Patents

Literature

472 results about "Thin film circuits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

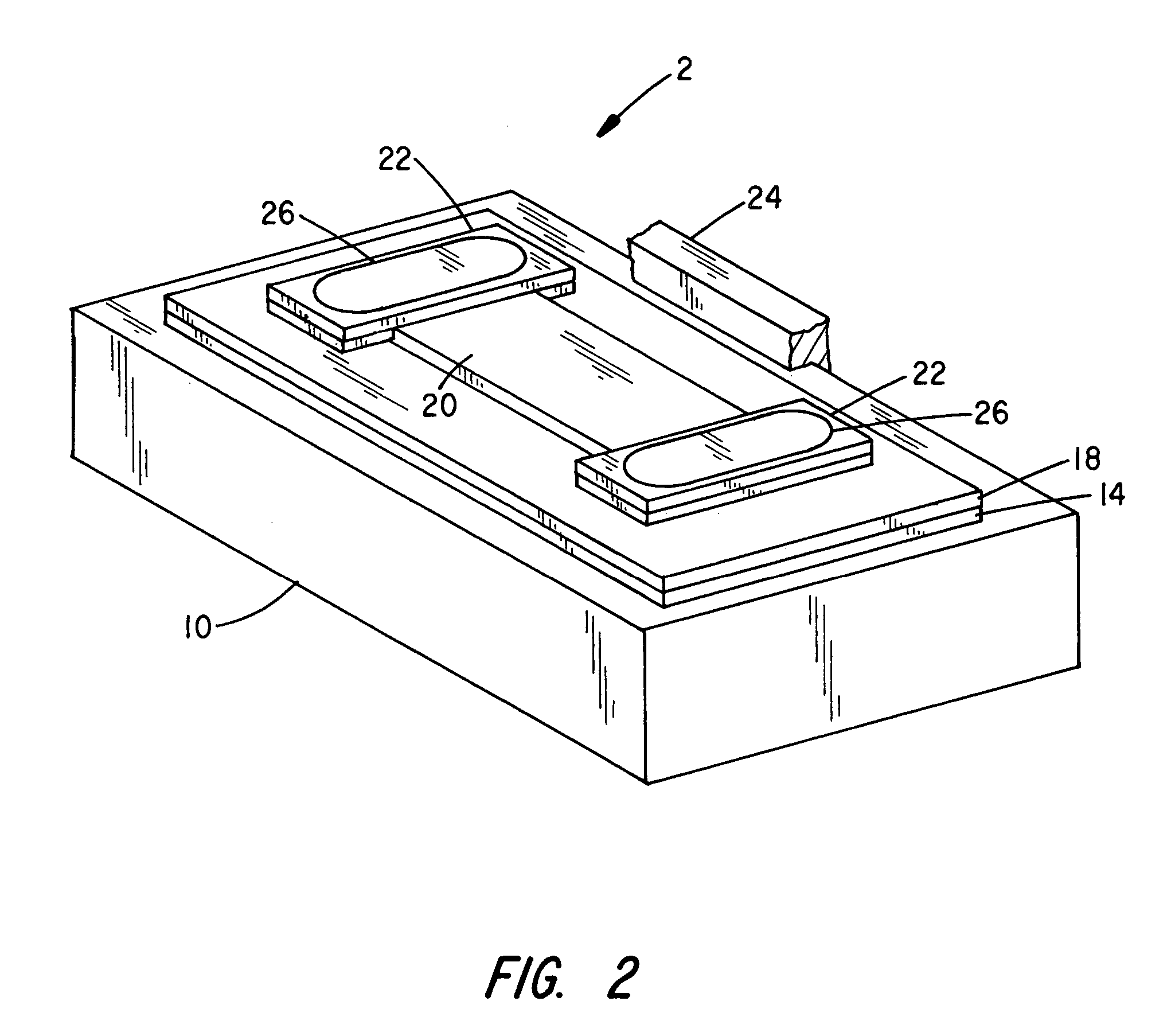

Thermal measurments of electronic devices during operation

InactiveUS20050114068A1Thermometer detailsThermometers using material expansion/contactionElectricityEngineering

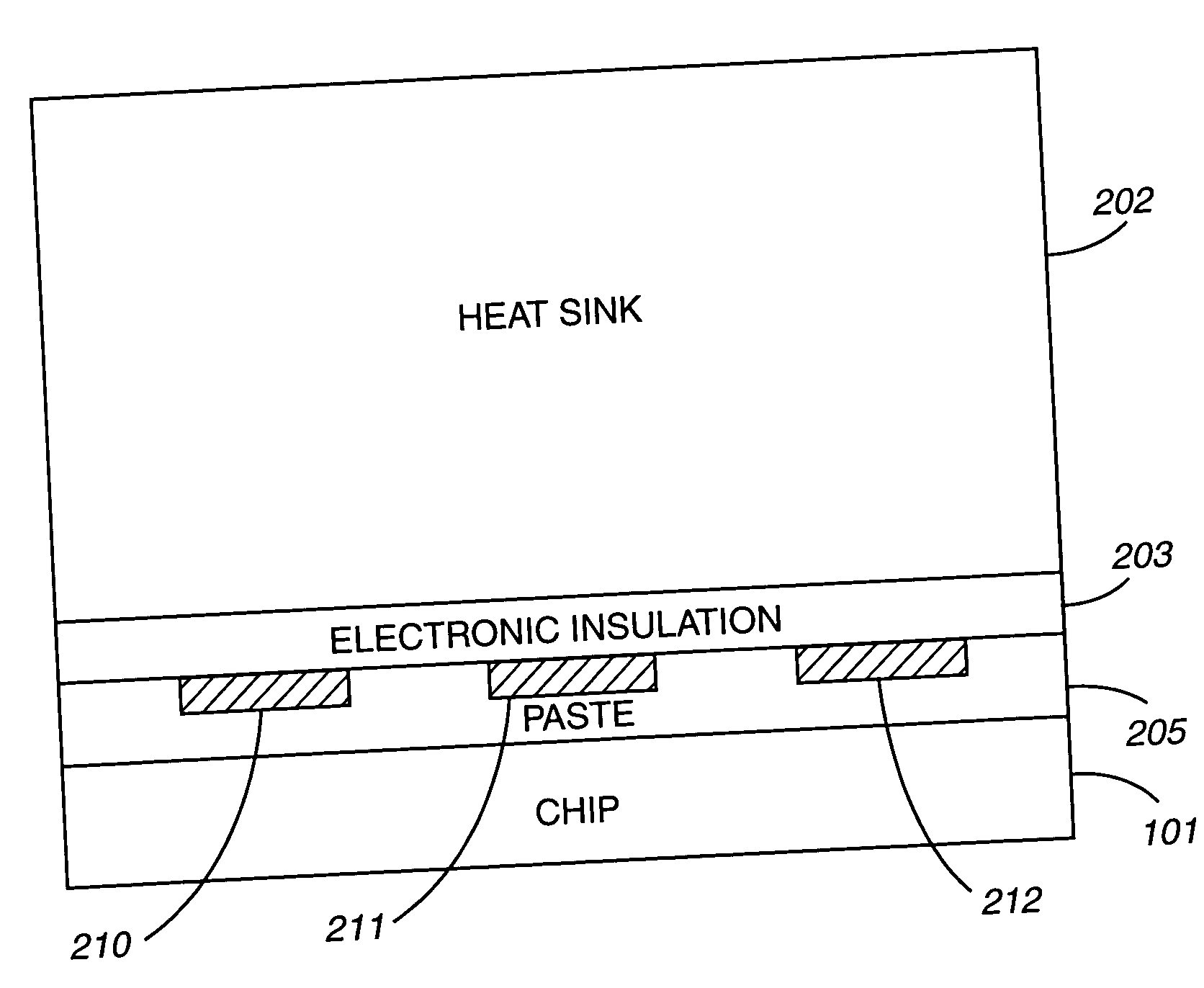

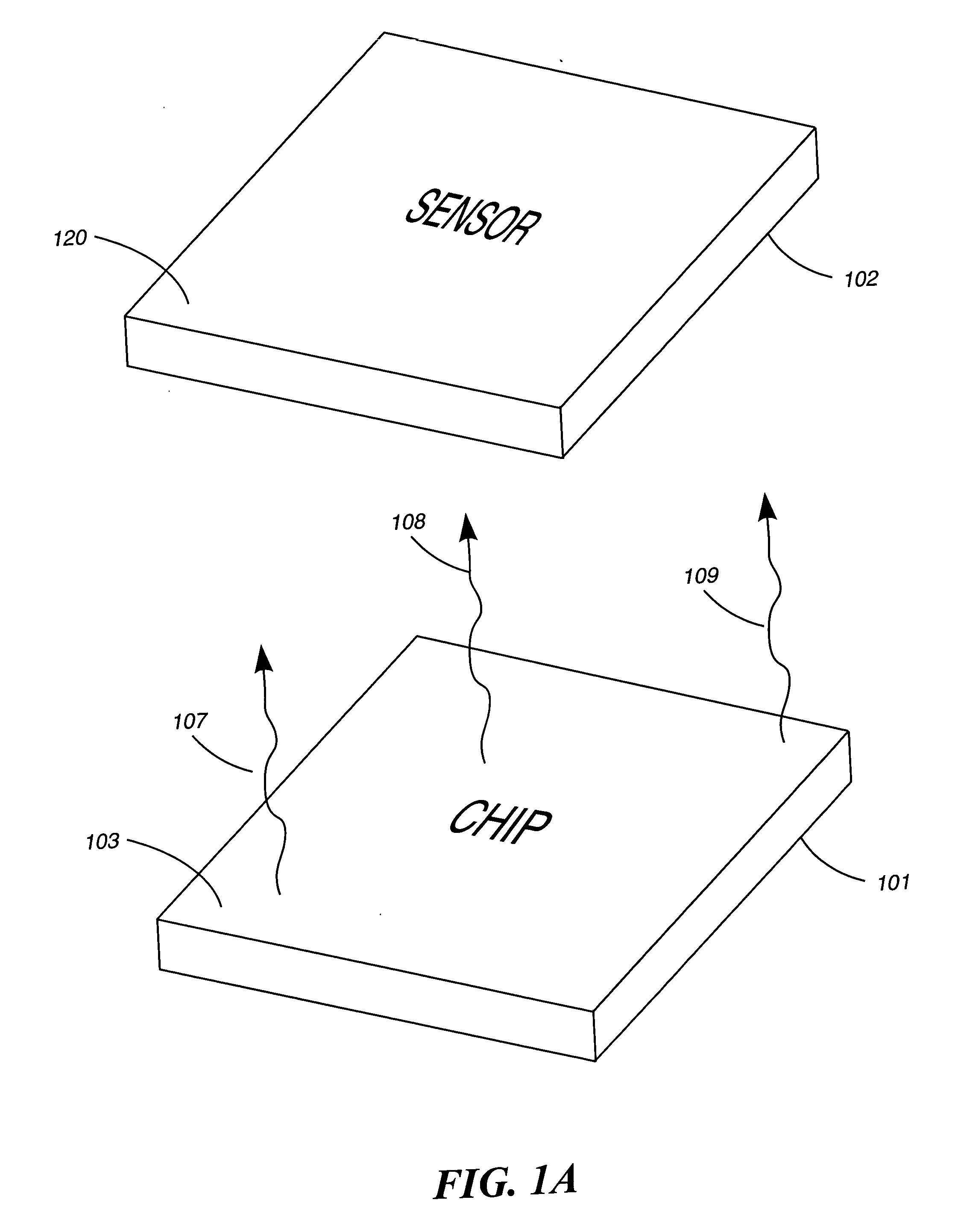

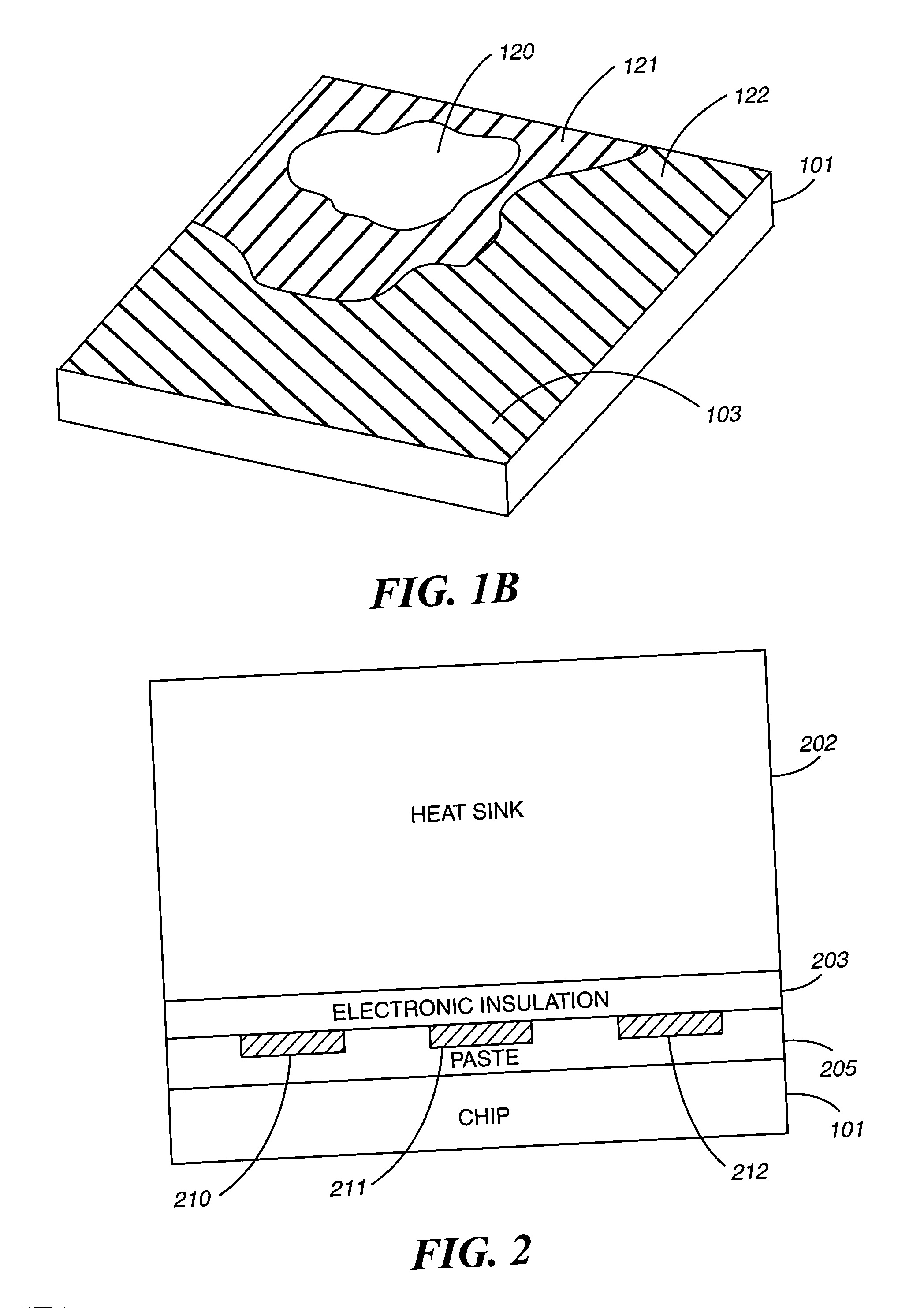

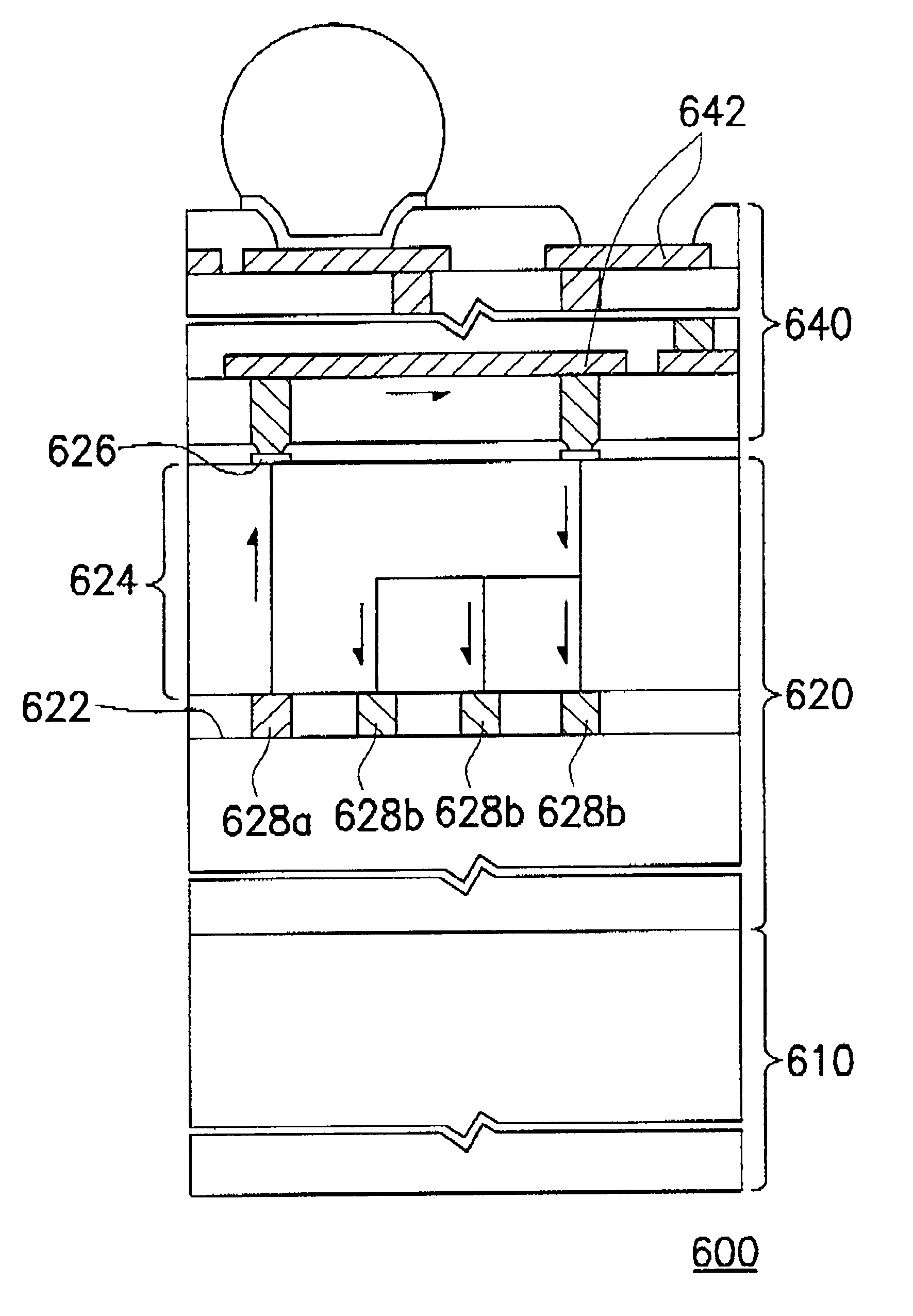

A system and method for measuring thermal distributions of an electronic device during operation is disclosed. The system includes an electronic device, a heat sink adjacent to the electronic device and an electrical-insulating layer disposed on the electronic device so as to separate the electronic device and the heat sink. The system further includes a plurality of thermal sensors located on the electrical-insulating layer, each of the plurality of thermal sensors in a different location. The plurality of thermal sensors is located within one or more thin film circuit layers disposed adjacent to the electrical insulating layer. The system further includes a module for receiving thermal information from the plurality of thermal sensors during operation of the electronic device. The system further includes a processor coupled to the module for generating a thermal distribution of the electronic device based on the thermal information received from the plurality of thermal sensors.

Owner:IBM CORP

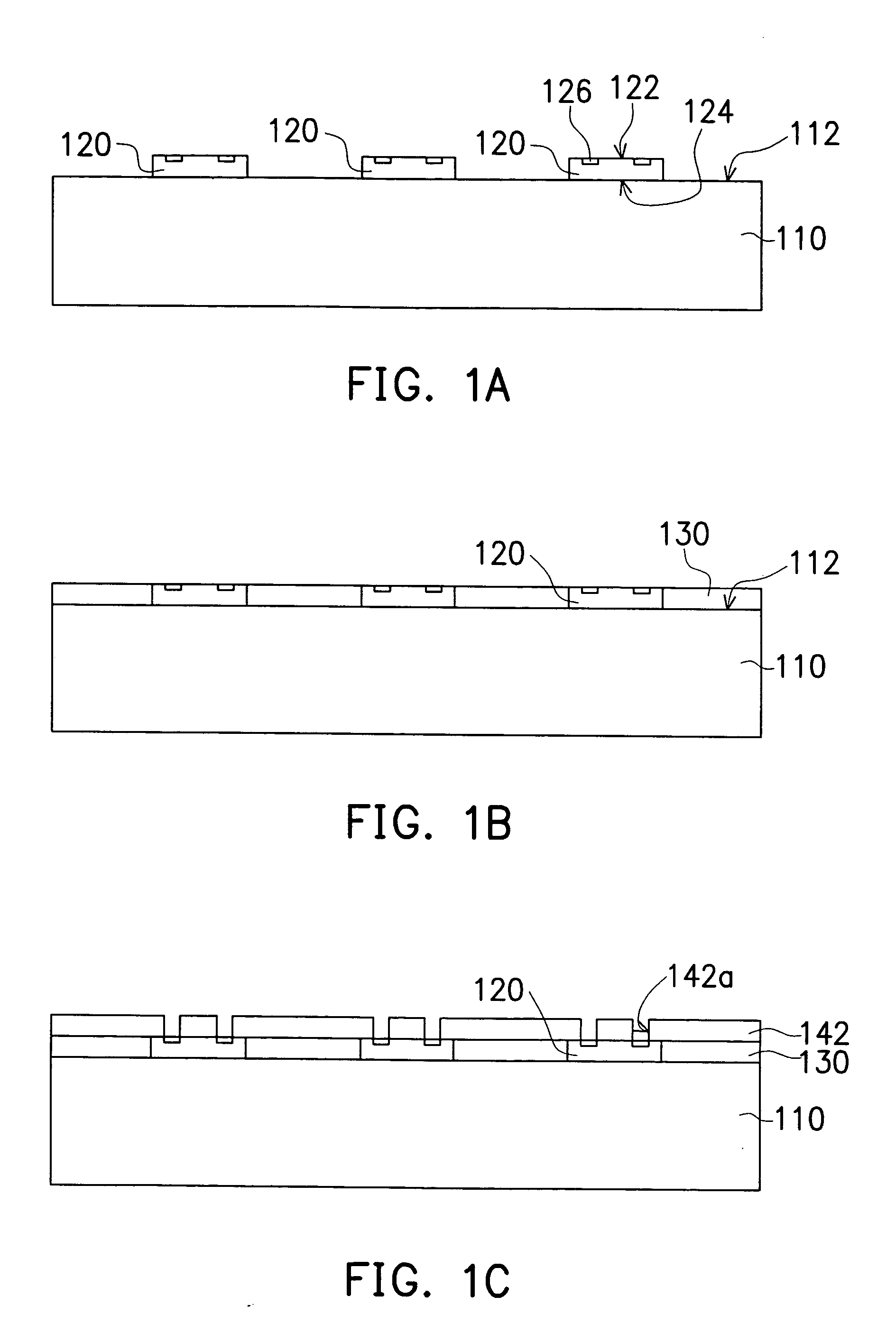

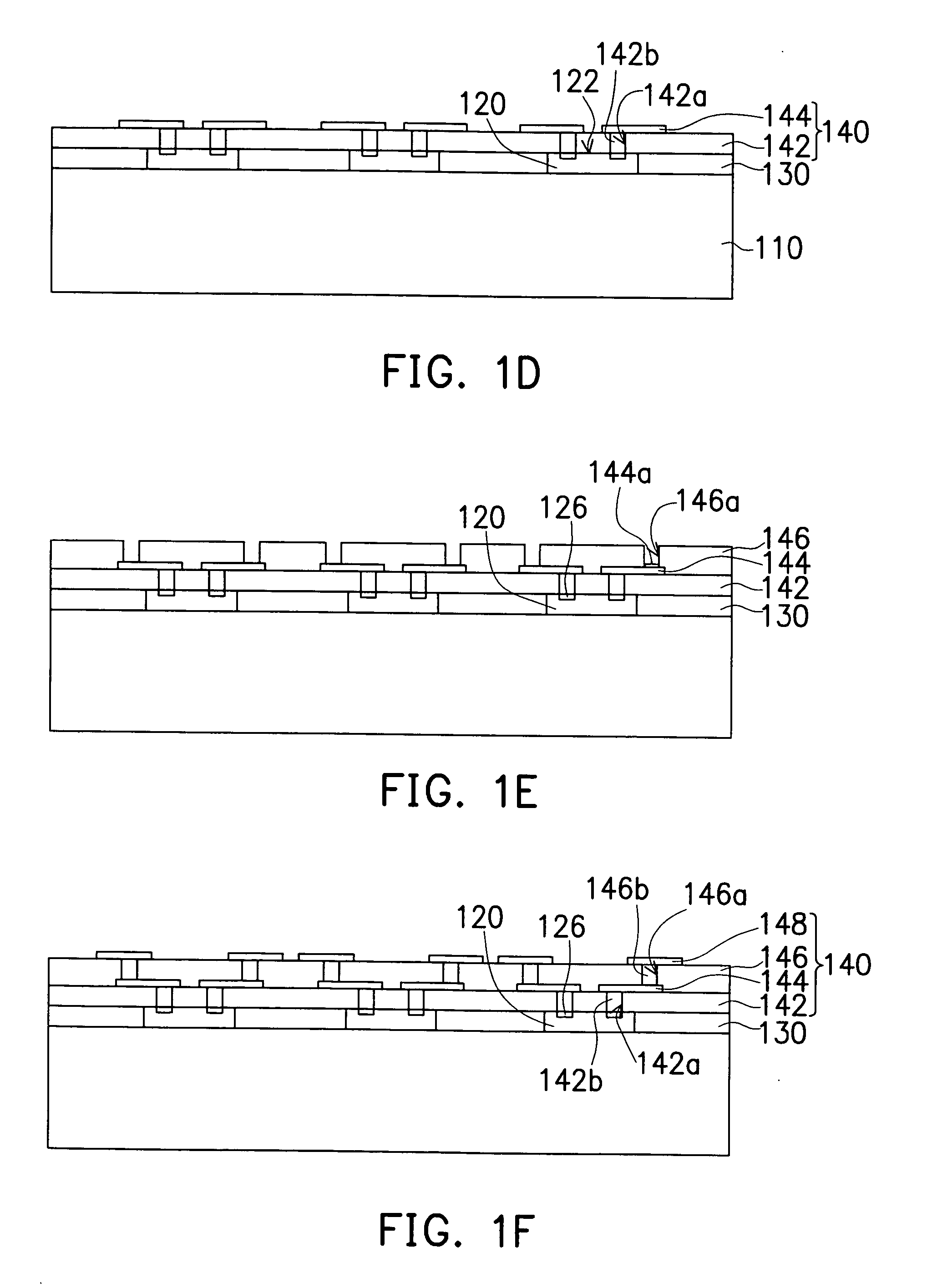

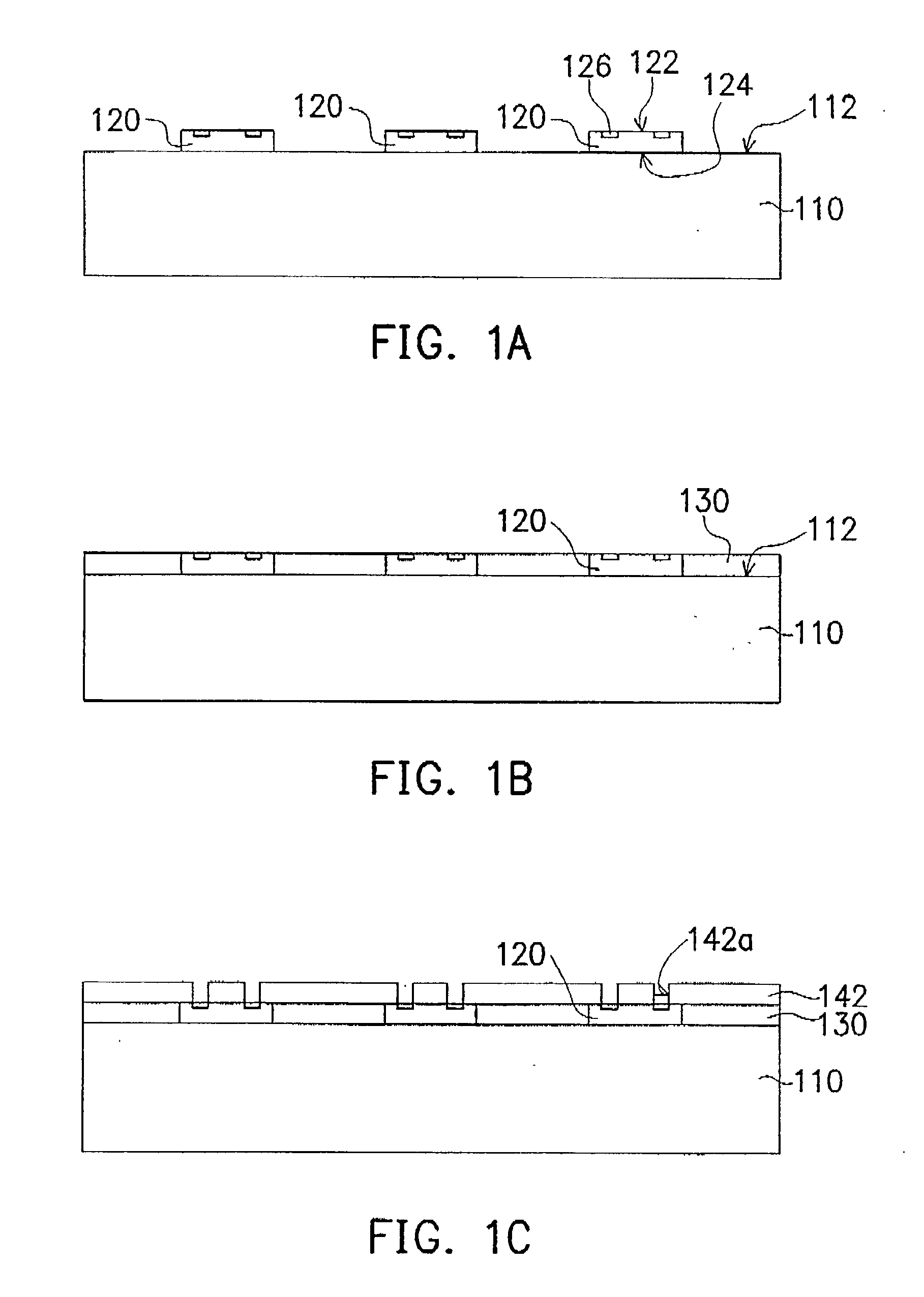

Integrated chip package structure using ceramic substrate and method of manufacturing the same

InactiveUS6800941B2Semiconductor/solid-state device detailsSolid-state devicesThin film circuitsExternal circuit

An integrated chip package structure and method of manufacturing the same is by adhering dies on a ceramic substrate and forming a thin-film circuit layer on top of the dies and the ceramic substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

