Patents

Literature

166results about How to "Easy lamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum coupled tool apparatus for dry transfer printing semiconductor elements

InactiveUS8261660B2Improvement in printing yield and placement accuracy and fidelityReduce pressureMechanical working/deformationDecorative surface effectsEngineeringThin glass

Owner:X DISPLAY CO TECH LTD

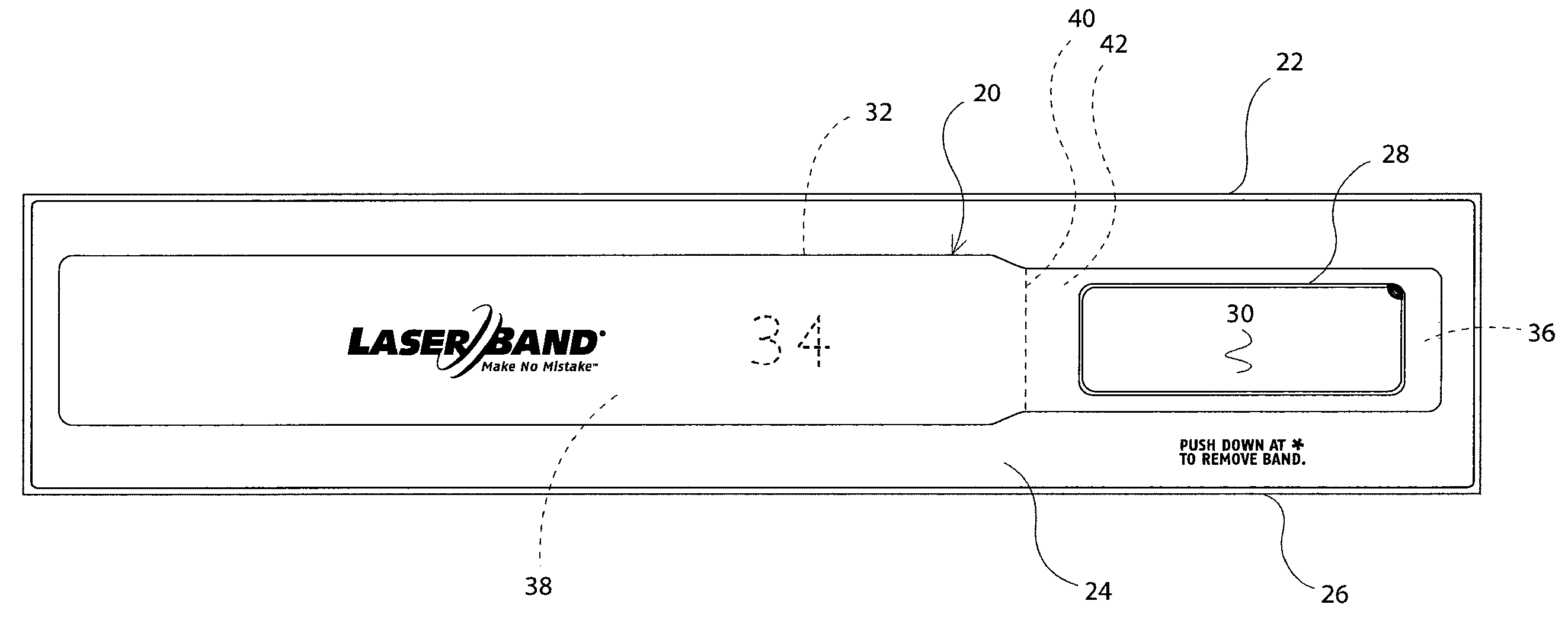

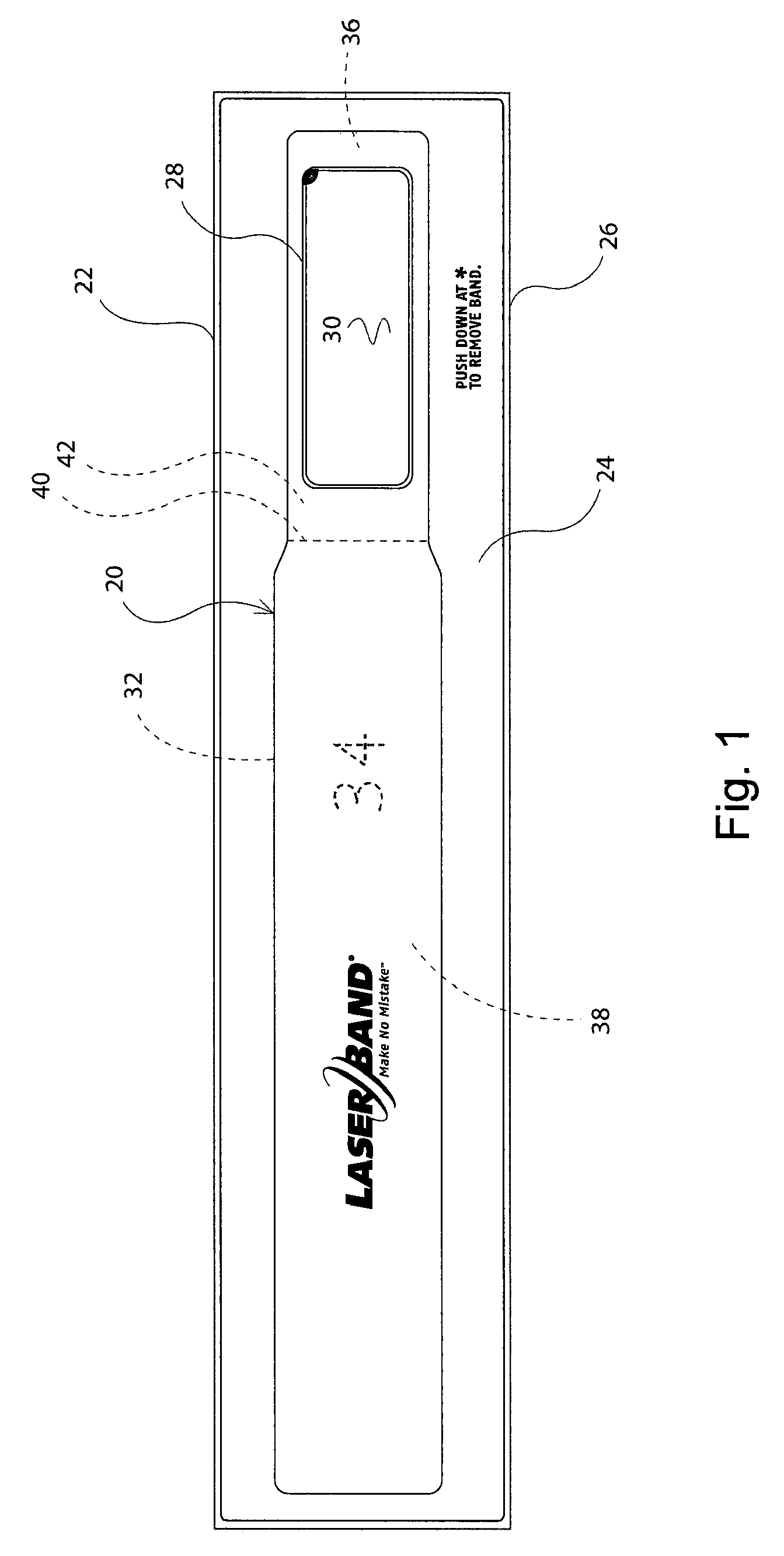

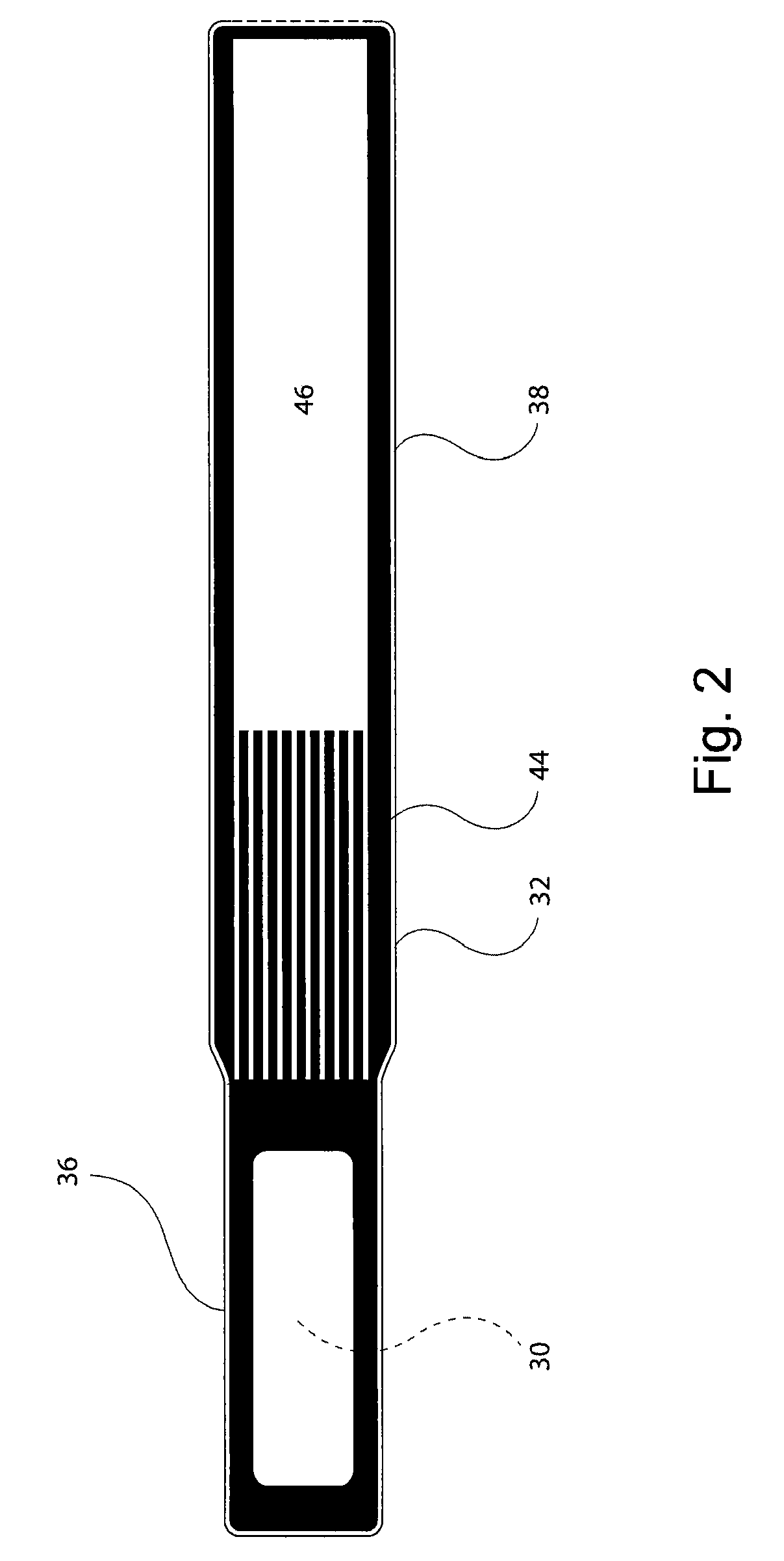

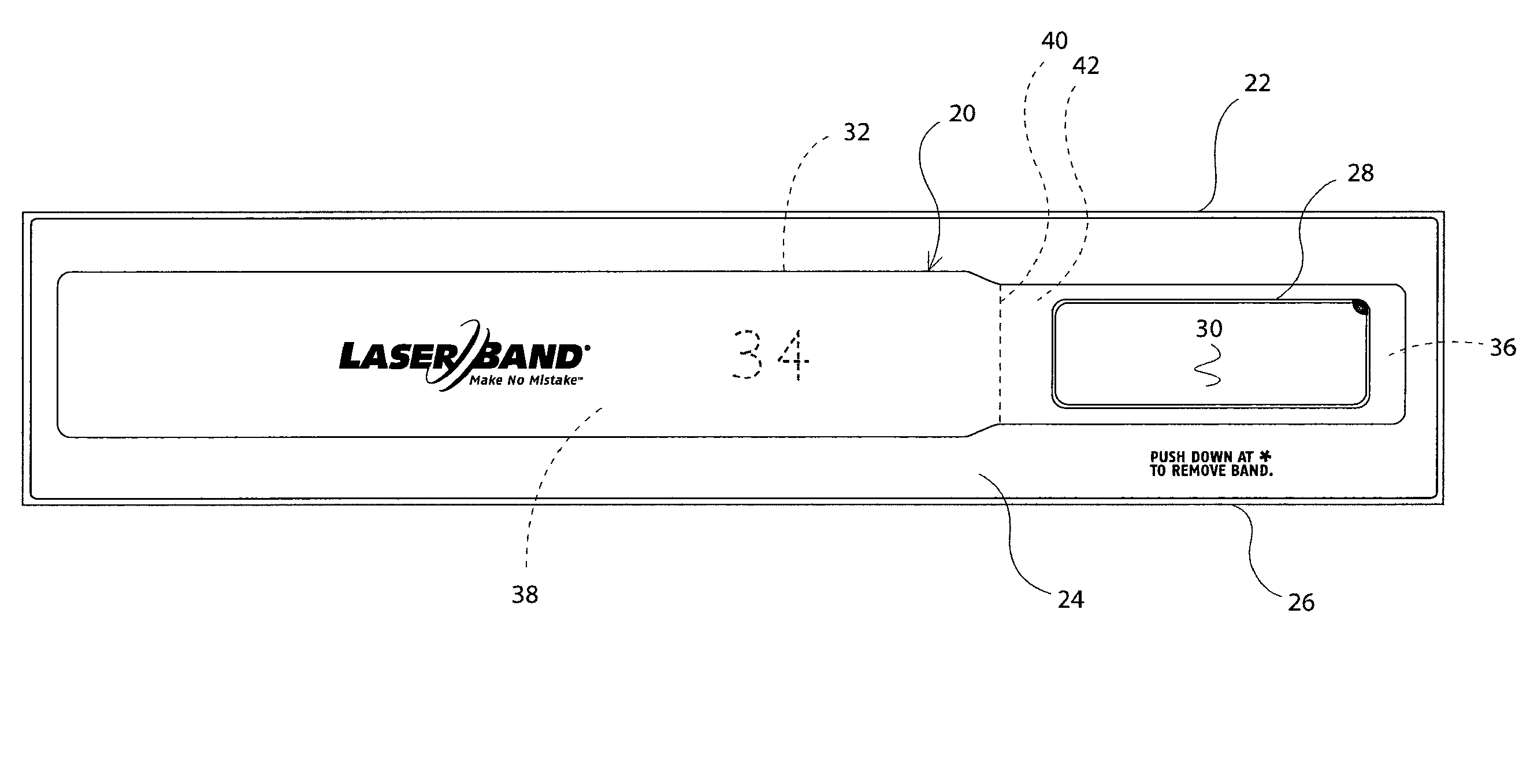

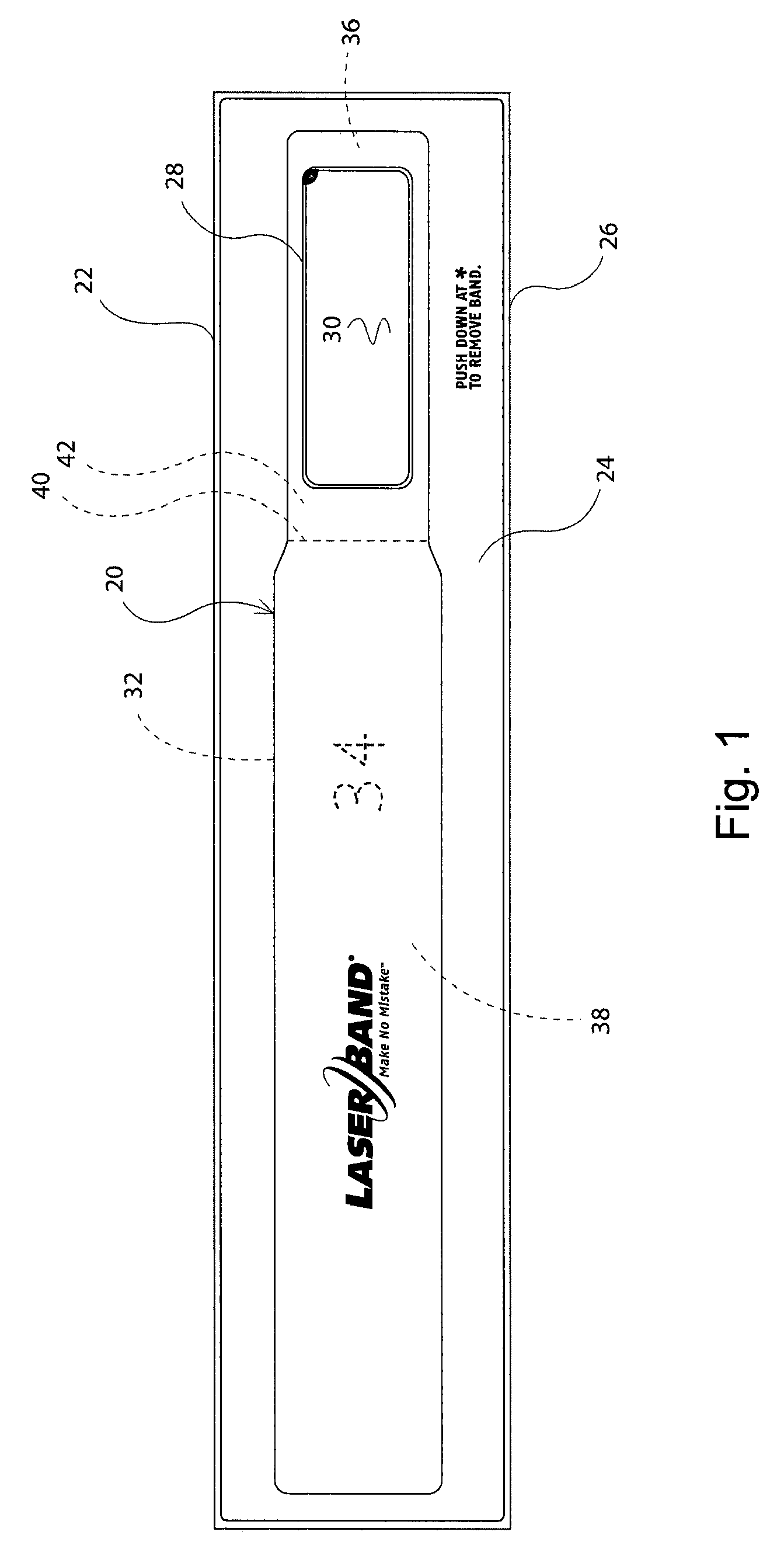

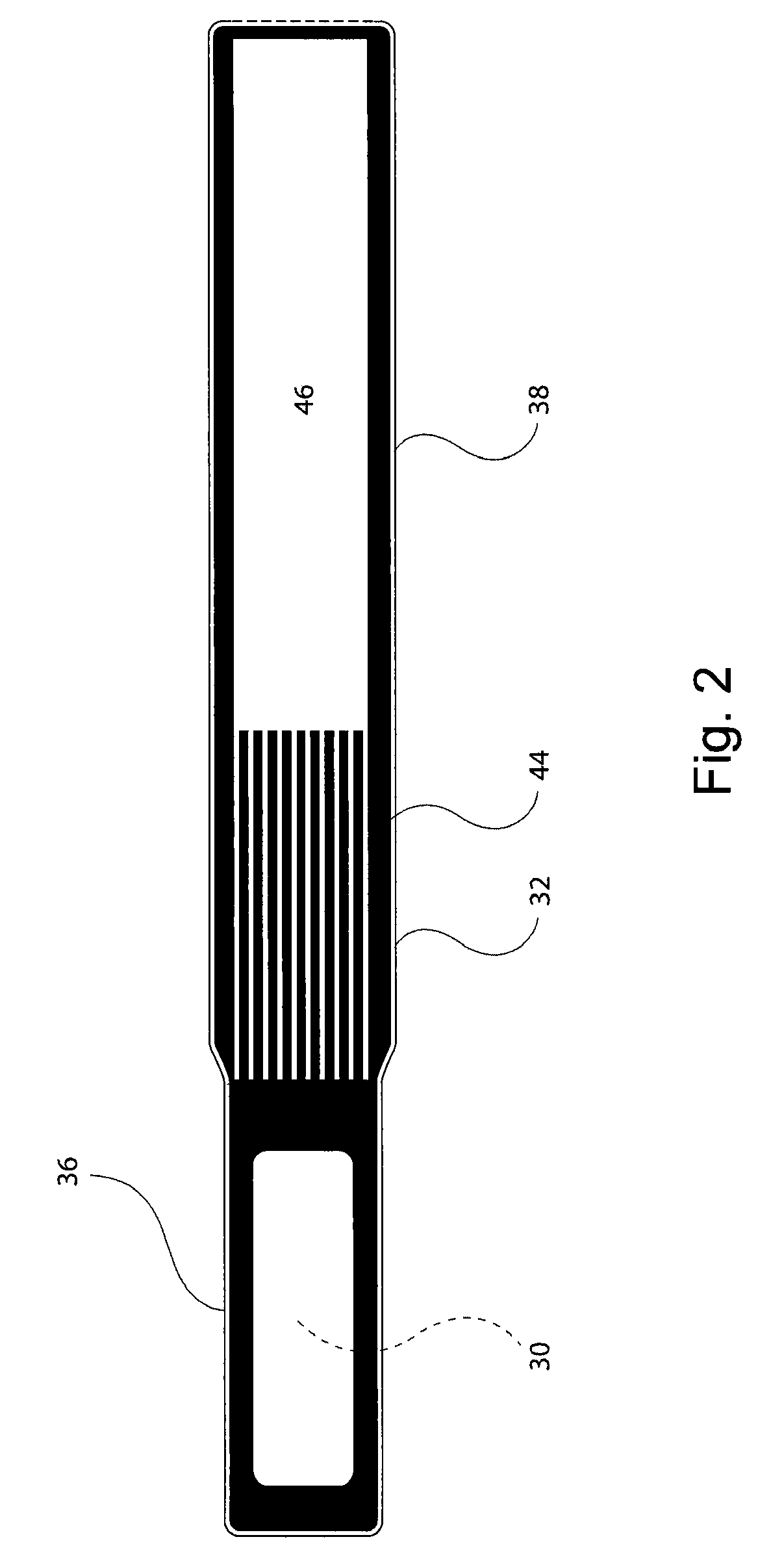

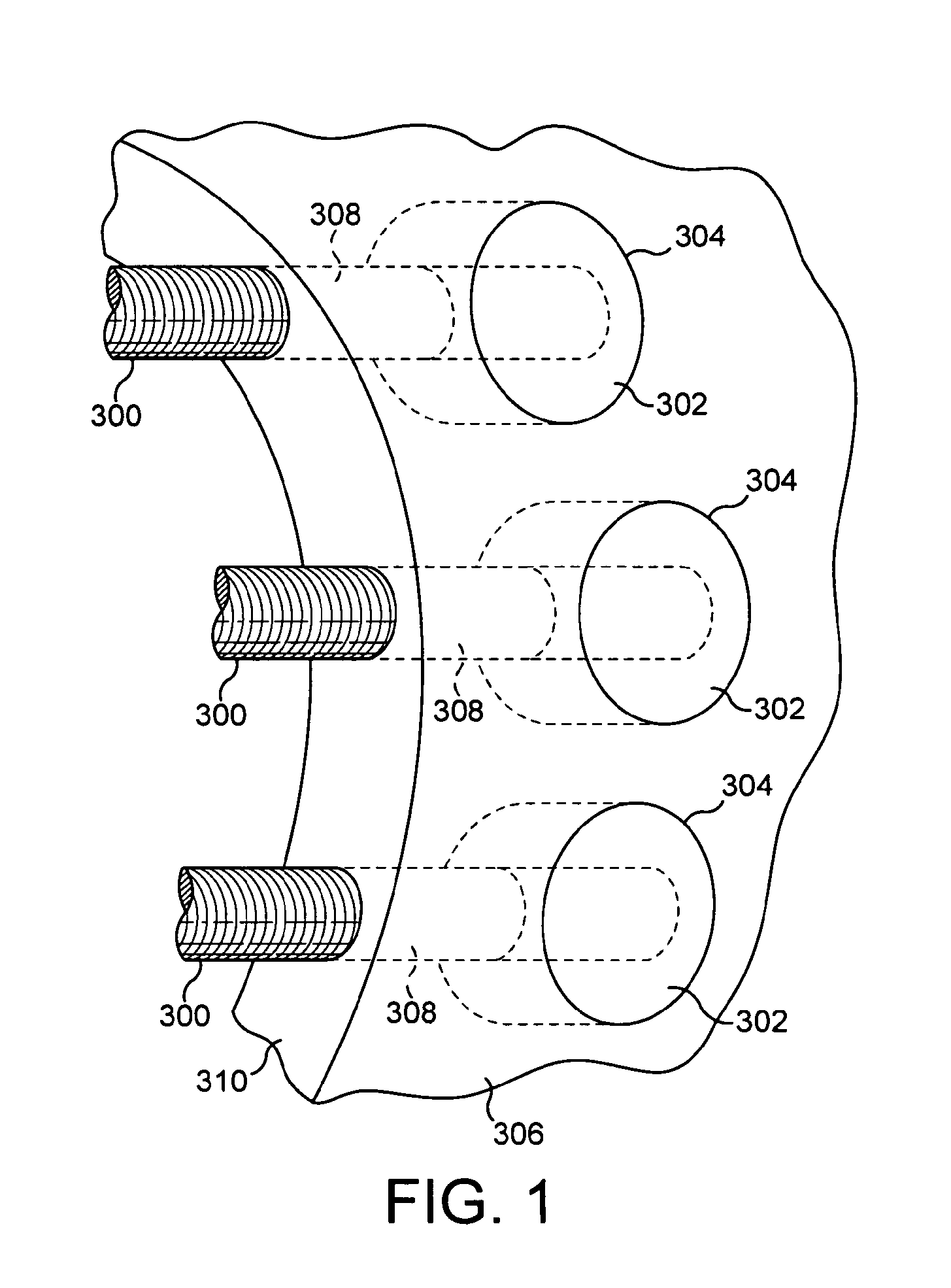

Wrap Around Self Laminating Wristband

ActiveUS20090277061A1Easy laminationQuick and easy methodStampsData processing applicationsBusiness formsEngineering

A wrap around, self laminating wristband comprises a substantially transparent laminate strap with an imaging area for receiving printed information and one or more layers of adhesive adjacent the imaging area so that as the strap is wrapped around itself to overlie the imaging area it laminates it. Alternate embodiments provide for a snap closure to secure the wristband instead of adhesive, forming the imaging area with a coating of a thermally sensitive or active print material, adding one or more labels for common use with the wristband, forming the wristband in a page of multiple wristbands or with labels or separately, forming the wristband as part of a printer processible business form, and providing the wristband forms either with or without labels in a continuous fan fold or roll format.

Owner:ZEBRA TECH CORP

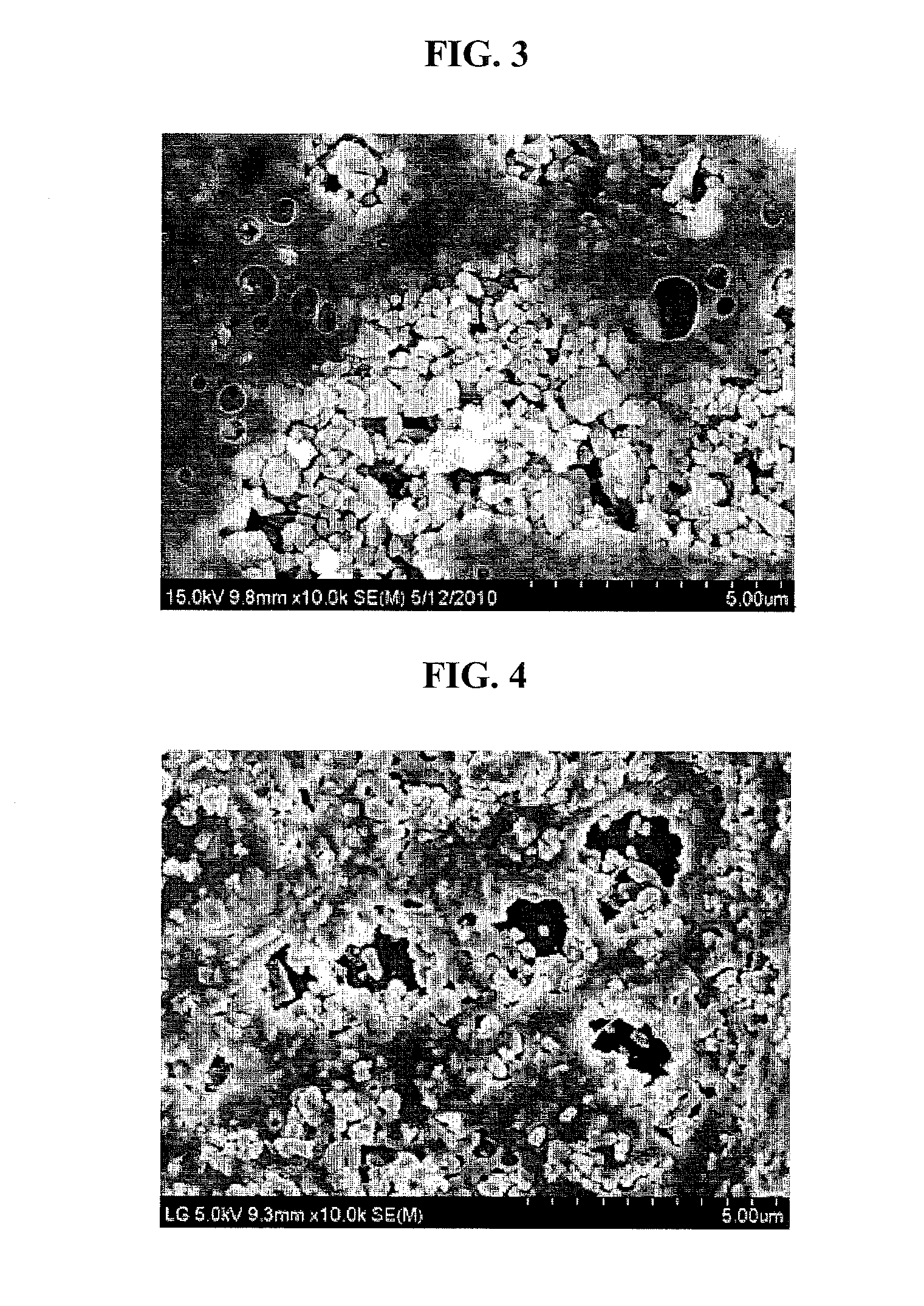

Method for manufacturing separator, separator manufactured therefrom and method for manufacturing electrochemical device having the same

ActiveUS20110259505A1Improve adhesionEasy laminationLamination ancillary operationsCell seperators/membranes/diaphragms/spacersInorganic particleInorganic particles

Disclosed is a method for manufacturing a separator for an electrochemical device. The method contributes to formation of a separator with good bondability to electrodes and prevents inorganic particles from detaching during an assembling process of an electrochemical device.

