Method for preparing highly flame-retardant nonwoven fabric

A non-woven, high flame retardant technology, applied in the field of preparation of high flame retardant non-woven fabrics, can solve the problems that the non-woven fabric cannot widely meet the requirements, the mechanical properties and air permeability of the non-woven fabric are lacking, etc. Easy operation and control, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

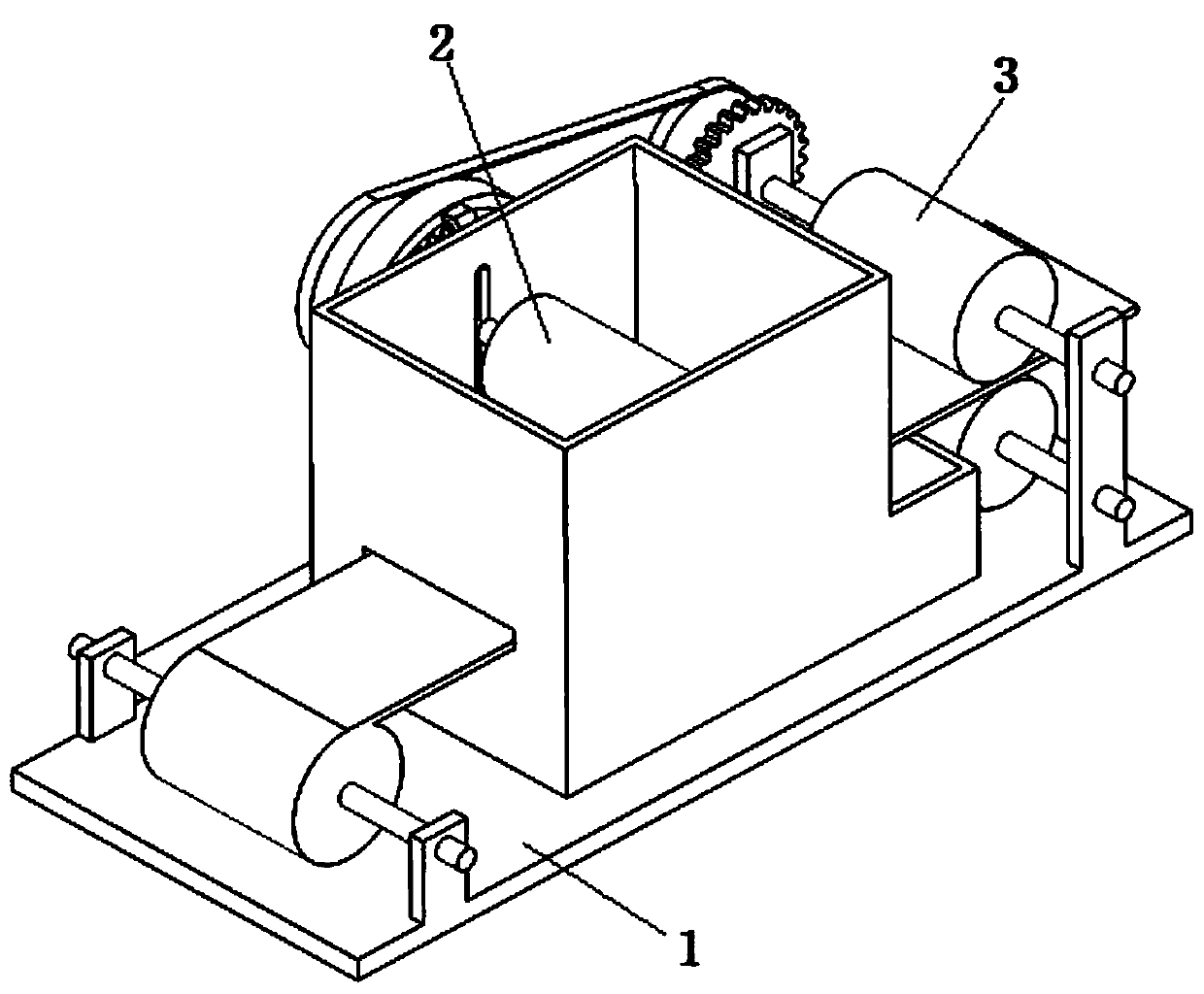

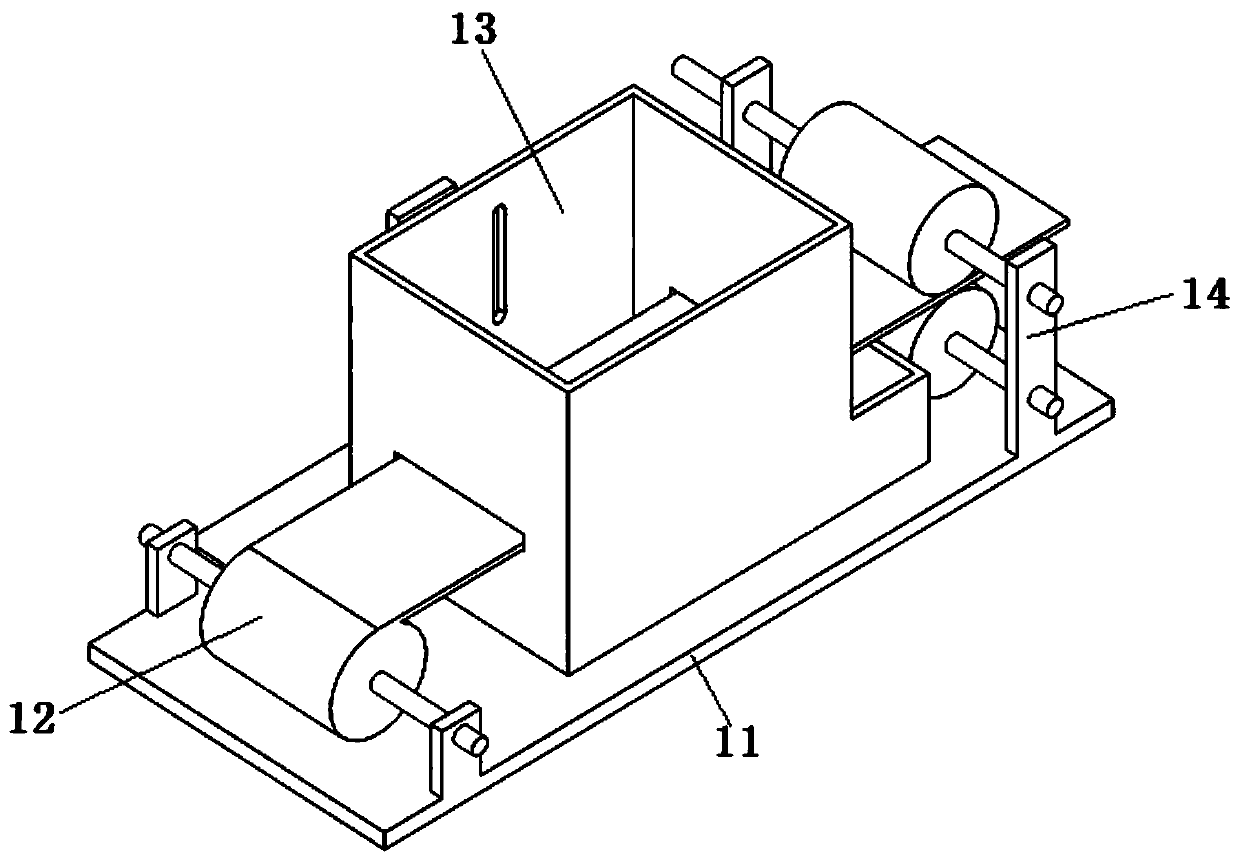

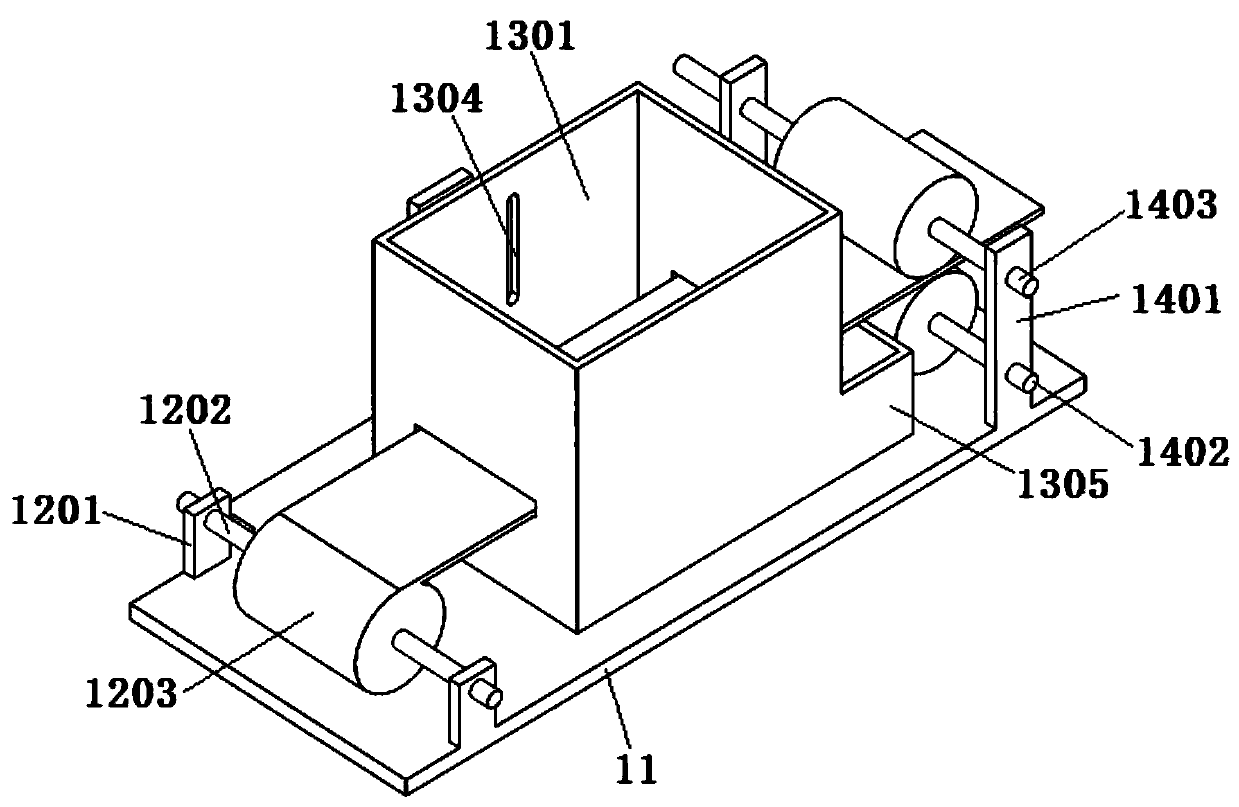

Image

Examples

preparation example Construction

[0044] A method for preparing a highly flame-retardant nonwoven fabric, comprising the steps of:

[0045] The first step, polypropylene raw material processing: rinse the polypropylene with deionized water, send it to the hopper type hot air dryer for convection drying, the drying temperature is 140-145 ° C, and the drying time is 1-3 hours;

[0046] The second step, mixing: according to the following parts by weight: 70-80 parts of polypropylene, 10-13 parts of maleic anhydride grafted polypropylene, 1.3-2.1 parts of degradation agent, 14.5-16.5 parts of plant fiber, 0.2-0.3 parts of antioxidant parts, 0.1-0.2 parts of coupling agent, and 0.1-0.2 parts of processing aids Weigh each raw material, send it into a screw extruder, and carry out melt mixing;