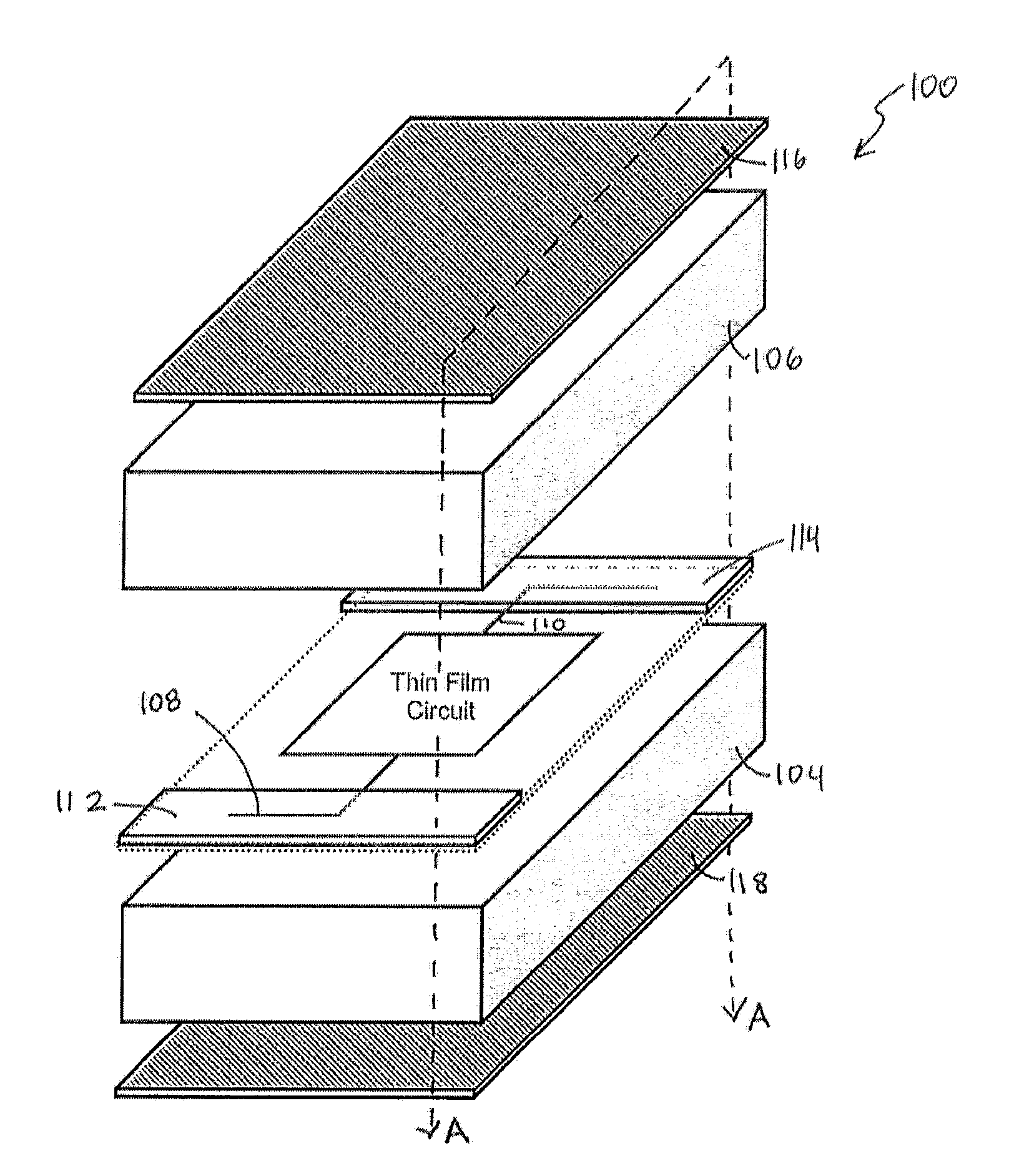

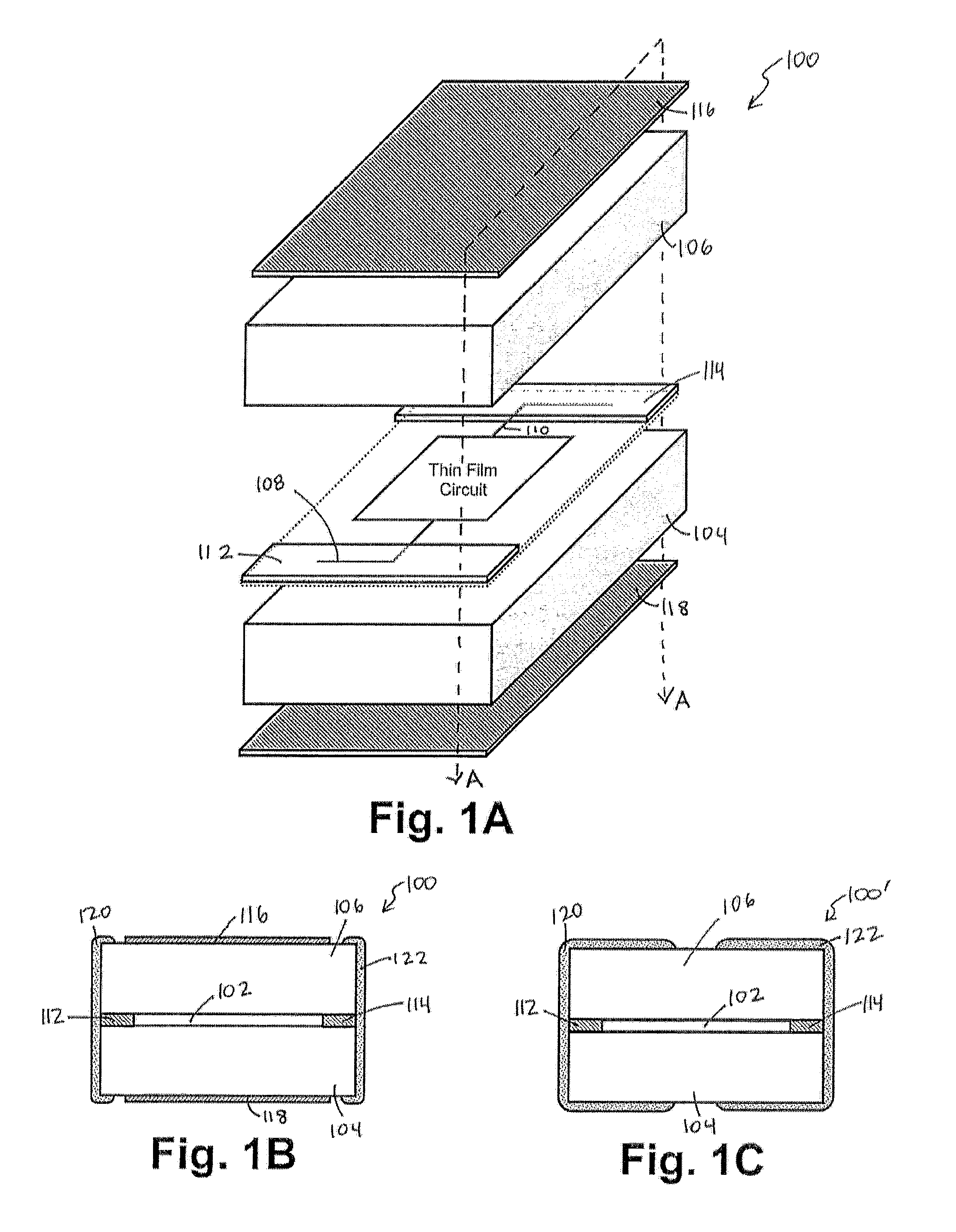

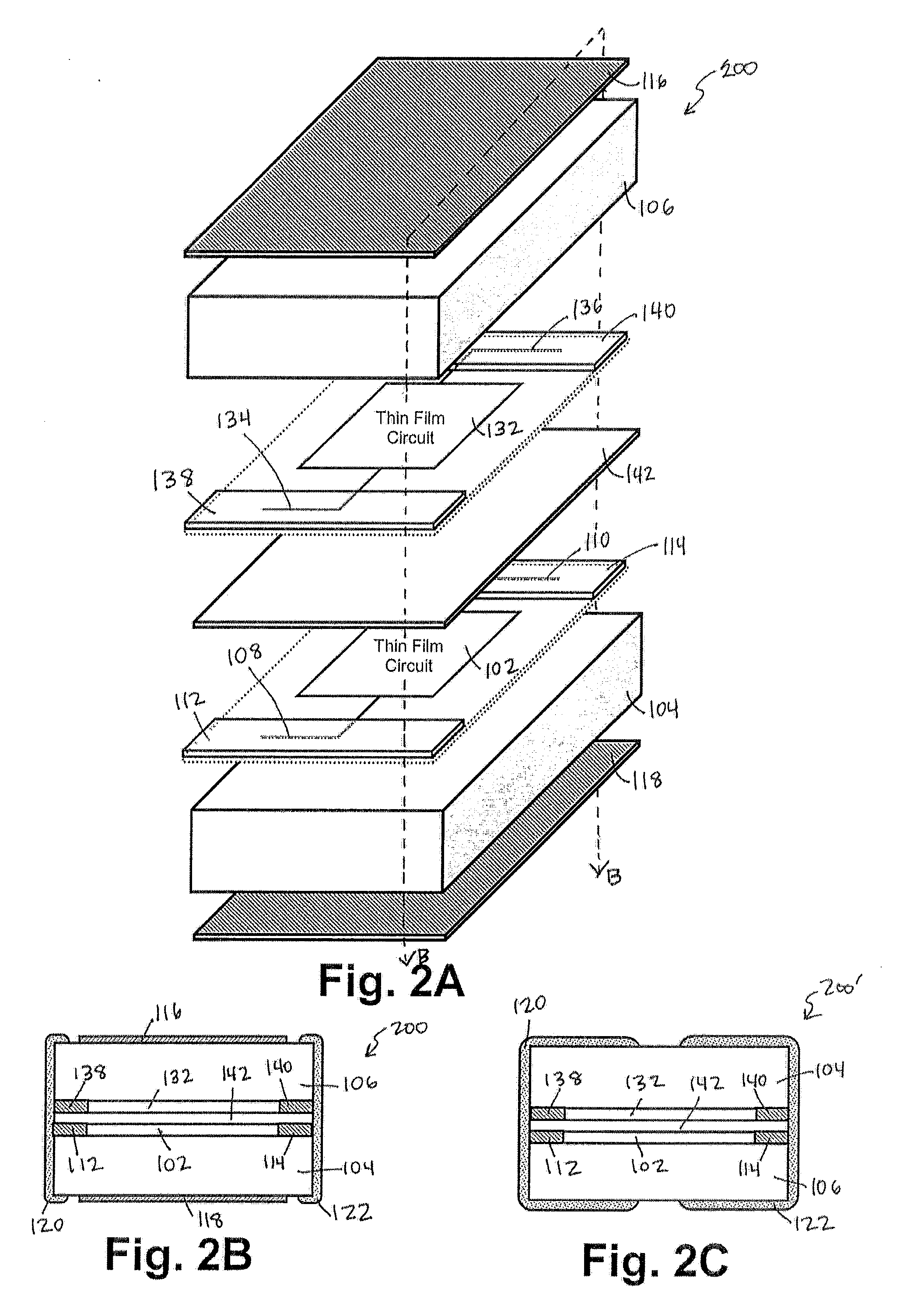

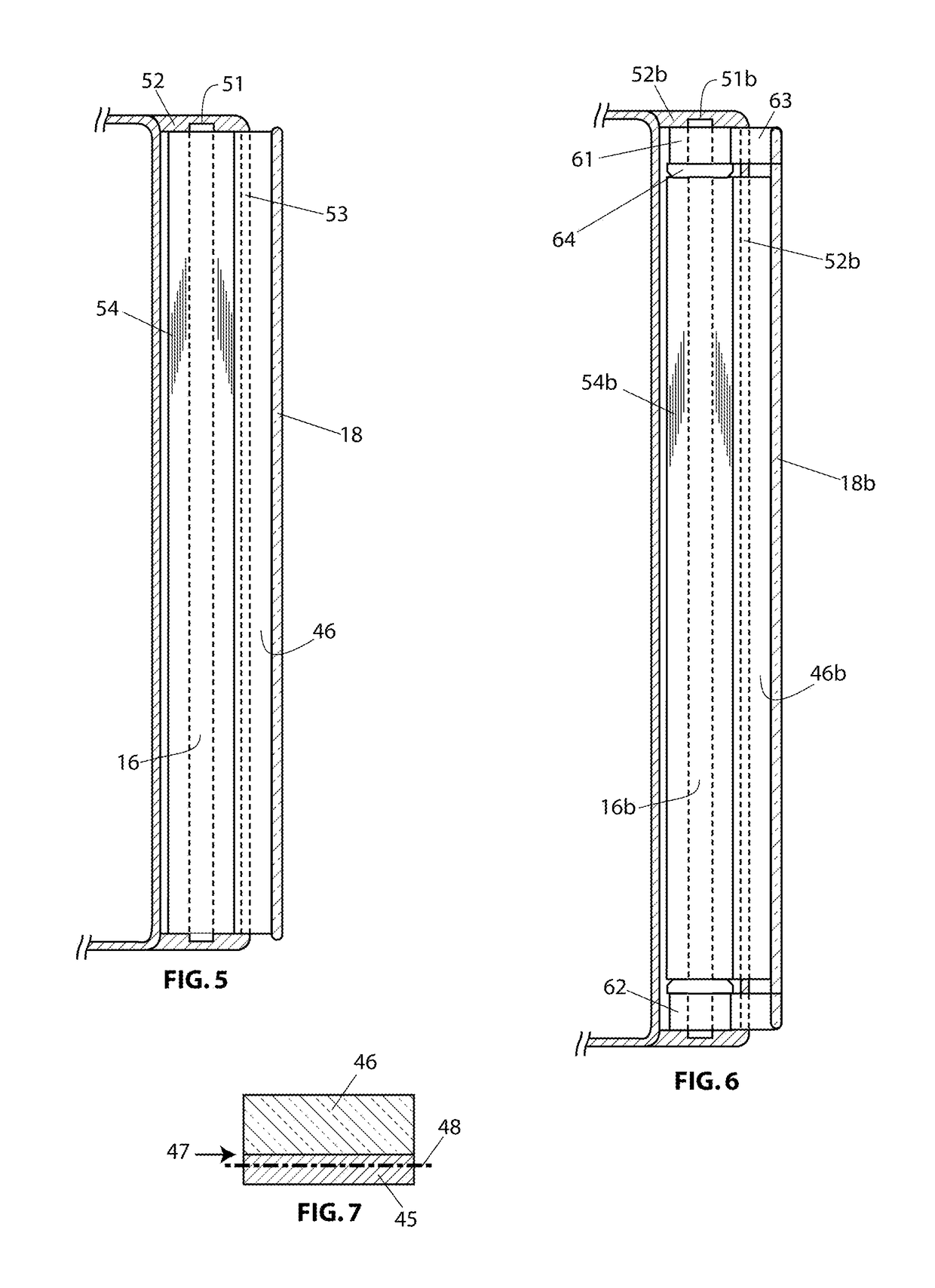

Thin film surface mount components

ActiveUS20110090665A1Lowering termination costImprove functionalityMultiple-port networksDigital data processing detailsSurface mountingConductive polymer

Surface mount components and related methods of manufacture involve one or more thin film circuits provided between first and second insulating substrates. The thin film circuits may include one or more passive components, including resistors, capacitors, inductors, arrays of one or more passive components, networks or filters of multiple passive components. Such thin film circuit(s) can be sandwiched between first and second insulating substrates with internal conductive pads being exposed between the substrates on end and / or side surfaces of the surface mount component. The exposed conductive pads are then electrically connected to external terminations. The external terminations may include a variety of different materials, including at least one layer of conductive polymer and may be formed as termination stripes, end caps or the like. Optional shield layers may also be provided on top and / or bottom device surfaces to protect the surface mount components from signal interference. For embodiments where one or more thin film circuits are provided between insulating base and cover substrates, such thin film circuit(s) can be formed with conductive pads that extend to and are initially exposed along one or more surfaces of the resultant component. The cover substrate is formed with a plurality of conductive elements (e.g., internal active electrodes, internal anchor electrodes and / or external anchor electrodes) that are designed to generally align with the conductive pads formed on the base substrate such that conductive element portions are exposed in groups along one or more peripheral surfaces of a device. External plated terminations are then formed directly to the exposed portions of the conductive elements.

Owner:KYOCERA AVX COMPONENTS CORP

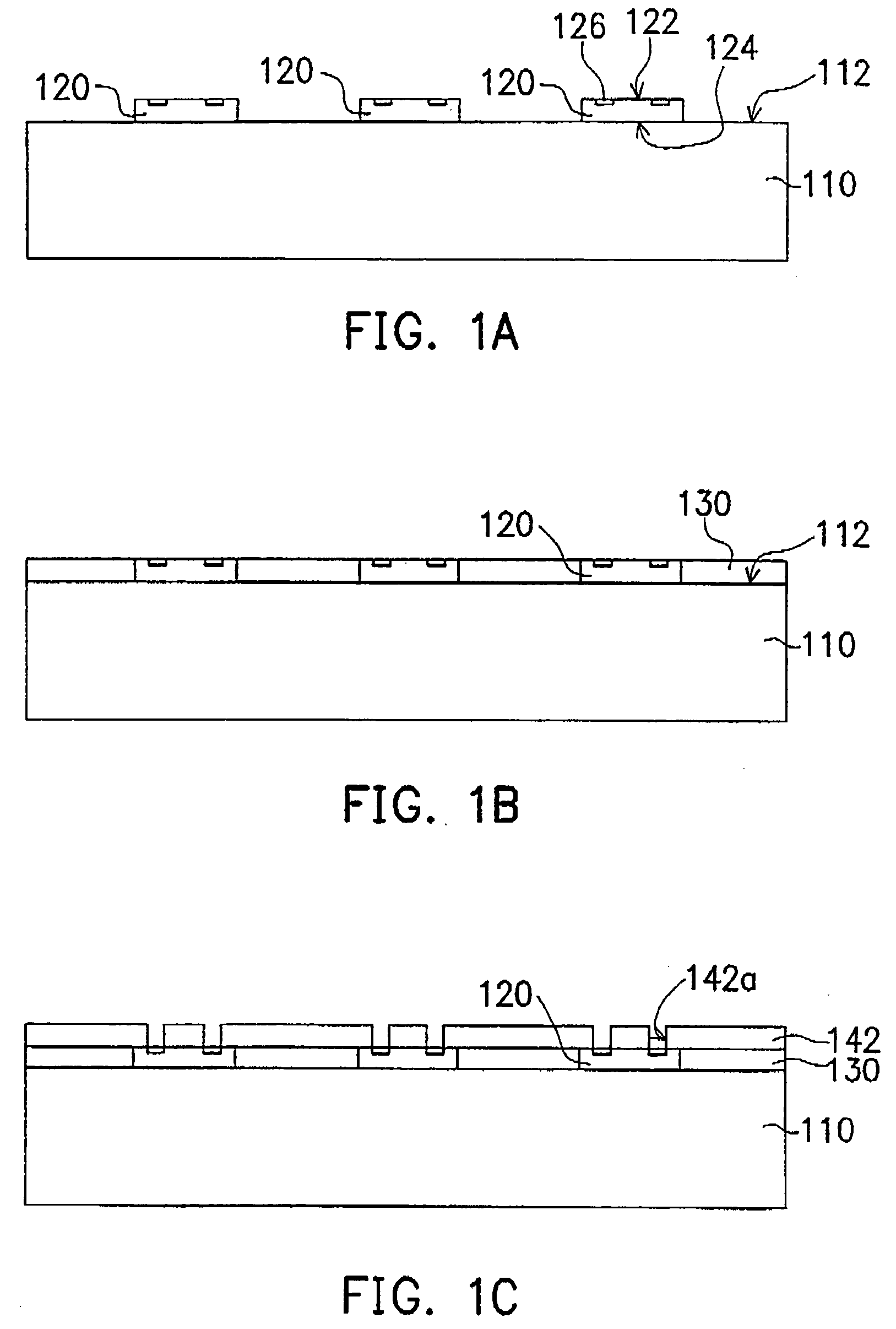

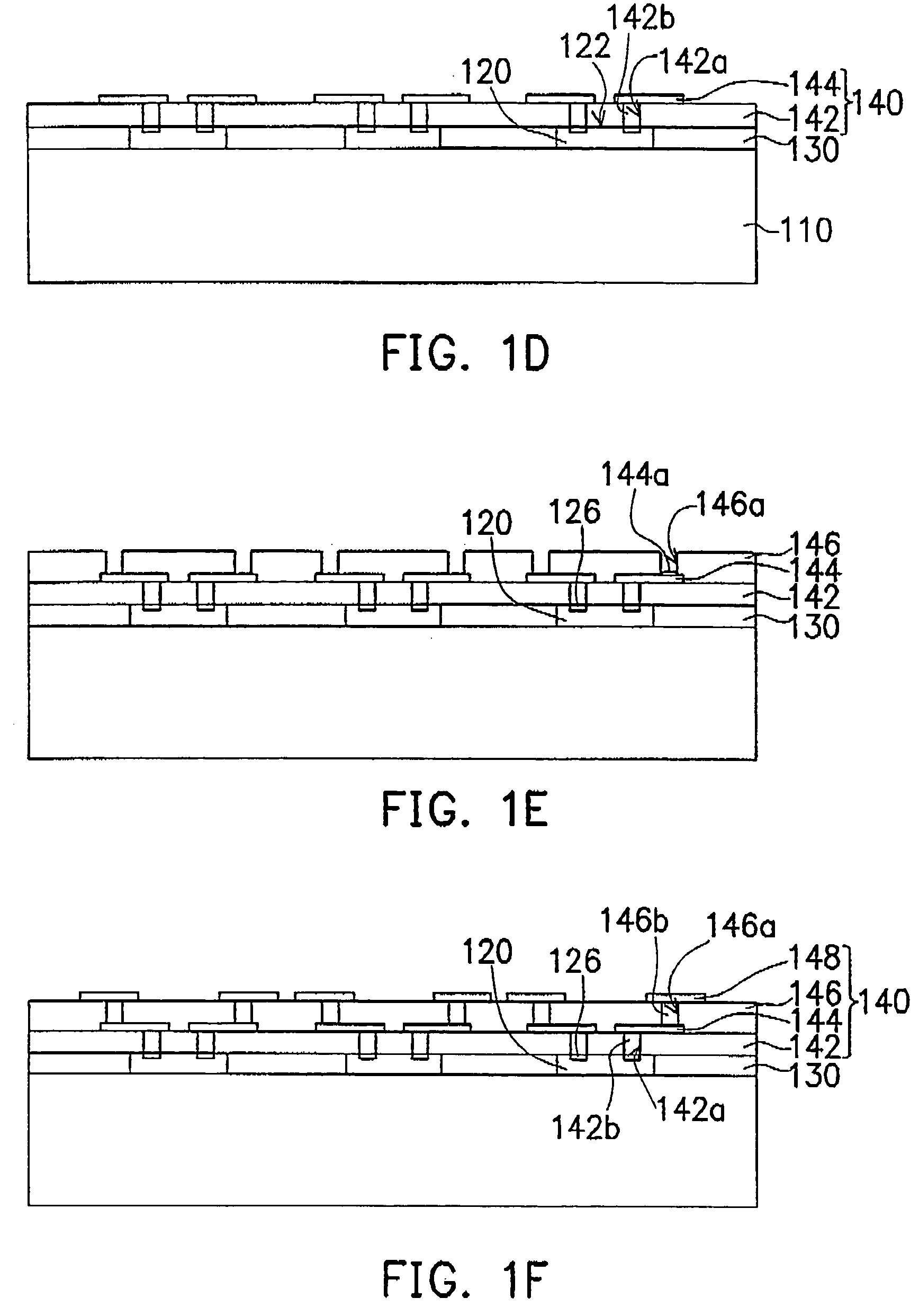

Integrated chip package structure using organic substrate and method of manufacturing the same

InactiveUS7413929B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringThin film circuits

An integrated chip package structure and method of manufacturing the same is by adhering dies on an organic substrate and forming a thin-film circuit layer on top of the dies and the organic substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

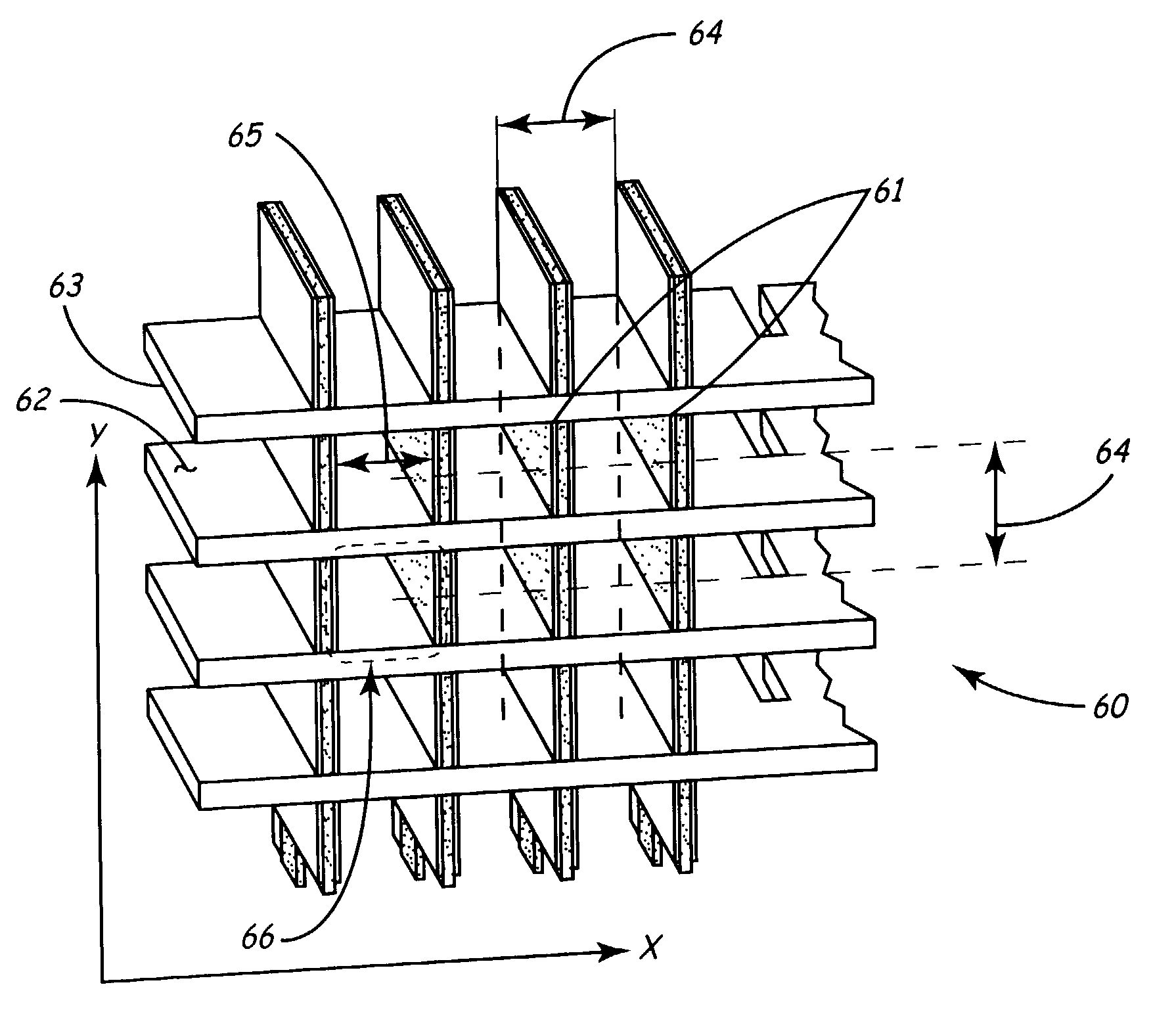

Method and structure for phased array antenna interconnect using an array of substrate slats

InactiveUS6950062B1Wide rangeShorten the counting processAntenna arrays manufactureDelay linesBeam steeringControl circuit

A phased array antenna is formed from an array of apertures having walls containing phase shifter devices for phase shifting and beam steering a radiated beam of the phased array antenna. The phase shifter devices are interconnected with an interconnect structure formed from substrate slats that form the walls of the apertures. The substrate slats may be thin film circuitized column slats having a metal substrate, dielectric layers, metal bias / control circuitry, a shielding layer, and circuit terminations to connect to a phase shifter device attached to the substrate slat.

Owner:ROCKWELL COLLINS INC

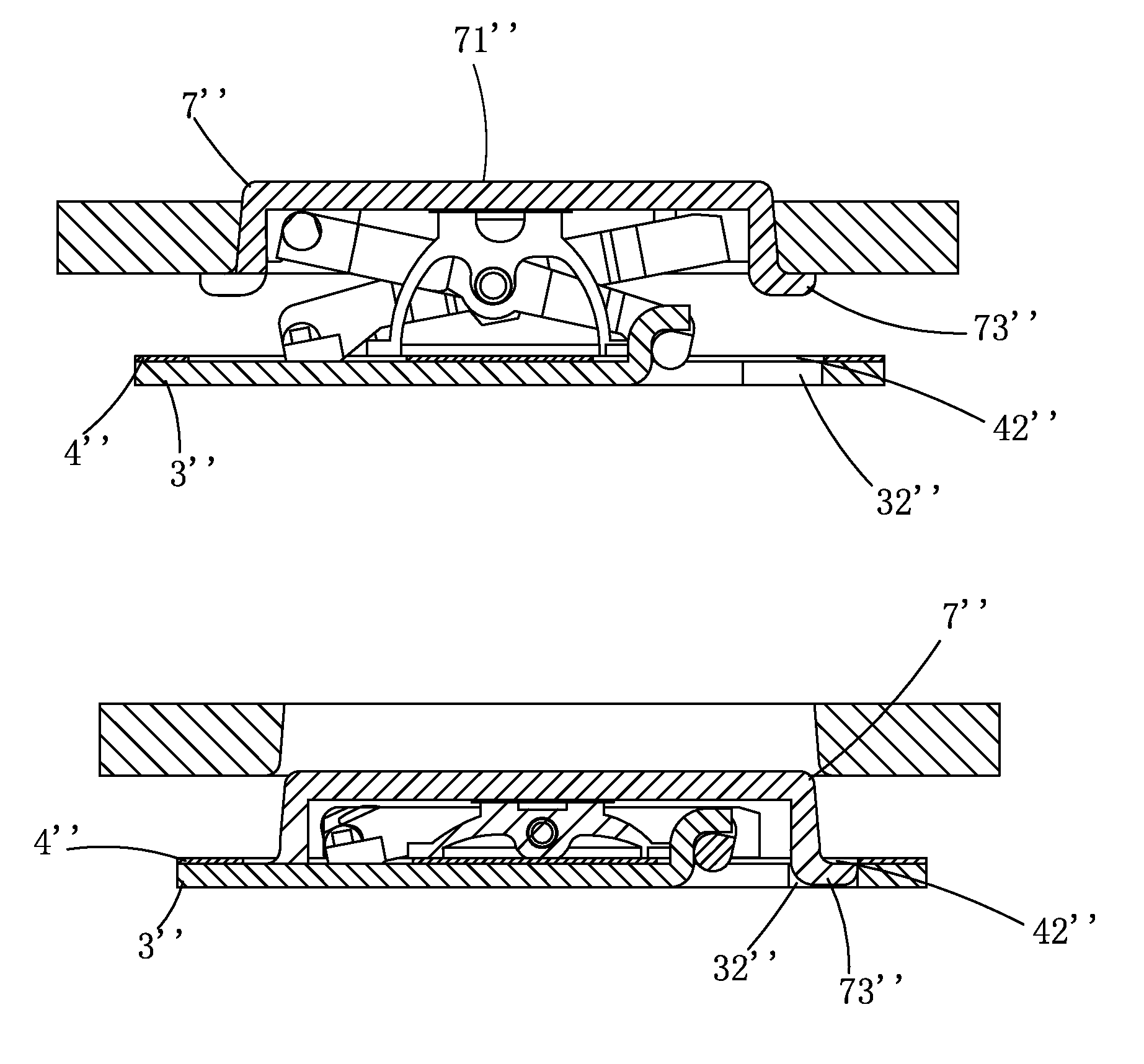

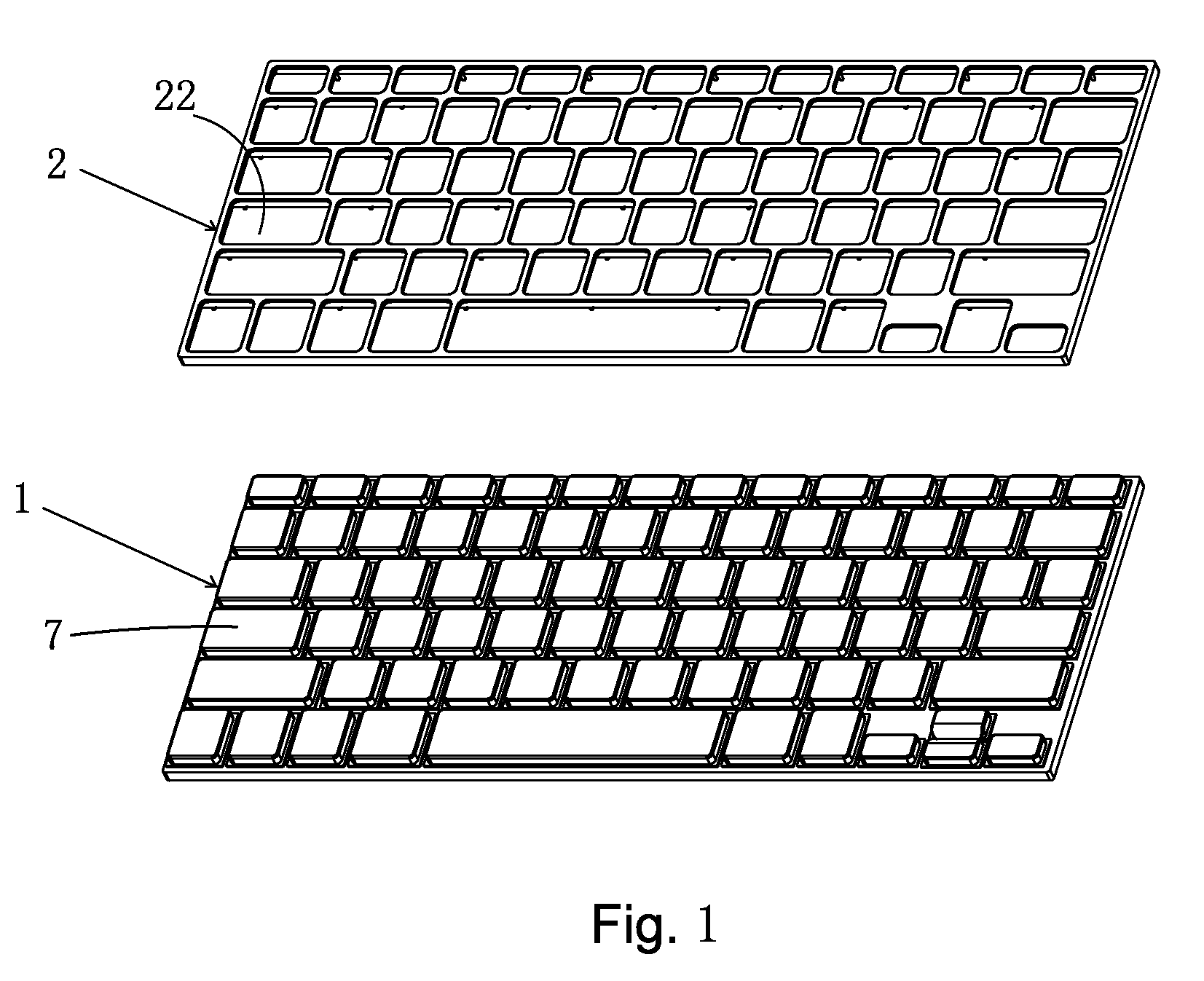

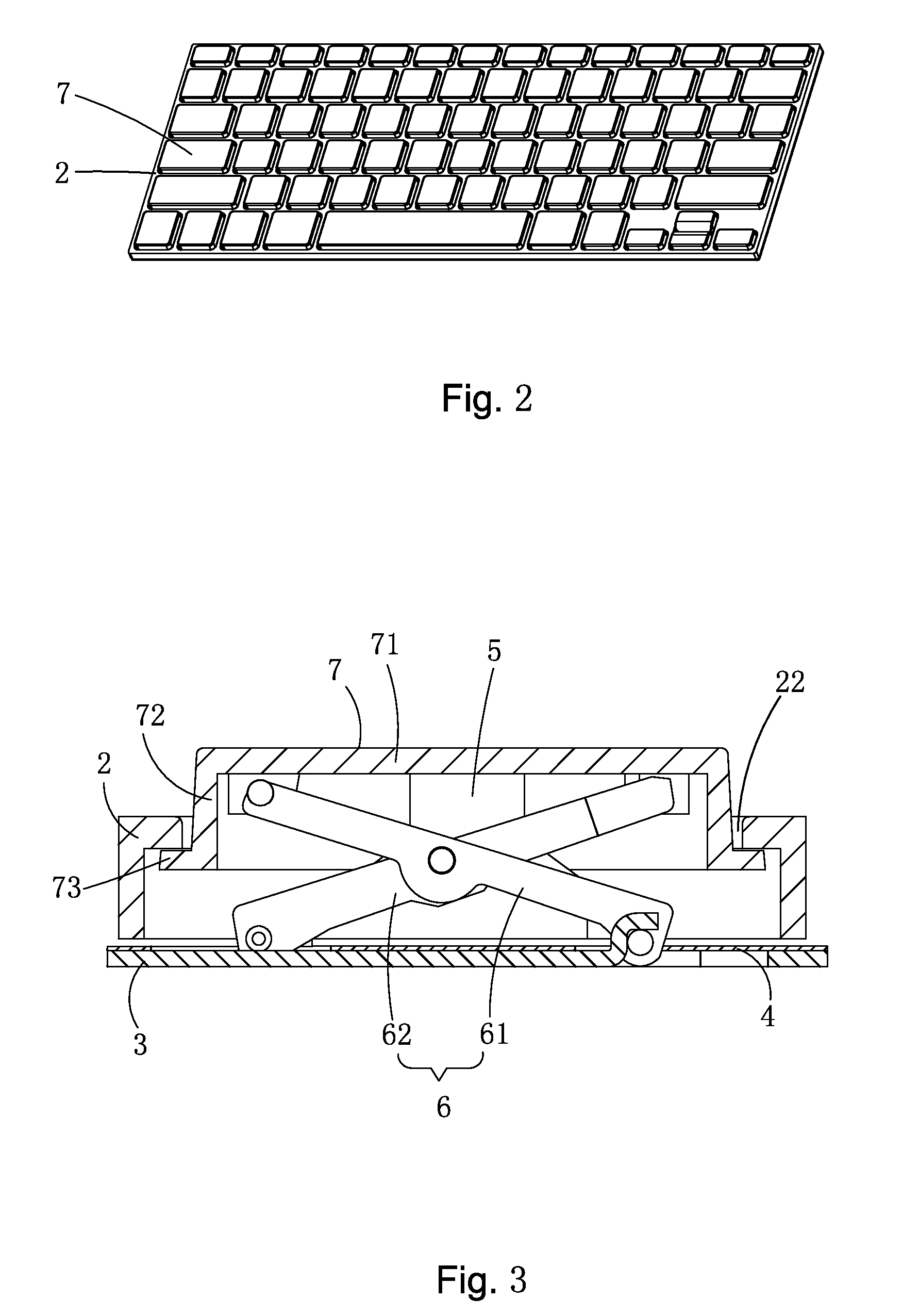

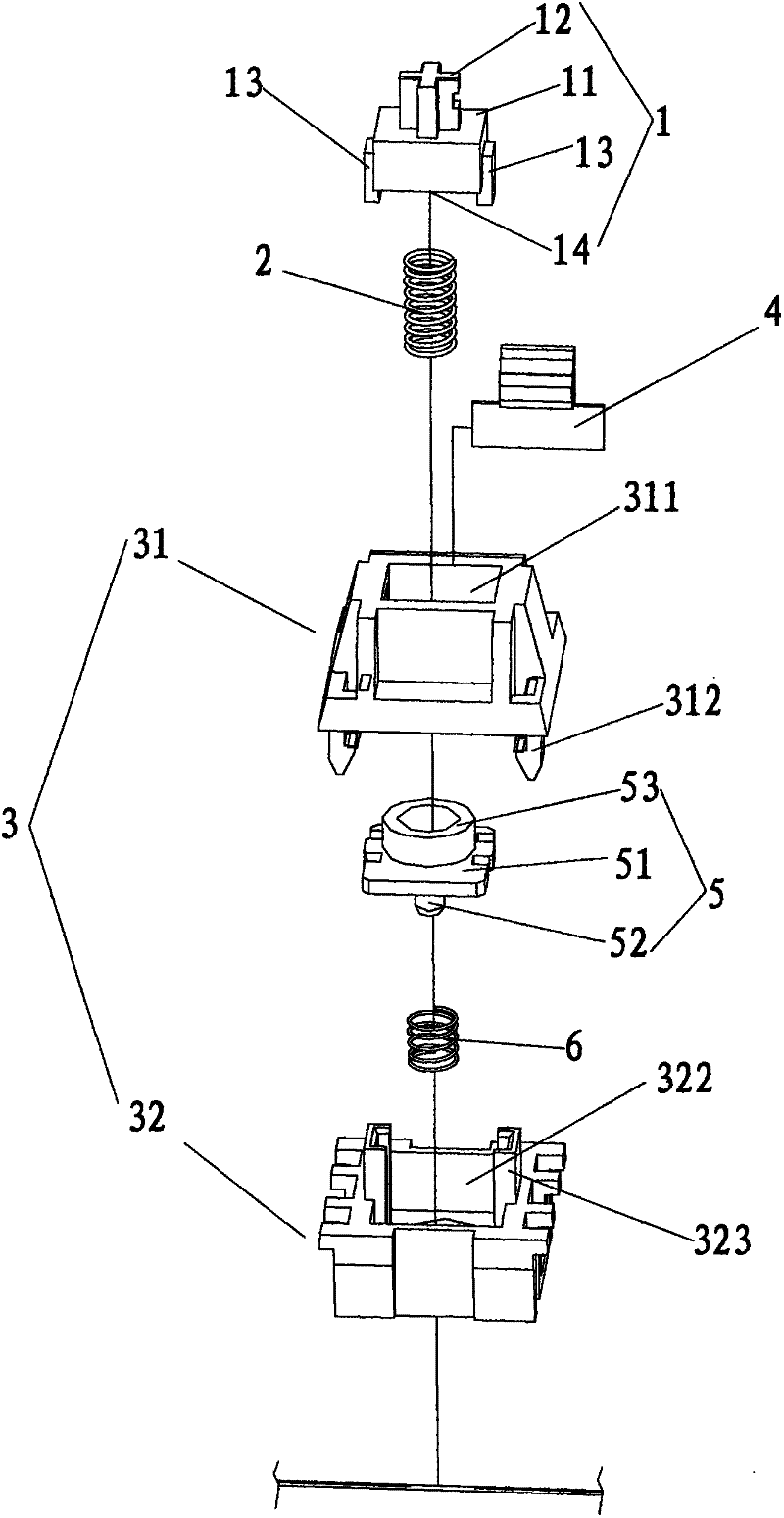

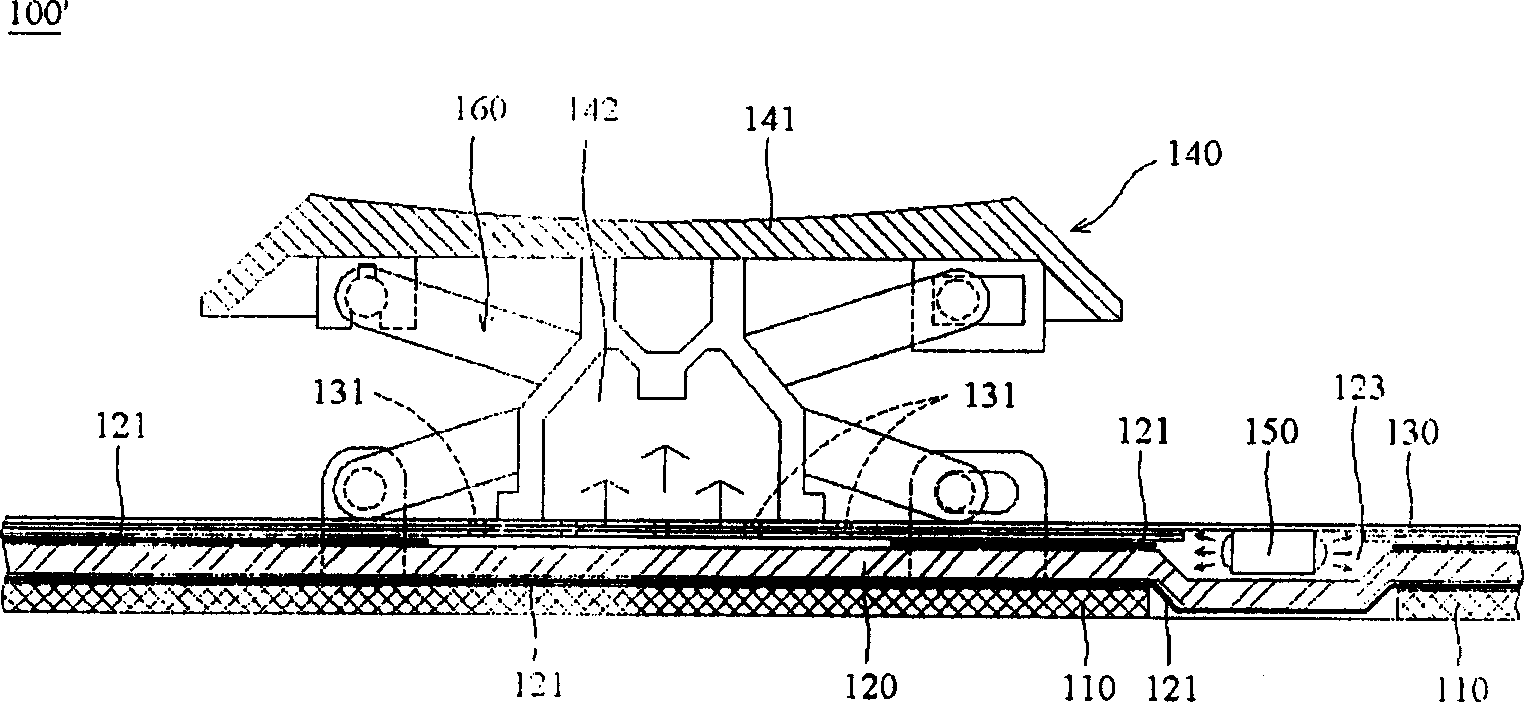

Keyboard preventable keycaps from breaking off

InactiveUS8791378B2Effectively prevent the keycap from breaking offStable and efficient and durable to useEmergency actuatorsContact mechanismsMiniaturizationMechanical engineering

The present invention provides a keyboard preventable keycaps from breaking off, which comprises a keyboard main body, and a limit board fixed to the keyboard main body. The keyboard main body comprises a base board, a thin film circuit board mounted on the base board, an elastic body mounted above the thin film circuit board, a scissors structure, and a keycap. The center of the scissors structure is provided with a hollow part. The elastic body is located above the thin film circuit board and in the hollow part at the center of the scissors structure. The keycap is located on the elastic body. The scissors structure is mounted to the keycap and passes through the thin film circuit board to be moveably mounted to the base board. The keycap comprises a top surface and side surfaces connected with the top surface, and the side surface is provided with a locking part extending outwards therefrom. The limit board is provided with a plurality of openings corresponding to keycaps, the keycaps pass through the openings, and the limit board covers the locking parts. The present invention can effectively prevent the keycap from breaking off under an external force. Furthermore, the present invention has a certain dustproof function, has more stable keycaps, is efficient and durable to use, and facilitates miniaturization of the keyboard.

