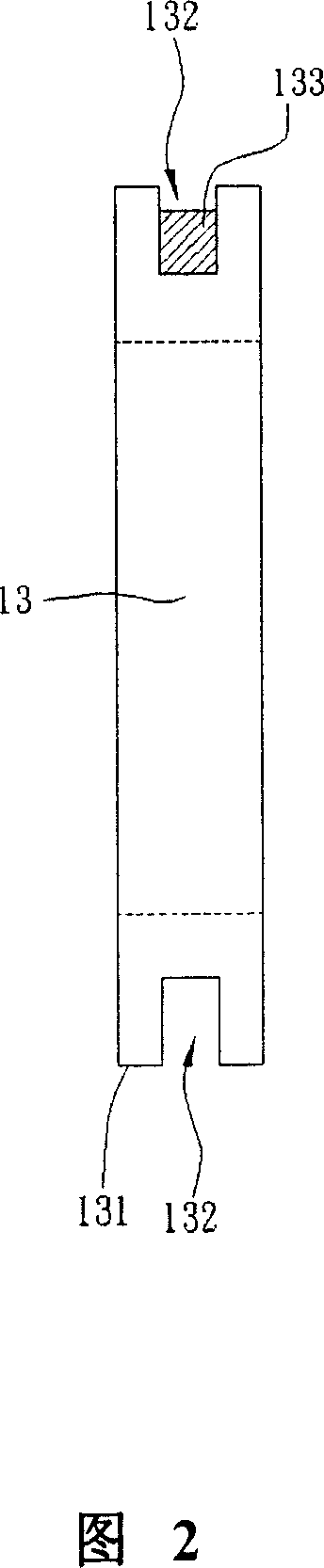

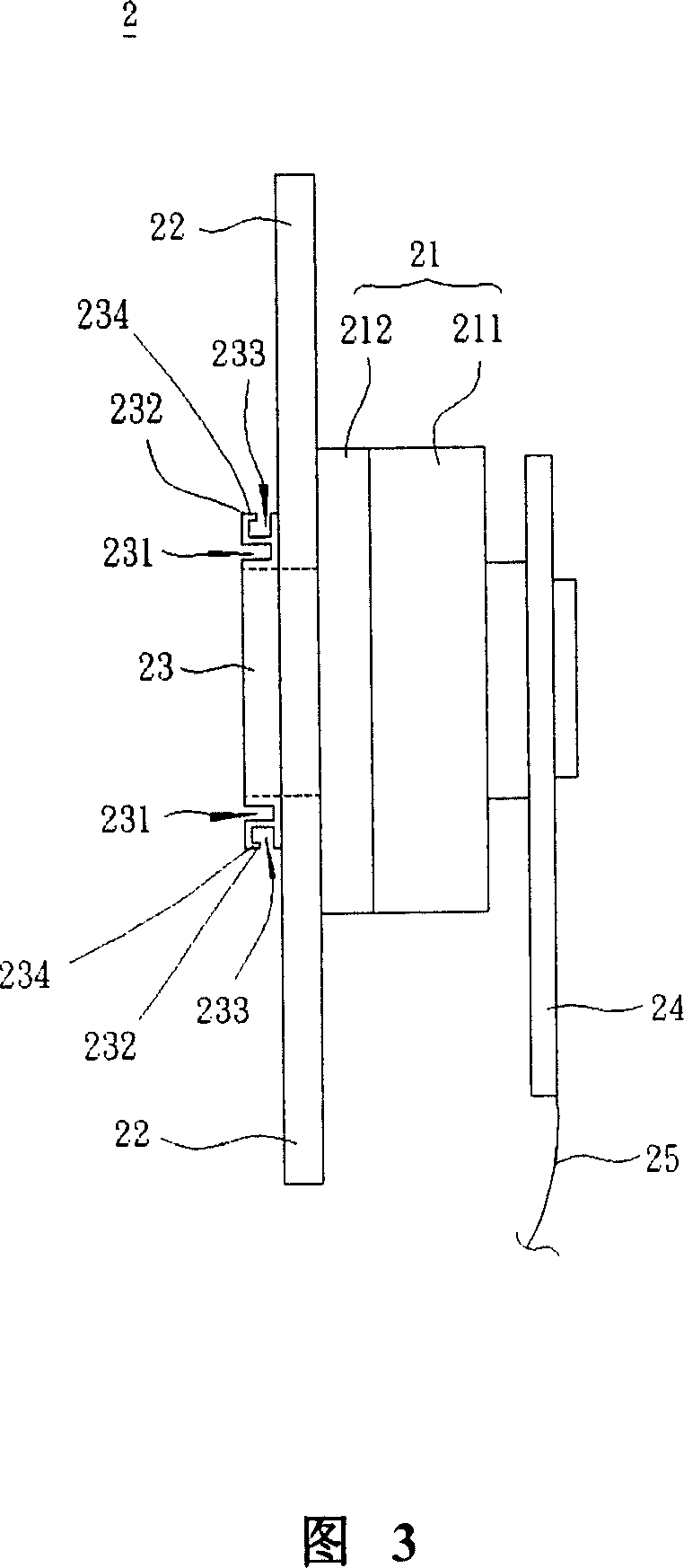

Detachable balancing optical assembly

InactiveCN1940774AImprove good rateLow costElectrography/magnetographyMountingsEngineeringColor wheel

A balanced optical component of detachable type is prepared as setting motor at one side of color wheel and coverage plate at another side of color wheel, setting a force exerting region on one surface of coverage plate as said surface being set opposite to color wheel.

Owner:PRODISC TECH INC

Hydraulic expansion type chuck for workpiece clamping machining

The invention discloses a hydraulic expansion type chuck for workpiece clamping machining, and belongs to the field of chucks. The hydraulic expansion type chuck comprises a chuck main body, a plurality of uniformly distributed mounting grooves are dug in the inner wall of the chuck main body, a pair of first sliding grooves are dug in the inner walls of the mounting grooves, first sliding blocks are slidably connected into the first sliding grooves, a fixing block is fixedly connected between the pair of first sliding blocks, an arc-shaped clamping plate is fixedly connected to the outer end of the fixing block, clamping grooves are dug in the bottom walls of the mounting grooves, hydraulic rods are mounted in the clamping grooves, a top plate is fixedly connected to the right ends of the hydraulic rods, and the top plate is fixedly connected with the fixing block. A plurality of evenly-distributed working grooves are dug at the upper end of the chuck main body, a workpiece can be better clamped, three jaws still firmly grab the workpiece when power is suddenly off, the workpiece is not prone to flying out of the chuck main body, and therefore the safety of using the chuck main body is effectively improved.

