Preparation method of high-flux and anti-pollution reverse osmosis membrane and application of membrane

A reverse osmosis membrane, anti-pollution technology, used in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc. It is convenient for industrial scale-up production, the negative charge potential is reduced, and the hydrophilicity is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 (blank control embodiment group)

[0057] Prepare an aqueous solution of 8% by weight of p-phenylenediamine, soak the polysulfone support layer for 5 minutes, take it out and dry it.

[0058] Prepare a 1.0% by weight terephthaloyl chloride n-heptane solution, soak the polysulfone support layer for 5 minutes, take it out and evaporate it to dryness. Observe the surface of the membrane, immerse in pure water after the excess solution on the surface volatilizes, soak for 30 seconds, and rinse with clean water to obtain a reverse osmosis membrane.

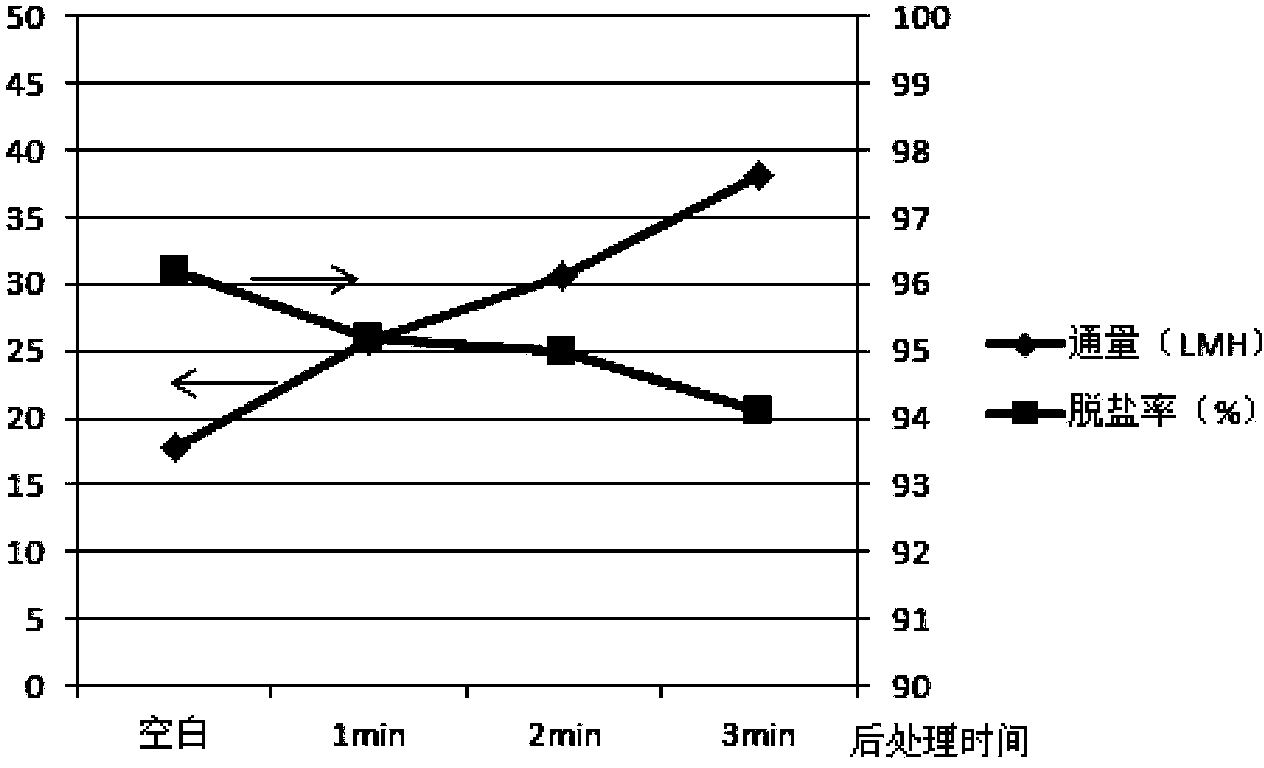

[0059] Gained reverse osmosis membrane was operated continuously for 5 days in 250ppm NaCl solution, and the flux and desalination rate of the membrane were tested every other day, and the results were as follows Figure 6 shown.

