Patents

Literature

303results about How to "Convenient construction work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

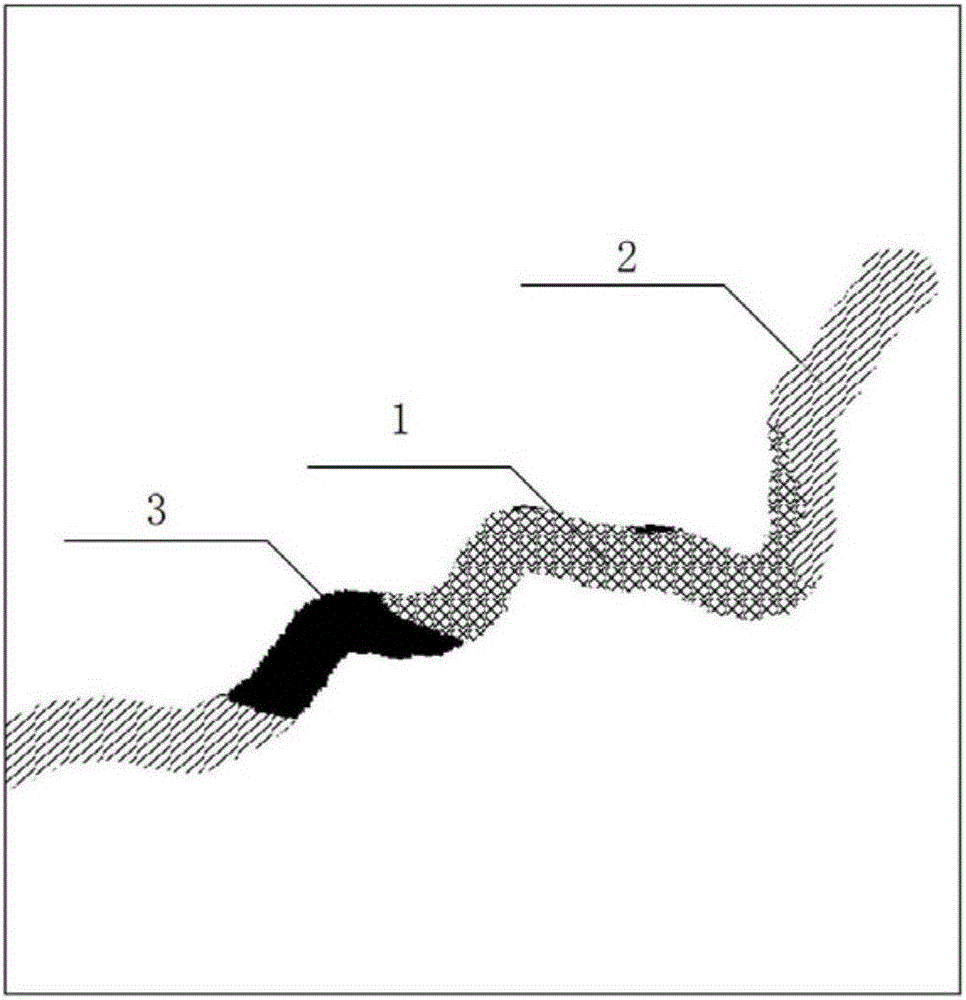

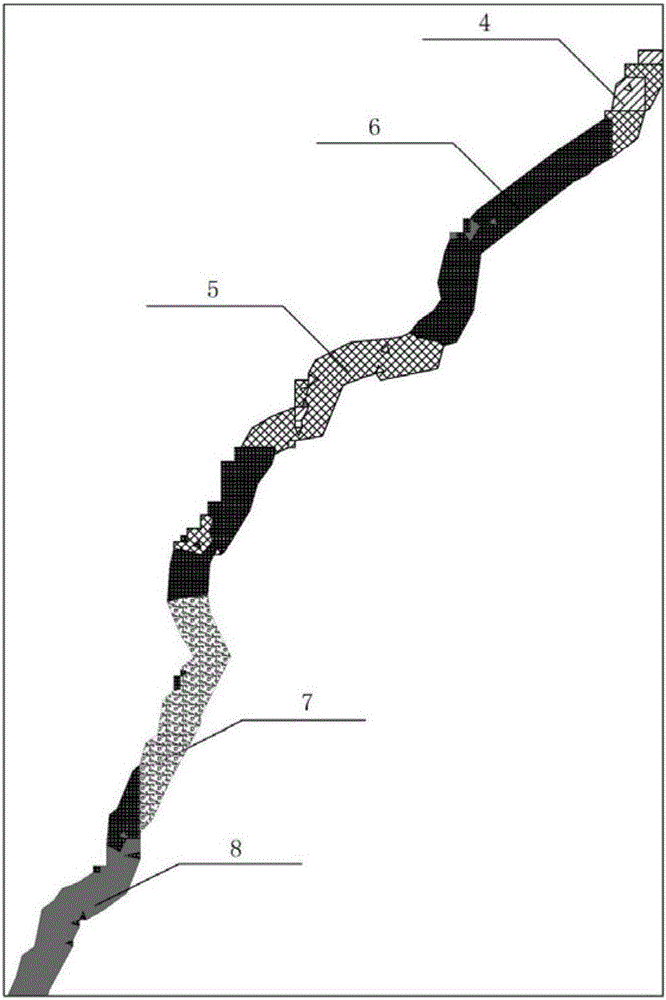

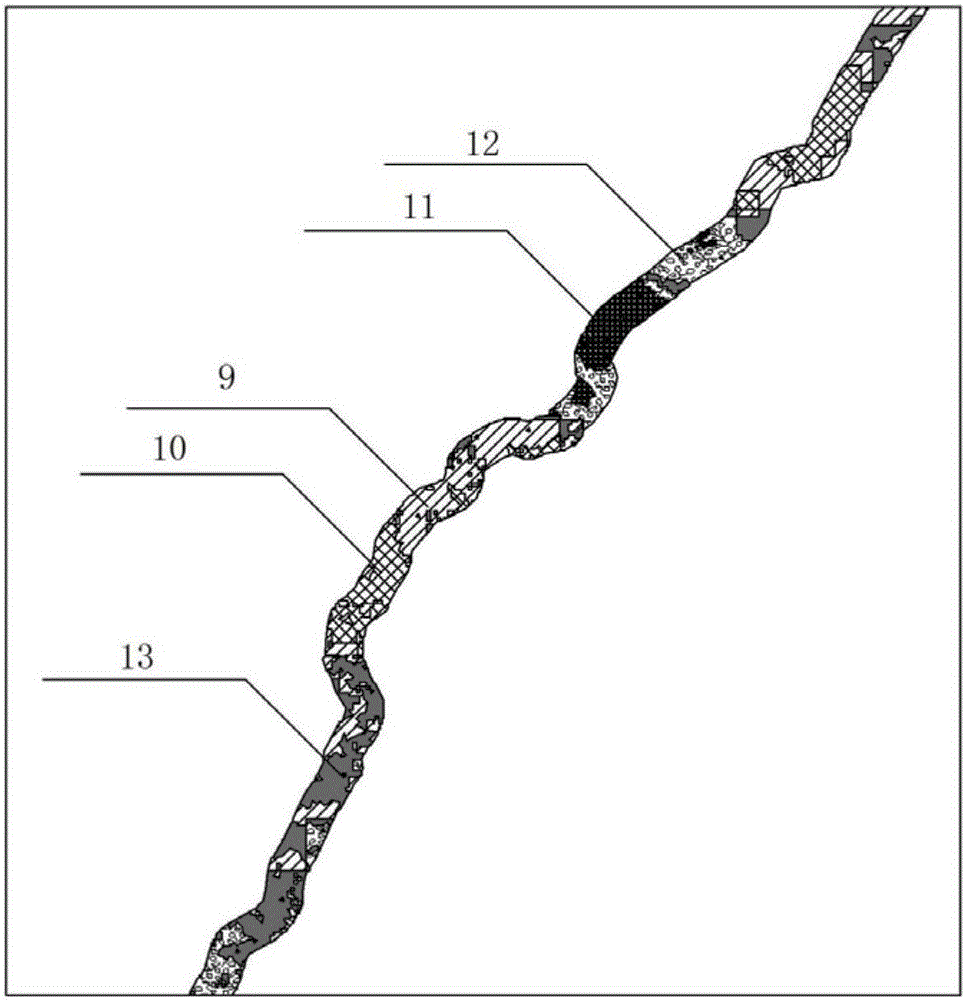

Turf protection utilization method

ActiveCN106416652AImprove targetingHigh feasibilityAgriculture tools and machinesHops/wine cultivationRoad engineeringEngineering

A turf protection utilization method is provided for turf protection utilization programming and planning, and comprises the following steps: delimiting a turf protection level according to nature vegetation types and coverage; delimiting a vegetation retrieval level according to rainfall, temperature and soil factors; carrying out field investigation to check two said levels; superposing and delimiting a plurality of ecology control sections; determining the turf excavating technology according to the vegetation types and coverage in each ecology control section; selecting three protection technologies according to road engineering construction progress and turf utilization time intervals, wherein the three technologies include piled stacking, layered stacking, and skeleton layered temporary planting; determining three planting modes according to wind erosion and water erosion characteristics and propagation coefficients, wherein the three planting modes include a chessboard type, a tic-tac-toe mode and a bar stripped mode. The method can scientifically unify turf protection and utilization planning, storage and utilization, thus providing best ecology benefits; the turf protection utilization method is practical in applications.

Owner:CHINA ACAD OF TRANSPORTATION SCI

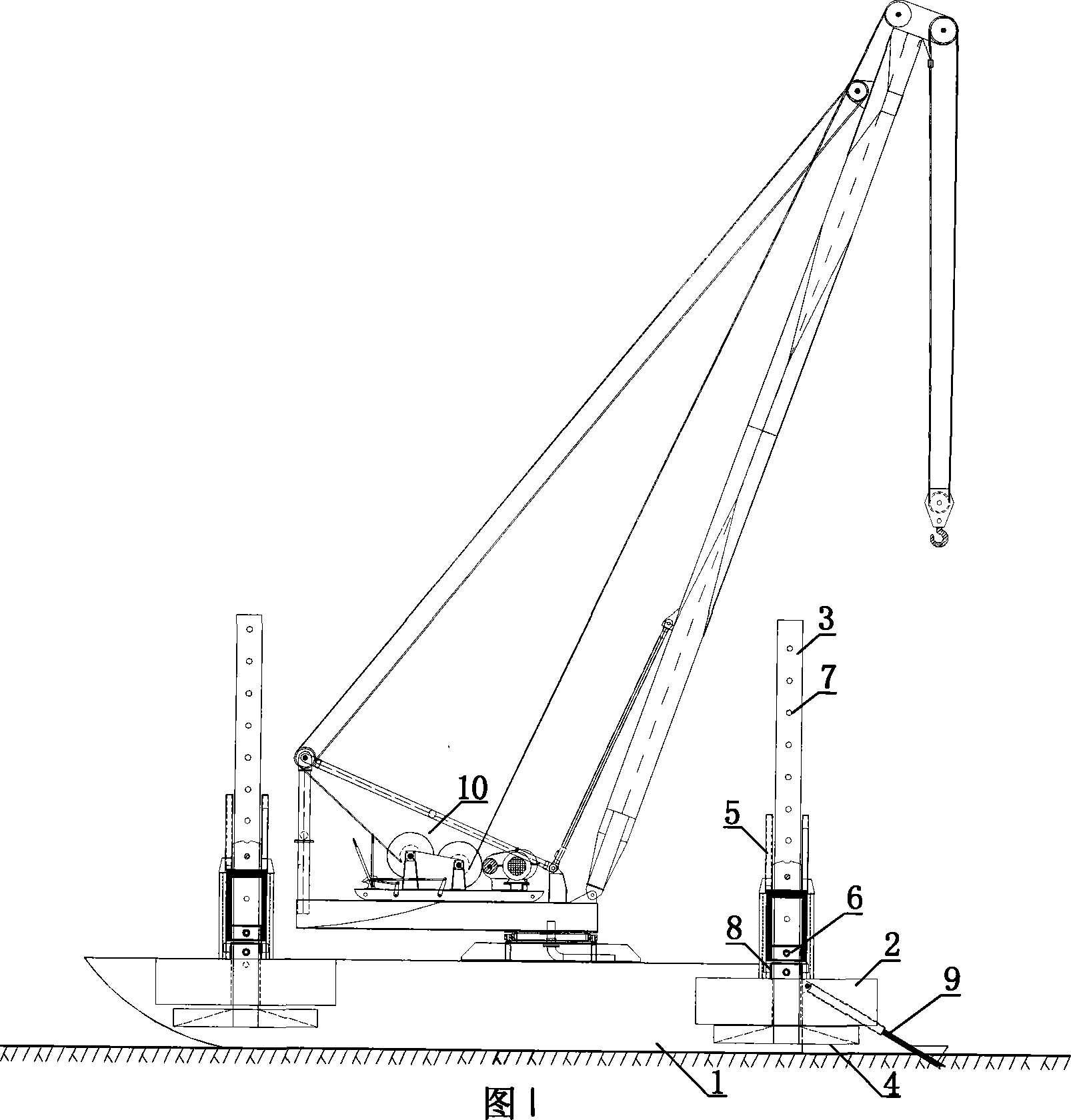

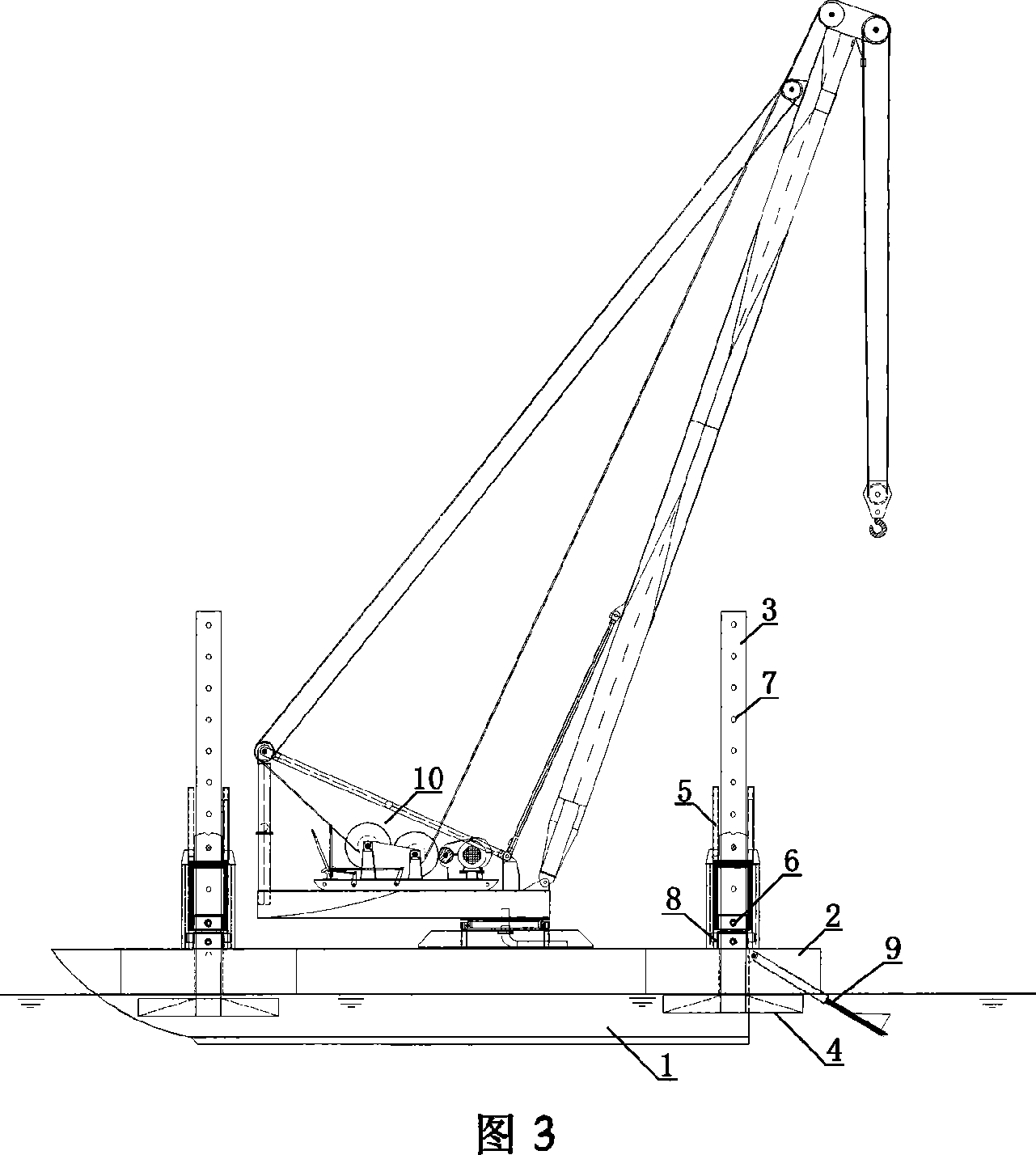

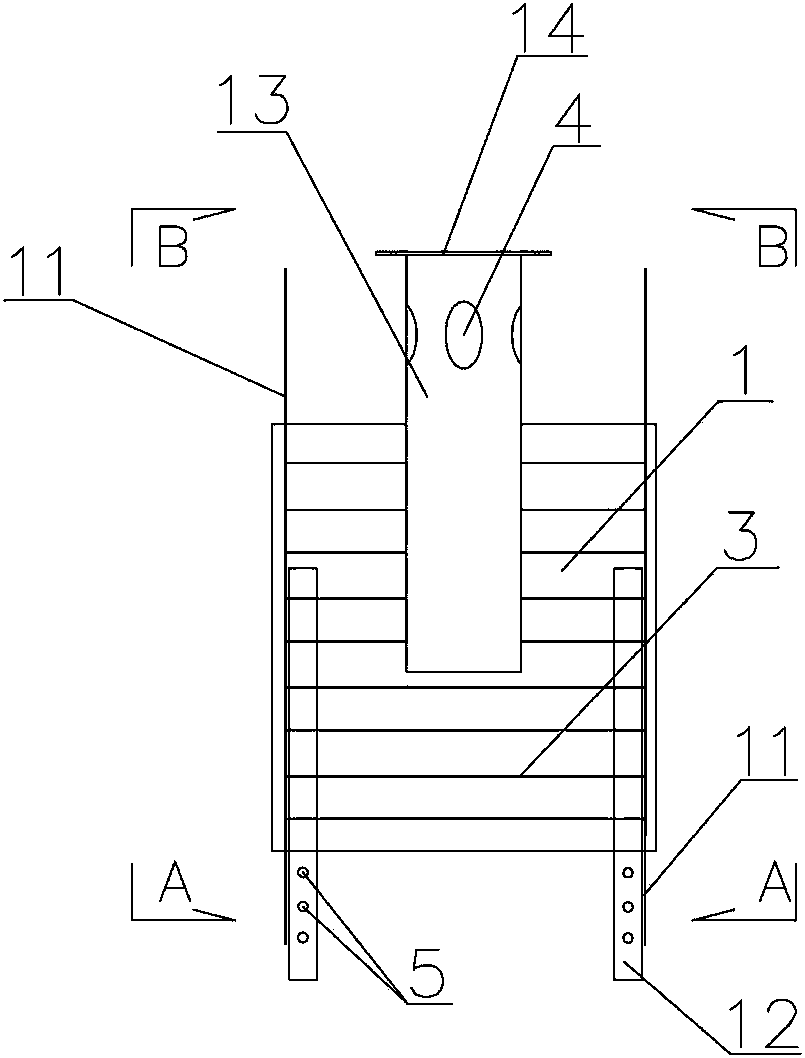

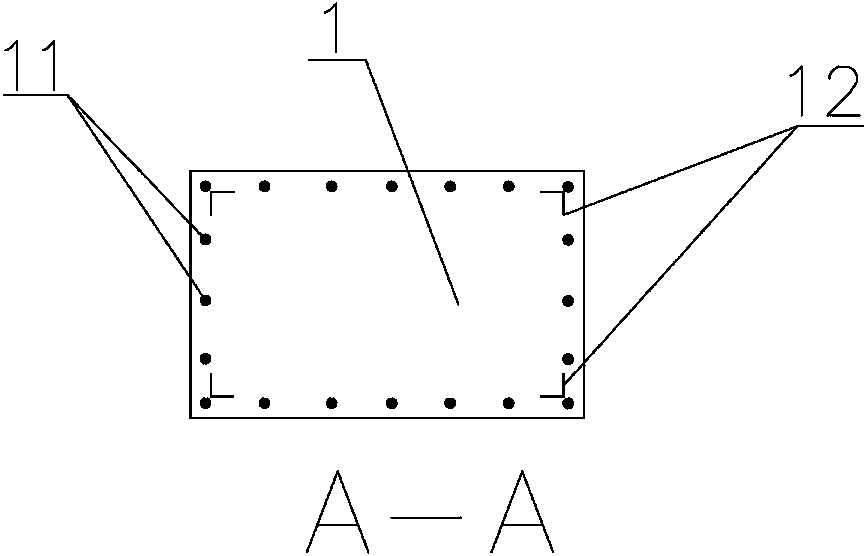

Beach working hoister

InactiveCN101062751AAvoid swingingConvenient construction workCranesMarine engineeringBuilding construction

The offshore operation sinker wheel machine comprises the main floating box, stable floating box, leg well, lift hydraulic jack, push hydraulic jack, crane, with each part detachable. The main floating box is in enclosed boat structure, with the middle installed with crane, fore and back installed with linking beam, with the end installed with stabilizing floating box that installs with leg well and lift hydraulic jack and push hydraulic jack at the rear of the main floating box. Due to the tow jacks, it can solve the displacement of the sinker wheel machine. The crane can meet the needs for construction and goods unloading. It mainly applies to offshore hoisting operation or loading alike jobs.

Owner:何富荣

Prefabricated column and precast construction method thereof

ActiveCN104088397AFirmly connectedNo technical quality requirementsStrutsBuilding material handlingArchitectural engineeringRebar

The invention relates to a prefabricated column and a precast construction method. The prefabricated column comprises a lower prefabricated column and an upper prefabricated column matching the lower prefabricated column, a first vertical steel bar extending out of the upper and lower ends of the lower prefabricated column is arranged in the lower prefabricated column, the lower end of the lower prefabricated column is provided with a first connection member, the upper end of the lower prefabricated column is provided with a first steel pipe and a first flange plate welded to the top surface of the first steel pipe, a second vertical steel bar extending out of the upper and lower ends of the upper prefabricated column is arranged in the upper prefabricated column, the upper end of the upper prefabricated column is provided with a second connection member, the lower end of the upper prefabricated column is provided with a second steel pipe and a second flange plate welded to the top surface of the second steel pipe, the top of a second pre-embedded steel pipe is in a butt connection relationship with two auxiliary steel pipes, the first flange plate and the second flange plate are in a butt connection relationship by bolts, the first connection member is connected to the second connection member by threads, and the first vertical steel bar and the second vertical steel bar are bound by stirrups. The prefabricated column can be constructed simply, has a low price, and is suitable for buildings having high floor height and large column sectional area.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

