Electric vacuum cleaner

A vacuum cleaner and electric technology, applied in the installation of electrical equipment and other directions, can solve the problems of insertion error, inaccuracy of suction holes and suction ports, electric fan failure, etc., to prevent misuse, easy to use, easy to assemble and disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

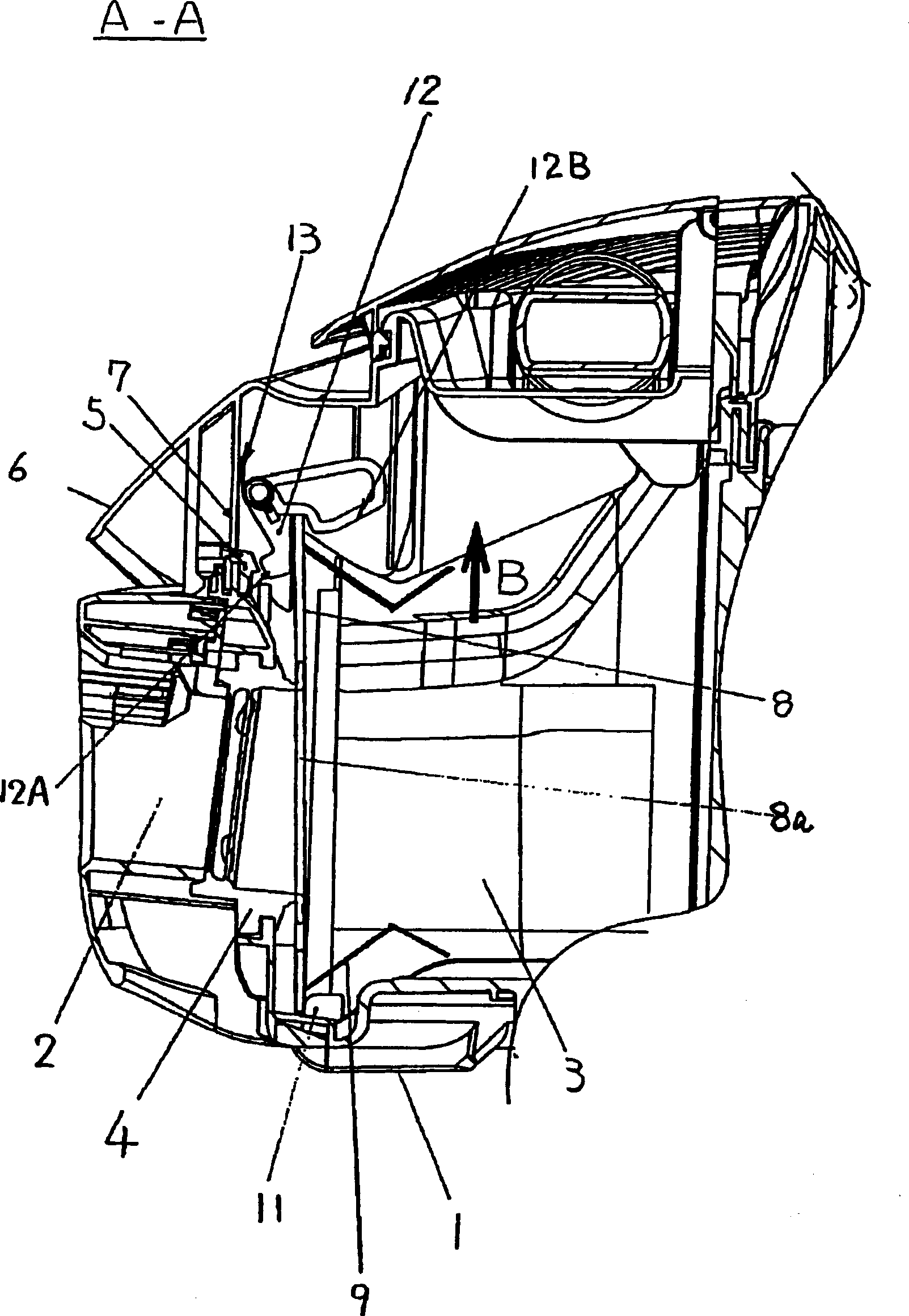

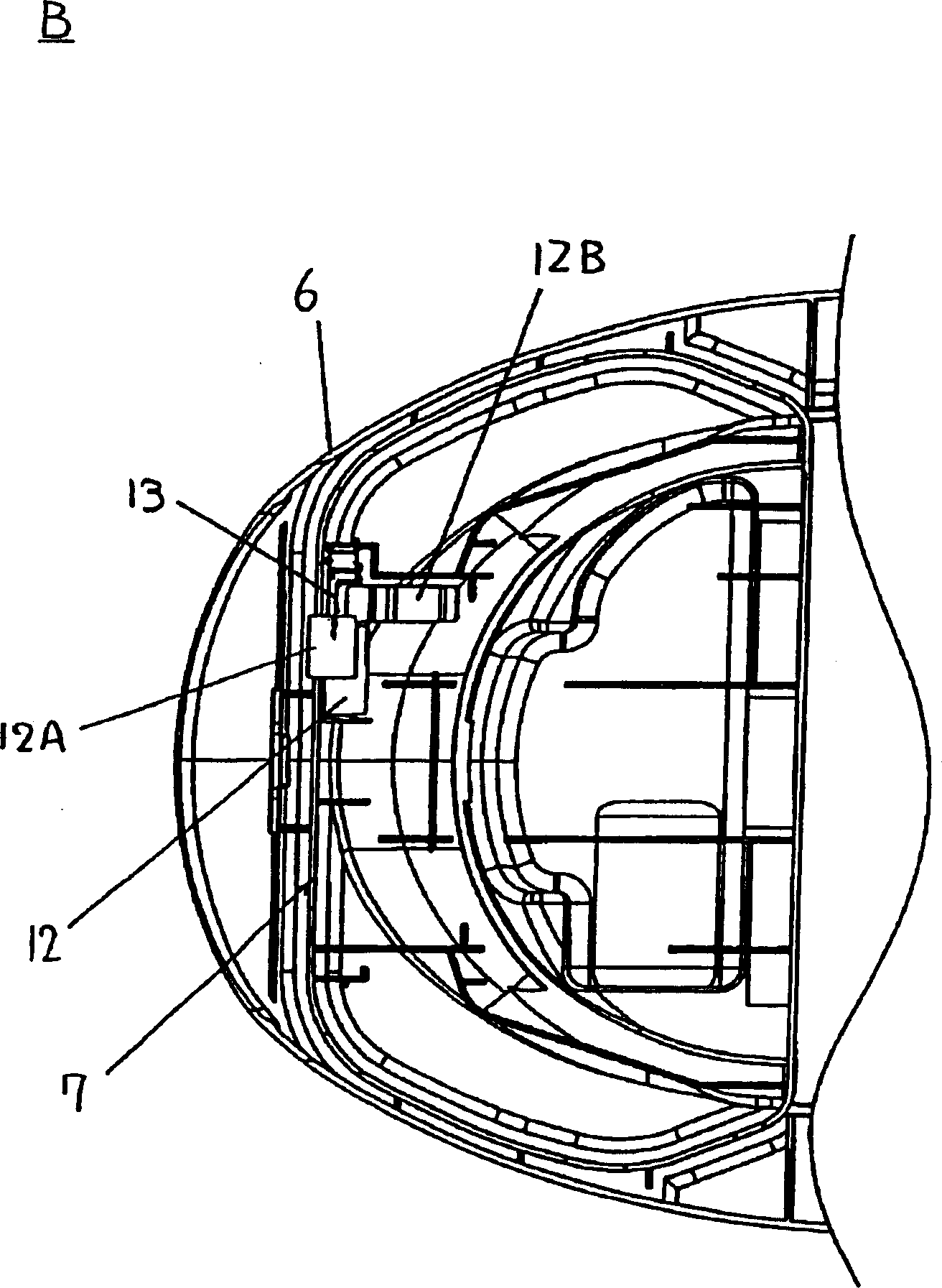

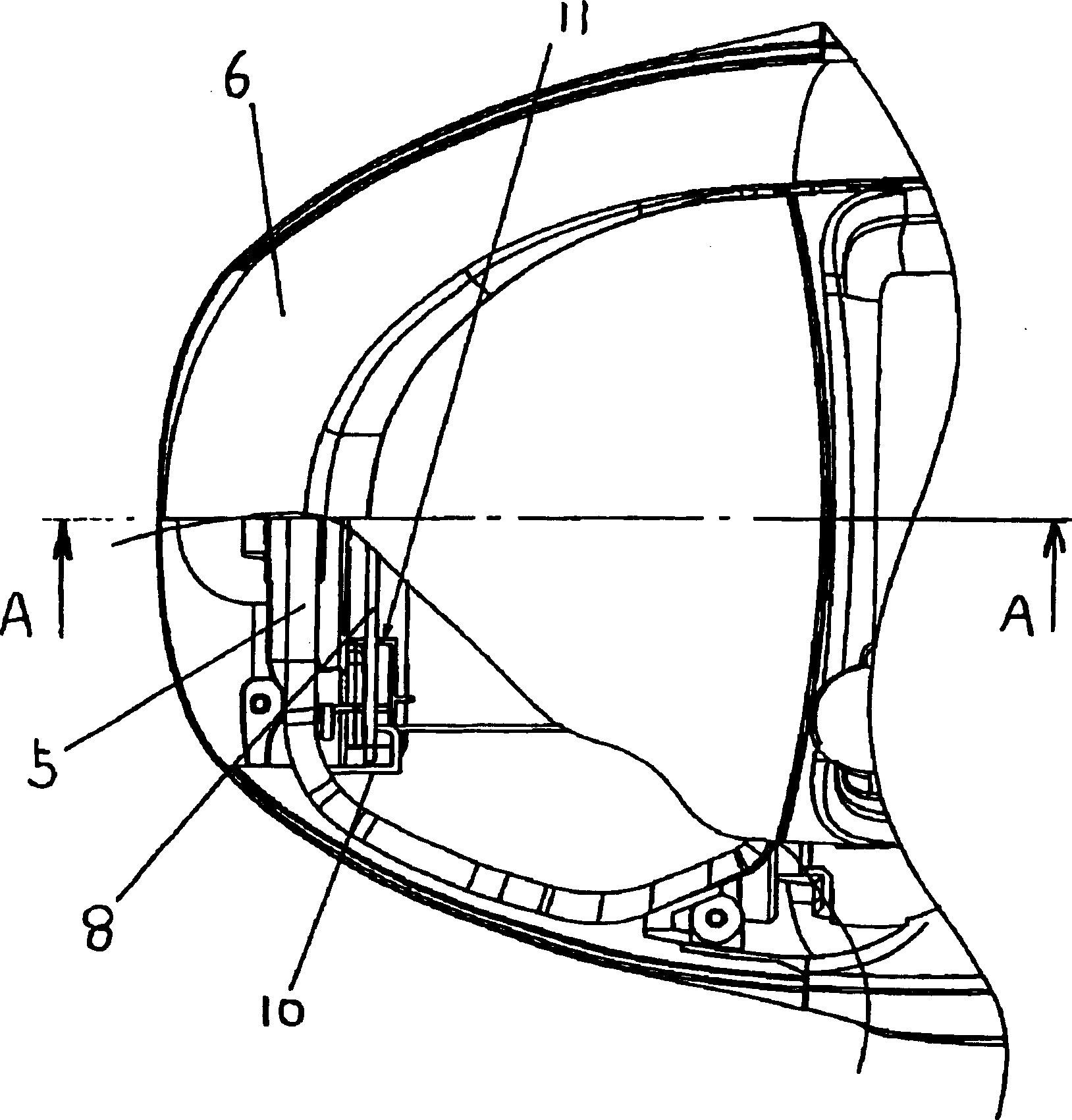

[0023] Use below Figure 1 to Figure 6 An embodiment of the present invention will be described. However, it should be noted that the scope of the present invention is not limited by such examples.

[0024] Such as figure 1 , 2 Shown in and 3, 1 is vacuum cleaner body, wherein is provided with electric blower chamber (not shown in the figure), the place ahead of this electric blower chamber is the dust collecting chamber 3 that is provided with suction port 2, and electric blower ( not shown in the figure). The suction port 2 is provided with a first sealing member 4 for achieving airtightness between the vacuum cleaner body 1 and the hose (not shown in the figure). In addition, the top of the dust collection chamber 3 is open, and the second sealing member 5 is provided on the entire upper edge of the open part. 6 is a cover that can rotate freely with the rear of the vacuum cleaner body as a fulcrum, and is used to collect dust. The opening above chamber 3 is partially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com