Seabed optical cable branch joint box and connection process thereof

A joint box and branch technology, which is applied in the field of submarine optical cable branch joint box and its connection technology, can solve the problems of waste of resources and laying costs, and achieve the effect of ensuring strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

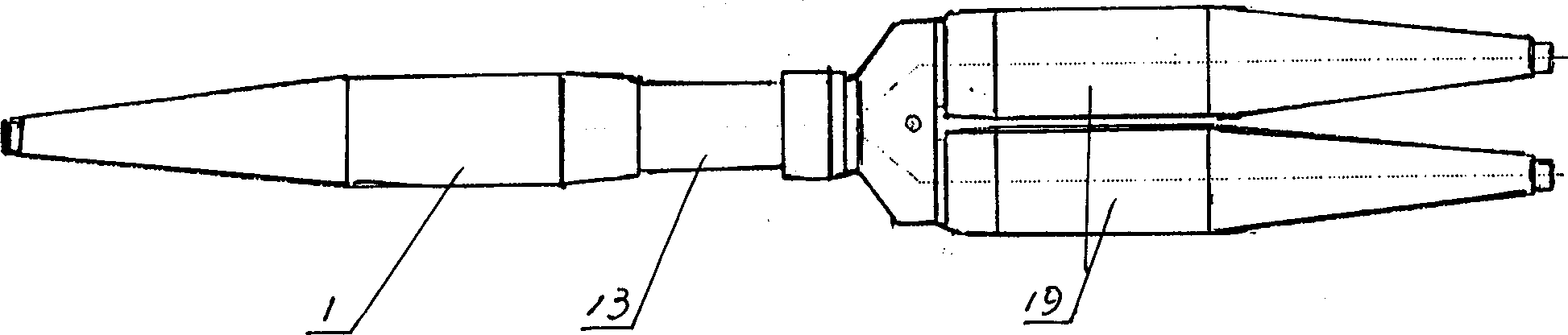

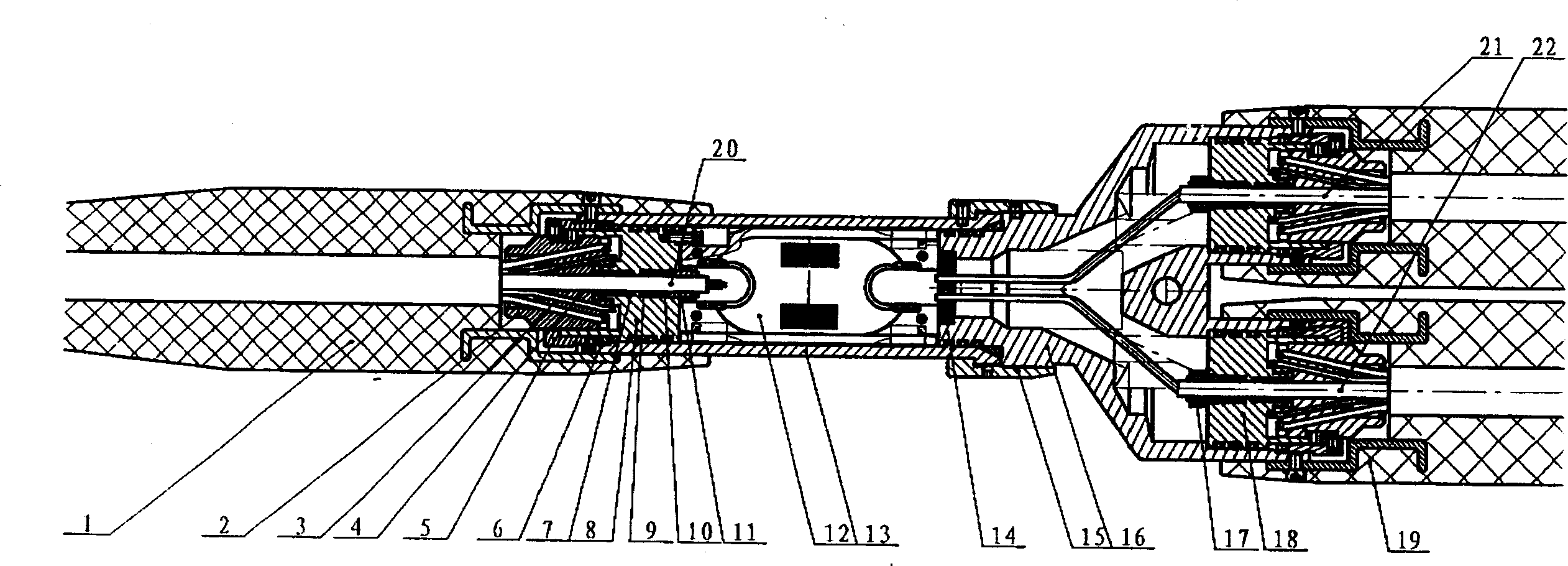

[0021] Refer to attached figure 1 , 2 , the submarine cable branch joint box structure includes the main cable bending limiter (1), the outer cone (2), the middle cone (3), the cone shaft (4), the bearing nut (5), the push sleeve (6), "O" ring bushing (7), sealing seat (8), support ring (9), pressure ring (10), locking shaft (11), tray (12), sealing cylinder (13), branch Splitter sleeve (14), bearing nut of branch seat (15), branch seat (16), lock nut (17), branch sealing seat (18), branch bending limiter (19), main cable (20 ), branch 1 (21), branch 1 (22).

[0022] The submarine cable branch joint box is connected as follows:

[0023] The tray (12) is connected in the middle of the sealing seat (8) and the branch seat (16) through the positioning shaft; the outer cone (2), the middle cone (3) and the cone shaft (4) form a three-piece fixture, It is connected with the sealing seat body (8) and the branch sealing seat (18); the sealing cylinder body (13) is set on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com