Patents

Literature

134 results about "Aminopropanols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

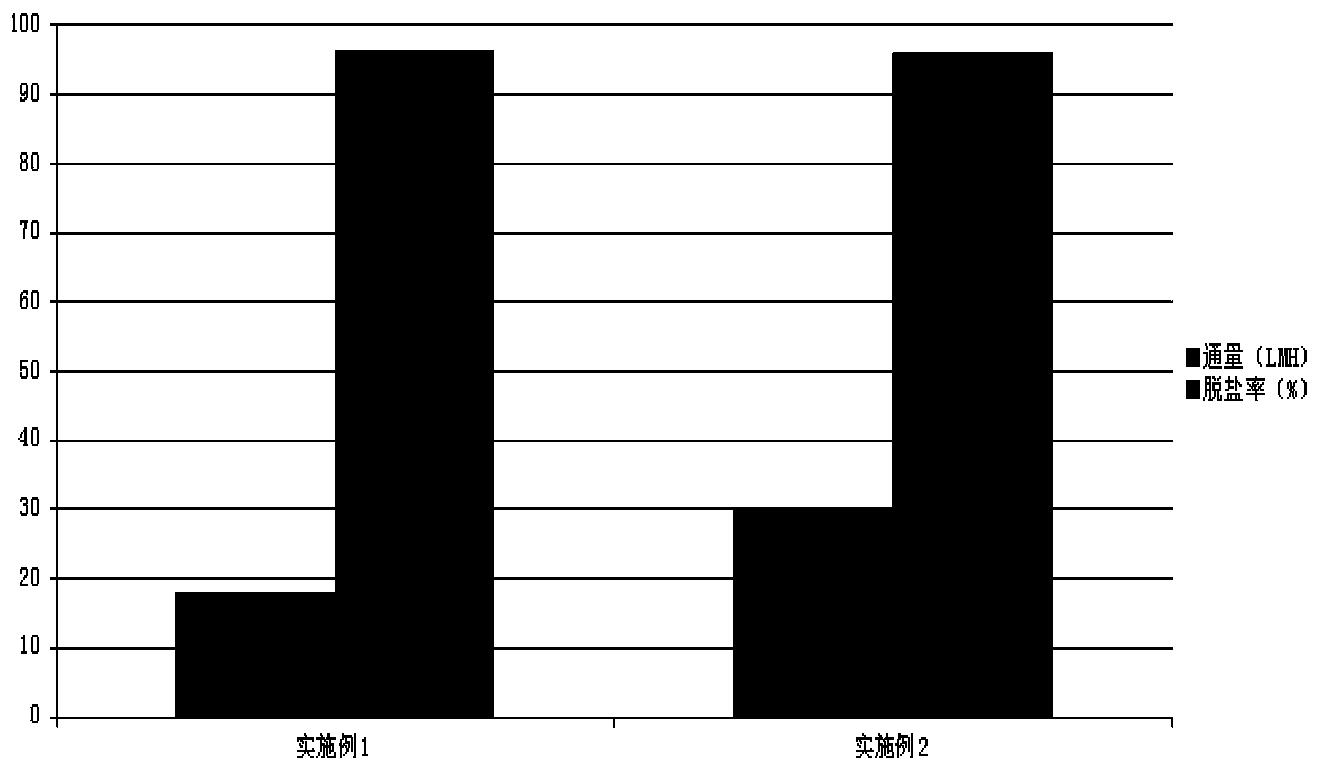

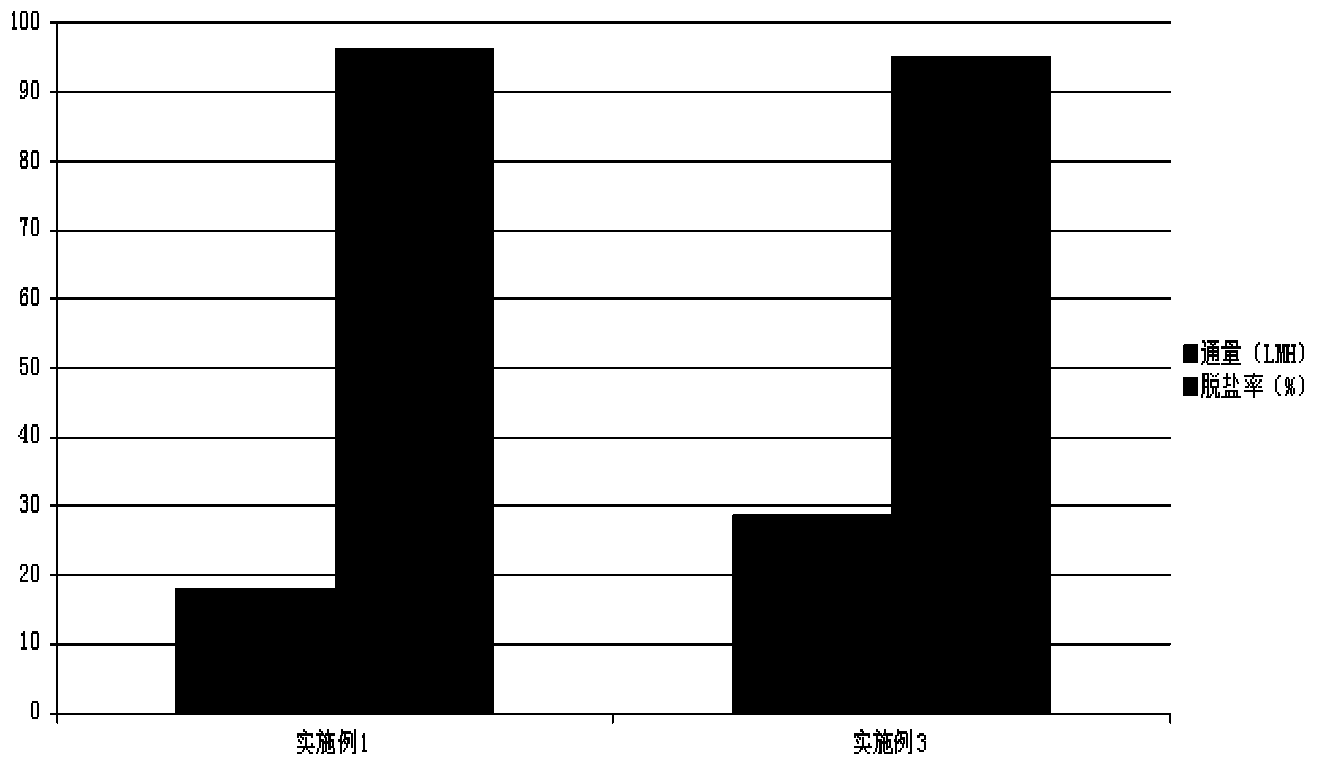

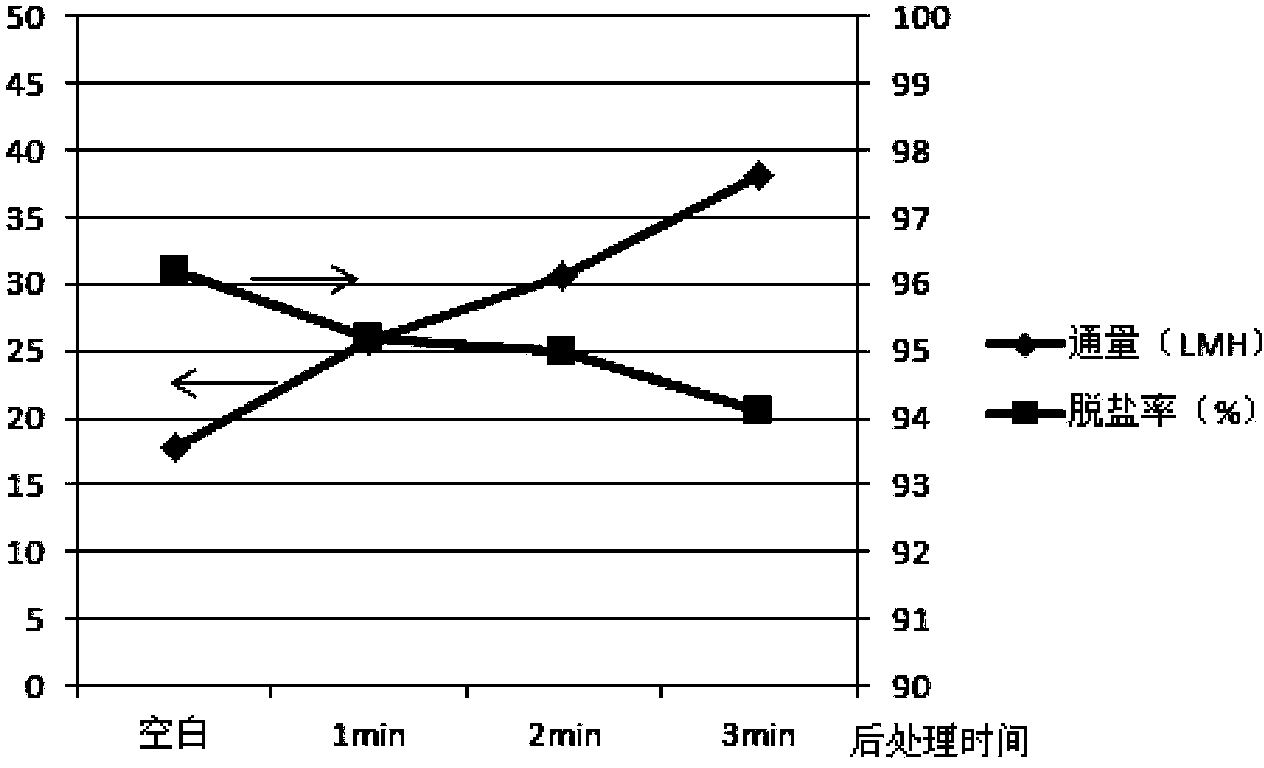

Preparation method of high-flux and anti-pollution reverse osmosis membrane and application of membrane

InactiveCN104226123AImprove hydrophilicitySimple structureSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh fluxReverse osmosis

The invention provides a preparation method of a high-flux and anti-pollution reverse osmosis membrane. The preparation method of the high-flux and anti-pollution reverse osmosis membrane comprises the following steps: soaking a support layer in an aqueous solution with multifunctional aromatic amine compounds, taking the support layer out, drying the support layer, then soaking the support layer in a multifunctional acyl chloride oil phase solution, volatilizing and drying the support layer, then soaking the support layer in a modifier for 10-600 seconds, taking the support layer out and poaching the support layer in pure water to obtain the high-flux and anti-pollution reverse osmosis membrane, wherein the modifier is selected from any one of monoethanolamine, diethanol amine, triethanolamine, dimethylaminoethanol, diethylaminoethanol, 2-amino-propanol, dimethyl amine isopropyl alcohol, 3-amino-isopropyl alcohol and the like. According to the high-flux and anti-pollution reverse osmosis membrane prepared by the method, the hydrophilcity of the membrane can be improved; the salt removing rate remains at the level before modification; the charge performance of the membrane surface is reduced; the effect of shielding pollution of the charge substances in the running water is reduced; the high-flux and anti-pollution reverse osmosis membrane is suitable for industrial production and capable of meeting the requirements for long-term operation under the ultra-low voltage condition.