Embodiment 2

[0061] Prepare a 0.1% by weight aqueous solution of o-phenylenediamine, soak the polysulfone support layer for 10 minutes, take it out and dry it.

[0062] Prepare a cyclohexane solution of 0.02% by weight of isophthaloyl chloride, then soak the polysulfone support layer for 10 minutes, take it out and evaporate it to dryness, then quickly immerse it in diethylaminoethanol with a mass concentration of 99.5%, soak for 10 minutes, Remove the diaphragm, evaporate to dryness, and rinse with water to obtain a reverse osmosis membrane.

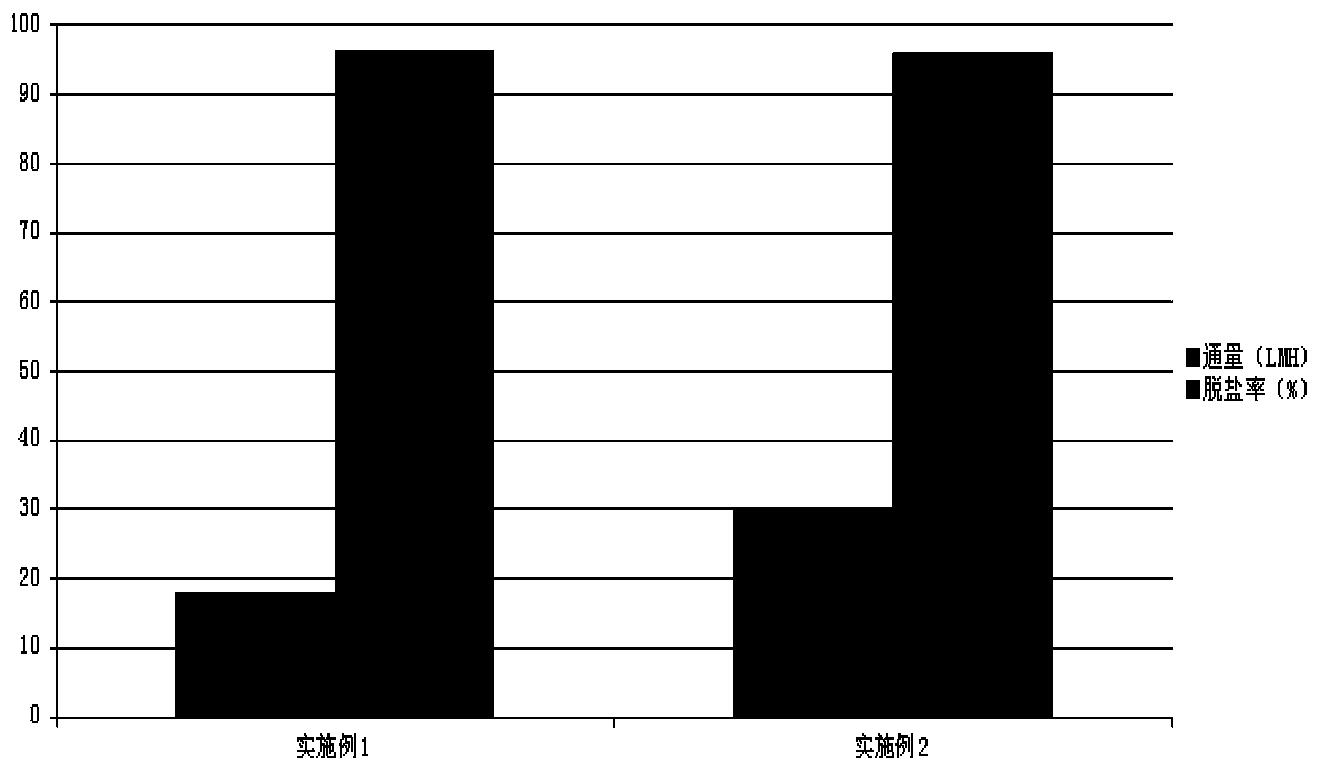

[0063] Test its flux and desalination rate, and compare with embodiment 1, the result is as follows figure 1 shown.

