Patents

Literature

414results about How to "Won't spill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

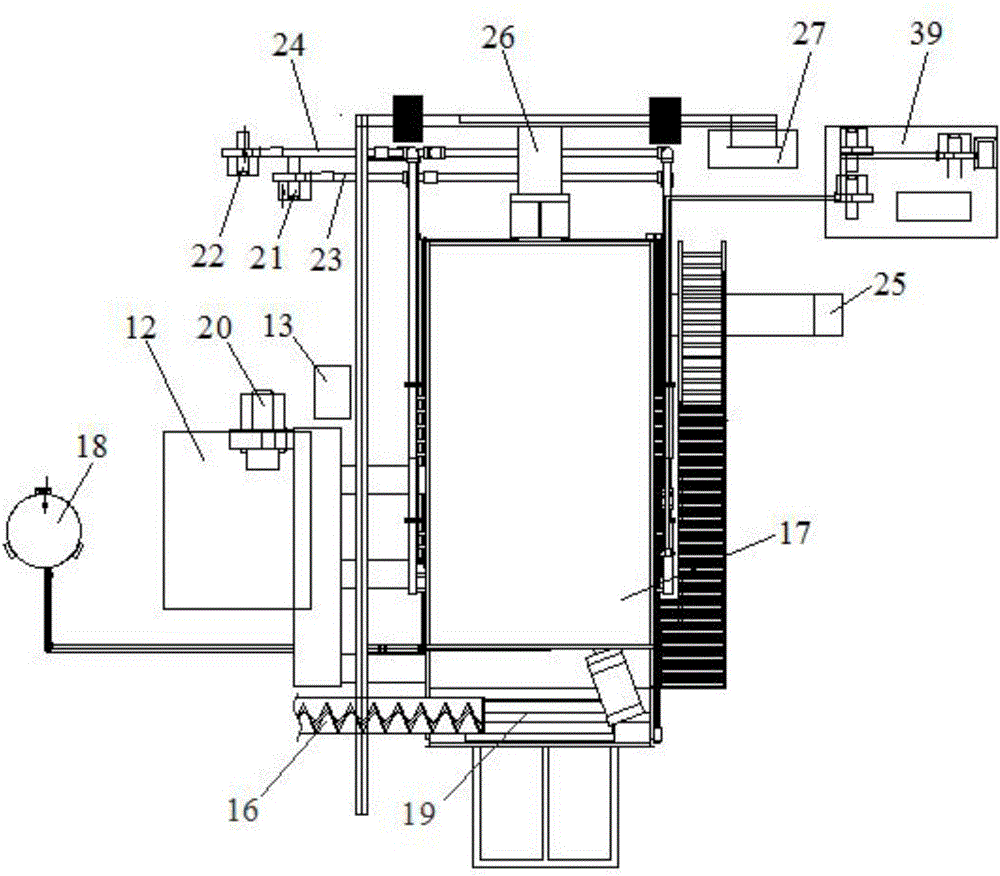

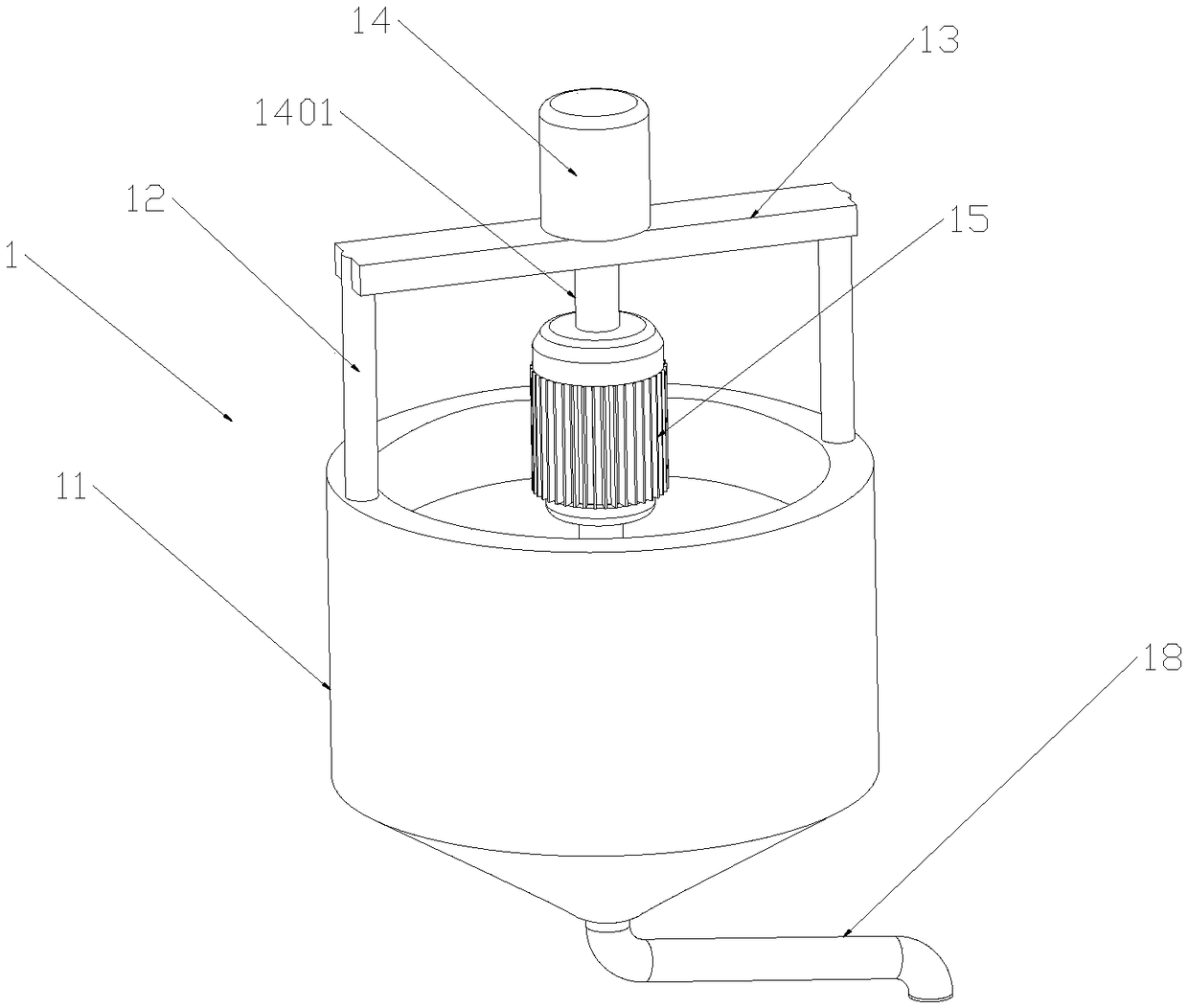

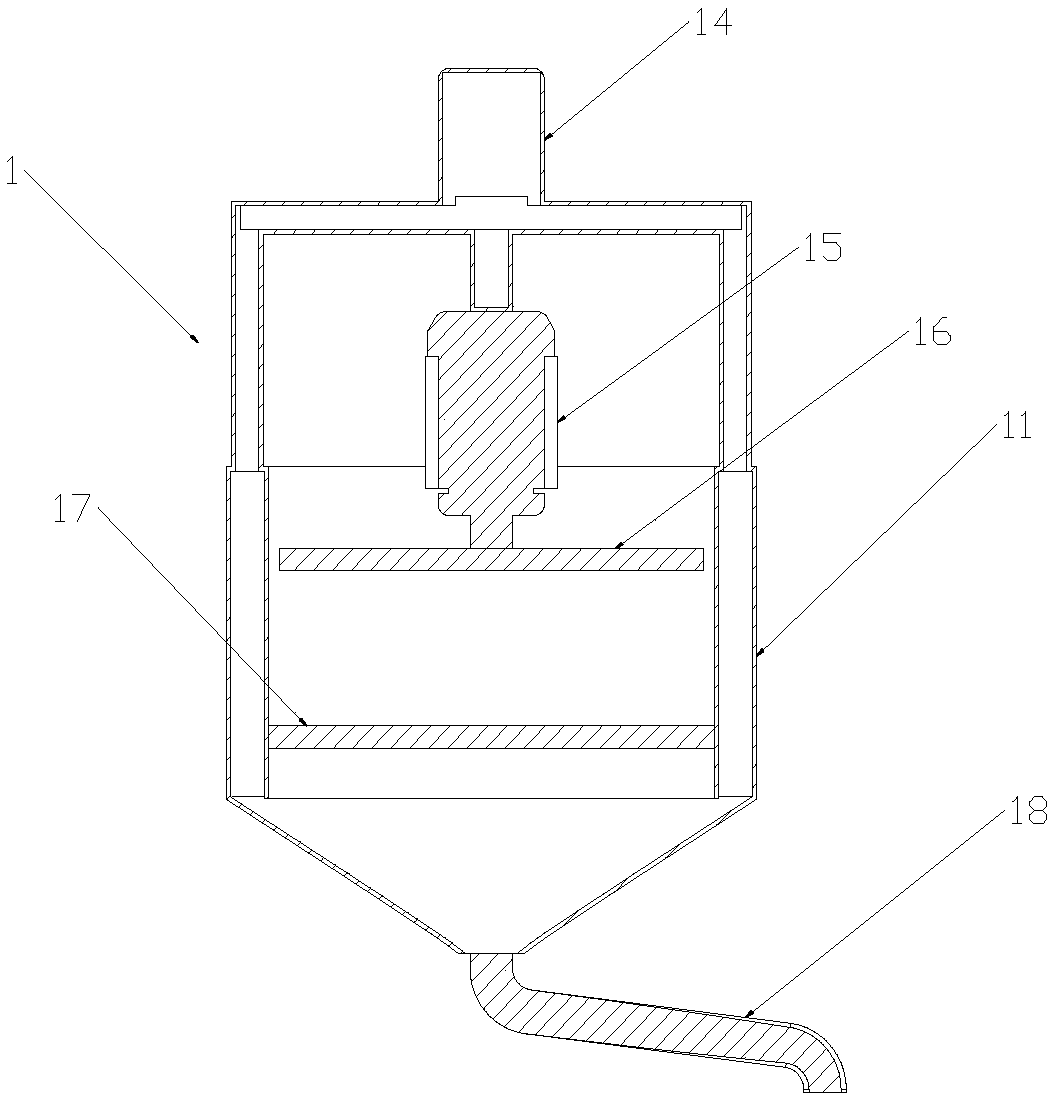

Automatic soil remediation equipment for controlling soil contamination

InactiveCN106734147ANo manual operationIncrease flexibilityContaminated soil reclamationSoil remediationEngineering

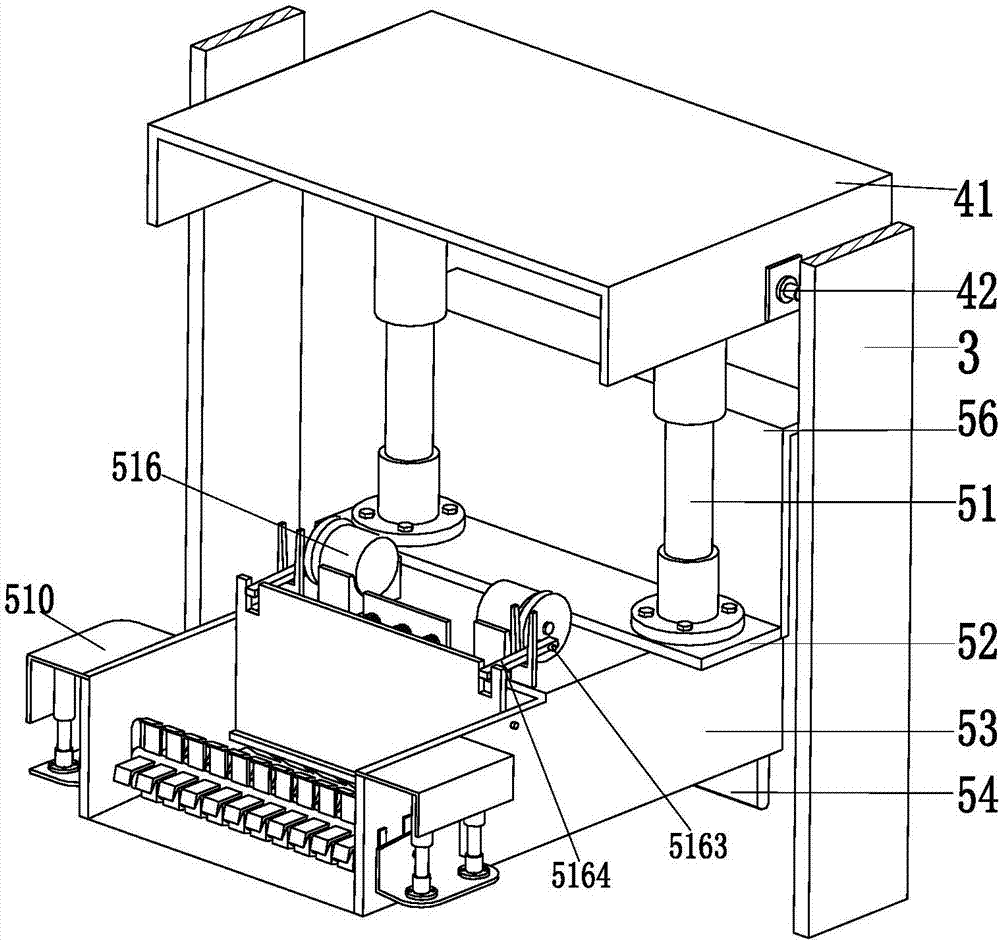

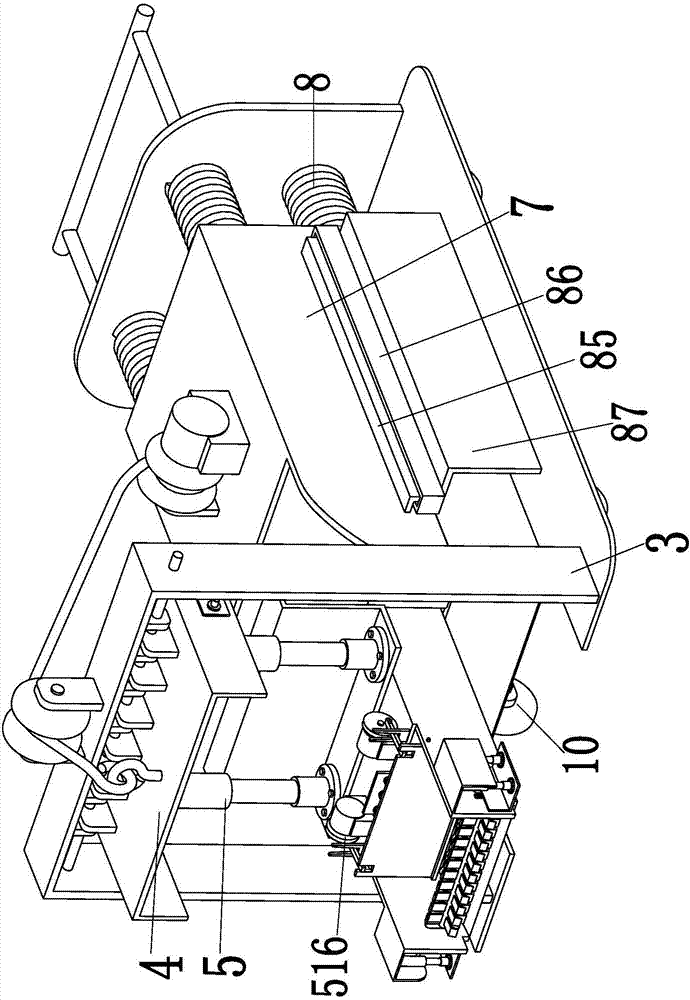

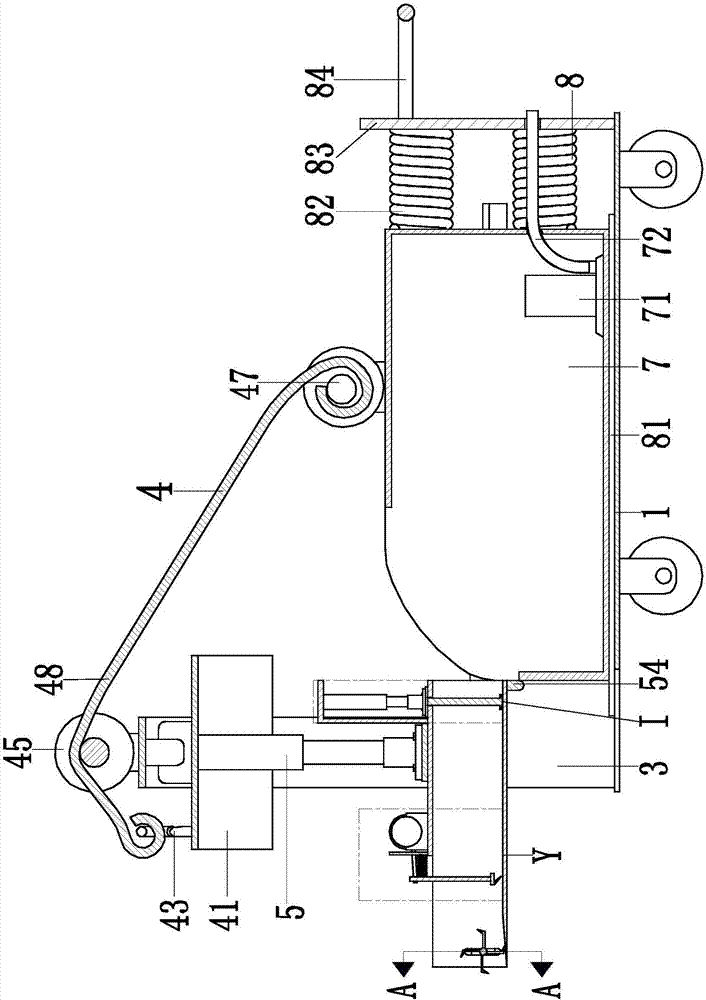

The invention relates to automatic soil remediation equipment for controlling soil contamination. The automatic soil remediation equipment for controlling soil contamination comprises a base plate. A moving mechanism is arranged at the lower end of the base plate. An oil fetching mechanism is arranged on the outer side of the left end of the base plate. A conveying mechanism which inclines from bottom to top is arranged at the left end of the base plate. A dispersing mechanism is arranged in the middle of the base plate and can be used for dispersing soil blocks in soil needing to be remediated so that the soil needing to be remediated can be remediated more comprehensively, and accordingly the soil remediation efficiency is improved. A spraying remediation mechanism is arranged at the right end of the base plate and can be used for treating the soil needing to be remediated, so that it is guaranteed that the soil needing to be remediated can make contact with soil remediating agents comprehensively, and working efficiency is improved accordingly. A flattening mechanism is arranged on the outer side of the right end of the base plate. By adoption of the automatic soil remediation equipment for controlling soil contamination, the function of mechanical and full-automatic soil remediation can be achieved, and manual operation is not needed; and the automatic soil remediation equipment for controlling soil contamination has the advantages of being easy to operate, high in working efficiency, low in soil remediation cost and the like.