Owner:BEIJING ORIGIN WATER FILM TECH

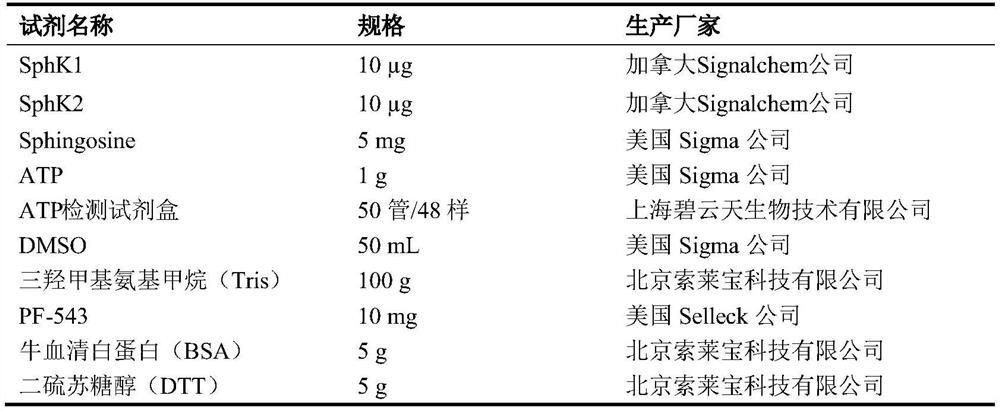

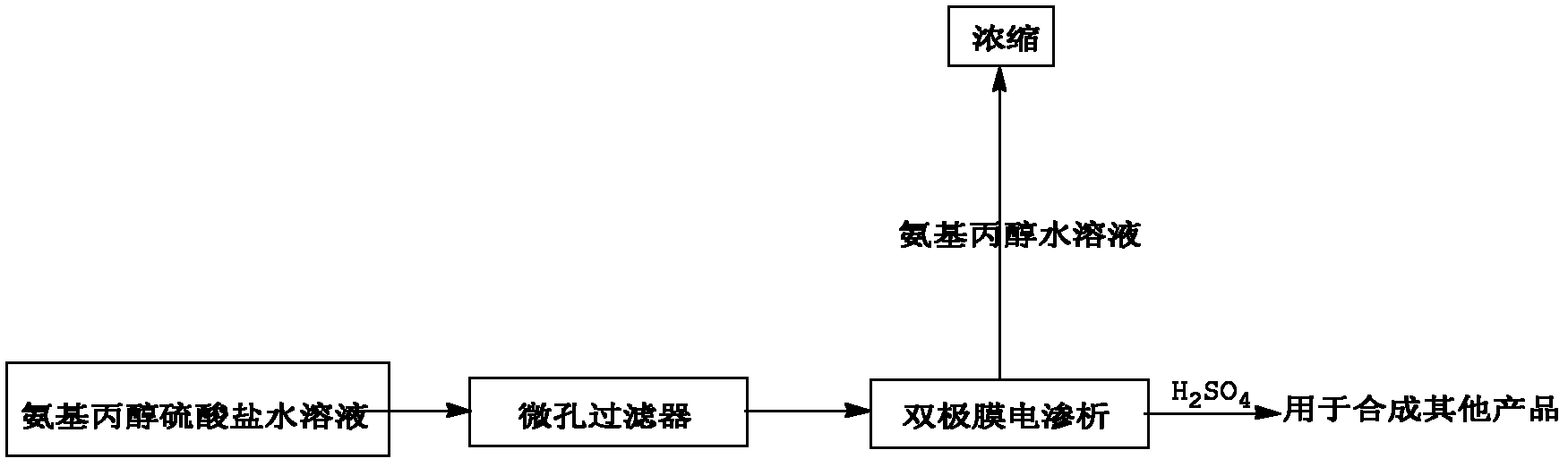

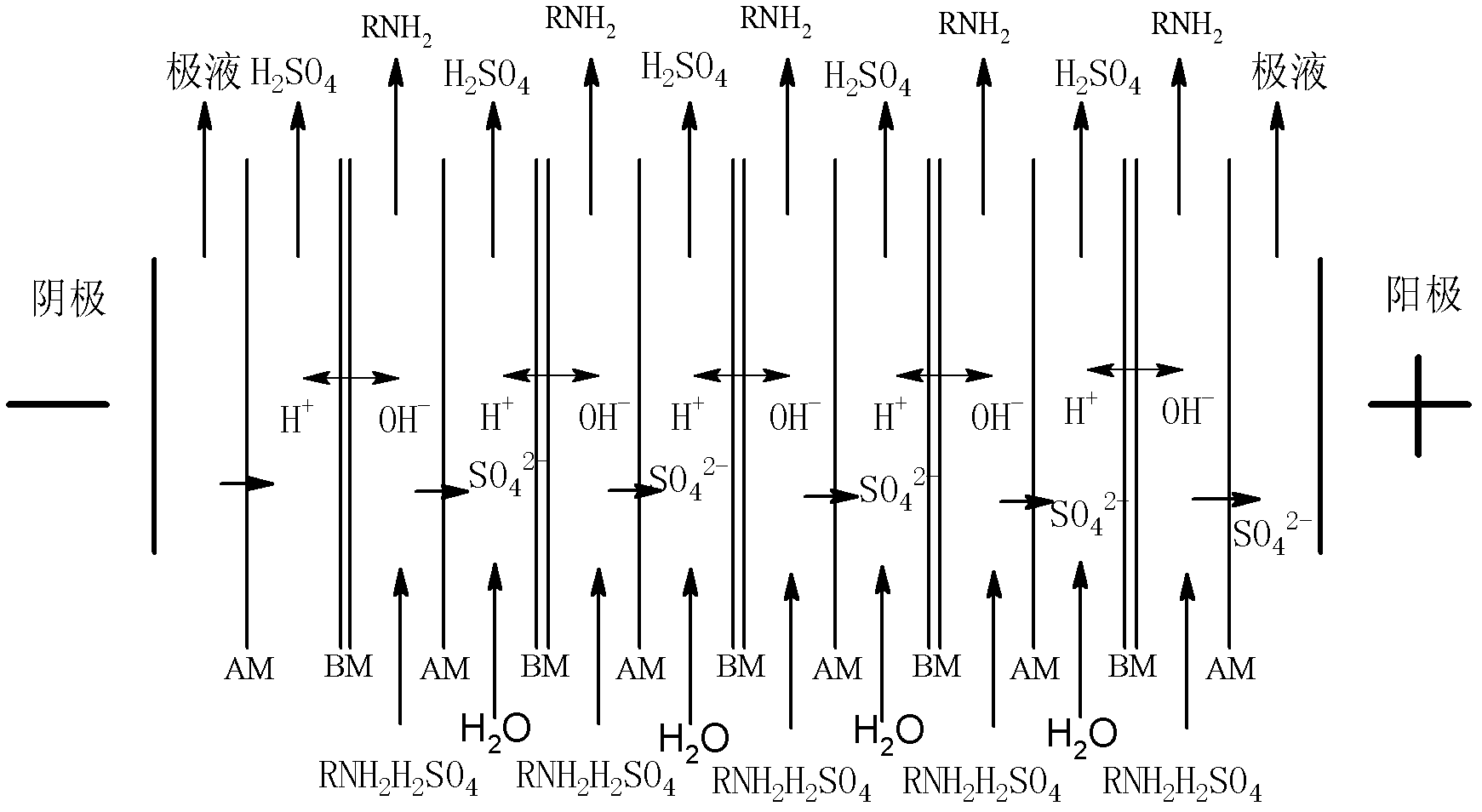

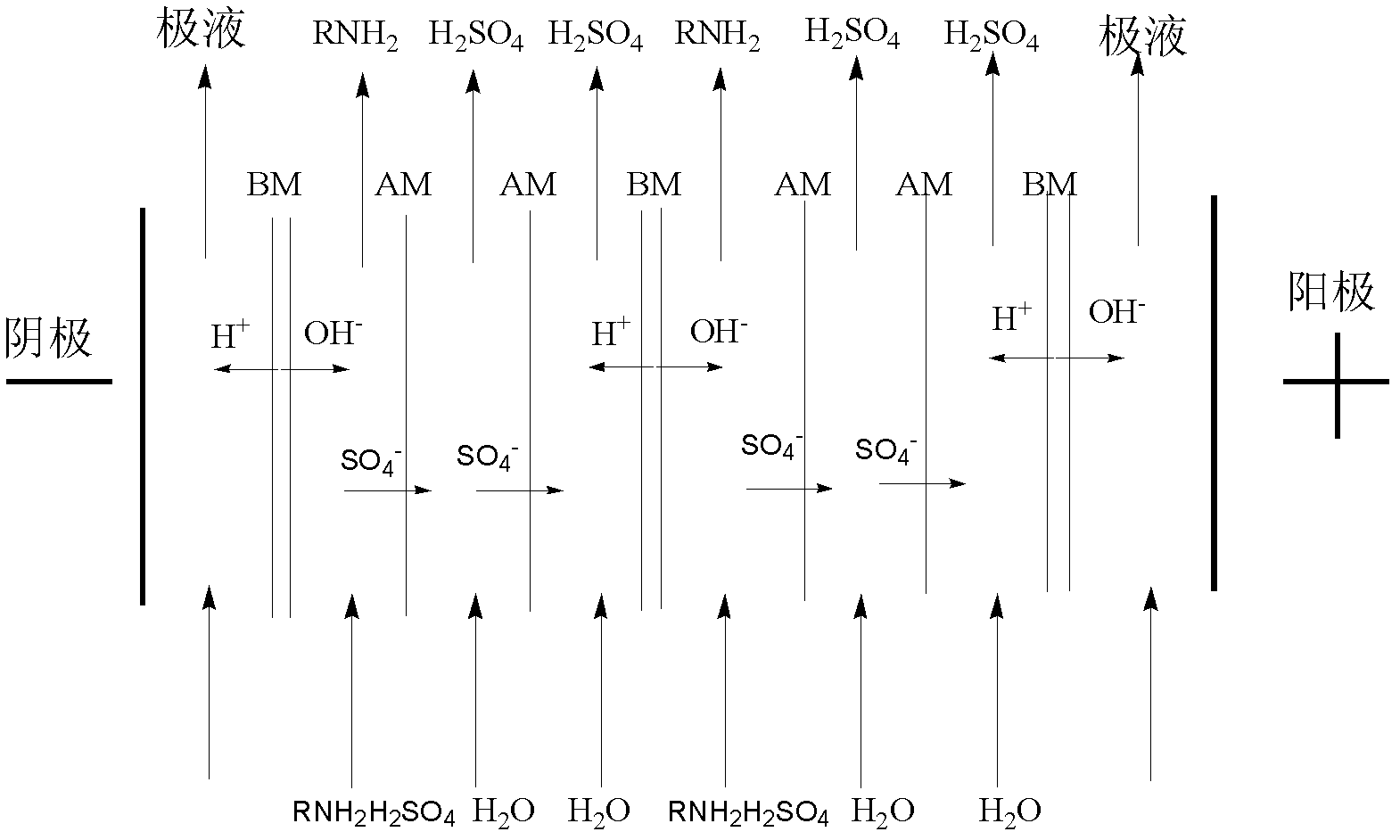

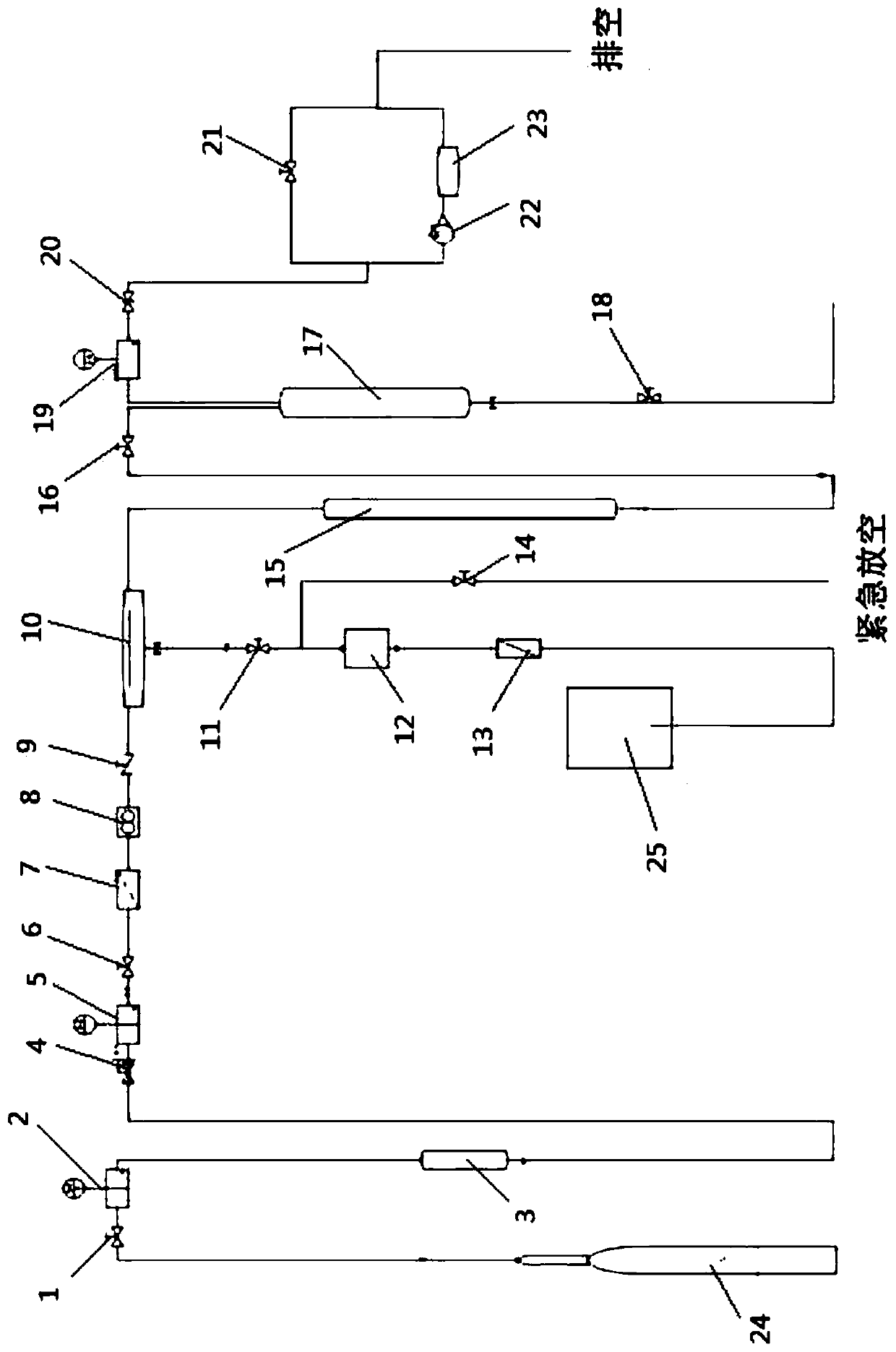

Method for preparing aminopropanol by bipolar membrane electrodialysis

InactiveCN102584606AShorten the production cycleHigh recovery rateSemi-permeable membranesOrganic compound preparationAcid waterPower flow

The invention discloses a method for preparing aminopropanol by bipolar membrane electrodialysis. The method comprises the steps that: aminopropanol sulphate water solution is used as a raw material and enters a material liquid chamber of a bipolar membrane electrodialysis device after being treated by a microporous filter, meanwhile, sulphuric acid water solution with the mass concentration being 0.1 percent is added into an acid chamber, sulphuric acid water solution with the mass concentration being 0.4 percent is added into a pole liquid chamber, the current density of the bipolar membrane electrodialysis device is controlled to be 50 to 800 A / m<2>, the voltage is 20 to 200V, the temperature is 5 to 40 DEG C, an electrodialysis separation chamber carries out circulation cooling through frozen brine in a circulation coil pipe in the operation process, when the electrical conductivity of the material liquid chamber is reduced to 2000mus / cm, the operation is stopped, the material liquid chamber and the acid chamber respectively obtain aminopropanol water solution and sulphuric acid water solution, and the aminopropanol water solution is concentrated to obtain aminopropanol. When the bipolar membrane electrodialysis technology is adopted for preparing the aminopropanol, the production period is short, the aminopropanol recovery rate is high, the energy consumption is obviously reduced, and the sulphuric acid quality is high.