Owner:TORAY BATTERY SEPARATOR FILM +1

Wet-lay flame barrier

InactiveUS20060068675A1Increase speedExtension of timeDomestic upholsteryLayered productsFiberGlass fiber

Nonwoven wet-lay flame barrier of the invention comprises a blend of water dispersible fibers, that are inherently fire resistant and nonshrinking to direct flame, along with water dispersible fibers extruded from polymers made with halogenated monomers and optionally including fiberglass and wood pulp, being together thermally bonded with a binder resin in a wet-lay manufacturing process to provide a relatively thin, but dense, durable flame barrier with excellent tensile, and durability properties in the end use application. The wet-lay flame barrier of this invention also allows for the manufacture of open flame resistant composite articles, while also permitting the continued use of conventional non-flame retardant dress cover fabrics, conventional non-flame retardant fiberfills and conventional non-flame retardant polyurethane foams.

Owner:HANDERMANN ALAN C +3

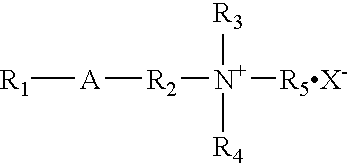

Electromagnetic-wave-shielding adhesive film, process for producing the same, and method of shielding adherend from electromagnetic wave

ActiveCN101120627AHeat resistanceImprove bending resistanceMagnetic/electric field screeningSemiconductor/solid-state device detailsIsocyanatePrepolymer

An electromagnetic-wave-shielding adhesive film which comprises a base film and a curable conductive adhesive layer (I), wherein the curable conductive adhesive layer (I) comprises: a polyurethane-polyurea resin (A) prepared by reacting a polyamino compound (e) with a urethane prepolymer (d) having an isocyanate group at an end and obtained by reacting a carboxylated diol compound (a), a polyol (b) which has a number-average molecular weight of 500-8,000 and is not a carboxylated diol compound, and an organic diisocyanate (c); an epoxy resin (B) having two or more epoxy groups; and a conductive filler.

Owner:TOYO INK SC HOLD CO LTD

Packaging technology for crystal silicon solar-energy photovoltaic battery unit

The invention discloses packaging technology for a crystal silicon solar-energy photovoltaic battery unit, which comprises the following steps of front welding, back concatenation, laminated laying, component lamination, battery trimming, framing, junction box welding, packaging testing and warehousing, and has the advantages that the packaging technology removes bubbles by lamination and vacuum-pumping so as to have good lamination effect, performs fractionated lamination so as to ensure that the relative position of a component string, glass and the like is stable and the lamination quality is high, and has short curing time and high production efficiency.

