Non-bracket closure method for upper cross beam of steel tower and construction system

A technology without brackets and beams, used in bridges, bridge construction, bridge forms, etc., can solve the problems of increasing steel consumption, increasing construction costs, and occupying a large space, saving construction costs, facilitating construction operations, and occupying less space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

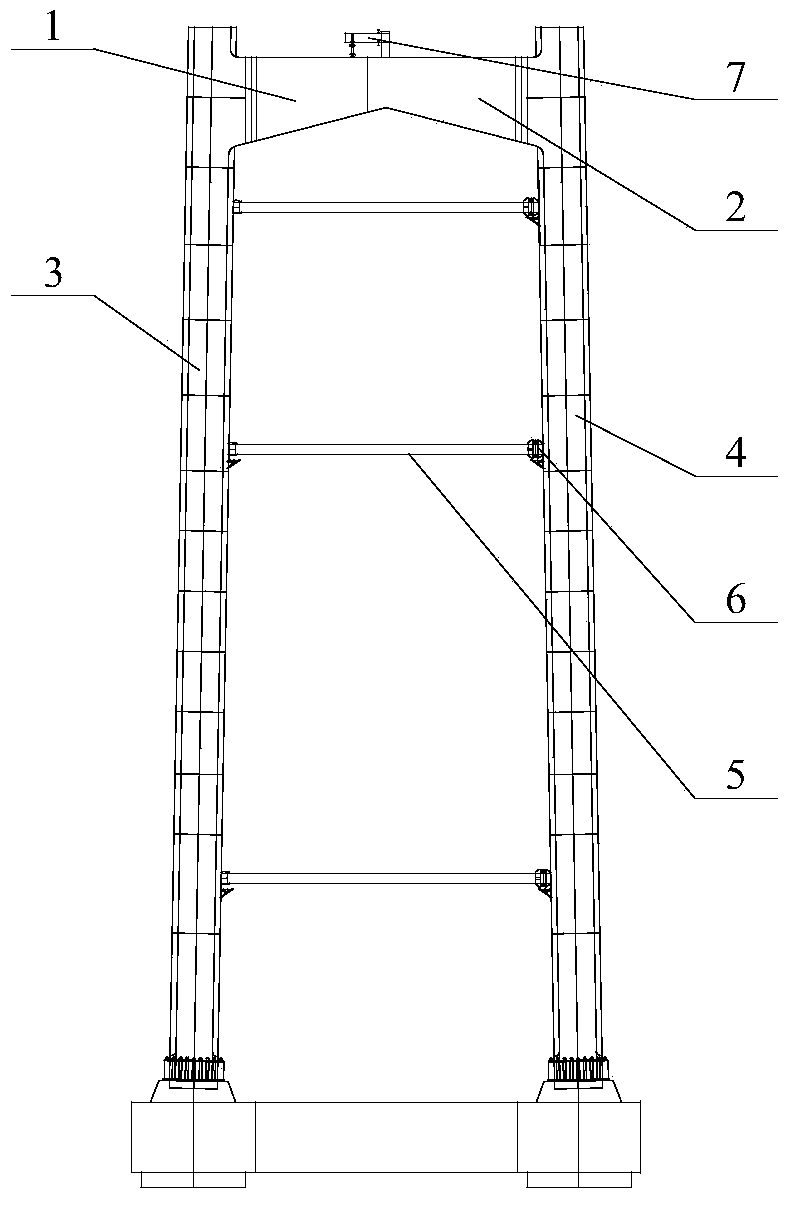

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the method for closing the upper beam of a steel tower without support provided by the present invention, the upper beam includes a left upper beam 1 and a right upper beam 2 that are hoisted and spliced together, and includes the following steps,

