Patents

Literature

192results about "Threadless stopper insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

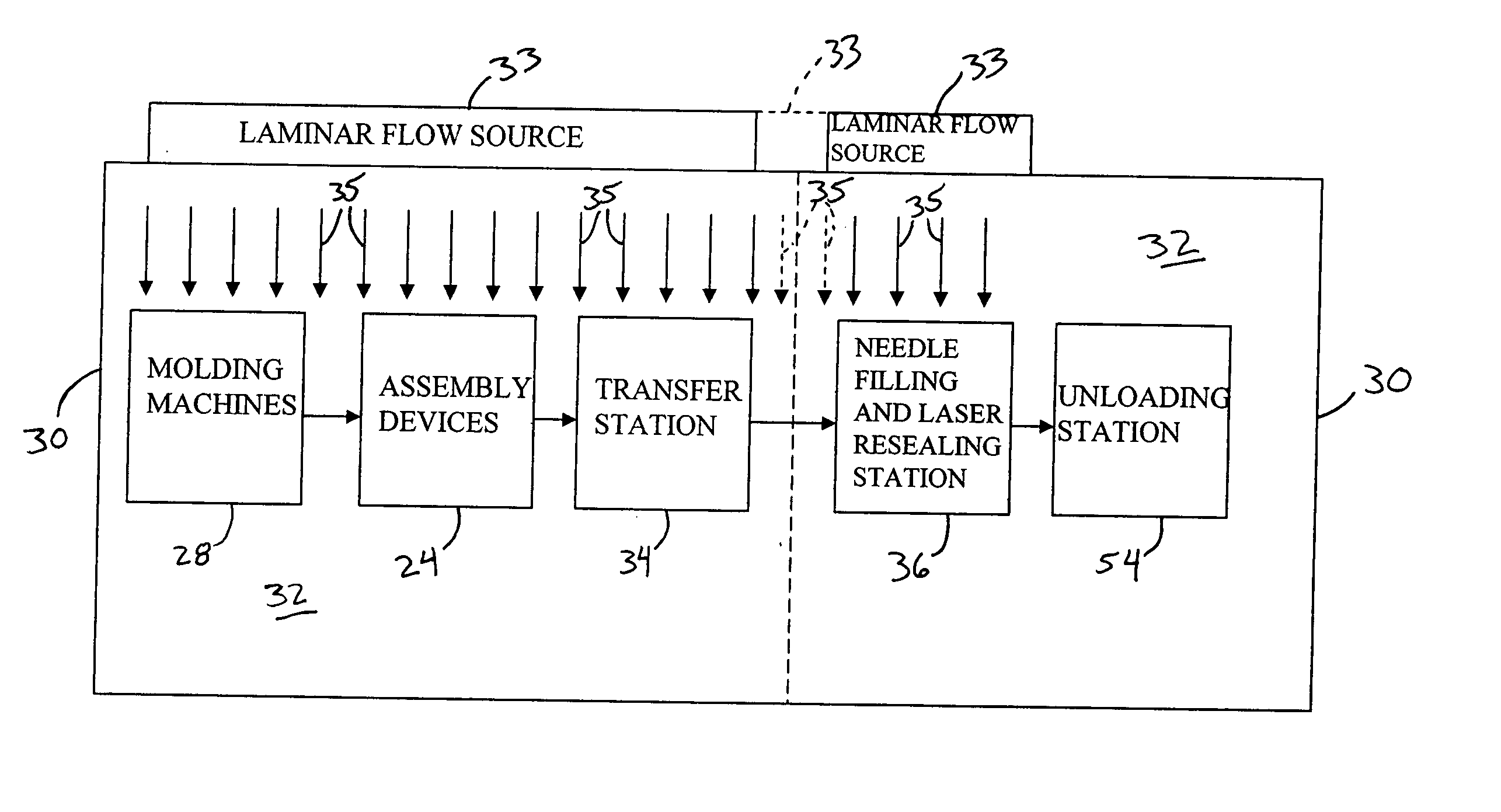

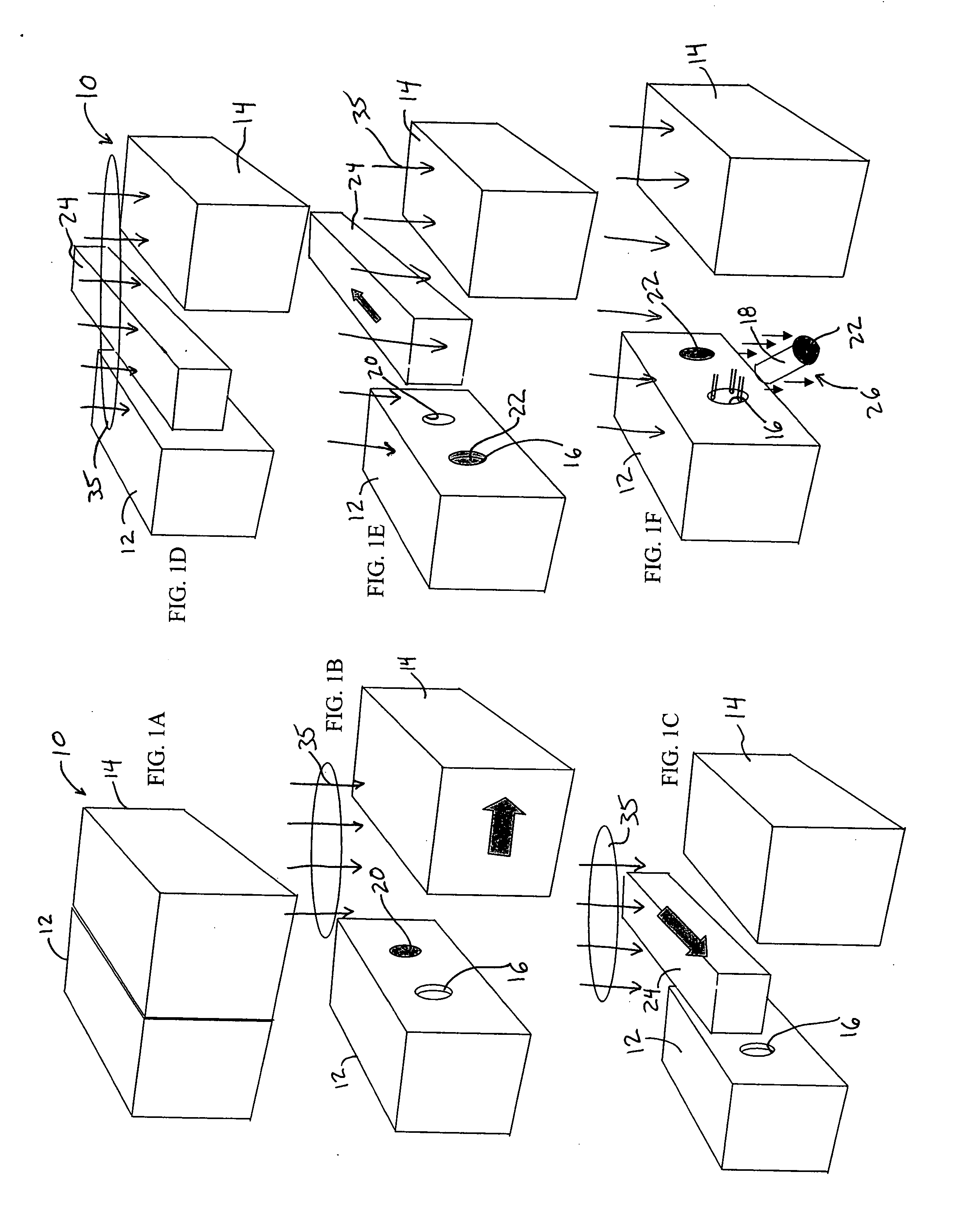

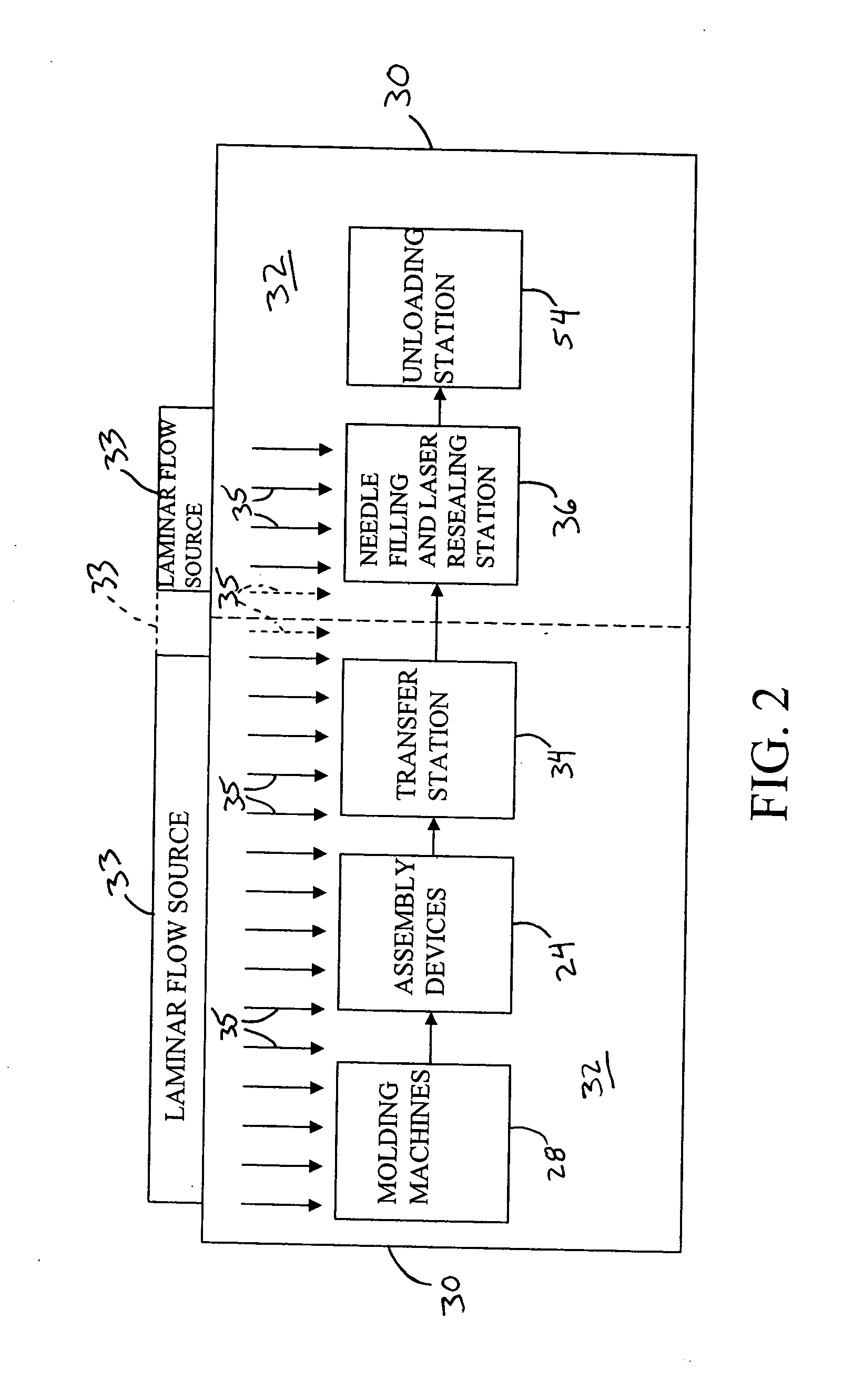

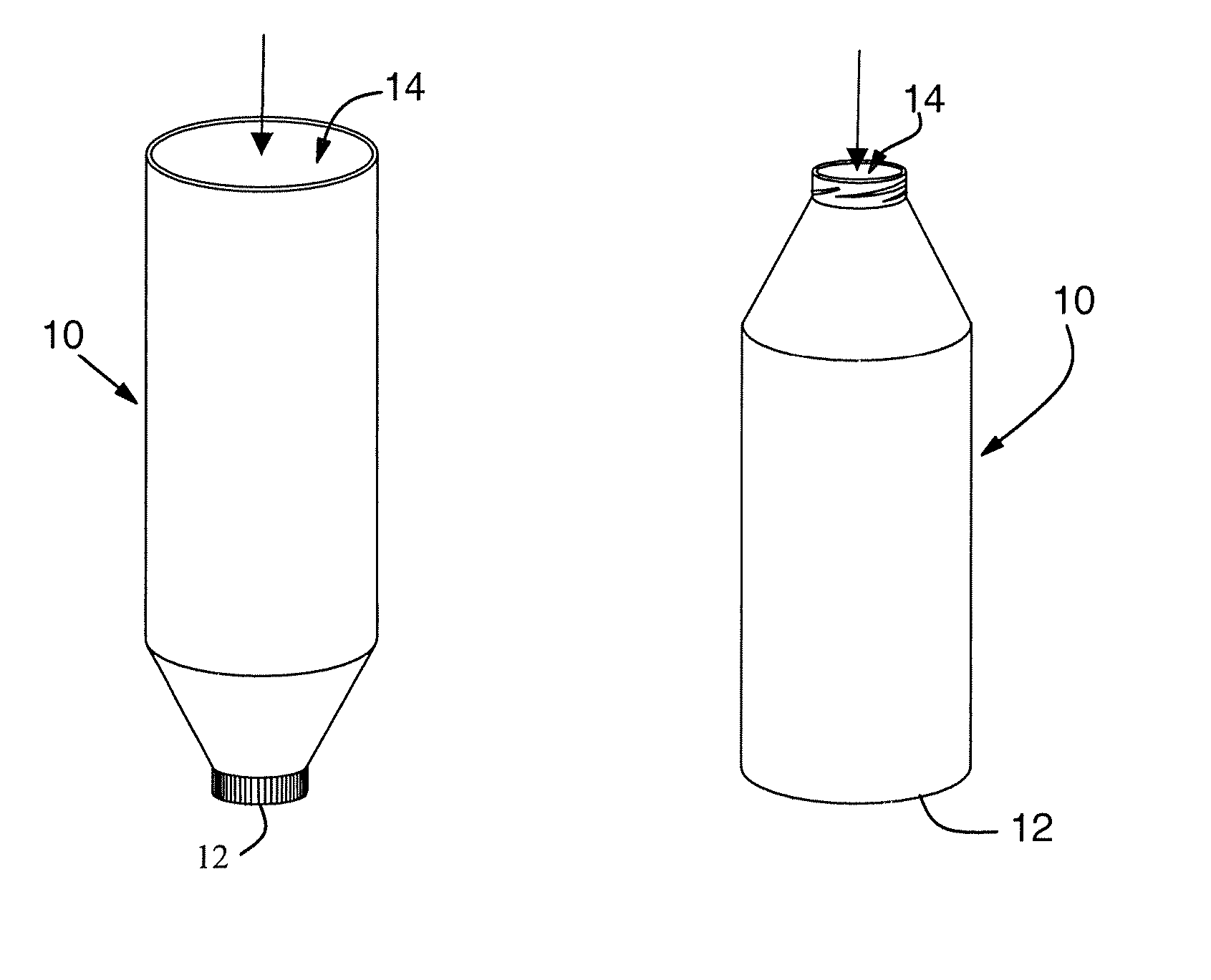

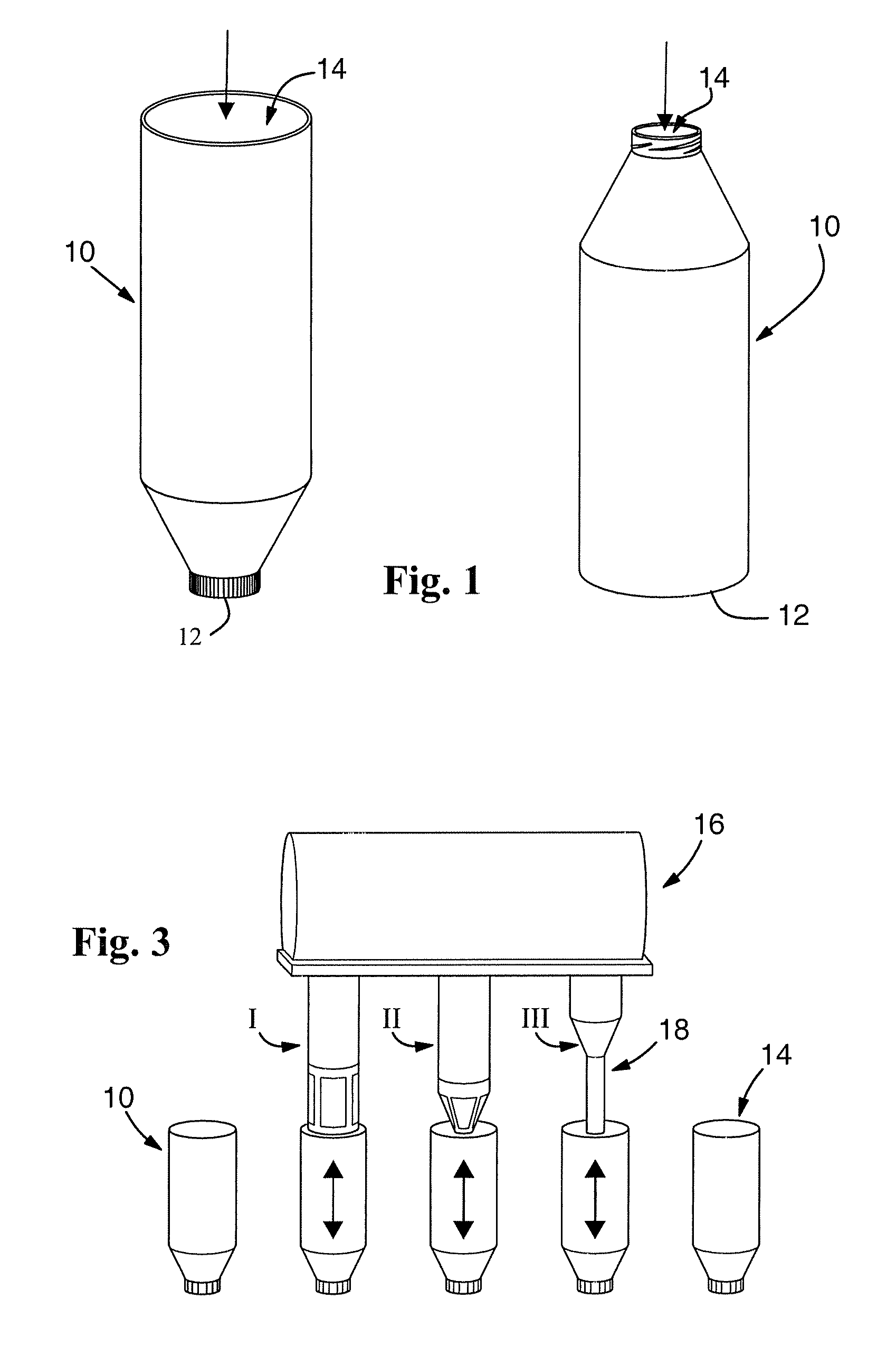

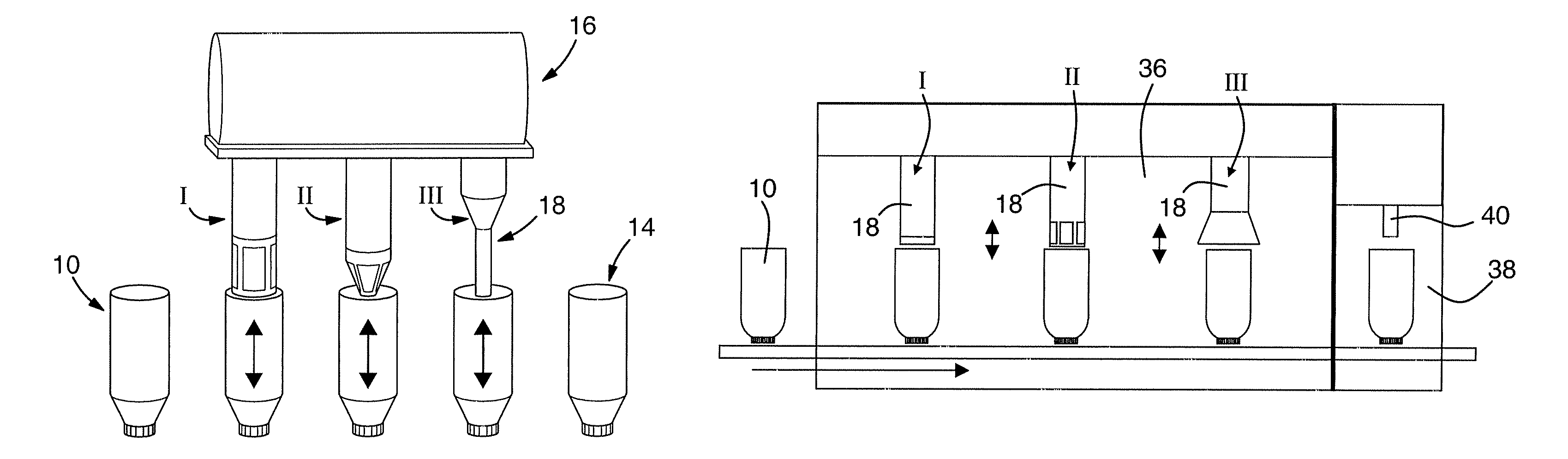

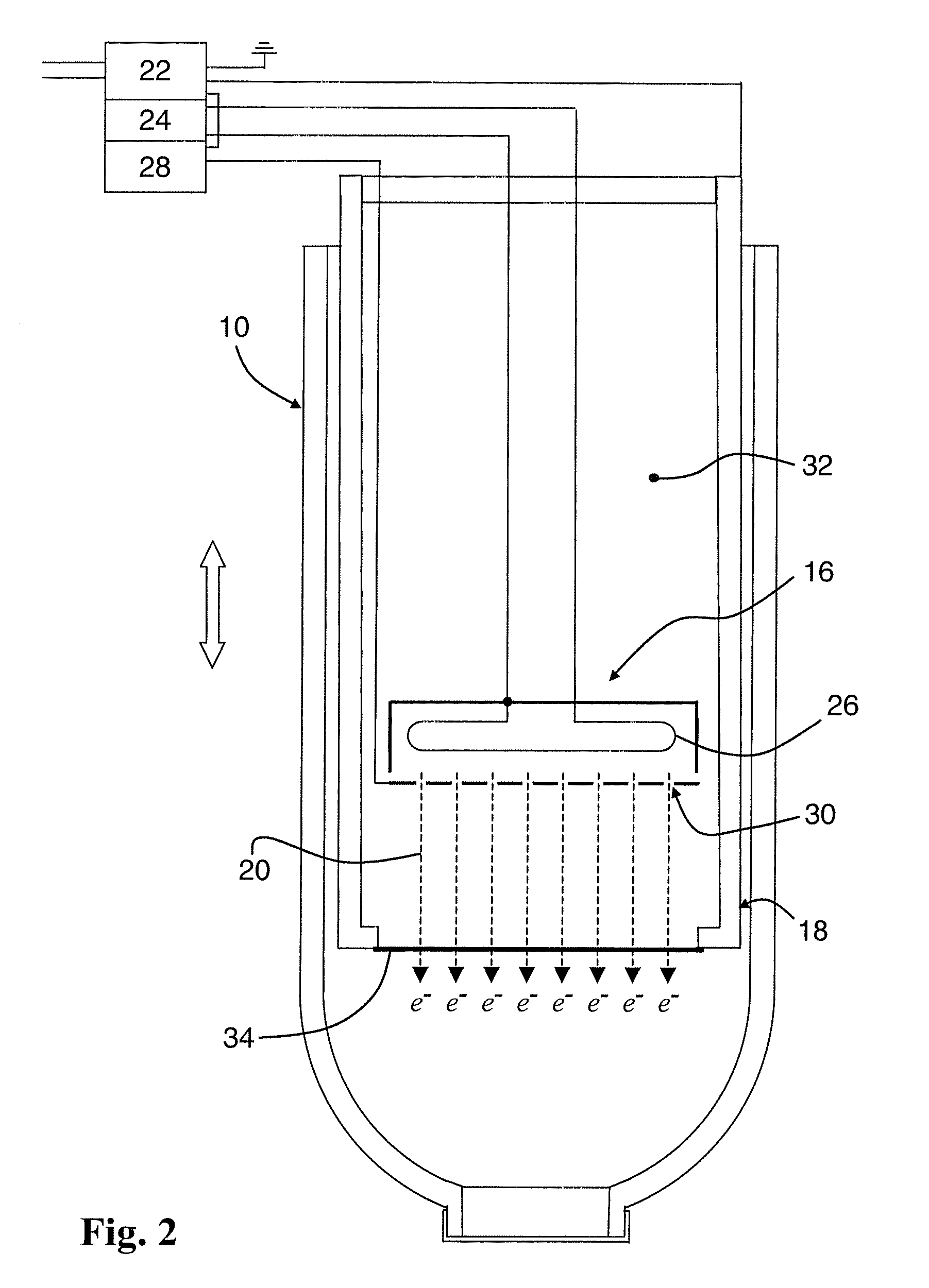

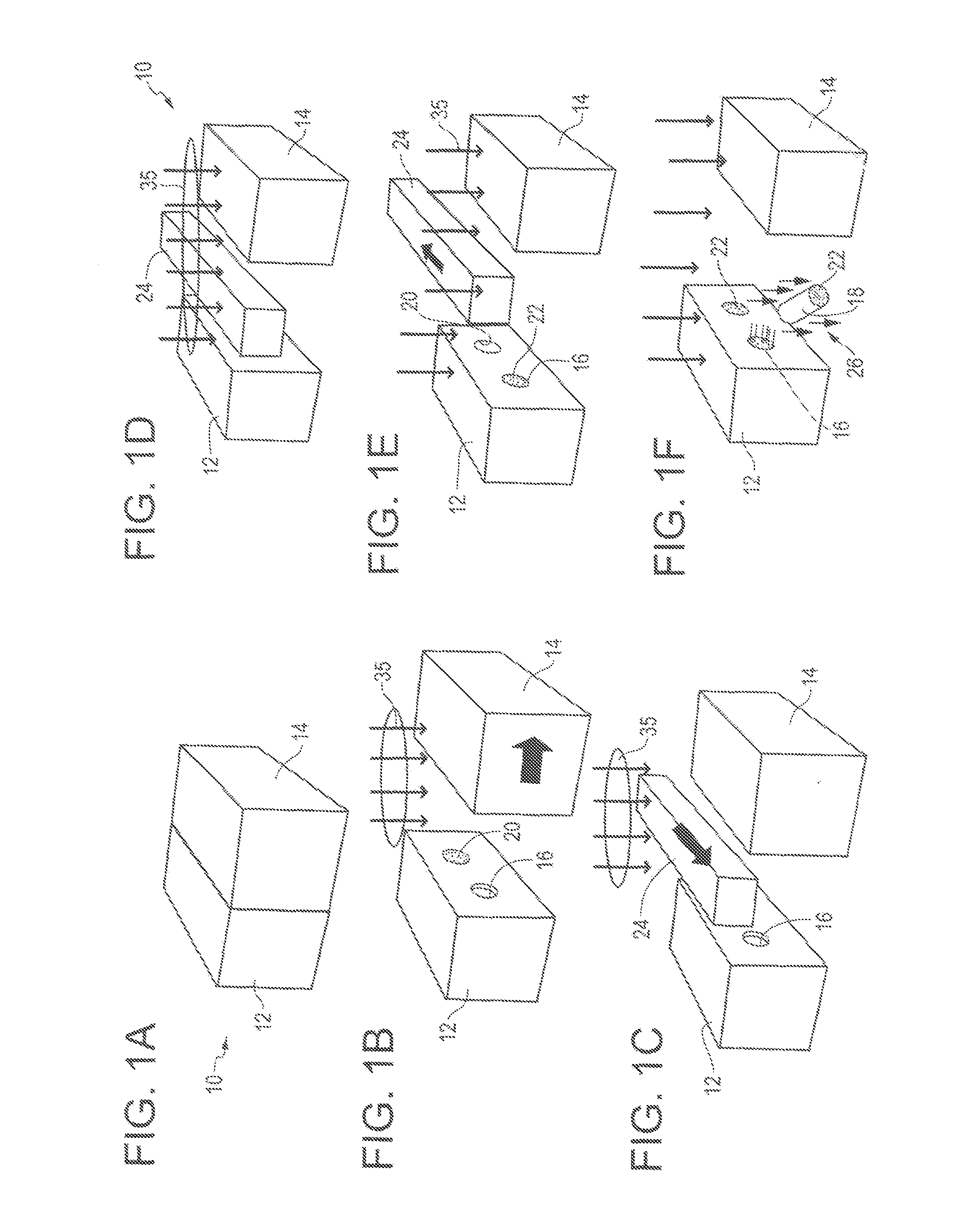

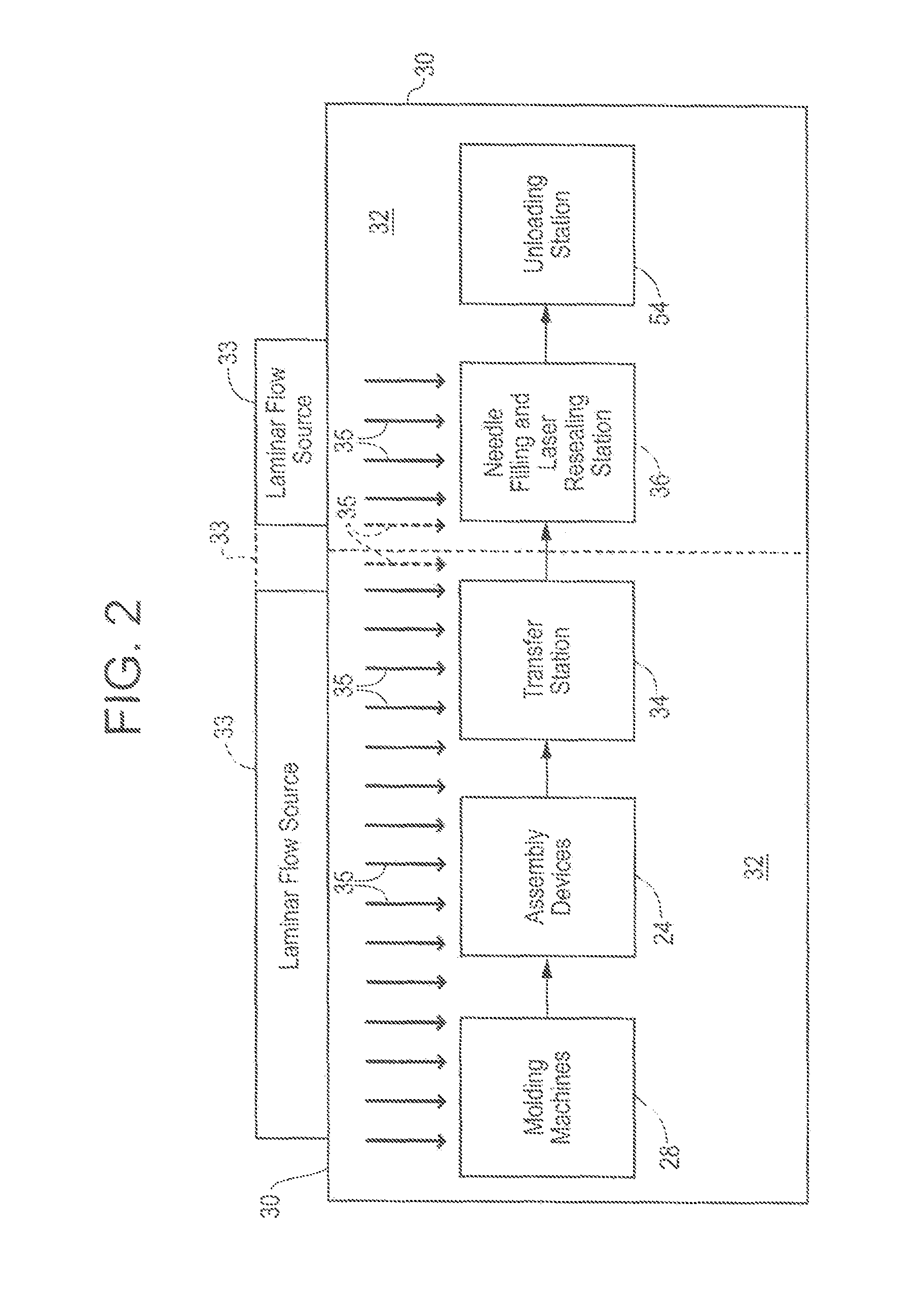

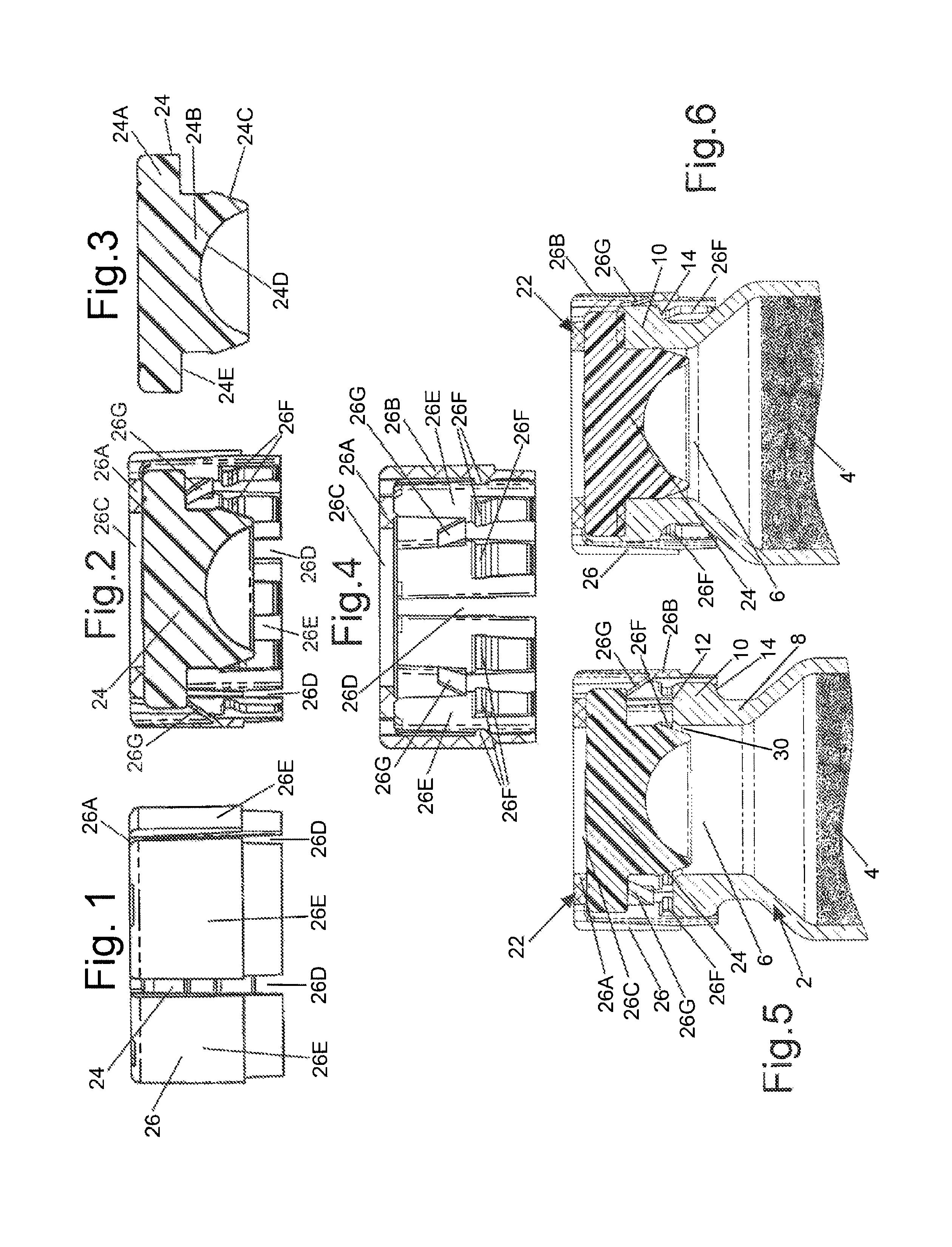

Method for molding and assembling containers with stoppers and filling same

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

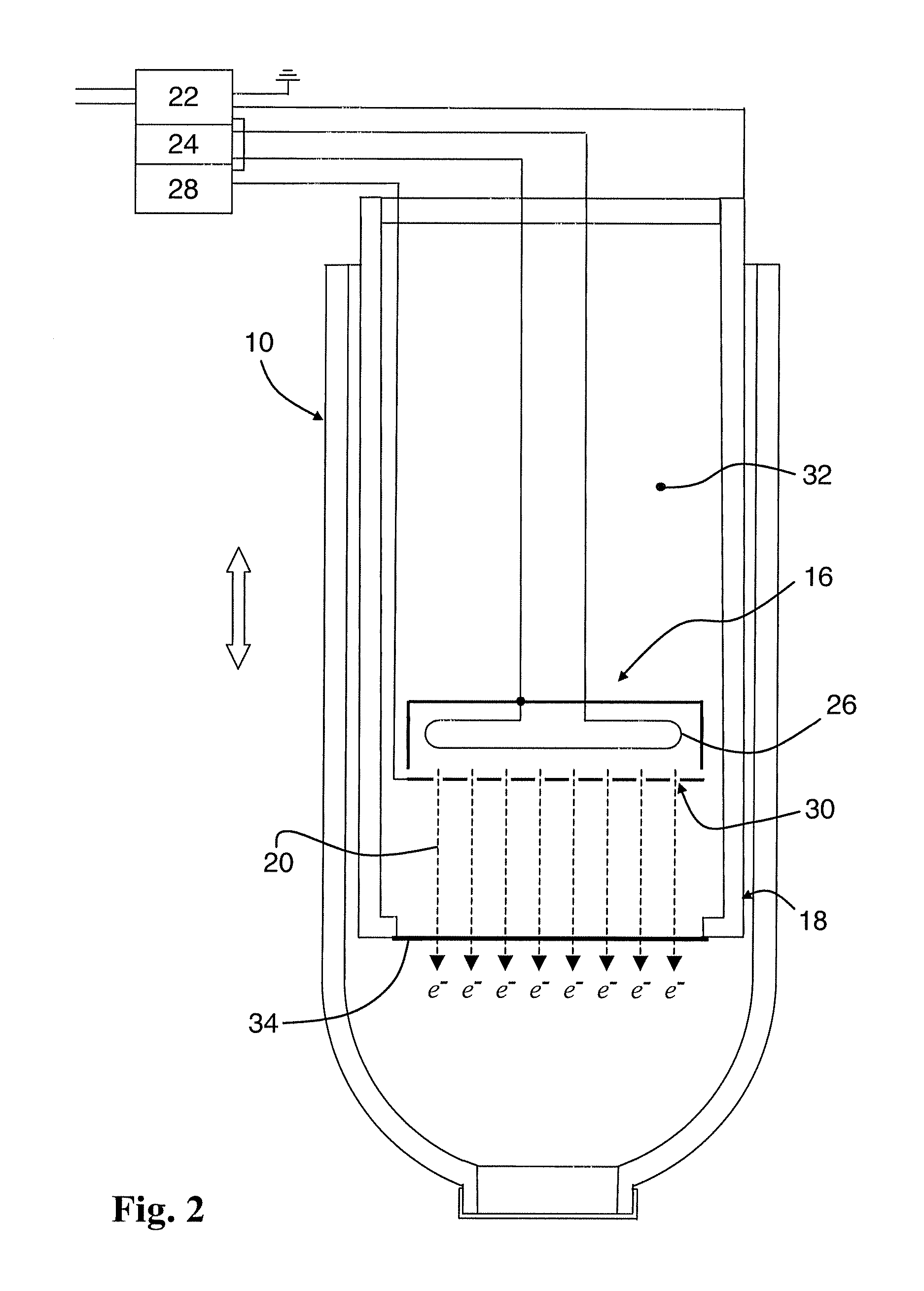

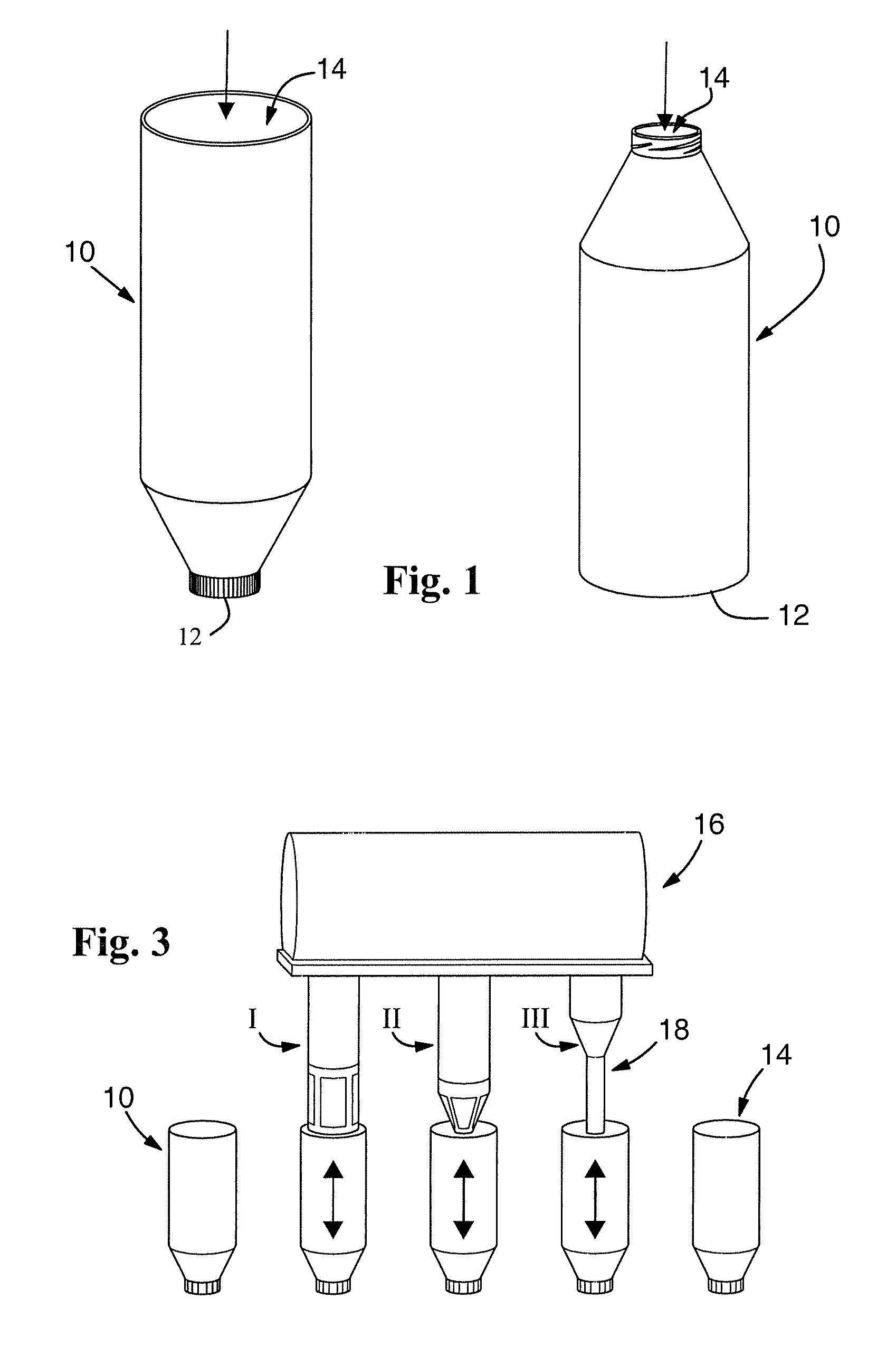

Method of sterilizing packages

ActiveUS20070283667A1Even dosePackage sterilisationLavatory sanitoryPhysicsElectron beam irradiation

A method for sterilizing at least partly formed packages with electron beam irradiation in a packaging machine involves sterilizing each of at least two at least partially separate areas of the package by way of a respective electron beam sterilizing device, with each of the sterilizing devices being adapted to characteristics of each respective one of the two areas, and also performing a respective relative movement between the package and each of the electron beam sterilizing devices, which movements are adapted for the sterilization of each respective one of the two areas with the sterilizing devices.