Owner:SHENZHEN DOKING TECH CO LTD

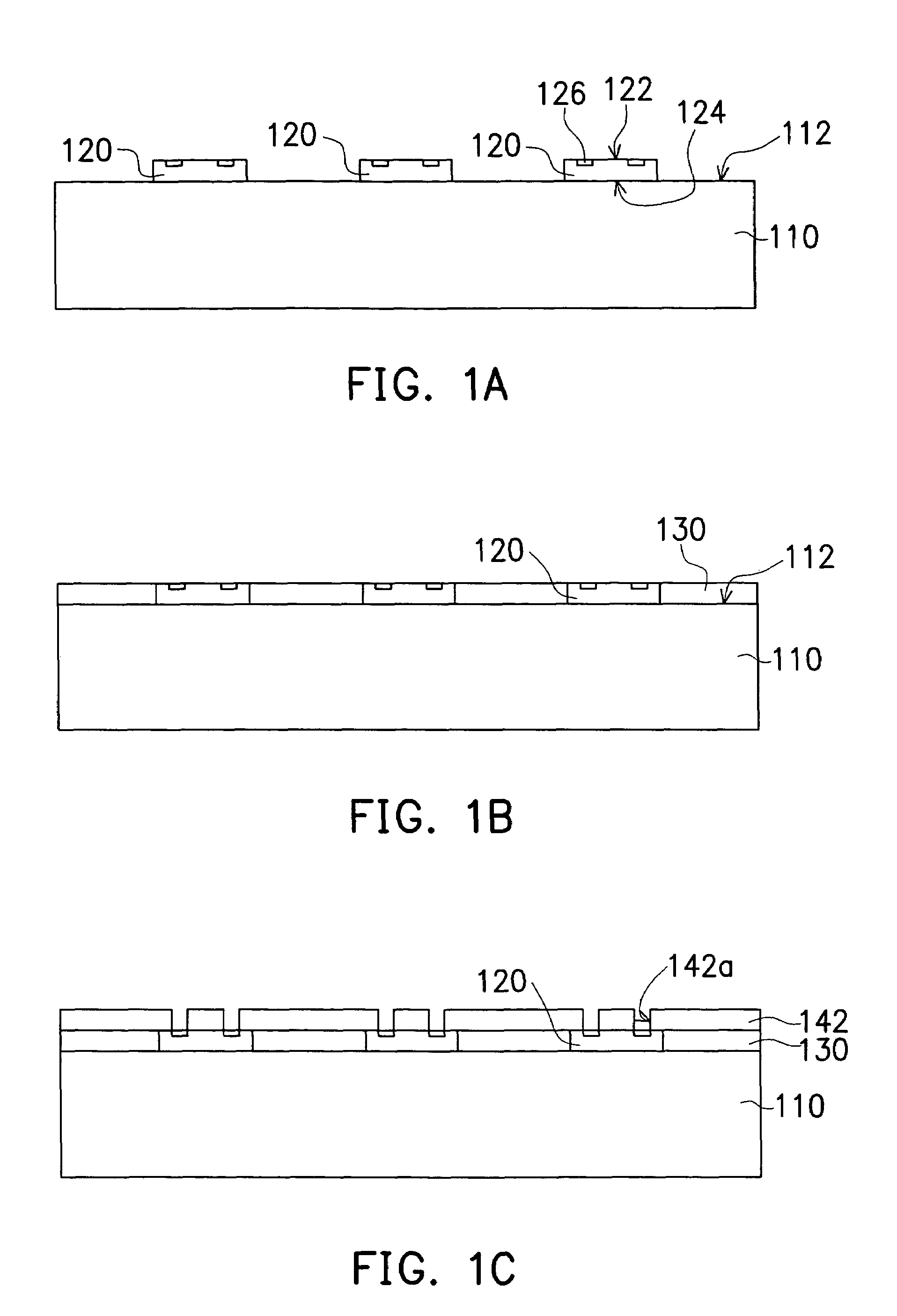

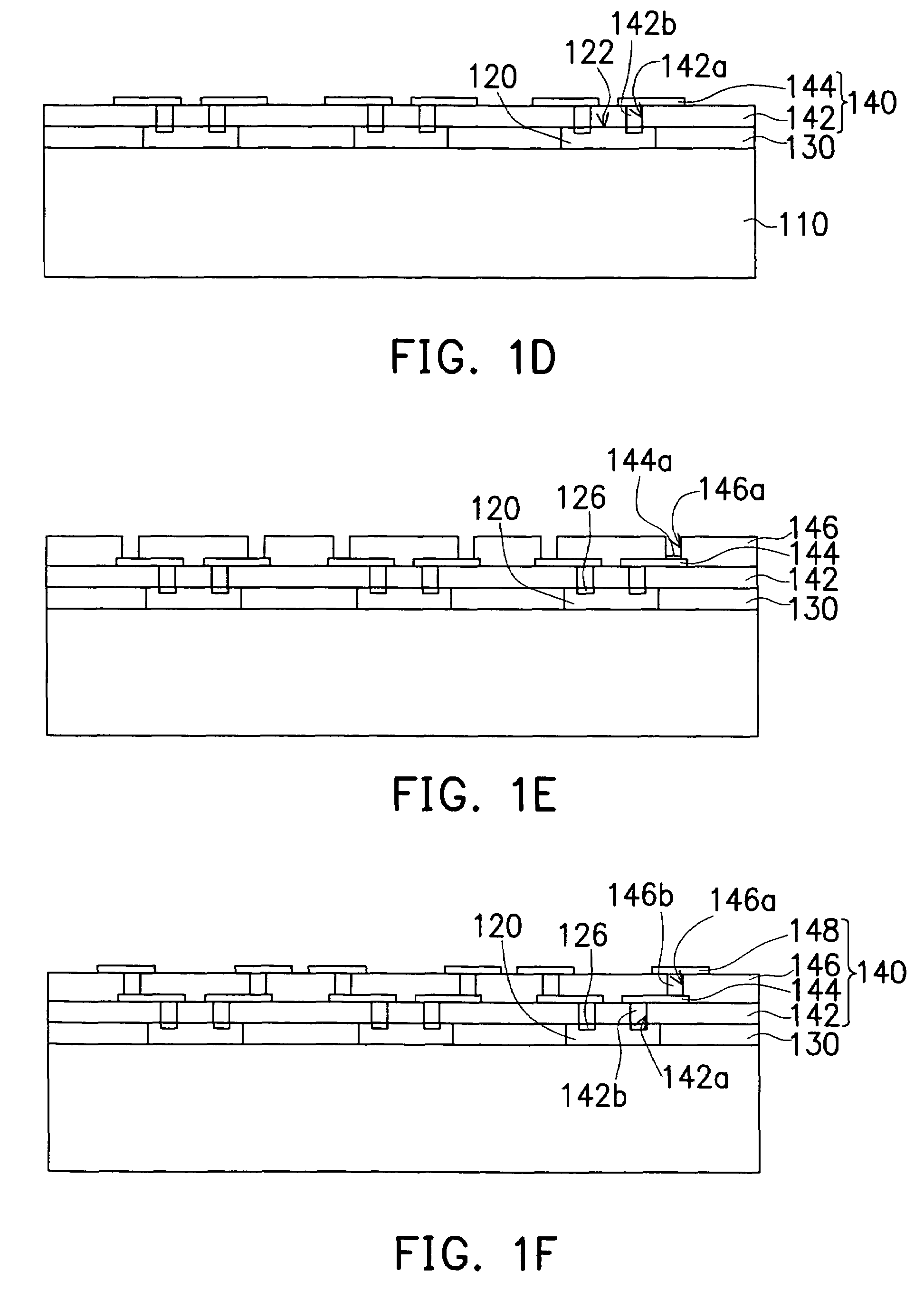

Method for fabricating chip package

InactiveUS7271033B2Semiconductor/solid-state device detailsSolid-state devicesThin film circuitsExternal circuit

An integrated chip package structure and method of manufacturing the same is by adhering dies on a metal substrate and forming a thin-film circuit layer on top of the dies and the metal substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

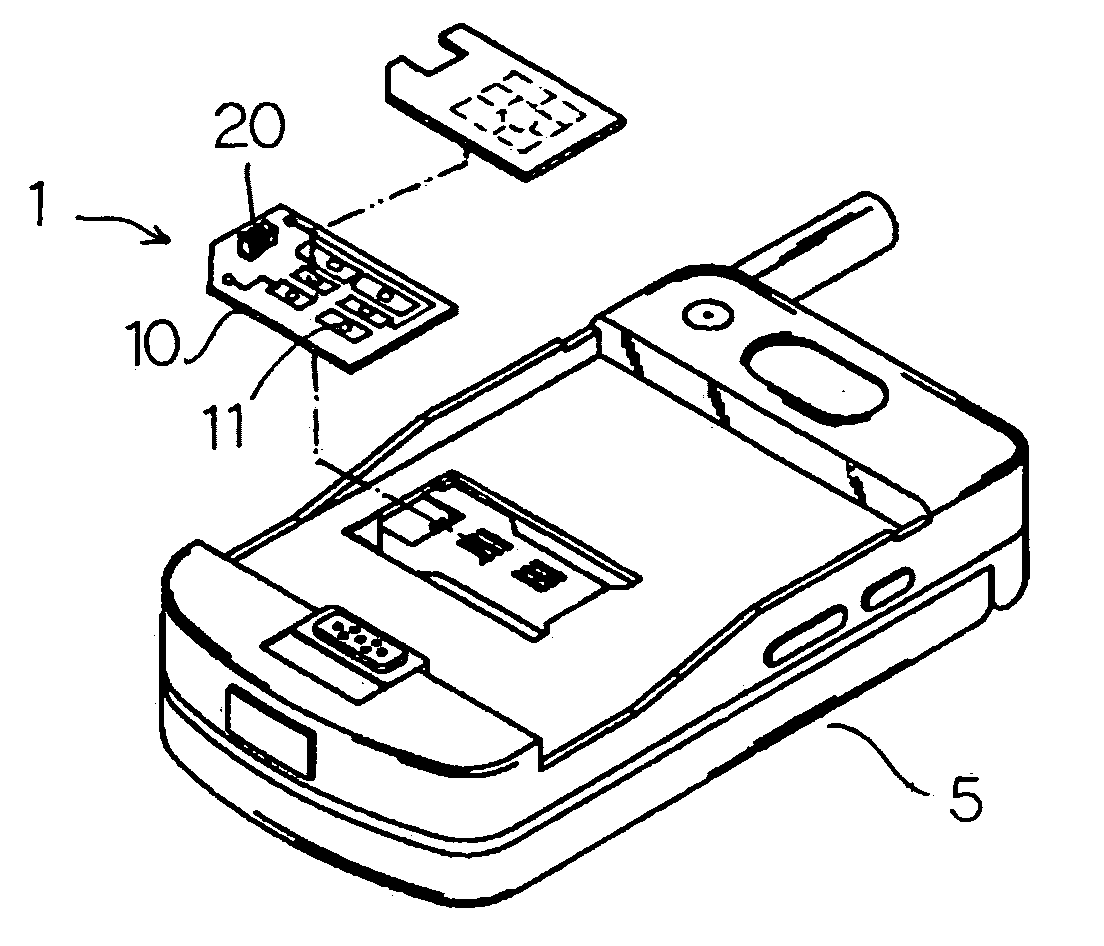

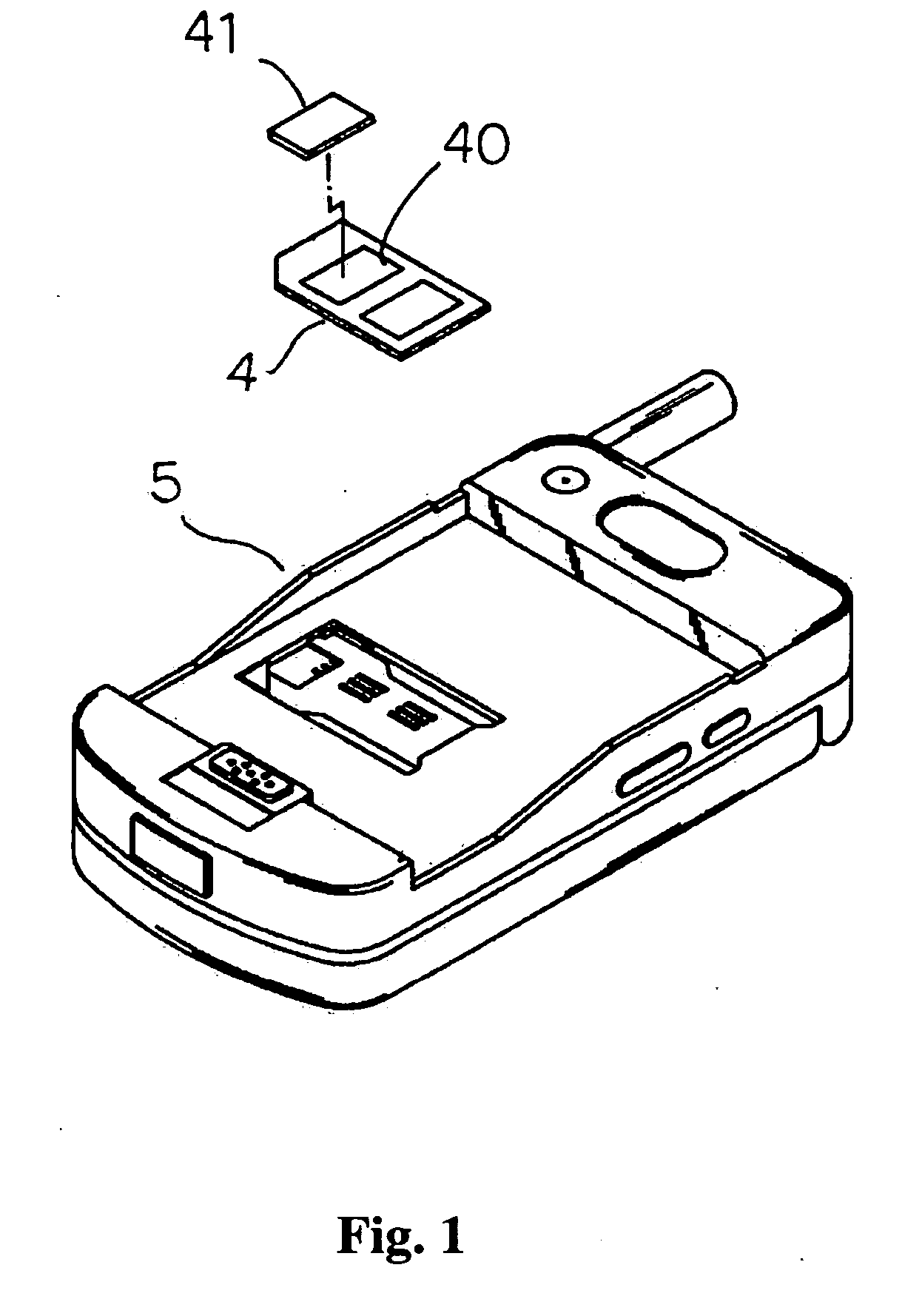

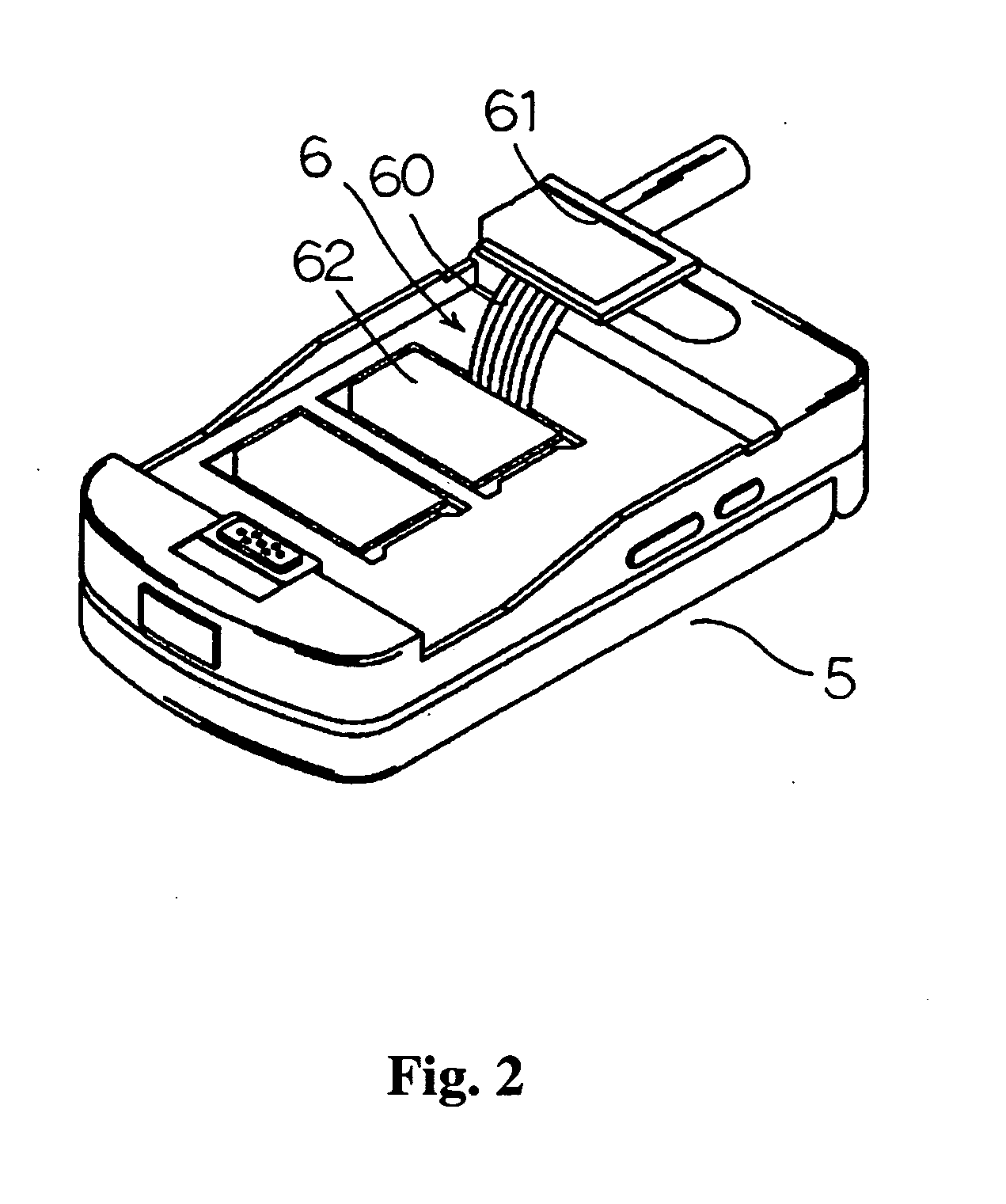

Functional module improvement structure for expanded and enhanced SIM card

InactiveUS20070262156A1Convenience of practicalPractical purposeDevices with card reading facilitySubstation equipmentElectricityElectrical connection

This invention relates to a functional module structural improvement for expanded and enhanced SIM card comprising of an user identification module and a SIM card; the user identification module is formed by thin film circuit board, the surface is installed with electrical connection points and a control chip, the control chip is built in with: operational interface and functional selection items, application information of the original line number, and more than one sets of new number information, operational interfaces, functional selection items, application information; it can provide the user with more diversified and total functional interface application as well as multi-number selection and usage switching, the convenience and effectiveness of usage can thus be greatly enhanced.

Owner:LEISON TECH +1

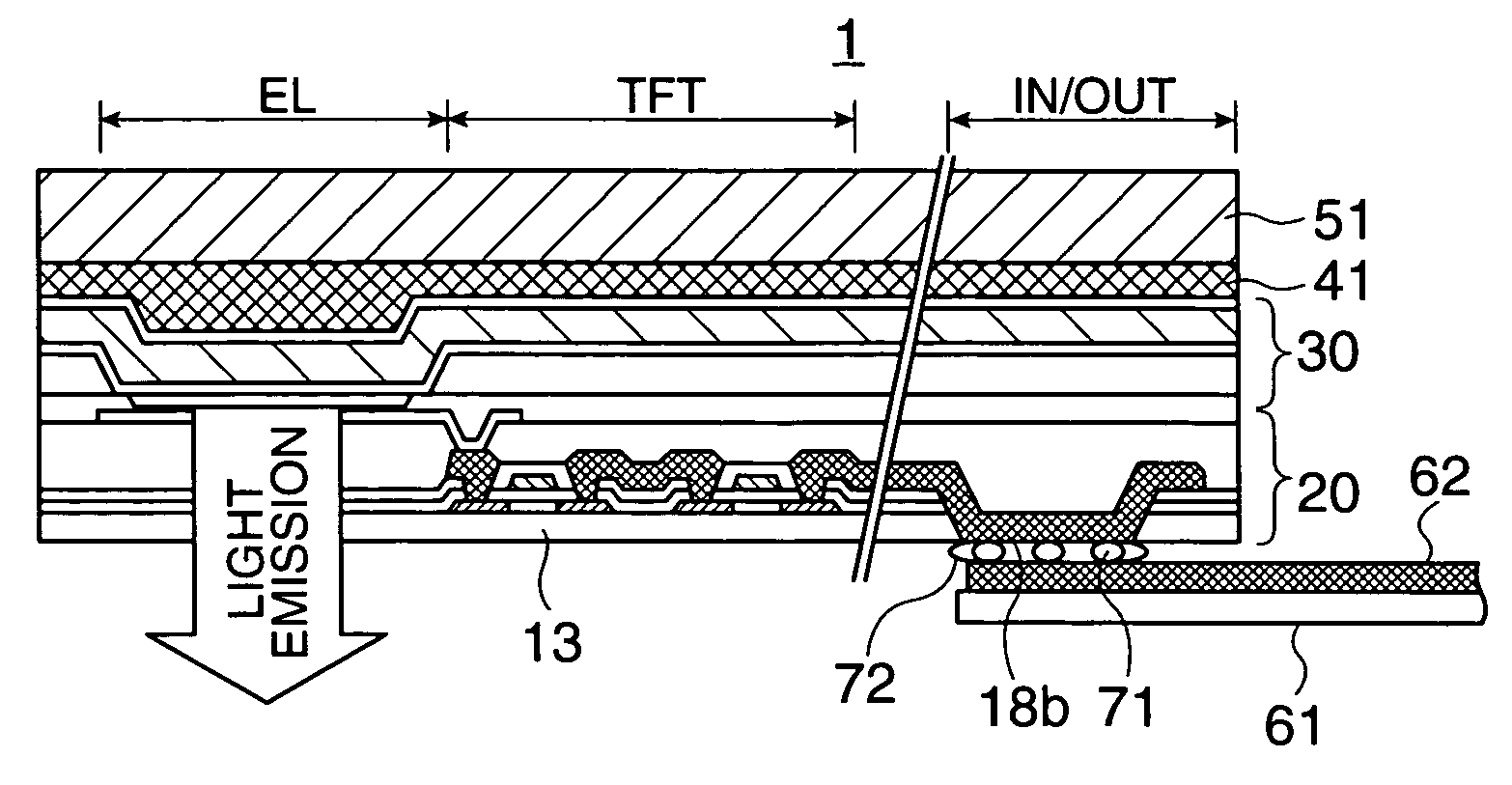

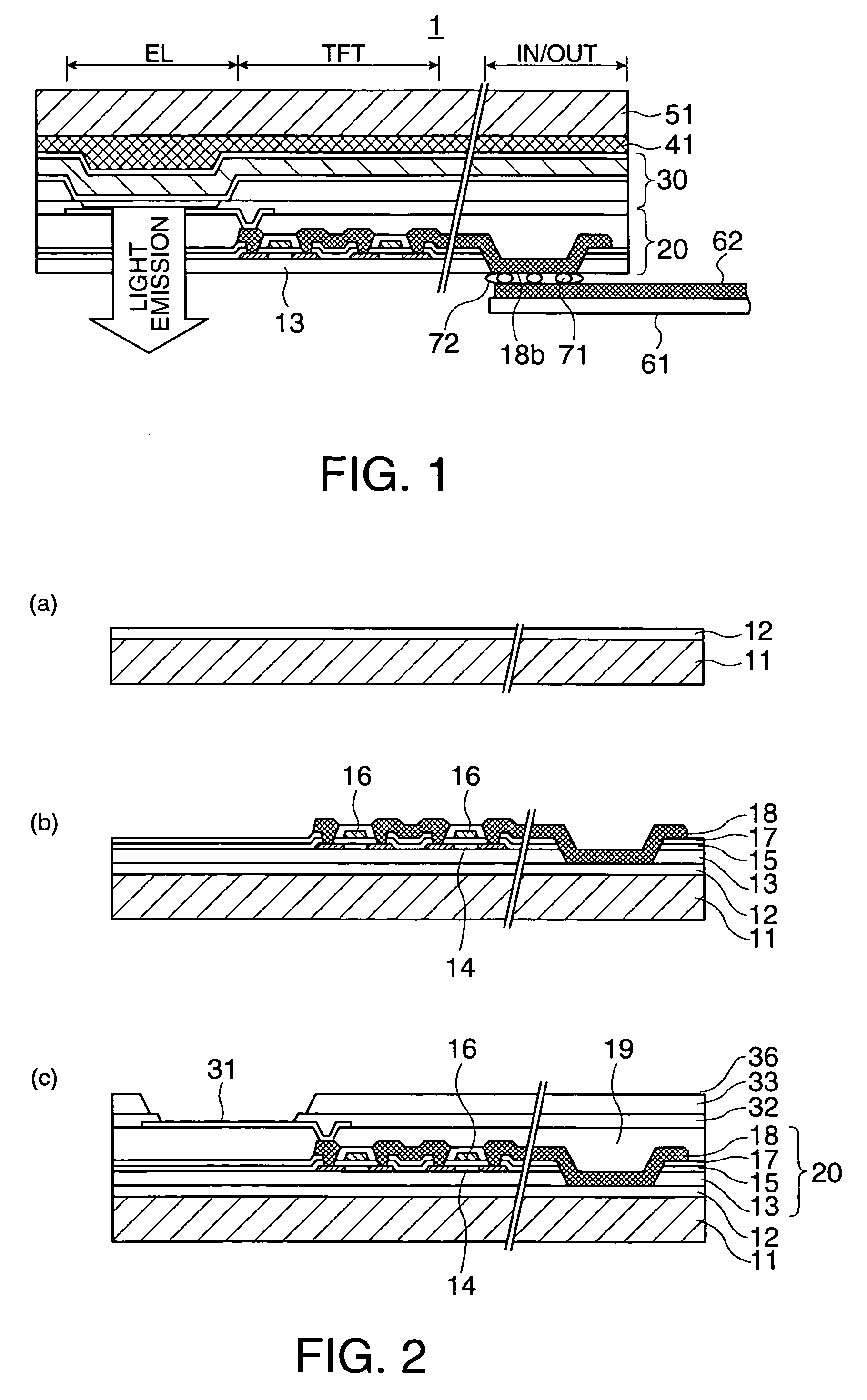

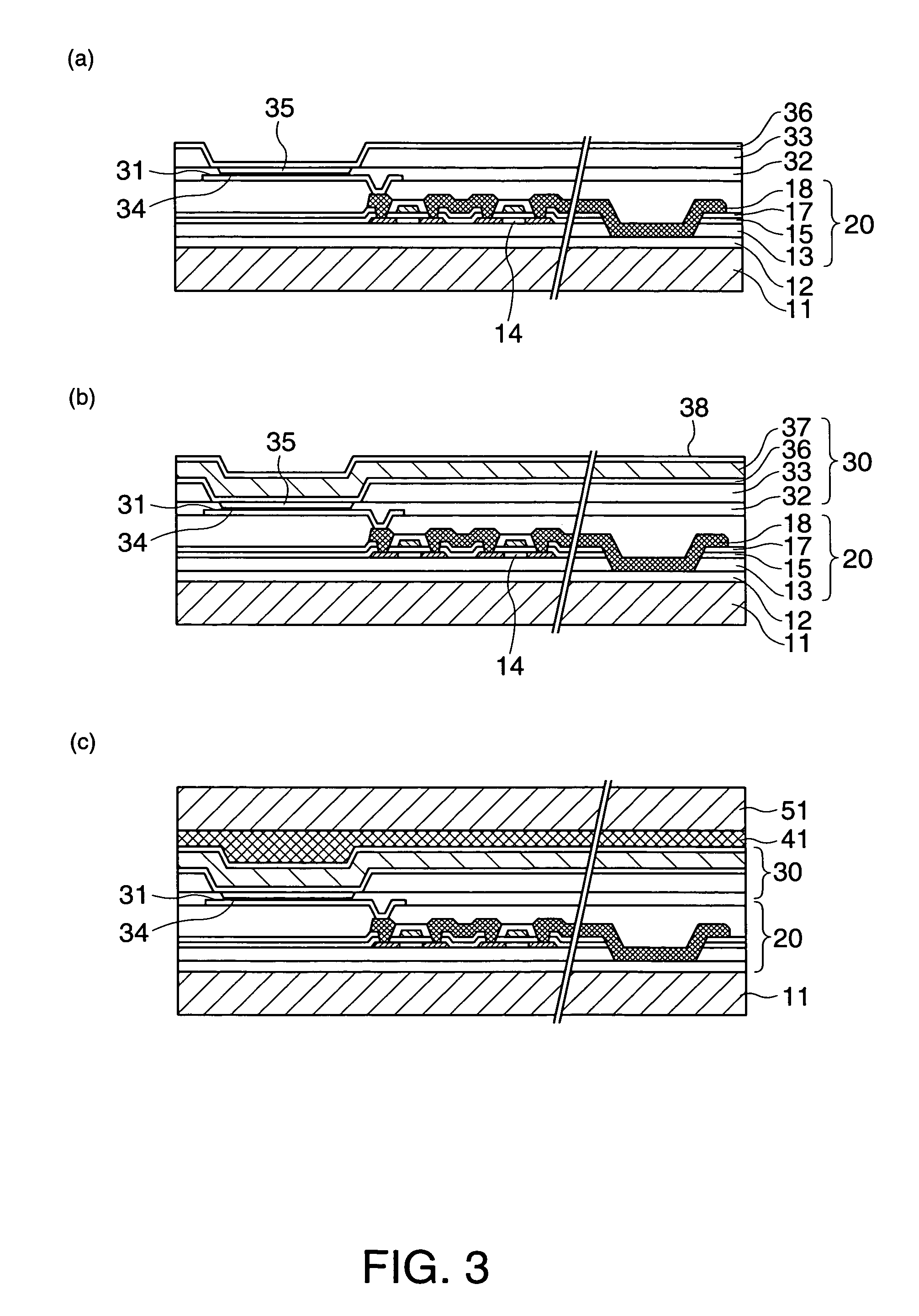

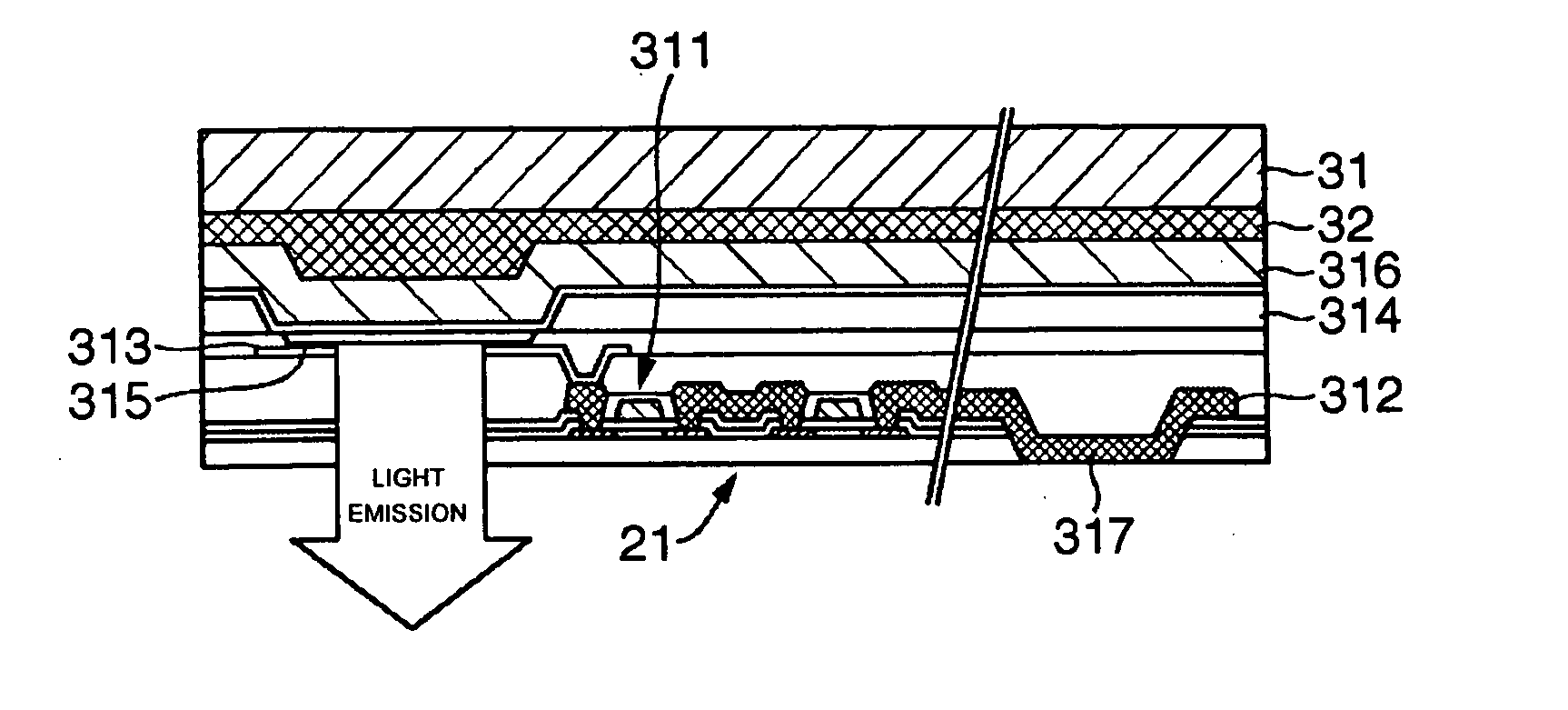

Organic EL display device, electronic equipment, and method for manufacturing the same

ActiveUS7342354B2Increase the number ofComplicated processingDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOptoelectronics

To provide a sheet-shaped organic EL display device having a reduced thickness, an organic EL display device includes a substrate serving as both a protective layer to reduce or prevent permeation of moisture, oxygen, and the like into the inside and a support layer for film formation, a laminate which is provided on a under layer by film formation and which includes a thin film circuit layer carrying an electric circuit and an organic EL light emitting layer carrying an organic EL light emitting element, and an adhesive layer joining the above-described laminate and the above-described substrate. The above-described organic EL light emitting element radiates the emitted light toward the above-described under layer side. In this manner, a low-profile organic EL display device can be provided.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

Photocuring and thermocuring conductive adhesive and preparation method

ActiveCN102127386ALiquidConnectivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention discloses a photocuring and thermocuring conductive adhesive, which is prepared by mixing photosensitive high polymer, diluent monomer, conducting particles, photoinitiator, polymerization inhibitor, epoxy resin, epoxy active diluting agent, latent curing agent and latent promoting agent, grinding the mixture, and stirring and dispersing in a planetary manner. The curing temperature of the product is low, and deep curing can be realized; after being cured, the adhesive has high adhesiveness and high solvent resistance; and the adhering strength is high, the resistivity is low, and the requirements of microelectronic packaging technique for LED chips, liquid crystal materials, glass substrates, thin film circuits, PCB circuit boards and the like can be met.

