Hydraulic oil production method and device

A hydraulic and two-way hydraulic pump technology, which is applied in the direction of mining fluid, earthwork drilling, liquid variable capacity machinery, etc., can solve the problems of increasing oil mining costs, short service life, low work efficiency, etc., and reduce equipment investment and operation Low cost, low wear, and the effect of reducing oil production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

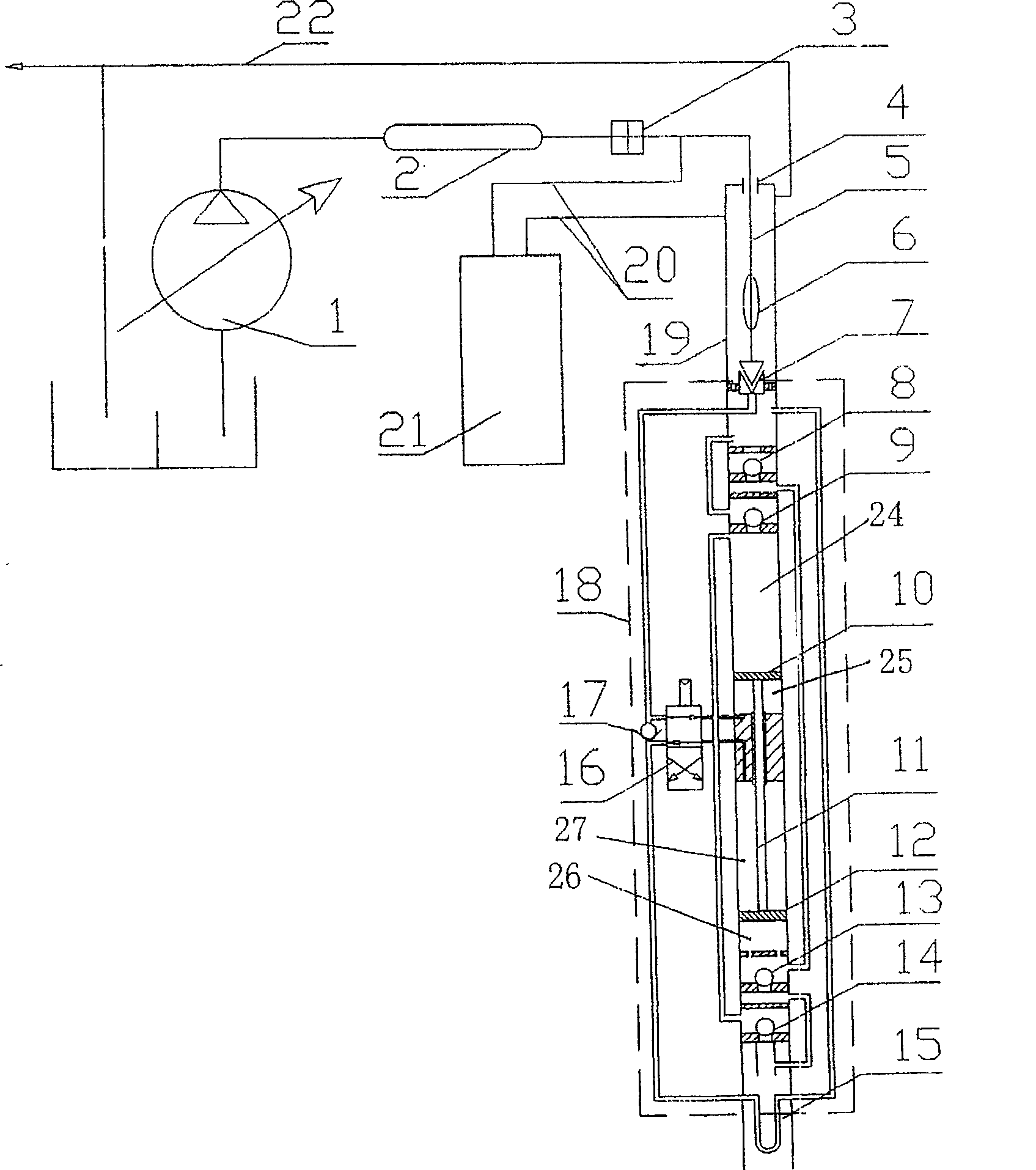

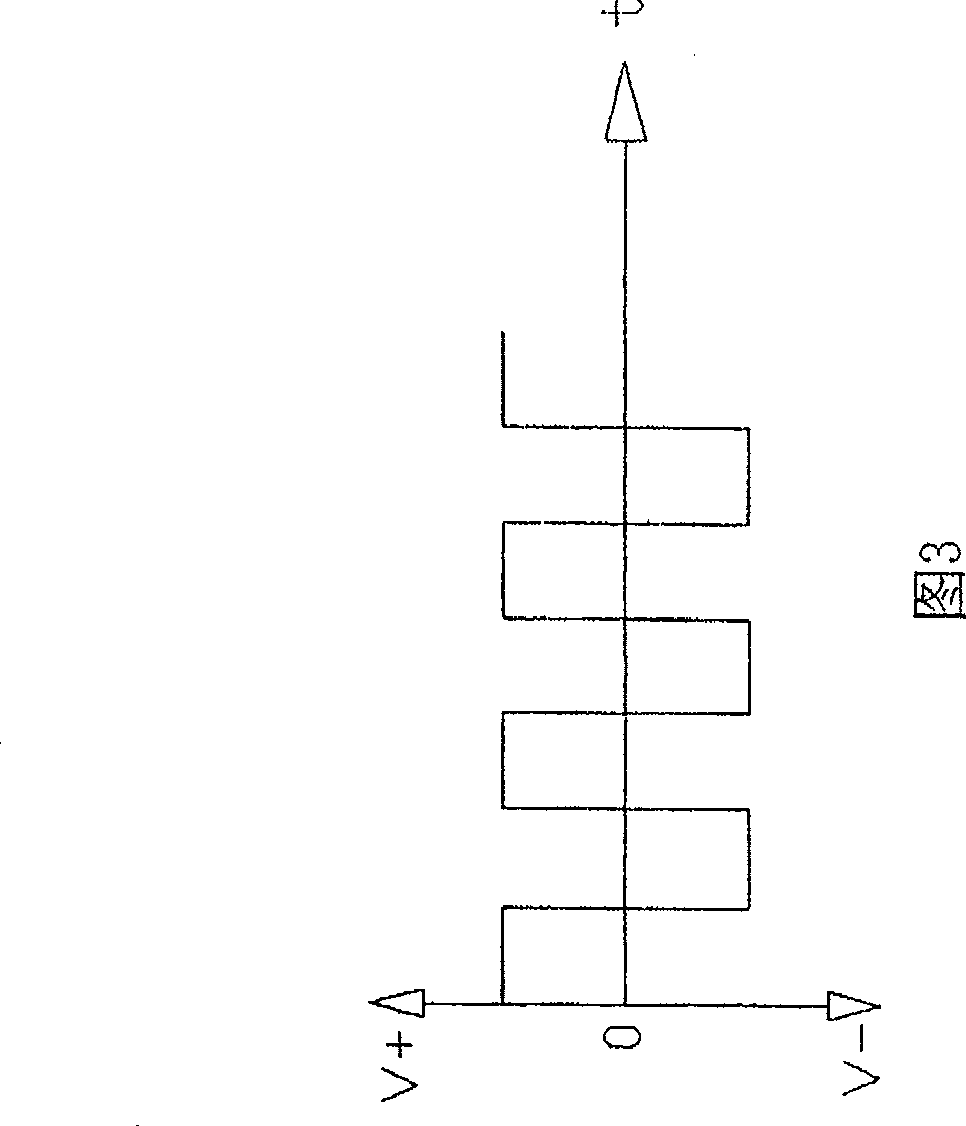

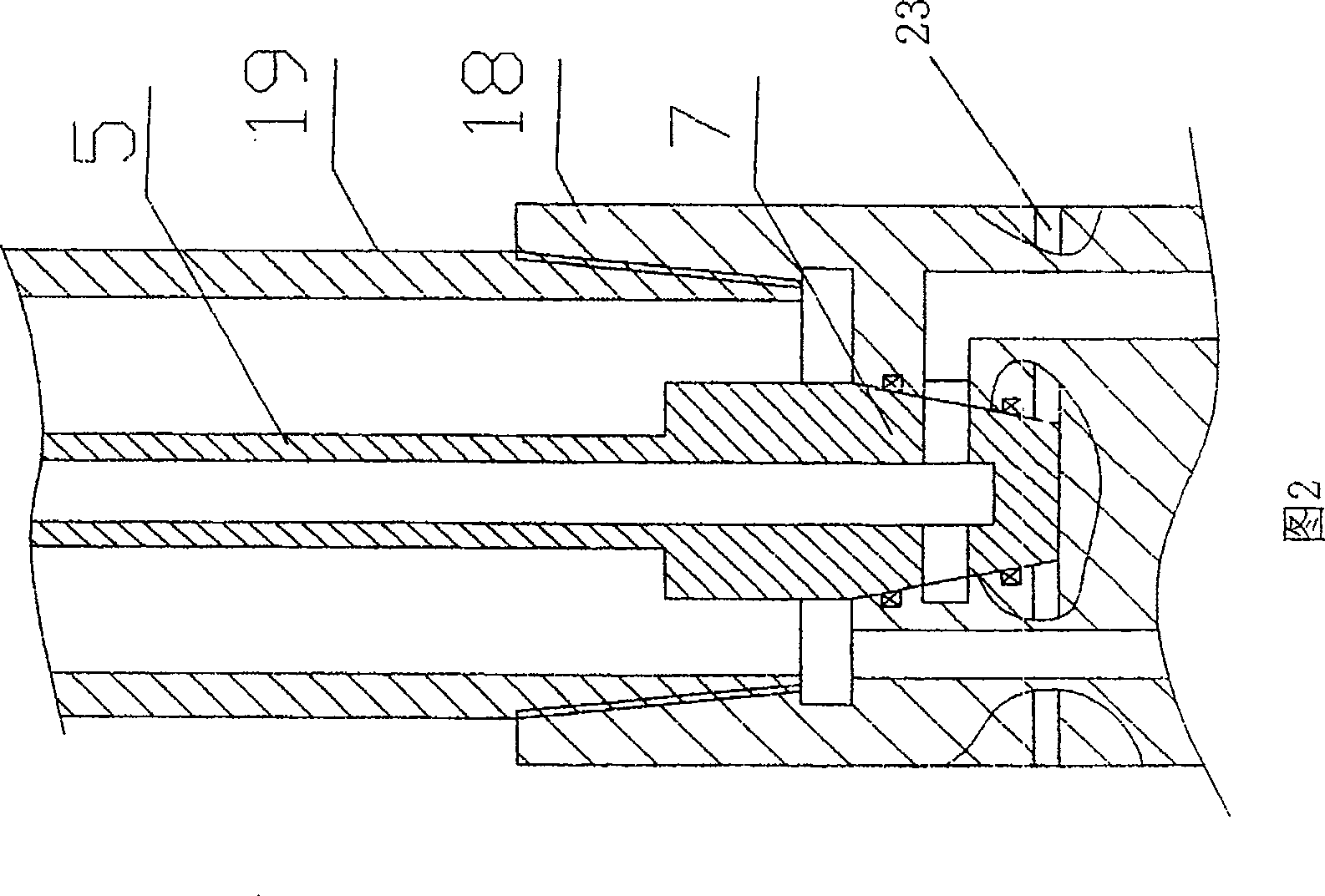

[0023] Embodiments of the present invention are described in detail in conjunction with the accompanying drawings, as figure 1 The surface hydraulic pump 1 shown is connected to the surface heater 2 through the power fluid pipeline, and the output end of the surface heater 2 is connected