Patents

Literature

210 results about "Every other day" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

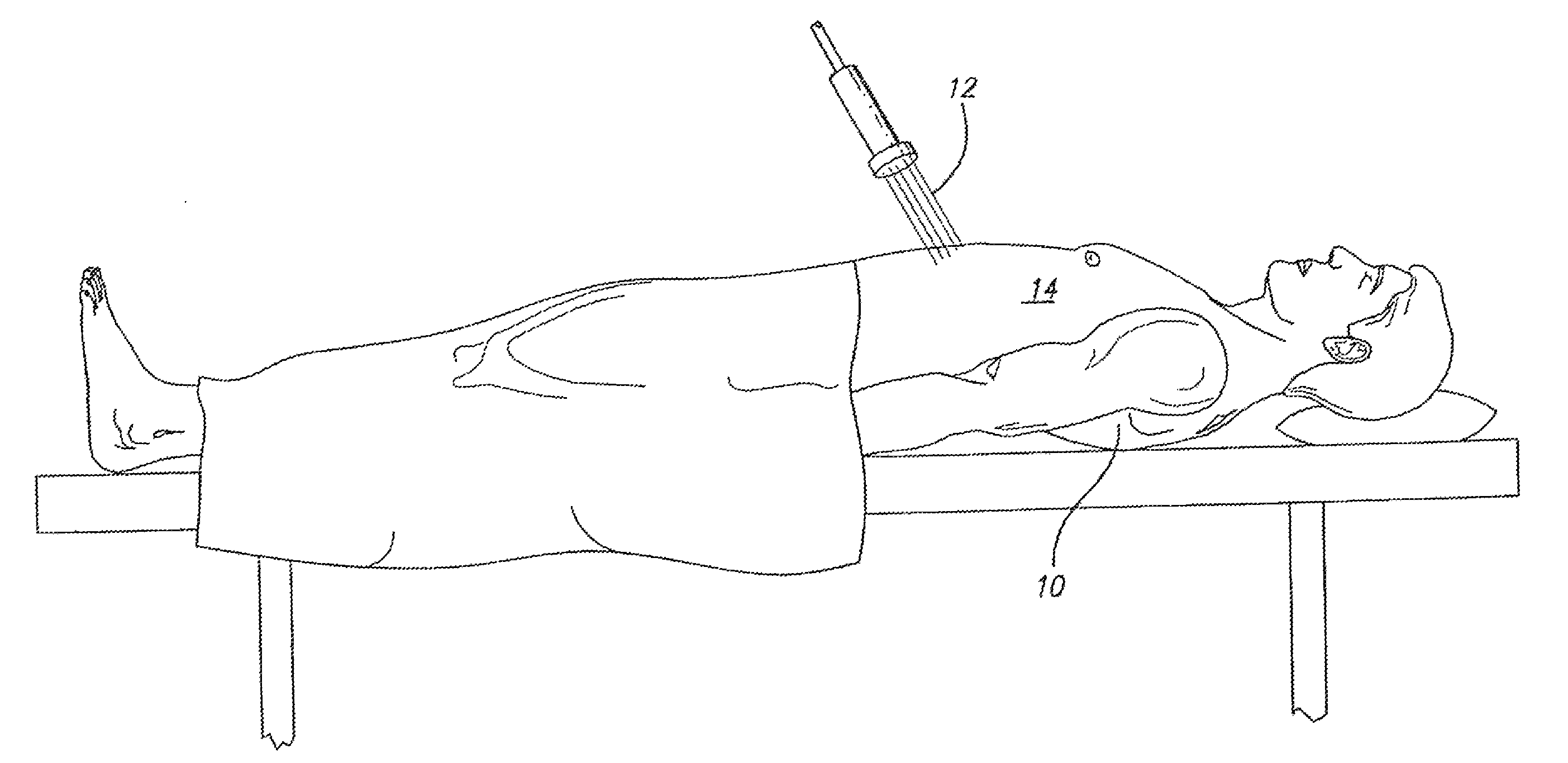

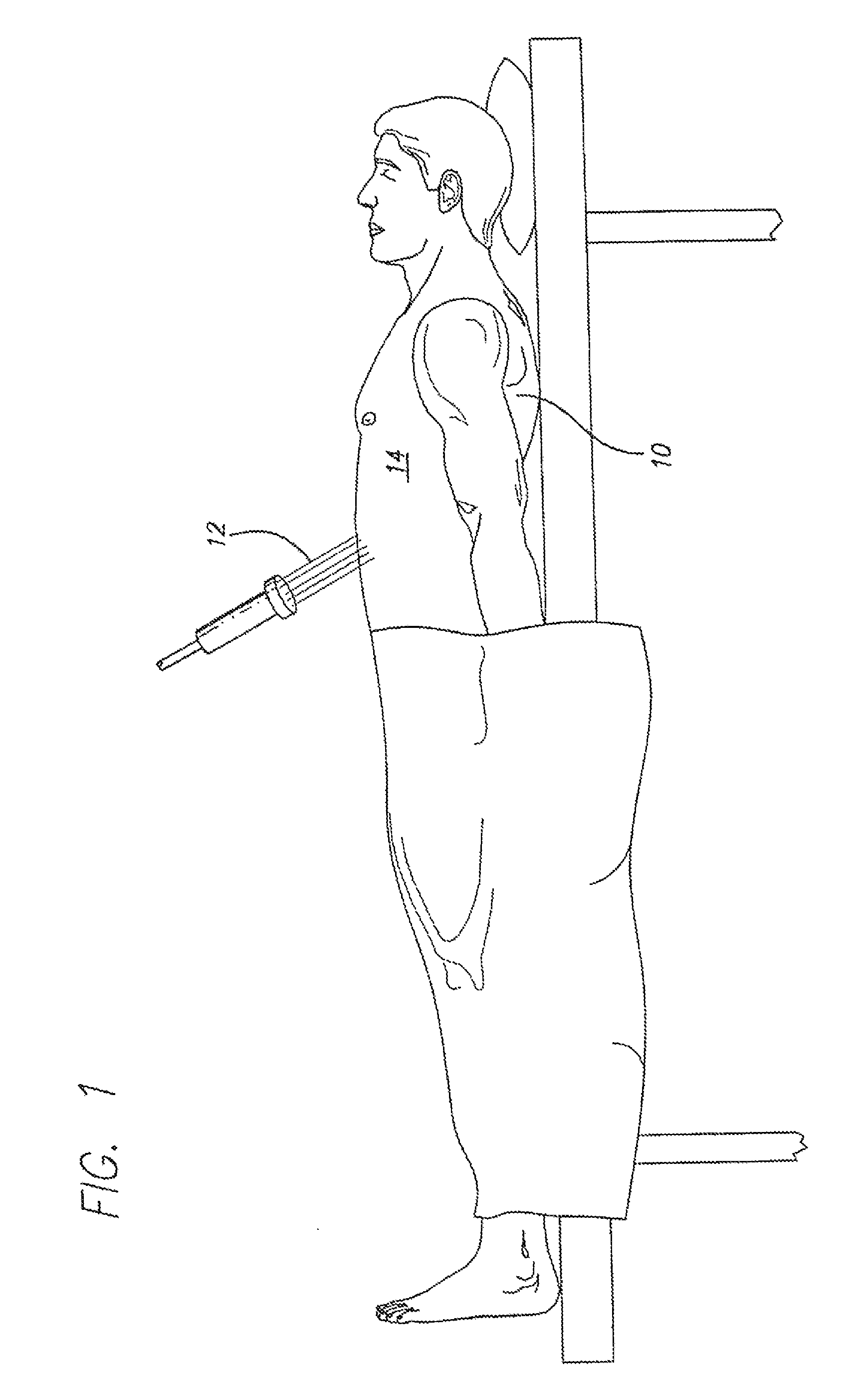

Non-invasive method for slimming a human body using laser energy of wavelengths shorter than 632 nm

A noninvasive method of slimming a patient's body by applying laser energy having a wavelength shorter than 632 nm externally through the skin of the patient. One or more areas of a patient's body, preferably the more fatty regions, such as the abdominal, buttock, lower back, thigh, bust or arm regions, is measured. Objective measurements are made of body criteria, including external dimension, percentage body fat, fat mass, or body mass. Sufficient laser energy, preferably in a range of 0.03-0.1 J / cm2, is applied to one or more of those areas to cause a reduction in the measurement in the lasered areas, as well as overall body slimming. The preferred embodiments use laser light at about 532 nm, 440 nm, or 405 nm. Preferably 18 mW or 25 mW laser diodes are used to apply laser energy at 0.03-0.1 J / cm2 for 15 minutes, every other day for 1-4 weeks, depending on the amount of slimming desired.

Owner:ERCHONIA CORP

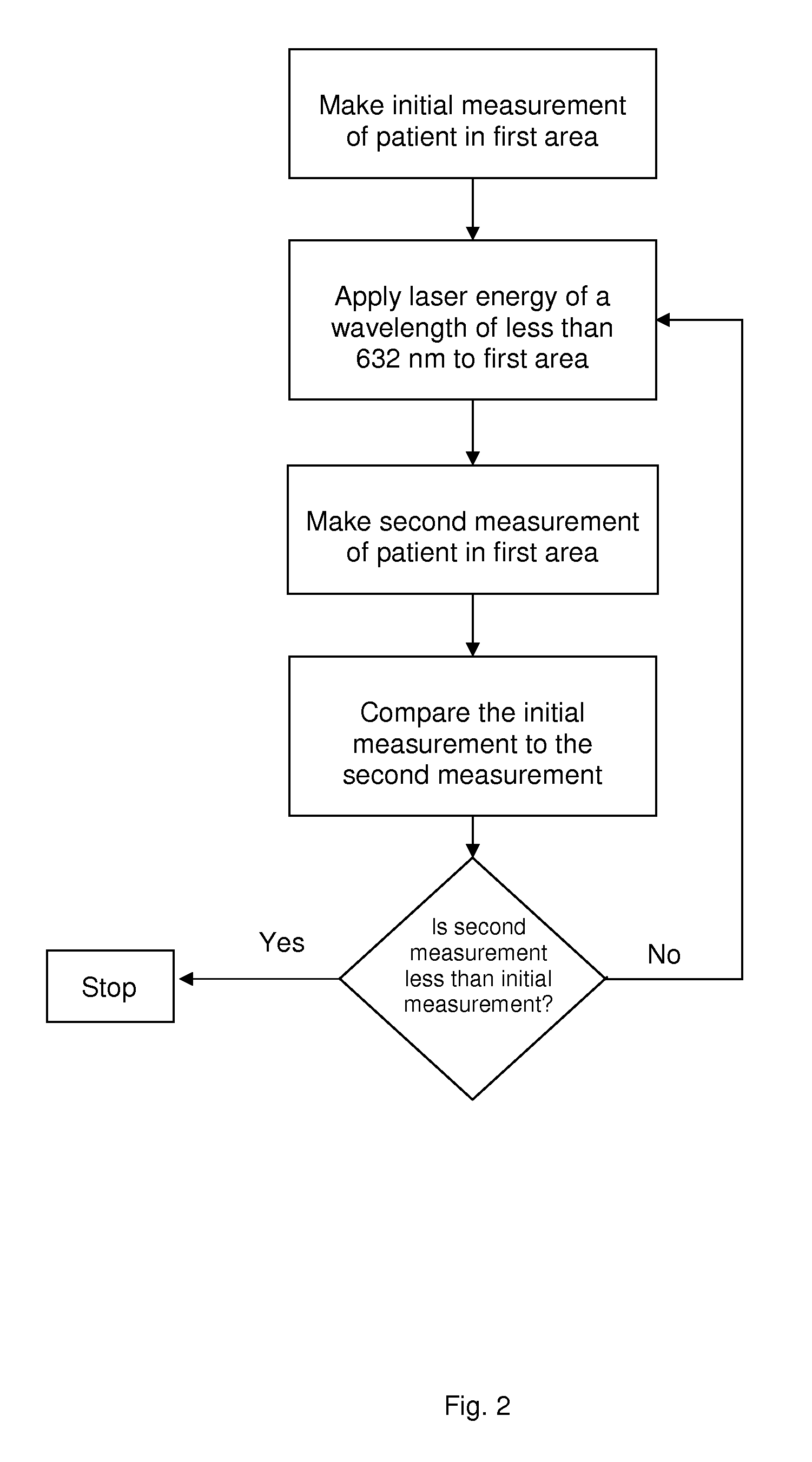

Inducing method for directionally differentiating human embryonic stem cells to corneal endothelial cells

