Patents

Literature

33results about How to "Improve fingerprint resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401AReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

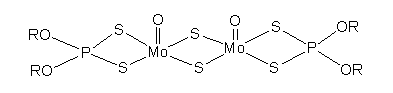

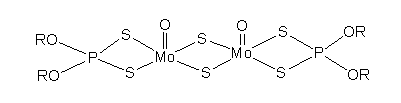

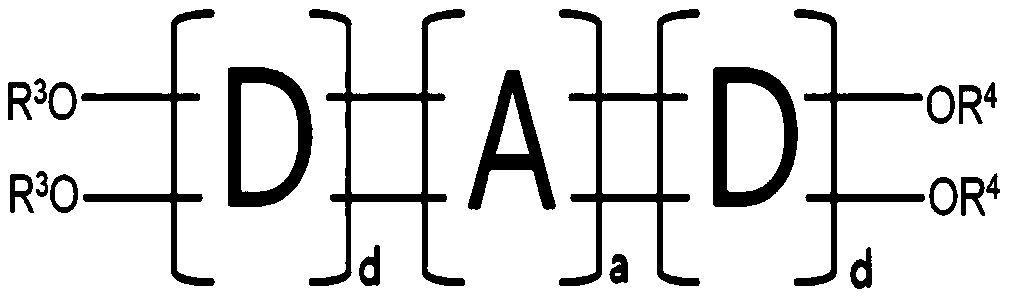

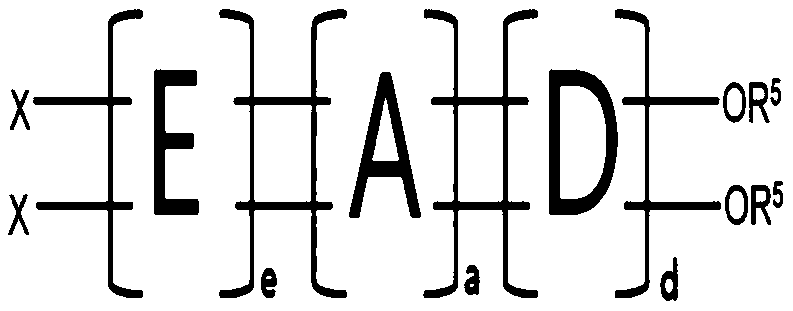

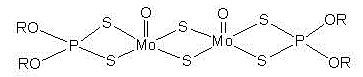

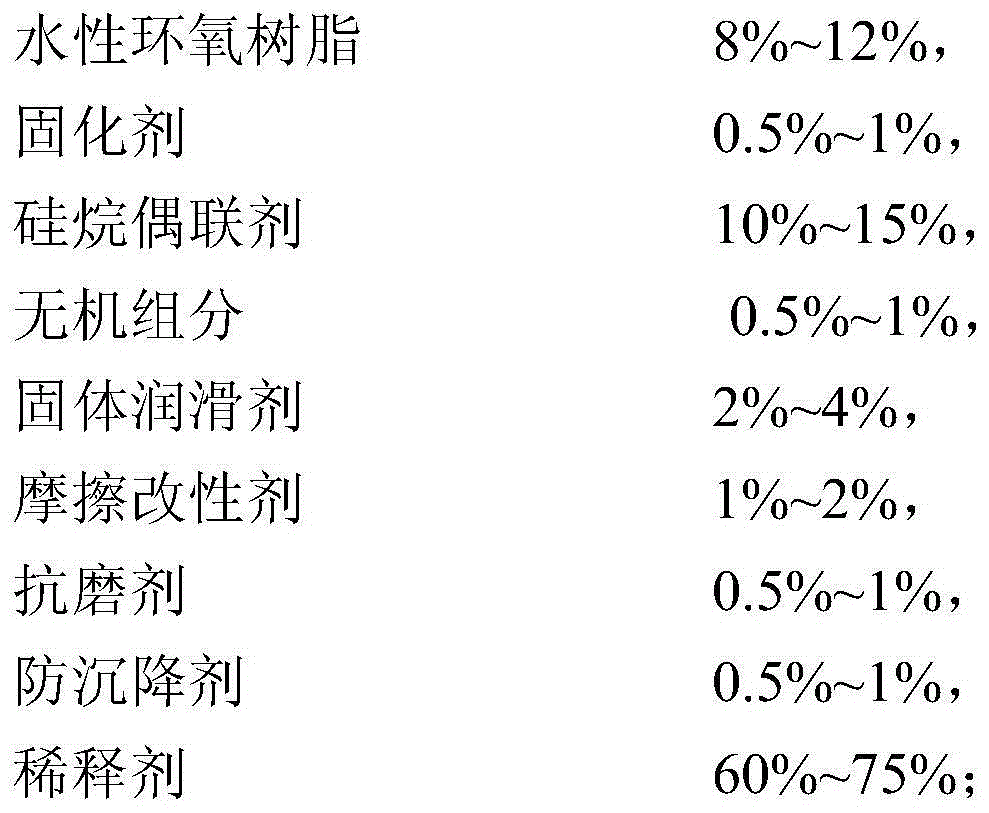

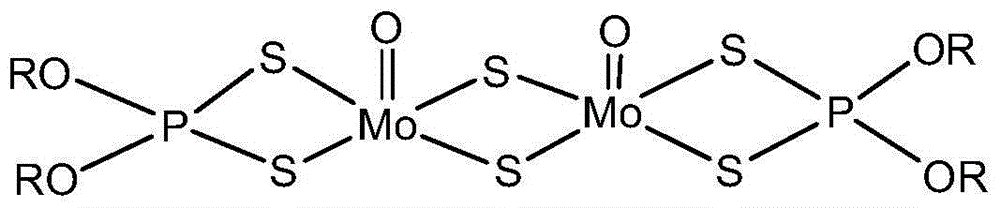

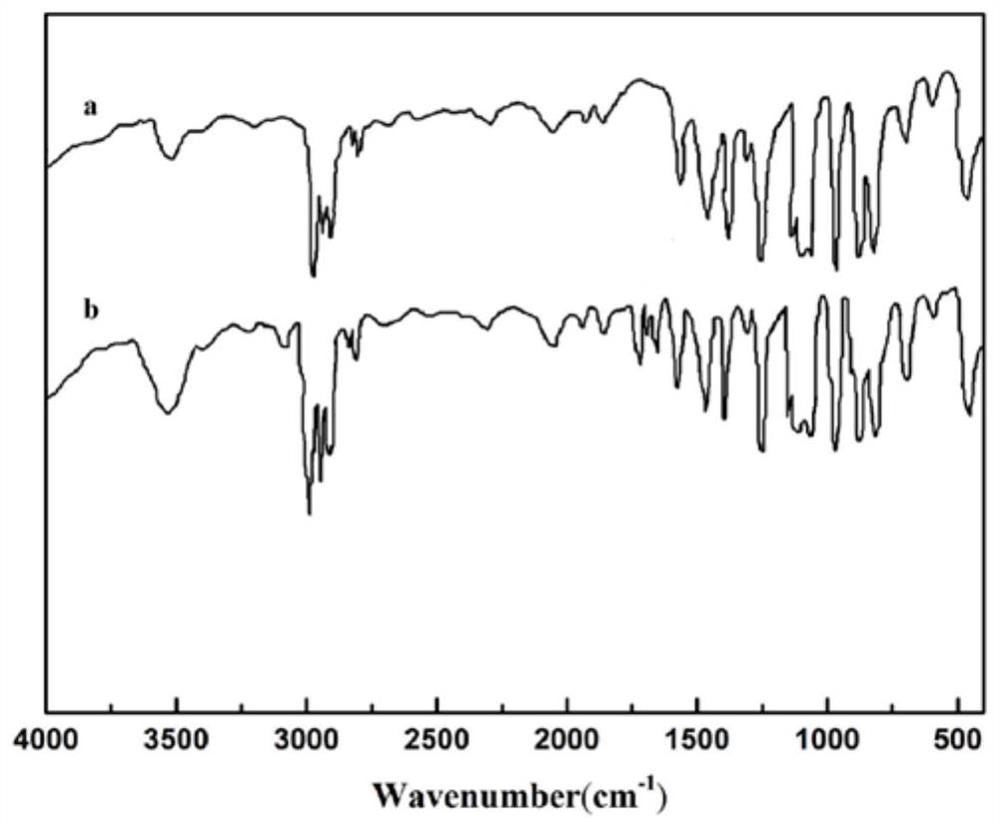

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

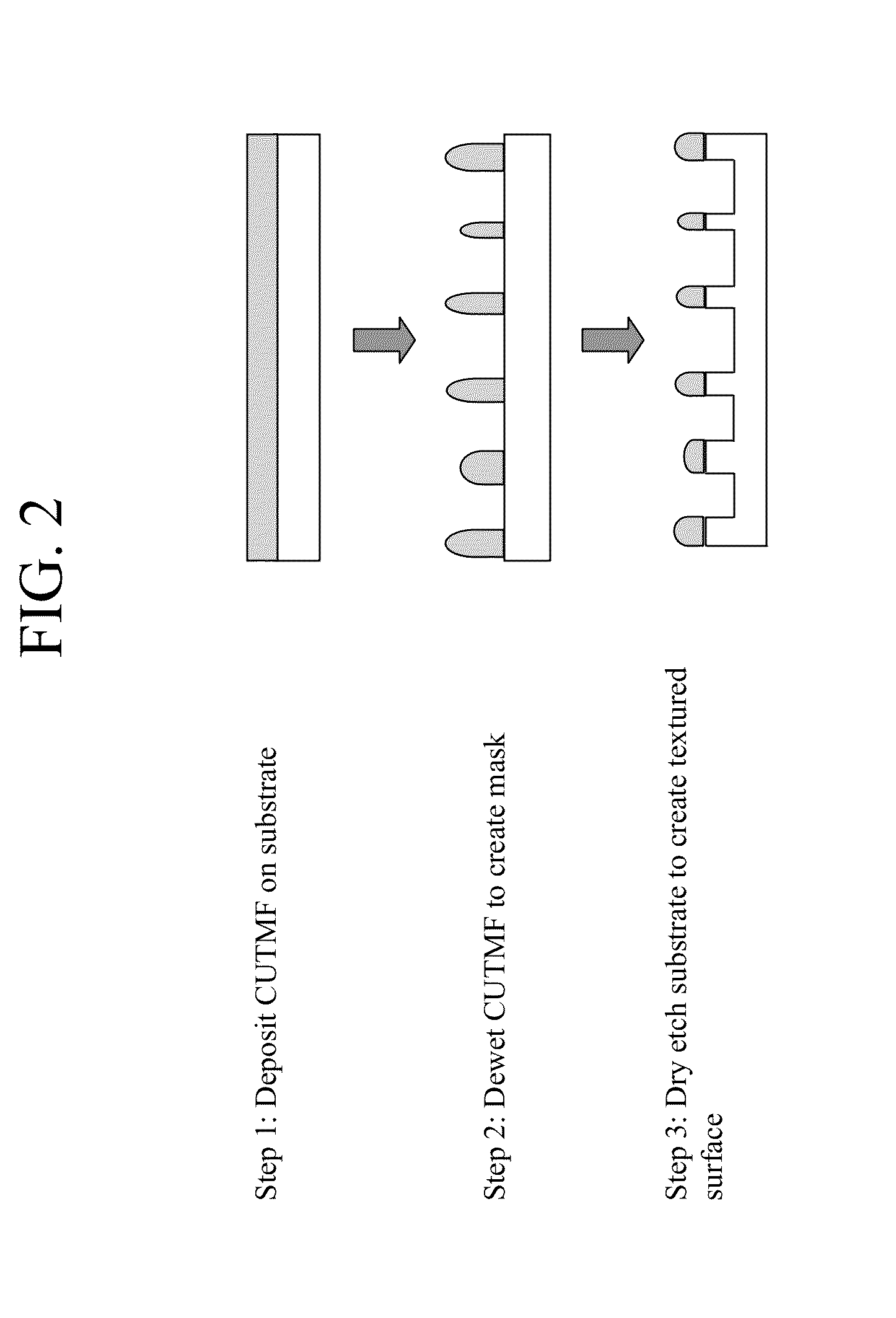

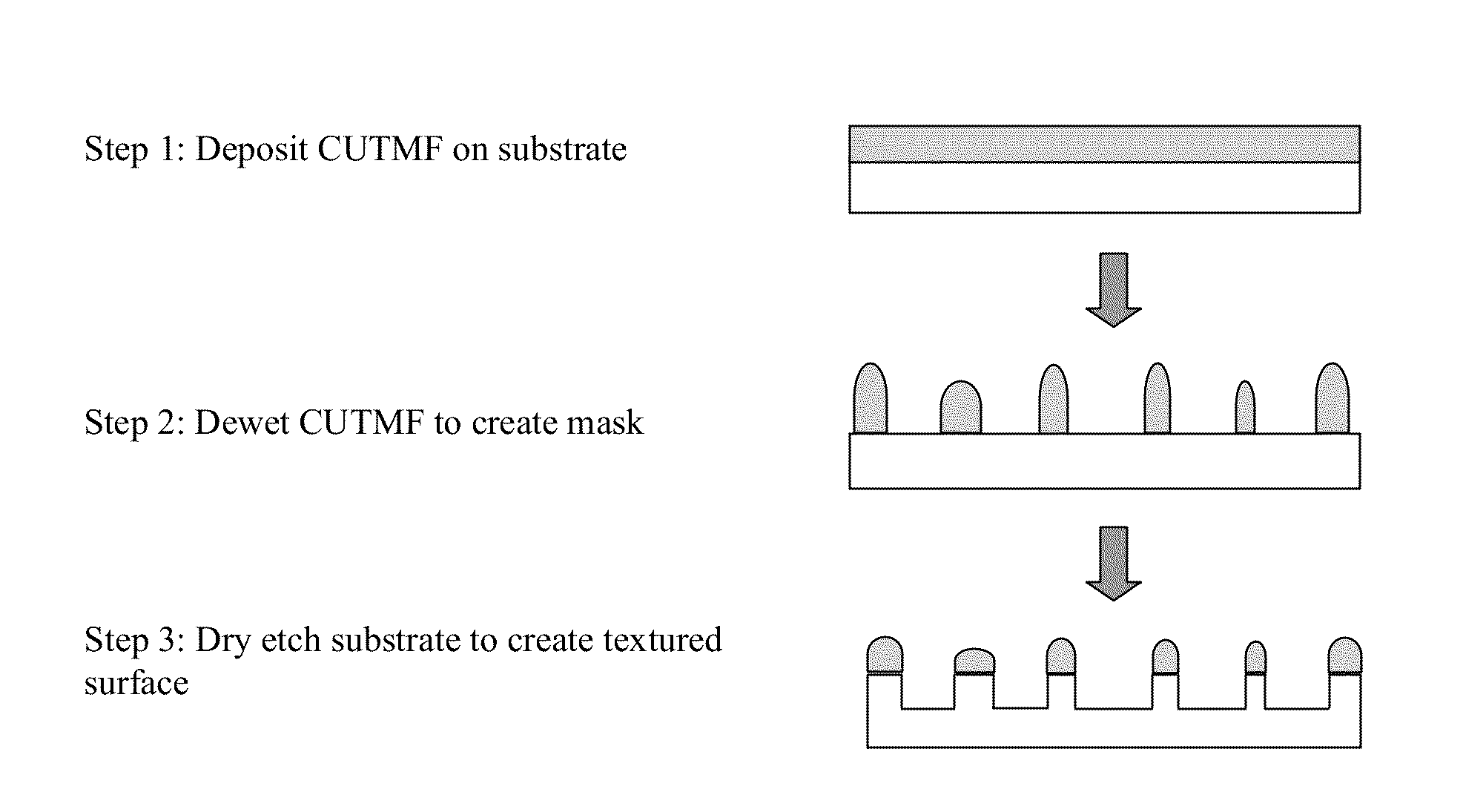

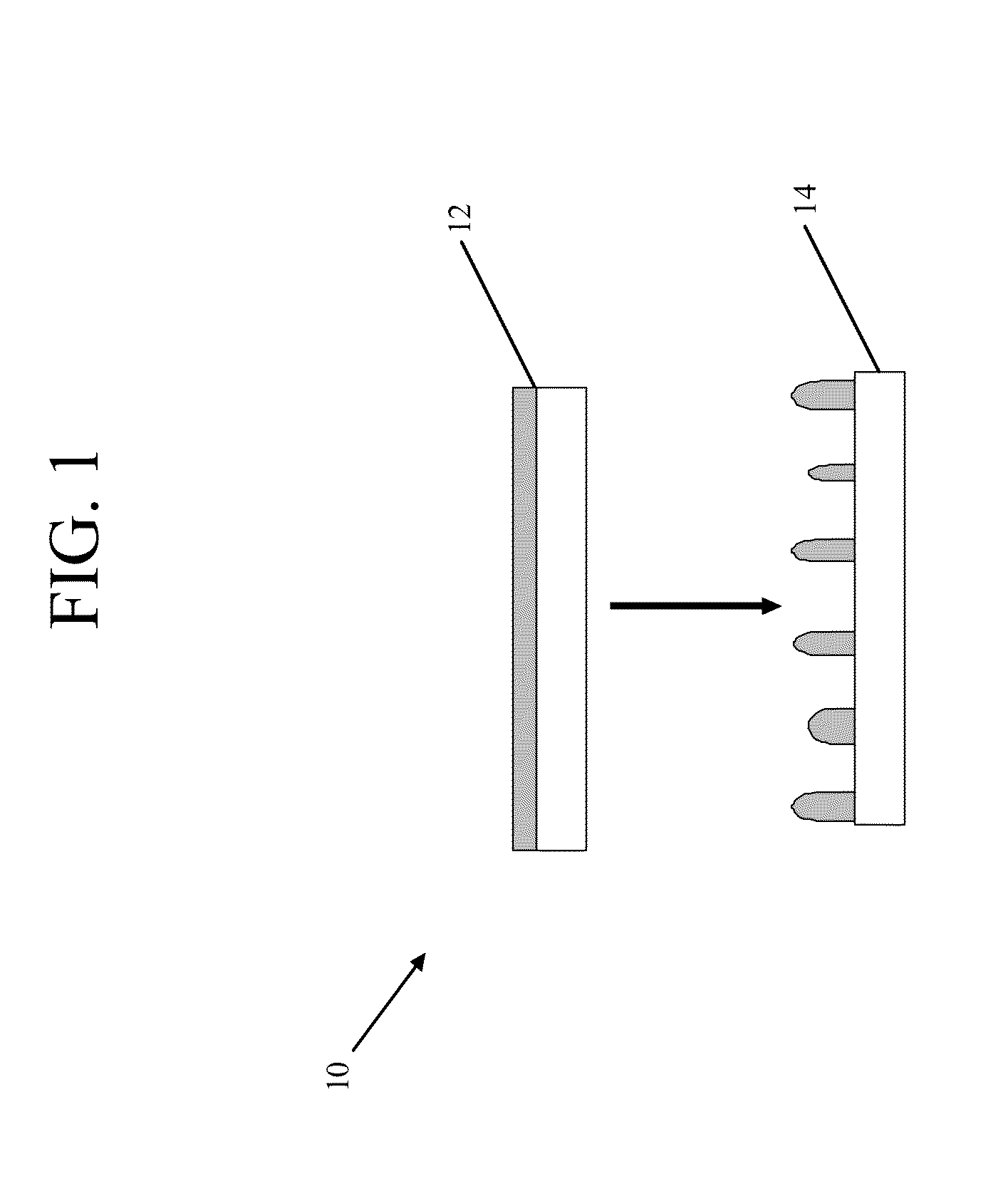

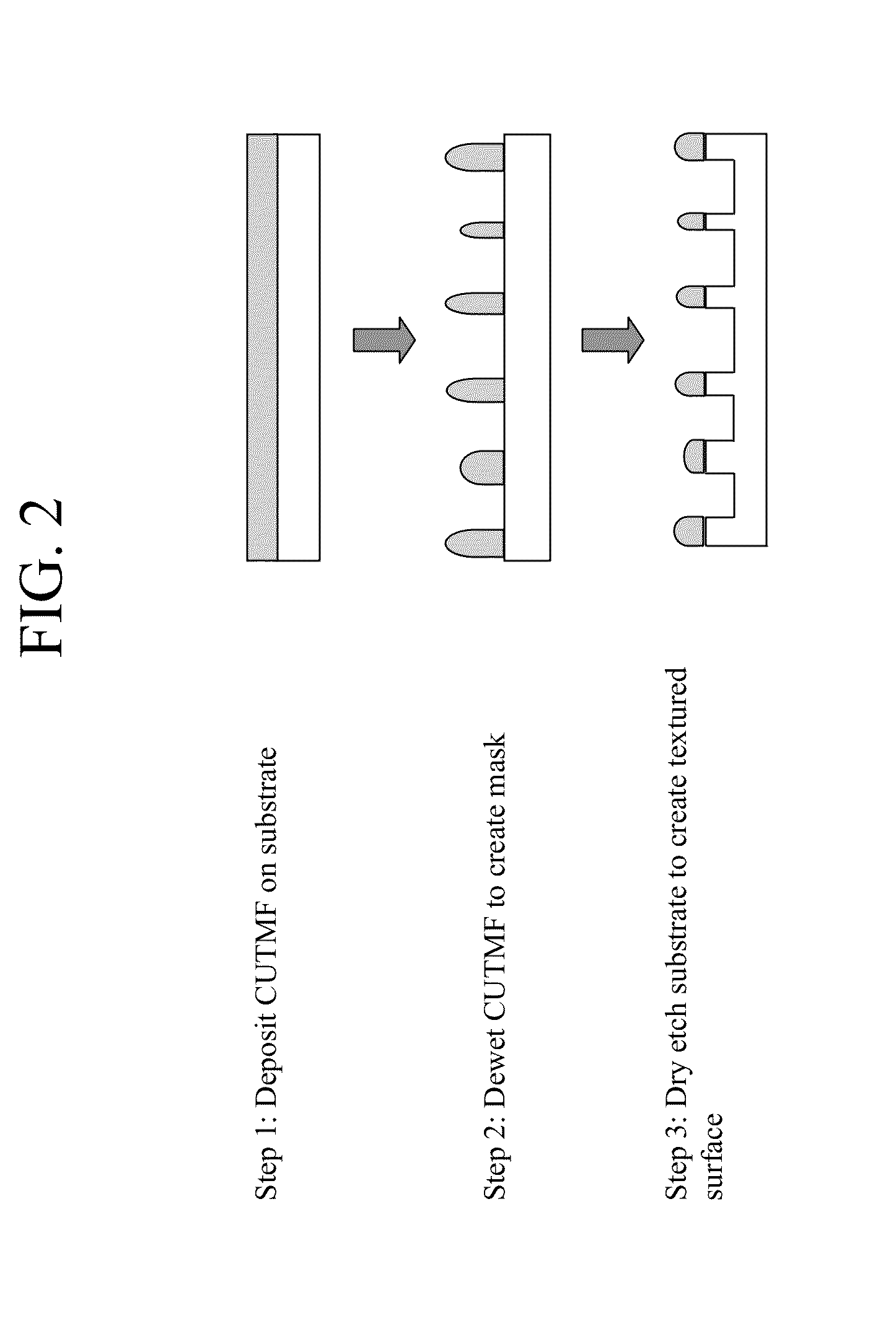

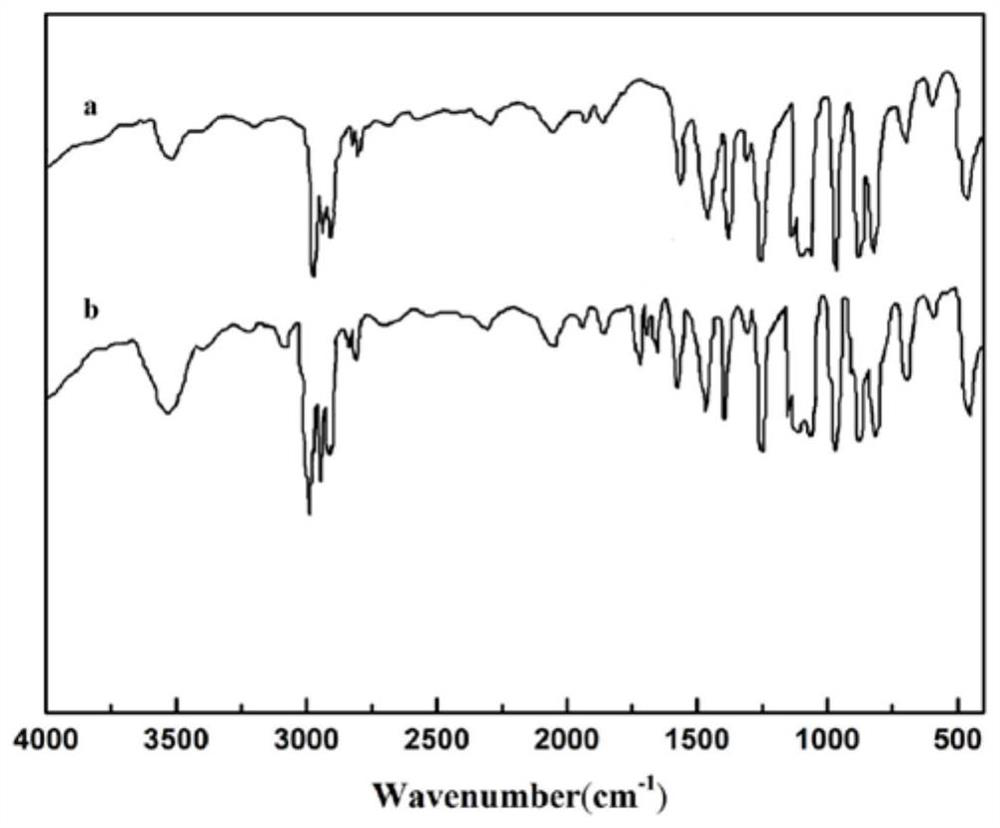

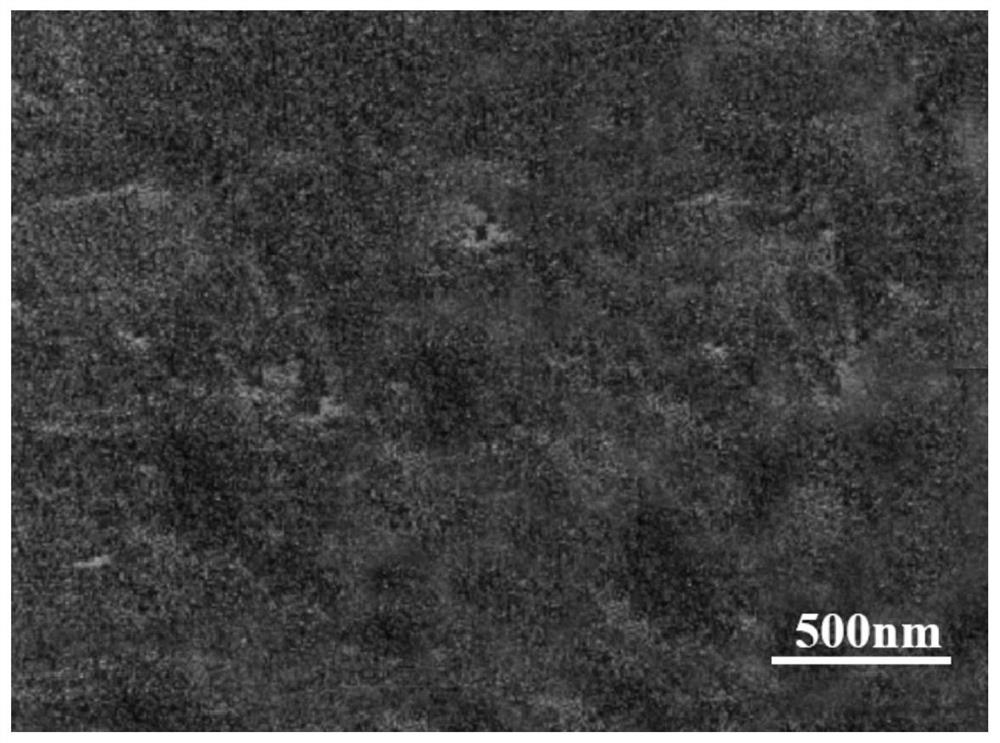

Textured surfaces and methods of making and using same

InactiveUS9023457B2Improve fingerprint resistanceNanotechFouling preventionNanostructureMaterials science

Owner:ICFO +2

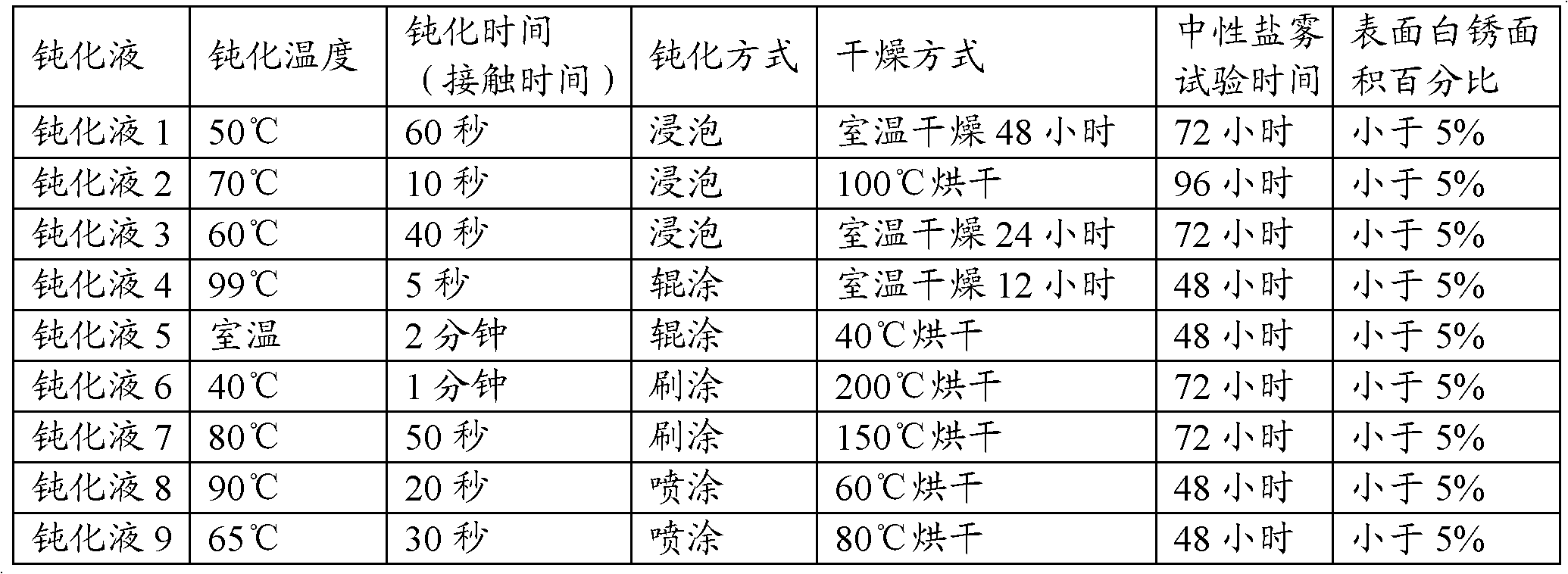

Passivating solution for plated metal

ActiveCN102312234ASolve pollutionPromote environmental protectionMetallic material coating processesChromium freeMolybdate

The invention relates to a chromium-free passivating solution for plated metal and a plating method thereof. The passivating solution comprises 0.001 to 30 g / L of vanadate and 0.01 to 30 g / L of molybdate, and can further comprise an aqueous solution of one or more selected from the group consisting of 1 to 300 g / L of phytic acid, 0.01 to 30 g / L of silane and 1 to 500 g / L of a resin. The passivating solution can be used for plated metal through immersion, spraying, roller coating or brush painting and forms a replacing layer and / or a covering layer on the surface of treated metal, which enables surface anti-corrosion performance of treated metal to be effectively enhanced; in addition, the passivating solution provided in the invention does not contain environment-polluting chromium of any valence state, which is beneficial for environmental protection.

