Chrome-free fingerprint-resistant environment-friendly coating and preparation method thereof

An environmentally friendly coating and anti-fingerprint technology, applied in the field of coatings, can solve problems such as poor corrosion resistance, short storage period, and poor product stability, and achieve the effects of low equipment requirements, improved adhesion, and fast film forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

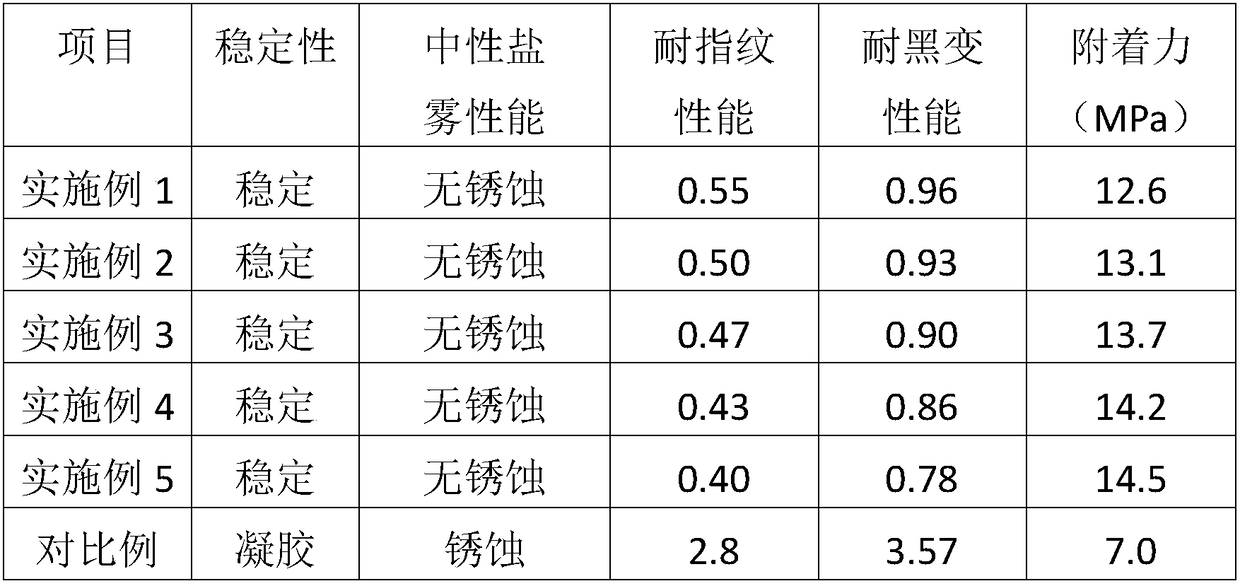

Examples

Embodiment 1

[0026] A chrome-free anti-fingerprint environmental protection coating, which is composed of the following components by weight: 40 parts of film-forming polycondensate, 5 parts of aminopropanol ascorbyl phosphate modified graphene oxide, 15 parts of epoxy resin, sodium hexametaphosphate 1 part, 1 part of polyacrylate leveling agent, 1 part of tributyl phosphate, 20 parts of water;

[0027] The preparation method of the film-forming condensation polymer comprises the following steps: dissolving 27 g of double-ended epoxy polyether modified silicone oil in 80 g of isopropanol, and adding 2,4-diamino-6-phenyl-1 , 10g of 3,5-triazine, stirred and reacted at 75°C for 10 hours under a nitrogen atmosphere, then precipitated in acetone, and baked in a vacuum oven at 70°C for 10 hours.

[0028] The preparation method of the aminopropanol ascorbyl phosphate modified graphene oxide comprises the following steps: dispersing 50 g of graphene oxide in 130 g of dichloromethane, and adding 1...

Embodiment 2

[0031] A chrome-free anti-fingerprint environmental protection coating, which is composed of the following components in parts by weight: 43 parts of film-forming polycondensate, 6 parts of aminopropanol ascorbyl phosphate modified graphene oxide, 17 parts of epoxy resin, sodium polycarboxylate 2 parts of salt, 2 parts of cellulose acetate leveling agent, 2 parts of defoamer Deqian 3100, 25 parts of water;

[0032] The preparation method of the film-forming polycondensate comprises the steps of: dissolving 27 g of double-ended epoxy polyether modified silicone oil in 95 g of ethylene glycol, and adding 2,4-diamino-6-phenyl-1 , 10g of 3,5-triazine, stirred and reacted at 78°C for 11 hours under a helium atmosphere, then precipitated in acetone, and baked in a vacuum oven at 73°C for 11 hours.

[0033] The preparation method of the aminopropanol ascorbyl phosphate modified graphene oxide comprises the following steps: dispersing 55 g of graphene oxide in 145 g of acetone, and ad...

Embodiment 3

[0036] A chromium-free anti-fingerprint environmental protection coating, which is composed of the following components in parts by weight: 46 parts of film-forming polycondensate, 7 parts of aminopropanol ascorbyl phosphate modified graphene oxide, 17 parts of epoxy resin, sodium hexametaphosphate 3 parts, 2 parts of polyvinyl butyral leveling agent, 3 parts of defoamer BYK088, 30 parts of water;

[0037] The preparation method of the film-forming polycondensate comprises the steps of: dissolving 27 g of double-ended epoxy polyether modified silicone oil in 105 g of n-butanol, and adding 2,4-diamino-6-phenyl-1 , 10g of 3,5-triazine, stirred and reacted at 81°C for 12 hours under a neon atmosphere, then precipitated in acetone, and baked in a vacuum oven at 77°C for 13 hours.

[0038]The preparation method of aminopropanol ascorbyl phosphate modified graphene oxide comprises the following steps: dispersing 60 g of graphene oxide in 160 g of acetonitrile, and adding 22 g of ami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com