Hoisting technology for giant acrylic plate

An acrylic board, hoisting technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of acrylic board damage, difficulty in installation, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

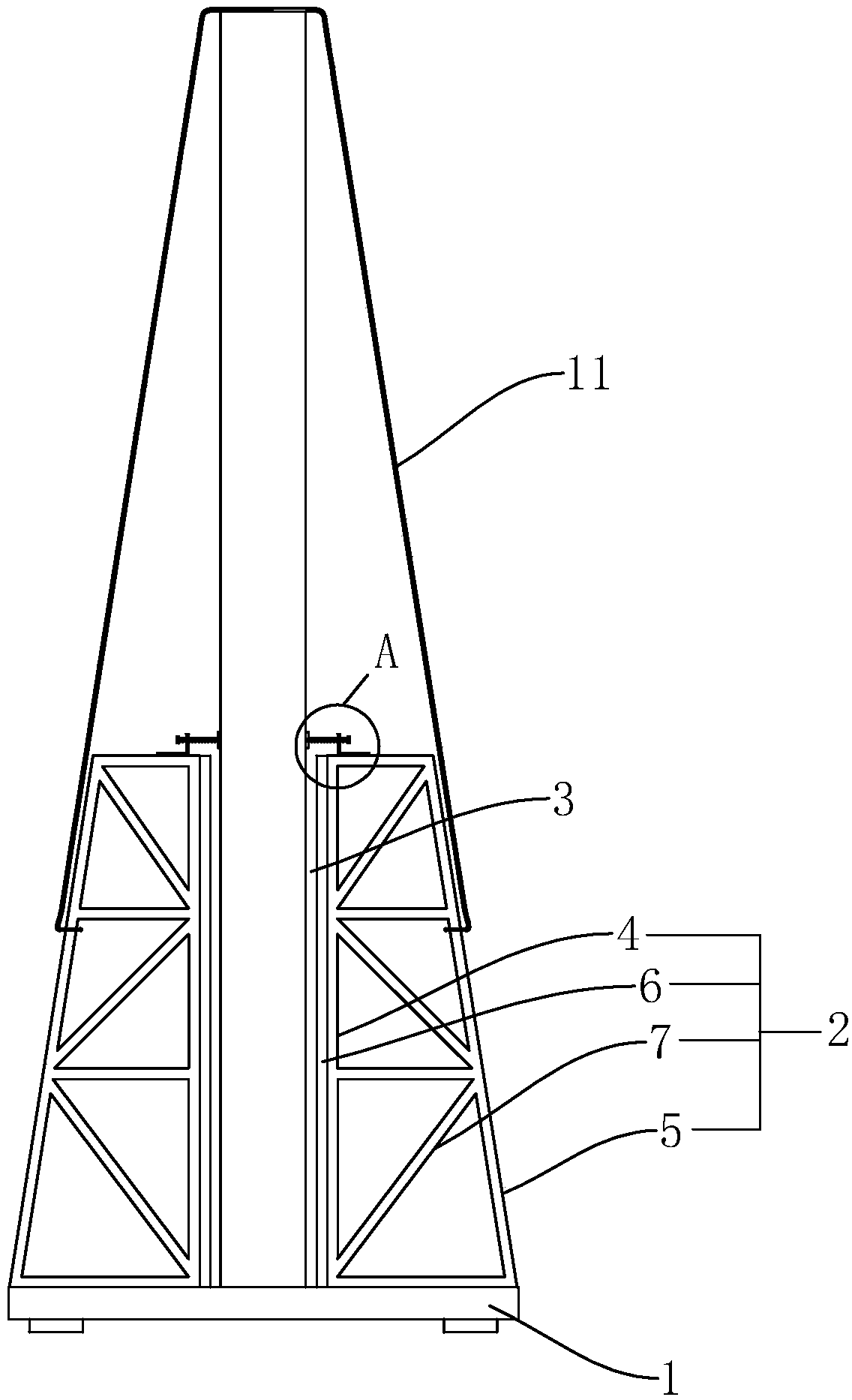

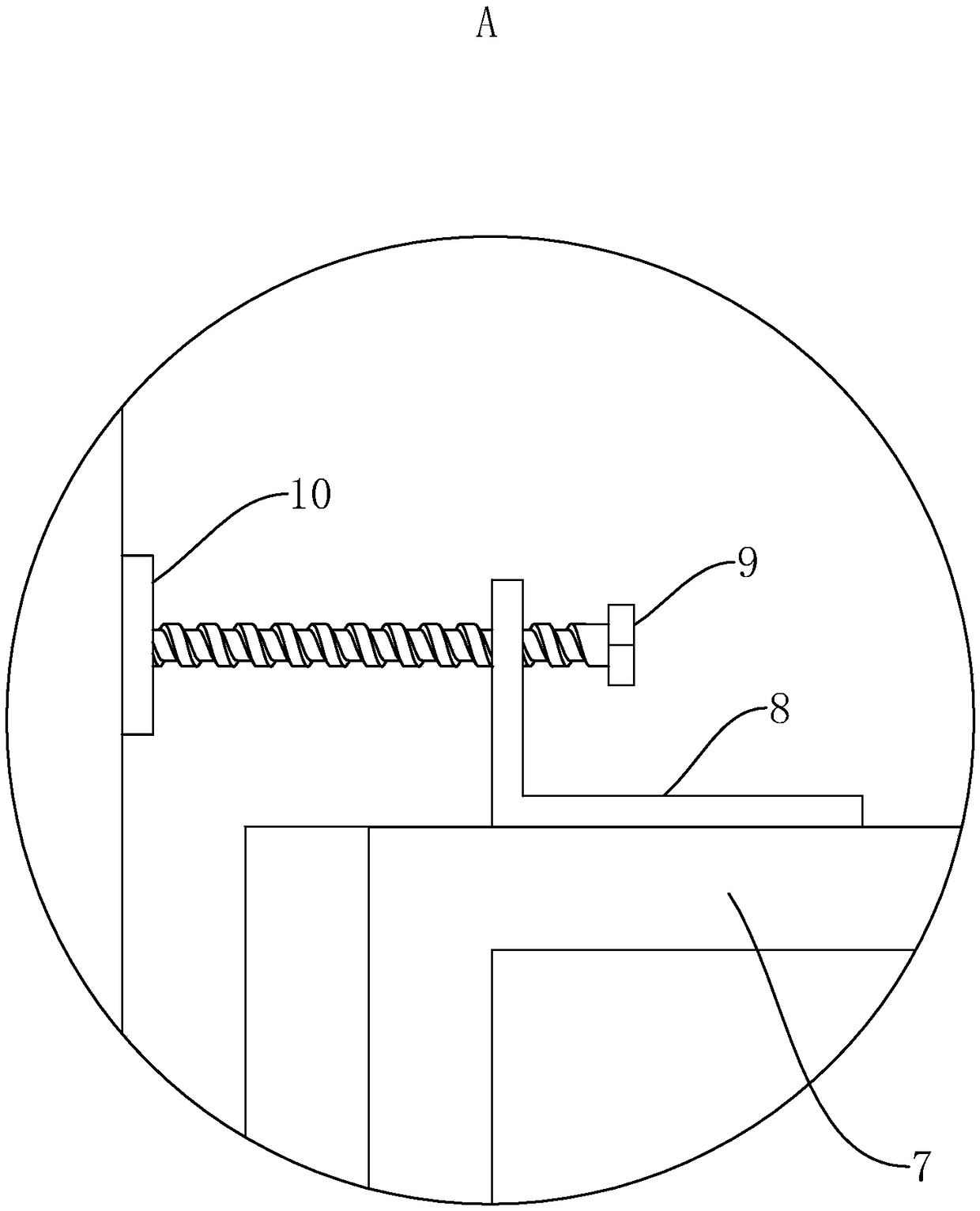

[0037] The present invention will be further described with reference to the accompanying drawings.

[0038] A hoisting process for giant acrylic panels, including:

[0039] A. Transport the acrylic board to the ground hoisting position

[0040] B. Prepare to hoist the acrylic plate after ensuring the safety of the crane, acrylic plate and ground support points

[0041] C. Use a 260T crane to hoist a 75T crane and a special transfer vehicle into the large fish tank

[0042] D. Fix the acrylic board with nylon fiber sling

[0043] Aiming at the acrylic board, which is of great value in this project, it is also fragile. When hoisting, the protective layer needs to be removed. If wire rope is used for hoisting, the edges and corners of the acrylic board will be damaged. Therefore, fiber flat slings are used as hoisting tools.

[0044] E. Use 160T crane and 25T crane to lift in cooperation

[0045] When lifting, first use a 160T crane to lift one side of the acrylic plate, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com