Owner:TETRA LAVAL HLDG & FINANCE SA

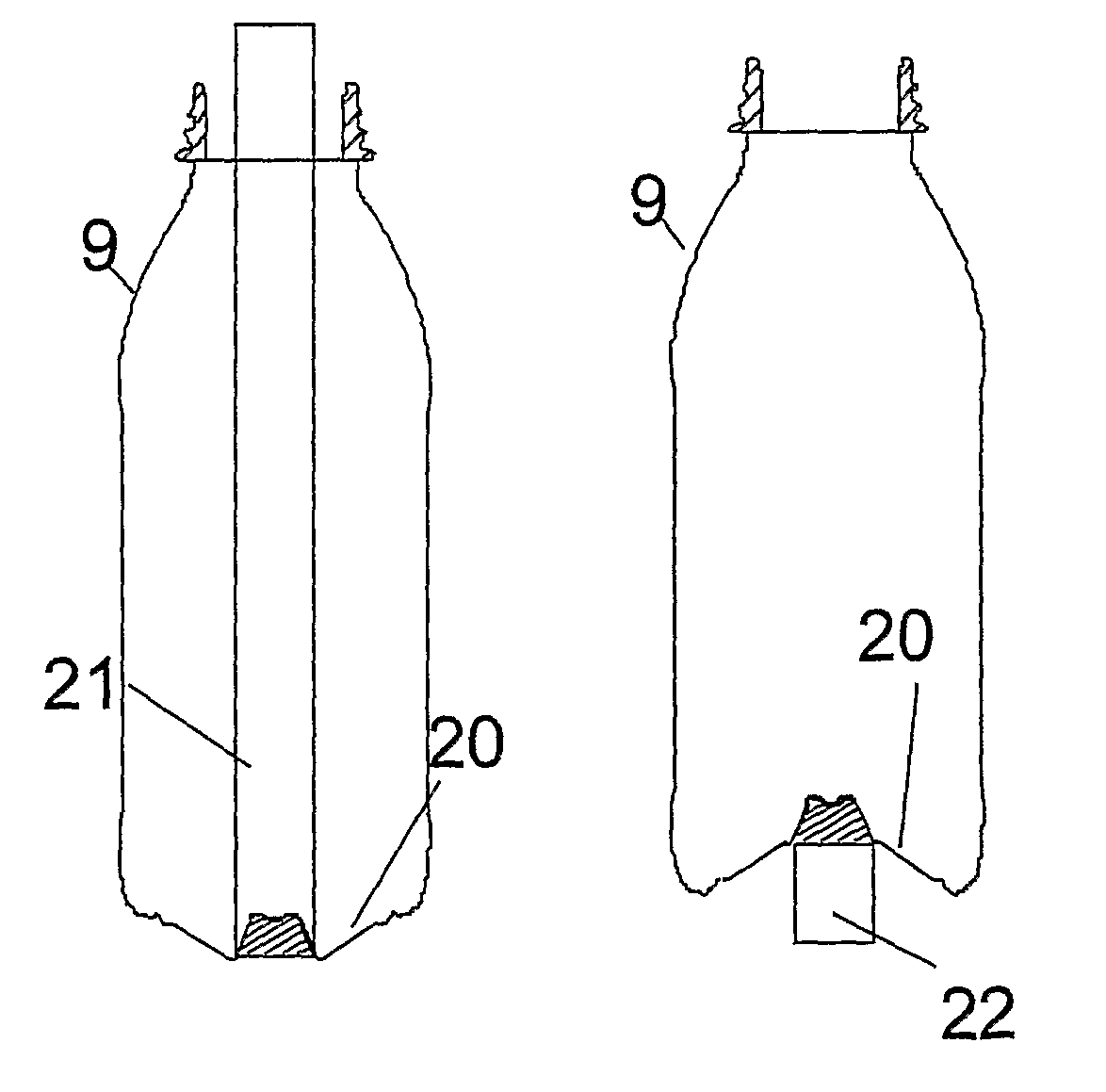

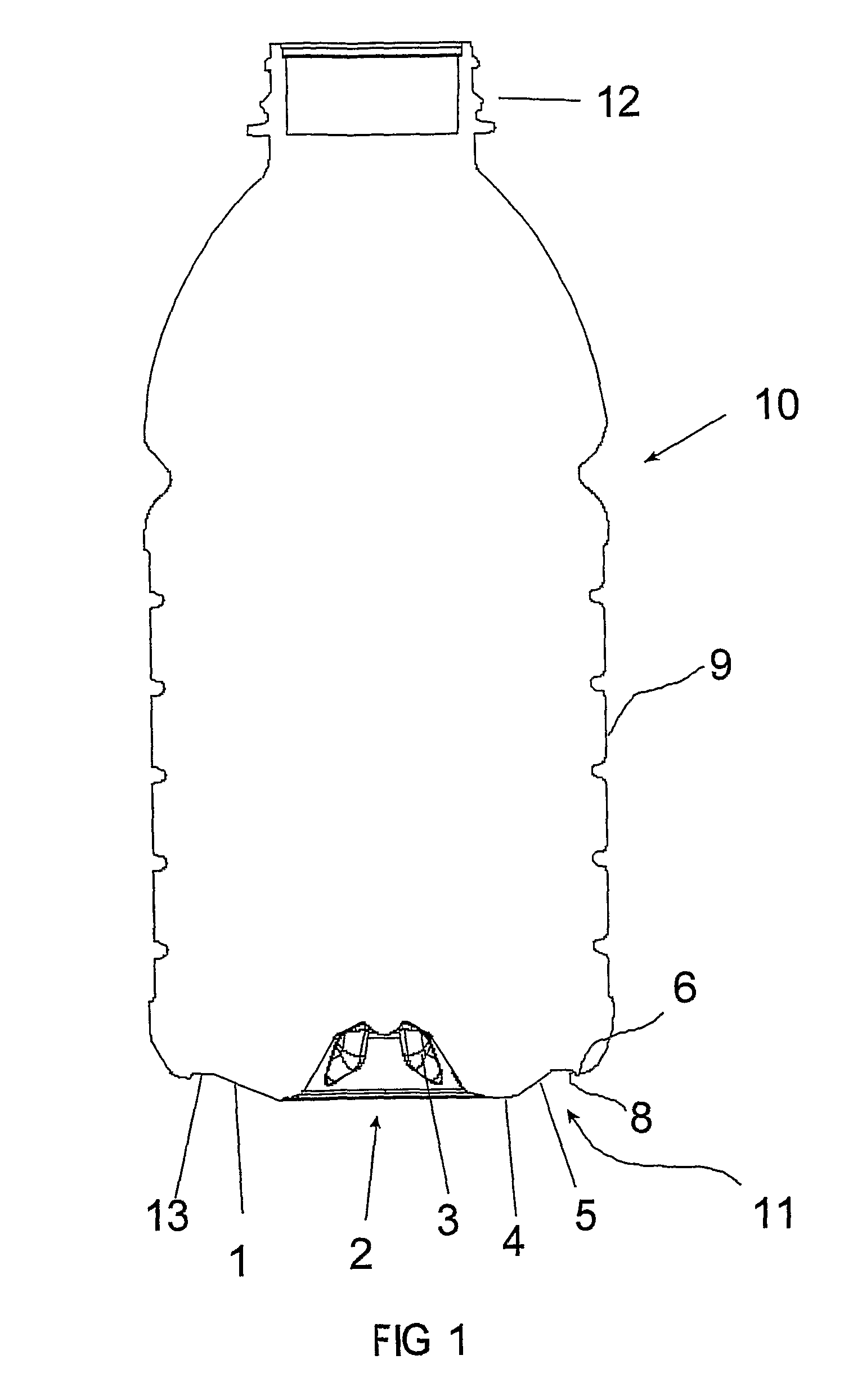

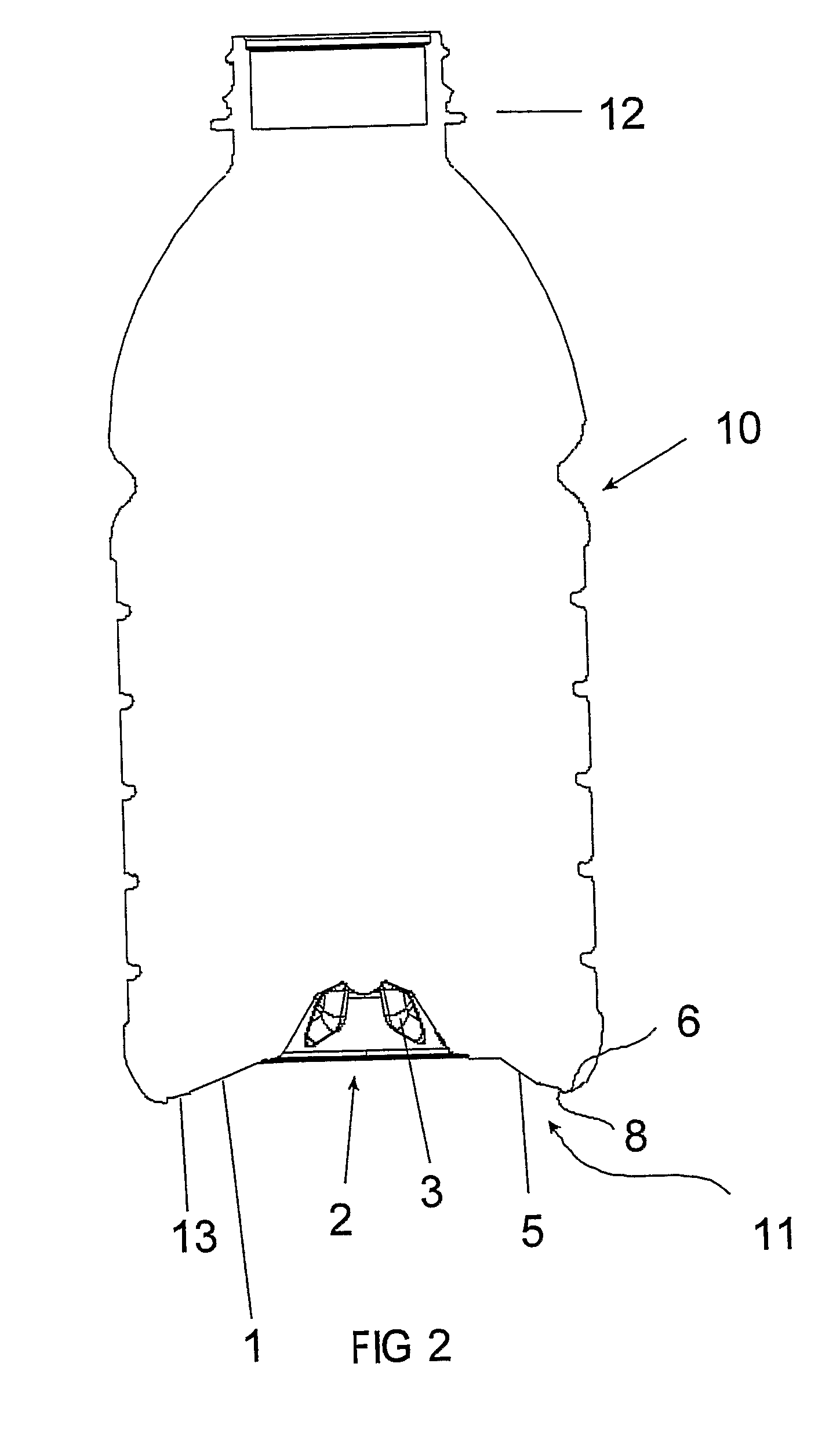

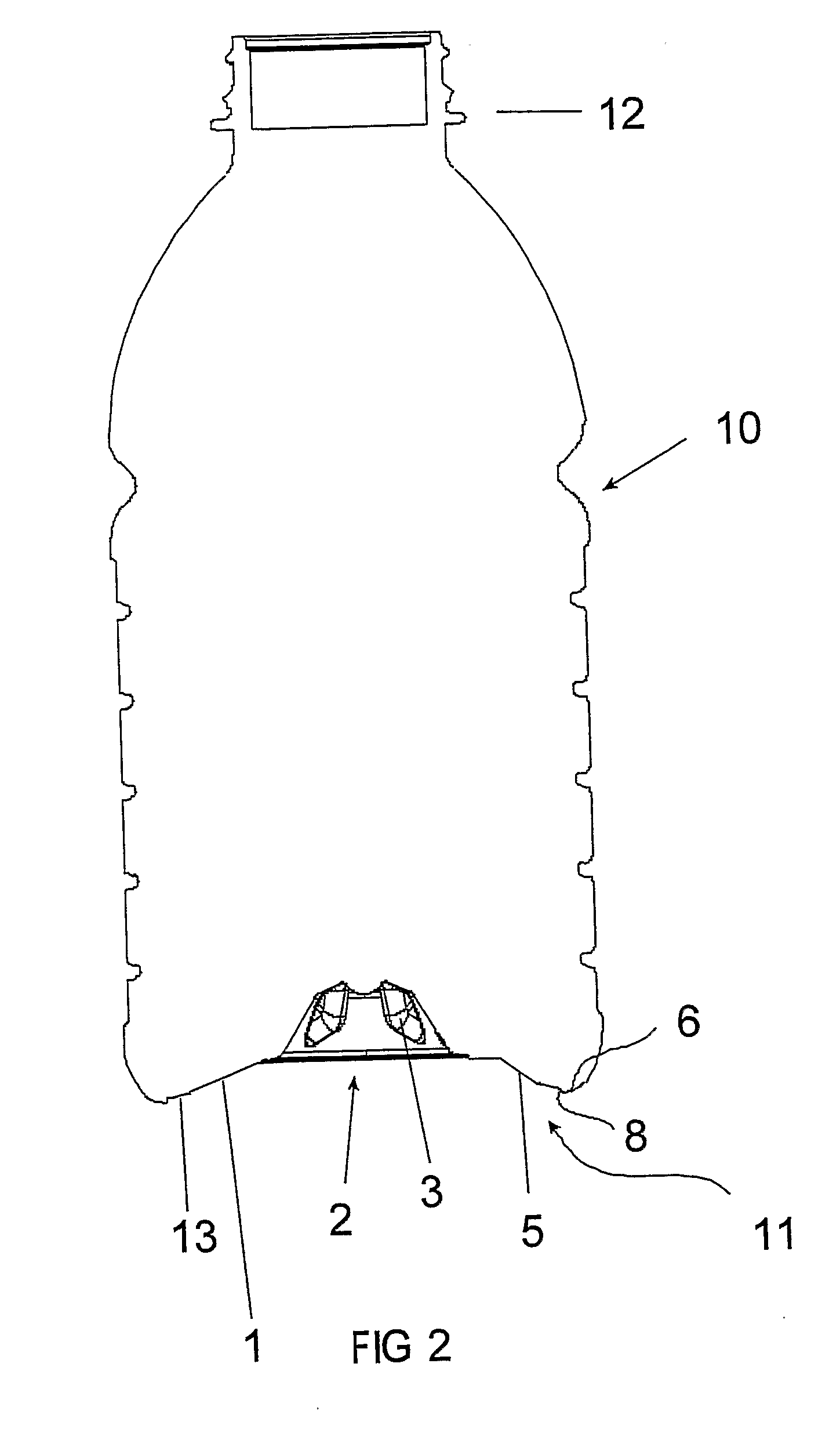

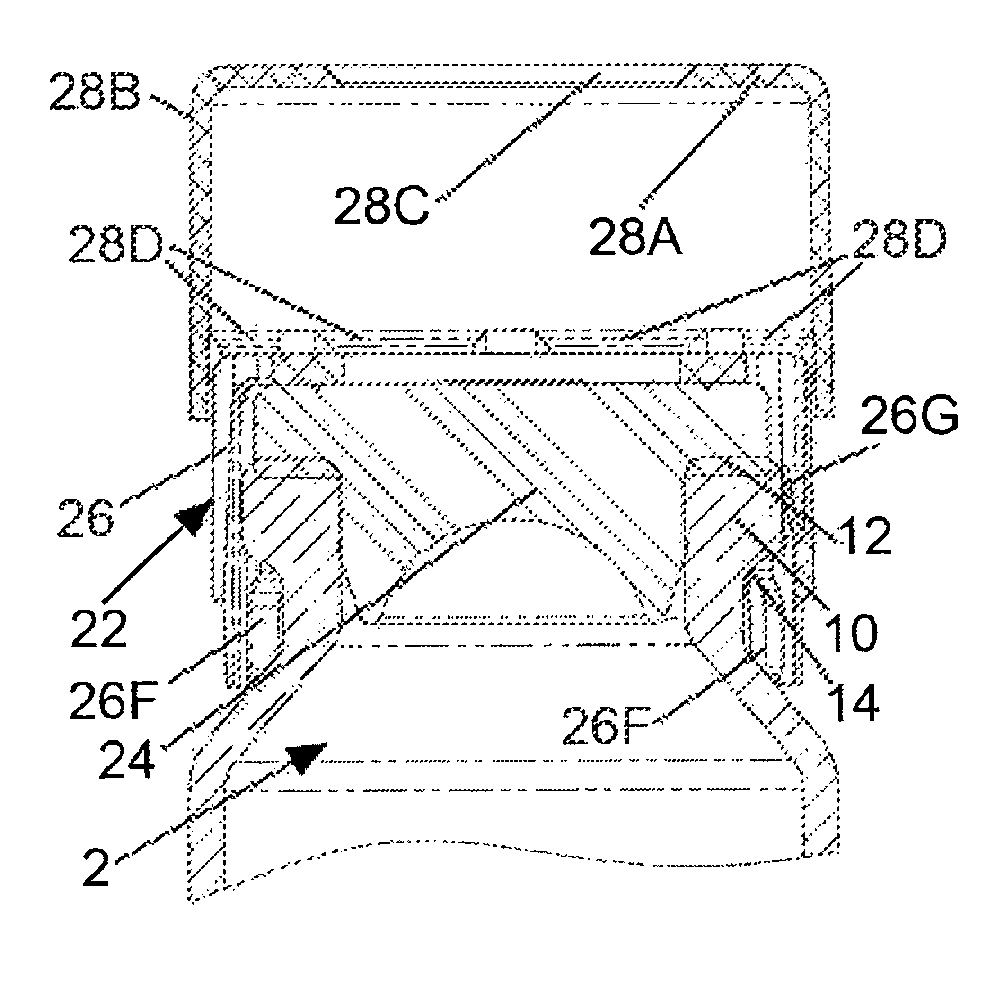

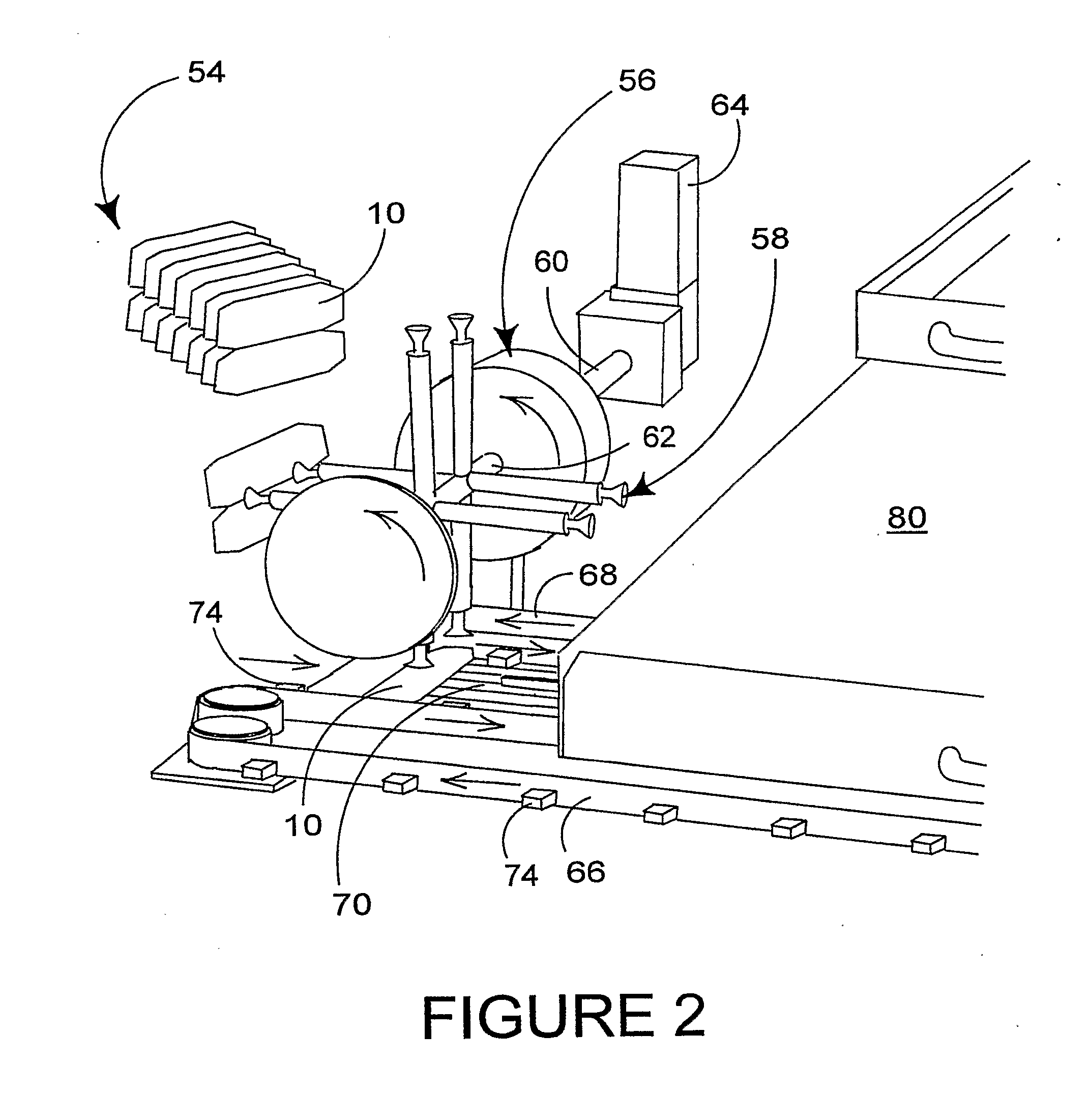

Method of processing a container and base cup structure for removal of vacuum pressure

InactiveUS8028498B2Easy to moveLow costSemiconductor/solid-state device manufacturingLarge containersVacuum pressureHandling system

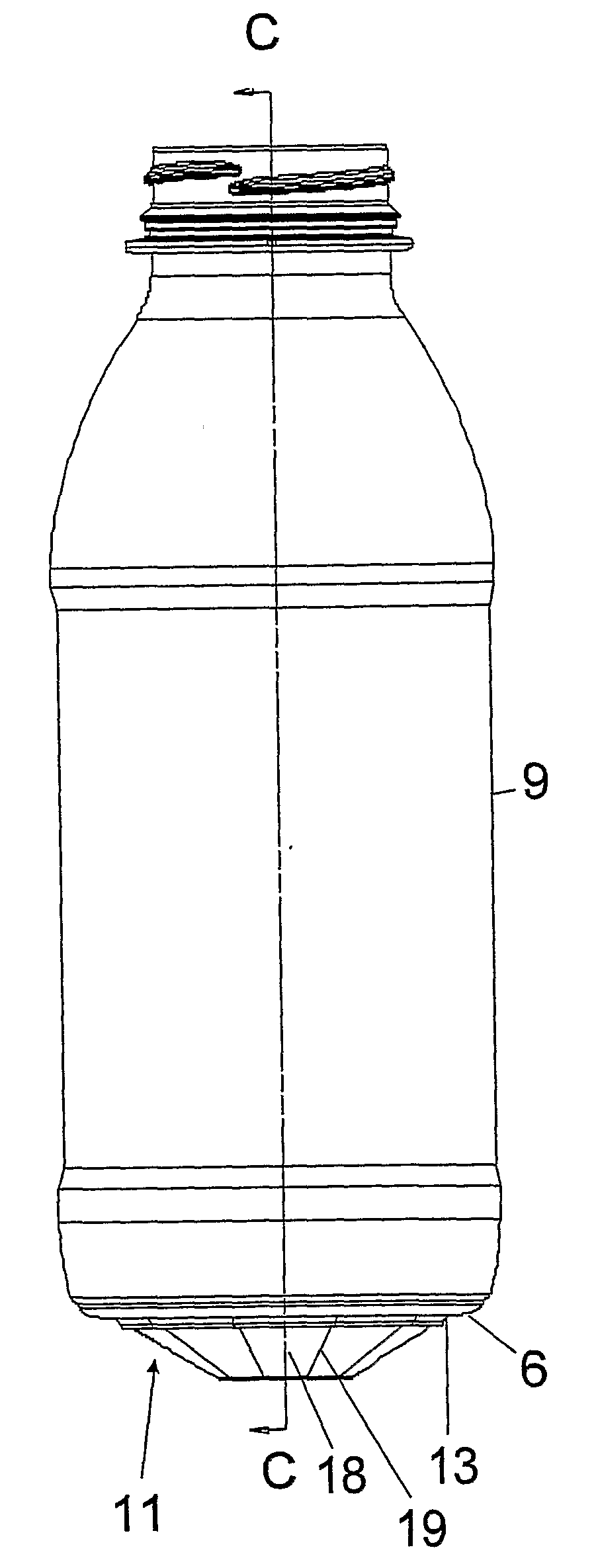

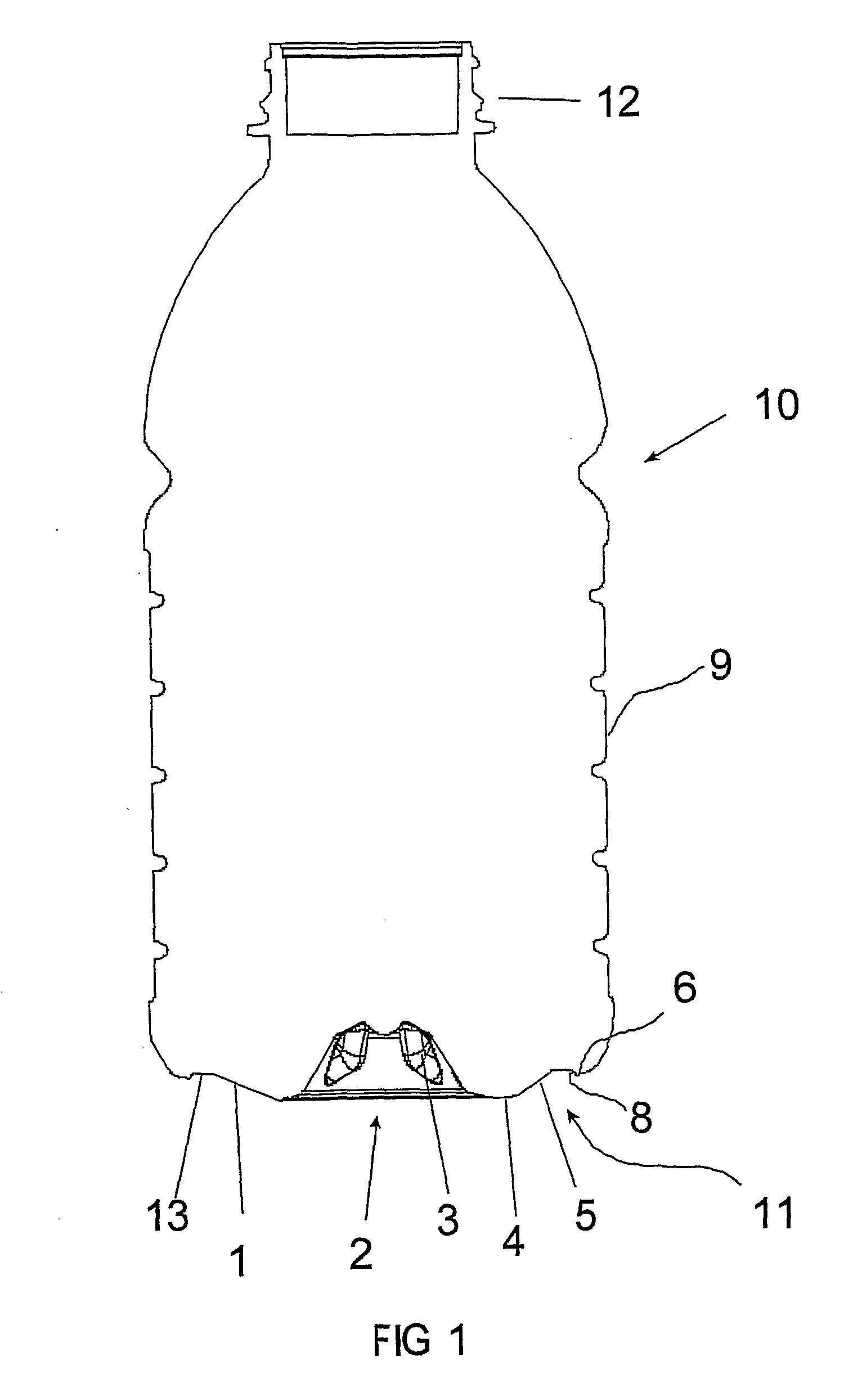

A Method of Processing a Container and Base Cup Structure For Removal of Vacuum Pressure A plastic container (10) has a wall extending to a lower portion including a pressure panel (20). The panel (20) is transversely oriented and can move from a downwardly inclined position providing a geometrically unstable configuration to an upwardly inclined position providing a geometrically stable configuration to control pressure change in the container. This movement may be provided by suitable actuating means such as rod (22). In the unstable configuration a base cup 50 or any other suitable holder can support the container and enable it to be conveyed in a container handling or processing system.

