Patents

Literature

36results about How to "No sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

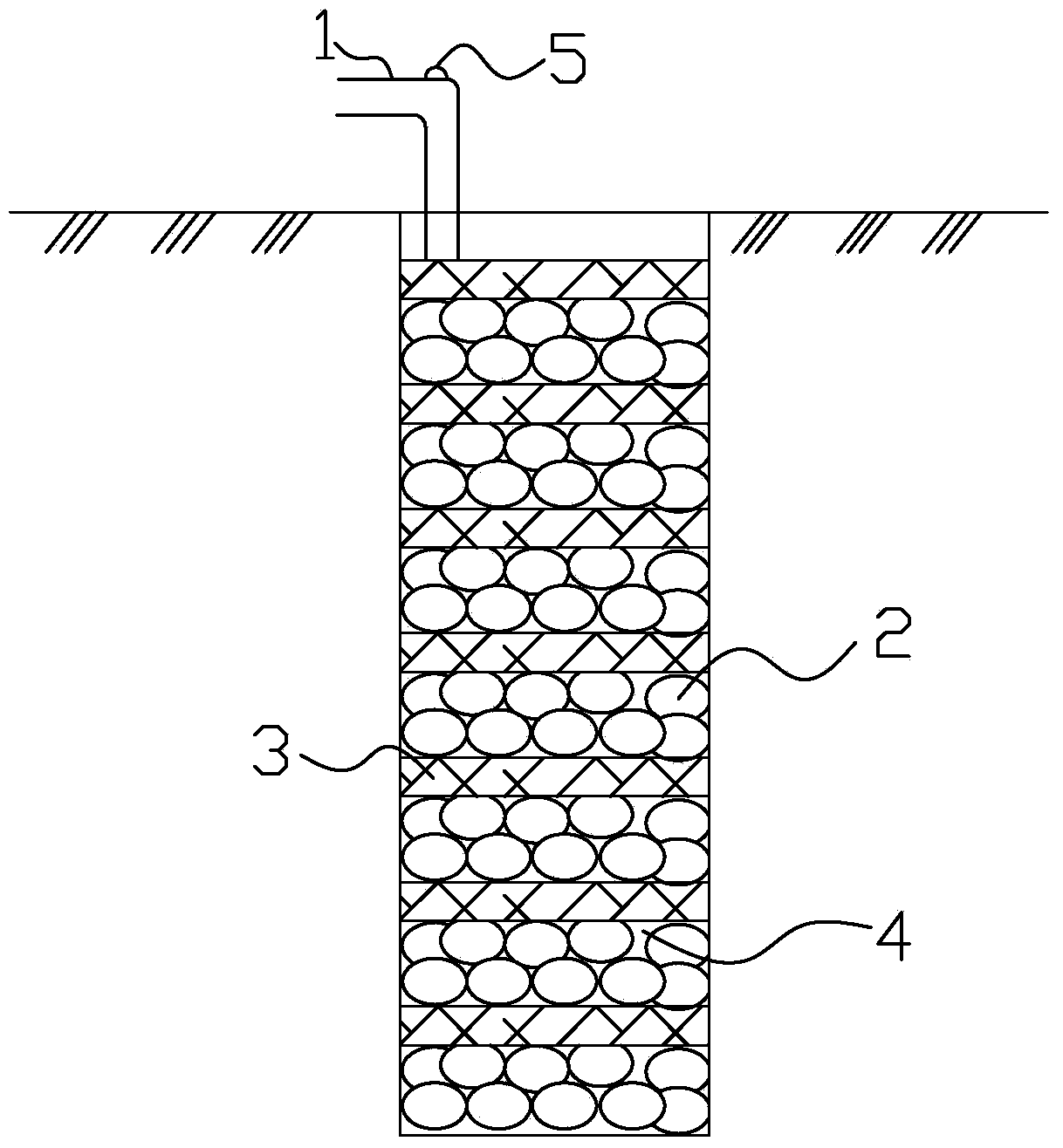

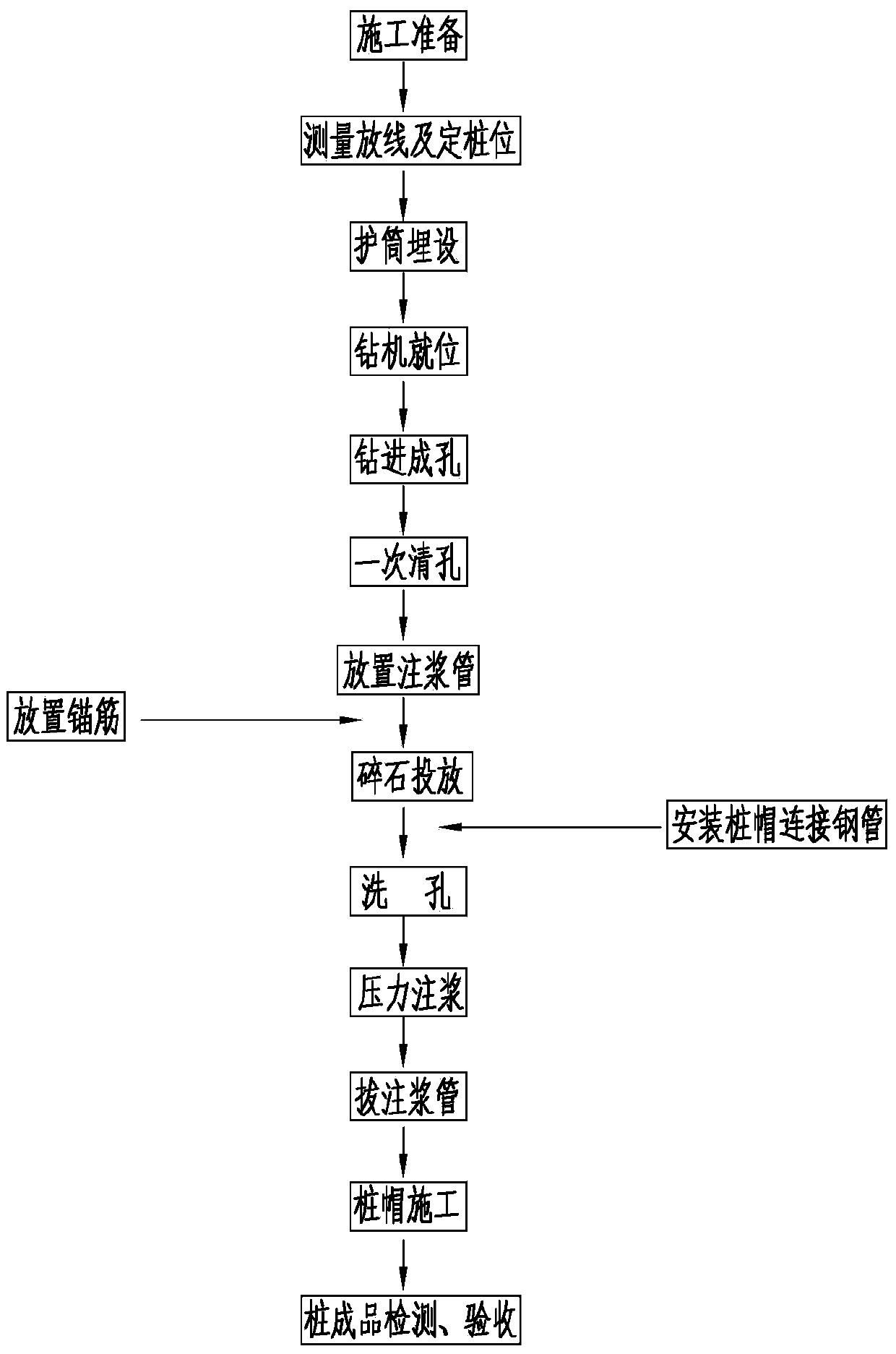

Construction method of gravel grouting pile

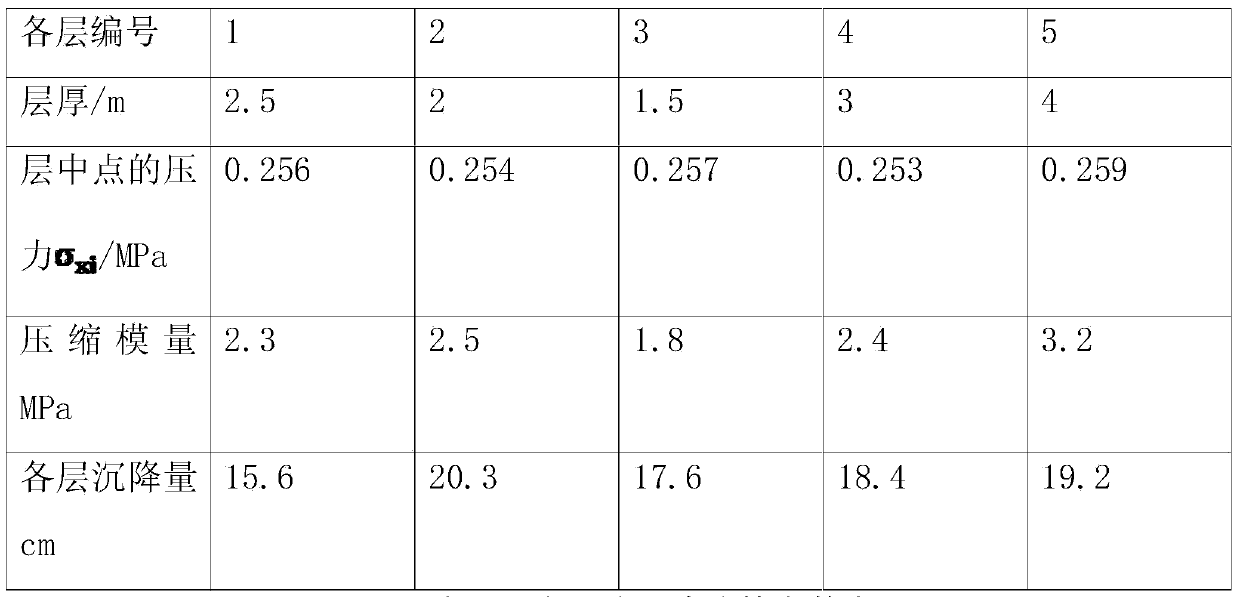

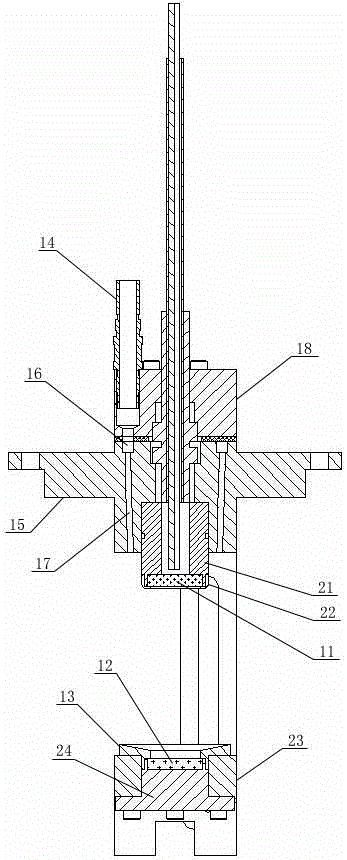

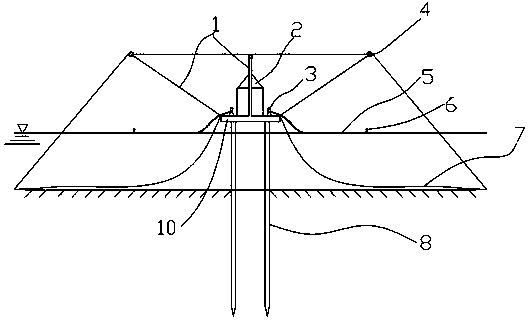

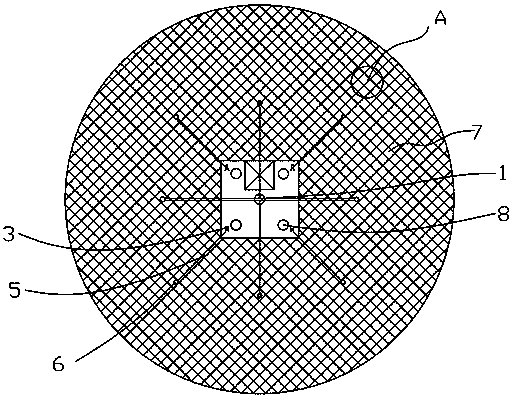

The invention discloses a construction method of a gravel grouting pile. The construction method comprises the following steps: (1) preparing for construction, (2) conducting measurement, paying off and positioning of the pile, (3) embedding a protective canister, (4) placing a drilling machine in place, (5) forming a hole by drilling, (6) cleaning the hole at a time, (7) placing a grouting pipe, (8) placing an anchor bar, (9) putting gravels in the hole, (10) installing a pile cap connecting steel pipe, (11) cleaning the hole, (12) conducting pressure grouting, (13) pulling the grouting pipe out, (14) constructing a pile cap, and (15) conducting detection and acceptance inspection on the finished pile. According to the construction method of the gravel grouting pile, the construction speed is high, the construction period is shortened, and compared with soft foundation treatment such as a prestressed pipe pile and a Y-type pile, the engineering investment is saved; the labor intensity is low, the construction is safe, and the construction method can be widely popularized and used; the gravel pile formed by cement and gravels is high in integrality and stability. The engineering drilling machine is adopted in a soft foundation to drill the hole in a rotating and cycling mode to form the pile, the disturbance to the foundation and the surrounding buildings is small, ground depression is controlled, and the construction method is small in vibration and low in noise during the construction and has good social benefits.