Owner:CHANGSHU FENGFAN POWER EQUIP +1

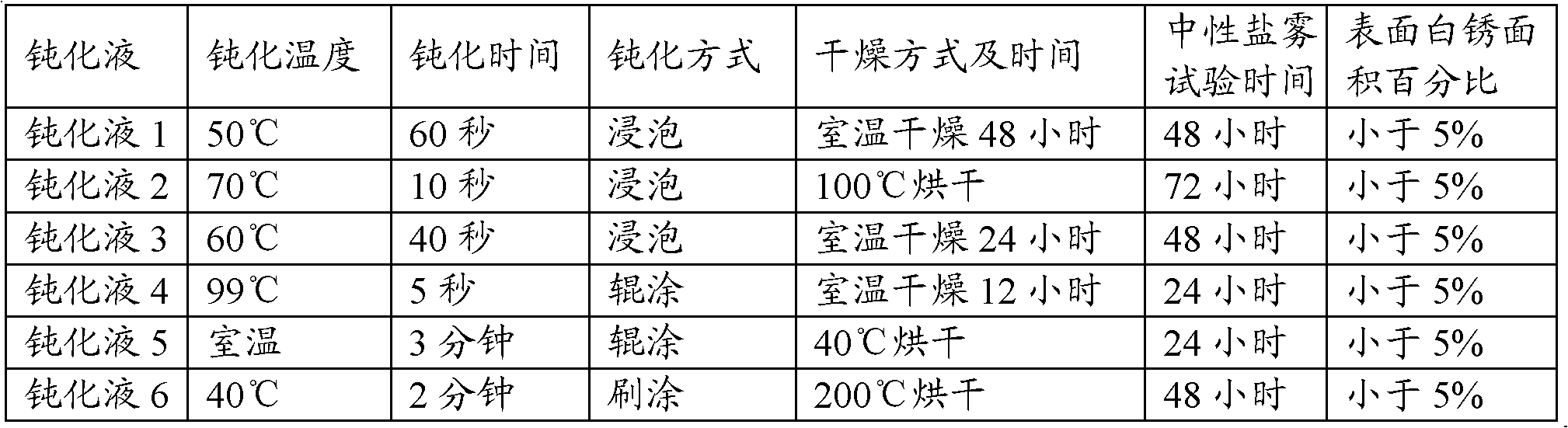

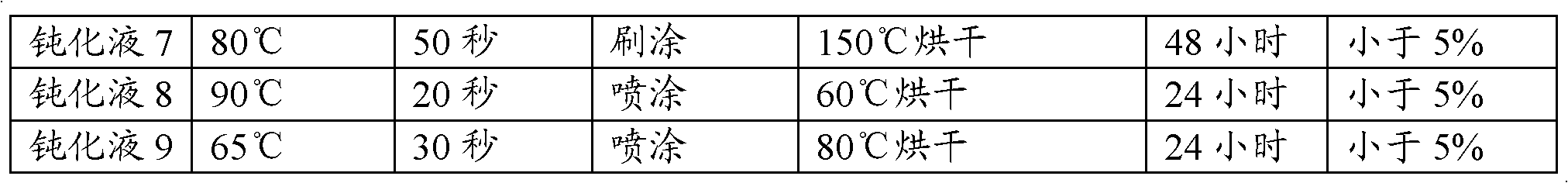

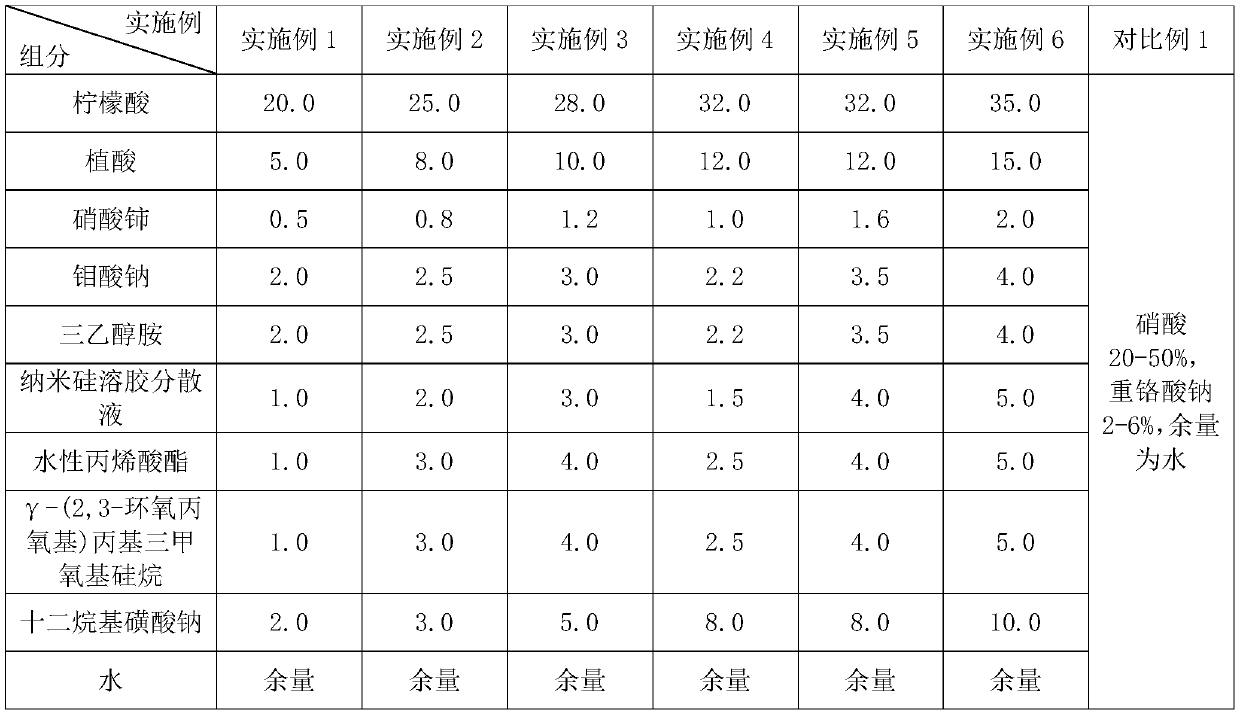

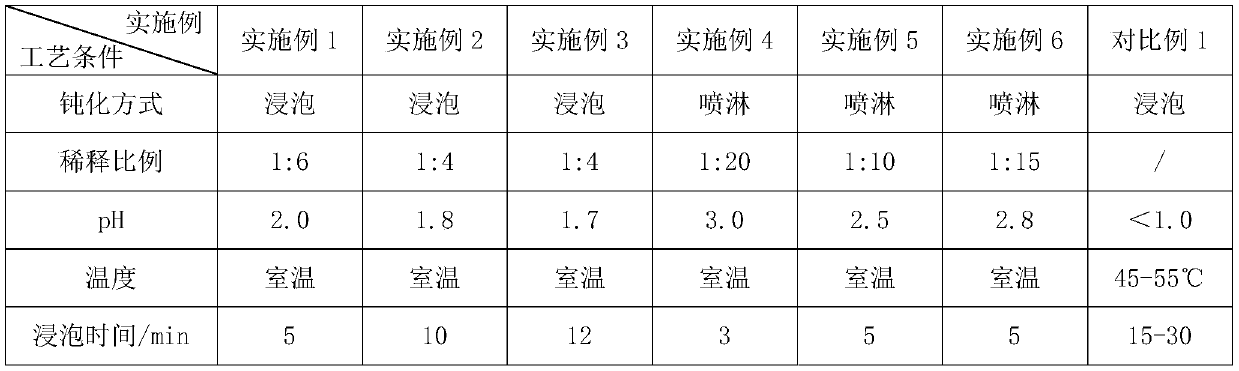

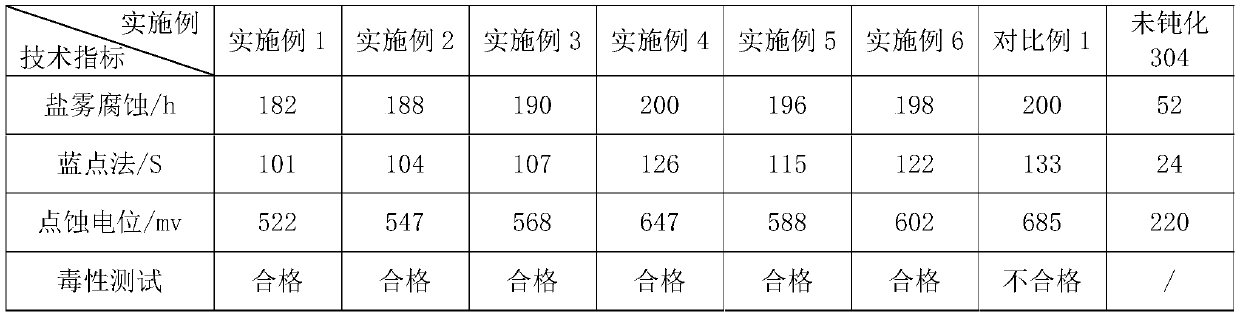

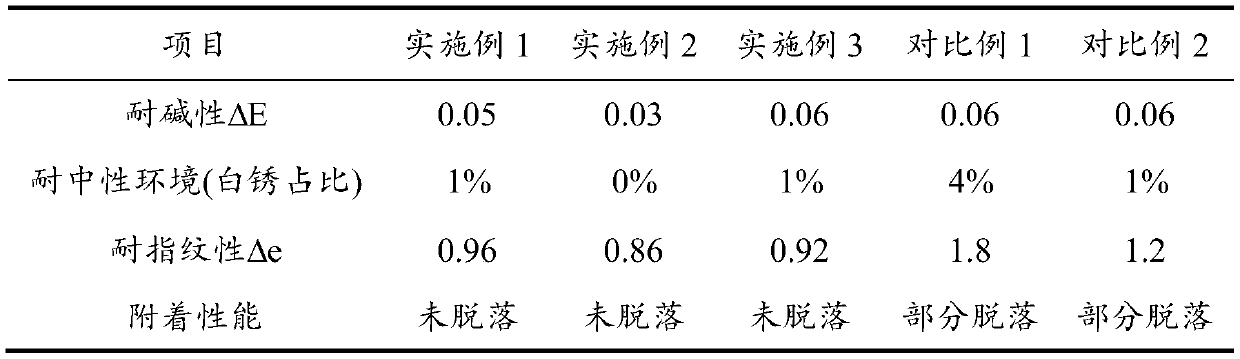

Organic and inorganic compound passivation solution and passivation method

ActiveCN110565084AImprove corrosion resistanceExtend your lifeMetallic material coating processesEpoxySilanes

Owner:JOMOO KITCHEN & BATHROOM

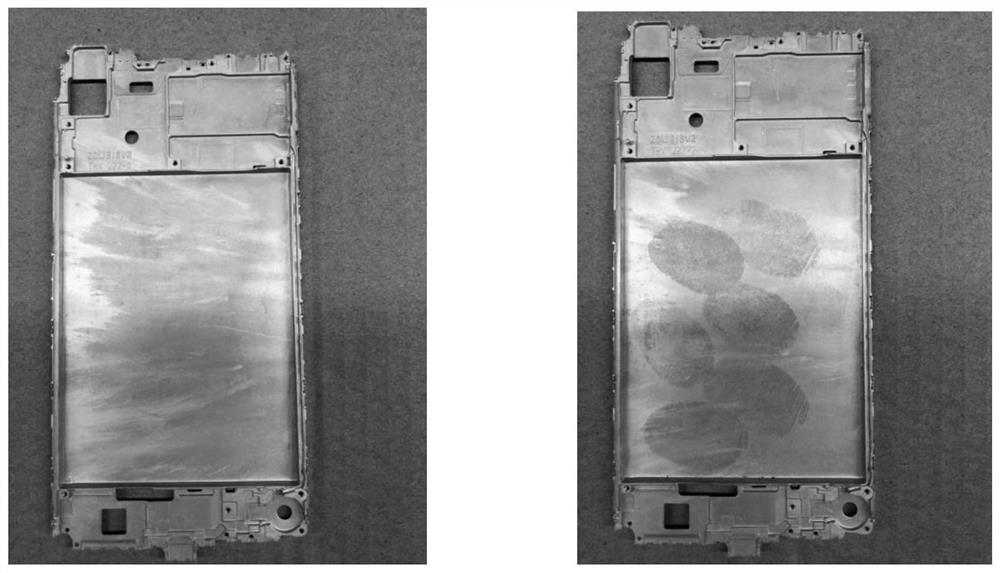

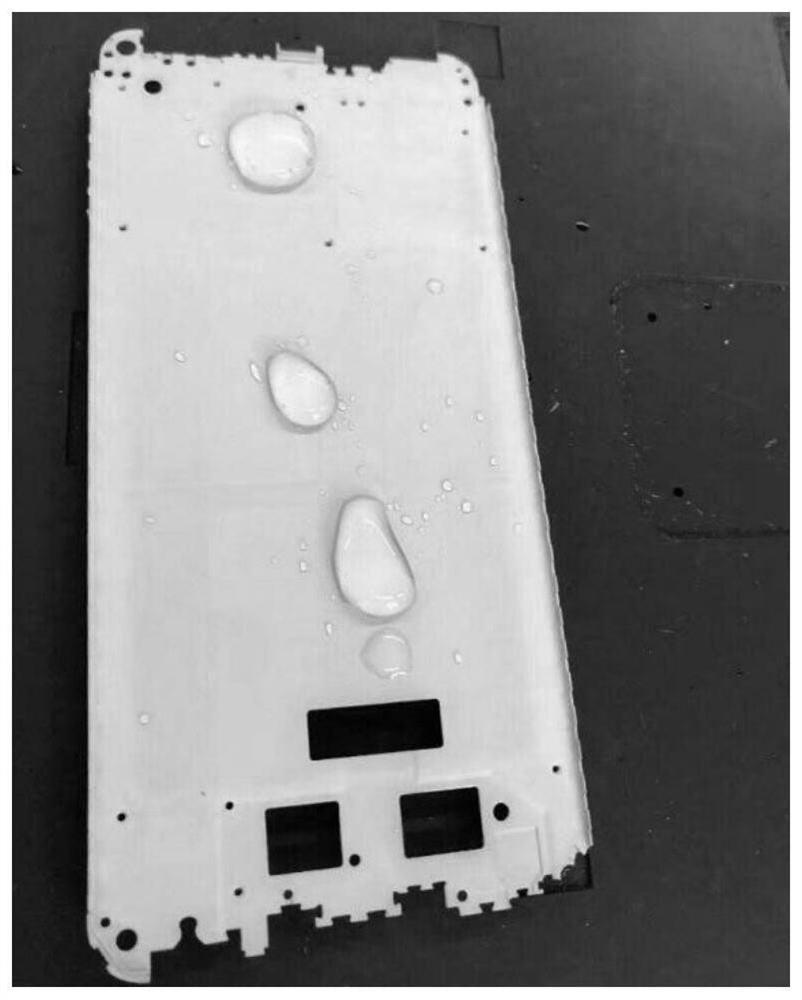

Fingerprint-resistant paint and preparation method thereof

The invention discloses a fingerprint-resistant paint and a preparation method thereof. The fingerprint-resistant paint comprises the following components in parts by weight: 50-60 parts of acrylic resin emulsion (solid content is 45%), 5-8 parts of silicasol, 4-7 parts of mixed wax slurry, 0.2-1 part of defoaming and leveling agent, 4-6 parts of film-forming cosolvent and 30-40 parts of deionized water. The fingerprint-resistant paint takes water as the main solution, and is added with aqueous high-molecular organic substances which have superior properties and are harmless to human bodies. A low surface tension structure is formed on surface of the added filler and the paint film, thereby greatly enhancing the fingerprint resistance of the steel sheet. The fingerprint-resistant paint can be coated on the surface of a hot galvanized steel sheet or electrogalvanized steel sheet in a mode of dip coating, curtain coating, roller coating, gasket coating or the like, so that fingerprints can not be attached to the surface. In addition, the paint is environment-friendly.

Owner:WUXI JINJIAN PAINTING

Textured surfaces and methods of making and using same

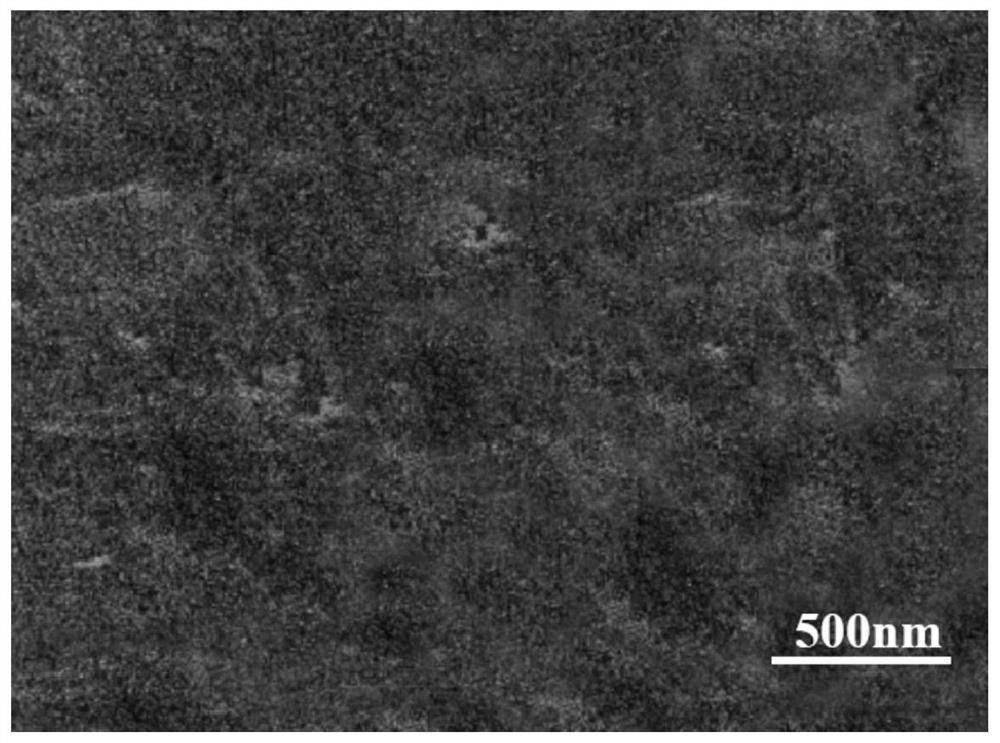

InactiveUS20130157007A1Improve fingerprint resistanceNanotechFouling preventionNanostructured metalNanostructure

