Patents

Literature

219results about "Filling using suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

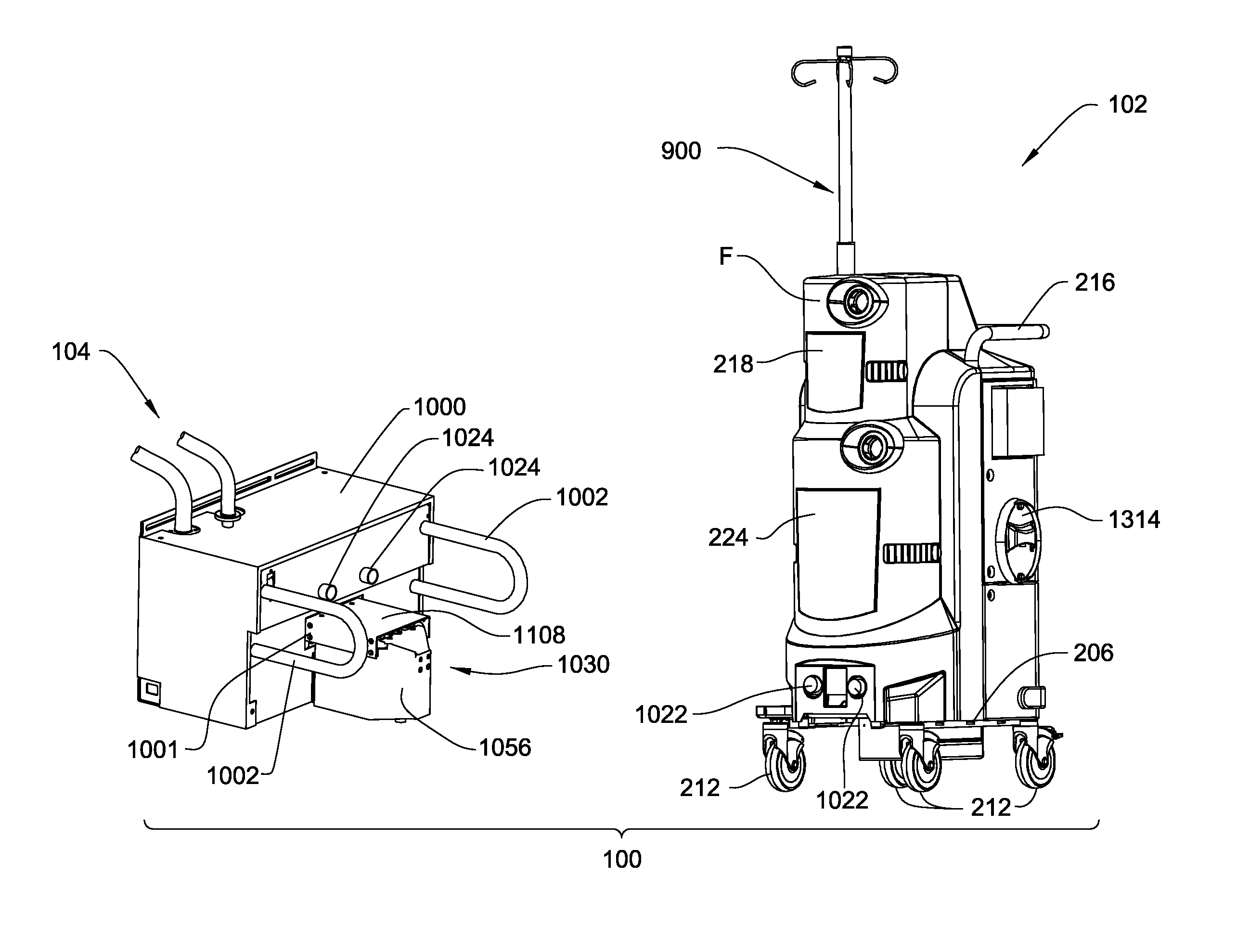

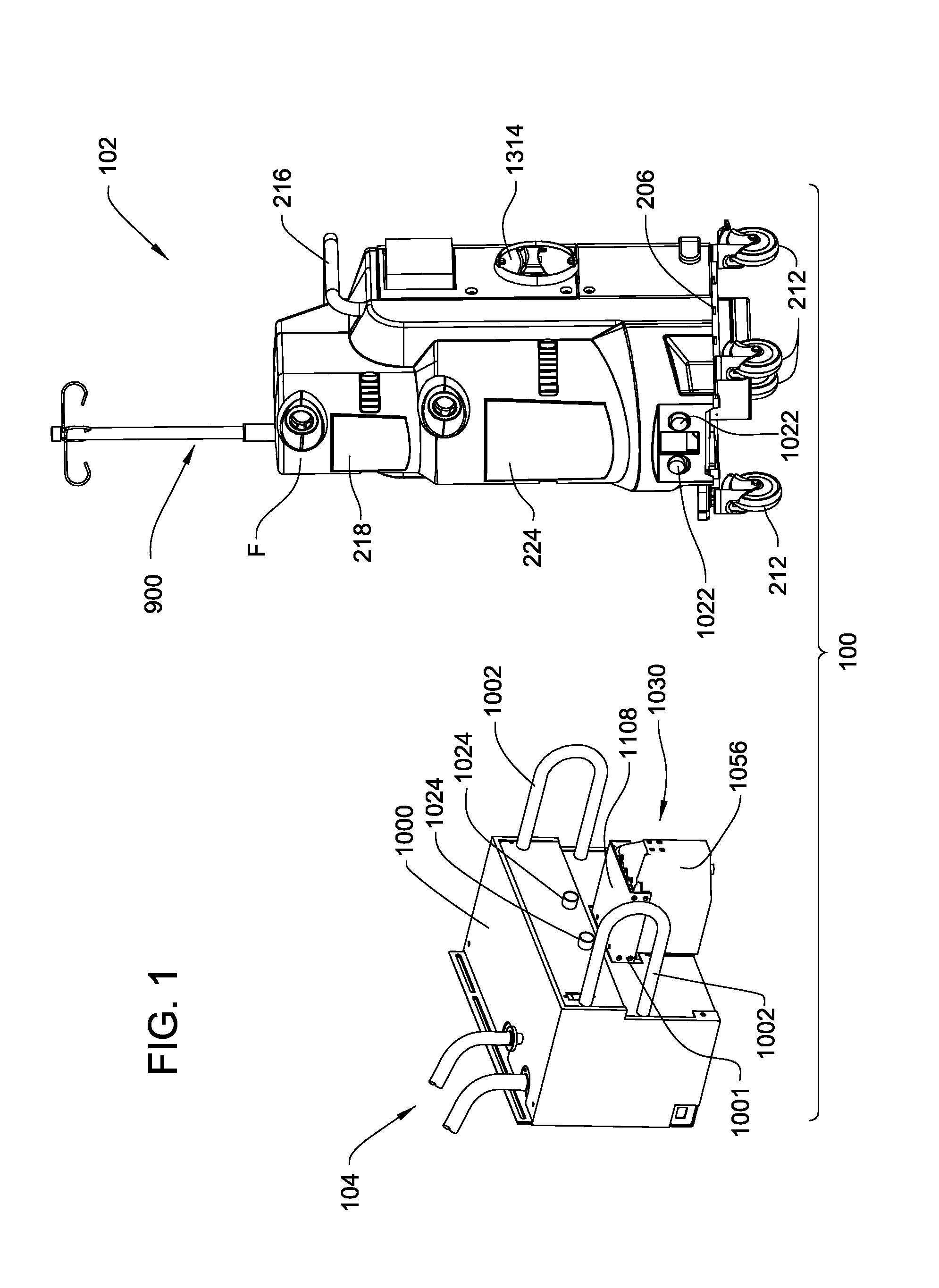

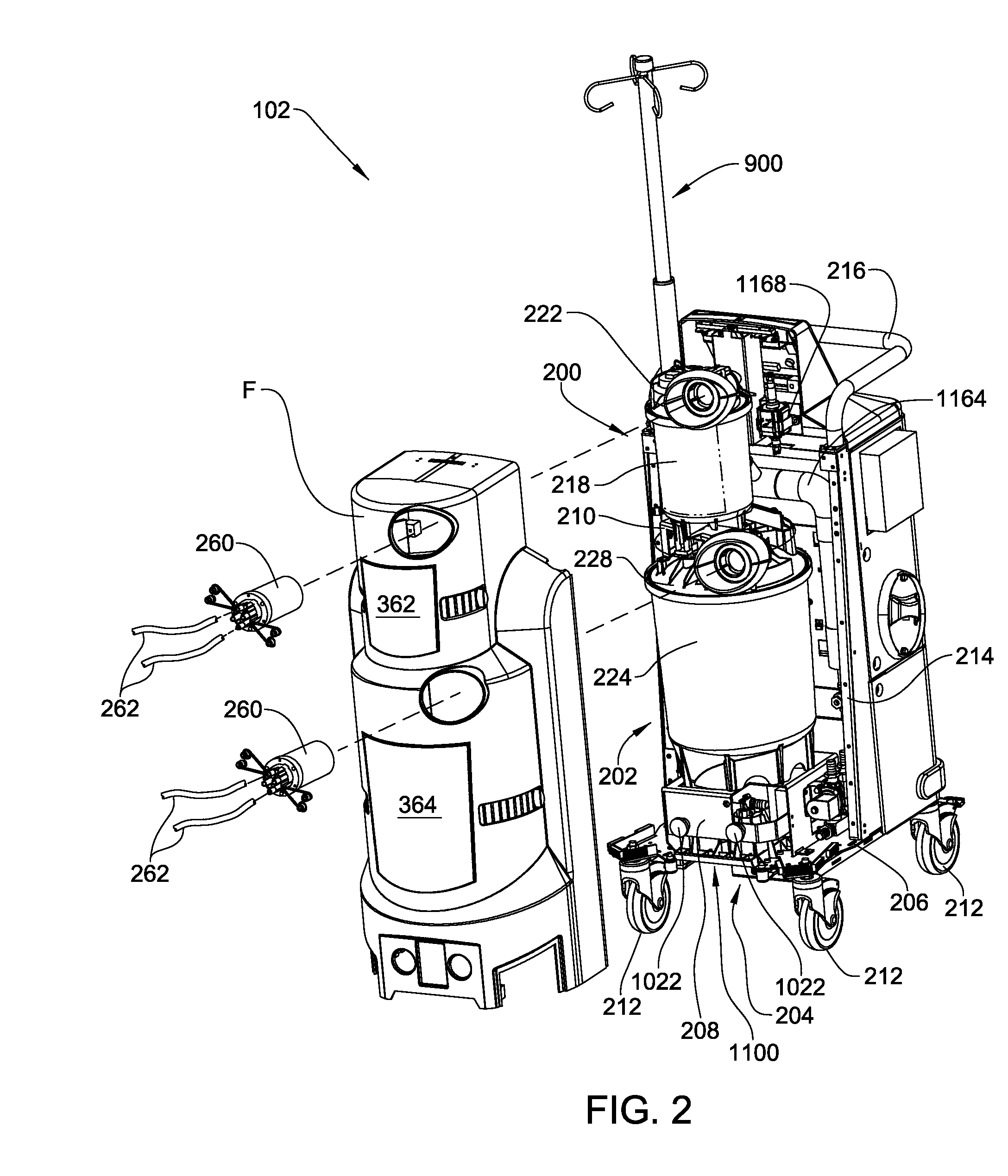

Medical/surgical waste collection unit including waste containers of different storage volumes with inter-container transfer valve and independently controlled vacuum levels

ActiveUS7621898B2Reduce in quantityLarge storage capacityMechanical apparatusDispersed particle filtrationDocking stationVacuum level

Owner:STRYKER CORP

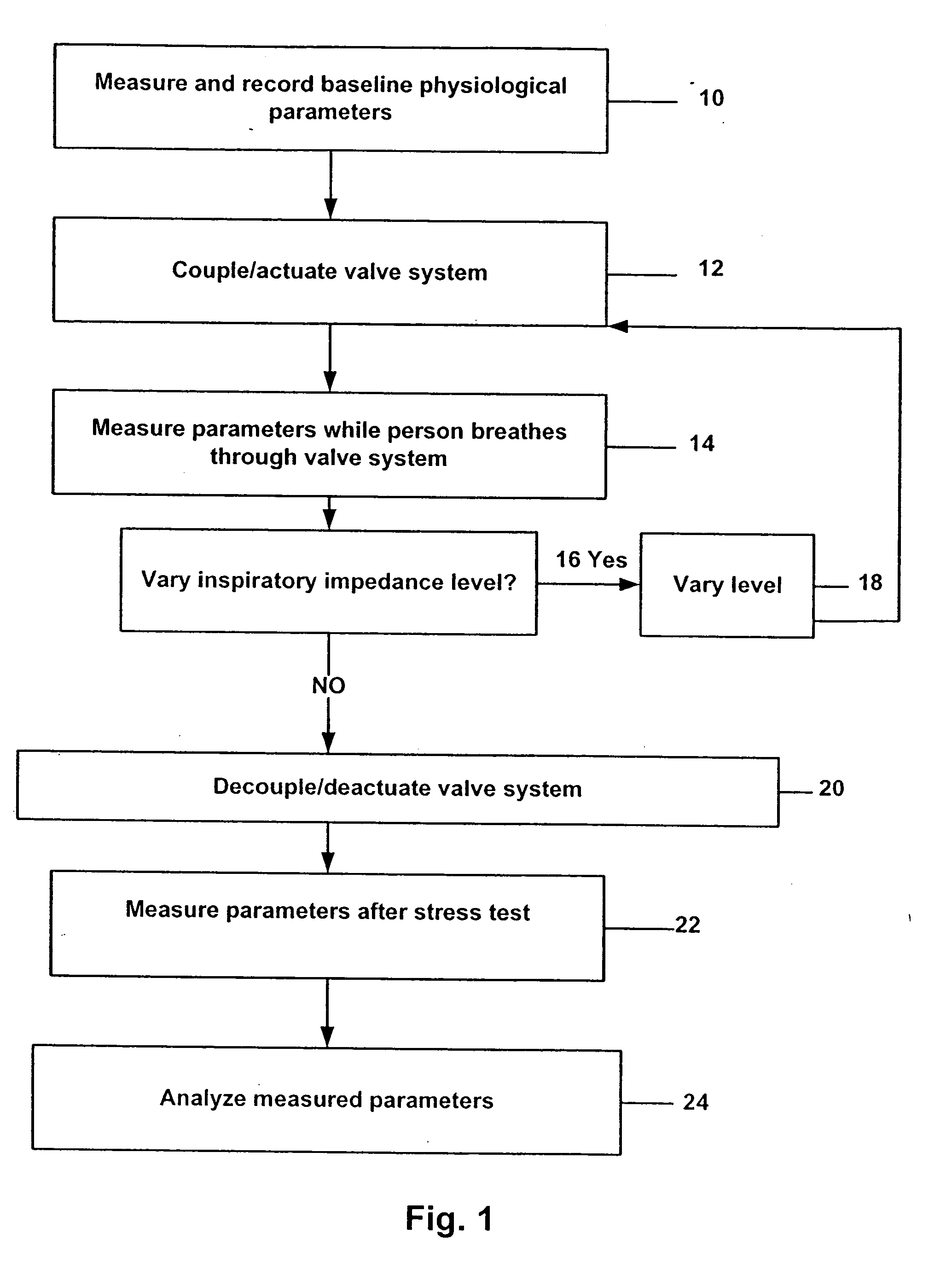

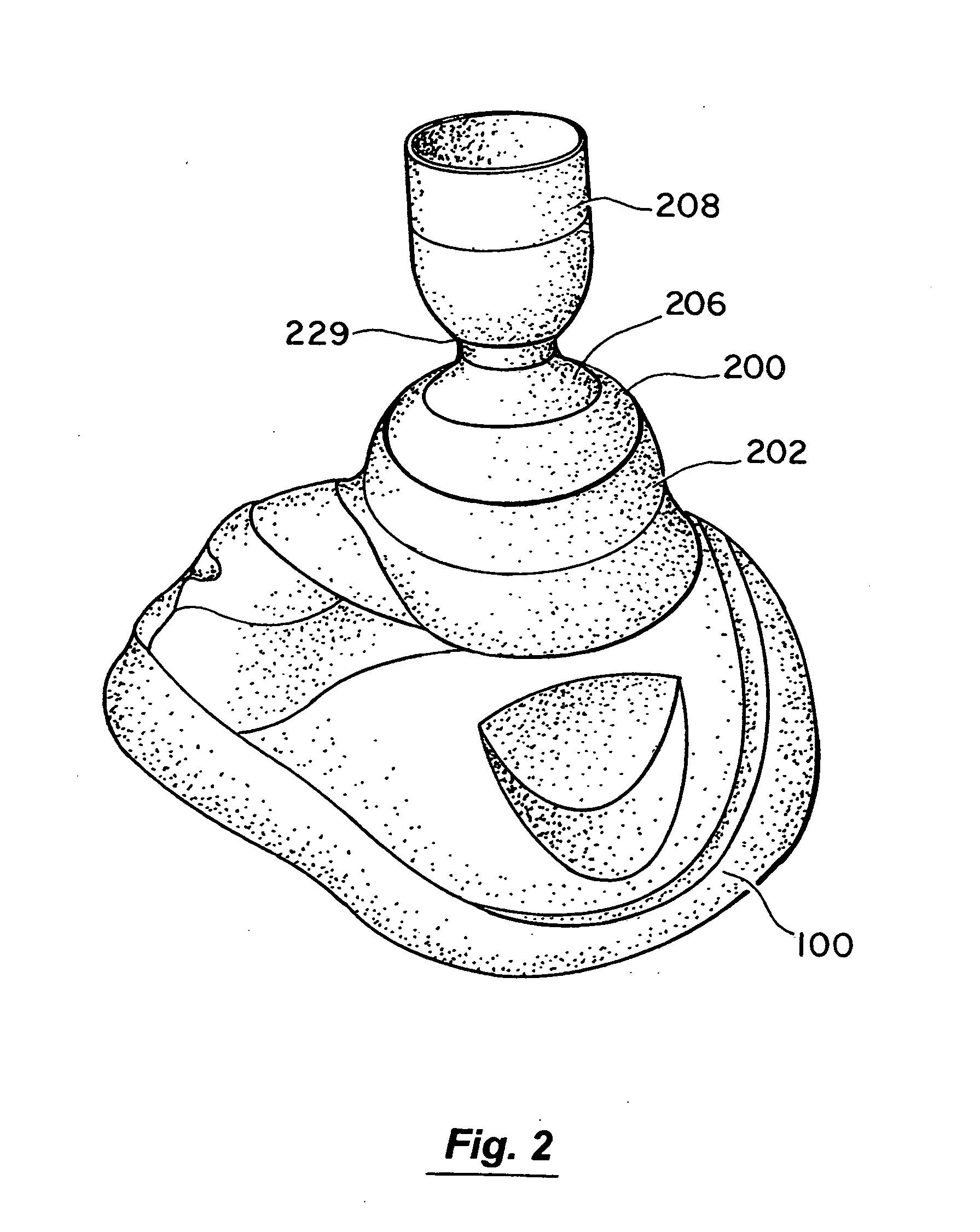

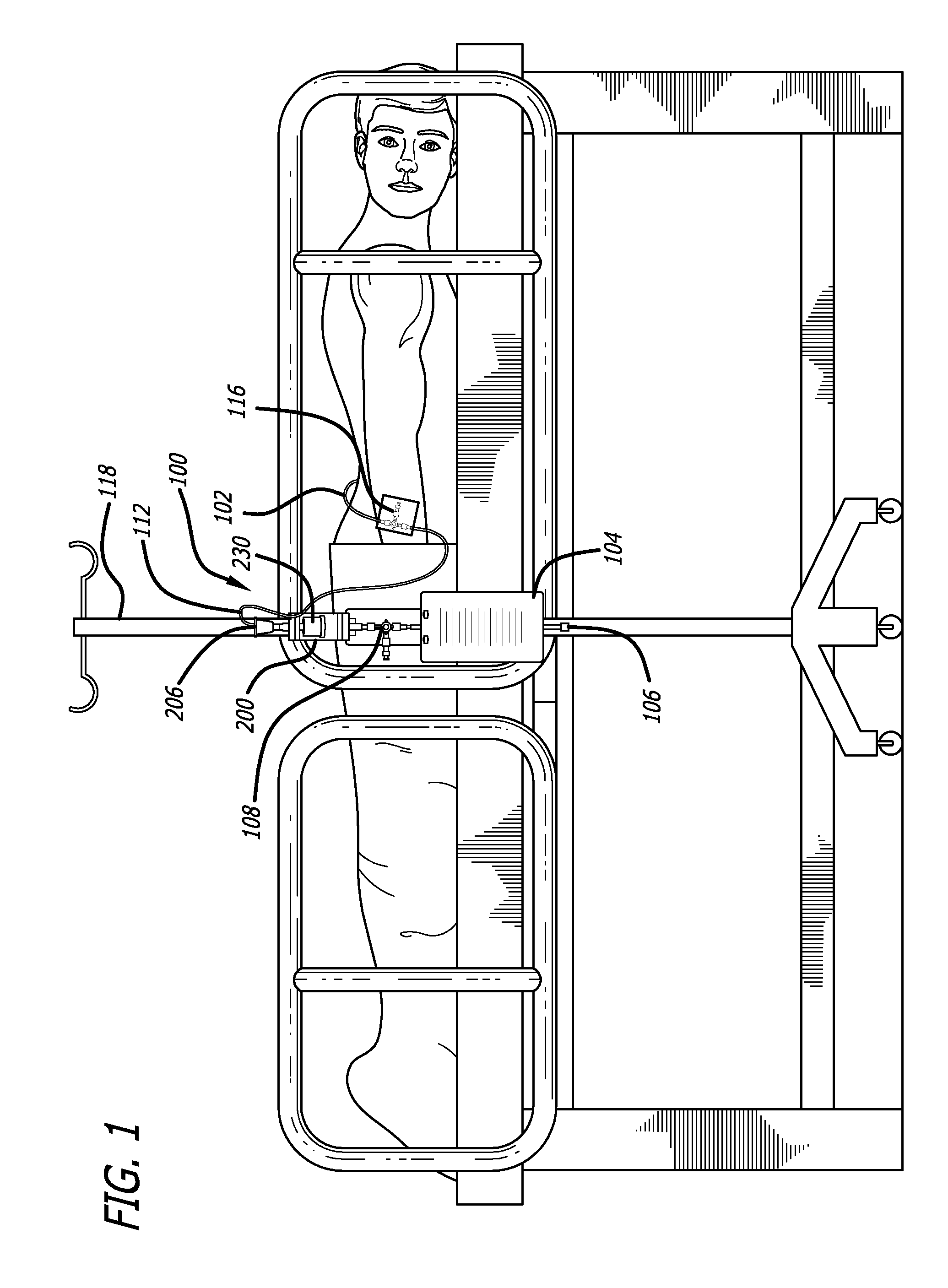

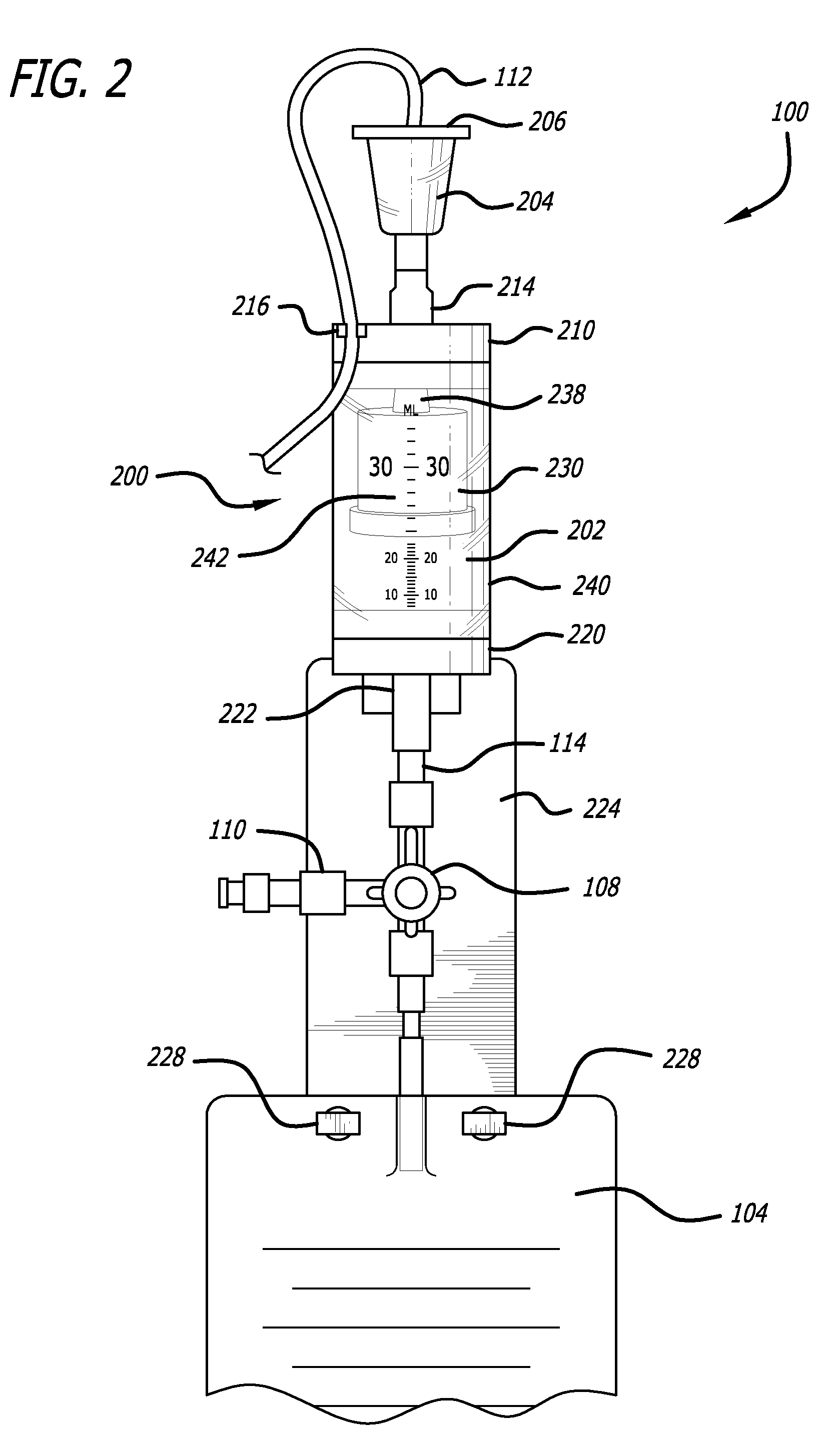

Stress test devices and methods

InactiveUS20050126567A1Good effectLower blood pressureRespiratorsFilling using suctionThoracic cavityIncreased blood flow

One method for diagnosing a cardiovascular-related condition in a breathing person comprises interfacing a valve system to the person's airway. The valve system is configured to decrease or prevent respiratory gas flow to the person's lungs during at least a portion of an inhalation event. The person is permitted to inhale and exhale through the valve system. During inhalation, the valve system functions to produce a vacuum within the thorax to increase blood flow back to the right heart of the person, thereby increasing blood circulation and blood pressure. Further, at least one physiological parameter is measured while the person inhales and exhales through the valve system. The measured parameter is evaluated to diagnose a cardiovascular condition.

Owner:ZOLL MEDICAL CORPORATION

Liquid pumping device

ActiveUS7093624B2Improve versatilityCrankshaftsFilling using suctionEngineeringMechanical engineering

A liquid pumping device includes a barrel, a cylinder, a conducting rod, a piston, an operation lever, and a cover. Thus, the liquid pumping device is operated automatically by the power source or operated manually by the operation lever to suck the liquid from the suction pipe into the inside of the barrel rapidly, so that the liquid pumping device is operated automatically and manually, thereby greatly enhancing the versatility of the liquid pumping device.