Owner:NINGBO SHENGHONG CONSTR ENG

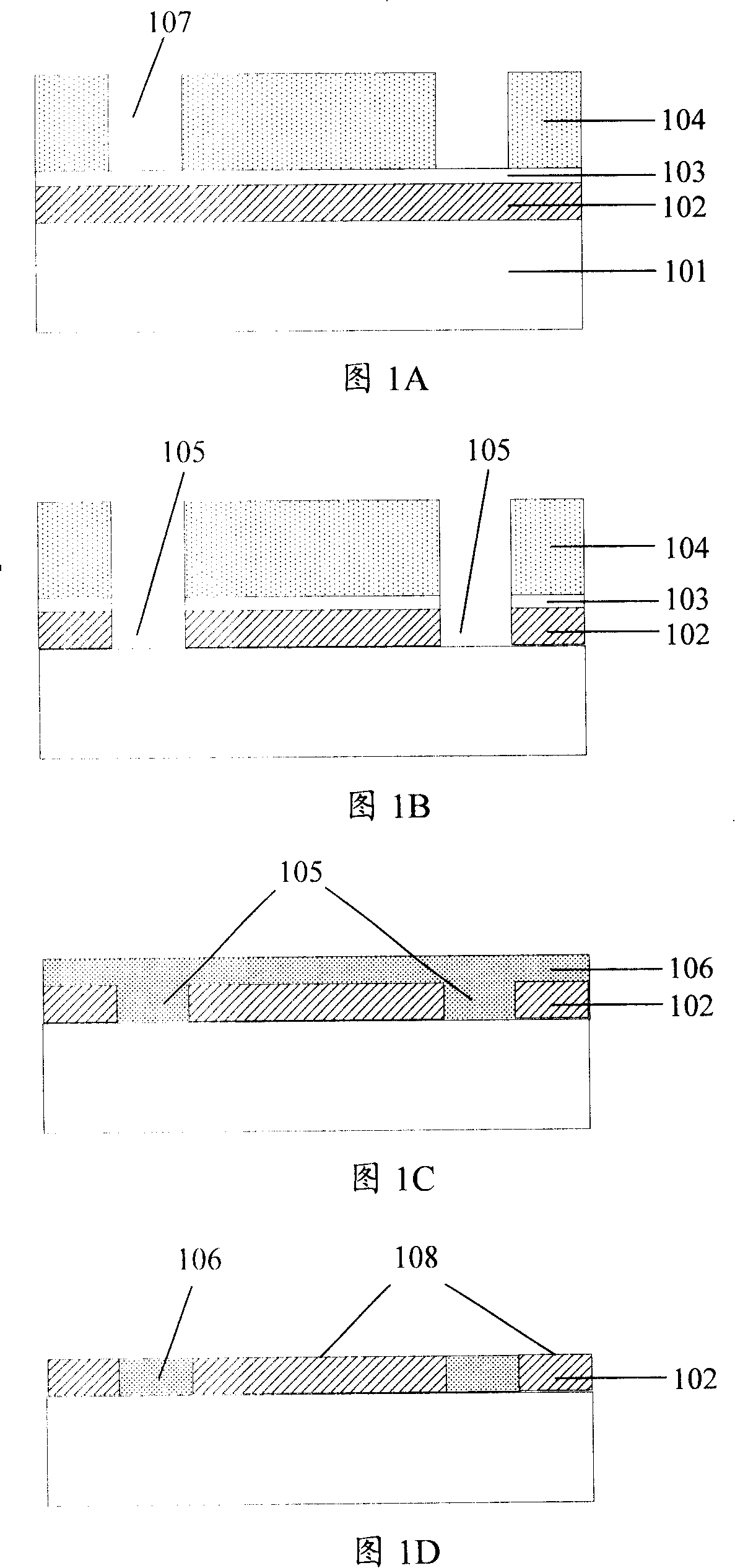

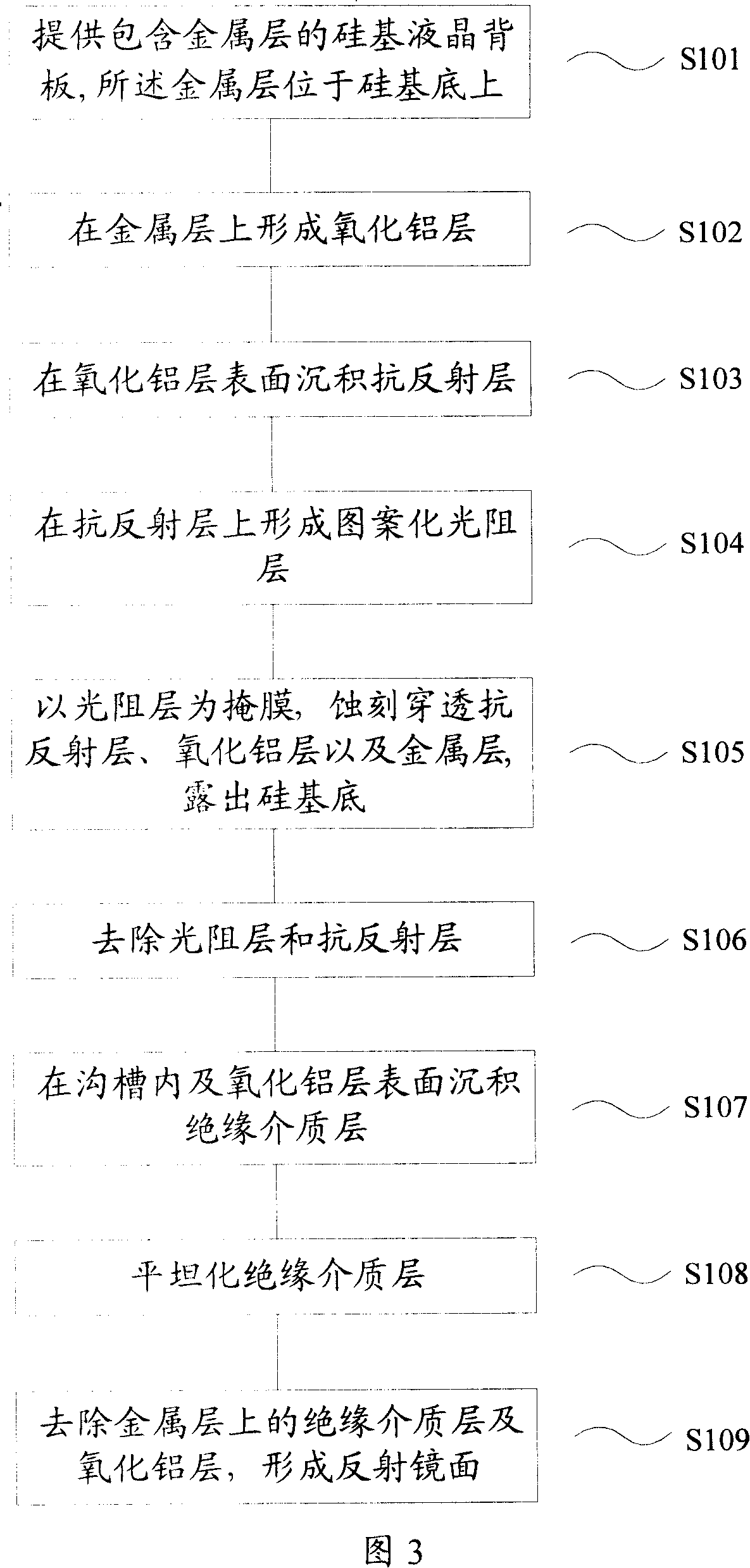

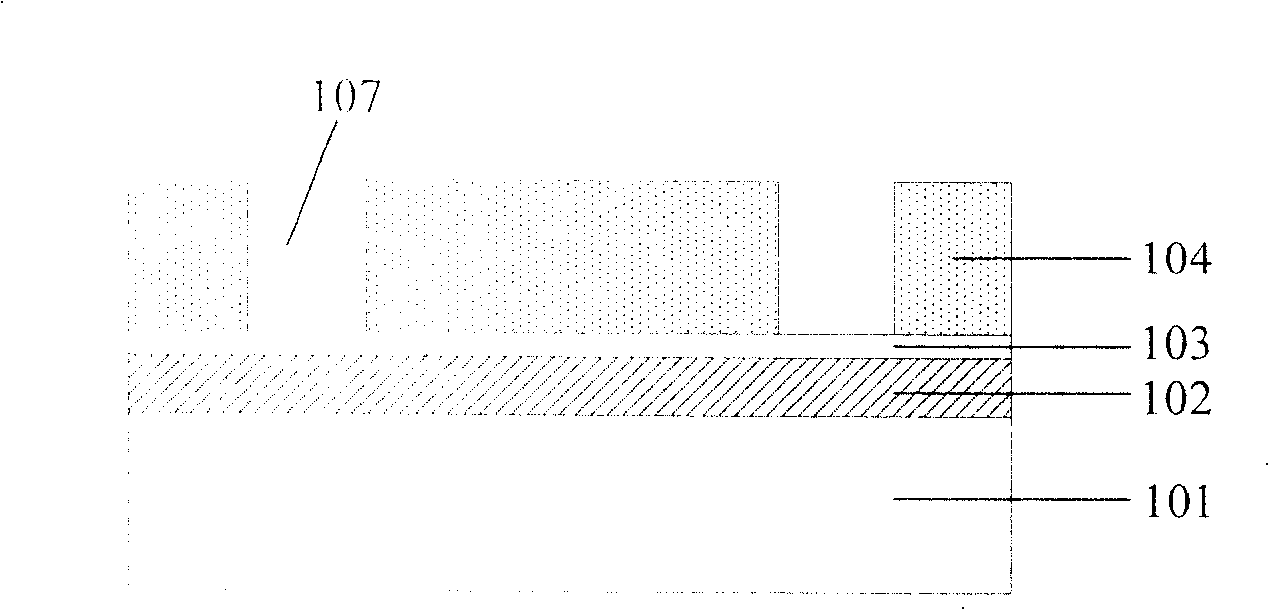

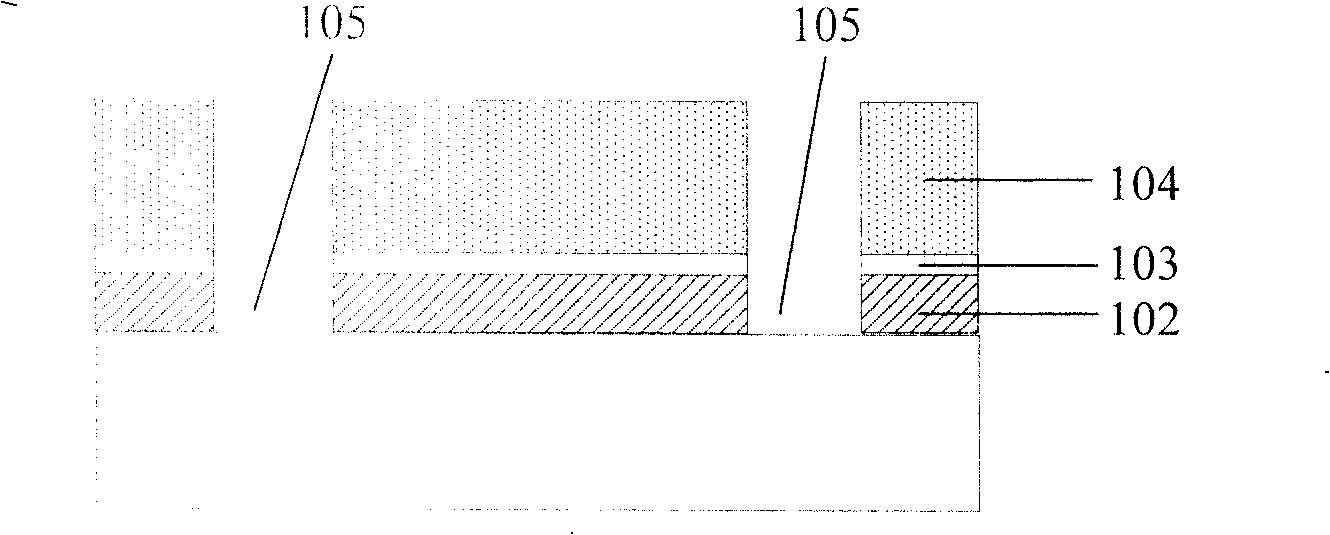

Manufacturing method for reflection mirror of silicon-based LCD device

ActiveCN101153969AThe probability of electrochemical reaction is reducedThe probability of electrochemical reaction is smallStatic indicating devicesPhotomechanical apparatusElectrochemical responseLiquid-crystal display

A reflective mirror face of silicon-based liquid crystal display device has the following preparation method: an alumina layer is formed on a metal layer; a silicon oxide layer is deposited on the alumina layer; an anti-reflecting layer is deposited on the surface of the silicon oxide layer; a pattern photoresistive layer is formed on the anti-reflecting layer; with the photoresistive layer as mask, the anti-reflecting layer, the silicon oxide layer, the alumina layer and the metal layer are etched and penetrated to reveal the silicon-based bottom; the photoresistive layer and the anti-reflecting layer are removed; insulated medium layers are deposited in a groove and on the surface of the silicon oxide layer; the insulated medium layers are evened out; the insulated medium layers, the silicon oxide layer and the alumina layer on the metal layer are removed to form a reflective mirror face. As the alumina layer and the silicon oxide layer are arranged on the surface of the metal layer, when the photoresistive layer and the anti-reflecting layer are removed by alkaline solution, the metal layer is protected by the alumina layer and the silicon oxide layer in order to have no electrochemistry reaction and no deboss in the reflective mirror face, thereby improving the quality of the reflective mirror face.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

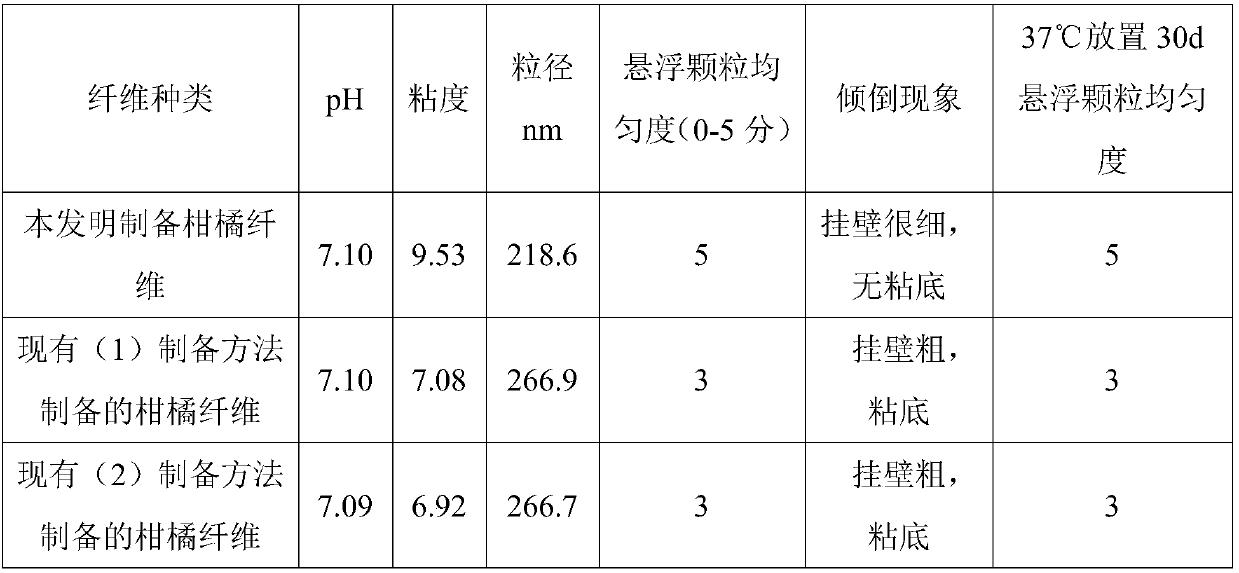

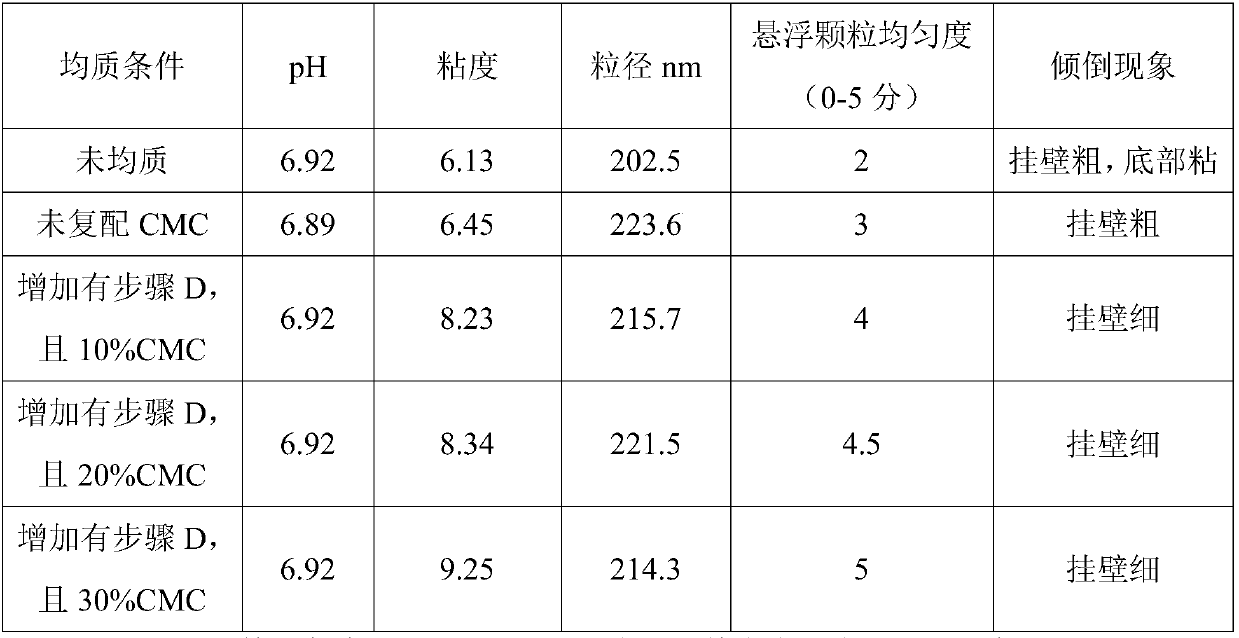

Suspension stabilizer, suspended particle peanut milk beverage and preparation method of suspension stabilizer and suspended particle peanut milk beverage

ActiveCN108013148AEvenly suspendedNo sinkingFood ingredientsMilk substitutesSuspended particlesCarboxymethyl cellulose

The invention relates to a suspension stabilizer, a suspended particle peanut milk beverage and a preparation method of the suspension stabilizer and the suspended particle peanut milk beverage, belonging to the technical field of foods. The suspension stabilizer contains a stabilizer A and a stabilizer B in a mass ratio of (1.5-3) to (1-2), wherein the stabilizer A contains the following components in percentage by mass: 5%-25% of citrus fibers, 10%-60% of microcrystalline cellulose, 10%-30% of sodium carboxymethyl cellulose, 40%-70% of glycerin fatty acid ester and 0-10% of xanthan gum. Theinvention further discloses the preparation method of the suspension stabilizer and the suspended particle peanut milk beverage. By utilizing fruit-vegetable fiber suspension stabilizer, after solid particles are added into the peanut milk beverage, particles are uniformly suspended in material liquid and are uniformly suspended but not precipitate in a UHT sterilization pipeline.

Owner:HEBEI BROS ILONG FOOD TECH LLC

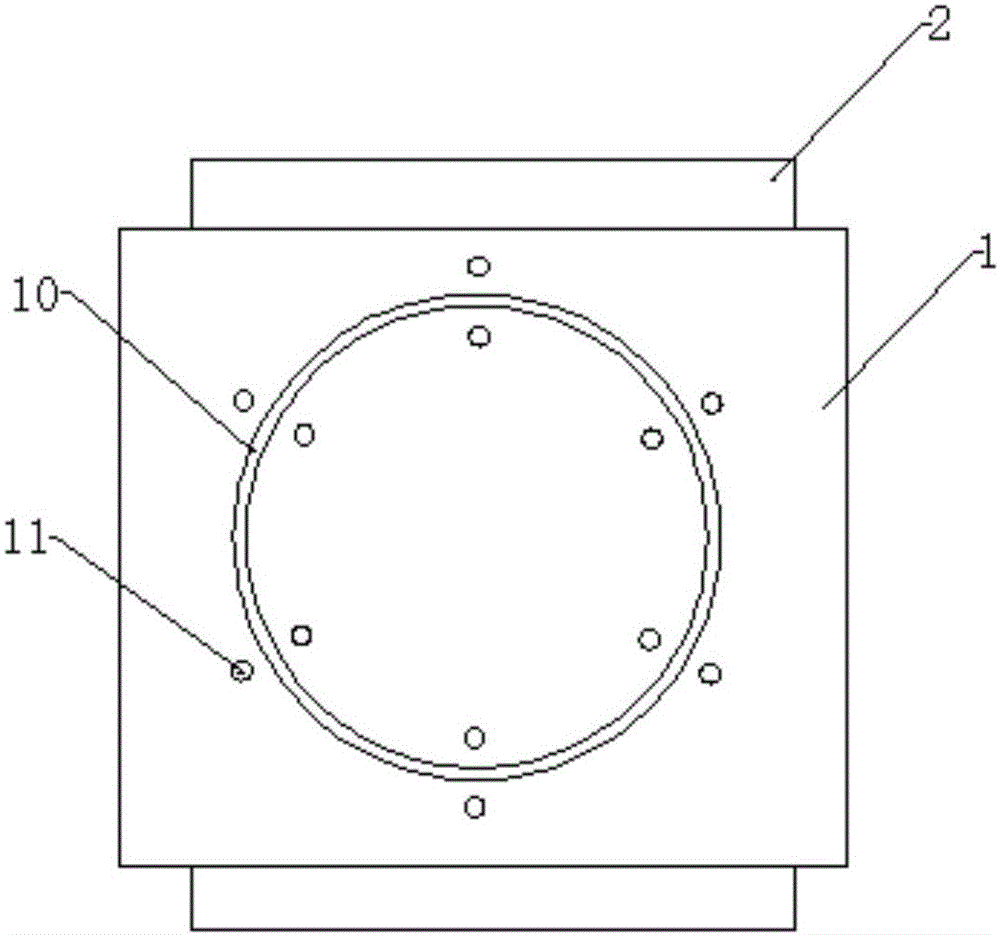

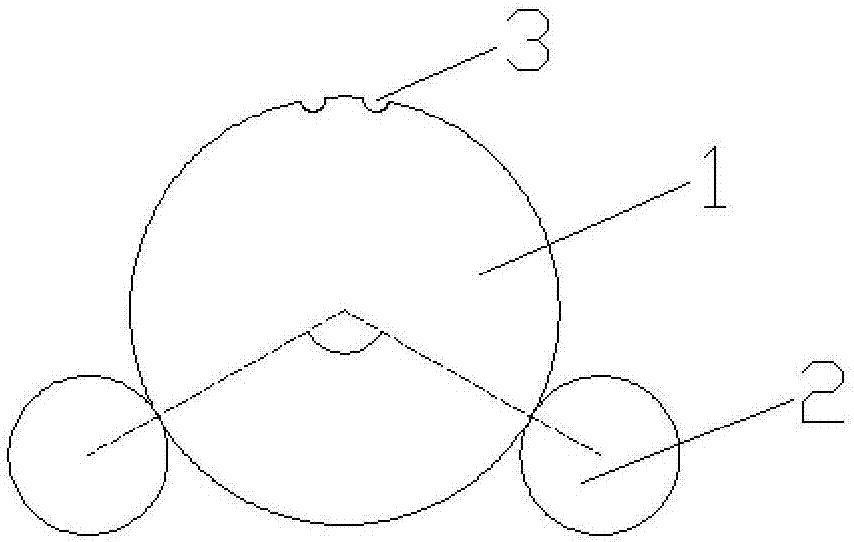

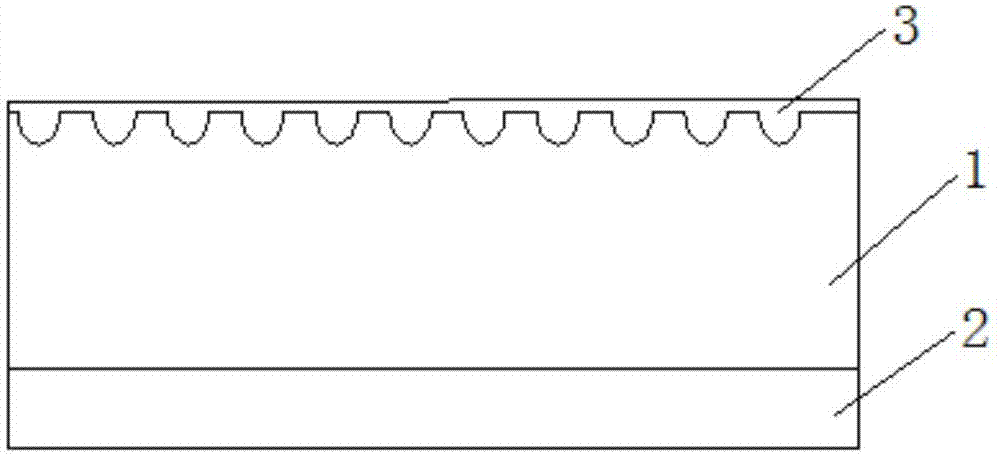

Die for cutting thin sheet and method for cutting thin sheet

InactiveCN106002039ANo sinkingThere will be no deformationWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingThin sheet

The invention provides a mold for thin plate cutting, which includes a tire board, cutting grooves are provided on the upper surface of the tire board, and the shape of the cutting grooves corresponds to the shape of workpieces to be processed. Magnets are arranged on the upper surface of the tire plate. When cutting, the thin plate is placed on the upper surface of the tire plate, and the cutting path of the laser follows the cutting groove on the tire plate. When the pressure gas acts on the thin plate, the entire thin plate can be supported by the tire plate, and there will be no sinking and deformation of the thin plate. The thin plate is firmly fixed on the tire plate through the magnet, which solves the problem of displacement of the thin plate during the cutting process and improves the machining accuracy of the cutting workpiece. The invention also provides a thin plate cutting method, which includes making cutting grooves of the mold, fixing the thin plate on the tire plate through magnets, and cutting along the cutting grooves with laser light.

Owner:四川新远宏机械设备有限公司

Au-Sn alloy electroplating liquid

The invention discloses an Au-Sn alloy electroplating liquid which consists of an Au compound, an organic acid Sn compound, a complexing agent, a pH buffering agent or stabilizing agent and a Sn<2+> antioxidant. Sinking is not generated in the processes of storing and using the Au-Sn alloy electroplating liquid disclosed by the invention; and the Au-Sn alloy electroplating liquid is stable in property, and dose not damage the fine corrosion inhibitor patterns on an electroplating piece substrate.

Owner:张家港舒马克电梯安装维修服务有限公司镀锌分公司

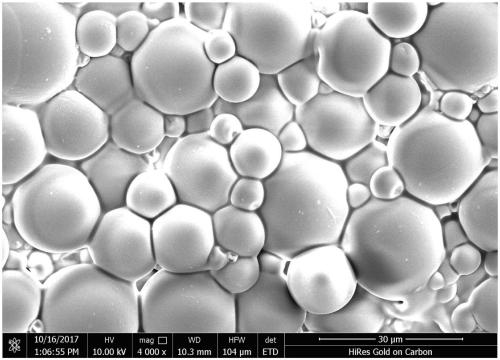

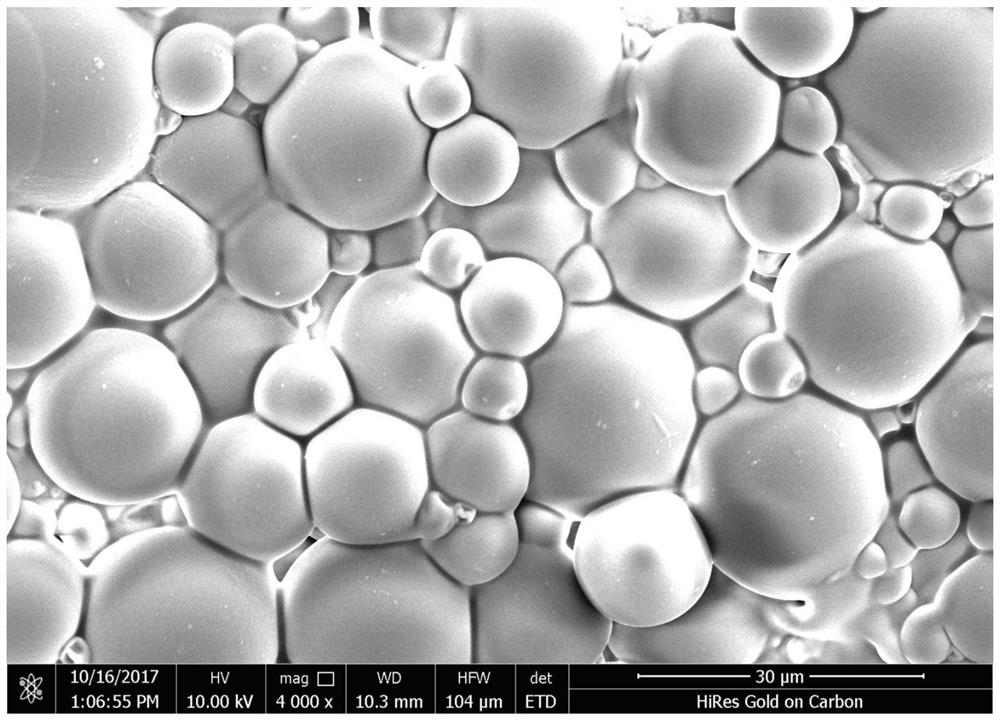

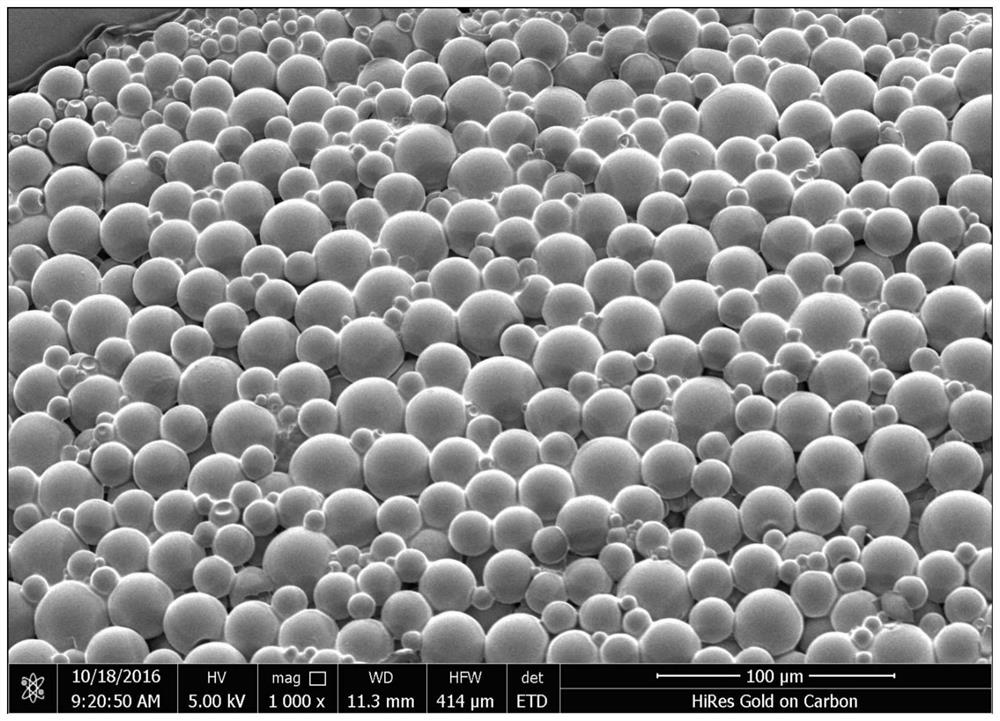

Multi-component net shell phase change microcapsule and preparation method thereof

ActiveCN109679584AThorough responseIncrease crosslink densityHeat-exchange elementsMicroballoon preparationDiethylenetriamineOil phase

The invention discloses a multi-component netted shell phase change microcapsule. A capsule core is a low-melting-point fatty acid ester or paraffin hydrocarbon compound; a capsule wall is resin whichis formed by reacting polyisocyanate with polyamine, oil-soluble polyol and water-soluble polyol respectively and has a polyurea polyurethane multi-component net structure. The invention also discloses a preparation method of the phase change microcapsule. The preparation method comprises the steps as follows: emulsifying oil phase and water phase medium solutions, adding water-soluble polyol, then, conducting a heating reaction, finally, adding water-soluble polyol and performing a thermal reaction to obtain the phase change microcapsule. A shell is formed by introducing reactions among monomers from inside of interfaces, and the reaction monomers are promoted to react completely when the reaction ends; the multi-component netted shell phase change microcapsule is prepared by reacting aliphatic isophorone diisocyanate with diethylenetriamine, oil-soluble polypropylene glycol with larger molecular weight and water-soluble polyol respectively, and the crosslinking density of the microcapsule wall is increased, so that the compactness and stability of the capsule wall are enhanced.