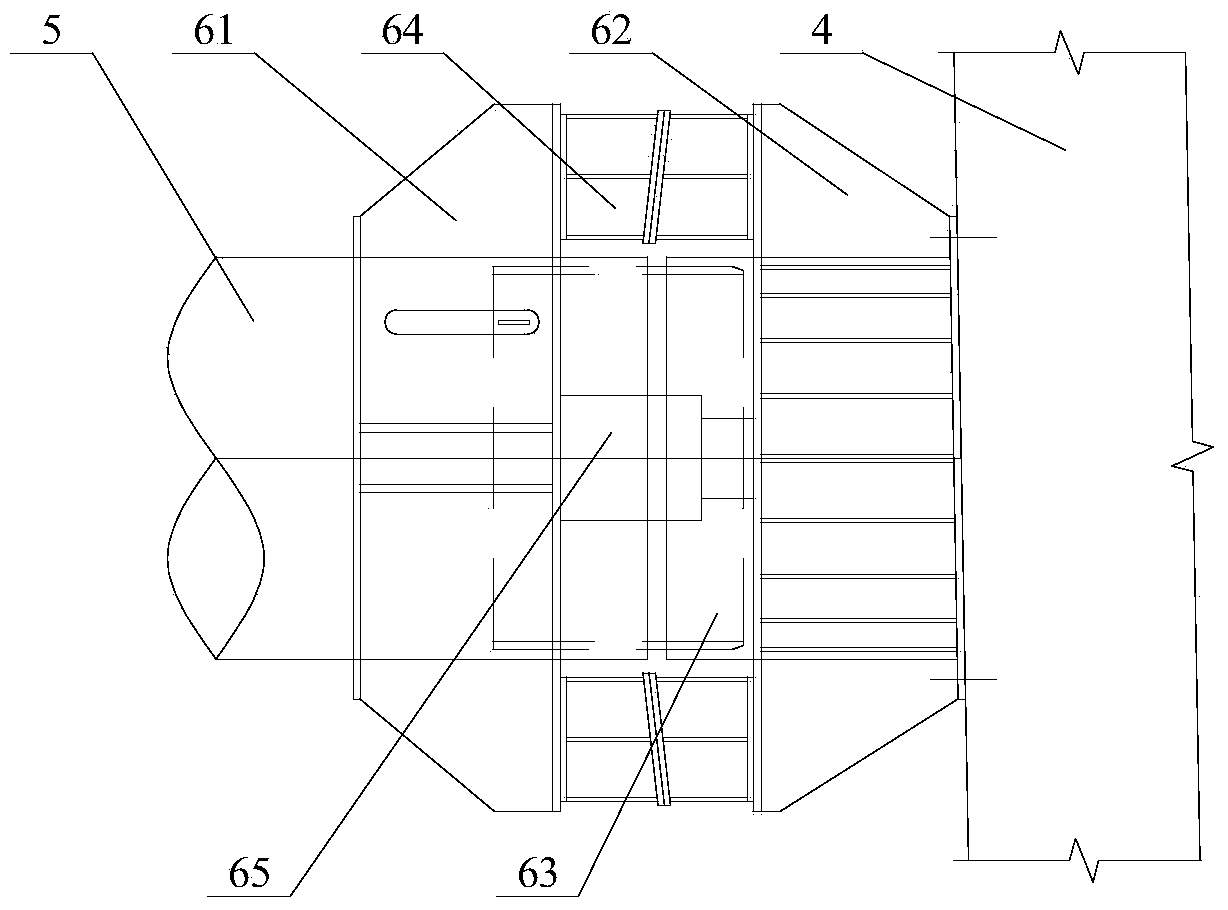

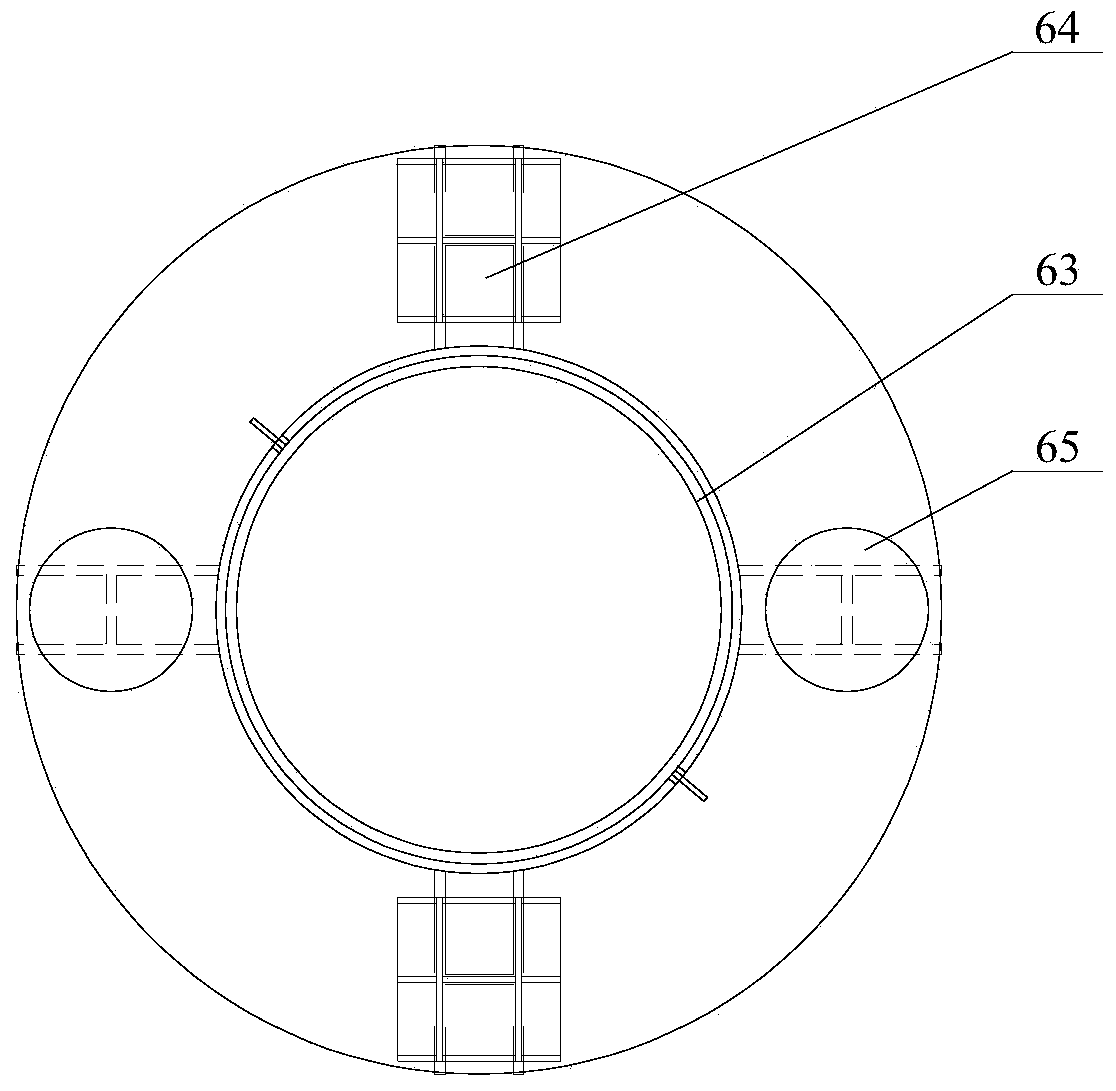

[0020] Step 1. Between the left and right steel tower columns 3 and 4 of the steel tower, three active cross braces 5 are arranged horizontally from top to bottom. One end of the active cross brace 5 is fixed on the inner surface of the left steel tower column 3, and the other end The active cross brace joint 6 is fixed on the inner side of the right steel tower column 4. The active cross brace joint 6 includes left and right pedestals 61, 62 and lining connecting pipe 63, and the other end of the active cross brace 5 passes through to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com