Owner:ZHEJIANG UNIV OF TECH +1

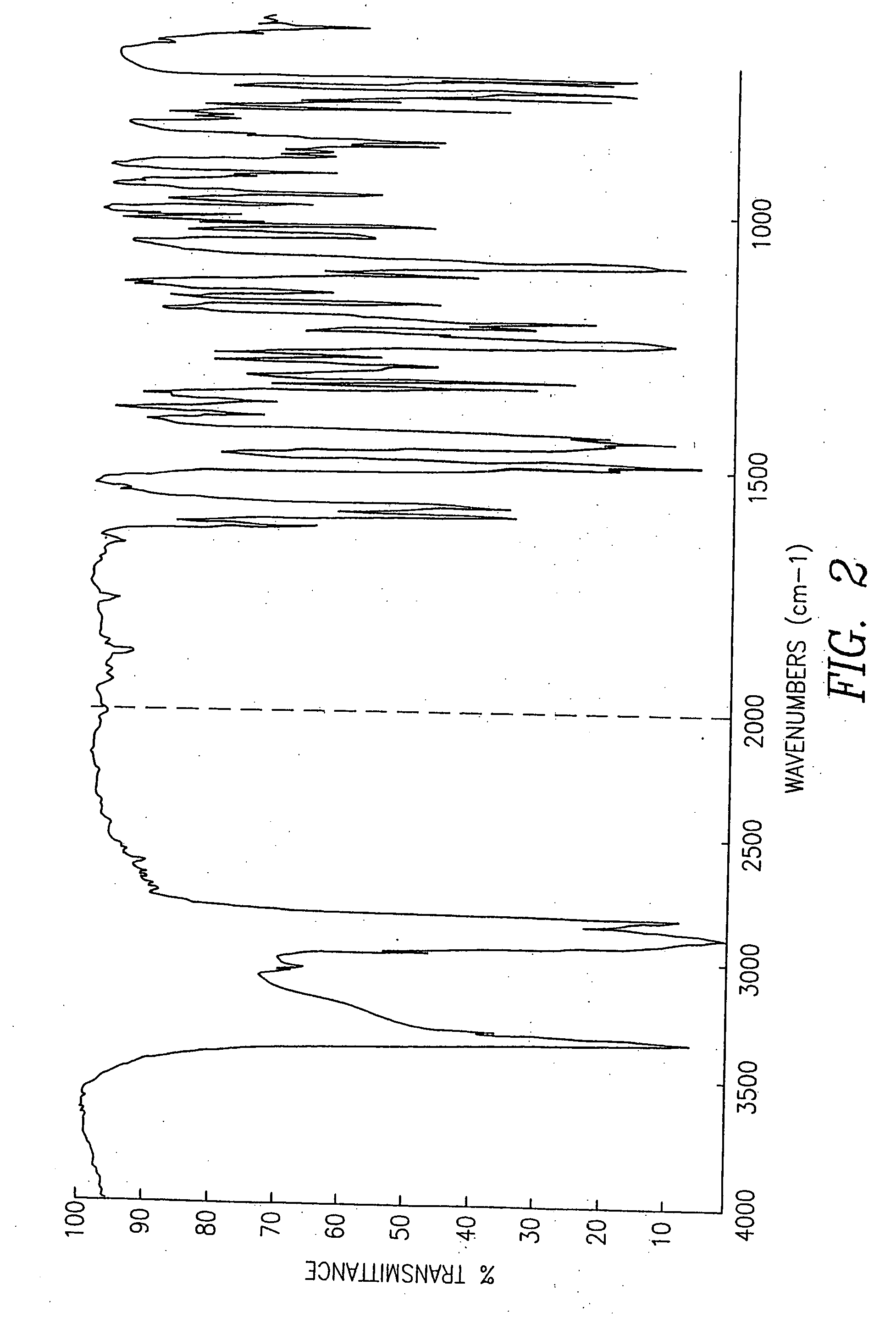

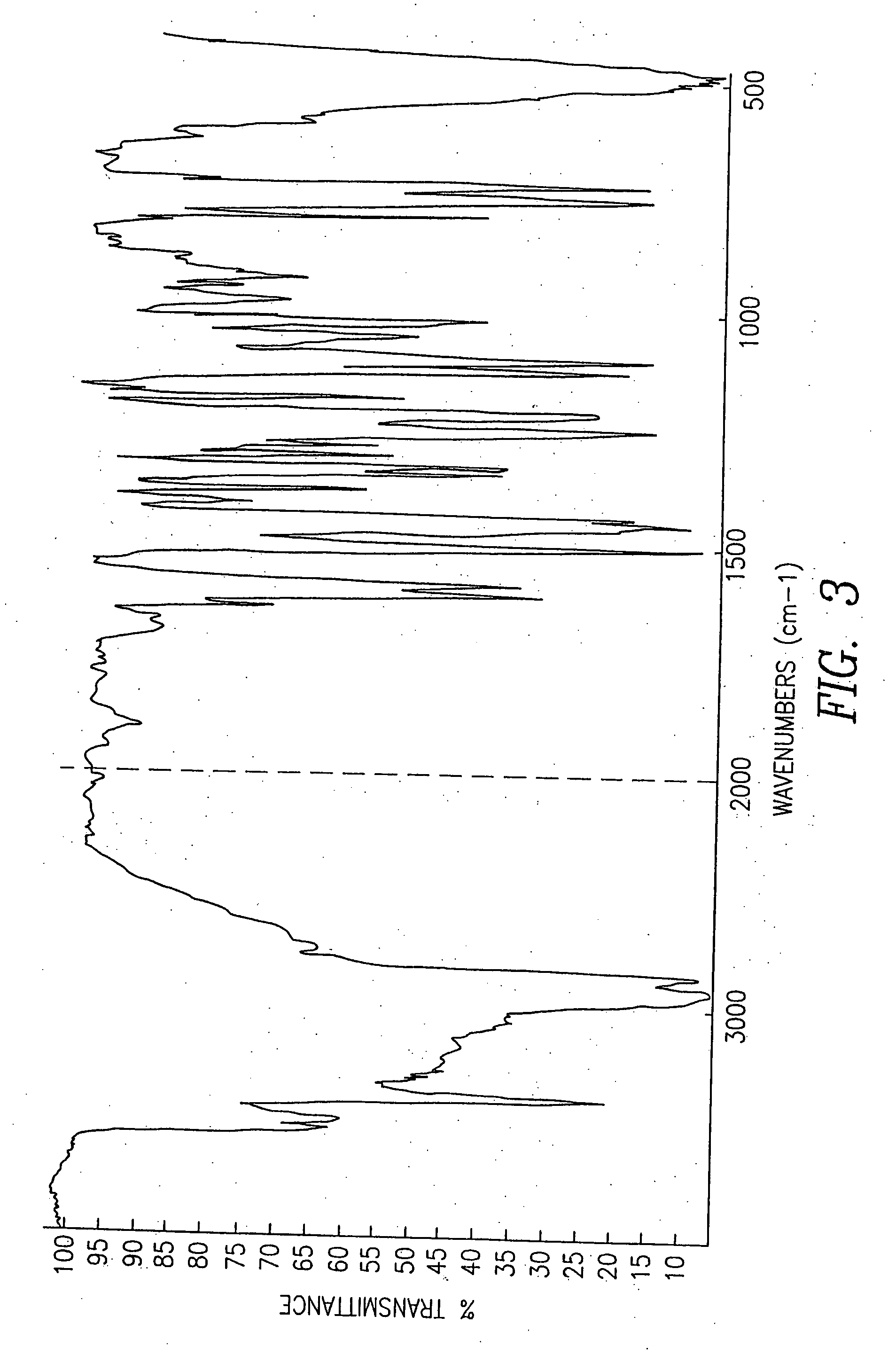

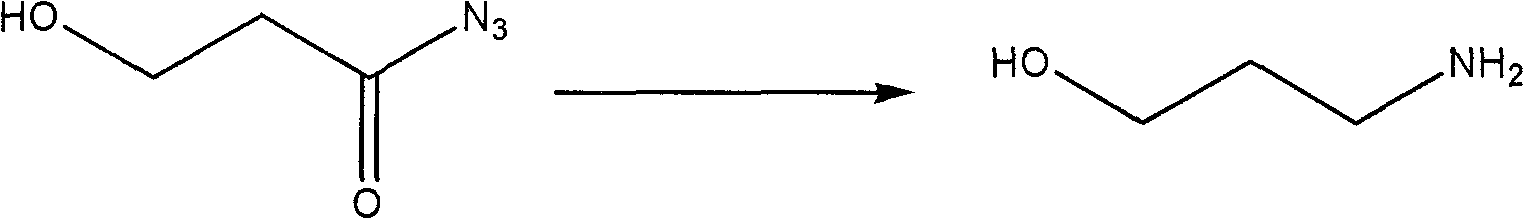

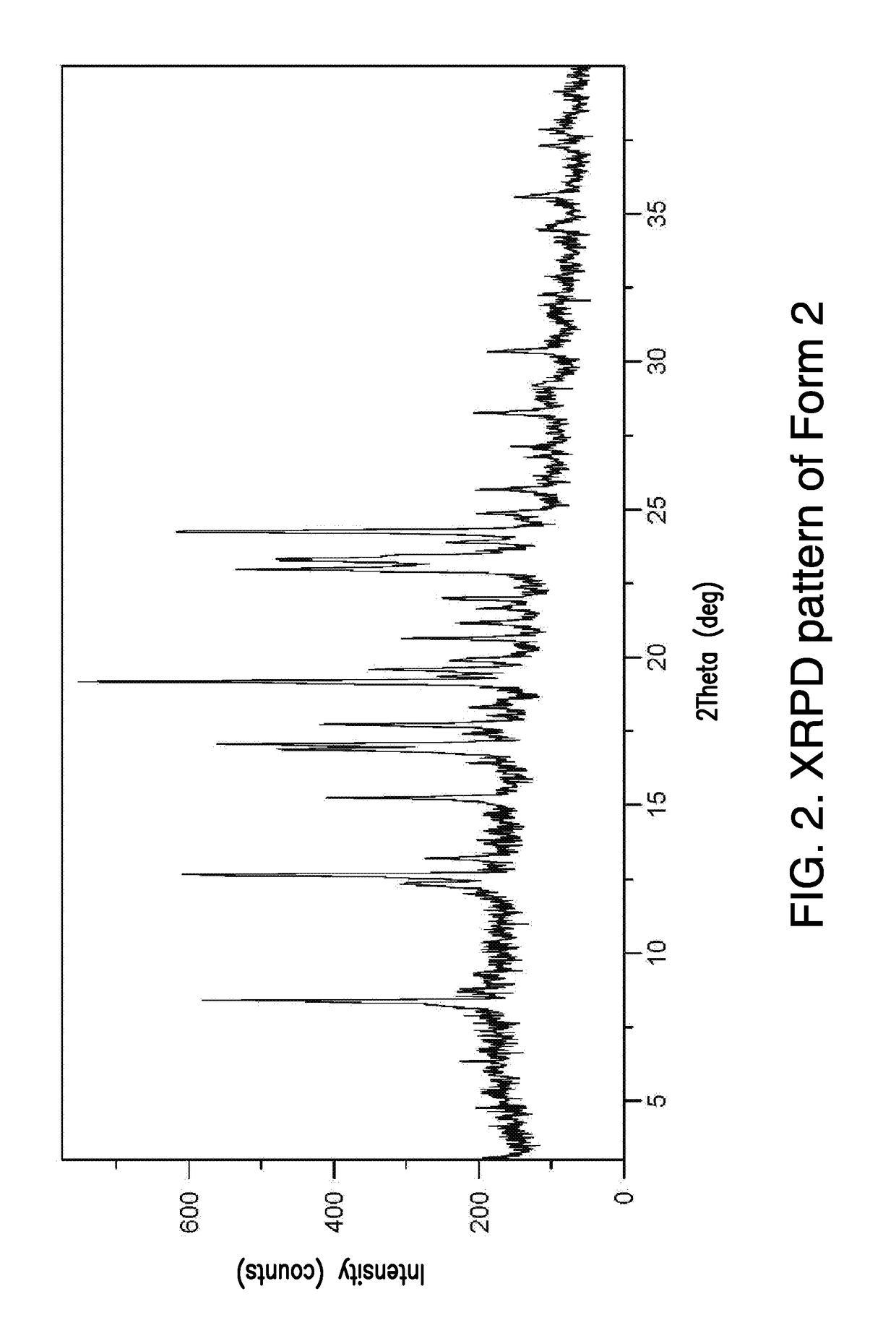

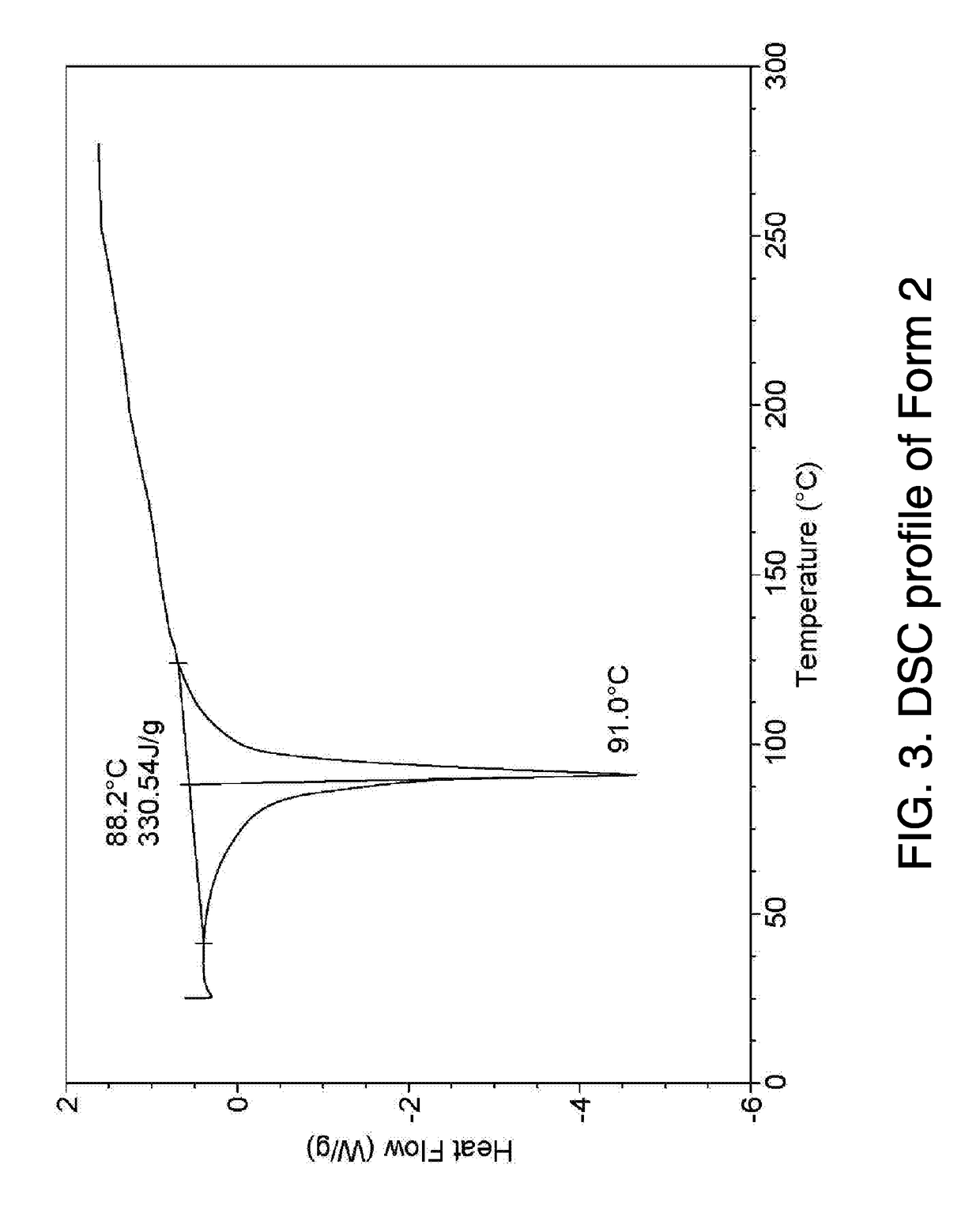

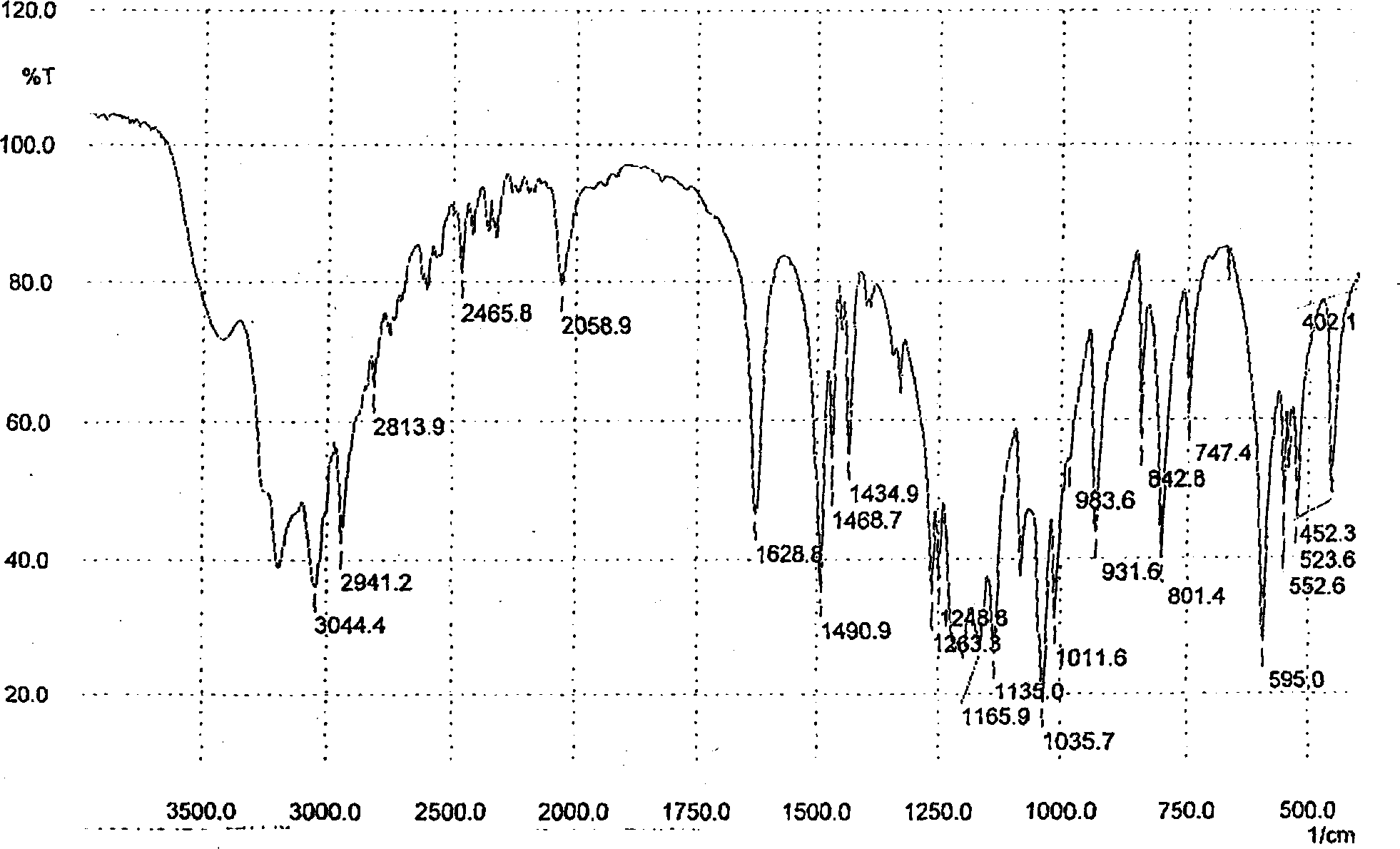

Pseudopolymorphic forms of carvedilol

InactiveUS20060148878A1Improve resorptionGood substanceBiocideOrganic chemistryEthyl phosphateIsopropyl alcohol

The present invention is concerned with pseudopolymorphic forms of 1-(4-carbazolyloxy)-3-[2-(2-methoxyphenoxy)ethylamino]-2-propanole (carvedilol) or of optically active forms or pharmaceutically acceptable salts thereof, processes for the preparation thereof and pharmaceutical compositions containing them.

Owner:PHARMCO PUERTO RICO INC

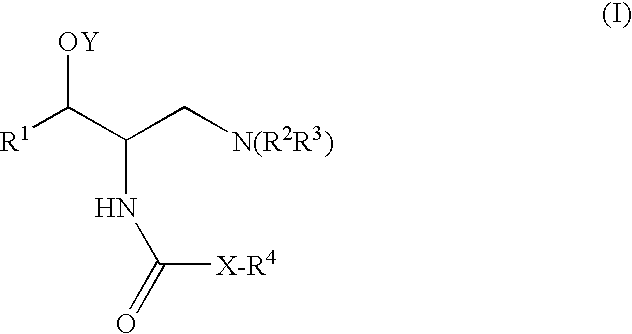

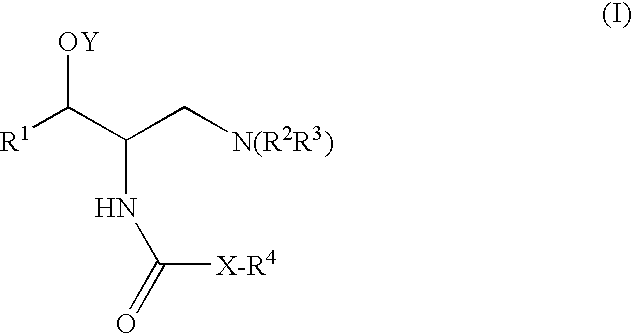

2-acylaminopropoanol-type glucosylceramide synthase inhibitors

InactiveUS8304447B2Inhibit synthesisHigh metabolic stabilityBiocideOrganic chemistryDiseaseLow glucose

Owner:GENZYME CORP

Method for preparing aminopropanol by electrolysis

InactiveCN101660171ALow costMild reaction conditionsOrganic chemistryElectrolysis componentsElectrolysisFiltration

A method for preparing aminopropanol by electrolysis comprises two steps, namely preparation of aminopropanol by electrolysis reduction of an amino acid cathode and purification; the method for preparing aminopropanol by electrolysis is characterized in that an ion exchange membrane is adopted to divide an electrolyzer into a negative chamber and a positive chamber; the concentration of the aminopropanol in catholyte is 0.3mol / L to 2.0mol / L; the pH of the catholyte is 1 to 4; the anolyte is sulfuric acid with mass percentage concentration of 2 percent to 20 percent; the temperature of the electrolyte is controlled to be from 30 DEG C to 60 DEG C; the current density is 200 A / m<2> to 2000 A / m<2>; and when electrolyte balance is reached, the aminopropanol is obtained after the catholyte experiences filtration, neutralization, re-filtration and distillation. The method for preparing aminopropanol by electrolysis has low production cost and no pollution in the production process.