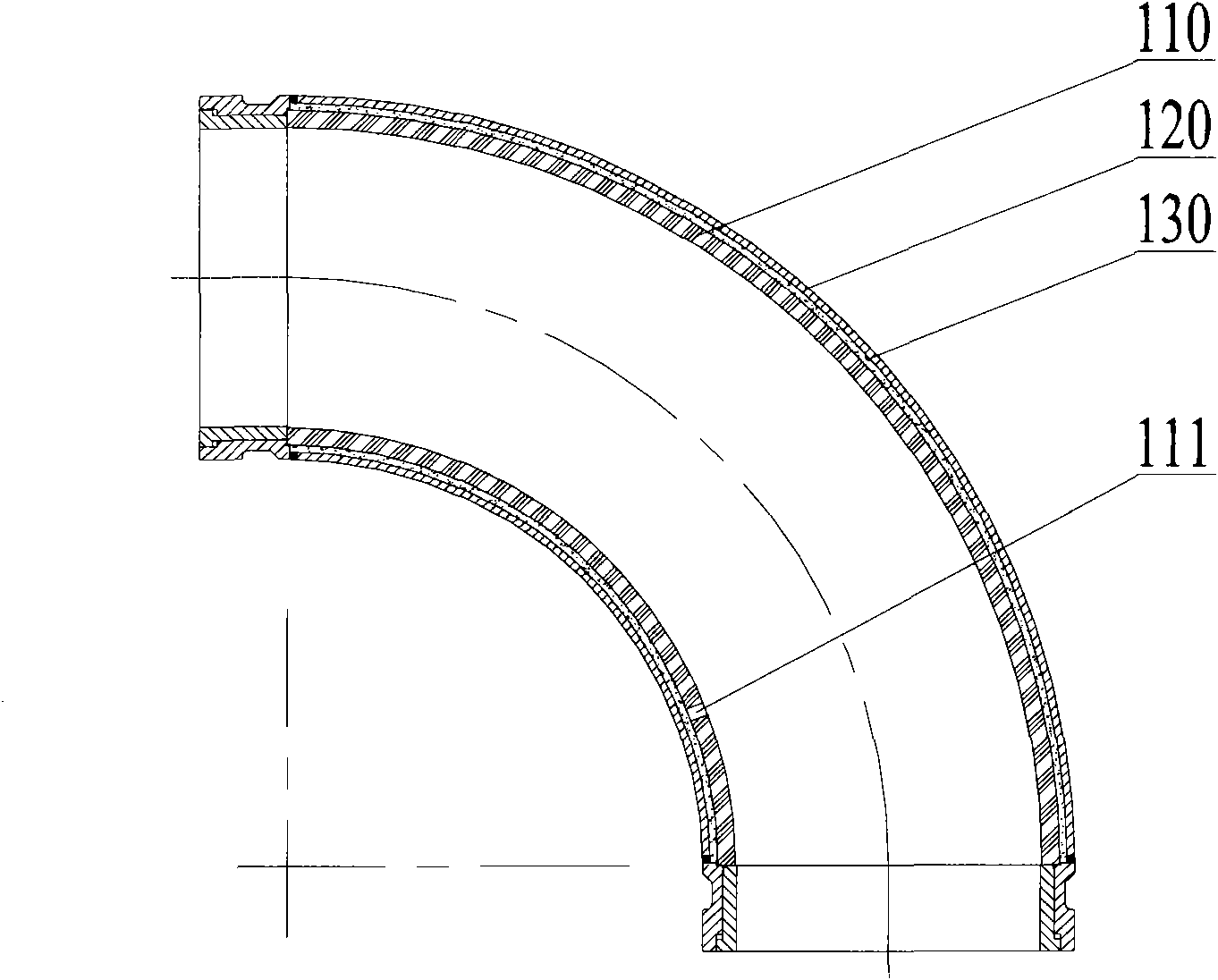

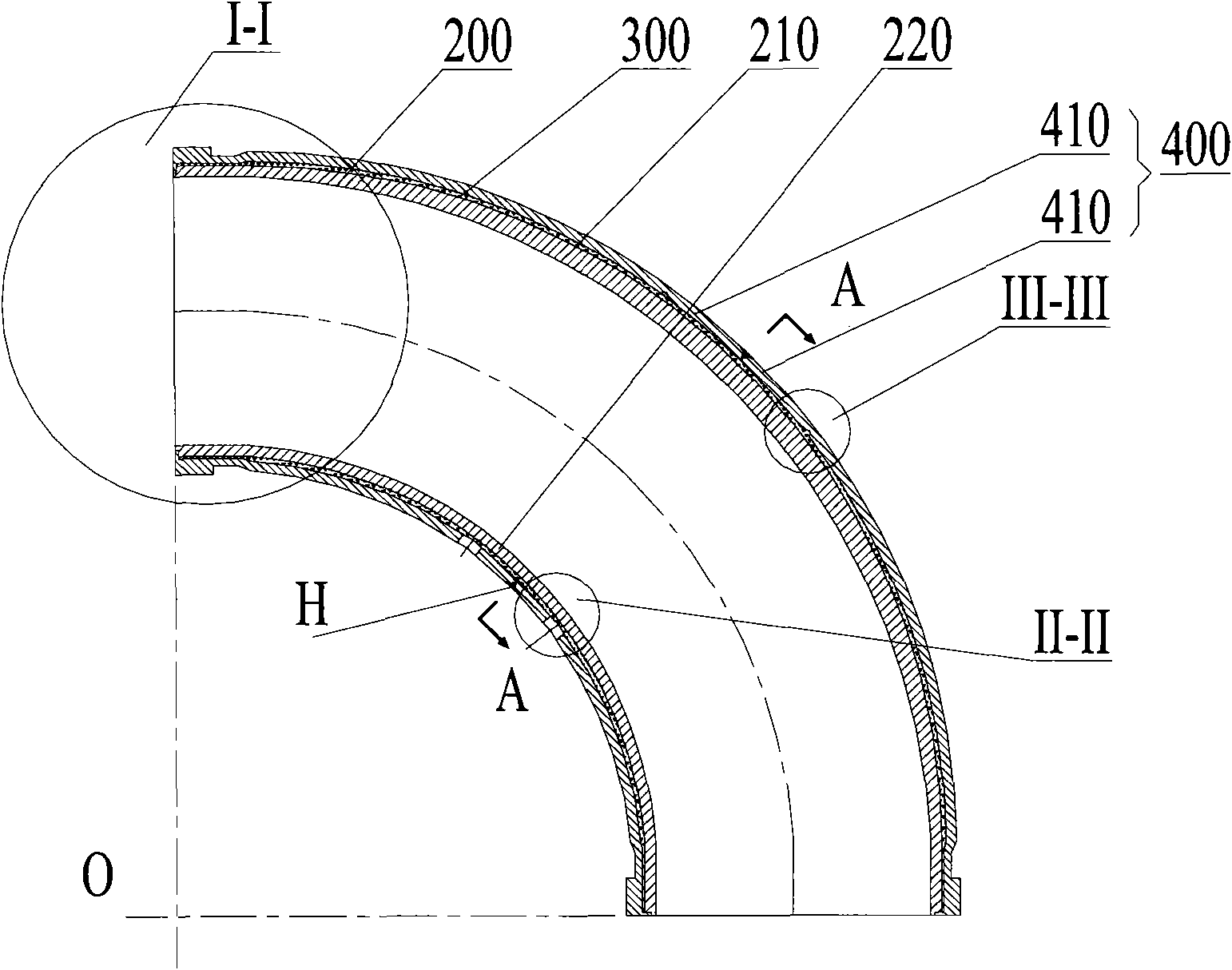

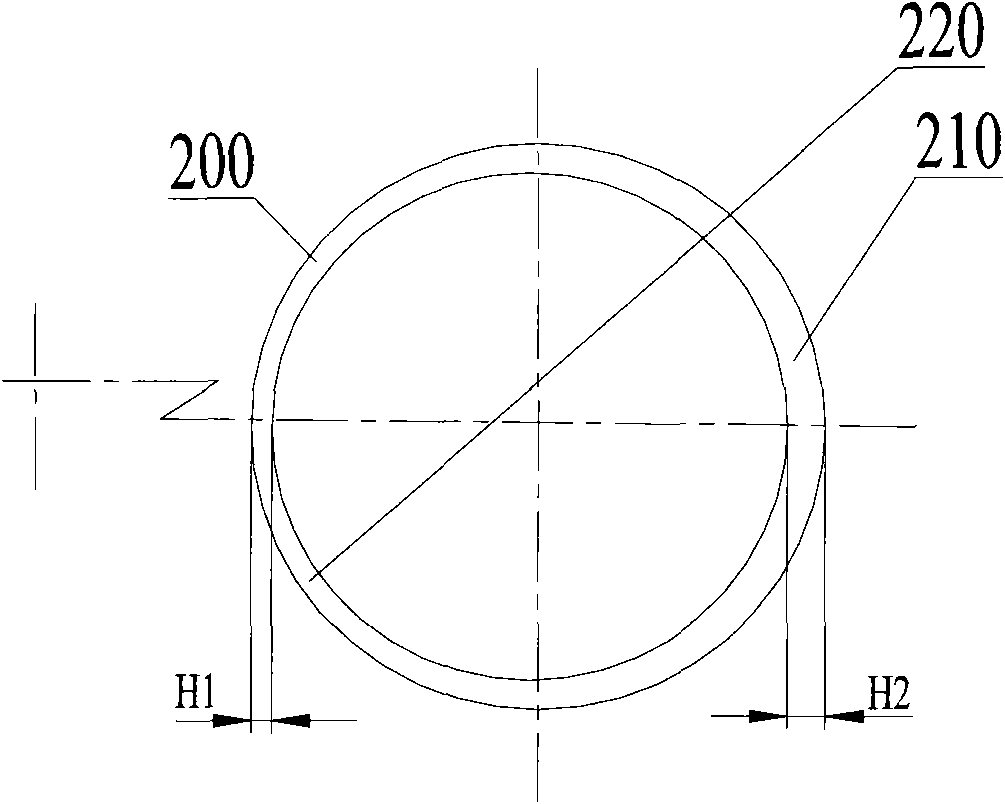

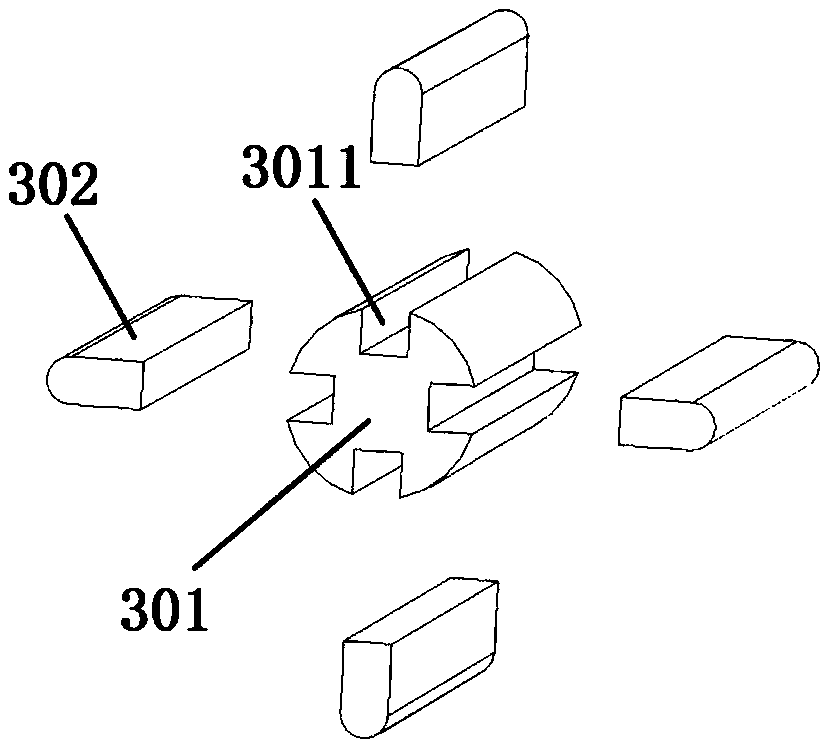

Conveying bent pipe, concrete conveyer and manufacturing method of same

InactiveCN101625060AReduce manufacturing costEasy to processBulk conveyorsRigid pipesManufacturing technologyEngineering

The invention discloses a conveying bent pipe, a concrete conveyer and a manufacturing method of the conveying bent pipe. The disclosed sequentially comprises an inner pipe, an outer pipe and a filling layer, and the outer pipe at least comprises two supporting pipes which are sequentially connected; the outer pipe of the conveying bent pipe has a split type structure and comprises two or more than two supporting pipes, thereby reducing the cost of the conveying bent pipe under the condition that the wearing resistance, the strength, the high toughness and the impact resistance are ensured. In an optimized technical scheme, the inner pipe and outer pipe are fixed by an adhesive layer to transfer the acting force of the inner pipe to the outer pipe, the supporting and protecting function of the inner pipe by the outer pipe is ensured, and safety of the conveying bent pipe can be increased. Because the inner pipe and the outer pipe can be mutually positioned by matching with an inner convex body and an inner notch, the manufacturing method of the conveying bent pipe not only can simplify a manufacturing technology in a conveying bent pipe manufacturing process, but also can reduce auxiliary mechanisms and reduce the manufacturing cost of the conveying bent pipe.

Owner:SANY HEAVY IND CO LTD (CN)

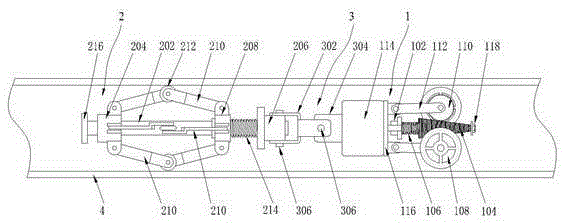

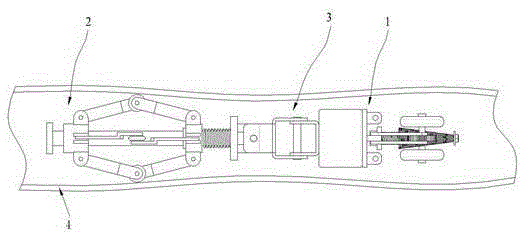

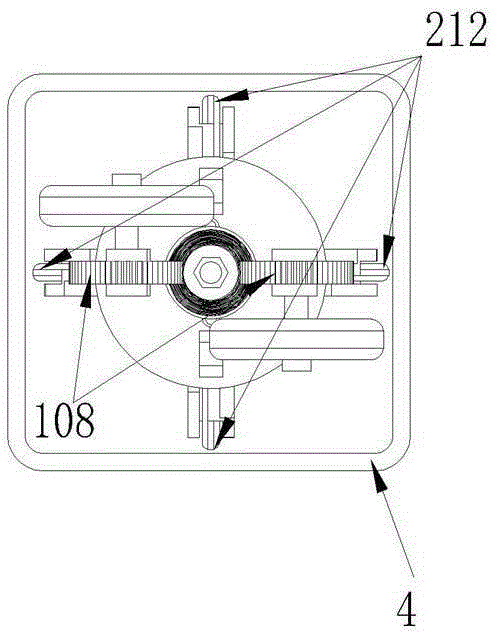

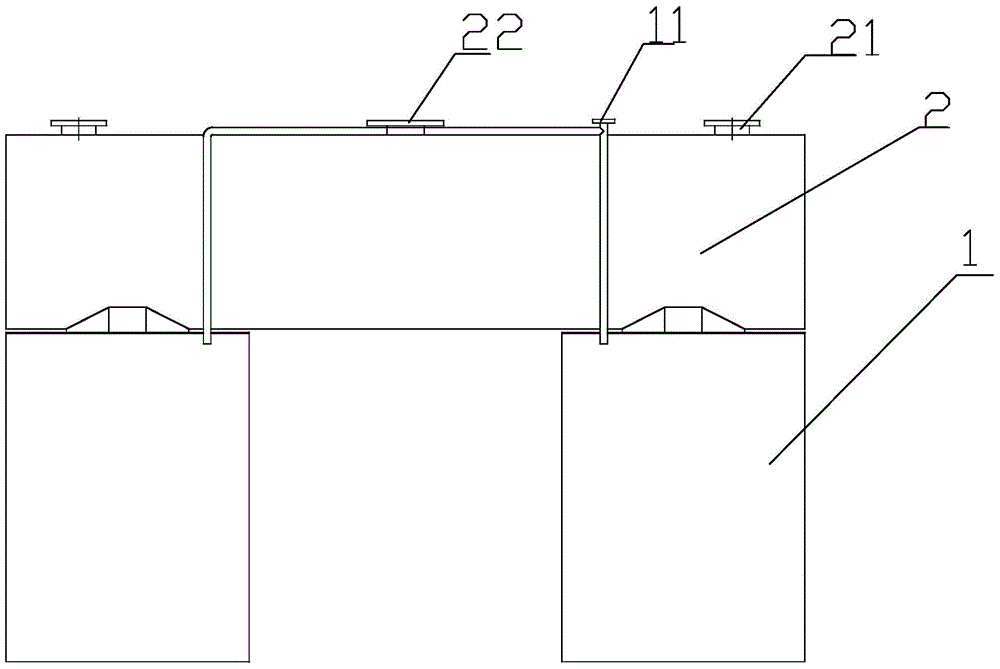

In-pipe walking robot

The invention discloses an in-pipe walking robot. The in-pipe walking robot comprises a running mechanism, a connecting rod assembly and a universal connecting mechanism connected with the running mechanism and the connecting rod assembly. The running mechanism comprises a transmission mechanism, a first pressure spring, two road wheels and two rocker connecting rods. The connecting rod assembly comprises a center rod, a front locking block, a rear locking block, a sliding block, at least two pairs of connecting rod slices, at least two pulleys and a second pressure spring. According to the in-pipe walking robot, the synergistic effect of worm gears, a worm and the first pressure spring is adopted, the close fit of the worm gears and the worm is retained, and the road wheels are made to roll on the inner wall of a pipe in a tightly attached mode. When the worm is in a shape of a taper or a circular truncated cone, the running mechanism can automatically adjust the interval of the worm gears in pipes with different diameters, so that the road wheels are ensured to make contact with the inner wall of the pipe all the time and the adhesive force is retained; due to the second pressure spring, the symmetrical pulleys are always pushed by the sliding block to make contact with the inner wall of the pipe, so that a flange plate is ensured to be positioned on the central axis of the pipe all the time, and an operating mechanism externally connected with the flange plate can run with the flange plate steadily.

Owner:S Z VICTOR AUTOMATION TECH

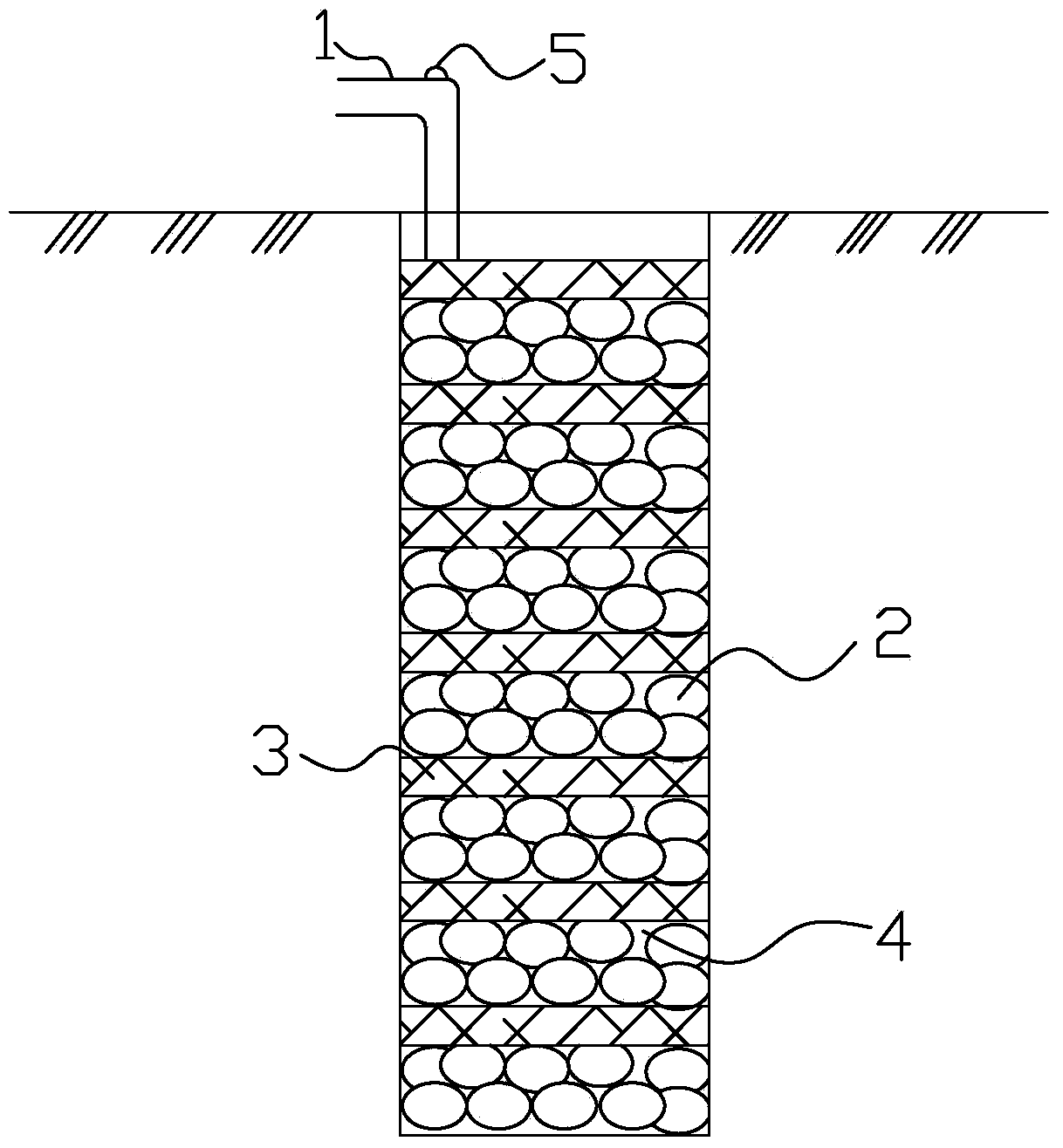

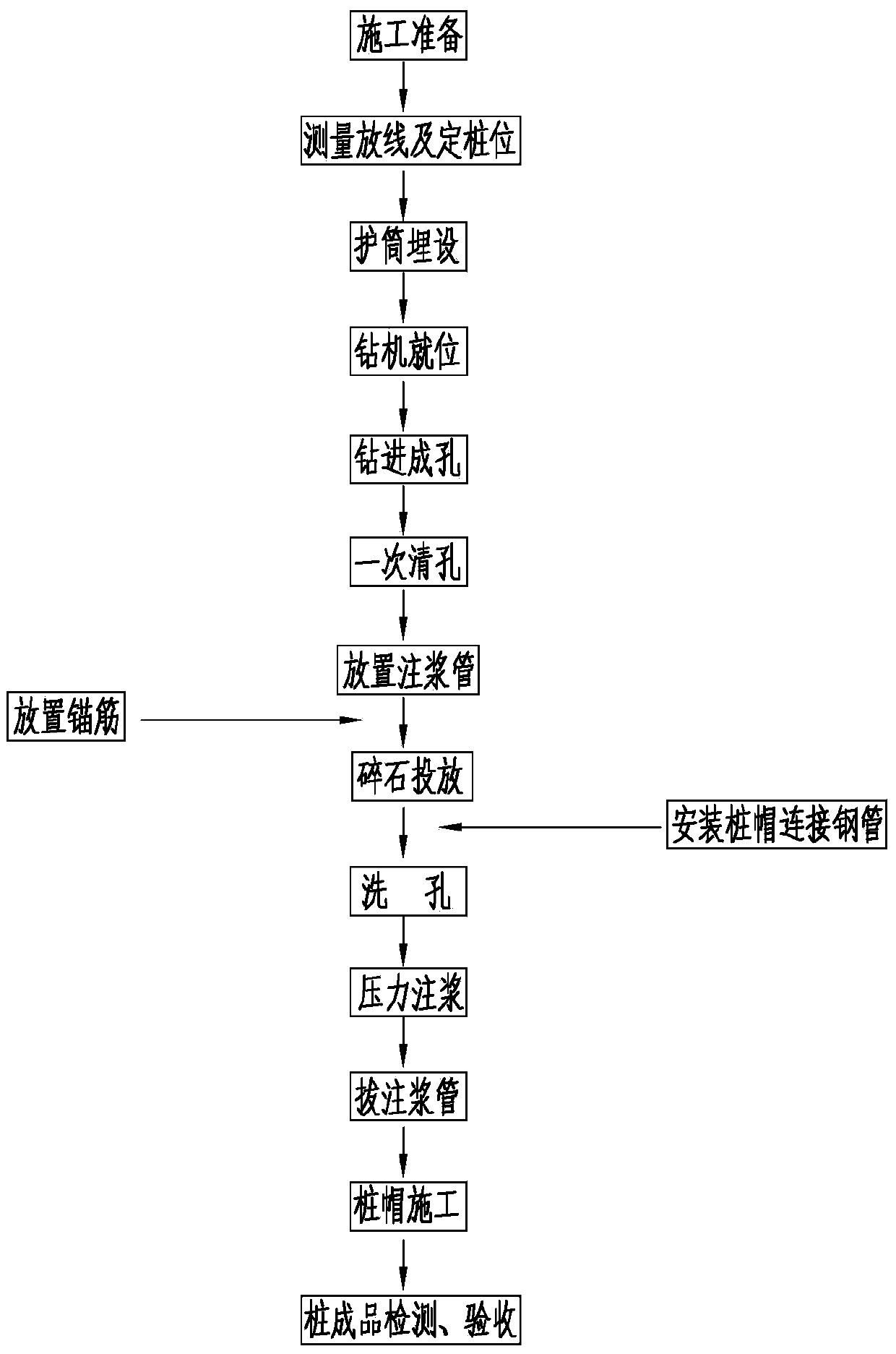

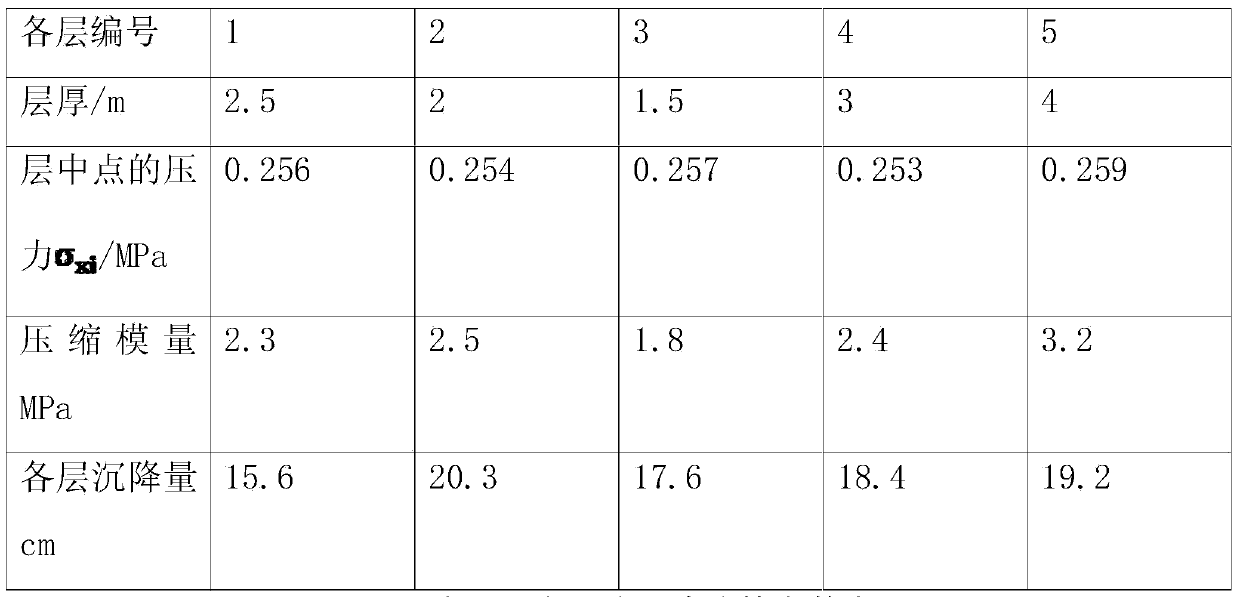

Construction method of gravel grouting pile

The invention discloses a construction method of a gravel grouting pile. The construction method comprises the following steps: (1) preparing for construction, (2) conducting measurement, paying off and positioning of the pile, (3) embedding a protective canister, (4) placing a drilling machine in place, (5) forming a hole by drilling, (6) cleaning the hole at a time, (7) placing a grouting pipe, (8) placing an anchor bar, (9) putting gravels in the hole, (10) installing a pile cap connecting steel pipe, (11) cleaning the hole, (12) conducting pressure grouting, (13) pulling the grouting pipe out, (14) constructing a pile cap, and (15) conducting detection and acceptance inspection on the finished pile. According to the construction method of the gravel grouting pile, the construction speed is high, the construction period is shortened, and compared with soft foundation treatment such as a prestressed pipe pile and a Y-type pile, the engineering investment is saved; the labor intensity is low, the construction is safe, and the construction method can be widely popularized and used; the gravel pile formed by cement and gravels is high in integrality and stability. The engineering drilling machine is adopted in a soft foundation to drill the hole in a rotating and cycling mode to form the pile, the disturbance to the foundation and the surrounding buildings is small, ground depression is controlled, and the construction method is small in vibration and low in noise during the construction and has good social benefits.

