Method for making rectangular deep cut-off ultra-narrow band pass filter

A manufacturing method and technology of optical filters, applied in the direction of optical filters, etc., can solve problems such as unfavorable stability, transmittance change, poor cutoff, etc., achieve high practical value, reduce control errors, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

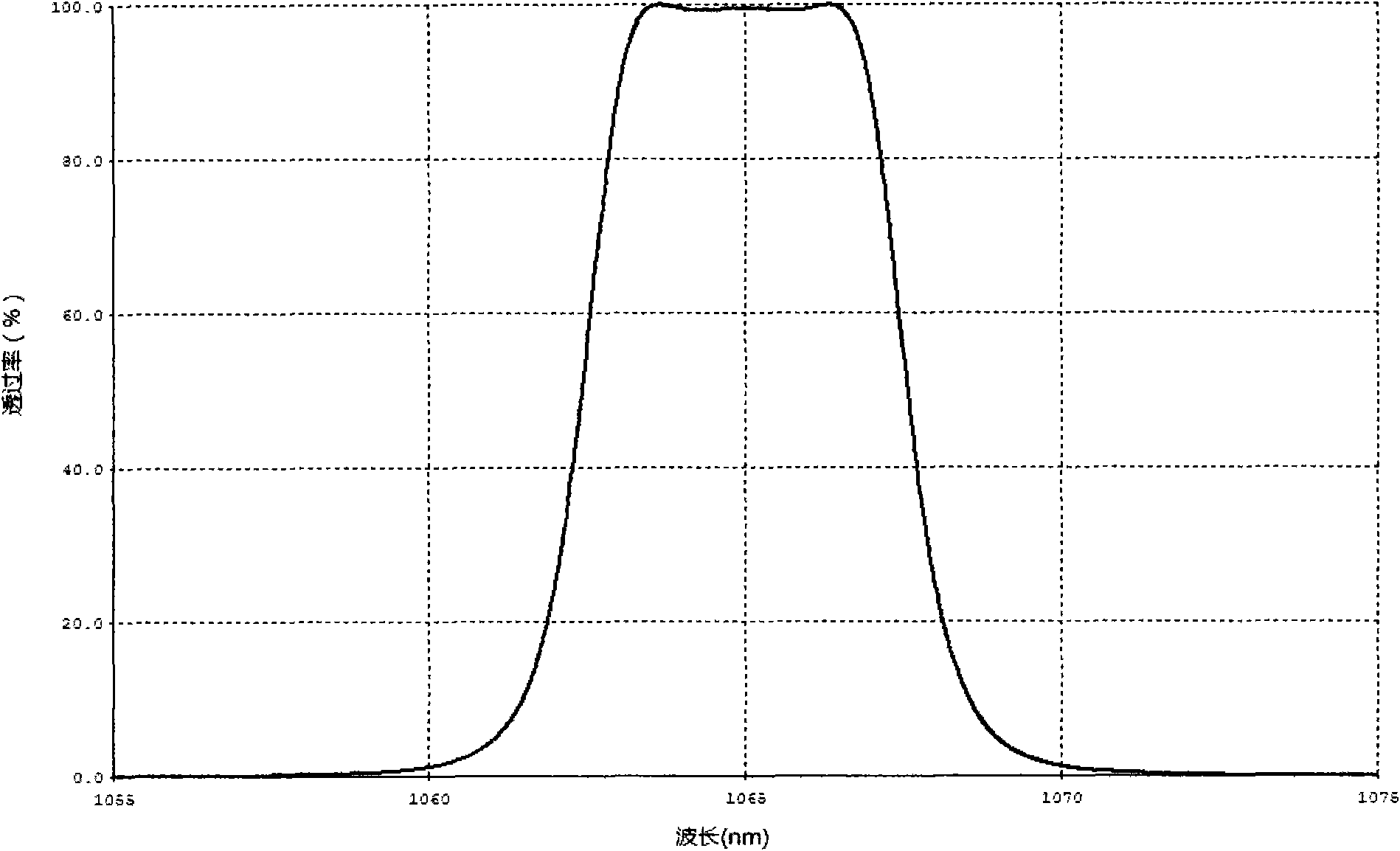

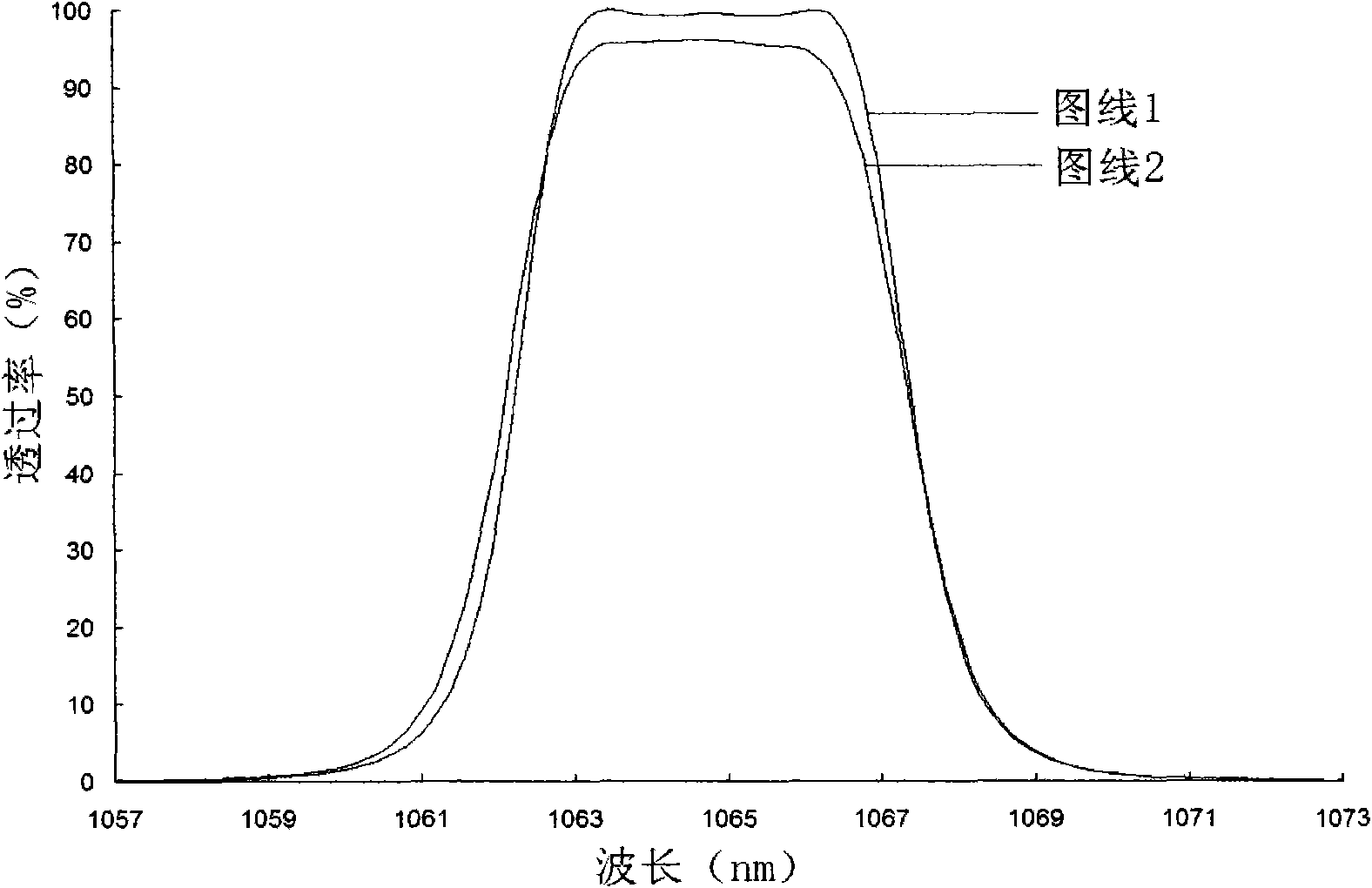

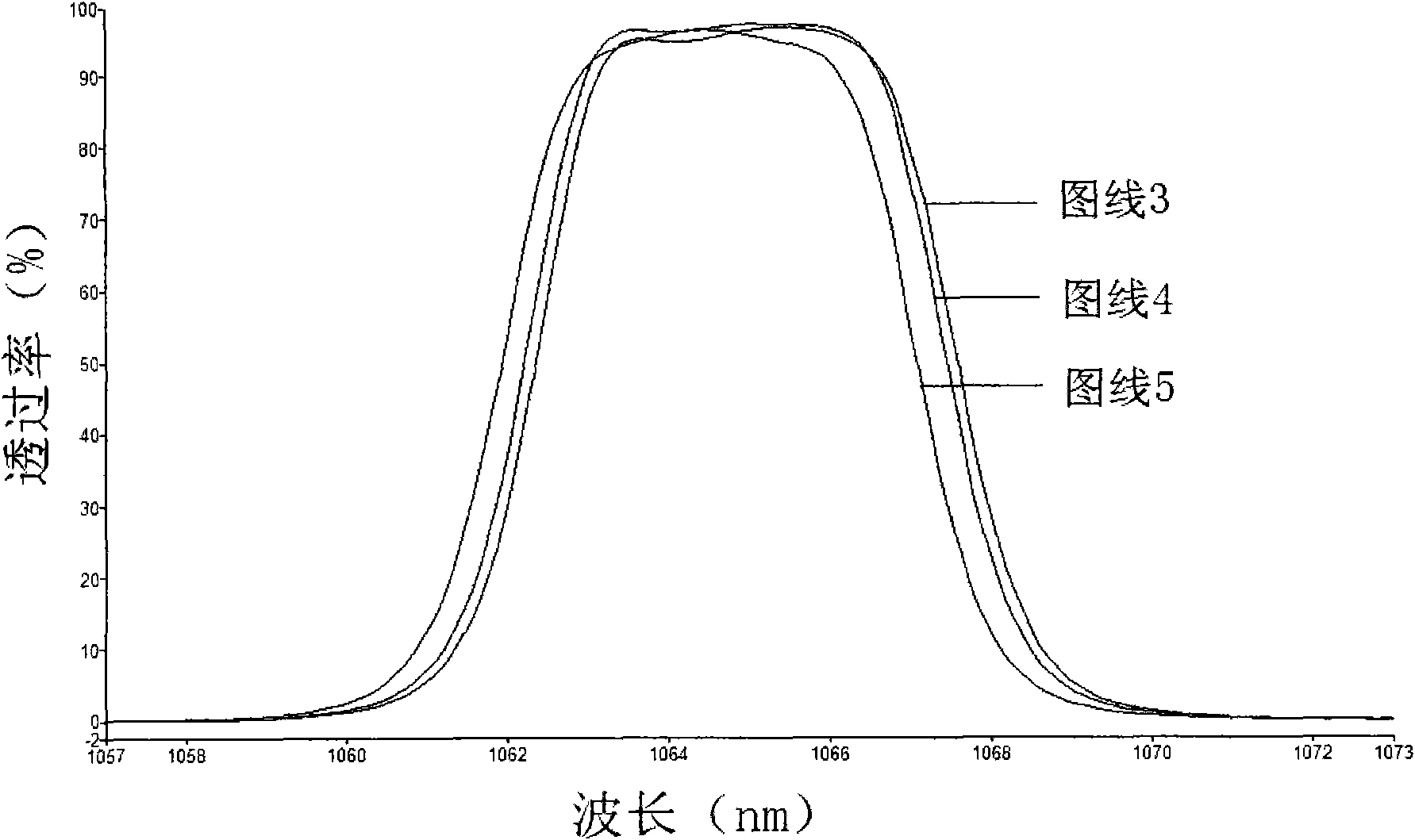

[0028] refer to figure 1 . In order to solve the shortcomings of single-cavity filters, for applications that require very strict filter performance, multi-cavity filter designs can usually be used to obtain better rectangularity and cut-off through the superposition of multiple interference cavities. degree and required passband width. According to the theoretical design curve of a rectangular deep-cut ultra-narrow bandpass filter working at 1064nm with a typical half-width of 5.2nm, firstly, determine the theoretical film system, and select Ta 2 o 5 As a high refractive index material, SiO 2 is a low refractive index material, with λ being 1064nm, respectively defining Ta 2 o 5 and SiO 2 The unit optical thicknesses at λ / 4 are H and L. The performance parameters of the optical filter include theoretical half-width, distribution value of 5-5.4nm, and the width of the region where the passband average transmittance is greater than or equal to 95%, and its width is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com