Owner:淮北煤炭师范学院 +1

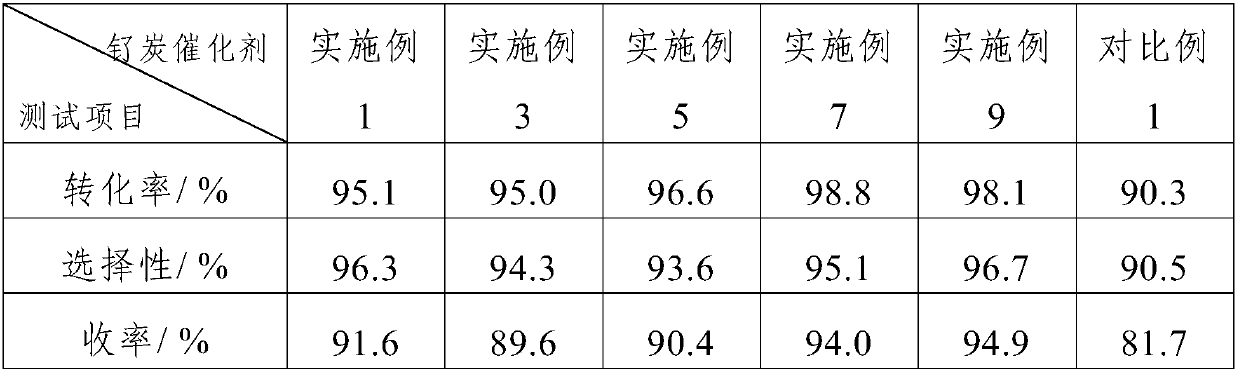

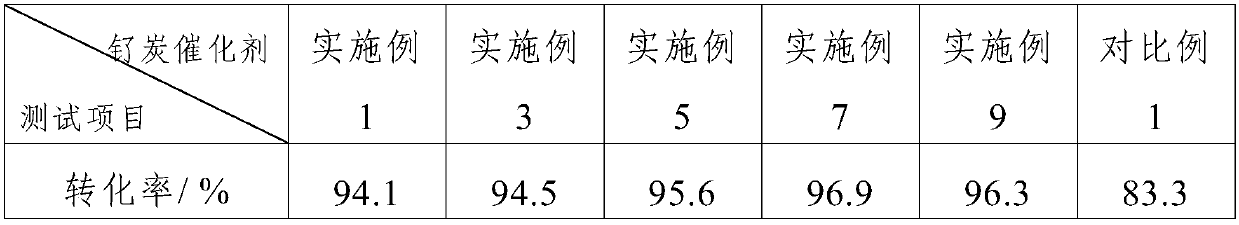

Catalyst, method for preparing 3-aminopropanol through catalyst, and adopted system

ActiveCN109806883AImprove quality space-time yieldHigh selectivityOrganic compound preparationCatalyst activation/preparationCarbon nanotubeAminopropanols

The invention discloses a loaded heterogeneous catalyst. The loaded heterogeneous catalyst is prepared from main active components, an assistant and a carrier or prepared from main active components and a carrier, wherein the assistant is prepared from one or two or more of elementary substances or oxides of Fe, Cu, Ru, Re, K, Zn and B, the carrier is prepared from one or two or more of graphite,activated carbon, a carbon nano tube, graphene, silicon dioxide, aluminum oxide, a molecular sieve, titanium dioxide and zirconium dioxide, and the loaded heterogeneous catalyst is prepared through anultrasonic loading method. By adopting the loaded heterogeneous catalyst for preparing 3-aminopropanol, (1) the mass space-time yield of the 3-aminopropanol is increased; (2) selectivity of the 3-aminopropanol is improved; (3) a reaction can be implemented under the low reaction pressure; (4) stability of a catalytic system is improved; and (5) process operation is easy, convenient and feasible,the one-time investment and production costs of production and subsequent separating devices are lowered, and large-scale continuous industrial production is easy to achieve.

Owner:ZHEJIANG NORMAL UNIVERSITY

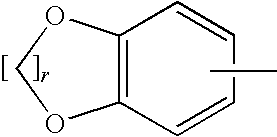

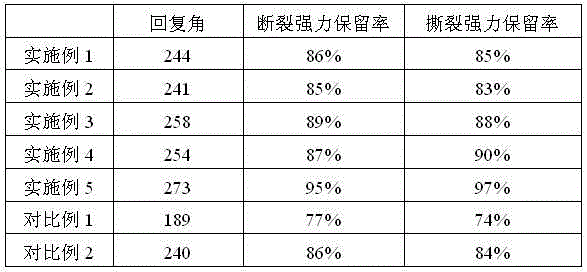

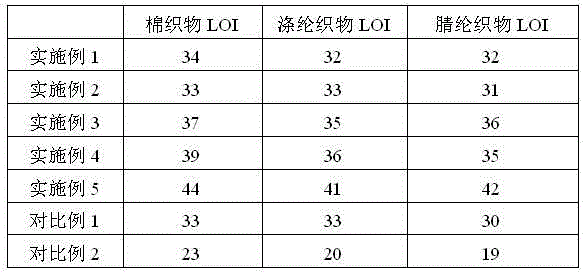

Flame-retardant anti-wrinkle finishing agent for fabric and preparation method and application thereof

ActiveCN104695233AIncreased flame retardant strengthImprove wrinkle resistanceVegetal fibresPhosphorous acidPhosphoric Acid Esters

The invention discloses a flame-retardant anti-wrinkle finishing agent for fabrics and a preparation method and application thereof. The flame-retardant anti-wrinkle finishing agent for fabrics comprises the following components in parts by weight: 8-15 parts of trimethyl phosphite, 4-9 parts of tri-isopropyl phosphite, 4-7 parts of triisopropyl borate, 3-7 parts of amino propanol ascorbyl phosphate, 8-15 parts of polyglycerol polyricinoleate, 14-20 parts of dimethyl silicone, 5-13 parts of dimethiconol stearate, 4-8 parts of secondary alcohol ethoxylate, 12-20 parts of propylene glycol and 300-400 parts of water. The preparation method comprises the following steps: mixing, heating, performing magnetic stirring, and the like. The anti-wrinkle property and the flame retardancy of a fabric treated by using the finishing agent are remarkably improved.

Owner:SUZHOU INST OF TRADE & COMMERCE

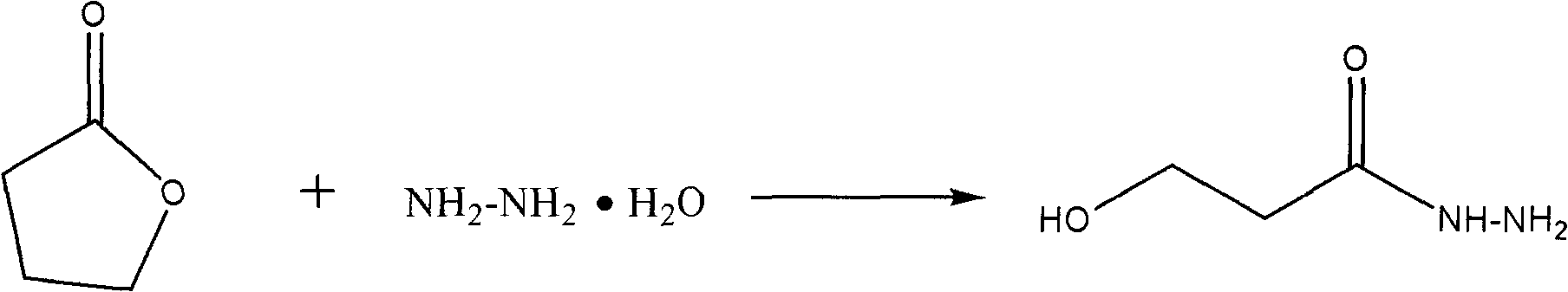

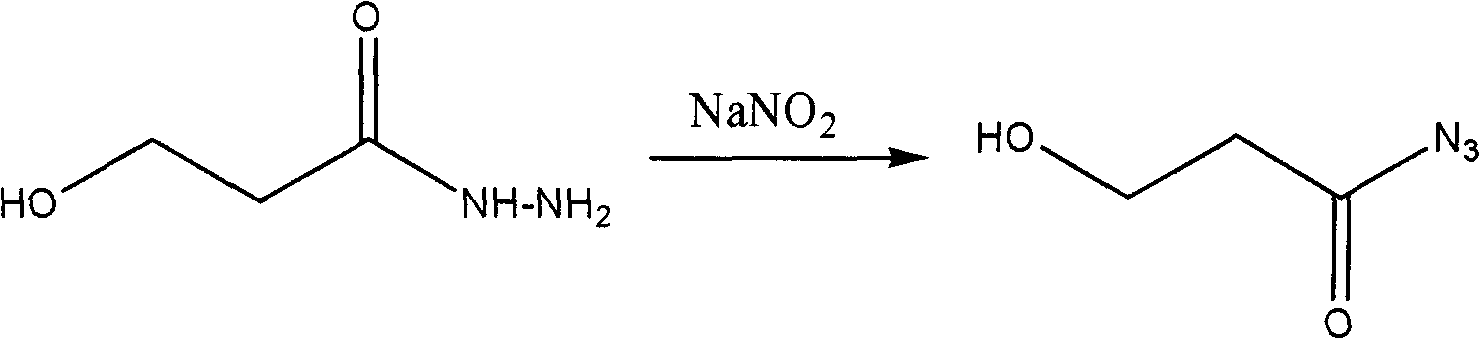

Process for synthesizing an aminopropanol

InactiveCN103012165ASimple stepsEasy to operateOrganic compound preparationAmino-hyroxy compound preparationAminopropanolsAqueous solution

The invention relates to a process for synthesizing a medicinal intermediate and particularly relates to a process for synthesizing an aminopropanol, which has the advantages of safe raw materials, high yield and mild reaction condition. According to the technical scheme of the invention, ring opening is carried out on 1,4-butyrolactone, serving as a raw material, under the action of hydrazine hydrate, the aqueous solution of sodium nitrite is added to generate acyl azide, and finally the rearranging is carried out to generate 3-aminopropanol.

Owner:李兰心

Therapeutically active compounds and their methods of use

Owner:SERVIER PHARM LLC

Process for preparing 3-amino propane sulfonic acid

InactiveCN1451652AMild reaction conditionsRaw materials are easy to getSulfonic acid preparation3-aminopropanesulfonic acidAminopropanols

A process for preparing 3-aminopropanesulfonic acid includes introducing hydrogen chloride gas into 3-aminopropanol, diluting with ethanol, cooling to educe out crystal as intermediate, preparing itsaqueous solution, sulfonating reaction with the aqueous solution of alkali-metal sulfite by reflux, acidifying by hydrochloric acid, filtering, and cooling to educe out the crystal of product.

Owner:四川科伦大药厂有限责任公司

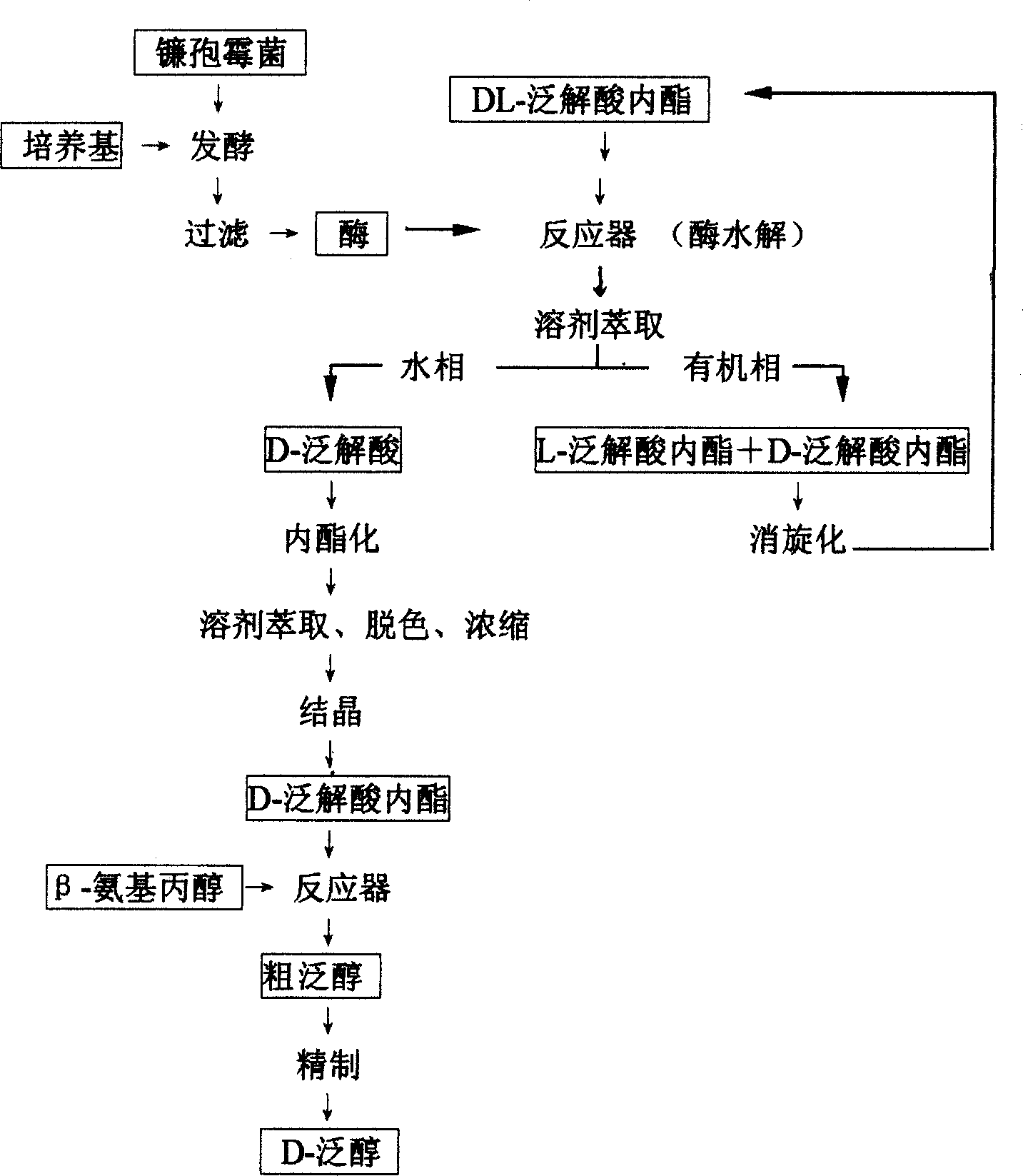

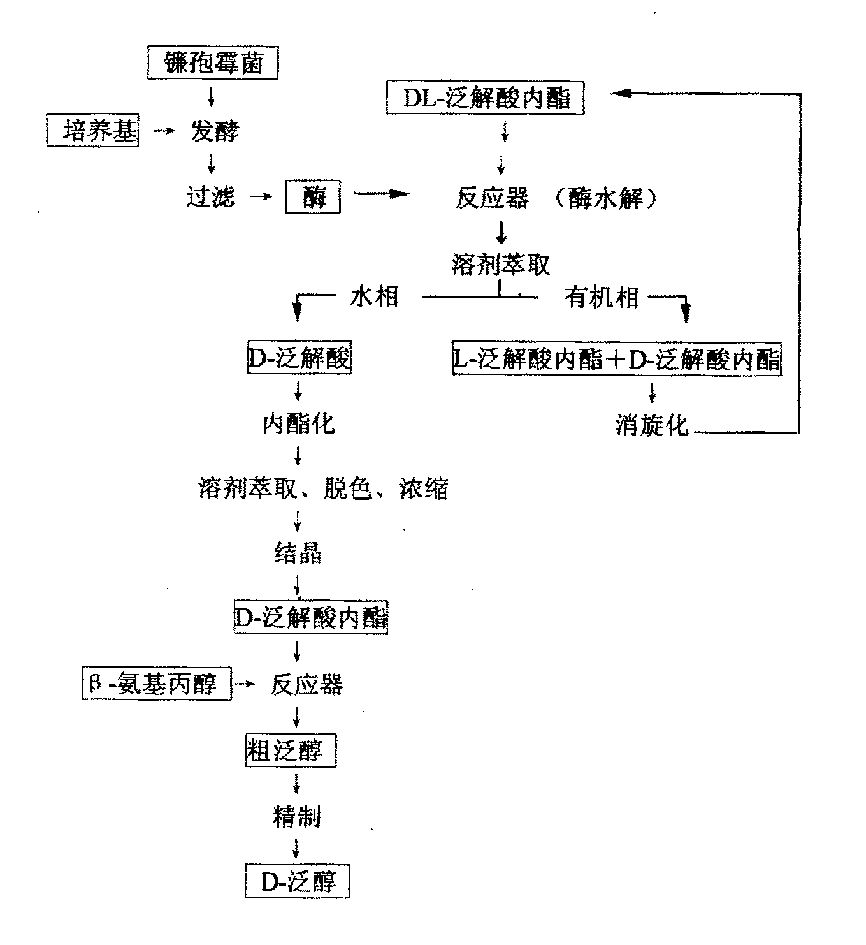

Method for preparing D-pantothenic alcohol by using microbial enzyme method

The present invention relates to a method for producing D-panalcohol by using D-pantoic acid lactone prepared by microbial enzymic hydrolysis anid beta-aminopropanol and making them produce reaction.This invention utilizes the microbial strain fusarium monoliforme SW-902 (i,e, CGMCC No.0536) which can high-produce D-pantoic acid lactone hydrolase and screened and preserved by the inventor to make fermentation and enzyme production, and then to make hydrolysis of DL-pantoic acid lactone, after lactonization of D-pantoic acid, so as to obtain pure product D-pantoic acid lactone, and the D-pantoic acid lactone and beta-aminopropanal are reacted to obtain the invented D-panalcohol.