The invention discloses an inducing method for directionally differentiating human embryonic stem cells to corneal endothelial cells. The method comprises the steps of: cultivating the human embryonic stem cells on a mouse embryonic fibroblast feed layer; sorting human embryonic stem cell clone groups in good state; grafting the groups on a human corneal stromal fibroblast layer processed by mitomycin C and cultivating for 7 days, wherein the human embryonic stem cells are differentiated to rosettes; separating and transferring the rosettes from the human corneal stromal fibroblast layer to a culture bottle; cultivating continuously for 7 days by using a neural crest stem cell culture medium; sorting the neural crest stem cells by a flow cytometry; adding the neural crest stem cells into the culture bottle; placing in a 5% CO2 incubator for incubating and cultivating at 37 DEG C by using a human corneal endothelial cell culture medium; changing the liquid every other day; and cultivating for about 10 days to obtain the corneal endothelial cells. The multiplication capacity of the corneal endothelial cells are similar to that of human corneal endothelial cells and the corneal endothelial cells can be transferred to 1-2 generations in vitro maximally. The corneal endothelial cells can be used as seed cells for cornea construction and transplant in tissue engineering.

Owner:SHANDONG UNIV

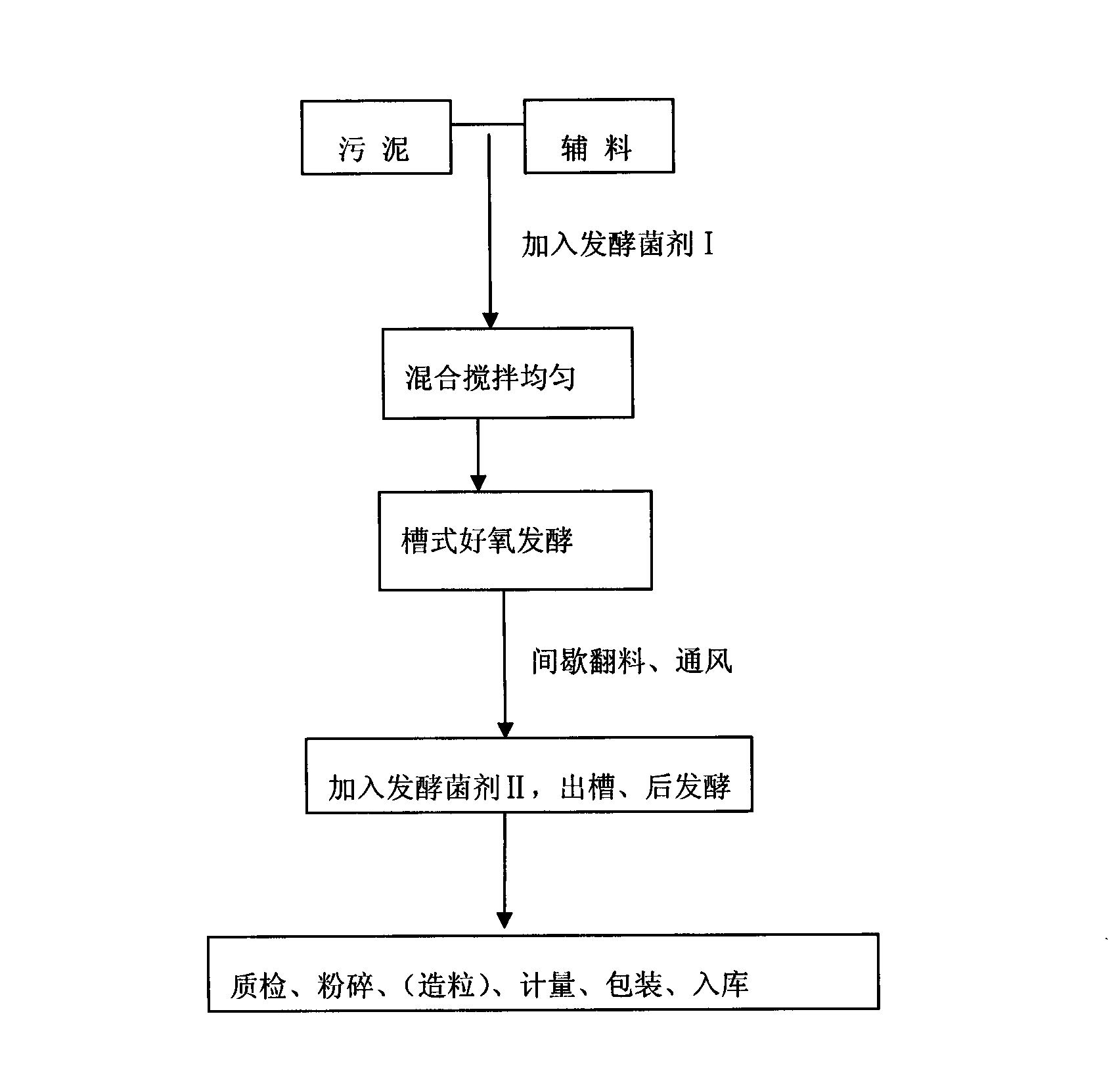

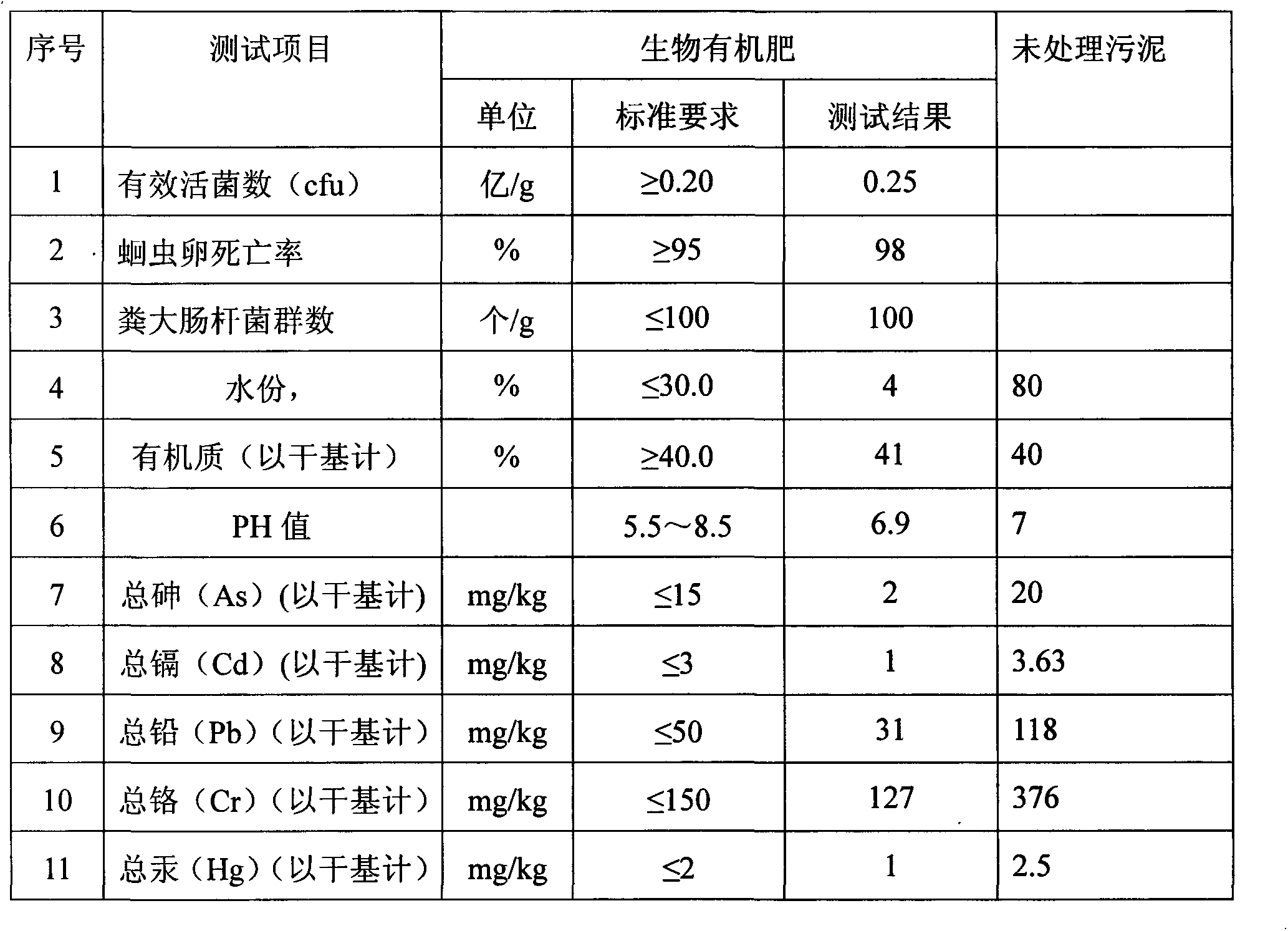

Method for making biological organic fertilizer by utilizing urban domestic sludge and special-purpose leavening agent of method

InactiveCN103319214AComplete degradation treatmentSolve protection problemsClimate change adaptationSewage/sludge fertilisersSludgeOrganic fertilizer

The invention discloses a method for making biological organic fertilizer by utilizing urban domestic sludge and special-purpose leaving agent of the method. The method comprises the following steps of: regulating the proportion of sludge and auxiliary materials, and adding high-temperature aerobic zymophyte I to an organic fertilizer fermentation tank for fermenting; turning the materials once when the material stack temperature is increased to about 50 DEG C; ventilating for two hours, and turning over the materials once every other day, controlling the temperature to 55 DEG C-65 DEG C, keeping for 3-4 days, killing a large number of pathogenic microorganisms and parasitic ovum in the sludge, continuously fermenting about 10 days in a fermentation tank until the sludge mixture is almost odorless and almost rotten; discharging the mixture out of the tank when the temperature is reduced to 40 DEG C for lower and the moisture is lowered to 40% or lower; adding fermented culture II for carrying out secondary fermentation after-ripening, and lowering the moisture content to 35% three days after carrying out the secondary fermentation; and finally, metering and storing the fermented materials which reach the requirements.