Owner:上海伊纯实业有限公司

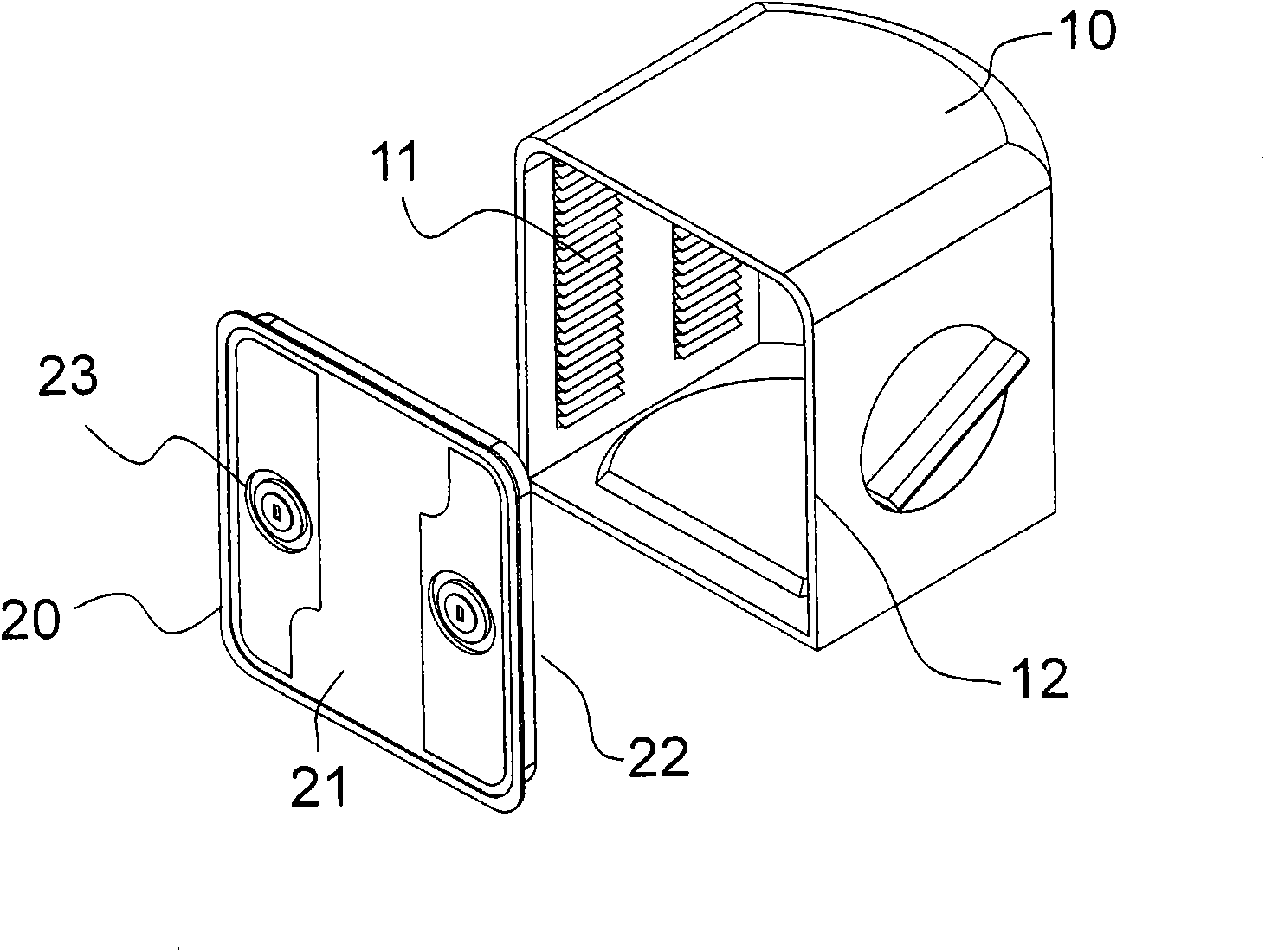

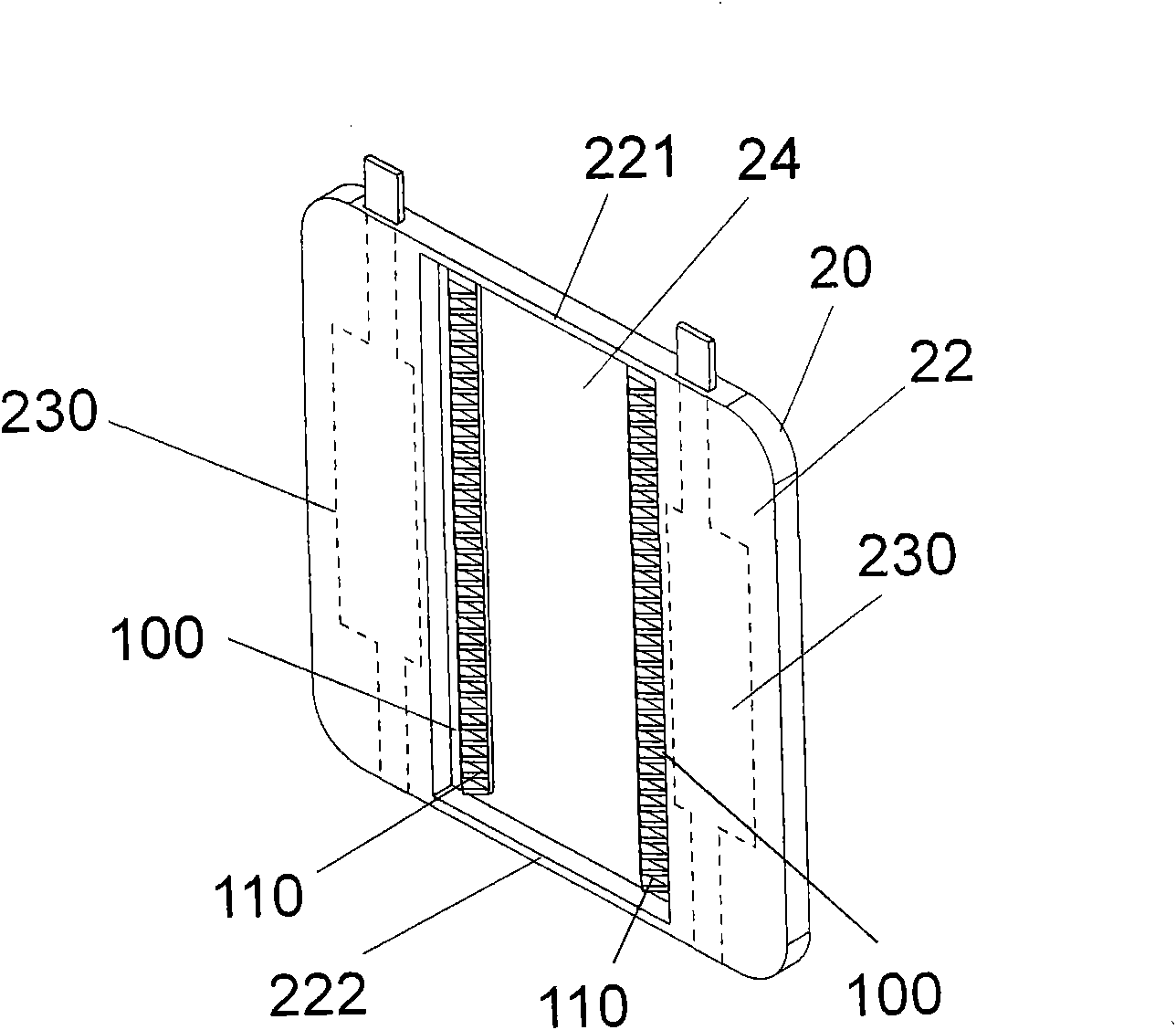

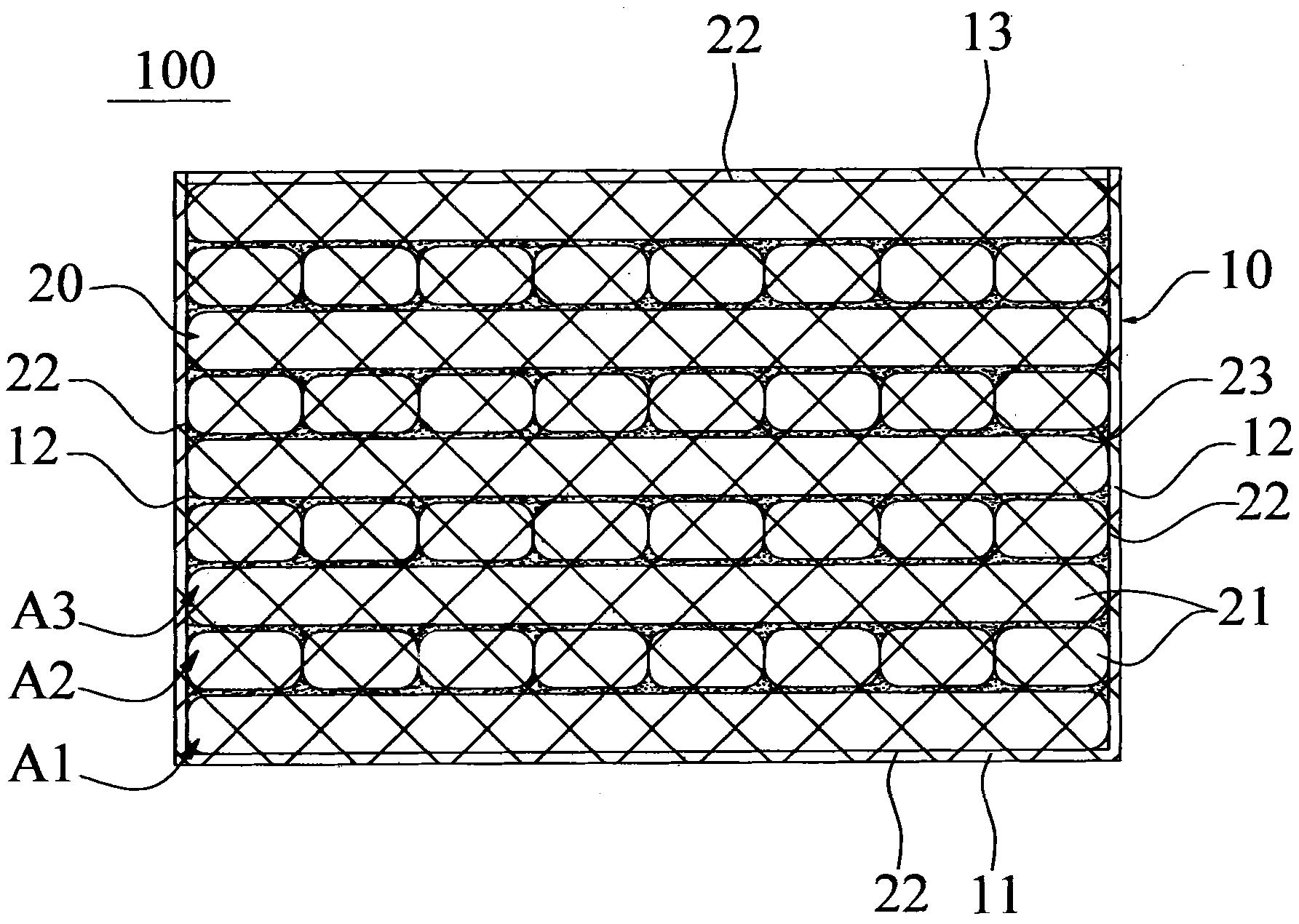

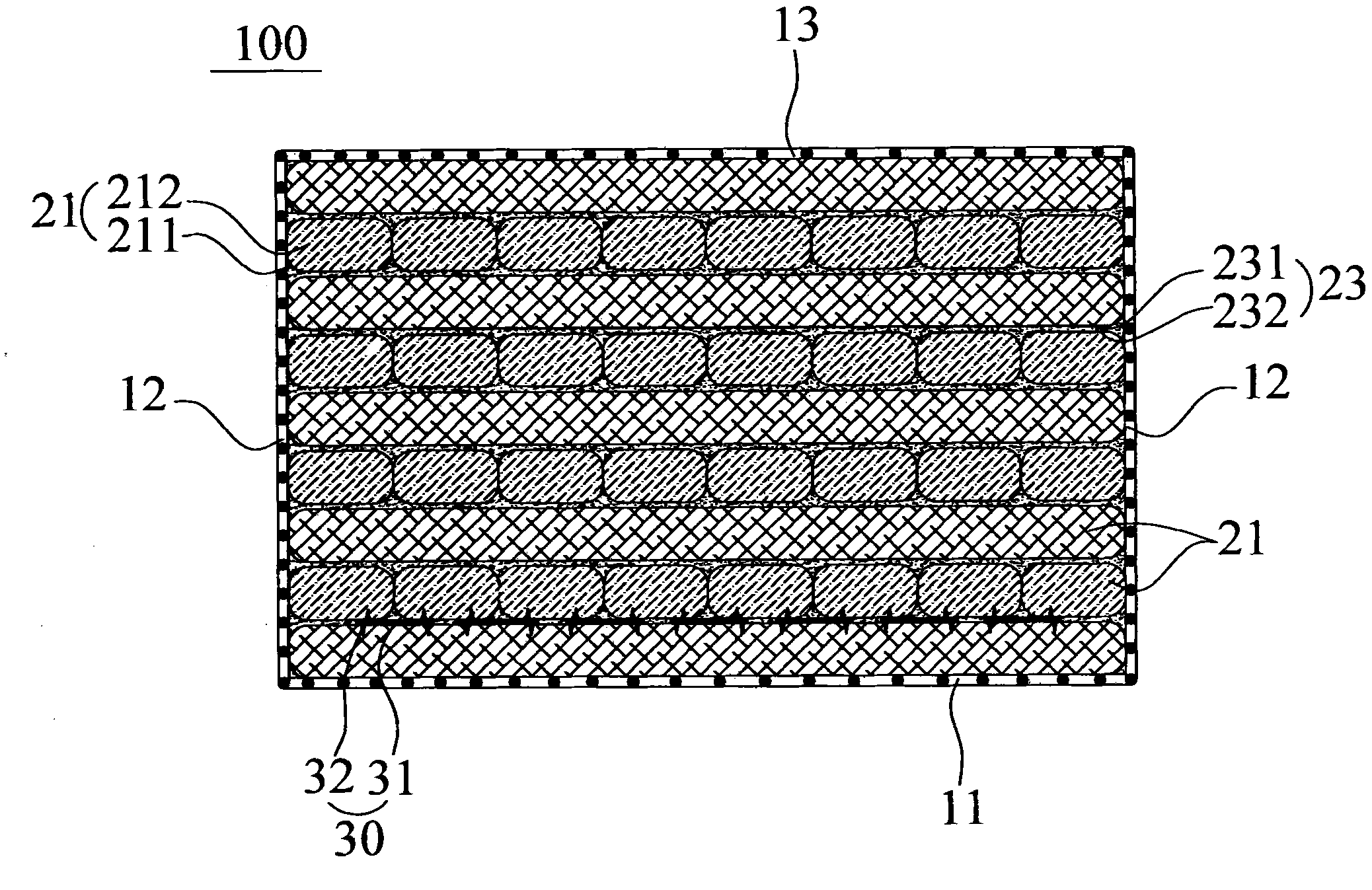

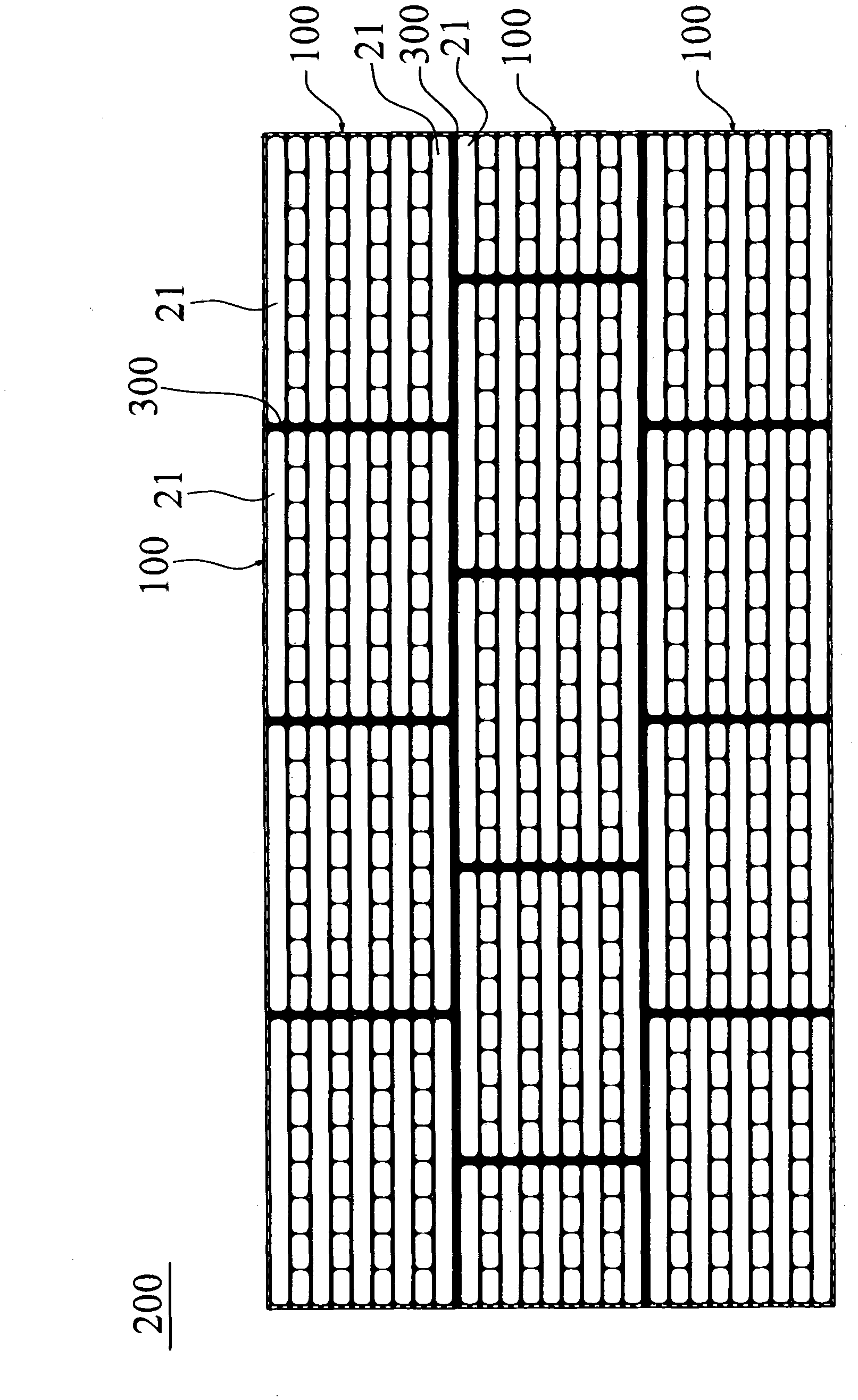

Front-opened cassette configured with inflatable strutting piece modules

ActiveCN101685790AStable supportPrevent movementSemiconductor/solid-state device manufacturingPackaging under vacuum/special atmosphereComputer moduleMechanical engineering

The invention provides a front-opened cassette configured with inflatable strutting piece modules, comprising a cassette body and a door body, wherein the cassette body consists of a pair of lateral walls, a top surface and a bottom surface; an opening is formed at one side of the cassette body, and a rear wall is formed on the other lateral side opposite to the opening; each lateral wall is configured with a strutting piece module for holding a plurality of wafers; one internal surface of the door body is jointed with the opening of the cassette body for protecting a plurality of wafers inside of the cassette body. The front-opened cassette is characterized in that an inflatable strutting piece module is arranged at the part of each lateral wall of the cassette body adjacent to the rear wall; a long slit is configured along the direction facing to the opening; an air inlet is configured at one end of the inflatable strutting piece module and connected with a gas valve at the bottom surface; and the inflatable strutting piece module is formed by a plurality of strutting ribs in a vertical arrangement at intervals.