Owner:HANGZHOU XINFU TECH CO LTD

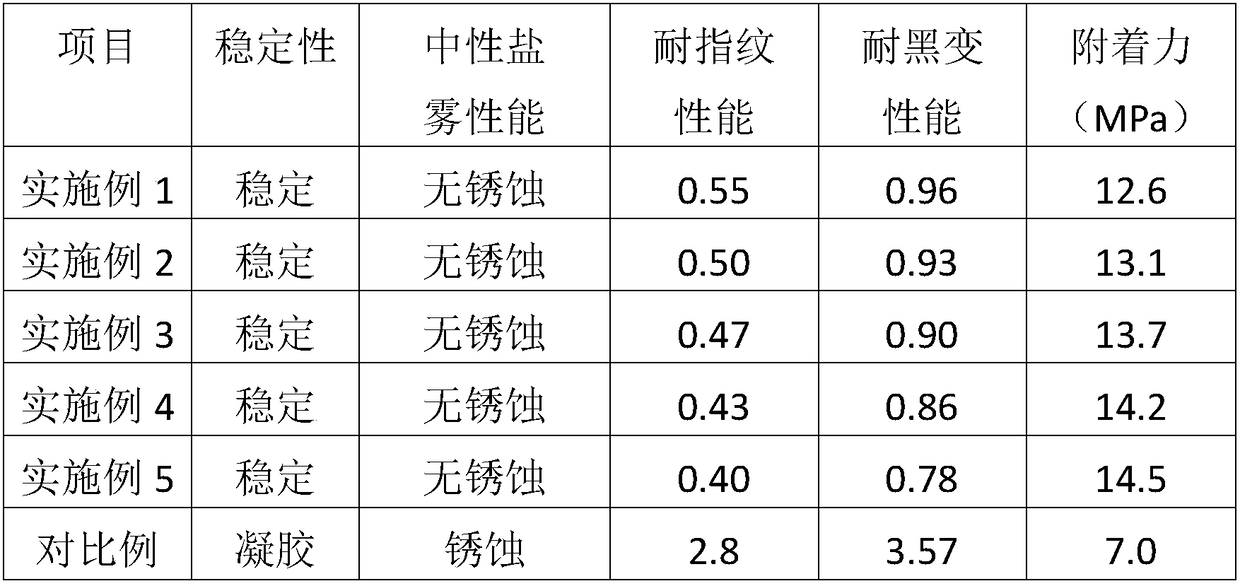

Chrome-free fingerprint-resistant environment-friendly coating and preparation method thereof

InactiveCN108117835ARaw materials are easy to getLow priceFireproof paintsAnti-corrosive paintsEpoxyPhosphate

The invention discloses a chrome-free fingerprint-resistant environment-friendly coating. The coating contains the following components in parts by weight: 40-50 parts of a film-forming condensation polymer, 5-8 parts of aminopropanol ascorbic acid phosphate modified graphene oxide, 15-20 parts of epoxy resin, 1-4 parts of a dispersing agent, 1-4 parts of a flatting agent, 1-4 parts of a defoamingagent and 20-40 parts of water. The invention further discloses a preparation method of the chrome-free fingerprint-resistant environment-friendly coating. The preparation method comprises the stepsof adding the film-forming condensation polymer into water, uniformly stirring, adding other components, stirring at a rotation speed of 800r / min-1300r / min for dispersion for 50-60 minutes, and filtering, so as to obtain a finished product. The chrome-free fingerprint-resistant environment-friendly coating has relatively excellent corrosion resistance, stability and alkali blackening resistance and is safe and environment-friendly in use.

Owner:SHENZHEN DA QUAI CHEM CO LTD

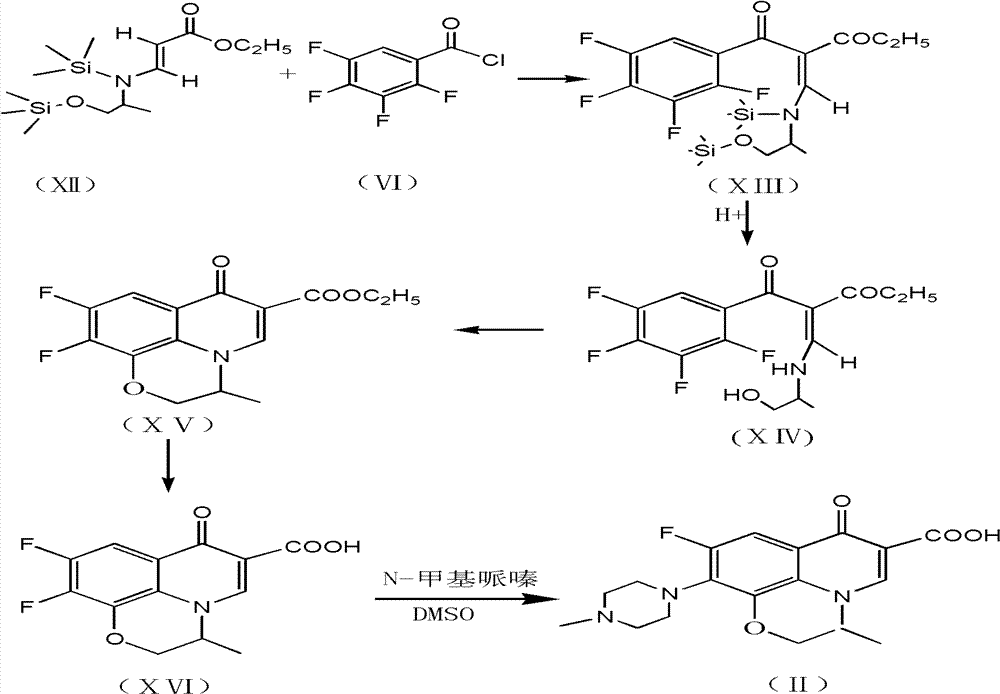

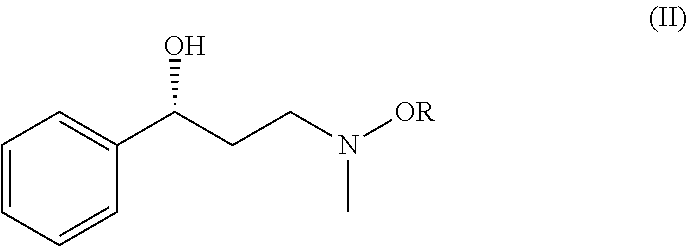

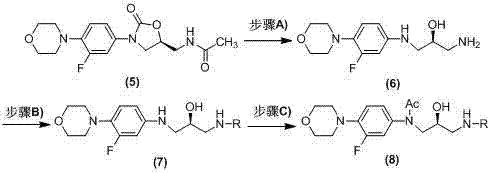

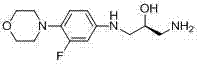

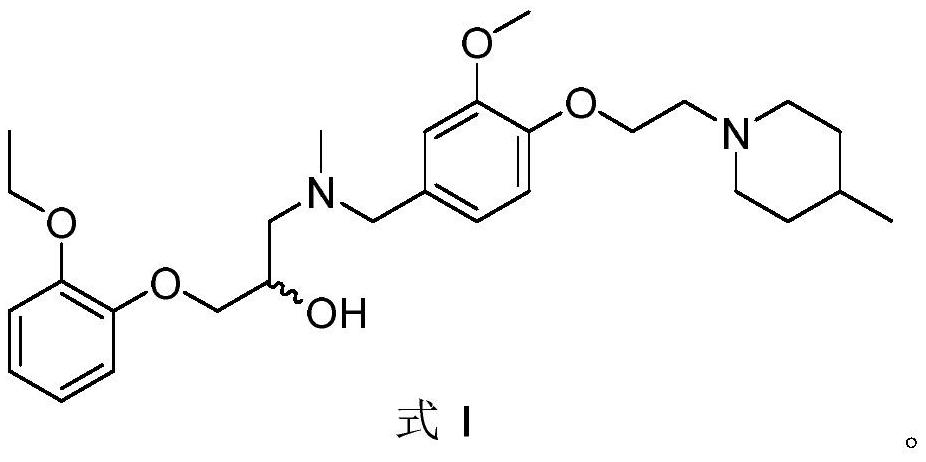

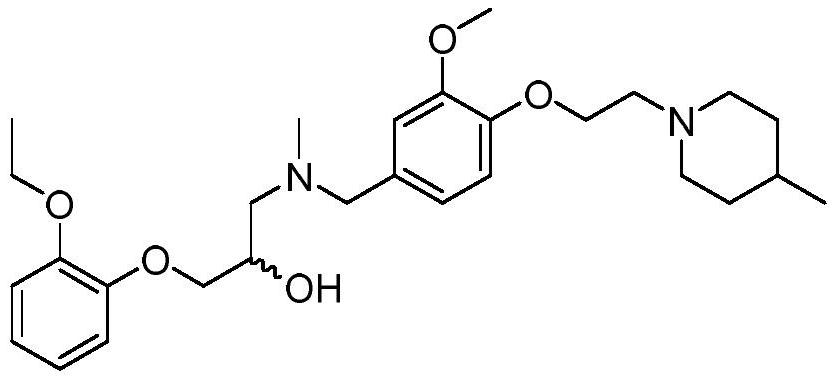

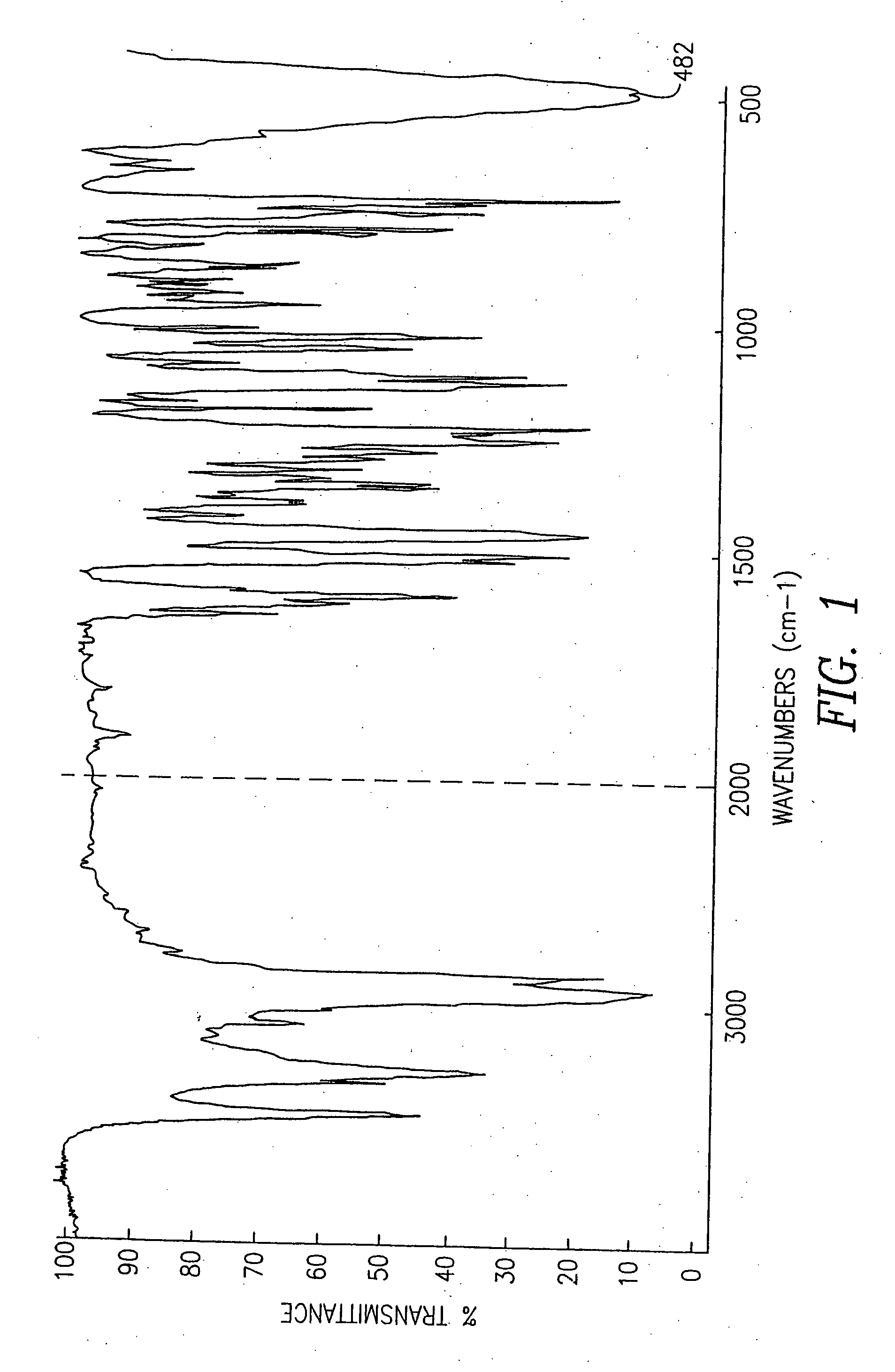

S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo

InactiveUS6989465B1Reduce usagePrevent steppingOrganic compound preparationOptically-active compound separationAlcoholMedicinal chemistry

The present invention relates to a novel compound S-(−)-1-{4-[2-(allyloxy)-ethyl] phenoxy}-3-isopropylamino propan-2-ol of formula 1 and to a process for the preparation thereof. More particularly the present invention relates to a process for preparing S-(−)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol of formula 1 by selective allylation of p-hydroxy phenyl ethanol. The present invention also relates to a process for conversion thereof to S-(−)-betaxolol of formula 2

Owner:COUNCIL OF SCI & IND RES

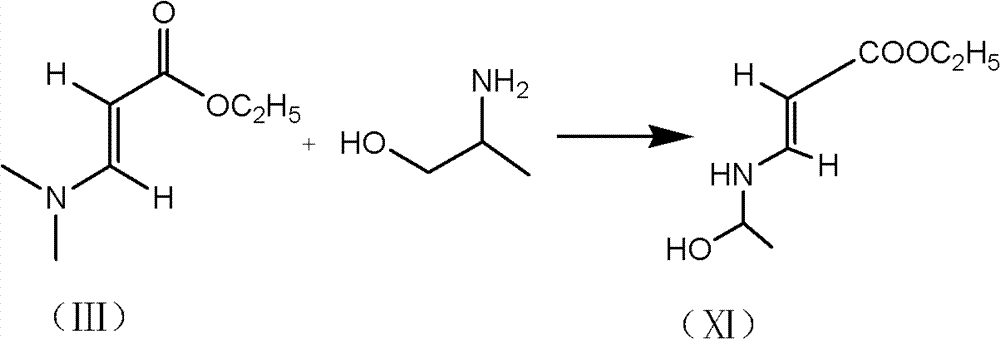

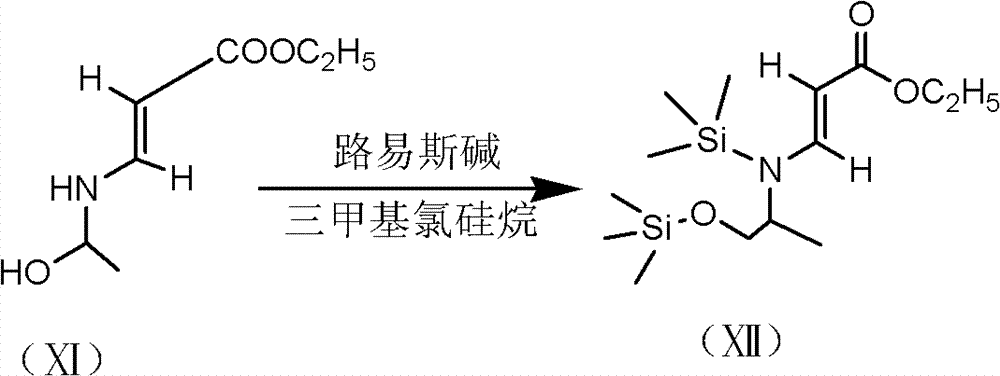

Preparation method of ofloxacin

ActiveCN103360410AReduce generationImprove utilization efficiencyOrganic chemistryBulk chemical productionPotassium fluorideOrganic layer

The invention provides a preparation method of ofloxacin. The preparation method comprises the following steps of: reacting (N,N)-dimethylamino ethyl acrylate with aminopropanols in methylbenzene; directly adding lewis base serving as a catalyst and trimethylchlorosilane to protect hydroxyl and amido; after reaction is completely finished, dropwise adding (2,3,4,5)-tetrafluorobenzoyl chloride; preserving heat; performing acid washing; removing protecting groups; concentrating an organic layer to obtain an oil layer; adding a proper amount of dimethyl formamide (DMF); diluting and dropwise adding backflow DMF having anhydrous potassium fluoride; recovering DMF and adding water to centrifuge; adding acid water into a solid to hydrolyze to obtain difluorocarboxylic acid; and completely reacting difluorocarboxylic acid and N-methyl piperazine in dimethylsulfoxide (DMSO) by using triethylamine as an acid-binding agent at 90-100 DEG C to obtain ofloxacin. According to the process, hydroxyl and amido are protected by using trimethylchlorosilane, so that the utilization degree of (2,3,4,5)-tetrafluorobenzoyl chloride is effectively increased, and the generation of impurities is reduced to ensure that the reaction yield of intermediate difluorocarboxylic acid is increased by 10 percent.