Owner:CO2 PAC

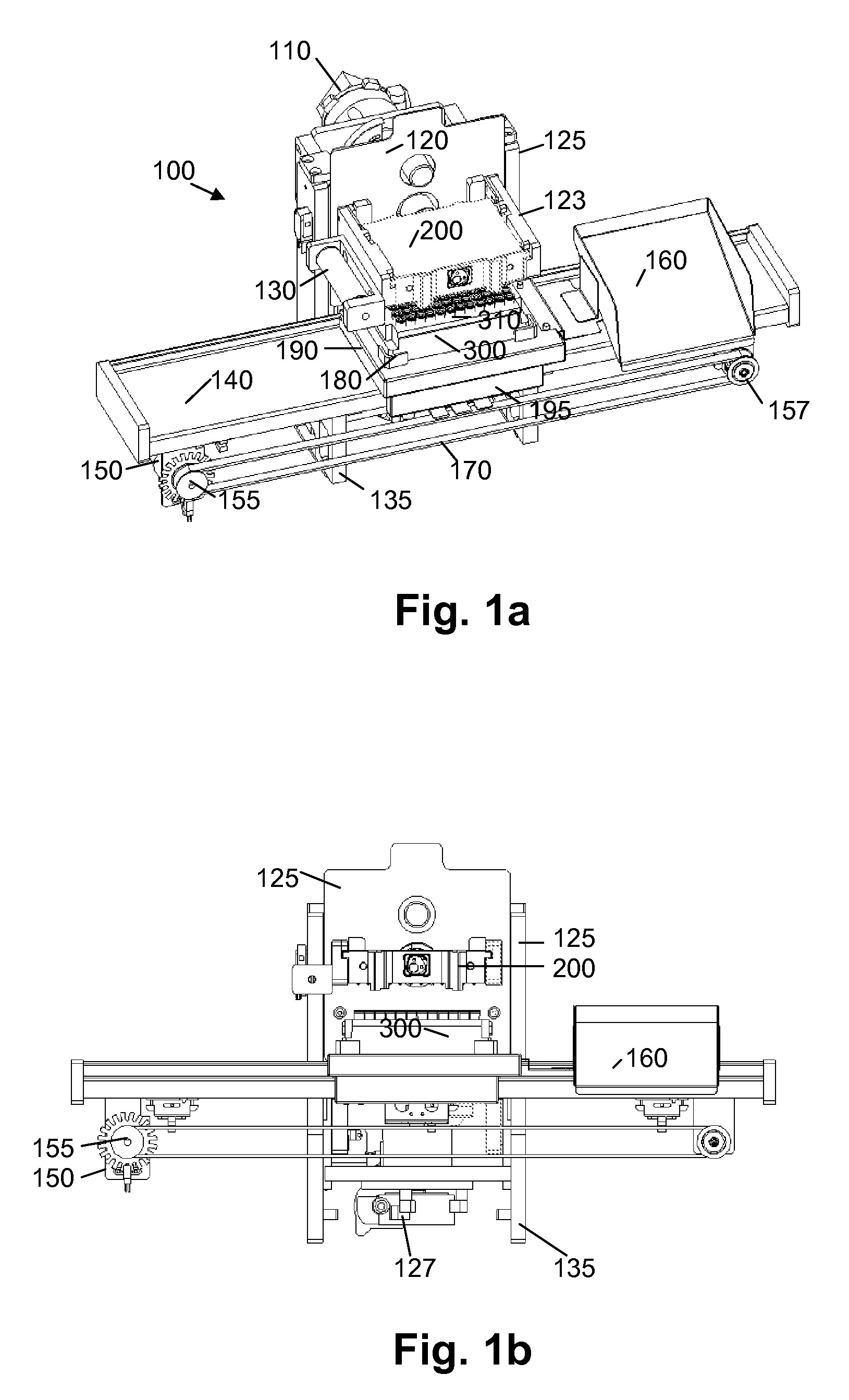

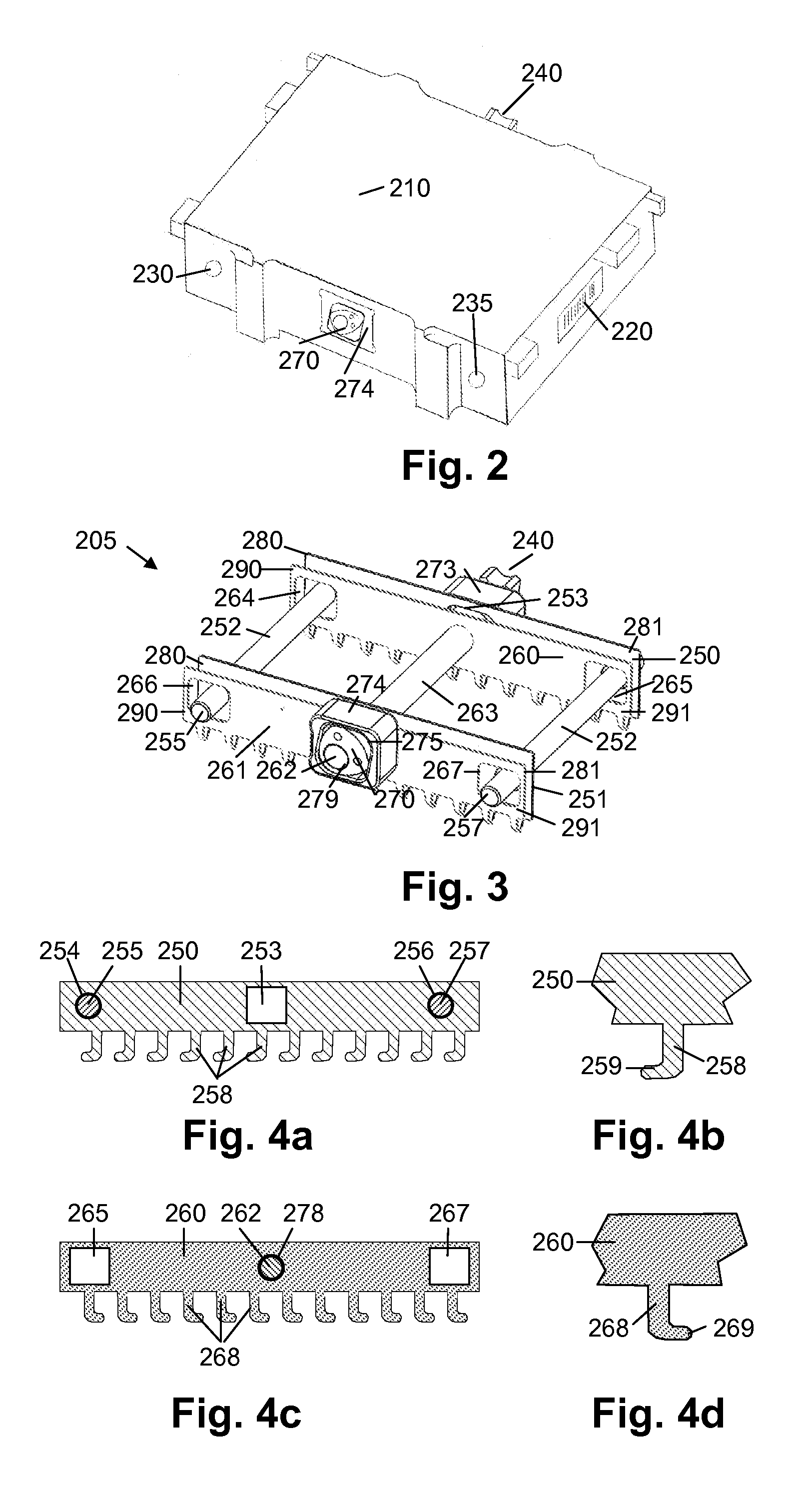

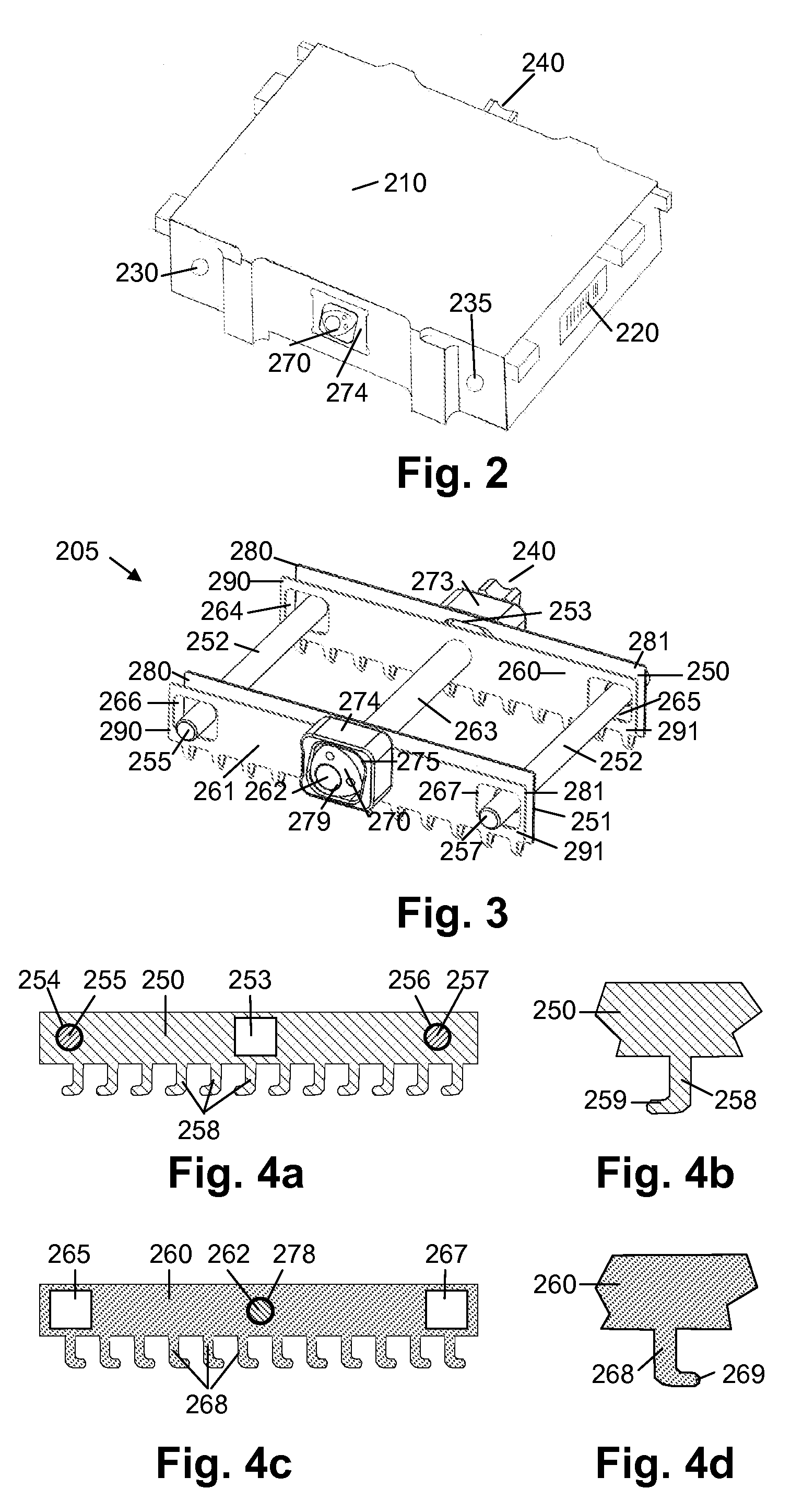

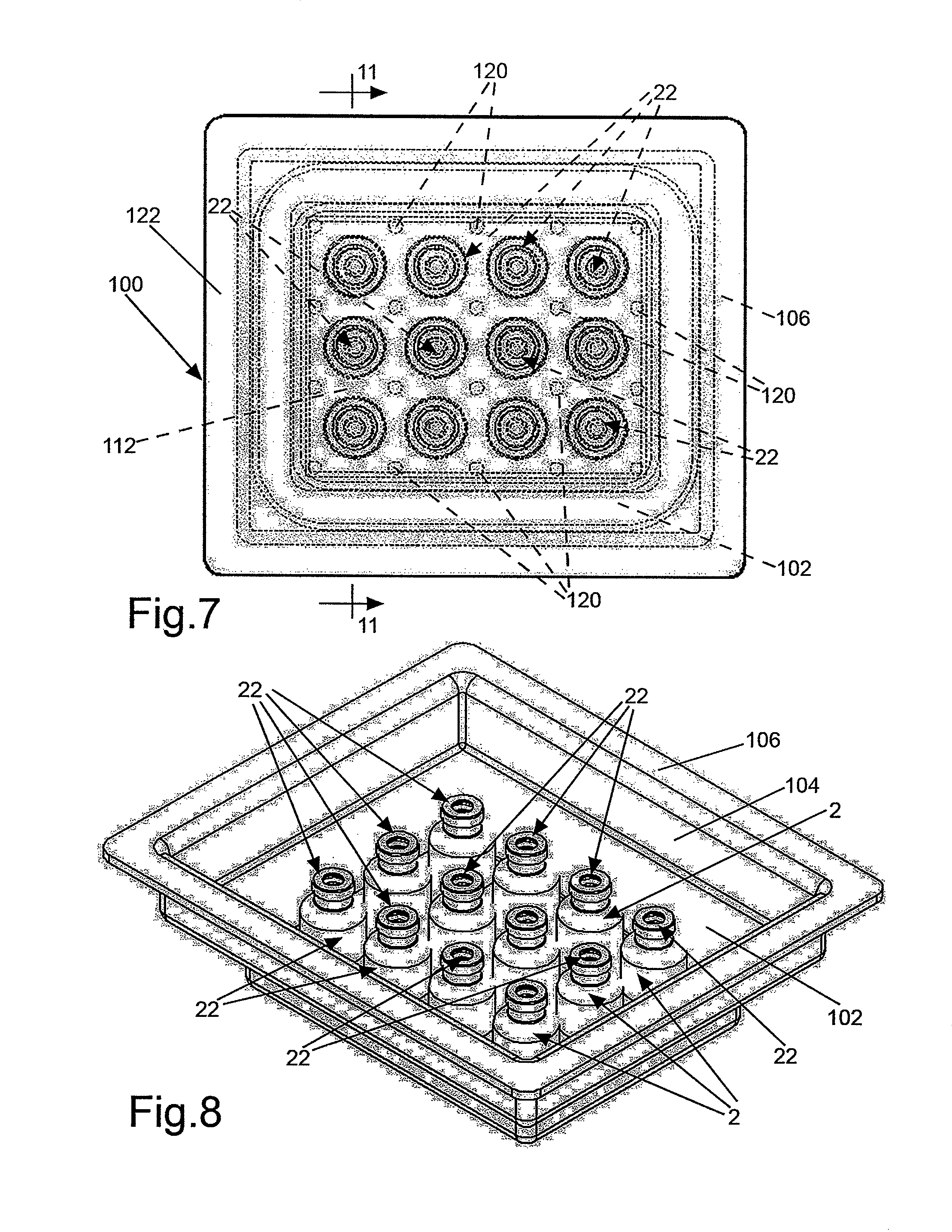

System and method for simultaneous capping/de-capping of storage containers in an array

The system for removing or replacing caps for vials in a fixed array includes a removable cartridge with a plurality of sets of gripper plates corresponding to the number of columns in the array. Each plate has a plurality of gripper arms corresponding to the number of rows in the array. The gripper arms have hooked ends which are oriented in opposite directions in each set of plates. Relative positioning of the gripper arms is varied by one or more rotating cams, which cause the gripper arms on one plate of each set to move relative to the gripper arms of the other plate(s) of the set, varying the combined width and / or relative angle of the gripper arms to manipulate a cap inserted into the end of each vial. The plurality of plate sets and gripper arms allow all vials in the array to be capped or de-capped simultaneously.

Owner:NEXUS BIOSYSTEMS INC

Method of sterilizing packages

Owner:TETRA LAVAL HLDG & FINANCE SA

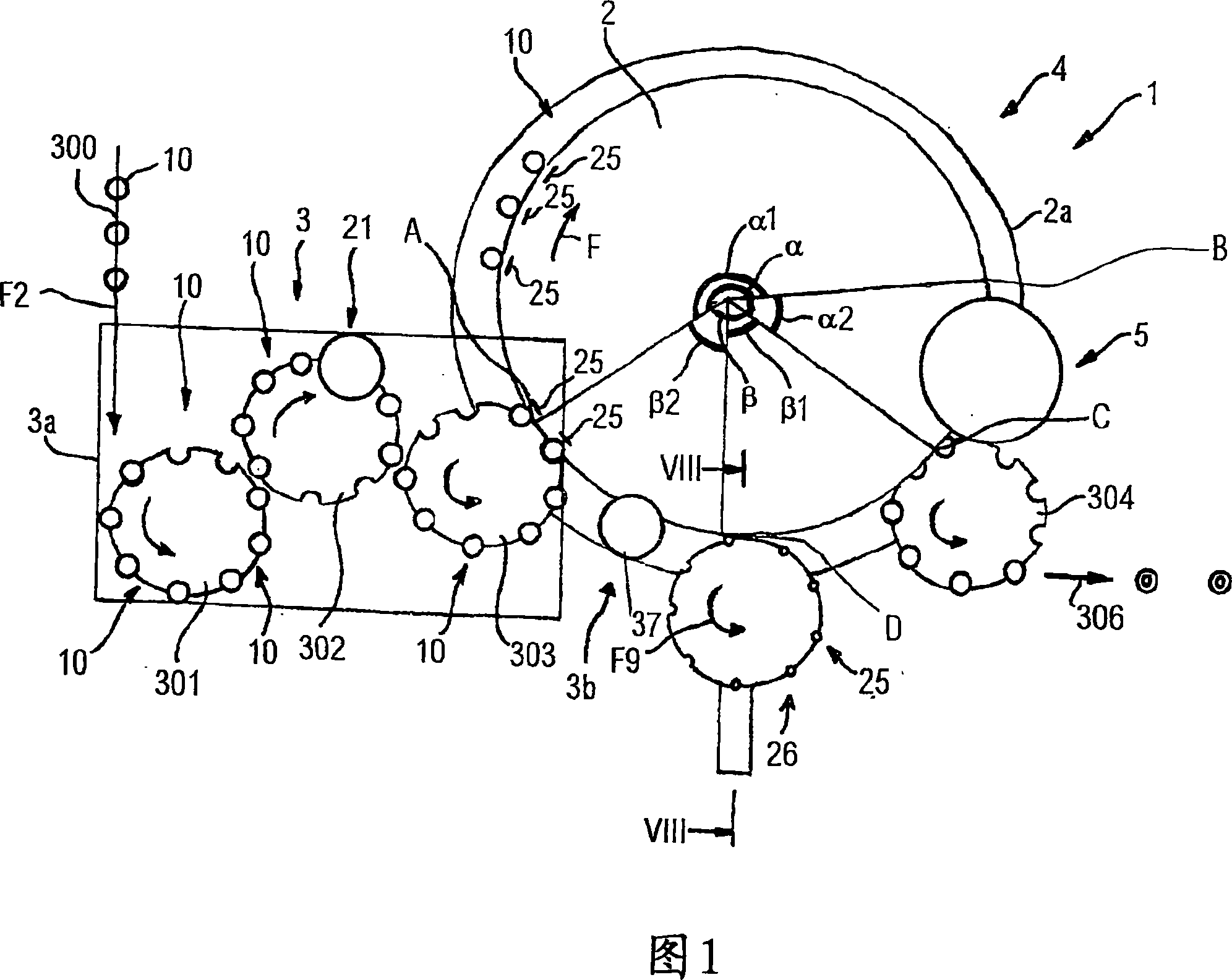

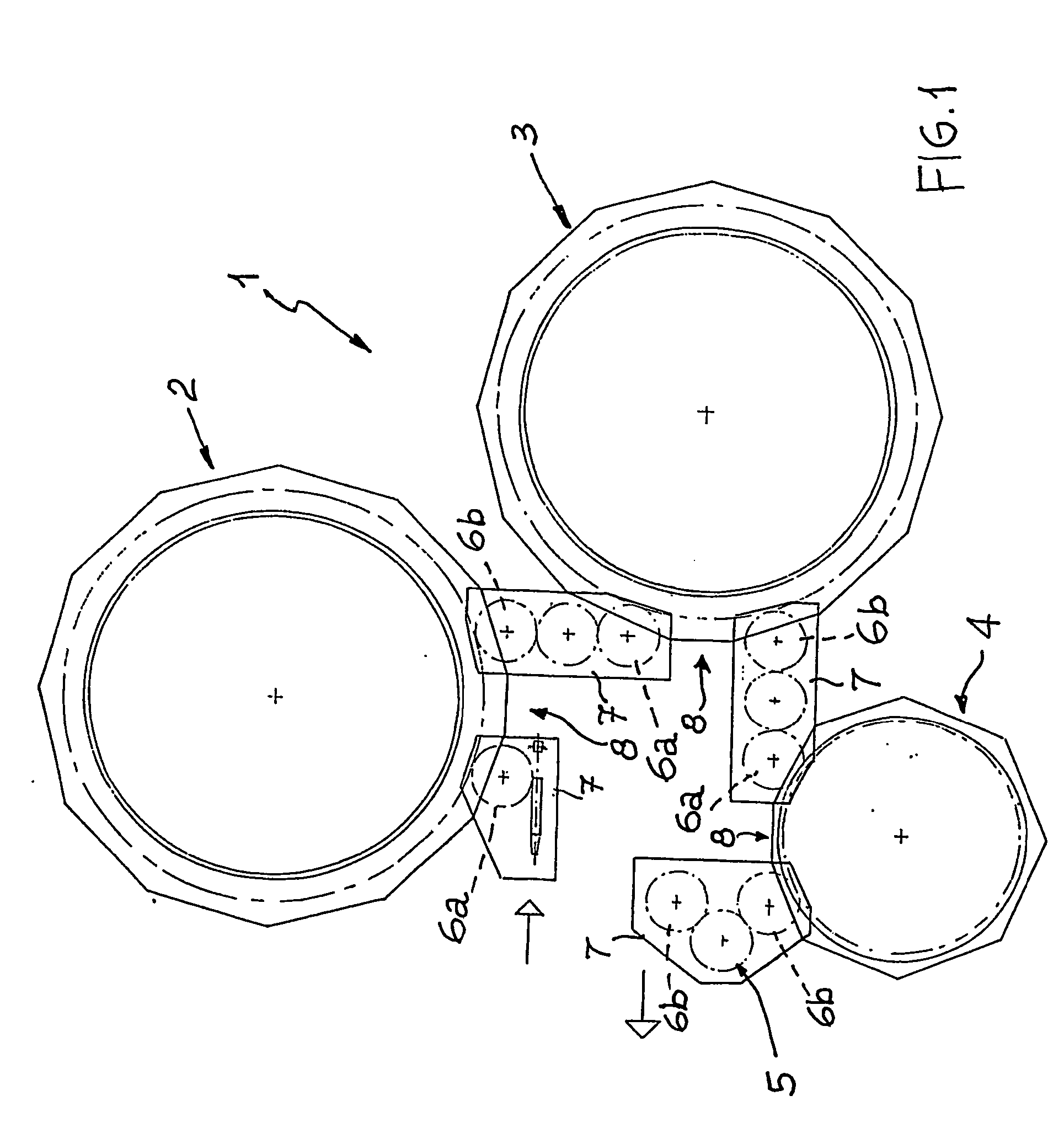

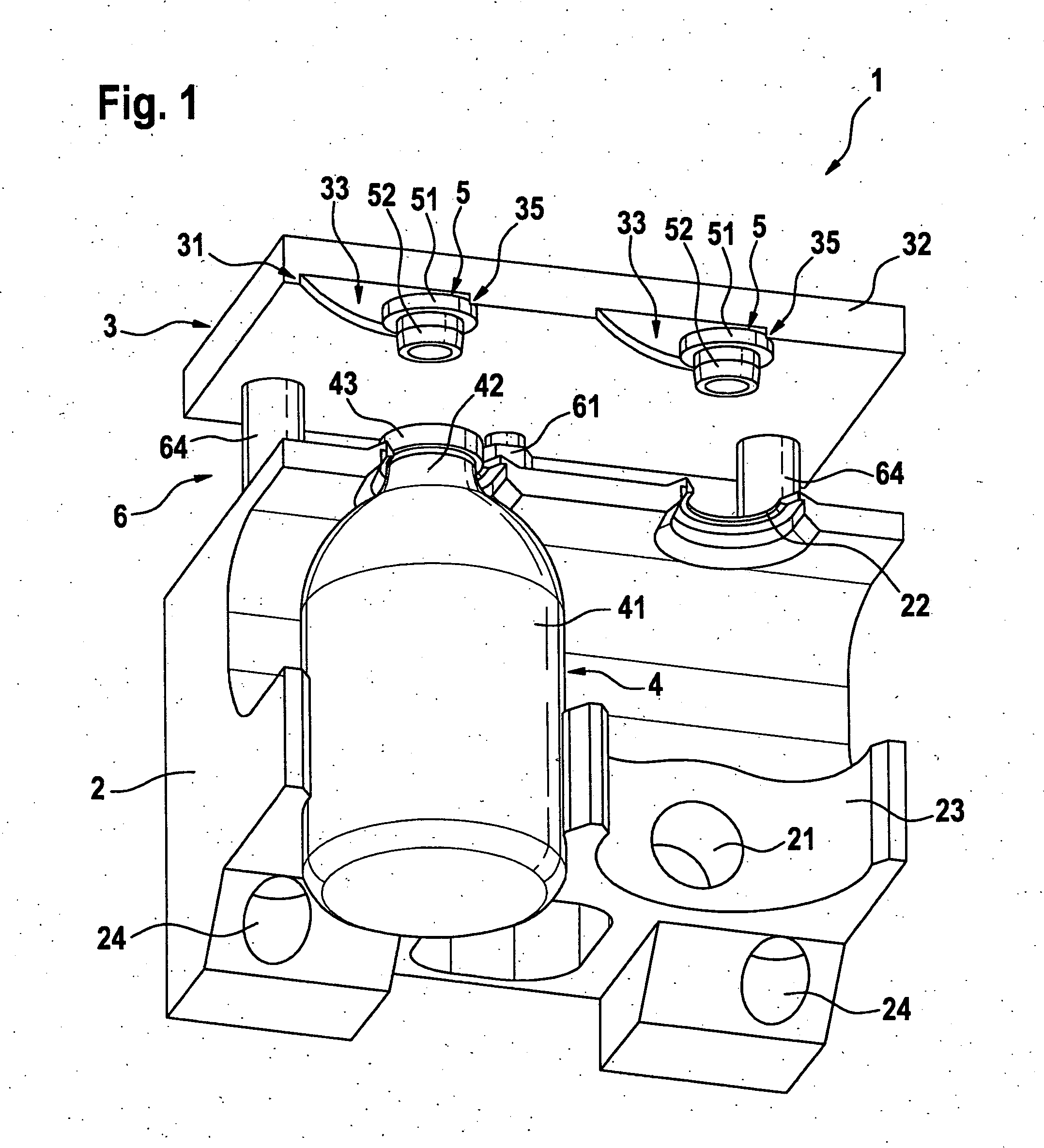

Apparatuses and methods for sterilising and filling components of packaging units, particularly bottles and/or caps

InactiveCN1968888AImprove sterilization efficiencyEffective sterilizationClosing machinesCapsEngineeringBottle

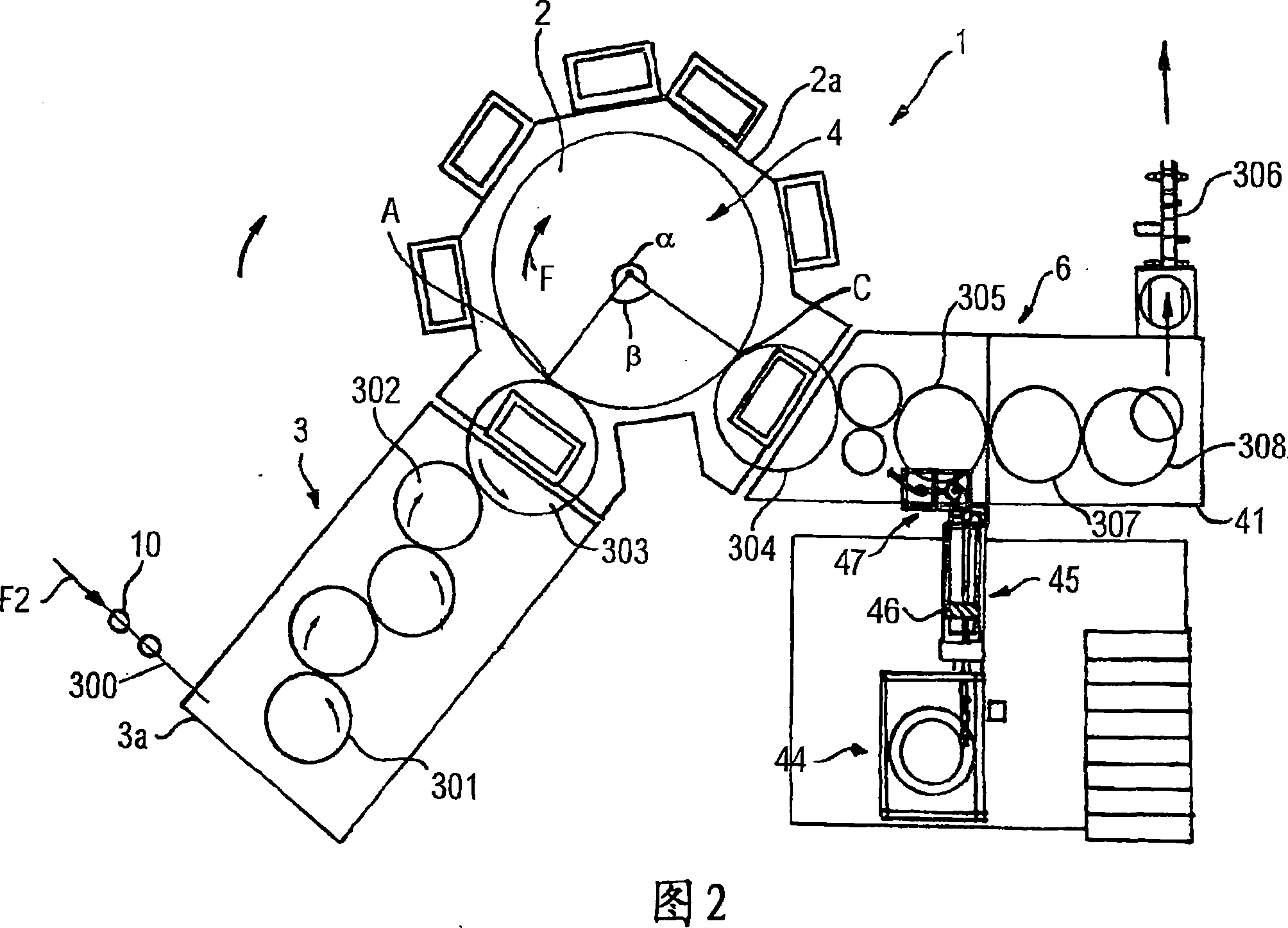

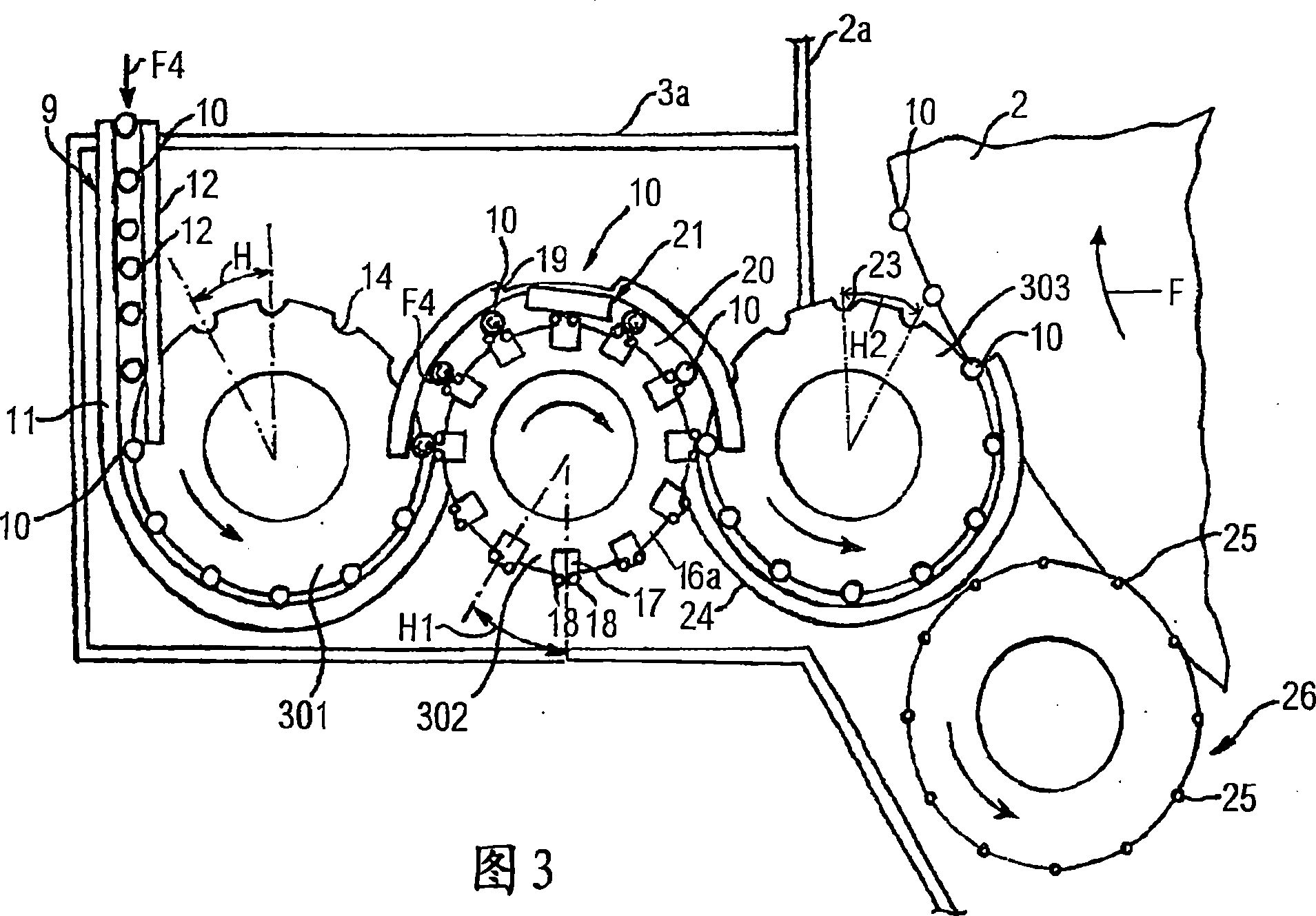

An apparatus comprises rotating conveying means (301, 302, 303, 2; 301, 160, 303, 2) for conveying along a curved path components (10, 25) of packaging units comprising containers (10) and container closures (25), filling means (30) for filling with a product said containers (10) on said rotating conveying means (301, 302, 303, 2; 301, 160, 303, 2), sterilising means (21, 37) for sterilising at least part of said components (10, 25) mounted along said path and comprising irradiating means arranged to emit radiation.

Owner:SIDEL S. P. A.

System and method for simultaneous capping/de-capping of storage containers in an array

The system for removing or replacing caps for vials in a fixed array includes a removable cartridge with a plurality of sets of gripper plates corresponding to the number of columns in the array. Each plate has a plurality of gripper arms corresponding to the number of rows in the array. The gripper arms have hooked ends which are oriented in opposite directions in each set of plates. Relative positioning of the gripper arms is varied by one or more rotating cams, which cause the gripper arms on one plate of each set to move relative to the gripper arms of the other plate(s) of the set, varying the combined width and / or relative angle of the gripper arms to manipulate a cap inserted into the end of each vial. The plurality of plate sets and gripper arms allow all vials in the array to be capped or de-capped simultaneously.