Owner:GUDENG PRECISION IND CO LTD

Ecological net cages and side slope retaining wall using same

InactiveCN101967830AEasy to moveEasy constructionExcavationsMarine site engineeringEngineeringRetaining wall

The invention relates to ecological net cages and a side slope retaining wall using the same. Each ecological net cages comprises cage body and infill in the cage body, wherein the infill is formed by stacking a plurality of ecological bags layer by layer and has a plurality of outer edge wall faces which lean against the bottom faces, top faces and side faces of grid wall faces correspondingly; the bag bodies of the ecological bags in adjacent layers are fixedly connected by a reinforcing layer, so that the ecological bags form a whole, the strength of the whole is improved obviously and the tensile performance of the whole is improved; the outer edge wall faces formed by the infill can be tightly jointed with the grid wall faces of the cage body for making the side edges flat without any dents, so that the wall can be stacked conveniently and the fixed connection layers between adjacent net cages are more uniform and the entire retaining wall is more stable, particularly the infill still retains a whole when the cage bodies are damaged; and thus, collapse is prevented and the service life of the retaining wall is prolonged effectively.

Owner:张宇顺

Anti-impact sound absorption material composition, anti-impact sound absorption board and preparation method thereof

InactiveCN108863161AImprove sound absorptionImprove impact resistanceNoise reduction constructionParticulatesAcoustic absorption

The invention provides an anti-impact sound absorption material composition, an anti-impact sound absorption board and a preparation method thereof and belongs to the technical field of sound and noise reduction materials. The anti-impact sound absorption material composition is prepared from the following components in percentage by mass: 2 percent to 10 percent of an adhesive and 90 percent to 98 percent of particulate matters; the adhesive comprises resin mixed liquid; the particulate matters comprise aeolian sand. The anti-impact sound absorption board comprises a sound absorption layer and a supporting layer; the sound absorption layer is arranged at one side of the supporting plate; the sound absorption layer is prepared from the anti-impact sound absorption material composition. Theanti-impact sound absorption board prepared from the anti-impact sound absorption material composition has relatively good sound absorption performance and anti-impact performance.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

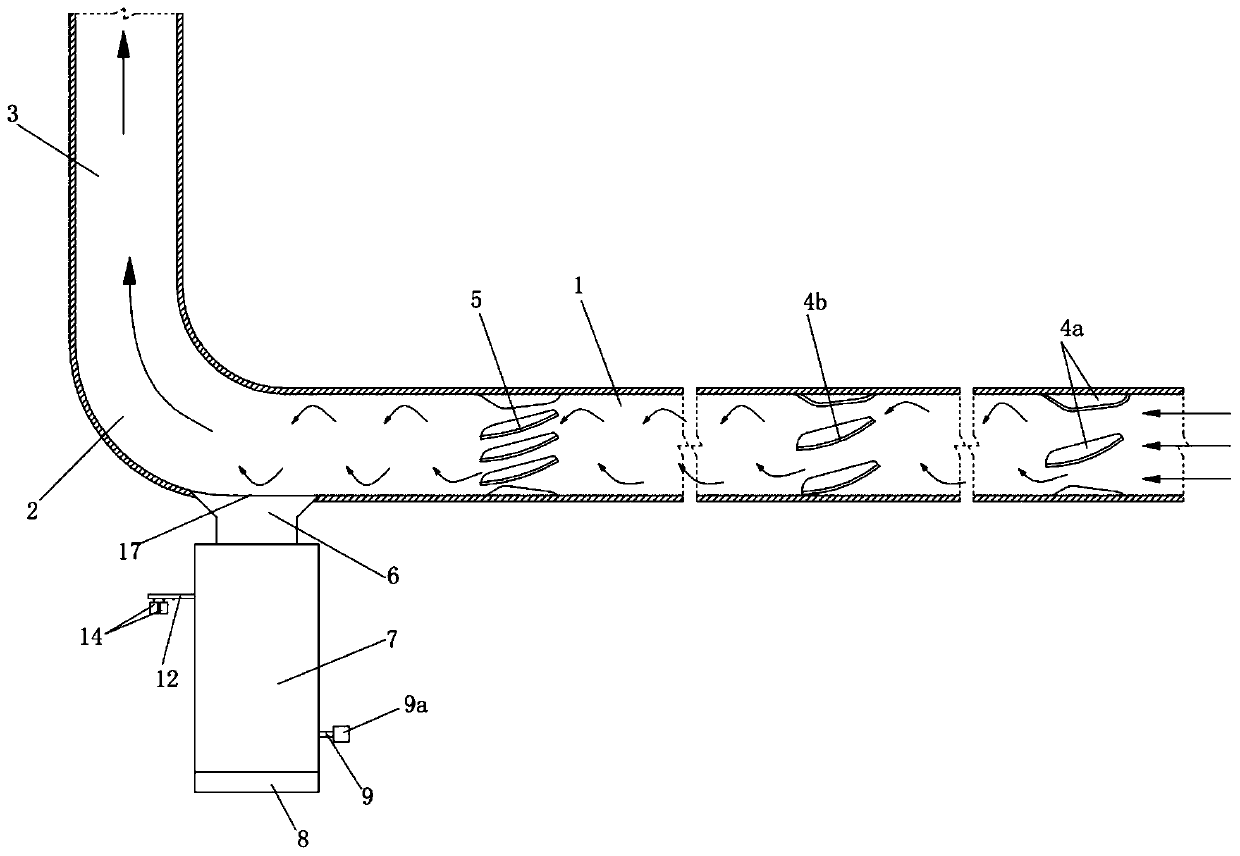

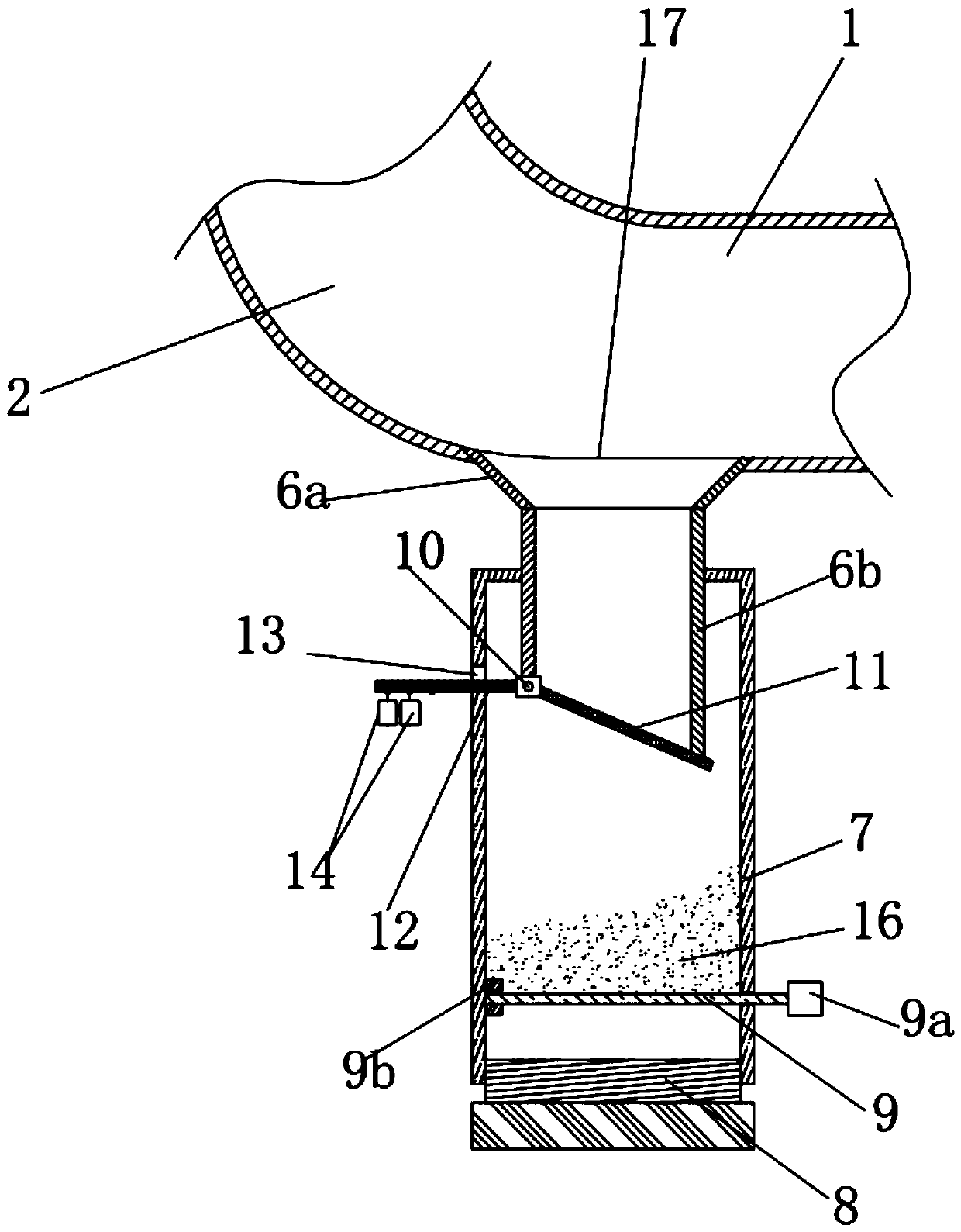

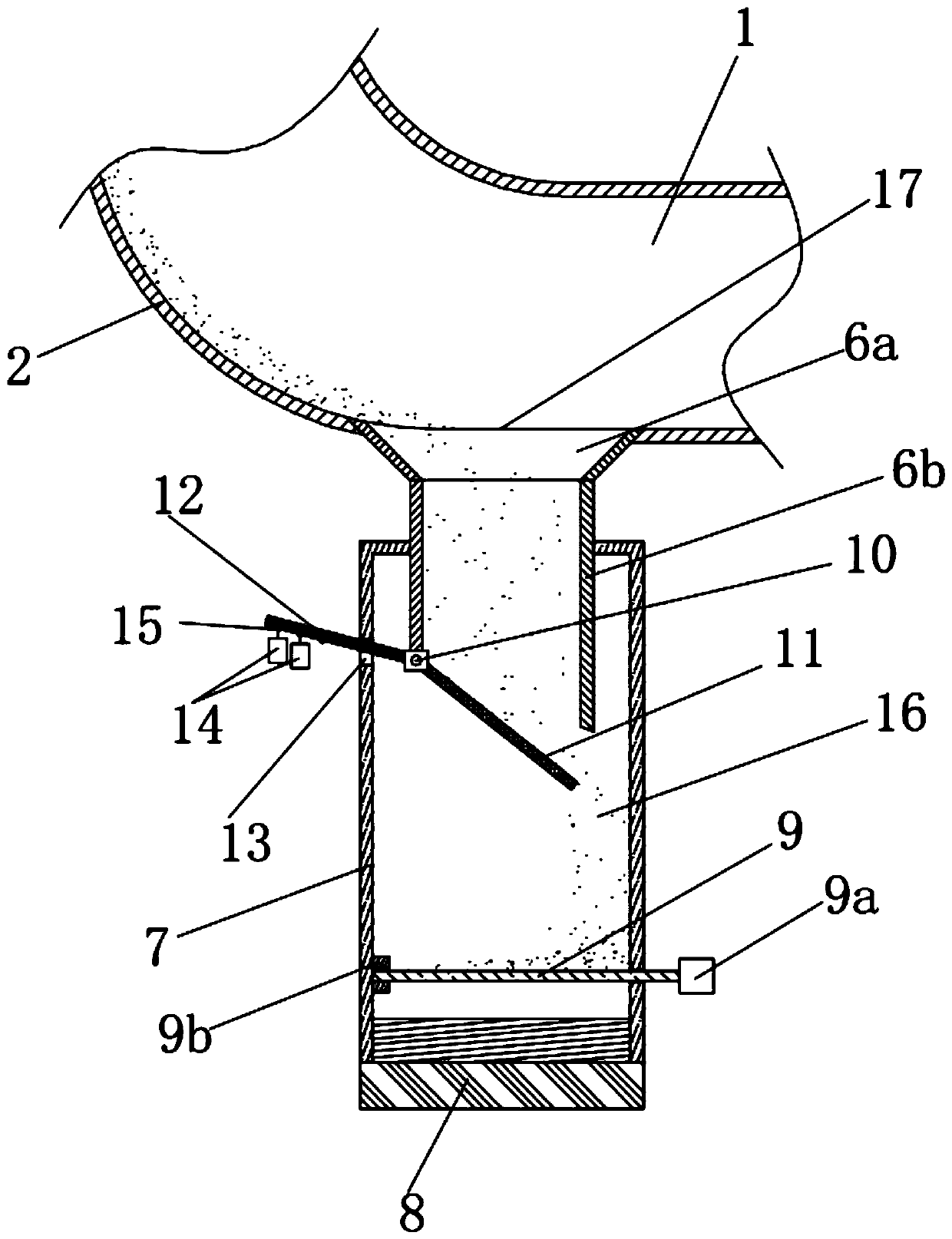

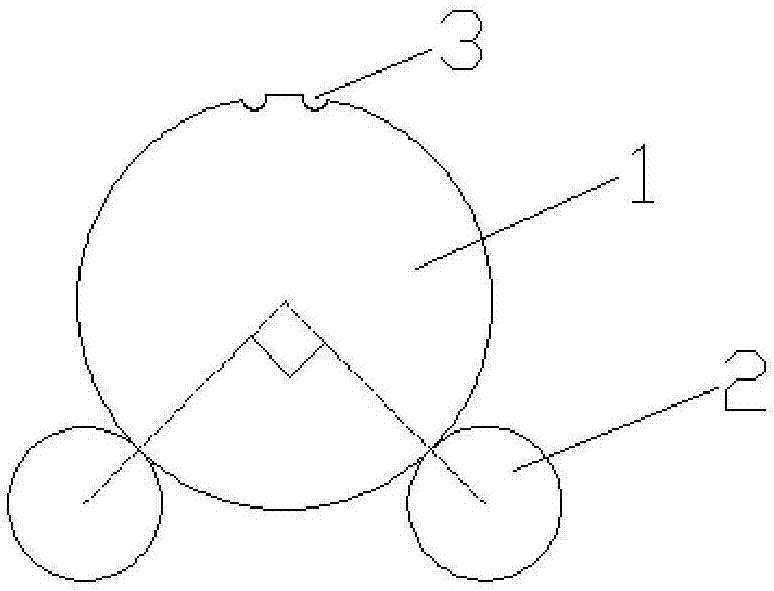

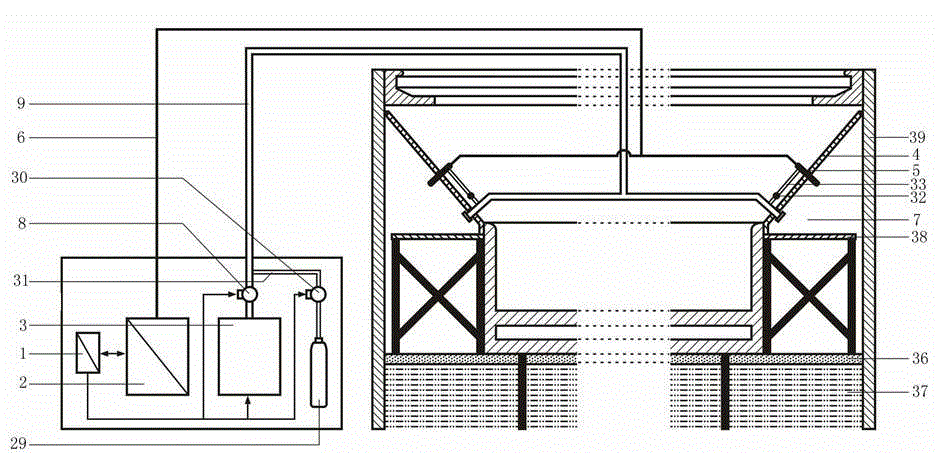

Multi-stage mixed flow primary air pipe anti-blocking system

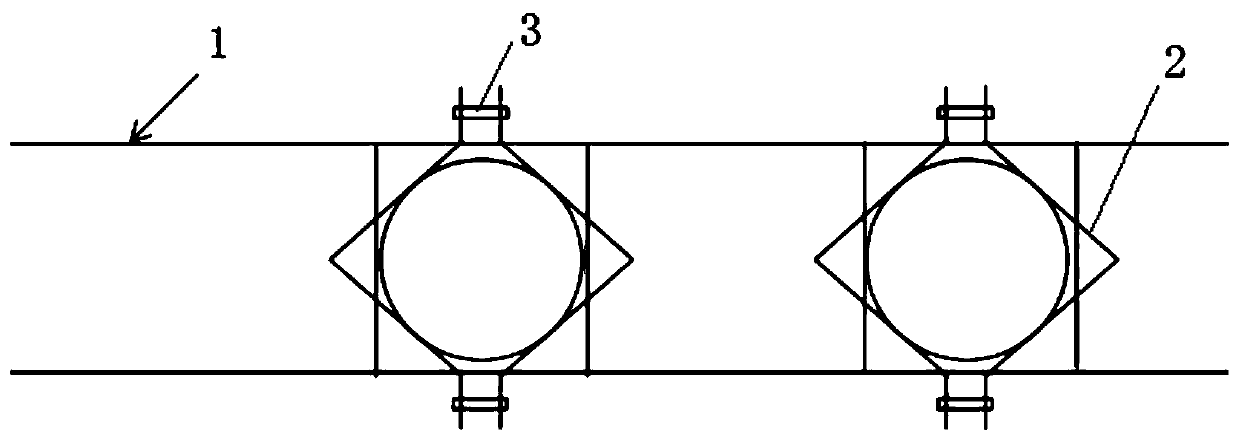

PendingCN111271725ASolve the blockageNo sinkingFuel feeding arrangementsAir/fuel supply for combustionThermodynamicsMixed flow

The invention relates to a multi-stage mixed flow primary air pipe anti-blocking system. According to the technical scheme, the multi-stage mixed flow primary air pipe anti-blocking system comprises aprimary air pipe; the primary air pipe is of a round hollow tubular structure formed by sequentially connecting a primary air pipe horizontal section, a bend transition section and a primary air pipevertical section together; and a first-stage swirler, a second-stage flow mixer and a third-stage flow mixer are sequentially arranged in the primary air pipe horizontal section in the pulverized coal conveying direction, a vertically-through pulverized coal deposit collecting opening is formed in the bottom of the junction of the primary air pipe horizontal section and the bend transition section, and a pulverized coal collecting device stretching downwards is connected to the pulverized coal deposit collecting opening. As the first-stage flow mixer, the second-stage flow mixer and the third-stage flow mixer are arranged in the primary air pipe horizontal section, primary air and pulverized coal are continuously subjected to rotational flow mixing, it is guaranteed that the pulverized coal does not sink or pile up to the maximum degree, finally the pulverized coal is fed into the primary air pipe vertical section through the bend transition section, and the pulverized coal collectingdevice is arranged on the junction of the primary air pipe horizontal section and the bend transition section to collect pulverized coal deposits.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Air-curtain breakwater

InactiveCN107419700AIncrease pressureNo additional pressure requiredBreakwatersQuaysExhaust pipeSediment

The invention discloses an air-curtain breakwater. A water pressing pipe is arranged at two sides of a bottom of an exhaust pipe separately, and is a cylindrical hollow pipe, the two water pressing pipes are symmetrically arranged relative to exhaust holes, the water pressing pipes are as long as a pipe body of the exhaust pipe, and included angles between the center of the exhaust pipe and the centers of the two water pressing pipes are 90-120 degrees; and the pipe diameter of the exhaust pipe is 2-3 times of the pipe diameter of each water pressing pipe. According to the air-curtain breakwater disclosed by the invention, the position of the exhaust pipe can be easily placed correctly, the case of incorrect positions of the exhaust holes in the exhaust pipe is avoided, and good exhaust effect and wave absorbing effect are achieved; the exhaust pipe is capable of floating and sinking in water with the water pressing pipes, and a depth position of the exhaust pipe in water is adjustable, so that blockage of sediments at a water bottom for the exhaust holes of the exhaust pipe can be avoided, and a pressure pressed in the exhaust pipe has no need to be increased with the increase of a water depth, so that low energy consumption is achieved; and the exhaust pipe has no need to always sink to the water bottom and is free from self-sinking.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

Method and device for inhibiting outer floating roof crude oil storage tank primary and secondary sealed space oil and gas combustion and explosion

ActiveCN104528219ADilution concentrationAchieve inert protectionLarge containersStorage tankCrude oil

The invention discloses a method and device for inhibiting outer floating roof crude oil storage tank primary and secondary sealed space oil and gas combustion and explosion. The method and device are mainly used for overcoming the combustible and explosive oil and gas space dangerousness caused by crude oil evaporation between primary sealed space and secondary sealed space of a crude oil storage tank area outer floating roof storage tank. A crude oil evaporation inhibitor is injected into the surface of crude oil; due to the fact that the density of the inhibitor is lower than that of the crude oil, the inhibitor will cover the surface of the crude oil and will not cause a sink or static charge accumulation problem, and crude oil evaporation is effectively inhibited. In addition, non-combustible and non-explosive gas produced by inhibitor evaporation dilutes the concentration of oil and gas inside the primary sealed space and secondary sealed space of the outer floating roof storage tank, and therefore inerting protection on the oil and gas space is achieved. The method and device are convenient and easy to implement and capable of being applied to safety protection of outer floating roof oil tanks and storage tanks of various shapes.