to the upper end of the hollow sucker rod 5 placed in the oil pipe 19 through the power fluid pipeline, the insulating pipe joint 3 The hollow sucker rod 5 is provided with an insulating centralizer 6, and the lower end is connected with the pump head of the downhole bidirectional hydraulic pump 18 through a frusto-conical hydraulic plug joint 7, as shown in Fig. 2 The two-way hydraulic pump 18 includes a pump cylinder, and a piston rod 11 with an upper piston 10 and a lower piston 12 at both ends is placed in the pump cylinder, and the two-position four-way stroke of switching the liquid channel can be realized according to the stroke positions of the upper and lower pistons 10 and 12 The rev...

Embodiment 2

[0025] No oil well electric heater and corresponding insulating pipe joint 3, insulating sealer 4 and insulating centralizer 6 are provided, and the rest is the same as that of embodiment 1.

[0026] When the present invention is in use, start the surface hydraulic pump 1 to send pressurized high-pressure water or high-pressure crude oil into the surface heater 2 along the pipeline, and the heated fluid medium carries high pressure and high temperature through the insulating pipe joint 3 and the wellhead insulating sealer 4 to enter In the hollow sucker rod 5 in the well column, and enter the upper hydraulic cylinder along the hydraulic joint 7 at the bottom of the hollow sucker rod 5, the power fluid pipeline, and a passage of the stroke reversing valve 16 in the two-way hydraulic pump assembly 18 25 makes it a high-pressure chamber and pushes the upper piston 10 upward, the cavity capacity of the upper pump chamber 24 becomes smaller and the pressure rises, and the crude oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com