Owner:YO LEE MFG

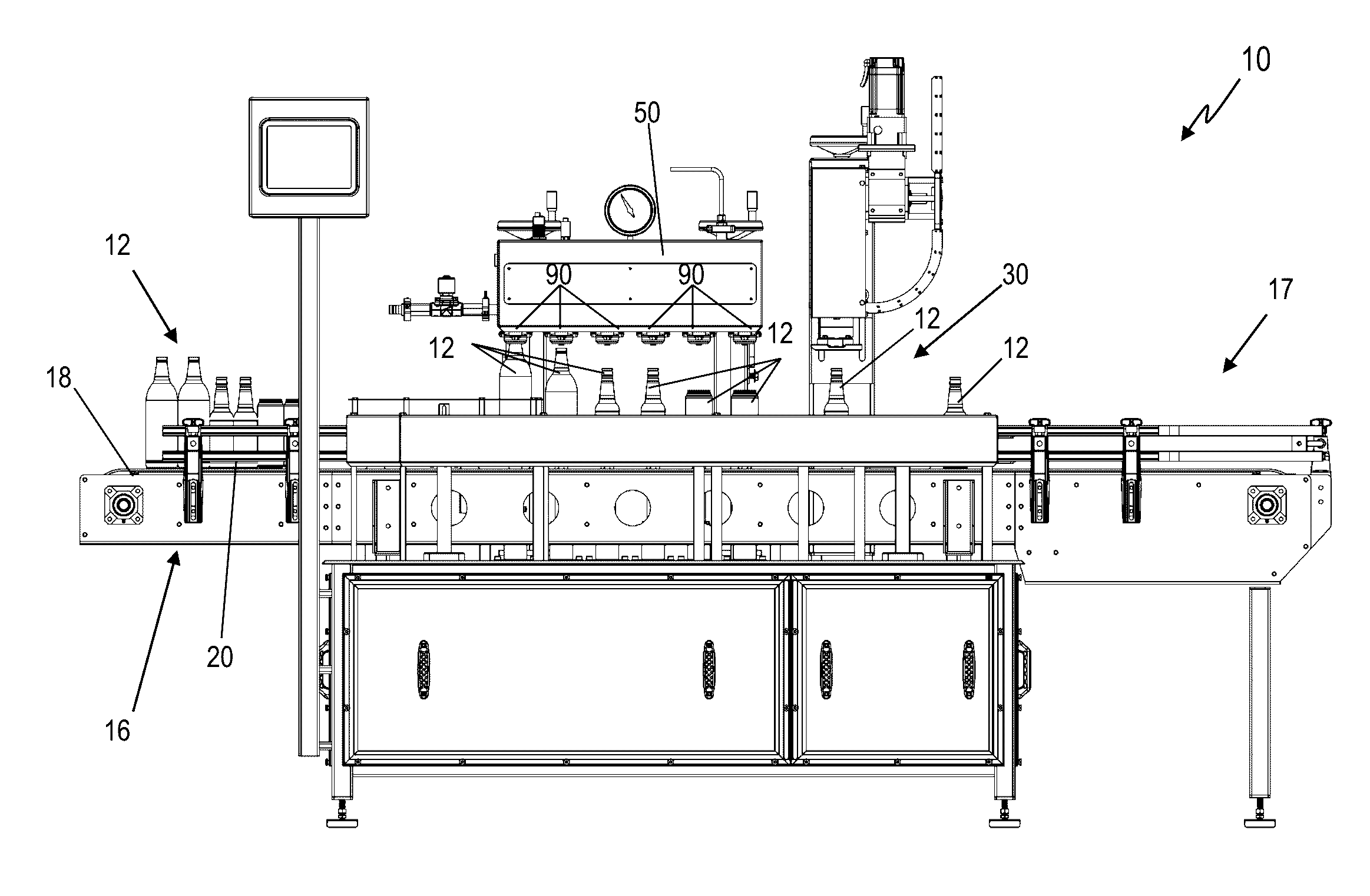

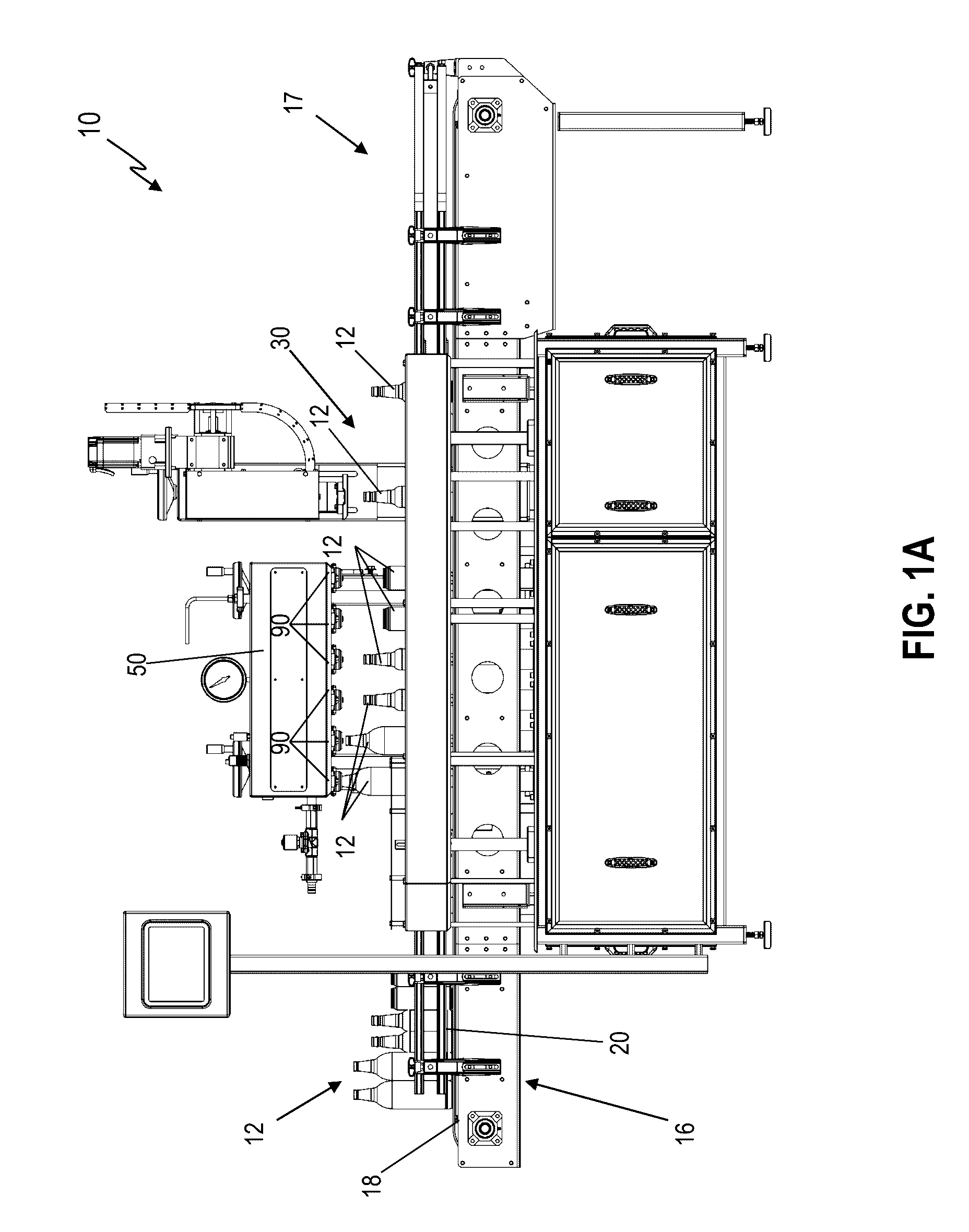

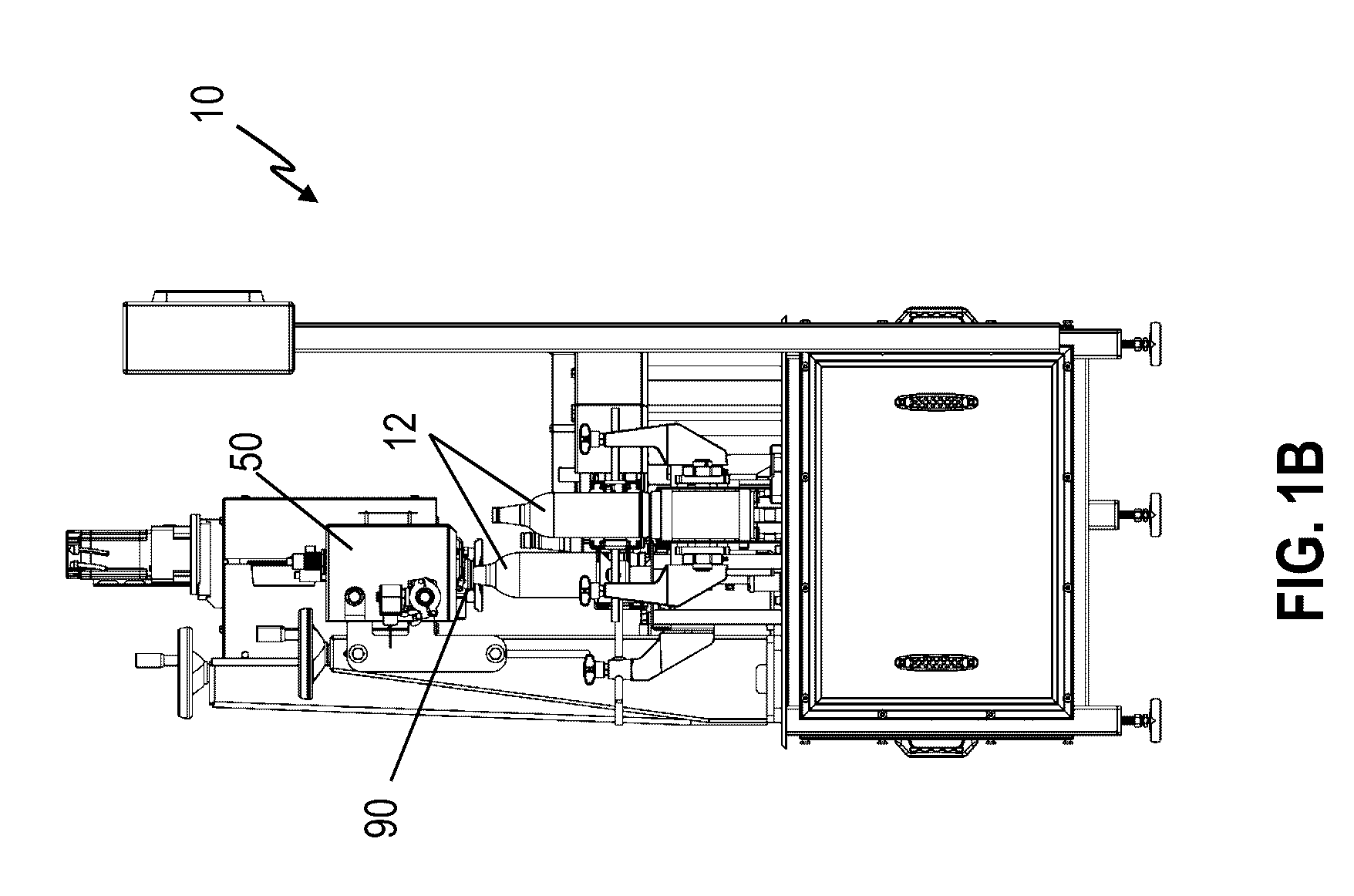

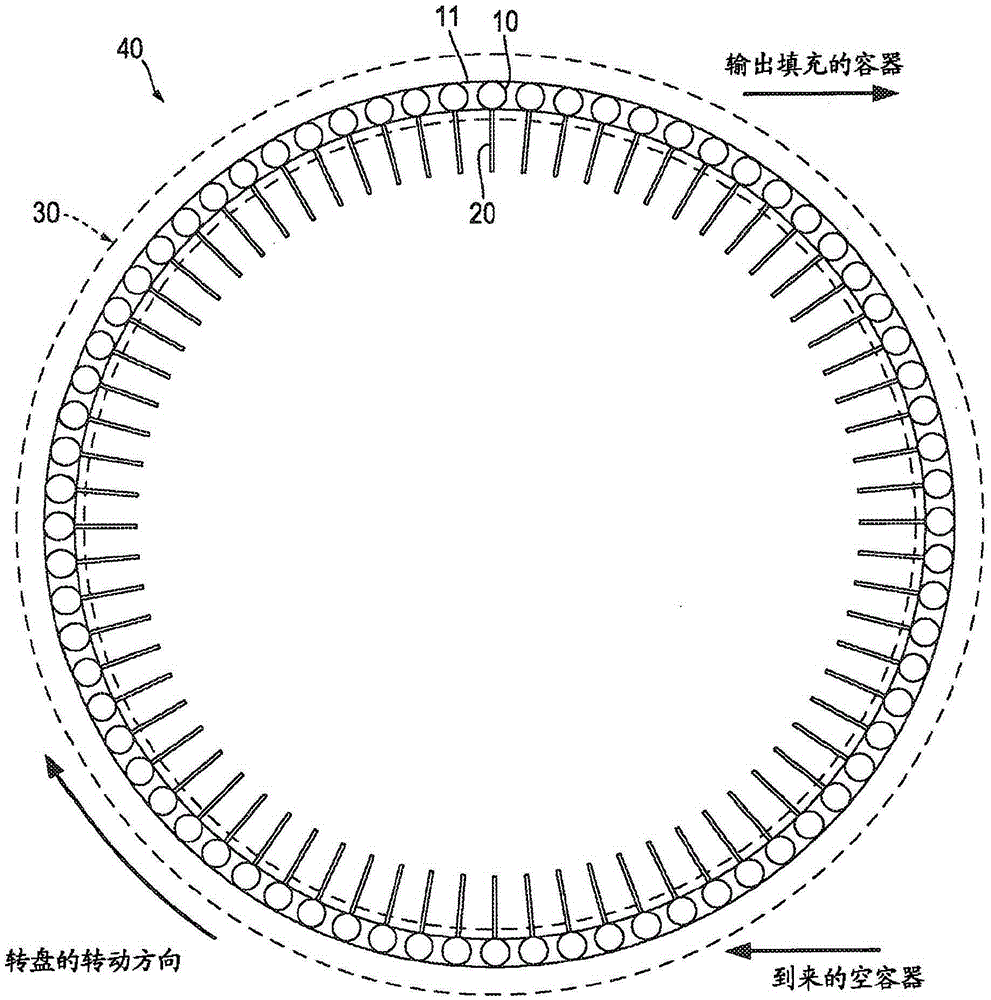

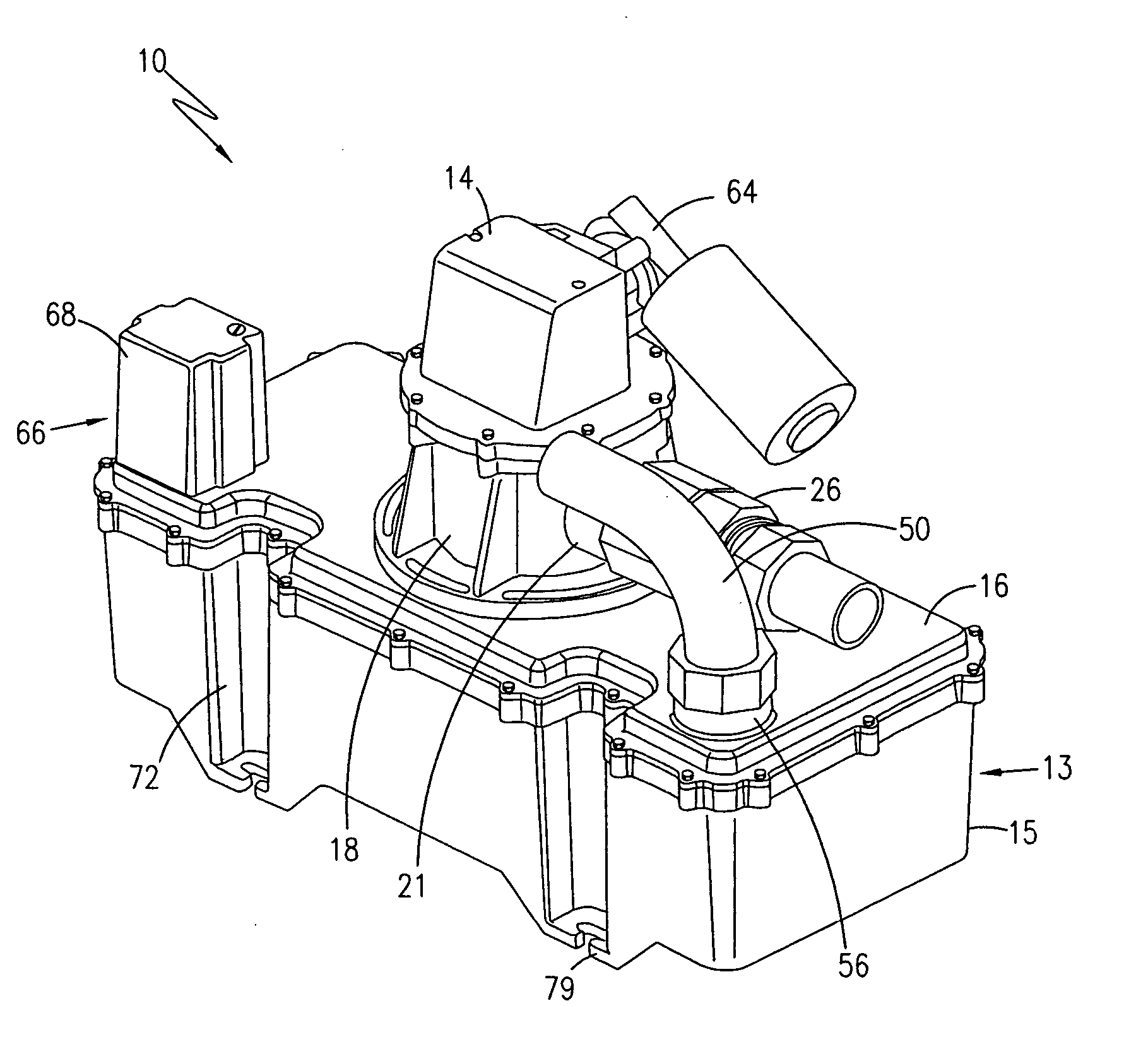

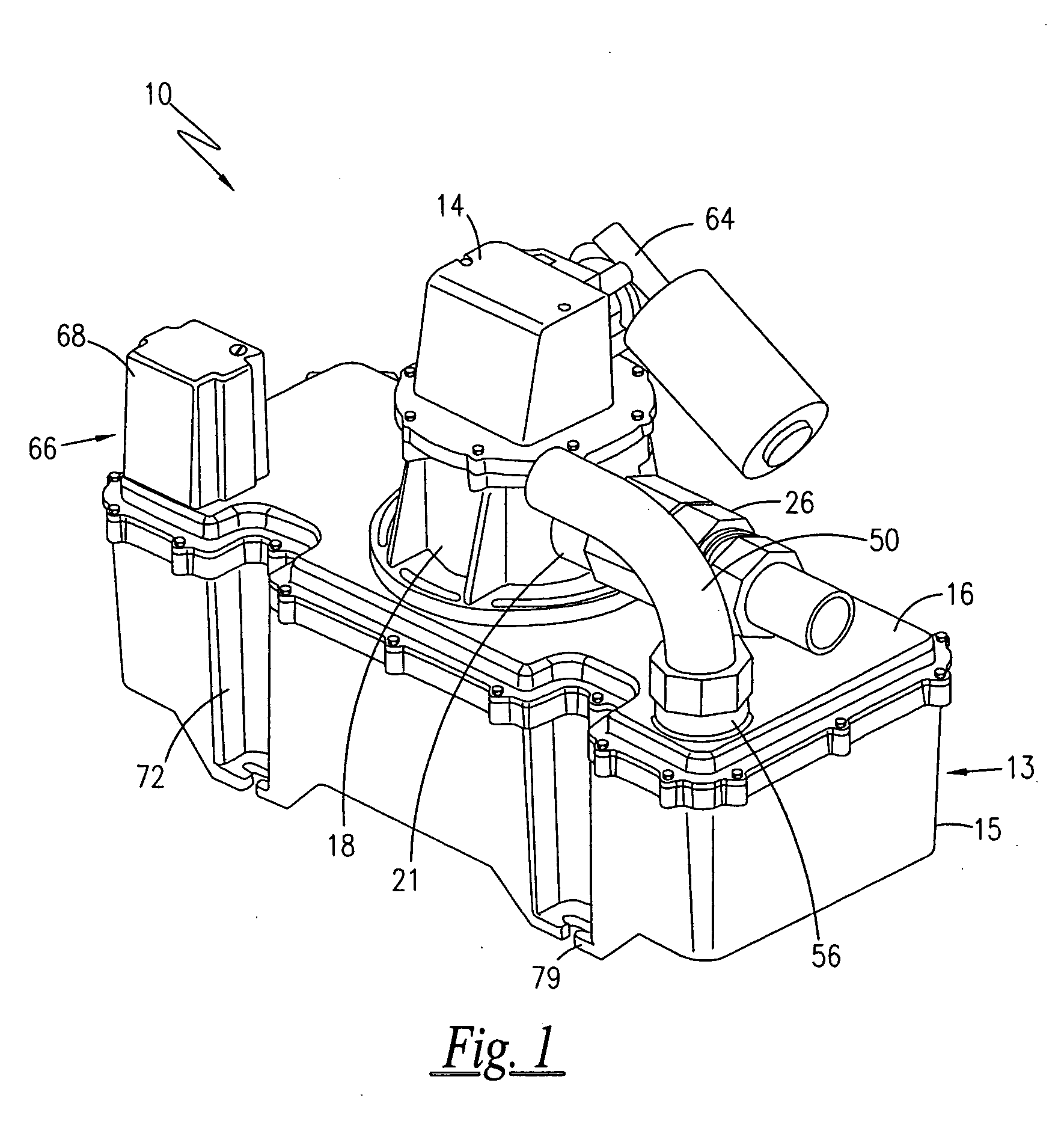

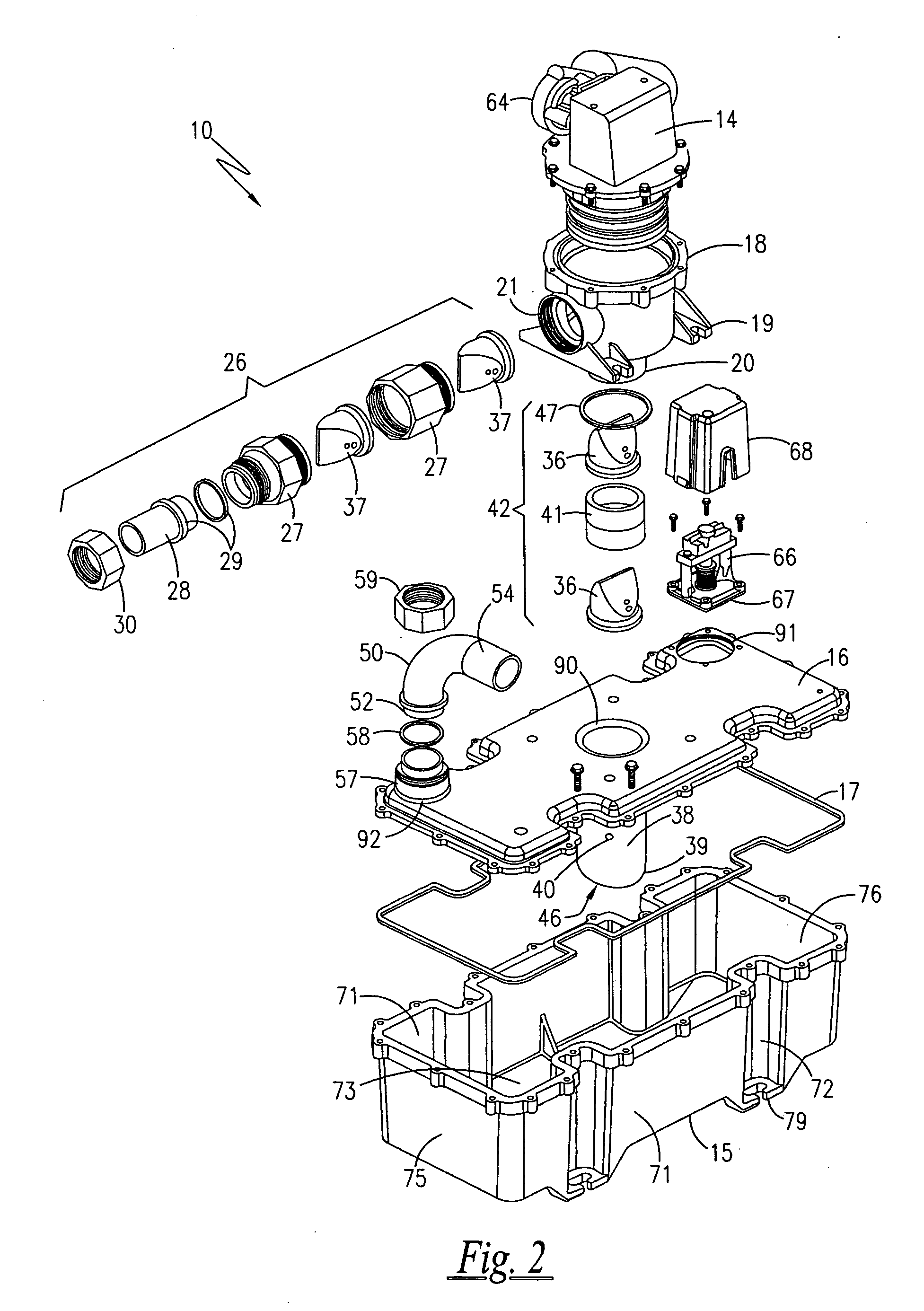

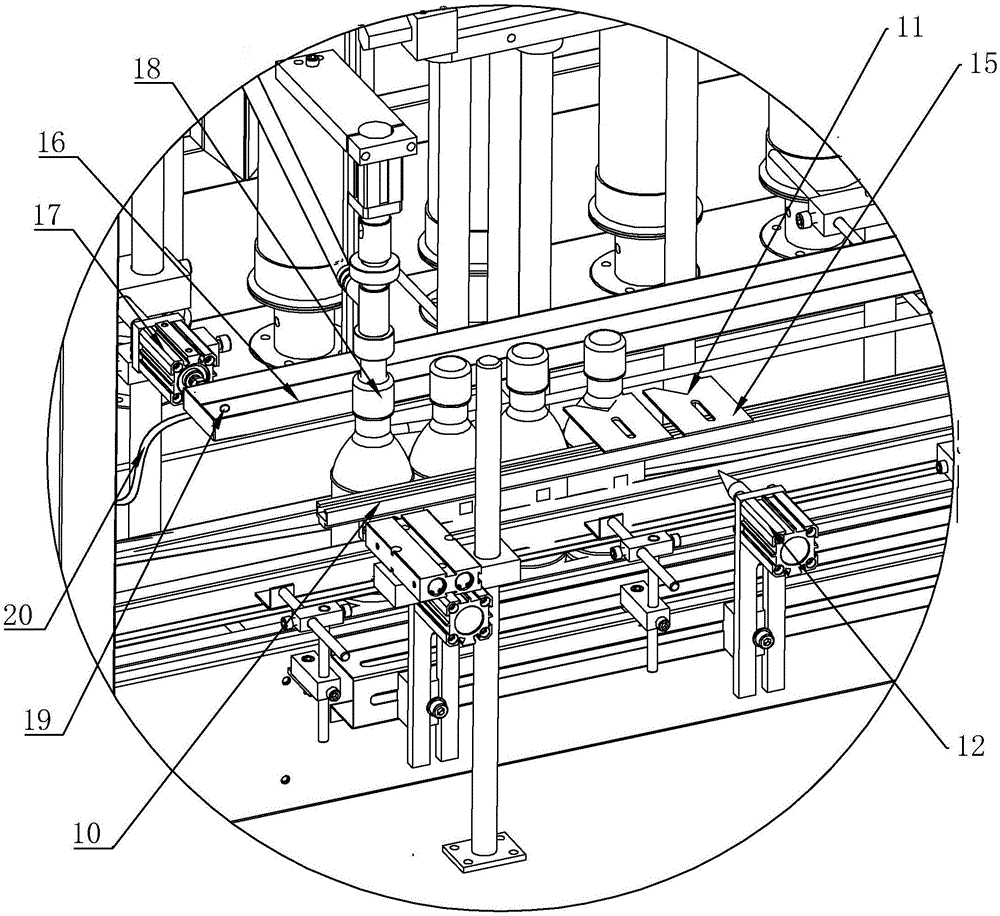

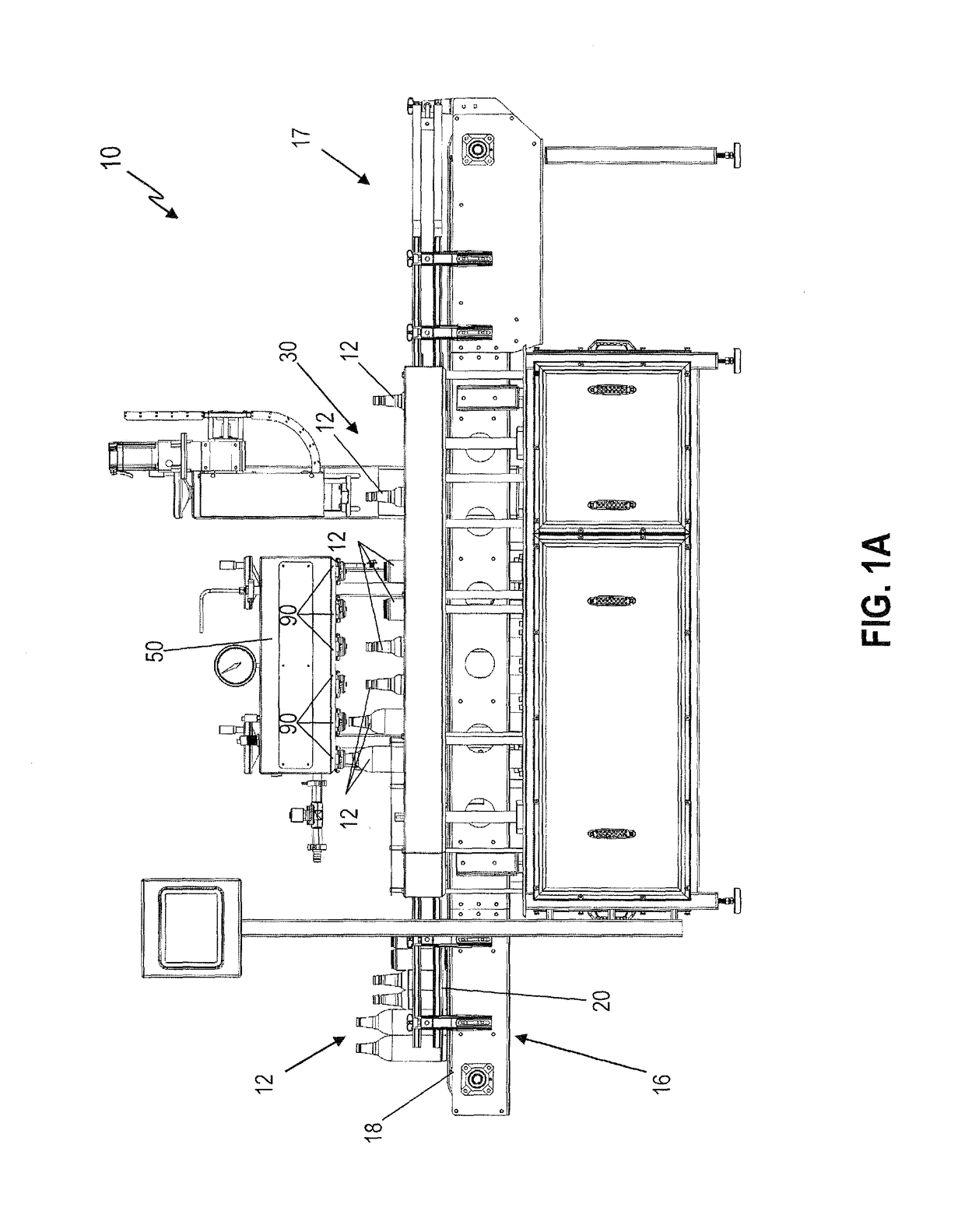

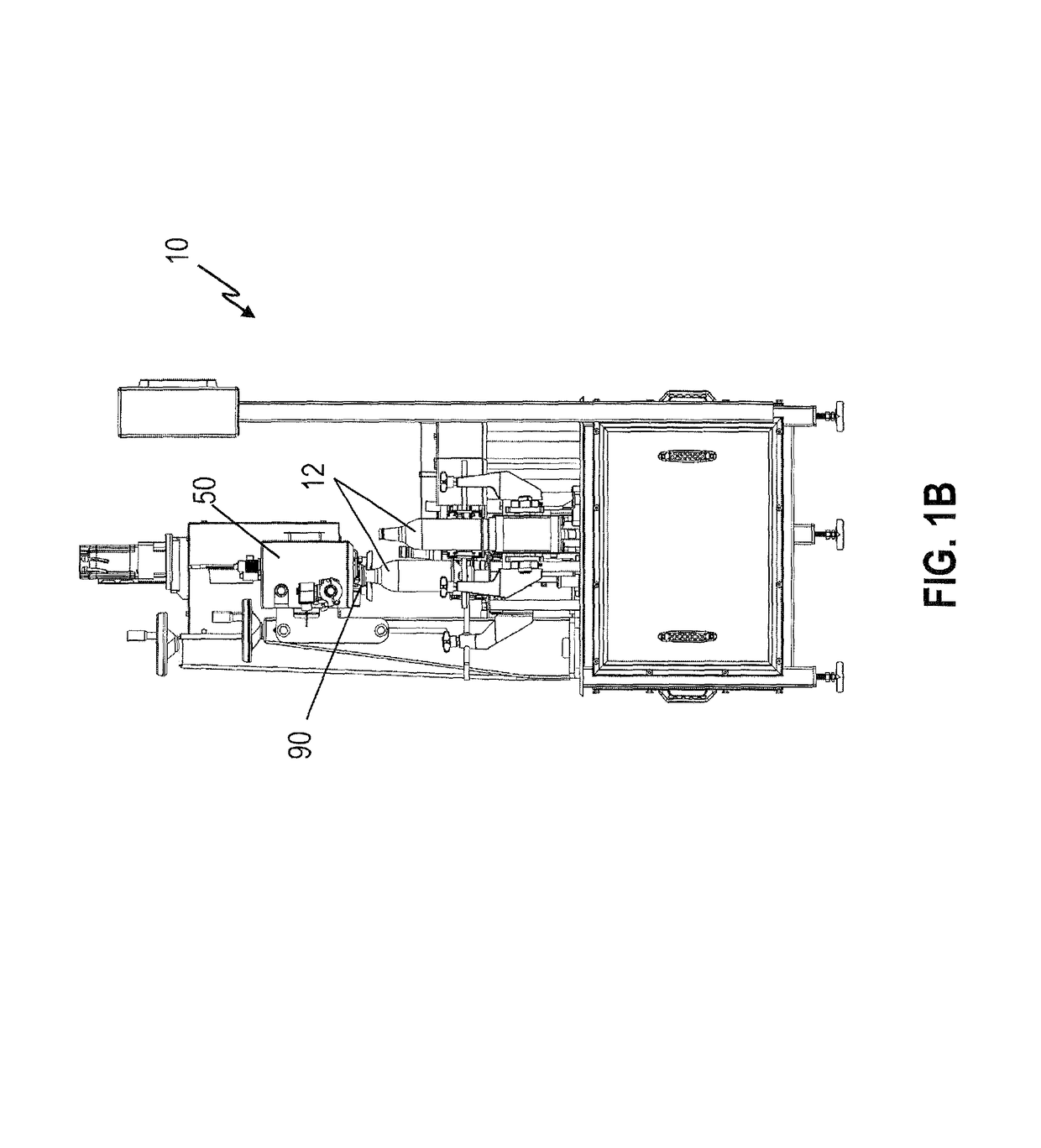

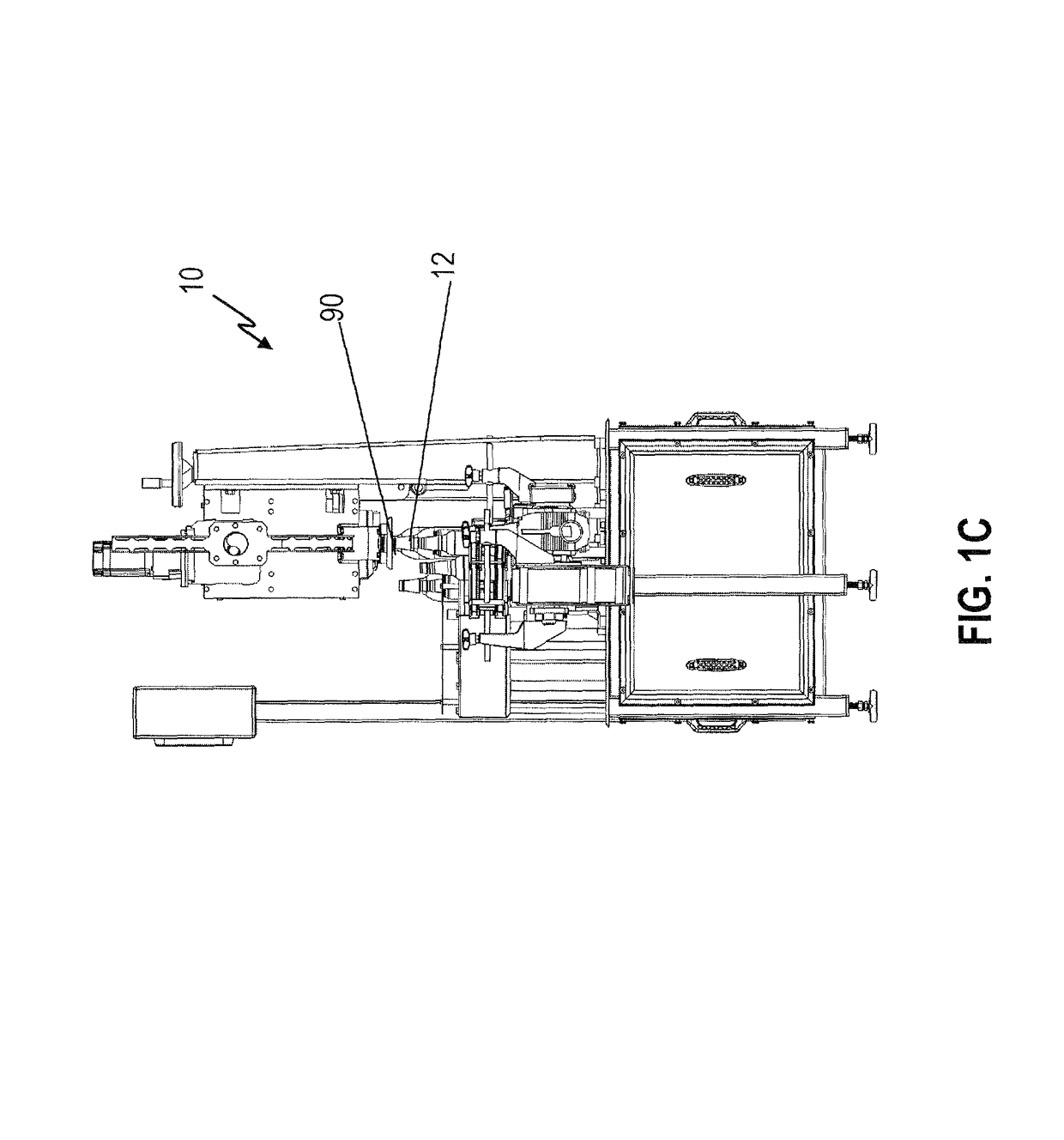

Multi-container filling machine, valves, and related technologies

An apparatus for filling differently sized containers with fluid includes a filling head having a fluid holding area. At least one multi-container filling nozzle connected to the filling head, wherein at least two containers with differently-sized openings are fillable with a quantity of fluid from the fluid holding area without changing the multi-container filling nozzle. Related methods and devices for filing containers with differently-sized openings with fluid without changing a fluid nozzle are also disclosed.