Owner:深圳市天佳实业有限公司

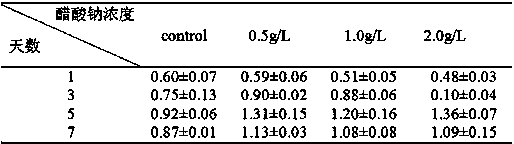

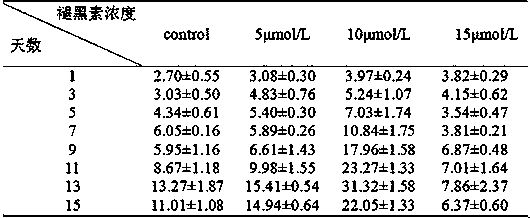

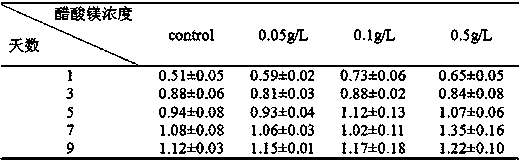

Method for increasing biomass and astaxanthin content of haematococcus pluvialis

InactiveCN108753620AIncrease biomassIncreased astaxanthin contentUnicellular algaeMicroorganism based processesSodium acetateBiology

The invention relates to a method for increasing biomass and astaxanthin content of haematococcus pluvialis, and belongs to the technical field of bioengineering. The method comprises steps as follows: a BBM culture medium with sodium acetate or magnesium acetate added is prepared firstly, after being sterilized, the BBM culture medium is inoculated with the haematococcus pluvialis cultured to theexponential phase until the concentration reaches 2.0*10<5>-2.5*10<5> cells / mL, culturing is performed at the temperature of 24-26 DEG C under the condition of light intensity being 2000-2500 lx, andsampling is performed every other day for biomass measurement; algae cells are collected when the biomass is maximum, diluted by the nitrogen-deficient BBM culture medium with melatonin added until the concentration is 2.0*10<5>-2.5*10<5> cells / mL, culturing is performed at the temperature of 26-28 DEG C under the condition of light intensity being 12000-14000 lx, and sampling is performed everyother day for astaxanthin content measurement. The method is simple and easy to operate, growth cycle of the haematococcus pluvialis can be shortened to a certain degree, and the biomass and the astaxanthin content of the haematococcus pluvialis are increased.

Owner:KUNMING UNIV OF SCI & TECH

Production method of eggs enriched in organic selenium and eggs enriched in organic selenium

InactiveCN102113631APromote absorptionNo risk of toxic effectsAnimal feeding stuffAccessory food factorsAnimal scienceFeed additive

The invention relates to a production method of eggs enriched in organic selenium, comprising the following steps: fully stirring and uniformly mixing an feed additive enriched in selenium and a general chicken feed so as to prepare a chicken feed enriched in selenium, which contains 7.5%-45% of the feed additive enriched in selenium and contains 0.3-1.7mg / kg of selenium finally, for standby; feeding chickens with the chicken feed enriched in selenium, and conducting dynamic detection on collected samples every other day until 10 days later when the selenium content in the eggs is 0.3-1.7mg / kg; and continuously feeding the chickens with the chicken feed enriched in selenium, and finally obtaining the eggs with the selenium content being kept at 0.3-1.7mg / kg stably. According to the production method, the selenium content in the egg exists in the form of organic selenium, so that the safety is good, the selenium is easy to absorb and utilize, and the selenium supplementing demands of different crowds can be met.

Owner:SUZHOU SETEK

Method for cultivating table grapes in high-cold and high-latitude area in winter

InactiveCN103518584ANo ripening abilityNo signs of agingCultivating equipmentsThermal insulationHigh latitude

The invention provides a method for cultivating table grapes in high-cold and high-latitude area in winter. The method comprises the following steps of building a garden, using a high-cold and high-latitude efficient energy-saving solar greenhouse to build the garden, planting and managing grapes, leaving grapes on vines to keep fresh, watering once when the grapes are grown, laying mulch films every other days, controlling the temperature in the greenhouse by controlling time for closing an air inlet, releasing a curtain and rolling up the curtain. When the external temperature decreases below 5 DEG C, thermal insulation is carried out to control the indoor temperature at 10 DEG C. When the external temperature decreases below -10 DEG C, the indoor temperature is controlled at 8 DEG C in day time and at 2 DEG C at night until the grapes are harvested to be sold. The grapes cultivated in the method can be harvested to be directly supplied to fruit markets, the step of storing and refreshing the grapes through chemical agents is removed, the problems of dry peduncles, grape falling, browning, rotting and the like are solved, refreshment of the grapes are achieved to the maximum degree, and meanwhile chemical agent residue is reduced. Furthermore, when the grapes are on grape vines, the sugar content of the grapes gradually increases, and the fruit quality is improved.

Owner:QINGHE COUNTY SHENNONG AGRI SCI & TECH DEMONSTRATION

Ecological planting method of oyster mushrooms

InactiveCN106613355APromote growthIncrease productionCalcareous fertilisersAnimal corpse fertilisersPolyesterOyster

The invention discloses an ecological planting method of oyster mushrooms. The ecological planting method of oyster mushrooms comprises the following steps: (1) pretreatment: preparing a culture substrate, then performing steam sterilization, then performing sterile drying, sorting oyster mushroom hyphae meeting agricultural standards, and preserving; (2) inoculation: under the aseptic environment, picking up oyster mushroom hyphae with the sterilized inoculating loop, inoculating into the culture substrate, performing bagging sealing by using a polyester film, keeping under dark environment, and observing whether the hyphae grow after one week; (3) cultivation: when the hyphae begin to differentiate to form a mushroom cap, transferring into a shady and cool ventilation greenhouse, supplementing the culture substrate every other day and removing hyphae infected by infectious microbes; and (4) mushroom production: after the mushroom caps are overgrown, continuously culturing for five days, and harvesting. Compared with the prior art, the growth of oyster mushrooms can be promoted by using the ecological planting method of oyster mushrooms, the yield of the oyster mushrooms can be increased by 0.5-1 time, the yield of single plants can be increased by 1-2kg, and nutritional values are high.

Owner:新平源健农业开发有限公司

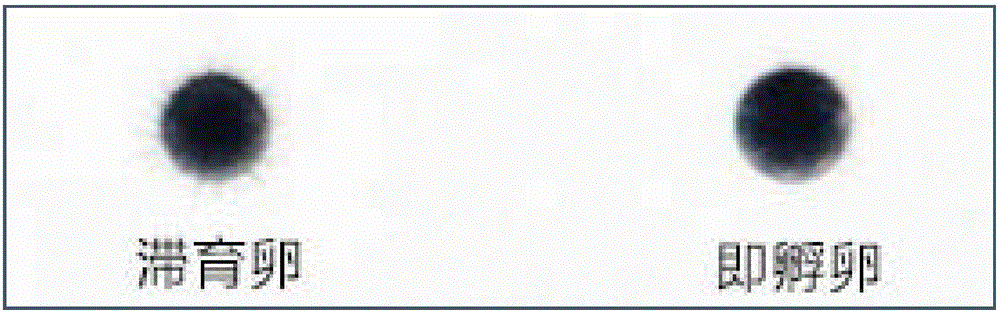

Method for inducing copepoda to produce diapause eggs

InactiveCN106577409AHarvest convenience methodImprove timelinessPisciculture and aquariaDiapauseDaphnia

Owner:XIAMEN UNIV

Making technology of sun vinegar

The invention discloses a making technology of sun vinegar. The technology includes: 1) porridge cooking: adding water into a pot, pouring rice and glutinous rice, and cooking the rice into 60-70% cooked porridge; 2) vinegar porridge fermentation: pouring the porridge into a vinegar vat, when the temperature of the porridge cools to less than 40DEG C, adding vinegar koji and performing stirring, conducting fermentation at 35-38DEG C for 14-16d, and performing stirring once respectively in the morning and evening every day; 3) making of fermented grains: taking out the vinegar porridge, mixing the vinegar porridge with bran evenly, then placing the mixture into a vinegar slot, and performing covering with a straw mat; 4) turnover of fermented grains and fermentation: at the end of making of fermented grains, turning over the fermented grains once every other day, controlling the fermentation temperature at 37-38DEG C, at the 9-11th day of fermentation, adding salt and turning over the fermented grains evenly, and further conducting fermentation for 5-6 days; 5) jar loading and basking of fermented grains: transferring the vinegar fermented grains into the vat of sunning ground, conducting compaction, performing sealing with salt, and conducting weather exposure for 2 years; 6) vinegar spraying: collecting the vinegar fermented grains, and spraying vinegar by a two-pool set spraying process; 7) vinegar basking: transferring the sprayed vinegar liquid to the sunning ground to conduct weather exposure for 2-3 months; and 8) sterilization and filling: sterilizing the vinegar liquid at a temperature of 95-100DEG C for 15-30min, and then performing canning. The technology provided by the invention is simple, and has no need of inoculation.