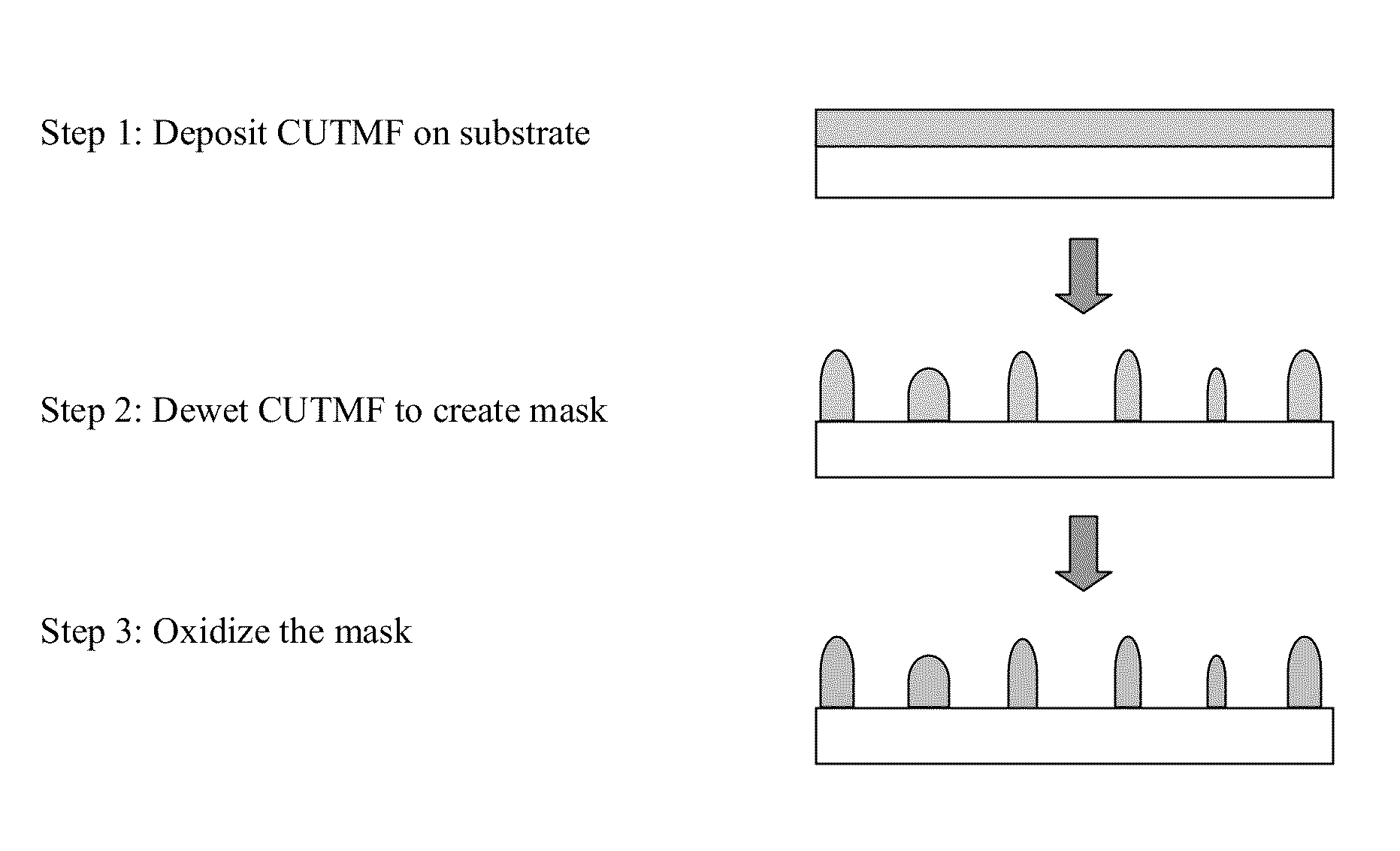

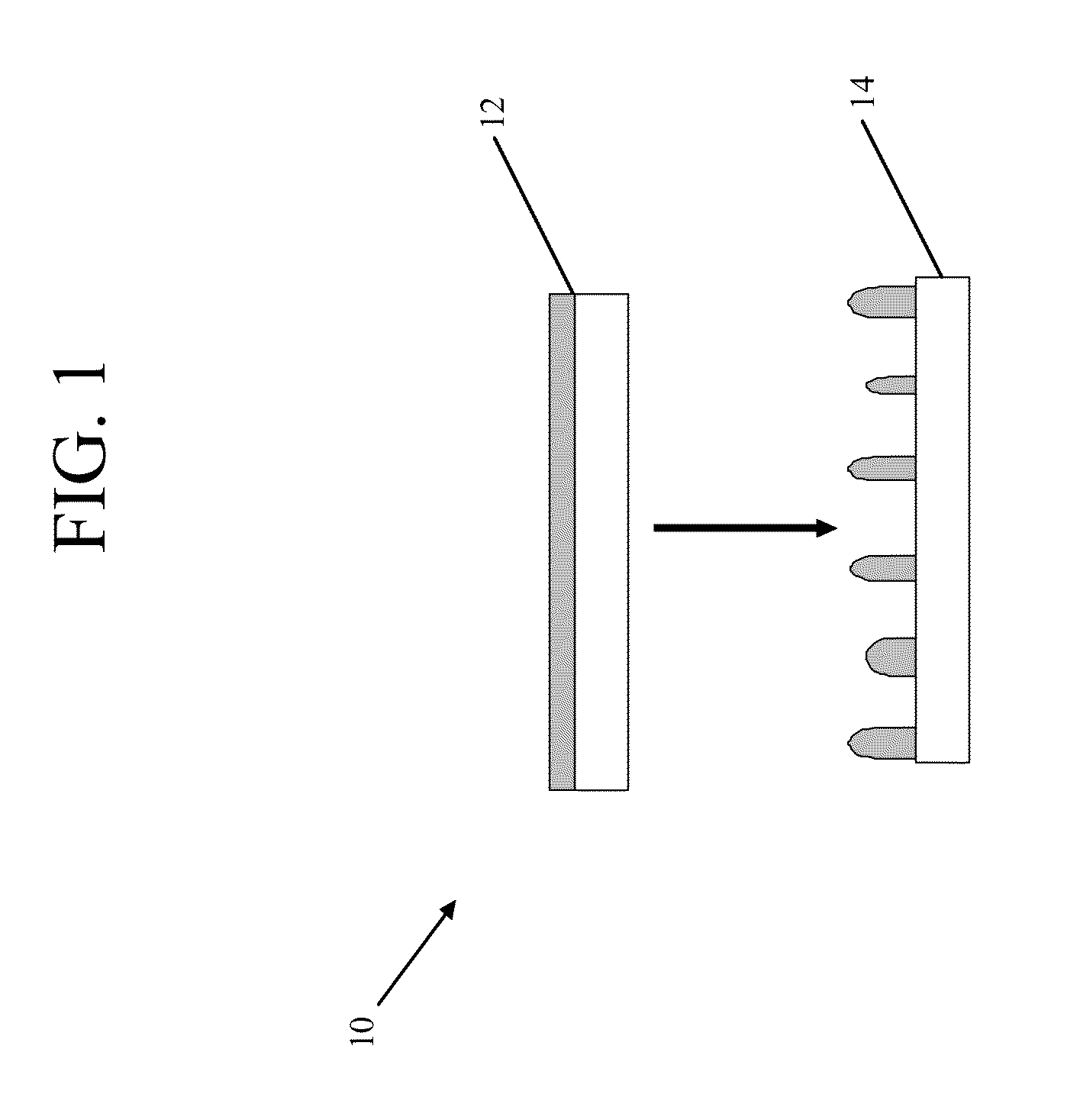

Described herein are various methods for making textured articles, textured articles that have improved fingerprint resistance, and methods of using the textured articles. The methods generally make use of masks comprising nanostructured metal-containing features to produce textured surfaces that also comprise nanostructured features. These nanostructured features in the textured surfaces can render the surfaces hydrophobic and oleophobic, thereby beneficially providing the articles with improved fingerprint resistance relative to similar or identical articles that lack the texturing.

Owner:ICFO +2

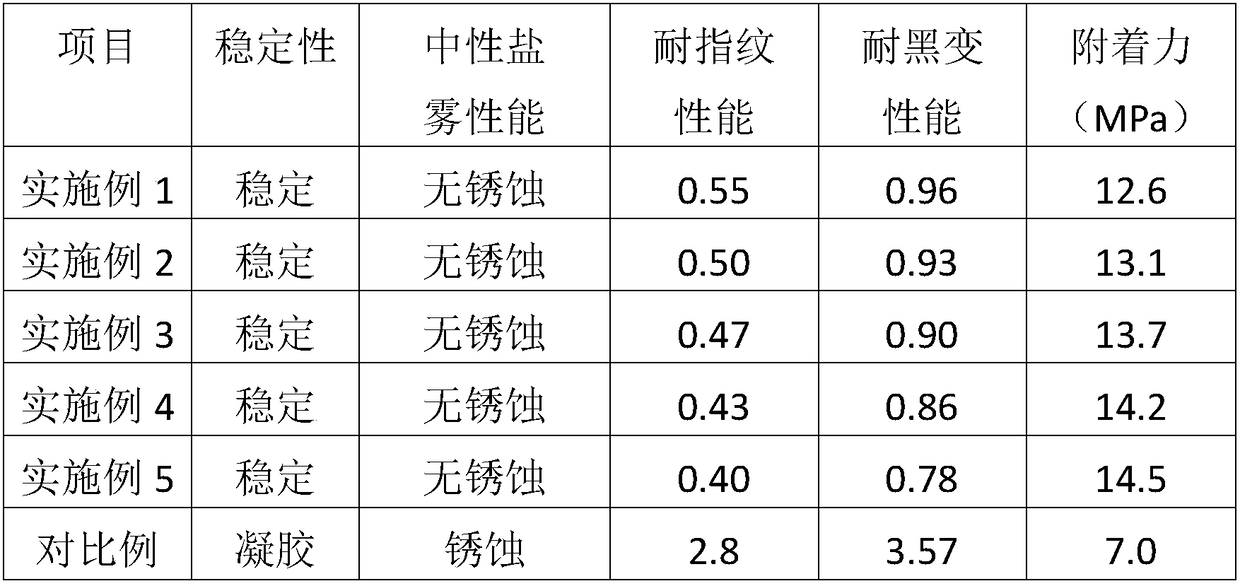

Chrome-free fingerprint-resistant environment-friendly coating and preparation method thereof

InactiveCN108117835ARaw materials are easy to getLow priceFireproof paintsAnti-corrosive paintsEpoxyPhosphate

The invention discloses a chrome-free fingerprint-resistant environment-friendly coating. The coating contains the following components in parts by weight: 40-50 parts of a film-forming condensation polymer, 5-8 parts of aminopropanol ascorbic acid phosphate modified graphene oxide, 15-20 parts of epoxy resin, 1-4 parts of a dispersing agent, 1-4 parts of a flatting agent, 1-4 parts of a defoamingagent and 20-40 parts of water. The invention further discloses a preparation method of the chrome-free fingerprint-resistant environment-friendly coating. The preparation method comprises the stepsof adding the film-forming condensation polymer into water, uniformly stirring, adding other components, stirring at a rotation speed of 800r / min-1300r / min for dispersion for 50-60 minutes, and filtering, so as to obtain a finished product. The chrome-free fingerprint-resistant environment-friendly coating has relatively excellent corrosion resistance, stability and alkali blackening resistance and is safe and environment-friendly in use.