Owner:NINGBO SHENGHONG CONSTR ENG

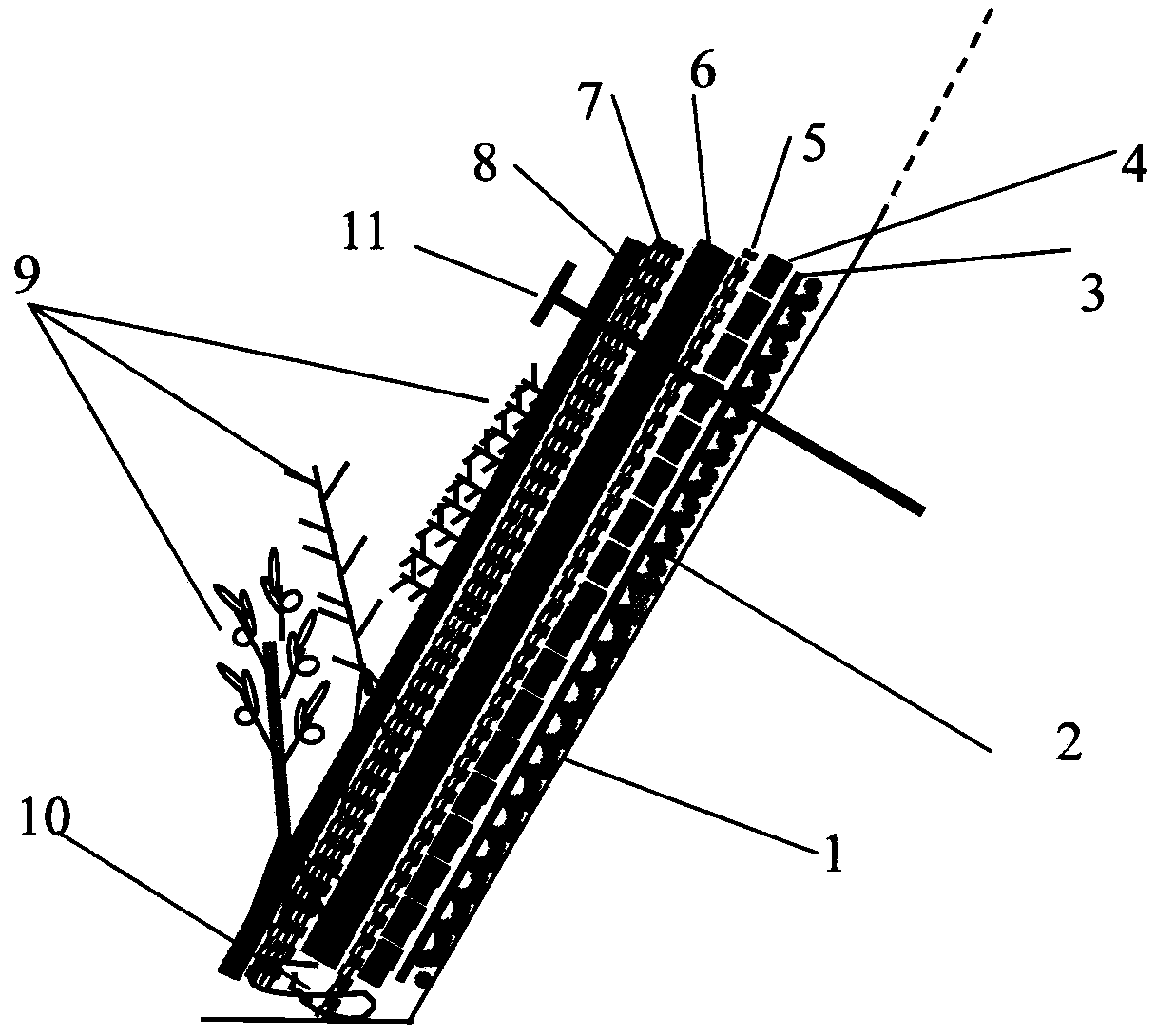

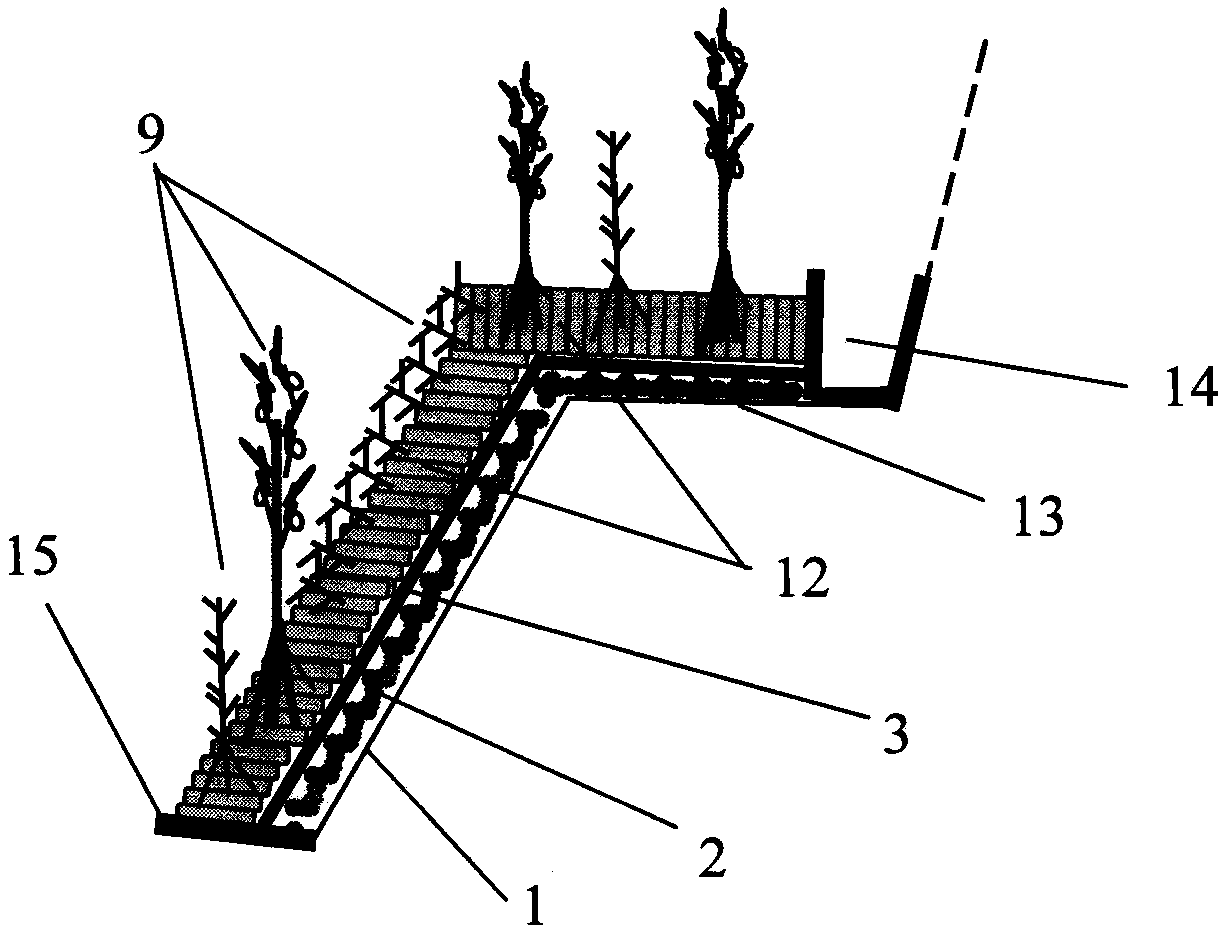

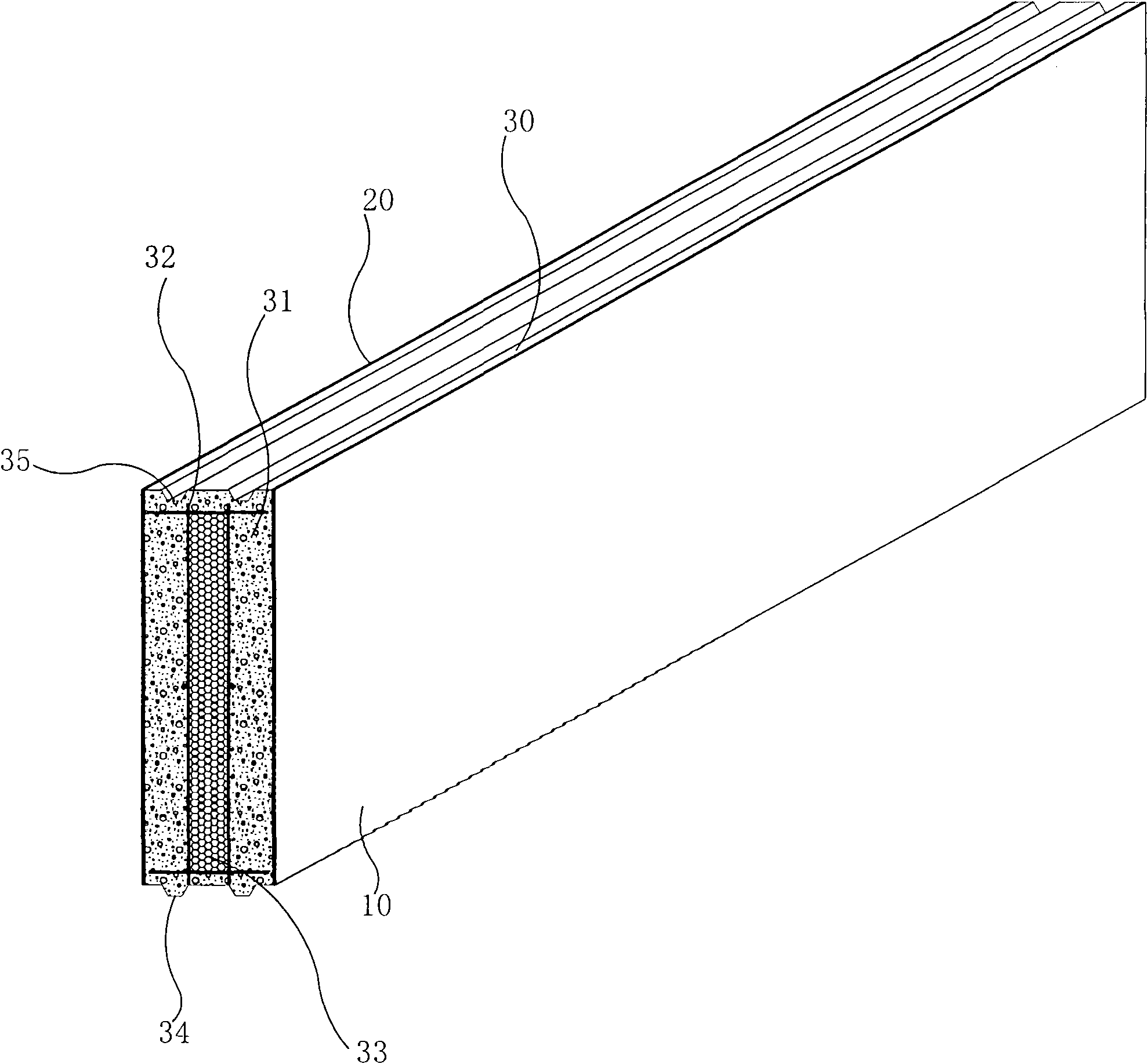

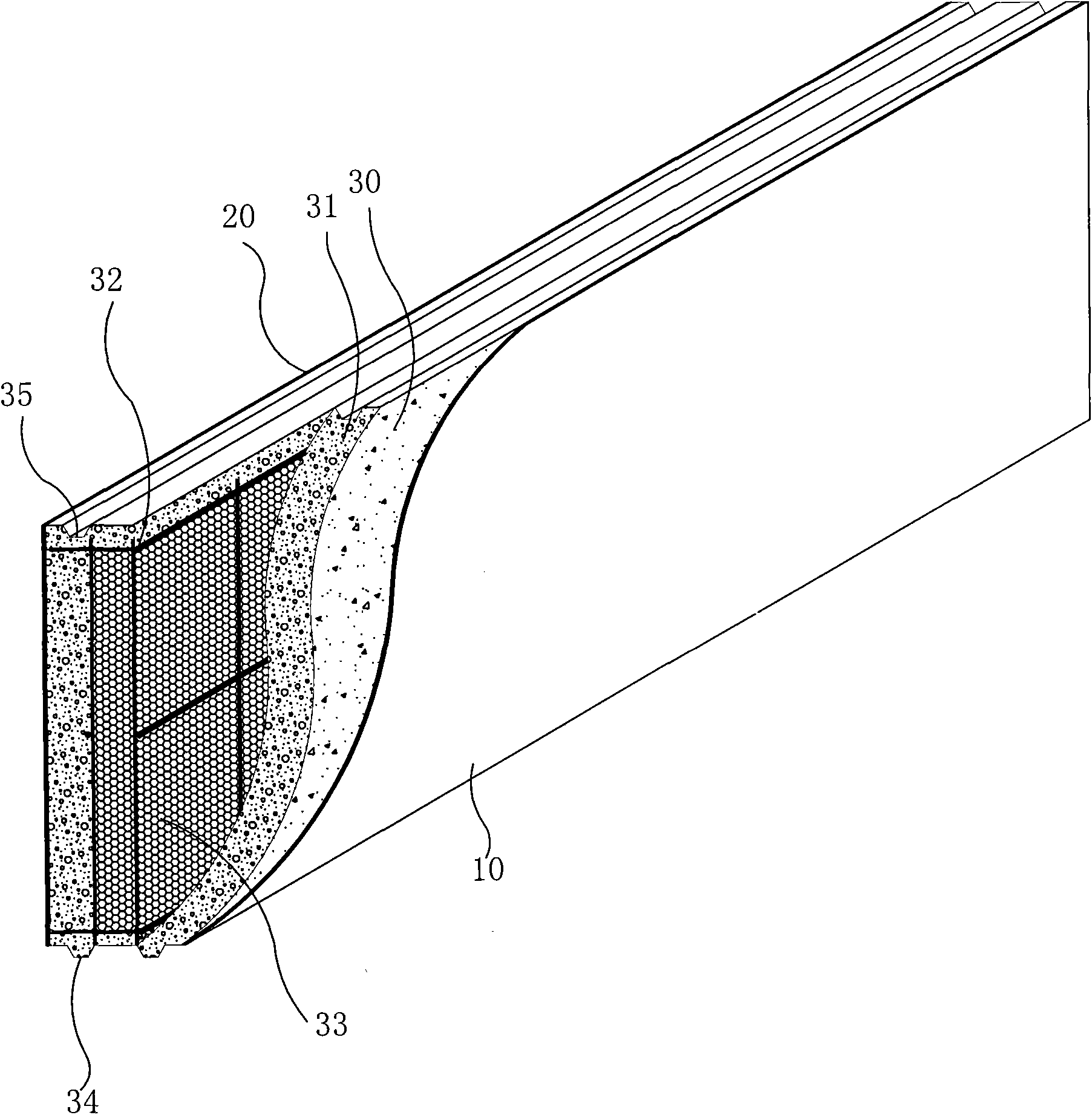

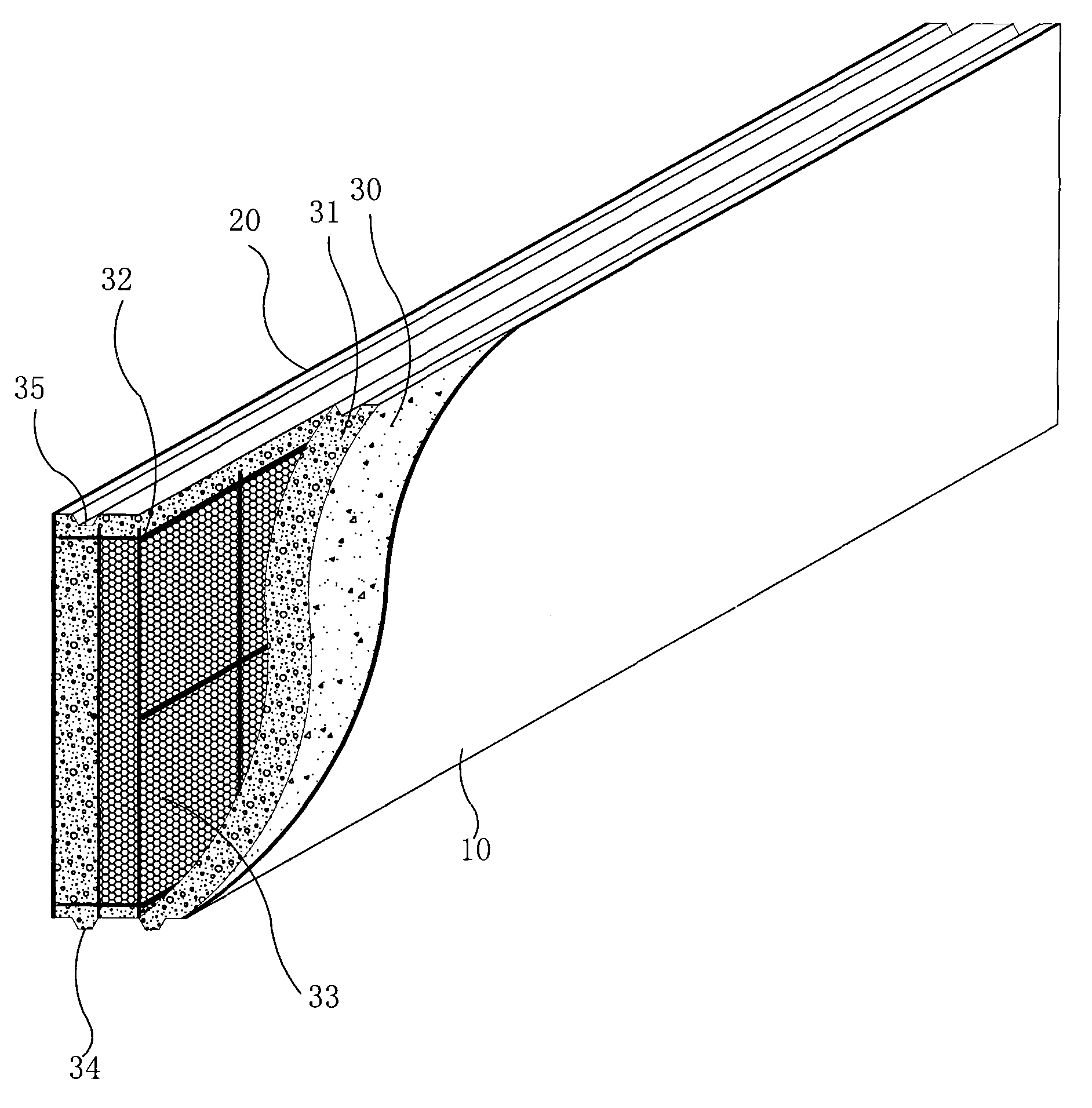

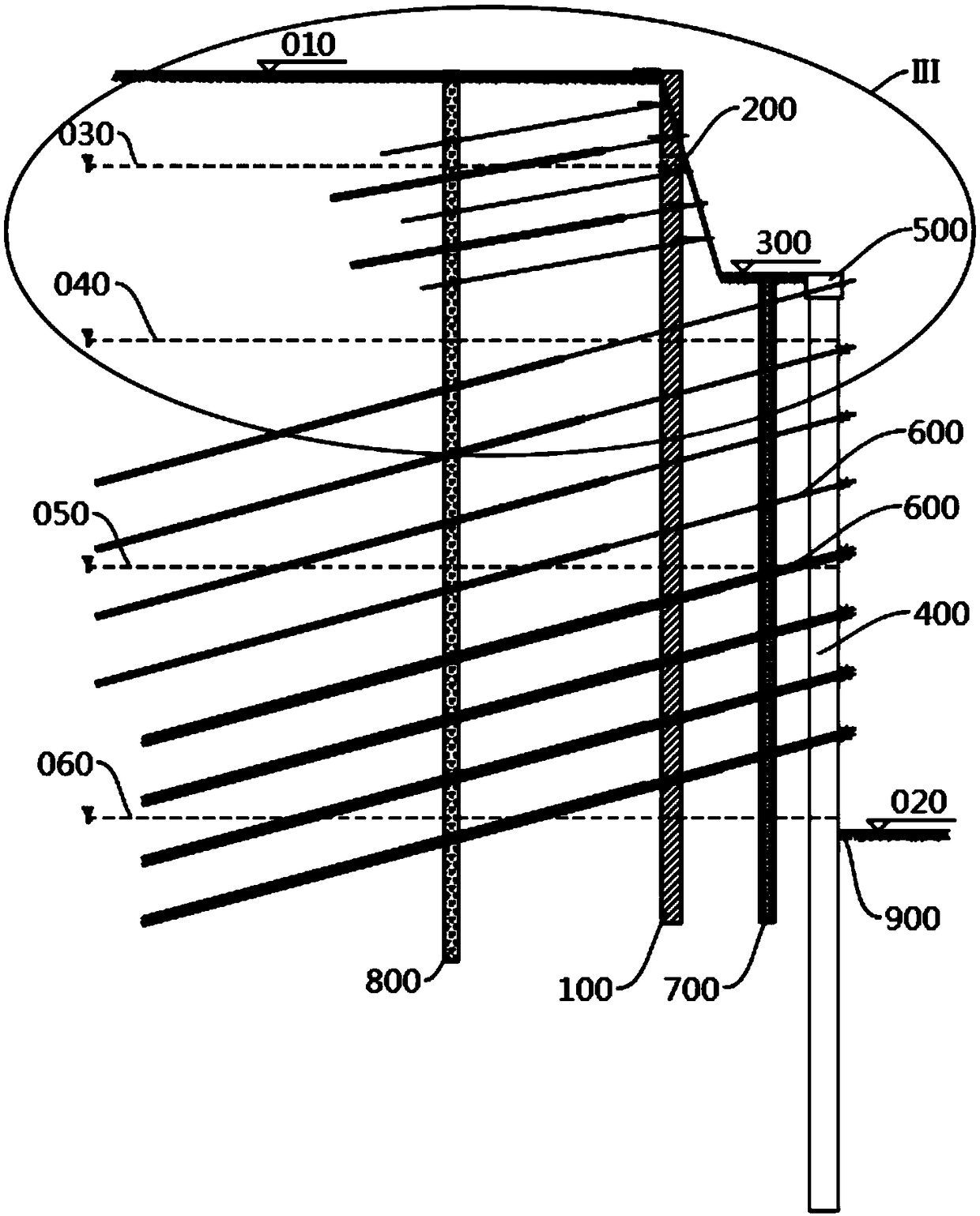

Ecological protection structure and method suitable for ardealite storage yard

The invention provides an ecological protection structure and an ecological protection method suitable for an ardealite storage yard. The structure of a modularization unit is that a flexible adhesion layer, an HDPE (high-density polyethylene) film with a certain specification, a plant fiber blanket with a certain specification, a vegetation inner net with a certain specification, a vegetation matrix layer with a certain specification, a vegetation outer net with a certain specification and a germplasm matrix layer with a certain specification are sequentially paved from inside to outside on the slope face of the shaped ardealite stack body; the edges of the vegetation inner net and the vegetation outer net are bound by binding wires and fixed by ground anchors; plants are planted in the germplasm matrix layer; along with the growth, the root systems of the plants penetrate through the vegetation outer net step by step to stretch to the vegetation matrix layer, the vegetation inner net and the plant fiber blanket, and the root systems mutually intersect with the vegetation matrix layer, the vegetation inner net and the plant fiber blanket to form the flexible blanket-shaped ecological protection structure composed of the plant root systems, the matrix, the double-layered nets and the HDPE film; the protection structure can be paved, spliced and planted in a modularization way; when the stack body is dug and ardealite is utilized, the protection structure can be moved along with the plants in the modularization way, the environment-friendly and safe problems of the whole storage yard can be ensured, and the front end sustaining discharge and the rear end sustaining excavation and utilization are not influenced.

Owner:SHENZHEN WANXINDA ECOLOGICAL ENVIRONMENT CO LTD

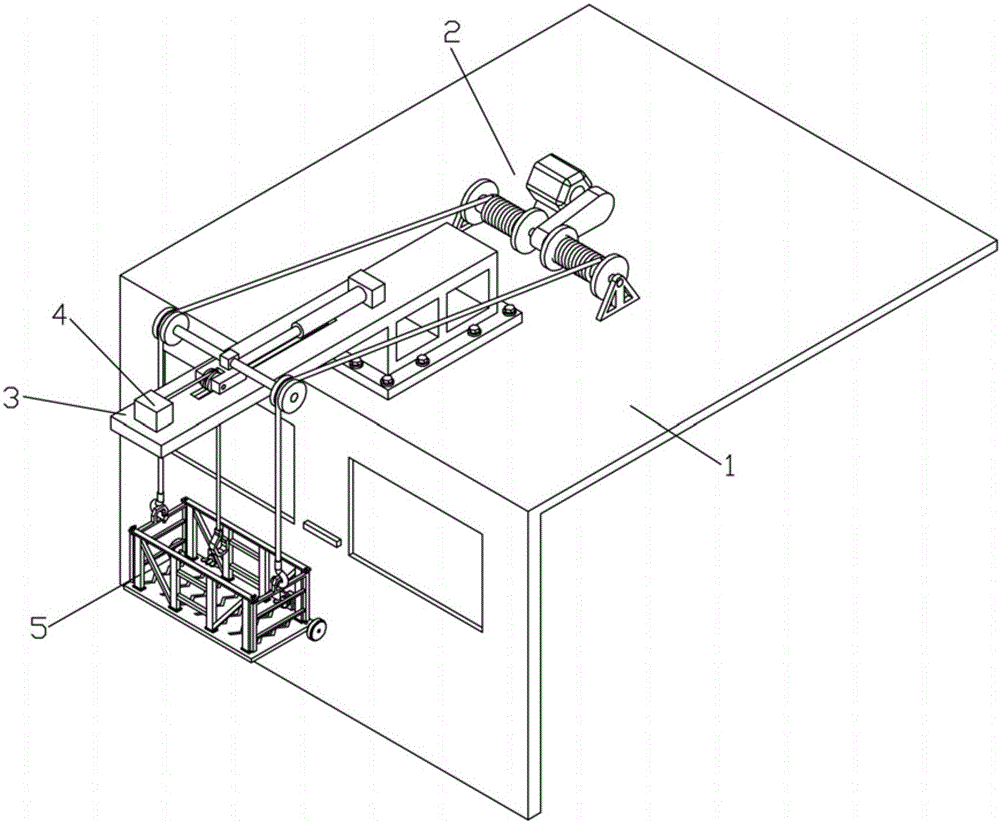

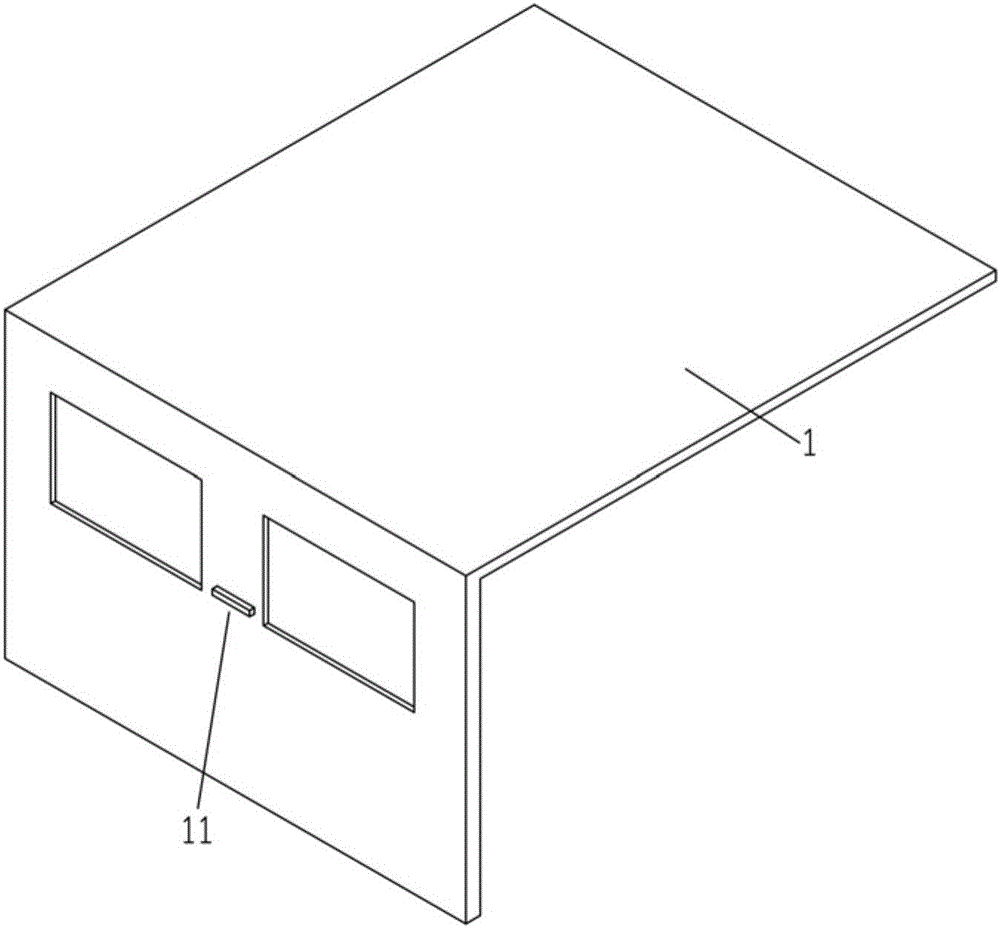

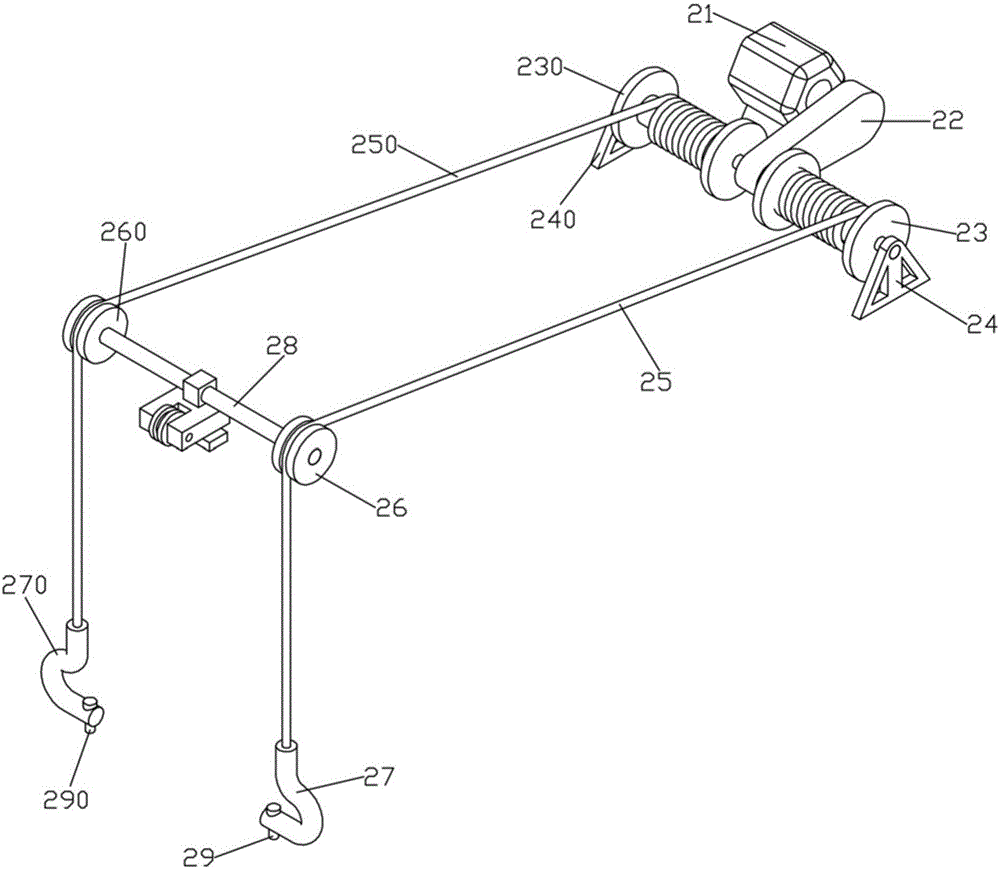

No-swing hanging basket device with automatic positioning function

InactiveCN105863235AAvoid shakingConvenient construction workBuilding support scaffoldsHanging basketMechanical engineering

The invention discloses a no-swing hanging basket device with an automatic positioning function. The no-swing hanging basket device comprises a hanging basket body, a lifting device connected with the upper end of the hanging basket body, a safety belt unit used for performing braking in emergency, a sliding mechanism, and a supporting frame used for fixing the safety belt unit, wherein the hanging basket body is positioned on the outer side of a wall body of a building; the lifting device and the supporting frame are fixedly mounted on a top cover of the building; the distance between the lifting device and the wall body of the building is greater than that between the supporting frame and the wall body of the building; the distance between the hanging basket body and the wall body of the building can be changed through the adjustment of the sliding mechanism. The no-swing hanging basket device can be tightly adsorbed to an outer wall, so as to realize automatic positioning and prevent a hanging basket from swinging at high altitude, and in addition, the distance between the hanging basket device and a wall surface can be further adjusted under the action of the sliding mechanism, so that construction operation of constructors is convenient.

Owner:FOSHAN LIANZHI XINCHUANG TECH CO LTD

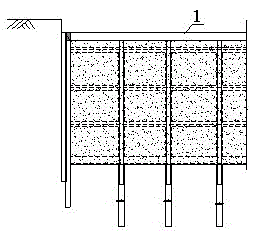

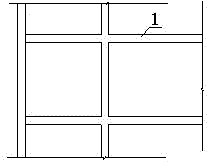

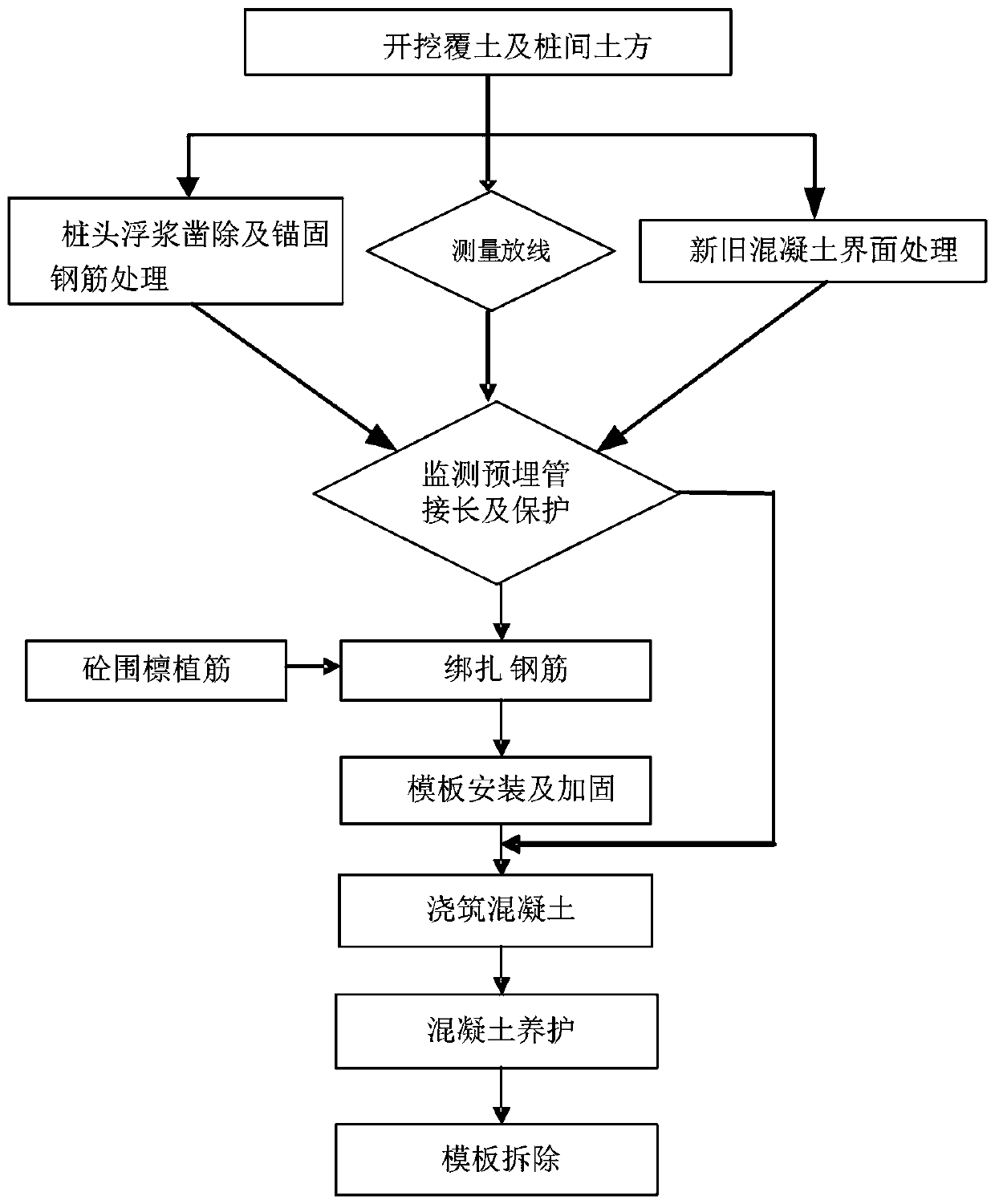

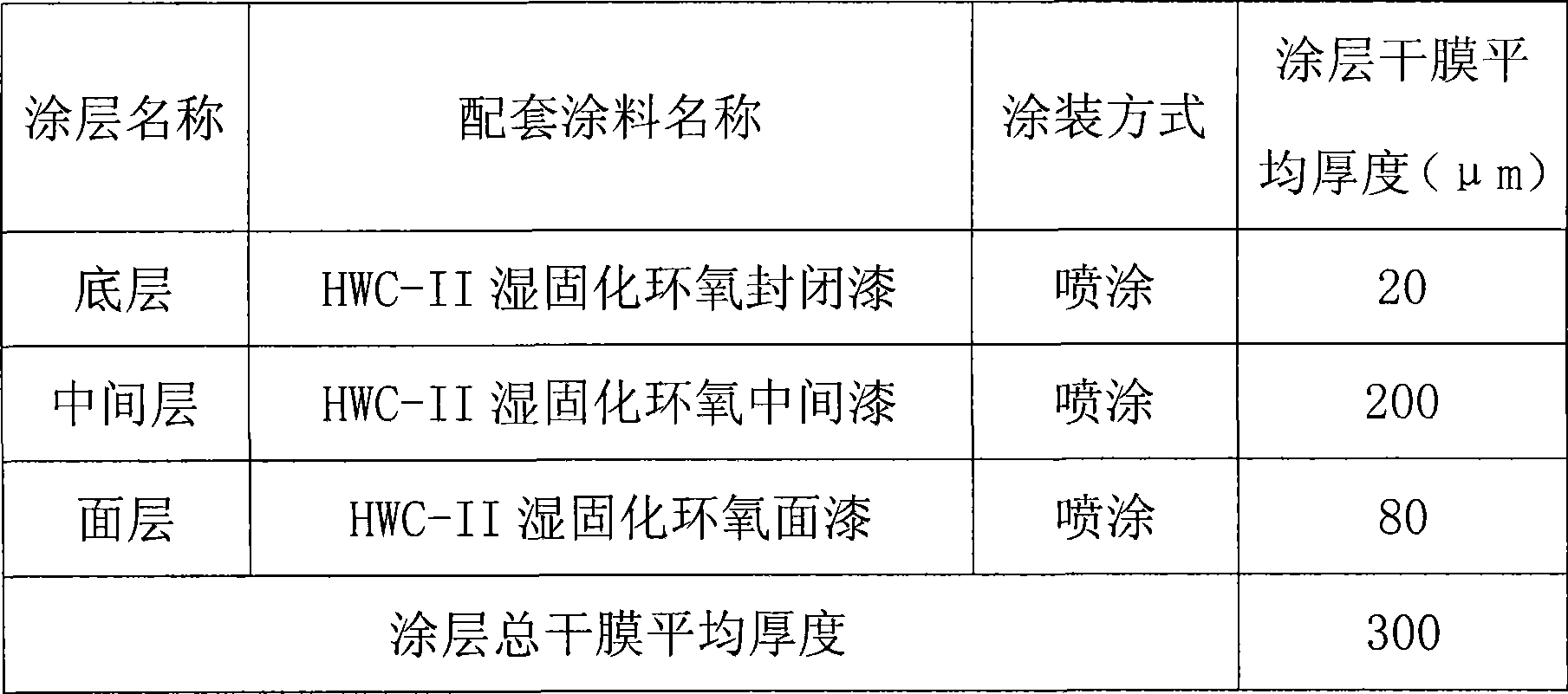

Construction method for temporary horizontal supports serving as permanent structural beams simultaneously of deep foundation pit