Owner:黄江龙

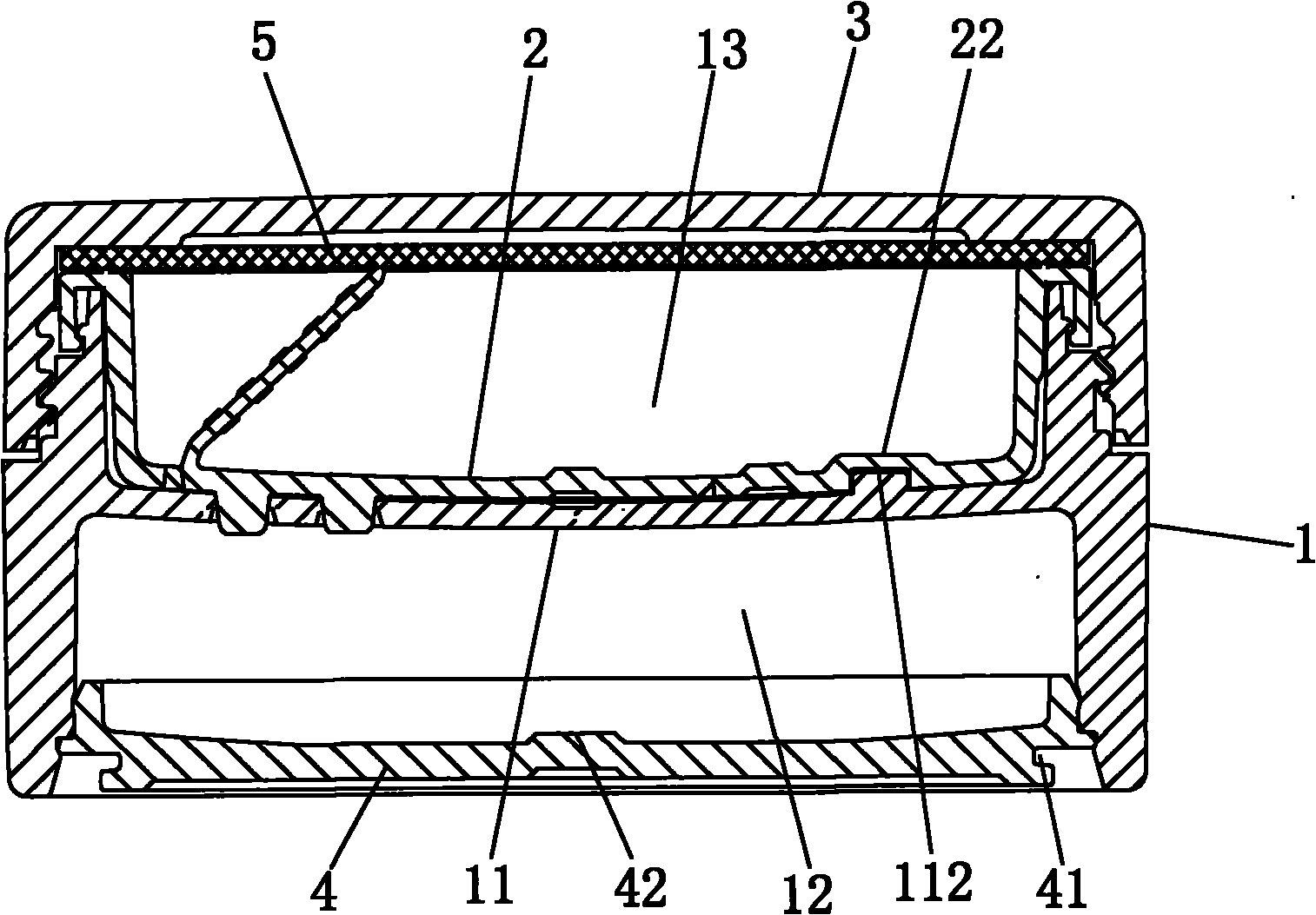

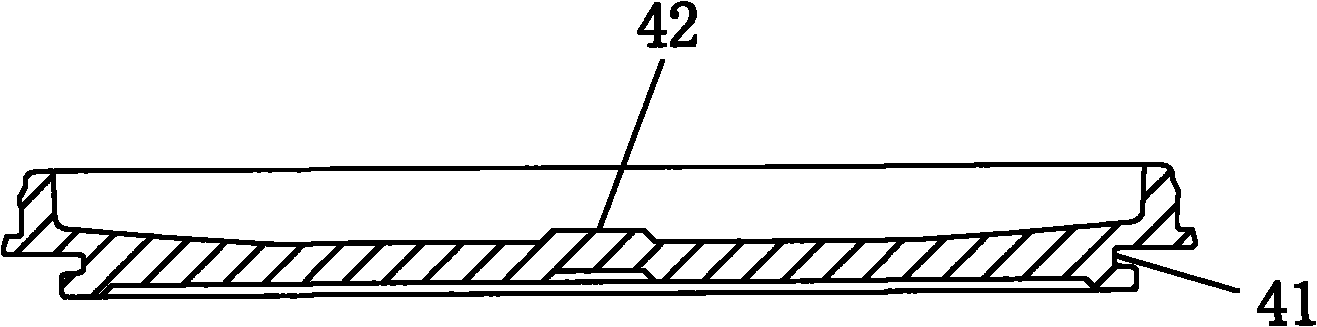

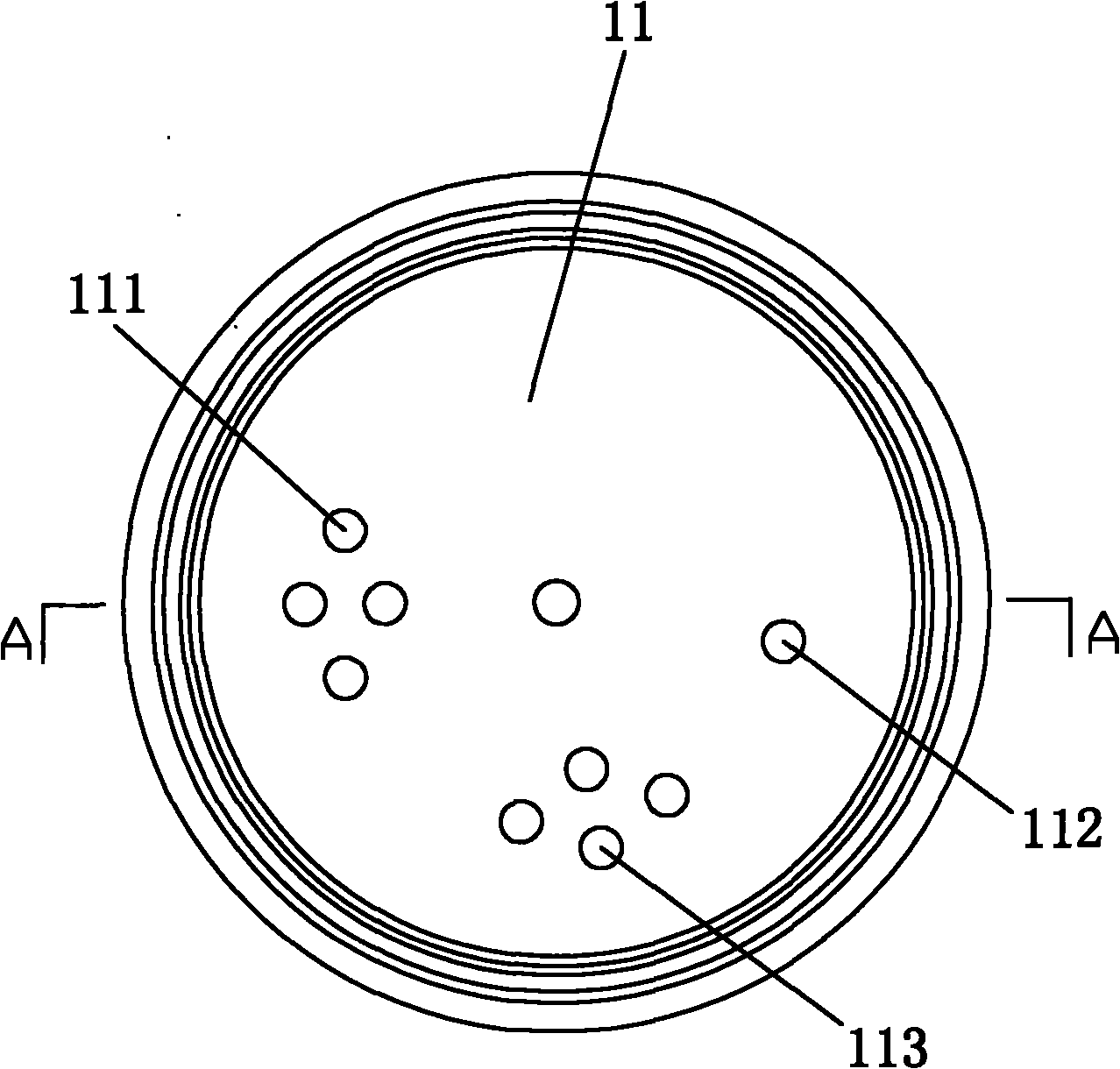

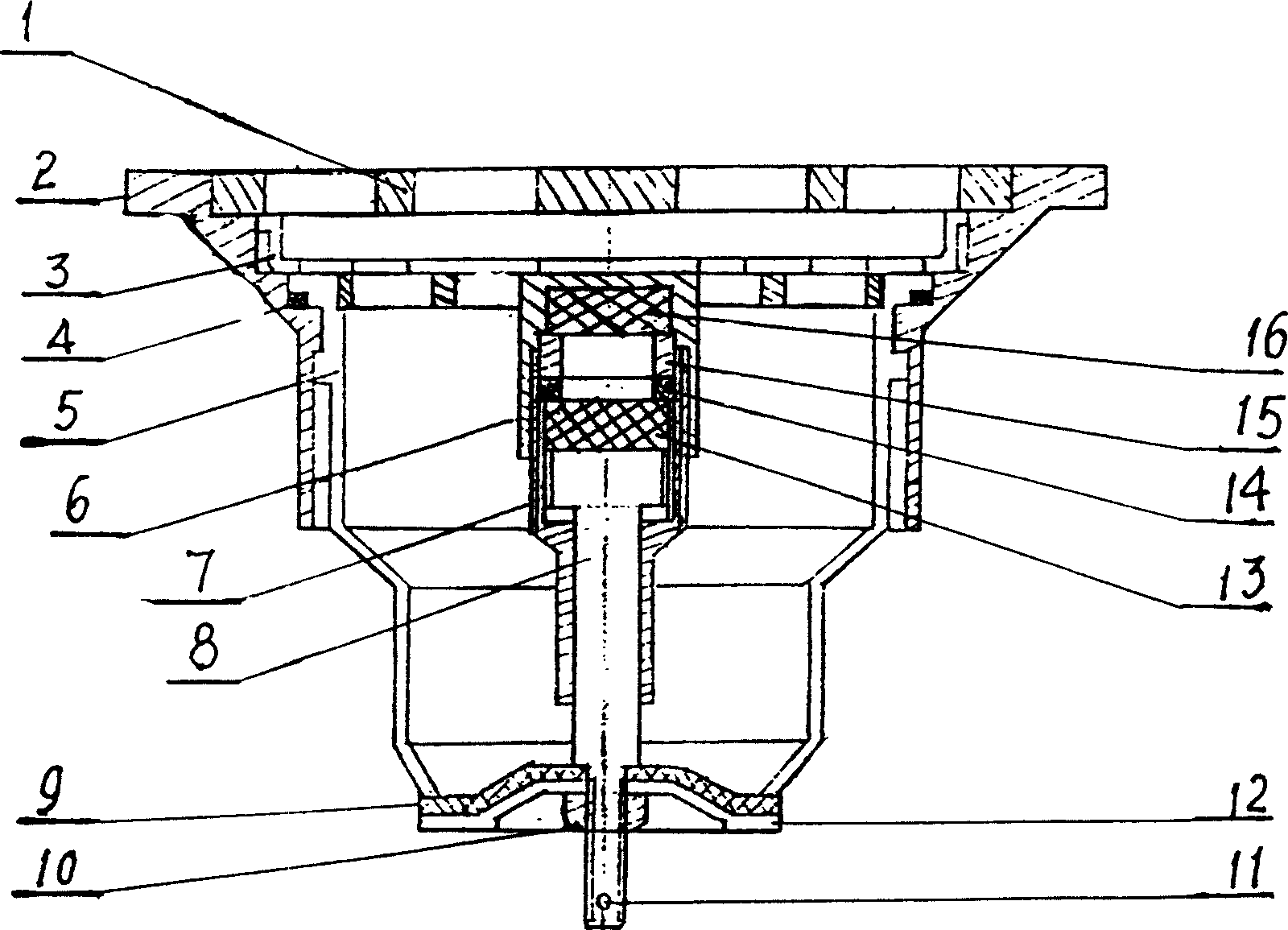

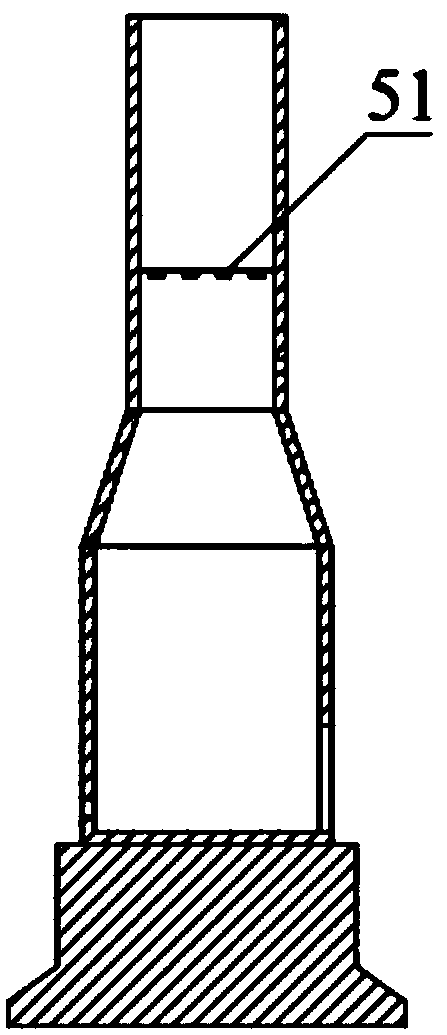

Improved structure of loose powder compact

ActiveCN101779858AWon't spillPackaging toiletriesPackaging cosmeticsMaterials scienceComposite material

The invention discloses an improved structure of a loose powder compact, which comprises a body, an inner sleeve and a cover. The use direction of the loose powder compact is taken as a standard; the body is of a hollow columnar shape, a lower end of the body is detachably fixed with a bottom plug, and the bottom plug can seal the lower end of the body; the upper part of the body is provided with a clapboard, and the clapboard divides the body into a loose powder accommodating cavity and a loose powder taking cavity; the inner sleeve is positioned in the loose powder taking cavity; the clapboard is provided with a plurality of clapboard powder outlets; the lower end face of the inner sleeve is provided with an inner sleeve powder outlet; the inner sleeve can fixedly rotate on the clapboard around a center of the inner sleeve, when the inner sleeve rotates at a position where the inner sleeve powder outlet is communicated with the clapboard powder outlets, the powder can be taken out; and when the inner sleeve seals the clapboard powder outlets, the powder cannot be spilled out in spite of shaking of the loose powder compact.

Owner:苏州洽兴塑胶有限公司

Automatic excrement cleaning machine for pig, cattle and sheep livestock breeding house special purpose

InactiveCN107135958AReduce labor intensityRealize the function of automatic cleaningAnimal housingFecesLivestock breeding

The invention relates to an automatic excrement cleaning machine for pigs, cattle, sheep and livestock pens, which includes a bottom plate, a support frame is installed on the bottom plate, a rotating conveying device is installed on the lower end of the supporting frame, a cleaning and collecting device is installed on the rotating conveying device, and a cleaning and collecting device is installed on the bottom plate. Rotary sweeping device, a collection box is installed on the upper end of the bottom plate, the collection box is connected with the adjustment device, the adjustment device is installed on the bottom plate, a cleaning device is installed on the collection box, a sweeping device is installed on the bottom plate, cleaning collection device, rotary conveying device, collection Box, adjusting device, cleaning device, rotary sweeping device and sweeping device cooperate with each other to complete the process of automatic cleaning of livestock manure. The invention can solve the problems of manual cleaning and collection of livestock pens in the cleaning process of existing small livestock pens, manual cleaning of livestock pens, manual cleaning of livestock pens, high labor intensity and low work efficiency, etc., and can realize livestock pens Automatic cleaning function.

Owner:安庆米锐智能科技有限公司

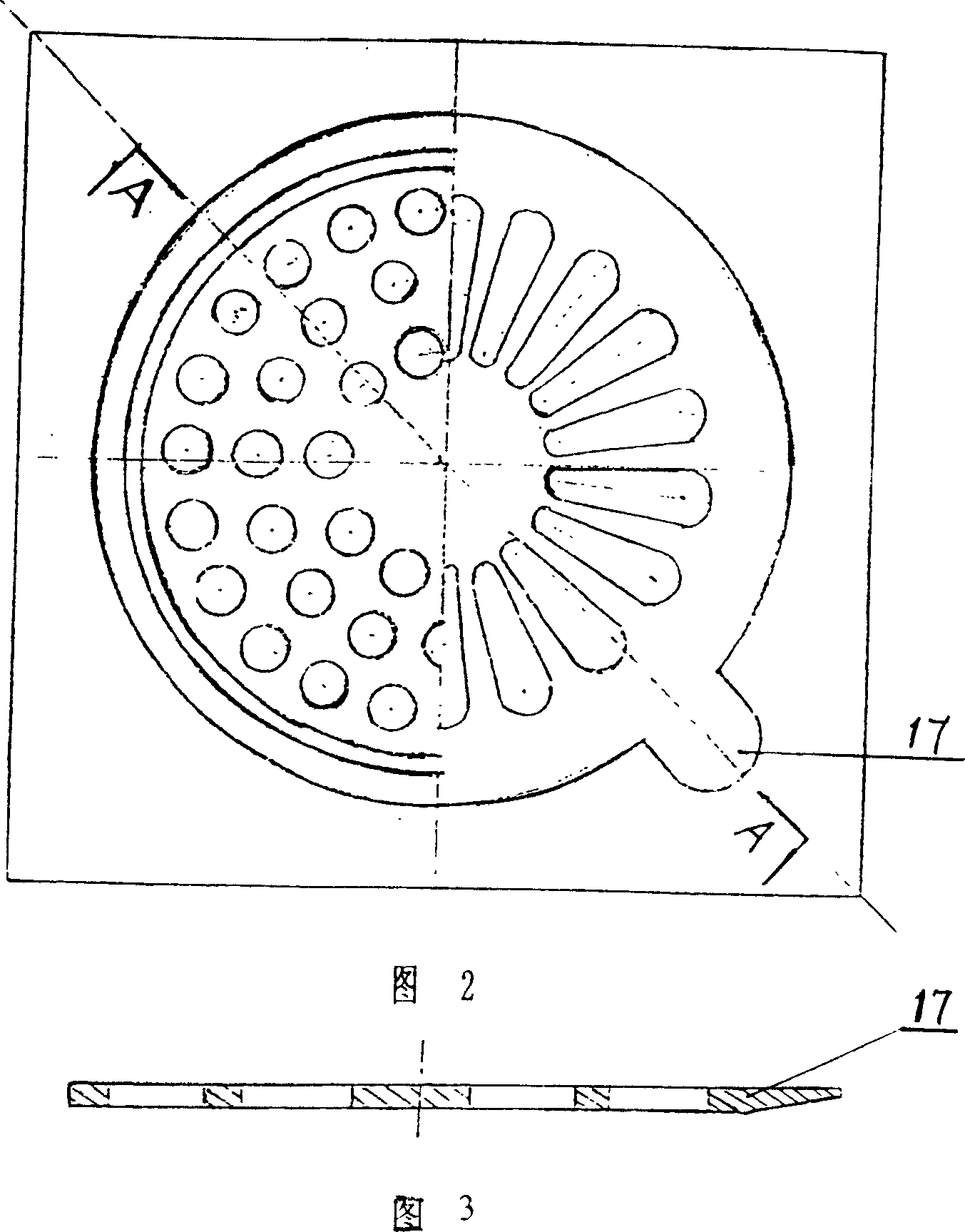

Self-sealing stinking-proof and anti-overflow floor drain

InactiveCN1667212AGuaranteed no water seal and deodorizationGuaranteed functionDomestic plumbingWater leakageEngineering

The invention relates to a self-sealed deodorization overflow-prevented floor drain. The principal part of the floor drain is set a bevel technology imbricated plate that has a knock-down block-type discharging pipe with tongue in it. There is sealed cushion at the bottom of the discharging pipe, and the dummy club matched to the tang on the inner wall of corresponding to the principal part of the floor drain is set outside of the pipe. Inner the discharging pipe there is discharging clamp plate with axial sleeve that has water leakage hole and an active discharging sewage storage pot. In the axial sleeve there is a clamp plate permanence magnet. The discharging clamp plate connects to the adjusting axial sleeve by screw. Lifting shaft is set in the adjusting axial sleeve and its top has lifting shaft permanence magnet. The self-sealed tie plate is connected to lining plank by locknut. The invention has a wide using foreground.

Owner:上海宝杨水暖洁具有限公司

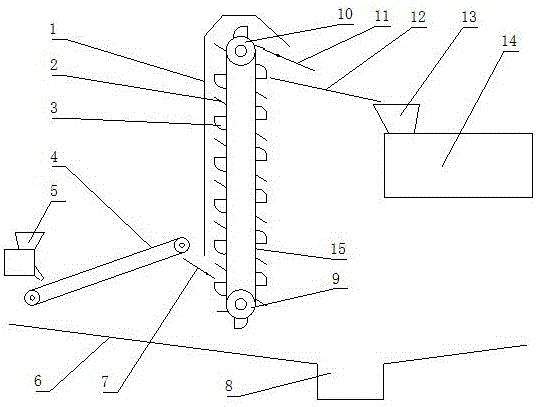

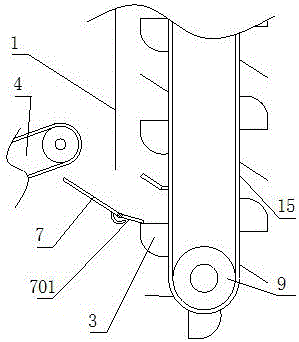

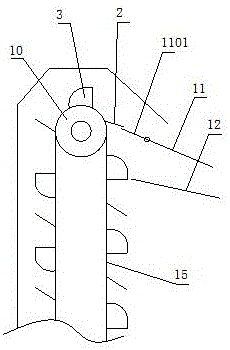

Broken glass feeding device

ActiveCN106494825AGuaranteed to fall intoBoost won't blockConveyorsConveyor partsEngineeringConveyor belt

The invention relates to a broken glass feeding device. A first guide plate is arranged between a breaking and feeding mechanism and a vertical lifting mechanism. A first movable plate located at the tail end of the first guide plate extends to the position above hoppers, and the effects that broken glass can drop into the corresponding hoppers and meanwhile the first movable plate cannot stop the hoppers and tilting plates from rising are guaranteed. A second guide plate is arranged between a discharging mechanism and the vertical lifting mechanism. A second movable plate located at the tail end of the second guide plate extends to the position below the tilting plates. When the hoppers get over the top end of a lifting conveyor belt, the broken glass can be discharged out of the hoppers to creep down onto the second movable plate and the second guide plate along the tilting plates, and meanwhile the second movable plate cannot stop the tilting plates and the hoppers from descending. Meanwhile, a second auxiliary guide plate is arranged below the second guide plate and used for receiving the broken glass falling off from the second guide plate and a small amount of broken glass falling off from the gaps between the tilting plates, and therefore the effect that the broken glass cannot be scattered is further ensured.

Owner:SHANDONG LEHE HOUSEWARES CO LTD

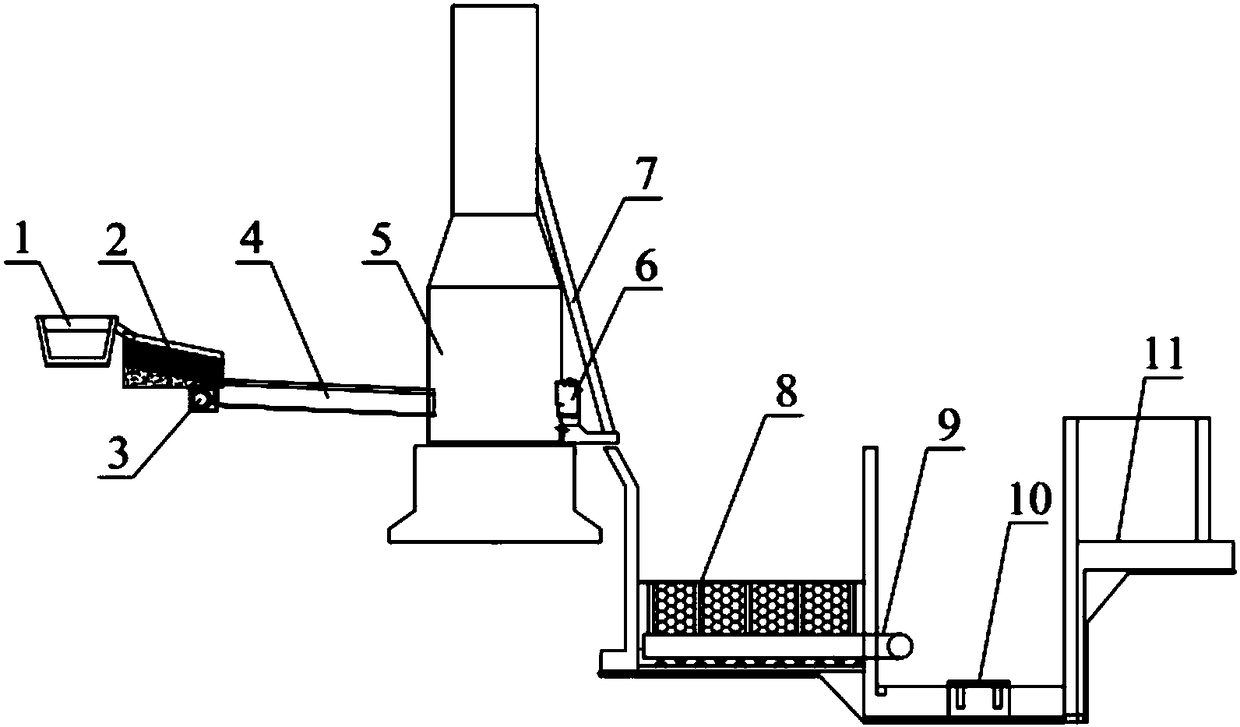

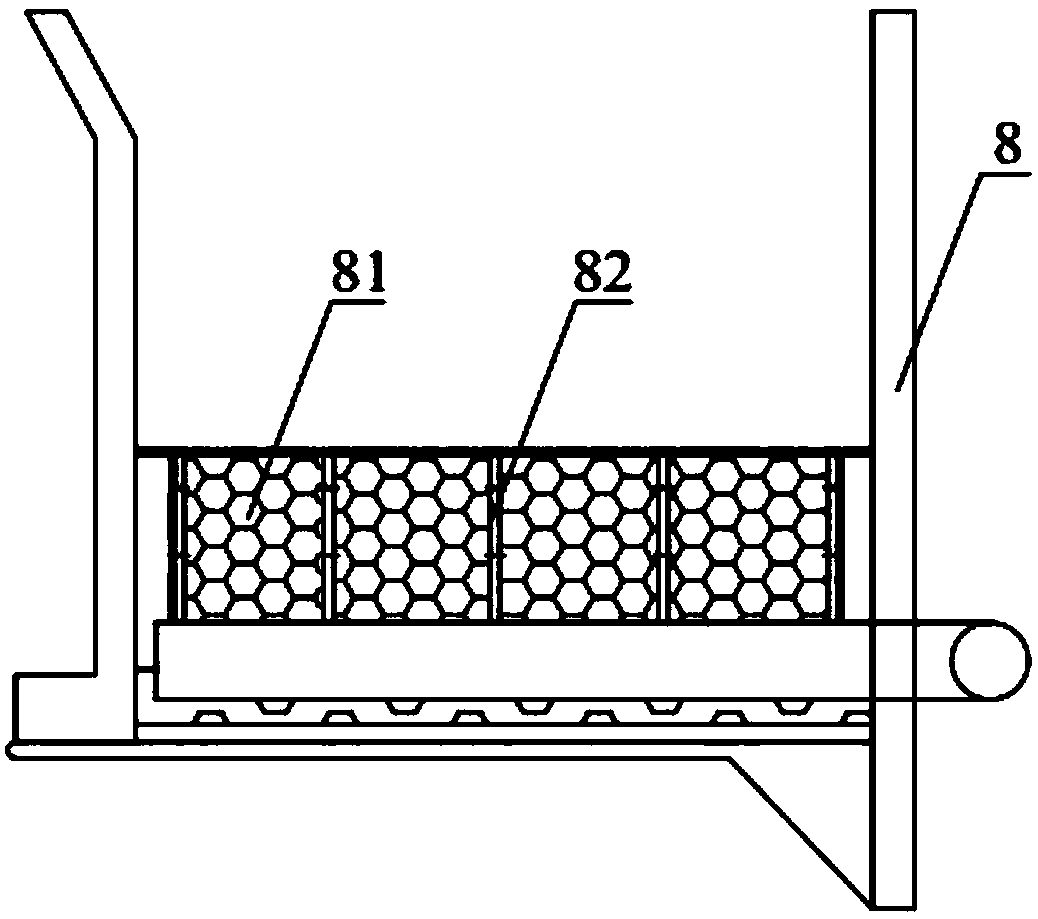

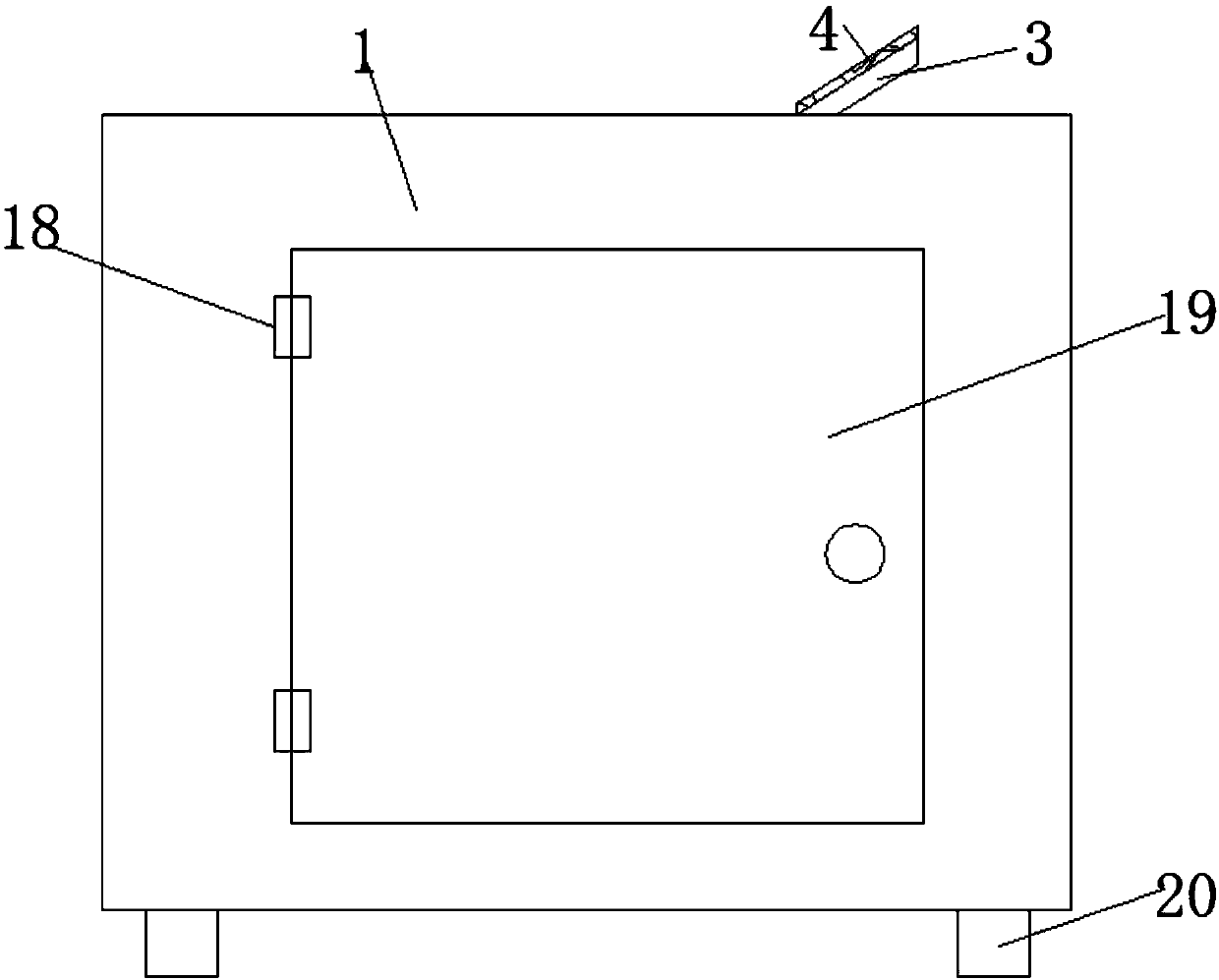

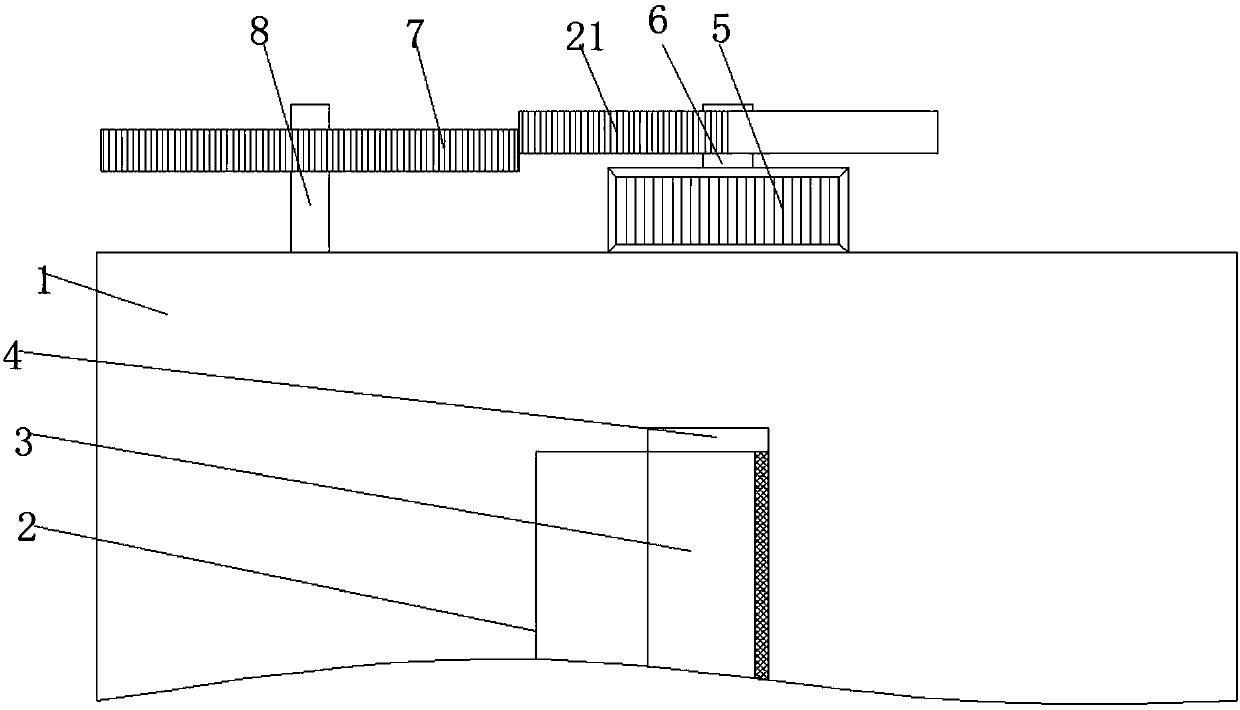

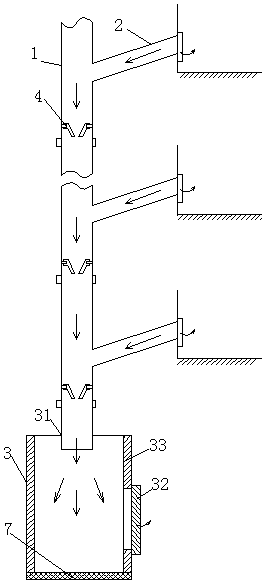

Garbage disposal combustion furnace and garbage disposal system

PendingCN107525082AReduce moisture contentTo achieve the goal of zero emissionsCombustion technology mitigationAir/fuel supply for combustionCombustion chamberFlue gas

The invention discloses a garbage disposal combustion furnace and a garbage disposal system. The combustion furnace comprises a furnace body, a blower is arranged on one side of the furnace body to ventilate a fire grate, a first combustion chamber and a second combustion chamber are sequentially arranged above the fire grate, a first secondary blower and a second secondary blower are arranged on the outside of the furnace body to ventilate the first combustion chamber and the second combustion chamber respectively, and full combustion of garbage and flue gas is facilitated. When temperature of the first combustion chamber reaches a preset value, an extraction pump extracts a garbage leachate from a leachate filter tank to spray to the first combustion chamber for gasification disposal, and the purpose of zero discharge of the garbage leachate is achieved; after the garbage is combusted in the first combustion chamber, flue gas enters the second combustion chamber for secondary high-temperature combustion, harmful substances in the flue gas are fully pyrolyzed, the flue gas combusted is disposed through a flue gas disposal part, generation of dioxin can be greatly reduced, and the flue gas finally discharged is allowed to meet the national discharge standard.