Owner:苏州市通吉汽车零部件有限公司

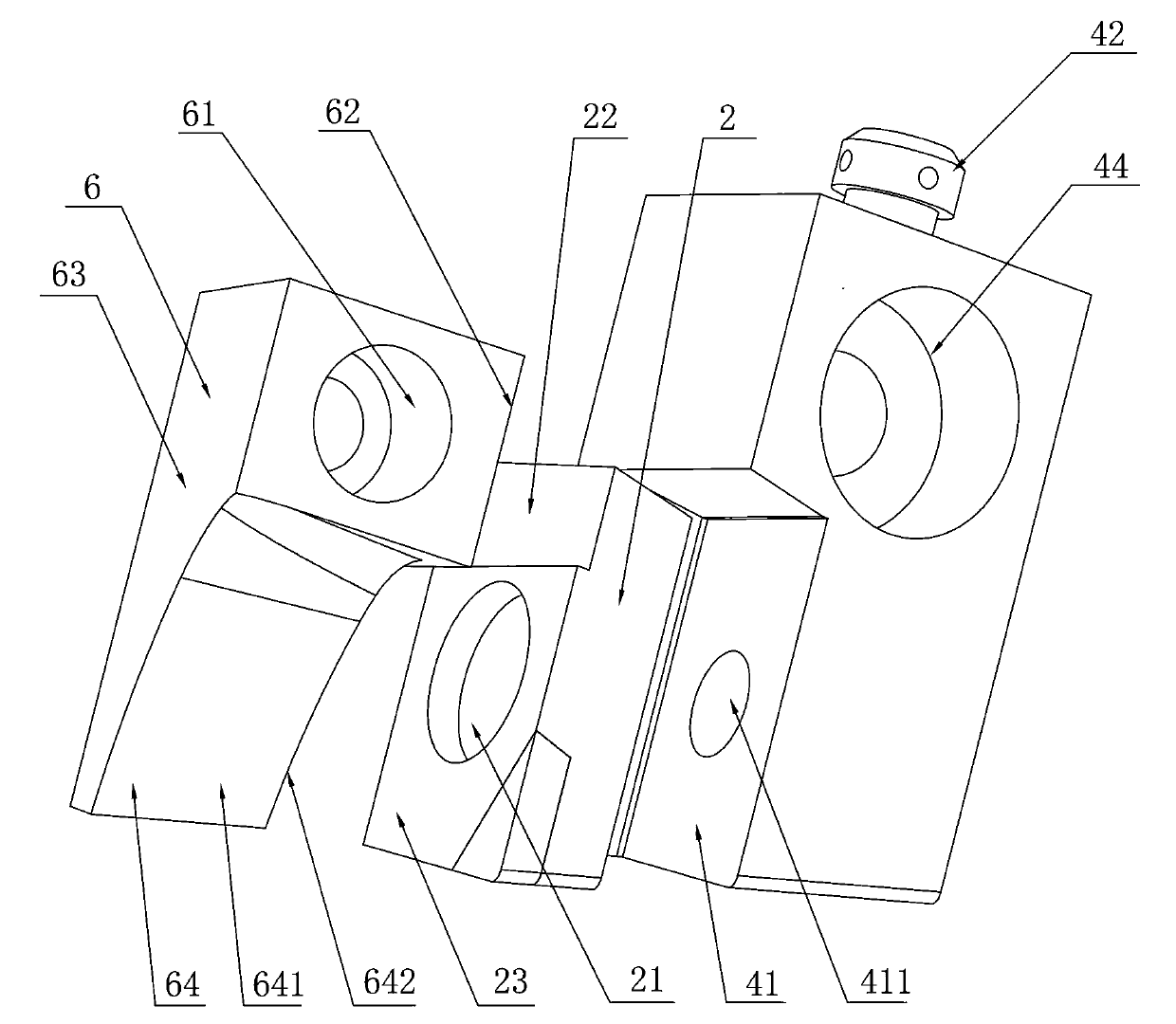

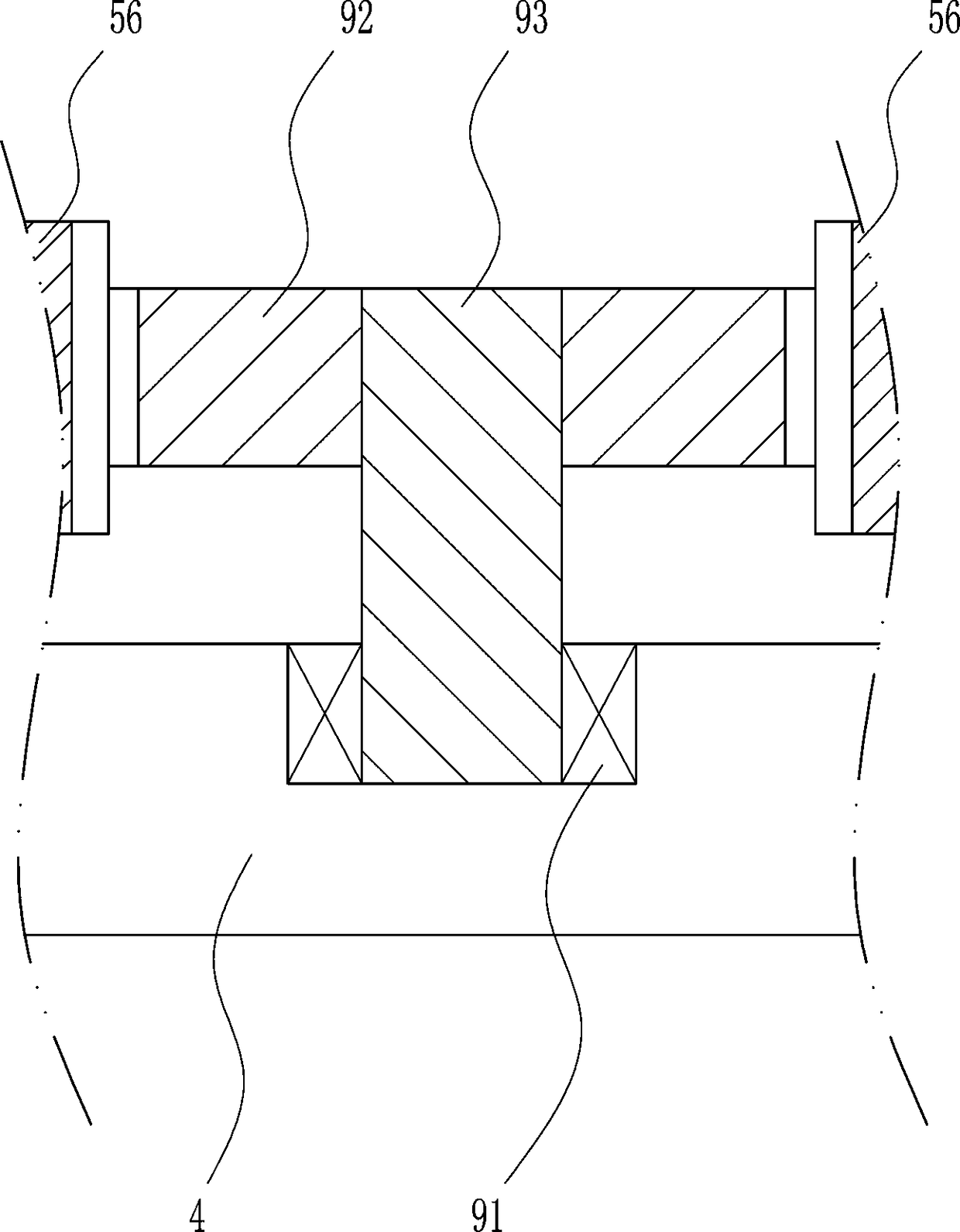

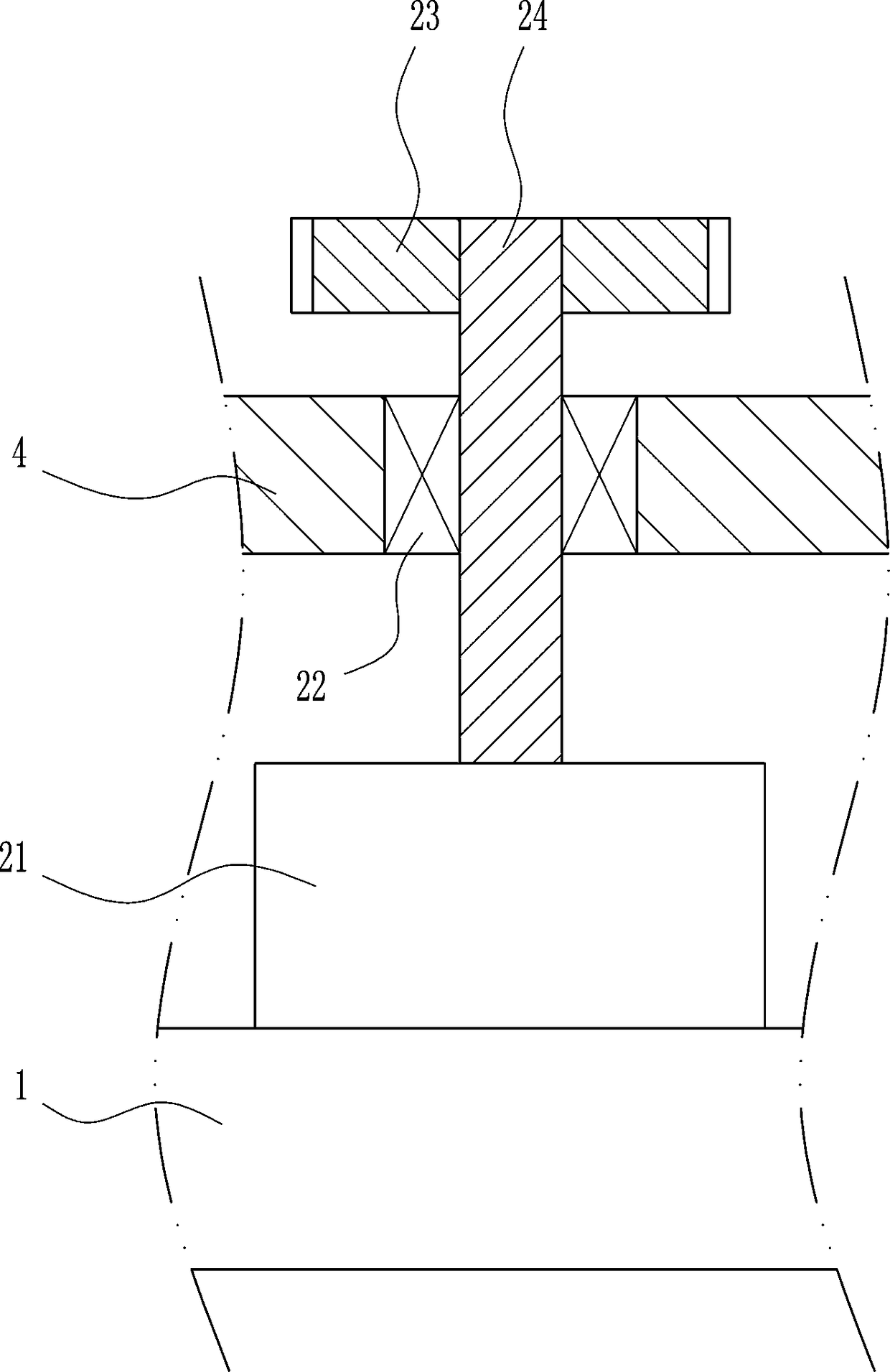

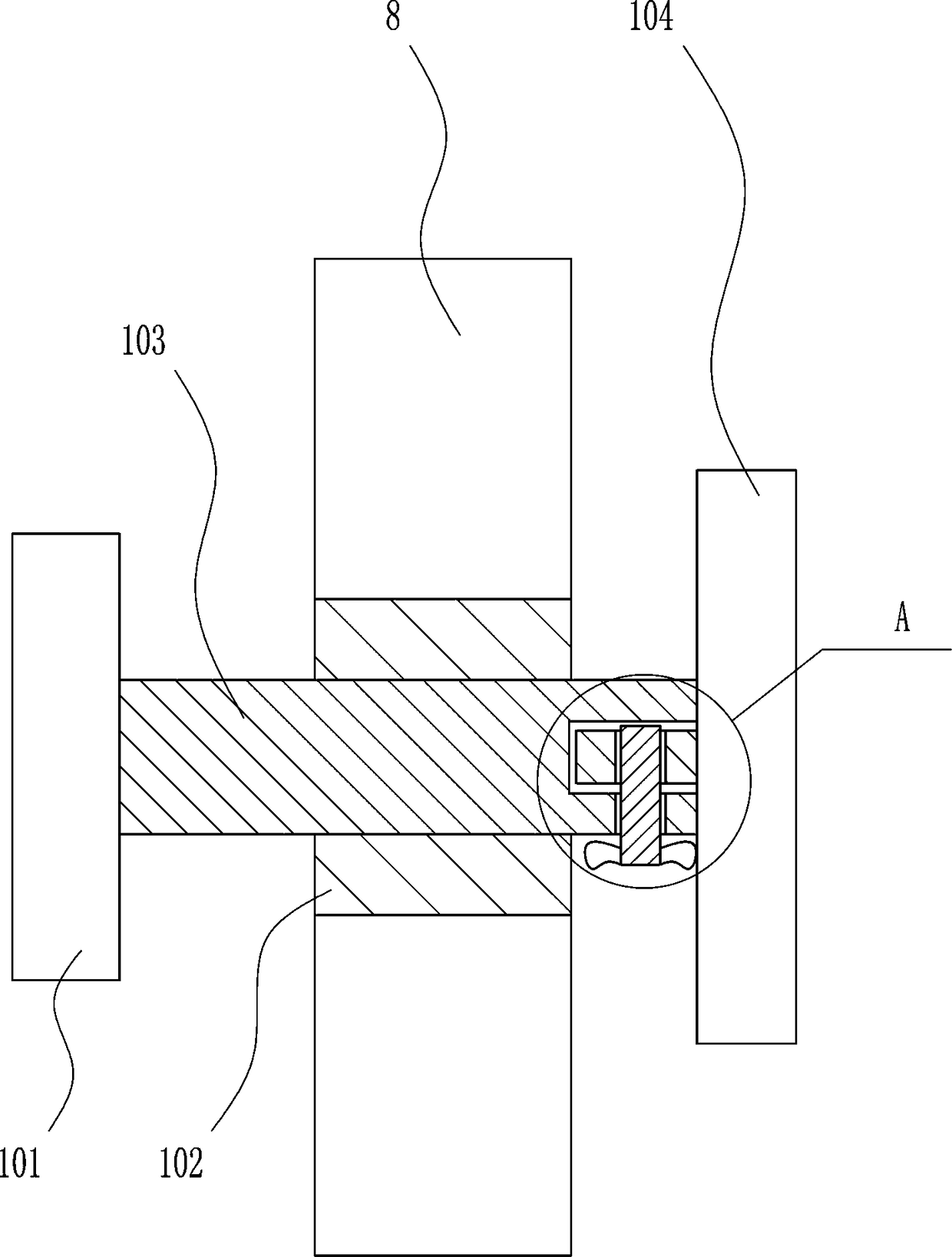

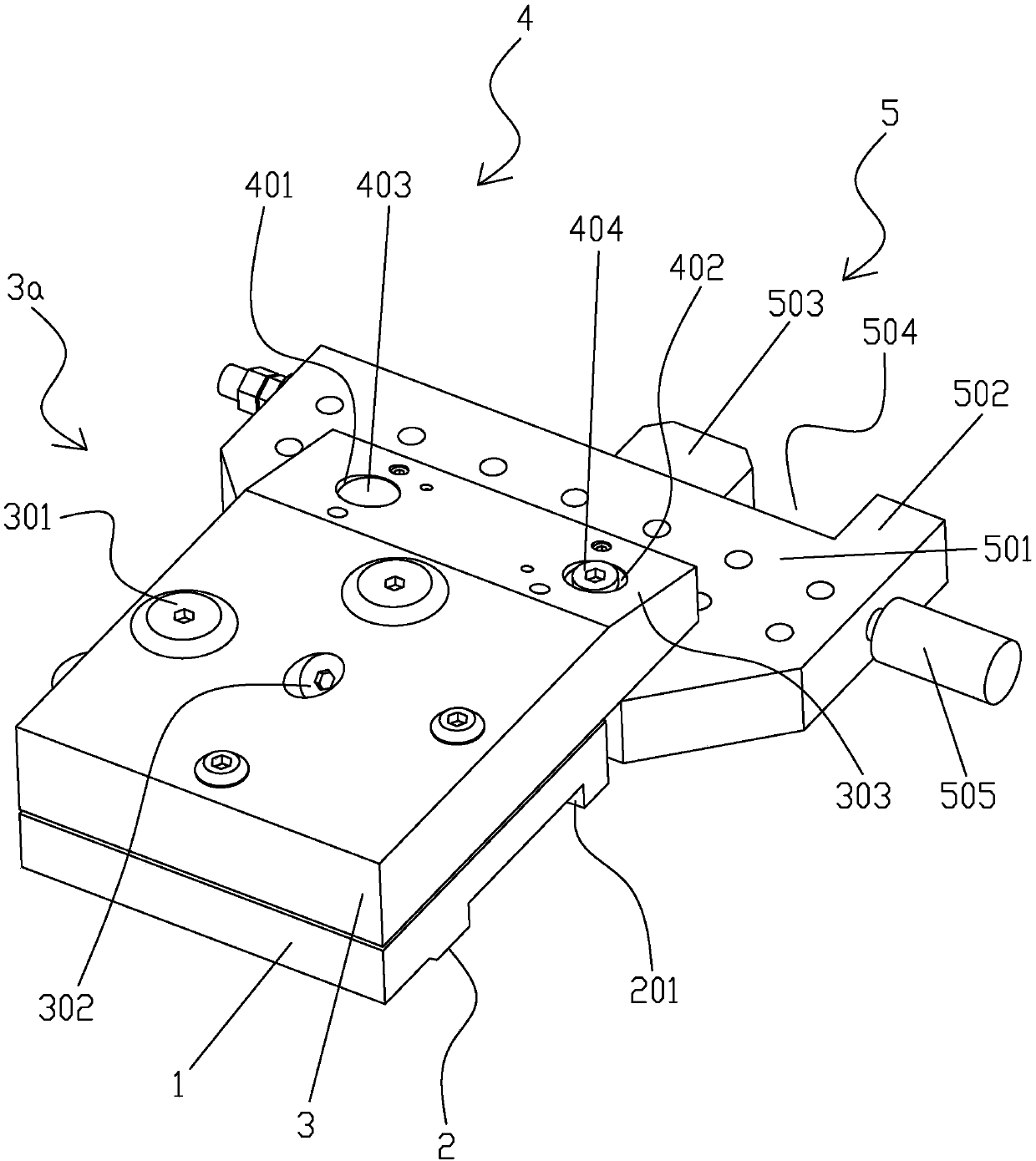

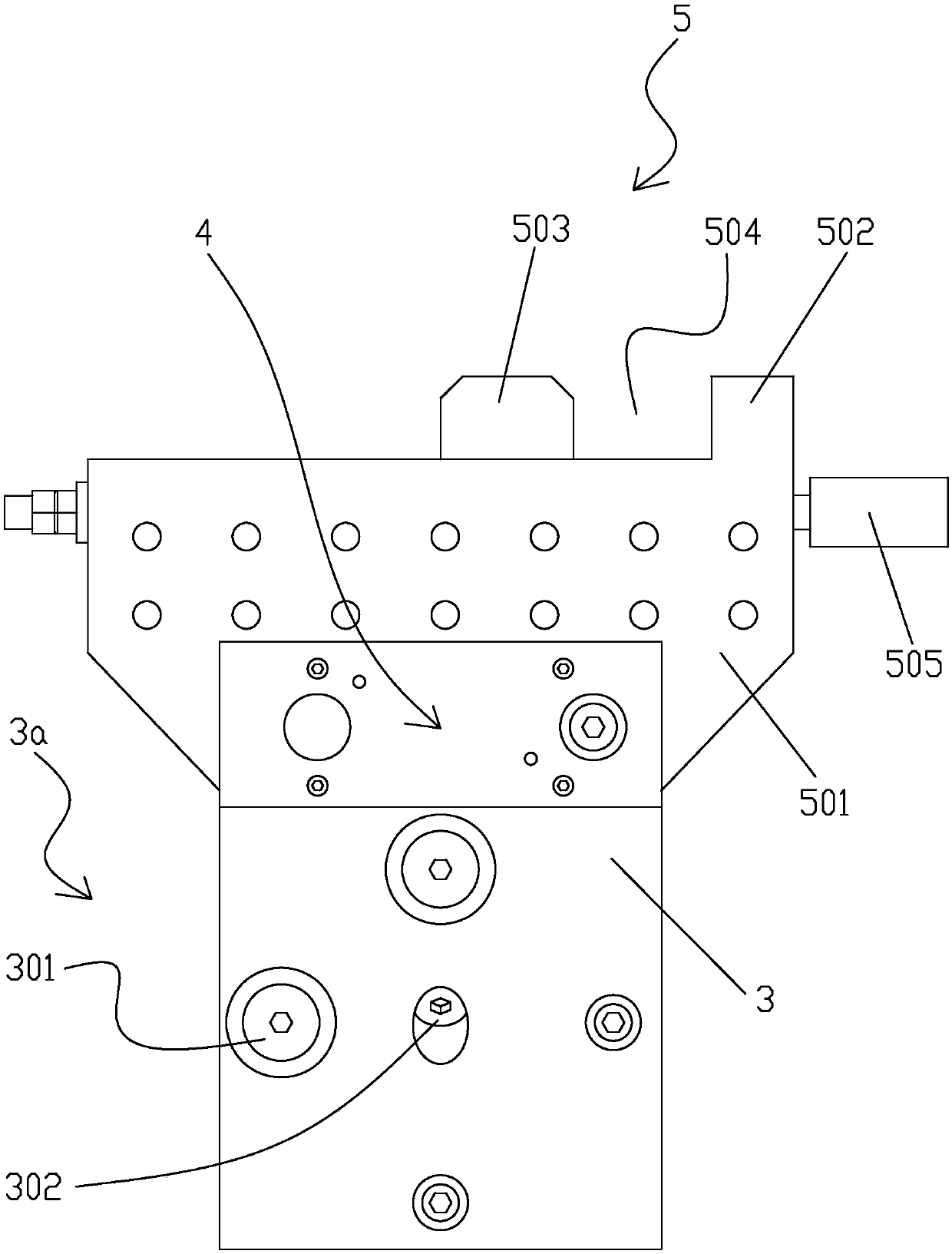

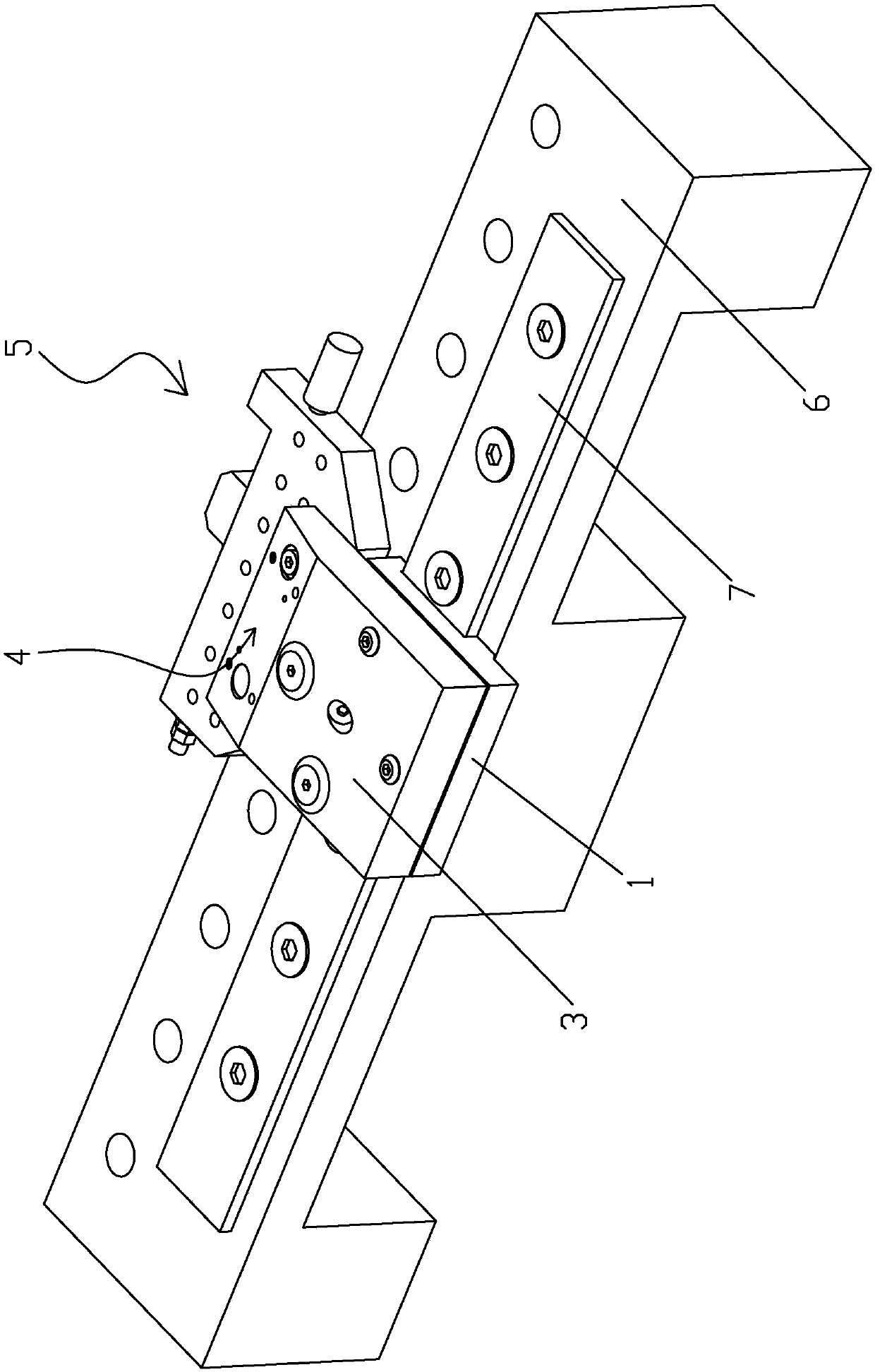

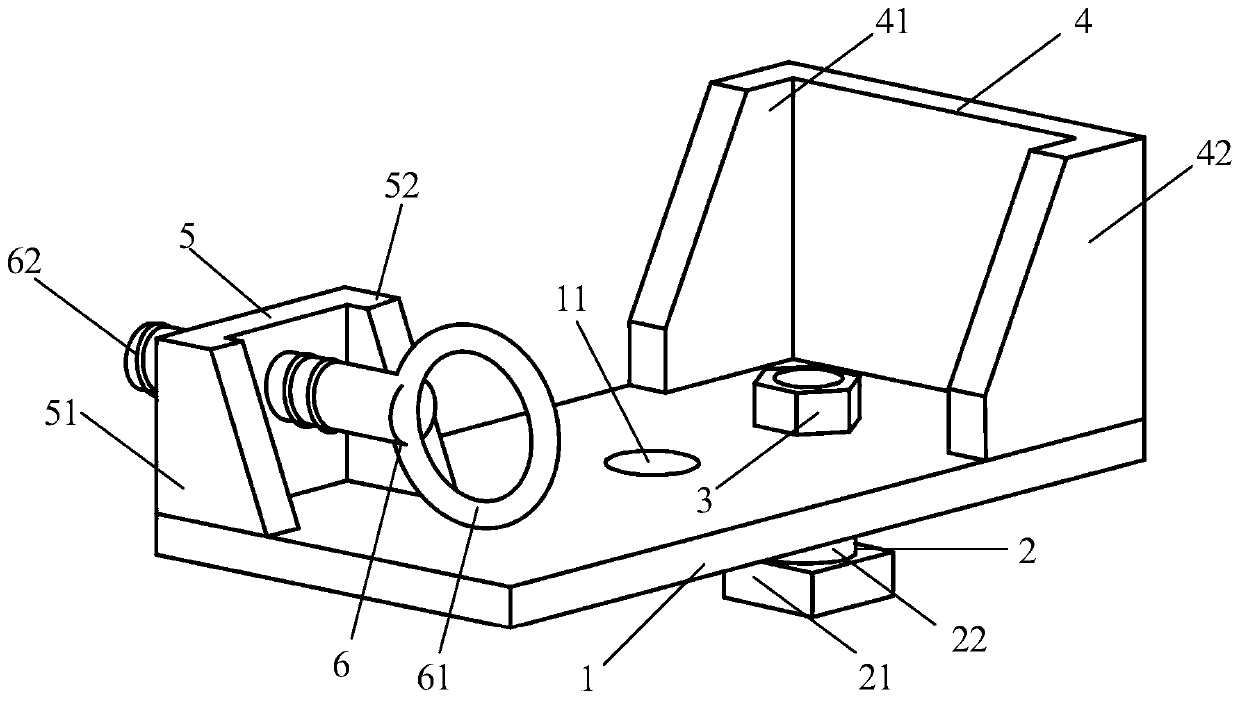

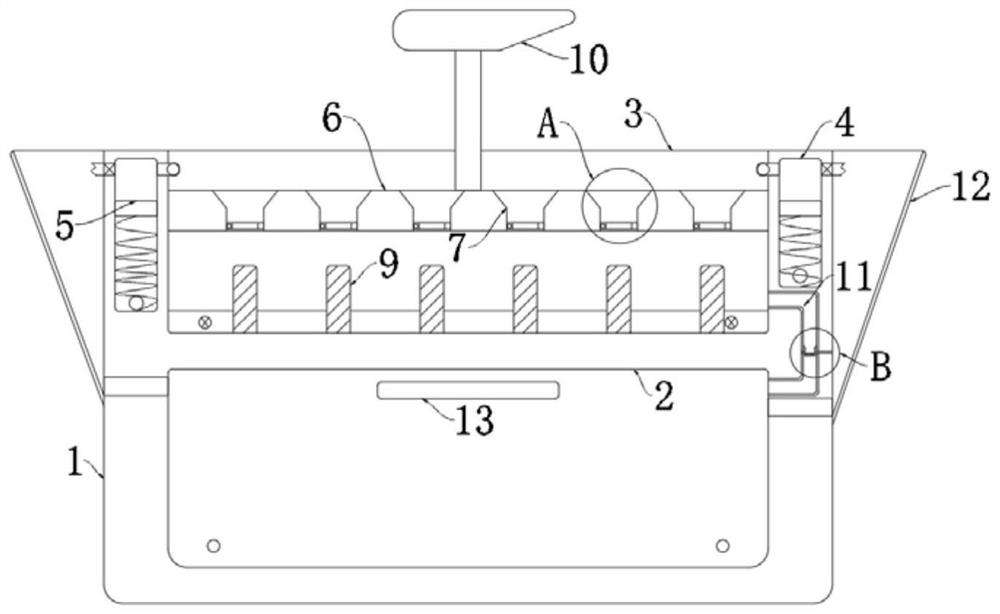

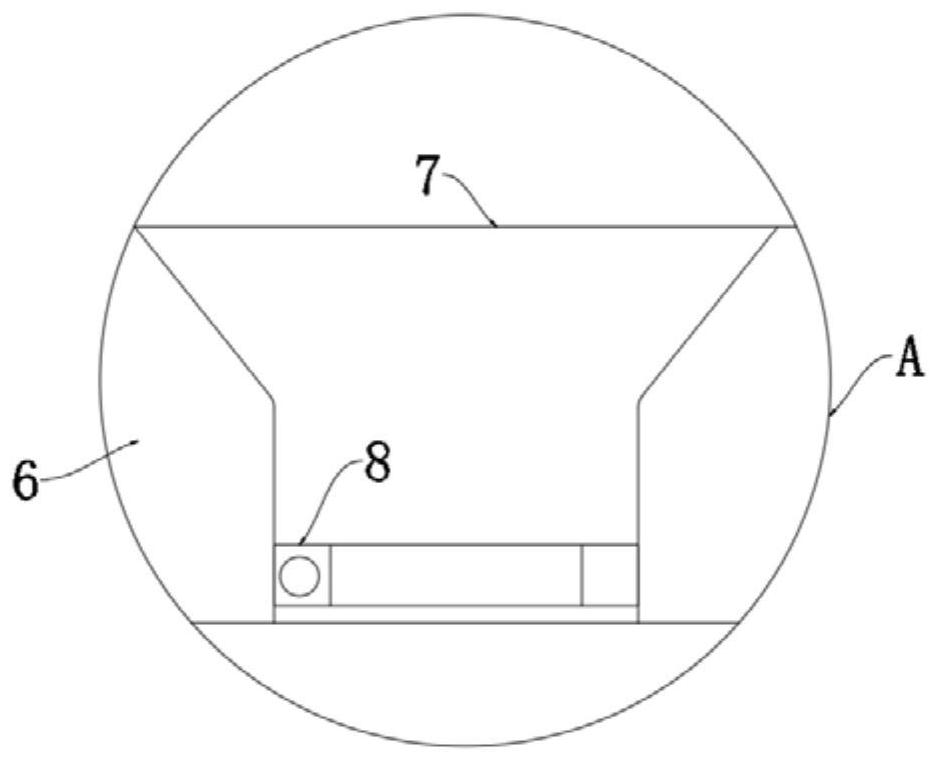

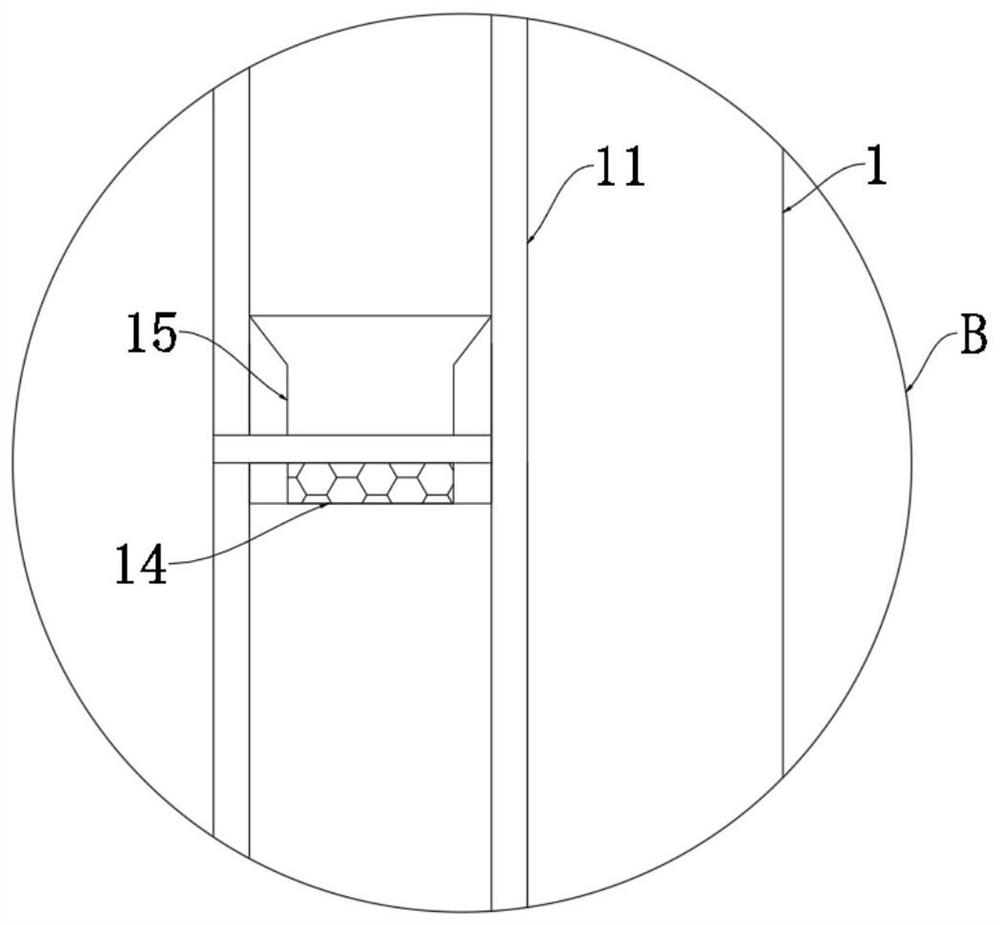

Accurate and efficient clamping fixture applied to low-speed wire cutting machining and clamping splicing table

PendingCN108015372ANot easy to fly outHigh precisionElectrical-based auxillary apparatusLow speedWire cutting

The invention discloses an accurate and efficient clamping fixture applied to low-speed wire cutting machining. The accurate and efficient clamping fixture applied to low-speed wire cutting machiningcomprises a base, an adjusting positioning part and a clamping device, wherein an installing connecting surface capable of being connected with a working machine table is arranged on any surface of the base; the adjusting positioning part is arranged on the base and further provided with an accurate positioning installing portion; and the clamping device is arranged on the accurate positioning installing portion, precisely connected with the accurate positioning installing portion, and used for clamping a workpiece. According to the technical scheme, the accurate and efficient clamping fixtureapplied to low-speed wire cutting machining has the characteristics that the accurate positioning installing portion is arranged on the adjusting positioning part and the clamping device is arrangedon the accurate positioning installing portion, so that when the workpiece is fixed, accurate and efficient clamping can be achieved, repeated clamping accuracy is high, errors are small, the workpiece is not prone to displacement in the machining process, machining accuracy and machining quality are guaranteed, and parts are stable, not prone to fly out of equipment and high in safety after beingclamped.

