Novel self-loading and-unloading mechanism

A new type of self-loading and unloading technology, which is applied in the direction of transportation, packaging, garbage storage, etc., can solve the problems of weak clamping, complicated hydraulic system, complicated control operation, etc., and achieve the effect of ensuring cleanliness, reducing leakage points, and simplifying the hydraulic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

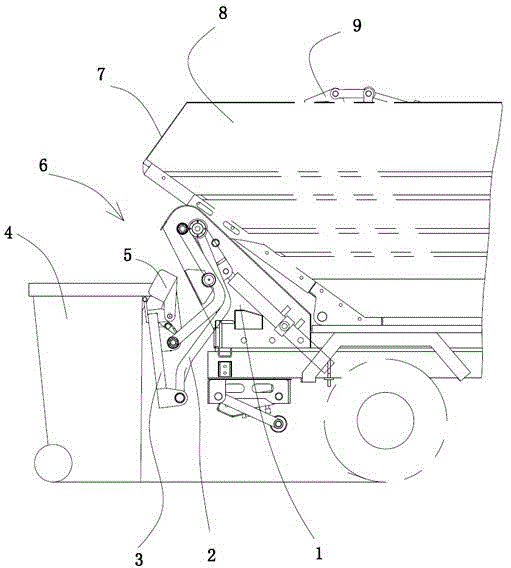

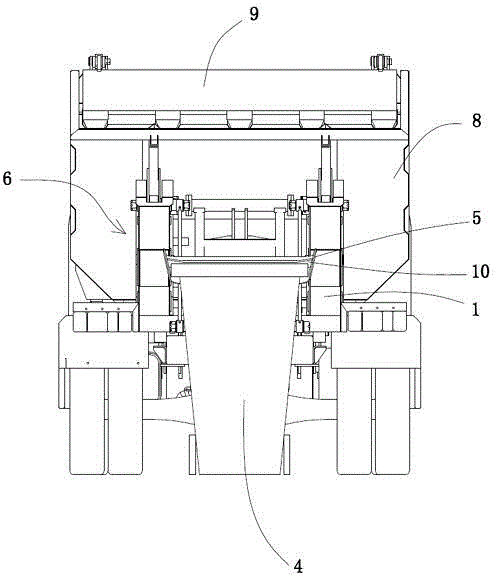

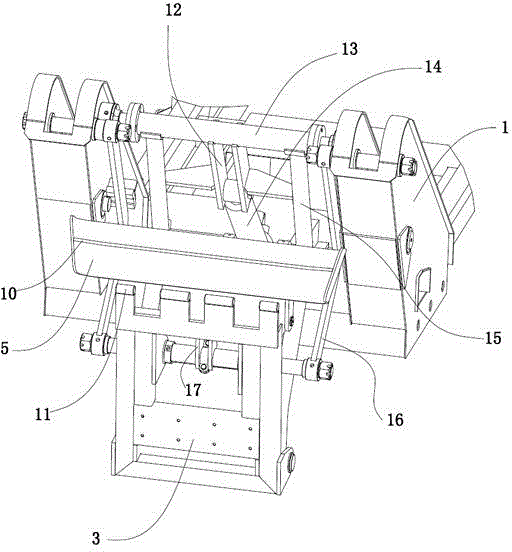

[0028] Embodiment: a kind of novel self-loading and unloading mechanism 6 (see attached figure 1 attached figure 2 attached image 3 ), including a bracket 1 fixed at the rear of the vehicle. A hydraulic cylinder 14 is hinged on the bracket. Two rotating arms 2 with different linear lengths are also hinged on the bracket. The ends of the two rotating arms are hinged with a base 3. The base is used for hanging bucket.

[0029]The short pivoting arm of straight line length is to adjust pivoting arm 16, and the long pivoting arm of straight line length is turning over pivoting arm 15. Wherein the adjusting arm is above the flipping arm, that is, the position where the adjusting arm is hinged to the base is above the base, the position where the flipping arm is hinged to the base is below the base, and the position where the adjusting arm is hinged to the bracket is higher than that of the flipping arm. The position hinged with the bracket is high. The two pivoting arms are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com