Owner:HUAIAN WEIHAO NEW ENERGY TECH

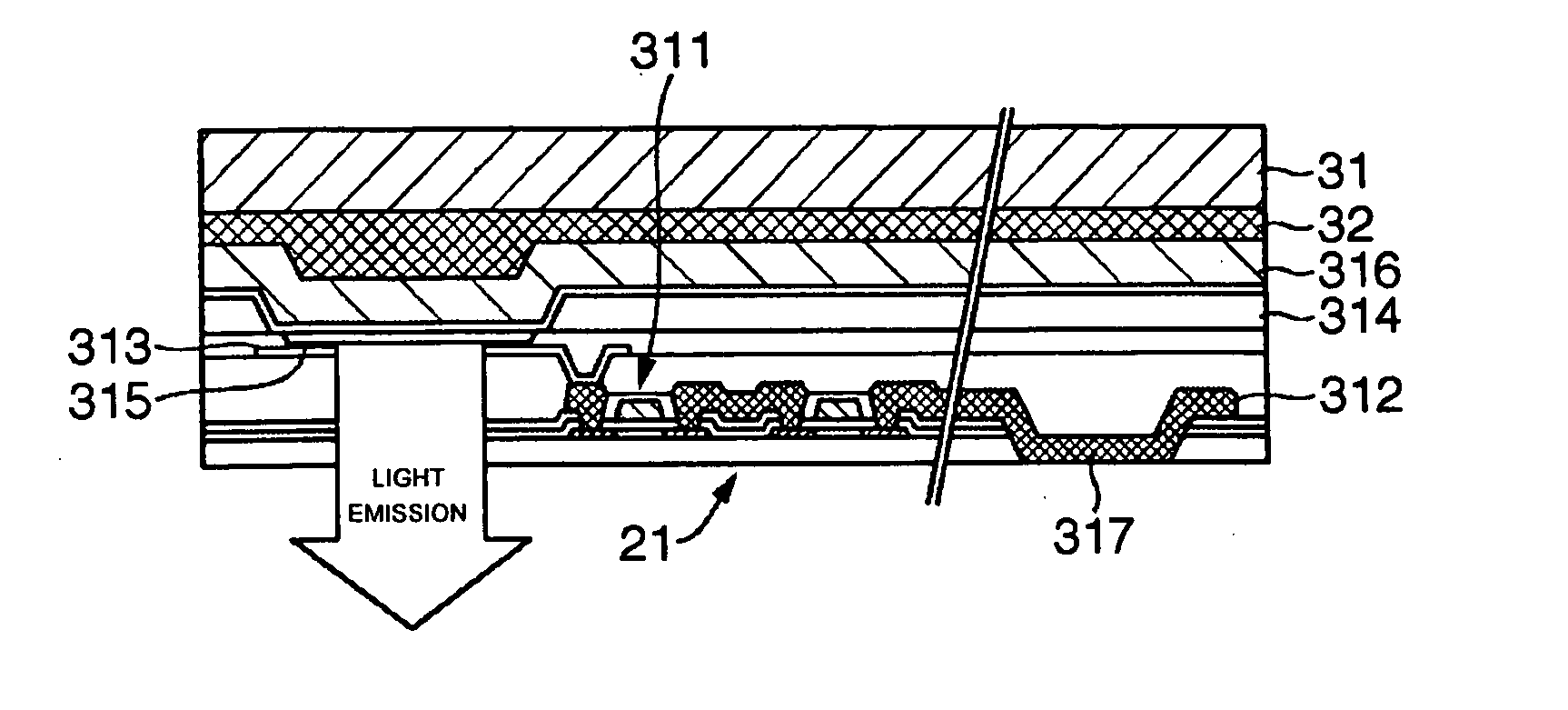

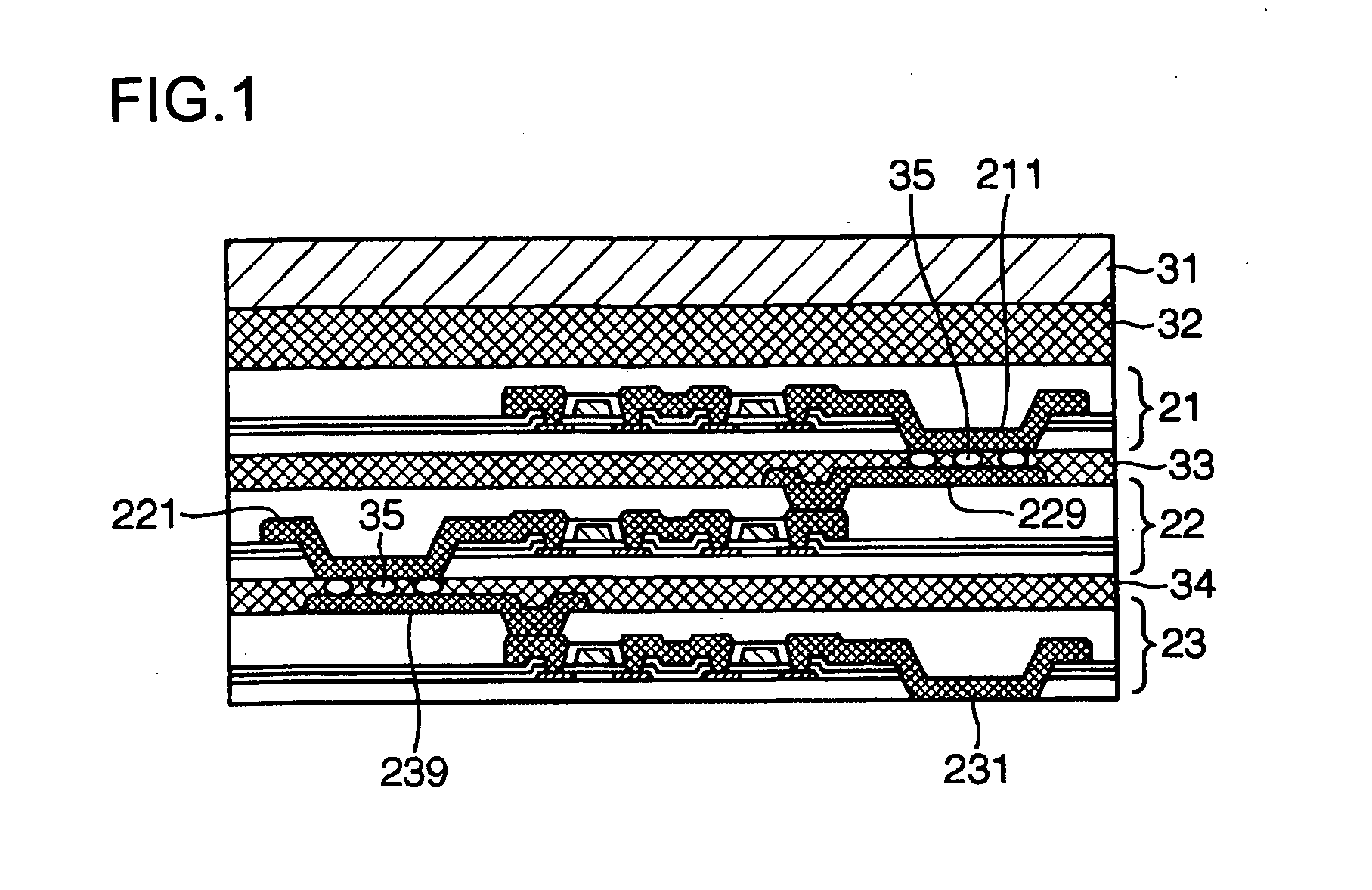

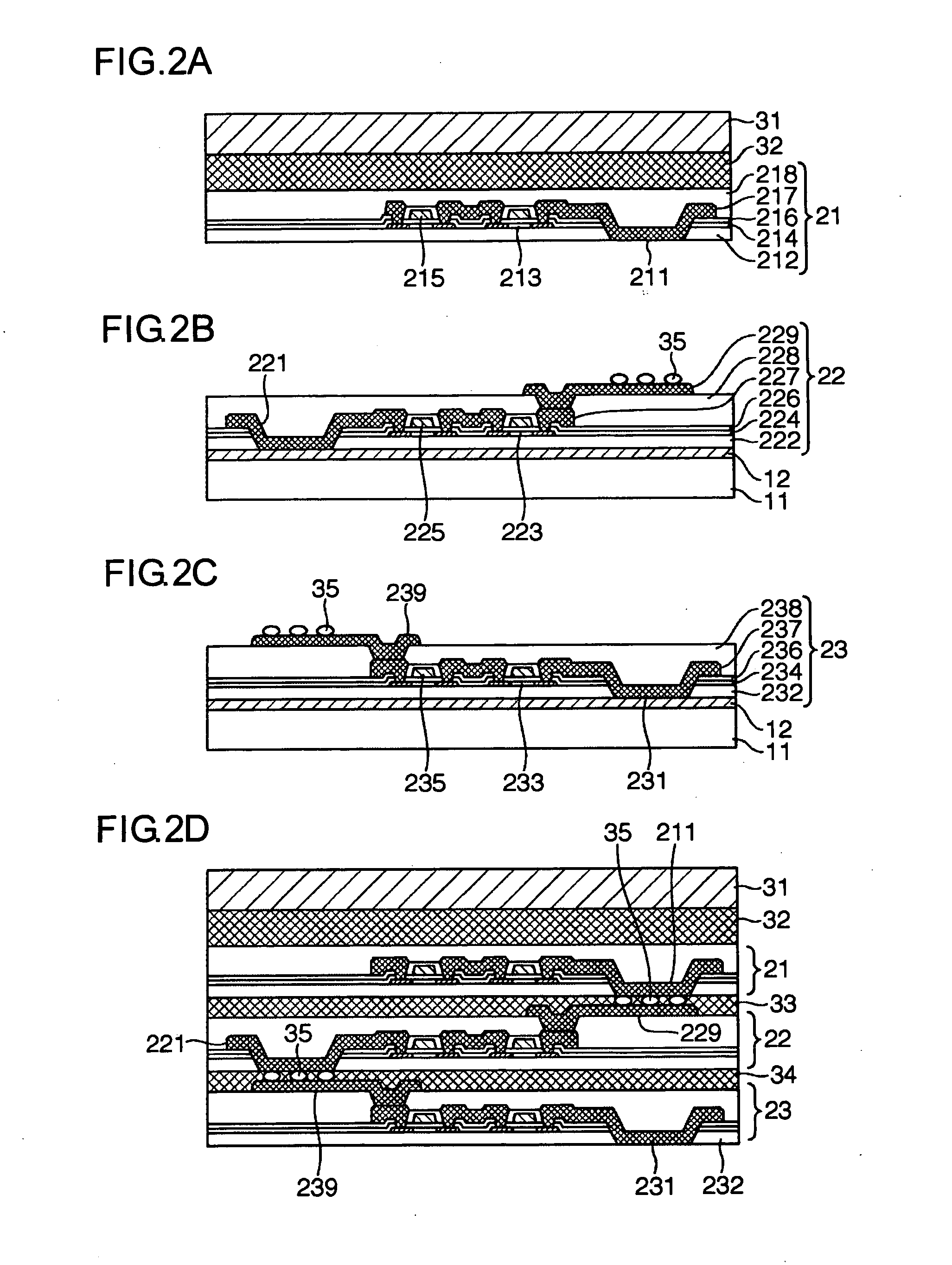

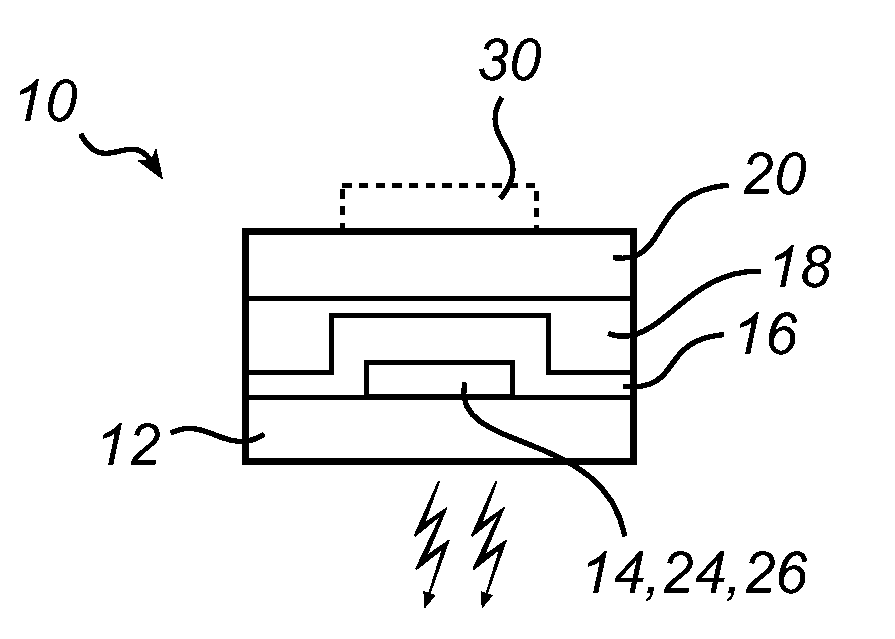

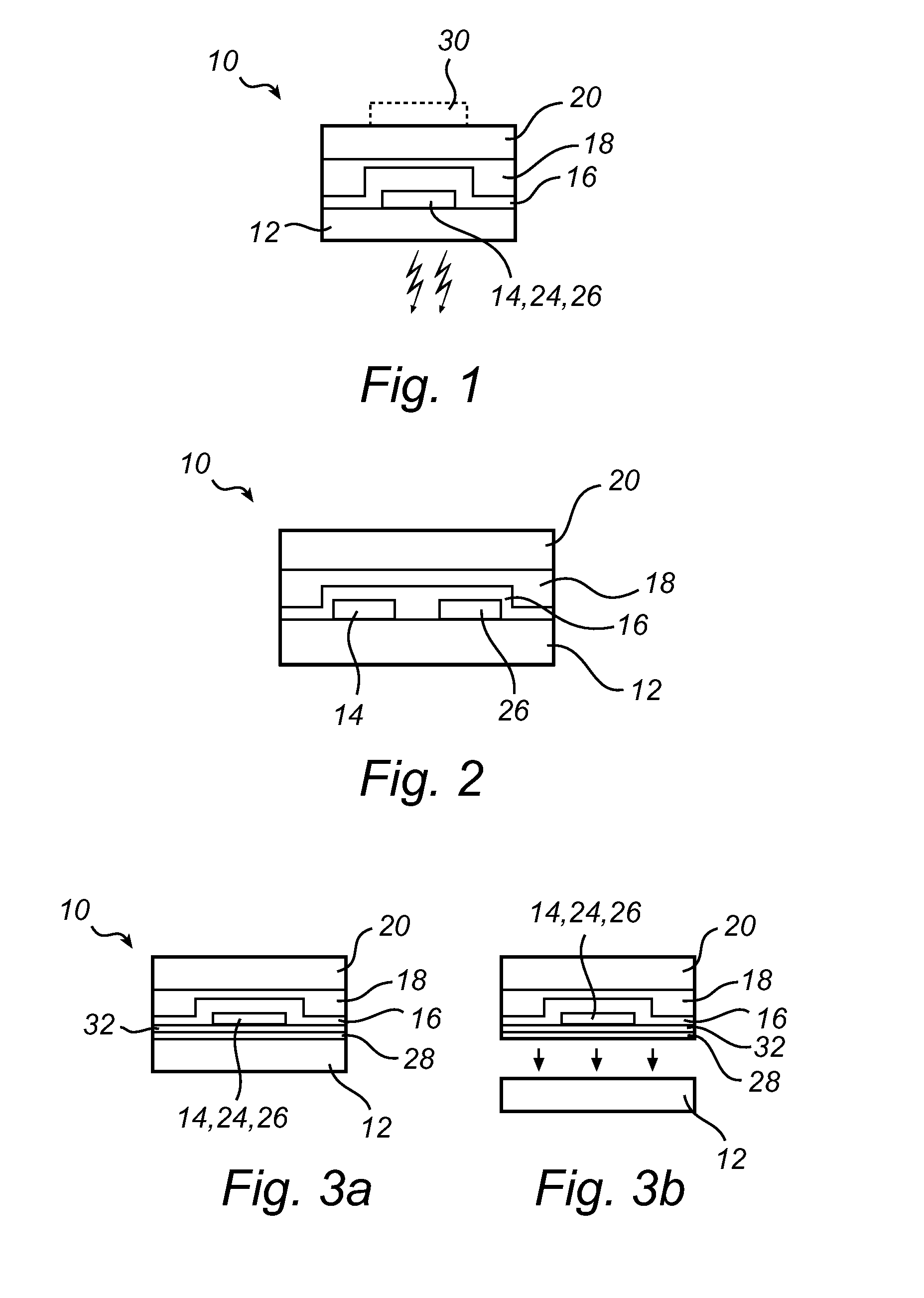

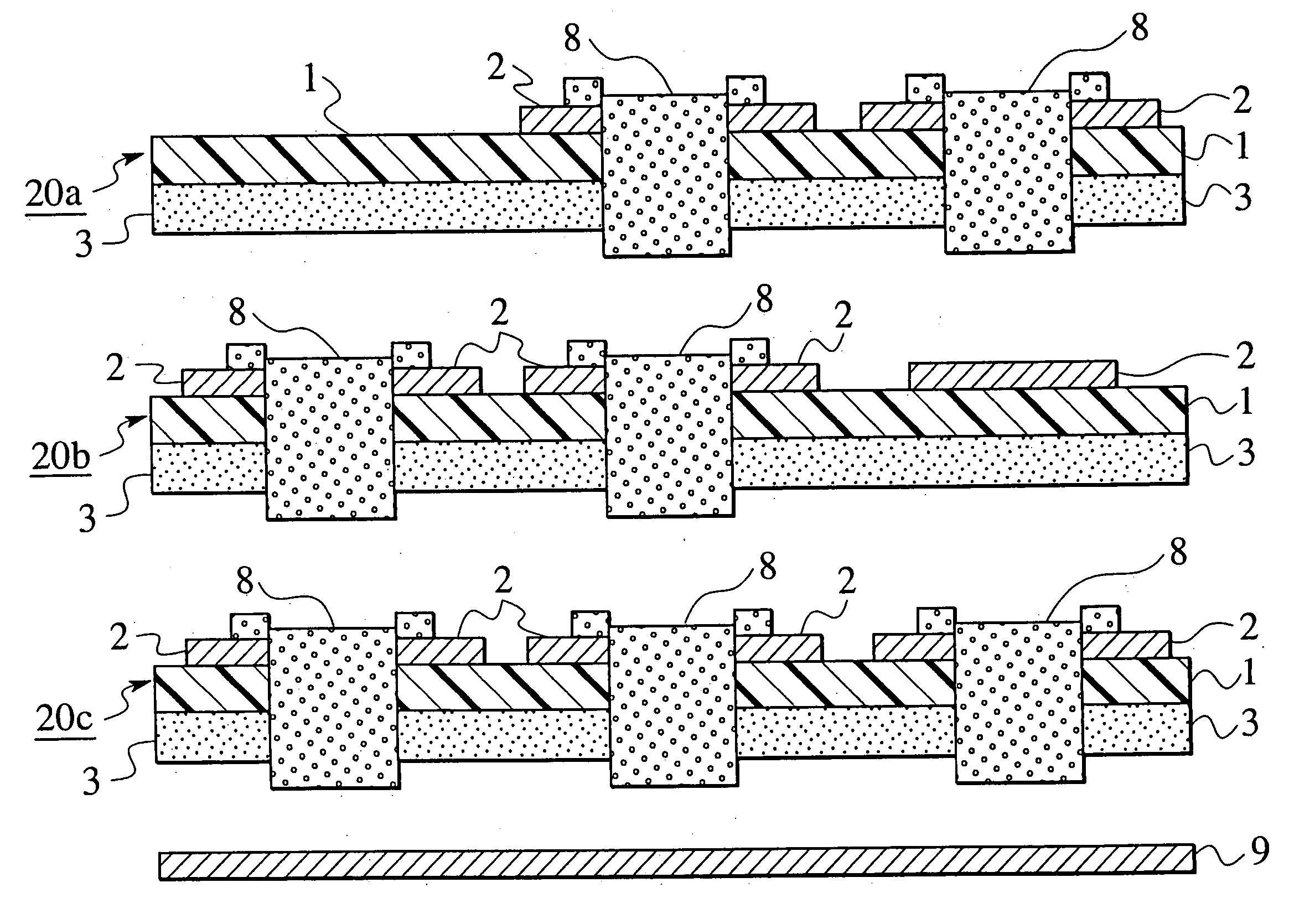

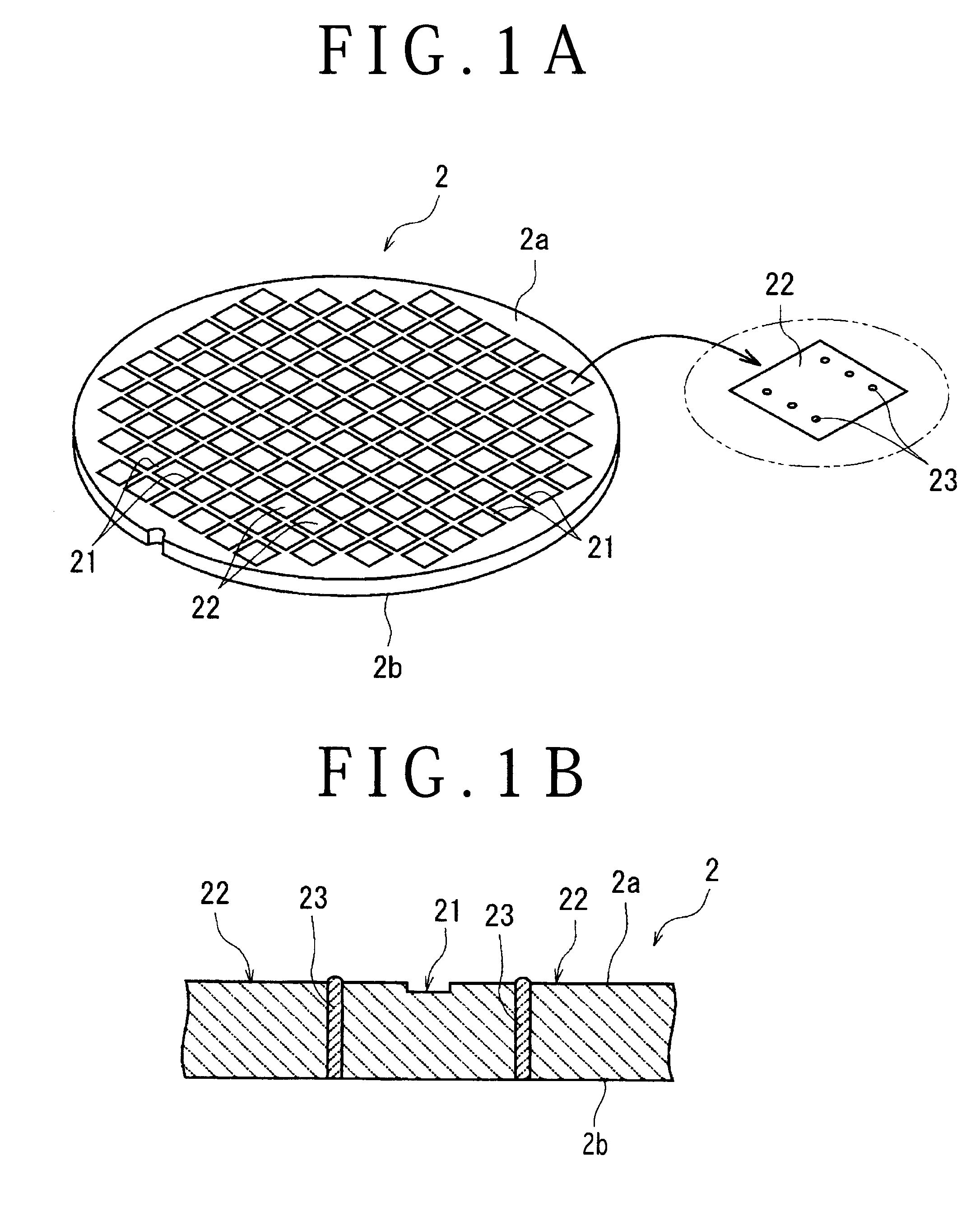

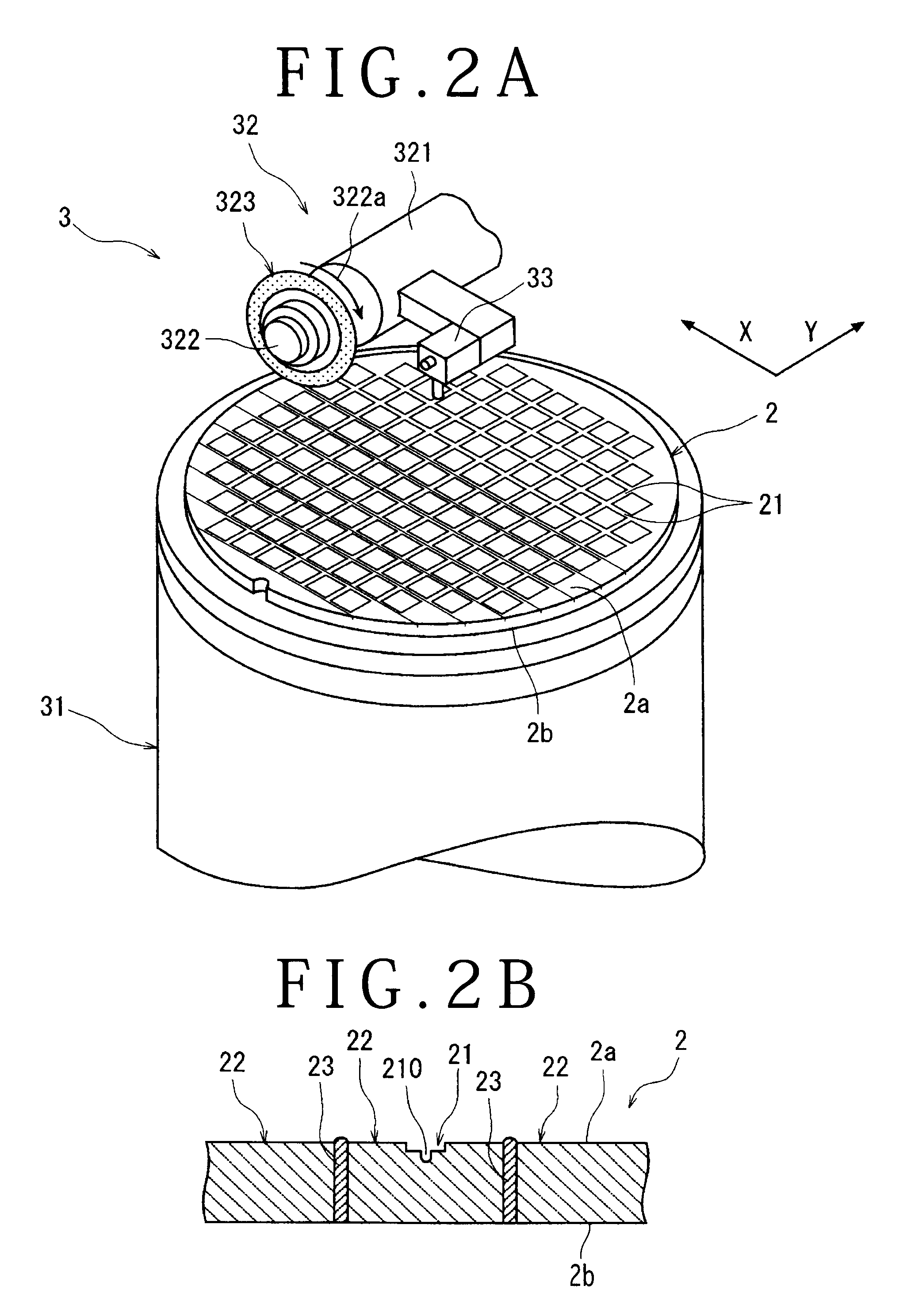

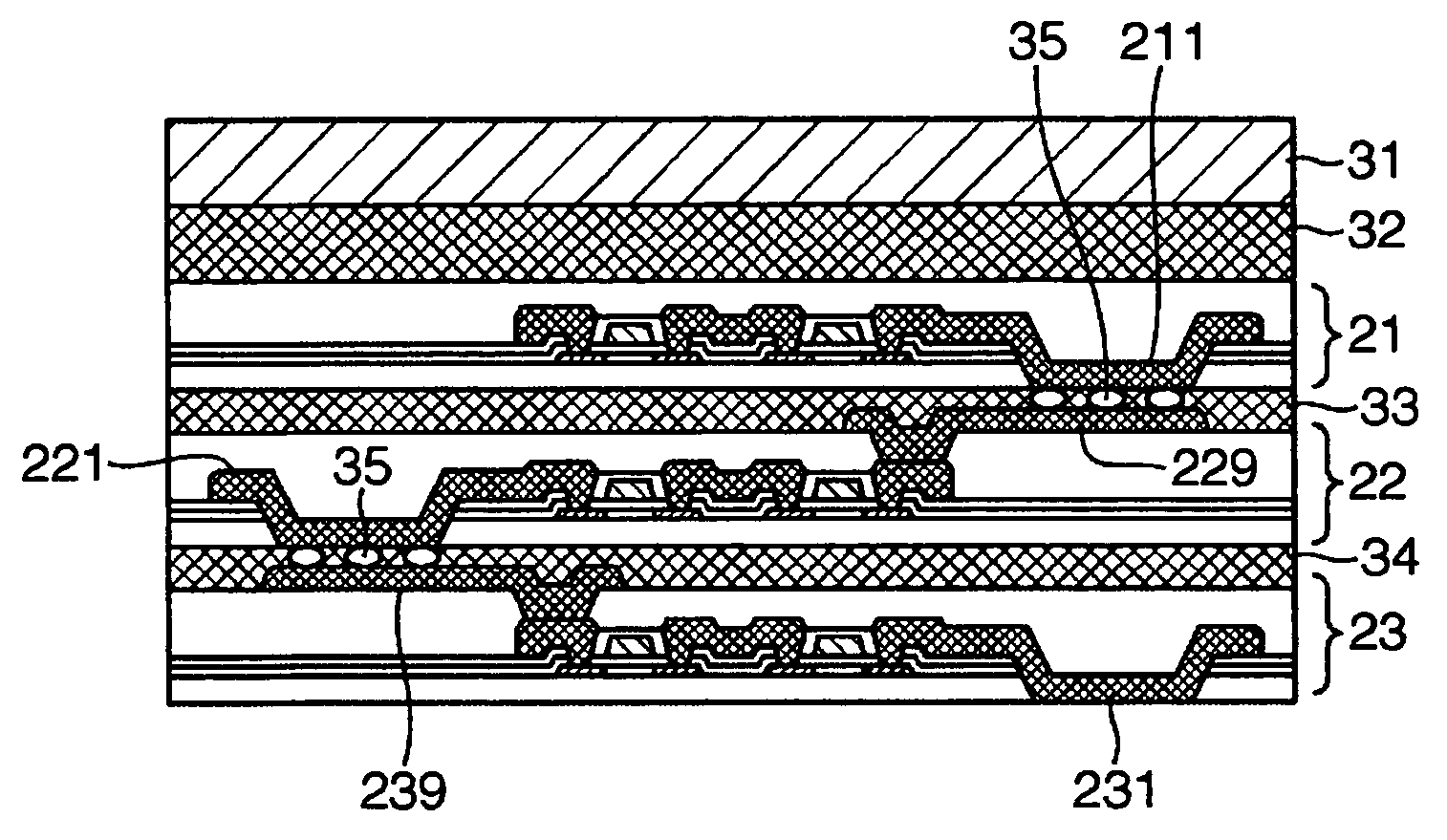

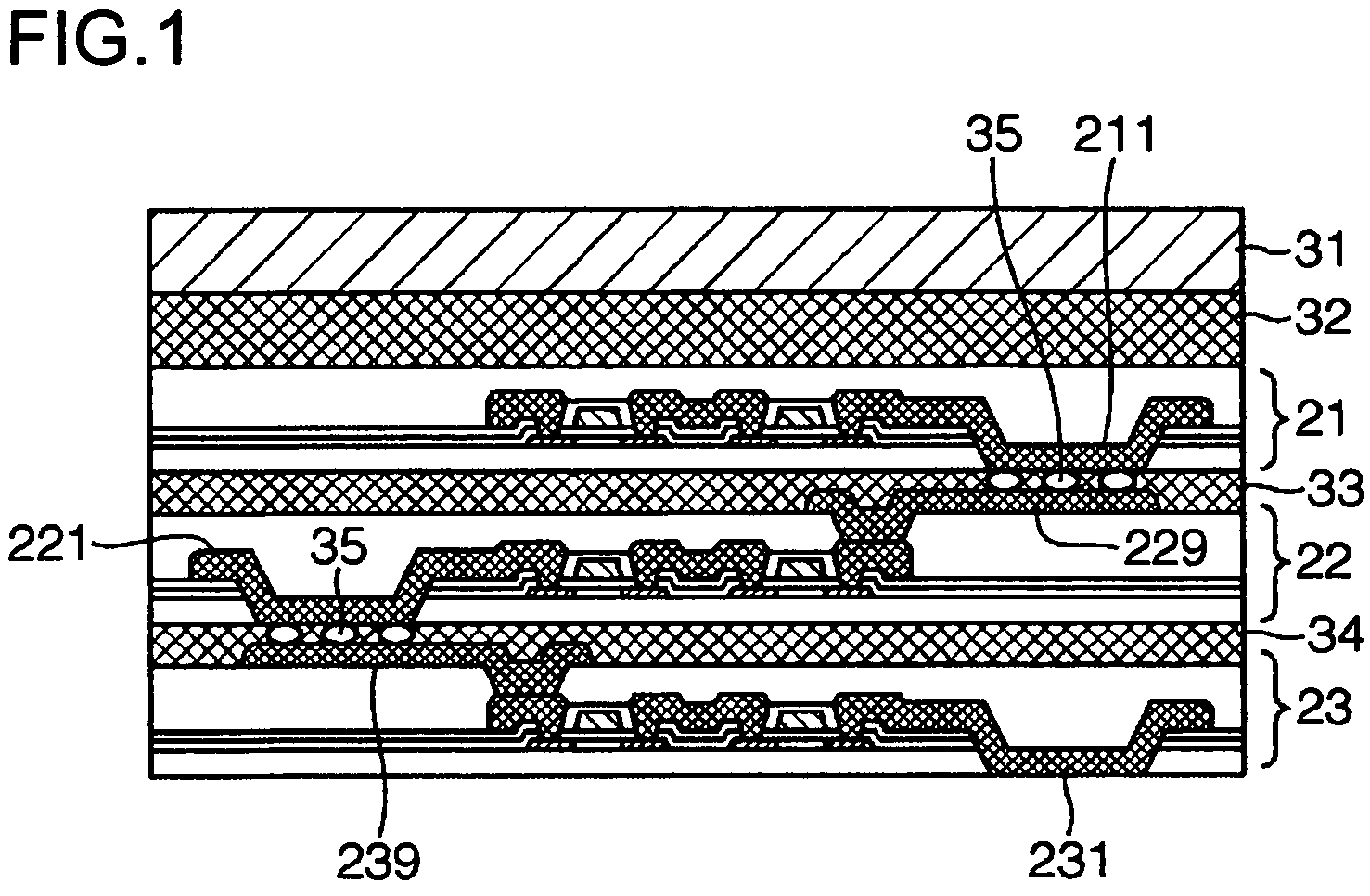

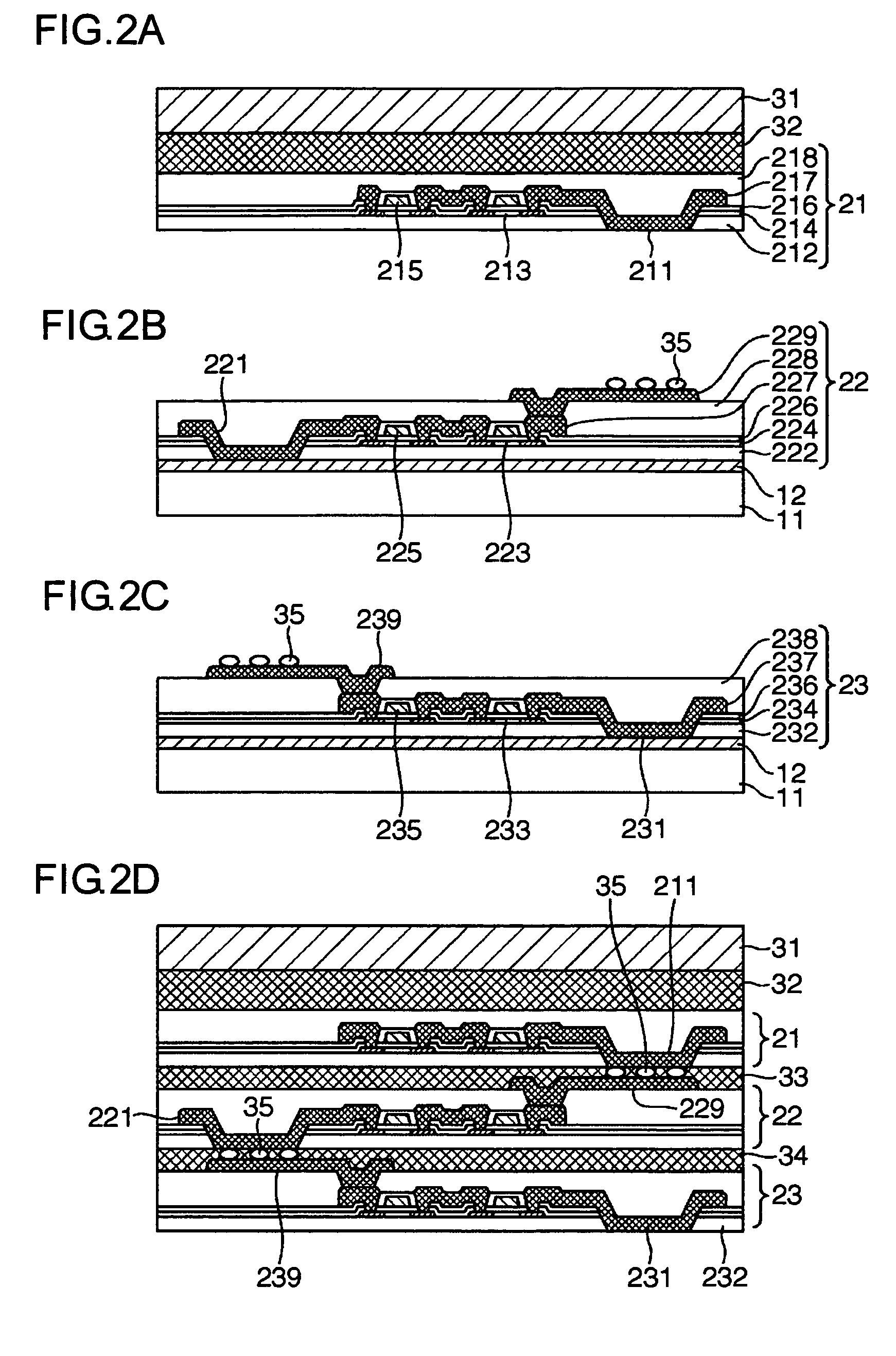

Thin film circuit device, manufacturing method thereof, electro-optical apparatus, and electronic system

InactiveUS20050006647A1Easy to implementHigh lamination precisionTransistorSemiconductor/solid-state device detailsElectronic systemsEngineering

To provide a thin film circuit device in which a three-dimensional circuit structure is realized, a thin film circuit device is formed of a first thin film circuit layer and a second thin film circuit layer laminated to each other. The first thin film circuit layer contains a first thin film circuit provided between an underlayer and a protective layer and a lower connection electrode connected to the first thin film circuit and exposed at a part of the bottom surface of the underlayer. The second thin film circuit layer contains a second thin film circuit provided between an underlayer and a protective layer, an upper connection electrode connected to the second thin film circuit and exposed at a part of the top surface of the protective layer, and a lower connection electrode connected to the second thin film circuit and exposed at a part of the bottom surface of the underlayer. The first and the second thin film circuits are bonded to each other so that the lower connection electrode of the first thin film circuit layer is electrically connected to the upper electrode of the second thin film circuit layer.

Owner:SEIKO EPSON CORP

Engineered stone

ActiveUS20070244222A1Small sizeEasy laminationNatural patternsSpecial ornamental structuresHigh intensitySynthetic resin

The present invention relates to an engineered stone composite produced from a mineral aggregate, a synthetic resin and a binder using compression and vibration to obtain a high strength mineral composite with a high mineral content and a method for its preparation.

Owner:SAFAS CORP

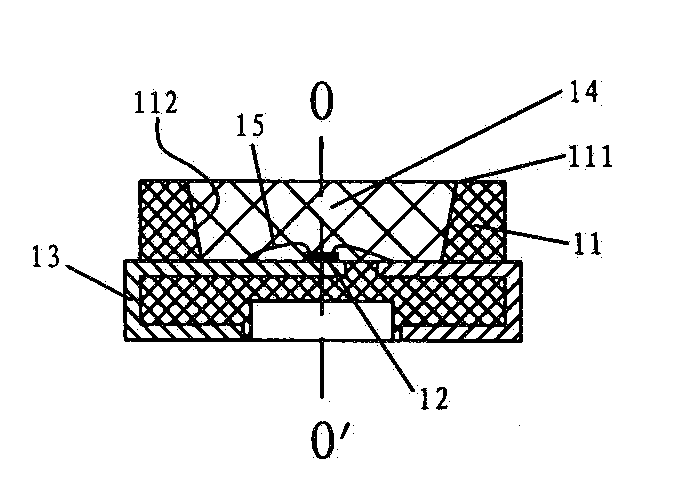

Integrated device

InactiveUS20090269621A1Improve sealingEasy laminationSolid-state devicesSemiconductor devicesEngineeringBiomedical engineering

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

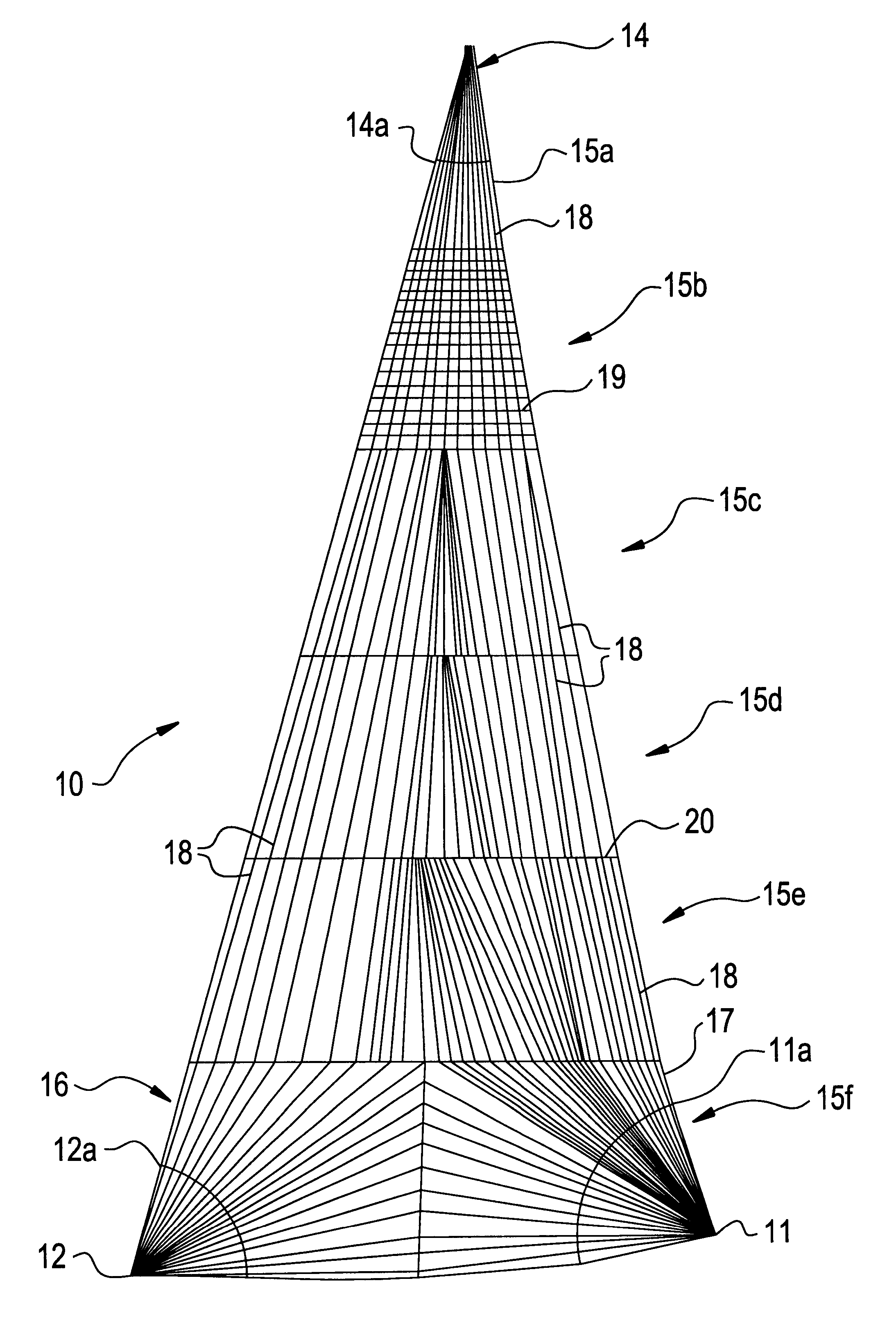

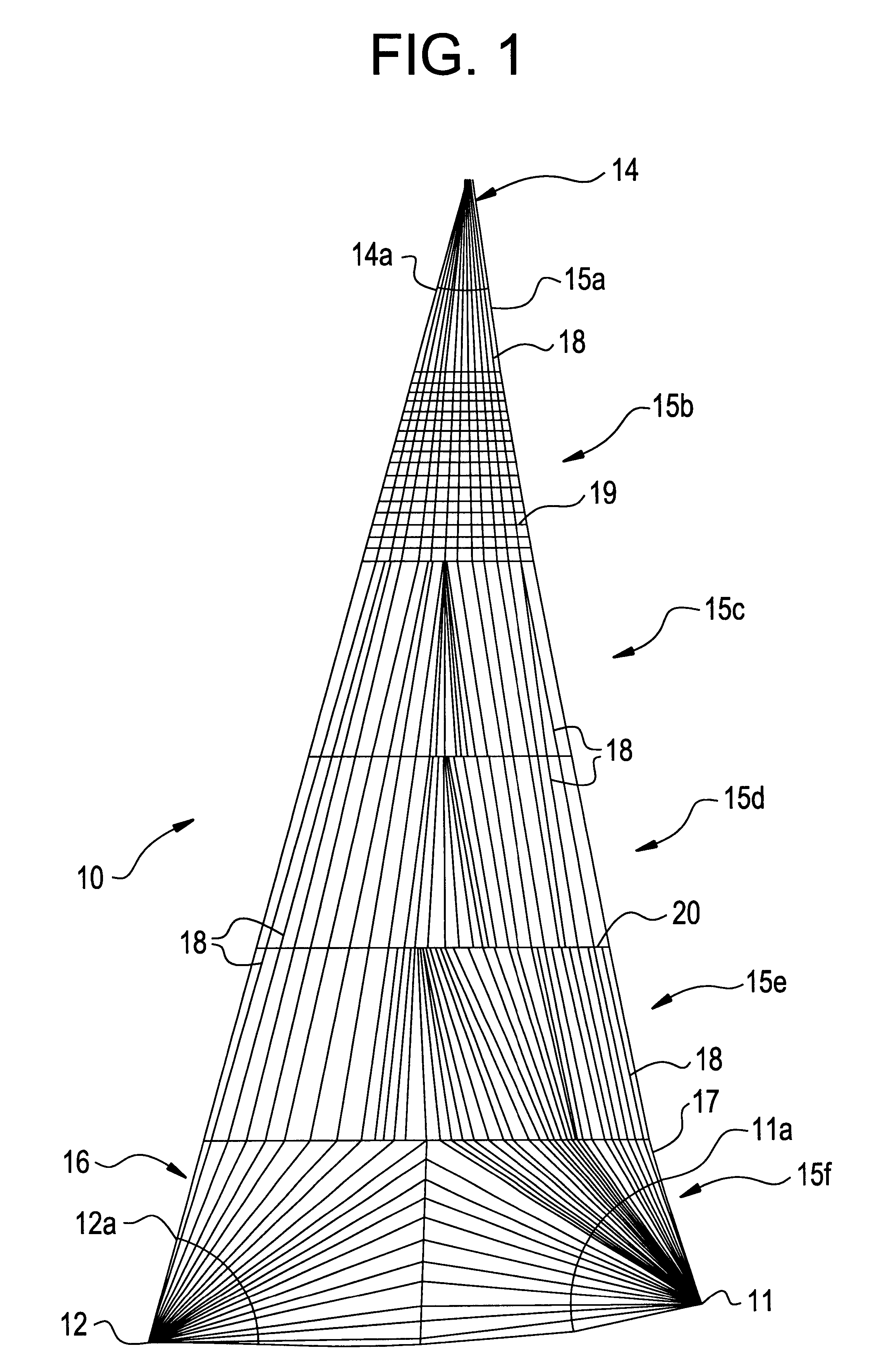

Sail of woven material and method of manufacture

InactiveUS6257160B1More material propertyImprove material performanceWoven fabricsNon-woven fabricsYarnEngineering

Fiber oriented sails made of woven panels of scrim type weave wherein warp yarns in the panels follow primary load paths in a sail and a method for making woven panels and sails.

