Medium-density fiberboard

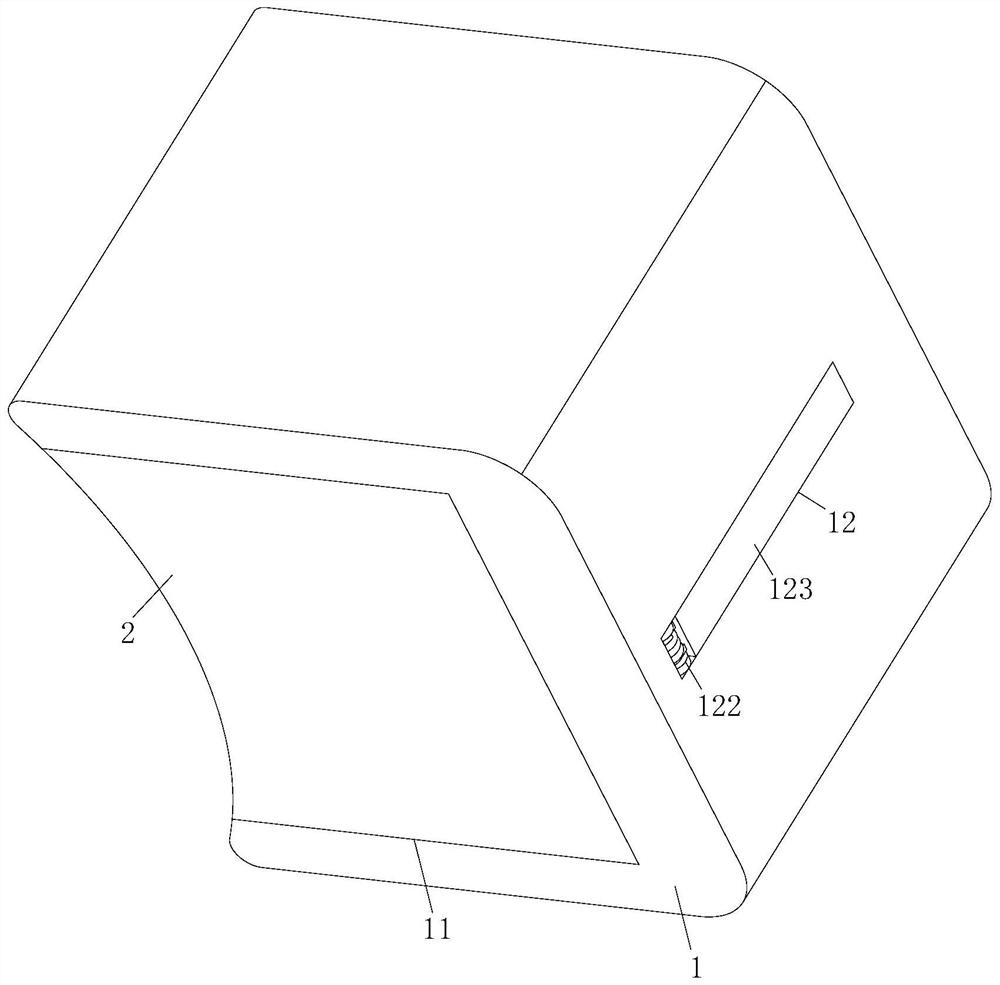

A fiberboard and medium-density technology, applied in the field of fiberboard, can solve the problems of medium-density fiberboard sinking, falling of objects and people, and small expansion and contraction, and achieve the improvement of stability and aesthetics, improve aesthetics, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

