Rear-earth magnet and its producing method

A technology of rare earth magnets and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., which can solve the problems of the reduction of residual magnetic flux density of rare earth magnets, the reduction of magnet processing efficiency, and the reduction of cutting and surface grinding processing efficiency and other problems, to achieve the effect of increased coercive force, inhibited particle growth, and good rectangularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

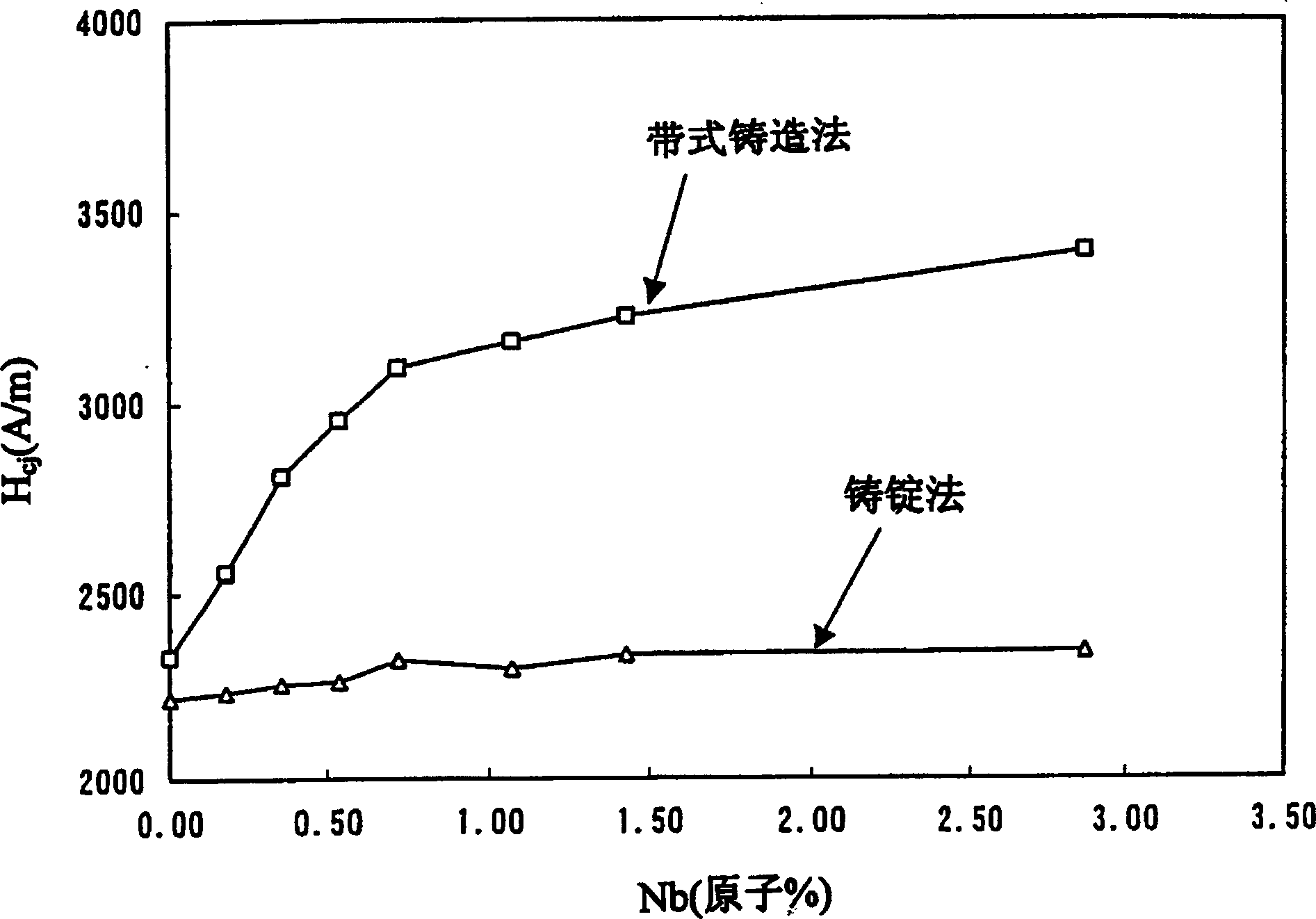