Owner:KEIRE FRED AIVARS

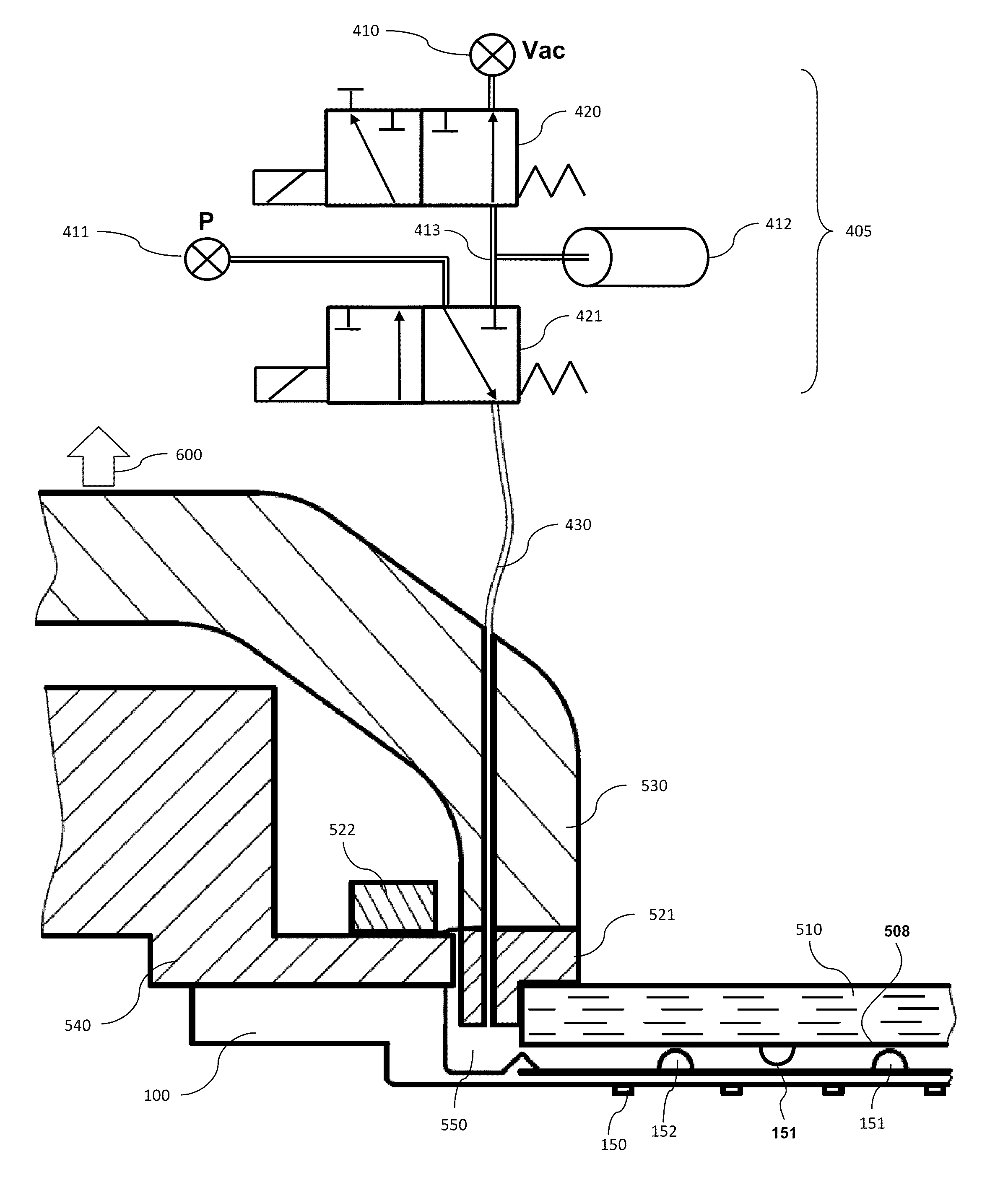

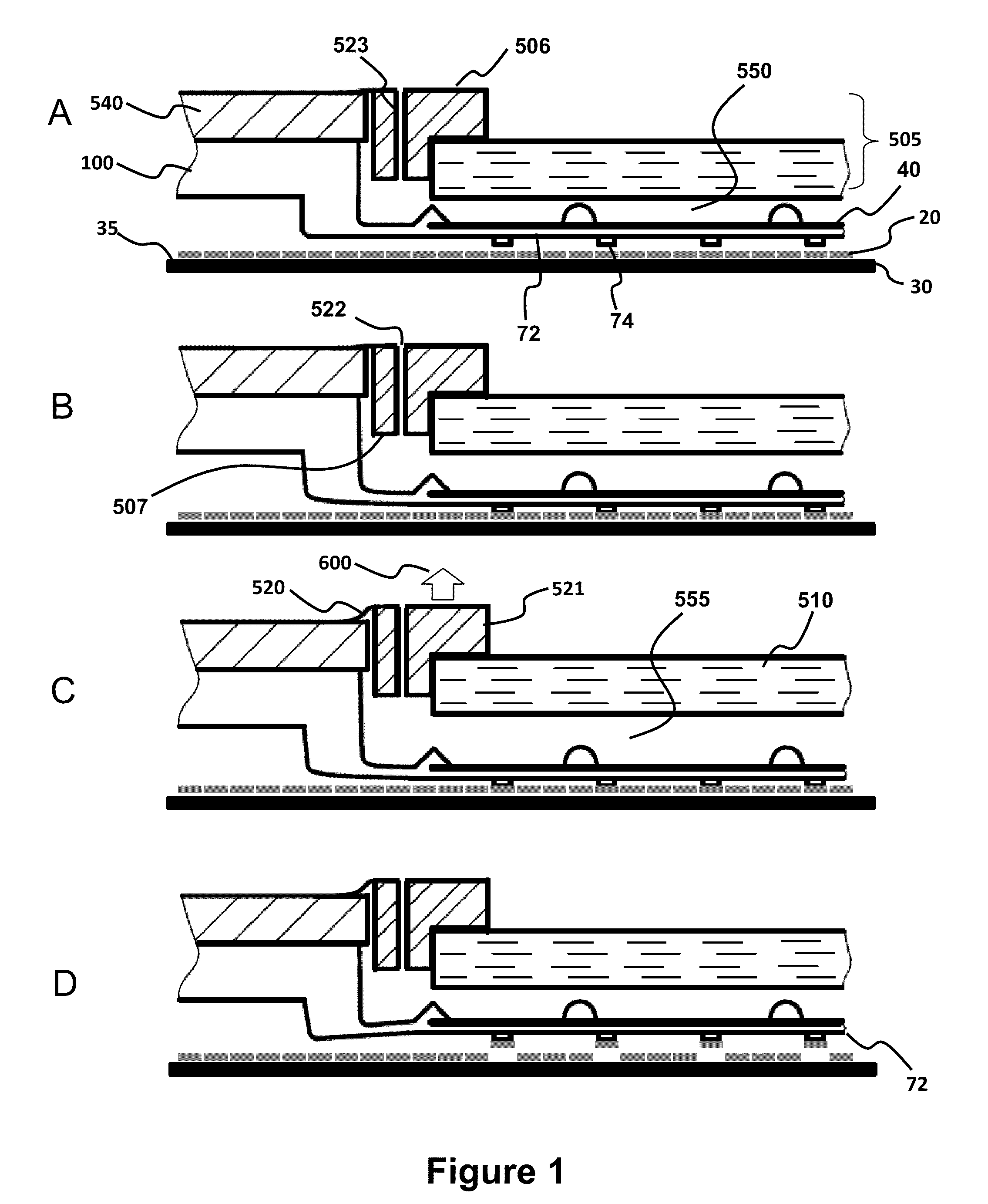

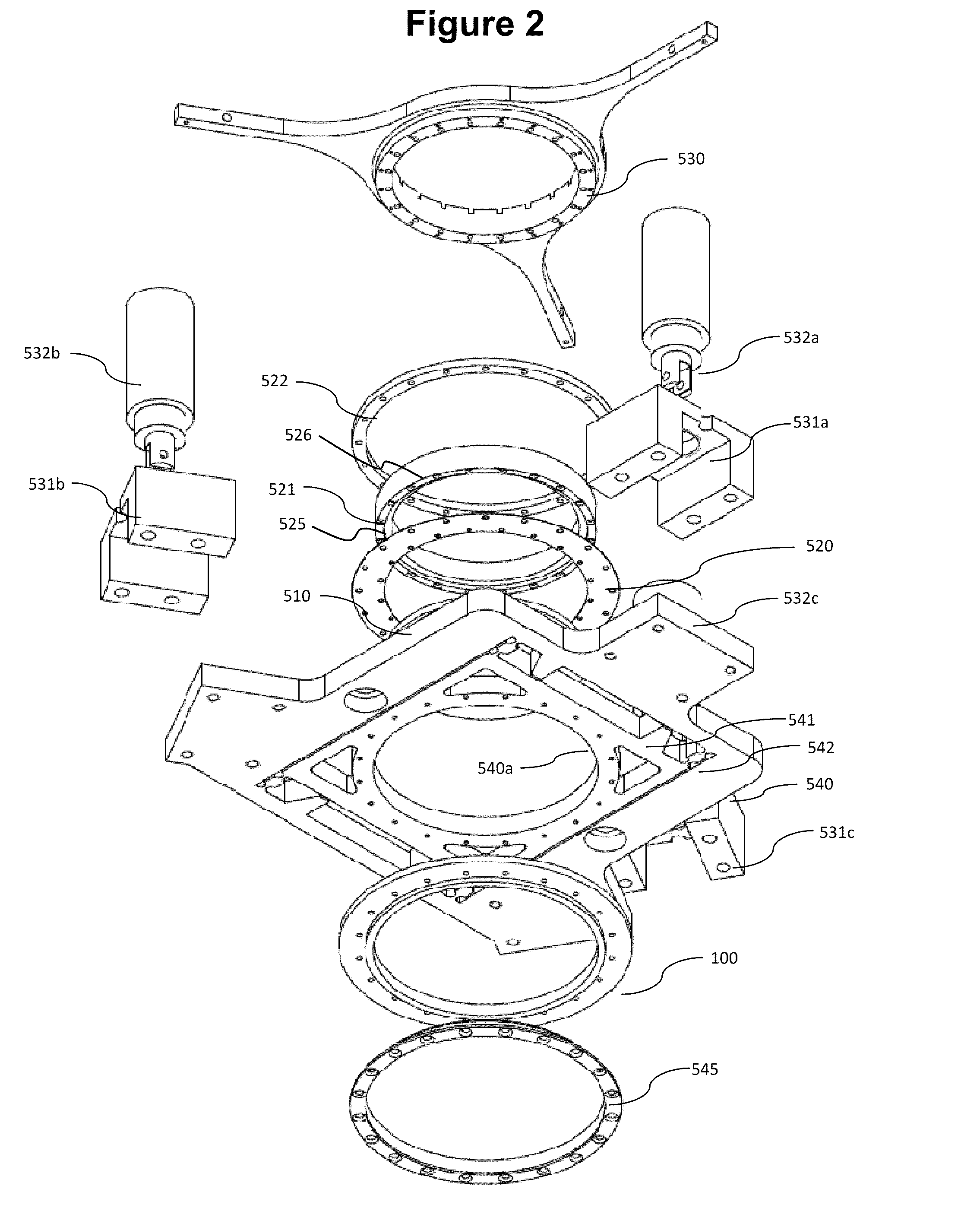

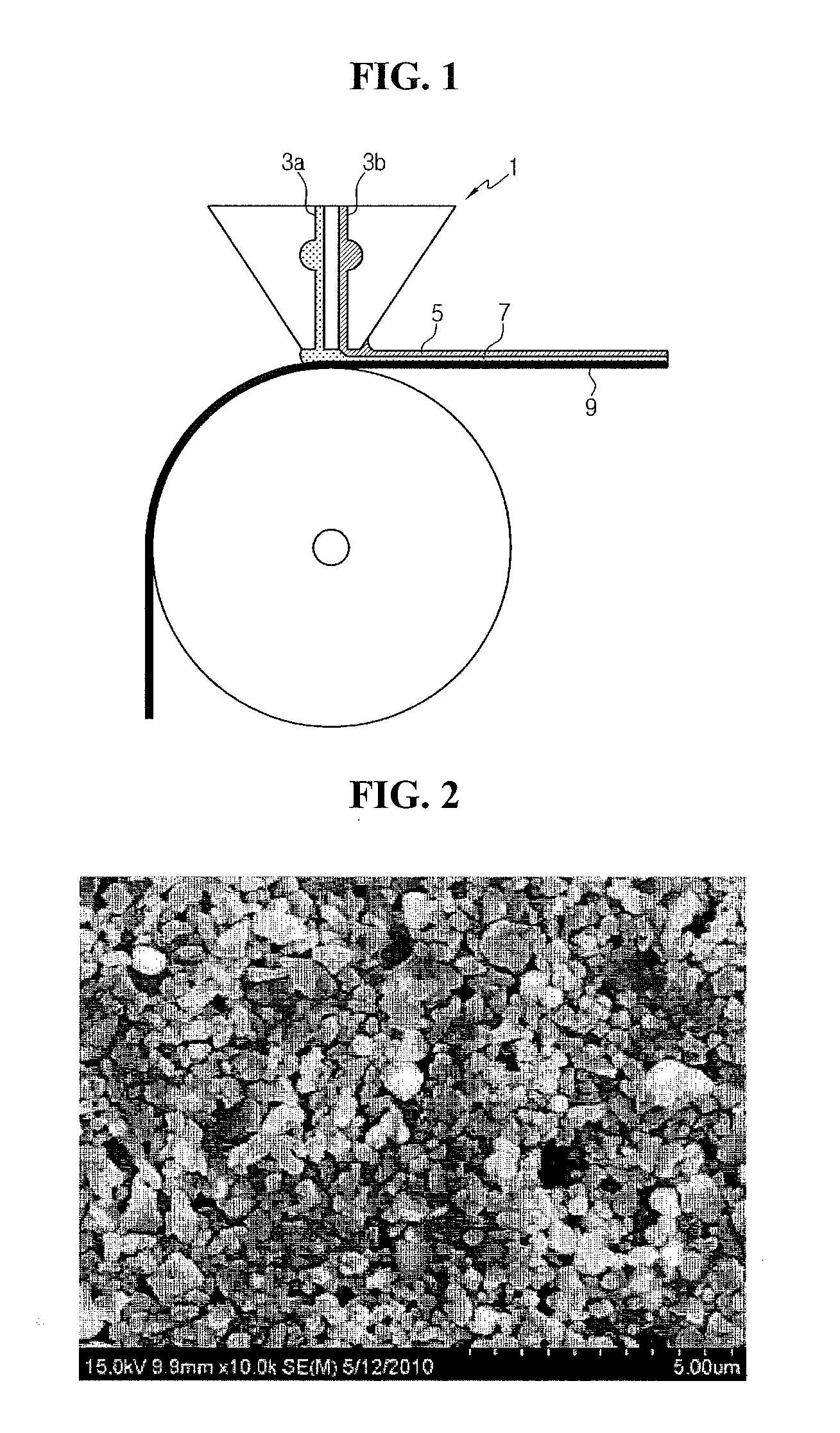

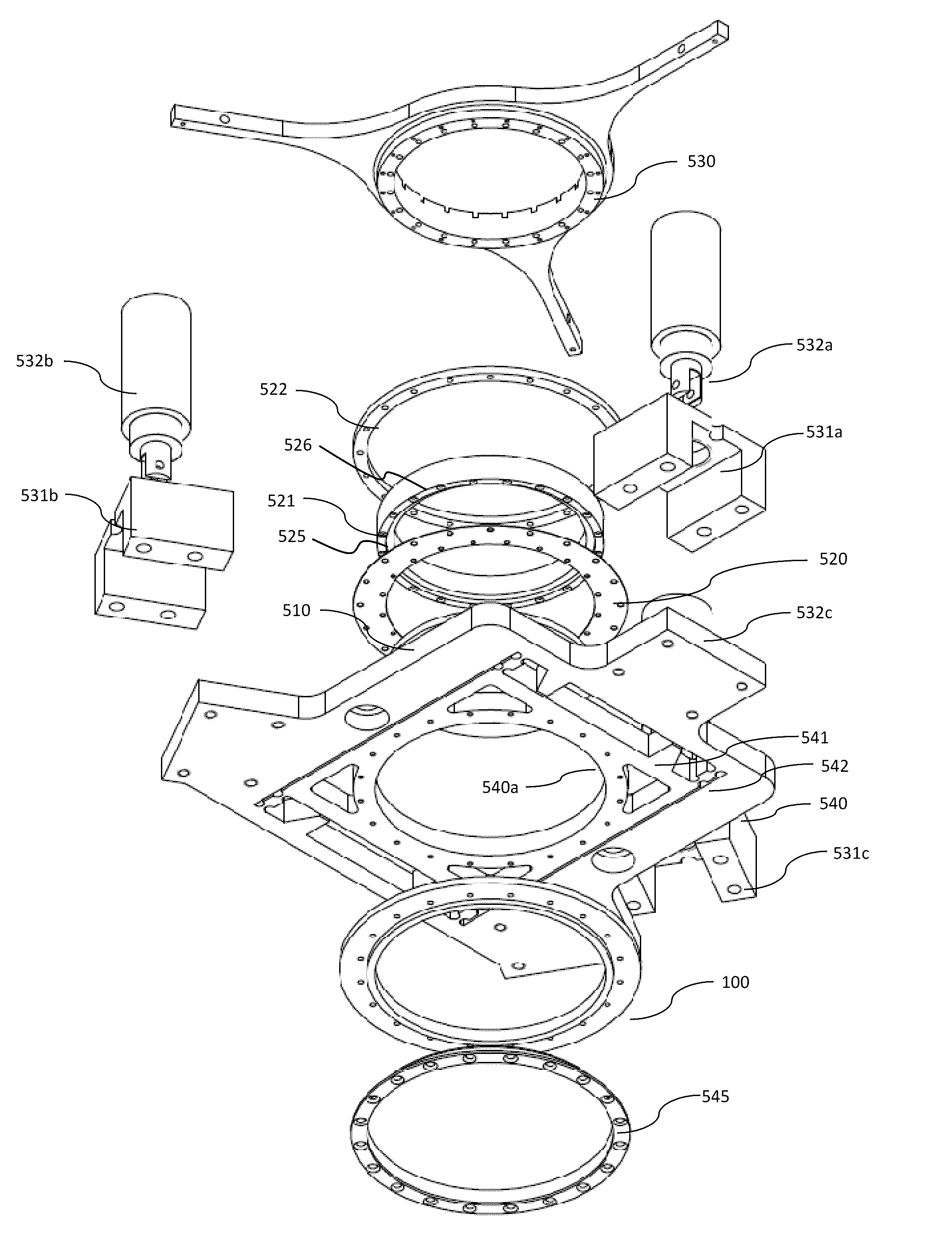

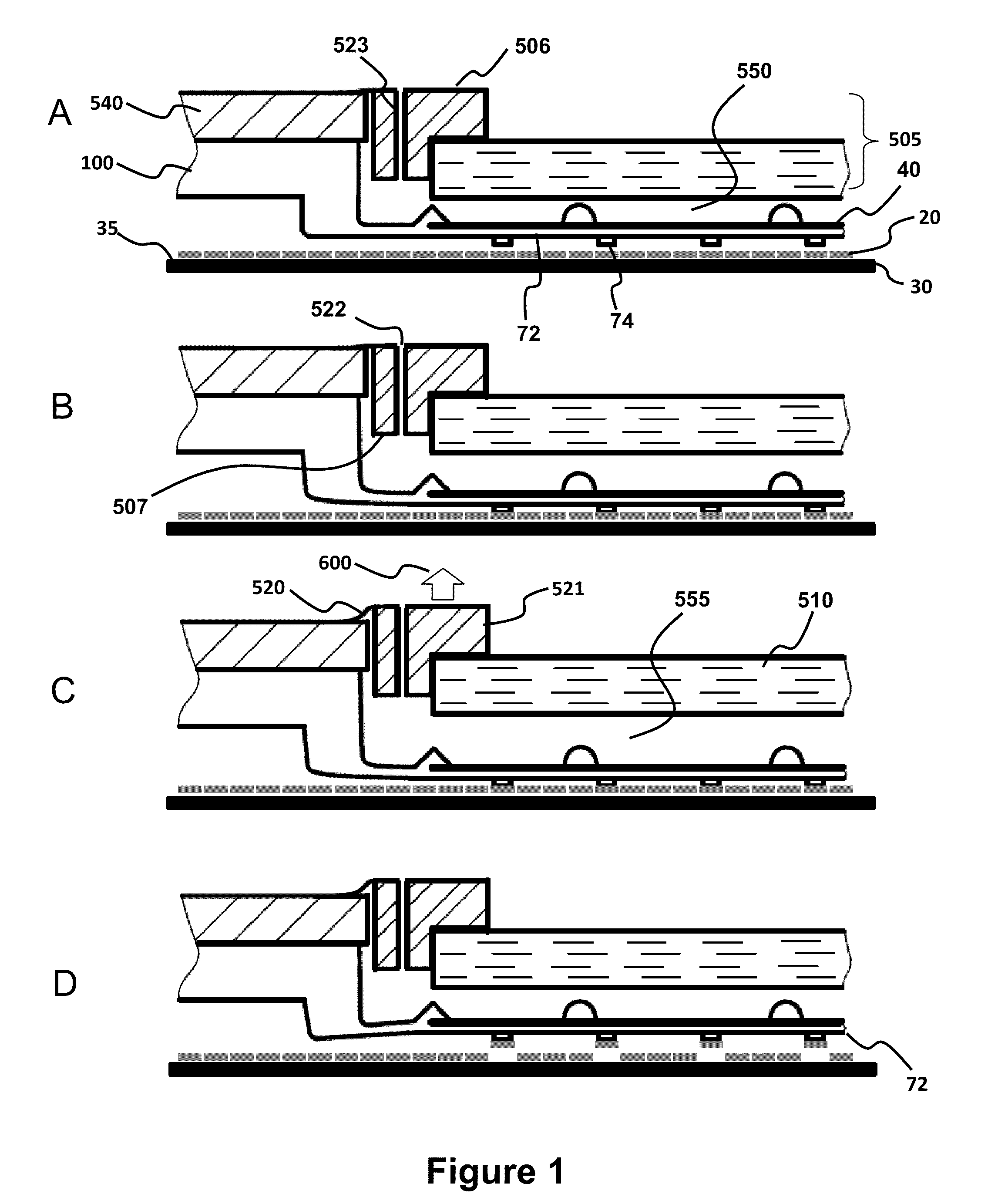

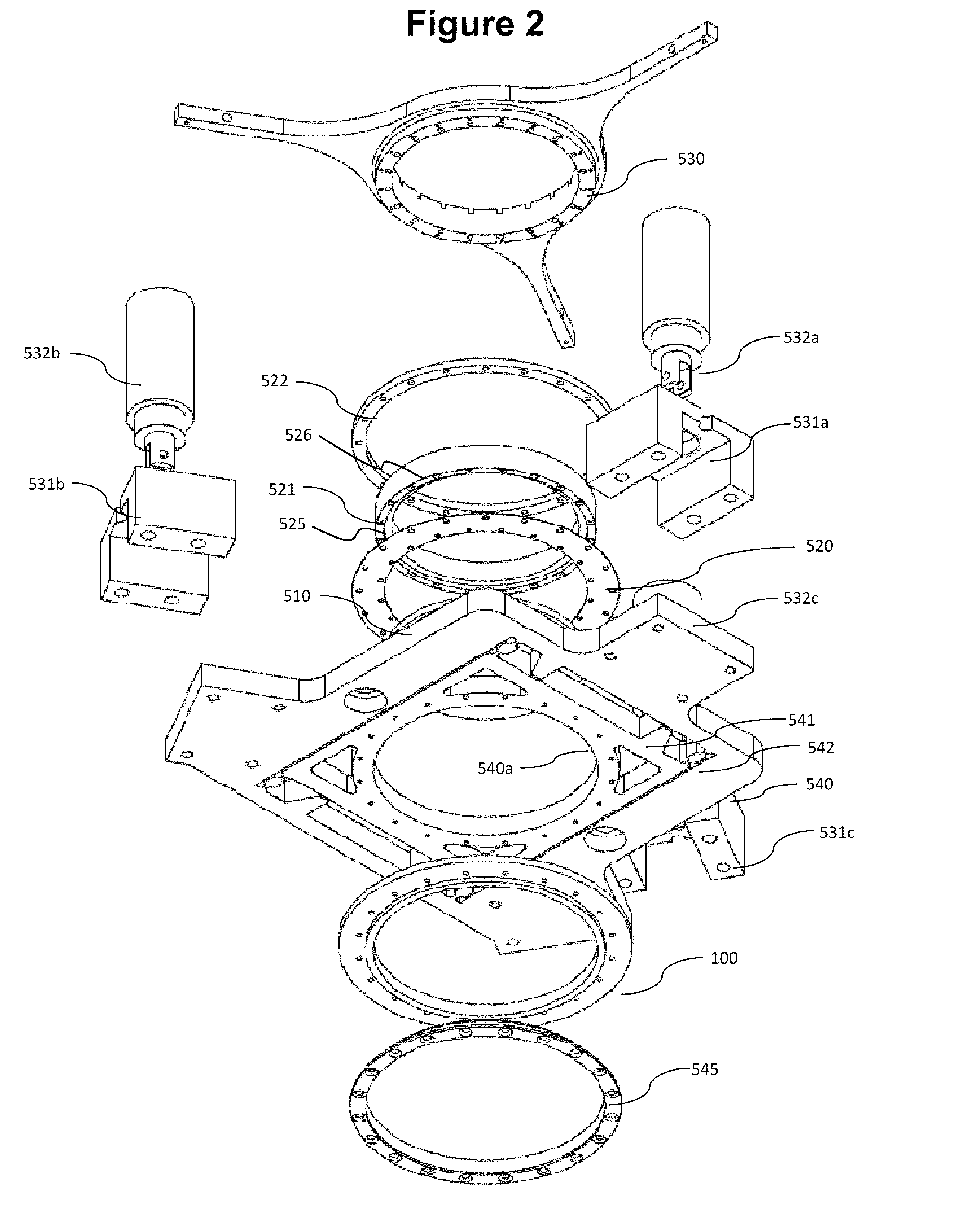

Vacuum Coupled Tool Apparatus for Dry Transfer Printing Semiconductor Elements

InactiveUS20110018158A1Shorten the timeReduce waiting timeMechanical working/deformationDecorative surface effectsDry transferSemiconductor components

Provided are an optimized tool apparatus and methods for dry transfer printing of semiconductor elements with high yield and good placement accuracy. The tool apparatus comprises a vacuum coupled fast peel apparatus that provides high pickup yield of the semiconductor elements. In an aspect, this vacuum coupled apparatus provides high pickup rates during pickup of the semiconductor elements from a donor / source wafer. Provided is a tool apparatus for dry transfer printing with a reinforced composite stamp having a thin glass-backing. The tool apparatus also comprises a pressure regulated micro-chamber which provides precise control of a composite stamp lamination and de-lamination. In an aspect, the micro-chamber has an internal cavity volume that is variably controlled, thereby providing precise control of the force on the stamp, and corresponding separation velocity, and improved semiconductor element pick-up and / or placement.

Owner:X DISPLAY CO TECH LTD

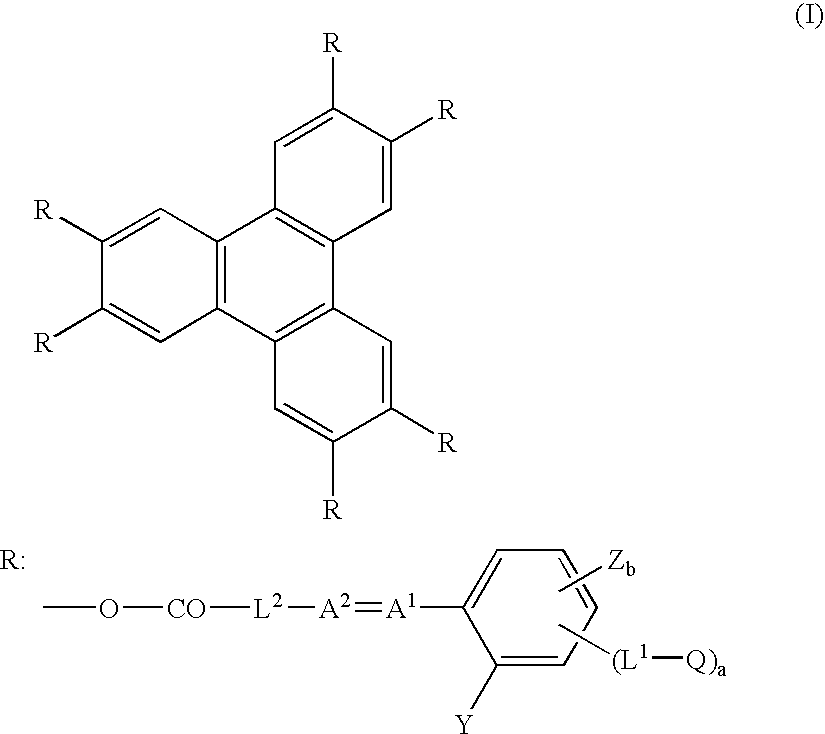

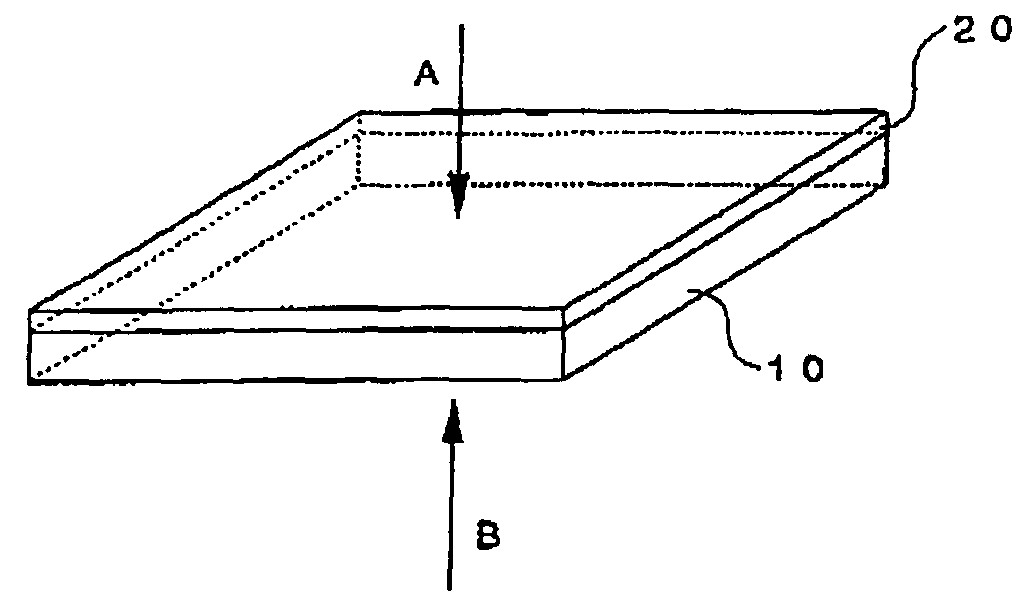

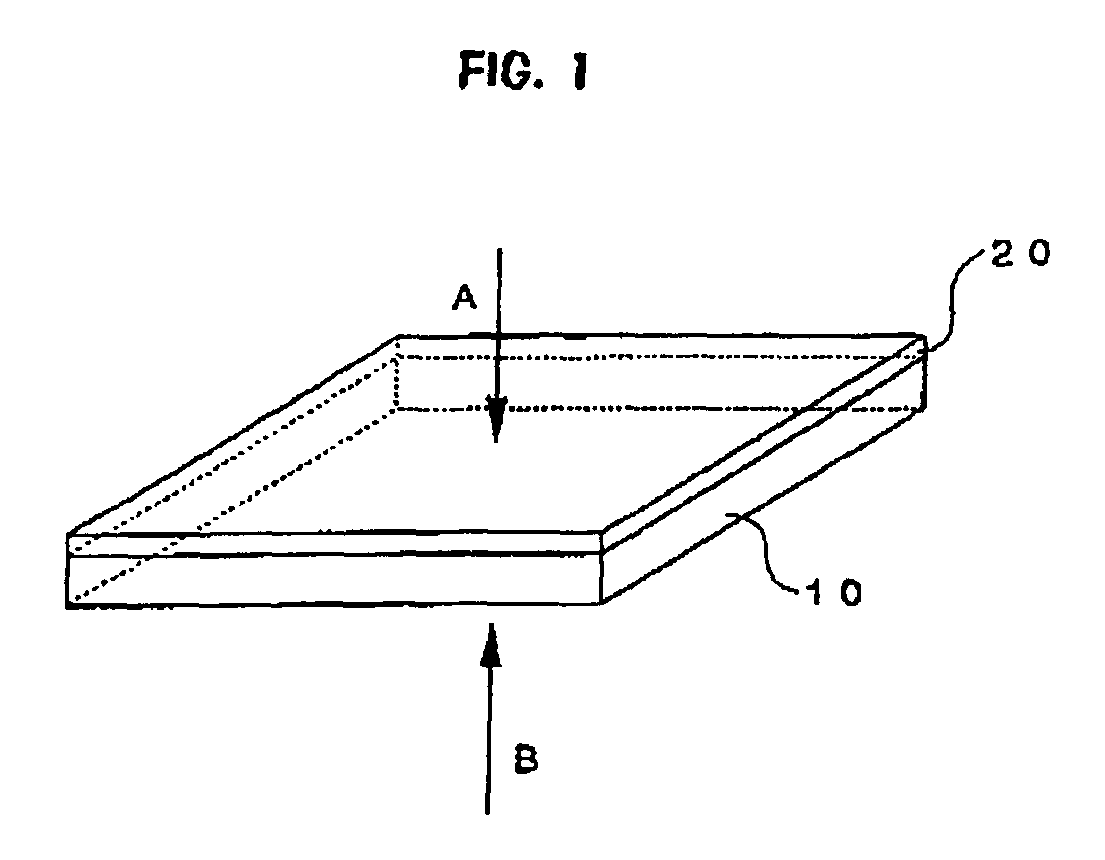

Optical compensatory sheet comprising transparent support and optically anisotropic layer

InactiveUS20040151846A1Improve productivityEasy laminationLiquid crystal compositionsThin material handlingRefractive indexChemistry

An optical compensatory sheet comprises a transparent support and an optically anisotropic layer. The optically anisotropic layer is formed from liquid crystal molecules. Three principal refractive indices of the optically anisotropic layer are different from each other.

Owner:FUJIFILM CORP

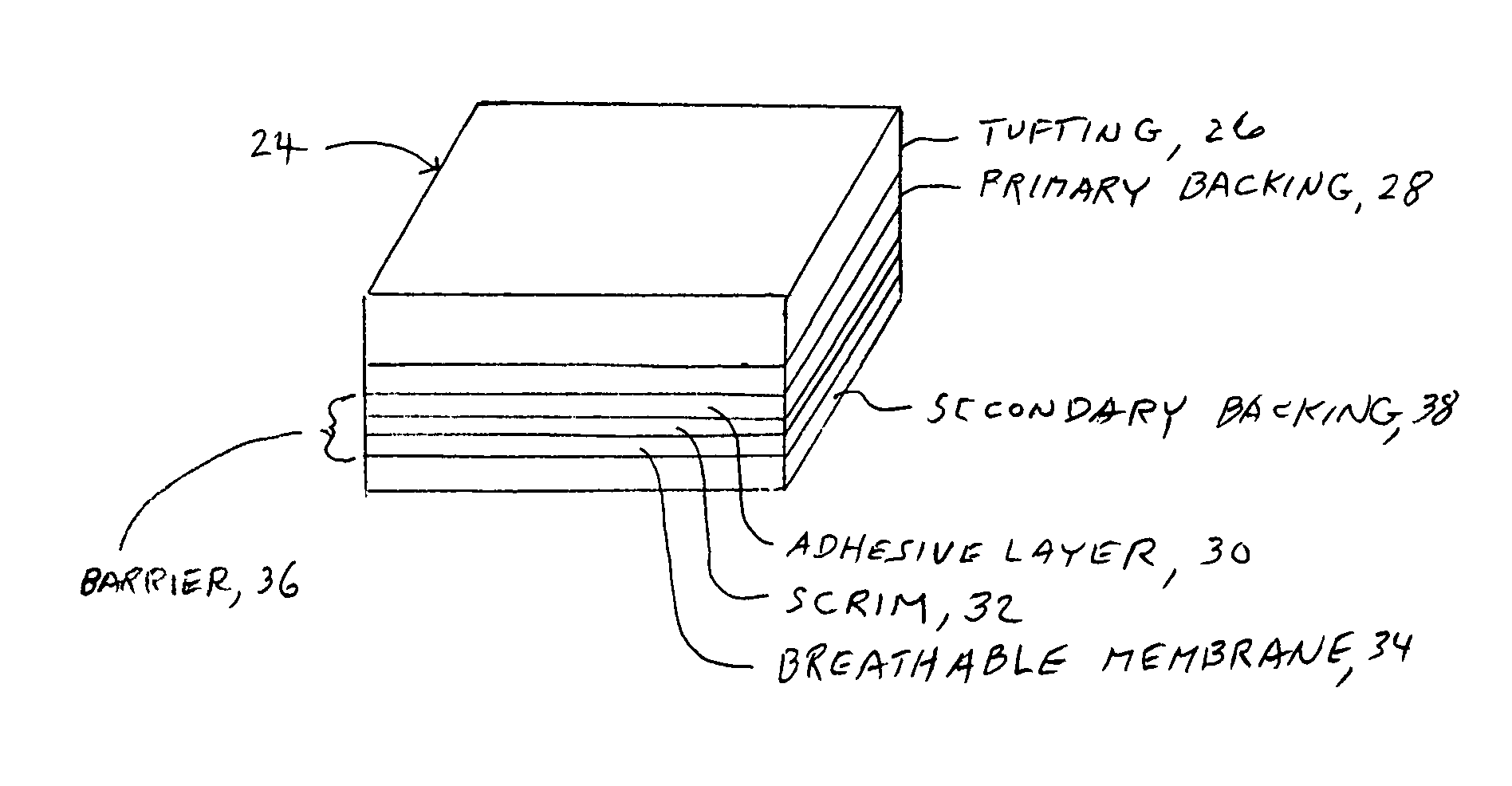

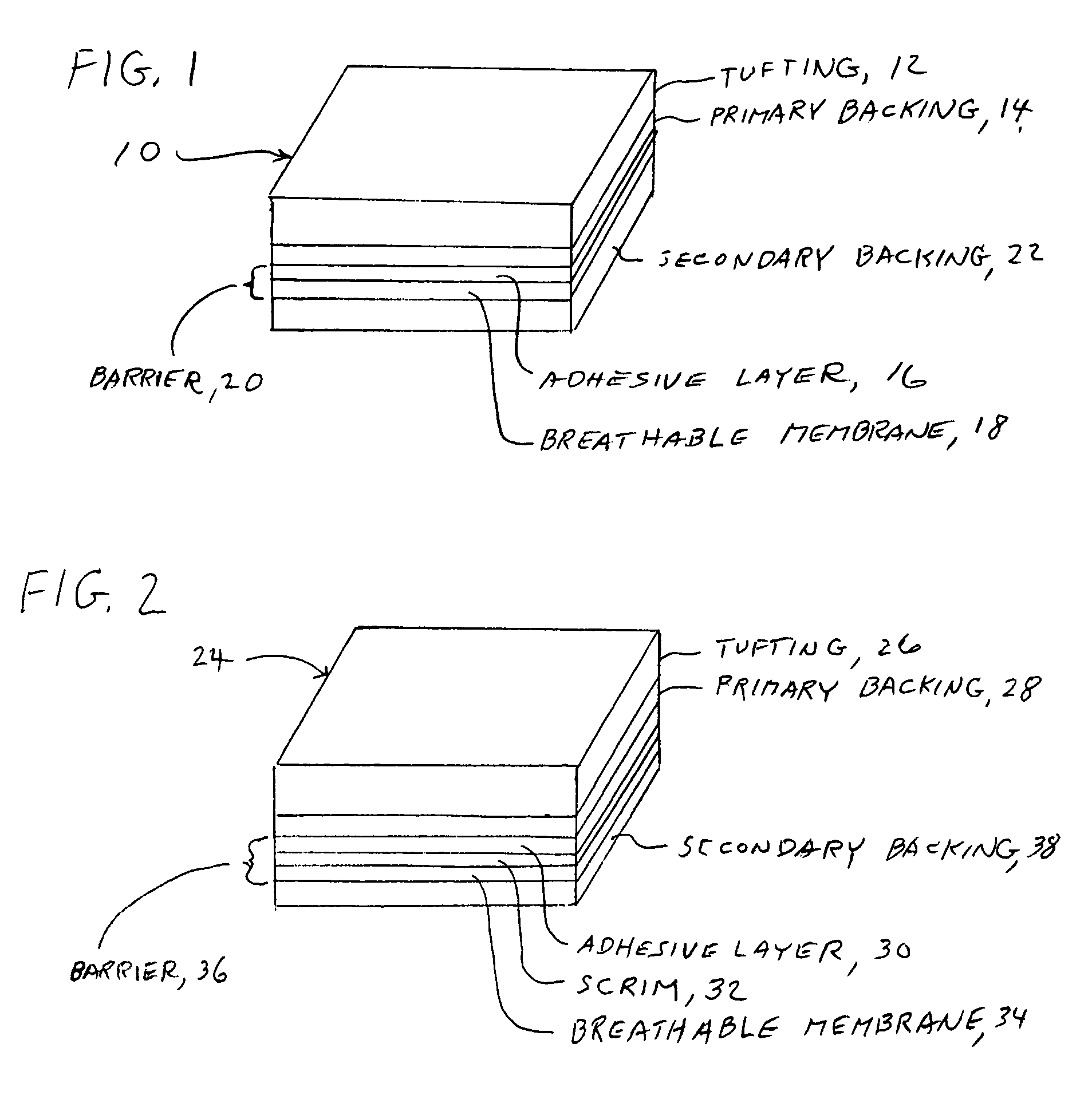

Construction of carpet with breathable membrane for eliminating moisture from surface covered by the carpet

A carpet has a layer of tufting supported on a primary backing layer. A breathable membrane is disposed along an interface between the primary backing layer and a secondary backing layer. A breathable membrane is disposed along an interface between the tufting layer and the backing layer, and adhesively secures the layer of tufting to the backing layer. The breathable membrane is permeable to water vapor but impervious to liquid water, while both the tufting layer and the backing layer are permeable to water vapor. In an alternative embodiment of the invention, a laminated barrier which includes the membrane, may be made of fibers, yarns, cross-laid scrim, or plastic netting, and the breathable membrane may be protected from abrasion with a floor by means of an apertured film laminated to the membrane.