Owner:ABC FILLERS INC

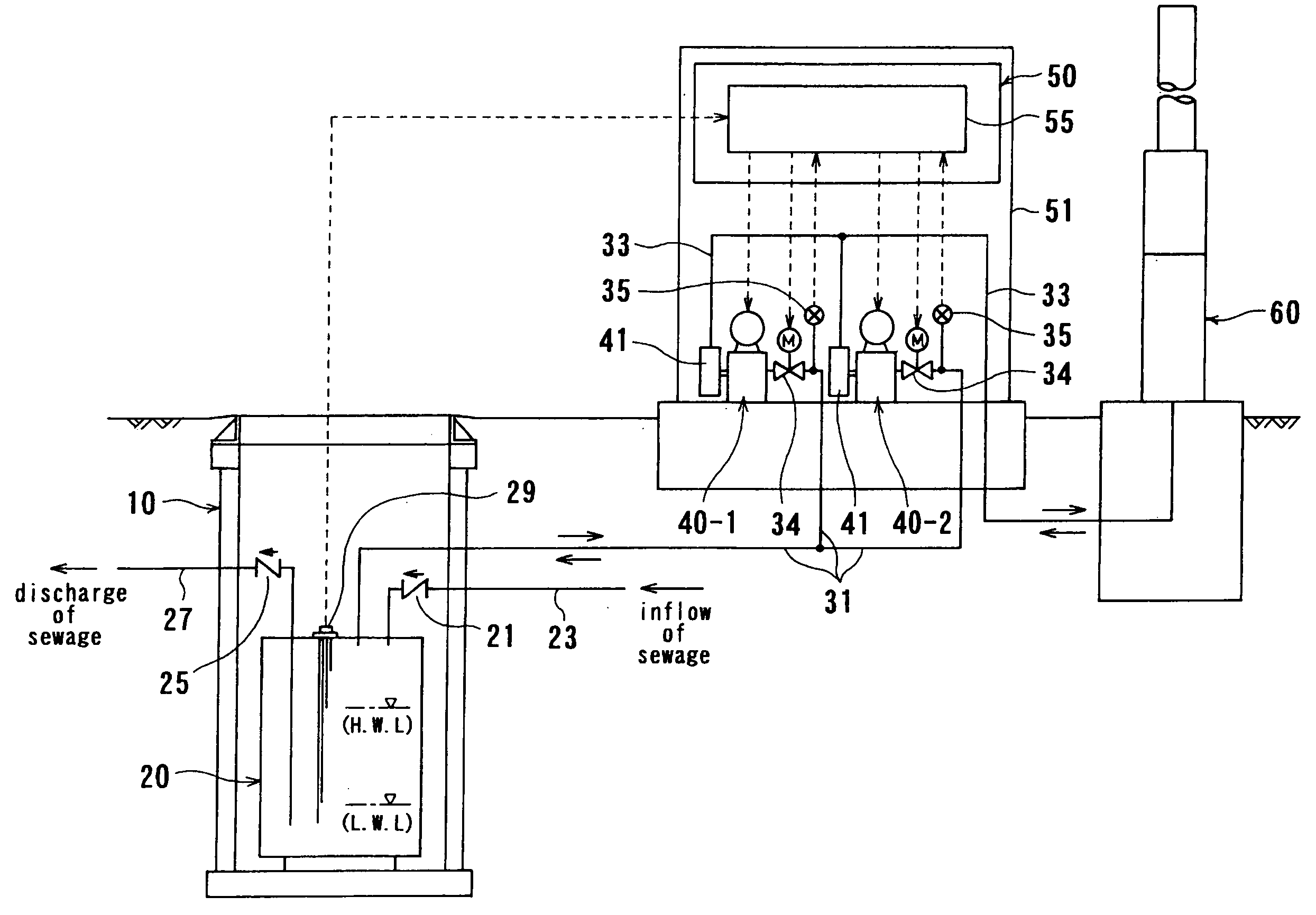

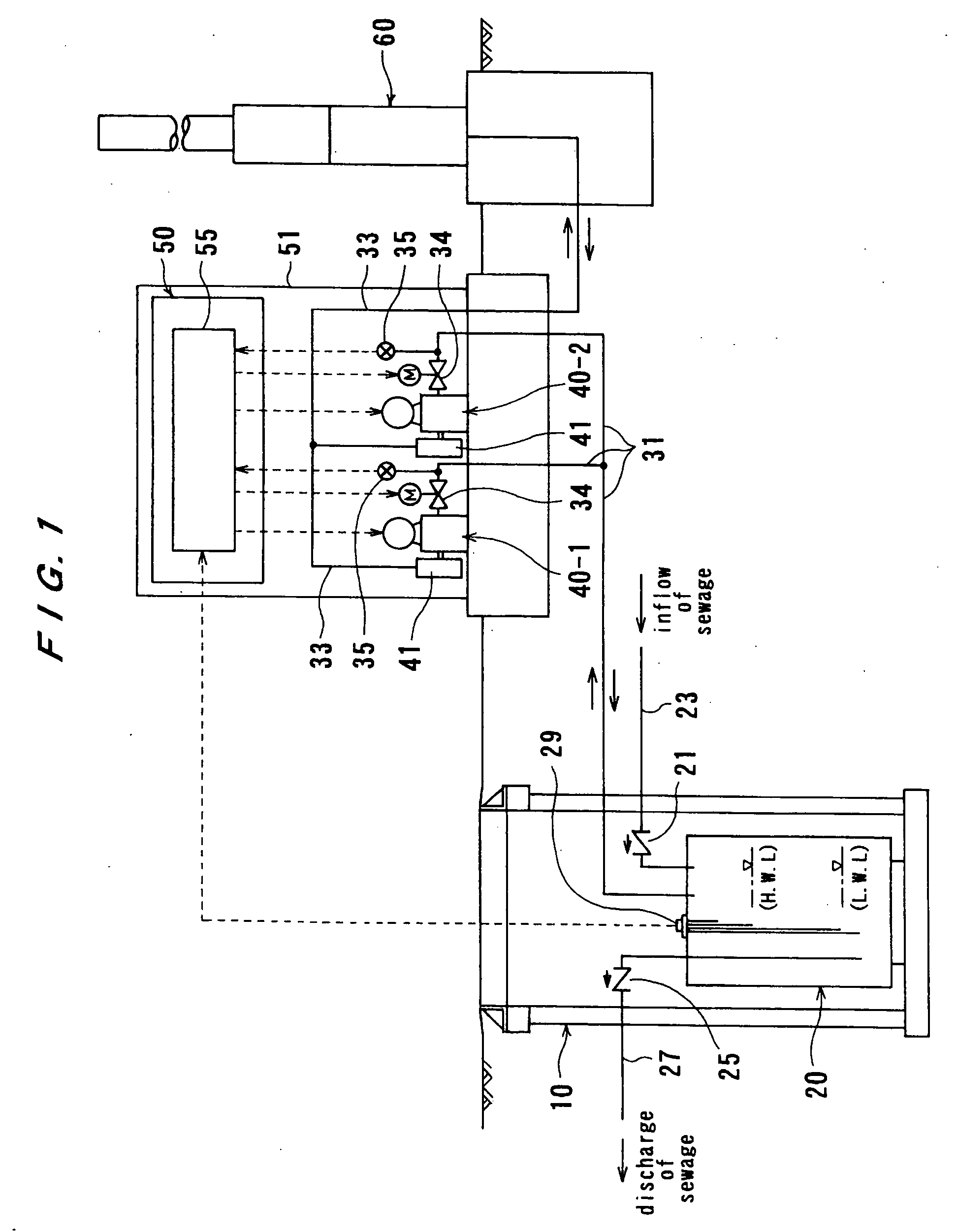

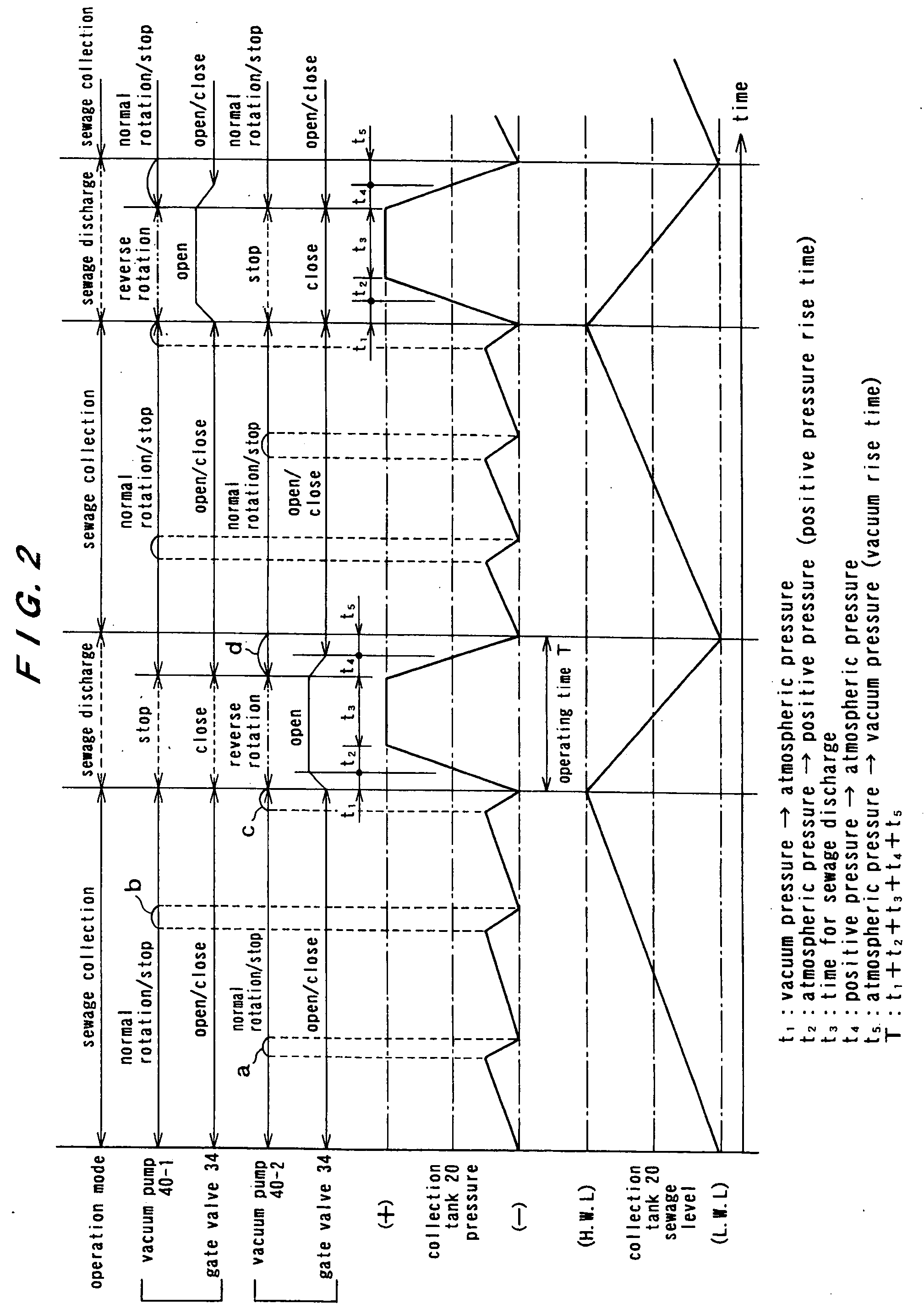

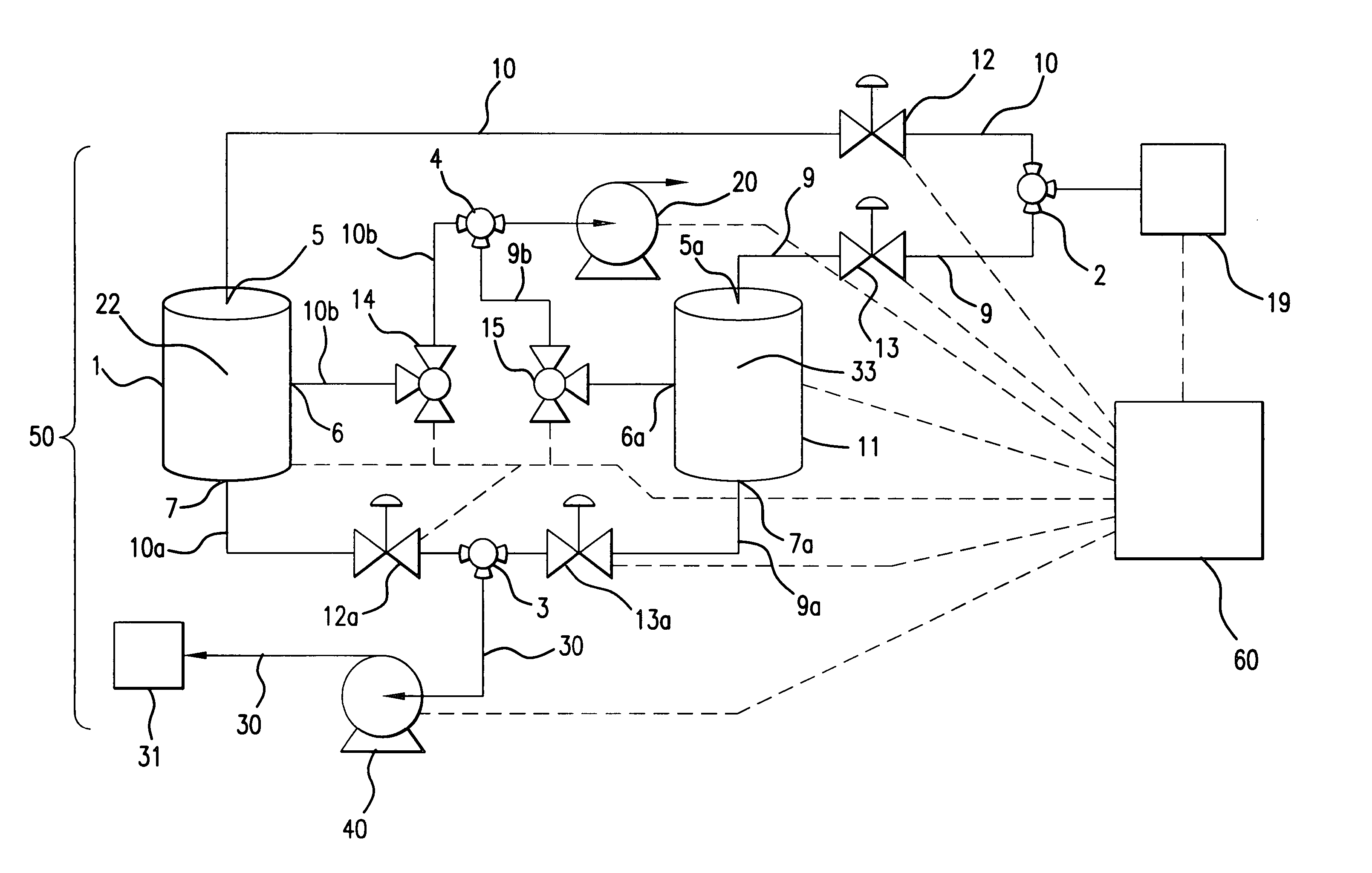

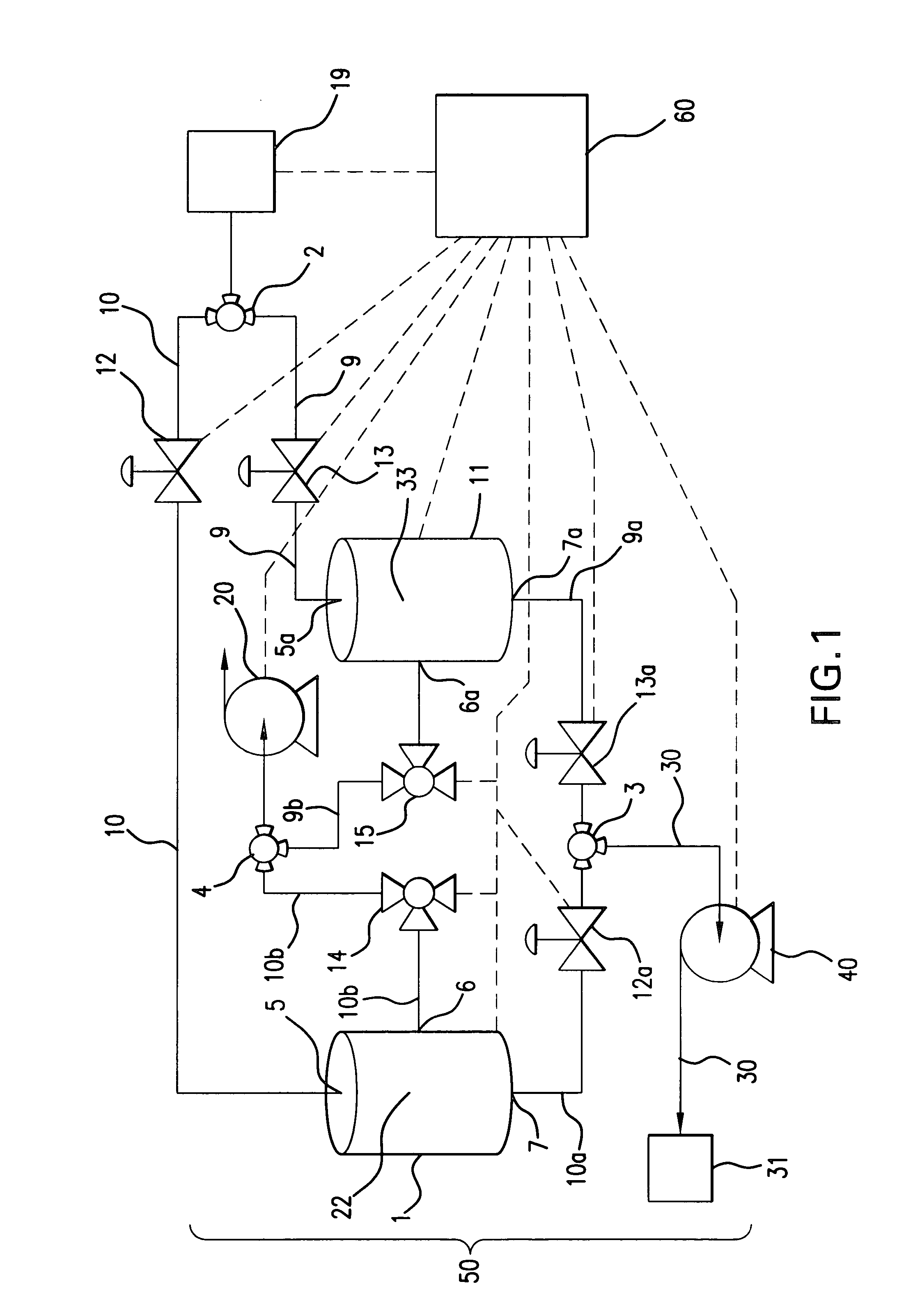

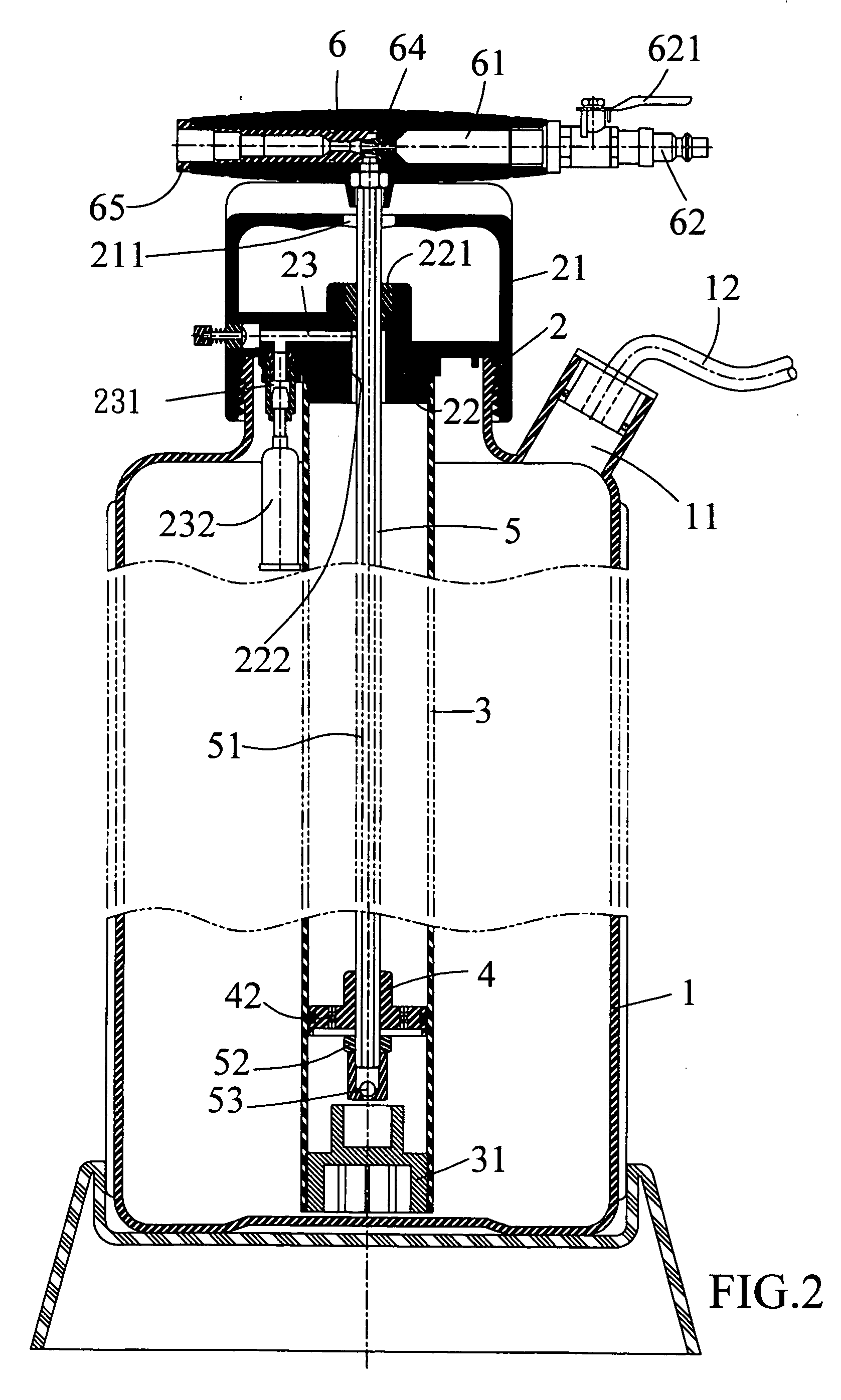

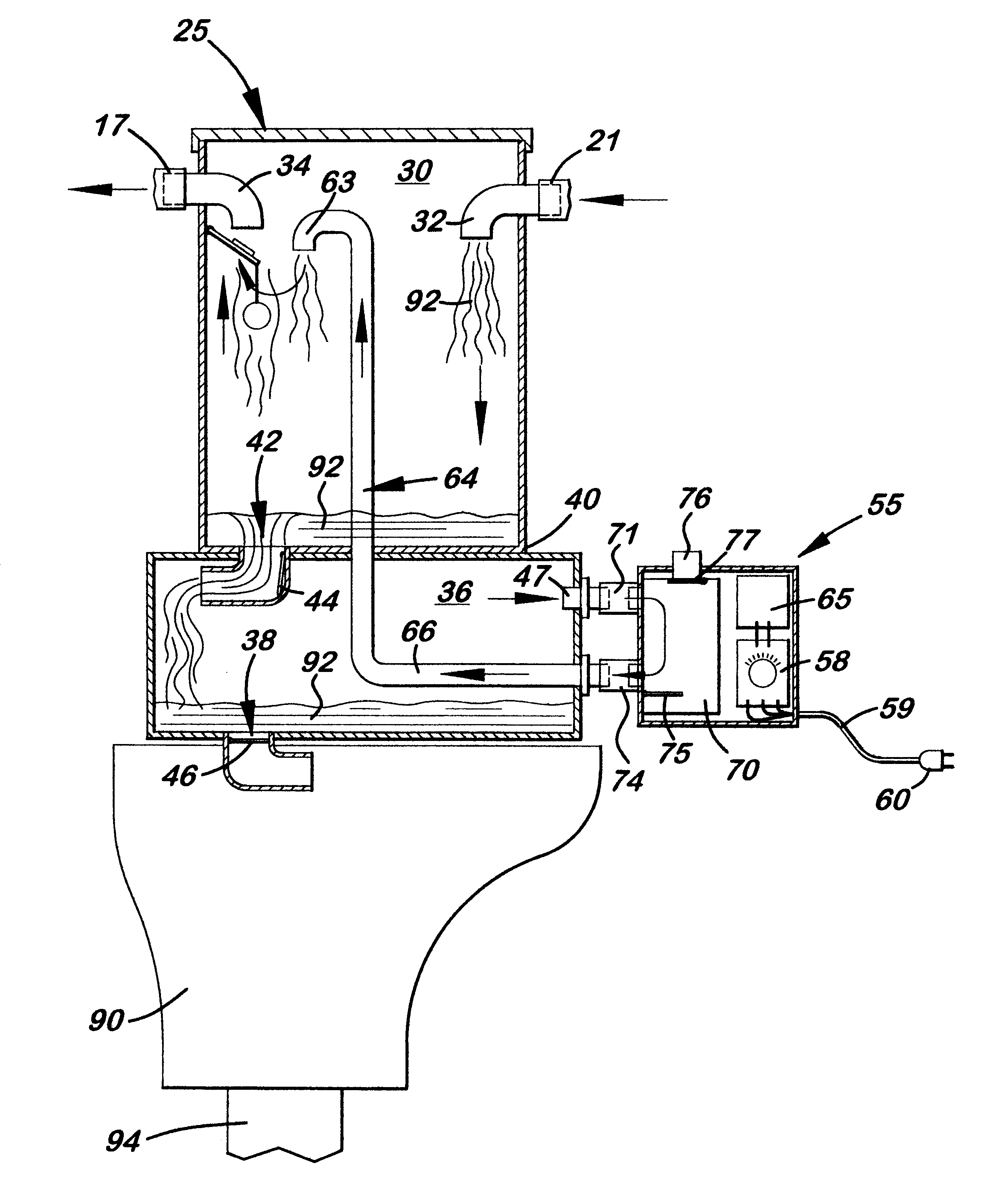

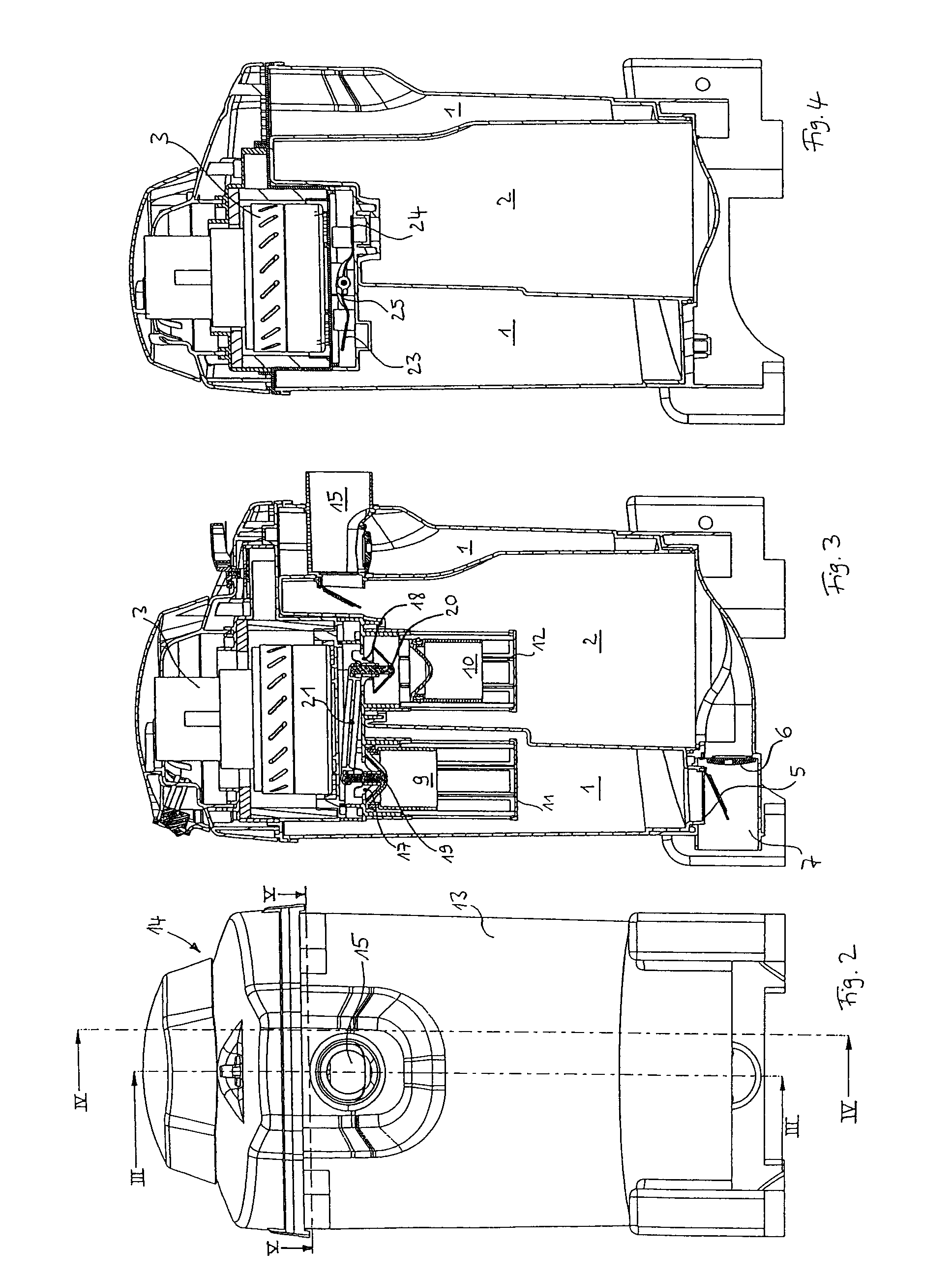

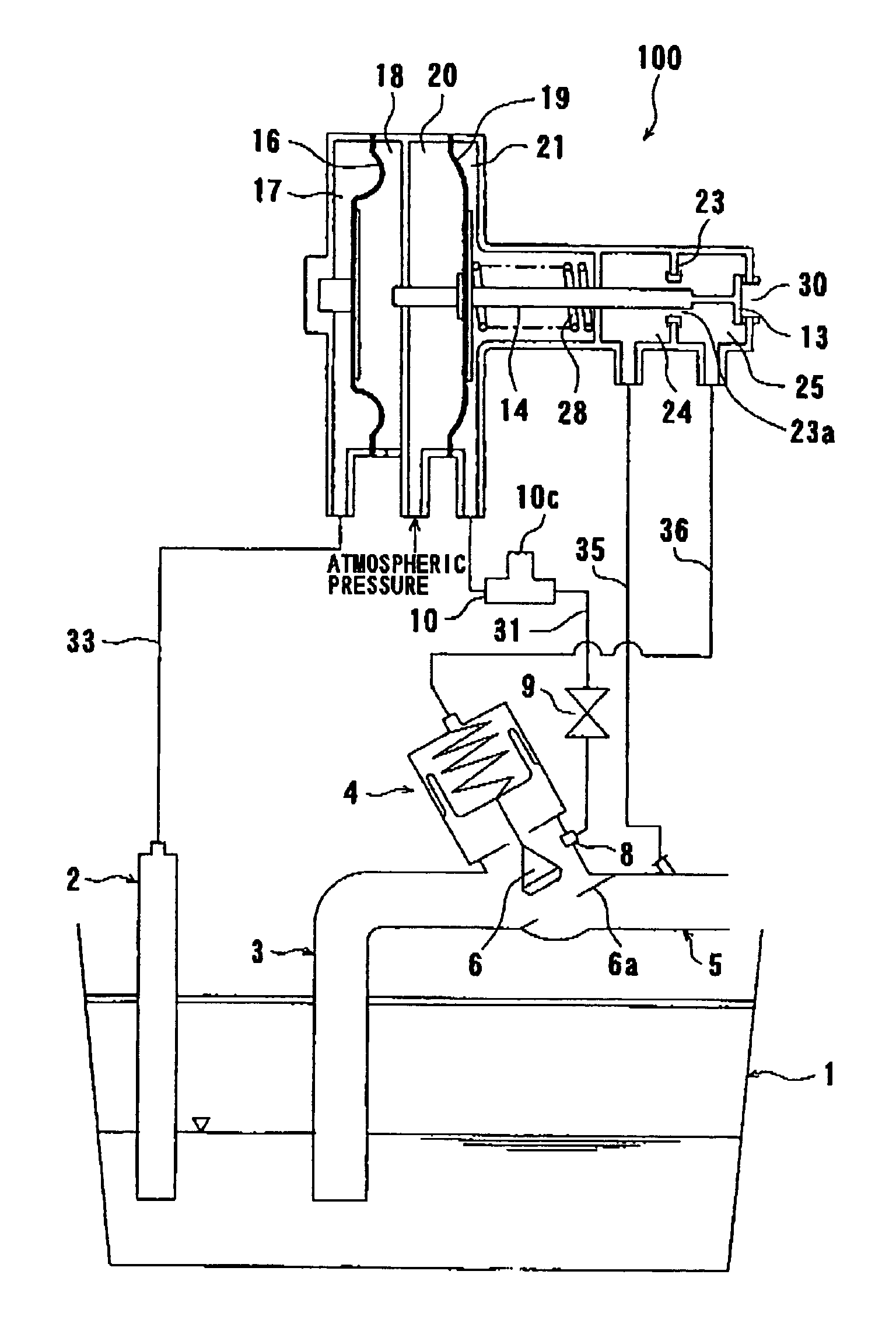

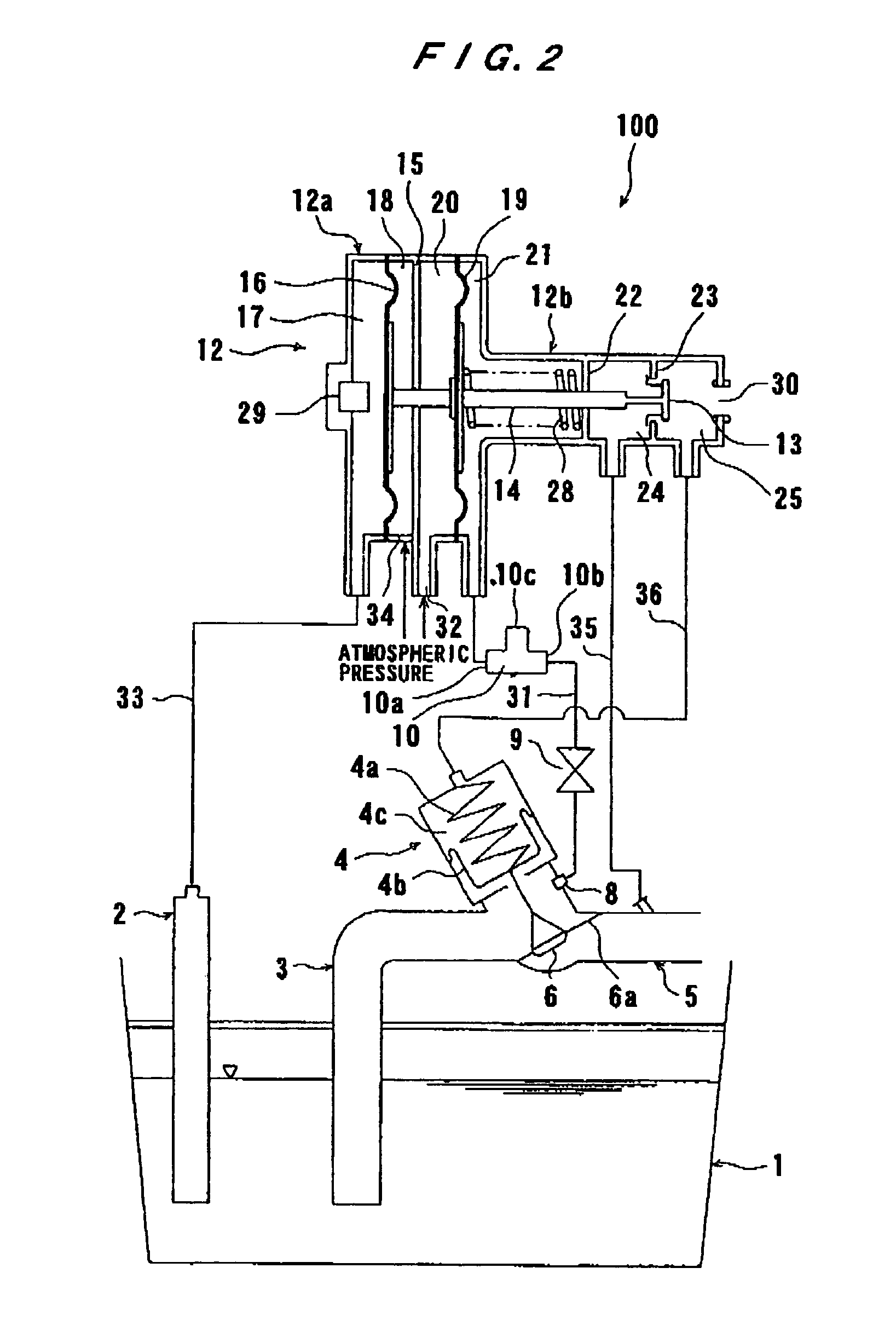

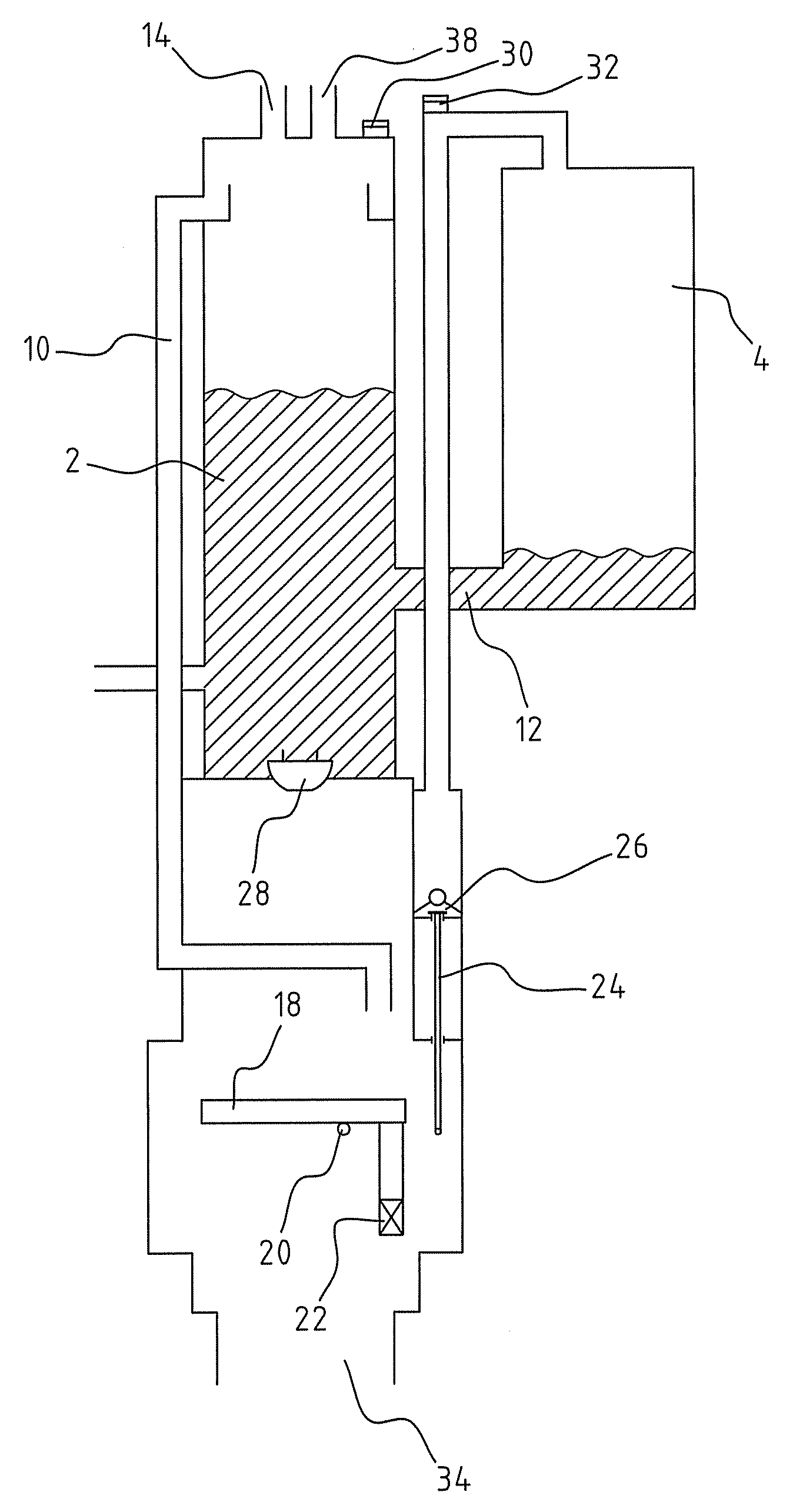

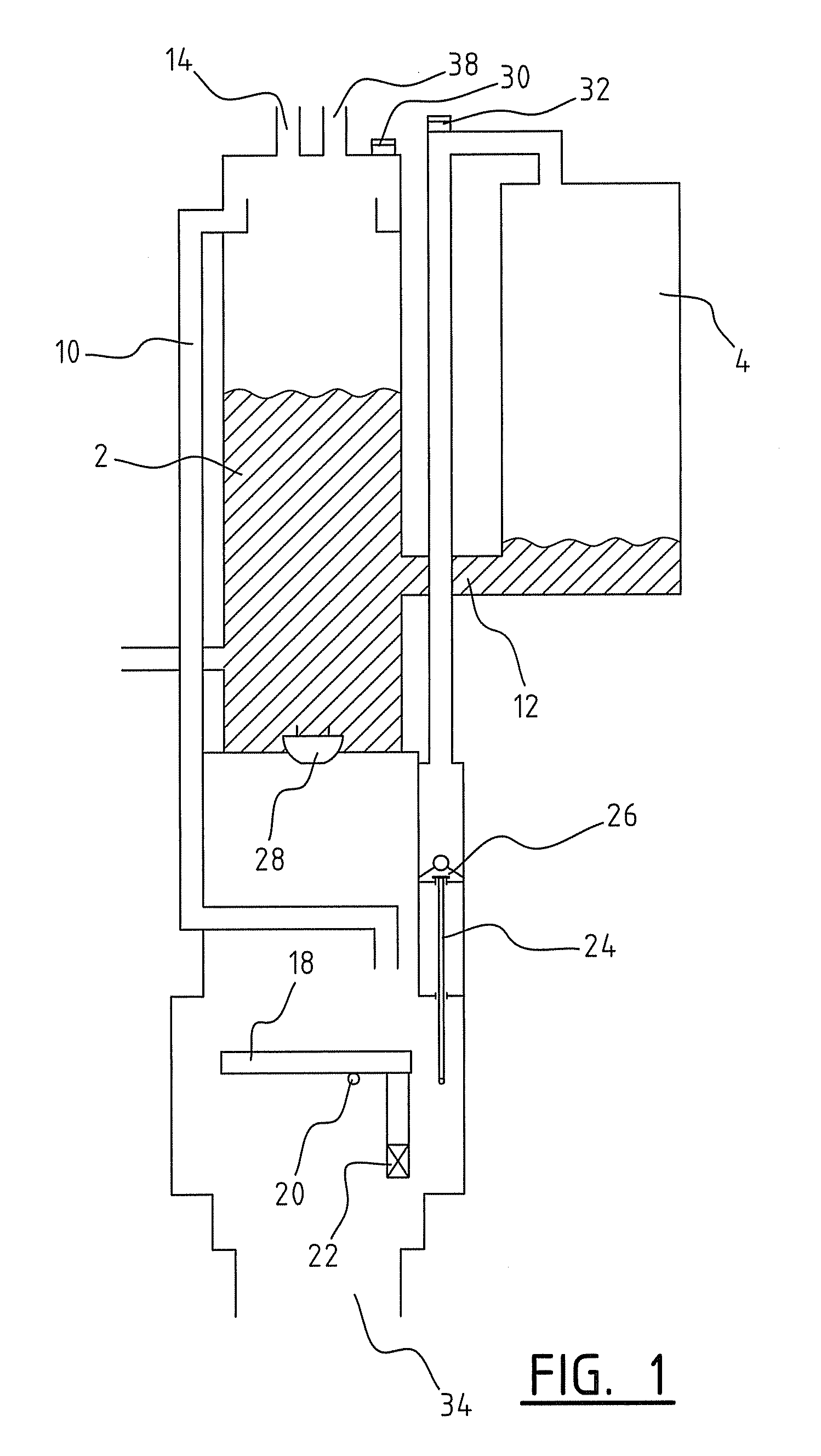

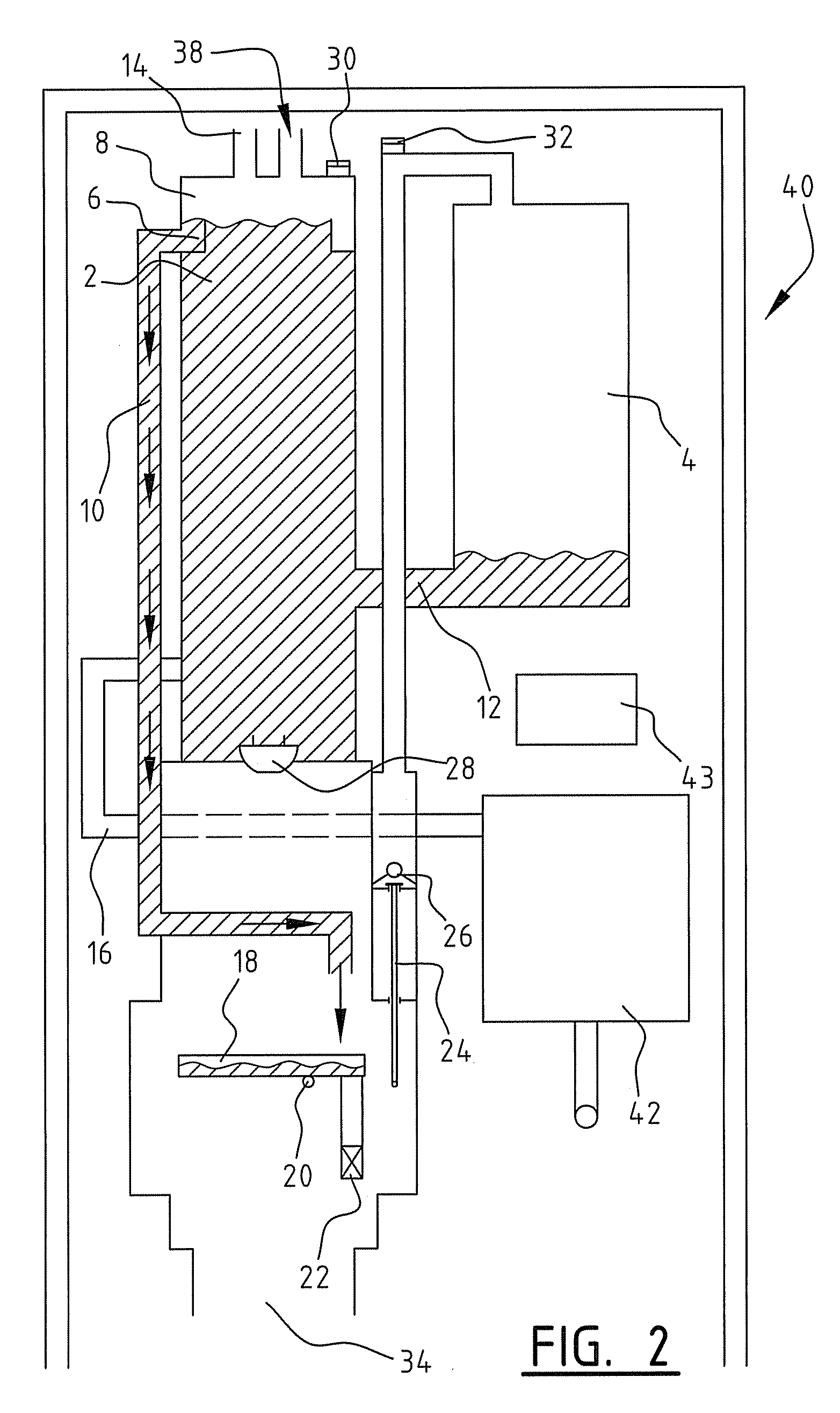

Vacuum station and the method for operating the same

ActiveUS20050016588A1Reduce facility costsImprove efficiencyFilling using suctionSewerage structuresSewageSewage treatment

A vacuum station is used for storing sewage from a vacuum sewage pipe and then delivering the sewage to a sewage treatment plant or the like. The vacuum station includes a collection tank for collecting sewage, a plurality of vacuum pumps for depressurizing and pressurizing an interior of the collection tank, and a controller for controlling the plurality of vacuum pumps. The controller controls at least one of the vacuum pumps so as to rotate in normal direction so that the interior of the collection tank is depressurized to collect sewage into the collection tank, and at least one of the vacuum pumps so as to rotate in reverse direction when the sewage in the collection tank reaches a predetermined sewage level so that the interior of the collection tank is pressurized to discharge the sewage from the collection tank.