Owner:东莞市新懿电子材料技术有限公司

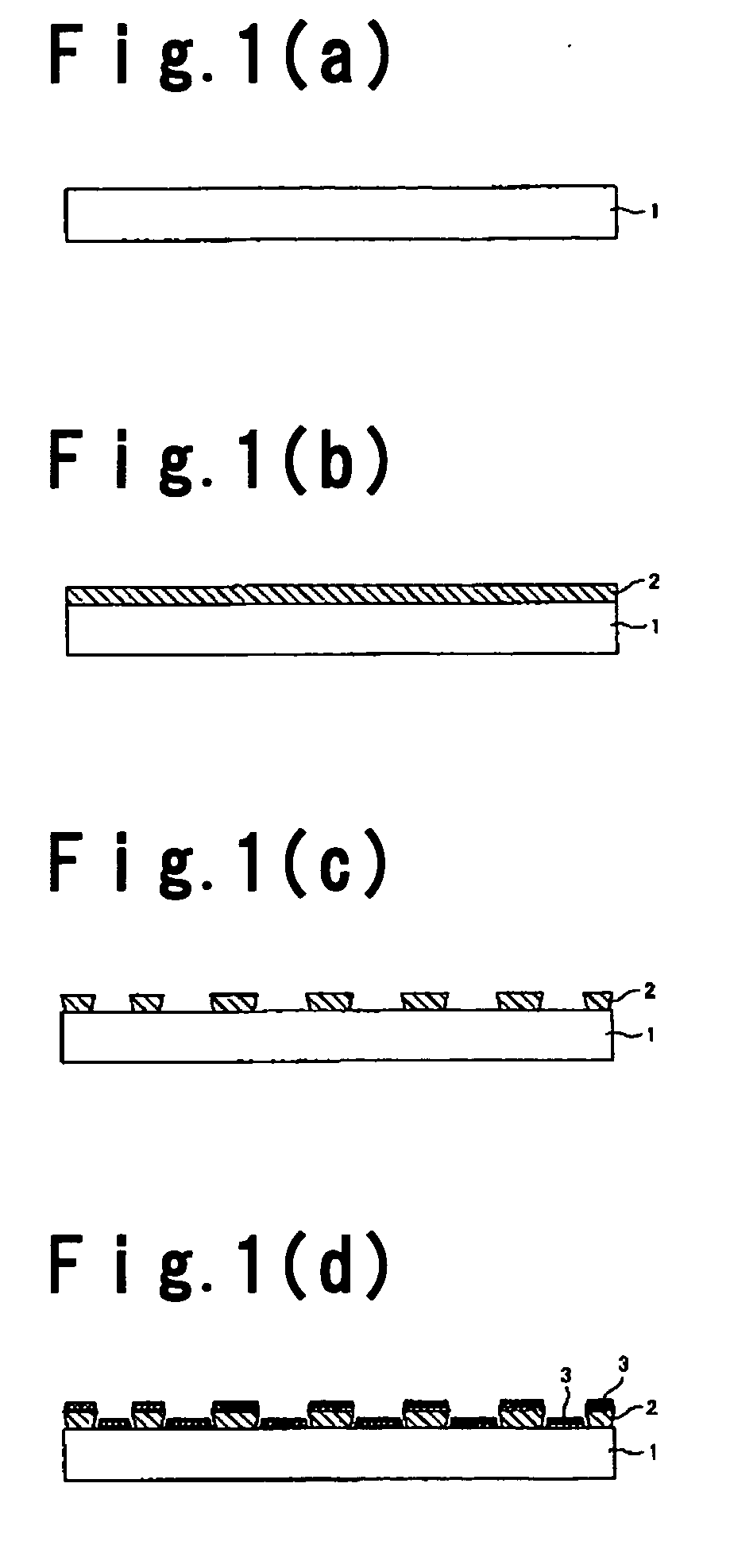

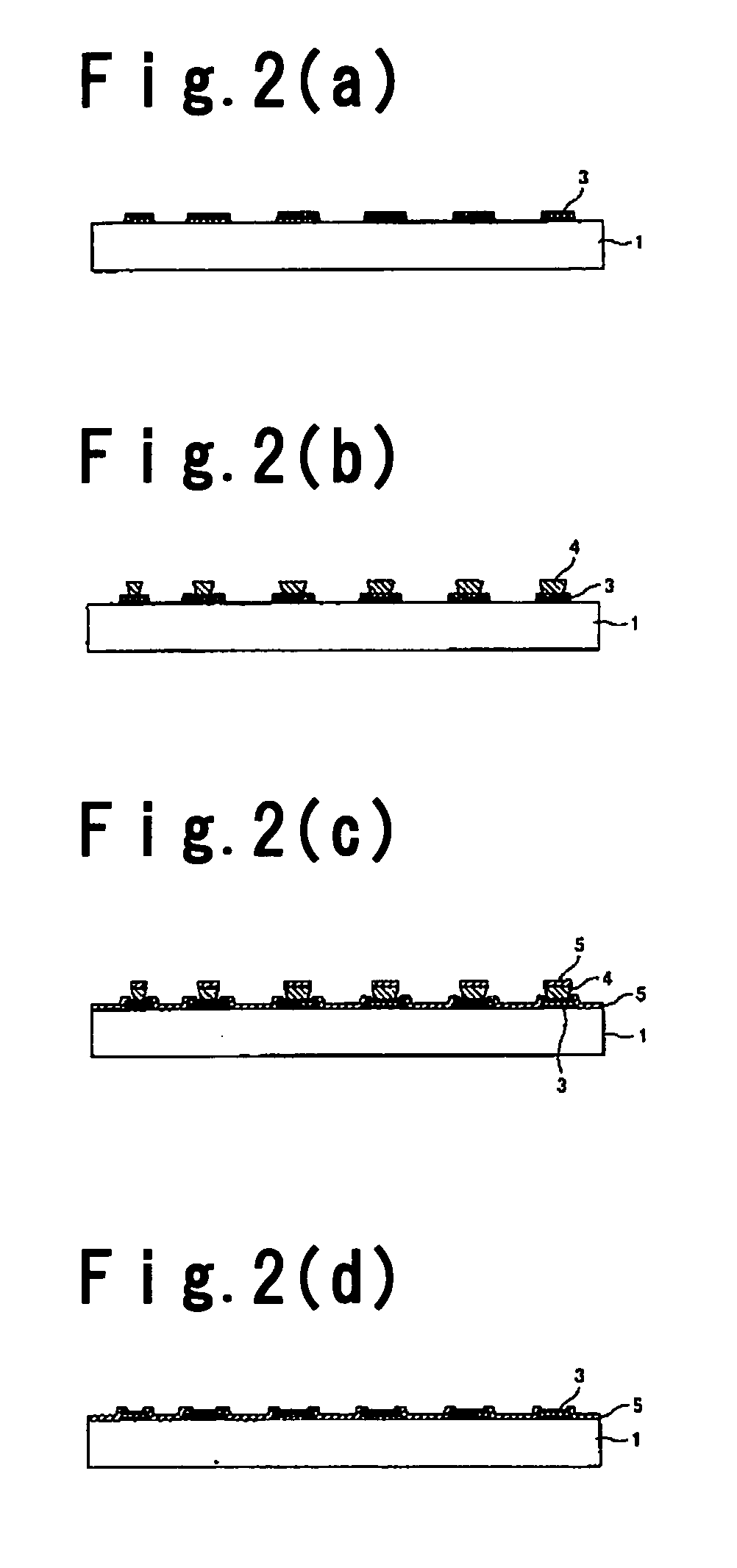

Pattern formation method, electronic circuit manufactured by the same, and electronic device using the same

InactiveUS20060240338A1Low costReduce environmental burdenPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringThin film circuits

There is provided a method for forming a continuous thin film circuit pattern with good precision, at low cost and with low environmental burden; an electronic circuit fabricated by the same, and an electronic device including the same. There are a step for forming a mask layer 2 on a substrate 1; a step for forming an opening pattern in the mask layer 2; a step for forming a thin film 3 on the substrate 1 and on the mask layer 2; and a step for removing, from the substrate 1, the mask layer 2 and a portion of the thin film 3 formed on the mask layer 2; wherein the opening pattern is formed under a dry condition.

Owner:ASAHI GLASS CO LTD

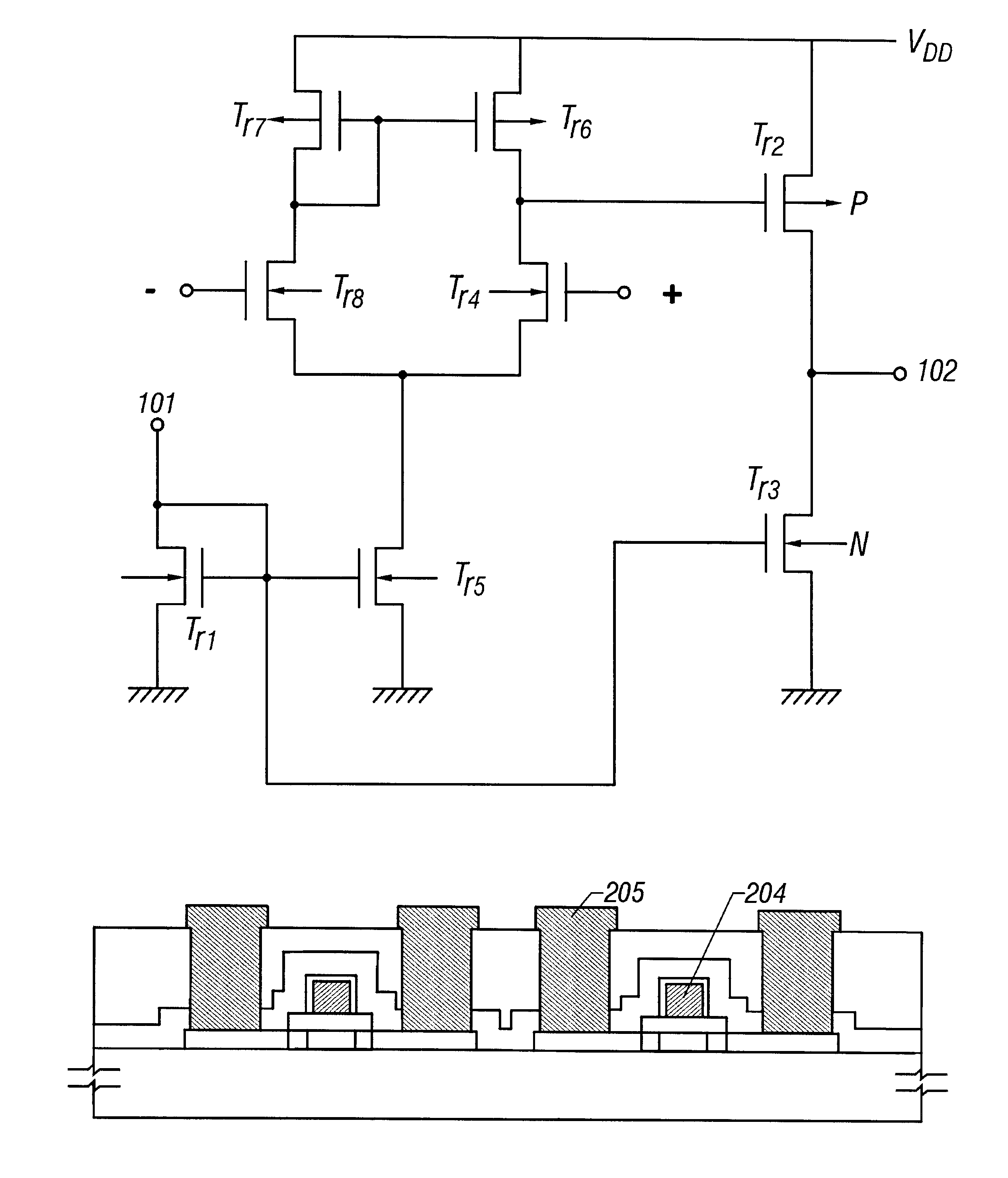

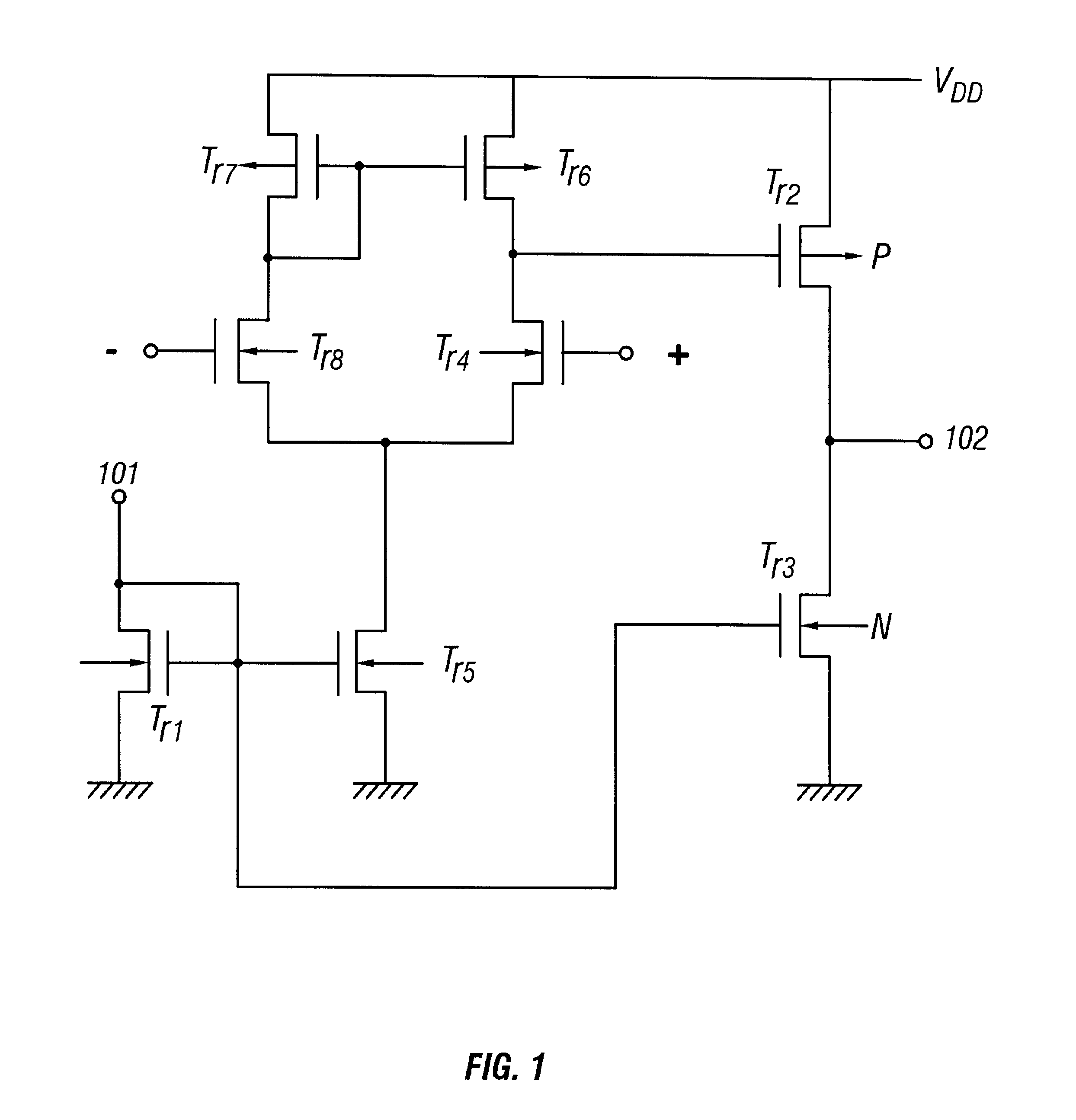

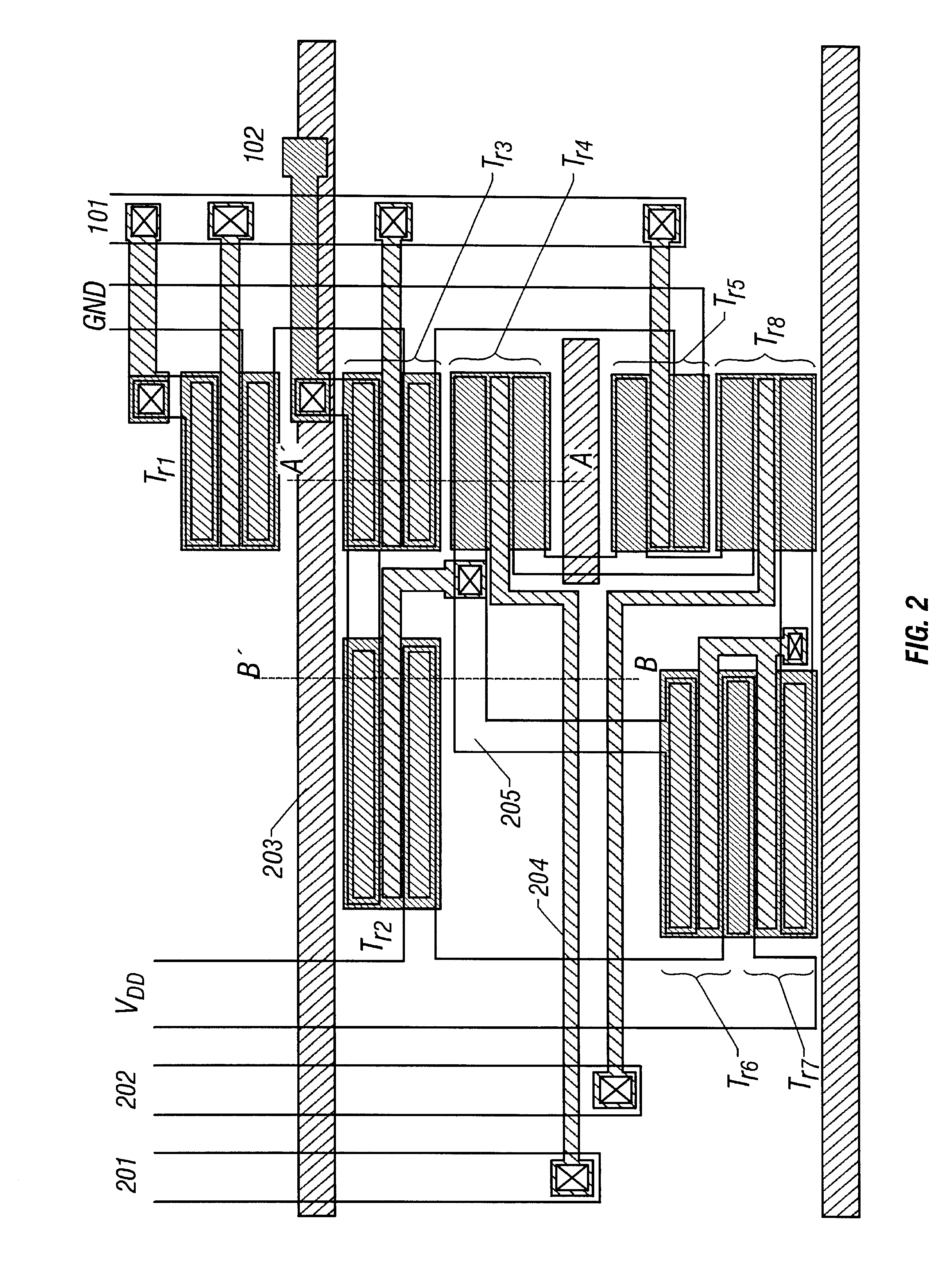

Thin film circuit with improved carrier mobility

InactiveUS6331718B1Eliminate the effects ofIncrease speedTransistorSolid-state devicesHemt circuitsCharge carrier mobility

A practical operational amplifier circuit is formed using thin film transistors.An operational amplifier circuit is formed by thin film transistors formed on a quartz substrate wherein 90% or more of n-channel type thin film transistors have mobility at a value of 260 cm2 / Vs or more and wherein 90% or more of p-channel type thin film transistors have mobility at a value of 150 cm2 / Vs or more. The thin film transistors have active layers formed using a crystalline silicon film fabricated using a metal element that promoted crystallization of silicon. The crystalline silicon film is a collection of a multiplicity of elongate crystal structures extending in a certain direction, and the above-described characteristics can be achieved by matching the extending direction and the moving direction of carriers.

Owner:SEMICON ENERGY LAB CO LTD

Electronic component with die and passive device

InactiveUS7345365B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

An integrated chip package structure and method of manufacturing the same is by adhering dies on an organic substrate and forming a thin-film circuit layer on top of the dies and the organic substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

Semiconductor device having a thin-film circuit element provided above an integrated circuit

InactiveUS6870256B2Avoid crosstalkSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

In a semiconductor device, re-wiring is provided on a circuit element formation region of a semiconductor substrate. A columnar electrode for connection with a circuit board is provided on the rewiring. A first insulating film is provided over the semiconductor substrate excluding a connection pad, and a ground potential layer connected to a ground potential is provided on an upper surface of the first insulating film. A re-wiring is provided over the ground potential layer with a second insulating film interposed. The ground potential layer serves as a barrier layer for preventing crosstalk between the re-wiring and circuit element formation region. A thin-film circuit element is provided on the second insulating film, and a second ground potential layer is provided as a second barrier layer over the thin-film circuit element with an insulating film interposed. Re-wiring is provided over the second ground potential layer.