Owner:GUIZHOU CHISHUIJINJIANG VINEGAR IND CO LTD

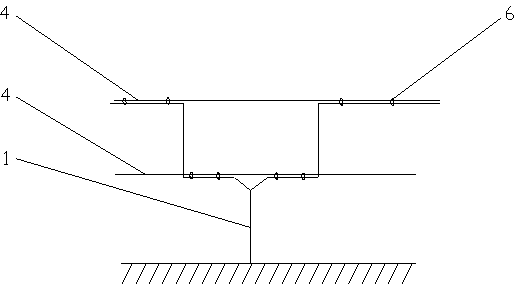

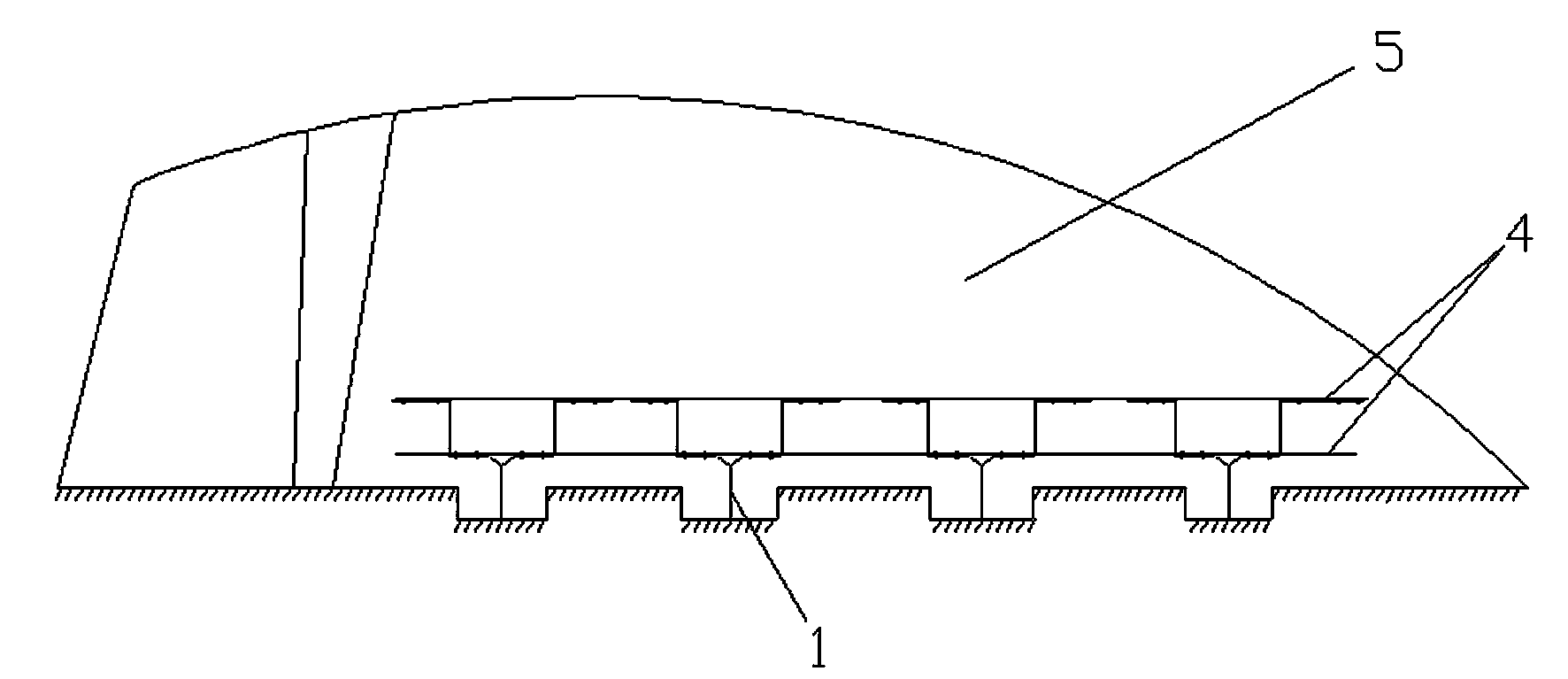

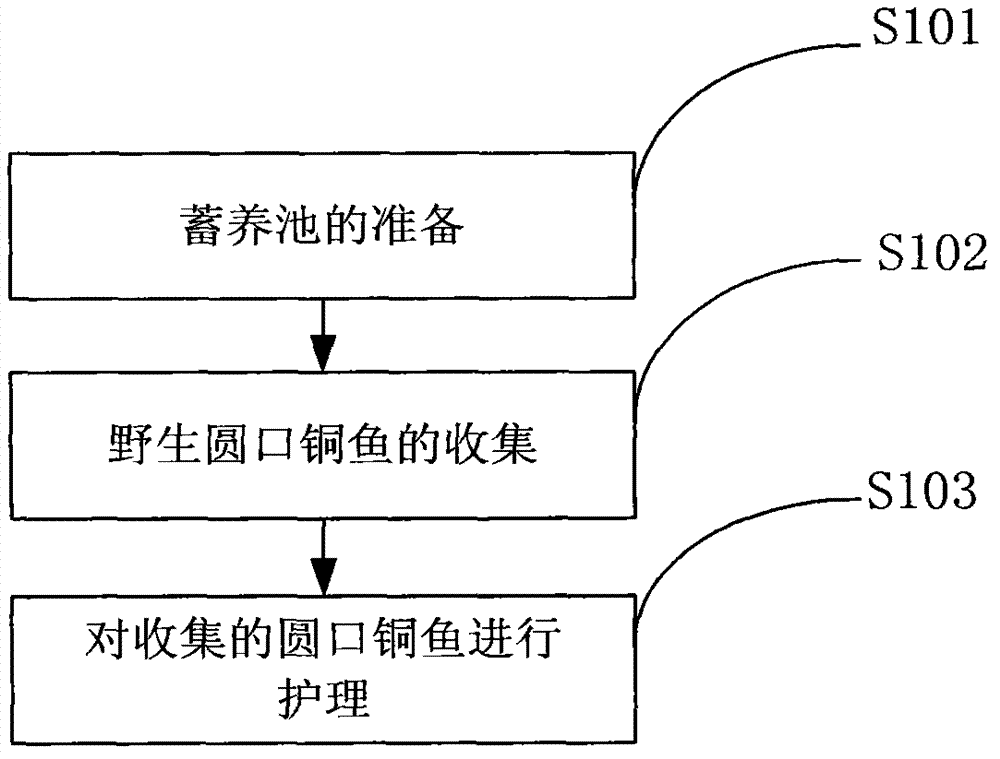

Method and injection liquid for nursing wild coreius guichenoti

InactiveCN103190364AAvoid infectionRelieve muscle fatigueClimate change adaptationPisciculture and aquariaAnti stressAntibiotic Y

The invention discloses a method for nursing wild coreius guichenoti. Nursing injection liquid is injected into fish according to the fish size, then water is packaged in a plastic bag and oxygenated, and the fish is transported to a culture place. Before the fish is placed into a pond, a 3% NaCl solution is used for soaking the fish for 10 minutes, erythromycin ointment is used for coating wounded portions, after the fish is placed into the pond, nursing injection liquid is injected to the fish one by one every other day twice, and culture management is conducted. The nursing injection liquid is mainly composed of antibiotics, anti-stress medicine and energy mixture. By means of corresponding medicine treatment, stress reaction of the coreius guichenoti is reduced, simultaneously inflammation of the fish body is diminished, exogenous nutrient substances are supplemented appropriately, and wild coreius guichenoti damage caused by fishing and transportation is recovered as soon as possible. Culture survival rate of the collected coreius guichenoti under the artificial condition is increased, enough population for researching domestication and artificial reproduction technology of the coreius guichenoti is provided, mass production of the coreius guichenoti and artificial breeding and releasing become possible, and a purpose of protecting the coreius guichenoti resource is achieved.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for regularly storing overwintering feed by utilizing nest box double-queen bee colony

The invention provides a method for regularly storing an overwintering feed by utilizing a nest box double-queen bee colony. The method comprises the following steps: (A) feeding the nest box double-queen bee colony accounting for one third of the full-field colony number with the overwintering feed in August and September, placing a plane isolation gate between the nest box and a relay box, the number of the standard overwintering feed comb which is fed to each nest box double-queen colony is more than or equal to 12; (B) at the beginning of August, the syrup is fed every other day until theempty nest comb in the box is filled with syrup, the capping rate reaches more than 90%, and at the beginning of September, the old pupae brood combs in the relay box are mutually exchanged with the large larvae combs or the new pupa brood combs in the nest box every 6-7 days, the two queen bees are enclosed and stopped to lay eggs in September 10th, the syrup is fed uninterruptedly until the capping rate of the honeycomb spleen can reach more than 90%. According to the method for storing the overwintering feed, the time is advanced to August and September, and the nest box double-queen bee colony is adopted, so that the advantages of the double-queen egg laying breeding overwintering bee are brought into full play.

Owner:吉林省养蜂科学研究所

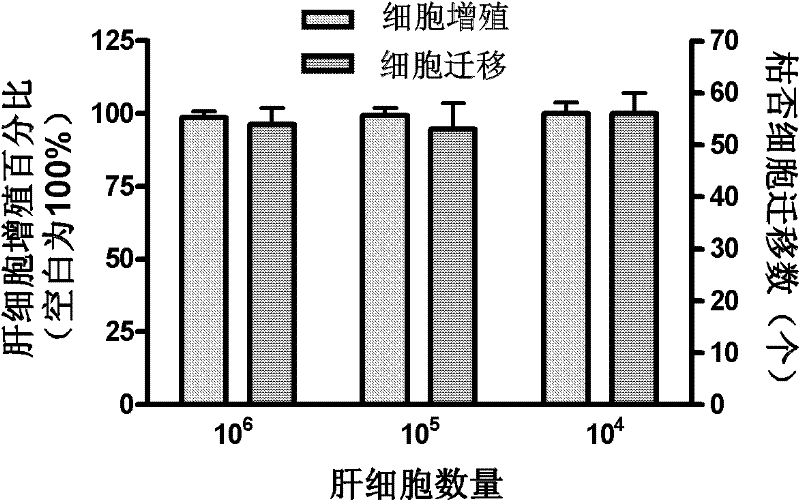

Co-culture system for liver cells and Kupffer cells and application thereof

InactiveCN102220281ADoes not affect proliferationRapid cultivationMicrobiological testing/measurementArtificial cell constructsSerum glutamate pyruvate transaminaseFactor ii

The invention discloses a co-culture system for liver cells and Kupffer cells and application thereof. The co-culture system is characterized in that in a Millicell double-layer culture room, 1-100 ng / mL LPS (lipopolysaccharides) is added into a culture medium, the Kuffer cells are cultured in the upper layer of the Millicell double-layer culture room, and the liver cells are cultured in the lower layer of the Millicell double-layer culture room; and half of the fresh culture medium is replaced every other day so as to keep the concentration of the LPS. The co-culture system for liver cells and Kupffer cells provided by the invention has the advantages that the Kupffer cells continuously secrete inflammatory cell factors (such as TNF-alpha) in vitro after being stimulated by the LPS; the liver cells can generate a great number of enzymes, such as AST (aspartate aminotransferase), ALT (alanine transaminase) and GGT (gamma-glutamyl transpeptidase) in the environment so as to stimulate the liver injury based on immunoreaction caused by the immune / inflammation response after the liver tissue undergoes virus infection in vivo; and moreover, the co-culture system is used for screening medicaments resisting immune liver injury according to the influence of the medicaments on the secretion amount of immune factors and the enzymatic activity.

Owner:SHAANXI INST FOR FOOD & DRUG CONTROL

Method for cultivating zinc-rich wheat

InactiveCN104823645AImprove fertilityImprove seedling rateFertilising methodsHorticultureSitodiplosis mosellanaOrganic fertilizer

The invention relates to a method for cultivating zinc-rich wheat. Before sowing, specially made organic fertilizer is mixed with planting soil, and the obtained mixture can kill take-all pathogens, and avoid take-all during cultivation. After the organic fertilizer is mixed with the planting soil, the fertility of the soil can be improved, and tillering of wheat can be more promoted before winter. Wheat seeds are soaked with specially made seed soaking liquid so that pathogens carried by the wheat seeds can be killed, and the wheat seeds soaked with the seed soaking liquid can quickly sprout. From the seedling stage to the tillering stage of wheat, leaf fertilizer is sprayed on the surfaces of leafbuds every other day, so that efficient tillering of wheat can be promoted. From the tillering stage to overwintering stage of wheat, the field is covered by straw, so that evaporation of water can be reduced, successful overwintering of wheat is ensured, effective tillering is ensured while ineffective tillering is controlled, and lodging is avoided. From blooming stage to filling stage of wheat, the leaf fertilizer is sprayed, so that the photosynthesis of wheat is promoted, and sitodiplosis mosellana and wheat aphids can be expelled and killed.