Owner:珠海市云筒环保设备有限公司

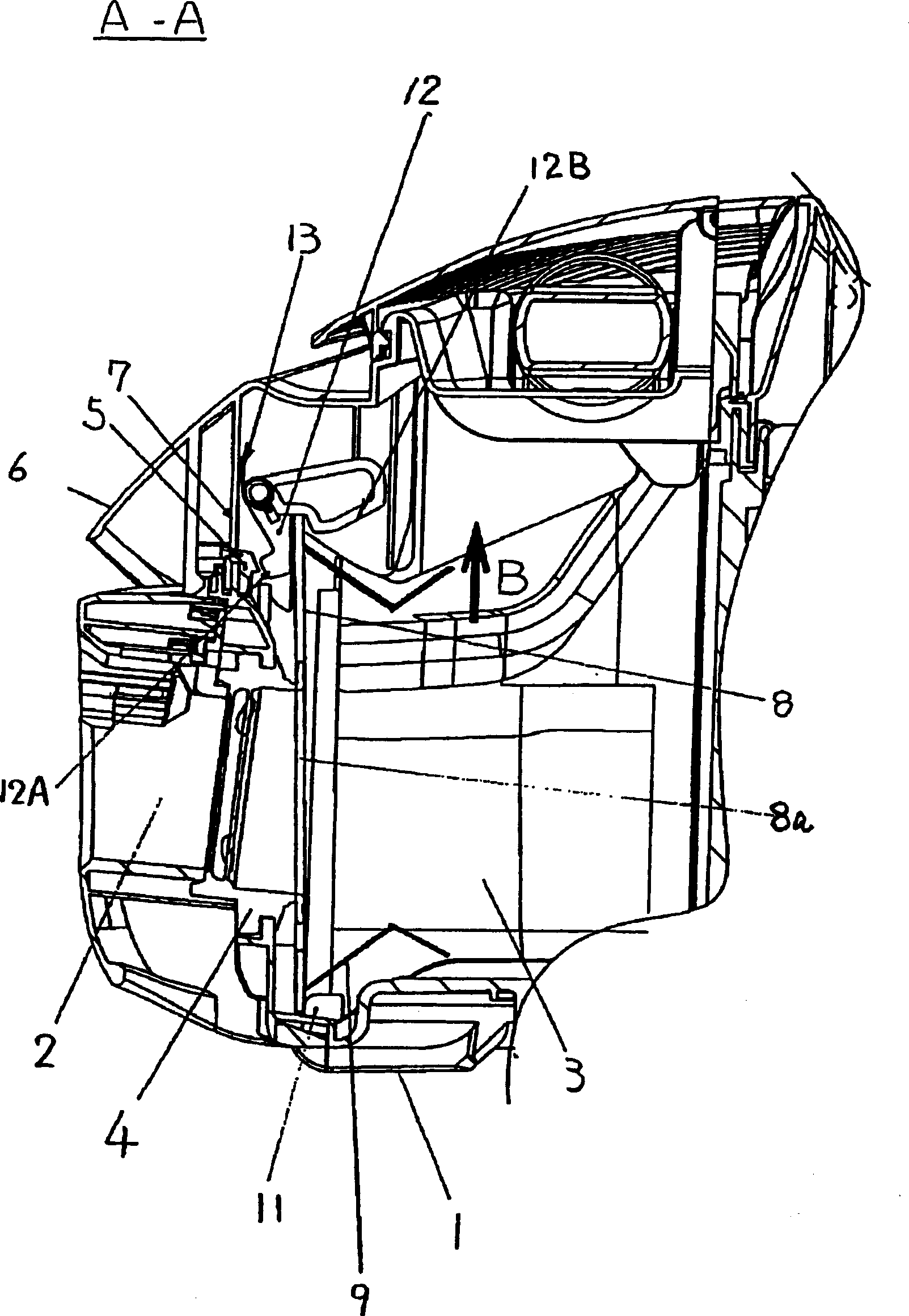

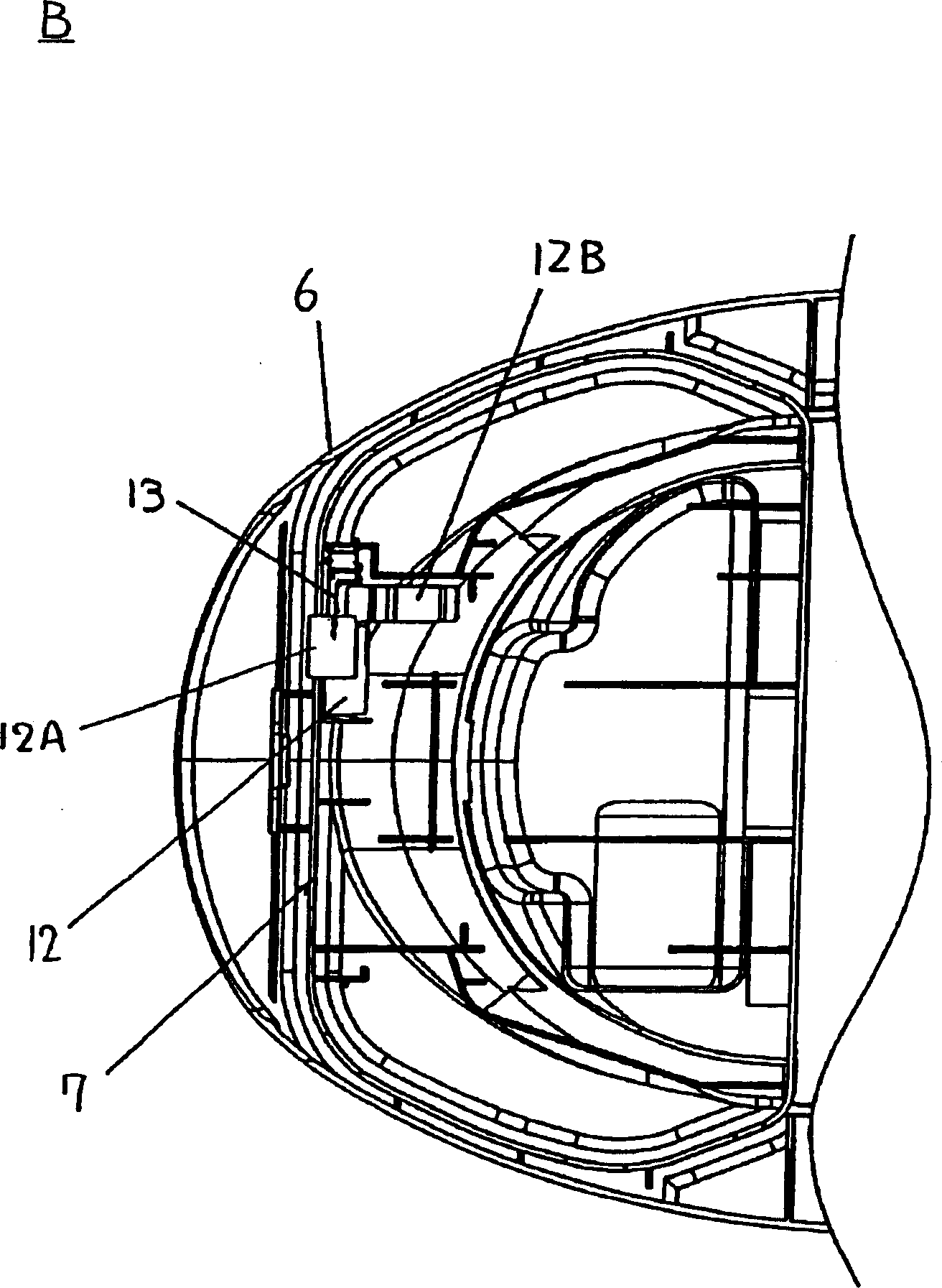

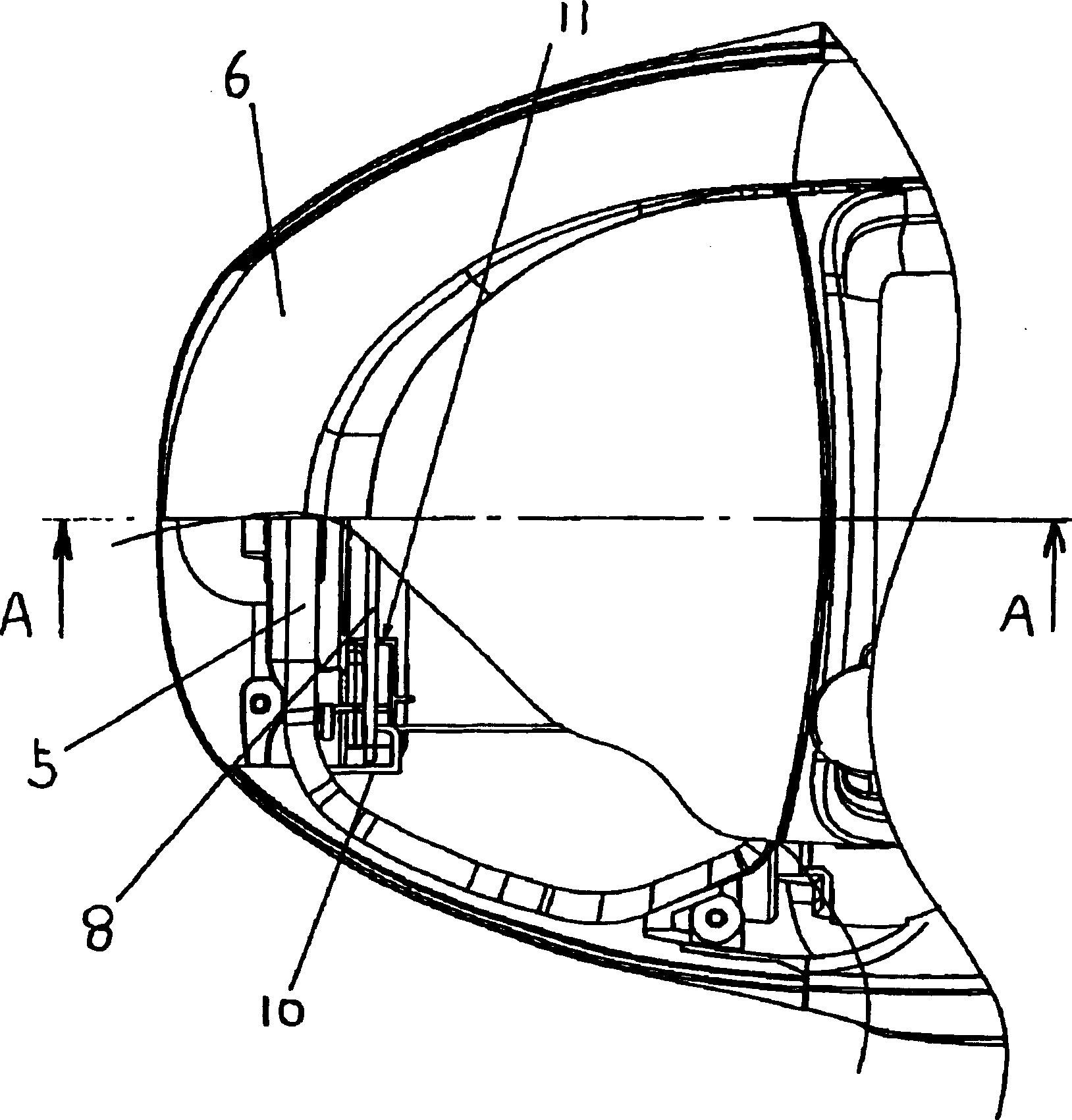

Electric vacuum cleaner

ActiveCN1860984AEasy to assemble and disassembleEasy to useElectric equipment installationEngineeringVacuum cleaner

The invention provides a vacuum cleaner which can not only prevent the dust collecting bag from being started by mistake, but also make the dust collecting bag easy to assemble and disassemble. A dust collecting bag (9) with a sack coaming plate (8) and a machine cover (6) covering the top of the dust collecting chamber in a rotatable manner. The dust bag detection body (12) is provided on the machine cover, and the dust collection bag detection body is provided with: a raised part (12A) to prevent the machine cover from entering the closed state when the dust collection bag is not installed in the dust collection chamber, and A detection part (12B) for detecting that the dust bag has been loaded into the dust chamber. When the detecting part detects that the dust collecting bag has been loaded into the dust collecting chamber, the protruding part is displaced to a position where the machine cover enters a closed state. In this way, not only can prevent the machine cover from being closed by mistake when the dust bag is not installed, but also, the assembly and disassembly of the dust bag can be carried out by only one action, and the assembly and disassembly will become easy.

Owner:PANASONIC CORP

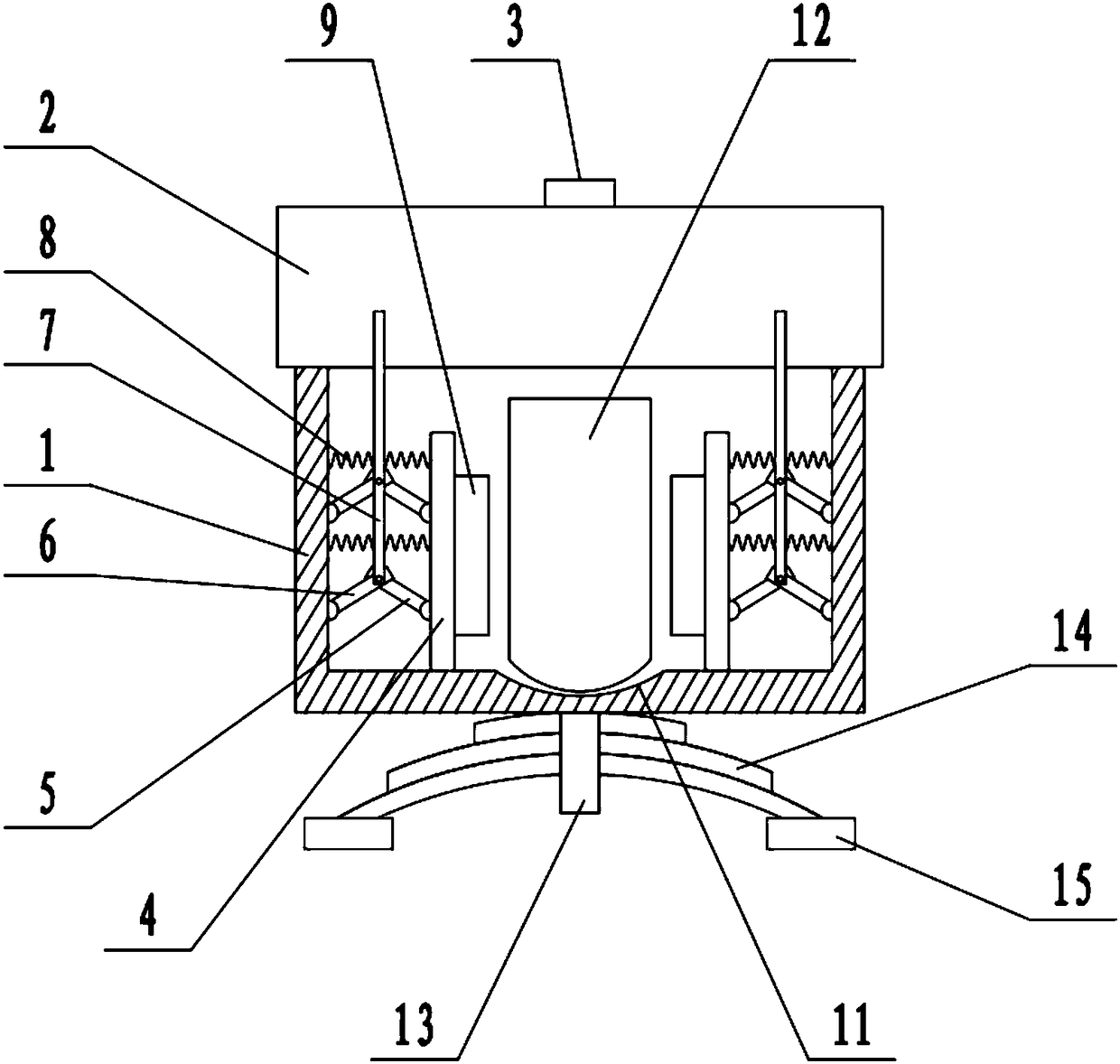

Sample storage box for gene detection

InactiveCN108569472AAvoid leaningEasy to take outContainers to prevent mechanical damageRigid containersEngineeringLeaf spring

The invention discloses a sample storage box for gene detection. The sample storage box comprises a box body, a box cover, a test tube and fixing blocks, wherein the box cover is hinged to the top ofthe box body; moving plates are arranged in the box body; a linkage device is arranged between each moving plate and the inner wall of the box body and comprises first connecting rods, second connecting rods and a moving rod, the first connecting rods are hinged with the side wall of the moving plate, the other ends of the first connecting rods are hinged with the second connecting rods, the otherends of the second connecting rods are hinged with the inner wall of the box body, and the moving rod is hinged to the joints of the first connecting rods and the second connecting rods. The test tube is placed in the box body, a certain damping action can be realized by means of leaf springs, the test tube is protected, after the box cover is closed, the test tube is tightly clamped by clampingplates, keeps stable and is prevented from being inclined, a sample in the test tube cannot be splashed due to inclination of the test tube, when the test tube is required to be taken out, the box cover is opened, the moving plates are driven under the action of tension springs to move towards the two sides, and the clamping plates and the test tube are separated accordingly.

Owner:青岛瑞思科生物科技有限公司

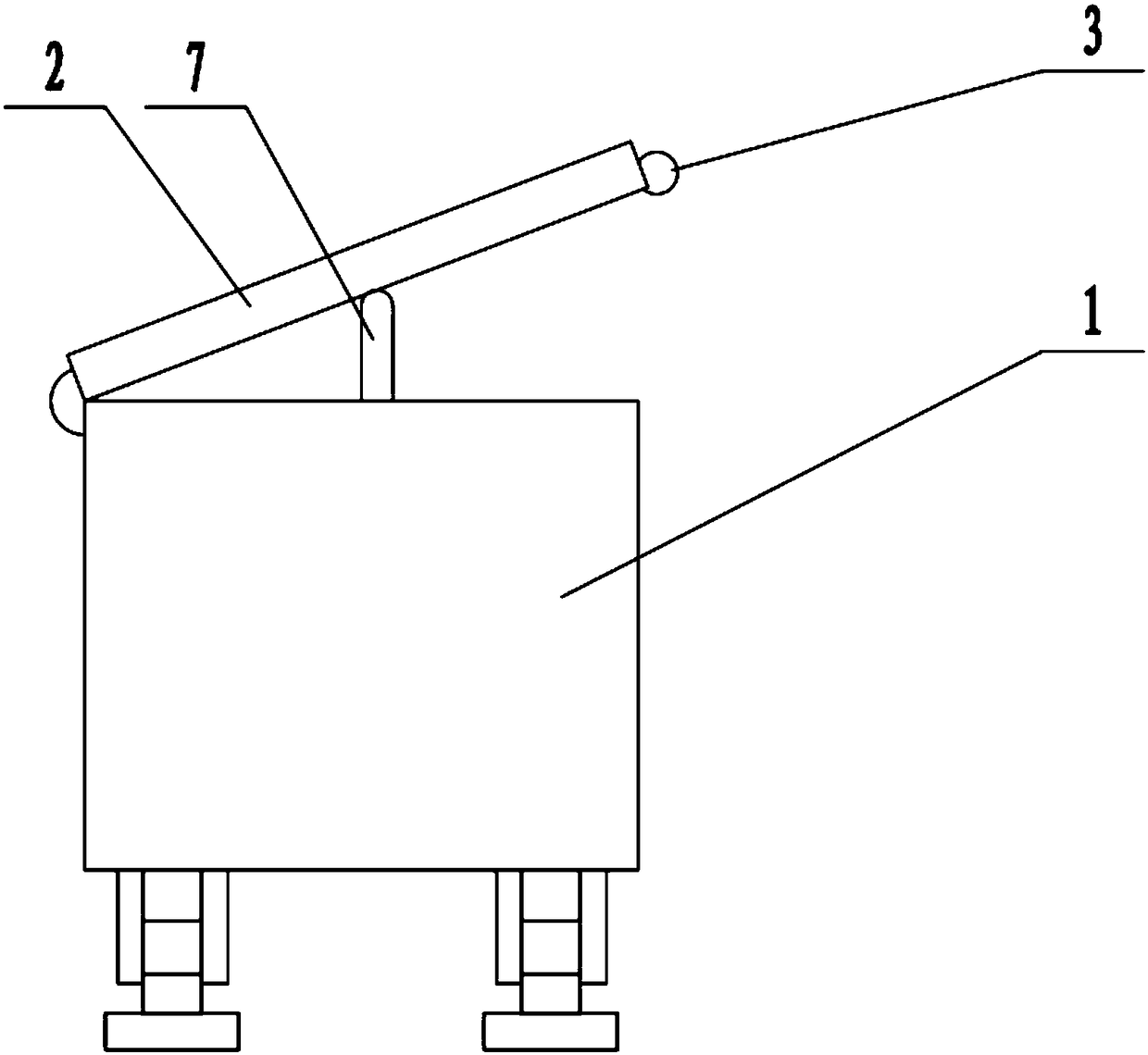

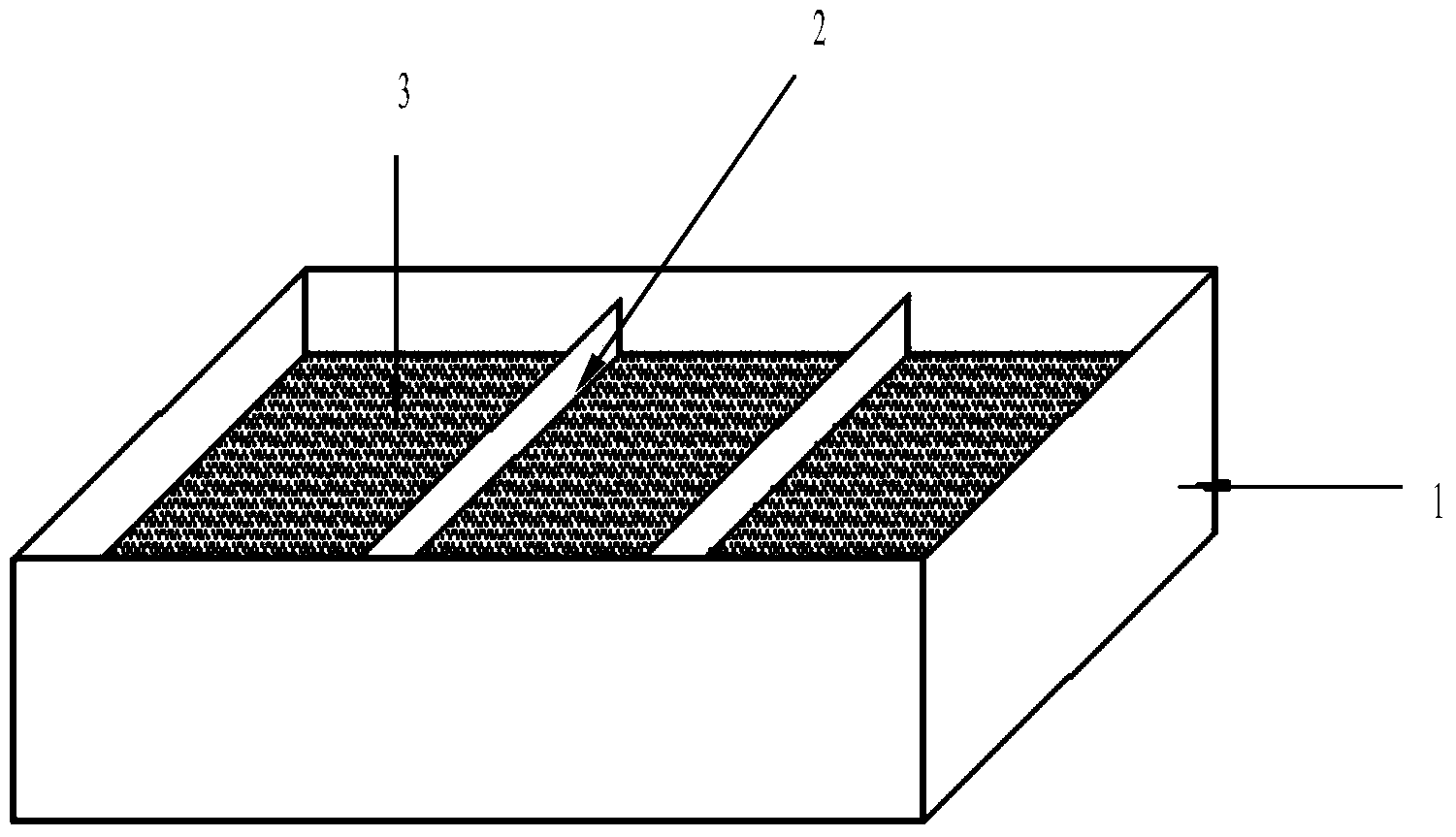

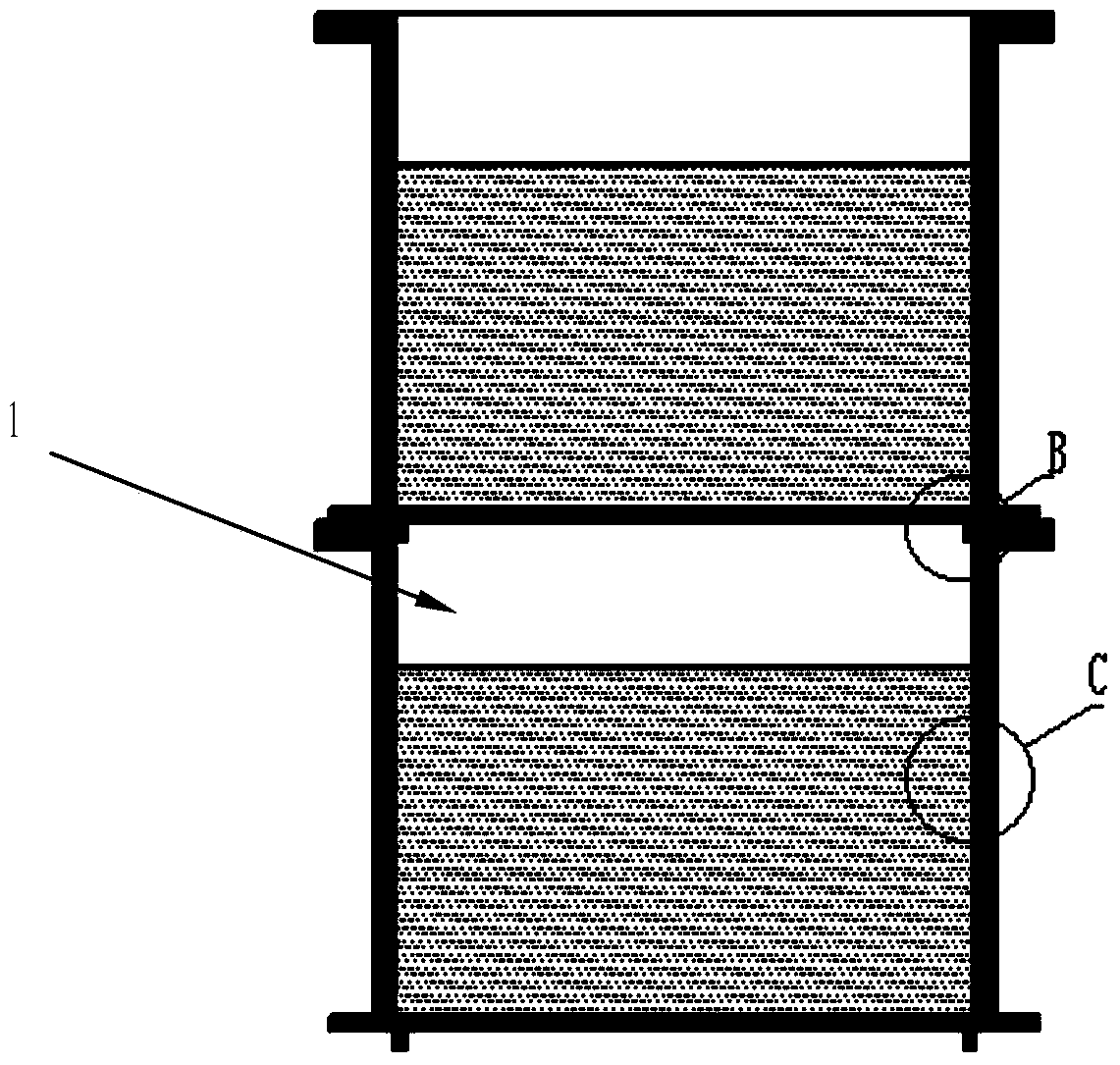

Waterlogged sponge energy absorption and vibration attenuation device

ActiveCN103590503AIncrease frictional resistanceHigh damping efficiencyShock proofingAbsorption effectEngineering

A waterlogged sponge energy absorption and vibration attenuation device comprises a water tank, a plurality of partition plates and sponges, wherein the water tank is divided into a plurality of blocks by the partition plates, through holes are formed in the bottoms of the partition plates, and the blocks are filled with the sponges. Compared with a traditional tuned liquid damper, the waterlogged sponge energy absorption and vibration attenuation device has the advantages that water flows back and forth in pores of the sponges in the process of fluctuation, the friction resistance is larger, and vibration attenuation efficiency is higher due to particularities, namely, the porosities, of the sponges in structure; meanwhile, due to the water absorption effect of the sponges, the water in the vibration attenuation water tank can not splash because of fluctuation, the water tank is filled with the water, and the water tank space can be utilized more effectively.