Owner:TOPFOND PHARMA CO LTD

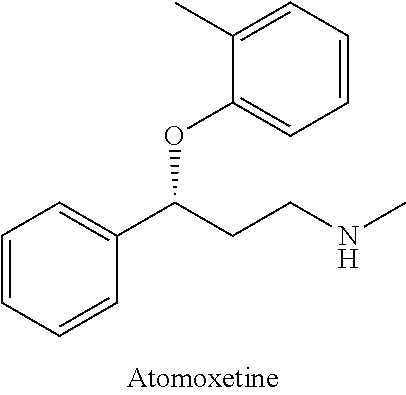

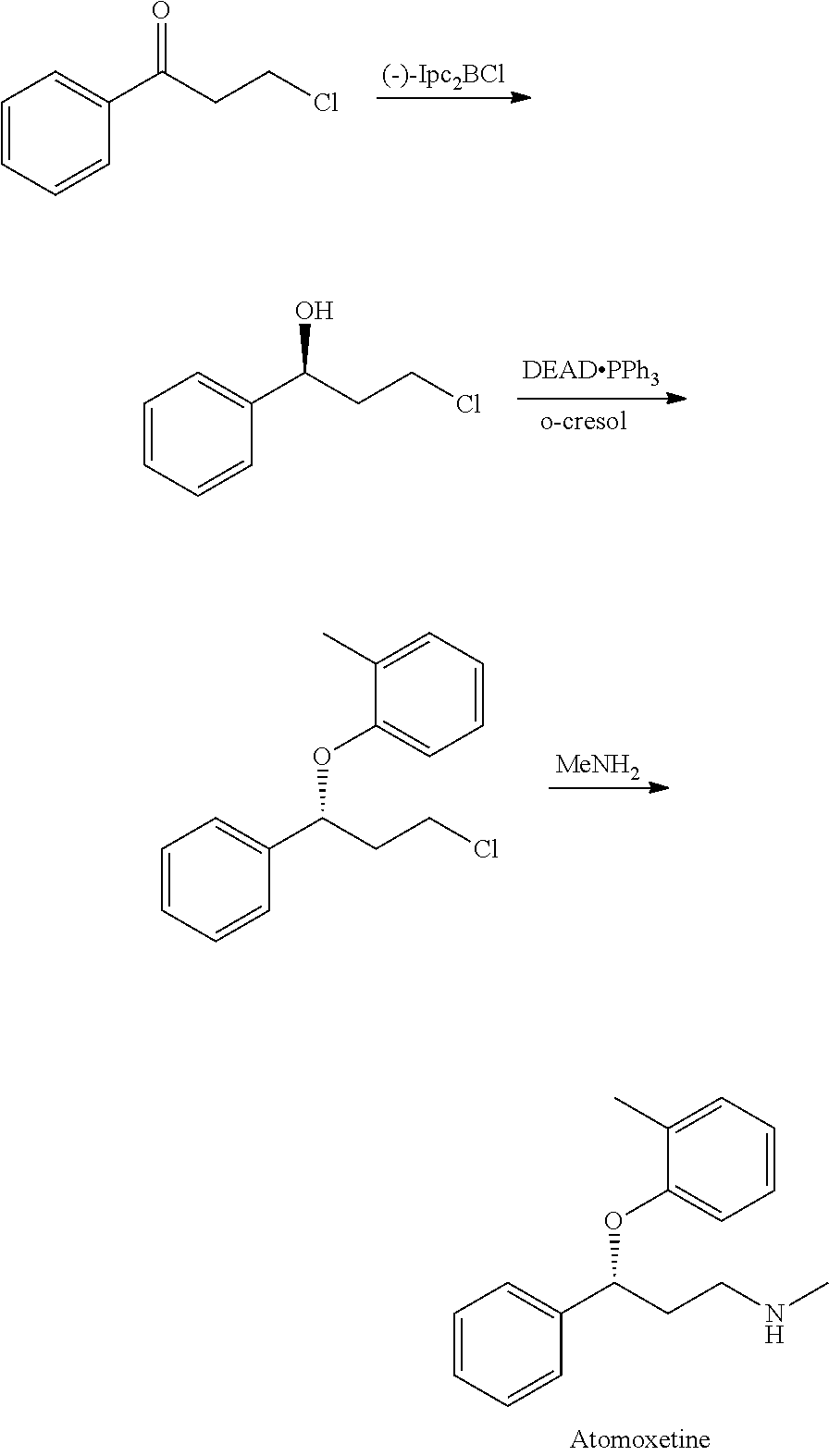

Method for preparing atomoxetine

ActiveUS20110319664A1Ecological and economicalOrganic compound preparationAmino-hyroxy compound preparationCombinatorial chemistryAtomoxetine

Owner:SCI PHARMTECH

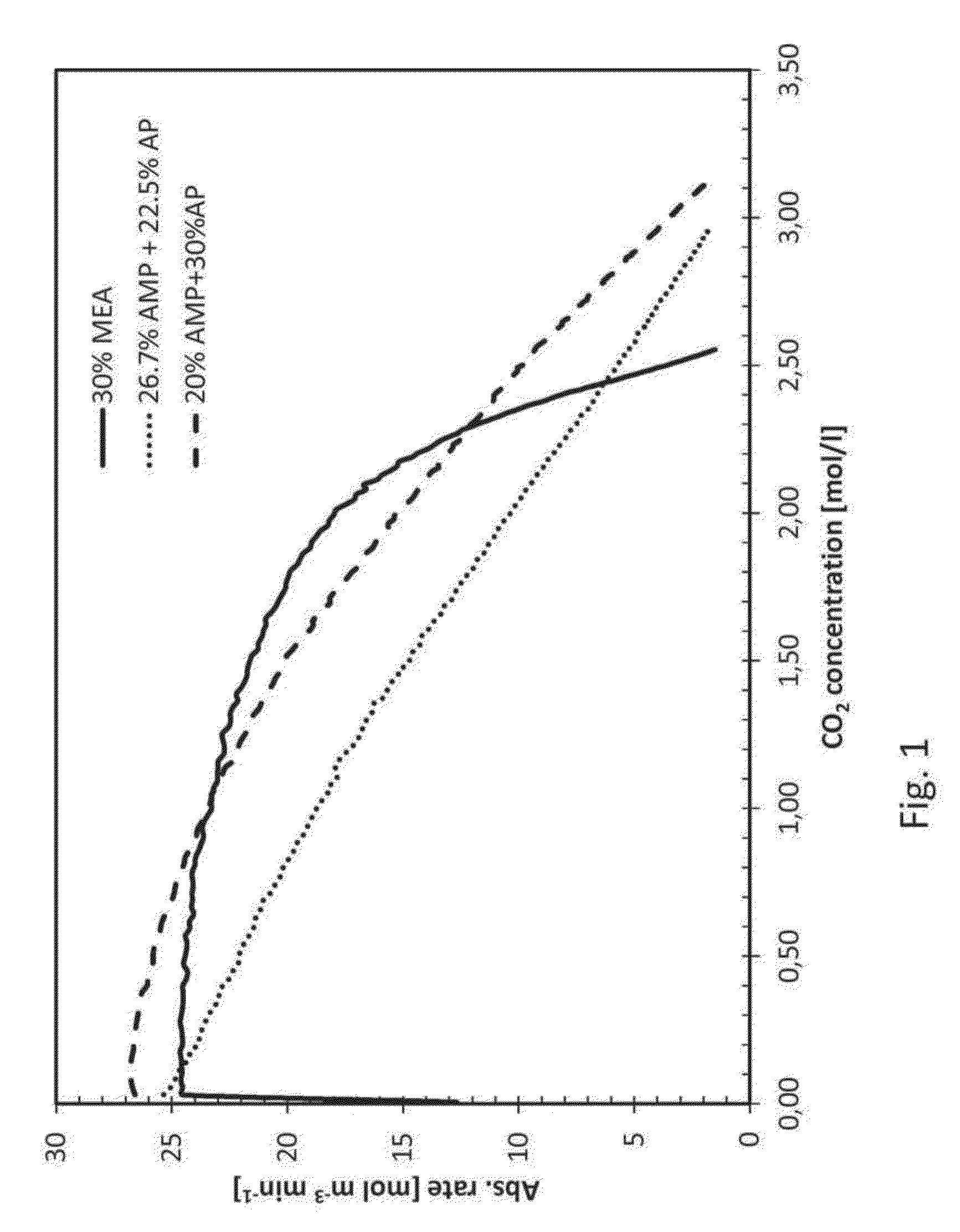

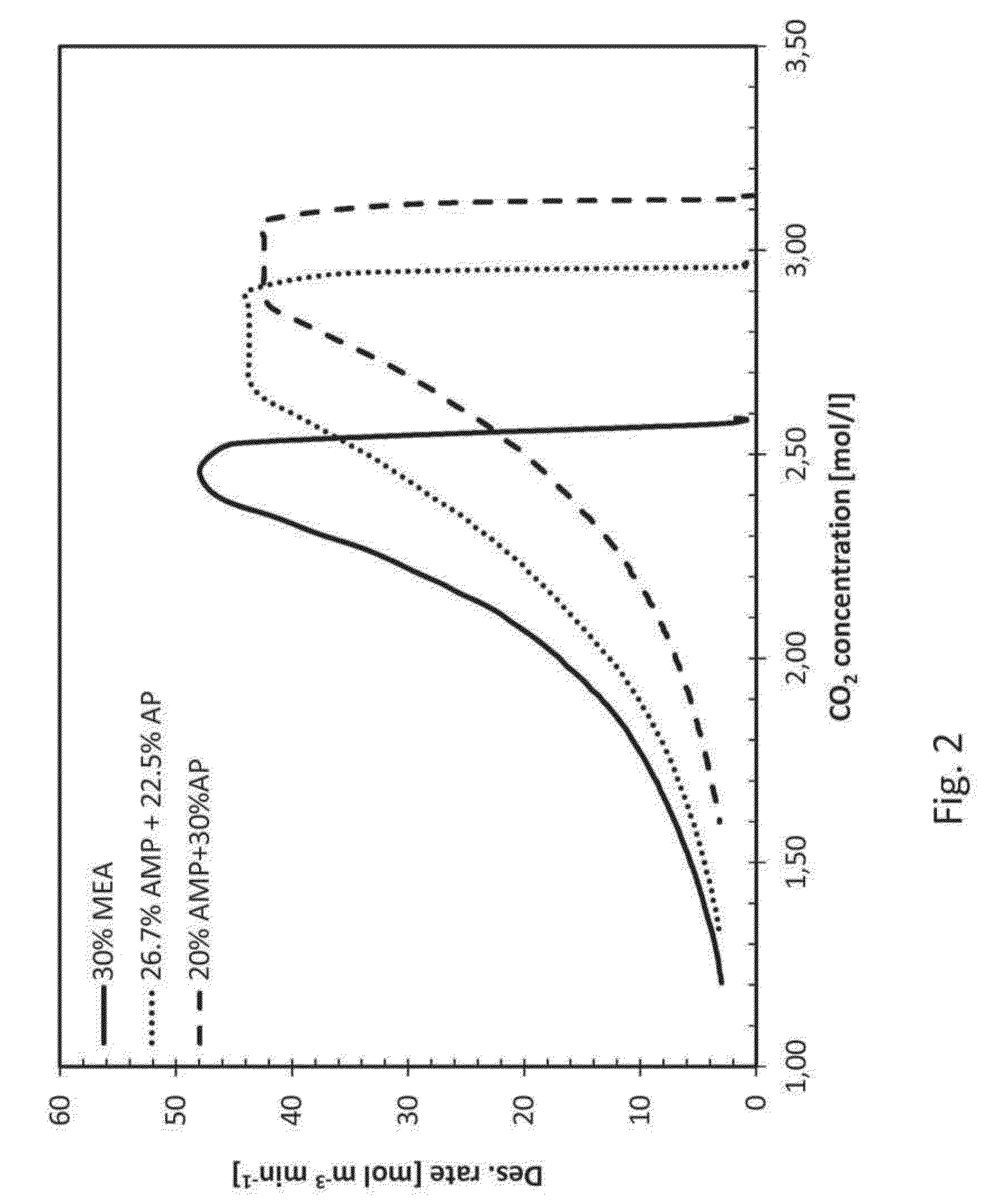

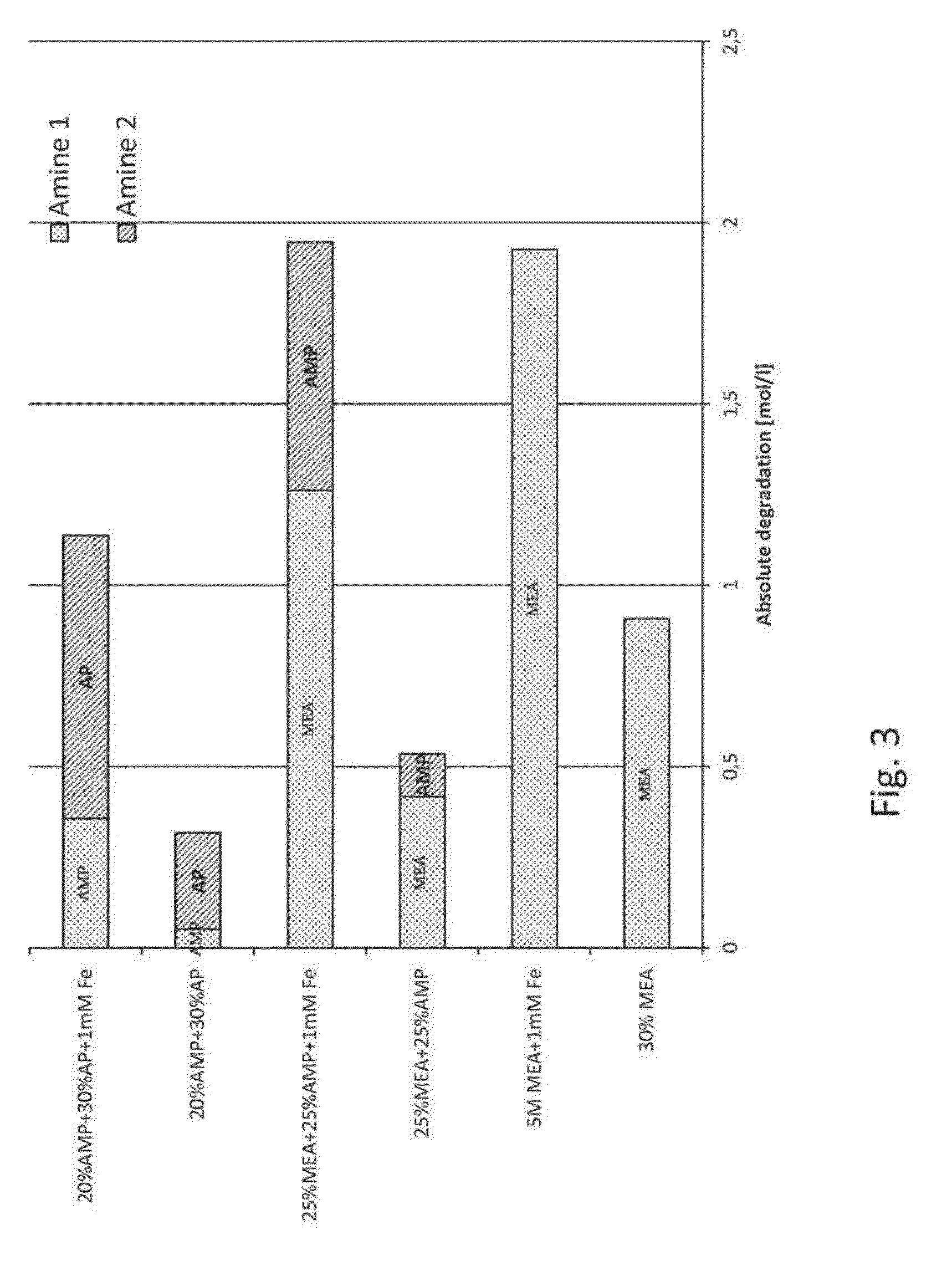

An aqueous co2 absorbent comprising 2-amino-2-methyl-1-propanol and 3-aminopropanol or 2-amino-2-methyl-1-propanol and 4-aminobutanol

InactiveUS20150306538A1Increase oxidative degradationLess corrosiveGas treatmentCarbon compounds1-PropanolAminopropanols

An aqueous CO2 absorbent comprising a combination of 2-amino-2-methyl-1-propanol (AMP) and 3-aminopropanol (AP), or AMP and 4-aminobutanol (AB), is described. A method for capturing CO2 from a CO2 containing gas using the mentioned absorbent, and the use of a combination of AMP and AP, or a combination of AMP and AB are also described.

Owner:AKER SOLUTIONS AS

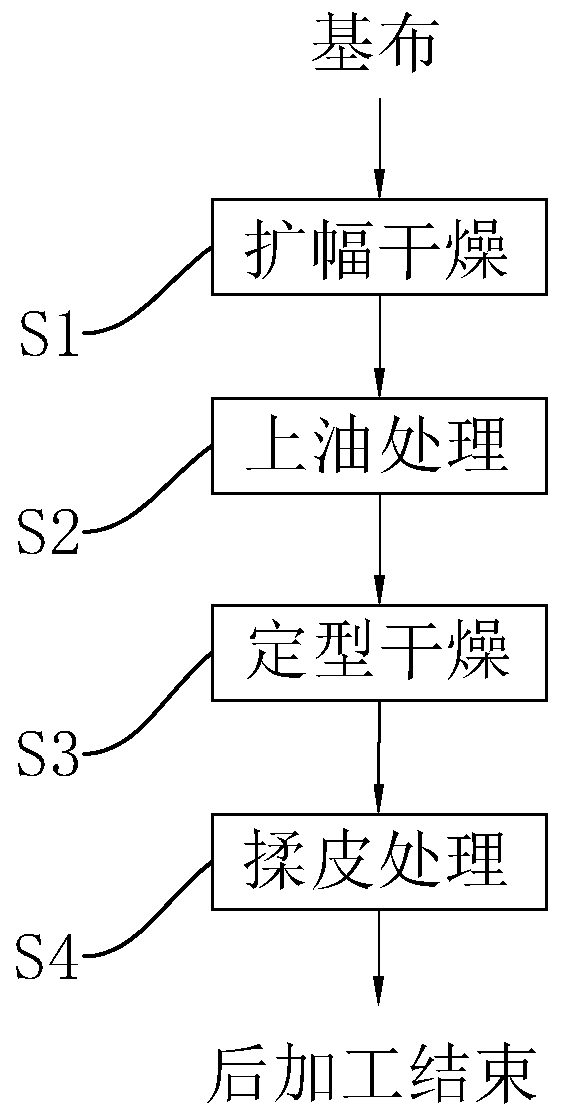

Base fabric post-processing technology for superfine fiber synthetic leather

ActiveCN110306315AHigh tear strengthAvoid wrinklesFabric breaking/softeningGrip property fibresKojic acidFiber

The invention relates to the technical field of preparation methods of superfine fiber synthetic leather, and discloses a base fabric post-processing technology of superfine fiber synthetic leather. Adecreased base fabric is treated by the technology comprising the following steps: S1, expanding and drying; S2, oiling, wherein the base fabric which is expanded and dried in step S1 is repeatedly soaked in an oiling agent. The oiling agent comprises the following chemical components in parts by weight: 40-60 parts of amino silicone oil, 30-50 parts of aminopropanol kojic acid phosphate, 6-9 parts of diatomite, 3-7 parts of talcum powder and 10-14 parts of a surfactant; S3, shaping and drying; and S4, carrying out puffing treatment. By using the oiling agent mentioned above, the tearing strength of the base fabric is improved.