Owner:VITALONG FIRE SAFETY GRP

Method for preparing highly flame-retardant nonwoven fabric

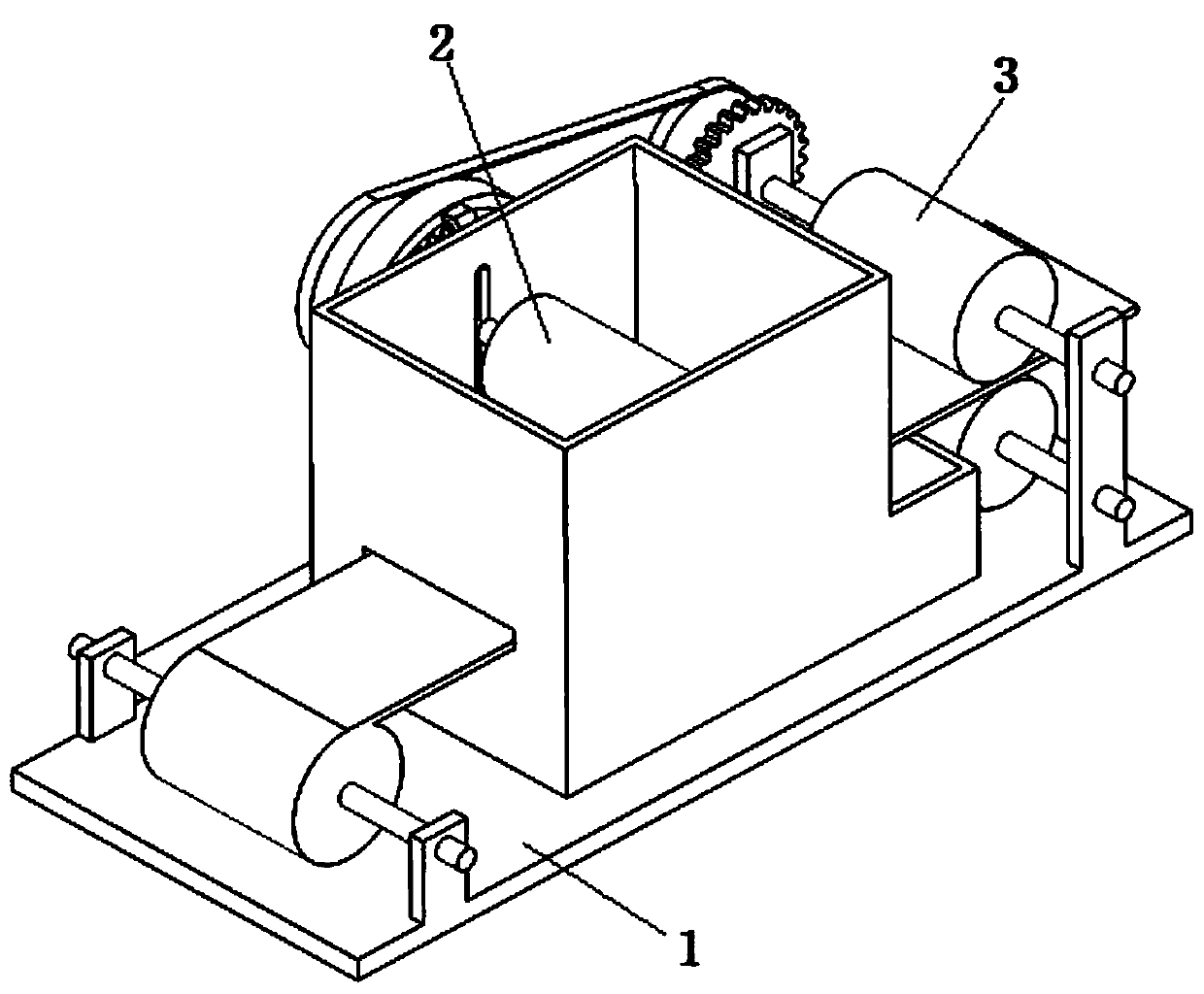

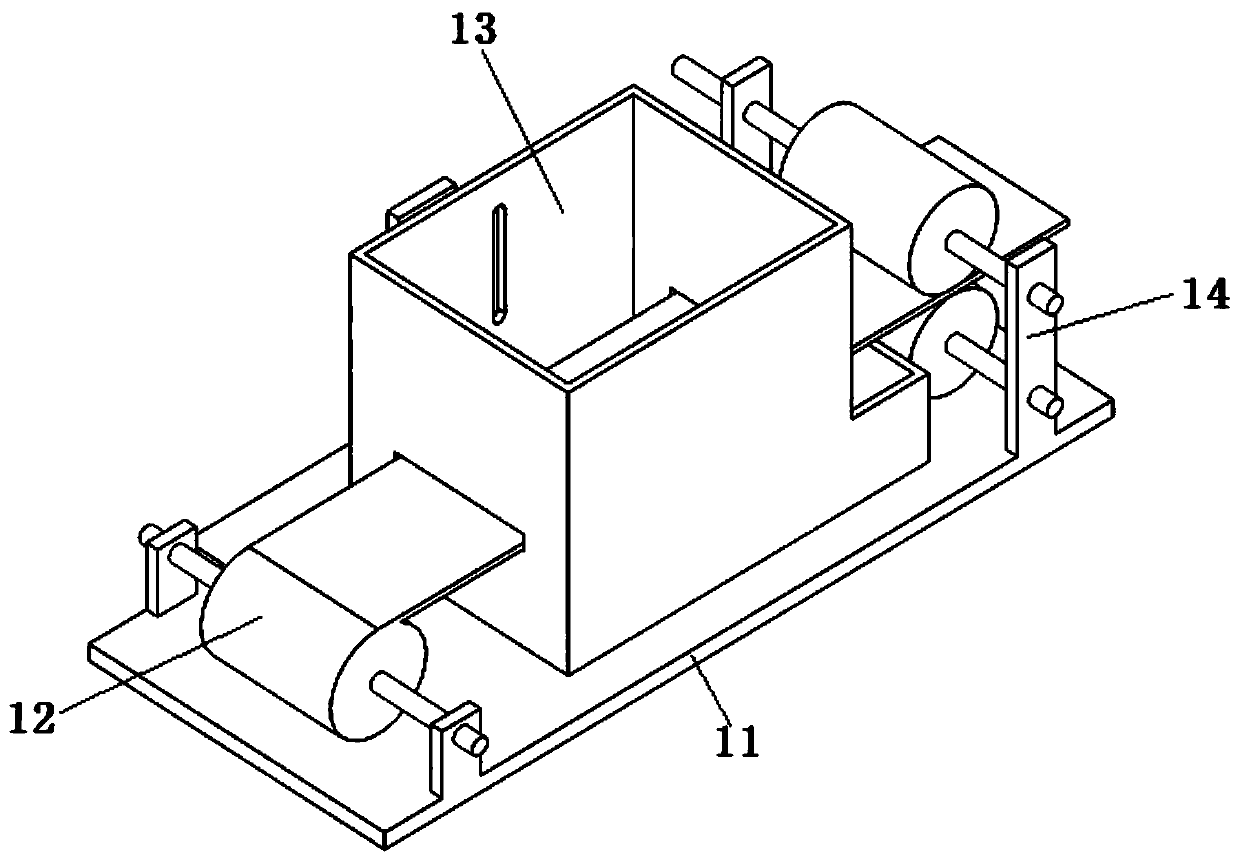

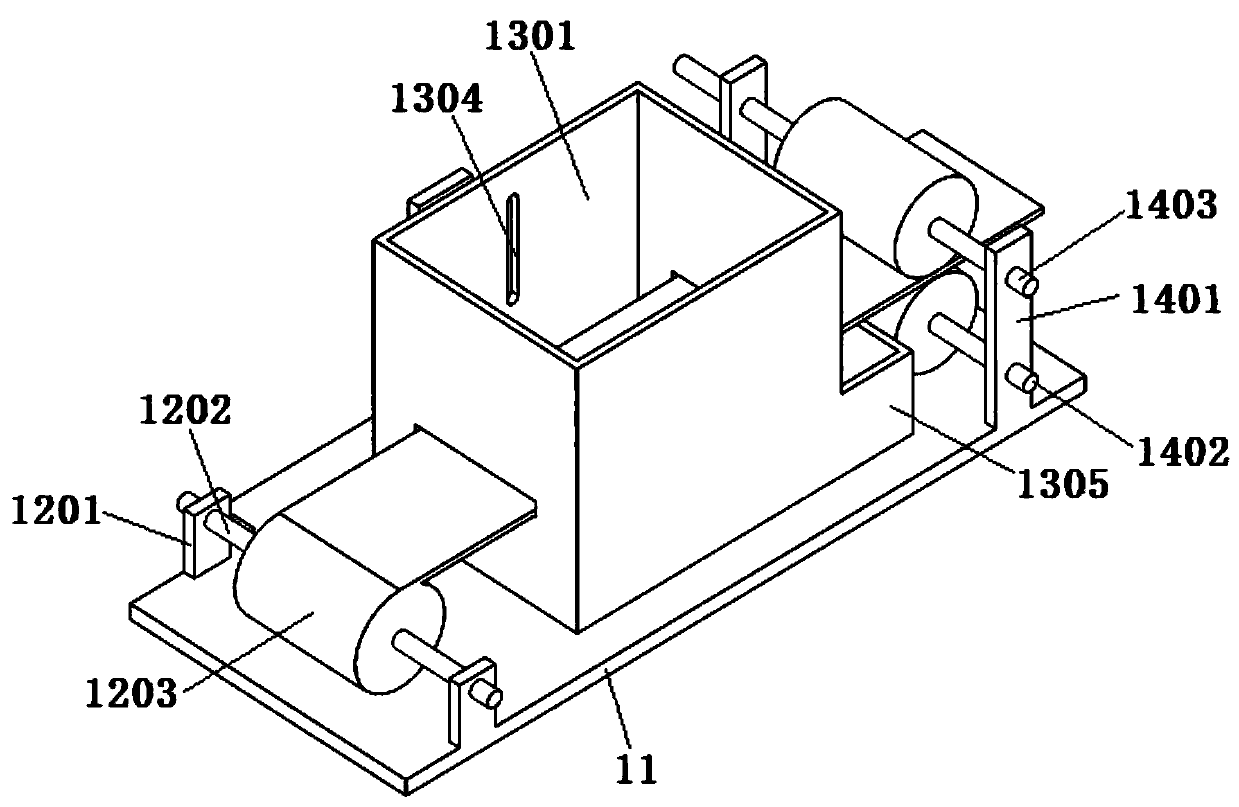

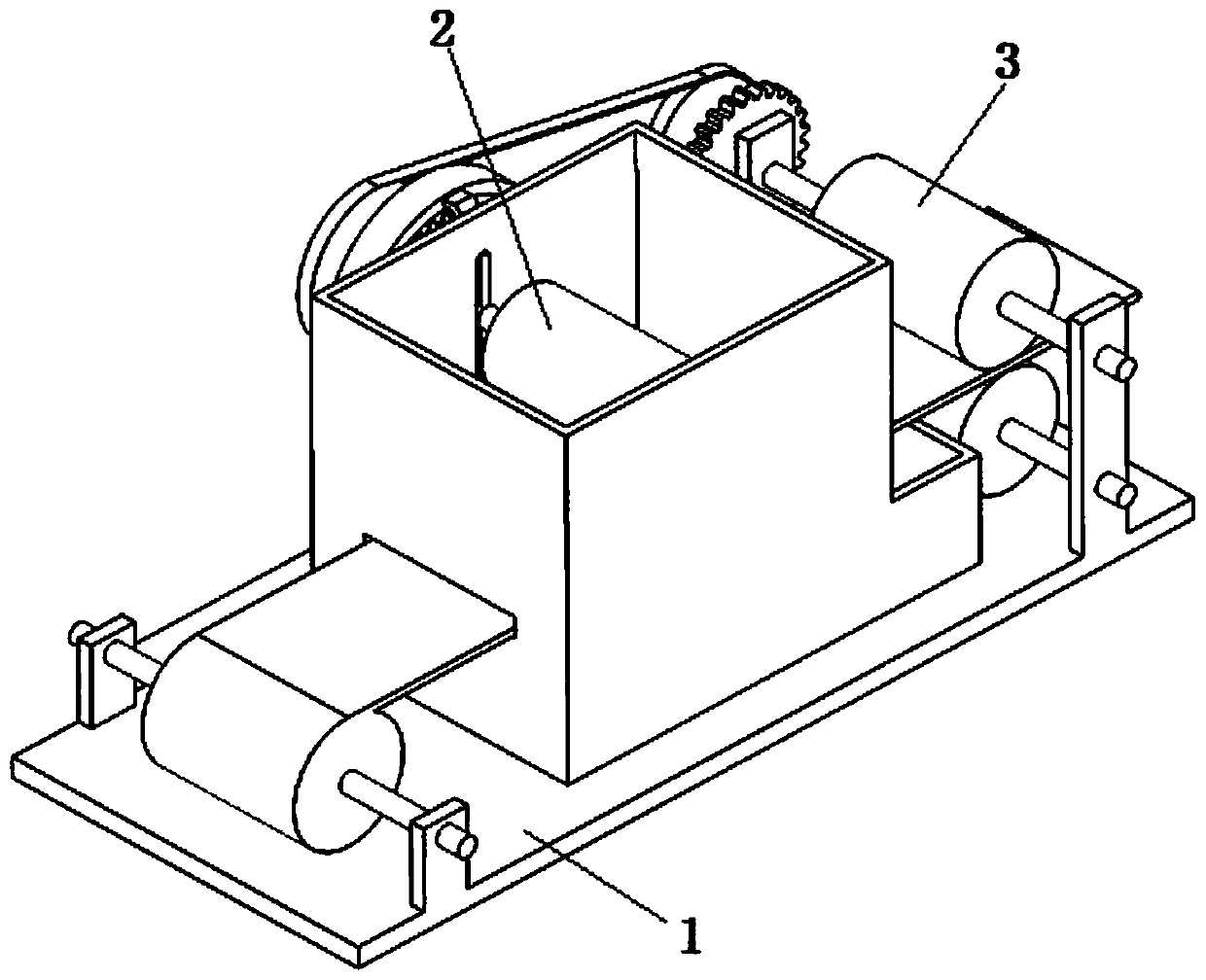

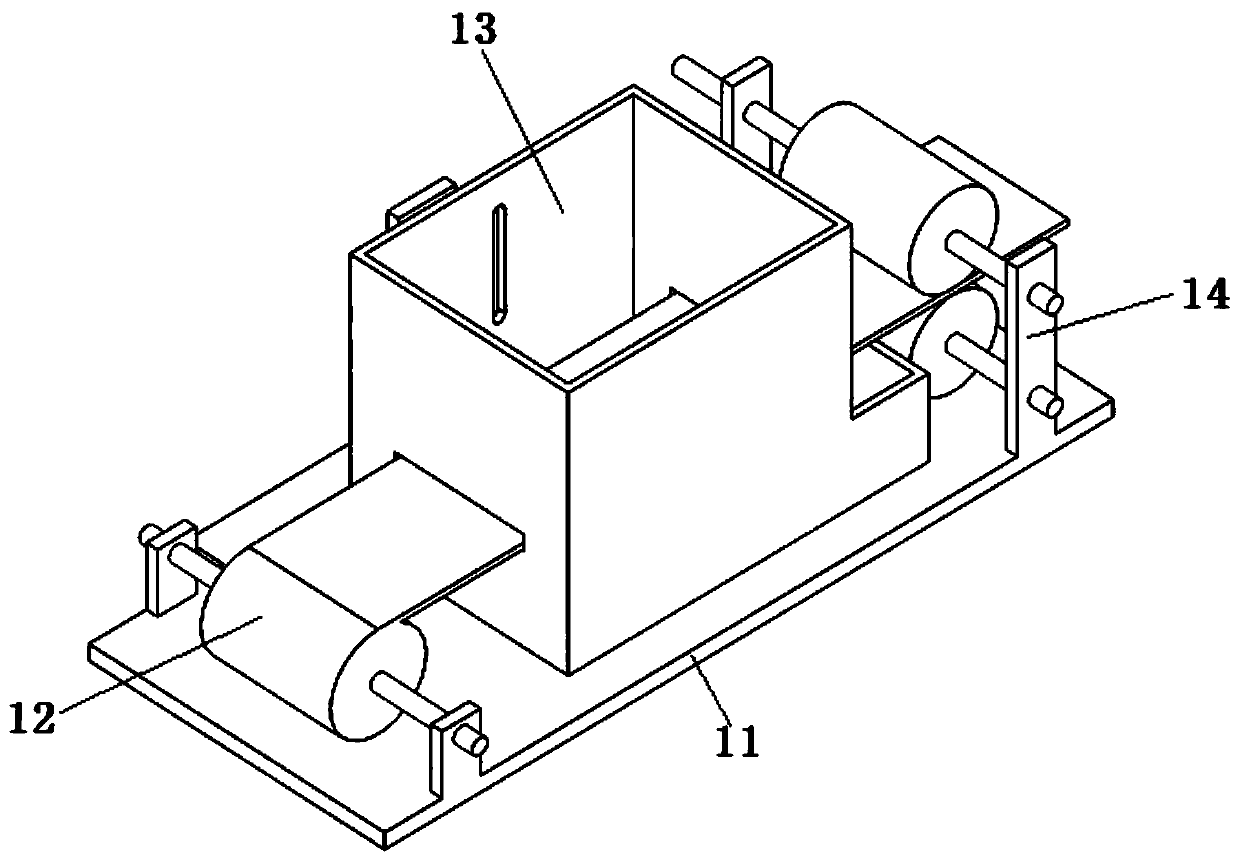

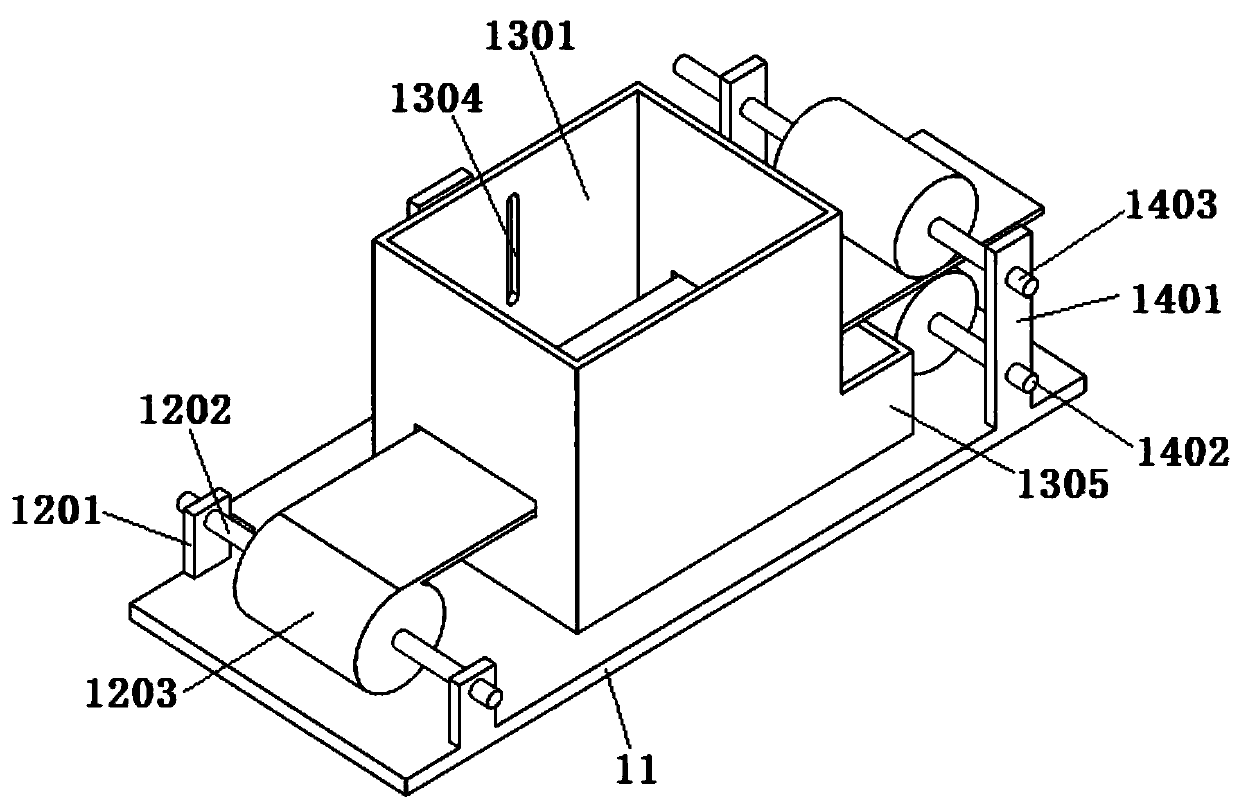

ActiveCN110747583AImprove the effect of wetting finishing solutionImprove the effect of flame retardant finishingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPolymer sciencePlant fibre

The invention discloses a method for preparing a highly flame-retardant nonwoven fabric, which comprises the steps of firstly, processing polypropylene material; secondly, mixing the material; thirdly, carrying out laying; fourthly, uniformly mixing a nitrogen-phosphorus flame retardant, organic montmorillonite, a penetrant and water according to a weight ratio to prepare a flame-retardant finishing solution; fifthly, carrying out flame-retardant finishing on the nonwoven fabric by a finishing processing device; and sixthly, drying to obtain the highly flame-retardant nonwoven fabric. Polypropylene, maleic anhydride grafted polypropylene and plant fibers are adopted as base materials to the nonwoven fabric, and isotactic polypropylene and maleic anhydride grafted polypropylene can improvethe physical and mechanical properties of the nonwoven fabric; Through the addition of a degradation agent and the plant fibers, the nonwoven fabric has good degradation performance and meets the requirements of modern environmental protection; In addition, the flame-retardant finishing is performed with the special finishing processing device, so that the nonwoven fabric is fully soaked with thefinishing solution, the finishing effect is improved, and the flame-retardant performance of the nonwoven fabric is further improved.