Owner:中山市凯鸿精密模具有限公司

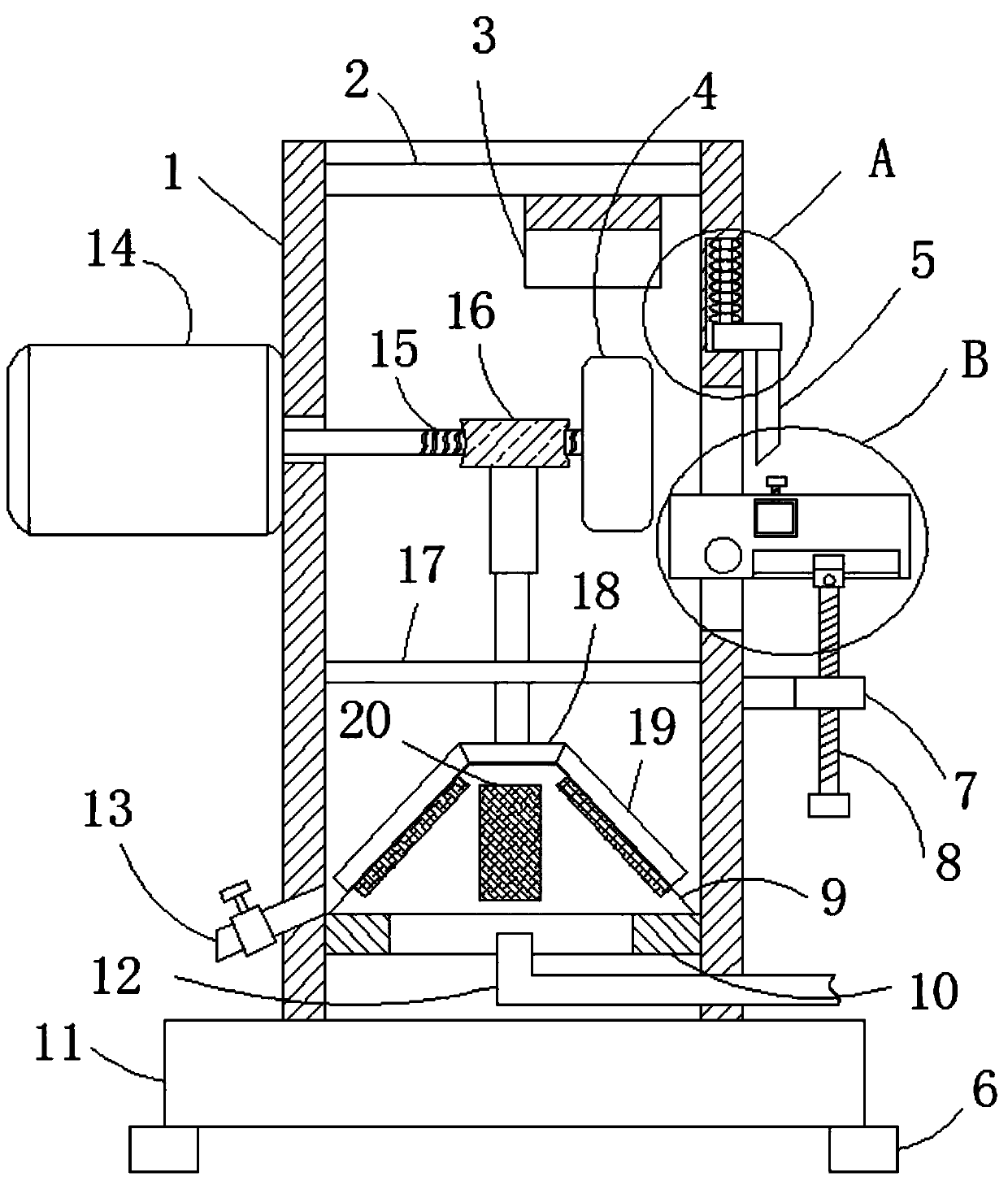

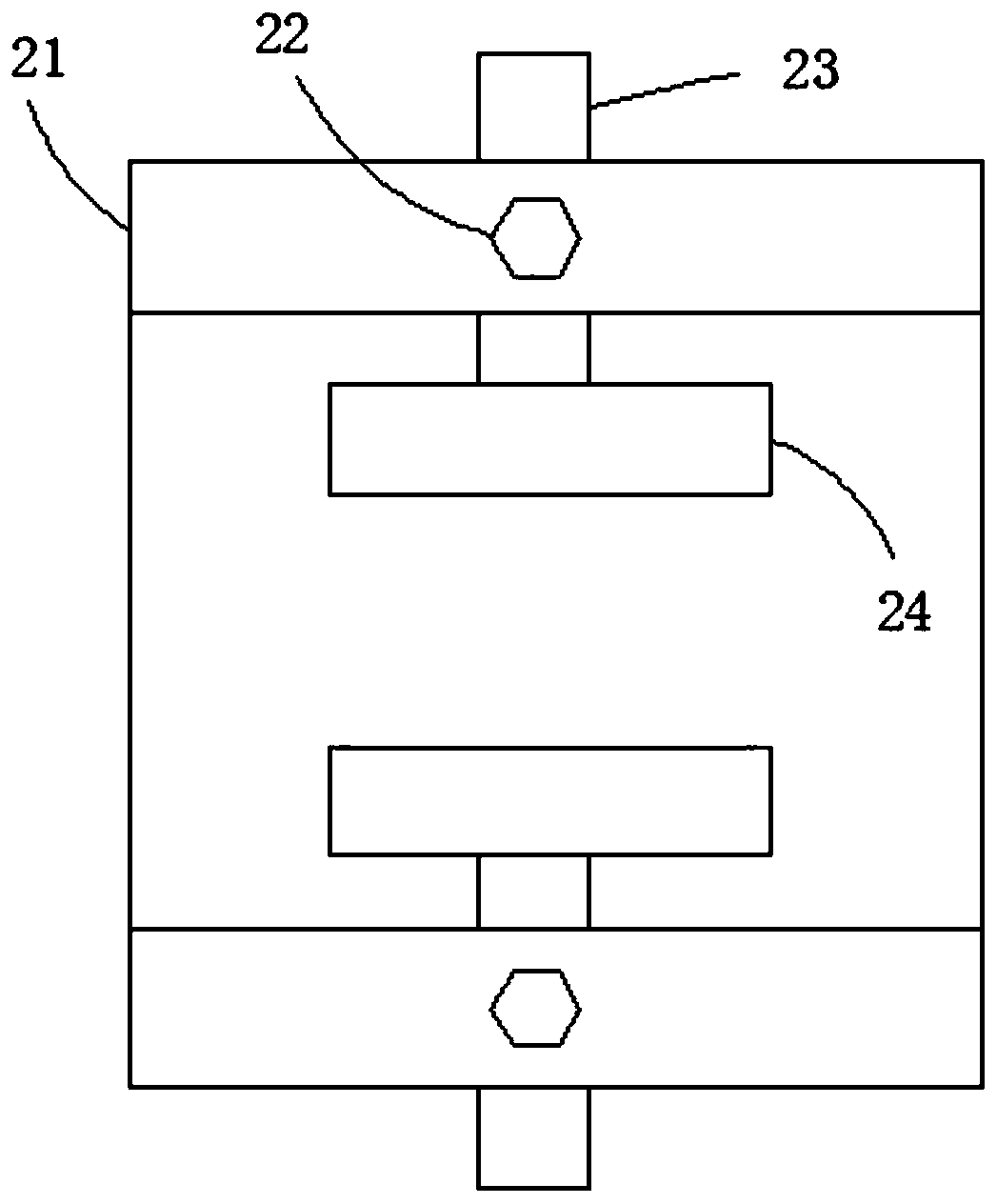

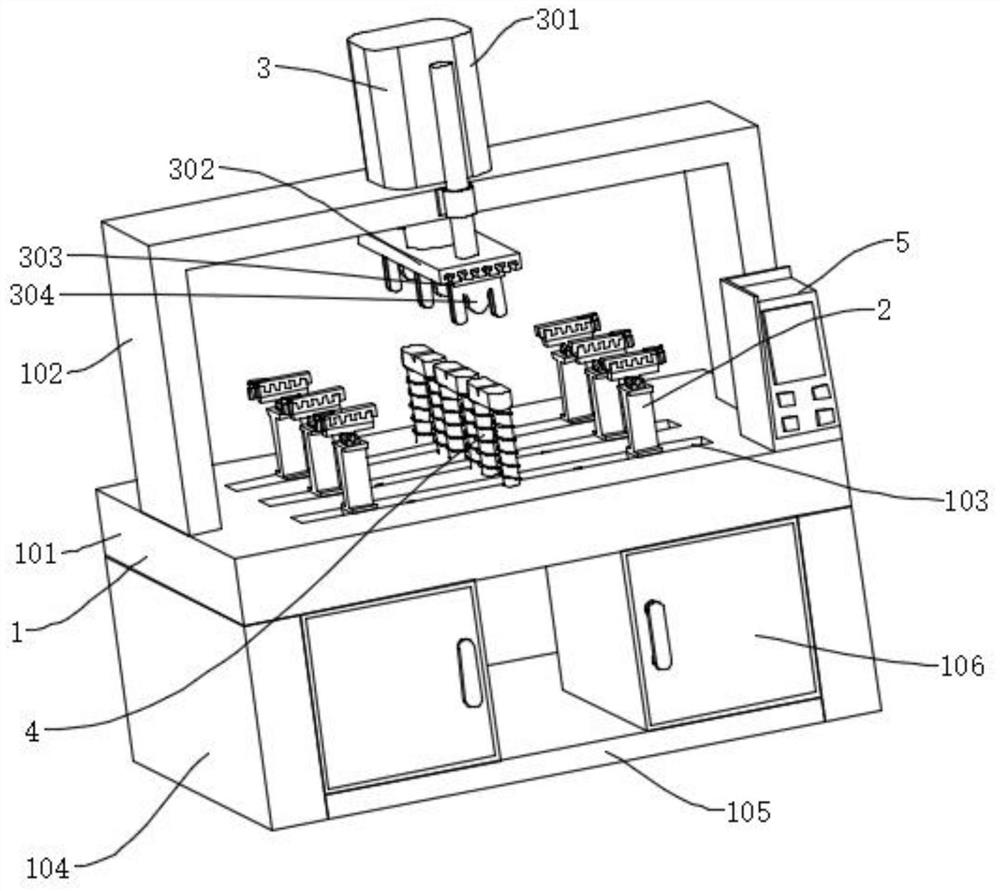

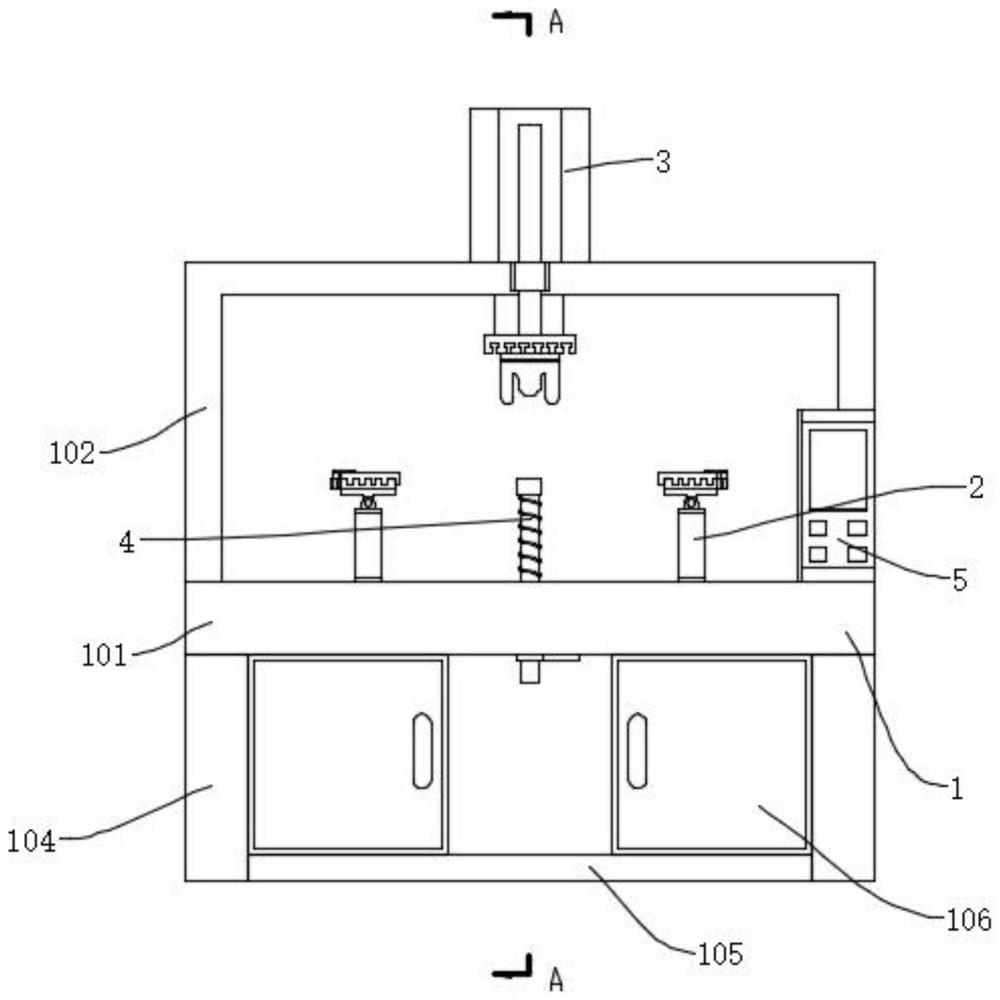

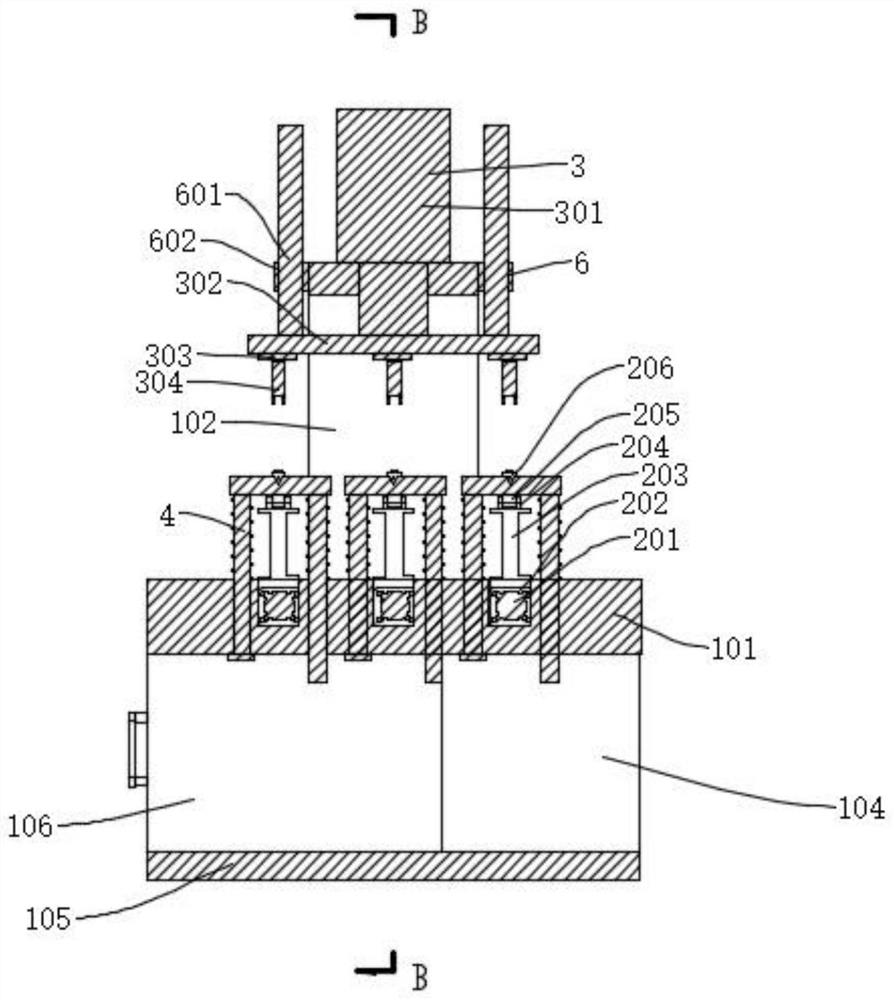

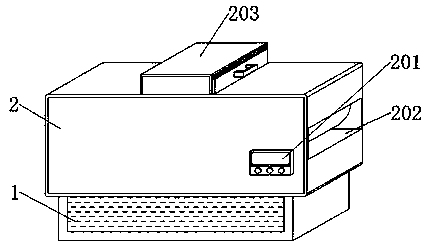

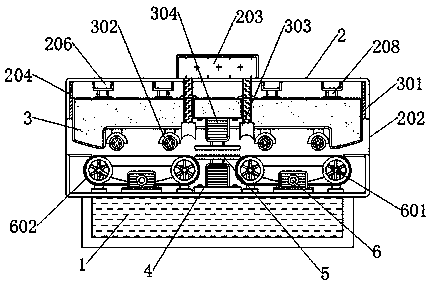

Bending strength detection device for new material production

InactiveCN112378781AImprove adaptabilityAvoid offsetMaterial strength using steady bending forcesFlexural strengthUltimate tensile strength

The invention discloses a bending strength detection device for new material production, the bending strength detection device comprises a support mechanism and a control panel, the support mechanismis mainly composed of a working plate and a frame, the bending strength detection device also comprises a discharge mechanism, an extrusion mechanism and a measurement mechanism, the top of the support mechanism is provided with three chutes, and the three chutes are equidistantly arranged front and back; a discharging mechanism is arranged on the inner side of each sliding groove and comprises atwo-way air cylinder, a sliding block, a supporting base and a discharging assembly, and the two-way air cylinders are connected to the centers of the inner sides of the sliding grooves through bolts.Through the arrangement of the discharging mechanism, the extrusion mechanism and the measurement mechanism, the detection function of three materials can be completed at a time, and the detection efficiency is improved; and through the arrangement of the discharging assembly, the safety of the whole equipment in the working process is improved.

Owner:李伟煜

Electric drill capable of achieving protection function diversification

ActiveCN111014778AEasy extractionPrevent splashPortable drilling machinesBoring/drilling componentsStructural engineeringDust particles

The invention discloses an electric drill capable of achieving protection function diversification, and belongs to the field of electric drills. The electric drill capable of achieving protection function diversification comprises an electric drill body, an installing base is movably connected to the electric drill body, a drill bit is inserted into the installing base, an anti-separation rod is fixedly connected to the outer end of the drill bit and located on the side close to the installing base, the side, far away from the installing base, of the anti-separation rod is provided with a shell body, the shell body is provided with a central round hole matched with the drill bit and a strip-shaped hole matched with the anti-separation rod, and the drill bit is inserted into the central round hole. Through the structures such as the anti-separation rod, the shell body and an adjusting rod body, the drill bit is not prone to flying out to hurt a worker, and the jammed drill bit can be conveniently pulled out; meanwhile, splashing of dust particles can be effectively blocked, the eyes of the worker are protected, and then the drilling security coefficient is improved; and in addition,the maximum hole depth can be determined in advance, and the consistency of the depths of multiple holes can be effectively kept.

