Intelligent rock drilling device for geological exploration

A technology for rock drilling equipment and geological exploration, which is applied in drilling equipment, drilling equipment and methods, and devices for extracting undisturbed cores, etc. performance and stability, improve work efficiency, and facilitate the effect of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

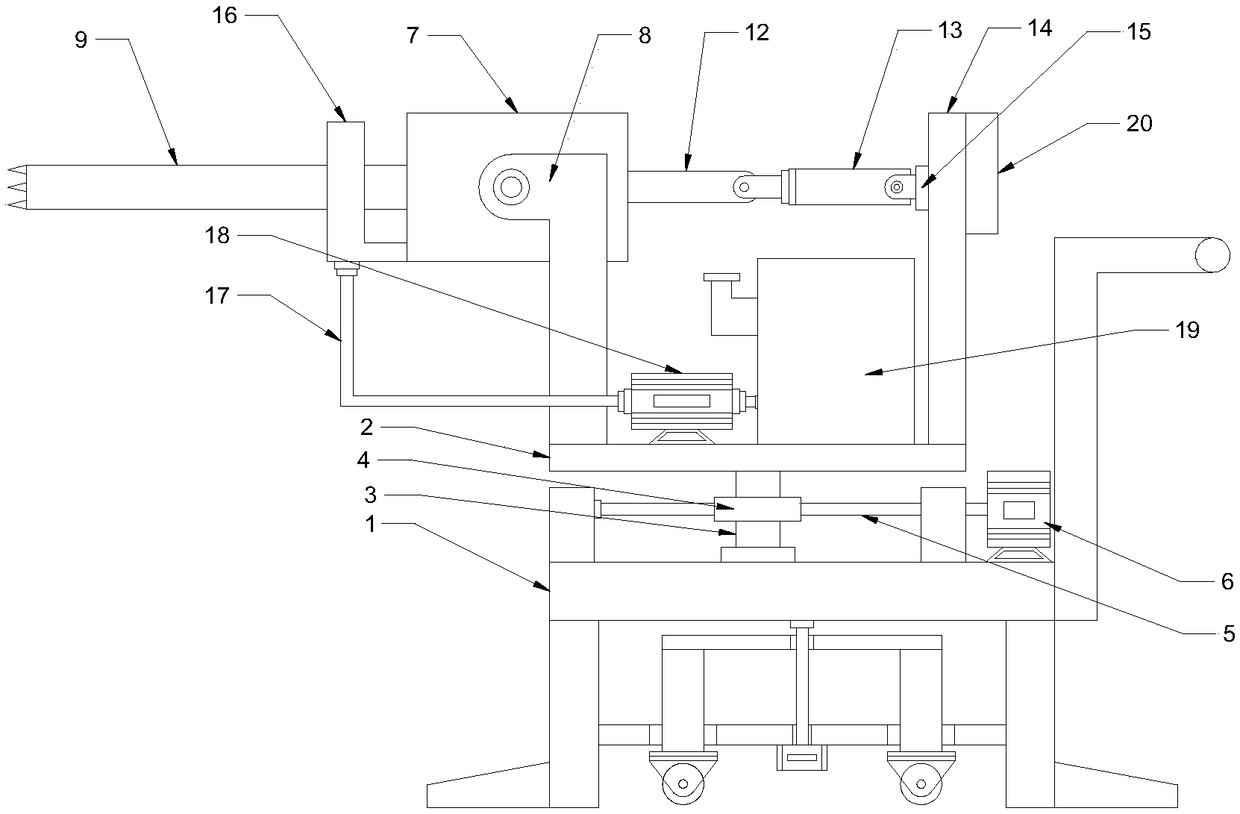

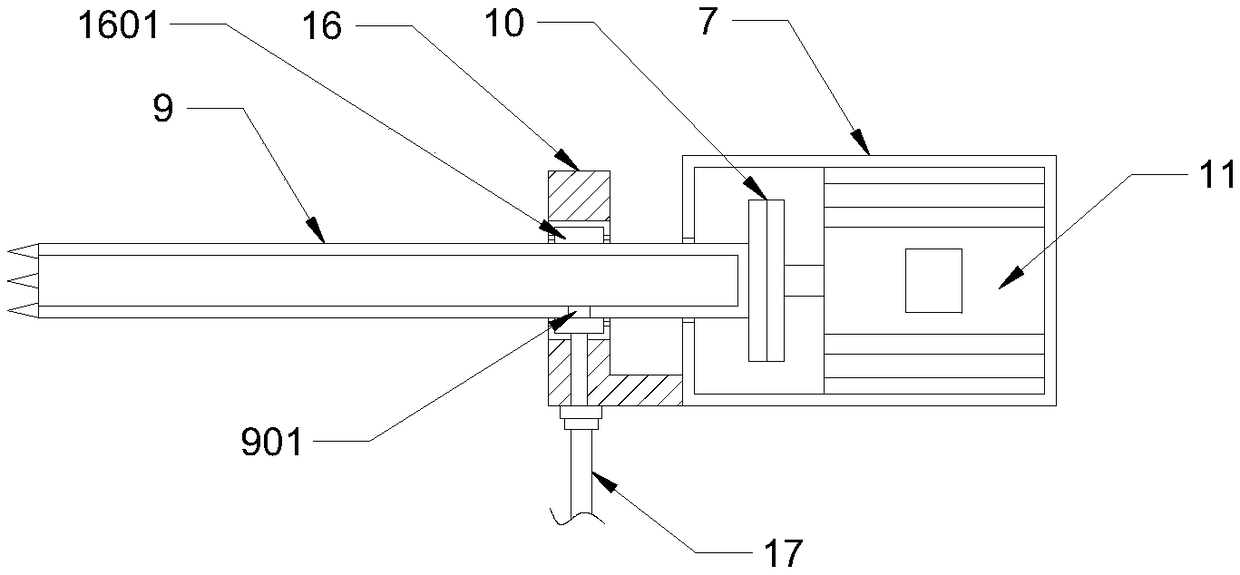

[0020] see Figure 1~2 , in an embodiment of the present invention, an intelligent rock drilling equipment for geological exploration, including a car body 1 and a drilling mechanism; the left side of the car body 1 is provided with a drilling mechanism, and the drilling mechanism includes a coring drill barrel 9 , the coring drill barrel 9 is connected with a drilling motor 11 through a coupling 11, and the drilling motor 11 is electrically connected with an external power supply to drive the core drilling barrel 9 to rotate; the drilling motor 11 is provided with a turret 7, The frame 7 is hinged with a support frame 8, the support frame 8 is fixedly connected with the rotating seat 2, the rear end of the rotating frame 7 is fixedly connected with a hinge plate 12, the hinge plate 12 is hinged with the piston rod of the hydraulic cylinder 13, and the hydraulic cylinder 13 is hinged through the hinge seat 15 Installing plate 14 is arranged, and installing plate 14 is fixedly ...