Owner:唐兴龙

Method for raising pigs with marbled pork

ActiveCN105052820AMeet to formPromote formationFood processingAnimal feeding stuffEvery Three DaysAnimal science

The present invention discloses a method for raising pigs with marbled pork, which includes: selecting boar piglets with four weeks pig age, in the fourth week to the eighth week, feeding the boar piglets with the first fodder at six am, twelve pm, four pm and seven pm every day, and massaging the boar piglets with olive oil every other day; in the ninth week to the nineteenth week, feeding the boar piglets with the second fodder at eight am, one pm and seven pm every day, massaging the boar piglets with olive oil every four days, and carrying out a sand bath massage on the boar piglets every other day; in the twentieth week to the twenty fourth week, feeding the boar piglets with the third fodder at eight am, one pm and seven pm every day, massaging the boar piglets with olive oil every three days, and massaging the boar piglets with beer every other day. A scientific method for raising pigs with marbled pork designed by the present invention can effectively improve the quality of marbled pork, and meanwhile effectively improve the quality and taste of pork.

Owner:镇沅农康畜牧科技有限公司

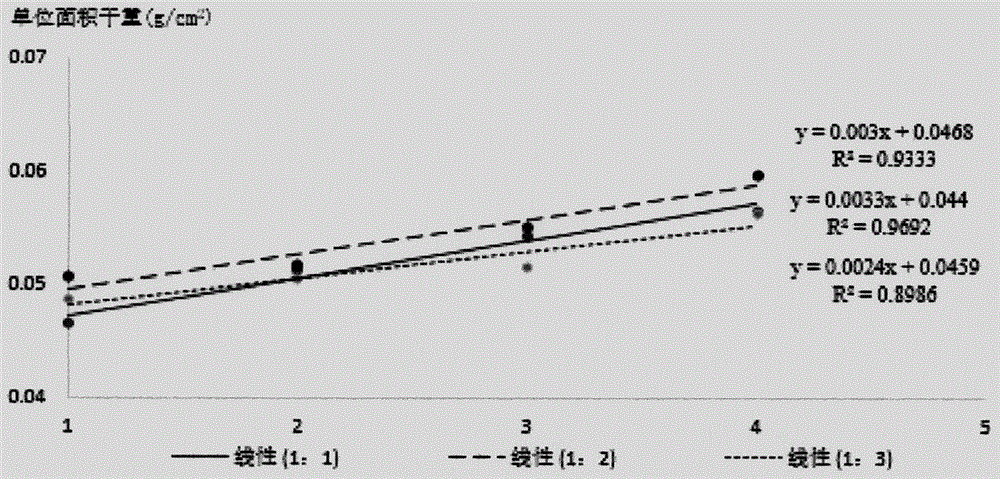

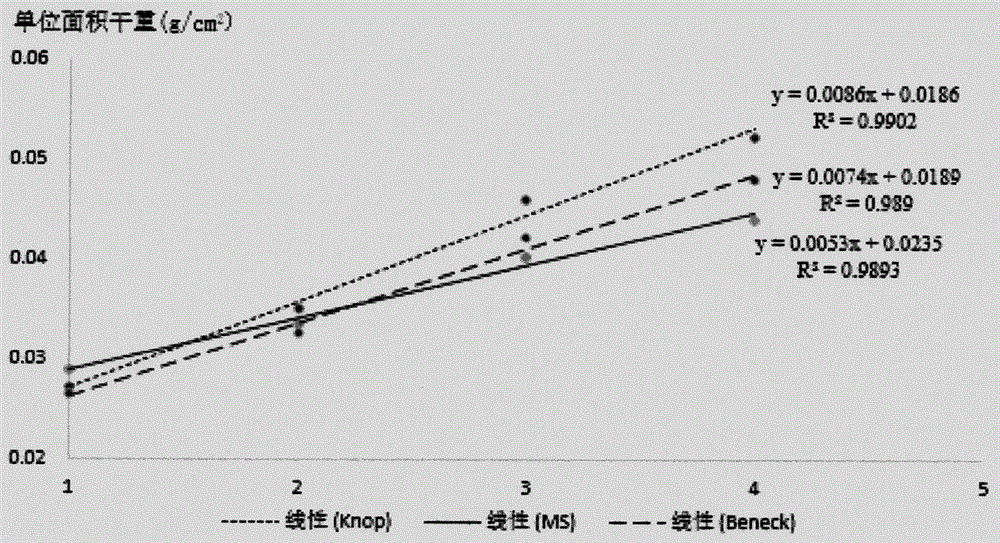

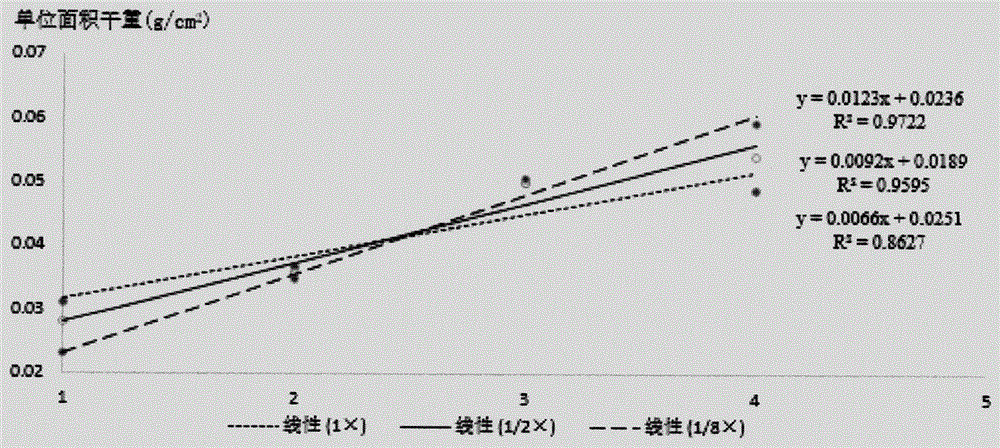

Culture method of brachytheciaceae

InactiveCN105475108AGrow fastEasy to operateGrowth substratesCulture mediaRoom temperatureNutrient solution

The invention discloses a culture method of brachytheciaceae. The culture method comprises the following steps: picking up brachytheciaceae growing in the field; spreading the brachytheciaceae on a culture substrate, wherein the culture substrate is obtained by mixing vermiculite and pearlite according to the volume ratio of 1:1; putting the spread brachytheciaceae at a place where the sun cannot shine on the spread brachytheciaceae directly; carrying out culture at the room temperature while keeping the humidity of 70-80%; pouring a nutrient solution every other day, wherein the pouring quantity is 1 to 2 ml / cm<2>, the nutrient solution is a Knop nutrient solution of which the concentration is 1 / 8, and the pH value of the nutrient solution is 6.0 to 6.5; pouring water every third day, wherein the pouring quantity is 2 to 4 ml / cm<2>. According to the culture method, the brachytheciaceae growing in the field is transplanted to the most proper substrate, the most proper nutrient solution is sprayed on the transplanted brachytheciaceae periodically, and the transplanted brachytheciaceae propagates indoor, so that the transplanted brachytheciaceae grows fast; no special requirements on experiment equipment are required; the operation is simple; the cost is low; popularization and application of brachytheciaceae are facilitated.

Owner:CHONGQING NORMAL UNIVERSITY

Chinese medicinal compound suppository for treating endometritis of livestock and preparation method thereof

InactiveCN101879240ANo antibiotic residue problemAvoid lostSuppositories deliveryPharmaceutical non-active ingredientsMilk cow'sBULK ACTIVE INGREDIENT

The invention relates to a traditional Chinese medicine, in particular to a Chinese medicinal compound suppository for treating endometritis of livestock and a preparation method thereof. The Chinese medicinal compound suppository is prepared by mixing 1 to 2 parts of golden thread, 1 part of cortex phellodendri, 1 part of lightyellow sophora root, 1 to 2 parts of leonurus heterophyllus, 1 to 2 parts of safflower, 1 to 2 parts of Chinese angelica, 1 part of astragalus and a suppository matrix. The method for preparing the Chinese medicinal compound suppository for treating the endometritis of the livestock comprises the following steps of: extraction of active ingredients of each traditional Chinese medicine, concentrating, drying, pulverizing and preparation of the suppository. The suppository has the advantages of pure Chinese medicinal preparation, no problem of antibiotic residues, stable medicinal quality and easy carrying and storage. For the acute endometritis and hidden endometritis of dairy cattle, the two Chinese medicinal suppositories are put into uteruses once every other day, and after the Chinese medicinal suppositories are used continuously for three times, the curative rate reaches 83 percent; and for the hidden endometritis of the dairy cattle during oestrum, the two suppositories are dissolved in 50 milliliters of physiological saline to perform the treatment of intrauterine administration, the suppositories are used once every other day and are used continuously for three times, and the curative rate reaches 62.5 percent.