Owner:浙江意达电器有限公司

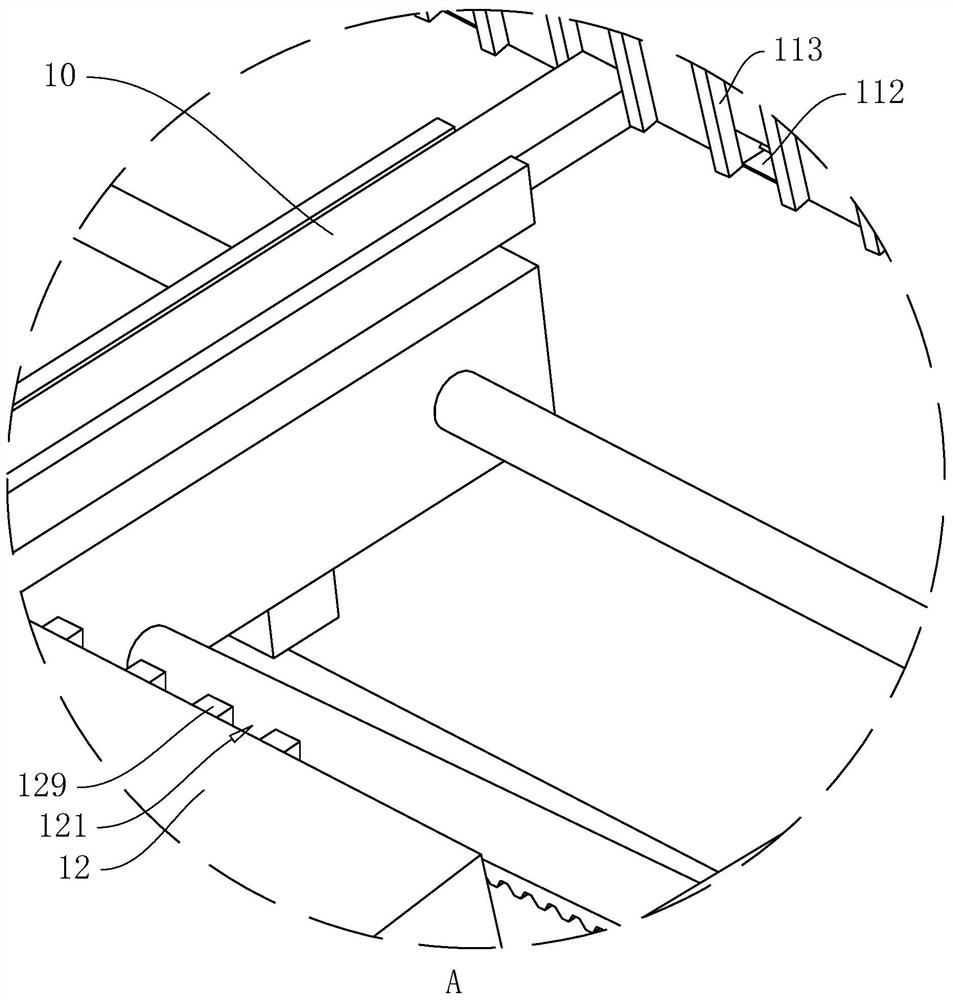

Sorting and discharging apparatus and sorting and discharging method of testing and sorting machine for MOS transistor

PendingCN112264332AQuick collectionQuick unloading operationDevices using optical meansSortingMechanical engineeringTransistor

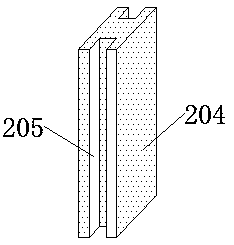

The application relates to a sorting and discharging apparatus and a sorting and discharging method of a testing and sorting machine for an MOS transistor. The apparatus comprises a sorting frame, wherein the sorting frame is fixedly connected with at least two guide rails; the sorting frame is provided with a sorting assembly which is used for guiding a material to the corresponding guide rail according to data transmitted by a detection device; a first material plate and a second material plate are fixedly connected onto the sorting frame; a storage space is formed between the first materialplate and the second material plate; feeding holes are formed in the first material plate; the feeding holes are communicated with the guide rails; the feeding holes are corresponding to ends of receiving boxes and are further close to the bottom of the sorting frame; discharge holes are formed in the second material plate; the discharge holes are far away from the bottom of the sorting frame; afeeding assembly is arranged on the sorting frame; the position of the first material plate is higher than that of the second material plate; a positioning assembly is arranged on the first material plate; and after the feeding assembly drives the receiving box to reach the storage space, the receiving box at an original position is jacked up by a newly reaching receiving box. The sorting and discharging apparatus has the effect of improving output efficiency.

Owner:SHENZHEN SHENGYUAN SEMICON +1

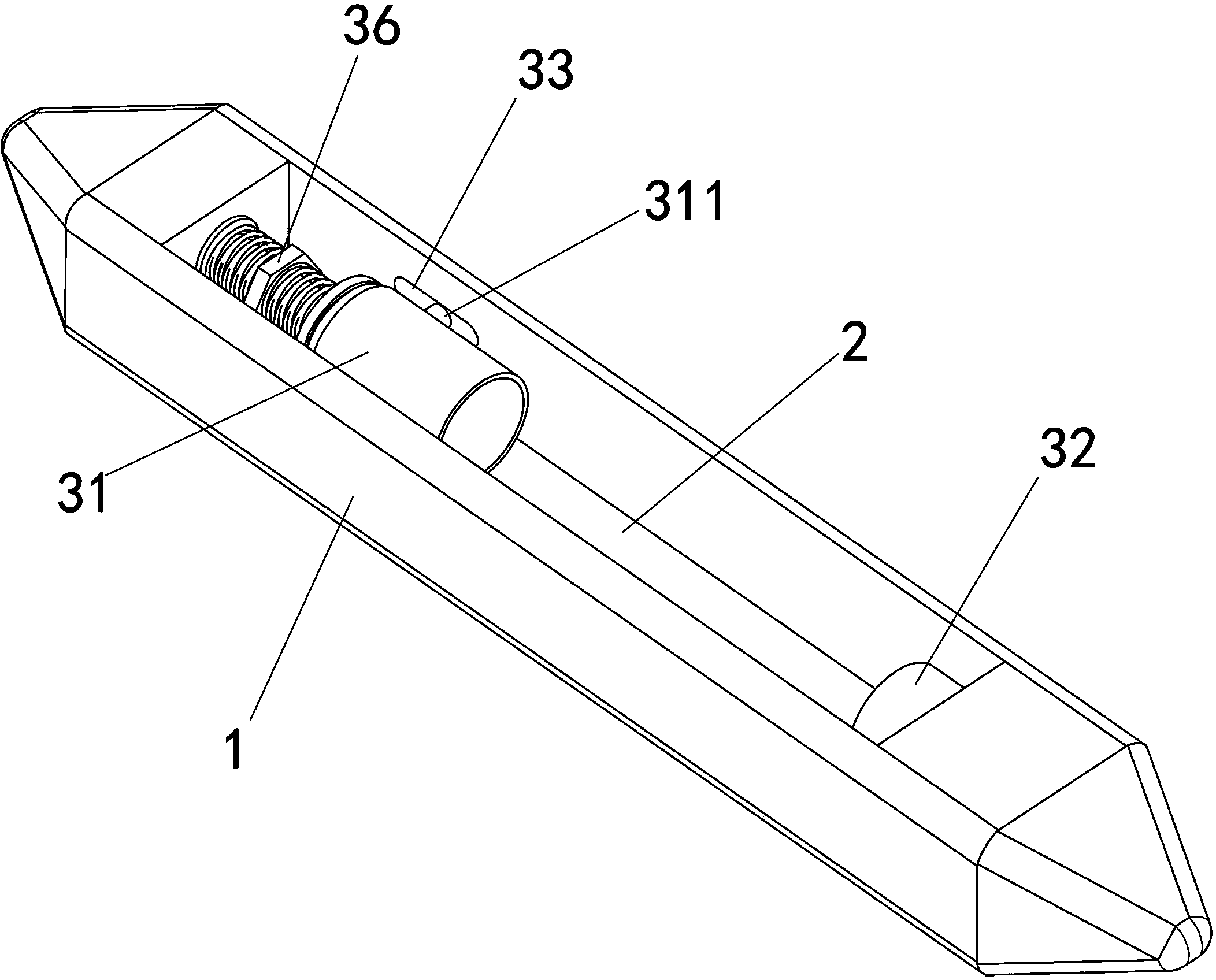

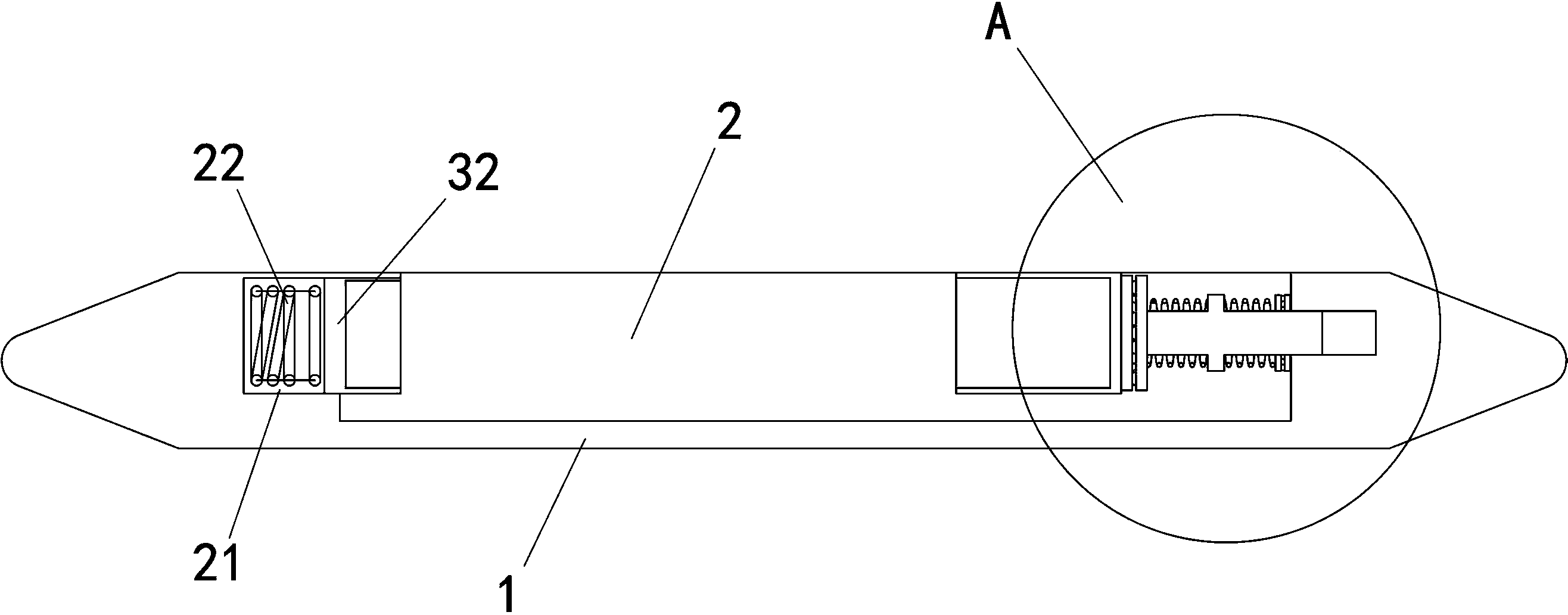

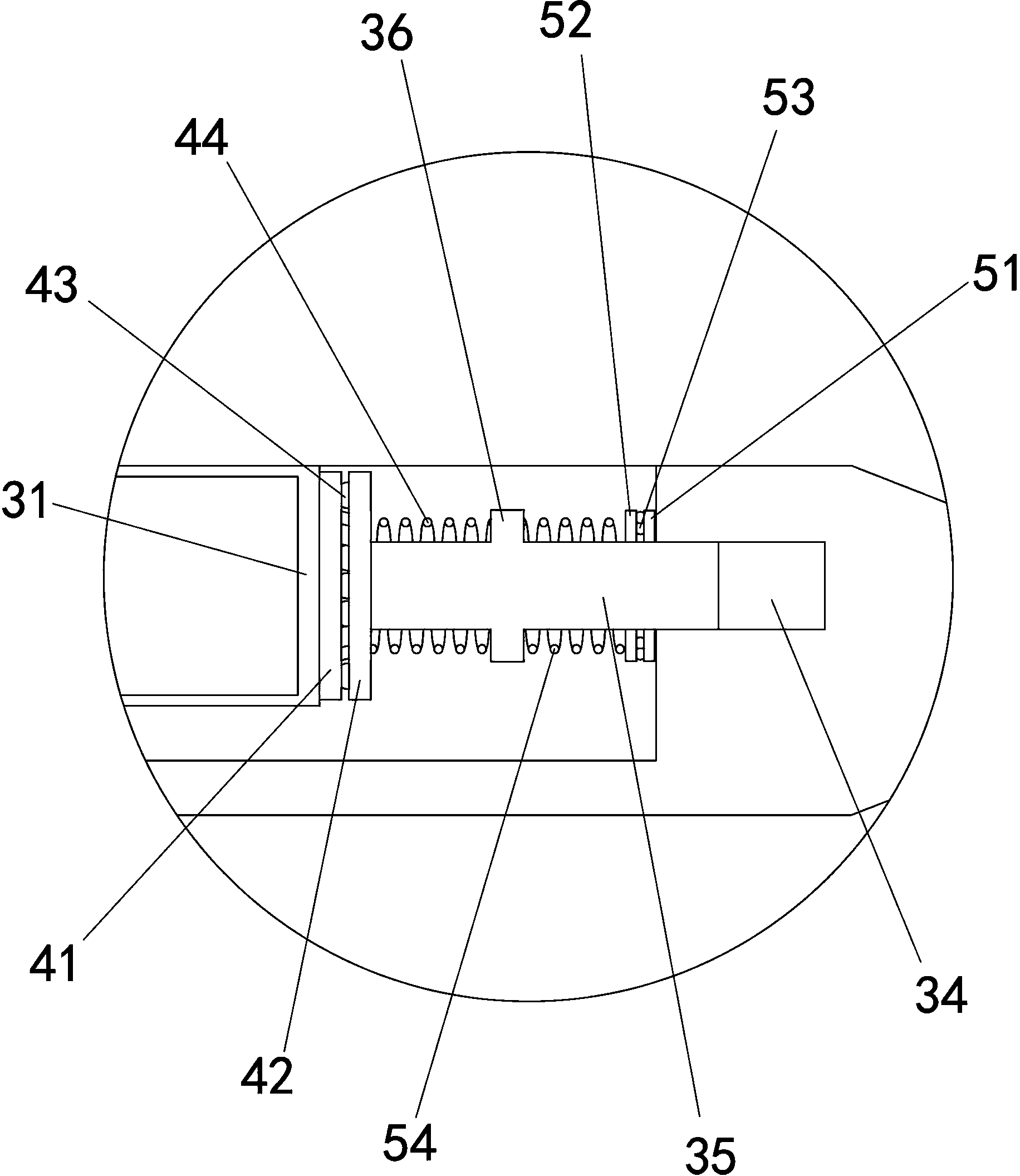

Shuttle

The invention relates to a loom in textile equipment, in particular to a shuttle. The shuttle comprises a shuttle body and a bobbin mounting structure arranged in a shuttle cavity in the shuttle; the bobbin mounting structure comprises a first sleeve, a second sleeve, sliding slots, a threaded hole, a screw and an adjusting body, wherein the first sleeve rotationally connected to the inner wall of the shuttle cavity is used for sleeving the end of a bobbin, the second sleeve is arranged with the first sleeve coaxially and oppositely and arranged to the inner wall of the shuttle cavity retractably, the sliding slots are arranged in the inner wall of the shuttle cavity and suitable for axial sliding of the first sleeve, the threaded hole is arranged in the inner cavity of the shuttle cavity, the screw is in threaded connection with the threaded hole and can axially butt against the first sleeve, and the adjusting block is fixedly connected to the screw; rotating shafts correspondingly falling into the corresponding sliding slots are arranged on two sides of the outer wall of the first sleeve respectively. The bobbin can be well stabilized, and the shuttle has good safety even if being applied to heavy looms.

Owner:南通开元投资开发集团有限公司

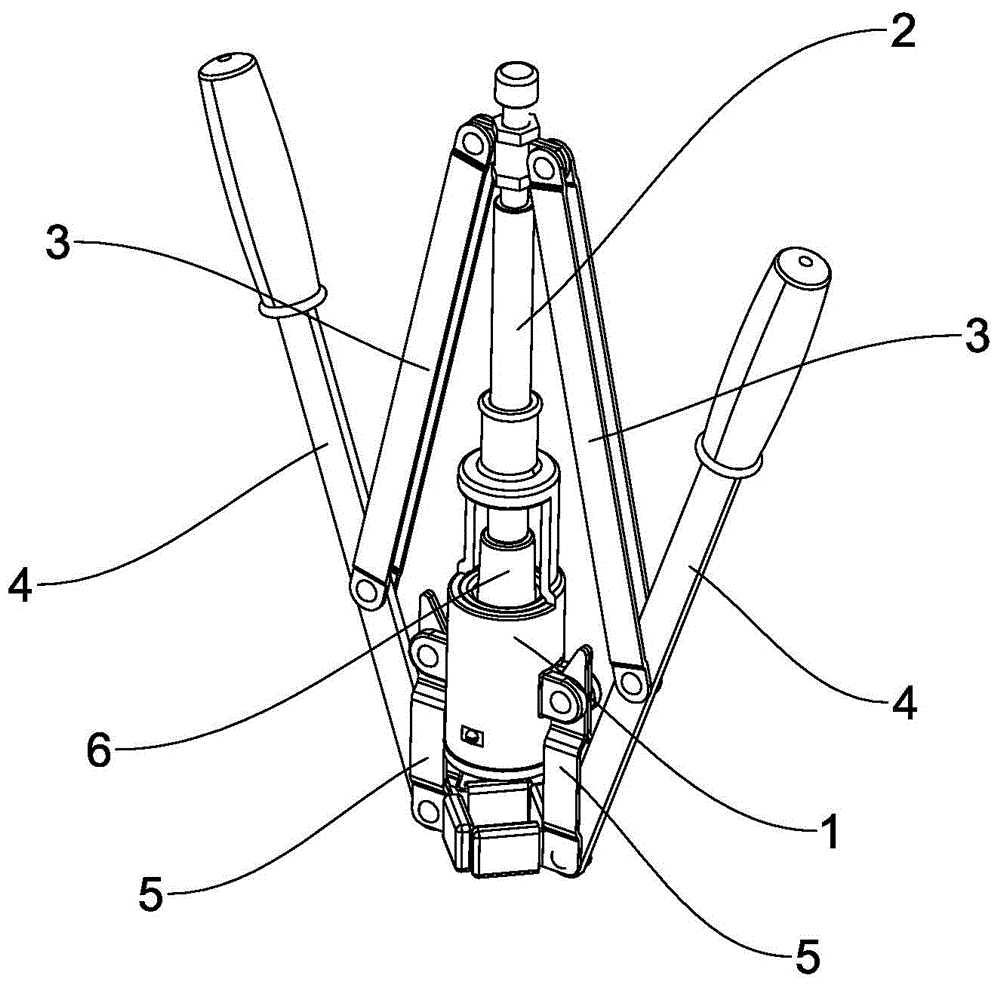

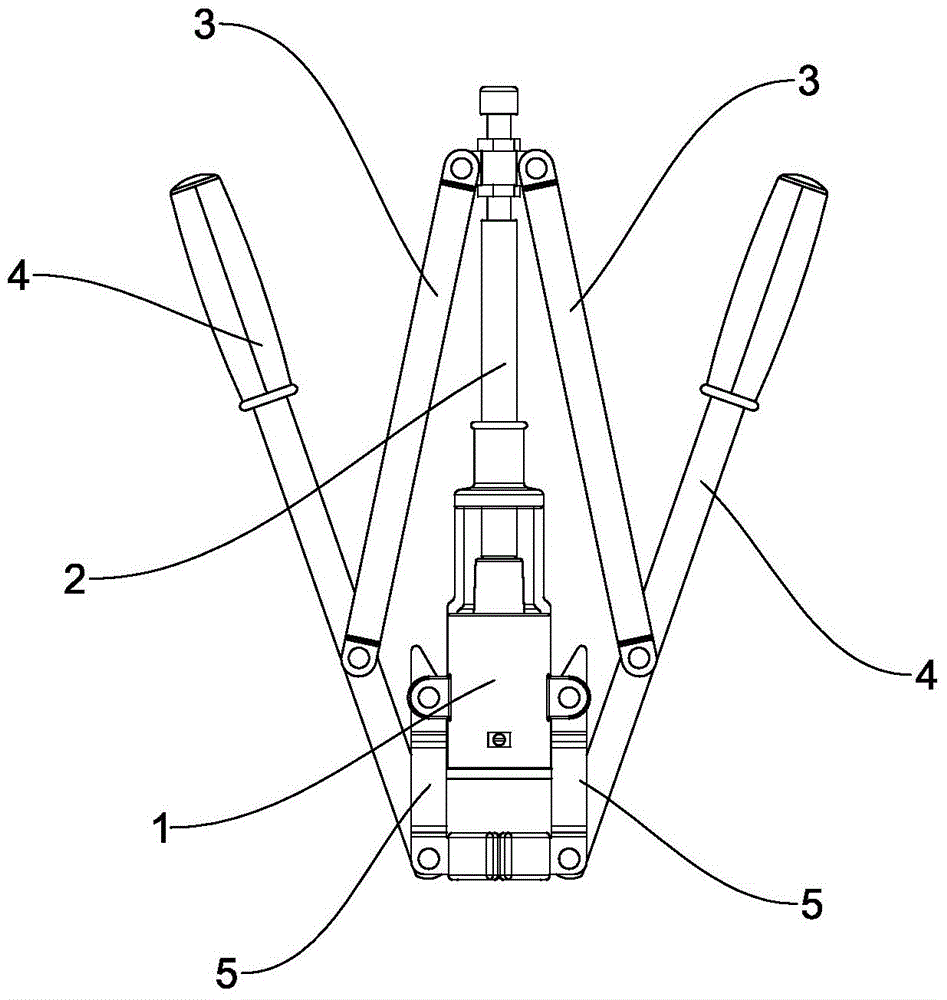

Deviation adjusting device of pumping unit

The invention provides a deviation adjusting device of a pumping unit, and belongs to the technical field of oil field development. The deviation adjusting device comprises a first bottom plate, a positioning bolt, a nut, a stressed back plate, a supporting plate and a centralizing ring, wherein a first through hole is formed in the first bottom plate, the positioning bolt penetrates through the first through hole from the bottom of the first bottom plate and is connected with the nut located above the first bottom plate, the stress back plate and the supporting plate are arranged above the first bottom plate and are perpendicular to the first bottom plate, a second through hole is formed in the supporting plate, the centralizing ring comprises a circular ring and a first column body, thecircular ring is connected with one end of the first column body, and the first column body penetrates through the second through hole and is movably connected with the second through hole. By the adoption of the deviation adjusting device, when the pumping unit is subjected to deviation adjustment, the stress direction of the jack is ensured to be perpendicular to the side surface of the oil pumping unit base in contact with the jack, so that the jack is not easy to fly out, and the safety risk is reduced.