ActiveCN104652443ALarge operating spaceLow densityArtificial islandsExcavationsRebarReinforced concrete

The invention particularly relates to a construction method for temporary horizontal supports serving as permanent structural beams simultaneously of a deep foundation pit. The method is characterized by comprising the steps of determining the position and parameters of the reinforced concrete temporary horizontal supports serving as permanent structural beams simultaneously; excavating first-layer earthworks, and constructing the first reinforced concrete temporary horizontal support; excavating the earthworks till the bottom elevation position of the second reinforced concrete temporary horizontal support, constructing the horizontal support, reserving reinforcing ribs on the horizontal support according to design requirements, constructing the third and lower horizontal supports till the foundation pit excavation is completed and bottom plate pouring is completed; connecting the reinforcing ribs reserved on the temporary horizontal supports with corresponding basement floor reinforcing ribs to form a whole, and manufacturing permanent structures of basement floors and the like; dismounting the first horizontal support; backfilling the foundation pit to complete construction. By the aid of the method, compared with a traditional forward building method, lots of building rubbish and high construction expenditures caused by later dismounting of the horizontal supports are saved through the steps.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Non-bracket closure method for upper cross beam of steel tower and construction system

ActiveCN103437297AConvenient construction workReduce construction costsSuspension bridgeBridge structural detailsArchitectural engineeringTower

The invention discloses a non-bracket closure method for an upper cross beam of a steel tower and a construction method. The non-bracket closure method for the upper cross beam of the steel tower comprises the following steps of: hoisting a right upper cross beam, pushing a horizontal jack, adjusting the distance between an active cross brace and a right steel tower column to offset the left-right displacement generated after hoisting the right upper cross beam on the right steel tower column, arranging a closure adjusting device at the top of the upper cross beam, pushing a vertical jack in the closure adjusting device to adjust the vertical displacement between the closure ports of the left and right upper cross beams, and adjusting the front-back displacement between the closure ports of the left and right upper cross beams through the pre-tightening force generated by tightening a bolt to realize closure of the left and right upper cross beams. According to the method and system disclosed by the invention, since the distance between the left and right steel tower columns is adjusted by use of the active cross brace and an active cross brace joint and the upper cross beams are mounted by a method of adjusting the horizontal and vertical displacement of the left and right upper cross beams by the closure adjusting device, the steel consumption is not increased, the construction cost is greatly saved, a small space is occupied, and the construction operation on the steel tower is facilitated.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

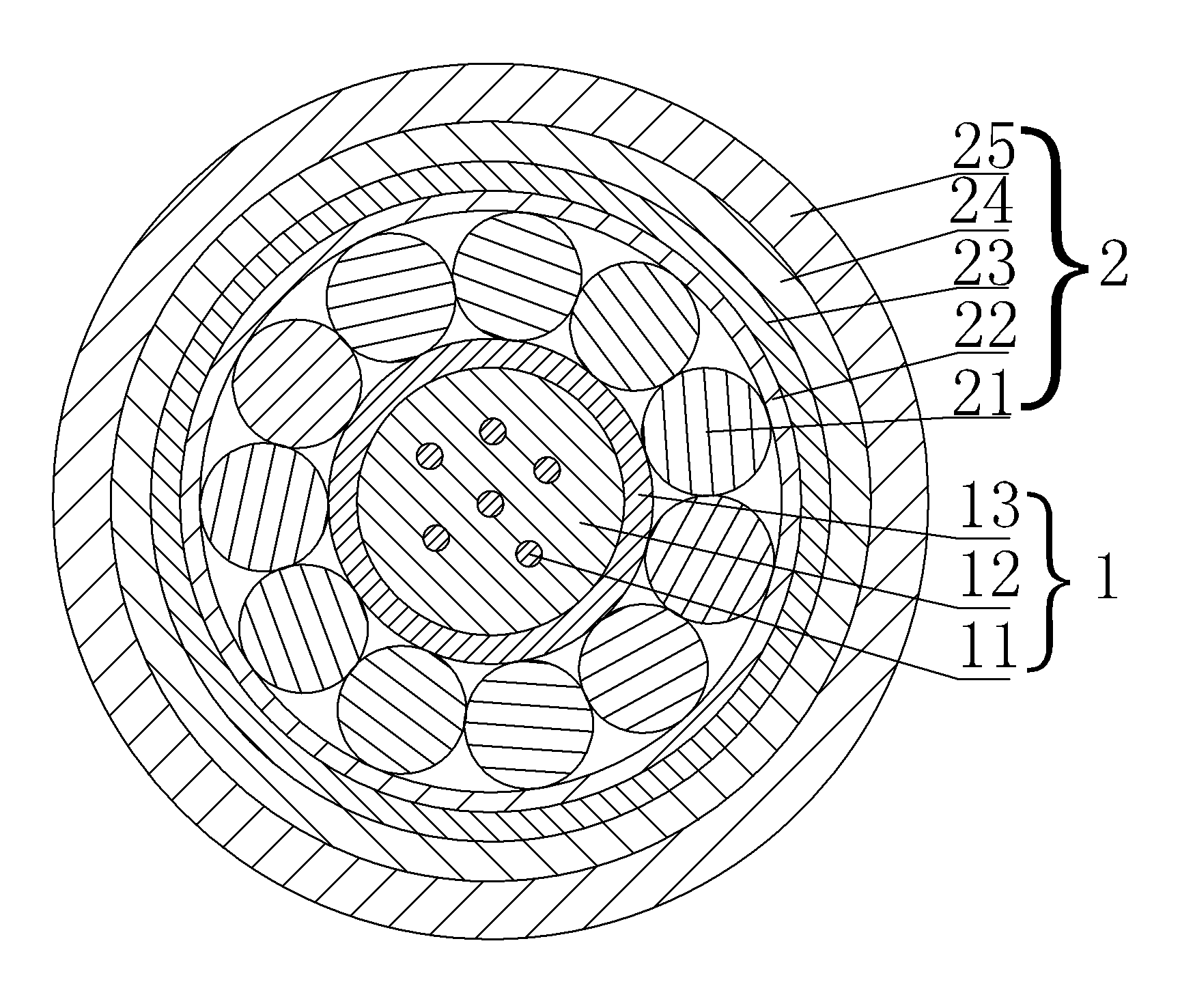

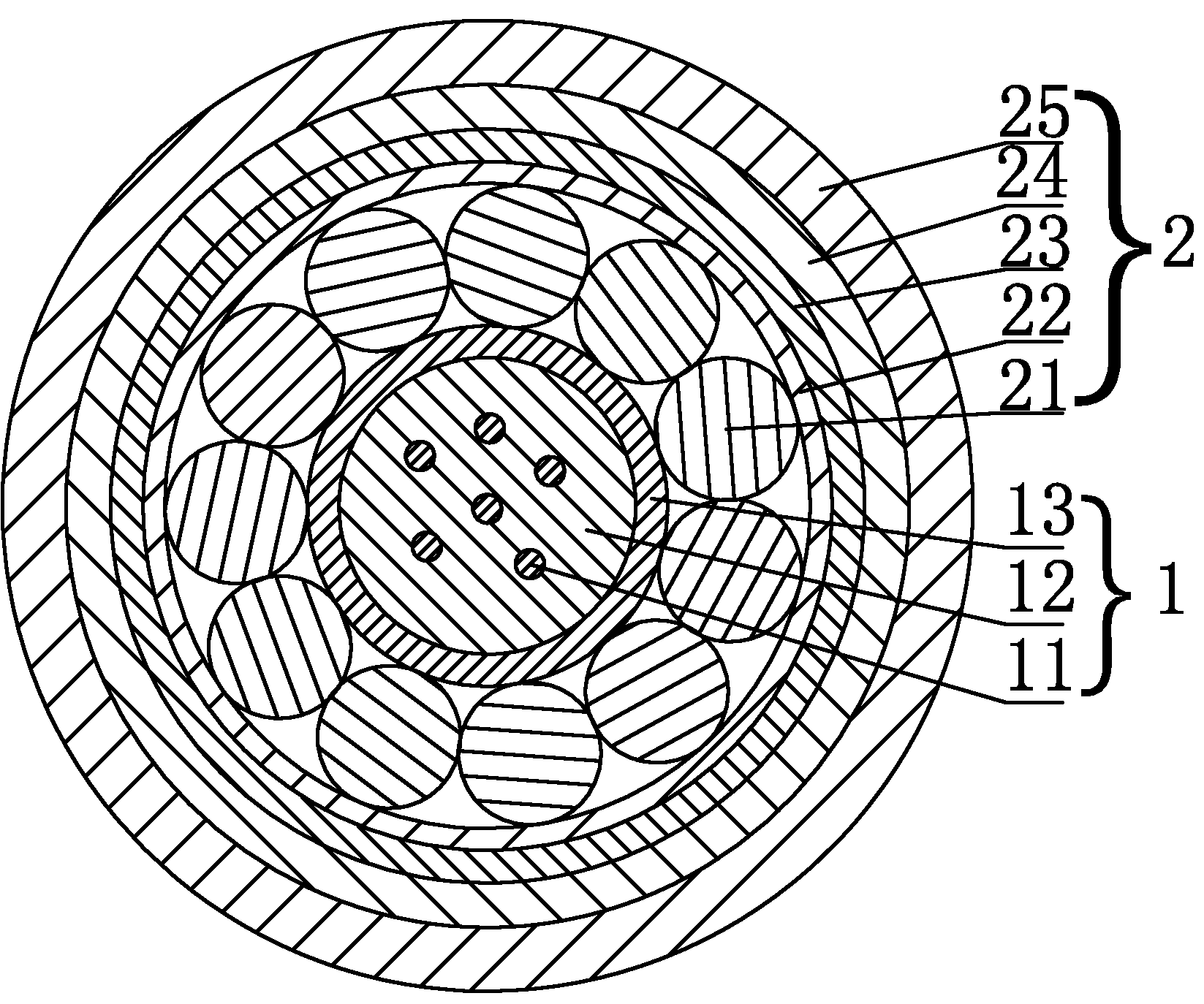

Central loose tube optical cable

InactiveCN102135655AImprove bending resistanceIncrease elasticityFibre mechanical structuresFiberEngineering

The invention discloses a central loose tube optical cable, which consists of a cable core and a sheath which is coated at the periphery of the cable core, wherein the cable core consists of a plurality of optical fibers, a loose sleeve which is coated outside the plurality of optical fibers, and fiber paste which is filled between the loose sleeve and the optical fibers; and the sheath consists of a plurality of steel wires which are arranged at the periphery of the cable core in a stranded mode, a binding layer which is coated at the peripheries of the plurality of steel wires, a waterproof tape which is coated at the periphery of the binding layer, a steel plastic composite tape which is longitudinally coated at the periphery of the waterproof tape, and a polyethylene protection layer which is extruded at the periphery of the steel plastic composite tape. Thinner steel wires are arranged at the periphery of the cable core in a stranded mode, so that the optical cable has excellent tensile property, lateral pressure resistance and bulletproof property, and the optical cable has small dimension and light weight and is convenience to construct.

Owner:SUZHOU WUJIANG SPECIAL CABLE NO 2 PLANT

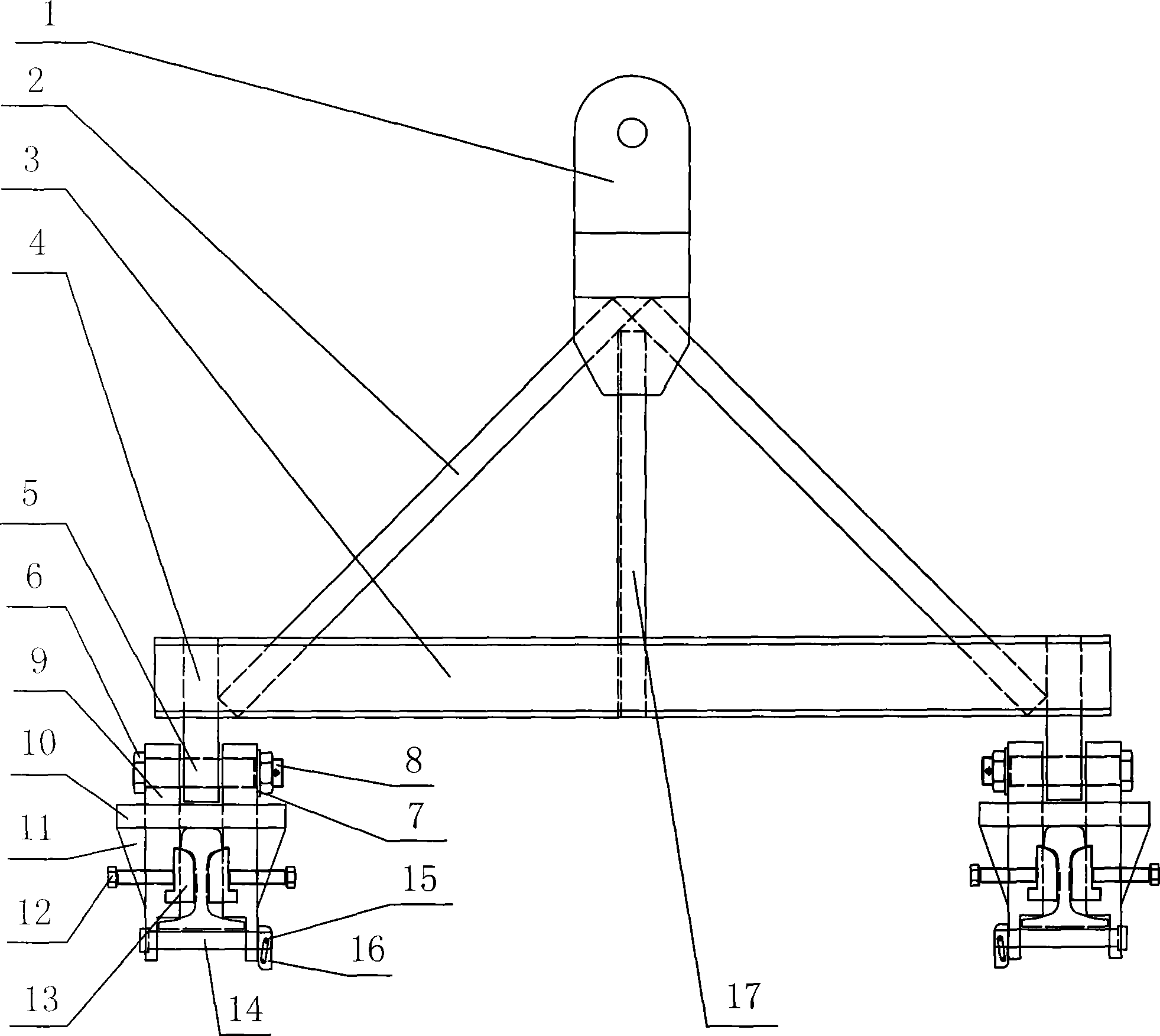

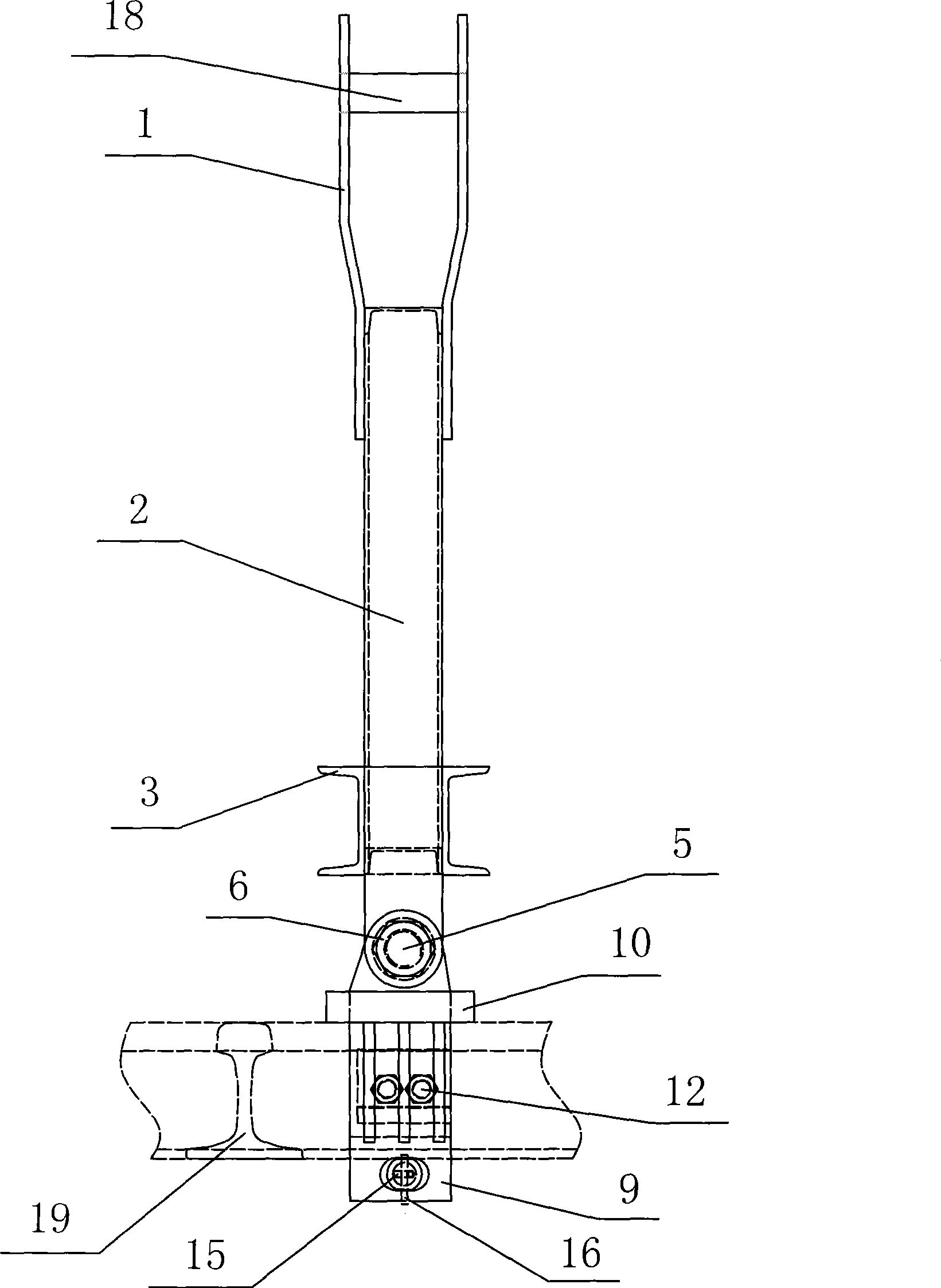

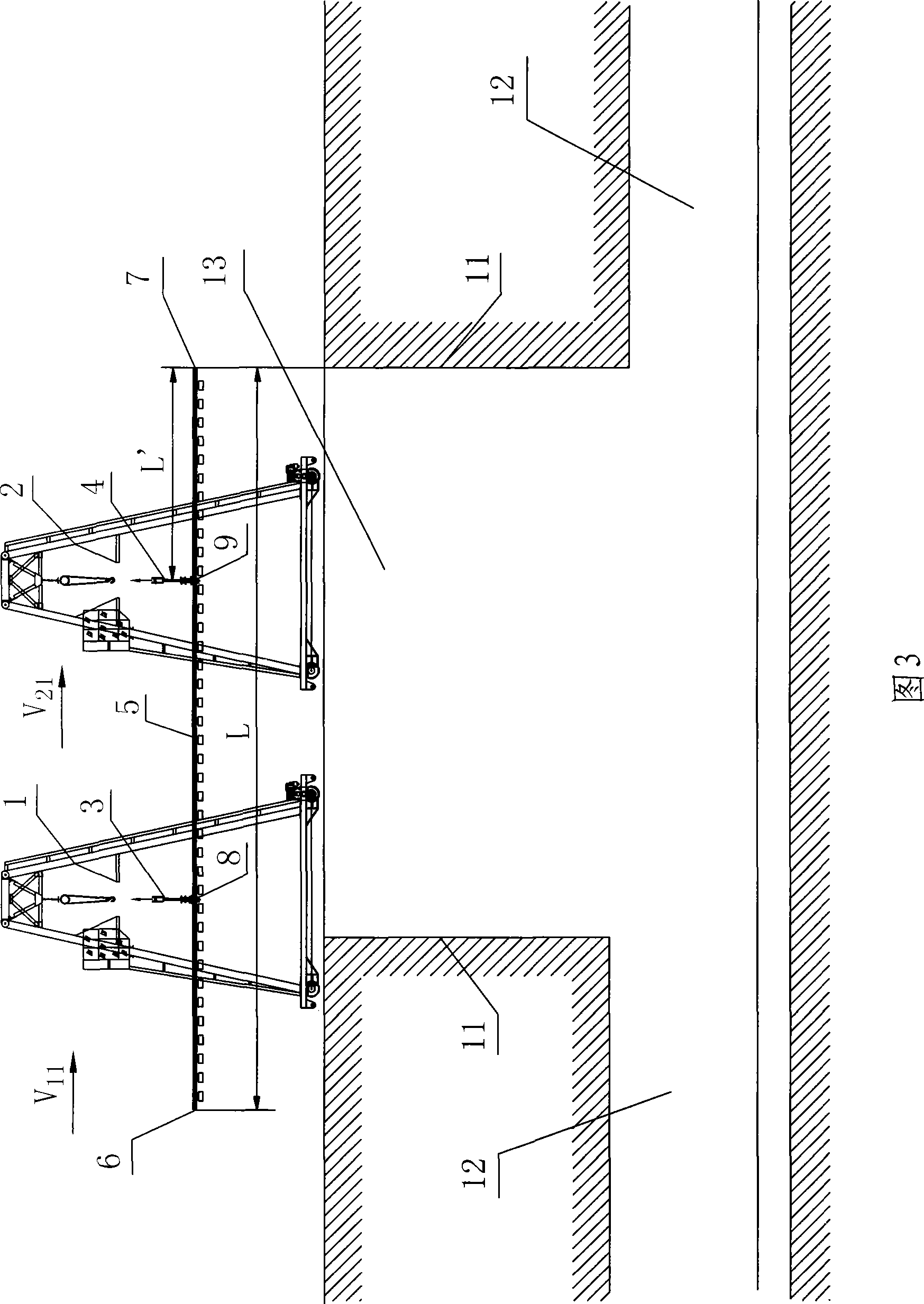

Arranging construction method of subway narrow shield well inclined hoisting rail

ActiveCN101413234ASimple structureSimple and fast operationRailway track constructionArchitectural engineeringGantry crane

The invention discloses a construction method for inclinedly and downward hoisting a track panel of a narrow shield well of a subway, which comprises the following steps: (a) a shield well is selected according to the length of the track panel; and (b) a left gantry crane and a right gantry crane are adopted to inclinedly and downward hoist the track panel through a track panel hoisting device respectively, wherein 1. after the horizontal hoisting, the left gantry crane and the right gantry crane synchronously move to the position above a feed opening from left to right; 2. the left gantry crane is still, and the right gantry crane travels toward the left and synchronously ensures that a large hook of the right gantry crane descends to cause the track panel to have an inclination angle of alpha; 3. the two gantry cranes synchronously move toward the right, and large hooks simultaneously descend; 4. the two gantry cranes continue moving synchronously toward the right, and the large hooks simultaneously descend; 5. the two gantry cranes move toward the right, and the running speed of the left gantry crane and the descending speed of the large hook of the left gantry crane are greater than those of the right gantry crane; and 6. the right gantry crane is still, and the large hook of the left gantry crane descends when the left gantry crane travels toward the left. The construction method has simple working procedures, simple and convenient operation, low construction cost, and high efficacy, and can effectively solve the construction problem of inclinedly and downward hoisting the track panel in the narrow shield well.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

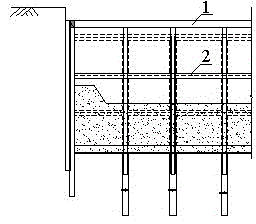

Excavation method for four-layer subway station foundation pit

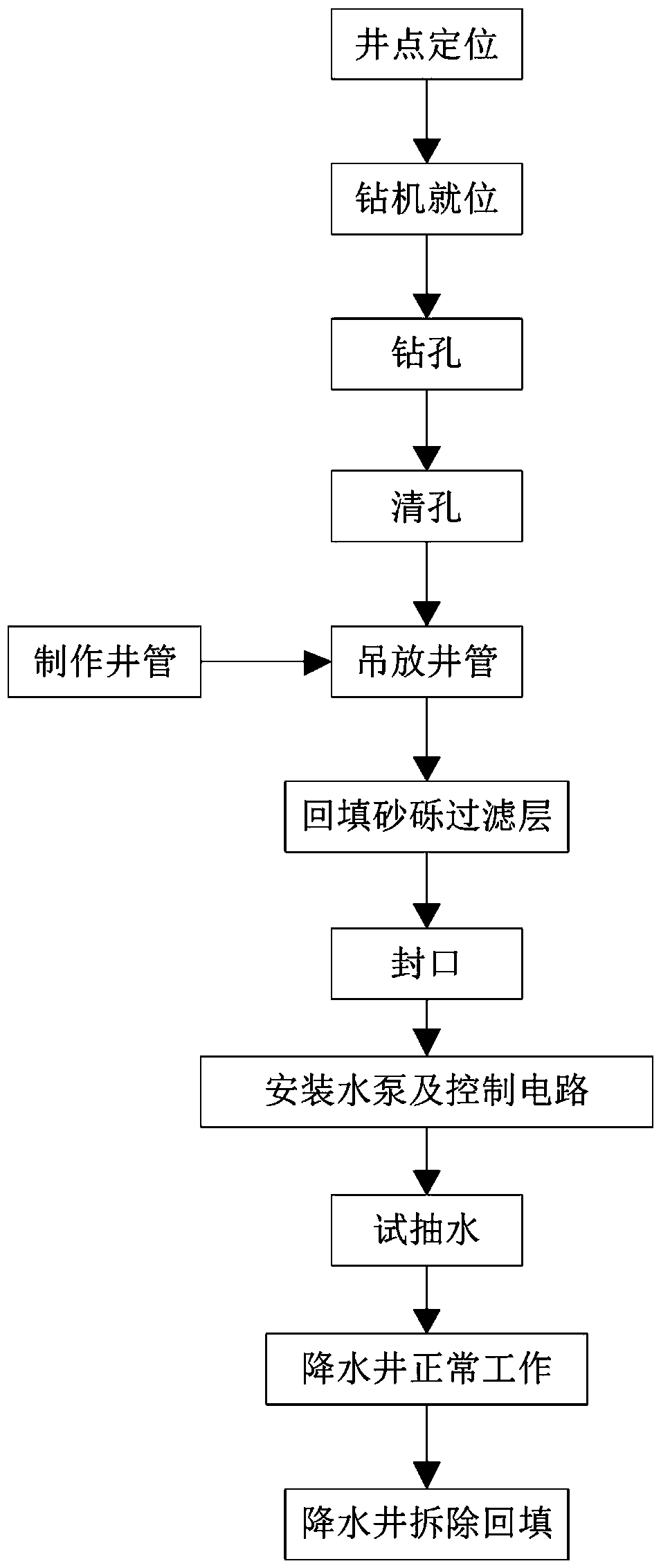

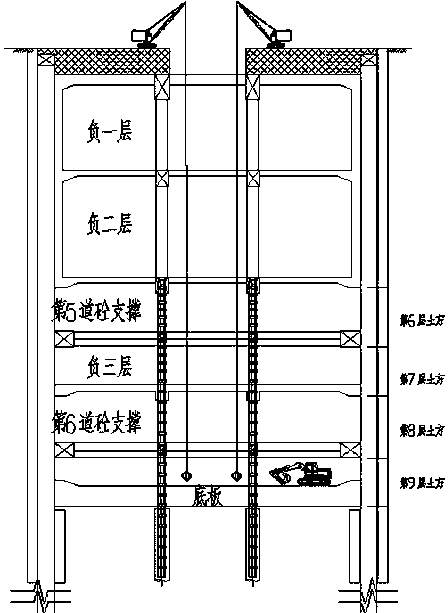

InactiveCN111576431AConvenient construction workReduce moisture contentArtificial islandsExcavationsStructural engineeringSubway station

The invention discloses an excavation method for a four-layer subway station foundation pit. The technical problem that stability cannot be guaranteed in a complex geographical environment of a multi-layer foundation pit excavation face in the prior art is solved. The method comprises the steps that S1, crown beams and first concrete supports are manufactured; S2, a water-reducing well is manufactured, and the water-reducing well comprises a recharge well in a pit and an observation well outside the pit; S3, earthwork is excavated, negative first and negative second floors are constructed by open-cut and continuous construction, and negative third and negative fourth floors are constructed by cover-cut and reverse construction; S4, a foundation pit support is arranged at the gap of earthwork excavation, and the foundation pit support is composed of 1, 5, 6 concrete supports and 2, 3 and 4 steel supports; and S5, a main body structure is constructed, finally the roof is backfilled, andthe foundation pit excavation is completed. The method has the beneficial technical effects that the safety coefficient is high, and the method can adapt to complex landform features.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

High-solid content and high-gloss anode electrophoretic coating and coating method thereof

ActiveCN104231799AEasy to makeImprove the level ofElectrophoretic coatingsPaints for electrolytic applicationsAcrylic resinAccelerated aging

The invention relates to a high-solid content and high-gloss anode electrophoretic coating which comprises the following components: an acrylic resin modified by glycidyl tertiary carboxylic ester, an amino resin of methyl-butyl compound ether and a catalyst, wherein the mass ratio of the acrylic resin modified by glycidyl tertiary carboxylic ester to the amino resin of methyl-butyl compound ether is 1 to (0.2-1). Compared with a common anode electrophoretic coating, the solid content of the high-solid content and high-gloss anode electrophoretic coating is increased by 60% to 70%, and the solvent content of the high-solid content and high-gloss anode electrophoretic coating is reduced by 5% to 25%. Thus, the high-solid content and high-gloss anode electrophoretic coating can be easily prepared into a high environment-friendly coating and is low in viscosity, thereby bringing convenience for construction operations. According to the high-solid content and high-gloss anode electrophoretic coating and a coating method thereof, the gloss of a coating layer is improved by 90% to 120%; the coating layer is good in levelling property and plumpness, attractive in appearance and excellent in decorative effect; in addition, the coating layer is good in acid resistance, i.e., the coating layer can resist sulfuric acid or 5% hydrochloric acid for 48 hours; and the coating layer is excellent in outdoor weatherability, i.e., the artificial accelerated aging time of the coating layer reaches above 1000 hours.