Owner:NINGXIA UNIVERSITY

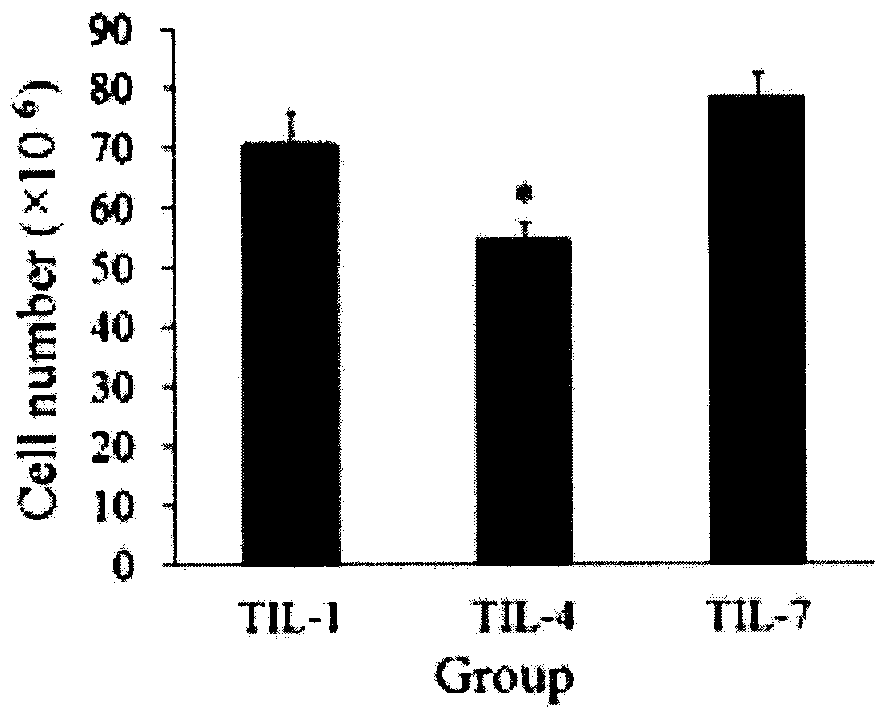

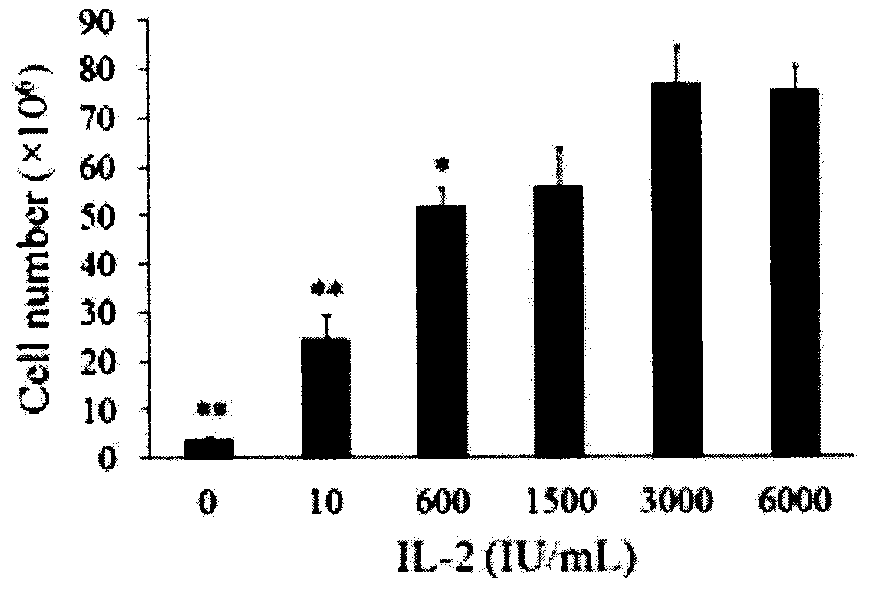

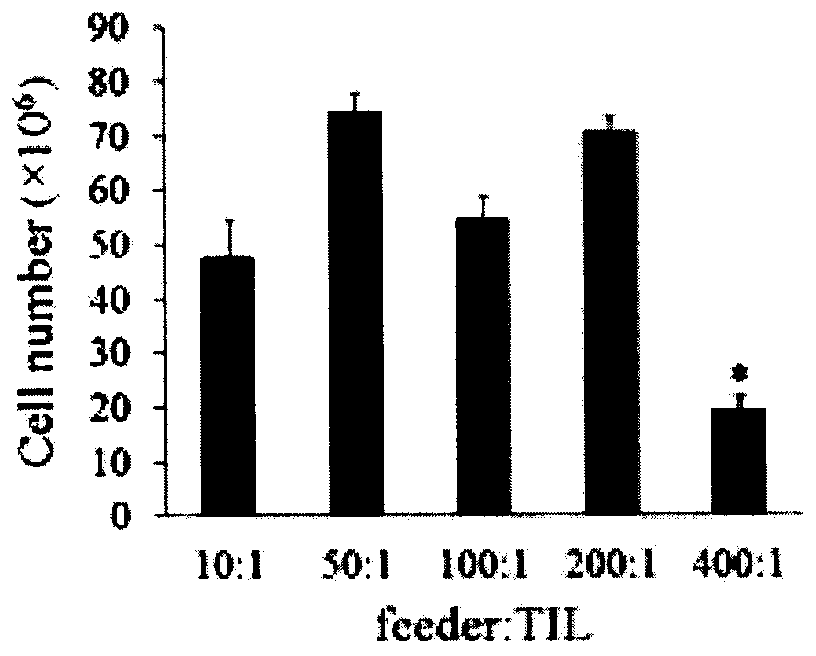

Method for rapidly and efficiently amplifying tumor infiltrating lymphocytes

The invention discloses a method for rapidly and efficiently amplifying tumor infiltrating lymphocytes. The method is mainly used for efficiently and rapidly amplifying tumor infiltrating lymphocytes (TIL) within a short period of time and basically realizing no influences on the phenotypes of the TIL. The method comprises: carrying out tumor tissue treatment, culturing liquid use, and IL-2 and OKT3 dosage and culturing treatment; taking 1-2mm<3> tissues from different areas of a liver cancer specimen, putting the tissues in the pores of a 24-pore plate, placing the pore plate in a culturing case, culturing, observing every other day, carrying out semis liquid replacement of the pore plate culturing liquid after the 5-6 day culture, carrying out semis liquid replacement of the pore plate culturing liquid every one or two days according to the TIL growth condition, collecting the TIL in all the pores once the 24-pore plate is full of the TIL, and culturing the TIL to form young TIL; and carrying out rapid in-vitro rapid amplification of the young TIL above 4000 times.

Owner:爱瑞康医疗投资管理(北京)有限公司

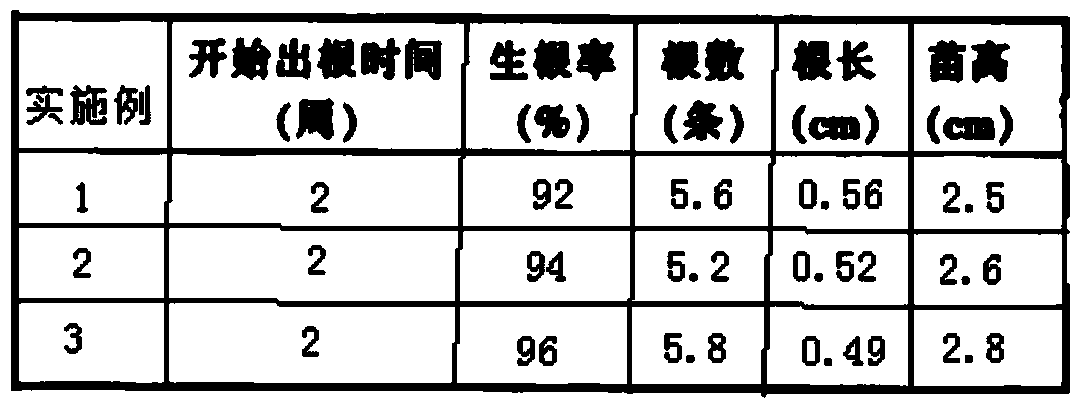

Sedum spectabile boreau leaf cutting reproducing method

The invention relates to a reproducing method for sedum spectabile boreau plants, in particular to a sedum spectabile boreau leaf cutting reproducing method. The sedum spectabile boreau leaf cutting reproducing method comprises the steps of (1) preparation before cutting, wherein pure turf media are put in a hole disc and watered thoroughly to be used, leaves of the middle upper portion of sedum spectabile boreau plants are selected, and the parts, with roots, of the leaves are cut down; (2) leaf cutting, the media in the holes of the hole disc are gashed, the cut of the bottom portions of the leaves are inserted into the gashed hole disc, the insertion depth is 2-3cm, and water is sprayed after backfill; (3) management after the cutting, wherein after the cutting of the leaves, water is sprayed one time every morning until 10-15 days later when roots are grown, and then water is sprayed one time every other day or every other two days; (4) transplantation, wherein the seedlings are transplanted in a garden after two months, and are watered after field planting. The sedum spectabile boreau leaf cutting reproducing method is reasonable in design, the survival rate by using the leaf cutting seedling can reach more than 95%, the survival plants are sound, and progeny inheritable characters are stable.

Owner:SHANXI ACAD OF AGRI SCI GARDENING RES INST

Strong strawberry seedling rooting culture method

InactiveCN104041410AIncrease productionQuality improvementHorticulture methodsPlant tissue cultureFragariaObserved Survival

The invention discloses a strong strawberry seedling rooting culture method. The method comprises the following steps: 1, seedling selection and disinfection; 2, strong seedling rooting culture: culturing at the temperature of 25-28DEG C under the light intensity of 2800-3000lx 12-15h every day for 3-5 weeks, and transplanting when the root length of 0.4-0.6cm; and 3, transplanting at an indoor temperature of 25-28DEG C for 15-20d, transplanting to nutrient soil in an aperture disk, watering every other day for 40-50d to maintain the water content of soil of above 80%, gradually reducing the watering frequency after new roots and new buds appear, colonizing in the field, and routinely managing. The strong strawberry seedling rooting culture method enables the transplanting survival rate to reach above 90% through the disinfection treatment of early stage selected seedlings, improvement of the basic culturing medium and components, and adjustment of culturing conditions, allows seedlings to grow strong, can effectively improve the output and quality of strawberries, and enhances the economic values of the strawberries.

Owner:卞佳林

Simple newly hatched silkworms gathering method for cooperative rearing of young silkworms

The invention relates to the technical field of cooperative rearing of young silkworms and provides a simple newly hatched silkworms gathering method for cooperative rearing of young silkworms. The method comprises the following steps: weighing graine and partitioning, conducting protection over darkness, and gathering the silkworms every other day. According to the simple newly hatched silkworms gathering method for cooperative rearing of the young silkworms, the newly hatched silkworms can be gathered by one person at a time, the zones are partitioned uniformly, the silkworms are not hurt, and the effects of saving cost and improving effect are achieved.

Owner:刘立志

Heavy metal curing agent for repairing vanadium ore contaminated soil and repairing method

ActiveCN104772331AHigh organic contentImprove fertilityContaminated soil reclamationNatural mineralGoethite

The invention discloses a heavy metal curing agent for repairing vanadium ore contaminated soil and a repairing method. The heavy metal curing agent consists of the following components in percentage by weight: 65-75% of goethite and 25-35% of protonated chitosan, and the goethite which is ground to be 50 meshes and the ground protonated chitosan are mixed uniformly; the method for repairing the vanadium ore contaminated soil with the heavy metal curing agent comprises the following steps: deeply ploughing the contaminated soil, applying the curing agent and uniformly raking, watering in the process of deep ploughing and uniformly raking, wherein watering is performed once every other day in a maintenance period; and curing for 1-2 weeks. According to the heavy metal curing agent disclosed by the invention, the goethite, which is taken as a natural mineral, is free from toxicity and pollution, and the protonated chitosan is also conducive to the improvement of organic matter content in the soil and the increase of soil fertility; therefore after the mixture is applied, the pH value of the soil is not significantly changed, and the toxicity leaching rate of vanadium and other heavy metals in the repaired soil can be effectively reduced.

Owner:TSINGHUA UNIV

Fresh-keeping technology for fresh-eating red jujubes

InactiveCN104585300APrevent frostbiteExtend effective shelf lifeFruits/vegetable preservation by freezing/coolingArtificial handPre cooling

The present invention discloses a fresh-keeping technology for fresh-eating red jujubes. The fresh-keeping technology comprises the following steps: (1) carrying out artificial hand picking of fresh red jujubes, then directly loading the fresh red jujubes into picking containers, and the picked and cased fresh red jujubes have characteristics of being completely filled and bright in color, and having a mature degree controlled at 80%-90% and green or red-and-green heads; (2) reducing the temperature of a storage room to 1 DEG C before pre-cooling the fresh red jujubes and keeping the temperature of the storage room in pre-cooling at 1 DEG C, carrying out disinfection and sterilization on the fresh red jujubes after the pre-cooling storage room is fully filled; (3) pouring the sterilized fresh red jujubes into long-term storage plastic boxes, and keeping the weight of each plastic box at 5kg-10kg; pushing the plastic boxes loaded with the fresh red jujube boxes into a constant temperature cold storage and carrying out standard stacking; setting the temperature of the constant temperature cold storage at 0 DEG C after the cold storage is fully filled; spraying an aqueous solution of potassium permanganate on ground; reducing the temperature of the constant temperature cold storage by 0.2 DEG C every other day; and spraying the aqueous solution of potassium permanganate on the ground every one week, and carrying out fumigation and disinfection by a fresh red jujube fresh-keeping aerosol in the constant temperature cold storage every 10 days. The fresh red jujube fresh-keeping technology can extend the effective shelf life of the fresh red jujubes to 4-6 months.