Owner:PETROCHINA CO LTD

Cork presser used for cork

InactiveCN105217546ANot easy to fly outEasy to useThreadless stopper insertionCork stopperEngineering

The invention discloses a cork presser used for a cork. The cork presser comprises a cork pressing barrel and a cork pressing rod, wherein the cork pressing barrel comprises a supporting housing; the supporting housing comprises a supporting barrel, a cork placing opening and a connecting barrel; the cork placing opening is formed above the supporting barrel; the connecting barrel is arranged above the cork placing opening; and the cork pressing rod is in sliding connection with the connecting barrel. The cork presser used for the corker disclosed by the invention has the advantages that: the cork presser is provided with the supporting barrel and an extruding barrel, which are movably connected, is wider in scope of application, safe to use due to the fact that a bottle stopper does not fly out easily during cork pressing, and is relatively labor-saving to use because of a lever labor-saving structure.

Owner:季德贵

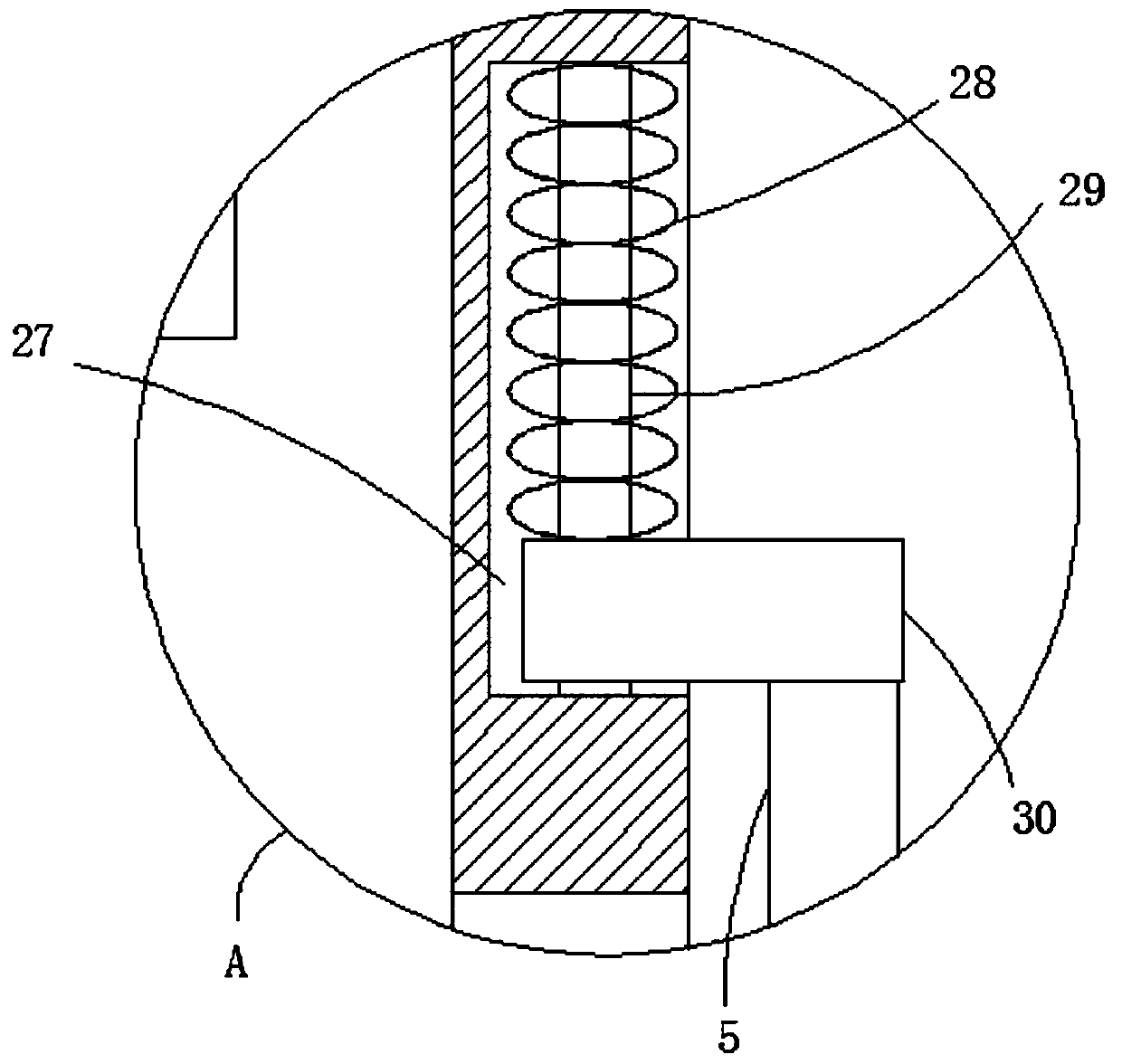

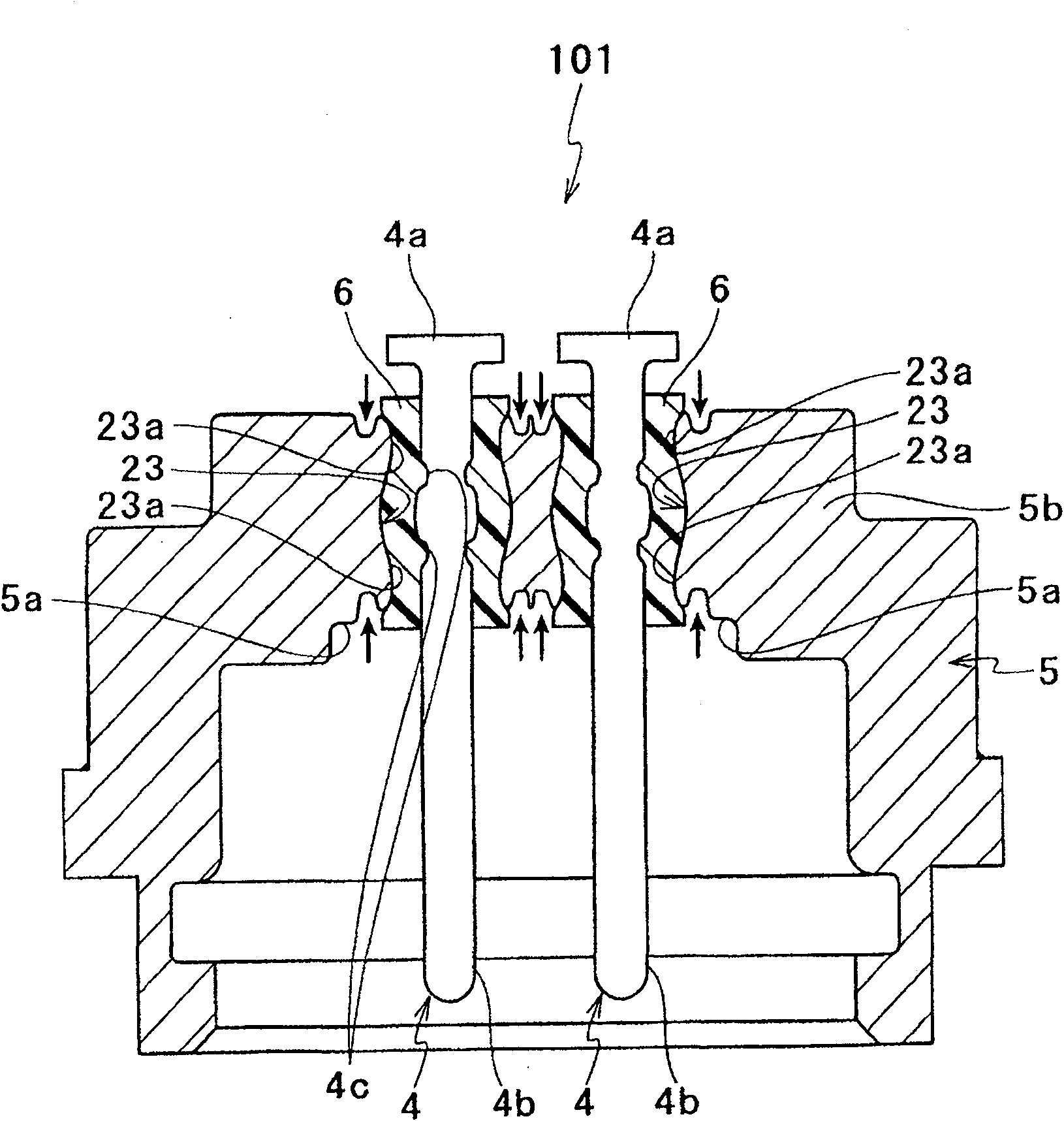

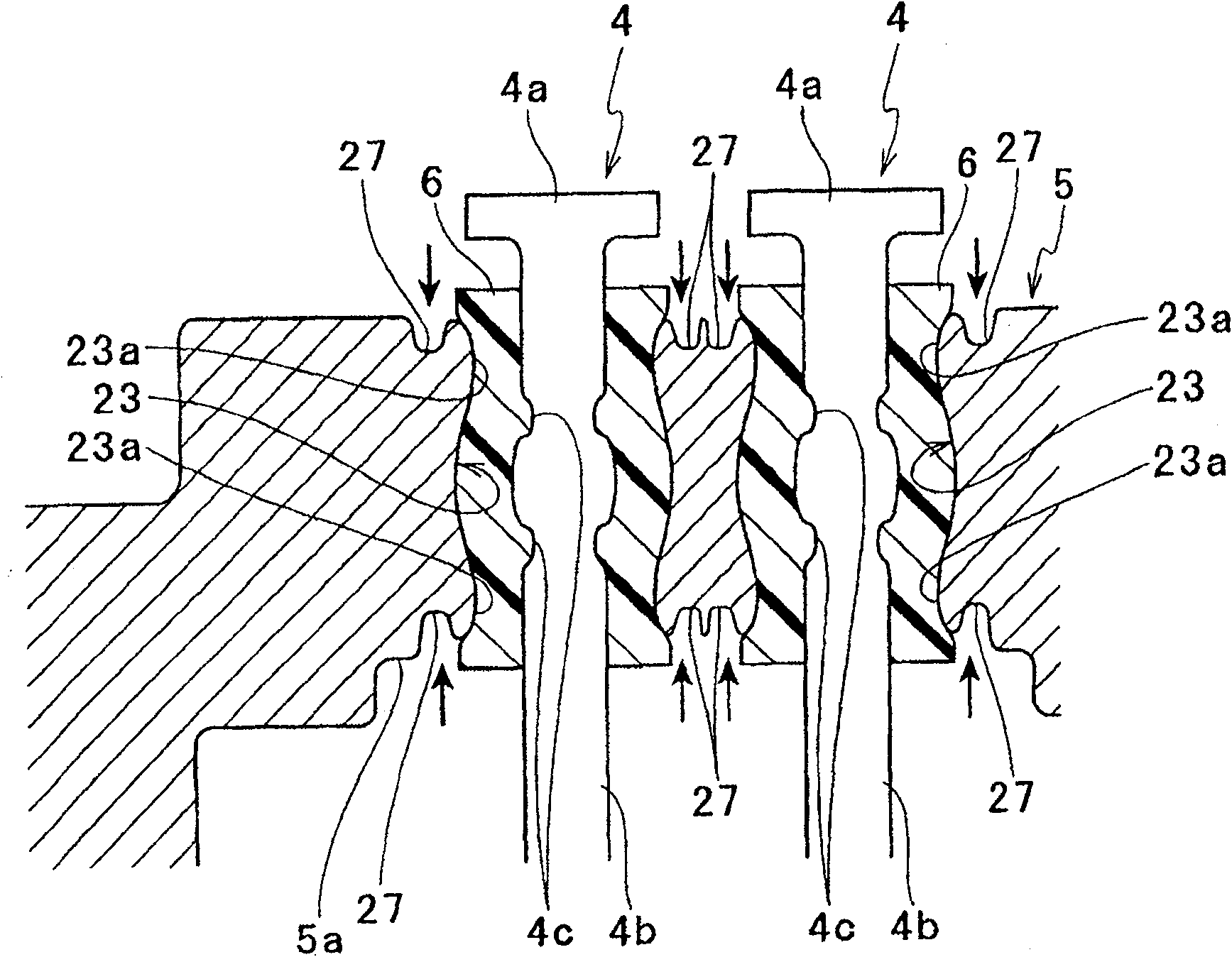

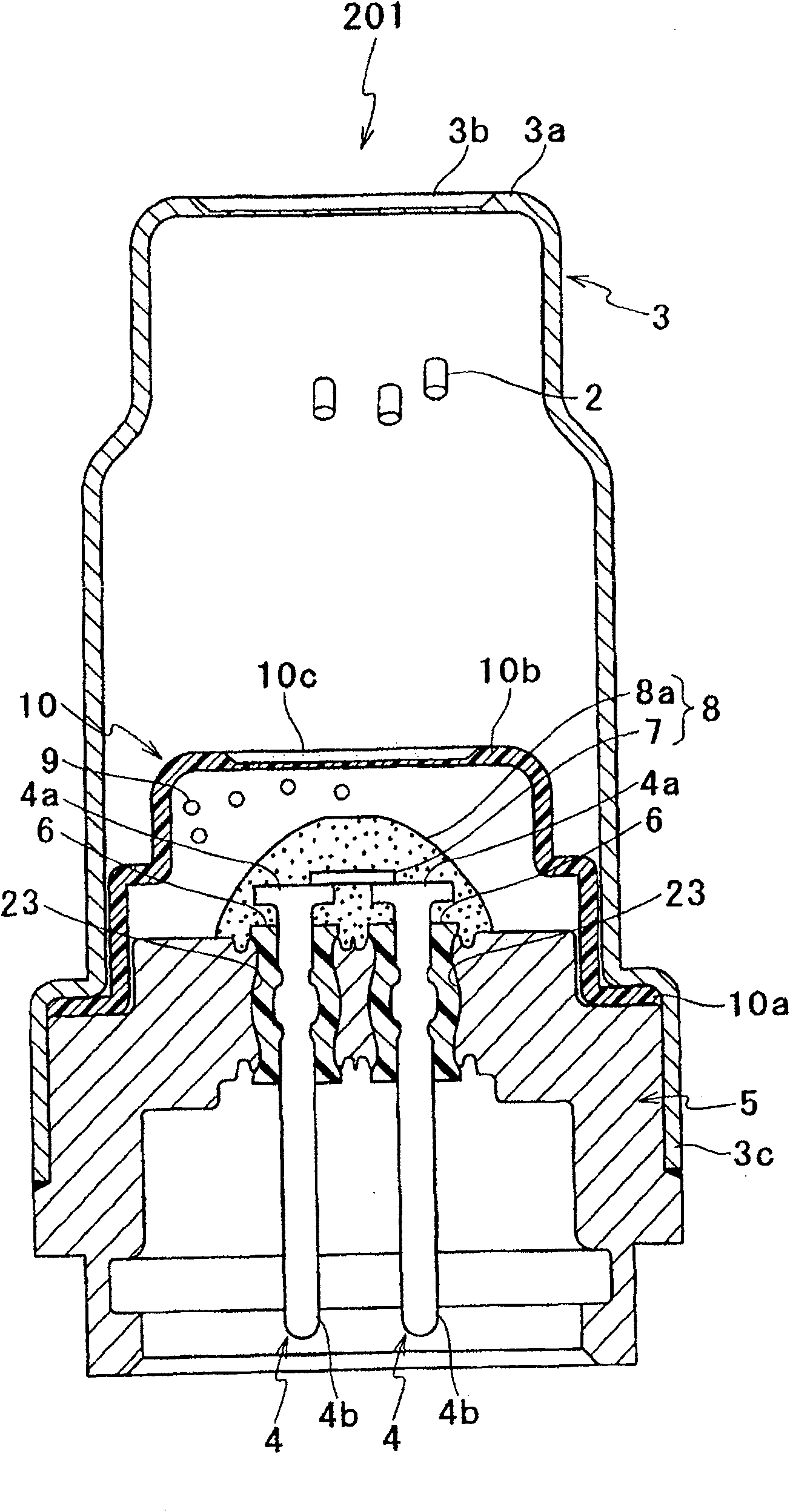

Metal holder with electrode pin, method of manufacturing the metal holder, and gas generator

InactiveCN100554046CReduce the numberNot easy to fly outBelt retractorsBlasting cartridgesEngineeringGas generator

The present invention provides a method for inexpensively manufacturing a metal holder with an electrode pin suitable for use as a gas generator and having excellent sealing properties. Even if the gas generator is operated at high temperature, the electrode pin is less likely to fly out. The present invention provides a metal holder with an electrode pin, a manufacturing method thereof, and a gas generator having the metal holder with an electrode pin. The metal holder with an electrode pin is characterized by having A metal holder (5) and two or more electrode pins (4) for conducting electricity, the head portion (4a) of each of the electrode pins (4) having a diameter larger than the terminal portion (4b) of the electrode pin (4) with a diameter of Each electrode pin (4) is fixed in the hole (23) via the plastic member (6), and has a reduced diameter portion (23a) in a part of the hole (23).

Owner:NIPPON KAYAKU CO LTD

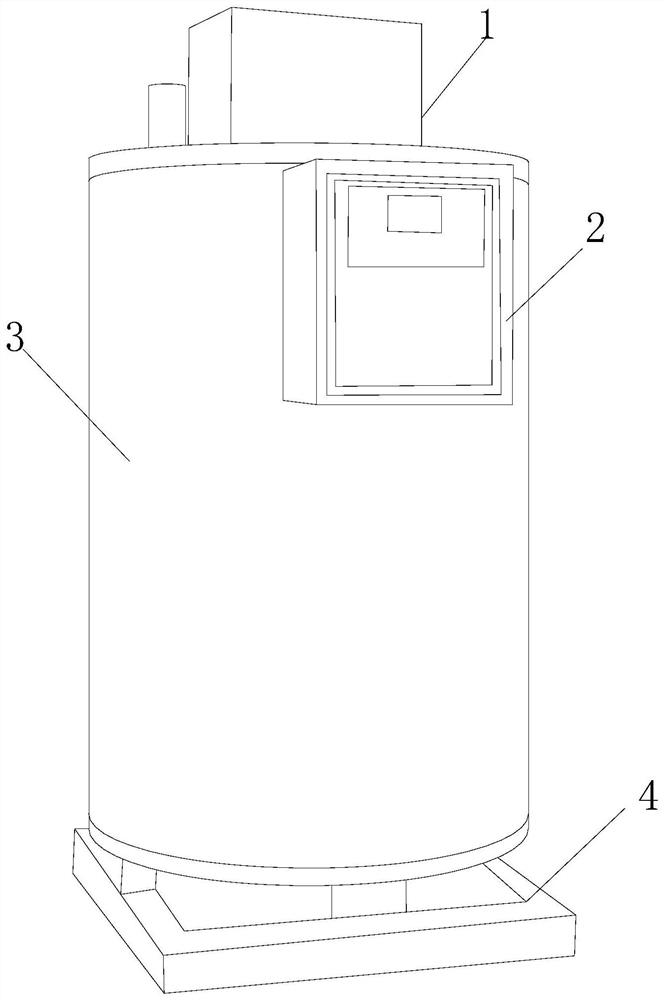

Multi-tube type efficient energy-saving environment-friendly boiler

The invention discloses a multi-tube type efficient energy-saving environment-friendly boiler which structurally comprises a motor, a keyboard box, a main machine and a rack. The keyboard box is electrically connected with the interior of the main machine through the motor, the bottom of the main machine is connected with the rack in a welded mode, and the main machine comprises a flue, a flame guide tube, a driving piece, a nozzle, an auxiliary structure and a butt joint device. The driving piece is fixedly connected to the bottom of the flue. One end of the driving piece is buckled and connected to one end of the flame guide tube. The auxiliary structure and the butt joint device are arranged outside the flame guide tube. The flame guide tube is communicated with the nozzle through the auxiliary structure. The stable and balanced state of the flame guide tube can be kept by gradually improving the mass gravity center point pressed down on the flame guide tube through angle changes inthe middles of press-fit pieces and overturning of pressing pieces, so that the problems that the circle center of a flame guide tube can hardly be aligned to the circle center of a nozzle and the flame guide tube cannot be accurately communicated with the nozzle on the same concentric circle because the flame guide tube bears uneven stress and shakes around are avoided.