Owner:CASIO COMPUTER CO LTD

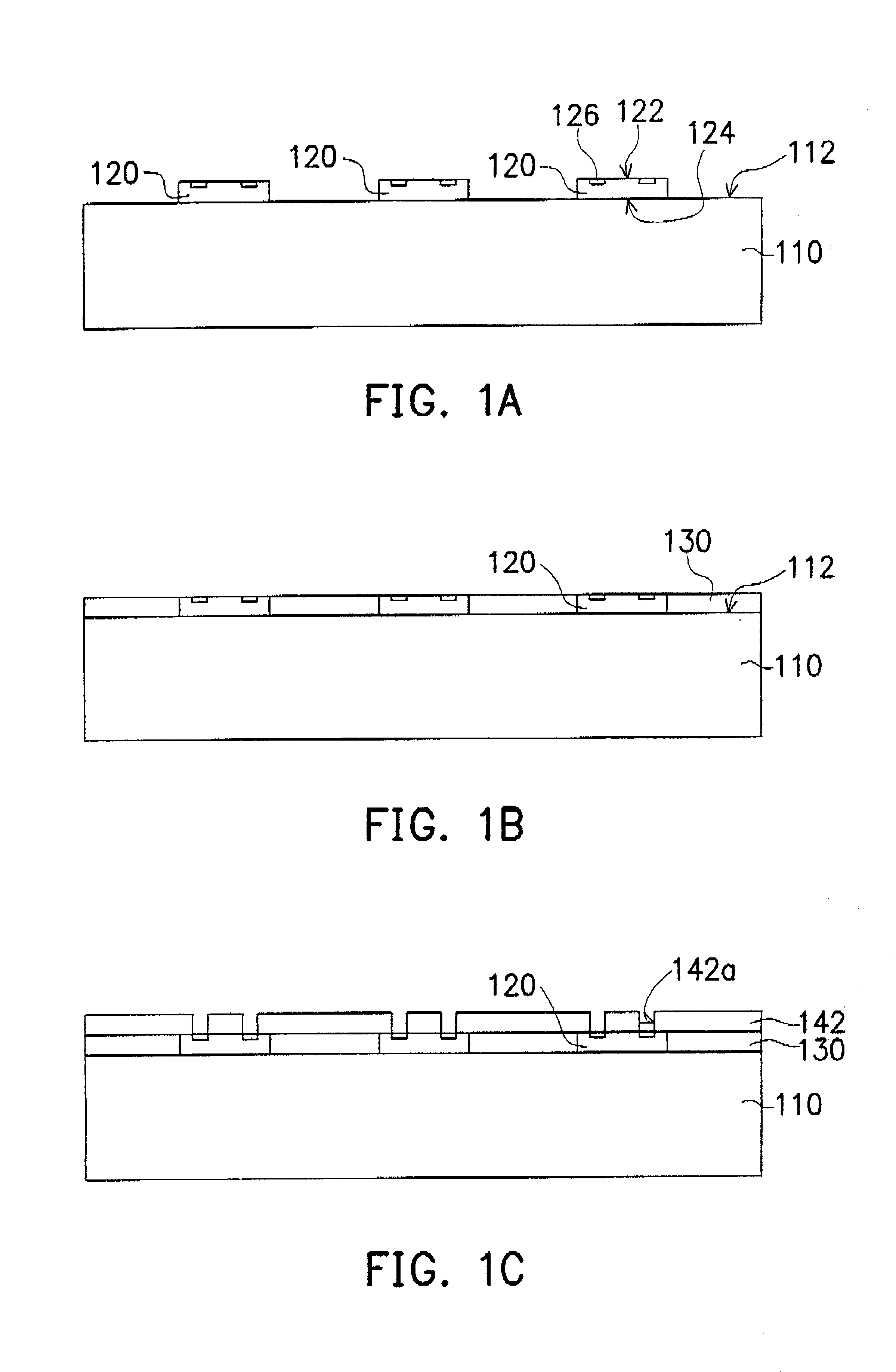

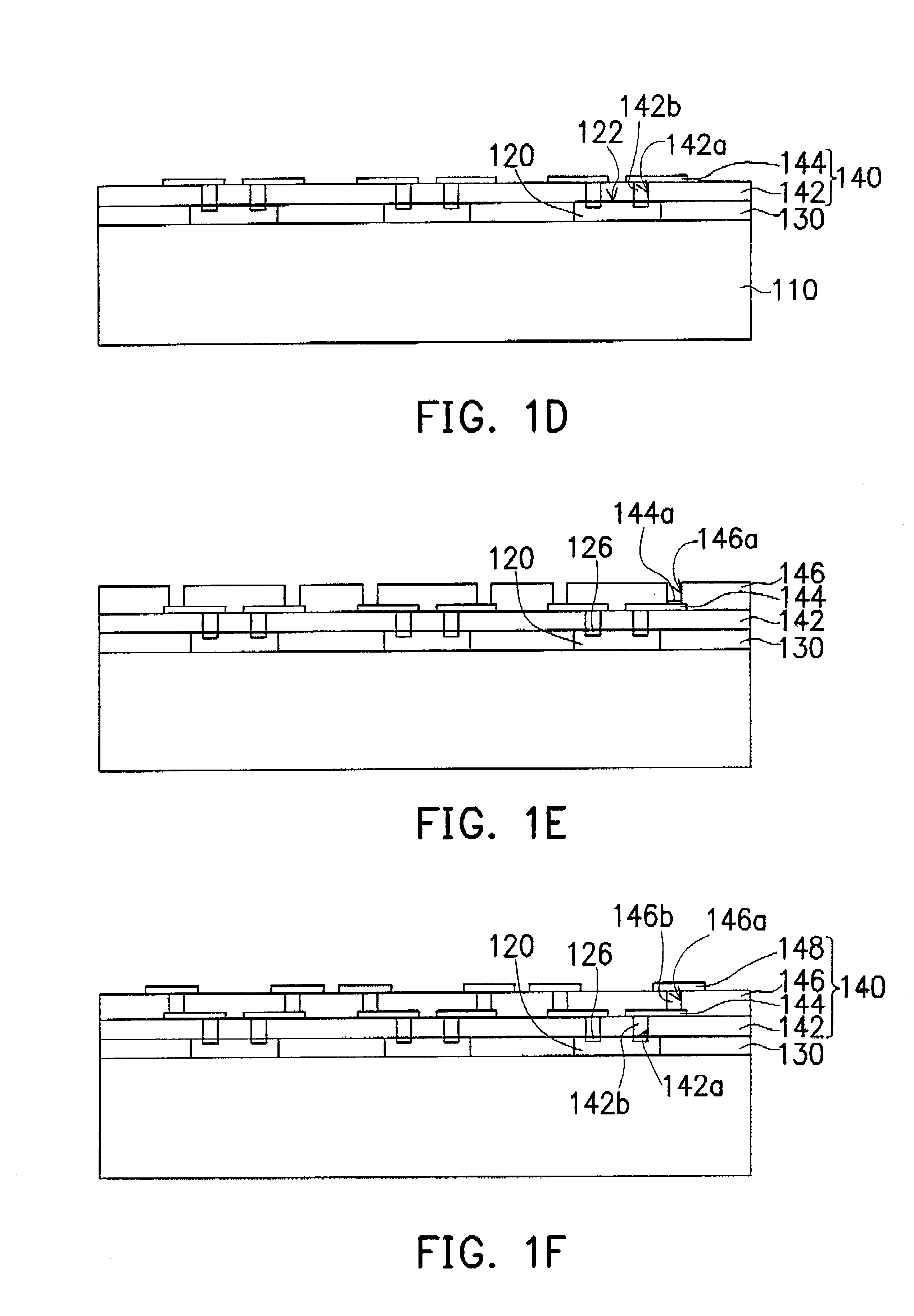

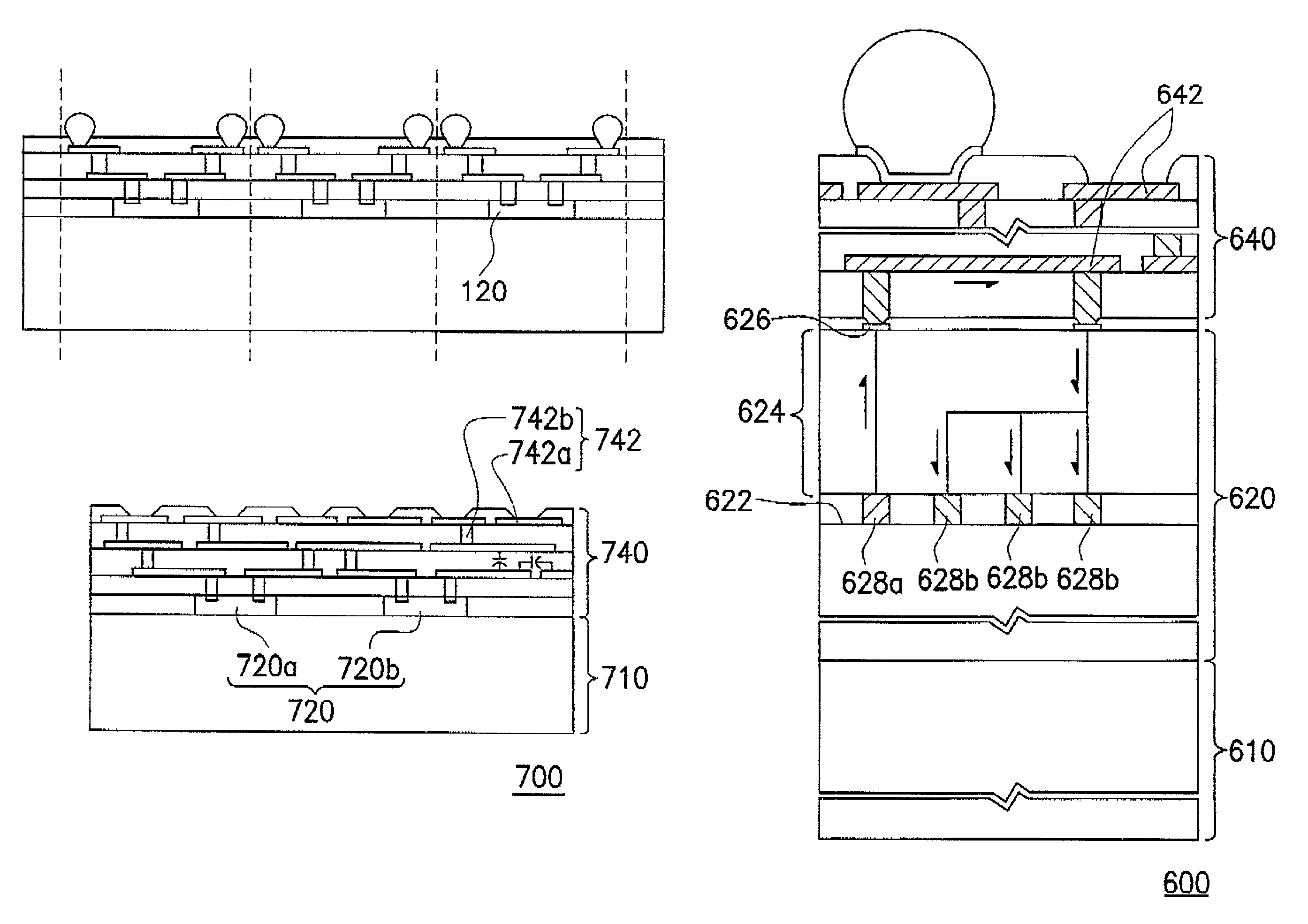

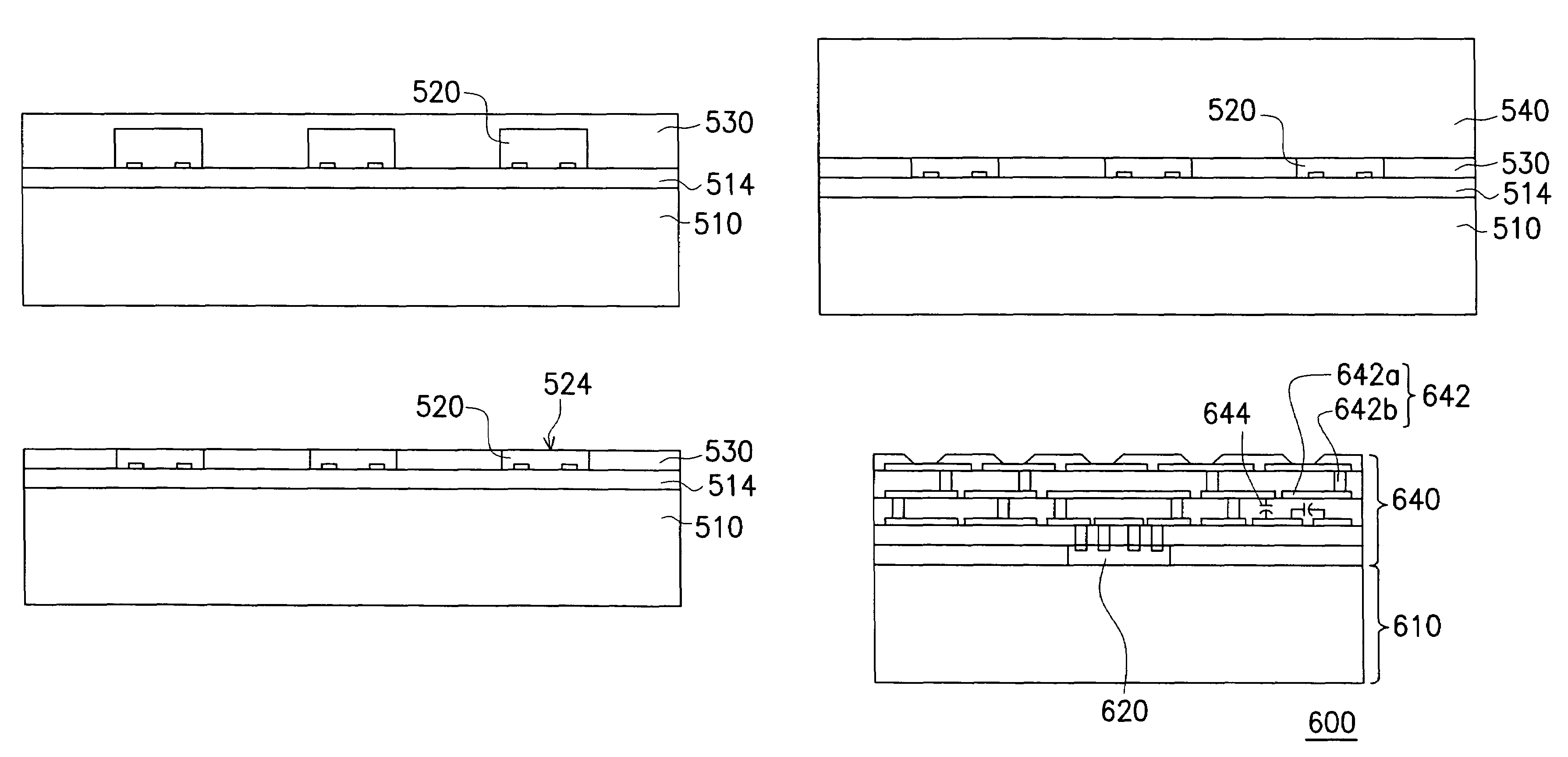

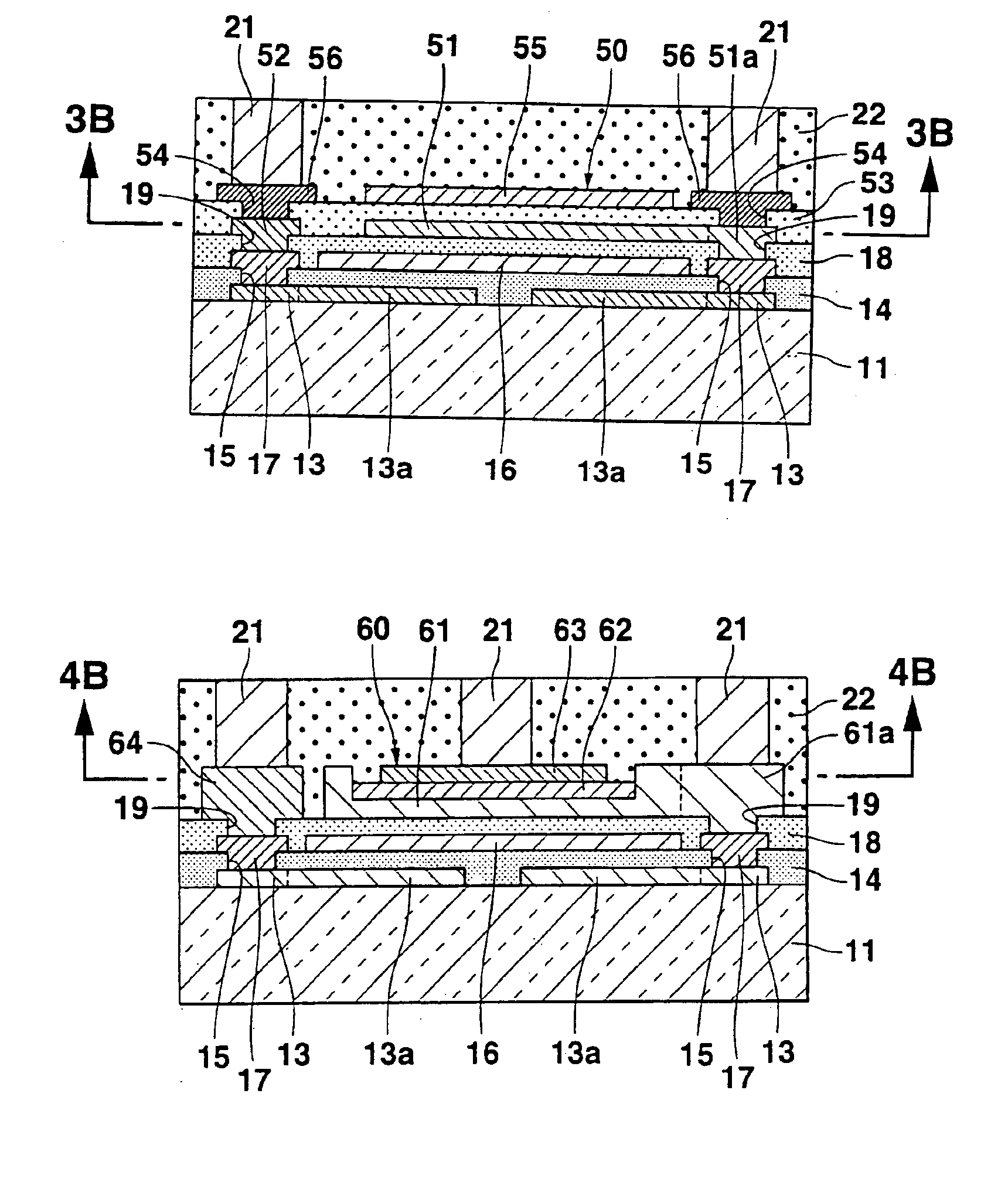

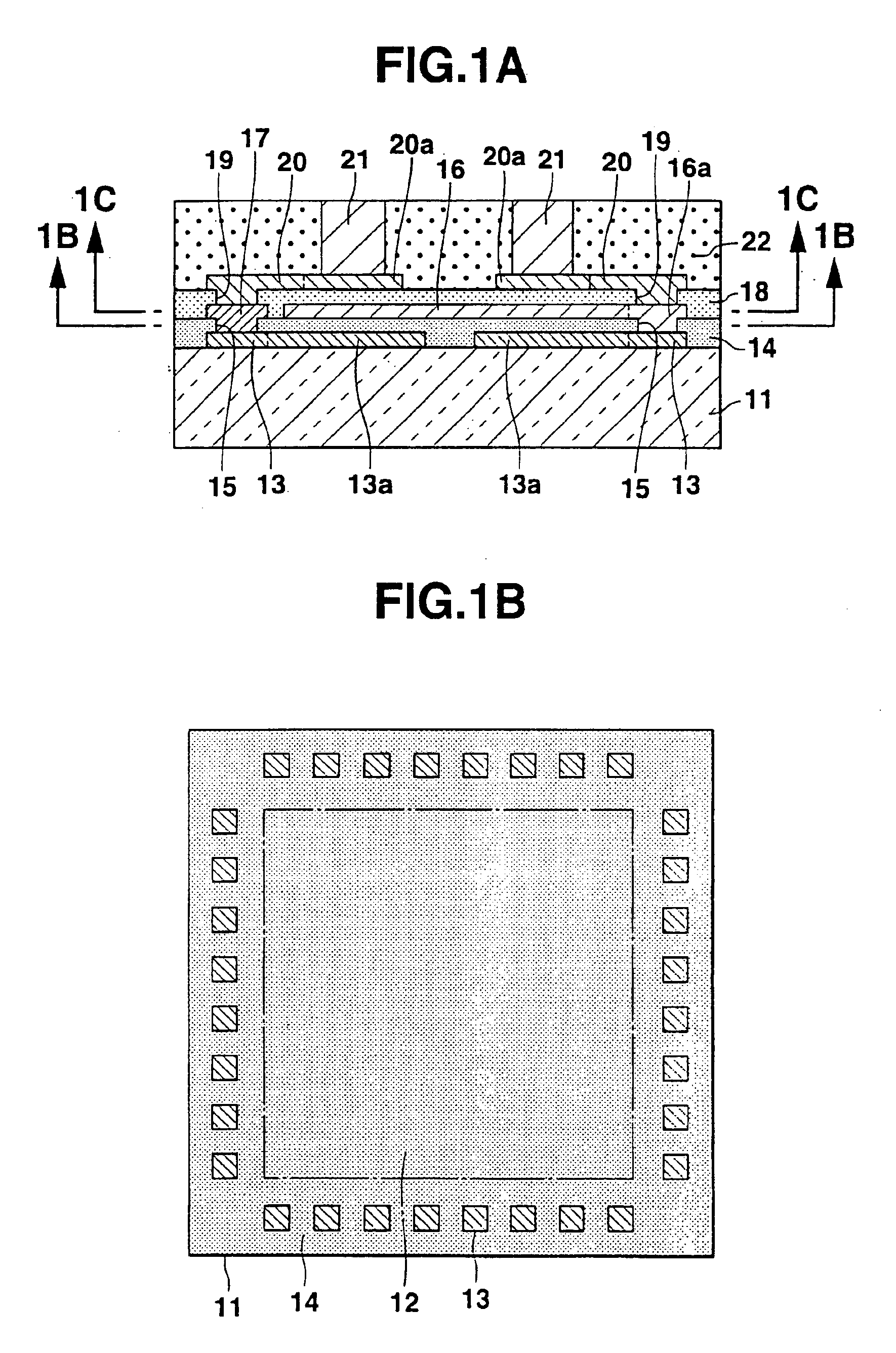

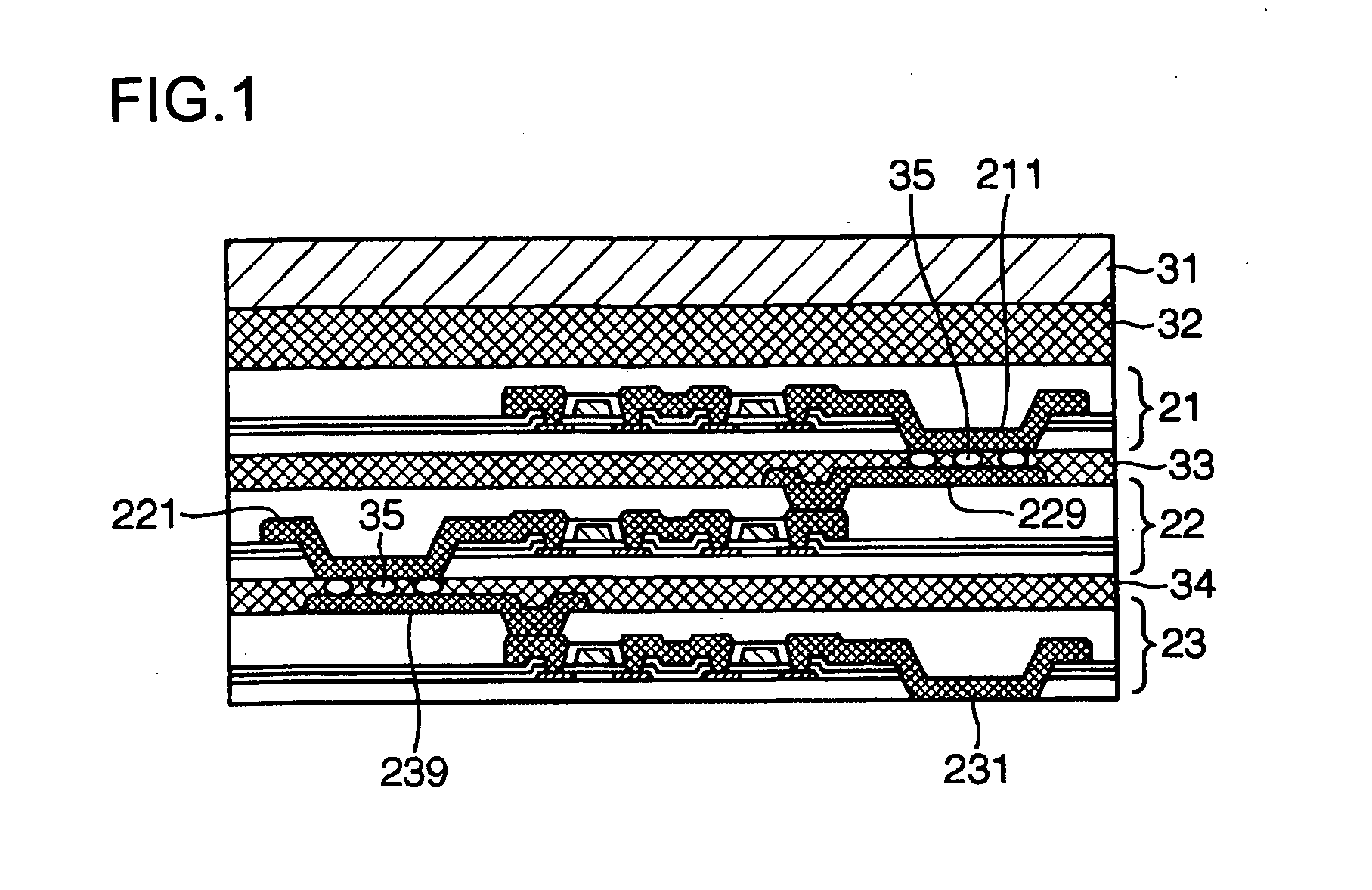

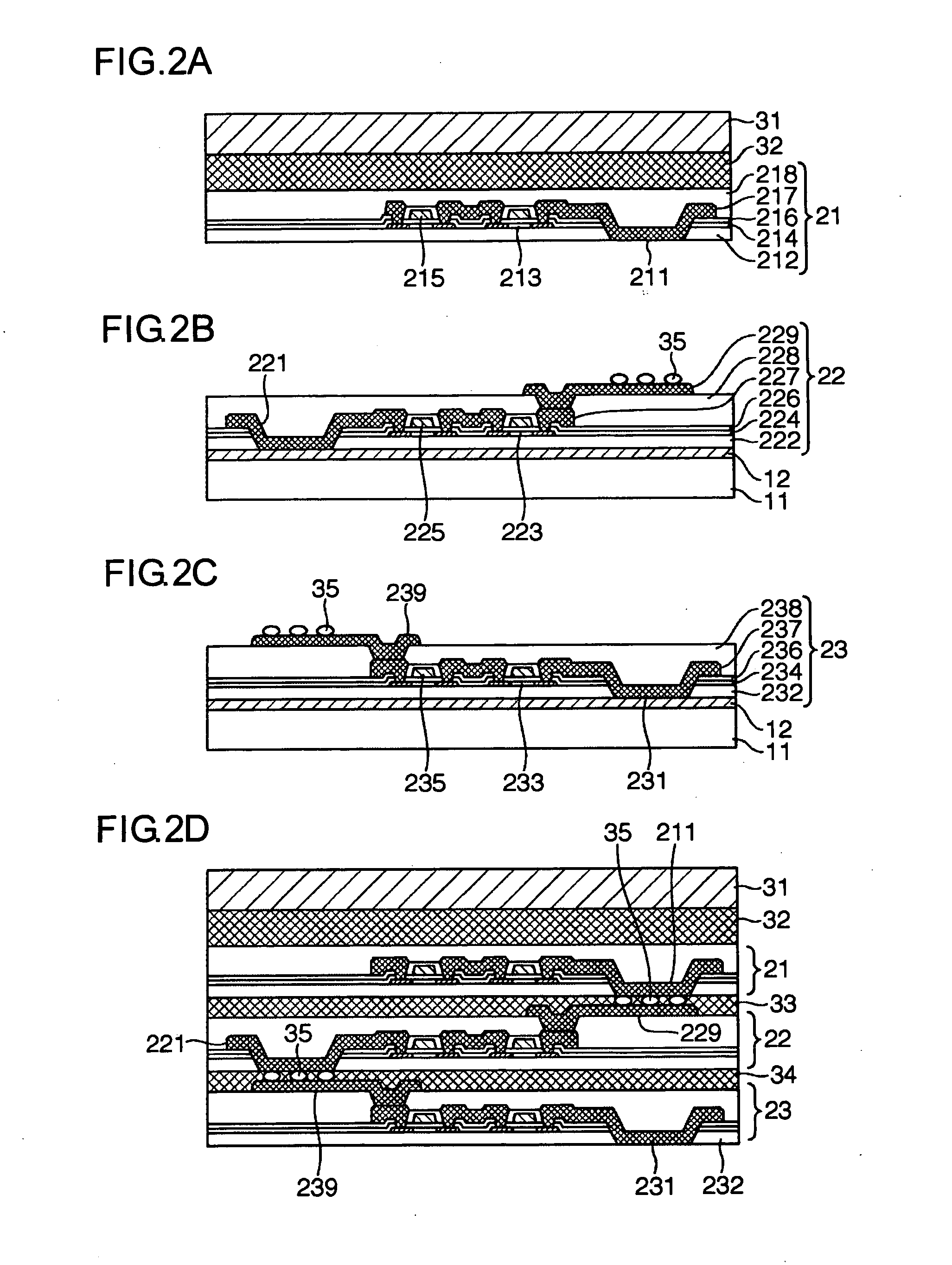

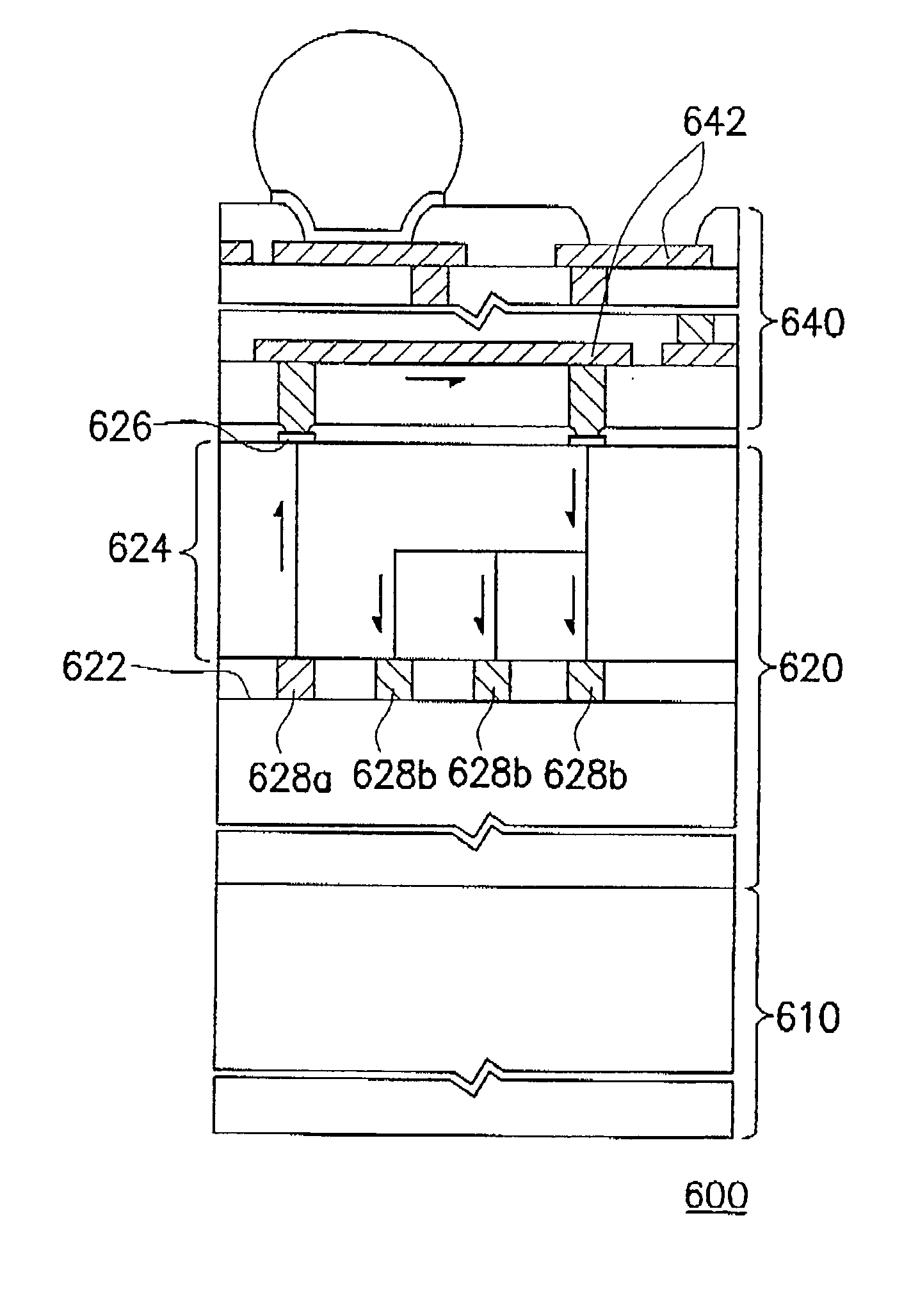

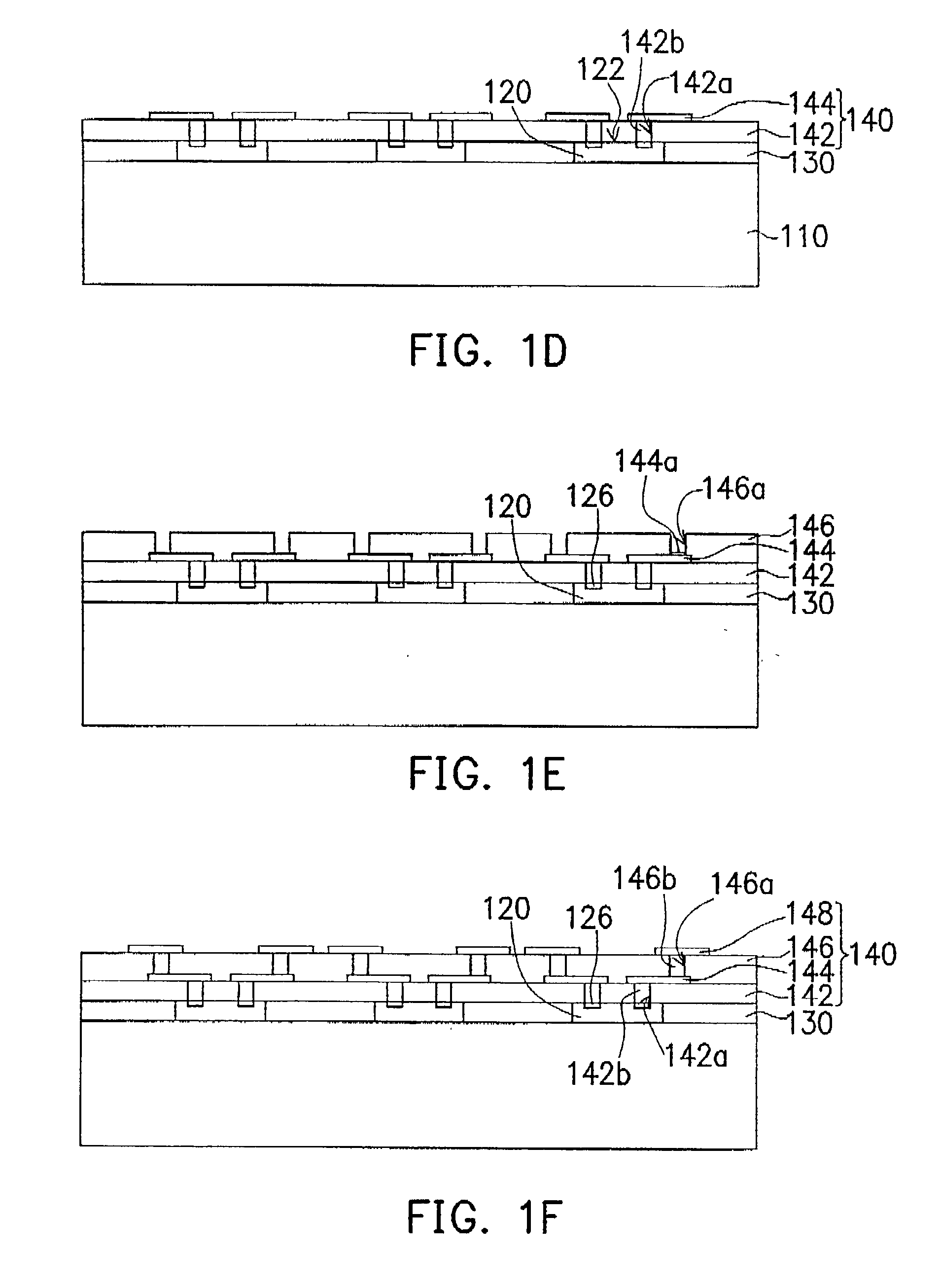

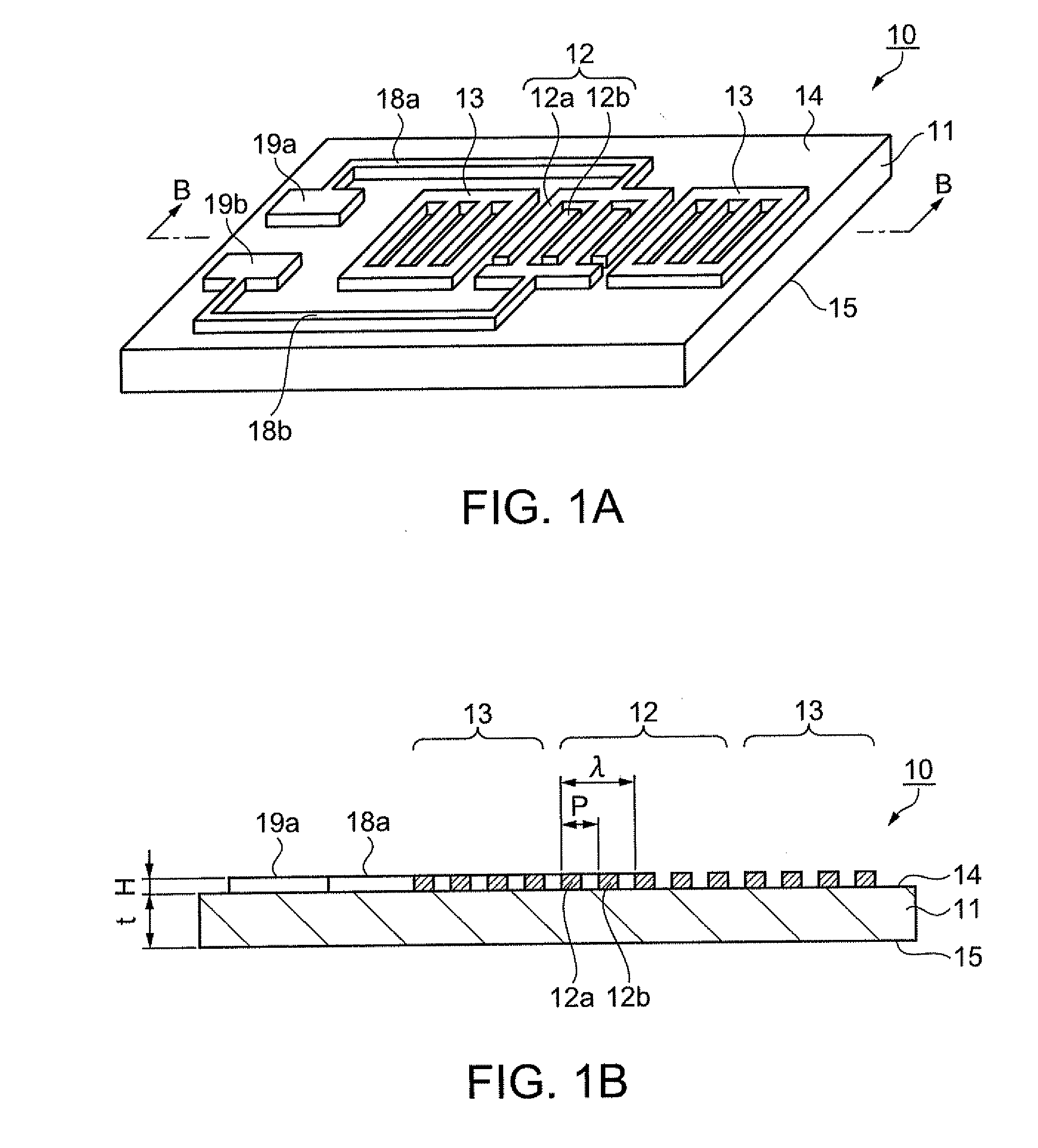

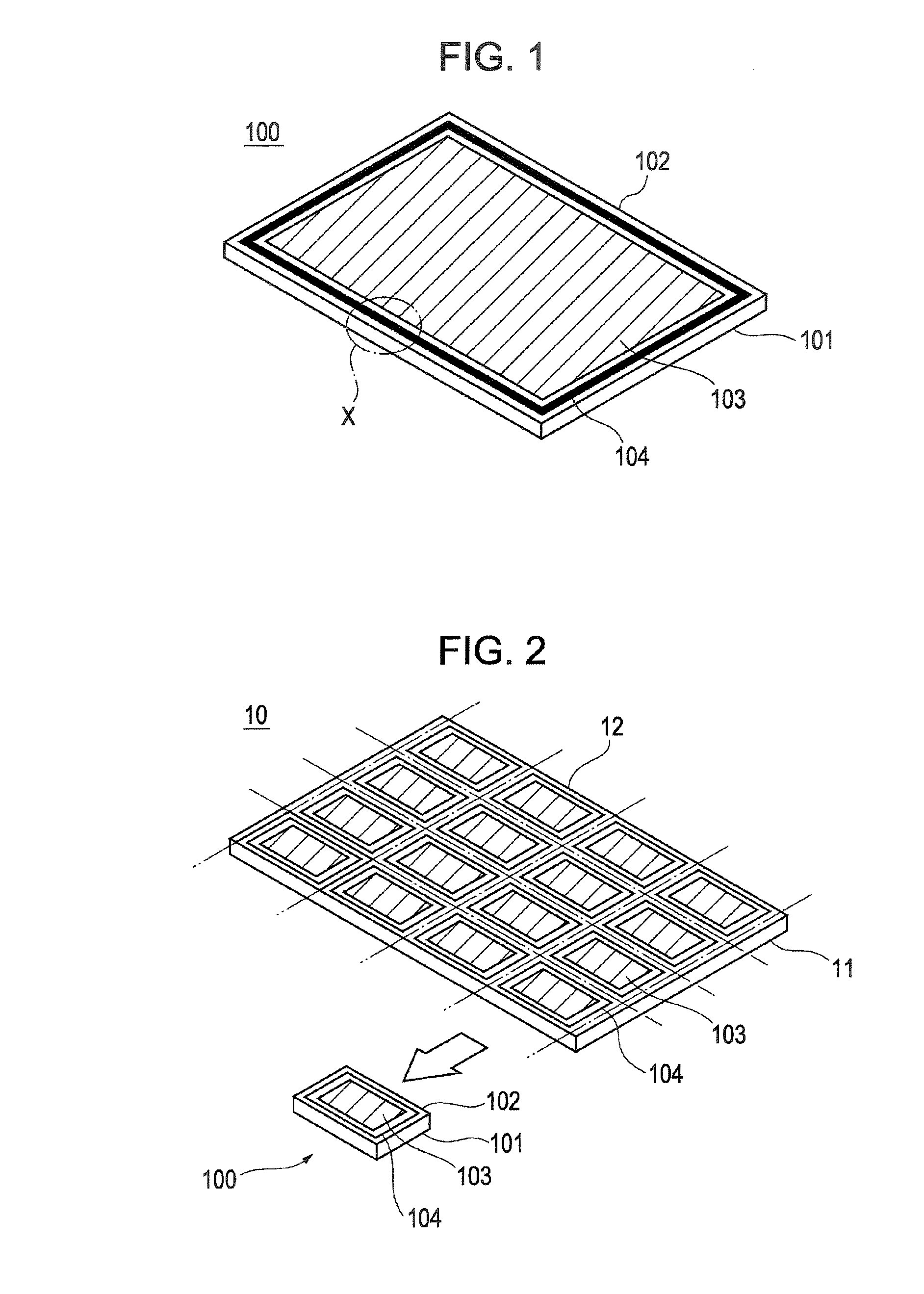

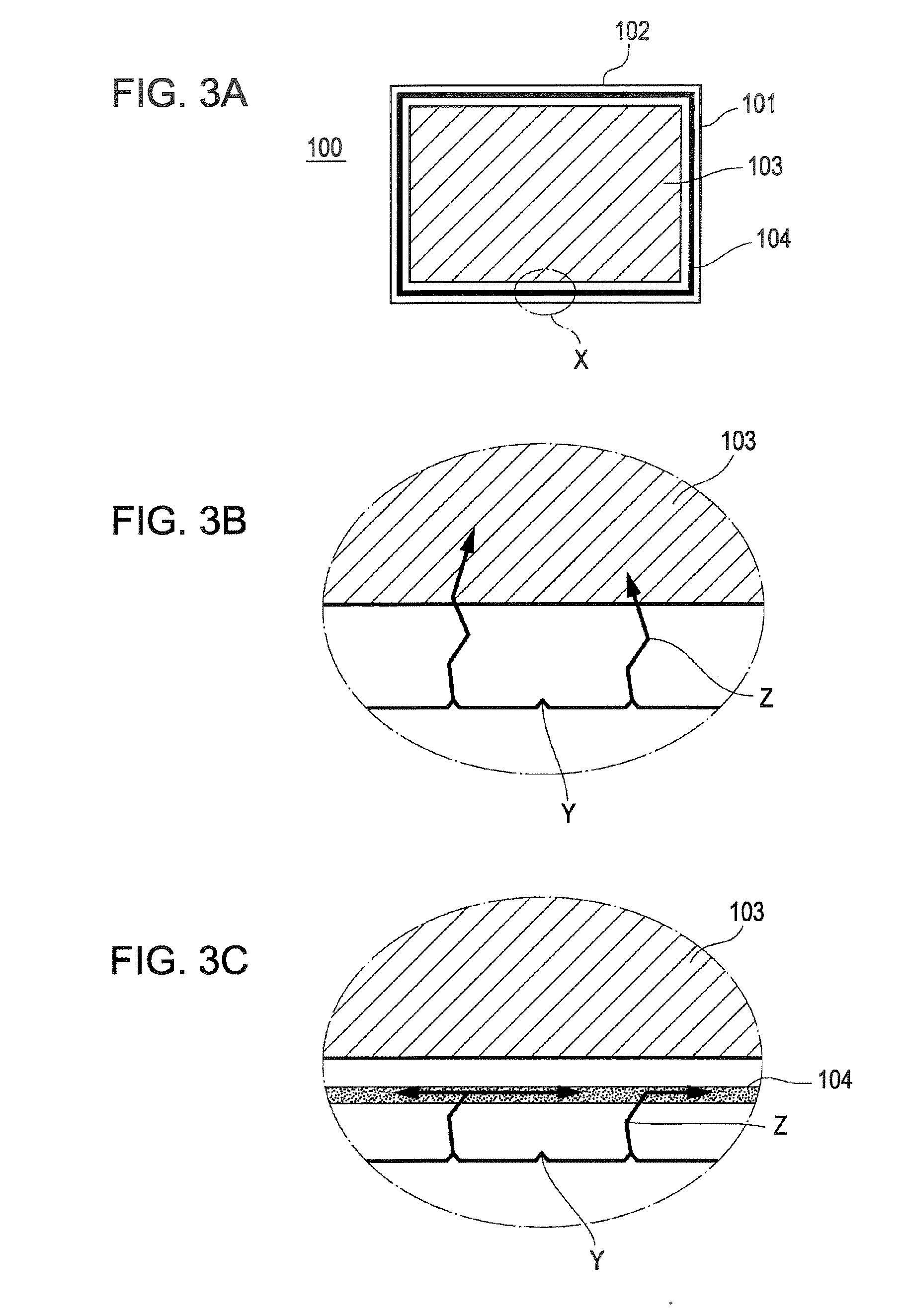

Thin film circuit device, manufacturing method thereof, electro-optical apparatus, and electronic system

InactiveUS20050006647A1Easy to implementHigh lamination precisionTransistorSemiconductor/solid-state device detailsElectronic systemsEngineering

To provide a thin film circuit device in which a three-dimensional circuit structure is realized, a thin film circuit device is formed of a first thin film circuit layer and a second thin film circuit layer laminated to each other. The first thin film circuit layer contains a first thin film circuit provided between an underlayer and a protective layer and a lower connection electrode connected to the first thin film circuit and exposed at a part of the bottom surface of the underlayer. The second thin film circuit layer contains a second thin film circuit provided between an underlayer and a protective layer, an upper connection electrode connected to the second thin film circuit and exposed at a part of the top surface of the protective layer, and a lower connection electrode connected to the second thin film circuit and exposed at a part of the bottom surface of the underlayer. The first and the second thin film circuits are bonded to each other so that the lower connection electrode of the first thin film circuit layer is electrically connected to the upper electrode of the second thin film circuit layer.

Owner:SEIKO EPSON CORP

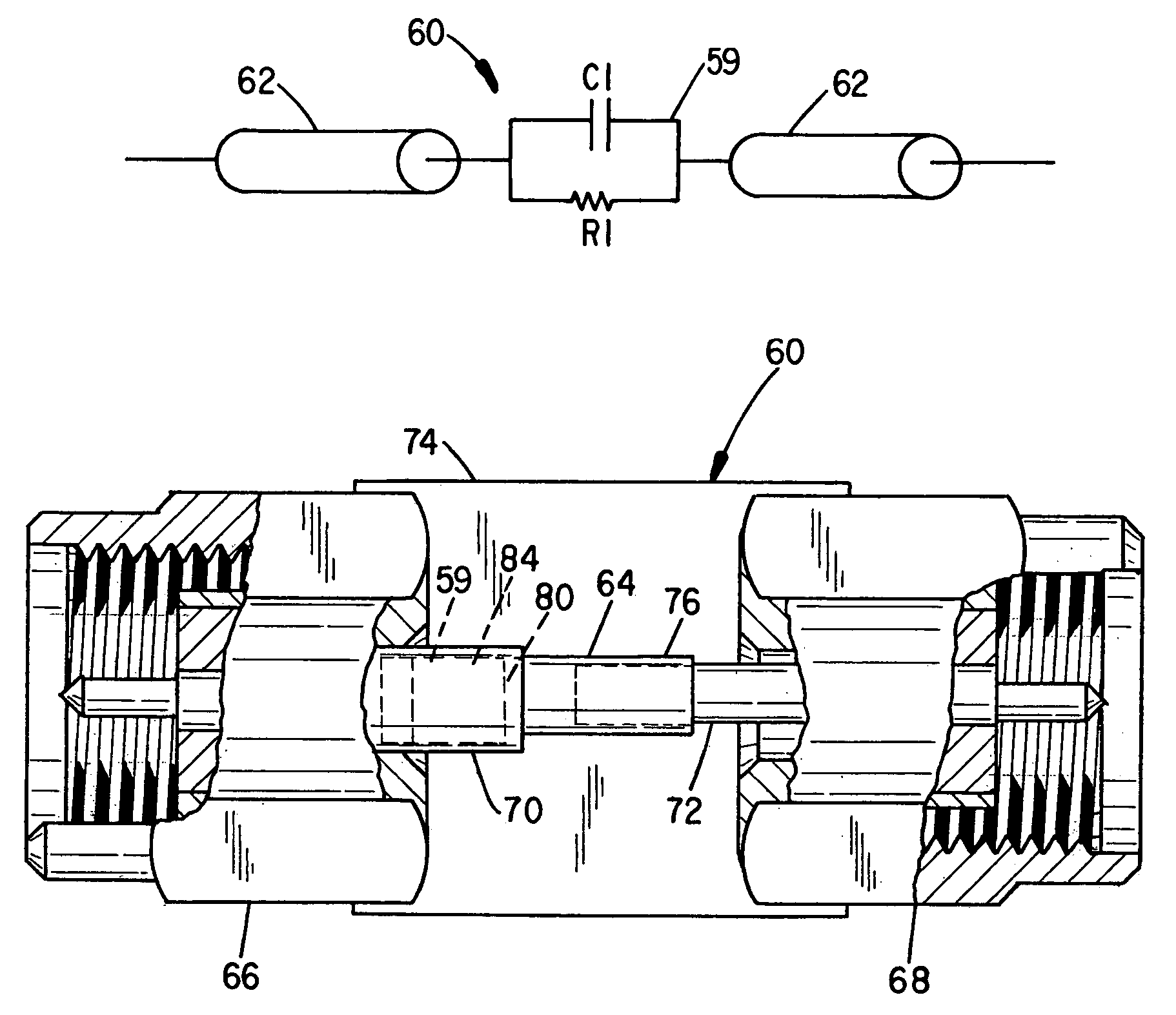

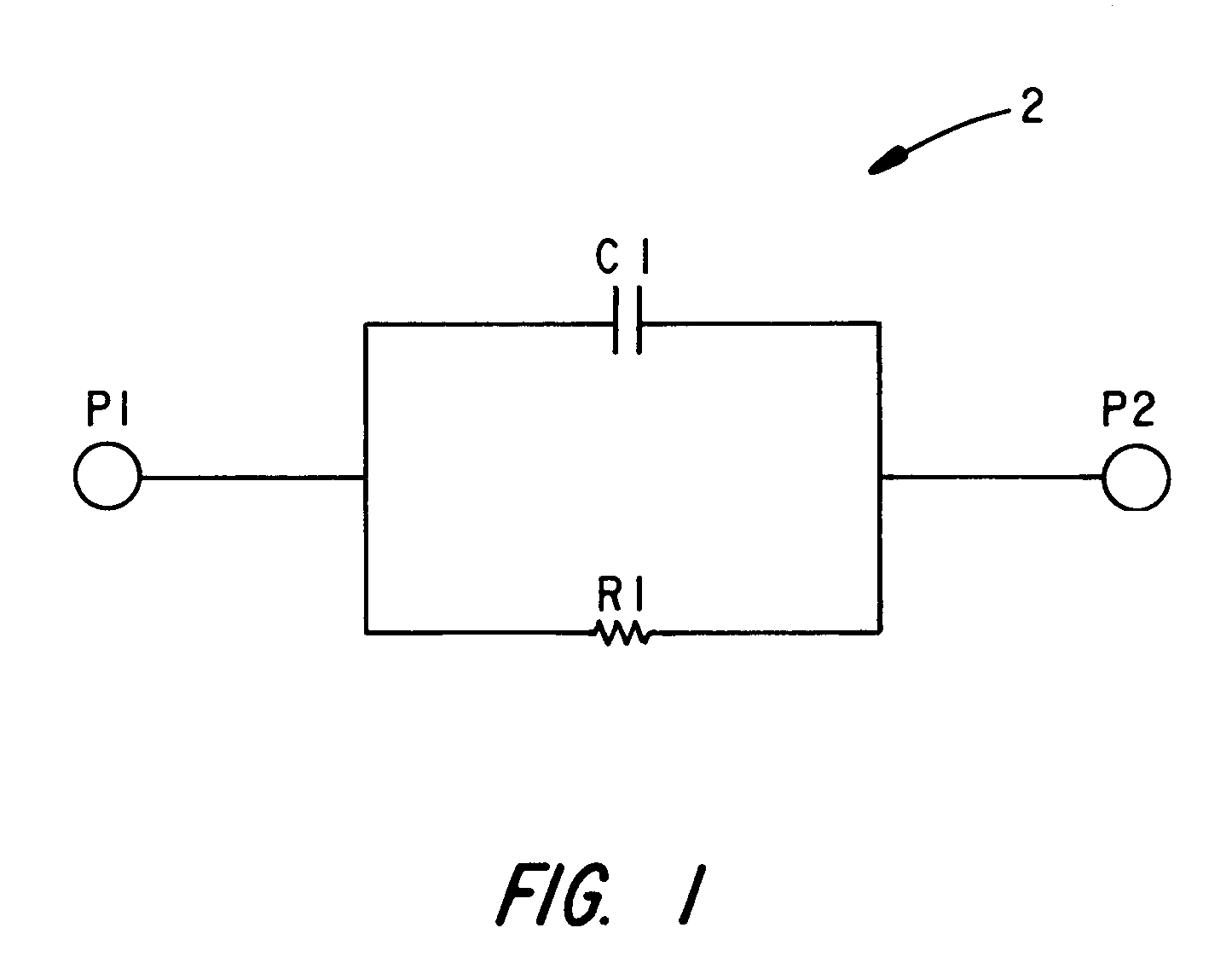

Impedance qualization module

InactiveUS7200010B2Reduce signalingImprove board performanceMultiple-port networksTwo pole connectionsElectrical conductorCoupling

A thin film circuit module constructed for serial coupling to circuit conductors at printed and transmission line circuits. In one form of equalizer construction, thin film circuit elements are deposited on a supporting substrate and wherein a capacitor plate is defined a circuit resistor. Two connector applications serially couple the equalizer modules to trace conductors of a motherboard connector block and to cylindrical core conductors of a coaxial connector. Other hybrid equalizer constructions provide modules constructed of thin film resistors and pick-and-placed capacitors mounted piggyback to an equalizer module substrate.