Owner:郎溪县鑫泽涂料有限公司

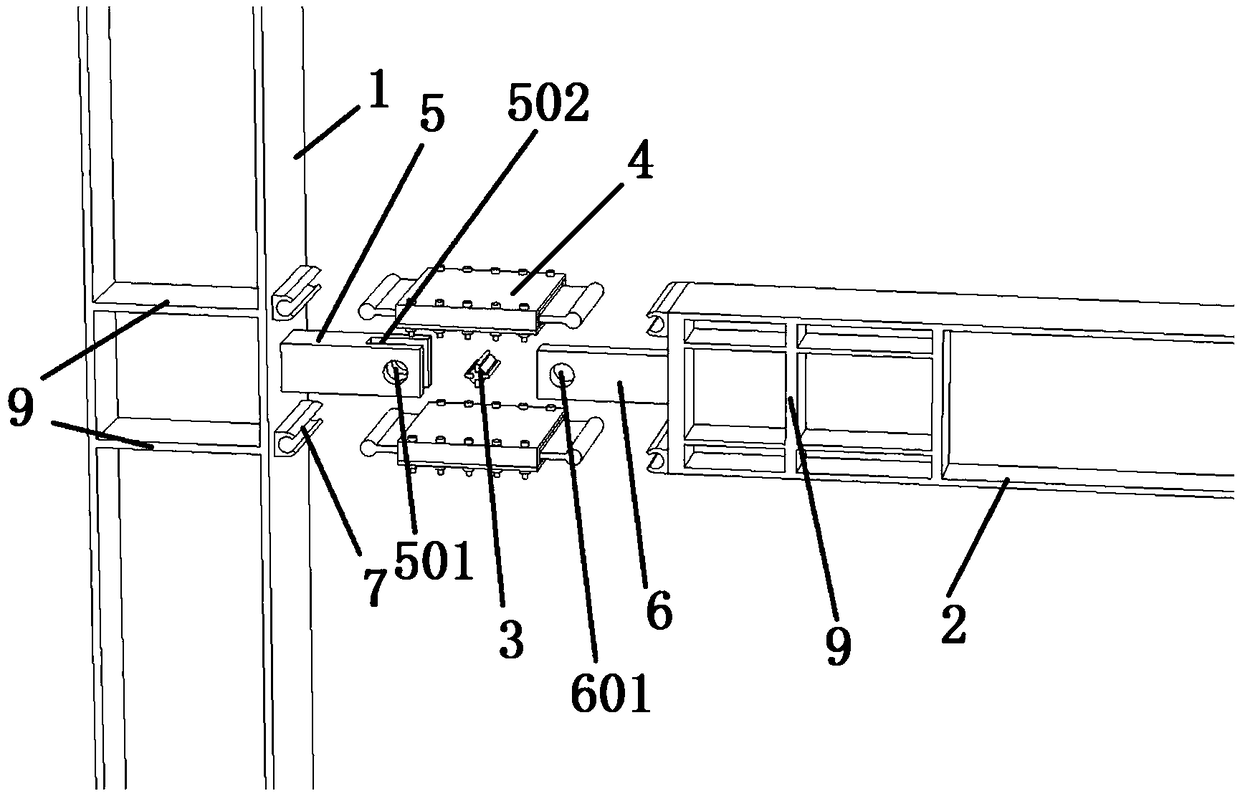

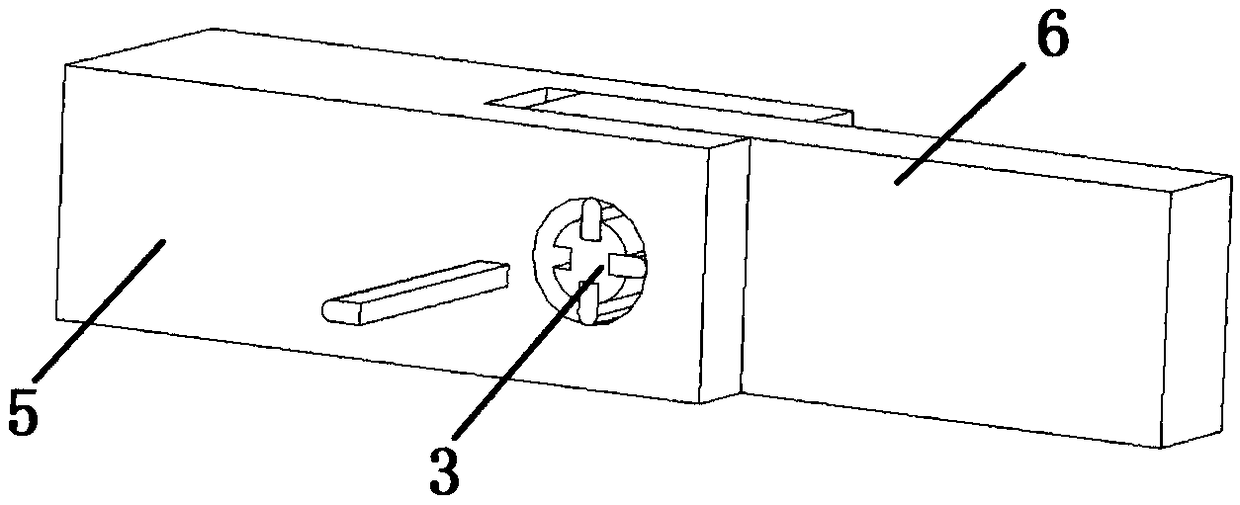

Beam column connection node

PendingCN108978866AReduce the Chances of Serious LossImprove the ability to withstand shear forceProtective buildings/sheltersShock proofingArchitectural engineeringBeam column

The invention provides a beam column connection node, including a first connecting plate, a second connecting plate, a hinge pin and at least two energy dissipating parts, the first connecting plate is connected with a side face of a prefabricated column, the second connecting plate is connected with an end face of a prefabricated beam, the first connecting plate and the second connecting plate are connected through the hinge pin, the two sides of the first connecting plate are respectively provided with the energy dissipating parts, the two ends of the energy dissipating parts are respectively hinged to the prefabricated column and the prefabricated beam, the two ends of the energy dissipation parts are provided with connecting columns, connecting seats are respectively arranged on the prefabricated column and the prefabricated beam, the connecting seats are provided with through holes penetrating through two ends thereof, side walls of the connecting seats are provided with connecting ports, the connecting ports extend along the axial directions of the connecting seats and communicate with the through holes, the connecting columns are inserted into the through holes, and maintainelasticity during an earthquake and serious structural loss is reduced, multi-level fortification is realized, connection is convenient, quick and efficient mounting on a construction site can be realized, and post-earthquake maintenance is facilitated.

Owner:GUANGZHOU UNIVERSITY

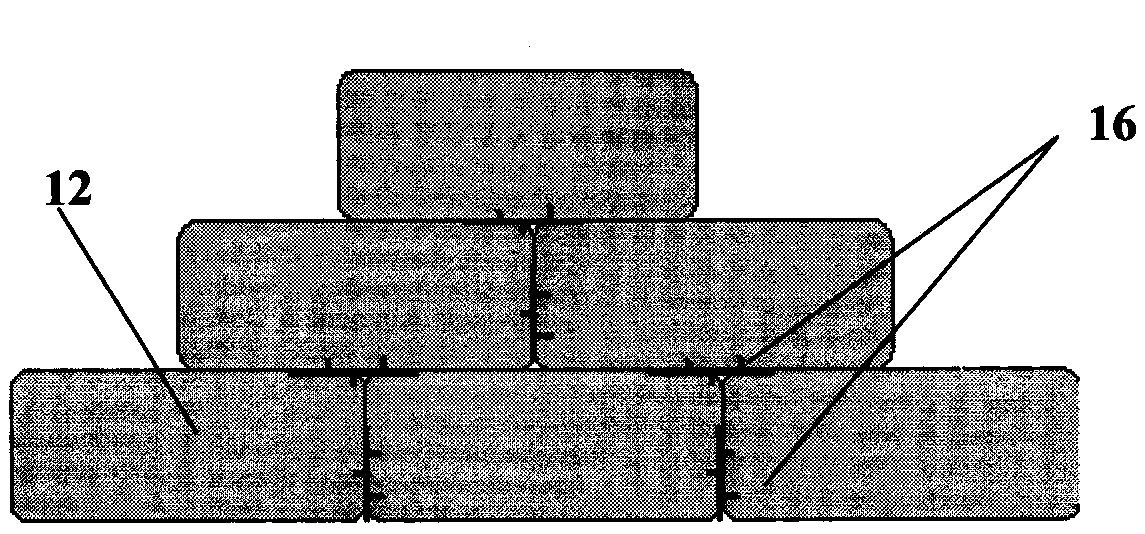

Sandwich composite external wallboard

InactiveCN102312515AReasonable structural designThe installation is firmClimate change adaptationBuilding reinforcementsExpanded clay aggregatePolystyrene

The invention relates to a sandwich composite external wallboard, which is characterized in that the external wallboard comprises panels on two end faces; a lightweight aggregate concrete sandwich layer is filled between the panels; the middle of the sandwich layer is that a reinforcing mesh is embedded in a polystyrene foam board; and building lightweight aggregate concrete filled structures of ceramic particle, ceramic sand and pearlite are distributed on other parts of the sandwich layer. The novel composite external wallboard is rational in structural design and firm to install and fix. Besides the advantages of the current external wall body, the external wallboard has the advantages of good heat insulation coefficient, good wind resistant capacity, convenience and quickness for construction and installation, good joint integral firmness and stability and high integral intensity. The earthquake resisting capacity and the safety performance of buildings can be greatly increased.

Owner:马国晏

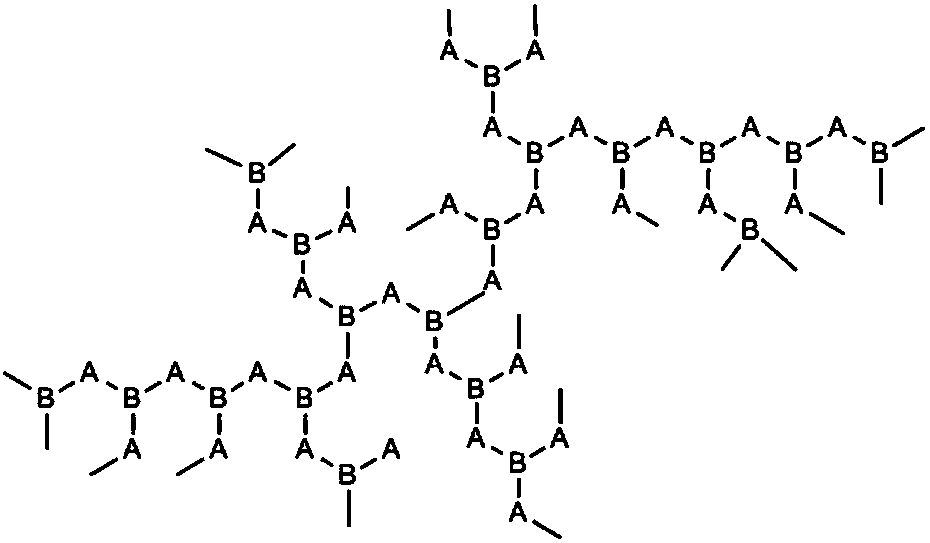

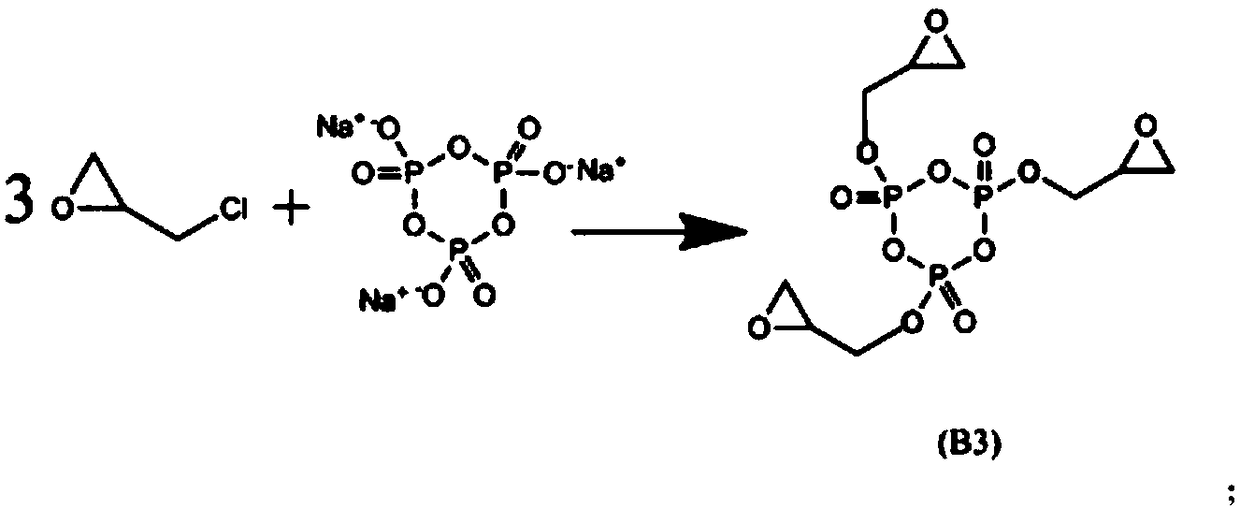

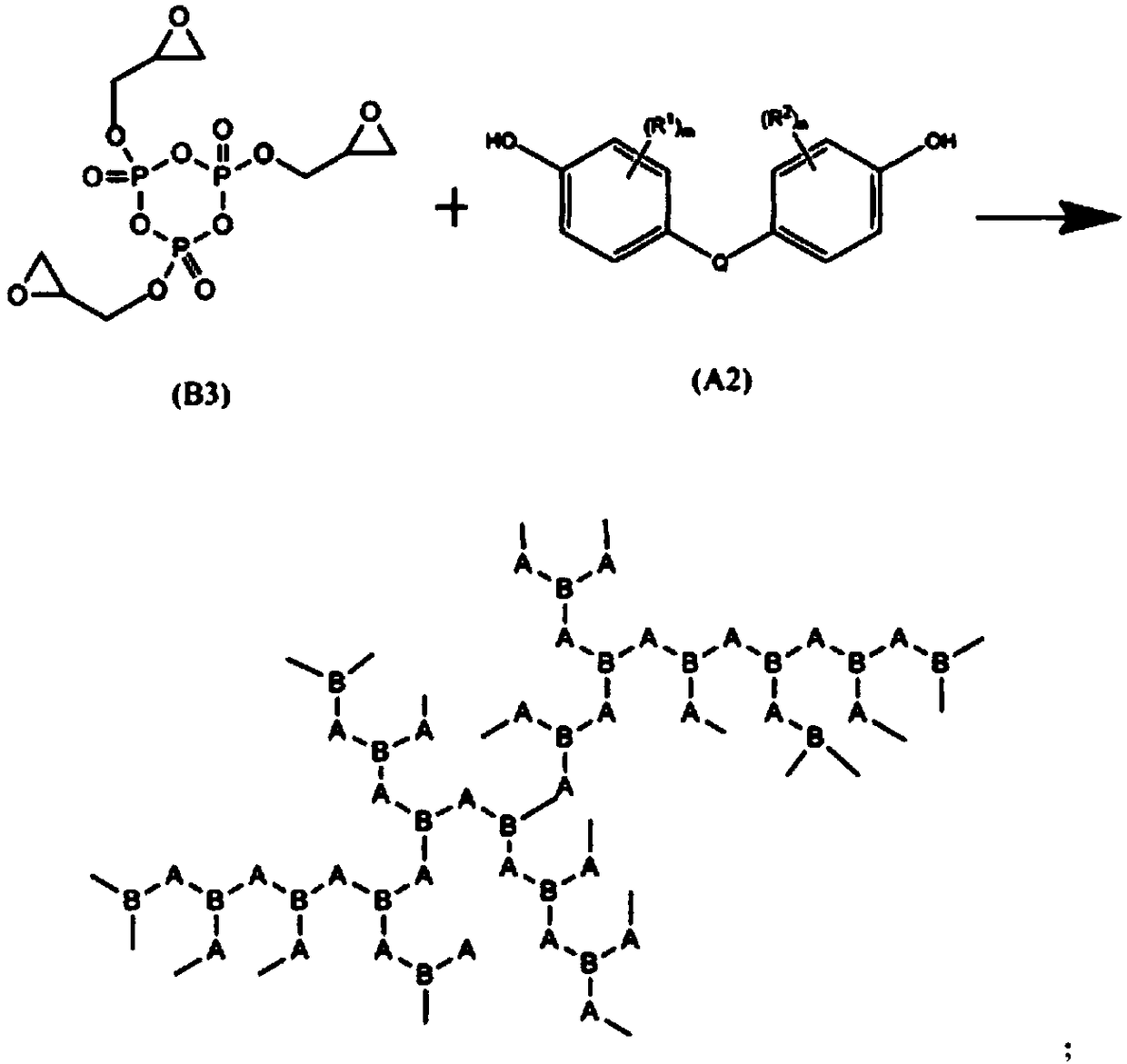

Epoxy-terminated hyperbranched polyphosphate and preparation method thereof

The invention relates to epoxy-terminated hyperbranched polyphosphate and a preparation method thereof, aiming at solving the technical problems that in the prior art, epoxy resin is lower in relativemolecular mass, poorer in corrosion resistance, higher in viscosity and troublesome in construction, the toxicity of curing agent varieties for the epoxy resin is larger, and the epoxy resin is moreaffected by the environment. The epoxy-terminated hyperbranched polyphosphate provided by the invention is prepared adding a branching agent into tri-epichloropropyl trimetaphosphate (B3), and enabling the tri-epichloropropyl trimetaphosphate (B3) and the branching agent to be subjected to an epoxide ring-opening reaction so as to obtain the epoxy-terminated hyperbranched polyphosphate. Furthermore, the invention also provides the preparation method of the epoxy-terminated hyperbranched polyphosphate. The epoxy-terminated hyperbranched polyphosphate and the preparation method thereof can be widely applied to the technical field of organic synthesis.

Owner:SHANDONG RUNKE CHEM +1

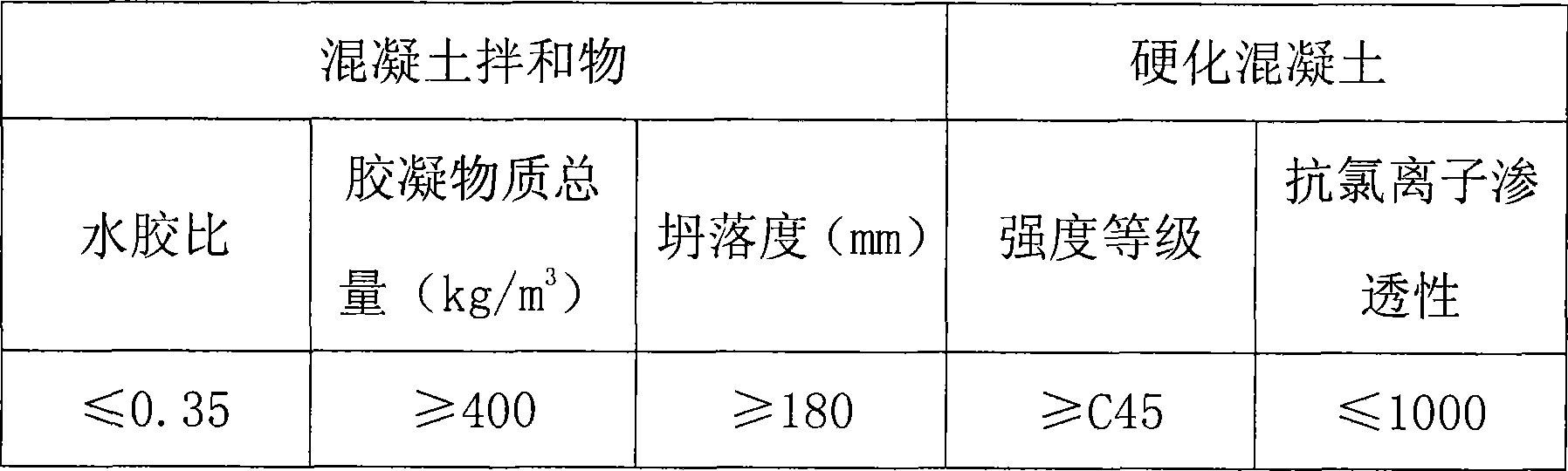

Maintenance and reinforcement method for old dock

InactiveCN101487248AIdeal for repair and reinforcementReasonable structureArtificial islandsUnderwater structuresFiberCarbon fibers

The invention provides a method for maintaining and reinforcing old docks, relating to the maintenance of old docks. The method comprises the specific steps as follows: step 1:a construction platform is established; step 2: damaged concrete is removed; step 3: reinforcement is derusted; step 4: rebar is used for reinforcement; step 5: rust retardant agent is brushed; step 6: a sacrificial anode is installed; step 7: a template is installed; step 8: concrete interfacial agent is brushed; step 9: concrete is poured; step 10: carbon fiber is used for reinforcement; and step 11: anti-corrosion paint is coated. The method for maintaining and reinforcing old stocks is simple, the construction platform has reasonable structure, is easy to be established, safety, reliability and excellent anti-wave performance, meanwhile, the method is compatible with practical construction requirement and cost-saving requirement, has ideal effect for maintaining and reinforcing old stocks and facilitates the construction and operation of the workers.

Owner:吴希民 +5

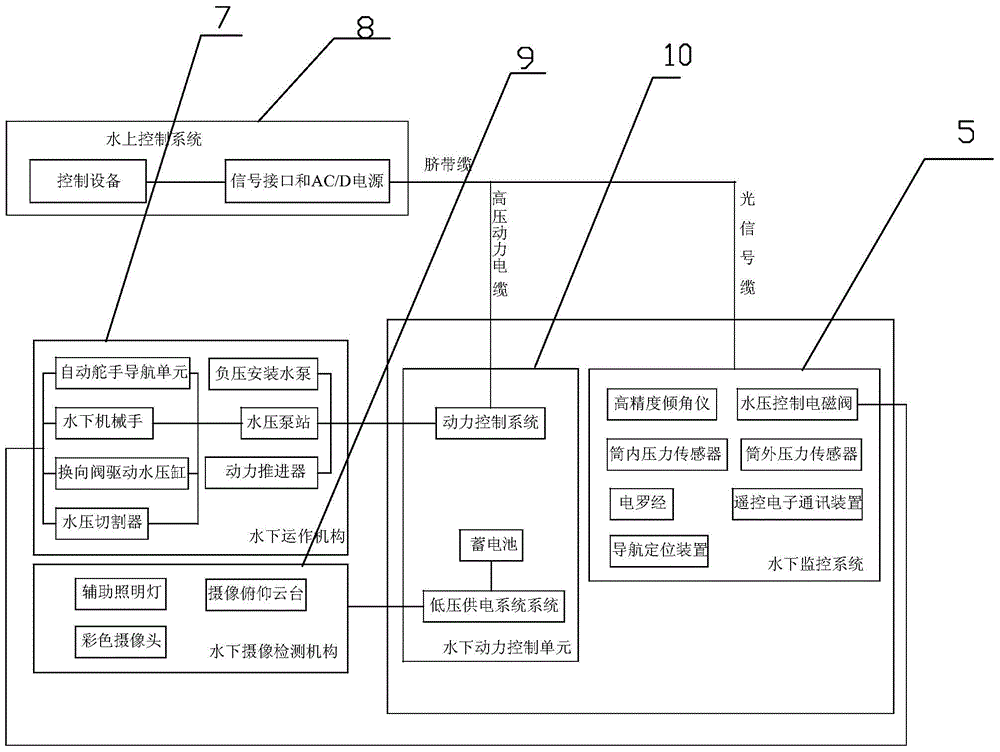

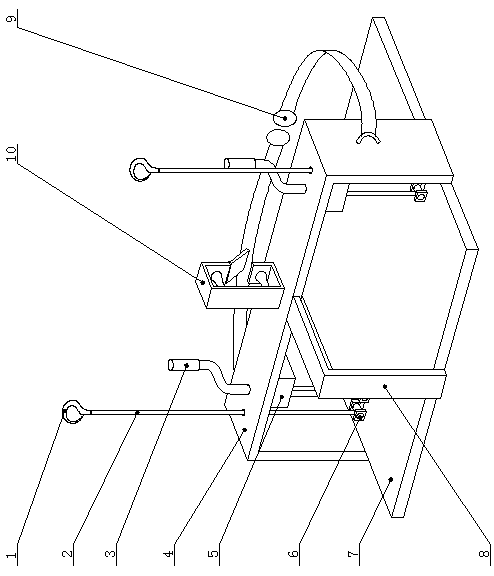

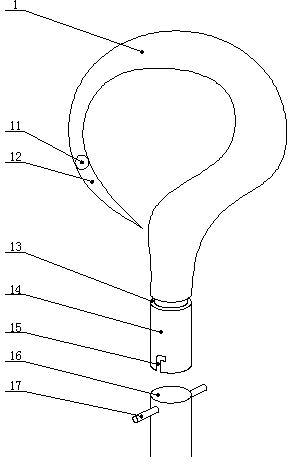

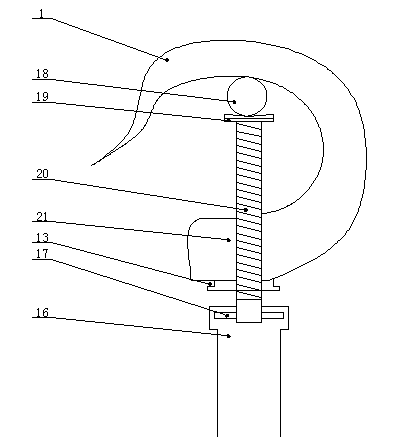

Deepwater suction-type gravity foundation and deepwater mounting device and deepwater mounting method thereof

ActiveCN103603364ASimple structureSave large floating cranes and transport vesselsFoundation engineeringEngineeringDeep water