Owner:TSINGHUA UNIV

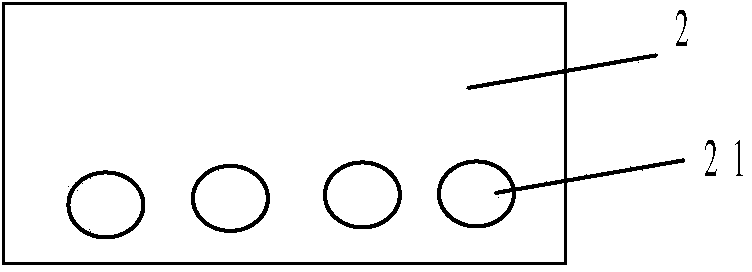

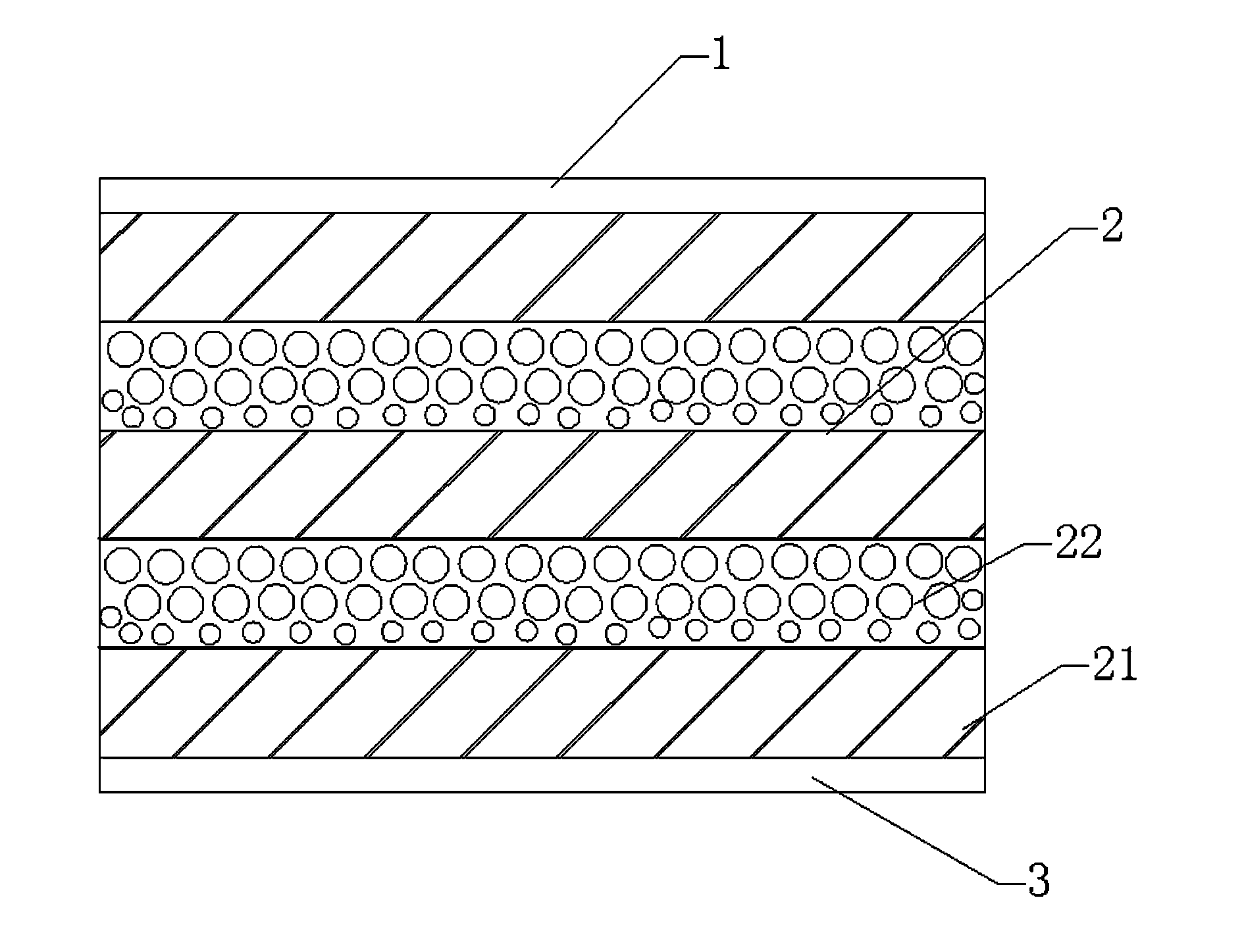

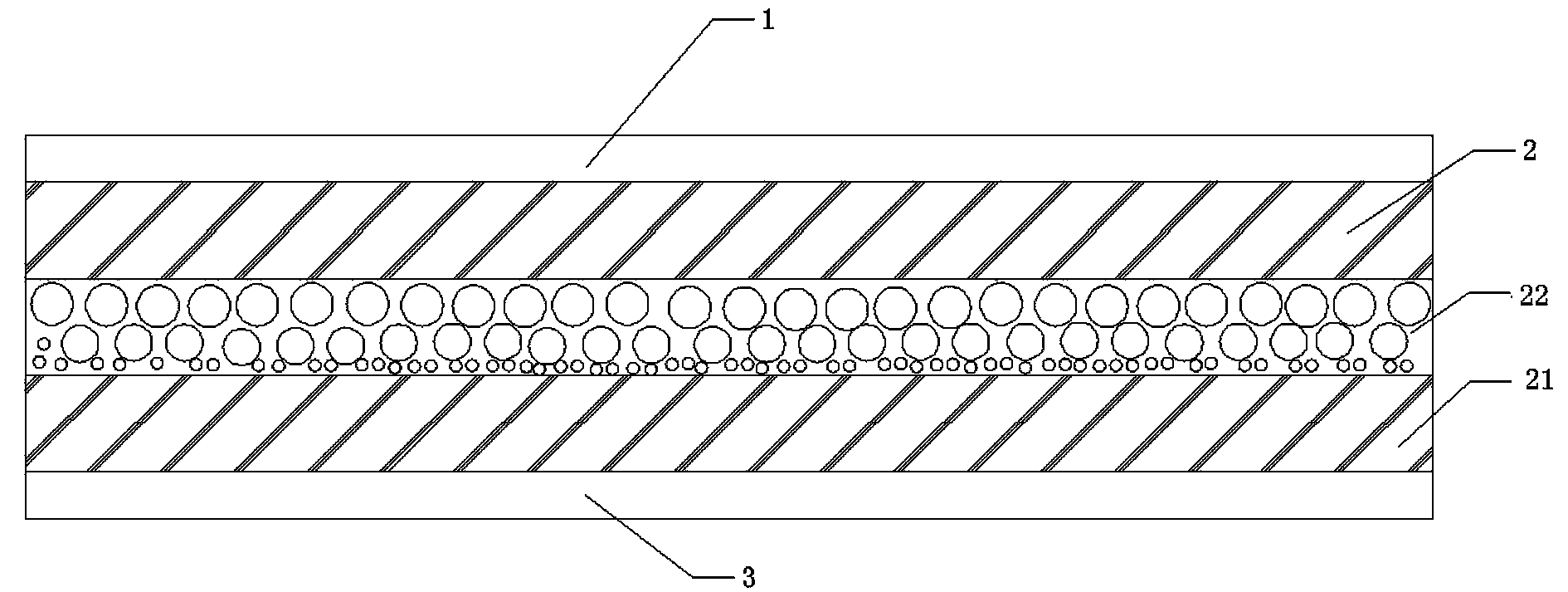

Water-absorption core body for hygienic product and production technology thereof

The invention provides a water-absorption core body for a hygienic product. The water-absorption core body for the hygienic product comprises an upper isolating layer, a water absorption layer and a lower isolating layer, wherein the water absorption layer is formed by more than two instantaneous absorption layers and more than one water locking layer in a vertically stacked mode, and the instantaneous absorption layers are arranged on the top layer and the bottom layer of the water absorption layer respectively; each instantaneous absorption layer comprises, by weight, 50-90% of wood pulp fibers and 10-50% of adhesives, and the wood pulp fibers and the adhesives are mixed to form the instantaneous absorption layers; each water locking layer is formed by macromolecule water absorption particles, and the weight of the macromolecule water absorption particles accounts for 15-75% of the weight of the water absorption layer; the upper isolating layer or the lower isolating layer is made of ES fiber layers or dust-free paper or non-woven fabric. According to the water-absorption core body for the hygienic product, due to the fact that the upper isolating layer and the lower isolating layer are adopted, wood pulp dust cannot be generated in the production process, and the water absorption particles cannot easily go out; due to the fact that combination between the instantaneous absorption layers and the water locking layers is adopted, the water absorption speed is high, the quantity of absorbed water is large, water locking performance is good, and the dry and clean state can be kept all the time.

Owner:浙江振宇吸水材料科技有限公司

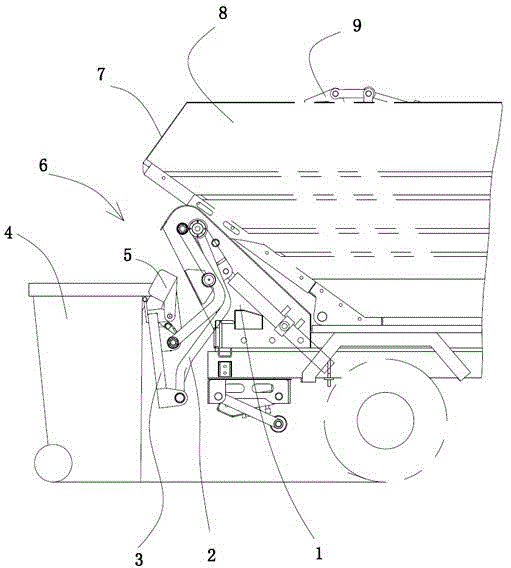

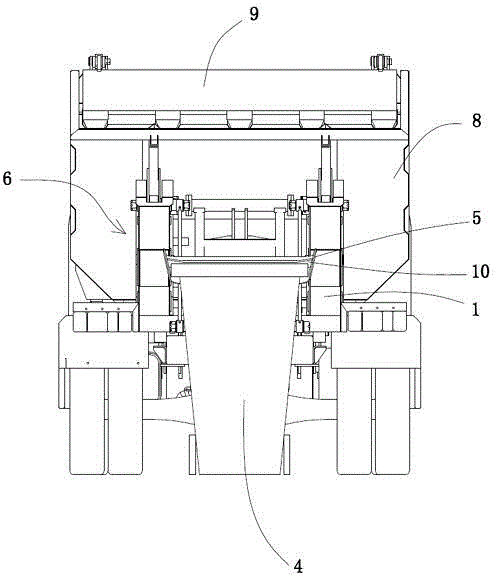

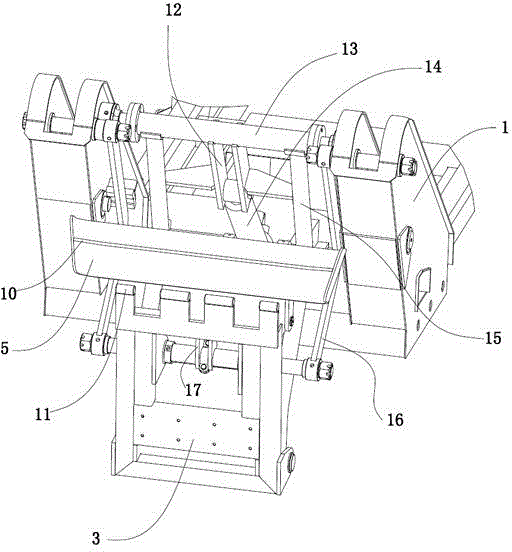

Novel self-loading and-unloading mechanism

The invention relates to a novel self-loading and unloading mechanism. The novel self-loading mechanism comprises a support fixed on a vehicle, wherein two rotating arms with different linear lengths are hinged between the support and a base; a hydraulic cylinder is hinged between one of the rotating arms and the support; the two rotating arms are matched with each other to drive the base to overturn; a garbage bin hanging plate is arranged on the base; a garbage bin pressing plate is further hinged to the base; a rotary push rod is fixed on the garbage bin pressing plate; a garbage bin hanging cam is fixed on the rotating arm corresponding to the rotary push rod; the garbage bin hanging cam is matched with the rotary push rod to drive the garbage bin pressing plate to rotate and is matched with the garbage bin hanging plate to achieve clamping operation. The garbage bin hanging cam is matched with the rotary push rod to enable the garbage bin pressing plate to rotate around a hinge position so as to achieve mutual approach or departure between the garbage bin pressing plate and the garbage bin hanging plate; the garbage bin pressing plate approaches the garbage bin hanging plate to clamp the upper edge of a garbage bin; in the rotating and lifting process of the base, a clamping force always exists, so that the garbage bin does not swing and the steadiness of the garbage bin is improved.

Owner:ZHONGQI COMML VEHICLE CO LTD HANGZHOU

Freezing setting machine for shoes and boots

The invention discloses a freezing setting machine for shoes and boots. An evaporator is arranged on the inner face of a top plate of the freezing setting machine, an air flow channel is preinstalled on the upper half portion of the center of the freezing setting machine, a cooling exhaust fan is arranged on the lower half portion of the center of the freezing setting machine, a freezing system cools down air in the air flow channel and the air is blown downwards to a U-shaped conveying crawler belt which is in a shape that the center is lower than two sides, the crawler belt is formed by connecting two ends of a plurality of placing plates of triangle plates in series through chains, the tip end of the triangle plate faces upward, the crawler belt rotates repeatedly in a direction along a corresponding rail through a gear set, space is reserved between the placing plates, and a reversed-n-shaped spacing plate in a shape that the center is lower that two sides is arranged in the center of the crawler belt and abuts against the crawler belt. The freezing system lowers the temperature of the air in the air flow channel, then the air converts into cold air and is blown out downwards through the cooling exhaust fan, with the cooperation of the U-shaped conveying crawler belt, a shoe body which is sent in is lowered from high to low to a low point in the center, the cold air naturally gathers in the center, speed of the low-temperature setting of the shoe body is accelerated, local very low temperature is provided, and a freezing circulation effect is improved.

Owner:CHUAN CHYI MACHINE

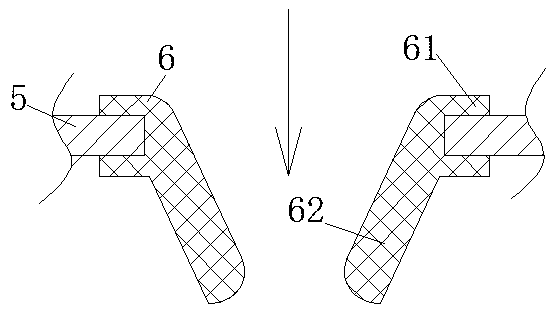

Bottom-filtration-process slag treatment method for ferroalloy submerged arc furnace

ActiveCN108220511AImprove granulation effectReduce generationRecycling and recovery technologiesPunchingFiltration

The invention discloses a bottom-filtration-process slag treatment method for a ferroalloy submerged arc furnace and belongs to the technical field of ferroalloy submerged arc furnace. The method comprises the following steps of making molten slag overflow into a molten slag ditch via a slag tank; performing crushing, water quenching and pelletizing on the slag which flows from the molten slag ditch into a waste slag ditch by high-speed water flow sprayed out of a punching box; making a slag and water mixture flow from the water granulated slag ditch into a buffer tower and continuing to coolthe slag and water mixture; making the slag and water mixture inside the buffer tower directly flow into a filter tank via an outlet device; filtering the water inside the filter tank by using a filter pipe, and conveying the water to a slag treatment water pool by using a water pump; conveying the water inside the water pool to the punching box in order to realize slag punching and cyclic utilization; and grabbing out the water granulated slag from the filter tank by using a water granulated slag grabbing hopper. The method disclosed by the invention is simple in process and reasonable in procedures, commendably guarantees the granulation degree of the slag, realizes more complete slag and water separation, greatly reduces emission of steam, reduces environmental pollution and realizes simple industrial implementation.

Owner:马钢集团设计研究院有限责任公司

High water-soluble povidone-iodine cream

InactiveCN1454602AQuality improvementNot volatilePharmaceutical non-active ingredientsSynthetic polymeric active ingredientsSolubilityPolymer science

The invention is a kind of high water-solubility povidone iodine film agent, it is made from povidone iodine and high water-solubility filming material polyethylene alcohol, the weight ratio is 1:1-1:100, the polyethylene alcohol is selected from the first class polyethylene alcohol by which the film agent is made up, the film agent can be dissolved in half an hour at 37 deg.C, such as polyethylene alcohol 05-88, 04-88, and the compound of them at any rate. The manufacturing method is: the povidone iodine is added to the water and heated to 40-100 deg.C, after it is dissolved, the polyethylene alcohol and plasticizer are added and heated under 80-100 deg.C for an hour, they are dissolved evenly; they are cooled to 40-70% and are mixed to remove bubbles, then they are placed on the board, they are dried under 60-100 deg.C for 30-60 minutes, removes the film and slices them into pieces.

Owner:李勤耕

Prestressed concrete wet joint construction robot capable of realizing automated dabbing and slotting

InactiveCN107858933AReduce labor intensityEasy to moveBridge erection/assemblyBuilding material handlingArchitectural engineeringPrestressed concrete

The invention relates to a prestressed concrete wet joint construction robot capable of automatic chiseling and grooving. The lower end of the adjustment device is provided with a chisel and slotting device, and the lower end of the chisel slotting device is provided with a crushing and recycling device. The flange is installed on the lifting support plate, the middle part of the lifting support plate is provided with a lifting hole, the lifting hole is provided with a lifting drive mechanism, and the upper end of the lifting drive mechanism is provided with a lifting fixing mechanism. The present invention can solve the problem existing in the existing wet joint chiseling and grooving process that requires manual construction with the help of existing chiseling equipment, and manually controls the chisel construction according to the depth of the joint, and can realize automatic chiseling of wet joint construction function of the slot.

Owner:吴丹

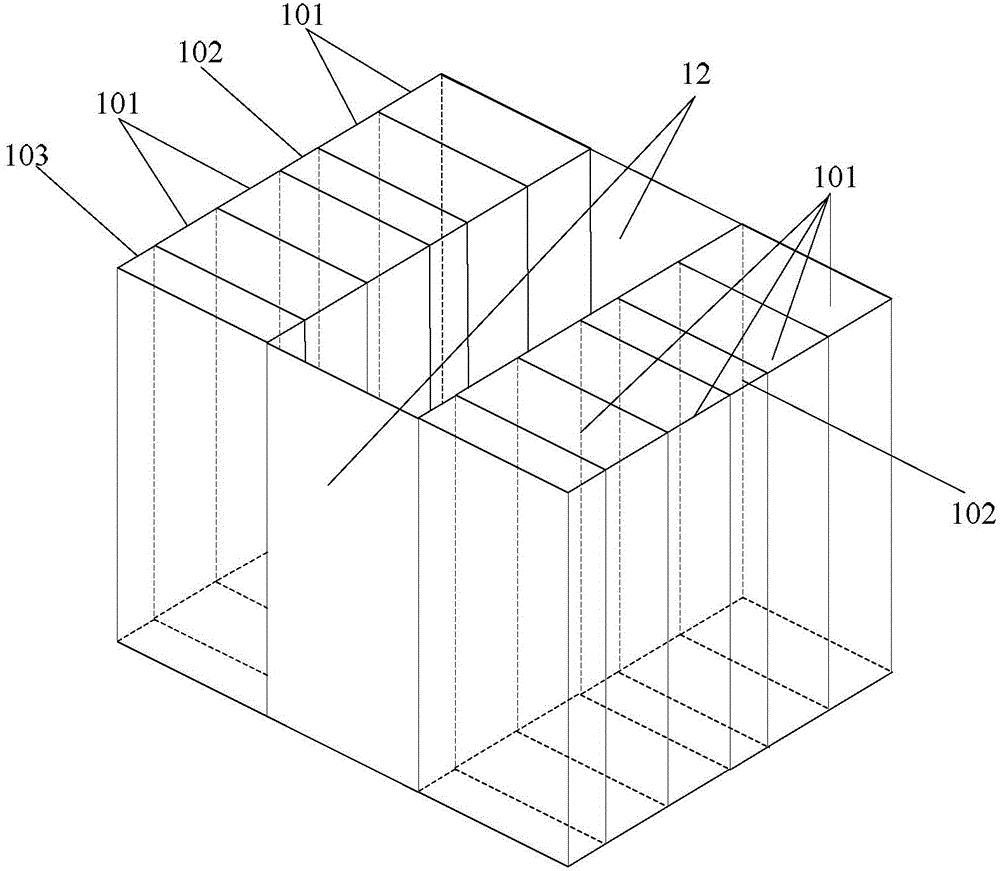

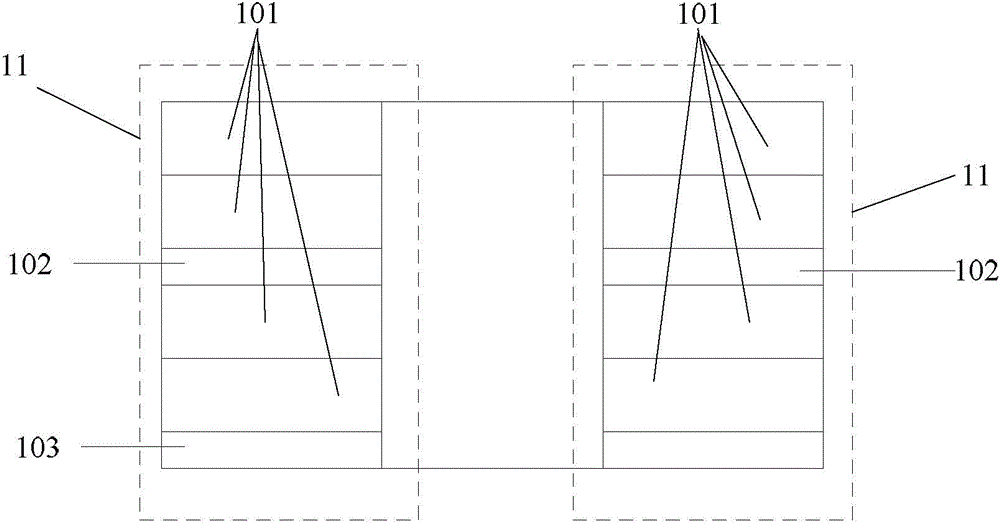

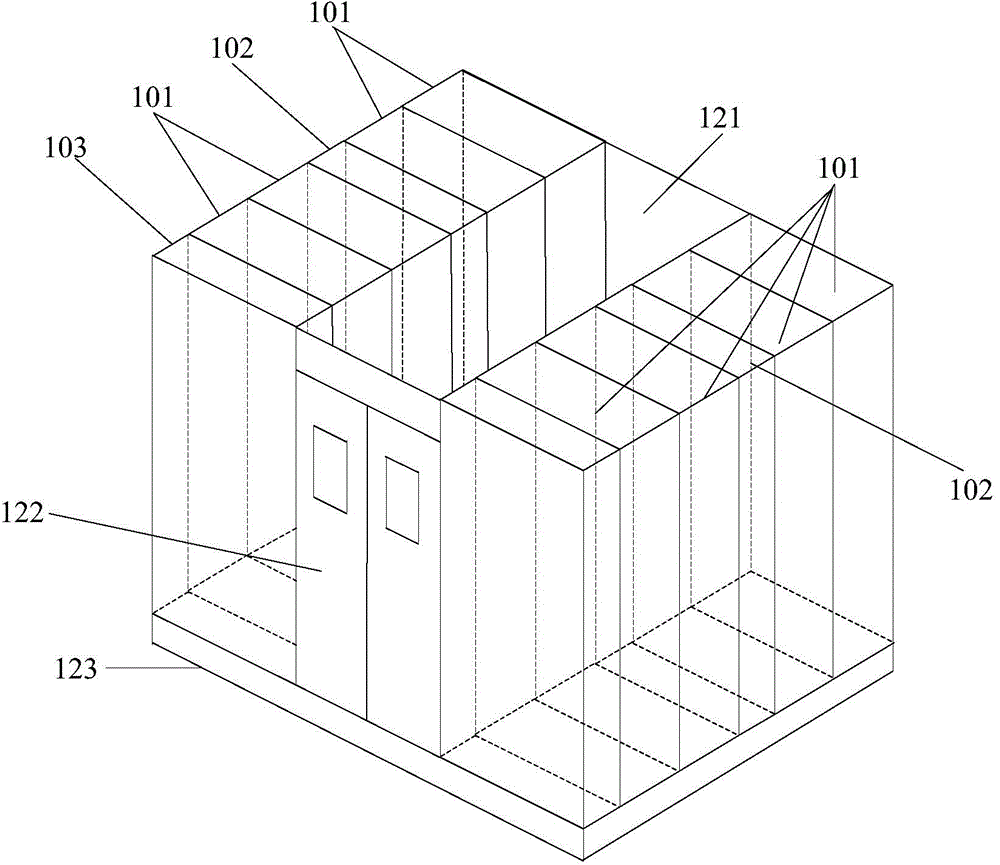

Modularized data room

ActiveCN105275232AIncrease or decrease quantityMeet application needsDucting arrangementsServersElectronic systemsModularity

An embodiment of the invention discloses a modularized data room. The modularized data room comprises a data cabinet sub-system, a cooling sub-system, and a power distribution sub-system. The data cabinet sub-system comprises two rows of data cabinet groups. Each row of data cabinet group comprises at least a data cabinet. The cooling sub-system comprises at least a cooling unit. The at least a cooling unit is arranged in the two rows of data cabinet groups. The at least a data cabinet and the least a cooling unit are provided with interfaces connected with the power distribution sub-system, and are connected with the power distribution sub-system through the interfaces. The modularized data room also comprises a closed sub-system. The closed sub-system seals channels between the two rows of data cabinet groups to make the channels be cold / hot channels.

Owner:ZTE CORP

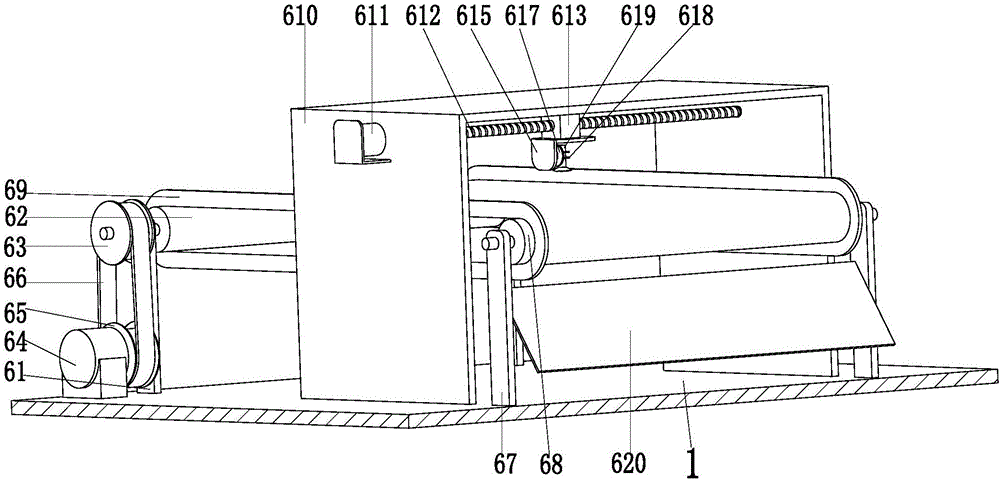

Solid beverage automatic shaping and conveying equipment

InactiveCN109480158AWon't spillGuaranteed intermittent feedingRotary stirring mixersTransportation and packagingDrive wheelEngineering

The invention discloses solid beverage automatic shaping and conveying equipment. The solid beverage automatic shaping and conveying equipment comprises a grinding device, a stirring device, a liquidblocking device, a rotating mechanism, a pushing device, a conveying frame and a base, wherein the grinding device comprises a cylinder, a first motor, a grinding disk and a mesh screen; the stirringdevice comprises a stirring barrel, a second motor and a stirring mechanism; a flow limiting mechanism is arranged at the bottom end of the stirring barrel; the liquid blocking device comprises a third motor, a driving wheel and a driven wheel; and the rotating mechanism comprises a semicircle bottom disk and a rotary disk; and the pushing device comprises a fourth motor and the like. According tothe solid beverage automatic shaping and conveying equipment disclosed by the invention, the rotating speed of the third motor and the rotating speed of the fourth motor are adjusted to appropriate rotating speeds, liquid which flows out from an L-shaped pipeline can just be completely injected into a rotating liquid box, so that intermittent feeding is guaranteed, and automated operation is realized; besides, the solid beverage automatic shaping and conveying equipment is provided with the flow limiting mechanism, and through twisting a threaded rod, enclosing and flow limiting can be realized; and in the stirring course of a solid beverage, liquid cannot spill, the magnitude of flow capacity can be controlled, and then the volume of liquid which flows in the liquid box is further controlled.