Owner:义乌市鸿晟无纺布有限公司

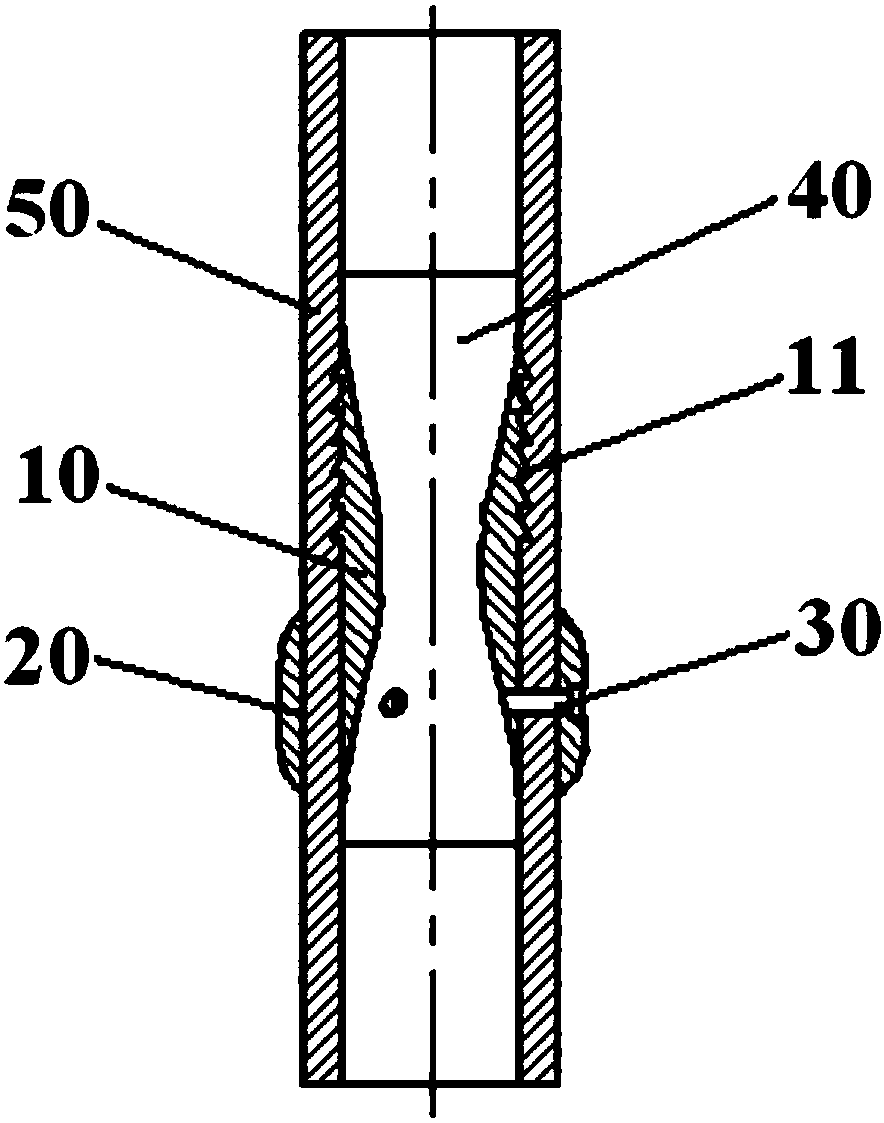

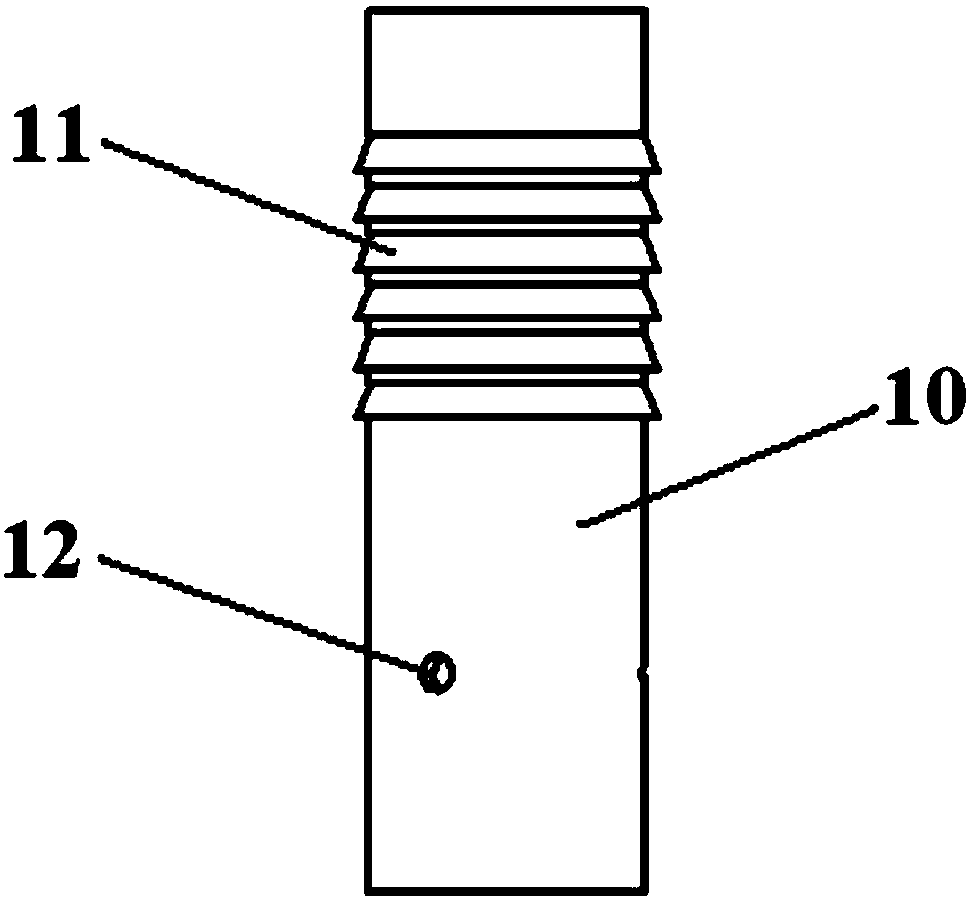

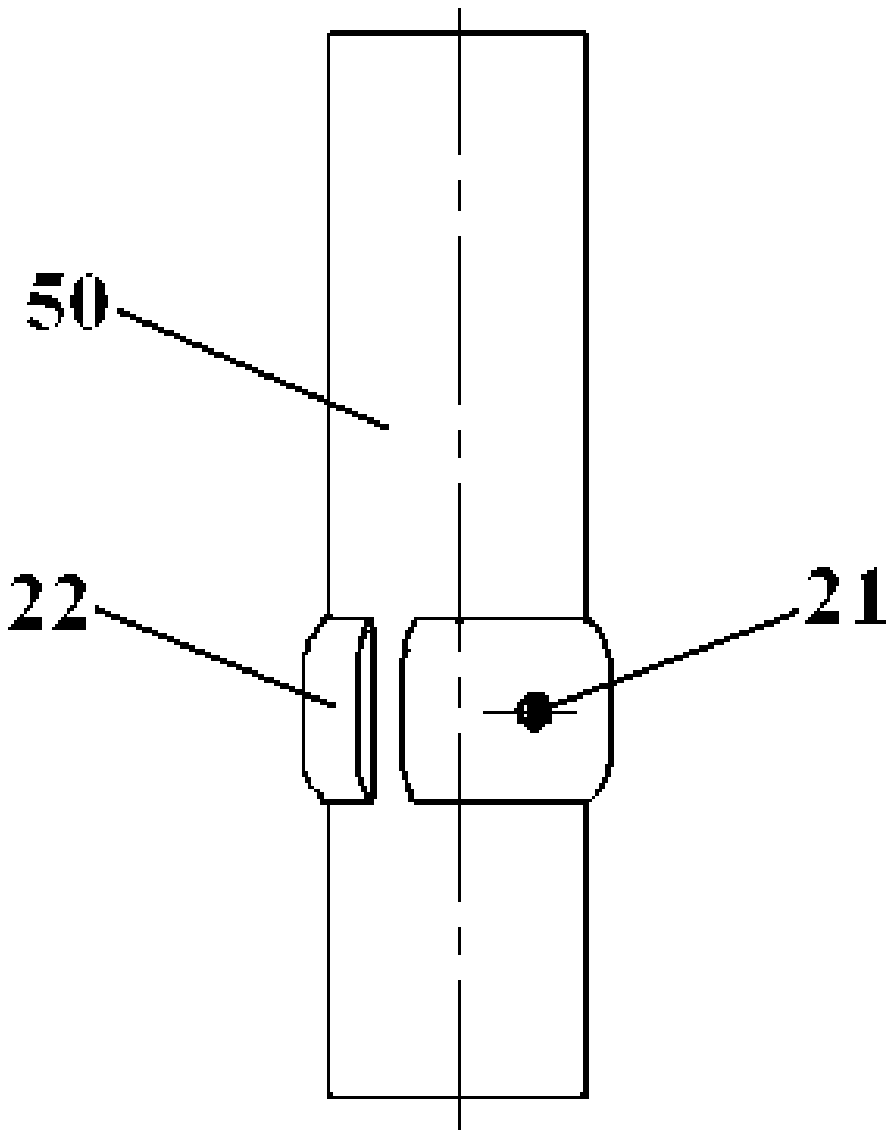

Artificial isthmus prosthesis

PendingCN107595442ANo sinkingEasy to sinkBone implantJoint implantsArtificial hip jointsFemoral component

The invention provides an artificial isthmus prosthesis. The artificial isthmus prosthesis comprises an isthmus portion and a fixing portion. The isthmus portion is arranged at a preset position in afemoral marrow cavity, and is provided with an isthmus structure matched with femoral components. The fixing portion is detachably connected with the isthmus portion to fix the isthmus portion to thepreset position. The artificial isthmus prosthesis has the advantages that the isthmus of a patient is reconstructed in case of isthmus damage or loss of the patient during artificial hip replacement,and accordingly, sinking of the femoral components is avoided; the problem of proneness to femoral component sinking due to isthmus damage or loss of the patient during artificial hip replacement inthe prior art is solved.

Owner:BEIJING AKEC MEDICAL

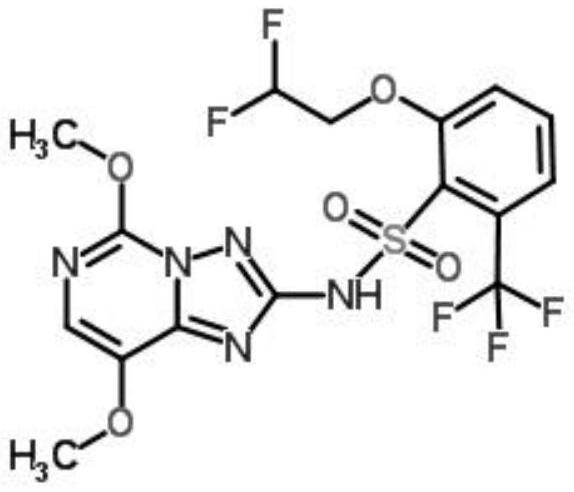

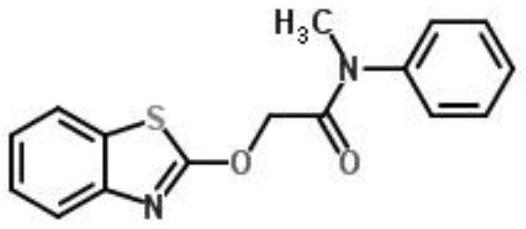

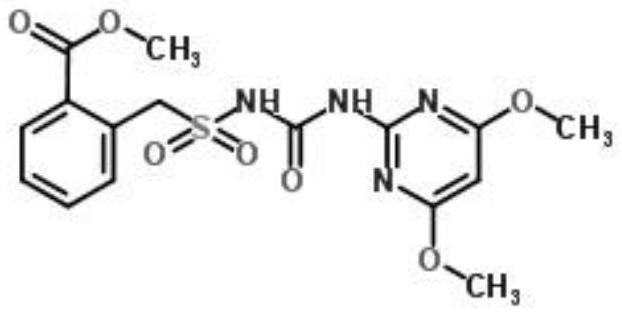

Paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl as well as preparation method and application thereof

PendingCN112155014AEffective controlImprove the effect of prevention and controlBiocideAnimal repellantsBensulfuron methylActive ingredient

The invention relates to a paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl as well as a preparation method and application of the paddy field weeding granule. The granule comprises a A-phase component, a B-phase component and a C-phase component, wherein the A-phase component comprises 70%-95% of a granule carrier, the B-phase component comprises 0.1%-30% of functional mother powder containing three active ingredients, namely penoxsulam, mefenacet and bensulfuron methyl, and the C-phase component contains 1%-40% of a coalescing agent; and the coalescing agent comprises a binder, an inducer and a warning color. The paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl is scientific and reasonable in design, is prepared by a coating film forming method, is good in film forming, glossy, good in wear resistance, free of caking, falling and dust, high in safety, capable of being separately spread, capable of being mixed witha fertilizer to be spread, convenient, rapid, easy to operate and capable of reducing labor.

Owner:TIANJIN HIGHPOINT PLANT PROTECTION

Medium-density fiberboard

InactiveCN112501970AImprove stabilityImproved stability and aestheticsSingle unit pavingsTemporary pavingsMedium density fiberboardEngineering

The invention belongs to the technical field of fiberboards, and particularly relates to a medium-density fiberboard which comprises a main board, an extension plate and a pressing plate. The main board is arranged to be a cuboid, one side surface of the main board is arranged to be an arc surface, and a first groove is formed in one side surface of the main board. One surface of the first grooveis connected with the bottom of the main board, and the extension plate is connected into the first groove in a sliding mode. The surface, close to the groove bottom of the first groove, of the extension plate is obliquely arranged, and the extension plate can slide into the first groove. An L-shaped groove is formed in the other side surface of the main board. One end of the L-shaped groove is connected with the groove bottom of the first groove. The structural performance of the medium-density fiberboard is improved while the original material performance of the medium-density fiberboard isguaranteed so that the medium-density fiberboard does not sink when being placed on a humid soil pavement by a worker, and the stability of the medium-density fiberboard is improved; and meanwhile, the attractive effect of the medium-density fiberboard cannot be influenced.

Owner:梁日飞

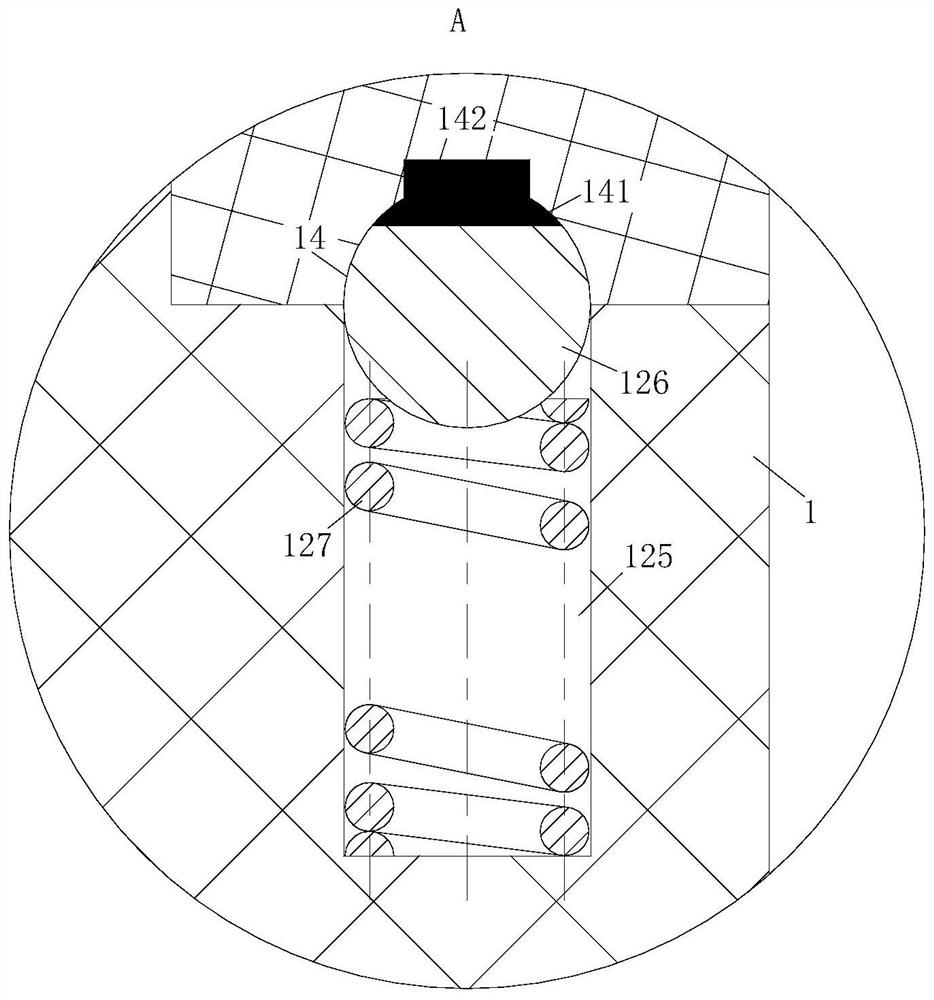

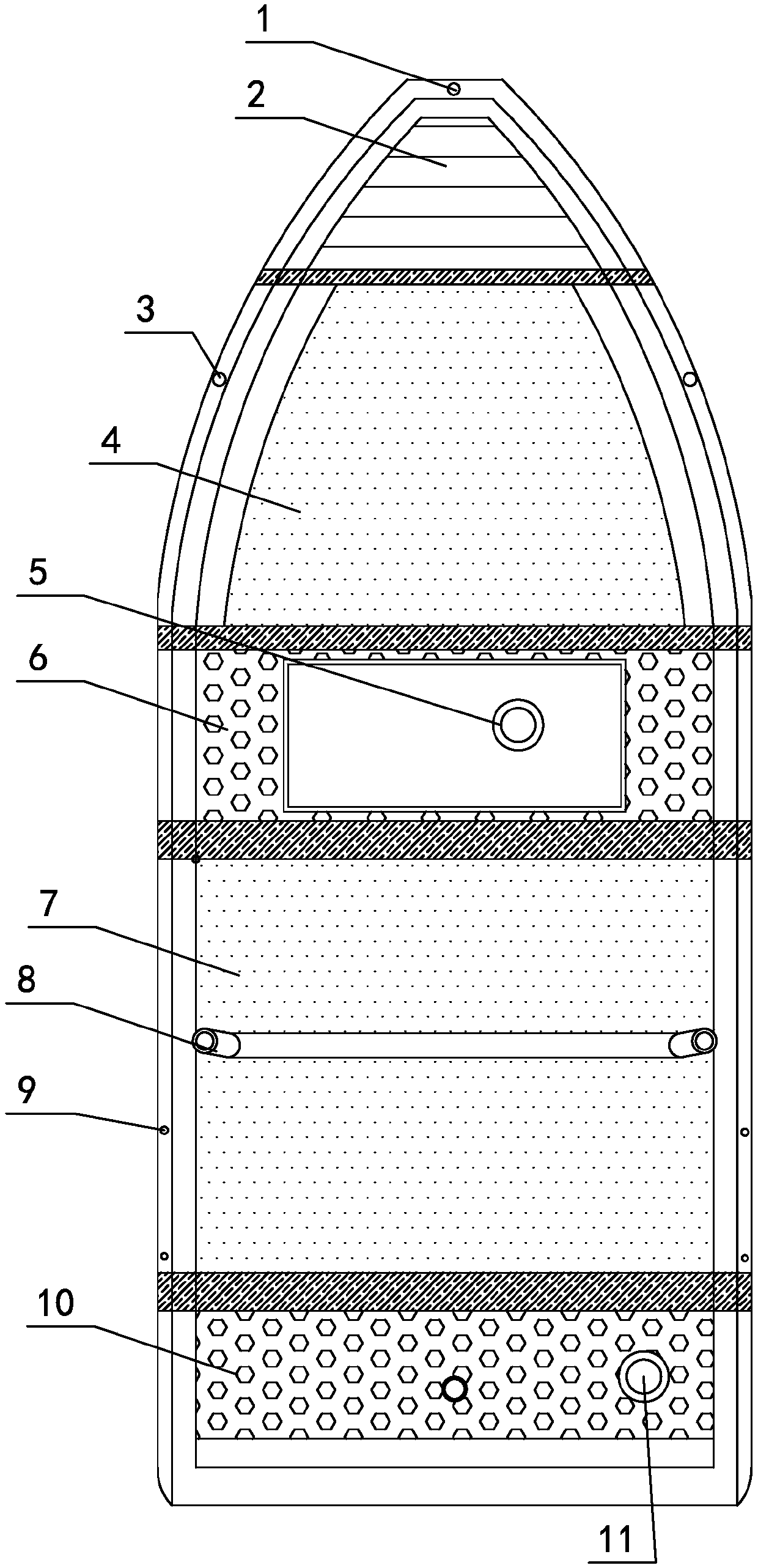

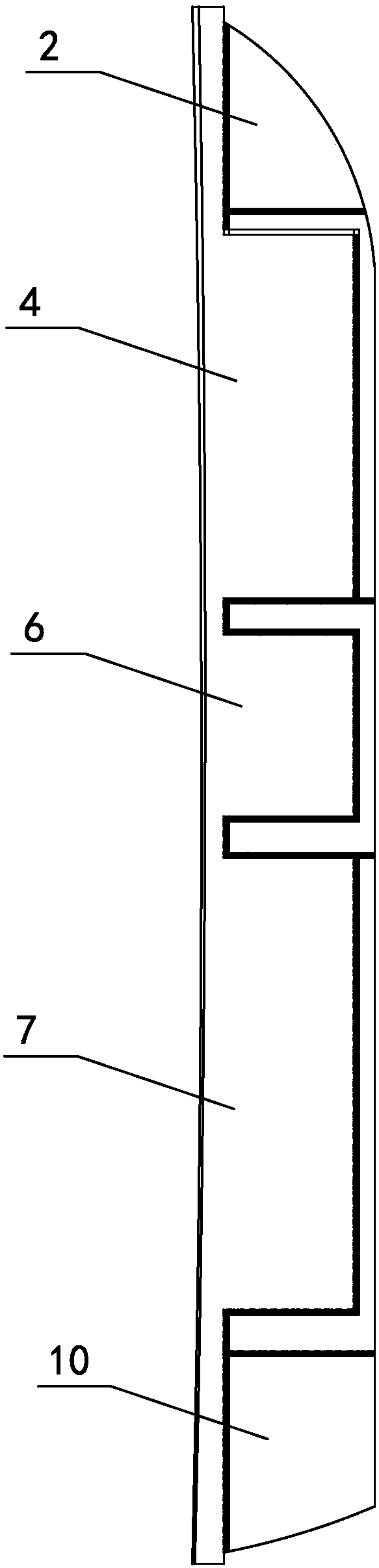

Novel plastic boat

InactiveCN107697223ASimple structureGuaranteed integrityHull interior subdivisionNon-magnetic metal hullsMarine engineeringWater Movements

The invention relates to a new type of plastic boat, which belongs to the technical field of plastic boat design, and includes a hull made of plastic. There are five compartments in the rear engine compartment, each compartment adopts a hollow double-layer design structure, and each compartment is an independent airtight structure, and the entire hull is made by rotational molding segmented integral molding technology. Since the whole plastic boat is made by rotomolding segmented integral molding technology, each cabin adopts a hollow double-layer design structure, which ensures the integrity of the whole plastic boat, and does not use any welding or glue connection or other connection methods In addition, each cabin is an independent airtight structure, which can ensure that when the plastic boat is moving in the water, if it is hit by a sharp object on a reef and causes local damage, it will not affect the sealing of other cabins, so as to ensure sufficient buoyancy to ensure safety.