Owner:MARTZ JOEL D

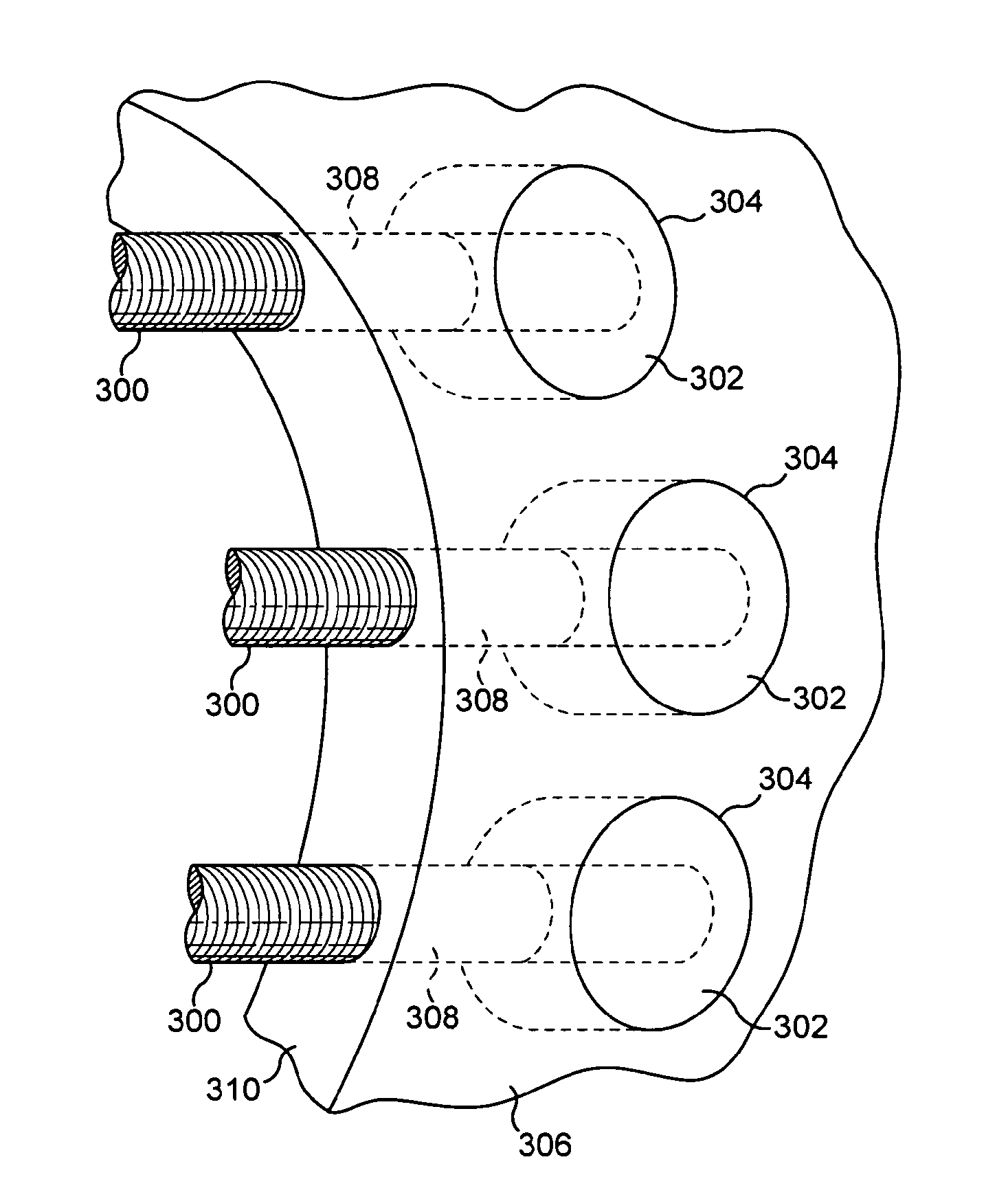

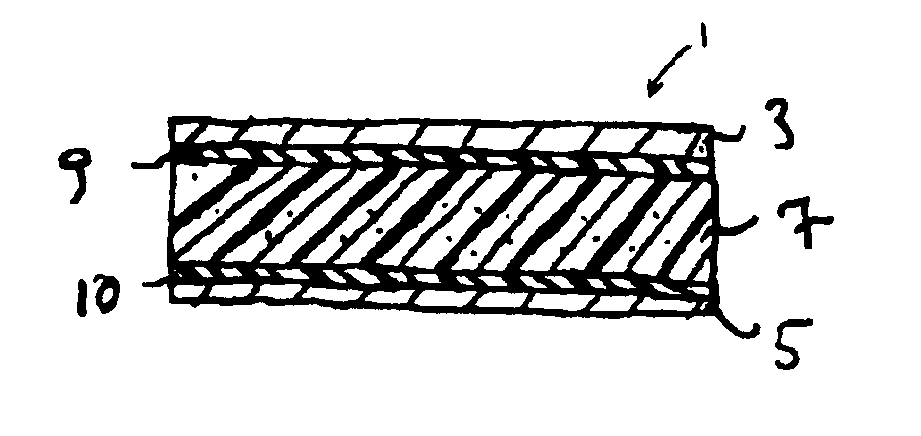

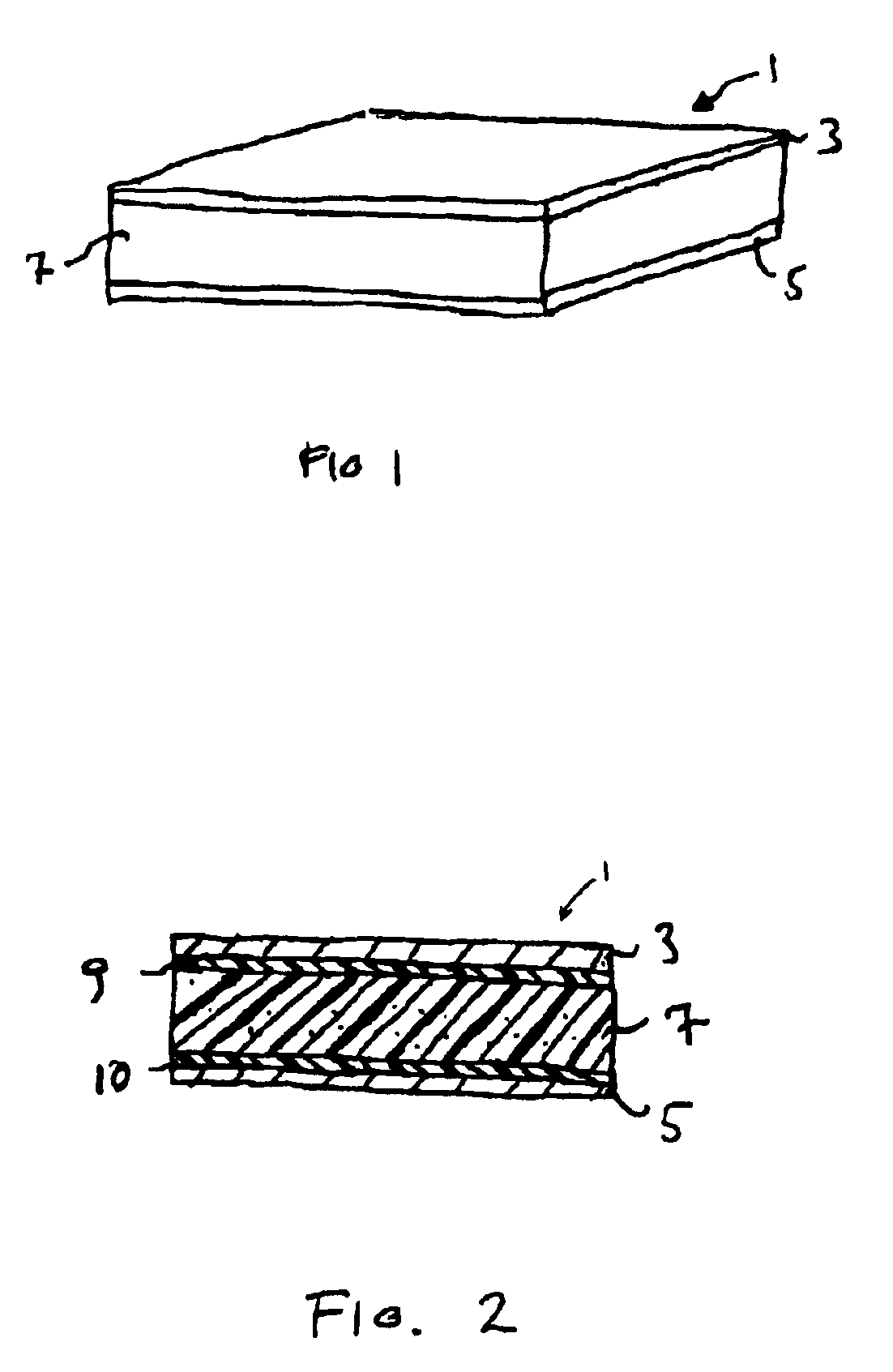

Wrap around self laminating wristband

ActiveUS8109021B2Easy laminationQuick and easy methodStampsData processing applicationsAdhesiveEngineering

A wrap around, self laminating wristband comprises a substantially transparent laminate strap with an imaging area for receiving printed information and one or more layers of adhesive adjacent the imaging area so that as the strap is wrapped around itself to overlie the imaging area it laminates it. Alternate embodiments provide for a snap closure to secure the wristband instead of adhesive, forming the imaging area with a coating of a thermally sensitive or active print material, adding one or more labels for common use with the wristband, forming the wristband in a page of multiple wristbands or with labels or separately, forming the wristband as part of a printer processable business form, and providing the wristband forms either with or without labels in a continuous fan fold or roll format.

Owner:ZEBRA TECH CORP

Separator with improved ease of handling

ActiveCN1929164AImprove bendabilityImprove bending resistanceLi-accumulatorsCell component detailsFiberCeramic coating

Robust separator which has, on a substrate and in the voids of the substrate, which comprises fibers of an electrically nonconductive material, an electrically nonconductive coating comprising oxide particles which are adhesively bonded to one another and to the substrate by an inorganic adhesive and comprise at least one oxide selected from Al2O3, ZrO2 and SiO2, polymer particles also being present in the ceramic coating in addition to the oxide particles of Al2O3, ZrO2 and / or SiO2. These separators have particularly good handling properties since they are mechanically very stable.

Owner:EVONIK DEGUSSA GMBH

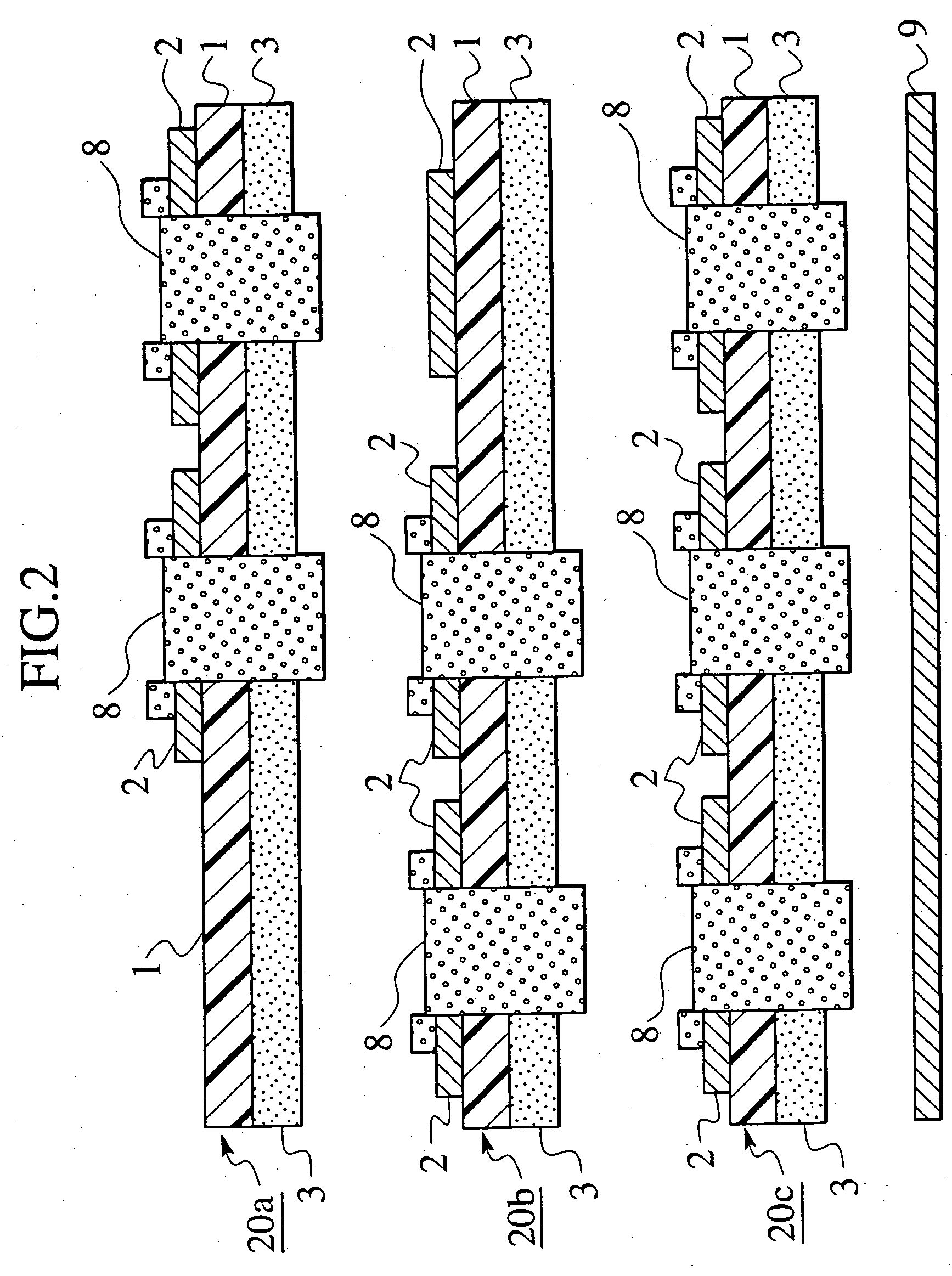

Multilayer wiring board assembly, multilayer wiring board assembly component and method of manufacture thereof

InactiveUS20050016765A1Improve heat resistanceEasy laminationPrinted circuit assemblingInsulating substrate metal adhesion improvementConductive pasteCopper plating

A multilayer wiring board assembly, a multilayer wiring board assembly component, and a method of manufacture thereof. The multilayer wiring board assembly is formed by laminating together a plurality of multilayer wiring board assembly components having a flexible resin film with a copper foil bonded to one surface and an adhesive layer bonded to the other surface, opening a through hole in the copper plated resin film through the cooper foil, resin film, and the adhesive layer, and filling the through hole with a conductive paste projecting from the adhesive layer and laterally extending beyond through hole opening of the copper foil.

Owner:THE FUJIKURA CABLE WORKS LTD

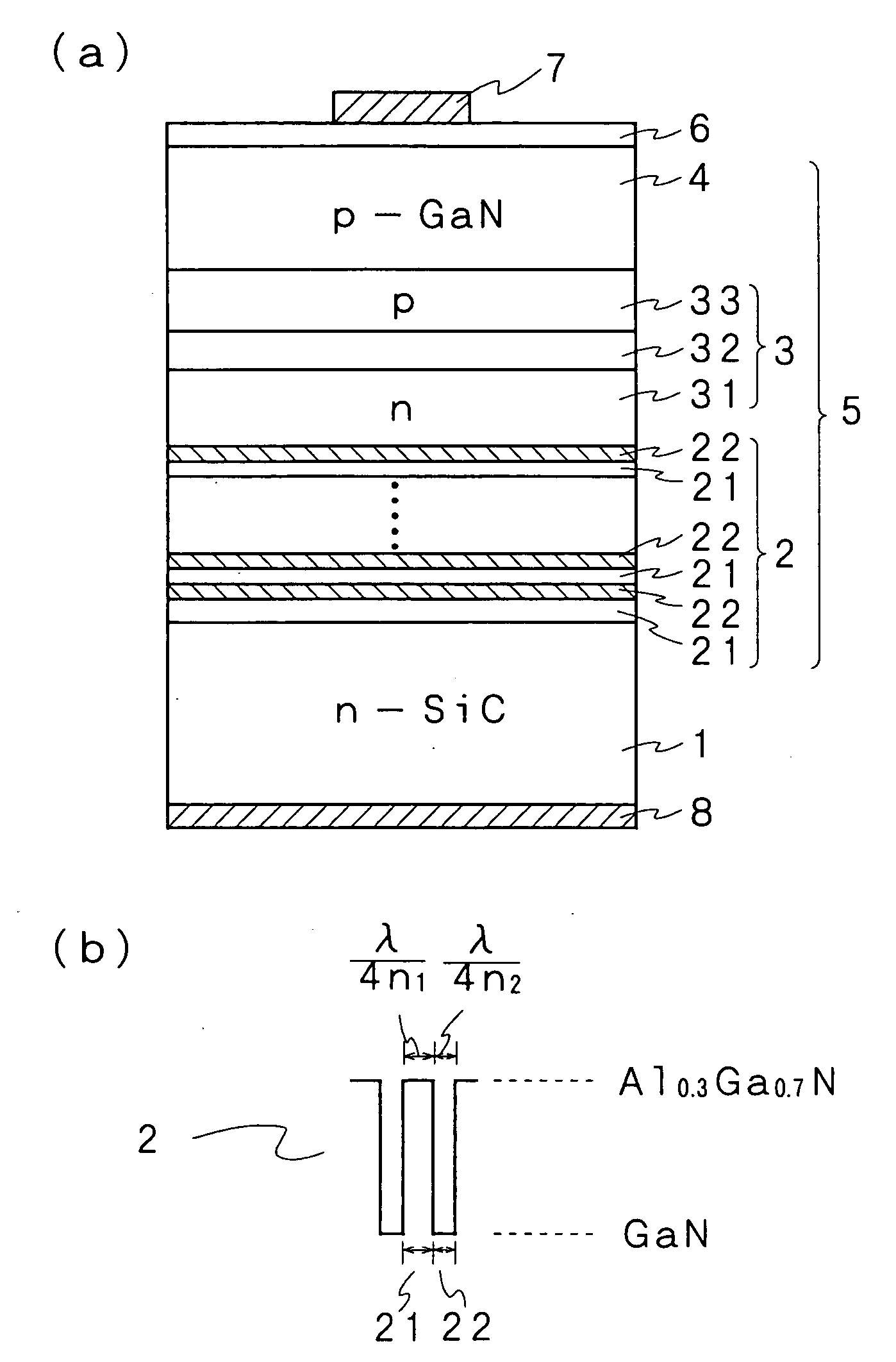

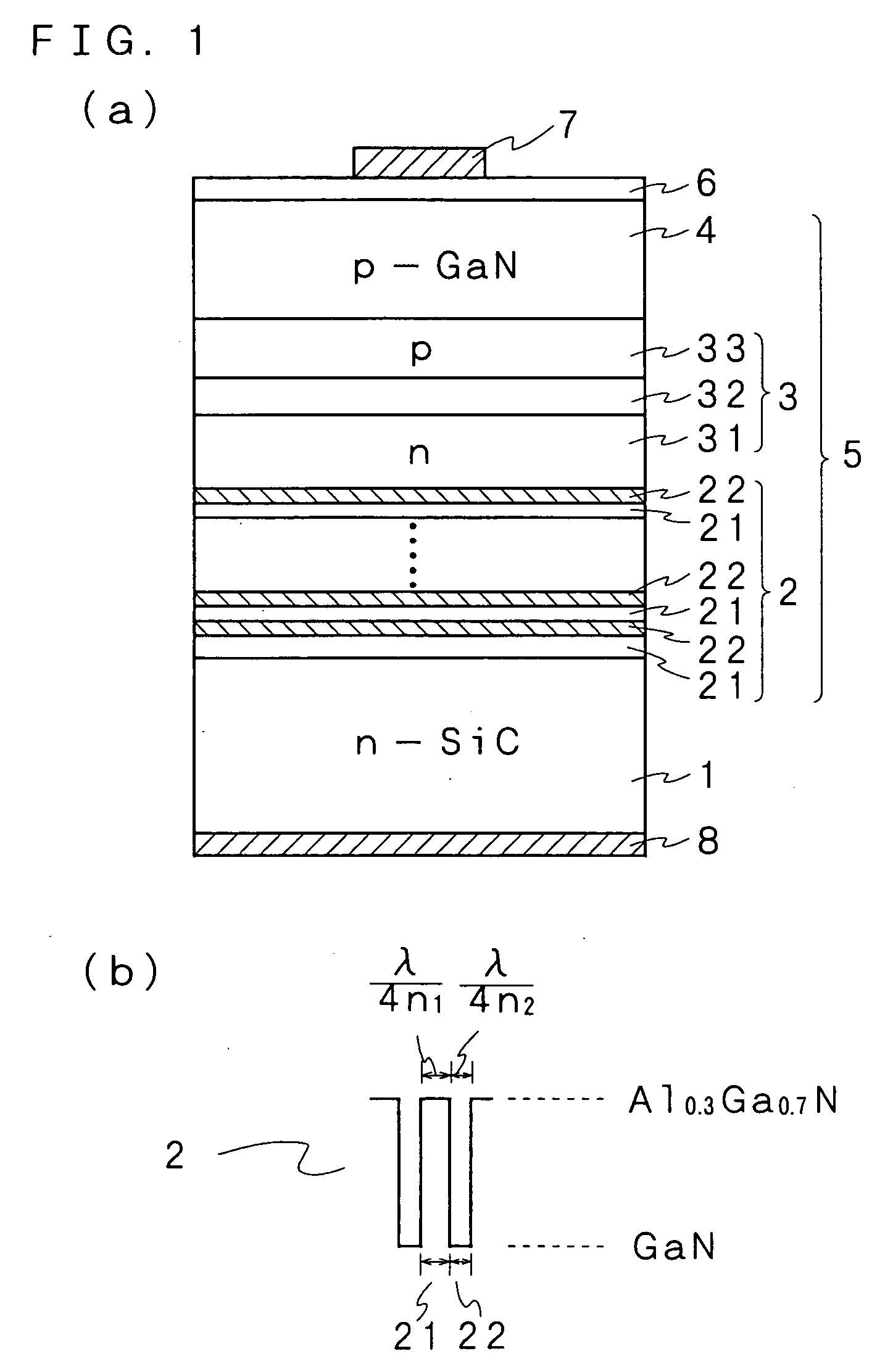

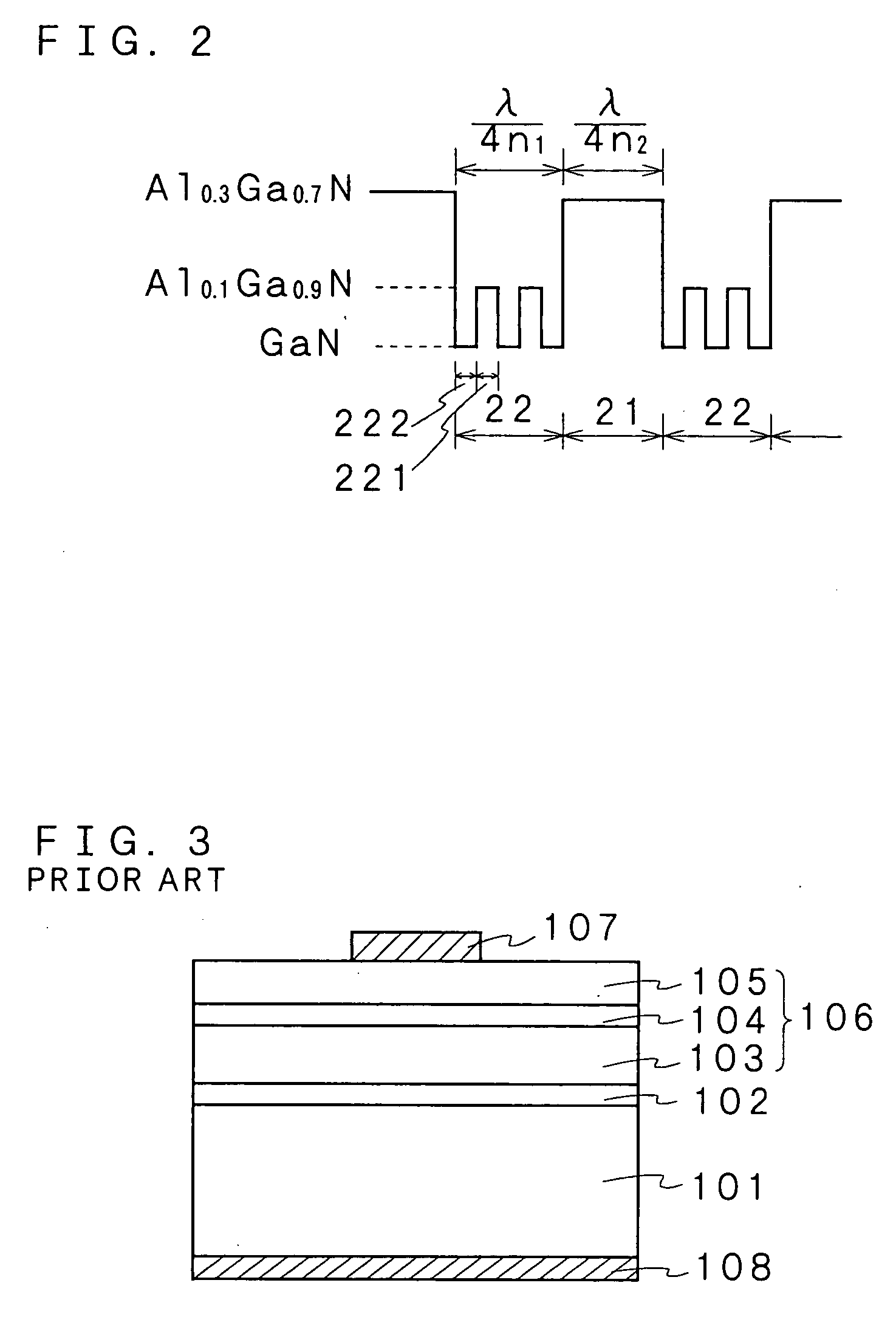

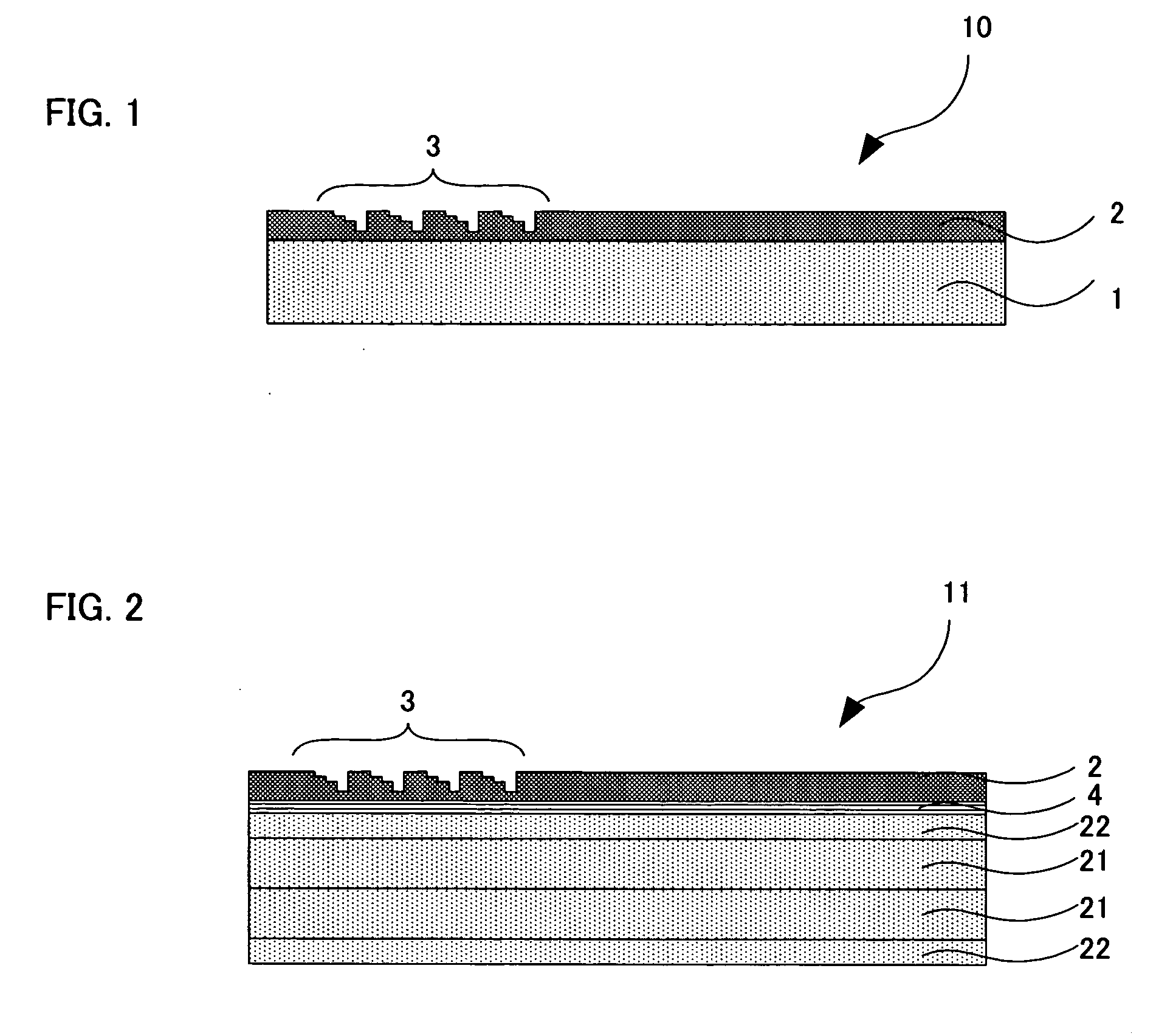

Nitride Semiconductor Light Emitting Device

InactiveUS20090127572A1Improve quality of filmKeep conductivitySemiconductor lasersSemiconductor devicesSic substratePhysics

There is provided a nitride semiconductor light emitting device capable of inhibiting output deterioration of light emission caused by quality deterioration of a nitride semiconductor layer due to lattice-mismatching between a substrate and the nitride semiconductor layer, and utilizing light traveling to the substrate efficiently, while forming a light emitting device of a vertical type which has one electrode on a back surface of the substrate by using the substrate made of SiC. A light reflecting layer (2) which is formed by laminating low refractive index layers (21) and high refractive index layers (22) having different refractive indices alternately is directly provided on the SiC substrate (1), and a semiconductor lamination portion (5) which is formed by laminating nitride semiconductor layers so as to form at least a light emitting layer forming portion (3) is provided on the light reflecting layer (2). An upper electrode (7) is provided on an upper surface side of the semiconductor lamination portion (5), and a lower electrode (8) is provided on a back surface of the SiC substrate (1).