Owner:SHENZHEN DA QUAI CHEM CO LTD

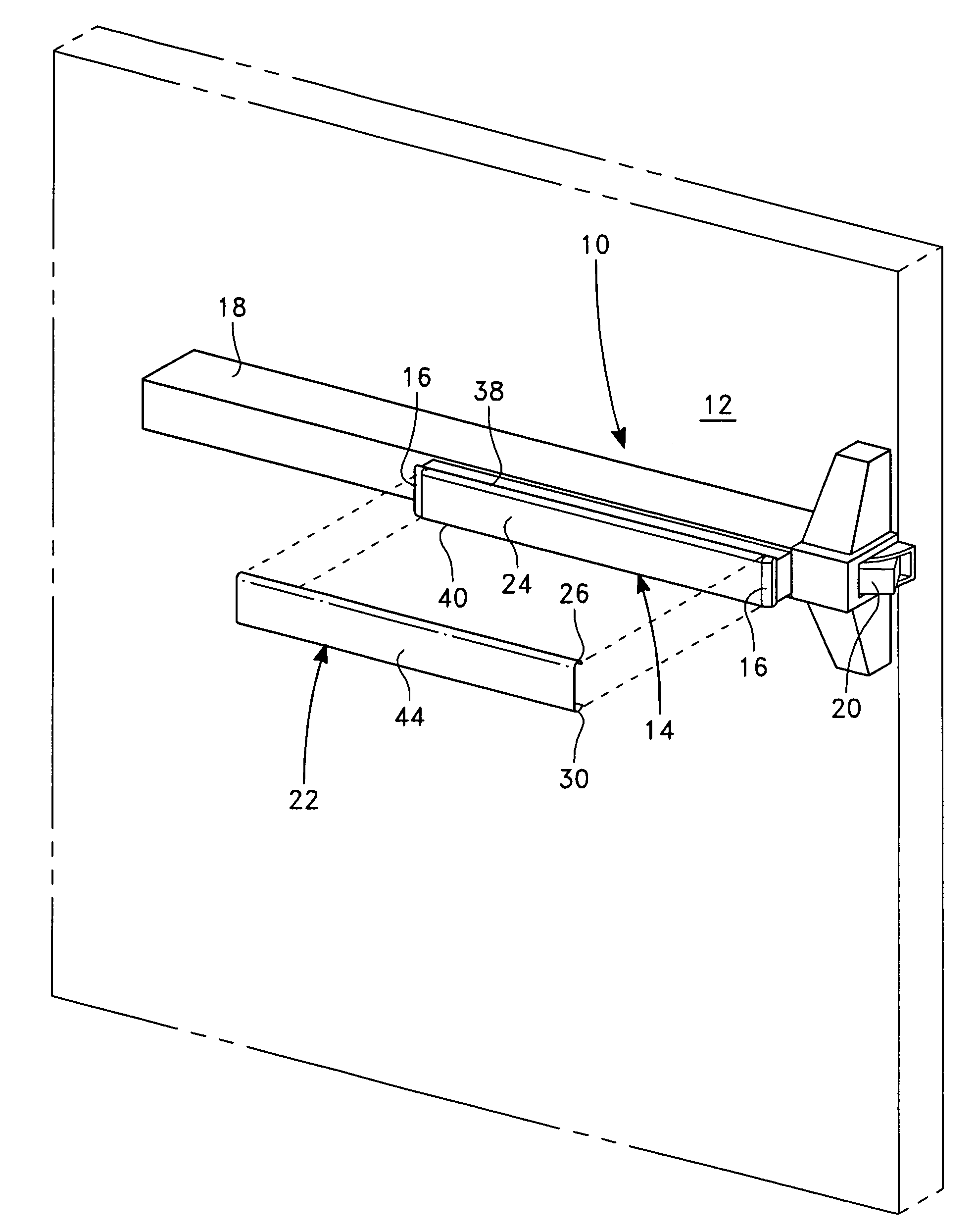

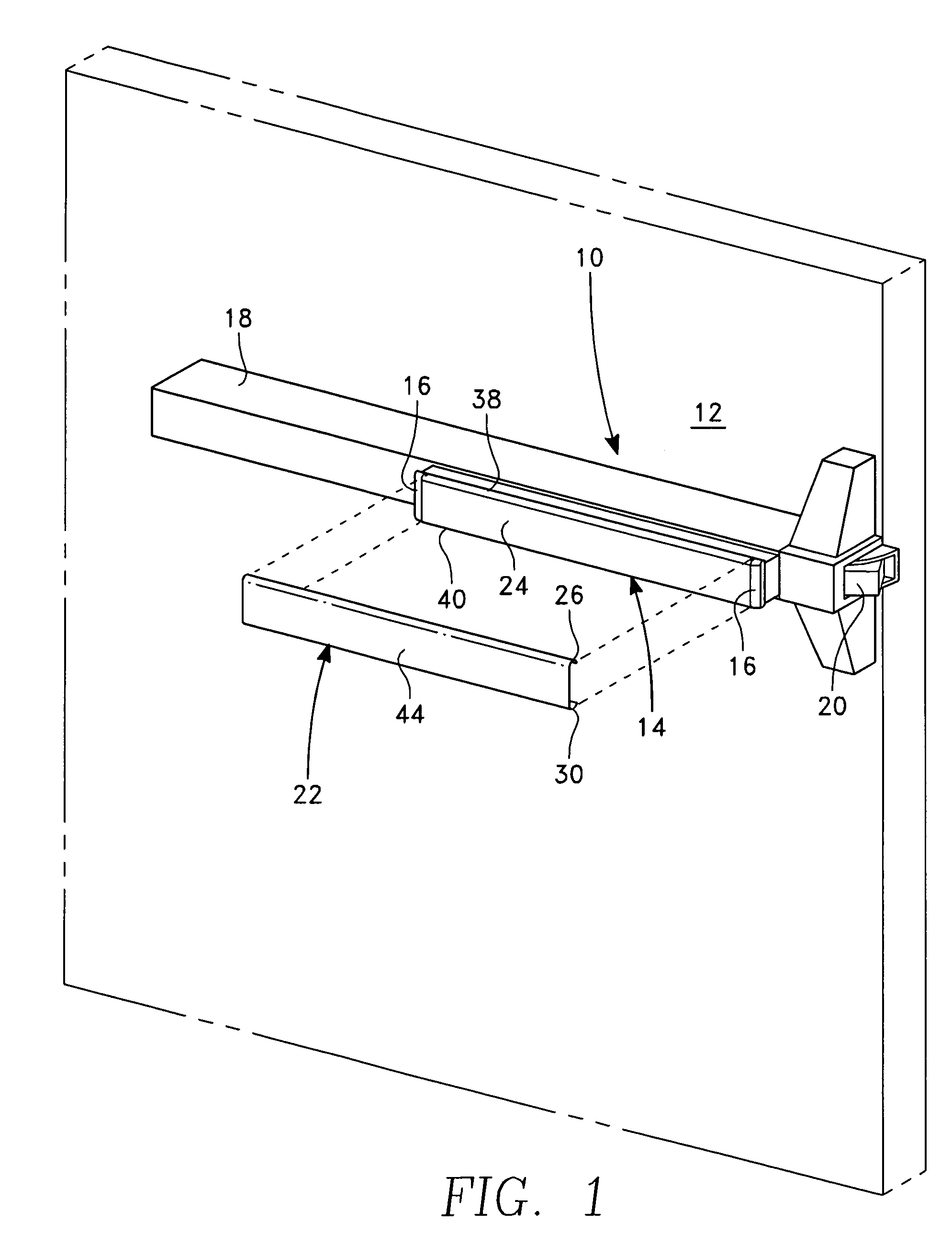

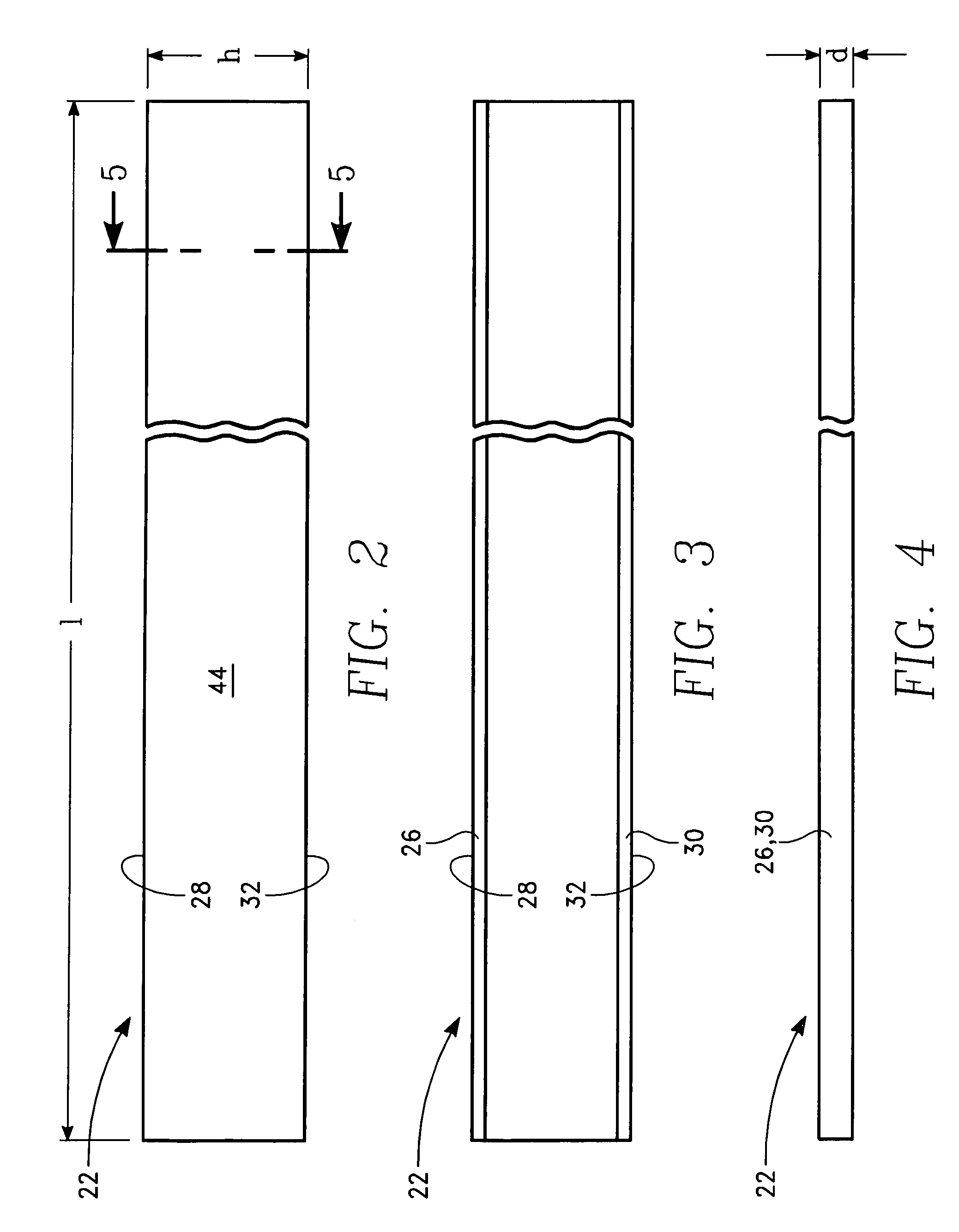

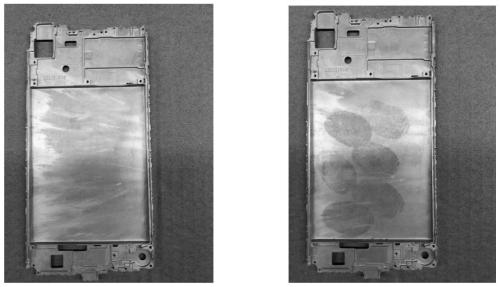

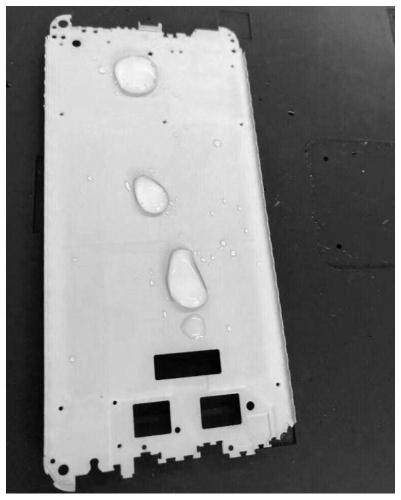

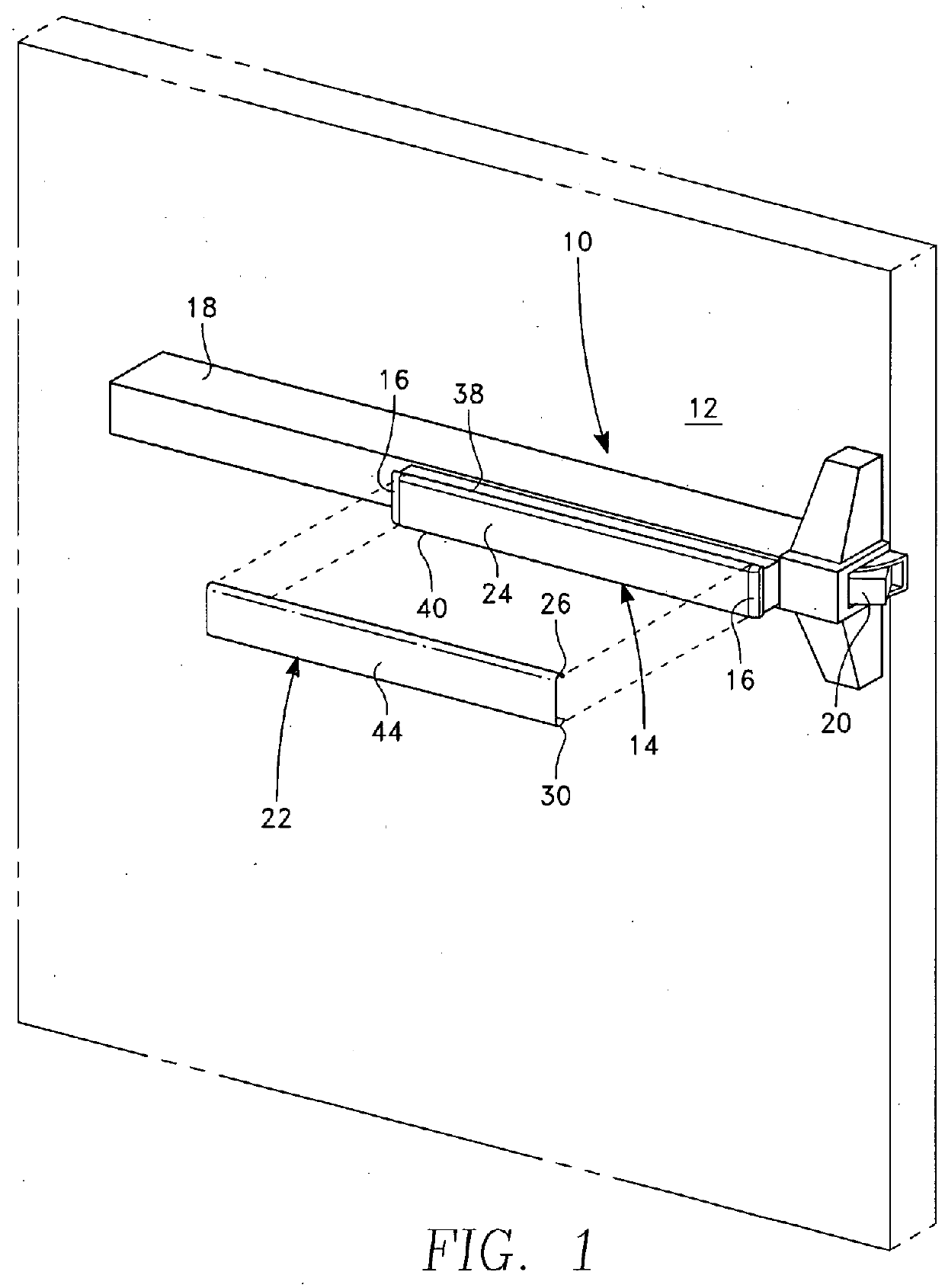

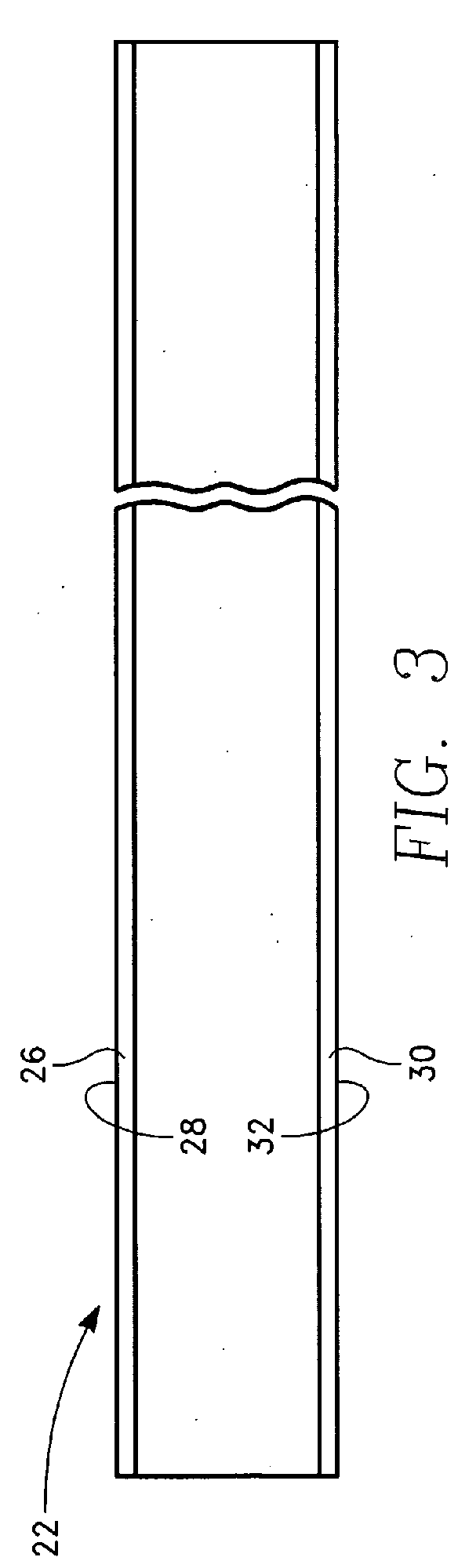

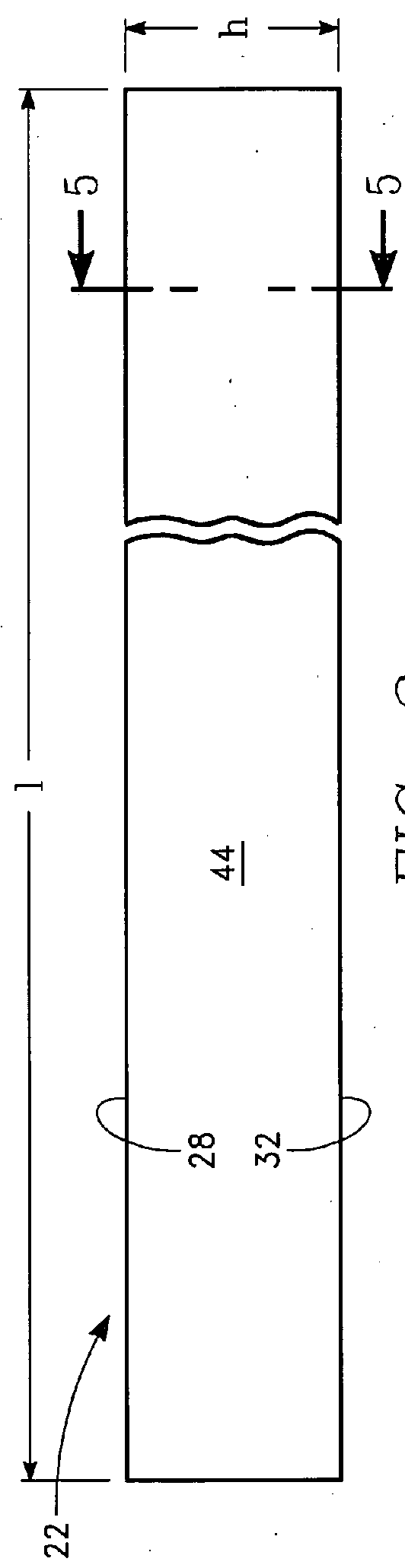

Cover trim for a push bar of an exit device

ActiveUS9194156B2Easily affixedImprove fingerprint resistancePolishing machinesWing handlesEngineeringMechanical engineering

An easily installable and preferably antimicrobial cover trim for a push bar of an exit device for a door, as well as a method for increasing fingerprint resistance of metal touch surfaces.

Owner:TRIANGLE BRASS MFG

High-hardness scratch-proof and fingerprint-resistant sealant on metal surface

ActiveCN110157313ASimple preparation stepsImprove product hardnessFireproof paintsAntifouling/underwater paintsSolventFingerprint

The invention relates to the field of preparation of sealants and provides a high-hardness scratch-proof and fingerprint-resistant sealant on a metal surface. Raw materials of the sealant at least comprise a water-based resin, water-borne silicone oil, fatty alcohol polyether, an alkali reagent and a solvent. The invention furthermore provides a preparation method and a using method of the sealant.

Owner:东莞市瑞欧表面处理科技有限公司

Cover trim for a push bar of an exit device

PendingUS20160032616A1Easily affixedImprove fingerprint resistancePolishing machinesWing handlesEngineeringFingerprint

A method of easily installing a preferably antimicrobial cover trim to a push bar of an exit device for a door, as well as a method for increasing fingerprint resistance of metal touch surfaces.

Owner:TRIANGLE BRASS MFG

Transparent substrate having reinforced surfaces and method for manufacturing same

ActiveCN106062053AExcellent surface hardnessImprove fingerprint resistanceSynthetic resin layered productsElectrical equipmentHeat resistanceHardness

The present invention relates to a transparent substrate having reinforced surfaces and a method for manufacturing same, and more specifically, to a transparent substrate having reinforced surfaces and a method for manufacturing same, which is capable of significantly improving surface hardness by treating the surfaces with a silsesquioxane complex polymer including, in a single polymer, a silsesquioxane ladder chain and a cage-type silsesquioxane which have a specific structure, and which has improved fingerprint resistance, scratch resistance, pollution resistance, heat resistance, light transmission, and haze characteristics.