Owner:LICE SCI & TECH SHANGHAI

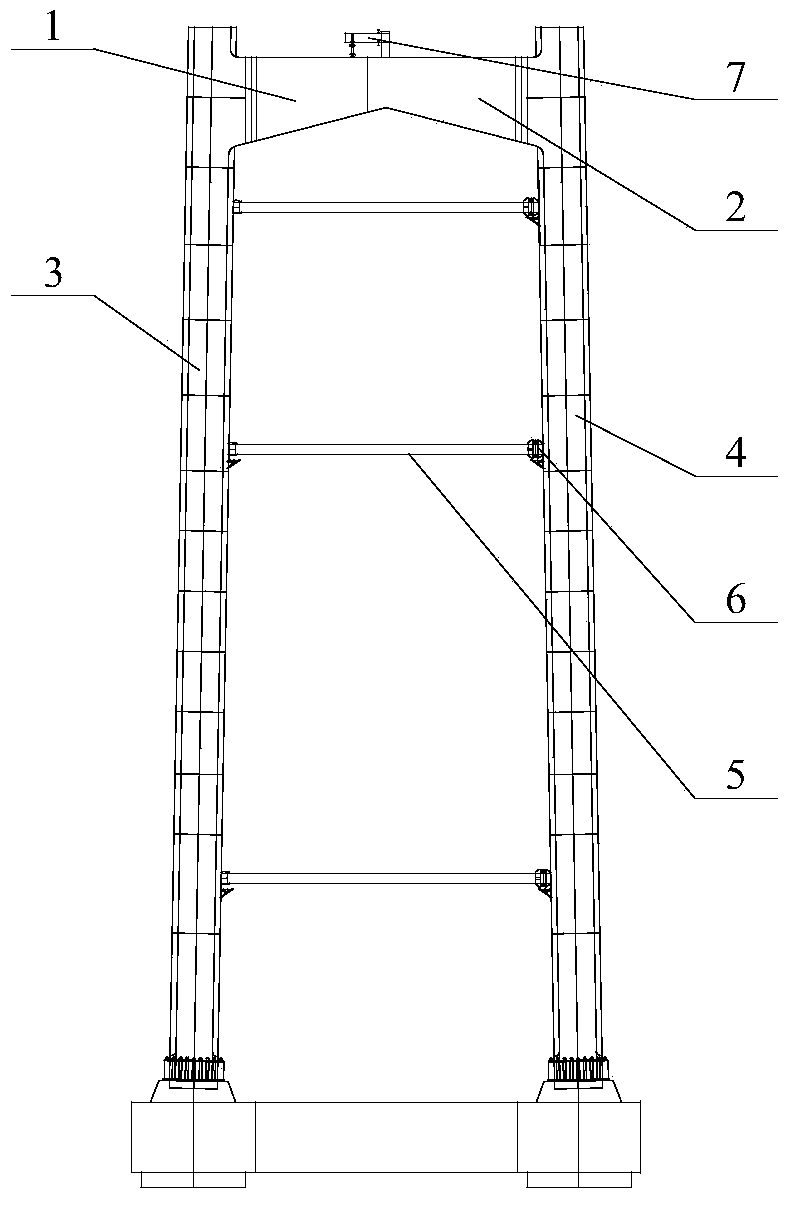

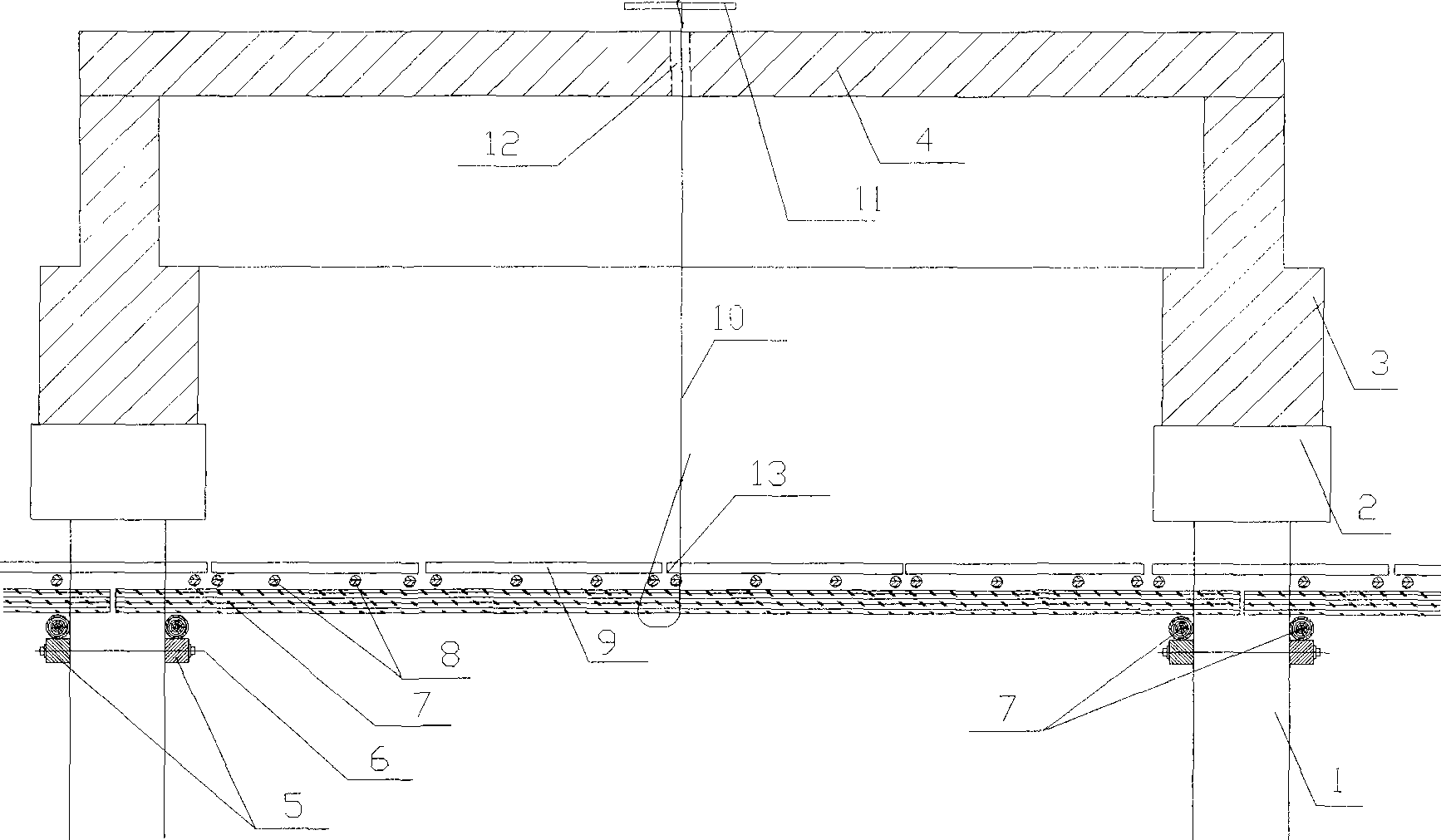

Lift for outdoor substation bus operation

InactiveCN103311848AAchieve vertical liftQuick and easy construction workLifting devicesApparatus for overhead lines/cablesDrive wheelEngineering

The invention relates to a lift for outdoor substation bus operation. The life for the outdoor substation bus operation comprises a base, a steel frame, a lifter and a glider, wherein the steel frame is fixed on the base, and the lifter and the glider are arranged on the steel frame. The lift for the outdoor substation bus operation is characterized in that the middle and rear potion of the base stretches across the groove steel frame; the lifter is disposed on both sides of a lower end surface of a crossbeam of the steel frame; a crank of the lifter passes through the crossbeam and exposes on an upper end surface of crossbeam; wheels are arranged on both ends of the base; steel cables of the lifter first bypass the wheels downwards and then pass through the crossbeam of the steel frame, and the top end of the steel cables are connected with a hook; the glider is arranged in the middle of the crossbeam; a drive mechanism provided with a pair of a worm wheel and a worm shaft which are engaged with each other is installed inside the lifter; a rotation shaft of the worm shaft is in linkage with a driven wheel which is engaged with a driving wheel; a rotation shaft of the driving wheel stretches out of a shell of the lifter to be connected with the crank; and a rotation shaft of the worm wheel is in linkage with a rope wheel with cables wound around. The lift for the outdoor substation bus operation is capable of allowing staff to sit in a hanging basket and to turn a handle of the lift to achieve vertical lift. Furthermore, with the drive mechanism for increasing the speed of the lifting, the speed of the lift is fast so that work efficiency is improved.

Owner:STATE GRID CORP OF CHINA +1

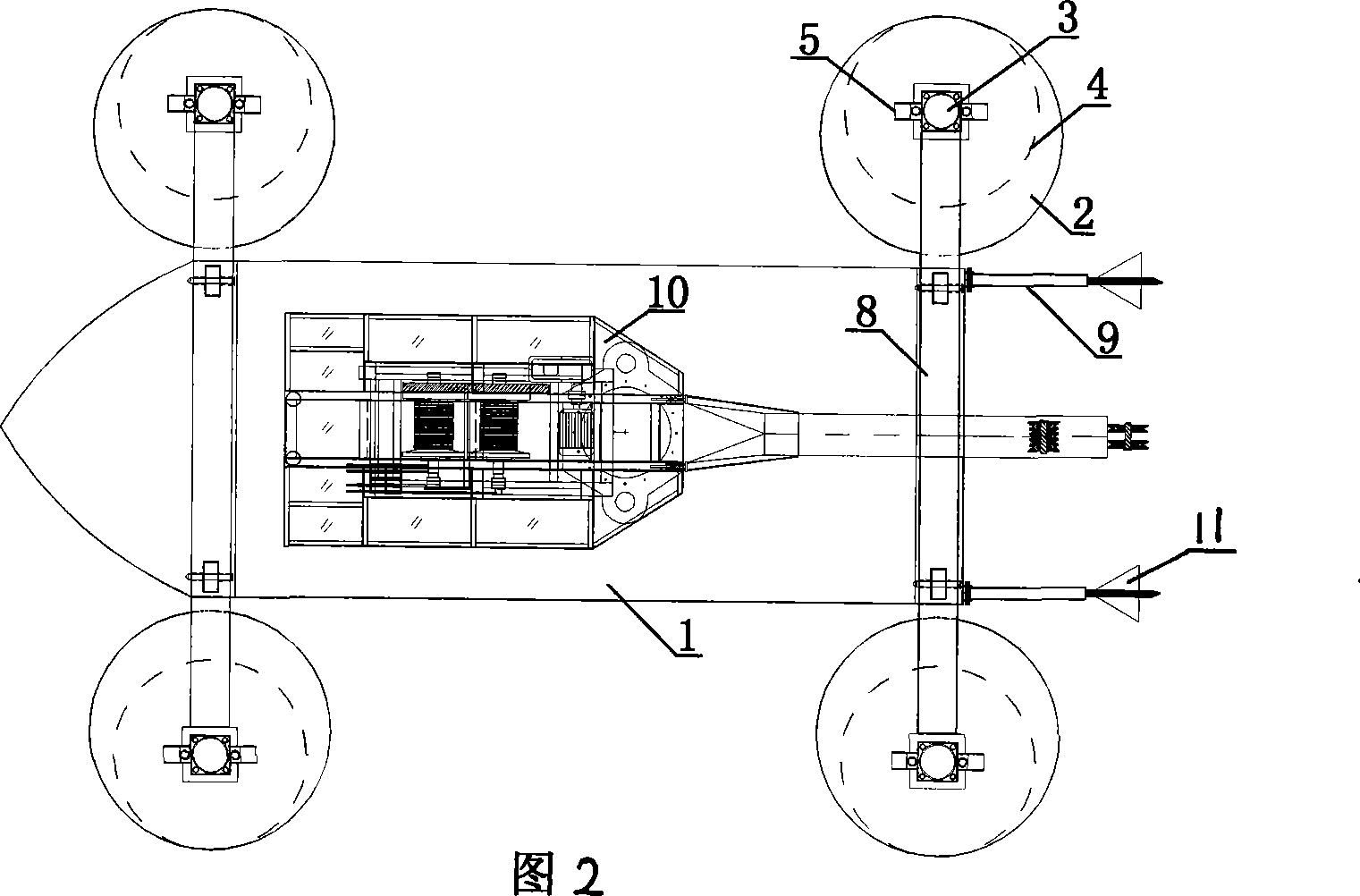

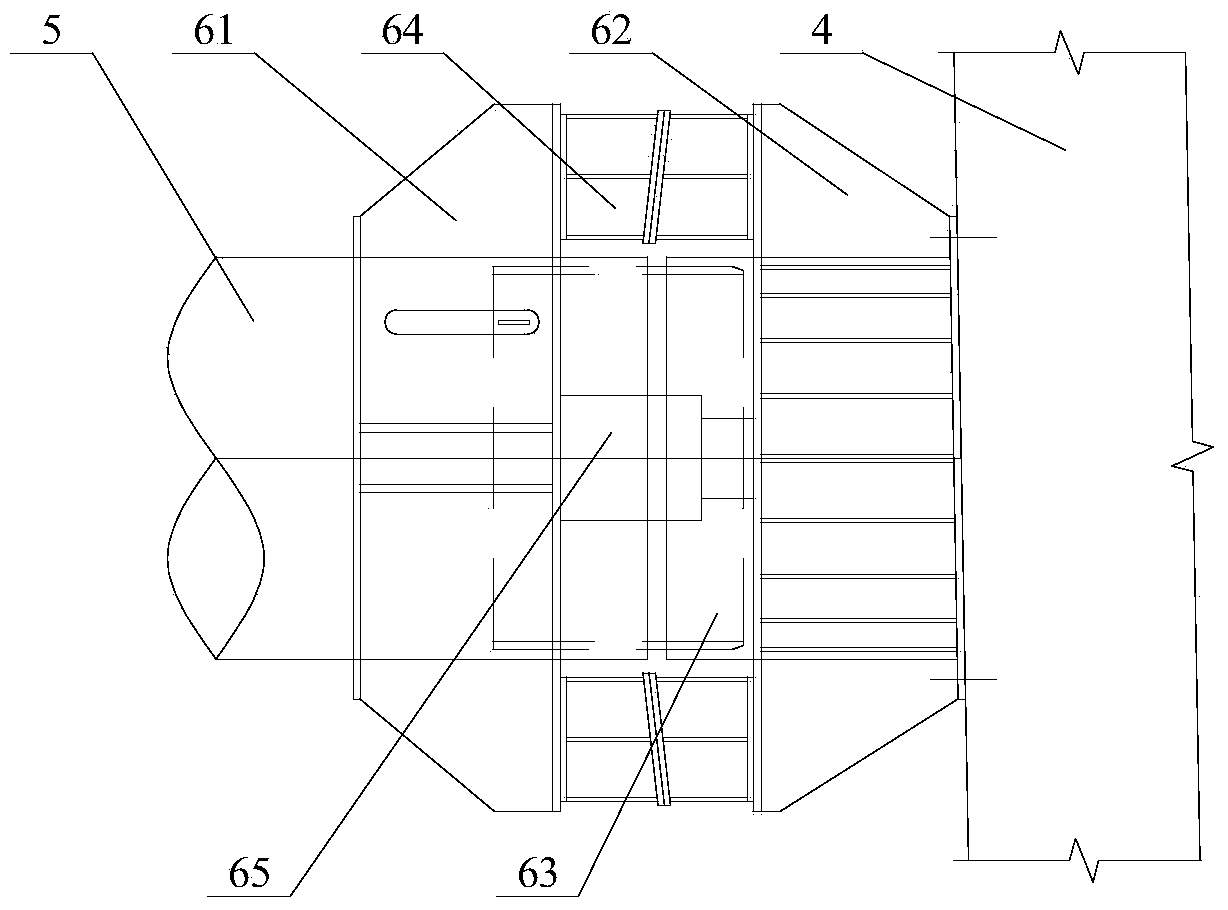

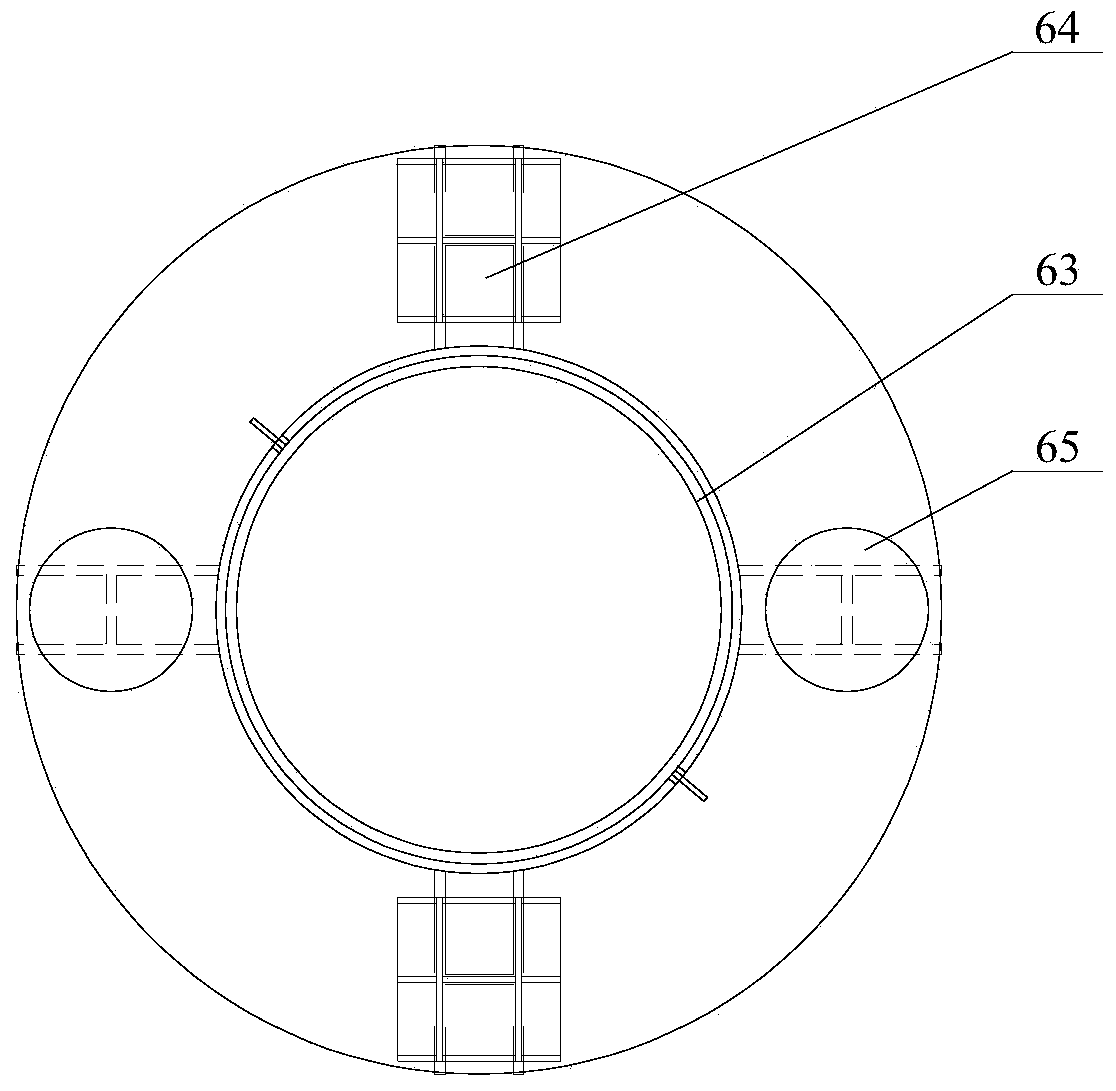

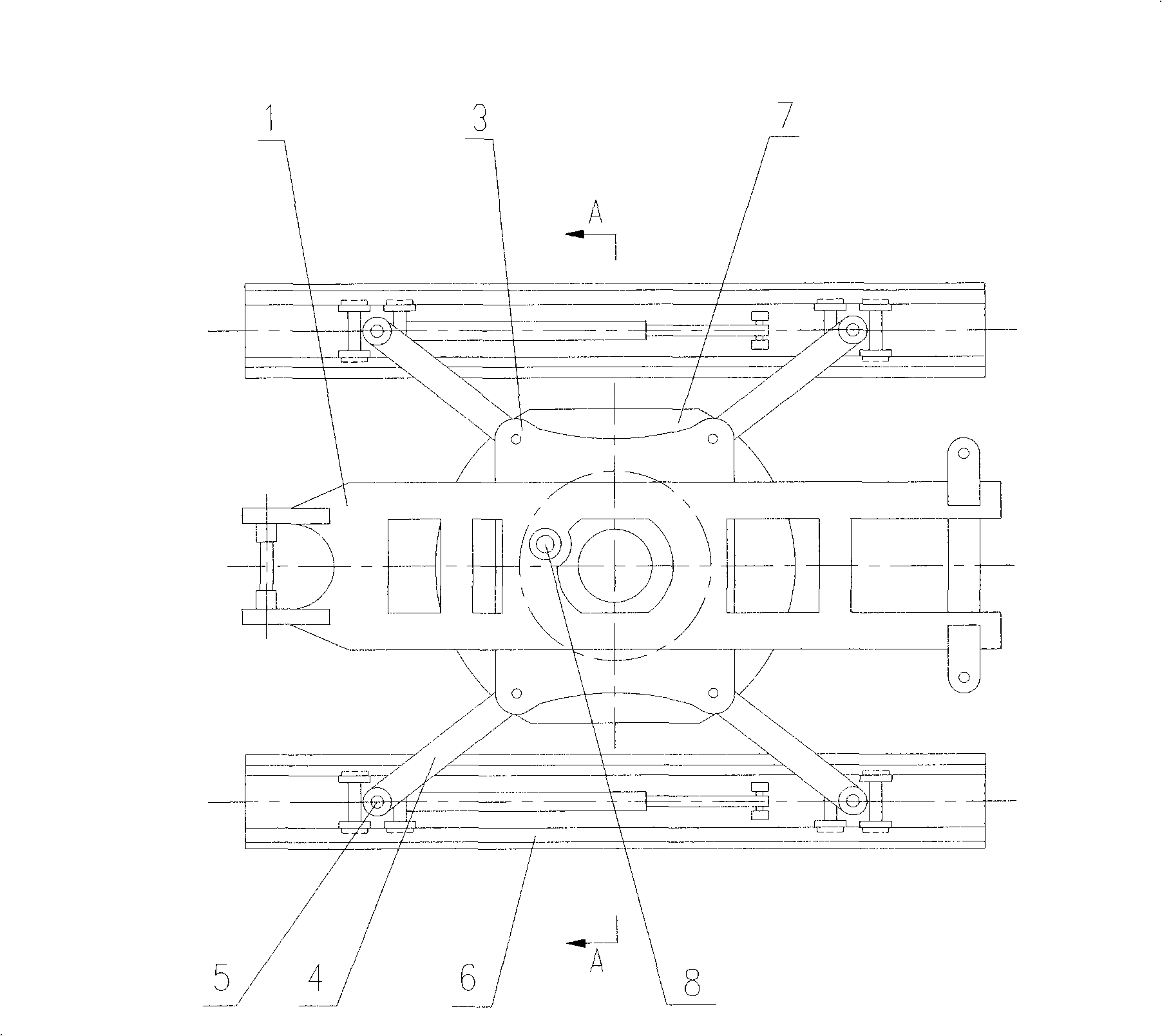

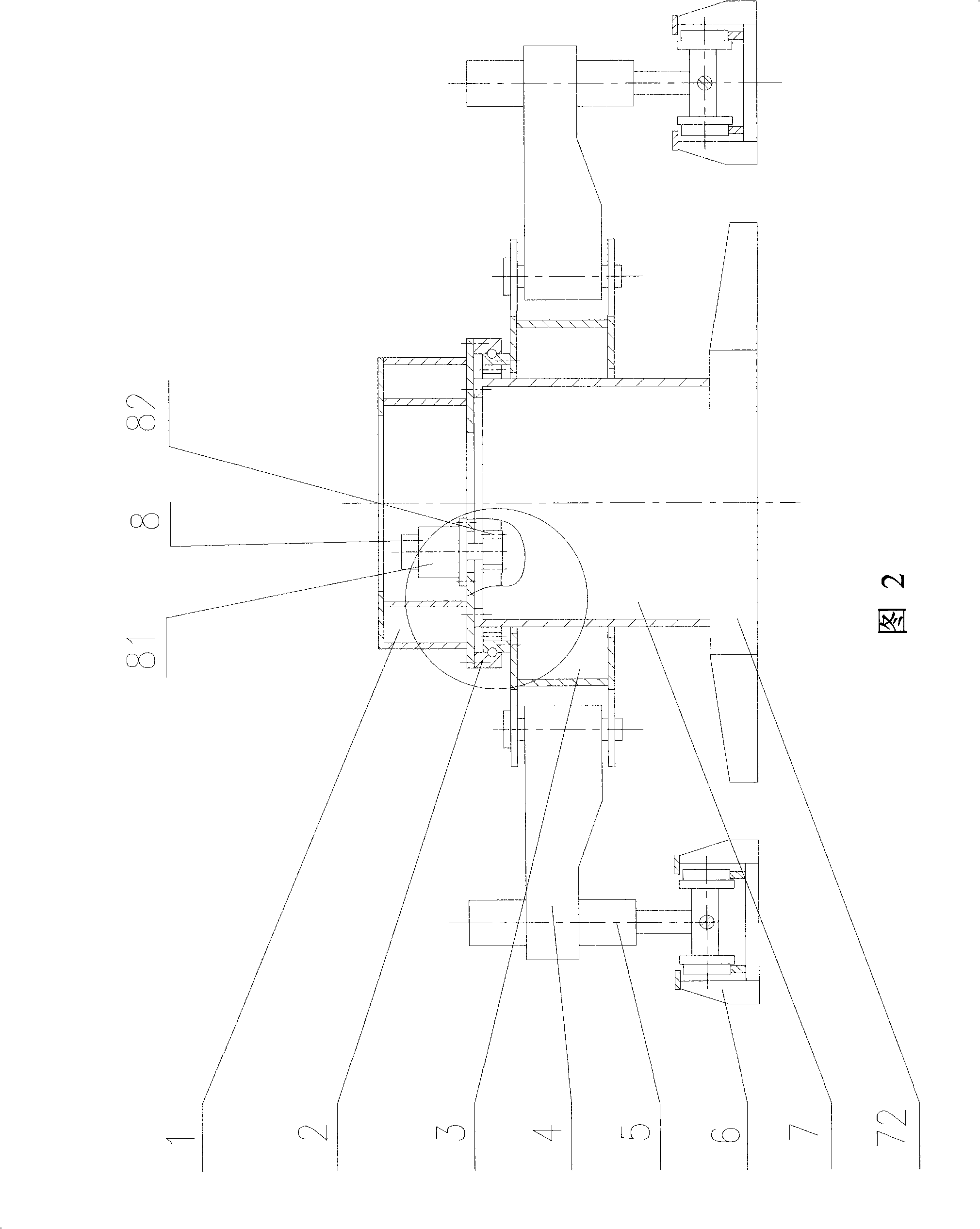

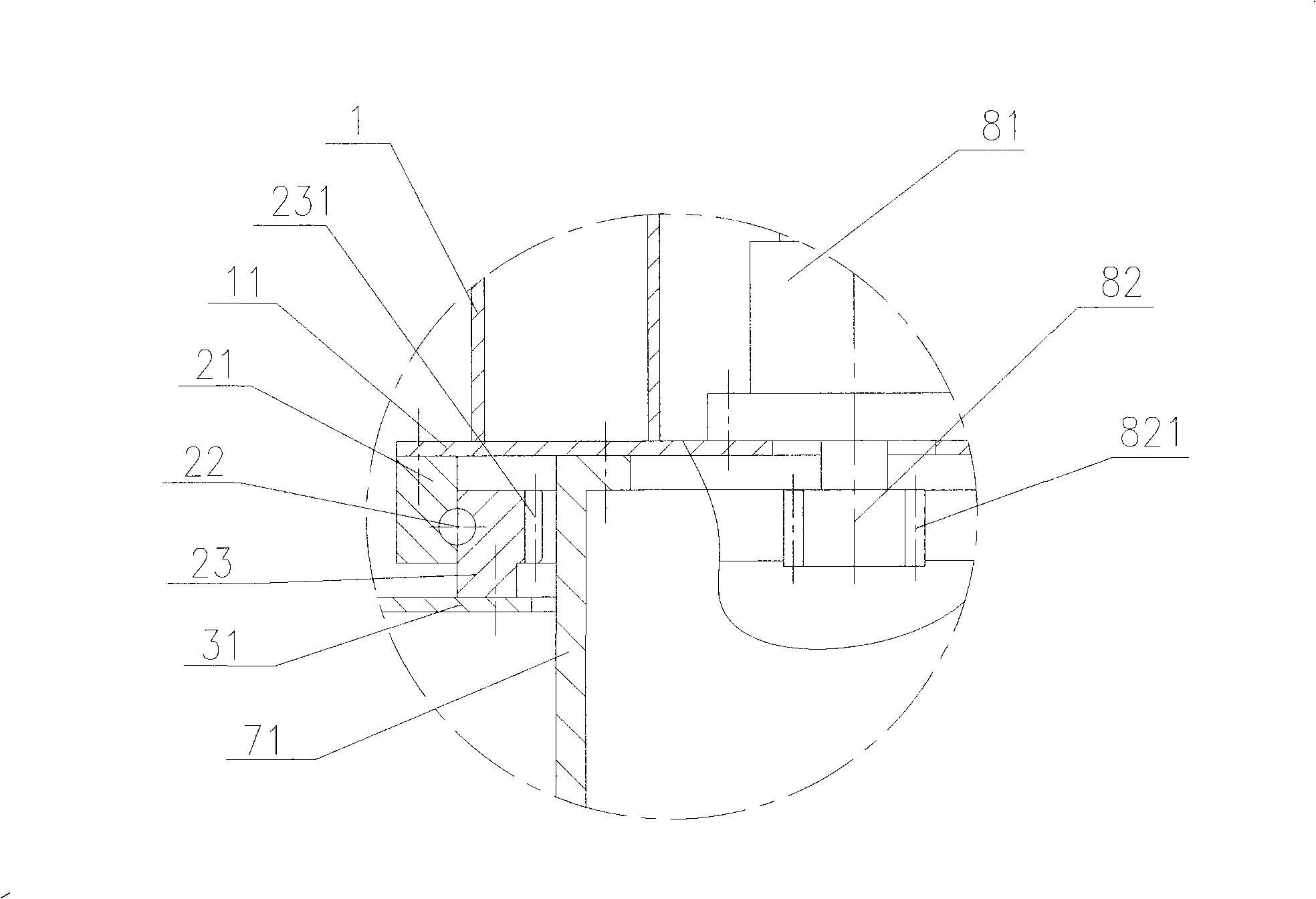

Walking type pile-driving frame turning and running mechanism

InactiveCN101265705AHigh positioning accuracyConvenient construction workBulkheads/pilesEngineeringMechanical engineering

The invention discloses a steering movement mechanism of walking-type pile driving frame. A system composed of an inner ring (23), a support beam (3), a support arm (4), an oil cylinder (5) and a walking mechanism (6) and a system composed of an outer ring (21), a main platform (1) and a support tray (7) enables the walking mechanism (6) to rotate around the support tray (7) under the action of a drive mechanism (8) and enables the pile frame to move forward or backward under the action of a travelling car and the oil cylinder in the walking mechanism (6) and further enables the walking-type pile driving frame to walk rotatably. The mechanism is capable of facilitating the walking-type pile driving frame in field operation and improving the operation efficiency and the positioning accuracy of the pile footing.

