Electromagnetic-wave-shielding adhesive film, process for producing the same, and method of shielding adherend from electromagnetic wave

A technology for bonding films and conductive adhesives, used in conductive adhesives, magnetic field/electric field shielding, adhesive types, etc. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

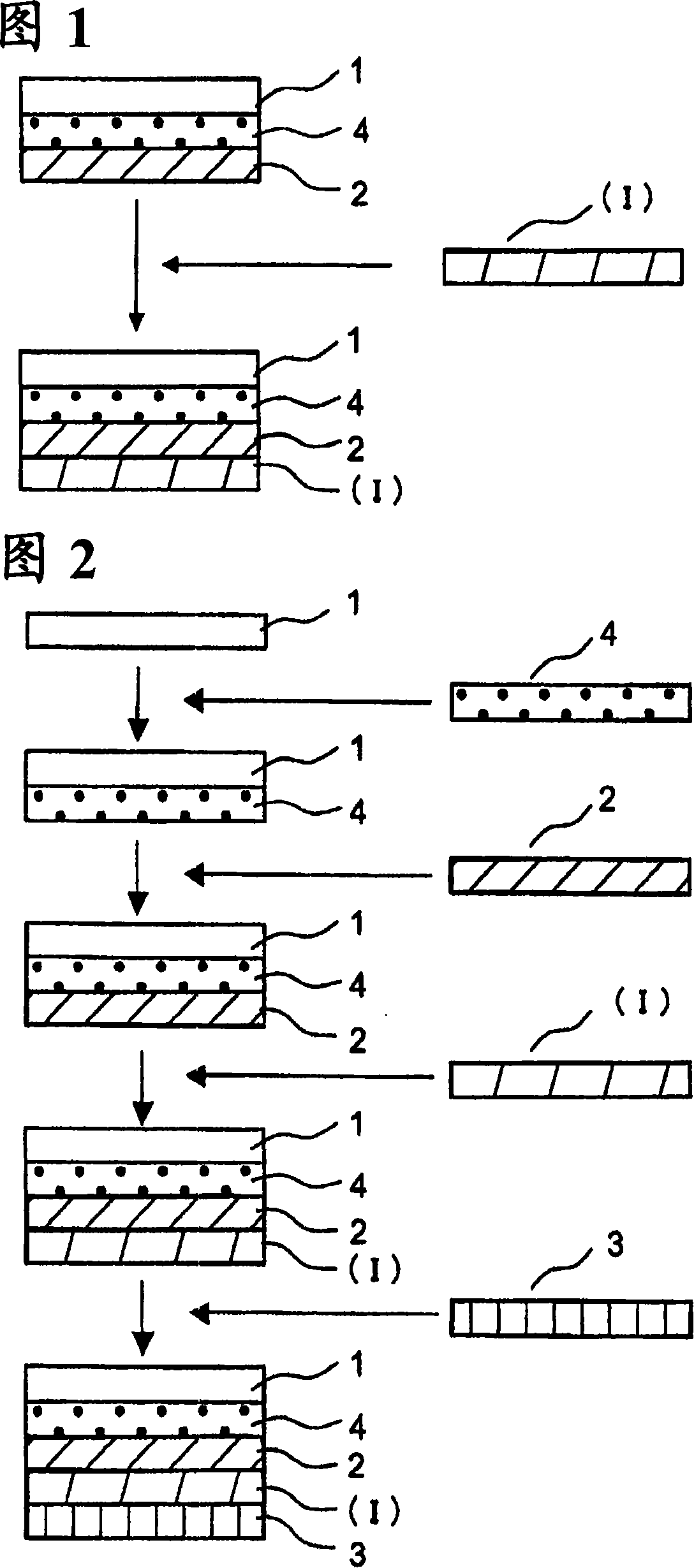

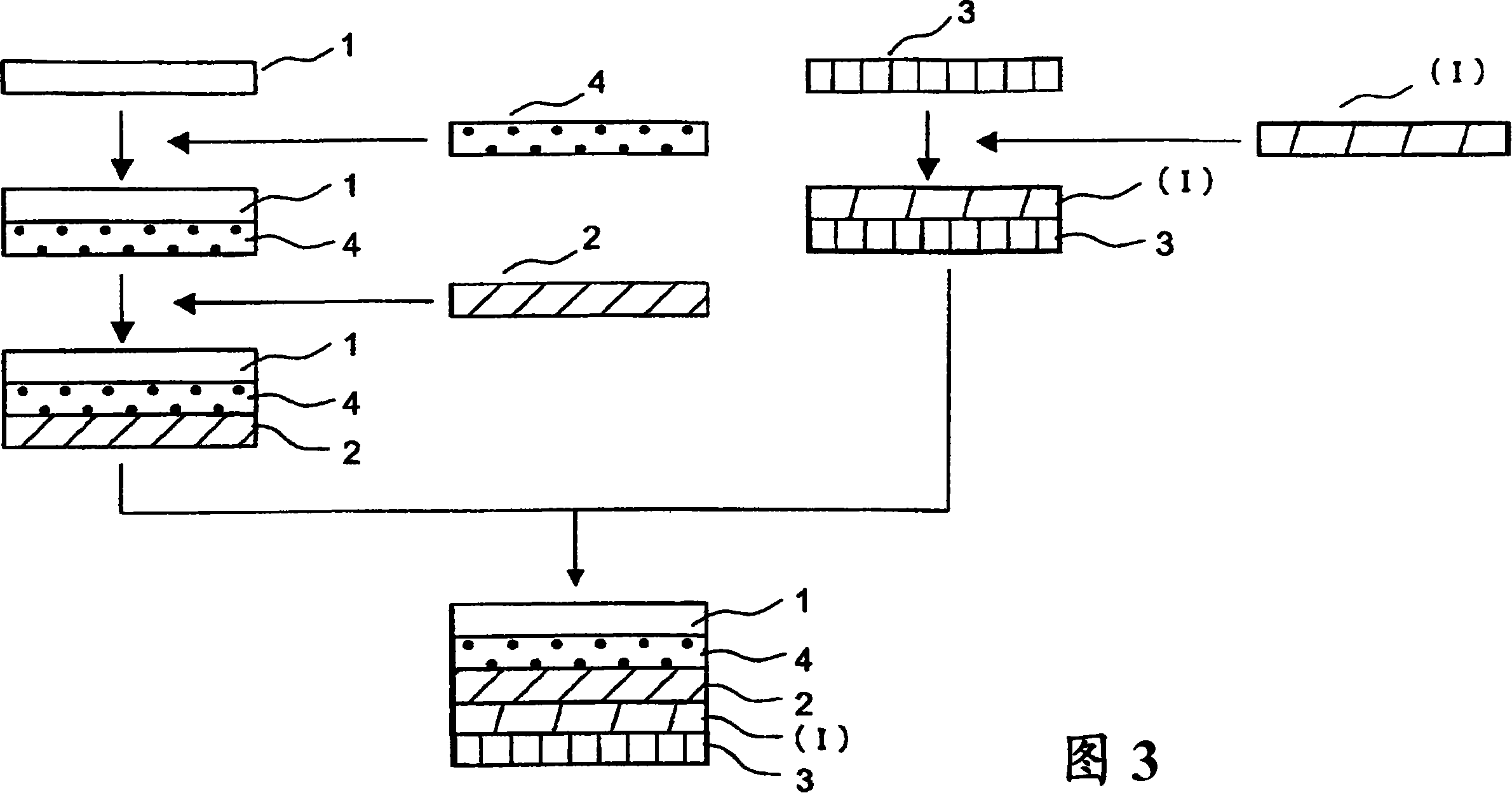

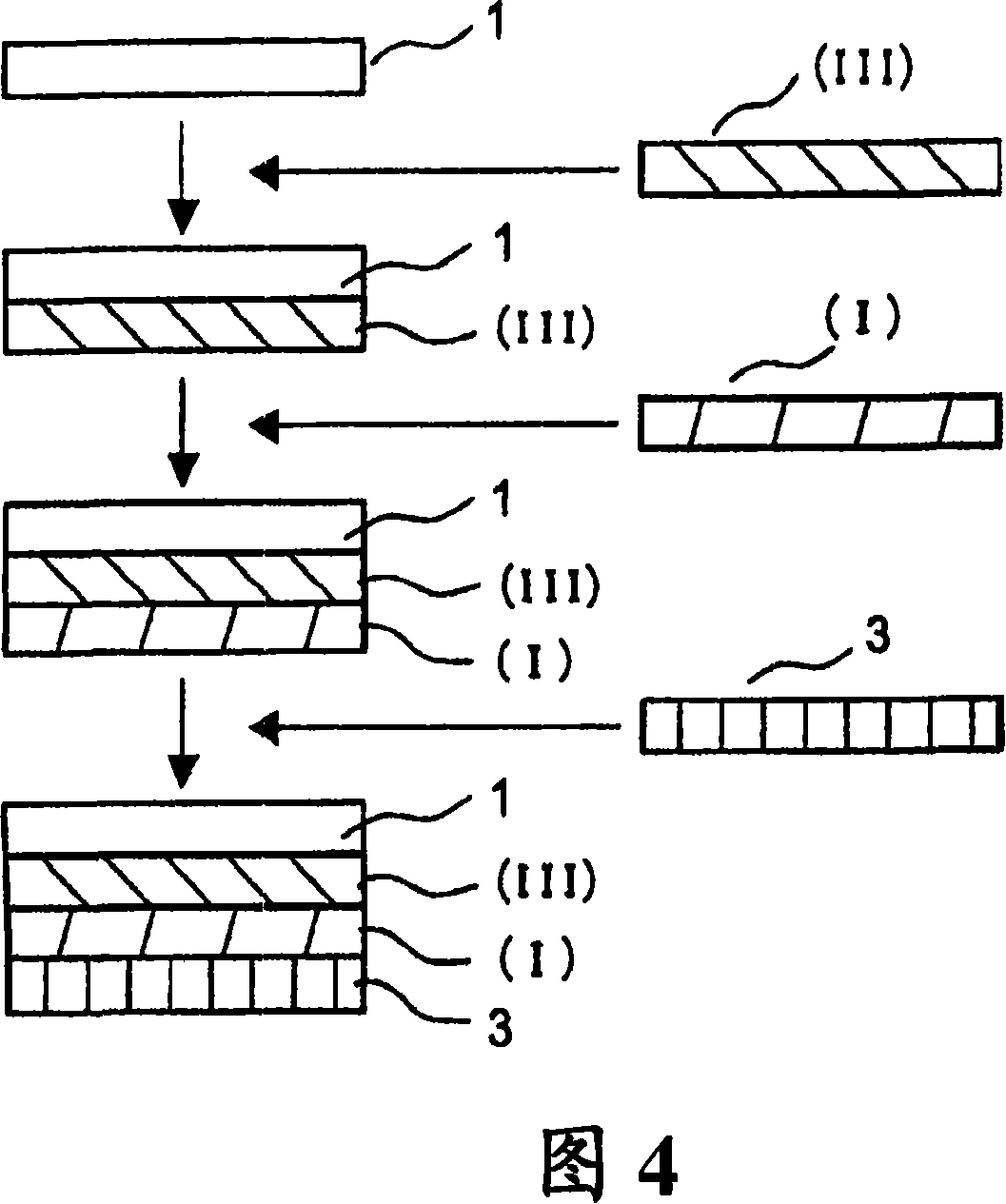

Method used

Image

Examples

Embodiment 1

[0235] With respect to 333 parts of polyurethane polyurea resin solutions (A-1), add 20 parts of bisphenol A type epoxy resins ("Epicoat 828" produced by Japan Epikisilesin, epoxy equivalent = 189g / eq), obtain bonding resin composition. 180 parts of flaky silver powder ("AgXF-301" manufactured by Fukuda Metal Foil Powder Co., Ltd.) was added to 353 parts of this adhesive resin composition, and stirred and mixed to obtain a curable conductive adhesive composition.