Owner:NEXUS BIOSYSTEMS INC

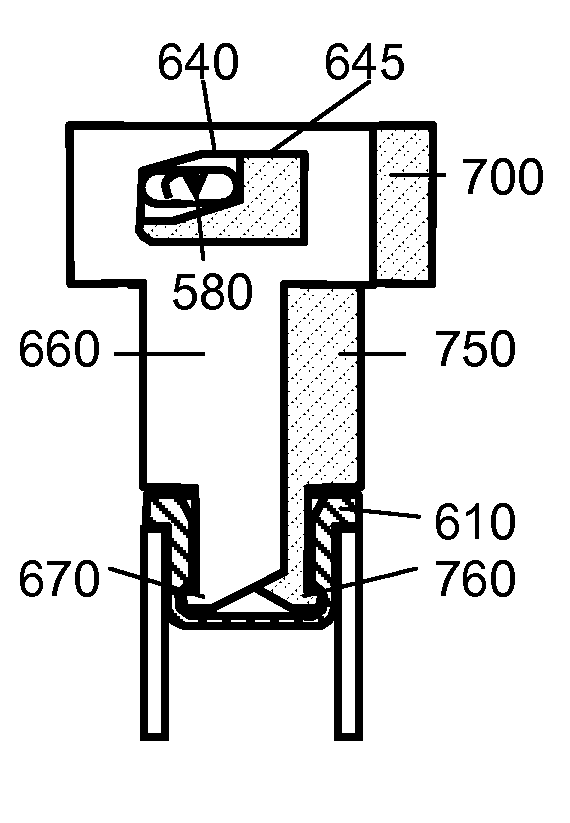

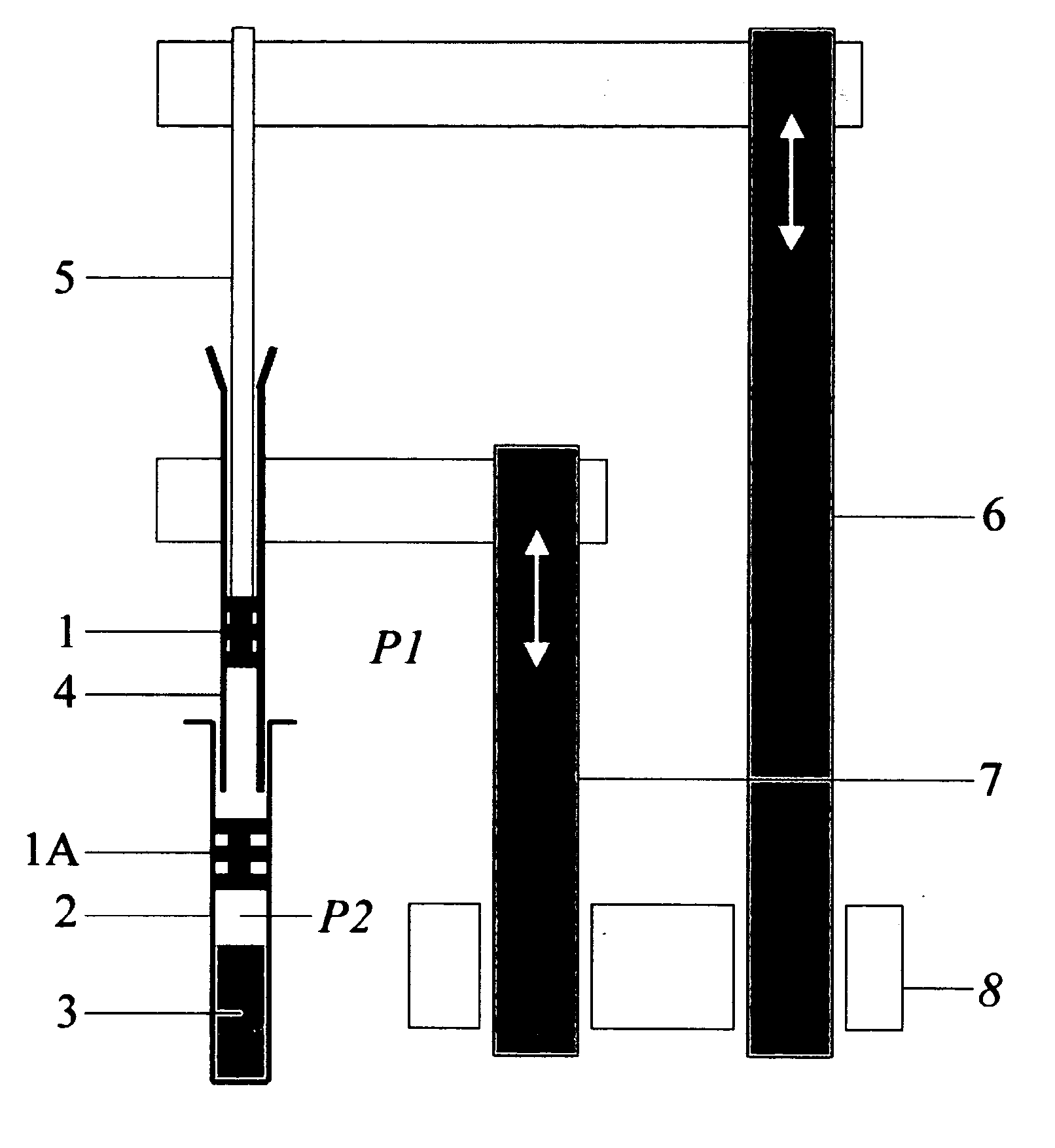

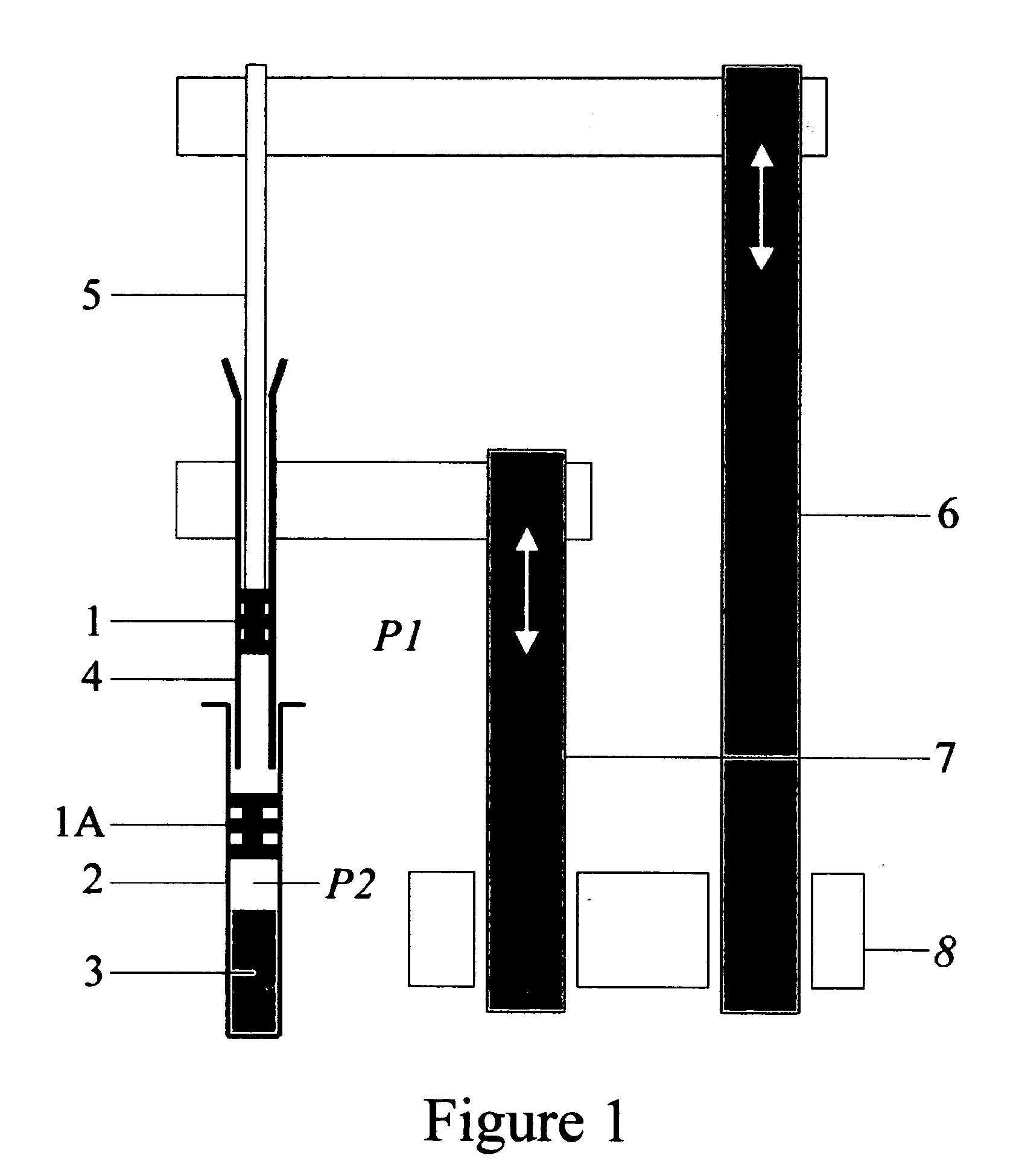

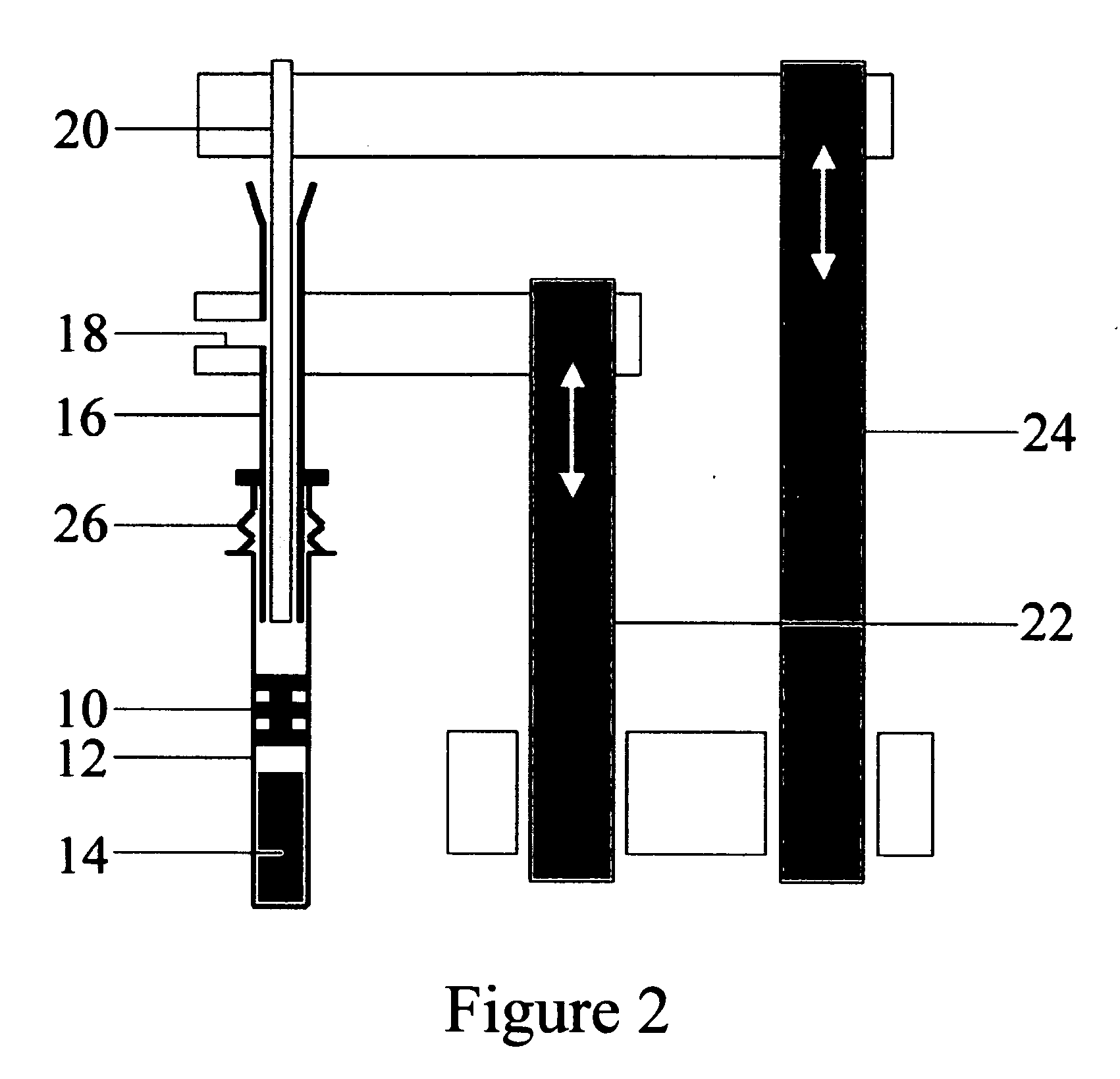

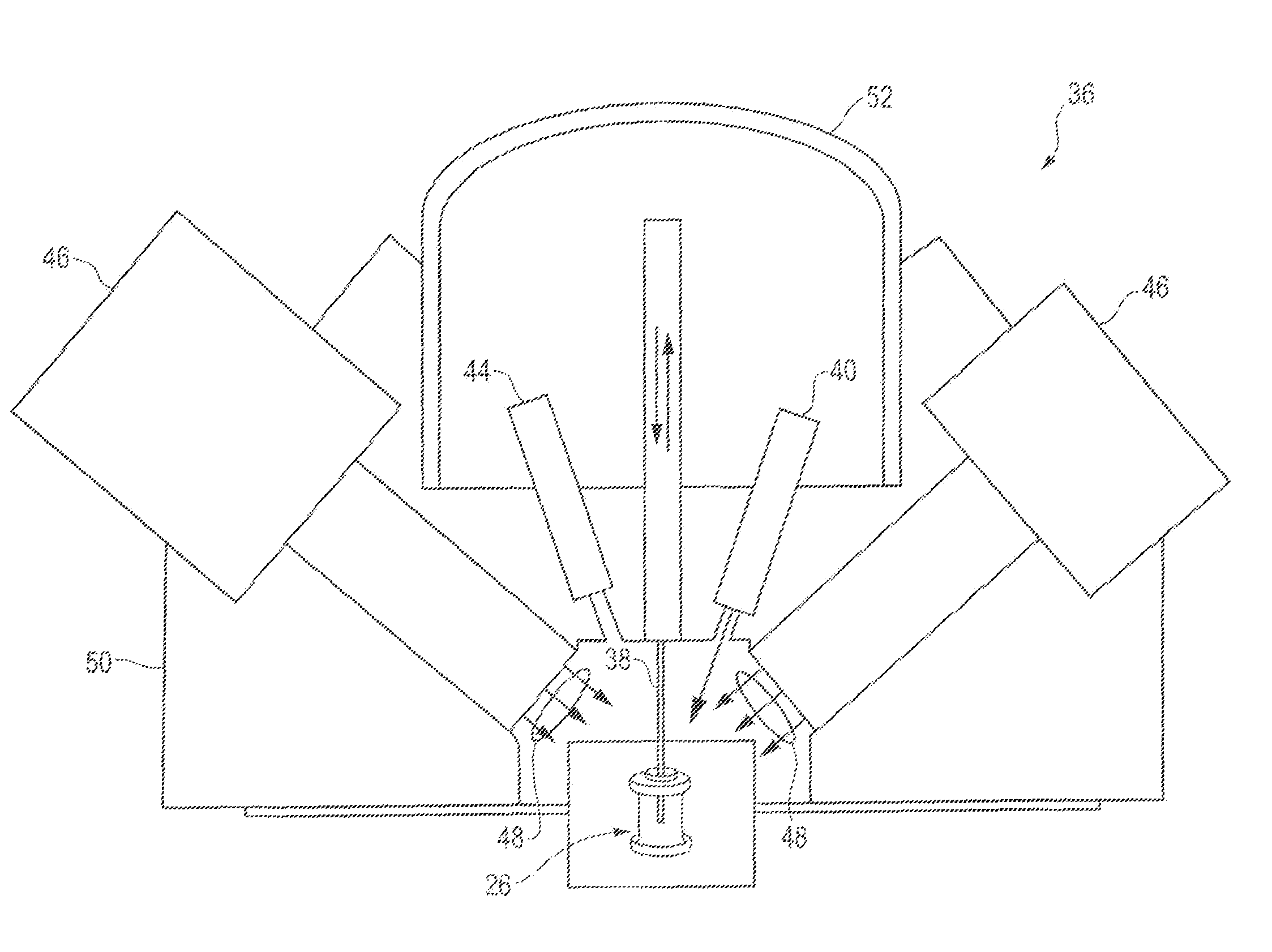

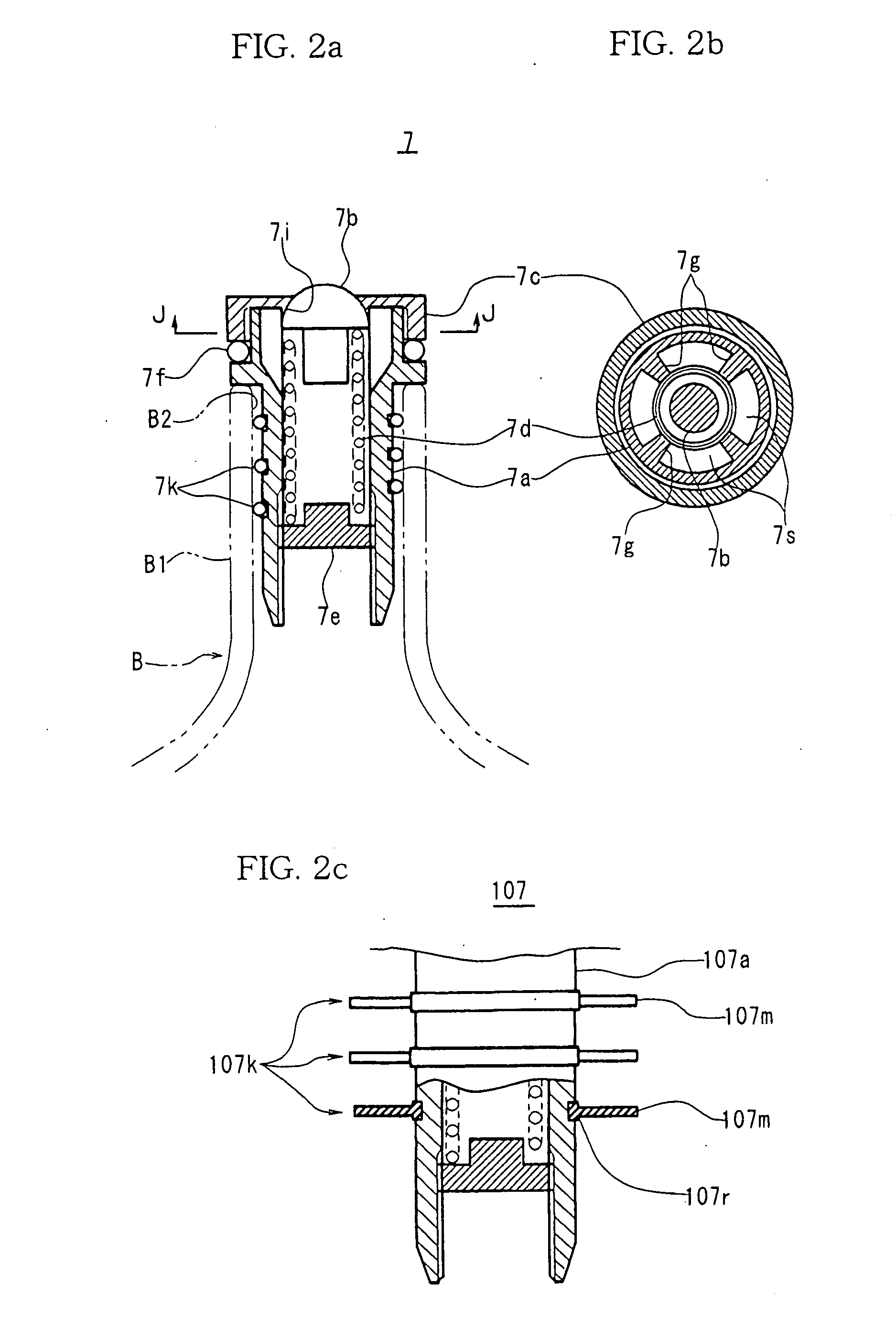

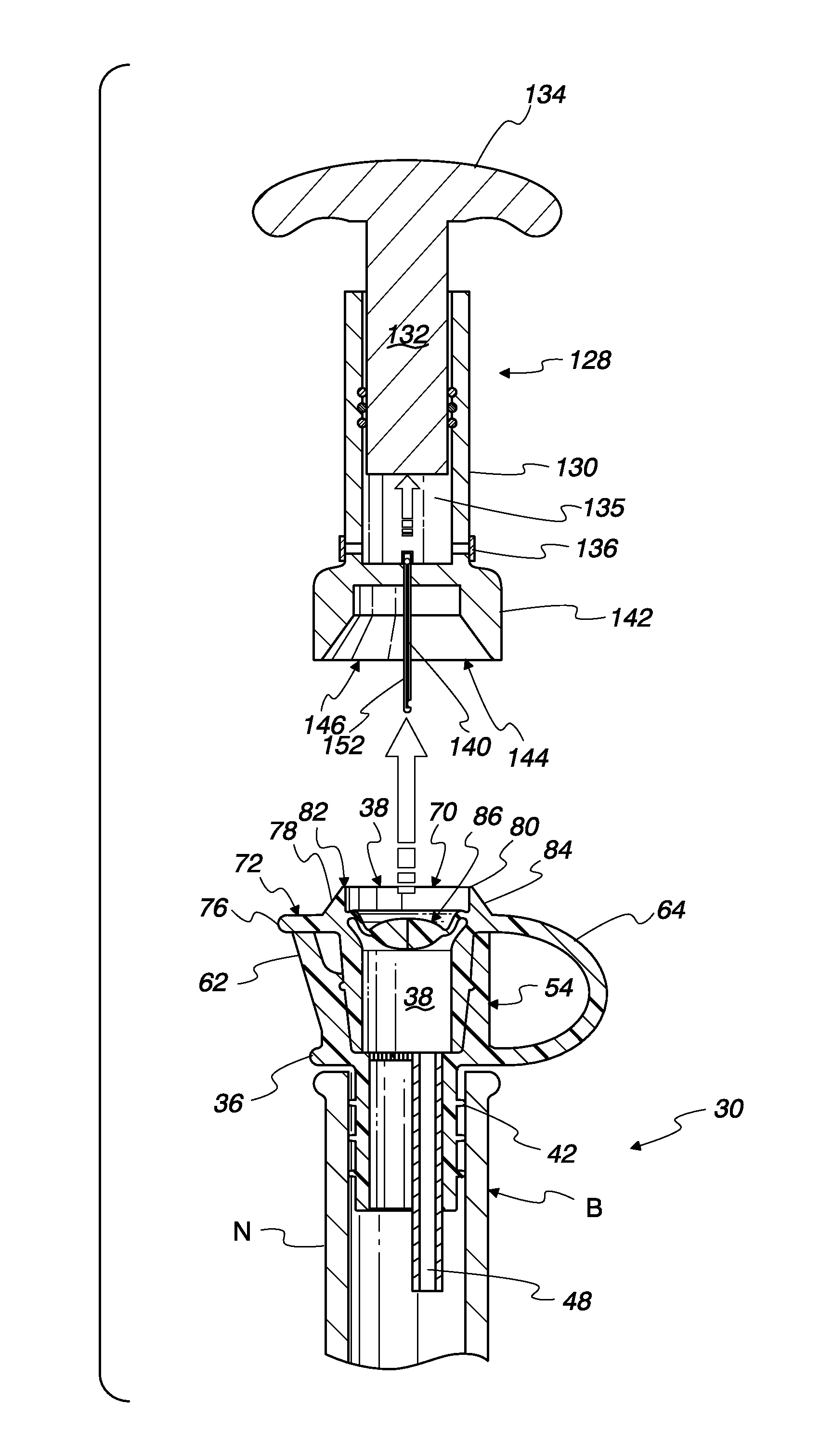

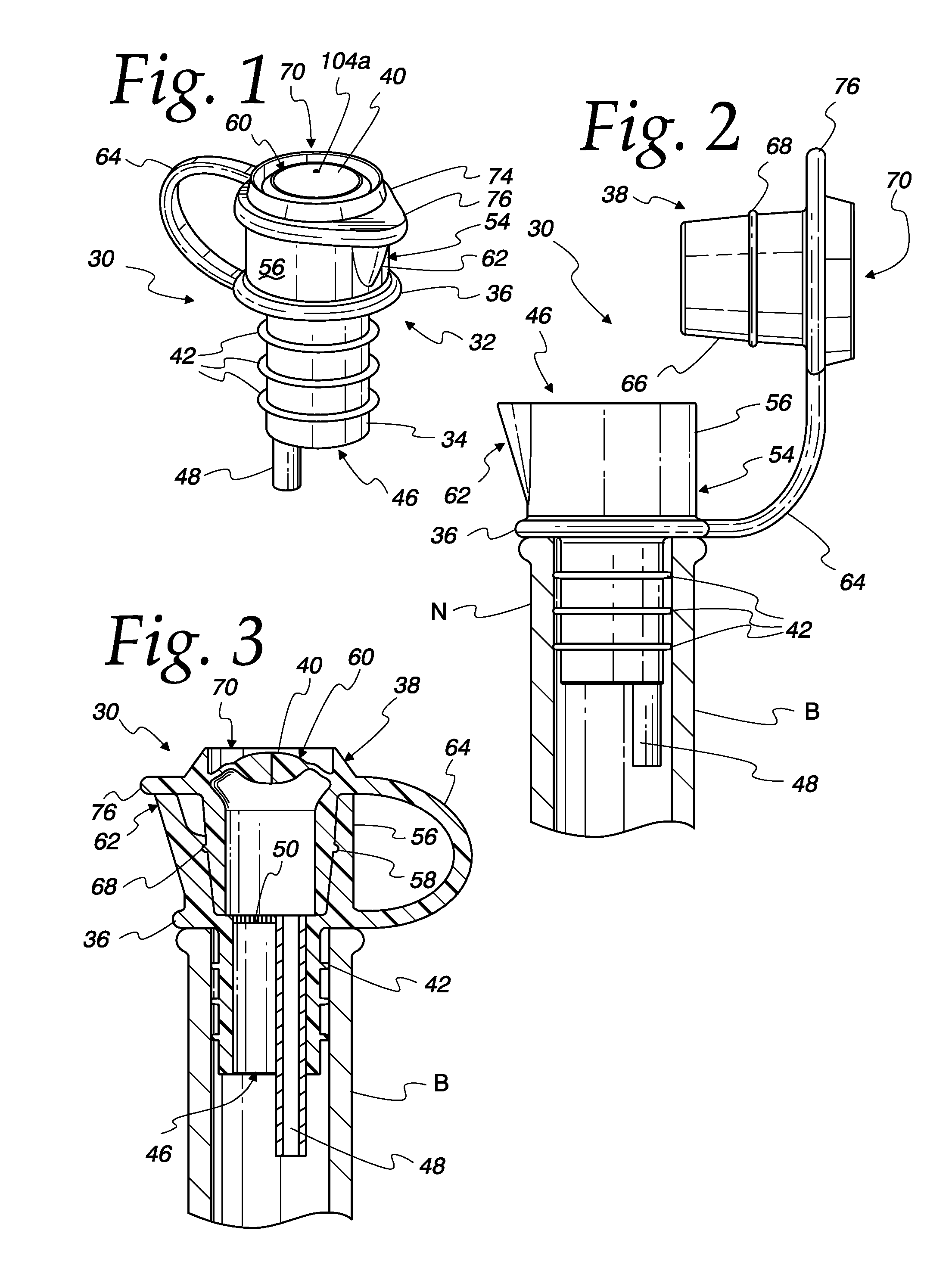

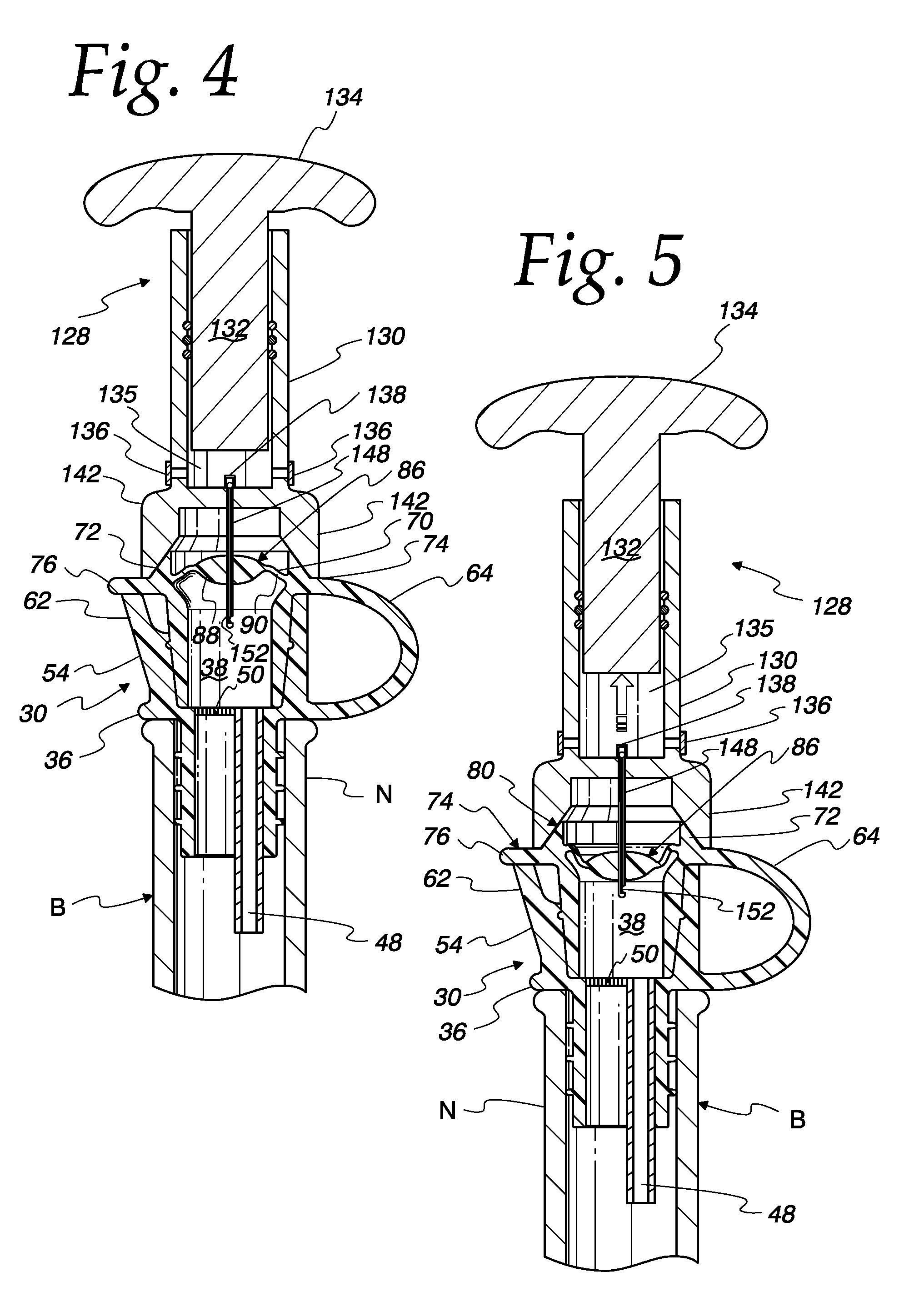

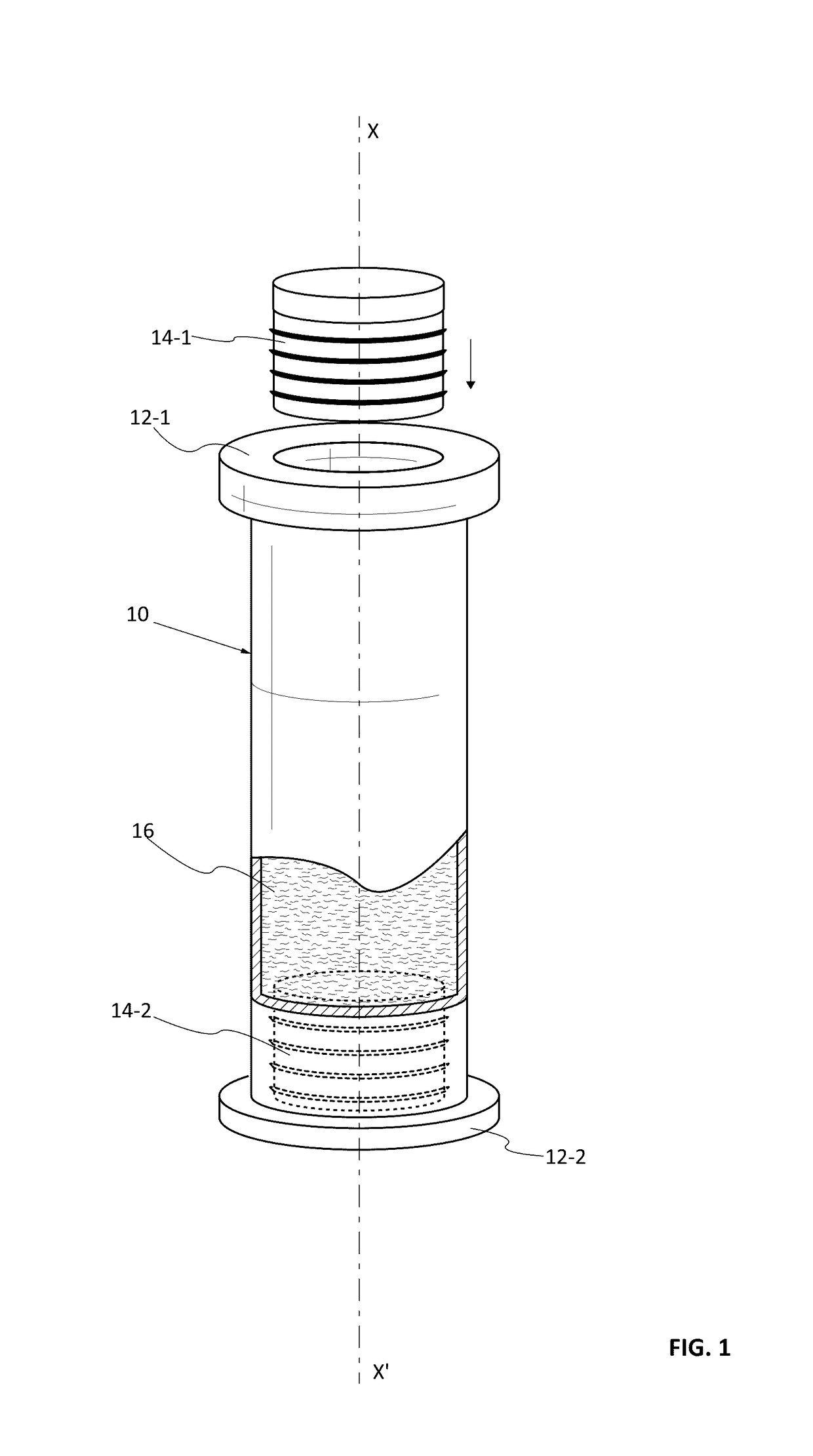

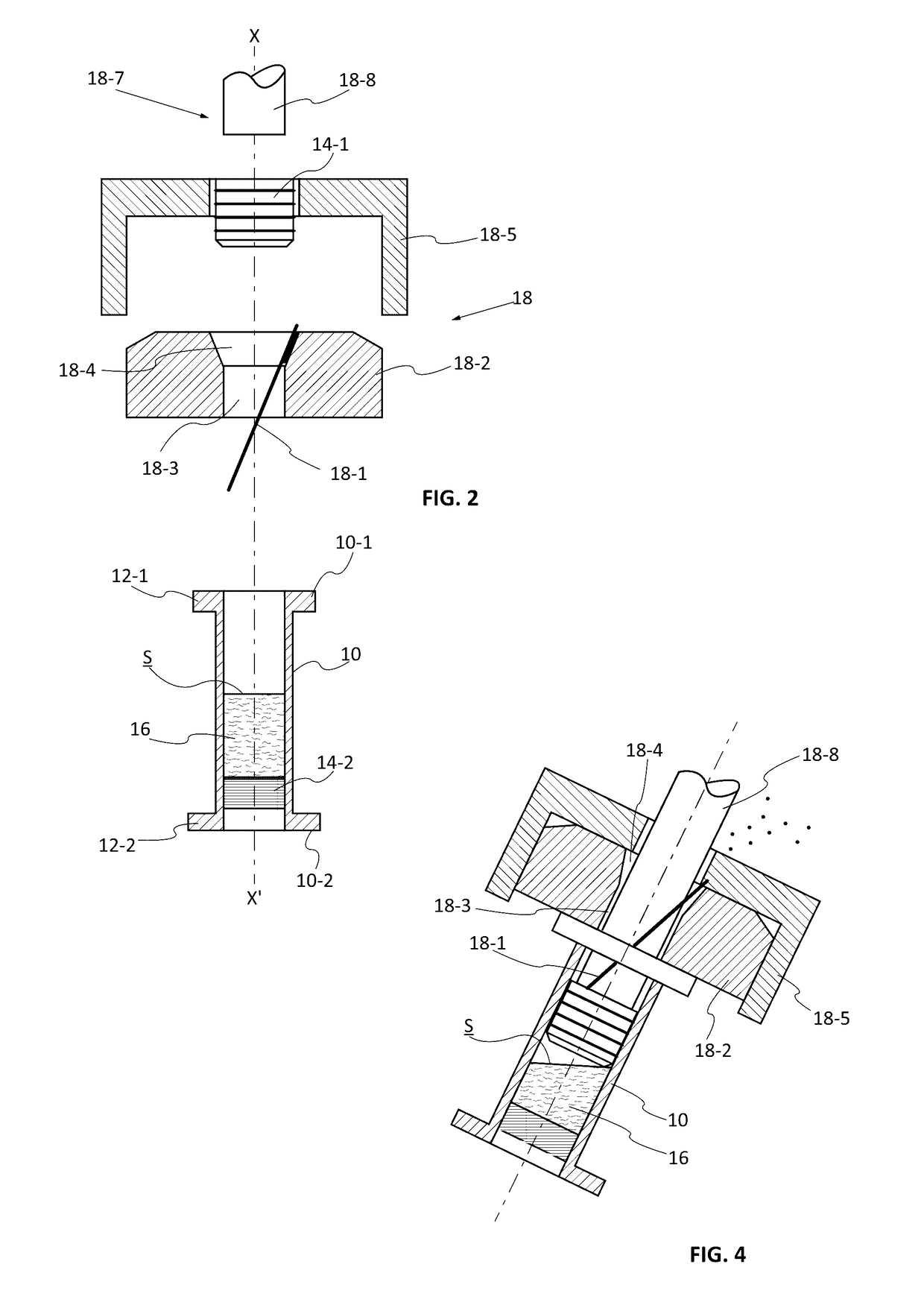

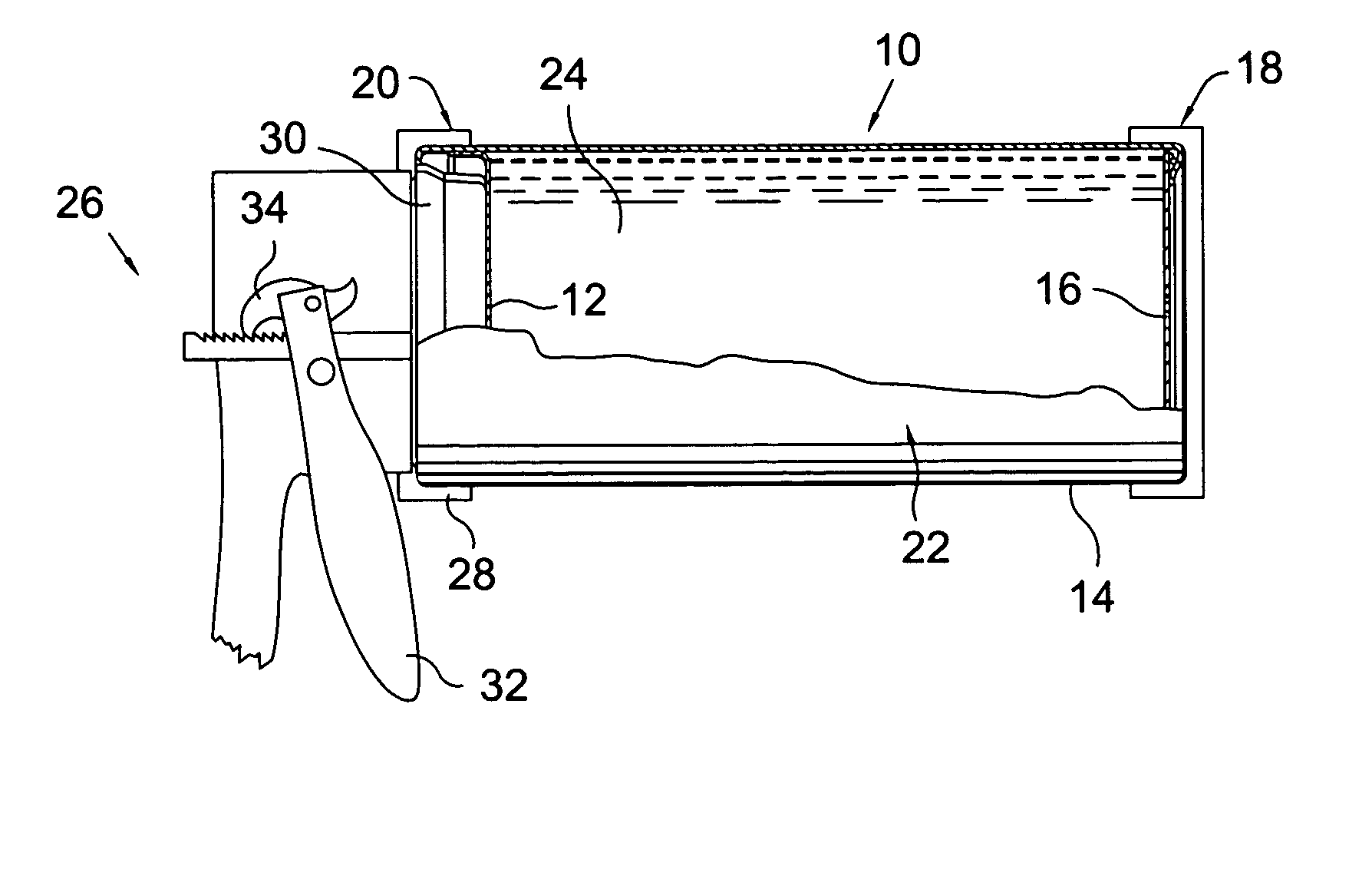

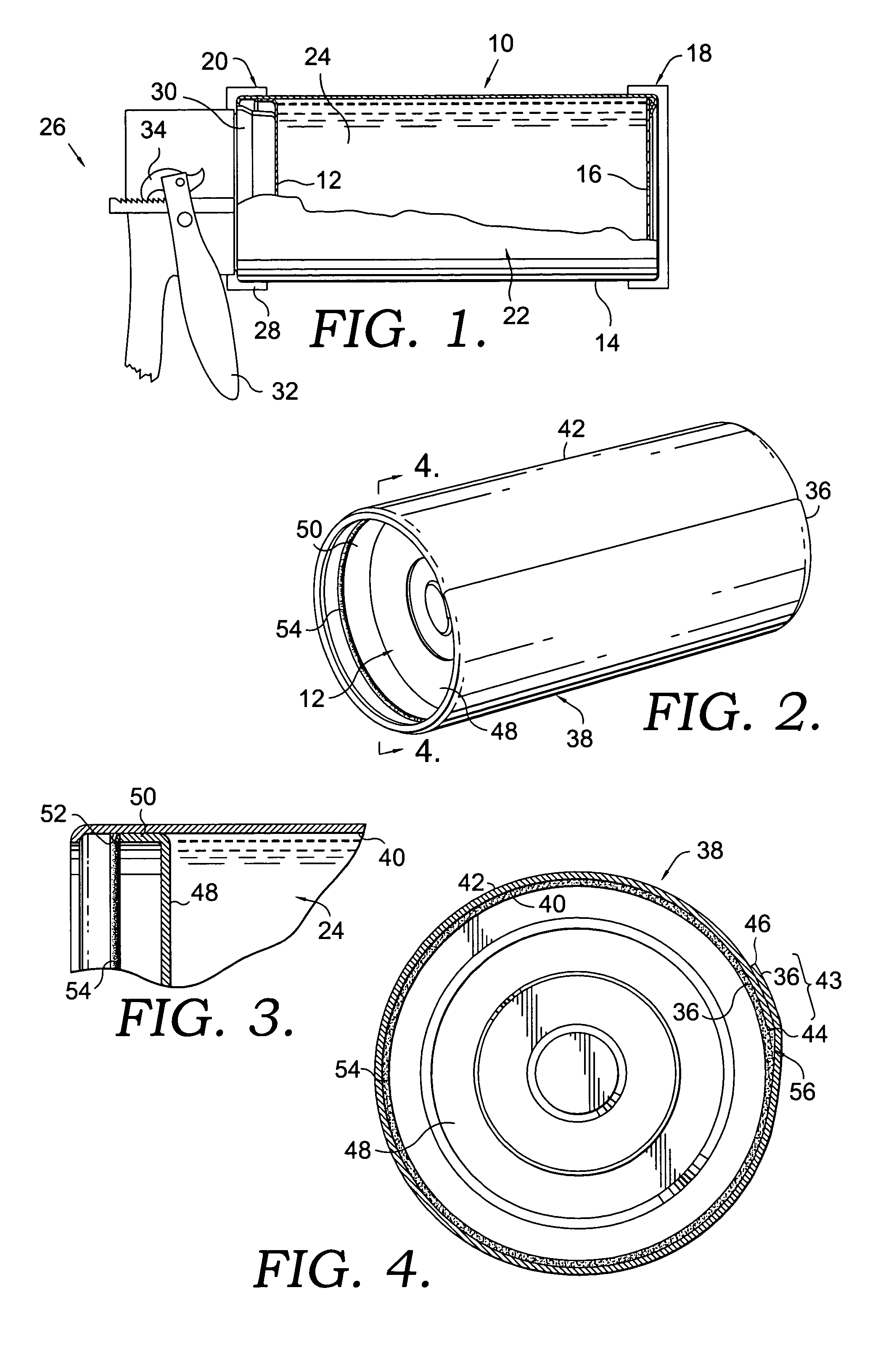

Method and apparatus to insert stoppers into prefilled syringes

InactiveUS20060168916A1Speed up the processReduces entrapped airLiquid materialThreadless stopper insertionPrefilled SyringeBiomedical engineering

An apparatus and method for inserting a stopper into a medical syringe minimizing the amount of entrapped air between the stopper and the contained liquid. The apparatus in a first embodiment utilizes a vacuum to assist inserting the stopper within the syringe. In a second embodiment a vacuum is used to transport the stopper and cause the insertion into the syringe. This method eliminates a mechanical device that transports the stopper to the syringe.

Owner:BASCO TECH

Method for closing containers by means of a closure in a gripping device

Owner:ROBERT BOSCH GMBH

Method for molding and assembling containers with stoppers and filling same

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

Method of Processing a Container and Base Cup Structure for Removal of Vacuum Pressure

InactiveUS20080298938A1Low costEasy to moveBottlesSemiconductor/solid-state device manufacturingVacuum pressureHandling system

A Method of Processing a Container and Base Cup Structure For Removal of Vacuum Pressure A plastic container (10) has a wall extending to a lower portion including a pressure panel (20). The panel (20) is transversely oriented and can move from a downwardly inclined position providing a geometrically unstable configuration to an upwardly inclined position providing a geometrically stable configuration to control pressure change in the container. This movement may be provided by suitable actuating means such as rod (22). In the unstable configuration a base cup 50 or any other suitable holder can support the container and enable it to be conveyed in a container handling or processing system.

