Anti-theft lock core and unlocking method

An anti-theft lock cylinder and unlocking technology, which is used in building locks, non-mechanical transmission-operated locks, time registers, etc., can solve problems such as failure to unlock normally, large driving motor current, vibration, weak strong magnetic protection, etc., to avoid Poor anti-theft ability, stable unlocking cam, avoid excessive bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

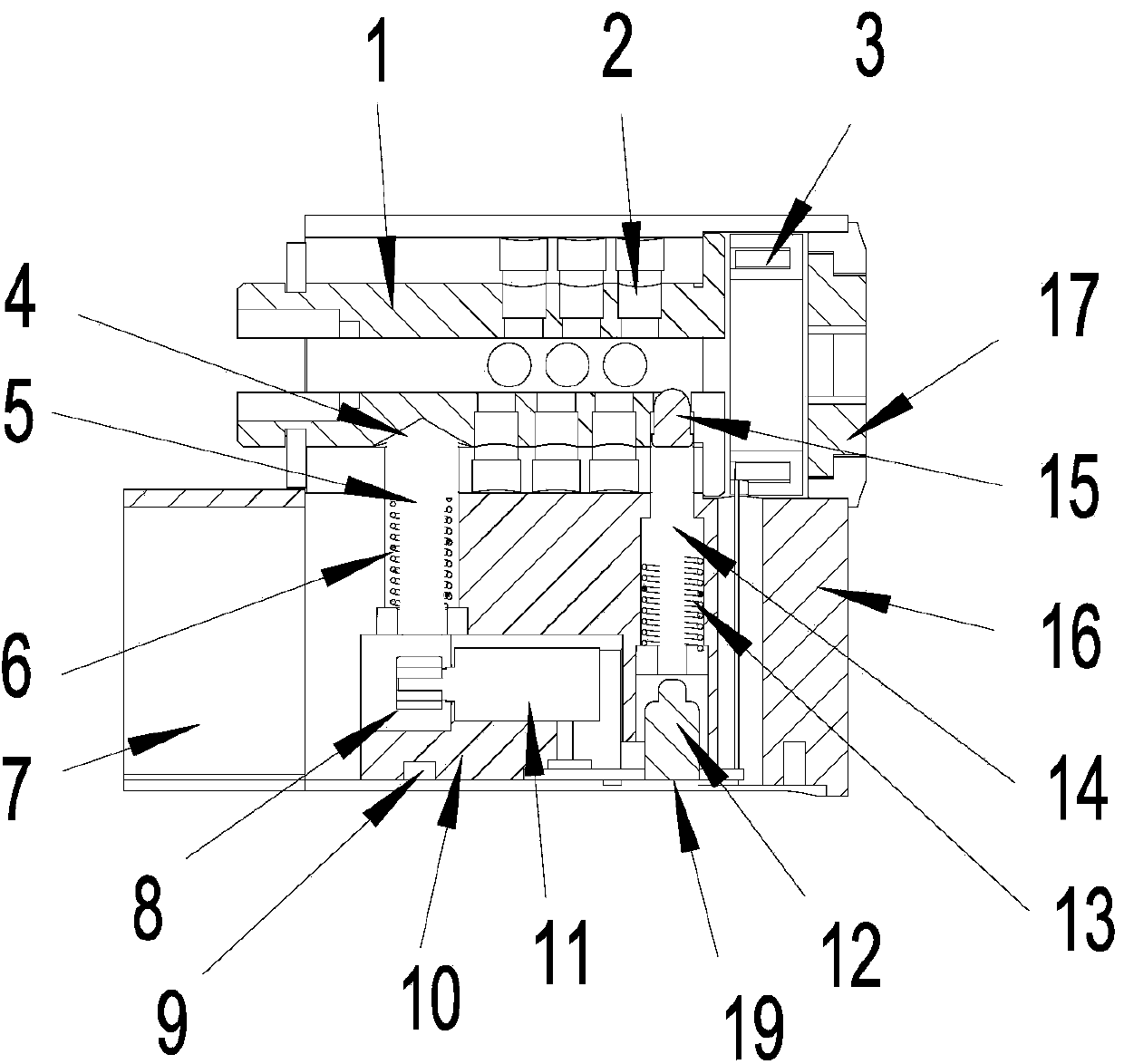

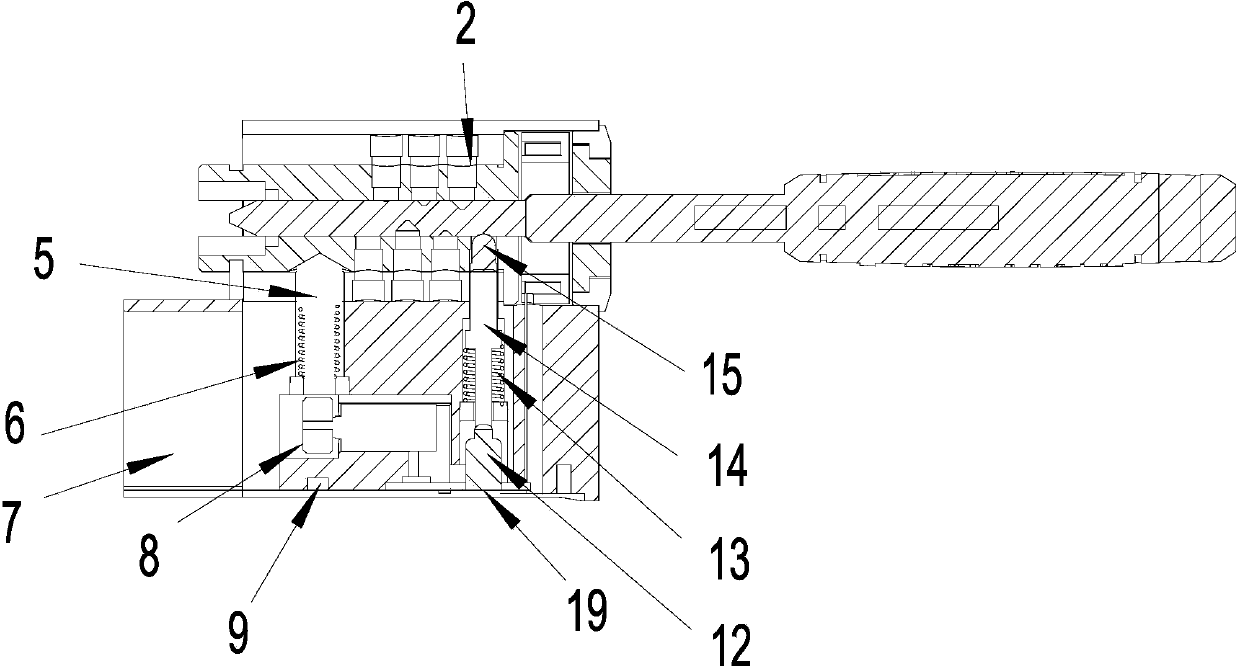

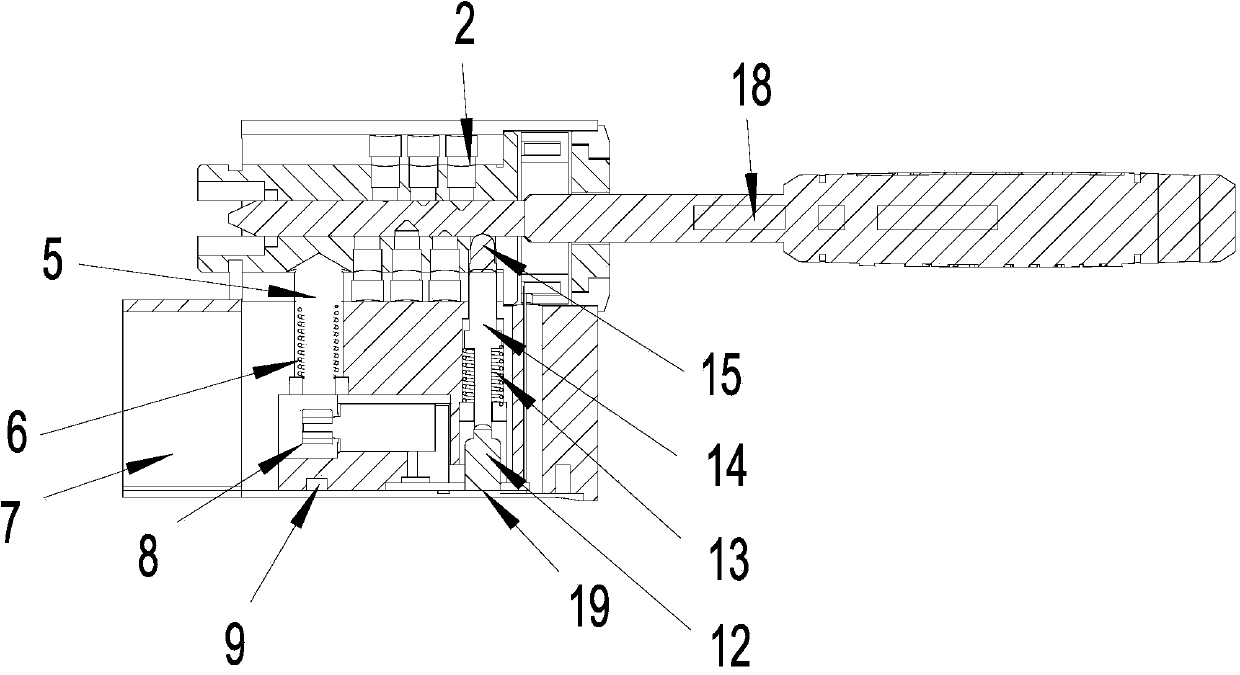

[0025] Such as figure 1 As shown in the anti-theft lock cylinder of the present invention, an unlocking motor 11 and an electrical compartment 7 are provided in the lock cylinder housing 16, and a lock cylinder 1, a mechanical pin 2 and an induction coil 3 are also provided, and a lockhole is also provided at the entrance of the lockhole Cover 17, in order to protect keyhole. A trigger pin 15 is provided near the entrance of the lock hole in the lock core shell 16 , and a part of the trigger pin 15 is located in the lock hole in the lock cylinder 1 . When an object is inserted into the lockhole, the inserted object will press the trigger pin 15, and the trigger pin 15 will make the trigger lever 14 provided with the trigger lever spring 13 contact with the contact 12 connected to the circuit board 19 according to the pressure of the inserted object. After the object exits the keyhole, the trigger pin 15 loses pressure, and the trigger lever 14 resets under the action of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com