Owner:新疆麦立德保鲜技术开发有限责任公司

Method for quickly identifying tobacco variety resistance to bacterial wilt

InactiveCN105557343AEnsure consistencyGuaranteed repeatabilityPlant tissue cultureHorticulture methodsPlant rootsNicotiana tabacum

The invention relates to a method for quickly identifying tobacco variety resistance to bacterial wilt. The method comprises the following steps: respectively selecting 10 sterile tobacco seedlings which grow to be at a 4-6-leaf-age stage on a 1 / 2 MS culture medium and are nearly consistent in plant size, removing the MS culture medium attached onto the peripheries of clean root systems in a super-clean workbench, soaking plant roots in bacterial suspension liquid for 30 minutes after the roots are cut by scissors, absorbing up the redundant bacterial suspension liquid on the surfaces of the roots by using a piece of sterile filter paper, newly planting in the MS culture medium, soaking the roots in sterile water as a control, culturing for 16 hours at the temperature of 30 DEG C and under the photoperiod condition that the light illuminance is 26001x, observing and recording disease conditions every other day and calculating disease indexes according to the disease severity.

Owner:中国烟草总公司福建省公司

Fragrance pig breeding method

InactiveCN105918248AMeet growth needsFull exerciseFood processingAnimal feeding stuffDiseaseAdult stage

The invention discloses a fragrance pig breeding method, belongs to the technical field of livestock breeding and aims to solve the problems of physical deterioration and low disease resistance of fragrance pigs due to addition of fish meal and other additives in an existing breeding process of fragrance pigs. The fragrance pig breeding method comprises two stages: the first stage refers to the infant stage, in the first stage, fragrance pigs are fed with infant feed weighing 1.7%-2% of the fragrance pigs from the eighteenth day since the fragrance pigs are born and fed five times a day, and the infant feed is prepared from 7-13 parts of corn, 2-3 parts of bran coat, 3-7 pars of bean meal, 2-4 parts of wheat bran and 1-2 parts of ensilage; the second stage refers to the adult stage, in the second stage, when the weight of each fragrance pig reaches 9 kg or above, the fragrance pigs are fed with adult feed weighing 2.7%-3.3% of the fragrance pigs and feed four times a day, the adult feed is prepared from 8-14 parts of corn, 5-7 parts of bran coat, 1-2 parts of bean meal, 3-4 parts of wheat bran and 1-2 parts of ensilage, and the fragrance pigs are driven to the outside every other day and stay on the outside for half a day. According to the breeding method, the fragrance pigs in different stages are reasonably fed and are allowed to go outside to exercise, so that the disease resistance of the fragrance pigs is improved.

Owner:贵州务川金辉煌农牧科技有限公司

Method for preparing organic fertilizer on basis of urban household garbage

InactiveCN105330350AComplete degradation treatmentSolve protection problemsClimate change adaptationOrganic fertilisersContinuous fermentationLitter

The invention discloses a method for preparing organic fertilizer on the basis of urban household garbage. The method comprises the following steps that organic materials selected from the urban household garbage, auxiliary materials and microbial fermentation strains are evenly mixed in a biological organic fertilizer fermentation tank, standing is conducted for 24 h at room temperature, turning over of materials is conducted for 1-3 times at the temperature ranging from 40 DEG C to 55 DEG C, ventilation is conducted for 1-4 h, and standing is conducted for 22-25 h; continuous fermentation is conducted for 14-18 days at the temperature ranging from 55 DEG C to 65 DEG C till the mixture does not have a foul smell, the water content of the whole system is adjusted to 35 wt%, the temperature is adjusted to below 40 DEG C, and the mixture can be taken out from the tank, wherein turning over of the mixed materials is conducted once every other day. According to the method for preparing the organic fertilizer on the basis of the urban household garbage, degradation treatment on the urban household garbage is thorough, the environmental protection problem brought by the urban household garbage is solved, and large-scale production can be achieved.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

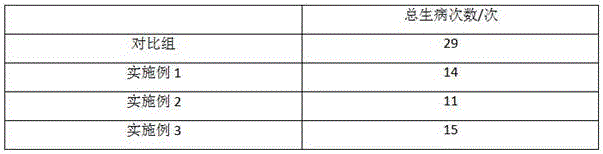

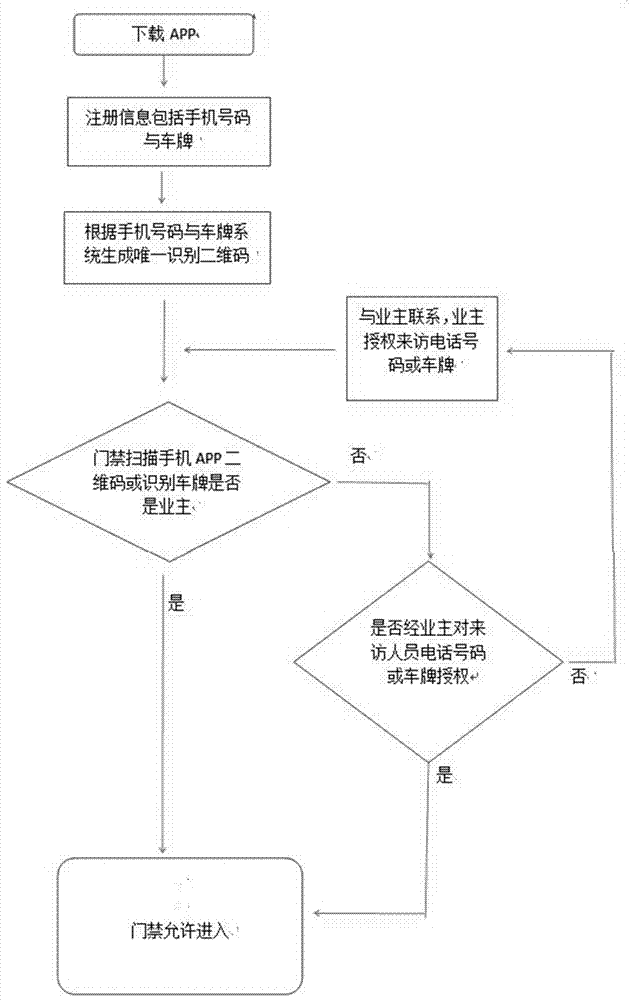

Vehicle authorization access system and management method

The invention discloses a vehicle authorization access system which comprises an information acquisition system, an owner database, a temporary database, a network communication system and a control system, wherein the information acquisition system realizes acquisition of vehicle information; the owner database has the authorization of increasing license plates of accessed vehicles for temporary data by logging-in of mobile phone APP; the network communication system realizes network communication of the information acquisition system, the owner database, the temporary database and the control system; the control system realizes judgment whether the license plate is in the owner database and the temporary database and realizes brake opening and closing; and in combination of a mobile payment manner, a real unmanned parking system is realized. The management method comprises the following steps: communicating visited personnel with a visitor in advance, inputting the license plate of the visited vehicle by the visited personnel in the mobile phone APP system, so that the vehicle with the license plate can automatically enter to be allowed to visit the temporary database, the validity of the temporary database is 24 o'clock in the same evening or automatically fails according to the cell or in specified unit time, and the validity fails every other day.

Owner:贵州联智讯科技有限公司

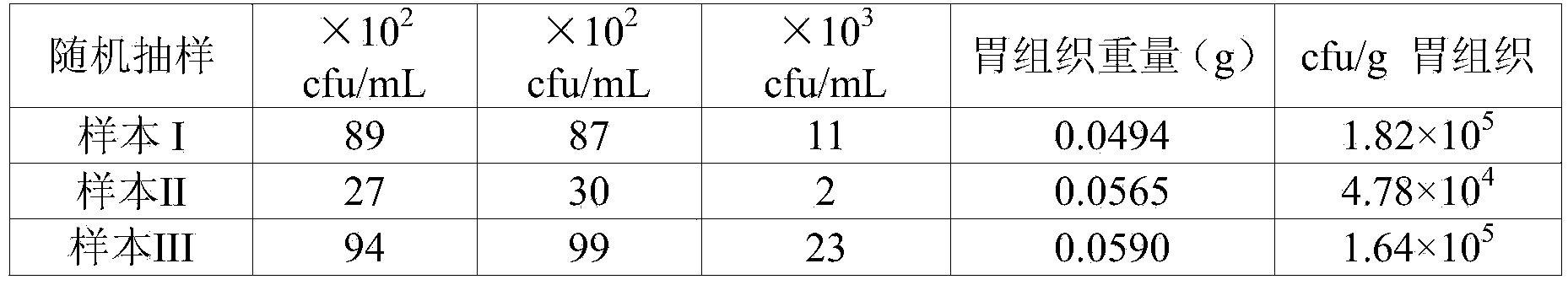

Modeling method of helicobacter pylori infection animal model

ActiveCN103446576AShort experiment timeReduce the number of operationsOrganic active ingredientsBacteria material medical ingredientsAntibiotic YBiology

The invention discloses a modeling method of a helicobacter pylori infection animal model. The modeling method comprises the steps of: 1, by using a 4-weeks old female C57BL / 6 mouse as the experimental animal, performing intra-gastric administration for 3 to 7 days by mixed antibiotic, wherein the mixed antibiotic is composed of gentamicin, vancomycin and nystatin; 2, raising the C57BL / 6 mouse which has been subjected to the intra-gastric administration in the step 1, for 6 to 8 days; 3, inoculating helicobacter pylori: fasting the C57BL / 6 mouse obtained in the step 2, carrying out intra-gastric administration by helicobacter pylori, and feeding after 8 to 12 hours, wherein the inoculating in the step 3 is performed one time every other day, and performed 2 to 4 times in total; and 4, raising the mouse which has been inoculated for 2 to 4 times in the step 3. In the modeling method provided by the invention, the experimental time is short, the operation time is less, the order of magnitude of the helicobacter pylori infection is high, and the infection time is endurable; the model can be widely used for the method of helicobacter pylori infection animal in related researches.

Owner:BRIGHT DAIRY & FOOD

High-yield laying hen breeding method

InactiveCN107306884AImprove fertilityIncrease egg productionAnimal feeding stuffEvery Three DaysAnimal science

The invention provides a high-yield laying hen breeding method. The method comprises the following steps of 1, implementing a brooding period, wherein healthy and disease-free chicks are selected and placed in a brooding house, the chicks are placed at the temperature of 34-36 DEG C to be bred, wherein the temperature is lowered by 2 degrees every week, till the temperature reaches 24 DEG C, and heat supplying equipment is utilized to supply heat; the humidity is 70%, when the chicks are born not soon, the chicks are illuminated for 24 h every day, and the illumination duration is reduced by 1 h every three days; the chicks are subjected to all-day-feeding from the day when the chicks are born till the chicks are 6 weeks old, and the chicks intake food freely; when the chicks are 7 weeks old to 8 weeks old, the chicks are fed with feed every other day; 2, implementing a growing period, wherein the laying hens of 9 weeks old to 18 weeks old are placed on a growing house; 3, implementing an egg laying period, the laying hens of 19 weeks old are fed every day, the situation that every hen is fed with 105 g of feed is every day is maintained, and when the laying hens are 46-72 weeks old, the laying hens are fed every day; 4, adding of a traditional Chinese medicine composition; 5, conducting epidemic prevention; 6, improving the environment of the chick houses. The high-yield laying hen breeding method which effectively increases the egg laying rate is provided.