Owner:ROHM CO LTD

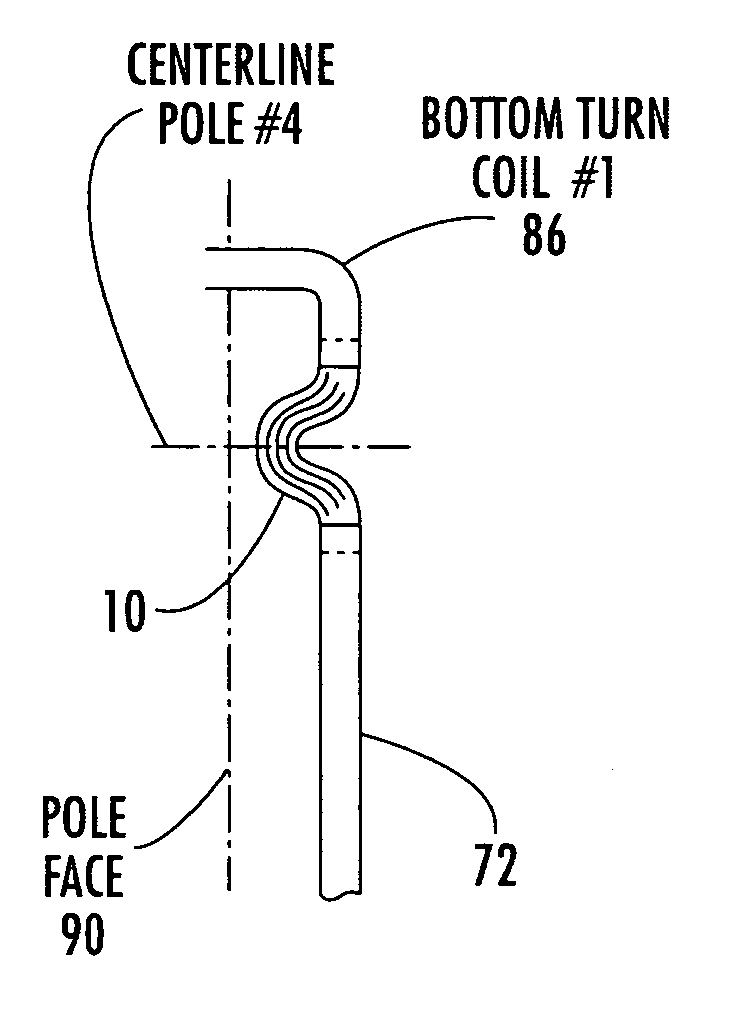

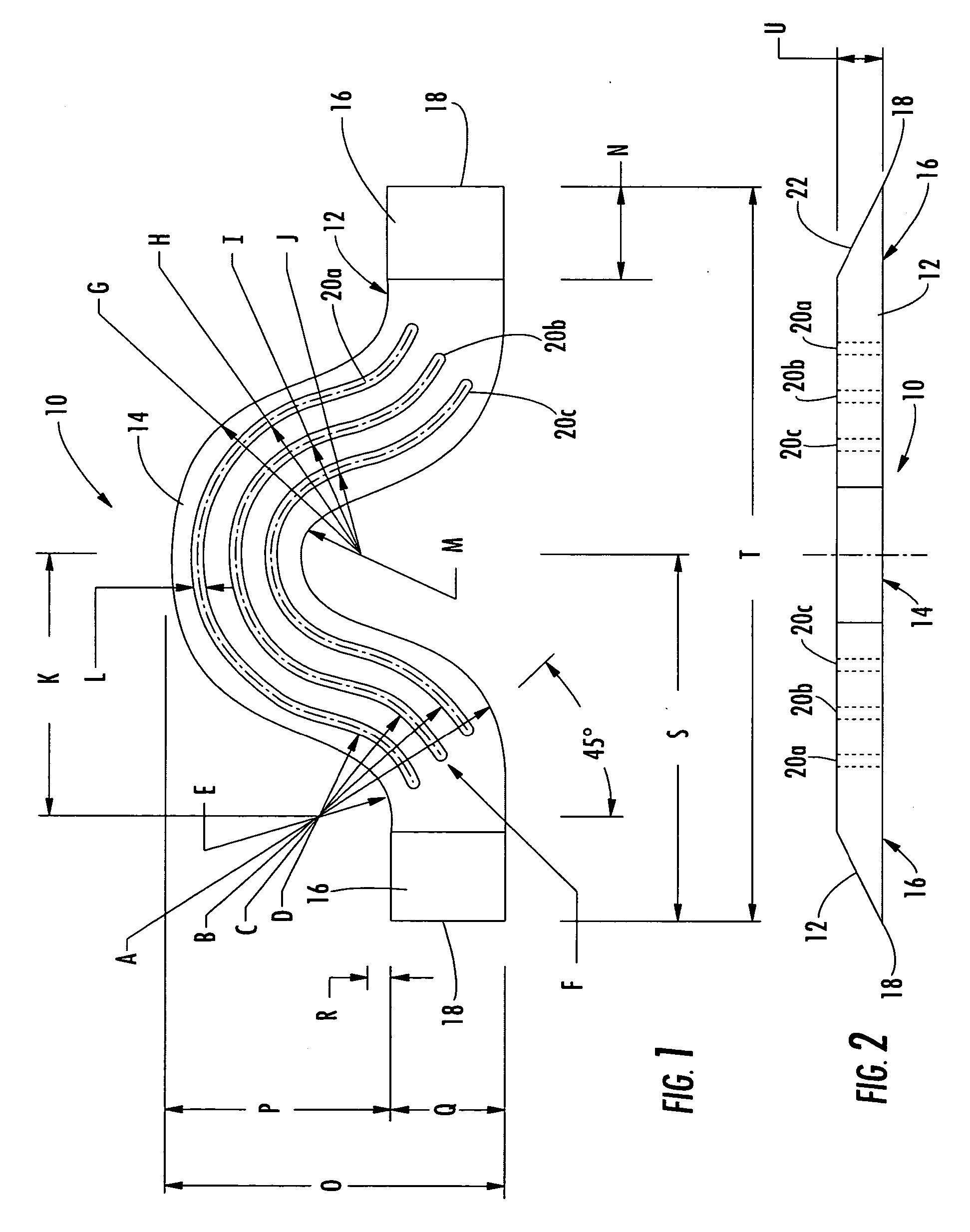

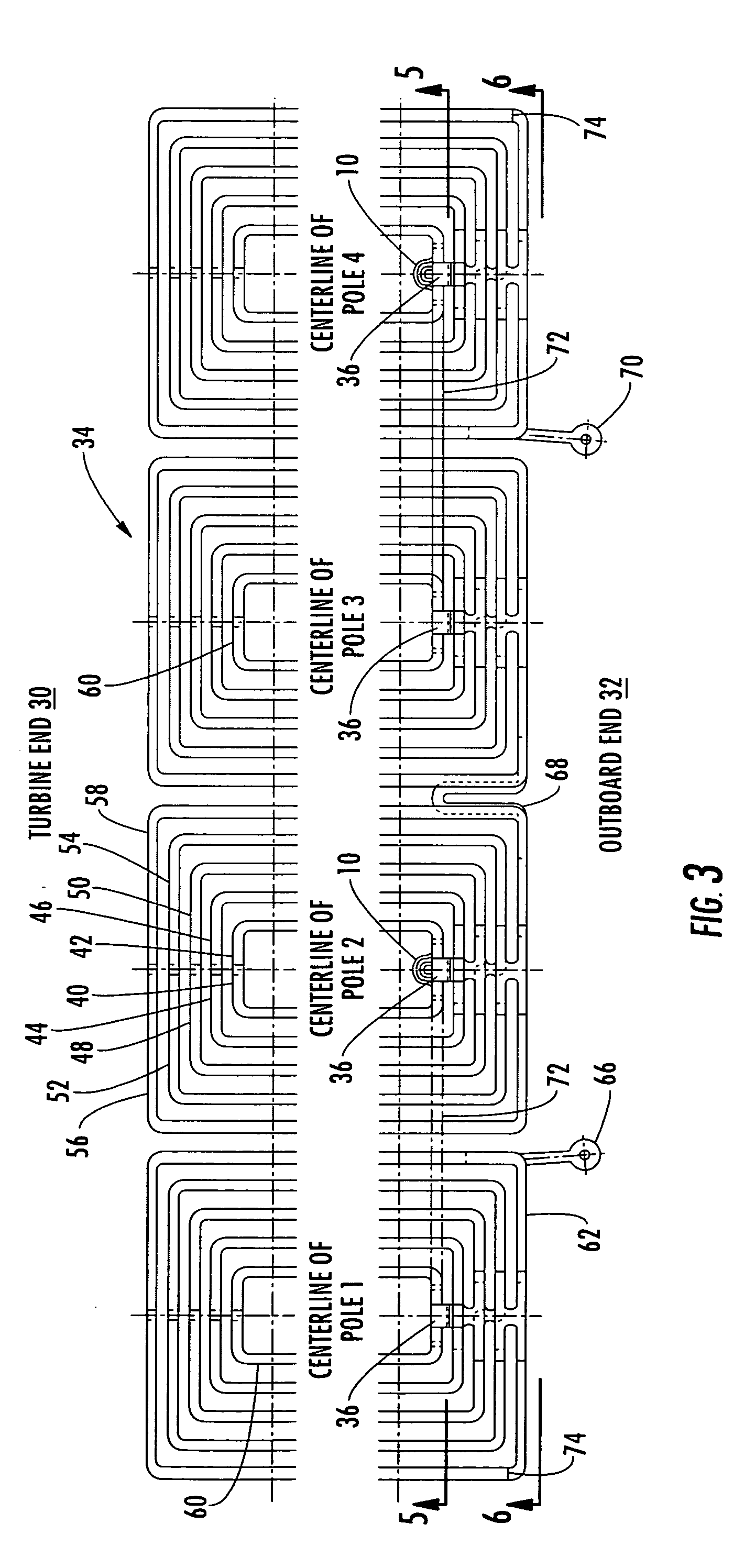

Flexible rotor pole crossover for a generator

ActiveUS20050285469A1Good flexibilityAvoid easy installationWindingsMagnetic circuit rotating partsMagnetic polesEngineering

A generator includes a shaft and rotor body defining poles and a winding positioned around the shaft on the rotor body. A rotor pole crossover is aligned to the shaft and connects ends of the winding between adjacent poles. The rotor pole crossover includes a body member having a curved medial section and opposing legs extending outwardly from the curved medial section that connect to the ends of the winding. The curved medial section has at least one slot formed therein to add flexibility to the rotor pole crossover.

Owner:SIEMENS ENERGY INC

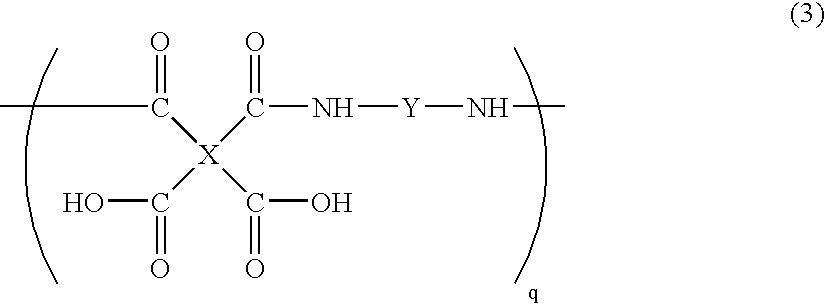

Adhesive composition, adhesive film, and method of producing semiconductor device

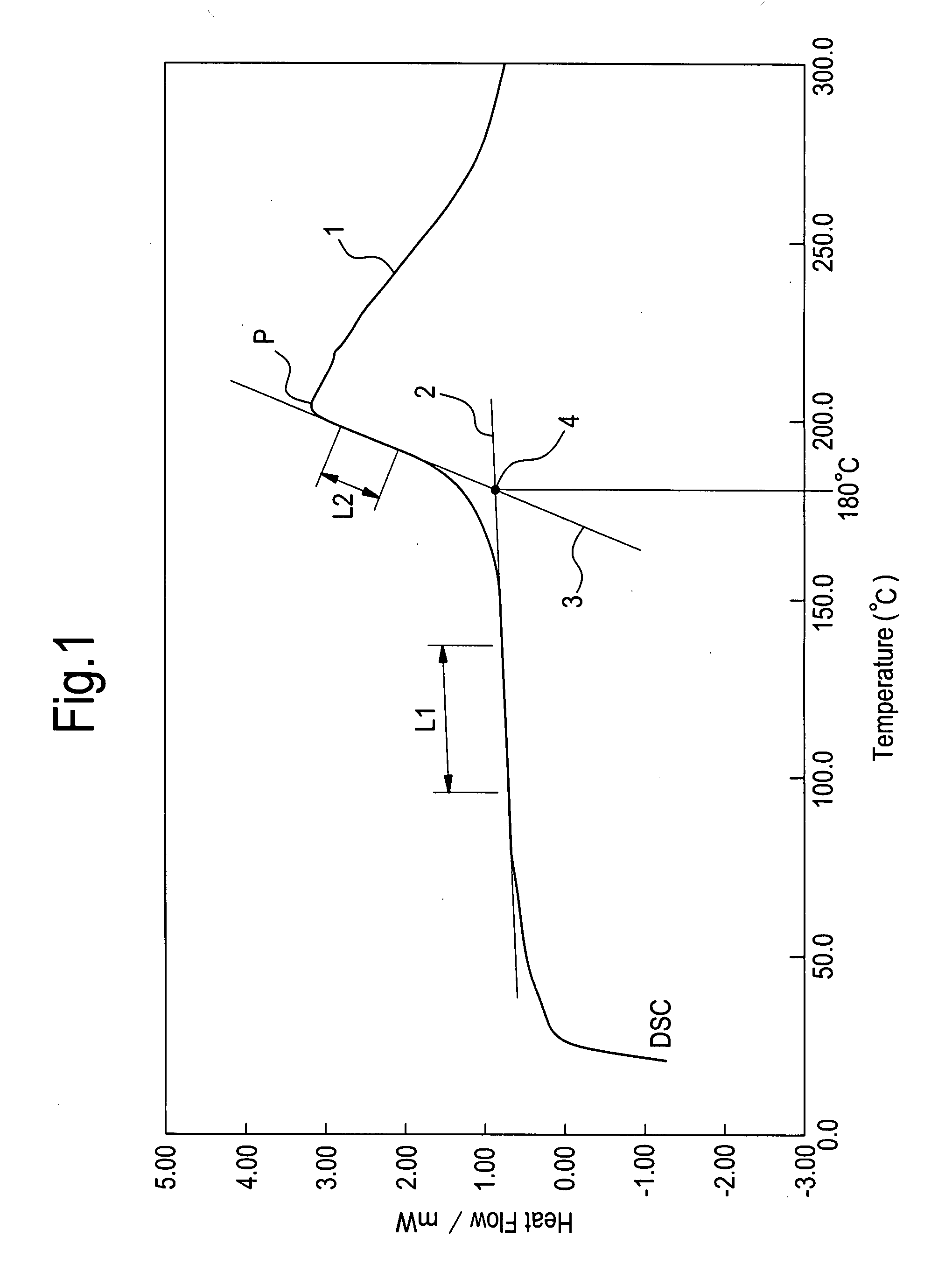

InactiveUS20070191552A1High bonding strengthLow elastic modulusFilm/foil adhesivesSynthetic resin layered productsHeat resistanceSemiconductor

Provided is an adhesive composition, which exhibits a melt viscosity at 40 to 80° C. of not more than 10,000 Pa·s, and which after heating for a period of 1 minute to 2 hours at a temperature within a range from 80° C. to (T+50)° C., exhibits a melt viscosity at a temperature of 100° C. to (T+30)° C. that is within a range from 100 to 10,000 Pa·s (wherein, T represents the curing start temperature for the composition). The adhesive composition is capable of forming a cured product that exhibits excellent filling of substrates with finely patterned circuits, excellent lamination performance at low temperatures, a low elastic modulus, and excellent levels of adhesion and heat resistance. The adhesive composition is useful for providing an adhesive film and for producing a semiconductor device.