Owner:CO2 PAC

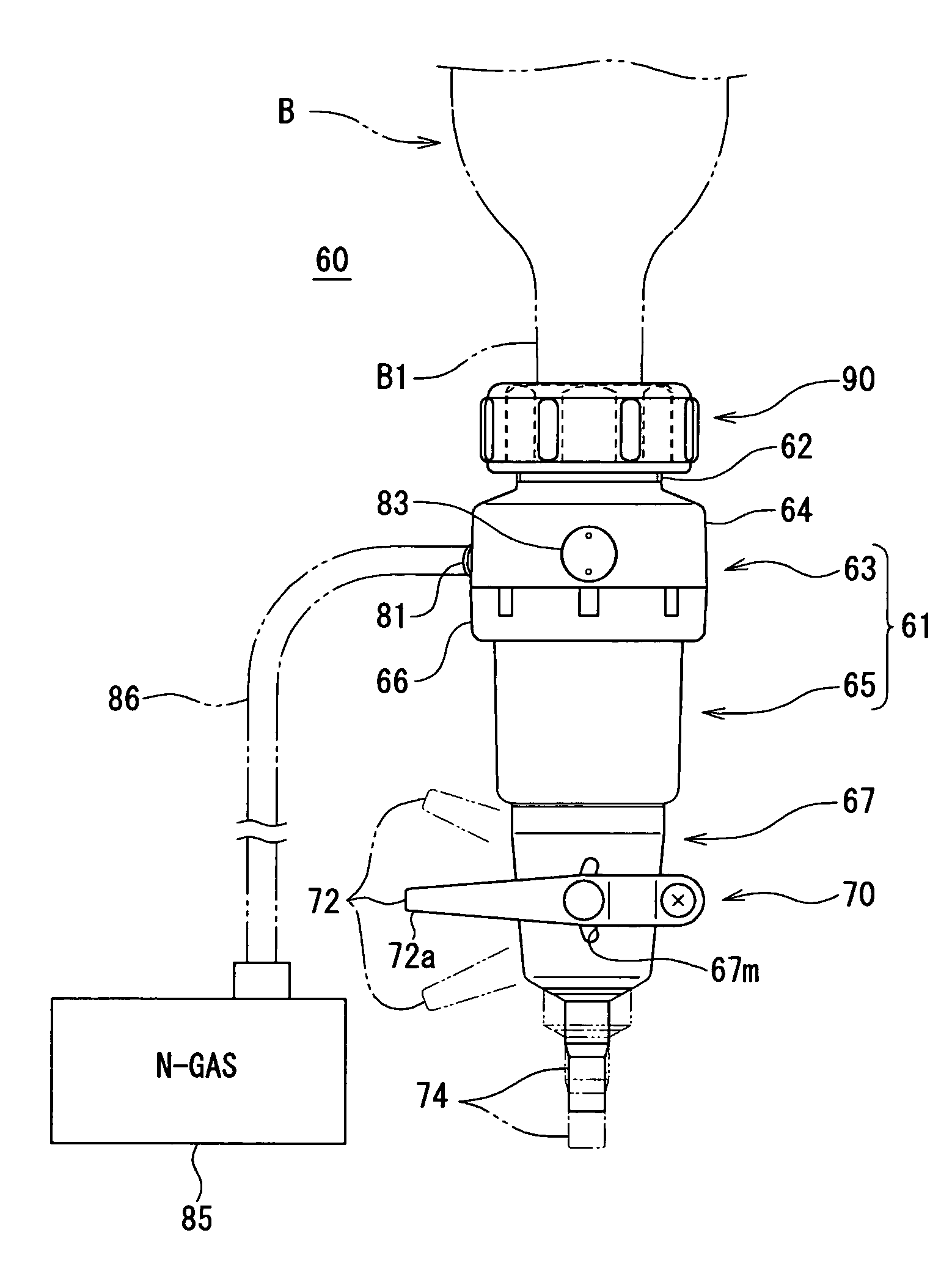

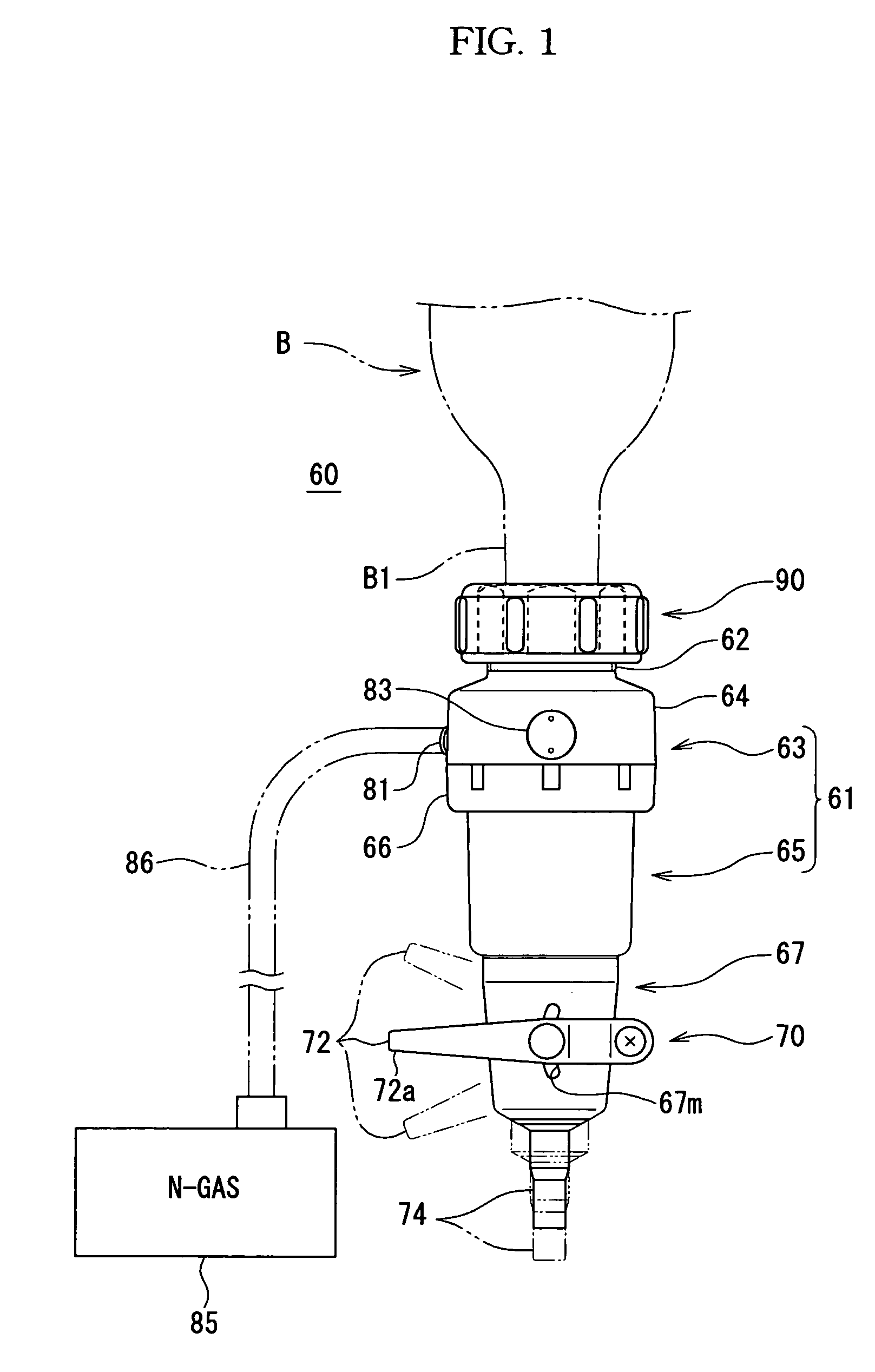

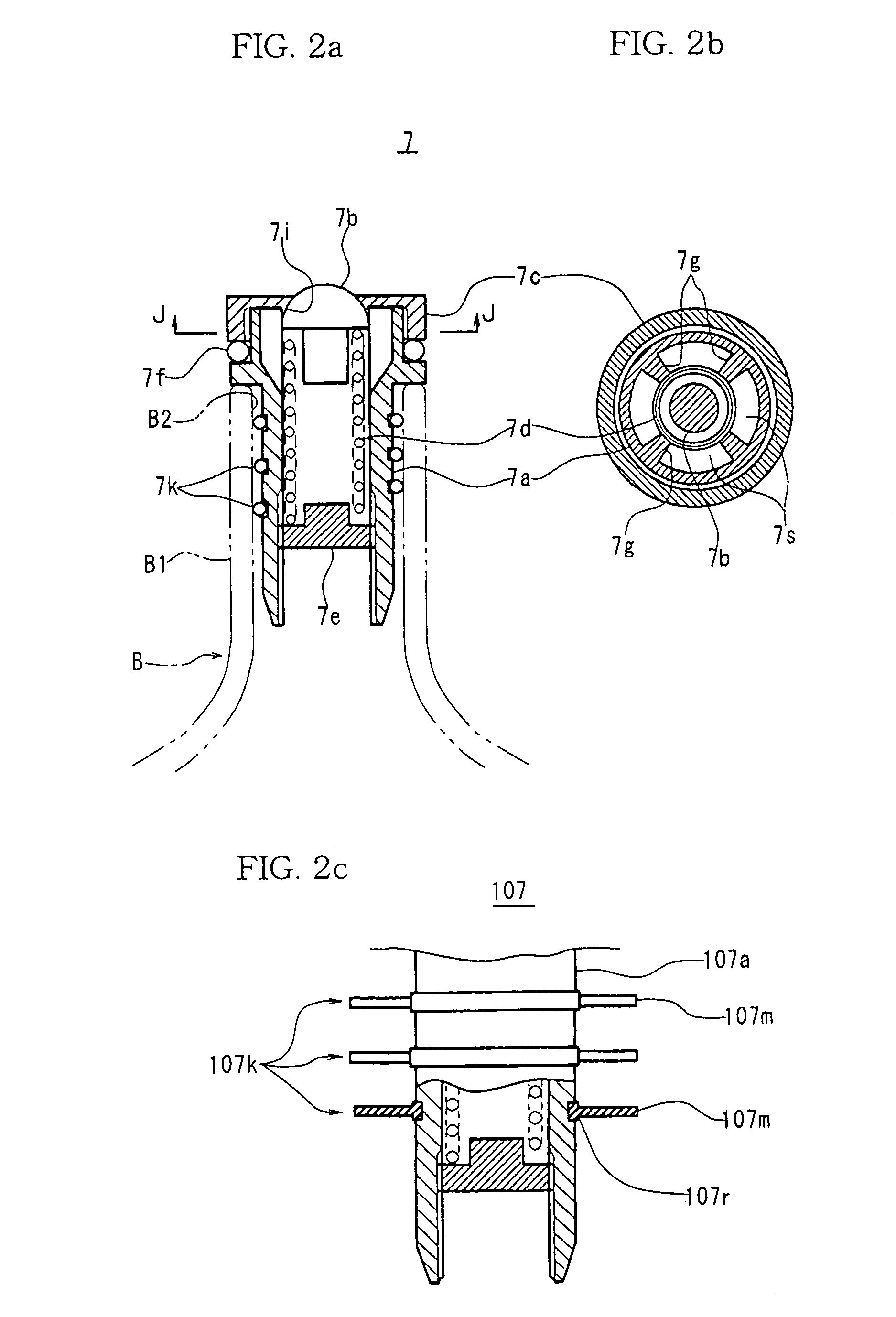

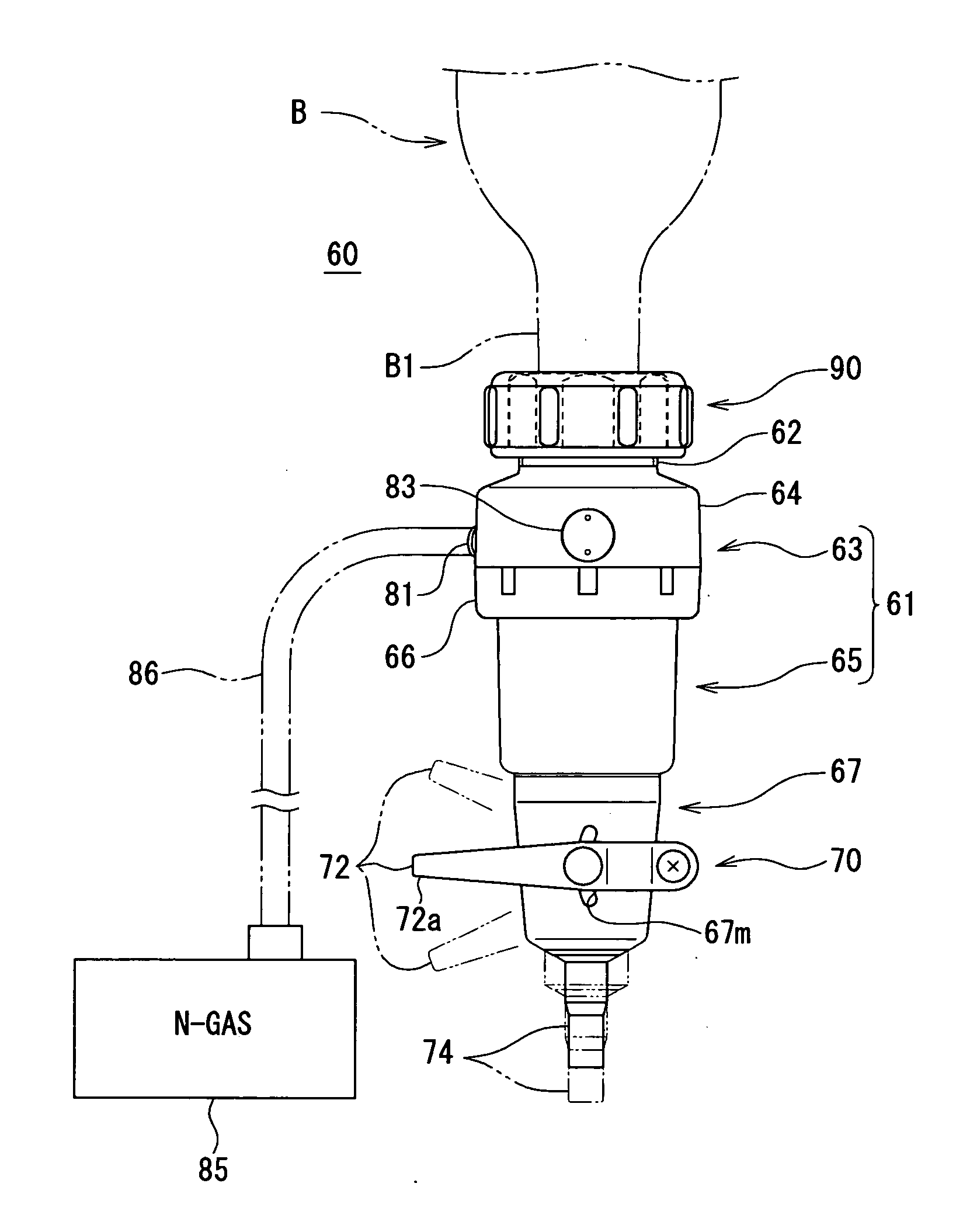

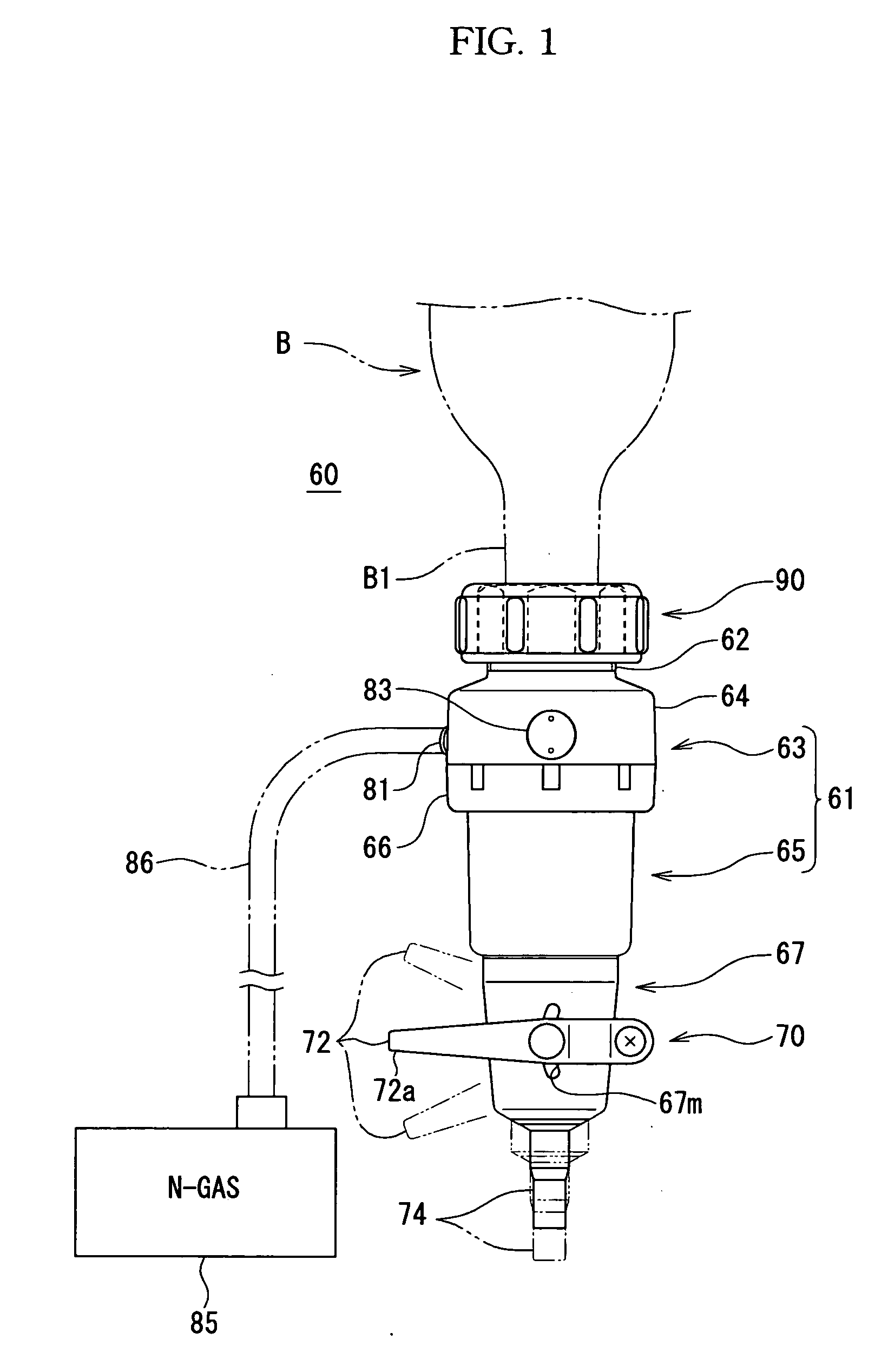

Device unit, and system for fluid extraction

InactiveUS7287670B2Easy to operateIncrease temperatureContracting/expanding measuring chambersPower operated devicesEngineeringProduct gas

A fluid extracting device is structured to be capable of extracting only a predetermined amount of a fluid such as wine or the like while a deterioration preventive gas is being supplied to a bottle B and the fluid extracting device (60), which are coupled to each other in an airtight state. Consequently, the partial extraction in a plurality of operations is made possible without causing quality deterioration of the fluid such as wine or the like even after the bottle is once opened. Further, such a structure is provided that the fluid extracting devices (60) having a large number of bottles of wine or the like attached thereto are mounted on a display table at a wine bar or the like.

Owner:YOSHIDA

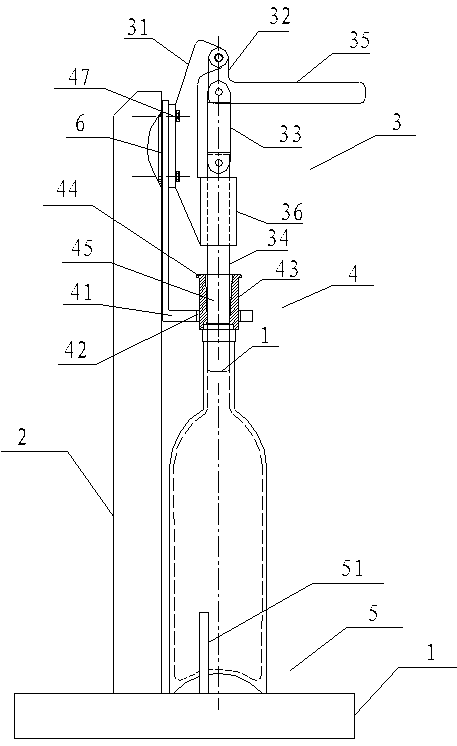

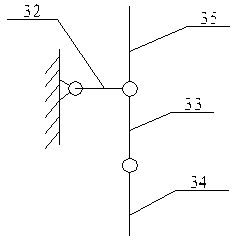

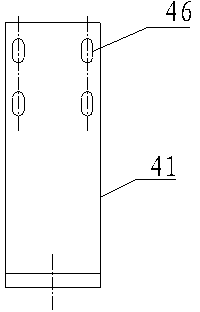

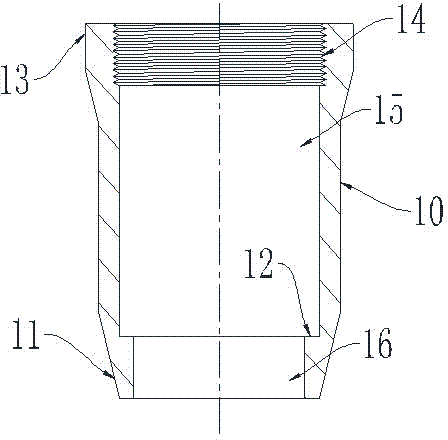

Cork pressing device

InactiveCN103159151AQuick compressionGuaranteed to press in correctlyThreadless stopper insertionEngineeringMechanical engineering

The invention discloses a cork pressing device. The cork pressing device comprises a support base plate and a support vertical plate, wherein the support base plate and the support vertical plate are mutually perpendicular. The support vertical plate is provided with a cork pressing mechanism, and a cork guide mechanism arranged below the cork pressing mechanism. The support base plate is provided with a locating mechanism used for fixing objects to be pressed. Centers of the cork pressing mechanism, the cork guide mechanism and the locating mechanism are collinear. The cork pressing mechanism is a crank-link mechanism. The support vertical plate is further provided with a slotted hole used for adjusting the height of the cork pressing mechanism. By rotating a crank, a cork can be pressed fast, operation is simple and convenient, much time and labor do not need to be consumed, and sealing efficiency is improved. By arranging the cork guide mechanism, the cork can be pressed correctly. Meanwhile, by arranging the locating mechanism, the objects to be pressed can be located accurately. By arranging the slotted hole used for adjusting the height of the cork pressing mechanism in the support vertical plate, adjustment can be carried out according to the height of the objects to be pressed. The cork pressing device is strong in genenrality.

Owner:苏州微纳过滤设备有限公司

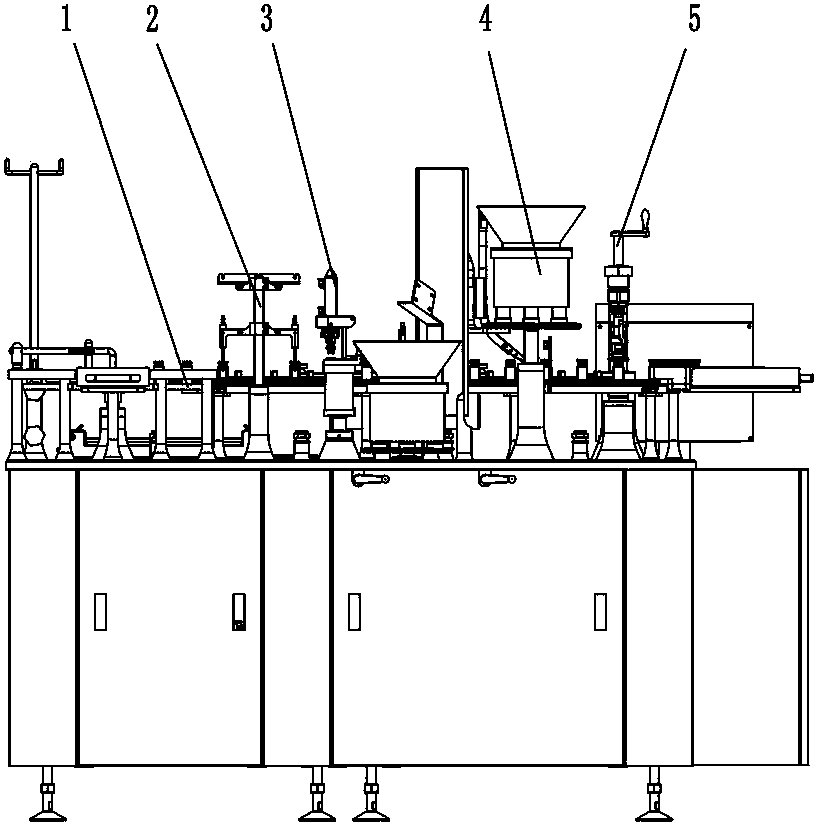

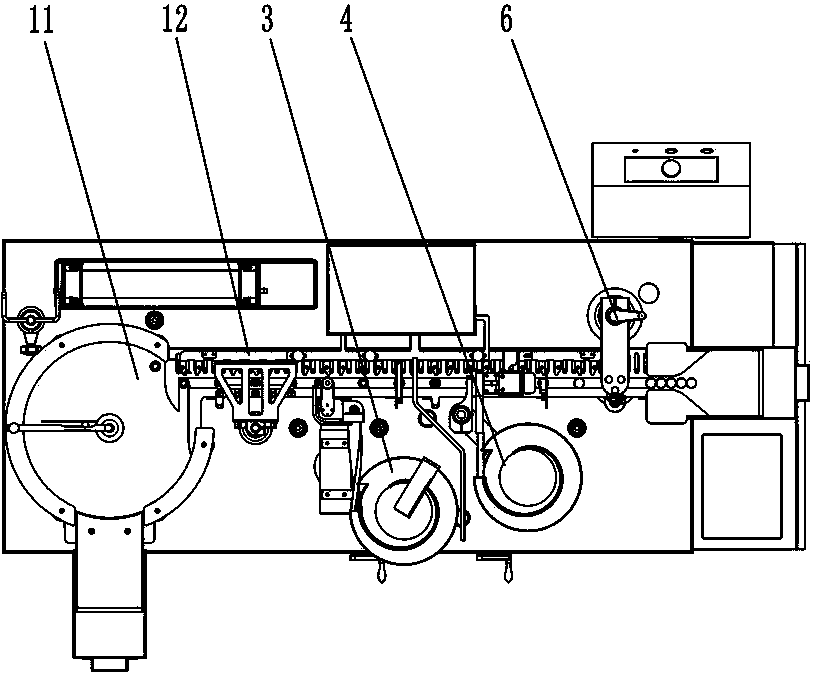

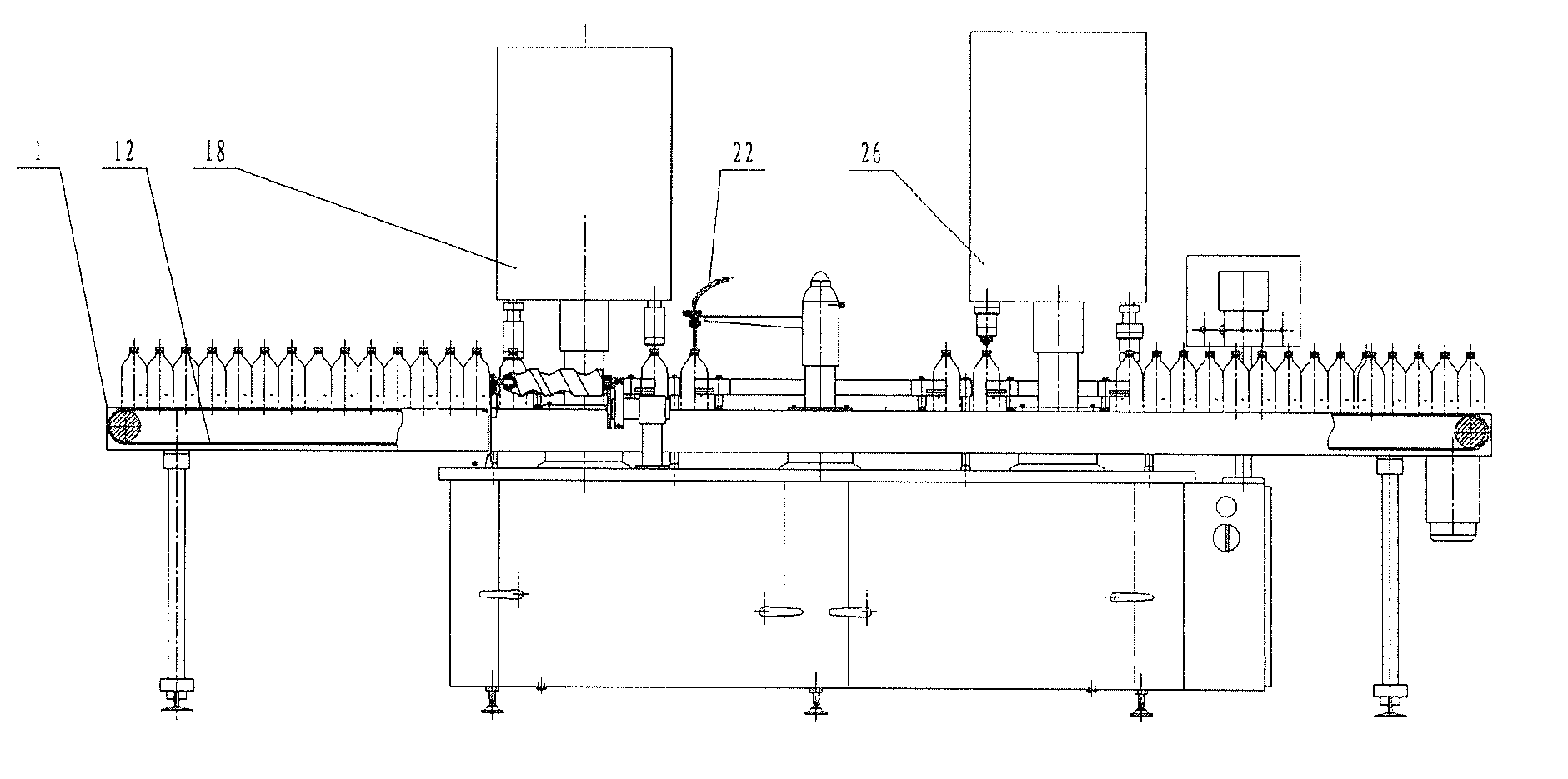

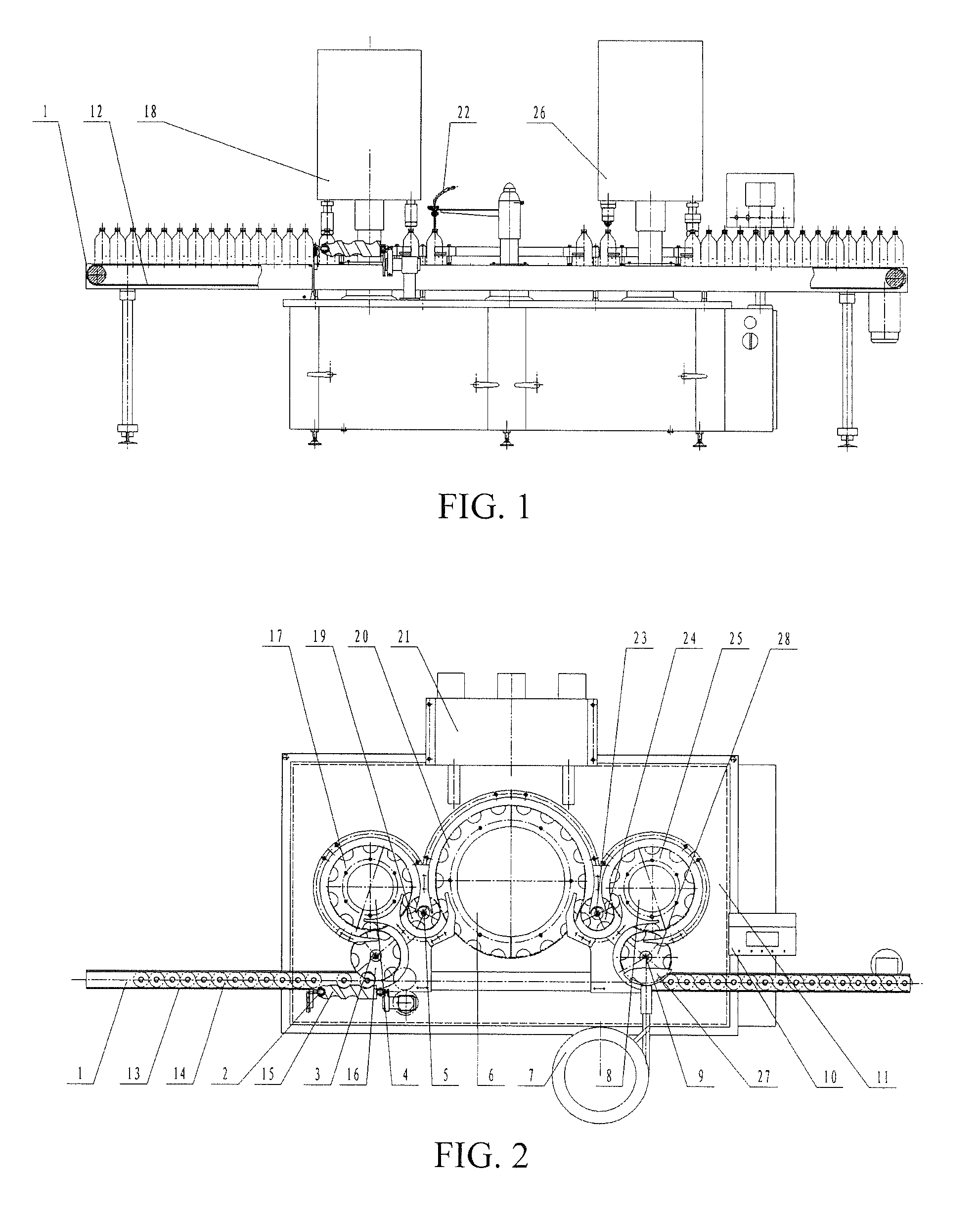

Filling-capping integrated machine

ActiveCN103964359ACompact structureSmall footprintCapsClosure using capsBiochemical engineeringBottle

The invention discloses a filling-capping integrated machine which comprises a bottle body conveying device, a filling device, a plug adding device, a cap handing device and a capping device, wherein the filling device, the plug adding device, the cap handing device and the capping device are sequentially arranged in the bottle conveying direction of the bottle body conveying device; the bottle body conveying device comprises a bottle unscramblingdisc component and a bottle moving component butted with the bottle unscrambling disc component; the bottle moving component comprises a bottle supporting bottom track, a bottle stirring plate, a bottle stirring support and a bottle stirring plate driving component; the bottle stirring plate is arranged on the bottle stirring support and above the bottle supporting bottom track; the bottle stirring support is connected with the bottle stirring plate driving component; the bottle feeding direction of the bottle unscramblingdisc component is perpendicular to the bottle supporting bottom track. The filling-capping integrated machine disclosed by the invention has the advantages that the structure is compact, the occupied space is small, the operation is convenient and the cost is reduced.