Owner:THIN FILM TECH

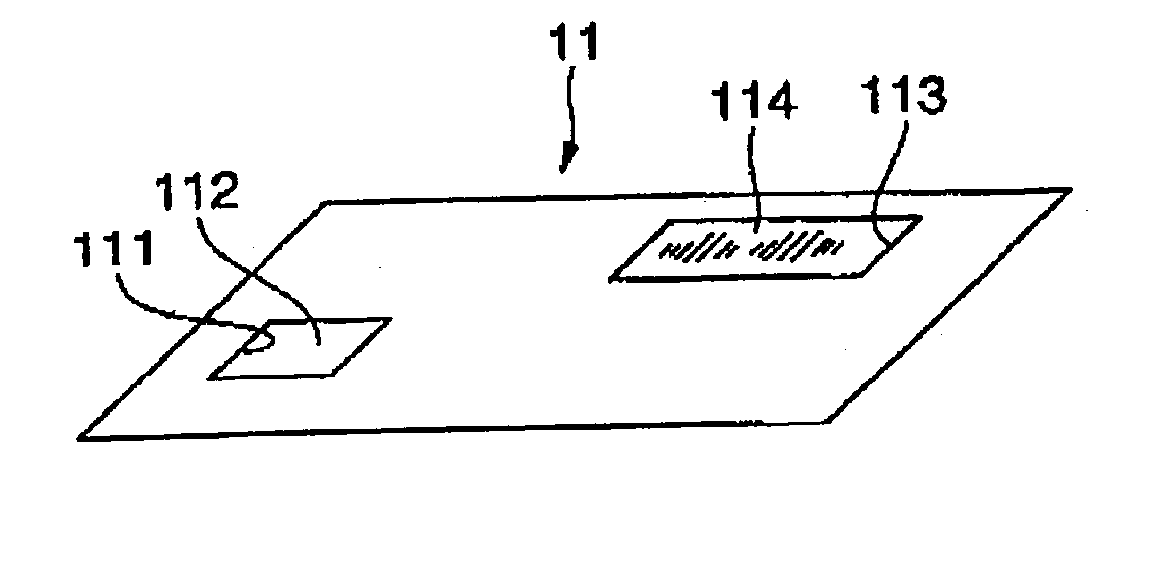

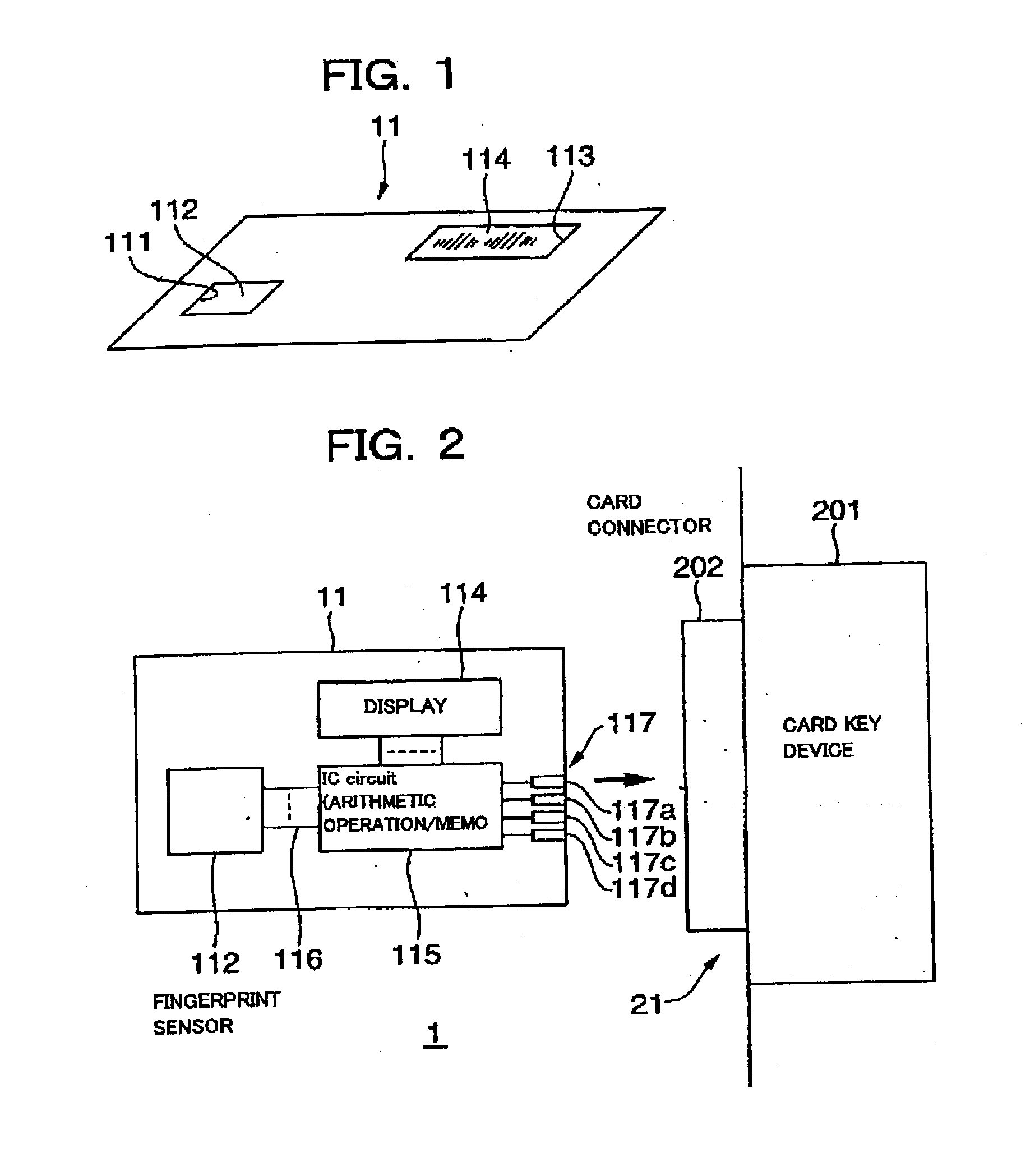

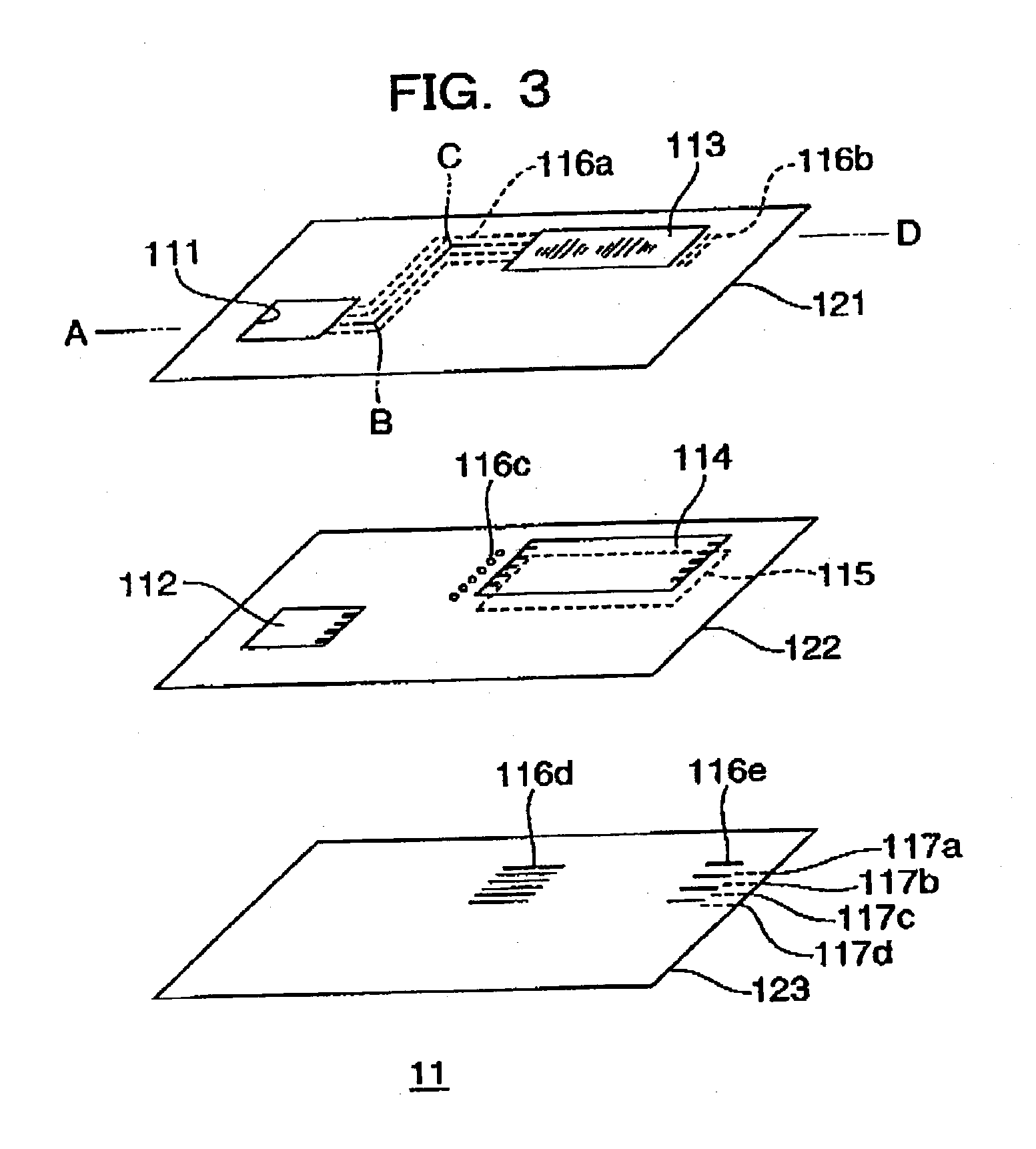

IC card and method of manufacturing the same

InactiveUS20030209362A1Improve securityEasily brokenOther printing matterPrinted electric component incorporationSignal processing circuitsEngineering

The invention provides an IC card in which it is difficult to separate IC chips from the IC card. In accordance with the invention, an IC card formed by laminating a plurality of substrates can include a sensor for identifying an authorized person, a signal processing circuit for processing the identification based on an output from the sensor and a card-shaped card medium containing the sensor and the signal processing circuit. At least the signal processing circuit can include a thin film circuit which is sufficiently thinner than the card medium and contains a material which is dissolvable equally to or more than the card medium.

Owner:SEIKO EPSON CORP

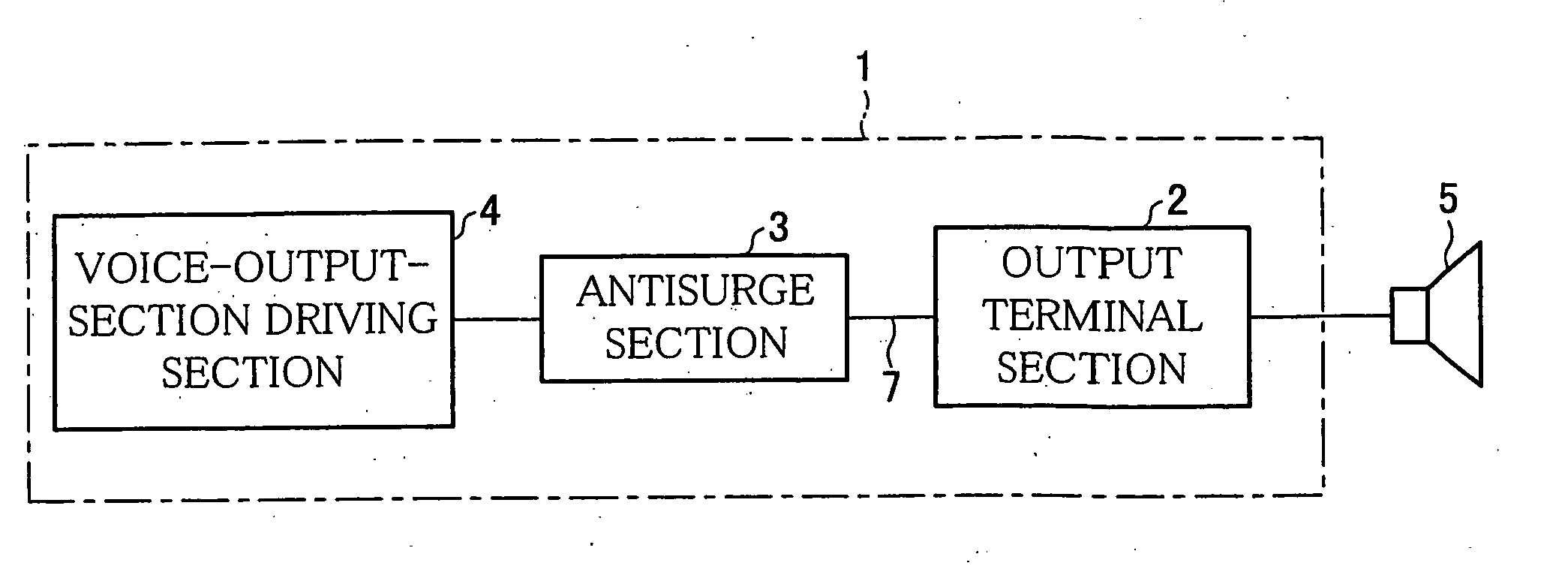

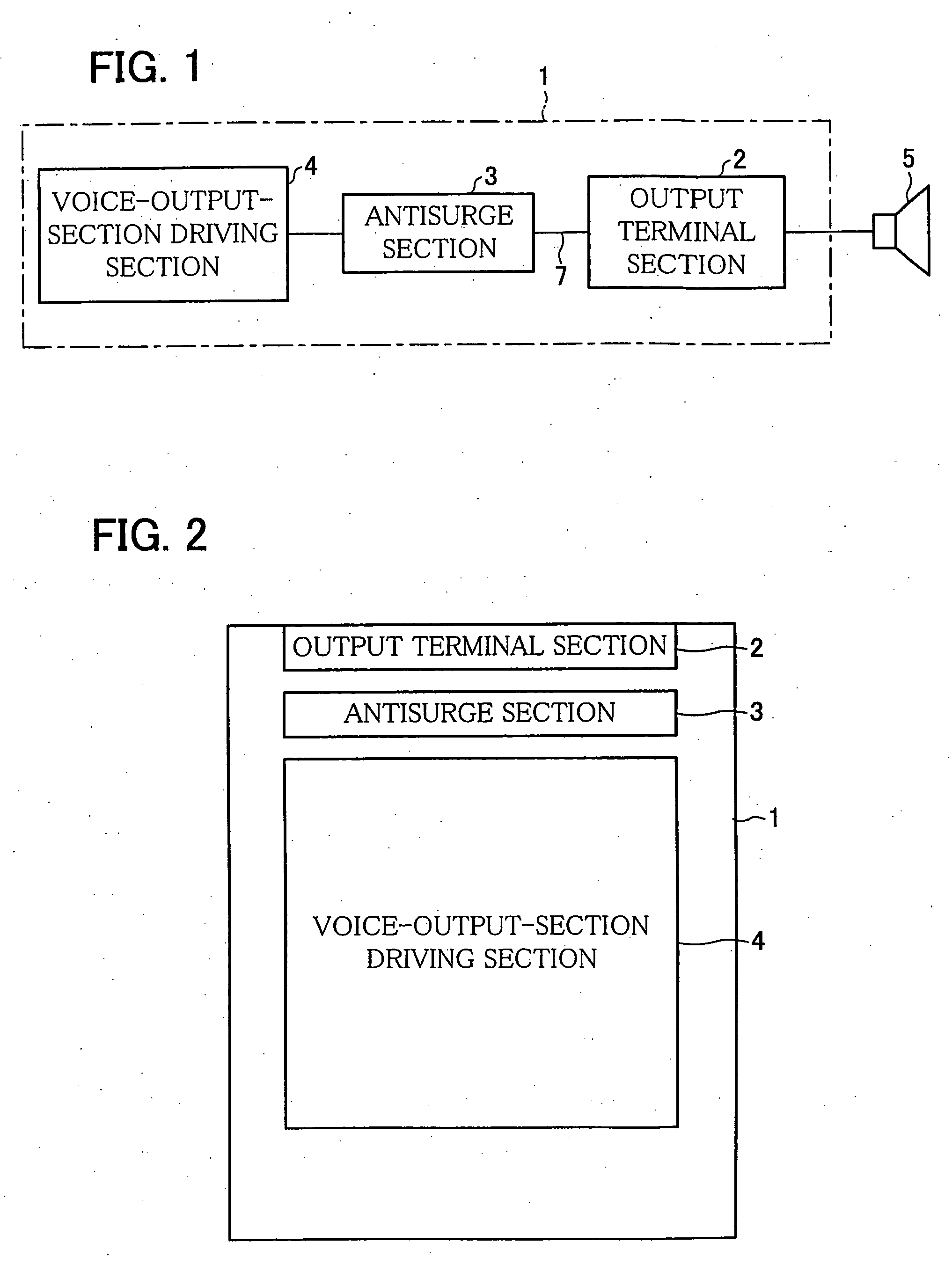

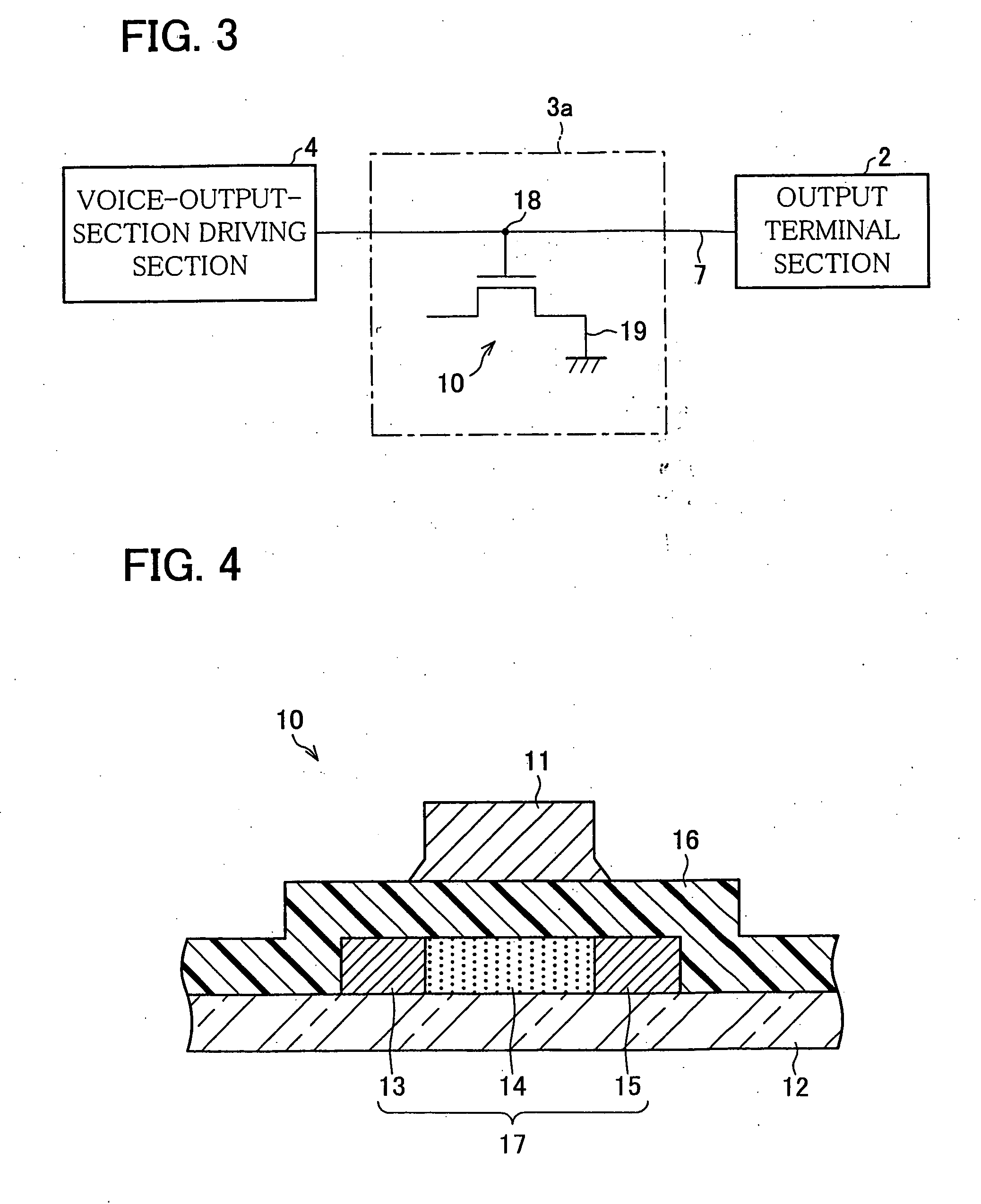

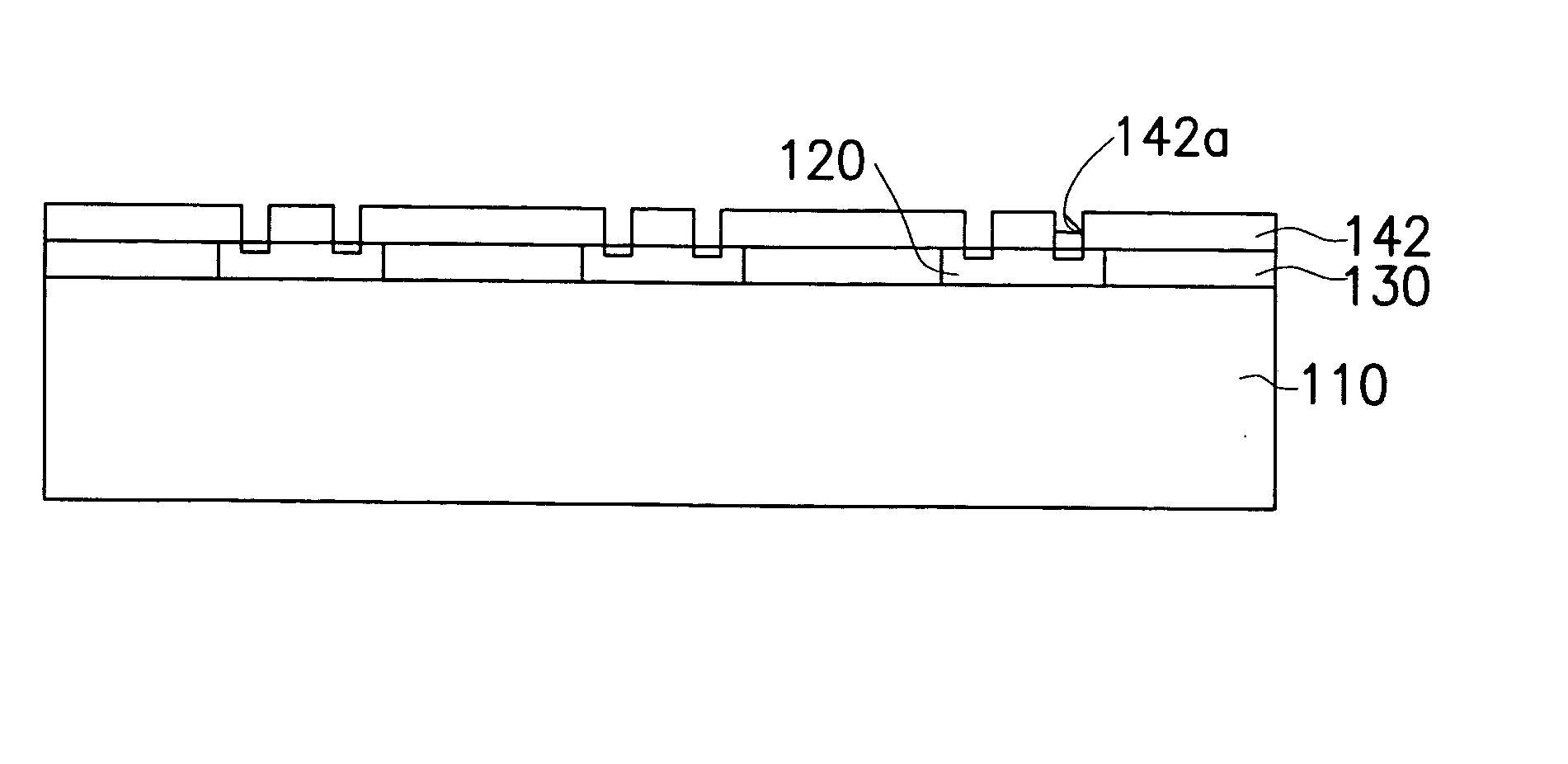

Thin film circuit substrate, piezoelectric speaker device, display device, and sound-generating display device

InactiveUS20050237685A1Avoid damageExcessive chargingTransistorStatic indicating devicesDisplay deviceLoudspeaker

A thin film circuit substrate is provided with a voice-output-section driving section, formed of a thin film layer on an insulative substrate, for driving a voice output section. An antisurge section, provided on a wiring between the voice-output-section driving section and an output terminal section thereof, includes an antisurge element. When a surge voltage is applied to the wiring, the antisurge element, monolithically formed on the thin film circuit substrate, connects the wiring to the ground so as to pass a current (surge current), generated by the surge voltage applied to the wiring, to the ground. This makes it possible to provide a thin film circuit substrate which is monolithically provided with a function which can protect a circuit section when a voltage exceeding a predetermined range is applied to the wiring linking the circuit section with an input terminal section or an output terminal section.

Owner:SHARP KK

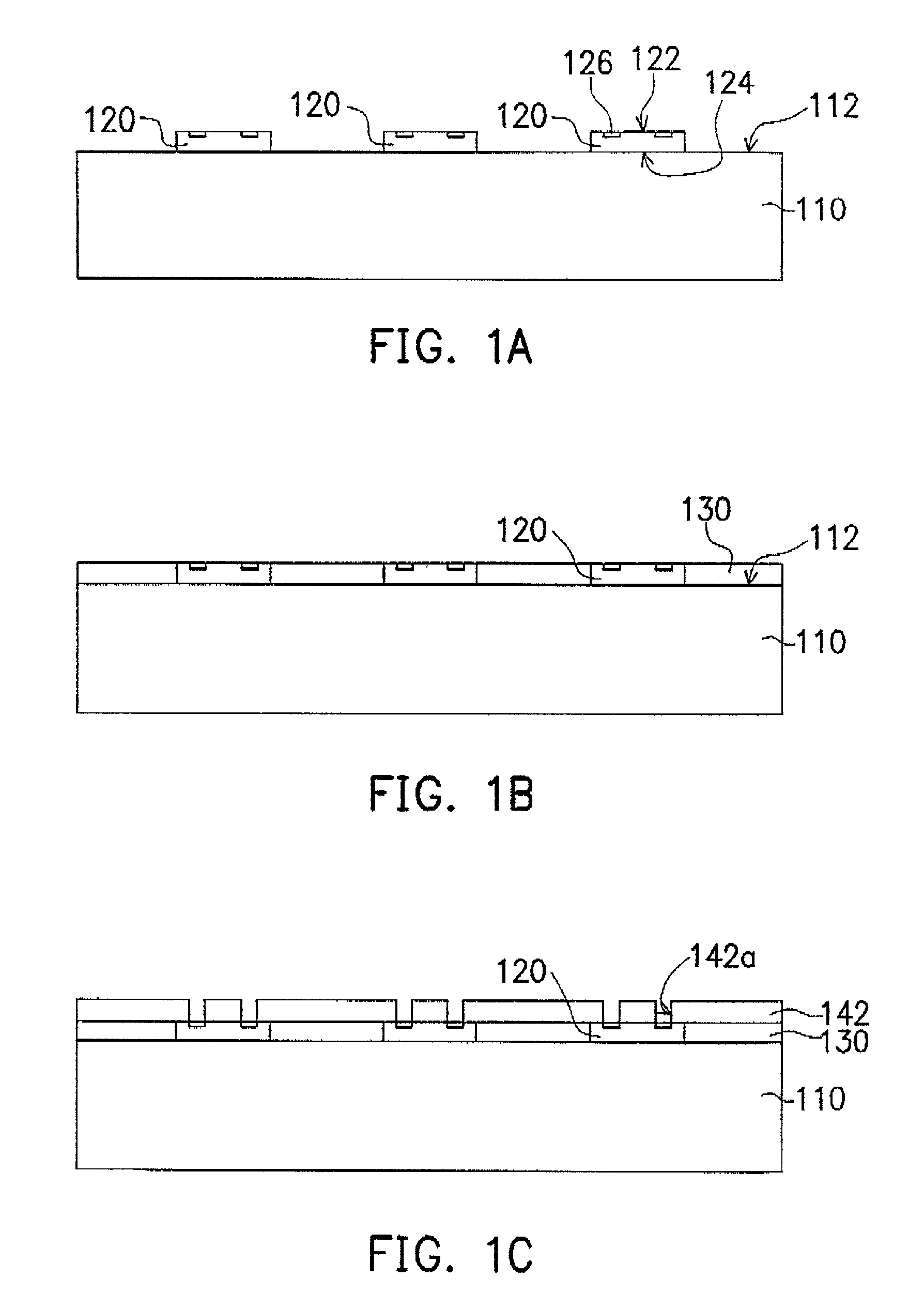

Integrated chip package structure using metal substrate and method of manufacturing the same

InactiveUS20050121771A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringThin film circuits

An integrated chip package structure and method of manufacturing the same is by adhering dies on a metal substrate and forming a thin-film circuit layer on top of the dies and the metal substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

Integrated chip package structure using silicon substrate and method of manufacturing the same

InactiveUS20030124835A1Semiconductor/solid-state device detailsSolid-state devicesThin film circuitsExternal circuit

An integrated chip package structure and method of manufacturing the same is by adhering dies on a silicon substrate and forming a thin-film circuit layer on top of the dies and the silicon substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

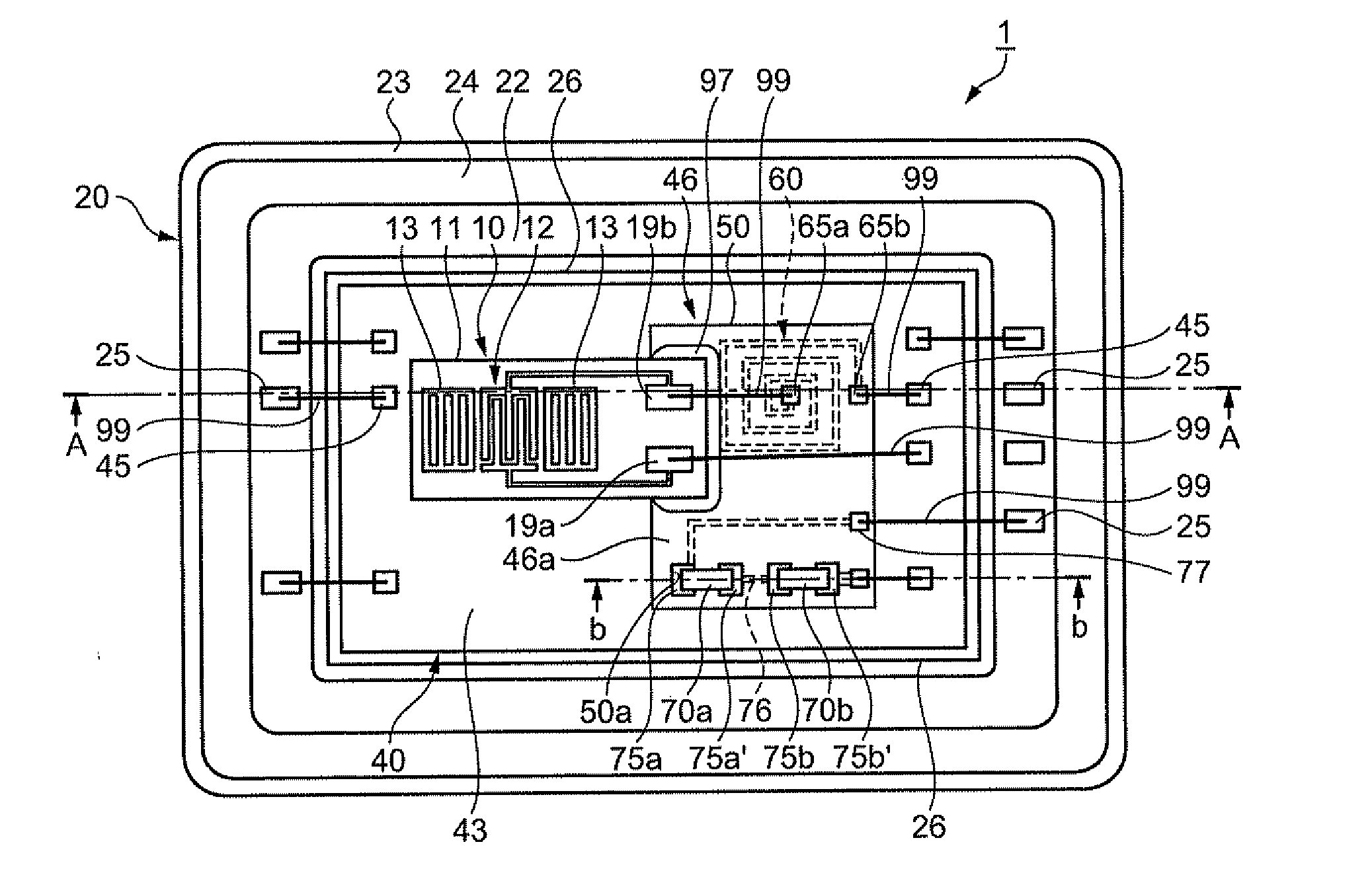

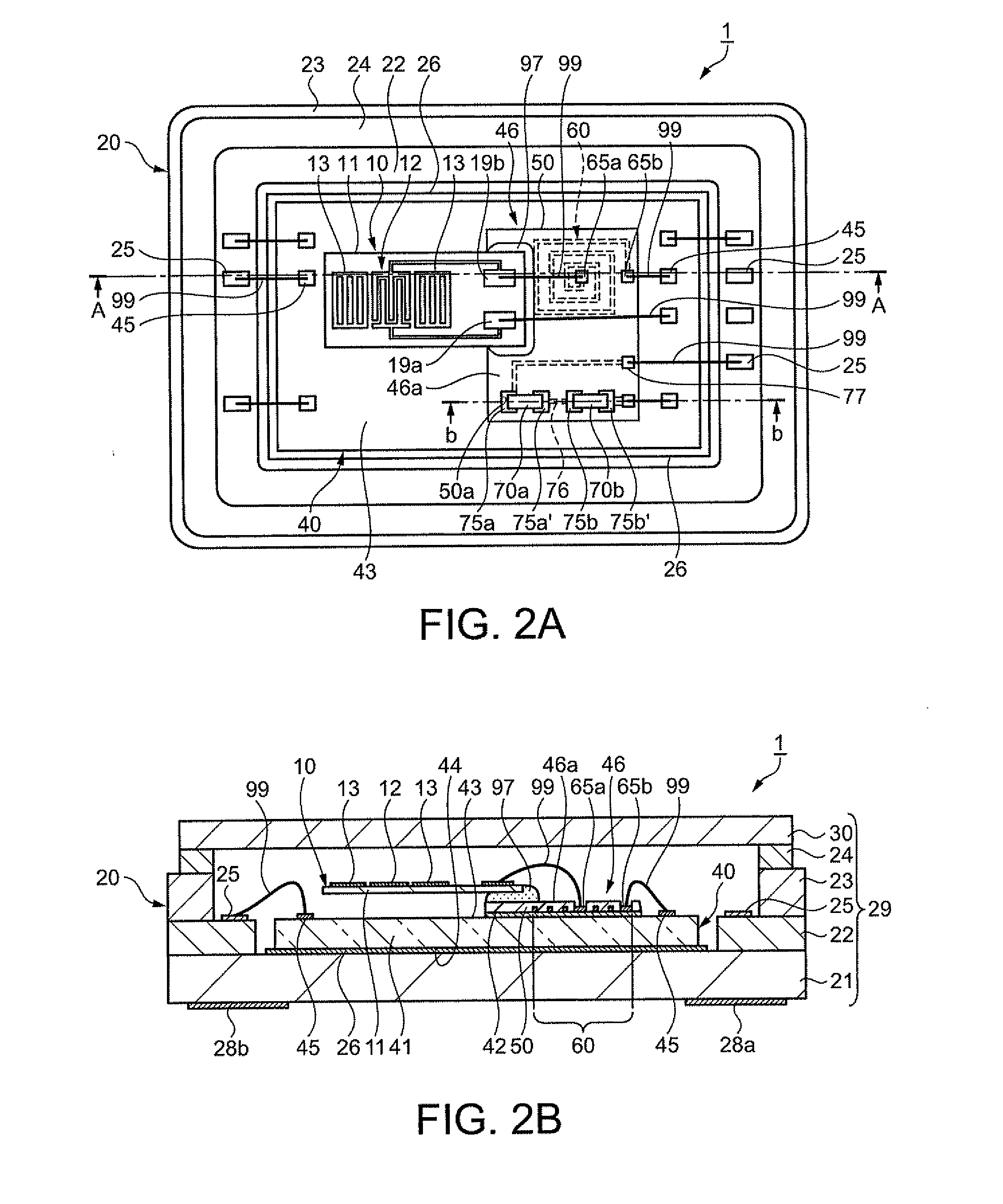

Piezoelectric oscillator and transmitter

InactiveUS20090023400A1Improve space efficiencyImprove impact resistanceOscillations generatorsTransmissionPiezoelectric actuatorsThin film circuits

A piezoelectric oscillator includes: a piezoelectric resonator element having a piezoelectric substrate and an excitation electrode formed on a surface of the piezoelectric substrate; a semiconductor circuit element provided with an oscillation circuit for oscillating the piezoelectric resonator element and having a first insulating film formed on a principal surface; a package for airtightly housing the semiconductor circuit element and the piezoelectric resonator element; and a protruding section having at least of a thin film circuit component formed on the first insulating film and connected to the oscillation circuit; and a second insulating film formed on the first insulating film and covering the thin film circuit component. In the oscillator, the piezoelectric resonator element is fixed to an upper surface of the protruding section,