[0064] In addition, the obtained reverse osmosis membrane was continuously operated in 250ppm NaCl solution for 5 days, and the flux and desalination rate of the membrane were tested every other day, and the results were as follows: Figure 7 shown.

Embodiment 3

[0066] Prepare a 10% by weight aqueous solution of p-phenylenediamine, soak the polysulfone support layer for 10 seconds, take it out and dry it.

[0067] Prepare an isoparaffin solution of 1.0% by weight of isophthaloyl chloride+1.0% of isophthaloyl chloride, then soak the polysulfone support layer for 10 seconds, take it out and evaporate it to dryness, and then quickly immerse in 2 -In aminopropanol, soak for 10 seconds, remove the diaphragm, evaporate to dry, rinse with water to obtain a reverse osmosis membrane.

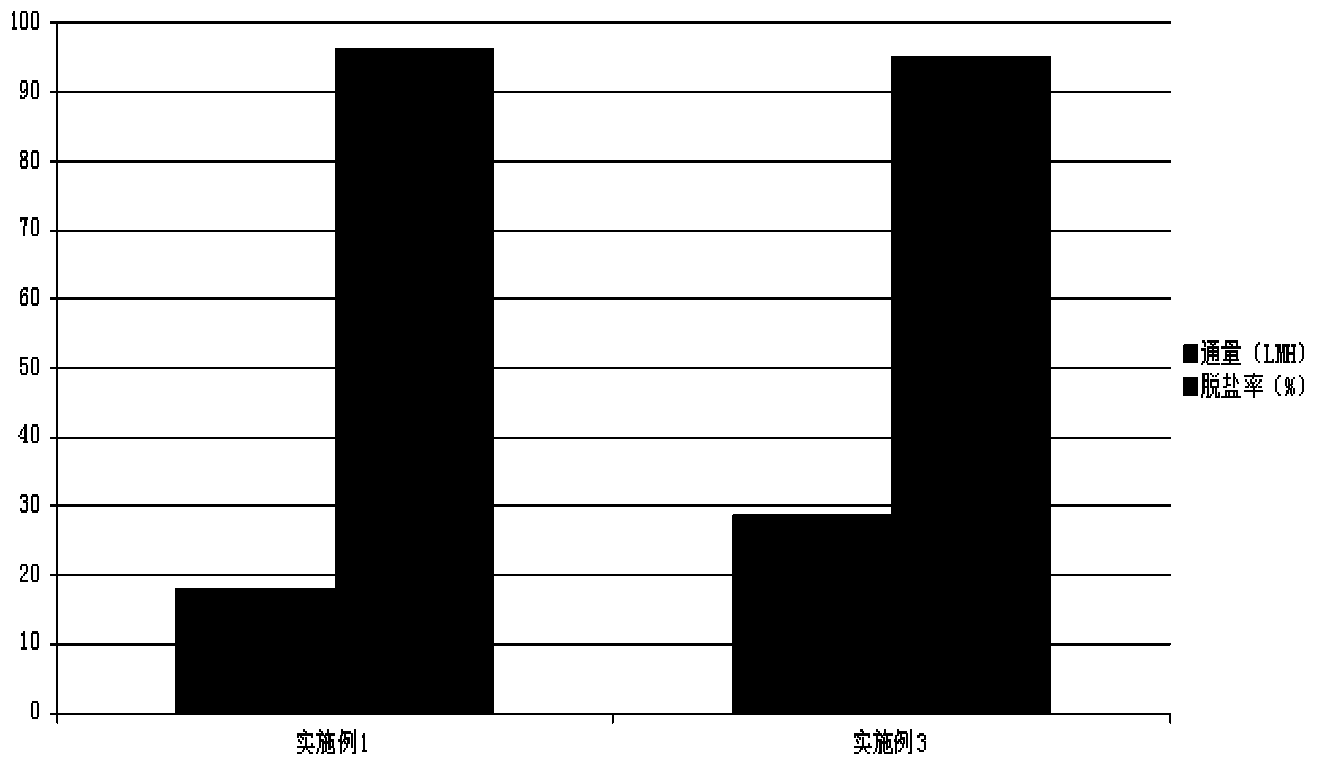

[0068] Test its flux and desalination rate, and compare with embodiment 1, the result is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com