Owner:EBARA CORP

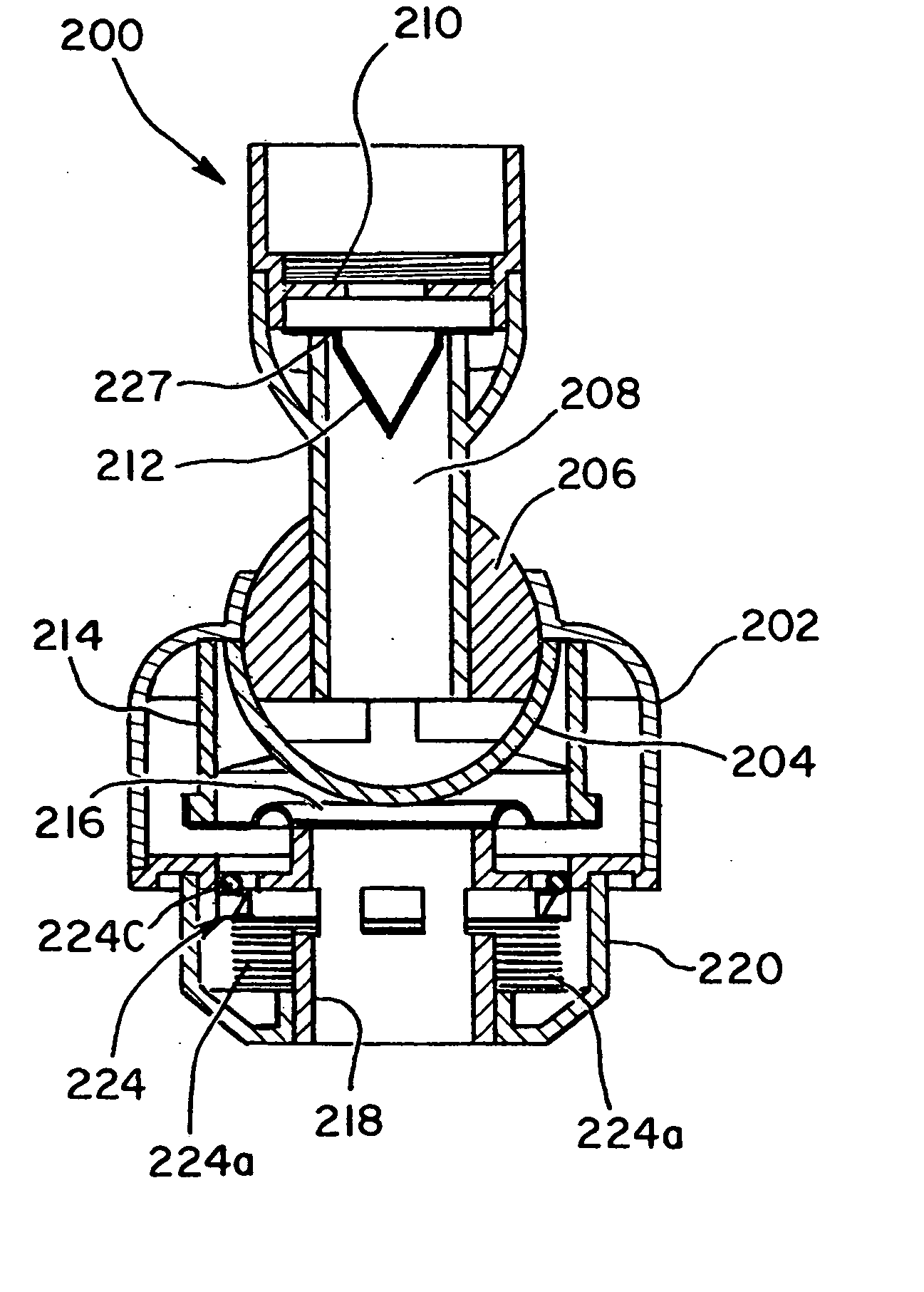

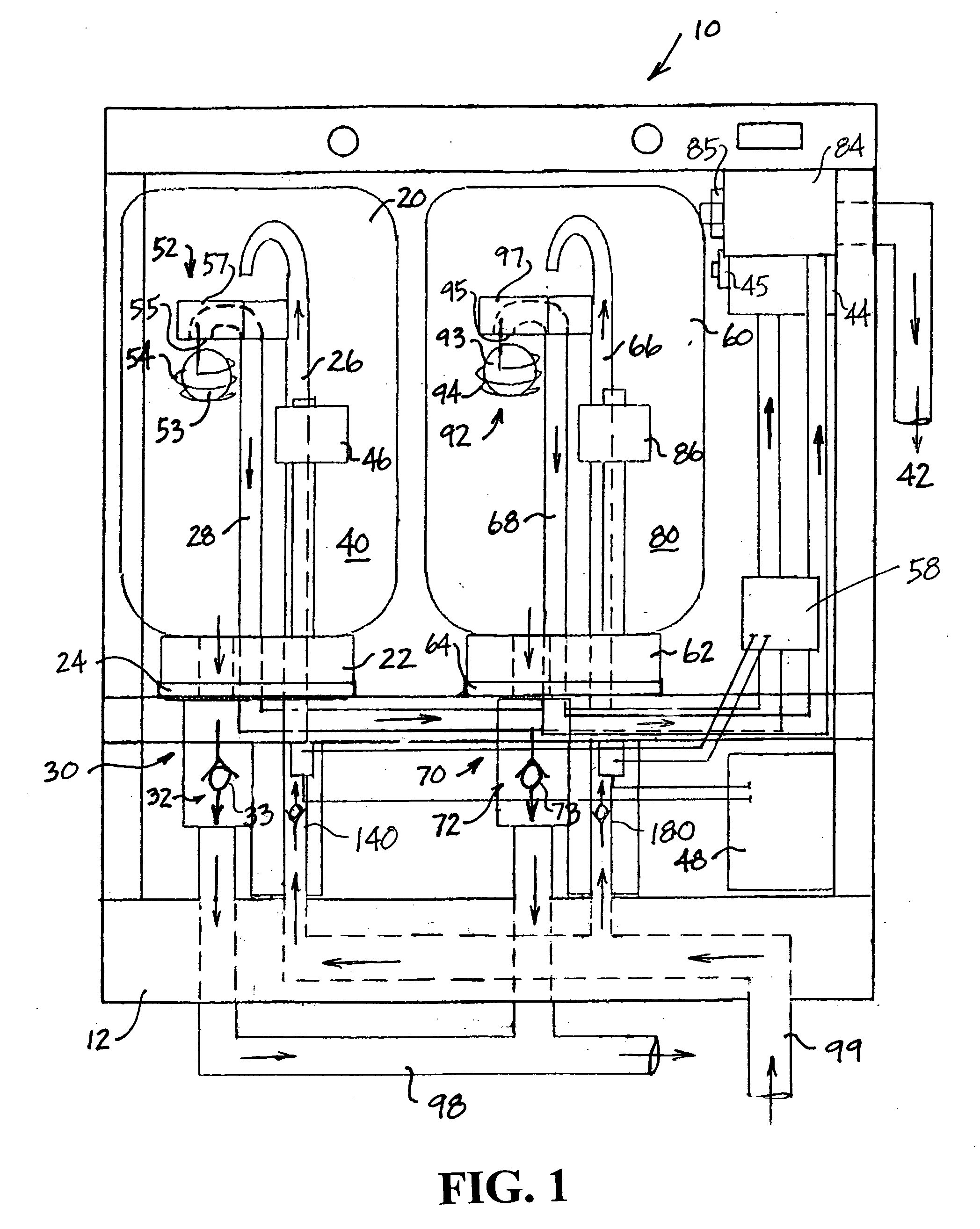

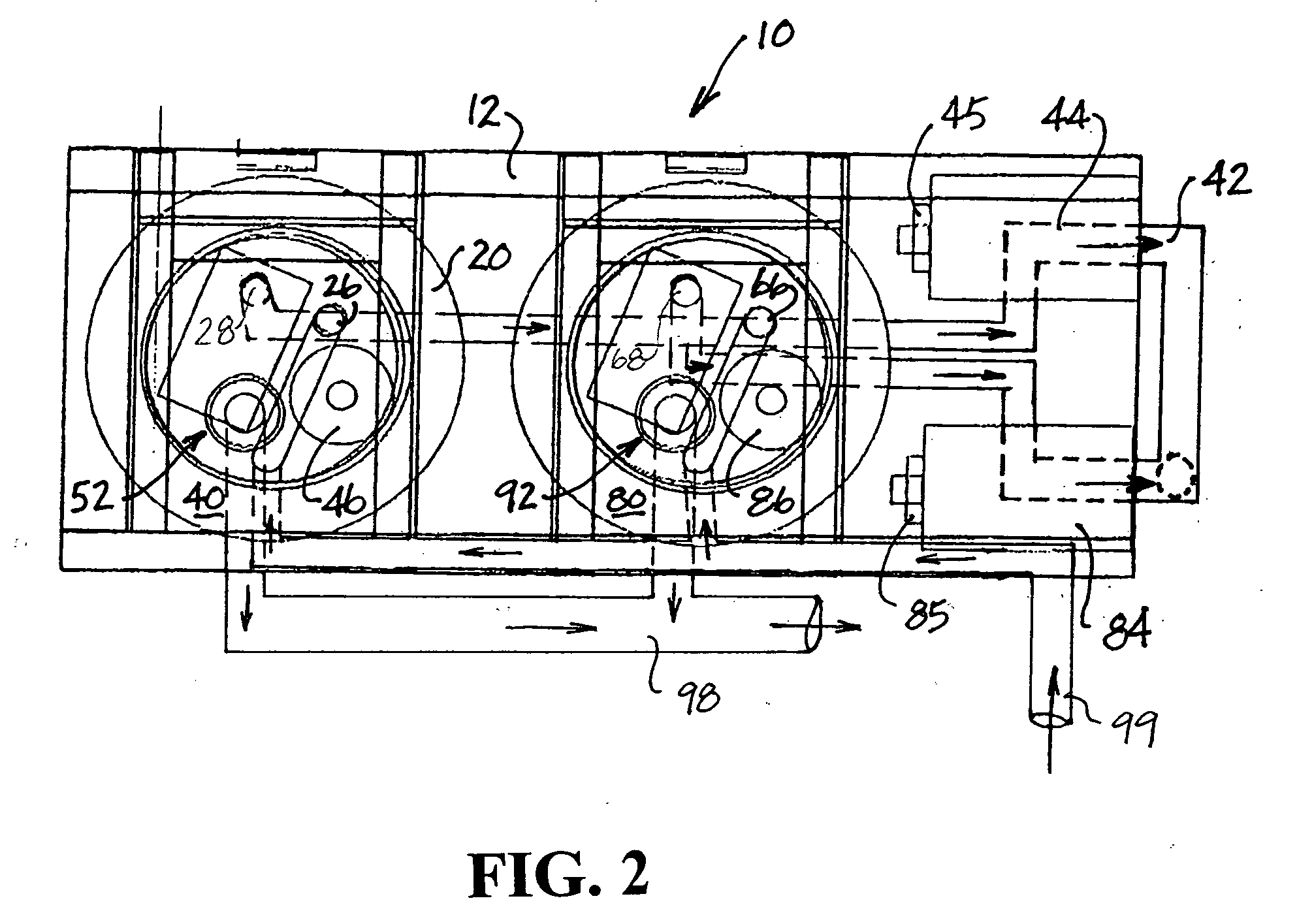

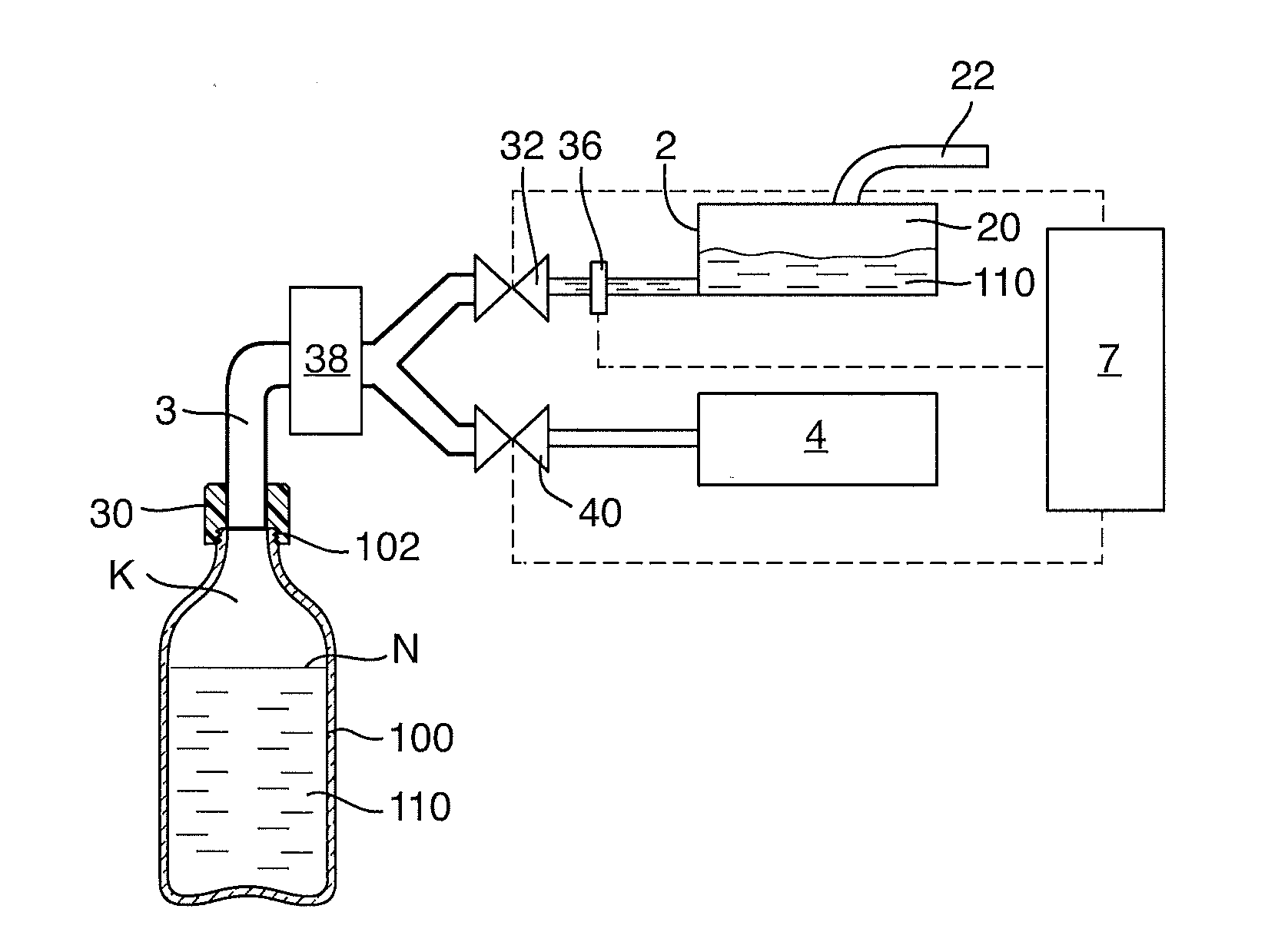

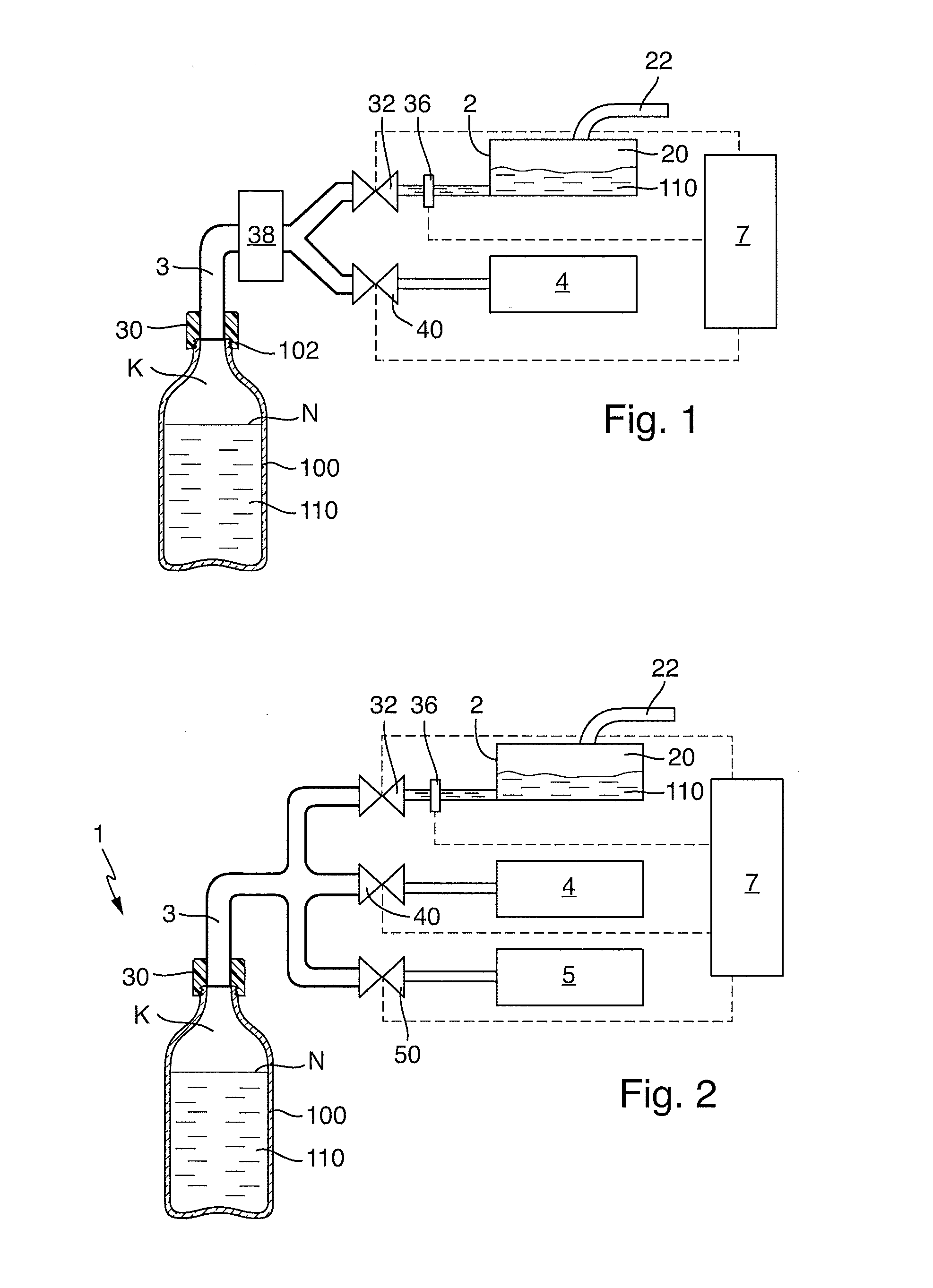

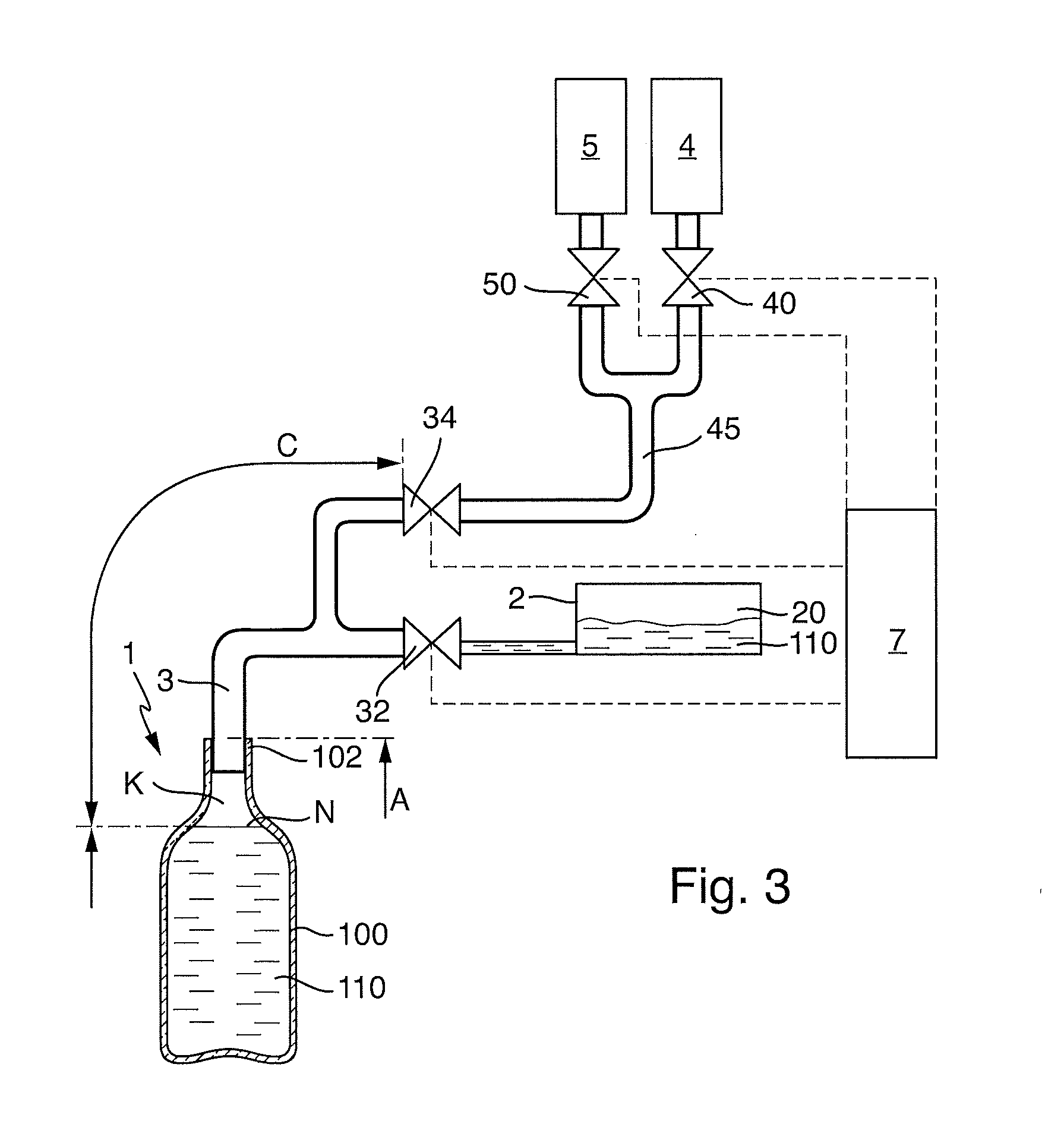

Apparatus for continuously aspirating a fluid from a fluid source

An apparatus for continuously aspirating a fluid from a fluid source. A vacuum source is operatively connected to a first container forming a first chamber and a second container forming a second chamber. A fluid collection tube provides communication between the fluid source and each of the first chamber and the second chamber. A first level sensor is positioned within the first chamber and a second level sensor is positioned within the second chamber. Upon receiving a signal generated by one of the first level sensor and the second level sensor, a relay responsively exposes a vacuum within one of the first chamber and the second chamber to continuously aspirate at least a portion of the fluid from the fluid source. A shut-off valve is preferably positioned within each of the first chamber and the second chamber to prevent communication between the vacuum source and the corresponding chamber with a fluid level within the chamber at a fluid level setpoint.

Owner:MDTECH

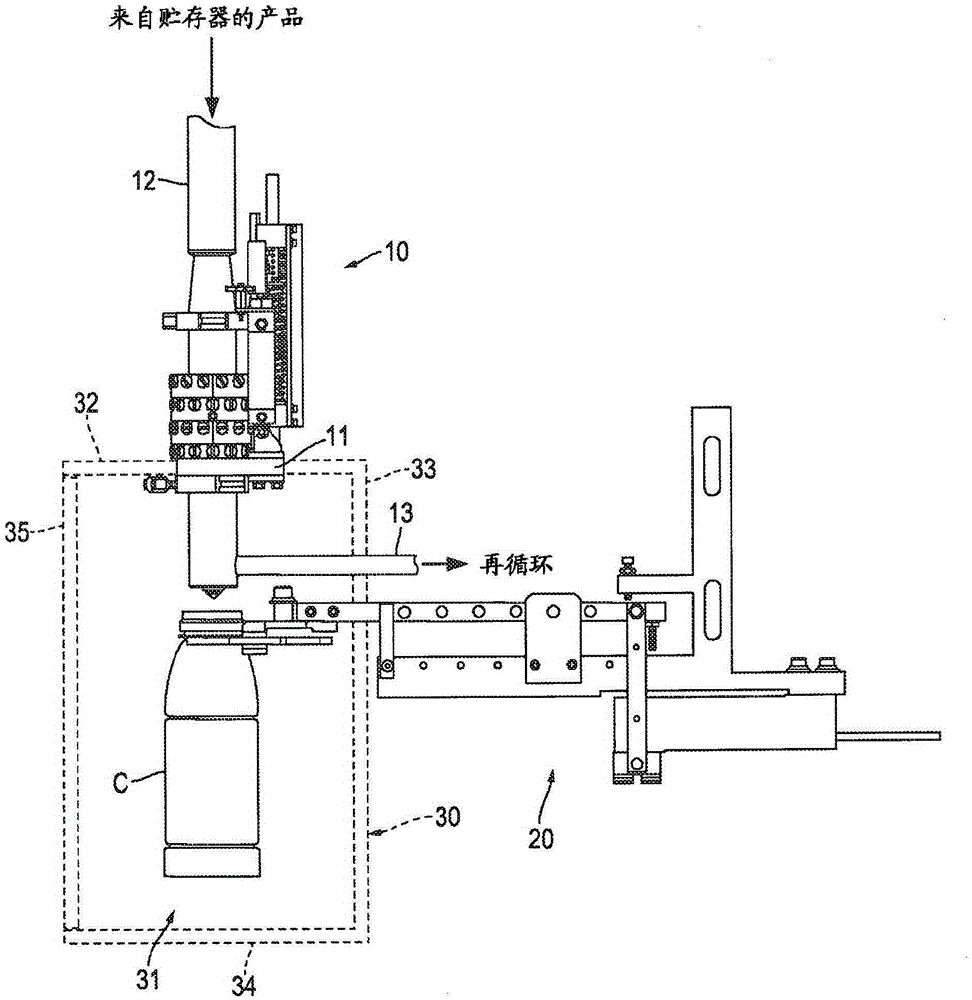

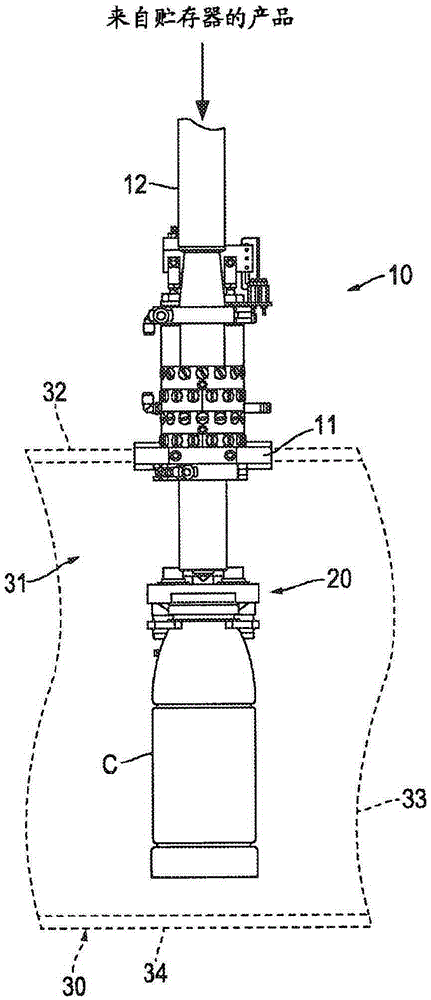

Container filling system and valve for same

ActiveCN105229353AFilling using suctionOperating means/releasing devices for valvesControl systemMechanical engineering

A container filling valve may include a shuttle and a drive sleeve that are magnetically coupled. Movement of the drive sleeve may move the shuttle from a position in which the filling valve is closed to a position in which the filling valve is open. A container handling arm may include a distal end configured to hold a container and a proximal end that includes a load cell. A low flow setpoint system may be configured to arrest closing of a filling valve when that filling valve is partially closed. A pressure control system may be configured to maintain a desired pressure in a reservoir or in a flow path from that reservoir. A product recirculation system may be configured to adjust flow rate in the product recirculation system.

Owner:PEPSICO INC

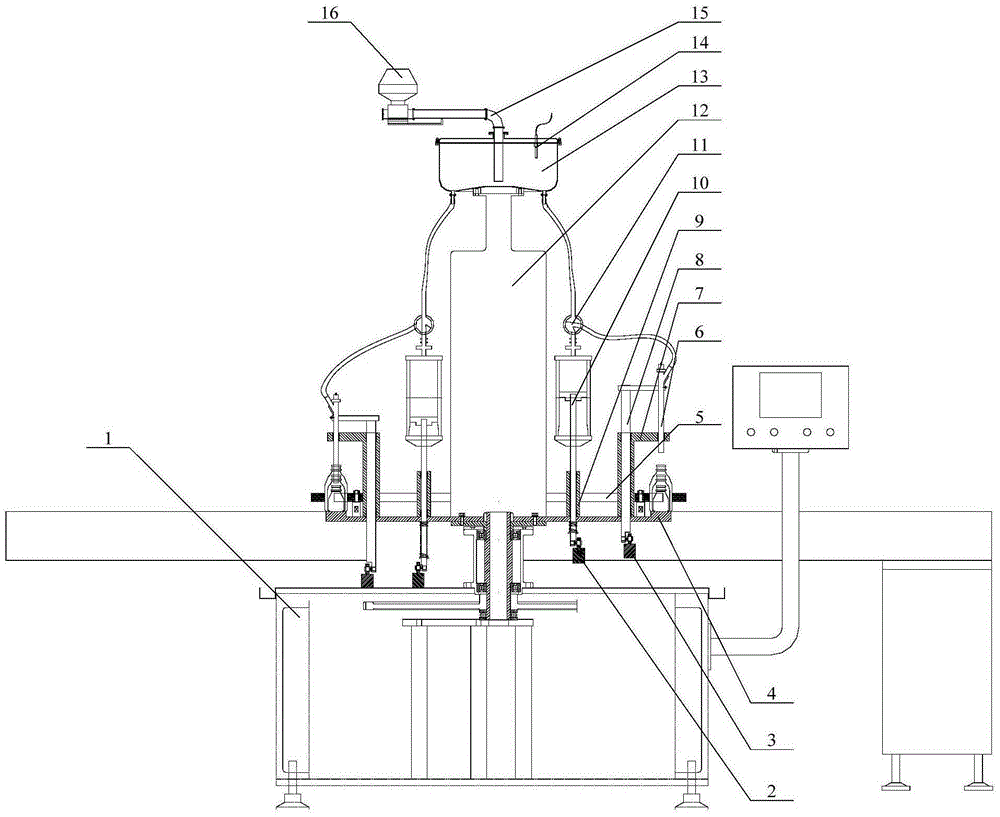

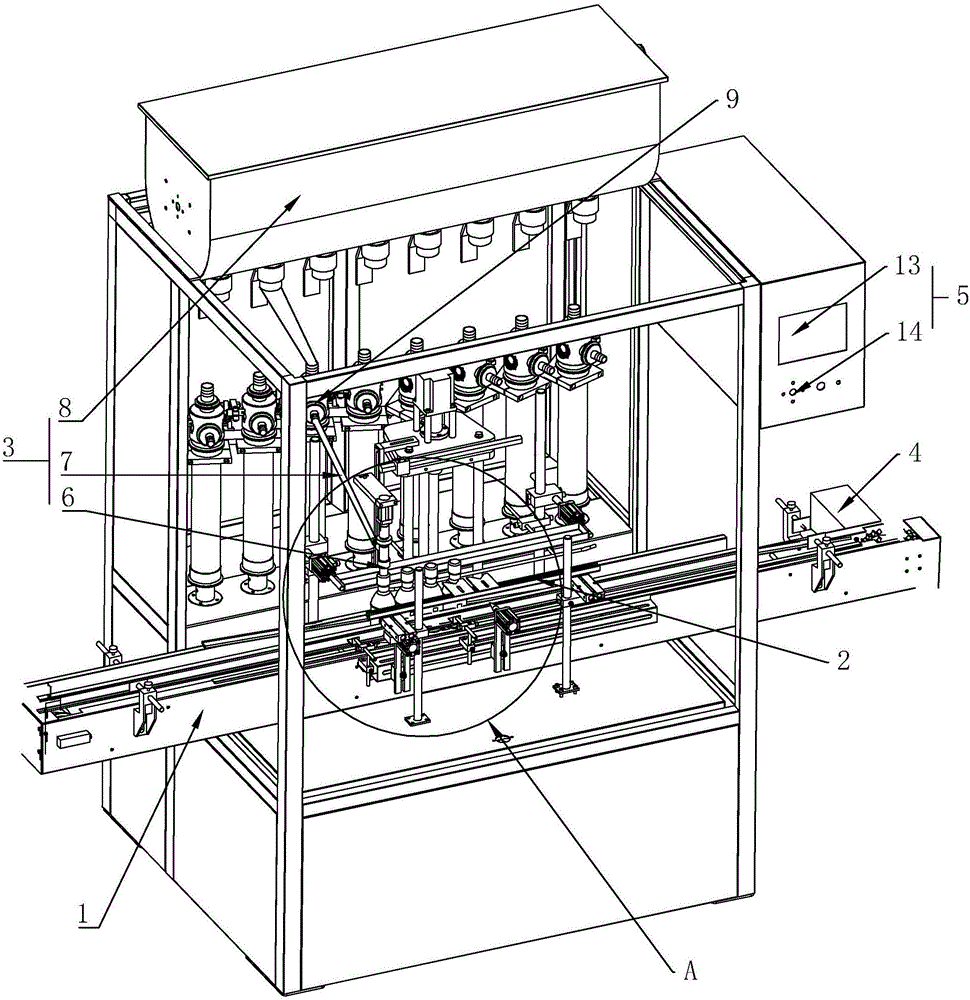

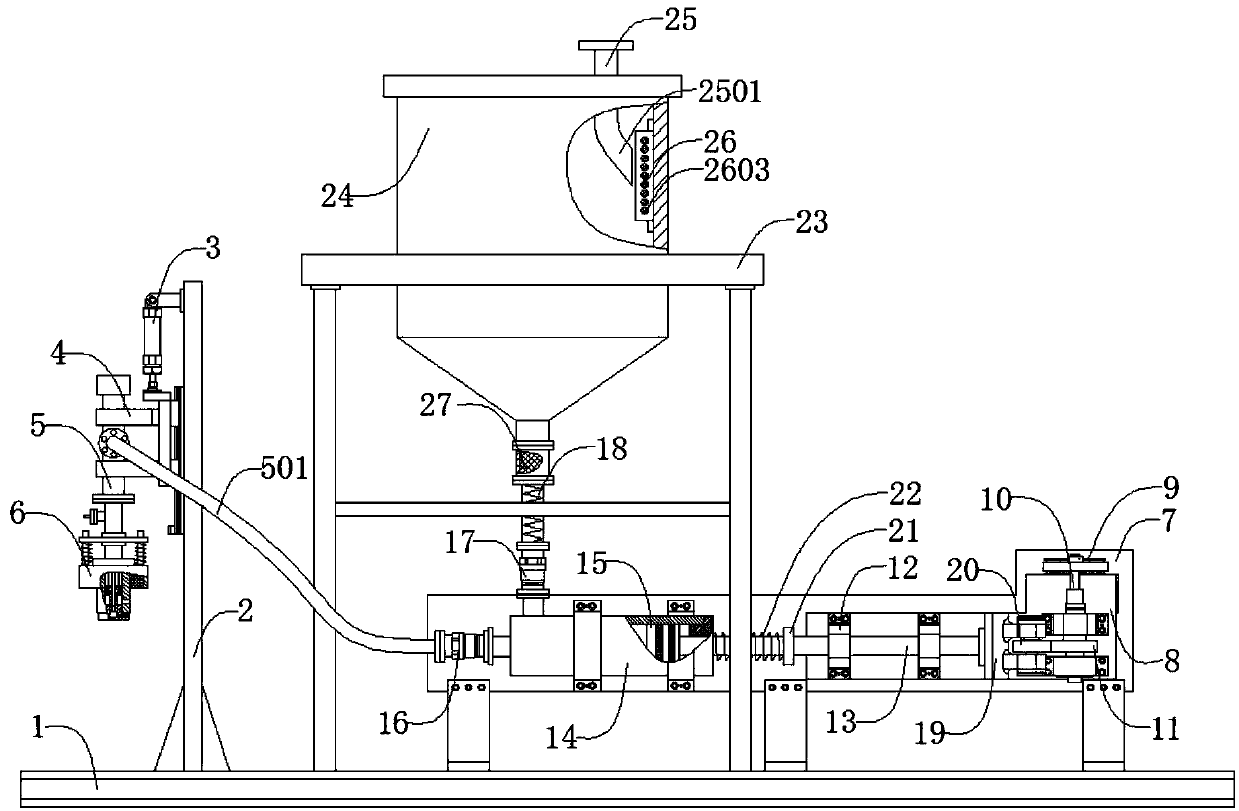

Filling machine

ActiveCN105174169AAchieve dischargeEfficient dischargeFilling using suctionLiquid storage tankEngineering

The invention discloses a filling machine. The filling machine comprises a filling station located on a machine frame. The filling station comprises a plunger pump, a filling device and a pneumatic corner valve, wherein a pump body of the plunger pump is fixed to a rotary base plate, and a piston rod of the plunger pump is connected with a first lifting device; a filling nozzle of the filling device is aligned with a bottle opening of a preparation bottle; the pneumatic corner valve comprises an inlet and two outlets, the inlet is communicated with a high-position liquid storage tank, one outlet is communicated with an opening in the pump body of the plunger pump, and the other outlet is communicated with the filling nozzle. Liquid medicine is sucked in and pressed out through the plunger pump, the requirement for the preparation bottle is not strict, and the filling machine can be adaptive to most preparation bottles; the quantity of liquid medicine sucked in and discharged by the plunger pump can be accurately controlled by adjusting the expansion amount of the piston rod, so that the filling quantity is accurately controlled. By controlling the lifting frequency of the first lifting device, the first lifting device can be matched with other equipment on a production line, the production speed is guaranteed, and production efficiency is improved. Moreover, the filling machine is simple in structure, convenient to disassemble, wash and maintain, and low in manufacturing and using cost.

Owner:长沙汇一制药机械有限公司

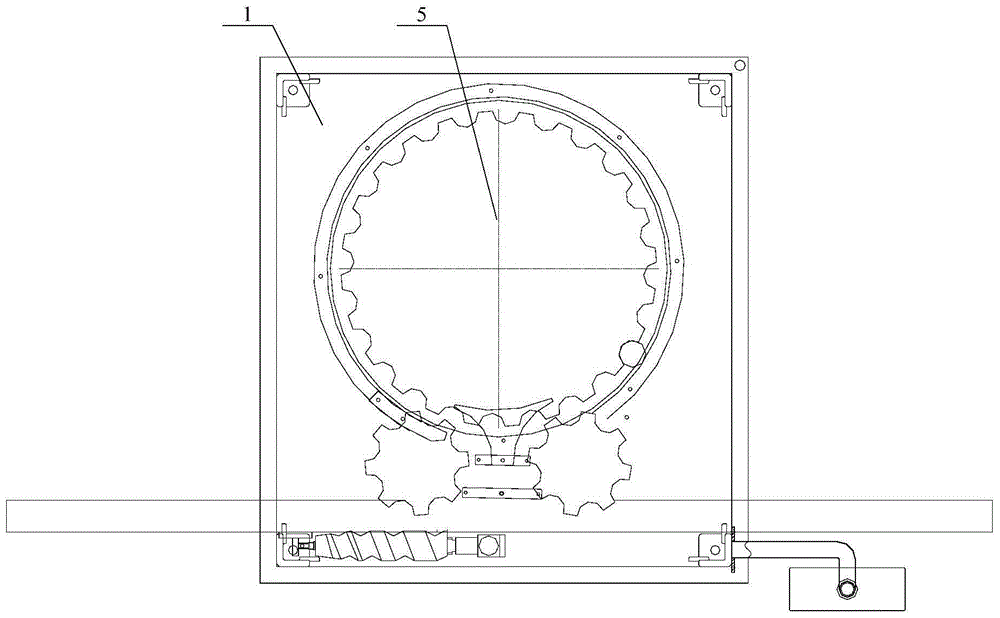

Method and equipment for vacuum quantitative filling of filling and sealing machine

ActiveCN101704495AHigh degree of automationLarge amount of processingFilling using suctionBottle-handling machinesLiquid productEngineering

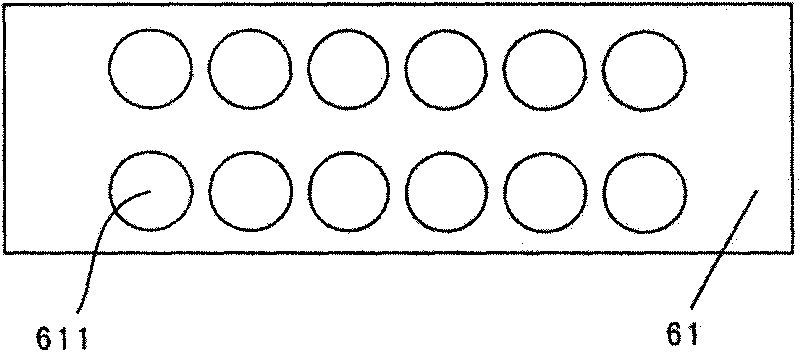

The invention relates to a method and equipment for vacuum quantitative filling of a filling and sealing machine. The method comprises the following steps: a plurality of bottle holding plates are fixed on a driving chain and the driving chain is driven by a bottle holding plate to run; filling bottles are placed in all bottle holding holes of the bottle holding plates; the driving chain stops running when the bottle holding plates run to the lower part of a fluid reservoir, and at the moment, the filling bottles are supported on bottle mouth pressing plates by bottle supporting devices, and liquids flow into the filling bottles from lower openings of filling nozzles; and when the liquids inside the filling bottles are filled to liquid surfaces and parallel and level to lower openings of suction pipes, surplus liquids can be suctioned away by vacuum suction pipes, thus realizing quantitative filling. The filling nozzles, the bottle supporting devices and a transmission system all have specific structures, high degree of automation, and also large treatment quantity and extremely high efficiency. The structure is easy to demount and wash, thus guaranteeing sanitation indexes. The equipment and the method can be used for filling all liquid products.