[0047] The temperature control of the 1-6 zones of the screw extruder is as follows: Zone 1: 135-150°C; Zone 2: 160-190°C; Zone 3: 195-210°C; Zone 4: 210-220°C; Zone 5: 220- 225°C; Zone 6: 220-225°C;

[0048] The polypropyl...

Embodiment 1

[0070] A method for preparing a highly flame-retardant nonwoven fabric, comprising the steps of:

[0071] The first step, polypropylene raw material processing: rinse the polypropylene with deionized water, and send it to a hopper-type hot air dryer for convective drying. The drying temperature is 140°C and the drying time is 3 hours;

[0072] The second step, mixing: according to the following parts by weight: 70 parts of polypropylene, 10-13 parts of maleic anhydride grafted polypropylene, 1.3 parts of degradation agent, 14.5 parts of plant fiber, 0.2 part of antioxidant, 0.1 part of coupling agent, 0.1 part of processing aid Weigh each raw material, send it into a screw extruder, and carry out melt mixing;

[0073] The third step is to form a web: the melt enters the melt-blown die, extrudes through the spinneret hole on the die, and then is drawn by a hot air flow, the fiber is cooled and solidified, deposited on the receiving device, and rolled into a web. That is, non-w...

Embodiment 2

[0080] A method for preparing a highly flame-retardant nonwoven fabric, comprising the steps of:

[0081] The first step, polypropylene raw material processing: rinse the polypropylene with deionized water, and send it to a hopper-type hot air dryer for convection drying. The drying temperature is 143°C and the drying time is 2 hours;

[0082] The second step, mixing: according to the following parts by weight: 75 parts of polypropylene, 11.5 parts of maleic anhydride grafted polypropylene, 1.8 parts of degradation agent, 15.5 parts of plant fiber, 0.25 part of antioxidant, 0.15 part of coupling agent, processing aid 0.15 part of agent weighs each raw material, sends into screw extruder, melts and mixes;

[0083] The third step is to form a web: the melt enters the melt-blown die, extrudes through the spinneret hole on the die, and then is drawn by a hot air flow, the fiber is cooled and solidified, deposited on the receiving device, and rolled into a web. That is, non-woven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com