Owner:邯郸市火炬锅炉有限公司

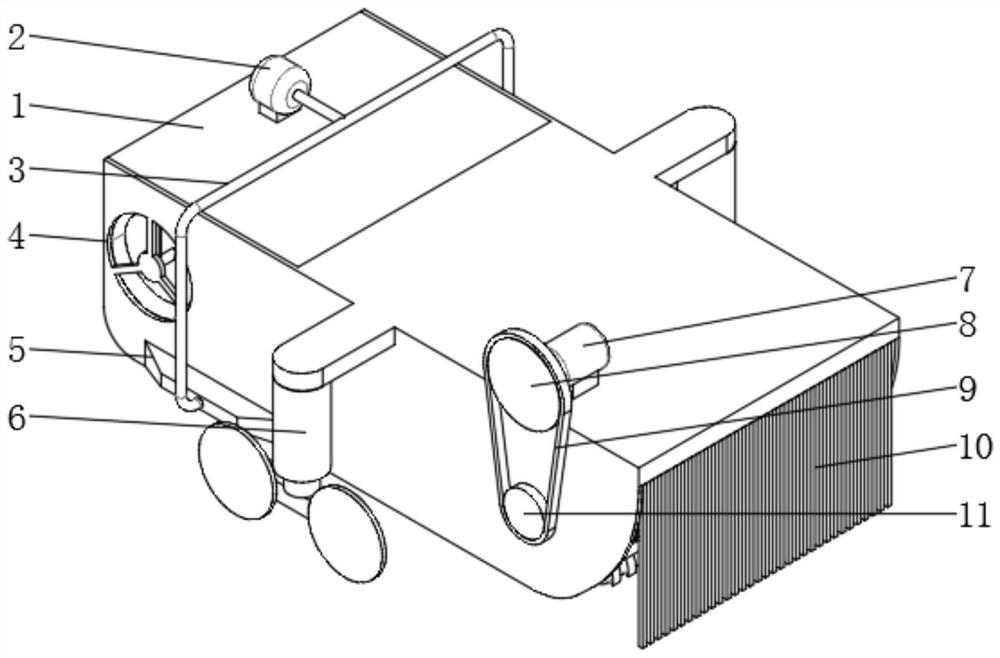

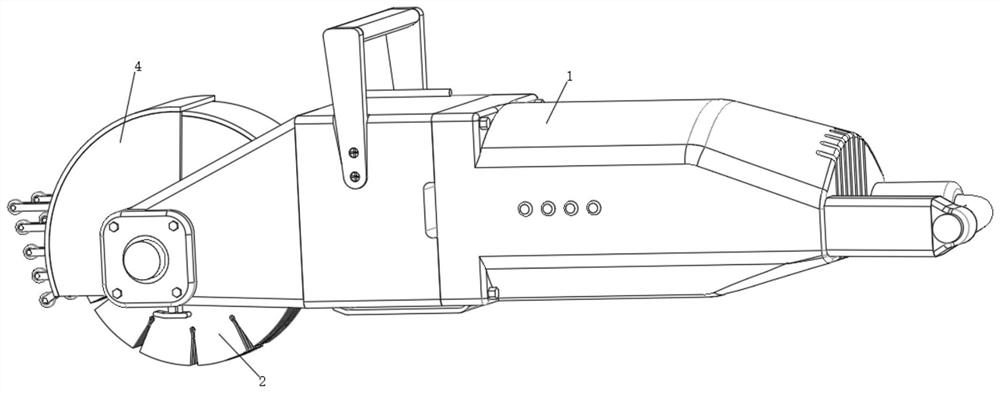

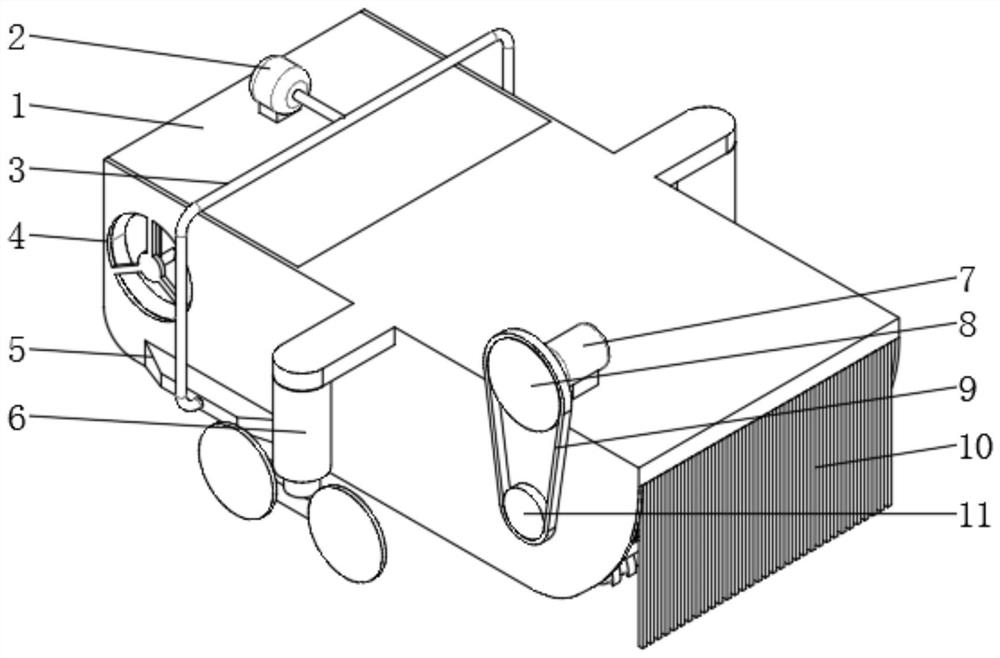

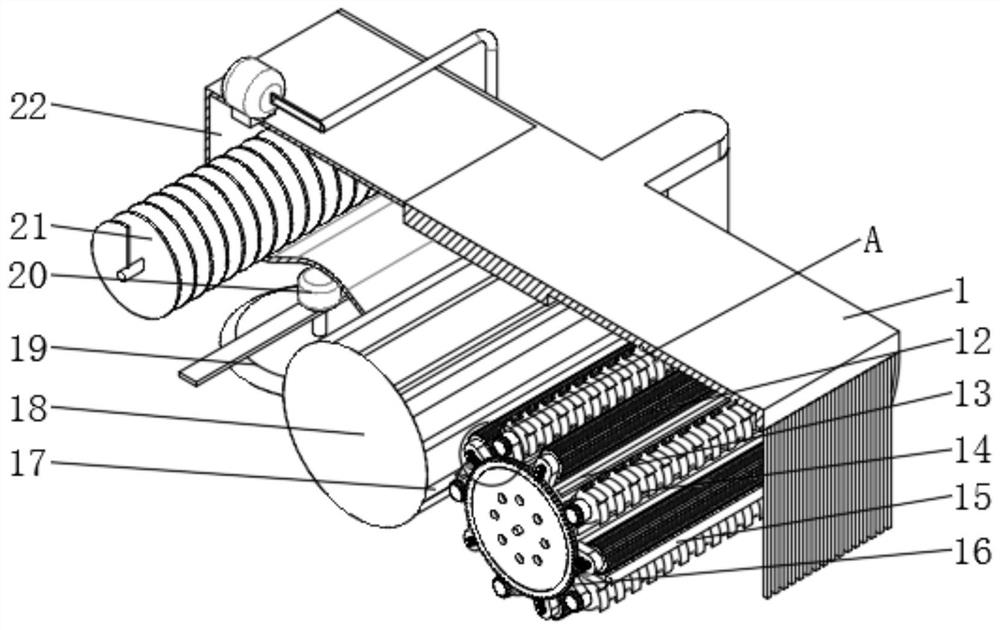

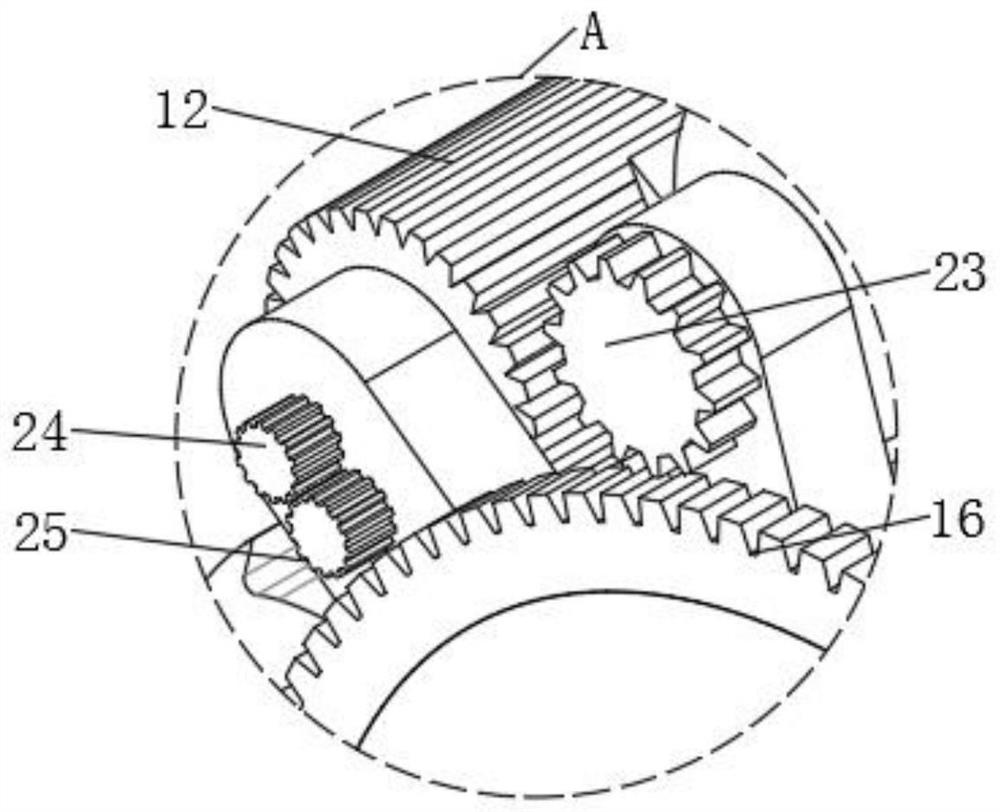

Municipal old road milling device

ActiveCN113622274ACan't touchIncrease speedPlastic recyclingDirt cleaningPavement maintenanceAgricultural engineering

The invention discloses a municipal old road milling device, and relates to the field of pavement maintenance, the old municipal road milling device comprises a treatment box, the top of the treatment box is provided with a driving assembly, the inner walls of the two sides of the treatment box are rotatably provided with rotary drums, and the two sides of the outer side walls of the rotary drums are fixedly provided with a plurality of support connecting plates which are distributed at equal intervals. Through the arrangement of the driving assembly, the transmission assembly, the rotary drum, the crushing rollers and the milling wheels, the driving assembly provides power to enable the rotary drum to rotate, the rotary drum rotates rapidly, and the milling wheels and the crushing rollers which are distributed on a supporting connecting plate and a supporting mounting plate at equal intervals are made to rotate through the transmission assembly; the transmission assembly enables the rotating speed of the crushing roller to be higher than that of the milling wheel and the rotating directions of the crushing roller and the milling wheel to be opposite, the milling wheel mills a road surface, particles are generated and thrown between the crushing roller and the rotary drum to be crushed, the rotating speed of the crushing roller is higher than that of the milling wheel, so that the situation of material blockage is avoided, and cement crushed into particles is thrown to the rear part by the whole rotary drum.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

Calcium carbonate powder dispersing method

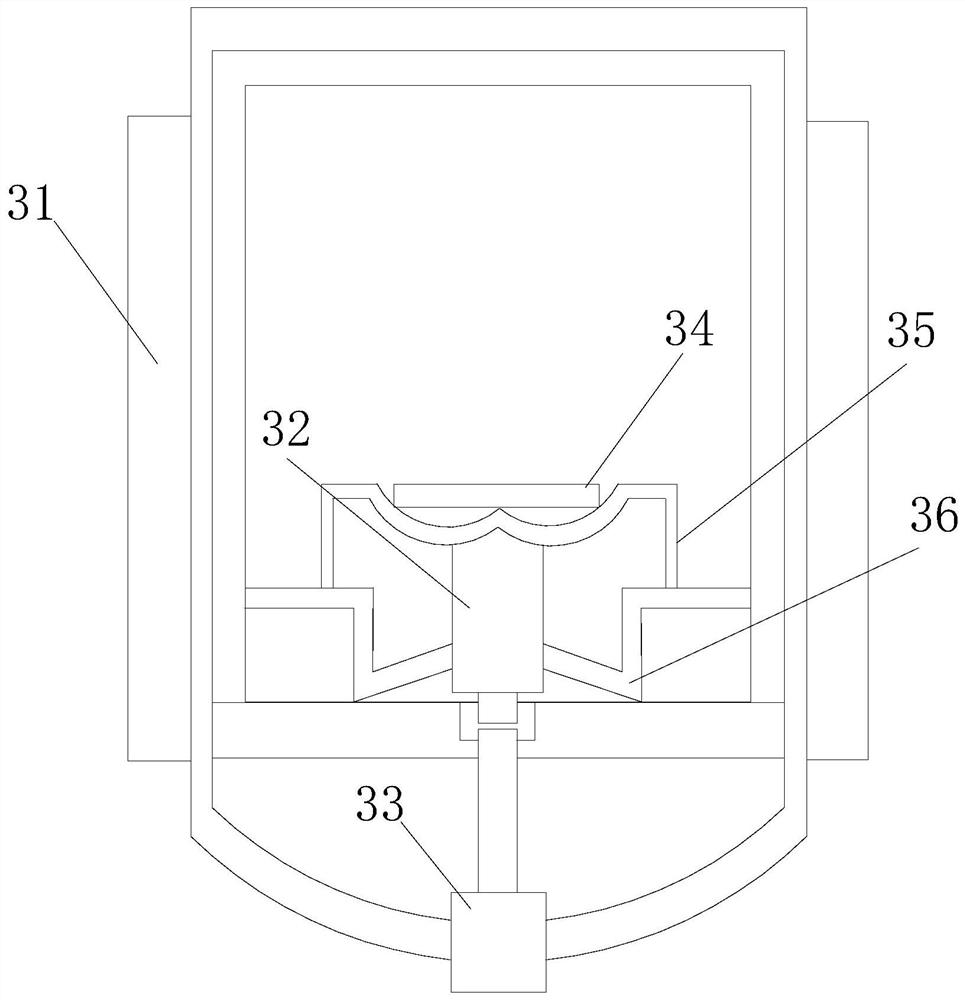

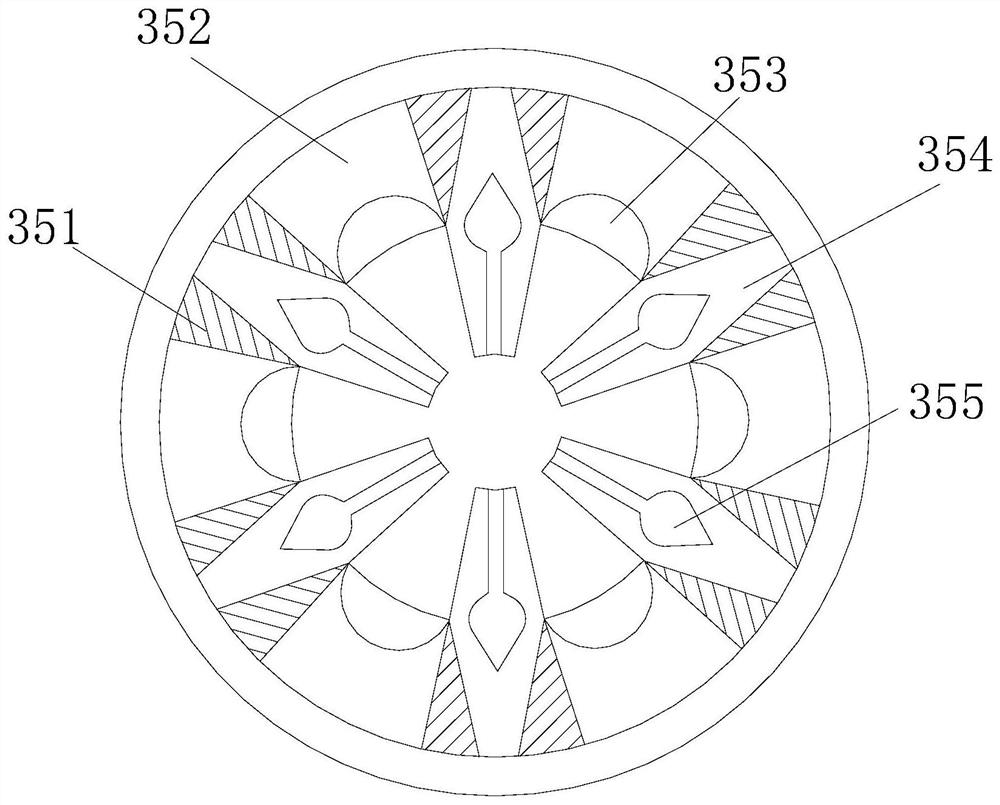

InactiveCN109157996ANot easy to fly outGood dispersionCalcium/strontium/barium carbonatesFlow mixersCentrifugal forceMaterials science

The invention discloses a calcium carbonate powder dispersing method. The calcium carbonate powder dispersing method is characterized by particularly comprising the following steps: 1, throwing calcium carbonate powder with blocks into a dispersing device, wherein the dispersing device comprises a shell and a centrifugal device, and the centrifugal device comprises a centrifugal disk I, a centrifugal disk II, a rotating shaft and a shaft sleeve; 2, colliding the blocks with the centrifugal disk I to realize collision and dispersion for the first time; 3, dispersing to the periphery through thecentrifugal effect of the centrifugal disk I and colliding with the inner wall of the shell to realize collision and dispersion for the second time; 4, colliding the blocks with the centrifugal diskII to realize collision and dispersion for the third time; and 5, dispersing to the periphery through the centrifugal effect of the centrifugal disk II and colliding with the inner wall of the shell to realize collision and dispersion for the fourth time, and discharging after collision and dispersion for many times. By the calcium carbonate powder dispersing method, the agglomerated calcium carbonate powder can be dispersed rapidly; and the calcium carbonate powder dispersing method has the advantages of high efficiency and good dispersing effect.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

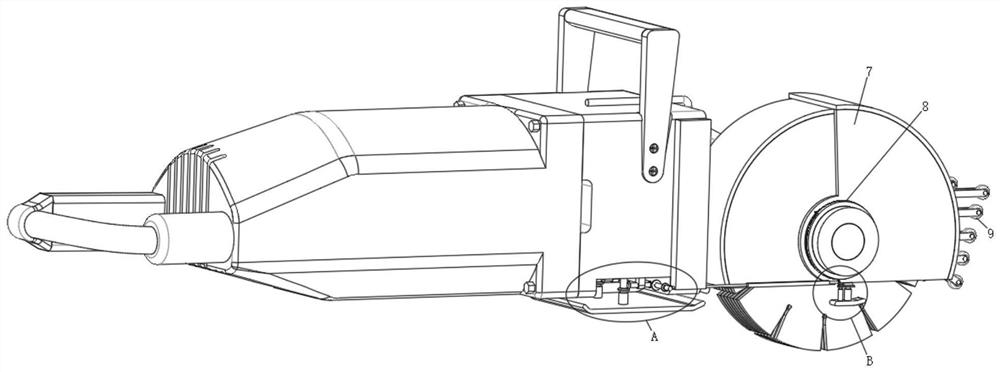

Automatic grooving equipment for water and electricity installation

ActiveCN112847818ASave time at workImprove securityPortable grinding machinesWorking accessoriesWater pipeStructural engineering

The invention discloses automatic grooving equipment for water and electricity installation. The automatic grooving equipment for water and electricity installation comprises a grooving machine main body, a protection mechanism, an adjusting mechanism and a synchronous mechanism, wherein the end part of the grooving machine main body is provided with a grooving cutter for grooving a wall surface, and the protection cover part of the grooving machine main body is provided with a water pipe for supplying water; the protection mechanism is installed on the outer side of a protection cover of the grooving machine main body, so that the protection mechanism can be automatically opened when the protection mechanism passes through the wall surface of the internal corner of a wall for grooving; the adjusting mechanism is installed in a installation groove of the grooving machine main body, so that the grooving machine main body can rotate the adjusting mechanism corresponding to different groove depths before grooving; the synchronous mechanism is installed on one side of the protection mechanism and is separated from or in butt joint with the adjusting mechanism through rotation of the protection mechanism. According to the automatic grooving equipment for water and electricity installation, the protection mechanism can automatically open the protection cover when the grooving cutter passes through the internal corner, so that opening and closing of the protection cover can be achieved without shutdown, and the working time is saved; mud is always located in the protection cover, and the mud is not easy to splash out, so that the implementation of a user is not hindered, and the safety is higher.