Owner:DONG GUAN SHI LONG JIN WEI BEVERAGE & FOOD

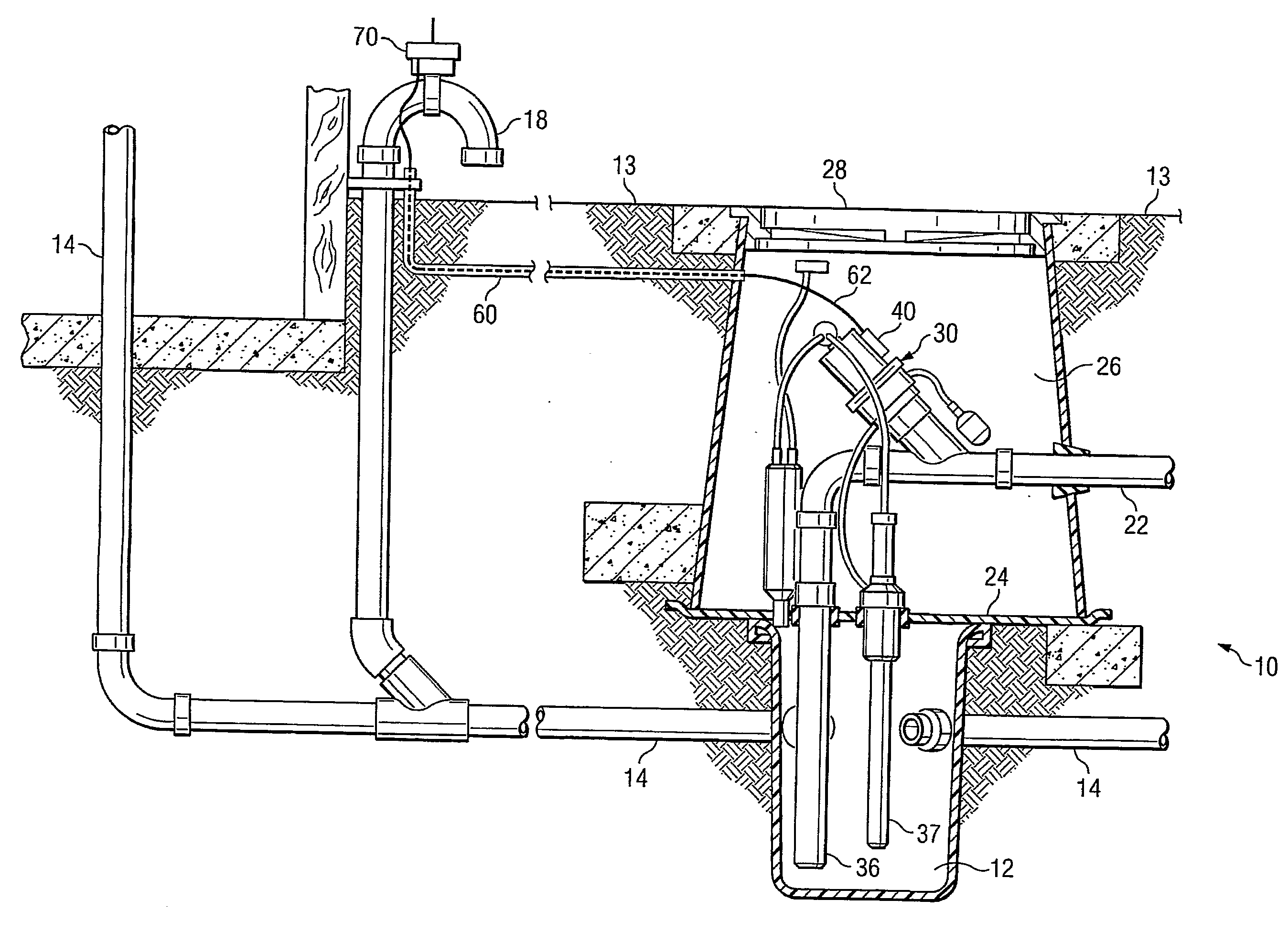

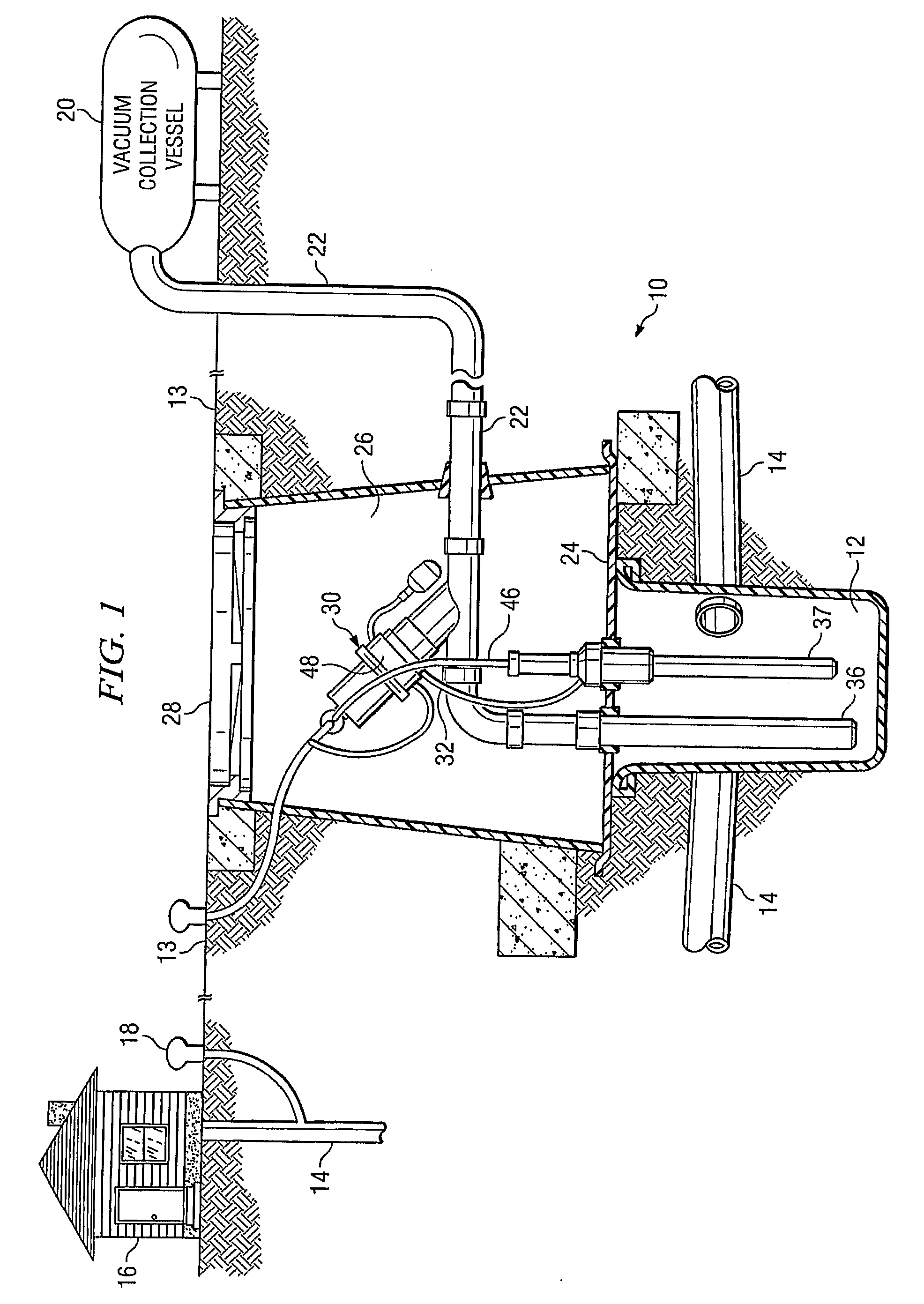

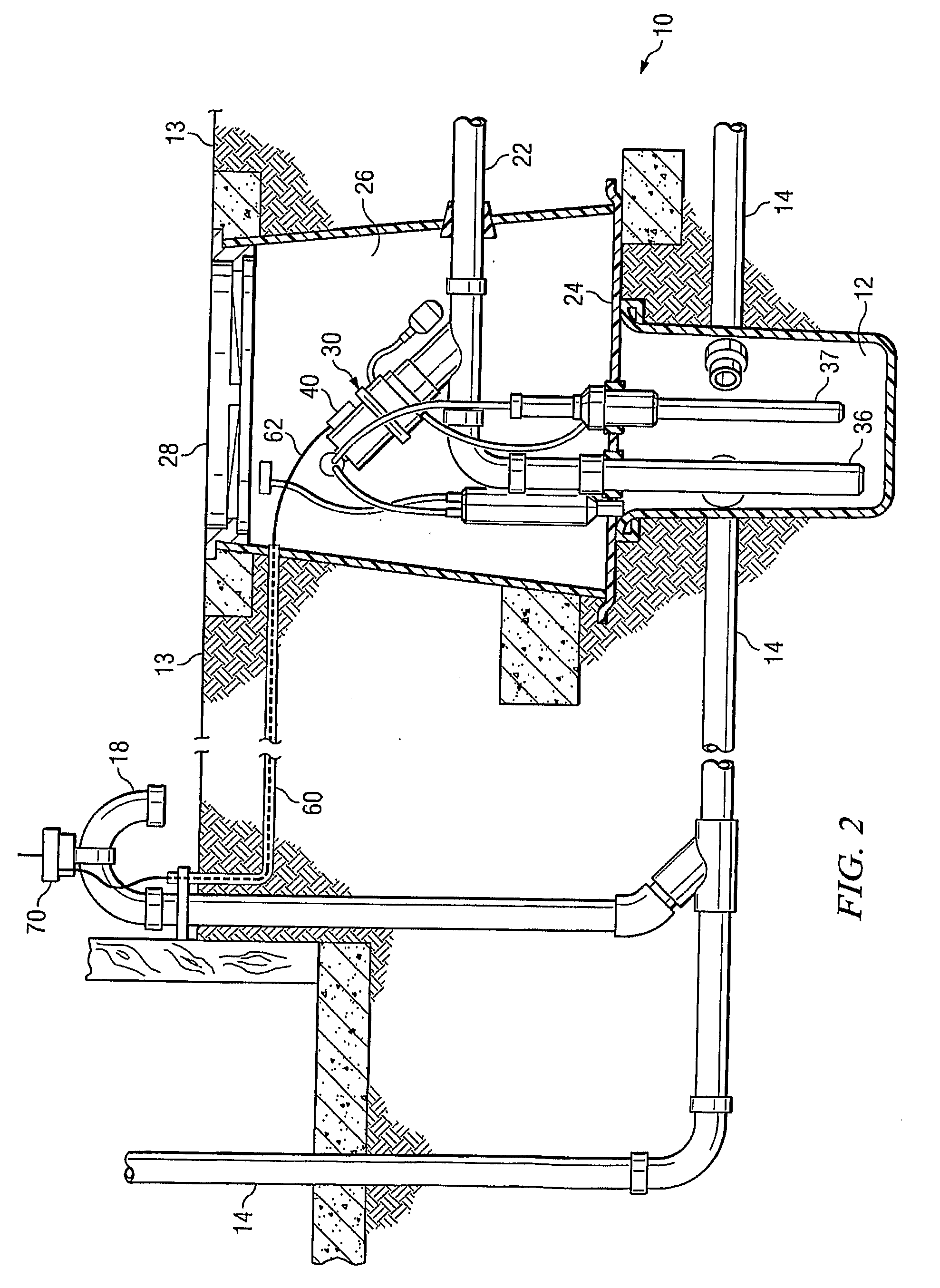

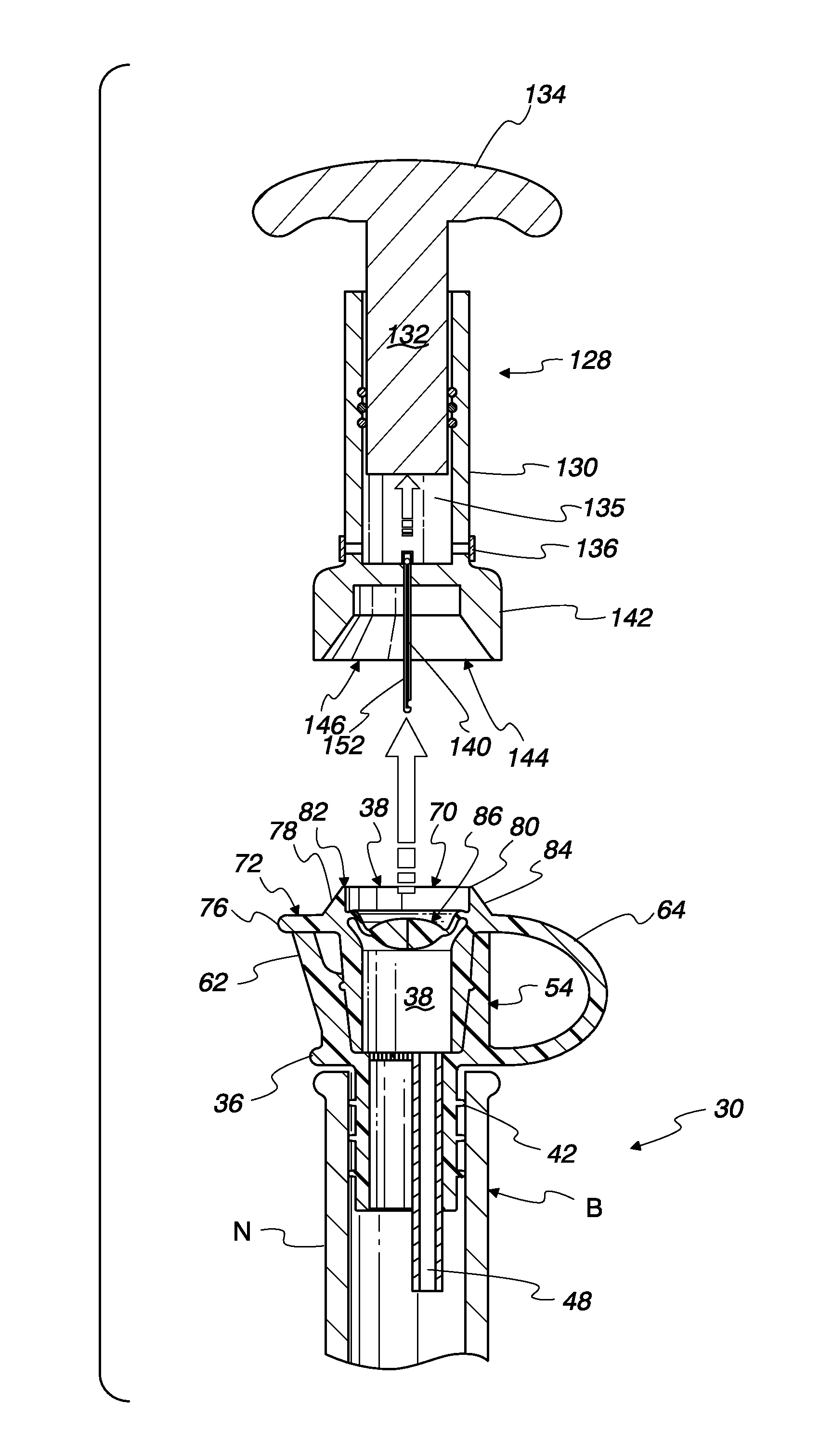

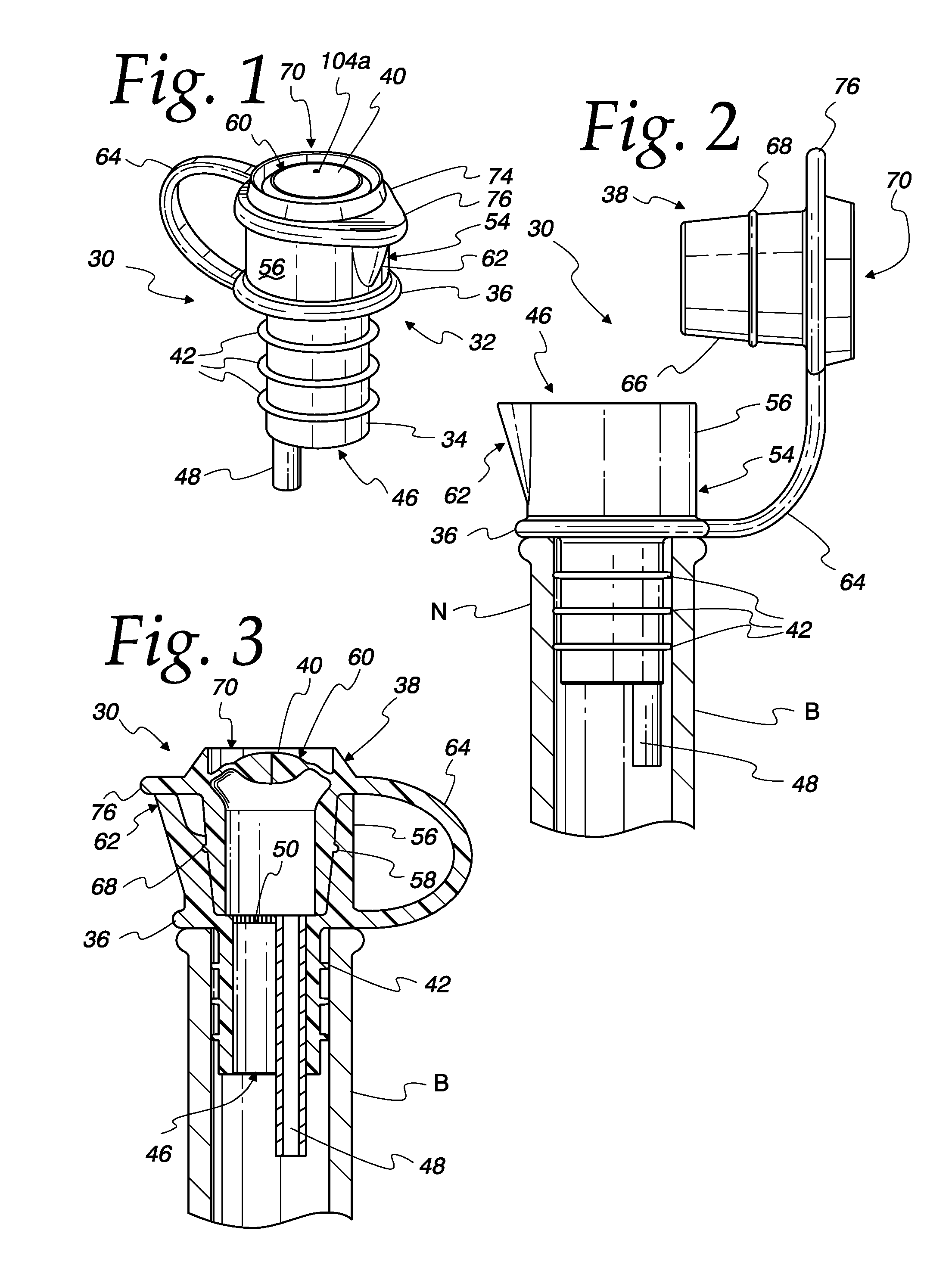

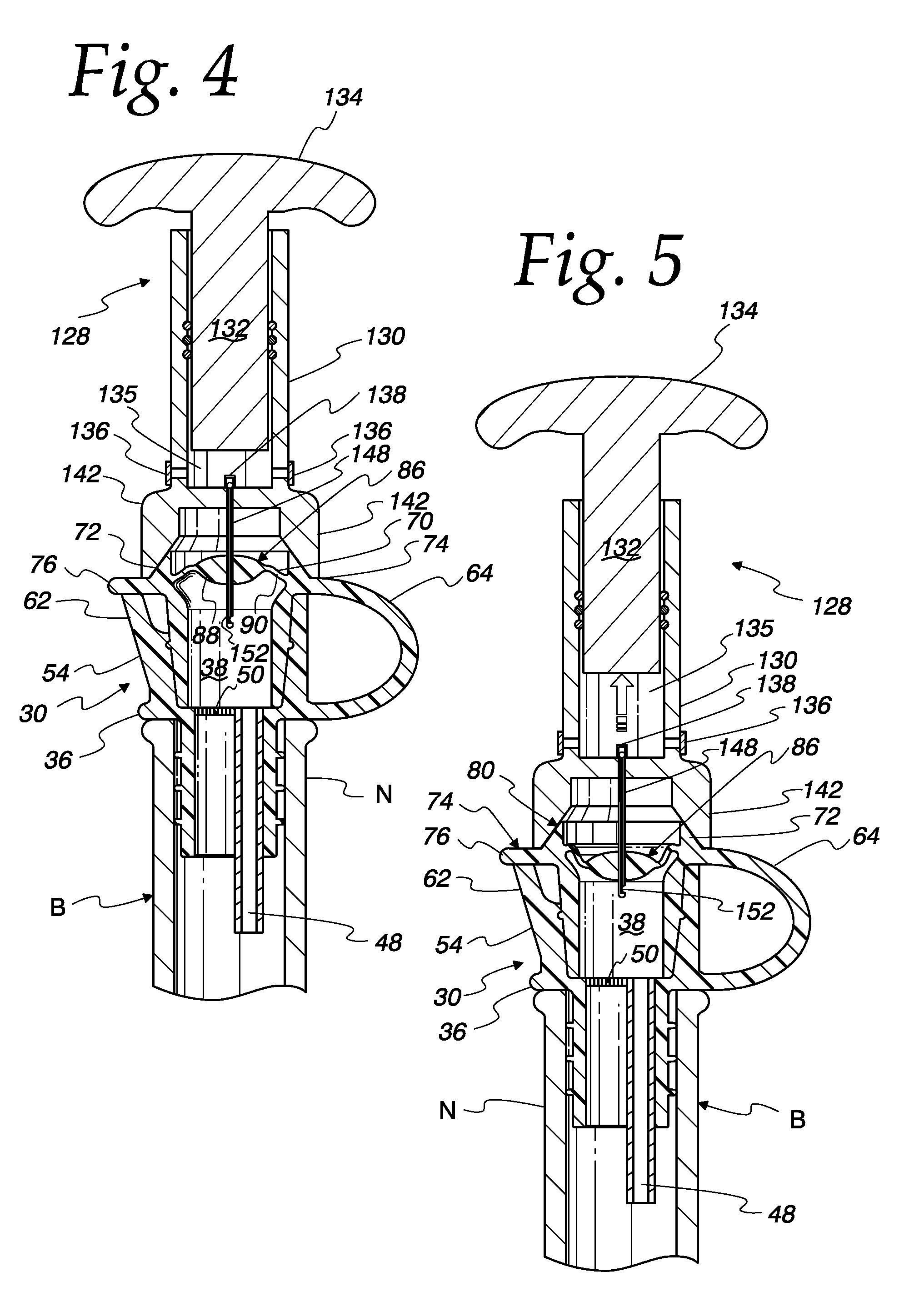

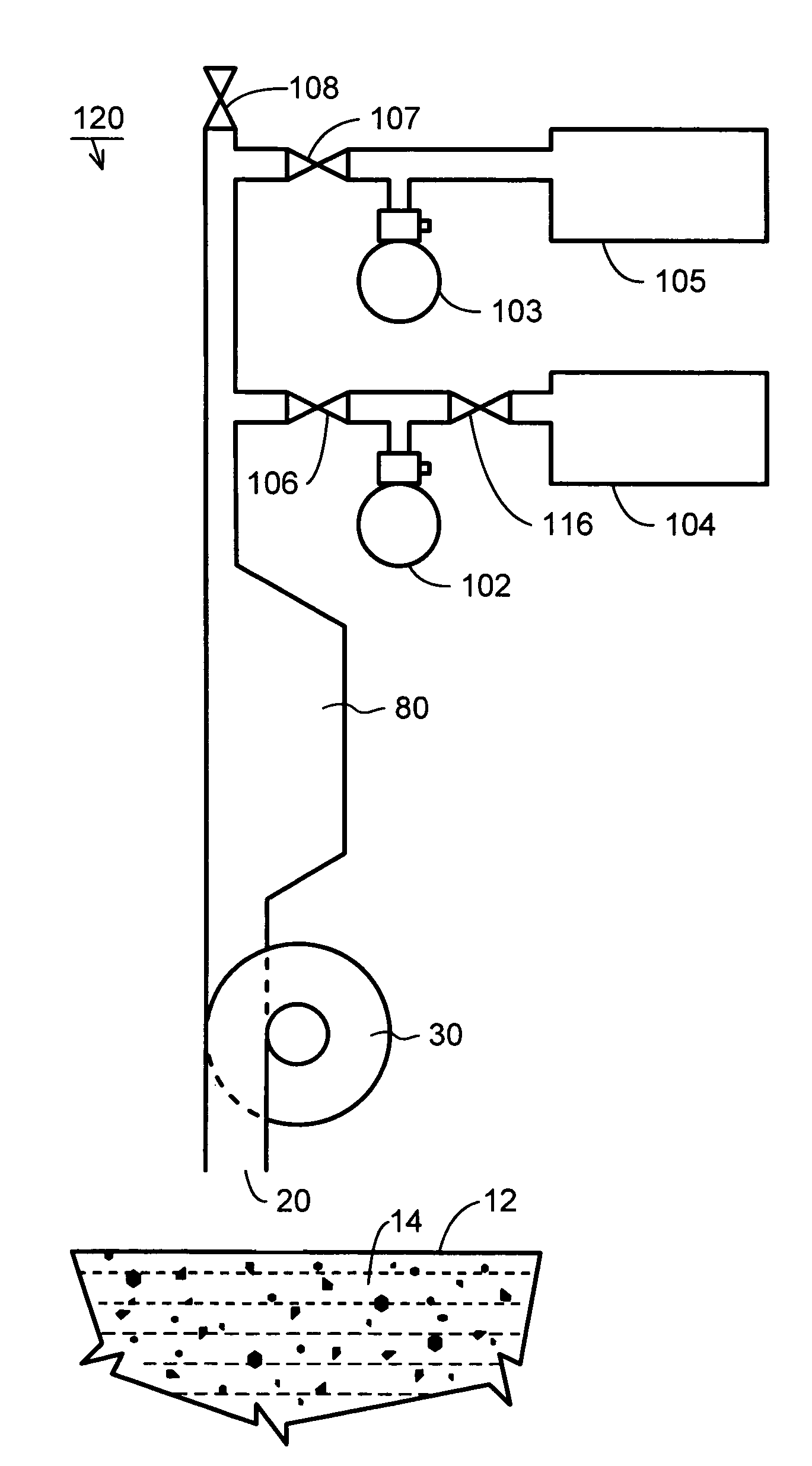

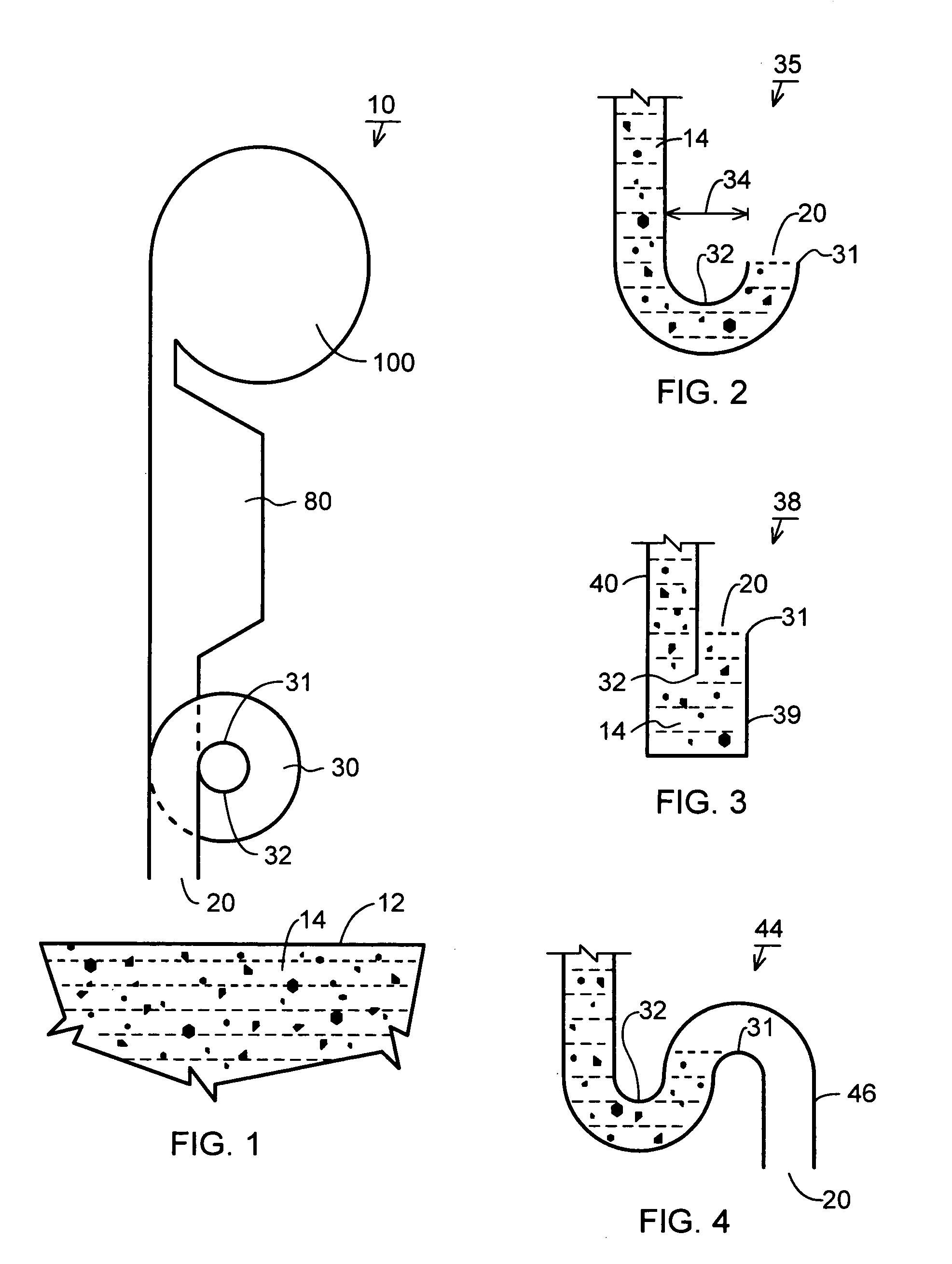

Vacuum Sewage System with Wireless Alarm

A vacuum sewage system is provided having a sump pit (12) and a collection station (20) connected by a conduit (22). When a vacuum interface valve (30) is opened sewage is transported from the sump pit to the collection station by a pressure differential. A valve position sensor (40) associated with the valve is sensed by a valve monitoring system. The monitoring system is adapted to broadcast a wireless signal of valve status. A computer receives the broadcast signal and notifies an operator of the valve condition.

Owner:AIRVAC

Vacuum Bottle Stopper for Wine, Inert Gas Supply and Method

InactiveUS20150259186A1Avoid and minimize effectReliably and efficiently madeFilling using suctionClosuresWine bottleEngineering

Owner:HALEYS CORKER INC

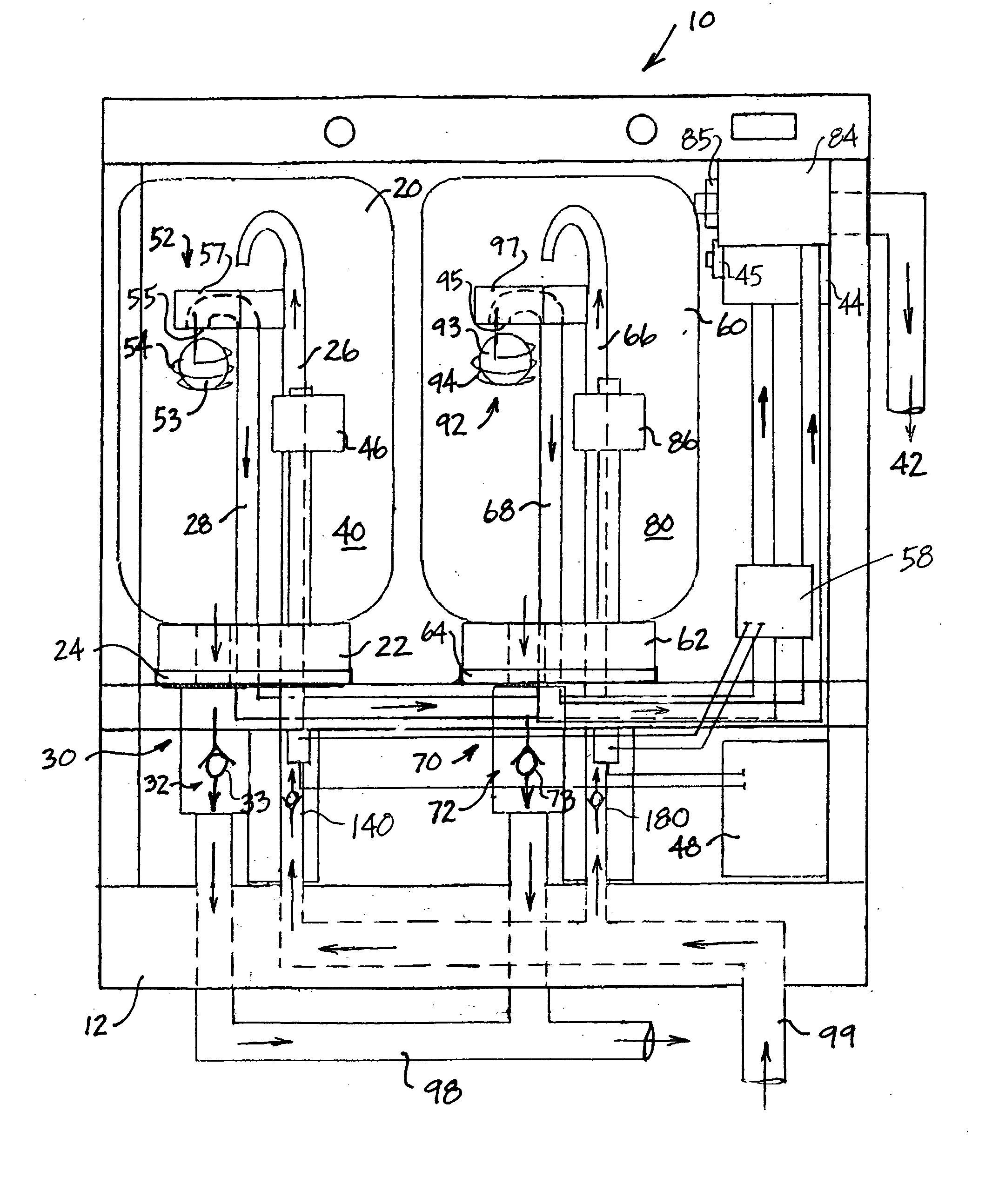

Automated vacuum waste handling system

This invention relates to an automated vacuum liquid waste handling system having two or more waste vessels, with a liquid-level sensor, a means for filling the waste vessels with waste, a means for switching from the first waste vessel, once full, to one or more other waste vessels that are not full, and a means for simultaneously removing said waste from the first full waste vessel to output holding stations and filling another waste vessel so that waste collection is not interrupted.