Owner:浙江永祥合成材料有限公司

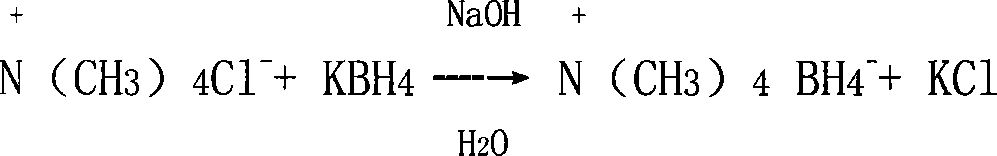

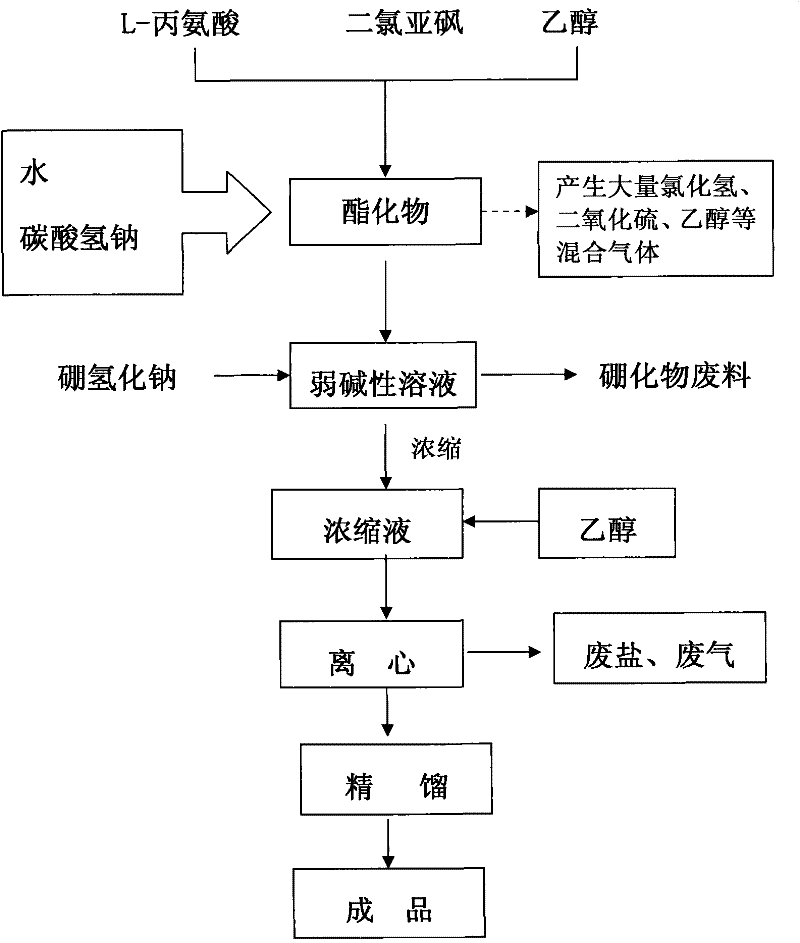

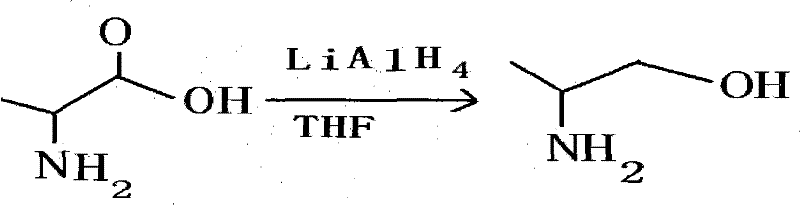

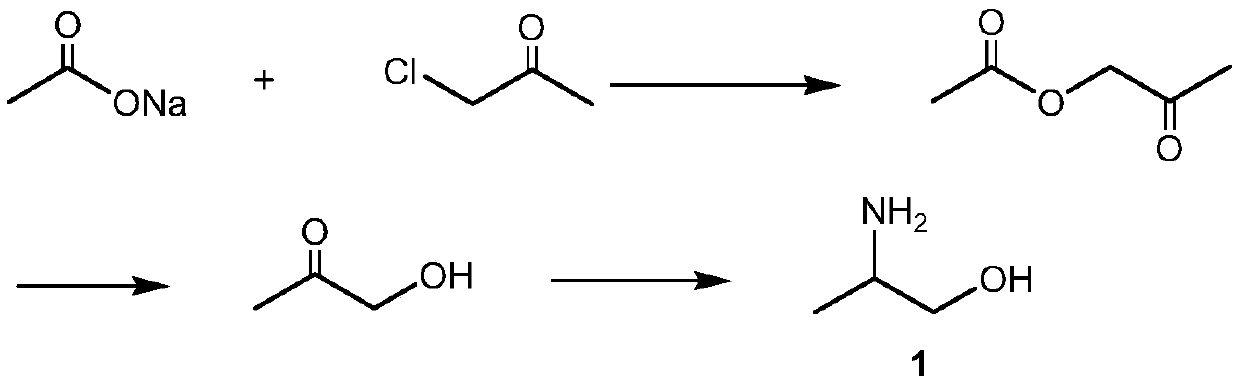

Method for synthesizing L-2-amino propanol

InactiveCN101200431AReduce unit consumptionLow costOrganic compound preparationAmino-hyroxy compound preparationPropanolPotassium borohydride

The invention discloses a method for the synthesis of L-2-aminopropanol. L-alanine is taken as starting material, and L-alanine is esterified, and then is reduced for 0.5-2h in organic solvent with tetramethylammonium borohydride as reducing agent; subsequently, is separated after reduction for 2-6h under 35-55 DEG C. The tetramethylammonium borohydride is prepared by the reaction of potassium borohydride with tetramethylammonium chloride, sodium chloride is added during reaction, the reacted product is separated by removing part of water crystallization. The yield of one crystallization separation is greater than or equal to 98 percent, and purification is not required and the product can be used to reduction directly. Since the method adopts the novel reducing agent, the original 2 tons of potassium borohydride required by each ton of L-2- aminopropanol is reduced to 1.25 tons, and as a result, the cost of levofloxacin is largely reduced.

Owner:HEFEI UNIV OF TECH

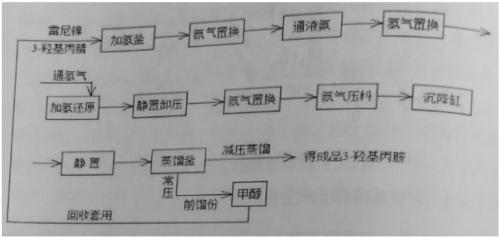

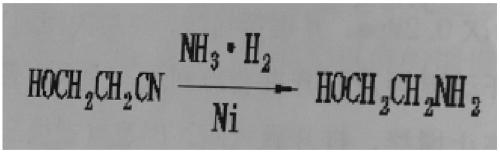

Preparation method of 3-aminopropanol

ActiveCN109456207AIncrease profitSimple processOrganic compound preparationChemical recyclingDistillationNitrogen gas

The invention provides a preparation method of 3-aminopropanol, which is high in conversion rate. The invention adopts the following technical scheme: adding 3-hydroxypropionitrile into a reactor witha nickel catalyst and silver nitrate, and then adding an amine reagent under nitrogen; then introducing hydrogen into the reactor, stirring for reducing reaction, and performing precipitation and distillation to prepare the 3-aminopropanol. The raw materials are high in utilization rate; the separation process is simple and clear; the energy consumption is low; the production cost of a product islow; and the solvent and the catalyst can be recycled for use.

Owner:昆山市祥和精细化工厂

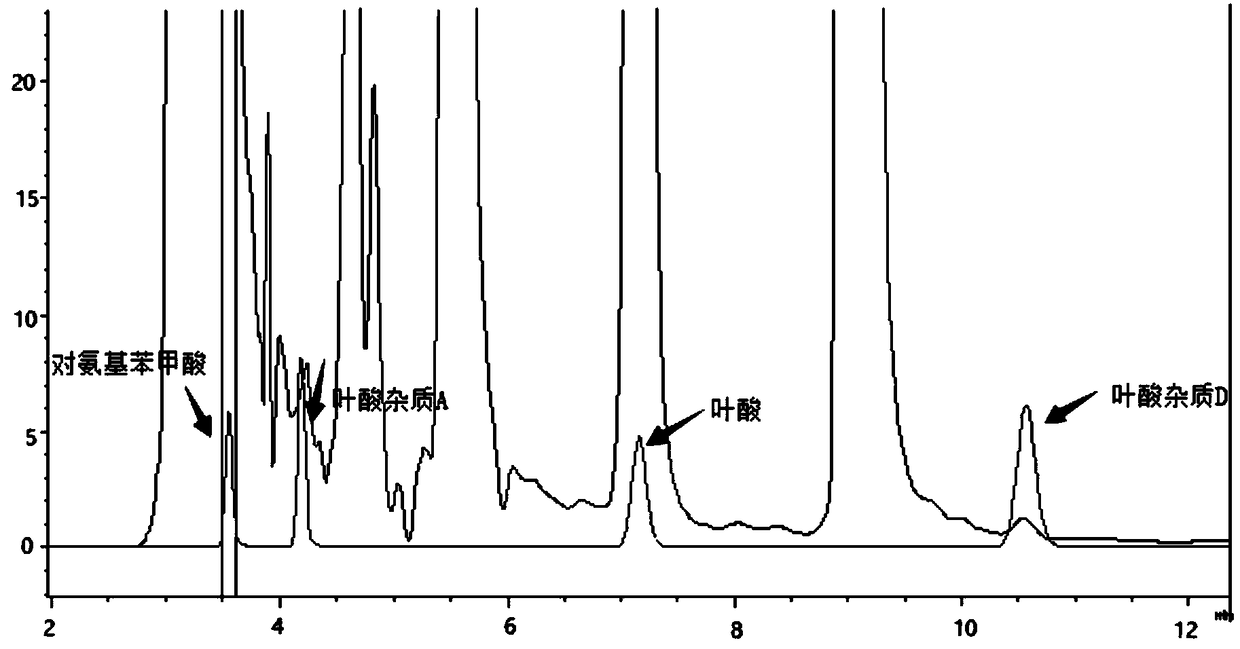

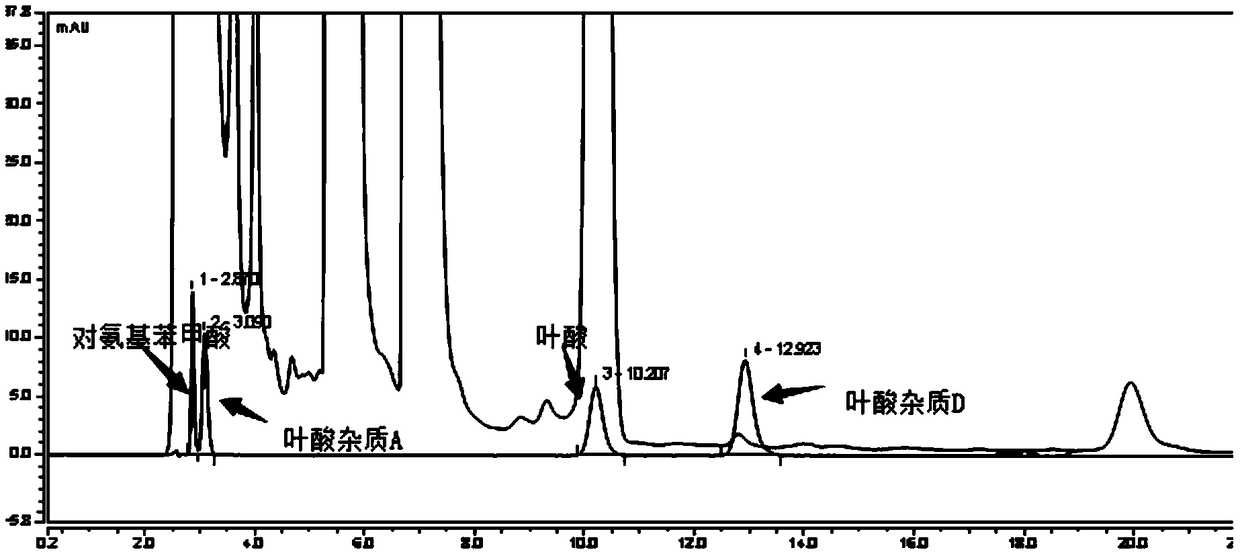

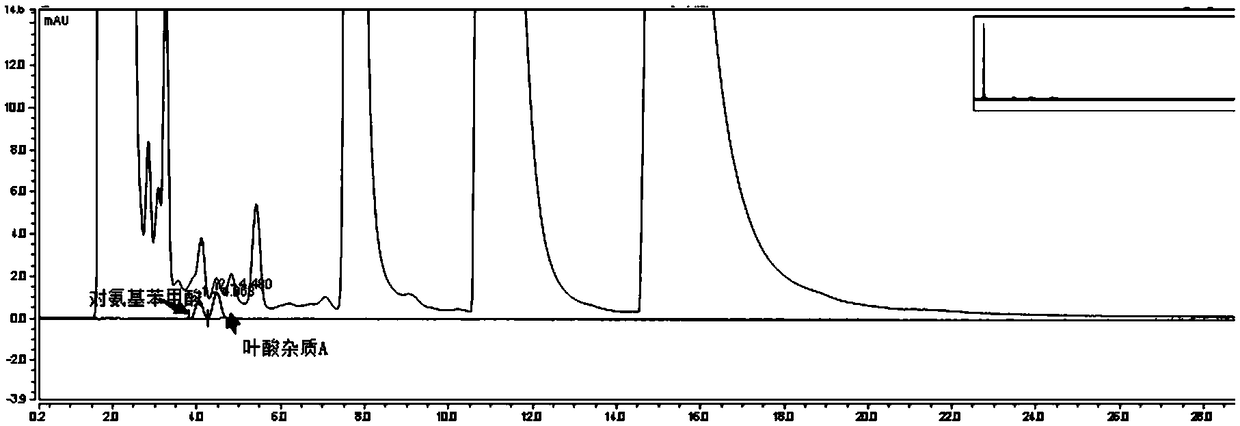

Impurity analysis method for multiple vitamin preparations

ActiveCN109239230ALong retention timeStrong UV Absorbing PropertiesComponent separationP-Aminobenzoic acidVitamin Preparations

The invention relates to an impurity analysis method for multiple vitamin preparations. The method comprises the following steps of preparing a test solution of the vitamin preparations; dissolving o-phthalaldehyde and 2-mercaptoethanol based on a mass ratio of 1 to (2-5) in methanol, adding a boric acid buffer solution, and adjusting the pH value to 3-5 to obtain a derivatization reagent; and taking the test solution, adding the derivatization reagent to carry out online derivatization reaction, and injecting the derivatized test solution into a high performance liquid chromatograph, therebydetecting impurities in the test solution. According to the method, folic acid impurity A, folic acid impurity D, p-aminobenzoic acid and 3-aminopropanol in the vitamin preparations can be effectivelydetected; and the method is high in sensitivity and good in specificity.