Owner:中核华辰建筑工程有限公司

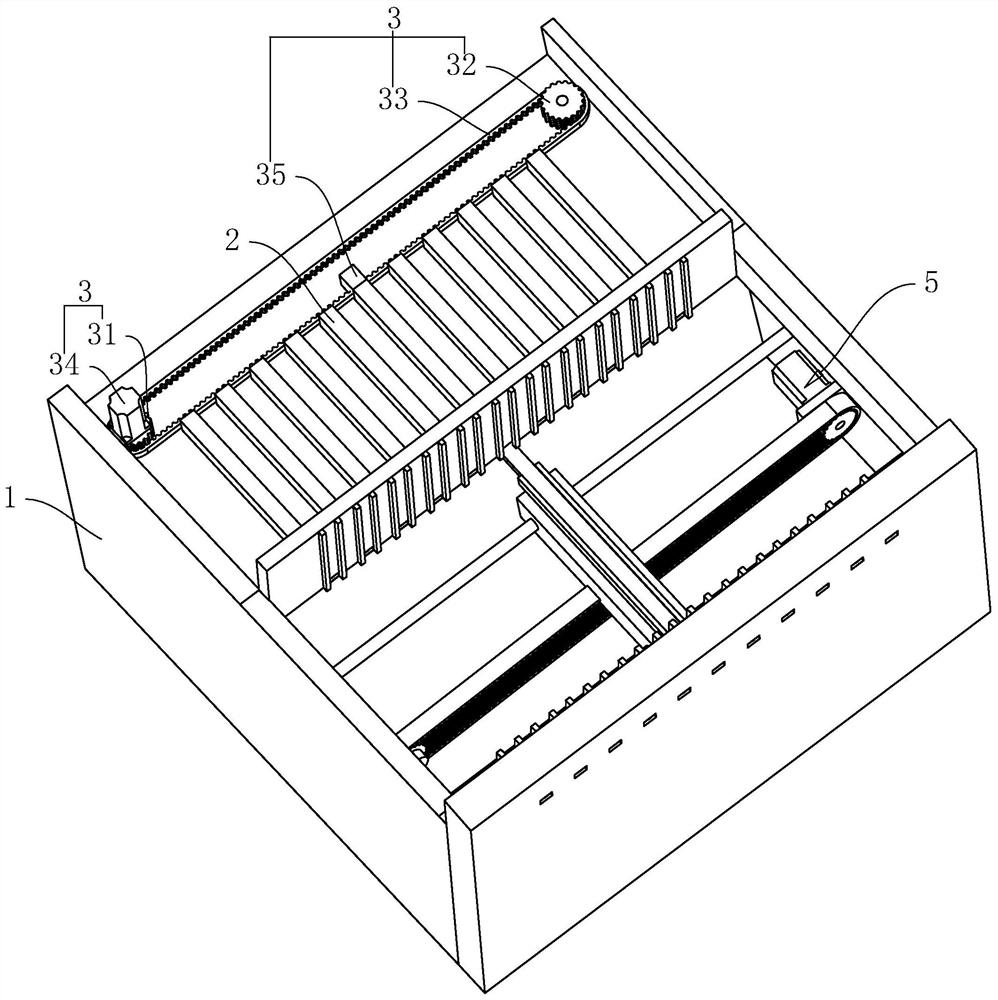

Polishing device for PVC door skin of paint-free door

ActiveCN109746818ANot easy to fly outImprove polishing effectPolishing machinesGrinding machine componentsEngineeringControl switch

The invention provides a polishing device for PVC door skin of a paint-free door. The polishing device for the PVC door skin of the paint-free door comprises a base, a machine body, a control switch,openings, a dust collector, guide rails, bayonets, a connection base, a spring, a connection rod, an upper polishing board, connection blocks, protrusions, guide wheels, dust collecting openings, an upper polishing motor, a lower polishing motor, polishing discs, a conveying motor, idler wheels and conveying belts; the machine body is fixedly installed on the base; the control switch is fixedly installed on the front surface of the machine body; the openings are formed in the left end and the right end of the machine body; the dust collector is fixedly installed on the top of the machine body;the guide rails are fixedly installed at the left end and the right end of the inner wall of the machine body; and the bayonets are formed in the left ends and the right ends of the guide rails. A paint-free door plate can be fixed in the polishing process, the upper end and the lower end of the paint-free door plate can be polished at the same time, the polishing effect is better, dust generatedduring working can be collected by the device, the device is sanitary and environmentally friendly, and practicability of the device is enhanced.

Owner:浙江标隆新材料有限公司

Rock-soil body catastrophe simulation detection device and detection method

ActiveCN111308049AEasy to recycle waterNot prone to flyingEarth material testingExtreme weatherSoil science

The invention relates to a rock-soil body catastrophe simulation detection device and detection method and belongs to the technical field of rock-soil detection simulation tests. The device comprisesa simulation sandbox box filled with rock and soil piles, the interior of the simulation sandbox box is hollow; an air blowing fan is arranged on the inner side wall of the simulation sandbox box; anexhaust hole is formed in the side wall, opposite to the air blowing fan, in the simulation sandbox box; a sand blocking piece is arranged on the outer wall, right opposite to the exhaust hole, of thesimulation sandbox box; the sand blocking piece is used for normally discharging air out of the simulation sandbox box to prevent flying sand from flying out of the simulation sandbox; and a placingplate for placing a rock-soil pile is arranged on the bottom wall of the simulation sandbox box, and a driving assembly for driving the placing plate to shake on the horizontal plane is arranged in the simulation sandbox box. The invention has the advantage that the geological influence of fierce wind and earthquakes on a rock-soil body in extreme weather can be simulated conveniently.

Owner:四川省兴冶岩土工程检测有限责任公司

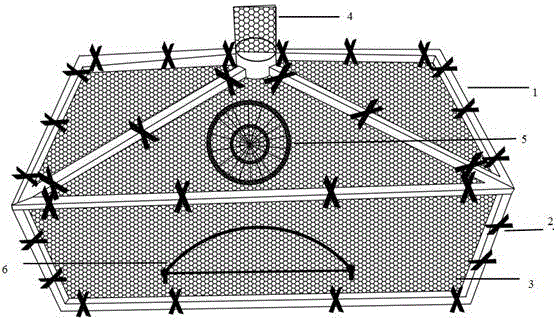

A field insect trapping device

ActiveCN112889772BNot easy to fly outImprove capture abilityGeneral water supply conservationStationary filtering element filtersTrappingEngineering

The invention discloses an insect trapping device for field use, comprising a treatment box, a water tank is arranged in the treatment box, and a capture box containing a small amount of water is arranged on the upper side of the water tank; Both are provided with cavities, and the two cavities are sealed and slidably connected with magnetic slide plugs, and the magnetic slide plugs and the inner bottom of the cavities are elastically connected by a first spring; the upper end of the cavities is provided with a A water inlet pipe that communicates with the water tank, the water inlet pipe is provided with a one-way valve that only allows water to enter the cavity from the water tank; the upper end of the cavity is provided with a water outlet pipe that communicates with the capture tank, and the water outlet pipe is provided with only a A one-way valve that allows water to enter the capture box from the cavity; a magnetic slide plate matched with a magnetic slide plug is slidably connected in the capture box. The present invention has a reasonable structure, can capture wild insects, and can also automatically clean the device.

Owner:湖南天长农业科技发展有限公司 +1

Milling device for old municipal roads

ActiveCN113622274BCan't touchPrevent getting involvedPlastic recyclingDirt cleaningPavement maintenanceAgricultural engineering

The invention discloses an old road milling device for municipal roads, which relates to the field of pavement maintenance. Both sides of the wall are fixedly installed with a plurality of equally spaced support connecting plates. The present invention is provided with a driving component, a transmission component, a rotating drum, a crushing roller and a milling wheel. The driving component provides power to make the rotating drum rotate, and the rotating drum rotates rapidly through the transmission component to make the supporting connecting plate and the supporting mounting plate equidistant. The distributed milling wheel and pulverizing roller rotate, and the transmission assembly makes the rotation speed of the pulverizing roller higher than that of the milling wheel and the rotation direction is opposite. For crushing, because the rotation speed of the crushing roller is higher than the rotation speed of the milling wheel, there will be no jamming, and the cement crushed into particles will be thrown to the rear by the entire drum.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

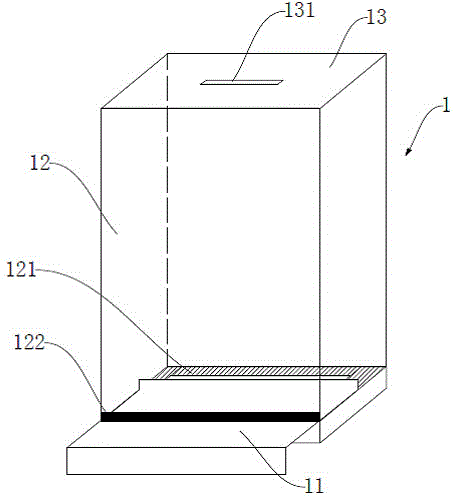

Bar code paper recovery box of public storage cabinet

The invention discloses a bar code paper recovery box of a public storage cabinet, which is characterized by comprising a box body fixed on the storage cabinet, wherein the box body is in an enclosed structure consisting of a bottom plate, a side surrounding body and an upper cover; a rectangular opening is formed in the upper surface of the upper cover and allows bar code paper to pass through; a flange and a barrier strip for placing the bottom plate are arranged at the bottom end of the side surrounding body; and the bottom plate is limited by the barrier strip on the flange to move in a horizontal direction. The box is simple in structure and lower in cost; when the box is in use, the bar code paper does not fly out easily; the box has a good storage effect; the box body is convenient to clean and treat; and the box is convenient to popularize and apply.

Owner:JIANGYIN SHENJIAN WASTE MATERIAL RECYCLING

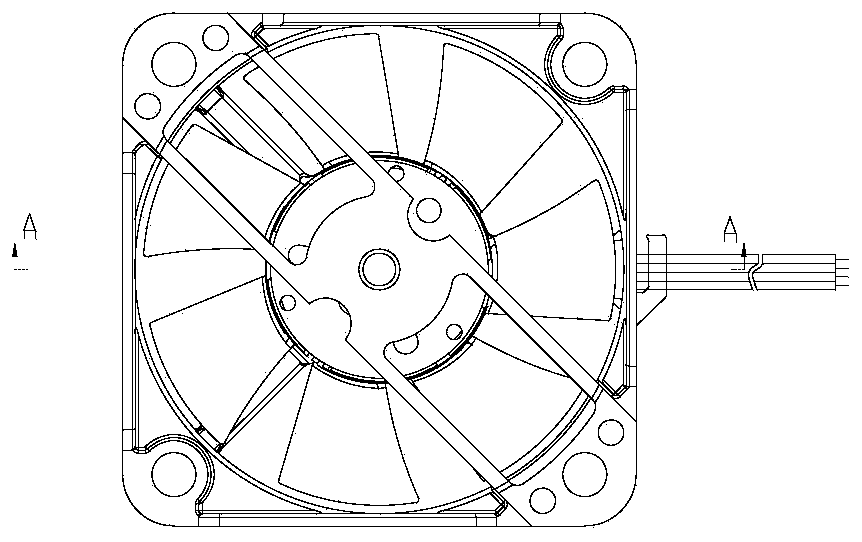

High-temperature-resistant direct-current brushless cooling fan

InactiveCN110410345AImprove cooling effectReduce temperature risePump componentsMechanical energy handlingEngineeringFan blade

The invention discloses a high-temperature-resistant direct-current brushless cooling fan. The high-temperature-resistant direct-current brushless cooling fan comprises a machine shell, a bearing sleeve is fixed at the lower portion inside the machine shell, the bearing sleeve is wrapped around a bearing, a shaft matched with the bearing is arranged in the bearing in a penetrating manner, the bottom of the bearing sleeve penetrates out of the machine shell, moreover, at least one heat dissipation hole is formed in the bottom of the bearing sleeve, a driving circuit board is further arranged atthe upper portion of the bottom of the machine shell, a layer of yoke plate is arranged above the driving circuit board, the shaft, the bearing and the bearing sleeve all penetrate through the driving circuit board and the yoke plate, two hollow coils are arranged on the yoke plate and are symmetrically distributed on the two sides of the shaft, leads of the hollow coils are connected with the driving circuit board, the leads are led out of the driving circuit board to be outside of the machine shell, the upper portion of the shaft is connected with integrally formed fan blades, and magneticsteel is arranged at the positions, opposite to the hollow coils, of the lower surfaces of the fan blades. Due to the hollow coil structure, cooling of the coils is facilitated, and the temperature rise is effectively reduced; the ferrite magnetic steel with quite good temperature resistance is used, and the cost performance is high so that the magnetic force of the magnetic steel can be adjustedquite easily only by increasing the thickness of the magnetic steel.

Owner:风下电机(山东)有限公司

Indoor aphid and aphidius avenae propagation device

The invention discloses an indoor aphid and aphid wasp multiplication device, which comprises a bracket, on which a grid is arranged so that the grid passes through the bracket to form a closed area, and an opening is arranged on the top of the area, and A bee collecting bag is arranged at the opening position, and a collecting bag with telescopic function is arranged on the grid. The present invention adopts a structural frame composed of brackets and grids, and rationally arranges it so that it can be used as a proliferation facility for aphids and aphids, and can effectively avoid death caused by aphids crowding gaps and disability caused by sharp corners. The phenomenon occurs, and at the same time avoids mixing with other insects. The design of the double zipper opening is not only convenient for watering, fertilizing, and changing plants during the multiplication process, but also effectively prevents winged aphids or aphids from flying out. The design of the upper collection bag is conducive to collecting the top aphids and can Make it difficult for aphids to fly out.