Owner:MERCK & CO INC

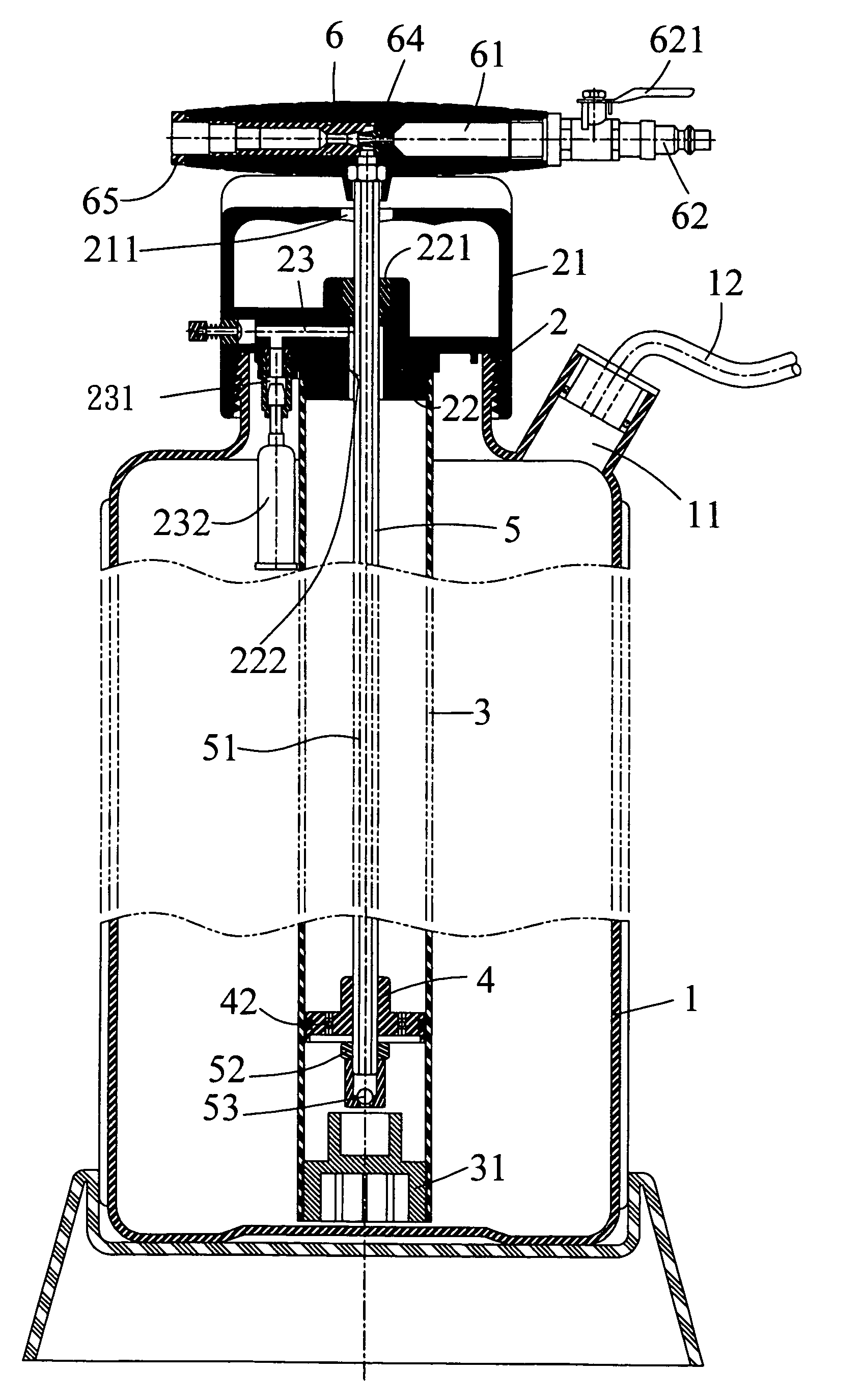

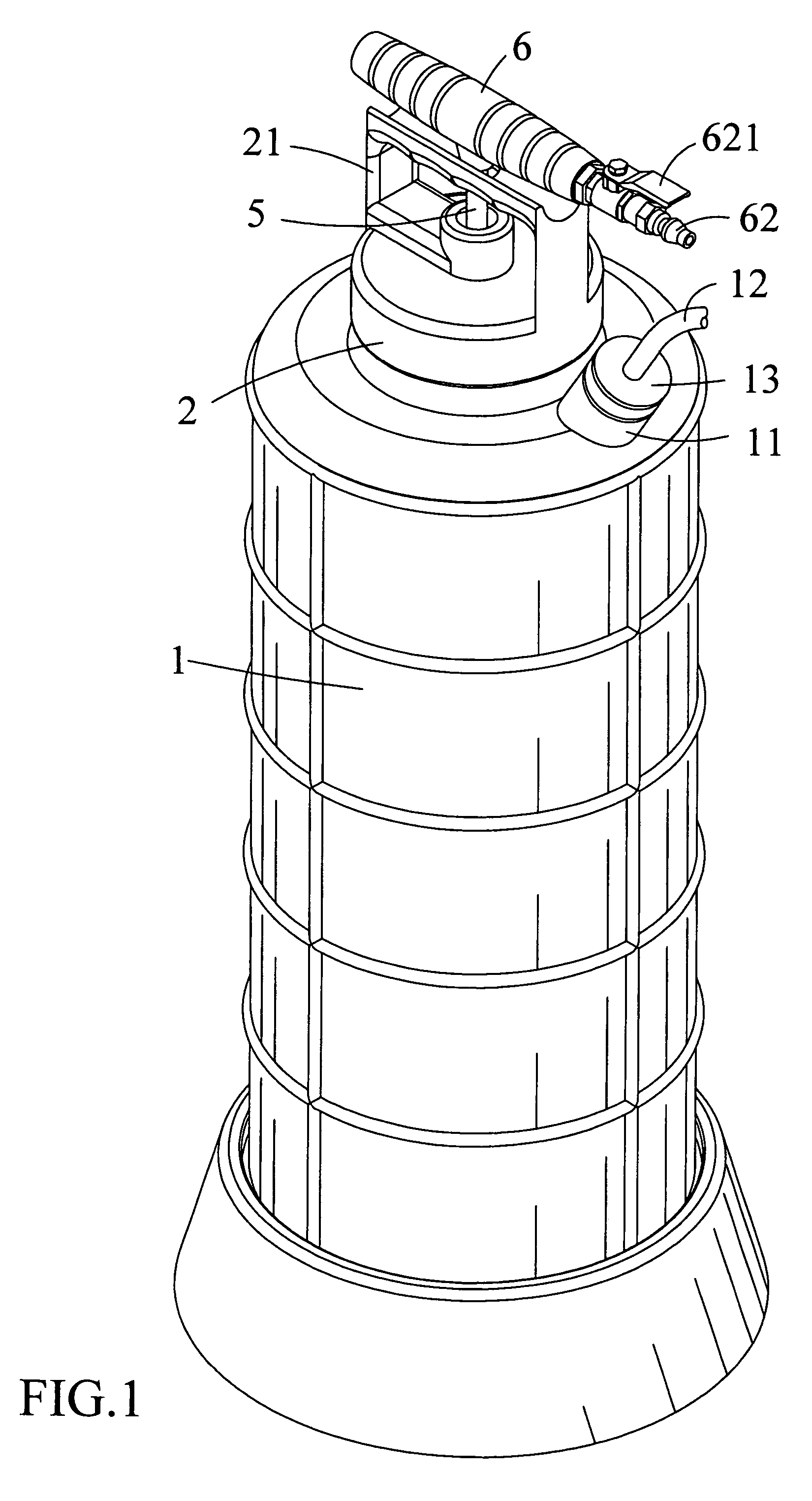

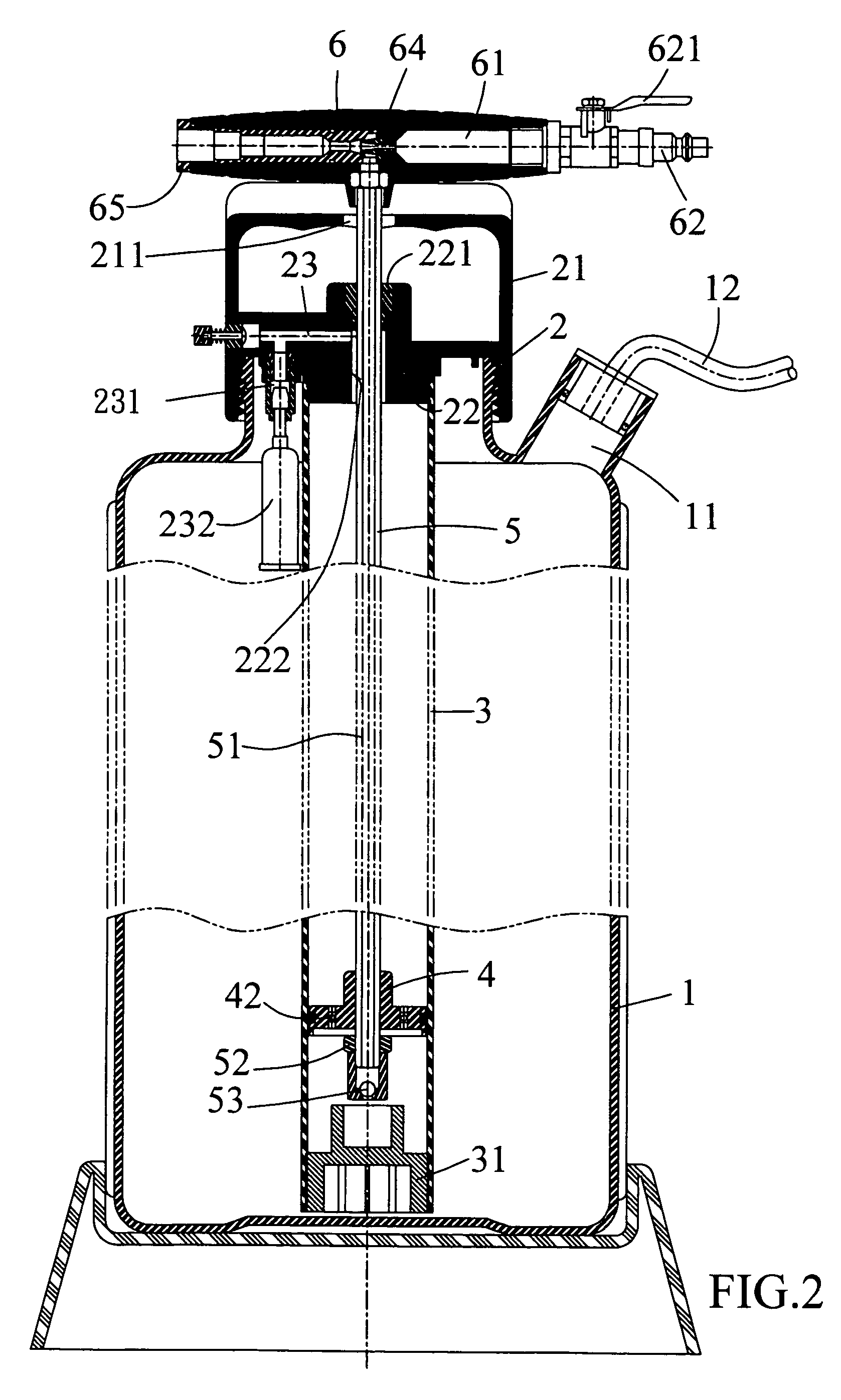

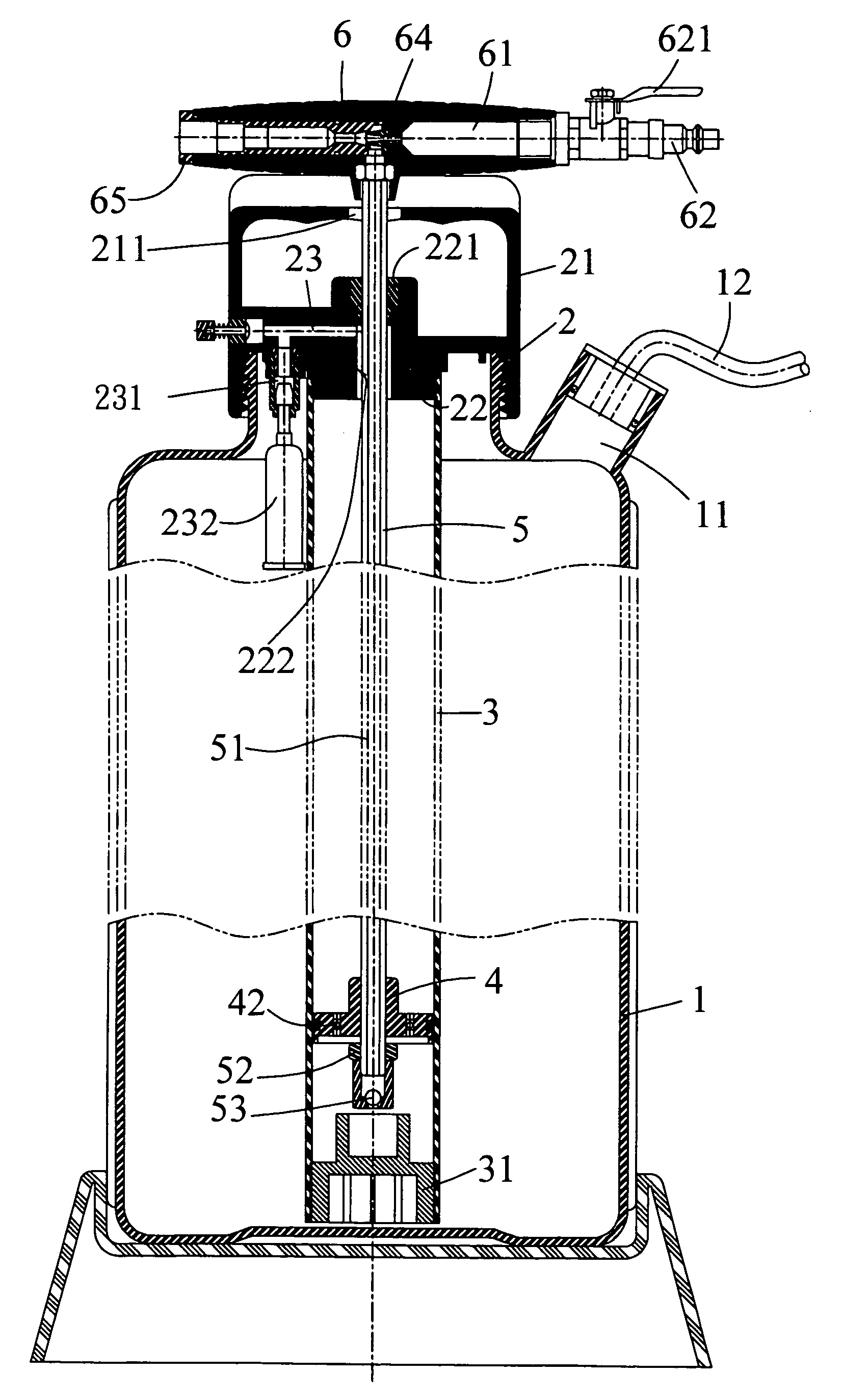

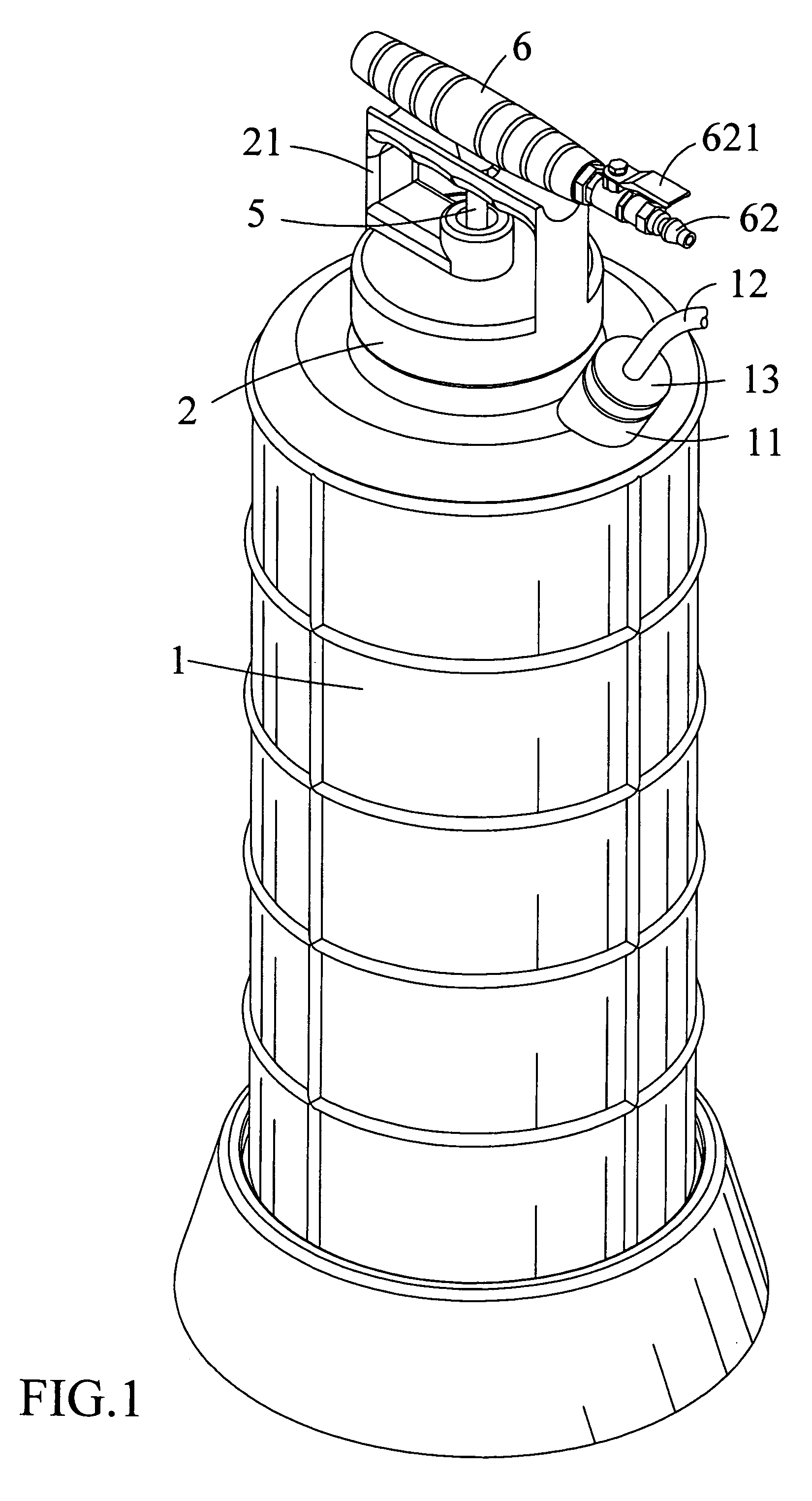

Liquid pumping device

ActiveUS20060027608A1Improve versatilityCrankshaftsFilling using suctionMechanical engineeringPiston

A liquid pumping device includes a barrel, a cylinder, a conducting rod, a piston, an operation lever, and a cover. Thus, the liquid pumping device is operated automatically by the power source or operated manually by the operation lever to suck the liquid from the suction pipe into the inside of the barrel rapidly, so that the liquid pumping device is operated automatically and manually, thereby greatly enhancing the versatility of the liquid pumping device.

Owner:YO LEE MFG

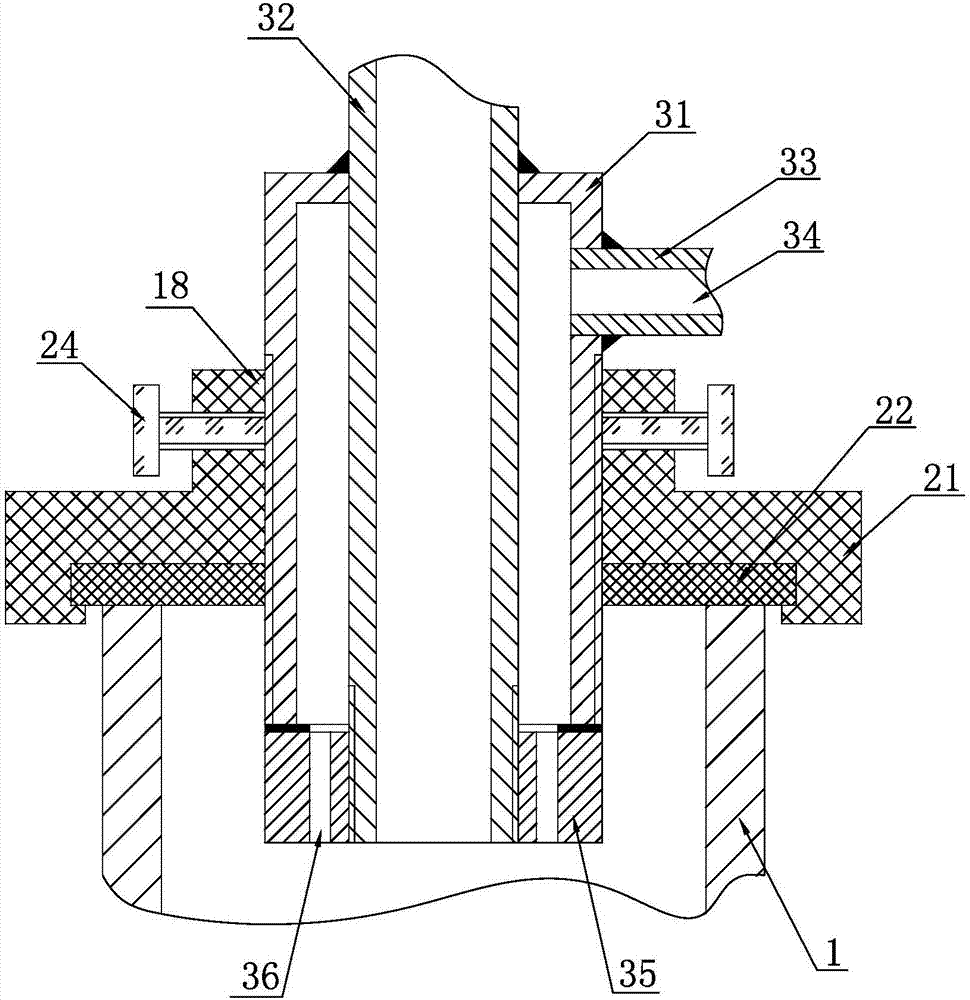

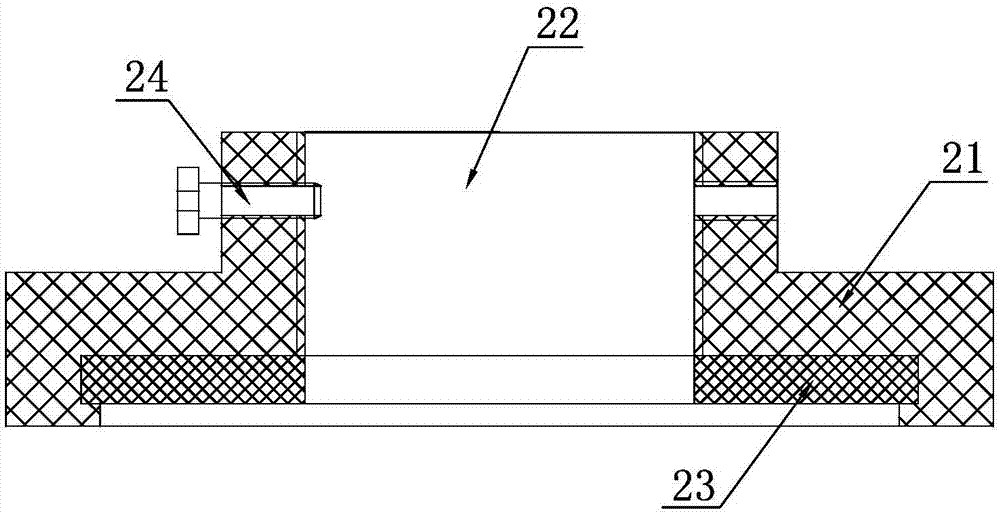

Vacuum tank assembly

A vacuum tank assembly is provided for use on an RV or a boat and includes a two-piece vacuum tank. The two-piece vacuum tank includes a body and a removable top with a gasket located between the body and removable top. A dip tube is integrated into the removable top, thus, forming an opening in the removable top and thereby reducing maintenance problems associated with mechanically attached dip tube assemblies. A vacuum pump is provided to pump the waste out of the vacuum tank into a holding tank.

Owner:DOMETIC APPLIANCES

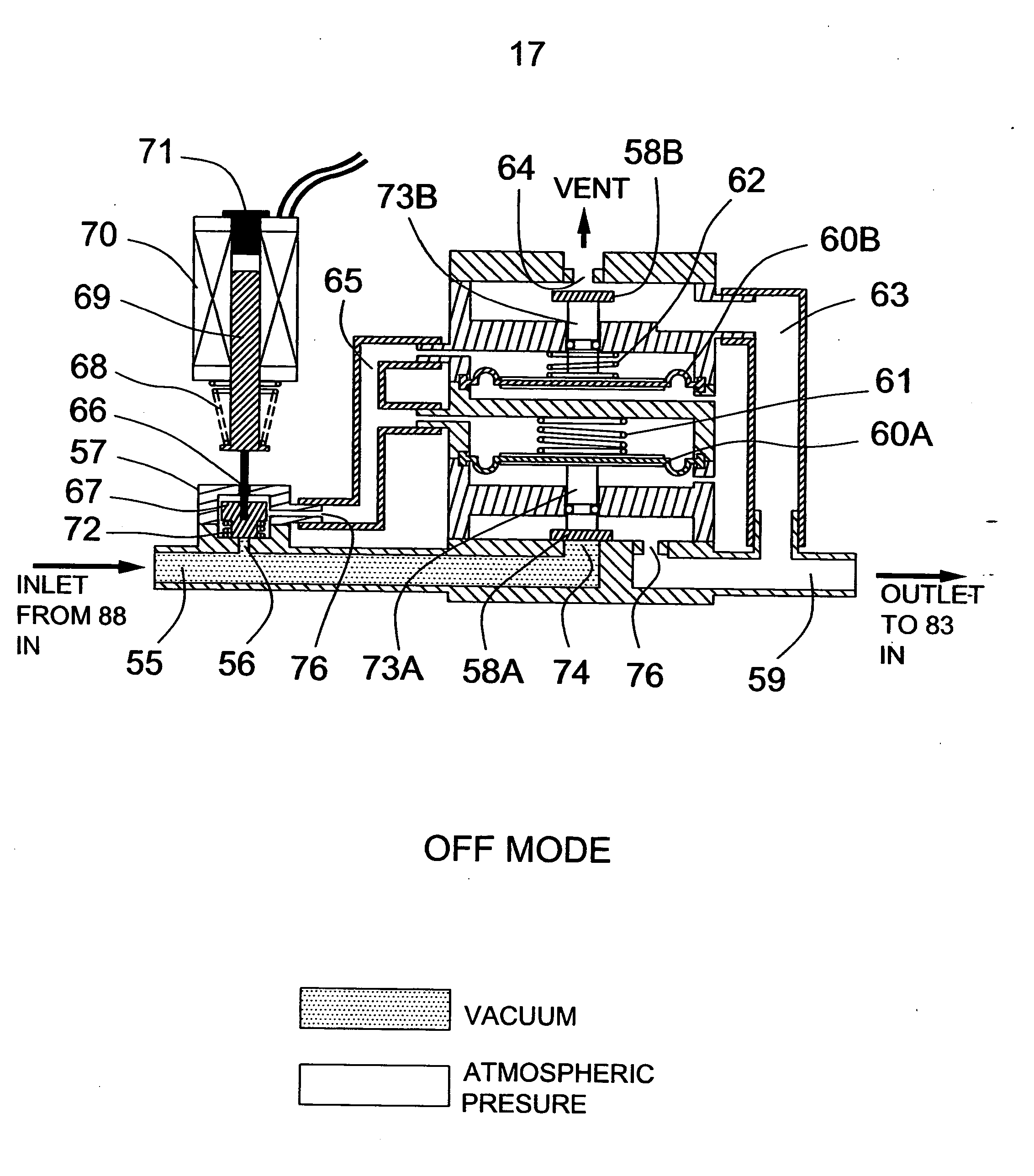

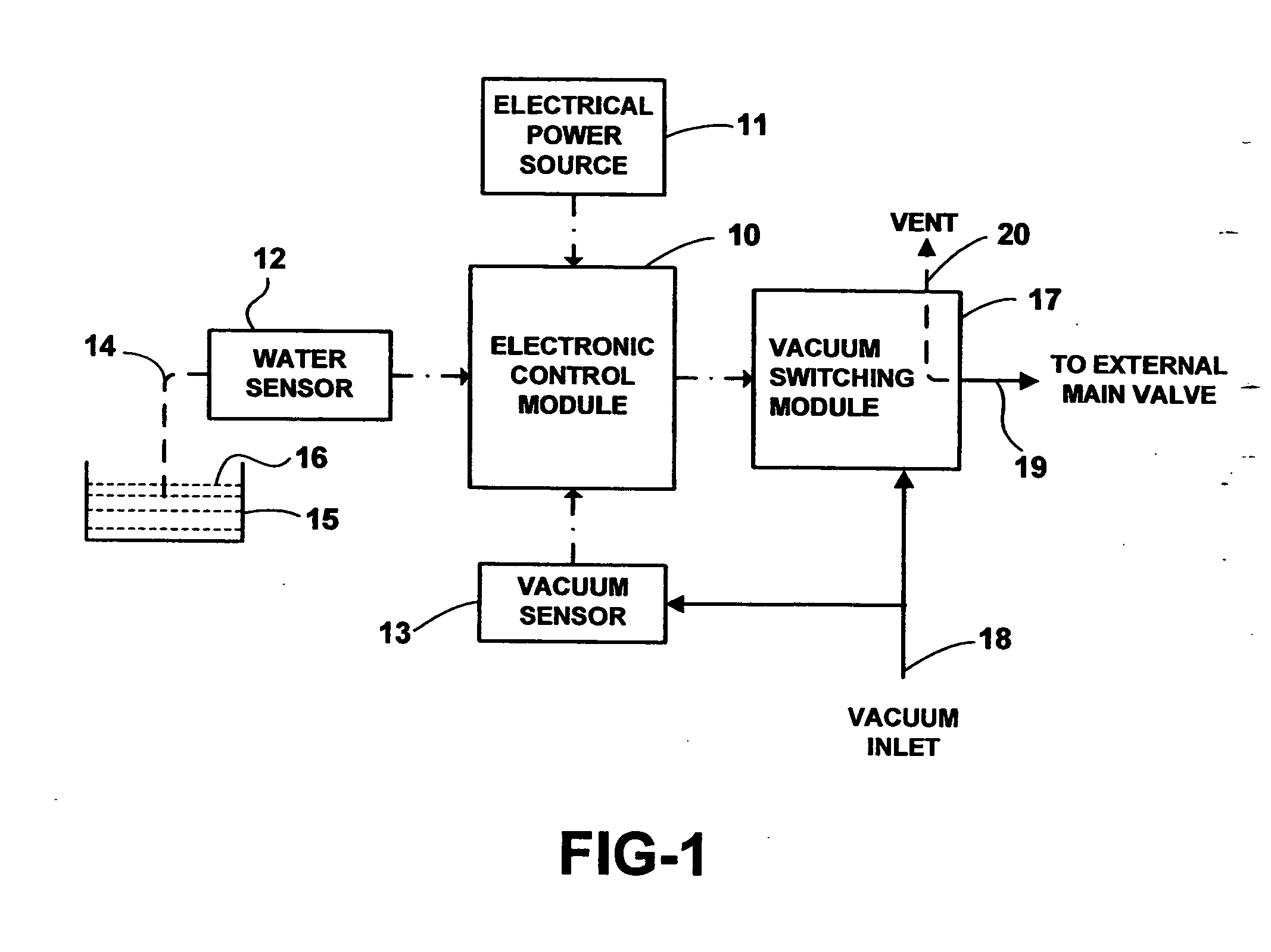

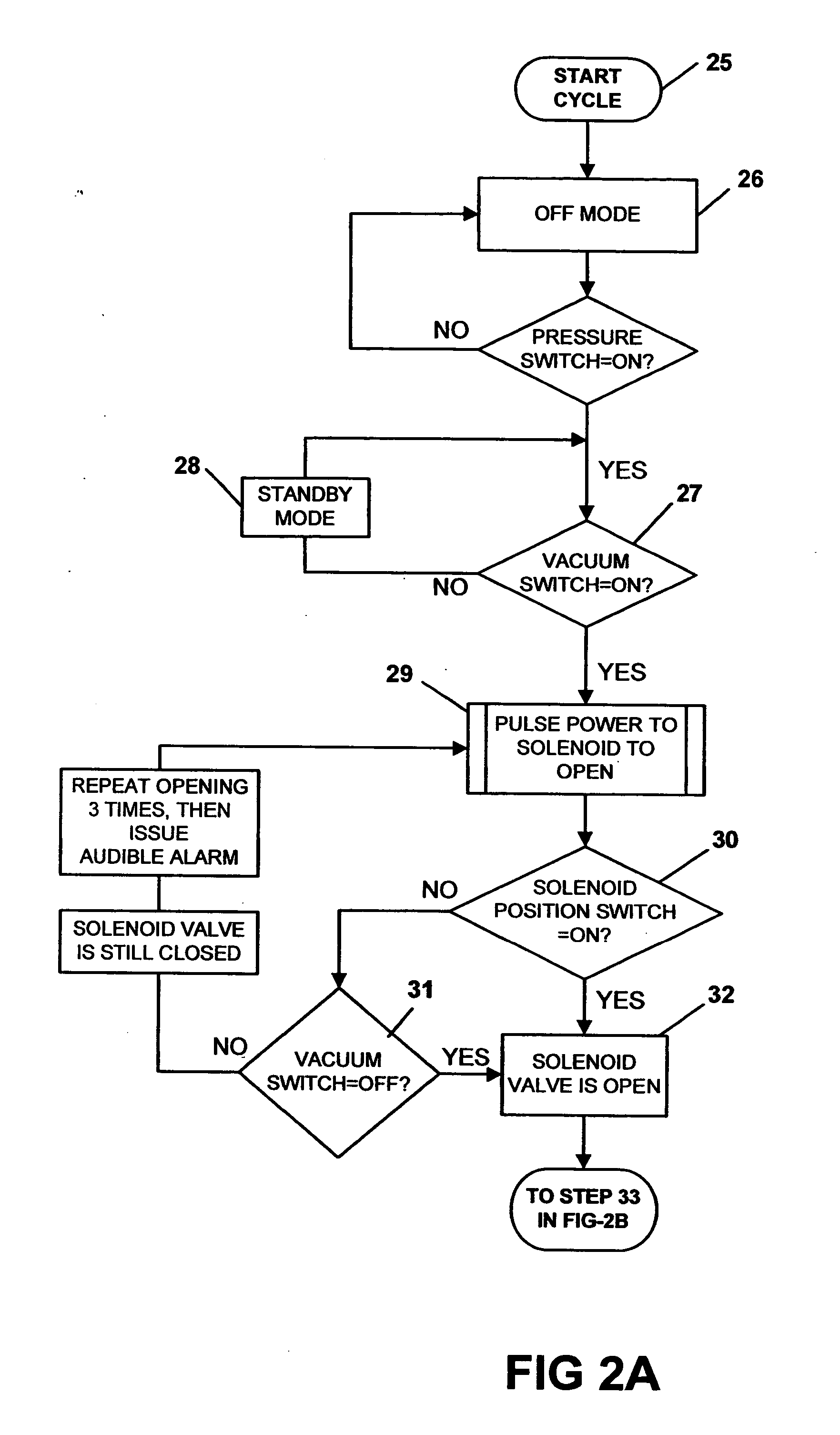

Water flow controller

InactiveUS20060213561A1Function increaseImprove accuracy and precisionFilling using suctionOperating means/releasing devices for valvesElectricityVacuum pressure

An apparatus for controlling water flow is provided. The apparatus is a novel electronic water controller capable of operation using a battery-type power source, and providing for achievement of long battery life. The apparatus generally comprises an electronic control module, a vacuum pressure sensor, a trigger switch, a vacuum switching module and a means to electrically connect the electronic control module to a power source.

Owner:TIWET JOHN

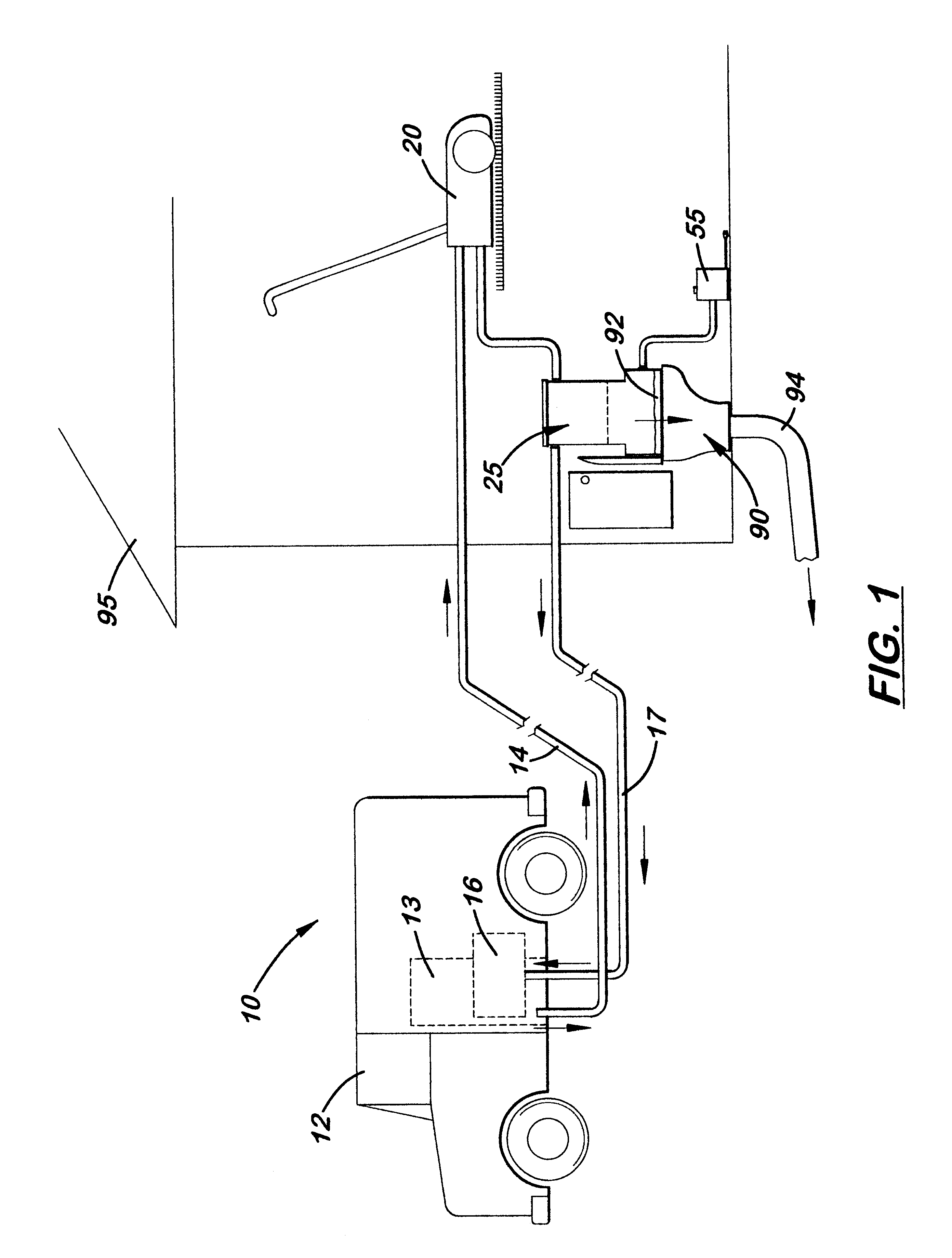

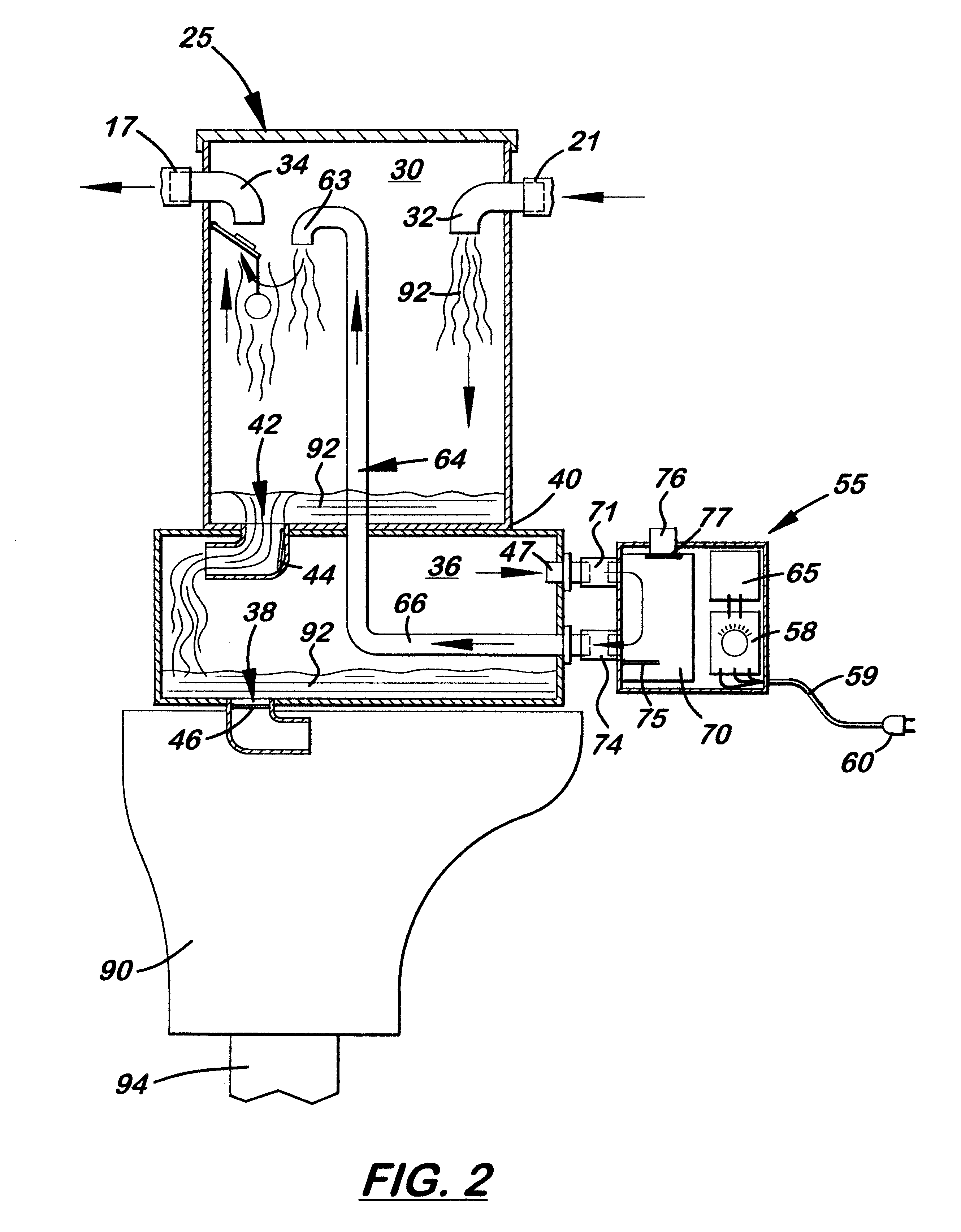

Continuous carpet cleaning system

A carpet cleaning system that delivers heated cleaning water from a truck to a carpet cleaning apparatus and an improved waste disposal tank designed to receive the waste water and deposit it into the toilet or sewer drain when the disposal tank is full. The disposal tank is divided into an upper primary recovery tank and a lower recovery tank. A main vacuum line and waste water return line are connected to the primary recovery tank. Disposed between the primary and secondary recovery tanks is a first check valve that controls the flow of waste water therebetween. Connected over the outlet port on the secondary recovery tank is a second check valve that operates in opposite direction to the first check valve. Attached to the secondary recovery tank is an air control valve that controls the flow of air from the primary recovery tank or the outside air into the secondary recovery tank. A timer or a float valve is connected to the air control valve to selectively control its operation. When the air control valve is inactivated, the air pressures in the tanks are equal and sub-atmospheric. When the air control valve is activated, the flow of air between the tanks is discontinued and outside air is able to flow into the secondary recovery tank. When outside air enters the secondary recovery tank, the first check valve closes to maintain vacuum pressure inside the primary recovery tank for cleaning, and the second check valve opens to allow discharge of the waste water from the secondary recovery tank.