Owner:罗燕辉

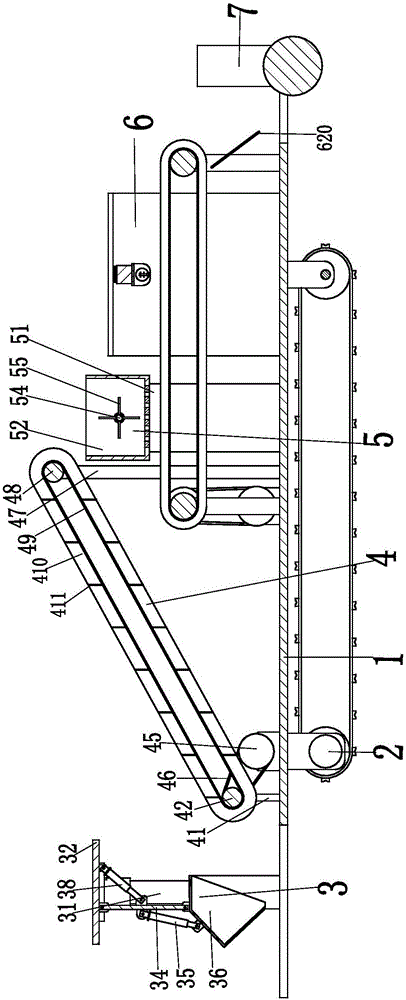

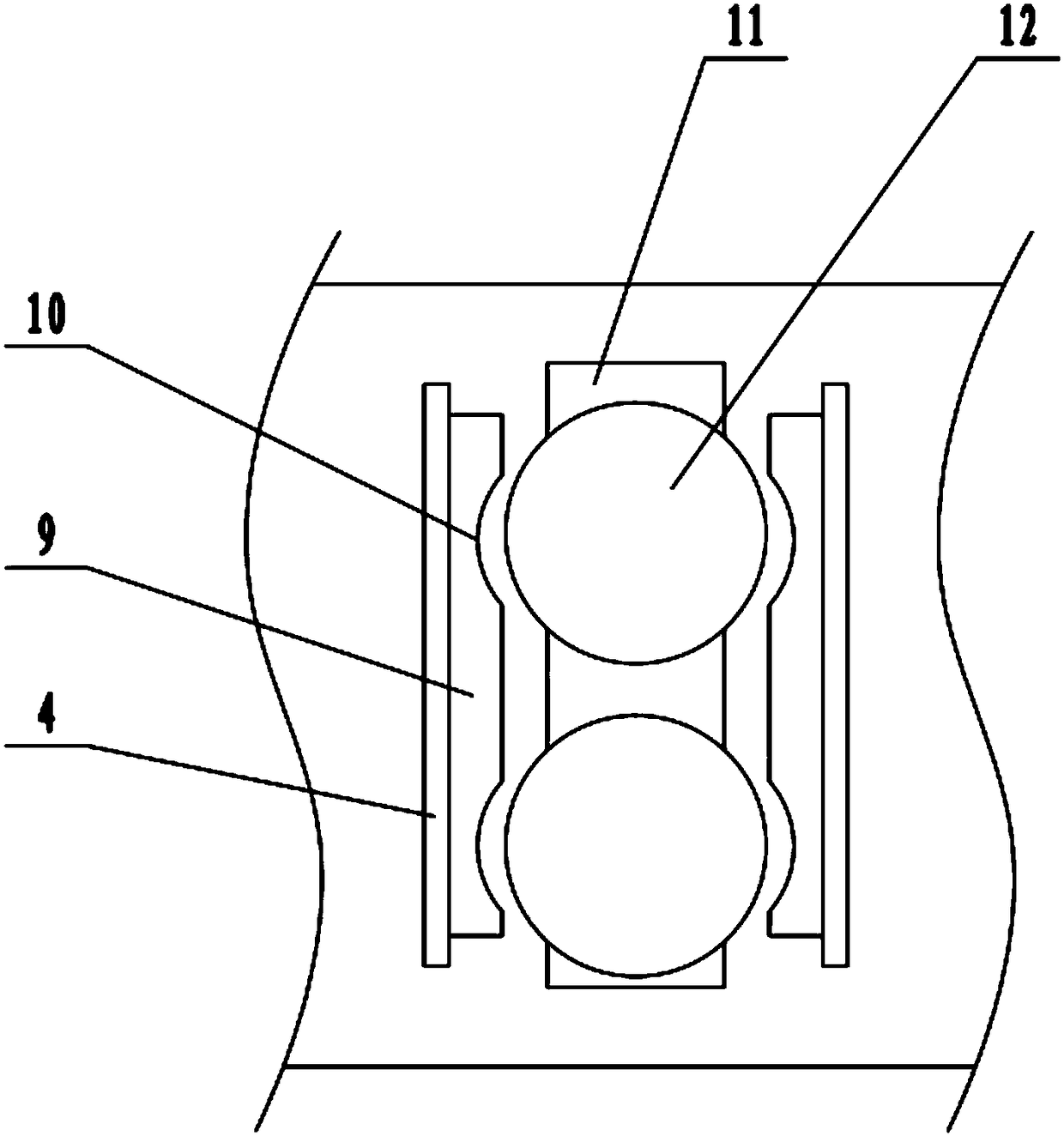

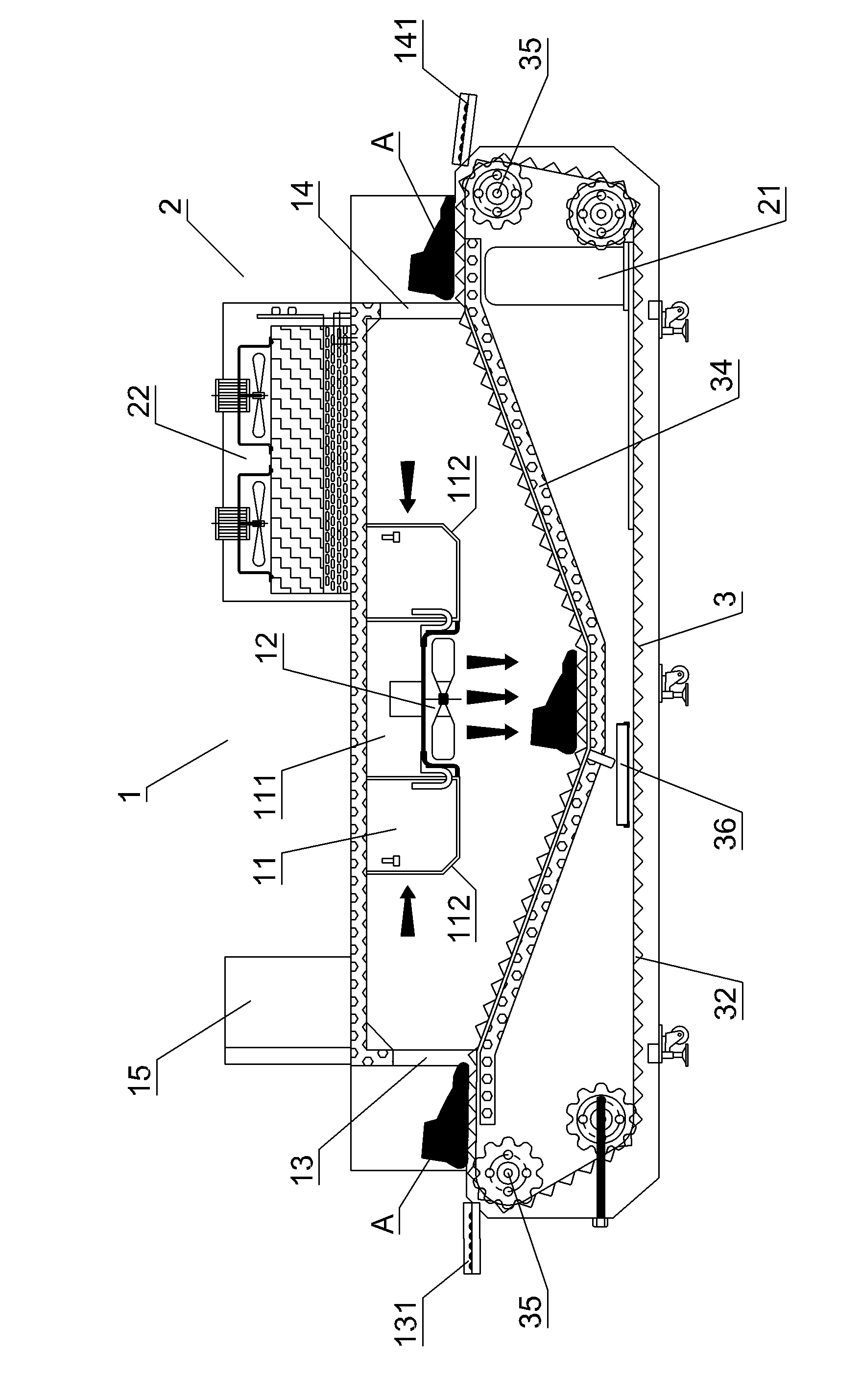

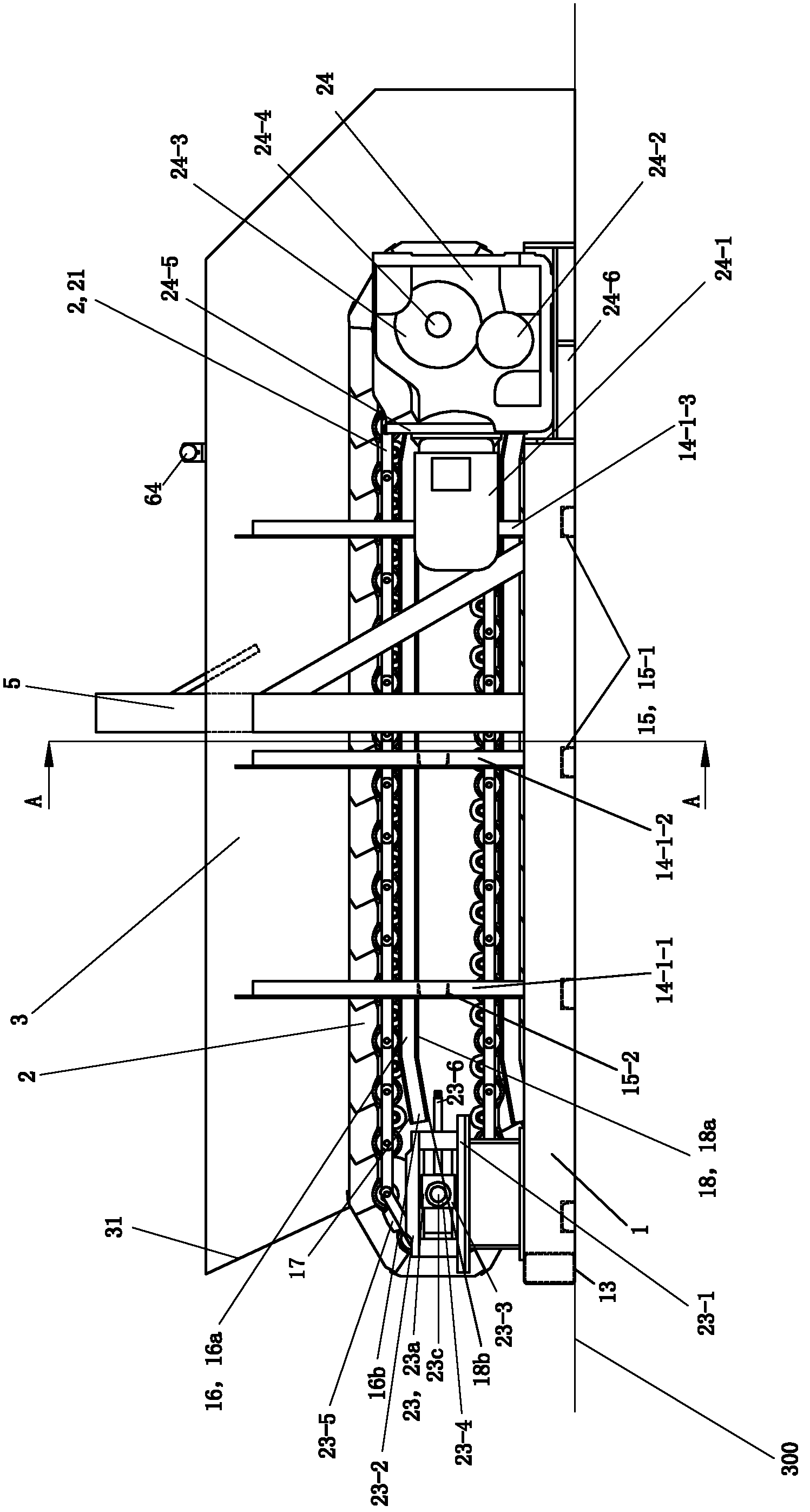

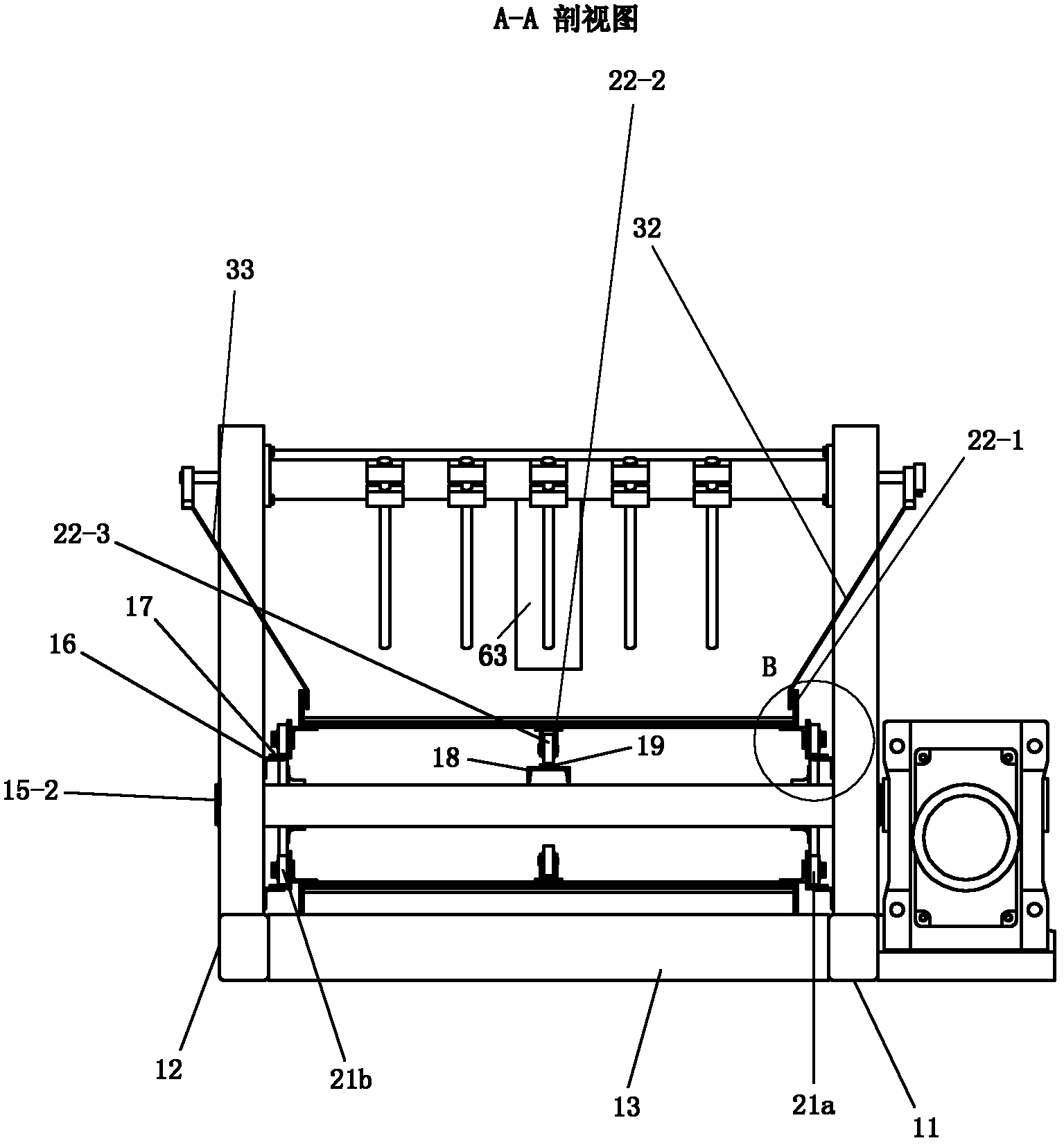

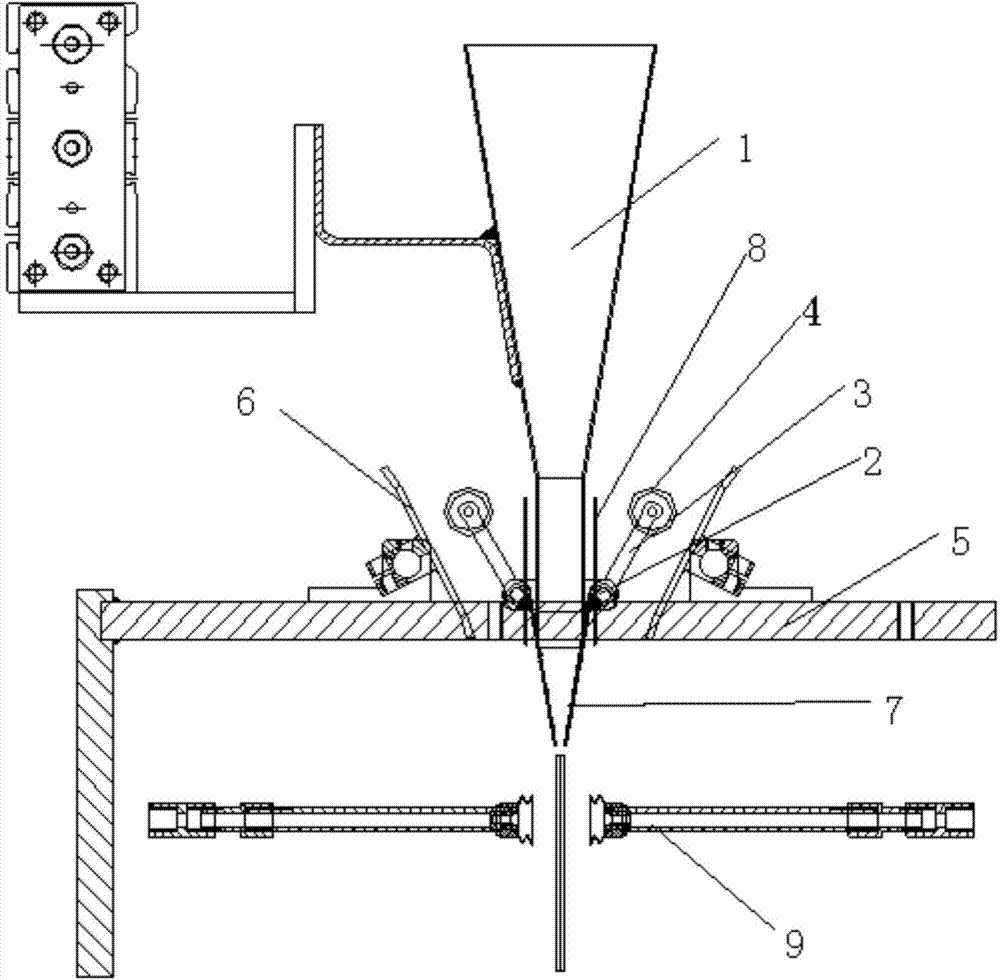

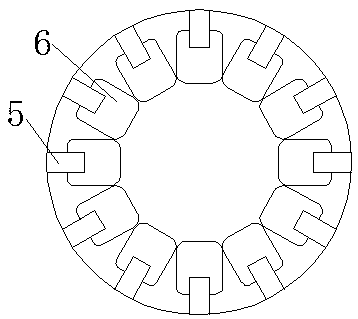

Garbage feeder

InactiveCN102491056AGuaranteed continuous feedingGuaranteed thicknessConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention discloses a garbage feeder, which comprises a machine frame, a conveying device and a guiding tank, wherein the conveying device is arranged on the machine frame; and the guiding tank is fixed on the machine frame and positioned above and on the right side of the conveying device. The garbage feeder is characterized by also comprising a blending device and a feed level feedback device. The machine frame comprises supporting posts, a connecting cross beam and supporting wheel bearers, wherein 1 to 3 supporting wheel bearers are used. Each feeding plate of the conveying device hasa roller support, the number of the roller supports is the same as that of the supporting wheel bearers, and each roller support is rotationally connected with a corresponding supporting roller. The supporting roller of each corresponding feeding plate is contacted with a supporting wheel bearer in a rolling manner. The blending device comprises a main frame body and comb teeth. The comb teeth are arranged on the main frame body. The blending device is arranged in the middle of the left and right direction of the machine frame. The comb teeth are positioned above the conveying device. The feed level feedback device is transversely spun over the guiding tank from the front to the back and is positioned above the part, which is on the right side of the blending device, of the conveying device.

Owner:江苏金陵环保科技有限公司

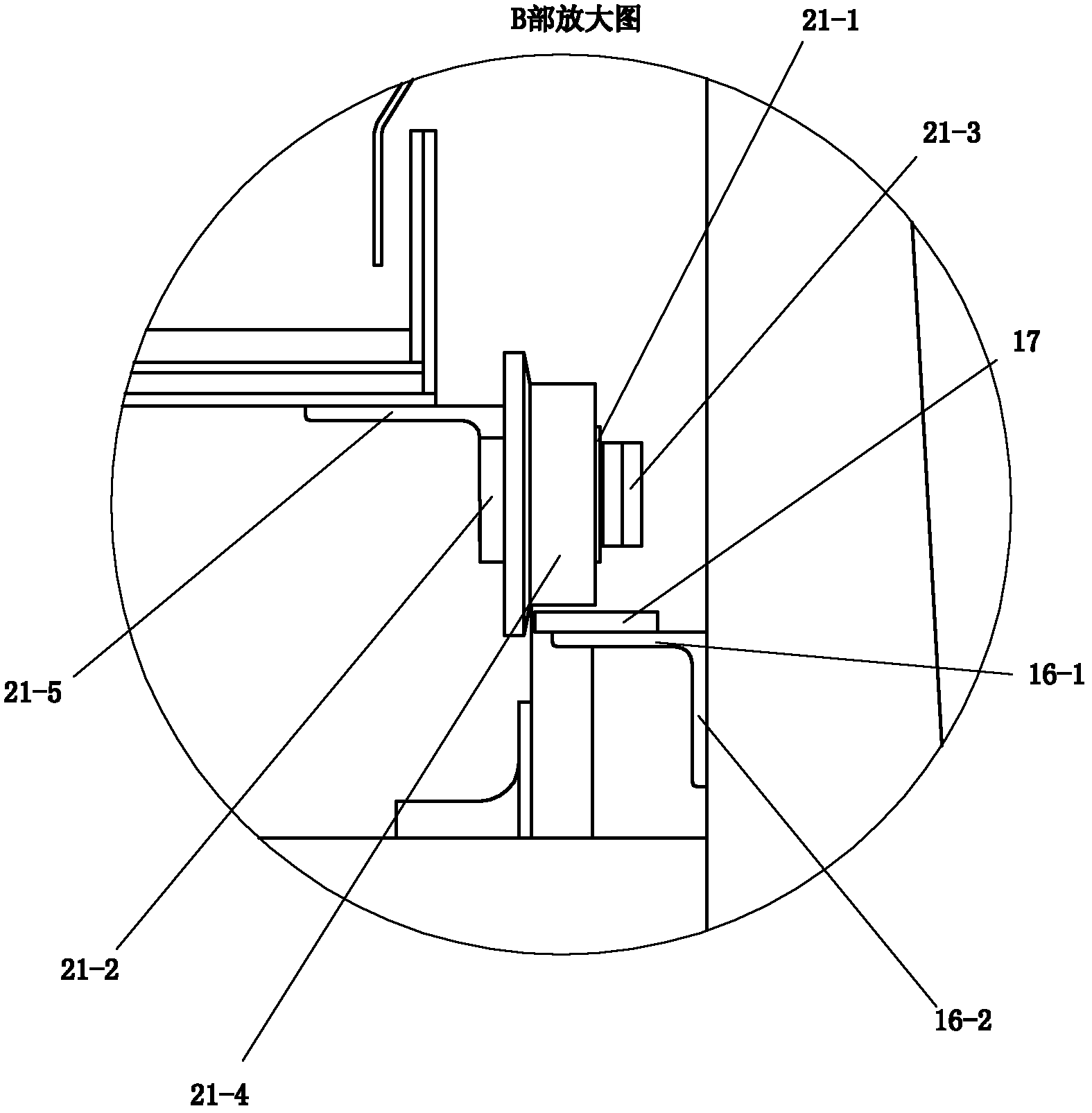

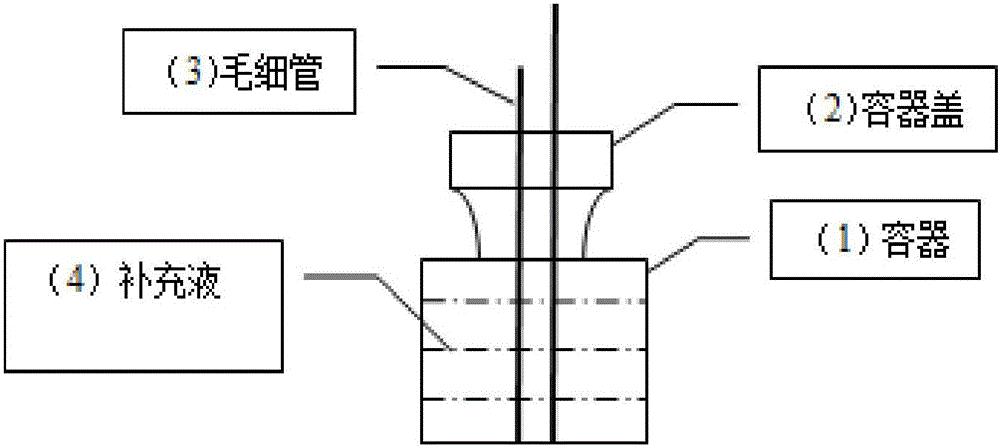

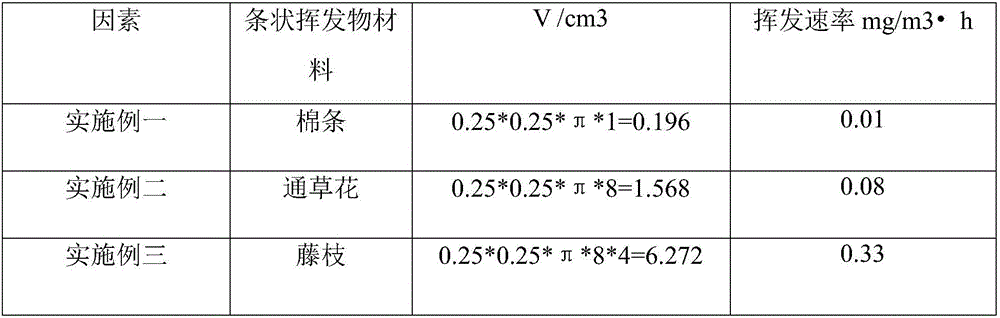

Chlorine dioxide sustained-release device and chlorine dioxide replenisher thereof

The invention relates to a chlorine dioxide slow-release device and its replenishment liquid, in particular to a chlorine dioxide slow-release device and its replenishment liquid for epidemic prevention and disinfection, food antisepsis and air purification. The device includes three parts: a container, a container cover, and a strip-shaped volatile matter. The supplement liquid includes the following parts by weight: 1-15 parts of sodium chlorite, 1-15 parts of activator, 1-10 parts of thickener, 1-5 parts of stabilizer, 0.5-2 parts of air barrier agent, 53-5 parts of purified water 95.5 servings. The beneficial effect of the device is to stably preserve the activated chlorine dioxide liquid, and to control the amount of moisture and air in contact with the strip-shaped volatiles by increasing and / or reducing the total area exposed to the strip-shaped volatiles in the air. Control the amount of chlorine dioxide released. According to the scale prompt on the container, when the chlorine dioxide liquid drops to a certain level, open the container cover, add replenishing liquid, and it can be recycled. It has the advantages of simple preparation process, low cost, convenient use and environmental protection.

