Soft foundation reinforcement treatment method of vacuum preloading combined with dredging and filling mud

A soft foundation treatment and soft foundation reinforcement technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of low consolidation degree of dredging fill soil layer, construction operations, low shear strength, etc., and achieve drainage Good consolidation effect, ensure the overall stability, and speed up the effect of consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

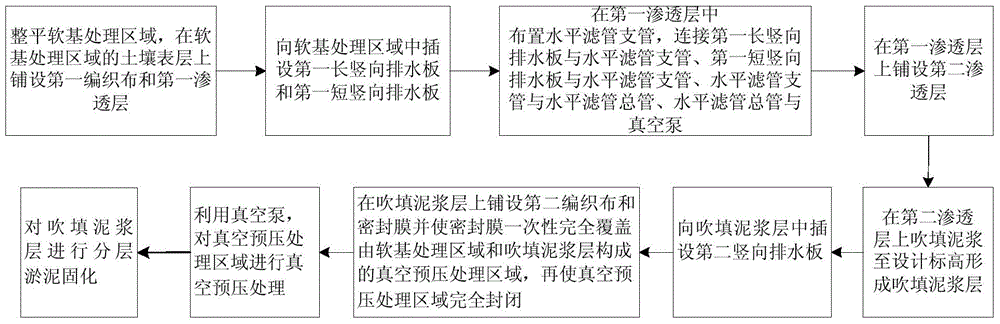

[0036] The present invention proposes a soft foundation reinforcement treatment method combined with vacuum preloading and dredging mud, and its overall realization block diagram is as follows figure 1 As shown, it includes the following steps:

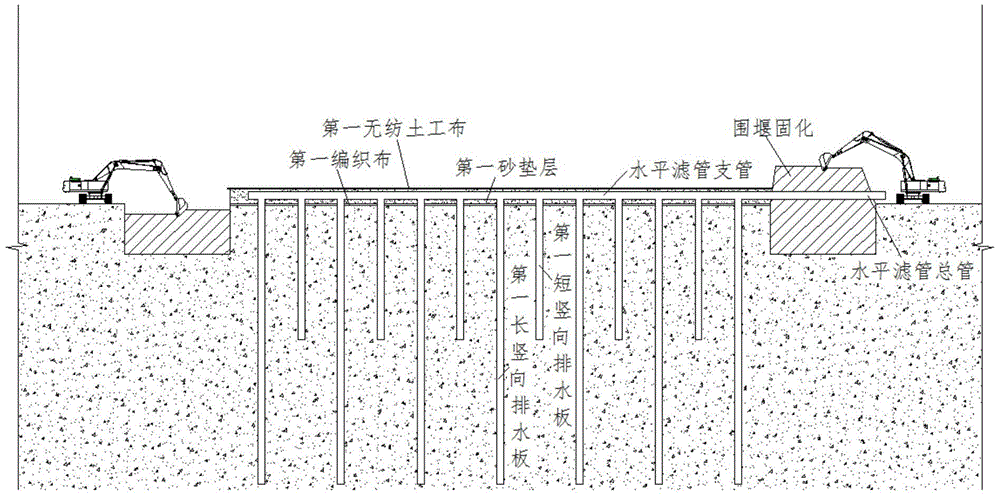

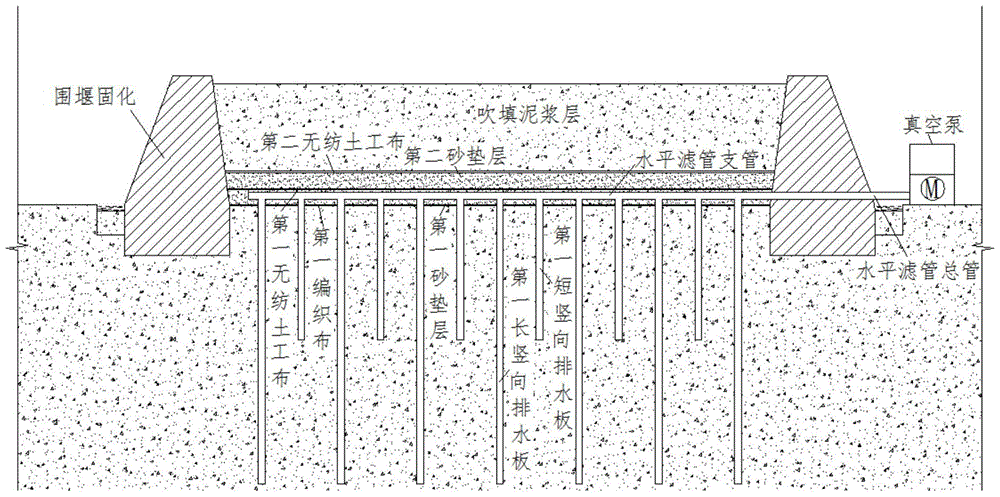

[0037] ①Level the soft foundation treatment area, and then lay a layer of first woven cloth on the soil surface of the soft foundation treatment area, and then lay a layer of sand on the first woven cloth to form the first sand cushion, and then lay a layer of sand on the first sand The cushion layer is covered with a layer of first non-woven geotextile, and the first permeable layer is composed of the first sand cushion layer and the first non-woven geotextile.

[0038] Here, the purpose of leveling the soft foundation treatment area is to ensure that the self-weight stress of the subsequent dredgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com