Owner:NASETH JR DONALD

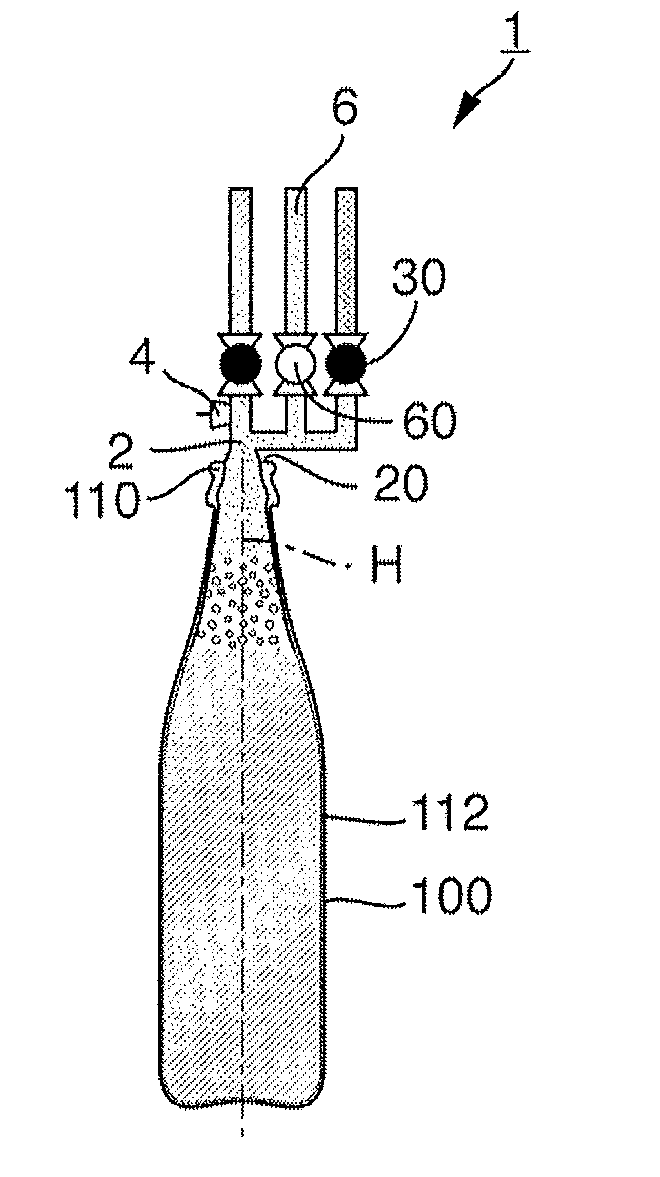

Method and device for filling a container

ActiveUS20150284234A1Short filling timeEasy to fillFilling using suctionFilling using counterpressurePositive pressureEngineering

A method for filling a container with a filling product in, for example, a beverage bottling plant is described. The method includes providing a filling product under a positive pressure, evacuating the container to be filled to achieve a negative pressure, and feeding the filling product into the container.

Owner:KRONES AG

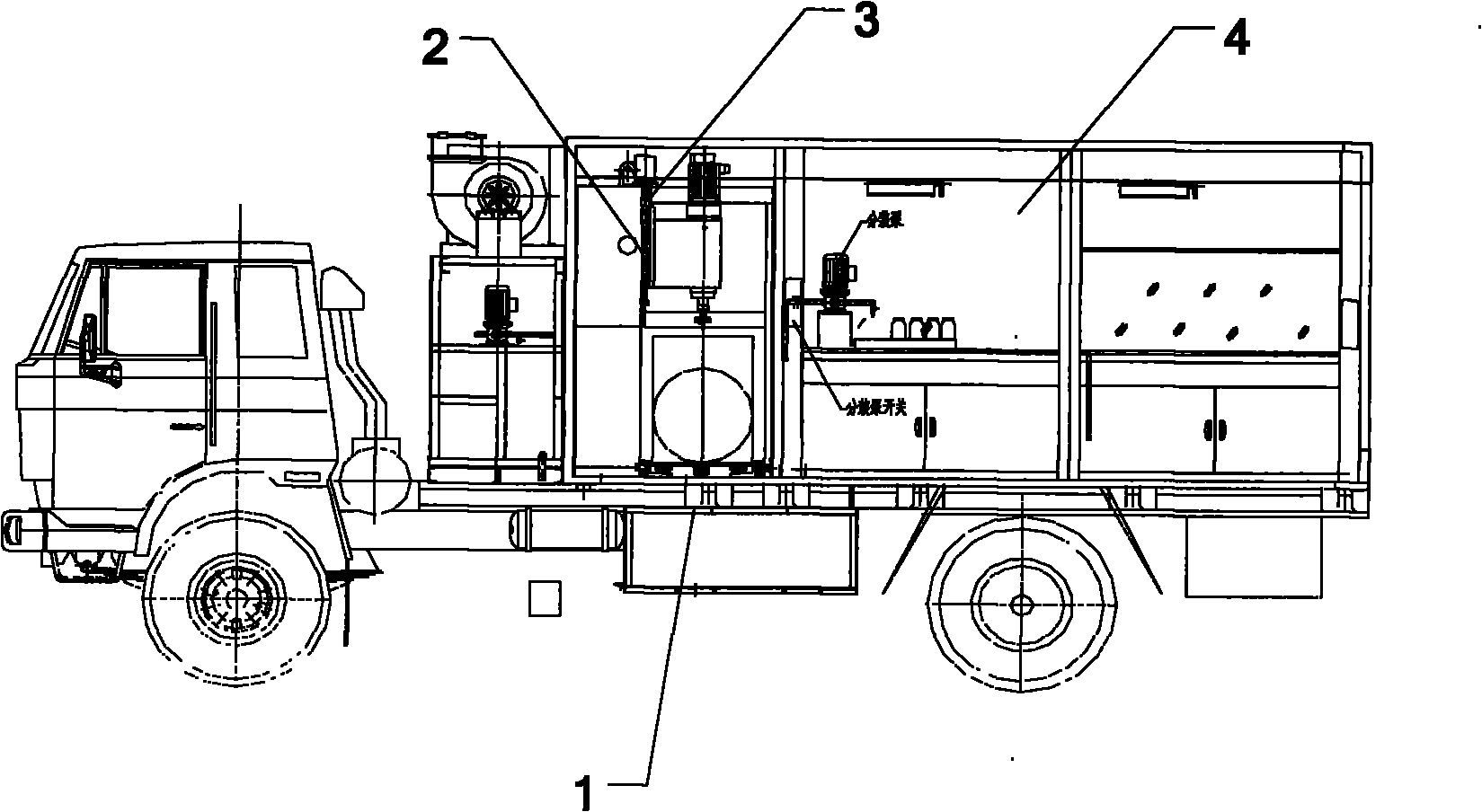

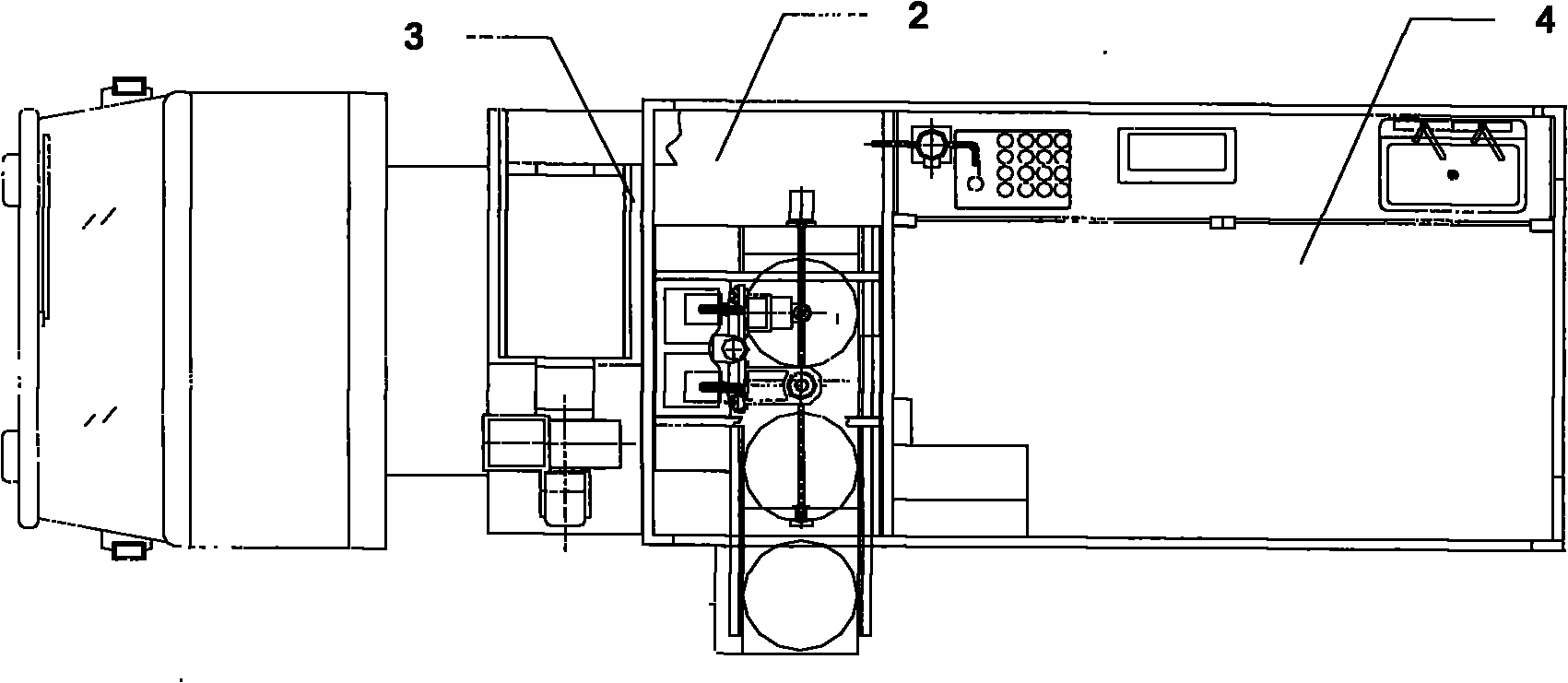

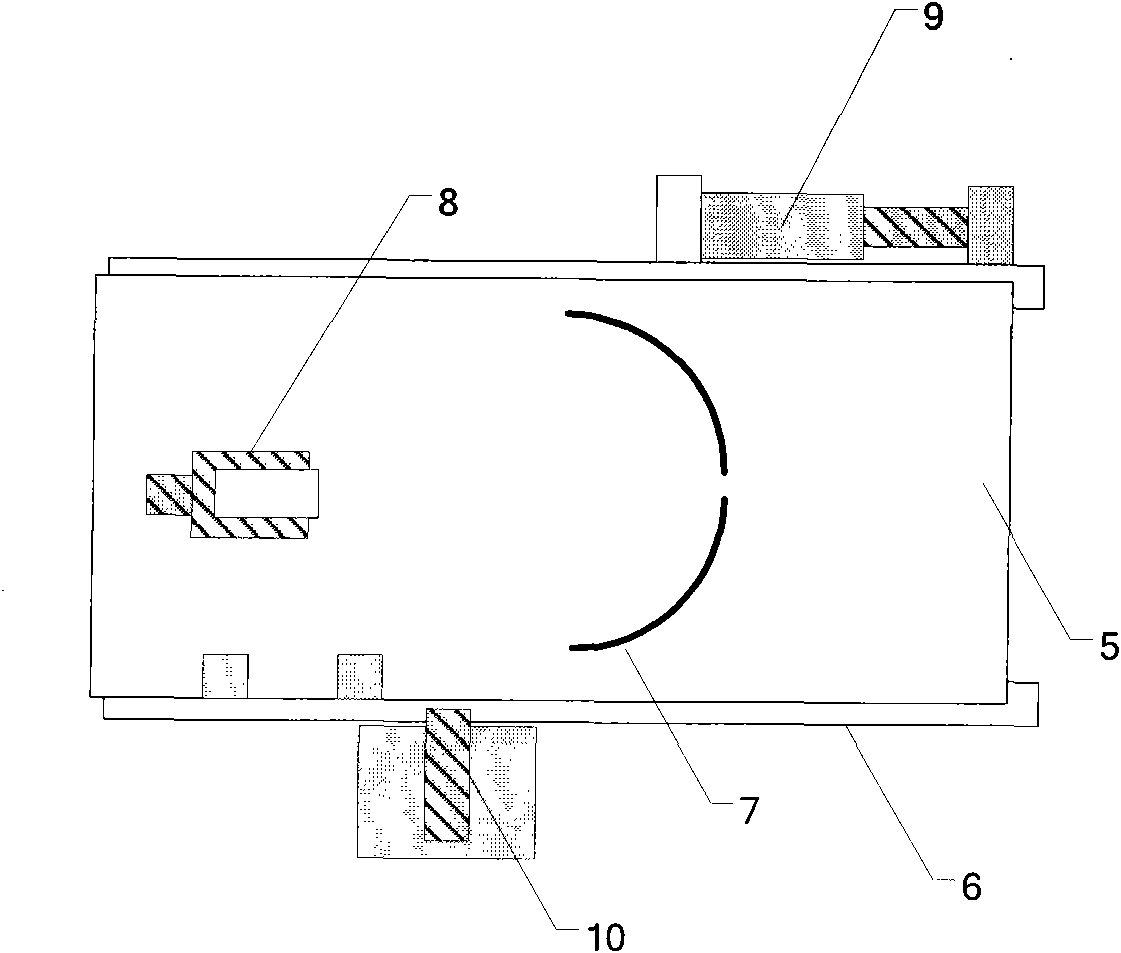

Mobile type liquid hazardous chemical sub-packaging device and sub-packaging method

The invention relates to a mobile type hazardous chemical sub-packaging device, which comprises a delivery unit, a punching unit, a suction pipe delivery unit and a sub-packaging unit. The mobile type hazardous chemical sub-packaging device is arranged in a carriage of a vehicle, wherein the carriage of the vehicle consists of two carriage bodies; the carriage body on the front side is provided with the delivery unit, the punching unit and the suction pipe delivery unit; the carriage body on the back side is provided with the sub-packaging unit; the carriage body on the front side and the carriage body on the back side are connected with each other only through suction pipes; the delivery unit is connected with a vehicle base plate; the punching unit is positioned in the carriage body on the front side and is connected with a fixed support through a lifting table; the suction pipe delivery unit and the punching unit are positioned in the same carriage body, the suction pipe delivery unit is connected with a side plate of the carriage body on the front side of the vehicle, and the suction pipes are arranged in the suction pipe delivery unit; and the sub-packaging unit is positioned in the carriage body on the back side of the vehicle, and is connected with the suction pipes. The mobile type hazardous chemical sub-packaging device has high degree of automation, is convenient to operate and use, has high safety, reduces the working strength of operating staffs and ensures the safety of the operating staffs.

Owner:BEIHANG UNIV +2

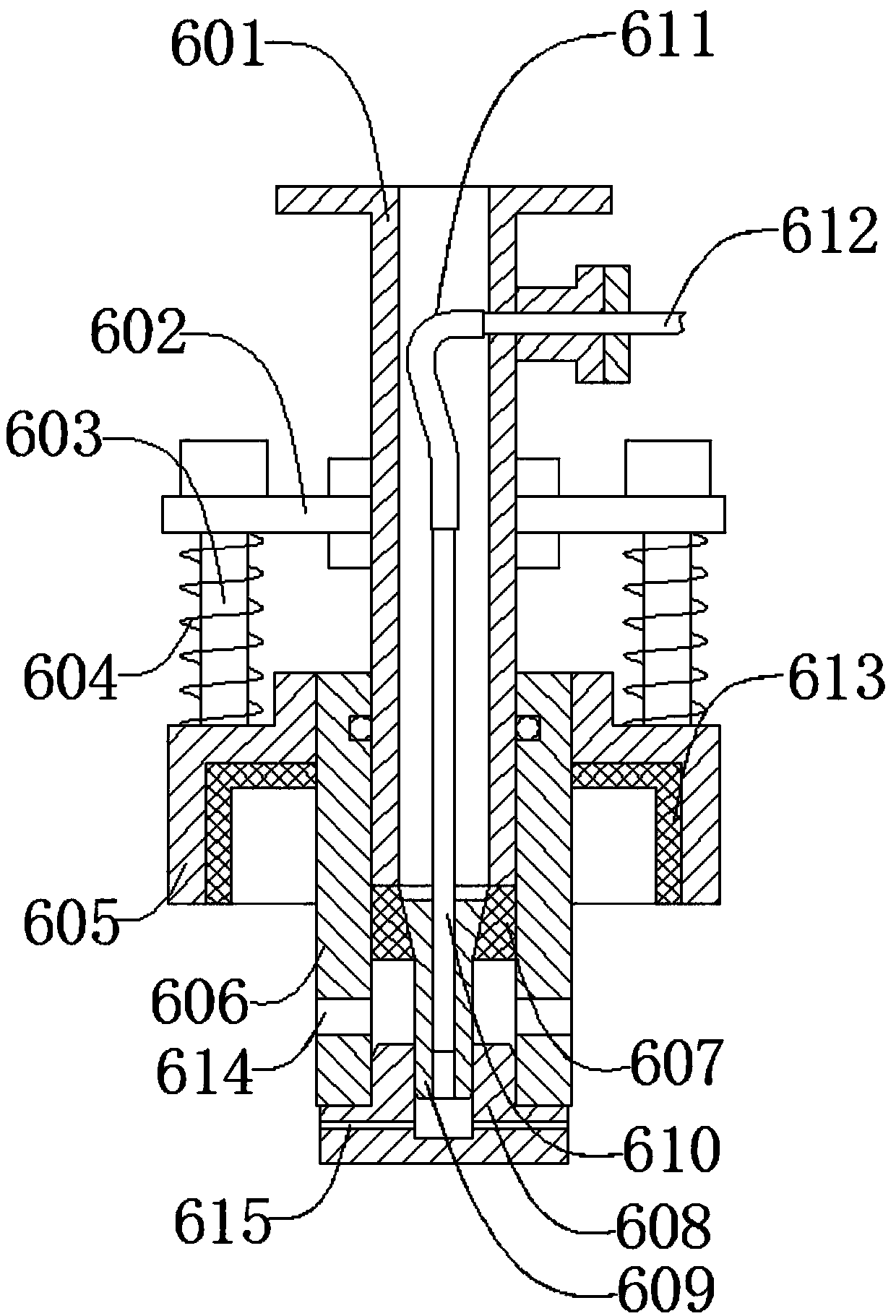

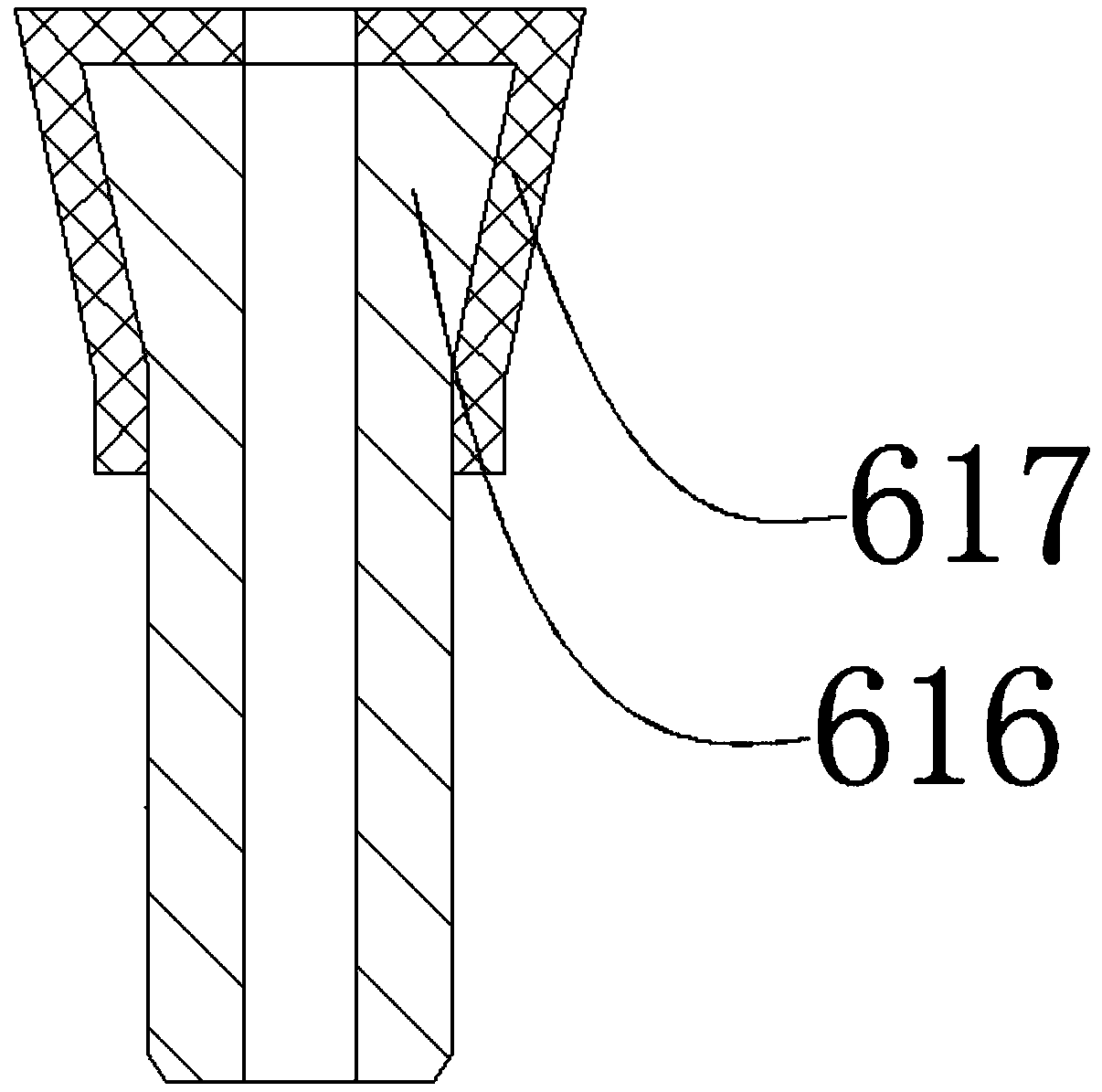

Filling equipment convenient to operate

InactiveCN106082080AAccurate positioning accuracyPrecise and fast responseFilling using suctionEngineeringBottle

The invention aims to design filling equipment convenient to operate. The filling equipment comprises a rack, wherein a transport unit, a clamping device, a filling device, a weighing device and a display control device are arranged on the rack; a liquid storage bottle is transported to a position below the filling device through the transport unit; filling operation is implemented after the clamping device is utilized for clamping; the weighing device is used for weighing weight, before and after filling operation, of the liquid storage bottle, and transmitting the weight data to the display control device; the display control device is used for displaying corresponding data, and controlling and regulating the filling device to output amount of the filled liquid; a filling head is movably connected onto the rack through a lifting device; a material receiving plate is connected above the transport unit; the material receiving plate moves front and back through a moving device; when the filling head descends to discharge, the material receiving plate is moved out from a position above the transport unit; and when the filling head collects a liquid to ascend, the material receiving plate moves to a position above the transport unit.

Owner:WENZHOU YOULIAN MACHINERY MFG

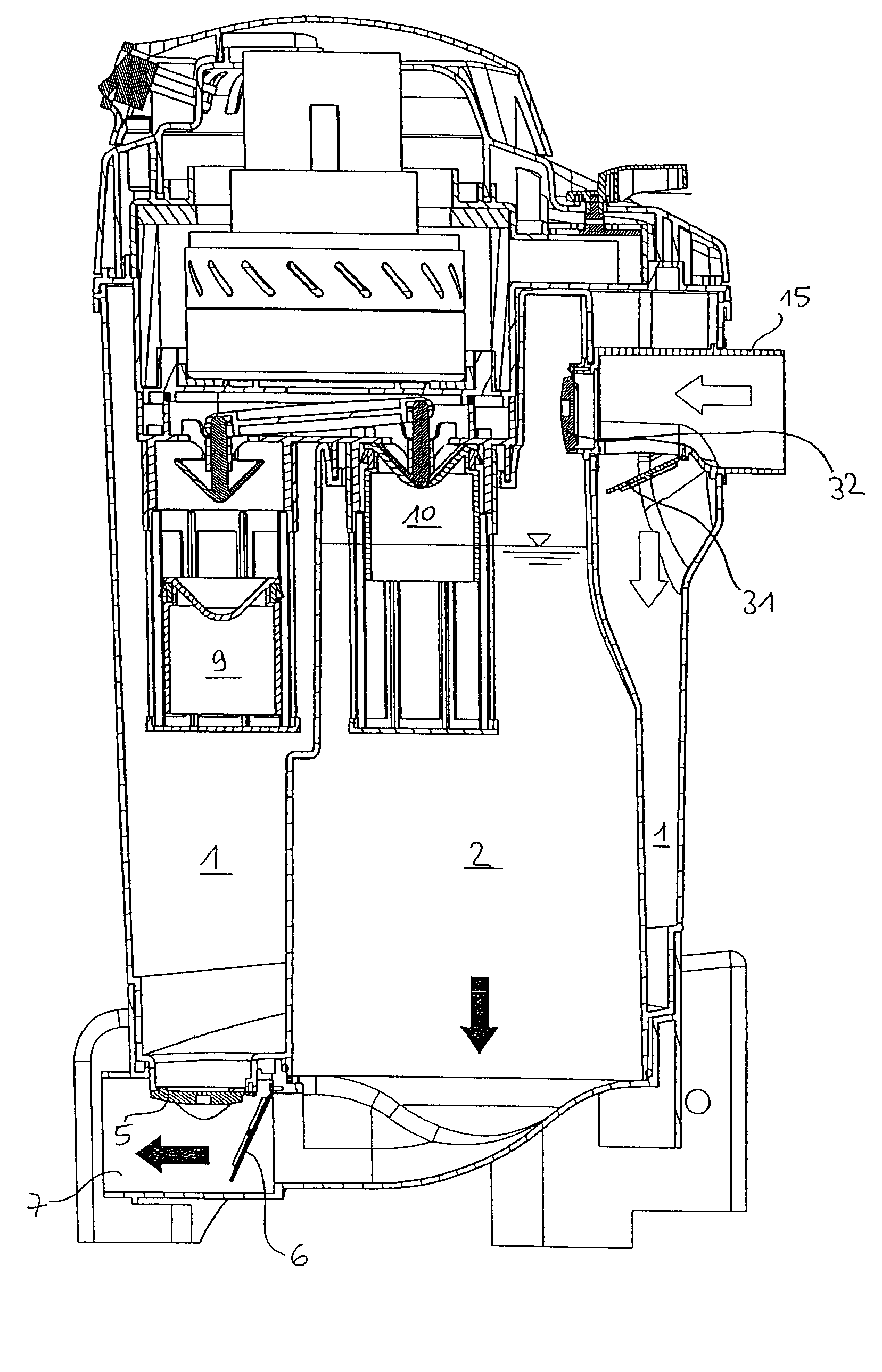

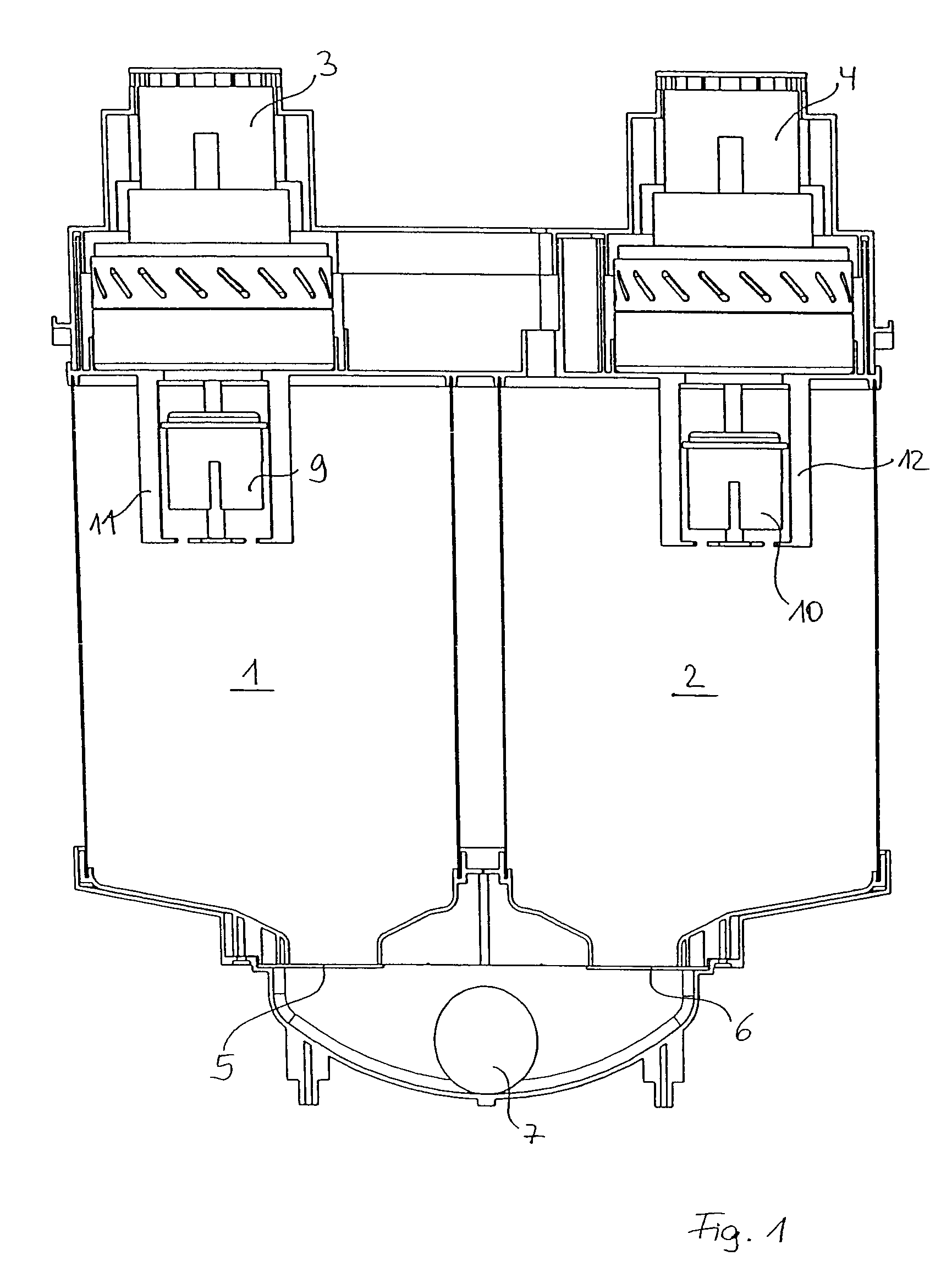

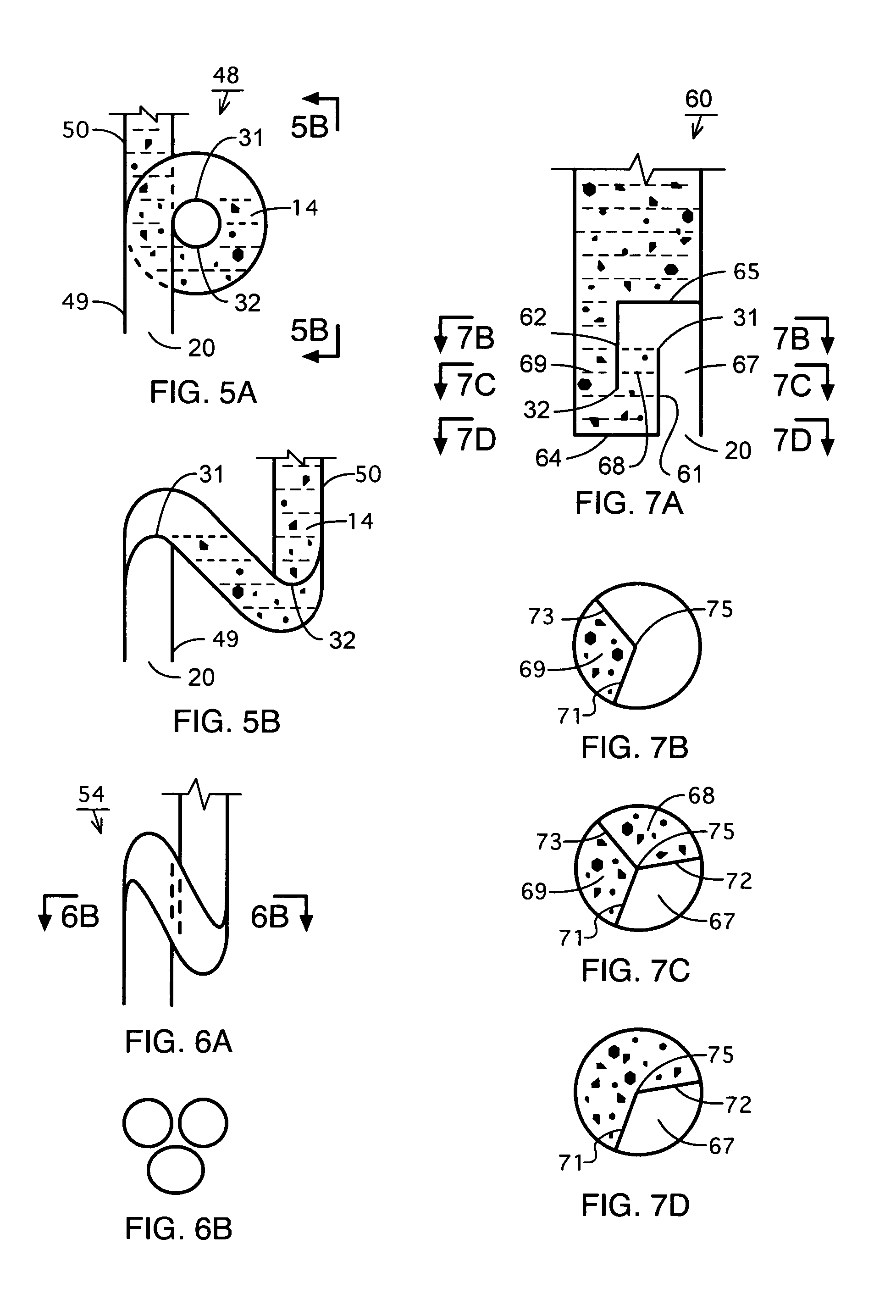

Liquid aspirator

ActiveUS7814926B2Guaranteed continuous performanceMore efficientFilling using suctionSewerage structuresSludgeEngineering

A liquid aspirator, in particular for liquids containing solids such as sludge, has a receptacle into which liquid can be sucked in by an aspirator motor through a vacuum connector and from which the liquid can drain through a drainage. The receptacle has at least two separate receiving chambers and a control that controls that the receiving chambers are filled alternatingly with liquid while the receiving chambers that are not being filled are drained. The receiving chambers are sealable relative to the vacuum side of the aspirator motor by main valves that are preferably mechanically connected.

Owner:OASE GMBH

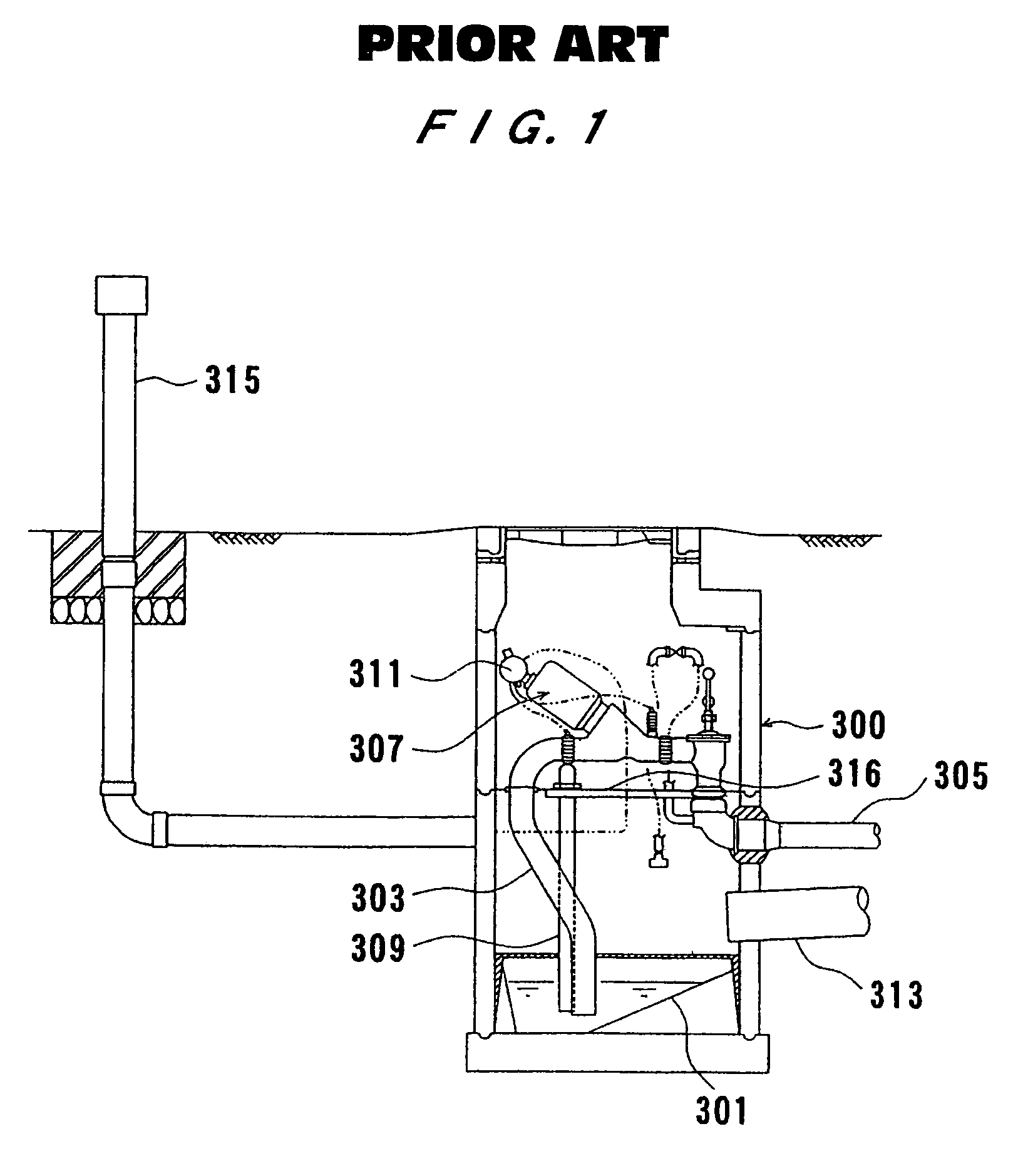

Vacuum valve controller

ActiveUS7013909B2Remodeled easily and inexpensivelyFilling using suctionSewerage structuresPressure transmissionSewage

The present invention provides a vacuum valve controller for opening and closing a vacuum valve mounted on an end of a pipe of a vacuum system that is part of a vacuum sewage system. A vacuum valve controller includes a pressure sensor for converting a water level of sewage in a sewage pit into a pressure, a vacuum valve opening and closing mechanism for opening and closing the vacuum valve according to a variation of the pressure detected by the pressure sensor, an open-state holding mechanism for holding the vacuum valve open until air is drawn in through the suction pipe after sewage is drawn in through a suction pipe, and a pressure transmitting mechanism for transmitting a pressure upstream of the vacuum valve in the suction pipe to the open-state holding mechanism to detect when air is drawn in through the suction pipe.

Owner:EBARA CORP

Liquid fertilizer filling machine

The invention discloses a liquid fertilizer filling machine. The liquid fertilizer filling machine comprises a base, a vertical frame, an air cylinder, a sliding seat, a filling tube, a filling nozzle, a vertical plate, a support plate, a driving mechanism, a rotating shaft and a cam, wherein two guide sleeves, a push rod, a cylinder body, a piston, a first one-way valve, a second one-way valve, asoft connector, a sliding plate, a guide wheel, a limiting ring, a first spring, a support, a material barrel, a liquid inlet pipe with the elbow being arranged at the bottom, a buffer mechanism anda filtering mechanism are arranged in parallel with the support plate. According to the liquid fertilizer filling machine, the structure is simple, each time the cam rotates once, the liquid fertilizer in the material barrel is sucked into the cylinder body and a packaging bottle is filled with the liquid fertilizer with equal volume, so that the automatic and quantitative filling is realized; meanwhile, the filling nozzle is adopted for sealing filling, the liquid fertilizer is prevented from splashing, the waste of raw materials is avoided, and the environment of the working site is prevented from being polluted.