Owner:DONGJIN SEMICHEM CO LTD

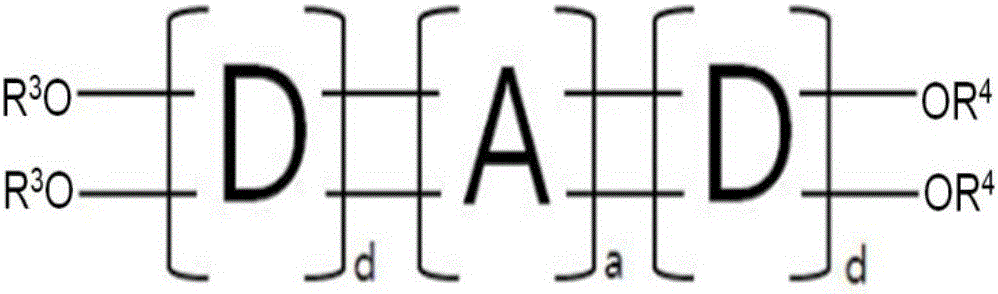

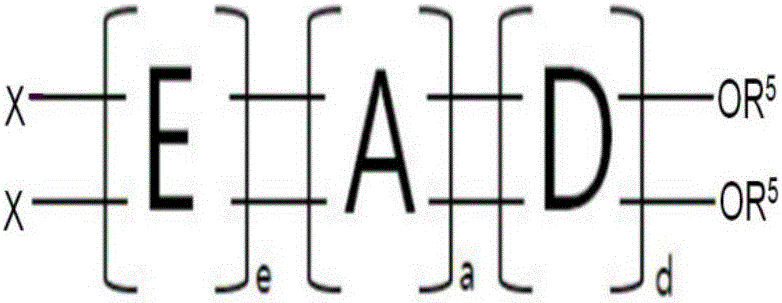

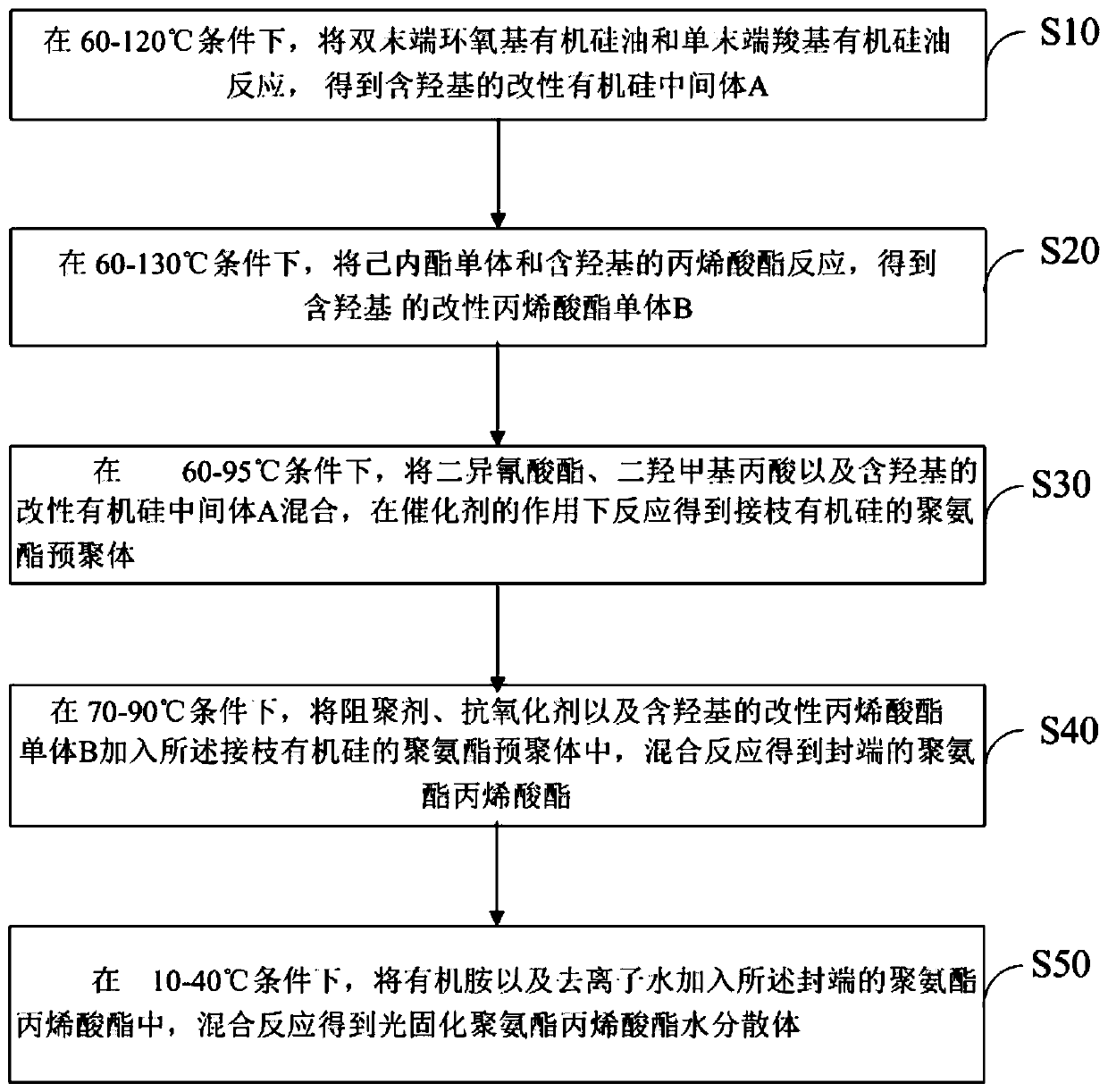

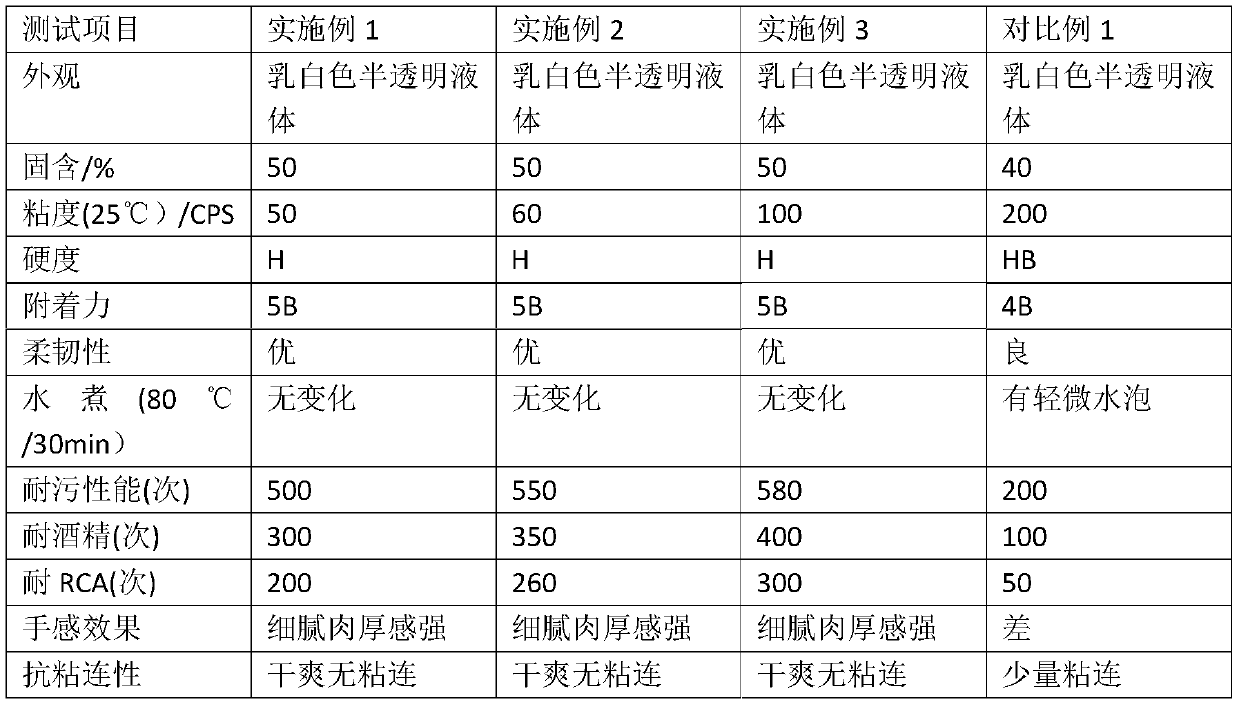

Light-cured urethane acrylate aqueous dispersion and preparation method thereof

InactiveCN110606932AImprove slipImprove fingerprint resistanceAntifouling/underwater paintsPaints with biocidesAntioxidantUrethane acrylate

The invention discloses a photo-cured urethane acrylate aqueous dispersion and a preparation method thereof, the method comprises the following steps: reacting double-terminal epoxy organic silicone oil with single-terminal carboxyl organic silicone oil to obtain a hydroxyl-containing modified organic silicon intermediate A; reacting a caprolactone monomer with hydroxyl-containing acrylate to obtain a hydroxyl-containing modified acrylate monomer B; mixing diisocyanate, dimethylolpropionic acid and the hydroxyl-containing modified organic silicon intermediate A, and performing a reaction to obtain an organic silicon grafted polyurethane prepolymer; adding a polymerization inhibitor, an antioxidant and a hydroxyl-containing modified acrylate monomer B into the organosilicone grafted polyurethane prepolymer, and performing a reaction to obtain terminated urethane acrylate; and adding organic amine and deionized water into the terminated urethane acrylate, and performing a reaction to obtain the photo-cured urethane acrylate aqueous dispersion. After a paint film is formed by the product, the product is strong and durable in stain resistance and graffiti resistance, and has good elastic hand feeling and adhesion resistance.

Owner:广东昊辉新材料有限公司

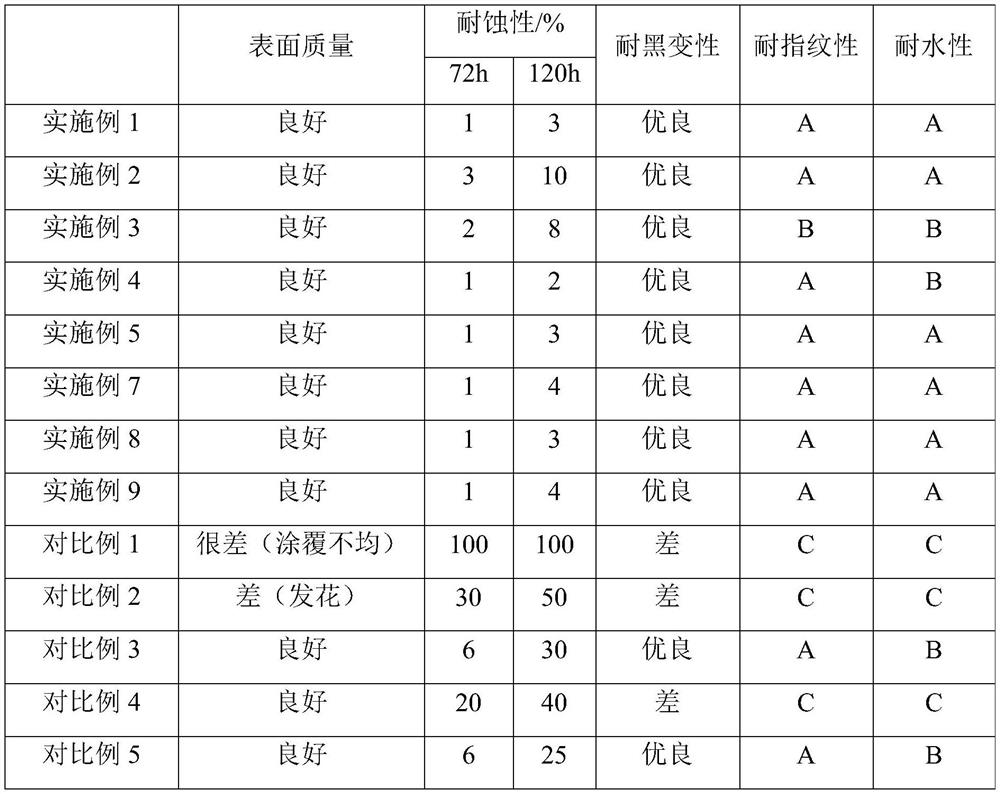

Zinc-aluminum-magnesium plating layer surface treating agent as well as preparation method and use method thereof

ActiveCN112538306AImprove densification performanceHinder contactHot-dipping/immersion processesAnti-corrosive paintsFluorideSILICONE DIOXIDE

The invention discloses a zinc-aluminum-magnesium plating layer surface treating agent as well as a preparation method and a use method thereof, and belongs to the technical field of zinc-aluminum-magnesium alloy plating layer steel plate surface treatment. In order to meet the requirements of household appliances and automobile users on blackening resistance and environmental friendliness of hot-dip galvanized aluminum-magnesium alloy coated steel plates, the invention provides a zinc-aluminum-magnesium plating layer surface treating agent which comprises 1-5 parts of fluoride, 3-10 parts ofperiodate, 0.5-5 parts of weakly alkaline medium, 20-50 parts of water-based organic resin, 5-15 parts of colloidal silicon dioxide and 100 parts of water. Fluoride and periodate react with Mg on thesurface of a plating layer under the weak alkaline condition to generate a compact film layer, water-based organic resin adheres to the surface of the plating layer, gaps are filled with colloidal silicon dioxide, contact between the plating layer and water vapor and oxygen in the environment is effectively hindered, and the corrosion resistance, blackening resistance, water resistance and fingerprint resistance of the surface coating are remarkably improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Chromate-free passivation solution applied to electrogalvanizing, and passivation technology for same

ActiveCN111155077AImprove corrosion resistanceQuality improvementMetallic material coating processesSodium phosphatesZinc alloys

The invention belongs to the technical field of electrogalvanizing technologies and specifically relates to a chromate-free passivation solution applied to electrogalvanizing, and a passivation technology for the same. The chromate-free passivation solution applied to electrogalvanizing provided by the invention comprises, by weight, the constituents including 10-28 parts of ammonium molybdate, 5-15 parts of sodium phosphate, 1-5 parts of cerous nitrate, 15-30 parts of nitric acid with a mass concentration of 60%-75%, 3-15 parts of tartaric acid, 1.5-3.5 parts of a complexing agent, 2-9 partsof a film formation assistance agent and 40-70 parts of deionized water. Through use of the chromate-free passivation solution applied to electrogalvanizing provided by the invention, stability and weather resistance of a passivation film are enhanced, a zinc alloy material can be protected effectively, external corrosion is avoided, the service life is effectively prolonged; and the chromate-freepassivation solution is a good passivation solution which can take the place of a chromate passivation solution.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

Fingerprint-resistance layer used for goods shelf and preparing method

InactiveCN110317511AGood weather resistanceImprove wear resistanceCoatingsSpecial surfacesEpoxyResin coating

The invention belongs to the technical field of steel structure surface modification, and particularly relates to a fingerprint-resistance layer for a goods shelf and a preparing method. The fingerprint-resistance layer is composed of a fingerprint-resistance coating layer and an epoxy resin coating layer; the epoxy resin coating layer coats the steel surface of a carbon structure of the goods shelf, and the fingerprint-resistance coating layer coats the epoxy resin coating layer. The goods shelf member coated with the epoxy resin coating layer is coated with the fingerprint-resistance coatinglayer, the defects that traditional fingerprint-resistance coatings or coatings directly coat galvanized steel sheets, thus zinc layers for production of goods shelves are easily molten, the connecting strength of welding points is lowered, and shedding easily occurs are overcome, and the weather fastness, wear resistance and fingerprint resistance of the surface of the goods shelf are improved.

Owner:苏州大林金属制品有限公司

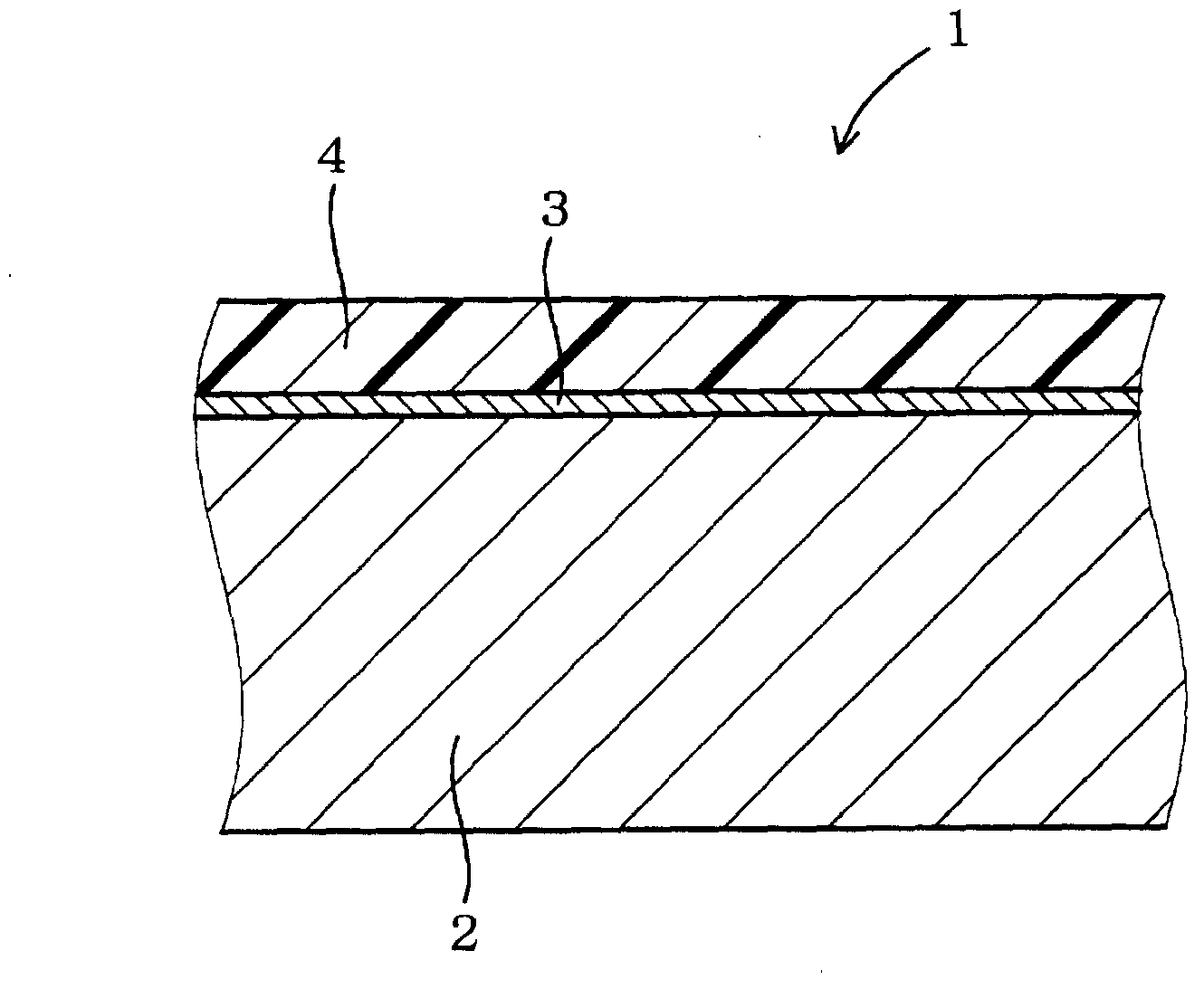

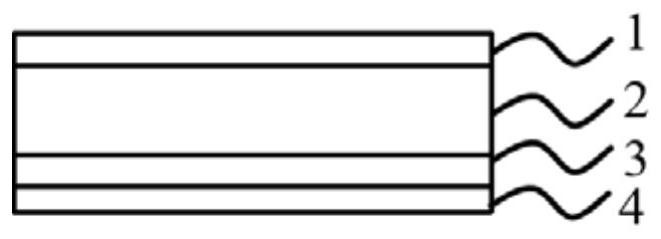

Conductive precoated aluminum alloy sheet

InactiveCN102762313AReduce tightnessReduced processing performancePretreated surfacesCoatingsColloidal silicaVitrification

Provided is a conductive precoated aluminum alloy sheet (1) which comprises a substrate (2) formed from an aluminum alloy sheet, a chemical conversion film (3) formed on one or both surfaces of the substrate (2), and a resin coating (4) formed on the chemical conversion film (3). The resin coating (4) comprises, at a specific mixture ratio, a urethane resin having a glass transition point of 100 C to 150 C, a colloidal silica having a primary particle diameter of 5 to 80 nm, and an inner wax having a primary particle diameter of 0.05 to 5 [mu]m and a molecular weight of 1,000 to 16,000. Thickness (T) of the resin coating (4) is 0.05 to 1.0 [mu]m, and surface roughness (Ra) of the substrate (2) is 0.1 to 0.8 [mu]m. Furthermore, T / Ra is 0.07 to 4.0.

Owner:SUMITOMO LIGHT METAL INDS LTD

Silver halide photosensitive material

InactiveUS20060024623A1Sufficient glossinessQuality improvementPhotosensitive material auxillary/base layersSilver halide emulsionsCLARITYColloid

The present invention relates to a silver halide photographic material comprising a paper support having resin layers coated on both sides of a base paper, and in particular, to a silver halide photographic material exhibiting superior glossiness and improved sharpness, long-term stability, fingerprint resistance and pressure resistance. The silver halide photographic material comprising on one side of the paper support having resin coat layers on both sides of a base paper, one or more light-sensitive layers and one or more light-insensitive layers, wherein after the photographic material of an L-size (having a length of 89 mm in a machine direction of the base paper and a length of 127 mm vertical to the machine direction) is processed, the photographic material exhibits an image clarity (C-value) of 20% to 60% which is determined using a 1.0 mm optical wedge in accordance with JIS K 7105; and the photographic material comprising a light-insensitive hydrophilic colloid layer between a light-sensitive layer closest to the support and the support.

