Arranging construction method of subway narrow shield well inclined hoisting rail

A construction method and technology for shield tunneling, which are applied in the directions of track, track laying, track maintenance, etc., can solve the problems of not having reserved rail discharge openings, requiring many construction personnel, and poor discharge opening conditions, etc. Safety and stability, solving the effect of increasing welding rail joints, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

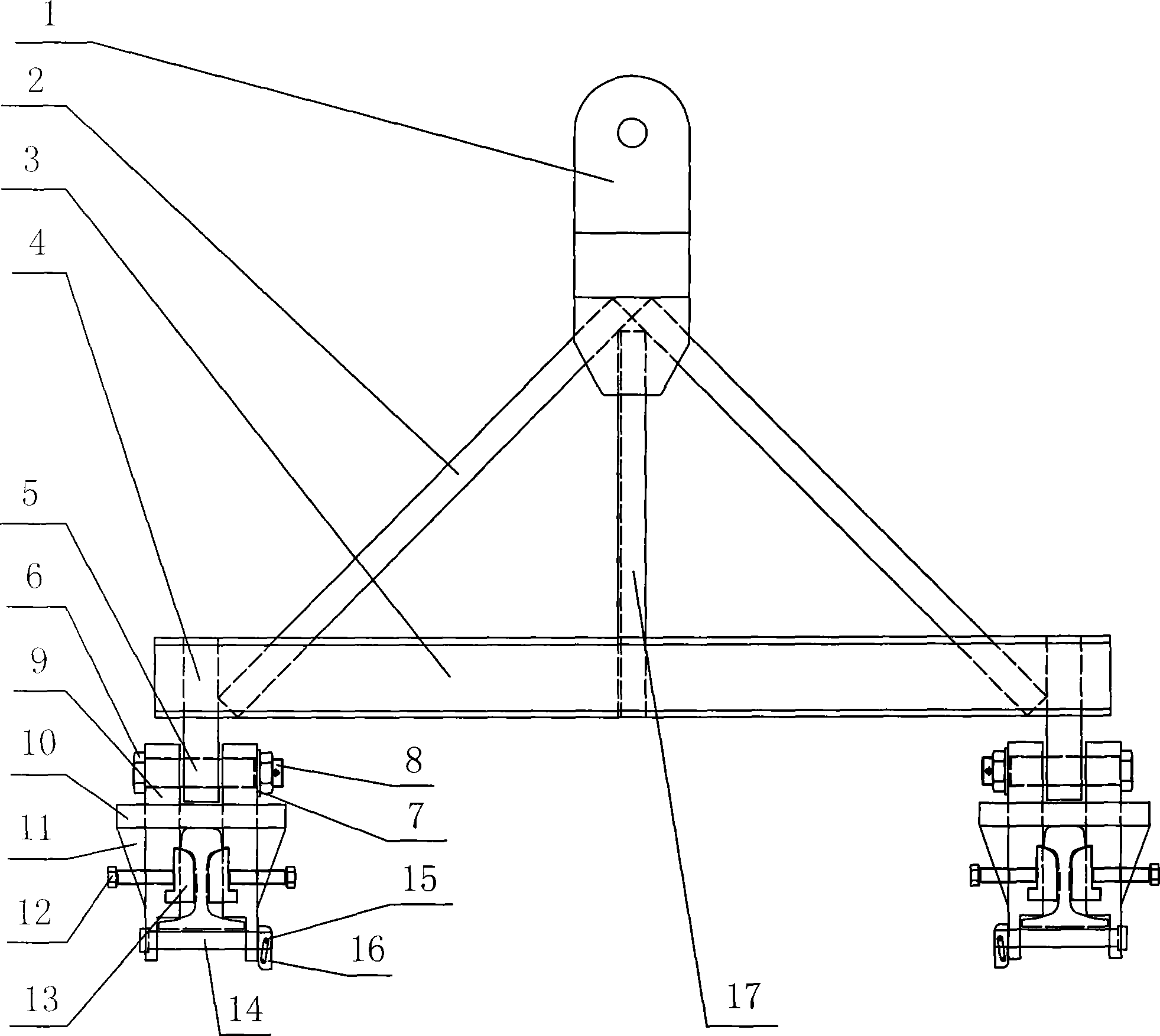

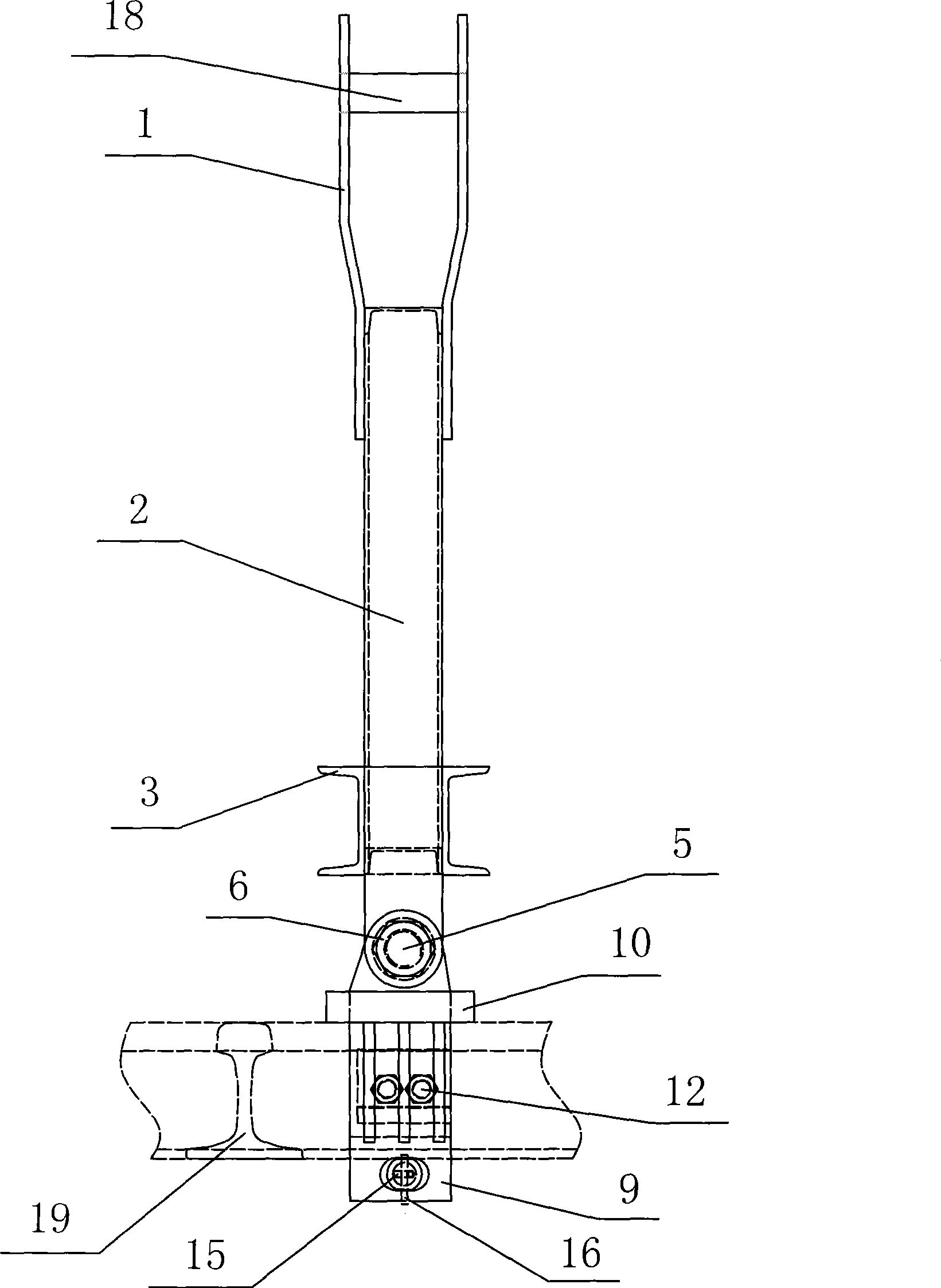

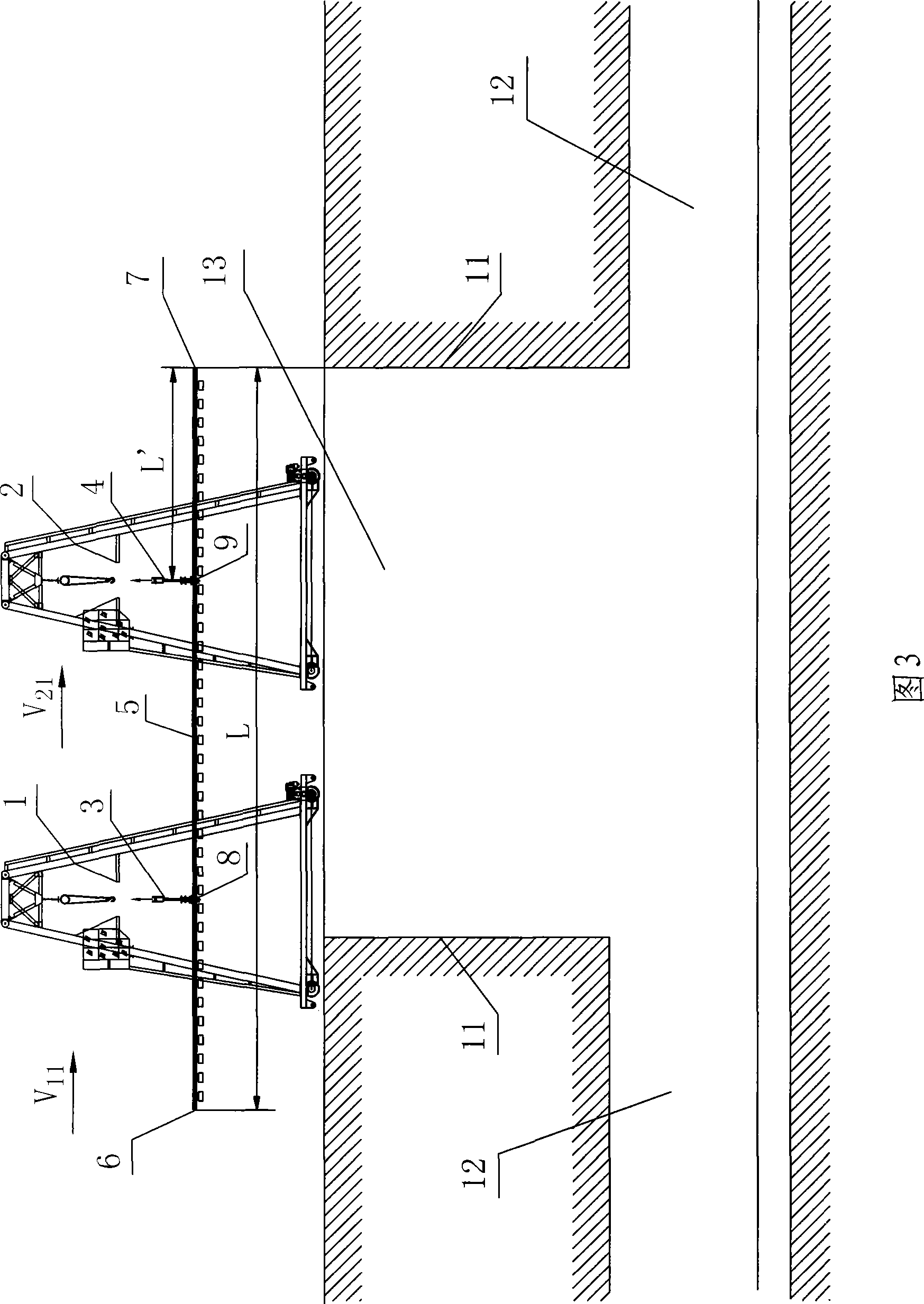

[0048] The present invention relates to a construction method for lifting the rail row in a narrow shield tunnel of a subway under tilt. The rail row 5 is hoisted by two left and right gantry cranes respectively through the rail row hoisting device. For the left-right symmetry of the symmetrical point, the method includes the following steps:

[0049] The first step, as shown in Figure 9, is to verify the width of the feeding port 13 of the selected shield well according to the length L of the lowered suspension rail row 5: the width of the feeding port 13 of the selected shield well L 0 ≥ L - L ′ L L 2 - ( h - h ′ - h ′ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com