Owner:TRUKING TECH LTD

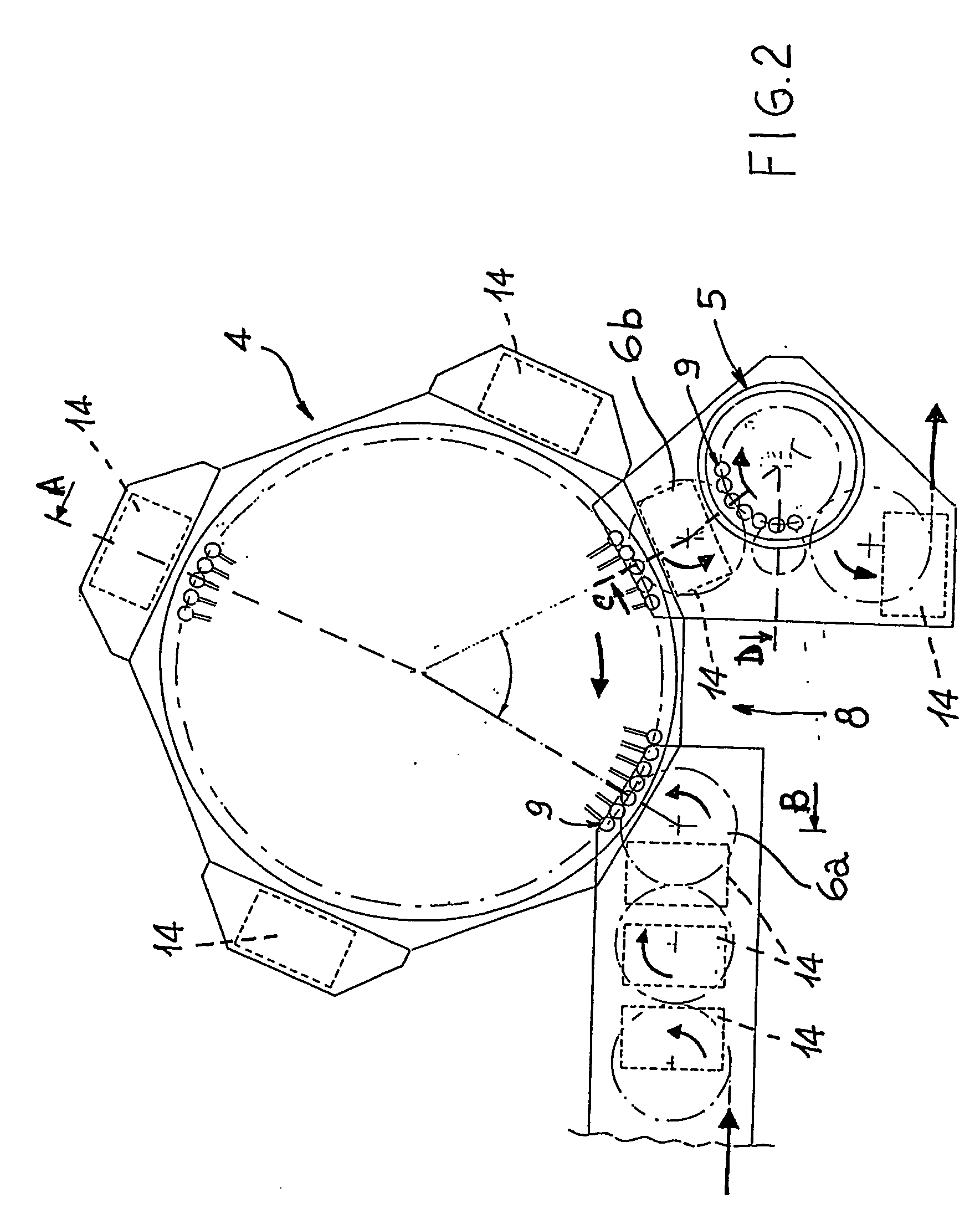

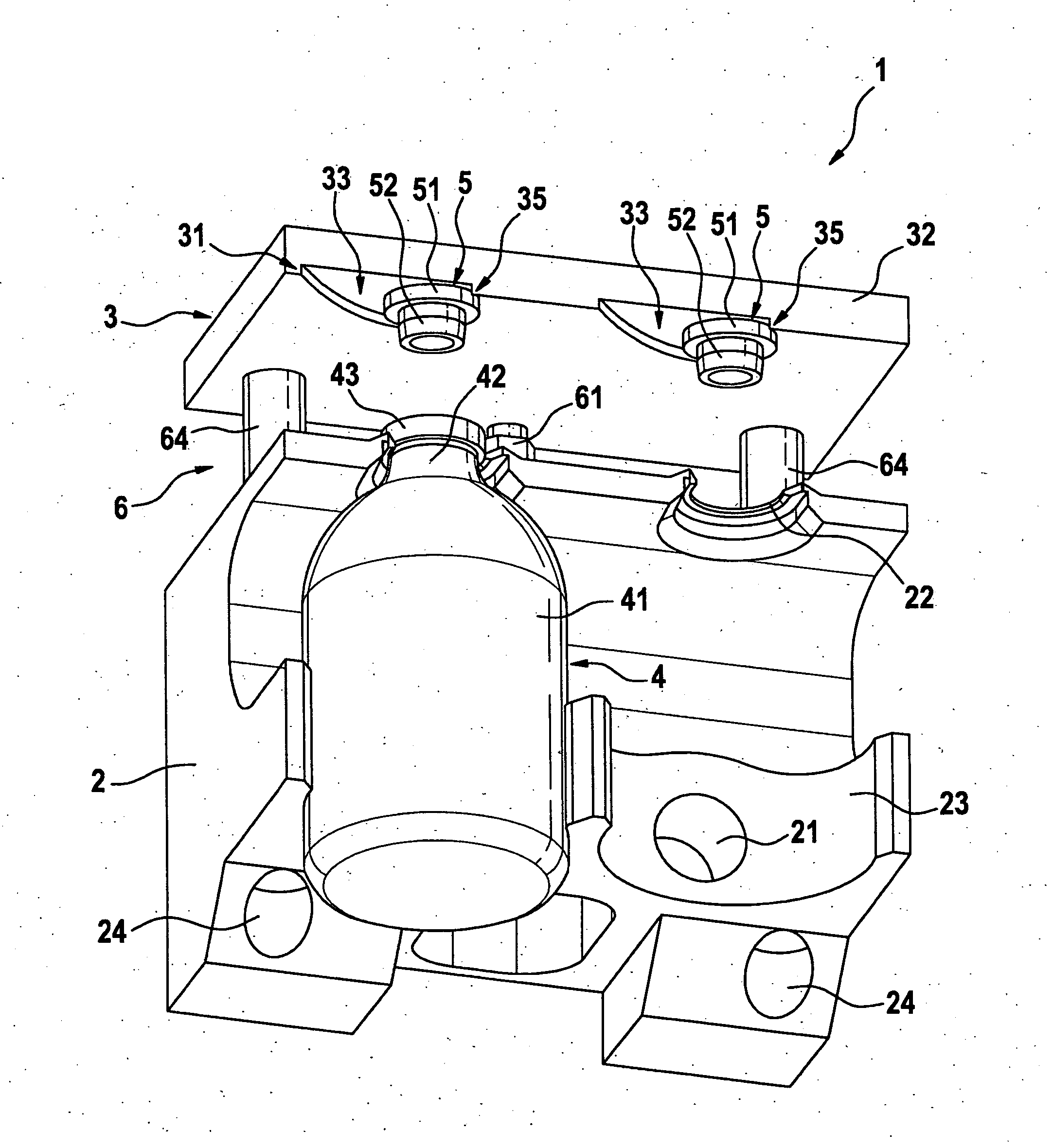

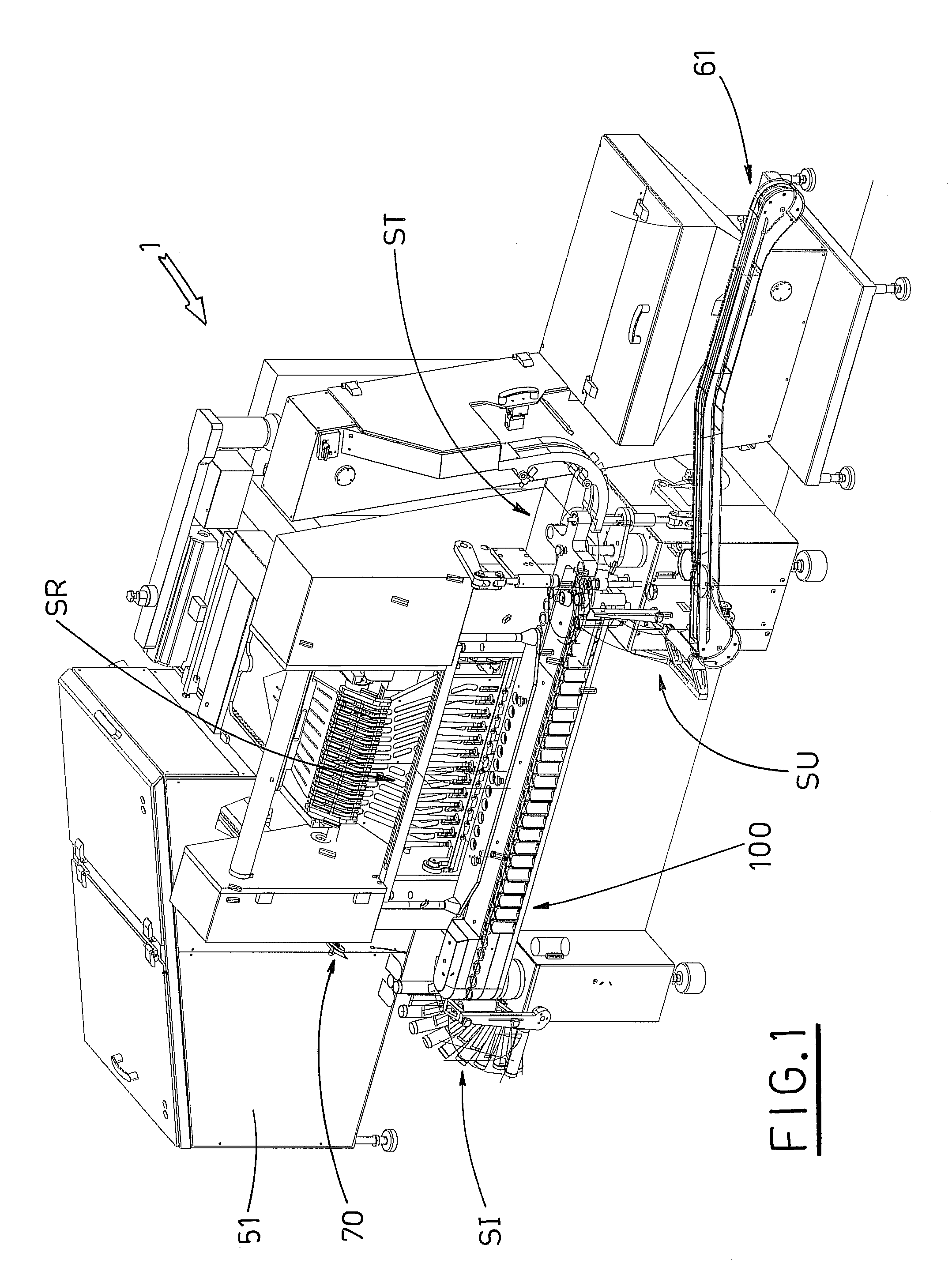

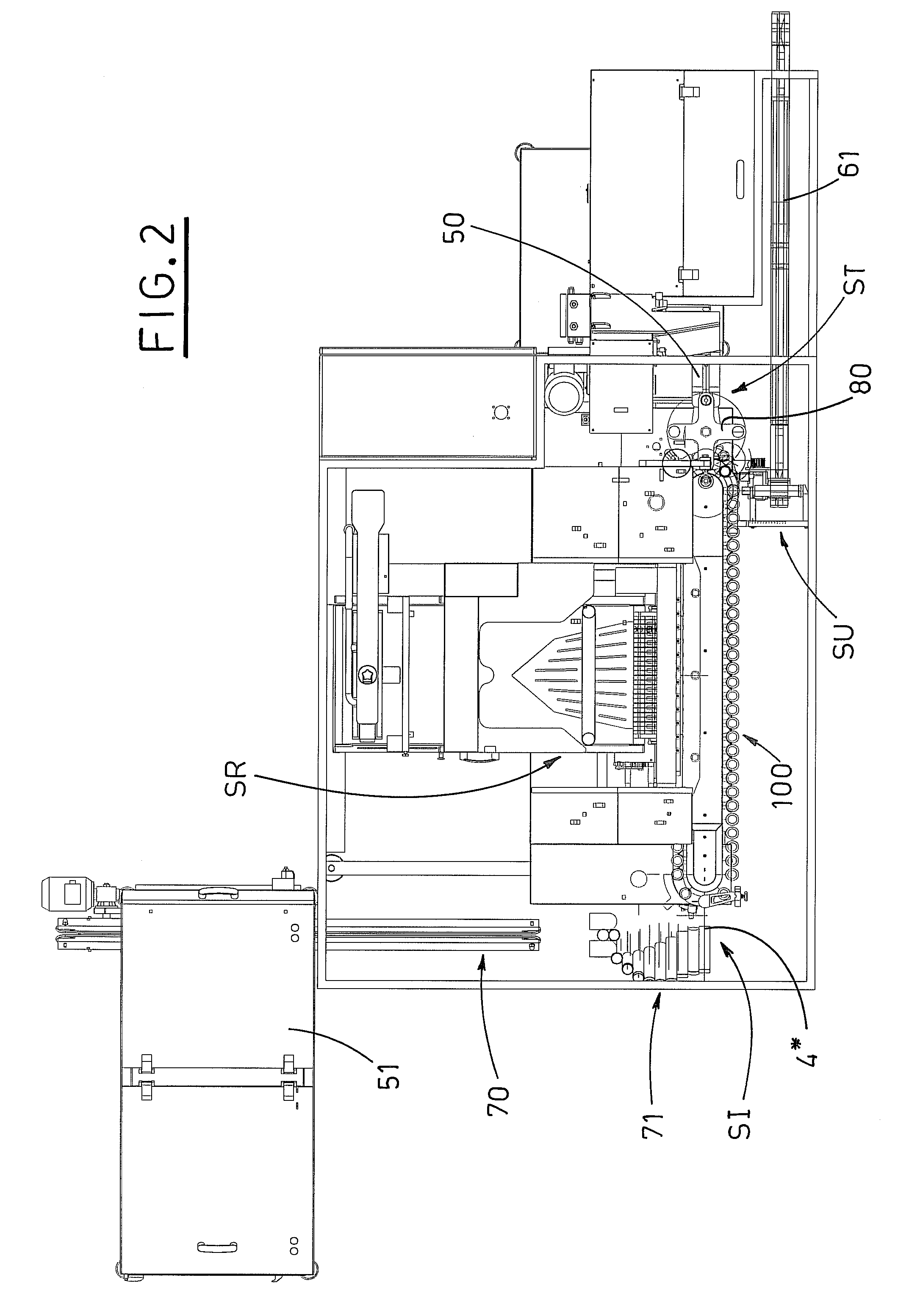

Machine for the aseptic treatment of containers in bottling plant

InactiveUS20060059862A1Simple and economical mannerDrawback can be obviatedLiquid fillingSolid materialAseptic processing

Machine for the aseptic treatment of containers (10) in bottling plant, of the rotary type provided with a plurality of stations (9) for treating the containers and so shaped as to cause the treatment of the containers to take place under substantially sterile conditions, is characterised in that it comprises sealing means that separate a non sterile area (11) of the machine from an area (12) maintained under sterile conditions and in which the treated containers (10) transit, said means comprising a fixed annular channel (15) at least partially filled with liquid in which slides a concentric annular element (16) associated with the rotating part (11).

Owner:SIDEL HLDG & TECH

Device unit, and system for fluid extraction

InactiveUS20050230414A1Increase temperatureEasy to operatePower operated devicesContracting/expanding measuring chambersProduct gasEngineering

A fluid extracting device is structured to be capable of extracting only a predetermined amount of a fluid such as wine or the like while a deterioration preventive gas is being supplied to a bottle B and the fluid extracting device (60), which are coupled to each other in an airtight state. Consequently, the partial extraction in a plurality of operations is made possible without causing quality deterioration of the fluid such as wine or the like even after the bottle is once opened. Further, such a structure is provided that the fluid extracting devices (60) having a large number of bottles of wine or the like attached thereto are mounted on a display table at a wine bar or the like.

Owner:YOSHIDA

Vacuum Bottle Stopper for Wine, Inert Gas Supply and Method

InactiveUS20150259186A1Avoid and minimize effectReliably and efficiently madeFilling using suctionClosuresWine bottleEngineering

Owner:HALEYS CORKER INC

Cap systems and methods for sealing pharmaceutical vials

A capping system and method of use for sealing injectable drugs within vials is disclosed. The system includes a closure assembly and a locking cap. The closure assembly includes a retainer member and a resilient stopper located within the retainer member. The retainer member is arranged to be disposed on the vial whereupon a gap results between the stopper and the vial. The retainer member is movable to close that gap. The locking cap is used to permanently seal the vial.

Owner:GENESIS PACKAGING TECH +1

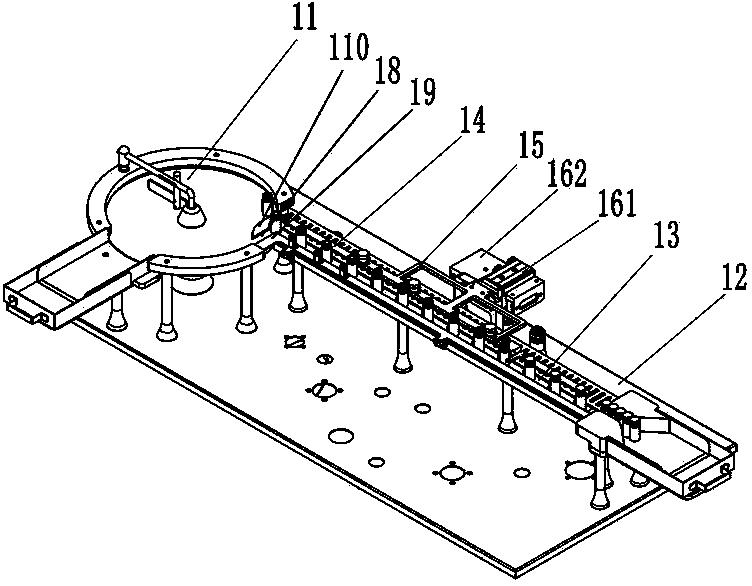

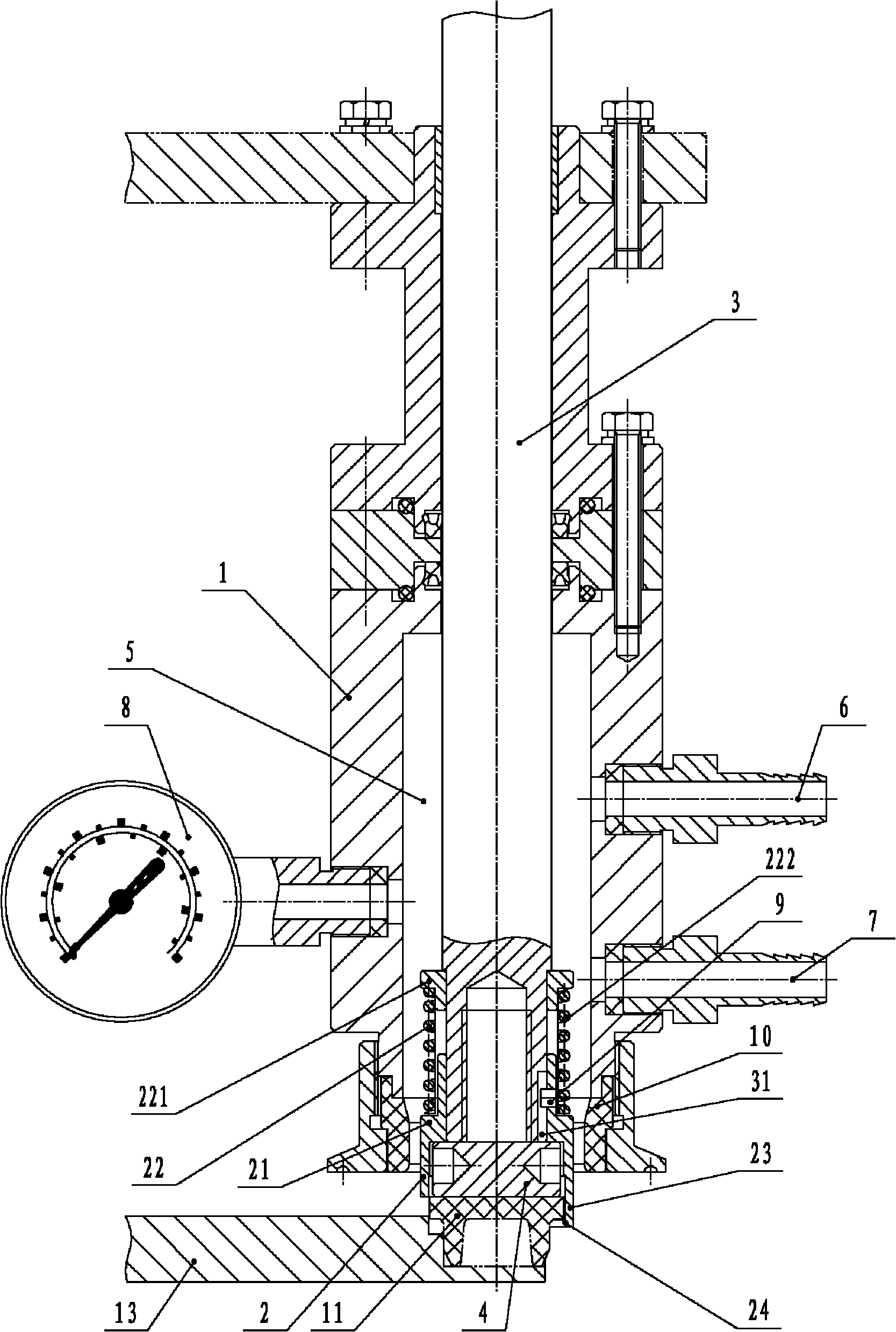

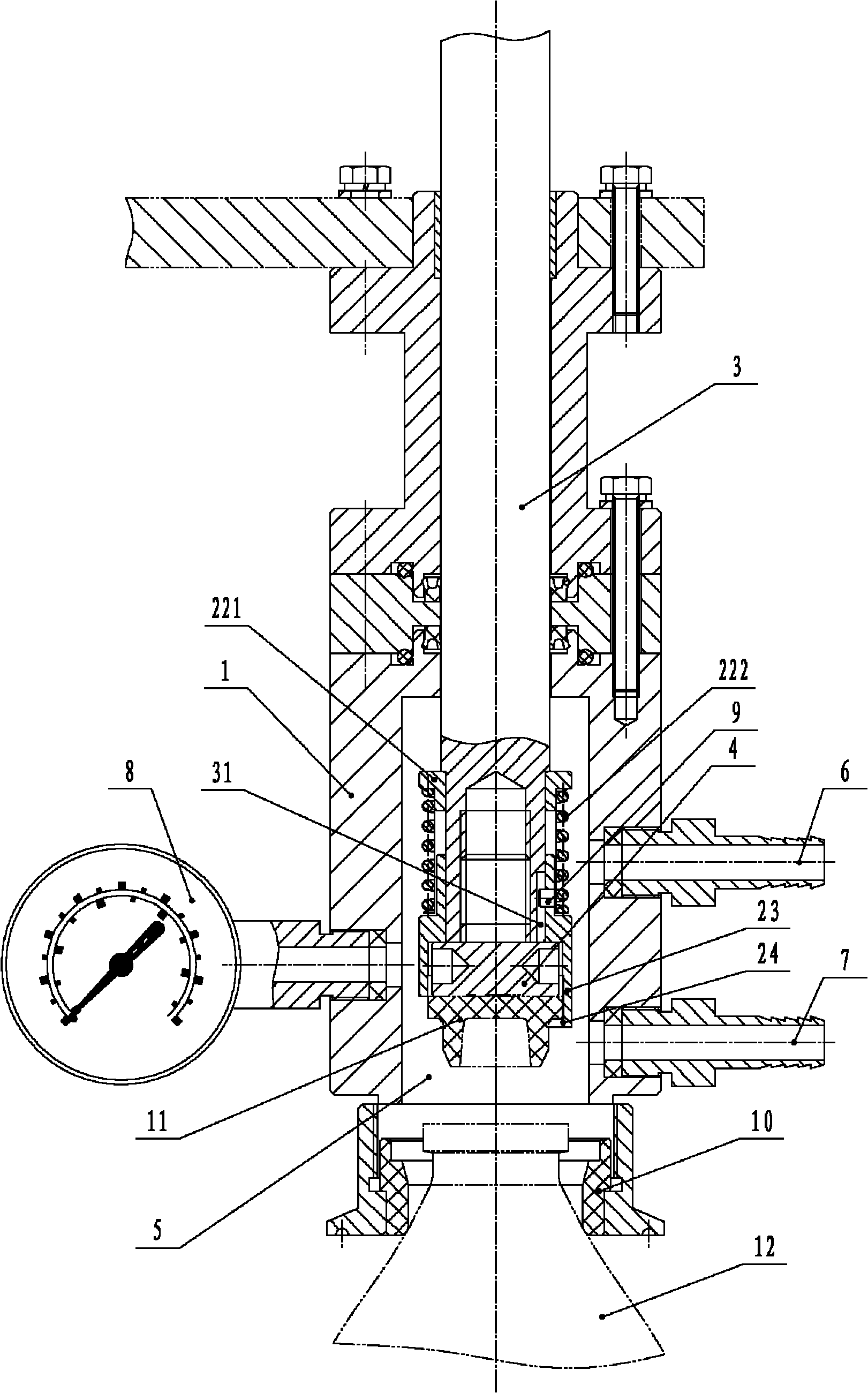

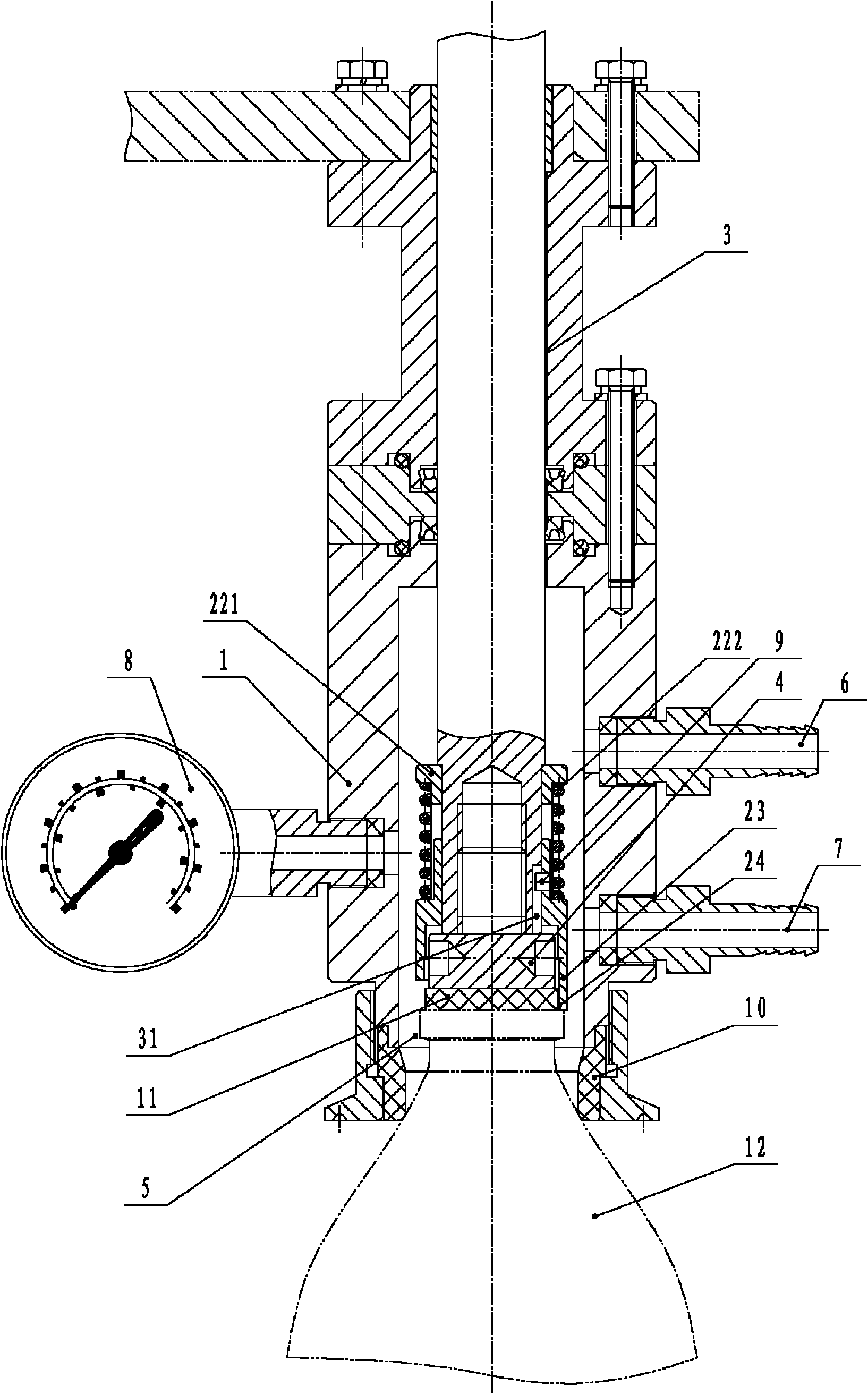

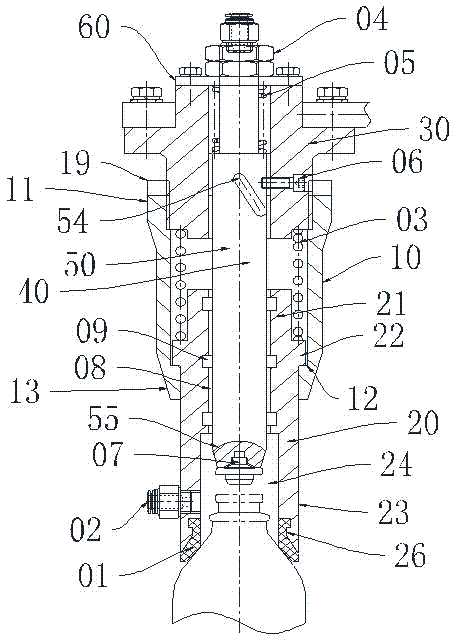

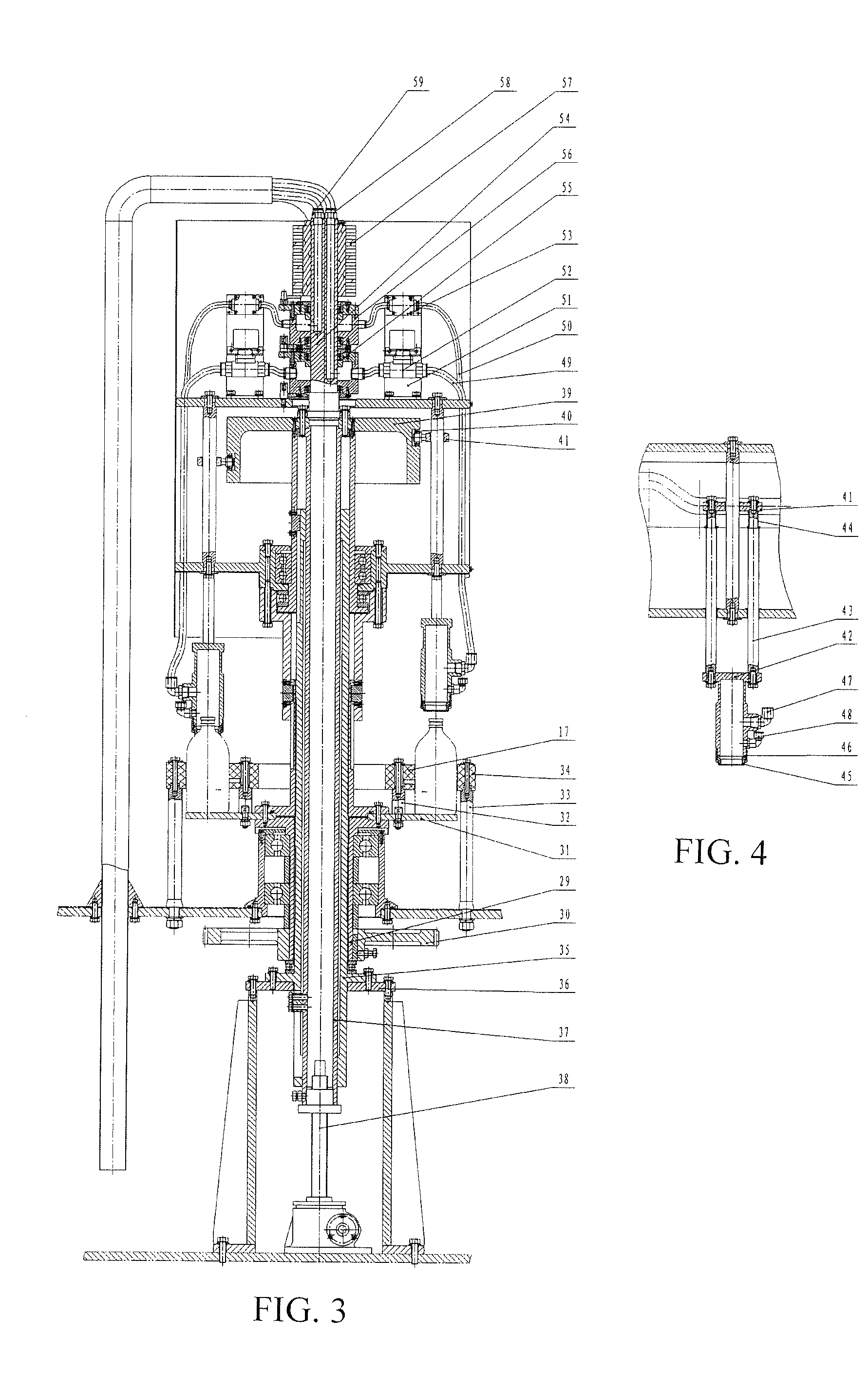

Vacuum-pumping and nitrogen-filling plug-adding apparatus

ActiveCN102009753AImprove packaging yieldPrevent prolapsePackaging by pressurising/gasifyingThreadless stopper insertionVacuum pumpingNitrogen

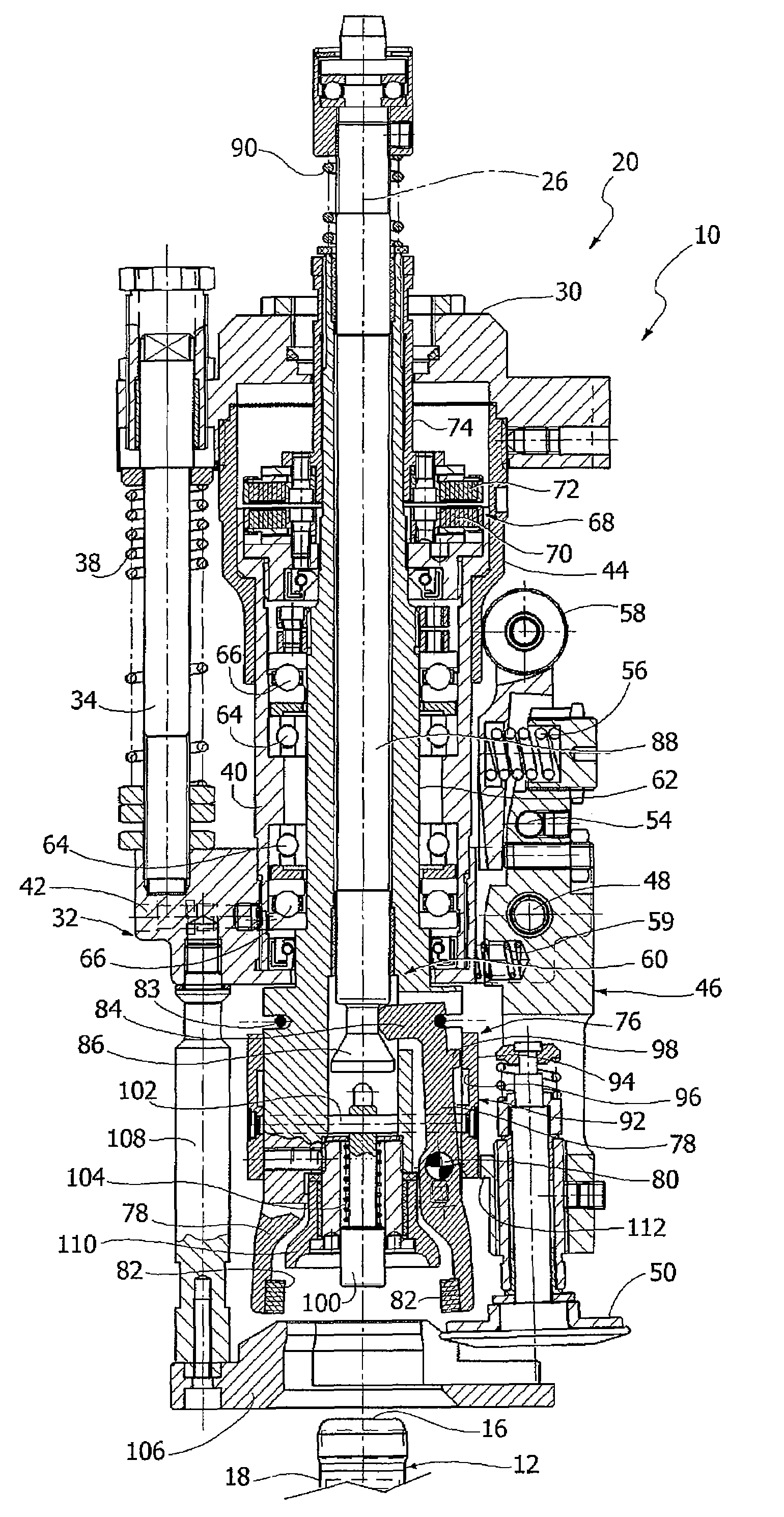

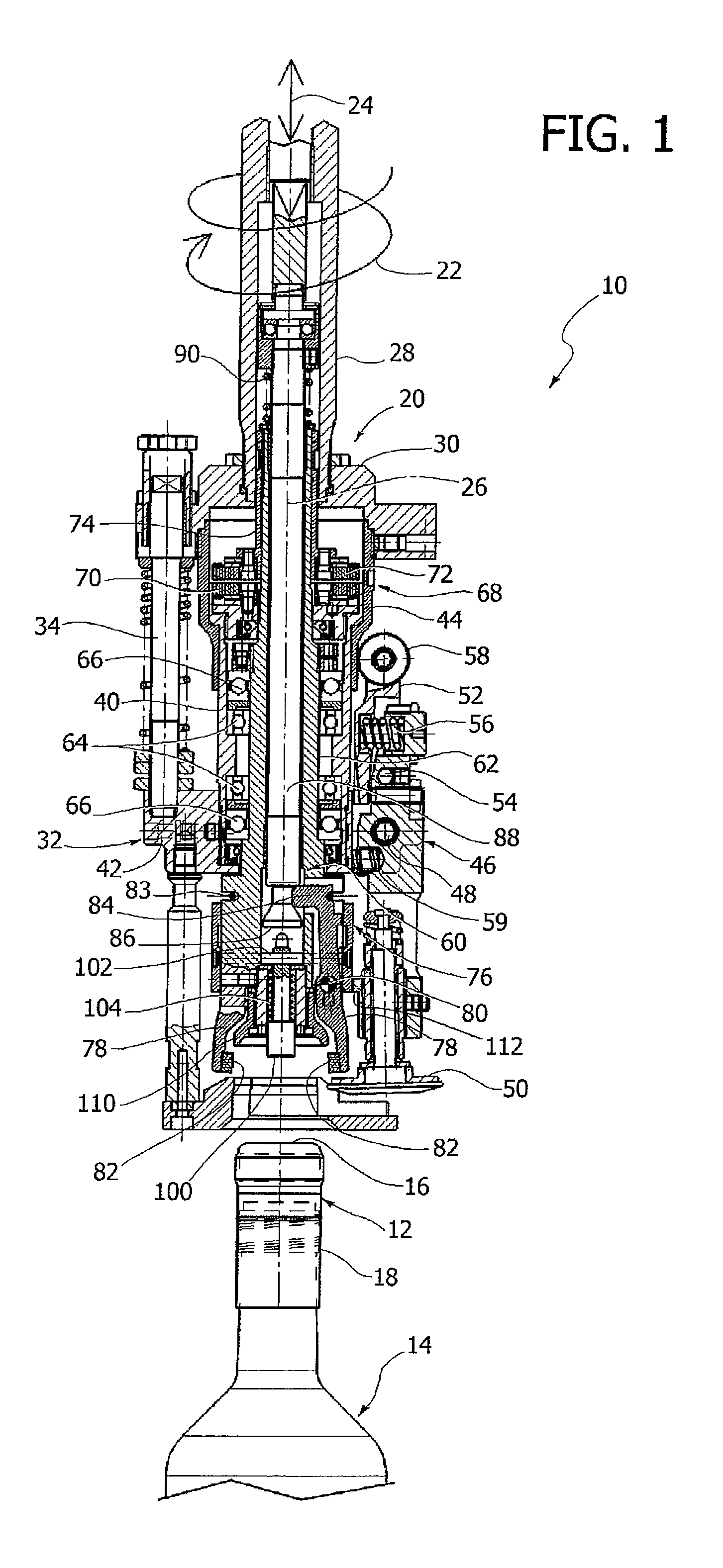

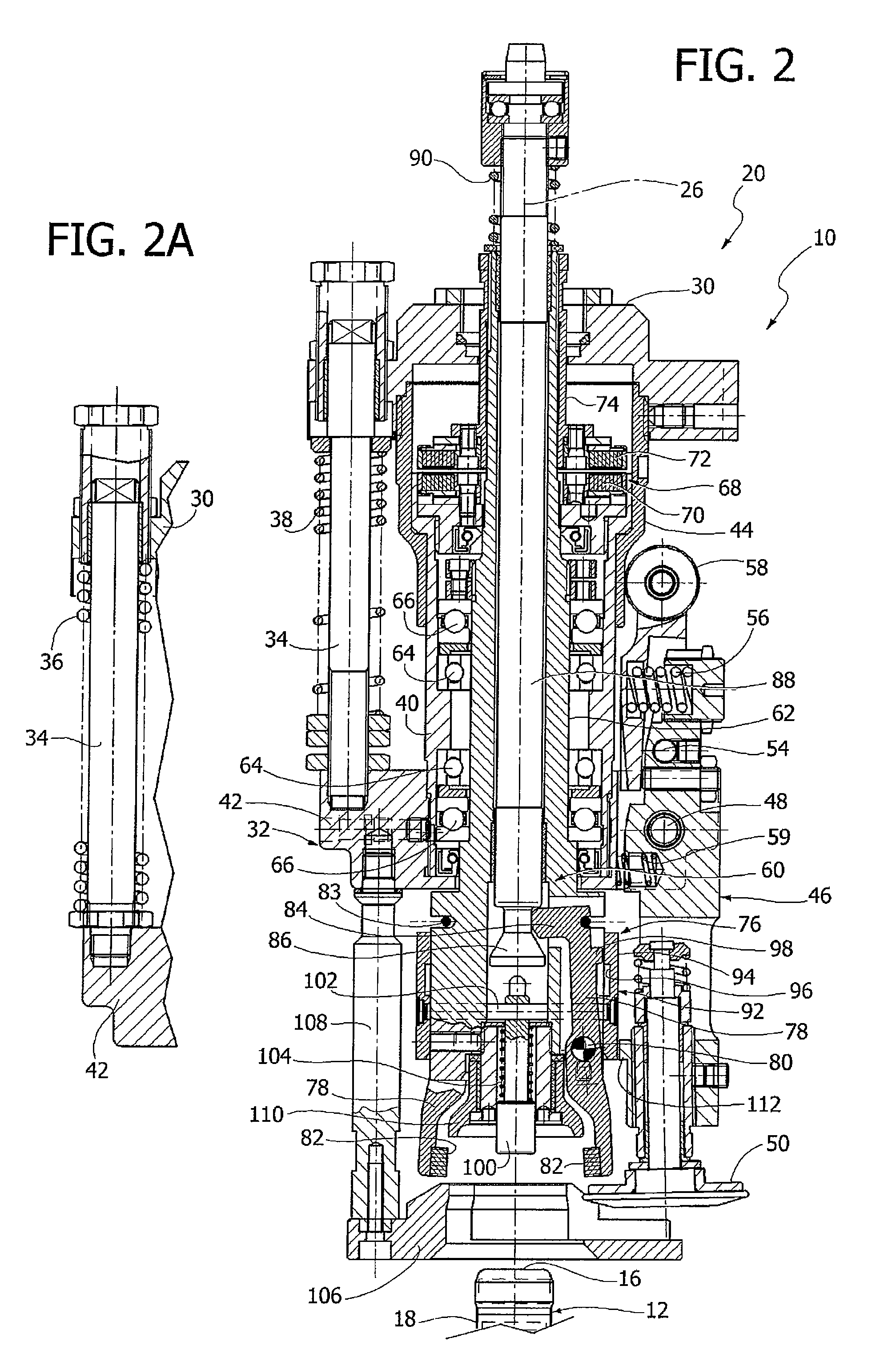

The invention discloses a vacuum-pumping and nitrogen-filling apparatus with plugs. The apparatus comprises a lifting shaft and a connecting sleeve with a vacuum-pumping and nitrogen-filling cavity inside; the connecting sleeve is jointed with the lifting shaft whose lower part is placed in the vacuum-pumping and nitrogen-filling cavity. The lower part of the lifting shaft is equipped with a plug pressing head and a plug-taking mechanism; the plug-taking mechanism comprises a plug-taking head and a plug-taking head return mechanism which is installed on the lifting shaft. The upper part of plug-taking head is sleeved around the lifting shaft and a plug pressing head, and connected with the plug-taking head return mechanism; the lower part of the plug-taking head is equipped with a C-shaped chucking part used for chucking rubber plugs. The invention possesses the advantages of simple compact structure, low cost and raising packaging yield rate.