Owner:SEIKO EPSON CORP

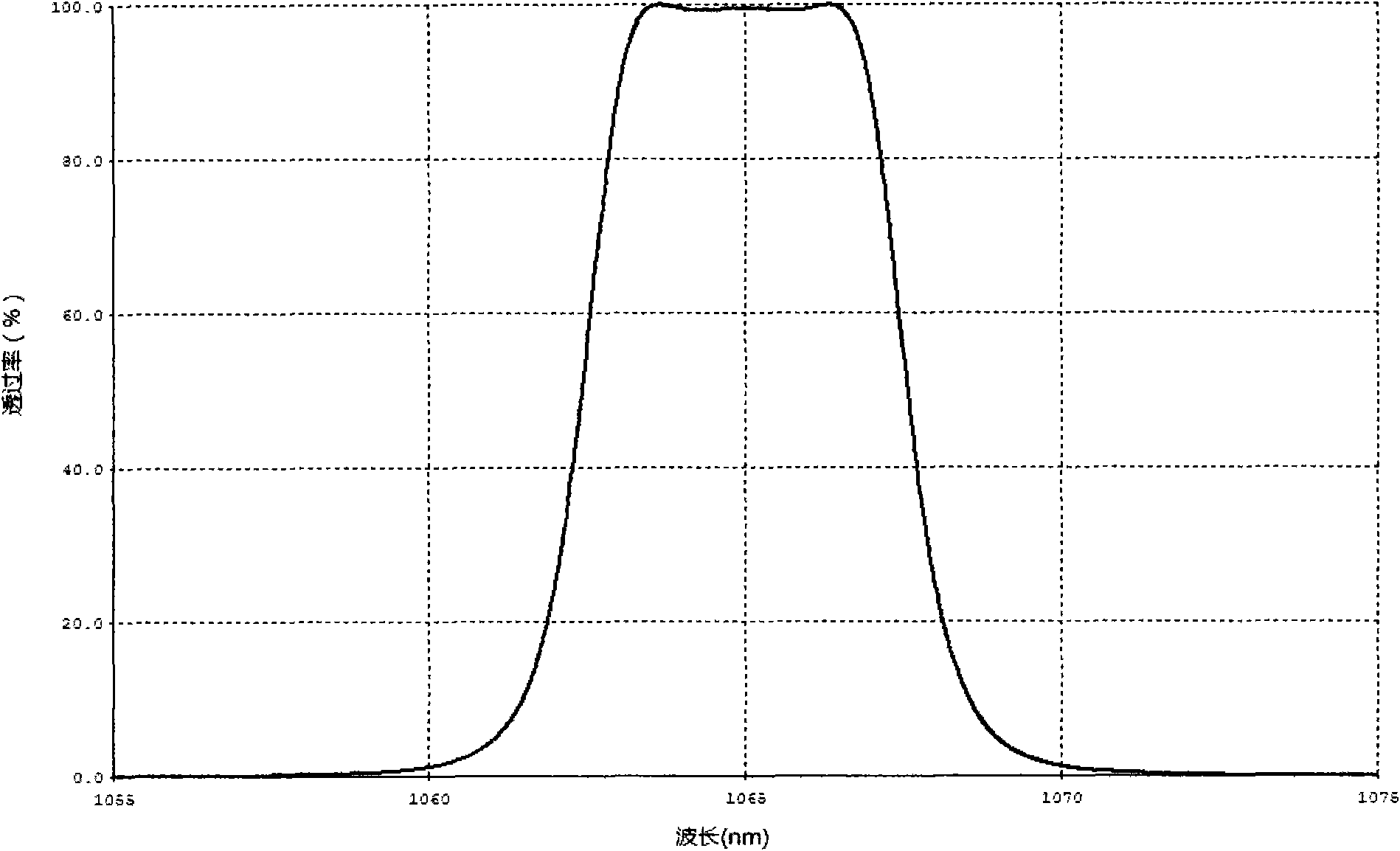

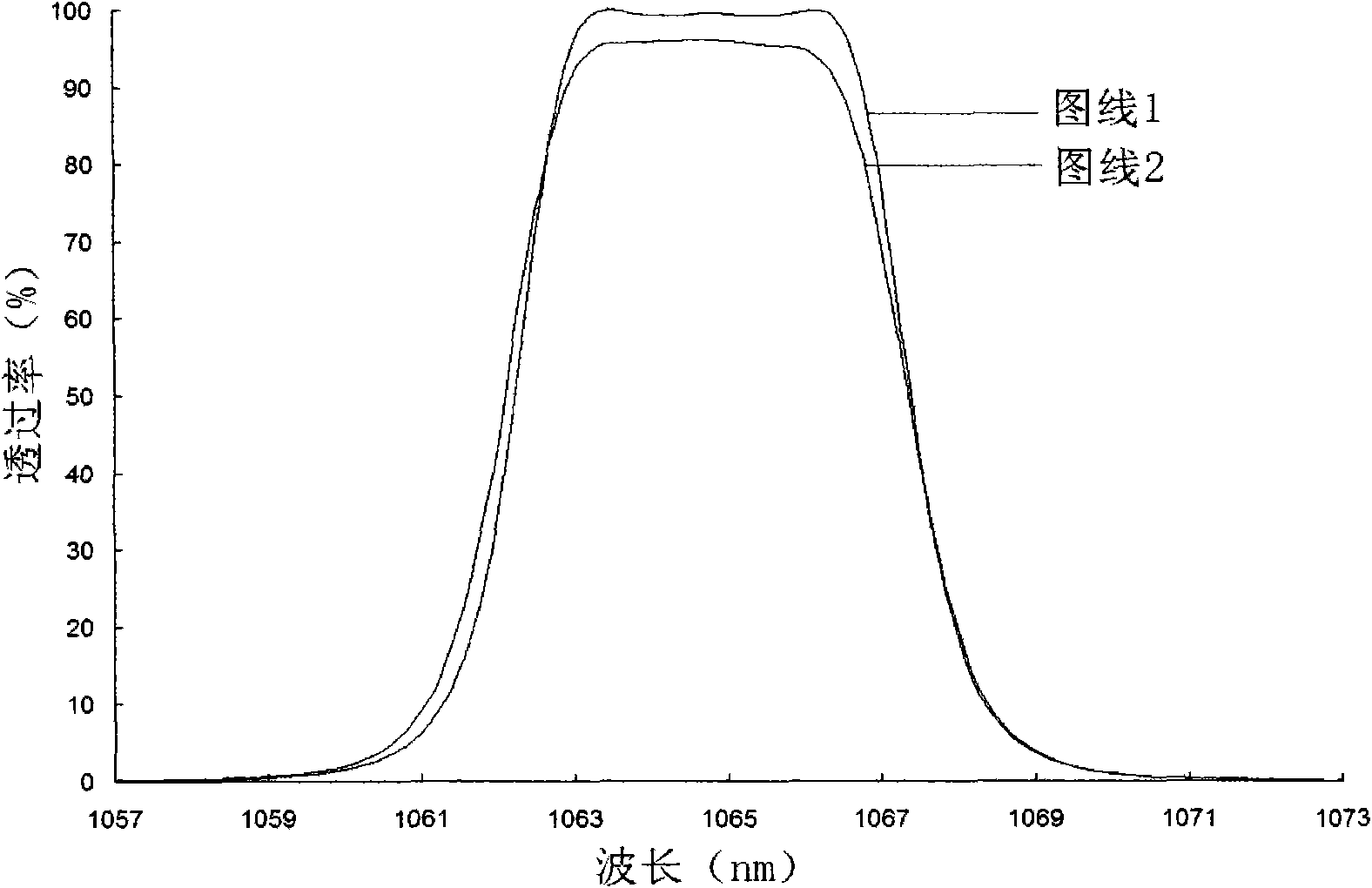

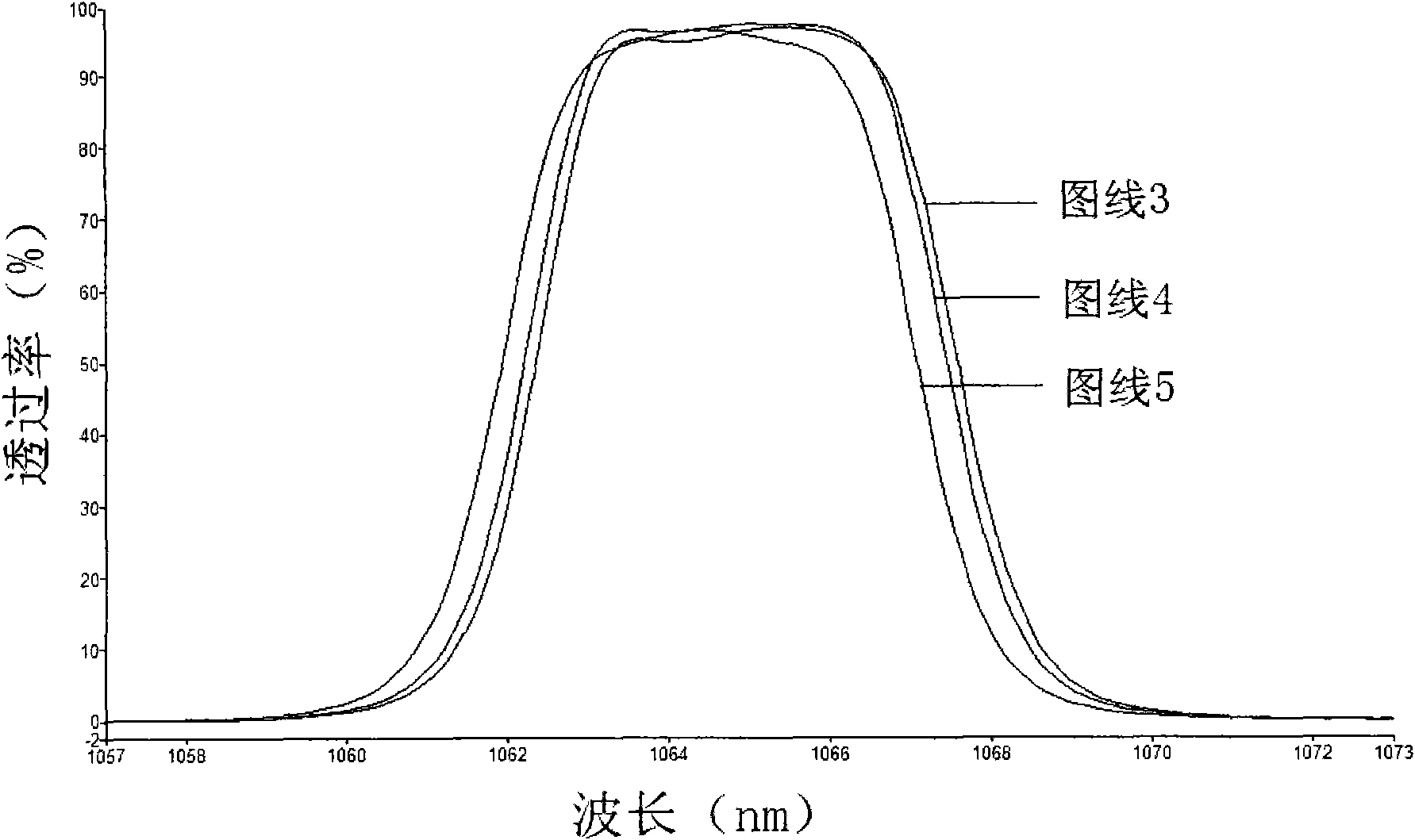

Method for making rectangular deep cut-off ultra-narrow band pass filter

InactiveCN102141645AHigh rectangularityHigh cutoffOptical filtersBandpass filteringAutomatic control

The invention provides a method for making deep cut-off ultra-narrow band pass filter. By adopting the method, the effective area and the cut-off of the bandpass filter can be obviously improved and error negative effects can be effectively controlled. The method comprises the following steps of: 1, determining a theoretical film, selecting Ta2O5 as a high-reflectivity material and SiO2 as a low-reflectivity material on the basis of a typical film structure of a multi-cavity optical filter, respectively defining H and L to be the unit optical thickness of the Ta2O5 and the SiO2 on lambda fourth by taking lambda as an operating wavelength of the optical filter, and determining the film structure of the optical filter by using film design software thin film circuit (TFC) Calc on a computer according to performance parameters required by the ultra-narrow band pass filter; 2, making a template control file for automatic control of a coating machine by using the full-automatic coating machine according to the obtained theoretical film structure; and 3, loading selected coating materials in the coating machine and automatically completing the making of the optical filter through a control mode of eccentric monitoring by the coating machine according to a selected template.

Owner:SOUTH WEST INST OF TECHN PHYSICS

Thin-film circuit device, method for manufacturing thin-film circuit device, and electronic apparatus

ActiveUS20070173031A1Low costEfficient preparationSemiconductor/solid-state device detailsCooking-vessel lids/coversUltimate tensile strengthThin film circuits

A thin-film circuit device includes a substrate and a thin-film circuit layer, disposed on the substrate, having an element region and a low-strength region. The element region includes thin-film elements. The low-strength region extends between an end portion of the thin-film circuit layer and the element region and has a mechanical strength less than that of the surroundings of the low-strength region.