Owner:GUIZHOU UNIV

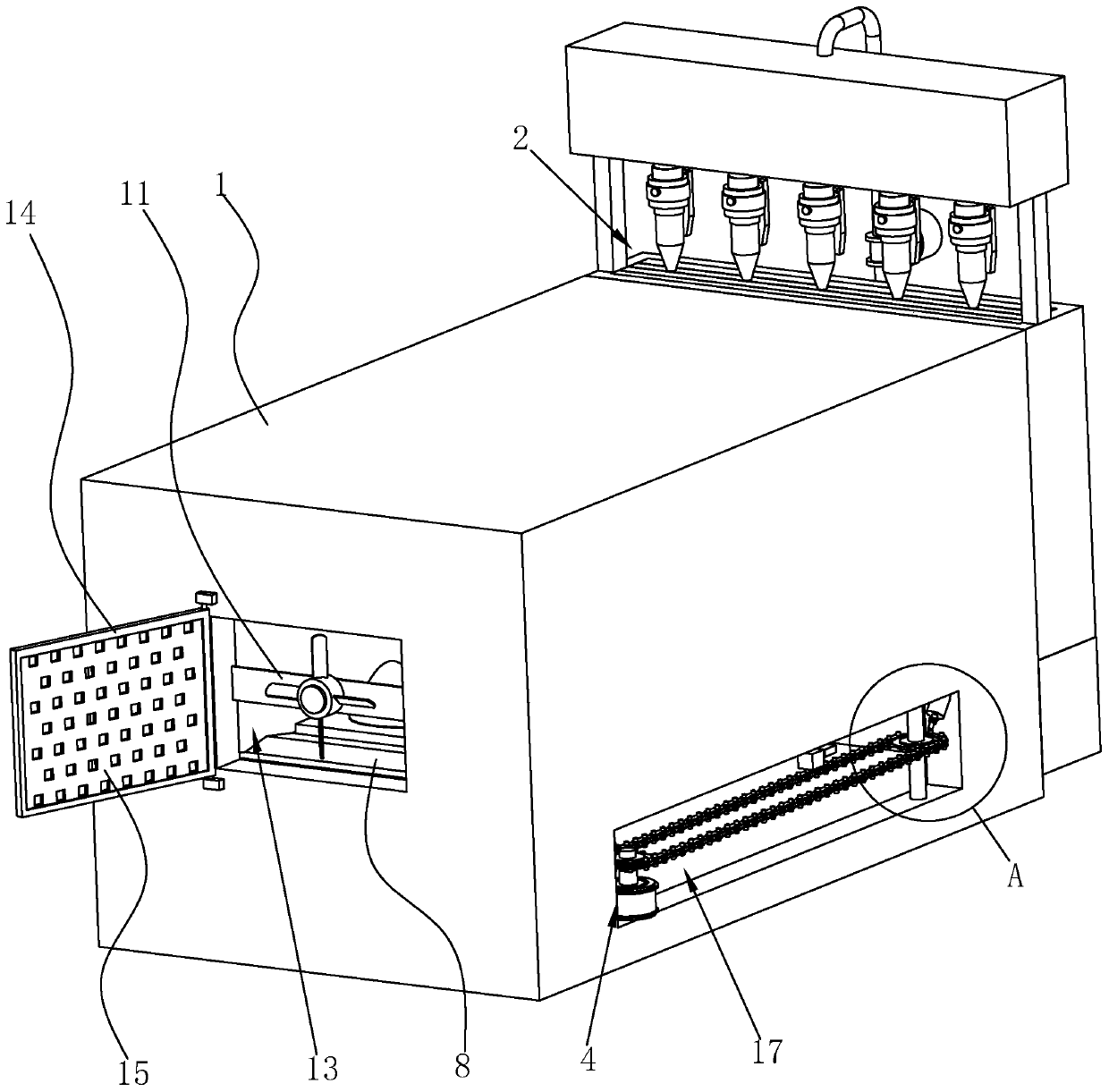

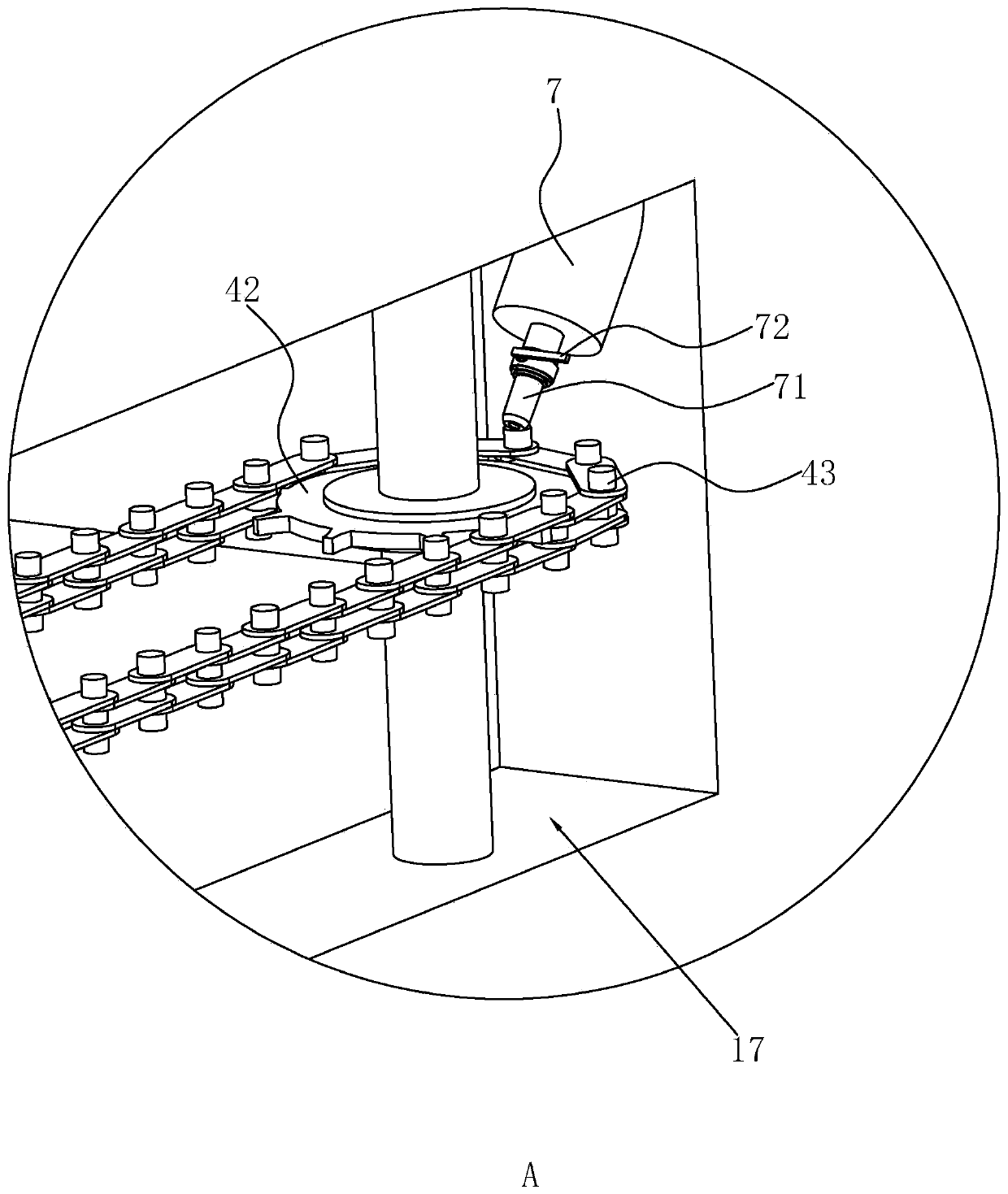

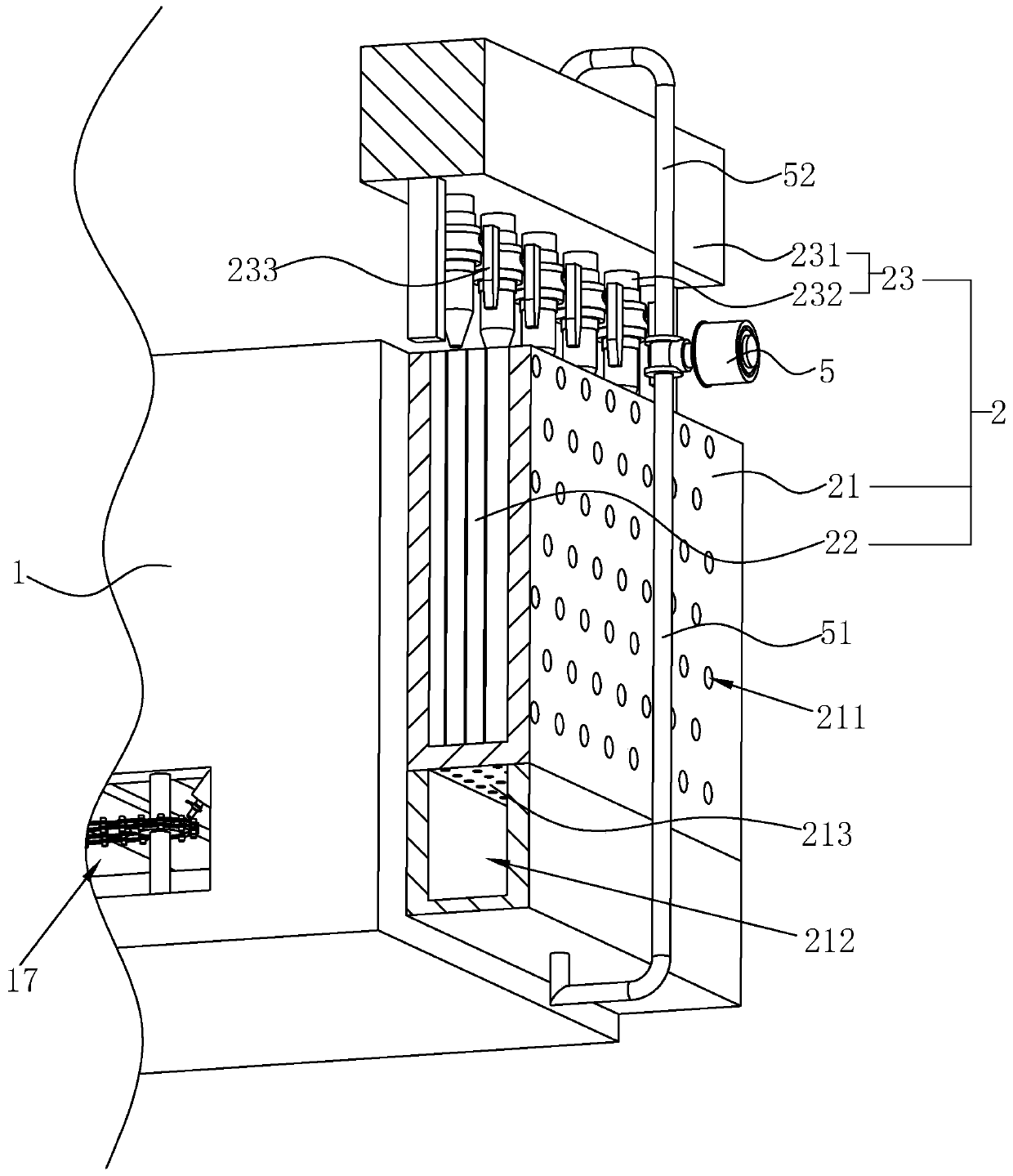

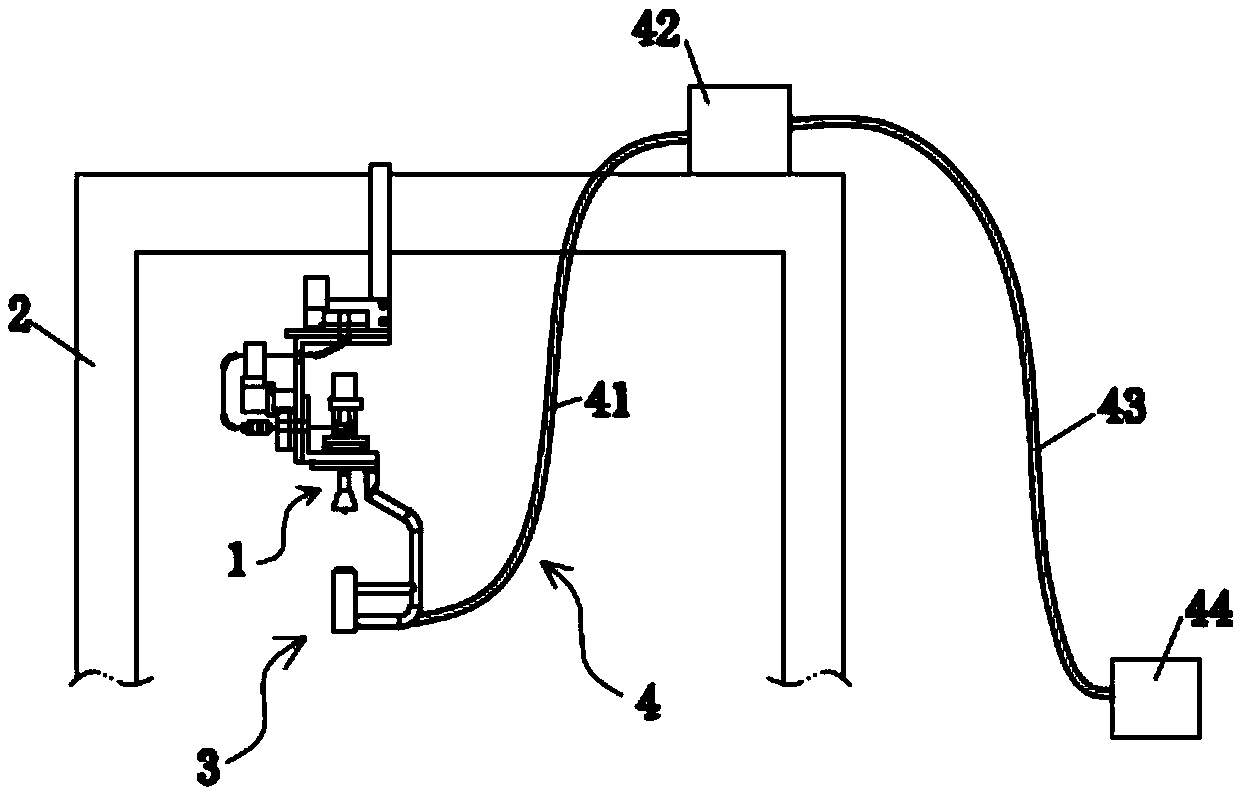

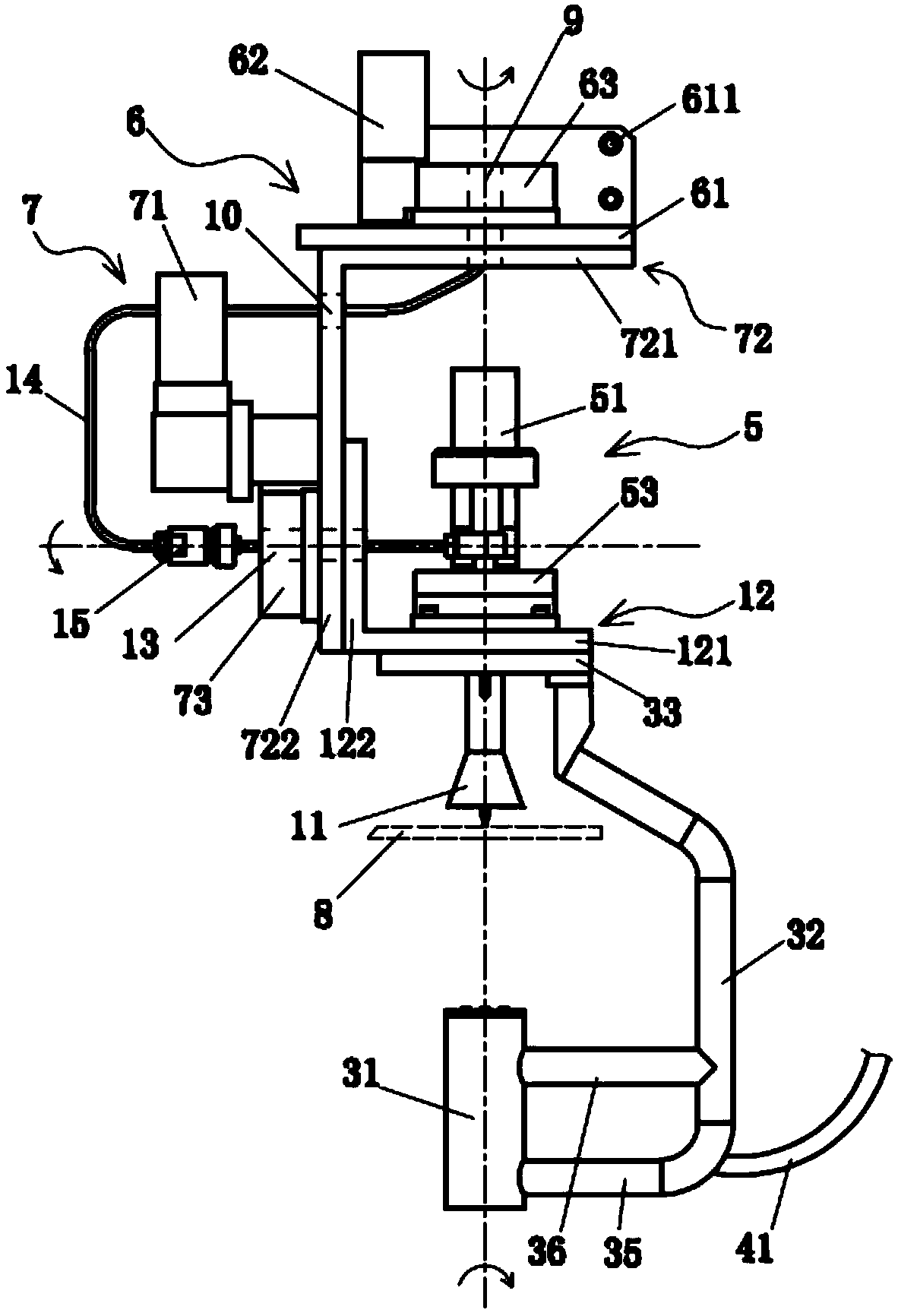

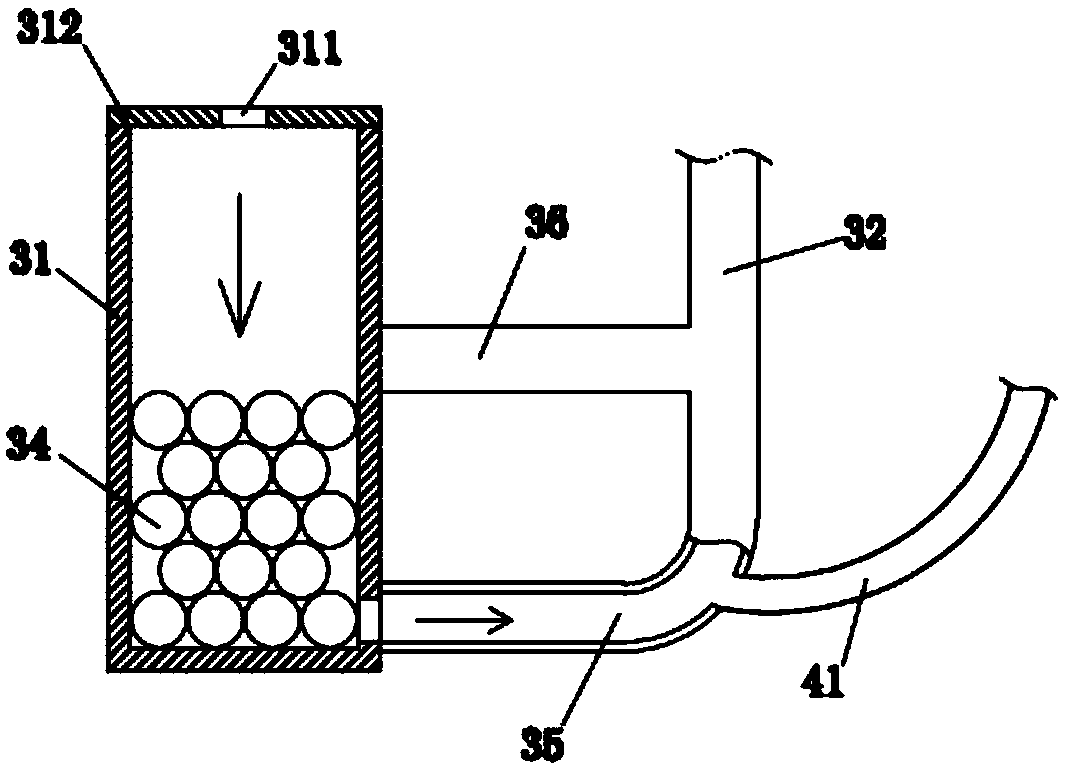

A water jet machine tool with a mobile water sand collection device

ActiveCN106799684BNot easy to fly outGuaranteed smoothnessAbrasive feedersAbrasive machine appurtenancesDot matrixMovable type

The invention discloses a water-jet cutter machine tool provided with a movable type water and sand collecting device. The water-jet cutter machine tool comprises a cutter head component and a moving frame capable of allowing the cutter head component to move in the horizontal direction and in the vertical direction; and the cutter head component comprises a nozzle. The water-jet cutter machine tool further comprises a collecting device body which moves along with the nozzle and is used for collecting a water and sand mixture blown out by the nozzle; the collecting device body comprises a container; a water collecting hole is formed in the outer wall of the container, and is opposite to the nozzle; a connecting piece is arranged on the container; a first driving mechanism capable of allowing the collecting device body to rotate around the axis of the nozzle is connected between the connecting piece and the cutter head component; and the container is connected with a drainage device. The water-jet cutter machine tool provided with the movable type water and sand collecting device moving along with the nozzle can cut a workpiece fixed by a flexible dot matrix tool system, and the machining field is wider. Furthermore, the connecting piece on the collecting device body can not collide the workpiece under the control of the first driving mechanism, so that the smoothness of the cutting process of the workpiece is guaranteed.

Owner:广州华臻机械设备有限公司

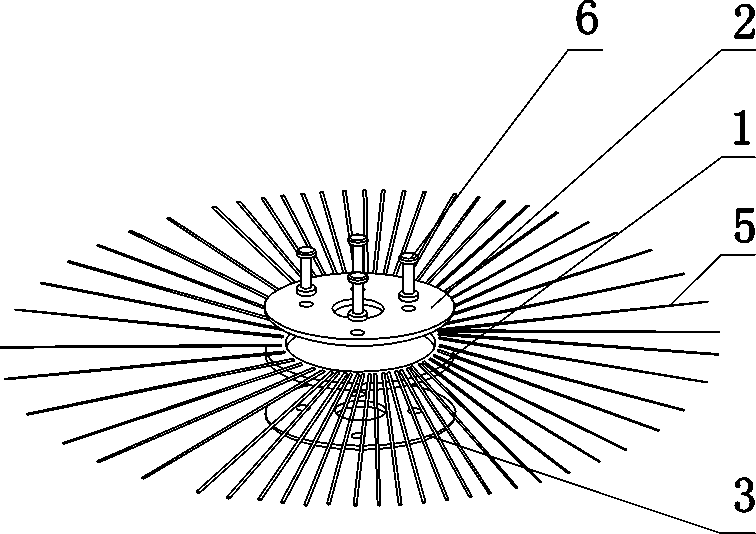

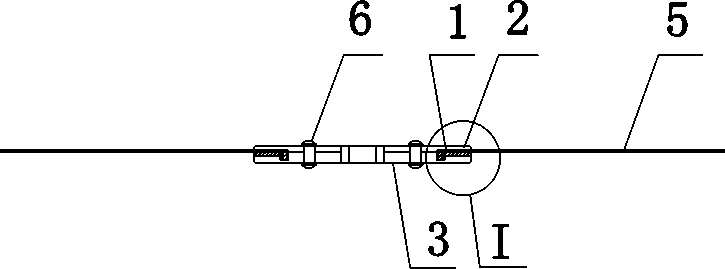

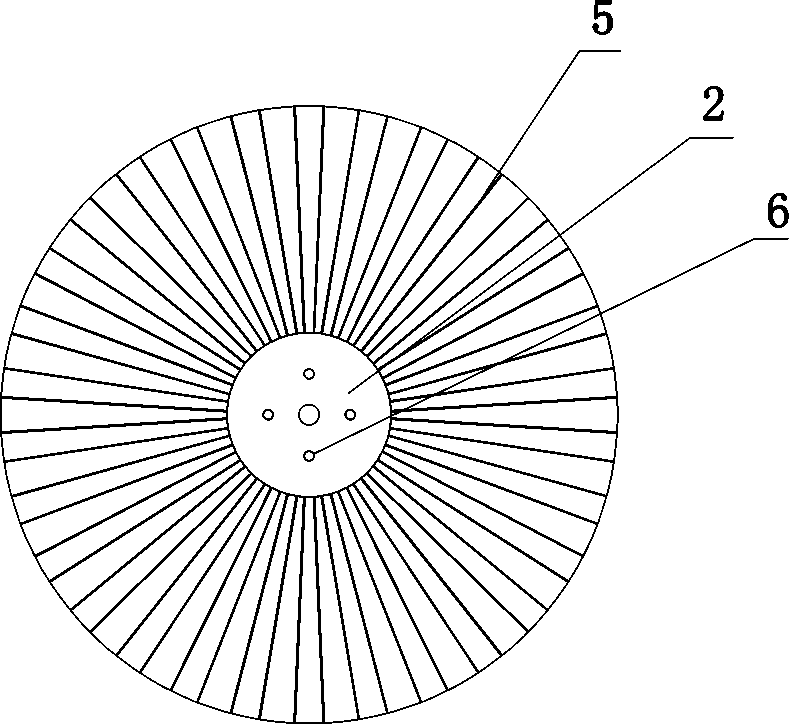

Lightweight fastening type opening mesh separator

InactiveCN109107279ASimple structureReduce weightDispersed particle separationEngineeringBatch production

The invention discloses a lightweight fastening type opening mesh separator, which has a circular fixing disc, wherein the top surface and the bottom surface of the circular fixing disc is respectively provided with an upper pressing cover and a lower pressing cover, the outer edge of the circular fixing disc is provided with a circle of a plurality of axial through holes, each two through holes form a group, U-shaped metal rods are respectively inserted in each group of the through holes, both ends of the U-shaped metal rod are simultaneously inserted from one ends of one group of the throughholes to achieve the bottom, and are bent and folded to attach to the disc surface of the circular fixing disc so as to form radial mesh arrangement, the upper pressing cover and the lower pressing cover are integrally connected to the circular fixing disc by screws, and the upper pressing cover or the lower pressing cover presses and fixes the U-shaped metal rods. According to the present invention, the lightweight fastening type opening mesh separator has advantages of simple structure, light weight, molded batch production, reduced production cost, energy saving and environmental protection, wherein various components can be replaced, recovered and reused.

Owner:湖北六翼环保设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com