Owner:重庆赛普实业有限公司

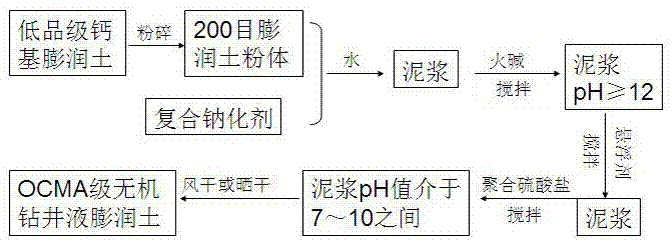

Preparation method of inorganic bentonite for drilling fluid

The invention relates to a preparation method of inorganic bentonite for drilling fluid. The preparation method specifically comprises the following steps: (1) taking low-grade calcium-based bentonite for crushing, adding a composite sodium agent into the bentonite, uniformly mixing to obtain a mixture, dissolving the mixture into water, regulating the pH value to be greater than or equal to 12 by caustic soda, and uniformly stirring, thereby obtaining mud for later use; (2) adding an inorganic composite suspending agent into mud prepared in the step (1), uniformly stirring, then adding polymerized sulfate to enable the pH value of the mud to be 7-10, filtering after uniformly stirring, taking precipitates to remove water to obtain the inorganic bentonite for the drilling fluid. According to the preparation method disclosed by the invention, the low-grade calcium-based bentonite is adopted to prepare OCMA-grade inorganic bentonite for the drilling fluid, so that a low-grade bentonite purifying step is omitted, a processing process of inorganic pulping bentonite is optimized, an organic high polymer material is not added in a preparation process, production cost of the bentonite is reduced, and the product pulping rate is high, so that the high-additional-value utilization of low-grade bentonite resources is realized.

Owner:LUOYANG INST OF SCI & TECH

Composition with skin-lightening effect and preparation method thereof

ActiveCN106038465BGood skin careAdjust colorCosmetic preparationsToilet preparationsCelluloseMedicine

The invention discloses a composition with a skin color brightening effect and a preparation method thereof. The composition is prepared from, by mass, 0.1%-2.0% of pearl powder, 0.5%-1.5% of sodium polyacrylate, 1.0%-4.0% of talcum powder subjected to surface treatment with triethoxycaprylylsilane, 0.5%-4.0% of mica, 0.05%-0.3% of mixture of xanthan gum, hectorite and cellulose, 2.0%-8.0% of 1,3-propylene glycol and 0.3%-0.8% of preservative. According to the composite, the skincare effect and skin color brightening can be perfectly combined, slight shell-like gloss is brought to skin, and the face contour is more stereoscopic; the composition has the advantage of being good in stability.

Owner:广州卡洛莱化妆品有限公司

Integrated management platform for feeding, trapping and catching

The invention discloses an integrated management platform for feeding, trapping and catching, and belongs to the technical field of seine cultivation engineering. The integrated management platform comprises a support platform, platform support piles are connected to the lower side of the support platform, feeding devices are evenly distributed around the support platform, a control room is arranged above the support platform, a lifting device is installed in front of the control room and connected to one end of a main catching net through a steel rope, and the other end of the main catching net is connected to the support platform. According to the integrated management platform, the entire integrated management platform consists of five important parts of the control room, the support platform, the main catching net, the feeding devices and the lifting device; operators only need to control in the control room to realize fully automated operation of the platform; and the operating platform also applies to large-scale shallow sea cultivation, will not be affected in a harsh weather environment, is simple in construction, is economic and friendly to environment, and has universality and sustainability.

Owner:ZHEJIANG OCEAN UNIV

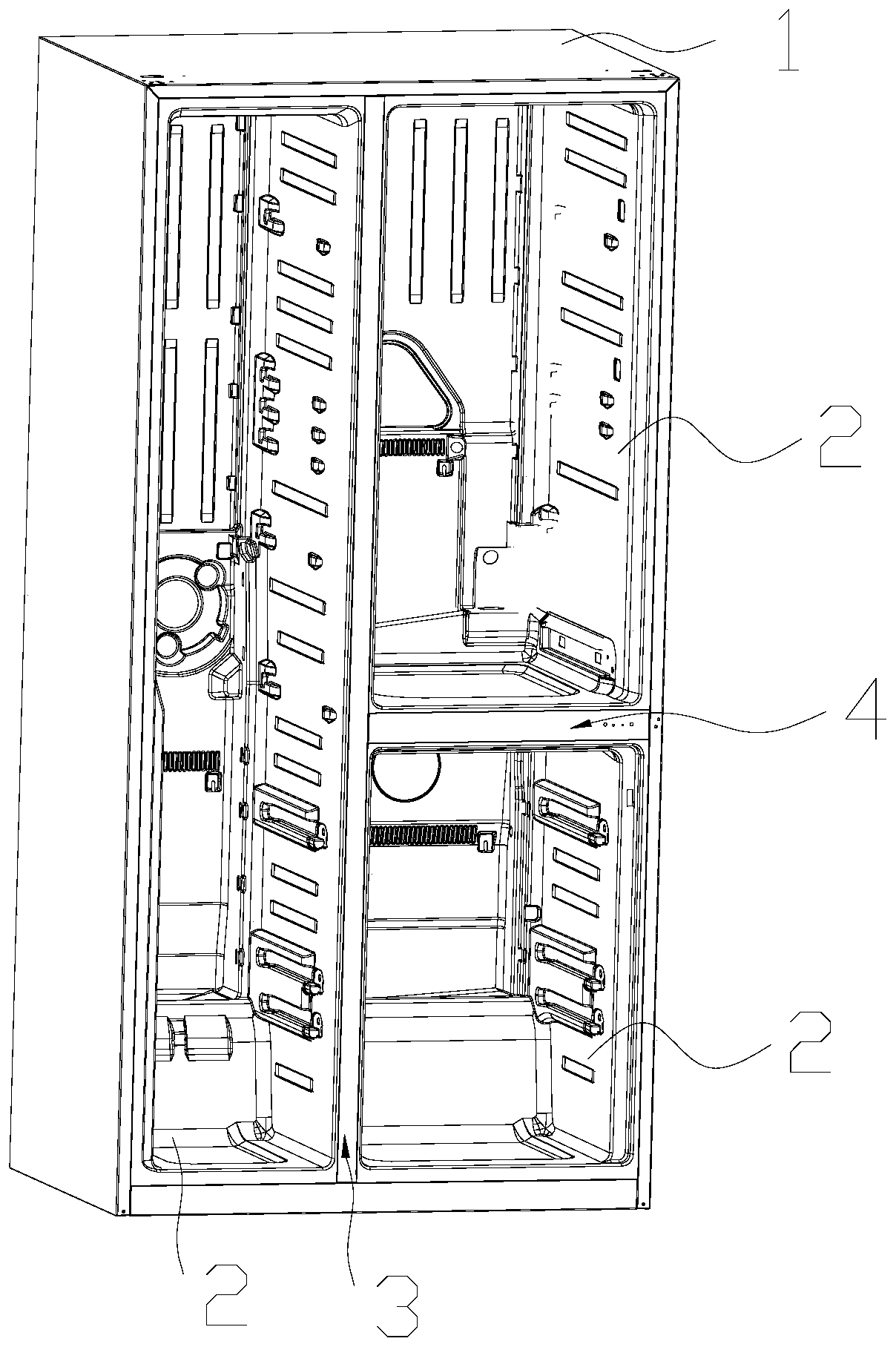

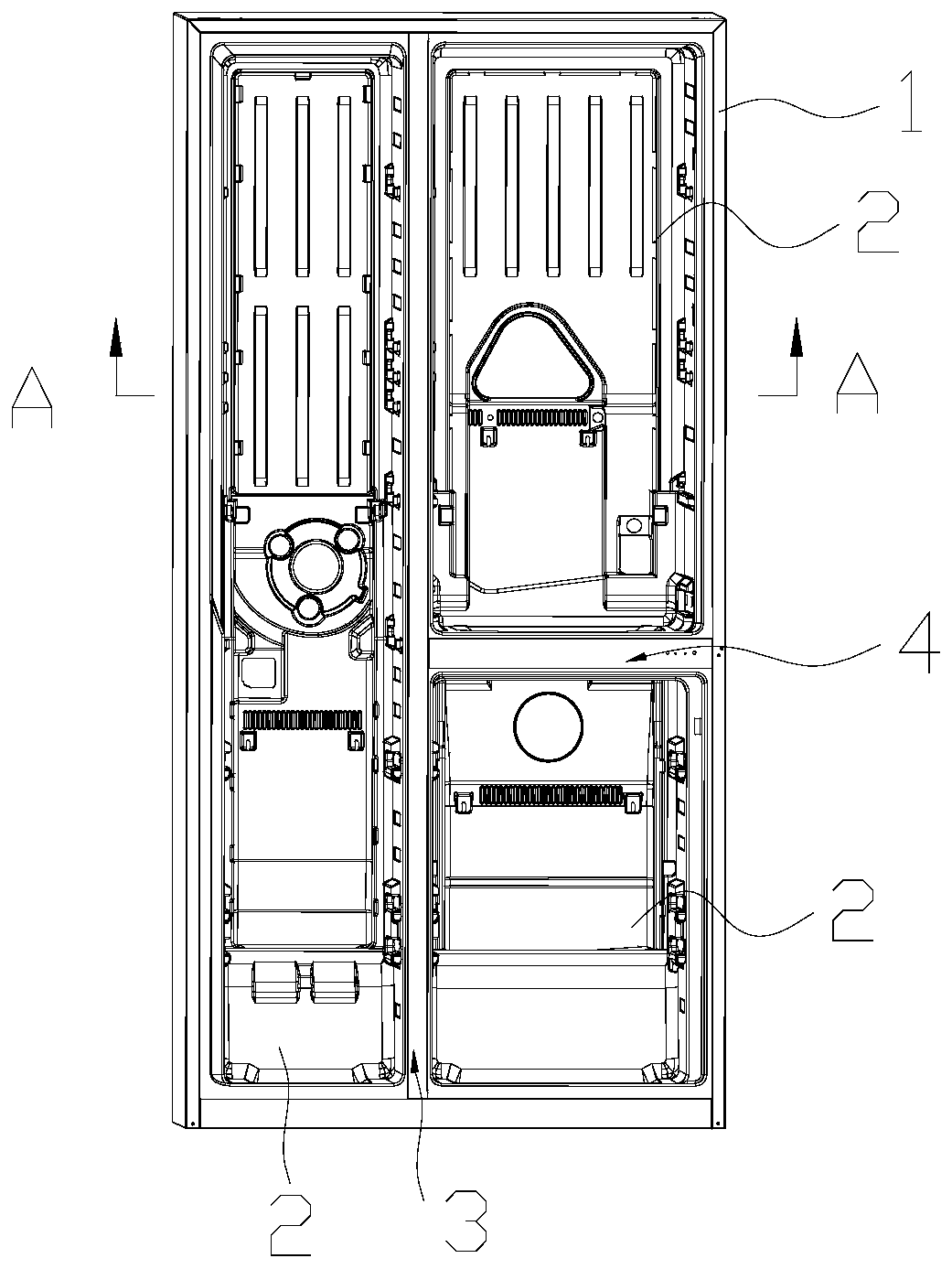

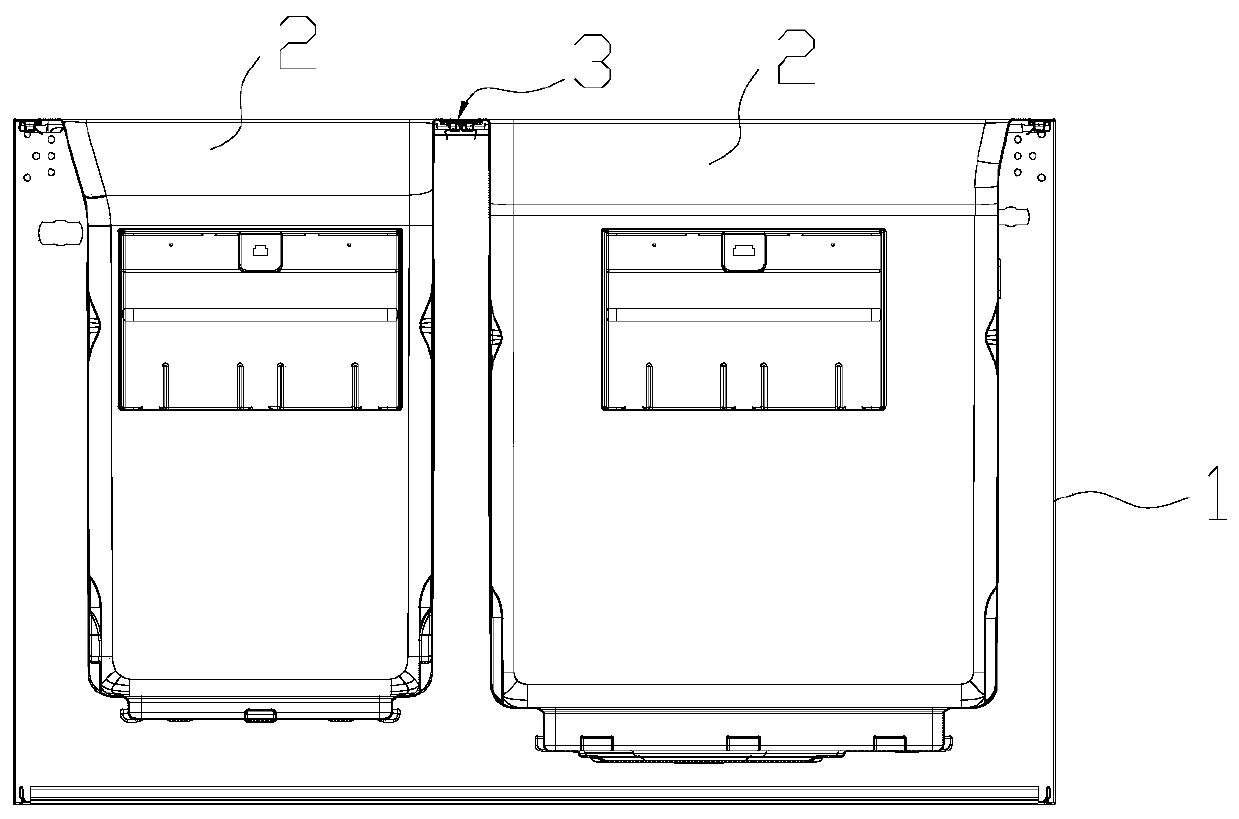

Refrigerator

ActiveCN111336758APrevent movementAvoid flash seamsDomestic cooling apparatusLighting and heating apparatusIceboxEngineering

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Composition with skin color brightening effect and preparation method thereof

ActiveCN106038465AGood skin careAdjust colorCosmetic preparationsToilet preparationsCelluloseMedicine

The invention discloses a composition with a skin color brightening effect and a preparation method thereof. The composition is prepared from, by mass, 0.1%-2.0% of pearl powder, 0.5%-1.5% of sodium polyacrylate, 1.0%-4.0% of talcum powder subjected to surface treatment with triethoxycaprylylsilane, 0.5%-4.0% of mica, 0.05%-0.3% of mixture of xanthan gum, hectorite and cellulose, 2.0%-8.0% of 1,3-propylene glycol and 0.3%-0.8% of preservative. According to the composite, the skincare effect and skin color brightening can be perfectly combined, slight shell-like gloss is brought to skin, and the face contour is more stereoscopic; the composition has the advantage of being good in stability.

Owner:广州卡洛莱化妆品有限公司

A kind of phase-change microcapsule of multi-component reticular shell and preparation method thereof

ActiveCN109679584BThorough responseIncrease crosslink densityHeat-exchange elementsMicroballoon preparationPolymer scienceOil phase

The multi-component network shell phase-change microcapsule disclosed by the present invention has a capsule core of fatty acid ester or paraffin hydrocarbon compound with a low melting point; The alcohol reacts to form a resin with a polyurea polyurethane multicomponent network. The invention also discloses a preparation method of the phase change microcapsule, which comprises: emulsifying the oil phase and the water phase medium solution, adding water-soluble polyamine, then heating up for reaction, and finally adding water-soluble polyhydric alcohol for heat preservation reaction. The present invention introduces the reaction between the monomers from the inside of the interface to form a shell, so that the reaction monomers are completely reacted at the end of the reaction; The oil-soluble polypropylene glycol and the water-soluble polyol are reacted to prepare phase-change microcapsules with a multi-component network shell, and the cross-linking density of the microcapsule wall is increased, thereby enhancing the compactness and stability of the capsule wall.

Owner:上海伊纯实业有限公司

A kind of phase change microcapsule with polyurethane network structure and preparation method thereof

ActiveCN107096475BIncrease crosslink densityImprove compactnessHeat-exchange elementsMicroballoon preparationPolymer sciencePolyol

The invention discloses a phase-change microcapsule with a polyurethane net structure. The phase-change microcapsule comprises two parts, i.e., a capsule core and a capsule wall, wherein the capsule core is an aliphatic ester or paraffin hydrocarbon compound with a low melting point, and the capsule wall is resin with a polyurethane net structure formed by a reaction of polyisocyanate and polyol. The phase-change microcapsule overcomes environmental protection problems caused by formaldehyde during in-situ polymerization. The invention also discloses a preparation method for the phase-change microcapsule. The preparation method comprises the following concrete steps: step 1, preparing an oil-phase medium solution; step 2, preparing a water-phase medium solution; step 3, preparing an emulsification suspension: mixing the oil-phase medium solution prepared in the step 1 and the water-phase medium solution prepared in the step 2 and preparing the emulsification suspension under the action of a high-sheer emulsifying machine; step 4, subjecting the emulsification suspension prepared in the step 3 to a mixing reaction with water-soluble reaction monomers; and step 5, successively carrying out heating for a reaction, cooling and discharging so as to obtain the phase-change microcapsule with the polyurethane net structure.