Owner:CHINESE MEDICINES GUANGZHOU

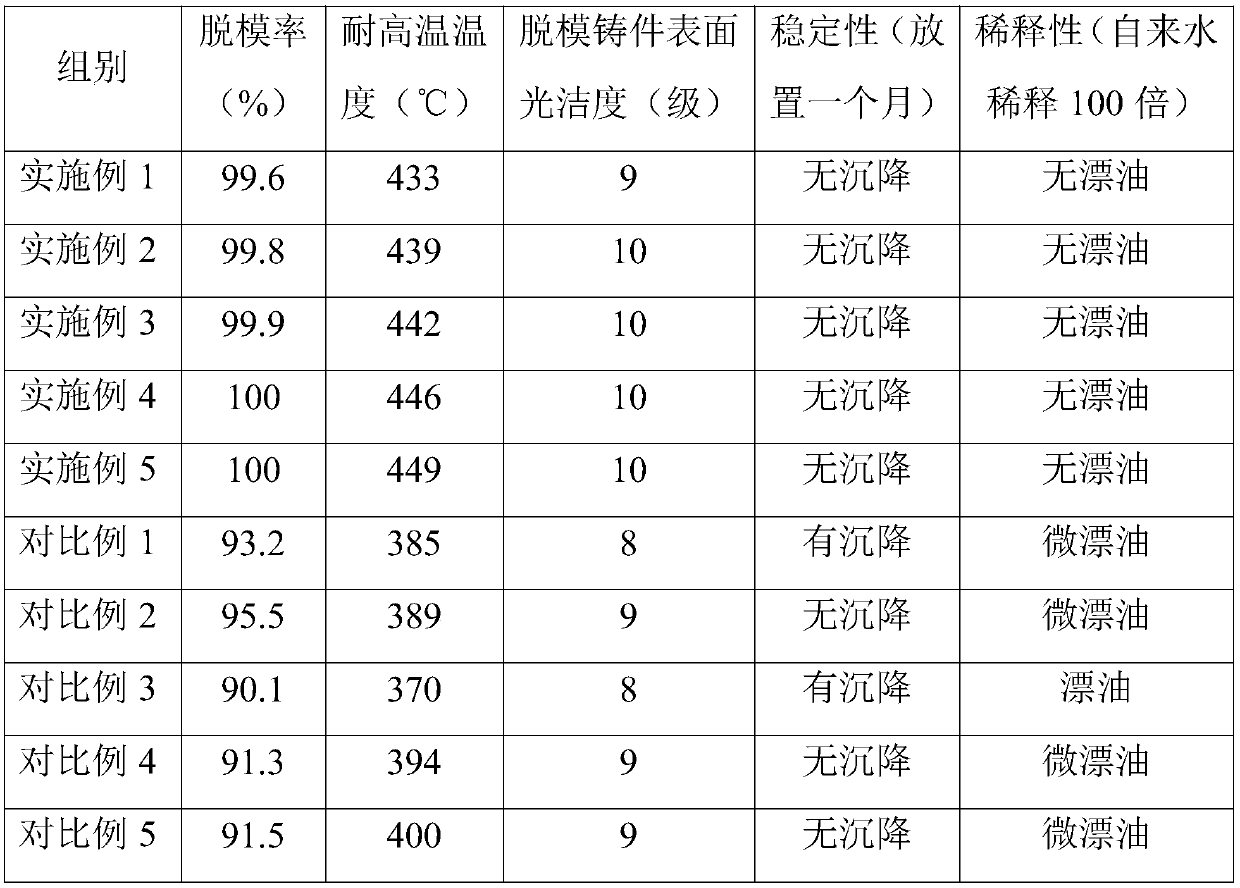

Metal pressure casting releasing agent and preparing method thereof

The invention discloses a metal pressure casting releasing agent. The releasing agent comprises, by mass percent, 8 to 15% of epoxy soybean oil modified amino silicone oil, 20 to 30% of Tween 80-ricinoleic acid n-hexadecyl ester-oxprenolol glucosiduronide copolymer, 2 to 5% of 1-hexadecanaminium,2-hydroxy-N-(2-hydroxyethyl)-N,N-dimethyl-,chloride, 1 to 4% of aminopropanol ascorbic acid phosphate,2 to 4% of an emulsifying agent, 0.5 to 1.2% of a defoaming agent and the balance water. The invention further discloses a preparing method of the metal pressure casting releasing agent. The metal pressure casting releasing agent has the good lubricating and mold releasing performance under the high temperature environment, stability is good, when a casting after pressure casting is separated froma mold, mold releasing is easy, smoothness on the surface of the casting after mold releasing is high, and the mold protection effect is good.

Owner:HUNAN QIWEI TECH CO LTD

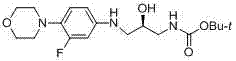

Salt of 3-amino-2-propanol acetamide compound, as well as preparation method and use thereof

InactiveCN103483294AAvoid degradationImprove stabilityOrganic chemistryBulk chemical productionBenzoic acidO-Phosphoric Acid

The invention discloses a salt (I) of a 3-amino-2-propanol acetamide compound, and also discloses a preparation method of the salt, and use of the salt as a reference substance or a standard substance of related substance in quality control of a linezolid preparation. In a formula, A represents boric acid, phosphoric acid, C1-8 fatty acid, trifluoroacetic acid, benzoic acid, salicylic acid, phthalic acid, mandelic acid, oxalic acid, maleic acid, fumaric acid, succinic acid, tartaric acid, citric acid, methanesulfonic acid, ethanesulfonic acid, benzenesulfonic acid, and p-toluenesulfonic acid; n represents 1 / 2 or 1; the compound is a racemate, an (S)-optical isomer or an (R)-optical isomer.

Owner:SICHUAN UNIV

Metal surface zinc-nickel alloy electroplating solution and electroplating process

The invention discloses a metal surface zinc-nickel alloy electroplating solution. The formula of the electroplating solution comprises 20-50 g / L of zinc oxide, 10-20 g / L of nickel sulfate, 120-160 g / L of sodium hydroxide, 10-30 g / L of a complexing agent, 0.5-5 g / L of an additive and 1-5 g / L of a brightening agent, wherein the complexing agent is composed of ammonium citrate, triethanolamine and 1, 3-diamino-2-propanol according to the mass ratio of 1: (1-3): (3-5), the additive is composed of sodium phytate and hexadecyl trimethyl ammonium bromide according to the mass ratio of 1: (3-5), thebrightening agent is composed of saccharin, vanillin, 2-butyne-1, 4-diol and sodium allysulfonate according to the mass ratio of (5-10): (1-3): (3-5): 1. The electroplating solution can provide a bright zinc-nickel alloy coating with refined grains, improves the deep plating capability and dispersion performance of the coating, and is particularly suitable for electroplating of long-tube-shaped workpieces.

Owner:上海炫帝实业有限公司

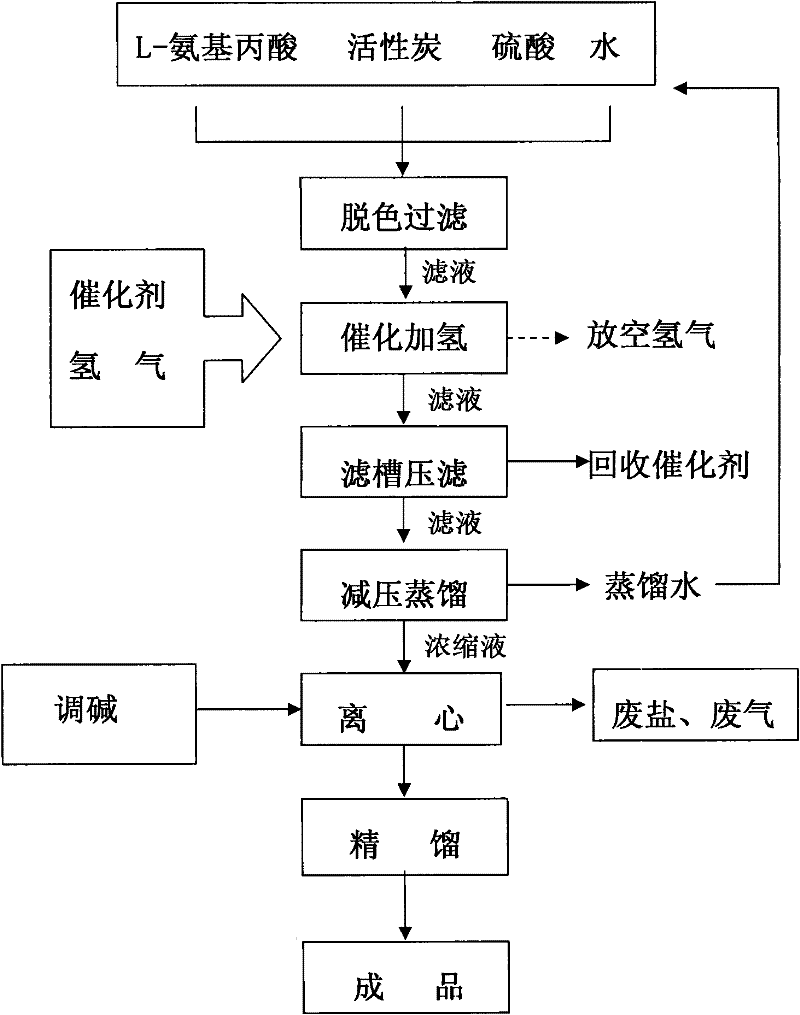

Synthetic method of L-aminopropanol

InactiveCN101648879BHigh yieldReduce generationOrganic compound preparationAmino-hyroxy compound preparationOrganic solventRuthenium

The invention provides a preparation method of L-aminopropanol, using L-alanine and H2 as main raw materials and carbon ruthenium as a catalyst to carry out direct catalytic hydrogenation to synthesize the L-aminopropanol. The method increases the selectivity of process reaction, accelerates reaction speed and shortens reaction step, thereby greatly reducing the production cost, increasing the L-aminopropanol yield, reducing the production of harmful wastes and realizing the greenization of the reaction process; and the aspects of energy saving and emission reduction of SOD and SO2 are obviously improved in order to realize less environment pollution. Any organic solvent is not added to the whole reaction process, thereby reducing the emission of pollutants, and protecting environment.

Owner:浙江凯迪药业有限公司

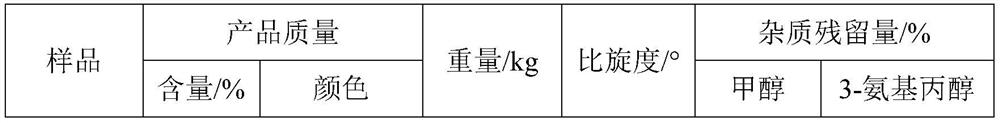

Preparation method and application of ruthenium carbon catalyst used for preparation of L-aminopropanol

InactiveCN107715870AEvenly dispersedEvenly distributedOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonReduction treatment

The invention provides a preparation method for an aruthenium carbon catalyst used for the preparation of L-aminopropanol. The method includes the following steps that 1, pretreatment is conducted onactivated carbon; 2, a soluble ruthenium compound and a soluble salt of an auxiliary agent are dissolved in a solvent, and a precursor solution is obtained; 3, the precursor solution is added in the activated carbon through atomization and dispersion, after uniform stirring, slurry is obtained, and then pH value adjustment, adsorption, filtration and washing are conducted; 4, after the solvent issubjected to beating, high-temperature and high-pressure reduction treatment is conducted, then, filtration and washing are sequentially conducted, and a ruthenium carbon catalyst is obtained. The invention further provides a method for applying the catalyst to the preparation of L-aminopropanol through catalytic hydrogenation of L-alanine. The prepared aruthenium carbon catalyst is high in activity and suitable for the preparation of L-aminopropanol through catalytic hydrogenation of L-alanine, the product yield is more than 90%, the catalyst performance is stable, the reaction time is short,and the catalyst is used repeatedly and has good repeatability.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Polylactic acid preparation method

InactiveCN105542154AHigh capping rateEasy to makeTert-Butyloxycarbonyl protecting groupTrifluoroacetic acid

The invention discloses a polylactic acid preparation method, belongs to the field of preparation of polylactic acid, and concretely provides an aminopolylactic acid preparation method with simple preparation process and high amino termination rate. The aminopolylactic acid preparation method comprises the following steps: reacting tert-butoxycarbonyl carbonic anhydride with aminopropanol to synthesize tert-butyloxycarbonyl aminopropanol, initiating ring-opening polymerization of L-lactide with tert-butyloxycarbonyl aminopropanol as an initiator under the catalysis of stannous octoate to synthesize tert-butyloxycarbonylamino-terminated polylactic acid, carrying out trifluoroacetic acid treatment to remove a tert-butyloxycarbonyl group to obtain amino-terminated polylactic acid, and initiating ring-opening polymerization of w-benzyloxycarbonyl-L-lysine-N-carboxylic anhydride with aminopolylactic acid as a macromolecular initiator to synthesize polylactic acid-polylysine. The method has a simple preparation process, and the polylactic acid-polylysine prepared in the invention has a high amino termination rate.

Owner:SHAANXI YUHANG ELECTRONICS

Preparation method of D-panthenol

PendingCN112174845ALess impuritiesHigh purityOrganic compound preparationCarboxylic acid amide separation/purificationPropanolReaction temperature

The invention provides a preparation method of dianhydrol. The preparation method comprises the following steps: carrying out acylation reaction on D-pantoic acid lactone and 3-aminopropanol in a solvent to obtain a mixed solution containing D-panthenol, wherein the reaction temperature of the acylation reaction is 10-35 DEG C. The yield of the D-panthenol obtained by the preparation method is high, and the purity is high; meanwhile, the recovered solvent can be continuously used, and is safe and environment-friendly.

Owner:安徽泰格生物科技有限公司

Preparation method of 3-aminopropanol

ActiveCN111056963AAtom utilization is highLower requirementCarboxylic acid nitrile preparationOrganic compound preparationPropanolPtru catalyst

The invention relates to a preparation method of 3-aminopropanol, wherein the preparation method comprises the following steps: (1) carrying out a reaction on acrylonitrile with benzyl alcohol under the catalysis of a base catalyst, and separating the obtained reaction solution to obtain 3-benzyloxypropionitrile; and (2) in a liquid-phase reaction system in the presence of a hydrogenation catalyst, carrying out a hydrogenation reaction on the 3-benzyloxypropionitrile, separating the obtained reaction liquid to obtain 3-aminopropanol, and recycling the obtained by-product toluene as an extractant in the step (1).

Owner:SHANDONG NHU FINE CHEM SCI & TECH CO LTD +2

Preparation method and application of compound

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

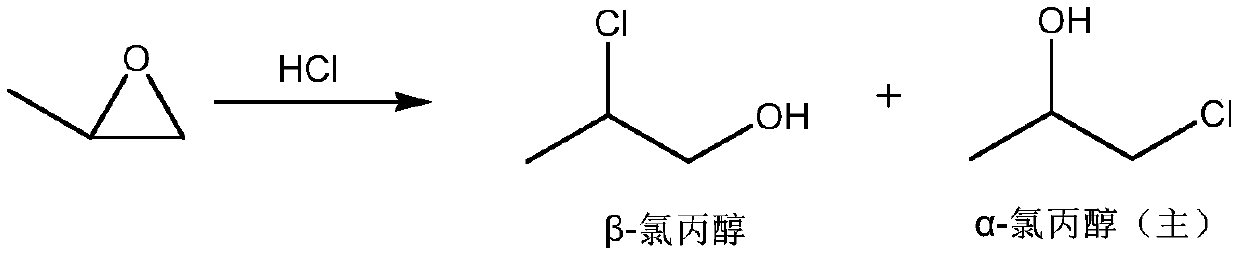

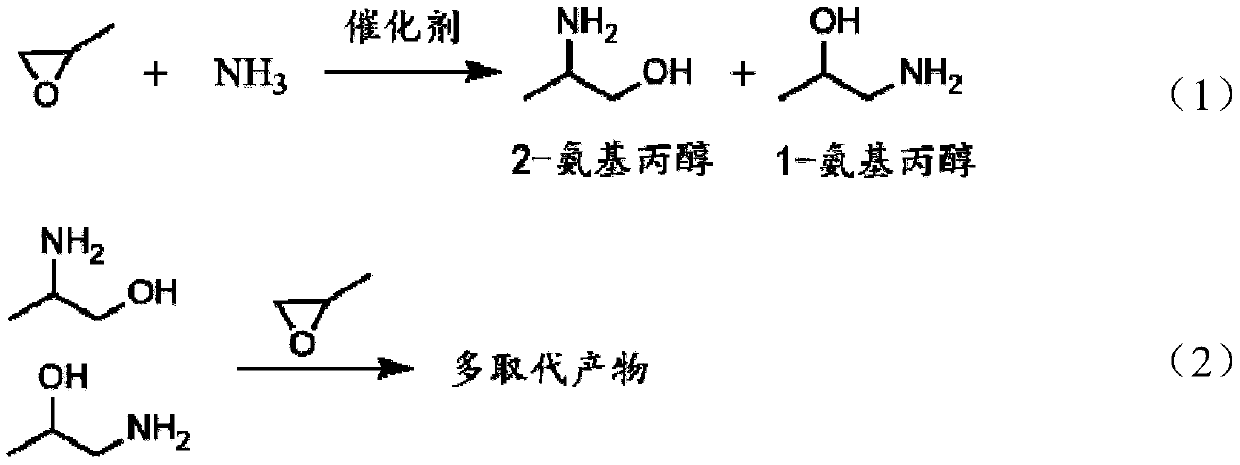

Synthesis method of 2-aminopropanol

ActiveCN110981738AReduce generationAtom economy is highOrganic compound preparationAmino-hyroxy compound preparationPropanolPtru catalyst

The invention discloses a synthesis method of 2-aminopropanol. According to the method, epoxypropane and liquid ammonia are taken as raw materials, epoxypropane and liquid ammonia are introduced intoa fixed bed reactor, the molar ratio of epoxypropane to liquid ammonia is 1: (5-20), and under the action of a rare earth modified catalyst, reaction is carried out for 10-60s at the temperature of 100-200 DEG C, so that 2-aminopropanol is obtained. The method is reasonable in process, simple and convenient to operate, high in atom economy and low in emission of three wastes, and meets the requirements of industrial production.

Owner:杭州新本立医药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo](https://images-eureka.patsnap.com/patent_img/5cb0837c-51a6-4a83-93d4-99f65b85117c/US06989465-20060124-C00001.png)

![S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo](https://images-eureka.patsnap.com/patent_img/5cb0837c-51a6-4a83-93d4-99f65b85117c/US06989465-20060124-C00002.png)

![S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo S-(-)-1-{4-[2-(allyloxy)-ethyl]phenoxy}-3-isopropylamino propan-2-ol, process for preparation thereof and process for preparation of S-(-)betaxolo](https://images-eureka.patsnap.com/patent_img/5cb0837c-51a6-4a83-93d4-99f65b85117c/US06989465-20060124-C00003.png)