Owner:KONICA MINOLTA PHOTO IMAGING

Modified PC hardening liquid formula and preparation method thereof

InactiveCN111440527AHigh hardnessHigh light transmittanceAntifouling/underwater paintsPaints with biocidesAlcoholUrethane acrylate

The invention relates to a modified PC hardening liquid formula and a preparation method thereof. The formula comprises 40-60 parts of urethane acrylate, 12-18 parts of an ester solvent, 8-12 parts ofan alcohol solvent, 4-6 parts of a photosensitizer and 1.6-2.4 parts of a leveling agent. The method comprises the following steps: putting urethane acrylate into a container; adding a photosensitizer; adding an ester solvent, and soaking; adding an alcohol solvent, and stirring by using a high-speed stirrer; and finally, adding a proper amount of leveling agent, stirring, standing and packaging.The formula has the beneficial effects that the effects of scratch resistance, dirt resistance, fingerprint resistance and the like are improved; meanwhile, the light transmittance of the base material is also integrally improved and the energy loss and the environmental pollution are reduced so that the energy-saving and environment-friendly effects of the base material are achieved; use is convenient, cost is low, the effect is good, and wide application and popularization are facilitated; the raw materials are scientific and environment-friendly, the production process is simple and the product is easy to process.

Owner:GREATECH MOLD & PLASTIC

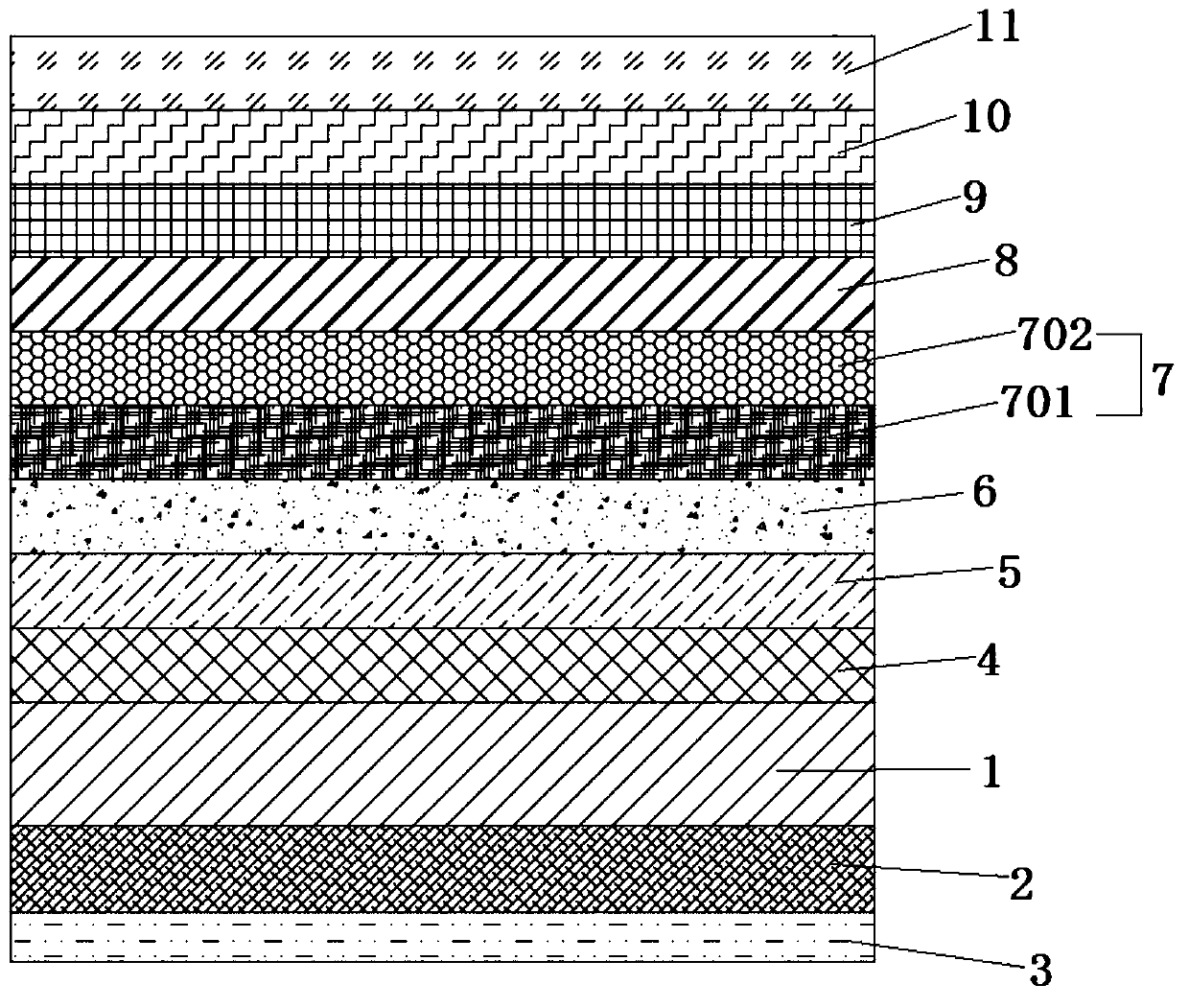

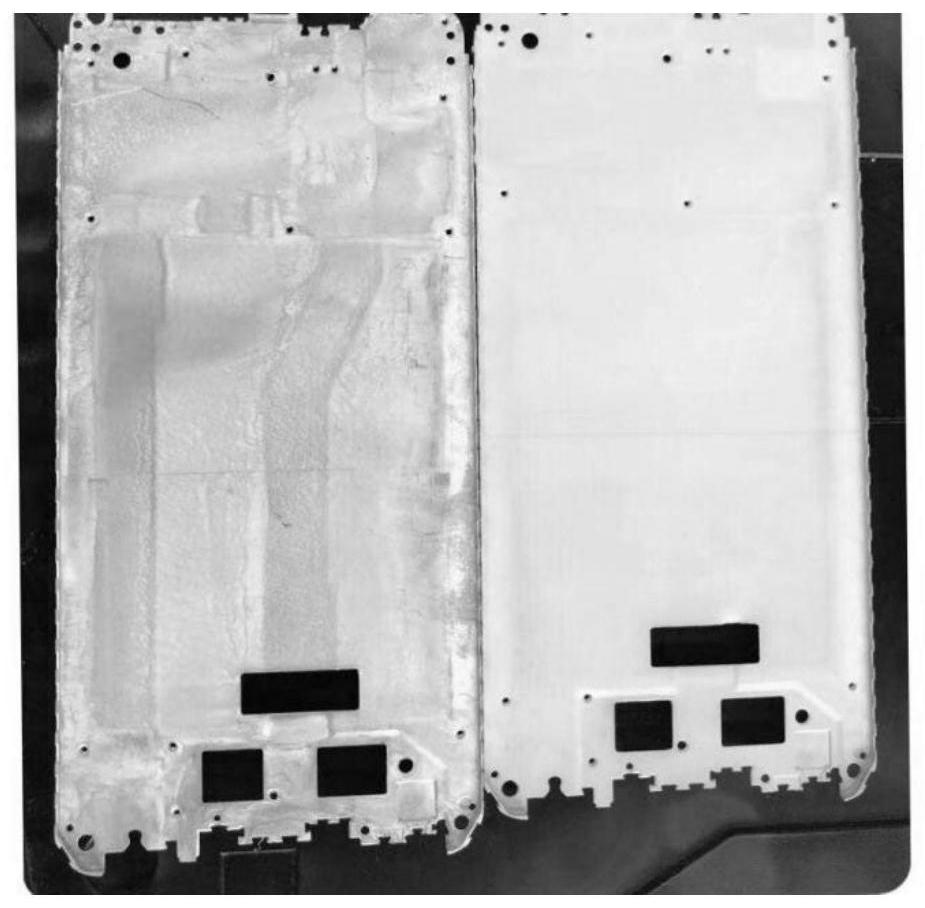

Fine surface fingerprint resistance VCM plate

PendingCN110421927AGood lookingHigh surface hardnessDomestic cooling apparatusLighting and heating apparatusChromium freeAdhesive

The invention discloses a fine surface fingerprint resistance VCM plate, which relates to the technical field of metal composite materials. The VCM plate includes a substrate; a chromium-free passivation layer is uniformly sprayed on the lower surface of the substrate; a back paint layer is uniformly sprayed on the surface of the chromium-free passivation layer; and a polyurethane primer layer, afilm adhesive layer, a back adhesive layer, a bonding layer, a brushed texture structure layer, a fine surface frosted layer, and a UV layer are sequentially disposed on the upward of the upper surface of the substrate. Through the effect of the substrate, the chromium-free passivation layer, the back paint layer, the polyurethane primer layer, the film adhesive layer, the back adhesive layer, thebonding layer, the brushed texture structure layer, the fine surface frosted layer, and the UV layer, the VCM plate has the effects of improving the surface hardness of the VCM plate, reducing a condition of easy scratching in production, improving the fingerprint resistance performance, and facilitating adhesion of frosted particles.

Owner:合肥禾盛新型材料有限公司

Zinc-aluminum-magnesium coating surface treatment agent and preparation method and use method thereof

ActiveCN112538306BImprove densification performanceHinder contactHot-dipping/immersion processesAnti-corrosive paintsColloidal silicaMg alloys

The invention discloses a zinc-aluminum-magnesium coating surface treatment agent and a preparation method and a use method thereof, belonging to the technical field of zinc-aluminum-magnesium alloy coating steel plate surface treatment. The invention provides a surface treatment agent for zinc-aluminum-magnesium coating, which comprises 1-5 parts of fluoride, high iodine 3-10 parts of acid salt, 0.5-5 parts of weak alkaline medium, 20-50 parts of water-based organic resin, 5-15 parts of colloidal silica and 100 parts of water. In the invention, fluoride and periodate react with Mg on the surface of the coating layer under weak alkaline conditions to form a dense film layer, the water-based organic resin adheres to the surface of the coating layer, and the colloidal silica is filled in the gap, which effectively hinders the coating layer. The contact with water vapor and oxygen in the environment significantly improves the corrosion resistance, blackening resistance, water resistance and fingerprint resistance of the surface coating.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Non-composite release film protective film for silver mirror glass laser cutting

ActiveCN113478110AProtect against damageImprove machining accuracyLaser beam welding apparatusHeat-affected zoneFilm base

The invention discloses a non-composite release film protective film for silver mirror glass laser cutting. The protective film comprises a functional layer, a film base material layer, an adhesive layer and a silicon resin layer, wherein the adhesive layer covers one side of the film base material, the functional layer covers the other side of the film base material layer, the surface of the adhesive layer is covered with a silicon resin layer formed by silicon resin containing a modified silane coupling agent, the modified silane coupling agent is formed by modifying methyl triisopropoxy silane by N-benzoyl quinine tert-butyl ester, the obtained protective film has excellent heat resistance, water resistance and stain resistance, is used for laser cutting of silver mirror glass, and can effectively protect the silver mirror glass from being damaged by pollutants such as gasified smoke dust and burning and melting fly slag generated in the laser cutting process, so that a product with relatively high yield is obtained; and meanwhile, the protective film can absorb low-energy light focused on the periphery of a light spot by the laser beam, so that the line width of a heat affected zone on the upper surface of the cut material is reduced, and the machining precision of a machined device is improved.

Owner:无锡昌盛胶粘制品有限公司

A metal surface high hardness anti-scratch, anti-fingerprint sealant

ActiveCN110157313BAppearance has no effectAppearance effectFireproof paintsAntifouling/underwater paintsPolymer scienceSilicone oil

The invention relates to the field of preparation of sealants, and provides a high-hardness, scratch-resistant, and fingerprint-resistant sealant on metal surfaces. The raw materials include at least water-based resin, water-based silicone oil, fatty alcohol polyether, alkali reagent, and solvent; The preparation method and use method of the sealing agent.

Owner:东莞市瑞欧表面处理科技有限公司

Silver halide photographic material

InactiveUS7105286B2Sufficient glossinessQuality improvementPhotosensitive material auxillary/base layersSilver halide emulsionsColloidC-value

The present invention relates to a silver halide photographic material comprising a paper support having resin layers coated on both sides of a base paper, and in particular, to a silver halide photographic material exhibiting superior glossiness and improved sharpness, long-term stability, fingerprint resistance and pressure resistance. The silver halide photographic material comprising on one side of the paper support having resin coat layers on both sides of a base paper, one or more light-sensitive layers and one or more light-insensitive layers, wherein after the photographic material of an L-size (having a length of 89 mm in a machine direction of the base paper and a length of 127 mm vertical to the machine direction) is processed, the photographic material exhibits an image clarity (C-value) of 20% to 60% which is determined using a 1.0 mm optical wedge in accordance with JIS K 7105; and the photographic material comprising a light-insensitive hydrophilic colloid layer between a light-sensitive layer closest to the support and the support.

