Sandwich composite external wallboard

A composite exterior wall panel and sandwich technology, which is applied in the direction of climate change adaptation, structural elements, building components, etc., can solve the problems of inability to meet the thermal insulation and energy saving requirements of exterior walls, poor structural stability and seismic performance, and comprehensive cost and cost Advanced problems, to achieve the effect of meeting the requirements of thermal insulation and energy saving, the installation and fixing are firm, and the overall cost of construction is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

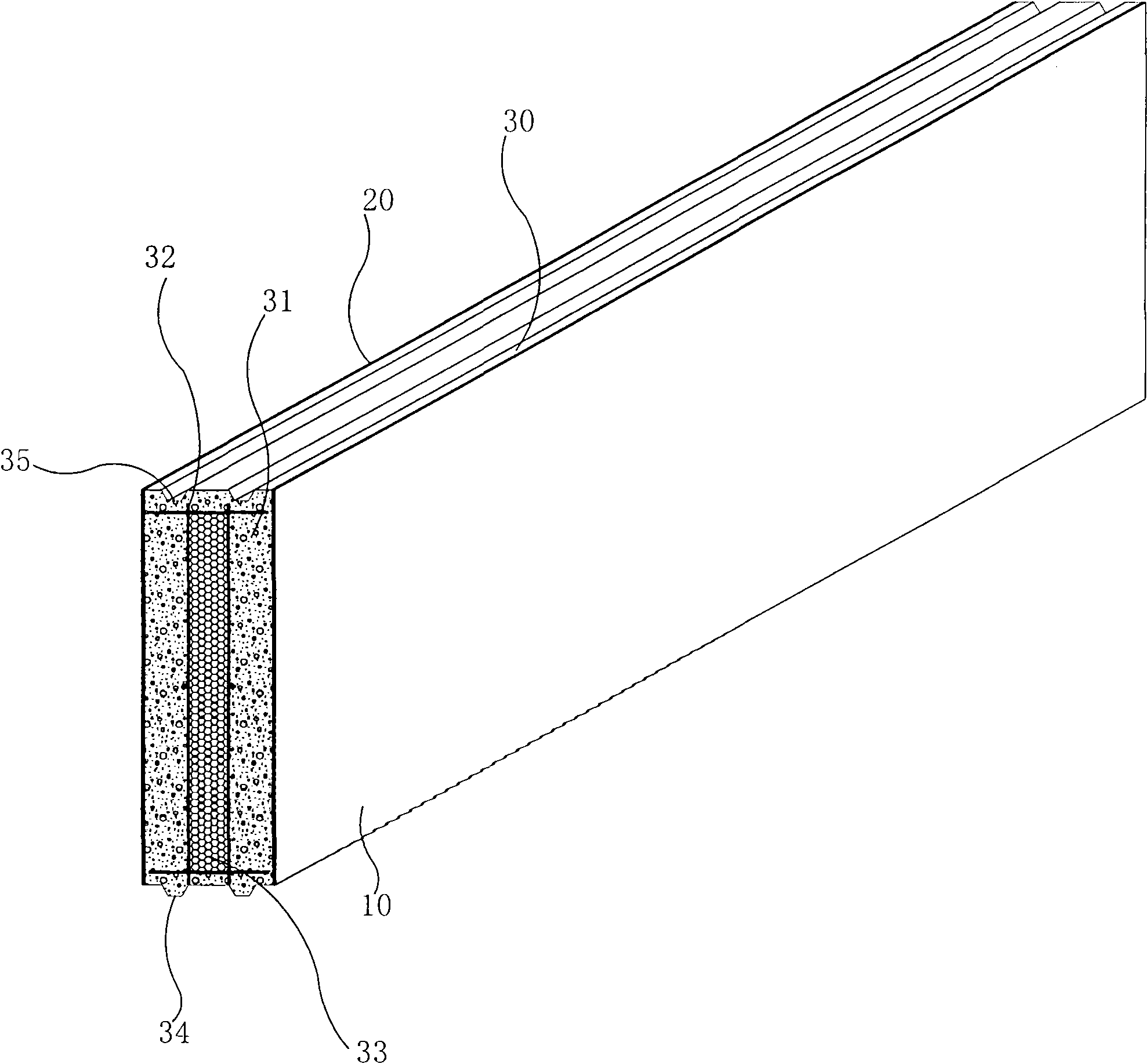

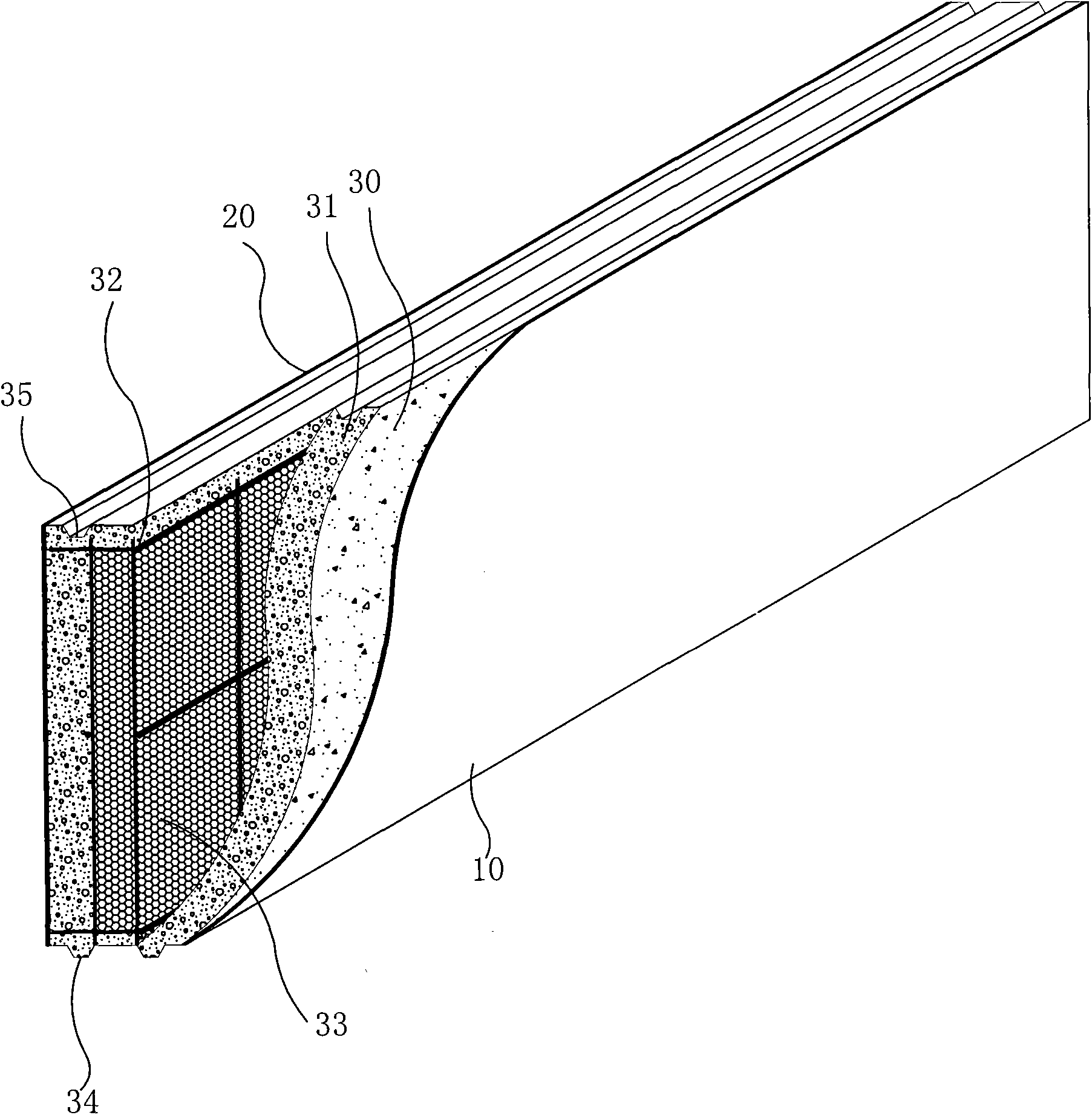

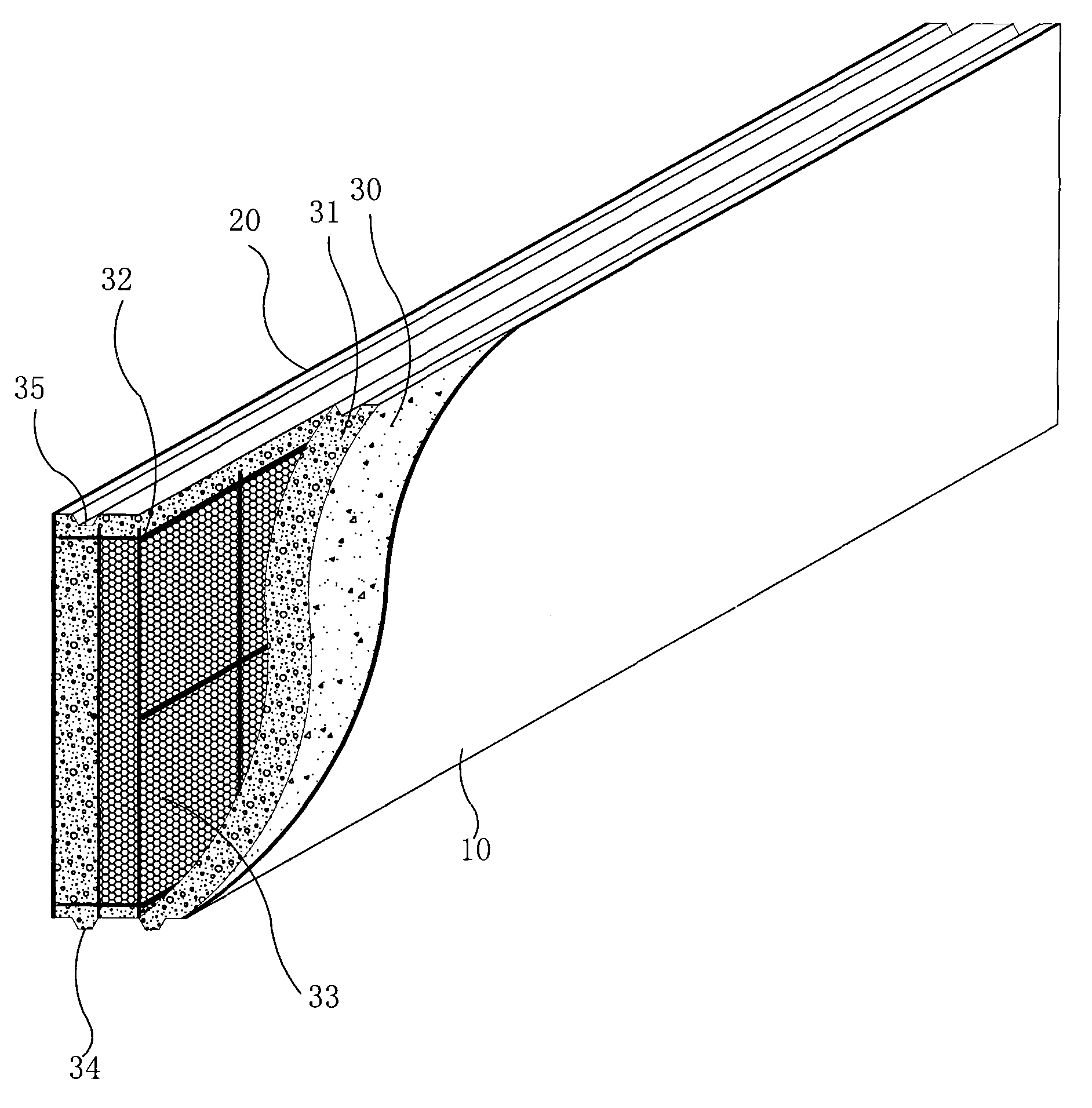

[0021] Such as Figure 1-2 As shown, the sandwich composite exterior wall panel is composed of two side panels 10, 20 and core material layers 30, 31, 32, 33, the sandwich composite exterior wall panel is a cuboid wall panel structure, the side of the exterior wall panel The end faces are provided with interfitting mortise joints, and the tenon joints are respectively located on the long side end faces of the wall panels. The tenon joint is a tenon 34 and a tenon groove 35 , the tenon 34 is a protruding edge with a trapezoidal cross section, and the tenon groove 35 is a trapezoidal groove matched therewith. The specifications and models of the exterior wall panels are: length × width × thickness (1000-3000mm) × (600-610mm) × (150-200mm). A core material layer is filled in the middle of the light aggregate concrete, and the core material layer is a building light aggregate concrete filling structure in which a reinforced mesh 32 is embedded with a polystyrene foam board 33 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com