Embodiment 2

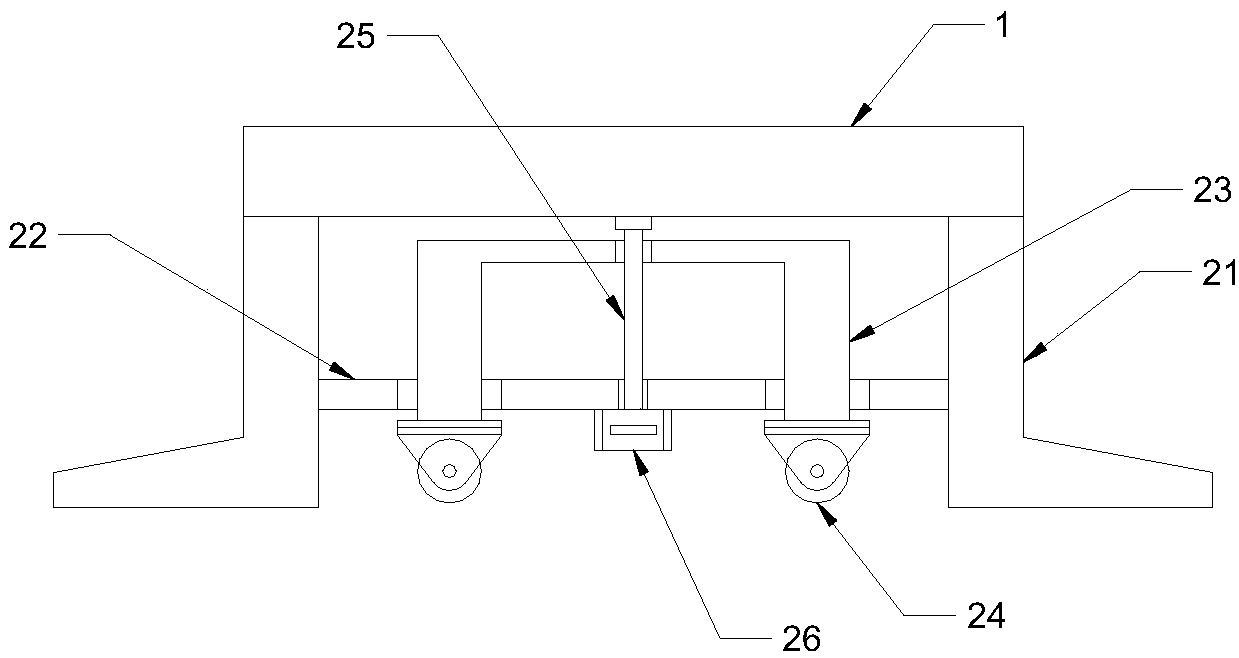

[0025] see figure 1 with image 3 , the difference between this embodiment and Embodiment 1 is that: the lower end of the vehicle body 1 is fixedly connected with support legs 21, between the support legs 21 is fixedly connected with a partition 22, below the partition 22 is provided with a roller 24, and the roller 24 is rotatably connected Wheel frame 23 is arranged, and wheel frame 23 is slidingly connected with support leg 21 inner wall, and wheel frame 23 runs through dividing plate 22, is provided with through hole on dividing plate 22, and wheel frame 23 runs through and is screwed with screw mandrel 25, and screw mandrel 25 is connected with Screw motor 26, screw motor 26 is fixedly connected with partition plate 22 by bolts, screw motor 26 is electrically connected with external power supply, screw motor 26 drives screw rod 25 to rotate, screw rod 25 drives wheel frame 23 and roller 24 to Moving down makes the rollers 24 contact with the ground, which facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com