Owner:SEIKO EPSON CORP

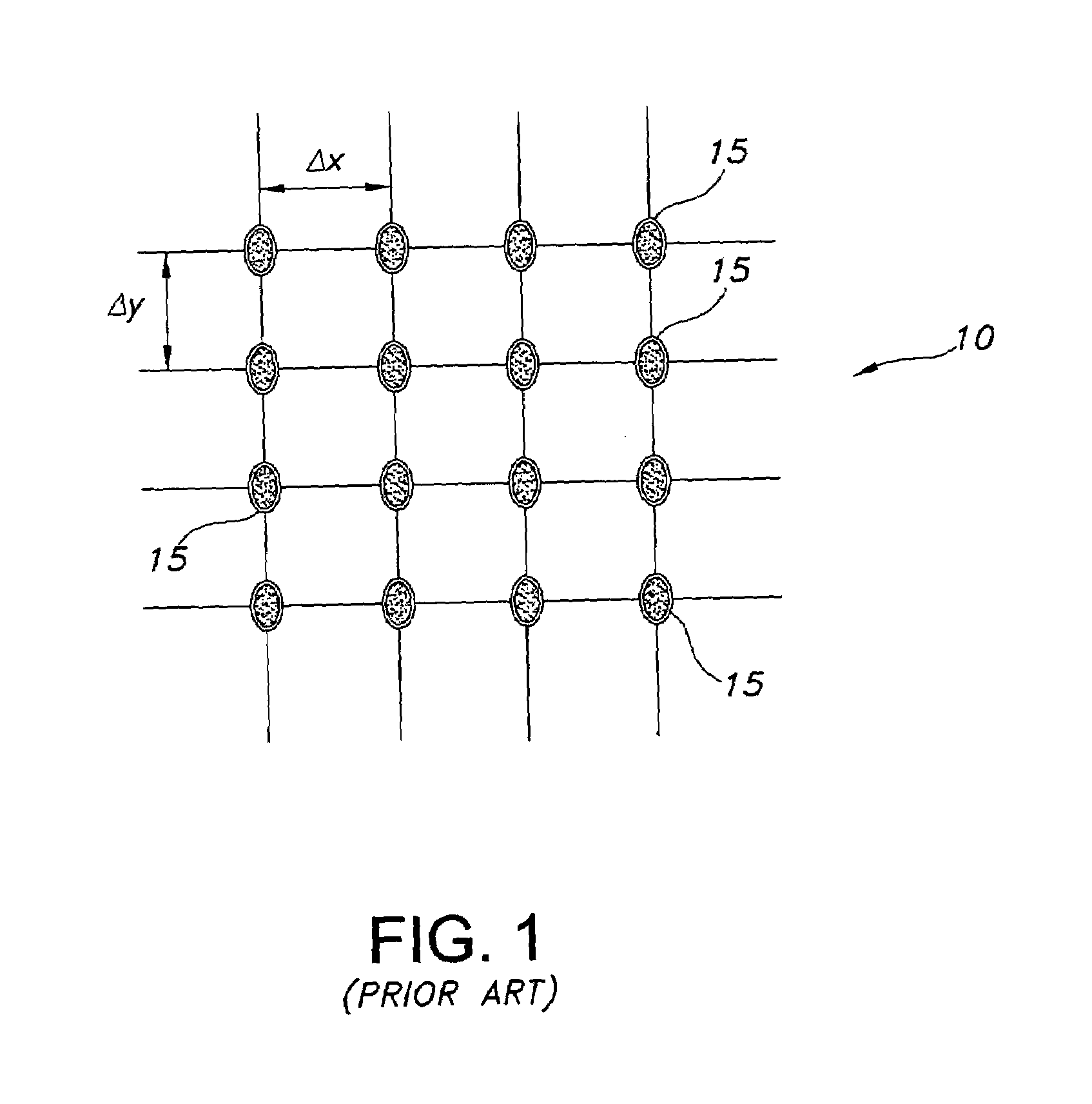

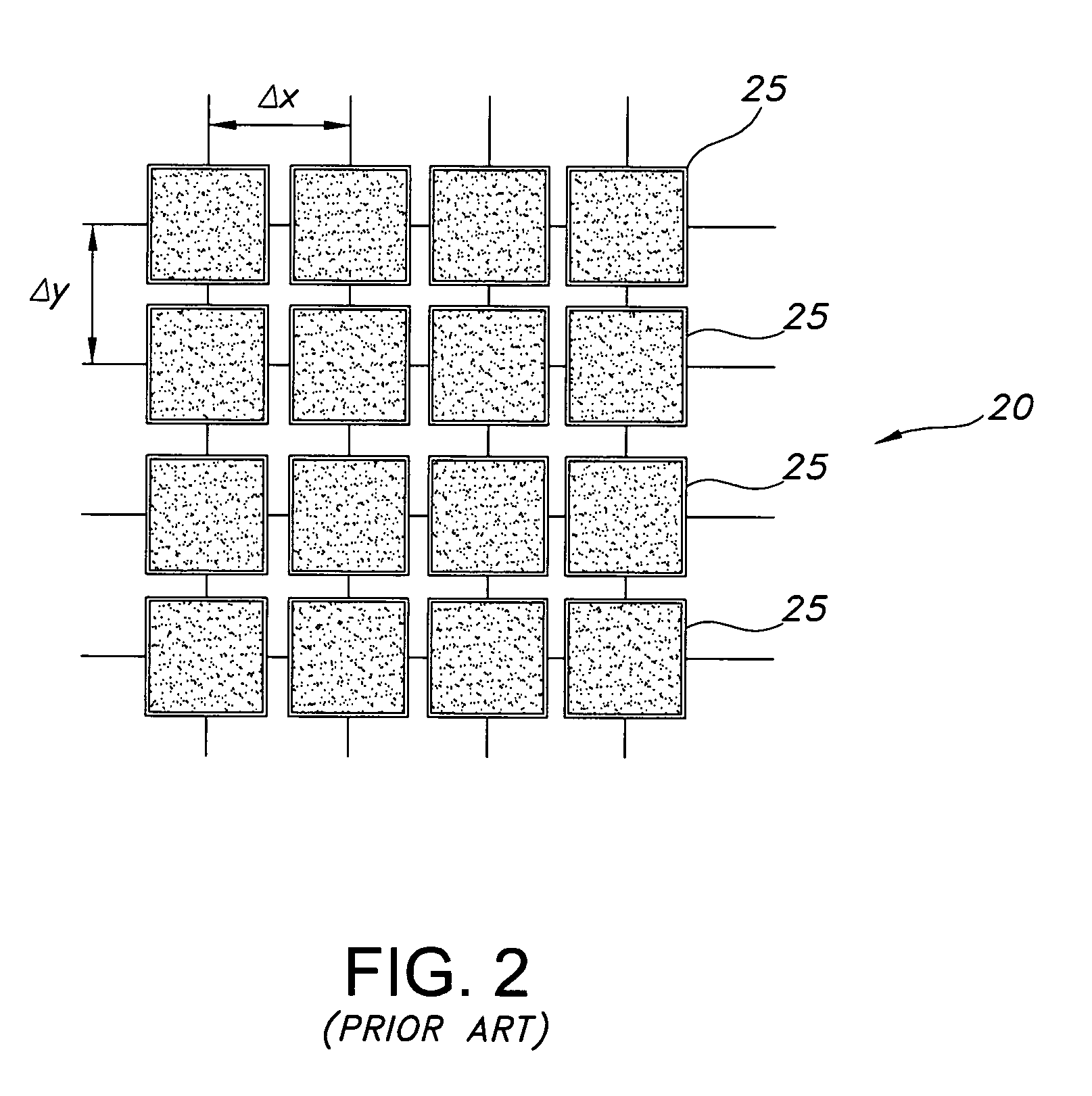

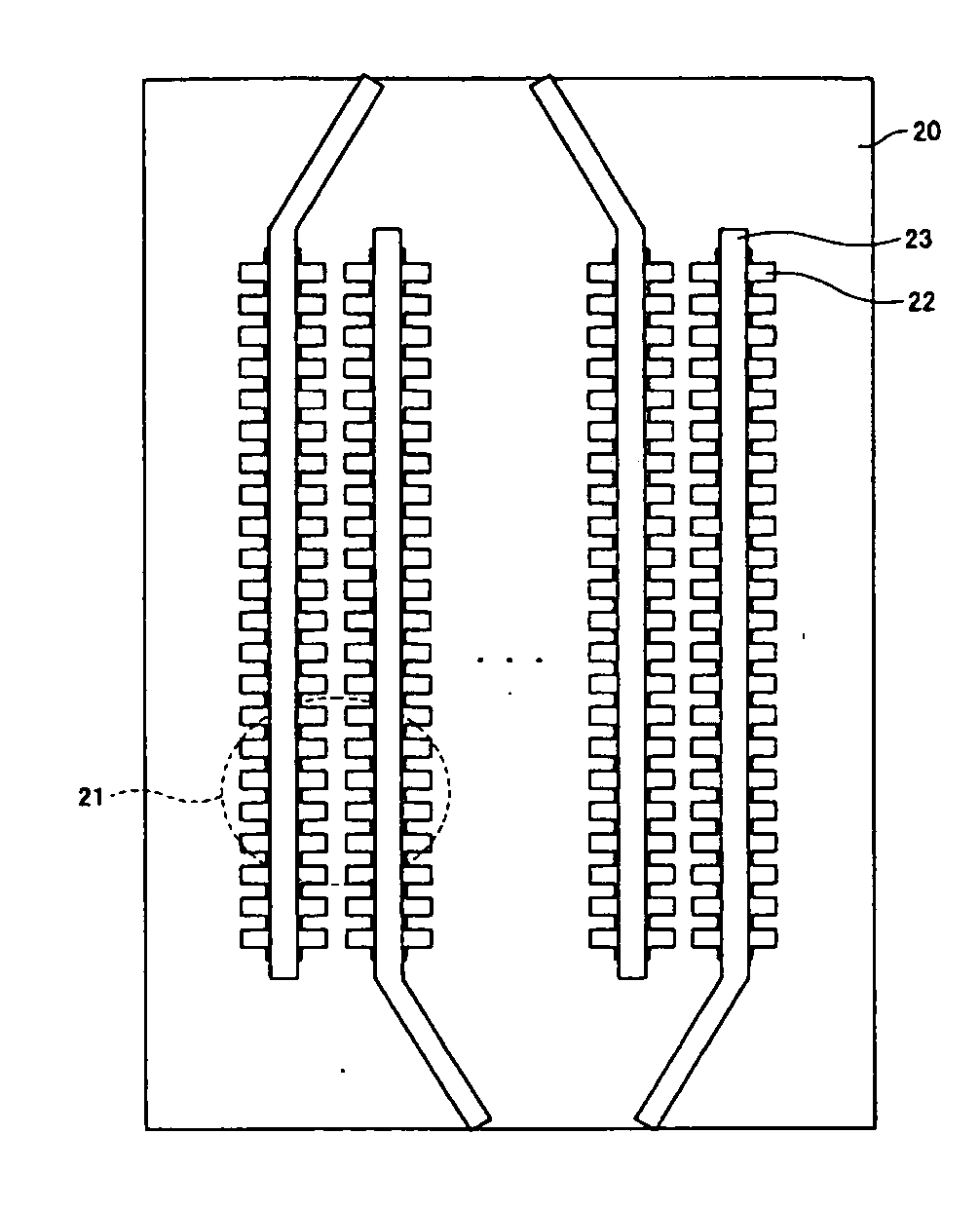

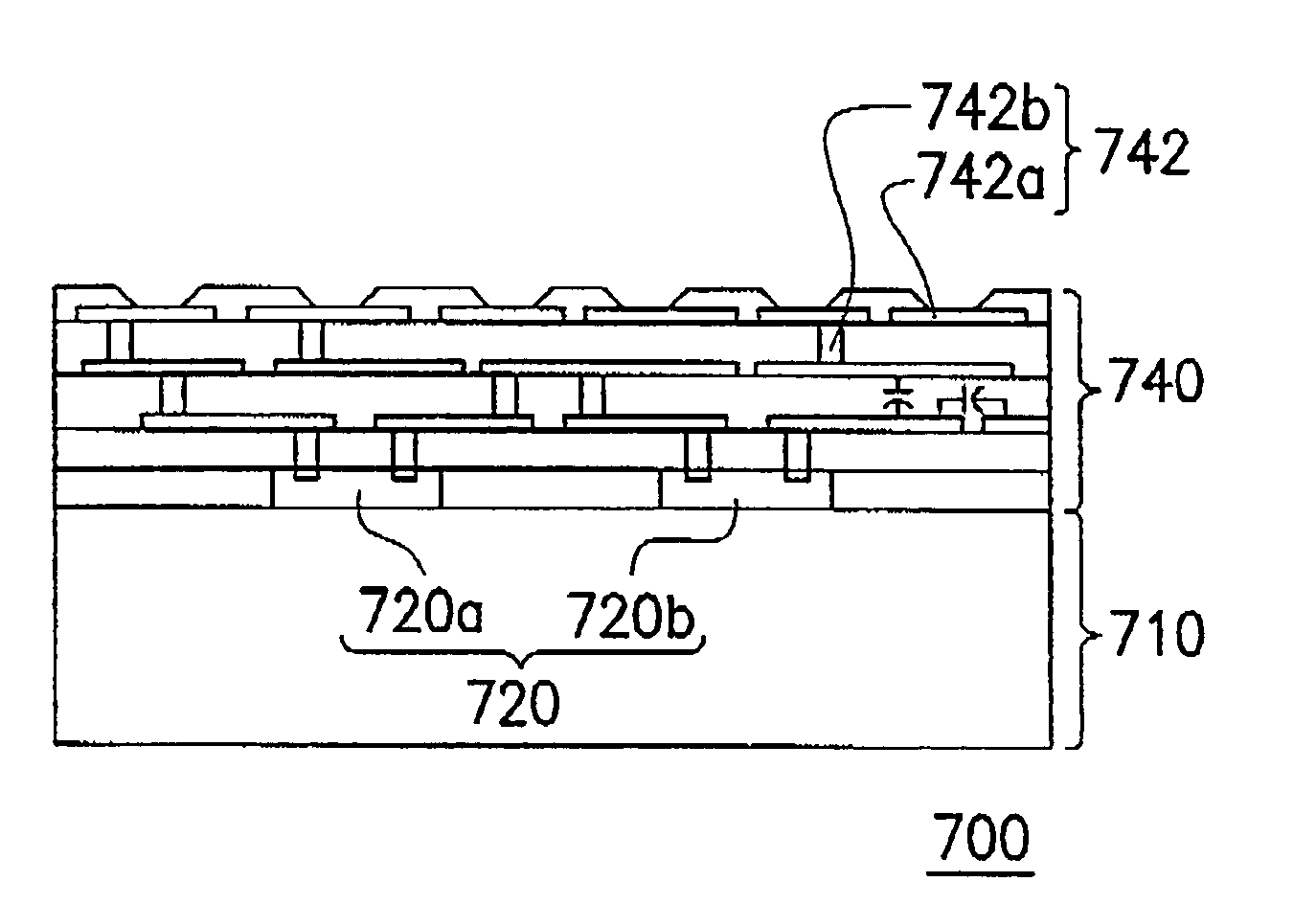

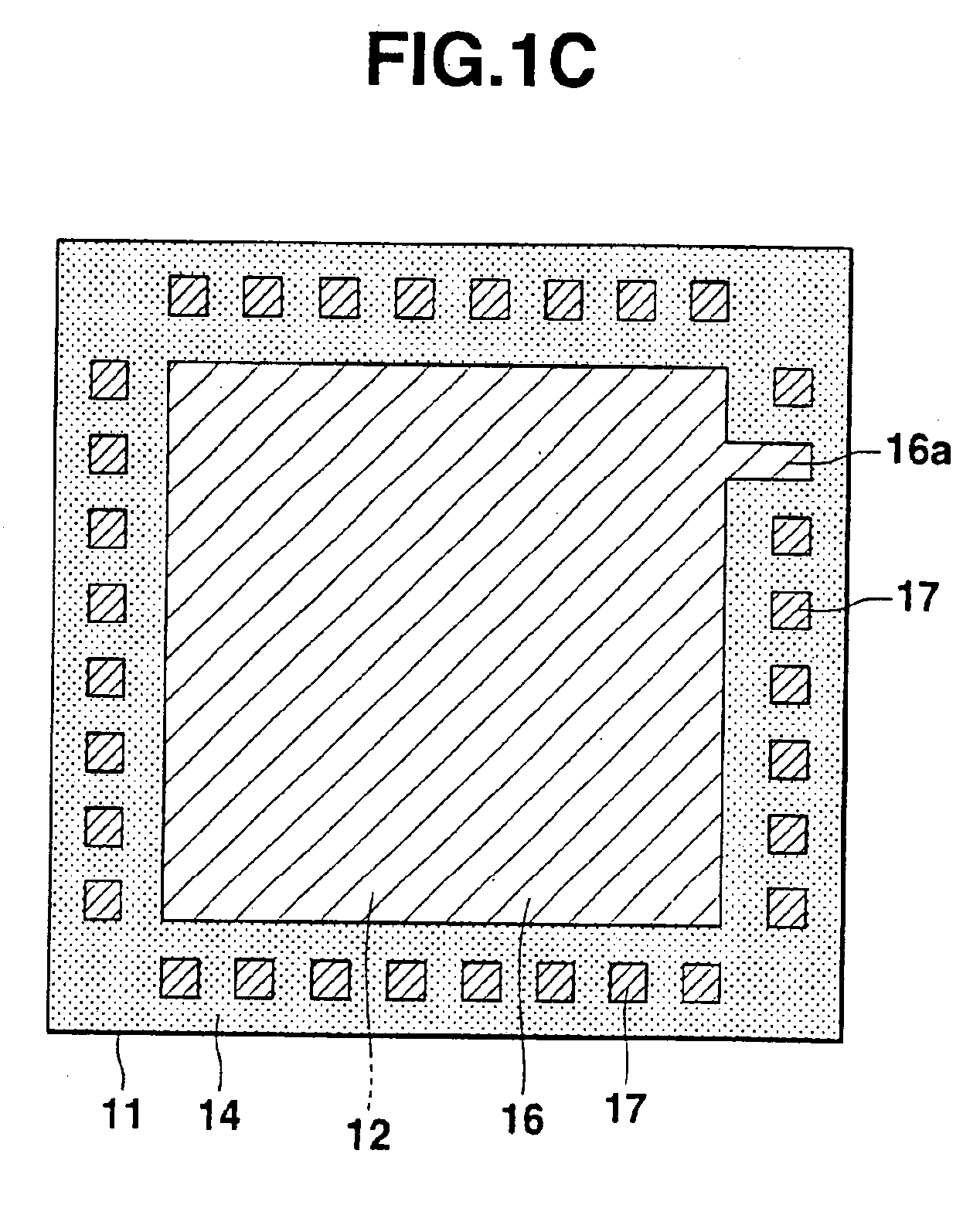

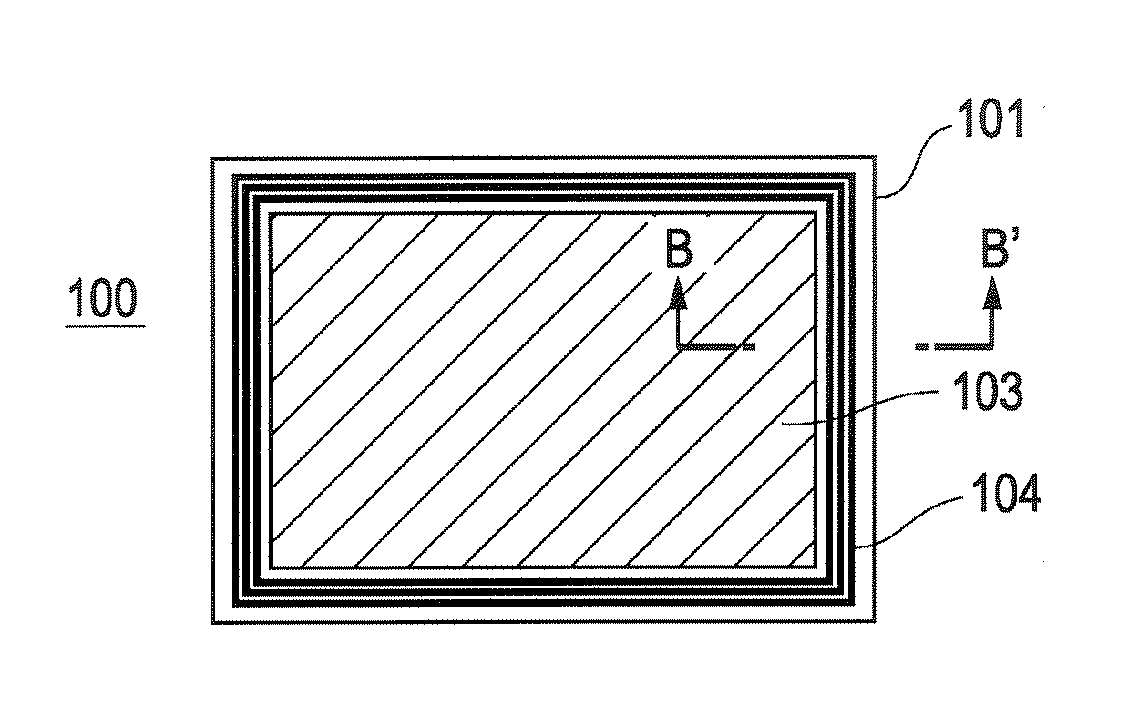

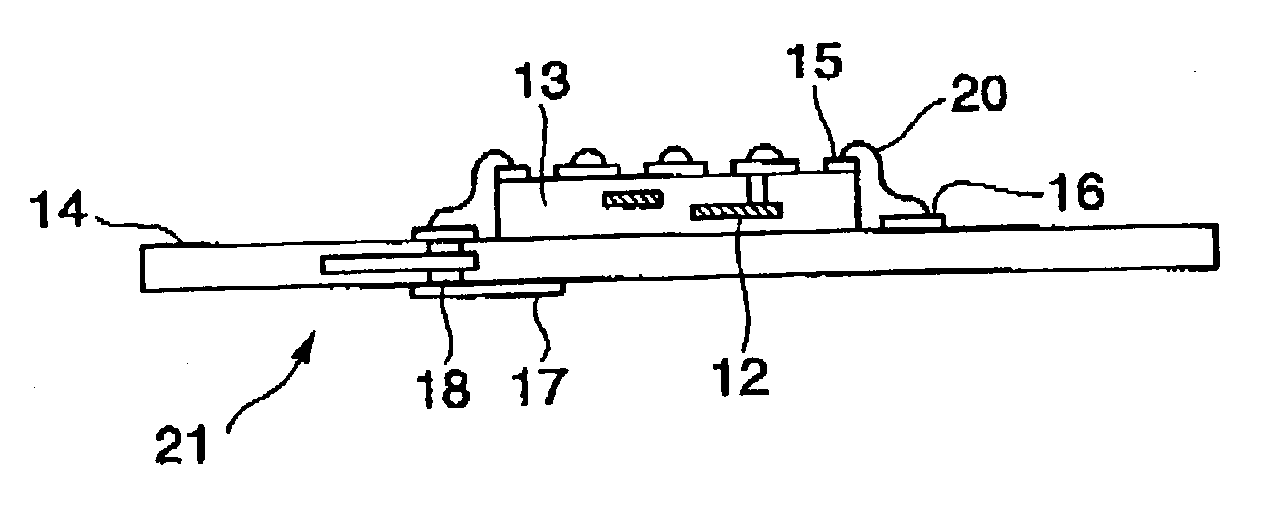

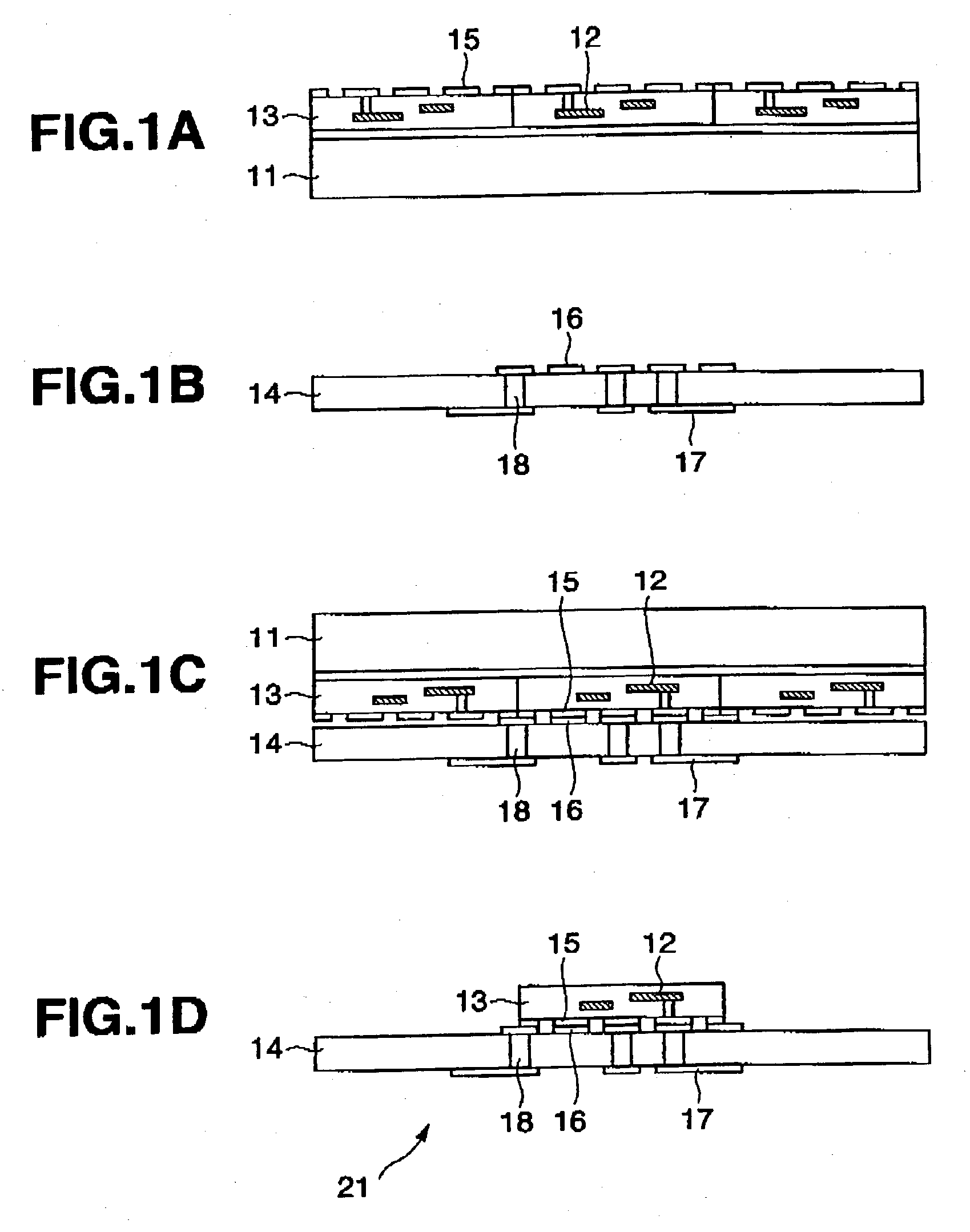

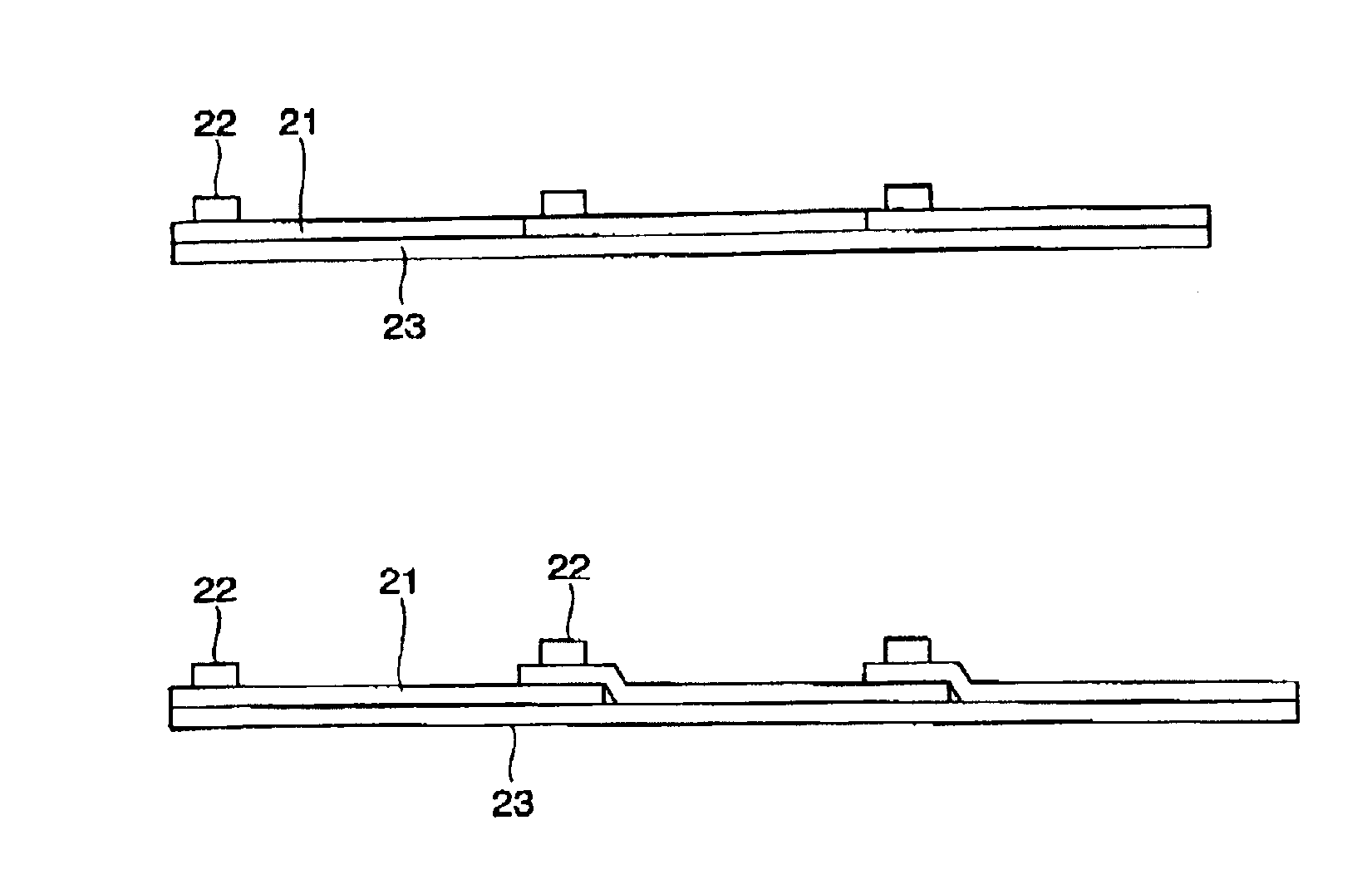

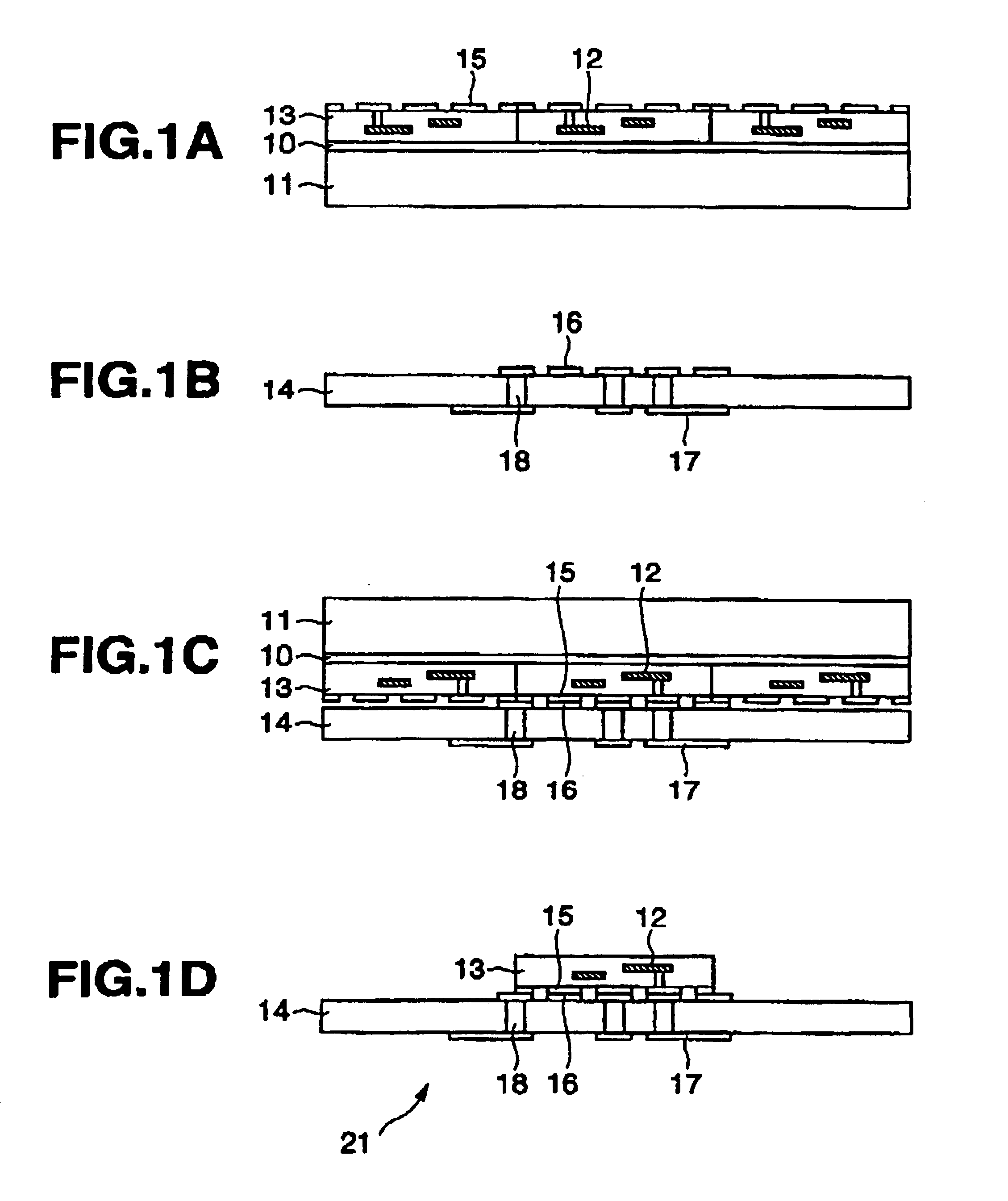

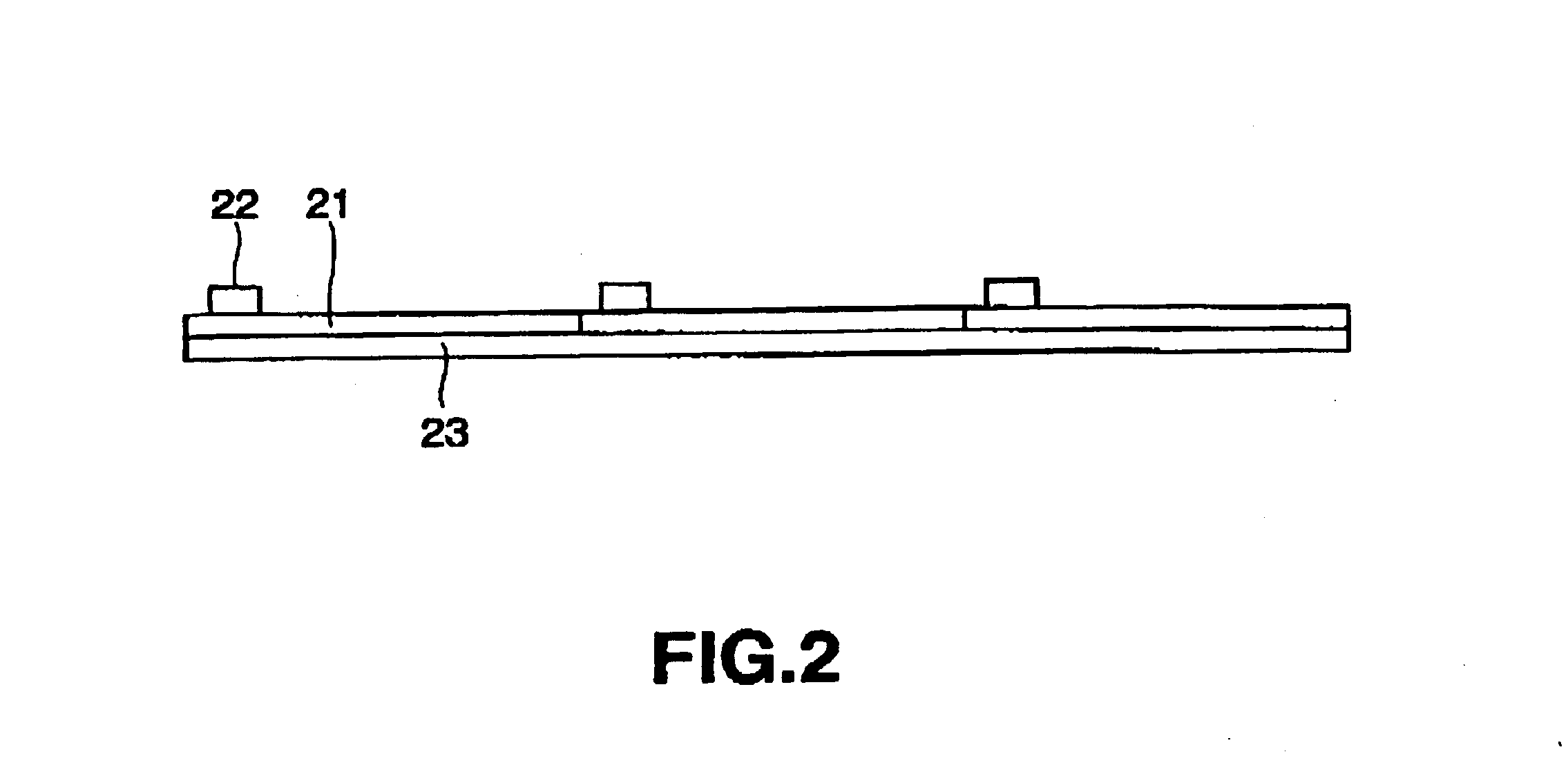

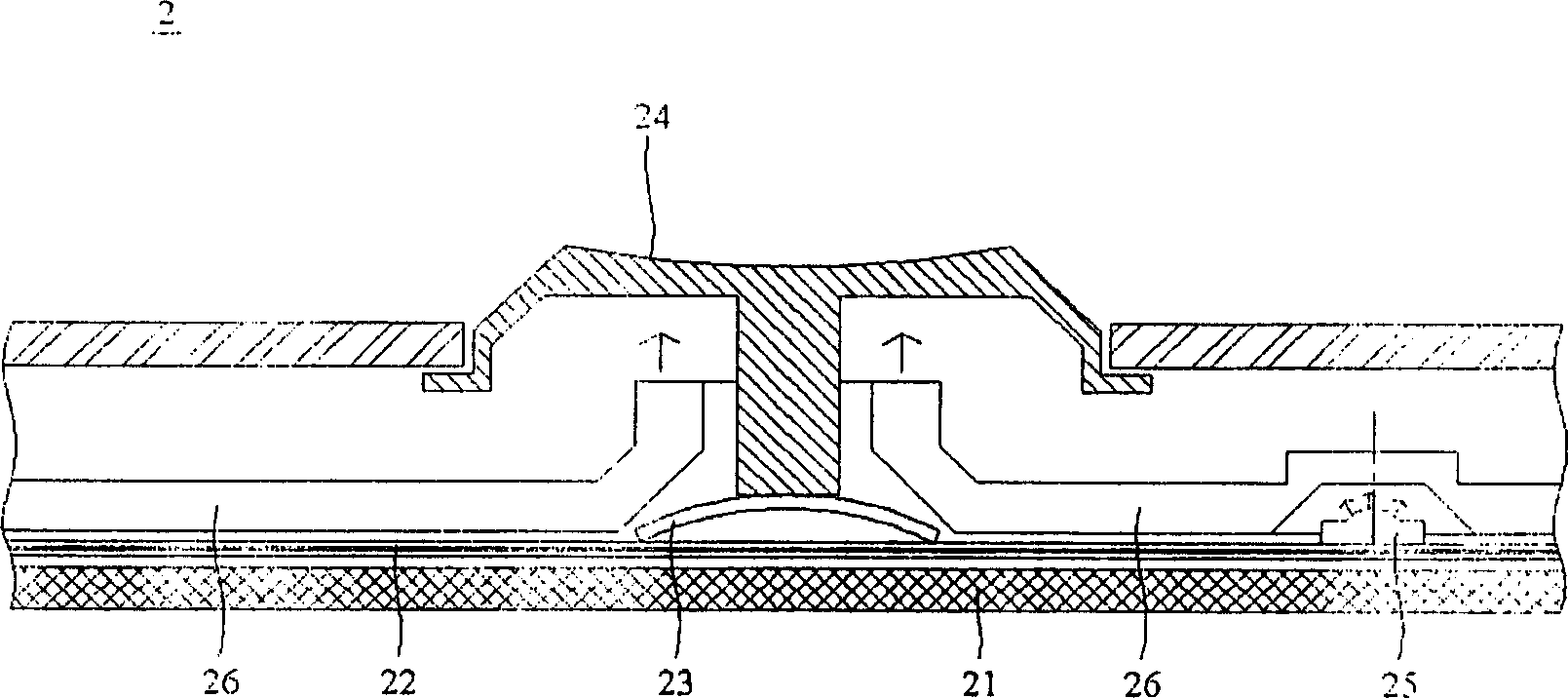

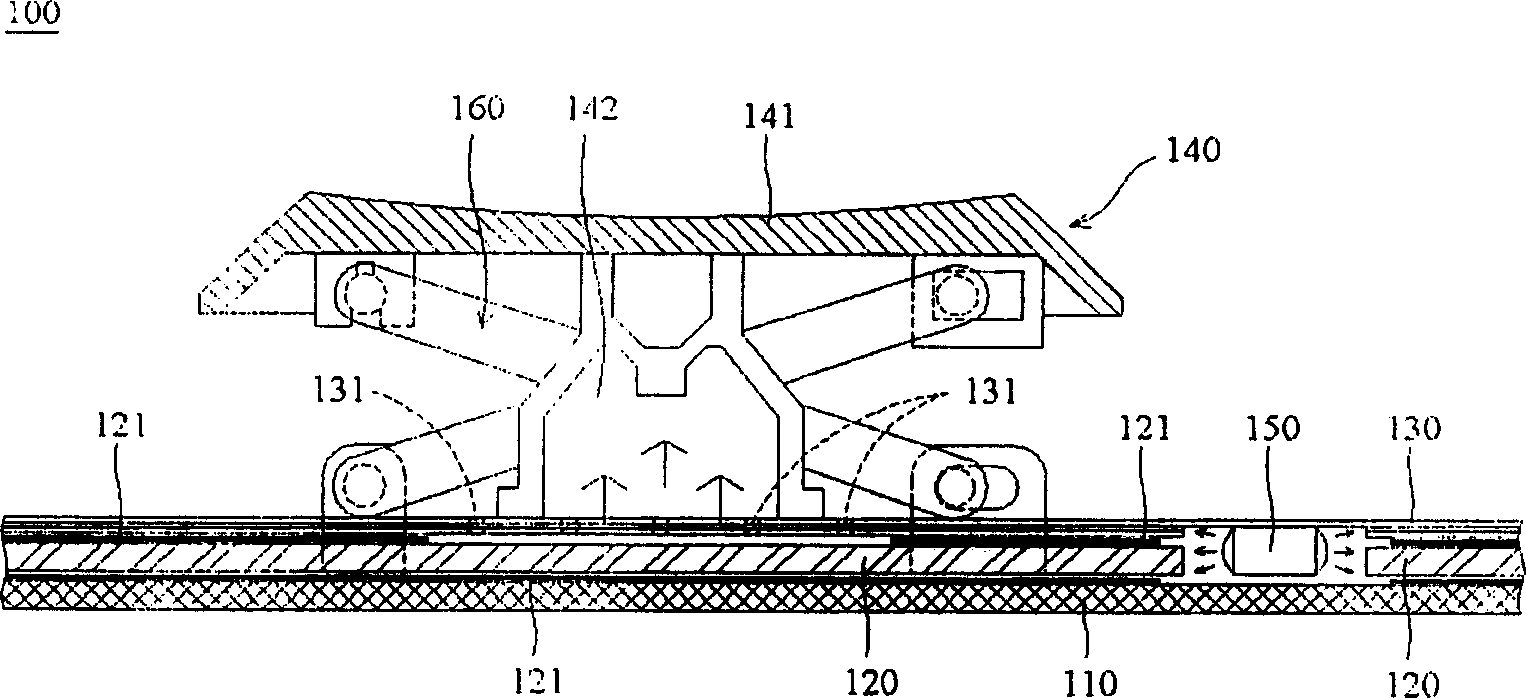

Semiconductor device and manufacturing method thereof, electro optic device, liquid crystal display device, electronics device

ActiveUS20040080032A1Easy to carryTransistorSemiconductor/solid-state device detailsLiquid-crystal displayDevice material

The present invention aims to manufacture a large size semiconductor device with the inter-substrate transcription technology of thin film circuits. Enlargement is enabled by disposing a plurality of second substrates (21) in a tile shape. As the second substrate (21), a print substrate or flexible print circuit having double-sided wiring or multilayer wiring is employed. The plurality of second substrates (21) is driven independently, and the plurality of second substrates (21) is made to mutually overlap, and a drive circuit (23) is disposed at such overlapping portion. Moreover, the plurality of second substrates (21) is made to mutually overlap, and the mutual circuits are connected at such overlapping portion.

Owner:SAMSUNG ELECTRONICS CO LTD

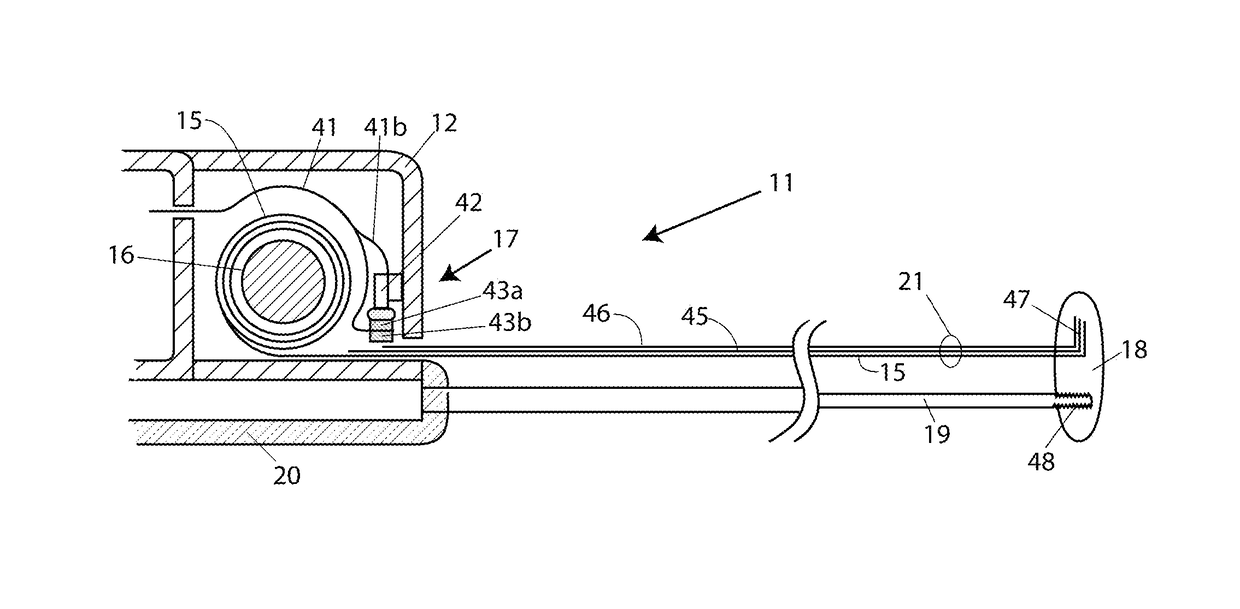

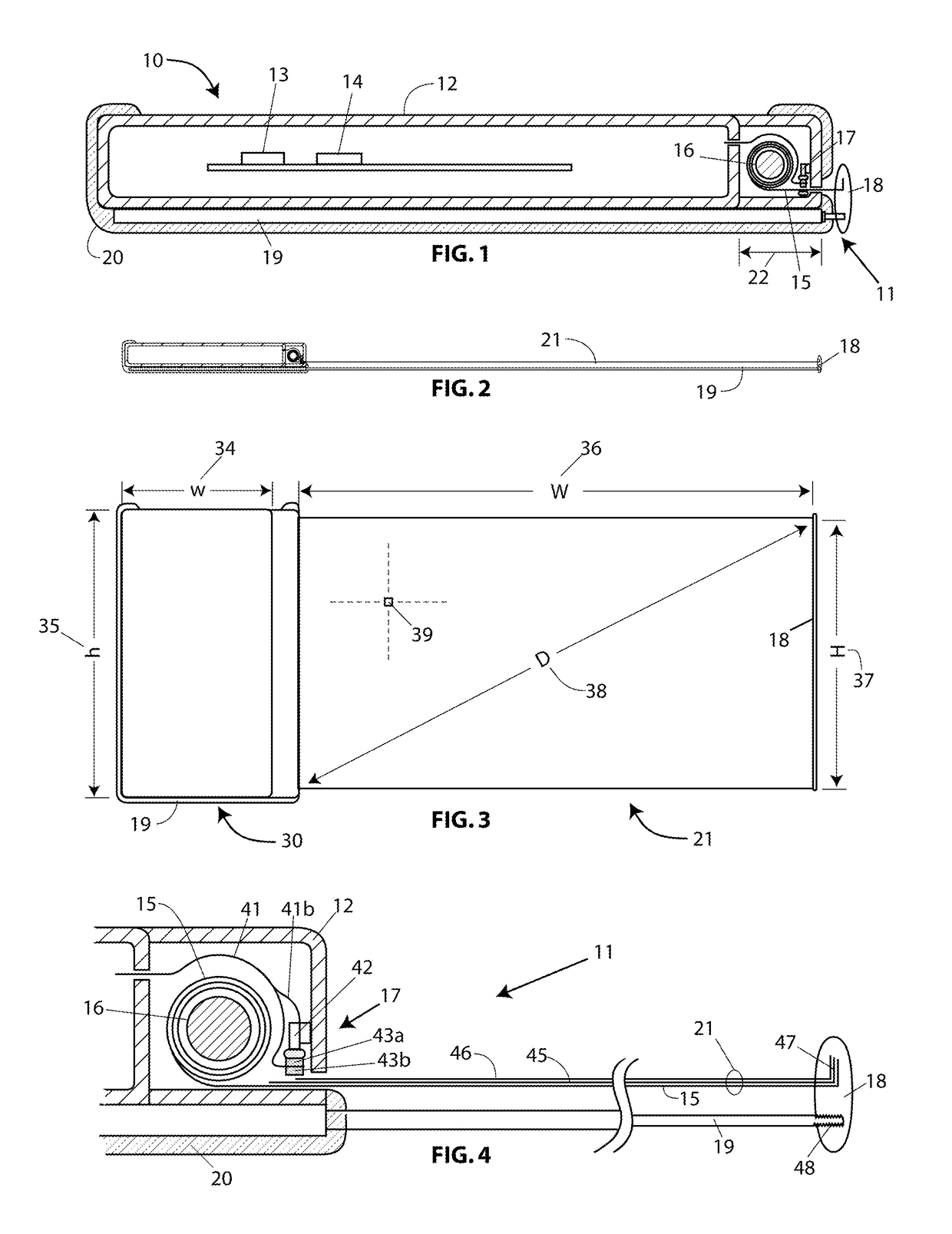

Method and system for deploying a flexible device

InactiveUS10082826B1Increase display areaDetails for portable computersIdentification meansComputer scienceThin film circuits

A device includes a processor and memory coupled to the processor. The memory is encoded with instructions that are executable by the processor to provide content signals. The device also includes a display screen extendable to present an extended portion comprising display pixels configured to display content using the content signals. The display screen comprises a scroll element which may provide a base substrate on which thin film circuits are fabricated, and may also provide motive force during retraction. The scroll element is attached to a pull bar and the pull bar is attached to an extensible support member that provides support during extension and retraction of the display screen.

Owner:I BLADES

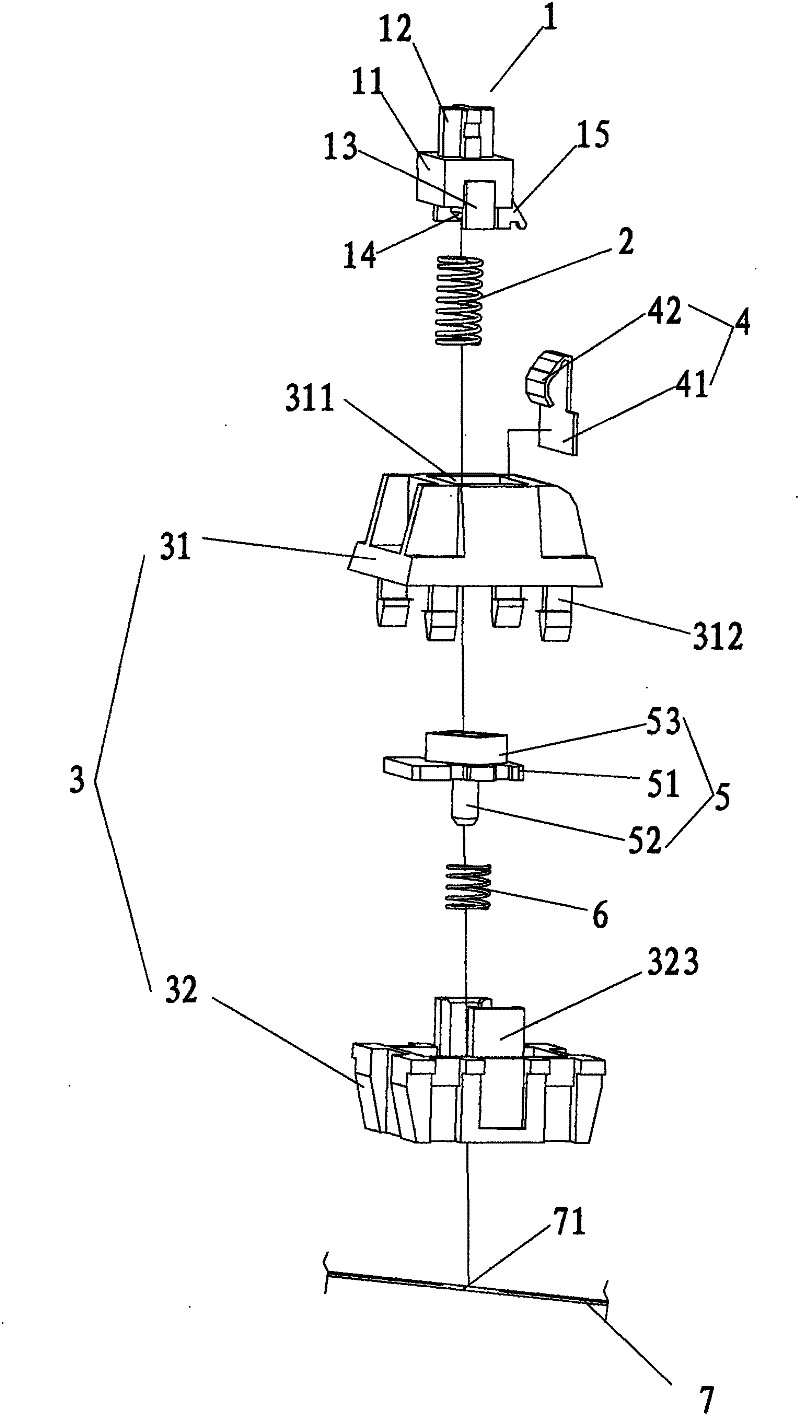

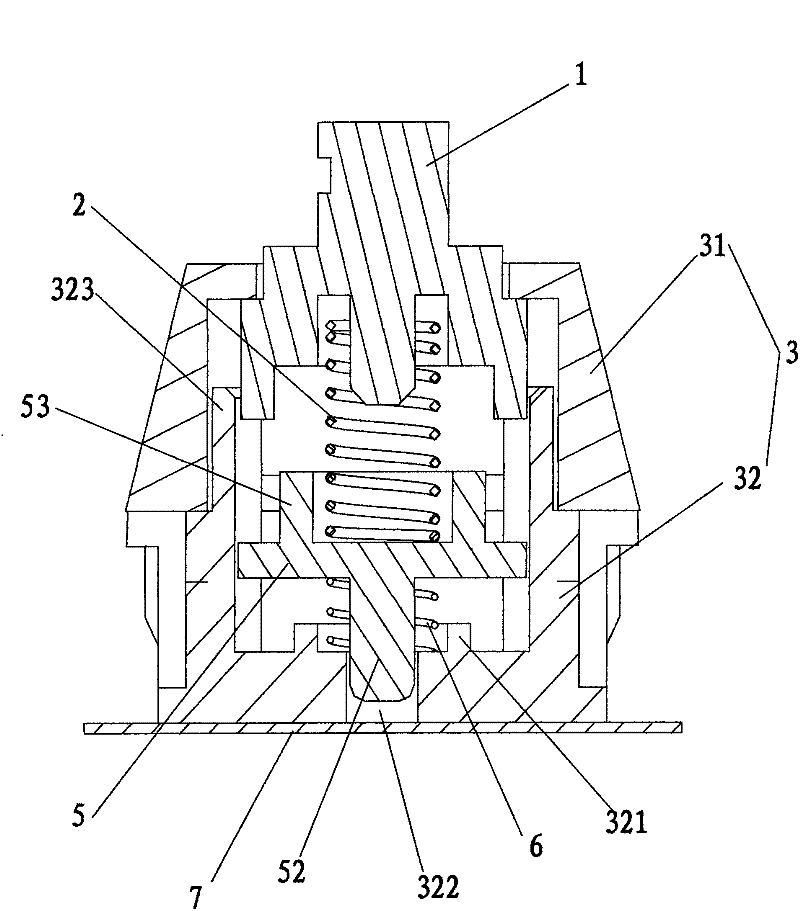

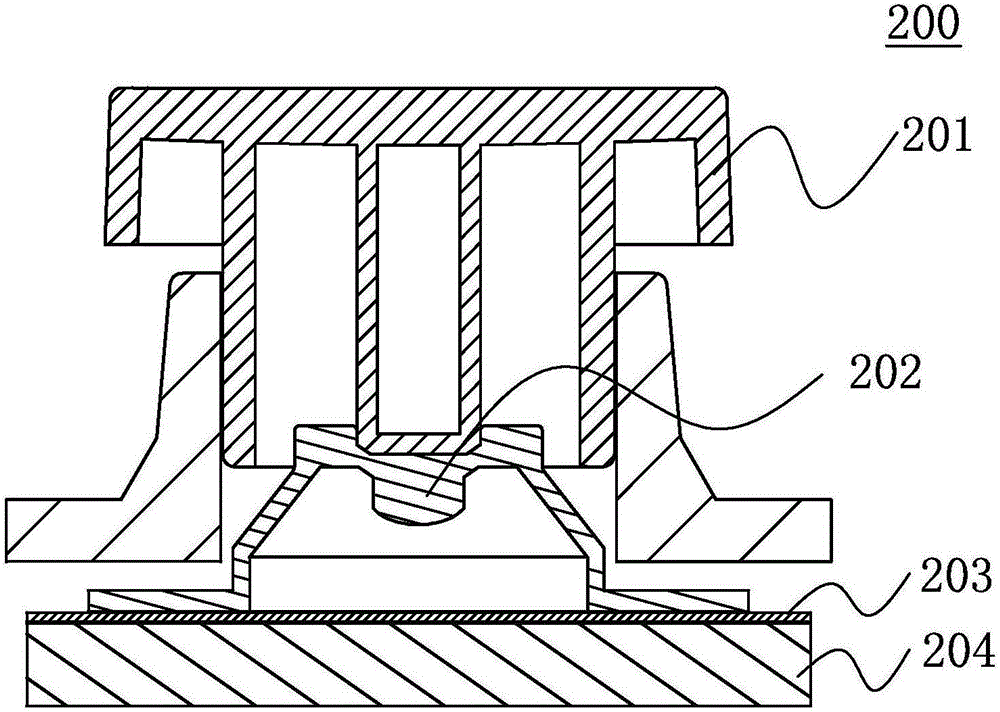

A key structure and a keyboard using it

InactiveCN102299017AFeel goodHigh sensitivityElectric switchesEmergency springsKey pressingHeavy load

Disclosed are a keying structure and a keyboard applying same. The keying structure includes a switch button, a heavy load spring, a switch shell, a striking pillar, a light load spring and a thin film circuit, wherein the switch button is clamped at the upper end of the switch shell, the heavy load spring is arranged underneath the switch button, the striking pillar is arranged within the switch shell, and the striking pillar is arranged under the heavy load spring, the light load spring is arranged underneath the striking pillar and the thin film circuit is arranged underneath the light load spring. During use, the switch button is pressed with a hand and, depressed under pressure, transfers a down force to the heavy load spring; the heavy load spring transfers the down force to the striking pillar, and the striking pillar depresses the light load spring to make the lower part of the striking pillar contact with the thin film circuit, thus making the thin film circuit conduct. The sensitivity of the present invention is high, the invention also has a downward idle motion, improving the feel to the hand for the player, and is low in cost.

Owner:袁建君

Method of manufacturing a semiconductor device having adjoining substrates

InactiveUS7101729B2Easy to manufactureEfficient use ofTransistorElectroluminescent light sourcesDevice materialThin membrane

The present invention aims to manufacture a large size semiconductor device with the inter-substrate transcription technology of thin film circuits. Enlargement is enabled by disposing a plurality of second substrates (21) in a tile shape. As the second substrate (21), a print substrate or flexible print circuit having double-sided wiring or multilayer wiring is employed. The plurality of second substrates (21) is driven independently, and the plurality of second substrates (21) is made to mutually overlap, and a drive circuit (23) is disposed at such overlapping portion. Moreover, the plurality of second substrates (21) is made to mutually overlap, and the mutual circuits are connected at such overlapping portion.

Owner:SAMSUNG ELECTRONICS CO LTD

Manufacturing method for curved surface film circuit based on 3D printing technology

ActiveCN105448800ALow production costLow costSemiconductor/solid-state device manufacturingComputer printingMetal membrane

The invention discloses a manufacturing method for a curved surface film circuit based on 3D printing technology. The manufacturing method comprises steps of a, arranging a matrix metal film, arranging a matrix metallic film on a curved surface structure, b, coating photoresist, performing spinning coating of the photoresist on the metal film obtained in the step a, c printing out a masking film board with a circuit microstructure through a 3D printer, d exposing, d performing exposure processing by arranging the masking film board on the curved surface coated with the photoresist, and obtaining the curved surface structure after exposure, e developing images, arranging the curved surface structure in the step d in a developing agent for image development and obtaining the curved surface structure after image development, and f corroding, using a corrodent to corrode the curved surface structure obtained from the step 4 after the masking film board is taken off. The invention can realize the film circuit manufacture in a real sense; the cost is low and the batch production can be realized; and the accuracy is high and the realized curved surface film circuit can be in any curved surface shape.

Owner:INST OF DONGGUAN TONGJI UNIV

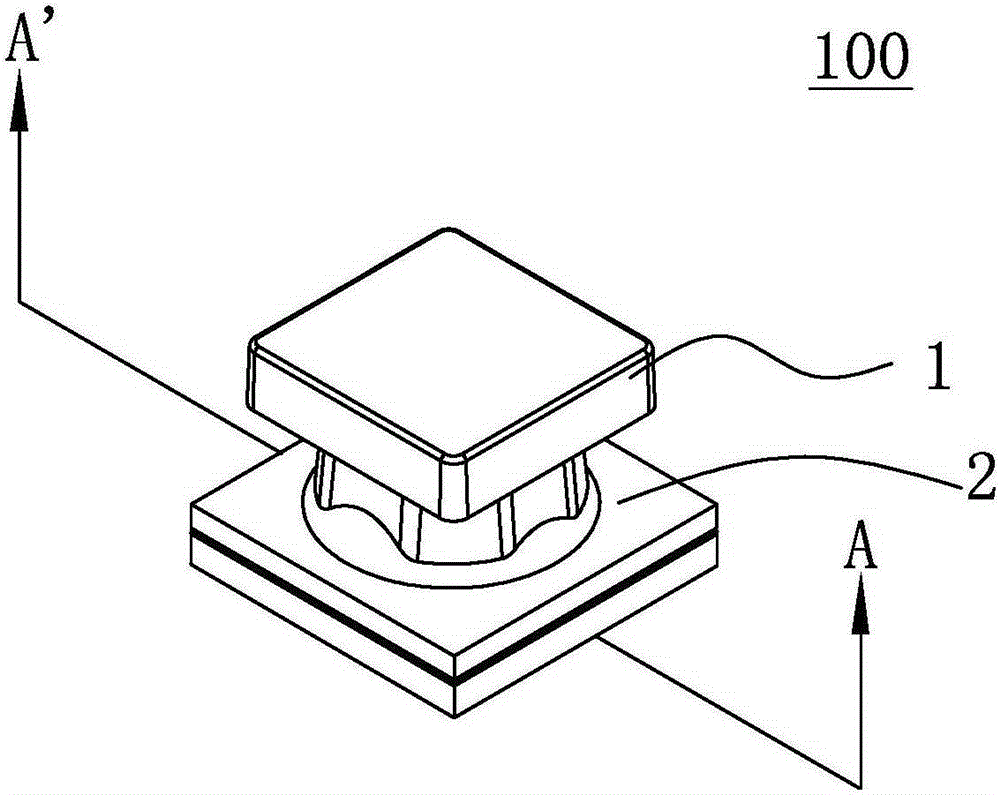

Keyboard structure

The keyboard structure fids one base board, one light conductor, one thin film circuit board, one button assembly and one light-emitting assembly. The light conductor is set on the base board, and the thin film circuit board is set on the light conductor. The button assembly is set on the thin film circuit board and has one key cap and one elastic body, which is between the key cap and the thin film circuit board. The light-emitting assembly is near the light conductor and below the thin film circuit board, and the light the light-emitting assembly emits is conducted to the elastic body and the key cap via the light conductor.

Owner:DARFON ELECTRONICS CORP

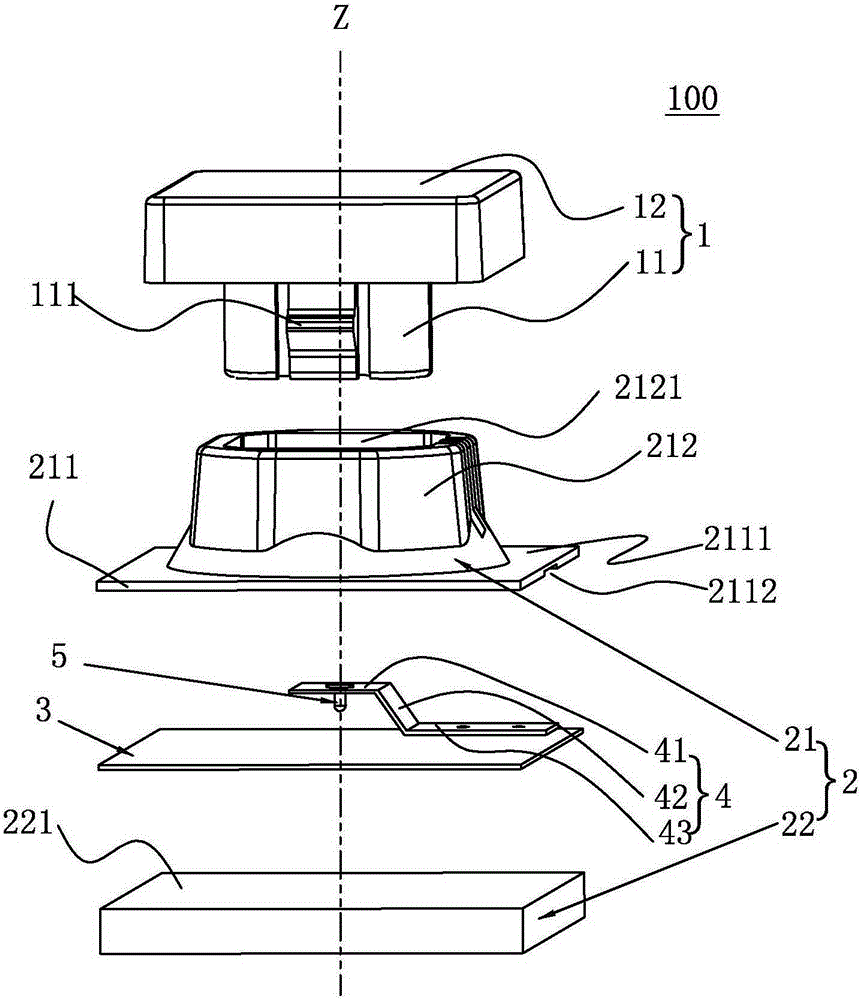

Keyboard key and keyboard

InactiveCN105206456ADoes not cause hand feeling deviationLow costEmergency actuatorsElectric switchesKey pressingElastic component

The invention provides a keyboard key which can provide good hand feeling. The keyboard key comprises a key cap, a base, a thin-film circuit board, an elastic component and a contact piece, and is characterized in that one end of the elastic component is arranged on the base, and the other end of the elastic component is suspended in the air; the contact piece is arranged on the elastic component; when the keyboard key stays at a free state, the key cap is located at a first position, and a first distance is reserved between the contact piece and the thin-film circuit board; when the key cap moves towards the base from the first position along a first direction, the keycap is pressed against the elastic component until the key cap moves to a second position, and the contact piece is pressed against the thin-film circuit board; and when the key cap continues to move towards the base along the first direction from the second position, the key cap continues to be pressed against the elastic component and further enables the contact piece to have elastic deformation in the first direction until the key cap moves to a third position, and the contact piece continues to be pressed against the thin-film circuit board in the process of moving from the second position to the third position of the key cap.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com