[0236] Next, a polyethylene terephthalate film ("SA-125PET" produced by Unichika) with a thickness of 125 μm was used as a reinforcing film, and a micro-adhesive with heat resistance was applied using a micro gravure coater. ("BPS5525" manufactured by Toyo Ink Manufacturing Co., Ltd.) was dried to a thickness of 2 µm (dry film thickness) to form a slight adhesive layer. A 9 μm-thick polyphenylene sulfide film (“Trelina 3030” manufactured by Toray) was laminated as a base film on the micro-adhesive layer to obtain a...

Embodiment 2

[0239] With respect to 333 parts of polyurethane polyurea resin solutions (A-2), add 10 parts of bisphenol A type epoxy resins ("Epicoat 828" produced by Japan Epikisilesin, epoxy equivalent = 189g / eq), 0.7 parts of micro Dicyandiamide ("Epiquiy DICY 7" manufactured by Japan Epoch Resin) and 0.1 part of imidazole-based curing accelerator ("PN-40" manufactured by Ajinomoto Fain Techno) were pulverized to obtain an adhesive resin composition. 166 parts of flaky silver powder ("AgXF-301" produced by Fukuda Metal Foil Powder Co., Ltd.) was added to 343.8 parts of this adhesive resin composition, and stirred and mixed to obtain a curable conductive adhesive composition.

[0240] Next, a polyethylene terephthalate film ("SA-125PET" produced by Unichika) with a thickness of 125 μm was used as a reinforcing film, and a micro-adhesive with heat resistance was applied using a micro gravure coater. ("BPS5525" manufactured by Toyo Ink Manufacturing Co., Ltd.) was dried to a thickness of 2...

Embodiment 3-11

[0243] Except using the polyurethane polyurea resin solution, epoxy resin and flaky silver powder of the type and amount shown in Table 1 and Table 2, repeat the operation of Example 1 to prepare various curable conductive adhesive compositions, prepare Electromagnetic shielding adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com