Owner:SHIN ETSU CHEM IND CO LTD

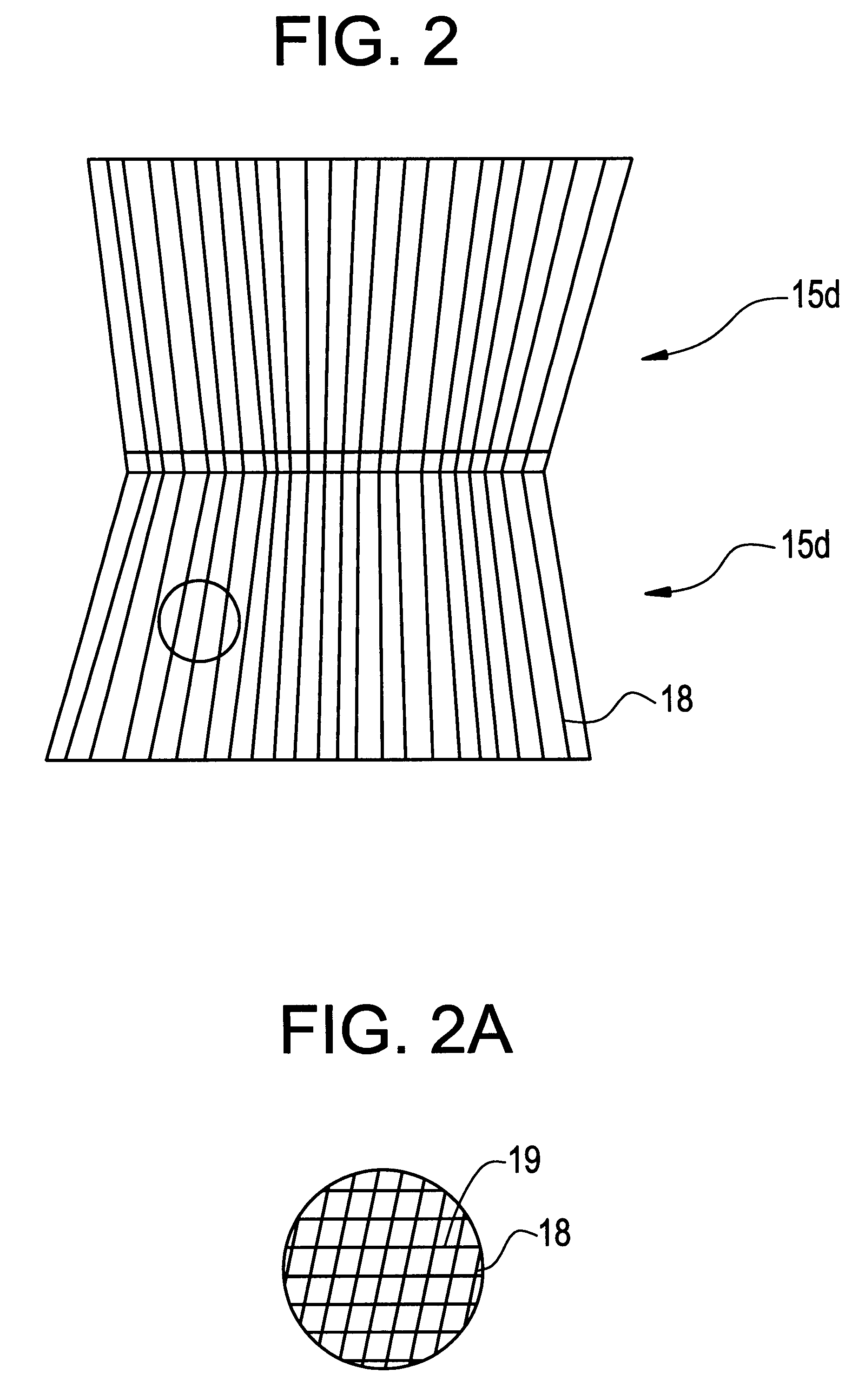

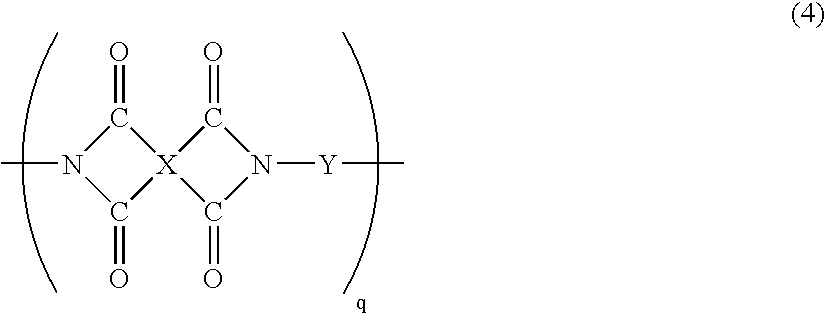

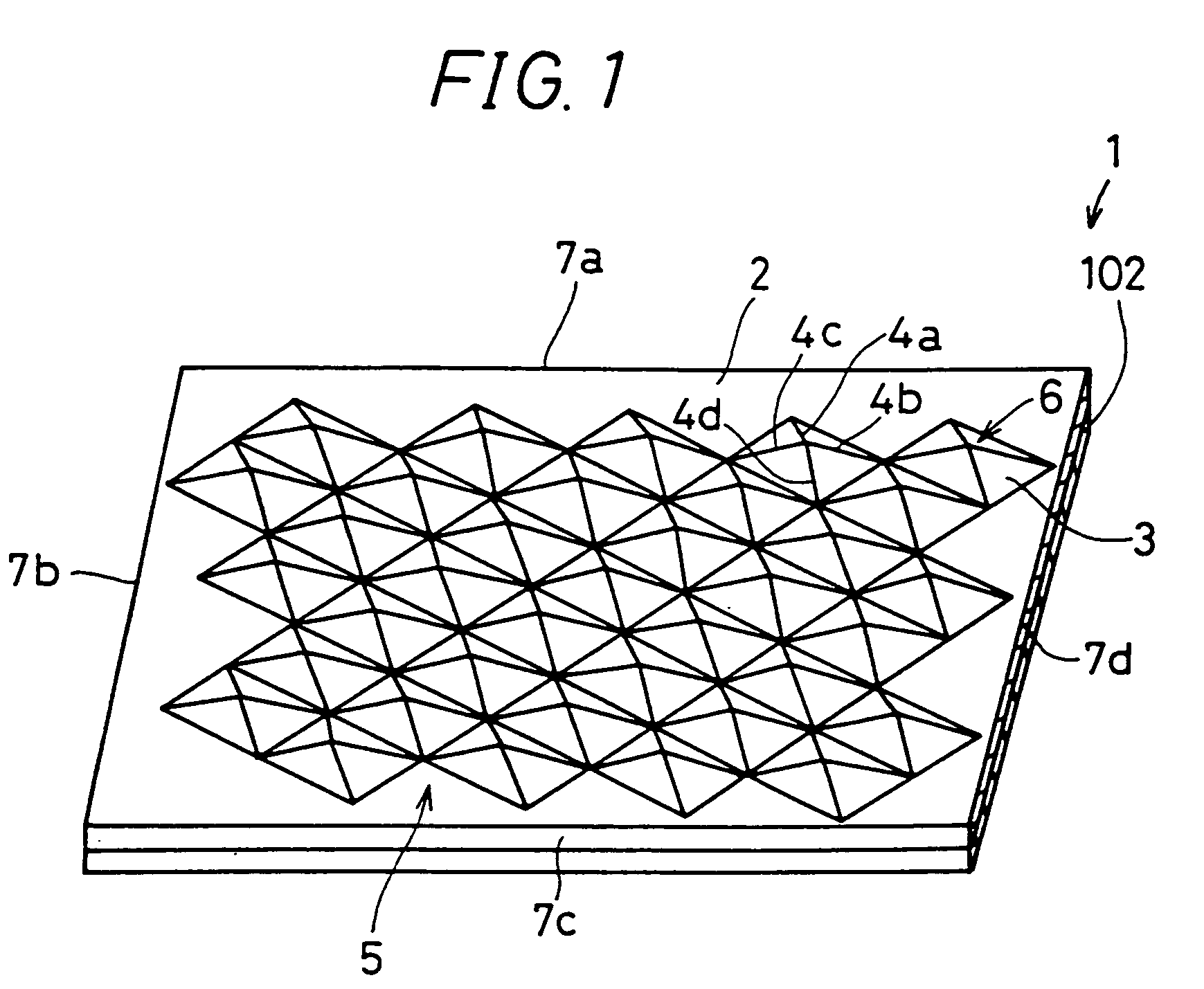

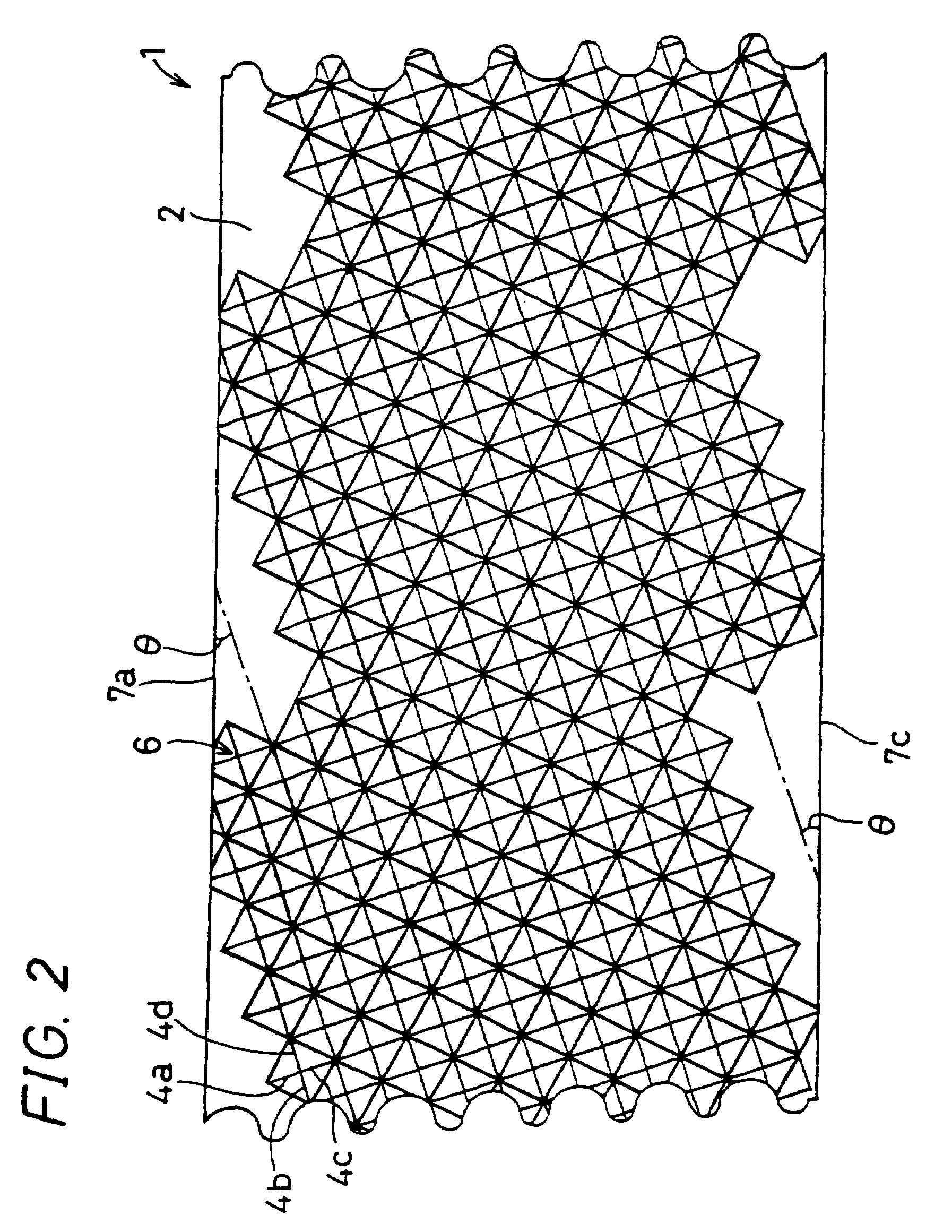

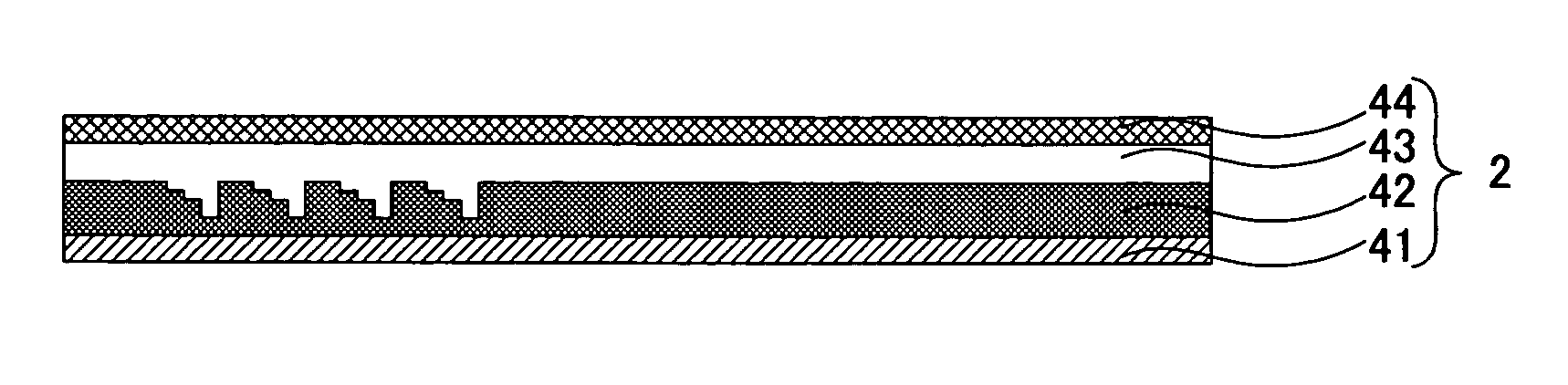

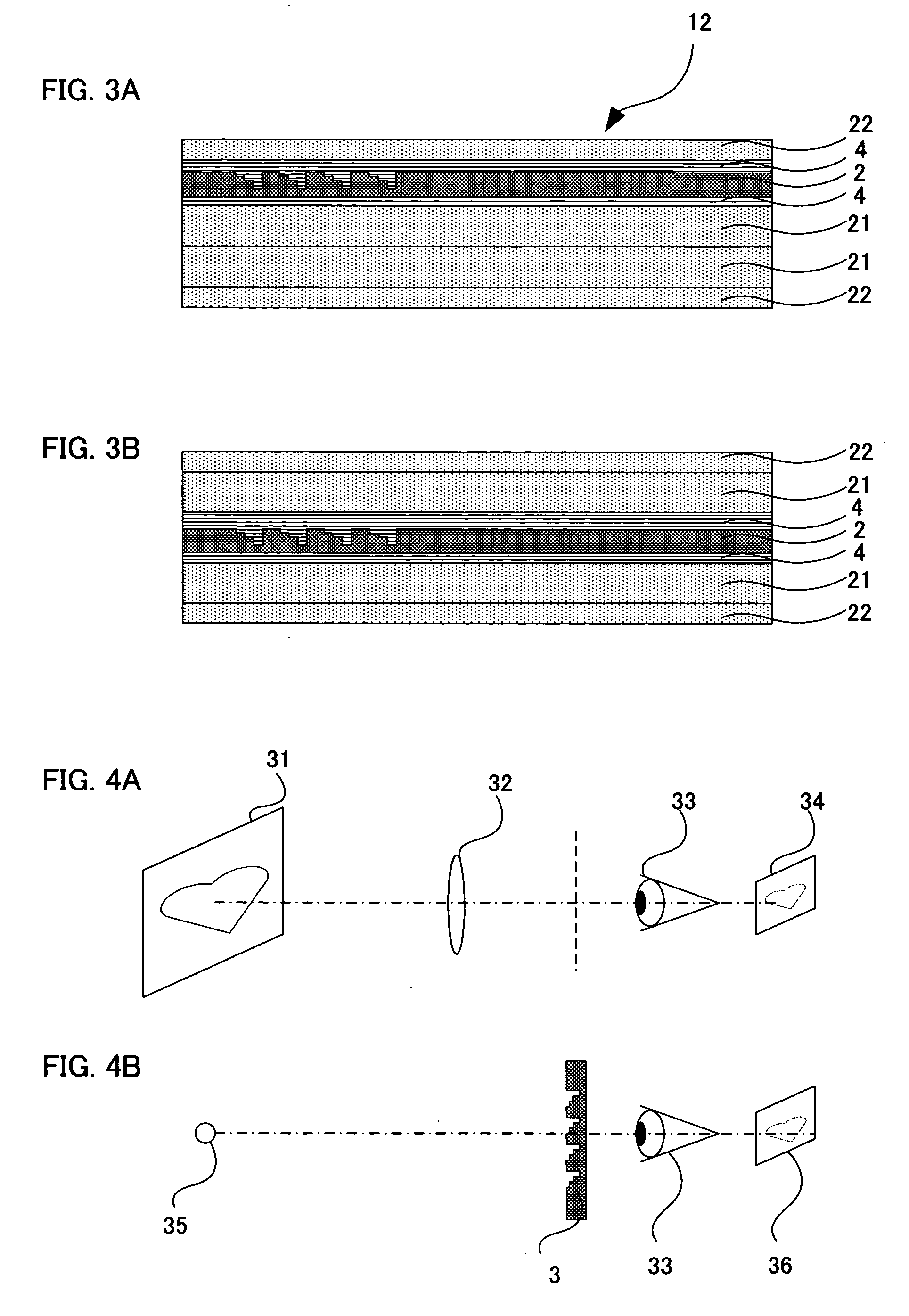

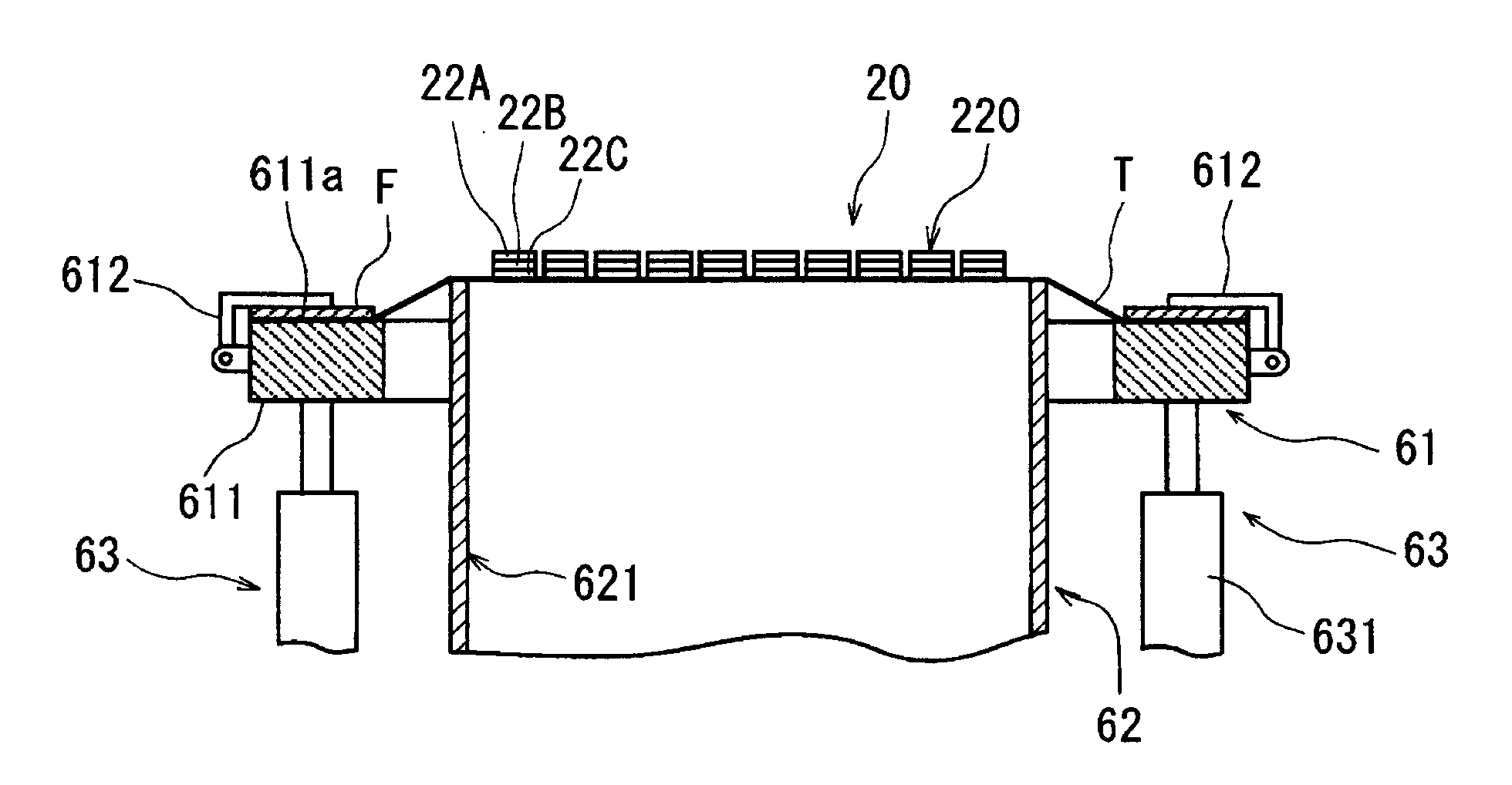

Optical film, light reflective film, liquid crystal display panel, method and apparatus for producing an optical film, method of producing a die roller, and method and apparatus for laminating an optical film

InactiveUS7317501B2Easily laminated to substratePrevent moiréMechanical working/deformationMirrorsLiquid-crystal displayLight reflection

An object of the invention is to provide a light reflective film which can prevent moire fringes from occurring. A rough face in which a plurality of rows of pyramidal convex portions that are linearly continuous are adjacently formed in parallel with one another is formed on one face of a die film. The rows of convex portions that are linearly continuous are inclined at a predetermined angle with respect to an edge of the die film. An optical film is produced by transferring the die film. A light reflective film is produced by vapor-depositing a light reflection film on the optical film. In a liquid crystal display panel having the light reflective film, the pitch of occurring moire fringes becomes so small that the moire fringes cannot be visually seen, and moire fringes can be prevented from occurring.

Owner:SHARP KK

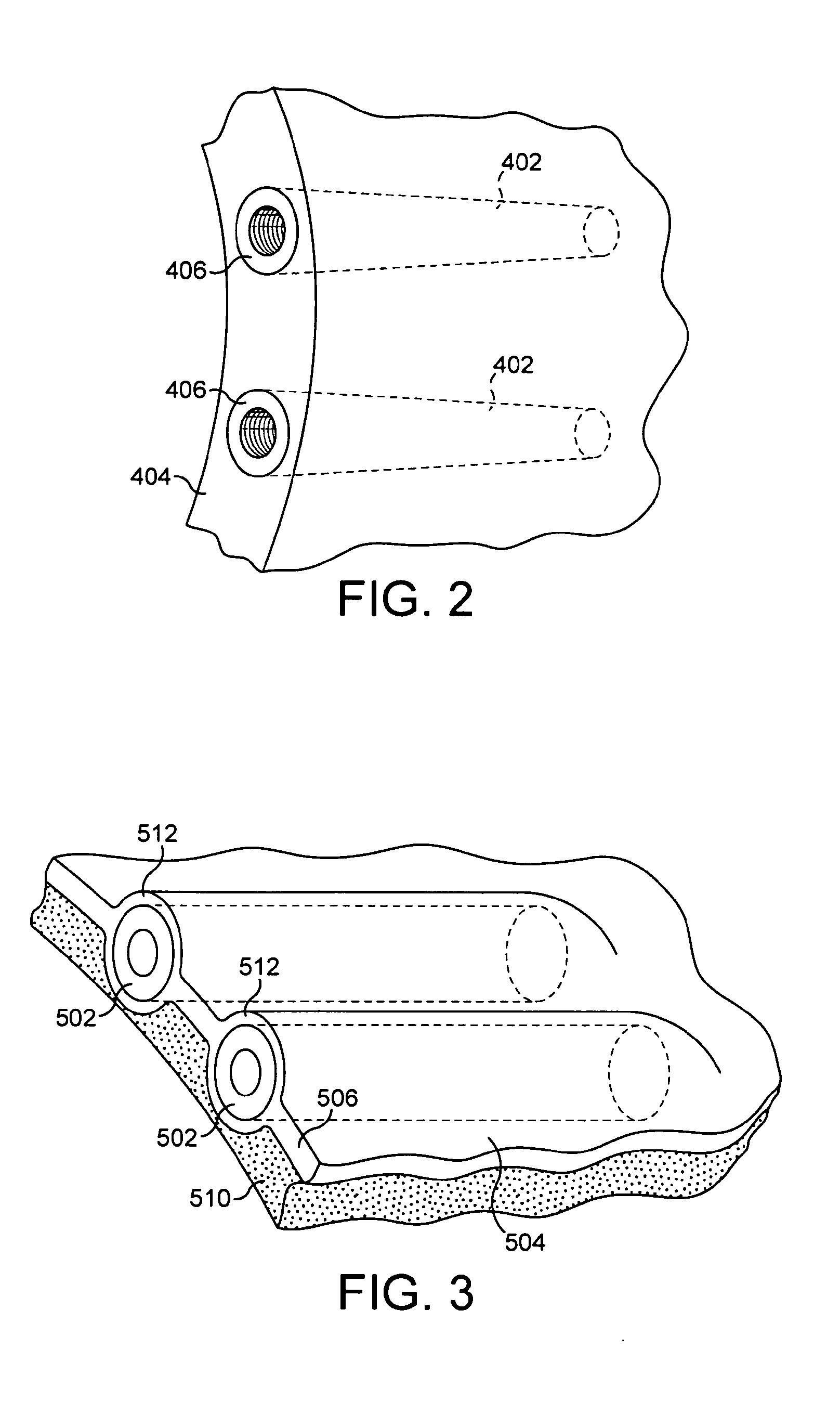

Wind or tidal turbine blade having an attachment

A wind or tidal turbine blade having an attachment, the attachment including: a support portion of the turbine blade, the support portion having opposite surfaces; an insert adapted to mount a bolt for attaching the support portion to another structure; and a mounting for fitting the insert to the support portion, the mounting including a layer extending over a front face of the insert and bonded to the opposite surfaces of the support portion on opposite sides of the insert, the layer permitting passage of a bolt therethrough to or from the insert.

Owner:GURIT (UK) LTD

Transparent card with hologram, and apparatus or recognizing transparent card with hologram

ActiveUS20070008595A1Improve securitySimple designOther printing matterInstrumentsComputer scienceFourier transform

A main object of the present invention is to provide a transparent card with a hologram having the excellent design property and a high security property. The present invention achieves the object by providing a transparent card with a hologram, characterized by comprising a configuration with a transparent card substrate made of a resin transparent with respect to a visible light, and a hologram layer having a computer generated hologram part to function as a transmission type Fourier transform lens laminated.

Owner:DAI NIPPON PRINTING CO LTD

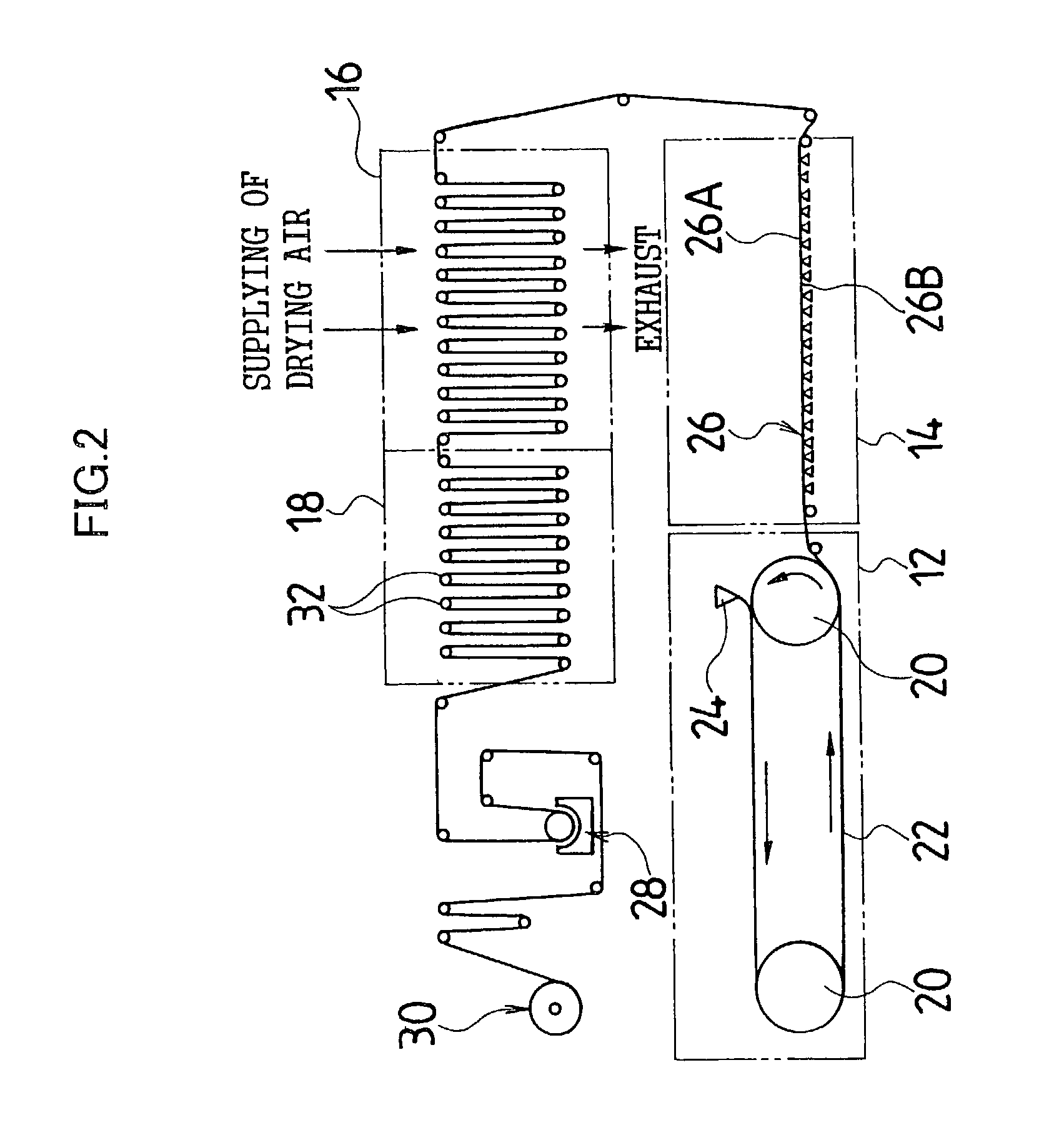

Laminated film for electrophotography and method for producing same, and image forming method

InactiveUS7070860B2Easy laminationHigh resolutionStampsSynthetic resin layered productsImage formationEngineering

The invention provides an electrophotographic laminated film and a method for producing the electrophotographic laminated film. The electrophotographic laminated film comprises a substrate and at least one of a coating layer and a function control means provided on a surface of the substrate. The uppermost layer of the coating layer has a surface resistance in a range of 1.0×108 to 1.0×1013 Ω / □. The surface of the substrate preferably comprises at least one of a polycarbonate resin and a polyallylate resin. At least one of the coating layer and the function control means is preferably formed by providing a coating liquid. Further, a solvent contained in the coating liquid is preferably permits at least one of the coating layer and function control means to be formed while dissolving the surface of the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

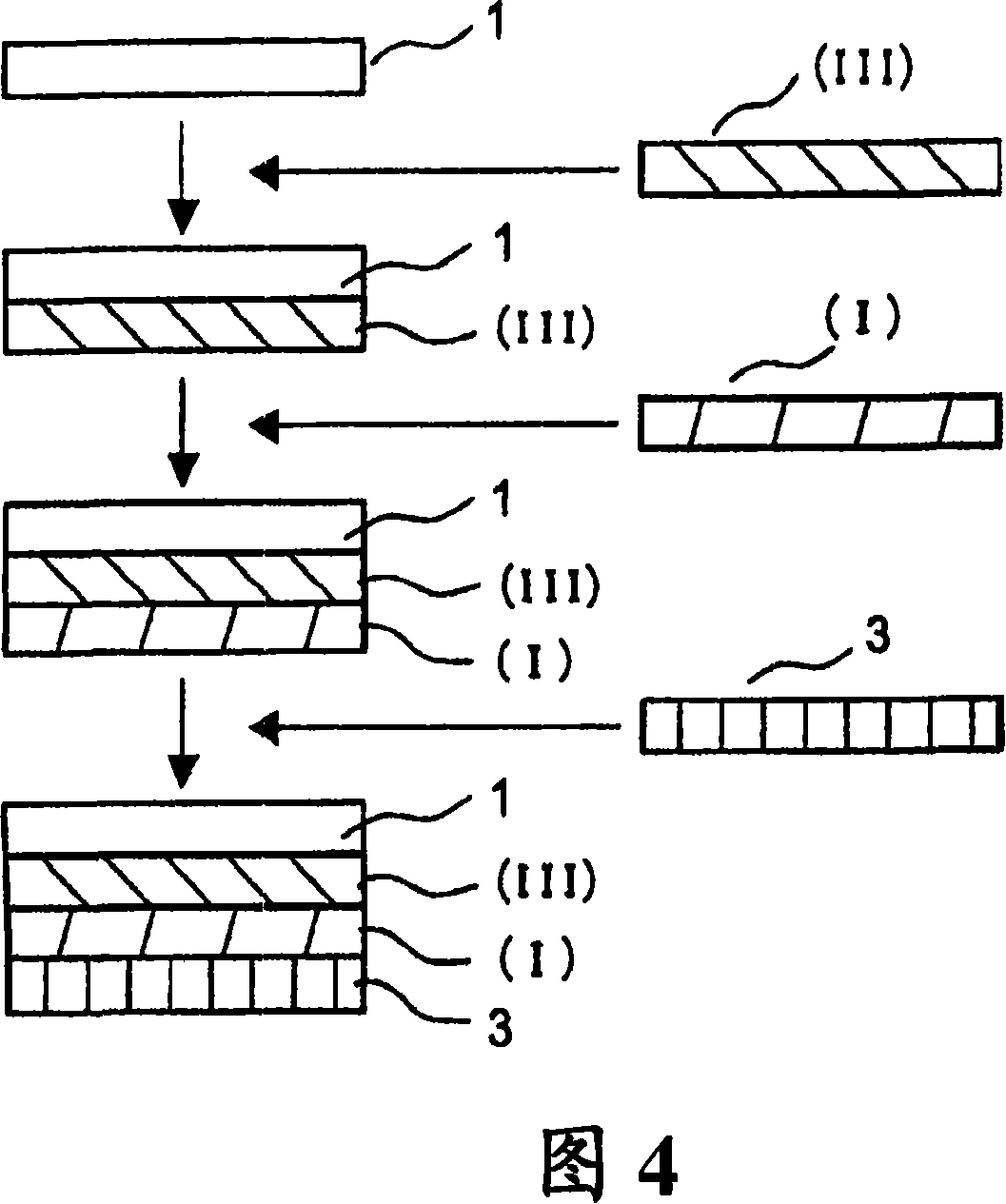

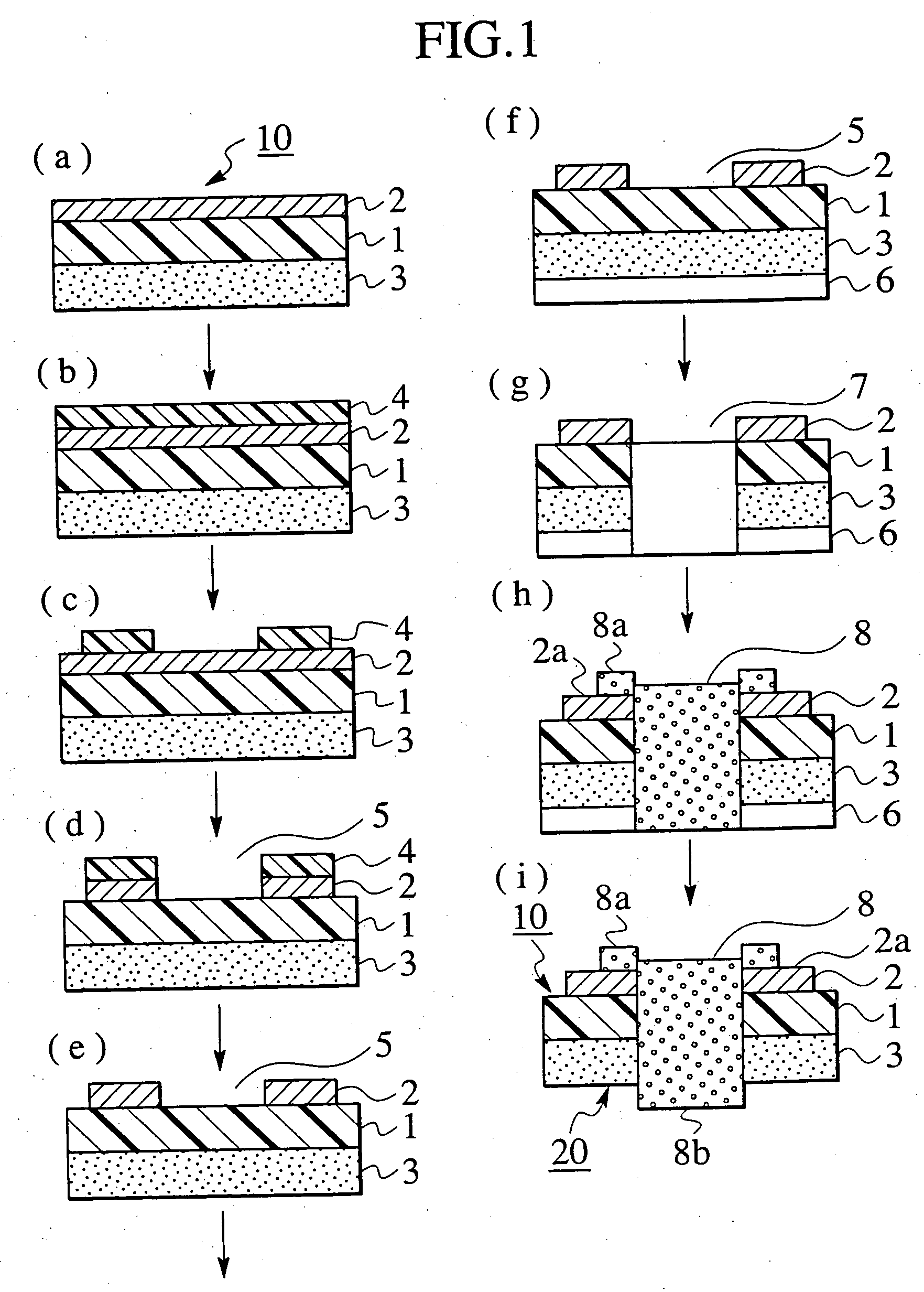

Stacked device manufacturing method

ActiveUS20100099221A1Reduce thicknessThickness minimizationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrode

A stacked device manufacturing method including a kerf forming step of forming a kerf on the front side of each of plural wafers along each street, the kerf having a depth corresponding to a predetermined finished thickness of each wafer, a first stacking step of stacking a first one of the wafers and a second one of the wafers in such a manner that the front side of the second wafer is opposed to the front side of the first wafer and that the electrodes of the second wafer are respectively bonded to the electrodes of the first wafer, a first back grinding step of grinding the back side of the second wafer to expose each kerf of the second wafer to the back side of the second wafer, a second stacking step of stacking a third one of the wafers to the second wafer in such a manner that the front side of the third wafer is opposed to the back side of the second wafer and that the electrodes of the third wafer are respectively bonded to the electrodes of the second wafer, and a second back grinding step of grinding the back side of the third wafer to expose each kerf of the third wafer to the back side of the third wafer.

Owner:DISCO CORP

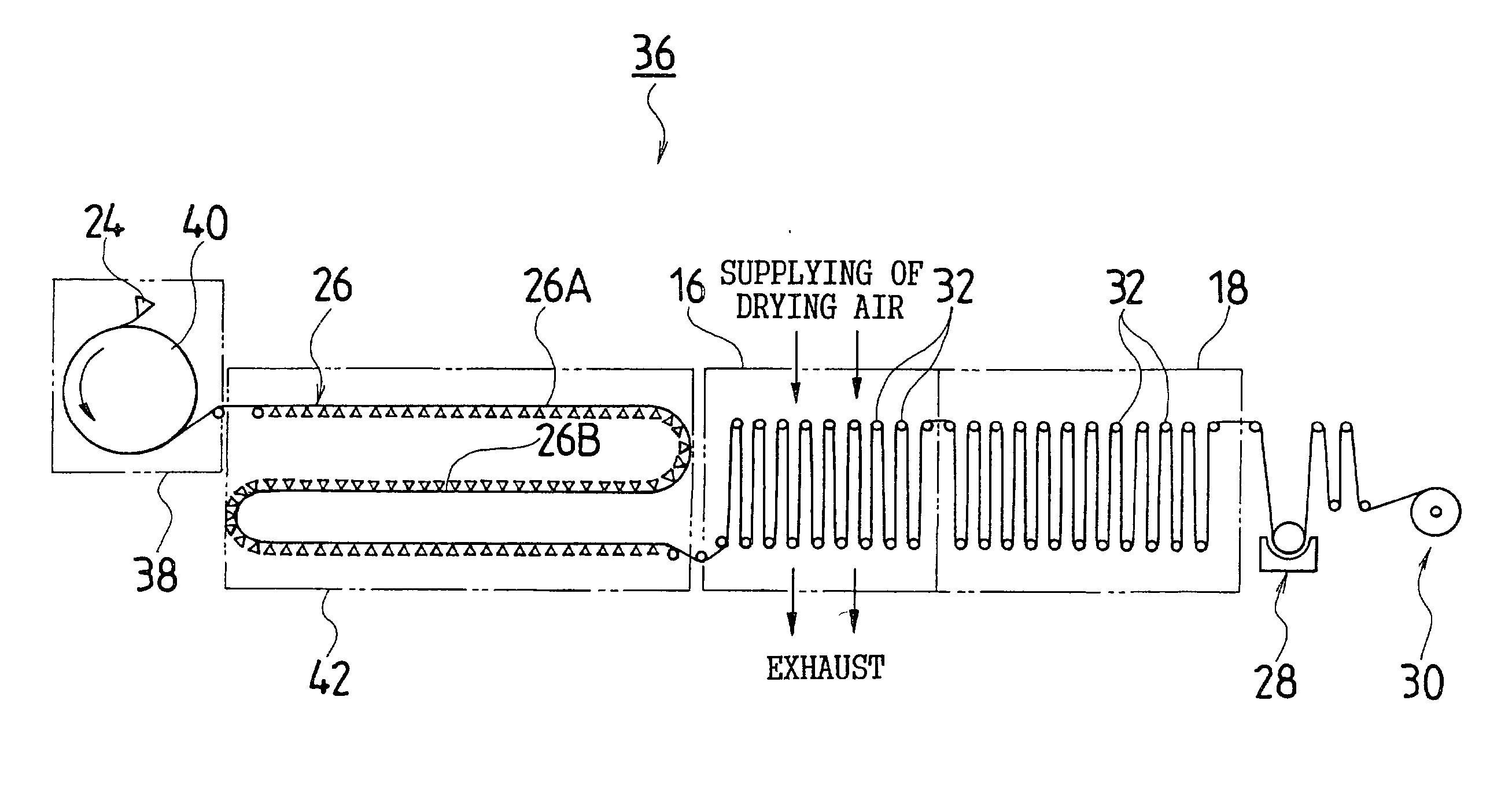

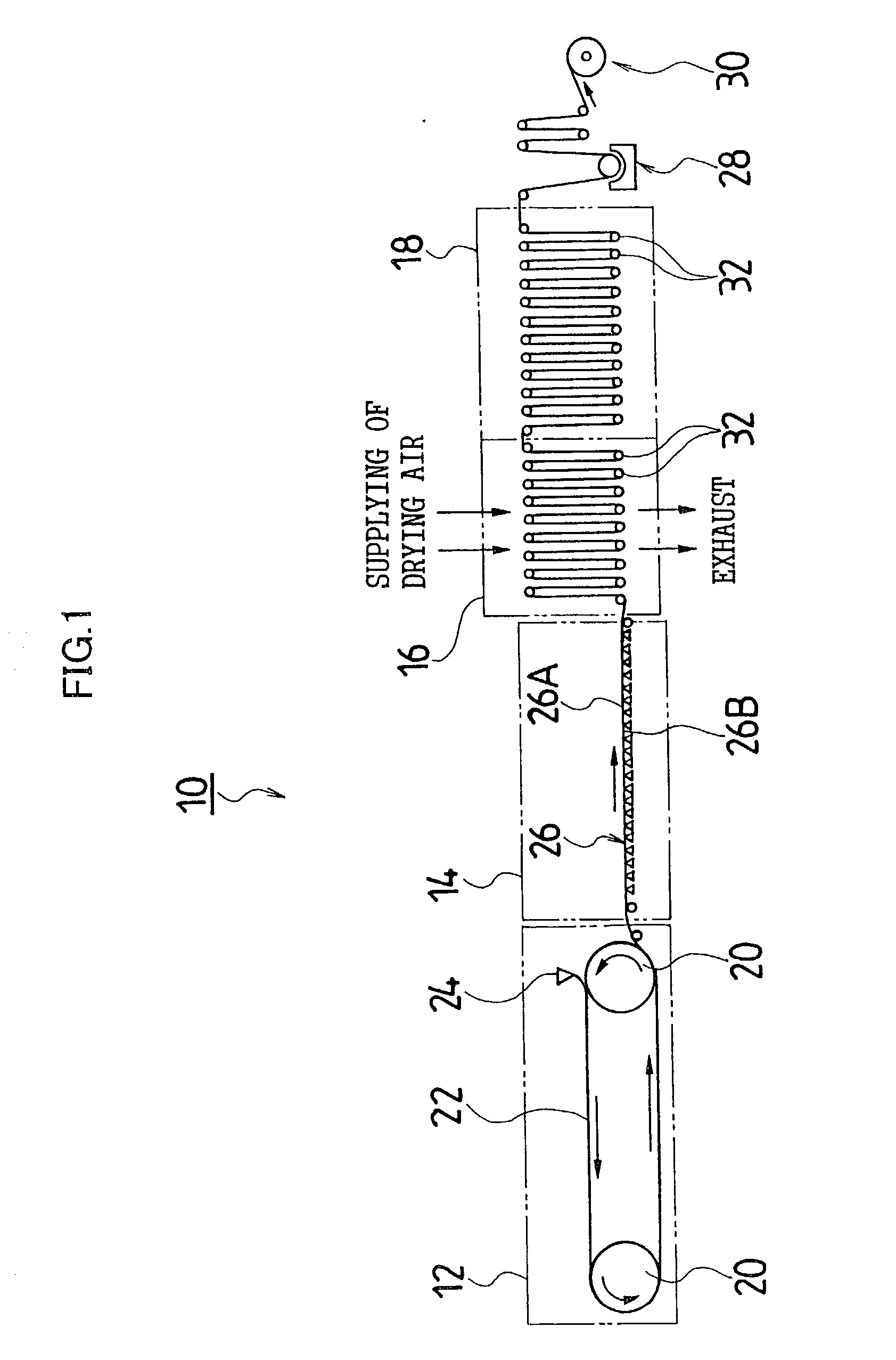

Cellulose acylate film and polarizing plate using the same

InactiveUS20030096093A1Easy to processDegree of curling in waterSynthetic resin layered productsCellulosic plastic layered productsCelluloseAir velocity

The cellulose acylate film has a lower degree of curling in water and is excellent in its processability, as a film suitable for manufacturing a polarizing plate. At least one portion of roll drying parts of a film manufacturing apparatus has a high-temperature drying zone where drying air having a temperature of 115° C. or more is blown on the film to dry thereof. In the high-temperature drying zone, the drying air is supplied by any of the methods as follows: (1) the drying air is blown on a substrate side of the film; (2) the drying air is blown on an air side of the film such that the drying air velocity becomes 3 m / s or less; and (3) the drying air is blown on both sides of the film. The film thus manufactured is provided with characteristics that a curvature radius of curling when the film is dipped in water at 25° C. is 25 mm or more and a ratio between a plasticizer content of the substrate side and a plasticizer content of the air side when the film is divided into two portions along the thickness direction thereof is from 1.2 to 2.0.