Owner:安宁赢鹏种养殖有限公司

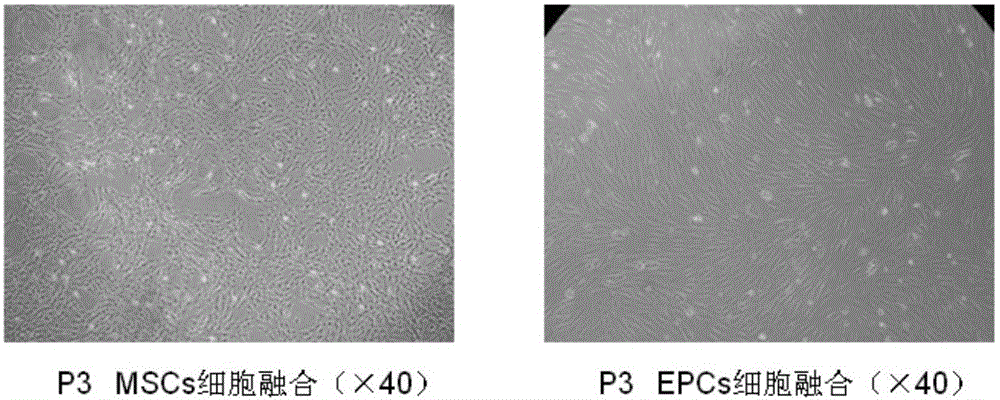

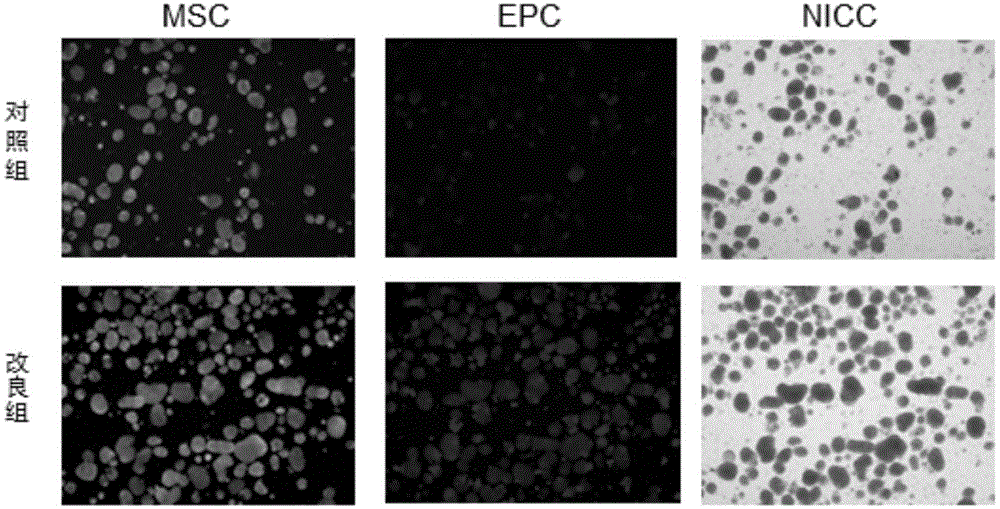

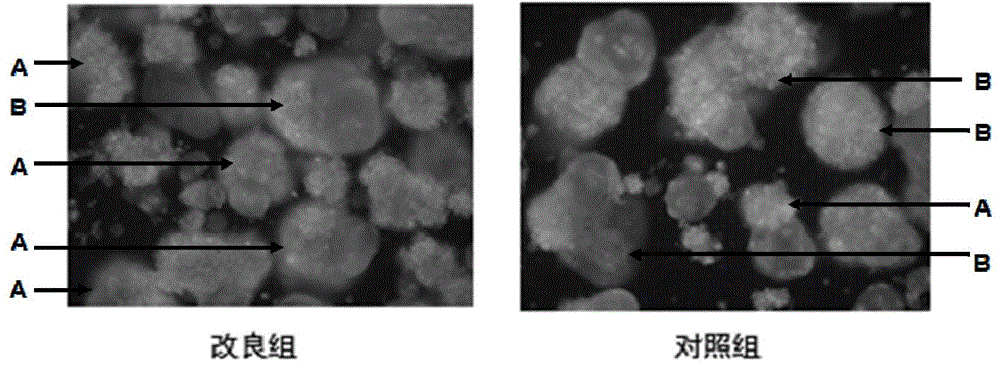

Improved stem/progenitor cell and regenerative porcine islet cell co-culturing method

InactiveCN104371969AImprove survival rateReduce apoptosis rateArtificial cell constructsSkeletal/connective tissue cellsIslet cellsApoptosis

The invention discloses an improved stem / progenitor cell and regenerative porcine islet cell co-culturing method. The method comprises the following steps: culturing NICCs by using a complete medium for 3d, re-suspending three kinds of cells by using the complete medium according to a cell quantity ratio of NICCs (IEQ): EPCs (P3-P5): MSCs (P3-P5) of 1:8:8-1:12:12, placing in an anchorage-independent culture dish or culture bottle, co-culturing in a 37DEG C thermotank for 8-12h without shaking, transferring the cells into a culture dish or culture bottle with the medium containing area about 6 times the above culture dish or culture bottle, continuously culturing, and replacing a culture solution once every other day. The method has the advantages of increase of the NICC coating efficiency of the MSCs and the EPCs, reduction of the cell apoptosis rate, increase of the cell viability, and improvement of the cell culture yield, and is an improved simple, stable and efficient stem cell and regenerative porcine islet cell co-culturing method.

Owner:HUNAN XENO LIFE SCI

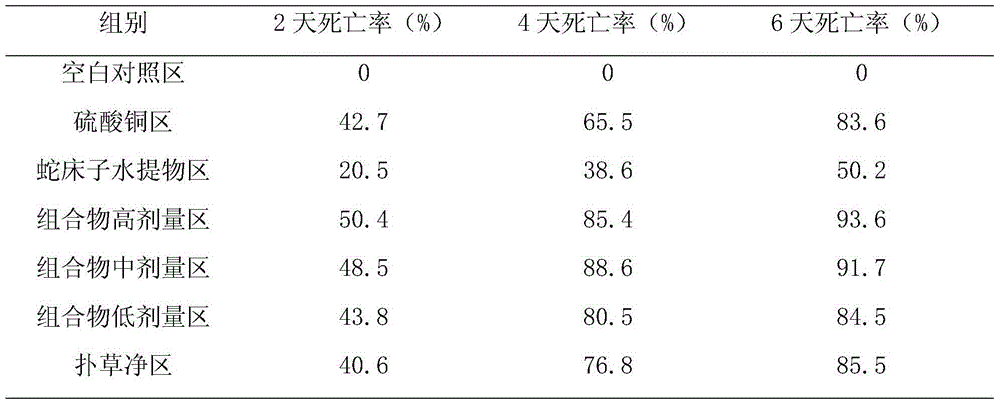

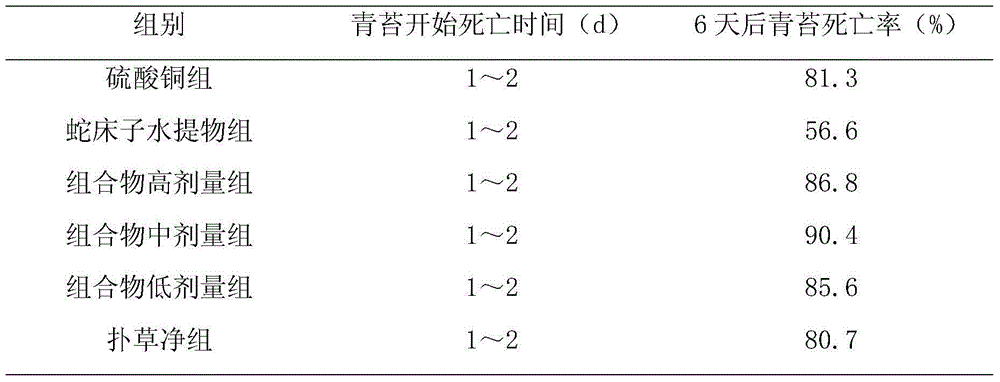

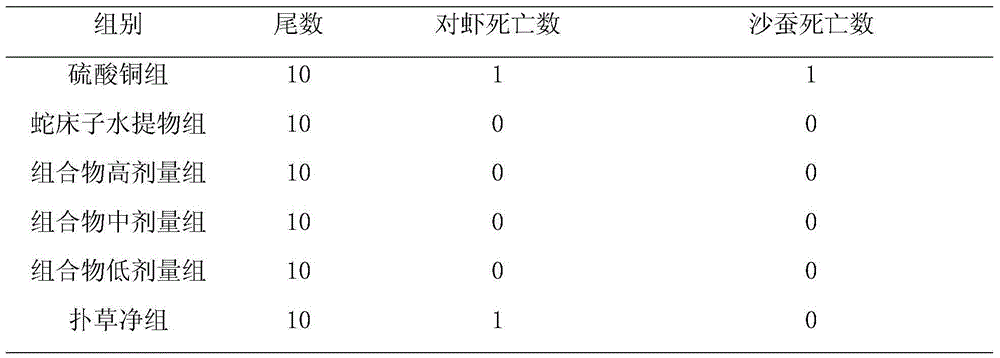

Medicinal composition and method for preventing and controlling growth of moss in fritillaria planting greenhouse

ActiveCN103598214ANo side effectsImprove the effect of moss controlBiocideAnimal repellantsGreenhouseCurative effect

The invention provides a medicinal composition for preventing and controlling moss. The medicinal composition is formed by uniformly mixing 0.1-10 parts by weight of copper sulfate and 1-50 parts by weight of fructus cnidii water extract. The medicinal composition is mainly used for removing moss on a soil surface or in a pool, and the effect of the medicinal composition is superior to that of single copper sulfate and prometryn. The invention also provides a method for preventing and controlling growth of moss in a fritillaria planting greenhouse. The method comprises the following steps: keeping ventilation in the greenhouse, and illuminating for 1-2 hours every other day; mixing the copper sulfate and the fructus cnidii water extract, adding water into the mixture so as to prepare a medicinal liquid; spraying the medicinal liquid in a dosage of 500-800ml per square meter on the soil surface in the fritillaria planting greenhouse. The medicinal composition is small in dosage and durable in drug effect, cannot cause hazard to the environment, and can be used for overcoming the defect of drug residues of existing chemicals; meanwhile, the method has the advantages of simplicity in operation, safety in use and exact curative effect.

Owner:薛刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com