Owner:兰州泰坦生物科技有限责任公司

Waste scrap treatment device for machining

InactiveCN107717612AEasy to handleEasy to recycleMaintainance and safety accessoriesLitterConveyor belt

The invention discloses a waste treatment device for mechanical processing, which comprises a working box, a feeding trough is opened on the right side of the top of the working box, and a transport swash plate is fixedly connected to the right side of the feeding chute, and the transport swash plate Both the front and the back are fixedly connected with a limit block, and the center of the back of the working box is fixedly connected with a first motor. In the present invention, during the rotation of the second rotating shaft, the first conveyor belt and the second conveyor belt can rotate together, and the waste chips are transported from right to left, and are absorbed by the first magnet block, so that the metal waste chips move on the second transmission belt , the leftmost part of the paper scraps falls to the first waste treatment box, and the metal scraps continue to move on the second conveyor belt and move to the rotating rod. Due to the magnetism of the first magnet block, the distance is getting farther and farther, making The mixed metal falls into the second waste treatment device, and the metal waste and waste paper can be separated, which is convenient for processing and recycling.

Owner:赵顺豪

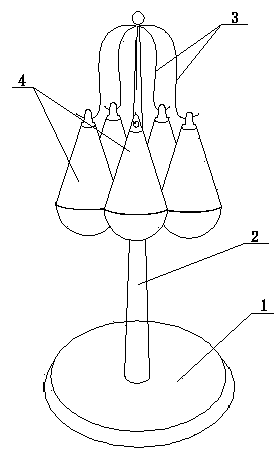

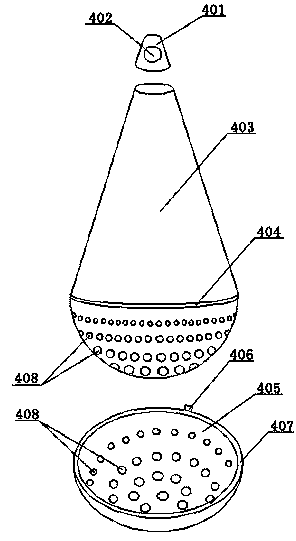

Hanging condiment container

A hanging condiment container comprises a base, a rotating shaft, hooks and condiment bottles. Each condiment bottle is composed of a cap, a bottle body and an outer cambered cover, the cap is provided with a through hole convenient to hang, the bottle body is provided with an upper conical end and a lower hemispherical end, and the outer cambered cover can rotate along the joint of the upper and lower ends of the bottle body; scattering holes are formed in the lower end portion and the outer conical cover of the bottle body. By the arrangement, kitchen space can be saved, condiments can be taken by pushing aside a lug, convenience and rapidness can be achieved, the amount of the condiments taken can be adjusted through the scattering holes in the bottom of the condiment bottle, even scattering can be guaranteed, convenience in cleaning is brought, no water is accumulated at the bottom, ventilation is good, the condiment bottle does not fall over when conveniently placed on a table top, and spilling of the condiments never occurs.

Owner:HENAN UNIV OF SCI & TECH

Discharging bag opening mechanism for horizontal packing machine

The invention discloses a discharging bag opening mechanism for a horizontal packing machine. The discharging bag opening mechanism comprises a discharging hopper capable of being lifted up and down, rotating shafts are respectively arranged on the two sides of a discharging port of the discharging hopper in a rotating mode, bag opening rods inclining and opening to the outer side are fixedly arranged in the middles of the rotating shaft, bag opening idler wheels are arranged at the upper ends of the bag opening rods, the bag opening idler wheels are in rolling fit with bag opening idler wheel blocking plates on fixed support plates on the two sides of the bag opening idler wheels, bag opening pieces are arranged at the upper end of the bag opening rods, torsion spring are arranged on the rotating shafts on the two sides of the bag opening rods, one end of each torsion spring is buckled on the bag opening piece, bag opening suckers are arranged under the bag opening pieces and on the outer sides of the bag opening pieces, the bag opening suckers and the discharging hopper are respectively driven by an air cylinder to move. According to the structural design of the discharging bag opening mechanism, the bag opening pieces which can be automatically opened and closed along discharging are arranged under the discharging hopper, and accordingly feeding convenience in bag openings is guaranteed. In feeding, the bag openings are stable in structure. Meanwhile, materials are prevented from scattering, and the using requirements are met.

Owner:ANHUI ZENGRAN PACKAGING SCI & TECH

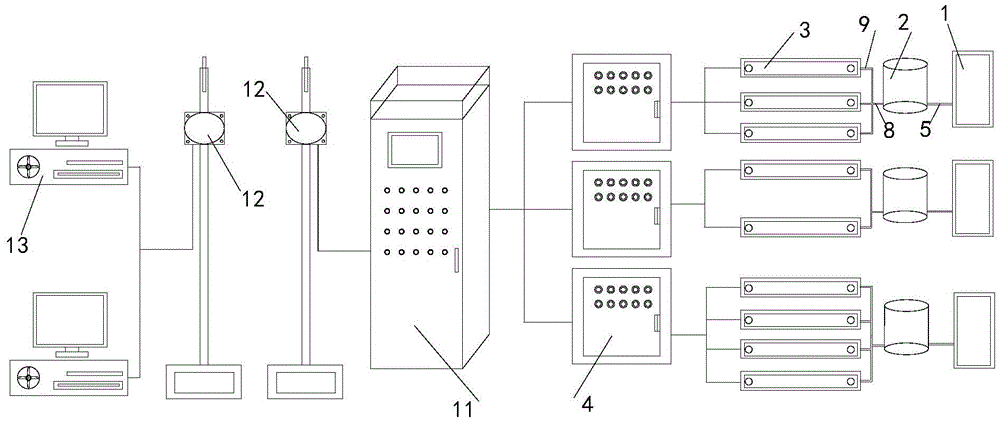

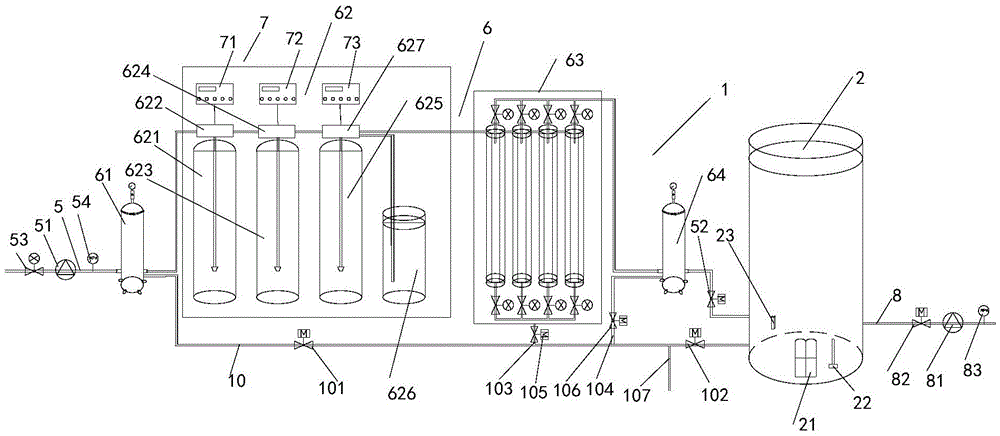

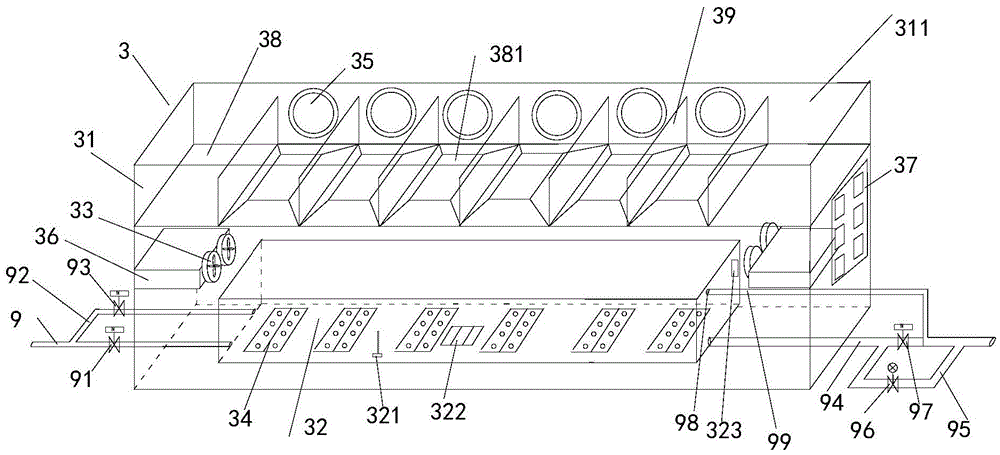

Air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method

InactiveCN105617798APrecision FiltrationEasily brokenGas treatmentUsing liquid separation agentWater storage tankWater source

The invention relates to an air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method. The system comprises a water quality filtering and softening device, a water storage tank, a dry fog dust suppression device and a local controller. An adjustable atomization plate in the dry fog dust suppression device scatters and atomizes a constant-temperature water source which is filtered and softened through the water quality filtering and softening device in the water storage tank, a large amount of micron-grade dry fog and negative ions are produced, a frequency conversion high pressure centrifugal fan in the dry fog dust suppression device blows the large amount of micron-grade dry fog and negative ions out of the dry fog dust suppression device, then the dust is adsorbed, condensed and precipitated, and therefore the purpose of dust removal is achieved. Millimeter-grade visible dust particles can be effectively treated, micrometer-grade inhalable dust particles can also be effectively treated, pollution of dust on the atmosphere is lowered, the work environment of on-site workers is improved, and occupational disease occurrence rate is lowered; the system is small in occupied area, safe and convenient to operate and high in practicability and is controlled in a full-automatic mode.

Owner:刘坤

Municipal solid waste disposal device

The invention relates to a municipal solid waste disposal device. Generally, inhabitants place waste in a corridor, and throw the waste into a waste container on the ground near a building when the inhabitants go downstairs; since the waste is placed in the corridor for a period of time, unpleasant odor can be generated in the corridor; and meanwhile, a top cover of the waste container on the ground is open generally, and often the waste can not be disposed in time, thereby affecting district environment severely. In order to solve the above problems, a pipeline directly communicating with theinterior of a ground waste collection bin is specially arranged in each household, and each pipeline is internally provided with a buffer device used for reducing the waste falling speed; noise generated by waste falling is reduced; meanwhile, the top of the waste collection bin is closed; the side face of the waste collection bin is provided with a waste door which is opened by waste disposal personnel only; in this way, municipal solid waste does not need to be placed in the corridor, but directly enters the waste collection bin; the odor of the waste in the closed waste collection bin doesnot leak, and the cleanliness of the district environment is ensured; and the grade of air in a community is improved.

