Central loose tube optical cable

A bundled tube, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of inconvenient optical cable laying, no steel-plastic composite layer, heavy weight, etc., to achieve superior bending resistance, lateral pressure resistance, ballistic resistance, and convenient construction. Work, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

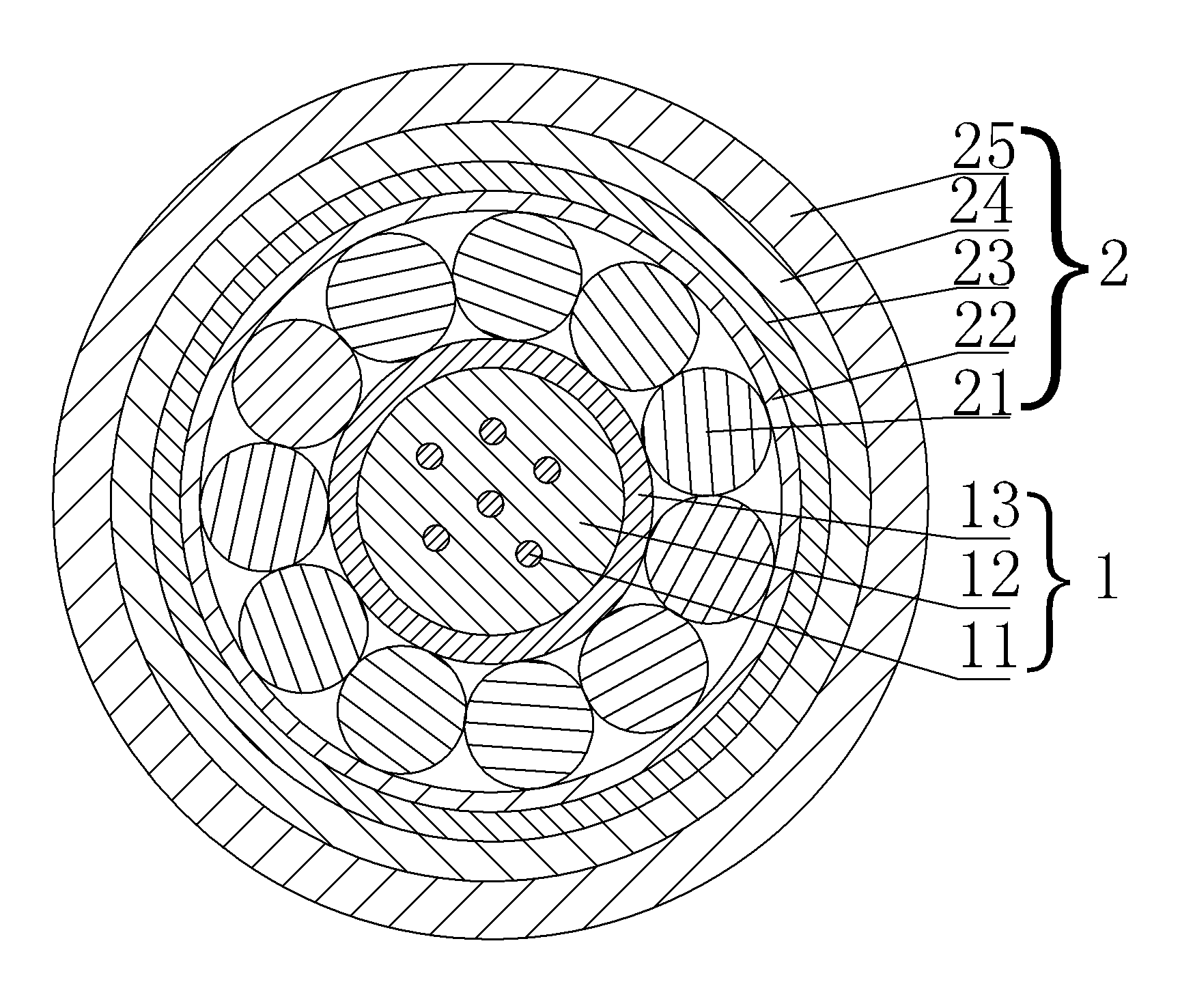

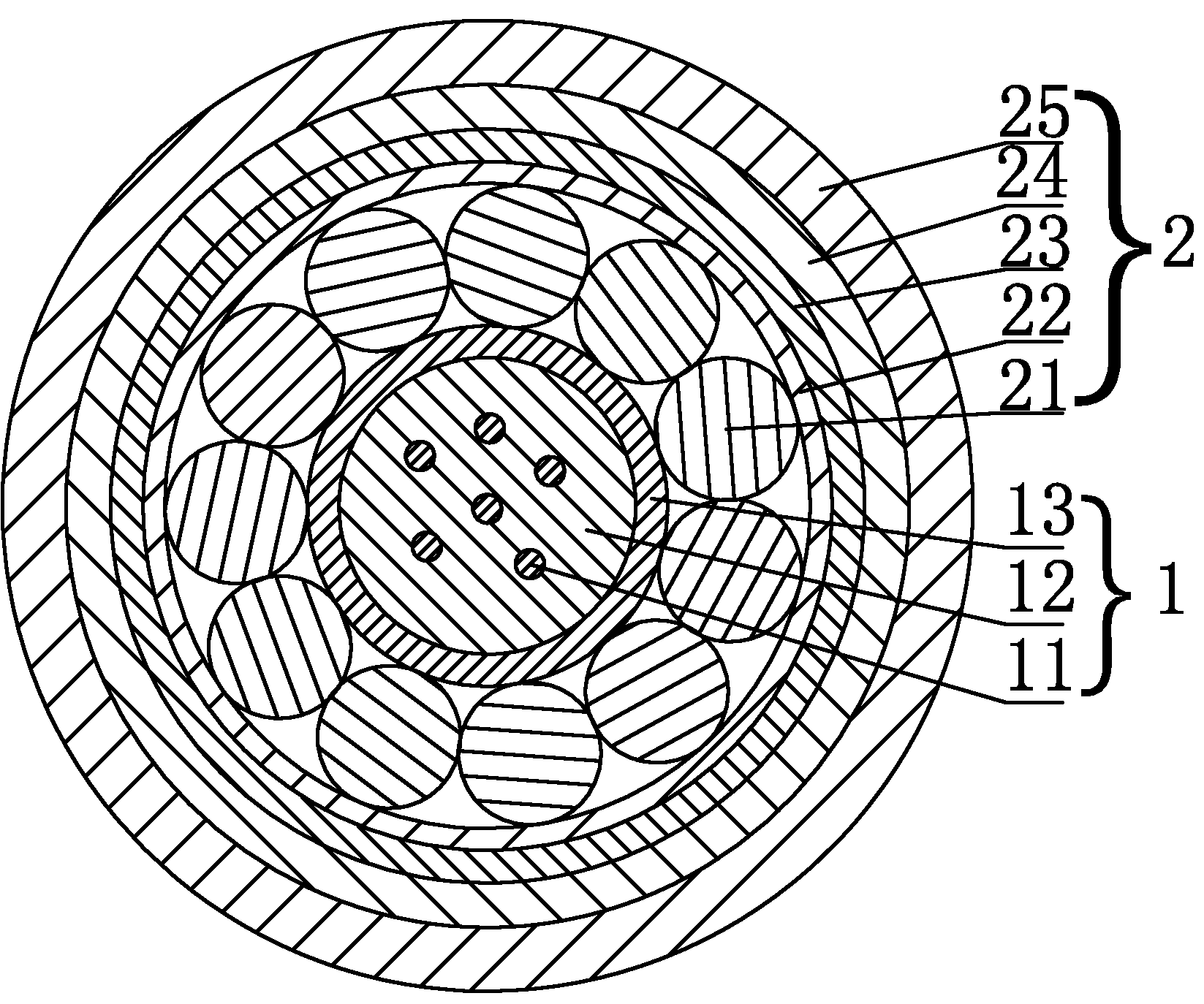

[0017] like figure 1 As shown, the central bundle tube optical cable is composed of a cable core 1 and a sheath 2 covering the outer periphery of the cable core 1 and extending along the axis of the cable core.

[0018] In this embodiment, the cable core 1 is composed of six optical fibers 11 , a loose tube 13 wrapped around the six optical fibers 11 , and fiber paste 12 filled between the loose tube 13 and the six optical fibers 11 . The loose tube 13 is made of PBT plastic with excellent linear expansion; the fiber paste 12 can not only buffer the optical fiber from mechanical external force, but also prevent water, moisture, etc. from entering the optical fiber and causing the optical fiber to be damaged. In order to achieve the purpose of vertical water blocking.

[0019] In this embodiment, the sheath 2 is composed of eleven steel wires 21 twisted and arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com