Owner:KONICA MINOLTA PHOTO IMAGING

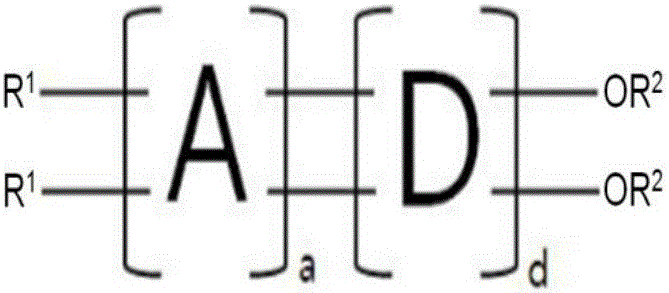

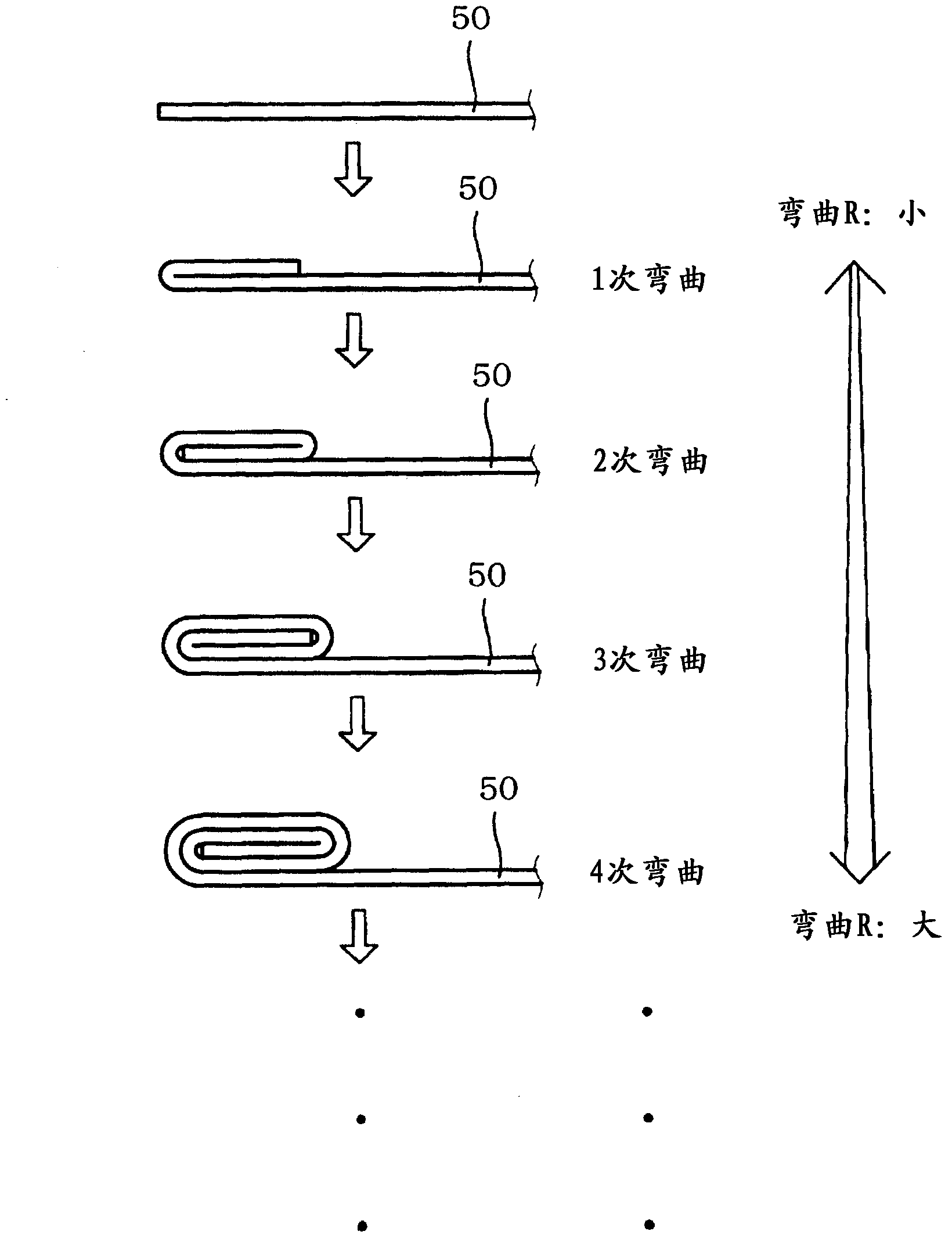

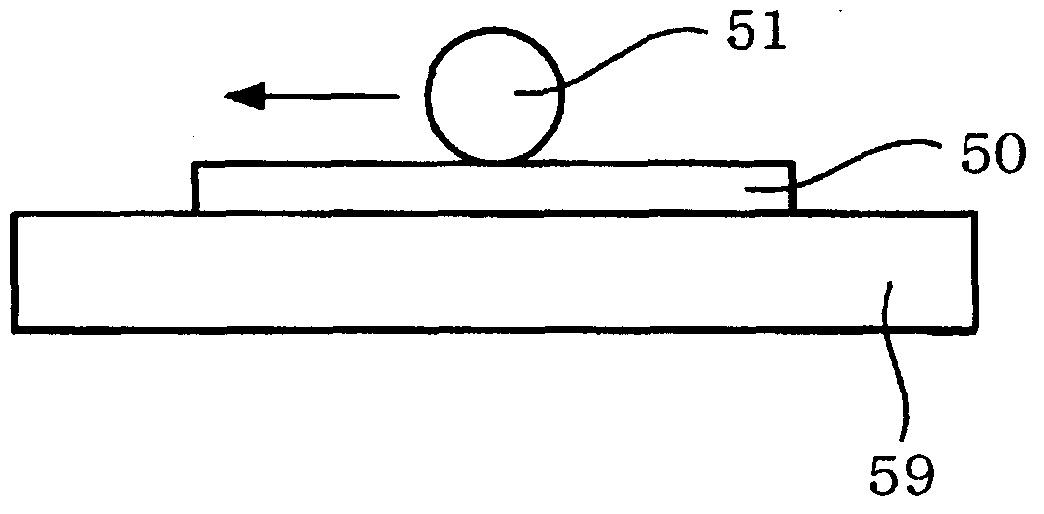

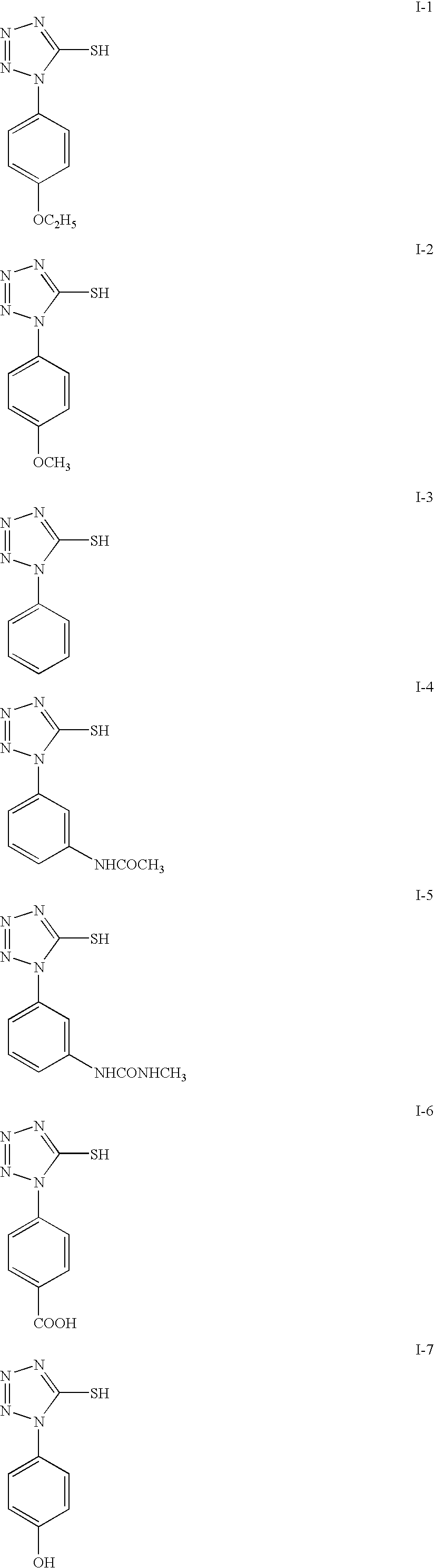

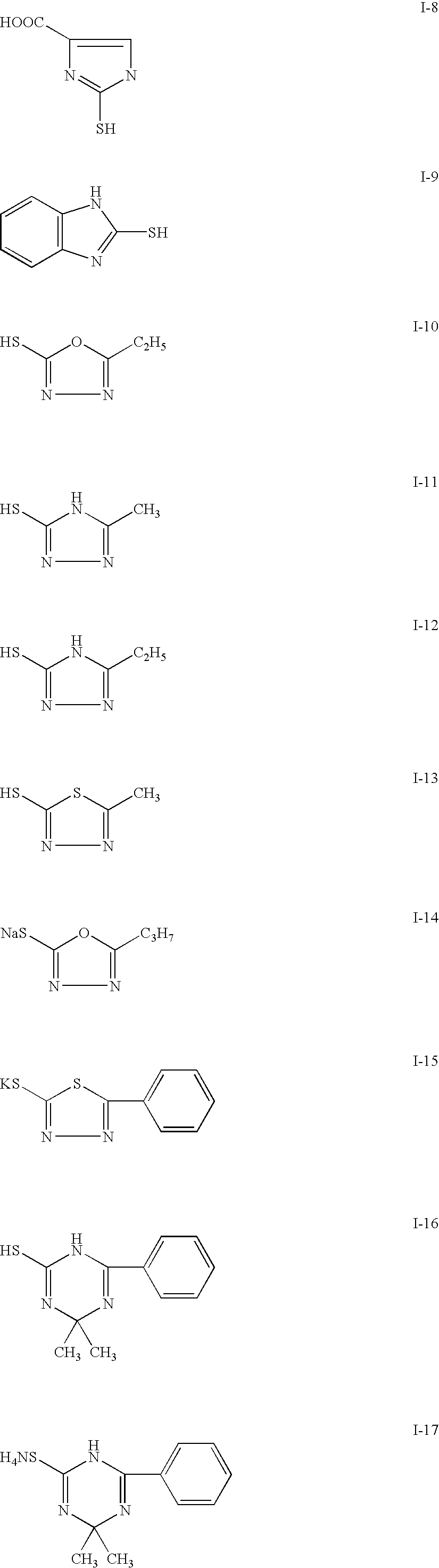

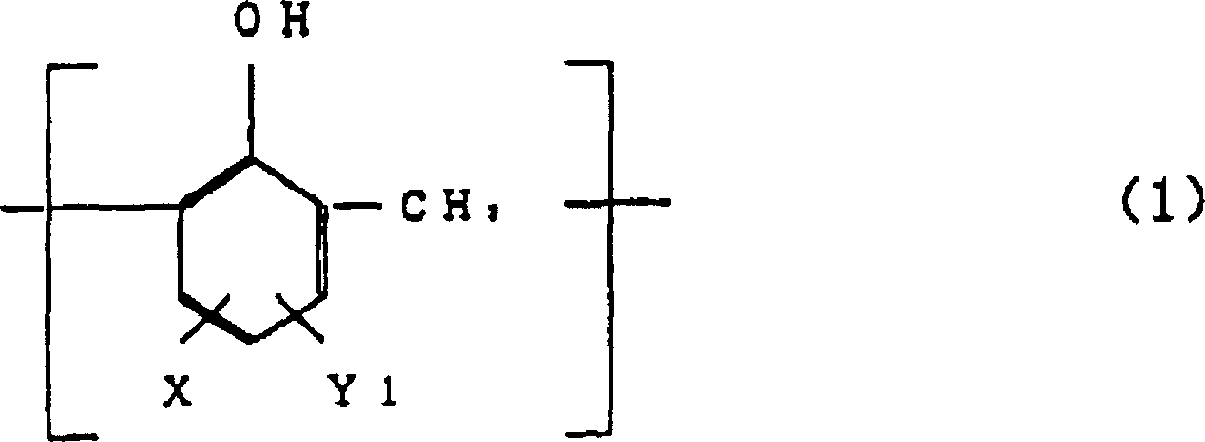

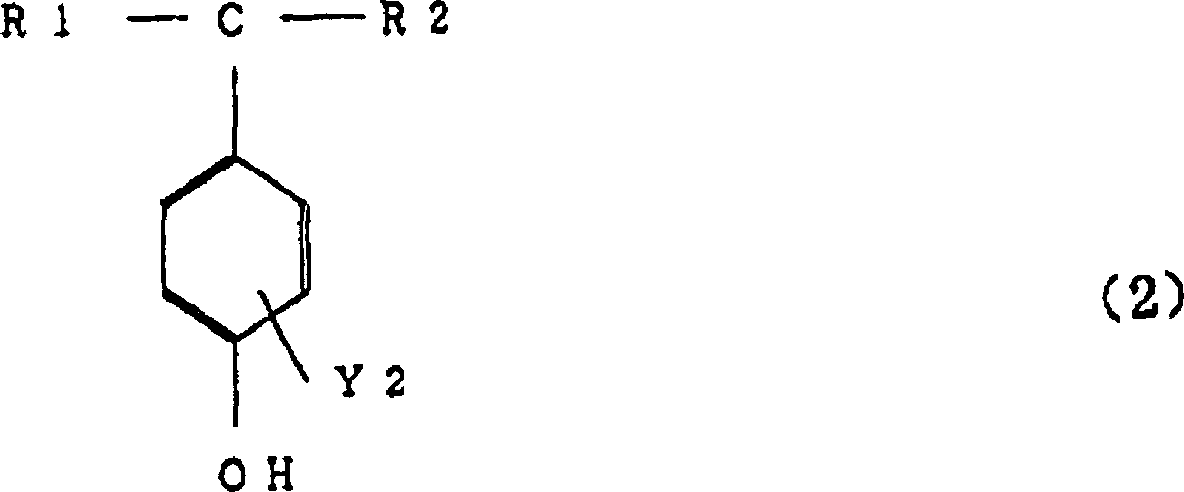

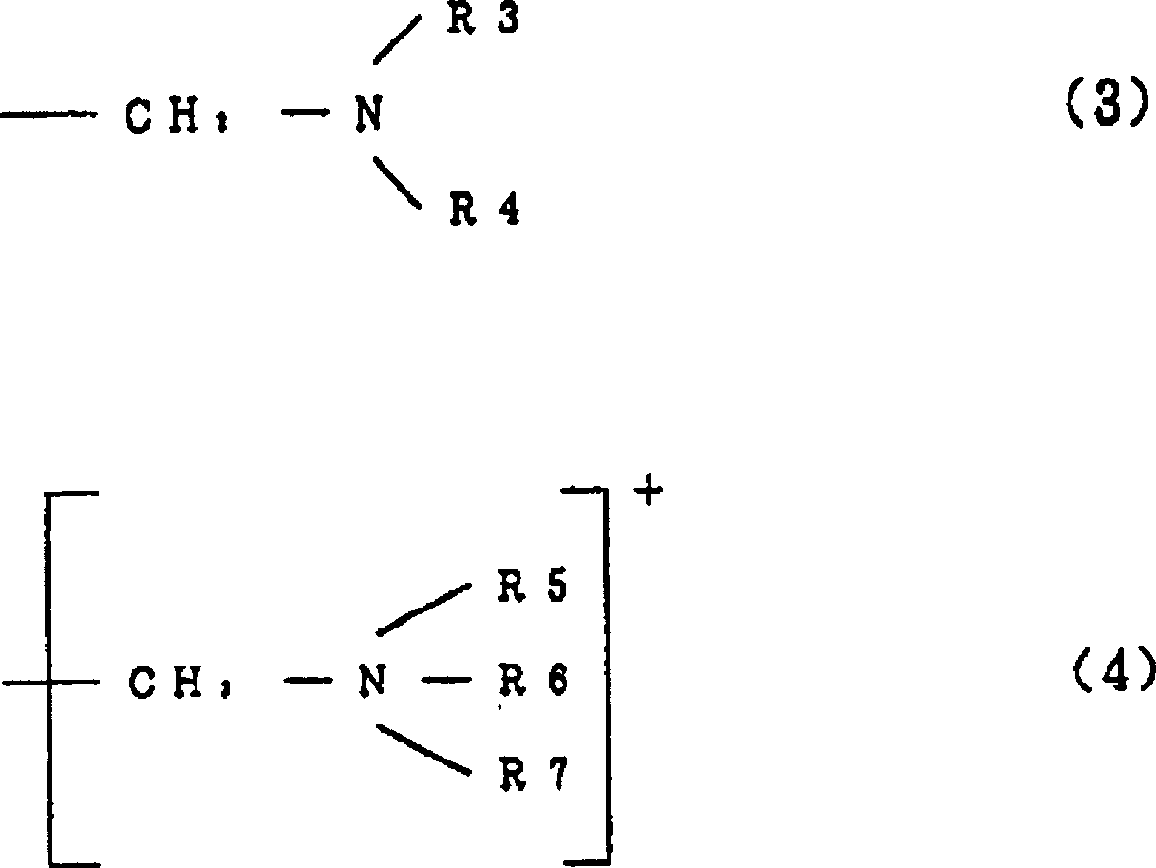

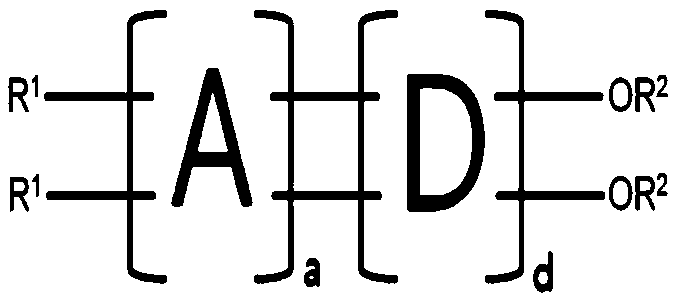

Metallic plate material having excellent properties such as: corrosion-resistant, coating, anti-finger printing and processing, and mfg. process thereefor

InactiveCN1179800CImprove corrosion resistanceExcellent fingerprint resistanceLiquid surface applicatorsAntifouling/underwater paintsChemical structureWax

A metal article whose surface is coated with a coating composition composed of (A) a silane coupling agent component, (B) a polymer component having a specific chemical structure, and (C) a wax component provides a chromium-free surface treated metal material with superior corrosion resistance, paintability, fingerprint resistance, and workability.

Owner:NIHON PARKERIZING

Surface-enhanced transparent substrate and manufacturing method thereof

ActiveCN106062053BExcellent surface hardnessImprove fingerprint resistanceSynthetic resin layered productsElectrical equipmentHeat resistanceOptoelectronics

Owner:DONGJIN SEMICHEM CO LTD

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401BReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Water base fingerprint-resisting paint for galvanized plate and preparation method thereof

The invention relates to paint composite and a preparation method thereof, in particular to fingerprint-resisting paint for manufacturing galvanized fingerprint-resisting plates and a preparation method thereof. The water base fingerprint-resisting paint which is used for the galvanized plates is characterized by being prepared from raw materials comprising waterborne resin, inorganic salt, silicasol, auxiliary agent A, auxiliary agent B and water, wherein the weight percentage of each raw material is as follows: the waterborne resin accounts for 15 to 30 percent, the inorganic salt accounts for 0.3 to 1.0 percent, the silicasol accounts for 5 to 10 percent, the auxiliary agent A accounts for 10 to 20 percent, the auxiliary agent B accounts for 4 to 10 percent and the water accounts for 50 to 65.7 percent, and the sum of weight percentage of the raw materials is 100 percent. The invention has the advantages of environmental protection and simple process. The paint composite can be sprayed on the surface of a hot galvanized steel plate, an electrogalvanized steel plate, an aluminum plated zinc plate or a cold-roll steel plate by the modes of dip-coating, spraying, roller painting, and the like, and the curing time is short and only lasts for 20 seconds to 1 minute; after the steel plates are sprayed, the requirements of the steel plates on corrosion resistance, alkali resistance, high temperature resistance, electrical conductivity, paintability, and the like can be met, and the fingerprint resistance of the steel plates can be greatly improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Chromium-free fingerprint-resistant coating

ActiveCN101121860BImprove hot sticky and cold brittle phenomenonSuitable for continuous roller coatingPolyurea/polyurethane coatingsWaxChromium free

The present invention is capable to settle the problems that existing fingerprint-proof paints containing chrome cause certain hazard to the environment during the preparation, storage and transportation, particularly to settle the problem of chrome pollution. The invention involves the following chemical compositions: water urethane resin (40 to 70wt percent), silicon dioxide sols (4 to 8wt percent), water teflon wax-dispersion (10 to 20wt percent), deionized water (20 to 40wt percent), EFTOP EF-112 (0.2 to 0.3wt percent), glycol (2 to 3wt percent) and Asekahate B-1019 (0.5 to 0.7wt percent).Water urethane resin is injected in to a reaction kettle, the silicon dioxide and water teflon wax-dispersion are added (agitating at the same time), and film-forming assistant is added, and then other assistants are put into the reaction kettle, and finally, the deionized water is added into the reaction kettle. The fingerprint-proof paint is achieved by agitating continuously for 15 to 30 minutes.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

A kind of chrome-free fingerprint-resistant environmental protection paint and preparation method thereof

InactiveCN108117835BRaw materials are easy to getLow priceFireproof paintsAnti-corrosive paintsEpoxyPhysical chemistry

Owner:SHENZHEN DA QUAI CHEM CO LTD

A non-composite release film protective film for laser cutting of silver mirror glass

ActiveCN113478110BProtect against damageImprove machining accuracyLaser beam welding apparatusHeat-affected zoneMeth-

The invention discloses a non-composite release film protective film for laser cutting of silver mirror glass; it comprises a functional layer, a film base material layer, an adhesive layer and a silicone resin layer; the adhesive layer covers one side of the film base material ; The functional layer is covered on the other side of the film substrate layer; wherein, the surface of the adhesive layer is covered with a silicone resin layer formed by a silicone resin containing a modified silane coupling agent; wherein the modified silane coupling agent consists of N Benzene Acyl quinine tert-butyl ester modified methyl triisopropoxysilane; the obtained protective film has excellent heat resistance, waterproof and stain resistance protective film, which is used for laser cutting of silver mirror glass, which can effectively Protect the silver mirror glass from the damage caused by gasification smoke, burning slag and other pollutants produced during the laser cutting process, and obtain a product with a high excellent rate; at the same time, the protective film can absorb the low energy of the laser beam focused on the periphery of the spot Light, thereby reducing the line width of the heat-affected zone on the upper surface of the material to be cut, so as to improve the processing accuracy of the processed device.

Owner:无锡昌盛胶粘制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com