Owner:吉帅

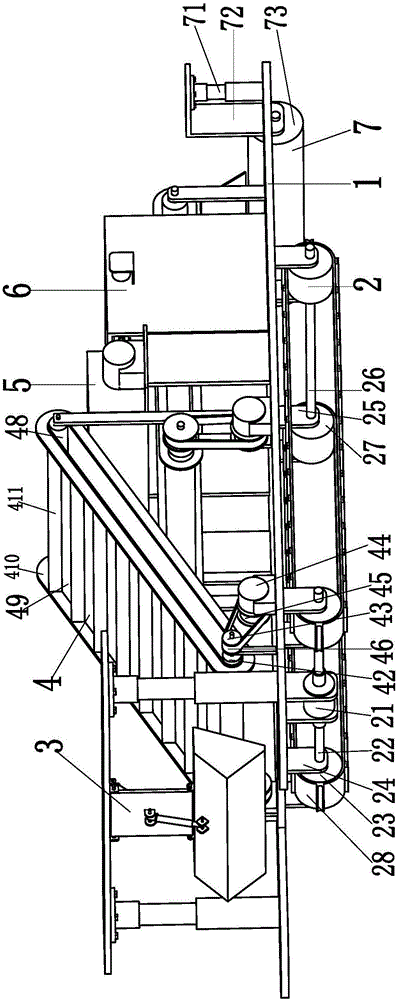

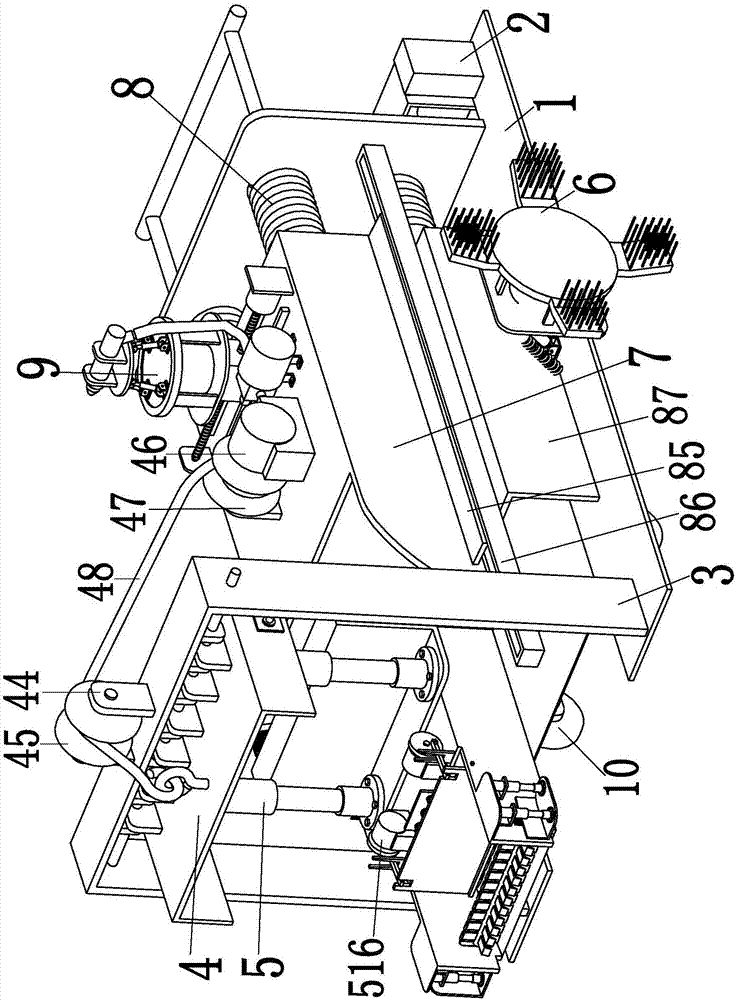

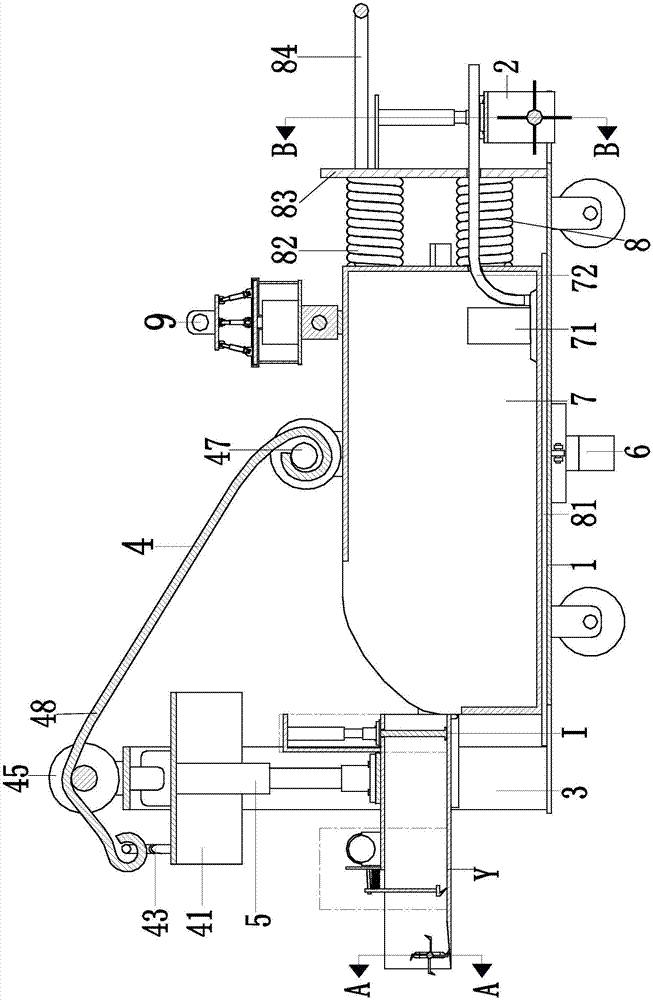

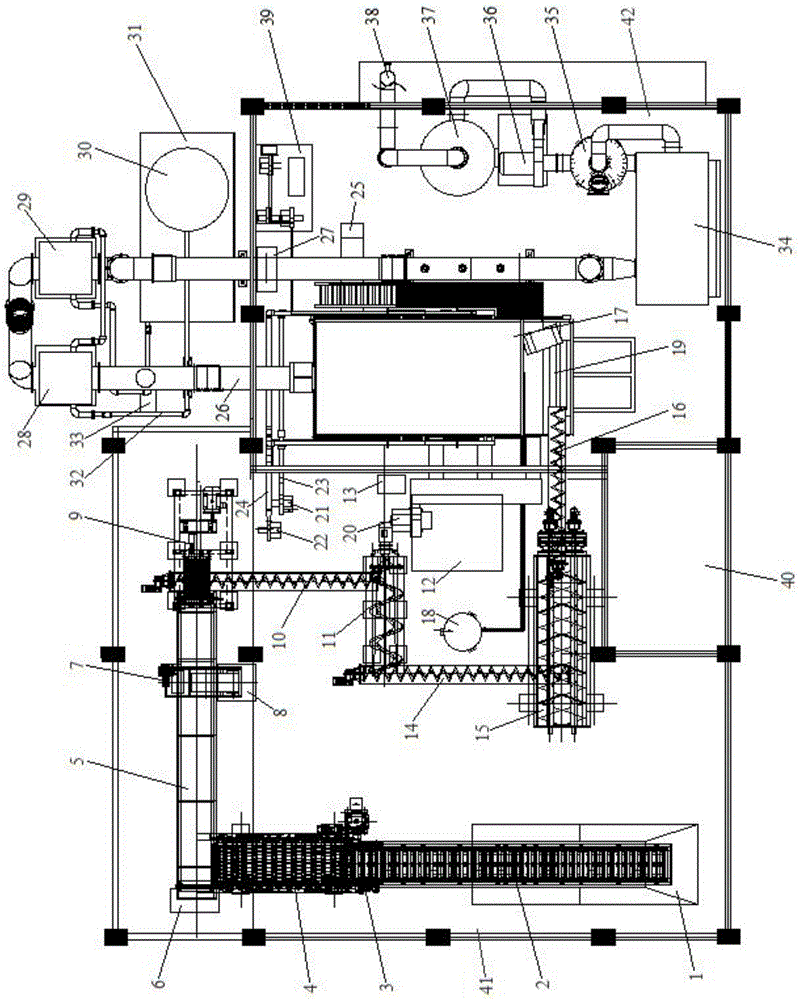

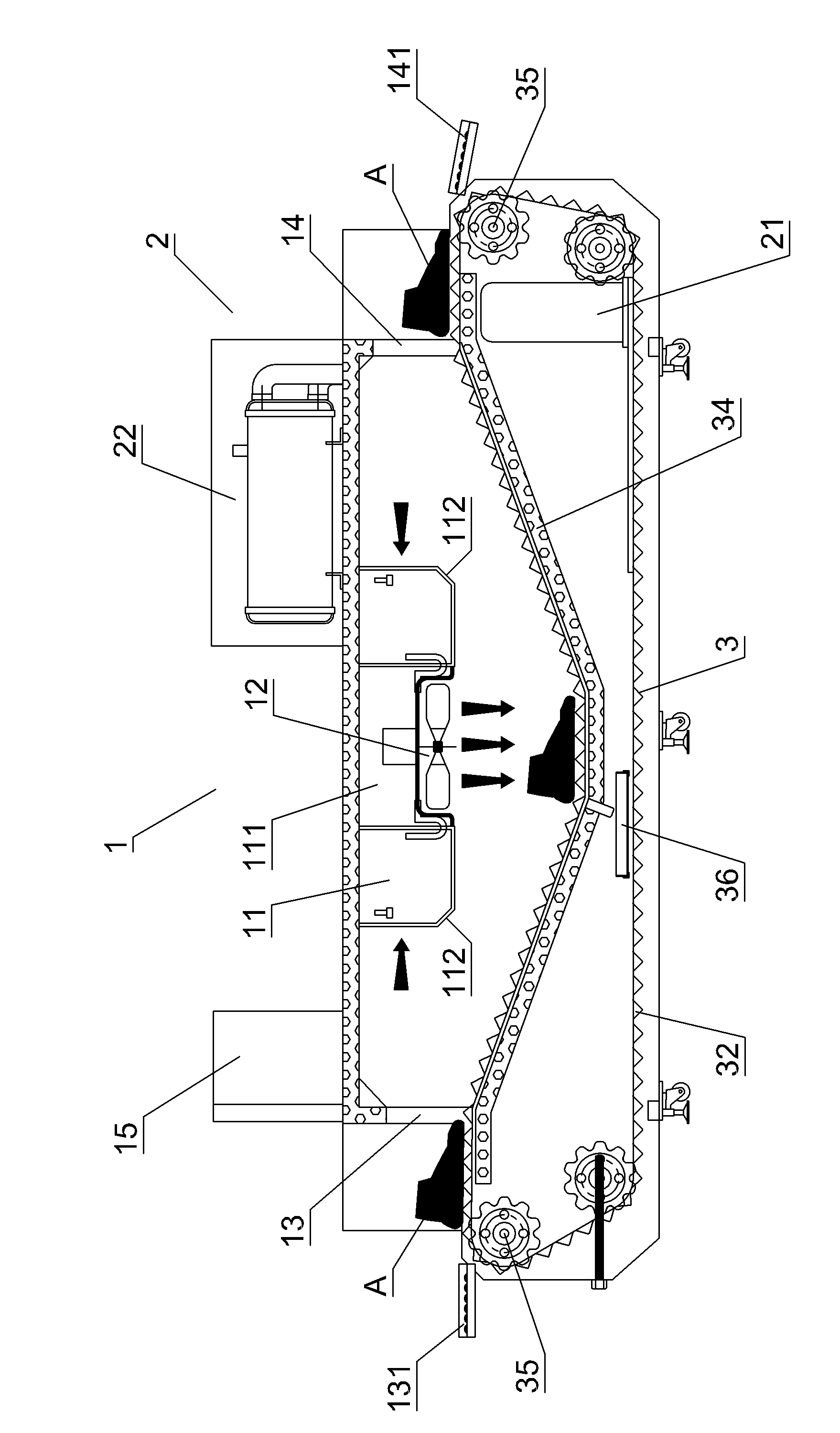

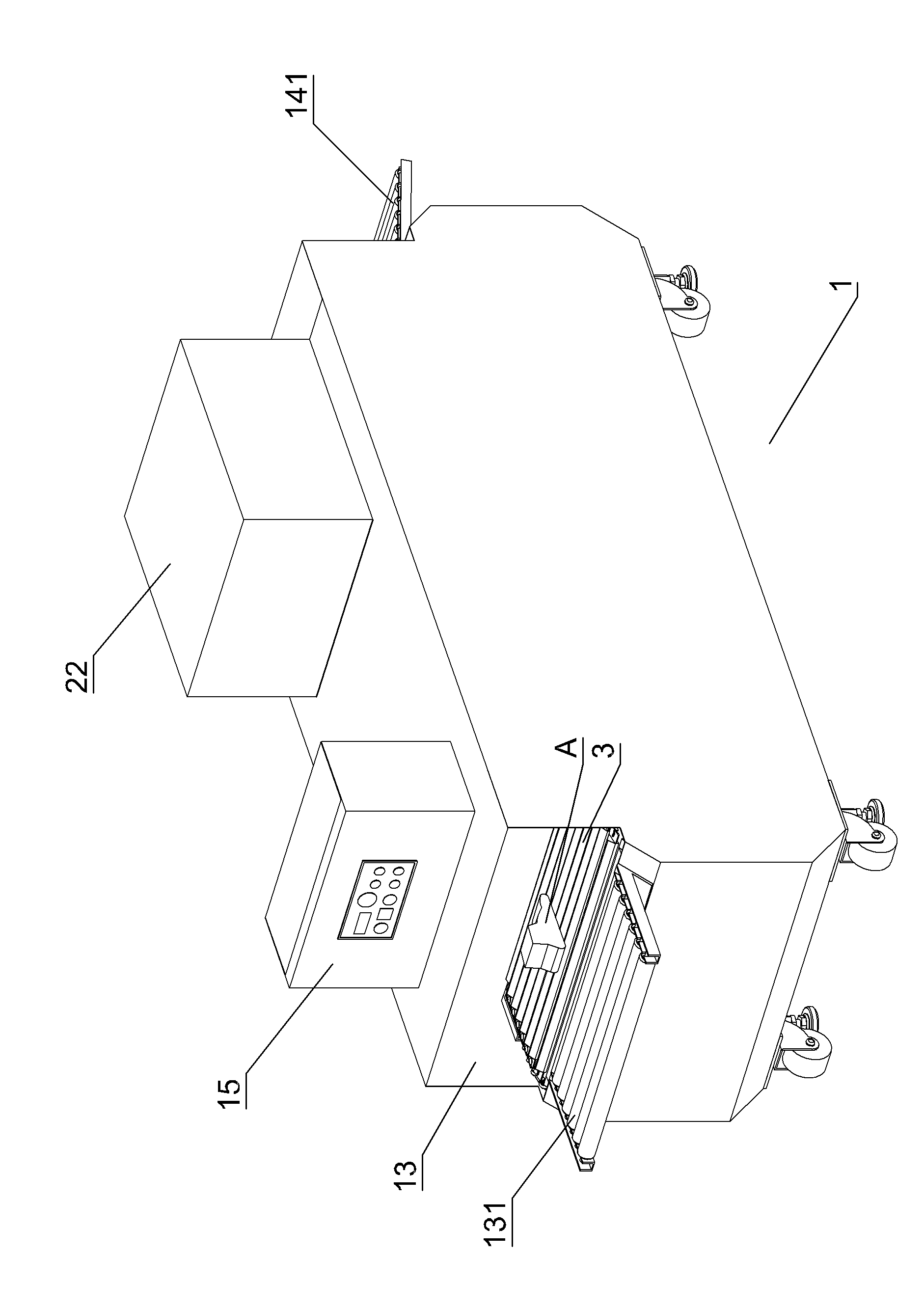

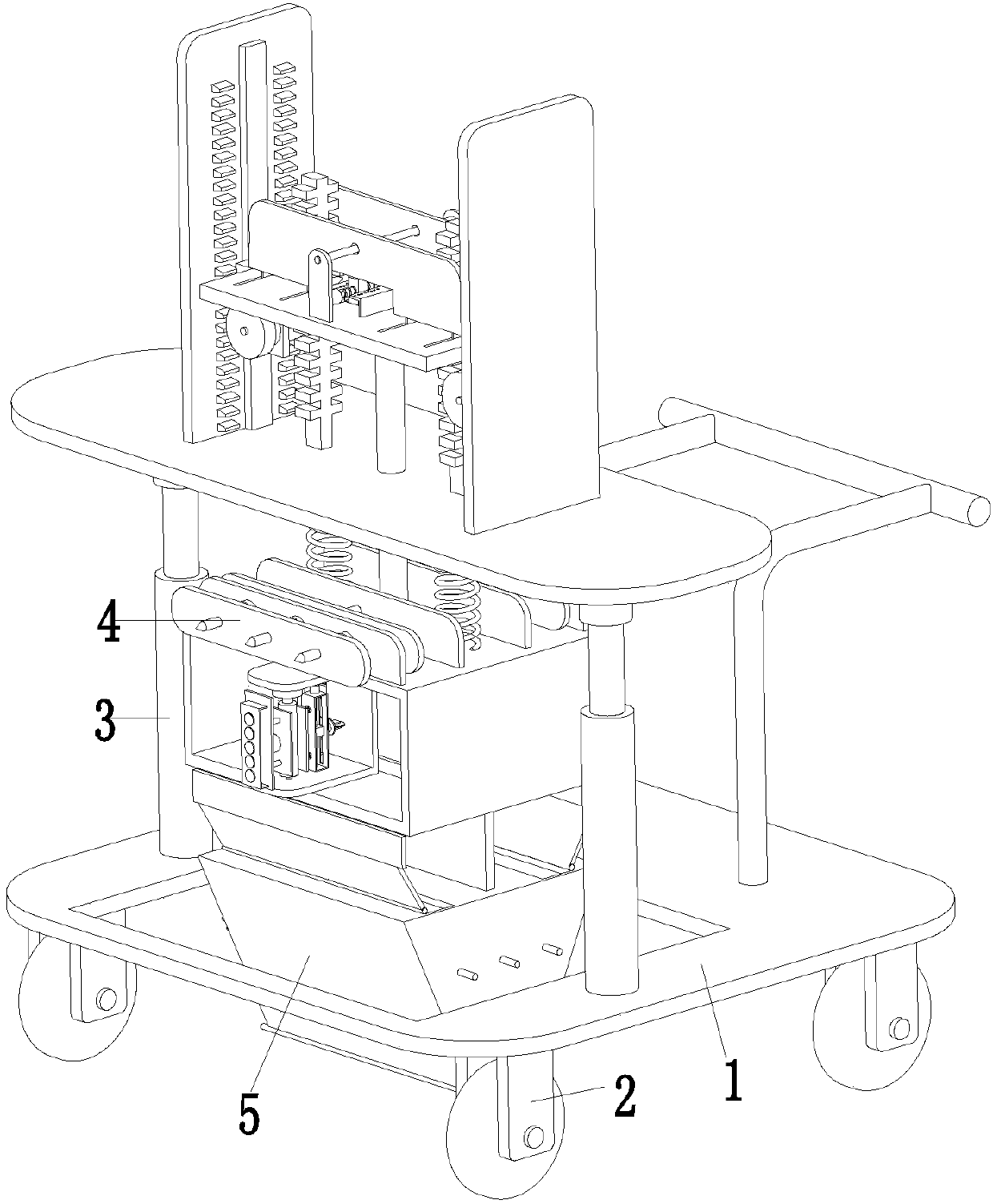

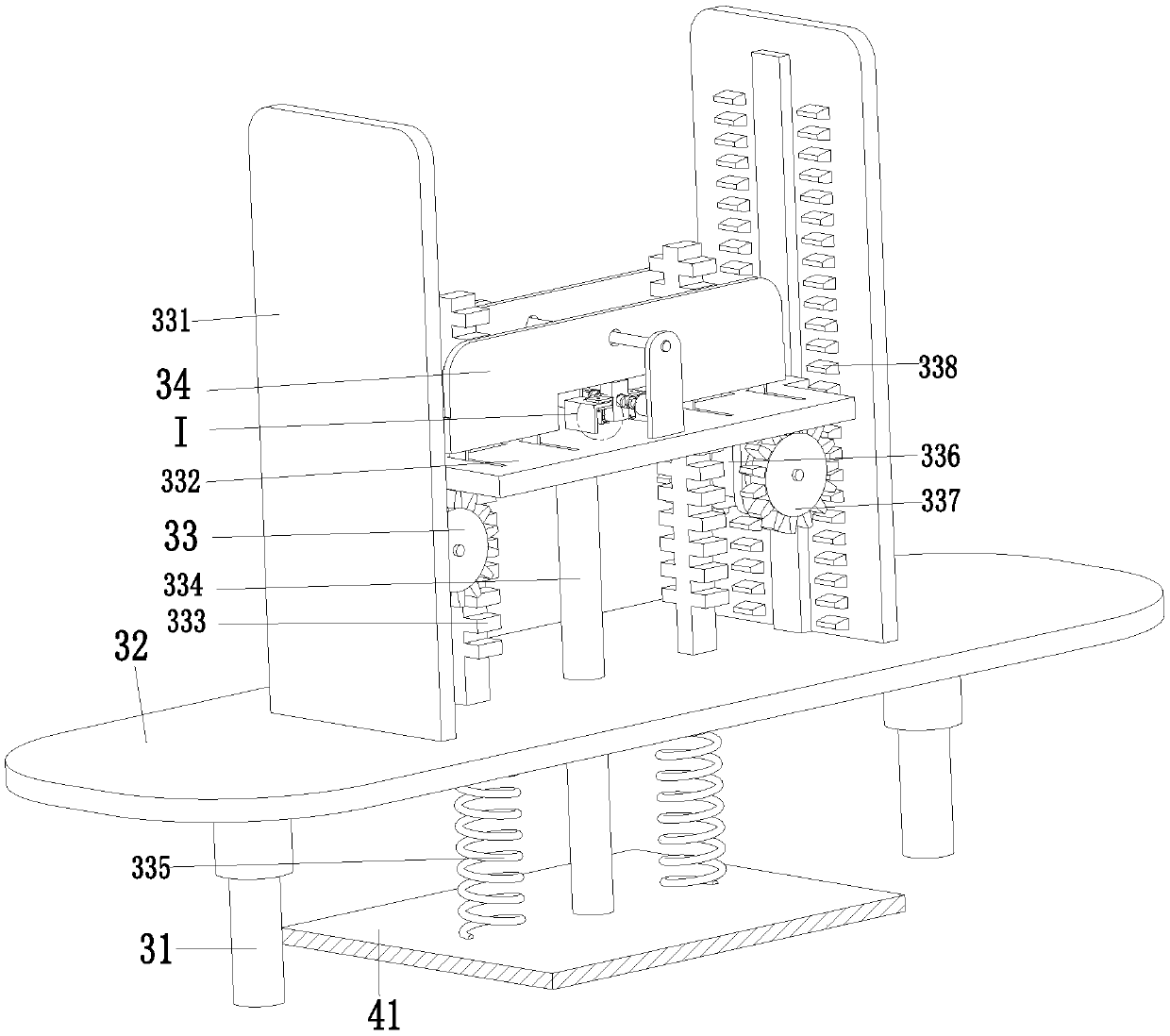

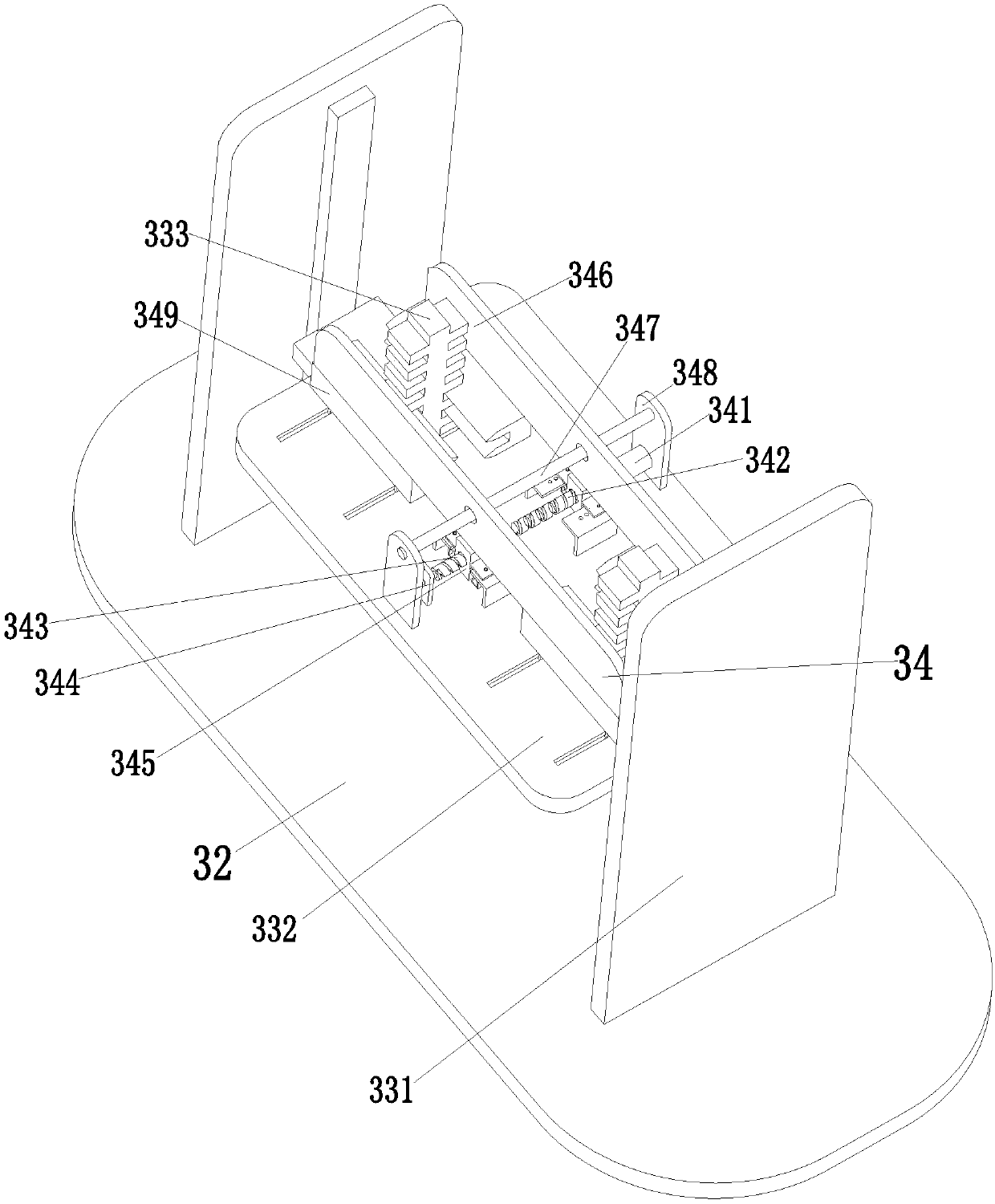

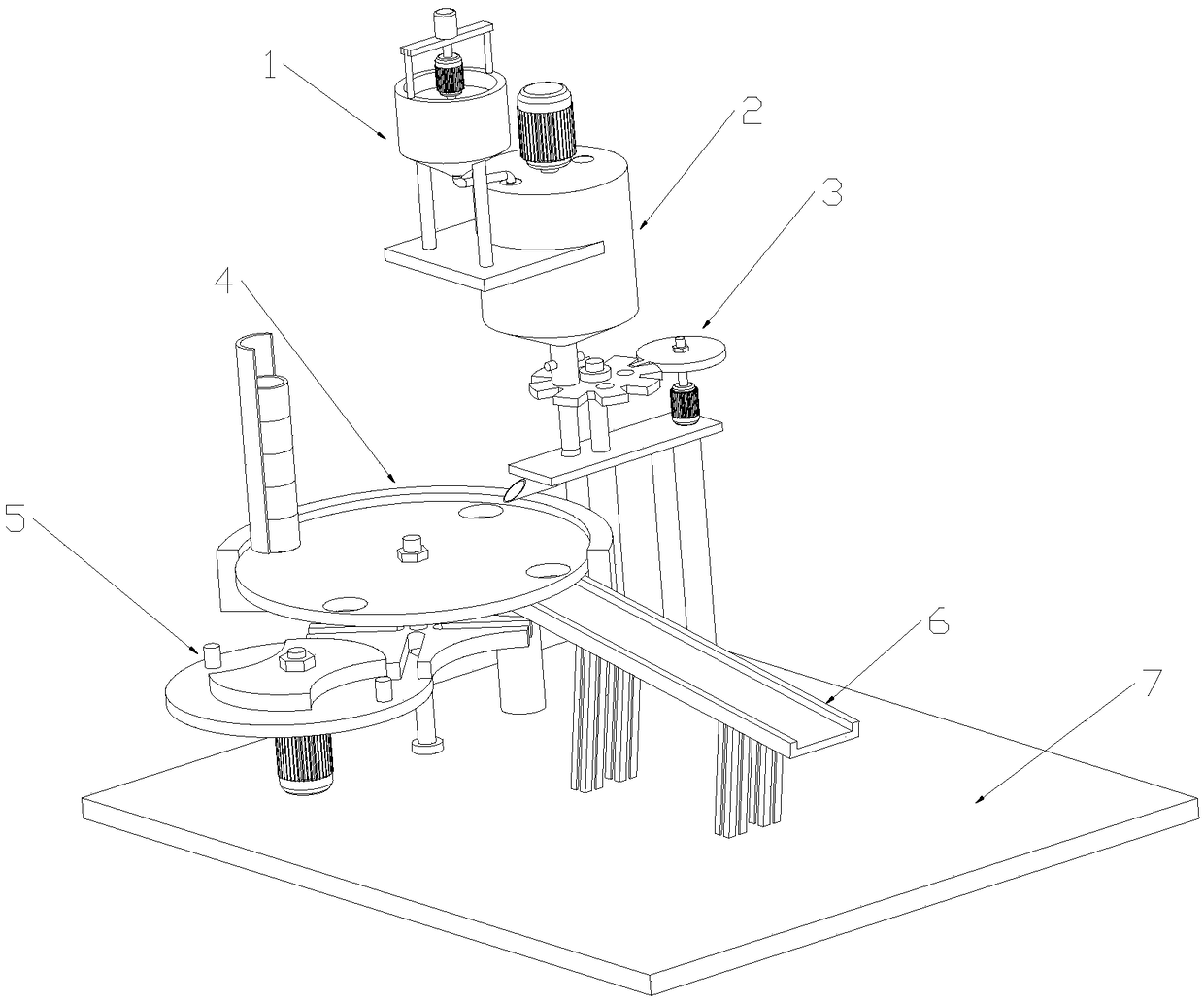

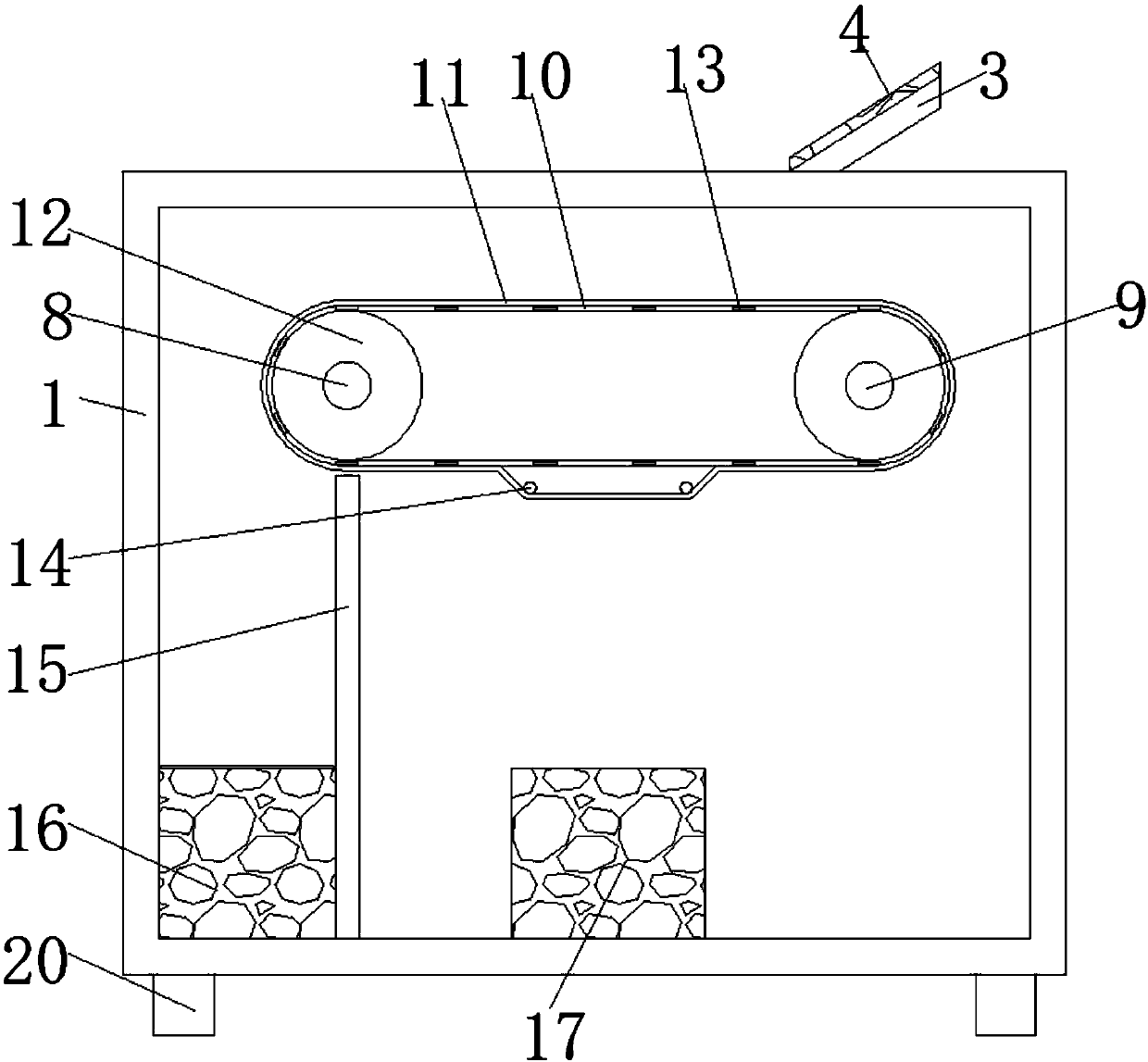

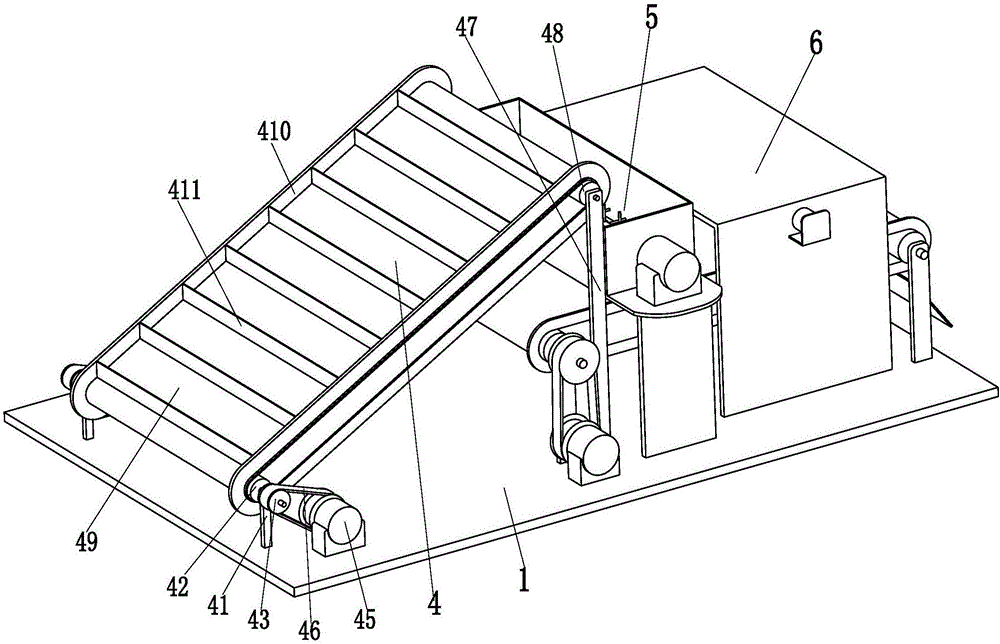

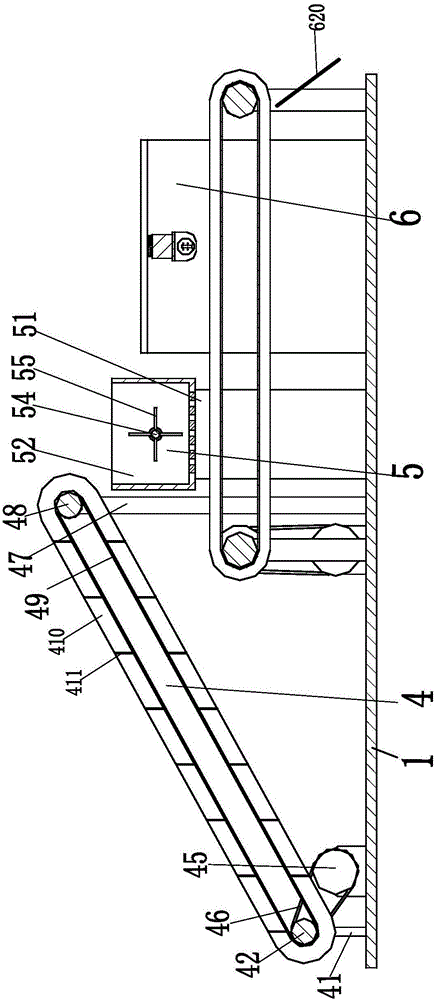

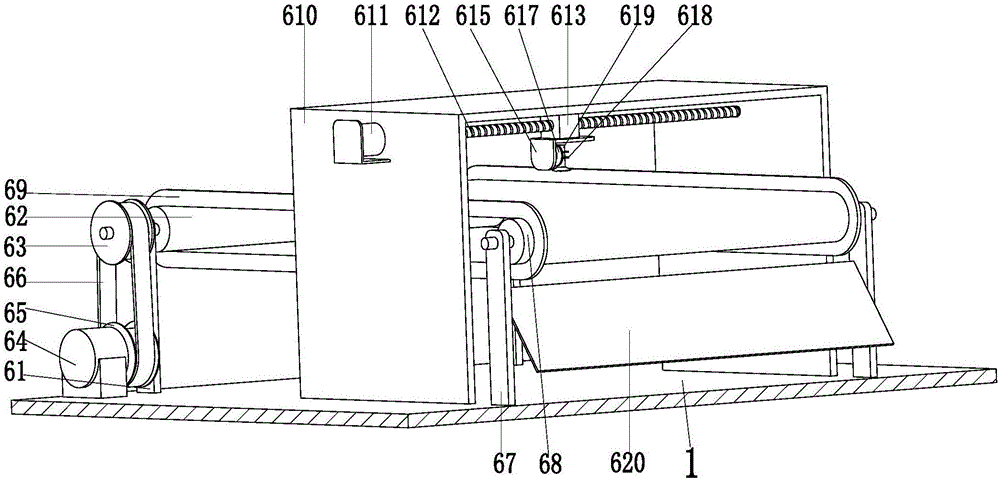

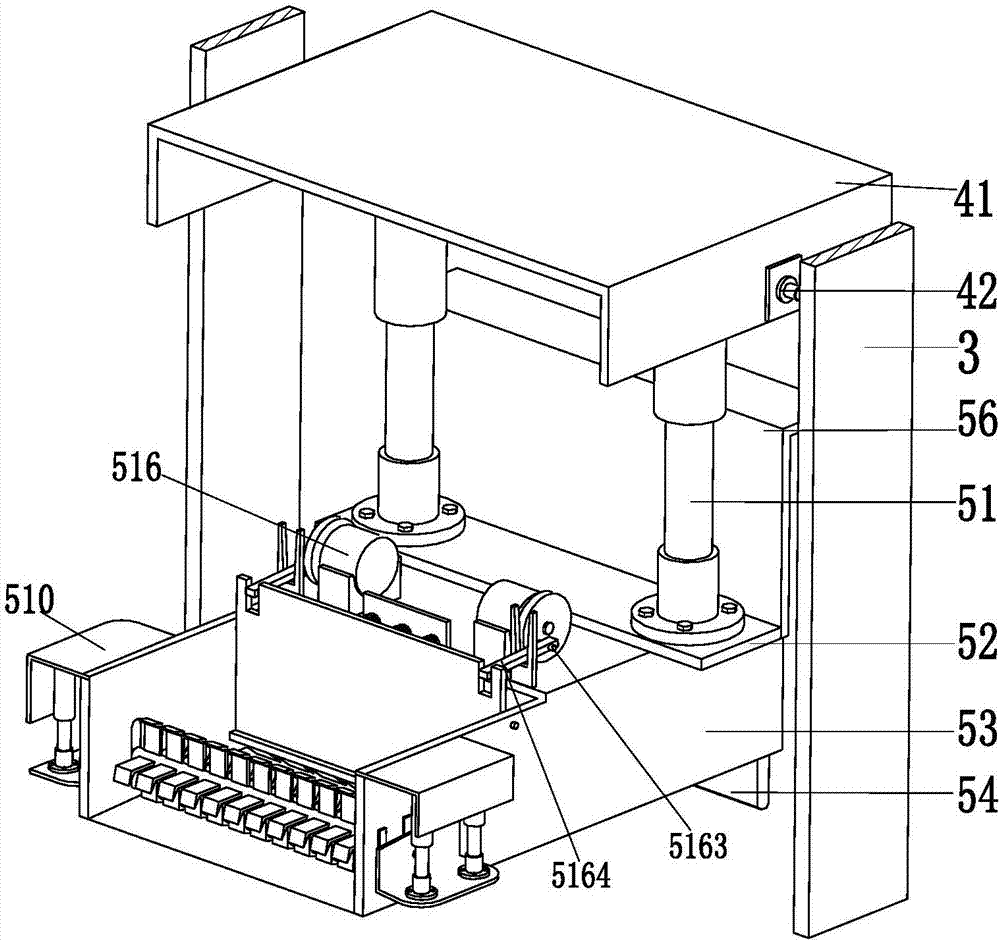

Automatic soil remediation machine special for soil pollution treatment

InactiveCN106623391AImprove efficiencyWon't spillContaminated soil reclamationEngineeringSoil remediation

The invention relates to an automatic soil remediation machine special for soil pollution treatment. The automatic soil remediation machine comprises a bottom plate, and a conveying mechanism which inclines from bottom to top is arranged at the left end of the bottom plate. According to the automatic soil remediation machine, soil requiring to be remediated is automatically excavated to the conveying mechanism through external excavating equipment, the conveying mechanism can convey soil requiring to be remediated, manual operation is not required, and the production cost is reduced; a dispersion mechanism is arranged in the middle of the bottom plate, the dispersion mechanism can disperse blocky soil in soil requiring to be remediated, and soil requiring to be remediated can be remediated more comprehensively, so that the soil remediation efficiency is improved; a spraying remediation mechanism is arranged at the right end of the bottom plate, the spraying remediation mechanism can treat soil requiring to be remediated, soil requiring to be remediated can be in comprehensive contact with a soil remediation agent, so that the working efficiency is improved; and a full-automatic remediation function can be achieved on polluted soil, manual operation is not required, and the automatic soil remediation machine has the characteristics that the operation is simple, the working efficiency is high, the soil remediation cost is low, and the like.

Owner:黄江龙

Automatic cleaning and collecting vehicle special for pig house excrement treatment

InactiveCN107251843APlay a limiting roleReduce labor intensityAnimal housingRenewable energy source integrationEngineeringBacteria

The invention relates to an automatic cleaning and collecting vehicle special for pig house excrement treatment. The vehicle comprises a bottom plate. A supporting frame is installed on the bottom plate. A rotary conveying device is installed at the lower end of the supporting frame. A sweeping and collecting device is installed on the rotary conveying device. A rotary sweeping device is installed on the bottom plate, a collecting box is installed at the upper end of the bottom plate, the collecting box is connected with an adjusting device, the adjusting device is installed on the bottom plate, and the sweeping and collecting device, the rotary conveying device, the collecting box and the adjusting device are used in cooperation to complete the process of automatic excrement cleaning and collecting. The problems that an existing cleaning tool needs to be manually used for cleaning a pig house in the existing small pig house cleaning process, collected excrement is manually conveyed to a designated position, bacteria in the pig house easily harm the human body, the labor intensity of manually cleaning the pig house is large, and the working efficiency is low can be solved, and the function of automatically cleaning the pig house can be achieved.