Owner:上海工程机械厂有限公司

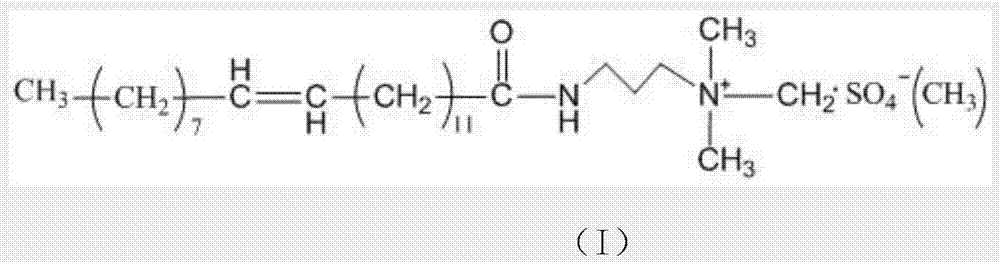

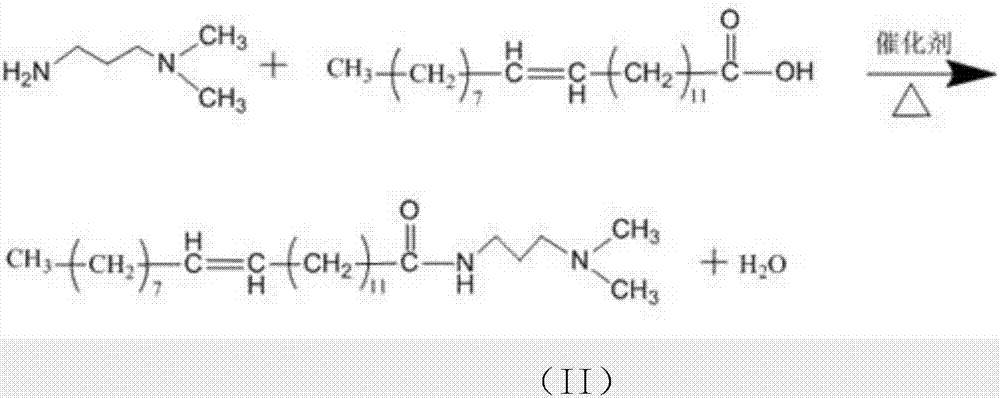

Clean steering acid fluid system containing erucyl alkyl quaternary ammonium salt surfactant

ActiveCN107325806AReduce pollutionImprove the effective diversion capacityOrganic compound preparationCarboxylic acid amides preparationAcid etchingHigh pressure

The invention aims to provide a clean steering acid fluid system with relatively low cost and high temperature resistance and high pressure resistance. In order to solve the technical problem, the clean steering acid fluid system is realized through the following technical scheme: the clean steering acid fluid system containing an erucyl alkyl quaternary ammonium salt surfactant comprises the erucyl alkyl quaternary ammonium salt surfactant, an acid fluid consisting of at least one inorganic acid or organic acid, a ferrous stability and a corrosion inhibitor. The erucyl alkyl quaternary ammonium salt surfactant is a surfactant with low molecular viscoelasticity, is free of residue or formation of filter cake, and is little in pollution to stratum, and the flow conductivity of cracks can be effectively improved. A gel breaker (for gel breaking when encountering oil or water) is not needed, the gel breaking is thorough, and residual liquid is extremely easy to discharge. The friction drag is low and is just 30% to 40% of water, the construction displacement selectivity range is large, and the requirement of different technology improvements can be realized. The system has good de-filtration characteristic and retarding performance, and the lengths of acid etching cracks can be greatly increased.

Owner:PETROCHINA CO LTD +4

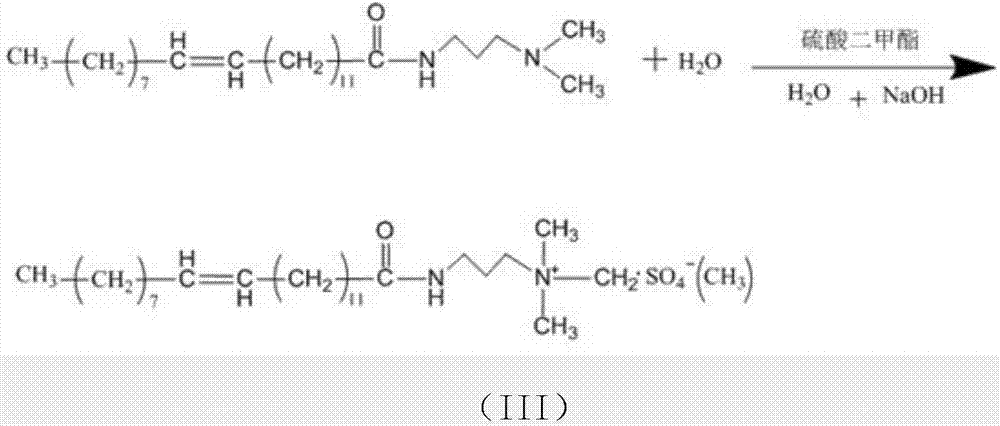

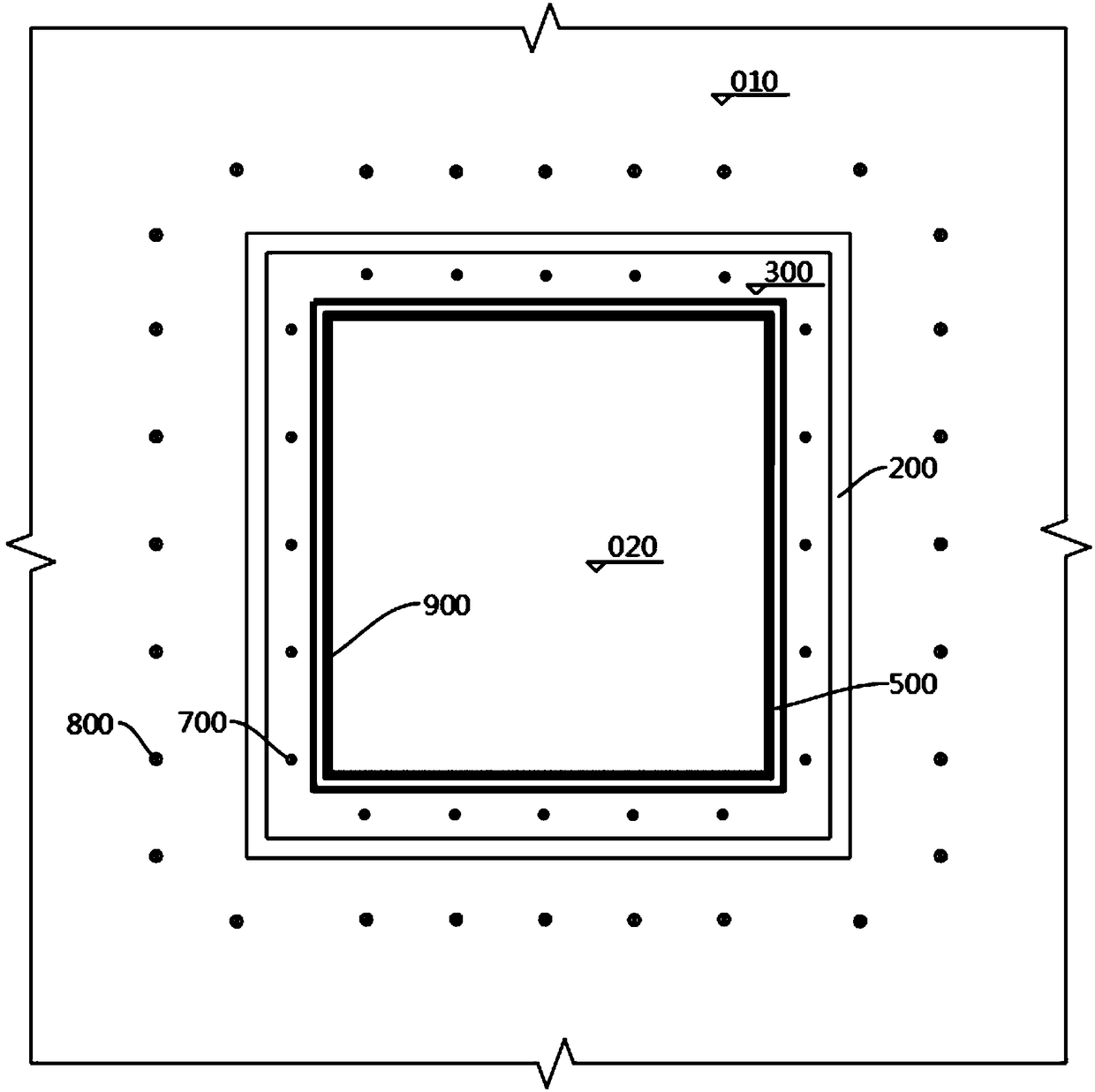

Foundation pit supporting structure and foundation pit supporting method

PendingCN109403350APlay a supporting roleConvenient construction workExcavationsInterior spacePre stress

The invention relates to the field of ultra-deep foundation pit supporting at underground-water-rich areas, in particular to a foundation pit supporting structure and a foundation pit supporting method. Supporting piles are arranged on the inner wall of a foundation pit; at least part of each supporting pile is buried underground; prestress anchor cables are arranged at an excavation part; water drainage wells are arranged at a soil body at the periphery of the foundation pit; each prestress anchor cable comprises a fixed end which is fixed on the inner wall of the foundation pit and an anchoring end which is deep in the soil body; the water drainage wells are arranged at positions close to the anchoring ends; and the distance between the well bottom of each water drainage well to the ground is greater than or equal to the distance between the corresponding anchoring end to the ground. According to the foundation pit supporting structure and the foundation pit supporting method, supporting of the ultra-deep foundation pit with a high underground water level is realized through the supporting structure consisting of the supporting piles, the prestress anchoring cables and the waterdrainage wells; the space in the foundation pit is not occupied by the supporting structure, so that deep foundation pit construction work for foundation pits with small areas is facilitated; besides,disassembly is not need, and later-period construction is not affected; and a later-period supporting effect is realized for the foundation pit.

Owner:SHANXI CONSTR ENG CO LTD

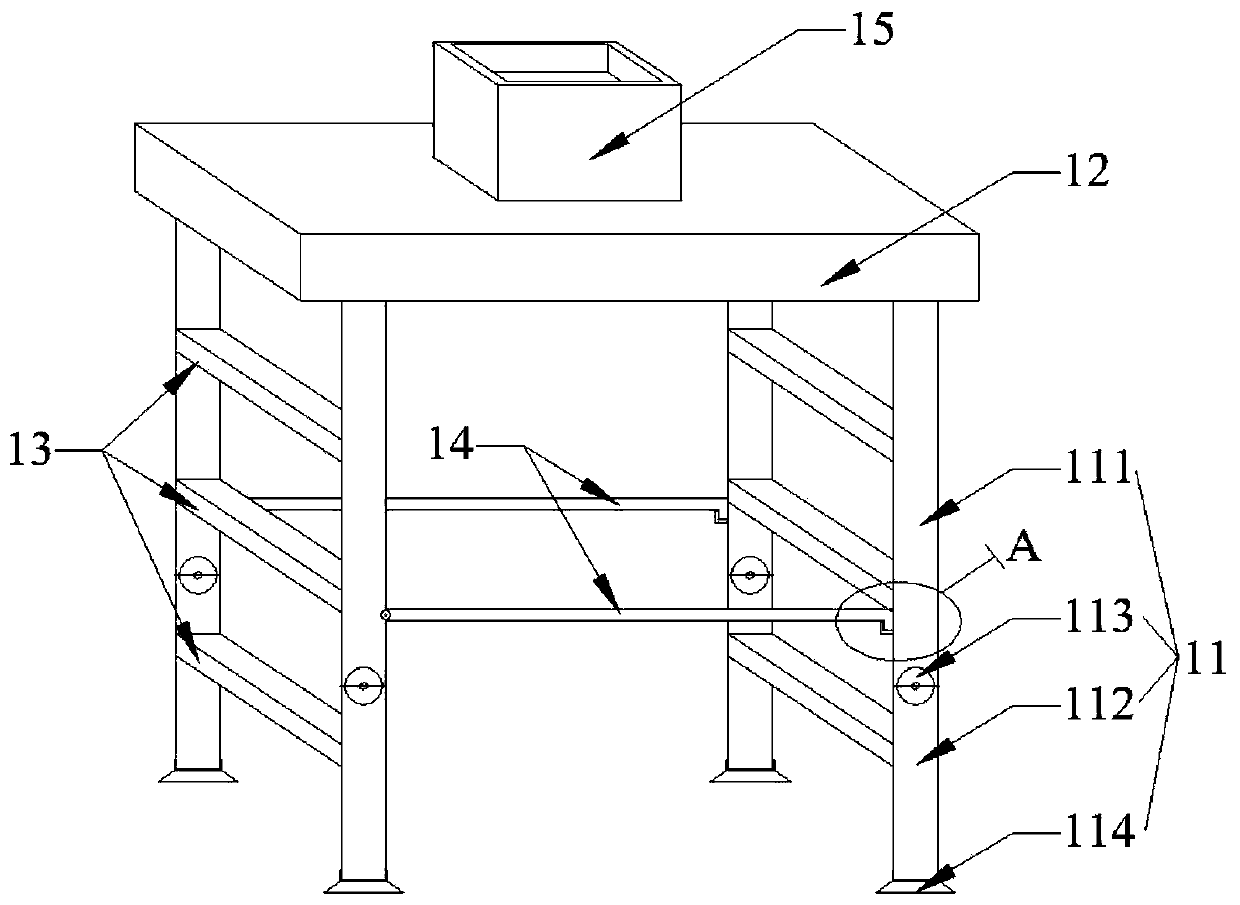

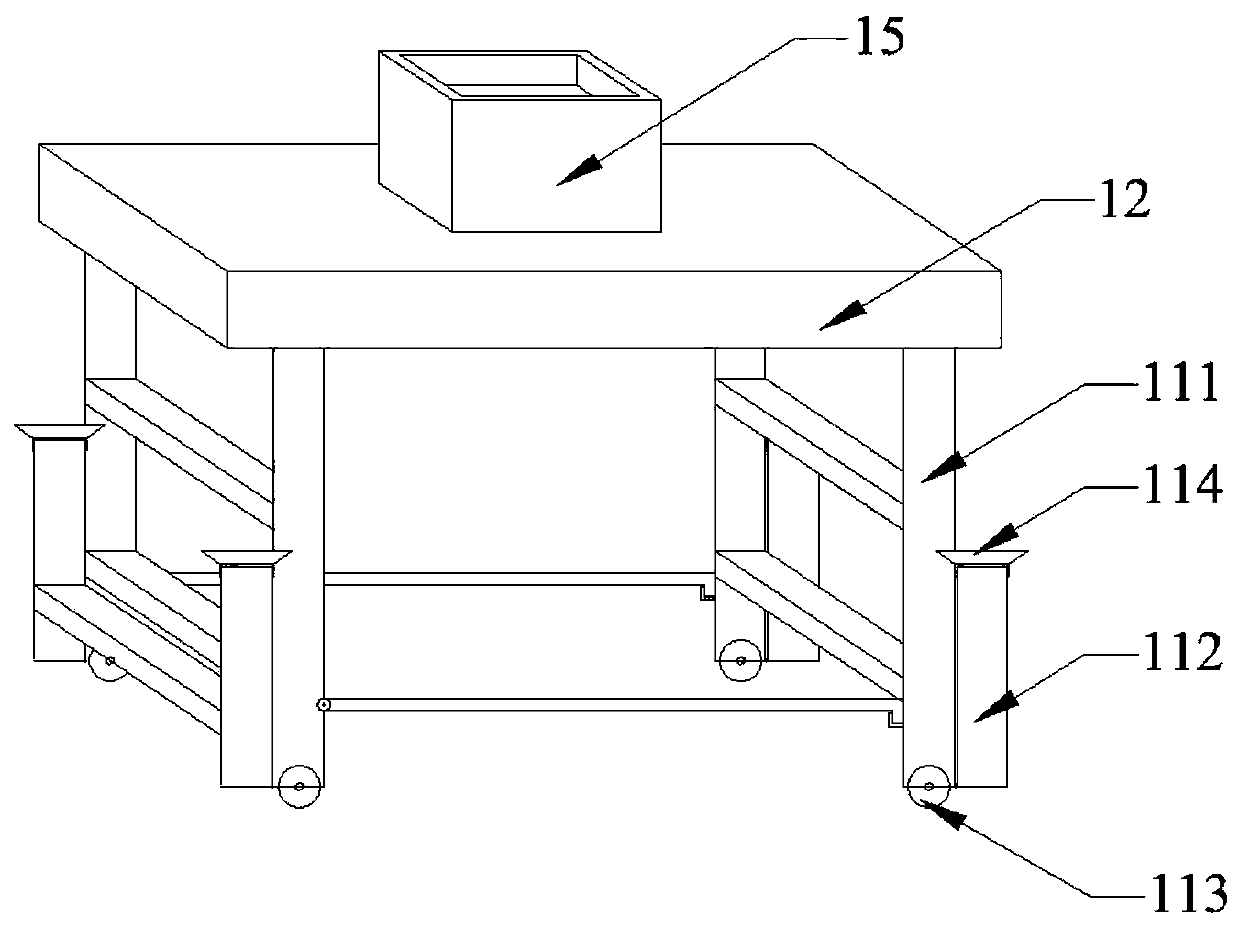

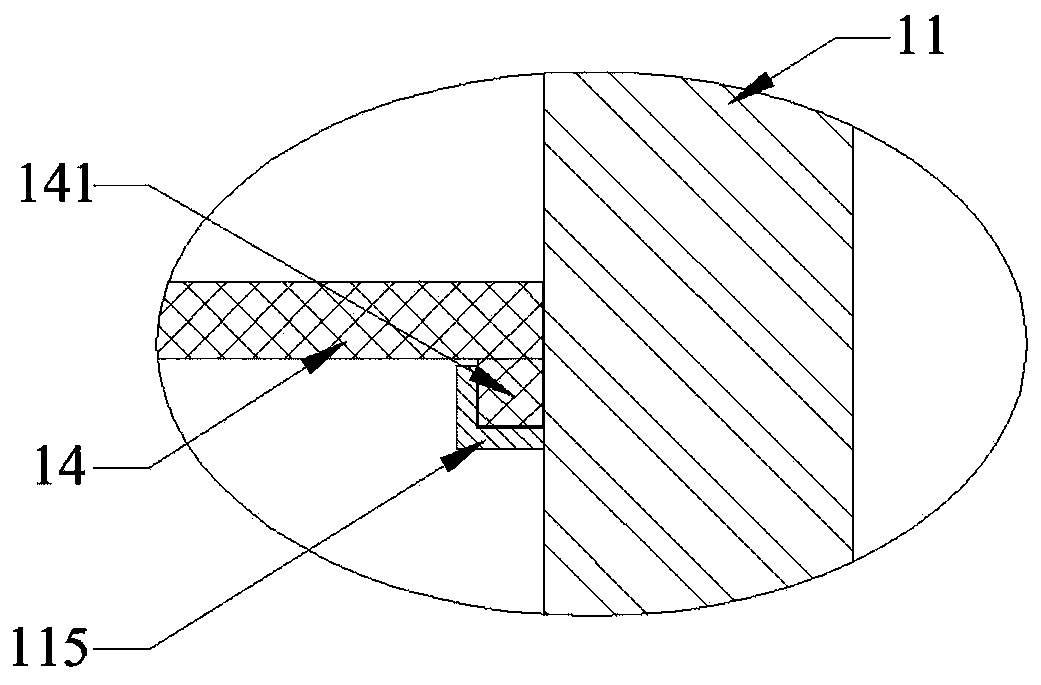

Building constructionplatform convenient to move

PendingCN110629994AEasy to moveConvenient construction workScaffold accessoriesArchitectural engineeringEngineering

The invention discloses a building construction platform convenient to move, and relates to the field of building equipment. The building construction platform comprises a plurality of support legs, asupport platform and a plurality of cross beams; the support legs at least comprise first support rods andsecond support rods, the first ends of the first support rods are hinged to the first ends ofthe second support rods, idler wheel structures are arranged at the first ends of the first support rods, and antiskid foot pads are arranged at the second ends of the second support rods; the support platform is fixedly connected with the second ends of the first support rods; and the multiple cross beams are fixed between the two support legs to form a stair structure. According to the buildingconstruction platform, the support legs are foldable, when the support legs are not folded, the landing ends are the antiskid foot pads, supporting is stable, the height of the support platform is high, and therefore, the construction operation is convenient; after folding, the landing ends are the idler wheel structures, the platform movement is convenient, moreover, the height is lowered afterfolding, and the door structure is advantageously passed through.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Intelligent rock drilling device for geological exploration

InactiveCN109162638AIncrease freedomExtended service lifeFlushingCore removalHydraulic cylinderGeological exploration

The invention discloses an intelligent rock drilling device for geological exploration. The intelligent rock drilling device comprises a vehicle body. A drilling mechanism is arranged at the left sideof the vehicle body and includes a core drilling drum; and a sleeve is arranged at one side, close to a rotating frame, of the core drilling drum. According to the invention, with the core drilling drum with a through hole and the sleeve with a water injection cavity, cooling water is injected into the core drilling drum by a water pump, so that the core drilling drum is cooled and the good dustreduction effect is realized. The service life of the drum is prolonged and the health of the worker is protected. With the rotating frame, a rotating base, a hydraulic cylinder and a worm gear driving mechanism, the core drilling drum has the high freedom degree and thus can carry out construction work at different angles, so that the work efficiency is improved. With a wheel frame and a lead screw driving mechanism, the roller is lifted, so that the mobility and stability of the device are enhanced.

Owner:EAST CHINA UNIV OF TECH

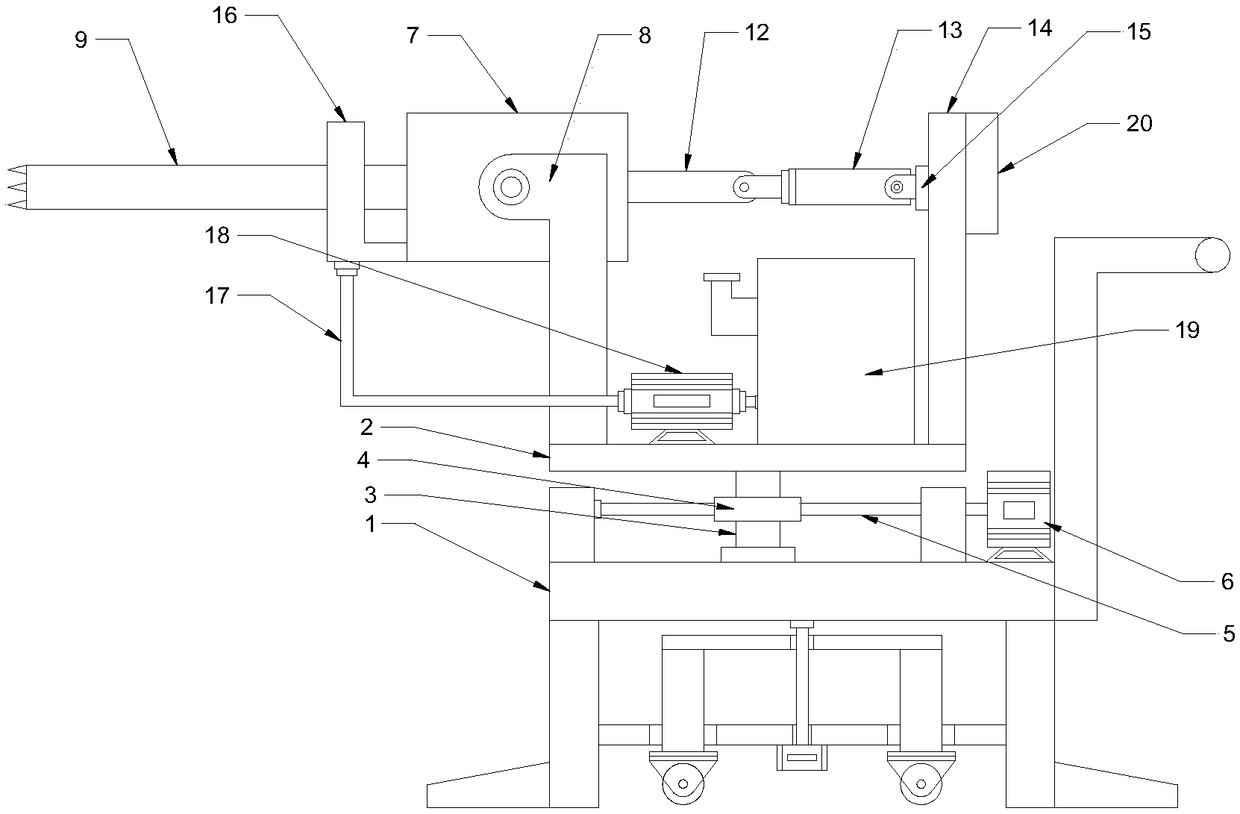

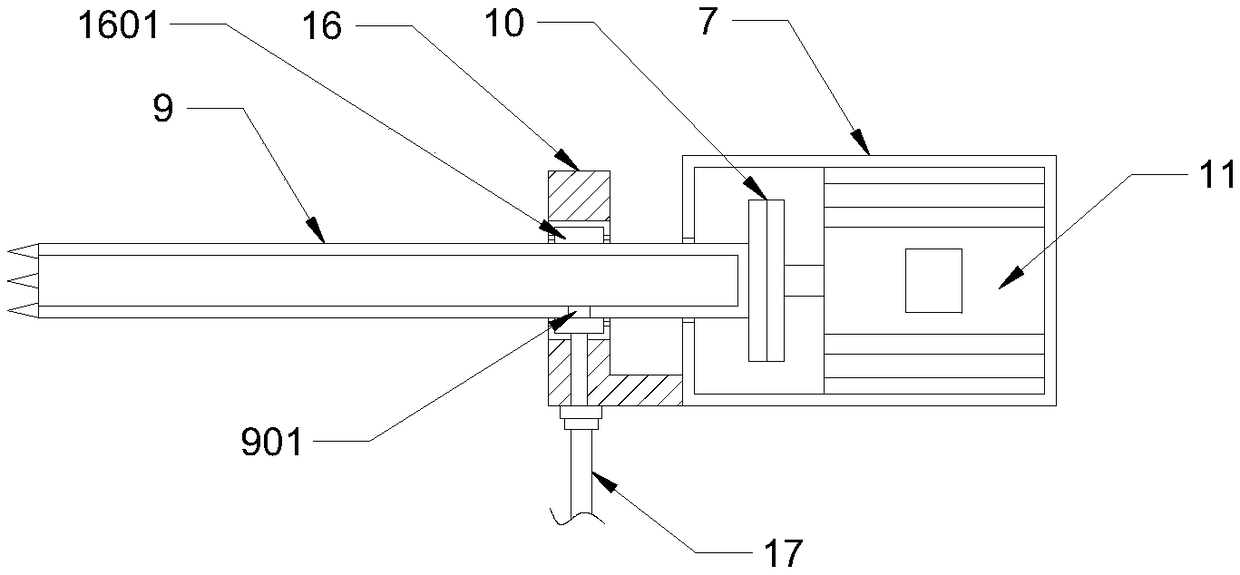

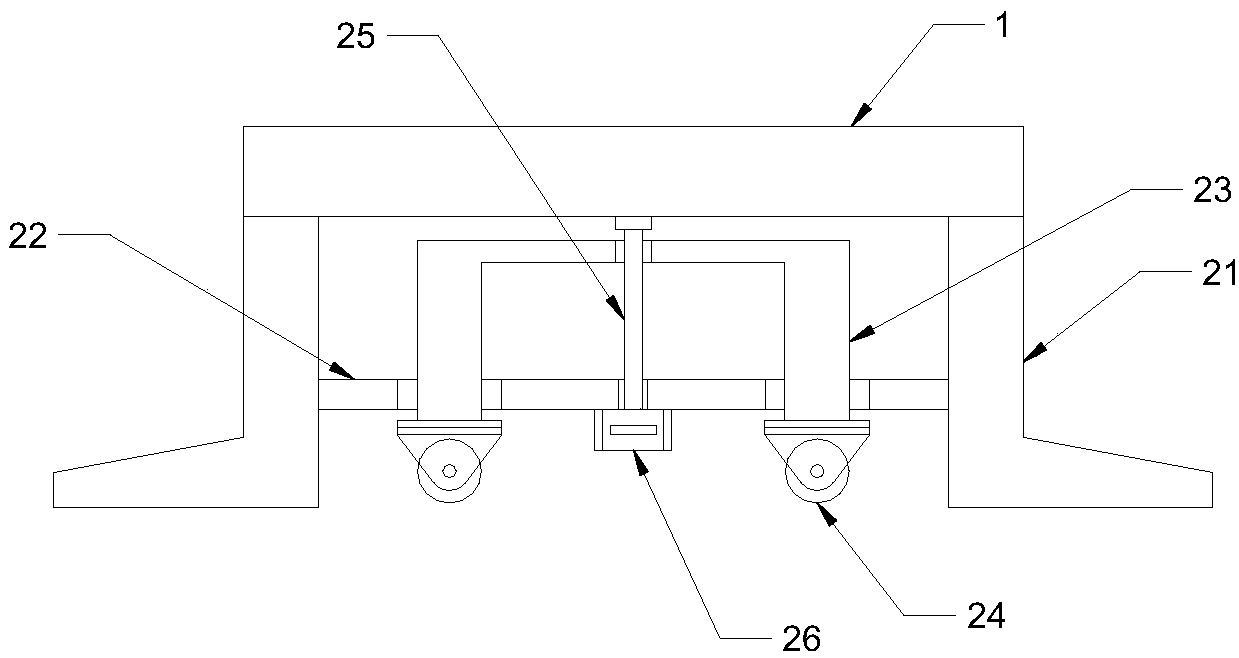

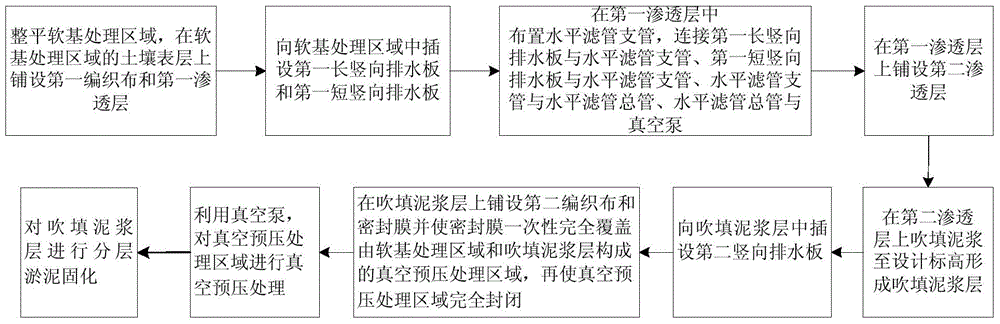

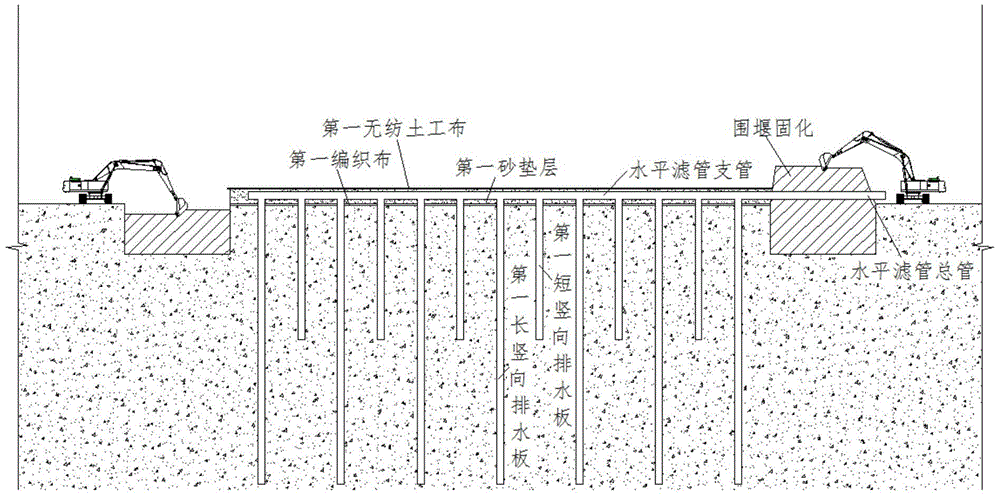

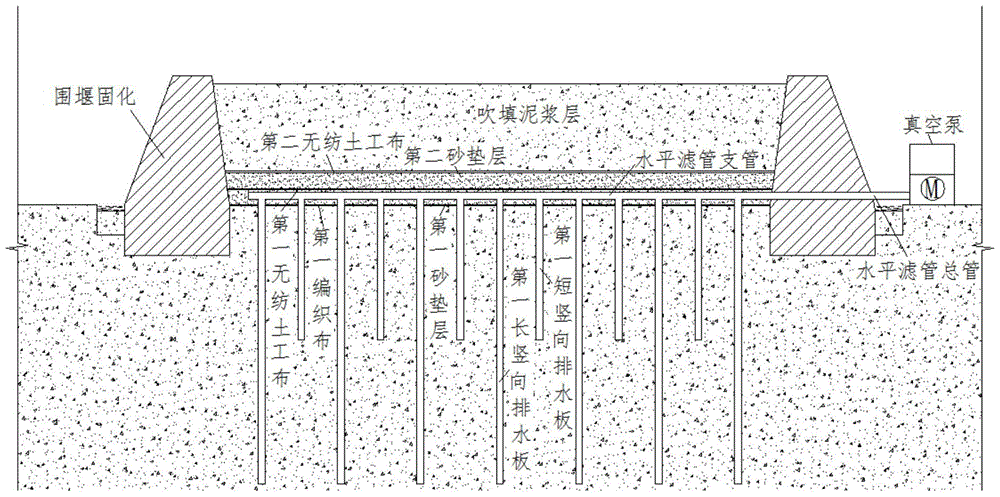

Soft foundation reinforcement treatment method of vacuum preloading combined with dredging and filling mud