Owner:浙江烯纺新材料科技有限公司

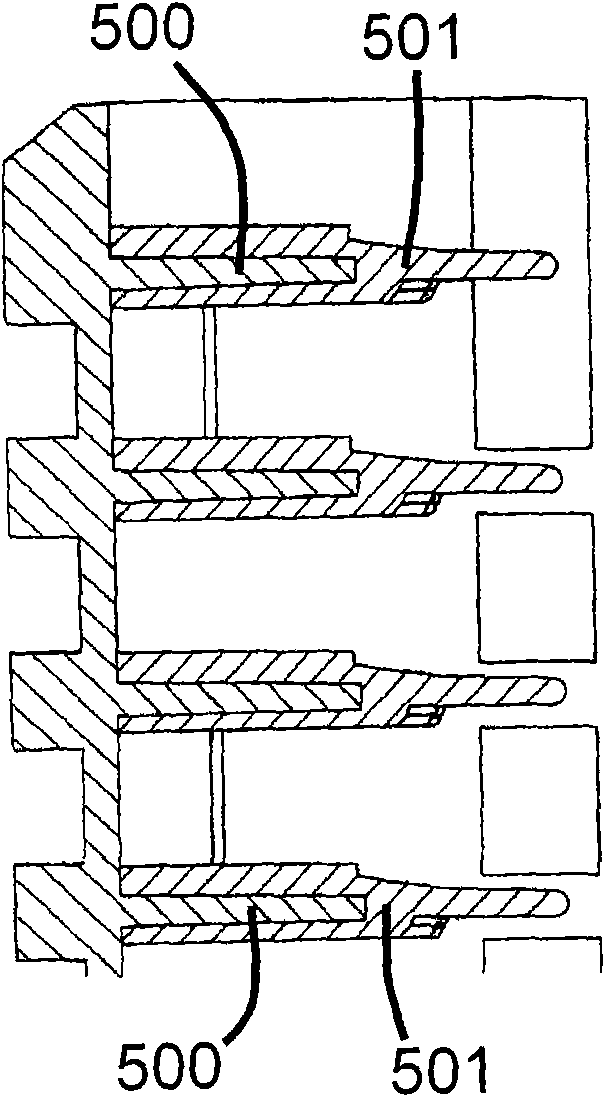

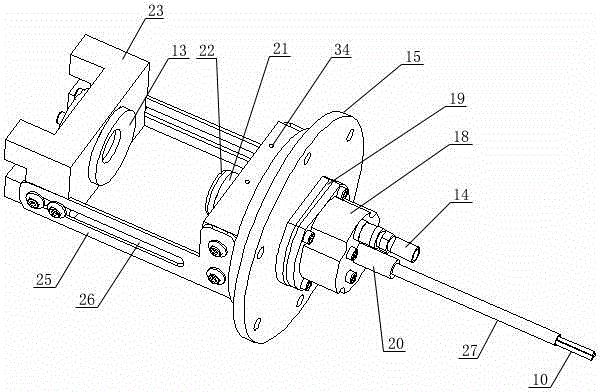

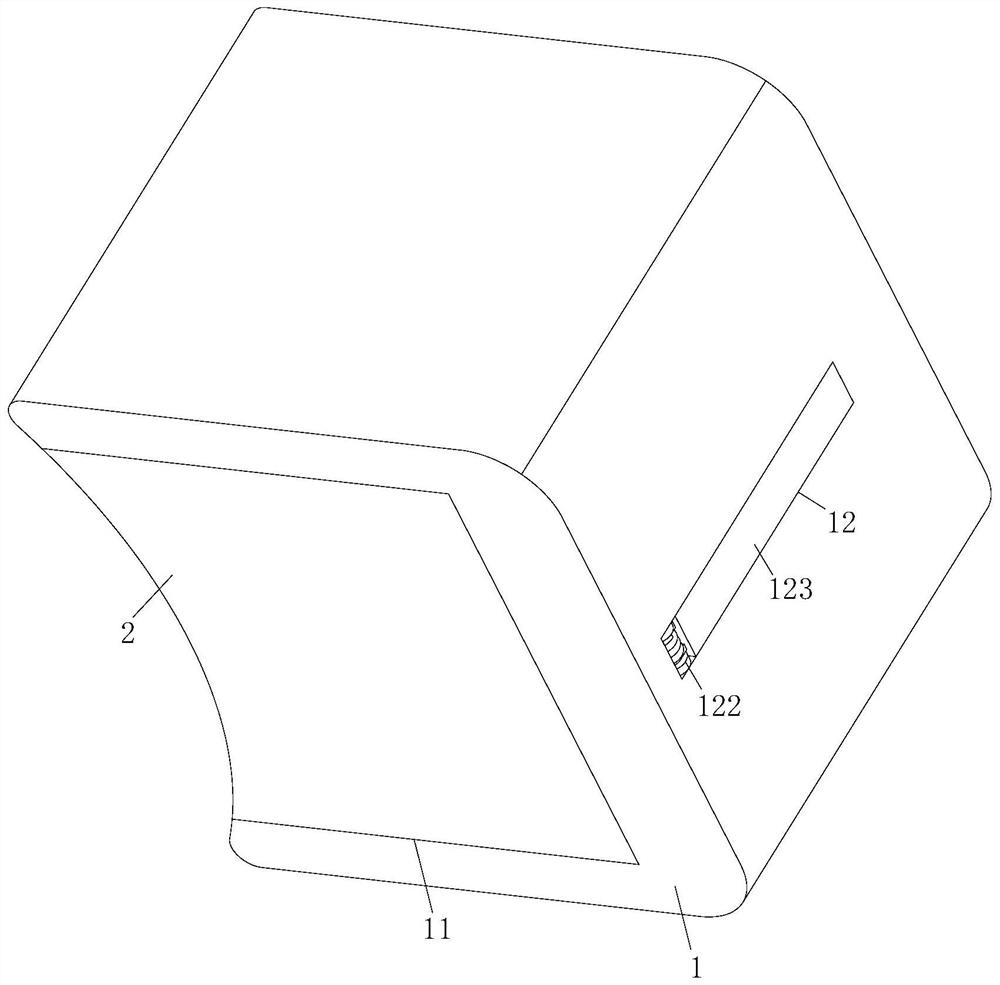

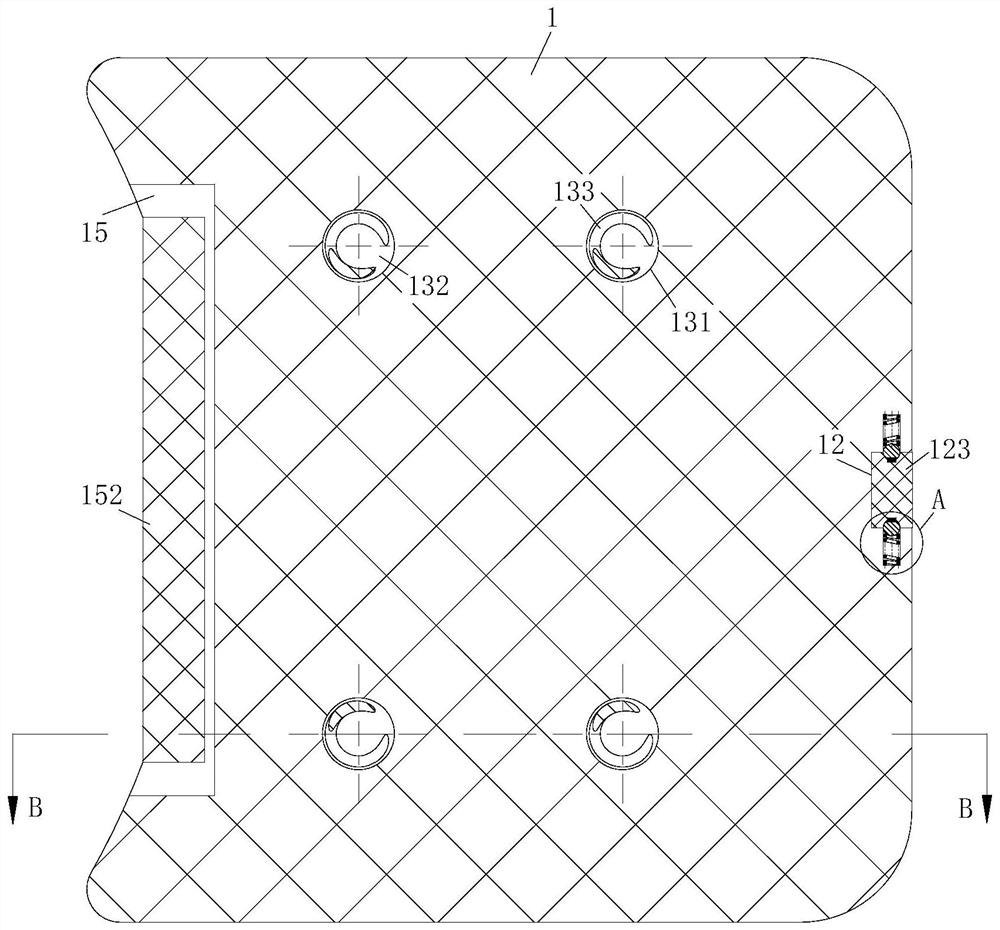

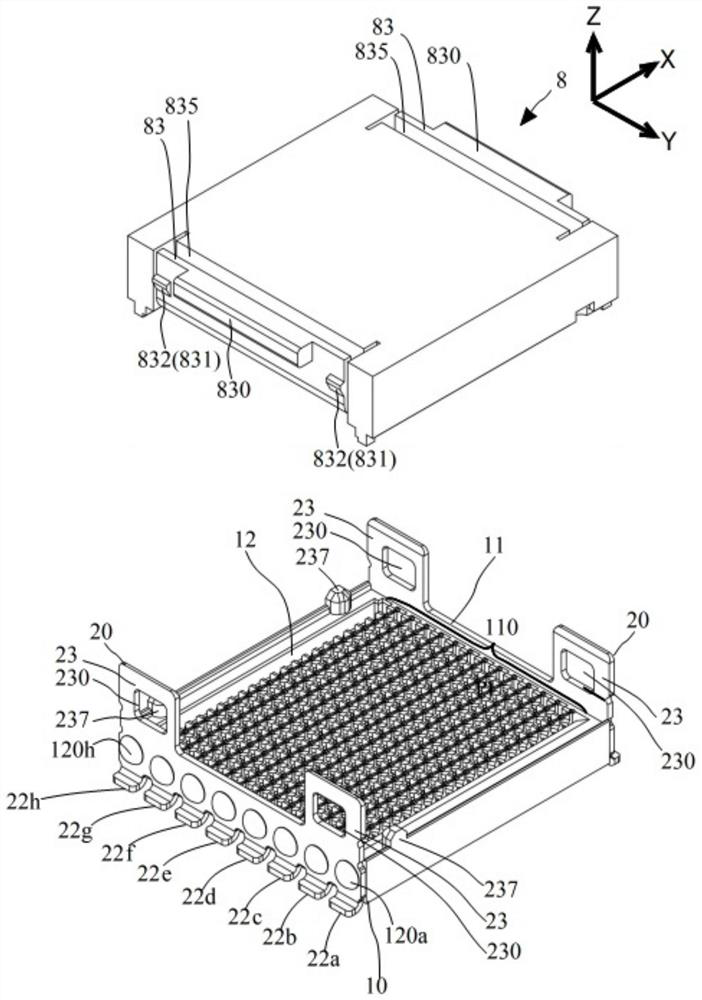

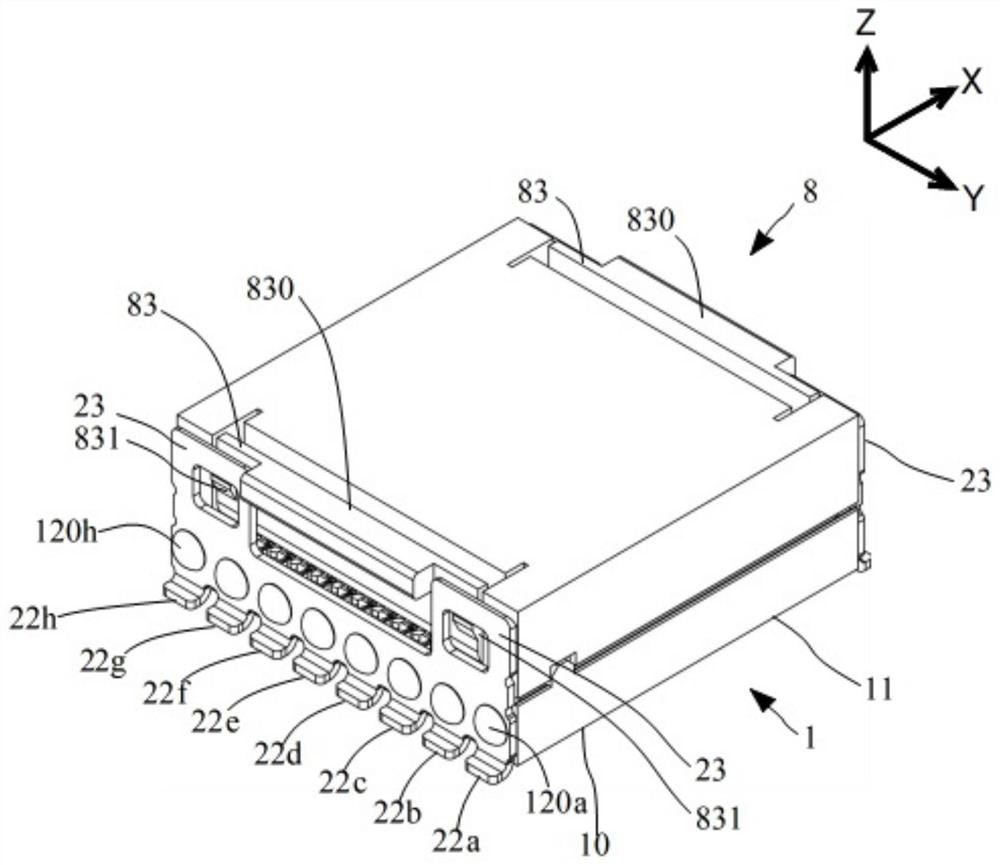

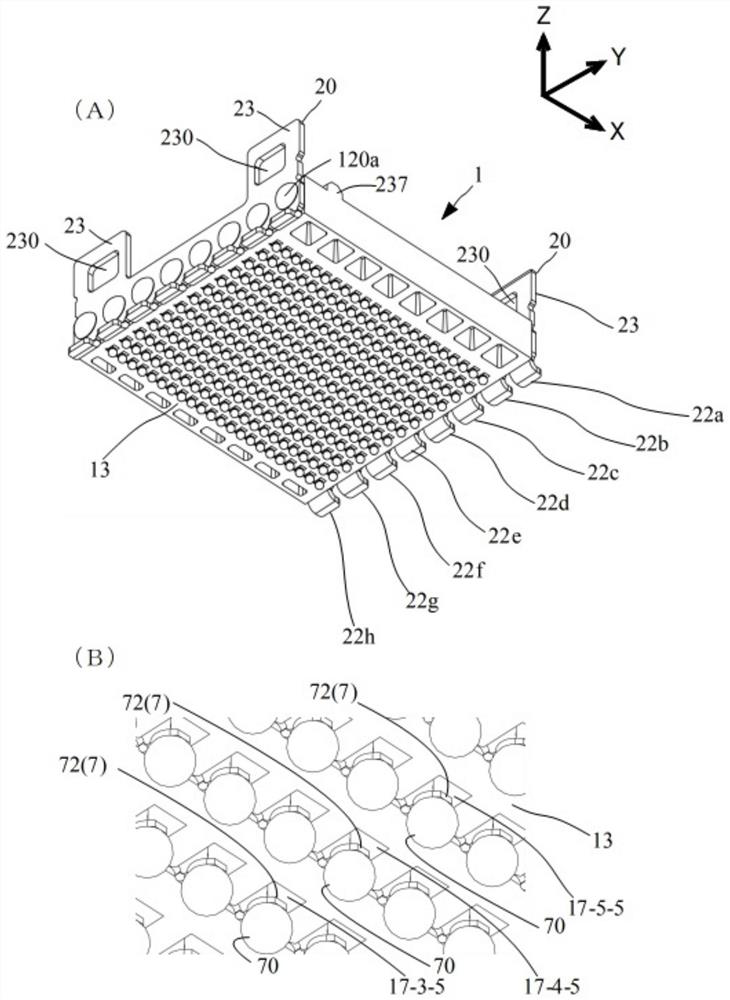

Socket, IC package, and method for mounting contact piece to connector housing

PendingCN113764947ANo sinkingHigh positioning accuracyContact member manufacturingContact member assembly/disassemblyStructural engineeringMechanical engineering

The invention provides a socket, an IC package, and a method for mounting a contact piece to a connector housing, wherein the socket can be accurately mounted at a target position on a substrate. The socket is provided with a housing having: a bottom part which serves as the bottom of an opening for accommodating an IC package and which is provided with a plurality of through-holes; two pairs of side wall parts that face each other with the opening therebetween, and are provided with a plurality of ribs that protrude outward on the pair of side wall parts; a plurality of contact pieces which pass through the plurality of through holes, are exposed to the opposite side of the opening, and are supported by the housing; and a bracket having a plurality of support holes, the ribs passing through the support holes and being fixed to the side surface of the housing. Therefore, a part of the lower end of the bracket extends to the lower side of the lower end of the shell and is bent outwards, and the bent part forms a mounting surface which is soldered on the substrate.

Owner:YAMAICHI ELECTRONICS +1

Manufacturing method for reflection mirror of silicon-based LCD device

ActiveCN100449365CThe probability of electrochemical reaction is reducedThe probability of electrochemical reaction is smallStatic indicating devicesPhotomechanical apparatusElectrochemical responseLiquid-crystal display

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of preparation method of tissue repair material

The invention relates to a preparation method of a tissue repair material. The preparation method comprises the following steps: carrying out pre-treatment; vibrating in an organic solvent to degrease; deactivating a virus with an ethanol solution; removing cells by high and low osmotic solutions; swelling in an acidic or alkaline liquid; and quickly lyophilizing and sterilizing. The thickness of the tissue repair material is increased by 2-4 times, and the material is loose and porous, small in change of mechanical property and degradation property and good in cell removal effect and has relatively high biosafety and biocompatibility. Due to the structural characteristics of proper thickness and looseness and porosity, the material is suitable for damage repair for filling damaged parts required by repair such as cartilage injury, skin and soft tissue defect, gingival recession and the like. Animal experiments verify that the repaired region after eight weeks has no depressed phenomena and is fully replaced by regenerated tissues. Moreover, the regenerated tissue and autologous tissue are healed well and are free of separating phenomenon, which verifies that the material can provide sufficient three-dimensional space for cell proliferation and crawl, so that the repaired region has good integration degree and filling degree, thereby realizing tissue repair and regeneration.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

A kind of preparation method of high flame-retardant non-woven fabric

ActiveCN110747583BImprove the effect of wetting finishing solutionImprove the effect of flame retardant finishingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPolymer sciencePlant fibre

The invention discloses a method for preparing a highly flame-retardant nonwoven fabric, which comprises the steps of firstly, processing polypropylene material; secondly, mixing the material; thirdly, carrying out laying; fourthly, uniformly mixing a nitrogen-phosphorus flame retardant, organic montmorillonite, a penetrant and water according to a weight ratio to prepare a flame-retardant finishing solution; fifthly, carrying out flame-retardant finishing on the nonwoven fabric by a finishing processing device; and sixthly, drying to obtain the highly flame-retardant nonwoven fabric. Polypropylene, maleic anhydride grafted polypropylene and plant fibers are adopted as base materials to the nonwoven fabric, and isotactic polypropylene and maleic anhydride grafted polypropylene can improvethe physical and mechanical properties of the nonwoven fabric; Through the addition of a degradation agent and the plant fibers, the nonwoven fabric has good degradation performance and meets the requirements of modern environmental protection; In addition, the flame-retardant finishing is performed with the special finishing processing device, so that the nonwoven fabric is fully soaked with thefinishing solution, the finishing effect is improved, and the flame-retardant performance of the nonwoven fabric is further improved.

Owner:义乌市鸿晟无纺布有限公司

Lower pipeline reinforcing device and method for replacement of cylinders of turbine

The invention discloses a lower pipeline reinforcing device and method for replacement of cylinders of a turbine. The lower pipeline reinforcing device comprises at least two transverse beams, at least two longitudinal beams and a clamping device, wherein the transverse beams and the longitudinal beams are crossed to define a channel for accommodating a pipeline, and the distance between the transverse beams which are oppositely arranged or the distance between the longitudinal beams which are oppositely arranged is equal to the outer diameter of the pipeline. The clamping device is fixed to the transverse beams or / and the longitudinal beams, is coaxial to the channel, and is used for applying annular clamping force to the pipeline. By means of the lower pipeline reinforcing device and method, the problems that when the high-medium-pressure cylinders of the turbine are replaced, after a lower pipeline is cut, during back-installation, precise assembly cannot be achieved, and the staggering rate is high can be solved, and the problem that reinforced groove steel is cut for the second time, and the working procedures are complicated can also be solved.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

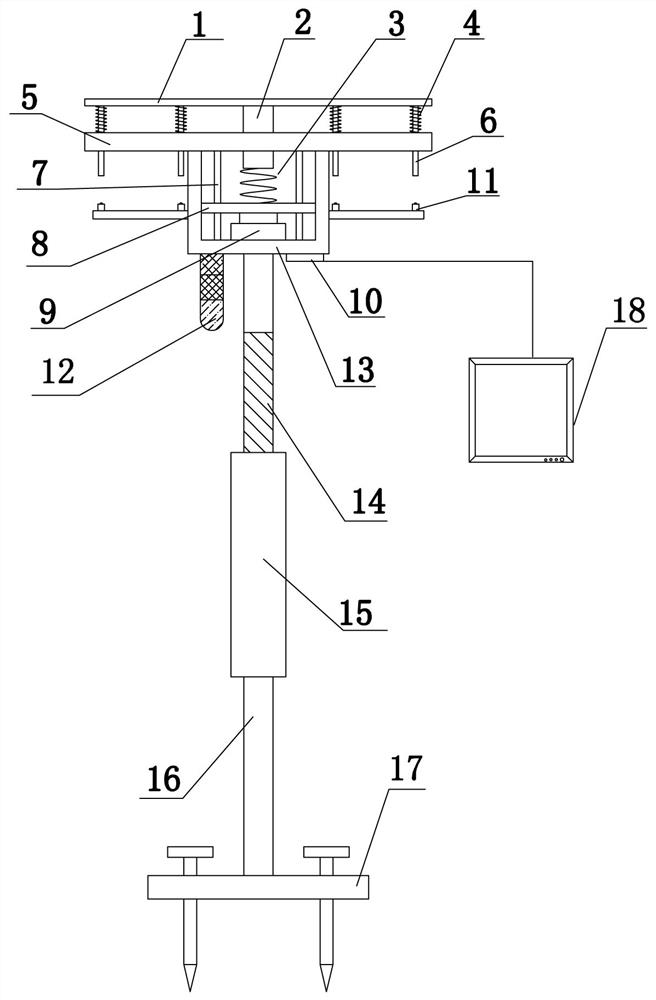

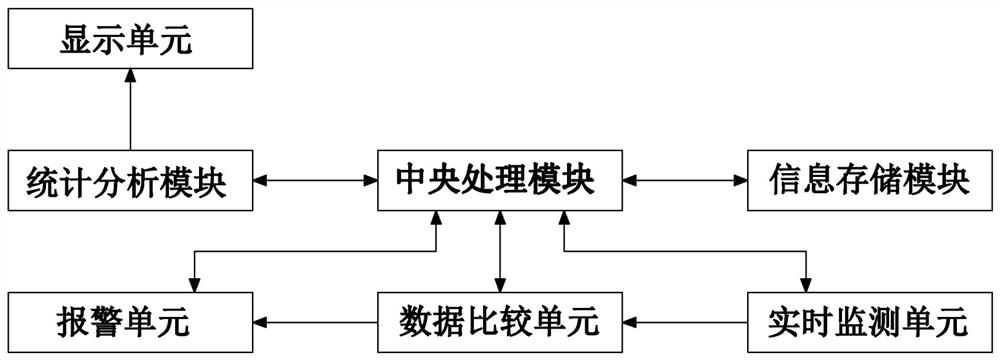

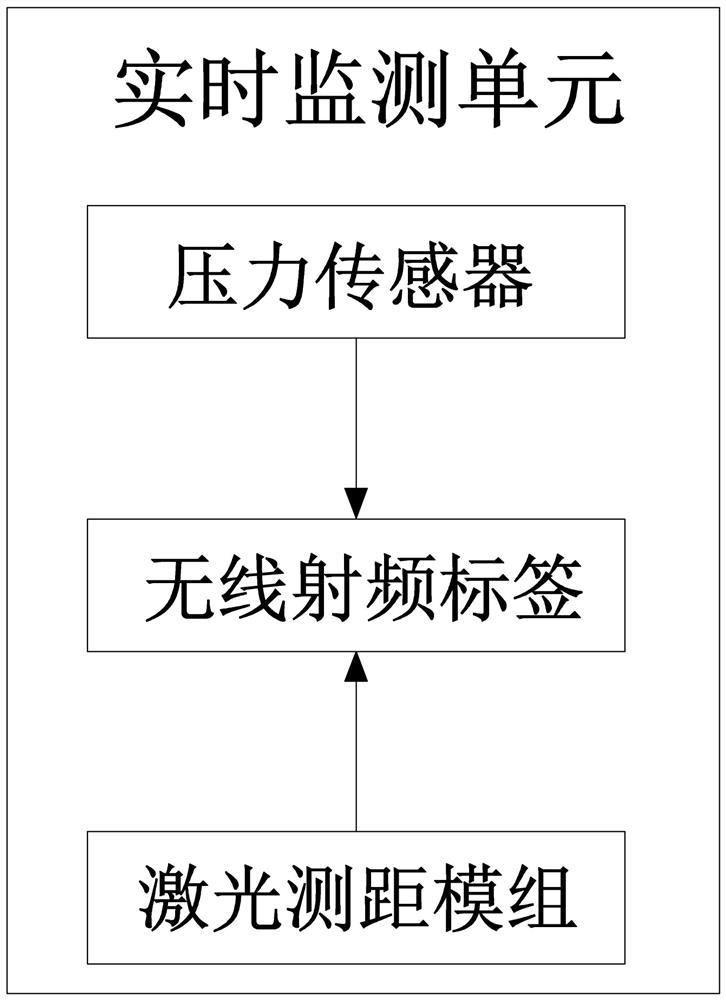

Monitoring and early warning device and method for stability of roadway roof

ActiveCN113804149AEnsure stability and securityImprove functionalityMeasurement devicesTotal factory controlLaser rangingAutomatic control

The invention relates to a monitoring and early warning device and method for the stability of a roadway roof. The monitoring and early warning device is characterized in that the device comprises a supporting mechanism, a real-time monitoring assembly arranged on the supporting mechanism, and an automatic control system; the supporting mechanism comprises a base and a lifting rod assembly; the real-time monitoring assembly comprises a U-shaped groove, a limiting plate, a pressure measuring plate, a guide column, a push plate, a guide rod, a sliding rod, a spring I, a spring II and a real-time monitoring unit composed of a pressure sensor, a wireless radio frequency tag, an alarm and a laser ranging module; and the automatic control system comprises a central processing module, an information storage module, a data comparison unit, a statistical analysis module, a real-time monitoring unit, an alarm unit and a display unit. The device has the advantages as follows: (1) the device integrates a supporting function and a monitoring function; and (2) the device can simultaneously monitor the pressure difference value and the settlement difference value change of a roadway roof in unit time on line, judge the stability of the roadway roof in real time, and perform early warning in time.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com