CRTS III type plate-type ballastless-track track-board fine-tuning frame

A technology of slab-type ballastless track and track slab, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problem of inability to locate the longitudinal position of the track slab, and achieve the effect of convenient construction and small appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

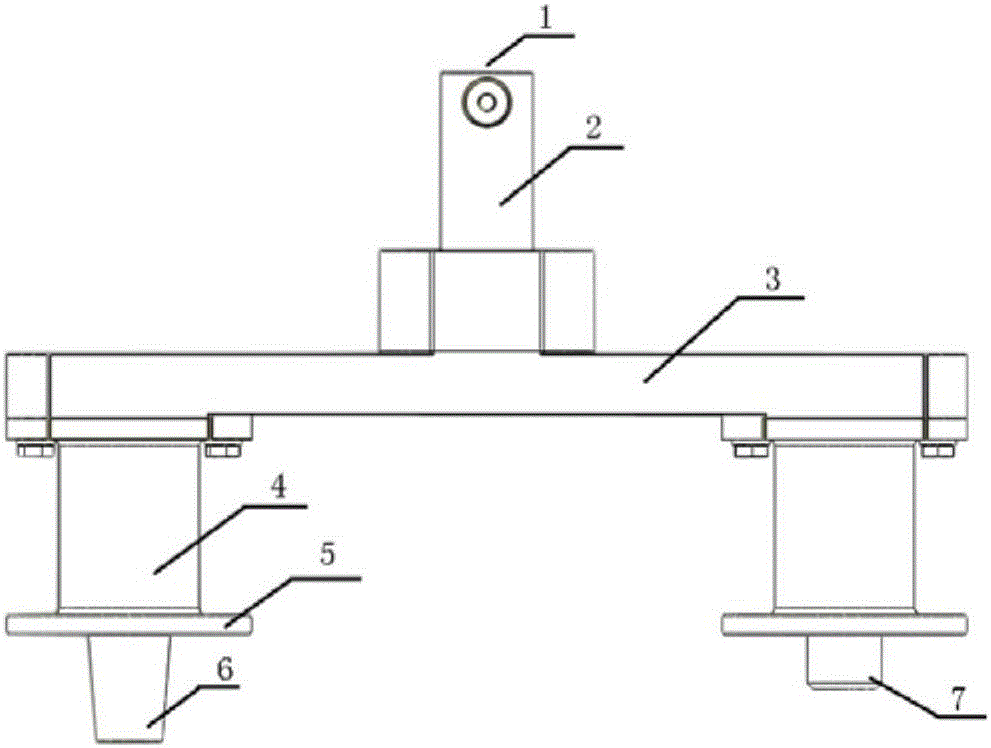

[0008] Such as figure 1 As shown, the present invention is a CRTSⅢ plate-type ballastless track track slab fine-tuning frame. A prism column 2 is arranged on the fine-tuning frame. A prism hole is opened in the center of the top of the prism column 2 for placing miniature prisms. . There is a crossbeam 3 under the prism column 2, and two cylindrical bases 4 are connected under the beam 3. The vertical axes of the two bases 4 and the prism column 2 are on the same straight line, and the axis of the prism column 2 is located at the axis of the two bases 4. on the connection center. One base 4 is a disc 5, and the disc 5 is a bolt hole tapered positioning pin 6, which is scalable, but the center of the circle is always consistent with the center of the disc 5; the other base 4 is a disc 5, and the disc 5 The following is the fixed positioning pin 7.

[0009] When in use, the prism hole is equipped with a miniature prism, the movable conical positioning pin is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com