Owner:TRUKING TECH LTD

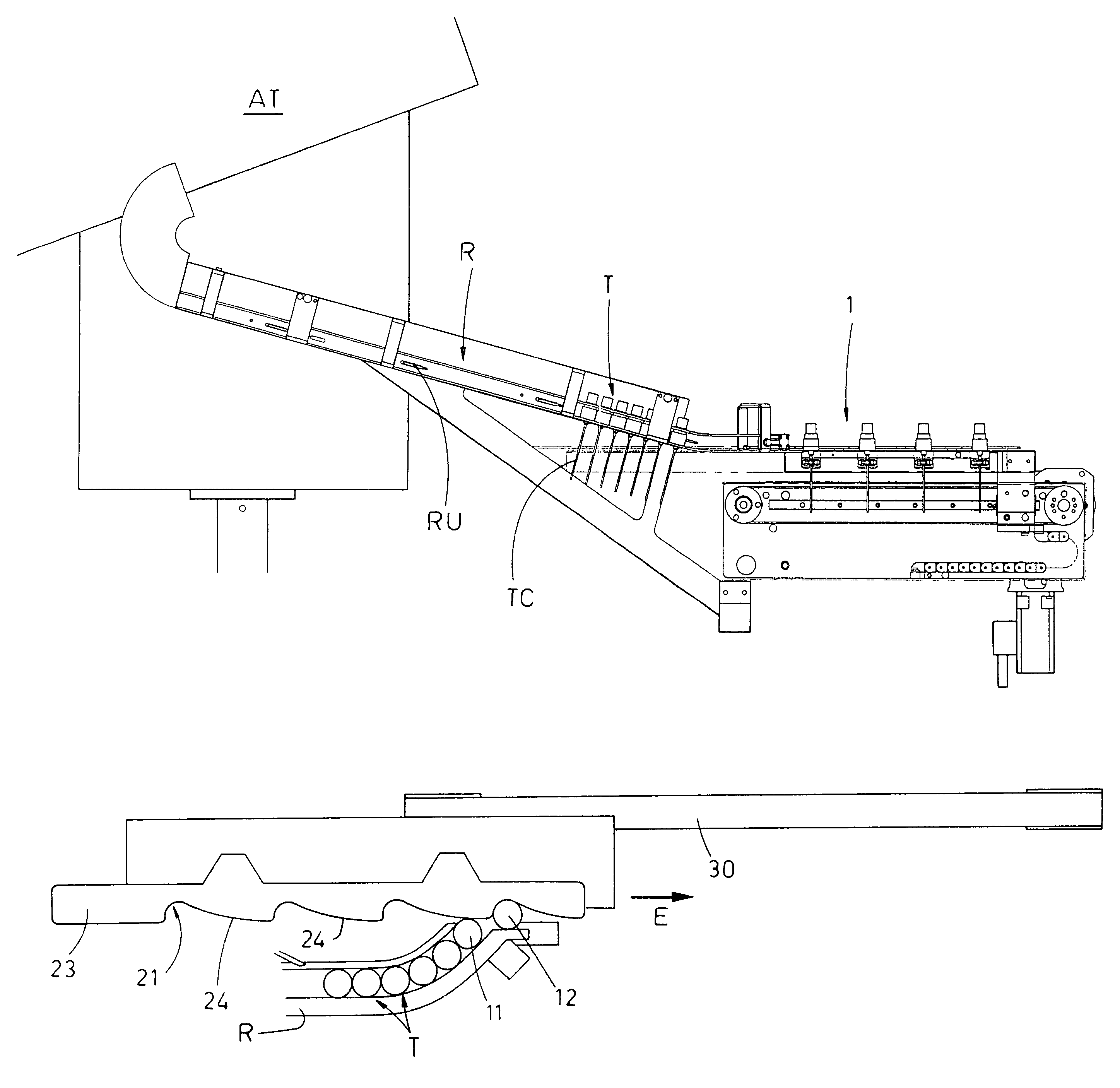

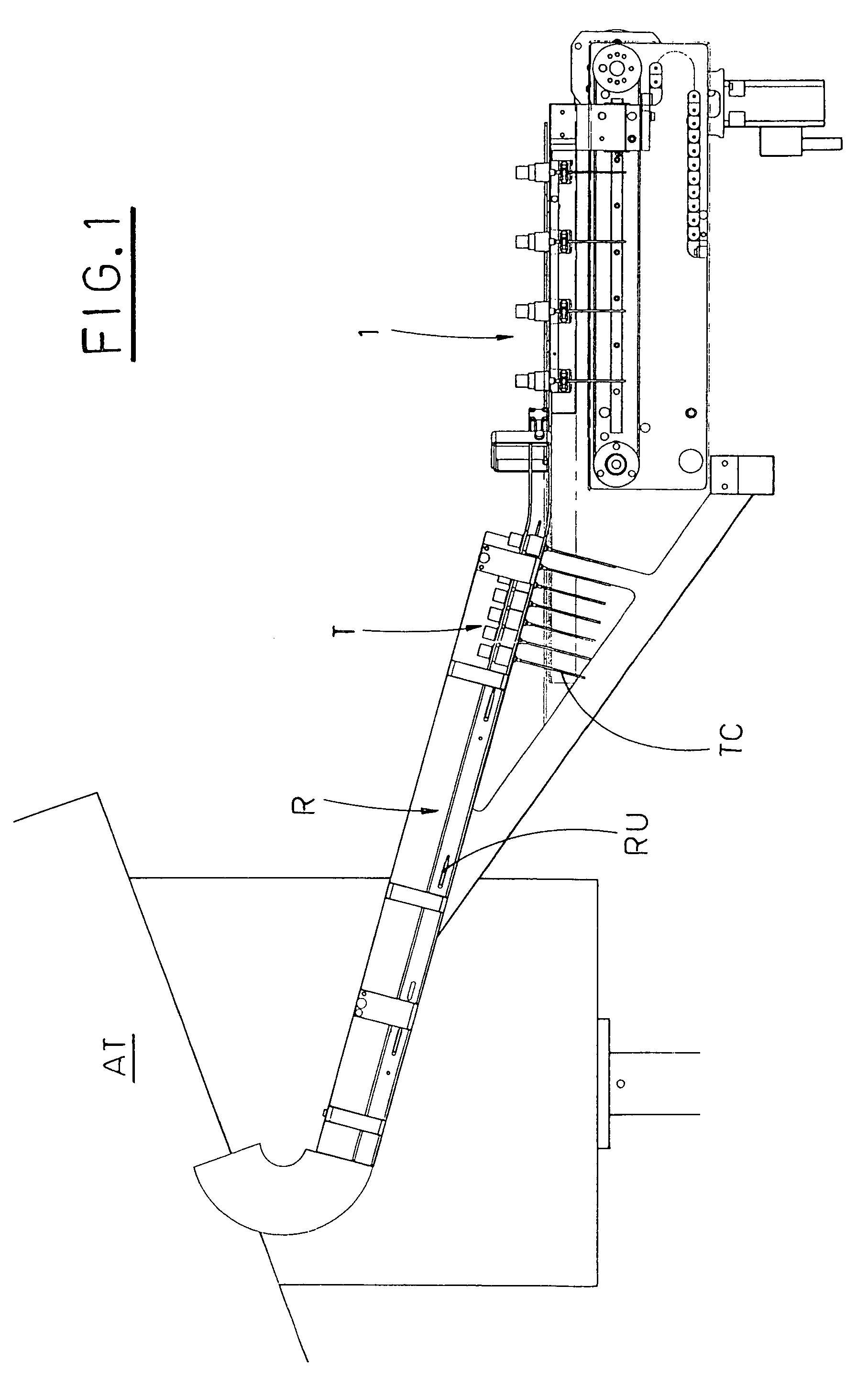

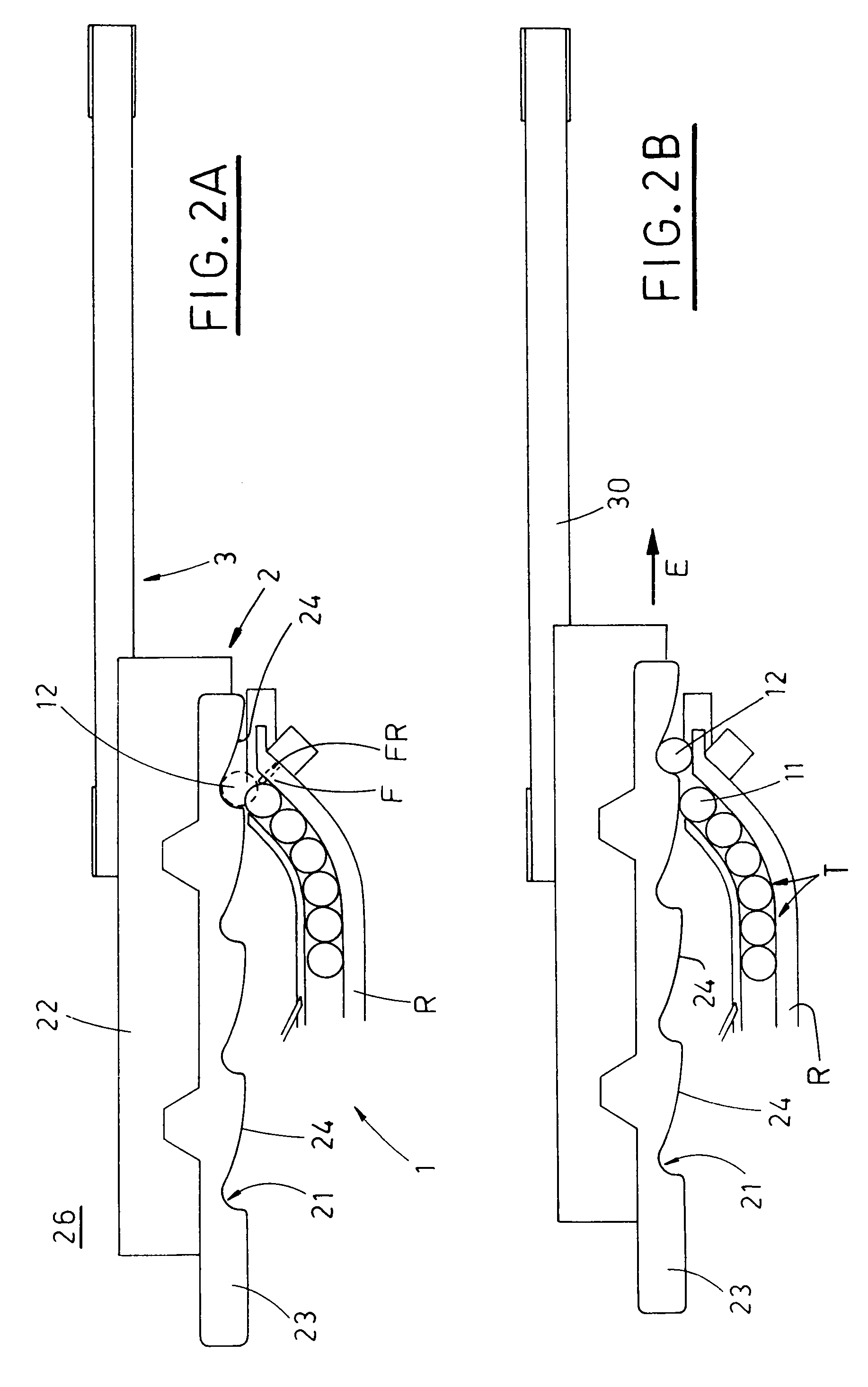

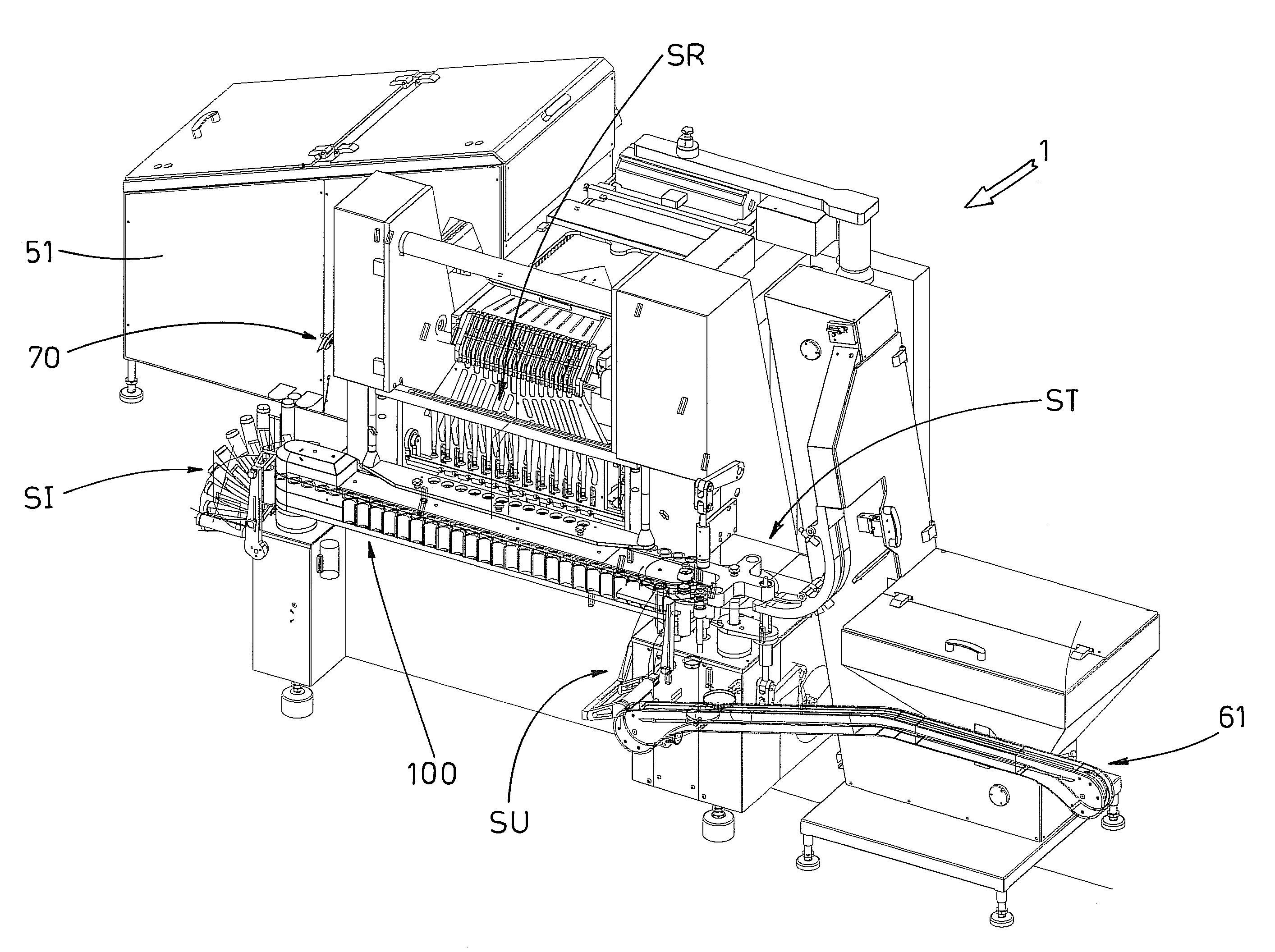

Device for singling out items coming from a feeder

In a device for singling out items coming from a feeder, with the feeder comprising an outlet channel for conveying the items an end section, compacting air jets are placed along the outlet channel for gathering the items one behind the other according to a continuous row, at the end section. The device is equipped with and abutment and catching comb for singling out a series of single and successive leading items of the row of items at the end section, and a driving belt moves the abutment and catching comb according to a direction of extraction at the end section, for abutting and catching a series of single and successive leading items and for transferring and placing the series of singled out items at a handling station.

Owner:MARCHESINI GROUP SPA

Screwing and rolling head for the application of pre-threaded caps

Screwing and rolling head for the application of pre-threaded caps on containers, comprising a first support, designed to be moved with a helical motion, a second support, which is mobile with respect to the first support in a longitudinal direction and is fixed in rotation with respect to the first support, a device for screwing caps, fixed in an axial direction with respect to the second support and rotatable with respect to the second support, a torque-limiter device, connected between the screwing device and the second support, and at least one oscillating arm, which carries a rolling element and is articulated to the second support about a transverse axis. The device for screwing caps comprises a gripper, which is mobile between an open position and a closed position and is designed to grip a cap along a side wall thereof, the movements of opening and closing of the gripper being controlled by a control rod, which is mobile in an axial direction.

Owner:AROL

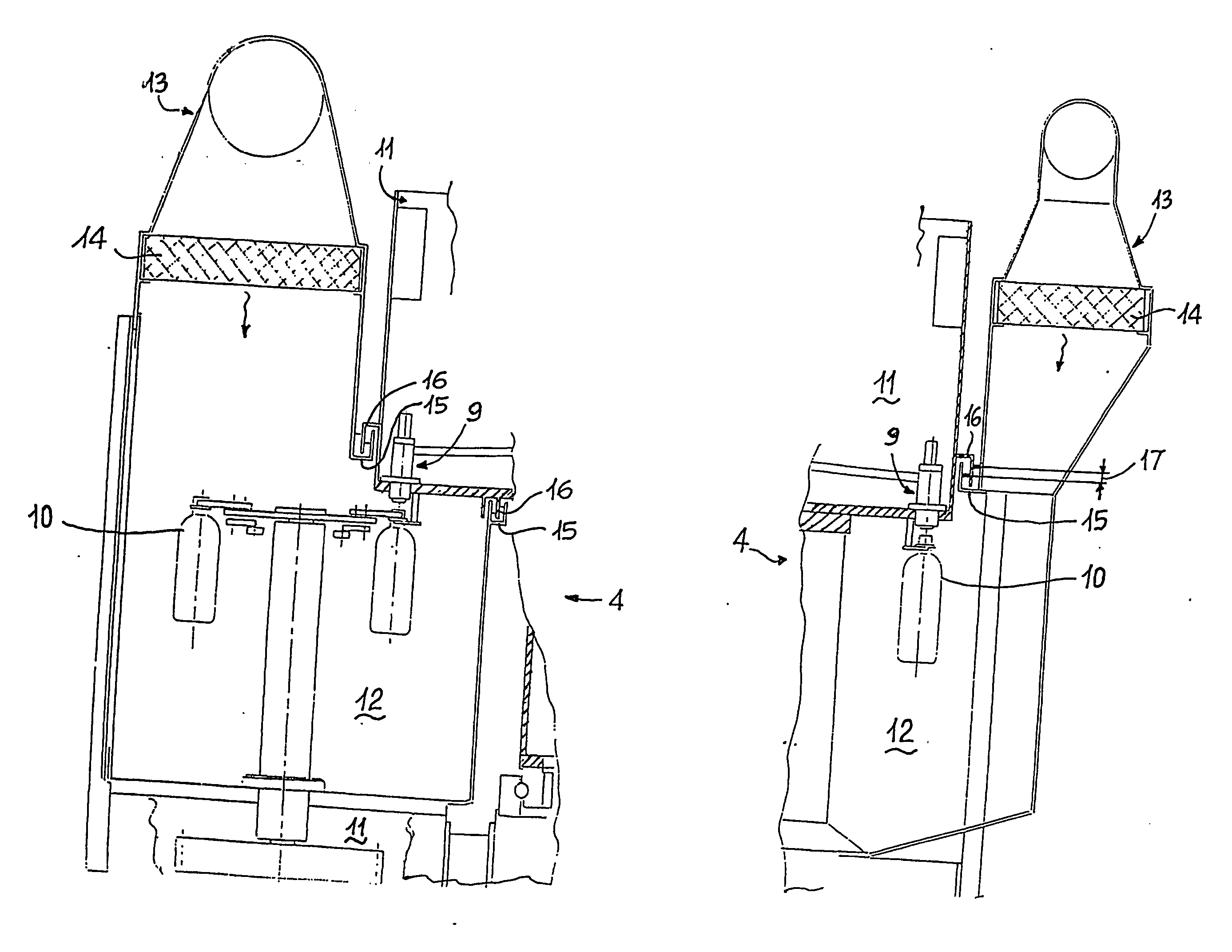

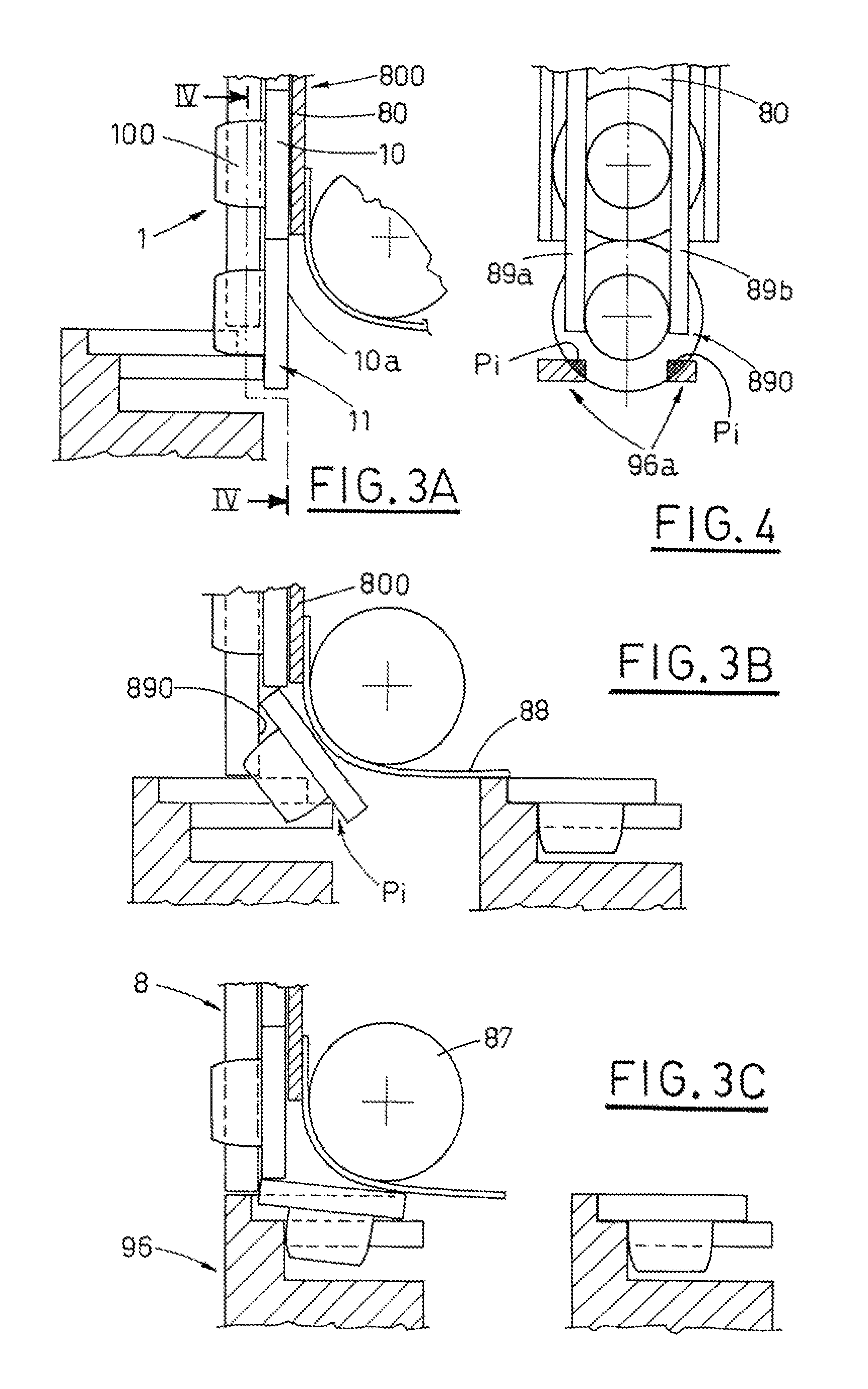

Method of sealing a container comprising at least one plug, particularly a carpule, insertion means and associated sealing line

Disclosed is a method of sealing a container with a liquid, the container including a body with an opening at at least one end and including at least one sealing plug, designed to seal the opening after filling, the filling defining a free surface S for filling, the filling having allowed a head space to remain in the container. The method includes: introduction of at least one rod parallel to an inside wall of the body of the container; mechanical insertion of the plug in the body, along the at least one insertion rod, generating at least one channel C, the air of the head space being evacuated between the plug and the rod; and withdrawal of the at least one rod while leaving the plug in place at the level of insertion of the preceding step. Also disclosed are the associated device and the industrial production line.

Owner:DISPOSABLE LAB

Machine for sealing carton

A packaging apparatus forms a completely sealed composite package. The apparatus employs a continuous process which involves conditioning a surface of the package substrate. The substrate includes an adhesive coating that can be reactivated by infra-red radiation and adheres the package substrate to a juxtaposed face of a second surface. The apparatus uses rollers (102, 104, 118, 120) to compress the two surfaces together to complete the construction process.

Owner:MEADWESTVACO PACKAGING SYST LLC

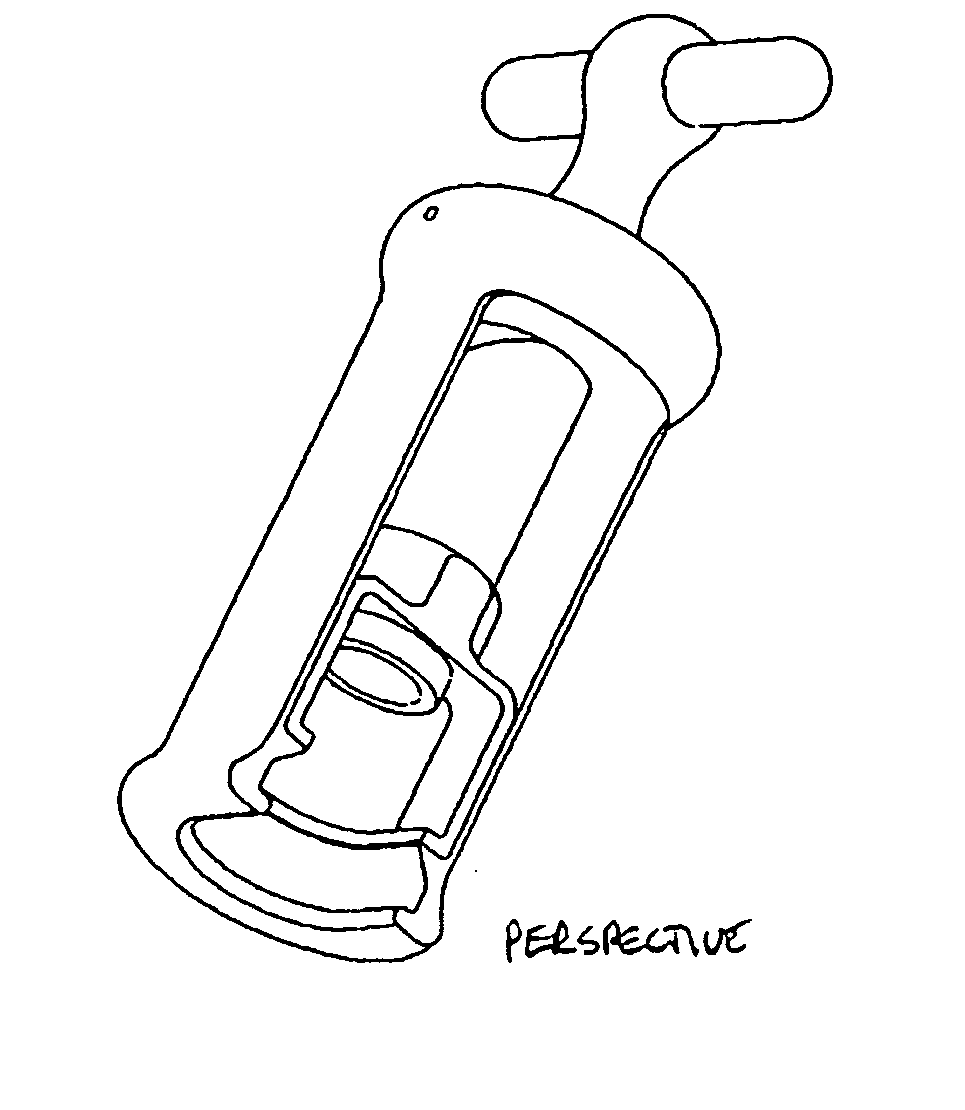

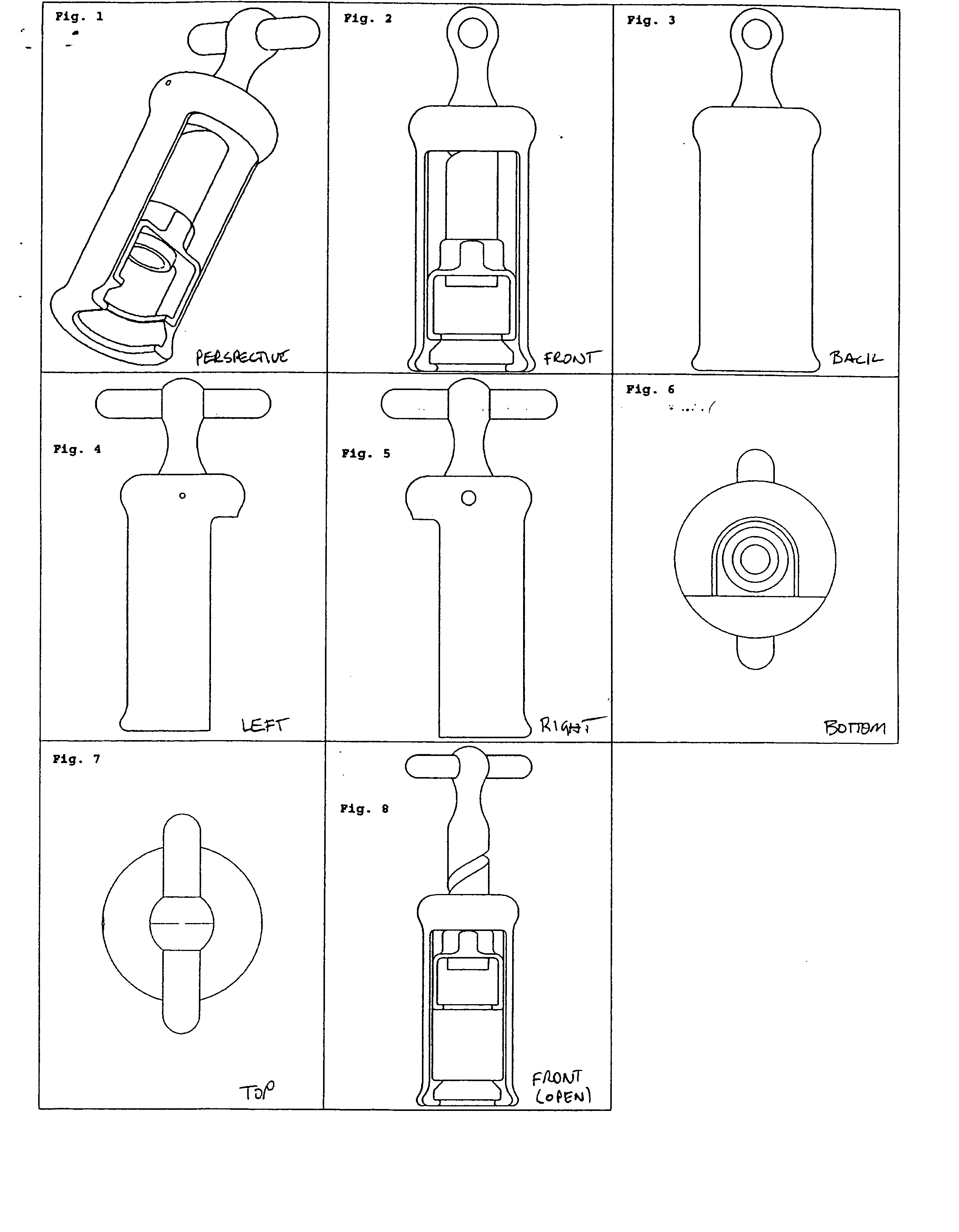

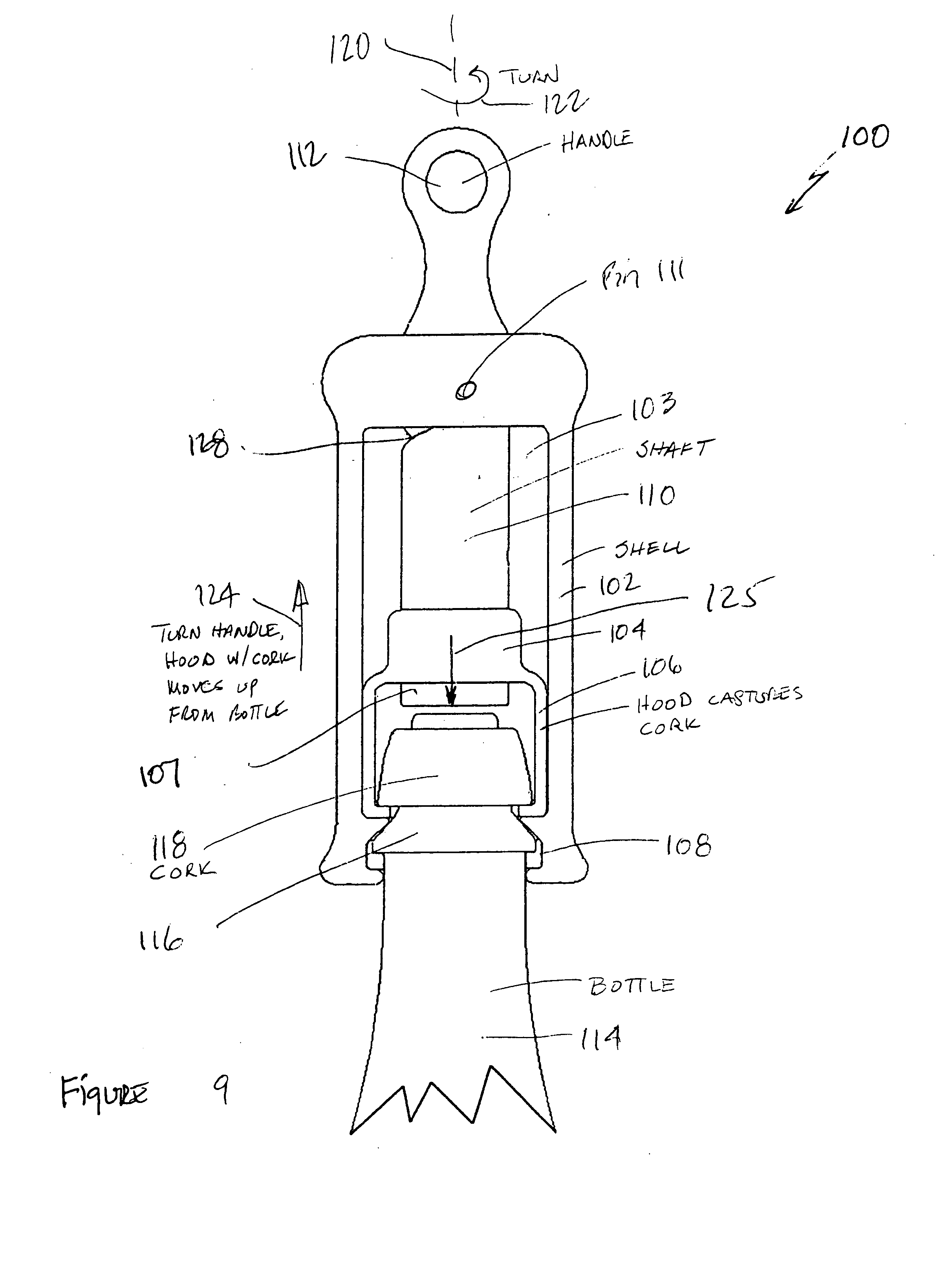

Bottle cork removal and installation tool

A bottle cork removal and insertion tool includes a shell formed with a center cylindrical partial bore within which is a hood that captures a cork from a bottle. The cork is positioned within the hood and the handle on an axial threaded shaft is rotated which advances the hood, and the captured cork, away from the bottle. A capturing plunger extends into the hood as the shaft is rotated in order to secure the cork in place in the hood. The threading on the shaft has a fine threaded portion to initiate the removal of the cork, and a coarse threaded portion to complete the removal in a single rotation. If desired, the cork can be positioned within the hood, the device positioned over a bottle top, and the cork can be re-inserted into the bottle by reversing the rotation of the threaded shaft.

Owner:REYNOLDS RICHARD ALLEN +1

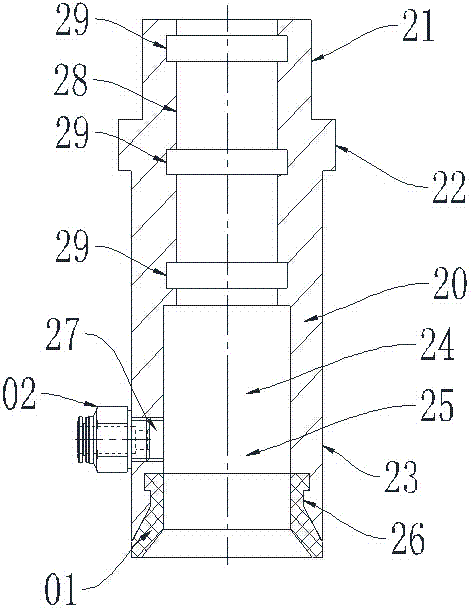

Integrated vacuum, air inflating and pressing device

ActiveCN104743480AReduced driving force requirementsAvoid destructionLiquid bottlingThreadless stopper insertionEngineeringAir exchange

The invention discloses an integrated vacuumizing, air inflating and pressing device for a medicine bottle. The integrated vacuumizing, air inflating and pressing device is used for overcoming the defect that a single device cannot achieve the operations of vacuumizing, air inflating and pressing in the prior art. The integrated vacuumizing, air inflating and pressing device comprises an air exchange sleeve, a mounting seat and a pressing mechanism. An air cavity chamber is arranged at the lower portion of the air exchange sleeve, and a sealing sleeve is arranged at the mouth portion arranged at the lower portion of the air cavity chamber. A connector is arranged at the lower portion of the air exchange sleeve, and the connector is communicated with the air cavity chamber. The air exchange sleeve is installed on the mounting seat, and the air exchange sleeve can move up and down. The lower portion of the pressing mechanism is arranged in the air exchange sleeve and is stretched into an air cavity, the upper portion of the pressing mechanism is installed on the mounting seat, and the upper portion of the pressing mechanism can move up and down. The integrated vacuumizing, air inflating and pressing device for the medicine bottle can complete the operation of vacuumizing, air inflating and pressing and has the advantage of being simple in structure.

Owner:湖南华尔特今朝科技有限公司

Gripping device for picking up containers and closures and for closing the containers

InactiveUS20110030316A1Flexible and economical productionProduced economicallyThreadless stopper insertionClamping mechanismMechanical engineeringEngineering

Owner:ROBERT BOSCH GMBH

Method of sealing a plug with a food sauce dispensing cartridge

A method of sealing a plug with a food sauce dispensing cartridge enables leak proof operation of the dispensing cartridge at the site of the plug. The plug, having a circumferential edge, is positioned within the dispensing cartridge and oriented such that the edge is adjacent to the cartridge sidewall. A layer of hot melt adhesive is then applied to the circumferential edge and flows into a gap created between the plug and the cartridge sidewall at a sideseam formed by an overlap region of the cartridge sidewall. The hot melt adhesive subsequently bonds the plug to the cartridge sidewall and prevents food sauce from moving past the circumferential edge of the plug and out of a containment region.