Owner:FUJIFILM HLDG CORP

Gas-barrier multilayer film

ActiveUS20120270058A1Less deteriorationImprove interlayer adhesionSynthetic resin layered productsCoatingsHigh humidityPlastic film

Provided is a gas-barrier multilayer film which is superior in gas-barrier properties and interlayer adhesion property, and which exhibits less deterioration in gas-barrier properties and is resistant to interlayer delamination even in prolonged exposure to a high-temperature and high-humidity environment or after a retort treatment. A gas-barrier multilayer film, wherein (A) a first inorganic thin film layer, (C) a gas-barrier resin composition layer, and (D) a second inorganic thin film layer are stacked in this order with or without intervention of other layers on at least one surface of a plastic film, the gas-barrier resin composition layer (C) is formed from a gas-barrier resin composition comprising (a) a gas-barrier resin including an ethylene-vinyl alcohol-based copolymer, (b) an inorganic layered compound, and (c) at least one additive selected from coupling agents and crosslinking agents, and the content of the inorganic layered compound (b) in the gas-barrier resin composition is from 0.1% by mass to 20% by mass based on 100% by mass in total of the gas-barrier resin (a), the inorganic layered compound (b), and the additive (c).

Owner:TOYO TOYOBO CO LTD

Electrical devices containing conductive polymers

InactiveUS6987440B2Improved electrodingImprove performanceResistor terminals/electrodesCurrent responsive resistorsConductive polymerMetal foil

An electrical device in which an element composed of a conductive polymer composition is positioned in contact with the first surface of a metal electrode, the first surface having a center line average roughness Ra and a reflection density RD, the product Ra times RD being 0.5 to 1.6 μm. The conductive polymer composition preferably exhibits PTC behavior. In a second embodiment an electrical device has an element composed of a conductive polymer composition in contact with the first surface of a metal electrode produced by providing a base metal foil having an Ra of at most 0.45 μm and depositing material onto the base metal foil to form a first surface having a product of Ra times RD of at least 0.14 μm. Other embodiments include electrical devices with metal electrodes made by pulse plating processes, and metal electrodes made by electrodeposition under diffusion-limited conditions. The electrical devices may be circuit protection devices and have improved electrical and physical properties.

Owner:LITTELFUSE INC

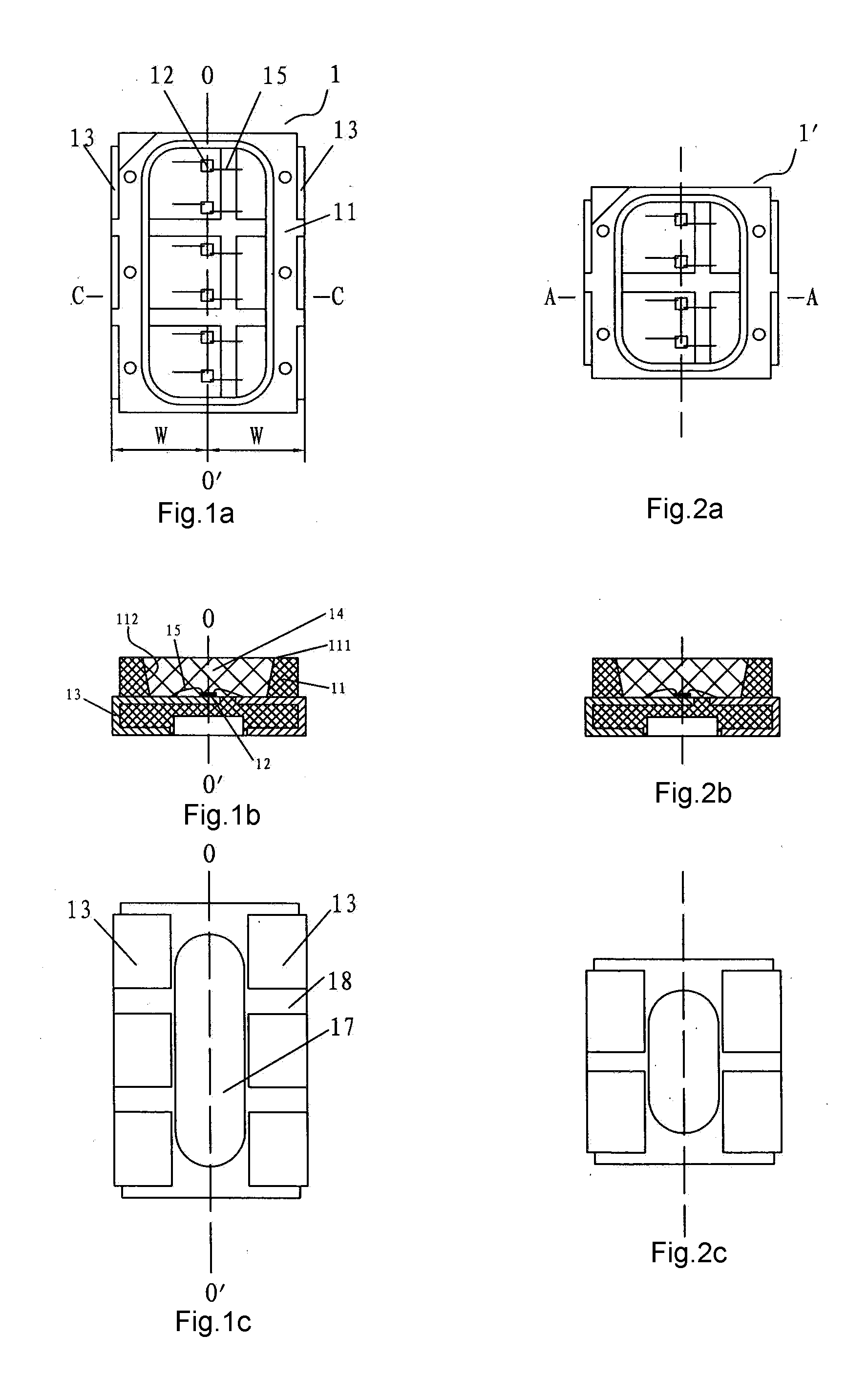

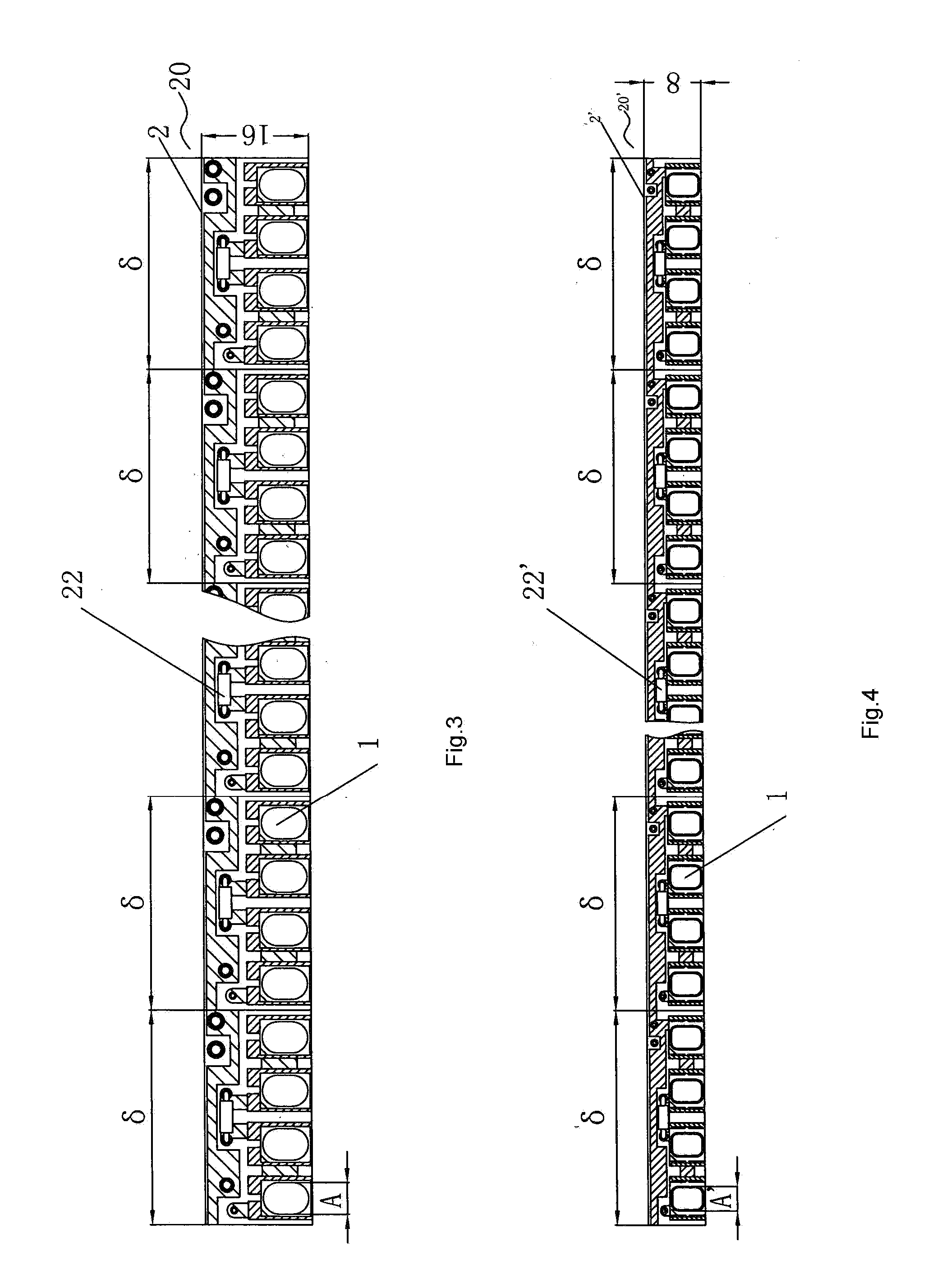

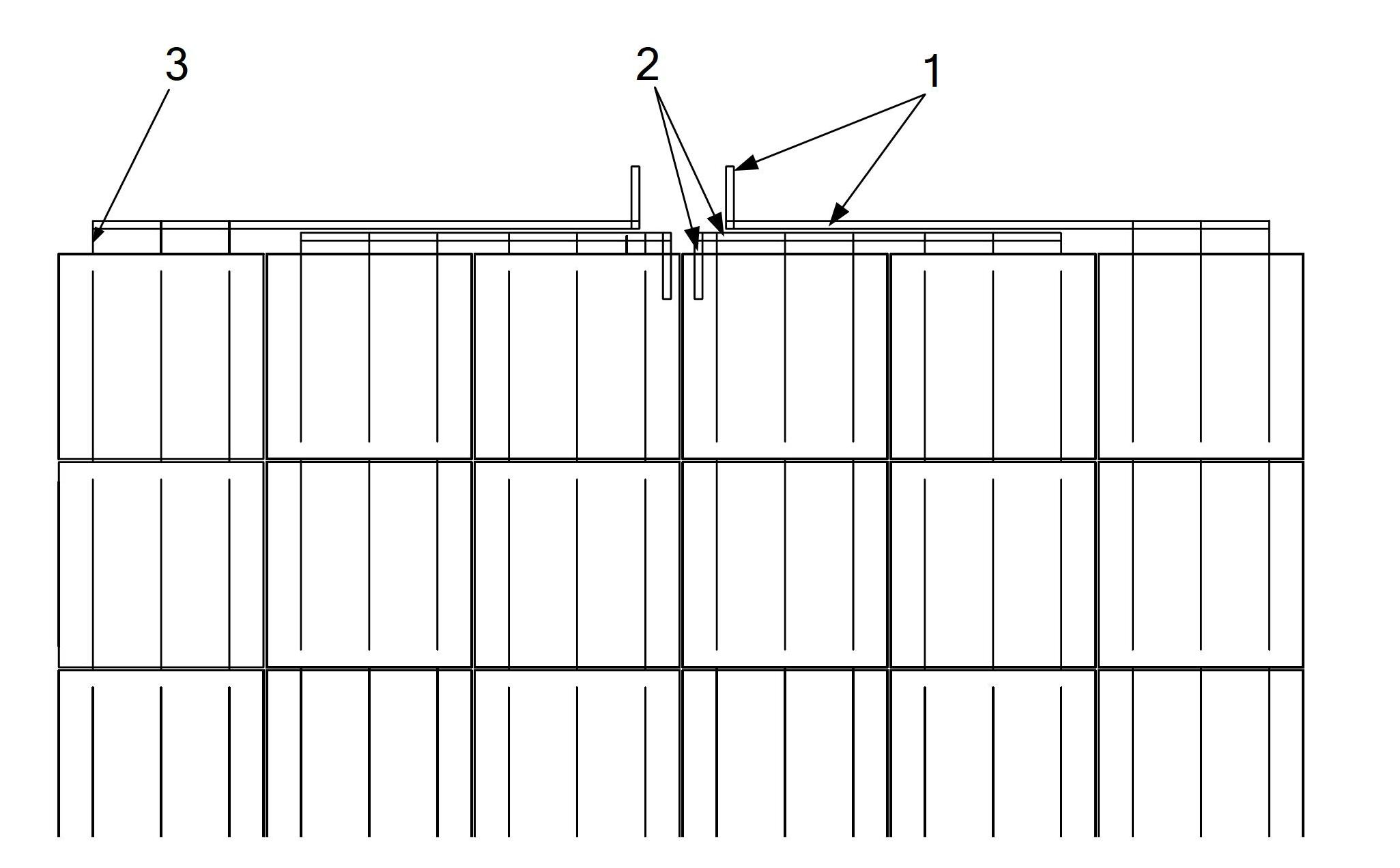

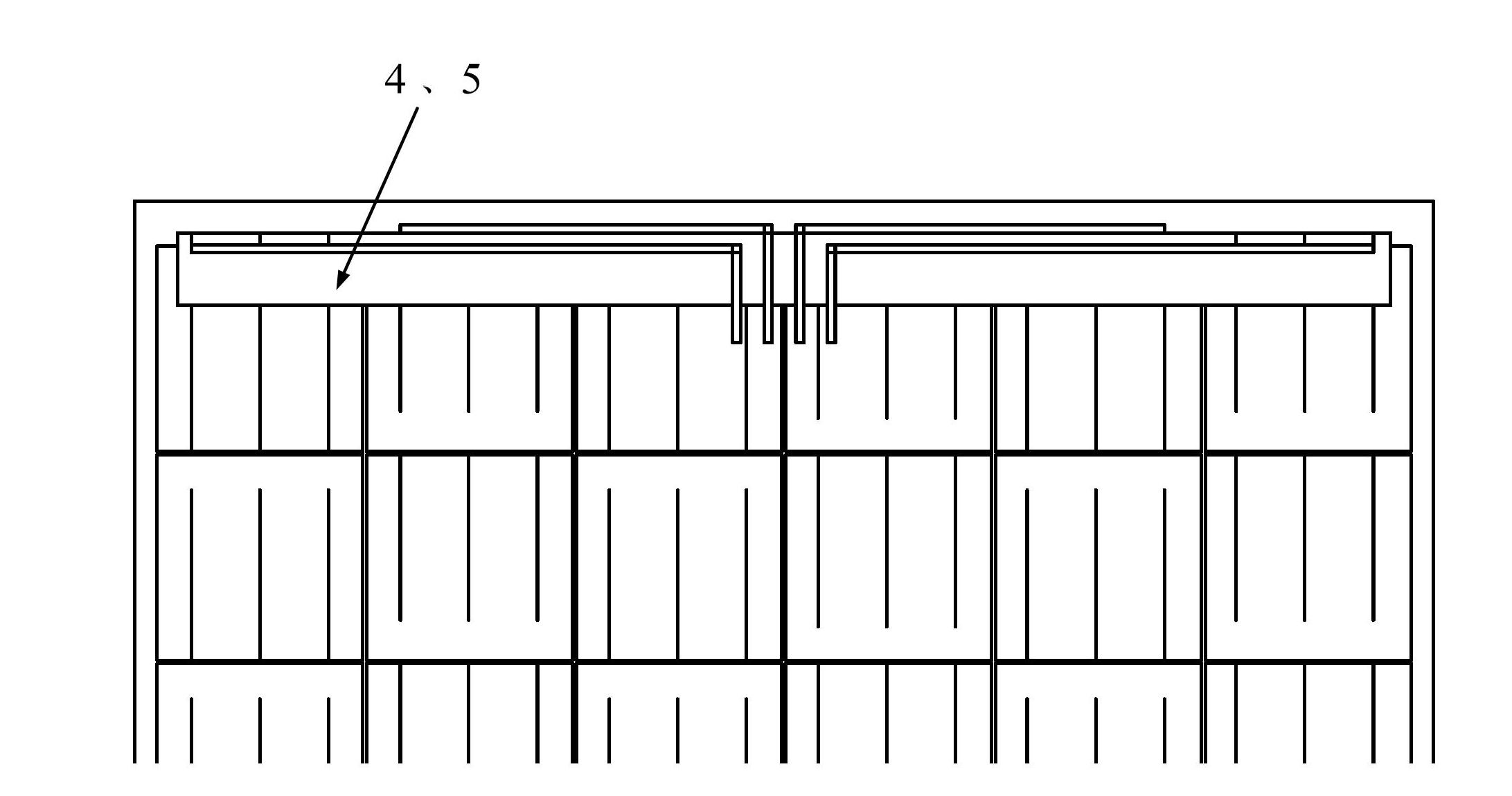

LED multi-chip bonding die and light strip using the same

InactiveUS20110210349A1High transparencyIncrease light energyPlanar light sourcesPoint-like light sourceCurrent limitingLight energy

An LED multi-chip bonding die (1) comprises a packaging enclosure, a plurality of LED chips and a packaging cover, wherein the chips are arranged in one line from top to bottom on the emitting platform. Large area electrodes are equipped on the packaging enclosure and the packaging cover is made of transparent silicon gel so that the bonding die can emit larger light energy and higher luminance via the packaging cover while the heat produced by the chips can be quickly dissipated by the electrodes. A light strip (20) equipped with the bonding die comprises a plurality of bonding die sections and circuit board (2) and each bonding die section (1) comprises four LED multi-chip bonding dies (1) and a current-limiting resistor in series circuit. Each series circuit is connected in parallel and circuit board (2) is printed circuit board which can provide a optimal heat-dissipating structure for chips of bonding die.

Owner:PAN DINGGUO

Solar photovoltaic module and manufacturing method for convergence belt leading wires of same

InactiveCN102664214AQuality assuranceAvoid the problem of cross-stackingFinal product manufacturePhotovoltaic energy generationEthylene-vinyl acetateBackplane

The invention discloses a method for manufacturing convergence belt leading wires of a solar photovoltaic module. The method comprises the following steps of: 1, welding a convergence belt and the leading wires of the convergence belt; 2, welding the convergence belt to welding belts led out of different areas of the solar photovoltaic module respectively, wherein the convergence belt at least comprises a first convergence belt and a second convergence belt which are welded with the different welding belts; 3, laying ethylene-vinyl acetate copolymer (EVA) strips and back plate strips between the different convergence belts as well as between the convergence belts and batteries of the solar photovoltaic module; and 4, laying EVAs and back plates on the solar photovoltaic module. When the convergence belt and the welding belts are welded in the step 2, gaps are formed between the first convergence belt and the second convergence belt in the height direction. According to the method, the gaps are formed between the convergence belts, and lead-out modes for the convergence belts can be improved, so that the problem that the convergence belts are superposed crosswisely is solved, and the quality of the solar photovoltaic module is guaranteed.

Owner:YINGLI ENERGY CHINA

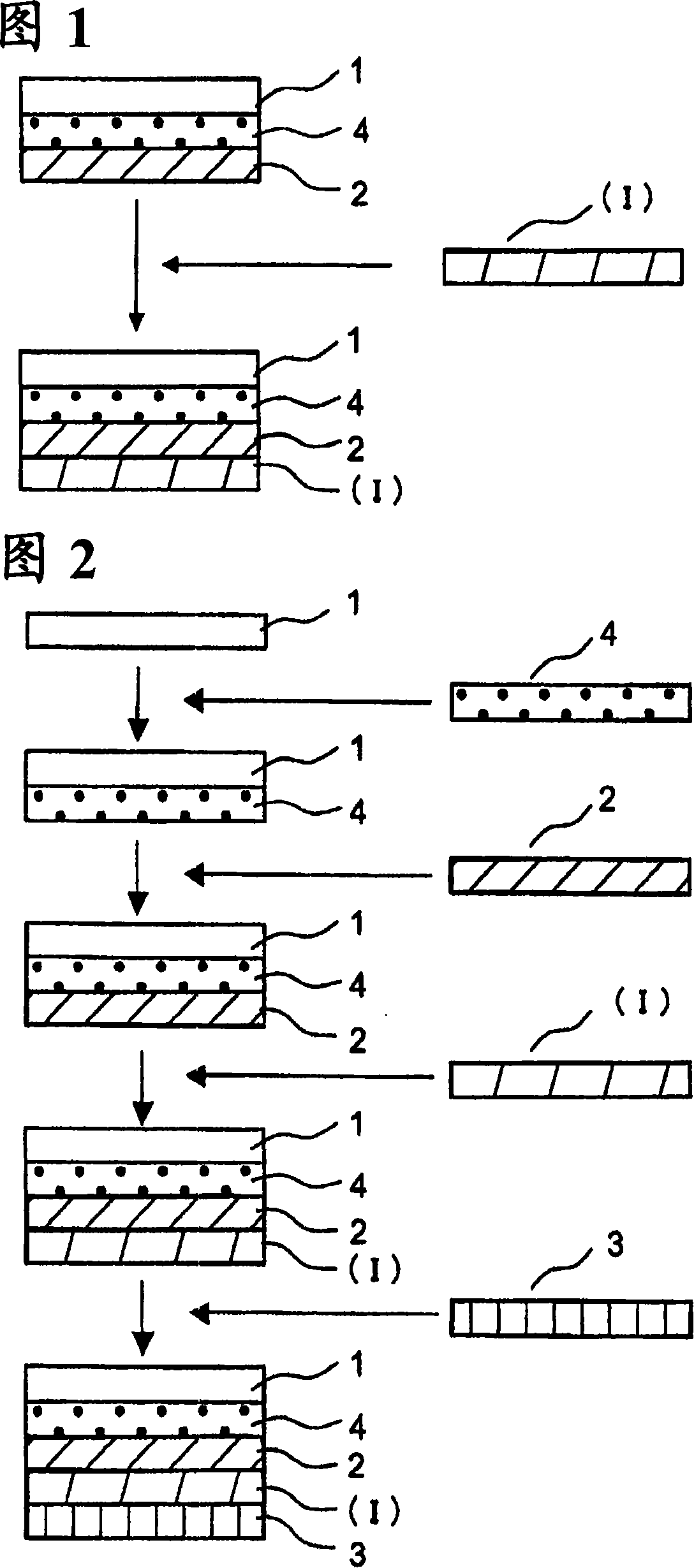

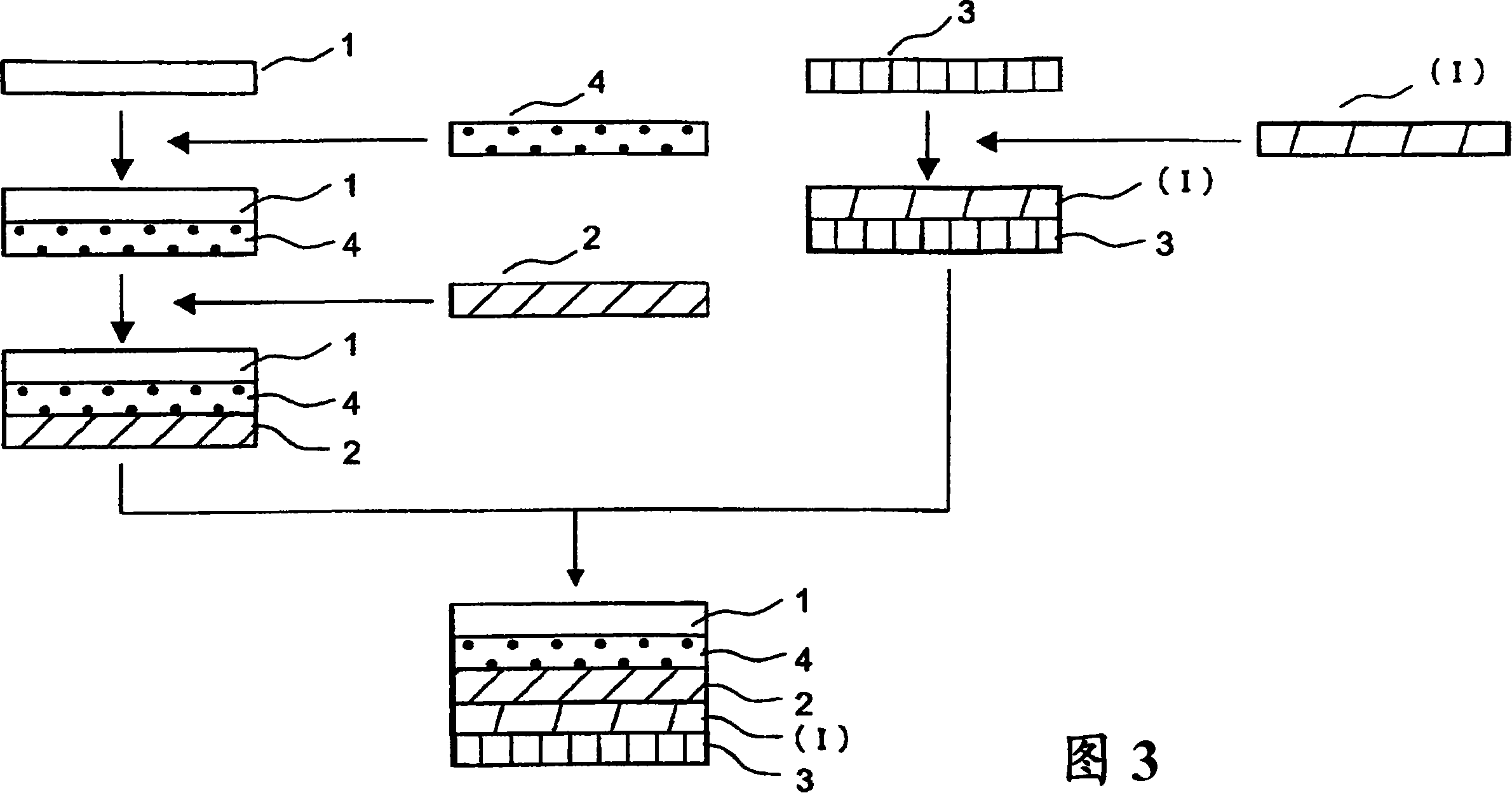

Thin film circuit device, manufacturing method thereof, electro-optical apparatus, and electronic system

InactiveUS7105422B2Easy laminationWell formedTransistorSemiconductor/solid-state device detailsElectronic systemsProtection layer

To provide a thin film circuit device in which a three-dimensional circuit structure is realized, a thin film circuit device is formed of a first thin film circuit layer and a second thin film circuit layer laminated to each other. The first thin film circuit layer contains a first thin film circuit provided between an underlayer and a protective layer and a lower connection electrode connected to the first thin film circuit and exposed at a part of the bottom surface of the underlayer. The second thin film circuit layer contains a second thin film circuit provided between an underlayer and a protective layer, an upper connection electrode connected to the second thin film circuit and exposed at a part of the top surface of the protective layer, and a lower connection electrode connected to the second thin film circuit and exposed at a part of the bottom surface of the underlayer. The first and the second thin film circuits are bonded to each other so that the lower connection electrode of the first thin film circuit layer is electrically connected to the upper electrode of the second thin film circuit layer.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com