ActiveCN104120710BSpeed up the consolidationShorten the consolidation cycleSoil preservationSludgeStructural engineering

The invention discloses a soft foundation reinforcement treatment method of vacuum preloading combined with dredging and filling mud. First, a first woven cloth and a first permeable layer are laid on the soil surface layer of the soft foundation treatment area; and then inserted into the soft foundation treatment area. Set up the first long vertical drainage board and the first short vertical drainage board, connect the horizontal filter pipe, and connect the vacuum pump; then lay the second permeable layer on the first permeable layer, according to the design elevation of the soft ground treatment area in the second The dredging and filling mud layer is formed on the permeable layer to the design elevation; then the second vertical drainage board is inserted into the dredging and filling mud layer; the second woven cloth and sealing film are laid in sequence on the dredging and filling mud layer; finally The vacuum preloading treatment area is vacuumed, and after the vacuuming is completed, the layered sludge solidification is carried out on the drained dredging mud layer; the advantage is that the consolidation period is short, and the bearing capacity of the treated dredged mud layer is high, which is convenient for construction The equipment works on it, and the treated foundation has a high bearing capacity and a high treatment depth.

Owner:宁波高新区围海工程技术开发有限公司

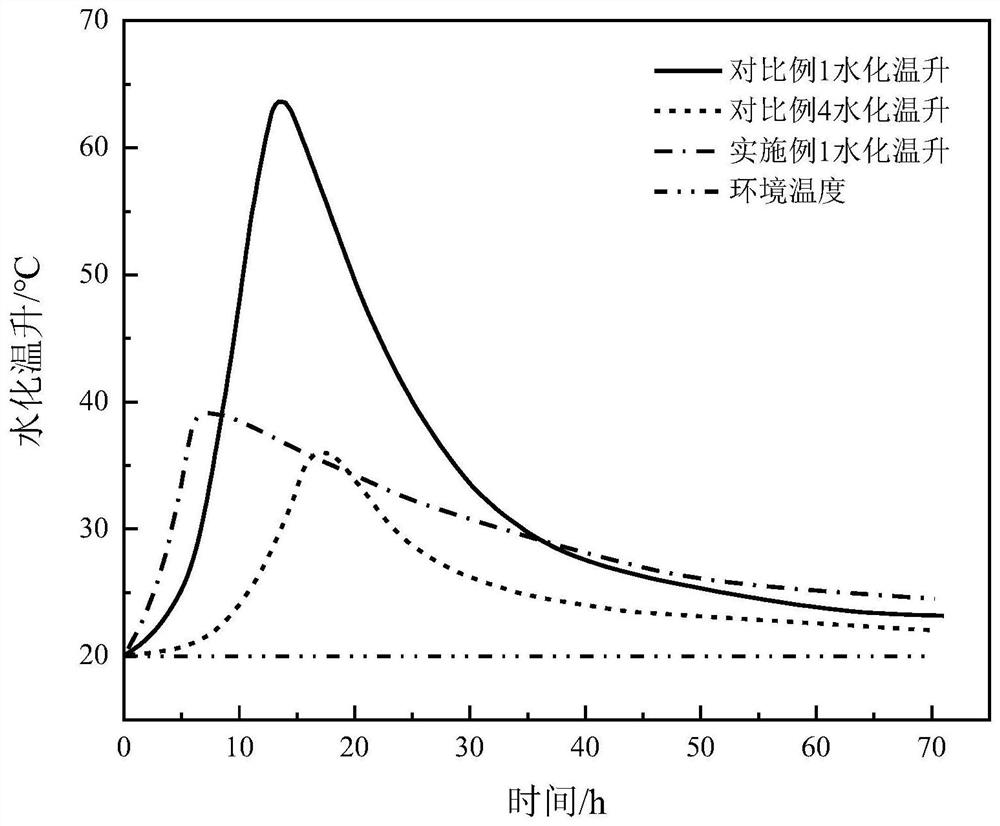

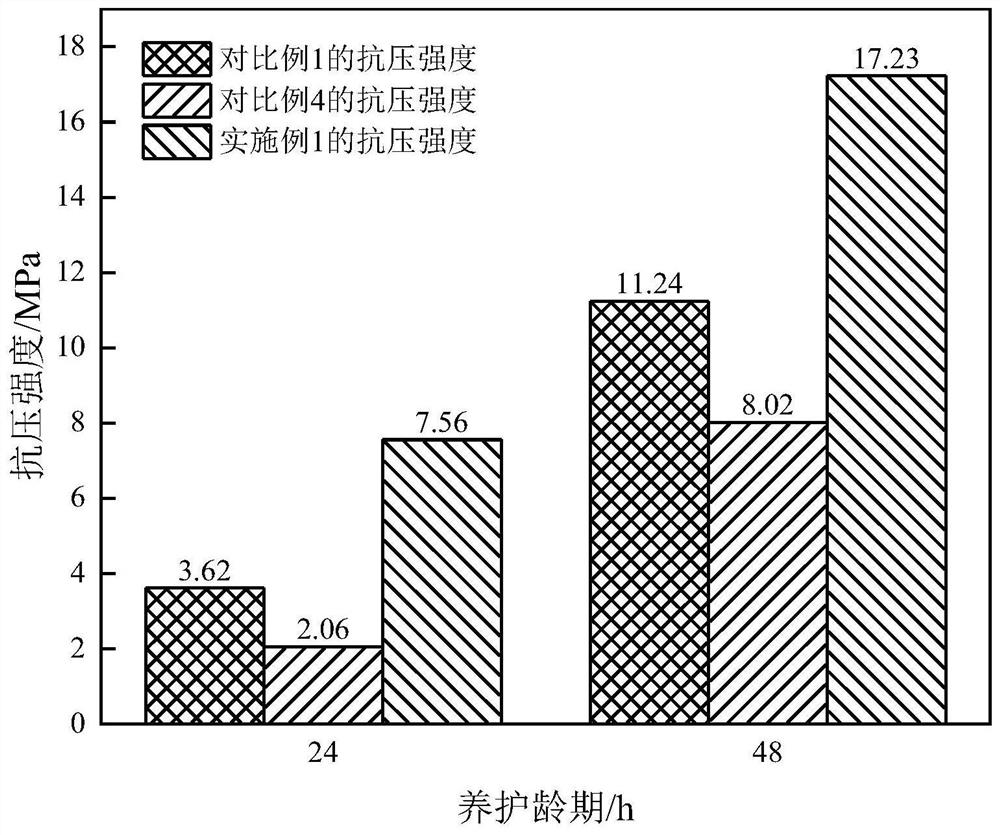

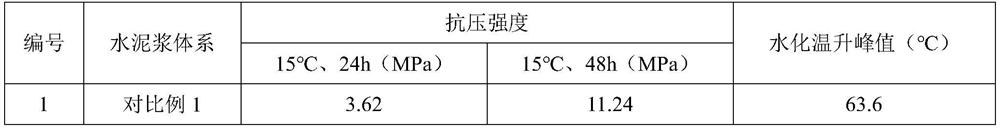

Composition and application of low-temperature and hydration synergistic low-heat early-strength cement slurry system

PendingCN113511850ALow heat of hydrationLow temperature early strengthDrilling compositionCalcium silicatePhysical chemistry

The invention discloses composition and application of a low-temperature and hydration synergistic low-heat early-strength cement slurry system. The low-heat early-strength cement slurry system is prepared from the following components in parts by weight: 100 parts of oil well cement, 70-100 parts of a low-hydration-heat active cementing material, 3.2-6.3 parts of a hydrated calcium silicate-polycarboxylic acid ether nano composite early strength agent, 1.8-5.4 parts of a low-temperature activator, 0.7-1.3 parts of a fluid loss agent, 0.3-0.6 part of a dispersing agent, 0.2-1.0 part of a defoaming agent, 15-20 parts of hollow glass beads and 60-92 parts of water. According to the cement slurry system, on the basis that a low-hydration-heat-activity cementing material is selected, the hydrated calcium silicate-polycarboxylate ether nano-composite early strength agent and the low-temperature activating agent are adopted and have a synergistic effect, and the compressive strength of set cement in the curing period is jointly promoted; and the cement slurry system has the characteristics of being small in hydration heat release, high in early strength and the like, and meanwhile, has the advantages of adjustable density, adjustable thickening time, good rheological property, low filter loss, short setting waiting time and the like, is suitable for well cementation of ocean deepwater surface layers and hydrate layers, and lays a solid foundation for development of ocean oil and gas resources.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

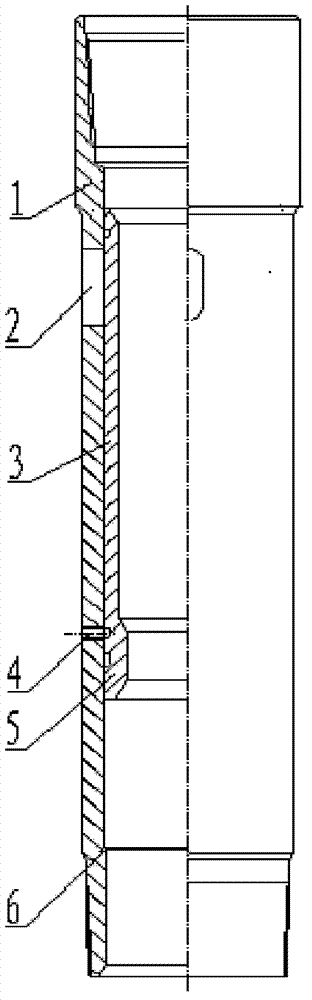

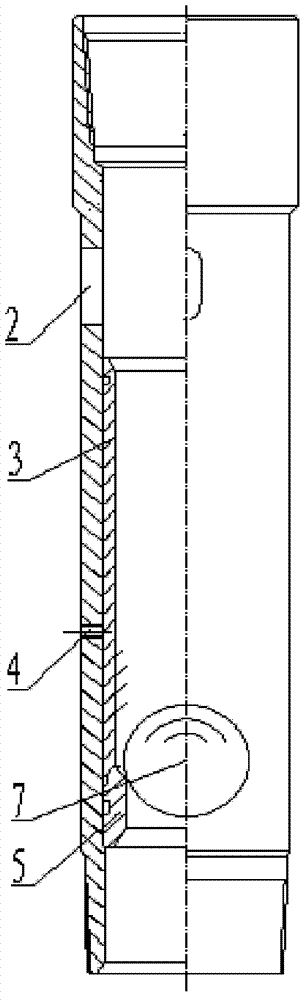

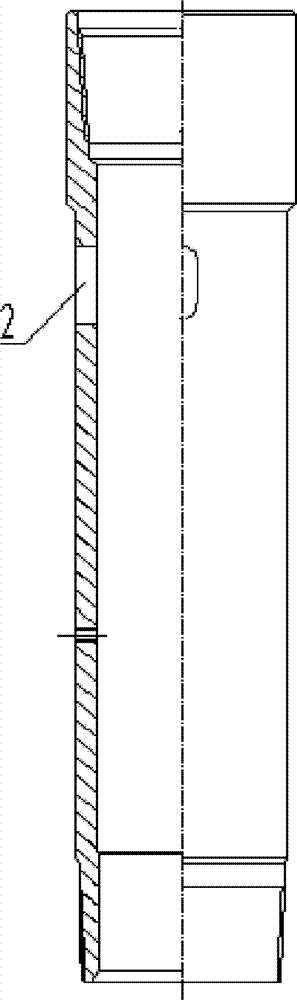

Sand blasting device allowing fracturing sliding sleeve to be fished

Disclosed is a sand blasting device allowing a fracturing sliding sleeve to be fished. The sand blasting device aims at overcoming defects that the liquid flow is unsmooth and construction operations for oil well sand production cannot be performed through a conventional sand flushing technology caused by retention of injected balls and sliding grooves in pipe strings after the fracturing construction operation. The device comprises a body, a sliding sleeve and a ball. The upper and lower ends of the body are provided with threads connected with a completion pipe string and a matched tool, an inner hole of the body is a big-end-up stepped hole, a straight hole longer than the sliding sleeve is formed in the middle, a radial through hole is formed in the upper end of the straight hole, and an inner boss of the lower end of the body is a limit face. The sliding sleeve is disposed in the straight hole in the middle of the body, the sliding sleeve and the body are radially fixed through a shear pin, and the radial through hole of the body is closed by the upper end of the sliding sleeve. An inner boss of the lower end of the sliding sleeve is a ball seat. The device has the advantages that the device is simple and reasonable in structure, easy to operate and safe and reliable; the inner sliding sleeve and the ball in a down-hole pipe string can be taken out through a conventional fishing technology, the inner drift diameter of a down-hole tool is guaranteed, convenience is provided for later construction operations, the operation cycle is shortened, and operation costs are reduced.

Owner:DAGANG OIL FIELD GRP +2

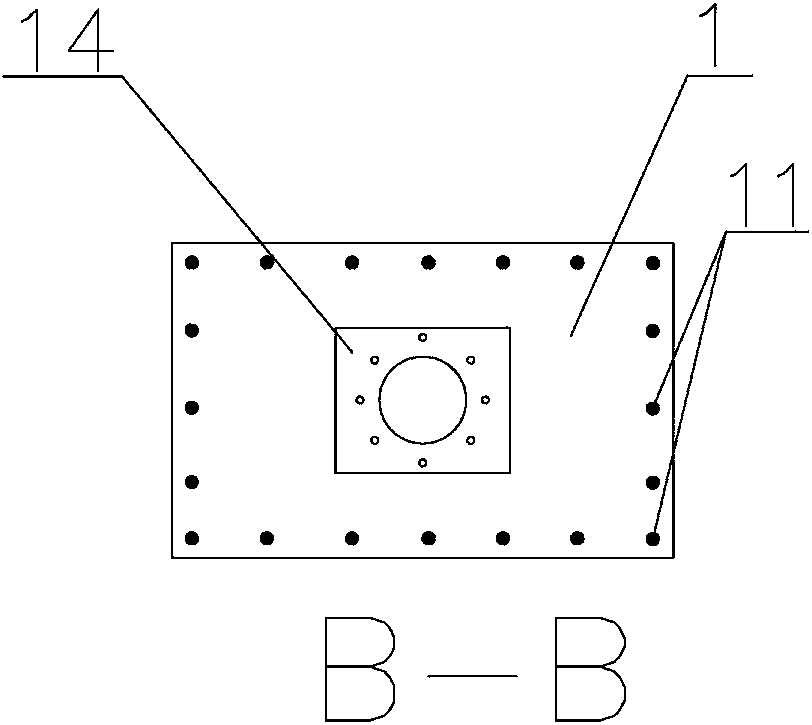

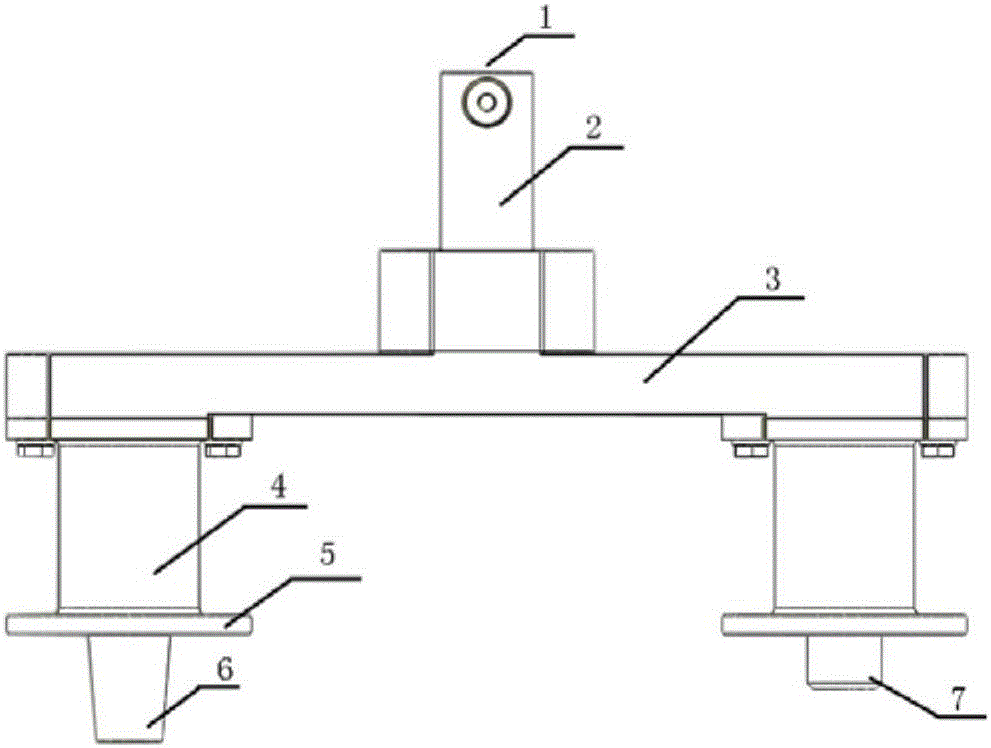

CRTS III type plate-type ballastless-track track-board fine-tuning frame

InactiveCN107178014ASmall form factorConvenient construction workRailway track constructionMeasuring apparatusCircular discPrism

The invention belongs to the field of high-speed-railway ballastless-track equipment, and relates to a track-board fine-tuning frame, in particular to a CRTS III type plate-type ballastless-track track-board fine-tuning frame. The CRTS III type plate-type ballastless-track track-board fine-tuning frame comprises a prism column. A prism hole is formed in the center of the top end of the prism column (2) and used for placing a micro prism, a cross beam (3) is arranged below the prism column, and two cylindrical bases (4) are connected with the lower portion of the cross beam (3); the vertical axes of the two bases (4) and the prism column (2) are located on the same straight line, the axis of the prism column (2) is located at the center of the link of the axes of the two bases (4), and discs (5) are arranged below the two bases correspondingly; and a fixed positioning pin (7) is arranged below one disc, a bolt-hole movable taper positioning pin (6) is arranged below the other disc, and the circle center of the movable taper positioning pin (6) is always consistent with the circle center of the corresponding disc (5). According to the CRTS III type plate-type ballastless-track track-board fine-tuning frame, the horizontal position, the longitudinal position and the elevation position of a track board can be detected simultaneously, the shape is small and exquisite, and construction operation is convenient.

Owner:屹兴轨道股份公司

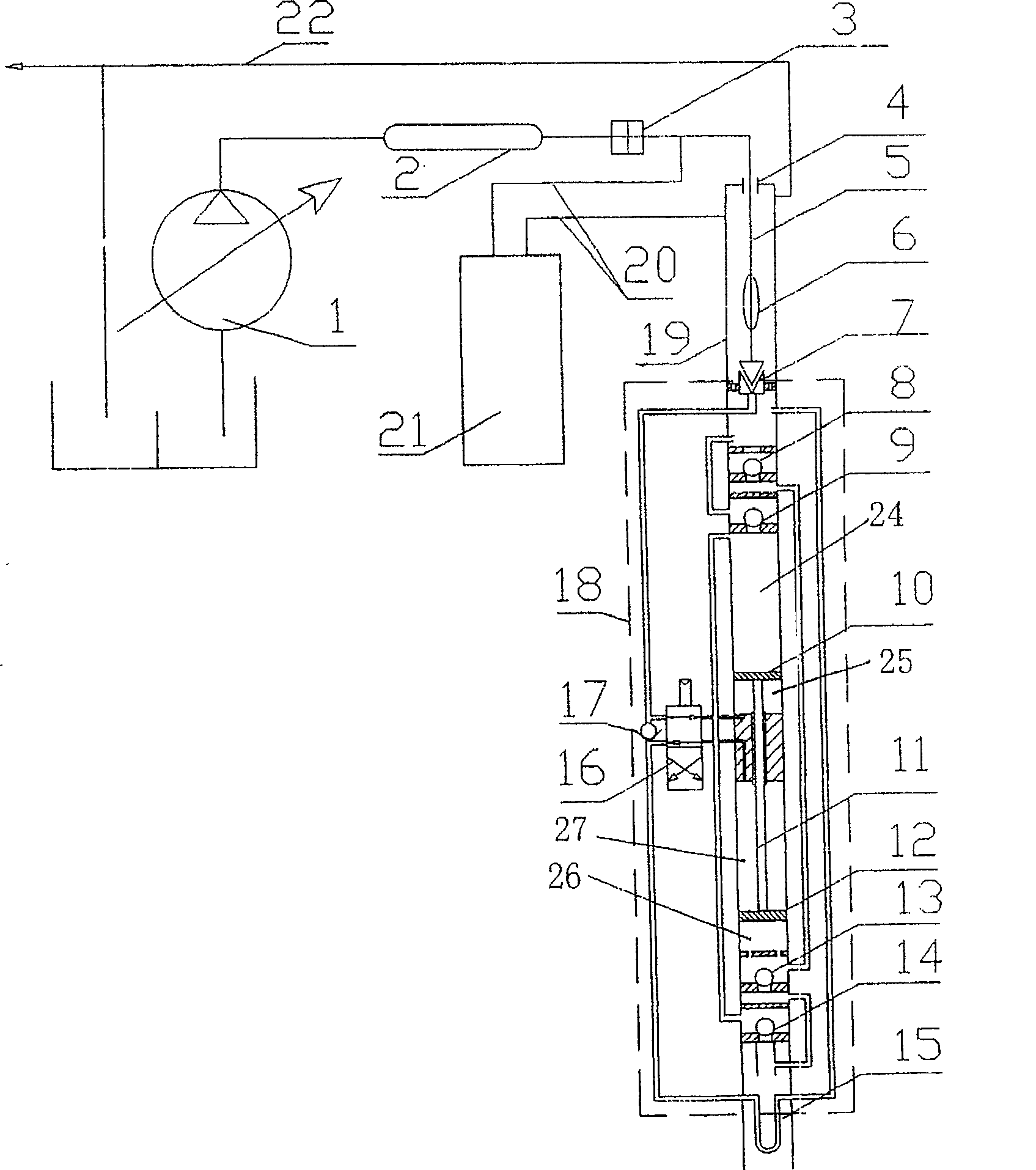

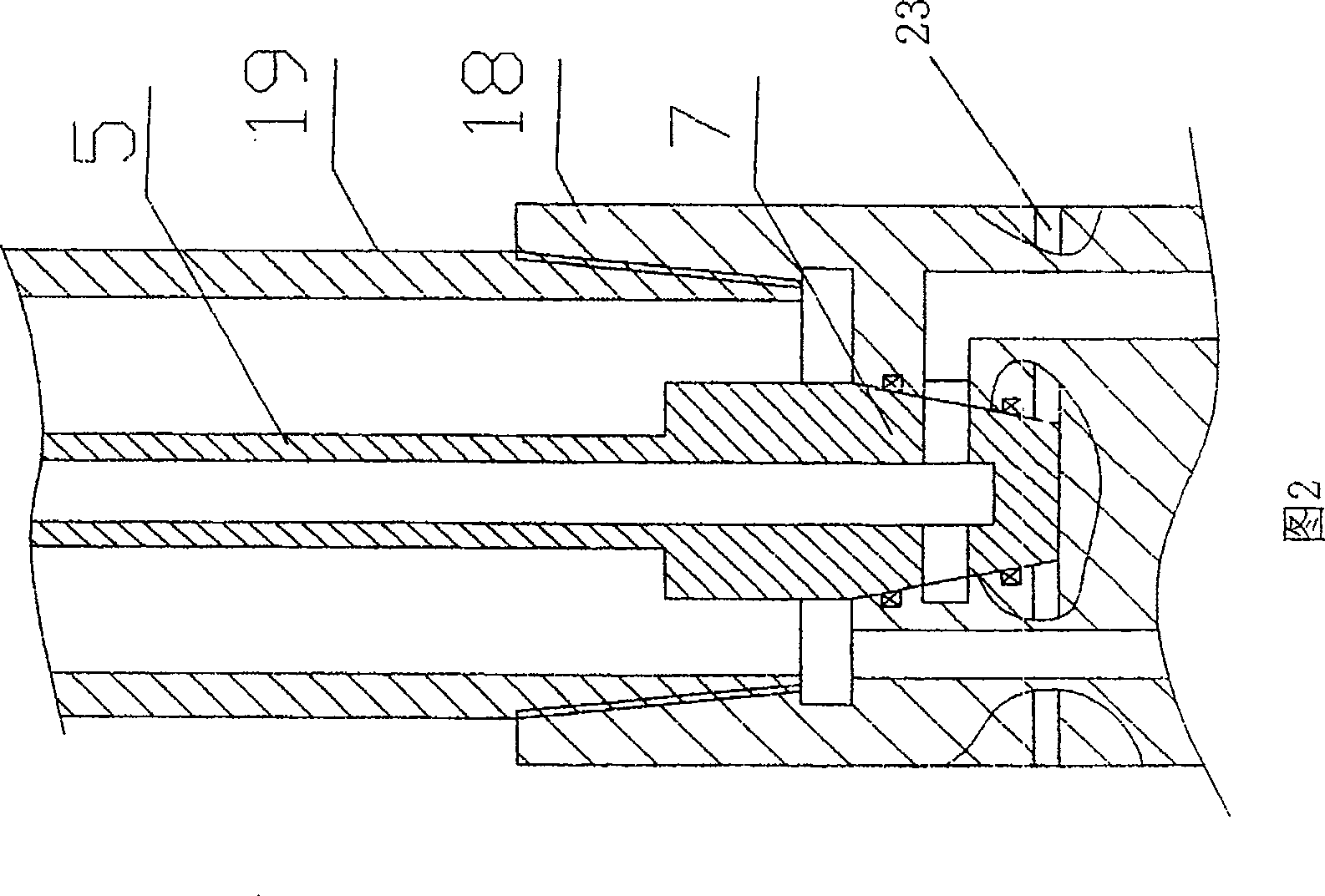

Hydraulic oil production method and device

InactiveCN100497882CReduce wearNo pollutionFlexible member pumpsFluid removalPipe fittingHydraulic pump

The hydraulic oil extraction device comprise a ground hydraulic power for supplying high temperature and high pressure power liquid, a ground heater, a hydraulic power pipe that connects through a hollow oil extracting pole in the oil pipe and a stroke change-over valve nested the piston rod on the dual direction hydraulic pump with the piston rod having pistons at both ends. From bottom to up of the upper pump, there exists an upper pump outlet valve and a bottom pump valve, which connect respectively with the oil pipe and the outlet of the inlet valve of the bottom pump below the bottom pump cavity. Inlet of the upper outlet valve connects with the outlet of the upper pump inlet valve under the bottom pump let valve though pipe fittings. Discharging end of the adynamia hydraulic pipe connects with one of the channel of the stroke change-over valve, and the discharging end connects with the oil pipe through the pump heating tail pipe. When the upper pump discharges oil, the bottom pump absorbs oil or vice versa. This continuous alternating circulation carries the crude oil to the ground, improves the oil extraction efficiency and it applies to all kinds of oils.

Owner:李莉 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com