Owner:HUHTAMAKI INC

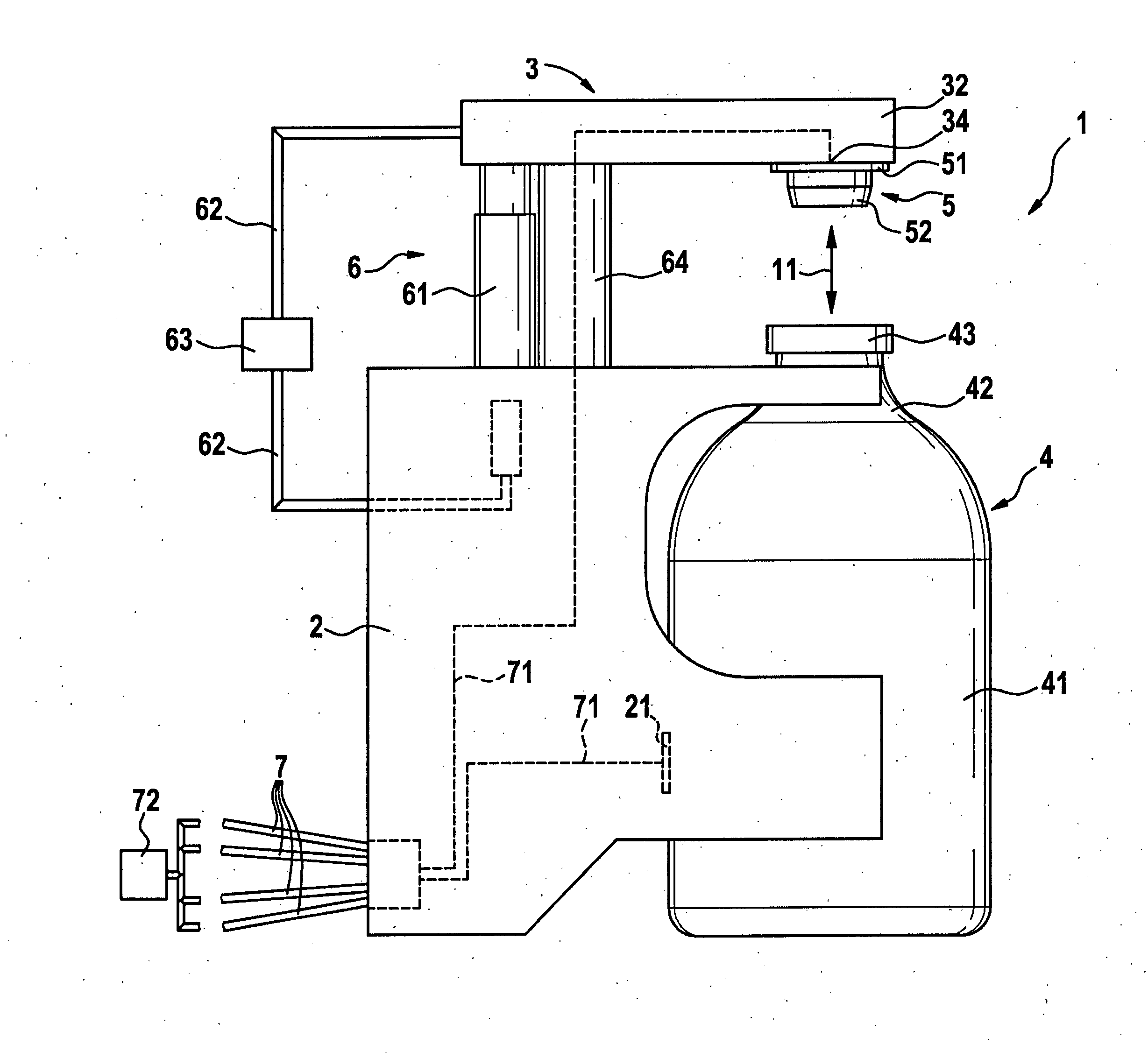

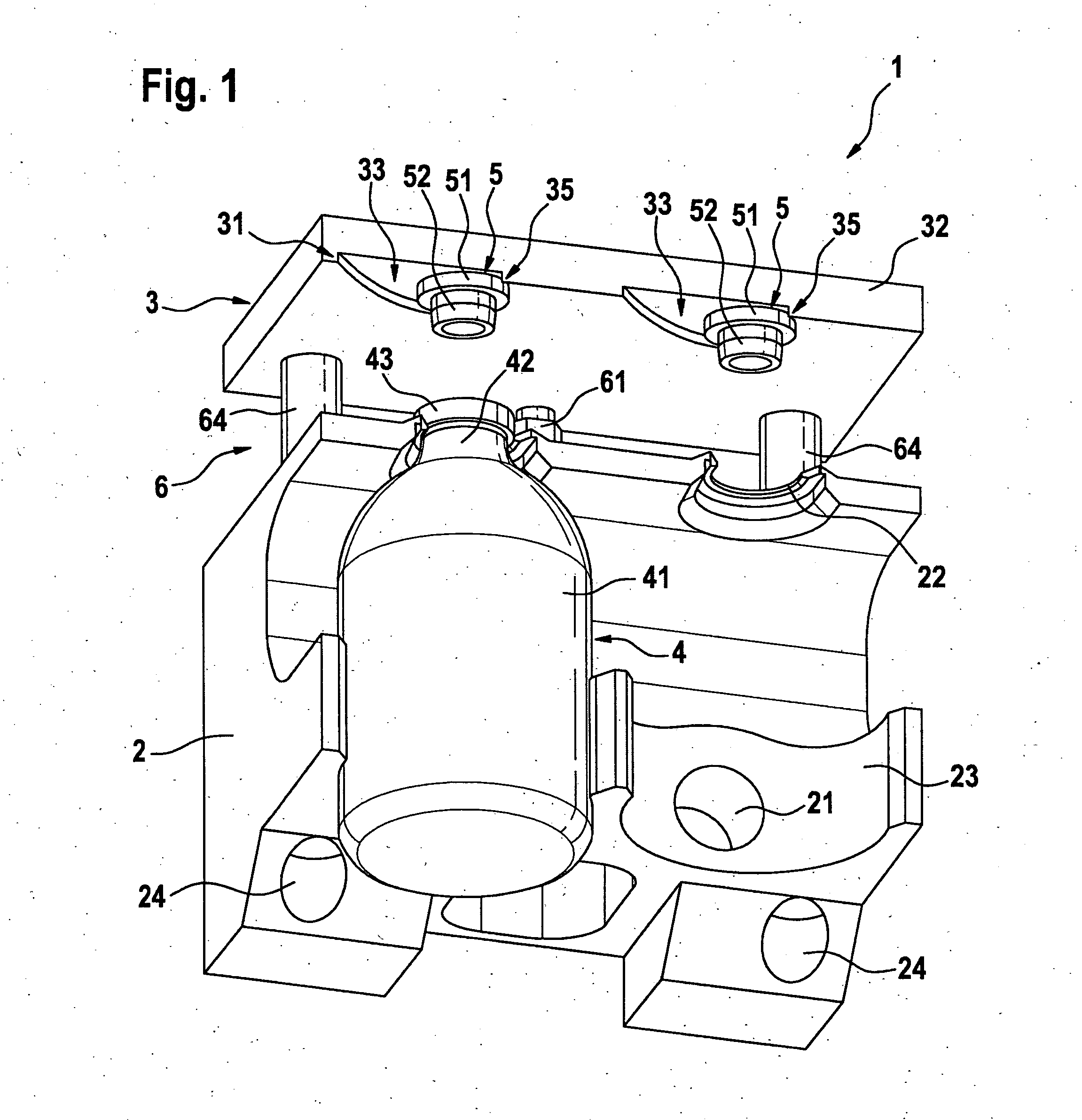

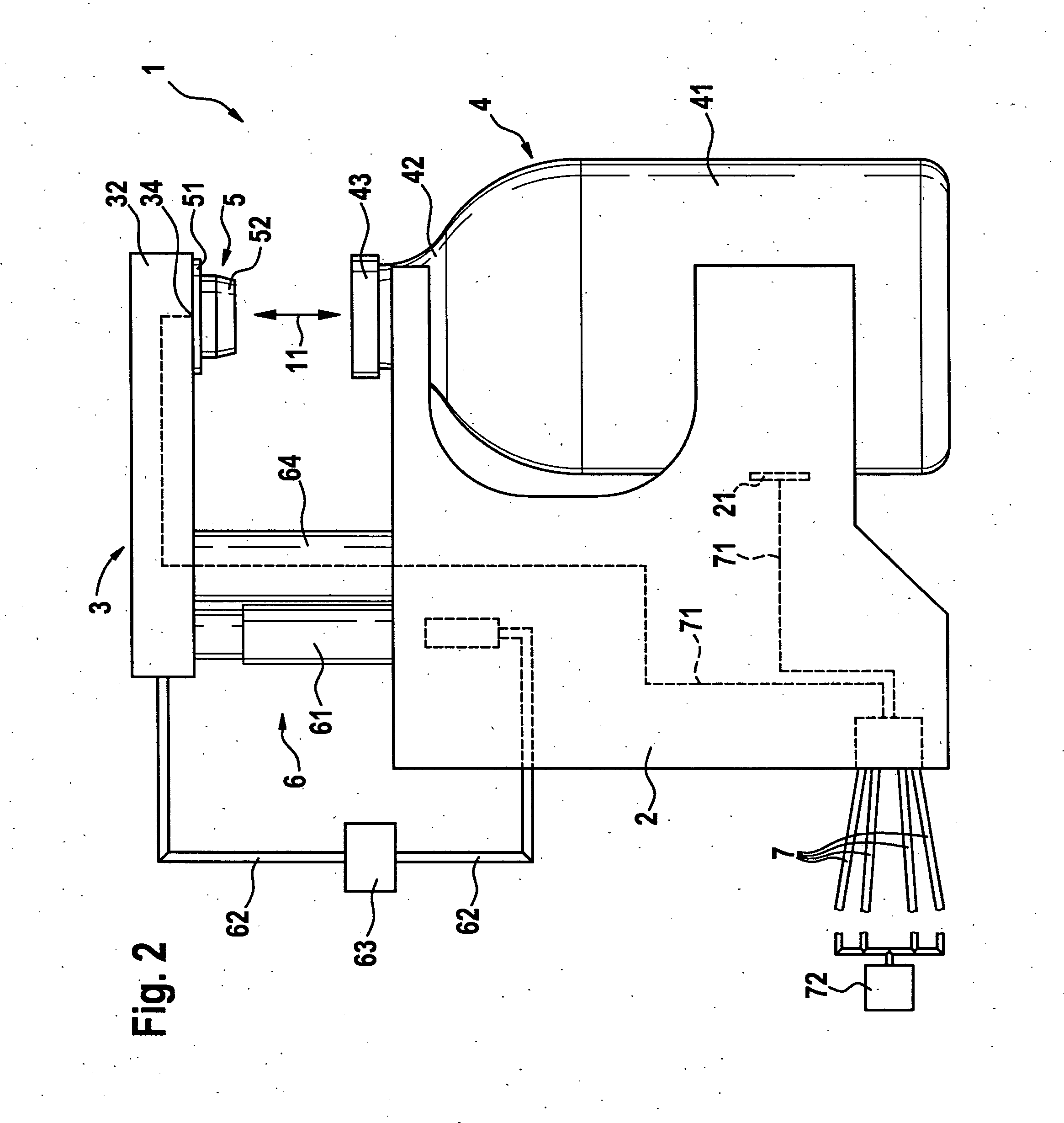

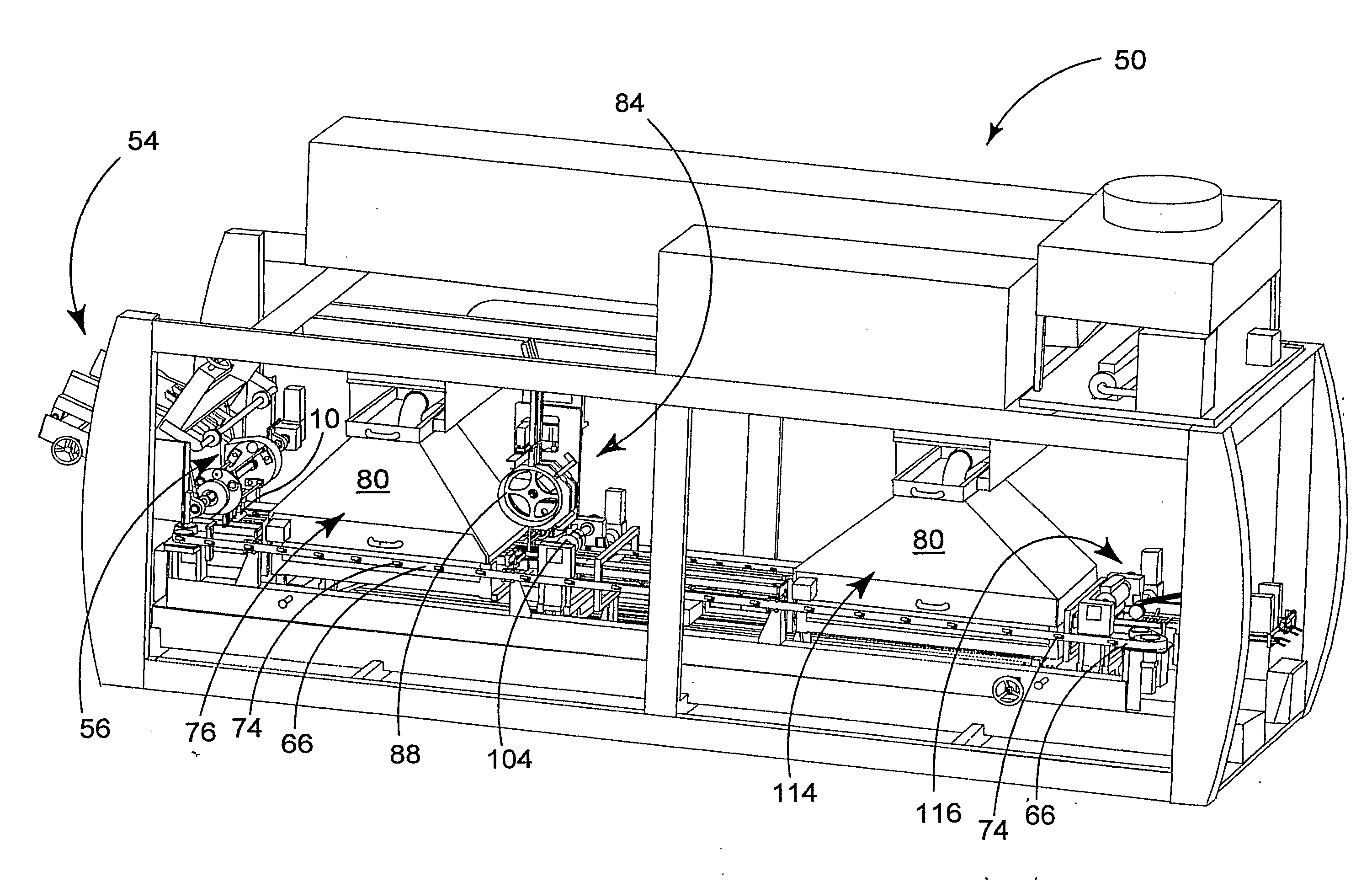

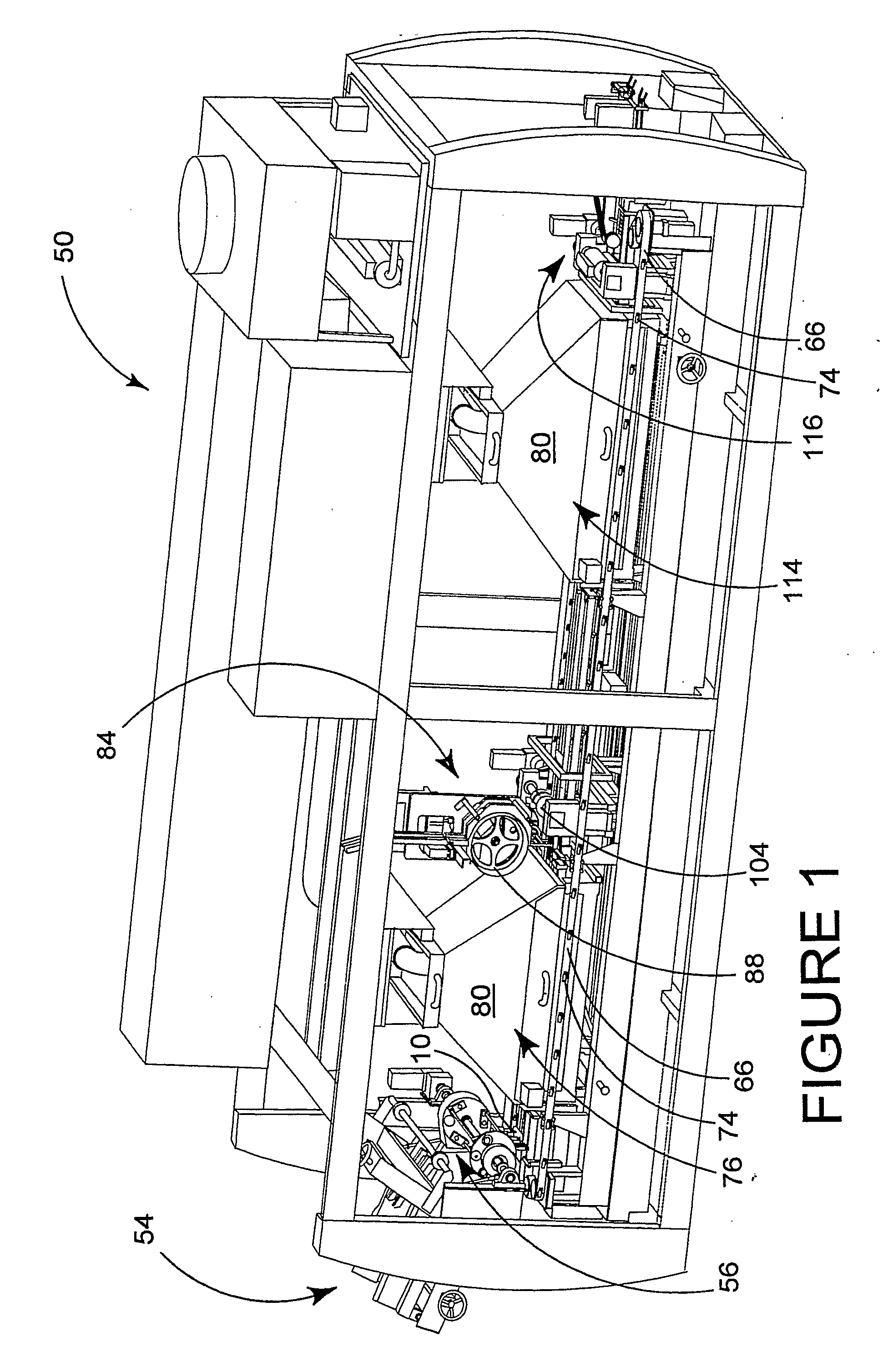

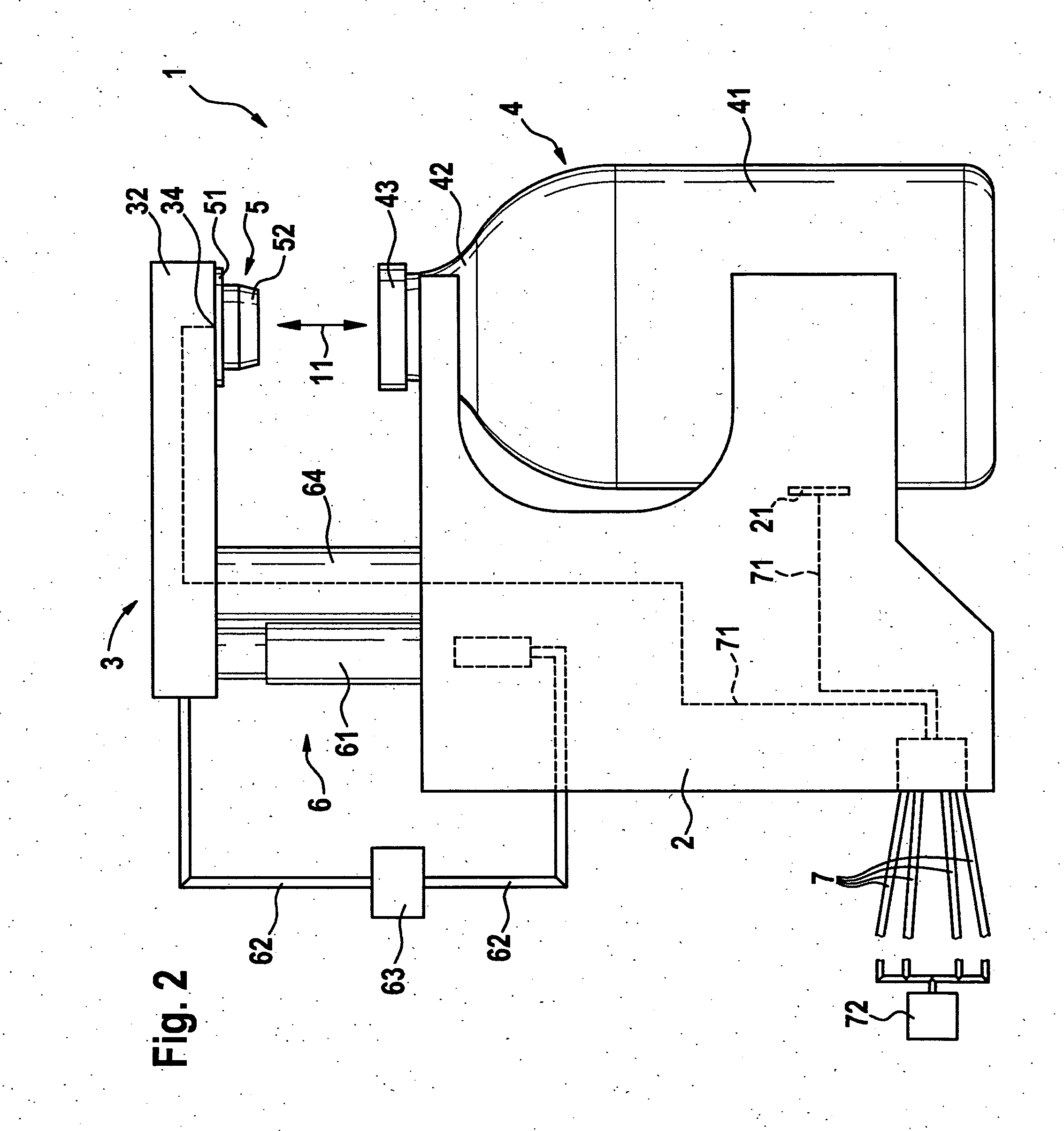

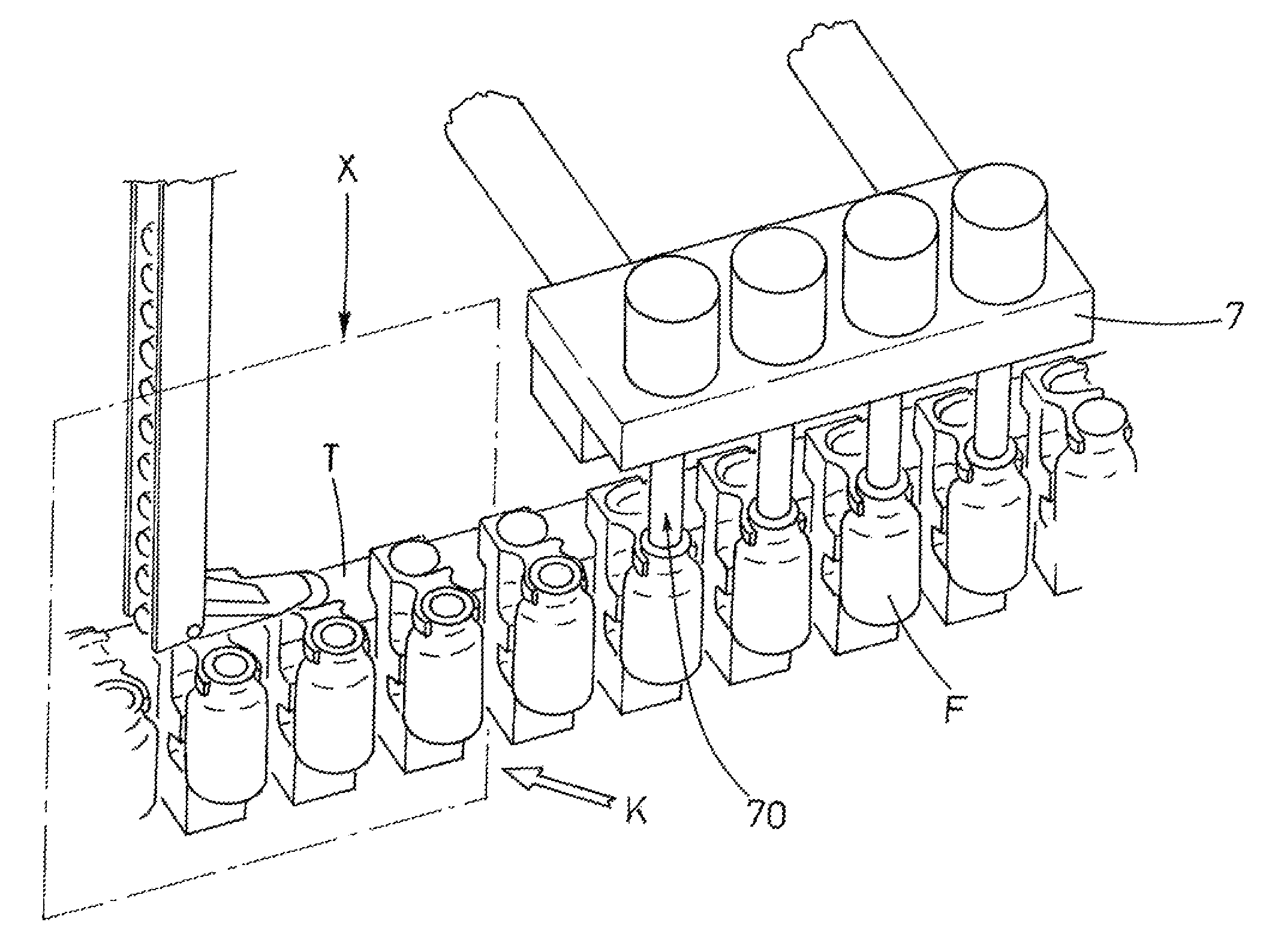

Large Transfusion Filing and Corking Machine

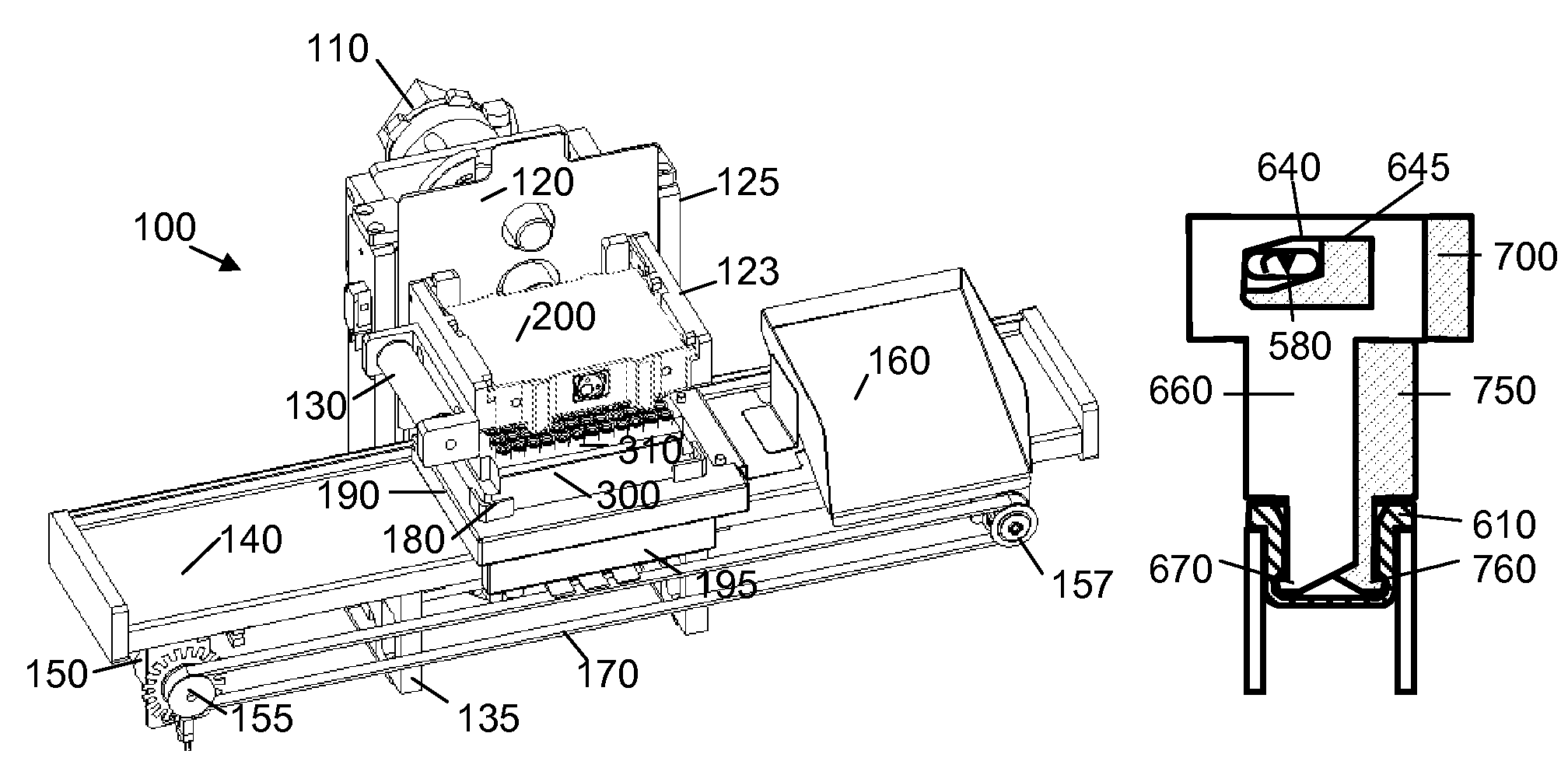

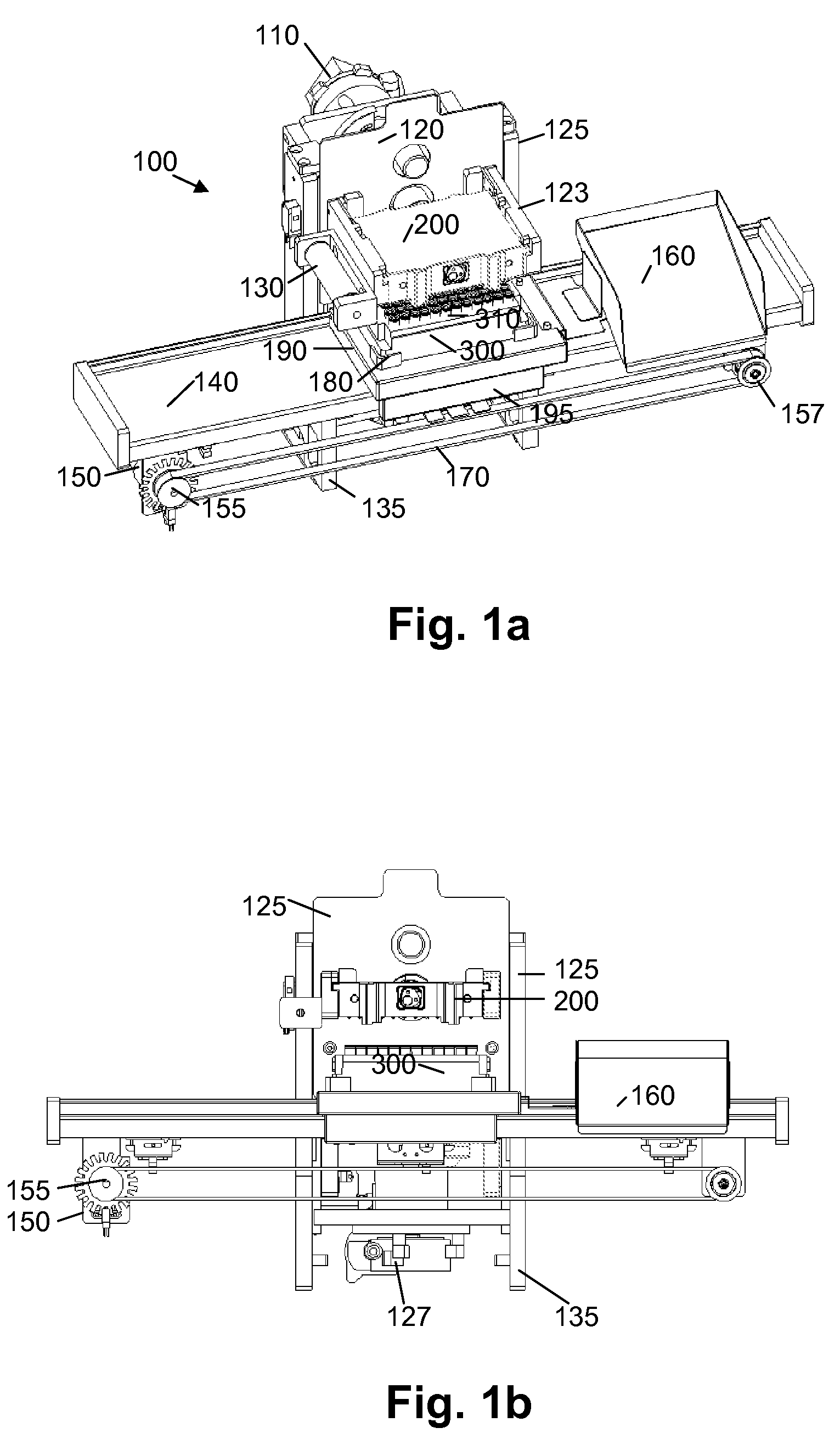

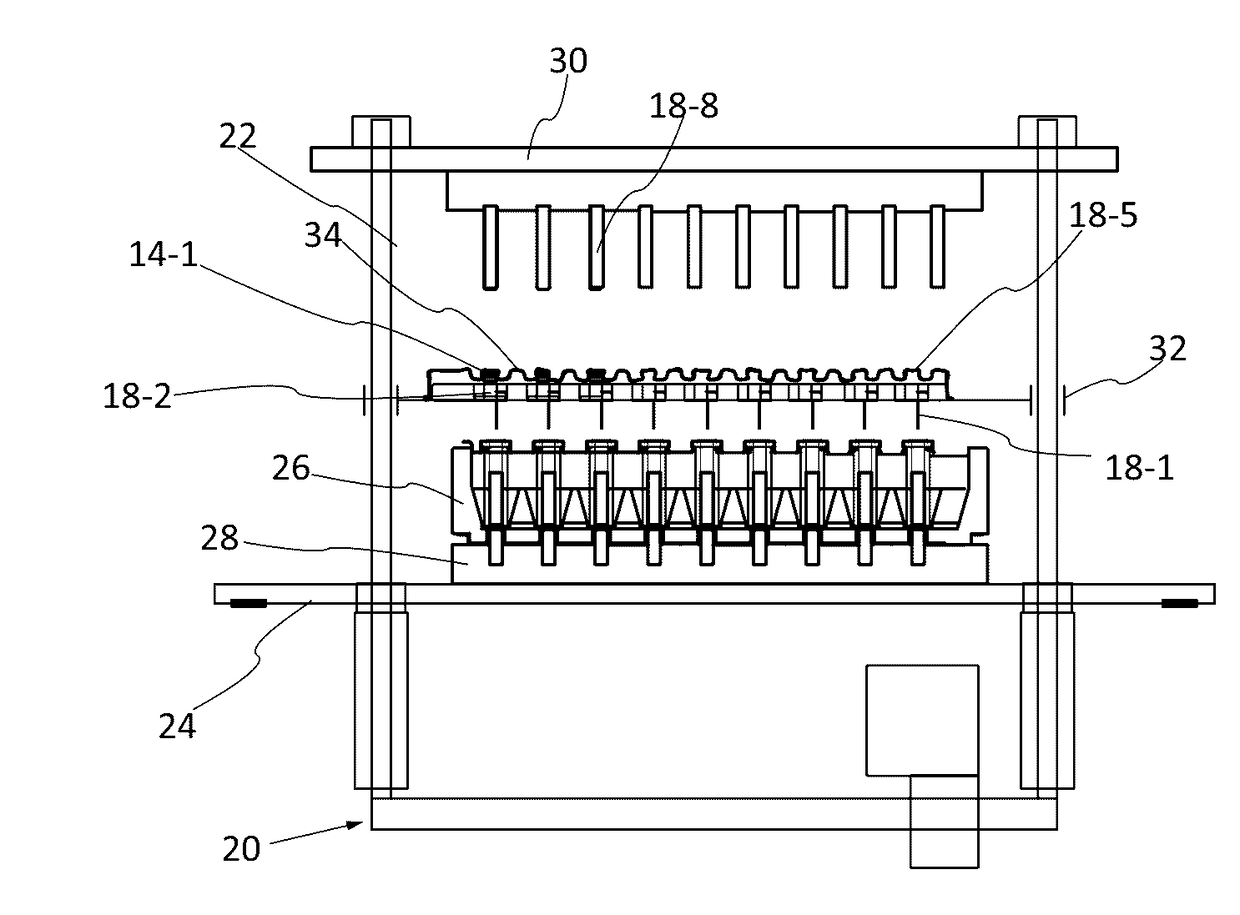

ActiveUS20110005168A1Simple structureLower levelSynchronising machinesSolid materialNitrogenElectric control

A large transfusion filling and corking machine includes a frame unit, an electric control unit, a bottle-in unit, a following and filling unit, a nitrogen-charging and corking unit, and a bottle-out transfer wheel unit. The bottle-in unit, the following and filling unit, the nitrogen-charging and corking unit, and the bottle-out transfer wheel unit are mounted on the frame unit and connected by turns. The nitrogen-charging and corking unit is connected with a cork-delivering unit. A nitrogen-precharging unit is arranged between the bottle-in unit and the following and filling unit, which is connected with the bottle-in unit through a bottle-in transfer wheel unit, and connected with the following and filling unit through a transitional transfer wheel unit.

Owner:TRUKING TECH LTD

Machine for packing stacks of disc-shaped articles inside rigid cylindrical containers

ActiveUS7610735B2Easy constructionImprove productivitySolid materialPackaging automatic controlEngineeringMechanical engineering

A machine for packing tablets inside rigid tubes exhibits: a supply line for supplying empty tubes arranged with vertical axes and mouths facing upwards; an inlet station wherein deflector organs operate which tip the cylindrical containers on sides thereof, and first organs which pick up individual thus-tipped containers and release the containers to corresponding gripping organs provided by a multiple conveyor; a filling station in which a plurality of supply units release a predetermined quantity of tablets, stacked one on the other, into paused tubes, borne by the multiple conveyor; a closing station containing devices which insert caps into the mouths of the filled containers borne by the multiple conveyor; an outlet station containing devices which pick up paused individual closed containers borne by the multiple conveyor and release the containers onto transporter organs.

Owner:MARCHESINI GROUP SPA

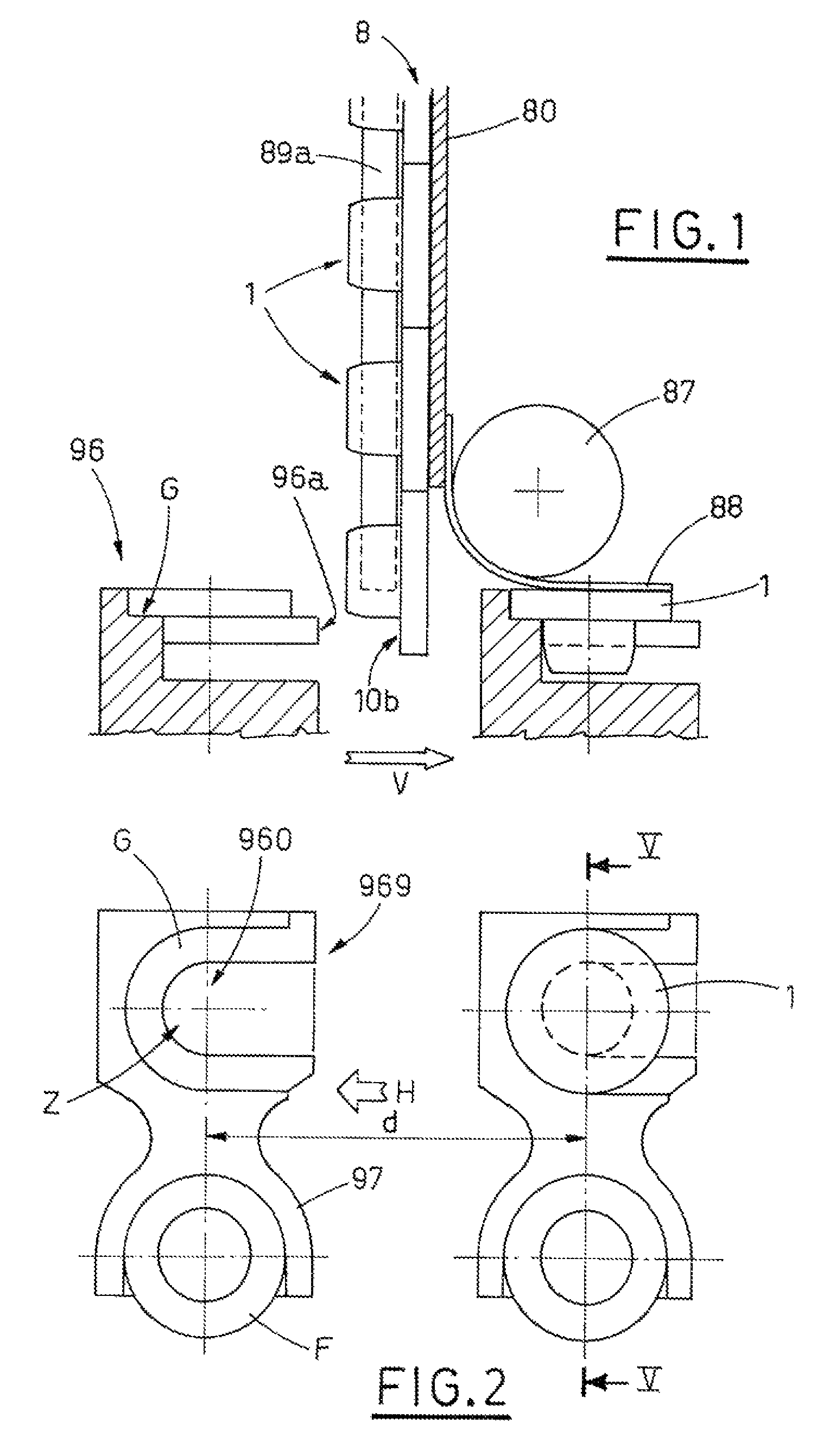

Apparatus for capping bottles and a method for realising the cap

An apparatus for capping bottles, comprising: gripping devices for bottles containing products, constrained to a transporter, each of which gripping devices exhibits on a side thereof a gripping means of a corresponding bottle, and on an opposite side thereof hooking-receiving-stabilizing organ of a cap; at least a channel for supplying caps, arranged superiorly of the transporter upstream of a capping zone overlying the hooking-receiving-stabilizing organs transiting below the channel, into which a row of caps is conveyed, a head cap of the row of caps being held elastically by a lower end of the supply channel in order to position an internal surface of a relative head such as to intercept a front head (96a) of an underlying hooking-receiving-stabilizing organ in order to enable the head cap, in combination with the advancing of the transporter and with the striking and guiding action exerted by the supply channel, to disengage from the supply channel in order to locate in the corresponding hooking-receiving-stabilizing organ, with the relative body facing downwards; at least a pick-up organ, located in the capping zone, operating in phase relation with a corresponding hooking-receiving-stabilizing organ, with the body thereof facing downwards; at least a pick-up organ destined to hook and extract the cap present therein, and to position the cap axially in an inlet mouth of the corresponding bottle supported by the gripping device flanking the hooking-receiving-stabilizing organ, in order to perform insertion of the body of the cap in the mouth of the bottle in order to close the bottle.

Owner:MARCHESINI GROUP SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com