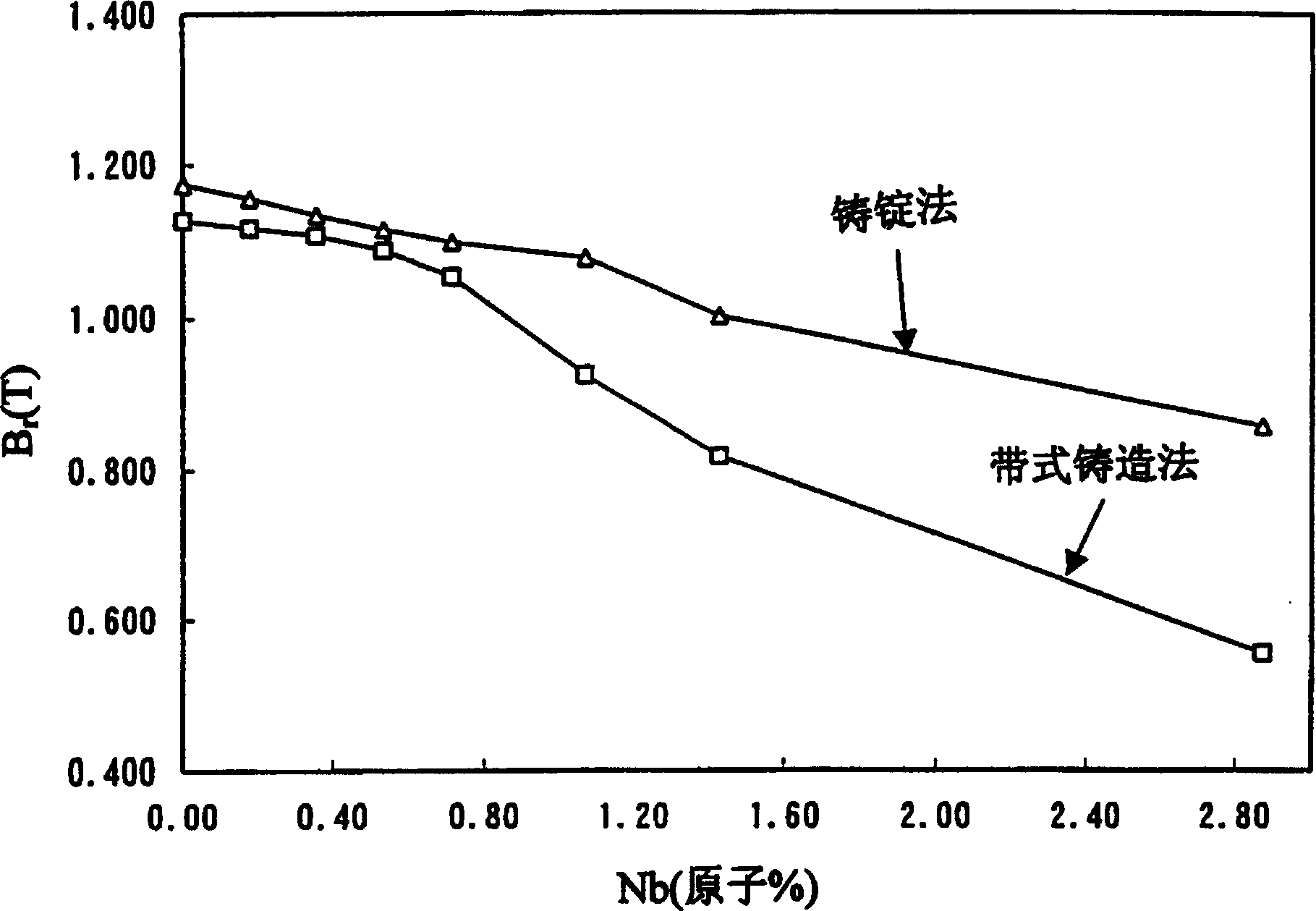

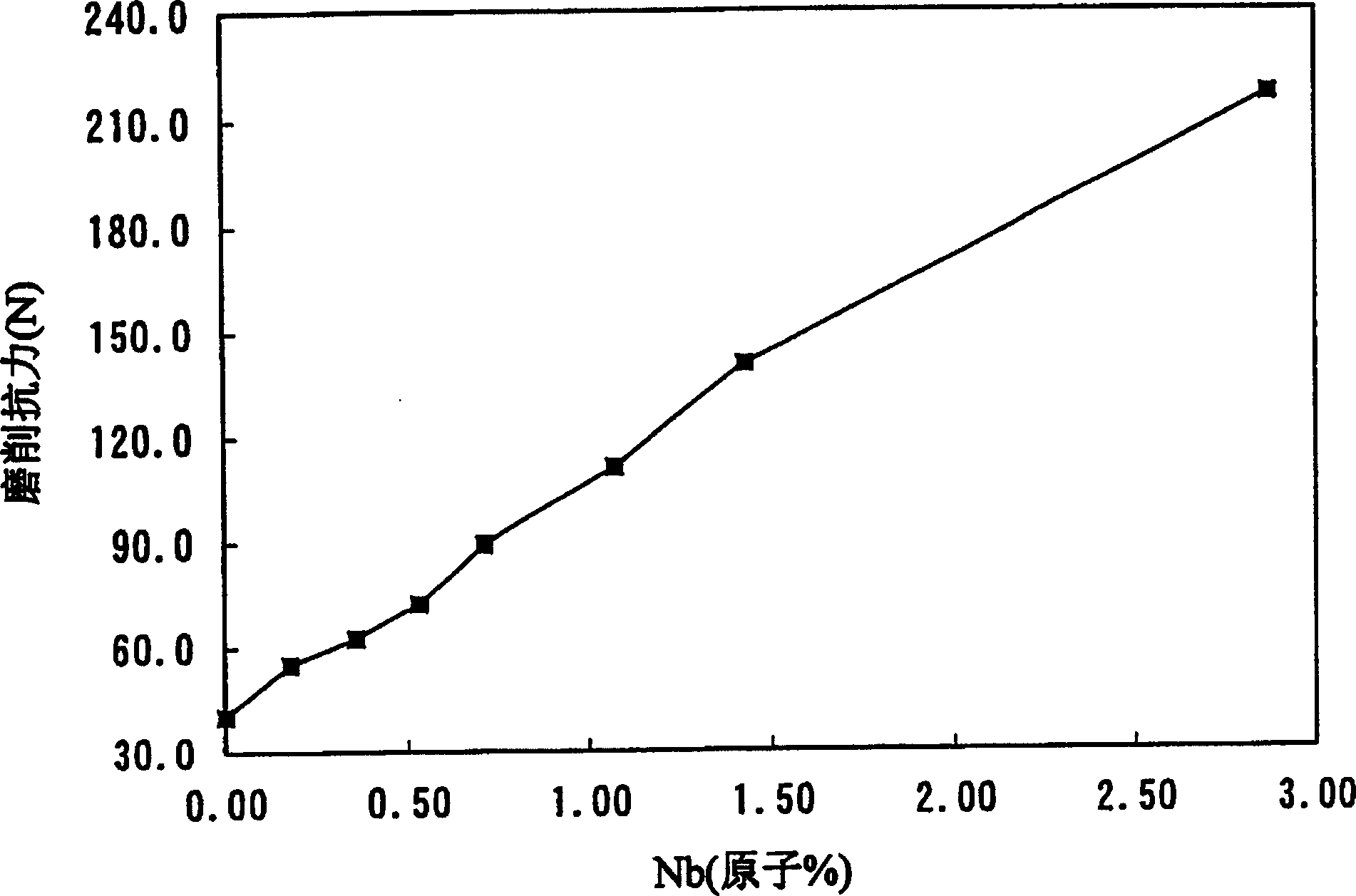

[0022] The present inventors found that, at 10 2 ~10 4 The cooling rate of K / s is used to rapidly cool the molten raw material alloy. When making a solidified alloy, only a small amount of Nb or Mo (less than 1.0 atomic % of the whole) is added, and these additives are evenly dispersed in the alloy structure, which can inhibit The remanent magnetic flux density and processability of the sintered magnets caused by the addition of metals to form borides are reduced, and the coercive force can be increased, and the squareness of the demagnetization curve can also be improved.

[0023] In the conventional ingot casting method, it is considered necessary to add a large amount of Nb or the like in order to increase the coercive force. However, when the strip casting method is used to produce the rapidly solidified alloy, if the same amount of Nb is added as in the past, the hardness of the final sintered magnet will be very high, resulting in the deformation of the surface grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com