Owner:安庆米锐智能科技有限公司

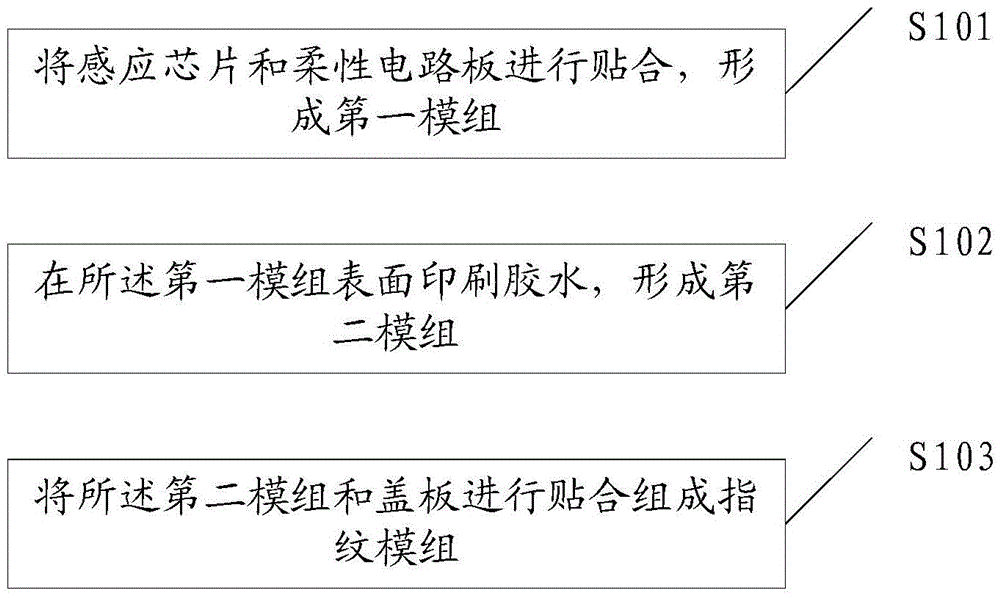

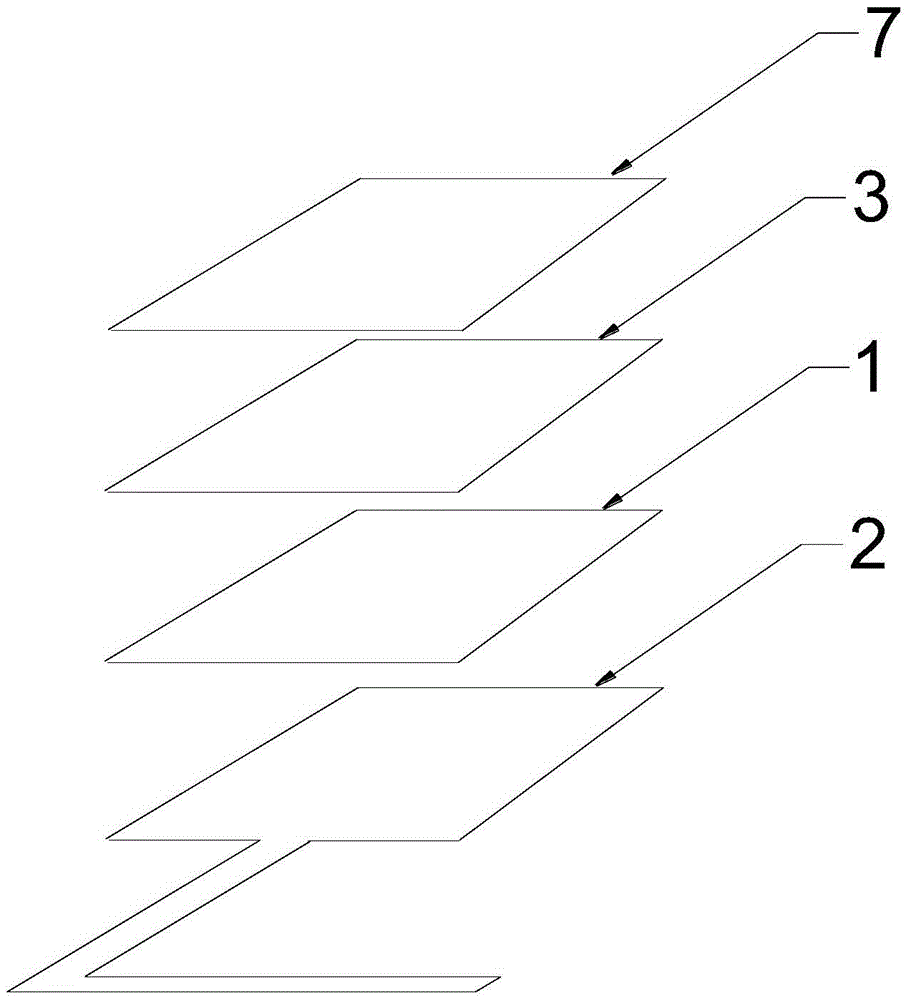

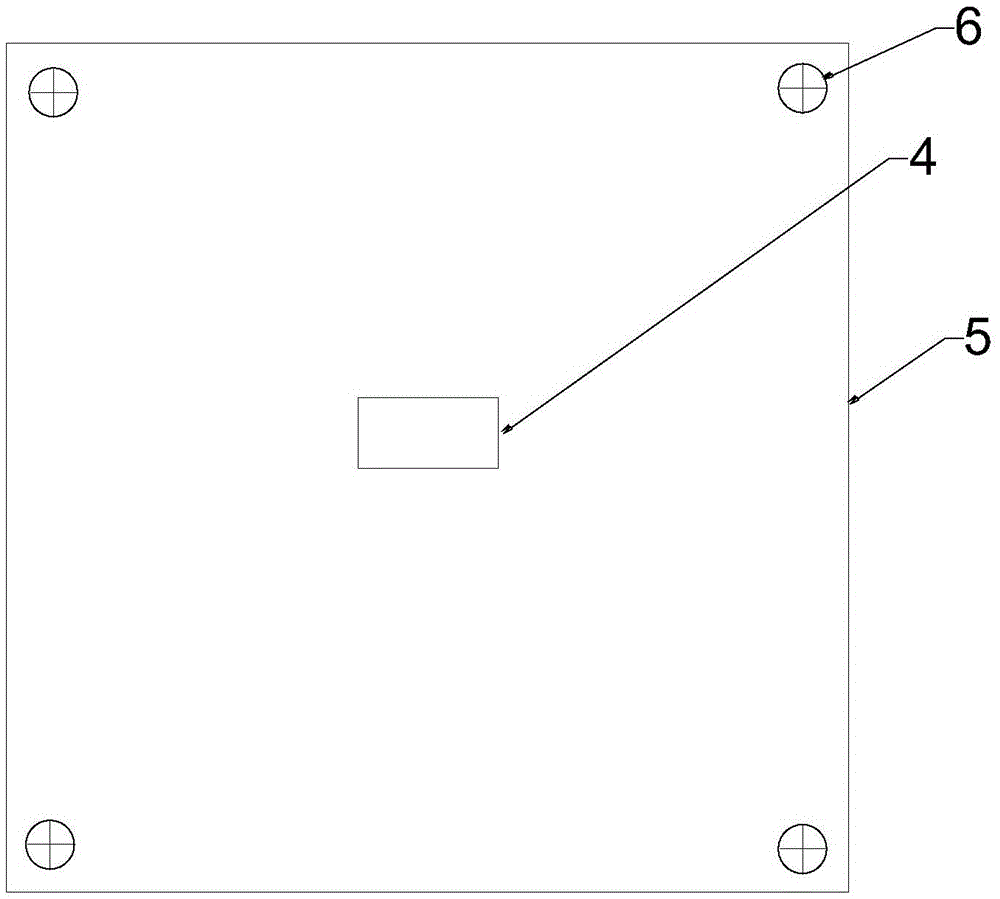

Fingerprint module manufacturing method

InactiveCN105678227AWon't spillUniform printingCharacter and pattern recognitionInput/output processes for data processingScreen printingFlexible circuits

The invention relates to the technical field, and specifically relates to a fingerprint module manufacturing method. The fingerprint module manufacturing method includes the steps: attaching an induction chip to a flexible printed circuit board so that a first module is formed; printing glue on the surface of the first module to form a second module; and attaching the second module to a cover plate to form a fingerprint module. During the process of the fingerprint module manufacturing method, a screen printing plate with hollow areas is introduced so that the glue is not overflowed and the glue can be uniformly printed on the induction chip when the glue is printed.

Owner:TOP TOUCH ELECTRONICS

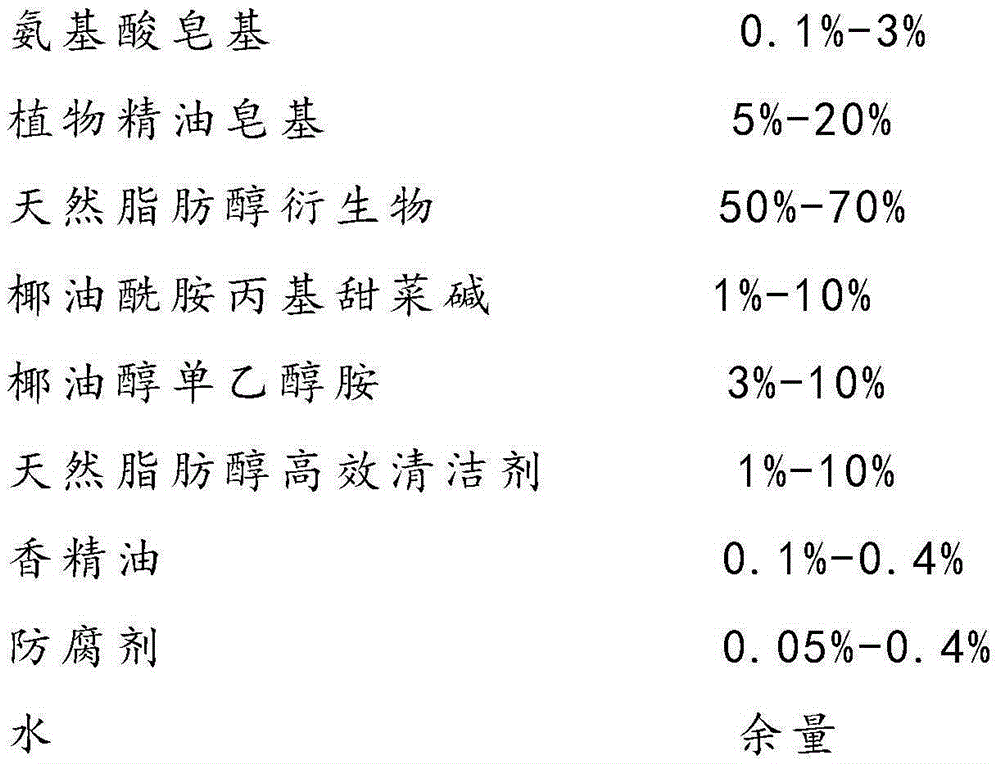

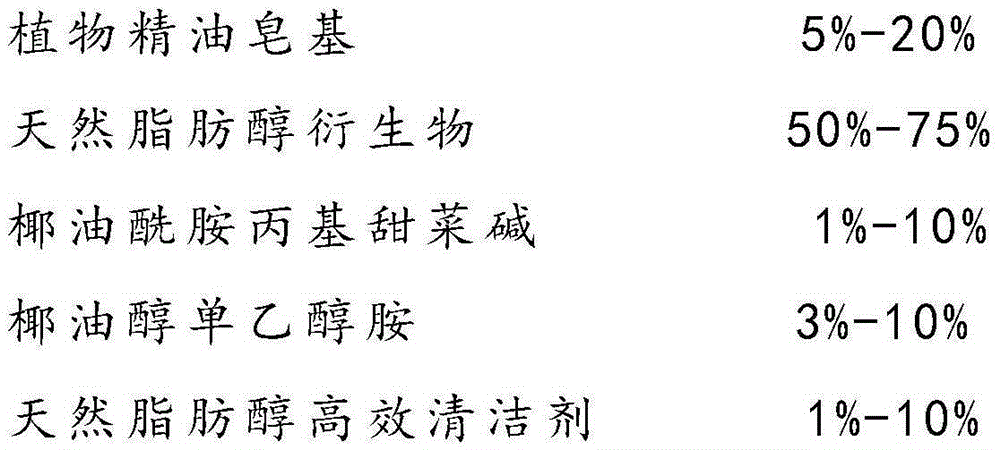

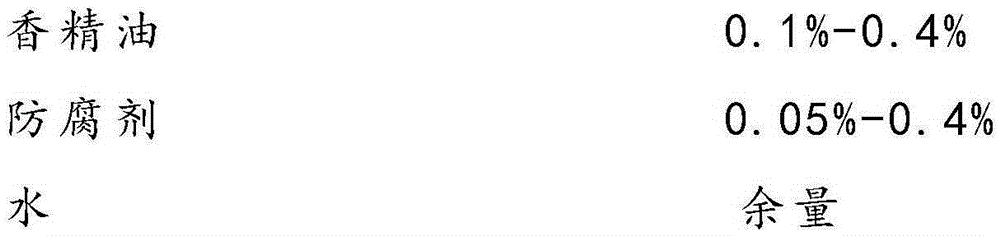

Laundry tablet

InactiveCN105296252AWon't spillEasy to useSurface-active non-soap compounds and soap mixture detergentsDetergent powders/flakes/sheetsPreservativeCocamidopropyl betaine

The invention discloses a laundry tablet. The laundry tablet comprises amino acid soap, vegetable essential oil soap, natural fatty alcohol derivative, cocamidopropyl betaine, dodecylalcohol monoethanolamine, natural fatty alcohol high-efficiency cleaning agent, essential oil, preservative and water. All raw materials are sequentially and uniformly mixed according to a weight ratio to obtain a mixture, and then the mixture is subjected to tabletting, sliced, coated and packed to form a finished product. By adopting a super-concentration nano technology, a washing product is made into a tablet shape, the size is small, no space is occupied, the laundry tablet can be carried along in business trip and touring; moreover, the cleaning capacity is higher compared with the equal amount of the washing product, the laundry tablet can be immediately dissolved in cold and hot water and also can be biologically degraded, the environment-friendly technical effect is guaranteed, more easiness in storage is realized, the situation such as leakage, caking and softening waste can be avoided, a nonwoven fabric after the laundry tablet is used can be used as a piece of cleaning cloth, and multiple functions can be realized.

Owner:张盛城

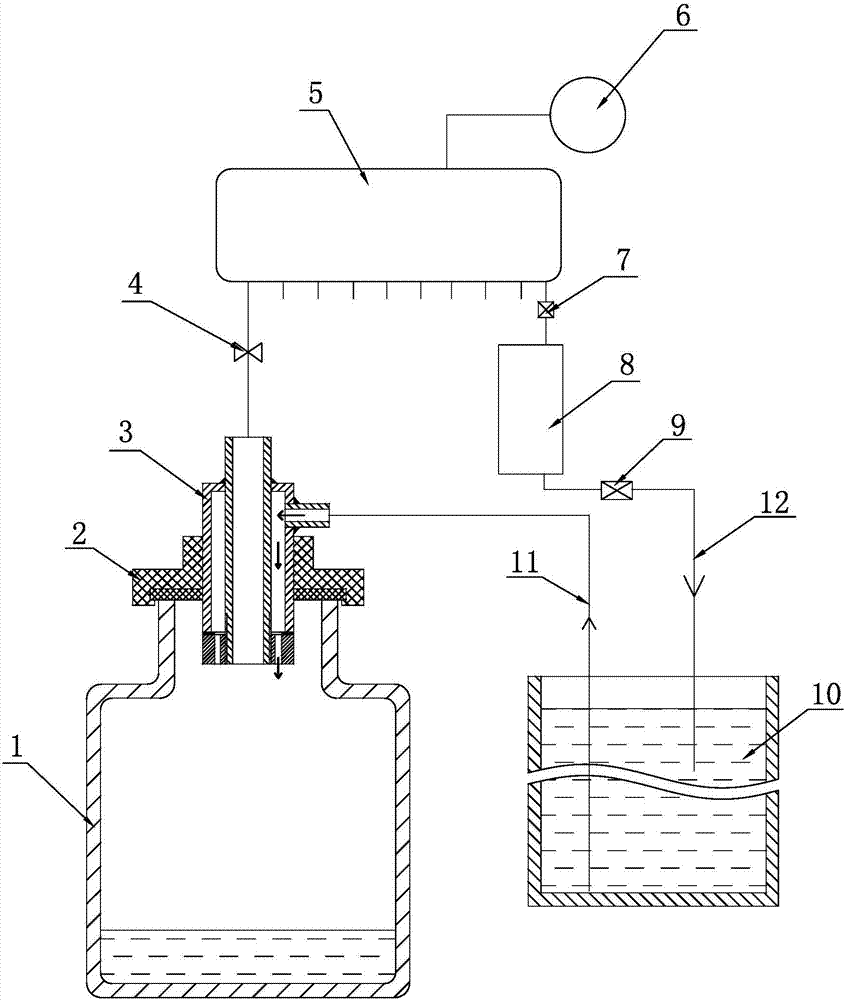

Negative pressure equal liquid level height control liquid filling device

InactiveCN107161933ASolve the problem of not being able to fill the bottle body at equal heightsWon't spillFilling using suctionEngineeringBottle

A liquid level control liquid filling device under negative pressure, including a bottle body, a bottle mouth sealing gland, a negative pressure filling head, a suction valve, a negative pressure chamber, a vacuum pump, an upper liquid discharge valve, a transitional liquid storage tank, The lower discharge valve and the material liquid tank, the negative pressure filling head is tightly fitted on the bottle mouth sealing gland, the lower end surface of the bottle mouth sealing gland is sealed and pressed with the bottle mouth, and the lower end surface of the negative pressure filling head extends In the bottle, the negative pressure channel of the negative pressure filling head communicates with the inner cavity of the negative pressure chamber, the liquid inlet channel of the negative pressure filling head communicates with the material liquid tank, and the negative pressure chamber passes through the upper discharge valve and the transitional liquid storage in turn. The tank and the lower drain valve communicate with the feed tank. It adopts the principle of negative pressure liquid suction, which can not only inject liquid into the bottle, but also suck the excess liquid back into the material liquid tank, and can realize equal height liquid level filling of various bottles, solving the problem of At present, ordinary liquid filling machines cannot fill the bottle body at equal heights. It meets the filling requirements of equal liquid level for special commodities such as canned fruit.

Owner:徐志明 +1

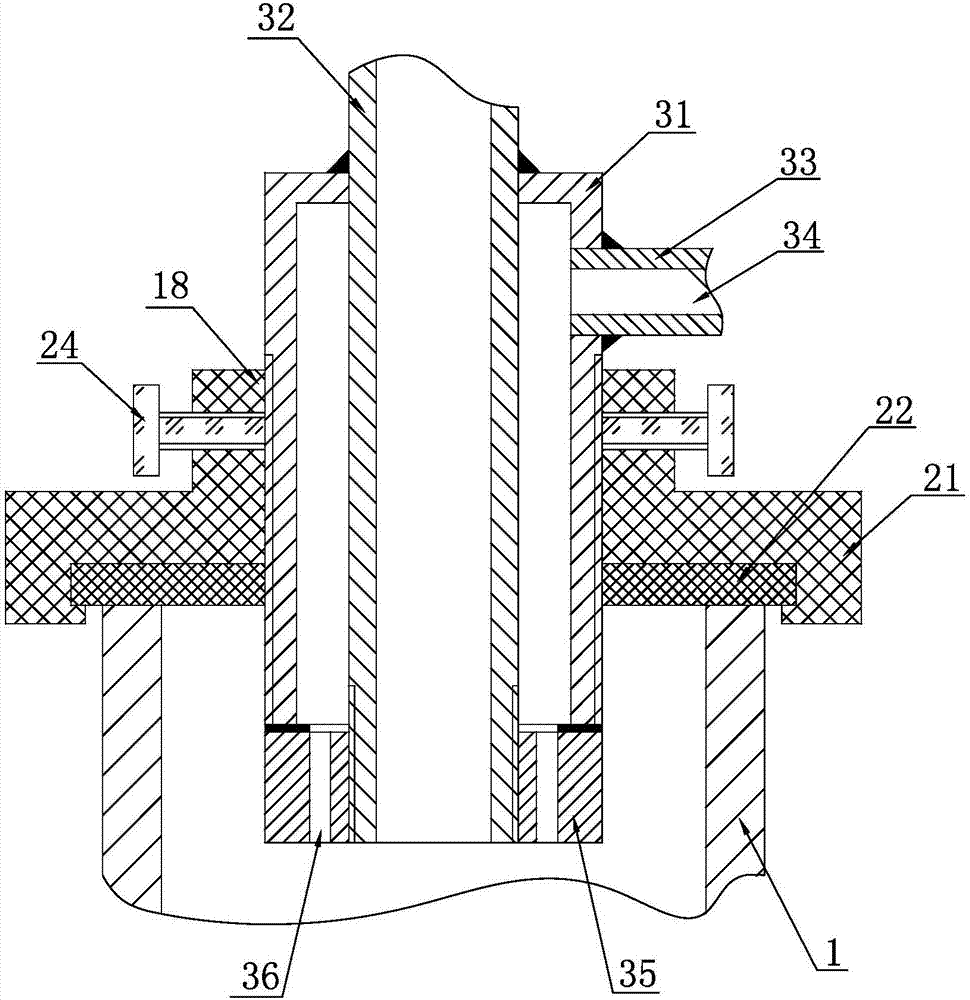

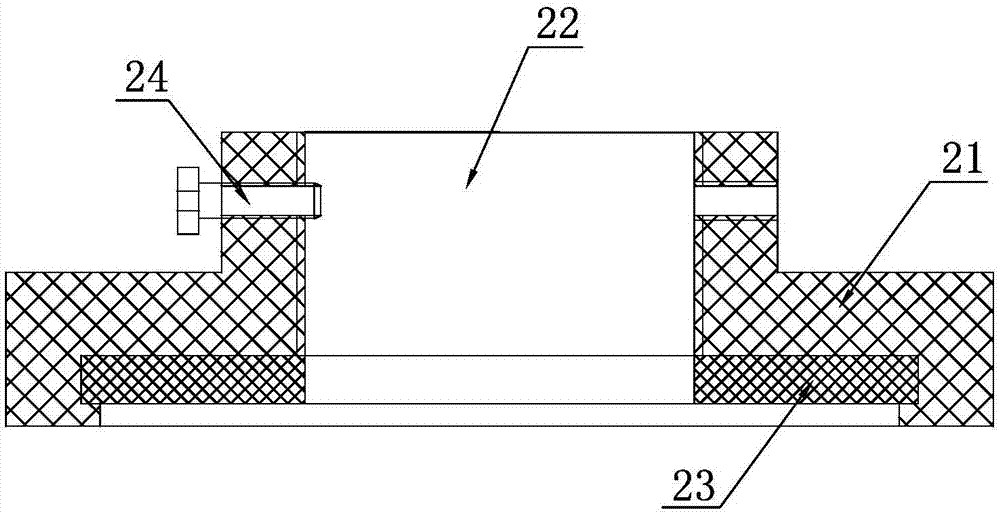

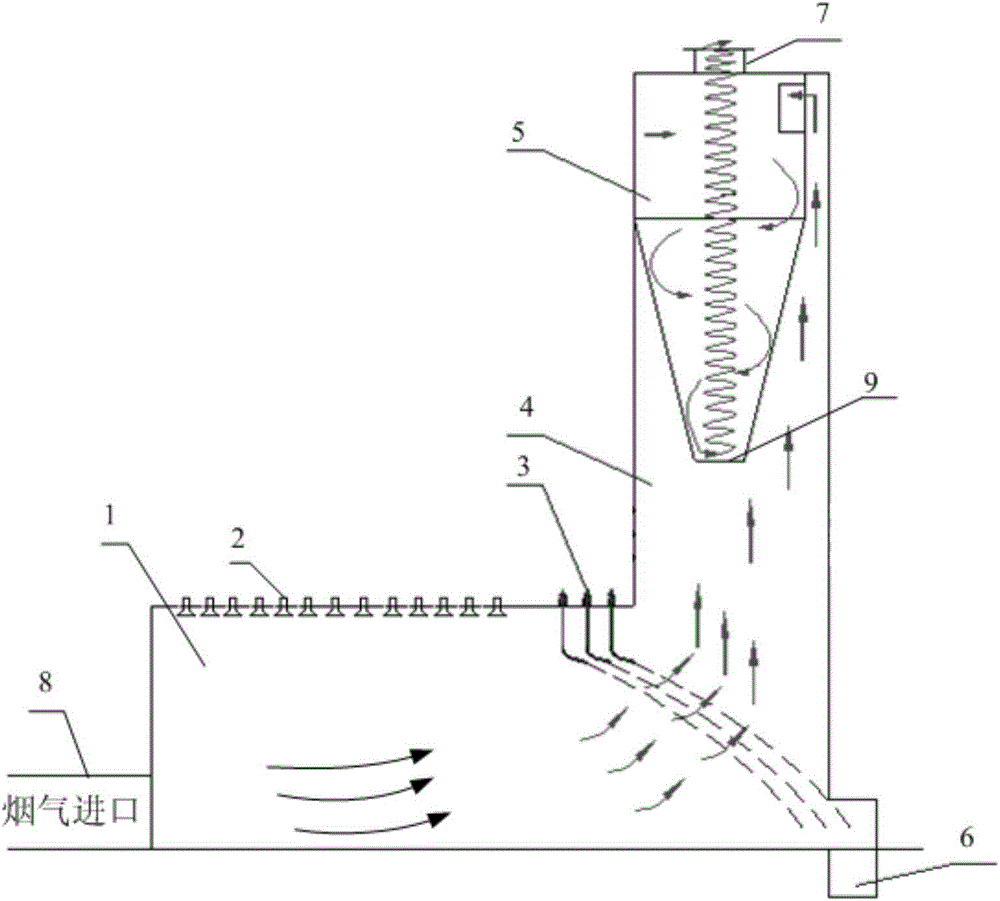

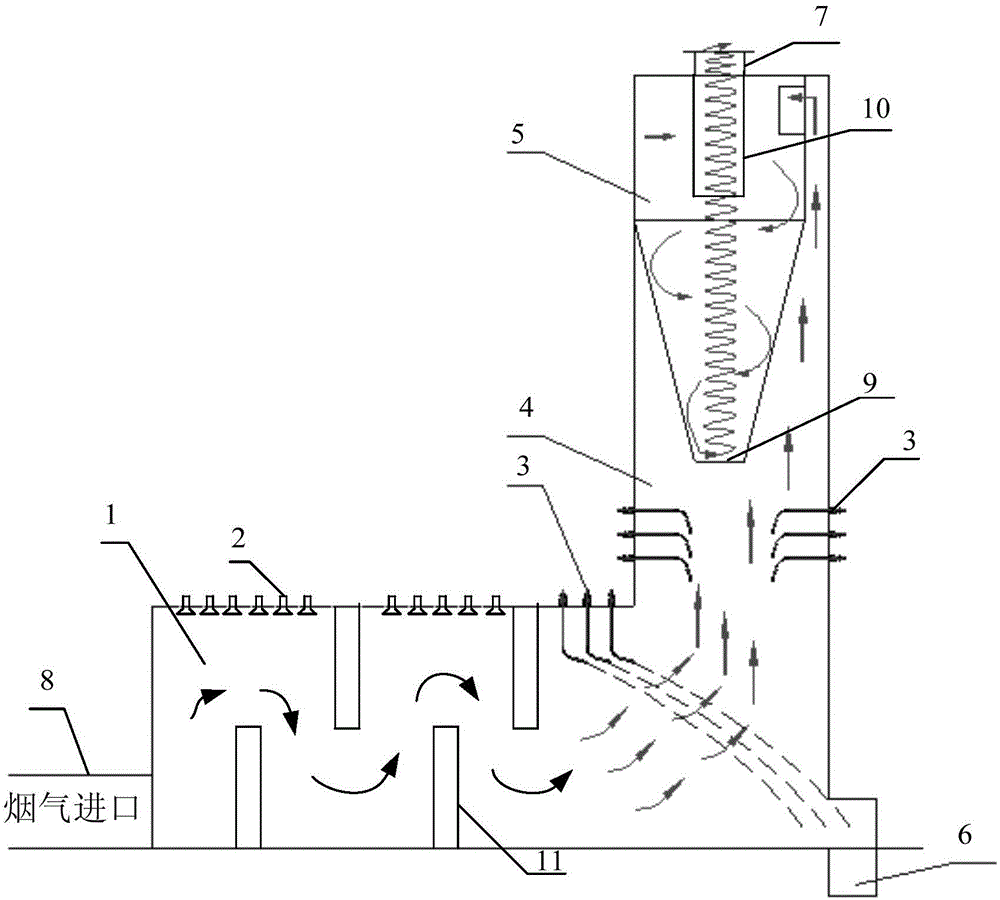

Sulfur and dust removal device

The invention provides a sulfur and dust removal device. The sulfur and dust removal device comprises a horizontal spray room, a sulfur removal spray head, a cooling spray head, a vertical chimney, a cyclone dust remover and a first sewage tank, wherein the vertical chimney is arranged above one side, far away from a flue gas inlet, of the horizontal spray room; the sulfur removal spray head is arranged at the top of one side, close to the flue gas inlet, of the horizontal spray room; the cooling spray head is arranged at the top of one side, close to the vertical chimney, of the horizontal spray room; the first sewage tank is arranged at the bottom of one side, far away from the flue gas inlet, of the horizontal spray room; the cyclone dust remover is arranged in the vertical chimney; a housing of the cyclone dust remover comprises a straight barrel section and a cone section; a gas outlet is formed in the top of the housing of the cyclone dust remover; the flue gas inlet is formed in the side surface at the upper part of the straight barrel section of the housing of the cyclone dust remover; a sewage outlet is formed in the lower end of the cone section of the housing of the cyclone dust remover; a second sewage tank is arranged below the sewage outlet. The sulfur and dust removal device is relatively good in sulfur and dust removal effects.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com