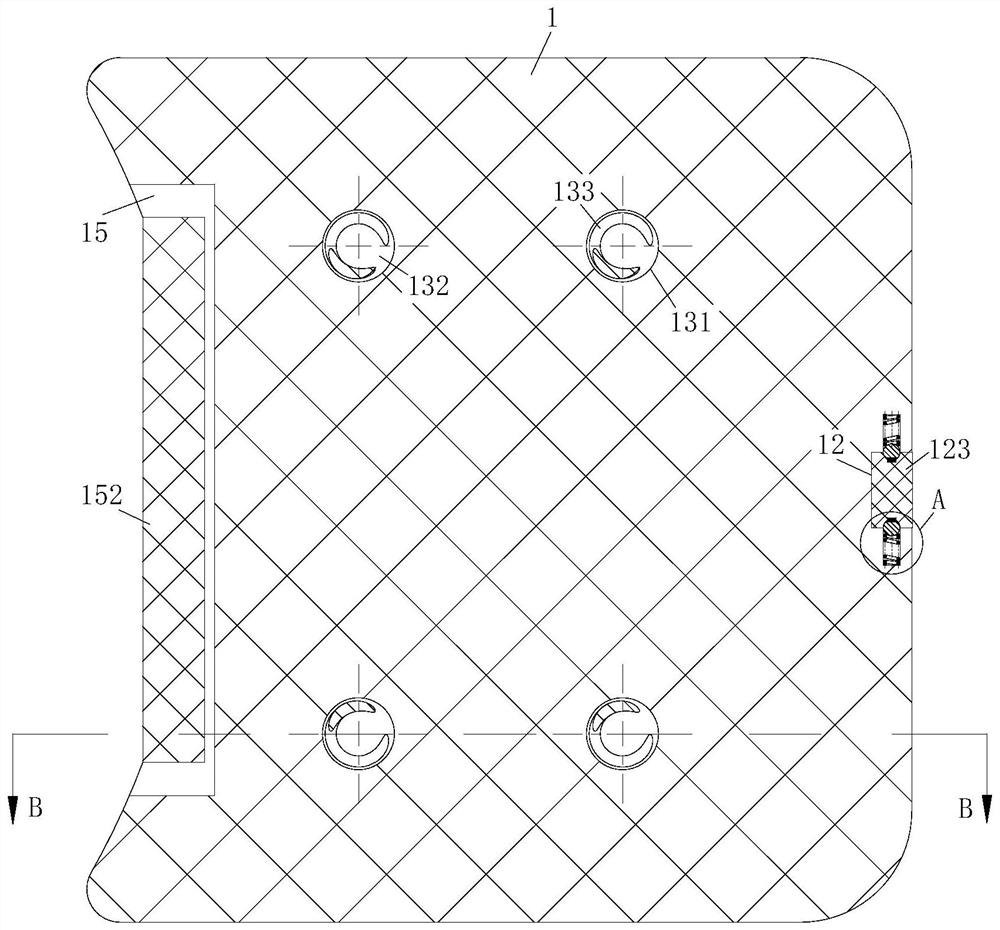

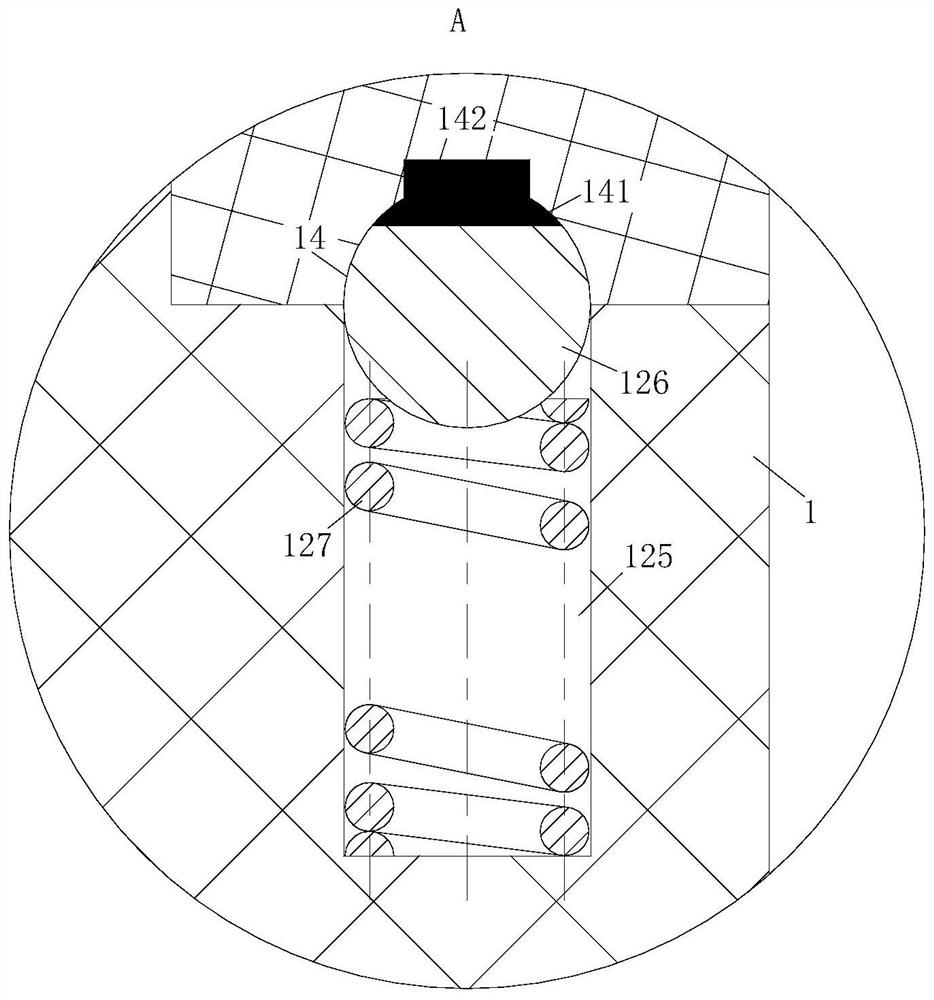

[0030] As an embodiment of the present invention, a blind hole 125 is arranged between the two groove walls of the L-shaped groove 12; a round block 126 is slidably connected in the blind hole 125, and a No. 2 spring is also arranged in the blind hole 125 127; one end of the No. 2 spring 127 is connected to the bottom of the blind hole 125, and the other end is connected to the round block 126; the round block 126 is in contact with the two side walls of the clamping plate 123 under the action of the No. 2 spring 127; During use, the clamping plate 123 is only stuck in the L-shaped groove 12 by the effect of the torsion spring, so that the clamping plate 123 shakes in the L-shaped groove 12 after the torsion spring is used for a long time, which affects the use effect and appearance of the MDF Therefore, after the clamping plate 123 is stuck in the L-shaped groove 12 in the present invention, the No. 2 spring 127 produces an elastic force after being pressed, so that the No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com