Owner:SUQIAN WOLVBAO ORGANIC AGRI DEV

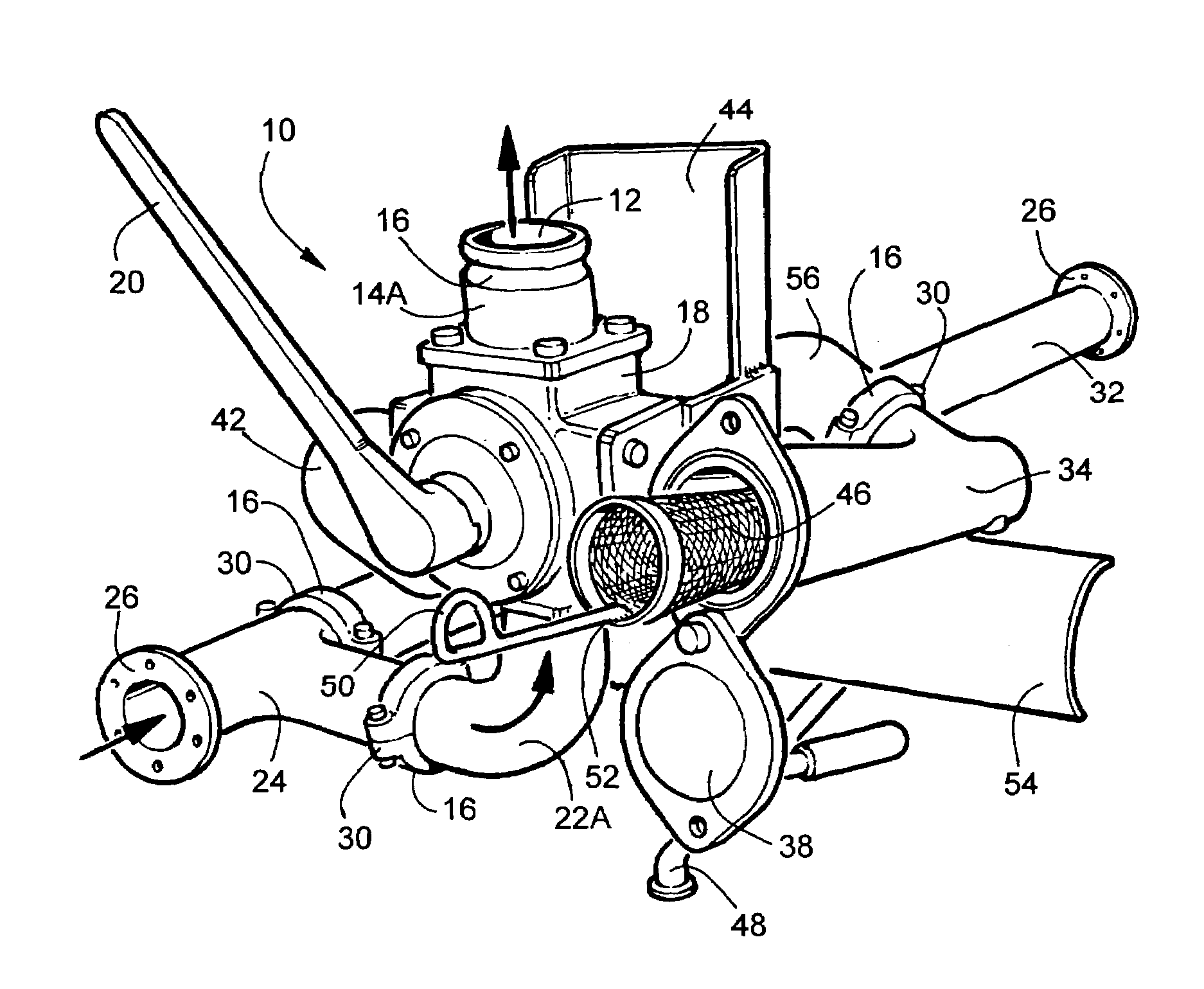

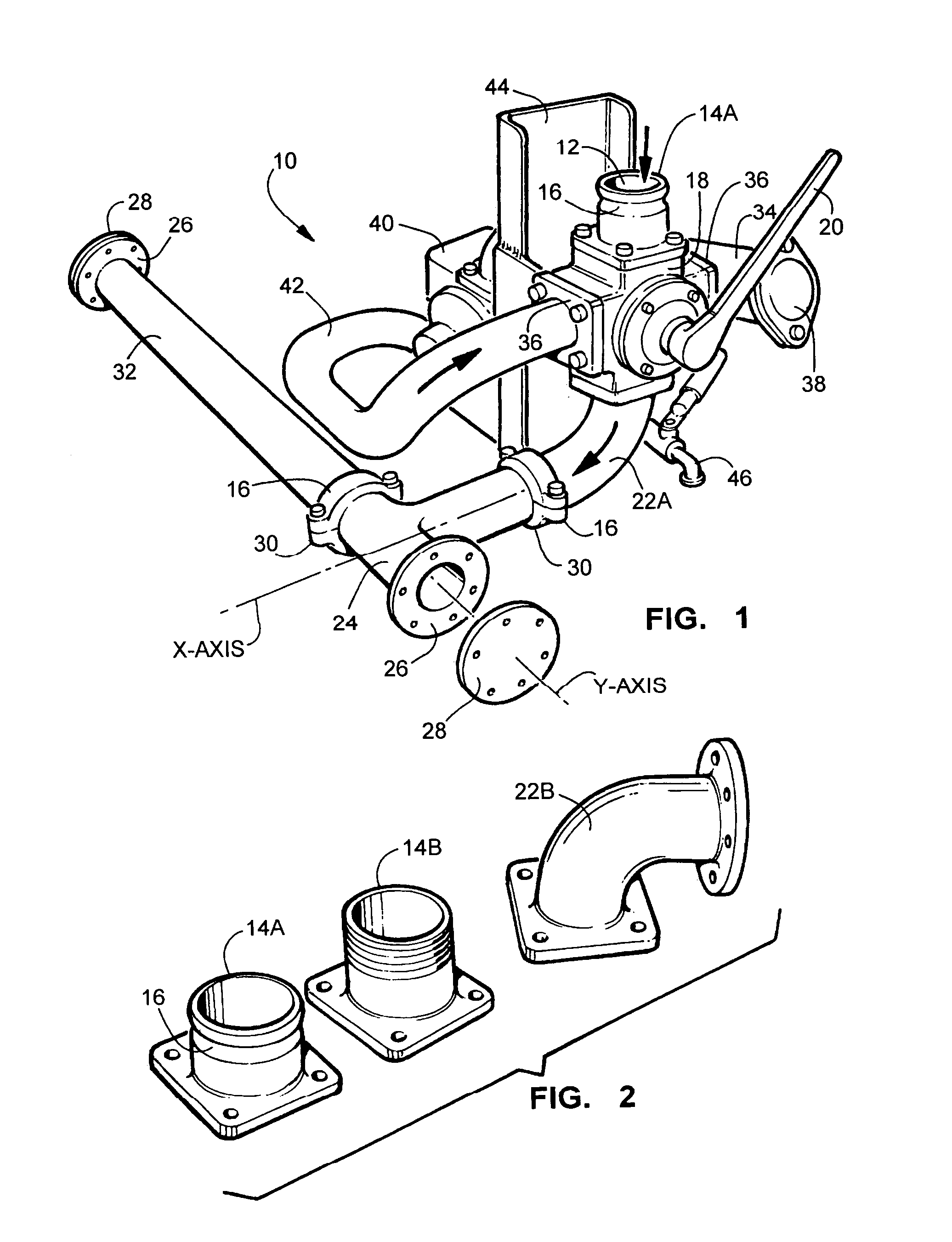

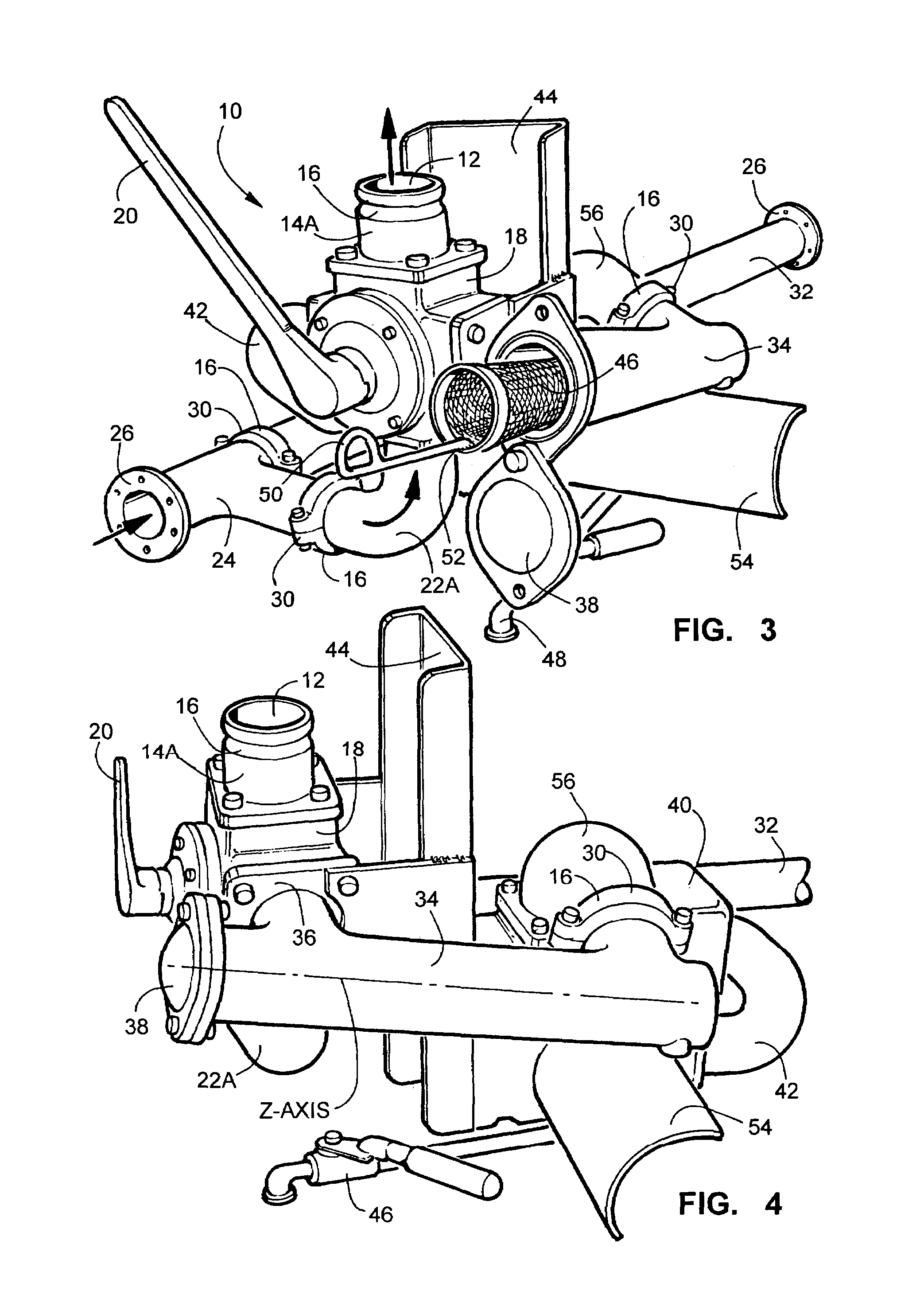

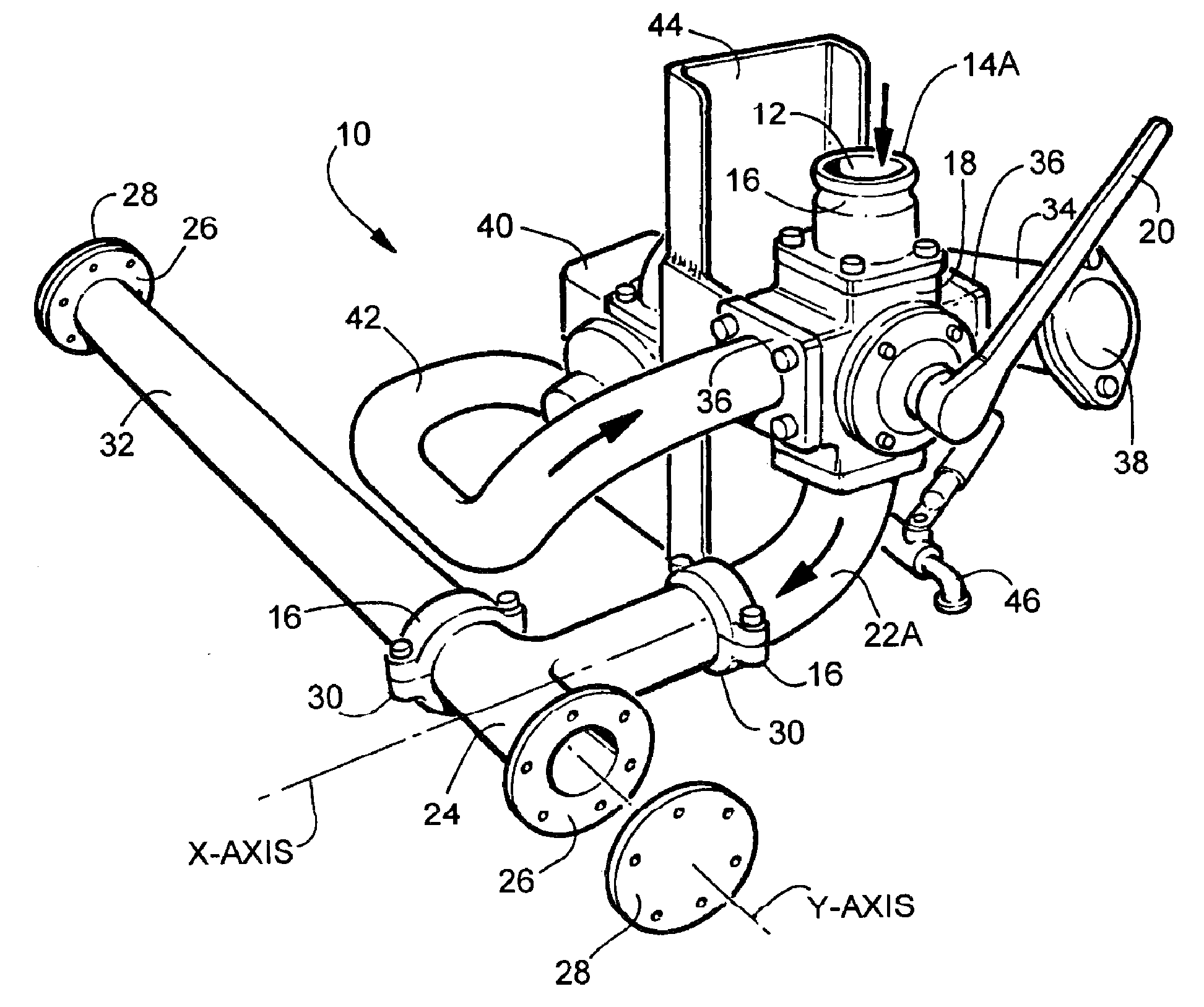

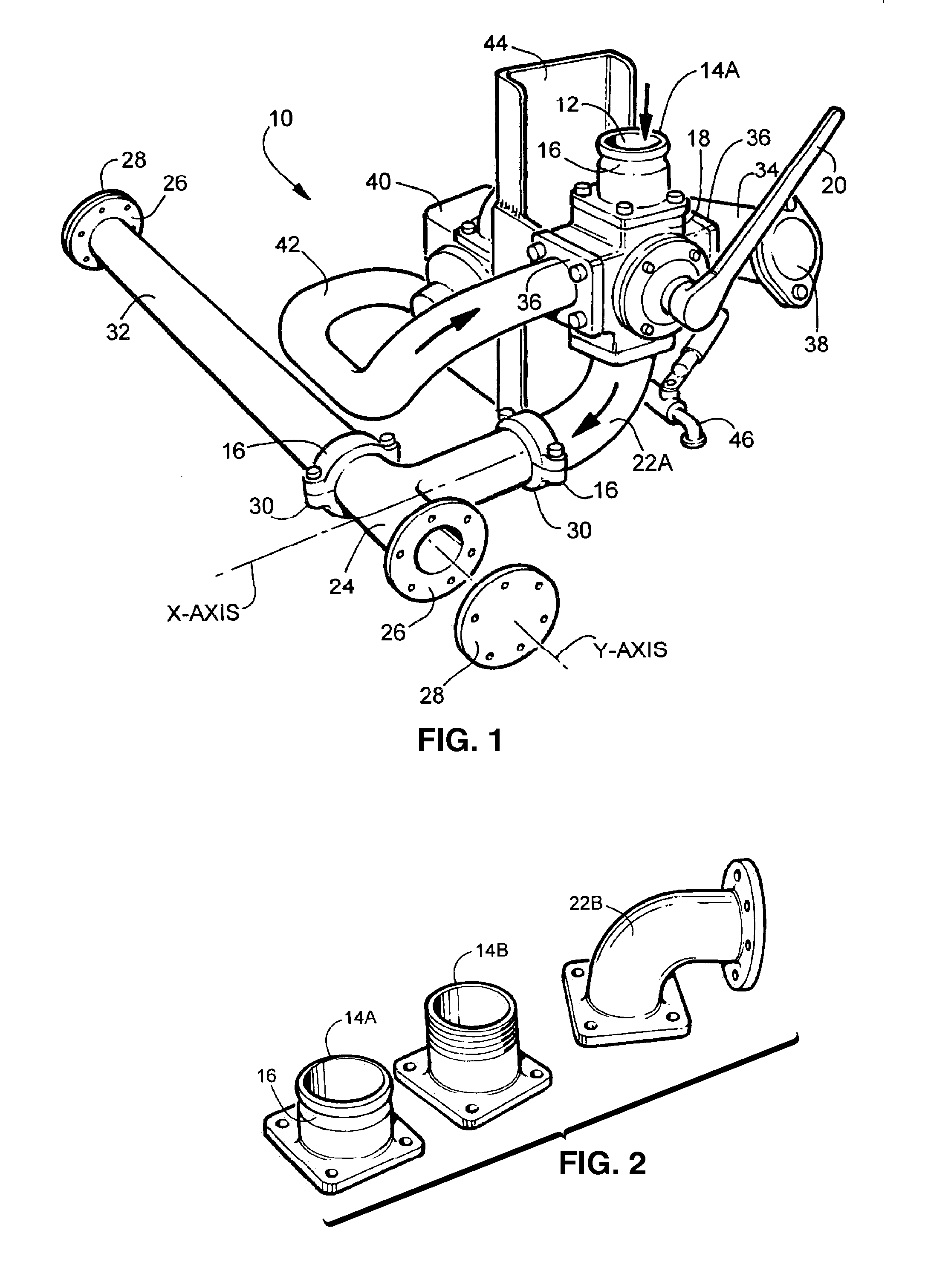

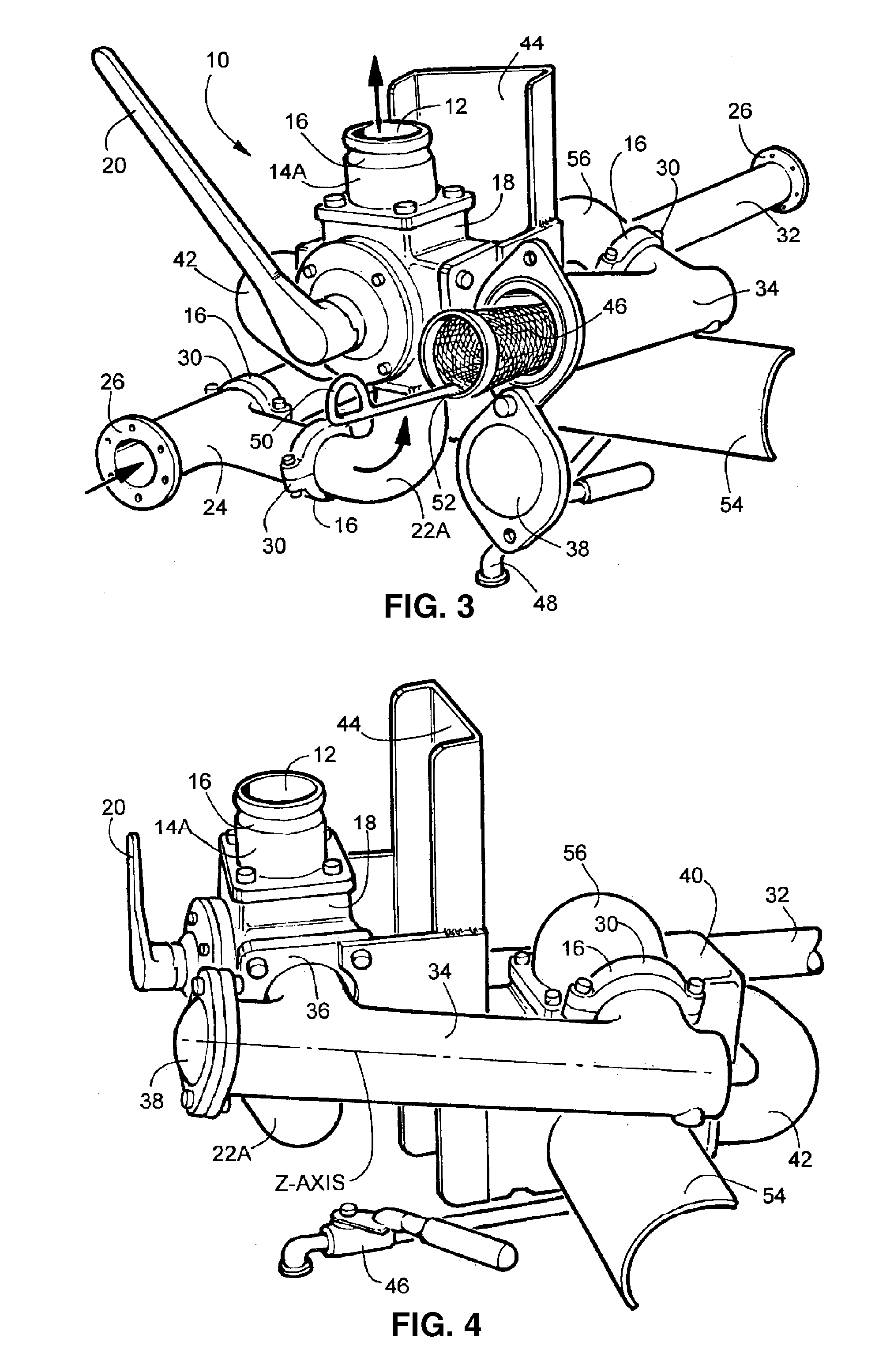

Manual bulk liquid pump control and distribution system

InactiveUS7124792B2Filling using suctionOperating means/releasing devices for valvesSystems designLine tubing

The present invention is directed to a manual bulk liquid pump control and distribution system that utilizes a single-handle manual operation for direction of flow and speed, along with providing a neutral position for standby. The system can be operated at a rate of 0 to 250 gallons per minute and be reversed with a single motion of the operating handle. The pump operates in one direction at a fixed RPM, resulting in longer pump life and safer operation. For added safety, the system utilizes the pump's relief valve for both discharge and suction operation. It has the ability of sucking the liquid out of the lines and hoses after each transfer operation. This system has an aluminum flow-reversing valve or two-way valve at the center of the design. This valve allows the flow of the product to be precisely controlled in either direction, along with the flow rate and pressure. This gives the operator the ability to control the product regardless of viscosity or volume. The system has been designed with pressure-tested manifolds and custom design brackets along with a sampling valve and an easily accessible angled strainer basket. The design allows for safe and convenient pump operation as well as for the proper handling of liquids during environmentally sensitive times.

Owner:SAFETY PUMPING SYST

Greywater System and Method for Applying Same

ActiveUS20080314457A1More compactMore efficientIndustrial water supply conservationPressure pumpsSiphonWater discharge

A device for reusing greywater includes: a water feed for supplying greywater; a collecting reservoir for collecting the supplied greywater; a storage tank for storing water; a siphoning device for siphoning water from the collecting reservoir to the storage tank; a water discharge for discharging stored water to a water user; a sewer outlet; and a control system.A method of siphoning water includes: supplying water to a collecting reservoir; detecting a predetermined water level in the collecting reservoir; operating a filling valve subject to the detected water level; and siphoning water via a siphon connection from the collecting reservoir to the storage tank.

Owner:HYDRALOOP INT BV

Multi-container filling machine, valves, and related technologies

An apparatus for filling differently sized containers with fluid includes a filling head having a fluid holding area. At least one multi-container filling nozzle connected to the filling head, wherein at least two containers with differently-sized openings are fillable with a quantity of fluid from the fluid holding area without changing the multi-container filling nozzle. Related methods and devices for filing containers with differently-sized openings with fluid without changing a fluid nozzle are also disclosed.

Owner:ABC FILLERS INC

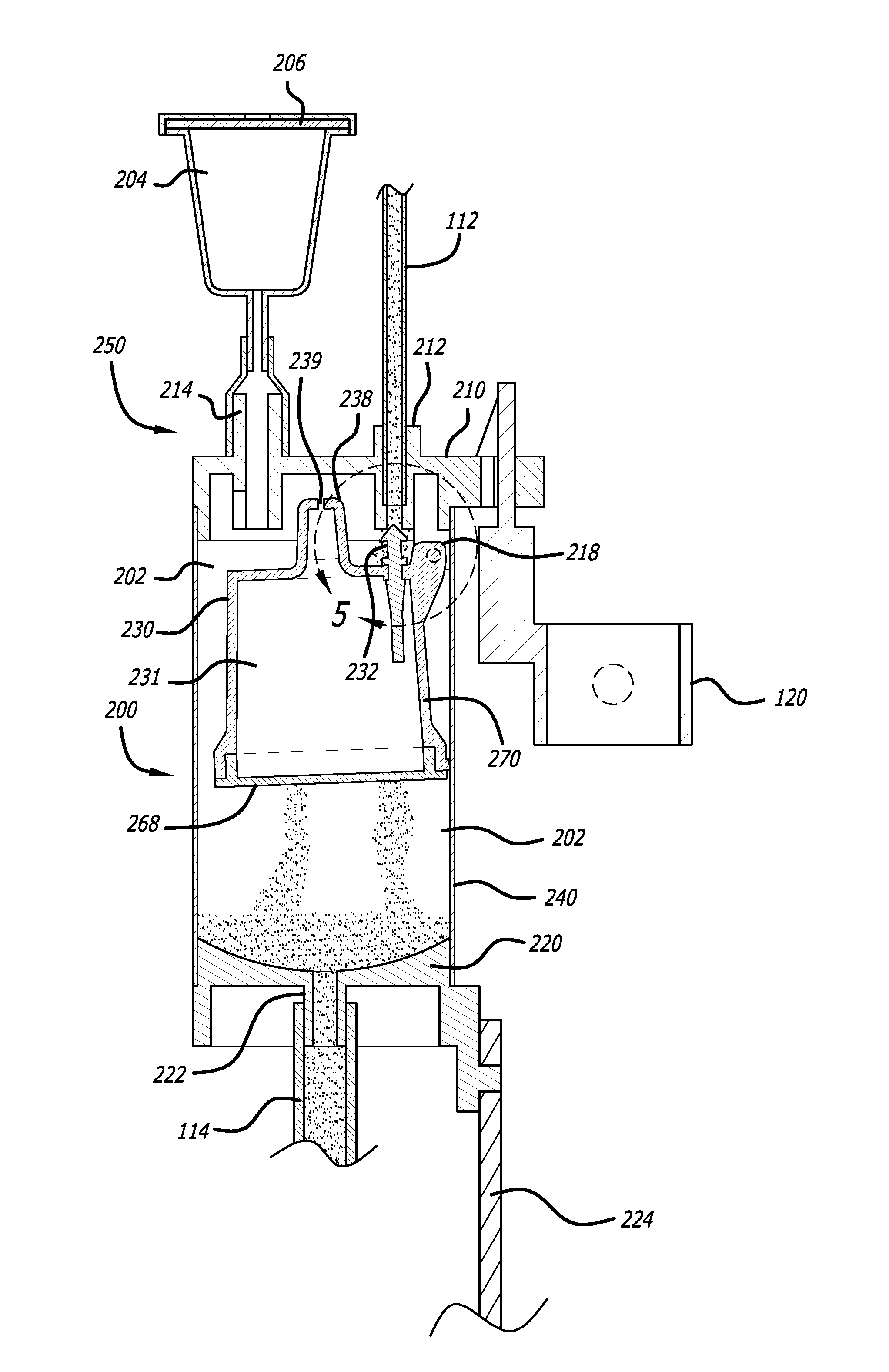

Volume limiting bodily fluid drainage system

ActiveUS8221366B2Avoid change in buoyancyPrevent movementFilling using suctionMedical devicesEngineeringBody fluid

Owner:INTEGRA LIFESCI +1

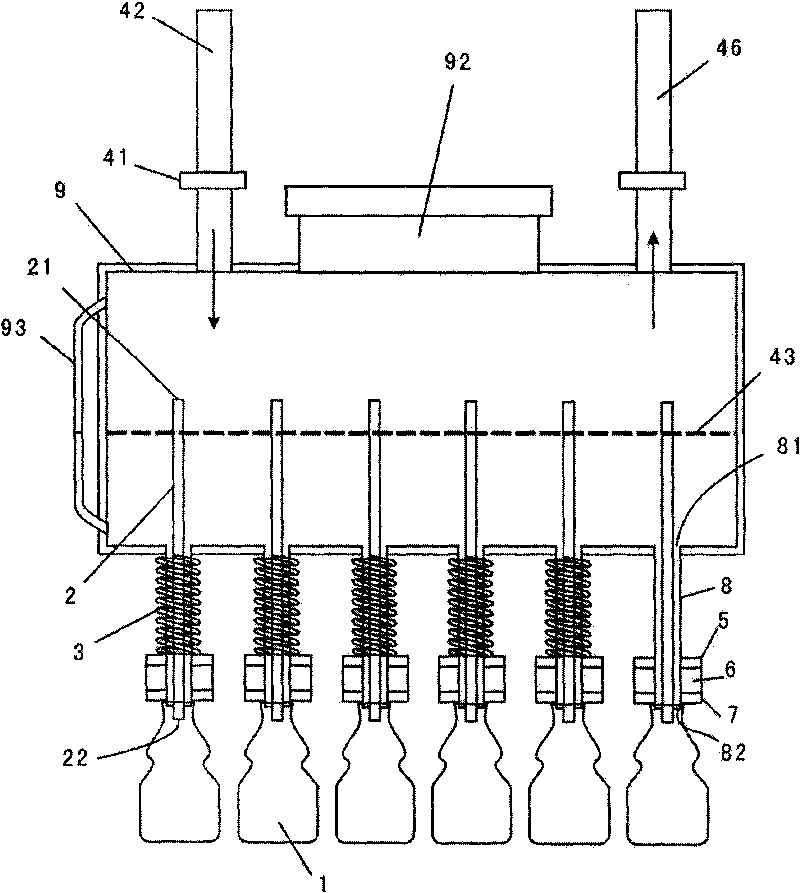

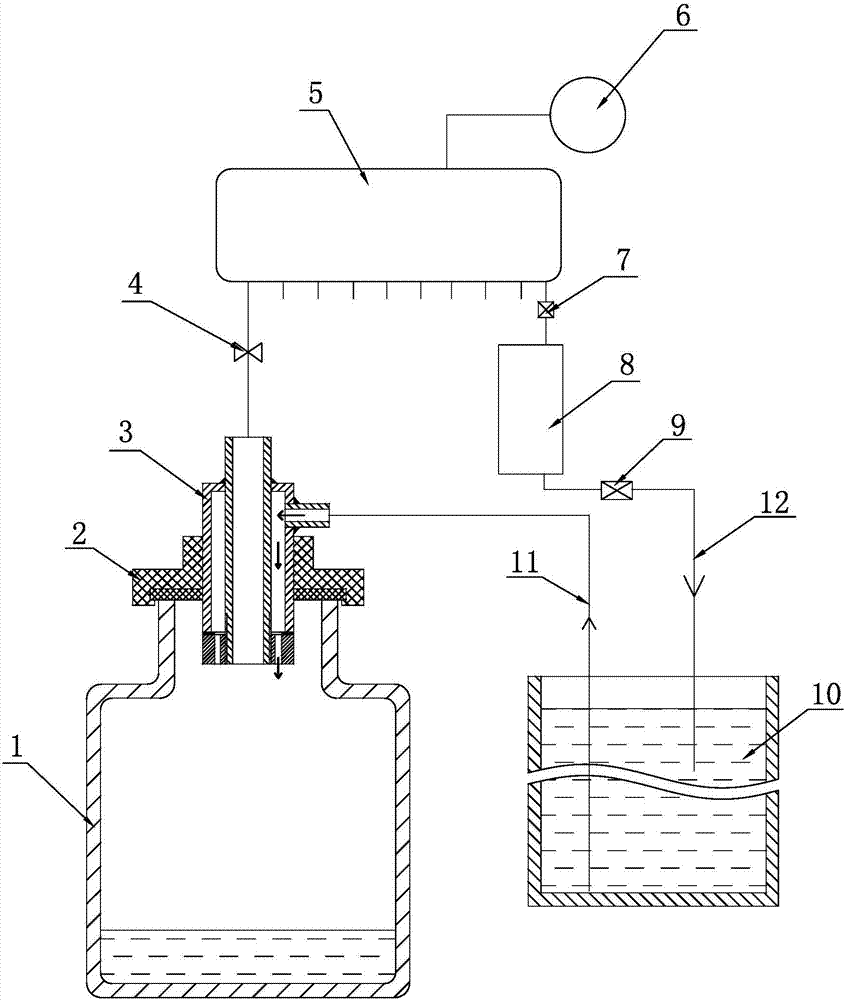

Negative pressure equal liquid level height control liquid filling device

InactiveCN107161933ASolve the problem of not being able to fill the bottle body at equal heightsWon't spillFilling using suctionEngineeringBottle

A liquid level control liquid filling device under negative pressure, including a bottle body, a bottle mouth sealing gland, a negative pressure filling head, a suction valve, a negative pressure chamber, a vacuum pump, an upper liquid discharge valve, a transitional liquid storage tank, The lower discharge valve and the material liquid tank, the negative pressure filling head is tightly fitted on the bottle mouth sealing gland, the lower end surface of the bottle mouth sealing gland is sealed and pressed with the bottle mouth, and the lower end surface of the negative pressure filling head extends In the bottle, the negative pressure channel of the negative pressure filling head communicates with the inner cavity of the negative pressure chamber, the liquid inlet channel of the negative pressure filling head communicates with the material liquid tank, and the negative pressure chamber passes through the upper discharge valve and the transitional liquid storage in turn. The tank and the lower drain valve communicate with the feed tank. It adopts the principle of negative pressure liquid suction, which can not only inject liquid into the bottle, but also suck the excess liquid back into the material liquid tank, and can realize equal height liquid level filling of various bottles, solving the problem of At present, ordinary liquid filling machines cannot fill the bottle body at equal heights. It meets the filling requirements of equal liquid level for special commodities such as canned fruit.

Owner:徐志明 +1

Devices and methods for extraction, transportation and/or release of material

Provided are methods and apparatuses for extracting, transporting and / or releasing various kinds of liquid and semi-liquid materials. The materials may have very high viscosity and may include solids. Generally speaking, the apparatus includes a container, a gateway that functions as a valve without moving parts, and a means for controlling air pressure within the container. In addition, the apparatus may include flexible hoses and / or a separator for separating the solids in the material from the liquids. Applications include industrial and manufacturing processes, construction, dredging, remediation, laboratory, and home-based uses. When used in wells, the invention can bail water, oil, and sediment (cleanout operations). The tools according to the present invention are scalable to nearly any size.

Owner:BECKHARDT DAVID

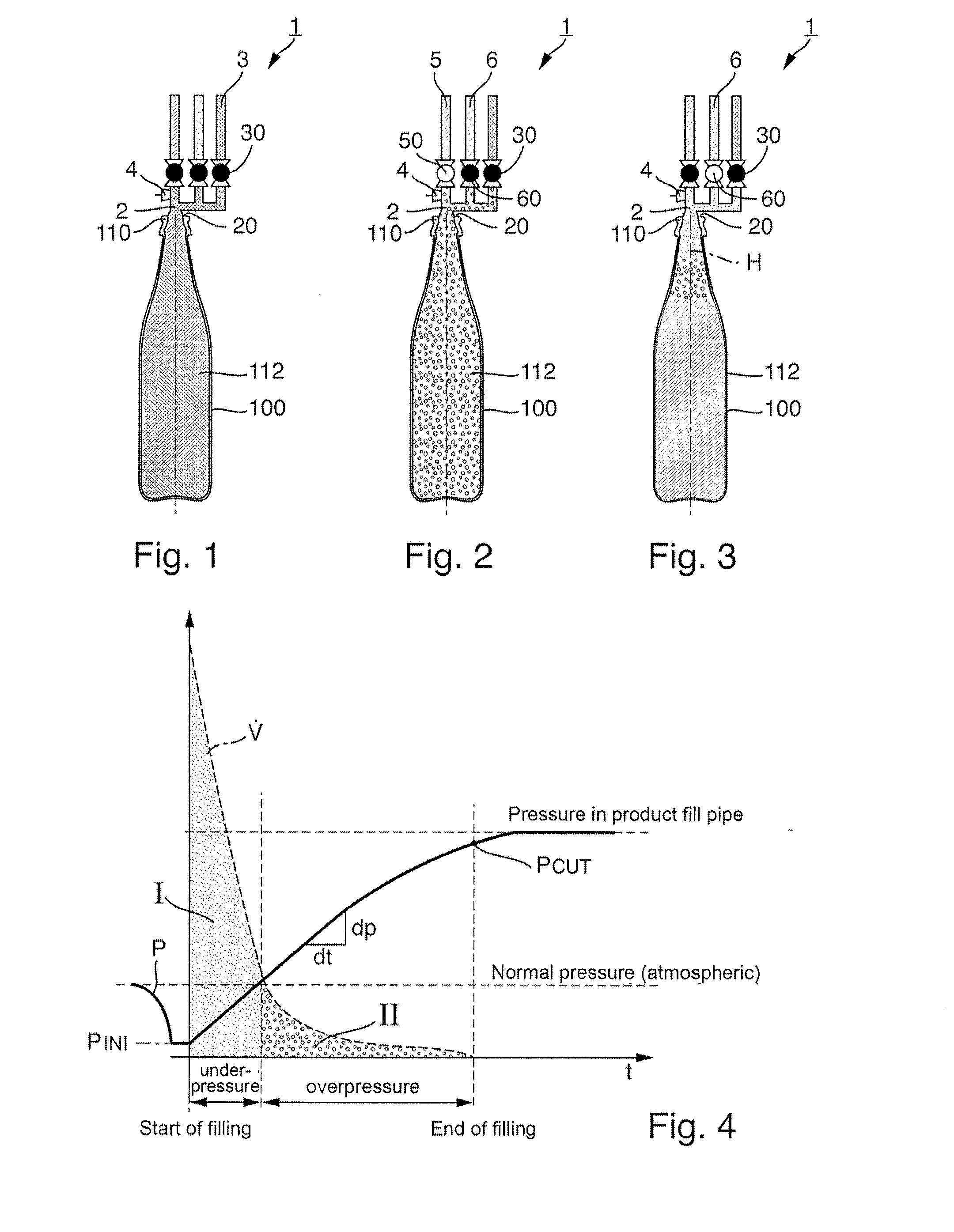

Method and device for filling a container to be filled with a filling product

ActiveUS20150284233A1Improve dose accuracyReduce complexityFilling using suctionFilling using counterpressureEngineeringMechanical engineering

A method for filling a container to be filled with a fill product is described. The method includes connecting the container to be filled with a product fill pipe, determining the initial pressure in the container to be filled, filling the container to be filled, and stopping the filling of the container when a predetermined cut-off pressure is reached in the container.

Owner:KRONES AG

Manual bulk liquid pump control and distribution system

ActiveUS20070102060A1Low operating pressureProcess safetyFilling using suctionOperating means/releasing devices for valvesControl flowDistribution system

The present invention is a pump control and distribution system consisting of a pump and reversing flow control valve with a single-handle to control flow direction and flow rate of a liquid. The system can be operated at a rate of 0 to 300 gallons per minute and the flow reversed or stopped with a single motion of the operating handle. The flow rate of the liquid can be precisely controlled in either direction, along with the liquid pressure. This allows the use of a constant speed pump turning in one direction and gives the operator the ability to control the product transfer regardless of viscosity or volume. A purge valve connected to the outlet of the pump is used to remove substantially all retained liquid in the system after transfer of liquid is complete. The system can be mounted to a vehicle for delivery of bulk liquids.

Owner:SAFETY PUMPING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com